Page 1

MES Interface Module User's Manual

-QJ71MES96

-SW1DNC-MESIF-E

(MX MESInterface)

Page 2

Page 3

SAFETY PRECAUTIONS

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The precautions given in this manual are concerned with only this product. For the safety precautions of the

programmable controller system, please read the User's Manual for the CPU module used.

In this manual, the safety instructions are ranked as " WARNING" and " CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING

When controlling a running programmable controller (e.g. data modification), create an interlock

circuit on sequence programs so that the whole system functions safely all the time.

Also, be sure to read the manual carefully and ensure safety before performing any other controls

such as operating status change.

Especially, when controlling a programmable controller from a remote location via network, problems

on the programmable controller side may not be dealt with promptly due to failure of data

communications.

Create an interlock circuit on a sequence program.

For the operation status of each station at a communication error, refer to the manual for that station.

Incorrect output or malfunctions may cause an accident.

Install a safety circuit external to the programmable controller that keeps the entire system safe even

when there are problems with the external power supply or the programmable controller.

Otherwise, trouble could result from erroneous output or erroneous operation.

When the programmable controller system security needs to be protected against illegal access from

an external device via a network, take measures at the user's discretion.

A

- 1

Page 4

[Design Precautions]

WARNING

Do not write any data to the "System area" in the buffer memory of the intelligent function module.

As for signals output from the programmable controller CPU to the intelligent function module, never

output (ON) a "Use prohibited" signal.

Doing these operations may cause malfunctions of the programmable controller system.

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100 mm (3.94 inch) or more from each other.

Not doing so could result in noise that would cause erroneous operation.

During registering each setting, do not power OFF the mounted module or reset the programmable

controller CPU.

Otherwise, data in the CompactFlash card will be undefined. Therefore, resetting and re-registering

data are required.

This may also cause a module failure or malfunctions.

[Installation Precautions]

CAUTION

Use the programmable controller under the environment specified in the User's Manual.

Using this programmable controller in an environment outside the range of the general specifications

could result in electric shock, fire, erroneous operation, and damage to or deterioration of the

product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect loading of the module can cause a malfunction, failure or drop.

When using the programmable controller in the environment of much vibration, tighten the module

with a screw.

A

- 2

Page 5

[Installation Precautions]

CAUTION

Completely turn off the externally supplied power used in the system before mounting or removing

the module.

Not doing so could result in damage to the product.

Tighten the screw in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to damage to the screw or module.

Do not directly touch the module's conductive parts or electronic components.

Touching the conductive parts could cause an operation failure or give damage to the module.

When connecting a connector, properly press, crimp, or solder it using the tools specified by the

manufacturer.

Incomplete connection may cause short-circuit, fire, and malfunctions.

Push the CompactFlash card into the CompactFlash card slot and install it securely.

After installing the CompactFlash card, check that it is inserted securely.

Failure to do so may cause malfunctions due to poor contact.

[Wiring Precautions]

CAUTION

Always store the communication cables and power cables connected to the module in the duct or fix

them in place with clamps.

Not doing so may cause swing, move, or poor connection of the cable, or damage of a module and/

or cable due to careless pull, resulting in malfunctions.

Install connectors securely to modules.

Tighten the screw in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to damage to the screw or module.

When disconnecting communication cables connected to the module, never pull on the cable

section.

When using a cable with a connector, disconnect it with holding the connector connected to the

module.

When the cable is pulled while connected to the module, this may cause malfunctions or module/

cable damage.

A

- 3

Page 6

[Wiring Precautions]

CAUTION

Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause fires, damage, or erroneous operation.

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

[Start-up and Maintenance Precautions]

WARNING

Do not touch any terminal during power distribution.

Doing so may cause malfunctions.

Always switch OFF the external supply power used by the system in all phases before cleaning or

retightening terminal screws.

Failure to do so may cause a failure or malfunctions of the module.

Loose screws may cause a drop of the module, short-circuit, or malfunctions.

Tightening screws excessively may damage the screws and/or the module, resulting in a drop of the

module, short-circuit, or malfunctions.

CAUTION

Do not disassemble or transform the module.

Doing so may cause a failure, malfunctions, personal injuries, and/or a fire.

Always shut OFF the external supply power used by the system in all phases before mounting or

removing a module.

Failure to do so may cause a failure or malfunctions of the module.

Do not install/remove the module to/from the base unit more than 50 times after the first use of the

product. (IEC 61131-2 compliant)

Failure to do so may cause malfunction.

Do not drop or apply any impact to the battery.

Doing so may damage the battery, resulting in a battery fluid leakage inside the battery.

If any impact has been applied, discard the battery and never use it.

Before handling a module, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause a failure or malfunctions of the module.

A

- 4

Page 7

[Operation Precautions]

WARNING

Make sure safety before controlling a running programmable controller (e.g. data modification).

Do not write any data to the "System area" in the buffer memory of the intelligent function module.

As for signals output from the programmable controller CPU to the intelligent function module, never

output (ON) a "Use prohibited" signal.

Doing these operations may cause malfunctions of the programmable controller system.

[Disposal Precautions]

CAUTION

When disposing of the product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to Appendix 9.)

[Transportation Precautions]

CAUTION

When transporting lithium batteries, make sure to treat them based on the transportation regulations.

(Refer to Appendix 8 for details of the relevant models.)

A

- 5

Page 8

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A

- 6

Page 9

REVISIONS

Correction

Addition

Change of a term

Correction

Correction

Addition

Correction

Correction

Addition

Change of section No.

Correction

Addition

The manual number is given on the bottom left of the back cover.

Print date Manual number Revision

Sept., 2006 SH(NA)-080644ENG-A First edition

Jan., 2007 SH(NA)-080644ENG-B

GENERIC TERMS AND ABBREVIATIONS, DEFINITIONS AND

DESCRIPTIONS OF TERMS, Chapter 1, Sections 2.2, 2.4.2, 2.5, 3.1, 3.2, 3.5,

4.2, 4.6.2, 5.2, 6.1.10, 7.7.1, 7.8.1, 7.9.1, 7.10.1, 7.11.1, 7.11.2, 7.12.5, 7.13.2,

7.13.4, 8.1, 8.2, 8.6, 10.2.1, 10.3.2, 10.3.3, Appendix 3.9

Sections 2.6, 2.6.1, 2.6.2, Appendix 1

Apr., 2007 SH(NA)-080644ENG-C

"PLC" was changed to "programmable controller".

GENERIC TERMS AND ABBREVIATIONS, Sections 2.2, 2.5, 3.2, 7.7, 7.7.1,

7.8.1, 7.11.1, 7.12.2, 10.2.1, Appendices 2, 4.6

Oct., 2007 SH(NA)-080644ENG-D

DEFINITIONS AND DESCRIPTIONS OF TERMS, PACKING LIST, Sections 2.2,

2.4.2, 2.6.2, 3.1, 3.3, 3.6.10, 4.1, 6.1.6, 6.1.9, 7.3.1, 7.4.5, 7.6.2, 7.6.4, 7.8.1,

7.8.3, 7.9.1, 7.10.1 to 7.10.3, 7.10.5, 7.11.1, 7.11.2, 7.12.5, 8.5, 8.8.1, 8.8.2,

10.2.1, Appendices 1.1, 3.1, 3.2, 3.8, 3.10, 3.13, 3.15, 3.16

Oct., 2007 SH(NA)-080644ENG-E

Jan., 2008 SH(NA)-080644ENG-F

Sept., 2008 SH(NA)-080644ENG-G

Sections 6.3.2, 7.8.2, Appendices 1.2, 3.5, 3.19, 3.20

Sections 3.3, 7.8, 7.11.1, 7.12.5, Appendices 3.8, 3.20

GENERIC TERMS AND ABBREVIATIONS, DEFINITIONS AND

DESCRIPTIONS OF TERMS, Sections 1.1, 2.2 to 2.4, 2.6.2, 3.1, 3.2, 4.4.1,

4.7.1, Chapter 5, Sections 6.1.9, 6.1.10, 7.2, 7.3.1, 7.3.4, 7.5 to 7.11, 7.12.5,

7.13.4, 8.1 to 8.3, 8.5, 10.2.1, 10.2.2, 10.3.3, Appendices 1.1, 3.3, 3.4, 3.6 to 3.13

Appendix 7

Appendix 7 Appendix 8

SAFETY PRECAUTIONS, COMPLIANCE WITH THE EMC AND LOW

VOLTAGE DIRECTIVES, GENERIC TERMS AND ABBREVIATIONS, Sections

2.1.1, 2.2, 2.4.1, 2.4.2, 2.5, 3.1, 3.2, 4.1, 4.7.2, 4.8.1, 5.1, 6.1.4, 7.11.1, 7.11.2,

8.2, 8.5, 10.1.3, 10.2.1, 10.3.3, Appendices 1.1, 4

Appendix 9

A

- 7

Page 10

The manual number is given on the bottom left of the back cover.

Correction

Correction

Addition

Correction

Correction

Correction

Correction

Correction

Addition

Change of section No.

Correction

Print date Manual number Revision

Jan., 2009 SH(NA)-080644ENG-H

Sections 2.2, 3.2, 6.1.4, 10.3.3, Appendices 1.1, 1.2

Jan., 2010 SH(NA)-080644ENG-I

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

DEFINITIONS AND DESCRIPTIONS OF TERMS, Sections 1.1, 2.3, 2.4.2, 2.5,

2.6.2, 3.1, 3.3, 4.3, 4.7.2, 4.8.1 to 4.8.3, 6.1.6, 6.1.9, 7.3.1, 7.3.4, 7.8.1, 7.9,

7.9.1, 7.10, 7.10.1, 7.11, 7.11.1, 7.12.5, 8.1, 8.2, 8.8.1, 10.2.1, 10.2.2, 10.3.2,

10.3.3,

Appendices 3.1, 3.10, 3.13 to 3.15, 3.19, 5, 7.1

CONDITIONS OF USE FOR THE PRODUCT

Sept., 2010 SH(NA)-080644ENG-J

HOW TO USE THIS MANUAL, GENERIC TERMS AND ABBREVIATIONS,

Sections 2.1 to 2.3, 2.4.1, 2.4.2, 3.1, 3.2, 5.1, 5.2, 7.7.1, 7.10.2, 7.12.6, 7.15, 8.3,

10.3.1, 10.3.3, Appendices 1.1, 3.7, 7.1, 7.2

Sept., 2011 SH(NA)-080644ENG-K

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES, Sections

2.4.1, 2.4.2, 2.6.2, 3.1, 3.2, 4.3, 7.7, 7.7.1, 7.9.1, 7.11.1, 7.11.2, 7.15, 8.2, 10.2.1,

10.3.3, Appendices 1.1, 3.7, 3.8, 3.10, 4.1, 4.2

Jun., 2012 SH(NA)-080644ENG-L

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES, Sections 2.2,

2.4.1, 2.4.2, 2.5, 3.2, 10.2.1, Appendix 3.7

Feb., 2013 SH(NA)-080644ENG-M

GENERIC TERMS AND ABBREVIATIONS, Sections 1.1, 1.2, 2.2, 2.4.2, 2.6.2,

3.1, 3.2, 3.3, 3.6.8, 5.1, 6.1.3, 7.3.1, 7.3.2, 7.8, 7.8.1, 7.8.2, 7.8.3, 7.9.1, 7.10.3,

7.10.5, 7.11, 7.11.1, 7.14, 7.15, 8.1, 8.2, 8.4.2, 8.5, 8.7, 8.8.1, 10.2.1, 10.2.2,

10.3.1, 10.3.3, Appendices 1.1, 3.8, 3.9, 3.10, 3.13, 3.14, 3.15

Oct., 2013 SH(NA)-080644ENG-N

GENERIC TERMS AND ABBREVIATIONS,

DEFINITIONS AND DESCRIPTIONS OF TERMS, Sections 1.1, 2.2, 2.4.1, 2.4.2,

2.5, 2.6.2, 3.1 to 3.3, 4.3, 5.1, 5.2, 6.1.2, 6.1.10, 7.6, 7.6.4, 7.9.1, 7.10, 7.10.1,

7.10.4, 7.11, 7.11.1, 7.13.5, 7.12.5, 8.1 to 8.3, 8.8.1, 8.8.2, 10.2.1, 10.2.2, 10.3.1,

10.3.3, Appendices 1.1, 1.2, 2.4, 3.3, 3.7, 3.10, 3.11, 3.13, 3.14, 7.1, 7.2

Jun., 2014 SH(NA)-080644ENG-O

A

- 8

Sections 6.1.7, 7.11.2, 7.11.3

Sections 6.1.7 to 6.1.10 6.1.8 to 6.1.11, 7.11.2 7.11.4

GENERIC TERMS AND ABBREVIATIONS, Sections 2.2, 2.4.1, 2.4.2, 3.1, 3.2,

3.3, 3.4.1, 3.4.2, 3.6.2, 3.6.3, 5.2, 6.1.7, 7.2, 7.7, 7.8.1, 7.9.1, 7.11.1, 7.13.6, 8.1,

8.2, 8.3, 10.2.1, 10.2.2, 10.3.1, 10.3.3, Appendices 1.1, 3.7, 3.10, 7.2

Page 11

The manual number is given on the bottom left of the back cover.

Correction

Addition

Correction

Print date Manual number Revision

Dec., 2014 SH(NA)-080644ENG-P

Sections 3.2, 4.7.1, 7.8.3, 10.2.1, 10.3.3

Sections 2.6.2

Feb., 2015 SH(NA)-080644ENG-Q

Sections 4.8.1

Japanese Manual Version SH-080643-R

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 2006 MITSUBISHI ELECTRIC CORPORATION

A

- 9

Page 12

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-Q Series of General Purpose Programmable Controllers.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series programmable controller you have purchased, so as to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT.................................................................................................. A - 6

REVISIONS.......................................................................................................................................................A - 7

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES.................................................................. A - 16

HOW TO USE THIS MANUAL ....................................................................................................................... A - 17

GENERIC TERMS AND ABBREVIATIONS................................................................................................... A - 20

DEFINITIONS AND DESCRIPTIONS OF TERMS ........................................................................................ A - 22

PACKING LIST .............................................................................................................................................. A - 24

CHAPTER 1 OVERVIEW 1 - 1 to 1 - 8

1.1 Features........................................................................................................................................... 1 - 2

1.2 MX MESInterface Software Configuration .......................................................................................1 - 8

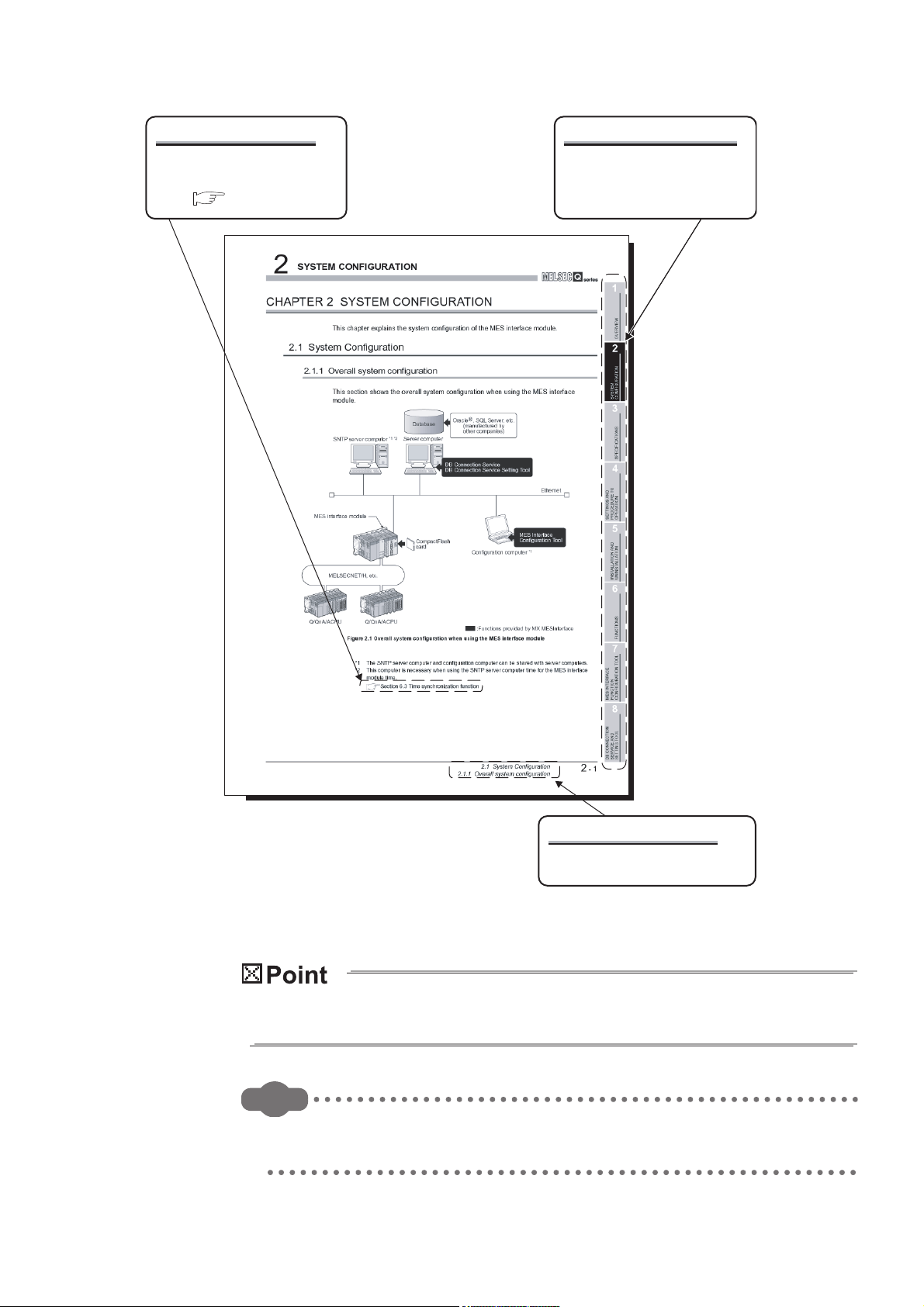

CHAPTER 2 SYSTEM CONFIGURATION 2 - 1 to 2 - 22

2.1 System Configuration ...................................................................................................................... 2 - 1

2.1.1 Overall system configuration .................................................................................................... 2 - 1

2.1.2 System configuration for installation ......................................................................................... 2 - 2

2.1.3 System configuration for initial setup ........................................................................................ 2 - 3

2.1.4 System configuration for operation ........................................................................................... 2 - 4

2.2 Applicable Systems ......................................................................................................................... 2 - 5

2.3 Connection System Equipment ....................................................................................................... 2 - 7

2.4 Operating Environment .................................................................................................................... 2 - 9

2.4.1 Configuration computer ............................................................................................................ 2 - 9

2.4.2 Server computer ..................................................................................................................... 2 - 11

2.4.3 Computer for developing XML processing applications.......................................................... 2 - 15

2.5 Checking Function Version and Serial Number ............................................................................. 2 - 16

2.6 Precautions for System Configuration ........................................................................................... 2 - 19

2.6.1 Precautions for using Redundant CPU................................................................................... 2 - 19

2.6.2 Precautions for using multiple CPU system............................................................................ 2 - 20

2.6.3 Precautions for using database .............................................................................................. 2 - 21

CHAPTER 3 SPECIFICATIONS 3 - 1 to 3 - 38

3.1 Performance Specifications ............................................................................................................. 3 - 1

3.2 Accessible Devices and Ranges ..................................................................................................... 3 - 5

3.3 Function List .................................................................................................................................. 3 - 12

A

- 10

Page 13

3.4 I/O Signals for Programmable Controller CPU .............................................................................. 3 - 16

3.4.1 I/O signal list ........................................................................................................................... 3 - 16

3.4.2 I/O signals details ................................................................................................................... 3 - 18

3.5 Buffer Memory List......................................................................................................................... 3 - 21

3.6 Buffer Memory Details ................................................................................................................... 3 - 26

3.6.1 Module status area ................................................................................................................. 3 - 26

3.6.2 Network connection status area .............................................................................................3 - 26

3.6.3 Network settings status area .................................................................................................. 3 - 27

3.6.4 Current error area ................................................................................................................... 3 - 28

3.6.5 Error log area.......................................................................................................................... 3 - 29

3.6.6 Sampling/monitoring cycle area .............................................................................................3 - 31

3.6.7 Tag status area....................................................................................................................... 3 - 31

3.6.8 Current tag data value area .................................................................................................... 3 - 33

3.6.9 Access target CPU setting status area ................................................................................... 3 - 36

3.6.10 Information linkage function area ........................................................................................... 3 - 37

CHAPTER 4 SETTINGS AND PROCEDURE TO OPERATION 4 - 1 to 4 - 25

4.1 Handling Precautions....................................................................................................................... 4 - 1

4.2 Settings and Procedure to Operation .............................................................................................. 4 - 2

4.3 Parts Names .................................................................................................................................... 4 - 6

4.4 Wiring............................................................................................................................................... 4 - 8

4.4.1 Wiring ....................................................................................................................................... 4 - 8

4.4.2 Wiring precautions.................................................................................................................... 4 - 8

4.5 Intelligent Function Module Switch Settings .................................................................................... 4 - 9

4.6 Self-diagnostics Test ..................................................................................................................... 4 - 12

4.6.1 Self-loopback test ................................................................................................................... 4 - 12

4.6.2 Hardware test ......................................................................................................................... 4 - 13

4.7 CompactFlash Card....................................................................................................................... 4 - 14

4.7.1 Precautions for using a CompactFlash card........................................................................... 4 - 14

4.7.2 Installation/removing the CompactFlash card ........................................................................ 4 - 15

4.8 Battery ........................................................................................................................................... 4 - 20

4.8.1 Battery specifications.............................................................................................................. 4 - 20

4.8.2 Mounting of battery................................................................................................................. 4 - 20

4.8.3 Battery replacement ............................................................................................................... 4 - 21

4.9 Operation without Mounting Battery ............................................................................................. 4 - 24

4.10 Removing Battery for Storage ....................................................................................................... 4 - 25

CHAPTER 5 INSTALLATION AND UNINSTALLATION 5 - 1 to 5 - 11

5.1 Installation........................................................................................................................................ 5 - 1

5.2 Uninstallation ................................................................................................................................... 5 - 9

CHAPTER 6 FUNCTIONS 6 - 1 to 6 - 24

6.1 DB Interface Function ...................................................................................................................... 6 - 1

A

- 11

Page 14

6.1.1 DB interface function operation ................................................................................................ 6 - 1

6.1.2 Job execution procedure .......................................................................................................... 6 - 2

6.1.3 Tag function .............................................................................................................................. 6 - 4

6.1.4 Trigger monitoring function ....................................................................................................... 6 - 5

6.1.5 Trigger buffering function.......................................................................................................... 6 - 7

6.1.6 SQL text transmission (Communication action)...................................................................... 6 - 10

6.1.7 Stored procedure call function (Communication action) ......................................................... 6 - 11

6.1.8 Arithmetic processing function (Operation action) .................................................................. 6 - 12

6.1.9 Program execution function .................................................................................................... 6 - 12

6.1.10 DB buffering function .............................................................................................................. 6 - 13

6.1.11 Precautions............................................................................................................................. 6 - 20

6.2 XML Processing Function.............................................................................................................. 6 - 22

6.3 Time Synchronization Function ..................................................................................................... 6 - 23

6.3.1 Using the SNTP time query result in the programmable controller CPU ................................ 6 - 23

6.3.2 Daylight saving time function .................................................................................................. 6 - 24

CHAPTER 7 MES INTERFACE FUNCTION CONFIGURATION TOOL 7 - 1 to 7 - 147

7.1 MES Interface Function Configuration Tool ..................................................................................... 7 - 1

7.2 Starting the MES Interface Function Configuration Tool ................................................................. 7 - 1

7.3 Screen Structure.............................................................................................................................. 7 - 2

7.3.1 Screen structure ....................................................................................................................... 7 - 2

7.3.2 Menu configuration ................................................................................................................... 7 - 4

7.3.3 Toolbar configuration ................................................................................................................ 7 - 6

7.3.4 Operations using the Edit items tree......................................................................................... 7 - 7

7.4 Project File Handling........................................................................................................................ 7 - 9

7.4.1 Creating a new project.............................................................................................................. 7 - 9

7.4.2 Opening a project ..................................................................................................................... 7 - 9

7.4.3 Saving a project ...................................................................................................................... 7 - 10

7.4.4 Importing a project .................................................................................................................. 7 - 11

7.4.5 Importing a CSV file................................................................................................................ 7 - 13

7.4.6 Exporting a CSV file................................................................................................................ 7 - 16

7.4.7 Printing a setting information file............................................................................................. 7 - 16

7.5 Project Setting ............................................................................................................................... 7 - 17

7.6 System Setting............................................................................................................................... 7 - 18

7.6.1 Setting items in Network setting ............................................................................................. 7 - 19

7.6.2 Setting items in Time synchronization setting......................................................................... 7 - 20

7.6.3 Setting items in Account setting.............................................................................................. 7 - 24

7.6.4 Setting items in DB buffering setting....................................................................................... 7 - 27

7.7 Access Target CPU Setting ........................................................................................................... 7 - 33

7.7.1 Setting items in Access target CPU setting ............................................................................ 7 - 34

7.8 Device Tag Setting ........................................................................................................................ 7 - 38

7.8.1 Setting items in Device Tag setting ........................................................................................7 - 39

7.8.2 Setting items in Array setting .................................................................................................. 7 - 43

7.8.3 Setting items in Component setting ........................................................................................ 7 - 45

7.9 Server Service Setting ................................................................................................................... 7 - 53

7.9.1 Setting items in Server Service setting ................................................................................... 7 - 54

A

- 12

Page 15

7.10 Job Setting..................................................................................................................................... 7 - 58

7.10.1 Setting items in Job setting..................................................................................................... 7 - 59

7.10.2 Setting items in Trigger conditions ......................................................................................... 7 - 62

7.10.3 Setting items in Program execution ........................................................................................7 - 75

7.10.4 Setting items in DB Buffering.................................................................................................. 7 - 79

7.10.5 Setting items for job cancellation ............................................................................................ 7 - 80

7.11 Job Setting - Actions...................................................................................................................... 7 - 81

7.11.1 Setting items in Communication action .................................................................................. 7 - 85

7.11.2 Setting items in Communication action (Select/Update/Insert/MultiSelect/Delete) ................ 7 - 92

7.11.3 Setting items in Communication action (Stored procedure) ................................................. 7 - 116

7.11.4 Setting items in Operation action.......................................................................................... 7 - 119

7.12 Online .......................................................................................................................................... 7 - 123

7.12.1 Setting the target MES interface module .............................................................................. 7 - 123

7.12.2 Writing the MES interface function settings .......................................................................... 7 - 124

7.12.3 Reading the MES interface function settings........................................................................ 7 - 126

7.12.4 Verifying the MES interface function settings ....................................................................... 7 - 126

7.12.5 Checking the working log of the MES interface module ....................................................... 7 - 127

7.12.6 Executing a job as a one-shot task....................................................................................... 7 - 134

7.13 Online - Remote operation........................................................................................................... 7 - 135

7.13.1 Checking the operation status of the MES interface function ............................................... 7 - 136

7.13.2 Manipulating the operation status of the MES interface function ......................................... 7 - 137

7.13.3 Checking the connection of the previous job execution ....................................................... 7 - 139

7.13.4 Changing the job status ........................................................................................................ 7 - 140

7.13.5 Checking the operation status of DB buffering ..................................................................... 7 - 141

7.13.6 Operating the DB buffering ................................................................................................... 7 - 142

7.13.7 Checking the operation status of the trigger buffering .......................................................... 7 - 143

7.13.8 Formatting the CompactFlash card ...................................................................................... 7 - 143

7.14 Help ............................................................................................................................................. 7 - 144

7.15 Precautions.................................................................................................................................. 7 - 145

CHAPTER 8 DB CONNECTION SERVICE AND SETTING TOOL 8 - 1 to 8 - 31

8.1 DB Connection Service Functions ................................................................................................... 8 - 1

8.2 Setting ODBC to the Database........................................................................................................ 8 - 6

8.3 Starting DB Connection Service Setting Tool ................................................................................ 8 - 13

8.4 Screen Structure of DB Connection Service Setting Tool ............................................................. 8 - 14

8.4.1 Screen structure ..................................................................................................................... 8 - 14

8.4.2 Menu configuration ................................................................................................................. 8 - 15

8.5 Setting Items of DB Connection Service Setting Tool ................................................................... 8 - 16

8.6 Importing/Exporting Files .............................................................................................................. 8 - 21

8.7 Help ............................................................................................................................................... 8 - 23

8.8 Output Log Specifications.............................................................................................................. 8 - 24

8.8.1 Access log .............................................................................................................................. 8 - 25

8.8.2 SQL failure log........................................................................................................................ 8 - 31

A

- 13

Page 16

CHAPTER 9 XML MESSAGE FORMAT 9 - 1 to 9 - 6

9.1 XML Message Format Definition ..................................................................................................... 9 - 2

9.2 XML Message Format Sending Method .......................................................................................... 9 - 4

9.2.1 XML message format sending method ..................................................................................... 9 - 4

9.2.2 Sample program ....................................................................................................................... 9 - 5

CHAPTER 10 TROUBLESHOOTING 10 - 1 to 10 - 54

10.1 Error Codes ................................................................................................................................... 10 - 2

10.1.1 Finding an error code.............................................................................................................. 10 - 2

10.1.2 Error types .............................................................................................................................. 10 - 3

10.1.3 System monitor....................................................................................................................... 10 - 4

10.2 Error Code List............................................................................................................................... 10 - 7

10.2.1 Error codes for the MES interface module.............................................................................. 10 - 7

10.2.2 Error codes of DB Connection Service ................................................................................. 10 - 24

10.2.3 Error codes returned in XML response messages ............................................................... 10 - 36

10.3 Troubleshooting by symptom....................................................................................................... 10 - 37

10.3.1 When using MES Interface Function Configuration Tool...................................................... 10 - 37

10.3.2 When using DB Connection Service Setting Tool ................................................................ 10 - 44

10.3.3 When operating the MES interface module .......................................................................... 10 - 45

APPENDICES App - 1 to App - 76

Appendix 1 Functions Added in MES Interface Module and MX MESInterface .....................................App - 1

Appendix 1.1 Addition of new functions.............................................................................................App - 1

Appendix 1.2 Operations of former versions .....................................................................................App - 4

Appendix 2 Usable Characters and ASCII Code Tables ........................................................................App - 6

Appendix 2.1 ASCII code table..........................................................................................................App - 6

Appendix 2.2 Characters that can be used for item names, component names, variable names,

etc. in the product ........................................................................................................App - 7

Appendix 2.3 Characters available for character string constants, etc..............................................App - 8

Appendix 2.4 Characters available for field names, table names, stored procedure names,etc. ......App - 8

Appendix 3 Setting Information File Format (CSV File Format) .............................................................App - 9

Appendix 3.1 Setting information files list..........................................................................................App - 9

Appendix 3.2 Setting information file format and editing precautions.............................................. App - 10

Appendix 3.3 SYSTEM.CSV ...........................................................................................................App - 13

Appendix 3.4 ACCOUNT.CSV ........................................................................................................App - 15

Appendix 3.5 DST.CSV...................................................................................................................App - 17

Appendix 3.6 DBBUF.CSV..............................................................................................................App - 19

Appendix 3.7 CPU.CSV................................................................................................................... App - 20

Appendix 3.8 TAG.CSV...................................................................................................................App - 24

Appendix 3.9 COMPONENT.CSV................................................................................................... App - 26

Appendix 3.10 SERVER.CSV ...........................................................................................................App - 28

Appendix 3.11 JOB.CSV ...................................................................................................................App - 30

Appendix 3.12 CONDITION.CSV......................................................................................................App - 32

Appendix 3.13 ACTION.CSV.............................................................................................................App - 36

Appendix 3.14 ACFIELD.CSV...........................................................................................................App - 39

Appendix 3.15 ACCONDITION.CSV................................................................................................. App - 41

Appendix 3.16 ACEXCEPTION.CSV ................................................................................................App - 43

A

- 14

Page 17

Appendix 3.17 ACOPERATION.CSV................................................................................................ App - 45

Appendix 3.18 REMOTE.CSV........................................................................................................... App - 48

Appendix 3.19 ORDERBY.CSV ........................................................................................................App - 50

Appendix 3.20 MULTISELECT.CSV .................................................................................................App - 51

Appendix 4 Processing Time................................................................................................................App - 53

Appendix 4.1 Product whose first five digits of serial No. is "13092" or later .................................. App - 53

Appendix 4.2 Product whose first five digits of serial No. is "09102" or later and "13091" or

earlier ........................................................................................................................App - 56

Appendix 4.3 Product whose first five digits of serial No. is "09101" or earlier ............................... App - 59

Appendix 5 External Dimensions.......................................................................................................... App - 61

Appendix 6 Data Collection Method for CPUs that cannot be Accessed Directly ................................App - 62

Appendix 7 Warning Messages in Windows(R) ...................................................................................App - 64

Appendix 7.1 Overview of warning messages ................................................................................App - 64

Appendix 7.2 Methods for disabling warning messages ................................................................. App - 65

Appendix 8 Transportation Precautions ............................................................................................... App - 73

Appendix 8.1 Controlled model .......................................................................................................App - 73

Appendix 8.2 Handling for shipping.................................................................................................App - 73

Appendix 9 Handling of Batteries and Devices with Built-in Batteries in EU Member States............... App - 74

Appendix 9.1 Disposal precautions ................................................................................................. App - 74

Appendix 9.2 Exportation precautions.............................................................................................App - 75

INDEX Index - 1 to Index - 2

A

- 15

Page 18

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage

Directives when incorporated into other machinery or equipment, certain measures

may be necessary. Please refer to one of the following manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance with

EMC and Low Voltage Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer

to one of the manuals listed under (1).

A

- 16

Page 19

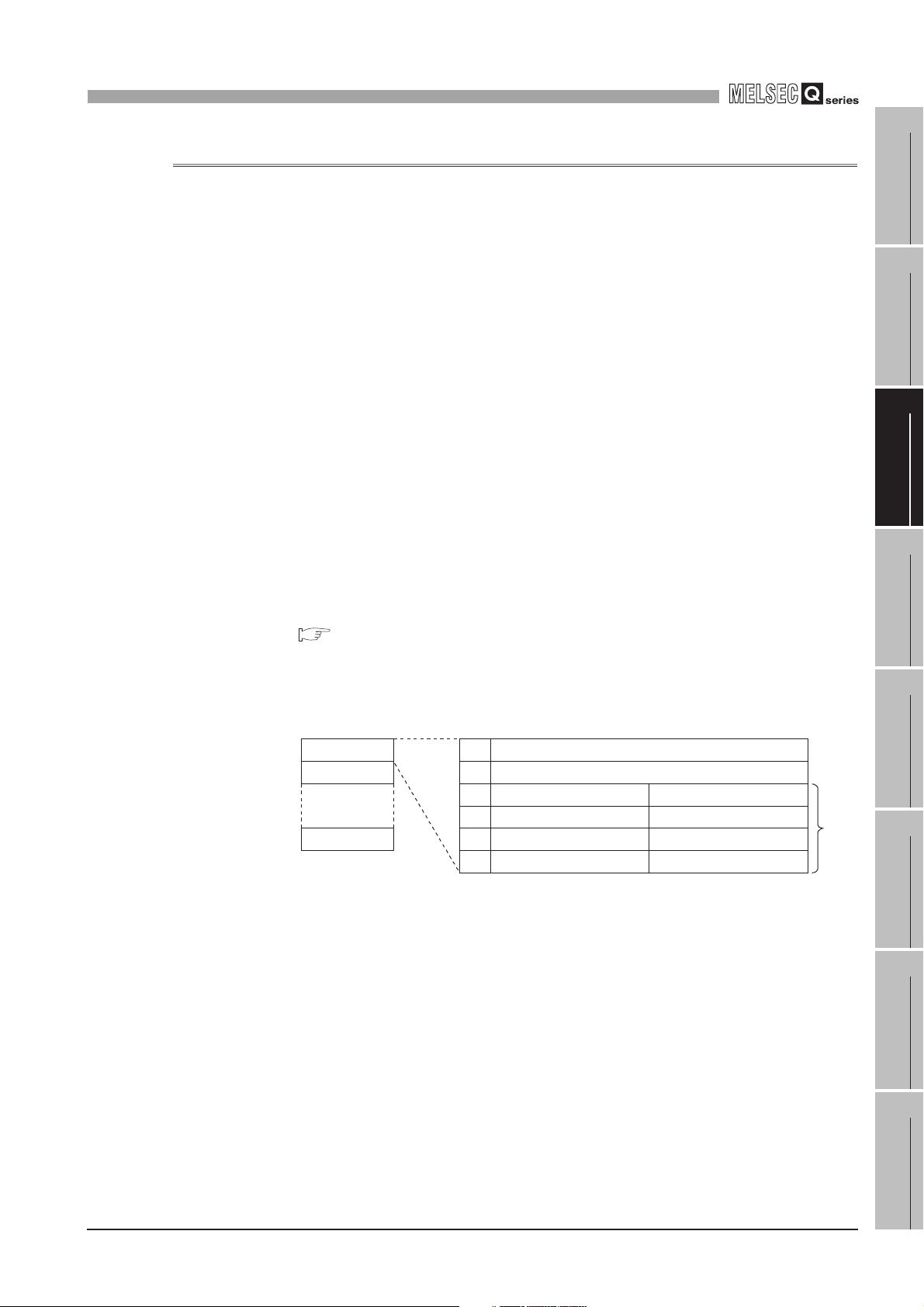

HOW TO USE THIS MANUAL

Section 7.6 ...... Explains a display method of the screen.

Section 7.6.1

Section 7.6.2

Section 7.6.3

Section 7.6.4

Explains setting items and

the setting methods of the screen.

* Sections 7.7 to 7.10 also provide explanations as indicated above.

This manual is organized by objective for using the QJ71MES96 MES interface module

and MX MESInterface Version 1 (SW1DNC-MESIF-E). Use this manual with referring to

the following.

(1) Features and software configuration

Section 1.1 covers the features.

Section 1.2 covers the MX MESInterface software configuration.

(2) System configuration, applicable systems, connection system equipment, and

operating environment

Section 2.1 covers the system configuration.

Section 2.2 covers the applicable systems.

Section 2.3 covers the connection system equipment.

Section 2.4 covers the operating environment.

(3) Performance specifications about the MES interface module

Section 3.1 covers the performance specifications.

Chapter 1 OVERVIEW

Chapter 2 SYSTEM CONFIGURATION

Chapter 3 SPECIFICATIONS

(4) Procedure up to MES interface Function module start-up

Chapter 4 SETTINGS AND PROCEDURE TO OPERATION

Section 4.2 covers the schematic procedure up to the MES interface module operation.

(5) Installation and uninstallation methods for MX MESInterface

Chapter 5 INSTALLATION AND UNINSTALLATION

CHAPTER 5 covers MX MESInterface installation and uninstallation methods.

(6) MES interface module functions

Chapter 6 FUNCTIONS

CHAPTER 6 covers the MES interface module functions.

(7) Setting method for MES Interface Function Configuration Tool

Chapter 7 MES INTERFACE FUNCTION CONFIGURATION TOOL

CHAPTER 7 covers the setting method of the MES Interface Function Configuration

Tool.

Section 7.6 to Section 7.10 provide explanations as indicated below.

A

- 17

Page 20

(8) Setting method for DB Connection Service

Chapter 8 DB CONNECTION SERVICE AND SETTING TOOL

CHAPTER 8 covers the functions and setting method for the DB Connection Service.

(9) XML message format

Chapter 9 XML MESSAGE FORMAT

CHAPTER 9 covers the XML message format.

(10)Methods for checking errors and the corrective actions

Chapter 10 TROUBLESHOOTING

CHAPTER 10 covers troubleshooting and lists the error codes.

A

- 18

Page 21

Remark

Displaying a reference

Displaying a chapter title

Reference in this manual and

reference manual are shown

with .

Index on the right of a page

clears the chapter of the page.

Displaying a section title

The section in which the open page

is included is clear.

The above is different from the actual page, as it is provided for explanation only.

In addition, this manual provides the following explanations.

Explains the matters to be especially noted, the functions and others related to the

description on that page.

Provides the reference destination related to the description on that page and the

convenient information.

A

- 19

Page 22

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to explain the QJ71MES96 MES interface module and MX MESInterface

Version 1 (SW1DNC-MESIF-E).

Generic term/abbreviation Description

Generic term for the A1NCPU, A0J2HCPU, A1SCPU, A1SHCPU, A1SJCPU, A1SJHCPU,

ACPU

C Controller module

Ethernet Generic term for 100BASE-TX, 10BASE-T, 10BASE5, and 10BASE2 network systems

Ethernet module Generic term for the E71, QE71, Q series E71, and L series E71

E71

GX Developer

LCPU

L series E71 Another term for the LJ71E71-100

MELSECNET/H Abbreviation for MELSECNET/H network system supporting the Q series

MELSECNET/10 Abbreviation for MELSECNET/10 network system supporting the AnU and QnA/Q4AR

MES interface module Abbreviation for the QJ71MES96 MES interface module

MX MESInterface Product name for the model name SW1DNC-MESIF-E

QCPU (A mode) Generic term for the Q02CPU-A, Q02HCPU-A, and Q06HCPU-A

QCPU (Q mode)

QC24(N)

QE71

QnACPU

Q series C24

Q series E71 Generic term for the QJ71E71-100, QJ71E71-B5, and QJ71E71-B2

RCPU Generic term for R04CPU, R08CPU, R16CPU, R32CPU, R120CPU

R series E71 Another term for the RJ71EN71

UC24

A2CCPU, A2CJCPU, A2NCPU, A2NCPU-S1, A2SCPU, A2SHCPU, A2ACPU, A2ACPU-S1,

A2UCPU, A2UCPU-S1, A2USCPU, A2USCPU-S1, A2USHCPU-S1, A3NCPU, A3ACPU,

A3UCPU, and A4UCPU

Generic term for the Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V, Q24DHCCPU-V, and

Q24DHCCPU-LS

Generic term for the AJ71E71N3-T, AJ71E71N-B5, AJ71E71N-B2, A1SJ71E71N3-T,

A1SJ71E71N-B5, and A1SJ71E71N-B2

Generic product name for the model names of the SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

SWnD5C-GPPW-EV, and SWnD5C-GPPW-EVA. (n = Version 4 or later)

- A designates a multiple-license product; -V designates a version upgraded product.

Generic term for the L02SCPU, L02SCPU-P, L02CPU, L02CPU-P, L06CPU, L06CPU-P,

L26CPU, L26CPU-P, L26CPU-BT, and L26CPU-PBT

Generic term for the Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU, Q12PRHCPU,

Q25PRHCPU, Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q04UDHCPU,

Q06UDHCPU, Q10UDHCPU, Q13UDHCPU, Q20UDHCPU, Q26UDHCPU, Q03UDECPU,

Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDEHCPU, Q20UDEHCPU,

Q26UDEHCPU, Q50UDEHCPU, Q100UDEHCPU, Q03UDVCPU, Q04UDVCPU,

Q06UDVCPU, Q13UDVCPU, and Q26UDVCPU

Generic term for the AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24,

A1SJ71QC24-R2, AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N,

A1SJ71QC24N-R2, A1SJ71QC24N1, and A1SJ71QC24N1-R2

Generic term for the AJ71QE71N3-T, AJ71QE71N-B5, AJ71QE71N-B2, A1SJ71QE71N3-T,

A1SJ71QE71N-B5, and A1SJ71QE71N-B2

Generic term for the Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU,

Q2ASHCPU-S1, Q3ACPU, Q4ACPU, and Q4ARCPU

Generic term for the QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, and

QJ71C24-R2

Generic term for the AJ71UC24, A1SJ71UC24-R2, A1SJ71UC24-R4, A1SJ71UC24-PRF,

A1SJ71C24-R2, A1SJ71C24-R4, A1SJ71C24-PRF, A1SCPUC24-R2, A2CCPUC24, and

A2CCPUC24-PRF

(To the next page)

A

- 20

Page 23

Generic term/abbreviation Description

Generic term for the following:

®

Windows® 7 Starter Operating System

®

Windows® 7 Home Premium Operating System

Windows® 7

Microsoft

Microsoft

Microsoft® Windows® 7 Professional Operating System

Microsoft® Windows® 7 Ultimate Operating System

®

Microsoft

Windows® 7 Enterprise Operating System

Generic term for the following:

®

Windows® 8 Operating System

®

Windows® 8 Enterprise Operating System

Windows® 8

Microsoft

Microsoft® Windows® 8 Pro Operating System

Microsoft

Generic term for the following:

®

Windows® 8.1 Operating System

®

Windows® 8.1 Pro Operating System

®

Windows® 8.1 Enterprise Operating System

Windows® 8.1

Microsoft

Microsoft

Microsoft

Generic term for the following:

Microsoft® Windows Vista® Home Basic Operating System

Windows Vista

®

Microsoft® Windows Vista® Home Premium Operating System

®

Microsoft

Windows Vista® Business Operating System

Microsoft® Windows Vista® Ultimate Operating System

Microsoft® Windows Vista® Enterprise Operating System

Generic term for the following:

®

Windows® XP

Microsoft

Windows® XP Professional Operating System

Microsoft® Windows® XP Home Edition Operating System

Computer link module (Serial

communication module)

Generic term for the UC24, QC24(N), and Q series C24

Especially when referring to the QC24(N) and Q series C24, they are written as "Serial

communication module".

(From the previous page)

A

- 21

Page 24

DEFINITIONS AND DESCRIPTIONS OF TERMS

The following table shows the definitions and descriptions of the terms used in this

manual.

Term Description

CSV

DB buffering

HTTP

Tag for Wonderware®

Historian

MES

ODBC

SNTP

SNTP server computer

SQL

URL

URL encode

XML

Item One setting group unit included each setting type for editing

Account

Action

System switching

COMMIT Processing for finalizing the changes to a database

CompactFlash card

(CF card)

Abbreviation for Comma Separated Values

Text file in which the data are aligned and set off by commas and double quotations

Function temporarily stores SQL text that failed to be sent due to a communication error and

resends the text when the communications have been recovered

Abbreviation for Hyper Text Transfer Protocol

Protocol to exchange XML format messages between the MES interface module and user

applications in the XML processing function

Name for data unit in the data base Wonderware® Historian.

Abbreviation for Manufacturing Execution Systems

Systems for controlling and monitoring the plant status in real time to optimize production

activities

The systems enable to speed up the responses to production plan and status changes that lead

to efficient production processes and optimization of production activities.

Abbreviation for Open DataBase Connectivity

Standard specifications for software to access databases

Abbreviation for Simple Network Time Protocol

Protocol for synchronizing computer time via a TCP/IP network

Computer that provides time information to the MES interface module

This computer can be shared with a server computer.

Abbreviation for Structured Query Language

Data manipulation language and used for relational database operations

Abbreviation for Uniform Resource Locator

Notation method for indicating the locations of information resources on the Internet

Converts character strings into characters can be used in URLs.

This designates percent encoding defined by RFC3986.

Abbreviation for eXtensible Markup Language

Markup language for describing documentation, data meanings, and structures

Designates the right to use the MES interface module or server computer, or an ID necessary for

their use.

Unit for processing defined in a job

There are [Communication action] for communicating with a database and [Operation action] for

operating tag component values.

[Communication action] is a processing unit for sending one SQL text (Select, Update, Insert,

MultiSelect, or Delete) or one stored procedure execution request.

[Operation action] is a processing unit of up to 20 dyadic operations.

Function for the Redundant CPU to switch between control system and standby system of the

redundant system. (Switching from control system to standby system, and vice versa.)

Storage card regulated by the [CF+ and CompactFlash Specification] issued by the Compact

Flash Association

This memory card is necessary for the MES interface module to operate the MES interface

function.

(To the next page)

A

- 22

Page 25

Term Description

Generic term for the services can be offered by a server computer to which DB Connection

Service is installed

Server service

Server computer

Job Unit for accessing a database

Stored procedure

Update settings

Configuration computer

Time zone

Tag component

(Component)

Data source

Database (DB) or

relational database

(RDB)

Table

Device

Device tag (Tag)

Trigger condition Startup conditions for job operation

There are database server service and application server service.

The database server service is a service for accessing a database.

The application server service is a service for linking with a program.

There are database server computers and application server computers.

The database server computer is a personal computer with a relational database which links

information with the MES interface module.

The application server computer is a personal computer with a program that operates upon

request from the MES interface module.

Stored procedure combines sequential processing procedures into one program against the

database, and save it to the database management system.

This executes processing based on the arguments received from MES interface module, and

returns the processing results to MES interface module.

Processing updates the MES interface module settings from MES Interface Function

Configuration Tool

Personal computer for configuring various settings required for the MES interface function in the

MES interface module

This computer can be shared with a server computer.

Standard time zone for each region of the world

Each nation uses the time difference ( 12 hours maximum) from the time at the Greenwich

Observatory in the United Kingdom (GMT) as the standard time. The region using the same time

difference is called a time zone.

The standard time for Japan is 9 hours ahead of the GMT.

In some nations, daylight time in which the clock is advanced for one hour is used in summer.

Generic term for a component (Device data) making up a device tag (Tag)

This data organizes the communications path, data type, device, etc. for access to each

programmable controller CPU device data as a single data unit.

Connection information necessary for accessing data using ODBC

®

With Windows

database can be accessed via ODBC by specifying the data source name in the MES interface

function.

Data management method that follows relational data model logic

One data is expressed as a collection of multiple items (Fields) and the data collection is

expressed as a table.

Data can be easily merged and selected using key data.

Data management format managed with relational databases

It is a two-dimensional table format composed of rows and columns.

Variety of memory data in the programmable controller

There are devices handled in units of bits and devices handled in units of words.

Data table that contains a set of information (Component) required to access the device data in

the programmable controller CPUs on the network

The MES interface module collects device data in units of tags at an interval defined in the tag.

, a data source name is assigned to connection information for management. The

(From the previous page)

(To the next page)

A

- 23

Page 26

(From the previous page)

Term Description

When trigger conditions (conditions for data transmission) of multiple jobs are met in a

concentrated manner, their data and trigger times are buffered in the module's internal memory so

Trigger buffering

Data separation

Daylight saving

(Summer time)

Handshake

Field Corresponds to a column in a relational database and indicates a type of data (Record attribute).

Variable (Temporary

variable)

Record

Rollback Processing for canceling changes to a database

that actions (data operation/transmission) can be executed later using the buffered data.

Even if the frequency of data transmission triggers is high, jobs are executed without missing any

trigger.

New data and old data are mixedly exists in units of 16 bits (1 word) in 32 bits data (2 words) or

larger data due to data reception timing.

The system in which clocks are set one hour ahead of standard time in a specific period of time in

summer.

For highly reliable processing, programmable controller CPU devices are used to manage

processing between the programmable controller CPU and MES interface module.

Variable that can be used in a single job for temporary storage of values selected from a database

and for writing operation values to a database or tag components

Corresponds to a row in a relational database. One row (Record) stores the values of multiple

columns (Fields).

PACKING LIST

The following table shows the products included to the QJ71MES96 MES interface

module and MX MESInterface Version 1 (SW1DNC-MESIF-E).

Model Product name Quantity

QJ71MES96

SW1DNC-MESIF-E MX MESInterface Version 1 (with one license) (CD-ROM) 1

SW1DNC-MESIF-EA MX MESInterface Version 1 (with multiple licenses) (CD-ROM) 1

QJ71MES96MES interface module 1

Battery (Q6BAT) 1

A

- 24

Page 27

1

OVERVIEW

CHAPTER 1 OVERVIEW

This manual explains the specifications, preparatory procedures, functions, and

troubleshooting for the MELSEC-Q series QJ71MES96 MES interface module (hereafter,

abbreviated as MES interface module).

When applying the following program examples to the actual system, make sure to

examine the applicability and confirm that it will not cause system control problems.

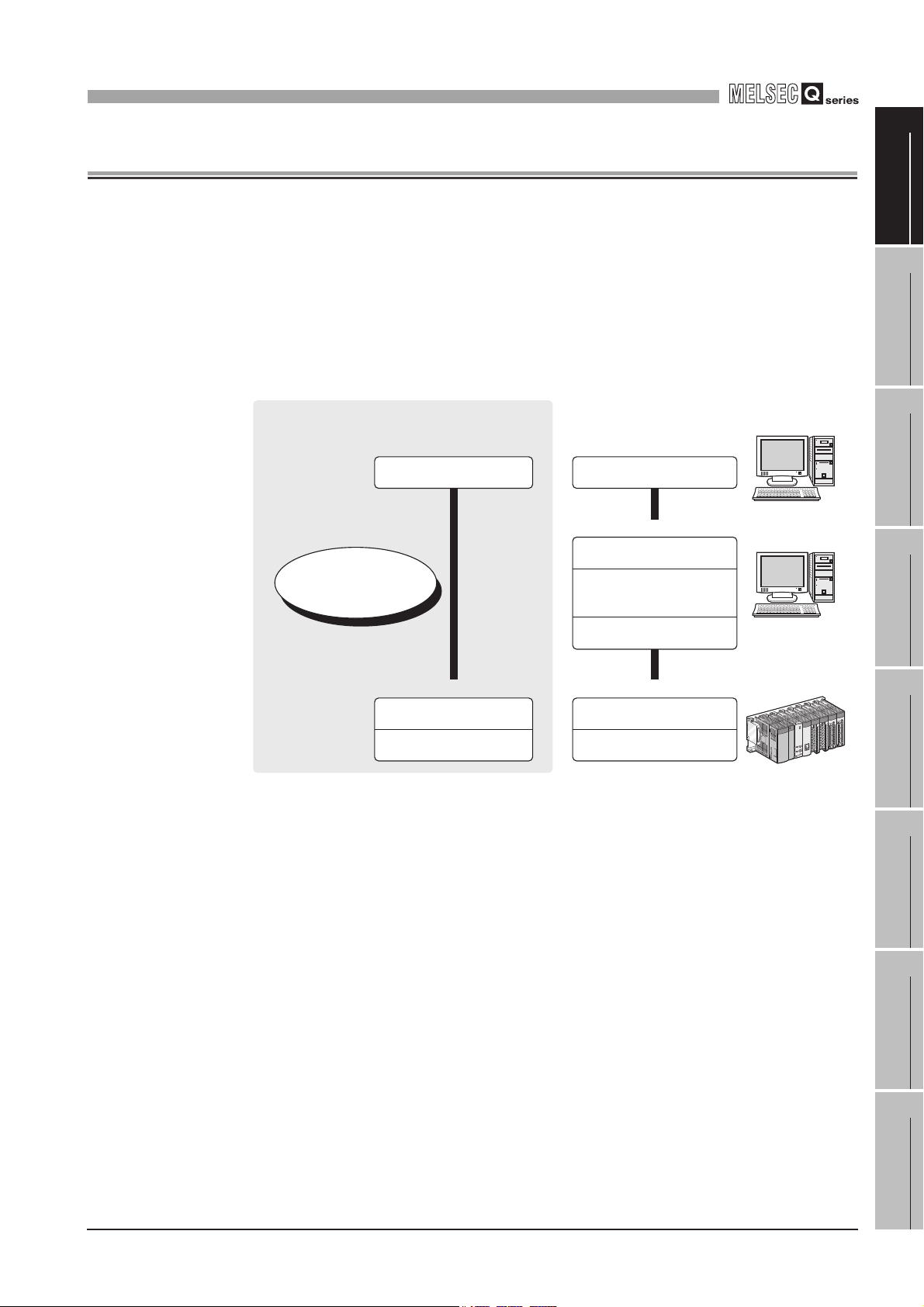

The MES interface module links the programmable controller (Production equipment)

device data with information system (Manufacturing Execution System) database without

communication gateways.

1

2

OVERVIEW

SYSTEM

CONFIGURATION

Information linkage using the MES interface module

<Manufacturing Execution System>

Information system

(Database)

Computerization via

communication gateways

is unnecessary.

<Production equipment> <Production equipment>

MES interface module

Programmable controller CPU

Figure 1.1 Information linkage using the MES interface module

SQL

XML

(Device data)

Conventional information linkage

without the MES interface module

<Manufacturing Execution System>

Information system

(Database)

<Communication gateway>

Host information system

communication processing

Data processing

(Operation processing,

logging, etc.)

Controller communication

Communication module

Programmable controller CPU

(Device data)

3

SPECIFICATIONS

4

SETTINGS AND

PROCEDURE TO

OPERATION

5

INSTALLATION AND

UNINSTALLATION

6

FUNCTIONS

7

MES INTERFACE

FUNCTION

CONFIGURATION TOOL

8

DB CONNECTION

SERVICE AND

SETTING TOOL

1

- 1

Page 28

1

OVERVIEW

1.1 Features

This section explains the features of MX MESInterface.

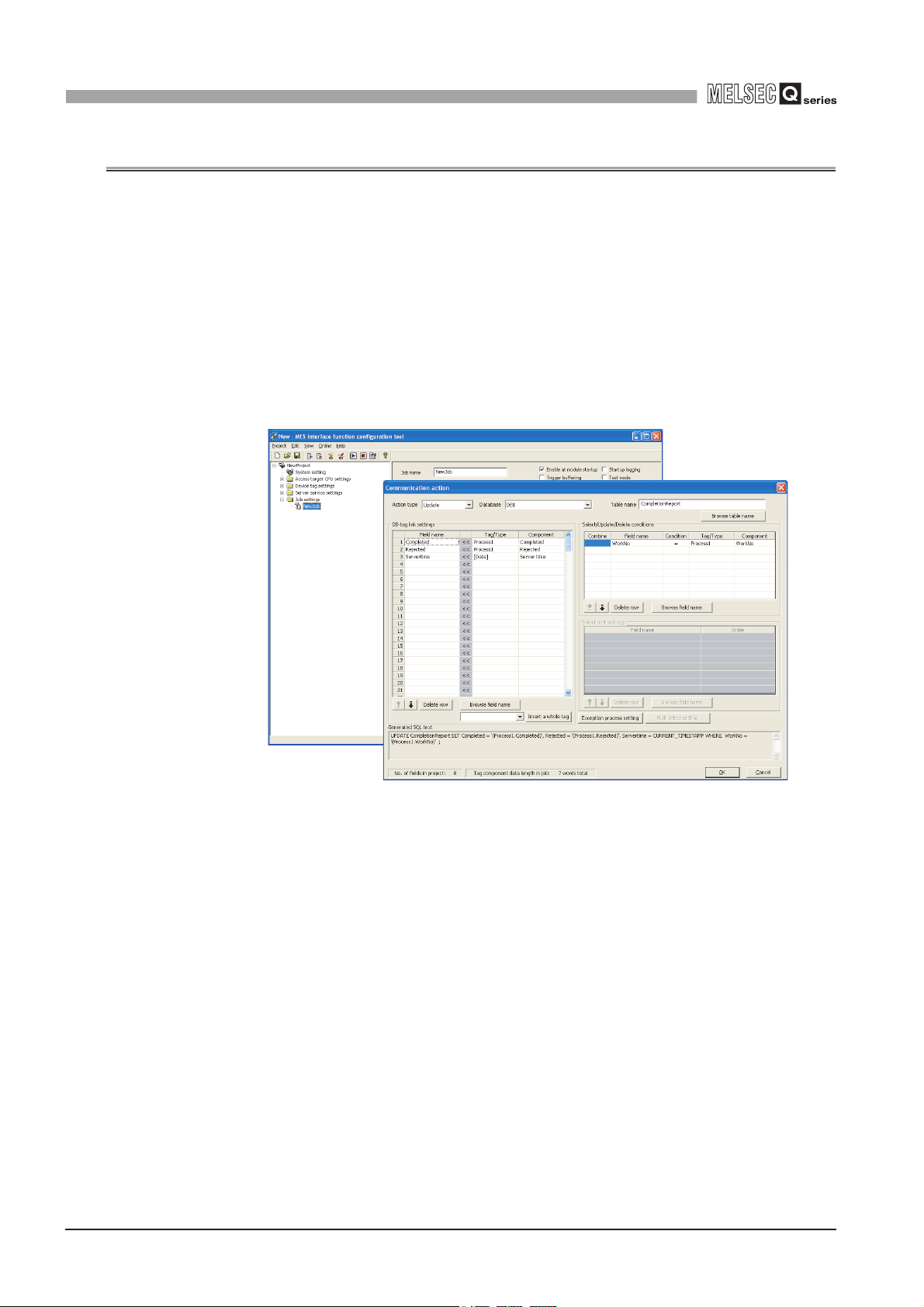

(1) Connection with the information system is enabled by simple settings without

program

Access to information system databases can be realized simply by making the

necessary settings with the setting tool.

There is no need to write programs for accessing databases, so the engineering costs

for system construction can be reduced and the work period can be shortened.

[MX MESInterface] - [MES interface function configuration tool]

1

- 2

Figure 1.2 [MX MESInterface] - [MES interface function configuration tool]

1.1 Features

Page 29

1

OVERVIEW

(2) The information system load can be reduced.

[MES interface module...]

Data can be monitored on the MES interface module side and when the conditions

are met, the data can be sent to the information system.

Also, the data can be operated and the results of the operations can be sent to the

information system.

This can reduce the information system loads compared to the conventional system

of constantly obtaining and monitoring data.

1

OVERVIEW

2

Conditions

met

[In the conventional system...]

Constantly obtaining/monitoring data

from information system are required.

Figure 1.3 Loads reduction of information system

Sends data as required.

<Information system>

<Information system>

Database

Database

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SETTINGS AND

PROCEDURE TO

OPERATION

5

INSTALLATION AND

UNINSTALLATION

1.1 Features

6

FUNCTIONS

7

MES INTERFACE

FUNCTION

CONFIGURATION TOOL

8

DB CONNECTION

SERVICE AND

SETTING TOOL

1

- 3

Page 30

1

OVERVIEW

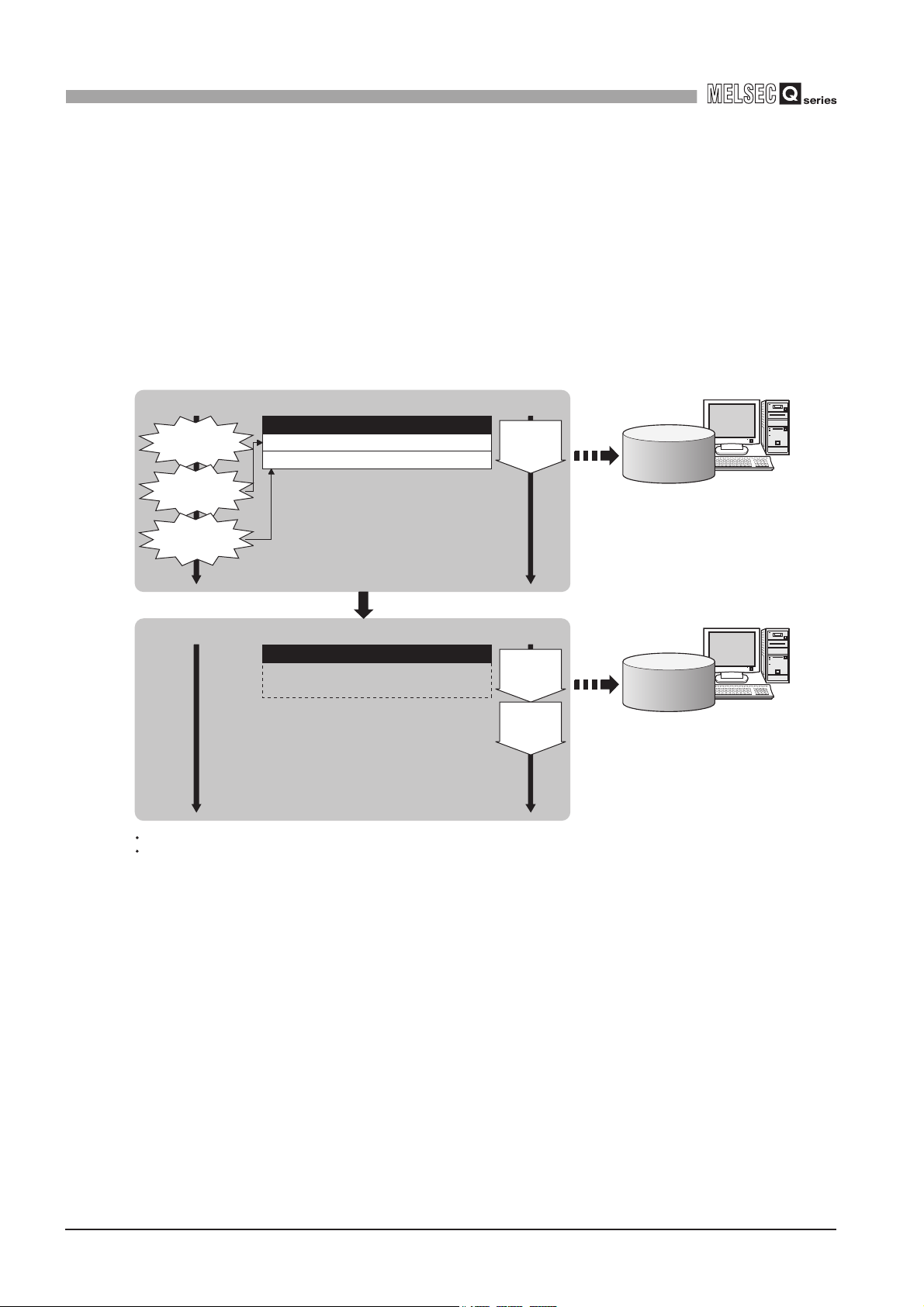

(3) Buffering function for reliable data acquisition/transmission

(a) Even if the frequency of data transmission triggers is high, no trigger will be

[MES interface module]

[When loads are concentrated]

Job 1-1)

Trigger conditions

met

Job 1-2)

Trigger conditions

met

Job 3-3)

Trigger conditions

met

Job 1-2) Trigger information (Tag data, time)

Job 3-3) Trigger information (Tag data, time)

missed. (Trigger buffering function)

When multiple sets of conditions for data transmission are met in a concentrated

manner, their data and trigger times can be buffered in the module's internal

memory.

After the loads are reduced, data operations and transmission are executed using

the buffered data.

Trigger buffer

Job 1-1)

Action

execution

Sending

data

Database

Executes action of Job 1-1), and

stores trigger information of Job 1-2)

and 3-3) in the trigger buffer.

Time

After loads have been reduced

[When loads are reduced]

Trigger buffer

Time Time

The numbers 1) to 3) show the order in which trigger conditions of respective jobs are met.

Job 1 and 3 are assumed to access the same database.

Figure 1.4 Data buffering in the case of load concentration

Job 1-2)

Action

execution

Job 3-3)

Action

execution

Time

Sending

data

After completing the action of Job 1-1),

executes actions of Job 1-2) and 3-3)

in this order based on the trigger buffer

information.

Database

1

- 4

1.1 Features

Page 31

1

OVERVIEW

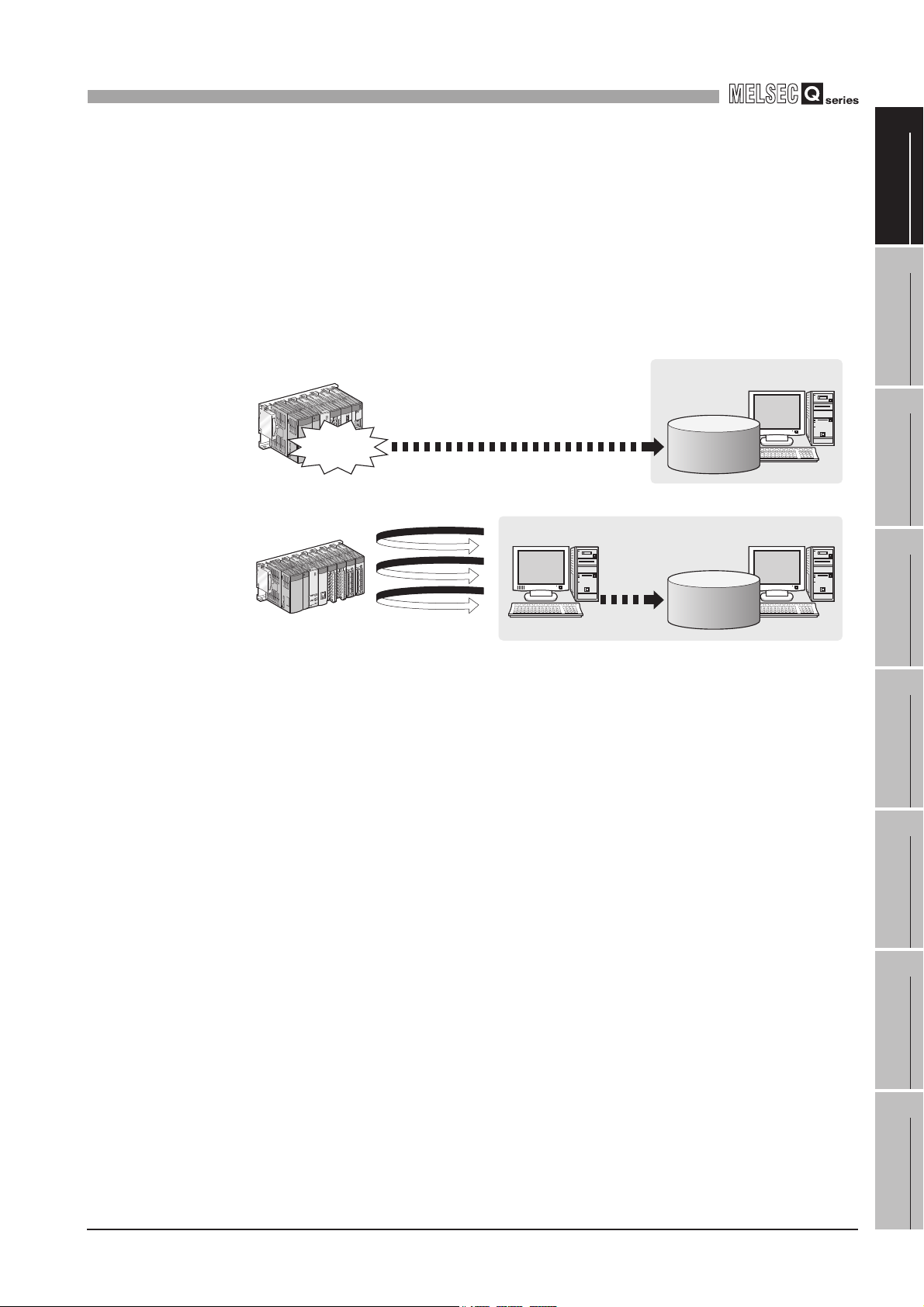

(b) Data to be send to the database are protected even if a communication error

occurs. (DB buffering function)

When an error occurs during performing communication with a database, stored

procedure execution requests or the SQL texts failed to send can be stored in a

CompactFlash card.

After the recovery, the buffered SQL texts or stored procedure execution requests

are automatically sent to the database. (Manual operation is also possible.)

Disconnected

Database

Insert...

Insert...

Insert...

Update...

1

2

3

OVERVIEW

SYSTEM

CONFIGURATION

SPECIFICATIONS

CompactFlash card

Recovered

Resend

Database

Insert...

Insert...

Insert...

Update...

CompactFlash card

Figure 1.5 Buffering of send data (SQL text) during a communication error

4

SETTINGS AND

PROCEDURE TO

OPERATION

5

INSTALLATION AND

UNINSTALLATION

6

FUNCTIONS

7

1.1 Features

MES INTERFACE

FUNCTION

CONFIGURATION TOOL

8

DB CONNECTION

SERVICE AND

SETTING TOOL

1

- 5

Page 32

1

OVERVIEW

(4) Log data are available in the event of an access error

After connection with a database, when there is a communication error, a log of the

error contents can be recorded to the database side.

Analyzing the log can protect data and analyze the error.

Database

DB Connection

Service

Access

log

Figure 1.6 Obtaining logs for access errors

(5) Directions from the information system can be realized.

Processing registered in the MES interface module can be started from information

system applications.

This enables to realize production directions from the information system.

Not only can data be sent to a database but it can also be received from a database.

This enables to download data such as production information from information

system databases.

<MES interface module>

2) Starts registered

processing.

(Job execution)

1) Instructs job execution.

3) Sends data.

SQL

failure

log

<Information system>

Database

1

- 6

<MES interface module>

1.1 Features

1) Instructs job execution.

2) Starts registered

processing.

(Job execution)

3) Sends data.

Figure 1.7 Realization of directions from the information system

<Information system>

Database

Page 33

1

OVERVIEW

(6) Supporting diverse databases

(7) Access independent of the database table configuration is possible.

When designing a new system, a wide range of database types can be selected.

Even when connecting to the existing system, the system can be transferred without

changing the existing database.

Freely designed database tables can be used for access to databases.

When designing a new system, not only the high flexibility of design, but when

connecting to the existing system, the system can be constructed without changing

the database tables.

1

2

OVERVIEW

SYSTEM

CONFIGURATION

(8) Time synchronization using SNTP is also possible.

The clocks for the MES interface module and the programmable controller CPU can

be set through communications with an SNTP server computer.

This enables to synchronize the time for the entire system.

3

SPECIFICATIONS

4

SETTINGS AND

PROCEDURE TO

OPERATION

5

INSTALLATION AND

UNINSTALLATION

6

1.1 Features

FUNCTIONS

7

MES INTERFACE

FUNCTION

CONFIGURATION TOOL

8

DB CONNECTION

SERVICE AND

SETTING TOOL

1

- 7

Page 34

1

OVERVIEW

1.2 MX MESInterface Software Configuration

This section explains the MX MESInterface software configuration.

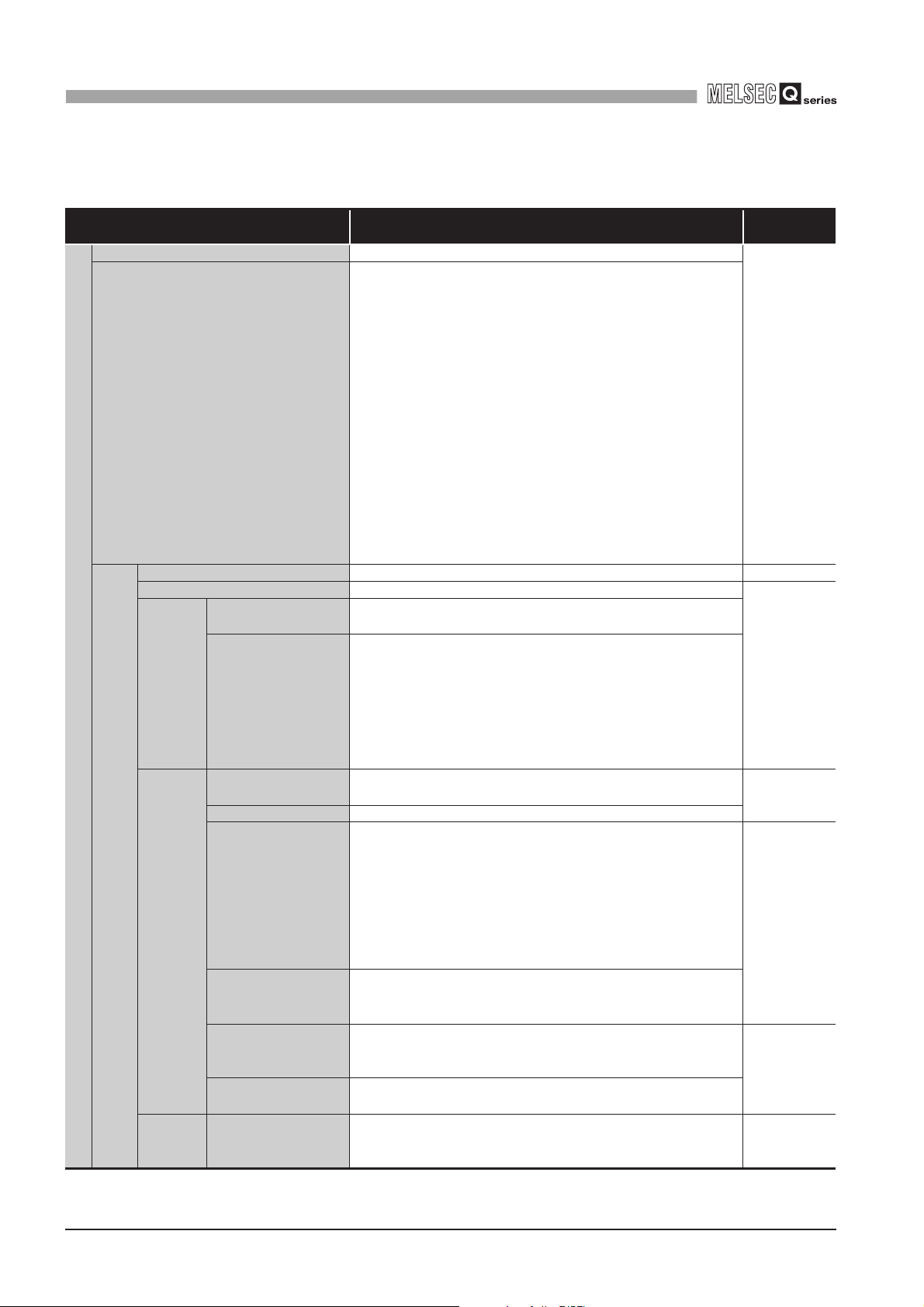

Table 1.1 MX MESInterface software configuration

Item Description

Installs each execution software (MES Interface Function Configuration Tool, DB

Installer

MES Interface Function

Configuration Tool

DB Connection Service

DB Connection Service

Setting Tool

Connection Service, and DB Connection Service Setting Tool) in each operating

environment.

Operates on a configuration computer and configures various settings required for the

MES interface function.

In addition to the configuration, the application tool offers features such as the operation

status check, working log check, or stop/restart operation.

Operates on the server computer and links databases with the MES interface module

and the MES Interface Function Configuration Tool.

Operates on the server computer and changes the settings of the DB Connection

Service.

Reference

section

CHAPTER 5

CHAPTER 7

CHAPTER 8

CHAPTER 8

1

- 8

1.2 MX MESInterface Software Configuration

Page 35

2