Page 1

SERVICE

MANUAL

MITSUBISHI

DIESEL

ENGINES

S4S

ses

March

2002

J..

!!!!I'D'!S~~!~!.

Page 2

Page 3

Foreword

This service manual is written to familiarize you with the maintenance of your S4S and S6S Diesel Engine. If

the engine is carefully maintained it will deliver a long productive life and efficient performance marked by

power and economy.

Before you attempt to inspect, disassemble, or repair the engine, read this manual carefully to leam more about

the engine and how to care for it properly. AHdescriptions, illustrations, specifications and serial numbers in

this manual are effective as of the date printing of this manual.

The information contained in this manual applies to the engine model produced at the time of publication.

It should be noted that specifications and design may change due to improvements made thereafter.

For

items other than those in this publication, refer to the operation

manual

for a unit on which the

engine is mounted,

How to Use This Manual

1. Parts in illustrations are numbered to correspond with references to these numbers in text.

2. Items or conditions to be inspected during disassembly are enclosed in a box in the disassembIed views:

I Clogged oil hole I

3. Maintenance standards for inspeetion and repair are described in text wherethey are relevant. For a quick

summary of maintenance standards refer to group 2 of this manual.

4. The sequence in which parts are to be reassembled is summarized below eaeh assembIed view.

Sueh as:

@

.....~.....

@

.....

@

.....

CD

5. Tightening torqueunder wet conditions is indieated as "(wet)" in text, drawings, andtables.When so indieated

as (wet), apply engine oil to the threaded portion of the fastener. Unless indieated as such, the tightening

torque is to be assumed in the dry condition.

6. Pay attention to the special notes, cautions and wamings.

Pub. No. 99616-10170

Page 4

Notes, Cautions, Warnings, Dangers

Notes, cautions, wamings, dangers are used in this manual to emphasize important or critical instructions or

advice.

(&OANGER)

&WARNING

(&CAUTION)

(NOTE)

'Ierms Used in This

Manual

Indicates the most serious specific potential hazard

resulting in serious bodily injury or death.

Indicates a specific potential hazard resulting in

bodily injury.

Indicates operating procedure, practice,etc., resulting

in personal injury or damage to or destruction

of

engine.

An operating procedure, condition, etc. that will help

you work more efficiently.

Beforeyou read this manual, note that the following special terms are used indimensional and otherspecifications.

Assembly Standard Indicates the dimension of a part, the dimension to be attained at the

time of reassembly or the standard performance. The value is rounded

to the nearest whole number needed for inspeetion and is different from

the design value.

Nominal Value Indicates the standard dimension of a part.

Repair Limit.. A part which has reached this limit must be repaired.

Service Limit A part which has reached this limit must be replaced.

Standard Clearance Indicates the clearanceto be obtained betweenmating parts atreassembly.

Page 5

SummaryofManual

Contents

Group

1.

General

2.

Maintenance

Standards

3.

Special

Tools

4.

Overhaul

Instructions

5. Adjustments,

Bench

Test,

Performance

Tests

6.

Engine

Auxiliaries

Removal

and

Installation

7.

Engine

Main Parts

8. Inlet

and

Exhaust

System

9. Lubrication

System

lO.Cooling

System

11.Fuel

System

12.Electrical

System

13.Workshop Tips

Contents

External

view,

engine

serial

number

location,

engine

model

and

application codes, specifications, tips on disassembly and reassembly.

Maintenance standards, tightening torques, sealants and lubricants.

A list

of

special tools required.

Determining when to overhaul the engine, testing compression pressure

Adjustment of valve clearance, fuel system bleeding, fuel injection

timing, no-load

minimum

and maximum speed setting, V-belt, bench

testing, performance tests.

Removal and installation of turbocharger, fuel injection pump, alternator,

water

pump,

starter, etc.

Disassembly, inspeetion and reassembly of the main parts, to include

cylinderhead and valve mechanism, flywheel, damper, timing gears and

camshaft, pistons, connecting rods, crankshaft, crankcase and tappets.

Disassembly, inspeetion and reassembly of inlet and exhaust system

(exhaust manifold).

Disassembly, inspeetion and reassembly oflubrication system, to inlcude

oil

pump,

oil filter, oil cooler, oil pressure relief valve and safety valve.

Disassembly, inspeetion and reassembly of cooling system, to include

water

pump

and thermostat.

Disassembly, inspeetion and reassembly

offuel

systern, to include fuel

filter

and

injection nozzles.

Disassembly, inspeetion and reassembly of electrical system, to include

starter, alternator, glow plugs and stop solenoid (option).

Basic

recommended

assembly procedures: oil seals, O-rings, bearings,

split pins and spring pins.

Page 6

Page 7

GENERAL

1. Outline 1- 2

1.1 External View 1- 2

1.2 Engine Serial NumberLocation 1- 6

1.3 Engine Model andApplication Codes 1- 6

2. Specifications 1- 7

3. Tips on Disassembly and Reassemb1y 1-13

3.1 Disassembly 1-13

3.2 Reassembly 1-13

Di

Page 8

GENERAL

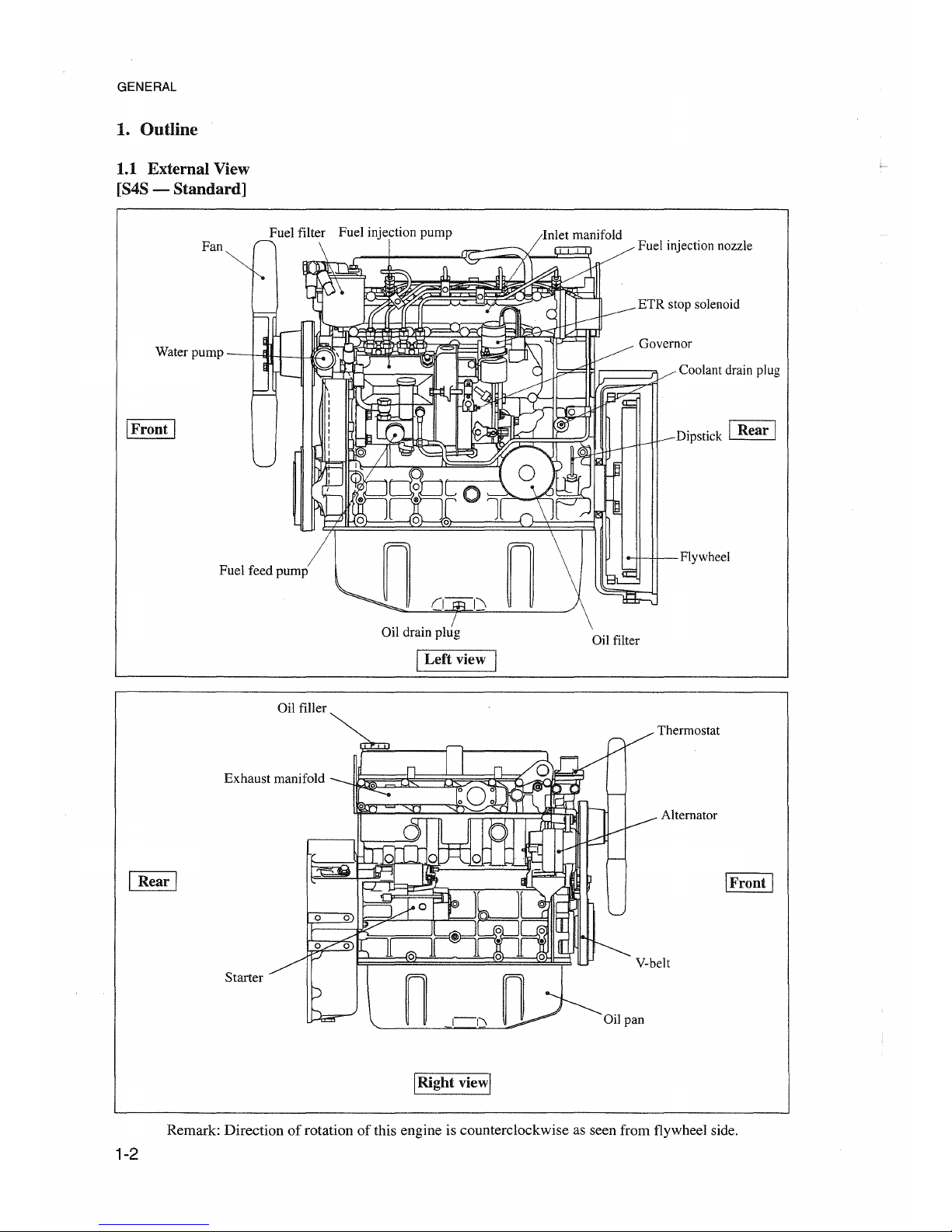

1. Outline

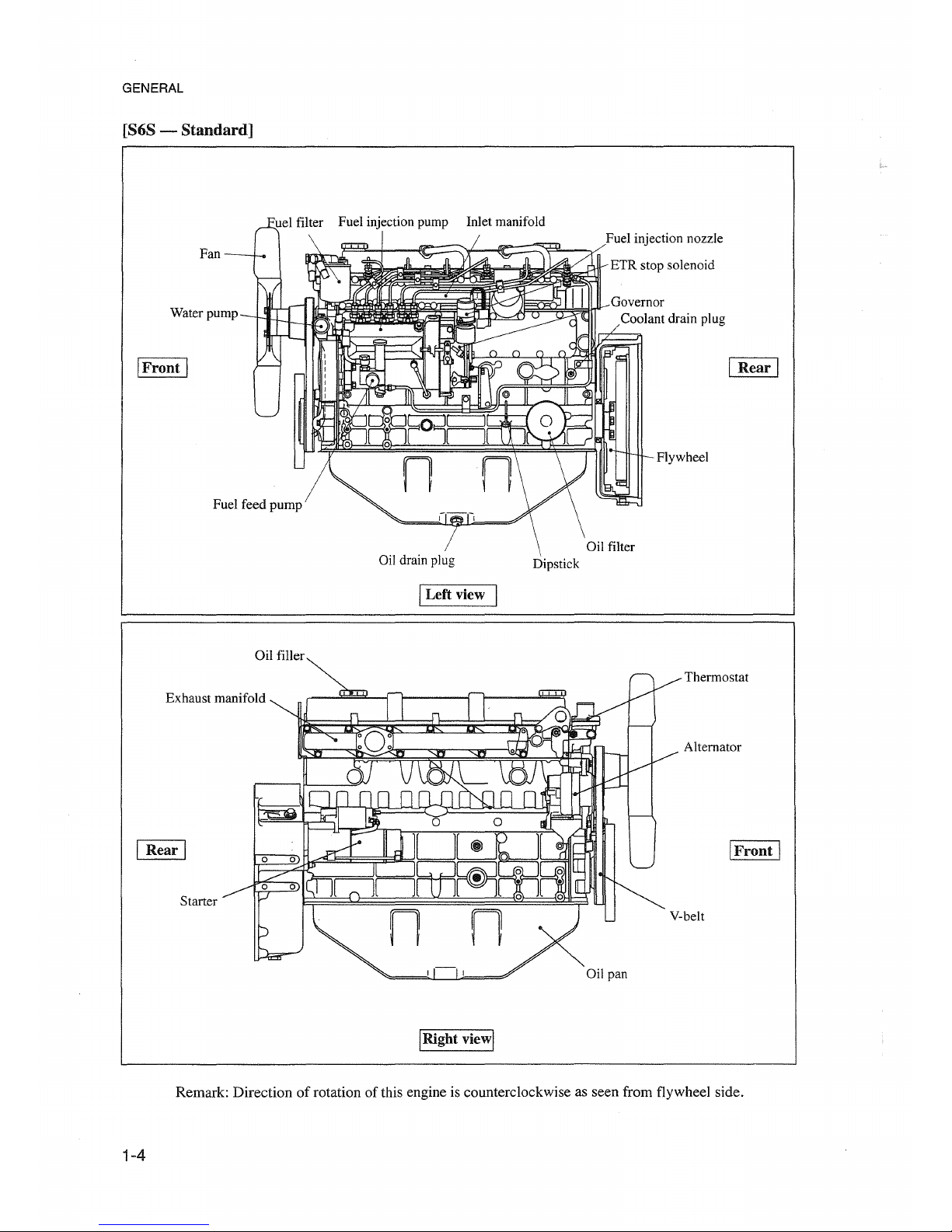

1.1 External View

[848 -

Standard]

Fuel filter Fuel injection pump

Fan

IFront I

Fuel feed pump

C'-I)

n

Inlet manifold

Fuel injection nozzle

ETR

stop solenoid

Governor

Coolant drain plug

Dipstick

IRear I

<>-tt-++--Flywheel

Oil drain plug

ILeft view

Oil filler

onfilter

Exhaust manifold

IRear I

Starter

n

I-I:)

Thermostat

Alternator

IFront I

V-belt

üil

pan

I

Right

viewl

Remark: Direction of rotation of this engine is counterclockwise as seen from flywheel side.

1-2

Page 9

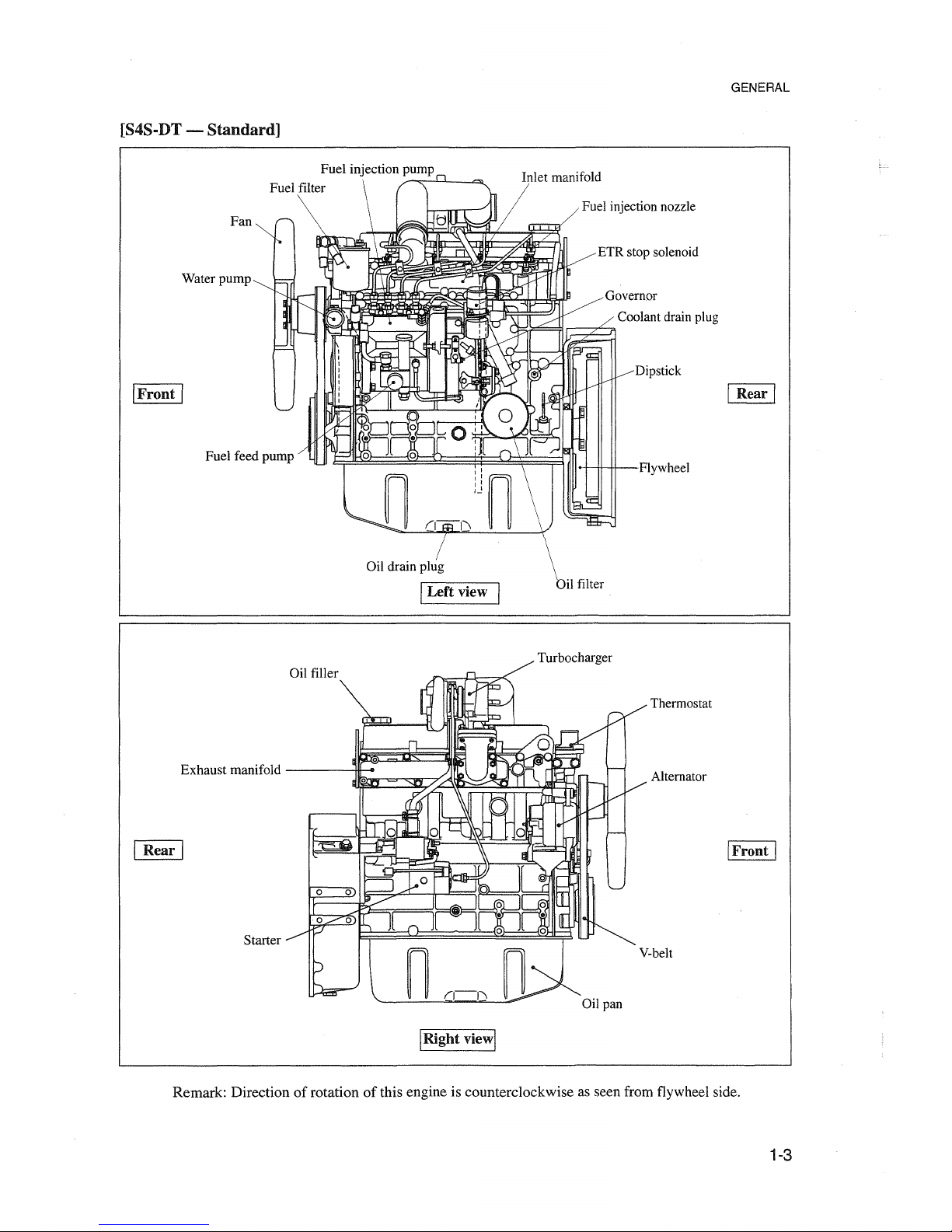

GENERAL

[S4S-DT - Standard]

IRear I

::n

"

.'

(I~I\

Fuel injection pump n

Fuel filter \

<,

I/In,

let manifold

h--.rT,----1JI

Fuel injection nozzle

Fan

~

rr-.

~

tJUI fT"i"T"i:

~

r~~

~?n'\~

I

hl

vETRstopsolenoid

Water

pump~

F -\.lIJ

11

(( --r

~Governor

I

~

;:,

Ip,~

-~

!

:;::

p

"/

/ Coolant drain plug

):

[l.l.AF::J"1"-

~

~

:::"

f'\f

r~

'Q

,

~

_

~!::L-

~.\

K"

Q.r-

~

~

I

",-

'"

Tb.

y

~

V Dipstick

13

--1.

~

~

___

0:/

ra

11

:

~

"\

V

~

(0

,0

/1, 0

ol--

~0,,~

,-'-

h>'

• F

;:;

:

I1

\

'--'-ol

Fuel feed pump -:

rUi;!=~~o?J;»-~~'-.-i~0Ë=Q:~~:

jl~~,

\~~r-~-dn

1111

~f--Ij'---H--FI

ywheel

IFront I

ondrain

PIL

I

Left

view I

on

filter

IFront I

Altemator

Thermostat

V-belt

Oil pan

Turbocharger

(1-1\

n

onfiller

Starter

Exhaust manifold

------.11ll-

~~~~~~

I

Rear

I

IRignt viewl

Remark: Direction of rotation

of

this engine is counterclockwise as seen from flywheel side.

1-3

Page 10

GENERAL

[868 - Standard]

uel filter Fuel injection pump lnlet manifold

I

Rear

I

Flywheel

Oil filter

Dipstick

Governor

t:~~~ah~~::~~r

Coolant drain plug

Oil drain plug

%~-1----le:::::~I-~e:::::~~--:v:

Fuel injection nozzle

1NI"bb!l;a

ETR stop solenoid

Fan

Water pump

I

Front

I

I

Left

view

Oil filler

Exhaust manifold

IRear I

Starter

Oilpan

Thermostat

Alternator

I

Front

I

V-belt

I

Right

viewl

Remark: Directionofrotation of this engine is counterclockwise as seen from flywheel side.

1-4

Page 11

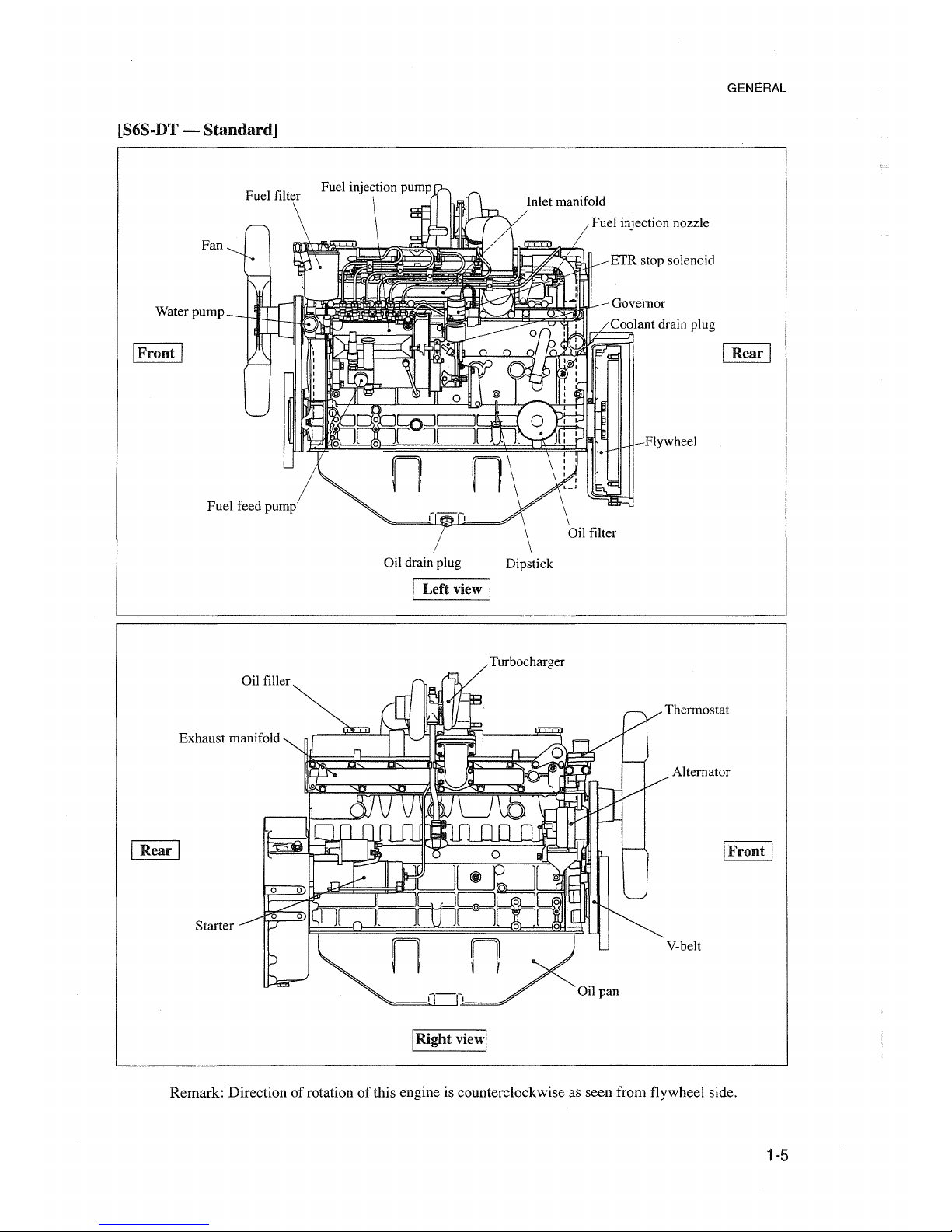

GENERAL

[S6S-DT-

Standard]

Fan

Water pump

IFront I

Gil filler

Exhaust manifold

IRea.. I

Starter

Fuel injection nozzle

ETR stop solenoid

).F~~~~~~

Governor

IRear I

Flywheel

Gil drain plug Dipstick

ILef! view I

Turbocharger

Thermostat

Alternator

IFront I

V-belt

Gil pan

IRight viewl

Remark:

Direction of rotation of this engine is counterclockwise as

seen

from flywheel side.

1-5

Page 12

GENERAL

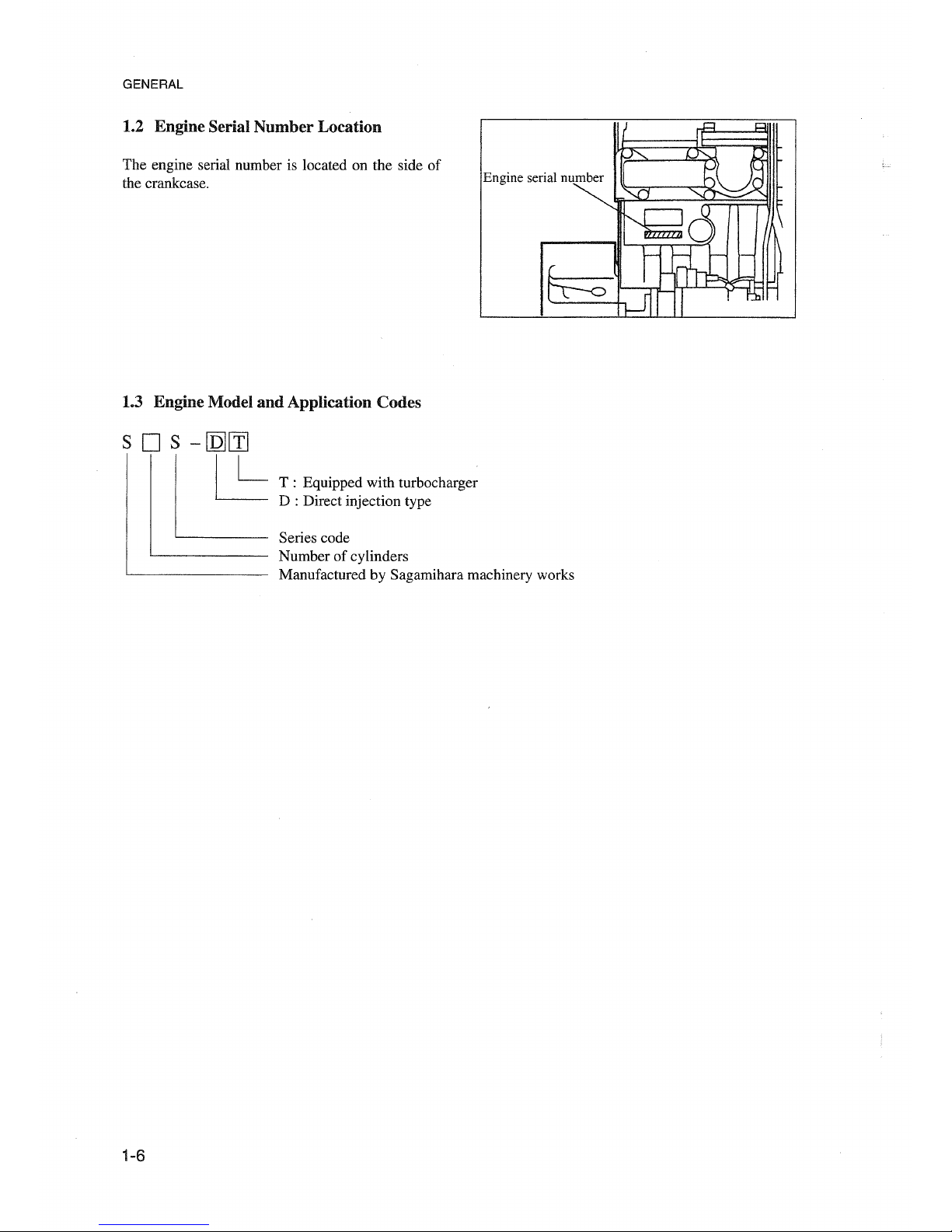

1.2 Engine Serlal Number Location

The engine serial number is located on the side of

the crankcase.

1.3 Engine Model

and

Application Codes

s D s -

[Q][ïJ

~

1-6

T : Equipped with turbocharger

D : Direct injection type

Series code

Number of cylinders

Manufactured by Sagamihara machinery works

Page 13

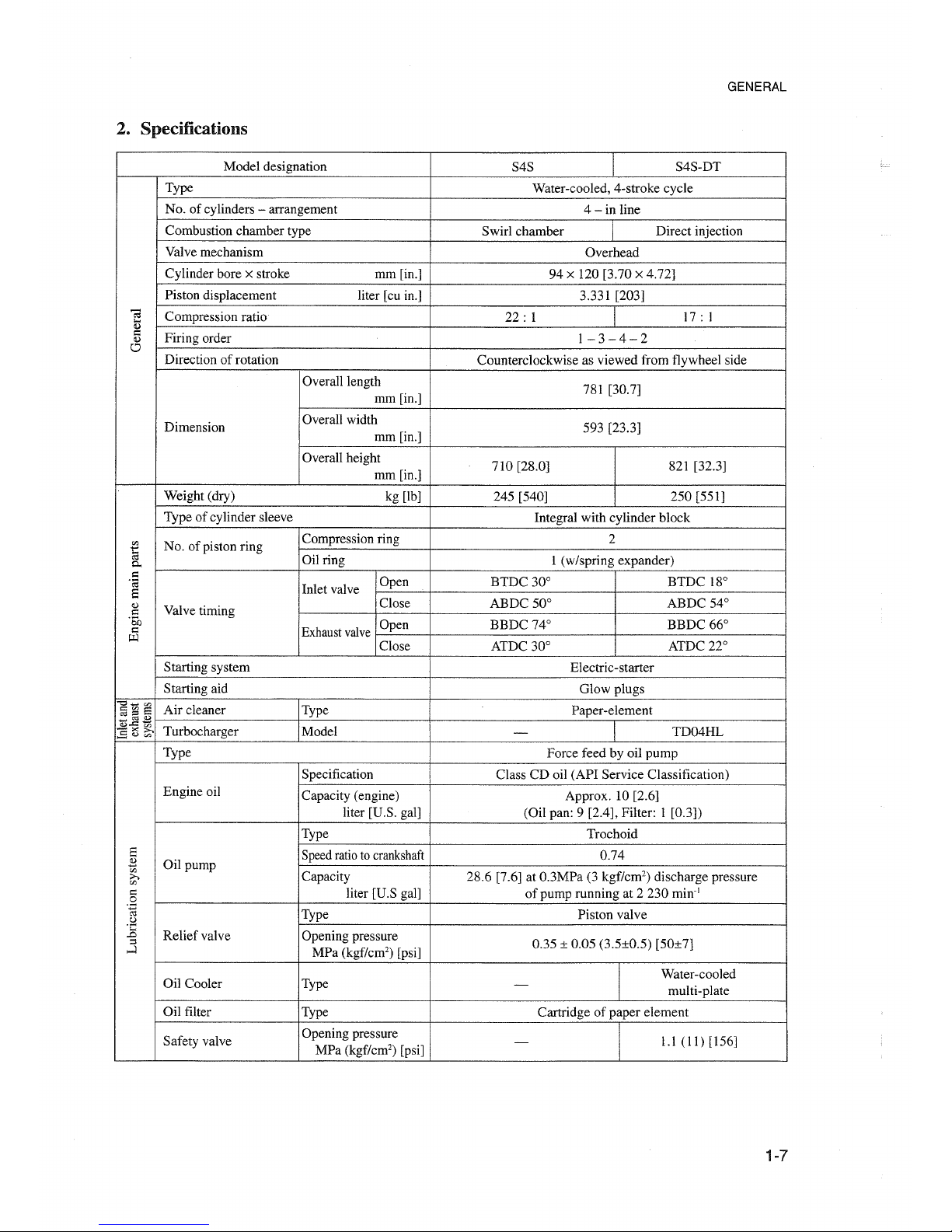

2. Specifieations

GENERAL

Model designation

S4S

S4S-DT

Type

Water-cooled, 4-stroke cycle

No. of cylinders

- arrangement

4-

in line

Combustion chamber type

Swirl chamber

Direct injection

Valve mechanism

Overhead

Cylinder bore

x stroke

mm[in.] 94

x 120 [3.70 x 4.72]

Piston displacement liter [cu in.]

3.331 [203]

";J

Compression ratio

22:

1

17:

1

...

<Ll

I:

Firing order

1-3-4-2

<Ll

0

Direction of rotation

Counterclockwise as viewed from flywheel side

Overall1ength

781 [30.7]

mm[in.]

Dimension

Overall width

593 [23.3]

mm[in.]

Overall height

710 [28.0]

821 [32.3]

mm[in.]

Weight (dry)

kg [Ib]

245 [540] 250[551]

Type of cylinder sleeve

Integral with cylinder block

Ol:>

No. of piston ring

Compression ring

2

~

0..

Oilring

1 (w/spring expander)

I:

Open BTDC 30° BTDC 18°

.e;

InIet valve

a

<Ll

Valve timing

Close

ABDC 50°

ABDC 54°

I:

·So

Open BBDC 74°

BBDC 66°

I:

Exhaust

valve

p:l

Close ATDC 30°

ATDC 22°

Starting system

Electric-starter

Starting aid

G10wplugs

"0_",

Air cleaner Type

Paper-element

§~e

"t).2

*

Turbocharger

Model TD04HL

-><>-.

-

~lUtI'.:l

Type

Force feed by oil pump

Specification

Class CD oil (API Service Classification)

Engine oil

Capacity (engine) Approx. 10 [2.6]

liter [U.S. gal] (Oil pan: 9 [2.4], Filter: 1 [0.3])

Type

Trochoid

a

Speedratioto

crankshaft

0.74

~

Oil pump

Ol:>

Capacity

28.6 [7.6] at 0.3MPa (3 kgf/cm") discharge pressure

;>,

Ol:>

I:

liter [U.S gal] of pump running at 2 230 min:'

0

.~

Type

Piston valve

u

·C

Re1iefva1ve

Opening pressure

..0

::l

0.35 ± 0.05 (3.5±0.5) [50±7]

....:l

MPa (kgf/cm") [psi]

Oil Cooler

I

Water-cooled

Type

-

multi-plate

Oil filter

Type Cartridge of paper element

Safety valve

Opening pressure

-

I

1.1

(11)

[156]

MPa (kgf/cm") [psi]

1-7

Page 14

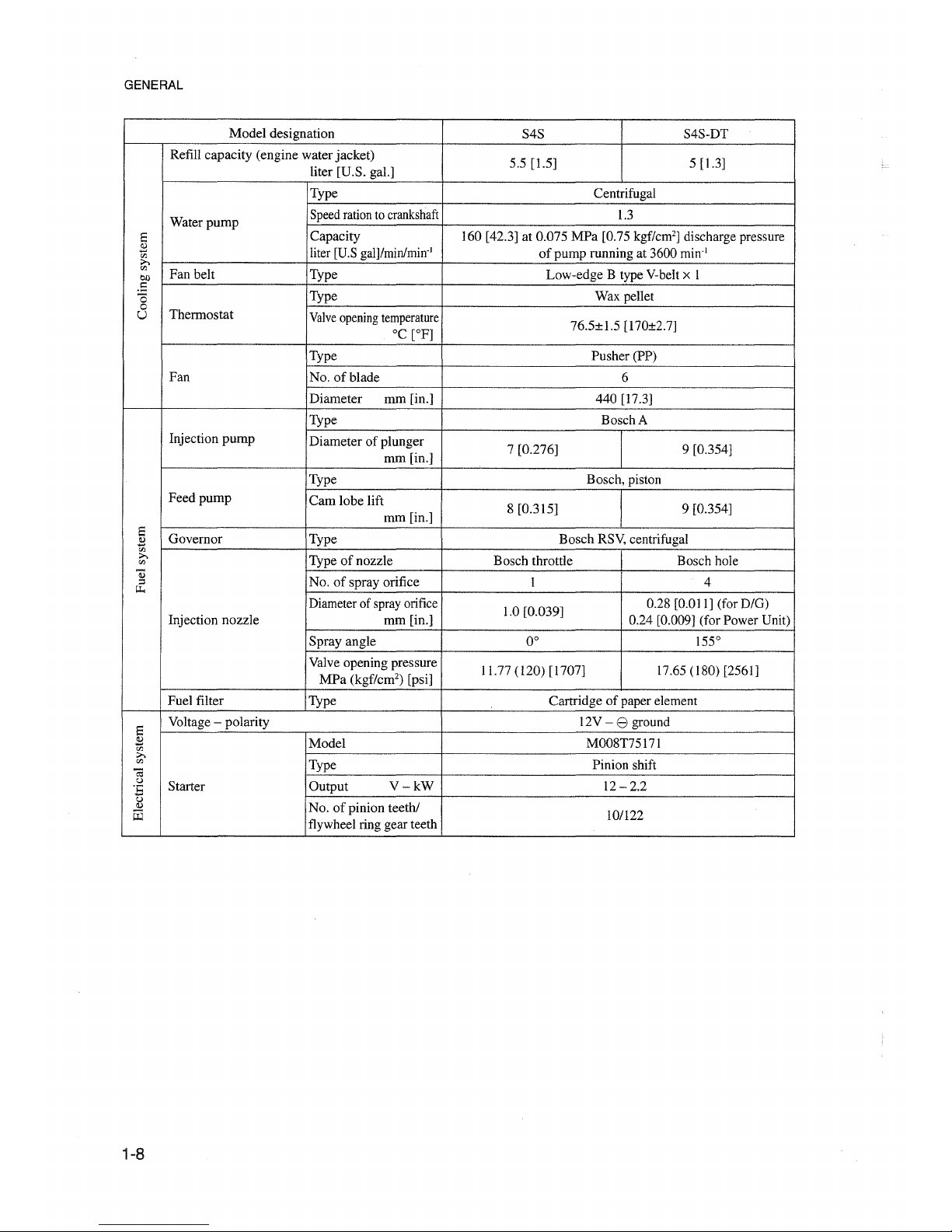

GENERAL

Model designation

S4S S4S-DT

Refill capacity (engine water jacket)

5.5 [1.5] 5 [1.3]

liter [U.S. gal.]

Type Centrifugal

Water

pump

Speedrationto

crankshaft

1.3

Ei

Capacity 160 [42.3] at 0.075 MPa [0.75 kgf/cm'] discharge pressure

2

liter [U.Sgalj/min/mirr'

of

pump running at 3600

min'

'Jl

;>,

'Jl

Fan belt

Type Low-edge B type V-belt x 1

eo

.S

Type Wax pellet

0

0

Thermostat

U

Valve

opening

temperature

°C

[OF]

76.5±1.5 [170±2.7]

Type Pusher (PP)

Fan

No.ofblade

6

Diameter

mm [in.]

440 [17.3]

Type Bosch A

Injection

pump

Diameter of plunger

7 [0.276] 9 [0.354]

mm [in.]

Type Bosch, piston

Feedpump

Cam

lobe lift

8 [0.315] 9 [0.354]

mm [in.]

Ei

Governor

Type Bosch RSV, centrifugal

2

co

;>,

Typeofnozz1e

Bosch throttle Bosch hole

'Jl

Q)

No.ofspray orifice

1 4

::l

~

Diameterof sprayorifice

1.0 [0.039]

0.28 [0.011] (for D/G)

Injection nozz1e

mm [in.]

0.24 [0.009] (for Power Unit)

Sprayangle

0° 155°

Valve opening pressure

11.77

(I20)

[1707] \7.65 (I 80) [2561]

MPa

(kgf/cm") [psi]

Fuel filter Type Cartridge of paper element

Ei

Voltage - polarity 12V - e ground

2

Model M008T75171

'Jl

;>,

'Jl

Type

Pinion shift

ë<i

Cl

Starter Output

V-kW

12 - 2.2

'5

Cl

Cl)

No.ofpinion teeth/

ü3

flywheel ring gear teeth

lO/l22

1-8

Page 15

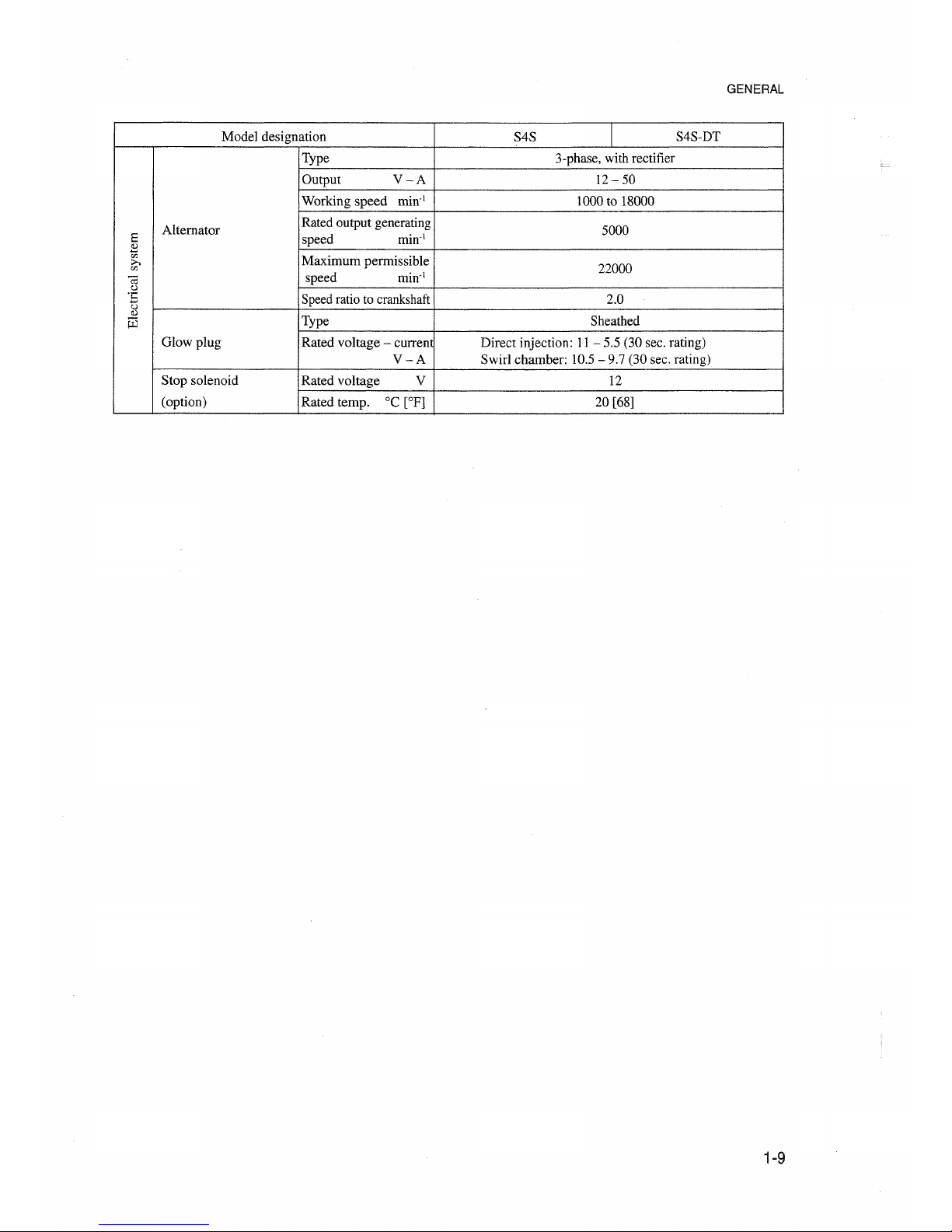

GENERAL

Model designation

S4S

I

S4S-DT

Type 3-phase, with rectifier

Output

V-A

12-50

Working

speed

min:'

1000 to 18000

Altemator

Rated output generating

5000

Ei

speed

min:'

s

<IJ

Maximum

perrnissib1e>-.

22000

co

C;;

speed

min:'

o

oE

Speed ratio to crankshaft 2.0

o

Il.l

iii

Type

Sheathed

G10w plug

Rated voltage - current Direct injection: 11

- 5.5 (30 sec. rating)

V-A

Swir1 chamber: 10.5 - 9.7 (30 sec. rating)

Stop solenoid

Rated voltage V 12

(option)

Rated temp.

oe

[OP]

20 [68]

1-9

Page 16

GENERAL

Model designation

S6S

S6S-DT

Type

Water-cooled, 4-stroke cycle

No. of cylinders

- arrangement

6-in

line

Combustion chamber type

Swirl chamber Direct injection

Valve mechanism

Overhead

Cylinder bore x stroke mm [in.]

94 x 120 [3.70 x 4.72]

Piston displacement liter [cu in.]

4.996 [305]

~

Compression ratio

22:

1

17:

1

...

Q)

:::

Firing order

I - 5

- 3 - 6 -2-4

Q)

Cl

Direction of rotation

Counterclockwise as viewed from flywheel side

Overall length

1033 [40.7] SG type, 1029 [40.5] SP type

mm[in.]

Dimension

Overall width

593 [23.3] 626 [24.6]

rum [in.]

Overall height

748 [29.4] 896 [35.3]

mm[in.]

Weight (dry) kg [Ib]

340 [750] 350 [772]

Type of cylinder sleeve

Integral with cylinder block

I!J

No. of piston ring

Compression ring

2

...

0::1

Oil ring I (w/spring expander)

0..

:::

Open

BTDC 30° BTDC 18°

.;:;

Inlet valve

8

Q)

Valve timing

Close

ABDC 50° ABDC 54°

:::

·öo

Open BBDC 74°

BBDC 66°

:::

Exhaust

valve

"'-l

Close

ATDC 30° ATDC 22°

Starting system Electric-starter

Starting aid

Glow plugs

"0_",

Air cleaner Type

Paper-element

a~E

~~*

Turbocharger Model

TE06H

-><>,

-

,.5CUoZl

Type

Force feed by oil pump

API

Service

Classification

CD

Engine oil

Refill capacity

Whole system: Approx. 12 liters [3.2 U.S. gal];

liter [U.S. gal.] Oil pan: II liters [2.9 U.S. gal]; Filter: I liters [0.3 U.S. gal]

Type

Trochoid

8

Speedratioto crankshaft

0.74

2

Oil pump

<J)

Capacity 38.7 [10.2] at 0.3 MPa (3 kgf/cm') discharge pressure

>.

<J)

e

liter [U.S gal]/min

of pump running at 2230

min'

0

.~

Type

Piston valve

o

Oil pressure

.e:

Opening pressure

.D

relief valve

::l

0.35±0.05 (3.5±0.5) [50±7]

....:l

MPa (kgf/cm") [psi]

Oil Cooler Type

Water-cooled

-

multi-plate

Oil filter Type Cartridge of paper element

Safety valve

Opening pressure

-

1.1(11)[156]

MPa (kgf/cm') [psi]

1-10

Page 17

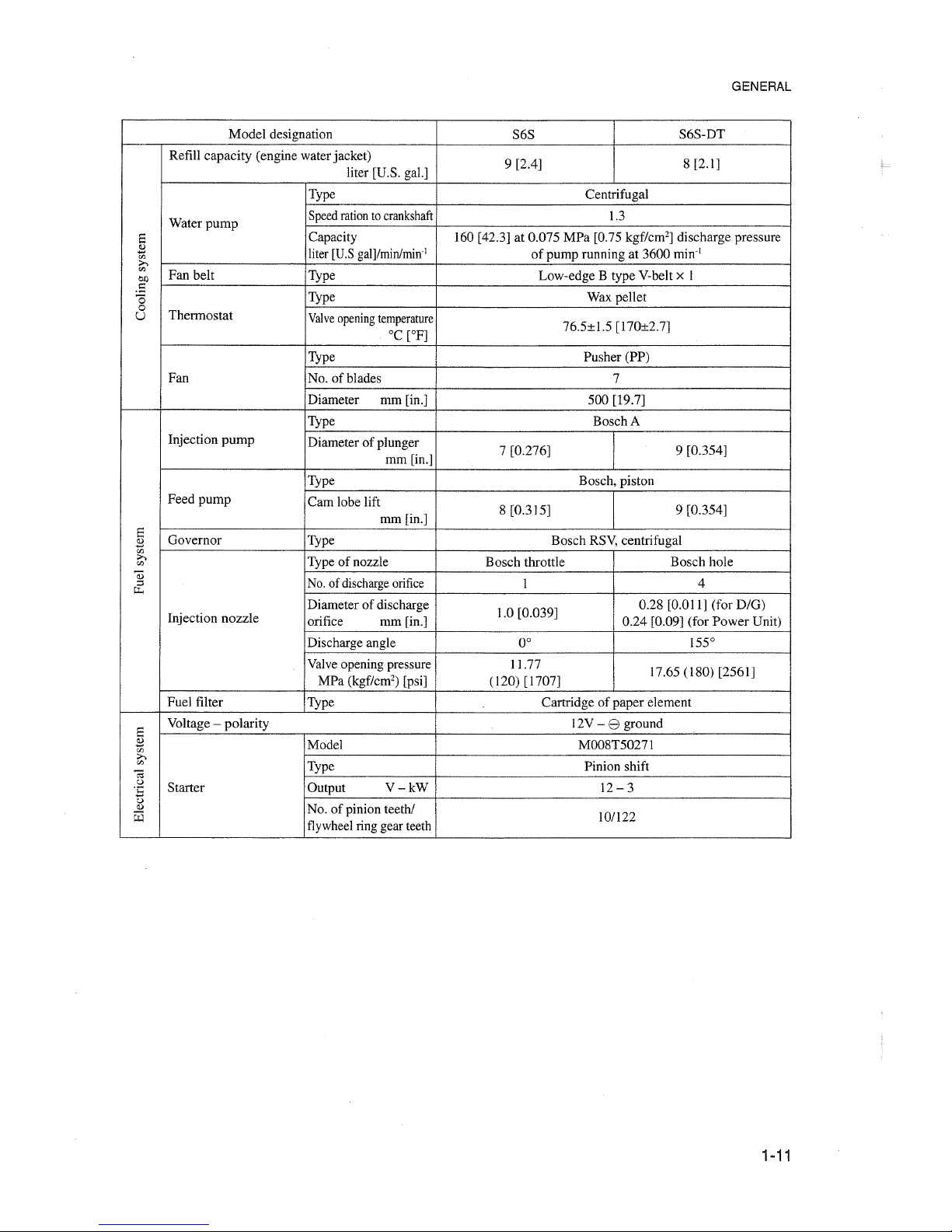

GENERAL

Model

designation

S6S

S6S-DT

Refill

capacity

(engine water jacket)

9 [2.4]

8 [2.1]

liter [U.S. gal.]

Type Centrifugal

Water

pump

Speedrationto

crankshaft

1.3

Ei

Capacity 160 [42.3] at 0.075

MPa

[0.75 kgf/cm"] discharge pressure

B

liter [U.S

gall/rnin/mirr'

of

pump

running at 3600 min'!

CI:l

;>,

CI:l

Fan belt Type

Low-edge B typeV-belt x I

en

.5

Type Wax pellet

Ö

0

Thermostat

U

Valve

opening

temperature

°C

[OF]

76.5±1.5 [170±2.7]

Type Pusher (PP)

Fan

No.

of

blades

7

Diameter mm [in.]

500

[19.7]

Type

Bosch A

Injection

pump

Diameterofplunger

7 [0.276] 9 [0.354]

mm[in.]

Type Bosch, piston

Feed

pump

Cam lobe lift

8 [0.315]

9 [0.354]

mm [in.]

Ei

Governor

Type Bosch RSV, centrifugal

B

CI:l

;>,

Typeofnozzle Bosch throttle Bosch hole

CI:l

03

No.of dischargeorifice

I

4

;:l

"'"

Diameterofdischarge

1.0 [0.039]

0.28 [0.011] (for

D/G)

Injection

nozzle

orifice

mm [in.]

0.24

[0.09] (for

Power

Unit)

Discharge angle 0°

155°

Valve opening pressure

11.77

17.65 (180) [2561]

MPa

(kgf/cm') [psi]

(120) [1707]

Fuel filter

Type Cartridge

of

paper element

Ei

Voltage -

polarity

12V - 8 ground

B

Model

M008T5027I

CI:l

;>,

CI:l

Type Pinion shift

ca

o

Starter Output

V-kW

12 - 3

"5

o

<I)

No.ofpinion teeth/

W

flywheel ring gear teeth

10/122

1-11

Page 18

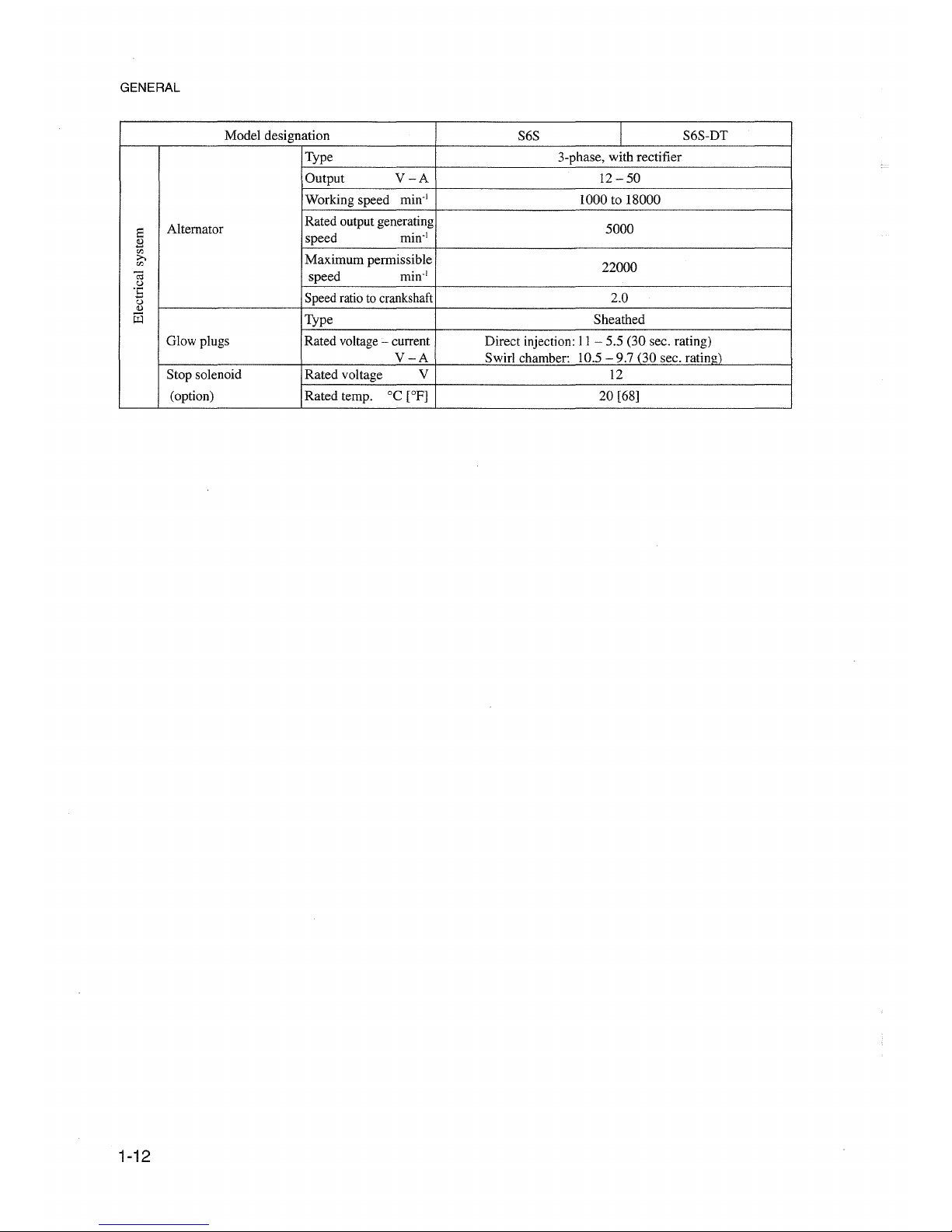

GENERAL

Model designation

S6S

I

S6S-DT

Type 3-phase, with rectifier

Output

V-A

12

-50

Working speed

min-I

1000 to 18000

a

Altemator

Rated output generating

5000

B

speed

min-I

'"

>.

Maximum permissible

'"

22000

'<'J

speed

min-I

.~

::

Speedratio tocrankshaft 2.0

o

<l.l

m

Type Sheathed

Glow plugs Rated voltage- current Direct injection:

11- 5.5 (30 sec. rating)

V-A

Swirl chamber: 10.5

-9.7

(30 sec. rating)

Stop solenoid Rated voltage V

12

(option) Rated temp.

°C

[OF]

20 [68]

1-12

Page 19

3. Tips on Disassembly

and

Reassembly

This

service

manual

covers

recommended

procedures to be followed when servicing diesel

engines. It also contains information on special

tools required and basic safety precautions.

It is the responsibility

of

service personnel to be

familiar with these requirements, precautions and

potential hazards and to discuss these points with

their foreman or supervisor.

Study this manual carefully and observe the

following general precautions to prevent serious

personal injury and to avoid

damagetothe

engine, equipment and parts.

3.1 Disassembly

(1) Use the correct tools and instruments. Serious

injury or damage to the engine can result from

using the wrong tools and instruments.

(2) Use an

overhaul

standorwork

bench

if

necessary. Also, use assembly bins to keep the

engine parts in order of removal.

(3) Lay down disassembiedorc1eanedparts in the

order in which they were removed. This will

save you time at reassembly.

(4) Pay attention to the marks on

assemblies,

components and parts for positionsordirections.

Put on your own marks, if necessary, to aid

reassembly.

(5) Carefully

check

each part for faults during

removal or cleaning. Signs of abnormal wear

will tell if parts or assemblies are functioning

improperly.

(6) When

liftingorcarrying

heavy

parts,

get

someone to help you if the part is too awkward

for one person to handle. Use jacks and chain

blocks when necessary.

GENERAL

3.2 Reassembly

(1)

Wash all engine parts, except oilseals,O-rings,

rubber seals, etc. in c1eaning solvent and dry

them with compressed air.

(2) Use only the correct tools and instruments.

(3) Use only

good

quality lubricating oils and

greases. Be sure to apply a coat of oil, grease,

or sealanttoparts as specified.(Referto section

3, of Group 2, "Maintenance Standards".)

(4) Use a torque wrench to tighten parts when

specified tightening torquesare required.(Refer

to

section2,of

Group2,"Maintenance

Standards".)

(5)

Replace

all

gaskets

and

packing.

Apply

appropriate amountof adhesiveor liquid gasket

when required.

1-13

Page 20

Page 21

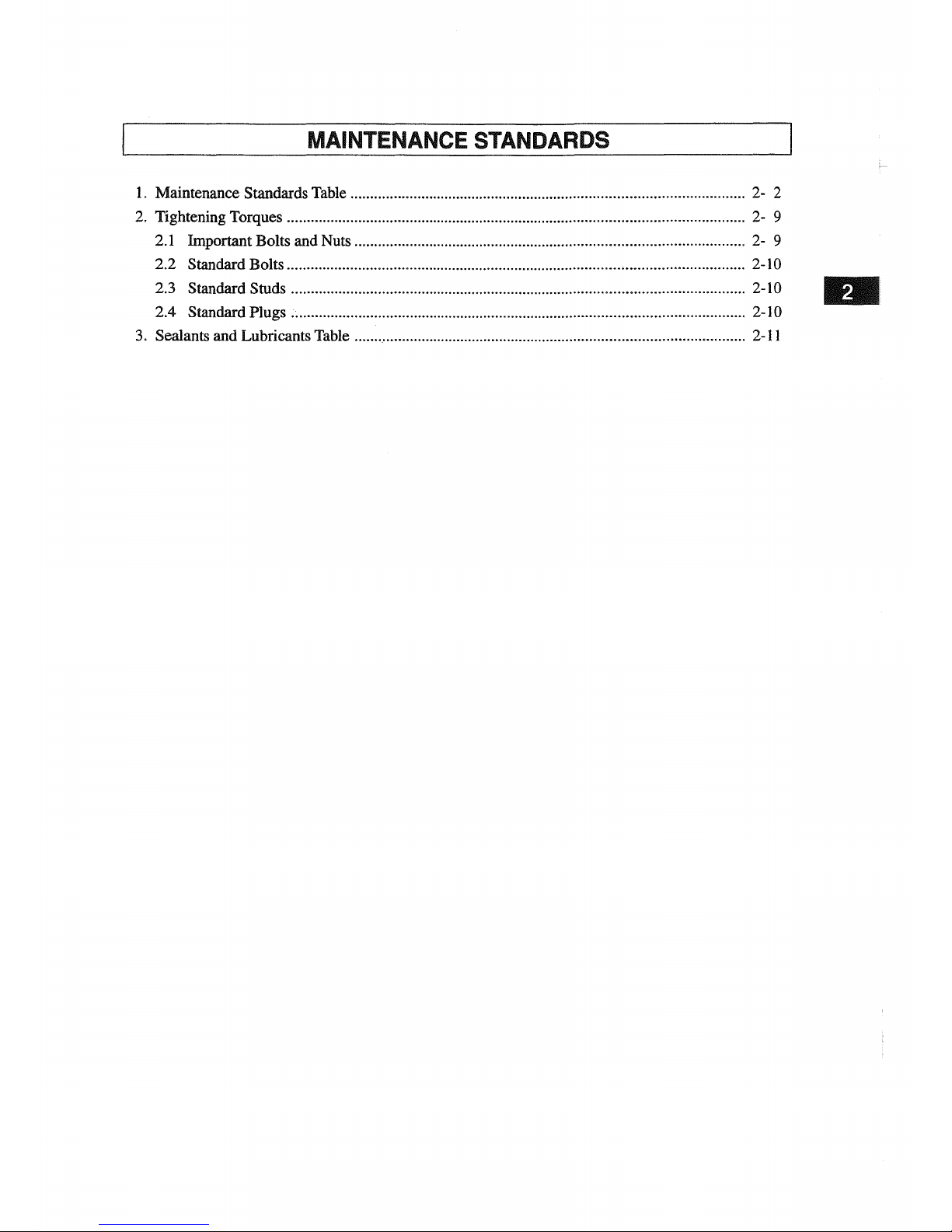

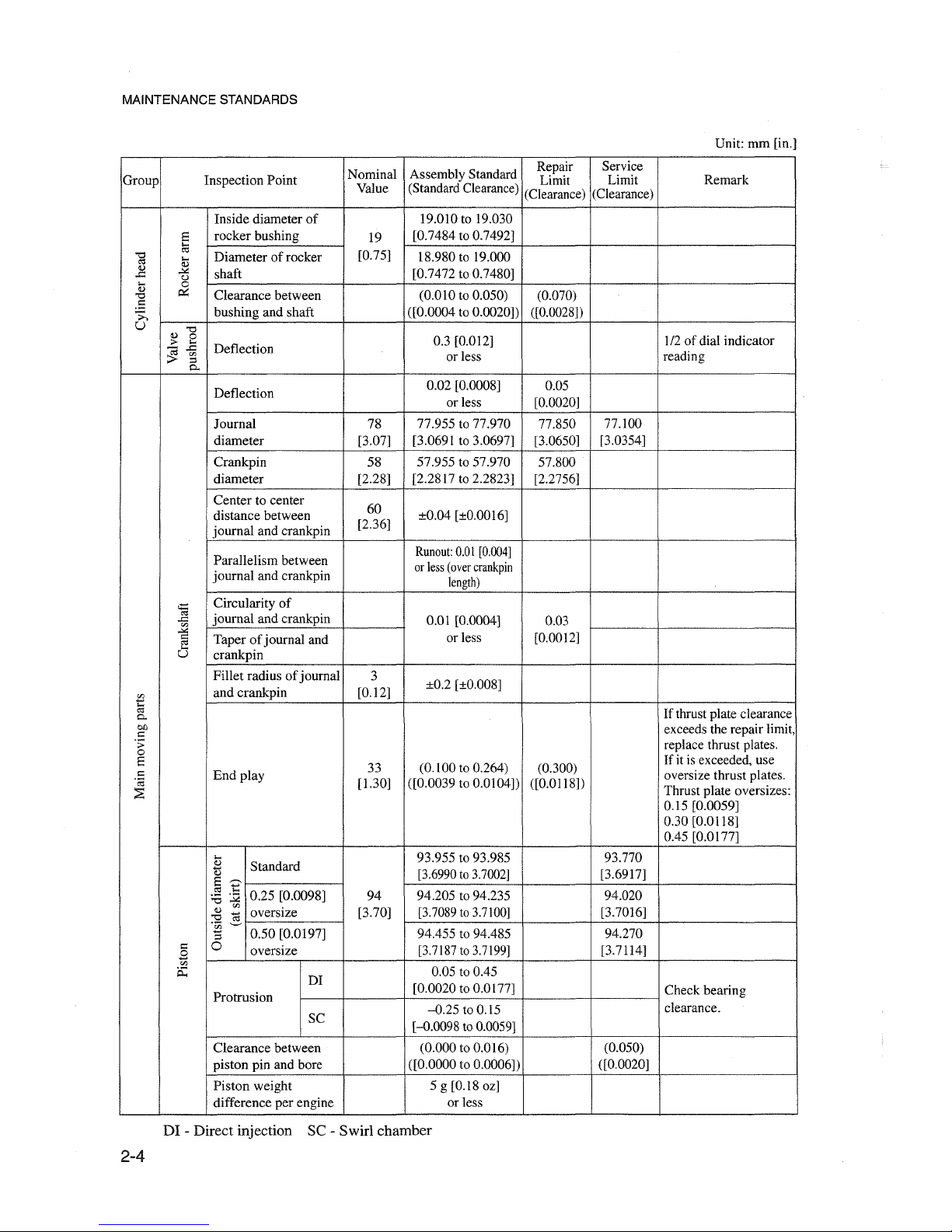

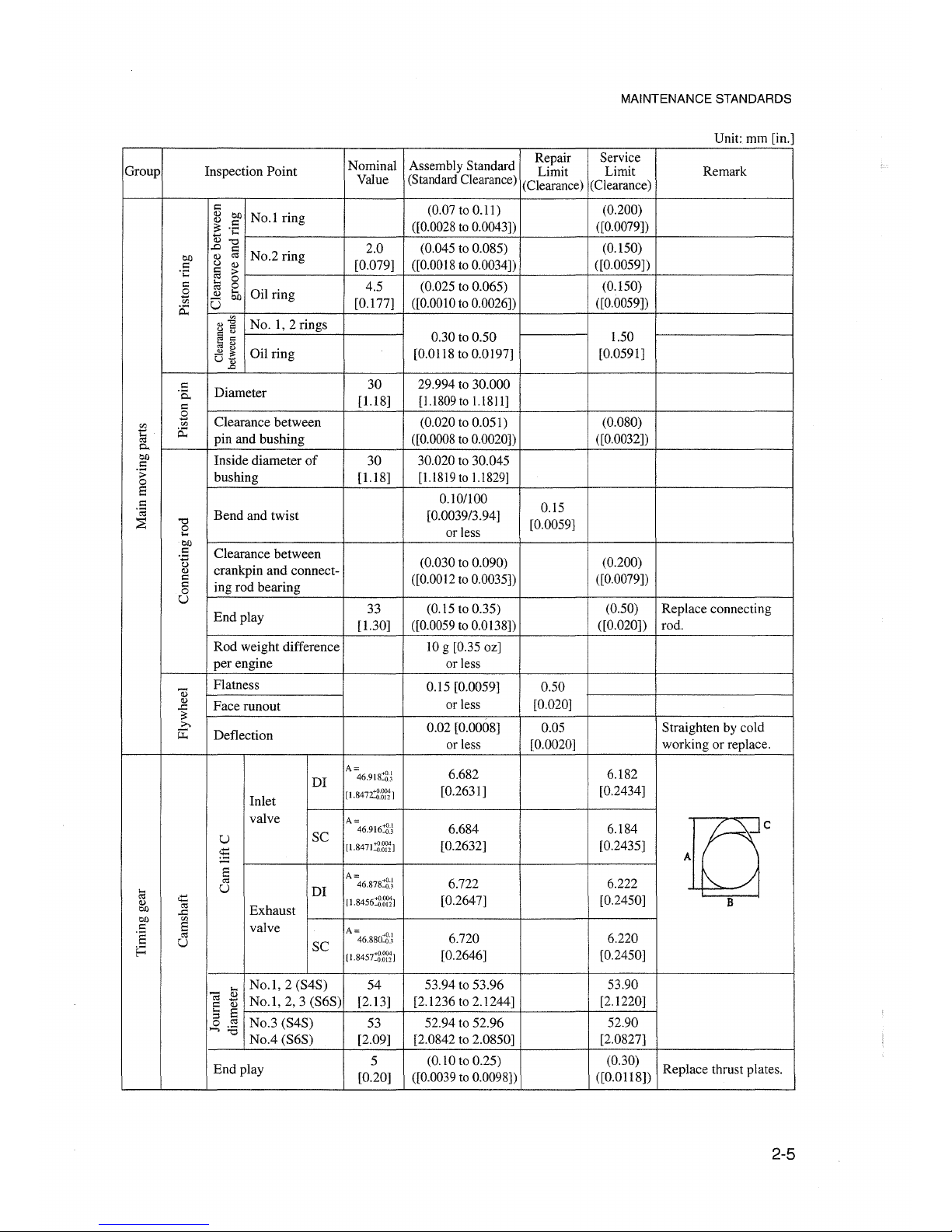

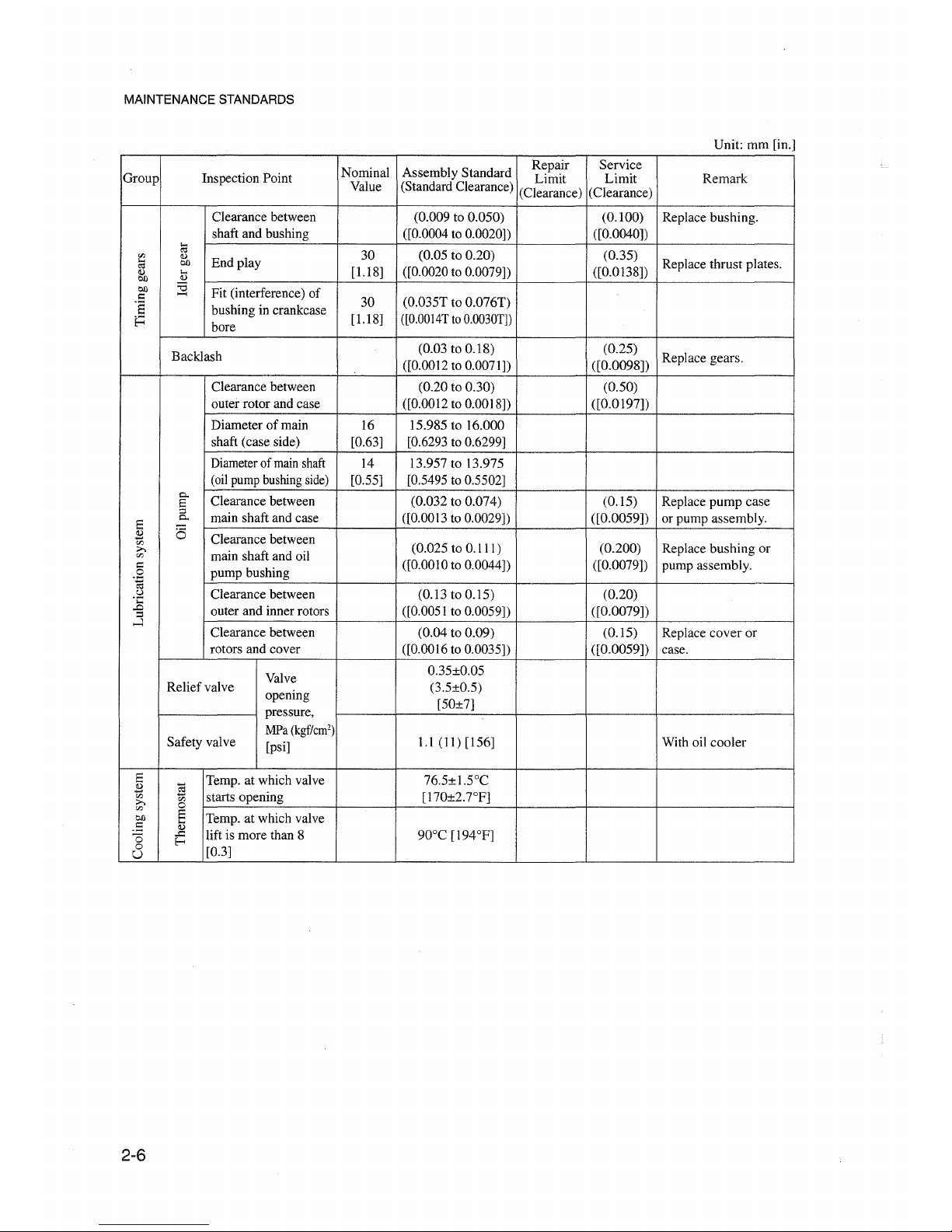

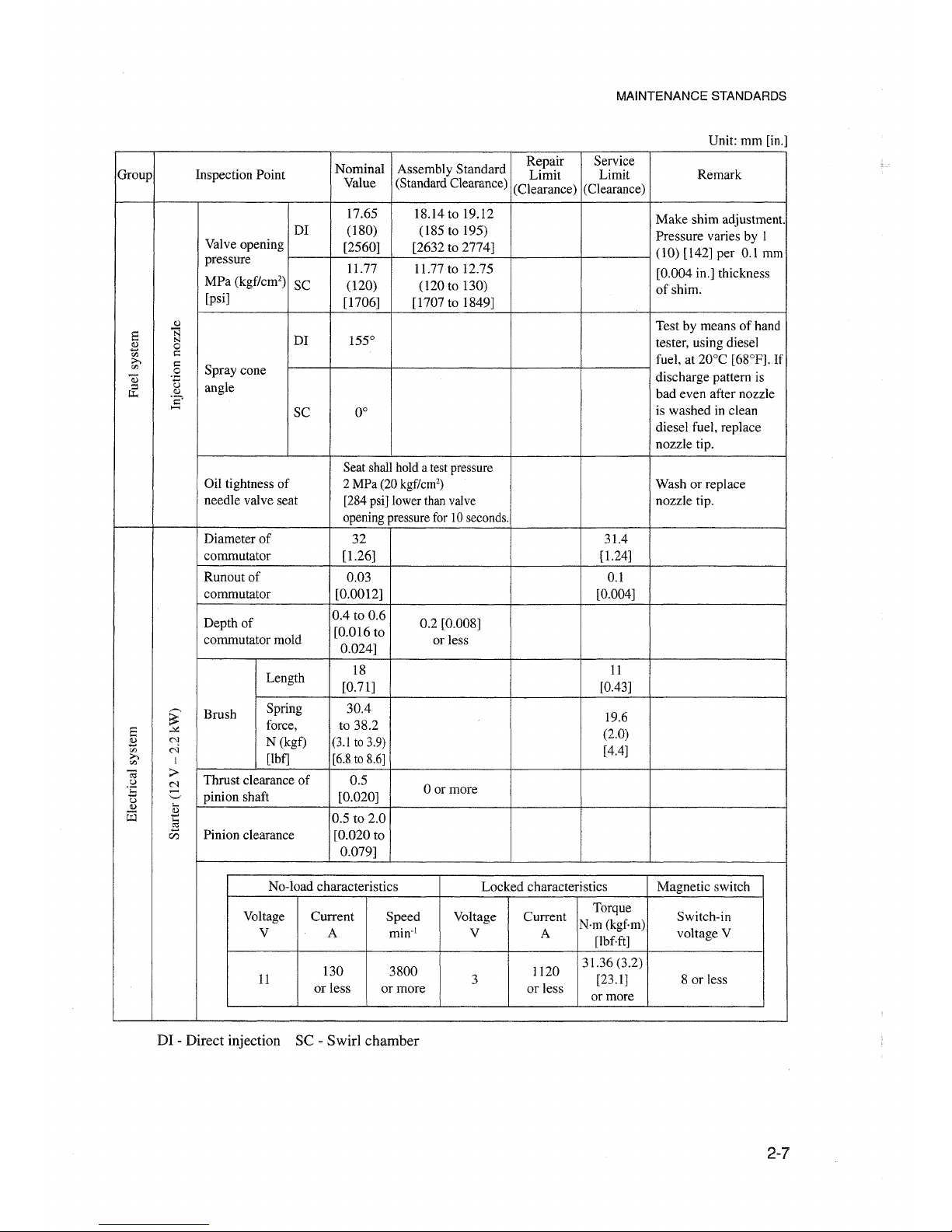

MAINTENANCE STANDARDS

1. Maintenance Standards Table 2- 2

2. Tightening Torques , 2- 9

2.1 Important Bolts and Nuts 2- 9

2.2 Standard Bolts 2-10

2.3 Standard Studs 2-10

2.4 Standard Plugs .. 2-10

3. Sealants and Lubricants Table

2-11

Page 22

MAINTENANCE STANDARDS

1. Maintenance Standards Table

Unit: mm [in.]

Nominal

Assembly

Standard

Repair

Service

Group Inspeetion Point

Limit

Limit Remark

Value (Standard Clearance)

(Clearance)

(Clearance)

Maximum min-I, (no-load)

According to engine

Adjust governor

Minimum min", (no-lead)

specification setting.

DI

2.9 (30) [427]

2.6

Oil and water temp.

Compression

at 300 min:'

(27) [384]

20 to

30°C

pressure

3.2 (33) [469]

2.8

[68 to 86°F]

Ml'atkgf/cm') [psi]

SC

at 300 min-I

(29)

[413]

0.3 to 0.5 (3 to 5) [43 to 71] 0.15 (1.5)

üil

temperature

Engine oil pressure

at 1500 min:'

[21.3]

70 to 90°C

0.1

(1) [14.2] or

more

at

0.05

(0.5)

[158 to 194°F]

MPa (kgf/cm") [psi] idling [7]

DI SC

Inlet

valves open

BTDC

18°

BTDC

30°

C;

Valve timing

Inlet

valves close

ABDC

54°

ABDC

50°

....

Exhaust

valves open

BBDC

66°

BBDC

74°

(1)

c

Exhaust

valves close

ATDC

22°

ATDC 30°

(1)

c

± 3°

(crank

angle) ± 3° (crank angle)

Valve clearance (cold)

Both

in1et and exhaust

0.25 [0.0098]

valves

The

timing for each

model

of

engine varies

according to its speci-

Fuel injection timing fication. Be sure to

verify the timing by

referring to the speci-

fications

of

each

model.

Push beIt inward with

V-belt deflection 12 [0.5], approx.

thumb

pressure and

measure

deflection.

,

"""'(1)

Warpage of gasket 0.05 [0.0020]

0.20

Regrindifwarpage

<=:",

~~

contact surface

or 1ess [0.0079]

is minor.

Uu

Inside diameter

94

94,000 to 94,035

94.200 94.700 Refinish cylinder to

...

[3.70] [3.7008to 3.7022]

[3.7087]

[3.7283] 0.25 [0.0098] or 0.50

(1)

[0.0197] oversize of

"0

0.01 [0.0004]

.5

Circularity

>..

or less

normal value by

U

honing and use the

Taper

0.015 [0.0006]

same

oversize pistons

(1)

or less

and piston rings.

'"

<:Il

u

~

If repair limit is

<=:

<:Il

reached, replace

...

U

-0.09

bearings.Ifis

01)

<=:

[-0.035] exceeded, regrind

.t:

Clearance between

(0.050 to 0.110)

~

(0200)

asjoumal

journals

and

use(1)

.D

bearing and journal ([0.0020 to 0.0043]) ([0.0079])

diameter undersize bearings.

<=:

'ca

which is Bearing undersizes:

::E

78 [3.07]

0.25 [0.0098]

0.50

[0.0197]

0.75 [0.0295]

DI - Direct injection SC - Swirl chamber

2-2

Page 23

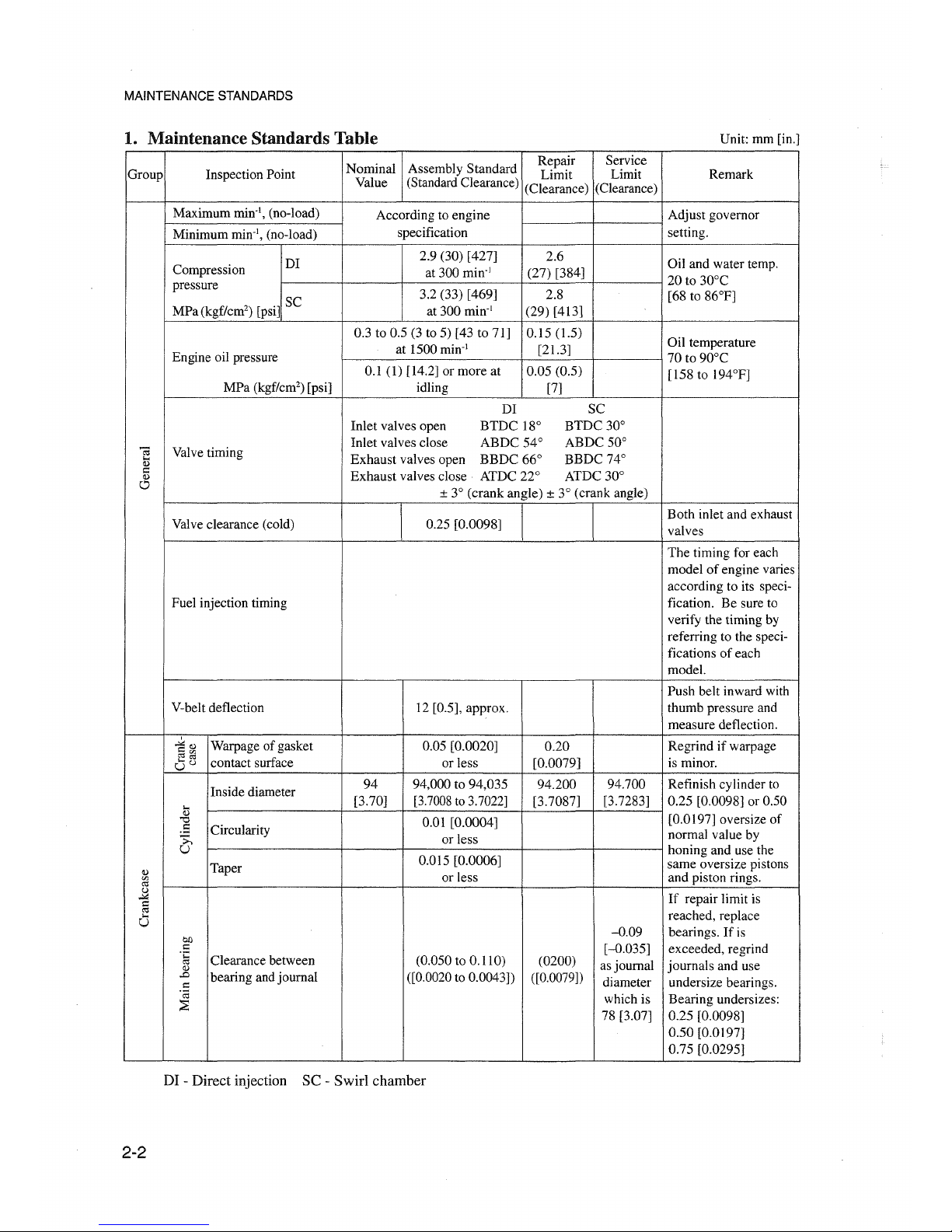

MAINTENANCE STANDARDS

Unit: mm [in.]

Nominal Assembly Standard

Repair

Service

Group Inspeetion Point

Limit Limit

Remark

Value (Standard Clearance)

(Clearance) (Clearance)

~

14.000 to 14.018 14.100

...

Inside diameter

0

..0

[0.5512 to 0.5519]

[0.5551]

Q)

0..

Clearance between

(0.016 to 0.052) (0.08)

If

it exceeds the repair

0..

~

tappet and bore

([0.0006 to 0.0021)) ([0.0031))

limit, replace tappets.

~

Front (0.070 to 0.118)

'"

and

([0.0028 to 0.0047))

<Il

If it exceeds the repair

~

~

midd1e

(without bushings)

(0.15) limit, refinish bores

§

5

...

..0

Clearance

(0.070 to 0.110) ([0.0059)) and install bushings,

U

~

between

<Il

Rear ([0.0028 to 0.0043)) or replace camshaft.

..0

camshaft

co

(without bushings)

a

journa1 and

<Il

U

(0.040 to 0.119)

If

it exceeds the repair

bore

(0.15)

([0.0016 to 0.0047))

([0.0059))

limit, rep1acebushings.

(with bushings)

Ream if necessary.

'0

Warpageofgasket 0.05 [0.0020]

0.20

Regrind if warpage is

<Il

<)

..c

contact surface

or less

[0.0079]

minor.

...

<)

'0

Compressed thickness

1.2

±0.05

.5

>-,

of gasket [0.05]

[±0.002]

U

Diameter

Inlet

7.940 to 7.955 7.900

va1ve

8 [0.3126 to 0.3132]

[0.3110]

~

ofva1ve

'0

Exhaust

[0.31]

7.920 to 7.940 7.850

'5 stern

co

va1ve

[0.3118 to 0.3126] [0.3091]

~

;>

(;J

Clearance

Inlet (0.065 to 0.095) (0.150)

;>

'0

between

valve

([0.0026 to 0.0037))

([0.0059])

=

<Il

guide and

Exhaust

(0.080 to 0.115)

(0.200)

~

;>

stern

va1ve

~

([0.0032 to 0.0045))

([0.0079))

Height to top

of

11.5

±0.1 [±0.004]

va1veguide

[0.45]

'0

Ang1e

30°

<Il

~

..0

Inlet 0.4

...

~

~

Valve

va1ve [0.016]

1.0

'0

±0.1 [±0.004]

.:::

sinkage [0.039]

è

;;,

ê<I

Exhaust

0.5

':l

U

~

va1ve'"[0.020]

~

;>

1.8

~

Width

IA

±0.14 [±0.0055]

Valve

[0.055] [0.071]

margin

Valve seat

Va~e

Up to 1.83

angle

sin age

Valve margin

2.13 [0.0839]

[o.onO] by

refacing

Free length

48.85 47.60

[1.92] [1.87]

eo

Squareness of ends

=

Squareness 1.50or less with respect to center

.t::

0..

line

'"

~

;>

Set length 43 [1.69]

~

Set force

176 to 196

147

N (kgf) [lbf]

(18 to 20)

(15)

[40 to 44]

[33]

2-3

Page 24

MAINTENANCE 8TANDARD8

Unit: mm [in.]

Nominal

Assembly Standard

Repair

Service

Group Inspeetion Point Limit

Limit Remark

Value

(Standard Clearance)

(Clearance)

(Clearance)

Inside diameter

of

19.010 to 19.030

S

rocker bushing

19

[0.7484 to 0.7492]

"0

a

Diameter of rocker

[0.75]

18.980 to 19.000

....

0::1

Q.}

Q.}

~

shaft [0.7472 to 0.7480]

.!:

u

à:3

0

"0

0:::

Clearance between

(0.010 to 0.050)

(0.070)

.S

;;.,

bushing and shaft

([0.0004 to 0.0020)) ([0.0028))

U

"0

Q.}

0

0.3 [0.012]

1/2

of

dial indicator

;;.-

....

Deflection

~

.!:

'"

or less

reading

:::s

0..

Deflection

0.02 [0.0008]

0.05

or less [0.0020]

Journal

78

77.955 to 77.970

77.850

77.100

diameter [3.07]

[3.0691 to 3.0697]

[3.0650]

[3.0354]

Crankpin

58

57.955 to 57.970

57.800

diameter [2.28] [2.2817 to 2.2823] [2.2756]

Center to center

60

distance between ±0.04 [±0.0016]

journal and crankpin

[2.36]

Parallelism between

Runout:

0.01

[0.004]

journal and crankpin

or

less

(over

crankpin

length)

<:i=:

Circularity of

""

journal and crankpin

.c

0.01 [0.0004]

0.03

'"

~

Taperofjournal and

or less [0.0012]

""

....

U

crankpin

Fillet radius

of

journal

3

±0.2 [±0.008]

.'!i

and crankpin [0.12]

....

0::1

If thrust plate clearance

0..

eo

exceeds the repair limit,

I:

.;;

replace thrust plates.

0

S

33

(0.100 to 0.264)

(0.300)

If it is exceeded, use

:::

End

play oversize thrust plates.

'ca

[1.30]

([0.0039 to 0.0104))

([0.0118))

::E

Thrust plate oversizes:

0.15 [0.0059]

0.30 [0.0118]

0.45 [0.0177]

....

93.955 to 93.985 93.770

Q.}

Standard

d)

[3.6990to

3.7002]

[3.6917]

S

~

0::1

....

0.25 [0.0098] 94 94.205 to 94.235 94.020

:a~

Q.}

'"

oversize [3.70] [3.7089to

3.7100]

[3.7016]

:9

:g

'"

"El

0.50 [0.0197] 94.455 to 94.485

94.270

I:

0

oversize

[3.7187to3.7199]

[3.7114]

.8

'"

p::;

DI

0.05 to 0.45

Protrusion

[0.0020 to 0.0177]

Check bearing

-0.25

to 0.15

clearance.

SC

[-0.0098 to 0.0059]

Clearance between

(0.000 to 0.016)

(0.050)

piston pin and bore ([0.0000 to 0.0006))

([0.0020]

Piston weight

5g[0.180z]

difference per engine

orless

DI - Direct injection SC - Swirl chamber

2-4

Page 25

MAINTENANCE STANDARDS

Unit: mm [in.]

Graup

Inspeetion Point

Repair Service

Nominal Assembly Standard Limit Limit

Value (Standard Clearance) (Clearance) (Clearance)

Remark

1.50

[0.0591]

(0.200)

([0.0079])

(0.150)

([0.0059])

(0.150)

([0.0059])

0.30 to 0.50

[0.0118 to 0.0197]

(0.07 to 0.11)

([0.0028to 0.0043])

(0.045 to 0.085)

([0.0018to 0.0034])

(0.025 to 0.065)

([0.0010to 0.0026])

2.0

[0.079]

4.5

[0.177]

No.1 ring

No.2 ring

Gil ring

~

g]

No.

1,2

rings

~

~

-

~

Gil

ring

U]

I::

Q) Cl)

~

.S

v~f-----~---+':':--------::+-----j-':'::------=':+----------j

..0

I::

Q) o:l

U Q)

§>t-------j-"--..........::.-+--------..........::.+----+-----+-----------i

~

g

~

5i:J

U

"0

o

...

Cl)

.S

~

I::

I::

o

U

Diameter

Clearance between

pin and bushing

Inside diameter

of

bushing

Bend

and twist

Clearance between

crankpin

and

conneet-

ing rad bearing

Endplay

30

[U8]

30

[U8]

33

[1.30]

29.994 to 30.000

[l.l809 to

l.l8

II]

(0.020 to 0.051)

([0.0008to 0.0020])

30.020 to 30.045

[l.l819 to l.l829]

0.10/100

[0.0039/3.94]

or less

(0.030 to 0.090)

([0.0012to 0.0035])

(0.15 to 0.35)

([0.0059to 0.0138])

0.15

[0.0059]

(0.080)

([0.0032])

(0.200)

([0.0079])

(0.50)

([0.020])

Replace connecting

rad.

Rad

weight difference

per

engine

JO

g [0.35 oz]

orless

Flatness

Face runout

Deflection

0.15 [0.0059]

or less

0.02 [0.0008]

or less

0.50

[0.020]

0.05

[0.0020]

Straighten by cold

working or replace.

DI

U

E

o:l

U

Inlet

valve

SC

DI

Exhaust

valve

SC

A

=46.918:'2)

[1.847:ti~1

A=

46.916:'2)

[1.8471:'2~1

A=

46.878::;N

11.8456:'2~1

A=

46.880:'2)

[1.8457:'2~1

6.682

[0.2631]

6.684

[0.2632]

6.722

[0.2647]

6.720

[0.2646]

6.182

[0.2434]

6.184

[0.2435]

6.222

[0.2450]

6.220

[0.2450]

Tcr

B

No.l,

2 (S4S)

No.l,

2,3

(S6S)

No.3 (S4S)

No.4

(S6S)

54

[2.13]

53

[2.09]

53.94 to 53.96

[2.1236 to 2.1244]

52.94 to 52.96

[2.0842 to 2.0850]

53.90

[2.1220]

52.90

[2.0827]

End

play

5

[0.20]

(0.JOto 0.25)

([0.0039 to 0.0098])

(0.30)

([0.0118])

Replace thrust plates.

2-5

Page 26

MAINTENANCE STANDARDS

Unit:mm

[in.]

Nominal Assembly Standard

Repair

Service

Group

Inspeetion Point

Limit

Limit

Remark

Value (Standard Clearance)

(Clearance) (Clearance)

Clearance between

(0.009 to 0.050) (0.100) Replace bushing.

shaft and bushing ([0.0004 to 0.0020]) ([0.0040])

~

30

(0.05 to 0.20) (0.35)

til

<l.l

End play

...

co

Replace thrust plates.

t'l

[1.18]

([0.0020 to 0.0079])

([0.0138])

<l.l

...

co

<l.l

co

::a

Fit (interference) of

l:

......

ï§

bushing in crankcase

30

(0.035T to 0.076T)

~

bore

[1.18]

([0.0014Tto0.0030T])

Backlash

(0.03 to 0.18) (0.25)

Replace gears.

([0.0012 to 0.0071]) ([0.0098])

Clearance between (0.20 to 0.30) (0.50)

outer rotor and case ([0.0012 to 0.0018]) ([0.0197])

Diameter of main

16 15.985 to 16.000

shaft (case side) [0.63]

[0.6293 to 0.6299]

Diameterof mainshaft

14 13.957 to 13.975

(oilpump bushingside) [0.55]

[0.5495 to 0.5502]

0..

Clearance between (0.032 to 0.074) (0.15)

Replace

pump

case

E

::>

main shaft and case ([0.0013 to 0.0029]) ([0.0059])

or pump assembly.

E

0..

.2

(5

Clearance between

til

(0.025 to 0.111) (0.200)

Replace bushing or

;..,

main shaft and oil

til

l:

pump bushing

([0.0010 to 0.0044]) ([0.0079])

pump assembly.

0

.~

.::l Clearance between

(0.13 to 0.15) (0.20)

...

..0

outer and inner rotors ([0.0051 to 0.0059]) ([0.0079])

::I

....l

Clearance between

(0.04 to 0.09)

(0.15)

Replace

cover

or

rotors and cover ([0.0016 to 0.0035]) ([0.0059])

case.

Valve

0.35±0.05

Reliefvalve

opening

(3.5±0.5)

[50±7]

pressure,

Safety valve

MPa

(kgfïcm')

1.1 (11) [156]

With oil

cooler

[psi]

E

g

Temp. at which valve

76.5±I.soC

.2

til

starts opening [170±2.7°F]

;..,

til

til

0

co

E

Temp. at which valve

.=

...

<l.l

lift is more than 8 90°C [194°F]

0

.J::

E-<

0

[0.3]

U

2-6

Page 27

MAINTENANCE STANDARDS

Unit: mrn [in.]

Nominal

Assembly Standard

Repair Service

Group Inspeetion Point

Limit

Limit Remark

Value (Standard Clearance)

(Clearance)

(Clearance)

17.65

18.14 to 19.12

Make

shirn adjustrnent.

DI

(180)

(l85

to 195)

Pressure varies by I

Valve opening

[2560]

[2632 to 2774]

(l0)

[142] per 0.1 mrn

pressure

11.77

II.77to

12.75

[0.004 in.] thickness

MPa

(kgf/cm')

SC

(120)

(l20

to 130)

ofshim.

[psi]

[1706]

[1707 to 1849]

Cl)

Test by meansofhand

a

N

N

DI

155°

tester, using diesel

s

0

'fJ

I:::

fuel, at 20°C [68°P]. If

>-.

I:::

o:

.S

Spray cone

Q)

Ü

angle

discharge pattern is

&;

Cl)

bad even after nozzle

ï?

.....

SC

0°

is washed in clean

diesel fuel, replace

nozzle tip.

Seat shallhold a testpressure

üil

tightness of

2 MPa (20

kgf/cm")

Wash or replace

needie valve seat

[284psi] lower thanvalve nozzle tip.

opening pressurefor 10seconds.

Diameter of

32

31.4

commutator [1.26] [1.24]

Runout of

0.03

0.\

commutator [0.0012]

[0.004]

Depth of

0.4

to 0.6

0.2 [0.008]

[0.016 to

commutator mold

0.024]

or less

Length

18

11

[0.71] [0.43]

~

Brush

Spring 30.4

19.6

a

""

force,

to 38.2

(2.0)

2:l

N

N (kgf) (3.1to 3.9)

'fJ

M

[4.4]

>-.

[Ibf]

[6.8to8.6]

'fJ

I

C;; :>

Thrust clearance of 0.5

u

N

oor more

OE

-

pinion shaft [0.020]

u

'-'

<1)

...

G:l

~

0.5 to 2.0

en

Pinion clearance

[0.020 to

0.079]

No-load characteristics

Locked

characteristics Magnetic switch

Voltage

Current

Speed Voltage Current

Torque

Switch-in

Nrn (kgf-m)

V A

min:'

V

A

[lbfft]

voltage V

130

3800

1120

31.36 (3.2)

11

3

[23.1]

8 or Iess

or less or

more

or less

or more

DI - Direct injection SC - Swirl chamber

2-7

Page 28

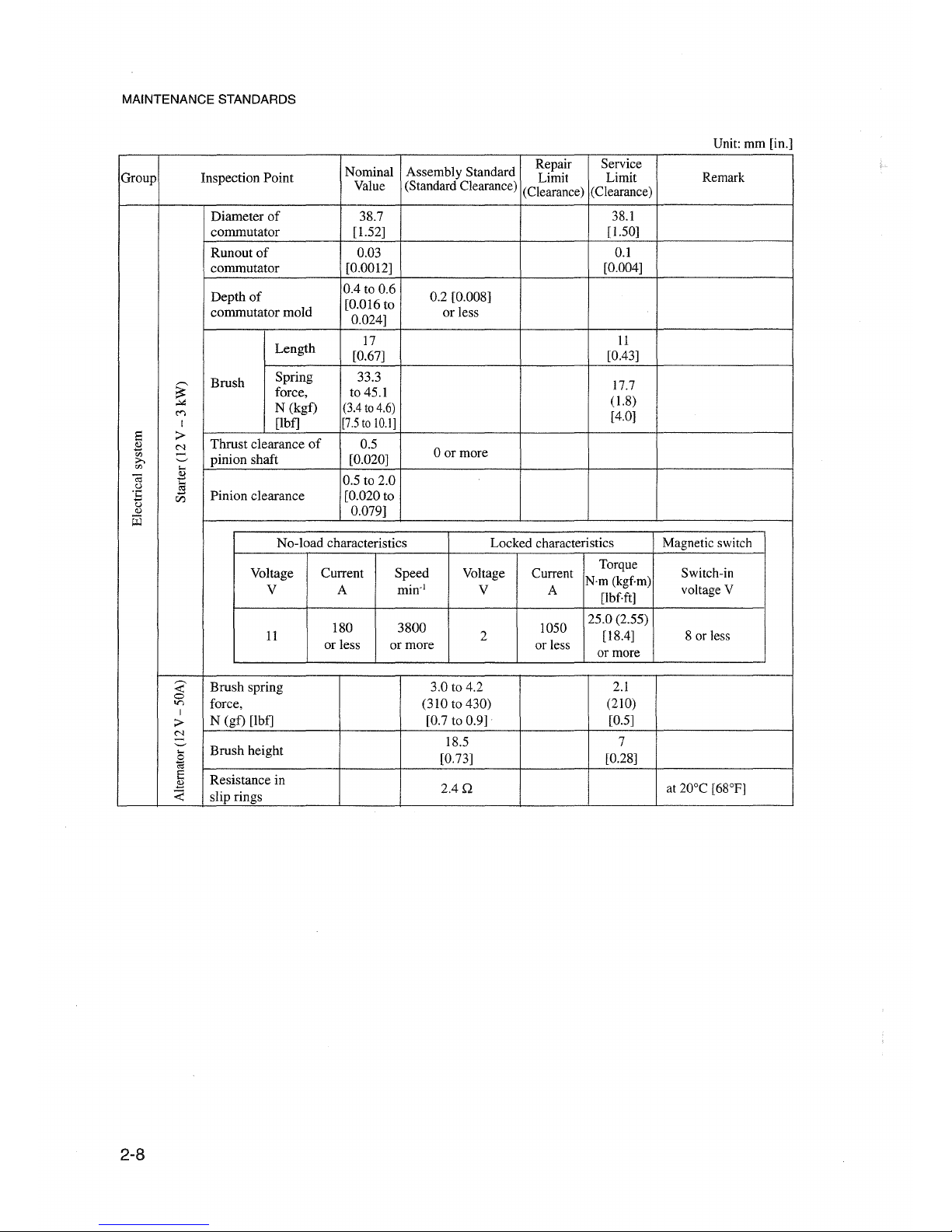

MAINTENANCE 8TANDARD8

Unit: mm [in.]

Nominal

Assembly Standard

Repair

Service

Group

Inspeetion Point

Limit

Limit

Remark

Value (Standard Clearance)

(Clearance)

(Clearance)

Diameter

of

38.7

38.1

commutator

[1.S2]

[I.SO]

Runout

of

0.03

0.1

commutator

[0.0012]

[0.004]

Depth

of

004

to 0.6

0.2 [0.008]

[0.016 to

commutator

mold

0.024]

or Iess

Length

17

11

[0.67]

[0.43]

,-..

Brush

Spring

33.3

17.7

~

force,

to

4S.1

..;.:

N (kgf) (3.4to 4.6)

(1.8)

c<)

[4.0]

I [Ibf] [7.5to

10.1]

Ei

>

Thrust clearance

of

O.S

~

C'1

oor more

on

-

pinion shaft

[0.020]

>-.

'-"'

on

....

-a

~

O.S

to 2.0

o

l§

oE

CZJ

Pinion clearance [0.020 to

()

0.079]

Il.l

~

No-laad

characteristics Locked characteristics Magnetic switch

Voltage

Current

Speed

Voltage

Current

Torque

Switch-in

Nrn

(kgf.m)

V

A

min:'

V

A

[lbf.ft]

voltage V

180

3800

lOS0

2S.0(2.S5)

11 2

[1804]

8 or less

or less or more

or less

or more

~

Brush spring 3.0 to 4.2

2.1

0

force, (310 to 430)

(210)

lr)

I

>

N (gf) [Ibf] [0.7 to 0.9]

[0.5]

N

'-"'

Brush height

18.S 7

....

[0.73]

[0.28]

~

E

Resistance in

B

2AQ

at 20°C [68°F]

~

slip rings

2-8

Page 29

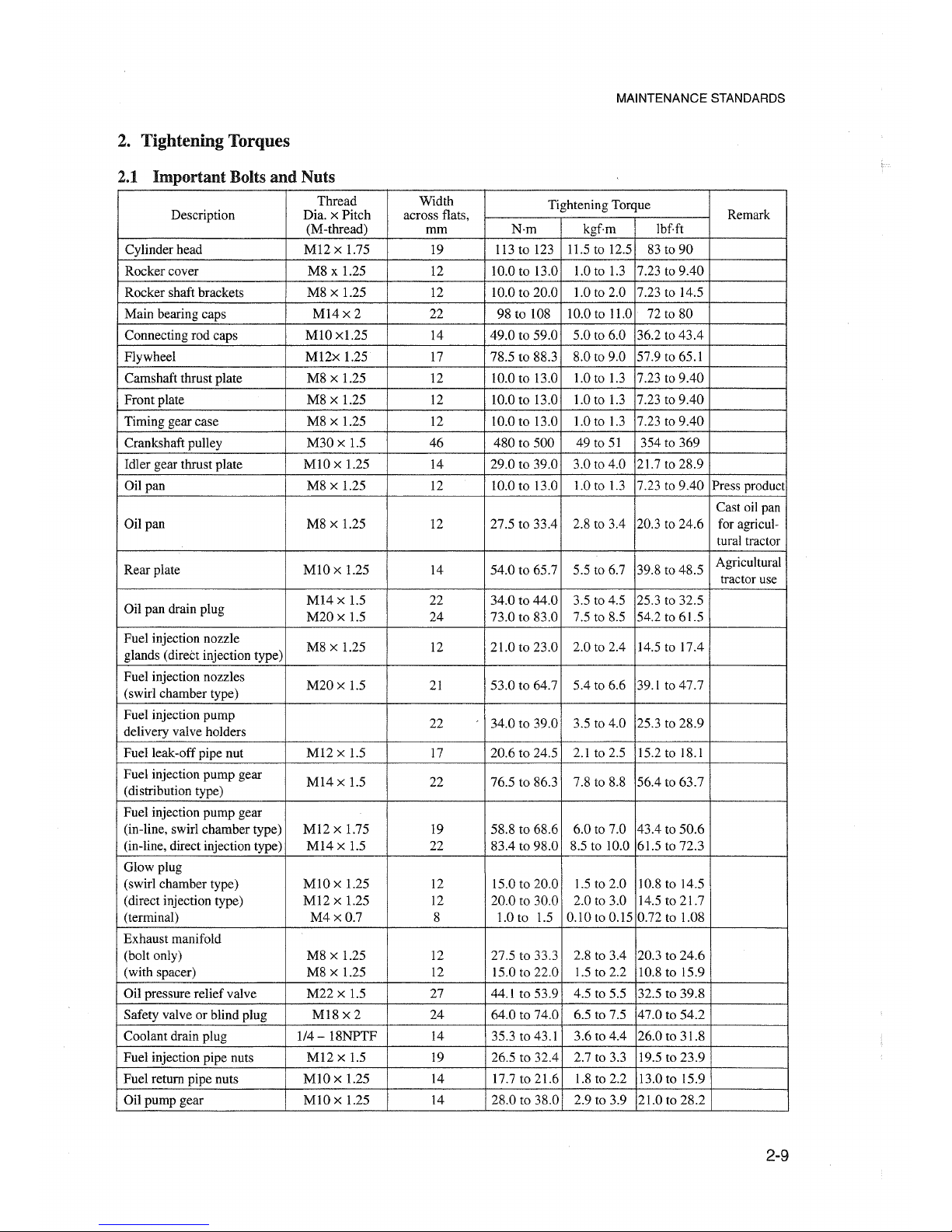

2. Tightening Torques

2.1 Important Bolts and Nuts

MAINTENANCE 8TANDARD8

Thread Width

Tightening Torque

Description

Dia. x Pitch

across flats,

Remark

(M-thread) mm

N·m

kgf-rn

IbHt

Cylinder head

M12 x 1.75

19 113 to 123

11.5 ta 12.5

83 ta 90

Rocker cover M8 x 1.25

12

10.0 to 13.0 1.0 ta 1.3

7.23 to 9.40

Rocker shaft brackets M8 x 1.25

12

10.0 ro 20.0 1.0 to 2.0 7.23 ta 14.5

Main bearing caps

M14x2

22

98 to 108

10.0 to 11.0 72 ta 80

Connecting rod caps

MlO

x 1.25

14

49.0 ta 59.0 5.0 to 6.0 36.2 ta

43.4

Flywheel

M12x

1.25

17 78.5 ta 88.3

8.0 ta 9.0 57.9 to 65.1

Camshaft thrust plate

M8 x 1.25

12 10.0 to 13.0 1.0 ta 1.3 7.23 ta

9.40

Front plate

M8 x 1.25

12 10.0 ta 13.0

1.0 to 1.3 7.23 to

9.40

Timing gear case M8 x 1.25

12 10.0 ta 13.0

1.0 to 1.3 7.23 to 9.40

Crankshaft pulley

M30

x 1.5

46 480 to 500

49 ro 51 354 to 369

Idler gear thrust plate

MlO x 1.25

14 29.0 to 39.0

3.0 to 4.0 21.7 ta 28.9

Oil pan

M8 x 1.25

12 10.0 to 13.0 1.0 ta 1.3 7.23 ro

9.40

Press product

Cast oil pan

Oil pan

M8 x 1.25

12 27.5 ta 33.4 2.8 to 3.4 20.3 to 24.6 for agricul-

tural tractor

Rear plate

MlO

x 1.25 14 54.0 ta 65.7 5.5 ta 6.7 39.8 to 48.5

Agricultural

tractor use

Oil pan drain plug

M14

x 1.5

22 34.0 ta 44.0

3.5 to 4.5

25.3 to 32.5

M20x

1.5

24 73.0 to 83.0 7.5 to 8.5

54.2 to 61.5

Fuel injection nozzle

M8 x 1.25

12 21.0 ta 23.0

2.0 ta 2.4 14.5 to 17.4

glands (direct injection type)

Fuel injection nozzles

M20x

1.5

21 53.0 to 64.7

5.4 ta 6.6 39.1 ta 47.7

(swirl chamber type)

Fuel injection pump

22 34.0 to 39.0

3.5 to 4.0 25.3 ta 28.9

delivery valve holders

Fuel leak-off pipe nut

M12

x 1.5

17 20.6 to 24.5

2.1 ta 2.5 15.2 ta 18.1

Fuel injection pump gear

M14

x 1.5

22 76.5 to 86.3

7.8 ta 8.8

56.4 to 63.7

(distribution type)

Fuel injection pump gear

(in-line, swirl chamber type)

M12

x 1.75 19 58.8 ta 68.6 6.0 ta 7.0 43.4 ta 50.6

(in-line, direct injection type)

M14

x 1.5

22 83.4 to 98.0 8.5 to 10.0 61.5 ta 72.3

Glow plug

(swirl chamber type)

MlO

x 1.25

12

15.0 to 20.0 1.5 to 2.0 10.8 ta 14.5

(direct injection type) M12 x 1.25 12 20.0 to 30.0 2.0 ta 3.0 14.5 to 21.7

(terminal)

M4xO.7

8

1.0 ta 1.5 0.10 ta 0.15 0.72 ta 1.08

Exhaust manifold

(balt only) M8 x 1.25

12 27.5 to 33.3

2.8 ta 3.4 20.3 to 24.6

(with spacer) M8 x 1.25

12 15.0 to 22.0

1.5 ta 2.2

10.8 to 15.9

Oil pressure reliefvalve

M22

x 1.5

27

44.1 ta 53.9 4.5 to 5.5

32.5

to 39.8

Safety valvearblind plug M18

x2

24 64.0 to 74.0 6.5 to 7.5 47.0 to

54.2

Coolant drain plug 1/4 - 18NPTF 14 35.3 to 43.1

3.6 to 4.4

26.0 ta 31.8

Fuel injection pipe nuts

M12

x 1.5

19 26.5 to 32.4 2.7 to 3.3 19.5 ta 23.9

Fuel return pipe nuts

MlO

x 1.25

14 17.7 ta 21.6

1.8 to 2.2 13.0 ta 15.9

Oil pump gear

MlO

x 1.25 14 28.0 ta 38.0 2.9 ta 3.9 21.0 to 28.2

2-9

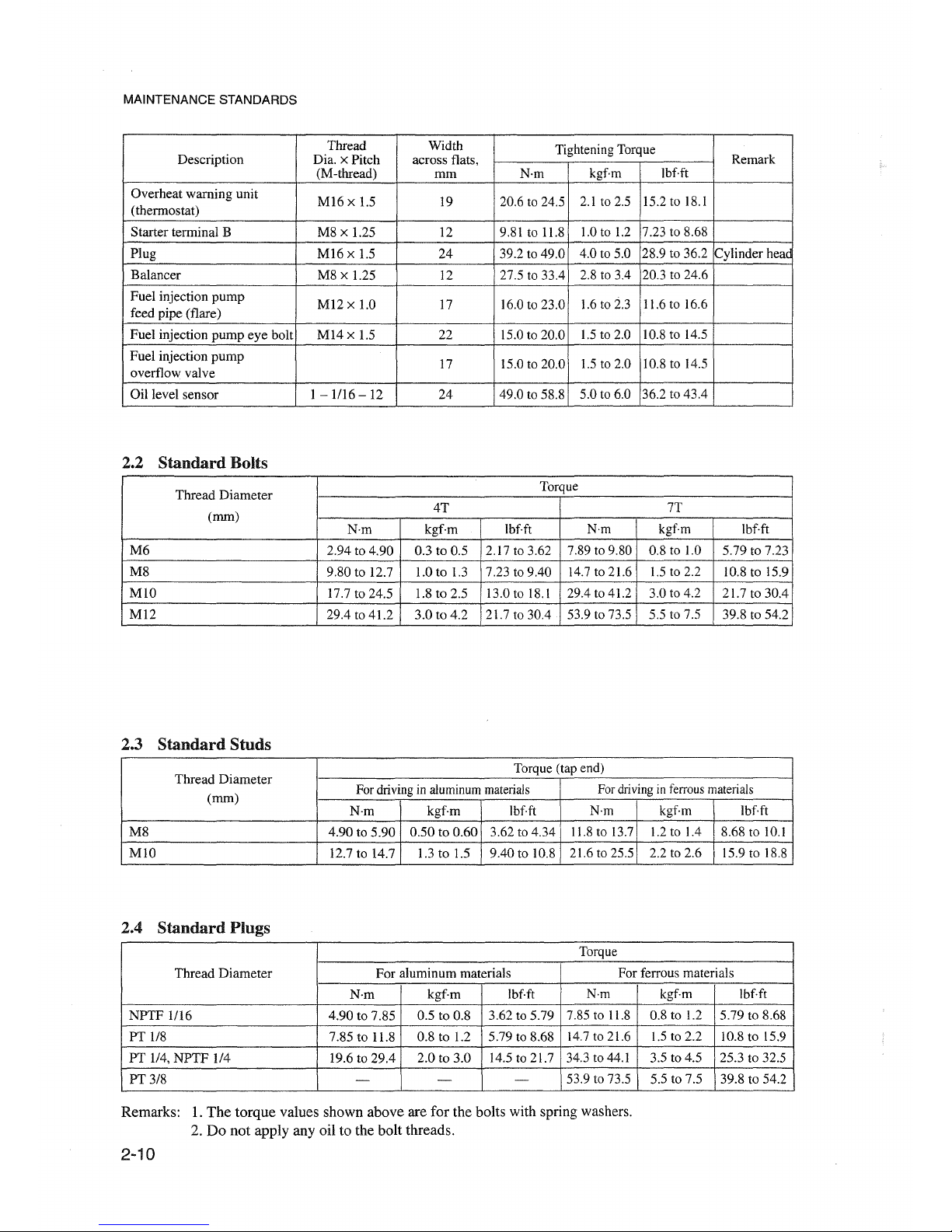

Page 30

MAINTENANCE STANDAROS

Thread Width

Tightening Torque

Description Dia. x Pitch across flats,

Remark

(M-thread)

mm

N·m

kgf-m lbf-ft

Overheat warning unit

M16 x 1.5 19 20.6 to 24.5

2.1 to 2.5 15.2 to 18.1

(thermostat)

Starter terminal B M8 x 1.25 12 9.81 to 11.8 1.0 to 1.2

7.23 to 8.68

Plug

M16 x 1.5 24 39.2 to 49.0

4.0 to 5.0 28.9 to 36.2 Cylinder head

Balancer

M8 x 1.25

12

27.5 to 33.4

2.8

to 3.4 20.3 to 24.6

Fuel injection

pump

M12 x 1.0

17

16.0 to 23.0 1.6 to 2.3

11.6

to 16.6

feed pipe (flare)

Fuel injection

pump

eye bolt

M14x

1.5 22 15.0 to 20.0

1.5 to 2.0 10.8 to 14.5

Fuel injection

pump

17

15.0 to 20.0

1.5 to 2.0 10.8 to 14.5

overflow valve

Oil level sensor

1-1/16-12

24 49.0 to 58.8

5.0 to 6.0 36.2 to 43.4

2.2

Standard

BoUs

Thread

Diameter

Torque

(mm)

4T

7T

N·m

kgf-rn lbf-ft N·m

kgf-rn

Ibf-ft

M6

2.94 to 4.90 0.3 to 0.5

2.17t03.62

7.89 to 9.80 0.8 to 1.0

5.79 to 7.23

M8

9.80 to 12.7 1.0 to 1.3 7.23 to 9.40

14.7 to 21.6 1.5 to 2.2

10.8 to 15.9

MlO

17.7t024.5

1.8 to 2.5

13.0 to 18.1 29.4 to 41.2

3.0 to 4.2

21.7 to 30.4

M12

29.4 to 41.2 3.0 to 4.2

21.7 to 30.4 53.9 to 73.5 5.5 to 7.5 39.8 to 54.2

2.3

Standard

Studs

Thread

Diameter

Torque (tap end)

(mm)

Fordriving in aluminummaterials

Fordrivinginferrousmaterials

N-m

kgf-m

lbf-ft

N·m

kgf-rn lbf-ft

M8 4.90 to 5.90 0.50 to 0.60 3.62 to 4.34

11.8to 13.7 1.2 to 1.4 8.68 to 10.1

MlO

12.7 to 14.7 1.3 to 1.5

9.40 to 10.8 21.6 to 25.5 2.2 to 2.6 15.9 to 18.8

2.4

Standard

Plugs

Torque

Thread

Diameter

For aluminum materials

For ferrous materials

N·m

kgfm

lbf-ft N·m

kgf-rn lbf-ft

NPTF

1/l6

4.90 to 7.85

0.5 to 0.8 3.62 to 5.79

7.85 to 11.8 0.8 to 1.2 5.79

to 8.68

PT 1/8 7.85 to 11.8 0.8 to 1.2 5.79 to 8.68

14.7 to 21.6 1.5 to 2.2 10.8 to 15.9

PT 1/4,

NPTF

1/4 19.6 to 29.4 2.0 to 3.0

14.5 to 21.7 34.3 to 44.1 3.5 to 4.5 25.3 to 32.5

PT3/8

-

-

- 53.9 to 73.5

5.5 to 7.5 39.8 to 54.2

Remarks: 1.

The

torque values shown above are for the balts with spring washers.

2. Do not apply any oil to the bolt threads.

2-10

Page 31

3. Sealants

and

Lubricants Table

MAINTENANCE STANDARDS

Apply to Mating part Sealant or Lubricant How to Use

üil

pan Crankcase Three Bond

12Ü?C

Apply to seal.

Rear bearing cap

Rear bearing cap Three Bond 1212

Apply to corners befare

seat on crankcase installing cap.

Side seals

Crankcase rear bearing cap

Three Bond 1212 Apply to side seals.

Cylinder head

Cylinder head Three Bond 1386D Apply to plug hole.

coolant hole plug

Crankcase coolant

Crankcase Three Bond l386D Apply to plug hole.

hole plug

Crankcase oil hole

Crankcase

Three Bond 1386D Apply to plug hole.

plug

Return oil hole

blind plug or pipe Crankcase Three Bond 1344 Apply to blind plug or pipe.

of crankcase

Crankshaft threads Crankshaft pulley nut Three Bond 1212

Apply to crankshaft thread before

tightening nut.

2-11

Page 32

Page 33

SPECIAL

rOOlS

Special

TooI

List 3-2

Page 34

SPECIAL TOOLS

Special

Tooi List

Taal name

Valve spring pusher

Valve guide remave

Valve guide installer

Stem seal installer

Valve seat insert

caulking

taal

Piston ring pliers

Part No.

30691--04500

32A91--o0300

3

2A91--o0

100

32A91-10200

Inlet valve:

36791--00200

Exhaust valve:

34491-03020

31391-12900

Shape

Use

Valve spring removal/

installation

Valve guide removal

Valve guide installation

Valve stem installation

Valve seat installation

Piston ring removal/

installation

Piston installer

34491--00200

®

Piston installation

Idler shaft puller

MH061077 Idler gear shaft removal

3-2

Page 35

SPECIALTOOLS

Tooi name Part No.

Shape

Use

Oil seal sleeve installer

30691-13010

set

Crankshaft rear oil seal sleeve

installation

Engine tuming

Compression pressure

measurement

Compression pressure

measurement

Compression pressure

measurement

58309-73100

Gage

adaptor 32A91-01100

(direct injection)

~

Gage adaptor

30691-21100

(swirl chamber)

~

Compression gage

33391-02100

Turning socket

Socket

34491-00300

Camshaft thrust plate and rocker

bracket installation

Connecting

rad

bushing puller

Camshaft bushing

instal1er set

MH061236

30691-00010

< ,

~

r

/-<~

j. / .,-'

Connecting rad bushing

rernoval/installation

Camshaft bushing removal!

installation

Oil

pump

bushing

instal1er

32A9]-00400

Oil pump bushing installation

3-3

Page 36

Page 37

OVERHAUL INSTRUCTIONS

1.

DeterminationofOverhaul

Timing

4-2

2.

Testing

the

Compression

Pressure

4-3

Page 38

OVERHAUL INSTRUCTIONS

1. Determlnation of OverhaulTiming

In most cases the engine should be overhauled when

the engine's compression pressure is low. Other

factors that indicatethe necessity of engineoverhaul

are as follows:

(a) Decreased power

(b) Increased fuel consumption

(c) Increased engine oil consumption

(d)

Increased

blow-by

gas volume

through

the

breather due to abrasion at the cylinder liner and

the piston ring

(e) Gas leakage due to poor seating of the inlet and

the exhaust valves

(f)

Starting problems

(g) Increased noise from engine parts

(h) Abnormal color of exhaustgas from engine after

warm-up

Any one or a combination of these symptoms may

indicate thatengine overhaul is required. Of the items

listed above some are not directly related to the

necessity of engine overhaul. Items (b) and

(f)

are

more likely to be affected substantially by

• Injection volume of the fuel injection pump

• Fuel injection timing

• Wearofinjection-pump plunger

• Fitting of the injection nozzle

• Condition of electrical equipment: battery,

starter, or altemator

Item

(d)

above,

however,

requires

special

consideration becausedecreased pressure due to wear

at the cylinder liner and the piston ring is one

ofthe

most

obvious

signs

that

the

engine

requires

overhauling.

The most effective way to make a decision is by

testing the compression pressure; other factors are

to be considered secondarily.

4-2

Page 39

2. Testlag the Compression Pressure

(1) Remove the injection nozzle from the cylinder

head where the compression pressure is to be

measured.

(2) On the direction injection type engine, attached

gage adaptor (32A9l-01100)tothecylinder, and

conneet thecompression gage (33391-02100) to

the adaptor.

On the swirlchambertype engine, attachthe gage

adaptor

(30691-21100) to the cylinder, and

conneetthecompression gage (33391-02100) to

the adaptor.

(3) Crank the engine by means of the starter, with

the governor stop lever pulled (the fuel supply

shut

off),

and

read

the

compression

gage

indication

when the

engine

running at the

specified speed.

(4)

If

the compression pressure is lower than the

repair limit, overhaul the engine.

r------

&CAUTION

1------

(a) Measure the compression pressure on all

cylinders.Itis

notagood

practice to

measure the compression pressure on only

few cylinders, andpresurnethe compression

on the remaining cylinders.

(b) Compression pressure varies with engine

speed. Check engine speed when measuring

the compression pressure.

Unit:

MPa

(kgf/cm") [psi]

Item

Assembly Repair

Standard Limit

Direct

2.9 2.6

injection

(30) (27)

Compression

[427] [384]

pressure

3.2 2.8

Swirl

(33) (29)

chamber

[469] [413]

.--------4

l

NOTE

Jr--------,

Measure the compression pressure with the

engine running at 300 min-I.

OVERHAUL INSTRUCTIONS

Measuring compression pressure (direct injection type)

Measuring compression pressure (swirl chamber type)

4-3

Page 40

OVERHAUL INSTRUCTIONS

......-------i[&CAUTION

JI-------.

(a) Measure the compression pressure atregular

intervals to obtain correct data.

(b) The compression pressure will be slightly

higher

ina new or overhauled engine due to

new piston rings, valve seats, etc. Pressure

will drop gradually by the wear of parts.

4-4

Page 41

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

1. Adjustments 5- 2

1.1 Valve Clearance 5- 2

1.2 Fuel System Bleeding 5- 3

1.3 Fuel Injection Timing 5- 4

1.4 No-load Minimum (Idling) Speed and Maximum Speed Setting 5- 5

1.5 V-belt Inspeetion and Adjustment 5-10

2. BenchTesting .. 5-11

2.1 Starting Up 5-11

2.2 Inspeetion After Starting Up 5-11

2.3 Bench Testing (Dynamometer) Conditions 5-11

2.4 Inspeetion and Adjustment After Bench Testing 5-11

3. Performance Tests 5-12

3.1 Engine Equipment Condition 5-12

3.2 Tests and Their Purposes 5-12

3.3 Other Inspections 5-12

3.4 Adjustment Engine Output 5-12

Page 42

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

1. Adjustments

1.1 ValveClearance

Valve clearance should be inspected and adjusted

when the engine is cold.

Unit: mm [in.]

Item Assembly Standard

Valveclearance

InIet

0.25 [0.0098]

(cold setting)

Exhaust

(l)

Inspeetion

(a) Inspeet the valve clearance in the injection

sequence.Tocheck, turn thecrankshaft by the

specified crank angle in the normal direction

to bring the piston to the top dead center of

the compression stroke.

Injection sequence

Crank angle

S4S

1-3-4-2

180

0

S6S

1-5-3-6-2-4

120

0

(b) Put socket (58309-73100) and ratchet handle

on the crankshaft pulley nut and turn the

crankshaft in the normal direction (clockwise

as seen from the front end).

Unit: mm [in]

Width across flats of

crankshaft pulley nut

46

[1.81]

(c) The top dead center on compression stroke

ofNo.1piston is identified by the timing mark

"0" (on the crankshaft pulley) being aligned

with the pointer on the gear case. With the

pistonsopositioned, boththe inlet and exhaust

valverocker anns are not being pushed up by

their pushrods.

(d) Insert afeeIer gage in between the rocker arm

and valve cap, and check the clearance.

5-2

ol

I!

I I I I

1401

Checking va1veclearance (turning)

Page 43

(2) Adjusting

(a) Loosen the loek nut of the adjusting screw.

Adjust the clearance by tuming the screw in

either direction to the extent that the gage is

slightly gripped between the rocker arm and

valve cap.

(b) After adjusting the clearance, tighten the loek

nut.Inspeet the clearance again and make sure

that it is correct.

1.2 Fuel System Bleeding

(l)

Fuel filter

(a) Loosen air vent plug on the fuel filter by

tuming it about 1.5 rotations.

(b) Unlock bleeding pump plunger by tuming it

counterclockwise, and operate the pump.

(c) Tighten the air vent plug when the fuel flows

without bubbles.

(2) Fuel injection pump

(a) Loosen air vent plug on the injection pump

by tuming it 1.5 rotations

(b) Unlock bleeding pump plunger by tuming

counterclockwise, and operate the pump.

(c) Tighten the air vent plug when the fuel flows

without bubbles.

,---------i(

&DANGER

11--

---,

When fuel overflows from the air vent plug, wipe

thoroughly with a cloth. Spilled fuel is a fire

hazard.

,----------1

NOTE

f----------,

If the vent plug is tightened before the bleeding

pump plunger is locked, fuel pressure acts on the

feed pump, making it difficult to restore the

plunger.

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

Adjusting valve clearance

Air vent plug

5-3

Page 44

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

1.3 Fuel Injection Timing

The injection timing varies according to the output,

speed and specifications of the engine. Be sure to

verify the timing by referring to the specifications.

(1) Bringing the No.l cylinder piston to thetop dead

center on compression stroke

(a) Put socket (58309-73100) on the crankshaft

pulley nut and turn the crankshaft in the

normal direction (clockwise as seenfrom the

front end).

(b) Stop turning the crankshaft when the timing

the mark

"0"

on the crankshaft pulley is

aligned with the pointer.

(c) Push down on the inlet and exhaust valve

rockerarms fortheNo.l cylinder tomake sure

they are not being pushed up by the pushrods

(the inlet and exhaust valves have some

clearance).

(2) Checking injection timing

(a) Remove delivery valve holder from the No.l

plungerofthe

injection

pump. Remove

delivery valve and spring from the holder.

Restore the holder to the pump.

(b) Conneet a spare injection pipe to the No.1

plunger, with its free end held downward so

that you can observe the fuel flow from that

end.

(c) Turn the crankshaft to bring the No.1 piston

to 60° position before top dead center on

compression stroke.

(d) While operating the priming pump to allow

the fuelto flowfrom theinjectionpipe, slowly

turn the crankshaft in the normal direction.

Stop turningthe crankshaft when thefuelflow

stops.

(e) Make sure the timing mark on the crankshaft

pulley is aligned with the pointer.

5-4

Ol

I I I I I

14Ql

Finding top dead center on compression stroke

Delivery valve

hOlde'--t

"""'

Spring

Delivery valve

_.=

,,,-,

Checking injection timing - I

(Removing delivery valve)

Checking injection timing

- 2

Page 45

(3) Adjusting injecting timing

(a) If the injection timing is retarded, move the

injection pump toward the crankcase. If the

timing is advanced, move the pump away

from the crankcase.

(b) One graduation of the scale on the injection

pump coupling changes the timing by 6° in

terms of crank angle.

1.4 No-lead

Minimum

(Idling) Speed

and

Maximum

Speed Setting

.-----------I(

&CAUTION

)f---------.

a)

The

no-Ioad minimum (idle) speed and

maximum speed are set for each engine on

the test bench at the factory. The set bolts

are sealed. These settingsareto be inspected

and adjusted at our authorized service shop

only.

b) After adjusting the govemorby breaking the

seals, be sure to re-seal all visible stoppers,

making them appear as if they were sealed

at the factory.

c)

When

inspecting

and

adjusting

these

settings, be on standby to operate the engine

stop lever manually in the event of engine

overrun.

For inspeetion and adjustment, warm up the engine

thoroughly until the coolant and oil temperature are

above 70°C [l58°F].

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

......

To retard

injection

timing

--~,.,.

Adjusting injection timing - I

Adjusting injection timing - 2

5-5

Page 46

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

(1) Starting engine

(a) Pull speedcontrollevertothe high speed side.

Operatethe starterswitch to crank the engine.

(b)

The

engine

will

fire up at 150

min-lof

cranking speed. When the engine fires, hold

the engine speed between 800 and 1000

min-I.

(c) When the engine runs with a steady speed,

move the speedcontrollever back to the idle

speed position.

(2) Setting no-Ioad minimum (idle) speed

Govemor

setbolt

-

Speed control lever

Low idle speed

set screw

Idlesub-spring

adjustingscrew

(a) Hold the speed control lever at the position

for no-Ioad minimum (idle) speed and setlow

idle speed set screw.

...----------JLt,CAUTION

1-----

__

If

a critical speed (the speed at which the engine

excessively vibrates due to torsional resonance)

might exist, shift the setting to a lower or higher

idle speed level.

(b) The engine speed will increase when the low

idle speed set screw is turned clockwise.

(c) Ifthe engine speedtends to fluctuate, turn idle

sub-spring adjusting screwclockwise to bring

this spring into slight contact with the tension

lever for eliminating fluctuation.

...----------JLt,CAUTION

1-----

__

Tightening the idle sub-spring adjusting screw

is likely to cause the engine to overspeed when

the load is removed during operation. Be sure to

tighten

this

adjusting

screw

just

enough

to

eliminate the unstable condition.

5-6

Low idle speed

set screw

Setting no-Ioad minimum (idle) speed

Idle sub-spring

adjusting screw

Setting idle sub-spring adjusting screw

Page 47

(3) Setting rack (maximum output)

(a) Hold the speed controllever at the position

for the indicated output and speed.

(b) Under this condition, check to be sure that

the engine is running in a steady state.

(c) With the engine running in a steady state,

adjust the ful1-load stopper bolt. Tighten or

loosen this bolt to find out the position where

the engine delivers the rated output.

(d)

Af

ter adjusting the stopper bolt, back it off

slowly

while

observing

the speed. Stop

backing off the stopper bolt just when the

engine speed begins todecreasefromthe rated

level and secure itin thatposition with itsloek

nut.

(e) At this time, the speed control lever should

be in the maximum speed position.

(f)

Tuming the fuIl-load stopper bolt clockwise

will increase the injection quantity (engine

output), and vice versa.

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

Settingrack

(maximum

output)

(4) Setting govemor (maximum speed)

(a) Apply fuIl load to the engine and hold the

speed control lever at the position for the

indicated maximum speed.

(b) Set govemor set bolt (maximum speed set

bolt) at the position for the indicated speed.

Governor

set bolt

Settinggovernor

(maximum

speed)

5-7

Page 48

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

(5) Deterrnining speed regulation (speed droop)

[I] Speed regulation upon removing load

(a) Run the engine with the speed control lever

set atthe position for the rated load and speed.

(b) Vnder this condition, remove the load to bring

the engine into no-load condition. Do not

move the speed contral lever.

(c)

The

engine

speed

will

increase

once

and

decrease and settle at a new steady state level

as

shown.

Read

the

highest

speed

(N2)

occurring in this transition and the speed

(N3)

af

ter

settling,

and

the

time

(tr)

from

the

momentofremoving the load at the initial

speedtbli) to the settling at the new level

(N3).

[2] Speed regulation upon applying load

With the engine runningunderno-loadcondition

subsequentto the condition mentionedin (b), [1],

above, and with the speed control lever held in

the same position as above, apply the prescribed

load instantaneously to the engine: the engine

speed will decrease once and increase, as shown,

and settle at a new steady state level. Read the

lowest speed (Ns) occurring in this transition and

the speed

(N6)

after settling, and the time (ts) from

N4toN6.

[3] Calculate the speed regulation

From the values obtained in [1]

and

[2], above,

compute

the

speed

regulation

for

each

load

change. A totaloffour percent values of speed

regulation are to be determined by using the

indicated forrnulas.

If the computer values are at varianee with the

prescribed values, "governor notch adjustment"

should be made to eliminate the varianee.

5-8

Speed regulation upon removing load

N,

Instantaneous speed Steady-state speed

regulation

(%)

regulation (%)

Nz-

NI

N3-NI

NI

X 100

NI

X 100

NI =initial speed, min-I, before load is

removed

N, = highest speed, min-I,during transitional

period

N3

=speed, min-I,at which the engine settles

after load is removed

ti =stabilization time

Speed

regUlatiO~n

upqn,applying load

N.

N,

Instantaneous speed Steady-state speed

regulation

(%)

regulation

(%)

N4-

Ns

N4-N6

N4

X 100

N4

X 100

N4

= initial speed, min-I, before load is

applied

Ns = lowest speed, min-I, during transitional

period

N6

=speed, min-I,at which the engine settles

after load is applied

tz = stabilization time

Page 49

(6) Setting no-load maximum speed (make governor

notch adjustment)

(a) This adjustment is to be made by turning the

adjustingscrew for theswivellevertoincrease

ordecrease the preload ofthe govemor spring.

(b) Togainaccess to the adjusting screw, remove

the plug at the top of the governor housing.

Turn the speed control lever all the way to

the low idle position: this will turn up the

swivellever, pointing the head oftheadjusting

screw toward the plug hole. Insert a flat-tip

screwdriver through the hole to catch the

screw head.

(c) Tightening the adjusting screw will increase

the preload of the governor spring to narrow

the

speed

regulation;

loosening

it will

decrease the preload to widen the regulation.

One notch corresponds to 1/4 turn

of

the

adjusting screw and to 3 to 5 speed change of

the engine speed.

(d) Changing the setting of this adjusting screw

changes the governorsetting (for limiting the

maximum speed). After making a governor

notch adjustment, be sure to readjust the

governor setting, as explained in (4), above.

(e) Tightening the adjusting screw, mentioned

above, will increase the maximumspeed, and

vice versa.

,---------i!h

CAUTION

1---------,

Never loosen the adjusting screw by more than

20 notches (5 turns) frorn the fully tightened

position, or the control action of the governor

will become hazardous.

(7) Seal the set bolts.

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

Adjusting speed reguJation

5-9

Page 50

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

1.5 V-belt Inspeetion

and

Adjustment

Push the belt inward with thumb pressure exerted

midway between the pulleys, as shown, to check the

belt tension (deflection).

If

the tension is incorrect,

loosen the adjusting bracket bolt and mounting bolt,

and move the altemator in or out.

Item

V-belt deflection

5-10

Unit: mm [in.]

Assembly Standard

12 [0.5]

Checking V-belt

Page 51

2. Bench Testing

An

overhauled

engine

should

be

tested

for

performance on a dynamometer. This test is also for

breaking in the major running parts of the engine.

To test the engine, follow the procedures described

below:

2.1

Starting

Up

(l)

Inspeetthe levels in the radiator, oil pan, and fuel

tank. Prime the fuel and cooling systems to bleed

air out.

(2) Crank the engine with the starter for 15 seconds

to permit lubricating oil to circulate through the

engine. Por this cranking, do not supply fuel to

the engine, placingthe stop lever in stop position.

(3)

Move

the

speed

control lever slightly in the

direction of increasing fuel injection, and turn

the starter switch to START to start the engine.

Do not move the control lever to the "full fuel

injection" position.

(4)After the engine starts, let it idle under no load

by operating the speed control lever.

2.2 Inspeetion

After

Starting

Up

Af

ter starting up

the

engine, check the foIlowing

points.

Ifyou

find anythingwrong, immediately stop

the engine, then investigate the cause.

(1) Lubricatingoil pressureshould be 0.3 to0.5 MPa

(3 to 5 kgf/cm") [43 to 71 psi] at rated speed or

0.1

MPa(lkgf/cm") [14.2 psi] at idling speed.

(2) Coolant temperature should be 75 to 85°C [167

to 185°P].

(3)

Lube

oil temperature should be 60°C to 95°C

[l40oP

to 203"F], (Varies according to engine

specifications.)

(4) Checkfor leakage of oil, coolant, fuel, especiaIly

oil

leakage

from

oil

pipe

connections

for

turbocharger lubrication.

(5) Knocking shoulddie away as coolant temperature

rises. No other defective noise should be heard.

(6)

Check

for exhaust color and abnormal odors.

ADJUSTMENTS, BENCH TEST,

PERFORMANCE

TESTS

2.3 Bench Testlng (Dynamometer)

Conditions

Step

Speed (min-I)

Load (PS) Time (min.)

1

1000

No-load

30

2 1500

25%

30

3

25%

10

-

(According to

4

engine specifi-

50%

10

-

5

cation)

75% 30

-

6

100%

20

2.4 Inspeetion

and

Adjustments Af

ter

Bench Testing

(a) Adjusting valve clearance

(b) Adjusting injection timing

(c) Re-tightening external bolts and nuts

5-11

Page 52

ADJUSTMENTS, BENCH TEST, PERFORMANCE TESTS

3. Performance Tests

There are various performance test procedures, and here the procedures for "Earth moving machinery

Engines, Part 1 : Test code

of

net power (JIS D 0006-1)" and "Earth moving machinery Engines, Part 2 :

standard format of specifications and tests methods of diesel engines (JIS D 0006-2)" are described. Other

test items may be required on application. Engine performance isjudged with integrated test results.

3.1 Engine Equipment Condition

Engine must be equipped with such standard auxiliaries as cooling fan, air cleaner and altemator.

3.2 Tests

and

TheirPurposes

(1) Operation load test

Conduct this test to evaluate engine output, torque, fuel consumption rate and governor performance under

various load conditions.

(2) Continuous load test

Operate the engine continuously for 10 hours at 90% load (continuous load application) of nominal net