Page 1

Mitsubishi Industrial Robot

RV-12SD Series

Standard Specifications Manual

(CR3D-701M/CR3D-701 Controller)

BFP-A8656

Page 2

Page 3

All teaching work must be carried out by an operator who has received special training.

(This also applies to maintenance work with the power source turned ON.)

Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures of

operating the robot, and to the measures to be taken when an error occurs or when

restarting. Carry out work following this plan. (This also applies to maintenance work

with the power source turned ON.)

Preparation of work plan

Prepare a device that allows operation to be stopped immediately during teaching work.

(This also applies to maintenance work with the power source turned ON.)

Setting of emergency stop switch

During teaching work, place a sign indicating that teaching work is in progress on the

start switch, etc. (This also applies to maintenance work with the power source turned

ON.)

Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the operator and

robot.

Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow

this method.

Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that

maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

Inspection before starting work

CAUTION

CAUTION

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

Safety Precautions

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

Use the robot within the environment given in the specifications. Failure to do so could

lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise

environment, etc.)

Transport the robot with the designated transportation posture. Transporting the robot

in a non-designated posture could lead to personal injuries or faults from dropping.

Always use the robot installed on a secure table. Use in an instable posture could lead

to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise source,

positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable. Failure to

observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the rated load

or tolerable torque. Exceeding these values could lead to alarms or faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to observe

this could lead to personal injuries or damage if the object comes off or flies off during

operation.

Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state could

lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure the

priority right for the robot control. Failure to observe this could lead to personal injuries

or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do so

could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with peripheral

devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic operation,

the door is locked or that the robot will automatically stop. Failure to do so could lead to

personal injuries.

Never carry out modifications based on personal judgments, or use non-designated

maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place hands

or fingers in the openings. Failure to observe this could lead to hands or fingers catching

depending on the posture.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

Page 5

Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during

automatic operation, the robot accuracy could be adversely affected.Moreover,

it may interfere with the peripheral device by drop or move by inertia of the arm.

Do not turn off the main power to the robot controller while rewriting the

internal information of the robot controller such as the program or parameters.

If the main power to the robot controller is turned off while in automatic

operation or rewriting the program or parameters, the internal information of the

robot controller may be damaged.

CAUTION

CAUTION

Page 6

■ Revision history

Date of print Specifications No. Details of revisions

2008-05-9 BFP-A8656 First print.

Page 7

■ Introduction

This series is a full-scale industrial vertical multi-joint type robot that is designed for use in machining processes

and assembling. This series supports the oil mist environment as standard, offering a variety of specifications

including clean specification and long-arm specification.

However, to comply with the target application, a work system having a well-balanced robot arm, peripheral

devices or robot and hand section must be structured.

When creating these standard specifications, we have edited them so that the Mitsubishi robot's characteristics

and specifications can be easily understood by users considering the implementation of robots. However, if there

are any unclear points, please contact your nearest Mitsubishi branch or dealer.

Mitsubishi hopes that you will consider these standard specifications and use our robots.

Note that in this specification document the specifications related to the robot arm is described "2 Robot arm" on

page 3 , the specifications related to the controller"3 Controller" on page 30 , and software functions and a com-

mand list "4 Software" on page 79 separately.

・ No part of this manual may be reproduced by any means or in any form, without prior consent

from Mitsubishi.

・ The contents of this manual are subject to change without notice.

・ The specifications values are based on Mitsubishi standard testing methods.

・ The information contained in this document has been written to be accurate as much as possible.

Please interpret that items not described in this document "cannot be performed.".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

・ Microsoft, Windows, Microsoft Windows NT are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Copyright(C) 2008 MITSUBISHI ELECTRIC CORPORATION

Page 8

Contents

i

Page

1 General configuration .................................................................................................................................................................... 1-1

1.1 Structural equipment ............................................................................................................................................................. 1-1

1.1.1 Standard structural equipment .................................................................................................................................. 1-1

1.1.2 Shipping special specifications ................................................................................................................................... 1-1

1.1.3 Options ................................................................................................................................................................................. 1-1

1.1.4 Maintenance parts ........................................................................................................................................................... 1-1

1.2 Model type combination of robot ...................................................................................................................................... 1-2

1.2.1 Combinations of robot arms and controllers ........................................................................................................ 1-2

1.2.2 How to identify the robot model ................................................................................................................................ 1-2

1.3 CE marking specifications .................................................................................................................................................... 1-3

1.4 Indirect export .......................................................................................................................................................................... 1-3

1.5 Instruction manuals ................................................................................................................................................................ 1-3

1.6 Contents of the structural equipment ............................................................................................................................ 1-4

1.6.1 Robot arm ........................................................................................................................................................................... 1-4

1.6.2 Controller ............................................................................................................................................................................ 1-5

1.6.3 CR1B-571 controller ...................................................................................................................................................... 1-5

1.6.4 CR2B-574 controller ...................................................................................................................................................... 1-6

1.7 Contents of the Option equipment and special specification .............................................................................. 1-7

2 Robot arm ........................................................................................................................................................................................... 2-9

2.1 Standard specifications ........................................................................................................................................................ 2-9

2.2 Definition of specifications ................................................................................................................................................ 2-10

2.2.1 Pose repeatability .......................................................................................................................................................... 2-10

2.2.2 Rated load (mass capacity) ....................................................................................................................................... 2-11

2.2.3 Relationships Among Mass Capacity, Speed, and Acceleration/Deceleration Speed ...................... 2-12

(1) Setting Load Capacity and Size (Hand Conditions) .................................................................................... 2-12

2.2.4 Vibrations at the Tip of the Arm during Low-Speed Operation of the Robot ..................................... 2-12

2.2.5 Protection specifications and working environment ....................................................................................... 2-13

(1) Types of protection specifications .................................................................................................................... 2-13

(2) About the use with the bad environment ........................................................................................................ 2-14

2.2.6 Clean specifications ...................................................................................................................................................... 2-15

(1) Types of clean specifications ............................................................................................................................... 2-15

2.3 Names of each part of the robot .................................................................................................................................... 2-16

2.4 Outside dimensions ・ Operating range diagram ........................................................................................................ 2-17

(1) RV-3SB/3SBC (6-axis type) ............................................................................................................................... 2-17

(2) RV-3SJB/3SJBC (5-axis type) .......................................................................................................................... 2-19

2.5 Tooling ........................................................................................................................................................................................ 2-21

2.5.1 Wiring and piping for hand .......................................................................................................................................... 2-21

2.5.2 Internal air piping ............................................................................................................................................................ 2-22

(1) General-purpose envi-ronment/Oil mist specifications ........................................................................... 2-22

(2) Clean type .................................................................................................................................................................... 2-22

2.5.3 Internal wiring for the pneumatic hand output cable ...................................................................................... 2-22

2.5.4 Internal wiring for the hand check input cable .................................................................................................. 2-22

2.5.5 Spare Wiring ..................................................................................................................................................................... 2-22

2.5.6 Wiring and piping system diagram for hand ......................................................................................................... 2-23

2.5.7 Electrical specifications of hand input/output .................................................................................................. 2-25

2.5.8 Air supply circuit example .......................................................................................................................................... 2-26

2.6 Shipping special specifications, options, and maintenance parts ...................................................................... 2-27

2.6.1 Shipping special specifications ................................................................................................................................. 2-27

(1) Machine cable ............................................................................................................................................................. 2-28

2.7 Options ....................................................................................................................................................................................... 2-29

(1) Machine cable extension ........................................................................................................................................ 2-30

(2) Changing the operating range .............................................................................................................................. 2-33

(3) Solenoid valve set ..................................................................................................................................................... 2-34

(4) Hand input cable ........................................................................................................................................................ 2-36

(5) Hand output cable ..................................................................................................................................................... 2-37

(6) Hand curl tube ............................................................................................................................................................ 2-38

2.8 Maintenance parts ................................................................................................................................................................. 2-39

Page 9

ii

Page

3 Controller ......................................................................................................................................................................................... 3-40

3.1 Standard specifications ...................................................................................................................................................... 3-40

3.1.1 Standard specifications .............................................................................................................................................. 3-40

3.1.2 Protection specifications and operating supply ............................................................................................... 3-42

3.2 Names of each part ............................................................................................................................................................. 3-43

3.3 Outside dimensions/Installation dimensions ............................................................................................................. 3-46

3.3.1 Outside dimensions ...................................................................................................................................................... 3-46

3.3.2 Installation dimensions ................................................................................................................................................ 3-48

3.4 External input/output ......................................................................................................................................................... 3-49

3.4.1 Types .................................................................................................................................................................................. 3-49

3.4.2 Explanation ....................................................................................................................................................................... 3-49

3.5 Dedicated input/output ...................................................................................................................................................... 3-50

3.6 Emergency stop input/output ......................................................................................................................................... 3-52

3.6.1 Connection of the external emergency stop ..................................................................................................... 3-52

3.6.2 Door switch function ................................................................................................................................................... 3-54

3.7 Parallel input/output unit .................................................................................................................................................. 3-55

3.8 Options ...................................................................................................................................................................................... 3-60

(1) Teaching pendant (T/B) ........................................................................................................................................ 3-61

(2) Pneumatic hand interface ..................................................................................................................................... 3-64

(3) Controller protection box ...................................................................................................................................... 3-67

(4) Expansion option box .............................................................................................................................................. 3-70

(5) Parallel I/O unit ......................................................................................................................................................... 3-72

(6) External I/O cable .................................................................................................................................................... 3-82

(7) Personal computer cable ....................................................................................................................................... 3-84

(8) Extended serial interface ....................................................................................................................................... 3-86

(9) CC-Link interface ..................................................................................................................................................... 3-88

(10) Ethernet interface .................................................................................................................................................. 3-90

(11) Additional axis interface ...................................................................................................................................... 3-92

(12) Extension memory cassette .............................................................................................................................. 3-94

(13) Personal computer support software/Personal computer support software mini ..................... 3-96

(14) Instruction Manual(bound edition) ................................................................................................................... 3-98

3.9 Maintenance parts ................................................................................................................................................................ 3-99

4 Software ......................................................................................................................................................................................... 4-100

4.1 List of commands ............................................................................................................................................................... 4-100

(1) The procedure of robot language selection ................................................................................................. 4-100

(2) MELFA-BASIC Ⅳ commands ........................................................................................................................... 4-101

4.2 List of parameters .............................................................................................................................................................. 4-103

(1) List of parameters .................................................................................................................................................. 4-103

(2) Change the display language / 表示言語の切り 替え ............................................................................ 4-105

5 Instruction Manual ...................................................................................................................................................................... 5-106

5.1 The details of each instruction manuals ................................................................................................................... 5-106

6 Safety .............................................................................................................................................................................................. 6-108

6.1 Safety ...................................................................................................................................................................................... 6-108

6.1.1 Self-diagnosis stop functions ................................................................................................................................ 6-108

6.1.2 External input/output signals that can be used for safety protection measures ........................... 6-108

6.1.3 Precautions for using robot .................................................................................................................................... 6-109

6.1.4 Safety measures for automatic operation ........................................................................................................ 6-109

6.1.5 Safety measures for teaching ................................................................................................................................ 6-109

6.1.6 Safety measures for maintenance and inspections, etc. ........................................................................... 6-109

6.1.7 Examples of safety measures ................................................................................................................................ 6-110

6.2 Working environment ......................................................................................................................................................... 6-112

6.3 Precautions for handling .................................................................................................................................................. 6-113

7Appendix ...........................................................................................................................................................................Appendix-114

Appendix 1 : Specifications discussion material ......................................................................................... Appendix-114

Page 10

1General configuration

Structural equipment

1-1

1 General configuration

1.1 Structural equipment

Structural equipment consists of the following types.

1.1.1 Standard structural equipment

The following items are enclosed as a standard.

(1) Robot arm

(2) Controller

(3) Machine cable

(4) Robot arm installation bolts

(5) Arm fixing bolts

(6) Safety manual, Instruction manual, CD-ROM (Instruction manual)

(7) Guarantee card

1.1.2 Shipping special specifications

Part of the standard structural equipment is changed at the time of factory shipment. Consequently, kindly confirm the delivery date.

To make changes to the specifications after shipment, service work must be performed at the work site or the

robot must be returned for service.

1.1.3 Options

Installation is possible after shipment. Customer needs to perform the installation work.

1.1.4 Maintenance parts

Consumable parts and spare parts for maintenance use.

For items not listed, contact the dealer where you made your purchase.

Page 11

1-2

Model type combination of robot

1General configuration

1.2 Model type combination of robot

The robot has decided the type corresponding to load, arm length, and environment specification. Please select

the robot matched with the use.

1.2.1 How to identify the robot model

RV-12SD L C -Sxx

( a ) ( b ) ( c ) ( d )

(a). RV-12SD.................................Indicates the RV-12SD series.

(b). L..................................................Indicates long arm type.

Examples)

Blank: Standard type.

L: Long arm type.

(c). C .................................................Indicates environment specification.

Examples)

Blank: Standard Specifications

C: Clean Specifications

(d). -SXX .........................................[1] Indicates a special model number.

[2] -SM

** ................ Indicates a specification with protection specifi-

cation controller.

1.2.2 Combination of the robot arm and the controller

Table 1-1 : Combination of the robot arm and the controller

1.3 Combination of the robot arm and the controllerIndirect export

If you intend to export robots bought from us, be sure to choose robots whose language setting parameter (LNG)

is set to English (ENG).

1.4 Instruction manuals

The instruction manuals supplied with the shipment are provided in electronic form in a CD-ROM, except for the

Safety Manual. This CD-ROM (electronic manual) includes instruction manuals in both Japanese and English versions. Please note that the instruction manuals are the same for both language settings (parameter LNG).

Protection specification

Robot arm

Arm length Controller

Stardard specification

RV-12SD standard arm

CR3D-701M

Note1)

Note1)protection specification. (IP54)

RV-12SDL Long arm

Clean specification

RV-12SDC standard arm

CR3D-701

RV-12SDLC Long arm

Page 12

1General configuration

Contents of the structural equipment

1-3

1.5 Contents of the structural equipment

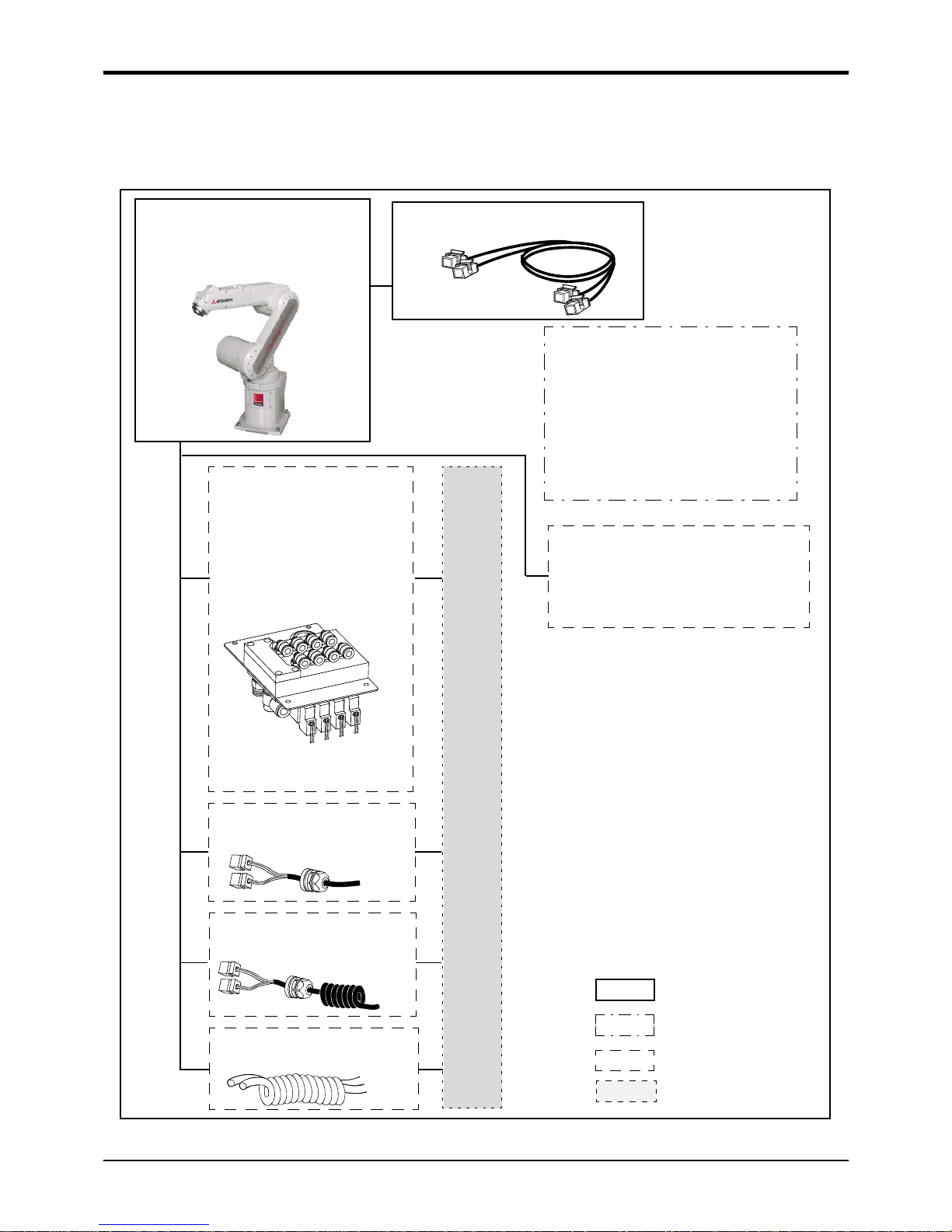

1.5.1 Robot arm

The list of structural equipment is shown in Fig. 1-1.

Fig.1-1 : Structural equipment (Robot arm)

Vertical six-axis

multiple-jointed type

(RV-12SD/12SDL/12SDC/12SDLC)

Hand output cable

・ 1S-GR35S-01 (4sets)

Hand input cable

・ 1S-HC25C-01

Solenoid valve set

(Hand output cable is attached)

<Sink type>

・ 1 set: 1S-VD01-01

・ 2 set: 1S-VD02-01

・ 3 set: 1S-VD03-01

・ 4 set: 1S-VD04-01

Hand curl tube

・ 4 set, 8pc.: 1N-ST0608C

Stopper for changing the operating range

of the J1 axis

・ Stopper part: 1S-DH-01

*This must be installed by the customer.

[Caution]

Standard configuration

Special shipping

Option

equipment

specifications

Prepared by customer

Pneumatic hand customer-manufactured parts

Note1) □□ refer the length.

Refer to Table 1-1 for datails.

Note2) Connect the extension cables to

the arm side of the standard 7 m

(for fixing) cable to extend.

Machine cable extension

(attached to the standard 7 m cable)

・ Fixed type: 1S- □□ CBL-02

・ Flexed type: 1D- □□ LCBL-02

Machine cable

(Standard product: 7m attachment)

Page 13

1-1

1 General configuration

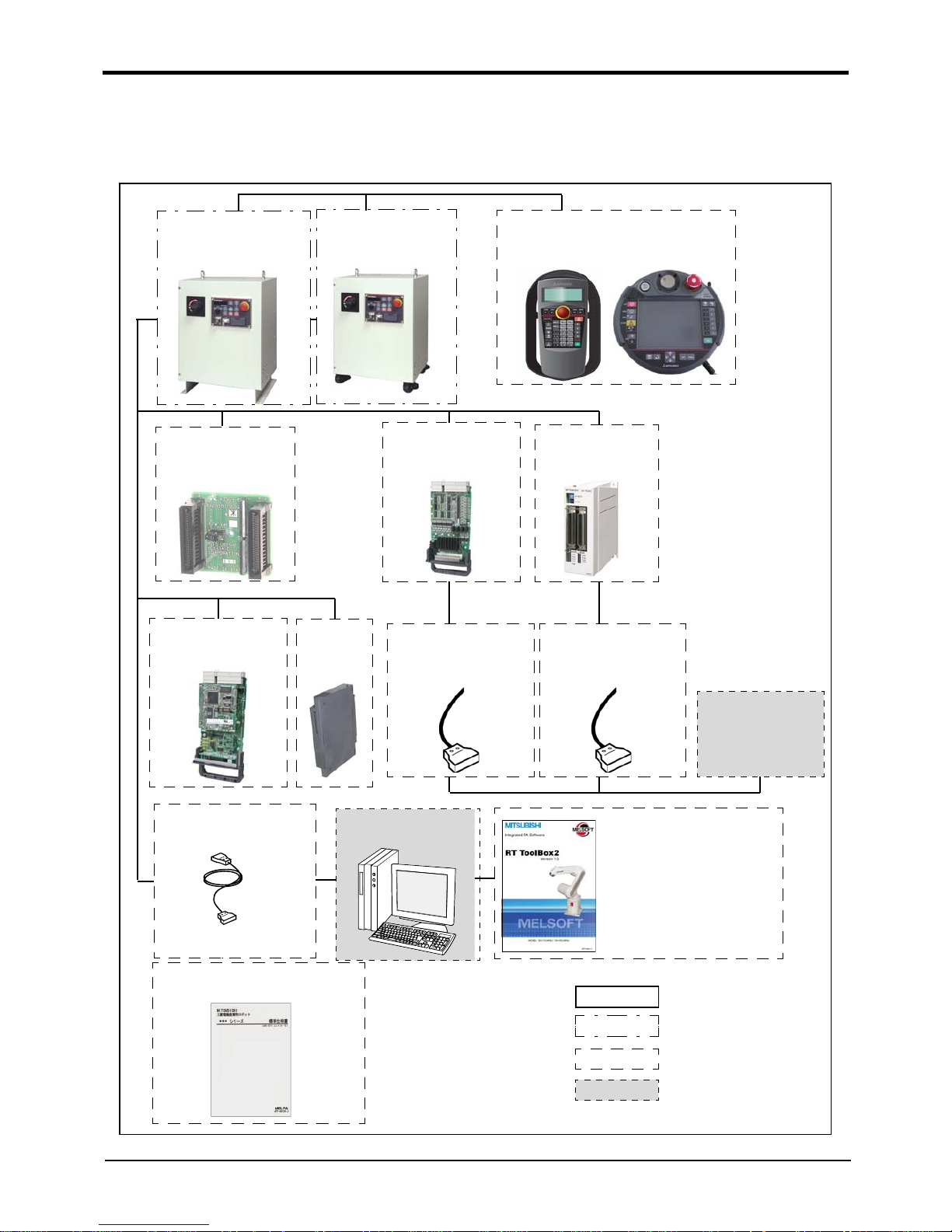

1.3.1 Controller

The devices shown below can be installed on the controller.

The controllers that can be connected differ depending on the model of the robot arm.

Fig.1-1 : Structural equipment

Pneumatic hand

interface

2A-RZ365

Teaching pendant (T/B)

R32TB

R56TB

Personal computer

Prepared by customer

RT Tool Box2

・ 3D-11C-WINJ(CD-ROM)

(MS-Windows2000/XP/Vista)

RT Tool Box2 mini

・ 3D-12C-WINJ(CD-ROM)

(MS-Windows2000/XP/Vista)

Instruction Manual(bound edition)

・ 5S-DC00-PE01

Controller

・ CR3D-701M(IP54 仕様)

ま たは

・ CR3D-701

Caster type

controller

CC-Link interface

2D-TZ576

Extension

memory

cassette

2D-TZ454

Parallel I/O interface

2D-TZ368

Parallel I/O unit

2A-RZ361/2A-RZ371

External I/O cable

・ 2D-CBL05 (5m)

・ 2D-CBL15 (15m)

PLC(Programmable

Logic Controller)

External device

Prepared by

customer

External I/O cable

・ 2A-CBL05 (5m)

・ 2A-CBL15 (15m)

Personal computer cable

2D-232CBL03M

(RS-232)

*)Refer to table 1-3 for

USB cable.

Standard configuration

Special shipping

Options

Prepared by customer

[Caution]

equipment

specifications

The photograph is the image figure.

Page 14

Contents of the Option equipment and special specification

1-1

1.4 Contents of the Option equipment and special specification

A list of all Optional equipments and special specifications are shown below.

Table 1-1 : The list of Option equipment and special specification

[Reference]:The recommendation products of the USB cable are shown below.

Table 1-2 : Recommendation article of the USB cable

Item Type Specifications

Classificati

on

Note1)

Note1)In the classification column, ○ refers to an option,and □ to a Shipping special specifications.

Descripsion

Stopper for changing the

operating range of the J1

axis

1S-DH-01

Stopper part

+ side: +135, +90, or +45 deg.

- side: -135, -90, or -45 deg.

One each of the following can be

selected: ± 170 deg. are used for

the standard specification.

○

This must be installed by the customer.

Extended machine cable 1S- □□ CBL-02 For fixing (Three sets for power,

signal and ground cable)

○ 5, 10, 15m

1S- □□ LCBL-02 For bending (Three sets for power,

signal and ground cable)

○ 5, 10, 15m

Solenoid valve set 1S-VD01-01 1 set (Sink type) ○

A solenoid valve set for the pneumatic hand

1S-VD02-01 2 set (Sink type) ○

1S-VD03-01 3 set (Sink type) ○

1S-VD04-01 4 set (Sink type) ○

Hand output cable

1S-GR35S-01

Robot side connector. One terminal

is not treated.

○

The cable is connected to the hand output connector by the customer.

Hand input cable

1S-HC25C-01 Robot side connector. One terminal

is not treated.

○

The cable is connected to the sensor by the customer.

Hand curl tube 1N-ST0602C For solenoid valve 1set.:Φ6x2 ○

Curl type air tube

1N-ST0604C For solenoid valve 2set.:Φ6x4 ○

1N-ST0606C For solenoid valve 3set.:Φ6x6 ○

1N-ST0608C For solenoid valve 4set.:Φ6x8 ○

Teaching pendant R32TB Cable length 7m ○

With 3-position deadman switch

R32TB-15 Cable length 15m ○

R56TB Cable length 7m ○

R56TB-15 Cable length 15m ○

Pneumatic hand interface

2A-RZ365 DO: 8 point (Sink type) ○

It is necessary when the hand output signal of the

robot arm is used.

Parallel I/O Interface

(Sink type)

2D-TZ368 (Sink type)

DO: 32 point (Sink type)/

DI : 32 point (Sink type)

Insulated type output signal (100mA/

point)

○

The card type external input-and-output.

Interface.Install to the slot of controller.

External I/O cable

(For Parallel I/O Interface)

2D-CBL05 5m ○

Use to connect the external peripheral device to

the parallel input/output interface.

2D-CBL15 15m ○

Parallel I/O Unit

2A-RZ361

DO: 32 point (Sink type)/

DI : 32 point (Sink type)

○

The unit for expansion the external input/output.

Electrical isolated Type

(100mA/Point)

2A-RZ371

DO: 32 point (Source type)/

DI : 32 point (Source type)

○

External I/O cable

(For Parallel I/O Unit)

2A-CBL05 5m ○

Use to connect the external peripheral device to

the parallel input/output unit

2A-CBL15 15m ○

Personal computer

cable

Note2)

Note2)The recommendation products of the USB cable are shown in Table 1-1.

2D-232CBL03M

RS-232C cable 3m for PC-AT compatible model

○

RT ToolBox2

(

Personal computer Sup-

port software)

3D-11C-WINE CD-ROM ○

MS-Windows2000/XP

/Vista

(With the simulation function)

RT ToolBox2 mini

(Personal computer Sup-

port software mini)

3D-12C-WINE CD-ROM ○ MS-Windows2000/XP/Vista

CC-Link interface

2D-TZ576

Local station (The local station alone

is supported.)

○ for MELSEC PLC with CC-Link connection.

Extended memory cassette

2D-TZ454

Teaching point number: 50,800

Steps number: 50,800

Program number: 512

○

The battery backup function is provided.

The value combined with the standard

Caster specifications

controller

CR3D-701/701M Specifications with casters □

The controller height

will be h =

615

Instruction Manual 5S-DC00-PE01 RV-12SD/12SDL series ○ A set of the instructions manual bookbinding editions

Page 15

1-2

Contents of the Option equipment and special specification

Be careful to the USB cable to apply neither the static electricity nor the noise.

Failure to observe this could lead to malfunc-tioning .

製 品 名 形 名 メ ー カ名

USB cable

(USB A type-USB B type)

USB2-30 ELECOM CO., LTD.

AU230 BUFFALO KOKUYO SUPPLY INC.

USB cable

(USB A type-USB mini B type)

KU-AMB530 SANWA SUPPLY INC.

USB-M53 ELECOM CO., LTD.

GT09-C20USB-SP MITSUBISHI ELECTRIC SYSTEM & SERVICE CO., LTD.

MR-J3USBCBL3M MITSUBISHI ELECTRIC CO., LTD.

USB adapter

(USB B type-USB mini B type)

AD-USBBFTM5M ELECOM CO., LTD.

Caution

Page 16

2Robot arm

Standard specifications

2-3

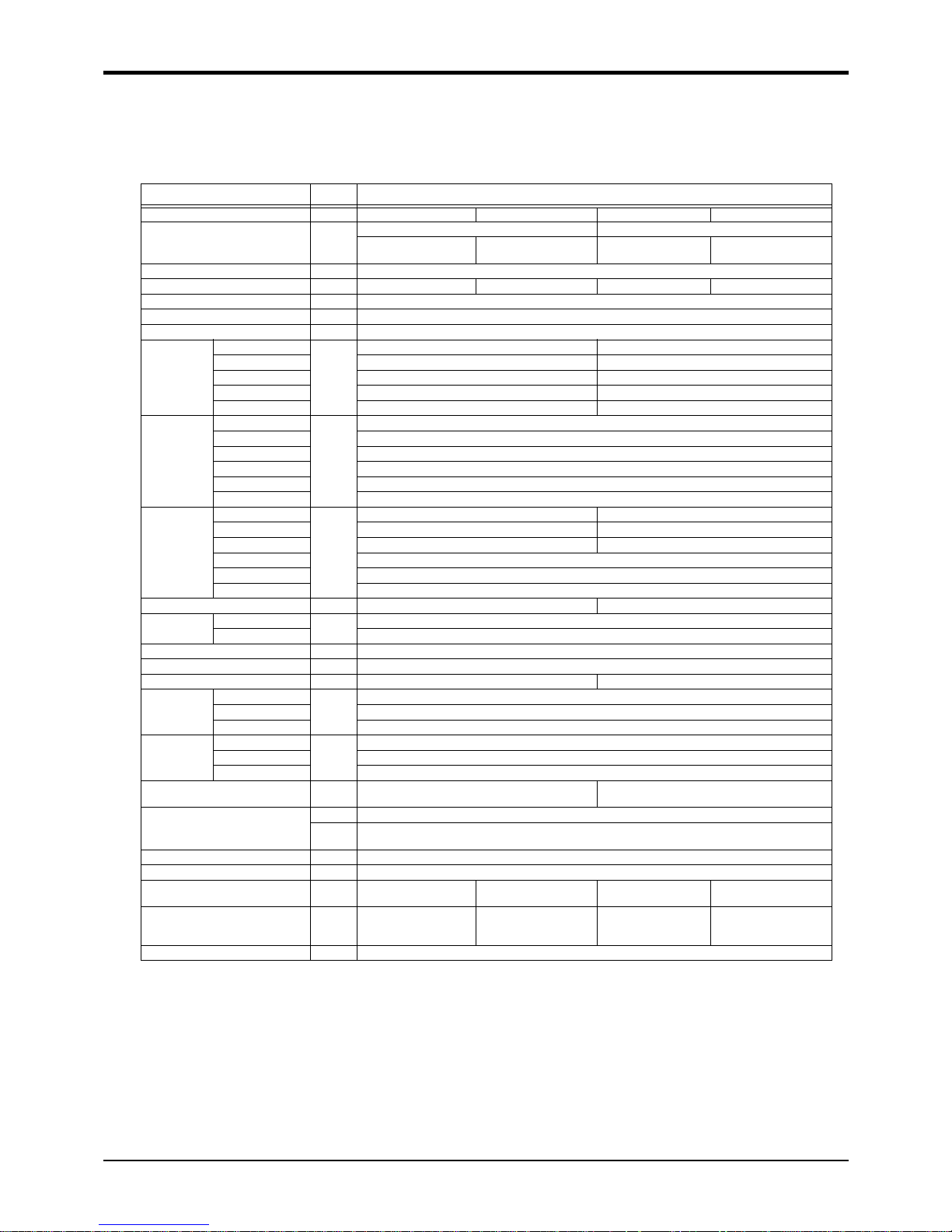

2 Robot arm

2.1 Standard specifications

2.1.1 Standard specifications

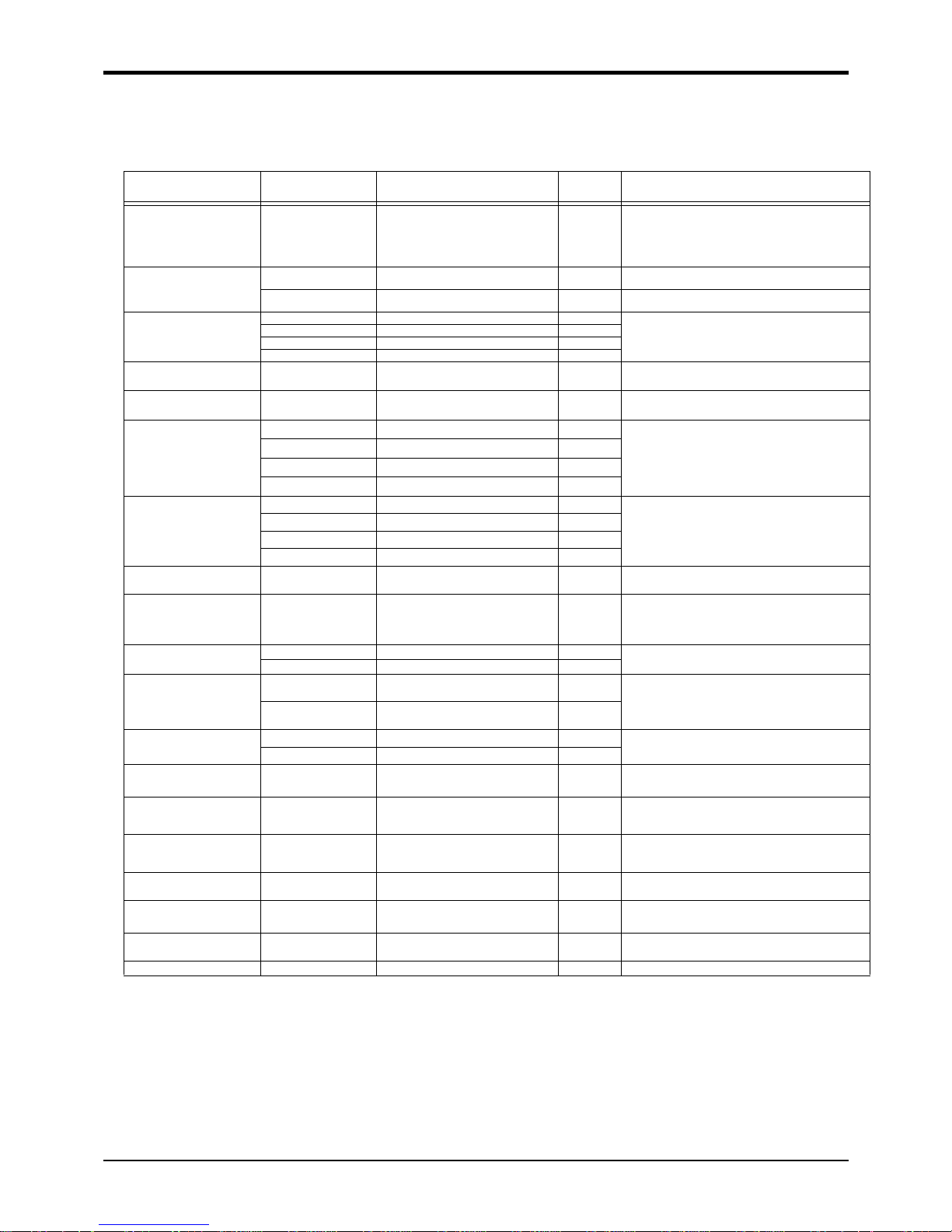

Table 2-1 : Tab Standard specifications of robot

Item Unit Specifications

Type RV-12SD RV-12SDC RV-12SDL RV-12SDLC

Type of robot

6-axis standard arm 6-axis long arm

Standard

Clean

(Special Specifications)

Standard

Clean

(Special Specifications)

Degree of freedom

6

Installation posture On floor, hanging On floor On floor, hangingOn floor

Structure Vertical, multiple-joint type

Drive system AC servo motor (brake provided on all axes)

Position detection method Absolute encoder

Arm length

Shoulder shift

mm

150 150

Upper arm 400 560

Fore arm 530 670

Elbow shift 80 80

Wrist length 97 97

Operating

range

Waist (J1)

Degree

340(-170 to +170)

Shoulder (J2) 230(-100 to +130)

Elbow (J3) 290(-130 to +160)

Wrist twist (J4) 320(-160 to +160)

Wrist pitch (J5) 240(-120 to +120)

Wrist roll (J6) 720(-360 to +360)

Speed of

motion

Waist (J1)

Degree/

s

276 230

Shoulder (J2) 230 172

Elbow (J3) 267 200

Wrist twist (J4) 352

Wrist pitch (J5) 375

Wrist roll (J6) 660

Maximum resultant velocity

Note1)

Note1) This is the value on the hand flange surface when all axes are combined.

mm/sec Approx. 9,600 Approx. 9,500

Load Maximum

Note2)

Note2) The maximum load capacity is the mass with the flange posture facing downword at the ± 10°limit.

kg

12

Rating 10

Pose repeatability

Note3)

Note3) The pose repeatability details are given in Page 6, "2.2.1 Pose repeatability"

mm ± 0.05

Ambient temperature ℃ 0 to 40

mass kg Approx. 93 Approx. 98

Allowable

moment load

Wrist twist (J4)

N・m

19.3

Wrist pitch (J5) 19.3

Wrist roll (J6) 11

Allowable

inertia

Wrist twist (J4)

kg ・ m

2

0.4

Wrist pitch (J5) 0.4

Wrist roll (J6) 0.14

Note4)

Note4) Up to 0.28kg・m2 can be supported by performing variable acceleration/deceleration control and also by setting the load

inertia.

Arm reachable radius froot p-axis

center point

mm 1,086 1,385

Tool wiring

Note5)

Note5) The air hand interface (option) is required when the tool (hand) output is used. Also, if the solenoid set (option) is

used, eight points of hand outputs are used for other options. 。

Hand input 8 point / hand output 8 point

Eight spare wires : AWG#27(0.1mm

2

)

(shielded)

Tool pneumatic pipes Primary side: Φ6 × 2 , Secondary side: Φ6 × 8

Supply pressure MPa 0.49 ± 10%

Protection specification

Note6)

Note6) The protection specification details are given in Page 7, "2.2.5 Protection specifications and working environment".

J1 to J3 axis : IP54

J4 to J6 axis : IP65

-

J1 to J3 axis : IP54

J4 to J6 axis : IP65

-

Degree of cleanliness

Note7)

Note7) The clean specification details are given in Page 9, "2.2.6 Clean specifications" .A down flow(0.3m/s or more) in the

clean room is the necessary conditions for the cleanliness.

-

10(0.3μm)

Internal suction

requirement

-

10(0.3μm)

Internal suction

requirement

Painting color Light gray (Equivalent to Munsell: 0.08GY7.64/0.81)

Page 17

2-4

Definition of specifications

2 Robot arm

2.2 Definition of specifications

The accuracy of pose repeatability mentioned in catalogs and in the specification manual is defined as follows.

2.2.1 Pose repeatability

For this robot, the pose repeatability is given in accordance with JIS 8432 (Pose repeatability). Note that the value

is based on 100 measurements (although 30 measurements are required according to JIS).

[Caution] The specified "pose repeatability" is not guaranteed to be satisfied under the following conditions.

[1] Operation pattern factors

1) When an operation that approaches from different directions and orientations are included in rela-

tion to the teaching position during repeated operations

2) When the speed at teaching and the speed at execution are different

[2] Load fluctuation factor

1) When work is present/absent in repeated operations

[3] Disturbance factor during operation

1) Even if approaching from the same direction and orientation to the teaching position, when the

power is turned OFF or a stop operation is performed halfway

[4] Temperature factors

1) When the operating environment temperature changes

2) When accuracy is required before and after a warm-up operation

[5] Factors due to differences in accuracy definition

1) When accuracy is required between a position set by a numeric value in the robot's internal coordinate system and a position within the actual space

2) When accuracy is required between a position generated by the pallet function

Note1)

and a posi-

tion within the actual space

Note1)

The pallet function is a function that teaches only the position of the work used as reference (3 to 4 points) and

obtains the remaining positions by calculations, for an operation that arranges works orderly or for an operation

that unloads orderly arranged works. By using this function, for example, in the case of an operation that arranges

works on grid points of 100 x 100, by teaching only three points of four corners, the remaining grid points are

automatically generated; thus, it is not necessary to teach all 10,000 points. For more information about the pallet

function, refer to the separate volume, "Instruction Manual/Detailed Explanation of Functions and Operations."

Page 18

2 Robot arm

Definition of specifications

2-5

2.2.2 Rated load (mass capacity)

The robot's mass capacity is expressed solely in terms of mass, but even for tools and works of similar mass,

eccentric loads will have some restrictions. When designing the tooling or when selecting a robot, consider the following issues.

(1) The tooling should have the value less or equal than the smaller of the tolerable inertia and the tolerable

moment found in Page 3, "Table 2-1 : Tab Standard specifications of robot"

(2) Fig. 2-1 shows the distribution dimensions for the center of gravity in the case where the volume of the

load is relatively small. Use this figure as a reference when designing the tooling.

(3) When the load is not mass, but force, you should design the tooling so that it does not exceed the value for

allowable moment described in Page 3, "Table 2-1 : Tab Standard specifications of robot"

[Caution] The mass capacity is greatly influenced by the operating speed of the robot and the motion posture.

Even if you are within the allowable range mentioned previously, an overload or generate an overcurrnt

alarm could occur. In such cases, it will be necessary to change the time setting for acceleration/deceleration, the operating speed, and the motion posture.

[Caution] The overhang amount of the load for the specified moment and inertia in this section is the dynamic limit

value determined by the motor driving each axis and by the capacity of the reduction gears. Consequently, accuracy cannot be guaranteed for the entire tooling area. Since accuracy is based on the center point of the mechanical interface surface, position accuracy can diminish as you go away from the

flange surface, or vibration can result, with tooling that is not rigid or that is long.

[Caution] Even within the allowable range previously mentioned, an overload alarm may be generated if an ascend-

ing operation continues at a micro-low speed. In such a case, it is necessary to increase the ascending

speed.

Fig.2-1:Position of center of gravity for loads (for loads with comparatively small volume): RV-12SD/12SDLSeries

80

80

112

112

200

200

197

277

0

Unit : mm

Rotation center for J6 axis

Rotation center for J5 axis

200

300 100

5.0kg

10.0kg

97

100

100

Page 19

2-6

Definition of specifications

2 Robot arm

2.2.3 Relationships Among Mass Capacity, Speed, and Acceleration/Deceleration Speed

This robot automatically sets the optimum acceleration and deceleration speeds and maximum speed, according

to the load capacity and size that have been set, and operates using these automatically set speeds.

To achieve that, it is necessary to correctly set the actual load data (mass and size of hand and work) to be used.

However, vibration, overheating and errors such as excessive margin of error and overload may occur,depending

on the robot operation pattern or ambient temperature. In such a case, change the setting value to the +20%

range. If a setting is performed in such a way that it falls below the mounted load, the life span of the mechanism

elements used in the robot may be shortened. In the case of a work requiring a high degree of accuracy, set up the

load correctly and use the robot by lowering the ratios of the acceleration and deceleration speeds.

(1) Setting Load Capacity and Size (Hand Conditions)

Set up the capacity and size of the hand with the "HNDDAT*" parameter (optimum acceleration/deceleration

setting parameter), and set up the capacity and size of the work with the "WRKDAT*" parameter. Numbers 0 to 8

can be used for the asterisk (*) part. Designate the "HNDDAT*" and "WRKDAT*" parameters to be used using

the "LOADSET" command in a program.

For more details, refer to the separate "Instruction Manual/Detailed Explanation of Functions and Operations."

It is the same meaning as "LOADSET 0.0" if not using the "LOADSET".

2.2.4 Vibrations at the Tip of the Arm during Low-Speed Operation of the Robot

Vibrations at the tip of the arm may increase substantially during the low-speed operation of the robot, depending

on the combination of robot operation, hand mass and hand inertia. This problem occurs when the vibration count

specific to the robot arm and the vibration count of the arm driving force are coming close to each other. These

vibrations at the tip of the arm can be reduced by taking the following measures:

1) Lower the robot's operating speed by approximately 5% from high speed using the OVRD instruction.

2) Change and move the teaching points of the robot.

3) Change the hand mass and hand inertia.

Page 20

2 Robot arm

Definition of specifications

2-7

2.2.5 Protection specifications and working environment

(1) Types of protection specifications

The robot arm has protection specifications that comply with the IEC Standards. The protection specifications

and applicable fields are shown in Table 2-2.

Even oil mist environment can be used in addition to the general environment.

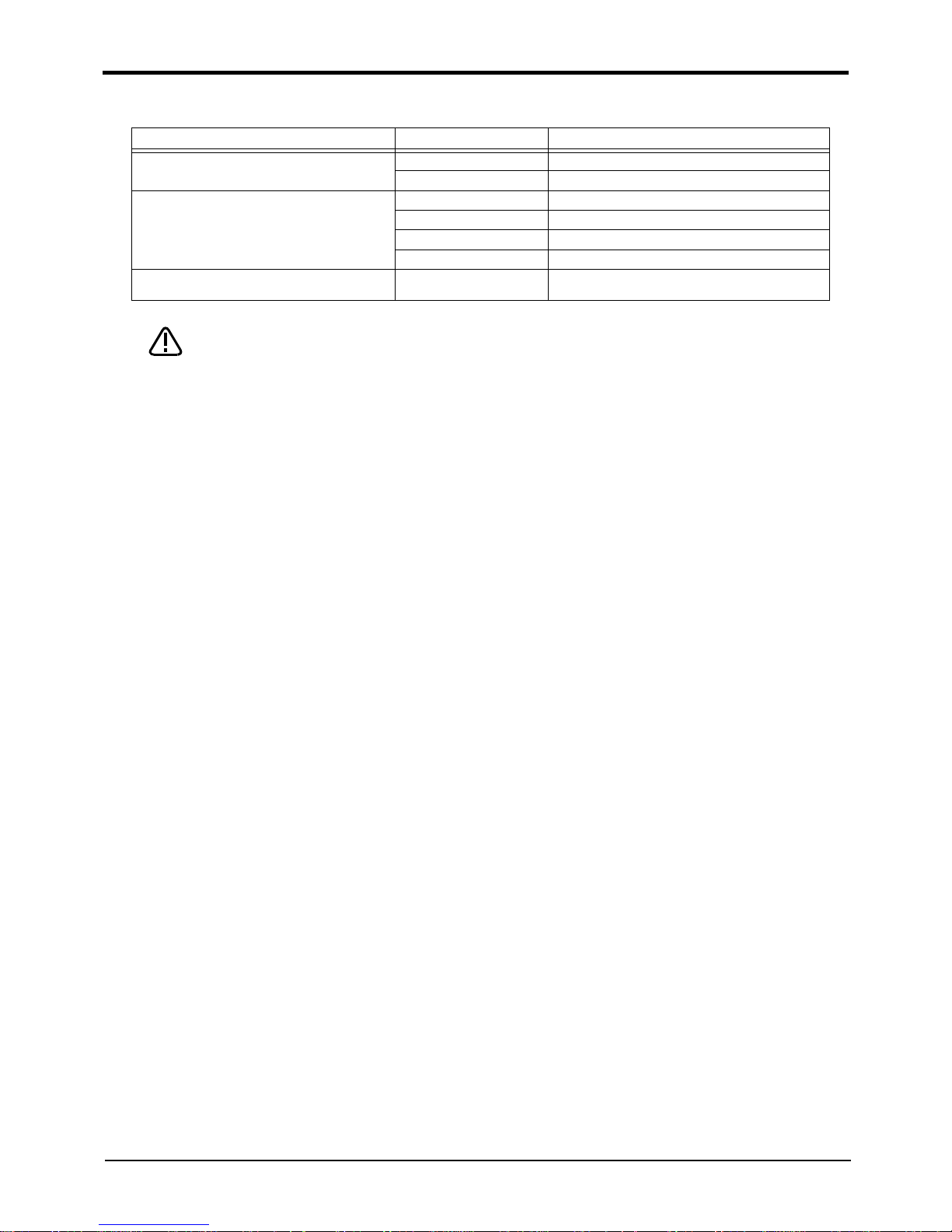

Table 2-2 : Protection specifications and applicable fields

The IEC IP symbols define the degree of protection against solids and fluids, and do not indicate a protective

structure against the entry of oil or water.

The evaluation regarding oil mist specifications has been confirmed with Mitsubishi's standard testing methods

using the cutting oils shown in Table 2-3

Table 2-3 : Tested cutting oil for oil mist specifications

【Information】

・ The IEC IP54

The IEC IP54 standard refers to protection structure designed to prevent any harmful effects by fresh water

scattering vertically onto the testing equipment in a radius of 180 degrees from a distance of 300 to 500 mm,

with 10 ± 0.5 liters of water every minute, at a water pressure of 80 to 100kPa , covering the entire area of

the robot with the exception of the installation section at 1 ㎡ per minute, for a total of 5 minutes or more.

・ The IEC IP65

Protection against water infiltration as specified in IP65 indicates a protective structure that is not harmfully

affected when 12.5± 5% liters of water is supplied from a test device at a position approx. 3m away in various

directions and a water pressure of 30kPa at the nozzle section. The water is filled one minute per 1m

2

of test

device surface area for a total of three minutes.

(2) About the use with the bad environment

This robot has protection methods that conform to IEC'sIP54 (for J1 to J3 axis) and IP65 (for J4 to J6 axis) standards (splashproof type). Recommended usage conditions.

1) The robot is designed for use in combination with machining device.

2) Please examine cutting oil referring to Table 2-3 used by a standard examination of our company.

3) Take measures so that the robot will not be exposed to water, oil and/or chips for a long period of time.

4) Protection performance can be improved by pressurizing the inside of the robot arm. Since the joint (AIR

PURGE) of phi 8 is prepared at the rear of the base section, please supply the dry air for pressurization from

The specification of the dry air for pressurization is shown in Table 2-4.

Table 2-4 :

Specification of the dry air for pressurization

The warranty is invalid for any faults that occur when the robot is used under the following conditions.

Type

Protection

specifications

(IEC Standards value)

Classification Applicable field Remarks

RV-12SD

RV-12SDL

IP54

(J1 to J3 axis)

General-purpose

environment specifications

General assembly

Slightly dusty environment

IP65

(J4 to J6 axis)

Oil mist specifications

Machine tool (cutting)

Machine shop with heavy oil mist

Dusty work shop

Note that if the cutting machine

contains abrasive materials, the

machine line will be shortened.

Name Maker Relevant JIS Main characteristics Application

Emulcut

FA-800

Kyodo Yushi Co., Ltd Class A1 No. 2 Water soluble cutting oil

・ Base oil........................................................50-60%

・ Surfactant and rust inhibitor ..............30-40%

・ Additives......................................................5% or less

・ Water ...........................................................The rest

Water soluble cutting oil

Emulcut

Specification The atmospheric pressure

dew point is -20 degree or

less.

0 to 0.01MPa

Page 21

2-8

Definition of specifications

2 Robot arm

Also, if the cover and/or other parts are damaged by interferences caused by the peripheral devices and the

robot, the protection specification (seal performance, etc.) may be degraded. Therefore, please pay extra attention

when handling the robot.

Refer to Page 91, "6.2 Working environment".

1) In surroundings that generate inflammable gases or corrosive gasses.

2) Atmosphere used excluding cutting oil shown in Table 2-3

3) Environment where the robot is exposed to water, oil and/or chips for a long period of time.

4) In surroundings where chips fall directly on the robot.In surroundings where the minimum diameter of chips

is less than 0.5mm.

5) Mist atmosphere exceeding the specification.

6) Pressurization by the dry air exceeding the specification of Table 2-4

Page 22

2 Robot arm

Definition of specifications

2-9

2.2.6 Clean specifications

(1) Types of clean specifications

The robot arm with clean specification is made by order. Please check the delivery schedule.

Table 2-5 : Clean specifications

Table 2-6 : Specifications of vacuum generation valve

■ Precautions for use

1) When using a device that moves or rotates the robot arm, the down flow may not be secured because of the

air flow. In this case, the degree of cleanliness cannot be ensured.

2) A Φ8 coupling is provided in the base section of the robot arm for suction inside the robot arm. When using

the robot, connect this coupling with the vacuum generating valve and vacuum pump (furnished by the customer).

* Install the vacuum generating valve downstream of the downflow or install a filter in the exhaust air sec-

tion so that the exhaust air from the vacuum generating valve does not affect cleanness.

Recommended filter: Exhaust filter EF300-02, Koganei Corporation

* If any vacuum pump is prepared by the customer, assure on the vacuum side flow rate 30 liters/min.(ANR)

or more .

3) When using the Mitsubishi standard option solenoid valve set, use the spare piping (Φ6 pneumatic hose) of

the primary piping to exhaust the air.

If the exhaust leaks into the robot arm, the degree of cleanliness could be affected.

Clean specifications Type Degree of cleanliness Internal suction

RV-12SDC-SA

RV-12SDLC-SA

10(0.3μm) Concentrated suction with vaccum generating valve. The use of a vacuum generating valve

is recommended.

Type Maker Air pressure

MEDT 14 KONEGAI CORPORATION 0.2 to 0.6 MPa

Page 23

2-10

Names of each part of the robot

2 Robot arm

2.3 Names of each part of the robot

Fig.2-2 : Names of each part of the robot

J5 axis

J6 axis

Fore arm

Mechanical interface

(Hand installation flange surface)

Upper arm

J1 axis

J2 axis

J3 axis

J4 axis

Base

Elbow block

Shoulder

+

-

+

-

+

-

+

-

+

-

+

-

Page 24

2 Robot arm

Outside dimensions ・ Operating range diagram

2-11

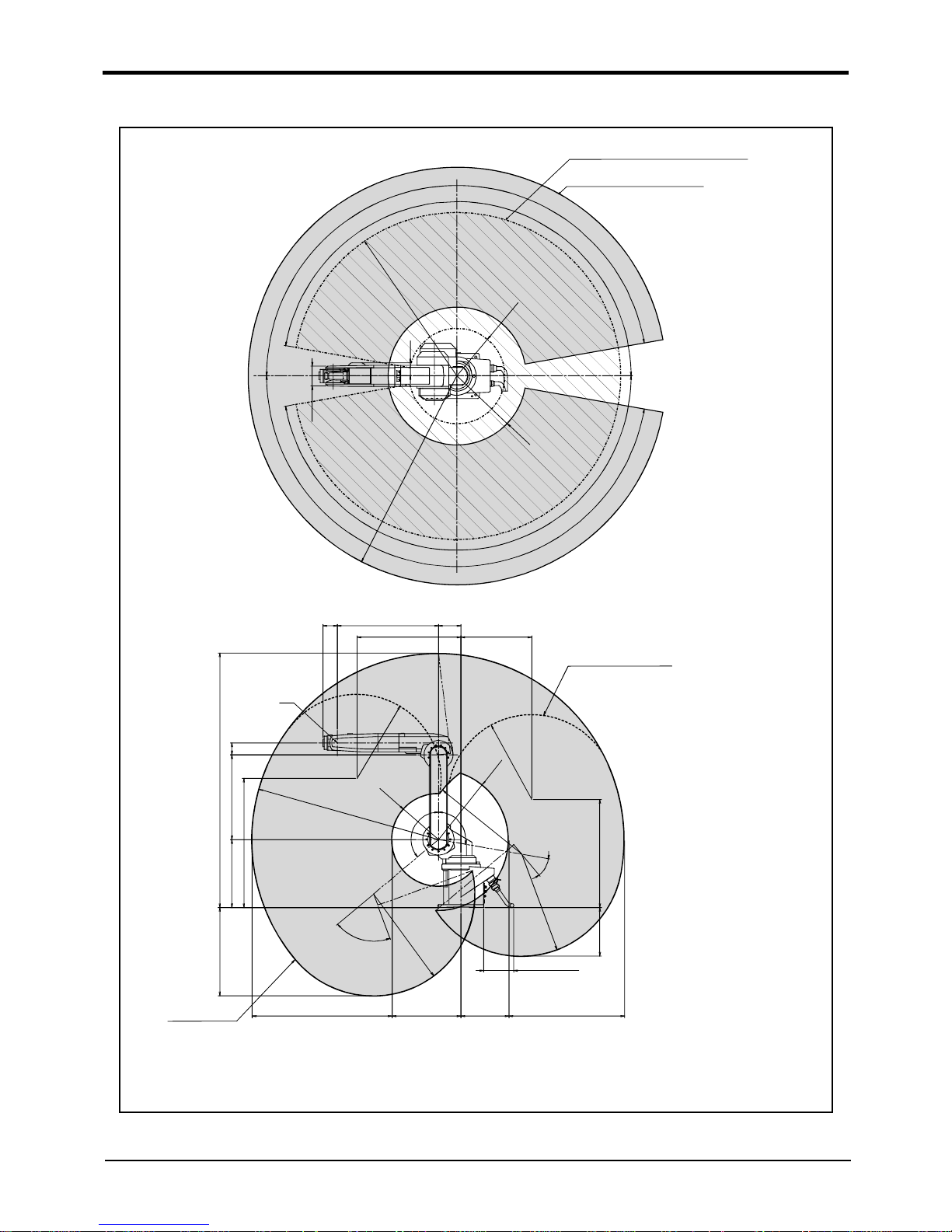

2.4 Outside dimensions ・ Operating range diagram

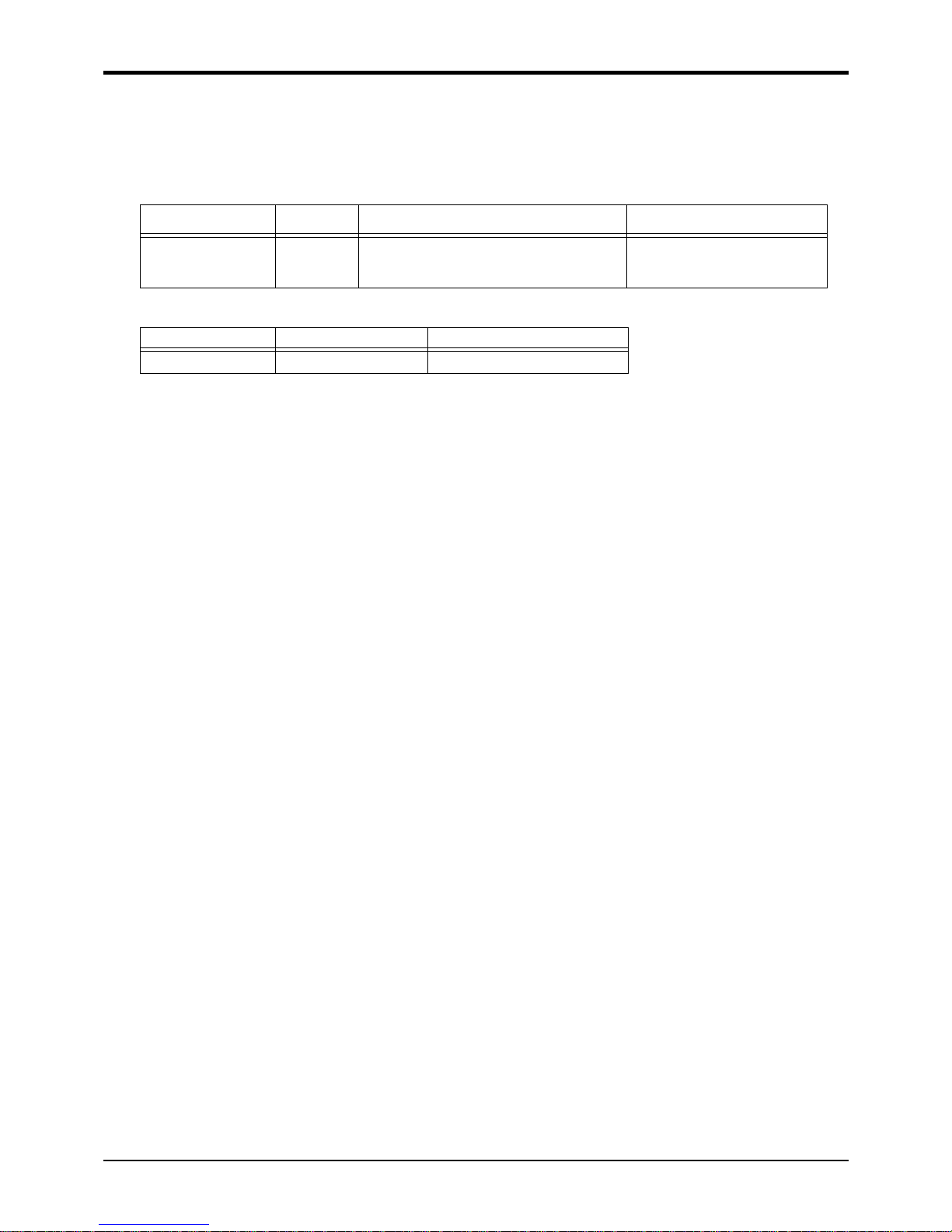

(1) RV-12SD/12SDC

Fig.2-3 : Outside dimensions : RV-12SD/12SDC

φ

40

4

5

°

φ25H7

+0.021

0

depth 9.5

φ50h8

-0.039

0

depth 8

4-M6 screw, depth 9

φ6H7

+0.012

0

depth 9

View A: Detail of mechanical interface

150

155

270

250

250

150155

100

125

4-φ14 installation hole

2-φ6 holes

(prepared holes for φ8 positioning pins)

View D bottom view drawing : Detail of installation dimension

(Installation)

6.3a

(Installation)

6.3a

530

97

120

150

63

97

120

106

80

400

220

450

20

115

150 200

258

R

5

7

φ

1

9

1

φ

2

0

8

R

1

1

9

A

B

C

Solenoid valve set

(option)

(Maintenance space)

Machine cable

50

130

φ88

89 93

89

140

214

230

215

161

164

393

172

50

50

44

93

20

(for customer use)

View C: Detail of screw holes for fixing wiring hookup

Screw holes for fixing

wiring hookup (M4)

Page 25

2-12

Outside dimensions ・ Operating range diagram

2 Robot arm

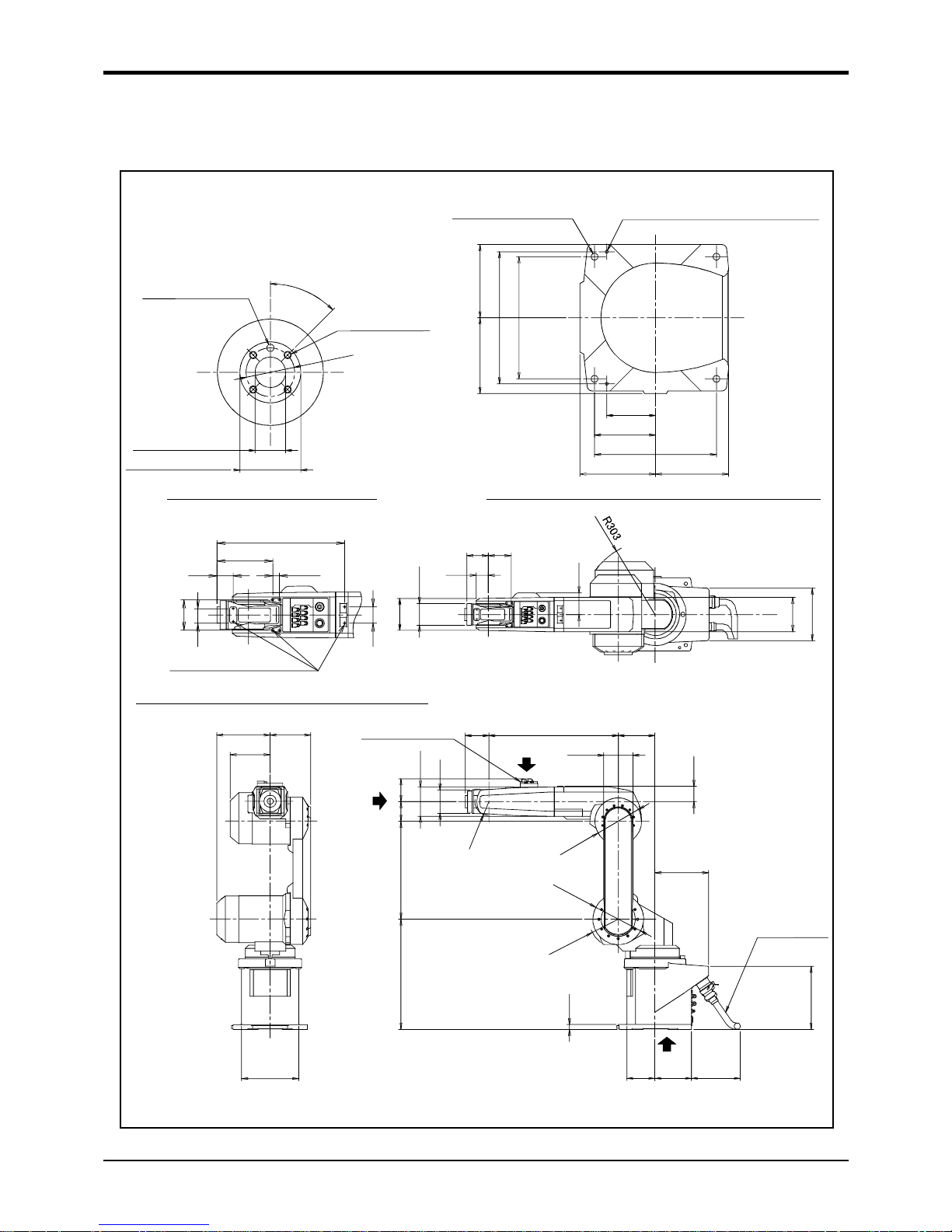

Fig.2-4 : Operating range diagram : RV-12SD/12SDC

1

7

0

°

1

7

0

°

1

7

0

°

1

7

0

°

P-point path: Reverse range

(alternate long and short dash line)

P-point path: Entire range

(solid line)

R

4

1

6

R

7

8

6

R

2

0

5

R

1

0

8

6

8

9

1

3

0

80

1386

400

450

784

R

9

3

6

R

2

6

6

R

4

0

0

R

4

0

0

R

3

5

5

R

5

36

R

5

3

6

R

5

3

6

7

0

°

1

0

0

°

1

3

0

°

646

4

0

°

581

205

416

670

97

530 150

569

349

P

Flange downward

limit line(dotted line)

343

156

P-point path

Rear surface area wide angle, narrow angle limit

*If the angle of axis J1 is -75deg <= J1 <= 75deg and the angle of axis J2 is -25deg <= J2 < 2deg,

then operating range is limited to J2 + J3 * 2 >= -258deg.

*If the angle of axis J1 is -75deg <= J1 <= 75 deg and the angle of axis J2 is -80deg <= J2 < -25deg,

then operating range is limited to J2 + J3 >= -141.5deg.

*If the angle of axis J1 is -75deg <= J1 <= 75 deg and the angle of axis J2 is J2 < -80deg,

then operating range is limited to 6.4 * J2 + J3 >= 573.5deg.

*If the angle of axis J1 is J1 <= -75 degree or J1 > 75 degree and the angle of axis J2 is -80deg <= J2 < 2 degree,

then operating range is limited to J2 + J3 * 2 >= -258 degree.

*If the angle of axis J1 is J1 <= -75deg or J1 > 75deg and the angle of axis J2 is J2 < -80deg ,

then o

p

erating range is limited to 2.4 * J2 + J3 >= -281 degree.

200 or more

Restriction on wide angle

in the rear section

Page 26

2 Robot arm

Outside dimensions ・ Operating range diagram

2-13

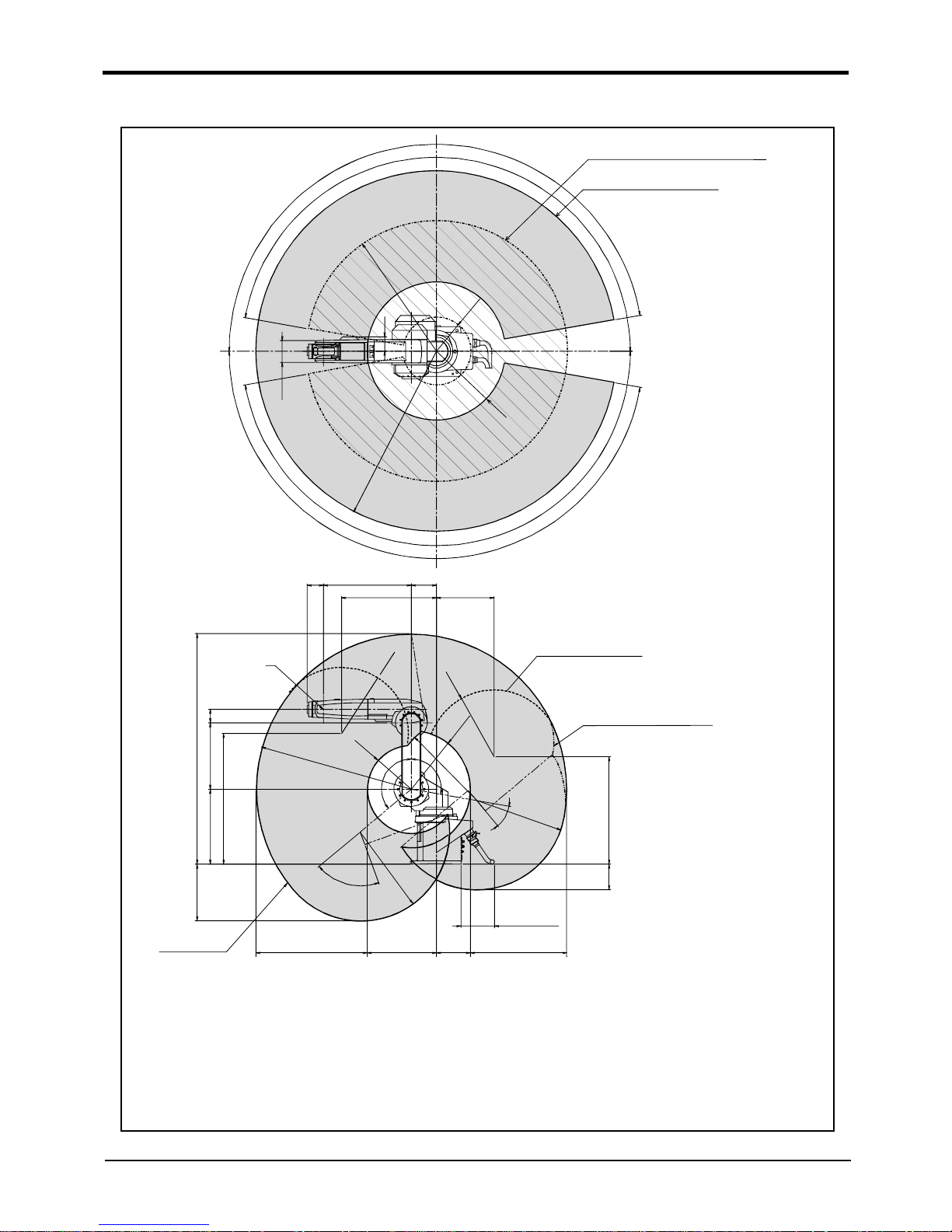

(2) RV-12SDL/12SDLC

Fig.2-5 : Outside dimensions : RV-12SDL/12SDLC

φ25H7

+0.021

0

depth 9.5

φ50h8

-0.039

0

depth 8

4-M6 screw, depth 9

φ6H7

+0.012

0

depth 9

φ

4

0

4

5

°

View A: Detail of mechanical interface

4-φ14 installation hole

150

155

270

250

250

150155

100

125

2-φ6 holes

(prepared holes for φ8 positioning pins)

View D bottom view drawing : Detail of installation dimension

(Installation)6.3a

(Installation)

6.3a

215

161

164

230

50

130

φ88

89 93

89

R

3

0

3

140

214

670

Solenoid valve set

(option)

97

124

150

63

97

120

106

80

560

220

450

20

115

150 200

258

R

5

7

φ

1

9

4

φ

2

0

8

R

1

1

9

(Maintenance space)

A

B

C

Machine cable

393

172

50

50

44

93

20

(for customer use)

View C: Detail of screw holes for fixing wiring hookup

Screw holes for fixing

wiring hookup (M4)

Page 27

2-14

Outside dimensions ・ Operating range diagram

2 Robot arm

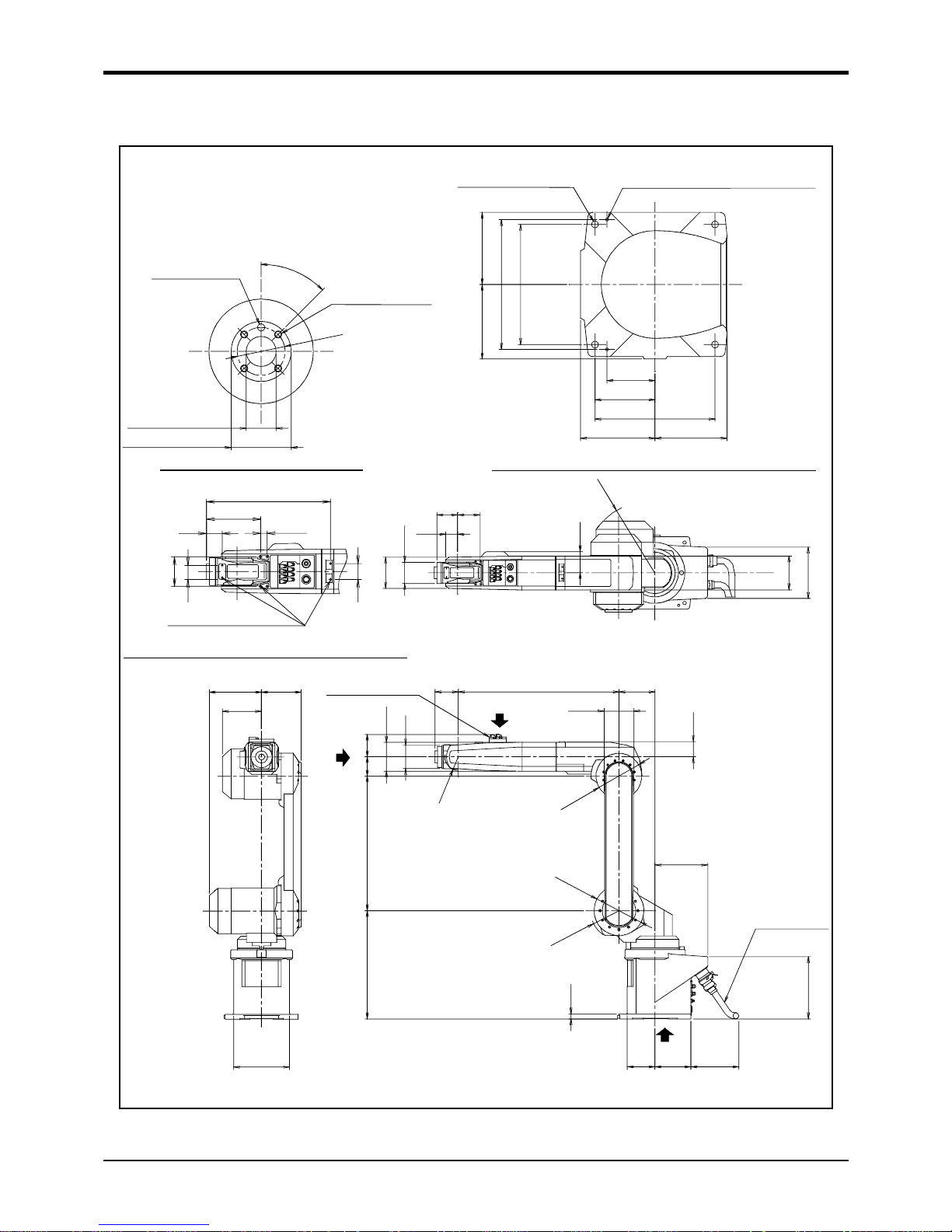

Operating range diagram : RV-12SDL/12SDLC

1

7

0

°

1

7

0

°

R

1

0

8

5

R

3

1

7

R

1

3

8

5

R

4

5

7

1

7

0

°

1

7

0

°

1

3

0

8

9

P-point path: Reverse range

(alternate long and short dash line)

P-point path: Entire range

(solid line)

768

317

928

457

80

1685

560

450

854

585

97

670

150

690 470

P

716

322

1

0

0

°

R

6

7

5

4

0

°

R

3

07

7

0

°

1

3

0

°

R

4

6

7

R

5

6

0

R

1

2

3

5

R

5

6

0

R

6

7

5

200 or more

R

6

7

3

Flange downward

limit line(dotted line)

P-point path

Rear surface area wide angle, narrow angle limit

*If the angle of axis J1 is -75deg <= J1 <= 75deg and the angle of axis J2 is J2 < -25deg ,

then operating range is limited to J2 + J3 >= -155 degree.

*If the angle of axis J1 is J1 <= -75deg or J1 > 75deg and the angle of axis J2 is J2 < -30deg ,

then operating range is limited to 0.54 * J2 + J3 >= -146.2 degree.

Page 28

2 Robot arm

Tooling

2-15

2.5 Tooling

2.5.1 Wiring and piping for hand

Shows the wiring and piping configuration for a standard-equipped hand.

Fig.2-6 : Wiring and piping for hand

Solenoid valve set (option)

* Use by connecting it with the hand

output signal connector.

(1)φ6 quick coupling

(3)Hand input signal connector

(4)Hand output signal connector

(2)φ6 quick coupling

(5)φ8 quick coupling

Note1)

Spare wiring

AIRIN

RETURN

CN2

CN1

AIRIN(φ6)

RETURN(φ6)

VACUUM(φ8)

AIR PARGE(φ8)

SPEAR WIRE INLET

Primary piping pneumatic hose

Hand input signal cable

Hand output signal cable

Secondary piping pneumatic hose (φ6)

(customer-prepared)

Connector and pneumatic coupling

No Name Qty.

Robot side (Robot arm side) Counter side (customer-prepared)

Manufacturer

Connectors, couplings Connector pins Connector Connector pins

(1) Coupling 8 KJL06-01S - - - SMC Corporation

(2) Coupling 2 UKBL6 - - - Koganei Corporation

(3) Connector 2 1-1717834-3 1318108-1 1-1318115-3 1318112-1 Tyco Electronics

AMP

(4) Connector 2 1-1717834-4 1318108-1 1-1318115-4 1318112-1 Tyco Electronics

AMP

(5) Coupling

Note1)

Note1) For dust suction in the clean specification

1 UKBL8 - - - Koganei Corporation

Page 29

2-16

Tooling

2 Robot arm

2.5.2 Internal air piping

(1) Standard type

1) The robot has two φ6 x 4 urethane hoses from the pneumatic entrance on the base section to the shoulder

cover.

2) One hose is the primary piping for the pneumatic equipment.The remaining pipe is used for air exhaust.

3) The optional solenoid is provided with a maximum of eight couplings for the φ6 air hose.

4) The pneumatic inlet in the base section has a φ6 pneumatic coupling bridge.

5) Refer to Page 24, "(3) Solenoid valve set" for details on the electronic valve set (optional).

6) Protection performance can be improved by pressurizing the inside of the robot arm. Since the joint (AIR

PURGE) of phi 8 is prepared at the rear of the base section, please supply the dry air for pressurization

from this joint. Refer to Page 7, "2.2.5 Protection specifications and working environment" for the details

of dry air.

(2) Clean type

1) The clean type basically includes the same piping as the standard type.

2) With the clean specification, a φ8 coupling is provided in the base section for suction inside the machine.

For use, connect it to the suction port of the vacuum pump or the coupling on the "VACUUM" side of the

vacuum generating valve. Moreover, to clean the exhaust from the vacuum pump or vacuum generator, use

the exhaust filter (prepared by the customer). Table 2-7 shows the specifications of the vacuum generating valve.

3) To use the vacuum pump, assure a flow rate of 30 liters/min. or more.

4) Use clean air as the air supplied to the vacuum generator.

Table 2-7 : Vacuum generating valve specifications

2.5.3 Internal wiring for the pneumatic hand output cable(Standard type/Clean type)

1) When the controller uses the optional pneumatic hand interface (2A-RZ365/RZ375), the hand output signal

works as the pneumatic hand cable.

2) The hand output primary cable extends from the connector PCB of the base section to the inside of the

forearm. (AWG#24(0.2mm

2

)x 2 : 8 cables) The cable terminals have connector bridges for eight hand out-

puts. The connector names are GR1 and GR2.

To extend the wiring to the outside of the arm, a separate cable (optional "hand output cable 1S-GR35S01" IP65 is recommended) is required.

2.5.4 Internal wiring for the hand check input cable(Standard type/Clean type)

1) The hand output primary cable extends from the connector PCB of the base section to the inside of the

forearm. (AWG#24(0.2mm

2

)x 2 : 8 cables) The cable terminals have connector bridges for eight hand inputs.

The connector names are HC1 and HC2. The terminal section is connected to the connector in the forearm section.

2) The hand check signal of the pneumatic hand is input by connecting this connector.

To extend the wiring to the outside of the arm, a separate cable (optional "hand input cable 1S-HC25C01" IP65 is recommended) is required.

2.5.5 Spare Wiring

(1) Standard type

As spare wiring, four pairs of cab tire cables (total of eight cores) are preinstalled between the base section and

the forearm side section. The connector is attached to both ends. Customer can be use. Refer to the separate

"Instruction Manual/ROBOT ARM SETUP & MAINTENANCE" for details.

Both ends of the wire terminals are unprocessed. Use them under the following circumstances:

● For folding as the hand output cable when installing the solenoid valve in outside the robot.

● For when installing six or more hand I/O points for the sensor in the hand section

(Connects to the parallel I/O general purpose input.)

Type Maker Air pressure

MEDT14 KONEGAI CORPORATION 0.2 to 0.6 MPa

Page 30

2 Robot arm

Tooling

2-17

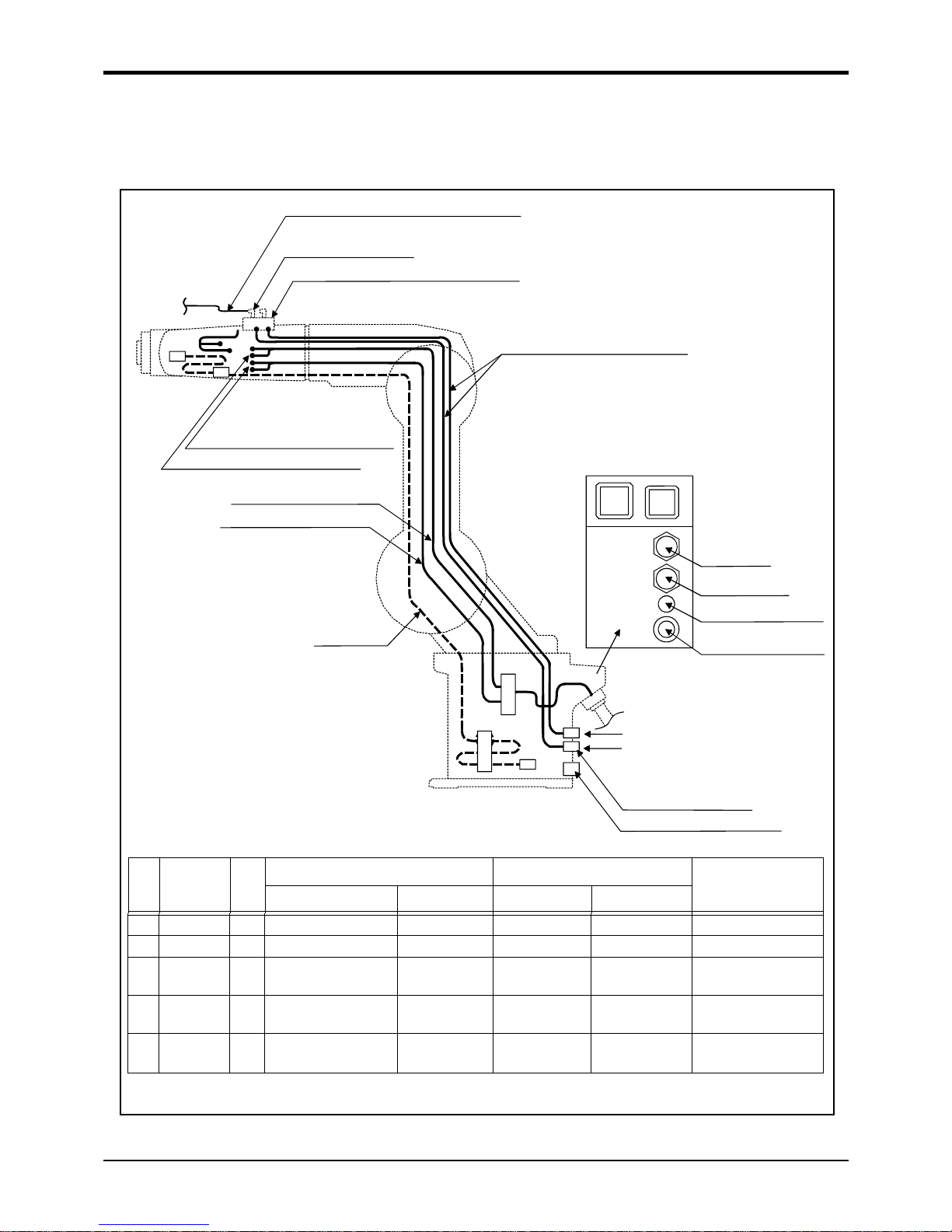

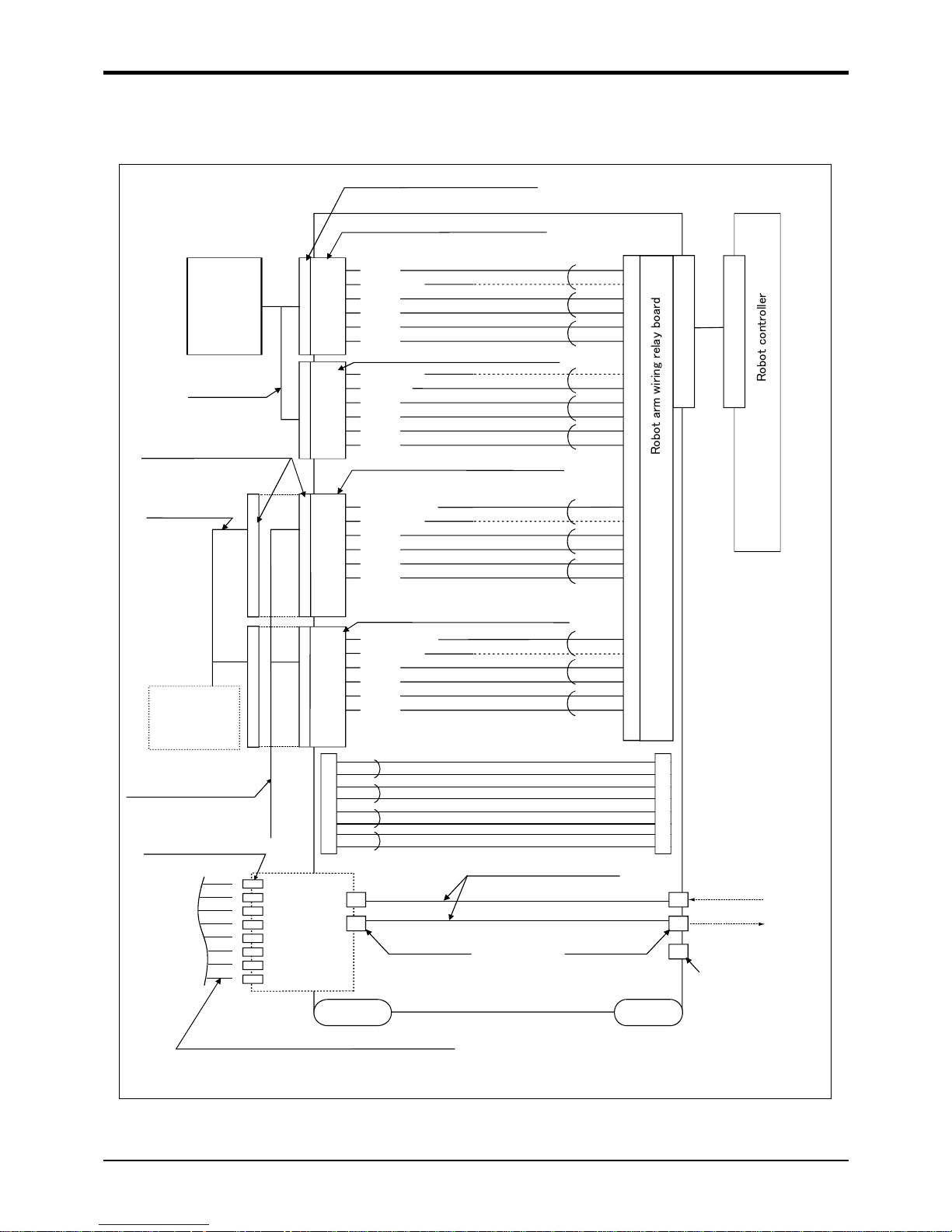

2.5.6 Wiring and piping system diagram for hand

Shows the wiring and piping configuration for a standard-equipped hand.

Fig.2-7 : Wiring and piping system diagram for hand and example the solenoid valve installation(Sink type)

<Reserved>

<24GND>

<HC 5>

<HC 6>

<HC 7>

<HC 8>

White

Black

Hand signal input connector (HC1 connector)

White

Black

White

Black

White

Black

White

Black

White

Black

White

Black

1-1717834-3

(Tyco Electronics AMP)

White

Black

White

Black

White

Black

White

Black

White

Black

1-1318115-3

(Tyco Electronics AMP)

Hand output cable

(option)

1-1717834-4

(Tyco Electronics AMP)

Hand signal output

connection connector

1-1318115-4

(Tyco Electronics AMP)

Secondary pneumatic hose piping (customer-prepared)

φ6 hose

Hand output cable

attached to the solenoid set

Hand input cable

(option)

φ6 quick coupling (1 to 8)

Hand signal input connection connector

Hand signal output connector (GR1 connector)

AIR IN

RETURN

A1

A2

A3

B1

B2

B3

<+24V>

<Reserved>

<HC 1>

<HC 2>

<HC 3>

<HC 4>

A1

A2

A3

A4

B1

B2

B3

B4

<+24V(COM)>

<Reserved>

<GR 1>

<GR 2>

<GR 3>

<GR 4>

<+24V(COM)>

<Reserved>

<GR 5>

<GR 6>

<GR 7>

<GR 8>

1

2

3

4

5

6

7

8

A1

A2

A3

B1

B2

B3

A1

A2

A3

A4

B1

B2

B3

B4

Solenoid set

(option)

valve mounting

section

φ6 quick coupling

φ6 quick coupling

φ6 hose

φ6 hose

Primary piping pneumatic hoses

Yellow

White

Red

Blue

Orange

Driving devices,

such as solenoid

and hand, provided

by the customer

Hand

prepared

by customer

R

o

b

o

t

a

r

m

w

i

r

i

n

g

r

e

l

a

y

b

o

a

r

d

R

o

b

o

t

c

o

n

t

r

o

l

l

e

r

Base

Forearm

Hand signal input connector (HC2 connector)

Hand signal output connector (GR2 connector)

Spare wiring AWG#28(0.1mm2)×6 (cab tire cables with the shield)

Green

Black

Brown

VACCUM

AIR PARGE

φ8

*Refer to Fig. 2-10 for Air

supply circuit example.

Page 31

2-18

Tooling

2 Robot arm

2.5.7 Electrical specifications of hand input/output

Table 2-8 : Electrical specifications of input circuit

Table 2-9 : Electrical specifications of output circuit

Note) An optional air hand interface (2A-RZ365/RZ375) is required to use hand output.

Item Specifications Internal circuit

Type DC input

<Sink type>

* HCn=HC1~HC8

No. of input points 8

Insulation method Photo-coupler insulation

Rated input voltage 12VDC/24VDC

Rated input current Approx. 3mA/approx. 7mA

Working voltage range DC10.2 to 26.4V(ripple rate within 5%)

ON voltage/ON current 8VDC or more/2mA or more

OFF voltage/OFF current 4VDC or less/1mA or less

Input resistance Approx. 3.3kΩ

Response time

OFF-ON 10ms or less(DC24V)

ON-OFF 10ms or less(DC24V)

Item Specification Internal circuit

Type Transistor output

<Sink type>

* GRn = GR1 ~ GR8

No. of output points 8

Insulation method Photo coupler insulation

Rated load voltage DC24V

Rated load voltage range DC21.6 to 26.4VDC

Max. current load 0.1A/ 1 point (100%)

Current leak with power OFF 0.1mA or less

Maximum voltage drop with power ON DC0.9V(TYP.)

Response time OFF-ON 2ms or less (hardware response time)

ON-OFF 2 ms or less (resistance load) (hardware response time)

Fuse rating 1.6A (each one common) Cannot be exchanged

3.3K

24V

0V(COM)

820

HCn

*

24V

24V

(Internal power supply)

*

GRn

Fuse

1.6A

0V

Page 32

2 Robot arm

2-19

2.5.8 Air supply circuit examplefor the hand

Fig. 2-8 shows an example of pneumatic supply circuitry for the hand.

(1) Place diodes parallel to the solenoid coil.

(2) When the factory pneumatic pressure drops, as a result of the hand clamp strength weakening, there can be

damage to the work. To prevent it, install a pressure switch to the source of the air as shown in Fig. 2-8 and

use the circuit described so that the robot stops when pressure drops. Use a hand with a spring-pressure

clamp, or a mechanical lock-type hand, that can be used in cases where the pressure switch becomes damaged.

(3) The optional hand and solenoid valve are of an oilless type. If they are used, don't use any lubricator.

Fig.2-8 : Air supply circuit example for the hand

Pressure switch

To the robot's air intake

(0.5MPa ±10%)

Pneumatic source

0.7MPa less

Filter

Regurater

Page 33

2-20

Options

2 Robot arm

2.6 Options

■ What are options?

There are a variety of options for the robot designed to make the setting up process easier for customer needs.

customer installation is required for the options. Options come in two types: "set options" and "single options".

1. Set options .......................................A combination of single options and parts that together, from a set for serving

some purpose.

2. Single options ..................................That are configured from the fewest number of required units of a part.

Please choose customer's purpose additionally.

Page 34

2 Robot arm

Options

2-21

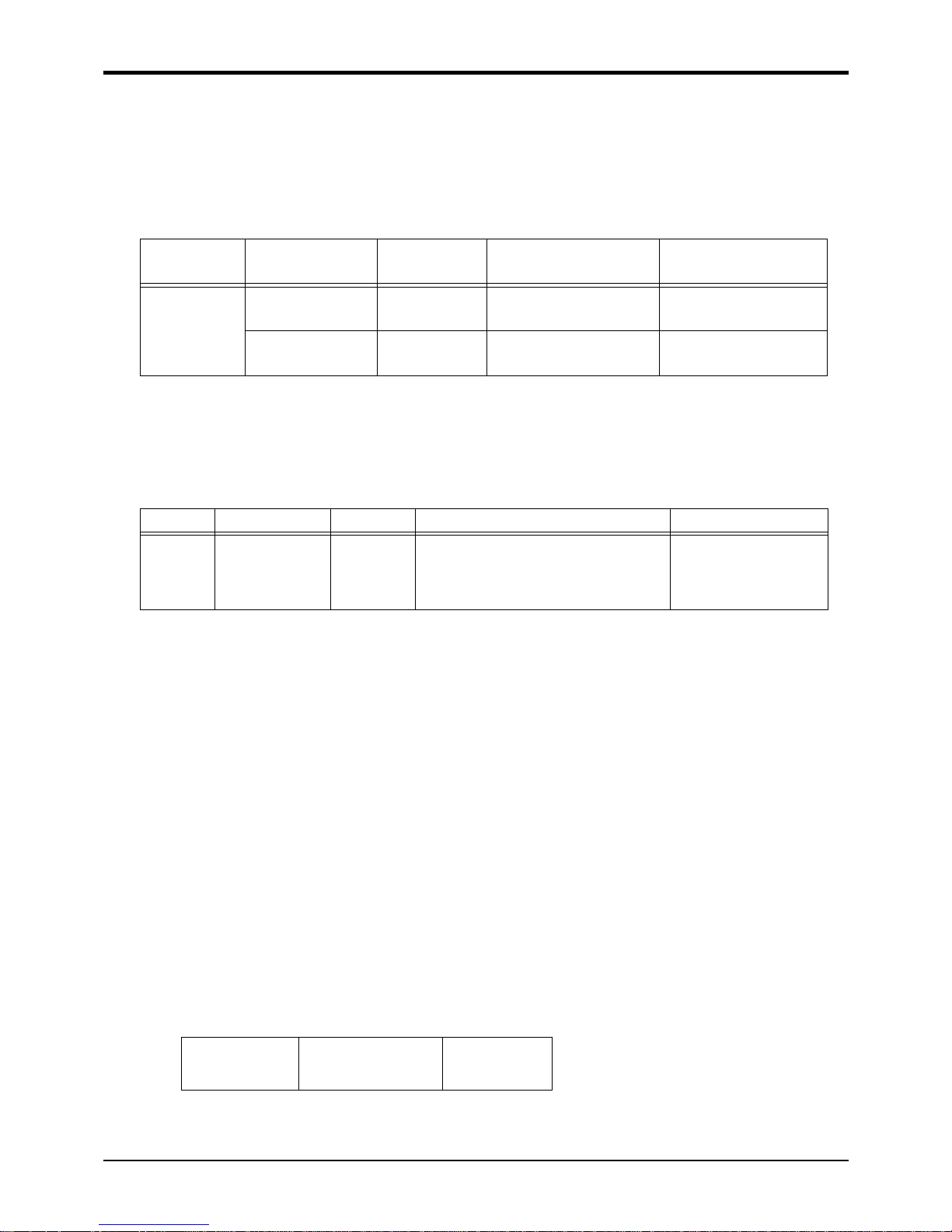

(1) Machine cable extension

■ Order type : ● Fixed type 1S- □□ CBL-02

● Flexed type 1S- □□ LCBL-02 Note) The numbers in the boxes □□ refer the length.

■ Outline

This cable is exchanged for the machine cable (5 m) that was supplied as standard to

extend the distance between the controller and the robot arm.

A fixed type and flexible type are available.

Exchanges after shipment will be charged (for packaging, shipping costs).

The fixing and flexible types are both configured of the motor signal cable,motor

power cable and ground cable.

■ Configuration

Table 2-10 : Configuration equipments and types

■ Specifications

The specifications for the fixed type cables are the same as those for standard cables.

Shows usage conditions for flexed type cables in Table 2-11.

Table 2-11 : Conditions for the flexed type cables

[Caution] The guidance of life count may greatly differ according to the usage state (items related to Table 2-11

and to the amount of silicon grease applied in the cable conduit.

[Caution] This option can be installed on clean-type, but its cleanliness is not under warranty.

Part name Type

Qty.

Remarks

Fixed Flexed

Fixed Set of signal and power cables 1S- □□ CBL-02 1 set -

5m, 10m, or 15m each

Note1)

Note1)The numbers in the boxes □□ refer the length.

Motor signal cable 1S- □□ CBL(S)-01 (1 cable) -

Motor power cable 1S- □□ CBL(P)-01 (1 cable) -

Ground cable BU284D339G △△ (1 cable) -

12m, 17m or 22m each

Note2)

Note2)The numbers in the boxes △△ refer the length.

△ = Length of standard 7 m + extension (5m, 10m, or 15m each)

Flexed Set of signal and power cables 1S- □□ LCBL-02 - 1 set

5m, 10m, or 15m each

Note1)

Motor signal cable 1S- □□ LCBL(S)-01 - (1 cable)

Motor power cable 1S- □□ LCBL(P)-01 - (1 cable)

Ground cable B U284D663 G △△ - (1 cable)

12m, 17m or 22m each

Note2)

Nylon clamp NK-14N - 2 pcs. for motor signal cable

Nylon clamp NK-18N -

2 pcs.

for motor power cable and

ground cable

Silicon rubber - 4 pcs.

Item Specifications

Minimum flexed radius 100R or more

Cable bare, etc., occupation rate 50% or less

Maximum movement speed 2000mm/s or less

Guidance of life count 7.5 million times

Environmental proof Oil-proof specification sheath

(for silicon grease, cable sliding lubricant type)

Cable configuration Motor signal cable φ7 x 6and φ1.7 x 1

Motor power cable φ8.9 x 3 and φ6.5 x 6

Ground cable φ7.5 × 1

Page 35

2-22

Options

2 Robot arm

■ Cable configuration