Mitsubishi Electronics QS90SR2SP-CC, QS90SR2SN-EX, QS90SR2SN-CC, QS90SR2SP-EX, QS90SR2SN-Q User Manual

Page 1

Safety Relay Module

User's Manual

-QS90SR2SP-Q

-QS90SR2SN-Q

-QS90SR2SP-CC

-QS90SR2SN-CC

-QS90SR2SP-EX

-QS90SR2SN-EX

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Always read these instructions before using this equipment.)

Before using the product, please read this manual, the relevant manuals introduced in this manual,

standard programmable controller manuals, and the safety standards carefully and pay full attention to

safety to handle the product correctly.

In this manual, the safety instructions are ranked as " WARNING" and " CAUTION".

Note that the CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[Design Precautions]

WARNING

● A safety relay module turns OFF all outputs by safety input or a failure of external power supply.

Create an external circuit to securely stop the power of hazard by turning OFF the outputs.

Incorrect configuration may result in an accident.

● When overcurrent due to such as load short-circuit or load current exceeding the rating flows for a

long time, it may cause smoke or fire. To prevent this, create external safety circuit such as a fuse.

● Create short-circuit current protection for a safety relay and a protection circuit such as a fuse and

breaker, outside a safety relay module.

● To inhibit a restart without manual operation after safety function of the safety relay module was

performed and outputs were turned OFF, create reset start-up circuit using such as a reset switch

outside the safety relay module.

● The safety relay module may consume excessive current due to a failure. If this occurs, the DC

power supply connected to the safety power supply part (+24V (SAFETY) and 24G (SAFETY)

terminals) of the module detects an overcurrent and may shut off the output. To the DC power supply

connected to the safety relay module, connect only the equipment and the devices that will not affect

the system even if they are simultaneously stopped due to power-off.

● Use an extension module whose input type is the same as that of the main module. The modules of

different input types (input P and N types) cannot be connected.

A - 1

Page 4

[Design Precautions]

CAUTION

● The safety category is evaluated by the whole equipment. Make sure that the whole equipment

meets the requirements before use.

● Use the programmable controller in an environment that meets the general specifications contained

in this manual.

Using this programmable controller in an environment outside the range of the general specifications

could result in electric shock, fire, erroneous operation, and damage to or deterioration of the

product.

● The life of safety relay used for the safety relay module depends on the open-close condition and

load. Be sure to operate the equipment by use conditions to make sure that the number of allowable

times that the relay opens/closes.

● Do not install the wiring of external devices or communication cables together with the main circuit or

power lines, or bring them close to each other. Keep a distance of 100mm (3.94 inch) or more

between them.

Not doing so could result in noise that would cause erroneous operation.

[Installation Precautions]

WARNING

● Do not use the product in flammable gas atmosphere or explosive gas atmosphere.

Doing so may result in fire or explosion due to such as an arc caused by opening/closing the relays.

CAUTION

● For Q series safety relay module, while pressing the module mounting lever located at the bottom of

a module, fully insert the module fixing projection into the fixing hole on the base unit. Then, mount

the module with the fixing hole as a supporting point.

Incorrect loading of the module can cause a malfunction, failure or drop.

When using the programmable controller in the environment of much vibration, tighten the module

with a screw.

Tighten the screw in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to damage to the screw or module.

● Make sure to fix CC-Link safety relay module and extension safety relay module with a DIN rail fixing

bracket.

A - 2

Page 5

[Installation Precautions]

CAUTION

● Be sure to shut off all phases of the external supply power used by the system before mounting/

removing a module.

Not doing so may result in damage to the product.

● When mounting a module, make room for 5cm (1.97 inch) or more at above and below of the module

for ventilation.

When powering ON a contact at 3A or more consecutively, make room for 5mm (0.20 inch) or more

at the sides of the contact for ventilation.

● Do not directly touch the module's conductive parts or electronic components.

Doing so may cause malfunctions or a failure.

● Securely connect connectors for each cable to the applied parts.

Not doing so may cause a malfunction due to poor connection.

[Wiring Precautions]

WARNING

● Be sure to shut off all phases of the external supply power used by the system before wiring.

Not completely turning off all power could result in electric shock or damage to the product.

● When energizing or operating the module after installation or wiring, be sure to close the attached

terminal cover.

Not doing so may result in electric shock.

A - 3

Page 6

CAUTION

● Ground the FG and LG terminals correctly.

Not doing so could result in electric shock or malfunctions.

● Wire the module correctly after confirming the rated voltage and terminal layout.

Connecting a power supply of a different rated voltage or incorrect wiring may cause a fire or failure.

● Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause a fire, failure, or malfunctions.

● Tighten a terminal block mounting screw, terminal screw, and module mounting screw within the

specified torque range.

If the terminal block mounting screw or terminal screw is too loose, it may cause a short circuit, fire,

or malfunctions. If too tight, it may damage the screw and/or the module, resulting in a drop of the

screw or module, a short circuit or malfunctions.

If the module mounting screw is too loose, it may cause a drop of the screw or module.

Over tightening the screw may cause a drop due to the damage of the screw or module.

● Be sure to fix the communication cables or power cables by ducts or clamps when connecting them

to the module.

Failure to do so may cause damage of the module or cables due to a wobble, unintentional shifting,

or accidental pull of the cables, or malfunctions due to poor contact of the cable.

A - 4

Page 7

[Wiring Precautions]

CAUTION

● When removing the connected communication cables or power cables, do not pull the cable with

grasping the cable part.

Remove the cable connected to the terminal block after loosening the terminal block screws.

Pulling the cable connected to a module may result in malfunctions or damage of the module or

cable.

● Use applicable solderless terminals and crimp them with a tool specified by maker.

Imperfect connections could result in short circuit, fires, or erroneous operation.

● A protective film is attached to the top of the Q series safety relay module to prevent foreign matter

such as wire chips from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

● Install our programmable controller in a control panel complying with the IP standard of 54 or more.

Wire the main power supply to the power supply module installed in a control panel through a

distribution terminal block.

Furthermore, the wiring and replacement of a power supply module have to be performed by a

maintenance worker who acquainted with shock protection.

For wiring method, refer to the QCPU User's Manual (Hardware Design, Maintenance and

Inspection).

● Do not install the control lines together with the communication cables or bring them close to each

other.

Doing so may cause a malfunction due to noise.

● Pay attention when using a flathead screwdriver to push the open/close button of the spring clamp

terminal block. Failure to do so can result in an injury.

[Startup and Maintenance Precautions]

WARNING

● Do not touch the terminals while power is on.

Doing so could result in electric shock.

● Turn off all phases of the external supply power used in the system when cleaning the module or

retightening the terminal block mounting screws, terminal screws, or module mounting screws.

Not doing so could result in electric shock.

Tighten a terminal block mounting screw and module mounting screw within the specified torque

range.

If the terminal block mounting screw is too loose, it may cause a short-circuit, fire or malfunctions.

If too tight, it may damage the screw and/or the module, resulting in a drop of the screw or module, a

short circuit or malfunctions.

If the module mounting screw is too loose, it may cause a drop of the screw or module.

Over tightening the screw may cause a drop due to the damage of the screw or module.

A - 5

Page 8

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or remodel the module. Doing so could cause a failure, malfunctions, injury, or

fire.

If the product is repaired or remodeled by other than the specified FA centers or us, the warranty is

not covered.

● A electric fuse for overcurrent prevention is incorporated in the control circuit part of the safety relay

module.

If the electric fuse operates, power OFF the module once, and power it ON again after resolving the

failure.

● Restrict the mounting/removal of a module, base unit, and terminal block up to 50 times (IEC611312-compliant), after the first use of the product.

Failure to do so may cause the module to malfunction due to poor contact of connector.

● Since the module case is made of resin, do not drop or apply any strong impact to the module.

Doing so may damage the module.

● Completely turn off the externally supplied power used in the system before mounting or removing

the module to/from the panel.

Not doing so may result in a failure or malfunctions of the module.

● Use any radio communication device such as a cellular phone or a PHS phone more than 25cm

(9.85 inch) away in all directions of the programmable controller.

Not doing so can cause a malfunction.

● Before touching the module, always touch grounded metal, etc. to discharge static electricity from

human body, etc.

Not doing so can cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

A - 6

Page 9

CONDITIONS OF USE FOR THE PRODUCT

(1) Although MELCO has obtained the certification for Product's compliance to the international safety

standard ISO13849-1 from TUV Rheinland, this fact does not guarantee that Product will be free

from any malfunction or failure. The user of this Product shall comply with any and all applicable

safety standard, regulation or law and take appropriate safety measures for the system in which the

Product is installed or used and shall take the second or third safety measures other than the

Product. MELCO is not liable for damages that could have been prevented by compliance with any

applicable safety standard, regulation or law.

(2) MELCO prohibits the use of Products with or in any application involving, and MELCO shall not be

liable for a default, a liability for defect warranty, a quality assurance, negligence or other tort and a

product liability in these applications.

(a) power plants,

(b) trains, railway systems, airplanes, airline operations, other transportation systems,

(c) hospitals, medical care, dialysis and life support facilities or equipment,

(d) amusement equipments,

(e) incineration and fuel devices,

(f) handling of nuclear or hazardous materials or chemicals,

(g) mining and drilling,

(h) and other applications where the level of risk to human life, health or property are elevated.

A - 7

Page 10

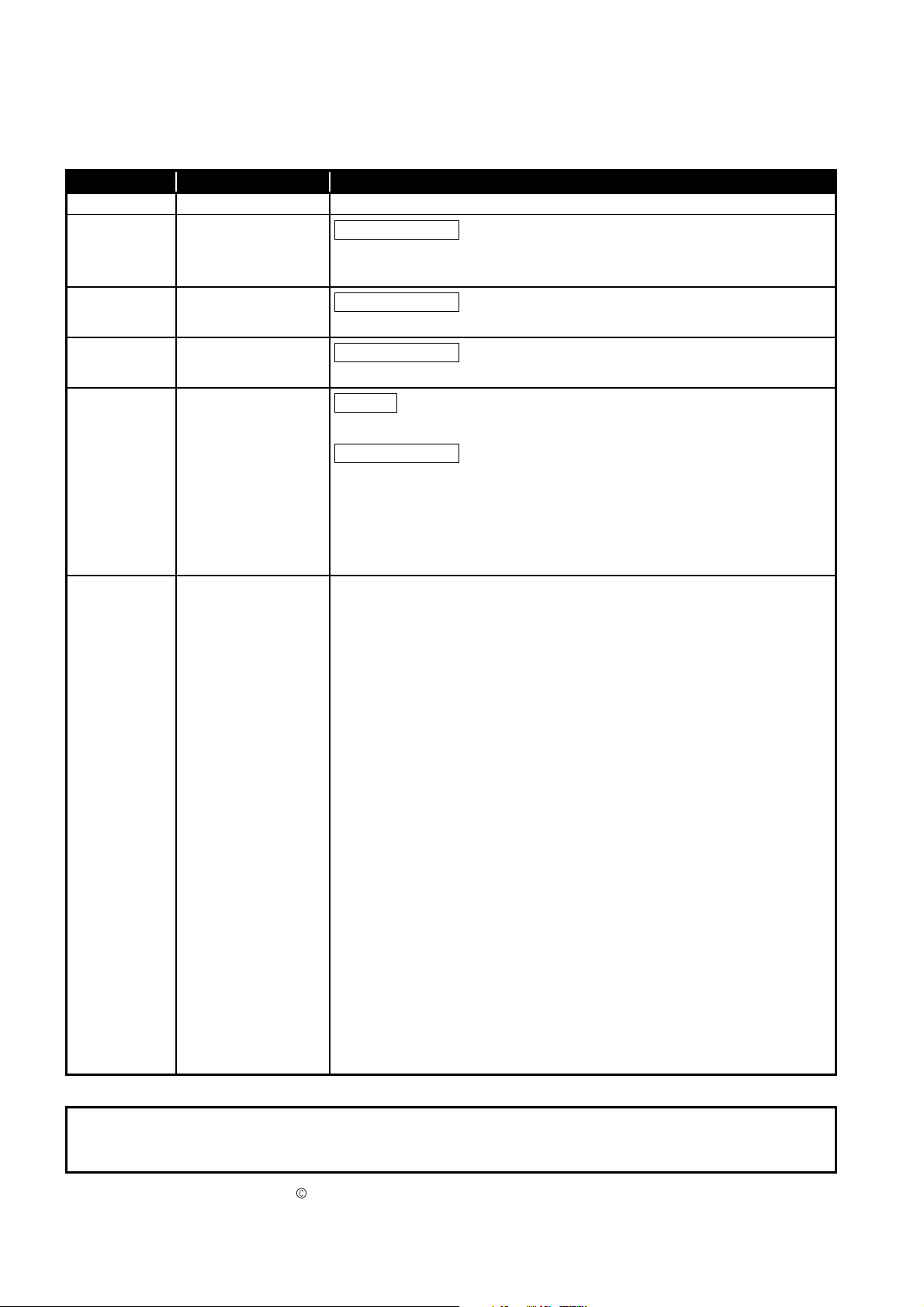

REVISIONS

Partial corrections

Partial corrections

Partial corrections

Addition

Partial corrections

* The manual number is given on the bottom left of the back cover.

Print date *Manual number Revision

Apr., 2008

SH(NA)-080746ENG-A

First edition

Jun., 2008 SH(NA)-080746ENG-B

Nov., 2008 SH(NA)-080746ENG-C

Jan., 2010 SH(NA)-080746ENG-D

Apr., 2015 SH(NA)-080746ENG-E

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES,

Section 5.1.1, 5.1.4, 5.2.1, 5.3.1, 6.1.2, 6.2.2, 6.3.2

Section 3.1, 3.2.2, 3.4.1, 5.4.1, 5.4.7

Section 2.2, 3.1, 3.2.1, 3.2.2, 3.3.1, 3.3.2, 3.4.1, 3.4.2, 5.4.1, 5.4.7

CONDITIONS OF USE FOR THE PRODUCT, Section 1.1, 2.3, 2.4

SAFETY PRECAUTIONS, ABOUT MANUALS, COMPLIANCE WITH THE EMC,

LOW VOLTAGE, AND MACHINERY DIRECTIVES, Section 1.3, 1.4, 2.2, 2.4,

3.1, 3.2.1, 3.3.1, 3.3.2, 3.4.2, 3.5, 3.6, Chapter 4, Section 4.3, 4.5, 5.1.1, 5.1.2,

5.1.3, 5.1.4, 5.2.1, 5.2.3, 5.2.4, 5.3.1, 5.3.2, 5.3.3, 5.4.1, 5.4.2, 5.4.3, 5.4.6, 5.4.7,

6.1.1, 6.1.2, 6.2.1, 6.2.2, 6.3.1, 6.3.2, APPENDIX 1.1

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

A - 8

Japanese Manual Version SH-080745-F

2008 MITSUBISHI ELECTRIC CORPORATION

Page 11

INTRODUCTION

Thank you for choosing the Mitsubishi safety relay module.

Before using this product, please read this manual carefully to develop full familiarity with the functions

and performance of the safety relay module to ensure correct use.

This product can be used for configuring safety functions of typical industrial machinery.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT..................................................................................................A - 7

REVISIONS.......................................................................................................................................................A - 8

INTRODUCTION...............................................................................................................................................A - 9

CONTENTS ......................................................................................................................................................A - 9

ABOUT MANUALS ......................................................................................................................................... A - 12

COMPLIANCE WITH THE EMC, LOW VOLTAGE, AND MACHINERY DIRECTIVES ..................................A - 13

GENERIC TERMS AND ABBREVIATIONS.................................................................................................... A - 14

PACKING LIST ...............................................................................................................................................A - 14

CHAPTER 1 OVERVIEW 1 - 1 to 1 - 5

1.1 Product List...................................................................................................................................... 1 - 1

1.2 About Safety Relay Module ............................................................................................................. 1 - 2

1.3 Features........................................................................................................................................... 1 - 3

1.4 Checking the Safety Relay Module Model .......................................................................................1 - 5

CHAPTER 2 SYSTEM CONFIGURATION 2 - 1 to 2 - 4

2.1 System Configuration ...................................................................................................................... 2 - 1

2.2 Applicable Systems ......................................................................................................................... 2 - 2

2.3 Module Replacement ....................................................................................................................... 2 - 4

2.4 Precautions for Use ......................................................................................................................... 2 - 4

CHAPTER 3 SPECIFICATIONS 3 - 1 to 3 - 15

3.1 General Specifications ..................................................................................................................... 3 - 1

3.2 Q Series Safety Relay Module Specifications ................................................................................. 3 - 2

3.2.1 QS90SR2SP-Q Q series safety relay module .......................................................................... 3 - 2

3.2.2 QS90SR2SN-Q Q series safety relay module.......................................................................... 3 - 4

3.3 CC-Link Safety Relay Module Specifications .................................................................................. 3 - 6

3.3.1 QS90SR2SP-CC CC-Link safety relay module ........................................................................ 3 - 6

3.3.2 QS90SR2SN-CC CC-Link safety relay module........................................................................ 3 - 8

3.4 Extension Safety Relay Module Specifications.............................................................................. 3 - 10

3.4.1 QS90SR2SP-EX extension safety relay module .................................................................... 3 - 10

3.4.2 QS90SR2SN-EX extension safety relay module .................................................................... 3 - 12

3.5 I/O Signals ..................................................................................................................................... 3 - 14

A - 9

Page 12

3.6 Cable Specifications ...................................................................................................................... 3 - 15

CHAPTER 4 FUNCTIONS 4 - 1 to 4 - 5

4.1 Dual Input Function.......................................................................................................................... 4 - 1

4.2 Start-up/off Check Function ............................................................................................................. 4 - 2

4.3 Start-up Method Selection Function ................................................................................................ 4 - 3

4.4 Safety Output Function .................................................................................................................... 4 - 3

4.5 Monitor Function .............................................................................................................................. 4 - 4

4.6 Partial Shutdown Function with Extension Module .......................................................................... 4 - 5

CHAPTER 5 SETTINGS AND PROCEDURES BEFORE OPERATION 5 - 1 to 5 - 35

5.1 Q Series Safety Relay Module......................................................................................................... 5 - 1

5.1.1 Start-up procedures .................................................................................................................. 5 - 1

5.1.2 Handling precautions ................................................................................................................ 5 - 3

5.1.3 Part names and settings ........................................................................................................... 5 - 4

5.1.4 Mounting/removal ..................................................................................................................... 5 - 6

5.2 CC-Link Safety Relay Module.......................................................................................................... 5 - 9

5.2.1 Start-up procedures .................................................................................................................. 5 - 9

5.2.2 Handling precautions .............................................................................................................. 5 - 11

5.2.3 Part names and settings ......................................................................................................... 5 - 12

5.2.4 Station number setting............................................................................................................ 5 - 14

5.2.5 Module installation direction ................................................................................................... 5 - 14

5.3 Extension Safety Relay Module..................................................................................................... 5 - 15

5.3.1 Start-up procedures ................................................................................................................ 5 - 15

5.3.2 Handling precautions .............................................................................................................. 5 - 17

5.3.3 Part names and settings ......................................................................................................... 5 - 18

5.3.4 Module installation direction ................................................................................................... 5 - 20

5.4 Wiring............................................................................................................................................. 5 - 21

5.4.1 Precautions for safety devices and wiring .............................................................................. 5 - 21

5.4.2 Spring clamp terminal block.................................................................................................... 5 - 30

5.4.3 Attaching/removing a terminal block....................................................................................... 5 - 33

5.4.4 Precautions for handling CC-Link dedicated cable ................................................................. 5 - 33

5.4.5 Connecting with CC-Link dedicated cables ............................................................................ 5 - 34

5.4.6 Precautions for wiring power supply ....................................................................................... 5 - 34

5.4.7 Connecting extension modules...............................................................................................5 - 35

CHAPTER 6 TROUBLESHOOTING 6 - 1 to 6 - 7

6.1 Q Series Safety Relay Module......................................................................................................... 6 - 2

6.1.1 Error check method with LED ................................................................................................... 6 - 2

6.1.2 Error check method with monitor signal.................................................................................... 6 - 3

6.2 CC-Link Safety Relay Module.......................................................................................................... 6 - 4

6.2.1 Error check method with LED ................................................................................................... 6 - 4

6.2.2 Error check method with monitor signal.................................................................................... 6 - 5

6.3 Extension Safety Relay Module....................................................................................................... 6 - 6

6.3.1 Error check method with LED ................................................................................................... 6 - 6

A - 10

Page 13

6.3.2 Error check method with monitor signal ................................................................................... 6 - 7

APPENDIX App - 1 to App - 4

Appendix 1 External Dimensions......................................................................................................... App - 1

Appendix 1.1 Q series safety relay module .................................................................................... App - 1

Appendix 1.2 CC-Link safety relay module ....................................................................................App - 2

Appendix 1.3 Extension safety relay module .................................................................................App - 3

A - 11

Page 14

ABOUT MANUALS

Related manuals

The manuals related to this product are shown below.

Refer to the following table when ordering required manuals.

Manual name

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

This manual explains the specifications of the CPU module, power supply module, base unit,

extension cable, and memory card.

(Sold separately.)

CC-Link System Master/Local Module Type AJ61BT11/A1SJ61BT11 User's Manual

This manual explains the system configuration, performance specifications, functions, handling,

wiring, and troubleshooting of the AJ61BT11 and A1SJ61BT11.

(Sold separately.)

CC-Link System Master/Local Module Type AJ61QBT11/A1SJ61QBT11 User's Manual

This manual explains the system configuration, performance specifications, functions, handling,

wiring, and troubleshooting of the AJ61QBT11 and A1SJ61QBT11.

(Sold separately.)

MELSEC-Q CC-Link System Master/Local Module User's Manual

This manual explains the system configuration, performance specifications, functions, handling,

wiring, and troubleshooting of the QJ61BT11N.

(Sold separately.)

Type Q80BD-J61BT11N/Q81BD-J61BT11 CC-Link System Master/Local Interface Board

User's Manual (For SW1DNC-CCBD2-B)

This manual explains the system configuration, performance specifications, functions, handling,

wiring, and troubleshooting of the Q80BD-J61BT11N and Q81BD-J61BT11.

(Sold separately.)

Manual number

(model code)

SH(NA)-080483ENG

(13JR73)

IB(NA)-66721

(13J872)

IB(NA)-66722

(13J873)

SH(NA)-080394E

(13JR64)

SH-080527ENG

(13JR77)

A - 12

Page 15

COMPLIANCE WITH THE EMC, LOW VOLTAGE, AND MACHINERY DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC, Low Voltage, and

Machinery Directives when incorporated into other machinery or equipment, certain

measures may be necessary. Please refer to one of the following manuals.

• User's manual for the CPU module used

• Safety Guidelines

(This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with

EMC, Low Voltage, and Machinery Directives.

(a) Sales representative in EU member states

The sales representative in EU member states is:

Company: Mitsubishi Electric Europe BV

Address: Gothaer Strasse 8,40880 Ratingen, Germany

(2) Additional measures

This product complies with the EMC, Low Voltage, and Machinery Directives. Before

using this product, please read this manual, the relevant manuals, the manuals for

standard programmable controllers, and the safety standards carefully and pay full

attention to safety to handle the product correctly.

The descriptions are based on the requirements of the Directives and the harmonized

standards. However, they do not guarantee that the entire machinery constructed

according to the descriptions complies with the EMC, Low Voltage, and Machinery

Directives.

The manufacture of the machinery must determine the testing method for compliance

and declare conformity to the EMC, Low Voltage, and Machinery Directives.

A - 13

Page 16

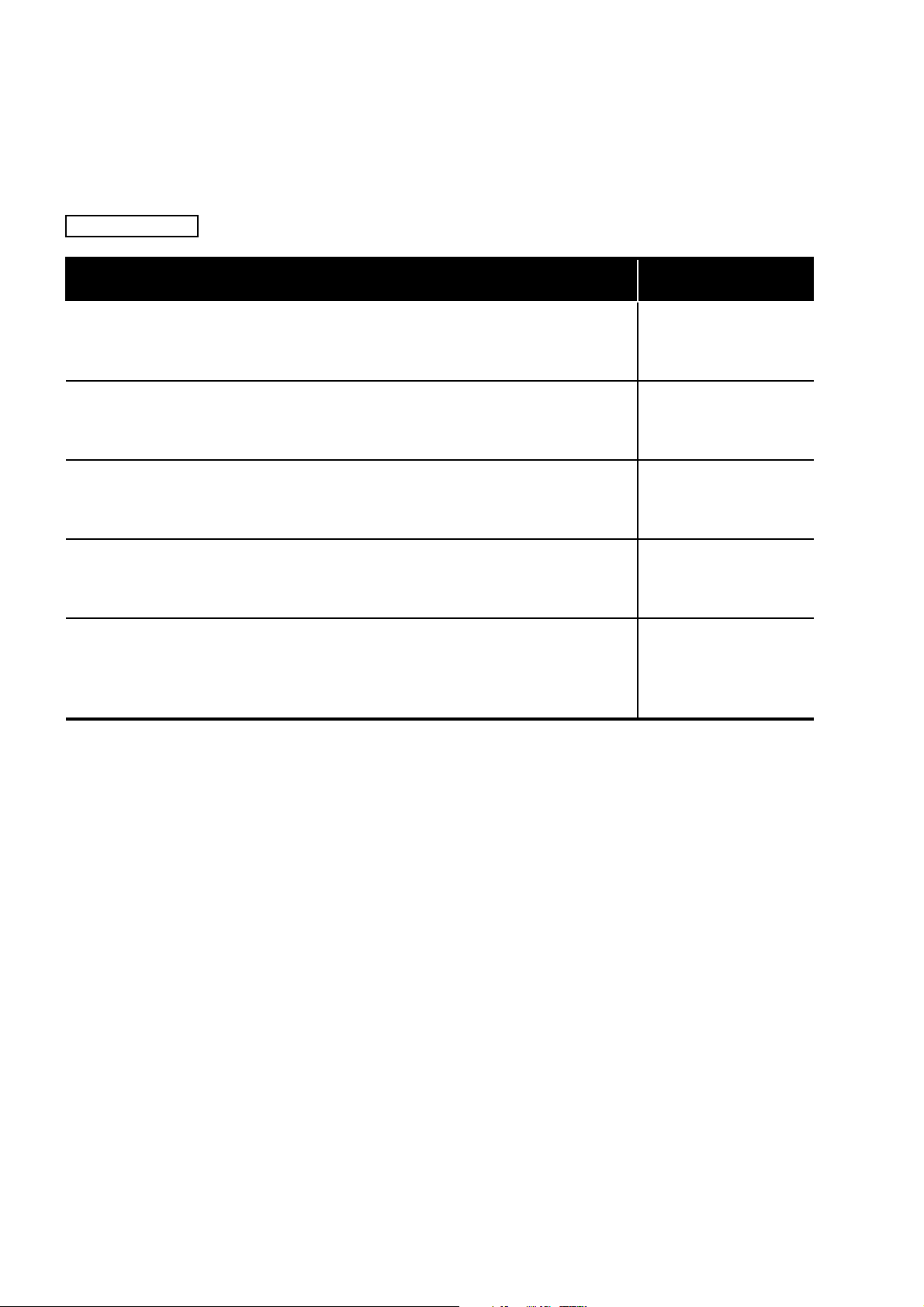

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to explain the safety relay module.

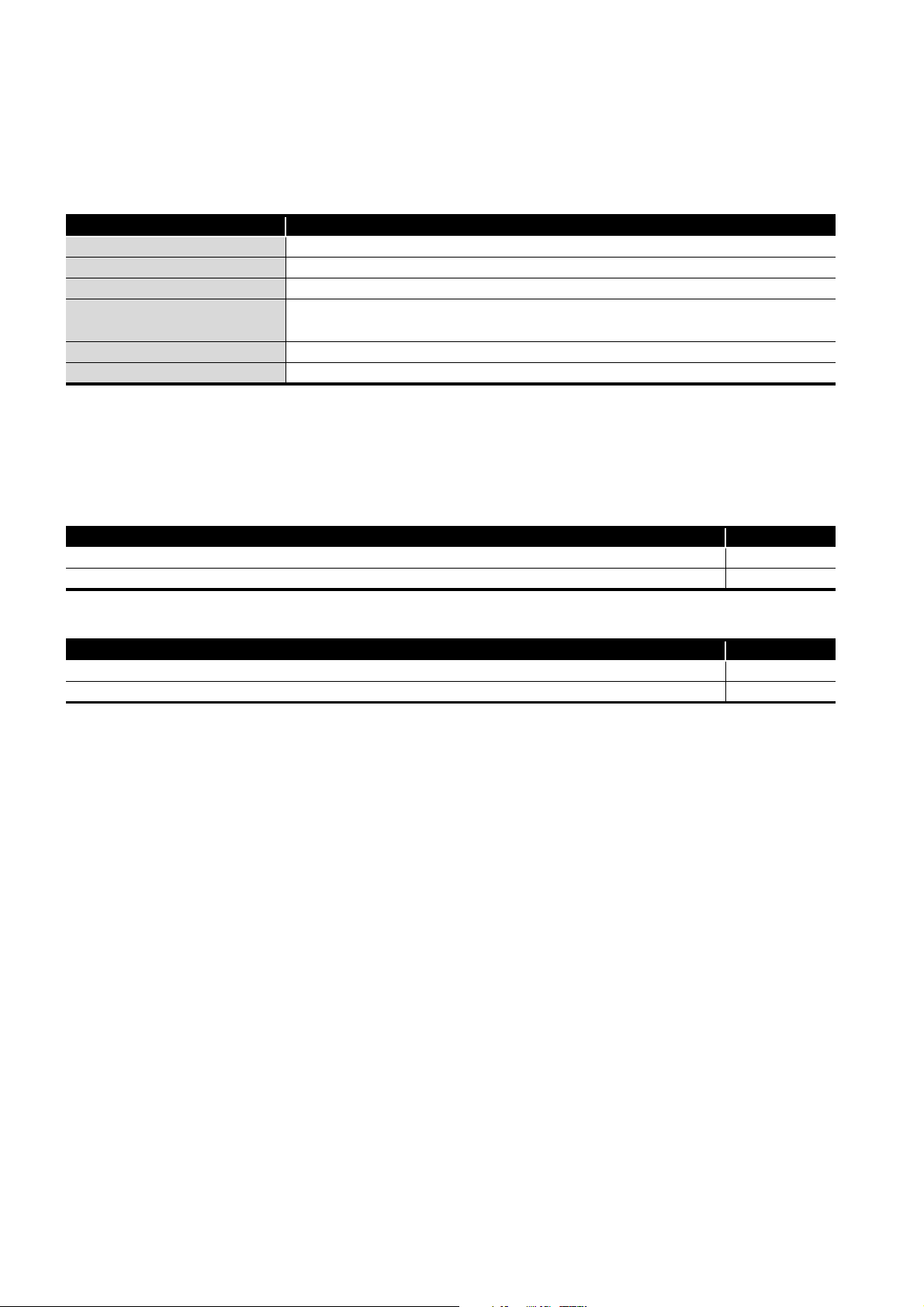

Generic term/abbreviation Description

Q series safety relay module Generic term for QS90SR2SP-Q and QS90SR2SN-Q

CC-Link safety relay module Generic term for QS90SR2SP-CC and QS90SR2SN-CC

Extension safety relay module Generic term for QS90SR2SP-EX and QS90SR2SN-EX

Safety relay module

Main module Generic term for Q series safety relay module and CC-Link safety relay module

Extension module Abbreviation for extension safety relay module

Generic term for Q series safety relay module, CC-Link safety relay module, and

extension safety relay module

PACKING LIST

The following tables show the packing list of each product.

(1) Safety relay module

Product Quantity

Safety relay module 1

Hardware manual 1

(2) Safety circuit part extension cable

Product Quantity

QS90CBL-SE01 1

QS90CBL-SE15 1

A - 14

Page 17

1

OVERVIEW

CHAPTER 1 OVERVIEW

This manual explains specifications, handling, and wiring methods of the safety relay

module.

1.1 Product List

Product name Model name Description

QS90SR2SP-Q

Q series safety relay module

QS90SR2SN-Q

QS90SR2SP-CC

CC-Link safety relay module

QS90SR2SN-CC

QS90SR2SP-EX

Extension safety relay module

QS90SR2SN-EX

Table 1.1 Product list

A safety relay module mounted on a MELSEC-Q series base unit

Input P type (Dual input with positive commons)

A safety relay module mounted on a MELSEC-Q series base unit

Input N type (Dual input with positive common and negative

common)

A safety relay module connected to the CC-Link network

Input P type (Dual input with positive commons)

A safety relay module connected to the CC-Link network

Input N type (Dual input with positive common and negative

common)

An extension safety relay module

Input P type (Dual input with positive commons)

An extension safety relay module

Input N type (Dual input with positive common and negative

common)

1

2

3

4

5

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

1.1 Product List

SETTINGS AND

PROCEDURES BEFORE

OPERATION

6

TROUBLESHOOTINGAPPENDIX

1 - 1

Page 18

1

OVERVIEW

1.2 About Safety Relay Module

The safety relay module achieves basic safety functions for emergency stop only by

wiring, without programming.

It is safety check type module whose output does not turn ON until all conditions of the

safety input (normally closed contact), off check input (normally closed contact), and startup switch (normally open contact) are met.

Using the module helps to reduce the man-hour taken for configuring a safety check

system.

Safety input

(Emergency stop switch, light curtain, etc.)

Safety input

Start-up input

Off check input

Start-up switch

Such as

electromagnetic

switch

Safety relay module

Figure 1.1 Safety relay module

1 - 2

1.2 About Safety Relay Module

Page 19

1

OVERVIEW

1.3 Features

1

This section explains features of the safety relay module.

(1) Obtaining the highest level of safety approval

The safety relay module obtained the highest safety approval (Category 4 of EN

ISO13849-1/performance level E) that the programmable controller can be gained

(In some conditions, Category 3/performance level D can be gained).

A system ensuring higher safety can be configured.

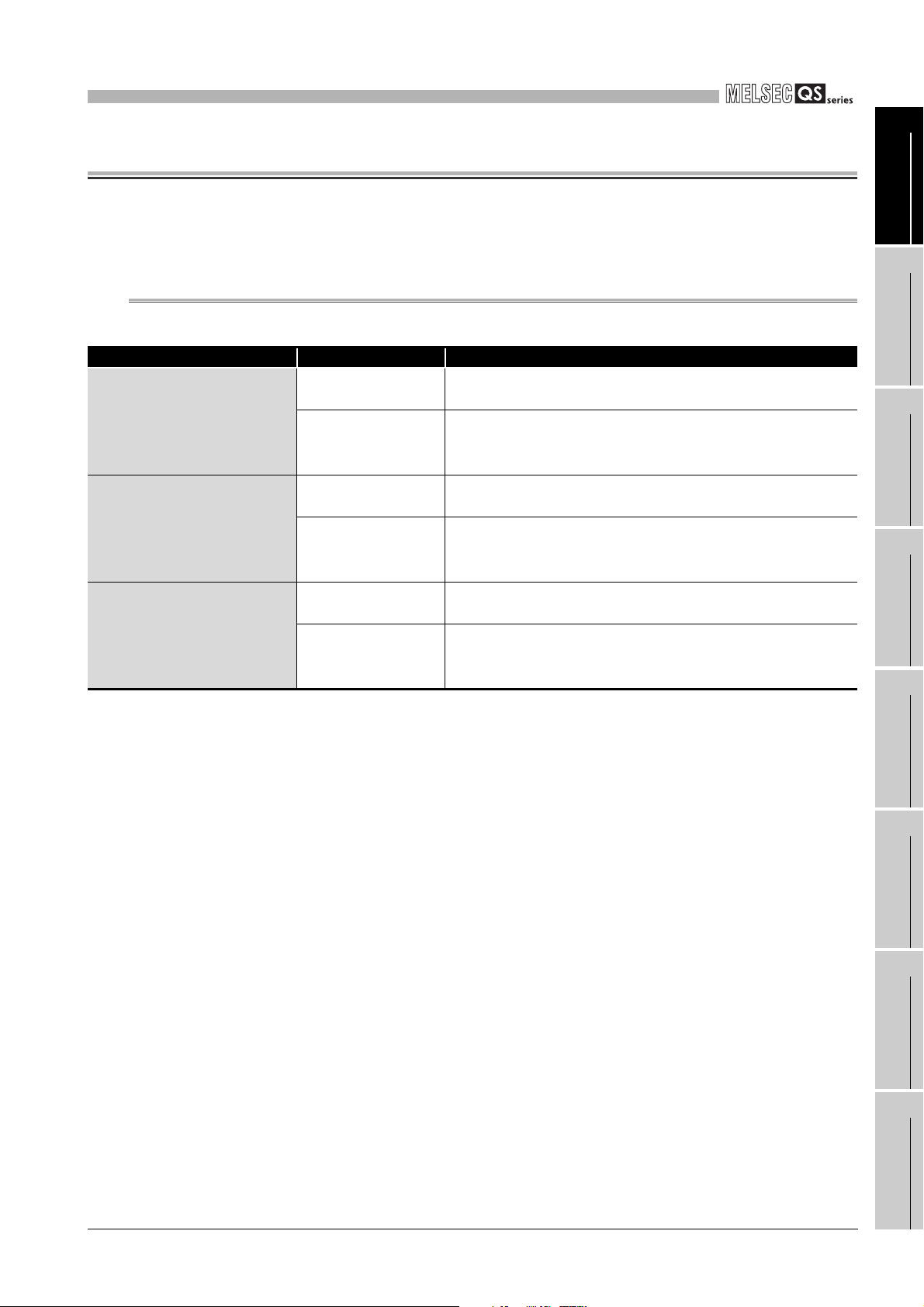

(2) Category 3 and Category 4 compliant

A system complying with Category 3 or Category 4 of EN ISO13849-1 can be

configured depending on the safety input device to be connected and rated current.

Table 1.2 Conditions for complying with each category

Condition

Dual input with positive

commons

(Input P type)

Dual input with positive

common and negative common

(Input N type)

Safety input device to be

connected

Contact-type

input device

Category 3 Category 4 Category 3

Category 4

Type 4 light

curtain

Not

connectable

Rated current

5.0A max. 3.6A max.

Category 3 or

Category 3 Category 4

Category 4

2

3

4

5

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

(3) Safety standards

Use this product according to the following safety standards.

Table 1.3 Safety standards

Region Standard

Global ISO13849-1: 2006, IEC60204-1/A1: 2008, IEC61496-1: 2012

Europe

North America UL508

EN ISO13849-1: 2008, EN60204-1/A1: 2009, EN61496-1: 2013,

EN50178: 1997, EN55011/A1: 2010, EN61000-6-2: 2005

(4) Monitoring safety control with the MELSEC-Q series is possible.

Mounting/connecting the safety relay module on/to existing MELSEC-Q series

programmable controller allows monitoring operating status of the whole safety relay

module and error status of the module.

SETTINGS AND

PROCEDURES BEFORE

6

OPERATION

TROUBLESHOOTINGAPPENDIX

1.3 Features

1 - 3

Page 20

1

Terminal block cover

OVERVIEW

(5) Small-scale safety control

The safety relay module is suited for small-scale safety control whose number of I/O

points is around 10.

(a) Programming is unnecessary.

Safety circuits can be easily created only by wiring, without programming and

settings.

Since an inspection on programming by safety certification organization is

unnecessary, the man-hour taken for obtaining the safety approval can be

omitted.

(b) Extension of safety circuit with extension module

By connecting extension safety relay modules, maximum 4 points of safety input

and maximum 4 points of safety output can be controlled.

(c) Safety control can be performed by itself.

Since a communication circuit for Q series programmable controller and CC-Link

is separated from a circuit for achieving the safety function, the safety relay

module can perform safety control by itself, independent of a failure of the Q

series programmable controller or CC-Link communication status.

(6) Fail safe

Fail safe can be achieved by inhibiting the safety relay module from starting when an

error occurs in safety input, start-up input, and/or internal circuit of the safety relay

module.

(7) Improvement of efficiency in wiring work

Using spring clamp terminal block allows to skip screw tightening work and to reduce

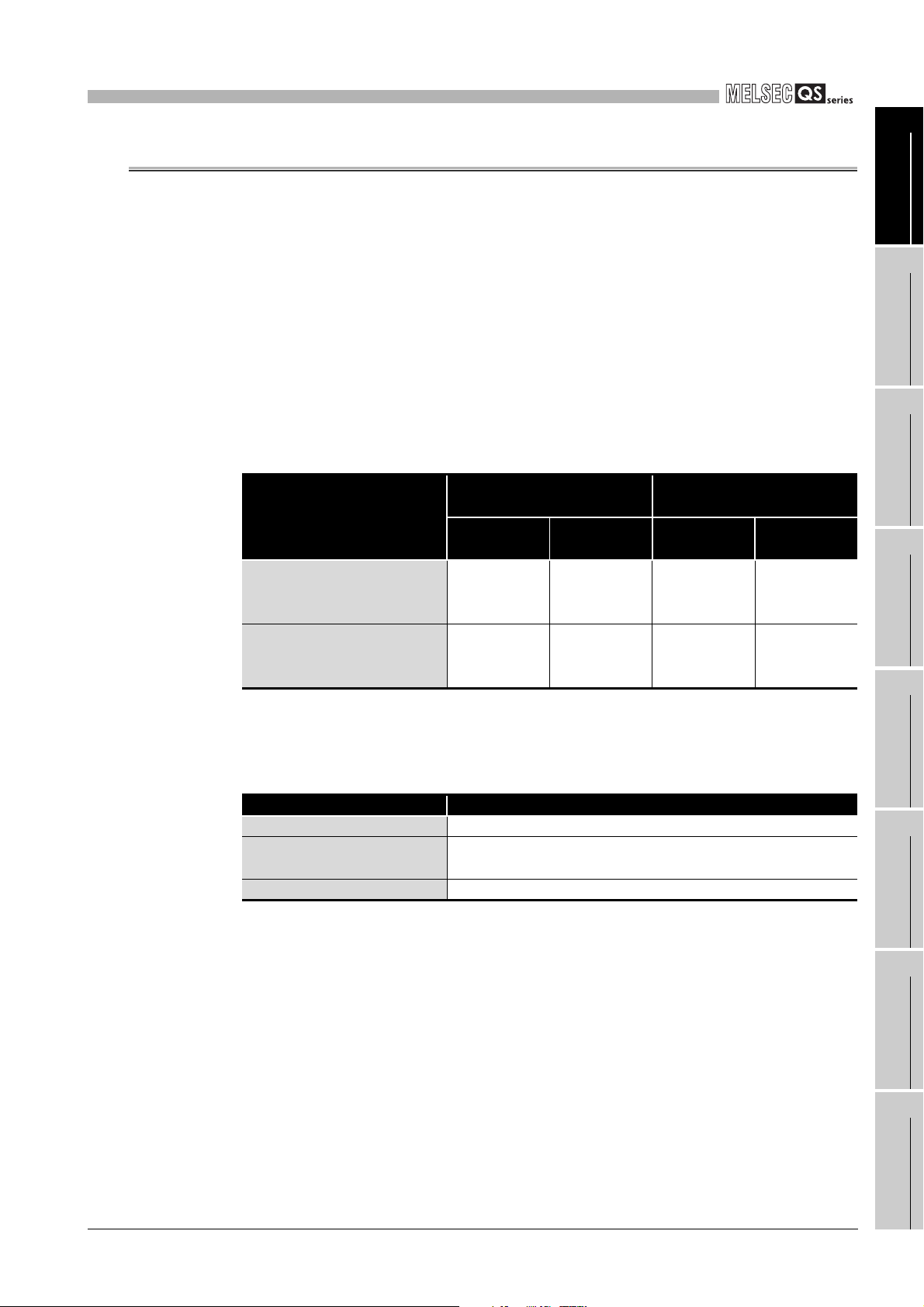

wiring work significantly.

(8) Connector insertion check

Using terminal block cover for connector insertion check prevents poor connection. If

the terminal block is not inserted securely, the terminal block cover does not close.

Figure 1.2 Terminal block cover

1 - 4

1.3 Features

Page 21

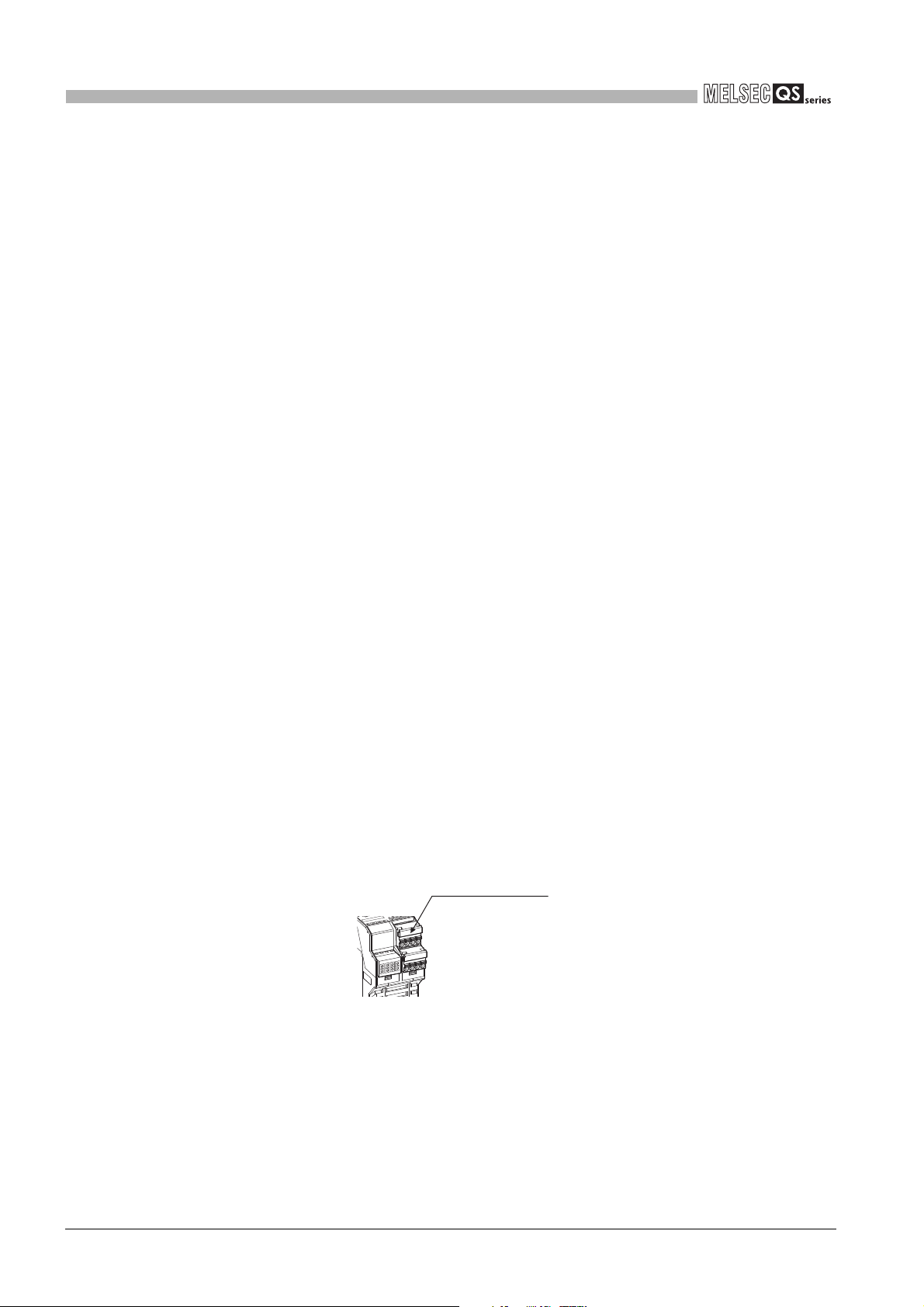

1

N: Input N type (dual input with positive common and negative common)

P: Input P type (dual input with positive commons)

EX: For extension

-

CC: For CC-Link

Q: For Q series

QS90SR2S P Q

OVERVIEW

1.4 Checking the Safety Relay Module Model

This section explains how to check the safety relay module model.

Figure 1.3 Checking the safety relay module model

1

2

3

4

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

SETTINGS AND

5

PROCEDURES BEFORE

6

FUNCTIONS

OPERATION

TROUBLESHOOTINGAPPENDIX

1.4 Checking the Safety Relay Module Model

1 - 5

Page 22

2

Power supply module

CPU module

Q series safety relay

module

Master station

Extension

safety

relay module

Extension

safety

relay module

Extension

safety

relay module

Extension

safety

relay module

Extension

safety

relay module

Extension

safety

relay module

Extension

safety

relay module

Remote I/O

station

CC-Link safety

relay module

CC-Link safety

relay module

Safety part

Communication part

Safety part

Communication part

SYSTEM CONFIGURATION

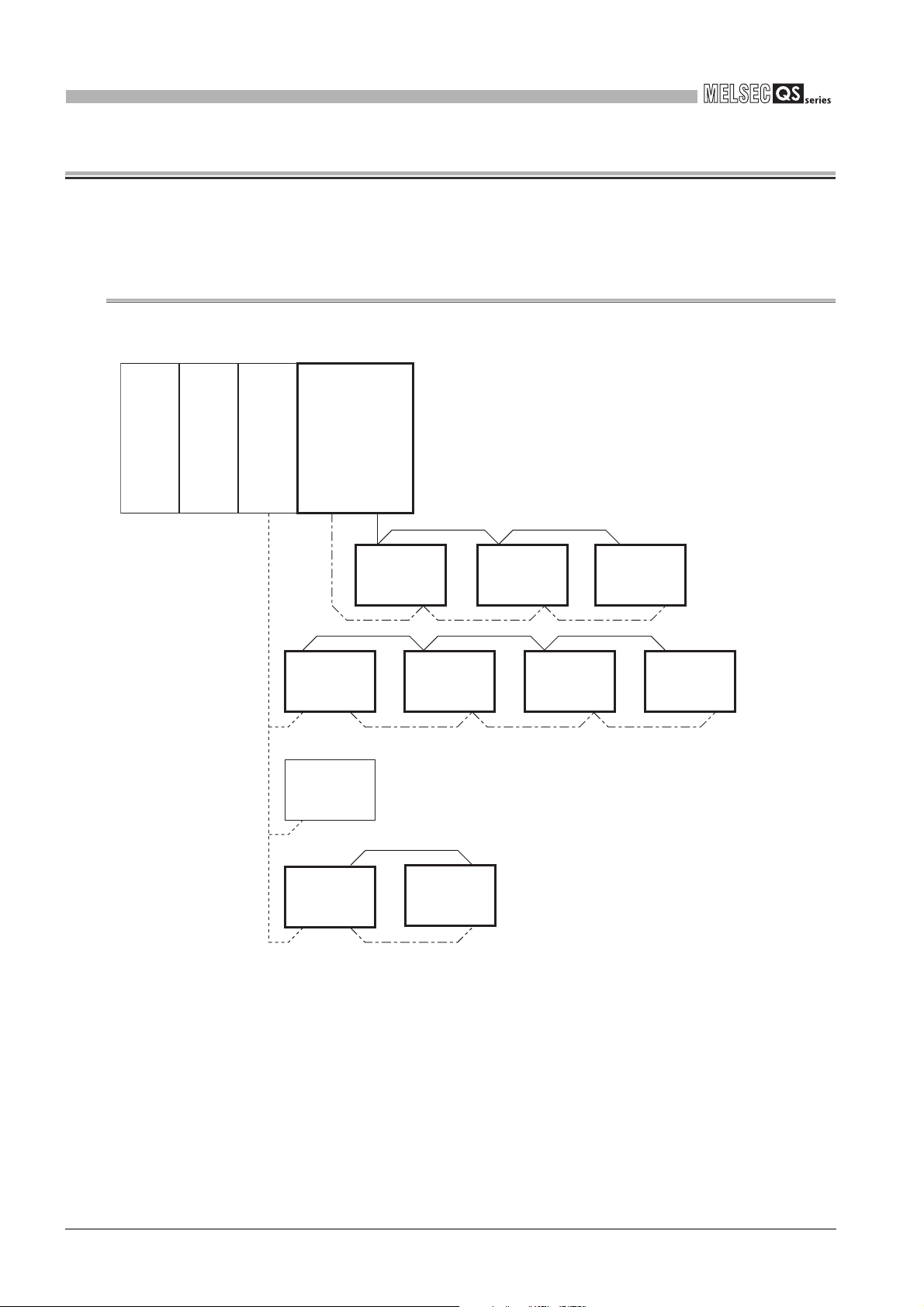

CHAPTER 2 SYSTEM CONFIGURATION

This chapter explains the system configuration, precautions for use, and system

equipment of the safety relay module.

2.1 System Configuration

Figure 2.1 shows system configuration using the safety relay module.

Figure 2.1 System configuration

2 - 1

2.1 System Configuration

Page 23

2

SYSTEM CONFIGURATION

2.2 Applicable Systems

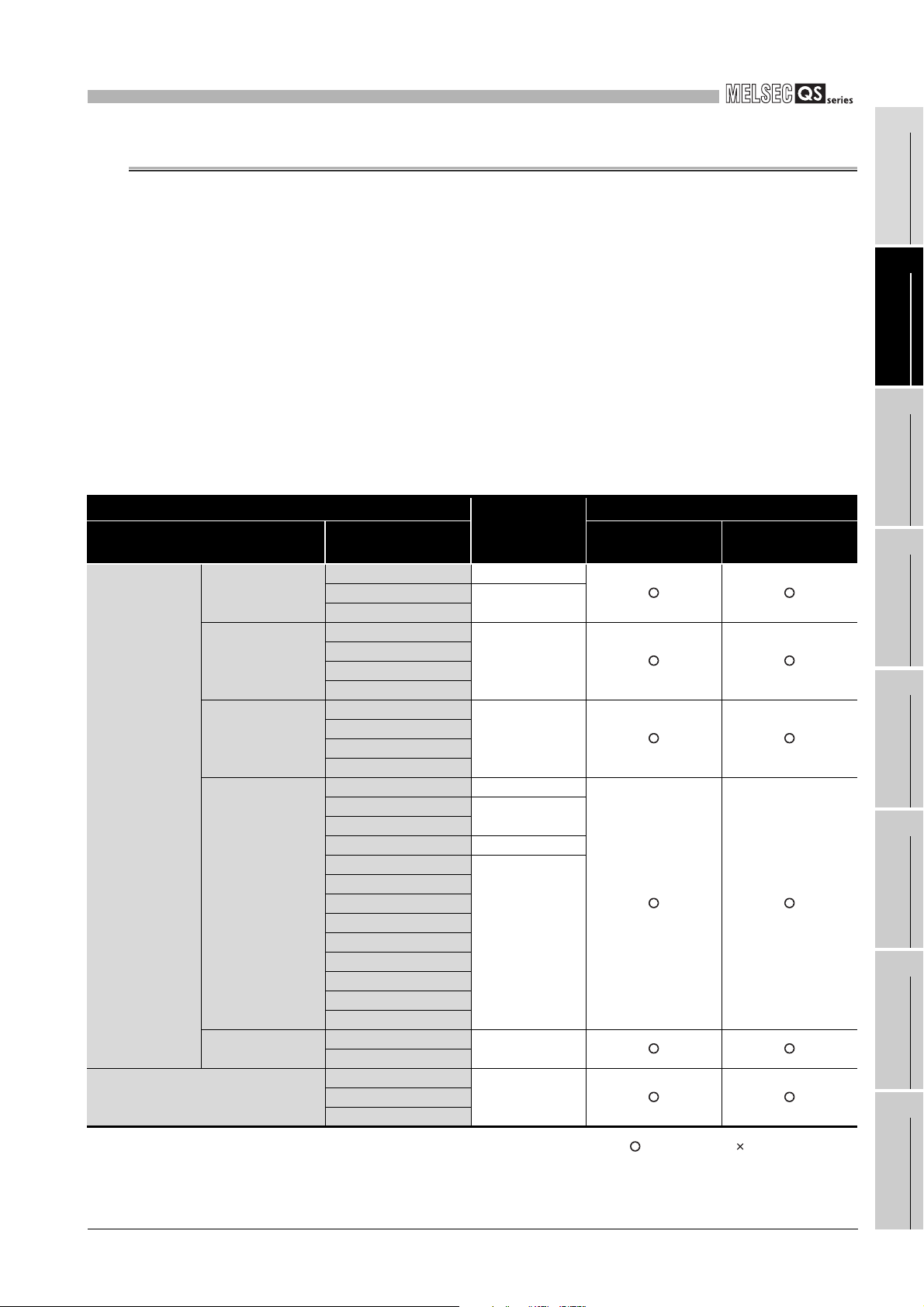

(1) Mountable modules, the number of mountable modules, and mountable base

units

(a) Q series safety relay module

1) When mounting to CPU module

Table 2.1 Applicable modules and the number of mountable modules

Mountable CPU module

CPU type CPU model Main base unit

Basic model QCPU

High Performance

model QCPU

Process CPU

Programmable

controller CPU

Universal model

QCPU

Redundant CPU

C Controller module

The following table shows the mountable CPU modules, the number of

mountable modules, and mountable base units of the Q series safety relay

module.

Shortage of power capacity may occur depending on the combination with

other mounted modules or the number of mounted modules.

When mounting modules, pay attention to the power capacity.

When shortage of power capacity occurs, review the combination of modules

to be mounted.

Number of

mountable

modules

Q00JCPU Up to 8

Q00CPU

Q01CPU

Q02(H)CPU

Q06HCPU

Q12HCPU

Q25HCPU

Q02PHCPU

Q06PHCPU

Q12PHCPU

Q25PHCPU

Q00UJCPU Up to 8

Q00UCPU

Q01UCPU

Q02UCPU Up to 18

Q03UD(E)CPU

Q04UD(E)HCPU

Q06UD(E)HCPU

Q10UD(E)HCPU

Q13UD(E)HCPU

Q20UD(E)HCPU

Q26UD(E)HCPU

Q50UDEHCPU

Q100UDEHCPU

Q12PRHCPU

Q25PRHCPU

Q06CCPU-V

Q06CCPU-V-B

Q12DCCPU-V

Up to 12

Up to 32

Up to 32

Up to 12

Up to 32

Up to 31

Up to 32

Mountable base unit

*1

*2

Extension base

unit

SETTINGS AND

1

2

SYSTEM

3

4

5

PROCEDURES BEFORE

6

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

OPERATION

TROUBLESHOOTINGAPPENDIX

: Mountable, : Not mountable

* 1: Limited within the range of the number of I/O points for the CPU module.

* 2: Mountable on any I/O slots of the mountable base unit.

2.2 Applicable Systems

2 - 2

Page 24

2

SYSTEM CONFIGURATION

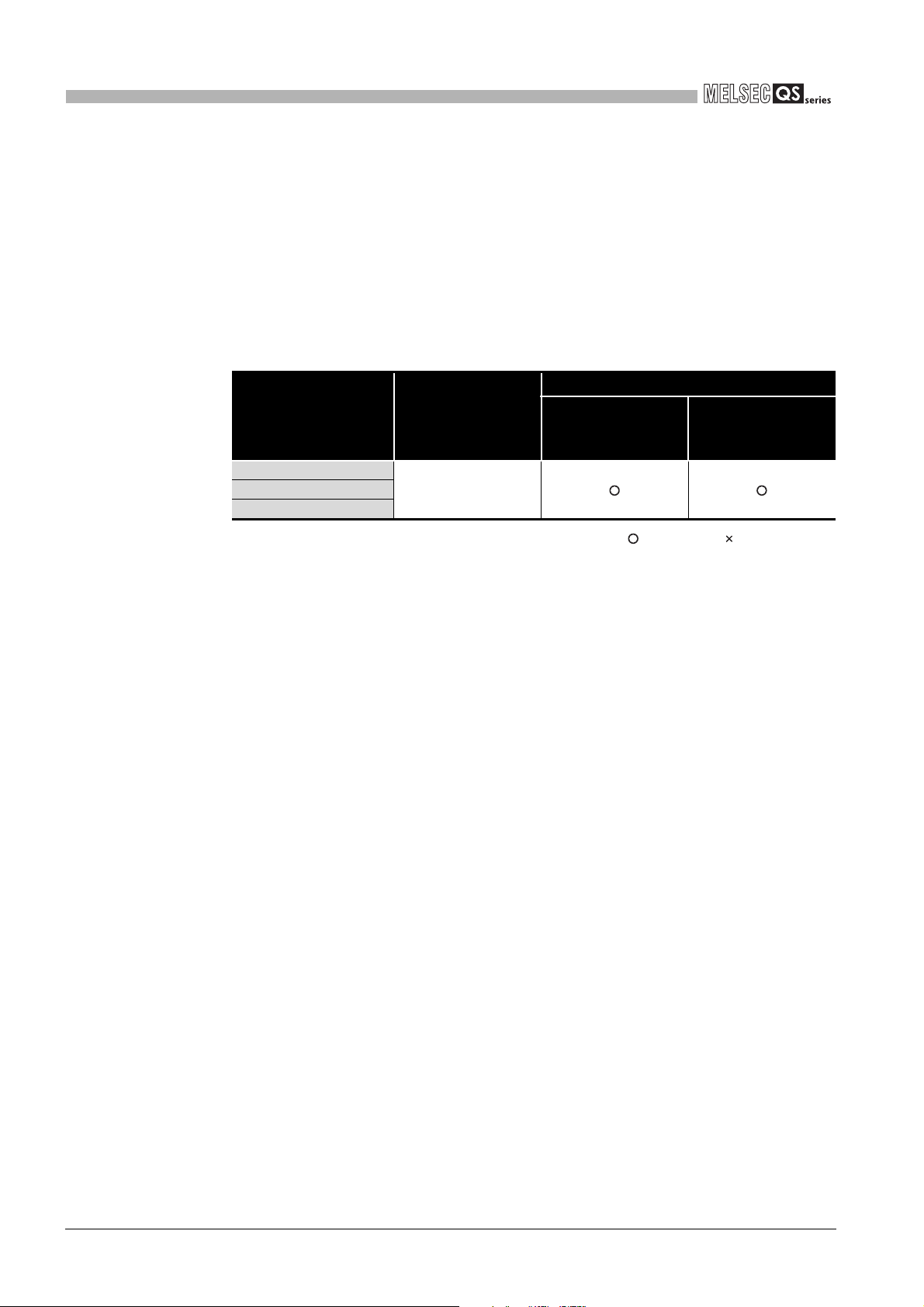

2) When mounting to remote I/O station in MELSECNET/H connection

The following table shows the mountable network modules, the number of

mountable modules, and mountable base units of the Q series safety relay

module.

Shortage of power capacity may occur depending on the combination with

other mounted modules or the number of mounted modules.

When mounting modules, pay attention to the power capacity.

When shortage of power capacity occurs, review the combination of modules

to be mounted.

Table 2.2 Network modules and the number of mountable modules

Mountable network

module

QJ72LP25-25

QJ72LP25G

QJ72BR15

Up to 32

Number of

mountable

modules

*1

Mountable base unit

Main base unit on

remote I/O station

*2

Extension base unit

on remote I/O

station

: Mountable, : Not mountable

* 1: Limited within the range of the number of I/O points for the network module.

* 2: Mountable on any I/O slots of the mountable base unit.

(b) CC-Link safety relay module

The CC-Link safety relay module is used as remote I/O station.

For system configuration of the CC-Link system, refer to the Control &

Communication Link System Master/Local Module User's Manual.

(c) Extension safety relay module

Up to three extension safety relay modules can be added to a Q series safety

relay module or CC-Link safety relay module.

For extension method, refer to Section 5.3.

2 - 3

2.2 Applicable Systems

Page 25

2

SYSTEM CONFIGURATION

2.3 Module Replacement

Replace the product according to the replacement cycle shown in the table below.

1

Module Module replacement cycle

Q series/CC-Link/Extension safety relay module 10 years

2.4 Precautions for Use

Users must prove that their entire safety system complies with the safety standards and

the Machinery Directive. The third-party certification organization will validate the safety of

product for the entire safety system, including a safety relay module and safety

components.

To establish a safety system, calculate the target performance level (PL) for each safety

application (safety function) based on the MTTFd and DCavg values of the safety relay

module and connected safety components. The calculation equation is shown in

ISO13849-1:2006.

MTTFd and DCavg of the safety relay module are shown in following.

Table 2.4 MTTFd and DCavg of the safety relay module

Module MTTFd DCavg

Safety relay module >100 years 99%

Table 2.3 Module replacement cycle

2

3

4

5

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

2.3 Module Replacement

SETTINGS AND

PROCEDURES BEFORE

OPERATION

6

TROUBLESHOOTINGAPPENDIX

2 - 4

Page 26

3

SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

3.1 General Specifications

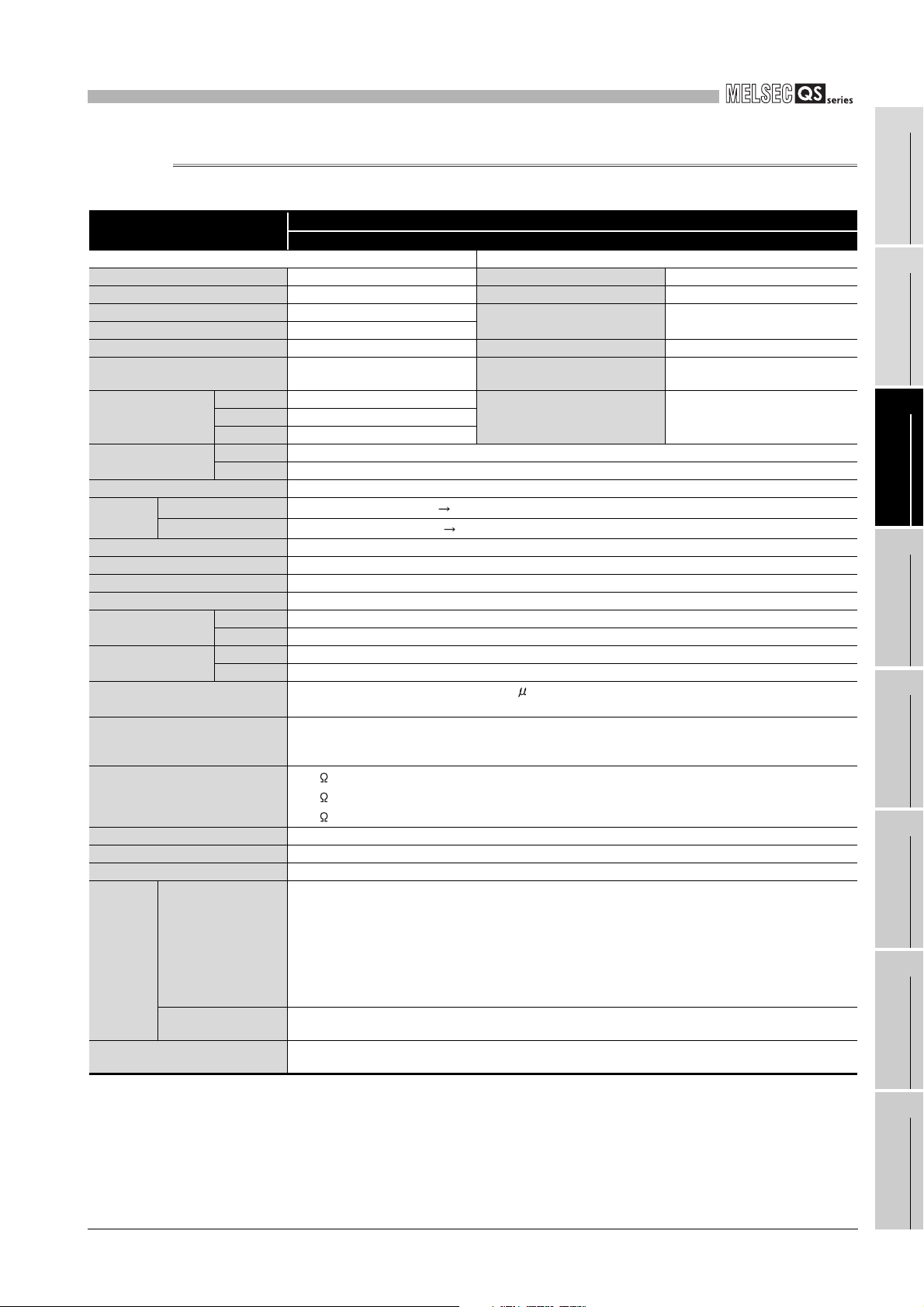

Table 3.1 shows the general specifications of the safety relay module.

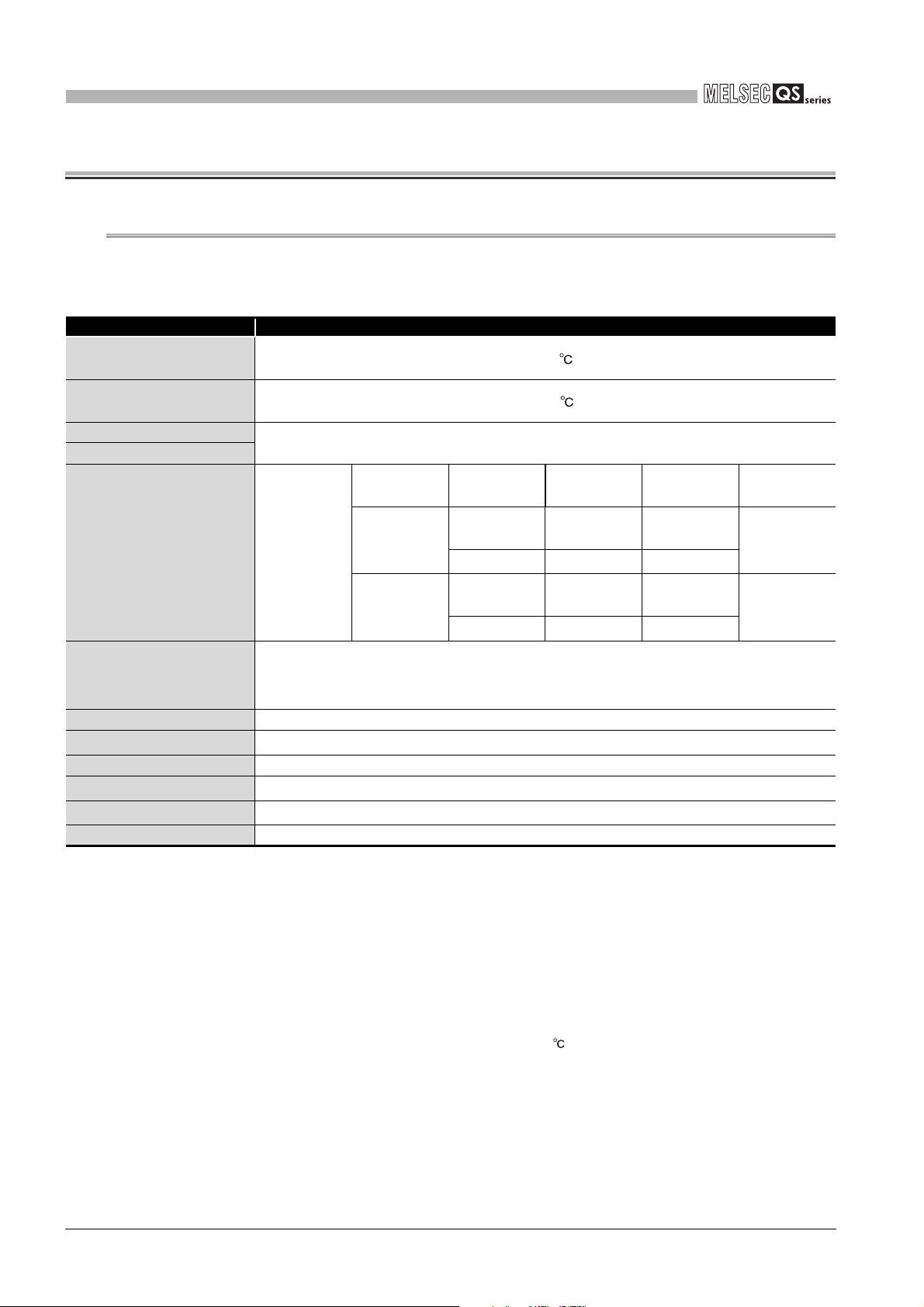

Table 3.1 General specifications

Item Specifications

Operating ambient

temperature

Storage ambient

temperature

Operating ambient humidity

Storage ambient humidity

JIS B 3502,

Vibration resistance

Shock resistance

Operating ambience No corrosive gases

Operating altitude

Installation location Inside of control panel of IP standard 54 or more

Overvoltage category

Pollution degree

Equipment class Class I

*4

*1

*2

IEC 61131-2

compliant

2

(147m/s

, duration of action 11ms, 3 times each in 3 directions X, Y, Z by sine half-wave

Under

intermittent

vibration

Under

continuous

vibration

30 to 85%RH, non-condensing

Frequency

5 to 8.4Hz -

8.4 to 150Hz

5 to 8.4Hz -

8.4 to 150Hz

JIS B 3502, IEC 61131-2 compliant

0 to 55

-25 to 75

acceleration

pulse)

0 to 2000m

III or less

2 or less

*3

Constant

2

9.8m/s

2

4.9m/s

amplitude

3.5mm

(0.14inch)

1.75mm

(0.069inch)

Half

-

-

Sweep count

10 times each

in X, Y, Z

directions

-

3 - 1

* 1: This indicates the section of the power supply to which the equipment is assumed to be

connected between the public electrical power distribution network and the machinery within the

premises.

Category III applies to devices in fixed equipment such as a switching device and industrial

machine.

The surge voltage withstand level of equipment for up to the rated voltage of 300V is 4000V.

* 2: This index indicates the degree to which a conductive material is generated in the environment

where the equipment is used.

Pollution degree 2 is when only non-conductive pollution occurs. However, temporary conductivity

may be produced due to incidental condensation.

* 3: The storage ambient temperature is -20 to 75 if the system includes any CC-Link safety relay

modules or extension safety relay modules.

* 4: Do not use or store the programmable controller under pressure higher than the atmospheric

pressure of altitude 0m.

Doing so may cause a malfunction.

When using the programmable controller under pressure, please contact your local Mitsubishi

office.

3.1 General Specifications

Page 27

3

SPECIFICATIONS

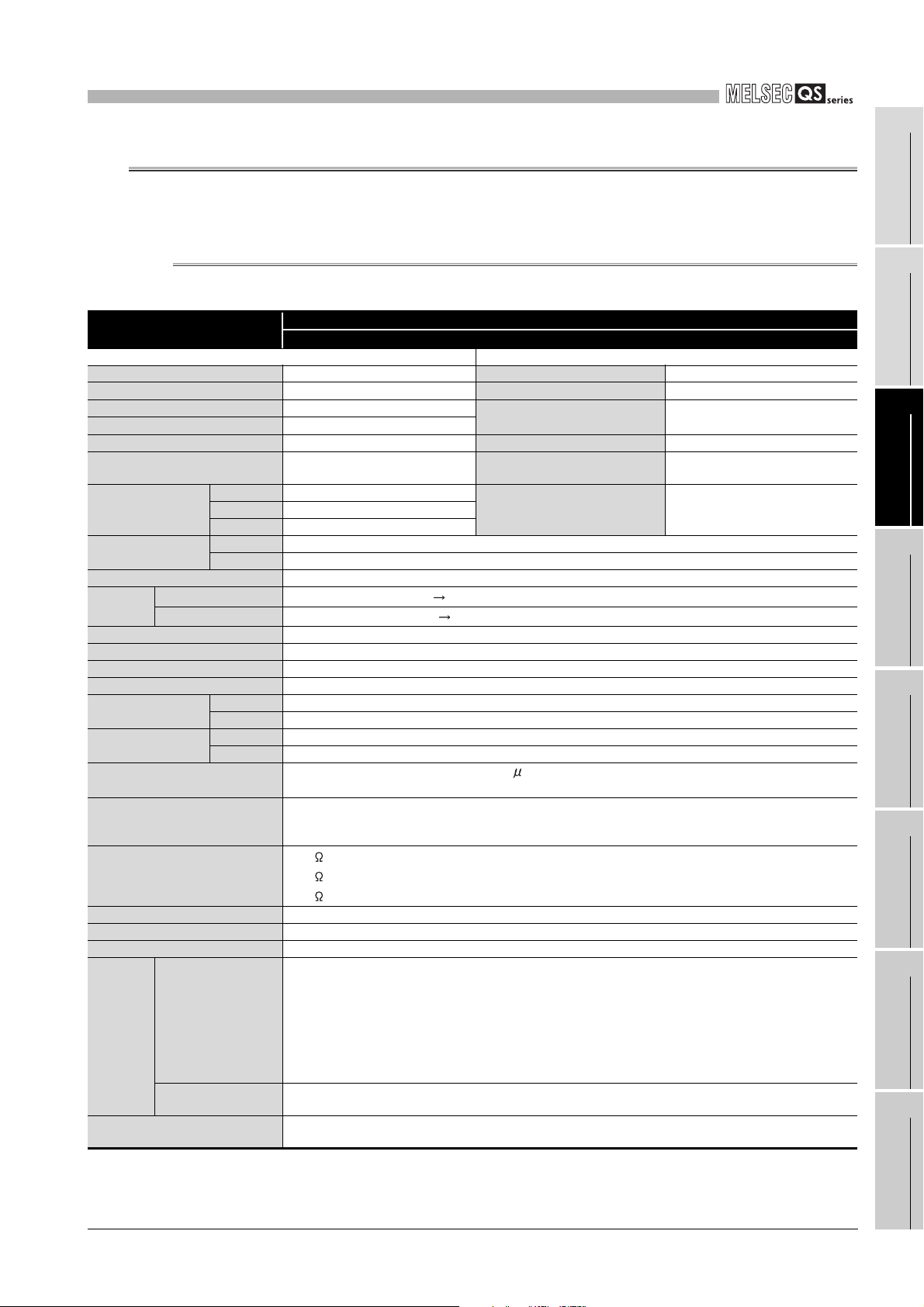

3.2 Q Series Safety Relay Module Specifications

This section explains the specifications of the Q series safety relay module.

1

3.2.1 QS90SR2SP-Q Q series safety relay module

Table 3.2 Performance specifications of QS90SR2SP-Q (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current 4.6mA (300mA at relay start-up) Minimum switching load 5VDC/5mA

Operating voltage range 20.4 to 26.4VDC

Typ e P typ e

Input format

X1 Positive common

Relay life

Maximum switching frequency 1,200 times/hour based on the rated control capacity

Response

time

Common wiring method All safety inputs and safety outputs are independent.

Number of extension modules Up to three extension safety relay modules can be connected.

Number of occupied I/O points 32 points, 2 slots (I/O assignment: Input)

Internal current consumption (5VDC) 0.09A

Module power supply

Safety power supply

Noise durability

Dielectric withstand voltage

Insulation resistance

Level of protection IP1X

Weight 0.37kg

External connection method Two-piece spring clamp terminal block

Applicable

wire size

Applicable solderless terminal (bar

terminal)

Time until output ON

Time until output OFF

Safety input part

Start-up input part

Safety power supply part

Module power supply

part

Extension

communication part

terminal block

Safety output part

terminal block

Mechanical Five million times or more

Electrical Hundred thousand times or more

50ms or less (safety input ON safety output ON)

20ms or less (safety input OFF safety output OFF)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 35mA (when not using extension module), 110mA (when using three extension modules)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 85mA (when not using extension module), 325mA (when using three extension modules)

DC type noise voltage: 500Vp-p, noise width: 1 s,

noise frequency: 25 to 60Hz (noise simulator condition)

2,500VAC/1mA or less for 1 minute between safety outputs

2,500VAC/1mA or less for 1 minute between safety input and safety output

2,500VAC/1mA or less for 1 minute between power supply and safety output

100M or more, measured with a 500VDC insulation resistance tester between safety outputs

100M or more, measured with a 500VDC insulation resistance tester between safety input and safety output

100M or more, measured with a 500VDC insulation resistance tester between power supply and safety output

AWG: 24 to 18, 0.2 to 0.75mm

AWG: 24 to 14, 0.2 to 2.5mm

Refer to Section 5.4.

2

2

Q series safety relay module

QS90SR2SP-Q

Rated load current

Maximum allowable voltage of

contact

Resistance load 250VAC/5A, 30VDC/5AX0 Positive common

*2

Category 3: 5.0A/point or less

Category 4: 3.6A/point or less

250VAC, 30VDC

OVERVIEW

2

SYSTEM

CONFIGURATION

3

*1

SPECIFICATIONS

4

FUNCTIONS

5

SETTINGS AND

PROCEDURES BEFORE

OPERATION

6

TROUBLESHOOTINGAPPENDIX

* 1: Category 4 is complied only when connecting a light curtain of Type 4.

* 2: Manual operation such as start-up switch operation is excluded.

3.2 Q Series Safety Relay Module Specifications

3.2.1 QS90SR2SP-Q Q series safety relay module

3 - 2

Page 28

3

Safety relay

Z21

M

Z20

Z11

Z10

Z01

MC0

MC1

Z00

Motor

EP

SLD

EG

EB

EA

COM1

X1

X0

24G

(SAFETY)

+24V

(SAFETY)

24VDC (Safety

power supply)

24VDC (Module

power supply)

COM0

24V IN

0V IN

Control

output 2

Control

output 1

XS1

XS0

MC0

MC1

Start-up

switch

24G

+24V

FG

K1K0

Internal

safety circuit

24VDC

TH

0.9A

Fuse

5A

TH

0.9A

Fuse

5A

Monitor

circuit

Q bus

I/F

circuit

GND

DC/DC

Safety light curtain

OUT

Safety circuit part

extension cable

or

safety part terminating

connector

Connected to an

extension module

SPECIFICATIONS

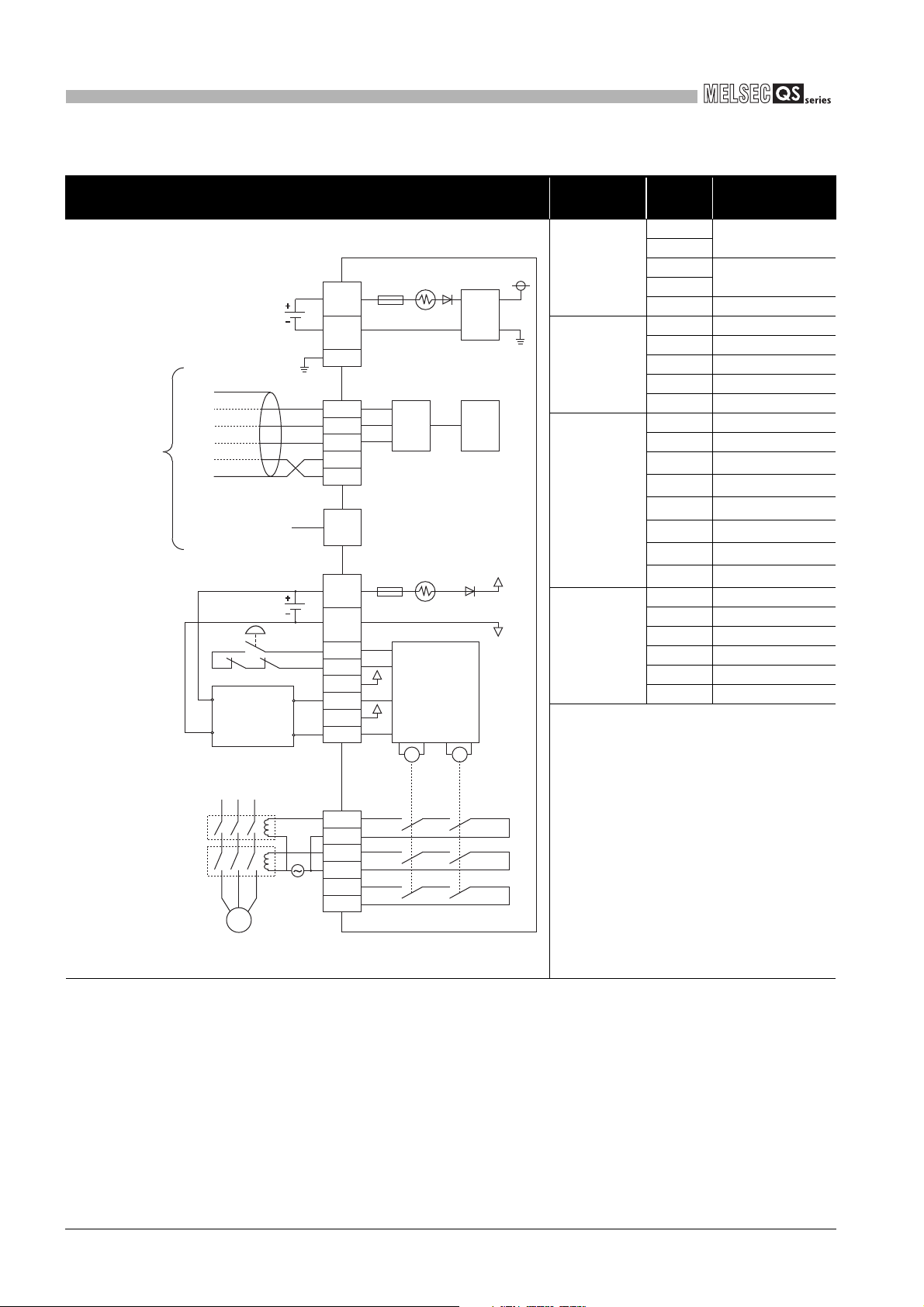

Table 3.2 Performance specifications of QS90SR2SP-Q (2/2)

External connection diagram Connector

Module power

supply part

Extension

communication

part

Safety input

part

Safety output

part

Pin

number

1

2

3

4

Signal name

+24V

24G

5FG

1EA

2EB

3EG

4SLD

5EP

1 +24V (SAFETY)

2 24G (SAFETY)

XS0

XS1

COM0

*4

X0

COM1

*4

X1

*3*4

*3*4

3

4

5

6

7

8

1Z00

2Z01

3Z10

4Z11

5Z20

6Z21

*5

*6

3 - 3

3.2 Q Series Safety Relay Module Specifications

3.2.1 QS90SR2SP-Q Q series safety relay module

* 3: When connecting an electromagnetic switch and such for output, connect its normally closed

contacts in series between XS0 and XS1.

* 4: Do not connect equipment other than a switch or sensor to each terminal of X0, X1, XS0, and XS1.

* 5: Common terminals for X0 and X1 differ. Connect X0 to COM0.

* 6: Common terminals for X0 and X1 differ. Connect X1 to COM1.

Page 29

3

SPECIFICATIONS

3.2.2 QS90SR2SN-Q Q series safety relay module

Table 3.3 Performance specifications of QS90SR2SN-Q (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current 4.6mA (300mA at relay start-up) Minimum switching load 5VDC/5mA

Operating voltage range 20.4 to 26.4VDC

Type N type

Input format

X1 Negative common

Relay life

Maximum switching frequency 1,200 times/hour based on the rated control capacity

Response

time

Common wiring method All safety inputs and safety outputs are independent.

Number of extension modules Up to three extension safety relay modules can be connected.

Number of occupied I/O points 32 points, 2 slots (I/O assignment: Input)

Internal current consumption (5VDC) 0.09A

Module power supply

Safety power supply

Noise durability

Dielectric withstand voltage

Insulation resistance

Level of protection IP1X

Weight 0.37kg

External connection method Two-piece spring clamp terminal block

Applicable

wire size

Applicable solderless terminal (bar

terminal)

Time until output ON

Time until output OFF

Safety input part

Start-up input part

Safety power supply part

Module power supply

part

Extension

communication part

terminal block

Safety output part

terminal block

Mechanical Five million times or more

Electrical Hundred thousand times or more

50ms or less (safety input ON safety output ON)

20ms or less (safety input OFF safety output OFF)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 35mA (when not using extension module), 110mA (when using three extension modules)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 85mA (when not using extension module), 325mA (when using three extension modules)

DC type noise voltage: 500Vp-p, noise width: 1 s,

noise frequency: 25 to 60Hz (noise simulator condition)

2,500VAC/1mA or less for 1 minute between safety outputs

2,500VAC/1mA or less for 1 minute between safety input and safety output

2,500VAC/1mA or less for 1 minute between power supply and safety output

100M or more, measured with a 500VDC insulation resistance tester between safety outputs

100M or more, measured with a 500VDC insulation resistance tester between safety input and safety output

100M or more, measured with a 500VDC insulation resistance tester between power supply and safety output

AWG: 24 to 18, 0.2 to 0.75mm

AWG: 24 to 14, 0.2 to 2.5mm

Refer to Section 5.4.

2

2

Q series safety relay module

QS90SR2SN-Q

Rated load current

Maximum allowable voltage of

contact

Resistance load 250VAC/5A, 30VDC/5AX0 Positive common

*1

Category 4: 3.6A/point or less

(Category 3: 5.0A/point or less)

250VAC, 30VDC

SETTINGS AND

1

2

SYSTEM

3

4

5

PROCEDURES BEFORE

6

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

OPERATION

TROUBLESHOOTINGAPPENDIX

* 1: Manual operation such as start-up switch operation is excluded.

3.2 Q Series Safety Relay Module Specifications

3.2.2 QS90SR2SN-Q Q series safety relay module

3 - 4

Page 30

3

Safety relay

Z21

M

Z20

Z11

Z10

Z01

MC0

MC1

Z00

Motor

EP

SLD

EG

EB

EA

COM1

X1

X0

24G

(SAFETY)

+24V

(SAFETY)

24VDC (Module

power supply)

COM0

XS1

XS0

MC0

MC1

Start-up

switch

24G

+24V

FG

K1K0

Internal

safety circuit

24VDC

TH

0.9A

Fuse

5A

TH

0.9A

Fuse

5A

Monitor

circuit

Q bus

I/F

circuit

GND

DC/DC

Safety door

Open

24VDC (Safety

power supply)

Safety

limit switch

OUT

Safety circuit part

extension cable

or

safety part terminating

connector

Connected to an

extension module

SPECIFICATIONS

Table 3.3 Performance specifications of QS90SR2SN-Q (2/2)

External connection diagram Connector

Module power

supply part

Extension

communication

part

Safety input

part

Safety output

part

Pin

number

1

2

3

4

Signal name

+24V

24G

5FG

1EA

2EB

3EG

4SLD

5EP

1 +24V (SAFETY)

2 24G (SAFETY)

XS0

XS1

COM0

*3

X0

COM1

*3

X1

*2*3

*2*3

3

4

5

6

7

8

1Z00

2Z01

3Z10

4Z11

5Z20

6Z21

*4

*5

* 2: When connecting an electromagnetic switch and such for output, connect its normally closed

contacts in series between XS0 and XS1.

* 3: Do not connect equipment other than a switch or sensor to each terminal of X0, X1, XS0, and XS1.

* 4: Common terminals for X0 and X1 differ. Connect X0 to COM0.

* 5: Common terminals for X0 and X1 differ. Connect X1 to COM1.

3 - 5

3.2 Q Series Safety Relay Module Specifications

3.2.2 QS90SR2SN-Q Q series safety relay module

Page 31

3

SPECIFICATIONS

3.3 CC-Link Safety Relay Module Specifications

This section explains the specifications of the CC-Link safety relay module.

1

3.3.1 QS90SR2SP-CC CC-Link safety relay module

Table 3.4 Performance specifications of QS90SR2SP-CC (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current

Operating voltage range 20.4 to 26.4VDC Maximum allowable voltage of contact 250VAC, 30VDC

Type P type

Input format

X1 Positive common

Relay life

Maximum switching frequency 1,200 times/hour based on the rated control capacity

Response

time

Common wiring method All safety inputs and safety outputs are independent.

Number of extension modules Up to three extension safety relay modules can be connected.

Number of occupied stations 32-point assigned per station (32 points used)

Module power supply

Safety power supply

Noise durability

Dielectric withstand voltage

Insulation resistance

Level of protection IP1X

Weight 0.37kg

External connection method Two-piece spring clamp terminal block

Applicable

wire size

Applicable solderless terminal (bar terminal) Refer to Section 5.4.

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (JIS C 2812 compliant)

Time until output ON

Time until output OFF

Safety input part

Start-up input part

Safety power supply part

Module power supply part

Safety output part terminal block

CC-Link part

Extension communication part

terminal block

Mechanical Five million times or more

Electrical Hundred thousand times or more

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 70mA (when not using extension module), 145mA (when using three extension modules)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 85mA (when not using extension module), 325mA (when using three extension modules)

4.6mA (300mA at relay startup)

50ms or less (safety input ON safety output ON)

20ms or less (safety input OFF safety output OFF)

DC type noise voltage: 500Vp-p, noise width: 1 s,

noise frequency: 25 to 60Hz (noise simulator condition)

2,500VAC/1mA or less for 1 minute between safety outputs

2,500VAC/1mA or less for 1 minute between safety input and safety output

2,500VAC/1mA or less for 1 minute between power supply and safety output

100M or more, measured with a 500VDC insulation resistance tester between safety outputs

100M or more, measured with a 500VDC insulation resistance tester between safety input and safety

output

100M or more, measured with a 500VDC insulation resistance tester between power supply and safety

output

AWG: 24 to 14, 0.2 to 2.5mm

AWG: 24 to 16, 0.2 to 1.25mm

CC-Link safety relay module

QS90SR2SP-CC

Rated load current

Minimum switching load 5VDC/5mA

Resistance load 250VAC/5A, 30VDC/5AX0 Positive common

*2

2

2

Category 3: 5.0A/point or less

Category 4: 3.6A/point or less

OVERVIEW

2

SYSTEM

CONFIGURATION

3

*1

SPECIFICATIONS

4

FUNCTIONS

5

SETTINGS AND

PROCEDURES BEFORE

OPERATION

6

TROUBLESHOOTINGAPPENDIX

* 1: Category 4 is complied only when connecting a light curtain of Type 4.

* 2: Manual operation such as start-up switch operation is excluded.

3.3 CC-Link Safety Relay Module Specifications

3.3.1 QS90SR2SP-CC CC-Link safety relay module

3 - 6

Page 32

Safety relay

Z21

M

Z20

Z11

Z10

Z01

MC0

MC1

Z00

Motor

EP

EG

EB

EA

COM(X1)

X1

X0

24G

(SAFETY)

+24V

(SAFETY)

24VDC (Safety

power supply)

24VDC (Module

power supply)

COM(X0)

24V IN

0V IN

Control

output 2

Control

output 1

XS1

XS0

MC0

MC1

Start-up

switch

24G

+24V

K1K0

Internal

safety circuit

24VDC

TH

0.9A

Fuse

5A

TH

0.9A

Fuse

5A

Monitor

circuit

GND

DC/DC

SLD

DG

DB

DA

CC-Link

circuit

Safety light curtain

OUT

Safety circuit part

extension cable

or

safety part terminating

connector

Connected to an

extension module

COM(X0) COM(X1)

3

SPECIFICATIONS

Table 3.4 Performance specifications of QS90SR2SP-CC (2/2)

External connection diagram Connector

Module power

supply part

CC-Link part

Extension

communication

part

Safety power

supply, start-up

input part

Safety input

part

Safety output

part 1

Safety output

part 2

Pin

number

1

2

3

4

Signal name

+24V

24G

1DA

2DB

3DG

4SLD

1EA

2EB

3EG

4EP

XS0

XS1

*3*4

*3*4

1

2

3 +24V (SAFETY)

4 24G (SAFETY)

1

COM(X0)

2

3

4

*4

X0

COM(X1)

*4

X1

1Empty

2Z00

3Z10

4Z20

1Empty

2Z01

3Z11

4Z21

*5

*5

3 - 7

3.3 CC-Link Safety Relay Module Specifications

3.3.1 QS90SR2SP-CC CC-Link safety relay module

* 3: When connecting an electromagnetic switch and such for output, connect its normally closed

contacts in series between XS0 and XS1.

* 4: Do not connect equipment other than a switch or sensor to each terminal of X0, X1, XS0, and XS1.

* 5: Common terminals for X0 and X1 differ. Pay attention to the printing on the module at wiring. In the

external connection diagram, they are represented as COM (X0) and COM (X1).

Page 33

3

SPECIFICATIONS

3.3.2 QS90SR2SN-CC CC-Link safety relay module

Table 3.5 Performance specifications of QS90SR2SN-CC (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current 4.6mA (300mA at relay start-up) Minimum switching load 5VDC/5mA

Operating voltage range 20.4 to 26.4VDC

Type N type

Input format

X1 Negative common

Relay life

Maximum switching frequency 1,200 times/hour based on the rated control capacity

Response time

Common wiring method All safety inputs and safety outputs are independent.

Number of extension modules Up to three extension safety relay modules can be connected.

Number of occupied stations 32-point assigned per station (32 points used)

Module power supply

Safety power supply

Noise durability

Dielectric withstand voltage

Insulation resistance

Level of protection IP1X

Weight 0.37kg

External connection method Two-piece spring clamp terminal block

Applicable wire

size

Applicable solderless terminal (bar terminal) Refer to Section 5.4.

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (JIS C 2812 compliant)

Time until output ON

Time until output OFF

Safety input part

Start-up input part

Safety power supply part

Module power supply part

Safety output part terminal

block

CC-Link part

Extension communication part

terminal block

Mechanical Five million times or more

Electrical Hundred thousand times or more

50ms or less (safety input ON safety output ON)

20ms or less (safety input OFF safety output OFF)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 70mA (when not using extension module), 145mA (when using three extension modules)

Voltage 24VDC (ripple ratio: within 5%) (allowable voltage range: 20.4 to 26.4VDC)

Current 85mA (when not using extension module), 325mA (when using three extension modules)

DC type noise voltage: 500Vp-p, noise width: 1 s,

noise frequency: 25 to 60Hz (noise simulator condition)

2,500VAC/1mA or less for 1 minute between safety outputs

2,500VAC/1mA or less for 1 minute between safety input and safety output

2,500VAC/1mA or less for 1 minute between power supply and safety output

100M or more, measured with a 500VDC insulation resistance tester between safety outputs

100M or more, measured with a 500VDC insulation resistance tester between safety input and safety

output

100M or more, measured with a 500VDC insulation resistance tester between power supply and safety

output

AWG: 24 to 14, 0.2 to 2.5mm

AWG: 24 to 16, 0.2 to 1.25mm

CC-Link safety relay module

QS90SR2SN-CC

Rated load current

Maximum allowable voltage of

contact

Resistance load 250VAC/5A, 30VDC/5AX0 Positive common

*1

2

2

Category 4: 3.6A/point or less

(Category 3: 5.0A/point or less)

250VAC, 30VDC

SETTINGS AND

1

2

SYSTEM

3

4

5

PROCEDURES BEFORE

6

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

OPERATION

TROUBLESHOOTINGAPPENDIX

* 1: Manual operation such as start-up switch operation is excluded.

3.3 CC-Link Safety Relay Module Specifications

3.3.2 QS90SR2SN-CC CC-Link safety relay module

3 - 8

Page 34

Safety relay

Z21

M

Z20

Z11

Z10

Z01

MC0

MC1

Z00

Motor

COM(X1)

X1

X0

24G

(SAFETY)

+24V

(SAFETY)

COM(X0)

XS1

XS0

MC0

MC1

Start-up

switch

K1K0

Internal

safety circuit

24VDC

TH

0.9A

Fuse

5A

GND

Safety door

Open

24VDC (Safety

power supply)

Safety

limit switch

EP

EG

EB

EA

24VDC (Module

power supply)

24G

+24V

TH

0.9A

Fuse

5A

Monitor

circuit

DC/DC

SLD

DG

DB

DA

CC-Link

circuit

OUT

Safety circuit part

extension cable

or

safety part terminating

connector

Connected to an

extension module

3

SPECIFICATIONS

Table 3.5 Performance specifications of QS90SR2SN-CC (2/2)

External connection diagram Connector

Module power

supply part

CC-Link part

Extension

communication

part

Safety power

supply, start-up

input part

Safety input

part

Safety output

part 1

Safety output

part 2

Pin

number

1

2

3

4

Signal name

+24V

24G

1DA

2DB

3DG

4SLD

1EA

2EB

3EG

4EP

XS0

XS1

*2*3

*2*3

1

2

3 +24V (SAFETY)

4 24G (SAFETY)

1

COM(X0)

2

3

4

*3

X0

COM(X1)

*3

X1

1Empty

2Z00

3Z10

4Z20

1Empty

2Z01

3Z11

4Z21

*4

*4

3 - 9

3.3 CC-Link Safety Relay Module Specifications

3.3.2 QS90SR2SN-CC CC-Link safety relay module

* 2: When connecting an electromagnetic switch and such for output, connect its normally closed

contacts in series between XS0 and XS1.

* 3: Do not connect equipment other than a switch or sensor to each terminal of X0, X1, XS0, and XS1.

* 4: Common terminals for X0 and X1 differ. Pay attention to the printing on the module at wiring. In the

external connection diagram, they are represented as COM (X0) and COM (X1).

COM(X0) COM(X1)

Page 35

3

SPECIFICATIONS

3.4 Extension Safety Relay Module Specifications

This section explains the specifications of the extension safety relay module.

1

3.4.1 QS90SR2SP-EX extension safety relay module

Table 3.6 Performance specifications of QS90SR2SP-EX (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current 4.6mA Minimum switching load 5VDC/5mA

Operating voltage range 20.4 to 26.4VDC

Type P t yp e

Input format

X1 Positive common

Relay life

Maximum switching frequency 1,200 times/hour based on the rated control capacity

Response

time

Common wiring method All safety inputs and safety outputs are independent.

Module power supply Voltage Supplied from Q series safety relay module or CC-Link safety relay module.

Safety power supply Voltage Supplied from Q series safety relay module or CC-Link safety relay module.

Noise durability

Dielectric withstand voltage

Insulation resistance

Level of protection IP1X

Weight 0.35kg

External connection method Two-piece spring clamp terminal block

Applicable

wire size

Applicable solderless terminal (bar

terminal)

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (JIS C 2812 compliant)

Time until output ON

Time until output OFF

Safety input part

Start-up input part

Safety power supply part

Safety output part

terminal block

Extension

communication part

terminal block

Mechanical Five million times or more

Electrical Hundred thousand times or more

50ms or less (safety input ON safety output ON)

20ms or less (safety input OFF safety output OFF)

DC type noise voltage: 500Vp-p, noise width: 1 s,

noise frequency: 25 to 60Hz (noise simulator condition)

2,500VAC/1mA or less for 1 minute between safety outputs

2,500VAC/1mA or less for 1 minute between safety input and safety output

2,500VAC/1mA or less for 1 minute between power supply and safety output

100M or more, measured with a 500VDC insulation resistance tester between safety outputs

100M or more, measured with a 500VDC insulation resistance tester between safety input and safety output

100M or more, measured with a 500VDC insulation resistance tester between power supply and safety output

AWG: 24 to 14, 0.2 to 2.5mm

AWG: 24 to 16, 0.2 to 1.25mm

Refer to Section 5.4.

2

Extension safety relay module

QS90SR2SP-EX

Rated load current

Maximum allowable voltage of

contact

Resistance load 250VAC/5A, 30VDC/5AX0 Positive common

*2

2

Category 3: 5.0A/point or less

Category 4: 3.6A/point or less

250VAC, 30VDC

OVERVIEW

2

SYSTEM

CONFIGURATION

3

*1

SPECIFICATIONS

4

FUNCTIONS

5

SETTINGS AND

PROCEDURES BEFORE

OPERATION

6

TROUBLESHOOTINGAPPENDIX

* 1: Category 4 is complied only when connecting a light curtain of Type 4.

* 2: Manual operation such as start-up switch operation is excluded.

3.4 Extension Safety Relay Module Specifications

3.4.1 QS90SR2SP-EX extension safety relay module

3 - 10

Page 36

COM(X0)

X0

X1

COM(X1)

Switches

Connected to a

main module

or

another extension

module

Connected to another

extension module

Connected to a

main module

or

another extension

module

Connected to another

extension module

Safety circuit part

extension cable

Safety circuit part

extension cable

or

safety part terminating

connector

IN

OUT

Monitor

circuit

Internal

safety circuit

K0 K1

Start-up

switch

MC1

MC0

XS0

XS1

EA

EB

EG

EP

Motor

Z00

MC1

MC0

Z01

Z10

Z11

Z20

M

Z21

Safety relay

COM(X0) COM(X1)

3

SPECIFICATIONS

Table 3.6 Performance specifications of QS90SR2SP-EX (2/2)

External connection diagram Connector

Extension

communication

part

Start-up input

part

Safety input

part

Safety output

part 1

Safety output

part 2

Pin

number

1EA

2EB

3EG

4EP

1

XS0

2

XS1

3Empty

4Empty

1

COM(X0)

2

X0

3

COM(X1)

4

X1

1Empty

2Z00

3Z10

4Z20

1Empty

2Z01

3Z11

4Z21

Signal name

*3*4

*3*4

*5

*4

*5

*4

* 3: When connecting an electromagnetic switch and such for output, connect its normally closed

contacts in series between XS0 and XS1.

* 4: Do not connect equipment other than a switch or sensor to each terminal of X0, X1, XS0, and XS1.

* 5: Common terminals for X0 and X1 differ. Pay attention to the printing on the module at wiring. In the

external connection diagram, they are represented as COM (X0) and COM (X1).

3 - 11

3.4 Extension Safety Relay Module Specifications

3.4.1 QS90SR2SP-EX extension safety relay module

Page 37

3

SPECIFICATIONS

3.4.2 QS90SR2SN-EX extension safety relay module

Table 3.7 Performance specifications of QS90SR2SN-EX (1/2)

Item

Input specifications Output specifications

Number of safety input points 1 safety input point (2 inputs) Number of safety output points 1 safety output point (3 outputs)

Number of other input points 1 start-up input point Insulation method Relay insulation

Insulation method Relay insulation

Safety input rated input voltage 24VDC (ripple ratio: within 5%)

Safety input rated input current 4.6mA Minimum switching load 5VDC/5mA

Operating voltage range 20.4 to 26.4VDC