Page 1

QSCPU User's Manual

(Hardware Design, Maintenance and Inspection)

-QS001CPU

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING

When a safety programmable controller detects an error in an external power supply or a failure in

programmable controller, it turns off all the outputs.

Create an external circuit to securely stop the power of hazard by turning off the outputs. Incorrect

configuration may result in an accident.

Create short current protection for a safety relay, and a protection circuit such as a fuse, and

breaker, outside a safety programmable controller.

When data/program change, or status control is performed from a personal computer to a running

safety programmable controller, create an interlock circuit outside the sequence program and safety

programmable controller to ensure that the whole system always operates safely.

For the operations to a safety programmable controller, pay full attention to safety by reading the

relevant manuals carefully, and establishing the operating procedure.

Furthermore, for the online operations performed from a personal computer to a safety CPU module,

the corrective actions against a communication error due to a cable connection fault, etc. should be

predetermined as a system.

A - 1

Page 4

[Design Precautions]

WARNING

All output signals from a safety CPU module to the CC-Link Safety system master module are

prohibited to use.

These signals can be found in the CC-Link Safety System Master Module User's Manual.

Do not turn ON or OFF these signals by sequence program, since turning ON/OFF these output

signals of the programmable controller system may cause malfunctions and safety operation cannot

be guaranteed.

All output signals from a safety CPU module to the CC-Link IE Field Safety Network master/local

module (with safety functions) are prohibited to use.

These signals can be found in the MELSEC-QS CC-Link IE Field Safety Network Master/Local

User's Manual.

Do not turn ON or OFF these signals by sequence program, since turning ON/OFF these output

signals of the programmable controller system may cause malfunctions and safety operation cannot

be guaranteed.

When a safety remote I/O module has detected a CC-Link Safety error, it turns off all the outputs.

Note that the outputs in a sequence program are not automatically turned off.

If a CC-Link Safety or CC-Link IE Field Network error has been detected, create a sequence

program that turns off the outputs in the program.

If the CC-Link Safety or CC-Link IE Field Network is restored with the outputs on, it may suddenly

operate and result in an accident.

To inhibit restart without manual operation after safety functions was performed and outputs were

turned OFF, create an interlock program which uses a reset button for restart.

To prevent an illegal operation and malfunction, do not connect a safety programmable controller to

the Internet or to a wireless LAN.

[Design Precautions]

CAUTION

Do not install the wires of external devices or communication cables together with the main circuit

lines or power cables. Keep a distance of 100mm (3.94 inch) or more between them.

Failure to do so may result in malfunction due to noise.

After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size.

Design circuits so that the entire system will always operate safely, regardless of the time.

A - 2

Page 5

[Installation Precautions]

CAUTION

Use the safety programmable controller in an environment that meets the general specifications in

this manual. Failure to do so may result in electric shock, fire, malfunction, or damage to or

deterioration of the product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect interconnection may cause malfunction, failure, or drop of the module.

Secure the module to the base unit with screws.

Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing the

module.

Failure to do so may result in damage to the product.

Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

Shut off the external power supply (all phases) used in the system before wiring.

Failure to do so may result in electric shock or damage to the product.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

A - 3

Page 6

[Wiring Precautions]

CAUTION

Individually ground the FG and LG terminals of the programmable controller with a ground

resistance of 100 or less.

Failure to do so may result in electric shock or malfunction.

Use a solderless terminal with insulation sleeve for wiring of a terminal block.

Use up to two solderless terminals for a single terminal.

Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when a terminal block screw comes

loose, resulting in failure.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Tighten the terminal block mounting screws, terminal screws, and module fixing screws within the

specified torque range.

Undertightening of the terminal block mounting screws or terminal screws can cause short circuit,

fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Undertightening of the module fixing screws can cause drop of the module.

Overtightening can damage the screw and/or module, resulting in drop.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

A - 4

Page 7

[Wiring Precautions]

CAUTION

Mitsubishi programmable controllers must be installed in control panels.

Connect the main power supply to the power supply module in the control panel through a relay

terminal block.

Wiring and replacement of a power supply module must be performed by qualified maintenance

personnel with knowledge of protection against electric shock.

(For the wiring methods, refer to Section 10.3.)

[Startup and Maintenance Precautions]

WARNING

Do not touch any terminal while power is on.

Doing so will cause electric shock.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, or solder the battery, or throw it into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block mounting screws, terminal screws, or module fixing screws.

Failure to do so may result in electric shock.

Tighten these screws within the specified torque range.

Undertightening of the terminal block mounting screws or terminal screws can cause short circuit,

fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Undertightening of the module fixing screws can cause drop of the module.

Overtightening can damage the screw and/or module, resulting in drop.

A - 5

Page 8

[Startup and Maintenance Precautions]

CAUTION

The online operations performed from a personal computer to a running safety programmable

controller (Program change when a safety CPU module is RUN, device test, and operating status

change such as RUN-STOP switching) have to be executed after the manual has been carefully

read and the safety has been ensured.

Following the operating procedure predetermined at designing, the operation has to be performed by

an instructed person.

When changing a program while a safety CPU module is RUN (Write during RUN), it may cause a

program breakdown in some operating conditions.

Fully understand the precautions described in the GX Developer's manual before use.

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

If the product is repaired or remodeled by other than the specified FA centers or us, the warranty is

not covered.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

Shut off the external power supply (all phases) used in the system before wiring.

Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit may cause malfunction.

Do not drop or apply shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or any shock is applied to it, dispose of it without using.

Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

A - 6

Page 9

[Disposal Precautions]

CAUTION

When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of battery regulations in EU member states, refer to Appendix 4.)

[Transportation Precautions]

CAUTION

When transporting lithium batteries, follow the transportation regulations.

(For details of the regulated models, refer to Appendix 3.)

A - 7

Page 10

CONDITIONS OF USE FOR THE PRODUCT

(1) Although MELCO has obtained the certification for Product's compliance to the international safety

standards IEC61508, EN954-1/ISO13849-1 from TUV Rheinland, this fact does not guarantee that

Product will be free from any malfunction or failure. The user of this Product shall comply with any

and all applicable safety standard, regulation or law and take appropriate safety measures for the

system in which the Product is installed or used and shall take the second or third safety measures

other than the Product. MELCO is not liable for damages that could have been prevented by

compliance with any applicable safety standard, regulation or law.

(2) MELCO prohibits the use of Products with or in any application involving, and MELCO shall not be

liable for a default, a liability for defect warranty, a quality assurance, negligence or other tort and a

product liability in these applications.

(a) power plants,

(b) trains, railway systems, airplanes, airline operations, other transportation systems,

(c) hospitals, medical care, dialysis and life support facilities or equipment,

(d) amusement equipments,

(e) incineration and fuel devices,

(f) handling of nuclear or hazardous materials or chemicals,

(g) mining and drilling,

(h) and other applications where the level of risk to human life, health or property are elevated.

A - 8

Page 11

REVISIONS

Correction

Addition

Correction

Addition

Correction

Addition

Change of a term

Correction

Correction

Addition

Correction

Addition

Correction

Correction

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Sep., 2006 SH(NA)-080626ENG-A First edition

May, 2007 SH(NA)-080626ENG-B

Section 2.2, 4.1, 5.1, 6.1, 9.1.1, 9.1.3, 10.1, 10.3.1, 10.3.2, 12.2.1, 12.2.10

Section 12.2.12

Apr., 2008 SH(NA)-080626ENG-C

ABOUT MANUALS, GENERIC TERMS AND ABBREVIATIONS, Section 1.1,

2.1, 4.2, 4.3, 4.4, 5.1, 5.3, 6.2, 8.1, 9.1.3, 9.1.4, 9.2.1, 10.2.1, 10.2.3, 10.3.1,

10.3.2, 11.1, 11.2, 12.2.1, 12.2.3, 12.2.4, 12.2.5, 12.2.7, 12.2.8, 12.2.9, 12.2.12,

12.3.1, 12.3.3, 12.3.4, 12.3.5, 12.3.6, 12.3.7, 12.3.8, 12.6, 12.7

Section 2.1.1, Appendix 2

Sep., 2008 SH(NA)-080626ENG-D

Section 10.2.1

SAFETY PRECAUTIONS, Section 7.1, Appendix 4

Apr., 2009 SH(NA)-080626ENG-E

"PLC" was changed to "programmable controller".

Feb., 2010 SH(NA)-080626ENG-F

Jul., 2010 SH(NA)-080626ENG-

May, 2011 SH(NA)-080626ENG-H

May, 2012 SH(NA)-080626ENG-I

ABOUT MANUALS GENERIC TERMS AND ABBREVIATIONS Chapter 1,

Section 2.1.1, Chapter 3, Chapter 9, Section 11.3.1, Section 11.3.2,

Section 12.3.3, Section 12.3.6

SAFETY PRECAUTIONS, Section 2.1, 4.1, 7.1.1, 7.1.2, Chapter 11, Section

11.3.1, 12.3.3, Appendix 1.1, Appendix 1.3

CONDITIONS OF USE FOR THE PRODUCT

G

SAFETY PRECAUTIONS, Section 1.1, 2.1, 2.1.1, 4.1, Chapter 9

Section 9.3

SAFETY PRECAUTIONS, ABOUT MANUALS, GENERIC TERMS AND

ABBREVIATIONS Section 1.1, 2.1, 2.1.1, 8.1, 9.1.3, 9.2.2, Chapter 10, Section

12.2.7, 12.3.1, 12.3.4, 12.3.5, 12.6, 12.7, Appendix 2

SAFETY PRECAUTIONS, Section 2.3, Chapter 3, Section 5.2, 5.3, 9.1.1, 9.2.1,

10.3.1, 12.6, Appendix 2

A - 9

Page 12

The manual number is given on the bottom left of the back cover.

Correction

Deletion

Correction

Print Date Manual Number Revision

Jun., 2013 SH(NA)-080626ENG-J

Section 2.1.1, 5.3, 9.1.5

Section 9.2.5

Feb., 2015 SH(NA)-080626ENG-K

Section 7.1.1

Japanese Manual Version SH-080607-K

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

C

2006 MITSUBISHI ELECTRIC CORPORATION

A - 10

Page 13

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-QS Series of Safety Programmable Controllers.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the QS series programmable controller you have purchased, so as to ensure correct

use.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT..................................................................................................A - 8

REVISIONS....................................................................................................................................................... A - 9

INTRODUCTION.............................................................................................................................................A - 11

CONTENTS ....................................................................................................................................................A - 11

ABOUT MANUALS .........................................................................................................................................A - 19

HOW THIS MANUAL IS ORGANIZED ...........................................................................................................A - 21

HOW TO USE THIS MANUAL........................................................................................................................ A - 22

GENERIC TERMS AND ABBREVIATIONS.................................................................................................... A - 23

PRECAUTIONS FOR USE .............................................................................................................................A - 24

CHAPTER1 OVERVIEW 1 - 1 to 1 - 7

1.1 Features........................................................................................................................................... 1 - 3

CHAPTER2 SYSTEM CONFIGURATION 2 - 1 to 2 - 7

2.1 System Configuration ...................................................................................................................... 2 - 1

2.1.1 Precautions for system configuration .......................................................................................2 - 4

2.2 Configuration of Peripheral Devices ................................................................................................ 2 - 5

2.3 Checking Serial Number and Function Version ............................................................................... 2 - 6

CHAPTER3 GENERAL SPECIFICATIONS 3 - 1 to 3 - 2

CHAPTER4 CPU MODULE 4 - 1 to 4 - 7

4.1 Performance Specifications ............................................................................................................. 4 - 1

4.2 Part Names...................................................................................................................................... 4 - 3

4.3 Switch Operation after Writing a Program ....................................................................................... 4 - 5

4.4 Reset Operation............................................................................................................................... 4 - 6

A - 11

Page 14

CHAPTER5 POWER SUPPLY MODULE 5 - 1 to 5 - 5

5.1 Specifications................................................................................................................................... 5 - 1

5.2 Precaution when connecting the uninterruptible power supply........................................................ 5 - 3

5.3 Names of Parts and Settings ........................................................................................................... 5 - 4

CHAPTER6 BASE UNIT 6 - 1 to 6 - 2

6.1 Specification .................................................................................................................................... 6 - 1

6.2 Part Names...................................................................................................................................... 6 - 2

CHAPTER7 BATTERY 7 - 1 to 7 - 2

7.1 Battery (Q6BAT) .............................................................................................................................. 7 - 1

7.1.1 Battery Specifications ............................................................................................................... 7 - 1

7.1.2 Installation of Battery ................................................................................................................ 7 - 2

CHAPTER8 CPU MODULE START-UP PROCEDURES 8 - 1 to 8 - 3

8.1 Procedure before Operating in SAFETY MODE.............................................................................. 8 - 1

CHAPTER9 EMC, LOW VOLTAGE, AND MACHINERY DIRECTIVES 9 - 1 to 9 - 13

9.1 Requirements for Conformance to EMC Directive........................................................................... 9 - 1

9.1.1 Standards relevant to the EMC Directive.................................................................................. 9 - 2

9.1.2 Installation in a control panel .................................................................................................... 9 - 3

9.1.3 Cables....................................................................................................................................... 9 - 4

9.1.4 Power Supply Module............................................................................................................... 9 - 7

9.1.5 Others....................................................................................................................................... 9 - 7

9.2 Requirement to Conform to the Low Voltage Directive.................................................................... 9 - 9

9.2.1 Standard applied for MELSEC-QS series programmable controller......................................... 9 - 9

9.2.2 MELSEC-QS series programmable controller selection........................................................... 9 - 9

9.2.3 Power supply .......................................................................................................................... 9 - 10

9.2.4 Control panel .......................................................................................................................... 9 - 10

9.2.5 External wiring ........................................................................................................................ 9 - 12

9.3 Requirements for compliance with the Machinery Directive .......................................................... 9 - 13

CHAPTER10 LOADING AND INSTALLATION 10 - 1 to 10 - 22

10.1 Calculating Heat Generation of programmable controller.............................................................. 10 - 3

10.2 Module Installation ......................................................................................................................... 10 - 5

10.2.1 Installation precautions ........................................................................................................... 10 - 5

10.2.2 Instructions for mounting the base unit................................................................................. 10 - 12

10.2.3 Installation and removal of module ....................................................................................... 10 - 15

10.3 Wiring........................................................................................................................................... 10 - 18

10.3.1 Wiring precautions................................................................................................................ 10 - 18

10.3.2 Connecting to the power supply module............................................................................... 10 - 22

A - 12

Page 15

CHAPTER11 MAINTENANCE AND INSPECTION 11 - 1 to 11 - 11

11.1 Daily Inspection ............................................................................................................................. 11 - 3

11.2 Periodic Inspection ........................................................................................................................ 11 - 4

11.3 Battery Life and Replacement Procedure......................................................................................11 - 5

11.3.1 Battery lives of CPU modules................................................................................................. 11 - 6

11.3.2 Replacement Procedure of the CPU Module Battery ............................................................. 11 - 8

11.4 When programmable controller Has been Stored without a Battery............................................ 11 - 10

11.5 When Battery Has Gone Flat during Storage of a programmable controller ............................... 11 - 11

CHAPTER12 TROUBLESHOOTING 12 - 1 to 12 - 101

12.1 Troubleshooting Basics ................................................................................................................. 12 - 1

12.2 Troubleshooting Flowchart ............................................................................................................ 12 - 2

12.2.1 Troubleshooting category flow................................................................................................ 12 - 2

12.2.2 Flowchart for when the ERR terminal (negative logic) is off (opened) ................................... 12 - 3

12.2.3 Flowchart for when the "POWER" LED turns off .................................................................... 12 - 5

12.2.4 When the "ALIVE" LED does not turn on or turns off ............................................................. 12 - 7

12.2.5 Flowchart for when the "RUN" LED turns off .......................................................................... 12 - 9

12.2.6 When the "RUN" LED flashes .............................................................................................. 12 - 10

12.2.7 Flowchart for when the "ERR." LED turns on or flashes ...................................................... 12 - 11

12.2.8 When the "USER" LED turns on........................................................................................... 12 - 14

12.2.9 When the "BAT." LED turns on............................................................................................. 12 - 15

12.2.10 Flowchart for when a program cannot be read ..................................................................... 12 - 16

12.2.11 Flowchart for when a program cannot be written ................................................................. 12 - 17

12.2.12 Flowchart for when the CPU cannot communicate with the GX Developer ......................... 12 - 18

12.3 Error Code List............................................................................................................................. 12 - 20

12.3.1 Error codes........................................................................................................................... 12 - 21

12.3.2 Reading an error code.......................................................................................................... 12 - 22

12.3.3 Error code list (1000 to 1999) ............................................................................................... 12 - 23

12.3.4 Error code list (2000 to 2999) ............................................................................................... 12 - 29

12.3.5 Error code list (3000 to 3999) ............................................................................................... 12 - 35

12.3.6 Error code list (4000 to 4999) ............................................................................................... 12 - 45

12.3.7 Error code list (5000 to 5999) ............................................................................................... 12 - 49

12.3.8 Error code list (8000 to 9000) ............................................................................................... 12 - 51

12.4 Clearing an error.......................................................................................................................... 12 - 65

12.5 Error codes returned to request source during communication with CPU module ...................... 12 - 68

12.6 Special Relay List ........................................................................................................................ 12 - 77

12.7 Special Register List .................................................................................................................... 12 - 83

APPENDICES App- 1 to App - 9

Appendix 1 External Dimensions..........................................................................................................App- 1

Appendix 1.1 CPU module ..............................................................................................................App- 1

Appendix 1.2 Power supply module ................................................................................................App- 2

Appendix 1.3 Main base unit ...........................................................................................................App- 3

Appendix 2 Safety CPU Module Upgrade ............................................................................................ App- 4

Appendix 3 Precautions for Battery Transportation.............................................................................. App- 6

A - 13

Page 16

Appendix 4 Handling of Batteries and Devices with Built-in Batteries in EU Member States............... App- 7

Appendix 4.1 Disposal precautions ................................................................................................. App- 7

Appendix 4.2 Exportation precautions .............................................................................................App- 8

INDEX Index- 1 to Index- 2

A - 14

Page 17

(Related manual).................QSCPU User's Manual (Function Explanation, Program Fundamentals)

CONTENTS

CHAPTER1 OVERVIEW

1.1 Features

1.2 Program Storage and Operation

1.3 Devices and Instructions Convenient for Programming

1.4 How to Check the Serial No. and Function Version

CHAPTER2 PERFORMANCE SPECIFICATION

CHAPTER3 SEQUENCE PROGRAM EXECUTION

3.1 Sequence Program

3.1.1 Sequence program description method

3.1.2 Sequsence program operation

3.2 Concept of Scan Time

3.3 Operation Processing

3.3.1 Initial processing

3.3.2 I/O refresh

3.3.3 END processing

3.4 RUN, STOP Operation Processing

3.5 Operation Processing during Momentary Power Failure

3.6 Data Clear Processing

3.7 Numeric Values which can be Used in Sequence Programs

3.7.1 BIN (Binary Code)

3.7.2 HEX (Hexadecimal)

3.7.3 BCD (Binary Coded Decimal)

CHAPTER4 I/O NUMBER ASSIGNMENT

4.1 Definition of I/O Number

4.2 Concept of I/O Number Assignment

4.2.1 I/O numbers of base unit

4.2.2 I/O numbers of remote station

4.3 I/O Assignment by GX Developer

4.3.1 Purpose of I/O assignment by GX Developer

4.3.2 Concept of I/O assignment using GX Developer

4.3.3 Examples of I/O Number Assignment

4.4 Checking the I/O Numbers

CHAPTER5 MEMORIES AND FILES HANDLED BY CPU MODULE

5.1 Memories by CPU Module

A - 15

Page 18

5.1.1 Memory configuration and storable data

5.1.2 Program memory

5.1.3 Standard ROM

5.1.4 Standard ROM program execution (boot run) and writing

5.2 Program File Structure

5.3 File Operation by GX Developer and Handling Precautions

5.3.1 File operation

5.3.2 Precautions for handling files

5.3.3 Memory capacities of files

5.3.4 File size units

CHAPTER6 FUNCTIONS

6.1 Function List

6.2 Safety CPU Operation Mode

6.2.1 Safety CPU operation mode

6.2.2 Checking safety CPU operation mode

6.2.3 Safety CPU operation mode switching

6.2.4 Operation of each function in each safety CPU operation mode and CPU operation status

6.2.5 Online operations that can be executed on the CPU module from GX Developer

6.3 CPU access password

6.4 PLC memory initialization

6.5 Setting to prevent continuous RUN in TEST MODE

6.6 Checking the ROM write count

6.7 Self-diagnostics Function

6.7.1 LED display for error

6.7.2 Cancel the error

6.8 Recording the operation contents and self-diagnostics error occurrence contents (operation/error history function)

6.9 Constant scan

6.10 Setting of Output (Y) Status when Changing between STOP and RUN

6.11 Clock Function

6.12 Remote Operation

6.12.1 Remote RUN/STOP

6.12.2 Remote RESET

6.12.3 Relationship of remote operation and CPU's RUN/STOP status

6.13 Monitor Function

6.14 Writing in Program during CPU Module RUN

6.14.1 Online change in ladder mode

6.15 Watchdog Timer(WDT)

6.16 Remote password

6.17 CPU Module System Display by GX Developer

6.18 LED Display

6.18.1 Method to turn off the LED

A - 16

Page 19

CHAPTER7 COMMUNICATION WITH INTELLIGENT FUNCTION MODULE

7.1 Communication with CC-Link Safety master module

7.2 Communication with CC-Link IE Field Network Master/Local Module (With Safety Functions)

7.3 Communication with CC-Link IE Controller Network Module or MELSECNET/H Module

7.4 Communication with Ethernet Module

7.5 Communication using intelligent function module dedicated instructions

CHAPTER8 PARAMETERS

8.1 PLC Parameters

8.2 Network Parameters

8.3 Remote Password

CHAPTER9 DEVICE EXPLANATION

9.1 Device List

9.2 Internal User Devices

9.2.1 Input (X)

9.2.2 Output (Y)

9.2.3 Internal relay (M)

9.2.4 Annunciator (F)

9.2.5 Edge relay (V)

9.2.6 Link relay (B)

9.2.7 Link special relay (SB)

9.2.8 Timer (T)

9.2.9 Counter (C)

9.2.10 Data register (D)

9.2.11 Link register (W)

9.2.12 Link special register (SW)

9.3 Internal System Devices

9.3.1 Special relay (SM)

9.3.2 Special register (SD)

9.4 Nesting (N)

9.5 Constants

9.5.1 Decimal constant (K)

9.5.2 Hexadecimal constant (H)

CHAPTER10 CPU MODULE PROCESSING TIME

10.1 Scan Time

10.1.1 Structure and calculation of scan time

10.1.2 Time required for each processing included in scan time

10.1.3 Factors that increase the scan time

10.2 Other Processing Times

CHAPTER11 PROCEDURE FOR WRITING PROGRAM TO CPU MODULE

A - 17

Page 20

11.1 Items to be examined for program creation

11.2 Procedure for writing program

11.3 Boot run procedure

APPENDICES

Appendix 1 Special Relay List

Appendix 2 Special Register List

Appendix 3 List of Parameter No

Appendix 4 Restrictions on Using CC-Link IE Controller Network Module with Safety CPU Module

Appendix 5 Restrictions on Using MELSECNET/H Module with Safety CPU Module

Appendix 6 Restrictions on Using Ethernet Module with Safety CPU Module

Appendix 7 Dedicated Instructions which can be used in Safety CPU Module

Appendix7.1 List of dedicated instructions

Appendix7.2 Programming using dedicated instructions

Appendix 8 Safety CPU Module Upgrade

Appendix 9 Access Range for Safety CPU Module

INDEX

A - 18

Page 21

ABOUT MANUALS

Introduction Manual

Read the following manual before designing and constructing a safety system.

Manual Name

Safety Application Guide

Explains the overview, construction method, laying and wiring examples, and application programs of the

safety-related system.

Related Manuals

The manual related to this product is shown below.

Please place an order as needed.

Manual No.

(Model Code)

SH-080613ENG

(13JR90)

(Sold separately)

Manual Name

QSCPU User's Manual (Function Explanation, Program Fundamentals)

Explains the functions, programming methods, devices and others that are necessary to create programs with the

QSCPU.

(Sold separately)

QSCPU Programming Manual (Common Instructions)

Explains how to use the sequence instructions, basic instructions, application instructions, and QSCPU dedicated

instructions.

(Sold separately)

CC-Link Safety System Master Module User's Manual

Explains the specifications, procedures and settings before operation, parameter settings, and troubleshooting of

the QS0J61BT12 CC-Link Safety system master module.

(Sold separately)

CC-Link Safety System Remote I/O Module User's Manual

Explains the specifications, procedures and settings before operation, parameter settings, and troubleshooting of

the CC-Link Safety system remote I/O modules.

(Sold separately)

MELSEC-QS CC-Link IE Field Network Master/Local Module User's Manual

Explains the specifications, procedures and settings before operation, parameter settings, and troubleshooting of

a CC-Link IE Field Network master/local module (with safety functions).

(Sold separately)

CC-Link IE Controller Network Reference Manual

Explains the system configuration, performance specifications, functions, handling, wiring, and troubleshooting of

CC-Link IE Controller Network.

(Sold separately)

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network)

Explains the specifications, procedures and settings before operation, parameter settings, programming, and

troubleshooting of a MELSECNET/H network system for PLC to PLC network.

(Sold separately)

Q Corresponding Ethernet Interface Module User's Manual (Basic)

Explains the specifications, procedures for data communication with external devices, line connection (open/

close), fixed buffer communication, random access buffer communication, and troubleshooting of the Ethernet

module.

(Sold separately)

Manual No.

(Model Code)

SH-080627ENG

(13JR93)

SH-080628ENG

(13JW01)

SH-080600ENG

(13JR88)

SH-080612ENG

(13JR89)

SH-080969ENG

(13JZ53)

SH-080668ENG

(13JV16)

SH-080049

(13JF92)

SH-080009

(13JL88)

A - 19

Page 22

Remark

Manual Name

Q Corresponding Ethernet Interface Module User's Manual (Application)

Explains the e-mail function, programmable controller CPU status monitoring function, communication function via

CC-Link IE Controller Network, MELSECNET/H or MELSECNET/10, communication function using the data link

instructions, file transfer function (FTP server) of the Ethernet module.

(Sold separately)

MELSEC-Q/L MELSEC Communication Protocol Reference Manual

Explains the communication methods and control procedures using the MC protocol, which is used by external

devices to read and write data of the programmable controller CPU via the serial communication module or

Ethernet module.

(Sold separately)

Printed materials are separately available for single item purchase. Order the

manual by quoting the manual number on the table above (Model code).

Manual No.

(Model Code)

SH-080010

(13JL89)

SH-080008

(13JF89)

A - 20

Page 23

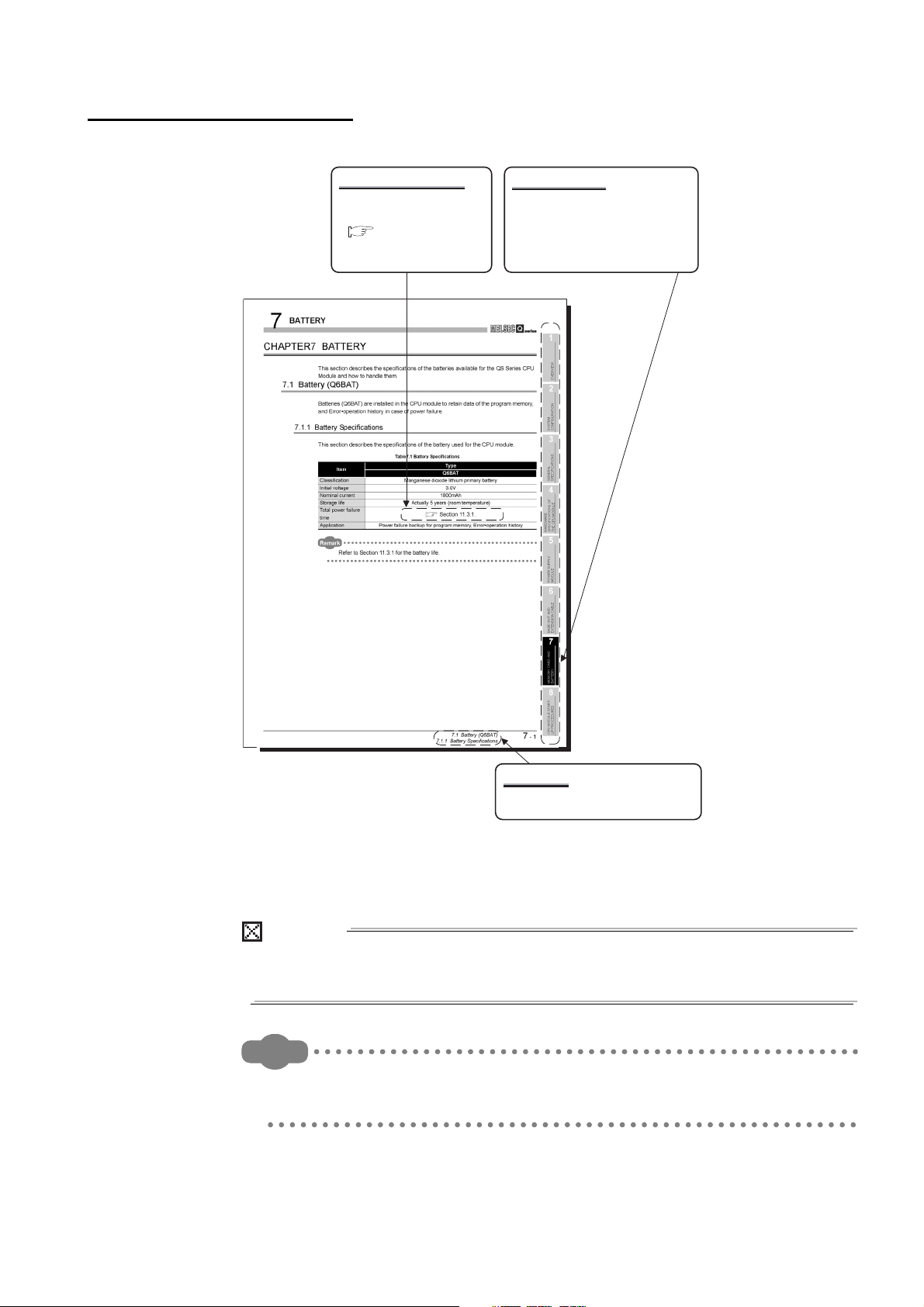

HOW THIS MANUAL IS ORGANIZED

POINT

Remark

Chapter heading

The index on the right side of the page

shows the chapter of the open page at a

glance.

Section title

The section of the open page is shown at a

glance.

Reference destination

A reference destination or

reference manual is marked

.

In addition, this manual provides the following explanations.

Explains the matters to be especially noted, the functions and others related to the

description on that page.

Provides the reference destination related to the description on that page and the

convenient information.

A - 21

Page 24

HOW TO USE THIS MANUAL

Remark

This manual is prepared for users to understand the hardware specifications of those

modules such as the CPU modules, power supply modules, and base units, maintenance

and inspections of the system, and troubleshooting required when you use QS series

programmable controllers.

The manual is classified roughly into three sections as shown below.

1) Chapters 1 and 2 Describe the outline of the CPU module and the system

2) Chapters 3 to 7 Describe the general specifications indicating the operating

3) Chapters 8 to 12 Describe the overall maintenance such as the installation of the

configuration.

The basics of the system configuration of CPU module are

described.

environments of the CPU module, power supply module, and base

units, and the performance specifications of these modules.

CPU module, daily inspections, and troubleshooting.

This manual does not explain the functions of the CPU module.

For these functions, refer to the manual shown below.

QSCPU User's Manual (Function Explanation, Program Fundamentals)

A - 22

Page 25

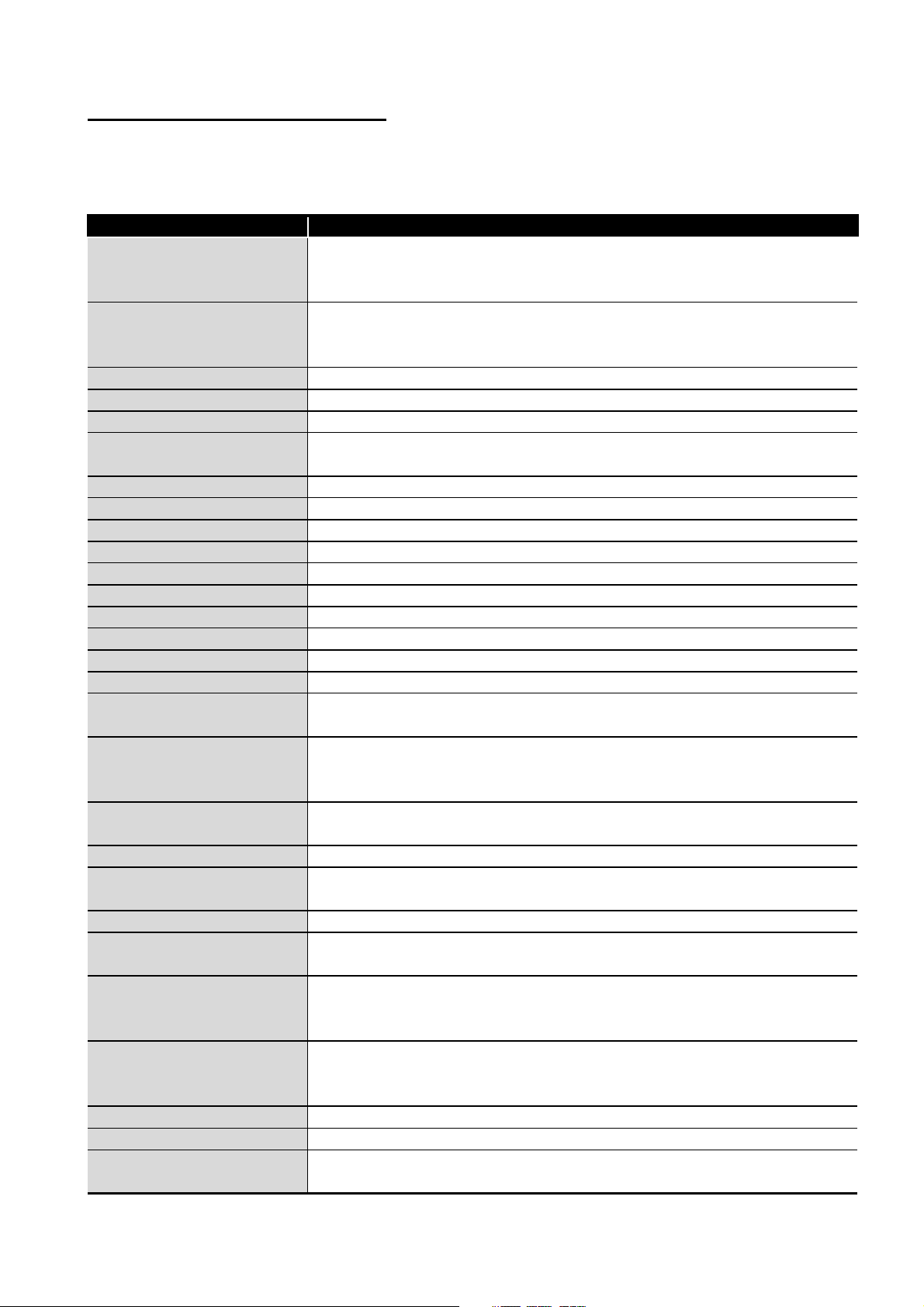

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to explain the QS series CPU modules.

Generic Term/Abbreviation Description

Generic term for safety CPU module, safety power supply module, safety main base

Safety programmable controller

Standard programmable controller

QS series Abbreviation for Mitsubishi safety programmable controller MELSEC-QS series

QS001CPU Abbreviation for the QS001CPU type safety CPU module

CPU module Other name for the QS001CPU

GX Developer

QS034B Abbreviation for the QS034B type safety main base unit

Base unit Other name for the QS034B

QS061P Abbreviation for the QS061P-A1 and QS061P-A2 type safety power supply modules

Power supply module Other name for the QS061P

QS0J61BT12 Abbreviation for the QS0J61BT12 type CC-Link Safety system master module

CC-Link Safety Abbreviation for the CC-Link Safety system

CC-Link Safety master module Other name for the QS061BT12

QS0J65BTS2-8D Abbreviation for the QS0J65BTS2-8D CC-Link Safety system remote I/O module

QS0J65BTS2-4T Abbreviation for the QS0J65BTS2-4T CC-Link Safety system remote I/O module

QS0J65BTB2-12DT Abbreviation for the QS0J65BTB2-12DT CC-Link Safety system remote I/O module

CC-Link Safety remote I/O

module

CC-Link IE Field Network master/

local module (with safety

functions)

CC-Link IE Controller Network

module

MELSECNET/H Abbreviation for the MELSECNET/H network system

MELSECNET/H module

Ethernet Abbreviation for the Ethernet network system

Ethernet module

Intelligent function module

Network module

Battery Abbreviation for the Q6BAT type battery

Blank cover Abbreviation for the QG60 type blank cover

GOT

unit, CC-Link safety master module, CC-Link safety remote I/O moduls, and CC-Link IE

Field Network master/local module (with safety functions).

Generic term of each module for MELSEC-Q series, MELSEC-L series, MELSEC-QnA

series, MELSEC-A series and MELSEC-FX series. (Used for distinction from safety

programmable controller.)

General product name for the models SW8D5C-GPPW-E, SW8D5C-GPPW-EA,

SW8D5C-GPPW-EV and SW8D5C-GPPW-EVA

Generic term for the QS0J65BTS2-8D, QS0J65BTS2-4T, and QS0J65BTB2-12DT

Abbreviation for the MELSEC-QS series CC-Link IE Field Network master/local module

Abbreviation for the QJ71GP21-SX and QJ71GP21S-SX CC-Link IE Controller Network

module

Abbreviation for the QJ71LP21-25, QJ71LP21S-25, QJ71LP21G, QJ71BR11

MELSECNET/H network module

Abbreviation for the QJ71E71-100, QJ71E71-B5, QJ71E71-B2 Ethernet interface

module

Generic term for the CC-Link Safety master module, CC-Link IE Field Network master/

local module (with safety functions), CC-Link IE Controller Network module,

MELSECNET/H module, and Ethernet module

Generic term for the CC-Link IE Field Network master/local module (with safety

functions), CC-Link IE Controller Network module, MELSECNET/H module, and

Ethernet module

Generic term for the Mitsubishi Graphic Operation Terminal GOT-A*** series, GOT-F***

series and GOT1000 series

A - 23

Page 26

PRECAUTIONS FOR USE

Precautions for the first use of the QS series CPU module

Precautions on battery

(1) When running the CPU module that has been stored without battery

(2) When running the CPU module that has been stored with battery longer than

When using a CPU module for the first time, the PLC memory needs to be initialized

using GX Developer.

For details of PLC memory initialization, refer to the following manual.

GX Developer Operating Manual (Safety Programmable Controller)

When, in the TEST MODE, running the CPU module that has been stored with the

battery removed, the memory needs to be formatted using GX Developer.

( Section 11.4)

the battery life

When, in the TEST MODE, running the CPU module that has been stored with the

battery exceeding its life, the memory needs to be formatted using GX Developer.

( Section 11.5)

A - 24

Page 27

1

OVERVIEW

CHAPTER1 OVERVIEW

This manual describes the hardware specifications and handling methods of the QS series

CPU module, QS001CPU. The manual also describes the specifications of the power

supply module, base, unit, and battery.

For the functions, programs, and devices of the QS series CPU module, refer to the

following.

QSCPU User's Manual (Function Explanation, Program Fundamentals)

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

4

5

6

7

CPU MODULE

POWER SUPPLY

MODULE

BASE UNIT

BATTERY

8

CPU MODULE START-

1 - 1

UP PROCEDURES

Page 28

1

Program

Fundamentals

Outline

Details

Details

Details

OVERVIEW

(1) List of QS Series CPU Module manuals

The QS series CPU module manuals are as shown below.

For details such as manual numbers, refer to "About Manuals" in this manual.

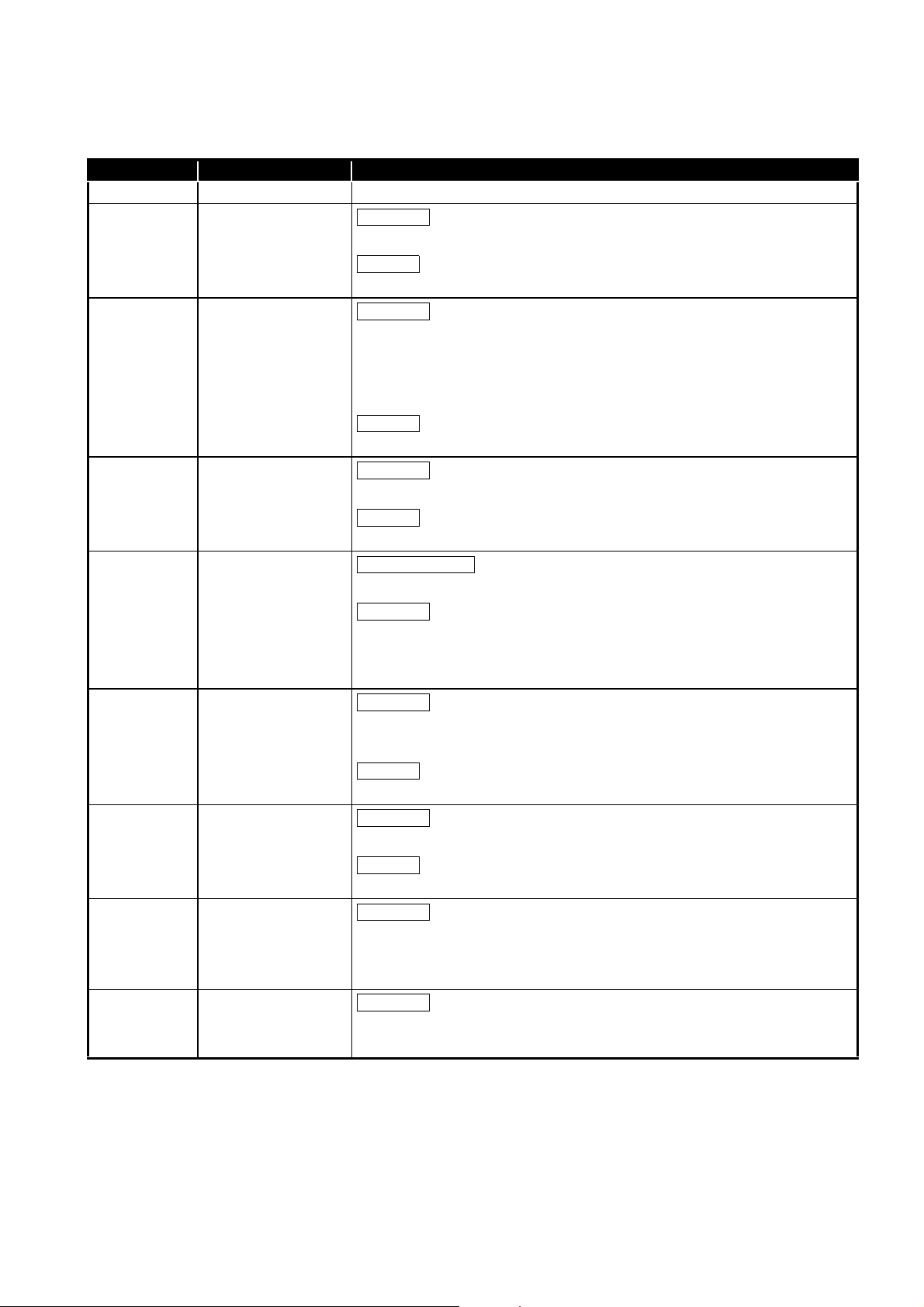

Table1.1 List of manuals of QS Series CPU module

Purpose

Confirmation of part names and

specifications of the CPU module

Confirmation of connection methods

for the power supply module and base

unit

Construction of the CPU system

(confirmation of start-up procedure

and I/O number assignment)

Confirmation of the sequence program

configuration and memory

Confirmation of the functions,

parameters, and devices of the CPU

module

Maintenance

and Inspection

QSCPU User's Manual

(Hardware Design,

Maintenance and

inspection)

Details

Details

Details

QSCPU User's Manual

(Function Explanation,

Program Fundamentals)

Common

Instructions

QSCPU Programming

Manual (Common

Instruction)

1 - 2

Confirmation of the troubleshooting

and error codes

Confirmation of usage of sequence

instructions, basic instructions,

application instructions, etc.

Details

Page 29

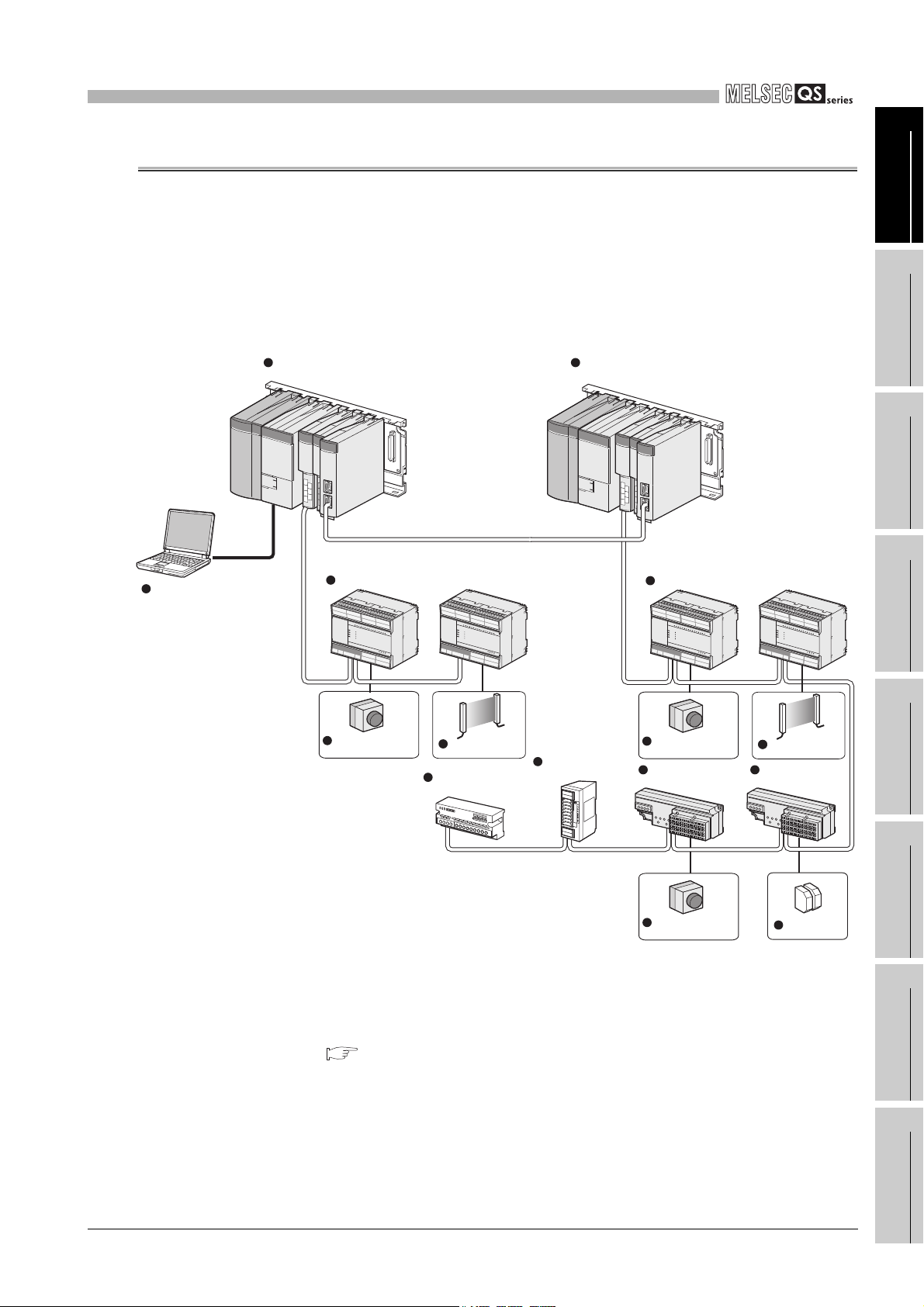

1

CC-Link Safety

GX Developer

(Version 8.40S or later)*1

CC-Link Safety remote I/O station

Standard remote I/O

station

Standard remote

device station

CC-Link Safety

remote I/O station

CC-Link Safety

remote I/O station

Light curtain

Emergency stop

switch

Safety relay

Emergency stop

switch

CC-Link Safety remote I/O station

Light curtain

Emergency stop

switch

CC-Link Safety

CC-Link IE field network

Power supply/CPU/CC-Link Safety master module/

CC-Link IE Field Network master/local module

(with safety functions)*2

Power supply/CPU/CC-Link Safety master module/

CC-Link IE Field Network master/local module

(with safety functions)*2

OVERVIEW

1.1 Features

The QS series CPU module has the following new features:

(1) Safety programmable controller system can be constructed

The QS series CPU module has acquired certification of the highest safety level (SIL3

of IEC 61508, Category 4 of EN 654-1, and Category 4 performance level "e" of EN

ISO 13849-1) applicable to programmable controllers.

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

* 1 : The available functions vary depending on the versions. For details, refer to Appendix 2.

* 2 : For details of the CC-Link IE Field Network master/local module (with safety functions), refer to the

Figure 1.1 Safety programmable controller system

following manual.

MELSEC-QS CC-Link IE Field Network Master/Local Module User's Manual

4

5

6

7

CPU MODULE

POWER SUPPLY

MODULE

BASE UNIT

1.1 Features

BATTERY

8

CPU MODULE START-

1 - 3

UP PROCEDURES

Page 30

1

OVERVIEW

(2) The safety CPU operation mode is equipped for safe system operation

The CPU module is equipped with two safety CPU operation modes. "SAFETY

MODE" for safe system operation and "TEST MODE" for system construction and

maintenance.

These two modes prevent the user's erroneous operations for safe system operation.

(a) SAFETY MODE

SAFETY MODE is a mode for safe system operation. This mode prohibits the

write operation from a programming tool and the device test operation during the

system operation.

(b) TEST MODE

TEST MODE is a mode for maintenance. This mode enables the write operation

from a programming tool and the device test operation to debug or maintain the

sequence program.

For the details of operations available in the SAFETY MODE and TEST MODE, refer

to the following manual.

QSCPU User's Manual (Function Explanation, Program Fundamentals)

(3) Enriched operation history and error history

The CPU module can record up to 3000 logs of user operations performed on the

CPU module, and errors occurred in the CPU module, CC-Link Safety, or CC-Link IE

Field Network.

User operations and errors will be recorded as operation/error history data in

chronological order.

Checking the operation/error history data helps users perform troubleshooting easier.

The contents recorded in the operation/error history are shown in Table1.2.

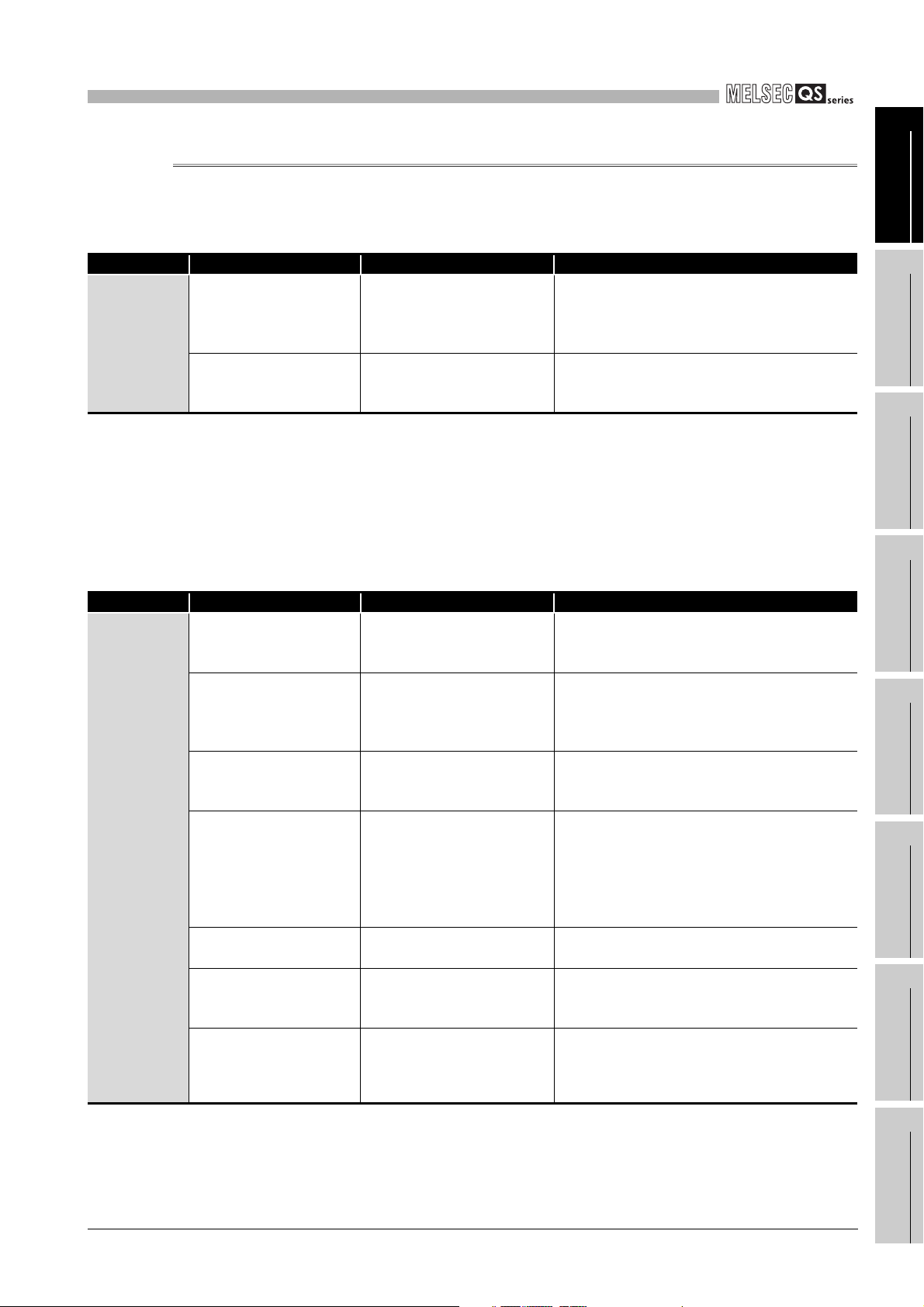

Table1.2 Recorded contents of operation/error history

Information Contents History Information per Entry

• Operation code

• Operation message

• Operation execution date

• Result code

• Operation attached information

• Error code

• Error message

• Occurrence date

• Error information category (common

information/individual information)

• Error information (common

information/individual information)

Operation

history

information

Error history

information

User's operations for the CPU module are

stored as a history.

(Operations which change the CPU module

status are recorded.)

The following errors are stored as a history.

• Error/failure detected by self-diagnostics

• Hardware error

• Error detected in CC-Link Safety

• Error detected in the CC-Link IE Field

Network

1 - 4

1.1 Features

Page 31

1

OVERVIEW

(4) Enhanced RAS

(a) Enhanced memory diagnostics

The memory diagnostics equipped with the CPU module are enhanced.

(b) Redundant CPU

The CPU module has two CPUs (CPU A and CPU B). The operation results of

CPU A/CPU B are compared, and output only when the results are matched so

that incorrect outputs can be prevented. (When the compared results are

mismatched, the system stops.)

CPU module

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

CPU

A

Operation

result

Figure 1.2 Redundant CPU

(c) Enhanced hardware diagnostics by hardware circuit

The diagnostic functions of the Table1.3 prevents incorrect outputs when a

hardware error which cannot be detected by the OS occurs.

Table1.3 Hardware diagnostics function added to the QS series CPU module

Diagnostics Diagnosis Contents

Overvoltage/

undervoltage detection

Clock stop detection The input clock stop to the CPU module internal circuit is detected.

Overvoltage or undervoltage is detected for the power supply voltage

provided from the power supply module to the CPU module.

Compare

CPU

B

Operation

result

Output when matched

4

5

6

GENERAL

SPECIFICATIONS

CPU MODULE

POWER SUPPLY

MODULE

1.1 Features

BASE UNIT

7

BATTERY

8

CPU MODULE START-

1 - 5

UP PROCEDURES

Page 32

1

Personal computer

USB

Personal computer

OVERVIEW

(5) USB interface is equipped

(6) Connectable with personal computers and standard programmable

The CPU module is equipped with the USB interface to communicate with a

programming tool.

Figure 1.3 Connection to a personal computer using USB

controllers

The CPU module can read data from the MELSOFT products installed in the personal

computer and also can communicate data between safety programmable controller

and standard programmable controller using dedicated instructions via CC-Link IE

Controller Network, MELSECNET/H, and/or Ethernet

Besides, the data of ladder monitor, device monitor, and operation/error history in the

safety programmable controller can be read using GOT.

*1

*2

.

1 - 6

1.1 Features

Figure 1.4 Connection with personal computer and standard programmable controller

* 1 : For an access range from GX Developer and a GOT to a safety CPU module, refer to the following

manual.

QSCPU User's Manual (Function Explanation, Program Fundamentals)

* 2 : An access to the CPU module can be restricted by using the remote password function.

Page 33

1

OVERVIEW

(7) Safety communication in the CC-Link IE Field Network

A CC-Link IE Field Network master/local module (with safety functions) enables

safety communication between safety CPU modules. In addition, safety and standard

communications can be used on the same network. These factors allow a safety

programmable controller to be simply added to the existing CC-Link IE Field Network.

CC-Link IE Field Network

master/local module

CC-Link IE Field Network master/local

Standard

communication

Personal computer

module (with safety functions)

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

Safety communication

: Standard communication

: Safety communication

Figure 1.5 Safety communication using the CC-Link IE Field Network

master/local module (with safety functions)

(8) Safety Standards

Use the product according to the following safety standards.

Table1.4 Safety Standards

Region Safety Standards

IEC61508 Parts 1-7:1998-2000, ISO13849-1:2006,

International

Europe

North America UL508, NFPA79-2007

IEC61131-2:2007, IEC61000-6-2:2005, IEC61000-6-4:2006,

IEC61784-3:2010, IEC60204-1:2006

EN954-1:1996, EN ISO13849-1:2008, EN61131-2:2007,

EN61000-6-2:2005, EN61000-6-4:2007

4

CPU MODULE

5

POWER SUPPLY

MODULE

6

BASE UNIT

7

BATTERY

1.1 Features

8

CPU MODULE START-

1 - 7

UP PROCEDURES

Page 34

2

QS034B base unit

QS001CPU CPU module

Battery for a CPU

(Q6BAT)

Power supply/intelligent function module

*1

SYSTEM CONFIGURATION

CHAPTER2 SYSTEM CONFIGURATION

This section describes the system configuration of the QS series CPU module cautions on

use of the system, and configured equipment.

2.1 System Configuration

The following figure shows the system configuration of the safety programmable controller

system when the QS series CPU module is used.

(1) System configuration when the CPU(QS001CPU) is used

2 - 1

* 1 : For mountable modules, refer to Section 2.1.1 "Precautions for system configuration".

2.1 System Configuration

Figure 2.1 System configuration

Page 35

2

r

SYSTEM CONFIGURATION

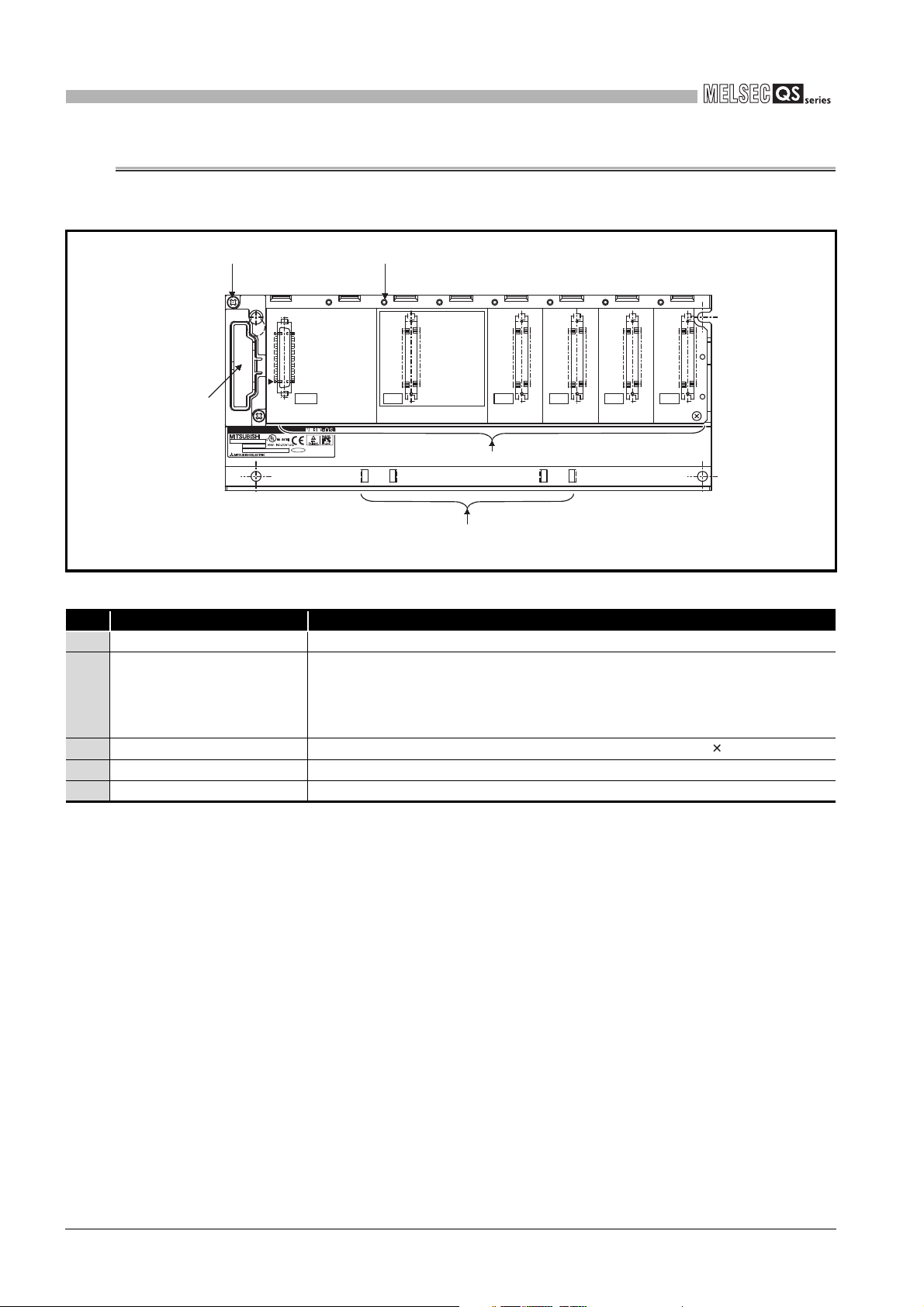

(2) System configuration overview

Base unit (QS034B)

CPU 0 1 2 3

1

Slot numbe

OVERVIEW

00 to 0F

10 to 1F

20 to 2F

CPU modulePower supply module

Figure 2.2 System configuration

Table2.1 Base unit and power supply module applicable to system configuration

Base unit model name QS034B

Maximum number of

mountable modules

Power supply module model

name

4 modules

QS061P-A1, QS061P-A2

Precautions

• The extension base unit cannot be connected.

• The multiple CPU system cannot be configured.

• The modules which can be mounted on the I/O slot are the intelligent function

module and blank cover only.

If a module other than the ones mentioned above is mounted, "MODULE

LAYOUT ERROR" (error code: 2125) is detected.

Note, however, that a "MODULE LAYOUT ERROR" is not detected for the

slot where "Empty" has been set in the I/O assignment setting of PLC

parameter.

• Bus connection for the GOT is not available. For the GOT connection, refer to

the following.

GOT1000 Series Connection Manual (Mitsubishi Products)

30 to 3F

I/O number

2

3

4

5

6

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

CPU MODULE

POWER SUPPLY

MODULE

BASE UNIT

7

BATTERY

8

CPU MODULE START-

2.1 System Configuration

2 - 2

UP PROCEDURES

Page 36

2

SYSTEM CONFIGURATION

Table2.2 Safety programmable controller products

Product Name Model Description

Safety main base unit

Safety power supply

module

Safety CPU module

CC-Link Safety master

module

CC-Link IE Field

Network master/local

module (with safety

functions)

* 1 : S-mark is a safety certification issued by Korea Occupational Safety and Health Agency (KOSHA).

QS034B

QS034B-K

QS061P-A1

QS061P-A2

QS061P-A1-K

QS061P-A2-K

QS001CPU

QS001CPU-K

QS0J61BT12

QS0J61BT12-K

QS0J71GF11-T2

A unit where a safety CPU module, safety power supply module,

and CC-Link Safety system master module are mounted

An S-mark

A module which is mounted on a safety main base unit and

supplies 100VAC to the system

A module which is mounted on a safety main base unit and

supplies 200VAC to the system

An S-mark

An S-mark

A module which is mounted on a safety main base unit and

performs logic operations for safety control

An S-mark

A module which is mounted on a safety main base unit and

establishes connection to CC-Link Safety

An S-mark

A module which is mounted on a safety main base unit and

establishes connection to CC-Link IE Field Network

*1

certified safety main base unit

*1

certified safety power supply module (100VAC)

*1

certified safety power supply module (200VAC)

*1

certified safety CPU module

*1

certified CC-Link Safety master module

2 - 3

2.1 System Configuration

Page 37

2

SYSTEM CONFIGURATION

2.1.1 Precautions for system configuration

(1) Modules mountable on the main base unit

Table2.3 lists the modules that can be mounted on the main base unit.

The number of mounted modules and functions are restricted depending on the

module type.

Table2.3 Modules mountable on the main base unit

Module Model

CPU module • QS001CPU Only one ---

Power supply module

CC-Link Safety master

module

CC-Link IE Field Network

master/local module (with

safety functions)

CC-Link IE Controller Network

module

MELSECNET/H module

Ethernet module

Blank cover • QG60 Up to four ---

• QS061P-A1

• QS061P-A2

• QS0J61BT12 Up to two ---

• QS0J71GF11-T2 Only one ---

• QJ71GP21-SX

• QJ71GP21S-SX

• QJ71LP21-25

• QJ71LP21S-25

• QJ71LP21G

• QJ71LP21GE

• QJ71BR11

• QJ71E71-B2

• QJ71E71-B5

• QJ71E71-100

Number of modules

mounted in one system

Only one (only one of the module

models)

Only one (only one of the models

among CC-Link IE Controller

Network modules and MELSECNET/

H modules)

Only one (only one of the module

models)

Remarks

• Serial number (first five digits):

“10041” or later

• Function version: D or later

• Serial number (first five digits):

“08102” or later

• Function version: D or later

---

---

1

2

3

4

5

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

CPU MODULE

(2) Module/Unit Replacement

Replace the module or unit according to the following replacement cycle.

Table2.4 Module/Unit Replacement

Module/Unit Replacement Cycle

Safety power supply module 5 years

Safety CPU module 10 years

Safety main base unit 10 years

CC-Link Safety master module 10 years

CC-Link IE Field Network master/local module (with

safety functions)

10 years

6

7

8

POWER SUPPLY

MODULE

BASE UNIT

BATTERY

2.1 System Configuration

2.1.1 Precautions for system configuration

2 - 4

CPU MODULE START-

UP PROCEDURES

Page 38

2

Personal computer

(GX Developer Version 8.40S or later)

USB cable*1

QS001CPU

SYSTEM CONFIGURATION

2.2 Configuration of Peripheral Devices

This section describes the configuration of the peripheral devices usable in the safety

programmable controller system.

* 1: For details of the USB cable, refer to "About the USB cable (QCPU (Q mode) compatible)" of the

following manual.

GX Developer Operating Manual

Figure 2.3 Configuration of peripheral devices

2 - 5

2.2 Configuration of Peripheral Devices

2.1.1 Precautions for system configuration

Page 39

2

SYSTEM CONFIGURATION

2.3 Checking Serial Number and Function Version

The serial number and function version of the CPU module can be checked on the rating

plate or the System monitor window in GX Developer.

1

OVERVIEW

(1) Checking on the rating plate

The rating plate is located on the side of the CPU module.

PASSED

MODEL

Serial No. (first 5 digits)

function version

SERIAL

080910000000000-A

Standard symbol for

conformance is described.

MADE IN JAPAN

Figure 2.4 Rating plate

(2) Checking on the front of the module

The serial number on the rating plate is printed on the front (at the bottom) of the

module.

2

3

4

5

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

CPU MODULE

Q S 0 0 1 C P U

A L I V E

R U N

E R R.

PULL

U S B

T E S T

U S E R

B A T.

090911090910001-B

Serial No.

Figure 2.5 Display on the front of the module

6

7

8

POWER SUPPLY

MODULE

BASE UNIT

BATTERY

2.3 Checking Serial Number and Function Version

CPU MODULE START-

2 - 6

UP PROCEDURES

Page 40

2

POINT

Serial number function version

SYSTEM CONFIGURATION

(3) Checking on the System monitor window (Product Information List window)

To display the window for checking the serial number and function version, select

[Diagnostics] [System monitor] and click the Product Information List button in GX

Developer.

On the window, the serial number and function version of intelligent function modules

can also be checked.

Figure 2.6 System monitor

The serial number displayed on the Product information list window of GX

Developer may differ from that on the rating plate and on the front of the module.

• The serial number on the rating plate indicates the management

information of the product.

• The serial number displayed on the Product Information List window

indicates the functional information of the product.

The functional information of the product is updated when a new function

is added.

2 - 7

2.3 Checking Serial Number and Function Version

Page 41

3

GENERAL SPECIFICATIONS

CHAPTER3 GENERAL SPECIFICATIONS

The performance specifications of QS series programmable controllers are shown in Table3.1.

Table3.1 General specifications

Item Specifications

Operating ambient temperature

Storage ambient temperature

Operating ambient humidity

Storage ambient humidity

Compliant

Vibration resistance

Shock resistance

Operating atmosphere No corrosive gases

Operating altitude

Installation location Inside a control panel

Overvoltage category

Pollution degree

Equipment class Class I

*3

*1

*2

with JIS B

3502 and

IEC 61131-2

Conforming to JIS B 3502 and IEC 61131-2 (147 m/s2, duration of action 11ms, 3 times

Under

intermittent

vibration

Under

continuous

vibration

each in 3 directions X, Y, Z by sine half-wave pulse)

5 to 95%RH, non-condensing

Frequency

5 to 8.4Hz ---- 3.5mm 10 times

8.4 to 150Hz

5 to 8.4Hz ---- 1.75mm

8.4 to 150Hz

0 to 55

-40 to 75

Constant

acceleration

0 to 2000m

II or less

2 or less

9.8m/s

4.9m/s

2

2

Half

amplitude

----

----

Sweep count

each in X, Y,

Z directions

----

1

2

3

4

5

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

CPU MODULE

*1 : This indicates the section of the power supply to which the equipment is assumed to be connected between the public

electrical power distribution network and the machinery within premises. Category II applies to equipment for which

electrical power is supplied from fixed facilities. The surge voltage withstand level for equipment with the rated voltage

of up to 300V is 2500V.

*2 : This index indicates the degree to which conductive material is generated in terms of the environment in which the

equipment is used. Pollution level 2 is when only non-conductive pollution occurs. A temporary conductivity caused by

condensing may be expected occasionally.

*3 : Do not use or store the programmable controller under pressure higher than the atmospheric pressure of altitude 0m.

Doing so may cause malfunction. When using the programmable controller under pressure, please consult your local

Mitsubishi Electric representative.

6

7

8

POWER SUPPLY

MODULE

BASE UNIT

BATTERY

CPU MODULE START-

3 - 1

UP PROCEDURES

Page 42

3

Memo

GENERAL SPECIFICATIONS

3 - 2

Page 43

4

CPU MODULE

CHAPTER4 CPU MODULE

1

4.1 Performance Specifications

Table4.1 shows the performance specifications of the CPU module.

Item QS001CPU Remarks

Control method Repetitive operation of stored program ----

I/O control mode Refresh mode ---Program

language

Processing speed

(sequence

instruction)

Constant scan

(Function for keeping regular scan

time)

Program capacity

Memory

*1

capacity

Max. number of

files stored

Sequence control

language

LD X0

MOV D0 D1

*1

Program memory

(drive 0)

Standard ROM

(drive 4)

Program memory

Standard ROM

Table4.1 Performance Specifications

Relay symbol language, function block. ----

0.10 s

0.35 s

1 to 2000ms

(in increments of 1ms)

14K steps

(56K bytes)

128K bytes ----

128K bytes ----

*2

3

*2

3

----

----

Setting by parameters.

----

----

----

2

3

4

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

CPU MODULE

No. of times of writing data into the

standard ROM

No. of I/O device points 6144 points(X/Y0 to 17FF)

No. of I/O points 1024 points(X/Y0 to 3FF)

*1 : The maximum number of executable sequence steps is as shown below.(Program capacity) - (File header size (default: 34 steps))

For the details, refer to the manual below.

QSCPU User's Manual (Function Explanation, Program Fundamentals)

*2 : Each of parameter, sequence program, SFC program, and device comment files can be stored.

Max.100000 times ----

No. of points

usable on

program

No. of points

accessible to the

actual I/O module

5

6

7

8

POWER SUPPLY

MODULE

BASE UNIT

BATTERY

4.1 Performance Specifications

CPU MODULE START-

4 - 1

UP PROCEDURES

Page 44

4

Remark

CPU MODULE

Table4.1 Performance Specifications (Continue)

Item QS001CPU Remarks

Internal relay [M] 6144 points by default (M0-6143) (changeable)

Link relay [B] 2048 points by default (B0 to 7FF) (changeable)

512 points by default (T0 to 511) (changeable)

(Sharing of low- and high-speed timers)

The low- and high-speed timers are specified by the instructions.

Timer [ T]

Retentive timer [ST]

No. of device points

Counter [C] Normal counter: 512 points by default (C0 to 511) (changeable)

Data register [D] 6144 points by default (D0 to 6143) (changeable)

Link register [W] 2048 points by default (W0 to 7FF) (changeable)

Annunciator [F] 1024 points by default (F0 to 1023) (changeable)

Edge relay [V] 1024 points by default (V0 to 1023) (changeable)

Link special relay [SB] 1536 points (SB0 to 5FF)

Link special register [SW] 1536 points (SW0 to 5FF)

Special relay [SM] 5120 points (SM0 to 5119)

Special register [SD] 5120 points (SD0 to 5119)

RUN/PAUSE contact

Timer function

Allowable instantaneous power failure

period

5VDC internal current consumption

H 98mm (3.86 inch) ----

External dimensions

Weight 0.29kg ----

Protection of degree IP2X ----

*3 : The value for the CPU module whose serial number (first four digits) is "1207" or earlier is 0.43A.

5VDC internal current consumption: 0.43A

W 55.2mm (2.17 inch) ----

D 114mm (4.49 inch) ----

The measurement unit of the low- and high-speed timers is set up by

parameters.

(Low-speed timer: 1 to 1000ms, 1ms unit, 100ms by default)

(High-speed timer: 0.1 to 100ms, 0.1ms unit, 10ms by default)

0 point by default

(sharing of the low- and high-speed retentive timers) (changeable)

The low- and high-speed retentive timers are specified

by the instructions.

The measurement unit of the low- and high-speed retentive timers

is set up by parameters.

(Low-speed retentive timer: 1 to 1000ms, 1ms unit, 100ms by default)

(High-speed retentive timer: 0.1 to 100ms, 0.1ms unit, 10ms by default)

One contact can be set up in X0 to 17FF for each of RUN. No PAUSE

contact.

Year, month, date, hour, minute, second and day-of-week

(leap year automatically identified)

Accuracy: -3.18 to +5.25s (TYP.+2.14s)/d at 0

Accuracy: -3.18 to +2.59s (TYP.+2.07s)/d at 25

Accuracy: -12.97 to +3.63s (TYP.-3.16s)/d at 55

Varies depending on the power supply module. ----

*3

0.58A

The number of points

can be changed within

the setting range.

( QSCPU User's

Manual

(Function

Explanation,

Program

Fundamentals)

The number of device

points is fixed.

Setting by parameters.

----

----

4 - 2

For the general specifications, refer to CHAPTER 3.

4.1 Performance Specifications

Page 45

4

STOP

RESET RUN

PULL

BAT.

USB

PULL

QS001CPU

TEST

USER

BAT.

ALIVE

RUN

ERR.

TEST

USER

BAT.

ALIVE

RUN

ERR.

3)

6)

7)

2)

1)

4)

5)

15)

1)

13)

14)

10)

9)

When opening the cover, put

your finger here.

CPU MODULE

4.2 Part Names

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

GENERAL

SPECIFICATIONS

4

CPU MODULE

Figure 4.1 Front face Figure 4.2 With front cover open

11)

5

6

POWER SUPPLY

MODULE

BASE UNIT

7

12)

8)

Figure 4.3 Side Face

BATTERY

8

4.2 Part Names

CPU MODULE START-

4 - 3

UP PROCEDURES

Page 46

4

On :

Normal

*1

Off : When the hardware watchdog timer error is detected

("ERR." LED is On.)

On :

TEST MODE

*1

Flash : When TEST MODE is switched to SAFETY MODE

The "TEST" LED turns off after reset.

(Flash interval: On 200ms/Off 200ms)

Off : SAFETY MODE

On :

During operation in "RUN"

*1

Off : During stop in "STOP" or when the error which stops the operation is detected

Flash : When parameters/program is written during STOP and the RUN/STOP/RESET

switch is moved from "STOP" to "RUN"

(Flash interval: On 200ms/Off 200ms)

On :

When the self-diagnostics error that will not stop operation, other than a battery

error, is detected

*1

Off : Normal

Flash : When the self-diagnostics error that will stop operation is detected

(Flash interval: On 200ms/Off 200ms)

When the reset operation is performed

(Flash interval: On 60ms/Off 60ms)

On :

When the annunciator (F) turns ON

*1

Off : Normal

On :

When a battery error has occurred due to the CPU battery voltage drop

*1

Off : Normal

RUN : Executes sequence program operation.

STOP : Stops sequence program operation.

RESET :

Performs hardware reset and operation initialization when an operation

error occurs. ( Section 4.4)

CPU MODULE

No. Name Application

1) Module fixing hook Hook used to fix the module to the base unit.

"ALIVE" LED

2)

(Green)

Indicates the operating mode of the CPU module.

"TEST" LED

3)

(Yellow)

Indicates the operating status of the CPU module.

"RUN" LED

4)

(Green)

"ERR." LED

5)

(Red)

Table4.2 Part Names

"USER" LED

6)

(Red)

"BAT." LED

7)

(Yellow)

8) Module loading lever Used to load the module to the safety base unit.

Connector used to connect to the USB compatible peripheral devices.

9)

USB connector

10)

RUN/STOP/RESET switch

11) Module fixing screw Screw used to fix a module to the base unit. (M3 screw)

12) Module fixing latch Latch used to fix a module to the base unit.

13) Battery Backup battery for the power failure compensation function of program memory.

14) Battery connector pin