Page 1

Mitsubishi Industrial Robot

RV-4/7/13/20FM-SE Series

INSTRUCTION MANUAL

ROBOT ARM SETUP & MAINTENANCE

BFP-A3324-C

Page 2

Page 3

All teaching work must be carried out by an operator who has received special

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

Safety Precautions

CAUTION

CAUTION

WARNING

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

training. (This also applies to maintenance work with the power source turned

ON.)

Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures

of operating the robot, and to the measures to be taken when an error occurs

or when restarting. Carry out work following this plan. (This also applies to

maintenance work with the power source turned ON.)

Preparation of work plan

Prepare a device that allows operation to be stopped immediately during

teaching work. (This also applies to maintenance work with the power source

turned ON.)

Setting of emergency stop switch

During teaching work, place a sign indicating that teaching work is in progress

on the start switch, etc. (This also applies to maintenance work with the power

source turned ON.)

Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the

operator and robot.

Installation of safety fence

Establish a set signaling method to the related operators for starting work, and

follow this method.

Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other

related devices, etc., and confirm that there are no errors.

Inspection before starting work

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

Refer to the actual "Safety Manual" for details.

When automatic operation of the robot is performed using multiple control

devices (GOT, programmable controller, push-button switch), the interlocking of

operation rights of the devices, etc. must be designed by the customer.

Use the robot within the environment given in the specifications. Failure to do

so could lead to a drop or reliability or faults. (Temperature, humidity,

atmosphere, noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting

the robot in a non-designated posture could lead to personal injuries or faults

from dropping.

Always use the robot installed on a secure table. Use in an instable posture

could lead to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to

personal injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation

before starting automatic operation. Failure to do so could lead to interference

with peripheral devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to

do so could lead to personal injuries.

Never carry out modifications based on personal judgments, or use nondesignated maintenance parts.

Failure to observe this could lead to faults or failures.

Page 5

When the robot arm has to be moved by hand from an external area, do not

WARNING

CAUTION

CAUTION

DANGER

DANGER

DANGER

CAUTION

CAUTION

place hands or fingers in the openings. Failure to observe this could lead to

hands or fingers catching depending on the posture.

Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during

automatic operation, the robot accuracy could be adversely affected. Moreover,

it may interfere with the peripheral device by drop or move by inertia of the arm.

Do not turn off the main power to the robot controller while rewriting the

internal information of the robot controller such as the program or parameters.

If the main power to the robot controller is turned off while in automatic

operation or rewriting the program or parameters, the internal information of the

robot controller may be damaged.

Do not connect the Handy GOT when using the GOT direct connection function

of this product. Failure to observe this may result in property damage or bodily

injury because the Handy GOT can automatically operate the robot regardless

of whether the operation rights are enabled or not.

Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

Attach the cap to the SSCNET III connector after disconnecting the SSCNET

III cable. If the cap is not attached, dirt or dust may adhere to the connector

pins, resulting in deterioration connector properties, and leading to malfunction.

Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not

being released. In order to prevent errors occurring, please be sure to check

that all functions (such as the teaching box emergency stop, customer emer

gency stop, and door switch) are working properly after the wiring setup is com

pleted.

Use the network equipments (personal computer, USB hub, LAN hub, etc)

confirmed by manufacturer. The thing unsuitable for the FA environment

(related with conformity, temperature or noise) exists in the equipments

connected to USB. When using network equipment, measures against the noise,

such as measures against EMI and the addition of the ferrite core, may be

necessary. Please fully confirm the operation by customer. Guarantee and

maintenance of the equipment on the market (usual office automa

equipment) cannot be performed.

tion

-

-

Page 6

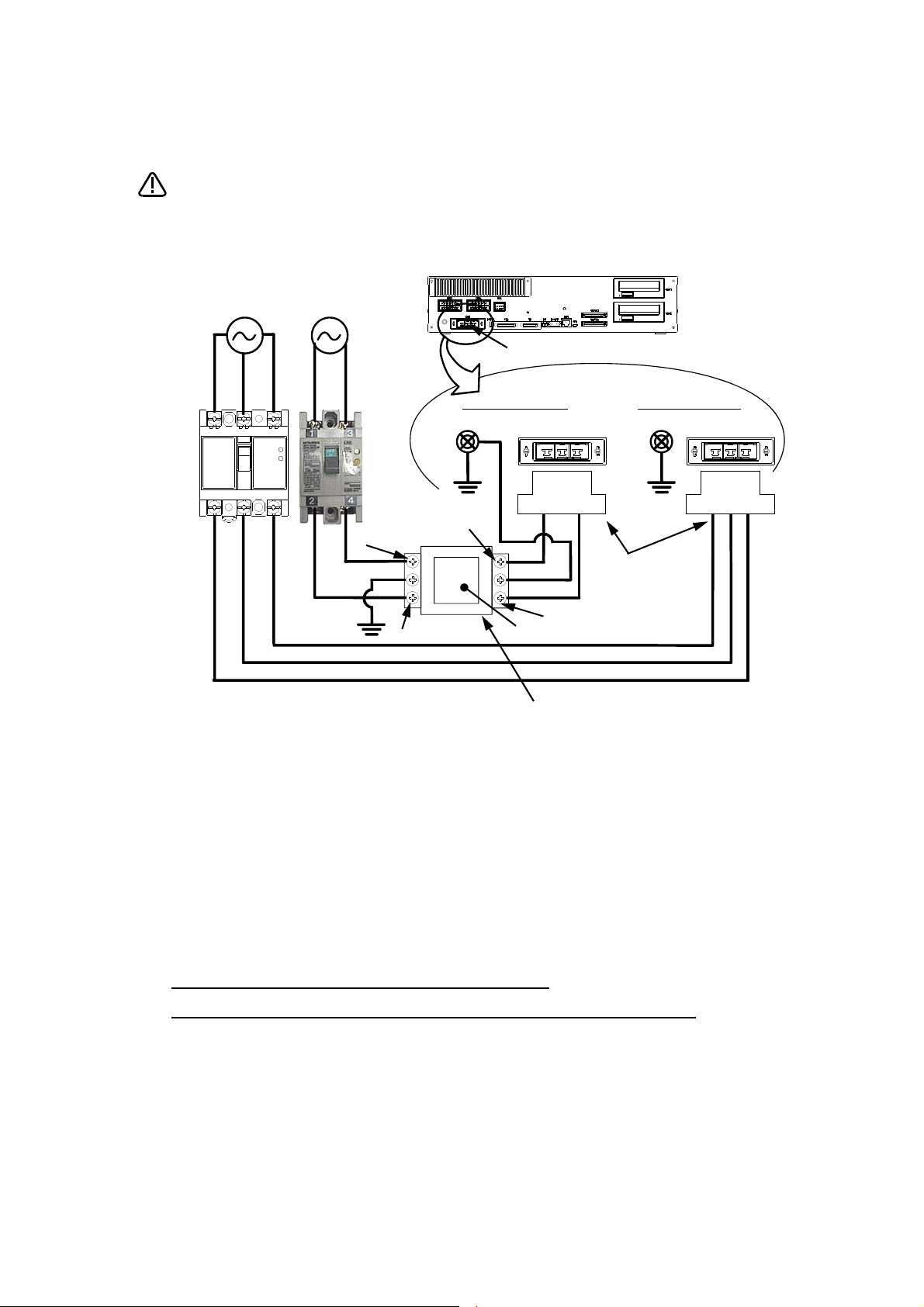

*CR751-D or CR751-Q controller

CAUTION

PE terminal

Grounding screw

Controller

ACIN connector

AC200V AC200V

Primary

Secondary

PE terminal

Grounding screw

123 123

ACIN connector

ACIN connector

Note 2)

Note 1) Crimping swage is recommended for connecting the attachment ACIN connector (soldering is also possible)

Recommendation compression tools: 234171-1(Tyco Electronics)

Note 2) The earth leakage breaker is the customer preparation. Always use the cover below.

Recommendation: For single primary power supply .........NV30FAU-2P-10A-AC100-240V-30mA, (Cover: TCS-05FA2)

For three primary power supply .......... NV30FAU-3P-10A-AC100-240V-30mA, (Cover: TCS-05FA3)

Note 3) If necessary, as shown in the figure, connects the noise filter between ACIN terminal blocks and primary power supply.

(Recommended noise filter: SUP-EL20-ER6 *OKAYA ELECTRIC INDUSTRIES)

Controller

<4> LINE/LOAD

<3> LINE/LOAD

<1> LINE/LOAD

<2> LINE/LOAD

Noise filter

Label

ACIN connector or

power cable

(Attachment)

Note 1)

For three phaseFor single phase

Three phase Single phase

Earth leak

-

age breaker

(NV)

Note 3)

* The controller is an

example.

Notes of the basic component are shown.

Please install the earth leakage breaker in the primary side supply power supply

of the controller of CR751-D or CR751-Q because of leakage protection.

1) Please prepare the following: Leakage current breaker (with the terminal cover), cable for connecting the

primary power supply (AWG #14 (2mm

2

or above).

(3.5mm

The secondary power cable (with the ACIN connector) for single phase or three phase power is supplied with

the product to match the specifications. When you build a cable suitable for your environment using the ACIN

connector and the ACIN terminal supplied, prepare a secondary power cable (AWG #14 (2mm

2) Confirm that the primary power matches the specifications.

3) Confirm that the primary power is OFF and that the earth leakage breaker power switch is OFF.

4) Connect the secondary power cable.

a) When using the supplied power cable with the ACIN connector

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

b) When building a power cable using the ACIN connector and the ACIN terminals supplied

Connect the ACIN terminals with the secondary power cable (prepared by customers), and insert the ACIN

terminals to the ACIN connector pins with the following numbers. Crimping caulking is recommended to

connect the ACIN terminals.

For single phase: 1 and 3

For three phase: 1, 2, and 3

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

5) Connect this ACIN connector to the ACIN connector on the front of the controller.

6) Connect the grounding cable to the PE terminal. (M4 screw)

7) Connect the primary power cable to the primary side terminal of the earth leakage breaker.

2

or above), cables to ground the primary power supply (AWG #12

2

) or above).

Page 7

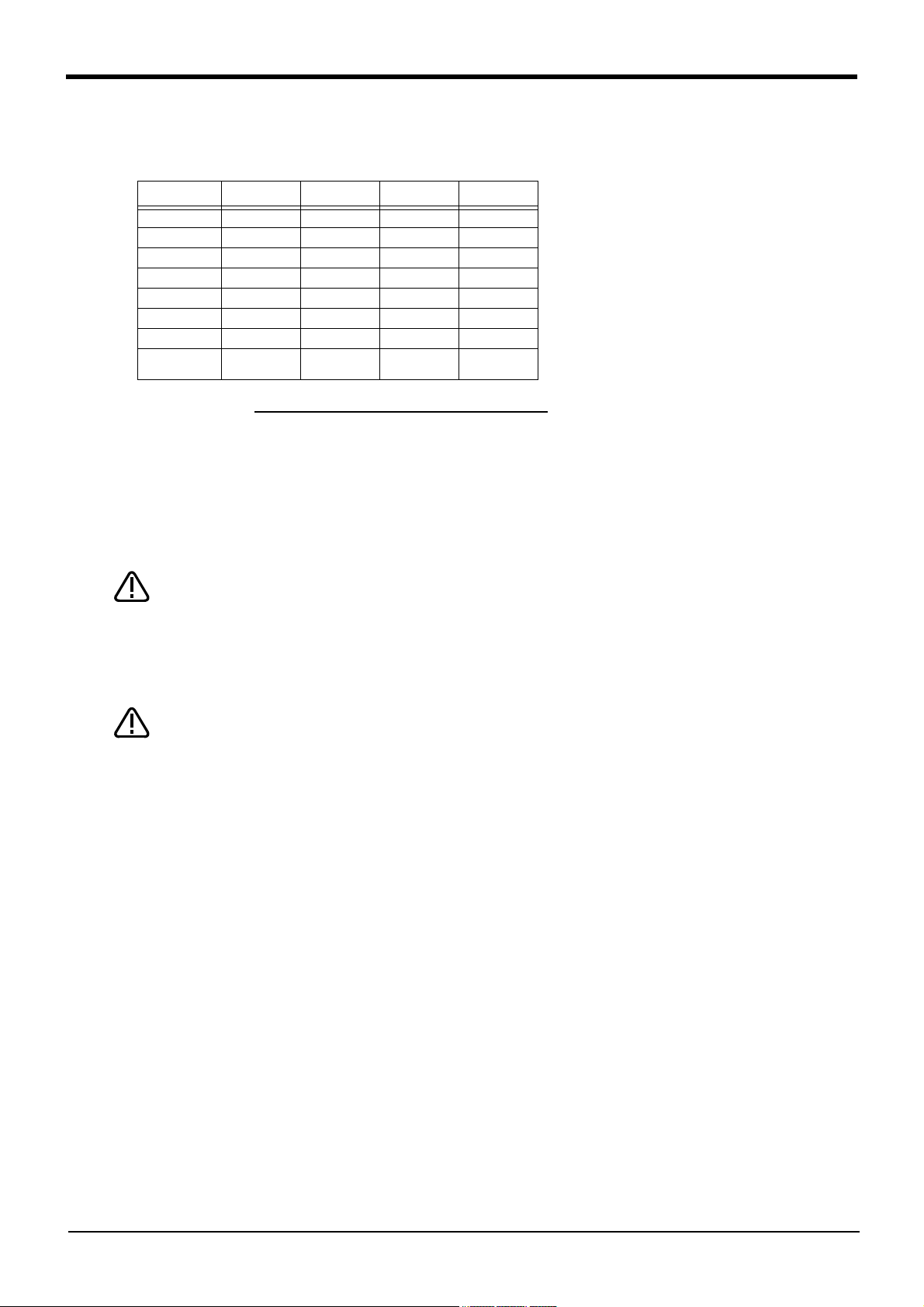

Revision history

Date of Point Instruction Manual No. Revision Details

2014-08-20 BFP-A3324 ・ First print

2014-12-23 BFP-A3324-B ・ ”(1) Replacing the battery (robot arm)” was changed.

2015-02-09 BFP-A3324-C ・ The special hexagon flange bolts are also used for SE1502 model.

・ Packing replacement procedure was added.

・ The explanation of the origin setting method were added. The description of the setting

range of ABS origin method was added.

・ The caution in lubrication was added.

・ The corporate logo mark of illustrations in this manual was changed.

・ In recommended grease gun, CH-400 was deleted and KH-120 was added.

・ Belt type of J3 and J4 axis timing belt of RV-4F series was corrected.

(error: J3 axis 381-3GT-6、 J4 axis 240-3GT-4)

Page 8

*Introduction

・ No part of this manual may be reproduced by any means or in any form, without prior consent from

Mitsubishi.

・ The details of this manual are subject to change without notice.

・ The information contained in this document has been written to be accurate as much as possible.

Please interpret that items not described in this document "cannot be performed." or "alarm may

occur".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

・ This specifications is original.

・ Company names and production names in this document are the trademarks or registered trademarks

of their respective owners.

Copyright(C) 2014-2015 MITSUBISHI ELECTRIC CORPORATION

Thank you for purchasing the Mitsubishi industrial robot.

This instruction manual explains the method of unpacking, installation and maintenance and inspection of

the robot arm.

Always read through this manual before starting use to ensure correct usage of the robot.

The information contained in this document has been written to be accurate as much as possible. Please

interpret that items not described in this document "cannot be performed."

This document explains for the following robot type.

Robot type ・ RV-4F/4FL series....................... Note) Indicates it as RV-4F series.

・ RV-7F/7FL series....................... Note) Indicates it as RV-7F series.

・ RV-7FLL

・ RV-13F/13FL series

・ RV-20F series

*1)

*1)

*1)

*1) Indicates it as "RV-13F series" for a general name of these robots.

Page 9

CONTENTS

Page

1 Before starting use .......................................................................................................................... 1-1

1.1 Using the instruction manuals ................................................................................................... 1-1

1.1.1 The details of each instruction manuals ............................................................................... 1-1

1.1.2 Symbols used in instruction manual .................................................................................... 1-2

1.2 Safety Precautions .................................................................................................................... 1-3

1.2.1 Precautions given in the separate Safety Manual ................................................................ 1-4

2 Unpacking to Installation .............................................................................................................................................................. 2-6

2.1 Confirming the product ......................................................................................................................................................... 2-6

2.2 Installation .................................................................................................................................................................................. 2-8

2.2.1 Unpacking ............................................................................................................................................................................ 2-8

2.2.2 Transportation procedures (Transporting with a crane) ................................................................................. 2-9

2.2.3 Installation procedures ................................................................................................................................................ 2-11

2.2.4 Grounding procedures .................................................................................................................................................. 2-13

(1) Grounding methods ................................................................................................................................................... 2-13

(2) Grounding procedures ............................................................................................................................................. 2-13

2.2.5 Connecting with the controller ................................................................................................................................ 2-14

(1) CR750 controller ....................................................................................................................................................... 2-14

(2) CR751 controller ....................................................................................................................................................... 2-16

2.3 Setting the origin ................................................................................................................................................................... 2-18

2.3.1 Installing the teaching pendant (T/B) ................................................................................................................... 2-18

(1) CR750 controller ....................................................................................................................................................... 2-18

(2) CR751 controller ....................................................................................................................................................... 2-19

2.3.2 Setting the origin with the origin data input method ...................................................................................... 2-20

(1) Confirming the origin data ..................................................................................................................................... 2-20

(2) Turning ON the control power ............................................................................................................................. 2-20

(3) Preparing the T/B ..................................................................................................................................................... 2-21

(4) Selecting the origin setting method ................................................................................................................... 2-22

(5) Inputting the origin data ......................................................................................................................................... 2-23

(6) Installing the CONBOX cover. ............................................................................................................................. 2-24

2.4 Confirming the operation .................................................................................................................................................... 2-25

(1) JOINT jog operation ................................................................................................................................................. 2-29

(2) XYZ jog operation ...................................................................................................................................................... 2-31

(3) TOOL jog operation .................................................................................................................................................. 2-33

(4) 3-axis XYZ jog operation ....................................................................................................................................... 2-35

(5) CYLNDER jog operation ......................................................................................................................................... 2-37

(6) Work jog operation ......................................................................................................... 2-39

3 Installing the option devices ..................................................................................................................................................... 3-47

3.1 Installing the J1 axis operating range change ........................................................................................................... 3-47

3.1.1 RV-4F/7F series ............................................................................................................................................................ 3-47

(1) Configuration ............................................................................................................................................................... 3-47

(2) Changeable angle ....................................................................................................................................................... 3-48

(3) Installation procedure .............................................................................................................................................. 3-50

(4) Setting the parameter ............................................................................................................................................. 3-51

(5) Check the operating range .................................................................................................................................... 3-51

3.1.2 RV-13F series ................................................................................................................................................................. 3-52

(1) Configuration ............................................................................................................................................................... 3-52

(2) Changeable ................................................................................................................................................................... 3-53

(3) Installation procedure .............................................................................................................................................. 3-54

(4) Setting the parameter ............................................................................................................................................. 3-56

(5) Check the operating range .................................................................................................................................... 3-56

3.2 Installing the solenoid valve set ...................................................................................................................................... 3-57

(1) RV-4F/7F series, RV-7FLL ................................................................................................................................. 3-58

(2) RV-13F/13FL series, RV-20F ............................................................................................................................. 3-64

3.3 Installing the hand input cable ......................................................................................................................................... 3-67

i

Page 10

CONTENTS

Page

3.4 Installing the hand output cable ...................................................................................................................................... 3-69

3.5 Installing the Forearm external wiring set/ Base external wiring set ............................................................. 3-72

(1) Installing the Forearm external wiring set ....................................................................................................... 3-72

(2) Installing the Base external wiring set ............................................................................................................. 3-73

4 Basic operations ............................................................................................................................................................................ 4-75

5 Maintenance and Inspection ..................................................................................................................................................... 5-76

5.1 Maintenance and inspection interval ............................................................................................................................. 5-76

5.2 Inspection items ..................................................................................................................................................................... 5-77

5.2.1 Daily inspection items .................................................................................................................................................. 5-77

5.2.2 Periodic inspection ........................................................................................................................................................ 5-78

5.3 Maintenance and inspection procedures ..................................................................................................................... 5-79

5.3.1 Robot arm structure ..................................................................................................................................................... 5-79

5.3.2 Installing/removing the cover ................................................................................................................................... 5-82

5.3.3 Inspection, maintenance and replacement of timing belt .............................................................................. 5-85

(1) Timing belt replacement period ......................................................................................................................... 5-85

(2) Inspection, maintenance and replacement of J1-axis timing belt (RV-4F/7F series only) ...... 5-86

(3) Inspection, maintenance and replacement of J3-axis timing belt (RV-4F/7F series only) ...... 5-87

(4) Inspection, maintenance and replacement of J4-axis timing belt ........................................................ 5-88

(5) Inspection, maintenance and replacement of J4-axis timing belt (For RV-13F series) ............. 5-89

(6) Inspection, maintenance and replacement of J5 axis timing belt ......................................................... 5-90

(7) Inspection, maintenance and replacement of J6-axis timing belt ........................................................ 5-92

(8) Timing belt tension ................................................................................................................................................... 5-94

5.3.4 Lubrication ........................................................................................................................................................................ 5-95

(1) Lubrication position and specifications ............................................................................................................ 5-95

(2) Lubrication method ................................................................................................................................................... 5-97

5.3.5 Replacing the backup battery ................................................................................................................................... 5-99

(1) Replacing the battery (robot arm) .........................

5.4 About Overhaul ................................................................................................................................................................... 5-101

5.5 Maintenance parts .............................................................................................................................................................. 5-102

5.6 Resetting the origin ........................................................................................................................................................... 5-104

5.6.1 Jig method ..................................................................................................................................................................... 5-105

(1) J1 axis origin setting ............................................................................................................................................. 5-106

(2) J2 axis origin setting ............................................................................................................................................. 5-108

(3) J3 axis origin setting ............................................................................................................................................. 5-111

(4) J4 axis origin setting ............................................................................................................................................. 5-114

(5) Origin setting of J5 axis and J6 axis (jig) ..................................................................................................... 5-116

5.6.2 ABS origin method ..................................................................................................................................................... 5-119

(1) Select the T/B ........................................................................................................................................................ 5-121

5.6.3 User origin method ..................................................................................................................................................... 5-123

5.6.4 Recording the origin data ........................................................................................................................................ 5-125

(1) Confirming the origin data label ........................................................................................................................ 5-125

(2) Confirming the origin data .................................................................................................................................. 5-125

(3) Recording the origin data .................................................................................................................................... 5-125

(4) Installing the cover ................................................................................................................................................ 5-125

6Appendix ............................................................................................................................................................................ Appendix-126

Appendix 1 : Configuration flag .......................................................................................................................... Appendix-126

.......................................................................................... 5-100

ii

Page 11

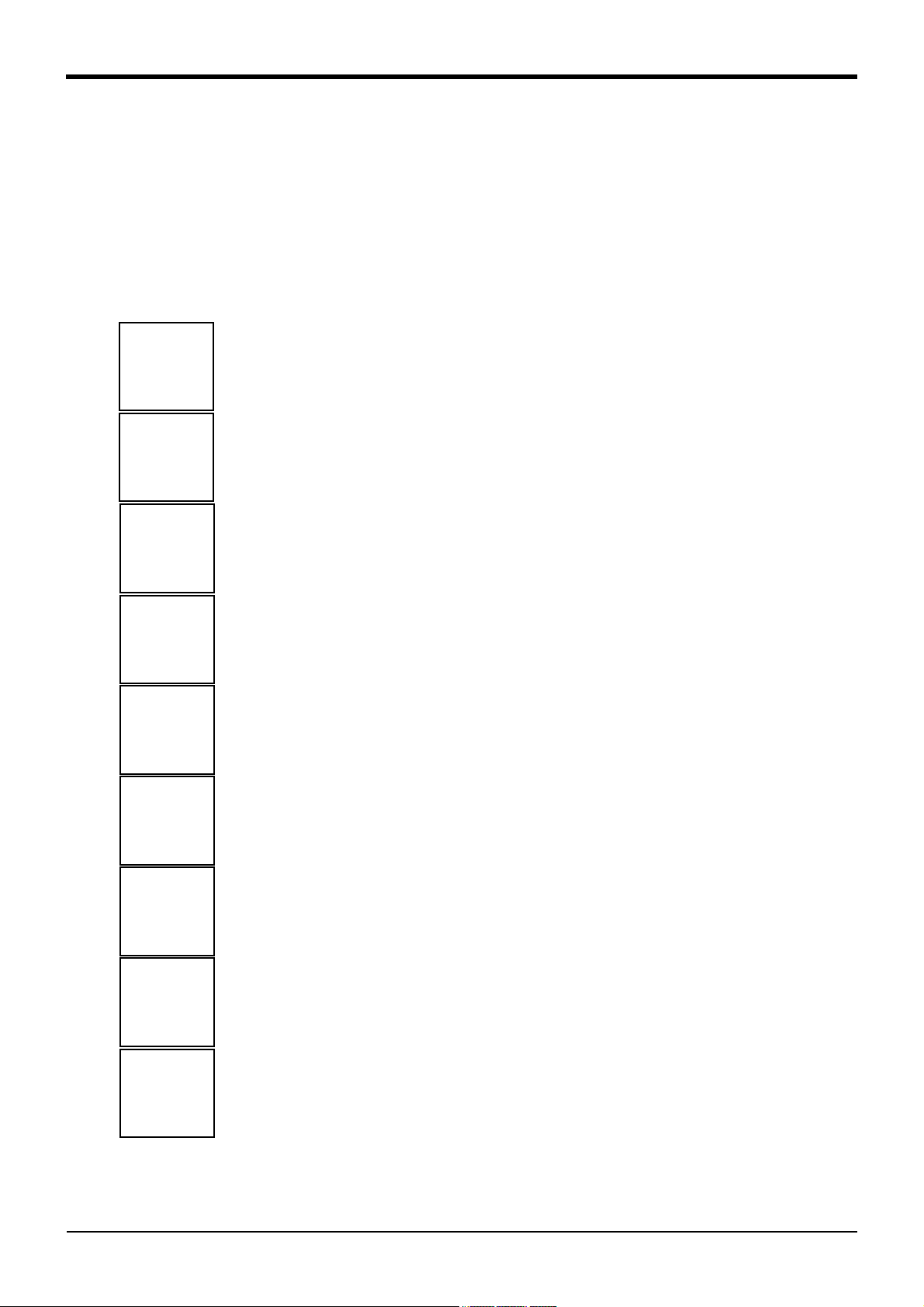

1Before starting use

Safety Manual

Standard

Specifications

Robot Arm

Setup &

Maintenance

Controller

Setup, Basic

Operation and

Maintenance

Detailed

Explanation of

Functions and

Operations

Troubleshooting

Additional

axis function

Tracking Func

-

tion Manual

Extended

Function

Instruction

Manual

1 Before starting use

This chapter explains the details and usage methods of the instruction manuals, the basic terminology and

the safety precautions. Moreover, handling and operation of a teaching pendant (T/B) are described based

on R32TB (R33TB) in instruction manuals. If using other T/B, such as R56TB (R57TB), refer to a supplied

instruction manual of the T/B.

1.1 Using the instruction manuals

1.1.1 The details of each instruction manuals

The contents and purposes of the documents enclosed with this product are shown below. Use these documents according to the application.

For special specifications, a separate instruction manual describing the special section may be enclosed.

Explains the common precautions and safety measures to be taken for robot handling, sys

tem design and manufacture to ensure safety of the operators involved with the robot.

Explains the product's standard specifications, factory-set special specifications, option

configuration and maintenance parts, etc. Precautions for safety and technology, when

incorporating the robot, are also explained.

Explains the procedures required to operate the robot arm (unpacking, transportation,

installation, confirmation of operation), and the maintenance and inspection procedures.

Explains the procedures required to operate the controller (unpacking, transportation,

installation, confirmation of operation), basic operation from creating the program to auto

-

matic operation, and the maintenance and inspection procedures.

Explains details on the functions and operations such as each function and operation, com

mands used in the program, connection with the external input/output device, and parame

ters, etc.

Explains the causes and remedies to be taken when an error occurs. Explanations are given

for each error No.

-

-

-

Explains the specifications, functions and operations of the additional axis control.

Explains the control function and specifications of conveyor tracking

Explains the detailed description of data configuration of shared memory, monitoring, and

operating procedures, about the PLC(CR750-Q/CR751-Q controller) and the GOT(CR750D/CR751-D controller).

Using the instruction manuals 1-1

Page 12

1Before starting use

DANGER

WARNING

CAUTION

1.1.2 Symbols used in instruction manual

The symbols and expressions shown in Table 1-1 are used throughout this instruction manual. Learn the

meaning of these symbols before reading this instruction manual.

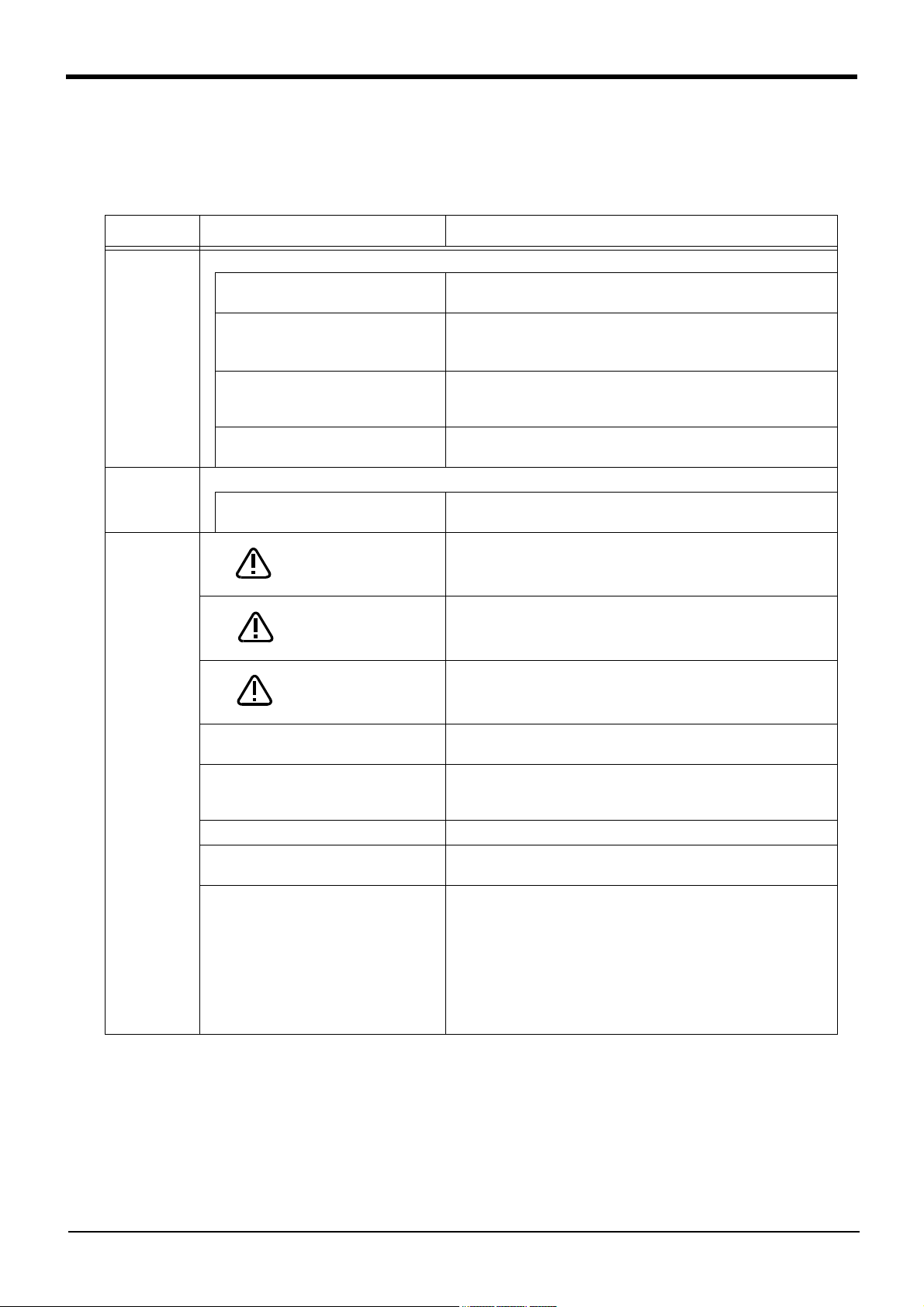

Table 1-1:Symbols in instruction manual

Terminology Item/Symbol Meaning

iQ Platform

Controller

The robot CPU unit or robot CPU

Item

The robot CPU system

Drive unit

Stand-alone type

Item

Symbol Precaution indicating cases where there is a risk of operator fatality or

Controller

Indicates the controller which controls the robot arm.

It consists of the robot CPU system and the drive unit.

Indicates the CPU unit for the robots which installed to the sequencer

base unit (Q3 □ DB) of MELSEC-Q series. It is connected with the

drive unit by the dedicated cable.

Multi-CPU system.

It consists of MELSEC units, such as the sequencer base unit, the

sequencer CPU unit, and the robot CPU unit, etc.

Indicates the box which mounts the servo amplifier for robot, and the

safety circuit, etc.

Indicates the box which arranged control parts, such as robot CPU,

servo amplifier, and the safety circuit.

serious injury if handling is mistaken. Always observe these precautions to safely use the robot.

Precaution indicating cases where the operator could be subject to

fatalities or serious injuries if handling is mistaken. Always observe

these precautions to safely use the robot.

Precaution indicating cases where operator could be subject to injury

or physical damage could occur if handling is mistaken. Always

observe these precautions to safely use the robot.

[JOG]

[RESET] + [EXE]

(A) (B)

T/B This indicates the teaching pendant.

O/P Indicates the operating panel on the front of controller or drive unit for

CR751 (Thin type)

CR751 (Heavy type)

If a word is enclosed in brackets or a box in the text, this refers to a

key on the teaching pendant.

This indicates to press the (B) key while holding down the (A) key.

In this example, the [RESET] key is pressed while holding down the

[EXE] key.

the controller which installed the operating panel

There are two kinds of CR751 controller; one is "Thin type" (the

height is 98mm) and the other is "Heavy type" (the height is 174mm),

each of which are different in height.

Thin type: CR751-03HD/Q, CR751-06HD/Q, CR751-12HD/Q,

CR751-20HD/Q, CR751-03HRD/Q, CR751-02VD/Q,

CR751-04VD/Q, CR751-04VJD/Q, CR751-07VD/Q.

Heavy type: CR751-13VD/Q, CR751-20VD/Q, CR751-07VLD/Q.

* Refer to separate Standard Specifications Manual for the outside

dimension of CR751 controller.

1-2 Using the instruction manuals

Page 13

1Before starting use

CAUTION

CAUTION

WARNING

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

1.2 Safety Precautions

Always read the following precautions and the separate "Safety Manual" before starting use of the robot to

learn the required measures to be taken.

All teaching work must be carried out by an operator who has received special

training. (This also applies to maintenance work with the power source turned ON.)

Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures of

operating the robot, and to the measures to be taken when an error occurs or when

restarting. Carry out work following this plan. (This also applies to maintenance

work with the power source turned ON.)

Preparation of work plan

Prepare a device that allows operation to be stopped immediately during teaching

work. (This also applies to maintenance work with the power source turned ON.)

Setting of emergency stop switch

During teaching work, place a sign indicating that teaching work is in progress on

the start switch, etc. (This also applies to maintenance work with the power source

turned ON.)

Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the operator

and robot.

Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow this method.

Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

Inspection before starting work

Safety Precautions 1-3

Page 14

1Before starting use

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

1.2.1 Precautions given in the separate Safety Manual

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

When automatic operation of the robot is performed using multiple control devices

(GOT, programmable controller, push-button switch), the interlocking of operation

rights of the devices, etc. must be designed by the customer.

Use the robot within the environment given in the specifications. Failure to do so

could lead to a drop or reliability or faults. (Temperature, humidity, atmosphere,

noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting the

robot in a non-designated posture could lead to personal injuries or faults from

dropping.

Always use the robot installed on a secure table. Use in an instable posture could

lead to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to personal

injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with

peripheral devices because of programming mistakes, etc.

1-4 Safety Precautions

Make sure that if the safety fence entrance door is opened during automatic operation, the door is locked or that the robot will automatically stop. Failure to do so

could lead to personal injuries.

Never carry out modifications based on personal judgments, or use non-designated maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place

hands or fingers in the openings. Failure to observe this could lead to hands or fingers catching depending on the posture.

Page 15

1Before starting use

CAUTION

CAUTION

CAUTION

DANGER

DANGER

DANGER

DANGER

CAUTION

CAUTION

Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF.

If the robot controller main power is turned OFF during automatic operation, the

robot accuracy could be adversely affected.

Do not turn off the main power to the robot controller while rewriting the internal

information of the robot controller such as the program or parameters. If the main

power to the robot controller is turned off while in automatic operation or rewriting

the program or parameters, the internal information of the robot controller may be

damaged.

Do not connect the Handy GOT when using the GOT direct connection function of

this product. Failure to observe this may result in property damage or bodily injury

because the Handy GOT can automatically operate the robot regardless of

whether the operation rights are enabled or not.

Do not connect the Handy GOT to a programmable controller when using an iQ

Platform compatible product with the CR750-Q/CR751-Q controller. Failure to

observe this may result in property damage or bodily injury because the Handy

GOT can automatically operate the robot regardless of whether the operation rights

are enabled or not.

Do not remove the SSCNET III cable while power is supplied to the multiple CPU

system or the servo amplifier. Do not look directly at light emitted from the tip of

SSCNET III connectors or SSCNET III cables of the Motion CPU or the servo

amplifier. Eye discomfort may be felt if exposed to the light. (Reference: SSCNET

III employs a Class 1 or equivalent light source as specified in JIS C 6802 and

IEC60825-1 (domestic standards in Japan).)

Do not remove the SSCNET III cable while power is supplied to the controller. Do

not look directly at light emitted from the tip of SSCNET III connectors or SSCNET

III cables. Eye discomfort may be felt if exposed to the light. (Reference: SSCNET

III employs a Class 1 or equivalent light source as specified in JIS C 6802 and

IEC60825-1 (domestic standards in Japan).)

Attach the cap to the SSCNET III connector after disconnecting the SSCNET III

cable. If the cap is not attached, dirt or dust may adhere to the connector pins,

resulting in deterioration connector properties, and leading to malfunction.

Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in failures, such as the emergency stop not

being released. In order to prevent from occurring, please be sure to check that all

functions (such as the teaching box emergency stop, customer emergency stop,

and door switch) are working properly after the wiring setup is completed

Use the network equipments (personal computer, USB hub, LAN hub, etc) confirmed by manufacturer. The thing unsuitable for the FA environment (related with

conformity, temperature or noise) exists in the equipments connected to USB.

When using network equipment, measures against the noise, such as measures

against EMI and the addition of the ferrite core, may be necessary. Please fully

confirm the operation by customer. Guarantee and maintenance of the equipment

on the market (usual office automation equipment) cannot be performed.

Safety Precautions 1-5

Page 16

2Unpacking to Installation

2 Unpacking to Installation

2.1 Confirming the product

The standard configuration of the robot arm, part of the purchased product, is shown in Table 2-1.

Confirm the parts.

Users who have purchased optional products should refer to the separate "Standard Specifications".

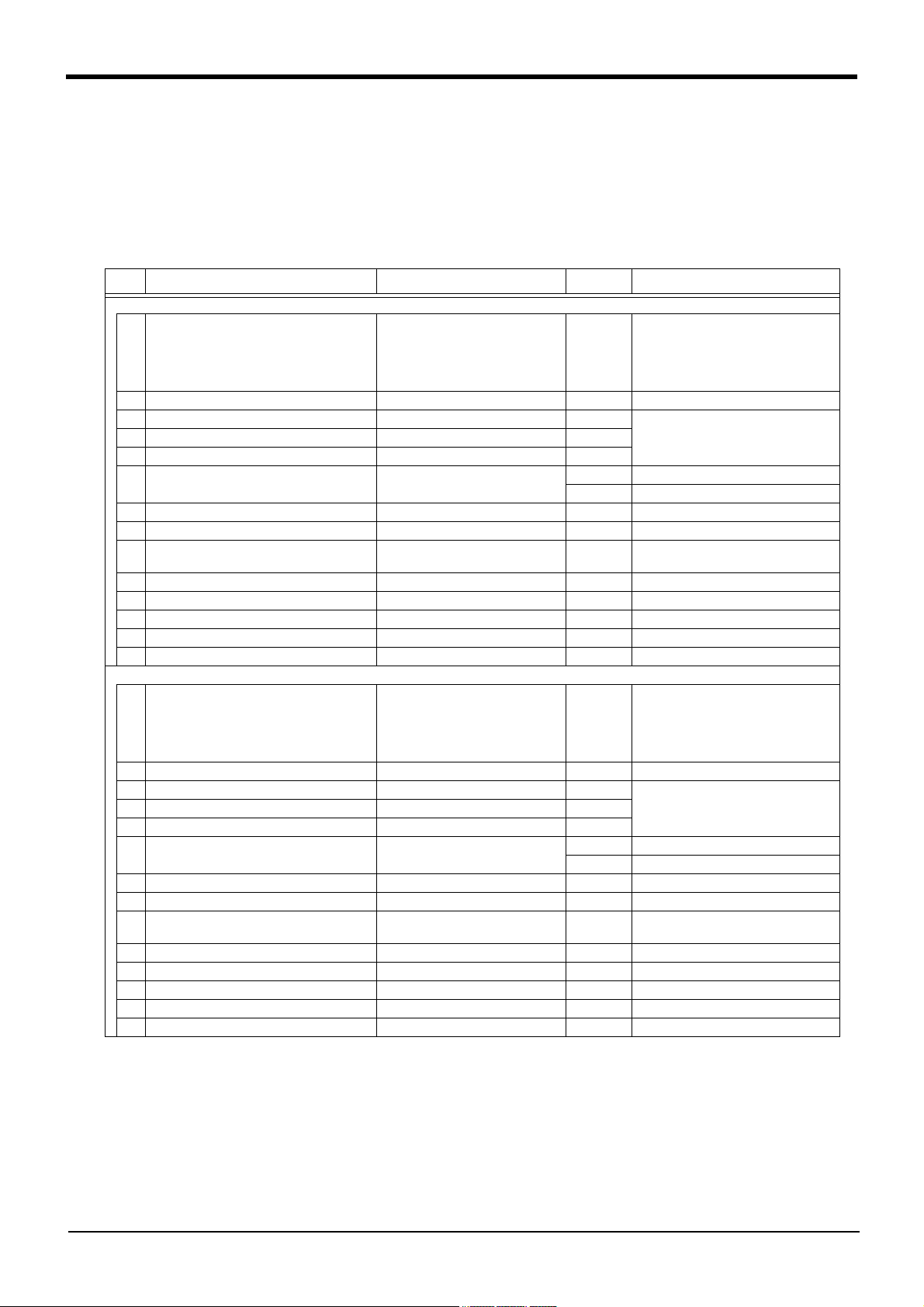

Table 2-1 : Standard configuration

No. Part name Type Qty. Remarks

RV-4F series

1 Robot arm RV-4FM-SExxxx

RV-4FLM-SExxxx

2 Guarantee card 1 copy

3 Installation bolts M8 x 40 4 pcs. For robot arm installation

4 Spring washer for installation bolts For M8 4 pcs.

5 Plain washer for installation bolts For M8 4 pcs.

6 Grease nipple WA-610 6 pc. For SExx01

7 Suspension fitting 2 sets

8 Suspension fitting installation bolt M6 x 20 6 pcs.

9 Plain washer for suspension fitting installa

tion bolt

10 Eye bolt M10 4 pcs.

11 Nut for eye bolt For M10 4 pcs.

12 Fixing plate 1 set

13 Fixing plate installation bolt M15 x 12 4 pcs.

14 Plain washer for fixing plate For M5 4 pcs.

RV-7F series

1 Robot arm RV-7FM-SExxxx

2 Guarantee card 1 copy

3 Installation bolts M8 x 40 4 pcs. For robot arm installation

4 Spring washer for installation bolts For M8 4 pcs.

5 Plain washer for installation bolts For M8 4 pcs.

6 Grease nipple WA-610 5 pcs. For SExx01

7 Suspension fitting 2 sets

8 Suspension fitting installation bolt M8 x 25 4 pcs.

9 Plain washer for suspension fitting installa

tion bolt

10 Eye bolt M10 4 pcs.

11 Nut for eye bolt For M10 4 pcs.

12 Fixing plate 1 set

13 Fixing plate installation bolt M15 x 12 4 pcs.

14 Plain washer for fixing plate For M5 4 pcs.

-

For M6 6 pcs.

RV-7FLM-SExxxx

-

For M8 4 pcs.

Each 1 unit SExxxx means the following.

SExx01: Chemical-resistant specifica

tions

SExx02: Food machinery grade H1

grease specifications

5 pc. For SExx02

Each 1 unit SExxxx means the following.

SExx01: Chemical-resistant specifica

tions

SExx02: Food machinery grade H1

grease specifications

4 pcs. For SExx02

-

-

2-6

Confirming the product

Page 17

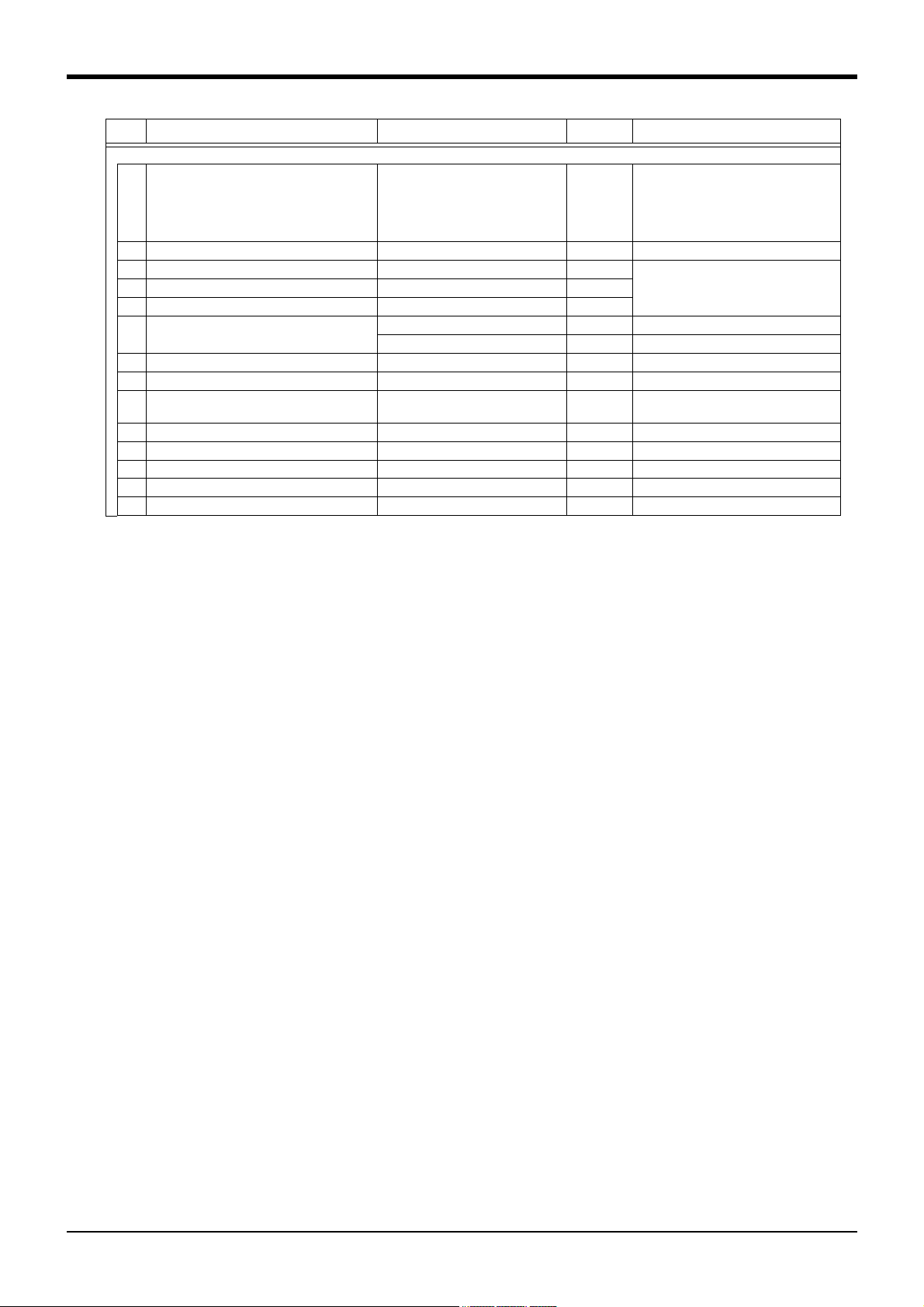

2Unpacking to Installation

No. Part name Type Qty. Remarks

RV-13F series

1 Robot arm RV-7FLLM-SExxxx

RV-13FM-SExxxx

RV-13FLM-SExxxx

RV-20FM-SExxxx

2 Guarantee card 1 copy

3 Installation bolts M12 x 55 4 pcs. For robot arm installation

4 Spring washer for installation bolts For M12 4 pcs.

5 Plain washer for installation bolts For M12 4 pcs.

6 Grease nipple WA-110 3 pcs.

WA-610 4 pcs.

7 Suspension fitting 2 sets

8 Suspension fitting installation bolt M10 x 45 4 pcs.

9 Plain washer for suspension fitting installa

tion bolt

10 Eye bolt M12 4 pcs.

11 Nut for eye bolt For M12 4 pcs.

12 Fixing plate 1 set

13 Fixing plate installation bolt M6 x 14 4 pcs.

14 Plain washer for fixing plate For M6 4 pcs.

-

For M10 4 pcs.

Each 1 unit SExxxx means the following.

SExx01: Chemical-resistant specifica

tions

SExx02: Food machinery grade H1

grease specifications

Note1) The numbers 3 to 6 are contained in the plastic bag of attachment in the robot arm.

The numbers 7 to 14 are mounted on the robot arm.

-

Confirming the product

2-7

Page 18

2Unpacking to Installation

②上ブタ

(a)

(b)

(c)

引き抜く

①テープ

フォークリフトの爪

挿入口

ロボット本体

!

CAUTION

!

Always unpack the

robot at a flat place.

The robot could tilt

over if unpacked at an

unstable place.

Pull off

<2> Upper lid

<1> Tape

The fork insertion

slots for a forklift truck

Robot arm

CAUTION

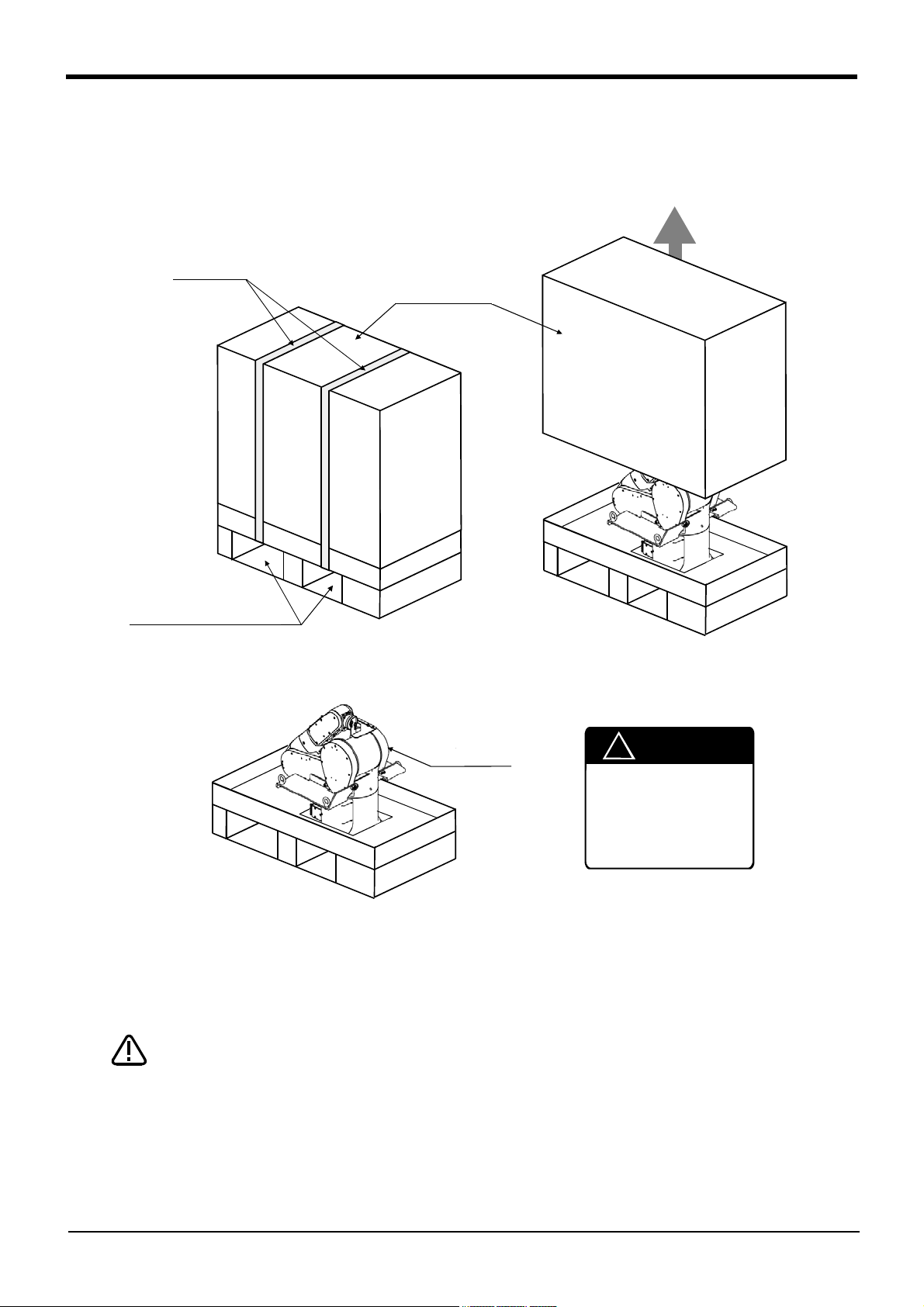

2.2 Installation

2.2.1 Unpacking

The robot is shipped from the factory in cardboard and plywood packing. Always refer to Fig. 2-1 and unpack the

robot.

Handle the robot arm according to "2.2.2Transportation procedures (Transporting with a crane)".

Fig.2-1 : Unpacking the robot arm

Always unpack the robot at a flat place. The robot could tilt over if unpacked at an

unstable place.

The unpacking process is shown below.

1) Using a knife, etc., slit the tape <1> fixing the upper lid <2> of the cardboard box. (Fig. 2-1 (a))

2) Pull the upper lid <2> of the cardboard box off with both hands. (Fig. 2-1 (b))

3) Remove the hexagon socket bolts <3> (four positions) connecting the sleeper and the base unit. (Fig. 2-1

2-8

Installation

(c))

4) This completes the unpacking.

Page 19

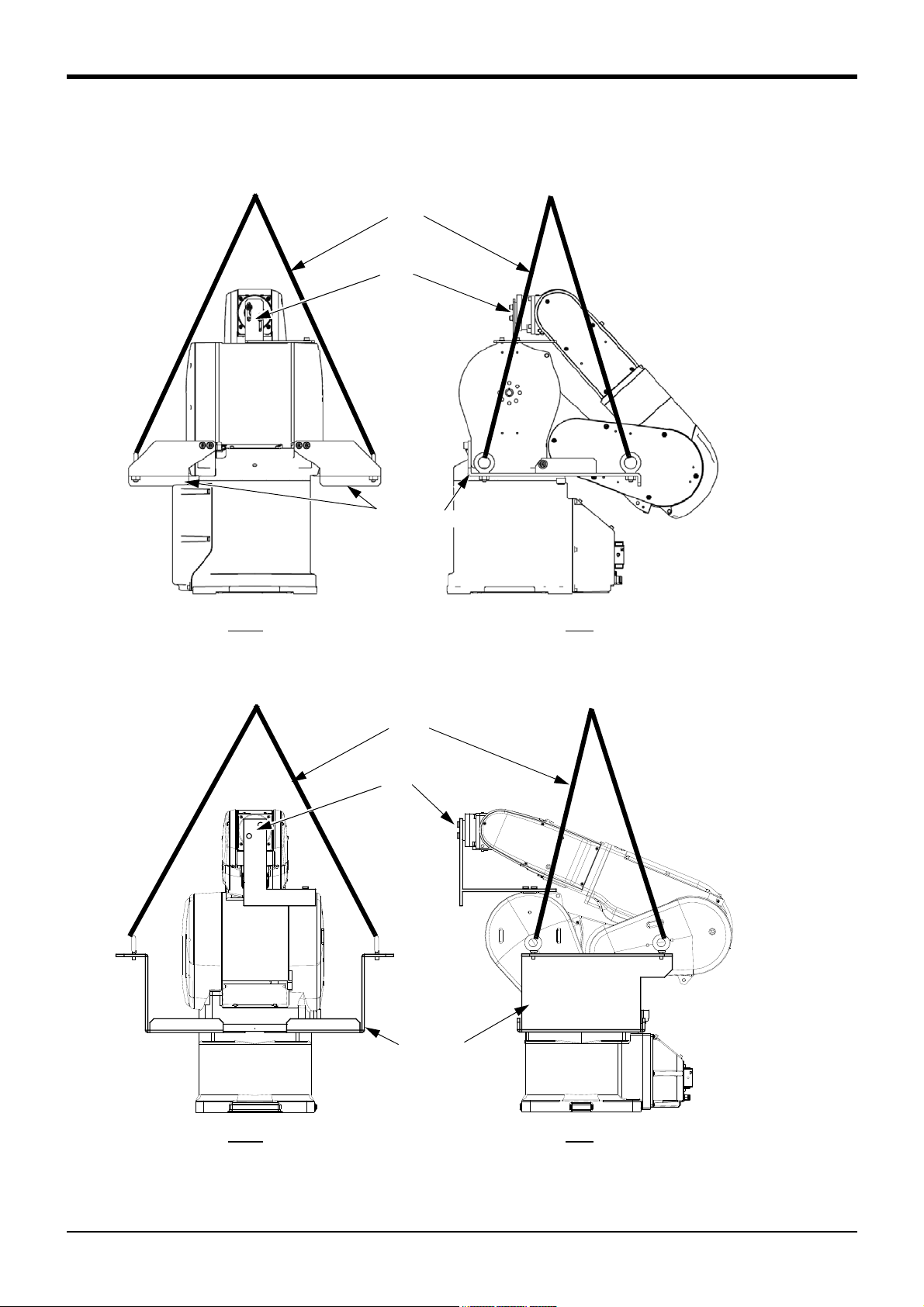

Front Side

Wire

Fixing plate

Suspension fitting

Mass

RV-4F: Approx. 39kg

RV-4FL: Approx. 41kg

RV-7F: Approx. 65kg

RV-7FL: Approx. 67kg

Note) The figure is the RV-4 F

series. The shape and

installation screw of the

suspension fitting of RV7F series differ.

RV-4F/RV-7F series

Front Side

Wire

Fixing plate

Suspension fitting

Mass

RV-13F series: Approx. 137kg

RV-13FL series: Approx. 145kg

RV-13F series

2Unpacking to Installation

2.2.2 Transportation procedures (Transporting with a crane)

The transportation procedure is shown in Fig. 2-2 for (RV-4F/7F series) and Fig. 2-3 (RV-13F series).

Fig.2-2 : Transportation procedure (transporting with a crane: RV-4F/7F series)

Fig.2-3 : Transportation procedure (transporting with a crane: RV-13F series)

Installation

2-9

Page 20

2Unpacking to Installation

1) Attach the suspension fittings to the left and right sides of the shoulder section, and securely fix with

screws and plain washers. (RV-4F series: M6x20, each three screws for the right and left. RV-7F series:

M8x25, each two screws for the right and left. RV-13F series: M10x45, each two screws for the right and

left.)

(The suspension fittings are mounted on robot arm at factory shipping)

2) Catch wires in the eye bolts installed on the suspension fittings, and quietly suspend the arm.

Note) At this time, make sure that the wires, etc., do not interfere with the robot arm or covers. Always

place cloth, etc., at interfering places.

3) When transferring to the installation place, take care not to apply vibration or impact.

4) After installing at the installation place, remove the above suspension fittings.

5) Always follow the above procedures and methods to transport the robot for secondary transportation, such

as when changing the installation position.

If the arm is directly suspended without using the specified suspension fittings, or if it is suspended in the

work posture, the configuration devices could be damaged, and the transportation workers will be subject to

risk due to an inadequate center of gravity position.

2-10

Installation

Page 21

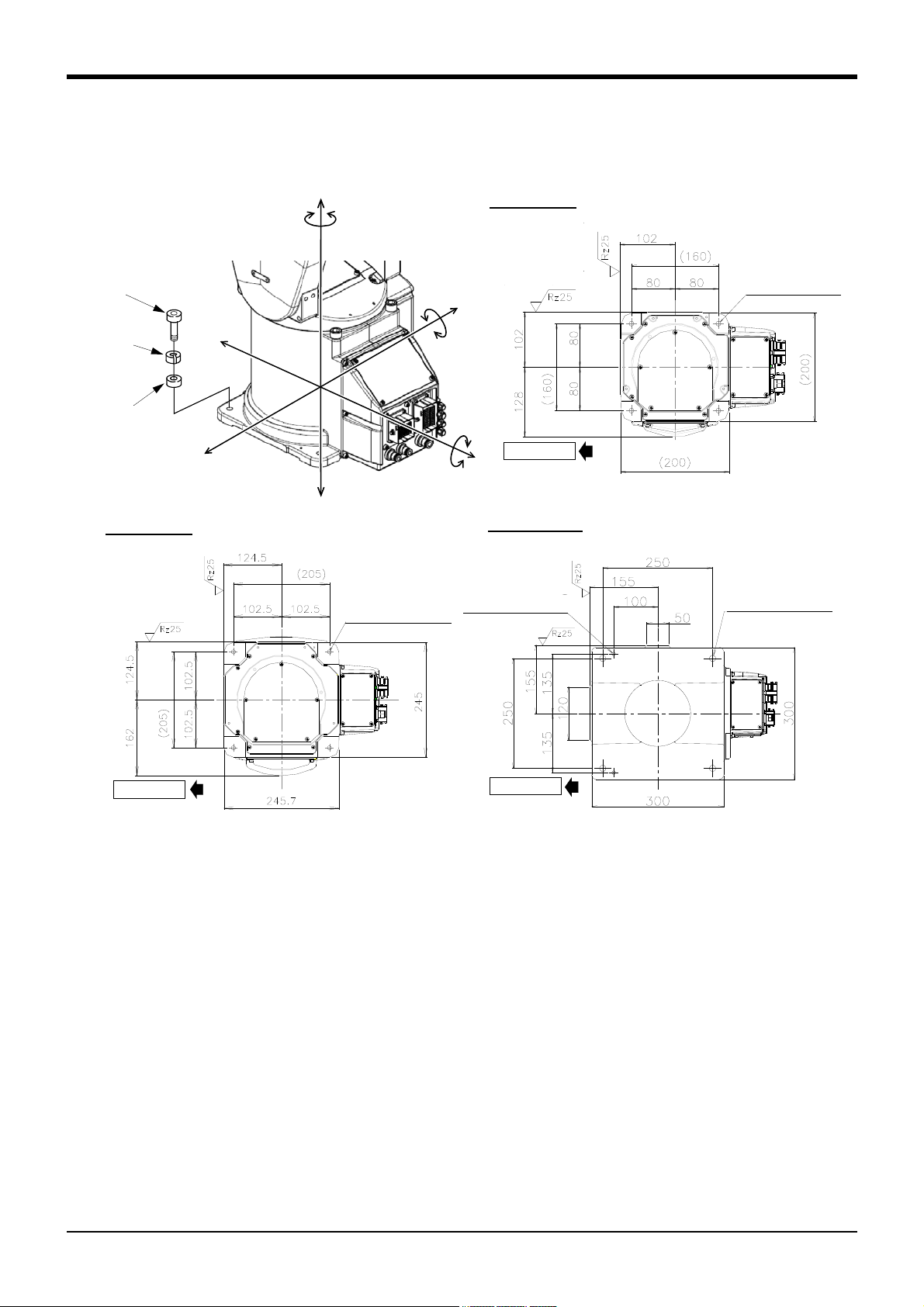

2.2.3 Installation procedures

ロボット前方

(Installation)

(Installation)

4-φ14 installation hole

Robot’s front

2-φ8H7 reamer bore

F

H

F

H

M

L

F

H

F

H

M

L

F

V

F

V

M

T

ロボット前方

RV-4F series

<Bottom view>

RV-

13F series

Plain washer

Spring

washer

RV-4F series, RV-7F series:

4-M8x40

RV-13F series:

4-M12x55

(Installation)

(Installation)

4-φ9 installation

hole

Robot’s front

ロボット前方

RV-7F series

(Installation)

(Installation)

4-φ9 installation hole

Robot’s front

The installation procedure of the robot arm is shown below.

2Unpacking to Installation

Fig.2-4 : Installation dimensions

1) The robot installation surface has been machine finished. Use the installation holes (RV-4F series and RV-

7F series: 4-φ9 holes, RV-13F series: 4-φ14 holes) opened at the four corners of the base, and securely

fix the robot with the enclosed installation bolts (RV-4F series and RV-7F series: M8 hexagon socket head

cap screws, RV-13F series: M12 hexagon socket head cap screws).

2) Installation of the robot arm is a very important step for ensuring the optimum functions of the robot.

Observe the following points when designing. Install the robot on a level surface.

3) It is recommended that the surface roughness of the table onto which the robot is to be installed by 6.3a or

more. If the installation surface is rough, the contact with the table will be poor, and positional deviation

could occur when the robot moves.

4) When installing, use a common table to prevent the position of the devices and jigs subject to robot work

from deviating.

5) The installation surface must have sufficient strength to withstand the arm reaction during operation, and

resistance against deformation and vibration caused by the static (dynamic) load of the robot arm and

peripheral devices, etc.

6) Remove the fixing plates after installing the robot. The fixing plate is needed in re-transportation. Please

keep it carefully.

7) When the robot is installed by hanging from the ceiling or on the wall, the MEGDIR parameter must be

changed. For more information about parameters and how to change the parameters, refer to the separate

"Instruction Manual/Detailed Explanation of Functions and Operations".

Installation

2-11

Page 22

2Unpacking to Installation

CAUTION

8) The installation surface must have sufficient strength to withstand the arm reaction during moving the robot

at high speed.

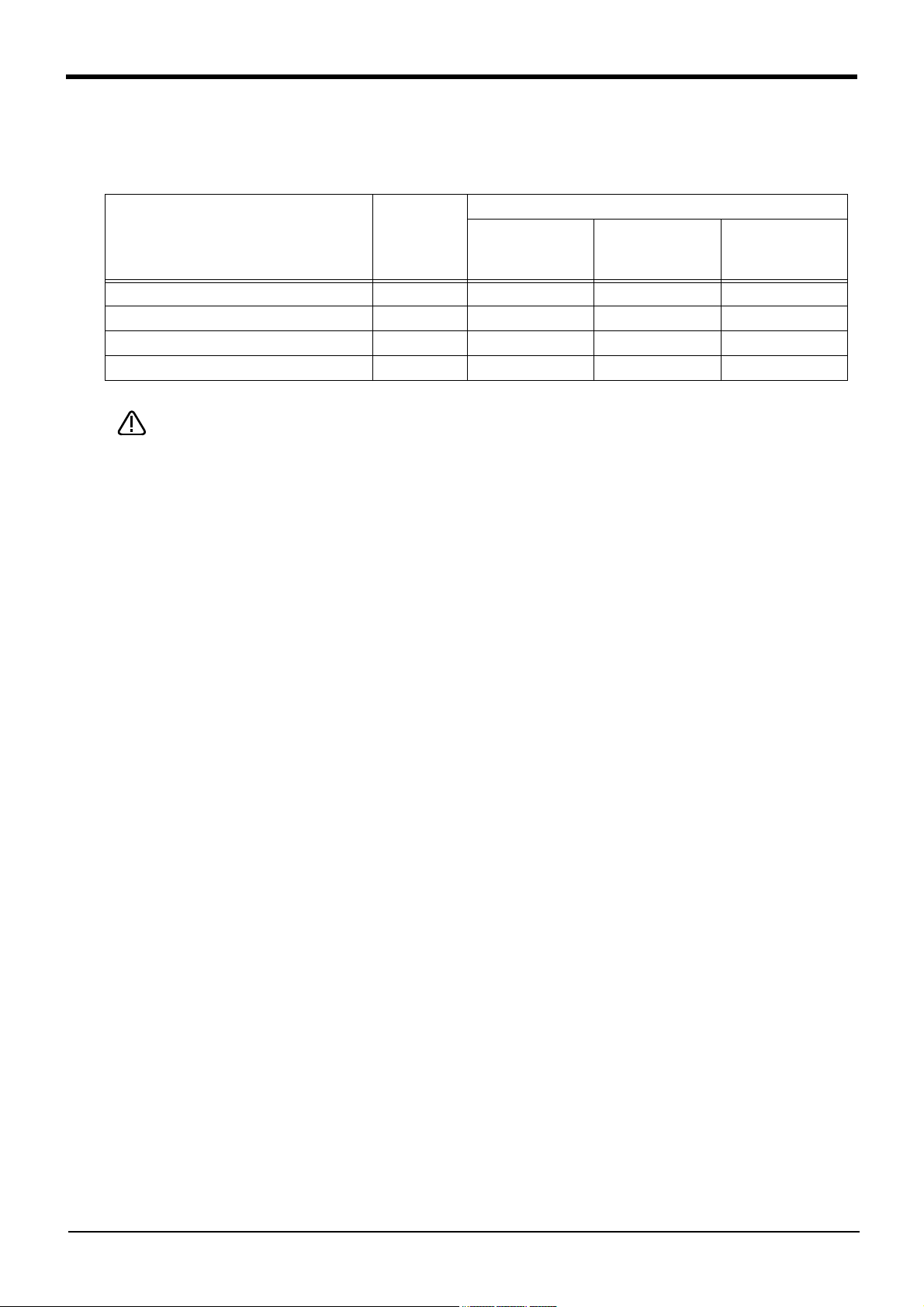

Table 2-2 : Strength of the installation side (reference)

Item Unit

Falling moment : M

Twist moment : M

Horizontal translation power : F

Vertical translation power : F

L

T

H

V

Please secure the maintenance space required for connection of the machine cable and

exchange the backup battery in the rear side, and also space for J1 axis belt in the right

side. And don't install the robot arm in the position where direct rays or the heat of

lighting hits. The skin temperature of the robot arm may rise, and the error may occur.

Value

RV-7FLL

RV-4F series RV-7F series

RV-13F series

RV-20F

N m 410 900 2,060

N m 400 900 2,060

N 700 1,000 1,750

N 1,200 1,700 2,900

2-12

Installation

Page 23

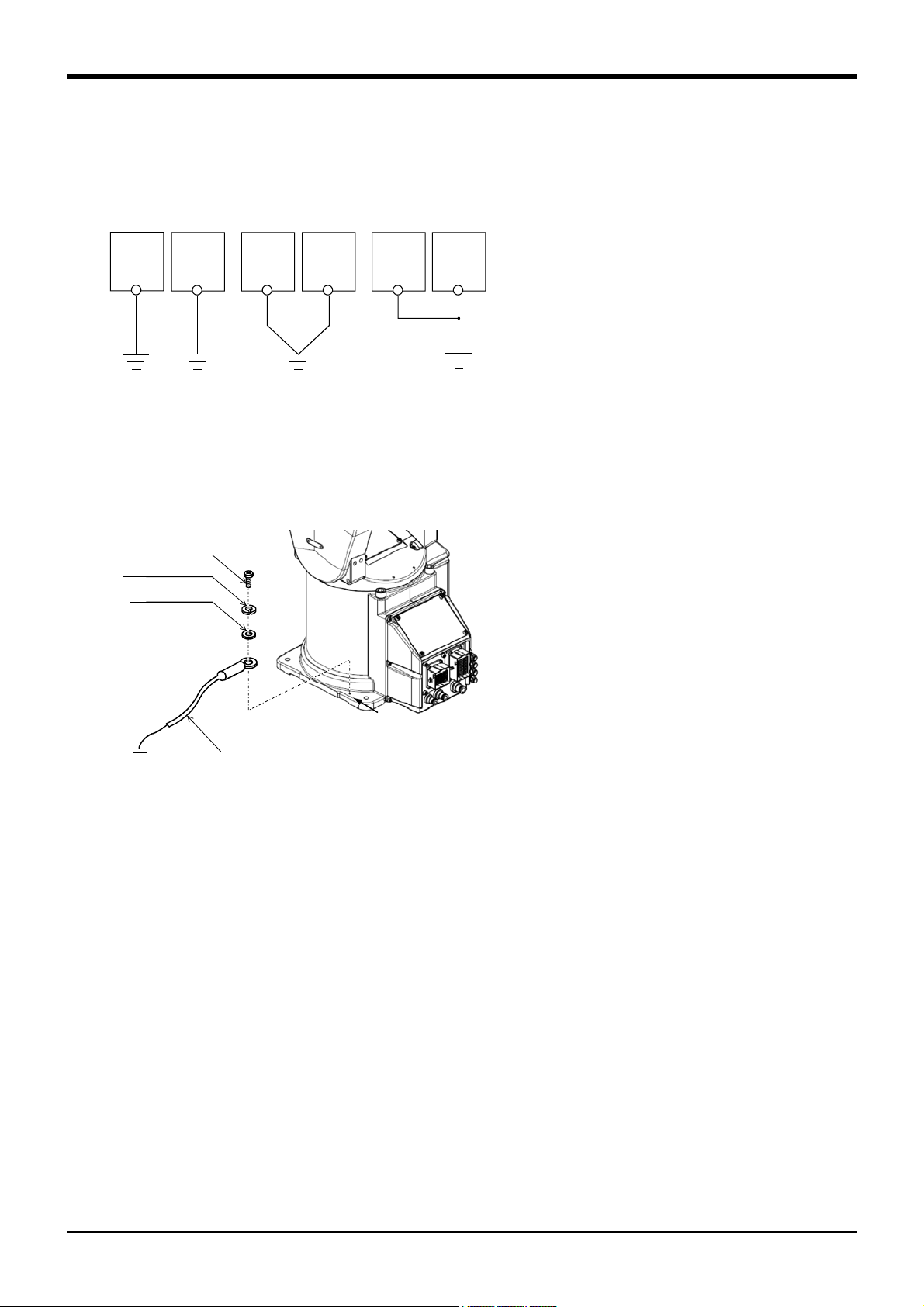

2.2.4 Grounding procedures

Robot arm

Controller

and

personal

computer

(a) Dedicated grounding

(Optimum)

(b) Common grounding

(Good)

(c) Common grounding

(Normal)

Robot arm

Controller

and

personal

computer

Robot arm

Controller

and

personal

computer

A

本体接地用ケーブル (AWG #11(4.2mm2)以上)

(お客様にてご手配ください)

Plain washer

Spring washer

M4x10

Robot grounding cable (AWG#11 (4.2mm2) or more)

(Prepared by customer)

Note) Although the figure is the example of RV-4F other types are

the same also.

(1) Grounding methods

Fig.2-5 : Grounding methods

(2) Grounding procedures

2Unpacking to Installation

1) There are three grounding methods as shown in

Fig. 2-5, but the dedicated grounding (Fig. 2-5 (a))

should be used for the robot arm and controller

when possible. (Refer to the separate " Controller

Setup, Basic Operation and Maintenance" for

details on the controller grounding.)

2) Use Class D grounding (grounding resistance

100Ω or less).

Dedicated grounding separated from the other

devices should be used.

2

3) Use a AWG#11(4.2mm

) or more stranded wire for

the grounding wire. The grounding point should be

as close to the robot arm and controller as possi

ble, and the length of the grounding wire should

be short.

-

Fig.2-6 : Connecting the grounding cable

1) Prepare the grounding cable (AWG#11(4.2mm2) or

more) and robot side installation screw and washer.

2) If there is rust or paint on the grounding screw

section (A), remove it with a file, etc.

3) Connect the grounding cable to the grounding

screw section.

Installation

2-13

Page 24

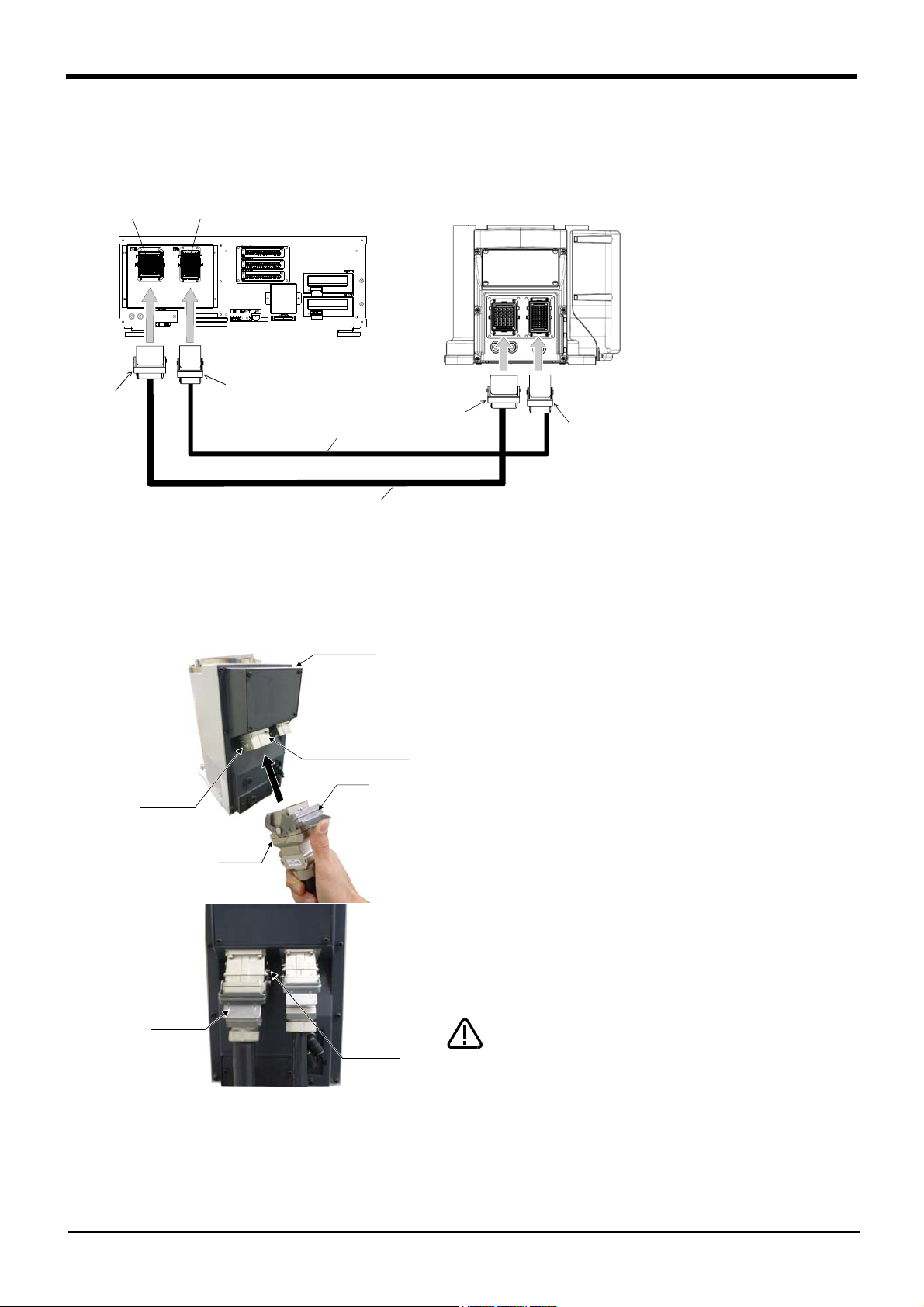

2Unpacking to Installation

CN1

CN2

ロボット本体

(ベース部背面)

ラッチ

ラッチ

モータ信号ケーブル

モータパワーケーブル

モータパワー

(CN1)

モータ信号

(CN2)

ラッチ

ラッチ

CN1

CN2

Motor power

(CN1)

Motor signal

(CN2)

Latch

Latch

Motor signal cable

Motor power cable

Latch

Latch

Robot arm

(Rear of the base.)

Note) Although the figure is the

example of RV-4F other types

are the same also.

固定フック

機器間ケーブル側コネクタ

ロボット本体

ロボット本体側コネクタ

突起部

Robot arm

Connector on the

robot arm side

Hook

Projection

Connector on the

machine cable side

固定フック

突起部

Hook

Projection

CAUTION

Be careful not to get your hand

pinched.

2.2.5 Connecting with the controller (1) CR750 controller

Fig.2-7 : Connecting the machine cables (CR750)

Carry out the following procedure after installing the controller referring to the separate "Controller Setup, Basic

Operation and Maintenance" manual. The procedure of connecting the machine cable is shown below.

1) Make sure that the power switch on the front of the

controller is turned OFF.

Note) Although the figure is RH-6FH, also in other robots

with same connector type, the connection method is

the same.

2) Connect the machine cable to its corresponding connector

on the robot arm side.

Note) Although the figure is RH-6FH, also in other robots

with same connector type, the connection method is

the same.

3) After connecting the connector, insert the hook attached

to the connector on the machine cable side to the rear of

the projection of the robot arm connector to fix securely in

place.

2-14

Installation

This complete the connection of machine cable.

Page 25

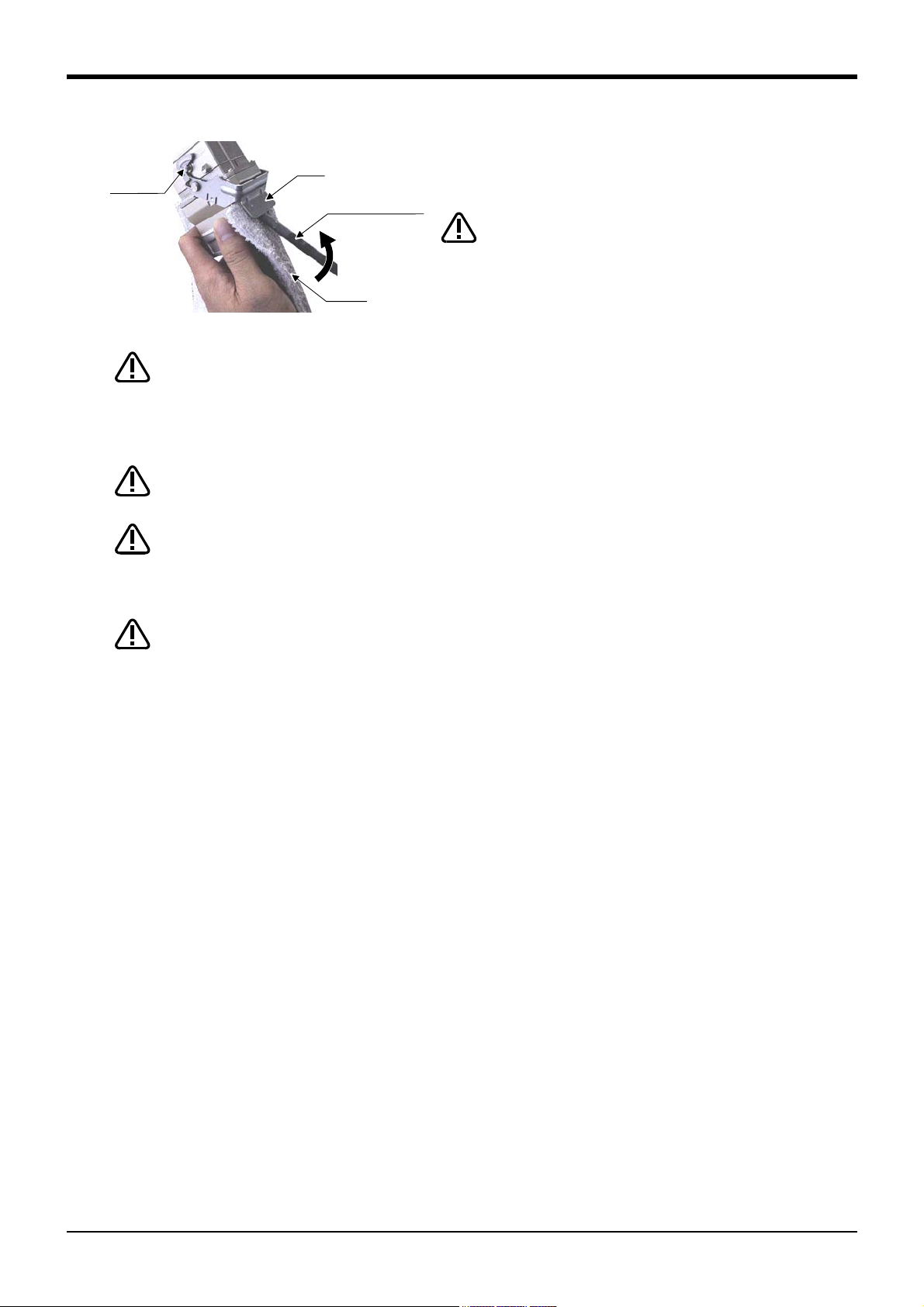

Hook

Minus screwdriver

Padding

Projection

CAUTION

When installing or removing the connector, to the connector

of the other party in parallel, install or remove. If load strong

against one side is applied, the connector pin may be

damaged and it may not be connected securely.

CAUTION

CAUTION

CAUTION

CAUTION

2Unpacking to Installation

To remove the cable, insert a minus screwdriver into the hook

while padding with a cloth, and remove the cable by lifting the

hook.

The machine cable connectors are dedicated for the controller side and robot arm

side, so take special care when connecting.

If connected incorrectly, the connector pins could bend or break. Thus, even if

connected correctly, the robot will not operate correctly, creating a dangerous

situation.

Take special care to the leading of the connection cable. If the cable is pulled with

force or bent excessively, wires could break or the connector could be damaged.

Connect the machine cable at the place without the effect of the dust or oil mist.

Please keep the dust and oil mist from being applied to of the robot-arm connector

section, in the condition that the machine cable is removed. Since it becomes the

cause of failure.

Please be careful not to catch the hand at installation and removal.

Installation

2-15

Page 26

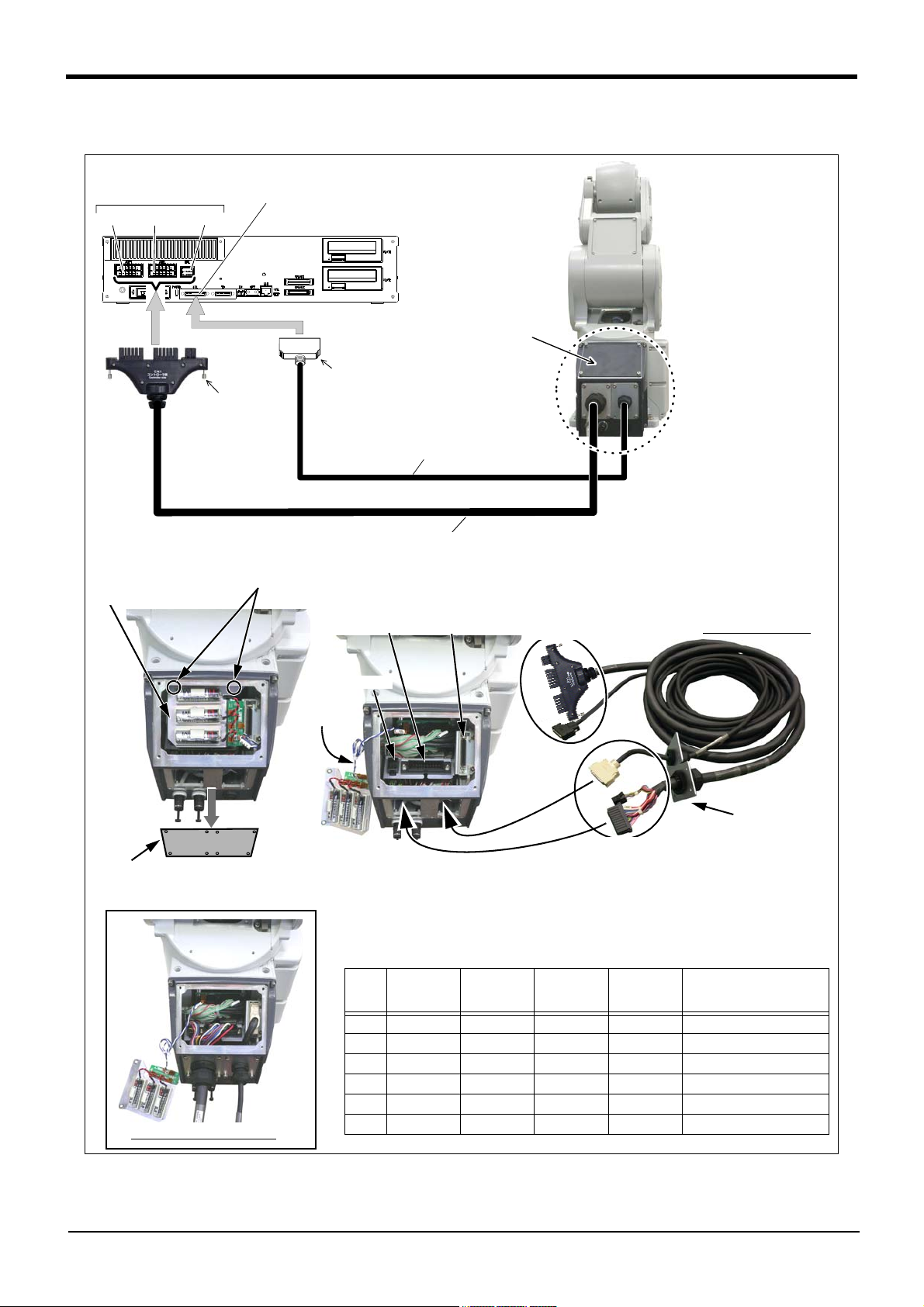

2Unpacking to Installation

Fixing screws (2 places)

モータ信号ケーブル

モータ電源ケーブル

モータ信号(CN2)

CN2

固定ネジ

(2箇所)

モータ電源(CN1)

AMP1 AMP2 BRK

CN1

コントローラ前面

ロボット本体

(背面)

CONBOXカバー

固定ネジ

(2箇所)

Motor power cable

Motor signal cable

CONBOX cover

Robot arm

Opposite side of figure

Motor signal (CN2)

Motor power (CN1)

Controller

Two fixing screws

Note1) Although the figure is RV-4F/

7F series controller, and RV13F series is also the same.

Note2) The robot arm photo is for

illustrative purposes only.

Refer to Table 2-3 for packing

pose of actual products.

Pass into

the opening

AMP1

AMP2 CN2

Machine cables

Controller side

Battery fixing plate

Note1)

Note2)

CON cover

(Eight fixing screws)

Robot arm side

Cable clamp fixing

plate

(Two plate with

four screws each)

Two fixing screws

Connection condition

Table 2-3 : The packing pose for each type (reference) (Unit: degree)

Axis RV-4F RV-4FL RV-7F RV-7FL

RV-7FLL, RV-13F/FL

RV-20F

J1 90 90 90 90 0

J2 -122 -121 -116 -115 -93

J3 162 165 158 164 160

J40000 0

J5 45 41 48 41 23

J60000 0

*1) Do not disconnect the battery cable connector. The origin data will be lost.

*2)

The size of the cable clamp fixed plate fixed screw (four screws each) is

M4x16.

*2)

Battery

cable

*1)

(2) CR751 controller

Fig.2-8 : Connecting the machine cables (CR751)

2-16

Installation

Page 27

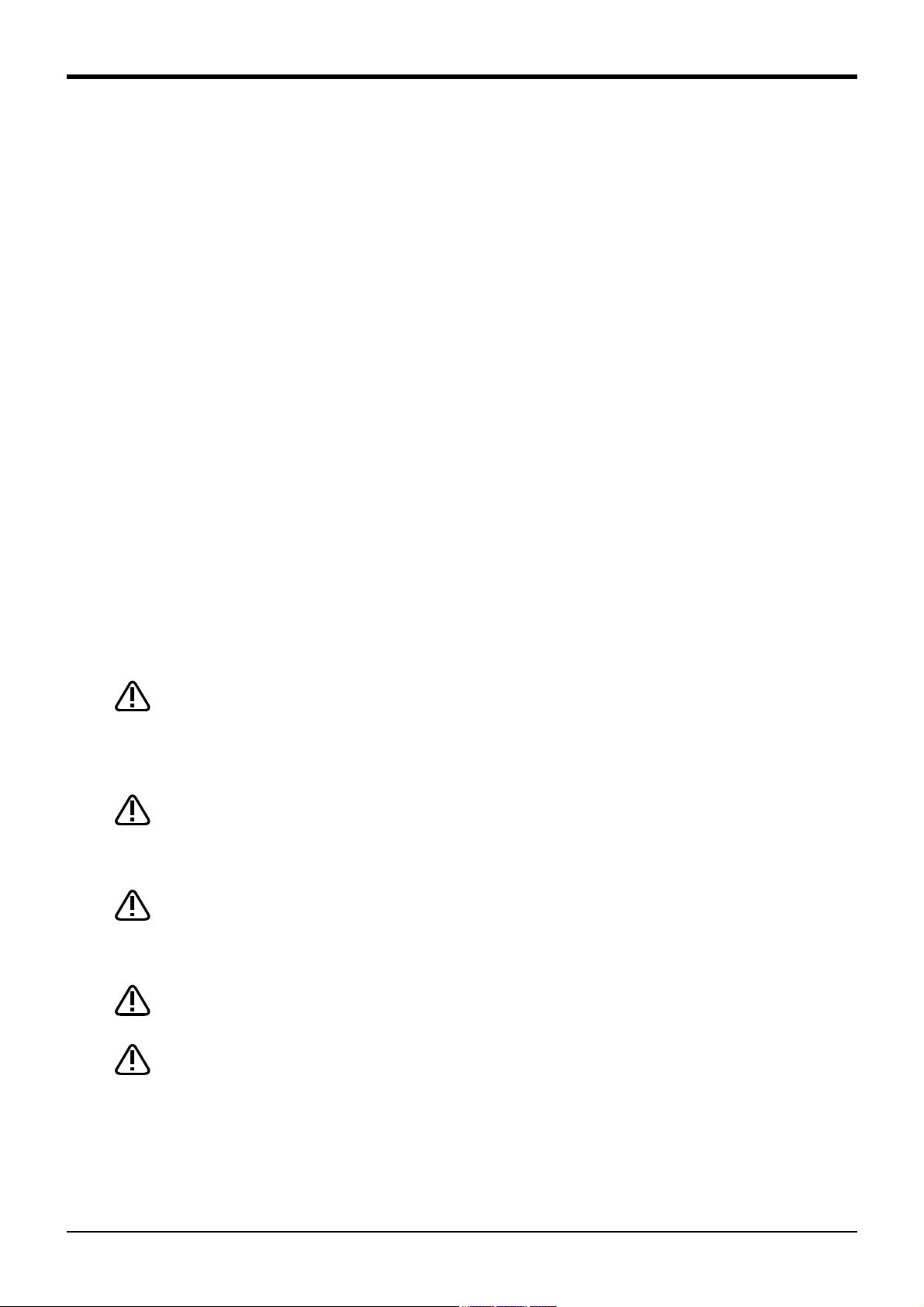

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Carry out the following procedure after installing the controller and the robot arm referring to the separate

"Controller Setup, Basic Operation and Maintenance" and Page 11, "2.2.3 Installation procedures".

And attach a cable fixation plate to the controller referring to the separate "Controller Setup, Basic Operation and

Maintenance" manual.

The connection outline is shown in Fig. 2-8.

1) Make sure that the power switch on the front of the controller is turned OFF.

Note) Although the figure is RV-4F series, also in other robots with same connector type, the connection

method is the same.

2) Connect the machine cable connectors to its corresponding connectors on the robot arm side.

a) Remove the four screws holding the CONBOX cover, and remove the cover. (Refer to Page 82, "5.3.2

Installing/removing the cover" for details.)

And, the CON cover is installed to the robot. Removes the eight fixing screws and removes the CON

cover. The opening which passes the connector is seen.

b) The battery fixing plate is inside the CONBOX cover. Remove the two fixing screws and remove the

battery fixing plate.

Note) Do not disconnect the battery cable connector. The origin data will be lost.

c) Feed the connectors of robot side to the opening on the back of the robot base and connect with the cor

responding connector. Connect the connector (AMP1, AMP2, CN2) securely.

d) Fix the cable clamp fixed plate of the machine cable with the attached fixing screw. Fix both cables

securely with the four screws, respectively.

e) Install the battery fixing plate securely as before. Be careful not to insert the cable.

f) Install the CONBOX cover securely as before. Be careful not to insert the cable.

3) Connect the machine cable to the corresponding connector of the controller. Connects the connector

(CN1(AMP1, AMP2, BRK), CN2) surely. Fix the two fixing screws securely, respectively. Tighten the fixing

screw of CN2 by 0.06-0.07 Nm.

2Unpacking to Installation

-

This complete the connection of machine cable.

The machine cable connectors are dedicated for the controller side and robot arm

side, so take special care when connecting.

If connected incorrectly, the connector pins could bend or break. Thus, even if

connected correctly, the robot will not operate correctly, creating a dangerous

situation.

Take special care to the leading of the connection cable. If the cable is pulled with

force or bent excessively, wires could break or the connector could be damaged. In

order to prevent a breaking of cables and a damage of connectors, always use the

controller after installing the attachment cable fixation plate.

Connect the machine cable at the place without the effect of the dust or oil mist.

Please keep the dust and oil mist from being applied to of the robot-arm connector

section, in the condition that the machine cable is removed. Since it becomes the

cause of failure.

Please be careful not to catch the hand at installation and removal.

Please do not disconnect the battery cable connector. If the connector is discon

nected, the robot origin data will be lost.

It is necessary to set the origin data again by ABS origin method. Refer to Page 119,

"5.6.2 ABS origin method" for details.

-

Installation

2-17

Page 28

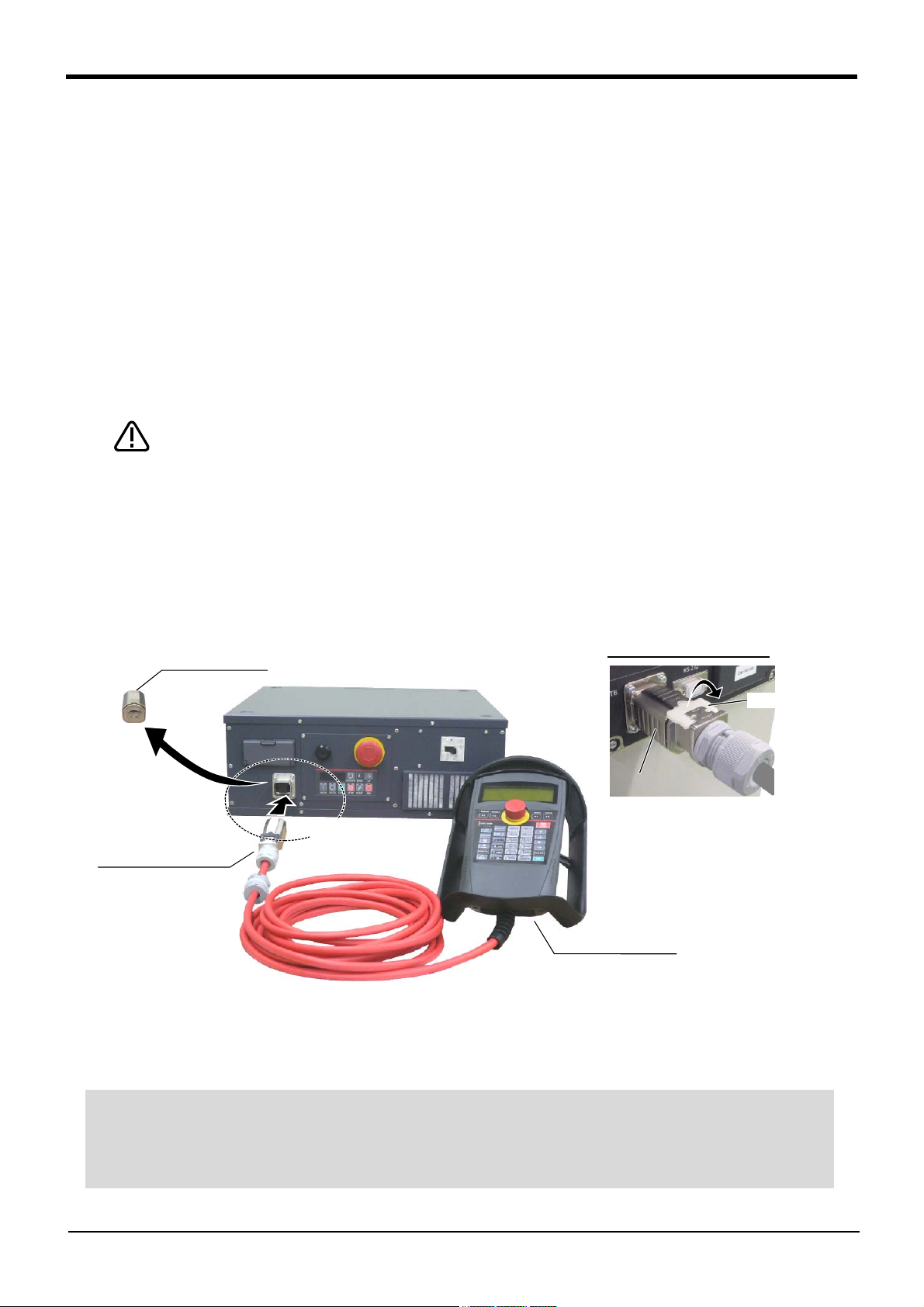

2Unpacking to Installation

CAUTION

ティーチングボックス

(T/B)

ダミーコネクタ

A

T/B接続用コネクタ

A部詳細

T/B接続用コネクタを取り外す時は、

ロック解除(ロックレバーを上側に起

こした状態)にし、B部のケースを手前

にスライドさせてラッチを外し引き抜き

ます。

ロックレバー

B

Dummy connector

T/B connector

Teaching pendant

(T/B)

Details of the A section

When removing the connector for

T/B connection, use lock release

(state which raised the lock lever to

the up side), make the case of the

B section slide to the front, and

remove and pull up out the latch.

Lock lever

Controller

◇◆◇ If error C0150 occurs ◇◆◇

At the time of the first power supply injection, error:C0150 (the serial number of the robot arm has not been

set up) occur the robot after purchase.

Parameter: Please input the serial number of the robot body into RBSERIAL. Refer to "instructions manual /

controller setup, and basic operation & maintenance" for the operation method.

2.3 Setting the origin

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

this step before starting work. This step must also be carried out if the combination of robot and controller being

used is changed.

There are several methods for setting the origin, but the origin data input method will be explained here. Refer to

Page 104, "5.6 Resetting the origin" for the other methods.

The teaching pendant is required for this operation.

[Caution] If the origin data at shipment is erased due to out of battery, it is necessary to set the origin again.

Refer to Page 104, "5.6 Resetting the origin" and reset the origin using the jig method or ABS method.

2.3.1 Installing the teaching pendant (T/B)

When installing and removing the T/B, turn off the controller power supply. If T/B is installed or removed in the

state of power supply ON, emergency stop alarm will occur.

If you use the robot wherein T/B is removed, please install the attached dummy connector. With the connector,

put the dummy connector or draw it out.

Please do not pull the cable of T/B strongly or do not bend it too much.

It becomes the breaking of a wire of the cable and the cause of breakage of the

connector. Please installing and removing so that stress does not start the cable

with the connector itself.

(1) CR750 controller

Explain the installation method of T/B below.

1) Check that the POWER (power supply) switch of the robot controller is OFF.

2) Connects T/B connector to the robot controller. Use as the upper surface the lock lever shown in Fig. 2-9,

and push in until there is sound.

Fig.2-9 : Installing and removing the T/B (CR750 controller)

The installation of T/B is finished.

2-18

Setting the origin

Page 29

A部

ティーチングボックス

(T/B)

T/B接続用コネクタ

A部詳細

手回しロック(2箇所)

Controller

T/B connector

Teaching pendant

Details of the A section

A

Hand lock (Two places)

T/B connector

Note) Although the figure is RV-4F/7F series controller,

and RV-13F series is also the same.

◇◆◇ If error C0150 occurs ◇◆◇

At the time of the first power supply injection, error:C0150 (the serial number of the robot arm has not been

set up) occur the robot after purchase.

Parameter: Please input the serial number of the robot body into RBSERIAL. Refer to "instructions manual /

controller setup, and basic operation & maintenance" for the operation method.

2Unpacking to Installation

(2) CR751 controller

Explain the installation method of T/B below.

1) Check that the POWER (power supply) switch of the robot controller is OFF.

2) Connect the T/B connector to the controller’s T/B connector. Make sure to fix it securely by fastening the

hand locks (in 2 places), as shown in Fig. 2-10.

Fig. 2-10 : Installing and removing the T/B (CR751controller)

The installation of T/B is finished.

Setting the origin

2-19

Page 30

2Unpacking to Installation

● Origin data history table (Origin Data History) Serial No.ES804008

(O: O(Alphabet), 0: Zero)

Note) Meanings of symbols in method column

E: Jig method

N: Not used

SP: Not used

Date Default . . . . . . . . .

DV!#S29

J 1 06DTYY

J2 2?HL9X

J 3 1CP55V

J4 T6!M$Y

J5 Z2IJ%Z

J 6 A12%Z0

Method E E・N・SP E・N・SPE・N・SP

WARNING

CAUTION

2.3.2 Setting the origin with the origin data input method (1) Confirming the origin data

Fig.2-11 : Origin data label (an example)

The origin data to be input is noted in the

origin data sheet enclosed with the arm,

or on the origin data history table

attached to the back side of the CON

-

BOX cover. (Refer to Fig. 2-11).

Referring to Page 82, "5.3.2 Installing/

removing the cover", remove the CON

-

BOX cover and confirm the value.

The value given in the default setting

column is the origin settings set with the

calibration jig before shipment.

Always install/remove the cover with the controller control power turned OFF.

Failure to do so could lead to physical damage or personal injury should the robot

start moving due to incorrect operations.

(2) Turning ON the control power

Confirm that there are no operators near the robot before turning the power ON.

1) Turn the controller [POWER] switch ON.

The CR750 controller turns ON the front power switch.

The CR751 controller turns ON the switch of the earth leakage breaker of installation outside.

2-20

Setting the origin

Page 31

(3) Preparing the T/B

下:

ENABLE

*ランプ点灯

上:DISABLE

T/B背面

Up: Disable

Down: Enable

(Lighting)

MODE

MANUAL AUTOMATIC

◇◆◇ Operating from the T/B ◇◆◇

Always set the mode of the controller to "MAMNUAL", and then set the T/B [ENABLE] switch to "ENABLE".

When the T/B is valid, only operations from the T/B are possible. Operations from the controller or external

signals will not be accepted.

2Unpacking to Installation

Next, prepare to use the T/B

1) Set the mode of the controller to "MANUAL".

(The figure is example for CR750 controller)

2) Set the T/B [ENABLE] switch to "ENABLE". The menu selection

screen will appear.

The following operations are carried out with the T/B.

Setting the origin

2-21

Page 32

2Unpacking to Installation

<MENU>

1.FILE/EDIT 2.RUN

3.PARAM. 4.ORIGIN/BRK

5.SET/INIT. 6.ENHANCED

CLOSE

123

<ORIGIN/BRAKE>

1.ORIGIN 2.BRAKE

CLOSE

123

<ORIGIN>

1.DATA 2.MECH

3.TOOL 4.ABS

5.USER

CLOSE

123

<ORIGIN> DATA

D:(■ )

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

◇◆◇ Selecting a menu ◇◆◇

The menu can be selected with one of the following methods.

A: Press the numeral key for the No. of the item to be selected.

B: Using the [ ↓ ] and [ ↑ ] keys, etc., move the cursor to the item to be selected, and then press the [INP] key.

◇◆◇ The input method of numeral ◇◆◇

The number can be inputted if the key displayed on the lower left of each key is pressed. Press the

[CHARACTER] key, and in the condition that "123" is displayed on the screen lower side, press the number key.

(4) Selecting the origin setting method

1) Press the [4] key on the menu screen, and display the

ORIGIN/BRAKE screen.

2) Press the [1] key on the ORIGIN/BRAKE screen, and

display the origin setting method selection screen.

3) Press the [1] key on the origin setting method selection

screen, and select the data input method.

4) Display the origin data input screen

2-22

Setting the origin

Page 33

<ORIGIN> DATA

D:(■ )

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

Origin data label

(D,J1,J2,J3,J4,J5,J6,J7,J8)

T/B screen

,

,

<ORIGIN> DATA

D:(

V )

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

<ORIGIN> DATA

D:(

V! )

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

<ORIGIN> DATA

D:(V!%S29)

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

<ORIGIN> DATA

D:(V!%S29)

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

:

:

:

<ORIGIN> DATA

D:(■ )

J1( ) J2( ) J3( )

J4( ) J5( ) J6( )

J7( ) J8( )

CLOSE

123

ABC

ABC

2Unpacking to Installation

(5) Inputting the origin data

Input the value confirmed in section Page 20, "(1)

Confirming the origin data".

The correspondence of the origin data label value and axis to

be input is shown in Fig. 2-12.

Fig.2-12 : Correspondence of origin data label and axis

The method for inputting the origin data is explained below. The value shown in Fig. 2-11 will be input as an

example.

1) Confirm that the cursor is at the "D" position on the T/B

display screen.

2) Input the D value "V!%S29".

Inputting "V"

Press the [CHARACTER] key and set to the character input

mode. (Condition that "ABC" was displayed under the

screen)

Press the [TUV] key three times. "V" will be set.

Inputting "!"

Press the [ , % ] key five times. "!" will be set.

Press the [ → ] key once and advance the cursor.

Press the [ , % ] key twice (input "%"), and press the [PQRS]

key four times (input "S").

Press the [CHARACTER] key and set to the numeral input

mode. (Condition that "123" was displayed under the

screen)

Press the [2] key (input "2"), and press the [9] key (input

"9").

"V!%S29" will appear at the "D" data on the teaching

pendant screen.

3) Press the [ ↓ ] key, and move the cursor to the J1 input

position.

4) Input the J1 value in the same manner as above.

5) Input the J2, J3, J4, J5 and J6 values in the same manner.

Setting the origin

2-23

Page 34

2Unpacking to Installation

<ORIGIN> DATA

D:( V!%S29)

J1( 06DTYY) J2( 2?HL9X) J3( 1CP55V)

J4( T6!MSY) J5( Z21J%Z) J6( A12%Z0)

J7( ) J8( )

CLOSE

ABC

<ORIGIN> DATA

CHANGE TO ORIGIN. OK?

No

123

Yes

◇◆◇ Moving the cursor ◇◆◇