Page 1

When considering to use this module for an atomic power, aerospace,

medical fields or passenger use mobile, please contact to a sales

representative beforehand.

Programmable Controller MELSEC iQ-R Series Energy Measuring Module

Model RE81WH

User’s Manual (Hardware)

・Before using this module, please read both this manual and Details carefully and pay full attention to safety to handle this module correctly.

・Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

The following manuals are also related to this module. Order each manual as needed, referring to the following list.

Energy Measuring module Model RE81WH User’s Manual (Details)

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage Directives when incorporating the Mitsubishi programmable

controller (EMC and Low Voltage Directives compliant) into other machinery or equipment, refer tothe MELSEC iQ-R Module Configuration

Manual “EMC and Low Voltage Directive”.

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is printed on the rating plate of the programmable controller.

(2) For this module

Fo

(1)This Energy Measuring module can measure various types of electric quantity just ONE module.

(2)Extensive monitoring function

(3)It also can measure the electric energy for a certain period.

MELSEC iQ-R Module Configuration Manual SH-081262ENG

r the compliance of this module with the EMC and Low Voltage Directives, refer totheUser’s Manual (Details).

1.Features

This Energy Measuring module can measure electric energy, reactive energy, current, voltage, electric power, power factor, frequency,

harmonic current and harmonic voltage. Both consumption and regeneration of the electric energy can be measured.

In addition to memorizing the maximum and minimum values, two types of alarm monitoring for upper and lower limit can be performed.

It can measure the electric energy for the duration of time for which the output device is on. This feature enables to acquire the electric

energy needed during device operation or energy per tact.

2. Checking packaged contents

The following items for this moduleare included in the package. Check that no it

・ Energy Measuring module x 1 ・ User’s Manual (Hardware) x 1

3. Safety Precautions

3.1Precautions for Operating Environment and Conditions

This module is premised on being used in pollution degree 2

from the pollution on another device side to be incorporated.

Overvoltage category of measuring circuit in this module is CAT III.

Do not use this product in the places listed below. Failure to follow the instruction may cause malfunctions and a life decrease of product.

・Places the ambient temperature exceeds the range 0 – 55ºC.

・Places the average daily temperature exceeds +35℃

・Places the relative humidity exceeds the range 5 –95% or places with dewfall.

・Altitude exceeds 2000 m.

・Places exposed to rain or water drop.

・Dust, corrosive gas, saline and oil smoke exist.

・Places in strong electromagnetic field or places large amounts of external noise exist.

・Vibration and impac

・Installed excluding the control panel.

This module is the open type device, which are designed to be housed within another device for prevention of electric shock. House the

module within the device such as the control panel before use. (Indoor use)

(Note 1) For the definition of the pollution degree and the over voltage category, refer to EN61010-1/2010.

3.2Matters concerning the preparation before use

・Use the module in the specified usage environ

・The setting of this module (phase system, primary voltage, primary current) is necessary before using it.

Refer to the User’s Manual (Details) about each setting method.

Manual name Manual number (Model code)

IB63D82(19W851)

s

ems are missing.

(Note1)

environment. When used in higher pollution degree, protect the module

(Note 1)

t exceed the specifications.

ment and conditions.

3.3 Installation and Wiring Precautions

Make sure to use the module by following cautions of this section. Improper use may impair protection provided bythis module.

・Shut off the external power supply for the module in all phases before installing or wiring. Failure to do so may cause an

electric shock or a damage of the module.

Danger

・Shut off the power supply for the module in all phases before installing or wiring. Failure to do so may cause an electric

shock or a damage, a fire on the module.

・Any person who is involved in the installation and the wiring of this Programmable Controller should be fully competent

to do the work.

・Secure the spatial distance more than 100 mm in all directions (other than back).

・Use the programmable controller in an environment that meets the general specifications in the MELSEC iQ-R Module

Configuration Manual.Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

After mountingthe module, ensure that the module fixing hook is securely applied on the base unit and the module is

・

surely mounted.Incorrect mounting may cause malfunctions, a failure or a drop of the module.

When using the Programmable Controller in an environment of frequent vibrations, fix the module with a screw.

・Tighten the screw within the specified torque range. Loose tightening can cause drop of the screw, short circuit or

malfunction. Over tightening can damage the screw and/or modul

・Do not directly touch any conductive part of the module. Doing so can cause malfunctions or a failure of the module.

・When using this module, make sure to use it in combination with the dedicated current sensor. Do not exceed the rating

of the module for input of the current sensor. A secondary side (5A) of transformer cannot directly input to this module.

For further details, refer to the manuals for the curren

module.

・The dedicated current sensor is used only for low voltage circuit. It cannot be used for a high voltage circuit. EMU2-CT5

and EMU-CT5-Ashould be used with secondary side (5A) of transformertransfixed. If it is connected with a high voltage

circuit by mistake, it may cause a burnoutof the device and a fire. It is critically dangerous. For the allowance maximum

voltage of current sensor, refer to the Us

・The dedicated current sensor has a polarity (directionality). Be careful about it when installing the module.

・Take care not entering any foreign objects such as strips and wire pieces into the module. It may cause a fire, a failure or

a malfunction.

・In order to prevent the module from incoming foreign objects such as wire pieces during wiring work, a foreign-object

Caution

preventive label is placed on the module. While a wiring work is perf

operating the system, peel off the label for heat release. If the foreign-object preventive label is not peeled off and the

system is in use, residual heat inside the module may reduce the product life.

・The wires to be connected to the module shall be placed in a duct or fixed together by clamping. If the electric wires are

not placed in the duct or clamped together, loosen wires or their movement or careless stretch may cause a break

the module or wire or a malfunction due to poor contact of electric wires.

・Use appropriate size of electric wires. If inappropriate size of electric wire is used, it may cause a fire due to generated

heat.

・In case using stranded wire, take measures so that the filament should not vary by using a bar terminal or by

processing the point twisted. Use the bar terminal appropriated for the size of electric wires. If inappropriate bar terminal

is

used, a wire breakage or a contact failure may occur, which may cause a devicemalfunction, a failure, a burnout or a

fire.

・After inserting the electric wire or a bar terminal, make sure that no missing insertion is existing.

Missing insertion may cause a malfunction, a fire, or an electric shockon the device.

・If the wires connected to the module are strongly pulled off, it may cause a malfunction or a breakage to the module or

the wire.

・Ensure the wiring to t

assignment. If the input voltage exceeds the rated voltage or the wiring is improper, it may cause a fire or a breakage.

・Do not exceed the specified voltage when doing an insulation resistance test and a commercial frequency withstand

voltage test.

・To prevent persons with little knowledge about electric equipment from electric shock, panel must be taken either

following measur

Lock the panel so that only those who get an education about electrical equipment and have sufficient knowledge can

unlock, or shut off power supply automatically uponopening the panel. Cover the dangerous voltage part of the module.

he module properly afterchecking the rated voltage and current of the product and the terminal pin

e.

er’s Manual (Details).

e, resulting in drop, short circuit, or malfunction.

t sensor to maintain the functionalities and the accuracy of the

ormed, keep the label on the module. Before

age of

3.4Precautions for Start-up and Maintenance

This module is not compliant for dealing / proving electric energy specified in a measurement law.

3.5Storage Precautions

3.6Disposal Precautions

3.7Packaging materials and this manual

・Use the product within the ratings specified in this manual. If it is used outside the ratings, it may cause not only a

malfunction or afailure but also afire or a burnout.

・Before operating the product, check that active bare wire etc. does not exist around the product. If any bare wire is

found, stop the operation immediately, and tak

・Do not disassemble or modify the module. It may cause a failure, a malfunction, an injury or a fire.

・Attaching and detaching the module must be performed after the power source is shut off for all outside phases. If all

phases are not shut off, it may cause an electric shock, a failure or a malfunction of the module.

・Do not touch powered wires. It may cause a malfunction.

・Tightening mounting screws and cleaning module must be per

Caution

phases. If all phases are not shut off, it may cause an electric shock, a failure or a malfunction of the module.

・Use a soft dry cloth to clean off dirt of the module surface.

・Do not let a chemical cloth remain on the surface for an extended period of time nor wipe the surface with thinner or

benzene.

・Check for the following items to use this module properly for a long time.

<Daily maintenance>

(1) No damage on this

<Periodical maintenance (Once every 6 months to 1 year) >

(4) No looseness with installation, wire connection to terminal blocks, and connector connection.

(Check these items under the electric outage condition.)

To store the module, turn off the power and remove wires, and put it in a plastic bag.

For long-time storage, avoid the following places. Failure to follow the instruction may cause a failure and reduced life of the module.

・Places the ambient temperature exceeds the range -25 -+75 ºC. ・Places the average daily temperature exceeds 35 ºC.

・Places the relative humidity exceeds the range 5 –95% or places with dewfall. ・Vibration and impact exceed the specifications

・Places with metal fragments or conductive substance are flying. ・Places exposed to rain, water drops or direct sunlight.

・Dust, corrosive gas, saline and oil smoke exist.

module (2) No abnormality with LED indicators (3) No abnormal noise, smell or heat.

e an appropriate action such as isolation protection.

formed after the power source is shut off for all outside

When disposing of this module, treat it as industrial waste.

For reduction of environmental load, packaging materials are produced with cardboard, and this manual is printed on recycled paper.

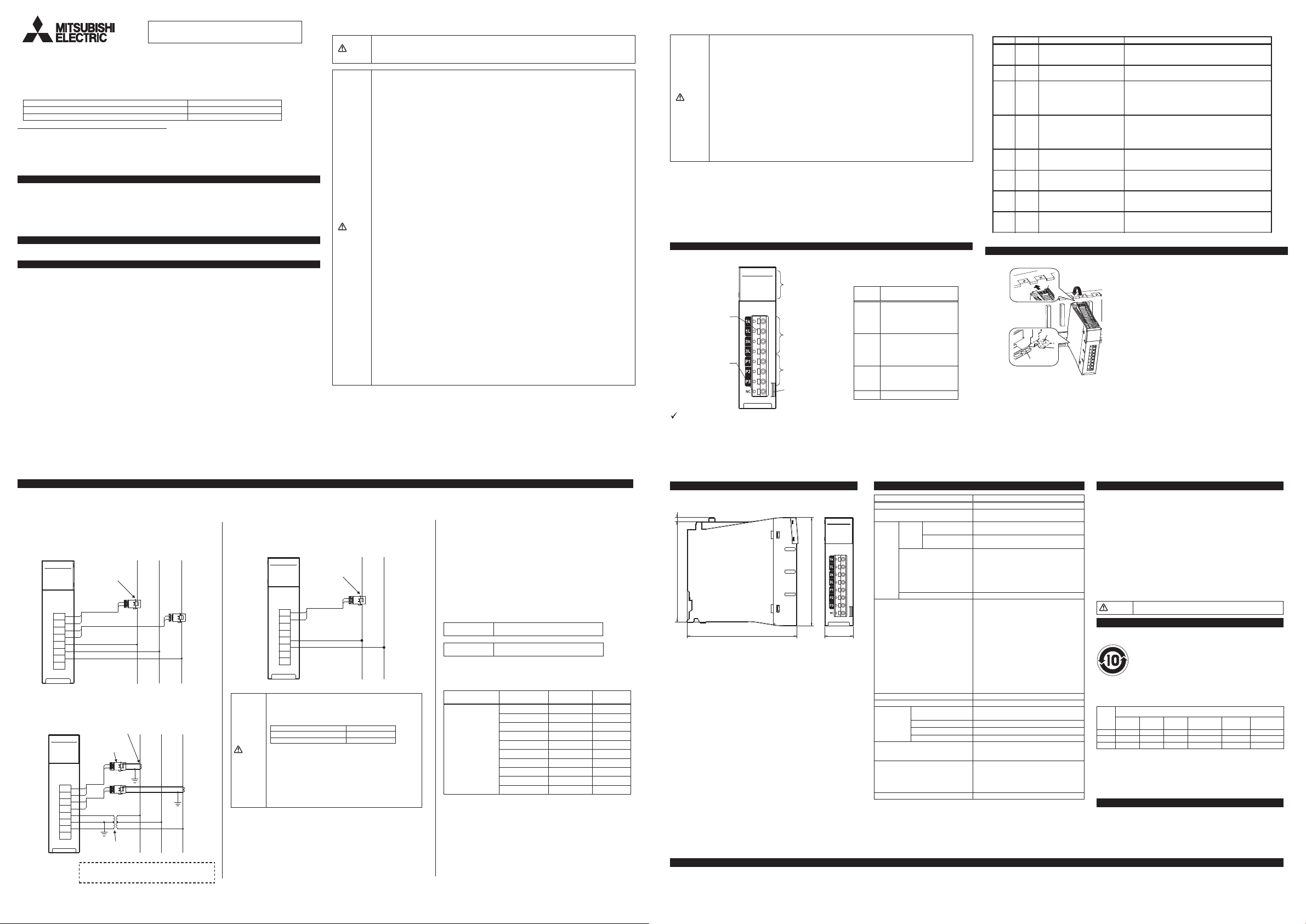

4. Name and function of each part

ERR

R

(1)LED

1

3

(2) Current input terminals

(3) Voltage input terminals

STRIP GAUGE

10

rovided below.

Operation status of

this module is

displayed.

Connect the current wire

of the measuring circuit

with the secondary

output of the dedicated

current sensor.

Connect the voltage input

wire of the measuring

circuit.

(6)Strip gauge

A gauge that is used

for checking the length

of stripped wire.

Names of signals of terminal block

Terminal

symbol

1k

1L

3k

3L

P1

P2

P3

Name of terminal

1-phase current inputterminal

(power source side)

1-phase current input terminal

(load side)

3-phase current input terminal

(power source side)

3-phase current input terminal

(load side)

1-phase voltage input terminal

2-phase voltage input terminal

3-phase voltage input terminal

NC Unused

4.1Names and functions of parts of RE81WH are p

RE81WH

RUN

MEA.

ALM1

ALM2

(4) Push button

Use this button to

insert a cable to the

terminal or to

remove them.

(5) Check hole

Use this for

continuity check to

the terminal. Use it

with a tester contact.

Supplementary-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check the stripping length using the strip gauge of this module.

4.2Names and functions of LEDs

The following describes names andfunctions of LEDs.

Name Color Role Indicator condition

RUN

Green

LED

MEA.

Green

LED

ALM1

Red

LED

ALM2

Red

LED

ERR

Red

LED

R

Green

.

LED

1 LED Green

3 LED Green

(Note 1) For details, refer to theUser’s Manual (Details).

5. Attaching and removing the module

5.1How to attach to the base unit

・Attach to the base unit of MELSEC iQ-R series base unit.

・When installing the module at a vibrating area with strong impact, tighten the module to the base unit using screws.

Fixing-Module screw (arranged by user): M3 × 12mm

Tightening torque of the fixing-module screws: 0.36 -0.48N・m

・Place the concave part of a module onto the guide of a base unit before mounting a module. Failure to do so ma

Displays the operation status of

this module.

Displays measuring status of this

module.

Displays alarm 1 occurrence

status.

Displays alarm 2 occurrence

status.

Displays error and the status of

this module.

Displays the status of

measurement (regeneration) of

this module.

Displays the status of

measurement (regeneration) at

side 1 of this module.

Displays the status of

measurement (regeneration) at

side 3 of this module.

(3)

(1)

(2)

ON: Normal operation

OFF: Internal power supply is off, error is in occurrence

ON: Measuring electric energy

OFF: No measuring electric energy (no measurement)

Flashing: Alarm 1 occurring

ON: Alarm 1 occurring → Not occurring

OFF: Alarm 1 not occurring

Flashing: Alarm 2 occurring

ON: Alarm 2 occurring → Not occurring

OFF: Alarm 2 not occurring

Flashing: Error in out of range of setting values

ON: Error in occurrence in hardware

OFF: Normal operation

ON: Measuring electric energy (regeneration)

OFF: Other than the above

ON: Measuring 1-phase electric energy (regeneration)

OFF* Other than the above

ON: Measuring 3-phase electric energy (regeneration)

OFF: Other than the above

1. When a cap is attached to the module connector of

the base unit, remove it.

2. Place the concave part (1) of themodule on to the

guide (2) of the base unit.

3. Push in the module until the module fixinghook (3)

snaps into place.

4.Check that the module fixing hook (3) hangs the

base unit and the module is mounted on the base

unit securely.

(Note 1)

in hardware.

( In the case of alarm 1 reset method =

self-retention)

( In the case of alarm 2 reset method =

self-retention)

(Note 2)

(Note 2)

y damage the module.

6. How to wire

6.1Wiring

Depending on the phase/wire system of the circuit, follow the wiring diagrams as below.

For connecting the current circuit, make sure to use the module in combination with the dedicated current sensor (Refer to 6.3 Current sensor) .

For attaching method of the current sensor and detailed specifications, refer to the User’s Manual (Details).

Single-phase 3-wire/three-phase 3-wire

RE81WH

ERR

RE81WH

ALM1

ALM2

1k

1l

3k

3l

P1

P2

P3

NC

RUN

MEA.

EMU-CT***-A model

R

Current sensor

1

(50/100/250/400/600)

3

Current transformer

(***/5A)

ERR

R

5A current sensor

1

EMU2-CT5

3

1k

1l

3k

3l

P1

P2

P3

NC

Voltage transformer

For gauge

*For a low voltage circuit, grounding of the

secondary sides of VT and CTis not necessary.

RUN

MEA.

ALM1

ALM2

Three-phase 3-wire

(with the voltage transformer/current transformer)

Power source side

2

1

(0)

(1)

K

k

l

L

k

l

Load side

Power source side

2

1

K

k

k

l

k

l

K

l

L

L

K

L

Load side

3

(2)

K

L

3

k

K

L

l

● Maximum voltage of the circuit connected to this module is 260V. For the circuit over this

voltage, use the transformer. Using the transformer, primary voltage is configurable up

to 6600V. Secondary voltage is fixed to 110 or 220V. (Special primary voltageof VT can be

set up to 6600Vin any, and special secondary voltage of VT can be set up to 220Vin any.)

● Make sure that before connecting the cable, the orie

for attachment. K to L is the correct direction. K: power source side, L: load side.

● Current sensor(excluding EMU2-CT5)is extendable up to 50 m.

● EMU2-CT5is extendable up to 10 m, using together with an extension cable.To extend

the wire further, use the current transformer CW-5S(L) for split-type instrument in

combination, extending the secondary wiring on CW-5S(L) side.

Single-phase 2-wire

RE81WH

RUN

MEA.

ALM1

ALM2

ERR

R

1

3

1k

1l

3k

3l

P1

P2

P3

NC

EMU-CT***-A model

Current sensor

(50/100/250/400/600)

・For protection against noise, transmission lines and input lines shall

not be placed close to or bound together with the power lines and

high voltage lines. Keep distance as below between them. (Except

for the terminal block.)

Condition Distance

Voltage line 600V or less 300 mm or more

Othervoltage line 600 mm or more

・The input wiring of the measurement circuit uses other signals cable

Caution

and separate cables, and shall not be affected by surge and the

instruction of the interchange side.

・The current sensors dedicated to this module EMU-CT400/600

resemble the split current transformer for general gauges CW-5SL

closely in appearance. However, characteristics are completely

different. Be sure to connect the dedicated current sensor.

Connecting CW-5SL to this

device, a burnout or a fire.

Power source side

1 2

K

k

l

L

Load side

module directly may cause failure of the

ntation of the current sensor is correct

●The available transform

For connection to P1 to P3 terminals on this module, connect the secondary of

transformer. Make sure that terminal symbols are correct.

●Do not ground the secondary side of the current sensor.

●Use insulation wire rather than basic insulation for the primary side cable of current

sensor.

6.2How to connect wires

●Use appropriate electric wires as described below.

●Stripping length of the used wire in use has to be 10 to 11mm.

Check the stripping length using the str

●When stranded wire is used, a bar terminal must be used.

●When attaching and detaching cables to/from the terminal, use the push button.

Check that the wire is securely inserted.

●Insert a wire to the terminal all the way until it touches the end.

<Applicable wire (Usable electric wire)>

Applicable wire

<Recommended bar terminal>

Recommended

crimping terminal

6.3Current sensor

Current sensor of this module are showed below. Please reference to manual of

current sensor.

Production name model Rated primary

Split type

current sensor

er ratio is 220/110 V to 6600/110 V.

ip gauge of this module.

Stranded wire: AWG 20-16

Single wire: AWG 24-16

TGV TC-1.25-11T (NICHIFU TERMINAL

INDUSTRIES CO.,LTD)

EMU-CT50-A 50

current[A]

EMU-CT50 50

EMU-CT100-A 100

EMU-CT100 100

EMU-CT250-A 250

EMU-CT250 250

EMU-CT400-A 400

EMU-CT600-A 600

EMU-CT5-A 5

EMU2-CT5 5

complies with

UL standard

×

○

×

○

×

○

○

○

×

○

7. Dimensions 8. Specifications 9. Warranty

Unit 〔mm〕

4

RE81WH

ERR

RUN

MEA.

ALM1

ALM2

Model RE81WH

Phase-wire system

R

1

3

Rating

98

107.1

106

27.8

STRIP GAUGE

10

Allowable tolerance of module

(excluding the current sensor)

Transient overvoltage Measurement circuit: CAT III

Measuring circuit count 1 circuit

Operating

environment

Commercial frequency withstand voltage

Standard

Installation area Inside a control panel

(

Note1): 0 -+50℃ (complies with UL standard

Item Specifications

Single-phase 2-wire / single-phase 3-wire /

Single-phase2-wire,

three-phase3-wire

Voltage

circuit

Single-phase 3-wire

Current circuit

Frequency 50/60Hz (Frequency automatically recognized)

Operating temperature

Operating humidity

Storage temperature -25- +75℃

Operating altitude 2000 m or below

three-phase 3-wire

110V,220V AC

110V AC (b/w 1-and 2-side, 2- and 3-side)

220V AC (b/w 1-and 3-side)

5A, 50A, 100A, 250A, 400A, 600AAC (The

dedicated split type current sensor is used. Each

value refers to the current at the primary side of

the current sensor.)

Configurable primary current when using 5A

sensor: 5A - 6000A

Secondary current maximum 66.66mA

Current: ±1.0%(100% of the rating)

Voltage:±1.0%(100%of the rating)

Electric power: ±1.0%(100% of the rating)

Reactive energy: ±1.0%(100% of the rating)

Apparent power: ±1.0% (100% of the rating)

Harmonic current: ±2.5% (100% of the rating)

Harmonic voltage:±2.5% (100%of the rating)

Frequency: ±1.0% (45 - 65Hzrange of the

rating)

Power factor: ±3.0%(against the electric angle

90°)

rgy: ±2.0%(5 -100% range of the

Electric ene

rating, power factor = 1)

Reactive energy: ±2.5%(10 -100%range of the

rating, power factor =0)

0 - +55℃ (Average daily temperature 35℃ or

below) (Note1)

5 -95%RH(No condensation)

Between voltage/current input terminals programmable controller power source and

GND terminals: 2210V AC 5sec

EMC: EN61131-2:2007

Safety standard: EN61131-2:2007

EN61326-1:2006

EN61010-1:2010

rd

UL61010-1:3

Edition

)

In case you have any questions or the product may have a failure, make an inquiry to

your nearest MITSUBISHI ELECTRIC CORPORATION office.

・The charge-free warranty period of the product shall be 36 months from the date of

your purchase or the date the product is delivered to your specified delivery location.

However, the maximum limit of the charge-free warranty period shall be s

months from the time of manufacture by defining the longest distribution period of the

product as 6 months after the product is shipped from our manufacturing factory. Also,

the charge-free warranty period for the replacement product shall not be extended

exceeding the charge-free warranty period for the original product.

・Our company shall not be liable to compensate for any loss arising from events not

attributable to

failure of the product, and loss, secondary loss, accident compensation, damage to

other products besides our products and other operations caused by a special reason

regardless of our company’s predictability in both within and beyond the charge-free

warranty period.

Caution

10. Content Poisonous Substance

(1) 电子信息产品污染控制标识

(2) 产品中有害物质的名称及含量

本产品中所含有的 6 种有害物质的名称、含有信息及含有部件如下表所示。

部件

名称

基板

箱子

铭牌

本表格依据SJ/T11364 的规定编制。

○:表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572

规定的限量要求以下。

×:表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T26572

规定的限量要求。

且虽然目前业界没有成熟的替代方案,但是符合欧盟RoHS指令要求。

11. Handling precautions

Precautionary note written in Korean

사용자안내문 A급 기기 (업무용 방송통신기자재)

이 기기는 업무용(A급) 전자파적합기기로서 판매자 또는

사용자는 이 점을 주의하시기 바라며, 가정외의 지역에서

사용하는 것을 목적으로 합니다.

12. Customer Service

MITSUBISHI ELECTRIC CORPORATION

HEAD OFFICE: TOKYO BUILDING, 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, Japan

Please refer to "catalog" or “user’s manual (Details)” for more detail.

our company, opportunity loss and lost earning of the customer due to

If an abnormal sound, bad-smelling, smoke, or heat breaks out of

this module, switch it off

根据《电器电子产品有害物质限制使用管理办法》,该标记适用于在

中国销售的电器电子产品,其中的数字为产品的环保使用期限。只要

遵守本产品在安全和使用方面的注意事项,从生产日算起的环保使用

期限内不会造成环境污染或对人体、财产产生深刻的影响。

注)产品正常使用废弃后,应按照国家和地方的法律法规完成该电器电

子产品的回收和再利用。

铅

(Pb) 汞 (Hg) 镉 (Cd)

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

promptly, and do not use it.

有害物质

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

et to 42

(PBDE)

Loading...

Loading...