PROFIBUS-DP Slave Module

User's Manual

-QJ71PB93D

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of

the programmable controller system, refer to the user’s manual for the CPU module used.

In this manual, the safety instructions are classified into two levels: " WARNING" and " CAUTION".

! !

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

!

[DESIGN PRECAUTIONS]

!

WARNING

When a communication error occurs on PROFIBUS-DP, the status of the faulty station is as

follows. Configure an interlock circuit in the sequence program using the communication status

information (input X1) so that the system can operate safely.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) The input data from the master station remains unchanged from the data prior to the

communication error.

(2) When the master station becomes faulty, the output status of the QJ71PB93D will be as in

the parameter settings of the master station.

(3) When any QJ71PB93D is down, the output state of other slave stations will be in

accordance with the parameter settings of the master station.

Do not output (turn on) the "Use prohibited" signal as the output signal to an intelligent function

module from the CPU module.

Writing data into the "system area" or outputting a signal for "Use prohibited" may cause system

malfunction in the programmable controller.

A - 1 A - 1

!

CAUTION

Do not install the PROFIBUS cables together with the main circuit lines or power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the programmable controller under the environment specified in the user's manual of the

CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

To mount the module, while pressing the module mounting lever in the lower part of the module,

fully insert the module fixing projection(s) into the hole(s) in the base unit and press the module

until it snaps into place.

Incorrect mounting may cause malfunctions, a failure, or a drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the

module with a screw.

Tighten the screws within the range of specified torque.

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damage to the screw and/or the module,

resulting in fallout, short circuits or malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing

the module.

Failure to do so may result in damage to the product.

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[WIRING PRECAUTIONS]

!

WARNING

Shut off the external power supply (all phases) used in the system before wiring the PROFIBUS

cables.

Failure to do so may result in failure or malfunctions of the module.

Be sure to shut off all phases of the external power supply used by the system before wiring

PROFIBUS cables.

Failure to do so may result in failure or malfunctions of the module.

A - 2 A - 2

!

CAUTION

Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter

can cause a fire, failure, or malfunction.

Place the PROFIBUS cables in a duct or clamp them.

If not, dangling cables may swing or inadvertently be pulled, resulting in damages to the module

or cables or malfunctions due to poor contact.

When disconnecting the PROFIBUS cable from the module, do not pull by holding the cable

section. To disconnect the cable, make sure to hold the connector which is coupled with the

module. Do not attempt to pull the cable to disconnect it from the module. It could damage the

module or the cable, or cause malfunction due to a poor contact of the cable.

A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

[STARTING AND MAINTENANCE PRECAUTIONS]

!

WARNING

Shut off the external power supply (all phases) used in the system before cleaning the module

or retightening the connector screws or module fixing screws.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

!

CAUTION

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing

the module.

Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not mount/remove the module to/from the base unit more

than 50 times (IEC 61131-2 compliant).

Exceeding the limit of 50 times may cause malfunction.

Before handling the module, touch a grounded metal object to discharge the static electricity

from the human body.

Failure to do so may cause the module to fail or malfunction.

A - 3 A - 3

[DISPOSAL PRECAUTIONS]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

A - 5 A - 5

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Mar., 2002 SH(NA)-080318E-A First Edition

Apr., 2004 SH(NA)-080318E-B

Correction

Section 2.1, 2.3, 3.1, 3.3.2, 3.5, 5.2.1, 7.3.1, 7.3.2, 9.5

Addition

SAFETY PRECAUTIONS

Aug., 2004 SH(NA)-080318E-C

Correction

SAFETY PRECAUTIONS, Section 5.2.1, Chapter 7, Section 8.1, 8.2

Aug., 2006 SH(NA)-080318E-D

Correction

SAFETY PRECAUTIONS, Conformation to the EMC Directive and Low

Voltage Instruction, Section 2.3, 3.1 to 3.5, 5.1, 5.5, 5.7.2, 8.1, 8.2, 9.5,

Appendix 2

Addition

About Manuals, About the Generic Terms and Abbreviations, Meanings

and Definitions of Terms, Section 1.1, 2.1, 2.2, 4.1.1 to 4.1.4, 5.2.1 to

5.2.3, 5.6, 5.7.1, Chapter 6, Section 6.1, 6.2, 7.1 to 7.4, Chapter 8,

Appendix 1

New Addition

Section 5.3

Section number change

Section 3.5 5.2, 3.5.1 to 3.5.3 5.2.1 to 5.2.3, 3.6 3.5, 5.1.1

5.2, 5.2 to 5.5 5.4 to 5.7

Jul., 2007 SH(NA)-080318E-E

Change of a term

"PLC" was changed to "programmable controller".

Correction

About the Generic Terms and Abbreviations, Section 2.1, 2.3, 3.1,

3.4.1, 5.5, 8.2 to 8.3, Appendix 1

Addition

Section 5.3.1, 5.4.1, 7.3.1, 7.3.2, 9.4

Section number change

Chapter 8(3) Section 8.1, Section 8.1 to 8.2 8.2 to 8.3

Nov., 2007 SH(NA)-080318E-F

Correction

Section 3.3.2, 3.4.1, 7.3.1

A - 6 A - 6

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Jun., 2015 SH(NA)-080318E-G

Correction

SAFETY PRECAUTIONS, COMPLIANCE WITH EMC AND LOW

VOLTAGE DIRECTIVES, ABOUT THE GENERIC TERMS AND

ABBREVIATIONS, MEANINGS AND DEFINITIONS OF THE TERMS,

Section 2.1, 2.4, Chapter 3, Section 4.1.2, 4.1.4, Chapter 5, Section

7.3.1, 7.3.2, 8.1, Chapter 9, Appendix 2

Addition

CONDITIONS OF USE FOR THE PRODUCT, Section 2.2

Section number change

Section 2.2 to 2.3 Section 2.3 to 2.4

Sep., 2018 SH(NA)-080318E-H

Correction

Related Manuals, Section 2.1, 2.4

Japanese Manual Version SH-080317-G

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

nses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

lice

rights which may occur as a result of using the contents noted in this manual.

2002 MITSUBISHI ELECTRIC CORPORATION

A - 7

A - 7

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric Programmable Controller MELSEC-Q Series.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the graphic operation terminal you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS ..............................................................................................................................A -

CONDITIONS OF USE FOR THE PRODUCT .............................................................................................A -

REVISIONS ....................................................................................................................................................A -

INTRODUCTION ............................................................................................................................................A -

CONTENTS ....................................................................................................................................................A -

MANUALS ..................................................................................................................................................... A -11

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES .............................................................. A -11

ABOUT THE GENERIC TERMS AND ABBREVIATIONS .......................................................................... A -12

MEANINGS AND DEFINITIONS OF THE TERMS ..................................................................................... A -13

PRODUCT CONFIGURATION .................................................................................................................... A -14

1 OVERVIEW 1- 1 to 1- 3

1

5

6

8

8

1.1 QJ71PB93D Features ............................................................................................................................. 1 - 2

2 SYSTEM CONFIGURATION 2- 1 to 2- 7

2.1 Applicable Systems .................................................................................................................................. 2- 1

2.2 When Used in a Redundant System ....................................................................................................... 2-

2.3 Precautions for Configuring a System ..................................................................................................... 2-

2.4 Checking Serial No. and Function Version ............................................................................................. 2-

4

4

5

3 SPECIFICATIONS 3- 1 to 3-22

3.1 Performance Specifications ..................................................................................................................... 3- 1

3.2 Network Configuration ............................................................................................................................. 3-

2

3.3 I/O Signal .................................................................................................................................................. 3- 3

3.3.1 I/O signal list ...................................................................................................................................... 3-

3.3.2 I/O signal detail description .............................................................................................................. 3-

3

4

3.4 Buffer Memory List ................................................................................................................................. 3-14

3.4.1 Buffer memory/configuration ............................................................................................................ 3-14

3.4.2 Buffer memory detail description ..................................................................................................... 3-15

3.5 Operation Mode ...................................................................................................................................... 3-22

4 FUNCTIONS 4- 1 to 4-12

4.1 Functions for Communication with Class 1 Master ................................................................................ 4- 1

4.1.1 I/O data communication function ...................................................................................................... 4-

1

4.1.2 I/O data separation prevention function ........................................................................................... 4- 4

4.1.3 Global control function ...................................................................................................................... 4-

7

4.1.4 Word data swapping function .......................................................................................................... 4-10

A - 8 A - 8

5 SETTINGS AND PROCEDURES BEFORE SYSTEM OPERATION 5- 1 to 5-25

5.1 Procedures before Operation .................................................................................................................. 5- 1

5.2 Parameter Setting to Master Station ....................................................................................................... 5-

5.2.1 Data module setting .......................................................................................................................... 5-

5.2.2 Data assignment mode setting ......................................................................................................... 5-

2

4

8

5.2.3 Swap setting ..................................................................................................................................... 5-11

5.3 Parameter Setting to Slave Station (QJ71PB93D) ................................................................................ 5-13

5.3.1 Setting FDL address and automatic refresh parameters ................................................................ 5-13

5.4 Installation ............................................................................................................................................... 5-18

5.4.1 Handling precautions ....................................................................................................................... 5-18

5.4.2 Installation environment ................................................................................................................... 5-18

5.5 Part Names ............................................................................................................................................. 5-19

5.6 Execution Method for Self-diagnosis ...................................................................................................... 5-20

5.7 Wiring....................................................................................................................................................... 5-22

5.7.1 PROFIBUS cable wiring................................................................................................................... 5-22

5.7.2 Wiring precautions ........................................................................................................................... 5-24

6 TRANSMISSION DELAY TIME 6- 1 to 6- 5

6.1 Transmission Delay Time of Output Receive (Master station QJ71PB93D) ..................................... 6- 4

6.2 Transmission Delay Time of Input Send (QJ71PB93D Master station) ............................................ 6-

5

7 PROGRAMMING 7- 1 to 7-22

7.1 Communication Sequence ..................................................................................................................... 7 - 1

7.2 Station Number Setting ........................................................................................................................... 7 -

7.3 Communication of I/O Data .................................................................................................................... 7 -

7.3.1 LUMP mode ..................................................................................................................................... 7 -

3

5

5

7.3.2 DIVIDED mode ................................................................................................................................ 7 -14

7.4 Global Control-driven Program Execution ............................................................................................ 7 -22

8 DEDICATED INSTRUCTIONS 8- 1 to 8- 4

8.1 Precautions for Execution of Dedicated Instructions ............................................................................. 8 - 1

8.2 G.BBLKRD .............................................................................................................................................. 8 -

8.3 G.BBLKWR ............................................................................................................................................. 8 -

3

4

9 TROUBLESHOOTING 9- 1 to 9- 5

9.1 LED-indicated Error Causes and Actions ............................................................................................... 9- 1

9.2 Checks and Actions for Network-related Faults ...................................................................................... 9-

9.3 Causes of Failure to Make Normal Data Communication and Actions to Be Taken ............................. 9-

9.4 Error Code List ......................................................................................................................................... 9-

9.5 Checking the QJ71PB93D Status by System Monitor of GX Works2 ................................................... 9-

1

2

3

4

A - 9 A - 9

APPENDICES APPX - 1 to APPX - 2

Appendix 1 External Dimensions .......................................................................................................... APPX - 1

INDEX INDEX - 1 to INDEX - 3

A - 10 A - 10

MANUALS

The following are manuals related to this product.

Request for the manuals as needed according to the chart below.

Related Manuals

Manual Name Manual Number

PROFIBUS-DP Master Module User's Manual

Describes the overview, system configuration, specifications, functions, procedures before system

operation, programming and dedicated instructions of the QJ71PB92V.

(Sold separately)

PROFIBUS-DP Interface Module User's Manual

Describes the overview, system configuration, specifications, functions, procedures before system

operation, programming and dedicated instructions of the QJ71PB92D.

(Sold separately)

SH-080572ENG

(13JR84)

SH-080127

(13JR22)

GX Configurator-DP Version7 Operating Manual

Explains the overview, installation method, screen operations, etc. of GX Configurator-DP Version 7.

(Sold separately)

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi Electric programmable controllers maintain EMC and

Low Voltage Directives when incorporated into other machinery or equipment,

certain measures may be necessary. Please refer to one of the following

manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) Additional measures

No additional measures are necessary for the compliance of this product with

EMC and Low Voltage Directives.

SH-080579ENG

(13JU54)

A - 11 A - 11

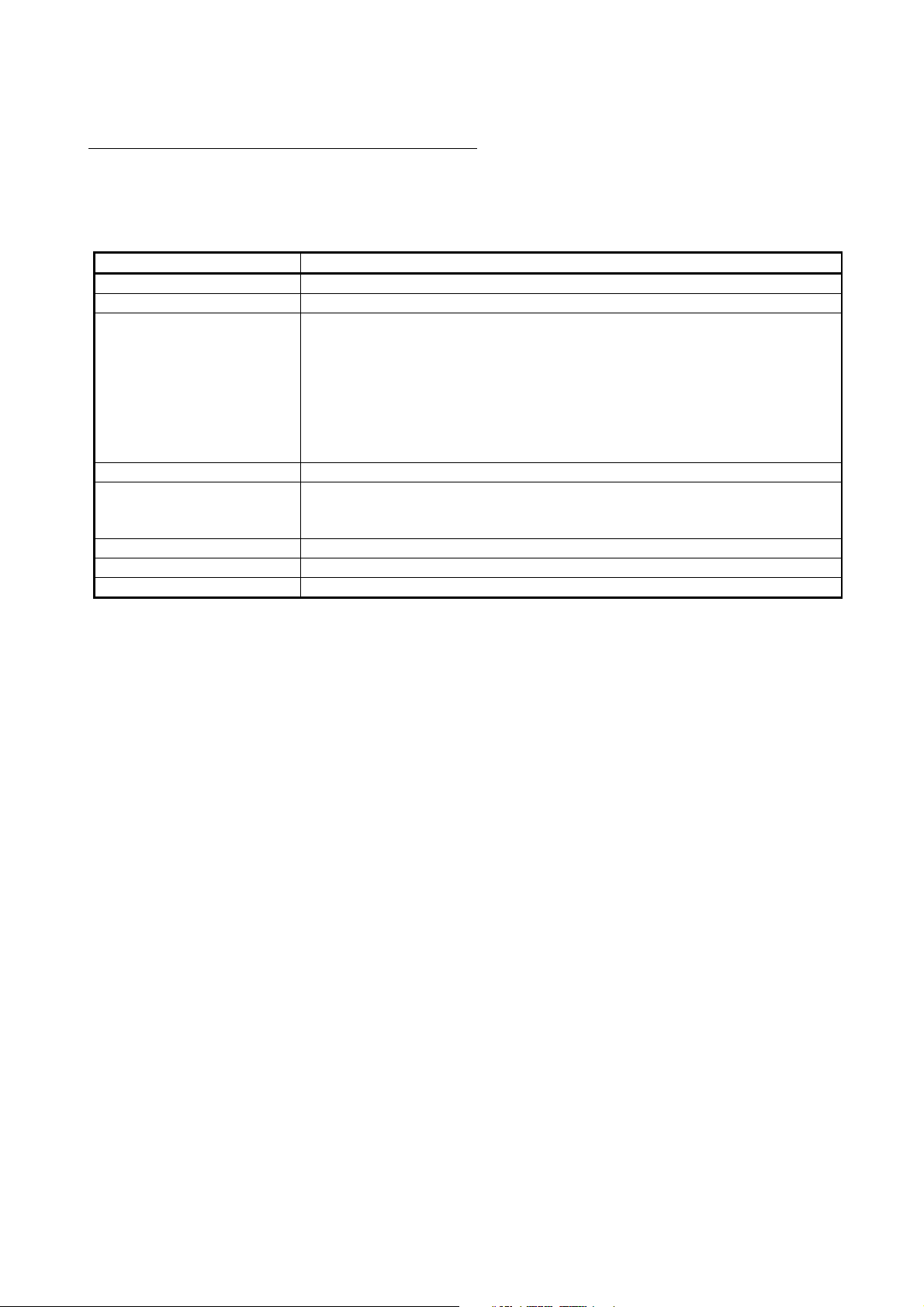

ABOUT THE GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to describe the Type QJ71PB93D PROFIBUS-DP slave module.

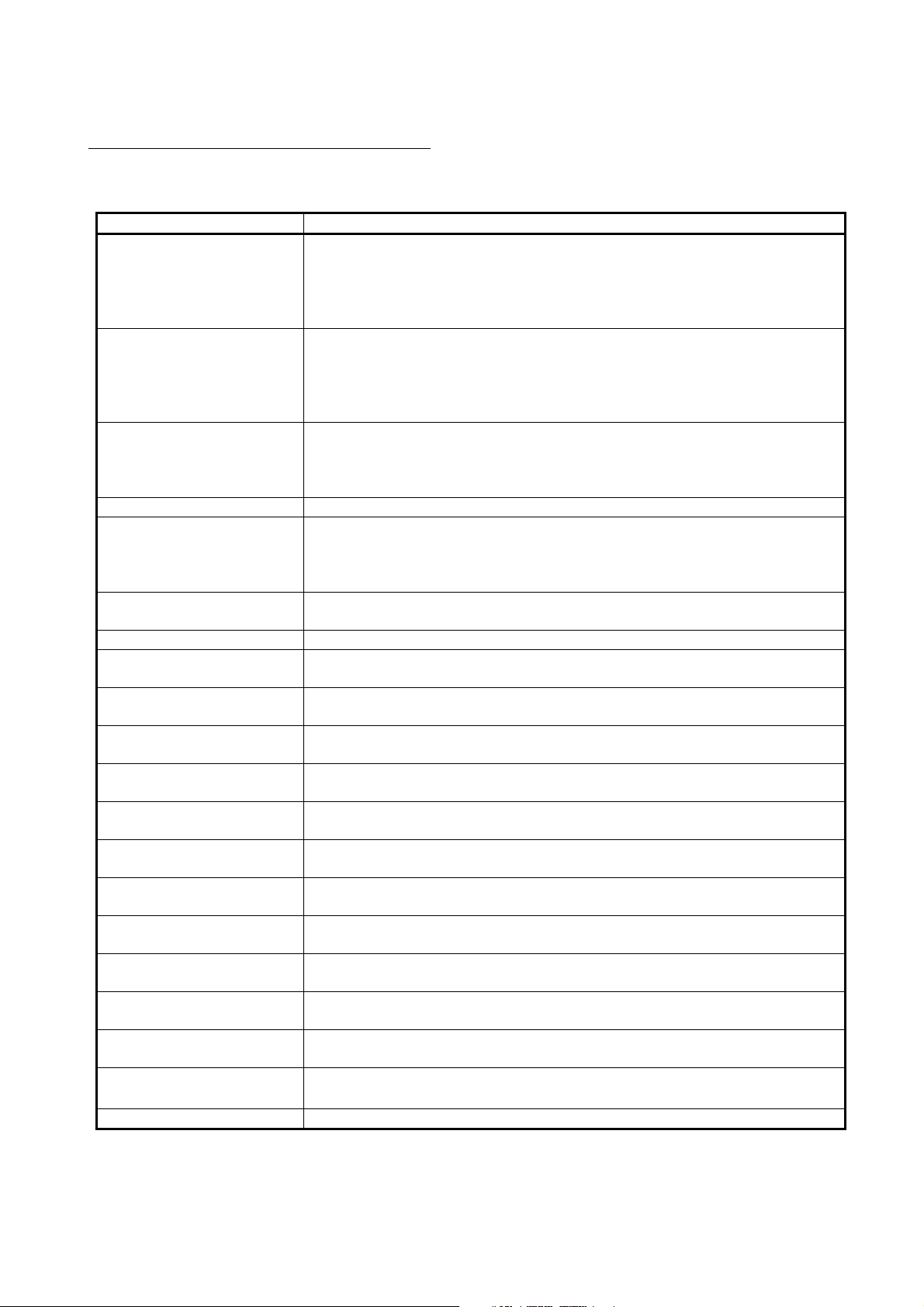

Generic Term/Abbreviation Description of the abbreviation/general terms

QJ71PB93D Abbreviation for the model QJ71PB93D PROFIBUS-DP slave module.

QJ71PB92V Abbreviation for the model QJ71PB92V PROFIBUS-DP master module.

Generic term for the Q00JCPU, Q00CPU, Q00UJCPU, Q00UCPU, Q01CPU,

Q01UCPU, Q02CPU, Q02HCPU, Q02PHCPU, Q02UCPU, Q03UDCPU, 03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06HCPU,

CPU module

GX Works2 The product name of the software package for the MELSEC programmable controllers

GX Configurator-DP

PROFIBUS-DP Abbreviation of PROFIBUS-DP network.

BBLKRD Abbreviation for G.BBLKRD.

BBLKWR Abbreviation for G.BBLKWR.

Q06PHCPU, Q06UDHCPU, Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU,

Q10UDEHCPU, Q12HCPU, Q12PHCPU, Q13UDHCPU, Q13UDVCPU,

Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q25HCPU, Q25PHCPU,

Q26UDHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

modules

The configurator for the QJ71PB93D

Generic term for the product name SWnD5C-PROFID-E ("n" means version 7 or

later.)

A - 12 A - 12

MEANINGS AND DEFINITIONS OF THE TERMS

The terms used in this manual have the following meanings and definitions.

Term Definition

A basic version of PROFIBUS-DP.

The following functions are executable:

PROFIBUS-DPV0

PROFIBUS-DPV1

PROFIBUS-DPV2

Class 1 master station A device exchanging I/O data with a slave stations. (QJ71PB92V, QJ71PB92D, etc.)

Class 2 master station

Slave station

Repeater A device used to connect different segments of PROFIBUS-DP.

Bus terminator

Configuration tool

GSD file

Station number

Slave parameter

I/O configuration information

(Data module)

Input data

Output data

Global control

Communication watchdog

timer

Extended diagnostic error

information

Bus cycle time

Module watchdog timer Watchdog timer in the QJ71PB93D.

I/O data exchange

Diagnostic information notification

etc.

A PROFIBUS-DP version for which the following functions have been added to the

basic functionality of PROFIBUS-DPV0.

Acyclic communication

Alarm function

etc.

A PROFIBUS-DP version for which the following functions have been added to the

PROFIBUS-DPV1 functionality.

Time stamping

etc.

A device that communicates with slave stations and checks their station number

settings and/or operation states.

The Class 2 master station is used as a master station for supervising the network,

which can start, maintain, and diagnose the system.

A device that exchanges I/O data with a Class 1 master station. (QJ71PB93D,

ST1H-PB, etc.)

A terminating resistor that is connected to either end of each segment on

PROFIBUS-DP.

Software used to set slave parameters, etc. and to write them to a master station.

(GX Configurator-DP, etc.)

An electronic file that contains parameters of a slave station.

The GSD file is used to set up the slave parameters on configuration tool.

The numbers assigned to a master station and slave stations.

The station number is set within the range from 0 to 125.

The parameter for a slave station, which is set on the master station.

The setting items are described on the GSD File.

Information on I/O configuration of a slave station.

Data sent by the QJ71PB93D and received by the master station. (data input by the

master station.)

Data sent by the master station and received by the QJ71PB93D. (data output by the

master station.)

This function enables synchronization command transmission for I/O data from a

Class 1 master station to slave stations.

Watchdog timer set in the slave parameter of the master station.

Diagnostic information specific to each slave station.

Each of slave stations notifies of it to the master station when an error is detected.

PROFIBUS-DP processing time for the master station to perform cyclic transfer with

each slave station.

A - 13 A - 13

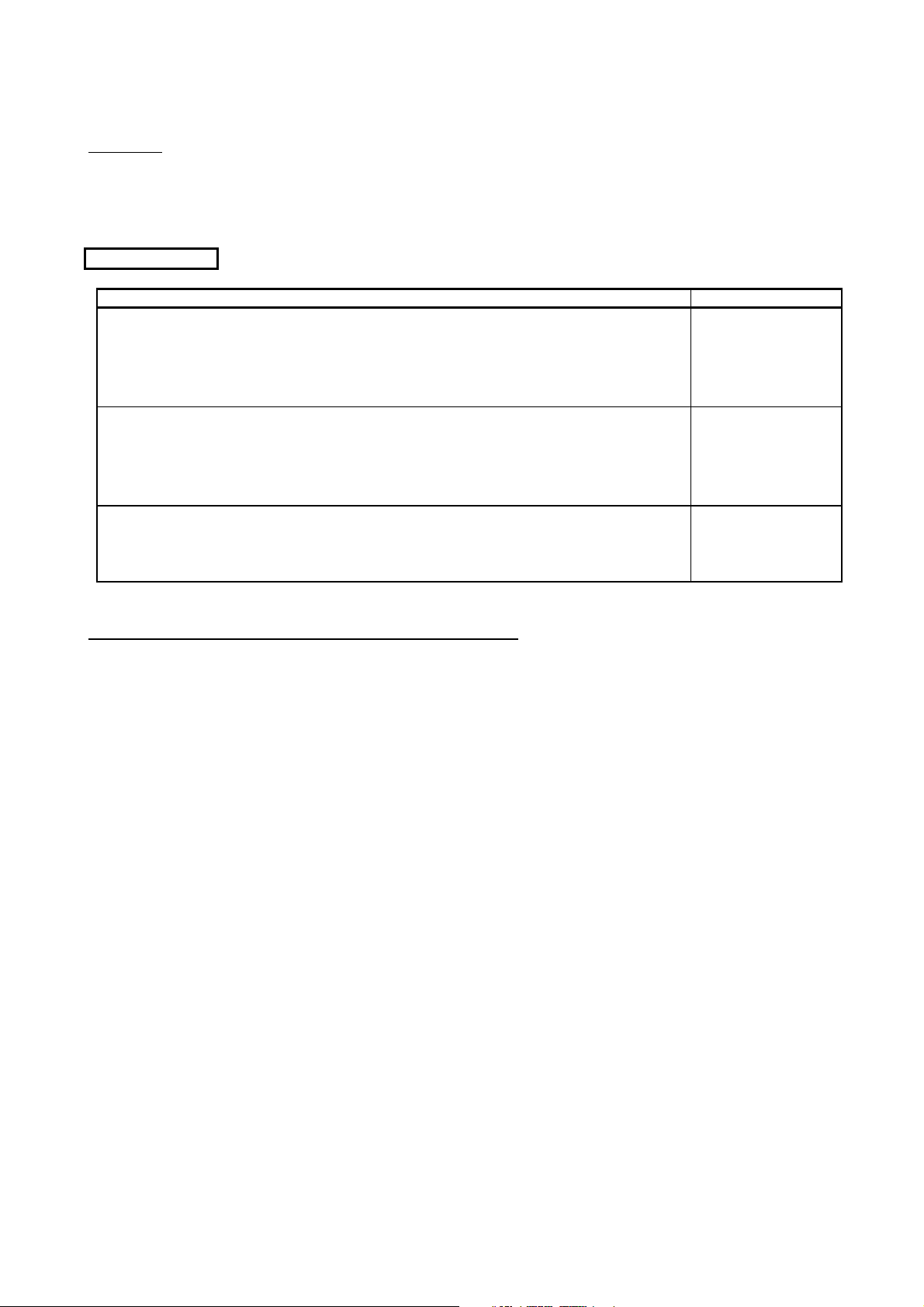

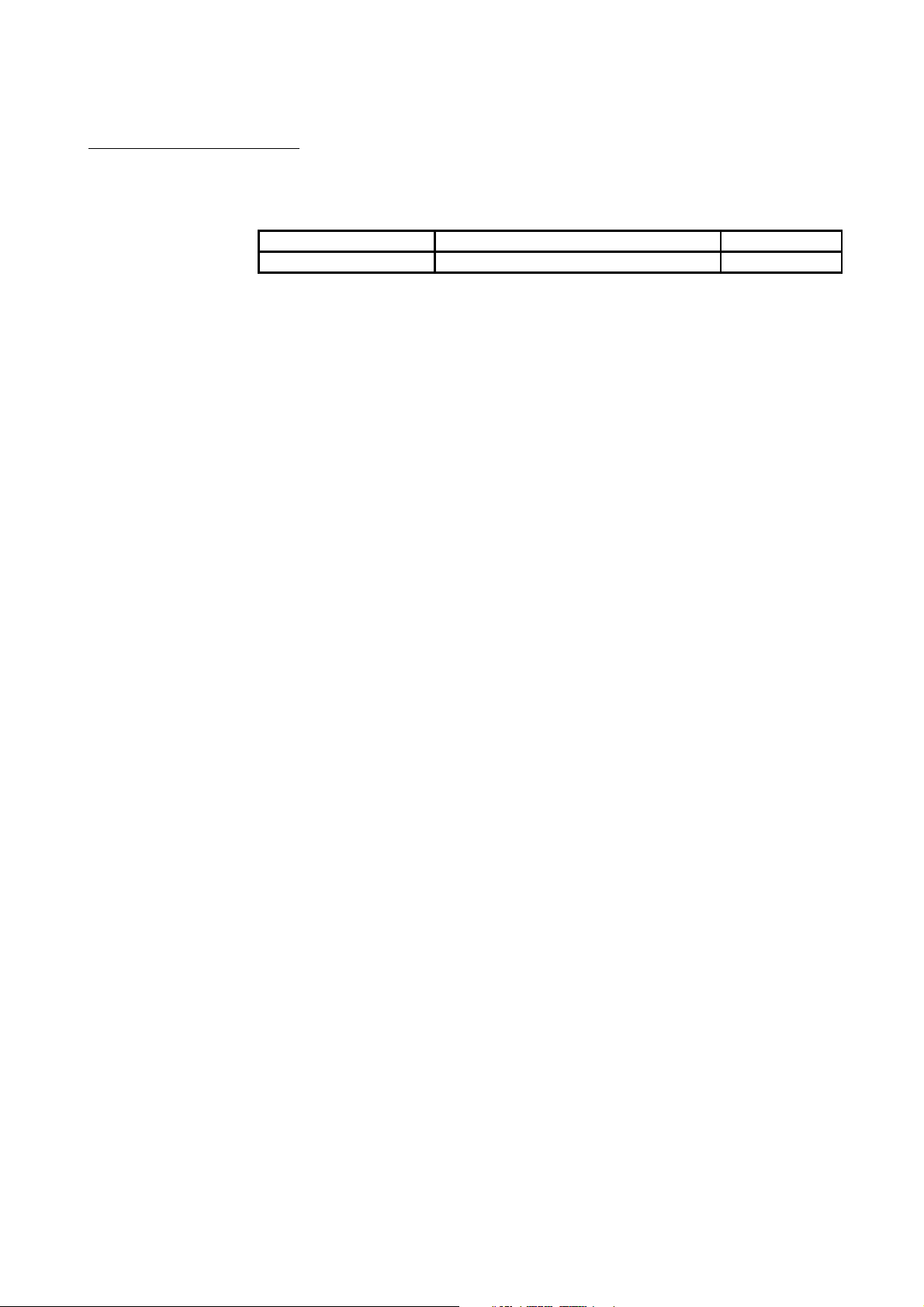

PRODUCT CONFIGURATION

The product configuration of this product is given in the table below.

QJ71PB93D QJ71PB93D PROFIBUS-DP slave module. 1

Model Product name Quantity

A - 14 A - 14

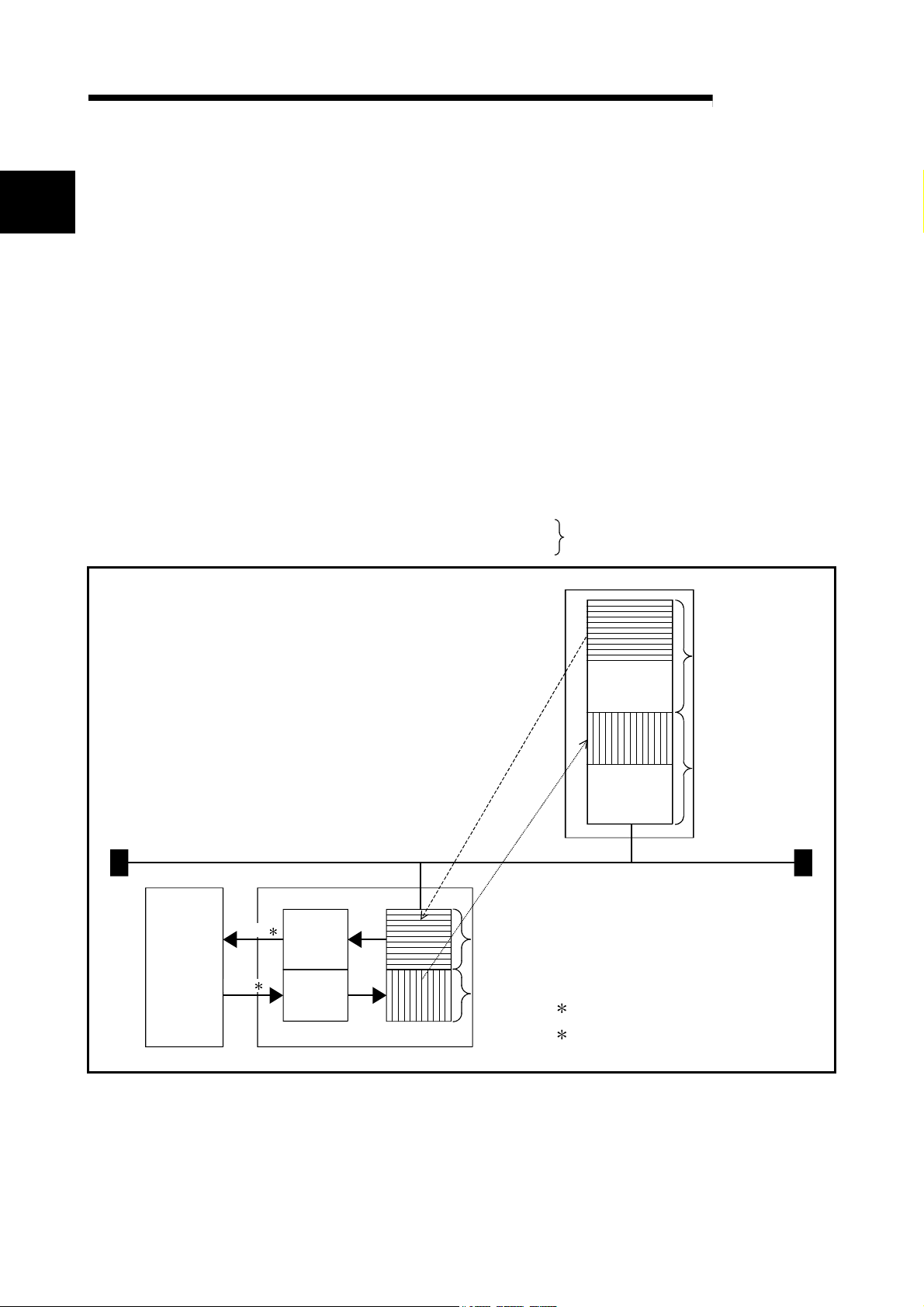

r

1 OVERVIEW

MELSEC-Q

1 OVERVIEW

Class 1 master station

(QJ71PB92V)

Bus terminator

This is the user's manual for the QJ71PB93D PROFIBUS-DP slave module (hereafter

abbreviated as "QJ71PB93D"), which is used to connect a MELSEC-Q series

programmable controller to a PROFIBUS-DP network.

The QJ71PB93D operates as a slave station in the PROFIBUS-DP network.

Slave station (QJ71PB93D) Slave station (MELSEC-ST system) Slave station

ST1PSD

ST1H-PB

RUN

SYS

AUX

RELEASE

RESET

PROFIBU S I/ F

ST1PDD

ERR

RUN ERR

RUN ERR

RUN

ERR

RUN ERR RUN ERR

11 21

11 21

.

AUX

Bus terminato

1

1 - 1 1 - 1

1 OVERVIEW

1.1 QJ71PB93D Features

1

MELSEC-Q

(1) Conformance with EN50170 Volume 2 (Part 1, 2, 3, 4, 8)

The module conforms with EN50170 Volume 2 (Part 1, 2, 3, 4, 8) and can

communicate with the master station as a PROFIBUS-DP slave station.

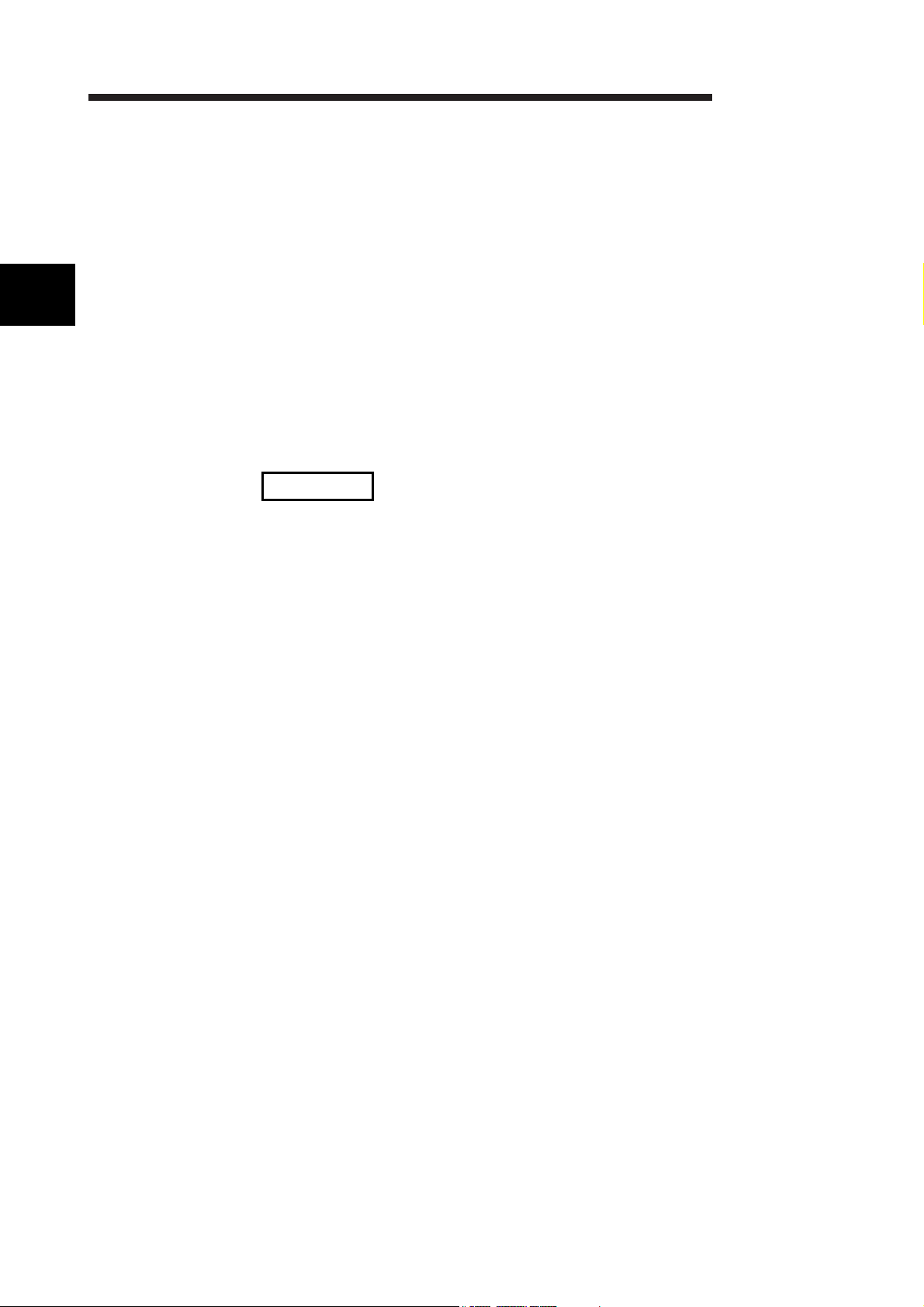

(2) I/O data communication with class 1 master station

The module can communicate I/O data with the class 1 master station (master

station that makes data communication cyclically with a slave station) of

PROFIBUS-DP.

The QJ71PB93D supports the PROFIBUS-DPV0 function.

PROFIBUS-DPV1 and PROFIBUS-DPV2, which are extended versions of

PROFIBUS-DP, are not supported.

(a) Available data size

The QJ71PB93D can handle the following size of data. (Refer to Section

4.1.1)

Input data : Max. 122 words

Output data : Max. 122 words

Max. 192 words in total

Class 1 master station

Output

image

Input

image

Bus terminator Bus terminator

PROFIBUS-DP network

Buffer memory

Read 1

Write 2

CPU module QJ71PB93D (slave station)

Output

receive

area

Input

send

area

(3) Communication can be made by merely setting the master station

Output

image

Input

image

1: Reads with BBLKRD/MOV/FROM instruction

or automatic refresh

2: Writes with BBLKWR/MOV/TO instruction or

automatic refresh

parameters

After you have set the parameters at the master station, the QJ71PB93D can

make communication by merely setting the station number. (Refer to Section 5.1)

1 - 2 1 - 2

1 OVERVIEW

MELSEC-Q

(4) Swapping of I/O data

When I/O data is sent/received from/to the master station, their upper and lower

bytes can be swapped.

Though PROFIBUS-DP handles the upper and lower bytes of I/O data differently

depending on the master station type, the I/O data need not be swapped in a

sequence program. (Refer to Section 4.1.4)

(5) Start/stop of refreshing the input send area

Refreshing of send data from the QJ71PB93D to the master station is

controllable by an output signal (Y00).

Providing an interlock disables the buffer memory data from being sent to the

master station at error occurrence. (Refer to Section 4.1.1)

(6) Extended trouble notification function

Data stored in the extended trouble information area of the buffer memory can be

sent to the master station as extended trouble information

faulty, for example.

When the host is not faulty anymore, notify the master station that there is no

fault. (Refer to Section 3.4.2(9))

: Diagnostics Information (device-related trouble information set by the user as

desired)

when the host is

(7) Compatibility with global control function

Compatibility with the global control function allows the updating of I/O data at the

QJ71PB93D to be controlled from the class 1 master station using the command

(SYNC, UNSYNC, FREEZE, UNFREEZE) sent by the class 1 master. (Refer to

Section 4.1.3)

(8) Communication with class 2 master station

The following communications can be made with the class 2 master station

(master station designed for network management to perform booting,

maintenance and diagnostics) of PROFIBUS-DP.

Read from input send area/output receive area

Read of I/O configuration information

Station number change

For the way to use each function, refer to the manual of the class 2 master

station used.

(9) I/O data separation prevention

For data transmission between the CPU module and buffer memory of

QJ71PB93D, automatic refresh or dedicated instruction are used to prevent I/O

data from being separated

: The data of specified sizes are not matched with each other.

. (Refer to Section 4.1.2)

(10) Compatibility with multiple CPU system

Even when a plurality of CPU modules are installed through the multiple CPU

system, this model can be controlled by any CPU module.

1 - 3 1 - 3

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

2.1 Applicable Systems

MELSEC-Q

2

This section describes applicable systems.

(1) Mountable modules, No. of mountable modules, and mountable

base unit

(a) When mounting with a CPU module

REMARKS

When using the module with a C Controller module, refer to the user's manual for

the C Controller module.

For the CPU modules, the number of modules, and base units mountable

to the QJ71PB93D, refer to user's manual for the CPU module used.

• User's Manual for the CPU module used (Hardware Design, Maintenance

and Inspection)

2 - 1 2 - 1

2 SYSTEM CONFIGURATION

POINT

(1) There are restrictions on the number of automatic refresh parameters that can

be set for CPU modules.

For details, refer to Section 5.3.1(5).

(2) To utilize the data consistency function and dedicated instruction, use a CPU

module whose first 5 digits of the serial No. is "02092" or later.

If this function is used in any other models, I/O data may be identified as invalid

values.

(b) When mounting to remote I/O station of MELSECNET/H

The QJ71PB93D cannot be mounted to remote I/O station of the

MELSECNET/H.

Mount it next to the CPU module on the MELSECNET/H remote master

station.

(2) Compatibility with a multiple CPU system

When using the QJ71PB93D in a multiple CPU system, refer to the User's

Manual (Multiple CPU System) for CPU module used.

(a) Compatible QJ71PB93D

The function version of the QJ71PB93D has been "B" from the first release

and it supports the multiple CPU system.

(3) Compatibility with online module change

The QJ71PB93D cannot be changed online.

(4) Applicable software packages

Please configure the system by combining QJ71PB93D and software package

as follows:

GX Works2: For setting CPU module parameters and creating sequence

programs (Required)

GX Configurator-DP : For setting the QJ71PB93D station number and automatic

refresh parameter

1 GX Configurator-DP is required when using automatic refresh.

The station number can also be set on a sequence program. (Refer to Section 5.3)

MELSEC-Q

2

1

2 - 2 2 - 2

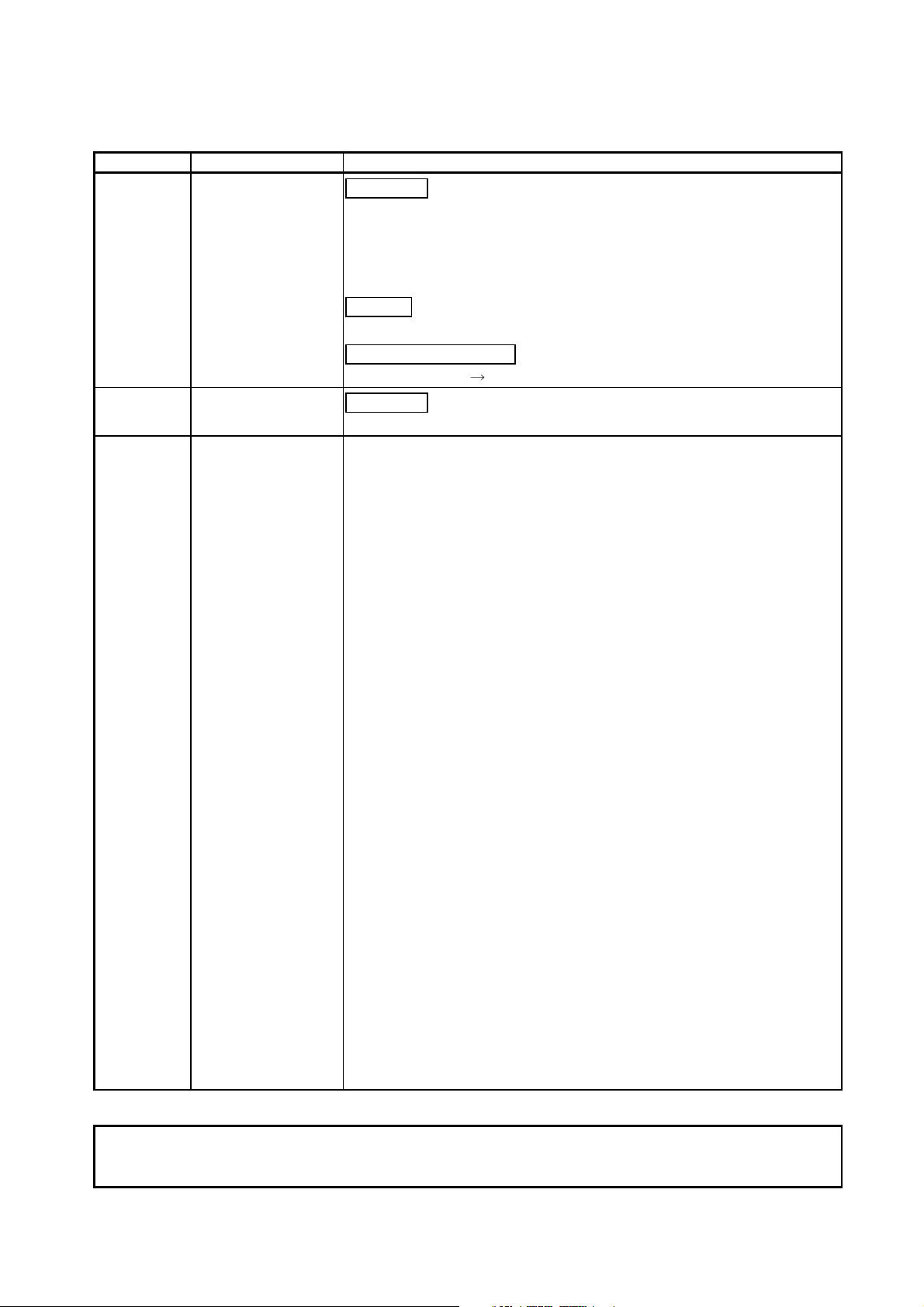

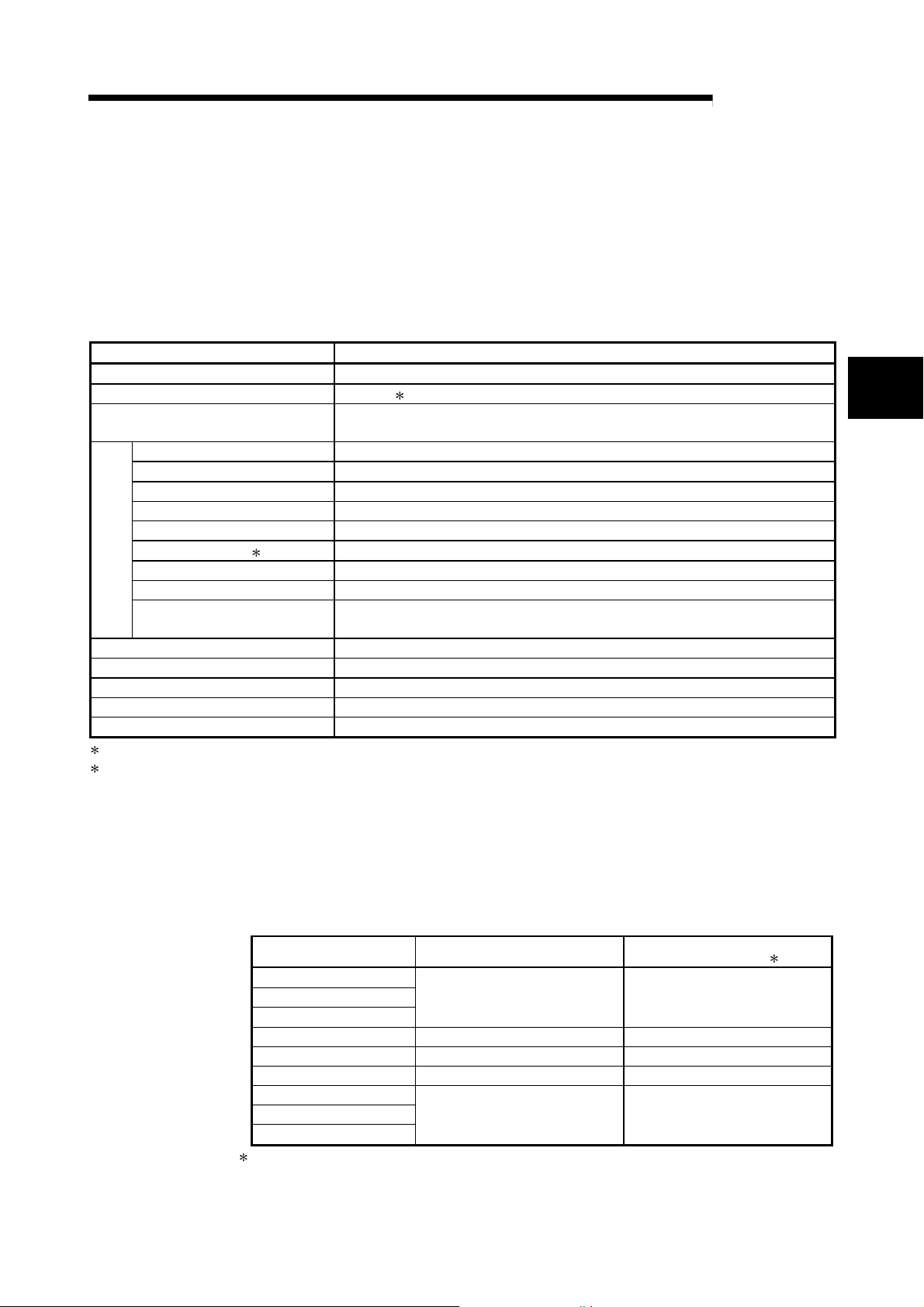

2 SYSTEM CONFIGURATION

MELSEC-Q

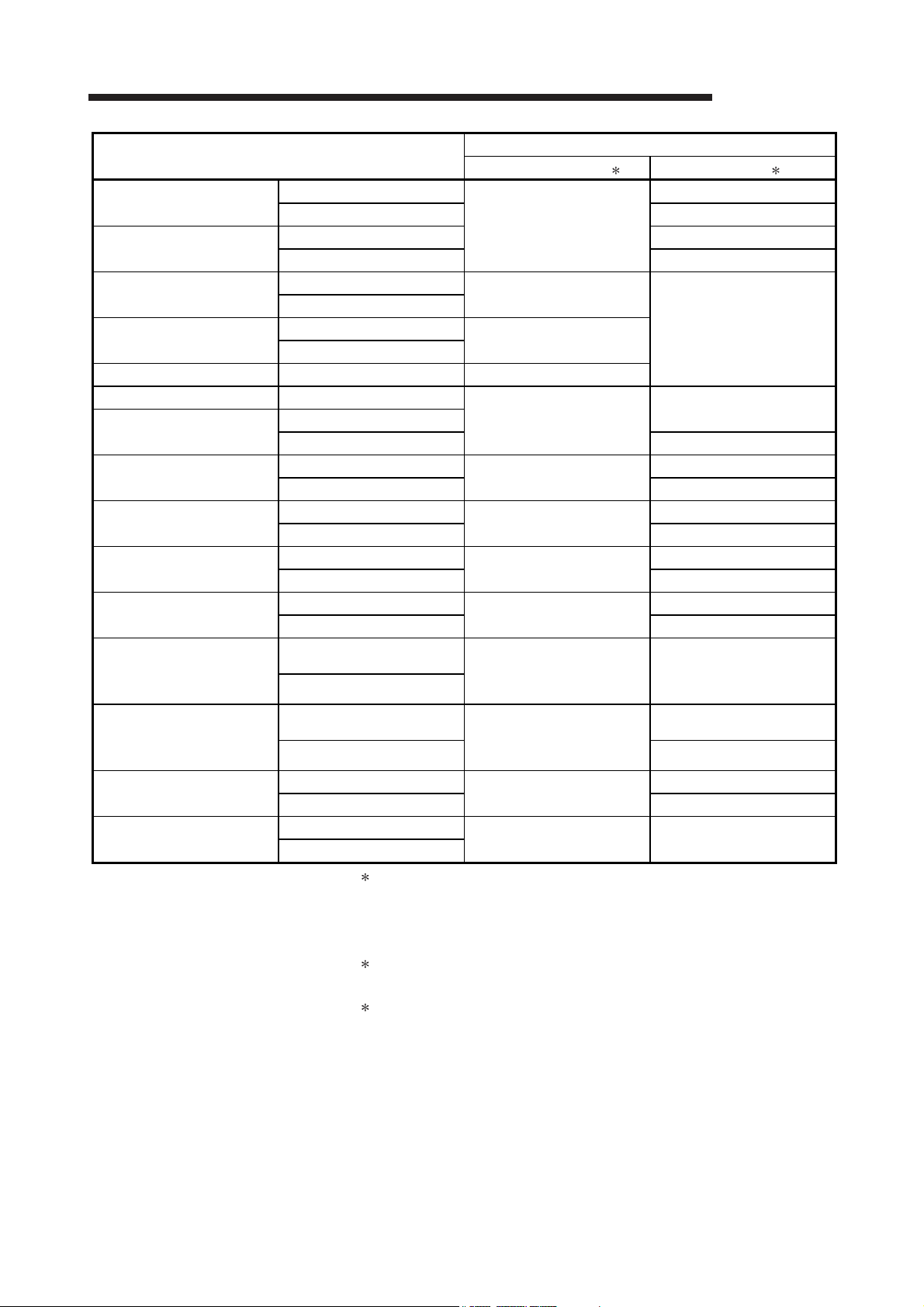

System

Q00J/Q00/Q01CPU

Q02/Q02H/Q06H/Q12H/

Q25HCPU

Q02PH/Q06PHCPU

Q12PH/Q25PHCPU

Q12PRH/Q25PRHCPU Redundant system Version 7.00A or later*3

Q00UJCPU Single CPU system

Q00U/Q01UCPU

Q02UCPU

Q03UD/Q04UDH/

Q06UDHCPU

Q10UDH/Q20UDHCPU

Q13UDH/Q26UDHCPU

Q03UDV/Q04UDV/

Q06UDV/Q13UDV/

Q26UDVCPU

Q03UDE/Q04UDEH/

Q06UDEH/Q13UDEH/

Q26UDEHCPU

Q10UDEH/Q20UDEHCPU

Q50UDEH/Q100UDEHCPU

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system Version 1.11M or later

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system Version 1.14Q or later

Single CPU system

Multiple CPU system

GX Configurator-DP1 GX Works22

Version 7.00A or later

Version 7.04E or later

Version 7.00A or later

Version 7.04E or later

Version 7.03D or later

Version 7.02C or later

Version 7.04E or later

Version 7.03D or later

Version 7.09K or later Version 1.95Z or later

Version 7.03D or later

Version 7.04E or later

Version 7.07H or later Version 1.25B or later

1 The operation mode of the QJ71PB93D cannot be changed using

GX Configurator-DP Version 7.03D or later.

Change the mode using operation mode change request area

(buffer memory address: 8CFH).

2 For how to use GX Configurator-DP and GX Works2 together,

refer to the GX Configurator-DP Operating Manual.

3 To mount the QJ71PB93D on an extension base unit, use GX

Configurator-DP Version 7.03D or later.

Software Version

Version 1.11M or later

Version 1.86Q or later

Version 1.11M or later

Version 1.11M or later

Version 1.11M or later

Version 1.11M or later

Version 1.11M or later

Version 1.11M or later

Version 1.11M or later

2 - 3 2 - 3

2 SYSTEM CONFIGURATION

2.2 When Used in a Redundant System

For the precautions on when using an extension base unit, refer to the User's Manual

(Redundant System) for the CPU module used.

2.3 Precautions for Configuring a System

(1) Precaution for station number setting

(a) If a station number different from the one of the currently operating station is

set during I/O data communication, the communication is suspended to

execute the setting.

It is restarted after completion of the station number setting.

(b) Do not change the operation mode during execution of the station number

setting.

Doing so may disable proper station number setting or mode change.

(2) Precaution for parameter writing

(a) If a parameter based on a station number setting different from the one of the

currently operating station is written to the QJ71PB93D that is exchanging I/O

data, the I/O data communication is suspended. It is restarted after

completion of parameter writing.

(b) Do not change the operation mode from the sequence program during

parameter writing.

Doing so may disable proper station number setting or mode change.

(c) Do not write parameters from multiple GX Configurator-DPs to a single

QJ71PB93D at the same time.

Doing so makes the parameter values of the QJ71PB93D incorrect.

(3) When switching the operation mode using Y11/X11 on the

sequence program

Be sure to switch the mode while the module READY signal (X1D) of the

QJ71PB93D is ON.

If data are read from or written to the buffer memory with the X1D status ignored,

the CPU module may detect an error to stop the sequence calculation.

MELSEC-Q

2 - 4 2 - 4

2 SYSTEM CONFIGURATION

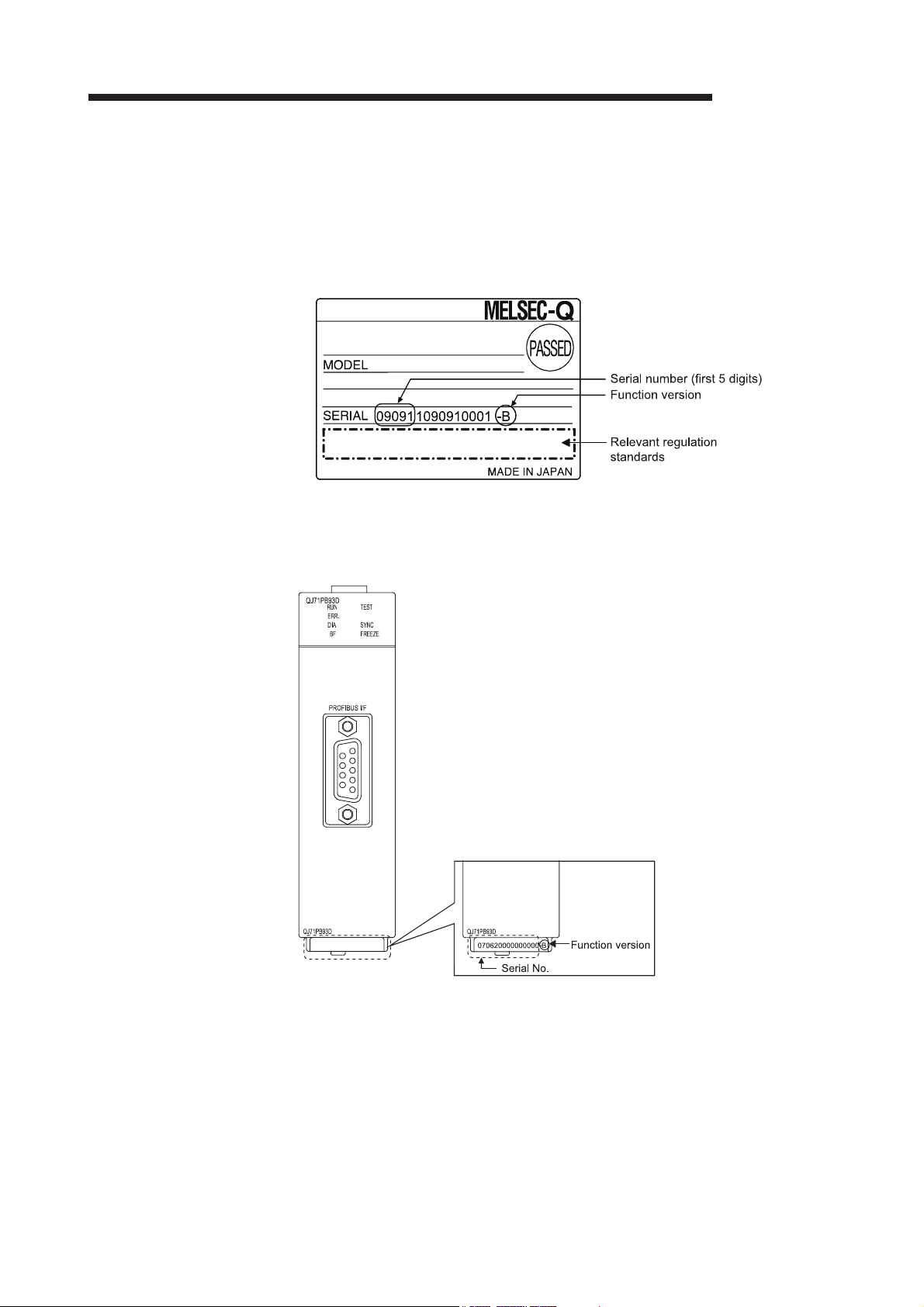

2.4 Checking Serial No. and Function Version

The serial No. and function version of the QJ71PB93D can be checked on the rating

plate, on the front of the module, and on the System monitor of GX Works2.

(1) Checking on the rating plate

The rating plate is located on the side of the QJ71PB93D.

MELSEC-Q

(2) Checking on the front of the module

The serial No. and function version on the rating plate are printed on the front (at

the bottom) of the module.

2 - 5 2 - 5

2 SYSTEM CONFIGURATION

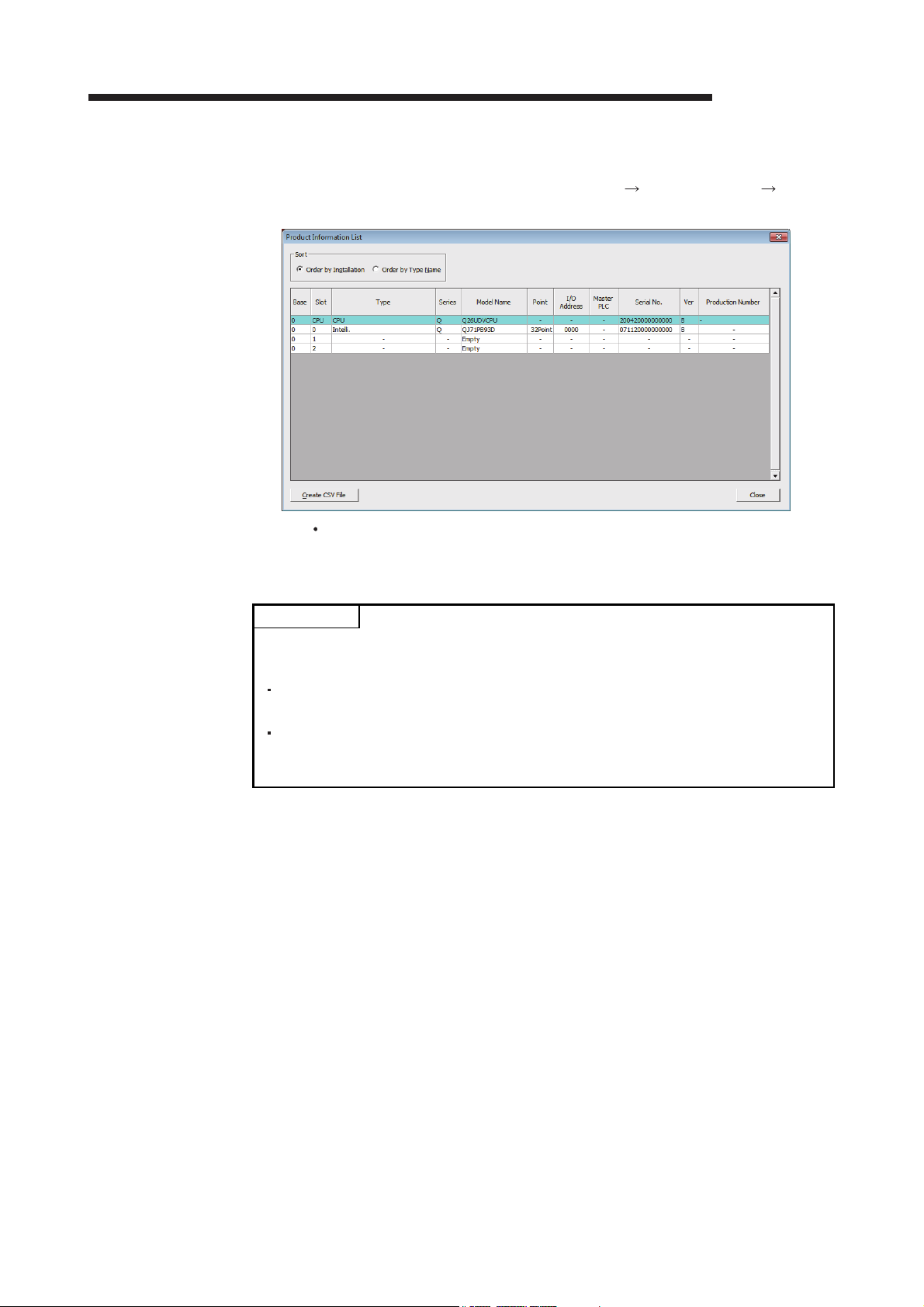

(3) Checking on the System monitor window (Product information list

window)

To display the System monitor, select [Diagnosis] [System monitor]

[Product information list] button of GX Works2.

MELSEC-Q

Product No.

"-" is displayed as QJ71PB93D does not support the product number

display.

POINT

The serial No. displayed on the Product Information List window of GX Works2 may

differ from that on the rating plate or on the front of the module.

The serial No. on the rated plate or on the front of the module indicates the

management information of the product.

The serial No. displayed on the Product Information List window of GX Works2

indicates the functional information of the product. The functional information of

the product will be updated when a function is added.

2 - 6 2 - 6

2 SYSTEM CONFIGURATION

MEMO

MELSEC-Q

2 - 7 2 - 7

3 SPECIFICATIONS

MELSEC-Q

3 SPECIFICATIONS

This chapter describes the performance specifications, network configuration, I/O

signals, buffer memory, and operation modes of the QJ71PB93D.

For the general specifications of the QJ71PB93D, refer to the User's Manual

3.1 Performance Specifications

Item Specifications

PROFIBUS-DP station type Slave station (Complies with EN50170 Volume2 (Part 1, 2, 3, 4, 8))

Station numbers that may be set 0 to 125 2

Max. number of data that may be

communicated

Electrical standard/characteristics Complies with EIA-RS485

Medium Shielded twisted pair cable (Type A) (Refer to Section 5.7.1)

Network topology Bus topology (Tree topology when repeaters are used)

Data link method Polling method

Encoding method NRZ

Transmission speed 1 9.6 kbps to 12 Mbps (Refer to (1) in this section)

Transmission distance Differs depending on the transmission speed (Refer to (1) in this section)

Maximum number of repeaters

Transmission specifications

Number of connectable modules

(Per segment)

Flash ROM write count Max. 10000 times

Number of occupied I/O points 32 points (I/O assignment : 32 intelligent points)

5VDC Internal power consumption 0.44 A

External dimensions 98(3.86) (H) 27.4(1.08) (W) 90(3.55) (D) [mm(inch)]

Weight 0.11 kg

1 Transmission speed control within +/- 0.3% (EN50170 Volume 2 compliant)

2 Factory-set to "126" (EN50170 Volume 2 compliant)

Set a station number within 0 to 125 for I/O data communication.

3 - 1 3 - 1

(Hardware Design, Maintenance and Inspection) for the CPU module used.

Number of I/O data is 192 words in total. (Size of I/O data is up to 122 words.)

3 units (Refer to

32 units (including repeaters)

(1) in this section)

For the noise immunity, withstand voltage, insulation resistance, and others in the

programmable controller system using this module, refer to the power supply module

specifications given in the User's Manual (Hardware Design, Maintenance and

Inspection) for the CPU module used.

(1) Transmission distance

Transmission Speed Transmission Distance

9.6 kbps

19.2 kbps

93.75 kbps

187.5 kbps 1000 m (3281 ft.)/segment 4000 m (13123 ft.)/network

500 kbps 400 m (1312 ft.)/segment 1600 m (5249 ft.)/network

1.5 Mbps 200 m (656 ft.)/segment 800 m (2625 ft.)/network

3 Mbps

6 Mbps

12 Mbps

3 The max. transmission distance in the table above is based on the case where 3 repeaters are used.

The calculation formula for the transmission distance extended using a repeater(s) is:

Max. transmission distance [m/network] = (Number of repeaters + 1) x Transmission distance [m/segment]

1200 m (3937 ft.)/segment 4800 m (15748 ft.)/network

100 m (328 ft.)/segment 400 m (1312 ft.)/network

Max. Transmission Distance when

Repeater is Used

3

3

r

r

3 SPECIFICATIONS

3.2 Network Configuration

MELSEC-Q

3

This section explains the basic PROFIBUS-DP configuration for using the QJ71PB93D

as a slave station.

(1) System equipment

The following table shows the equipment required for the PROFIBUS-DP system.

System Equipment Description

Slave station QJ71PB93D

Class 1 master station QJ71PB92V, QJ71PB92D, etc.

Configuration tool Configurator applicable to the master station

Repeater Required when 32 or more slave stations are connected

PROFIBUS cable

Bus terminator

Refer to section 5.7.1

(2) Network configuration

In the PROFIBUS-DP system configuration, the following conditions must be

satisfied:

(a) Number of connectable modules in the whole network (when repeaters are

used)

Master station + Slave station

1: Including the QJ71PB93D

(b) Number of connectable modules per segment

Master station + Slave station

1: Including the QJ71PB93D

2: A repeater is counted for both segments.

(c) Maximum number of repeaters

Up to 3 repeaters can be used for communication between master station

and the QJ71PB93D.

(d) Number of slave stations that are connectable to master station

The maximum number of slave stations that may be connected to one

master station depends on the specifications of the master station.

Master station

Bus terminator

1 126

1 + repeaters 2 32

Class 1

Bus terminato

QJ71

CPU

module

PB93D

Slave

Station No. 1

Slave

Station No. 2

Slave

Station No. 30

Bus terminator

QJ71

CPU

PB93D

module

Slave

Station No. 31

Slave

Station No. 32

Slave

Station No. 60

3 - 2 3 - 2

Repeater

Bus terminato

3 SPECIFICATIONS

MELSEC-Q

3.3 I/O Signal

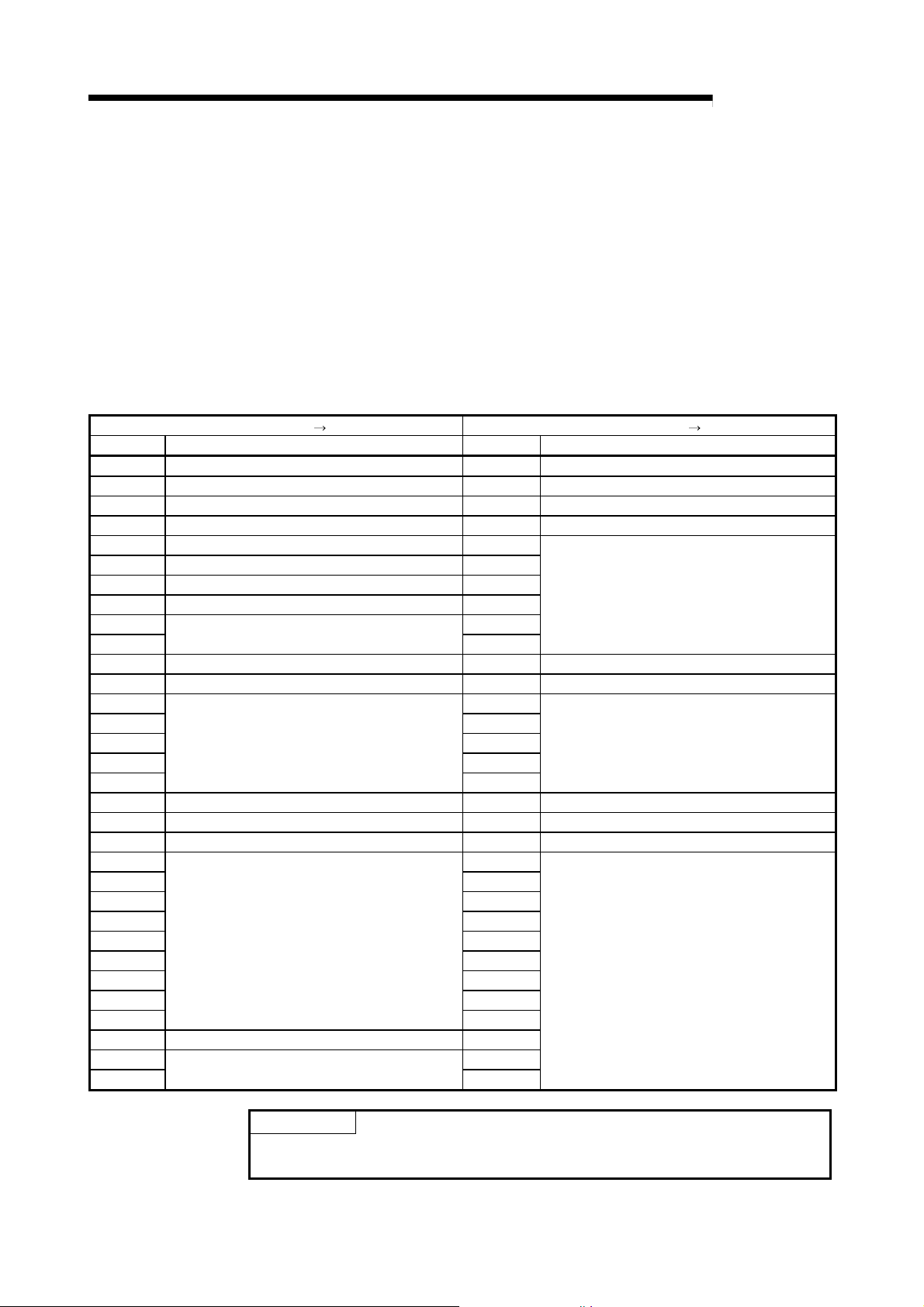

3.3.1 I/O signal list

The I/O signal configuration used in the QJ71PB93D and the data communications

with the CPU module are described below.

The following I/O signal assignment is based on the case where the start I/O No. of the

QJ71PB93D is "0000" (installed to slot 0 of the main base unit).

Device X represents an input signal from the QJ71PB93D to the CPU module.

Device Y shows an output signal from the CPU module to the QJ71PB93D.

Refer to the corresponding reference sections for details.

Signal direction: QJ71PB93D CPU module Signal direction: CPU module

Device No. Description Device No. Description

X00 Watchdog timer error Y00 Input send area refresh directive signal

X01 I/O communication signal Y01 Use prohibited

X02 Extension trouble notification completion signal Y02 Extension trouble notification request signal

X03 Module error signal Y03 Module error reset request signal

X04 Use prohibited Y04

X05 SYNC mode signal Y05

X06 SYNC receive signal Y06

X07 FREEZE mode signal Y07

X08

X09 Y09

X0A BBLKRD start request acceptance completion signal Y0A BBLKRD start request signal

X0B BBLKWR start request acceptance completion signal Y0B BBLKWR start request signal

X0C

X0D Y0D

X0E Y0E

X0F Y0F

X10 Y10

X11 Operation mode change completion signal Y11 Operation mode change request signal

X12 Use prohibited Y12 Use prohibited

X13 Station number change completion signal Y13 Station number change request signal

X14

X15 Y15

X16 Y16

X17 Y17

X18 Y18

X19 Y19

X1A Y1A

X1B Y1B

X1C Y1C

X1D Module READY signal Y1D

X1E

X1F Y1F

Use prohibited

Use prohibited

Use prohibited

Use prohibited

Y08

Y0C

Y14

Y1E

Use prohibited

Use prohibited

Use prohibited

POINT

Do not output (turn on) the "Use prohibited" signals.

Doing so may cause the programmable controller system malfunction.

QJ71PB93D

3 - 3 3 - 3

3 SPECIFICATIONS

3.3.2 I/O signal detail description

(1) Watchdog timer error (X00)

(a) This signal turns on when a watchdog timer error occurs on the

QJ71PB93D.

(b) The watchdog timer error (X00) does not turn off until the following

operation is performed.

Turning the programmable controller power off to on

Resetting the CPU module

If the signal turns on again, a hardware error may be the cause.

(2) I/O communication signal (X01)

(a) This signal turns on when the module is ready to communicate with the

Communication with

master station

master station properly.

(b) While the I/O communication signal (X01) is on, the output receive area is

updated to the output data sent from the master station.

(It is independent of the status of the input send area refresh directive

signal (Y00).)

(c) The I/O communication signal (X01) turns off when a communication time-

out error occurs due to a stop of communication with the master station.

However, if the communication watchdog timer setting in the master station

side parameters is "invalid", the I/O communication signal does not turn off

since a communication time-out error does not occur.

(The output data in the output receive area is held.)

Communication watchdog timer Setting

in Master Station Side Parameters

Invalid

Valid (2 to 65025)

The communication watchdog timer setting can be confirmed in the

"Current communication watchdog timer value (buffer memory address:

8D1

(d) Use this signal as a signal for interlocking output receive area read

performed with the MOV/FROM instruction.

H)" of the QJ71PB93D.

MELSEC-Q

Operation at Master Station Fault

No error

(I/O communication signal (X01) remains on)

Communication time-out error occurrence

(I/O communication signal (X01) turns off)

Communication in progressCommunication stop

Communication stop

I/O communication signal (X01) ONOFF OFF

Data update in output

receive area

Output receive area

(Buffer memory address :

to BFH)

0

H

Not updated Updated Not updated

MOV/FROM instruction

Execution of read from

output receive area

3 - 4 3 - 4

3 SPECIFICATIONS

(3) Extension trouble notification completion signal (X02)

When performing the extension trouble notification requests consecutively, provide

an interlock using the extension trouble notification completion signal (X02) in the

procedure shown above.

(4) Module error signal (X03)

Module error reset request signal (Y03)

Module error signal (X03)

MELSEC-Q

(a) The extension trouble notification completion signal (X02) turns on when

the extension trouble information is sent to the master station by turning on

the extension trouble notification request signal (Y02).

(While the I/O communication signal (X01) is off, the extension trouble

notification completion signal (X02) does not turn on since an extension

trouble notification request is ignored.)

(b) Turning off the extension trouble notification request signal (Y02) turns off

the extension trouble notification completion signal (X02).

I/O communication signal (X01)

Extension trouble notification

request signal (Y02)

Extension trouble notification

completion signal (X02)

Extension trouble information area

(Buffer memory address :

7f9

to 805H)

H

POINT

Extension trouble

notification request

Extension trouble

notification completion

MOV/TO

Instruction

Extension trouble

information write

(a) This signal turns on when an error occurs.

At this time, an error code is stored into the module error information area

(buffer memory address: 7F8

H)).

(b) This signal turns off when the error is reset by turning on the module error

reset request signal (Y03) or resetting the CPU, for example. At this time,

the ERR. LED goes off and the error code is cleared.

(c) The module error reset request signal (Y03) turns off after confirming that

the module error signal (X03) have turned off.

Error detection

Error reset

Module error information area

(Buffer memory address : 7F8H)

The error code is read from the buffer memory to the CPU module.

MOV/FROM

instruction

(5) SYNC mode signal (X05)

(a) This signal turns on when the QJ71PB93D is placed in the SYNC mode by

3 - 5 3 - 5

a SYNC request from the master station.

(b) The SYNC mode signal (X05) turns off when the SYNC mode is terminated

by an UNSYNC request from the master station, a communication stop or a

CPU reset.

3 SPECIFICATIONS

(6) SYNC receive signal (X06)

Request from master

MELSEC-Q

(c) The SYNC LED turns on/off in synchronization with the on/off of the SYNC

mode signal (X05).

(d) The SYNC mode signal (X05) turns off if a communication time-out error

occurs due to a stop of communication with the master station while the

SYNC mode signal (X05) is on.

However, if the communication watchdog timer setting in the master station

side parameters is "invalid", the SYNC mode signal (X05) does not turn off

since a communication time-out error does not occur. (The output data in

the output receive area is held.)

Communication watchdog timer

Setting in Master Station Side

Parameters

Invalid

Valid (2 to 65025)

Operation at Master Station Fault

No error

(SYNC mode signal (X05) remains on)

Communication time-out error occurrence

(SYNC mode signal (X05) turns off)

The communication watchdog timer setting can be confirmed in the

"Current communication watchdog timer value (buffer memory address:

8D1

H)" of the QJ71PB93D.

(a) The SYNC receive signal (X06) turns on receipt of a SYNC request from

the master station.

(b) While the SYNC mode signal (X05) is on, the receipt of a SYNC request

from the master station changes the on/off state of the SYNC receive signal

(X06).

At this time, the SYNC mode signal (X05) remains on.

(c) The SYNC receive signal (X06) turns off when the SYNC mode is

terminated by an UNSYNC request from the master station, a

communication stop or a CPU reset.

SYNC request

SYNC request SYNC request UNSYNC request

SYNC mode signal (X05)

SYNC receive signal (X06)

SYNC LED

Off OffOn

3 - 6 3 - 6

r

3 SPECIFICATIONS

(7) FREEZE mode signal (X07)

Request from maste

MELSEC-Q

(d) The SYNC receive signal (X06) turns off if a communication time-out error

occurs due to a stop of communication with the master station while the

SYNC receive signal (X06) is on.

However, if the communication watchdog timer setting in the master station

side parameters is "invalid", the SYNC receive signal (X06) does not turn

off since a communication time-out error does not occur. (The output data

in the output receive area is held.)

Communication watchdog timer

Setting in Master Station Side

Parameters

Invalid

Valid (2 to 65025)

Operation at Master Station Fault

No error

(SYNC receive signal (X06) remains on)

Communication time-out error occurrence

(SYNC receive signal (X06) turns off)

The communication watchdog timer setting can be confirmed in the

"Current communication watchdog timer value (buffer memory address:

8D1

H)" of the QJ71PB93D.

(a) The FREEZE mode signal (X07) turns on when the QJ71PB93D is placed

in the FREEZE mode by a FREEZE request from the master station.

(b) The FREEZE mode signal (X07) turns off when the FREEZE mode is

terminated by an UNFREEZE request from the master station, a

communication stop or a CPU reset.

(c) The FREEZE LED turns on/off in synchronization with the on/off of the

FREEZE mode signal (X07).

FREEZE request UNFREEZE request

FREEZE mode signal (X07)

FREEZE LED Off OffOn

3 - 7 3 - 7

3 SPECIFICATIONS

(8) BBLKRD start request acceptance completion signal (X0A)

MELSEC-Q

(d) The FREEZE mode signal (X07) turns off if a communication time-out error

occurs due to a stop of communication with the master station while the

FREEZE mode signal (X07) is on.

However, if the communication watchdog timer setting in the master station

side parameters is "invalid", the FREEZE mode signal (X07) does not turn

off since a communication time-out error does not occur. (The output data

in the output receive area is held.)

Communication watchdog timer

Setting in Master Station Side

Parameters

Invalid

Valid (2 to 65025)

Operation at Master Station Fault

No error

(FREEZE mode signal (X07) remains on)

Communication time-out error occurrence

(FREEZE mode signal (X07) turns off)

The communication watchdog timer setting can be confirmed in the

"Current communication watchdog timer value (buffer memory address:

8D1

H)" of the QJ71PB93D.

(a) This signal is used as an interlock condition signal to execute the dedicated

instruction BBLKRD.

(b) When the BBLKRD start request signal (Y0A) is turned on in the sequence

program, the BBLKRD start request acceptance completion signal (X0A)

turns on.

(c) When the BBLKRD start request signal (Y0A) is turned off in the sequence

program, the BBLKRD start request acceptance completion signal (X0A)

also turns off.

BBLKRD start request signal (Y0A)

BBLKRD start request acceptance

completion signal (X0A)

BBLKRD instruction

(9) BBLKWR start request acceptance completion signal (X0B)

(a) This signal is used as an interlock condition signal to execute the dedicated

3 - 8 3 - 8

instruction BBLKWR.

(b) When the BBLKWR start request signal (Y0B) is turned on in the sequence

program, the BBLKWR start request acceptance completion signal (X0B)

turns on.

3 SPECIFICATIONS

BBLKWR start request signal (Y0B)

BBLKWR start request acceptance

completion signal (X0B)

MELSEC-Q

(c) When the BBLKWR start request signal (Y0B) is turned off in the sequence

program, the BBLKWR start request acceptance completion signal (X0B)

also turns off.

BBLKWR instruction

(10) Operation mode change completion signal (X11)

(a) This signal turns on when an operation mode change is completed by

setting the required operation mode to the operation mode change request

area (buffer memory address: 8CF

change request signal (Y11).

At this time, the result is stored into the operation mode change result area

(buffer memory address: 8D0

(b) Turning off the operation mode change request signal (Y11) after

confirmation of the result turns off the operation mode change completion

signal (X11).

(c) This signal turns on at either normal or abnormal completion of an

operation mode change.

At abnormal completion, the operation mode change request is made

invalid and operation continues in the operation mode that had been used

Input send area refresh

directive signal (Y00)

Operation mode change

request signal (Y11)

before the change request was given.

H) and turning on the operation mode

H).

Operation mode change

completion signal (X11)

Operation mode change result area

(Buffer memory address: 2256(8D0

))

H

MOV/TO

instruction

Sets the operation mode

in "operation mode change

request area (Address : 8CF

)".

H

Change result of operation mode

MOV/FROM

instruction

Checks result in "operation mode

change result area (Address : 8D0

and "current operation mode

(Address : 8CE

)".

H

3 - 9 3 - 9

)"

H

3 SPECIFICATIONS

(11) Station number change completion signal (X13)

MELSEC-Q

(a) This signal turns on when the station number setting is completed by

setting the station number to the station number change request area

(buffer memory address: 203

H) and turning on the station number change

request signal (Y13).

(b) Check the setting result in the operation station number area (buffer

memory address: 201

address: 7F8

H) of the buffer memory.

H) and module error information area (buffer memory

(c) Turning off the station number change request signal (Y13) after

confirmation of the result turns off the station number change completion

signal (X13).

(d) If a station number error (error code: 1002

H) has occurred, the station

number change request is made invalid and operation continues with the

station number that had been used before the change request was given.

(e) Turning on the station number change request signal (Y13) suspends I/O

communication.

Turning on the station number change completion signal (X13) resumes I/O

communication.

Input send area refresh

directive signal (Y00)

Station number change

request signal (Y13)

Station number change

completion signal (X13)

Buffer memory

MOV/TO

instruction

Sets station number in "station

number change request area

(Address : 203

)".

H

Checks result in "operation station

number area (Address : 201

module error information area

(Address : 7F8

MOV/FROM

instruction

)".

H

),

H

(12) Module READY signal (X1D)

(a) This signal turns on when the QJ71PB93D is enabled for access from the

CPU module. (It turns on regardless of the operation mode.)

(b) This signal turns off when the QJ71PB93D is disabled for access from the

CPU module due to a module watchdog timer

error, hardware fault or like.

3 - 10 3 - 10

3 SPECIFICATIONS

(13) Input send area refresh directive signal (Y00)

I/O communication

signal (X01)

MELSEC-Q

(a) Turning on this signal during communication with the master station (I/O

communication signal (X01) = ON) starts data communication of the input

send area (buffer memory addresses: 100

H to 1BFH) in the buffer memory.

(b) Turning this signal off stops sending of the data in the input send area to

the master station. (0 data are sent.)

(c) While the I/O communication signal (X01) is off, ON of the input send area

refresh directive signal (Y00) is invalid.

(communication stop)

OFF

ON (during communication)

(communication stop)

OFF

Input send area refresh

directive signal (Y00)

Data send in input

send area

Data update in output

receive area

Not sent Sent

Not updated Updated Not updated

ONOFF

OFF

Not sent

ON

OFF

POINT

The following are the relationships between data send and receive of the

QJ71PB93D, which vary with the states of the I/O communication signal (X01) and

input send area refresh directive signal (Y00).

X01 State Y00 State Data in Output Receive Area/Input Send Area

Master station QJ71PB93D

Input

area

Not sent

Input

send area

OFF ON/OFF

Output

area

Not updated

Output

receive area

Master station QJ71PB93D

Input

area

Sent

Input

send area

ON

Output

area

Updated

Output

receive area

ON

Master station QJ71PB93D

Input

area

0 data sent

Input

send area

OFF

Output

area

Updated

Output

receive area

3 - 11 3 - 11

3 SPECIFICATIONS

(14) Extension trouble notification request signal (Y02)

To turn on/off Y02, provide an interlock using X02.

(15) Module error reset request signal (Y03)

(16) BBLKRD start request signal (Y0A)

MELSEC-Q

(a) Turning on the extension trouble notification request signal (Y02) sends the

data set in the extension trouble information area (buffer memory address:

7F9

H to 805H) to the master station as extension trouble information. (The

extension trouble notification request is ignored while the I/O

communication signal (X01) is off.)

(b) When you have checked that the extension trouble notification completion

signal (X02) is on, turn off the extension trouble notification request signal

(Y02).

(c) Refer to (3) in this section for the on/off timing.

POINT

(a) Turning on the module error reset request signal (Y03) resets the error of

(b) When you have checked that the module error signal (X03) is off, turn off

(c) Making an error reset clears the error code in the module error information

(d) Refer to (4) in this section for the on/off timing.

(a) This signal is used to start the processing of the dedicated instruction

(b) When the BBLKRD start request signal (Y0A) is turned on in the sequence

(c) When the BBLKRD start request signal (Y0A) is turned off from the

(d) Only when using the dedicated instruction BBLKRD, turn on the BBLKRD

the QJ71PB93D. (The module error signal (X03) turns off and the ERR.

LED goes off.)

the module error reset request signal (Y03).

area (buffer memory address: 7F8

BBLKRD.

When executing the dedicated instruction BBLKRD, always turn on the

BBLKRD start request signal (Y0A) to turn on the BBLKRD start request

acceptance completion signal (X0A) so that it is used as an interlock

condition.

program, the QJ71PB93D starts the processing of the dedicated instruction

BBLKRD.

sequence program, the processing of the dedicated instruction BBLKRD is

ignored.

start request signal (Y0A).

Note that, if the dedicated instruction BBLKRD is not executed after the

BBLKRD start request signal (Y0A) has been turned on, the transmission

delay time between the master and a slave stations is prolonged.

H).

3 - 12 3 - 12

3 SPECIFICATIONS

(17) BBLKWR start request signal (Y0B)

(18) Operation mode change request signal (Y11)

(19) Station number change request signal (Y13)

Station numbers can be set from the class 2 master station.

In this case, specifying "TRUE" for "No_Add_Chg" disables the station number

change on the QJ71PB93D.

The station number of the QJ71PB93D cannot be changed while the station

number change is disabled.

To change the station number again, clear the station number in the station number

change request area of the QJ71PB93D (buffer memory address: 515(203

cancel the disabled status. (Refer to Section 3.4.2 (6))

MELSEC-Q

(a) This signal is used to start the processing of the dedicated instruction

BBLKWR.

When executing the dedicated instruction BBLKRD, always turn on the

BBLKRD start request signal (Y0B) to turn on the BBLKRD start request

acceptance completion signal (X0B) so that it is used as an interlock

condition.

(b) When the BBLKWR start request signal (Y0B) is turned on in the sequence

program, the QJ71PB93D starts the processing of the dedicated instruction

BBLKWR.

(c) When the BBLKWR start request signal (Y0B) is turned off from the

sequence program, the processing of the dedicated instruction BBLKWR is

ignored.

(d) Only when using the dedicated instruction BBLKWR, turn on the BBLKWR

start request signal (Y0B).

Note that, if the dedicated instruction BBLKWR is not executed after the

BBLKWR start request signal (Y0B) has been turned on, the transmission

delay time between the master and a slave stations is prolonged.

(a) Turn on the operation mode change request signal (Y11) when changing

the operation mode to the one set in the operation mode change request

area (buffer memory address: 8CF

(b) When you have checked that the operation mode change completion signal

(X11) is on, turn off the operation mode change request signal (Y11).

(c) Refer to (10) in this section for the on/off timing.

(a) Turn on the station number change request signal (Y13) when changing the

station number to the one set in the station number change request area

(buffer memory address: 203

(b) When you have checked that the station number change completion signal

(X13) is on, turn off the station number change request signal (Y13).

(c) Refer to (11) in this section for the on/off timing.

POINT

H).

H).

H)) to

3 - 13 3 - 13

3 SPECIFICATIONS

MELSEC-Q

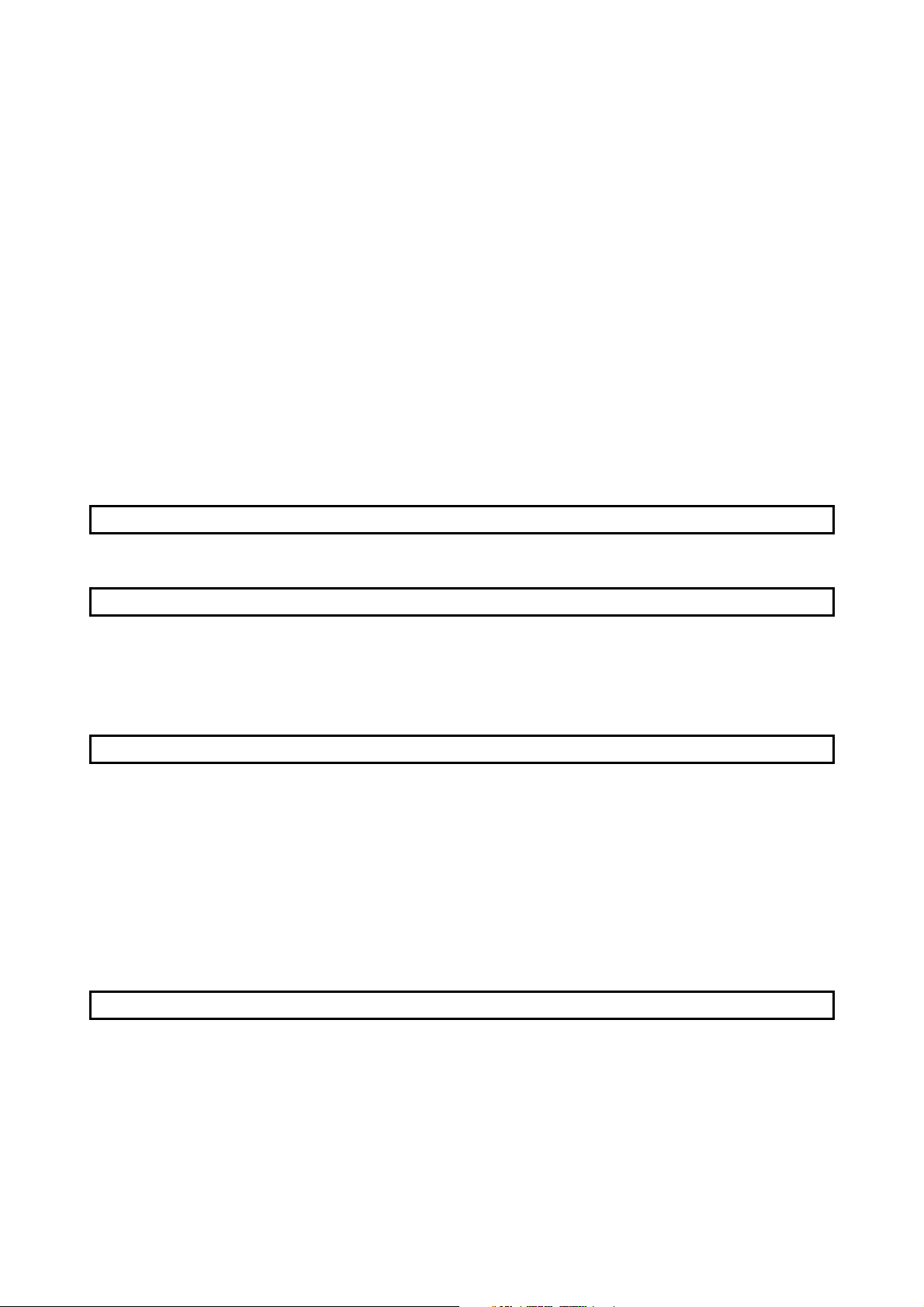

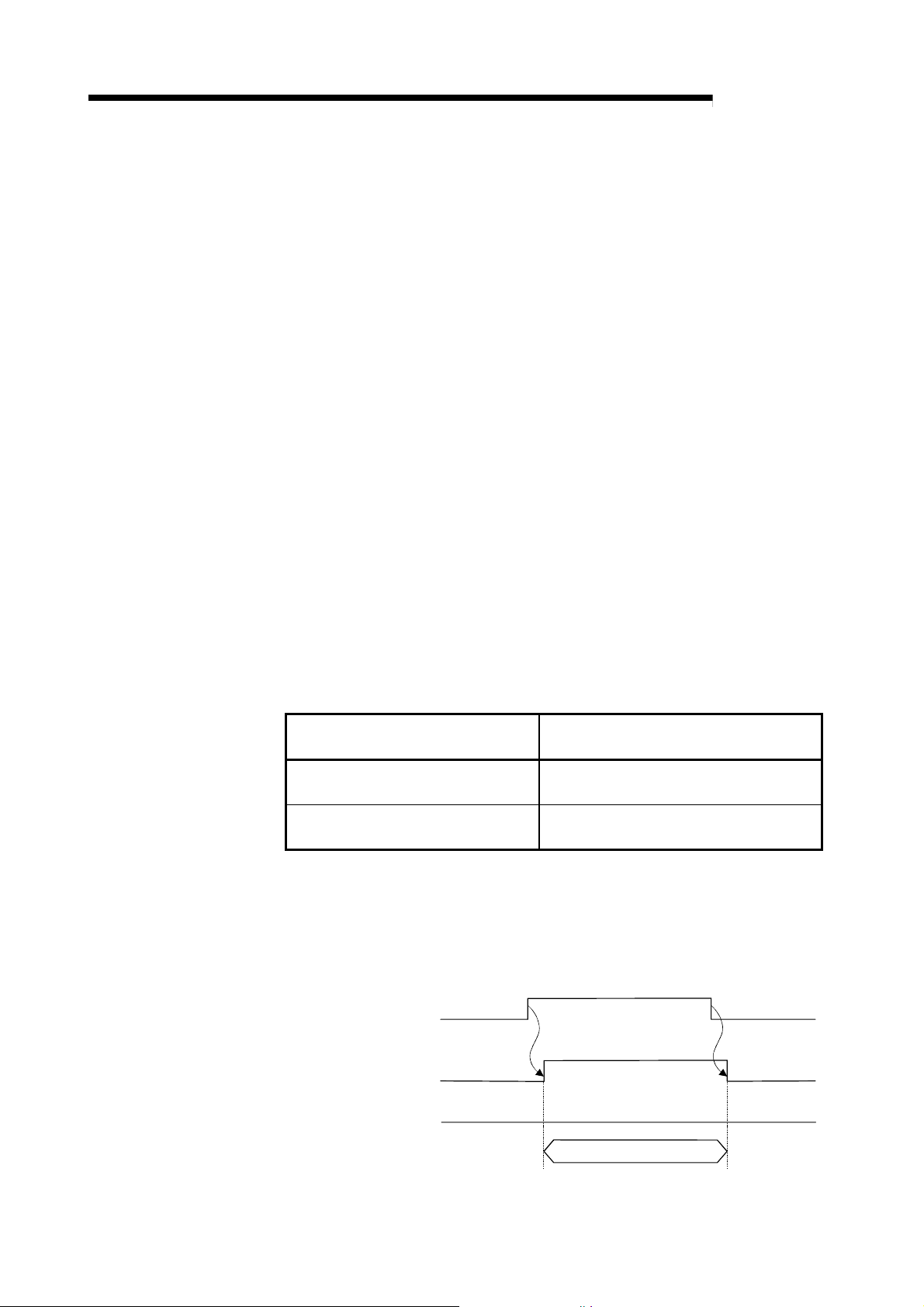

3.4 Buffer Memory List

3.4.1 Buffer memory/configuration

The configuration of the buffer memory used to receive and send data with the

Buffer memor y address

Hexadecimal decimal

0H

0

BFH

191

C0H

192

FFH

255

100H

256

1BFH

447

1C0H

448

1FFH

511

200H 512 Operation baud rate Stores the baud rate in current operation. Read

201H 513 Operation station number Stores the station number in current operation. Read

202H 514 Station number set on flash ROM Stores the station number saved on the flash ROM. Read

203H 515 Station number change request area

204H 516 Station number rewritabl e count to flash ROM

205H

517

7F7H

2039

7F8H 2040 Module error information Stores the error code detected by the QJ71PB93D. Read

2041

7F9H

805H

2053

2054

806H

8CDH

2253

8CEH 2254 Current operation mode Stores the operation mode in current operation. Read

8CFH 2255 Operation mode change request area

8D0H 2256 Operation mode change result

8D1H 2257 Current communication watchdog timer value Stores the communication watchdog timer value in current operation. Read

8D2H 2258 Self-diagnostic status type code display area Stores the diagnostic status type code at the time of self-diagnostics. Read

8D3H 2259 Swapping function setting status Stores the setting status of the swapping function in current operation. Read

8D4H

2260

8DFH

2271

8E0H

2272

8EBH

2283

8ECH

2284

8EFH

2287

8F0H

2288

8FBH

2299

2300

8FCH

AFFH

2815

QJ71PB93D and the CPU module is described below.

Area name Description Read/Write

Output receive area

System area (Use prohibited)

Input send area

System area (Use prohibited)

System area (Use prohibited)

Extension trouble information area

System area (Use prohibited)

System area (Use prohibited)

Output receive area used status Stores the current used status of the output receive area. Read

System area (Use prohibited)

Input send area used status Stores the current used status of the input send area. Read

System area (Use prohibited)

POINT

Stores the output data received from the master station.

(Max. usable range 122 words)

Used to set the input data to be sent to the master station.

(Max. usable range 122 words)

Used to set a new station number to be set in response to the station

number change request signal (Y13).

Stores the remaining number of times when the station number can be

saved onto the flash ROM during continuous operati on.

Used to set the extension trouble notification data to the master

station.

Used to set a new operation mode to be set in response to the

operation mode change request signal (Y11).

Stores the result of changing the operation mode in response to the

operation mode change request signal (Y11).

Do not write any data in the "system area (Use prohibited)" of the buffer memory.

If data is written to the "system area (Use prohibited)", there is a risk that the

programmable controller system may malfunction.

Read

Read/Write

Read/Write

Read

Read/Write

Read/Write

Read

3 - 14 3 - 14

3 SPECIFICATIONS

3.4.2 Buffer memory detail description

(1) Output receive area

Stores the output data received from the master station.

The structure varies with the data module setting and data assignment mode

setting in the slave parameters. (Refer to Section 5.2.1 to 5.2.3)

(2) Input send area

(buffer memory address 100H to 1BFH: Un\G256 to Un\G447)

Used to store the input data to be sent to the master station.

The structure varies with the data module setting and data assignment mode

setting in the slave parameters. (Refer to Section 5.2.1 to 5.2.3)

(3) Operation baud rate (buffer memory address 200H: Un\G512)

Stores the baud rate in current operation.

Baud rate not yet recognized 0000H

The stored value while the I/O communication signal (X01) is on is valid.

Use the master station parameter to set the baud rate of the PROFIBUS-DP.

(4) Operation station number (buffer memory address 201H: Un\G513)

Stores the station number of the QJ71PB93D in current operation.

The storage range is 0 to 126.

The stored value while the I/O communication signal (X01) is on is valid.

If the station number is not set (the station number is as set in the factory or has

been cleared), "126" is stored.

I/O data cannot be communicated if the station number is not set.

MELSEC-Q

(buffer memory address 0H to BFH: Un\G0 to Un\G191)

Baud Rate Stored Value

9.6 kbps 96E2H

19.2 kbps 19E3H

45.45 kbps 45E3H

93.75 kbps 93E3H

187.5 kbps 18E4H

500 kbps 05E5H

1.5 Mbps 15E5H

3 Mbps 03E6H

6 Mbps 06E6H

12 Mbps 12E6H

3 - 15 3 - 15

3 SPECIFICATIONS

(5) Station number set on flash ROM

(6) Station number change request area

(1) Saving the station number to the flash ROM enables the operation based on the

(2) At power-on or at CPU reset, "FFFE

(7) Station number rewritable count to flash ROM

MELSEC-Q

(buffer memory address 202H: Un\G514)

Stores the station number of the QJ71PB93D set to the flash ROM.

The storage range is 0 to 125.

If the station number is not set to the flash ROM (the station number is as set in

the factory or has been cleared), "FFFF

H" is stored.

(buffer memory address 203H: Un\G515)

Used to set any of the following values when setting a new station number of the

QJ71PB93D in response to the station number change request signal (Y13).

Set Value Description

Set a station number.

By turning on b8, the station number is saved onto the flash ROM.

Fixed to 0

0000H to 007DH or

0100

H to 017DH

FFFFH

POINT

0: Not save onto the flash ROM

1: Save onto the flash ROM

(Example 1) Set the station number to 12. (Not saved onto the flash

ROM): 000C

(Example 2) Set the station number to 12. (Saved onto the flash

ROM): 010C

Clears the station number.

After clearing, the operation station number is "126".

The station number set to the flash ROM is "FFFE

H

H

Set a station number within the

range from 0

H

to 7DH (0 to125).

H".

station number setting stored in the flash ROM even if the module is powered

off and on or the CPU module is reset.

H" is stored.

Turn on the station number change request signal (Y13) after storing a setting

value given in the above table.

Executing the station number change request with any invalid value results in a

station number error (error code: 1002

H).

(buffer memory address 204H: Un\G516)

Stores the remaining number of times when the station number setting can be

saved onto the flash ROM during operation.

The initial value is 60.

(a) Counting down the number of times

Every time the station number is changed on the flash ROM, the count is

decremented by 1.

The count is not decremented when station number setting is requested

with the same station number as the one saved on the flash ROM (buffer

memory address: 202

H).

b0b1b2b3b4b5b6b7b8b9b10b11b12b13b14b15

3 - 16 3 - 16

3 SPECIFICATIONS

(8) Module error information (buffer memory address 7F8H: Un\G2040)

(9) Extension trouble information area

MELSEC-Q