Page 1

High Speed Data Logger Module User's Manual

-QJ81DL96

-SW1DNN-DLUTL-E (High Speed Data Logger Module Tool)

Page 2

Page 3

SAFETY PRECAUTIONS

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

WARNING

(Always read these precautions before using this equipment)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

Note that these precautions apply only to this product. For the safety precautions of the programmable

controller system, please read the User's Manual for the CPU module used.

In this manual, the safety instructions are ranked as ' WARNING' and ' CAUTION'.

Note that the CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[Design precautions]

WARNING

Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable

controller. Failure to do so may result in an accident due to an incorrect output or malfunction.

For the operating status of each station after a communication failure, refer to relevant manuals for

the network. Erroneous outputs and malfunctions may lead to accidents. Not doing so can cause an

accident due to false output or malfunction.

To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

A - 1

Page 4

[Design precautions]

WARNING

When changing data of the running programmable controller from a peripheral connected to the

CPU module or from a personal computer connected to an intelligent function module or special

function module, configure an interlock circuit in the sequence program to ensure that the entire

system will always operate safely. For program modification and operating status change, read

relevant manuals carefully and ensure the safety before operation.

Especially in the above mentioned control operations that are performed from an external device to a

remote programmable controller, any problems on the programmable controller side may not be

dealt with promptly due to abnormal data communication. To prevent this, configure an interlock

circuit in the sequence program, and determine corrective actions to be taken between the external

device and CPU module in case of a communication failure.

Do not write any data in the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the programmable controller

CPU to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

CAUTION

Do not bundle the control wires and the communication cables with the main circuit and the power

wires, and do not install them close to each other. They should be installed at least 100 mm (3.94 in.)

away from each other. Failure to do so may generate noise that may cause malfunctions.

During registering each setting, do not power OFF the mounted module or reset the programmable

controller CPU.

Otherwise, data in the CompactFlash card will be undefined. Therefore, resetting and re-registering

data are required.

This may also cause a module failure or malfunctions.

A - 2

Page 5

[Installation precautions]

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

user's manual for the CPU module used. Using the programmable controller in any other operating

environments may cause electric shocks, fires or malfunctions, or may damage or degrade the

module.

While pressing the installation lever located at the bottom of module, insert the module fixing tab into

the fixing hole in the base unit until it stops. Then, securely mount the module with the fixing hole as

a supporting point.

If the module is not installed properly, it may cause the module to malfunction, fail or fall off.

Secure the module with screws especially when it is used in an environment where constant

vibrations may occur.

Be sure to tighten the screws using the specified torque. If the screws loose, it may cause the

module to short-circuit, malfunction or fall off. If the screws are tightened excessively, it may damage

the screws and cause the module to short-circuit, malfunction or fall off.

Before mounting/dismounting the module, be sure to shut off all phases of external power supply

used by the system.

Failure to do so may cause product damage.

Do not directly touch any conductive part or electronic component of the module.

This may cause the module to malfunction or fail.

Push the CompactFlash card into the CompactFlash card slot and install it securely.

After installing the CompactFlash card, check that it is inserted securely.

Failure to do so may cause malfunctions due to poor contact.

A - 3

Page 6

[Wiring precautions]

CAUTION

Connectors for external connection must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered.

If the connection is incomplete, it may cause the module to short circuit, catch fire, or malfunction.

Install connectors securely to modules.

Make sure to place the communication and power cables to be connected to the module in a duct or

fasten them using a clamp. If the cables are not placed in a duct or fastened with a clamp, their

positions may be unstable or moved, and they may be pulled inadvertently.

This may damage the module and the cables or cause the module to malfunction because of faulty

cable connections.

When disconnecting the communication and power cables from the module, do not pull the cables

by hand.

When disconnecting a cable with a connector, hold the connector to the module by hand and pull it

out to remove the cable.

When disconnecting a cable connected to a terminal block, loosen the screws on the terminal block

first before removing the cable. If a cable is pulled while being connected to the module, it may

cause the module to malfunction or damage the module and the cable.

Be careful not to let any foreign matter such as wire chips get inside the module. They may cause

fire, as well as breakdowns and malfunctions of the module.

A protective sheet is pasted on the upper part of the module in order to prevent foreign matter such

as wire chips to get inside the module while wiring.

Do not remove this protective sheet during wiring work.

However, be sure to remove the protective sheet before operating the module to allow heat radiation

during operation.

A - 4

Page 7

[Startup and maintenance precautions]

WARNING

Do not touch any terminal during power distribution.

Doing so may cause malfunctions.

Always switch OFF the external supply power used by the system in all phases before cleaning or

retightening terminal screws.

Failure to do so may cause a failure or malfunction of the module.

If the screws loose, it may cause the module to short-circuit, malfunction or fall off.

If the screws are tightened excessively, it may damage the screws and cause the module to shortcircuit, malfunction or fall off.

CAUTION

Do not disassemble or transform the module.

Doing so may cause a failure, malfunctions, personal injuries, and/or a fire.

Before mounting/dismounting the module, be sure to shut off all phases of external power supply

used by the system.

Failure to do so may cause product damage.

Do not install/remove the module to/from the base unit more than 50 times after the first use of the

product. (IEC 61131-2 compliant)

Failure to do so may cause malfunction.

Before handling a module, touch a grounded metal object to discharge the static electricity from your

body.

Failure to do so may cause a failure or malfunction of the module.

[Operating precautions]

WARNING

Ensure safety before controlling a running programmable controller (e.g. data modification).

Do not write any data in the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the programmable controller

CPU to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

[Disposal precautions]

CAUTION

Dispose of this product as an industrial waste.

A - 5

Page 8

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 6

Page 9

REVISIONS

Correction

Addition

Correction

*The manual number is given on the bottom left of the back cover.

Print date *Manual number Revision

Jun., 2009 SH-080818ENG-A First edition

Jun., 2009 SH-080818ENG-B

Oct., 2009 SH-080818ENG-C

Section 2.2

Section 3.4.2, Section 11.4.9, Appendix 8

HOW TO USE THIS MANUAL, Section 1.1, Section 2.1.3, Section 2.1.4,

Section 2.5, Section 3.1.1, Section 3.4, Section 3.8, Section 4.2.3, Section 4.5,

Section 7.5.2, Section 9.1, Section 11.2.4, Section 11.2.6, Section 11.2.7,

Section 11.2.9, Section 11.3.4, Section 11.4 to 11.4.8, Section 11.5.1,

Section 11.5.4, Section 11.5.8 to 11.5.12, Section 11.5.15, Section 11.6.1,

Section 11.6.4, Section 11.6.6 to 11.6.8, Section 11.6.10, Section 11.6.13,

Section 11.7.1, Section 11.7.3 to 11.7.7, Section 12.3, Section 13.1 to 13.1.9,

Section 14.3.4, Section 14.10.2, Section 14.10.3, Section 15.5, Section 15.6,

Section 17.1.1, Section 17.1.2, Section 17.2, Section 17.3.2 to 17.3.5,

Section 17.3.8, Section 17.3.9, Appendix 4.1, Appendix 5

Section 3.4.2 to 3.4.15 changed to Section 3.4.3 to 3.4.16

Appendix 8 changed to Appendix 9

A - 7

Page 10

Print date *Manual number Revision

Addition

Correction

Deletion

Correction

Addition

Correction

Correction

CONDITIONS OF USE FOR THE PRODUCT, RELATED MANUALS

Section 3.4.9, Section 3.8, Section 7.2.1, Section 7.2.2, Section 10.5,

Section 10.6, Section 11.2.10, Section 11.3.4, Section 11.3.5, Section 11.7.5,

Section 13.1.10, Chapter 14, Section 15.6, Section 17.3.10, Appendix 10

PRECAUTIONS FOR USE, INTRODUCTION, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS,

DEFINITIONS AND DESCRIPTIONS OF TERMS, Section 1.1, Section 1.3,

Section 2.1.1, Section 2.2, Section 2.3, Section 2.4, Section 2.5, Section 3.1,

Section 3.2, Section 3.3.1, Section 3.3.2, Section 3.4, Section 3.4.12,

Section 3.4.14, Section 3.4.16, Section 3.5, Section 4.2.1, Section 4.2.2,

Section 4.5, Chapter 5, Section 5.1, Section 5.2.1 to 5.2.3, Section 5.4,

Section 5.4.1 to 5.4.3, Chapter 6, Section 7.2, Section 7.5.4, Section 8.2,

Section 8.4.4, Section 9.2, Section 9.5.3, Section 10.3, Section 11.2,

Jun., 2010 SH-080818ENG-D

Section 11.2.2, Section 11.2.6, Section 11.2.7, Section 11.2.9,

Section 11.4.3 to 11.4.7, Section 11.5.1, Section 11.5.4 to 11.5.6,

Section 11.5.12, Section 11.5.15, Section 11.6.1, Section 11.6.4,

Section 11.6.7, Section 11.6.13, Section 11.6.14, Section 11.7.1,

Section 11.7.3, Chapter 12, Chapter 13, Section 13.1, Section 13.1.1,

Section 13.1.3, Section 13.1.4, Section 13.2, Section 15.5,

Section 15.7, Chapter 17, Section 17.2, Section 17.3.2, Section 17.3.3,

Section 17.3.8, Section 17.3.9, Appendix 4.1 to 4.3, Appendix 5, Appendix 9

Aug., 2010 SH-080818ENG-E

Dec., 2010 SH-080818ENG-F

Jun., 2011 SH-080818ENG-G

Section 3.4.9 to 3.4.16 changed to Section 3.4.10 to 3.4.17,

Section 3.8 changed to 3.9,

Section 5.2 to 5.3 changed to Section 5.1 to 5.2,

Section 11.3.4 changed to Section 11.3.6,

Section 11.7.5 to 11.7.8 changed to Section 11.7.6 to 11.7.9,

Section 15.6 changed to Section 15.7

Section 3.1.1, Section 3.1.2, Section 5.1, Section 5.5, Chapter 14

Section 2.3, Section 3.2, Section 3.3.2

Appendix 11

RELATED MANUALS, COMPLIANCE WITH THE EMC AND LOW VOLTAGE

DIRECTIVES, Section 3.1, Section 3.6.2, Section 4.4.2, Section 10.5,

Section 11.5.15, Section 11.6.13, Section 11.7.8, Section 15.7, Section 17.2,

Section 17.3.4

Section 3.1, Section 4.3, Section 11.2.10, Section 11.4.5, Section 11.5.15,

Section 11.6.13, Section 11.7.5, Section 11.7.8, Section 12.2, Section 17.1.2,

Section 17.2, Section 17.3.5

A - 8

Page 11

Print date *Manual number Revision

Addition

Correction

Correction

Correction

Addition

Correction

Correction

Addition

Correction

Section 16.3.3

Section 2.4, Section 3.2, Section 5.2.1, Section 10.3, Section 11.2.7,

Sep., 2011 SH-080818ENG-H

Section 11.2.8, Section 11.2.9, Section 11.2.10, Section 11.3.4,

Section 11.4.3, Section 11.4.4, Section 11.5.5, Section 11.5.6,

Section 11.5.15, Section 11.6.7, Section 11.6.14, Section 11.7.5,

Section 12.2, Section 12.4, Section 13.1.1, Section 13.2, Chapter 14,

Section 14.2.1, Section 14.5.1, Section 14.5.2, Section 17.3.9

Oct., 2011 SH-080818ENG-I

Mar., 2012 SH-080818ENG-J

Dec., 2012 SH-080818ENG-K

Jun., 2013 SH-080818ENG-L

PRECAUTIONS FOR USE, Section 2.3, Section 4.5, Section 10.3, Section 15.3,

Section 17.3.1, Section 17.3.4, Section 17.3.9, Appendix 5, Appendix 11

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

Section 1.1, Section 2.1.1, Section 2.2, Section 2.4, Section 3.1, Section 3.2,

Section 3.4.13, Section 3.6, Section 3.7.1, Section 3.7.2, Section 4.3,

Section 4.5, Section 10.5, Section 10.6, Section 11.4.3, Section 11.5.1,

Section 11.5.15, Section 11.6.1, Section 11.6.13, Section 11.7.4, Section 11.7.5,

Section 17.2, Section 17.3.6, Section 17.3.9, Appendix 5, Appendix 10

Section 2.6.2, Section 5.3.3, Chapter 14, Section 18.3.10, Appendix 12

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

Section 1.1, Section 1.3, Section 2.1.2, Section 2.1.4, Section 2.2, Section 2.3,

Section 2.4, Section 3.1, Section 3.2, Section 3.6.3, Section 4.5, Section 5.1,

Section 5.2, Chapter 6, Section 7.2.1, Section 7.2.2, Section 11.2.2,

Section 11.4.2, Section 11.5.10, Section 11.5.11, Section 13.3.2,

Chapter 14 to 17 changed to Chapter 15 to 18,Section 18.3.9, Appendix 4.1,

Appendix 5

PRECAUTIONS FOR USE, Section 2.3, Section 16.3, Section 18.3.1

Oct., 2013 SH-080818ENG-M

Section 2.7

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

DEFINITIONS AND DESCRIPTIONS OF TERMS, Section 1.1, Section 2.2,

Section 2.4, Section 2.5, Section 3.1, Section 3.2, Section 3.3.1, Section 3.3.2,

Section 3.4.1, Section 5.2, Section 5.2.1 to Section 5.2.3, Section 5.3.2,

Section 5.4, Section 7.2, Section 7.2.1, Section 8.2, Section 9.2, Section 10.1,

Section 10.3, Section 11.4.2, Section 11.4.4, Section 11.4.5, Section 11.5.4,

Section 11.5.15, Section 11.6.4, Section 11.6.13,

Section 11.7.3 to Section 11.7.5, Section 11.7.7, Section 11.7.8, Section 17.2,

Section 17.3.1, Section 17.3.3, Section 18.1.3, Section 18.2,

Section 18.3.1 to Section 18.3.2, Section 18.3.6, Section 18.3.9, Appendix 5

A - 9

Page 12

Print date *Manual number Revision

Addition

Correction

Correction

Addition

Correction

Addition

Correction

Correction

Correction

Appendix 8.2

Nov., 2013 SH-080818ENG-N

PRECAUTIONS FOR USE, Section 3.4.8, Section 4.5, Section 11.4.3,

Section 18.2, Section 18.3.4, Section 18.3.5, Appendix 5, Appendix 8

Apr., 2014 SH-080818ENG-O

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

Section 2.4, Section 3.1, Section 3.2, Section 5.2, Section 5.3.2, Section 5.4,

Section 10.3, Section 11.4.1, Section 13.3.2, Section 18.3.9, Appendix 5

Aug., 2014 SH-080818ENG-P Section 2.3, Section 11.4.1, Appendix 10

Dec., 2014 SH-080818ENG-Q

Section 2.6.3

Section 2.2, Section 3.2, Section 11.7.5, Section 18.3.2, Section 18.3.6

Section 2.6.4, Section 3.4.17

Sep., 2015 SH-080818ENG-R

Section 3.1, Section 3.4, Section 4.3, Section 4.5, Section 11.4.4, Section 18.2,

Appendix 5

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

Section 2.2, Section 2.4, Section 3.2, Section 3.4.6, Section 3.4.7, Section 4.5,

Mar., 2016 SH-080818ENG-S

Section 4.6.1, Section 4.6.2, Section 5.2, Section 5.2.1, Section 5.3.1,

Section 5.3.2, Section 5.4, Section 10.3, Section 10.4, Section 13.3.3,

Section 18.1.1, Section 18.2, Section 18.3.2, Section 18.3.6, Section 18.3.9,

Appendix 5, WARRANTY

Oct., 2016 SH-080818ENG-T

PRECAUTIONS FOR USE, Section 10.5, Section 16.3, Section 18.3.8

Japanese Manual Version SH-080801-U

This manual confers no industrial rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 2009 MITSUBISHI ELECTRIC CORPORATION

A - 10

Page 13

PRECAUTIONS FOR USE

Network connection precautions

Performance/specification precautions

This section explains the precautions in the order listed below.

Network connection precautions

Performance/specification precautions

Data logging, event logging, and report functions precautions

Other function precautions

Precautions when accessing the high speed data logger module

Security precautions

CompactFlash card precautions

Precautions when using a redundant system

Recipe function precautions

Precautions when using Logging File Conversion Tool

(1) Mail server and FTP server connections

When immediately turning the power ON after turning the power OFF, connections to

mail servers or FTP servers may fail.

Turn the programmable controller OFF, wait several minutes then turn it ON.

(1) Programmable controller CPU sequence scan time

When using the high speed data logger module, the programmable controller CPU

sequence scan time may increase. Design your system and programs keeping in

mind this increase in sequence scan time.

CHAPTER 17 PROCESSING TIME

(2) Network connection using Ethernet

When connecting to Ethernet network, basically configure the communication route to

the access target via Ethernet (twisted pair) cables and hubs.

Note that when accessing via wireless LAN (Wi-Fi) or router, an error such as timeout

or missing data occurs, and cannot be communicated properly depending on the

status of the equipment (wireless LAN (Wi-Fi) or router) on the network or the access

route.

(3) Time handled on the high speed data logger module

Two types of times handled on the high speed data logger module are available.

Programmable controller CPU time

Time obtained by the SNTP server function

For errors and the timing of setting the time, refer to the following sections.

Section 3.1 Performance Specifications

Section 11.4.2 Time synchronization setting

(4) High speed data sampling

The high speed data sampling function is not compatible with other stations' CPUs

routing the network.

A - 11

Page 14

(1) Data logging, event logging, and report functions

Data logging, event logging, and report functions precautions

(a) The data logging, event logging, and report functions of the high speed data

logger module are the best effort functions.

Since module processing time changes according to the settings and status of

other devices, it may not operate with the set data sampling interval. Run the

system by fully verifying the processing time of each function when constructing it.

For processing time, refer to the following chapter.

CHAPTER 17 PROCESSING TIME

(b) If data logging, event logging, or report functions are used, they have an affect on

the sequence scan time of the access target CPU. Run the system by fully

verifying the affect to the sequence scan time when constructing it. For the affect

to the sequence scan time, refer to the following section.

Section 17.3 Effect on Sequence Scanning Time

(c) If exponential format is selected for the data output format with the data logging,

event logging, or report setting, rounding errors will occur in the range of the

number of digits that exceed the number of digits set for the decimal part.

(d) If the result of the linear function transformation with the scaling function exceeds

the maximum or minimum range of the specified output format, the maximum or

minimum value is output in binary format. Therefore, when outputting in the binary

format, errors may occur in the output values.

(e) E-mail transmissions/file transfers via the saved file transfer function may take a

few seconds to tens of seconds depending on the network line/transmission size.

Target files may be deleted before e-mail transmission/file transfer completes

depending on the settings.

Review the file switching timing and the number of files saved setting and

lengthen the time until the file is deleted.

(f) When CSV files are opened with Excel, the date column's format is displayed in

Excel's default setting. Set the cell format as necessary.

(g) Since general data sampling specified data and report current value data are

sampled asynchronously with the sequence scan, data separation may occur. If

data separation must be prevented, set the number of device points sampled at

one time to less than the access units, or set the module to use high speed data

sampling.

®

(h) When CSV files are opened with Microsoft

displayed depending on the number of the data setting or number of file switching

lines.

In this case, open the CSV files with Microsoft

Excel® 2003, all the data may not be

®

Excel® 2007 or later, or text editor.

A - 12

Page 15

(2) Data logging function

(a) Immediately after switching the programmable controller system ON, if a trigger

occurs before sampling the number of lines of data before the trigger, the data

before the trigger may be a few lines less than the specified amount.

(b) When triggers continuously occur with the trigger logging function, triggers may

be discarded or the number of lines of data specified before the trigger may not be

output. For operation when triggers continuously occur, refer to the following

section.

Section 7.3.2 Trigger logging

(3) Report function

(a) Immediately after switching the programmable controller system ON, if a creation

trigger occurs when data does not exist in the data logging file, an error occurs in

the high speed data logger module. Configure and construct the system so that

the creation trigger occurs after data are saved in the data logging file.

(b) Report output takes time. Therefore, according to the data logging save setting,

the data logging file, including the data when the creation trigger occurs, may be

deleted before outputting the report has completed. In this situation, the data for

the specified number of records are not output, and an error occurs in the high

speed data logger module. Verify the points listed in the following section when

configuring and creating the system.

Section 9.3 Creation Trigger

(c) When creation triggers continuously occur, they may be discarded. For operation

when the creation trigger continuously occurs, refer to the following section.

Section 9.3 Creation Trigger

®

(d) When using Microsoft

2010 (32-bit version), or Microsoft

®

Basic

for Applications (abbreviated as VBA below).

Excel® 2003, Microsoft® Excel® 2007, Microsoft® Excel®

®

Excel® 2013 (32-bit version), install Visual

If VBA is not installed, the error message below is displayed when the layout

setting screen is started, and the layout settings cannot be configured.

"This workbook has lost its VBA Project, ActiveX Controls and any other

programmability-related features."

(e) The save format of the report file output by the report function is the xls format. A

®

portion of the functions added from Microsoft

(f) One of the following operating systems is required with installing Microsoft

®

Excel

2010 (32-bit version).

• Windows

• Windows Vista

• Windows

Note that Microsoft

®

XP Service Pack 3

®

Service Pack 1 or later

®

7 or later

®

Excel® 2010 (64-bit version) is not supported.

Excel® 2007 and later cannot be used.

®

(g) The following operating system is required with installing Microsoft

(32-bit version).

®

• Windows

Note that Microsoft

7 or later

®

Excel® 2013 (64-bit version) is not supported.

®

Excel® 2013

A - 13

Page 16

(1) Access target CPU setting ( Section 11.4.3)

Other function precautions

(a) When rewriting the Configuration Tool settings, power OFF to ON, or resetting the

CPU module, the high speed logger module prepares to communicate with the

access target CPU. Therefore, if a large number of access target CPUs are set,

several minutes are required for this preparation.

(b) The following conditions may affect the general sampling, FTP transfer function,

and e-mail function: when the CPU which does not exist in the access target CPU

is set, or the high speed data logger cannot communicate with the access target

CPU temporary because of the power interruption of access target CPU or

network failure.

Use high speed data logger modules with the status that can communicate with

the CPU set as access target CPU.

( Section 3.4.8 General data sampling delay time area (address: 800 to 805)

Appendix 8.2 Processing time of FTP transfer function and e-mail function)

(2) Time synchronization function ( Section 10.1)

(a) If implementing synchronization with the programmable controller CPU or SNTP

server time, the high speed data logger module's time is changed. When the

programmable controller CPU's time is changed or when restored after

communicating with the SNTP server fails, the high speed data logger module's

time may be greatly changed.

(b) Since there is inaccuracy in the clock element in the programmable controller

CPU and high speed data logger module, the time may be moved slightly forward

or backward when the time is synchronized.

Since changing the high speed logger unit's time affects the data logging, event

logging, and report cycles, the determination of time, and the time stamp,

configure the module to synchronize its time as little as possible.

A - 14

Page 17

(1) Web browser operations, settings

Precautions when accessing the high speed data logger module

In the local area network (LAN) setting of the Web browser, do not set a proxy server

for the local address. ( Section 5.3.1)

(2) FTP server function

(a) Because of FTP client side application restrictions, if the user name or password

is input incorrectly, end the FTP operation and redo the FTP connection from the

beginning.

FTP may not operate correctly by reentering the correct user name or password

with the 'user' FTP command.

(b) The maximum number of simultaneous connections to the FTP server is 10.

However, depending on the FTP client, it may make multiple simultaneous

connections, so an FTP client may not be able to login even if 10 clients are not

connected.

In this situation, shutdown all the FTP clients, then restart and connect them.

(c) If transferring many files at once with FTP, a 426 (Data connection error) may

occur.

In this situation, split the files up over multiple transfers and retransfer them.

(d) When using Internet Explorer as an FTP client, the user authentication screen

may not be displayed because of the Internet Explorer specification.

To enable the high speed data logger module's access authentication function,

enter the address in the following format.

ftp://<user name>:<password>@<high speed data logger module's address or

hostname>/

(e) When using Internet Explorer as an FTP client, data logging files, event logging

files, report files, and recipe files may not be opened directly because of the

Internet Explorer specification. Open those files after saving them to a personal

computer.

(f) When using Internet Explorer as an FTP client, because of the Internet Explorer

specification, errors may not be displayed even if the transfer failed when files are

transferred to the CompactFlash card which does not have enough free space.

Update the display and check if the files are transferred normally.

(3) Replacing old version module with new one

When a high speed data logger module is replaced, make sure to delete the

temporary Internet files of Web browser (cache) before accessing the high speed data

logger module. ( Section 10.3 POINT)

(4) Connecting GX LogViewer

The maximum number of connections for GX LogViewer to access high speed data

logger modules simultaneously is 2.

A - 15

Page 18

Although the high speed data logger module supports basic authentication (account

Security precautions

CompactFlash card precautions

setting) using user names and passwords, it does not completely protect the system from

illegal access.

Avoid accounts (user name, password) consisting of simple alphanumeric characters only,

and include some non-alphanumeric characters ($, &, ?) to create a complicated user

name and password.

(1) CompactFlash card file/directory names

(a) Do not create files*1 or folders on the CompactFlash card with a personal

computer.

If files or folders are created on the CompactFlash card with a personal computer,

they may be deleted.

*1: Excluding module operating files and recipe files

(b) Do not store files with file name containing unusable characters to CompactFlash

card.

For usable characters in file names, refer to the following section.

Appendix 4.2 Characters usable in file names, folder (directory) names

(2) CompactFlash card to be used

Use CompactFlash cards listed in Section 2.3.

Section 2.3 Connection System Equipment

If any other CompactFlash cards are used, a failure such as a data corruption on a

CompactFlash card or a system shutdown (SP.UNIT DOWN occurs in the

programmable controller CPU) may occur during an operation.

(3) When turning OFF or resetting programmable controller CPU

When a programmable controller CPU is turned OFF or reset while writing data to a

CompactFlash card, the processing to write data to a CompactFlash card may not be

completed. It may cause a loss of logging data during the processing, corruption of

data in the CompactFlash card that is being accessed, or occurrence of a file system

error. The file is automatically repaired when the high speed data logger module is

turned ON again, but it will not succeed in some cases.

The operation, turning OFF or resetting the high speed data logger module after

stopping file access, should be considered. For the important data, create backups by

performing a backup operation such as saving data to other media.

Section 16.6 (1) Stopping file access

A - 16

Page 19

(4) When ejecting or replacing the CompactFlash card

(a) Be sure to stop file access before ejecting or replacing the CompactFlash card.

Section 16.5 Operations for Ejecting and Reinserting CompactFlash Card

(b) Not following the procedure shown in Section 16.5 may cause a loss of logging

data during processing, corruption of data on the CompactFlash card while

accessing, or a file system error.

(c) If an error occurs on the CompactFlash card, refer to the following section.

Section 18.3.8 Troubleshooting related to data management, CompactFlash

cards

(d) High speed data logger module settings are saved to the CompactFlash card.

Therefore, the high speed logger module's IP address returns to the initial status

(192.168.3.3) without a CompactFlash card inserted in the module or when

turning the power OFF/ON or resetting the programmable controller CPU without

the settings written to the CompactFlash card. When necessary, read the current

settings before ejecting the CompactFlash card and after replacing the card,

promptly write those settings to the new card.

(5) CompactFlash card capacity

(a) Access speed to the CompactFlash card is affected by the amount of saved files.

In particular, access speed becomes extremely slow when saving files up to the

capacity limit of the CompactFlash card.

Use the CompactFlash card maintaining 10% or more free space on the card.

(b) A minimum size of the occupied file on the hard disk varies depending on the

CompactFlash card capacity. Therefore, the actual file size and the occupied file

size on the hard disk may differ.

(6) CompactFlash card diagnostic time

(a) The high speed data logger module performs a diagnostics (file recovery, etc.) of

the inserted CompactFlash card contents at the times listed below.

When power OFF to ON, resetting the CPU module

Inserting a CompactFlash card when powered ON

(b) The CompactFlash card diagnostic time takes longer when there are more files on

the card.

100 files takes approximately 5 seconds, 1000 files takes approximately 10

seconds.

(c) When many files are saved on the CompactFlash card, the following operations

require longer time. Delete unnecessary files.

CompactFlash card status (X1) startup time

Time before the high speed data logger module can start processing

(Module READY (X0) and module operating status (X5) startup time)

A - 17

Page 20

(7) CompactFlash card format

Precautions when using a redundant system

(a)

To format a CompactFlash card, use the high speed data logger module format function.

Section 13.1.6 CompactFlash card diagnostics

®

(b) Do not format a CompactFlash card using the Windows

(c) Do not reset the control CPU or turn the power OFF when formatting a

CompactFlash card.

(d) High speed data logger module settings are saved to the CompactFlash card.

Therefore, all settings are lost when formatting a card. When necessary, read the

current settings before formatting and promptly write those settings after

formatting. The high speed logger module's IP address returns to the initial status

(192.168.3.3) when turning the power OFF/ON or resetting the programmable

controller CPU without writing the settings to the CompactFlash card.

format function.

(8) CompactFlash card life duration (a limit for writing data)

The CompactFlash card has a life duration (a limit for writing data).

For details, refer to the following section.

Section 16.7 CompactFlash Card Life Duration

(9) About RECIPE folder

(a) A maximum number of recipe files that can be stored in the RECIPE folder is 256.

Storing large number of files in the RECIPE folder causes a longer processing

time for following operations. Delete unnecessary files.

Displaying or operating the file browser

Displaying a file list of recipe execution operation

Recipe execution operation

(b) Do not store files other than recipe files in the RECIPE folder.

(1) Mountable base unit

When using the high speed data logger module in a redundant system, be sure to

mount the module to the extension base unit for CPU/redundant power supply.

The high speed data logger module cannot be mounted to the main base unit in a

redundant system.

(2) "Access target CPU setting"

(a) When the high speed data logger module is mounted to the Redundant CPU, it

can only access the own station CPU. It cannot access CPUs of other stations.

(b) When the high speed data logger module is mounted to a unit other than the

Redundant CPU, it cannot access the Redundant CPU of other stations.

(3) Dedicated instructions

When the high speed data logger module is mounted to the Redundant CPU, the

dedicated instructions cannot be used. If any of those instructions are used, an

"OPERATION ERROR" occurs in the Redundant CPU.

A - 18

Page 21

(1) Recipe files

Recipe function precautions

Precautions when using Logging File Conversion Tool

(a) When a recipe file to which 253 or more records are set is opened in Microsoft®

®

2003, the entire file cannot be displayed. Edit the data using Microsoft®

Excel

®

Excel

2007 or later, text editor or recipe editor.

(b) For recipe file names, use the characters usable in file names and folder

(directory) names only. ( Appendix 4.2)

(2) Recipe execution operation

(a) Before performing the recipe execution operation, write the high speed data

logger module settings using the Configuration Tool, and set the module operating

status to "In operation".

The module operating status can be checked on the <<Module diagnostics>> tab

of the "Diagnostics" screen.

Section 13.1.1 Module diagnostics

(b) The recipe execution operation is performed to an own station CPU only. It cannot

be performed to other stations' CPUs.

(c) Do not power OFF or reset the programmable controller CPU during the recipe

execution operation. The recipe file being edited may be damaged.

Power OFF or reset the programmable controller CPU after confirming the

completion of the recipe execution operation.

(1) Logging files that can be converted

The Logging File Conversion Tool can convert only binary format logging files created

by high speed data logger module to CSV format logging files.

Other binary files cannot be converted.

(2) Conversion processing of float type

When the binary output format is [Float (single precision)] or [Float (double

precision)], the following error may occur between CSV file data values that are

created in the Conversion Tool and the high speed data logger module.

• Float (single precision):

Significant figures of 7th and later digits (the last digit for 7 significant figures)

• Float (double precision):

Significant figures of 15th and later digits (the last digit for less than 15 significant

figures)

A - 19

Page 22

Remark

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-Q series/MELSEC-L series general purpose

programmable controllers.

Before using the product, please read this manual and the relevant manuals carefully and develop familiarity

with the functions and performance of the programmable controller to handle the product correctly.

RELATED MANUALS

The manuals related to this product are shown below.

Refer to the following tables when ordering required manuals.

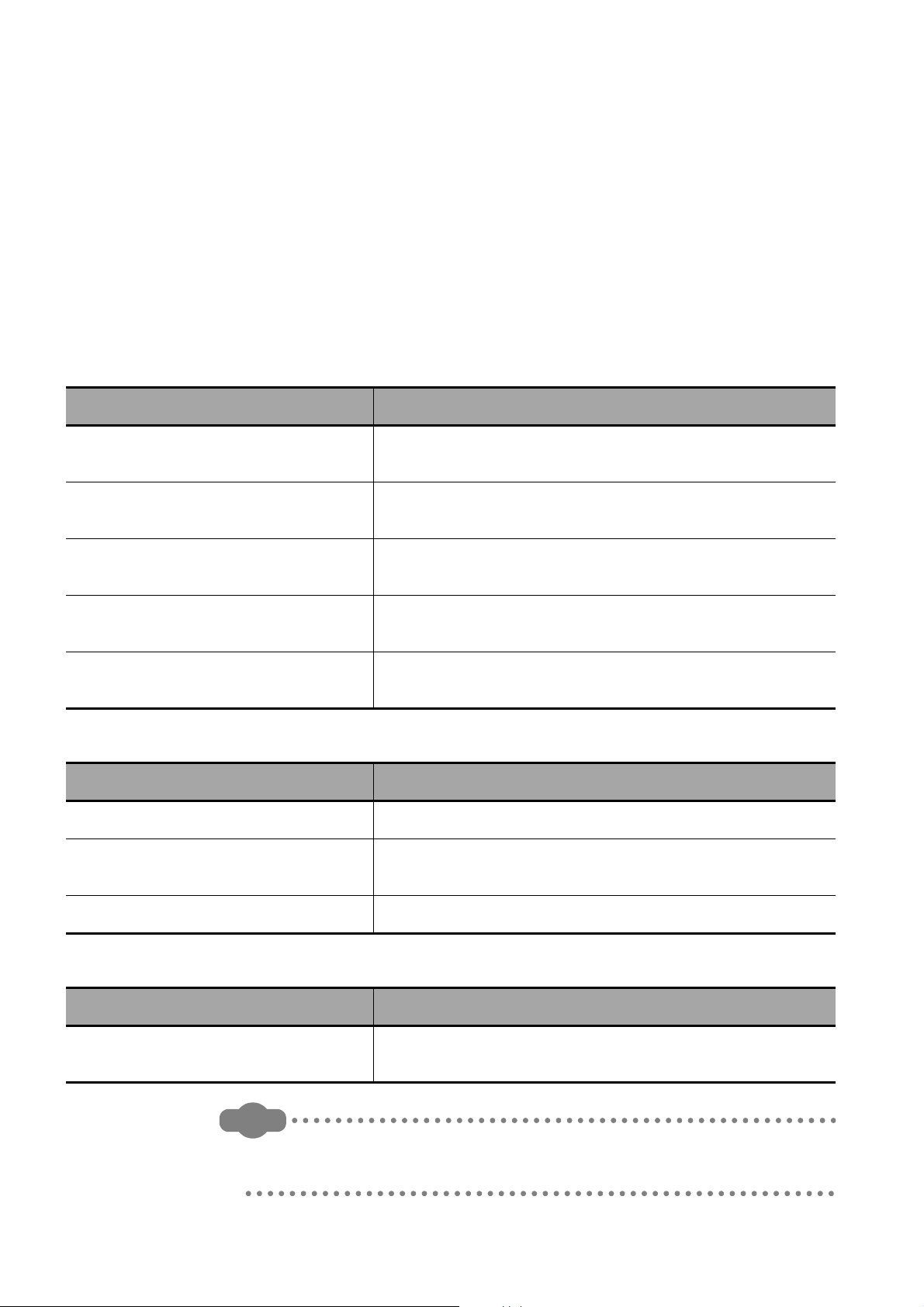

(1) CPU module user's manual

Manual name

<Manual number, Model code>

QCPU User's Manual

(Hardware Design, Maintenance and Inspection)

<SH-080483ENG, 13JR73>

Qn(H)/QnPH/QnPRHCPU User's Manual

(Function Explanation, Program Fundamentals)

<SH-080808ENG, 13JZ28>

QnUCPU User's Manual

(Function Explanation, Program Fundamentals)

<SH-080807ENG, 13JZ27>

MELSEC-L CPU Module User's Manual

(Function Explanation, Program Fundamentals)

<SH-080889ENG, 13JZ35>

C Controller Module User's Manual

(Hardware Design, Function Explanation)

<SH-080766ENG, 13JZ17>

Specifications of the hardware (CPU modules, power supply modules, base units,

batteries, and memory cards), system maintenance and inspection, and

troubleshooting.

Explains the programming methods, devices, and functions of Qn(H)/QnPH/

QnPRHCPU module.

Explains the programming methods, devices, and functions of QnUCPU module.

Explains the programming methods, devices, and functions of LCPU module.

Explains the programming methods, and functions of C controller module.

Description

(2) Operating manual

Manual name

<Manual number, Model code>

GX LogViewer Version 1 Operating Manual

<SH-080915ENG, 13JU68>

GX Works2 Version 1 Operating Manual

(Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

(3) Programming manual

Manual name

< Manual number, Model code >

MELSEC-Q/L Programming Manual

(Common Instruction)

<SH-080809ENG, 13JW10>

Manuals in printed form are sold separately for single purchase. Order a manual

by quoting the manual number (model code) listed in the table above.

Description

Explains the system configuration, functions, and operating methods of GX

LogViewer.

Explains the system configuration of GX Works2 and the functions common to

Simple project and Structured project such as parameter setting, operation method

for the online function.

Explains the methods for programming, printing, monitoring, and debugging in GX

Developer.

Description

Explains the details of instructions used in programming.

A - 20

Page 23

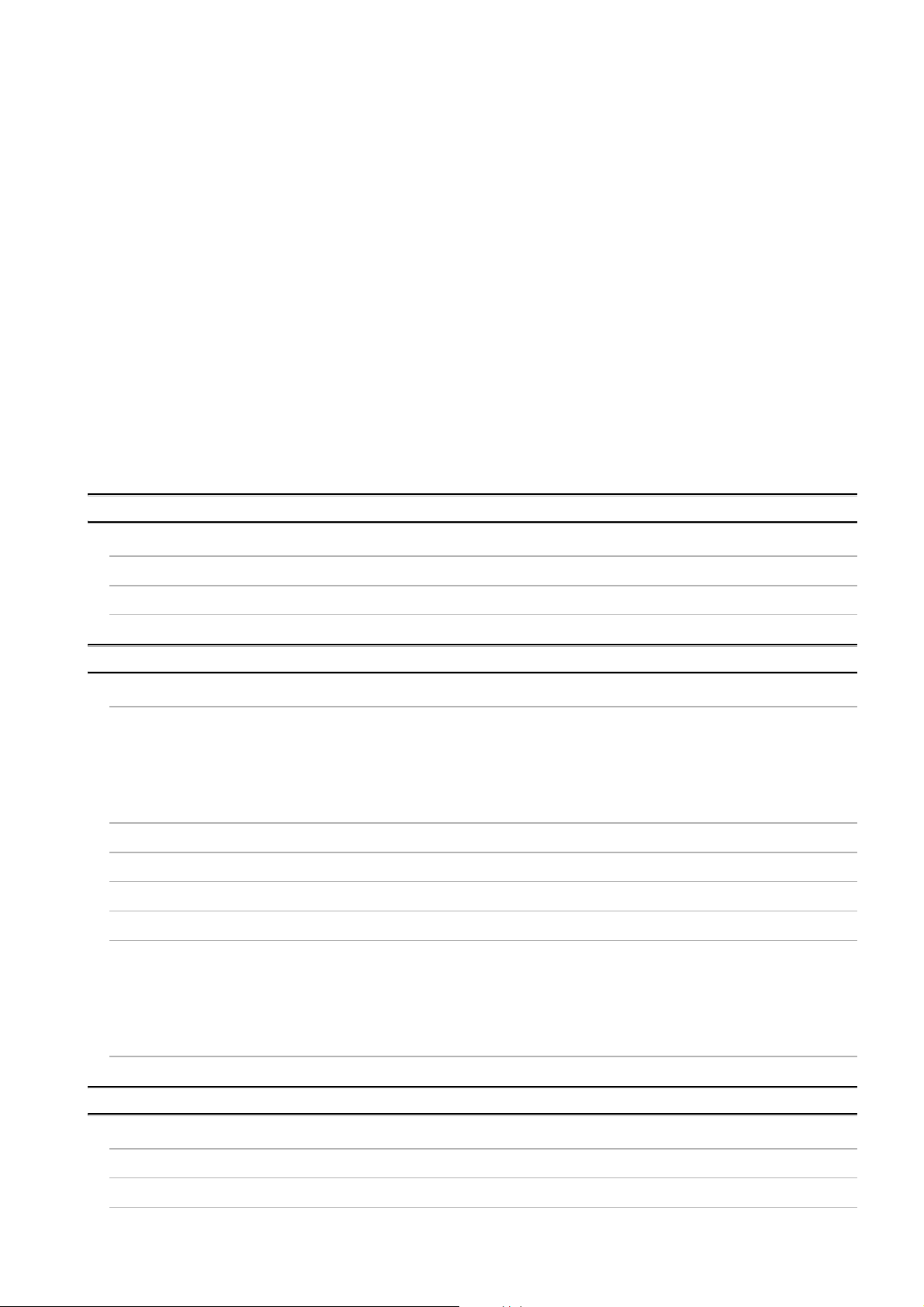

CONTENTS

SAFETY PRECAUTIONS ................................................................................................................................. A - 1

CONDITIONS OF USE FOR THE PRODUCT..................................................................................................A - 6

REVISIONS....................................................................................................................................................... A - 7

PRECAUTIONS FOR USE ............................................................................................................................ A - 11

INTRODUCTION............................................................................................................................................. A - 20

RELATED MANUALS .....................................................................................................................................A - 20

CONTENTS .................................................................................................................................................... A - 21

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES.......................................................... A - 29

HOW TO USE THIS MANUAL....................................................................................................................... A - 30

GENERIC TERMS AND ABBREVIATIONS................................................................................................... A - 32

DEFINITIONS AND DESCRIPTIONS OF TERMS ........................................................................................ A - 34

PACKING LIST .............................................................................................................................................. A - 35

CHAPTER 1 OVERVIEW 1 - 1 to 1 - 14

1.1 Features........................................................................................................................................... 1 - 1

1.2 Processing Overview ..................................................................................................................... 1 - 13

1.3 High Speed Data Logger Module Software Configuration............................................................. 1 - 14

CHAPTER 2 SYSTEM CONFIGURATION 2 - 1 to 2 - 18

2.1 System Configuration ...................................................................................................................... 2 - 1

2.1.1 Overall system configuration .................................................................................................... 2 - 1

2.1.2 System configuration when performing initial setup, maintenance, and inspection ................. 2 - 2

2.1.3 System configuration during operation ..................................................................................... 2 - 3

2.1.4 Precautions when directly connecting ...................................................................................... 2 - 4

2.2 Applicable Systems ......................................................................................................................... 2 - 6

2.3 Connection System Equipment ....................................................................................................... 2 - 9

2.4 Operating Environment.................................................................................................................. 2 - 10

2.5 How to Check the Function Version, Serial Number ..................................................................... 2 - 13

2.6 System Configuration Precautions ................................................................................................ 2 - 16

2.6.1 Precautions when using Redundant CPUs ............................................................................ 2 - 16

2.6.2 Precautions when using C Controller modules....................................................................... 2 - 16

2.6.3 Precautions for using multiple CPU system ........................................................................... 2 - 17

2.6.4 Precautions for using hubs ..................................................................................................... 2 - 17

2.7 Software Packages........................................................................................................................ 2 - 18

CHAPTER 3 SPECIFICATIONS 3 - 1 to 3 - 75

3.1 Performance Specifications ............................................................................................................. 3 - 1

3.2 Accessible Routes and Devices ...................................................................................................... 3 - 7

3.3 I/O Signals for the Programmable Controller CPU ........................................................................ 3 - 18

A - 21

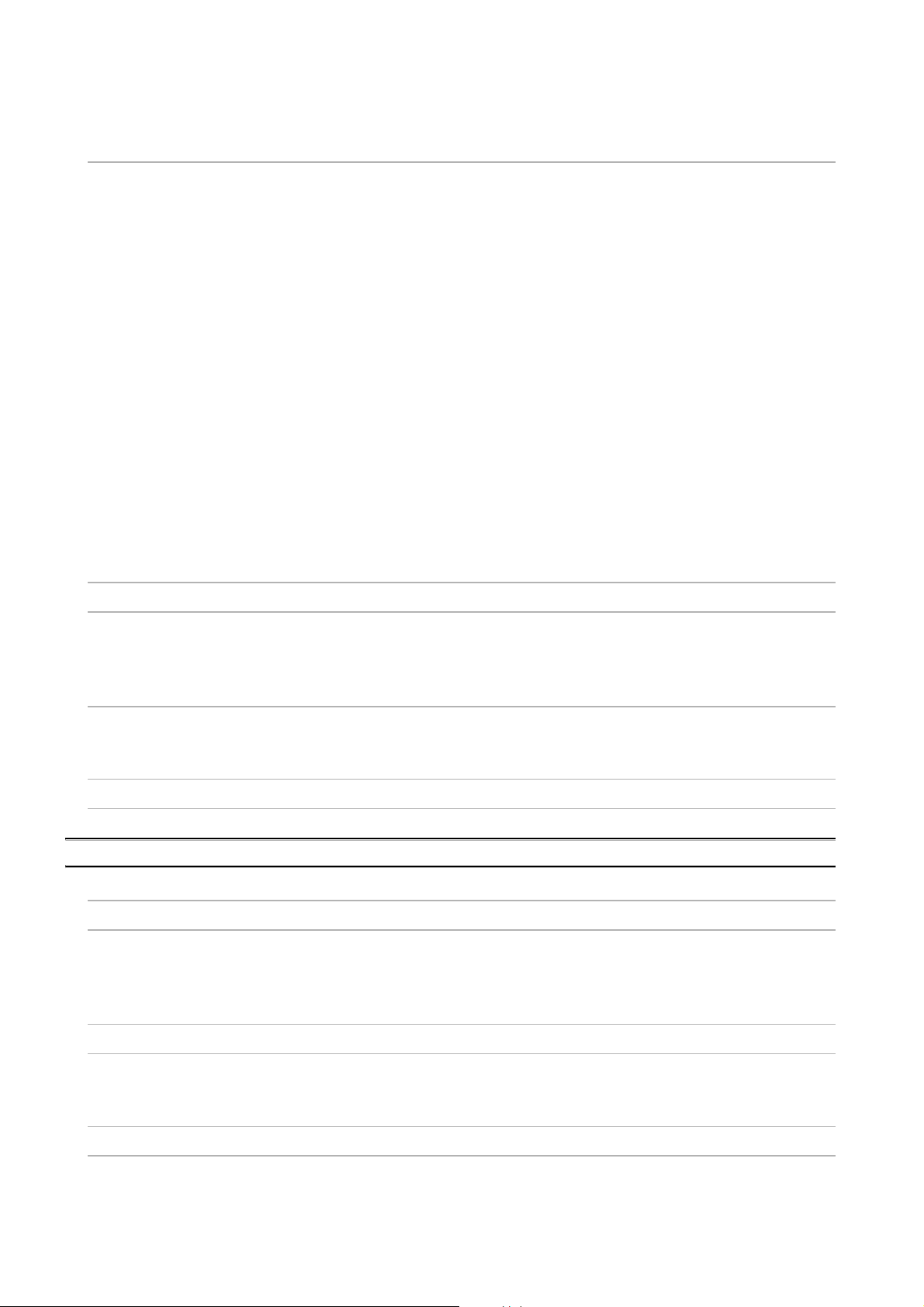

Page 24

3.3.1 I/O signal list ........................................................................................................................... 3 - 18

3.3.2 I/O signal details ..................................................................................................................... 3 - 20

3.4 Buffer Memory List......................................................................................................................... 3 - 24

3.4.1 Module status area (address: 0 to 20).................................................................................... 3 - 24

3.4.2 CompactFlash card information area (address: 21 to 25) ...................................................... 3 - 25

3.4.3 Network connection status area (address: 47 to 64) .............................................................. 3 - 25

3.4.4 Common setting status area (address: 70 to 80).................................................................... 3 - 25

3.4.5 Time synchronization information area (address: 100 to 109)................................................ 3 - 26

3.4.6 Current error area (address: 140 to 145)................................................................................ 3 - 27

3.4.7 Error log area (address: 150 to 247).......................................................................................3 - 28

3.4.8 General data sampling delay time area (address: 800 to 805)............................................... 3 - 29

3.4.9 Recipe file area (address: 810 to 841).................................................................................... 3 - 31

3.4.10 Access target CPU setting status area (address: 1500 to 1593)............................................ 3 - 32

3.4.11 Data logging status area (address: 2000 to 2989).................................................................. 3 - 34

3.4.12 Event logging status area (address: 3000 to 3989)................................................................ 3 - 38

3.4.13 Report creation status area (address: 4000 to 4989) ............................................................. 3 - 42

3.4.14 E-mail transmission status area (address: 5000 to 5992) ......................................................3 - 46

3.4.15 FTP server status area (address: 6000 to 6001) .................................................................... 3 - 50

3.4.16 FTP client status (PUT) area (address: 6002 to 7457) ........................................................... 3 - 51

3.4.17 FTP client setting area (address: 7999).................................................................................. 3 - 55

3.4.18 Event logging area (address: 10000 to 14095)....................................................................... 3 - 56

3.5 Directory Structure......................................................................................................................... 3 - 57

3.6 CSV File Format ............................................................................................................................ 3 - 58

3.6.1 CSV format specification ........................................................................................................ 3 - 58

3.6.2 Data logging file...................................................................................................................... 3 - 58

3.6.3 Event logging file .................................................................................................................... 3 - 62

3.7 Binary File Format ......................................................................................................................... 3 - 66

3.7.1 Data logging file...................................................................................................................... 3 - 66

3.7.2 Event logging file .................................................................................................................... 3 - 69

3.8 Recipe File Format ........................................................................................................................ 3 - 73

3.9 Range of Values per Output Format .............................................................................................. 3 - 75

CHAPTER 4 SETTINGS AND PROCEDURES UP TO OPERATION 4 - 1 to 4 - 20

4.1 Handling Precautions....................................................................................................................... 4 - 1

4.2 Configuration and Procedures Up to Operation............................................................................... 4 - 2

4.2.1 Procedure to operate by installing high speed data logger module Configuration Tool ........... 4 - 2

4.2.2 Procedure to operate without installing high speed data logger module Configuration Tool.... 4 - 5

4.2.3 High speed data logger module operation settings .................................................................. 4 - 9

4.3 Parts Names .................................................................................................................................. 4 - 10

4.4 Wiring............................................................................................................................................. 4 - 12

4.4.1 Wiring...................................................................................................................................... 4 - 12

4.4.2 Wiring precautions.................................................................................................................. 4 - 12

4.5 Intelligent Function Module Switch Setting .................................................................................... 4 - 14

4.6 Self-Diagnostics Tests ................................................................................................................... 4 - 18

4.6.1 Self-loopback test ................................................................................................................... 4 - 18

4.6.2 Hardware test ......................................................................................................................... 4 - 19

A - 22

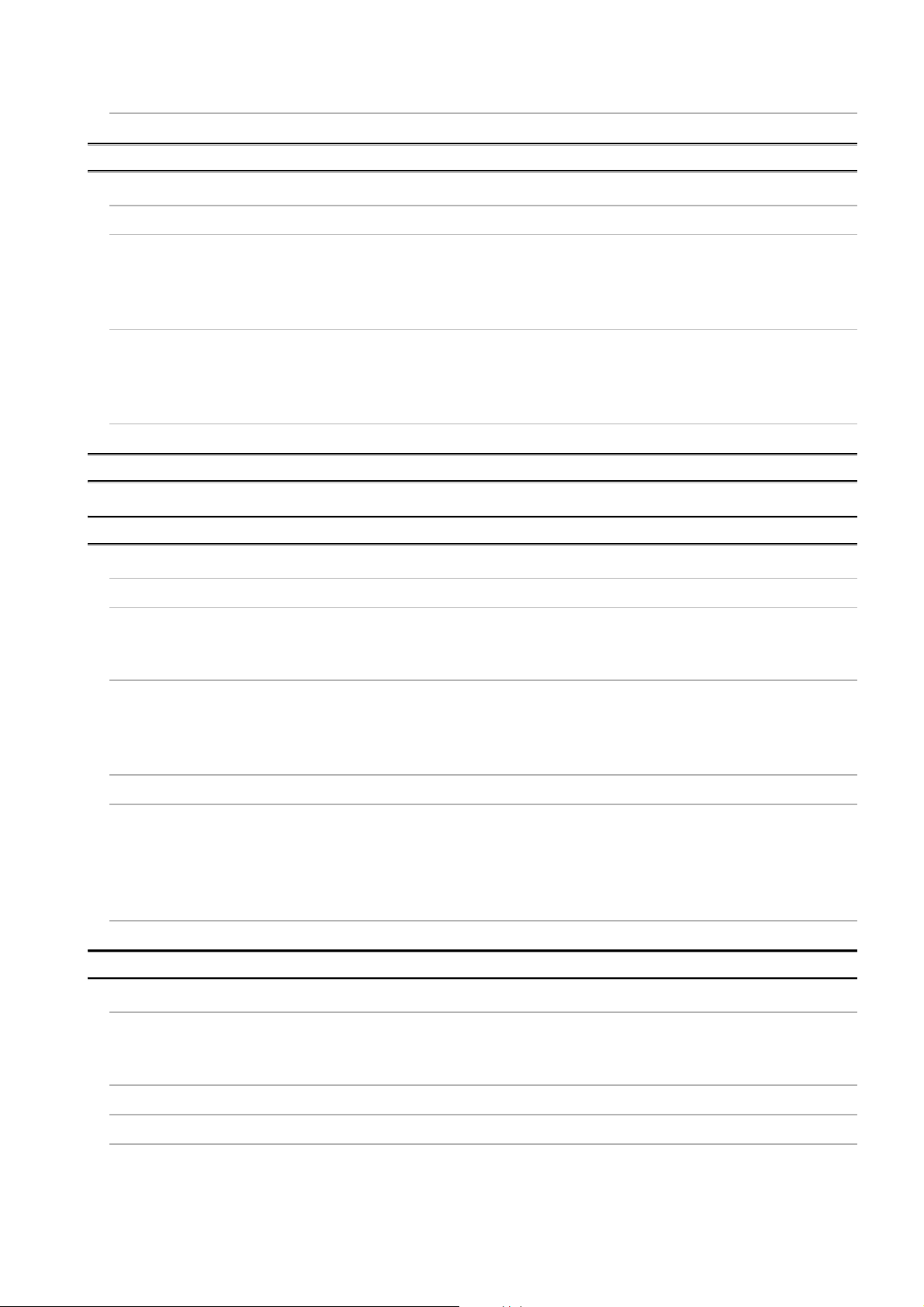

Page 25

4.7 Operations to Return the High Speed Data Logger Module to the Factory Default Status ........... 4 - 20

CHAPTER 5 HIGH SPEED DATA LOGGER MODULE TOOL STARTUP 5 - 1 to 5 - 18

5.1 Obtaining High Speed Data Logger Module Tool ............................................................................ 5 - 1

5.2 Installation........................................................................................................................................ 5 - 2

5.2.1 Installation procedure ............................................................................................................... 5 - 2

5.2.2 Upgrade procedure................................................................................................................... 5 - 7

5.2.3 Uninstallation procedure........................................................................................................... 5 - 9

5.3 Starting Configuration Tool ............................................................................................................ 5 - 12

5.3.1 Online startup ......................................................................................................................... 5 - 13

5.3.2 Offline startup (starting from the Start menu) ......................................................................... 5 - 18

5.3.3 Starting from GX LogViewer................................................................................................... 5 - 18

5.4 Starting Conversion Tool ............................................................................................................... 5 - 18

CHAPTER 6 FUNCTION LIST 6 - 1 to 6 - 2

CHAPTER 7 DATA LOGGING FUNCTION 7 - 1 to 7 - 21

7.1 Target Data...................................................................................................................................... 7 - 2

7.2 Target Data Sampling...................................................................................................................... 7 - 3

7.2.1 High speed data sampling ........................................................................................................ 7 - 4

7.2.2 General data sampling ............................................................................................................. 7 - 7

7.3 Logging Types ................................................................................................................................. 7 - 9

7.3.1 Continuous logging................................................................................................................... 7 - 9

7.3.2 Trigger logging.......................................................................................................................... 7 - 9

7.3.3 Trigger conditions ................................................................................................................... 7 - 13

7.4 Data Logging Periods .................................................................................................................... 7 - 16

7.5 Data Logging Files......................................................................................................................... 7 - 18

7.5.1 Data logging file save format .................................................................................................. 7 - 18

7.5.2 Saving data logging files......................................................................................................... 7 - 19

7.5.3 Data logging file save location................................................................................................ 7 - 20

7.5.4 Transferring data logging files ................................................................................................ 7 - 20

7.6 Missing Data .................................................................................................................................. 7 - 21

CHAPTER 8 EVENT LOGGING FUNCTION 8 - 1 to 8 - 12

8.1 Events.............................................................................................................................................. 8 - 2

8.1.1 Target data ............................................................................................................................... 8 - 2

8.1.2 Event conditions ....................................................................................................................... 8 - 3

8.2 Target Data Sampling...................................................................................................................... 8 - 7

8.3 Event Logging Periods..................................................................................................................... 8 - 9

8.4 Event Logging Files ....................................................................................................................... 8 - 10

8.4.1 Event logging file save format ................................................................................................ 8 - 10

8.4.2 Saving event logging files....................................................................................................... 8 - 10

8.4.3 Event logging file save location .............................................................................................. 8 - 10

A - 23

Page 26

8.4.4 Transferring event logging files............................................................................................... 8 - 11

8.5 E-mail Notification.......................................................................................................................... 8 - 12

CHAPTER 9 REPORT FUNCTION 9 - 1 to 9 - 9

9.1 Target Data...................................................................................................................................... 9 - 2

9.2 Creation Trigger and Current Value Data Sampling ........................................................................ 9 - 6

9.3 Creation Trigger............................................................................................................................... 9 - 8

9.4 Report Periods................................................................................................................................. 9 - 8

9.5 Report Files ..................................................................................................................................... 9 - 9

9.5.1 Saving report files..................................................................................................................... 9 - 9

9.5.2 Report file save location ........................................................................................................... 9 - 9

9.5.3 Transferring report files............................................................................................................. 9 - 9

CHAPTER 10 OTHER FUNCTIONS 10 - 1 to 10 - 18

10.1 Time Synchronization Function ..................................................................................................... 10 - 1

10.2 Auto Logging Function................................................................................................................... 10 - 5

10.3 File Access Function...................................................................................................................... 10 - 7

10.4 Access Authentication Function................................................................................................... 10 - 12

10.5 FTP Transfer Function................................................................................................................. 10 - 13

10.6 E-mail Function............................................................................................................................ 10 - 16

CHAPTER 11

11.1 Setting Operations Overview ......................................................................................................... 11 - 1

11.2 Screen Configuration and Common Operations............................................................................ 11 - 2

11.2.1 Main screen configuration....................................................................................................... 11 - 2

11.2.2 Menu configuration ................................................................................................................. 11 - 3

11.2.3 Toolbar configuration.............................................................................................................. 11 - 5

11.2.4 Operations using the edit items tree ....................................................................................... 11 - 6

11.2.5 Status bar ............................................................................................................................... 11 - 7

11.2.6 Common table operations....................................................................................................... 11 - 8

11.2.7 Data list................................................................................................................................. 11 - 10

11.2.8 Device batch replacement .................................................................................................... 11 - 12

11.2.9 Data setting screen............................................................................................................... 11 - 13

11.2.10 Importing global labels and device comments...................................................................... 11 - 15

FUNCTIONS OF CONFIGURATION TOOL (MODULE SETTINGS)

11 - 1 to 11 - 238

11.3 Project Management.................................................................................................................... 11 - 29

11.3.1 Creating a new project.......................................................................................................... 11 - 29

11.3.2 Opening a project ................................................................................................................. 11 - 29

11.3.3 Saving a project.................................................................................................................... 11 - 30

11.3.4 Importing settings from project file........................................................................................ 11 - 31

11.3.5 Exporting project to CSV file................................................................................................. 11 - 33

11.3.6 Exporting module operating file ............................................................................................ 11 - 34

11.4 Common Setting .......................................................................................................................... 11 - 35

11.4.1 Network setting..................................................................................................................... 11 - 36

A - 24

Page 27

11.4.2 Time synchronization setting ................................................................................................ 11 - 40

11.4.3 Access target CPU setting.................................................................................................... 11 - 46

11.4.4 FTP setting ........................................................................................................................... 11 - 59

11.4.5 E-mail setting........................................................................................................................ 11 - 62

11.4.6 Account setting ..................................................................................................................... 11 - 66

11.4.7 Auto logging setting .............................................................................................................. 11 - 71

11.4.8 High speed data sampling setting ........................................................................................ 11 - 74

11.4.9 CompactFlash card setting................................................................................................... 11 - 75

11.5 Data Logging Setting ................................................................................................................... 11 - 78

11.5.1 Data logging setting list ........................................................................................................ 11 - 78

11.5.2 Data logging setting screen transitions................................................................................. 11 - 80

11.5.3 Logging type/file format ........................................................................................................ 11 - 83

11.5.4 Sampling............................................................................................................................... 11 - 84

11.5.5 Data setting list ..................................................................................................................... 11 - 87

11.5.6 Data setting .......................................................................................................................... 11 - 89

11.5.7 Data batch insertion.............................................................................................................. 11 - 93

11.5.8 Period of time ....................................................................................................................... 11 - 95

11.5.9 Trigger ................................................................................................................................ 11 - 101

11.5.10 Trigger (single condition) .................................................................................................... 11 - 103

11.5.11 Trigger (compound condition).............................................................................................11 - 107

11.5.12 Number of logging lines...................................................................................................... 11 - 118

11.5.13 CSV output ......................................................................................................................... 11 - 122

11.5.14 Binary output ...................................................................................................................... 11 - 125

11.5.15 Save ................................................................................................................................... 11 - 126

11.5.16 Completion ......................................................................................................................... 11 - 144

11.6 Event Logging Setting................................................................................................................ 11 - 145

11.6.1 Event logging setting list..................................................................................................... 11 - 145

11.6.2 Event logging setting screen transitions ............................................................................. 11 - 147

11.6.3 File format........................................................................................................................... 11 - 149

11.6.4 Sampling............................................................................................................................. 11 - 150

11.6.5 Event setting list ................................................................................................................. 11 - 153

11.6.6 Event setting....................................................................................................................... 11 - 154

11.6.7 Event setting (single condition)........................................................................................... 11 - 155

11.6.8 Event setting (compound condition) ................................................................................... 11 - 159

11.6.9 Event batch insertion .......................................................................................................... 11 - 169

11.6.10 Period of time ..................................................................................................................... 11 - 171

11.6.11 CSV output ......................................................................................................................... 11 - 177

11.6.12 Binary output ...................................................................................................................... 11 - 178

11.6.13 Save ................................................................................................................................... 11 - 179

11.6.14 E-mail notice....................................................................................................................... 11 - 188

11.6.15 Completion ......................................................................................................................... 11 - 191

11.7 Report Setting............................................................................................................................ 11 - 192

11.7.1 Report setting list................................................................................................................ 11 - 192

11.7.2 Report setting screen transitions ........................................................................................ 11 - 194

11.7.3 Sampling............................................................................................................................. 11 - 196

11.7.4 Layout setting list................................................................................................................ 11 - 199

11.7.5 Layout setting ..................................................................................................................... 11 - 202

11.7.6 Creation trigger................................................................................................................... 11 - 219

11.7.7 Period of time ..................................................................................................................... 11 - 226

11.7.8 Save ................................................................................................................................... 11 - 232

A - 25

Page 28

11.7.9 Completion.......................................................................................................................... 11 - 238

CHAPTER 12

12.1 Transfer Setup ............................................................................................................................... 12 - 1

12.2 High Speed Data Logger Module Search ...................................................................................... 12 - 2

12.3 Writing Data ................................................................................................................................... 12 - 3

12.4 Reading Data................................................................................................................................. 12 - 4

12.5 Verifying Data ................................................................................................................................ 12 - 4

CHAPTER 13

13.1 Diagnostics .................................................................................................................................... 13 - 1

13.1.1 Module diagnostics................................................................................................................. 13 - 2

13.1.2 CPU access diagnostics ......................................................................................................... 13 - 5

13.1.3 FTP transfer diagnostics......................................................................................................... 13 - 6

13.1.4 E-mail send diagnostics.......................................................................................................... 13 - 7

13.1.5 Product information................................................................................................................. 13 - 8

13.1.6 CompactFlash card diagnostics.............................................................................................. 13 - 9

13.1.7 Data logging diagnostics....................................................................................................... 13 - 12

13.1.8 Event logging diagnostics..................................................................................................... 13 - 13

13.1.9 Report diagnostics................................................................................................................ 13 - 14

13.1.10 Ping test................................................................................................................................ 13 - 15

FUNCTIONS OF CONFIGURATION TOOL (WRITING/READING/VERIFYING DATA)