Page 1

ER’

S

MAN

U

A

L

ENTRAL

CO

NTROL (CENTER

CONSO

LE)

SC-S

L4-AE,

SC-S

L4-BE

ER’S MANUA

L

ENTRAL CONTROL SC-SL4-AE, SC-SL4-B

E

ENGLISH

ANUEL DE L’UTILISATE

UR

NSOLE CENTRALE SC-SL4-AE, SC-SL4-B

E

ANWENDERHANDB

UCH

auptsteuerpult SC-SL4-AE, SC-SL4-B

E

DEUTSCH

ISTRUZIONI PER L’US

O

NSOLE CENTRALE SC-SL4-AE, SC-SL4-B

E

ITALIANO

ANUAL DEL PROPIETARI

O

NSOLA CENTRAL SC-SL4-AE, SC-SL4-B

E

ESPAÑOL

EBRUIKERSHANDLEIDIN

G

ENTRALE CONSOLE SC-SL4-AE, SC-SL4-B

E

NEDERLANDS

KILAVUZU

ERKEZİ KOMSOL SC-SL4-AE, SC-SL4-B

E

ANUAL DO UTILIZAD

OR

ENTER CONSOLE SC-SL4-AE, SC-SL4-B

E

PORTUGUÊS

РУССКИЙ

ΕΛΛΗΝΙΚΑ

TÜRKÇE

FRANÇAIS

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИ

И

ЕНТРАЛЬНЫЙ КОНТРОЛЛЕР SC-SL4-AE, SC-SL4-B

E

ΔΗΓΙΕΣ ΧΡΗΣΗ

Σ

ΚΕΝΤΡΙΚΗ ΚΟΝΣΟΛΑ SC-SL4-AE, SC-SL4-B

E

PJZ012A

099

This center console complies with EMC Directive 89/336/EEC,

91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV Directive

E

C.

ette console centrale est conforme à la Directive EMC:

89/336/

EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV

irective 2

006/95/EC

.

Esta consola central cumple con la directiva EMC: 89/336

/

EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV

irectiva 2

006/95/EC

.

eze centrale console voldoet aan EMC Directive 89/336/EEC,

91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV Directiv

e

2

006/95/EC.

ieses Hauptsteuerpult erfüllt die EMC Direktiven 89/336

/

EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV

irektiven 2

006/95/EC.

uesta console centrale è conforme alla Direttiva EMC: 89/336

/

EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC, 2004/108/EC, LV

irettiva 2

006/95/EC

.

Esta consola central está em conformidade com a Directiva EMC 89/336/EEC 91/263/EEC

,

92/31/EEC, 93/68/EEC,

004/108/EC, e a Directiva LV 2006/95/EC

.

Αυτή

η κεντρική κονσόλα πληροί τις προδιαγραφές τη

ς

δηγίας EMC 89/336/EEC, 91/263/EEC, 92/31/EEC, 93/68/

EEC, 2004/108/EC και τη

ς Ο

δηγίας LV 2006/95/ της EC.

SC-SL4-AE

SC-SL4-BE

with Calculating Function /

avec fonction de calcul / mit Berechnungsfunktion /

on funzione di calcolo / Con función de cálculo /

et calculatiefunctie / com função de cálculo /

με λειτουργία υπολογισμού / с функцией вычисления /

esaplama Fonksiyonlu

)

Page 2

– 1 –

Thank you very much for employing the Central Control of Mitsubishi Heavy

Industries, Ltd.

Before using, read throughly this user’s manual for proper operation. After

reading, carefully store it for future reference. If any trouble should occur during

operation, it will be helpful. Also, read throughly the user’s manual which is

attached to the air conditioner.

Table of contents

Safety Precautions ■ ................................................................................................................................2

Introduction ■ ........................................................................................................................................... 4

Overview ...............................................................................................................................................4

Names and Functions of Parts ............................................................................................................. 4

Blocks, Groups ..................................................................................................................................... 4

Startup Screen ..................................................................................................................................... 5

Quick Reference Chart for Operations ................................................................................................. 6

Menu ..................................................................................................................................................... 7

OPERATOR MENU Screen .................................................................................................................. 8

All Blocks Display ................................................................................................................................. 9

Changeover Confi rmation Screen ........................................................................................................ 9

Icons ................................................................................................................................................... 10

Operation ■ ............................................................................................................................................ 11

Group Operation Settings (Monitor Group Status) ............................................................................. 11

Multiple Groups Operation Settings .................................................................................................... 14

Group Batch Operation ....................................................................................................................... 15

Schedule Settings ............................................................................................................................... 16

Viewing Detailed Unit Information.......................................................................................................21

Calculating Settings (SC-SL4-BE only) .............................................................................................. 22

Group Defi nition ..................................................................................................................................23

Block Defi nition ................................................................................................................................... 25

Time & Date Setting ...........................................................................................................................26

Convenient Functions ■ ......................................................................................................................... 27

Entering Numbers and Characters ..................................................................................................... 27

DISPLAY SETTING ............................................................................................................................28

Corrections for Power Outages ...........................................................................................................29

Using USB Memory ............................................................................................................................ 29

Operation Time History ....................................................................................................................... 30

LAN Settings ....................................................................................................................................... 31

Operator Settings ...............................................................................................................................32

Viewing Alarm History ........................................................................................................................33

System Information ............................................................................................................................. 33

Help .................................................................................................................................................... 33

Maintenance ■ ....................................................................................................................................... 34

Shut Down ■ .......................................................................................................................................... 35

Using MAINTENANCE MENU ■ ............................................................................................................ 36

SL Mode ............................................................................................................................................. 37

UNIT DEFINITION Settings (SC-SL4-BE only) .................................................................................. 38

Function Settings ................................................................................................................................ 39

Import/Export Confi guration File ......................................................................................................... 40

FACTORY CLEAR ..............................................................................................................................41

Language Setting ...............................................................................................................................42

Viewing Alarm History ........................................................................................................................42

Demand and Emergency Stop Settings .............................................................................................43

External Input Status .......................................................................................................................... 44

Maintenance User Setting .................................................................................................................. 44

Troubleshooting ■ .................................................................................................................................. 45

Installation ■ .......................................................................................................................................... 47

After Sales Service ■ ............................................................................................................................. 47

ENGLISH

Page 3

– 2 –

Safety Precautions

Before starting to use the central control, read these “Safety precautions” carefully to ensure proper operation of the central •

control.

The safety precautions are classifi ed as “• DANGER ” and “ CAUTION ”. Precautions as shown in the column “ DANGER ”

indicate that improper handling could have serious consequences like death, serious injury, etc.

“•

CAUTION ” might pose a serious problem, depending on the circumstances. Please observe these precautions with great

care, since they are essential to your safety.

Symbols which appear frequently in the text have the following meaning:•

Strictly prohibited.

Observe instructions with

great care.

Provide positive earthing.

When you have read the user’s manual, please keep it near at hand for consultation. If someone else takes over as operator, •

make sure that the manual is also passed on to the new operator.

INSTALLATION PRECAUTIONS ❚

DANGER

The central control must be installed by your dealer or a qualifi ed professional.

It is not advisable to install the central control yourself, as faulty handling may cause electric shock or fi re.

CAUTION

Make sure to perform grounding work. Depending on the place of installation, a leakage breaker

may be necessary.

Do not connect the ground wire to any gas pipes,

water pipes, lightning conductors or a ground wire

connected to telephones. Incomplete grounding may

cause electric shock.

If a leakage breaker is not installed, electric shock may

happen.

Consult your dealer.

OPERATION PRECAUTIONS ❚

DANGER

If the central control is damaged with water due to a

natural disaster such as a fl ood or a typhoon, consult

your dealer.

If the central control is under abnormal conditions, stop

the operation, turn the power supply switch off and consult

your dealer.

Operating the central control under such conditions

may lead to failure, electric shock and/or fi re.

Continuing operating the central control under abnormal

conditions may lead to failure, electric shock and/or fi re.

CAUTION

Do not handle with wet hands. Do not pull the connecting wire. Do not wash the central control with

water.

This may cause an electric shock

or failure.

If the core wire is disconnected,

it could cause a short-circuit.

It may cause electric shock or

failure.

A static electric discharge to the unit could cause a break-down.

Before performing operations, touch a grounded metal object and discharge any static electricity.

Page 4

– 3 –

PRECAUTIONS FOR RELOCATION OR REPAIR ❚

DANGER

Never modify or disassemble the central control. If it

requires service, consult your dealer.

If it is required to relocate the central control, consult

your dealer.

If servicing is inadequate, electric shock and/or

fi re may occur.

Improper installation of the central control may cause

electric shock and/or fi re.

The energy consumption calculated by this unit does not conform to OIML, and there are no guarantees

concerning the results of the calculations.

This unit calculates only energy consumption distribution (gas, electric power). You need to calculate

the air- conditioning rates.

Warning

This is a class A product. In a domestic environment, this product may cause radio interference in which case the user may be

required to take adequate measures. This unit is not for domestic use.

Page 5

– 4 –

Introduction

Overview

Central controls are made to collectively control air conditioning indoor units. All the controls such as unit monitoring,

operation, settings and scheduling can be done on the touch panel.

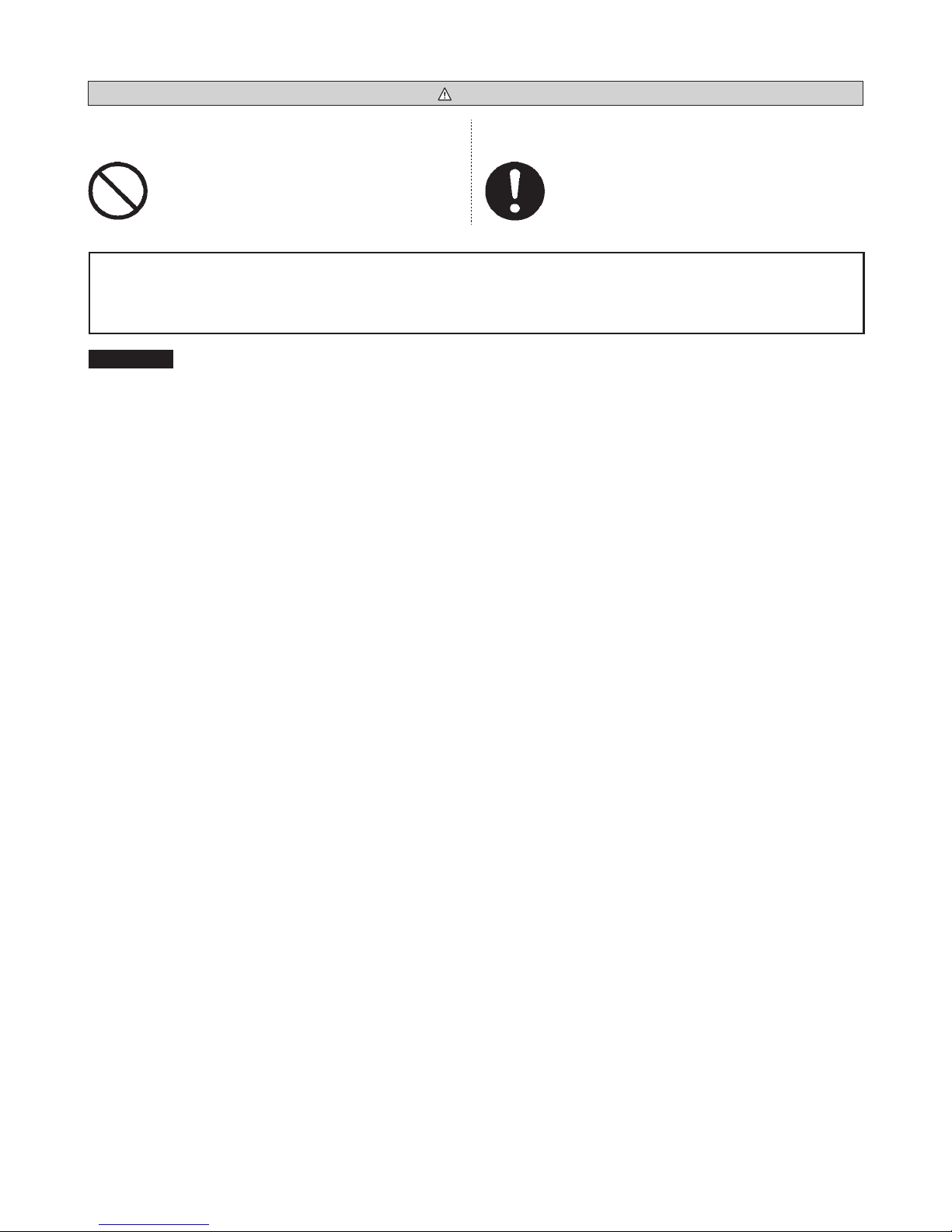

Names and Functions of Parts

Color LCD Display

The screens are displayed here. Operations

are performed by touching it with a fi nger.

USB Memory Slot

Insert the USB memory from the bottom.

Warning

Do not insert any USB device other than the bundled USB memory.

Front Cover

Reset switch

Press the switch that is placed innermost of small hole at the lower side of this

cover, using a straight clip or similar tool.

The screen may be locked depending on the static charge or external noise,

etc, but there is no trouble. In this case, the screen can be returned to normal

display by pressing the reset switch.

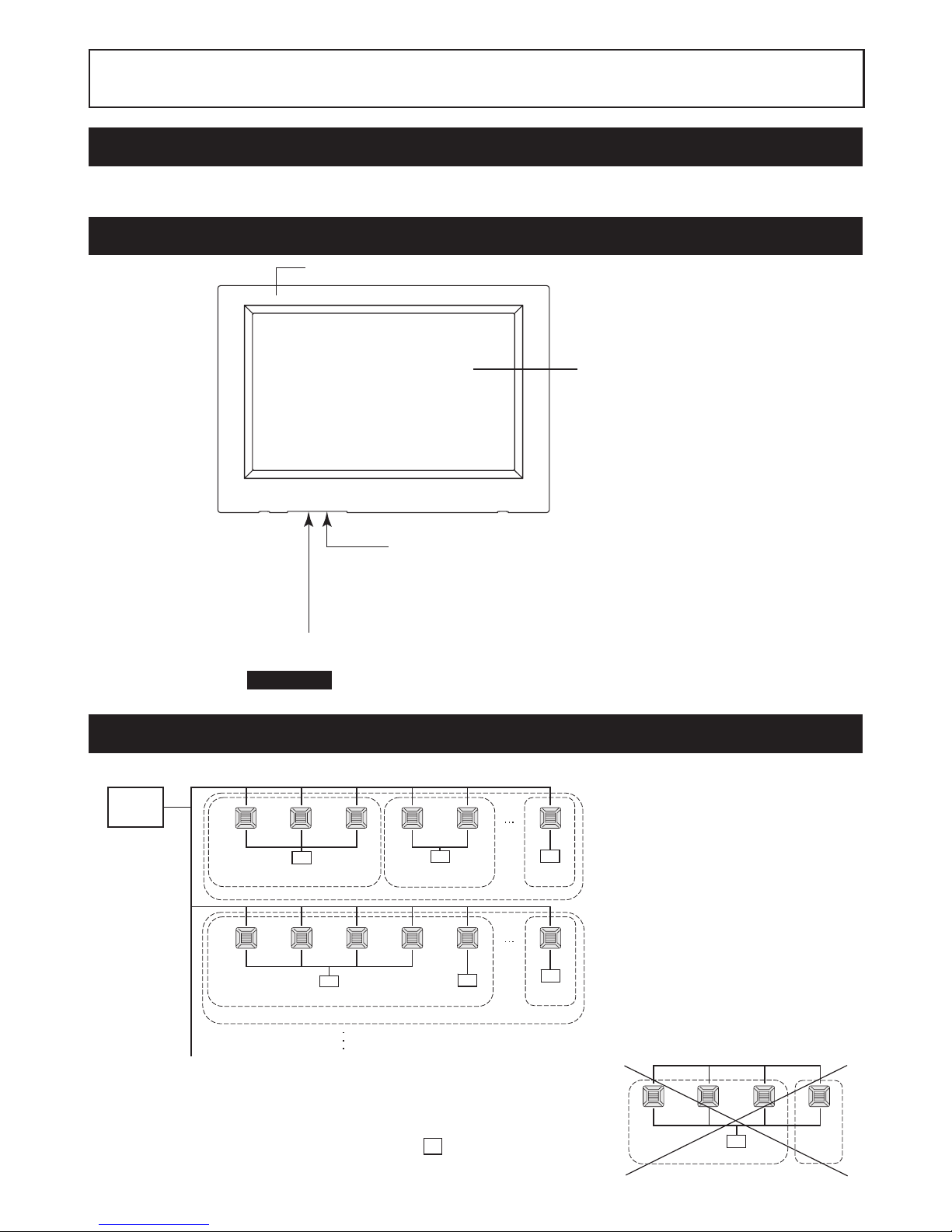

Blocks, Groups

[Example of Connections]

Air conditioner

1

Central

control

R

R

R

R

R

R

Air conditioner

16

Air conditioner

2

Air conditioner

17

Air conditioner

4

Air conditioner

19

Group 1

Group Q +1

Group 2

Block 2

Group Q

Group T

Air conditioner

3

Air conditioner

18

Air conditioner

5

Air conditioner

20

Block 1

Air conditioner

P

Air conditioner

R

A maximum of 16 air conditioner can be set up in one group.•

Do not use one remote controller for different groups of air conditioner.•

A maximum of 9 groups can be set up in one block.•

A maximum of 16 blocks can be set up.•

Air conditioner

1

R

Air conditioner

2

Air conditioner

4

Group 1 Group 2

Air conditioner

3

R : Remote controller

Page 6

– 5 –

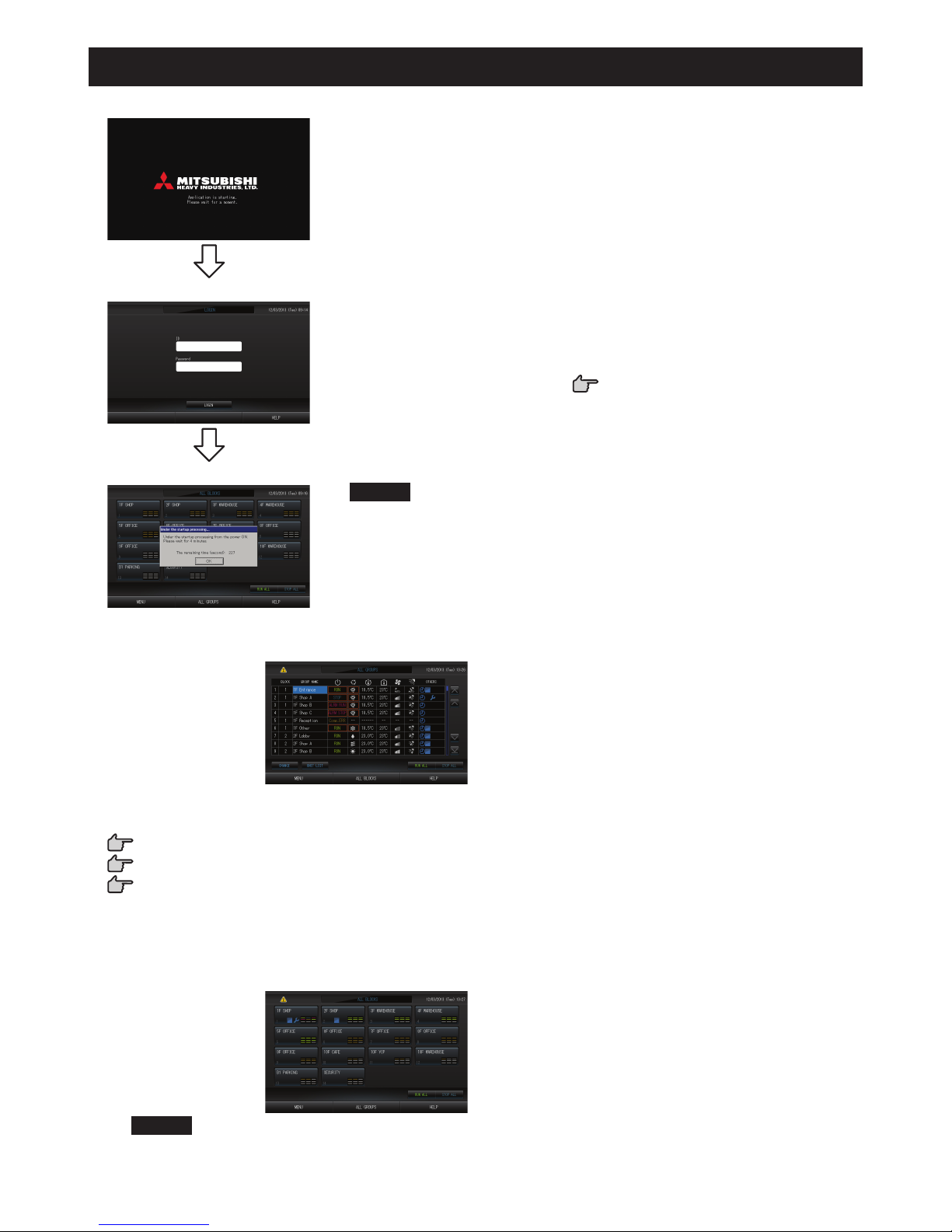

Startup Screen

[Startup Screen]

This screen is displayed at startup.

[Login screen]

The default ID and password are as follows:

Default ID:

Default password:

OPERATOR

123456

After logging in, change the default ID and password to your own.

Changing the ID and password

page 32

[Information Screen]

Note

It is not possible to do any setting when information screen is displayed.

ALL GROUPS Display•

This display appears the fi rst time the unit starts up or when block have not been registered. Make the initial settings

in the following order.

Time & Date Setting page 26

Group Defi nition page 23

Block Defi nition page 25

Once blocks are registered, it is very convenient because the status of all groups can be viewed on a single *

screen.

ALL BLOCKS Display•

When blocks have been registered, this display appears.

Note

It may take time for the settings to be read into the unit. Do not perform any operations until all the groups

that have been set are displayed. (This should take only a few minutes.)

Page 7

– 6 –

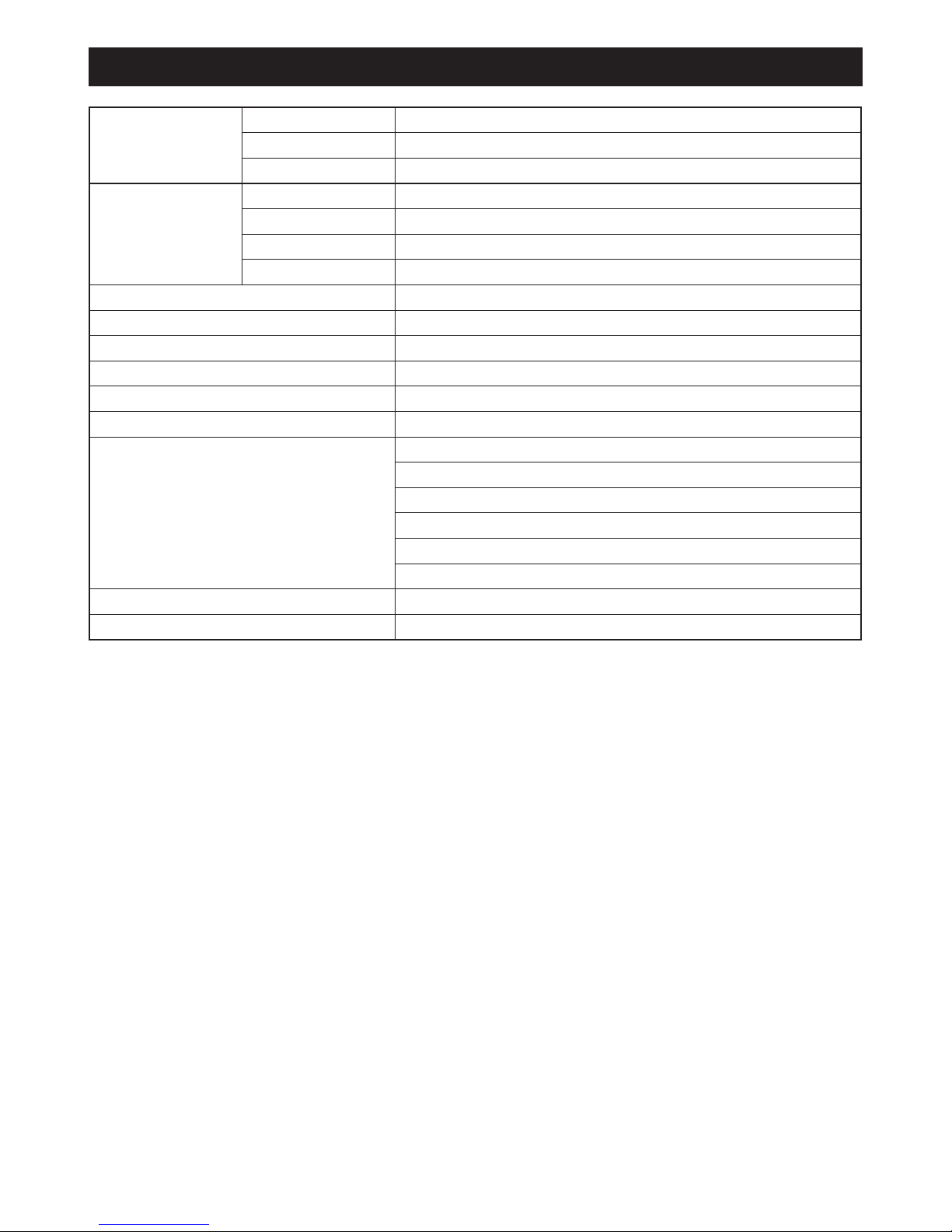

Quick Reference Chart for Operations

Initial settings Date & time Page 26 (Time & Date Setting)

Groups Page 23 (Group Defi nition)

Blocks Page 25 (Block Defi nition)

Viewing status All blocks Page 9 (All Blocks Display)

All groups Page 13 (ALL GROUPS screen)

Each group

Pages 11 & 13 (Group Operation Settings : GROUP(PANEL) & GROUP(LIST) screen)

Each unit Page 21 (Viewing Detailed Unit Information)

Group operation Page 11 (Group Operation Settings)

Multiple groups operation Page 14 (Multiple Groups Operation Settings)

Batch operation Page 15 (Group Batch Operation)

Setting and checking schedules Page 16 (Schedule Settings)

Making calculating settings (SC-SL4-BE only)

Page 22 (Calculating Settings)

Entering numbers and characters Page 27 (Entering Numbers and Characters)

Using convenient functions Page 28 (Display Setting)

Page 29 (Corrections for Power Outages)

Page 29 (Using USB Memory)

Page 33 (System Information)

Page 30 (Operation Time History)

Page 32 (Operator Settings)

Alarm history Page 33 and 42 (Viewing Alarm History)

Further Information Page 33 (Help)

Page 8

– 7 –

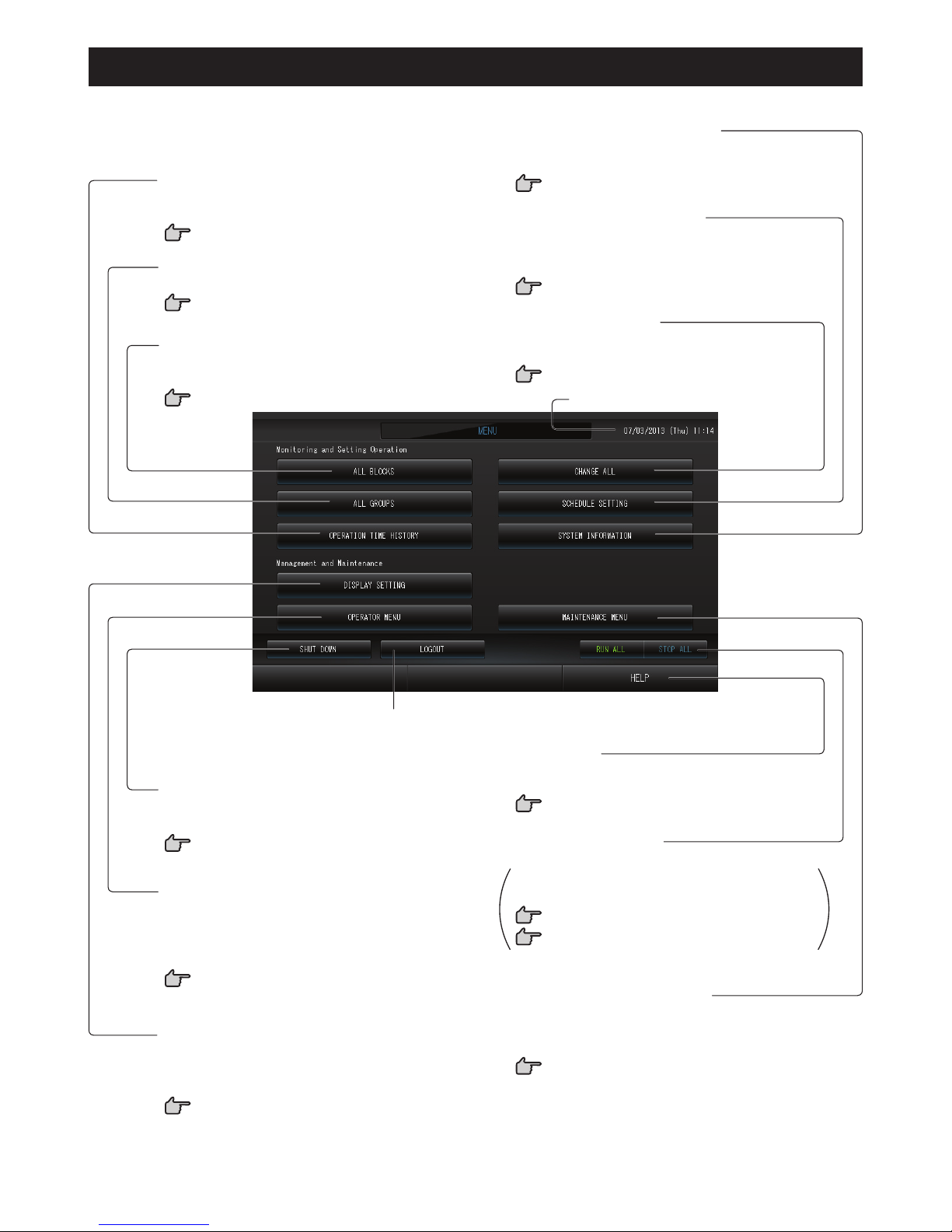

Menu

When the MENU button is pressed, the screen switches to the one shown below.

RUN/STOP ALL button

Stops running for groups set up for batch operation.

Settings can also be made for groups not set up

for batch operation.

page 23 1

page 24 56

CHANGE ALL button

Switches the screen for changing group batch

operation settings.

page 15

MAINTENANCE MENU button

Displays the MAINTENANCE MENU.

This button is displayed only when you have logged in using

the maintenance user ID.

page 36

OPERATION TIME HISTORY button

Displays operation time in graph format for each

group.

page 30

ALL GROUPS button

Displays all group names and status in a list.

page 13

ALL BLOCKS button

Displays a list of the names and status of all blocks

in a panel.

page 9

SHUT DOWN button

When it is known that there will be a power outage,

this button saves the settings.

page 35

SCHEDULE SETTING button

Switches the screen for setting air conditioning

operation schedules.

(If you have not set a group, this button is invalid.)

page 16

OPERATOR MENU button

Switches the screen for making group and block

settings, date and time settings and accounting

settings (SC-SL4-BE only) as well as viewing the

alarm history.

page 8

DISPLAY SETTING button

Sets the brightness of the display and the light-up

period of the backlight, or switches to screen cleaning

mode.

page 28

LOG OUT button.

Return to login screen.

Date and Time display

HELP button

Opens the screen for viewing detailed information

on the display content and operations.

page 33

SYSTEM INFORMATION button

Displays the central control version number and number

of units registered.

page 33

Page 9

– 8 –

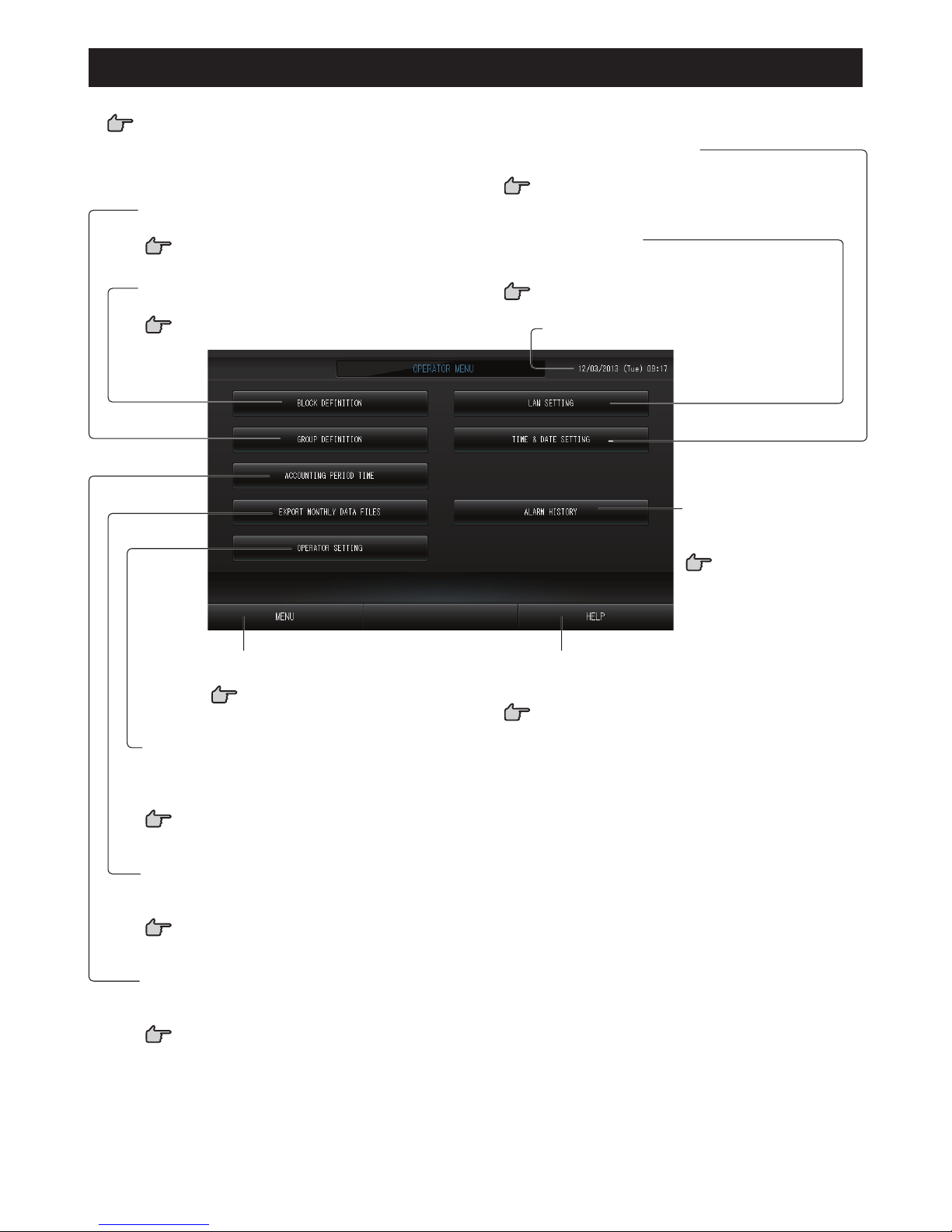

OPERATOR MENU Screen

This is displayed when the OPERATOR MENU button is pressed on the MENU screen.

page 7

TIME & DATE SETTING button

Switches the TIME & DATE SETTING screen.

page 26

EXPORT MONTHLY DATA FILES button

Switches to the screen used to export the accounting

period data and save it on a USB memory device.

page 29

OPERATOR SETTING button

Switches to the screen used to set the operator ID

and password, operator information, and security

lock.

page 32

Date and Time display

HELP button

Opens the screen for viewing detailed information on

the display content and operations.

page 33

MENU button

Returns to the MENU screen.

page 7

ALARM HISTORY button

Displays the Alarm History of

the units.

page 33

GROUP DEFINITION button

Switches the GROUP DEFINITION screen.

page 23

BLOCK DEFINITION button

Switches the BLOCK DEFINITION screen.

page 25

LAN SETTING button

Switches to the screen used to set the IP address,

subnet mask, and gateway address.

page 31

ACCOUNTING PERIOD TIME button

Switches to the screen used to set the start and end

time of the accounting period.

page 22

Page 10

– 9 –

All Blocks Display

This is displayed when the ALL BLOCKS button is pressed on the MENU screen. page 7

The names and the status of all blocks are displayed in the panels. Unestablished blocks or blocks without any

groups are not displayed. If a block button is pressed, the GROUP (PANEL) screen is displayed.

page 11

RUN/STOP ALL button

Stops running for groups set up for batch

operation.

Settings can also be made for groups

not set up for batch operation.

page 23 1

page 24 56

Date and Time display

MENU button

Returns to the MENU screen.

page 7

HELP button

Opens the Help.

page 33

ALL GROUPS button

Displays all groups.

page 13

Individual Block Displays•

Each group status display

The colors 1 – 9 show the status of the groups. As shown

in the right fi gure, it is arranged from small group number.

The colors have the following signifi cance.

(Green) Running

(Blue) Stopped

(Red) Malfunction

(Yellow) Communication error

(Gray) No groups

Block name

Block number

Filter Sign and Maintenance Indicator

Displayed when at least one group needs the cleaning of the

fi lters or maintenance.

page 10

1 2 3

4 5 6

7 8 9

Changeover Confi rmation Screen

This is a screen for confi rming the changes to various

settings. The text displayed varies according to the screen

called up, but the operation is as follows.

Press the Yes button to save the settings and to exit. Press

the No button to exit without saving your settings.

Page 11

– 10 –

Icons

Filter sign(1)

If at least one air conditioner in a block or group needs fi lter maintenance, this indicator lights up. When this

happens, clean the fi lters.

Maintenance Indicator(2)

When the maintenance indicator is lit for at least one air conditioner in a block or group, the maintenance

indicator is displayed. If the maintenance indicators are off on all units, the maintenance indicator turns off.

Contact your dealer if this indicator is on.

(Gray) Inspection, Inspection 1, Inspection 2

(Yellow) Backup operation (Inspection 3)

Scheduling(3)

This shows the groups that are the targets of the current day’s schedule.

Air direction(4)

This shows the status of louver operation.

Swinging

(AUTO)

Position 1

(STOP 1)

Position 2

(STOP 2)

Position 3

(STOP 3)

Position 4

(STOP 4)

Unit states(5)

The unit status is shown by fi gures.

Error stop (One or more units have been stopped because of malfunction.)

Please contact your dealer.

Demand (The external signal is inputted to the demand terminal.

page 24)

The target unit will switch to fan mode and remote controller operations are prohibited. When the external

signal is cancelled, the setting will return.

Emergency stop (The external signal is inputted to the emergency stop terminal.)

All units stop and operations are prohibited. When the emergency stop signal is cancelled, the remote

controller lock/unlock setting will return but the units remain stopped.

Page 12

– 11 –

Operation

Group Operation Settings (Monitor Group Status)

Press the ALL BLOCKS button on the MENU screen.1. page 7

Press the block you wish to set or monitor. 2.

The GROUP (PANEL) screen is displayed.

The group name, status, fi lter sign, maintenance, scheduling, temperature settings and room temperature can

be observed.

[GROUP (PANEL) screen]

3

4

4

Note

See Icons for the signifi cance of the icon displays. •

page 10

The running status, operating mode, temperature settings and room temperature are shown for the •

representative unit. When all units are stopped, stopped status is shown.

Groups that have the current day’s schedule settings show •

.

• being displayed means that these are lit for one or more units.

If the GROUP LIST button is pressed, the GROUP (LIST) is displayed. •

page 13

To display the units in a group, press the UNIT LIST button. •

page 21

<When running and stopping each group>

Press the panel of the group for which settings are to be made. 3.

The panel frame turns blue.

4. To run units Press the RUN button, and press the Yes button on the confi rmation screen.

The selected group starts running.

To stop units Press the STOP button, and press the Yes button on the confi rmation screen.

The selected group stops running.

When you do not want to set, press the No button.

<When making settings and changes on each group>

Press the panel of the group for which settings or changes are to be made. 3.

The panel frame turns blue.

Press the CHANGE button.4.

The screen for CHANGE screen is displayed. When the screen changes, no items are selected (the temperature

setting is blank). Set only the items that are to be set or changed.

Attention

A static electric discharge to the unit could cause a break-down.

Before performing operations, touch a grounded metal object and discharge any static electricity.

Page 13

– 12 –

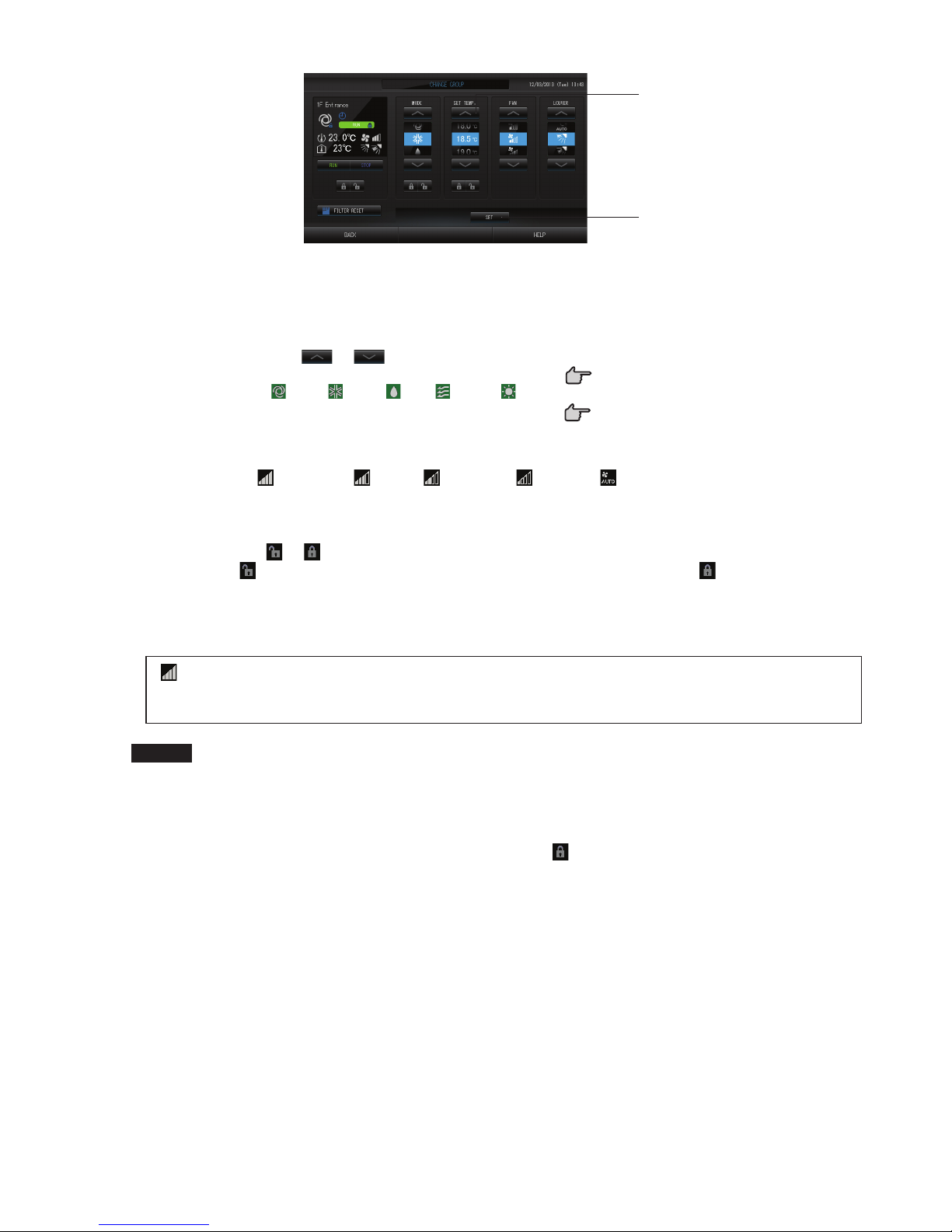

[CHANGE screen]

6

5

Press the button for the item to set or change. 5.

Run/Stop: Press the RUN or STOP button. ·

When the RUN button is selected, the operation starts, and when the STOP button is selected,

the operation stops.

SET TEMP.: Press •

or .

Set a temperature between 18°C and 30°C.

page 39

MODE: select ·

Auto, Cool, Dry, Fan or Heat by pressing the button.

Auto Mode can be valid in the MAINTENANCE MENU. *

page 39

This function can be applied to the indoor units, which are the cooling/heating free multi KXR, single ·

split PAC.

FAN: Select ·

(Powerful), (High), (Medium), (Low), or (AUTO), and press the button.

When using powerful mode, valid Powerful Fan on the MAINTENANCE MENU.*

When using automatic mode, valid the AUTO Fan on the MAINTENANCE MENU.*

Air direction: Select Auto, stop 1, stop 2, stop 3 or stop 4 and press the button. ·

LOCK: Press ·

or .

If

is pressed, remote controller operations are permitted, and if is pressed, they are

prohibited.

FILTER RESET: If the reset button is pressed, the fi lter sign turns off. ·

Press the SET button. Press the Yes button on the confi rmation screen. 6.

When you do not want to set or change, press the No button.

(Powerful mode)

Operates with the maximum fan speed.

It is suitable for heating or cooling the entire room thoroughly.

Note

If the BACK button is pressed, it returns to the previous screen. •

If individual lock/unlock is valid in the MAINTENANCE MENU, it is possible to set the remote controller •

operations to permit or prohibit each item such as run/stop, mode and temperature setting.

When individual lock/unlock are valid in the MAINTENANCE MENU, remote controller operations are •

prohibited if run/stop, mode and temperature setting are all

. (Some functions, such as reset of the fi lter

sign have been permitted.)

Page 14

– 13 –

The following method can also be used to set and ■

change operations on each group.

When making settings or changes in the GROUP ►

(LIST) screen

Press the GROUP LIST button in the GROUP (PANEL) 1.

screen.

page 11

The GROUP (LIST) screen is displayed.

[GROUP (LIST) screen]

2

3

Press the name of the group for which settings or changes are to be made. 2.

The group name is reverse highlighted, press the

or button.

Press the CHANGE button. 3.

The screen for CHANGE screen is displayed. Make the settings or changes.

page 12

Note

If the BACK button is pressed, it returns to the previous screen. •

Run is indicated when at least one unit is running. Malfunctions are indicated when at least one unit is not •

in good condition. Stop is indicated when all the units have stopped.

icon is displayed when at least one unit needs cleaning fi lter.

icon is displayed when at least one unit needs maintanance.

Operating mode, temperature setting, room temperature, fan speed and air direction show the state of the

representative unit.

The ones which are surrounded by red frames are the items which operations from the remote controller •

are prohibited in the group settings.

If the GROUP PANEL button is pressed, the GROUP (PANEL) screen is displayed.

•

page 11

When making settings or changes in the ALL GROUPS screen ►

Press the ALL GROUPS button on the MENU.1.

page 7

Press the name for the group to set or change. 2.

[ALL GROUPS screen]

2

3

The group name is reverse highlighted.

When the screen switches, the previously selected group name is selected. To change the page, press the

or button.

Press the CHANGE button.3.

The screen for CHANGE screen is displayed. Make the settings or changes.

page 12

Note

To display the units in a group, press the UNIT LIST button. •

page 21

To show all blocks, press the ALL BLOCKS button. •

page 9

The ones which are surrounded by red frames are the items which operations from the remote controller •

are prohibited in the group settings.

If the MENU button is pressed, the MENU screen is displayed. •

page 7

Page 15

– 14 –

Multiple Groups Operation Settings

This section shows how to operate multiple groups in the same block.

Press the ALL BLOCKS button on the MENU.1.

page 7

Press the block you wish to set. 2.

The GROUP (PANEL) screen is displayed.

[GROUP (PANEL) screen]

3

44

<When running and stopping multiple groups>

Press the panels of the groups for which settings are to be 3.

made (multiple groups can be selected).

The panel frame turns blue.

When you want to cancel, please press the panel of the group

again.

4.

To run units

Press the RUN button, and press the Yes

button on the confi rmation screen.

The selected group starts running.

To stop units

Press the STOP button, and press

the Yes button on the confirmation

screen.

The selected group stops running.

When you do not want to set, press the No button.

56

<When making settings and changes on multiple groups>

Press the panels of the groups for which settings or changes 3.

are to be made (multiple groups can be selected).

The panel frame turns blue.

When you want to cancel, please press the panel of the group

again.

Press the CHANGE button.4.

The screen to change groups is displayed. When the screen

changes, no items are selected (the temperature setting is blank).

Set only the items that are to be set or changed

Press the button for the item to set or change. 5.

Run/Stop: Press the RUN or STOP button. ·

With the RUN button, running starts, and with the

STOP button, running stops.

[Individual lock/unlock settings valid in Function

Setting]

This function can be applied to the indoor units,

which are the model KXE4 or later, and to the

remote controller, which is the model RC-E1

or later.

Temperature setting: Press • or .

Set a temperature between 18°C and 30°C.

page 39

Mode: Select ·

Auto, Cool, Dry, Fan or Heat by pressing the button.

When using Auto Mode, valid AUTO on the MAINTENANCE MENU.*

The Auto Mode can be valid for the cooling/heating free multi KXR, single split PAC.

LOCK: Press ·

or .

If

is pressed, remote controller operations are permitted, and if is pressed, they are

prohibited.

Fan speed: Select ·

(Powerful), (High), (Medium), (Low), or (AUTO), and press the button.

When using powerful mode, valid the Powerful Fan on the MAINTENANCE MENU.*

When using automatic mode, valid the AUTO Fan on the MAINTENANCE MENU.*

Air direction: select Auto, stop 1, stop 2, stop 3 or stop 4 and press the button. ·

FILTER RESET: If the reset button is pressed, the fi lter sign turns off. ·

Page 16

– 15 –

Press the SET button. Press the Yes button on the confi rmation screen. 6.

When you do not want to set, press the No button.

Note

If the BACK button is pressed, it returns to the previous screen. •

If individual lock/unlock is valid in the MAINTENANCE MENU, it is possible to set the remote controller •

operations to permit or prohibit each item such as run/stop, mode and temperature setting.

When individual lock/unlock are valid in the MAINTENANCE MENU, remote controller operations are •

prohibited if run/stop, mode and temperature setting are all

. (Some functions, such as reset of the fi lter

sign have been permitted.)

Group Batch Operation

This section shows how to set or change the detailed setting of Batch Operation.

Set the groups for batch operation in advance.

page 231, 2456

Press the CHANGE ALL button on the MENU screen.1.

page 7

The CHANGE ALL screen is displayed.

2

3

[Individual lock/unlock settings valid in

MAINTENANCE MENU]

This function can be applied to the indoor units,

which are the model KXE4 or later, and to the

remote controller, which is the model RC-E1

or later.

Note

When the screen changes, no items are selected (the temperature setting is blank). Set only the items that

are to be set or changed.

Press the button for item to set or change. 2.

Run/Stop: Press the RUN or STOP button. ·

When the RUN button, running starts, and when the STOP button, running stops.

Temperature setting: Press •

or .

Set a temperature between 18°C and 30°C.

page 39

Mode: Select ·

Auto, Cool, Dry, Fan or Heat by pressing the button.

When using Auto Mode, valid AUTO on the MAINTENANCE MENU. *

page 36

The Auto Mode can be valid for the cooling/heating free multi KXR, GHP-R series or later and single split

PAC.

LOCK: Press ·

or .

If

is pressed, remote controller operations are permitted, and if is pressed, they are

prohibited.

Fan speed: Select ·

(Powerful), (High), (Medium), (Low), or (AUTO), and press the button.

When using powerful mode, valid the Powerful Fan on the MAINTENANCE MENU.*

When using automatic mode, valid the AUTO Fan on the MAINTENANCE MENU.*

Air direction: select Auto, stop 1, stop 2, stop 3 or stop 4 and press the button. ·

FILTER RESET: If the reset button is pressed, the fi lter sign turns off. ·

Press the SET button. Press the Yes button on the confi rmation screen. 3.

When you do not want to set, press the No button.

Note

If the BACK button is pressed, it returns to the previous screen.•

If individual lock/unlock is valid in the MAINTENANCE MENU, it is possible to set the remote controller •

operations to permit or prohibit each item such as run/stop, mode and temperature setting.

When individual lock/unlock are valid in the MAINTENANCE MENU, remote controller operations are •

prohibited if run/stop, mode and temperature setting are all

. (Some functions such as reset of the fi lter

sign have been permitted.)

Page 17

– 16 –

Schedule Settings

Operating schedules can be set in group units. Sixteen schedules per day can be registered for operating time (in

minutes), run/stop, mode, prohibiting remote controller operations and temperature setting.

Set the detailed daily schedule (weekday, holiday, special 1, special 2) in advance.

page 17

Press the SCHEDULE SETTING button on the MENU screen. 1.

page 7

The SCHEDULE SETTING screen is displayed.

2

Setting the current day’s schedule ■

The operating schedule for the current day is set on each group.

Press the TODAY’S SCHEDULE button on the SCHEDULE SETTING screen. 2.

3

5

4

6

Press the group name.3.

Select the group on the Select Group screen.

page 19

<When setting a schedule for the current day>

Press the item to be changed on the list.4.

When “Time”, “Lock” or “SET TEMP.” cell are pressed, a detailed setting screen for each item is indicated.

page 19, 20

Change the “RUN/STOP” or “MODE” settings by pressing the appropriate item.

To change the page, press the

or button.

<When rewriting the schedule displayed for the current day to detailed daily schedule>

Select the detailed daily schedule such as WEEKDAY (green), HOLIDAY (red), SPECIAL1 (blue) or 5.

SPECIAL2 (yellow) button and press it.

Note

Set the operating schedule for the detailed daily schedule in advance. page 17

Press the SET button. Press the Yes button on the confi rmation screen. 6.

When the CLEAR button is pressed, the selections are cleared.

Note

Press the COPY button when copying the schedule between groups. • page 20

Page 18

– 17 –

Setting a detailed daily schedule ■

The detailed daily schedule is set for each group.

The schedule indicates WEEKDAY, HOLIDAY, SPECIAL1, SPECIAL2, and the operation can be set for

each group.

Press the DETAILED DAILY SCHEDULE button on the 2. SCHEDULE SETTING screen.

3

4

5

6

Press the group name.3.

Select the group on the Group Select screen.

page 19

Select the detailed daily schedule such as WEEKDAY (green), HOLIDAY (red), SPECIAL1 (blue) or 4.

SPECIAL2 (yellow) button and press it.

Press the item to be changed on the list.5.

When “Time”, “Lock” or “Temperature setting” buttons are pressed, a detailed setting screen for each item is

indicated.

page 19, 20

Change the “Run/Stop” or “MODE” setting by pressing the appropriate item.

To change the page, press the

or button.

Press the SET button. Press the Yes button on the confi rmation screen. 6.

When the CLEAR button is pressed, the selections are cleared.

Note

Press the COPY button when copying the schedule between groups. • page 20

Setting a yearly schedule ■

A yearly operating schedule is set on each group.

Press the YEARLY SCHEDULE button on the SCHEDULE SETTING screen. 2.

3

4

5

6

Press the group name.3.

Select the group on the Select Group screen.

page 19

Select the detailed daily schedule such as WEEKDAY (green), HOLIDAY (red), SPECIAL1 (blue) or 4.

SPECIAL2 (yellow) button and press it.

Note

Set the detailed daily schedule in advance. Noted above (Setting a detailed daily schedule)

Press the date (multiple dates can be selected).5.

The detailed daily schedule which you choose is applied to that day. However, the current day and the dates

which have elapsed can not be selected. Press the

or button to change the month.

Note

If the DEFAULT button is pressed, Saturday and Sunday are set as holidays and the others are set as

weekdays.

Page 19

– 18 –

Press the SET button. Press the Yes button on the confi rmation screen.6.

When you do not want to set, press the No button.

Pressing the COPY button brings up the Copy Schedule screen when copying between groups.•

page 20

Season Settings ■

Confi gure the mode setting when you have selected “SEASON” mode in the schedule settings.

Selecting “SEASON” mode valid you to subsequently change the operating mode and temperature setting

collectively at the turn of each season.

Press the SEASON SETTING button on the SCHEDULE SETTING screen.1.

3

2

4

Press the group name.2.

Select the group on the Group Select screen.

Select mode3.

COOL button:

When COOL is selected, set the operating mode of the group, for which “SEASON” is selected in the schedule,

to cooling, and you can set the temperature.

page 39

DRY button:

When DRY is selected, set the operating mode of the group, for which “SEASON” is selected in the schedule,

to drying, and you can set the temperature.

page 39

HEAT button:

When HEAT is selected, set the operating mode of the group, for which “SEASON” is selected in the schedule,

to heating, and you can set the temperature.

page 39

Press the SET button. Press the Yes button on the confi rmation screen.4.

If you do not want to make the setting, press the No button.

Note

Copy button:

Pressing the Copy button copies the season settings of the other group.

Page 20

– 19 –

Various screens ■

[Select Group screen]

1

2

Press the group name to be selected. 1.

The selected group name is reverse highlighted.

To change the page, press the PREV or NEXT button.

Press the OK button.2.

The selected group can be set.

When you do not want to set, press the CANCEL button. It returns to the previous screen.

[Schedule Time Setting screen]

1

2

Pressing 1. ▲▼ changes the hour and minutes (24 hour clock display).

Press the OK button.2.

The time is changed and the screen closes. Press the CANCEL button to cancel the change.

Pressing the CLEAR button clears the currently entered values and makes the entry empty.

[Remote Controller Lock/Unlock screen]

This is used to allow or prohibit remote controller

operations.

[Individual lock/unlock settings valid in MAINTENANCE

MENU]

1

2

21

Press the button of the items which are to be prohibited from the remote controller operation (multiple 1.

items can be selected).

Press the OK button.2.

The prohibited item changes and the screen closes.

Press the CANCEL button to cancel the change.

If the CLEAR button is pressed, the selected item is deselected.

Page 21

– 20 –

[Schedule Temperature Setting screen]

1

2

Pressing 1. ▲▼ changes the temperature. page 39

Press the OK button.2.

The temperature changes and the screen closes.

Press the CANCEL button to cancel the change.

Pressing the CLEAR button clears the currently entered values and makes the entry empty.

[Copy Schedule screen]

Select the groups that apply the chosen schedule.

1

2

Press the group name to be selected (multiple groups can be selected).1.

To change the page, press the PREV or NEXT button.

To select all groups, press the ALL GROUPS button. If you will cancel selecting all groups, press the ALL

GROUPS button again.

Press the COPY button. Press the Yes button on the confi rmation screen. 2.

The schedule of the group chosen on the screen is pasted to the groups checked in the list. When you do not

want to make the setting, press the No button.

Note

This is cancelled if the selected group is pressed once more. •

If the CANCEL button is pressed, it returns to the previous screen. •

Page 22

– 21 –

Viewing Detailed Unit Information

The unit numbers and status of each group can be observed.

Press the UNIT LIST button in the ALL GROUPS screen (1.

page 13) or if the UNIT LIST button is

pressed in the GROUP (PANEL) or GROUP (LIST) screen (

page 11, 13).

The units in the group are displayed.

To change the page, press the

or button.

Note

If the BACK button is pressed, it returns to the previous screen. •

UNIT No. display may differ from the fi guration. (Same as every other screen)•

Display is changed according to the SL communication system (

page 37).

Previous SL) [3-04] New SL) [005]

SuperLink No.

unit address unit address

Page 23

– 22 –

Calculating Settings (SC-SL4-BE only)

UNIT DEFINITION1

Set the unit defi nition on the MAINTENANCE MENU.

page 36

If you want to change the initial settings confi gured at the time of installation, contact your dealer.

Setting the period for calculation2

You can divide a day into two periods for calculation.

If it is not necessary to divide the period into two parts, you can set the period time for 0:00 - 24:00.

Press the ACCOUNTING PERIOD TIME button on the OPERATOR MENU screen. 1.

page 8

2

3

Press the hour or minute buttons for the start time or the end time.2.

Input the time.

Press the SET button. Press the Yes button on the confi rmation screen.3.

When you do not want to set, press the No button.

If the BACK button is pressed, it returns to the OPERATOR MENU screen.

Caution

The energy consumption calculated by this unit does not conform to OIML, and there are no

guarantees concerning the results of the calculations.

This unit calculates only energy consumption distribution (gas, electric power). You need to calculate

the air-conditioning rates.

The calculating data for twelve months are saved.

See page 29 (Using USB Memory) for the method for extracting calculating data.

Page 24

– 23 –

Group Defi nition

Selecting the groups to register and display the registered units1

[Initial GROUP DEFINITION screen]

Press the OPERATOR MENU button on the MENU.1.

page 7

Press the GROUP DEFINITION button on the OPERATOR 2.

MENU screen. page 8

The GROUP DEFINITION screen is displayed.

3

4

Initial GROUP DEFINITION screen may vary

according to the SL communication system.

(Example for previous SL setting)

1- 00

SuperLink No. Unit address

(Example for new SL setting)

005

Unit address

One indoor unit is registered with one group in

advance on the initial screen.

When registering the indoor unit to other groups,

register it with other group after deleting it

from the group, and moving it in the list of ALL

UNITS.

Press a group name.3.

When adding a group, press an empty group name area. When changing the settings for a registered group,

press that group name. The selected group is reverse highlighted. To change the page, press the

or

button.

Press the DETAIL button. 4.

The GROUP DEFINITION DETAILS screen is displayed.

5

11

12

9

14

6

13

8 10

7

Registering and changing the Group Name being set2

Press the Group Name.5.

Enter the name for the group.

page 27

Adding and deleting units making up the group3

<When adding units>

6. or directly press a unit name to select the unit from the list of All Units.

To change the page, press the

button or the button.

Press the ADD button. 7.

The selected unit is added to the list of Unit Entry and deleted from the list of All Unit.

<When deleting units>

Directly press a unit name to select the unit from the list of Unit Entry.8.

Press the DEL button. 9.

The selected unit is deleted from the list of Unit Entry and moved to the list of All Units.

Page 25

– 24 –

Setting the representative unit and demand4

Directly press a unit name to select the unit from the list of Unit Entry.10.

Press the Rep. cell. 11.

That unit is set as the representative unit, and an asterisk is placed to the left of its name in the display.

Representative unit: unit for which the status is shown when the group is displayed ·

Press the Demand cell.12.

That unit is set as for the demand operation, and a mark such as D1, D2, or D3 is placed to the right of its

name.

Demand: · A unit that shifts its set temperature by 2 deg C or switches to fan mode when there is an

external demand input, and then cannot be operated from the remote controller.

Note

By the demand input, it is possible to save on power costs by reducing the power consumption.

Operation of the unit when demand input is released, is conformed to nearest schedule before release time

of the day.

page 43

In case schedule of the day is not set, the unit is for the operation mode and remote controller permission/

prohibition setting which is just before the demand input.

Up to three demand levels can be set. In level 1, the set temperature of the air conditioner set to D1 shifts by

2 deg C (+2 deg C in cooling or dry mode or -2 deg C in heating mode). In level 2, the units set to D1 or D2

switch to fan mode. In level 3, the units set to D1, D2, or D3 switch to fan mode.

To use the demand control, a demand signal must be inputted. For more information, contact your installation *

contractor or dealer.

Setting and unsetting batch operation for the group5

Press the VALID or INVALID button.13.

VALID: group set up for batch operation ·

INVALID: group not set up for batch operation ·

Saving the settings6

Press the SET button. Press the Yes button on the confi rmation screen. 14.

The group settings are saved. When you do not want to save the settings, press the No button.

Note

1 to 16 units can be registered in a group. •

When you will delete all group defi nition, press the DELETE ALL SETTING button and enter your password •

Press the Yes button on the confi rmation screen.

Caution

All schedule settings are deleted too.

Attention

If an unconnected air conditioner is registered in a group, a “Communication error” may occur, affecting

communication of the whole system and causing an unintended operation to be performed. Do not register

unconnected units in a group.

Also note that, at the initial setting, one air conditioner is registered in one group in advance. If the unit is

an unconnected unit, it must be deleted individually. It is recommended that, when registering new groups,

you press the “DELETE ALL GROUPS” button to delete all groups once, and then register groups for

connected units. That certainly is an easier way to confi gure the settings as well as a sure method to prevent

communication errors.

Page 26

– 25 –

Block Defi nition

Attention

Register the group beforehand.

page 23

Selecting the blocks to defi ne and displaying the registered groups1

Press the OPERATOR MENU button on the MENU screen.1.

page 7

Press the BLOCK DEFINITION button on the OPERATOR MENU screen.2.

page 8

The BLOCK DEFINITION screen is displayed.

3

4

[Initial BLOCK DEFINITION screen]

When defi ning a new block, the block names and

registered groups are empty.

Select a block name.3.

When adding a block, select an empty BLOCK NAME cell. When changing the settings for a registered block,

press that BLOCK NAME. The selected block is reverse highlighted. To change the page, press the

or

button.

Press the DETAIL button.4.

The BLOCK DEFINITION DETAILS screen is displayed.

7

9

6

8

10

5

[

Initial BLOCK DEFINITION DETAILS screen

]

When defi ning a new block, the block names and

group entry area are empty.

Registering and changing the Block Name being set2

Press the BLOCK NAME button.5.

Enter the name for the block.

page 27

Page 27

– 26 –

Adding and deleting groups registered in a block3

<When adding groups>

6. or directly press the group name to select the group from the list of All Groups.

When changing the page, press the

or button.

Press the ADD button. 7.

The selected group is added to the group entry list and deleted from the list of All Groups.

<When deleting groups>

Directly8. press the group name to select the group from the list of Group Entry.

Press the DEL button. 9.

The selected group is deleted from the list of Group Entry and moved to the list of All Groups.

Saving the registrations and changes4

Press the SET button. Press the Yes button on the confi rmation screen. 10.

The block settings are saved. When you do not want to save the settings, press the No button.

Note

1 to 9 groups can be registered in a block. In addition, the maximum number of blocks is 16.•

Time & Date Setting

Press the MENU button and then press the OPERATOR MENU button.1. page 7

Press the TIME&DATE SETTING button on the SYSTEM CONFIGURATION screen.2.

page 8

[TIME & DATE SETTING screen]

3

4

Press the Day, Month, Year and Time buttons.3.

Input the current time and date.

page 27

Press the SET button, and press the Yes button on the confi rmation screen.4.

The specifi ed date and time are set at the 00 seconds. When you do not want to make the setting, press the

No button.

Note

It is not necessary to reset the time and date after recovering from a power outage.•

Page 28

– 27 –

Convenient Functions

Entering Numbers and Characters

Entering numbers ■

1

2

Press the button of the numerical value to input.1.

BS button : backspaces. (Deletes one number.)

CLEAR button : clears the input. (Deletes all numbers.)

Press the OK button.2.

The number is changed and the screen closes. Press the Cancel button to cancel the change.

Entering characters ■

1

2

3

Select Alphabet or Numeric and press the button.1.

Input the group name.2.

ABC button

: Inputs an uppercase alphabet

character.

BS button

:

Backspaces. (Deletes one character.)

abc button

: Inputs a lowercase alphabet

character.

SPC button

: Inputs a space.

123 button

: Inputs a number or symbol.

←→↑↓ buttons

: Moves the cursor.

Press the OK button.3.

The name is changed and the screen closes. Press the Cancel button to cancel the change.

The block or the group names can be inputted up to 16 characters.*

Page 29

– 28 –

DISPLAY SETTING

The brightness and backlight timeout settings can be confi gured, and the mode can be switched to screen

cleaning.

When changing the settings, take the following steps.

Press the DISPLAY SETTING button on the MENU screen.1.

page 7

[DISPLAY SETTING screen]

Cleaning Mode

The mode is switched to

screen cleaning.

3

2

Select the Brightness using the 2. buttons. (Factory default : 7)

Brightness for the monitor backlight can be selected.

Select the Backlight Timeout time using the 3.

buttons. (Factory default : 10)

Time from the last operation on the touch panel until the monitor backlight turns off can be selected.

Press the SET button.4.

Pressing the SET button applies the setting.

Page 30

– 29 –

Corrections for Power Outages

Data retained during a power outage ►

System settings defi ned in page 8 ·

Schedule settings confi gured in page 16 ·

Function settings confi gured in page 39 ·

Accounting data before a power outage ·

Data lost at a power outage ►

Operating and setup status of each indoor unit before

a power outage

(including operating mode, temperature setting, and

remote controller permit/prohibit setting)

When the power returns, the operation of each group will follow the closest schedule setting made before the power

returned. In case there are no settings of run/stop, operating mode, prohibiting remote controller operation and

temperature setting in the closest schedule setting, it will follow the second closest schedule setting made.

In case there are no schedule settings on that day, this central control will not send any operation signal to each

group.

You do not need to reset the clock after a power outage.

Using USB Memory

Attention

Be sure to use the bundled USB memory.•

Be sure to perform these operations after inserting the USB memory into the unit. •

page 4

The calculating data for twelve months are saved. Please save it to a PC through the USB memory •

within twelve months.

Do not operate while the display light of the USB memory is blinking fast. •

You may perform your operations or remove the USB memory only when the display light is blinking

slowly.

If the USB memory you use does not have a blinking light, please wait for a moment after each operation.

Remove the USB memory only after all operations have been completed.

Important!!

Be sure to use the bundled USB memory device. (The central control does not recognize commercially

available USB memory devices and cannot transfer data to them.)

<Transferring Monthly Data>

It is convenient if folders are created in the USB memory in advance.

Press the EXPORT MONTHLY DATA FILES button on the OPERATOR MENU.1.

[Import/Export screen]

2

Press the “EXPORT MONTHLY DATA FILES to USB” button.2.

Select the folder on the Folder Selection screen.

[Folder Selection screen]

4

3

Press the folder to be selected. 3.

To change the page, press the PREV or NEXT button.

Page 31

– 30 –

Press the OK button.4.

A confi rmation screen (Calculating data fi le export confi rmation screen) is displayed. Press the “OK” button on

the screen.

Note

If the CANCEL button is pressed, it returns to the previous screen.•

The “IMPORT CONFIGURATION FILES from USB” button is not needed.•

See the bundled CD-ROM for calculating on a PC.•

Important!!

Calculating Data

Follow the above procedure to transfer the calculating data to USB memory. (1)

Remove the USB memory from the central control and connect it to a PC.(2)

Insert the CD-ROM that was bundled with this unit into the PC and start the software. (3)

Operate the software according to the CD-ROM menu. (4)

There is no need to have the USB memory connected to this unit at all times. *

After installing the calculating data software, steps (3) and (4) are unnecessary. Operate the software *

with reference to the manual on the CD-ROM.

Operation Time History

The OPERATION TIME HISTORY screen displays a graph showing the accumulated daily operation time for 31

days by the group.

Press the OPERATION TIME HISTORY button on the MENU screen.1.

2

3

4

Selecting and viewing a group2.

Select a group for which you want to view the accumulated operation time.

Press a group to select. The selected group is displayed.

Selecting a date3.

Select a date for which you want to view the accumulated time.

Select a date using

button.

Press the EXPORT CSV FILE button4.

Save a CSV format data fi le of the accumulated operation time to the USB memory device.

Page 32

– 31 –

LAN Settings

You can set the IP address, subnet mask and gateway address of the central control.

Press the LAN SETTING button on the OPERATOR MENU screen.1.

2

3

4

5

Setting and viewing the IP Address (Factory default: 192.168.0.120)2.

Specify the IP address of the central control.

Press an IP address to set. The IP address is displayed.

Setting and viewing the Subnet Mask (Factory default: 255.255.255.0)3.

Specify the subnet mask of the central control.

Press a subnet mask to set. The subnet mask is displayed.

Setting and viewing the Default Gateway Address (Factory default: Blank)4.

Specify the Default Gateway address of the central control.

Press a Default Gateway address to set. The Default Gateway address is displayed.

Press the SET button.5.

Press the Cancel button to cancel the change.

Pressing the OPERATOR MENU button returns to the OPERATOR MENU.•

Page 33

– 32 –

Operator Settings

Specify the ID, password of the operator.

You can also valid or invalid the security lock.

Press the OPERATOR SETTING button on the OPERATOR MENU screen.1.

2

5

3

4

6

Setting and viewing the ID2.

Specify the operator’s ID.

Press ID to input an ID. The input ID is displayed.

Setting and viewing the Password3.

Specify the password of the central control.

Press Password to input a password. The input password is displayed.

Setting the operator information4.

You can specify the operator information.

Setting the Security Lock5.

You can valid or invalid the Security Lock *.

When the security lock is valid, the ID and password are required to return from the off status of the backlight. *

page 28

This enhances the security function.

Press the SET button.6.

Press the Cancel button to cancel the change.

Page 34

– 33 –

Viewing Alarm History

<Viewing the Alarm History>

Press the ALARM HISTORY button on the OPERATOR MENU screen.1.

page 8

Check the content on the ALARM HISTORY screen.

2

Press the OPERATOR MENU button.2.

This returns to the OPERATOR MENU screen.

System Information

The version of the Air-Conditioners Management System being used can be confi rmed.

Press the SYSTEM INFORMATION button on the MENU screen1.

page 7

2

After checking the content, press the MENU button.2.

System Information display closes.

Help

Press the HELP button. 1.

Details about the screen being displayed are shown.

Press the BACK button.2.

It returns to the previous screen.

Page 35

– 34 –

Maintenance

Wipe with a soft, dry cloth to clean. When it is very dirty, excluding the touch panel, use a neutral cleanser dissolved

in warm water to wipe it off and afterwards wipe that off with clean water.

Caution

Do not use paint thinner, organic solvents or strong acids.

The color may change and the paint may be removed.

Screen Cleaning Mode

Screen cleaning mode is provided to prevent the touch panel from responding when you touch the screen to

clean it.

Press the Cleaning Mode button on the DISPLAY SETTING screen.1.

page 28

Canceling the Screen cleaning mode2.

Return to previous screen by pressing the button in the order of 1.2.3.4.

Page 36

– 35 –

Shut Down

The confi rmation screen is displayed after the SHUT DOWN button is

pressed on the MENU screen and enter your password.

page 6.

When you press the Yes button, the screen switches to the one shown below (a).

Please wait until you get the message that shows “Please switch off the power supply.”

When you do not turn the power off, press the No button.

When the screen switches to the one shown below (b), you can turn the power off.

(a) (b)

Page 37

– 36 –

Using MAINTENANCE MENU

The MAINTENANCE MENU is provided for dealers and qualifi ed professionals responsible for maintaining the *

central control units.

When logging in with a normal operator’s ID, you are not permitted to operate the MAINTENANCE MENU.

MAINTENANCE MENU screen

This screen is displayed when the MAINTENANCE MENU button is pressed on the MENU screen.

page 7

(2)

(3)

(10)

(11)

(1)

(4)

(6)

(9)

(5)

(7)(8)

SL MODE(1).

New or previous Super Link communication system can be selected.

page 37

UNIT DEFINITION (SC-SL4-BE only)(2).

The type and capability values of the connected indoor units can be specifi ed.

page 38

FUNCTION SETTING(3).

You can confi gure the Fahrenheit or Celsius setting for the display temperature, valid or invalid “AUTO” operating

mode, valid or invalid “AUTO” fan speed, valid or invalid “Powerful Mode” fan speed, valid or invalid the remote

controller permit/prohibit setting, valid or invalid the individual permit/prohibit setting, permit or prohibit the

remote control timer operation, open or close the malfunction output, confi gure the upper and lower limit settings

of set temperature in cooling mode, and confi gure the lower limit setting of set temperature in heating mode.

page 39

IMPORT/EXPORT CONFIGURATION FILES(4).

Defi nition data can be saved to or read from the USB memory device.

page 40

FACTORY CLEAR(5).

You can reset settings to factory default, and initialize defi nition data, schedule data and operator’s ID and

password.

page 41

LANGUAGE SETTING(6).

The display language can be specifi ed.

You can also read or save language data from/to the USB memory device.

page 42

ALARM HISTORY(7).

Alarm history can be deleted or saved on the USB memory device.

page 42

DEMAND & EMERGENCY STOP SETTING(8).

You can invalid or valid schedule adjustment at the release of emergency stop or demand operation, and valid

or invalid running of the schedule during the demand operation.

page 43

EXTERNAL INPUT STATUS(9).

You can check the statuses of demand settings 1 and 2, the status of the emergency stop contact, and the

accumulated number of pulse inputs (eight points) of the current day.

page 44

VIRTUAL MODE SETTING(10).

The display can be checked by demonstration or using a character list.

You can also generate simulated states of air conditioner.

MAINTENANCE USER SETTING(11).

The maintenance user ID and password can be changed.

You can also register the maintenance user information.

page 44

Page 38

– 37 –

SL Mode

Confi gure the Super Link communication system setting. (Factory default: New)

Incorrect setting of SL mode cannot establish communication with some or all air conditioner.

Press the SL MODE button on the MAINTENANCE MENU screen.1.

2 3

4

New SL2.

Select this for new SL communication system. (Factory default setting)

Previous SL3.

Select this for previous SL communication system.

Press the SET button.4.

Pressing the SET button applies the setting.

Press the “YES button” on the confi rmation screen.

The setting applies after reboot.

Page 39

– 38 –

UNIT DEFINITION Settings (SC-SL4-BE only)

Unit Defi nition1

Press the UNIT DEFINITION button on the MAINTENANCE MENU screen.1.

page 8

The UNIT DEFINITION screen is displayed.

3

2

Press the item to be set or changed on the list.2.

Each time the “TYPE” item is pressed, the unit type changes.

MULTI1 : calculating according to the amount of refrigerant fl ow. Used for KX Series.

MULTI2 : thermo ON/OFF calculation. Used for KX Series.

ON/OFF : calculating according to the unit operating time. Used for KX series, PAC.

SINGLE : calculating only when compressor is turned ON. Applied to single split PAC air conditioner

that perform communication via super link adapter.

If the “CAPACITY” item is pressed, it can be changed. (0 – 200 [kW])

page 27

To change the page, press the

or button.

Note

Please select same item for same system of watt-hour meter or gas meter.•

When you select MULTI1 or MULTI2, fan mode units are out of calculation. To calculate the fan mode •

units, please select ON/OFF.

Standby energy used during night etc. is not included in the calculation, and does not equal the value •

of watt-hour meter or gas meter. Please correct the calculation by spreadsheet.

Press the SET button. Press the Yes button on the confi rmation screen. 3.

When you do not want to make the setting, press the No button.

Page 40

– 39 –

Function Settings

You can confi gure the valid/invalid setting of Auto Mode, Auto Fan and Remocon Lock/Unlock, as well as the settings

of the upper and lower limits of cooling temperature and the lower limit of heating temperature.

Press FUNCTION SETTING button on the MAINTENANCE MENU screen.1.

(5)

(9)

(10)

(11)

(3)

(7)(13)

(12)

(2)

(4)

(6)

(8)

Temp. Indication (Factory default: °C)(2).

This selects Fahrenheit or Celsius for the temperature display.

Valid/invalid setting of Auto Mode (Factory default: Invalid)(3).

This valid or invalid the Auto Mode button on the CHANGE screen and CHANGE ALL screen.

This function can be applied to the outdoor units, which are the cooling / heating free multi KXR, single split

PAC.

Do not use Auto Mode when other outdoor units other than those mentioned above are connected.

Please contact your dealer for more information.

Valid/invalid setting of Auto Fan Speed (Factory default: Invalid)(4).

Pressing the SET button applies the setting.

Valid/invalid setting of Fan Powerful Mode (Factory default: Invalid)(5).

This valid or invalid the Powerful Mode button on the CHANGE screen and CHANGE ALL screen.

Please contact your dealer for more information.

Valid/invalid setting of Remocon Lock/Unlock (Factory default: Valid)(6).

This valid or invalid the remote controller operation.

When connecting to multiple SL4 air conditioners, only one of them must be valid.

When an external input such as emergency stop is wired to this central control,

this function must be set to “valid”.

Valid/invalid setting of Individual Lock/Unlock (Factory default: Invalid)(7).

This valid or invalid permitting/prohibiting the individual operation such as run/stop, mode and temperature

settings of the remote controller.

This function can be applied to air conditioners EHP model KXE4 or later, and to remote controllers model

RC-E1 or later.

LOCK/UNLOCK setting of Remote Controller’s Timer (Factory default: UNLOCK)(8).

This permits or prohibits the remote controller’s timer operation of all the indoor units registered in the group.

OPEN/CLOSE setting of Malfunction Output (Normal) (Factory default: CLOSE)(9).

This sets the contact status in normal operation.

Upper Limit of Cool mode temp. (Factory default: 30°C)(10).

This sets the upper limit of temperature setting in cooling mode. (Include Auto,Dry,Fan)

Lower Limit of Cool mode temp. (Factory default:18°C)(11).

This sets the lower limit of temperature setting in cooling mode. (Include Auto,Dry,Fan)

Lower Limit of Heat mode temp. (Factory default:18°C)(12).

This sets the lower limit of temperature setting in heating mode.

Press the SET button.13.

Pressing the SET button applies the setting.

Page 41

– 40 –

Import/Export Confi guration File

Press IMPORT/EXPORT CONFIGURATION button on the MAINTENANCE MENU screen.1.

Attention

Be sure to perform these operations after inserting the USB memory into the unit. • page 4

Please do not operate while the display light of the USB memory is blinking fast. •

You may perform your operations or remove the USB memory only when the display light is blinking

slowly.

If the USB memory you use does not have a red blinking light, please wait for a moment after each

•

operation.

Remove the USB memory only after all operations have been completed.

Important!!

Be sure to use the bundled USB memory device. (The central control does not recognize commercially

available USB memory devices and cannot transfer data to them.)

<Transferring Confi guration Files>

It is convenient if folders are created in the USB memory in advance.

[Import/Export screen]

2

Press the EXPORT CONFIGURATION FILES to USB button.2.

Select the folder on the Folder Selection screen.

[Folder Selection screen]

4

3

Press the folder to be selected. 3.

To change the page, press the PREV or NEXT button.

Page 42

– 41 –

Press the OK button.4.

A confi rmation screen (Defi nition fi le backup confi rmation screen) is displayed. Press the “OK” button on either

of the screens.

Note

If the CANCEL button is pressed, it returns to the previous screen.•

<Transferring Confi guration fi le>

[Import/Export screen]

2

Press the Import Confi guration Files to USB button.2.

Select the folder on the Folder Selection screen.

page 29

By backing up the Confi guration fi le, the following data can be easily backed up;

Block and group defi nitions ·

Schedule settings ·

FACTORY CLEAR

Press the FACTORY CLEAR button on the MAINTENANCE MENU screen.1.

(2)

(3)

(4)

(5)

INITIALIZE TO FACTORY SETTING(2).

This resets the settings to factory default.

INITIALIZE CONFIGURATION FILES(3).

This initializes defi nition data.

INITIALIZE SCHEDULE SETTINGS(4).

This initializes schedule data.

INITIALIZE OPERATOR’S ID and PASSWORD(5).

This initializes the operator’s ID and password.

Press the “YES button” on the confi rmation screen.•

The setting applies after reboot.

Page 43

– 42 –

Language Setting

Press the LANGUAGE SETTING button on the MAINTENANCE MENU.1.

2

5

4

3

6

Press the “English” button. (Default setting)2.

The display language is set to English.

Other [***]3.

The display language is set to language data [***] that has been imported.

Press the SET button.4.

Pressing the SET button applies the setting.

IMPORT LANGUAGE FILES from USB (Central Control and Web Monitoring)5.

This reads language data from the USB memory device.

EXPORT LANGUAGE FILES to USB (Central Control and Web Monitoring)6.

This saves language data to the USB memory device.

Press the “YES button” on the confi rmation screen.•

The setting applies after reboot.

Viewing Alarm History

<Displaying Alarm History>

Press the ALARM HISTORY button on the MENTENANCE MENU screen.1.

page 8

Check the content on the ALARM HISTORY screen.

2

43 5

Press the date to be deleted.2.

The date is highlighted. Press

and change the content.

Press the DELETE button.3.

The selected alarm history item is deleted.

<Deleting all alarm history items>

Press the DELETE ALL button.4.

All alarm history items are deleted.

<Saving to the USB memory>

Press the EXPORT CSV FILE button.5.

The alarm history is saved on the USB memory device.

Page 44

– 43 –

Demand and Emergency Stop Settings

Press the DEMAND & EMERGENCY STOP SETTING button on the MAINTENANCE MENU screen.1.

(3)

(4)

(5)

(2)

Press the SET button.(2).

Pressing the SET button applies the setting.

RUN SCHEDULE after releasing the Emergency Stop. (Factory default: INVALID)(3).

You can valid or invalid running the schedule of the day after emergency stop is released.

RUN SCHEDULE after releasing the Demand control. (Factory default: INVALID)(4).