Page 1

Page 2

Page 3

• SAFETY PRECAUTIONS •

(You must read these cautions before using the product)

As for the use of the product, please carefully read this manual and the related manuals introduced later.

Also, please pay attention to safety adequately and manage the product correctly.

The safety cautions shown in this manual apply to the product only.

In this manual, the safety precautions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please store this manual in order to read whenever it is necessary. Also, always forward this manual to

the end users.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Precautions]

!

DANGER

• Install a safety circuit external to the programmable controller that keeps the entire system safe

even when there are problems with the external power supply or the programmable controller.

Otherwise, it may cause an output error or an operating error, resulting in an accident.

(1) Configure a circuit such as an emergency stop circuit and a protective circuit on the outside

of the programmable logic controller.

(2) When the programmable controller detects the following problems, it will stop calculation

and turn off all outputs.

• An overcurrent protective device or an overvoltage protective device in a power supply

module start running.

• A watchdog timer error or others is detected with self-checking function in the

programmable controller CPU.

All outputs may be turned on, when an error occurs in the part of I/O controlling or others

that the programmable controller CPU cannot detect. Build a fail safe circuit exterior to the

programmable controller to keep the entire system safe.

As for the fail safe circuit, refer to a CPU module User’s Manual.

• Configure a circuit that turns on an external power supply when the main power of

programmable controller is turned on. If the external power supply is turned on first, it could

result in an output error or an operating error.

A - 1

Page 4

[Design Precautions]

!

DANGER

• When connecting a peripheral device to the CPU module or connecting a personal computer or

others to an intelligent function module, always configure an interlock circuit in the sequence

program to ensure that the whole system always operate safely.

Also, make sure to read this manual carefully and check all operations for safety first before

executing other control (program changes, changes of operation status (and status control)) of

the operating sequence.

Especially for the control described above on the remote sequence from an external device, an

immediate action may not be taken for a programmable controller’s trouble due to a data

communication fault.

Configure the interlock circuit in the sequence program. Simultaneously a recovery method for

system, in which a data communications fault occurs, should be determined between the

external device and the programmable controller CPU.

[Startup/Maintenance Precaution]

!

CAUTION

• Make sure to read this manual carefully and check all operations for safety first before

connecting a peripheral device to an operating CPU module online (particularly program

changes, forced outputs, and changes of operation status). Otherwise, an operating error may

cause damage or problems with the modules.

A - 2

Page 5

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Dec., 1999 SH (NA) 080040-A First edition

Jun., 2001 SH (NA) 080040-B

Partial addition

About Manuals, Chapter 1, Chapter 2, Section 2.1, 3.1, 3.2, 3.3, 3.3.1,

4.2.3, 4.3.2, 4.3.5, Chapter 5, Section 5.1, 5.2, Chapter 6, Chapter 7,

Section 8.1, 8.2

Apr., 2002 SH (NA) 080040-C

Correction

Chapter 1, Chapter 7, Section 8.1, 8.2, 8.3, 8.4, 8.5

Jan., 2003 SH (NA) 080040-D • Addition of use of Basic model QCPU

• Addition of explanation of incomplete derivative

Overall reexamination

Mar., 2003 SH (NA) 080040-E • Addition of explanation of incomplete derivative to High Performance

model QCPU

Dec., 2003 SH (NA) 080040-F

Jun., 2004 SH (NA) 080040-G

Sep., 2006 SH (NA) 080040-H

Apr.,2007 SH (NA) 080040-I

Mar.,2008 SH (NA) 080040-J

Correction

Chapter 1

Addition of Redundant CPU

Partial addition

About Manuals, Chapter 1, Chapter 2, Section 2.1, 3.1.1, 3.1.3, 3.2.1,

3.2.3, 4.3.5, 5.1, 5.2, Chapter 6, Chapter 7, Section 8.1.1 to 8.1.4,

Section 9.1.1 to 9.1.5, 9.2, Appendix 1

Partial addition

Section 4.2.5, Appendix 2

Addition of Universal model QCPU

Addition module

Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU

Partial correction

GENERIC TERMS AND ABBREVIATIONS USED IN THIS MANUAL,

Chapter 1, Chapter 2, Section 2.1, 3.1.1, 3.1.3, 3.2.1, 3.2.3, 5.1, Chapter 6,

Chapter 7, 8.1.1 to 8.1.5, 9.1.1 to 9.1.5, Appendix 1

Addition of Universal model QCPU

Addition module

Q13UDHCPU, Q26UDHCPU

Partial correction

GENERIC TERMS AND ABBREVIATIONS USED IN THIS MANUAL,

Section 2.1, Appendix 1

A - 3

Page 6

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

May,2008 SH (NA) 080040-K

Revision due to the addition of Process CPU and Universal model QCPU

Addition module

Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q13UDEHCPU,

Q26UDEHCPU

Q02PHCPU, Q06PHCPU

Partial correction

GENERIC TERMS AND ABBREVIATIONS USED IN THIS MANUAL,

Section 2.1, Appendix 1

Japanese Manual Version SH-080022-K

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which

may occur as a result of using the contents noted in this manual.

© 1999 MITSUBISHI ELECTRIC CORPORATION

A - 4

Page 7

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-Q/QnA Series of Programmable Logic Controllers.

Please read this manual carefully so that the equipment is used to its optimum. A copy of this manual should

be forwarded to the end User.

CONTENTS

SAFETY CAUTIONS ......................................................................................................................................A- 1

REVISIONS .....................................................................................................................................................A- 3

CONTENTS.....................................................................................................................................................A- 5

About Manuals ................................................................................................................................................A- 8

Generic Terms and Abbreviations Used in This Manual ..............................................................................A-11

1. GENERAL DESCRIPTION 1 – 1 to 1 - 3

1.1 PID Processing Method ........................................................................................................................... 1 - 3

2. SYSTEM CONFIGURATION FOR PID CONTROL 2 - 1 to 2 - 2

2.1 Applicable PLC CPU ................................................................................................................................ 2 - 2

3. PID CONTROL SPECIFICATIONS 3 - 1 to 3 - 14

3.1 PID Control by Incomplete derivative ...................................................................................................... 3 - 1

3.1.1 Performance specifications............................................................................................................... 3 - 1

3.1.2 PID operation block diagram and operation expressions ................................................................ 3 - 2

3.1.3 PID control instruction list.................................................................................................................. 3 - 3

3.2 PID Control by Complete Derivative........................................................................................................ 3 - 8

3.2.1 Performance specifications............................................................................................................... 3 - 8

3.2.2 PID operation block diagram and operation expressions ................................................................ 3 - 9

3.2.3 PID control instruction list................................................................................................................ 3 - 10

4. FUNCTIONS OF PID CONTROL 4 - 1 to 4 - 14

4.1 Outline of PID Control .............................................................................................................................. 4 - 1

4.2 Functions of PID Control.......................................................................................................................... 4 - 2

4.2.1 Operation method.............................................................................................................................. 4 - 2

4.2.2 Forward operation and reverse operation ........................................................................................ 4 - 2

4.2.3 Proportionate operation (P operation) .............................................................................................. 4 - 4

4.2.4 Integrating operation (I operation) .................................................................................................... 4 - 5

4.2.5 Differentiating operation (D operation) ............................................................................................. 4 - 6

4.2.6 PID operation..................................................................................................................................... 4 - 8

4.3 Other Functions........................................................................................................................................ 4 - 9

4.3.1 Bumpless changeover function ........................................................................................................ 4 - 9

4.3.2 MV higher/lower limit control function ............................................................................................. 4 - 10

4.3.3 Monitorning PID control with the AD57(S1) (QnACPU only)......................................................... 4 - 11

4.3.4 Function for transfer to the SV storage device for the PV in manual mode .................................. 4 - 12

4.3.5 Changing the PID control data or input/output data setting range (QCPU only) ......................... 4 – 13

A - 5

Page 8

5. PID CONTROL PROCEDURE 5 - 1 to 5 - 24

5.1 PID Control Data ...................................................................................................................................... 5 - 4

5.1.1 Number of loops to be used and the number of loops to be executed in a single scan ............... 5 - 15

5.1.2 Sampling cycle ................................................................................................................................5 - 16

5.2 I/O Data .................................................................................................................................................. 5 - 18

6. PID CONTROL INSTRUCTIONS 6 - 1 to 6 - 2

7. HOW TO READ EXPLANATIONS FOR INSTRUCTIONS 7 - 1 to 7 - 2

8. INCOMPLETE DERIVATIVE PID CONTROL INSTRUCTIONS AND PROGRAM EXAMPLES

8 - 1 to 8 - 16

8.1 PID Control Instructions ........................................................................................................................... 8 - 1

8.1.1 PID control data settings S.PIDINIT,SP.PIDINIT .......................................... 8 - 2

8.1.2 PID operation S.PIDCONT,SP.PIDCONT................................... 8 - 3

8.1.3 Operation stop/start of designated loop no. S.PIDSTOP,SP.PIDSTOP,S.PIDRUN,SP.PIDRUN

.................................................................................................................................................................... 8 - 5

8.1.4 Parameter change at designated loop S.PIDPRMW,SP.PIDPRMW ................................8 - 6

8.2 PID Control Program Examples .............................................................................................................. 8 - 8

8.2.1 System configuration for program examples.................................................................................... 8 - 8

8.2.2 Program example for automatic mode PID control.......................................................................... 8 - 9

8.2.3 Program example for changing the PID control mode between automatic and manual .............. 8 - 13

9. COMPLETE DERIVATIVE PID CONTROL INSTRUCTIONS AND PROGRAM EXAMPLES 9 - 1 to 9 - 28

9.1 PID Control Instructions ........................................................................................................................... 9 - 1

9.1.1 PID control data settings PIDINIT,PIDINITP................................................. 9 - 2

9.1.2 PID control PIDCONT,PIDCONTP.......................................... 9 - 3

9.1.3 Monitoring PID control status (QnACPU only) PID57,PID57P....................................................... 9 - 5

9.1.4 Operation stop/start of designated loop no. PIDSTOP,PIDSTOPP,PIDRUN,PIDRUNP ......... 9 - 8

9.1.5 Parameter change at designated loop PIDPRMW,PIDPRMWP ....................................... 9 - 9

9.2 PID Control Program Examples (QCPU only) ...................................................................................... 9 - 11

9.2.1 System configuration for program examples.................................................................................. 9 - 11

9.2.2 Program example for automatic mode PID control........................................................................ 9 - 12

9.2.3 Program example for changing the PID control mode between automatic and manual .............. 9 - 15

9.3 PID Control Program Examples (QnACPU only).................................................................................. 9 - 19

9.3.1 System configuration for program examples.................................................................................. 9 - 19

9.3.2 Program example for automatic mode PID control........................................................................ 9 - 20

9.3.3 Program example for changing the PID control mode between automatic and manual ............. 9 – 24

A - 6

Page 9

APPENDIX APP - 1 to APP - 3

Appendix 1 Processing Time List .............................................................................................................APP - 1

Appendix 2 Anti-Reset Windup Measure .................................................................................................APP - 3

A - 7

Page 10

About Manuals

Related Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Manual Name

Manual Number

(Model Code)

QCPU User's Manual (Function Explanation, Program Fundamentals)

Describes the functions, programming procedures, devices, etc. necessary to create programs.

(Sold separately)

QnACPU Programming Manual (Fundamentals)

Describes how to create programs, the names of devices, parameters, and types of program.

(Sold separately)

QCPU (Q mode) /QnACPU Programming Manual (Common Instructions)

Describes how to use sequence instructions, basic instructions, and application instructions.

(Sold separately)

QnACPU Programming Manual (Special Function)

Describes the dedicated instructions for special function modules available when using the

Q2ACPU(S1), Q3ACPU, and Q4ACPU. (Sold separately)

QnACPU Programming Manual (AD57 Instructions)

Describes the dedicated instructions for controlling an AD57(S1) type CRT controller module available

when using the Q2ACPU(S1), Q3ACPU, or Q4ACPU. (Sold separately)

SH-080484ENG

(13JR73)

IB-66614

(13JF46)

SH-080039

(13JF58)

SH-4013

(13JF56)

IB-66617

(13JF49)

A - 8

Page 11

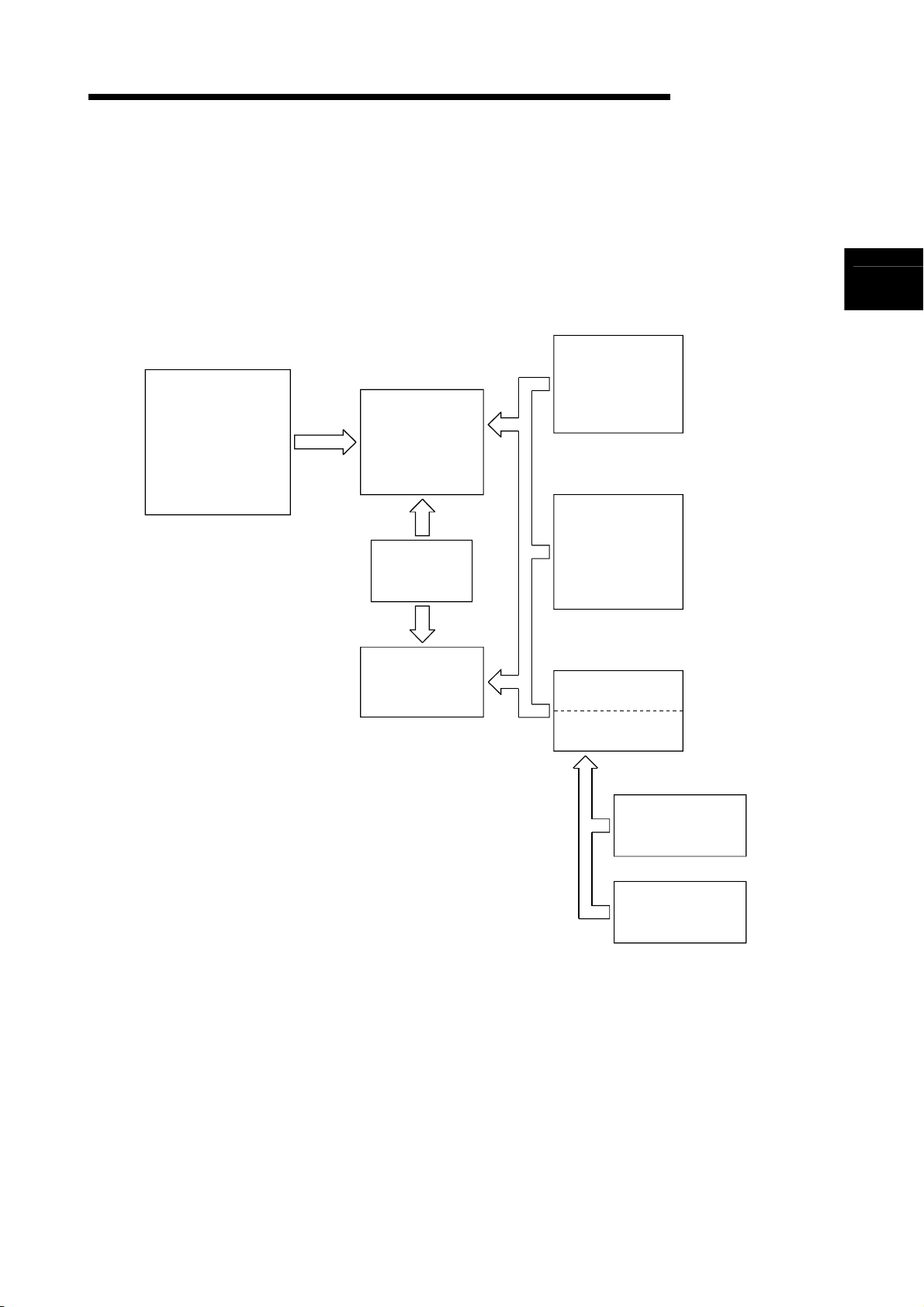

g

Before reading this manual, refer to the user's manual of the used CPU module or the

QnACPU Programming Manual (Fundamentals), and confirm which programs, I/O

processing, and devices can be used with the used CPU module.

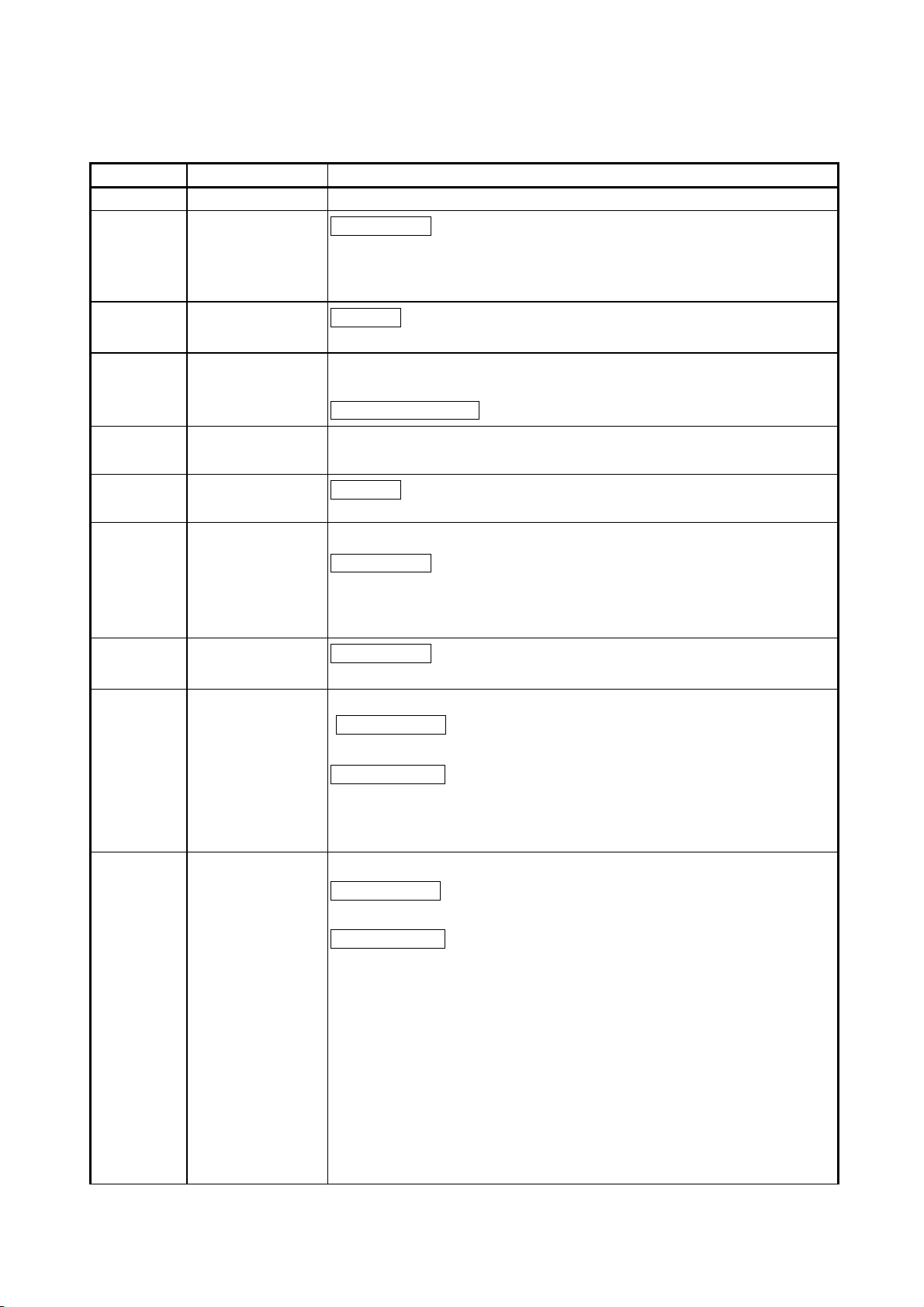

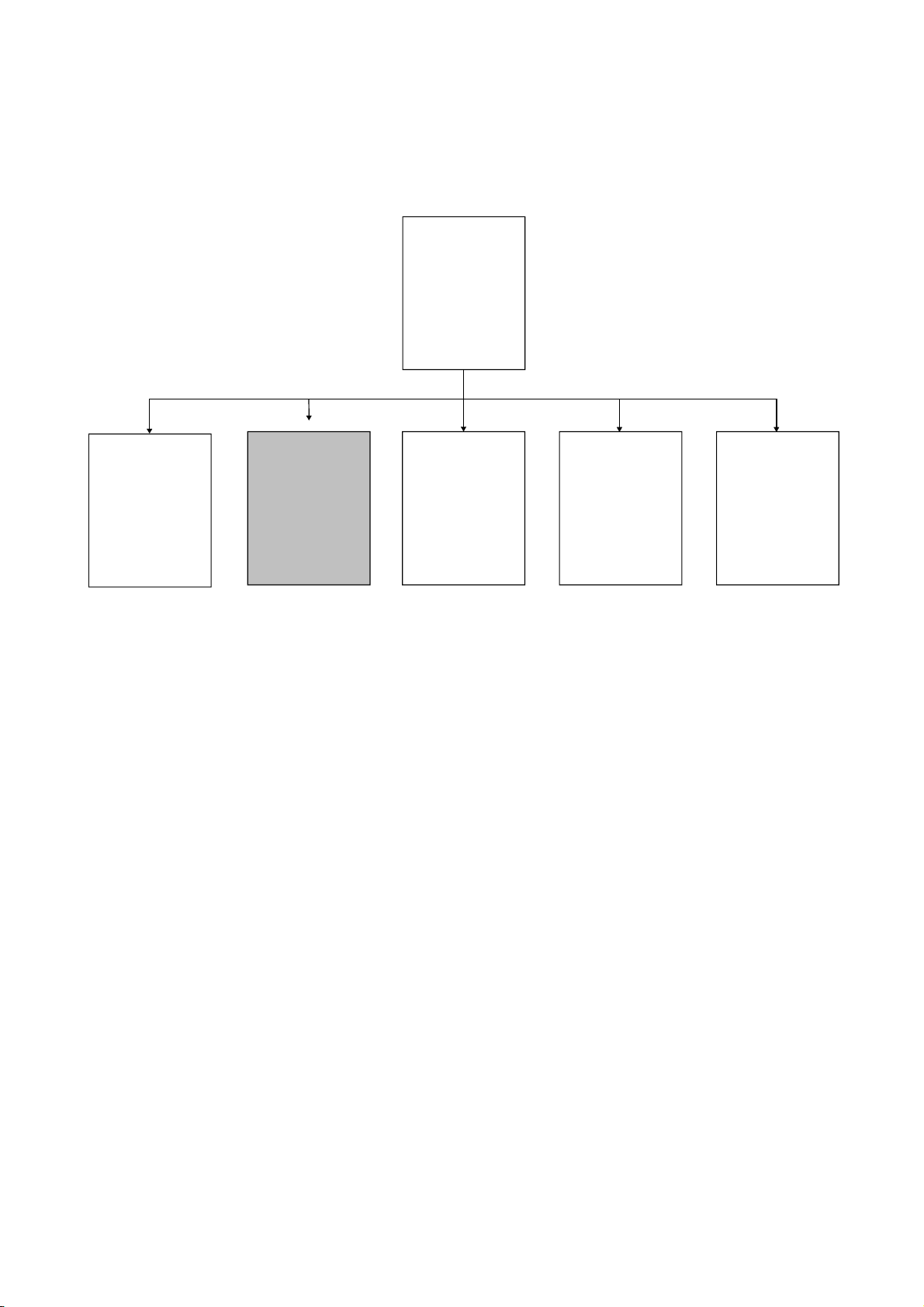

(1) When QCPU is used

QCPU (Q mode)/

QnACPU

Programming

Manual

(Common

Instructions)

Describes the

instructions other

than those given

on the ri

ht.

This manual

QCPU (Q mode)/

QnACPU

Programming

Manual

(PID Control

Instructions)

Describes the

instructions used for

PID control.

QCPU

User's Manual

(Function Explanation,

Program Fundamentals)

QCPU (Q mode)/

QnACPU

Programming

Manual

(SFC)

Describes SFC.

Describes the functions,

executable programs,

I/O processing and device

names of the QCPU.

QCPU (Q mode)

Programming

Manual

(MELSAP-L)

Describes MELSAP-L.

QCPU (Q mode)

Programming

Manual

(Structured Text)

Describes the

structured text.

A - 9

Page 12

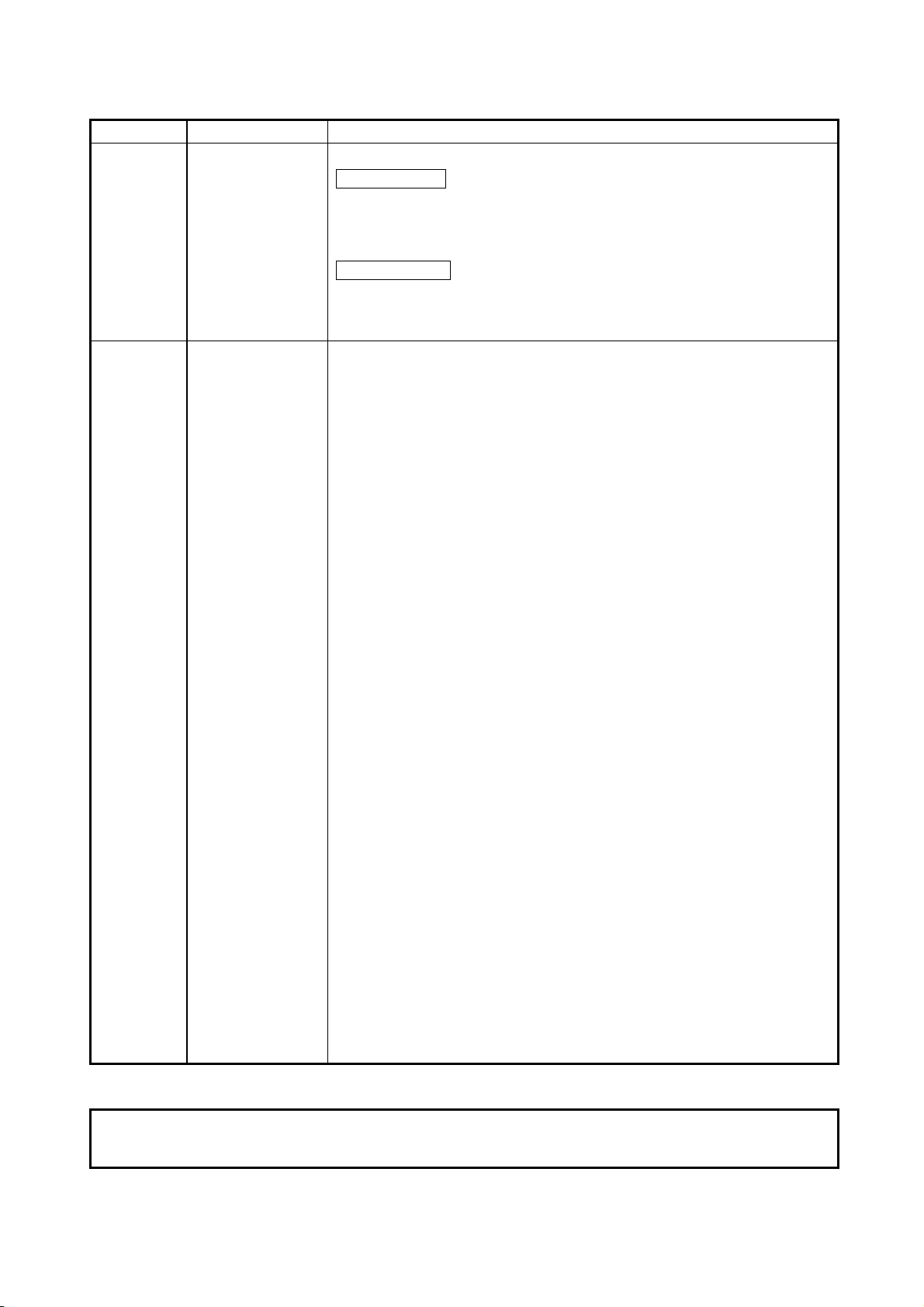

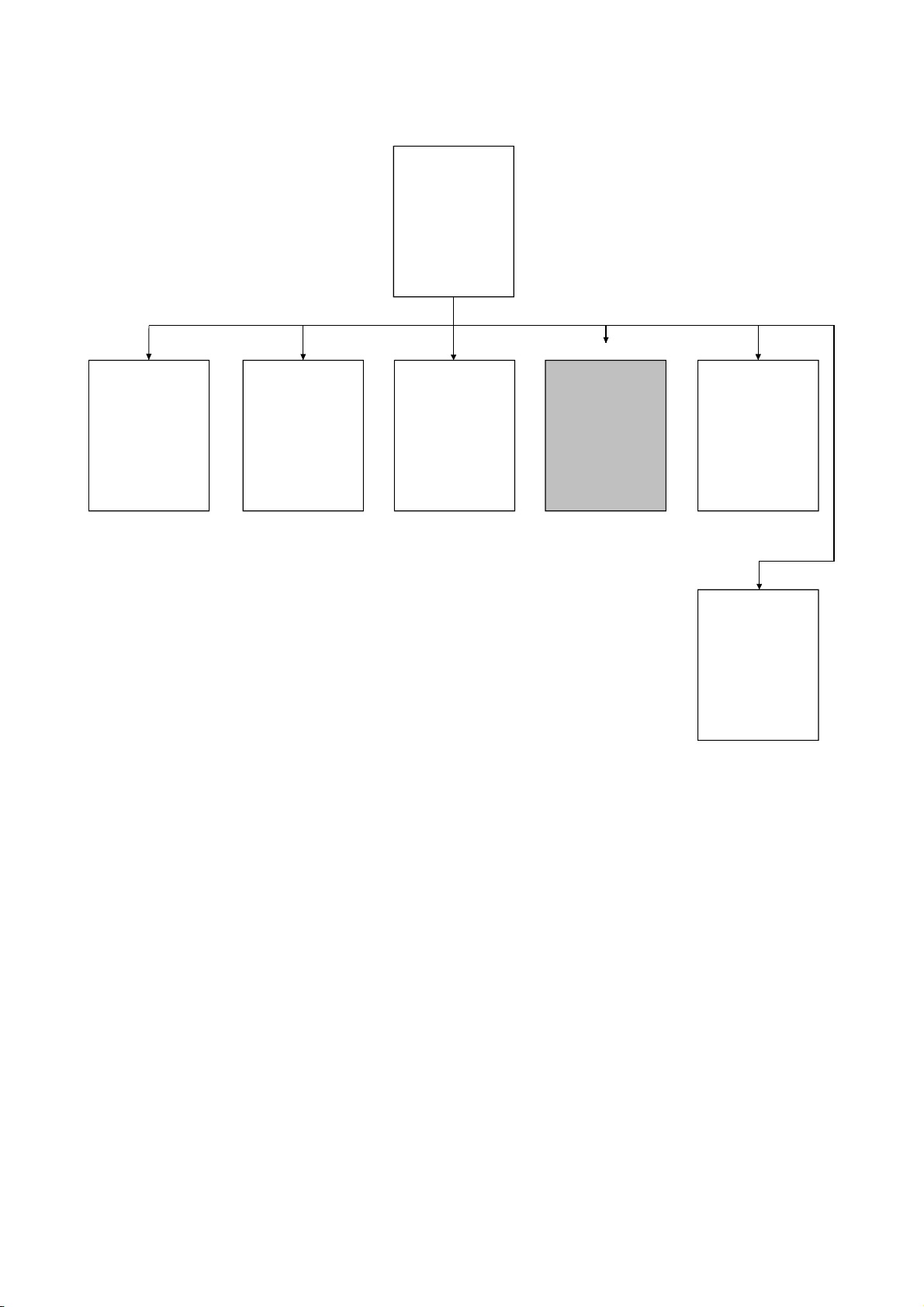

(2) When QnACPU is used

QCPU (Q mode)/

QnACPU

Programming

Manual

(Common

Instructions)

Describes the

instructions other

than those given

on the right.

QnACPU

Programming

Manual

(Special Function

Modules)

Describes the

instructions for the

special function

modules such as the

AJ71QC24 and

AJ71PT32-S3.

QnACPU

Programming

Manual

(Fundamentals)

QnACPU

Programming

Manual

(AD57 Commands)

Describes the AD57

commands for

controlling the

AD57/AD58.

Describes the programs, I/O processing,

device names, etc. that can be executed

by the QnACPU.

This manual

QCPU (Q mode)/

QnACPU

Programming

Manual

(PID Control

Instructions)

Describes the

instructions used

for PID control.

QCPU (Q mode)/

QnACPU

Programming

Manual

(SFC)

Describes SFC.

Q4ARCPU only

Q4ARCPU

Programming

Manual

(Application PID

Instructions)

Describes the

instructions used

for applied PID control.

A - 10

Page 13

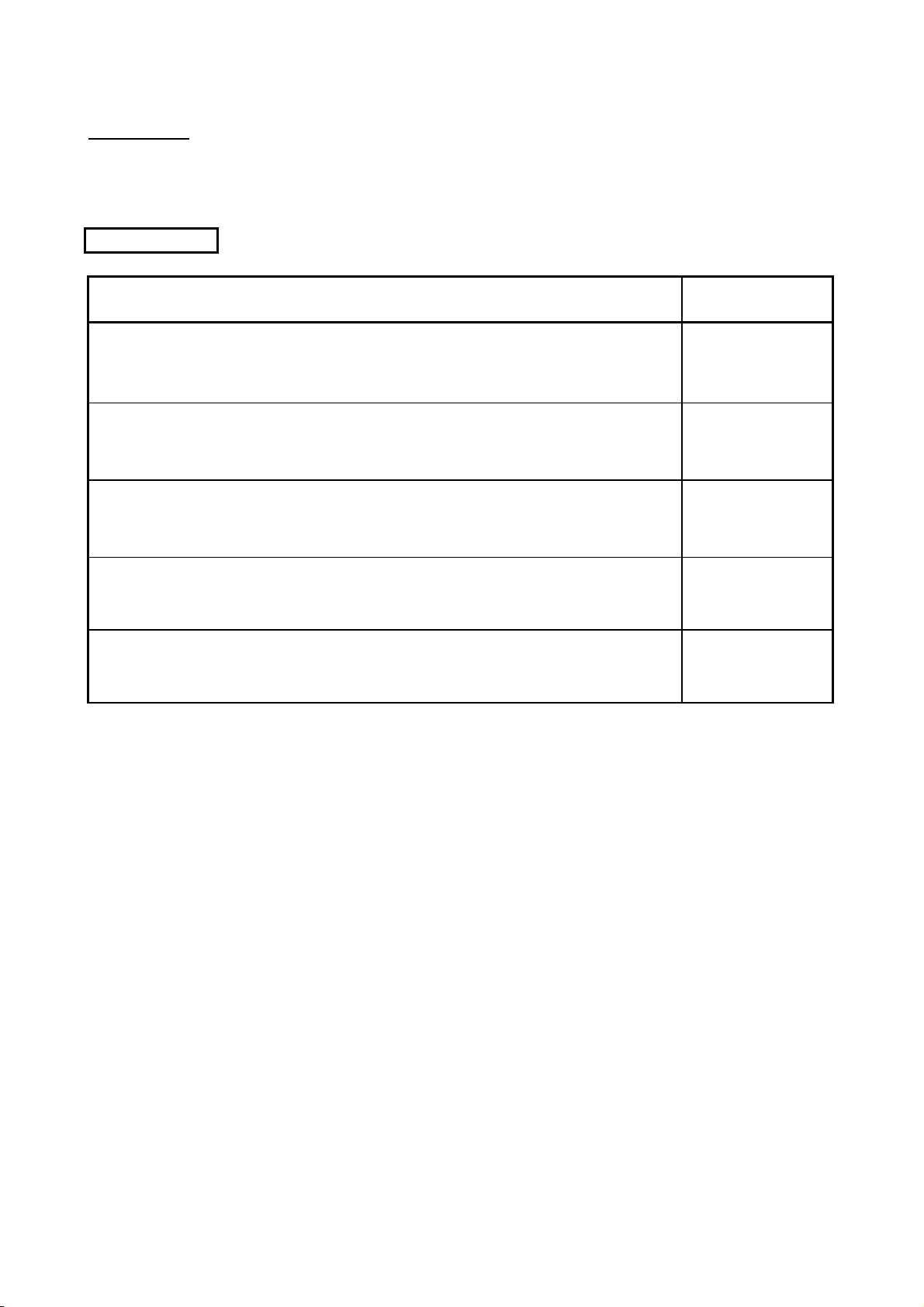

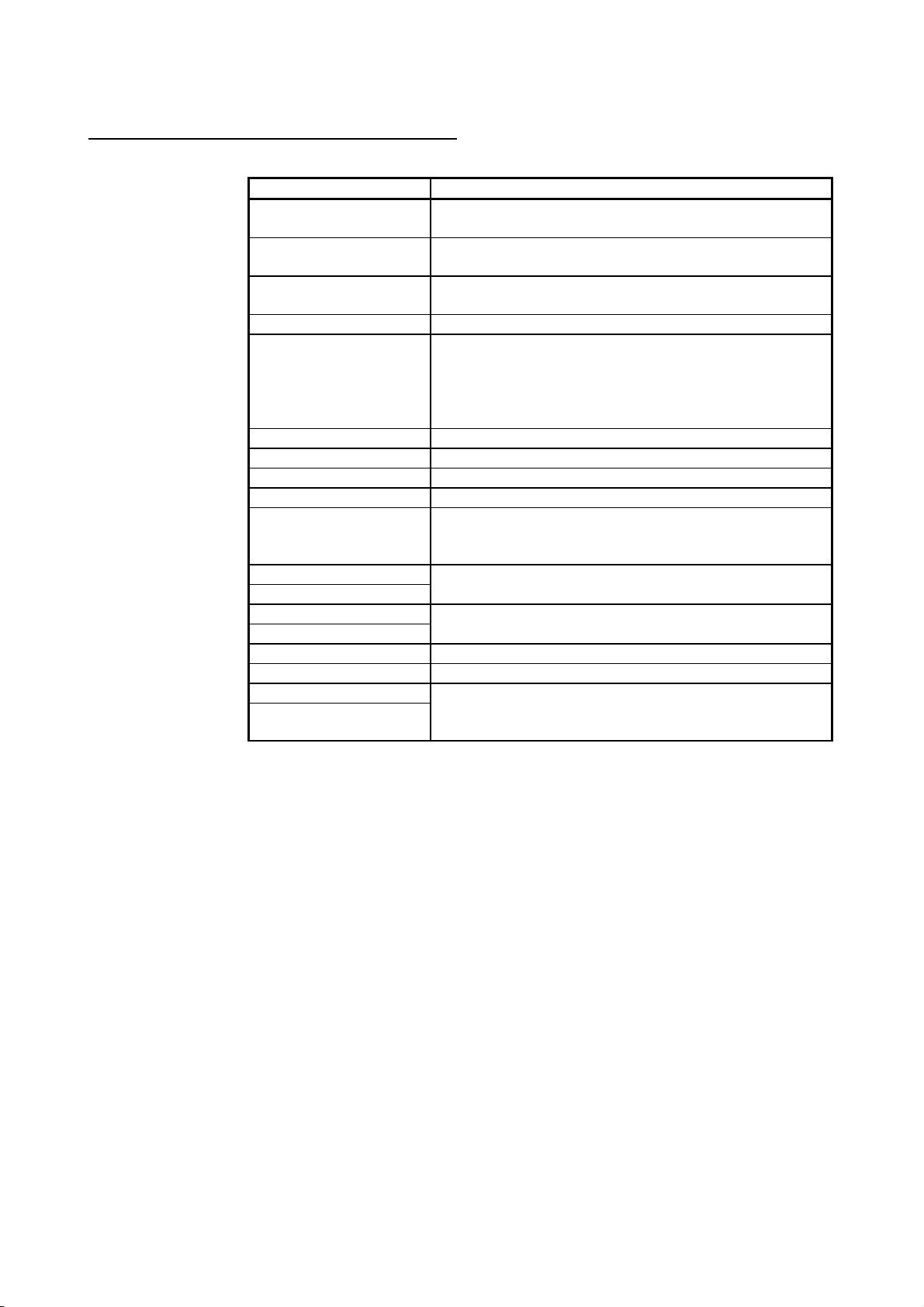

Generic Terms and Abbreviations Used in This Manual

This manual uses the following generic terms and abbreviations unless otherwise described.

Generic term/abbreviation Description of generic term/abbreviation

CPU module

QnACPU

QnA

Q4AR Abbreviation of Q4ARCPU

QCPU

QnCPU Abbreviation of Q02CPU

QnHCPU Abbreviation of Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU

QnPHCPU Abbreviation of Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

QnPRHCPU Abbreviation of Q12PRHCPU, Q25PRHCPU

QnUD(H)CPU

Basic model QCPU

Basic

High Performance model QCPU

High Performance

Process CPU Generic term of Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

Redundant CPU Generic term of Q12PRHCPU, Q25PRHCPU

Universal model QCPU

Universal

Generic term of Basic model QCPU, High Performance model QCPU,

Redundant CPU, Universal model QCPU, QnACPU

Abbreviation of Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1,

Q2ACPU, Q2ACPU-S1, Q3ACPU, Q4ACPU, Q4ARCPU

Abbreviation of Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1,

Q2ACPU, Q2ACPU-S1, Q3ACPU, Q4ACPU

Abbreviation of Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q12PRHCPU, Q25PRHCPU, Q02UCPU,

Q03UDCPU, Q04UDHCPU, Q06UDHCPU, Q13UDHCPU, Q26UDHCPU,

Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q13UDEHCPU,

Q26UDEHCPU

Abbreviation of Q03UDCPU, Q04UDHCPU, Q06UDHCPU,

Q13UDHCPU, Q26UDHCPU, Q03UDECPU, Q04UDEHCPU,

Q06UDEHCPU, Q13UDEHCPU, Q26UDEHCPU

Generic term of Q00JCPU, Q00CPU, Q01CPU

Generic term of Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU

Generic term of Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU,

Q13UDHCPU, Q26UDHCPU, Q03UDECPU, Q04UDEHCPU,

Q06UDEHCPU, Q13UDEHCPU, Q26UDEHCPU

A - 11

Page 14

MEMO

A - 12

Page 15

A

1. GENERAL DESCRIPTION

MELSEC-Q/Qn

1. GENERAL DESCRIPTION

This manual describes the sequence program instructions used to implement PID

control with any of the following CPU modules.

• Basic model QCPU (first five digits of serial No. are 04122 or later)

• High Performance model QCPU

• Redundant CPU

• Universal model QCPU

• QnACPU

The Basic model QCPU, High Performance model QCPU, Redundant CPU, and

Universal model QCPU have the instructions used to perform PID control by

incomplete derivative (PID control instructions) and the instructions used to perform

PID control by complete derivative (PID control instructions) as standard features.

The QnACPU has the instructions used to perform PID control by complete derivative

(PID control instructions) as standard features.

Since the incomplete derivative PID control instructions and complete derivative PID

control instructions are independent of each other, they can be executed at the same

time.

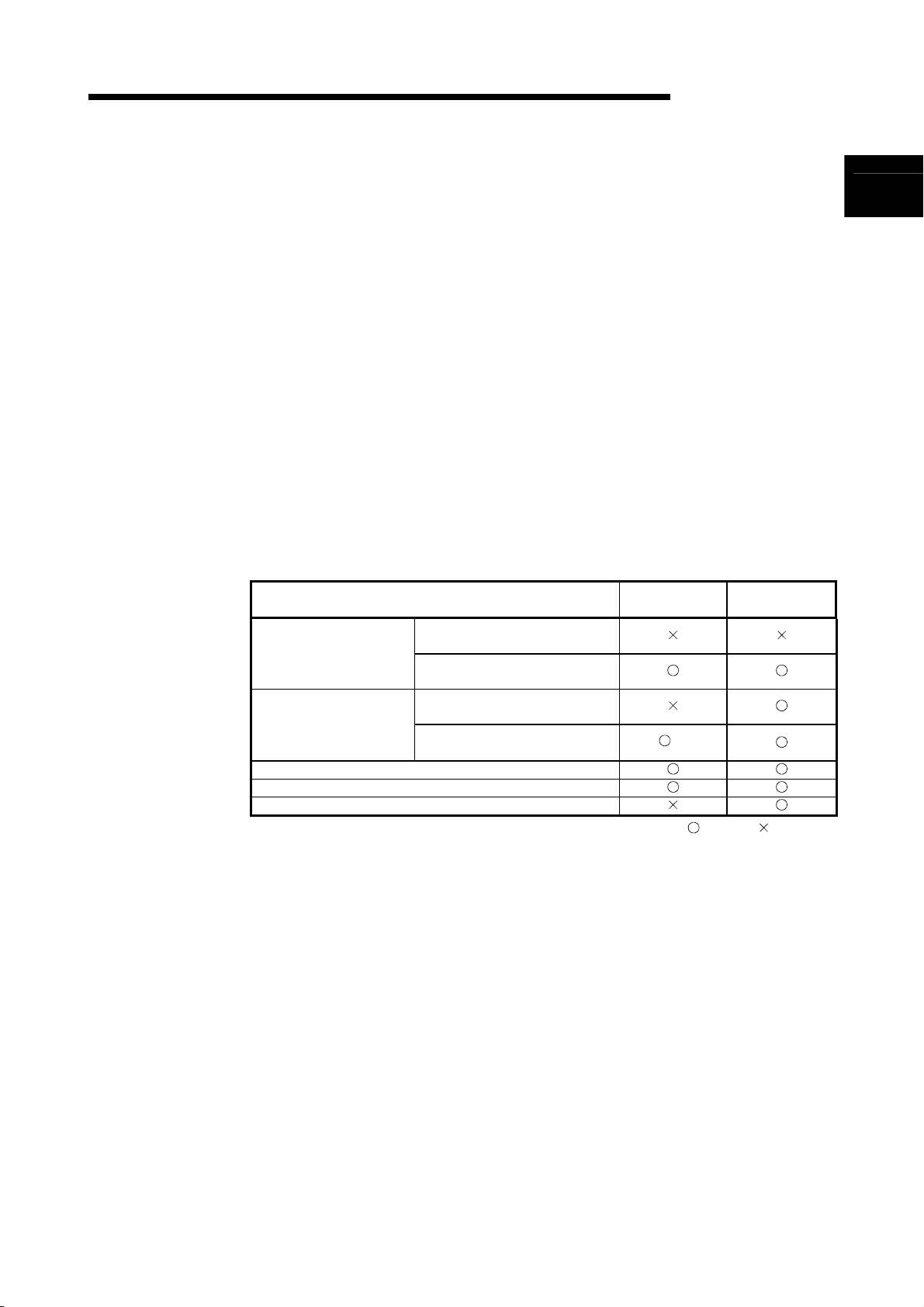

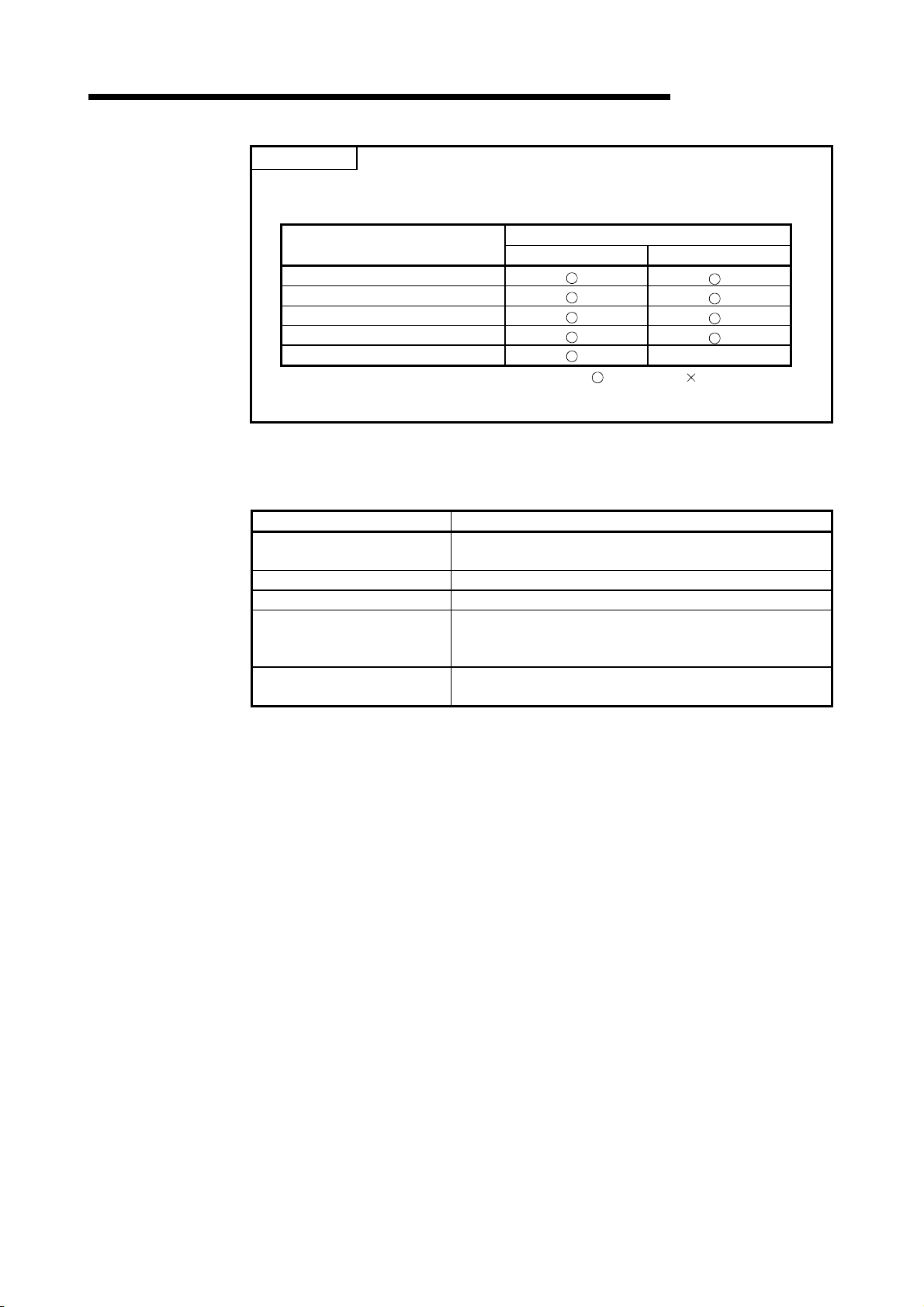

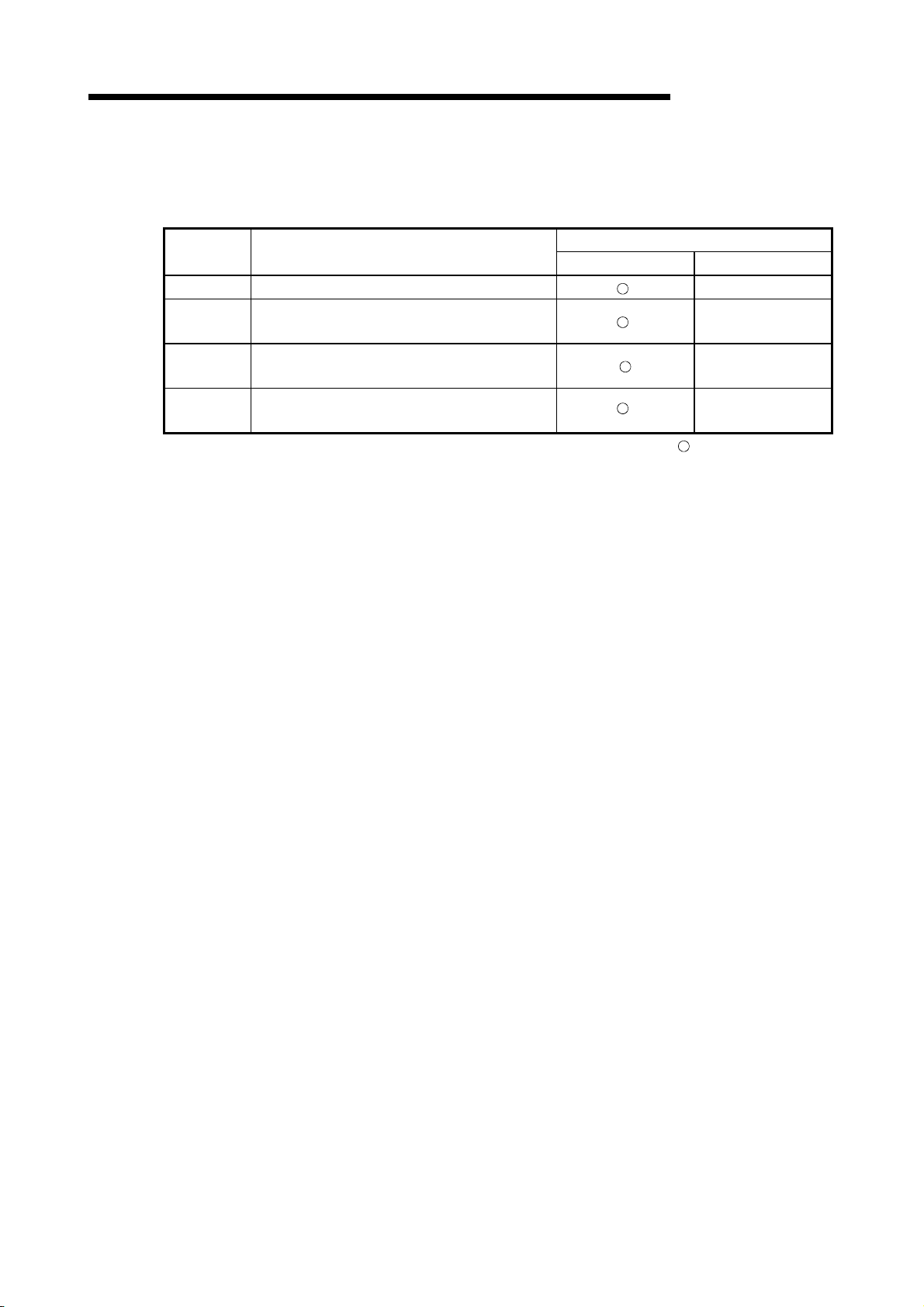

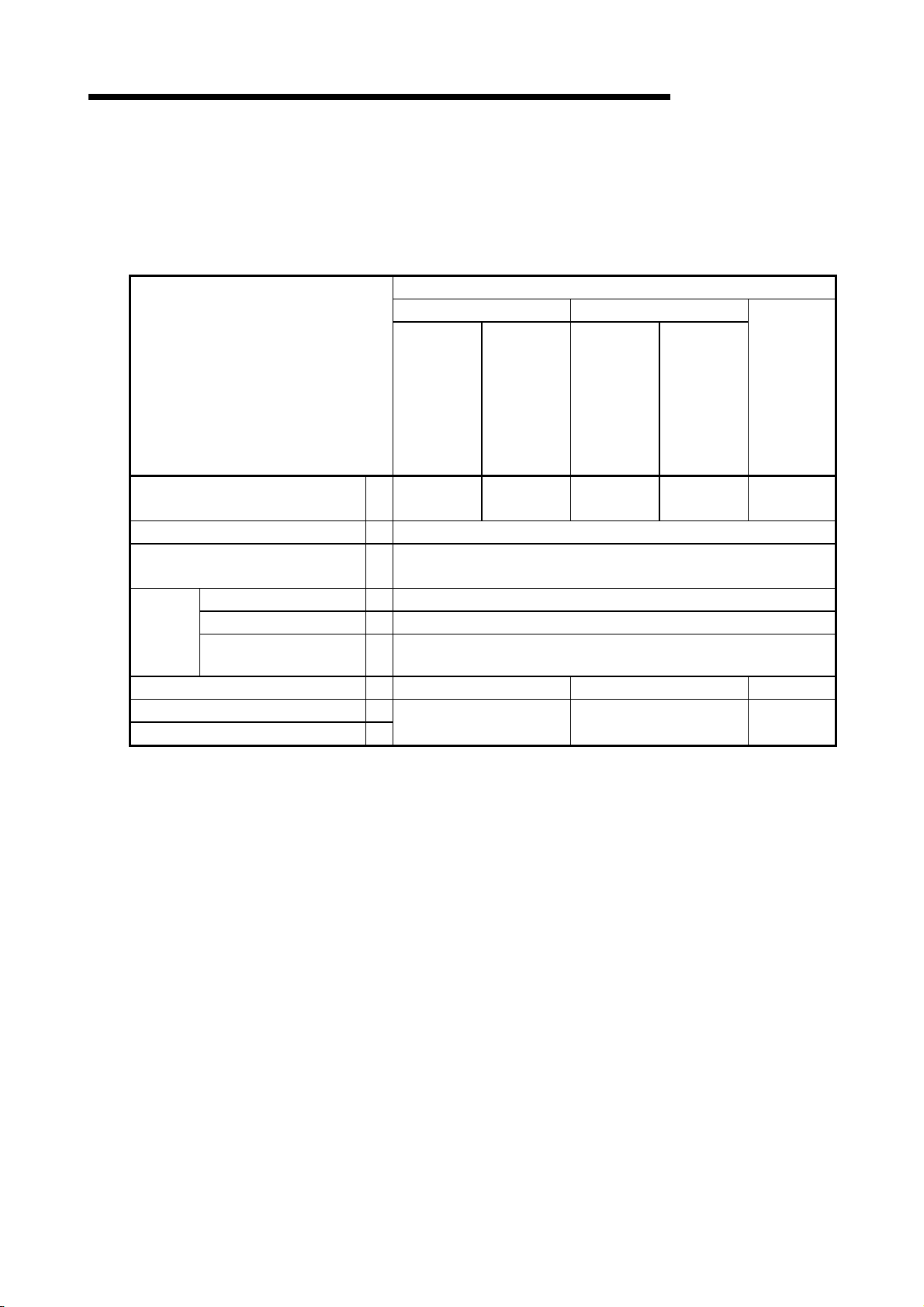

The following table indicates the CPU modules that can use the incomplete derivative

PID control instructions and complete derivative PID control instructions.

CPU Module Model Name

First five digits of serial No. are

Basic model QCPU

High Performance model

QCPU

Redundant CPU

Universal model QCPU

QnACPU

"04121" or earlier

First five digits of serial No. are

"04122" or later

First five digits of serial No. are

"05031" or earlier

First five digits of serial No. are

"05032" or later

*1: Version 7 or earlier version of GX Developer issues an “instruction code alarm” if it

loads a new CPU instruction realized with GX Developer Version 8.

Incomplete

Derivative

*1

: Usable, : Unusable

Complete

Derivative

1

1 - 1

Page 16

A

1. GENERAL DESCRIPTION

MELSEC-Q/Qn

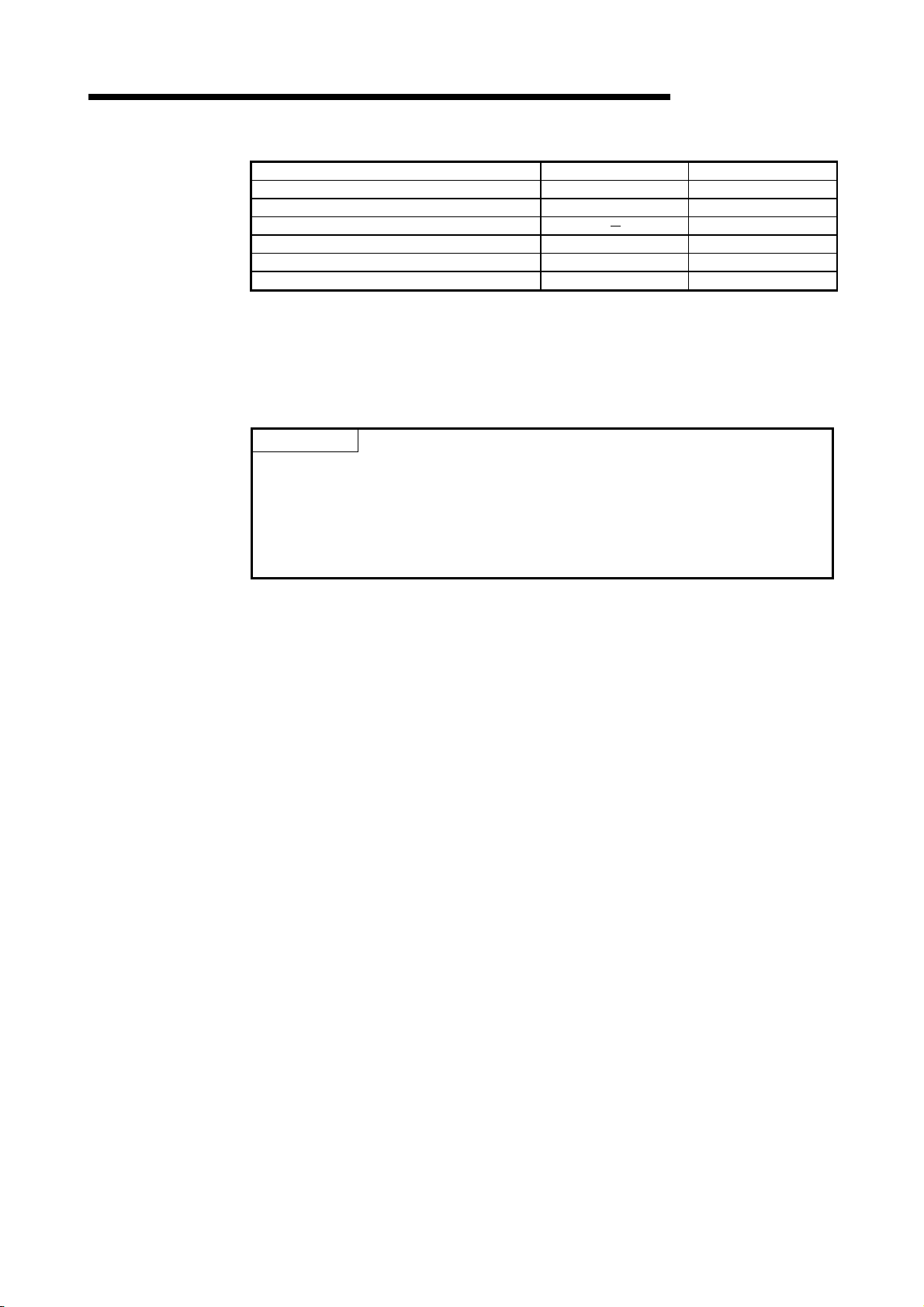

There are the following PID control instructions.

Classification Incomplete Derivative Complete Derivative

PID control data setting

PID operation

PID control status monitor

Specified loop No. operation stop

Specified loop No. operation start

Specified loop No. parameter change

S(P).PIDINIT PIDINIT(P)

S(P).PIDCONT PIDCONT(P)

PID57(P)

S(P).PIDSTOP PIDSTOP(P)

S(P).PIDRUN PIDRUN(P)

S(P).PIDPRMW PIDPRMW(P)

PID control via PID control instructions is implemented by combining the CPU module

with the A/D converter module and D/A converter module.

In the case of the QnACPU, the PID control status can be monitored using the

AD57(S1) CRT controller module.

POINT

(1) The Process CPU is not compatible with the PID control instructions described

in this manual.

To implement PID control using the Process CPU, use the process control

instructions described in the QnPHCPU/QnPRHCPU Programming Manual

(Process Control Instructions).

(2) The Redundant CPU can use the PID control instructions and process control

instructions.

1 - 2

Page 17

A

1. GENERAL DESCRIPTION

1.1 PID Processing Method

This section describes the processing method for PID control using PID control

Set value

SV

PV

instructions. (For details on PID operations, see Chapter 4.)

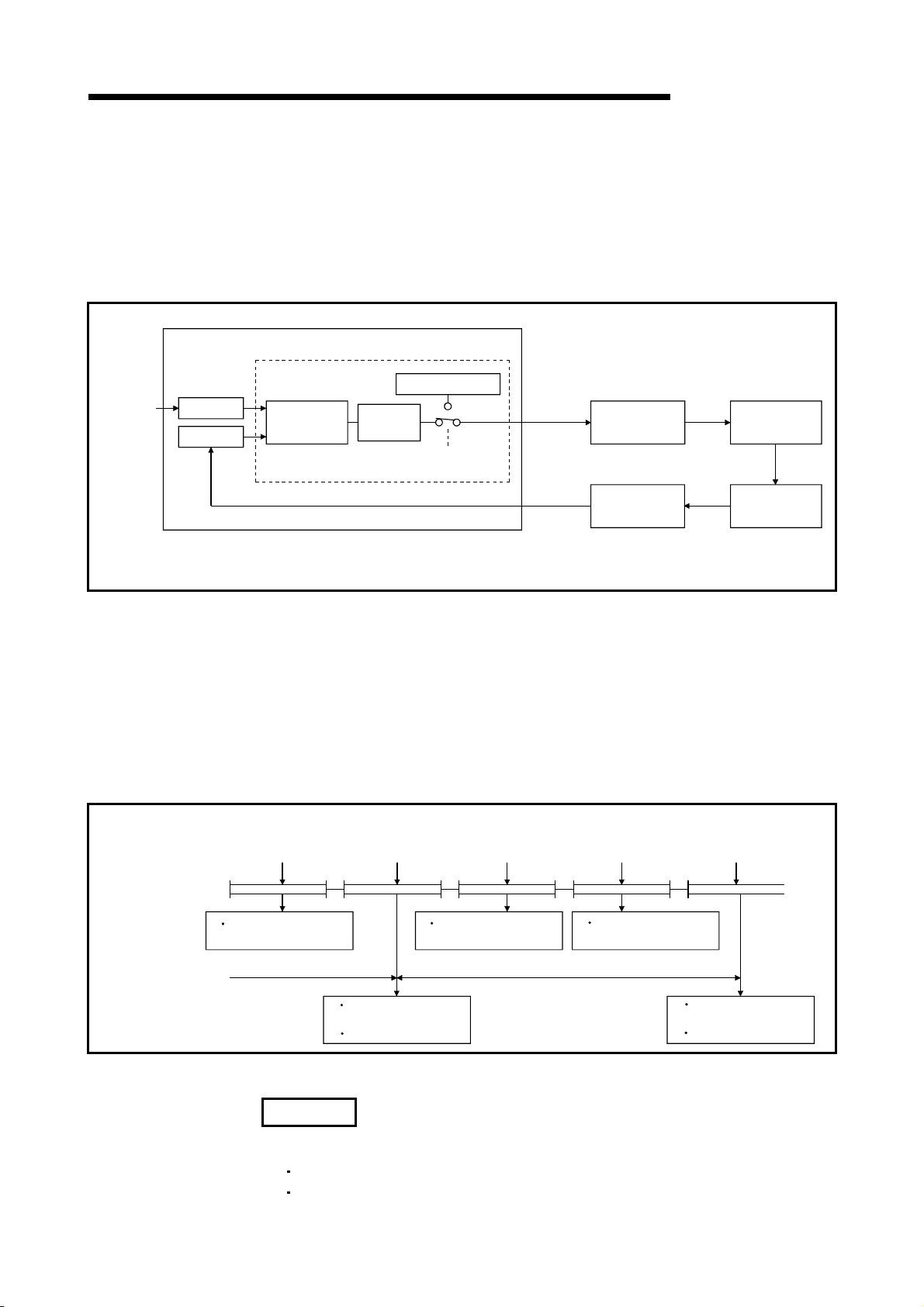

Execute PID control with PID control instructions by loading an A/D converter module

and a D/A converter module, as shown in Figure 1.1.

CPU module

PID control instructions

PID operation

Automatic

MV

Manual MV

Manual/automatic

changeover

MV

PV

D/A conversion

module

A/D conversion

module

MELSEC-Q/Qn

Controlled

system

Sensor

Sequence program

SV: Set Value

PV: Process Value

MV: Manipulated Value

Figure 1.1 Overview of PID Control Processing

In the PID control processing method, as shown in Figure 1.1, the PID operation is

executed using the set value (SV) and the process value (PV) read from the A/D

converter module, and the manipulated value (MV) is then calculated.

The calculated MV (manipulated value) is output to the D/A converter module.

When a PID operation instruction* is executed in a sequence program, the sampling

cycle is measured and a PID operation is performed.

PID operation in accordance with the PID operation instruction is executed in preset

sampling cycles.

PID operation

instruction

execution

Step 0

Measurement of

sampling cycle

Sampling cycle

PID operation

instruction

execution

Step 0 Step 0

END END END END

PID operation

instruction

execution

Measurement of

sampling cycle

PID operation

instruction

execution

Step 0 Step 0

Measurement of

sampling cycle

Sampling cycle

PID operation

instruction

execution

Measurement of

sampling cycle

PID operation

Measurement of

sampling cycle

PID operation

Figure 1. 2 Operation when PID Operation Instruction Executed

REMARK

*: There are the following PID operation instructions.

S.PIDCONT (incomplete derivative)

PIDCONT (complete derivative)

1 - 3

Page 18

A

1. GENERAL DESCRIPTION

MEMO

MELSEC-Q/Qn

1 - 4

Page 19

A

2. SYSTEM CONFIGURATION FOR PID CONTROL

MELSEC-Q/Qn

2. SYSTEM CONFIGURATION FOR PID CONTROL

This chapter describes the system configuration for PID control using the PID control

instructions.

For the modules that can be used to configure a system, refer to the following manual.

• Basic model QCPU, High Performance model QCPU, Universal model QCPU: MELSEC-Q DATA

BOOK

CPU module

• QnACPU: User's manual (details) of the used CPU module

Main base unit

Extension

cable

For PV (process value) input

A/D conversion

module

For MV (manipulated

value) output

D/A conversion

module

2

Extension base

unit

For PID control monitoring (Only QnACPU)

CRT control

module

AD57 or AD57-S1

only

CRT

Operation panel

2 - 1

Page 20

A

2. SYSTEM CONFIGURATION FOR PID CONTROL

POINT

SV, PV and MV used with the PID control instructions may be set either with the

fixed values of 0 to 2000 or to any values according to the used module.

Refer to Section 4.3.5 for details.

Basic model QCPU

High Performance model QCPU

Redundant CPU

Universal model QCPU

QnACPU

*: When the resolution of the A/D converter module or D/A converter module used for

I/O of PID control is other than 0 to 2000, convert the digital values into 0 to 2000.

CPU Module Type

2.1 Applicable PLC CPU

SV, PV, MV

0 to 2000 fixed *

: Can be set, : Cannot be set

MELSEC-Q/Qn

Any setting

×

Component Module

Basic model QCPU

High Performance model QCPU Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU

Redundant CPU Q12PRHCPU, Q25PRHCPU

Universal model QCPU

QnACPU

Q00JCPU, Q00CPU, Q01CPU

(First 5 digits of serial No. are 04122 or later)

Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU,

Q13UDHCPU, Q26UDHCPU, Q03UDECPU, Q04UDEHCPU,

Q06UDEHCPU, Q13UDEHCPU, Q26UDEHCPU

Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1

Q2ACPU, Q3ACPU, Q4ACPU, Q4ARCPU

2 - 2

Page 21

A

3. PID CONTROL SPECIFICATIONS

MELSEC-Q/Qn

3. PID CONTROL SPECIFICATIONS

This section gives the specifications PID operation using PID control instructions.

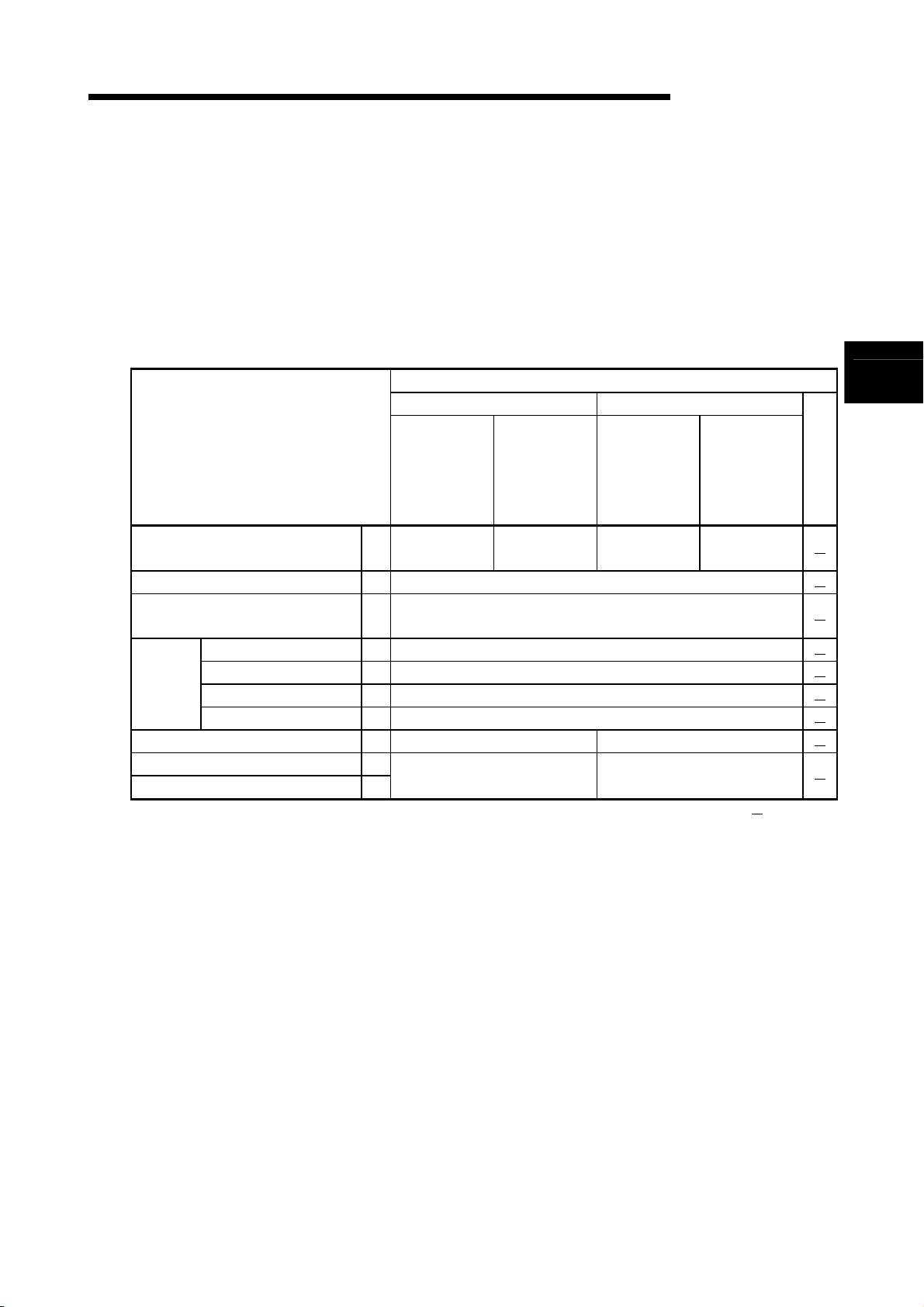

3.1 PID Control by incomplete derivative

3.1.1 Performance specifications

Number of PID control loops —

Sampling cycle TS 0.01 to 60.00 s

PID operation method —

PID

constant

setting

range

SV (set value) setting range SV 0 to 2000 -32768 to 32767

PV (process value) setting range

MV (manipulated value) output range

Proportional constant KP 0.01 to 100.00

Integral constant TI 0.1 to 3000.0 s

Derivative constant TD 0.00 to 300.00 s

Derivative gain KD 0.00 to 300.00

The performance specifications for PID control are tabled below.

Specifications

With PID limits Without PID limits

High Performance

Item

PV

MV

Basic model

QCPU

8 loops

(maximum)

-50 to 2050 -32768 to 32767

model QCPU,

Redundant CPU,

Universal model

QCPU

32 loops

(maximum)

Process value differentiation incomplete derivative

(forward operation/reverse operation)

Basic model

QCPU

8 loops

(maximum)

High Performance

model QCPU,

Redundant CPU,

Universal model

QCPU

32 loops

(maximum)

: Unusable

QnA

CPU

3

3 - 1

Page 22

A

3. PID CONTROL SPECIFICATIONS

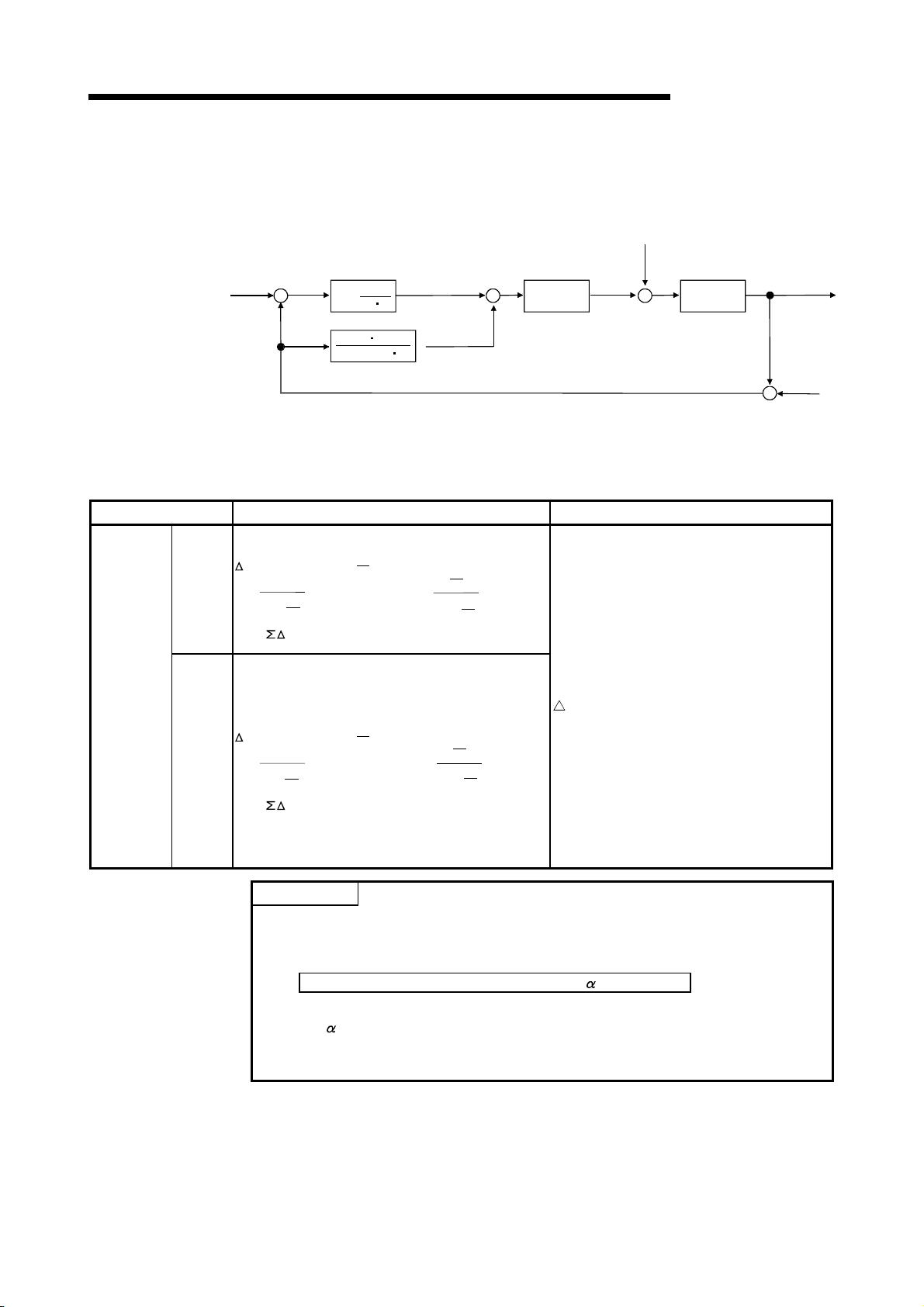

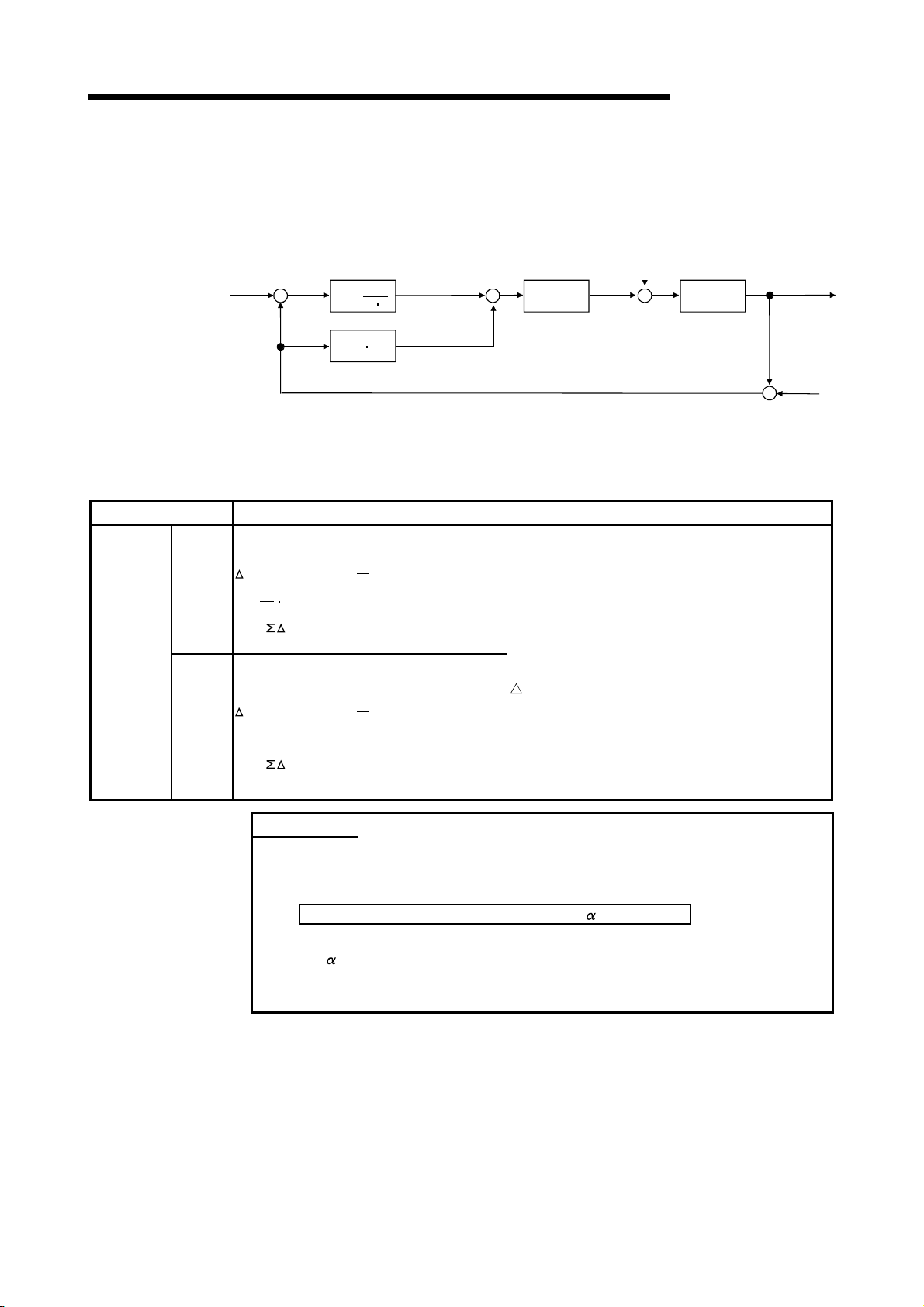

3.1.2 PID operation block diagram and operation expressions

MELSEC-Q/Qn

Name Operation Expressions Meanings of Symbols

Process

value

differentiation

Incomplete

derivative

Forward

operation

Reverse

operation

(1) The PID operation block diagram for incomplete derivative is shown below.

SV +

Set value

Disturbance

1

1

+

s

-

TI

(P)

TD S

1

+(TD/KD) s

(D)

(I)

+

-

Kp P

Gain

Manipulated

value

MV

W

+

Control

objective

(2) The operation expressions for PID control using PID control instructions are

indicated below.

EV

EV

n=PVfn*-SV

MV=Kp{(EVn-EV

T

TS+

D

T

D

K

D

Dn= (PVfn-2PV

MVn= MV

)+ EVn+Dn}

n-1

T

S

T

I

+PV

fn-1

fn-2

T

D

K

D

)+

D

n-1

T

D

+

T

S

K

D

n : Deviation in the present sampling cycle

EV

n-1 : Deviation in the preceding sampling

cycle

SV : Set value

fn : Process value of the present sampling

PV

cycle (after filtering)

fn-1 : Process value of the preceding

PV

sampling cycle (after filtering)

PVfn-2 : Process value of the sampling cycle

two cycles before (after filtering)

EV

n=SV-PVfn*

MV=Kp{(EVn-EV

T

TS+

D

T

D

K

D

Dn= (-PVfn+2PV

MVn= MV

POINT

T

)+ EVn+Dn}

n-1

T

S

I

-PV

fn-1

fn-2

T

D

K

D

)+

D

n-1

T

D

T

+

S

K

D

MV : Output change value

n : Present manipulation value

MV

n : Present derivative term

D

D

n-1 : Derivative term of the preceding

sampling cycle

P : Proportional constant

K

T

S : Sampling cycle

I : Integral constant

T

D : Derivative constant

T

K

D : Derivative gain

(1) *:PVfn is calculated using the following expression.

Therefore, it is the same as the PV (process value) of the input data as long

as the filter coefficient is not set for the input data.

Process Value after Filtering PV

fn= PVn+ (PVfn-1-PVn)

PVn : Process value of the present sampling cycle

: Filter coefficient

PV

fn-1 : Process value of the preceding sampling cycle (after filtering)

fn is stored in the I/O data area. (See Section 5.2)

(2) PV

Process

value

++

Detected

noise

PV

V

3 - 2

Page 23

A

3. PID CONTROL SPECIFICATIONS

3.1.3 PID control instruction list

MELSEC-Q/Qn

Name

S.PIDINIT Sets the reference data for PID operation. * ×

S.PIDCONT

S.PIDSTOP

S.PIDRUN

S.PIDPRMW

A list of the instructions used to execute PID control is given below.

Processing Details

Executes PID operation with the SV (set value)

and the PV (process value).

Stops or starts PID operation for the set loop No.

Changes the operation parameters for the

designated loop number to PID control data.

QCPU QnACPU

* ×

*

CPU Instruction

:

×

×

Usable, ×: Unusable

*: The Basic model QCPU, High Performance model QCPU, Redundant CPU and

Universal model QCPU allow selection of "with/without PID limits".

Refer to Sections 5.1 and 5.2 for details of the setting range when "with/without PID

limits" has been selected.

3 - 3

Page 24

A

3. PID CONTROL SPECIFICATIONS

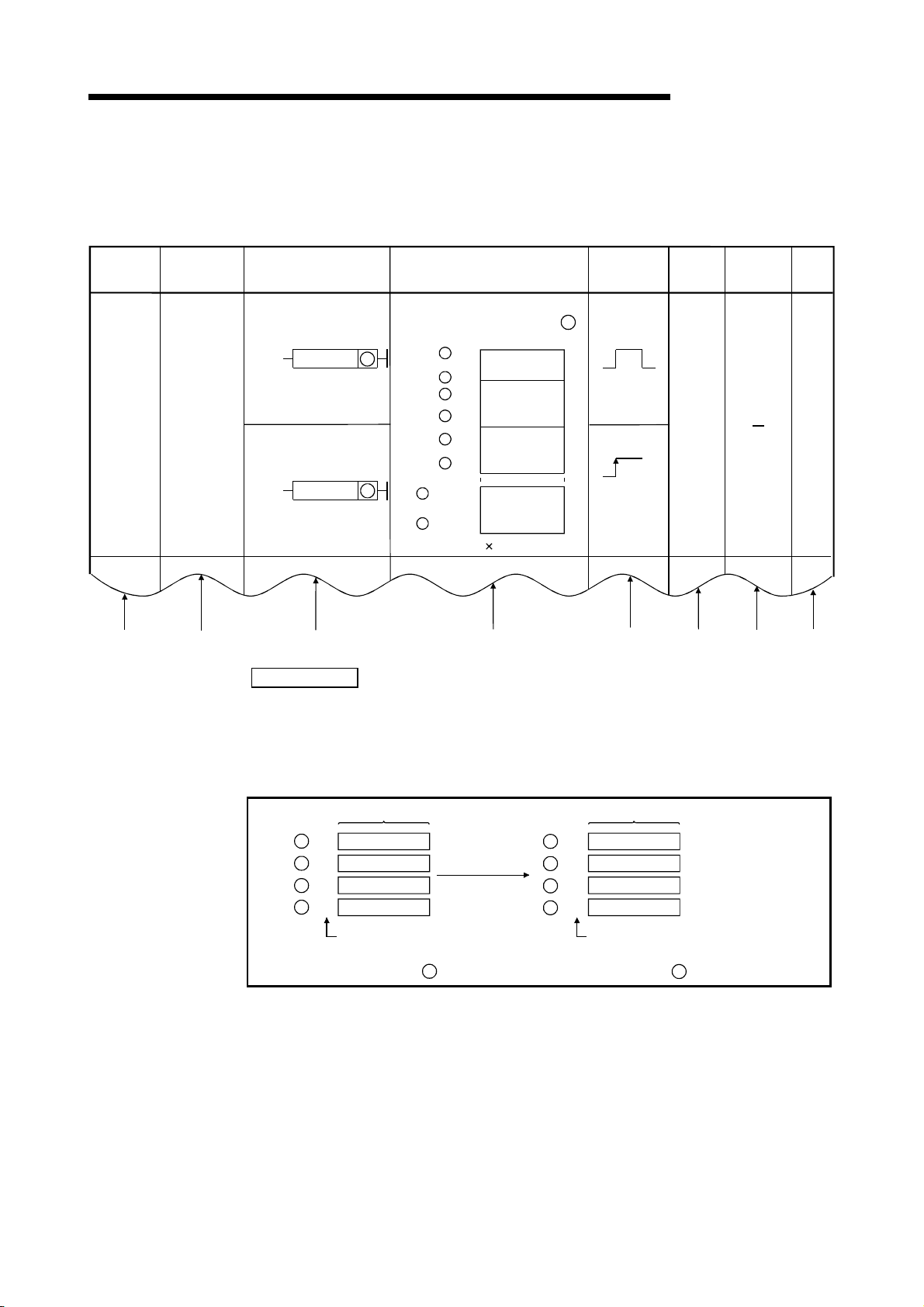

(1) PID control instruction list

The PID control instruction list has the format indicated below:

Table 3.1 How to Read the PID control Instruction List

Category

Contril

data

setting

Instruction

Symbol

S.PIDINIT 7

Ladder Format Processing Details

S.PIDINIT

SP.PIDINIT

S

S

Sets the PID control data stored in

the word device (designated by )

S

+ 0

Common data

to

to

+ 1

+ 2

+ 15

+ 16

+ 29

setting area

For loop 1

For loop 2

to

For loop n

S

S

S

S

S

S

+ (m+0)

to

S

+ (m+13)

m=(n-1) 14+2

S

Excution

Condition

MELSEC-Q/Qn

Number

of Basic

Steps

Subset

Processing

Page

8-2

(4)(3)(2)(1)

(5)

(8)(7)(6)

Explanation

(1) Classification of instructions according to their application.

(2) Instruction names written in a sequence program.

(3) Symbols used in the ladder diagram.

(4) Processing for each instruction.

16-bit data 16-bit data

S

+ 1S

+ 2S

+ 3S

Four consecutive device numbers

(beginning with the device number

designated for )

S

D

D + 1

D

+ 2

D

+ 3

Four consecutive device numbers

(beginning with the device number

designated for )

D

Fig. 3.1 Processing for Each Instruction

3 - 4

Page 25

A

3. PID CONTROL SPECIFICATIONS

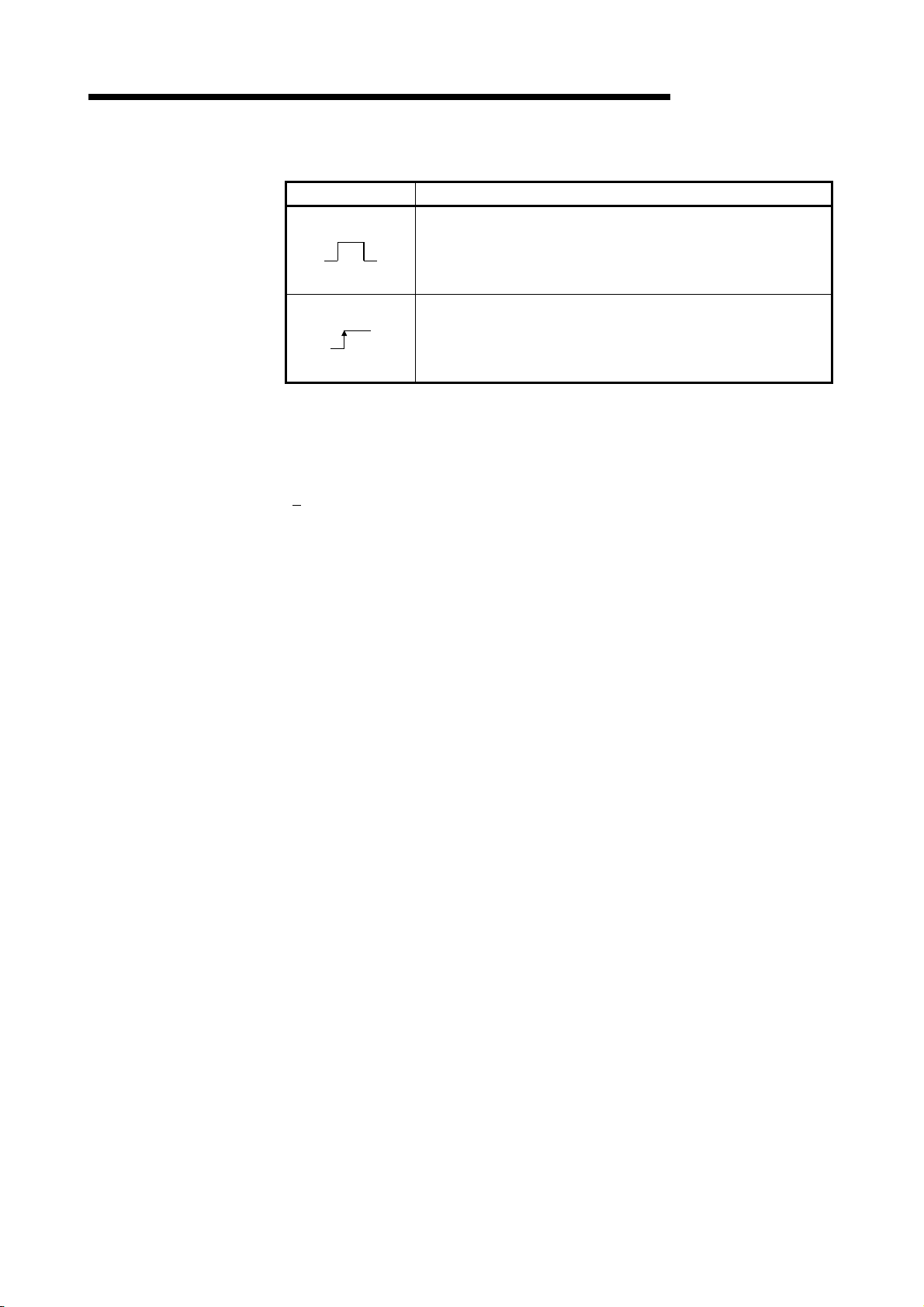

(5) The execution condition for each instruction. Details are given below.

Symbol Execution Condition

(6) Number of instruction steps

For details on the number of steps, refer to the QCPU (Q mode) /QnACPU

Programming Manual (Common Instructions).

(7)

A circle

indicates that subset processing is possible.

indicates that subset processing is impossible.

For details on subset processing, refer to the QCPU (Q mode) /QnACPU

Programming Manual (Common Instructions).

(8) Indicates the page number in this manual where a detailed description for the

instruction can be found.

MELSEC-Q/Qn

Indicates an instruction that is executed for the duration that the

condition for its execution is ON.

When the condition before the instruction is OFF, the instruction is

not executed and no processing is carried out.

Indicates an instruction that is executed once only at the leading

edge (OFF to ON) of the condition for its execution; thereafter the

instruction will not be executed, and no processing will be carried

out, even if the condition is ON.

3 - 5

Page 26

A

3. PID CONTROL SPECIFICATIONS

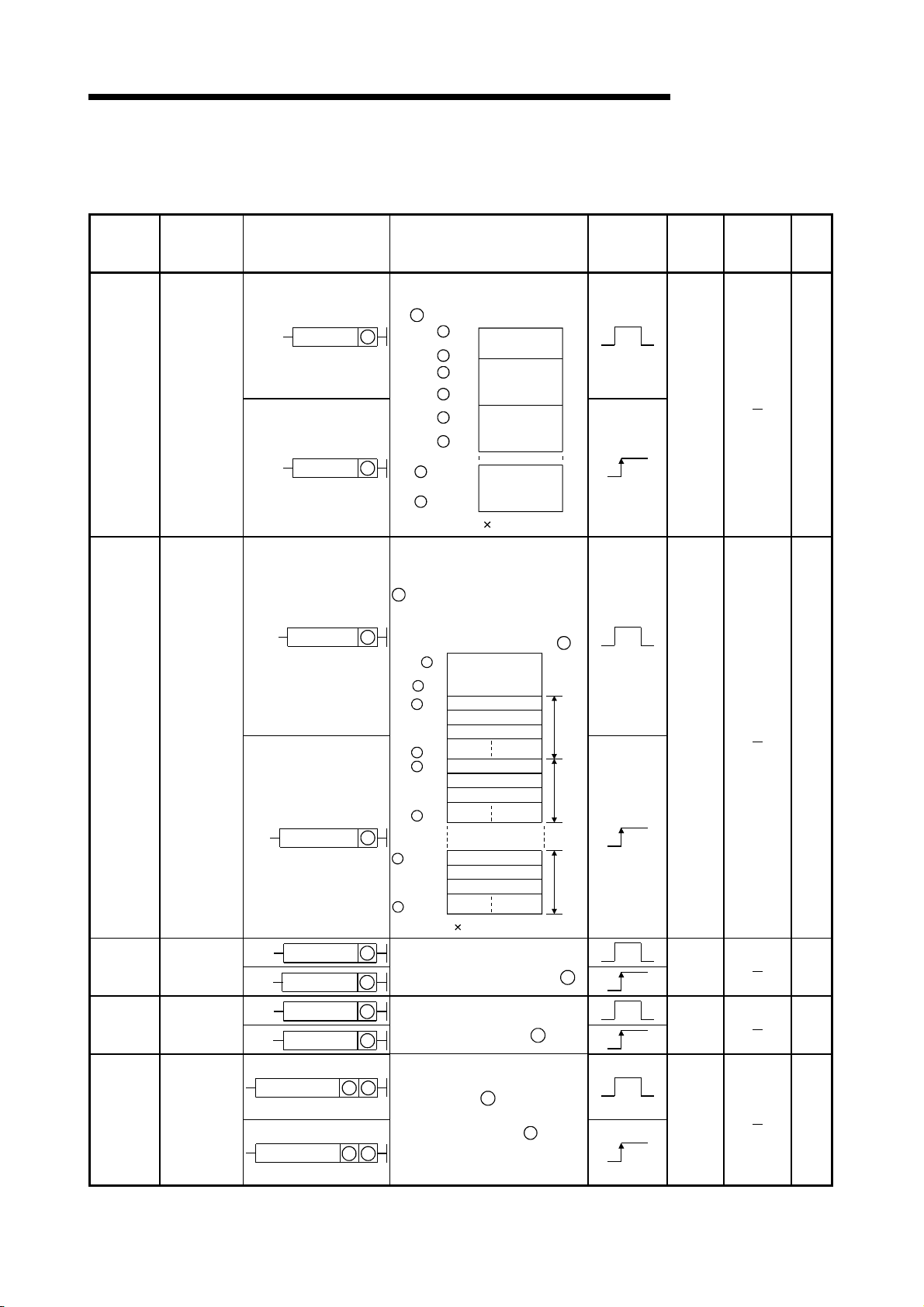

A PID control instruction list is given in Table 3.2.

Table 3.2 PID Control Instruction List

MELSEC-Q/Qn

Category

PID

Control

data

setting

PID

operation

Instruction

Symbol

S.PIDINIT

S.PIDCONT

Ladder Format Processing Details

Sets the PID control data stored

in the word device (designated

).

by

S

S

+ 0

S.PIDINIT S

SP.PIDINIT

S

S

+ (m+0)

to

S

+ (m+13)

Common data

to

to

+ 1

+ 2

+ 15

+ 16

+ 29

setting area

For loop 1

For loop 2

For loop n

S

S

S

S

S

m=(n-1) 14+2

to

Executes PID operation with

the SV (set value) and the PV

(process value) designated by

and stores the PID

S

operation results in the MV

S.PIDCONT S

SP.PIDCONT

(manipulated value) area of the

word device designated by

S

Common data

to

S

S

to

S

S

to

S

S

S

+ (m+0)

to

S

+ (m+22)

m=(n-1) 23+10

setting area

+ 9

SV setting area

+ 10

PV setting area

MV value stor age area

+ 32

SV setting area

+ 33

PV setting area

MV value stor age area

+ 55

SV setting area

PV setting area

MV value stor age area

.

S

For

loop 1

For

loop 2

For

loop n

Execution

Condition

Number

of Basic

Steps

7

7

Subset

Processing

Page

8-2

8-3

Operation

stop

Operation

start

Parameter

change

S.PIDSTOP

S.PIDRUN

S.PIDPRMW

S.PIDSTOP

SP.PIDSTOP

S.PIDRUN

SP.PIDRUN

S.PIDPRMW

SP.PIDPRMW

n

Stops the PID operation at the

loop number designated by n.

n

n

Starts the operation at the loop

number designated by

n

n

.

7

8-5

6

8-5

Changes the operation

n

n

parameter for the loop number

S

designated by n to the PID

control data stored in the word

device designated by S

S

8

8-6

3 - 6

Page 27

A

3. PID CONTROL SPECIFICATIONS

POINT

(1) "PID operation by incomplete derivative" and "PID operation by complete

derivative" can be executed simultaneously since they are independent.

(2) When the S(P).PIDINIT instruction has been used to make initialization, use the

S(P).PIDCONT instruction to perform PID operation.

To stop and start the PID operation of the specified loop No. and to change the

PID control data, use the S(P).PIDSTOP, S(P).PIDRUN and S(P).PIDPRMW

instructions accordingly.

MELSEC-Q/Qn

3 - 7

Page 28

A

3. PID CONTROL SPECIFICATIONS

3.2 PID Control by Complete Derivative

3.2.1 Performance specifications

MELSEC-Q/Qn

Number of PID control loops —

Sampling cycle TS 0.01 to 60.00 s

PID operation method —

PID

constant

setting

range

SV (set value) setting range SV 0 to 2000 -32768 to 32767 0 to 2000

PV (process value) setting range

MV (manipulated value) output range

Proportional constant KP 0.01 to 100.00

Integral constant TI 0.1 to 3000.0 s

Derivative constant T

The performance specifications for PID control are tabled below.

Specification

With PID limits Without PID limits

High

Performance

Item

Basic model

QCPU

8 loops

(maximum)

D 0.00 to 300.00 s

PV

MV

model QCPU,

Redundant

CPU,

Universal model

QCPU

32 loops

(maximum)

Process value differentiation complete derivative

(forward operation/reverse operation)

-50 to 2050 -32768 to 32767 -50 to 2050

Basic model

QCPU

Universal model

8 loops

(maximum)

High

Performance

model QCPU,

Redundant

CPU,

QCPU

32 loops

(maximum)

QnACPU

32 loops

(maximum)

3 - 8

Page 29

A

3. PID CONTROL SPECIFICATIONS

3.2.2 PID operation block diagram and operation expressions

MELSEC-Q/Qn

Name Operation Expressions Meanings of Symbols

Process

value

differentiation

Complete

derivative

Forward

operation

Reverse

operation

(1) The PID operation block diagram for complete derivative is shown below.

SV +

Set value

Disturbance

1

1

+

T

(P)

T

(D)

I S

(I)

D S

-

+

-

Kp P

Gain

Manipulated

value

MV

W

+

+

Control

objective

(2) The operation expressions for PID operation using PID control instructions are

indicated below.

EV

EVn=PVfn*-SV

S

fn-1

T

T

I

+PV

fn-2

MV=Kp{(EVn-EVn-1)+ EVn+Dn}

T

D

Dn= (PVfn-2PV

T

S

MVn= MV

)

n : Deviation in the present sampling cycle

EV

n-1 : Deviation in the preceding sampling cycle

SV : Set value

fn : Process value of the present sampling cycle

PV

(after filtering)

PVfn-1 : Process value of the preceding sampling

cycle (after filtering)

PVfn-2 : Process value of the sampling cycle two

cycles before (after filtering)

EVn=SV-PVfn*

T

fn-1

T

-PV

S

I

fn-2

MV=Kp{(EVn-EVn-1)+ EVn+Dn}

T

D

Dn= (-PVfn+2PV

T

S

MVn= MV

POINT

)

MV : Output change value

MV

n : Present manipulation value

n : Present derivative term

D

P : Proportional constant

K

T

S : Sampling cycle

I : Integral constant

T

D : Derivative constant

T

(1) *:PVfn is calculated using the following expression.

Therefore, it is the same as the PV (process value) of the input data as long

as the filter coefficient is not set for the input data.

Process Value after Filtering PV

fn= PVn+ (PVfn-1-PVn)

PVn : Process value of the present sampling cycle

: Filter coefficient

PV

fn-1 : Process value of the preceding sampling cycle (after filtering)

(2) PV

fn is stored in the I/O data area. (See Section 5.2)

Process

value

++

Detected

noise

PV

V

3 - 9

Page 30

A

3. PID CONTROL SPECIFICATIONS

3.2.3 PID control instruction list

MELSEC-Q/Qn

Name

PIDINIT Sets the reference data for PID operation. *

PIDCONT

PID57

PIDSTOP

PIDRUN

PIDPRMW

A list of the instructions used to execute PID control is given below.

Processing Details

Executes PID operation with the SV (set value)

and the PV (process value).

Used to monitor the results of PID operation at an

AD57(S1).

Stops or starts PID operation for the set loop No.

Changes the operation parameters for the

designated loop number to PID control data.

QCPU QnACPU

*

×

*

CPU Instruction

:

Usable, ×: Unusable

*: The Basic model QCPU, High Performance model QCPU, Redundant CPU and

Universal model QCPU allow selection of "with/without PID limits".

Refer to Sections 5.1 and 5.2 for details of the setting range when "with/without PID

limits" has been selected.

3 - 10

Page 31

A

3. PID CONTROL SPECIFICATIONS

(1) The PID control instruction list

The PID control instruction list has the format indicated below:

Table 3.3 How to Read the PID control Instruction List

Category

PID

control

data

setting

Instruction

Symbol

PIDINIT 29-2

Ladder Format Processing Details

PIDINIT

PIDINITP

S

S

Sets the PID control data stored in

the word device (designated by )

S

+ 0

Common data

to

to

+ 1

+ 2

+ 11

+ 12

+ 21

setting area

For loop 1

For loop 2

to

For loop n

S

S

S

S

S

S

+ (m+0)

to

S

+ (m+9)

m=(n-1) 10+2

S

Excution

Condition

MELSEC-Q/Qn

Number

of Basic

Steps

Subset

Processing

Page

(8)(7)(6)(5)(4)(3)(2)(1)

Explanation

(1) Classification of instructions according to their application.

(2) Instruction names written in a sequence program.

(3) Symbols used in the ladder diagram.

(4) Processing for each instruction.

16-bit data 16-bit data

S

+ 1S

+ 2S

+ 3S

Four consecutive device numbers

(beginning with the device number

designated for )

S

D

D + 1

D

+ 2

D

+ 3

Four consecutive device numbers

(beginning with the device number

designated for )

D

Fig. 3.2 Processing for Each Instruction

3 - 11

Page 32

A

3. PID CONTROL SPECIFICATIONS

(5) The execution condition for each instruction. Details are given below.

Symbol Execution Condition

(6) Number of instruction steps

For details on the number of steps, refer to the QCPU (Q mode) /QnACPU

Programming Manual (Common Instructions).

(7)

A circle

indicates that subset processing is possible.

indicates that subset processing is impossible.

For details on subset processing, refer to the QCPU (Q mode) /QnACPU

Programming Manual (Common Instructions).

(8) Indicates the page number in this manual where a detailed description for the

instruction can be found.

MELSEC-Q/Qn

Indicates an instruction that is executed for the duration that the

condition for its execution is ON.

When the condition before the instruction is OFF, the instruction is

not executed and no processing is carried out.

Indicates an instruction that is executed once only at the leading

edge (OFF to ON) of the condition for its execution; thereafter the

instruction will not be executed, and no processing will be carried

out, even if the condition is ON.

3 - 12

Page 33

A

3. PID CONTROL SPECIFICATIONS

A PID control instruction list is given in Table 3.4.

Table 3.4 PID Control Instruction List

MELSEC-Q/Qn

Category

Instruction

Symbol

PID

control

data

PIDINIT

setting

PID

operation

PIDCONT

Monitoring PID57

Ladder Format Processing Details

Sets the PID control data stored

in the word device (designated

by

).

PIDINIT

PIDINITP

S

S

S

S

S

S

to

S

S

to

S

S

+ (m+0)

to

S

+ (m+9)

m=(n-1) 10+2

+ 0

+ 1

+ 2

+ 11

+ 12

+ 21

Common data

setting area

For loop 1

For loop 2

to

For loop n

Executes PID operation with

the SV (set value) and the PV

(process value) designated by

and stores the PID

S

operation results in the MV

PIDCONT

S

(manipulated value) area of the

word device designated by

S

+ 0

Common da ta

to

S

S

to

S

S

to

S

setting area

+ 9

SV setting area

+ 10

PV setting area

MV value star age area

+ 27

SV setting area

+ 28

PV setting area

MV value star age area

+ 45

PIDCONTP S

S

S

SV setting area

+ (m+0)

PV setting area

to

MV value star age area

+ (m+17)

m=(n-1) 18+10

Monitors the PID operation

results for the AD57 (S1)

PID57

S1

n

(designated by

S2

n

: First I/O number of the

n

).

AD57(S1)

S1

: Monitor screen number

1:Loop 1 to loop 8

2:Loop 9 to loop16

PID57P

S1

S2

n

3:Loop17 to loop24

4:Loop25 to loop32

S2

: Initial screen display

request

.

S

For

loop 1

For

loop 2

For

loop n

Execution

Condition

Number

of Basic

Steps

2

2

4

Subset

Processing

Page

9-2

9-3

9-5

3 - 13

Page 34

A

3. PID CONTROL SPECIFICATIONS

Table 3.4 PID Control Instruction List

MELSEC-Q/Qn

Category

Operation

stop

Operation

start

Parameter

change

Instruction

Symbol

PIDSTOP

PIDRUN

PIDPRMW

Ladder Format Processing Details

PIDSTOP

PIDSTOPP

PIDRUN

PIDRUNP

PIDPRMW

PIDPRMWP

POINT

n

Stops the PID operation at the

loop number designated by n.

n

n

Starts the operation at the loop

number designated by

n

Changes the operation

n

n

parameter for the loop number

S

designated by

control data stored in the word

device designated by

S

n

to the PID

Execution

Condition

n

.

S

Number

of Basic

Steps

Subset

Processing

2

2

3

(1) "PID operation by incomplete derivative" and "PID operation by complete

derivative" can be executed simultaneously since they are independent.

(2) When the PIDINIT(P) instruction was used to make initialization, use the

PIDCONT(P) instruction to perform PID operation.

To stop and start the PID operation of the specified loop No. and to change the

PID control data, use the PIDSTOP(P) instruction, PIDRUN(P) instruction and

PIDPRMW(P) instruction.

Page

9-8

9-8

9-9

3 - 14

Page 35

A

4. FUNCTIONS OF PID CONTROL

MELSEC-Q/Qn

4. FUNCTIONS OF PID CONTROL

This chapter describes PID control performed using the PID control instructions.

4.1 Outline of PID Control

PID control is applicable to process control in which factors such as flowrate, velocity,

air flow volume, temperature, tension, mixing ratio, etc. must be controlled. The control

Set value

for maintaining the control object at the preset value is shown in the diagram below:

CPU module

PID control instructions

Manual MV

SV

PID operation

PV

Manual/automatic

changeover

Fig. 4.1 Application of PID Control Process Control

During PID control, the value measured by the sensor (process value) is compared

with the preset value (set value). The output value (manipulated value) is then adjusted

in order to eliminate the difference between the process value and the set value.

The MV (manipulated value) is calculated by combining the proportional operation (P),

the integral operation (I), and the derivative operation (D) so that the PV is brought to

the same value as the SV quickly and precisely.

The MV is made large when the difference between the PV and the SV is large so as

to bring the PV close to the SV quickly. As the difference between the PV and the SV

gets smaller, a smaller MV is used to bring the PV to the same value as the SV

gradually and accurately.

MV

D/A conversion

module

A/D conversion

module

SV: Set Value

PV: Process Value

MV: Manipulated Value

Controlled

system

Sensor

4

4 - 1

Page 36

A

4. FUNCTIONS OF PID CONTROL

4.2 Functions of PID Control

The operation methods for PID control with the PID control instructions are the velocity

type and process value derivative type. The following describes the control executed

for both of these methods:

4.2.1 Operation method

(1) Velocity type operation

The velocity type operation calculates amounts of changes in the MVs

(manipulated values) during PID operation.The actual MV is the accumulated

amount of change of the MV calculated for each sampling cycle.

(2) Process value derivative type operation

The process value derivative type operation executes PID operations by

differentiating the PV (process value).

Because the deviation is not subject to differentiation, sudden changes in the

output due to differentiation of the changes in the deviation generated by

changing the set value can be reduced.

4.2.2 Forward operation and reverse operation

MELSEC-Q/Qn

Either forward operation or reverse operation can be selected to designate the

direction of PID control.

(1) In forward operation, the MV (manipulated value) increases as the PV (process

value) increases beyond the SV (set value).

(2) In reverse operation, the MV increases as the PV decreases below the SV.

(3) In forward operation and reverse operation, the MV becomes larger as the

difference between the SV and the PV increases.

(4) The figure below shows the relationships among forward operation and reverse

operation and the MV, the PV, and the SV.

(MV)

Reverse

operation

(SV)

(PV)

Forward

operation

4 - 2

Page 37

A

)

4. FUNCTIONS OF PID CONTROL

(5) The figure below shows examples of process control with forward operation and

reverse operation:

Process value

MELSEC-Q/Qn

Set value

Temperature

Forward operation (for cooling)

Set value

Time

Temperature

Reverse operation (for heating

Process value

Time

4 - 3

Page 38

A

4. FUNCTIONS OF PID CONTROL

4.2.3 Proportional operation (P operation)

The control method for proportional operation is described below.

(1) In proportional operation, an MV (manipulated value) proportional to the deviation

(the difference between the set value and process value) is obtained.

(2) The relationship between E (deviation) and the MV is expressed by the following

formula:

MV=Kp • E

Kp is a proportional constant and is called the "proportional gain".

Condition

When proportional gain Kp is

smaller

When proportional gain Kp is

larger

(3) The proportional operation in step response with a constant E (deviation) is

illustrated in Fig. 4.2.

MELSEC-Q/Qn

Proportional Operation

Control operation gets slower.

Control operation gets faster.

However, hunting is more likely to occur.

DeviationMV

Time

Time

Kp

E

.

E

Fig. 4.2 Proportional Operation with a Constant Deviation

(4) A certain error produced relative to a set value is called an offset.

An offset is produced in proportional operation.

Set value Offset Set value Offset

t t

4 - 4

Page 39

A

4. FUNCTIONS OF PID CONTROL

4.2.4 Integral operation (I operation)

The control method for integral operation is described below.

(1) In the integral operation, the MV (manipulated value) changes continuously to

zero deviation when it occurs.

This operation can eliminate the offset that is unavoidable in proportional

operation.

(2) The time required for the MV in integral operation to reach the MV for proportional

operation after the generation of deviation is called the integral time. Integral time

is expressed as T

Condition

When integral time TI is

shorter

When integral time TI is longer Integrating effect decreases and the time to

(3) The integral operation in step response with a constant E (deviation) is illustrated

in Fig. 4.3.

MELSEC-Q/Qn

I.

Integral Operation

Integrating effect increases and the time to

eliminate the offset becomes shorter.

However, hunting is more likely to occur.

eliminate the offset becomes longer.

Deviation

E

Time

MV in "P + I" operations

MV

T

I

Time

MV value in I operation

.

Kp

E

MV value in

P operation

Fig. 4.3 Integral Operation with a Constant Deviation

(4) Integral operation is always used in combination with proportional operation (PI

operation) or with proportional and derivative operations (PID operation).

Integral operation cannot be used independently.

4 - 5

Page 40

A

4. FUNCTIONS OF PID CONTROL

4.2.5 Derivative operation (D operation)

The control method for derivative operation is described below.

(1) In derivative operation, an MV (manipulated value) proportional to the deviation

change rate is added to the system value to zero deviation when it occurs.

This operation prevents significant fluctuation at the control objective due to

external disturbances.

(2) The time required for the MV in the derivative operation to reach the MV for the

proportional operation after the generation of deviation is called the derivative

time. Derivative time is expressed as T

Condition

When derivative time TD is

shorter

When derivative time TD is

longer

(3) The derivative operation when the deviation is a constant value stepped response

is shown in Fig. 4.4.

MELSEC-Q/Qn

D.

Derivative Operation

Differentiating effect decreases.

Differentiating effect increases.

However, hunting of short cycle is more likely

to occur.

Time

Time

DV

K DV

P

Manipulated value for proportional operation

Deviation

Manipulated

value

T

D

Fig. 4.4 Derivative operation when the deviation is a constant

(4) Derivative operation is always used in combination with proportional operation

(PD operation) or with proportional and integral operations (PID operation).

Derivative operation cannot be used independently.

4 - 6

Page 41

A

4. FUNCTIONS OF PID CONTROL

REMARK

About the differences between complete derivative and incomplete derivative

[Incomplete derivative]

Incomplete derivative is PID control that has a primary delay filter in the input of a

derivative term.

The S.PIDCONT instruction is the incomplete derivative PID control instruction.

Incomplete derivative is effective for the following cases.

• Control susceptible to high-frequency noise

• When energy effective to actuate an operation end is not given when a step

change occurs in a complete derivative system

[Complete derivative]

Complete derivative is PID control that uses the input of a derivative term as it is.

The PIDCONT instruction is the complete derivative PID control instruction.

Input

PV

Incomplate derivative

Primary

delay filter

Derivative

term

TD s

1 TD s

MELSEC-Q/Qn

PV 1/

1/ Derivative gain

Time

Time

Complete derivative

Derivative term

TD s

Larger

Time

4 - 7

Page 42

A

4. FUNCTIONS OF PID CONTROL

4.2.6 PID operation

The control method when proportional operation (P operation), integral operation (I

operation), and derivative operation (D operation) are used in combination is described

below.

(1) During PID operation, the system is controlled by the MV (manipulated value)

calculated in the (P + I + D) operation.

(2) PID operation in step response with a constant E (deviation) is illustrated in Fig.

Deviation

4.5.

Deviation

MELSEC-Q/Qn

PID

PID

MV

Time

Incomplete derivative

MV

Complete derivative

Time

Fig. 4.5 PID Operation with Constant Deviation

4 - 8

Page 43

A

4. FUNCTIONS OF PID CONTROL

4.3 Other Functions

During PID control using the PID control instructions, MV upper/lower limit control is

automatically executed by the bumpless changeover function explained below.

4.3.1 Bumpless changeover function

(1) This function controls the MV (manipulated value) continuously when the control

mode is changed between manual and automatic.

(2) When the mode is changed (between manual and automatic), data is transferred

between the "MV area for automatic mode (automatic MV)" and "MV area for

manual mode (manual MV)" as described below.

The control mode is changed in the I/O data area (see Section 5.2).

(a) Changing from the manual ...........

mode to the automatic mode

(b) Changing from the automatic .......

mode to the manual mode

POINT

(1) Manual and automatic modes of PID control:

1) Automatic mode

PID operation is executed with a PID control instruction.

The control object is controlled according to the calculated MV.

2) Manual mode

PID operation is not executed. The MV is calculated by the user and the

(2) The loop set in the manual mode stores the PV (process value) in the set value

control object is controlled according to the user-calculated MV.

area every sampling cycle.

MELSEC-Q/Qn

The MV in the manual mode is transmitted to

the MV area for the automatic mode.

The MV in the automatic mode is transmitted

to the MV area for the manual mode.

4 - 9

Page 44

A

4. FUNCTIONS OF PID CONTROL

4.3.2 MV upper/lower limit control function

(1) The MV upper/lower limit control function controls the upper or lower limit of the MV

calculated in the PID operation. This function is only effective in the automatic

mode. It cannot be executed in the manual mode.

(2) By setting the MV upper limit (MVHL) and the MV lower limit (MVLL), the MV

calculated in the PID operation can be controlled within the range between the

limits.

EV (deviation)

MVHL

(MV upper limit)

MVLL

(MV lower limit)

Fig. 4.6 Operation in Accordance with the MV Upper/Lower limit

MELSEC-Q/Qn

MV

without limit

AUTO

control

MV

AUTO

(3) When the MV upper/lower limit control is used, the MV is controlled as illustrated

above.

A MVHL (MV upper limit) and MVLL (MV lower limit) takes on a value between -50

and 2050 or a user-defined value (except the QnACPU).

The following are the default settings:

• Upper limit ..................2000 (Or user-defined value)

• Lower limit ..................0 (Or user-defined value)

The value set for the upper limit must not be smaller than the value set for the lower

limit.

An error will occur if it is.

4 - 10

Page 45

A

4. FUNCTIONS OF PID CONTROL

4.3.3 Monitoring PID control with the AD57(S1) (QnACPU only)

The PID control operation results can be monitored in a bar graph with an AD57(S1)

CRT controller unit.

(1) The monitor screen displays the monitored information of eight loops beginning

Bar graph display

The SV, PV, and MV of each loop

are displayed as percentages in a

bar graph.

If the MV percentage is in the

range of -2.5% MV 0%, a " "

will bedisplayed at the 0% position.

If the MV percentage is between

100% and 102.5%, a " " will be

displayed above the bar graph.

Limit operation status display

If an SV, PV, and/or MV limiter is

activated, the corresponding

character is highligted.

with the designated loop number.

Loop number display

Display the loop number (1 to 32).

LOOP 1 LOOP 2 LOOP 3 LOOP 4 LOOP 5 LOOP 6 LOOP 7 LOOP 8

M

SP

SV 50 %

PV 40 %

MV 73 %

PV MV

100

80

60

40

20

0

M

SP

SV 91 %

PV 95 %

MV 21 %

PV MV

100

80

60

40

20

0

Device display

Display the device in which the

PID data (SV and PV) are stored.

100

80

60

40

20

0

M

SP

SV 30 %

PV 60 %

MV 50 %

PV MV

100

80

60

40

20

0

M

S

P

SV 88 %

PV 10 %

MV 100 %

PV MV

100

80

60

40

20

0

SP

SV 40 %

PV 15 %

MV 83 %

PV MV

MELSEC-Q/Qn

Device number display

Display the first device number

of the devices in which the PID

value (SV and PV) are stored.

DEVICE R NO. 80

100

80

60

40

20

0

M

SPM

SV 100 %

PV 45 %

MV 100 %

PV MV

100

80

60

40

20

0

SPM

SV 61 %

PV 0 %

MV 92 %

PV MV

100

80

60

40

20

0

M

SP

SV 5 %

PV 1 %

MV 25 %

PV MV

Present value display

The SV, PV, and MV present values

for each loop are displayed as

percentages.

Alarm status display

If the PV exceeds the preset PVL

and/or the MV exceeds the preset

MVL, the corresponding character

is highlighted.

POINT

The SV, PV, and MV present value are displayed as percentages of 2000.

SV

PV

MV

100 (%)

100 (%)

100 (%)

1) SV percentage display ...............

2) PV percentage display ...............

3) MV percentage display...............

2000

2000

2000

(2) Use the PID57 instruction to execute monitoring with an AD57(S1).

See Section 9.1.3 for details on the PID57 instruction.

4 - 11

Page 46

A

4. FUNCTIONS OF PID CONTROL

MELSEC-Q/Qn

4.3.4 Function for transfer to the SV storage device for the PV in manual mode

When using the PID control instruction to perform PID control, execute the PID

PID Bumpless Processing Flag

SM794

(Incomplete derivative)

operation instruction also in the manual mode.

In the manual mode, it is possible to select whether the PV imported from the A/D

converter module is transferred to the SV storage device or not when the PID

operation instruction is executed, depending on the ON/OFF status of the PID

bumpless processing flag (SM774, SM794).

SM774

(Complete derivative)

OFF

ON

POINT

• The PV is transferred to the SV storage device when the PID operation

instruction is executed.

• When the manual mode is switched to the automatic mode, the MV

output in the manual mode is continued.

• When the SV is changed after switching to the automatic mode,

control is performed to achieve the SV, starting from the MV output in

the manual mode.

• The PV is not transferred to the SV storage device when the PID

operation instruction is executed.

• When the manual mode is switched to the automatic mode, control is

performed to achieve the SV, starting from the MV output in the

manual mode.

• Before switching to the automatic mode, store the SV into the SV

storage device.

Operation

Depending on whether SM774/SM794 is ON or OFF, there are the following

differences in control when the manual mode is switched to the automatic mode.

• When SM774/SM794 is OFF, the PV is transferred to the SV storage device.

Therefore, there is no difference between the PV and SV when the manual mode

is switched to the automatic mode.

Hence, an abrupt change does not occur in MV at the time of mode switching.

Instead, since the SV after mode switching differs from the target value in the

automatic mode, the user should change the SV to the target value step by step

in the sequence program.

• When SM774/SM794 is ON, the PV is not transferred to the SV storage device.

Therefore, there is a difference between the PV and SV when the manual mode

is switched to the automatic mode.

If the difference is large at the time of mode switching, an abrupt change may

occur in MV.

Use this method in a system where the mode is switched when the PV has fully

neared the SV.

PID control in the automatic mode can be executed immediately without the SV

being changed step by step in the sequence program.

REMARK

The SV and PV are stored into the devices specified in the I/O data area with the

PID operation instruction.

4 - 12

Page 47

A

4. FUNCTIONS OF PID CONTROL

MELSEC-Q/Qn

4.3.5 Changing the PID control data or input/output data setting range (QCPU only)

The setting ranges of the following data of the PID control data (refer to Section 5.1)

and I/O data (refer to Section 5.2) can be changed as desired by user setting.

Item Set Data

MV lower limit value

PID control data

I/O data

To make the user setting valid, turn the bit corresponding to the relevant loop of the

PID limit setting special register (SD774, SD775, SD794, SD795) to "1".

PID Limit Setting Special Register

Incomplete derivative Complete derivative

SD794 SD774

SD795 SD775

POINT

The Basic model QCPU has 8 loops.

b0 to b7 of SD774 and SD794 are valid.

b15

0/1

b15

0/1

MV upper limit value

MV change rate limit value

PV change rate limit value

SV

PV

Automatic MV

PV after filtering

Manual MV

Setting Range

b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

0/1

LOOP 15

LOOP 16

b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

0/1

LOOP 31

LOOP 32

LOOP 8

0: With PID limit (system fixed value)

1: Without PID limit (user setting)

0/1b10/1

0/1b10/1

b0

LOOP 1

LOOP 2

b0

LOOP 17

LOOP 18

4 - 13

Page 48

A

4. FUNCTIONS OF PID CONTROL

MEMO

MELSEC-Q/Qn

4 - 14

Page 49

A

5. PID CONTROL PROCEDURE

MELSEC-Q/Qn

5. PID CONTROL PROCEDURE

Changing the PID control data

Changing the SV (set value)

Automatic/manual mode change

of MV (manipulated value)

The programming procedure required to execute PID control is shown below.

Programming Procedure

Setting the PID control data

Set the PID control data in the

word devices.

Executing the PID control data

setting instruction *

Enter in the CPU module the PID

control data set in the word devices

by executing the PID control data

setting instruction.

Setting the initial processing flag

Set the initial processing flag in

the I/O data.

Setting the SV (set value)

Set the SV (set value) in the

I/O data.

See Section 5.1 for details on the

setting items and setting procedure.

See Section 8.1.1/9.1.1 for details on the

instruction.

See Section 5.2 for details on

I/O data.

See Section 5.2 for details on

I/O data.

5

Select manual mode?

NO (automatic mode)

Selecting automatic MV control

Set the manual/automatic selection

for I/O data to automatic

Reading/setting the PV

After reading the data from the A/D

converter module, set it in the PV

area of the I/O data area.

(1)

(2)

YES (manual mode)

Selecting manual MV control

Set the manual/automatic selection

for I/O data to manual.

Setting the manually controlled

MV (MV

Set the manual MV(MV

the I/O data.

MAN

See Section

5.2 for details

on I/O data.

)

) in

MAN

REMARK

*: The following instructions are available as the PID control data setting instructions.

S.PIDINIT (incomplete derivative)

PIDINIT (complete derivative)

5 - 1

Page 50

A

5. PID CONTROL PROCEDURE

MELSEC-Q/Qn

(2)(1)

Executing the PID operation

instruction

Using the PID operation instruction,

execute PID operation based on the

PID control data set in the word

devices and the I/O data.

Outputting the MV (manipulated

value)

The MV obtained from the PID

operation result is read, and written

to the D/A converter module.

Mounitoring with the AD57(S1)

(QnACPU only)

Using an AD57(S1) monitor the

controlled conditions by executing

a PID57 instruction.

1

*

See Section 8.1.2/9.1.2 for details on

the instruction.

The MV, obtained from the PID

operation result, is stored in the

I/O data area.

See Section 5.2 for details on

I/O data.

See Section 9.1.3 for details on

the instruction.

Thus step is not necessary

when monitoring with an

AD57(S1) is not required.

POINT

• Registering or changing the PID control data per sequence program scan will

present no problem.

However, execute the the PID control data setting instructions *

2

when you

registered or changed the PID control data.

If you do not execute the PID control data setting instructions instruction, the data

registered or the correction made to the PID control data will not be reflected at

the execution of the the PID operation instructions.

• You need not execute the PID control data setting instructions when using the

parameter change instruction *

3

to change the PID control data per loop.

REMARK

*1: The following instructions are available as the PID operation instructions.

S.PIDCONT (incomplete derivative)

PIDCONT (complete derivative)

*2: The following instructions are available as the PID control data setting

instructions.

S.PIDINIT (incomplete derivative)

PIDINIT (complete derivative)

*3: The following instructions are available as the parameter change instructions.

S. PIDPRMW (incomplete derivative)

PIDPRMW (complete derivative)

5 - 2

Page 51

A

5. PID CONTROL PROCEDURE

MEMO

MELSEC-Q/Qn

5 - 3

Page 52

A

5. PID CONTROL PROCEDURE

5.1 PID Control Data

MELSEC-Q/Qn

Common

setting

data

Data for

each loop

Data

No.

1

2

1

2

3

4

5

6

(1) PID control data is used to set the reference values for PID operation.

Store the PID control data into the CPU module with the PID control data setting

instruction before executing PID operation instruction

The PID control data is classified into two types, "common data for all loops" and

"data for individual loops".

(a) For Basic model QCPU

Table 5.1 PID Control Data List

Data Item Description

Number of

loops

Number of

loops in one

scan

Selection of

operational