Q2AS(H)CPU(S1)

Mitsubishi Programmable Controller

User's Manual

(Hardware)

Thank you for purchasing the Mitsubishi programmable logic controller

MELSEC-QnA series.

Prior to use, please read both this and relevant manual

thoroughly to fully understand the product.

MODEL

MODEL

CODE

IB(NA)-66677-H(0810)MEE

Q2ASCPU-U(H/W)-E

13J857

©1996 MITSUBISHI ELECTRIC CORPORATION

SAFETY PRECAUTIONS

(Be sure to read these instructions before use.)

Before using the product, read this and relevant manuals carefully and handle the

product correctly with full attention to safety.

In this manual, SAFETY PRECAUTIONS are classified into 2 levels:

"DANGER" and "CAUTION".

Indicates that incorrect handling may cause hazardous

DANGER

conditions, resulting in death or severe injury.

CAUTION

Under some circumstances, failure to observe the

instructions may also lead to serious results.

Be sure to observe the instructions of both levels to ensure the safety.

Please keep this manual in a safe place for future reference and also pass this

manual on to the end user.

Indicates that incorrect handling may cause hazardous

conditions, resulting in minor or moderate injury and/or

property damage.

CAUTION level

[DESIGN PRECAUTIONS]

DANGER

Create a safety circuit outside the programmable controller to ensure the

whole system will operate safely even if an external power failure or a

programmable controller failure occurs.

Otherwise, incorrect output or malfunction may cause an accident.

(1) For an emergency stop circuit, protection circuit and interlock circuit that

is designed for incompatible actions such as forward/reverse rotation or

for damage prevention such as the upper/lower limit setting in

positioning, any of them must be created outside the programmable

controller.

Install the emergency stop switch outsid the controlpanel so that workers

can operate it easily.

A-1

[DESIGN PRECAUTIONS]

DANGER

(2) When the programmable controller detects the following error

conditions, it stops the operation and turn off all the outputs.

The overcurrent protection device or overvoltage protection device of

the power supply module is activated.

The programmable controller CPU detects an error such as a

watchdog timer error by the self-diagnostics function.

In the case of an error of a part such as an I/O control part that cannot

be detected by the programmable controller CPU, all the outputs may

turn on. In order to make all machines operate safely in such a case, set

up a fail-safe circuit or a specific mechanism outside the programmable

controller.

Refer to "LOADING AND INSTALLATION" in this manual for example

fail safe circuits.

(3) Depending on the failure of the output module’s relay or transistor, the

output status may remain ON or OFF incorrectly. For output signals that

may lead to a serious accident, create an external monitoring circuit.

If load current more than the rating or overcurrent due to a short circuit

in the load has flowed in the output module for a long time, it may

cause a fire and smoke. Provide an external safety device such as a

fuse.

Design a circuit so that the external power will be supplied after

power-up of the programmable controller.

Activating the external power supply prior to the programmable

controller may result in an accident due to incorrect output or

malfunction.

For the operation status of each station at a communication error in

data link, refer to the respective data link manual.

The communication error may result in an accident due to incorrect

output or malfunction.

A-2

[DESIGN PRECAUTIONS]

DANGER

When controlling a running programmable controller (data modification) by

connecting a peripheral device to the CPU module or a PC to a special

function module, create an interlock circuit on sequence programs so that the

whole system functions safely all the time.

Also, before performing any other controls (e.g. program modification,

operating status change (status control)), read the manual carefully and

ensure the safety.

In these controls, especially the one from an external device to a

programmable controller in a remote location, some programmable controller

side problem may not be resolved immediately due to failure of data

communications.

To prevent this, create an interlock circuit on sequence programs and

establish corrective procedures for communication failure between the

external device and the programmable controller CPU.

When setting up the system, do not allow any empty slot on the base unit.

If any slot is left empty, be sure to use a blank cover (A1SG60) or a dummy

module (A1SG62) for it.

When using the extension base unit, A1S52B(S1), A1S55B(S1) or

A1S58B(S1), attach the included dustproof cover to the module in slot 0.

Otherwise, internal parts of the module may be flied in the short circuit test or

when an overcurrent or overvoltage is accidentally applied to external I/O

section.

CAUTION

Do not install the control lines or communication cables together with the

main circuit or power lines, or bring them close to each other.

Keep a distance of 100mm (3.94inch) or more between them.

Failure to do so may cause malfunctions due to noise.

If having read register R outside the allowable range with the MOV

instruction, the file register data will be FFFF

H. Using this as it is may cause

malfunctions. Pay attention not to use any out-of-range file register when

designing sequence programs. For instruction details, refer to the

programming manual.

When an output module is used to control the lamp load, heater, solenoid

valve, etc., a large current (ten times larger than the normal one) may flow at

the time that the output status changes from OFF to ON. Take some

preventive measures such as replacing the output module with the one of a

suitable current rating.

A-3

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller under the environment specified in the

user’s manual.

Otherwise, it may cause electric shocks, fires, malfunctions, product

deterioration or damage.

Insert the module fixing projection into the fixing hole in the base unit and

then tighten the module mounting screw within the specified torque.

When no screw is tightened, even if the module is installed correctly, it may

cause malfunctions, a failure or a drop of the module.

Tightening the screw excessively may damage the screw and/or the module,

resulting in a drop of the module, a short circuit or malfunctions.

Connect the extension cable to the connector of the base unit or module.

Check the cable for incomplete connection after connecting it.

Poor electrical contact may cause incorrect inputs and/or outputs.

Insert the memory card and fully press it to the memory card connector.

Check for incomplete connection after installing it.

Poor electrical contact may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the

system before mounting or removing the module. Failure to do so may

damage the module.

Do not directly touch the conductive part or electronic components of the

module.

Doing so may cause malfunctions or a failure of the module.

A-4

[WIRING PRECAUTIONS]

DANGER

Be sure to shut off all phases of the external power supply used by the

system before wiring.

Failure to do so may result in an electric shock or damage of the product.

Before energizing and operating the system after wiring, be sure to attach the

terminal cover supplied with the product.

Failure to do so may cause an electric shock.

CAUTION

Always ground the FG and LG terminals to the protective ground conductor.

Failure to do so may cause an electric shock or malfunctions.

Wire the module correctly after confirming the rated voltage and terminal

layout.

Connecting a power supply of a different voltage rating or incorrect wiring

may cause a fire or failure.

Do not connect multiple power supply modules to one module in parallel.

The power supply modules may be heated, resulting in a fire or failure.

Press, crimp or properly solder the connector for external connection with the

specified tool.

Incomplete connection may cause a short circuit, fire or malfunctions.

Tighten terminal screws within the specified torque range. If the screw is too

loose, it may cause a short circuit, fire or malfunctions.

If too tight, it may damage the screw and/or the module, resulting in a short

circuit or malfunctions.

Carefully prevent foreign matter such as dust or wire chips from entering the

module.

Failure to do so may cause a fire, failure or malfunctions.

Install our programmable controller in a control panel for use.

Wire the main power supply to the power supply module installed in a control

panel through a distribution terminal block.

Furthermore, the wiring and replacement of a power supply module have to

be performed by a maintenance worker who acquainted with shock

protection.

(For the wiring methods, refer to Type Q2AS(H)CPU(S1) User’s Manual.)

A-5

[STARTUP AND MAINTENANCE PRECAUTIONS]

DANGER

Do not touch any terminal during power distribution.

Doing so may cause an electric shock.

Properly connect batteries. Do not charge, disassemble, heat or throw them

into the fire and do not make them short-circuited and soldered. Incorrect

battery handling may cause personal injuries or a fire due to exothermic heat,

burst and/or ignition.

Be sure to shut off all phases of the external power supply used by the

system before cleaning or retightening the terminal screws or module

mounting screws.

Failure to do so may result in an electric shock.

If they are too loose, it may cause a short circuit or malfunctions.

If too tight, it may cause damage to the screws and/or module, resulting in an

accidental drop of the module, short circuit or malfunctions.

CAUTION

When performing online operations (especially, program modification, forced

output or operating status change) by connecting a peripheral device to the

running CPU module, read the manual carefully and ensure the safety.

Incorrect operation will cause mechanical damage or accidents.

Do not disassemble or modify each of modules.

Doing so may cause failure, malfunctions, personal injuries and/or a fire.

When using a wireless communication device such as a mobile phone, keep

a distance of 25cm (9.84inch) or more from the programmable controller in

all directions.

Failure to do so may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the

system before mounting or removing the module.

Failure to do so may result in failure or malfunctions of the module.

Do not drop or apply any impact to the battery.

Doing so may damage the battery, resulting in electrolyte spillage inside the

battery.

If any impact has been applied, discard the battery and never use it.

Do not install/remove the terminal block more than 50 times after the first use

of the product. (IEC 61131-2 compliant)

Before handling modules, touch a grounded metal object to discharge the

static electricity from the human body.

Failure to do so may cause failure or malfunctions of the module.

A-6

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of the product, treat it as an industrial waste.

When disposing of batteries, separate them from other wastes according to

the local regulations.

(For details of the battery directive in EU member states, refer to the

Q2AS(H)CPU(S1) User's Manual.)

[TRANSPORTATION PRECAUTIONS]

CAUTION

When transporting lithium batteries, make sure to treat them based on the

transportation regulations. (Refer to Chapter 7 for details of the relevant

models.)

A-7

REVISIONS

*The manual number is given on the bottom right of the front cover.

Print Date *Manual Number Revision

Jan., 1996 IB(NA) 66677-A First edition

Sep., 1998 IB(NA) 66677-B

Correction

SAFETY PRECAUTIONS, Section 4.5.2

Addition

Specifications, Performance specifications,

EMC standards,

Low-Voltage instruction

Deletion

I/O module specifications and connections

Dec., 2002 IB(NA) 66677-C Equivalent to Japanese version E

Correction

SAFETY PRECAUTIONS, 1.1, Chapter 3,

Section 4.2, 4.3.1, 4.3.2, 4.5.2, Chapter 5,

Chapter 6, Section 6.2

Dec., 2003 IB(NA) 66677-D

Addition of model

A1SY42P

Jul., 2005 IB(NA) 66677-E

Addition

Chapter 7, Section 7.1, 7.2

Correction

SAFETY PRECAUTIONS, Section 5.2.1,

5.2.2, 5.3.1, 5.3.2, 6.2

Correction

SAFETY PRECAUTIONS, Section 1.1,

Chapter 3, Section 3.1, 3.1.1, 3.1.2, 3.1.3,

3.2, 3.2.4, 3.2.7, 4.1.1, 4.2, 4.3.1, 4.3.2,

4.3.3, 4.3.4, 4.4, 6.2, 6.3

Section change

Section 6.1, 6.2 are changed to Section 6.2,

6.3, respectively.

A-8

*The manual number is given on the bottom right of the front cover.

Print Date *Manual Number Revision

Oct., 2006 IB(NA) 66677-F

May, 2007 IB(NA) 66677-G

Oct., 2008 IB(NA) 66677-H

Addition of model

A1SY40P, A1SY41P

Addition

Section 6.5, 6.6, 6.7, 6.8, 6.9, 6.10

Correction

SAFETY PRECAUTIONS, Section 1.1,

3.1.3, 3.2.4, 3.2.6, 4.1.1, 4.1.3, 4.3.2, 4.3.3,

4.3.4, 5.2.1, 5.2.2, Chapter 6

Partial Correction

Section 3.1.1, 3.1.3, 3.1.4, 3.2.7, 4.3.3,

4.3.4, 5.2.1, 6.3

Partial Correction

SAFETY PRECAUTIONS, Section 1.1, 3.1,

3.1.1, 3.1.2, 3.1.3, 3.2, 3.2.1, 3.2.2, 3.2.3,

3.2.4, 3.2.5, 3.2.6, 3.2.7, 4.1.3, 4.2, 4.3.3,

4.3.4, 4.5.2, 5.1.1, 5.2.1, Chapter 6

Japanese Manual Version IB(NA)68653-J

This manual confers no industrial property rights or any rights of any other kind,

nor dose it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

©1996 Mitsubishi Electric Corporation

A-9

CONTENTS

1. SPECIFICATIONS .....................................................................................................1

1.1 SPECIFICATIONS.................................................................................................1

2. PERFORMANCE SPECIFICATION..........................................................................2

2.1 QnASCPU Module Performance Specification .....................................................2

3. EMC DIRECTIVES AND LOW VOLTAGE DIRECTIVES ........................................3

3.1 Requirements for Compliance with EMC Directives .............................................3

3.1.1 EMC standard.................................................................................................4

3.1.2 Installation instructions for EMC Directive......................................................5

3.1.3 Cables.............................................................................................................6

3.1.4 Power supply module ...................................................................................11

3.1.5 Base unit .......................................................................................................11

3.1.6 Ferrite core....................................................................................................11

3.1.7 Noise filter (power supply line filter)..............................................................12

3.2 Requirements for Compliance with Low Voltage Directives................................13

3.2.1 Standard applied for MELSEC-QnA series programmable controller .........13

3.2.2 Precautions when using the MELSEC-QnA series programmable controller

...............................................................................................................................13

3.2.3 Power supply ................................................................................................14

3.2.4 Control panel.................................................................................................15

3.2.5 Module installation ........................................................................................16

3.2.6 Grounding .....................................................................................................16

3.2.7 External wiring ..............................................................................................16

4. LOADING AND INSTALLATION ............................................................................17

4.1 Installing the Module............................................................................................17

4.1.1 Notes on handling the module......................................................................17

4.1.2 Installation environment................................................................................18

4.1.3 Notes on installing the base unit...................................................................19

4.2 Fail-safe Circuit Concept .....................................................................................21

4.3 Wiring ...................................................................................................................27

4.3.1 Power supply module specifications ............................................................27

4.3.2 Part names and settings...............................................................................29

4.3.3 Wiring instructions ........................................................................................30

4.3.4 Wiring to module terminals ...........................................................................35

4.4 Precautions when Connecting the Uninterruptive Power Supply (UPS).............36

4.5 Part names and Settings .....................................................................................37

4.5.1 Part names and settings...............................................................................37

4.5.2 Relation between switch operation and the LED indication .........................39

5. SPECIFICATION AND CONNECTION OF I/O MODULES

5.1 Input modules ......................................................................................................41

5.1.1 Input module specifications ..........................................................................41

5.1.2 Input module connections.............................................................................43

5.2 Output modules....................................................................................................47

5.2.1 Output module specifications .......................................................................47

5.2.2 Output module connections..........................................................................49

5.3 Input/output combined modules ..........................................................................57

5.3.1 Input/output combined module specifications ..............................................57

5.3.2 Input/output composite module connections................................................59

.........................................41

A-10

6. ERROR CODE......................................................................................................... 61

6.1 Error Code Type ..................................................................................................62

6.2 Reading Error Code.............................................................................................62

6.3 Error Code List.....................................................................................................63

6.4 Canceling of Errors............................................................................................225

7. TRANSPORTATION PRECAUTIONS..................................................................226

7.1 Relevant Models................................................................................................226

7.2 Transportation Guidelines .................................................................................226

A-11

This manual explains safety precautions, I/O module wiring, and error codes regarding the

Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, and Q2ASHCPU-S1 (hereinafter, these are all referred

to as Q2ASCPU).

About this manual

The following tables show the manuals relevant to this product. Refer to these tables when you

order a manual, if necessary.

Detailed Manual

Manual title

type Q2AS(H)CPU(S1) User's Manual

This manual explains performance, functions, and handling of the Q2ASCPU,

Q2ASCPU-S1, Q2ASHCPU, and Q2ASHCPU-S1, power supply, memory

rd, specifications, and handling of the base unit.

ca

(sold separately)

Relavant Manuals

Manual title

QnACPU-GUIDEBOOK

This manual explains how to create a program, write the program using the

CPU module, and debug the program. This manual is designed for first-time

users of the QnACPU. It also explains some applications of the QnACPU.

(sold separately)

QnACPU PROGRAMMING MANUAL (Fundamentals)

This manual describes programming methods, device names, and

parameters required to create a program. It also describes various types of

programs.

(sold separately)

QCPU(Q mode)/QnACPU PROGRAMMING MANUAL

(Common Instructions)

This manual explains how to use sequence instructions, basic instructions,

and application instructions.

(sold separately)

QnACPU PROGRAMMING MANUAL (Special Function)

This manual describes specific instructions for a special function module for

the QnACPU.

(sold separately)

QnACPU PROGRAMMING MANUAL (AD57 Instructions)

This manual describes specific instructions for controlling the AD57(S1) type

CRT controller module from the QnACPU.

(sold separately)

Manual number

(Type code)

SH-3599

(13J858)

Manual number

(Type code)

IB-66606

(13JF10)

IB-66614

(13JF46)

SH080039

(13JF58)

SH-4013

(13JF56)

IB-66617

(13JF49)

A-12

Manual title

QCPU(Q mode)/QnACPU PROGRAMMING MANUAL

(PID Control Instructions)

This manual describes specific instructions for PID control for the QnACPU.

(sold separately)

QCPU(Q mode)/QnACPU PROGRAMMING MANUAL (SFC)

This manual describes the system configuration, performance specifications

functions, programming, debugging procedures, and the error codes of the

SW0SRX-SAP3 and SW0NX-SAP3.

(sold separately)

Ans Module type I/O User's Manual

This manual describes the specifications for the compact building block type

I/O modules.

(sold separately)

Manual number

(Type code)

SH-080040

(13JF59)

SH-080041

(13JF60)

IB-66541

(13JF81)

A-13

1. SPECIFICATIONS

1.1 SPECIFICATIONS

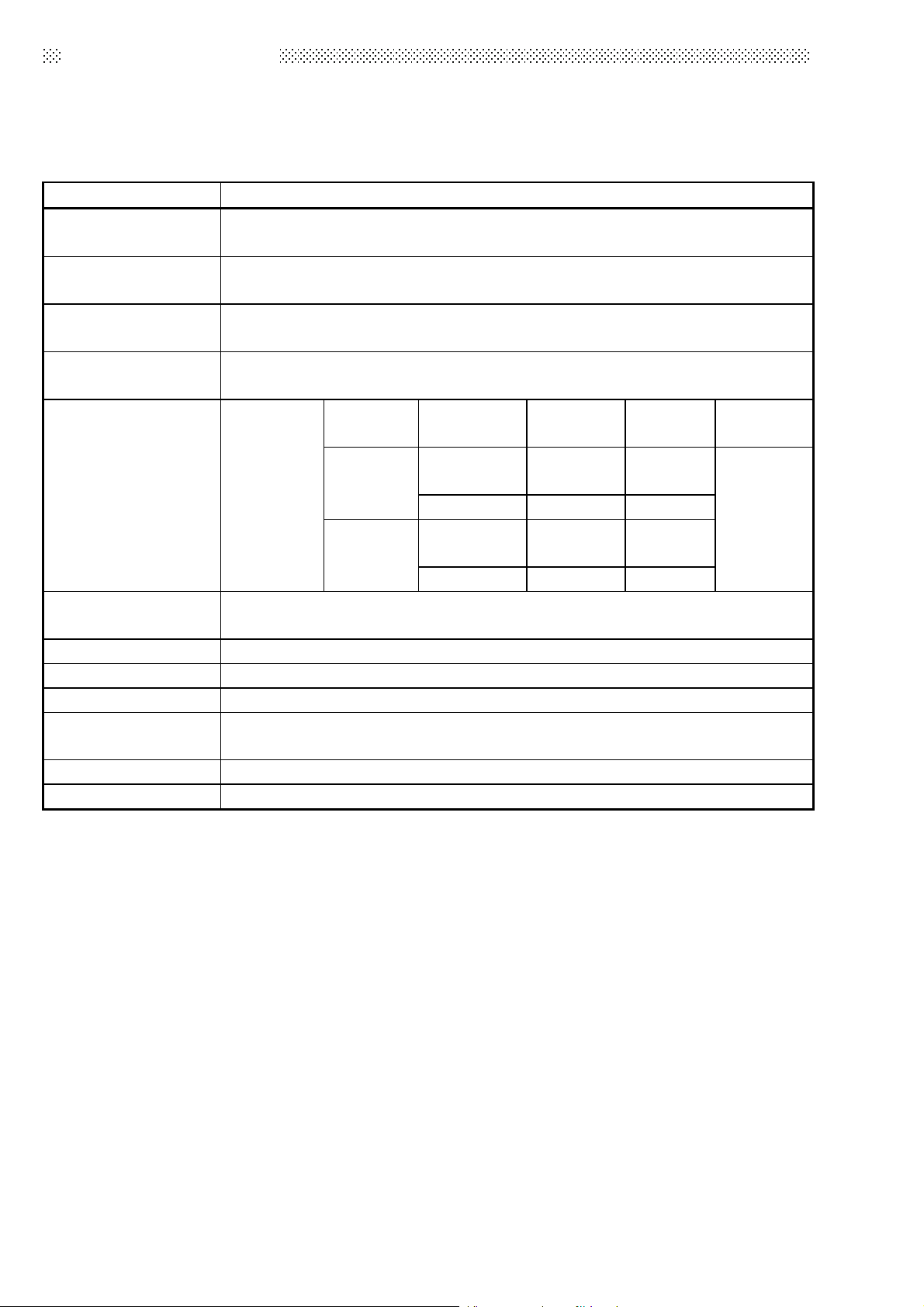

Table 1.1 General specification

Item Specifications

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Ambient storage

humidity

Frequency Acceleration Amplitude

Conforming

Vibration resistance

Shock resistance

Operating ambience No corrosive gases

Operating elevation *3 2000m (6562ft.) max.

Installation location Control panel

Over voltage category

*1

Pollution level *2 2 max.

Equipment category Class I

to JIS B

3502, IEC

61131-2

Under

intermitten

t vibration

Under

continuous

vibration

(147 m/s

10 to 90 % RH, No-condensing

10 to 90 % RH, No-condensing

10 to 57Hz ⎯⎯

57 to 150Hz 9.8m/s

10 to 57Hz ⎯⎯

57 to 150Hz 4.9m/s

Conforming to JIS B 3502, IEC 61131-2

2

, 3 times in each of 3 directions X Y Z)

0 to 55 °C

−20 to 75 °C

II max.

0.075mm

(0.003in.)

2

⎯⎯

0.035mm

(0.001in.)

2

⎯⎯

No. of

sweeps

10 times

each in

X, Y, Z

directions

(for 80min.)

*1: This indicates the section of the power supply to which the equipment is assumed to be

connected between the public electrical power distribution network and the machinery within

premises. Category II applies to equipment for which electrical power is supplied from fixed

facilities. The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

*2: This index indicates the degree to which conductive material is generated in terms of the

environment in which the equipment is used. Pollution level 2 is when only non-conductive

pollution occurs. A temporary conductivity caused by condensing must be expected

occasionally.

*3: Do not use or store the programmable controller in the environment when the pressure is

higher than the atmospheric pressure at sea level. Otherwise, malfunction may result. To use

the programmable controller in high-pressure environment, contact your nearest Mitsubishi

representative.

1

2. PERFORMANCE SPECIFICATION

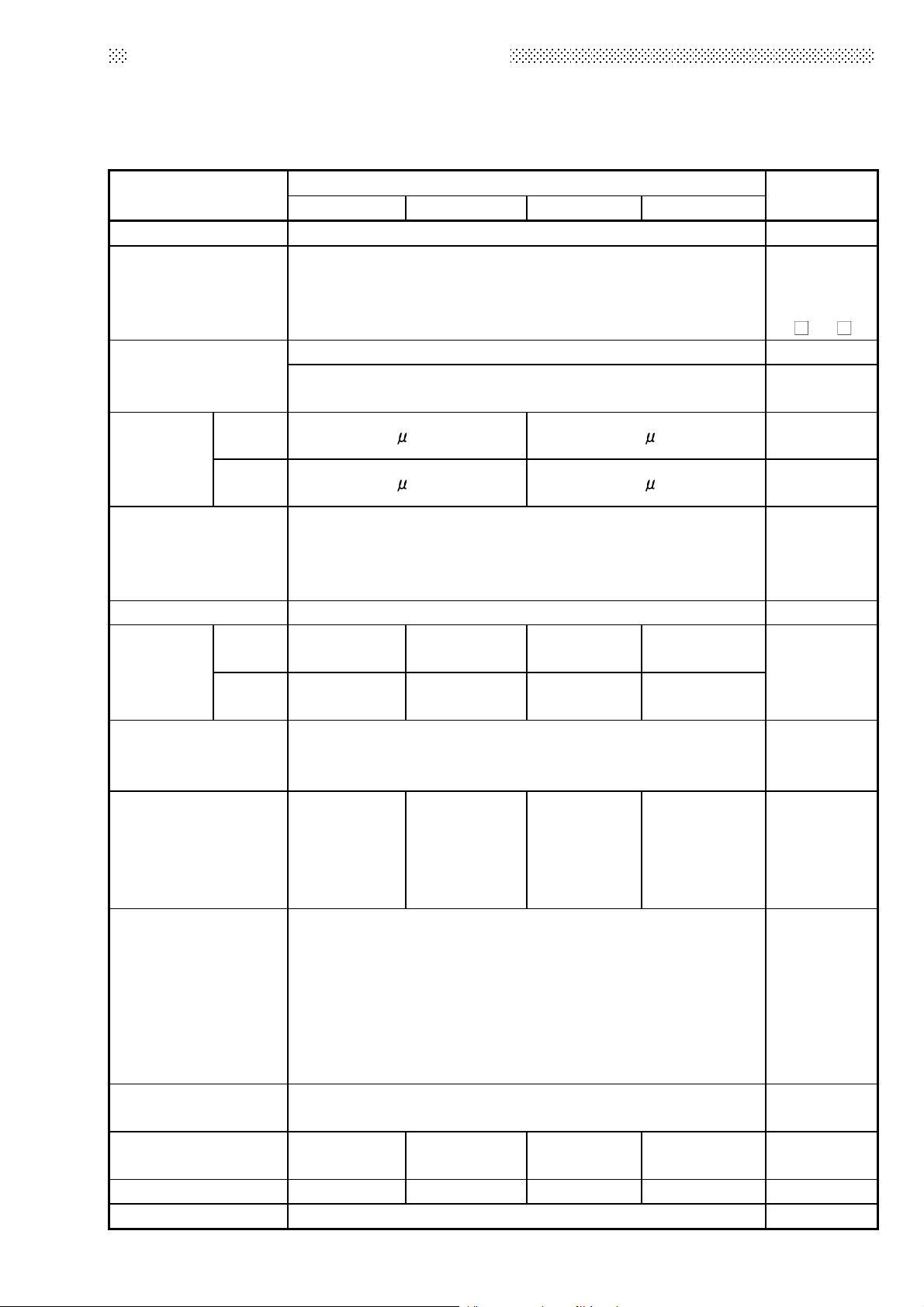

2.1 QnASCPU Module Performance Specification

Performance specification of Q2ASCPU module is as follows:

Item

Control method Repetitive operation of stored program

I/O control method Refresh mode

Programming

language

Processing

speed

(sequence

instructions)

Constant scan

(Function that makes

scan time constant)

Memory capacity Capacity of loading memory cards (2036 kbyte maximum)

Program

capacity

I/O device points 8192 points (X/Y0 to 1FFF)

I/O points

Clock function

Allowable momentary

power failure period

5 VDC Internal current

consumption

Mass 0.5 kg 0.5 kg 0.5 kg 0.5 kg

External dimension 130(H) × 54.5(W) × 110(D) (5.12 × 2.15 × 4.33) mm (inch)

LD 0.2 s/step 0.075 s/step

MOV 0.6

Number

of steps

Number

of files

Q2ASCPU Q2ASCPU-S1

Sequence control dedicated language

Relay symbol language, logic symbolic language, MELSAP3

s/step 0.225 s/step

5 to 2000 ms (configurable in multiple of 5 ms module)

28 k steps

maximum

28 files 60 files 28 files 60 files

512 points

(X/Y0 to 1FF)

Year, month, date, hour, minute, second, day of week

Accuracy : -1.7 to +4.9s (TYP. +1.7s) / d at 0 depress

centigrade

Accuracy : -1.0 to +5.2s (TYP. +2.2s) / d at 25 depress

centigrade

Accuracy : -7.3 to +2.5s (TYP. -1.9s) / d at 55 depress

centigrade

0.3 A 0.3 A 0.7 A 0.7 A

60 k steps

maximum

1024 points

(X/Y0 to 3FF)

(auto-detects leap years)

By power supply module

Model

Q2ASHCPU Q2ASHCPU-S1

(SFC)

28 k steps

maximum

512 points

(X/Y0 to 1FF)

60 k steps

maximum

1024 points

(X/Y0 to 3FF)

Remark

I/O enabled by

specifying

direct I/O

, DY )

(DX

Set

parameter

values to

specify

Number of

usable points

in program

Number of

points

accessible to

actual I/O

modules

2

3. EMC DIRECTIVES AND LOW VOLTAGE DIRECTIVES

The products sold in the European countries have been required by law to comply

with the EMC Directives and Low Voltage Directives of the EU Directives since

1996 and 1997, respectively.

The manufacturers must confirm by self-declaration that their products meet the

requirements of these directives, and put the CE mark on the products.

3.1 Requirements for Compliance with EMC Directives

The EMC Directives specifies emission and immunity criteria and requires the

products to meet both of them, i.e., not to emit excessive electromagnetic

interference (emission): to be immune to electromagnetic interference outside

(immunity).

Guidelines for complying the machinery including MELSEC-QnA series

programmable controller with the EMC Directives are provided in Section 3.1.1 to

3.1.6 below.

The guidelines are created based on the requirements of the regulations and

relevant standards, however, they do not guarantee that the machinery

constructed according to them will not comply with the Directives.

Therefore, the manufacturer of the machinery must finally determine how to make

it comply with the EMC Directives: if it is actually compliant with the EMC

Directives.

3

3.1.1 EMC standards

When the programmable controller is installed following the directions given in this

manual its EMC performance is compliant to the following standards and levels as

required by the EMC directive.

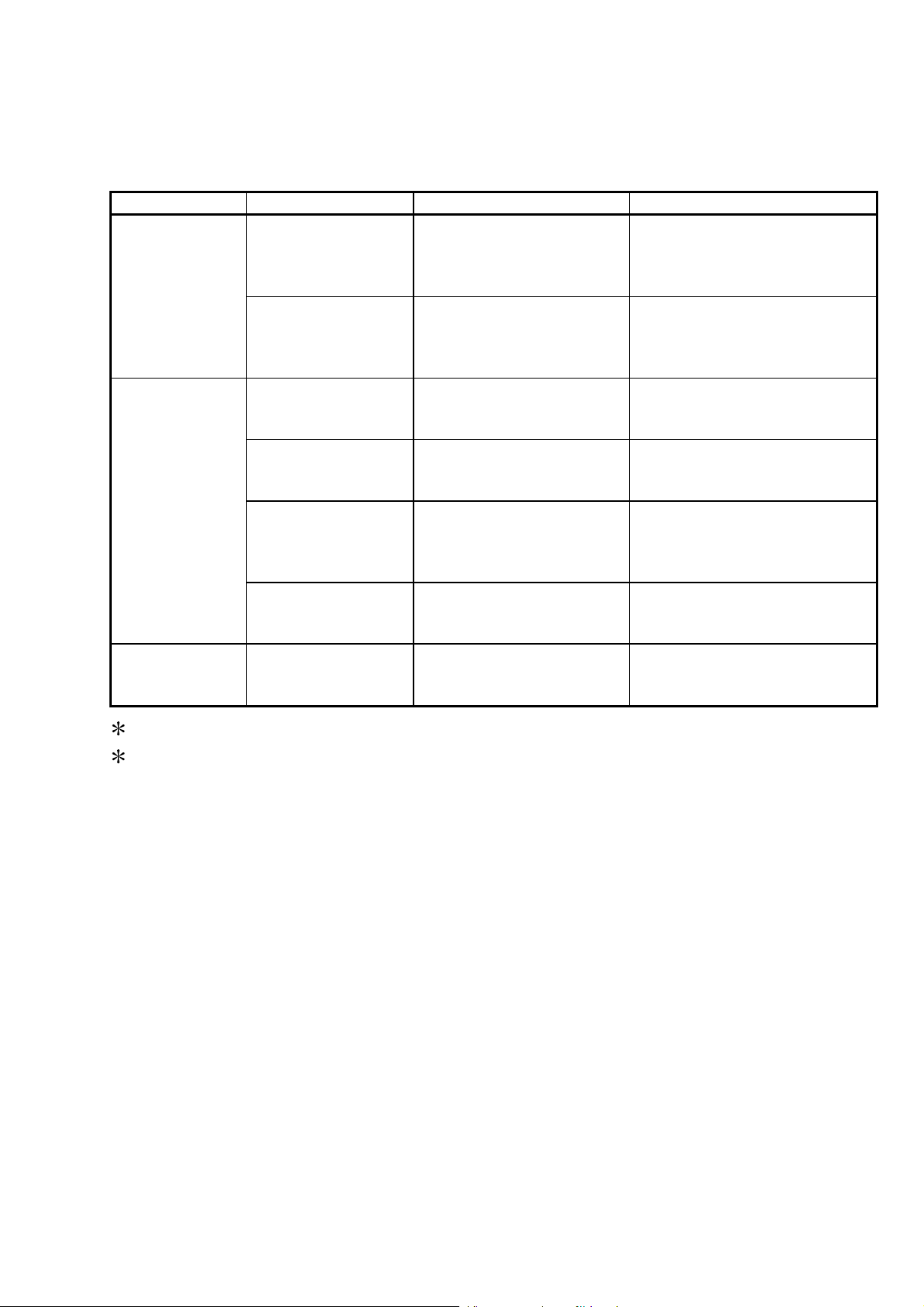

Specifications Test Item Test Description Standard Values

30M-230 M Hz QP: 30dBμ V/m

EN61000-6-4

(2001)

EN61131-2/A12

(2000)

EN61000-6-2

(2001)

EN55011 *2

Radiated noise

EN55011 *2

Conduction noise

EN61000-4-2 *2

Static electricity

immunity

EN61000-4-4 *2

First transient burst

noise

EN61000-4-12 *2

Damped oscillatory

wave

EN61000-4-3 *2

Radiated

electromagnetic field

EN61000-4-6 *2

Conduction noise

Measure the emission

released by the product.

Measure the emission

released by the product to

the power line.

Immunity test by applying

static electricity to the

module enclosure.

Immunity test by applying

burst noise to the power

line and signal line.

Immunity test in which a

damped oscillatory wave is

superimposed on the

power line.

Immunity test by applying a

radiated electric field to the

product.

Immunity test by inducting

an electromagnetic field in

the power line signal line.

(30m measurement) *1

230M-1000MHz QP: 37dBμ

V/m (30m measurement) *1

150k-500kHz QP:

79dB, Mean: 66dB*1

500k-30MHz QP:

73dB, Mean: 60dB *1

4kV contact discharge

8kV air discharge

2kV Power line

1kv Signal line

1kv

10V/m, 26-1000MHz

10 V/ms, 0.15-80MHZ, 80% AM

modulation@1kHz

1: QP: Quasi-peak value, Mean: Average value

2: The programmable controller is an open type device (device installed to

another device) and must be installed in a conductive control panel.

The tests for the corresponding items were performed while the

programmable controller was installed inside the control panel.

4

3.1.2 Installation instructions for EMC Directive

The programmable controller is open equipment and must be installed within a

control cabinet for use.* This not only ensures safety but also ensues effective

shielding of programmable controller-generated electromagnetic noise.

* : Also, each network remote station needs to be installed inside the control

panel.

However, the waterproof type remote station can be installed outside the

control panel.

(1) Control cabinet

(a) Use a conductive control cabinet.

(b) When attaching the control cabinet's top plate or base plate, mask

painting and weld so that good surface contact can be made between

the cabinet and plate.

(c) To ensure good electrical contact with the control cabinet, mask the paint

on the installation bolts of the inner plate in the control cabinet so that

contact between surfaces can be ensured over the widest possible area.

(d) Earth the control cabinet with a thick wire so that a low impedance

connection to ground can be ensured even at high frequencies.

(e) Holes made in the control cabinet must be 10 cm (3.94 in.) diameter or

less. If the holes are 10 cm (3.94 in.) or larger, radio frequency noise

may be emitted.

(f) Lock the control panel so that only those who are trained and have

acquiredenough knowledge of electric facilities can open the control

panel.

(2) Connection of power and earth wires

Earthing and power supply wires for the programmable controller system

must be connected as described below.

(a) Provide an earthing point near the power supply module. Earth the

power supply's LG and FG terminals (LG: Line Ground, FG: Frame

Ground) with the thickest and shortest wire possible. (The wire length

must be 30 cm (11.81 in.) or shorter.) The LG and FG terminals function

is to pass the noise generated in the programmable controller system to

the ground, so an impedance that is as low as possible must be ensured.

In addition, make sure to wire the ground cable short as the wires are

used to relieve the noise, the wire itself carries large noise content and

thus short wiring means that the wire is prevented from acting as an

antenna.

(b) The earth wire led from the earthing point must be twisted with the power

supply wires. By twisting with the earthing wire, noise flowing from the

power supply wires can be relieved to the earthing. However, if a filter is

installed on the power supply wires, the wires and the earthing wire may

not need to be twisted.

5

n

3.1.3 Cables

The cables pulled out of the control panel contain a high frequency noise

component. On the outside of the control panel, therefore, they serve as

antennas to emit noise.

Ensure to use shielded cables for the cables, which are connected to the I/O

modules, special modules and those pulled out to outside of the control panel.

Mounting ferrite core is not required except some types of CPU however, noise

emanated via the cable can be restrained using it.

The use of a shielded cable also increases noise resistance. The signal lines

(including common line) connected to the programmable controller input/output

modules and intelligent modules use shielded cables to assure noise resistance,

as a condition, standardized on EN61131-2/A12 (2000).

If a shielded cable is not used or not earthed correctly, the noise resistance will

be less than the rated value

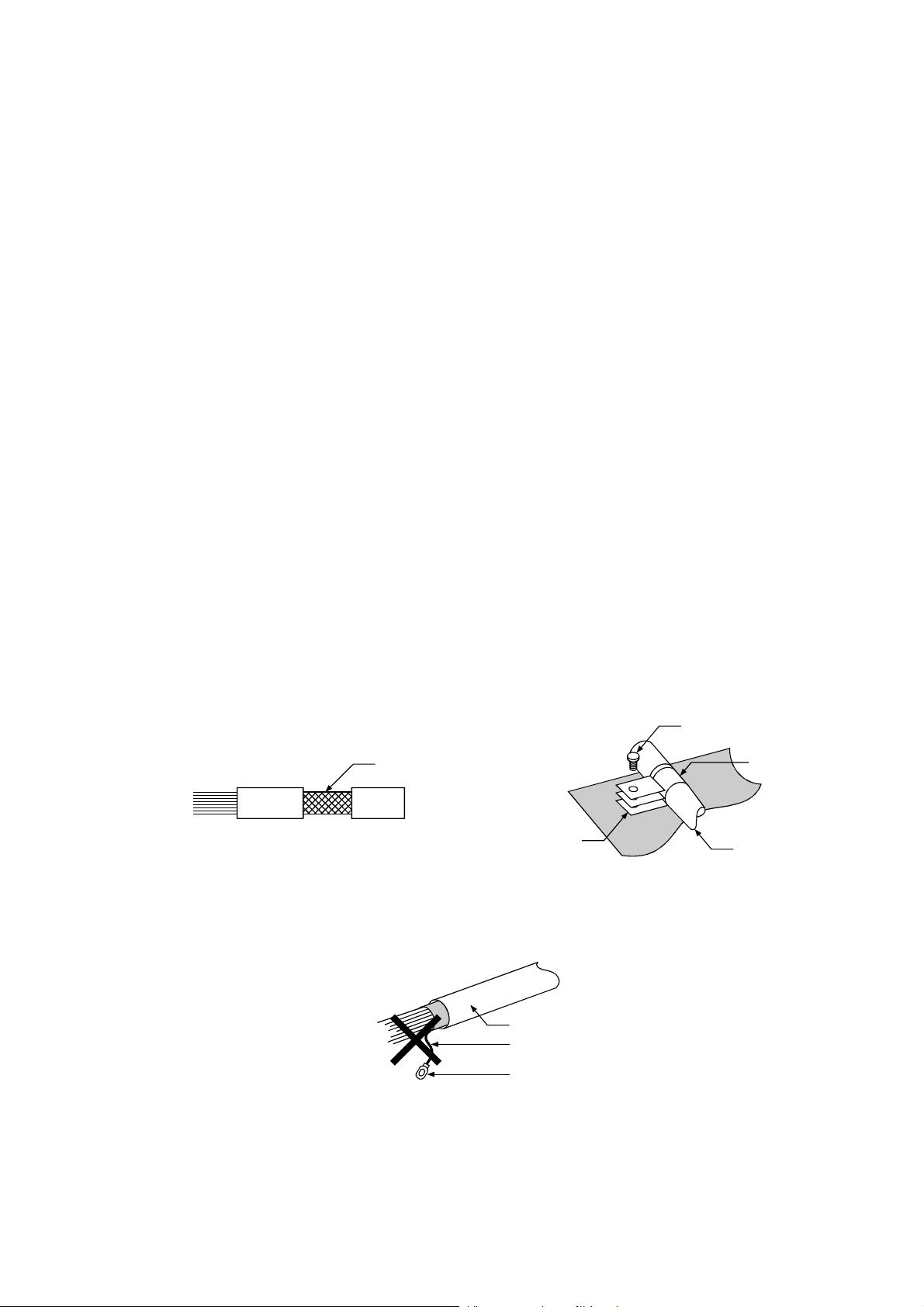

(1) Earthing of shielded of cables

(a) Earth the shield of the shielded cable as near the unit as possible taking

care so that the earthed cables are not induced electromagnetically by

the cable to be earthed.

(b) Take appropriate measures so that the shield section of the shielded

cable from which the outer cover was partly removed for exposure is

earthed to the control panel on an increased contact surface. A clamp

may also be used as shown in the figure below. In this case, however,

apply a cover to the painted inner wall surface of the control panel which

comes in contact with the clamp.

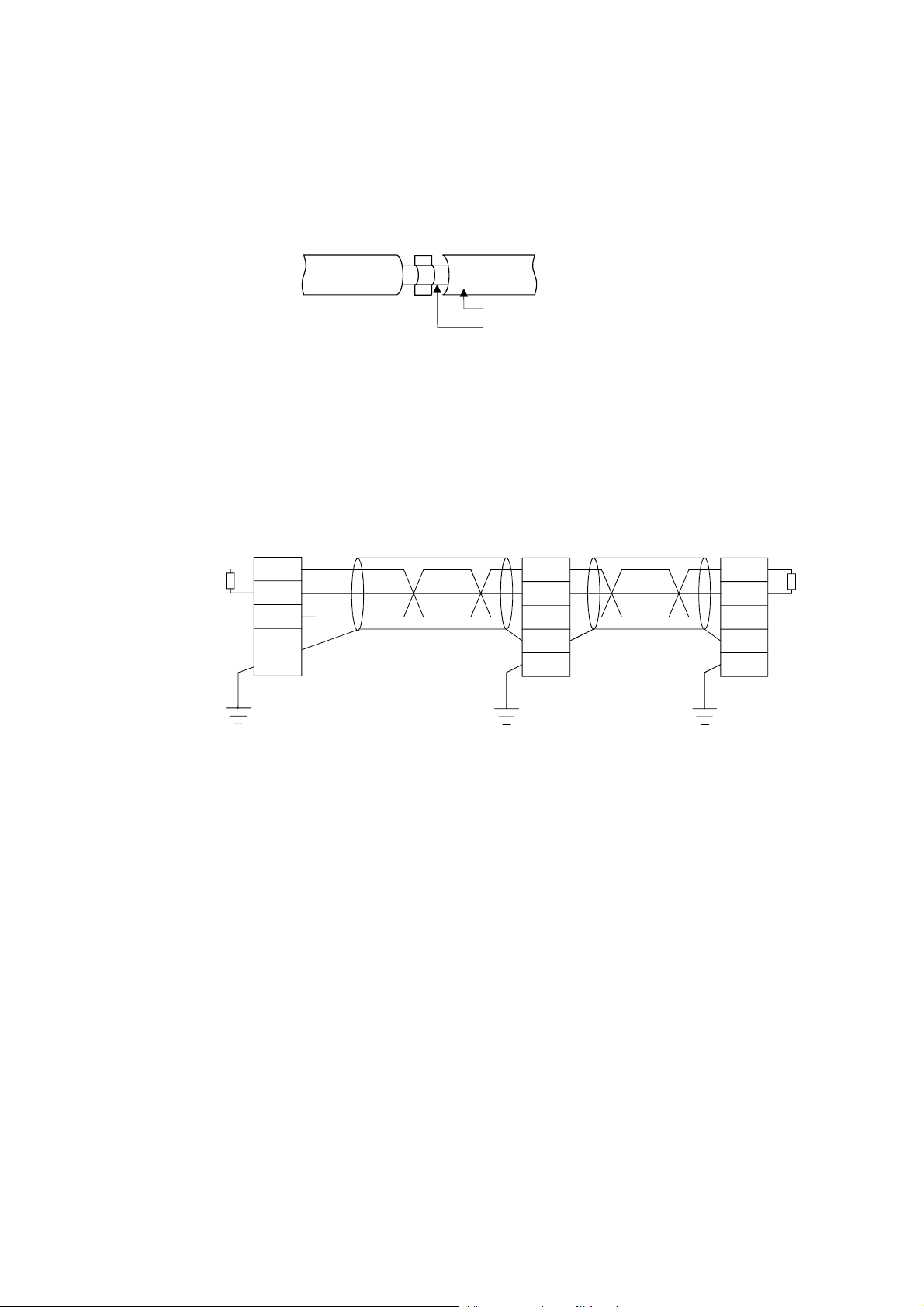

Screw

Shield sectio

Clamp fitting

Paint mask

Shielded cable

Note) The method of earthing by soldering a wire onto the shield section of

the shielded cable as shown below is not recommended. The high

frequency impedance will increase and the shield will be ineffective.

Shielded cable

Wire

Crimp terminal

6

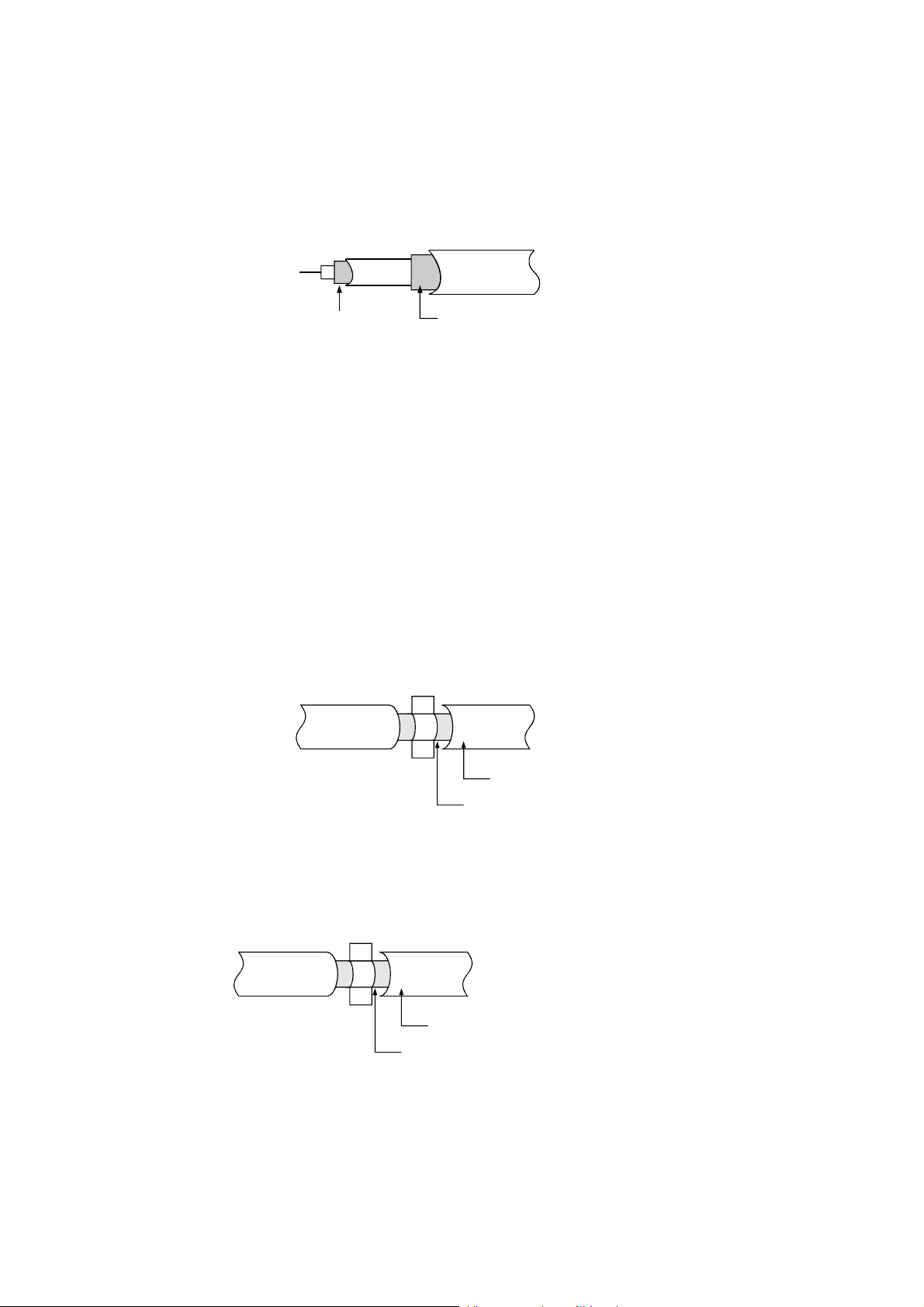

(2) MELSECNET (II) and MELSECNET/10 units

(a) Use a double-shielded coaxial cable for the MELSECNET unit which

uses coaxial cables. Noise in the range of 30 MHz or higher in radiation

noise can be suppressed by the use of double-shielded coaxial cables

(Mitsubishi Cable: 5C-2V-CCY). Earth the outer shield to the ground.

The precautions on shielding to be followed are the same as those

stated in item (1) above.

Earth this sectionShield

(b) Ensure to attach a ferrite core to the double-shielded coaxial cable

connected to the MELSECNET unit. In addition, position the ferrite core

on each cable near the outlet of the control panel. TDK-make ZCAT3035

ferrite core is recommended.

(3) Ethernet module

Precautions to be followed when AUI cables and coaxial cables are used

are described below.

(a) Ensure to earth also the AUI cables connected to the 10BASE5

connectors of the A1SJ71QE71-B5. Because the AUI cable is of the

shielded type, as shown in the figure below, partly remove the outer

cover of it, and earth the exposed shield section to the ground on the

widest contact surface.

AUI cable

Shield

(b) Use shielded twisted pair cables as the twisted pair cables*1 connected

to the 10BASE-T connectors. For the shielded twisted pair cables, strip

part of the outer cover and earth the exposed shield section to the

ground on the widest contact surface as shown below.

Shielded twisted pair cables

Shield

Refer to (1) for the earthing of the shield.

*1: Make sure to install a ferrite core for the cable.

As a ferrite core, ZCAT2035 manufactured by TDK is recommended.

7

(c) Always use double-shielded coaxial cables as the coaxial cables*2

connected to the 10BASE2 connectors. Earth the double-shielded

coaxial cable by connecting its outer shield to the ground.

Earth hereShield

Refer to (1) for the earthing of the shield.

*2: Make sure to install a ferrite core for the cable.

As a ferrite core, ZCAT2035 manufactured by TDK is recommended.

Ethernet is the registered trademark of XEROX, Co.,LTD

(4) I/O and other communication cables

For the I/O signal lines (including common line) and other communication

cables (RS-232, RS-422, etc), if extracted to the outside of the control panel,

also ensure to earth the shield section of these lines and cables in the same

manner as in item (1) above.

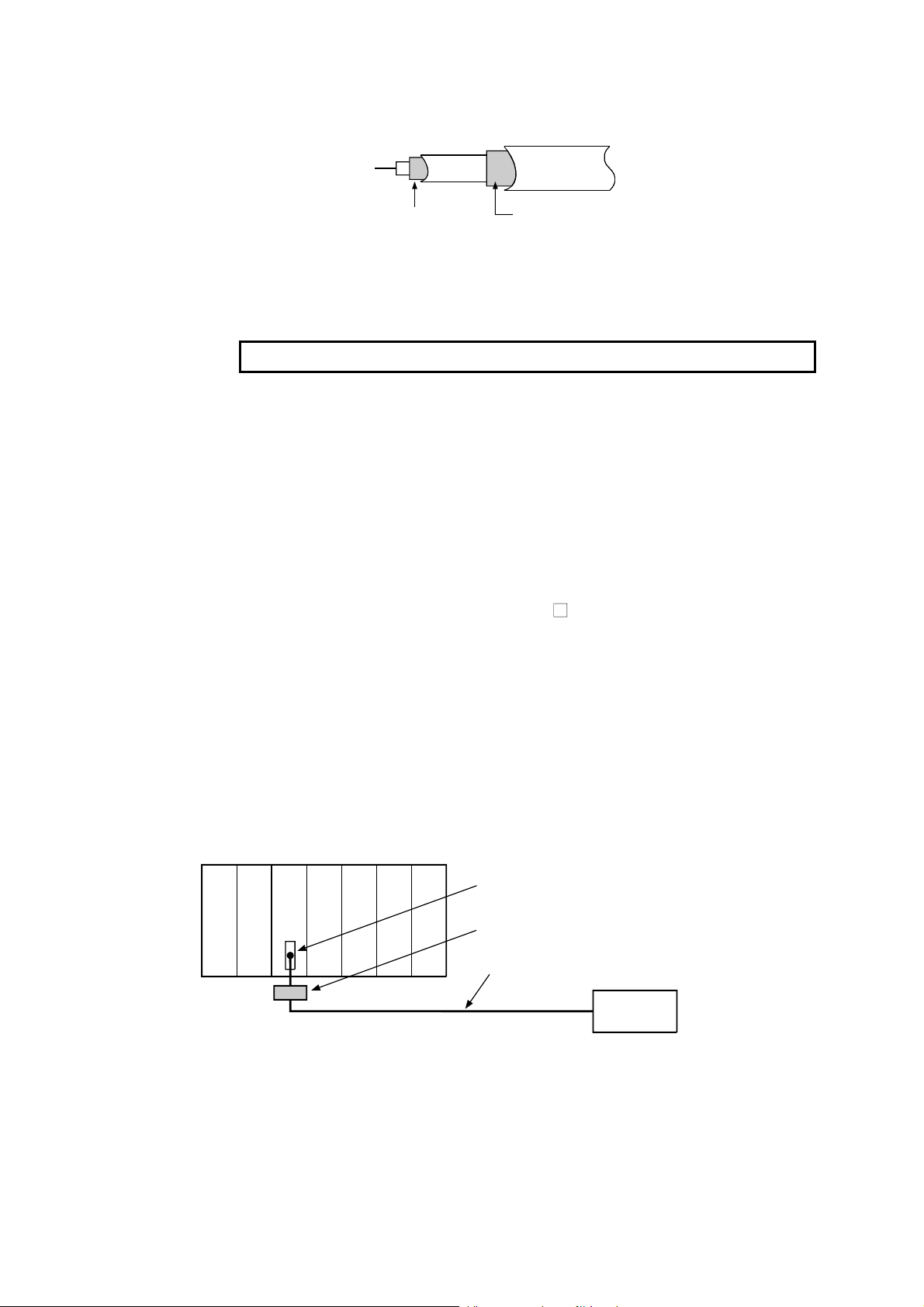

(5) Positioning Modules

Precautions to be followed when the machinery conforming to the EMC

Directive is configured using the A1SD75P

-S3 are described below.

(a) When wiring with a 2 m (6.56 ft.) or less cable

• Ground the shield section of the external wiring cable with the cable

clamp.

(Ground the shield at the closest location to the A1SD75 external

wiring connector.)

• Wire the external wiring cable to the drive unit and external device with

the shortest practicable length of cable.

• Install the drive unit in the same panel.

y

l

p

e

p

l

u

u

s

d

r

o

e

m

w

o

P

e

l

5

e

u

l

7

d

u

D

o

d

S

o

m

1

m

A

U

P

C

External wiring connector

Cable clamp

External wiring cable (within 2 m (6.56 ft.))

Drive unit

8

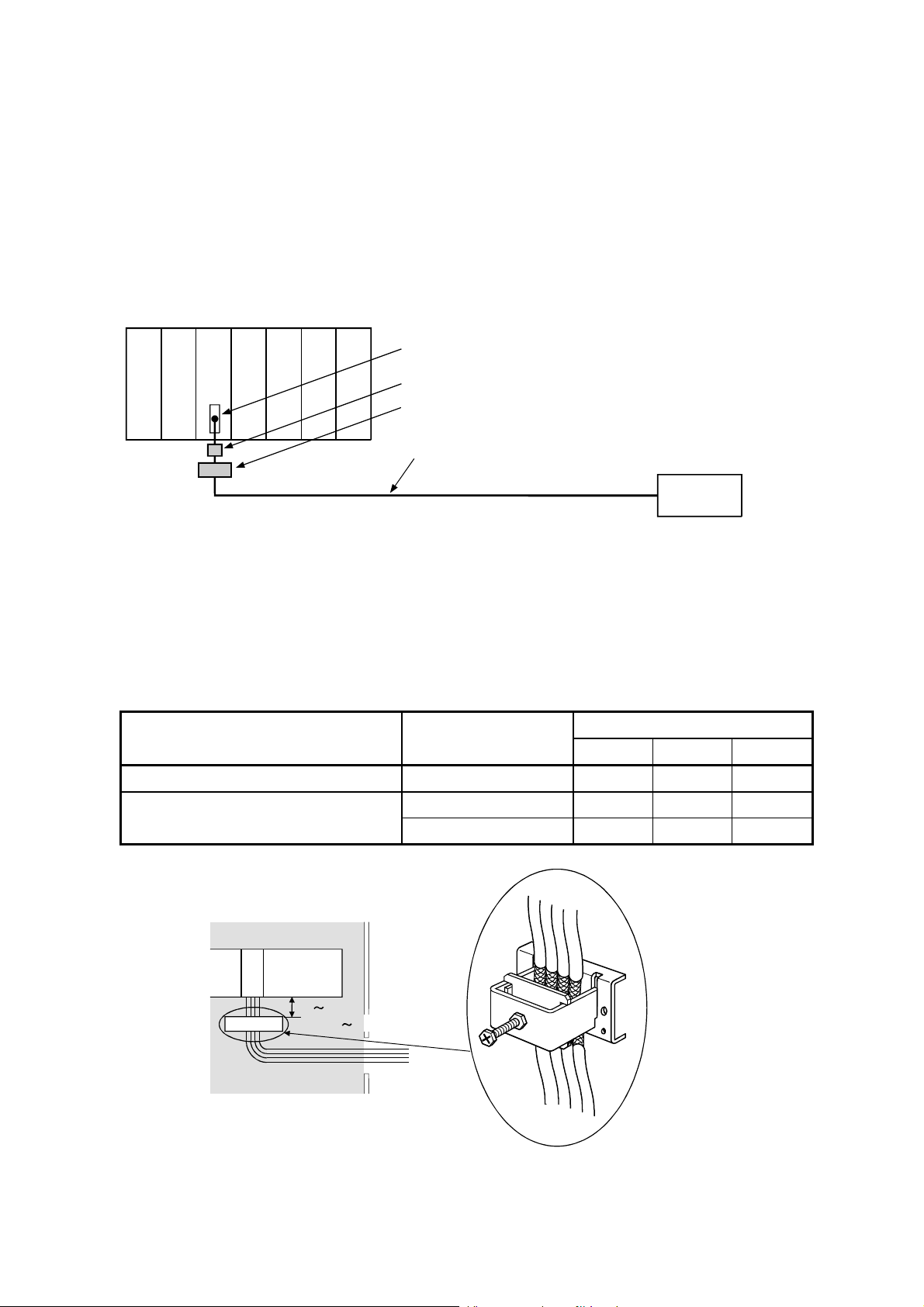

(b) When wiring with cable that exceeds 2 m (6.56 ft.), but is 10 m (32.81 ft.)

or less

• Ground the shield section of the external wiring cable with the cable

clamp.

(Ground the shield at the closest location to the A1SD75 external

wiring connector.)

• Install a ferrite core.

• Wire the external wiring cable to the drive unit and external device with

the shortest practicable length of cable.

y

l

p

e

p

l

u

u

s

d

r

o

e

m

w

o

P

e

l

5

u

e

7

l

d

u

D

o

d

S

o

m

1

m

A

U

P

C

External wiring connector

Ferrite core

Cable clamp

External wiring cable (2 m to 10 m (6.56 ft. to 32.81 ft.))

Drive unit

(c) Ferrite core and cable clamp types and required quantities

• Cable clamp

Type: AD75CK (Mitsubishi Electric)

• Ferrite core

Type: ZCAT3035-1330 (TDK ferrite core)

• Required quantity

Cable length Prepared part

Within 2 m (6.56 ft.) AD75CK 1 1 1

2 m (6.56 ft.) to 10m (32.81 ft.)

AD75CK 1 1 1

ZCAT3035-1330 1 2 3

1 axis 2 axes 3 axes

Inside control panel

A1SD75

Required Qty

20 30cm

AD75CK

(7.87 11.81inch)

9

(6) CC-Link Module

(a) Be sure to ground the cable shield that is connected to the CC-Link

module close to the exit of control panel or to any of the CC-Link stations

within 30 cm (11.81 in.) from the module or stations.

The CC-Link dedicated cable is a shielded cable. As shown in the

illustration below, remove a portion of the outer covering and ground as

large a surface area of the exposed shield part as possible.

CC-Link dedicated cable

Shield

(b) Always use the specified CC-Link dedicated cable.

(c) The CC-Link module, the CC-Link stations and the FG line inside the

control panel should be connected at the FG terminal as shown in the

diagram below.

[Simplified diagram]

Local module

DA

DB

Terminal

DG

SLD

resistor

FG

Terminal

resistor

Master module

(Blue)

DA

(White)

DB

(Yellow)

DG

SLD

FG

CC-Link

dedicated

cable

Remote module

DA

DB

DG

SLD

FG

CC-Link

dedicated

cable

(d) Power line connecting to the external power supply terminal (compliant

with I/O power port of CE standard) should be 30m (98.43 ft.) or less.

Power line connecting to module power supply terminal (compliant with

main power port of CE standard) should be 10m (32.81 ft.) or less.

(e) A power line connecting to the analog input of the following modules

should be 30cm or less.

• AJ65BT-64RD3

• AJ65BT-64RD4

• AJ65BT-68TD

(7) Measures against static electricity

When using an insulation displacement connector without connector cover,

a connected cable for the connector is thin in applicable wire size and

coating. Therefore, note that the module may cause an electric discharge

failure.

As measures against the failure, using pressure-displacement type

connector whose applicable wire size is thick or soldering type connector is

recommended.

10

3.1.4 Power supply module

The precautions required for each power supply module are described below.

Always observe the items noted as precautions.

Model Precautions

A1S61PN, A1S62PN

A1S63P 1

Make sure to short and ground the LG and FG

terminals.

Use the 24VDC panel power equipment conforming to

the EU Directive.

2

1: If sufficient filter circuitry is built into the 24 VDC external power supply

module, the noise generated by A1S63P will be absorbed by that filter

circuit, so a line filter may not be required.

Filtering circuitry of version F or later of A1S63P is improved so that a

external line filter is not required.

2: To ensure the compliance with CE (EN6111-21/A11), make sure to short

the LG and FG terminals using a wire of 6 to 7cm.

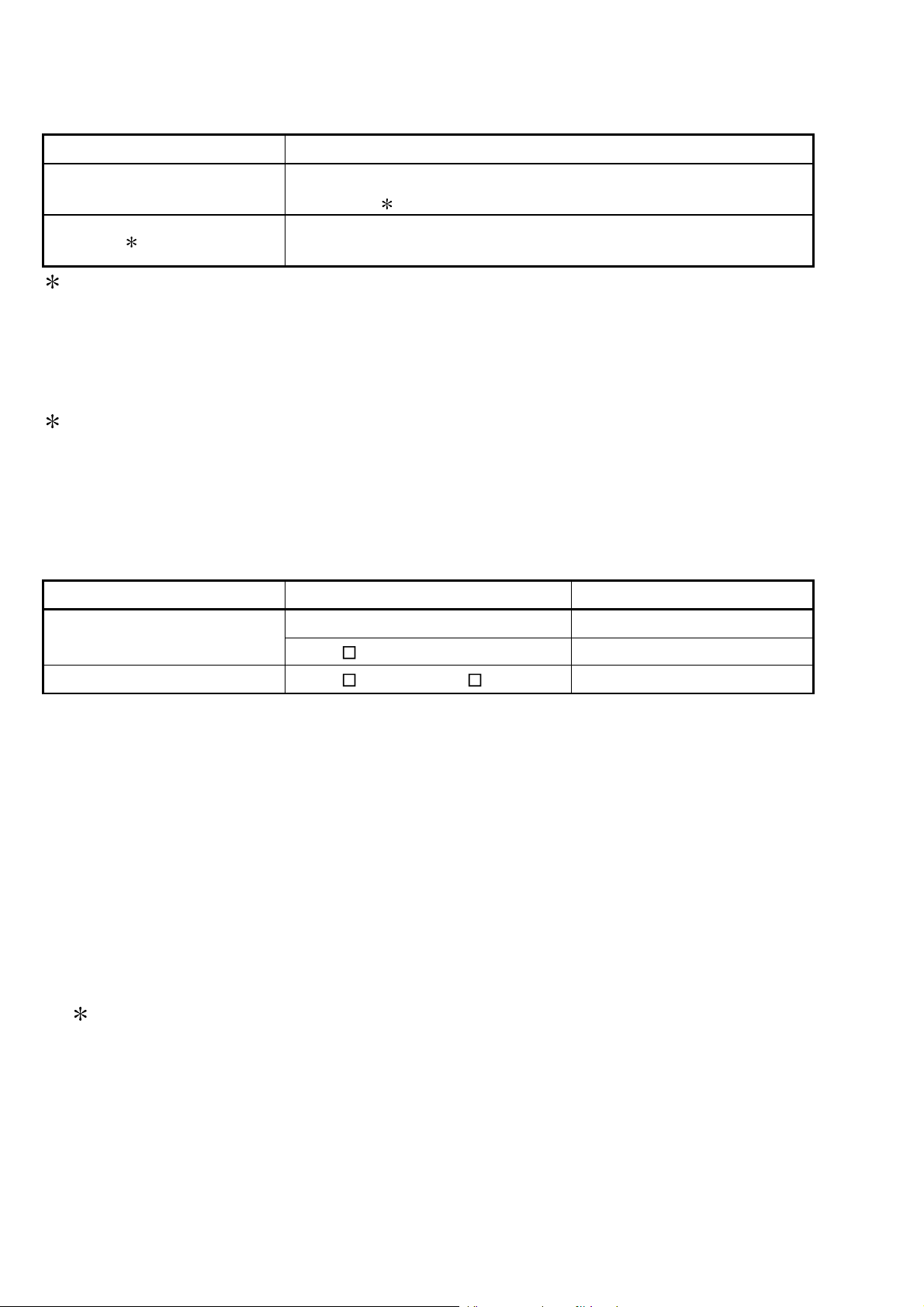

3.1.5 Base unit

The following table shows models of base units that are compatible with EMC

instructions.

Type Model name Applicability

Main base unit

A1S38HBEU Applicable

A1S3

B, A1S38HB Not applicable

Extension base unit A1S5 B(S1), A1S6 B(S1) Applicable

3.1.6 Ferrite core

Use of ferrite cores is effective in reducing the conduction noise in the band of

about 10 MHz and radiated noise in 30 to 100 MHz band.

It is recommended to attach ferrite cores when the shield of the shielded cable

coming out of control panel does not work effectively, or when emission of the

conduction noise from the power line has to be suppressed.*1 The ferrite cores

used in our tests are TDK's ZCAT3035.

It should be noted that the ferrite cores should be fitted to the cables in the

position immediately before they are pulled out of the enclosure. If the fitting

position is improper, the ferrite will not produce any effect.

1:To response with CE (EN61131-2/A12), make sure to mount 2 or more

ferrite cores onto the power supply line. The mounting position should be

as near the power supply module as possible.

Ferrite core

Type: ZCAT2235-1030A (TDK ferrite core)

11

3.1.7 Noise filter (power supply line filter)

A noise filter is a component which has an effect on conducted noise. With the

exception of some models, it is not required to fit the noise filter to the power

supply line, but fitting it can further suppress noise. (The noise filter has the

effect of reducing conducted noise of 10 M Hz or less.) Use any of the following

noise filters (double

type filters) or equivalent.

Model name FN343-3/01 FN660-6/06 ZHC2203-11

Manufacturer SCHAFFNER SCHAFFNER TDK

Rated current 3 A 6 A 3 A

Rated voltage 250 V

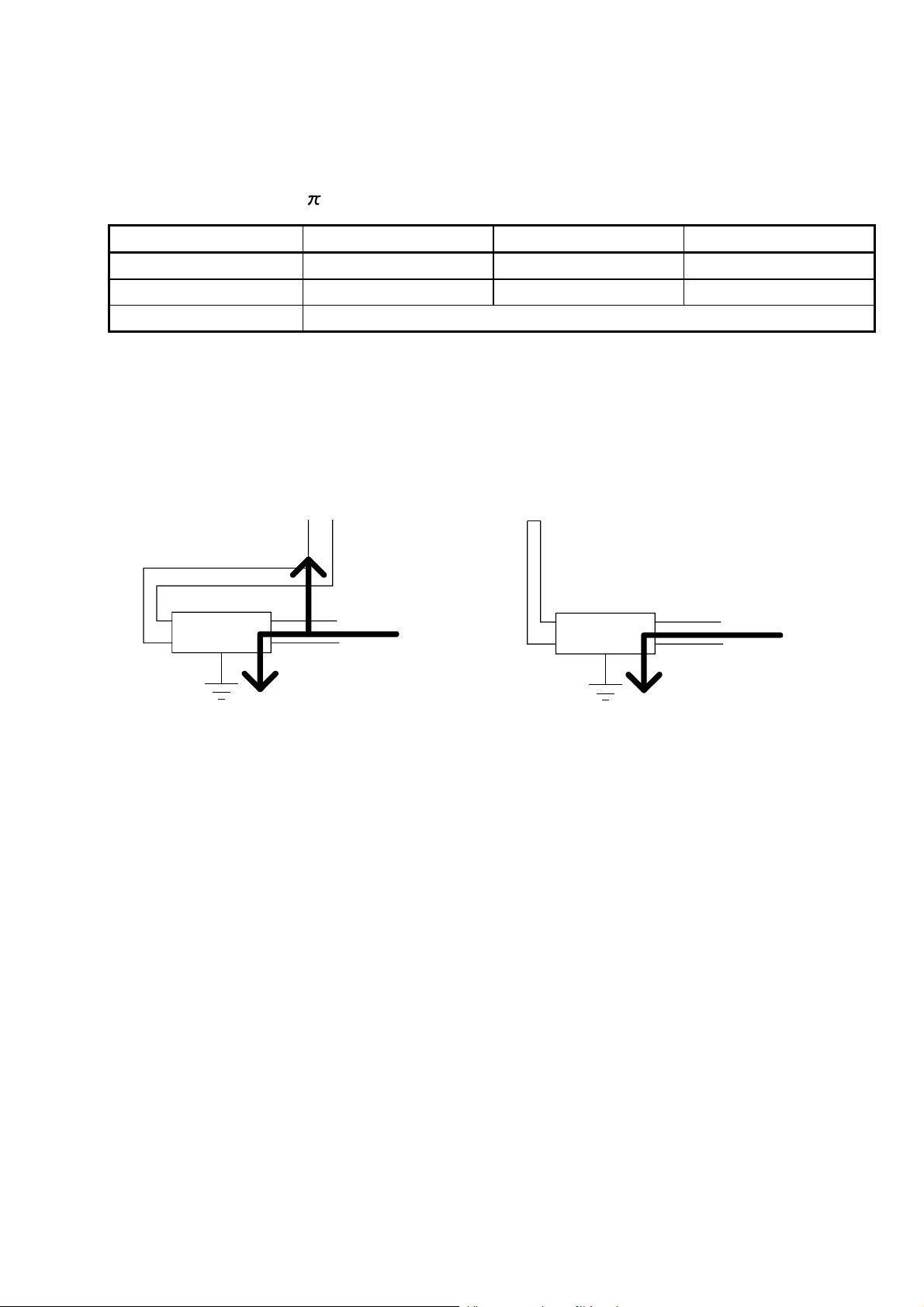

The precautions required when installing a noise filter are described below.

(1) Do not bundle the wires on the input side and output side of the noise filter.

When bundled, the output side noise will be induced into the input side

wires from which the noise was filtered.

Input side

(power supply side)

Induction

Filter

Input side

(power supply side)

Filter

Output side

(device side)

Output side

(device side)

(a) The noise will be

included when the input

(b) Separate and lay the

input and output wires.

and output wires are

bundled.

(2) Earth the noise filter earthing terminal to the control cabinet with the shortest

wire possible (approx. 10 cm (3.94 in.)).

12

3.2 Requirements for Compliance with Low Voltage Directives

The Low Voltage Directives apply to the electrical equipment operating from 50

to 1000VAC or 75 to 1500VDC; the manufacturer must ensure the adequate

safety of the equipment.

Guidelines for installation and wiring of MELSEC-QnA series programmable

controller are provided in Section 3.2.1 to 3.2.7 for the purpose of compliance

with the EMC Directives.

The guidelines are created based on the requirements of the regulations and

relevant standards, however, they do not guarantee that the machinery

constructed according to them will comply with the Directives.

Therefore, the manufacturer of the machinery must finally determine how to

make it comply with the EMC Directives: if it is actually compliant with the EMC

Directives.

3.2.1 Standard applied for MELSEC-QnA series programmable controller

The standard applied for MELSEC-QnA series programmable controller series

is EN61010-1 safety of devices used in measurement rooms, control rooms, or

laboratories.

For the modules which operate with the rated voltage of 50 VAC/75 VDC or

above, we have developed new models that conform to the above standard.

For the modules which operate with the rated voltage under 50 VAC/75 VDC,

the conventional models can be used, because they are out of the low voltage

directive application range.

3.2.2 Precautions when using the MELSEC-QnA series programmable controller

Module selection

(1) Power module

For a power module with rated input voltage of 100/200 VAC, select a model in

which the internal part between the first order and second order is intensively

insulated, because it generates hazardous voltage (voltage of 42.4 V or more at

the peak) area.

For a power module with 24 VDC rated input, a conventional model can be used.

(2) I/O module

For I/O module with rated input voltage of 100/200 VAC, select a model in

which the internal area between the first order and second order is

intensively insulated, because it has hazardous voltage area.

For I/O module with 24 VDC rated input, a conventional model can be used.

(3) CPU module, memory cassette, base unit

Conventional models can be used for these modules, because they only

have a 5 VDC circuit inside.

(4) Special function module

Conventional models can be used for the special modules including analog

module, network module, and positioning module, because the rated voltage

is 24 VDC or smaller.

(5) Display device

Use the CE-marked product.

13

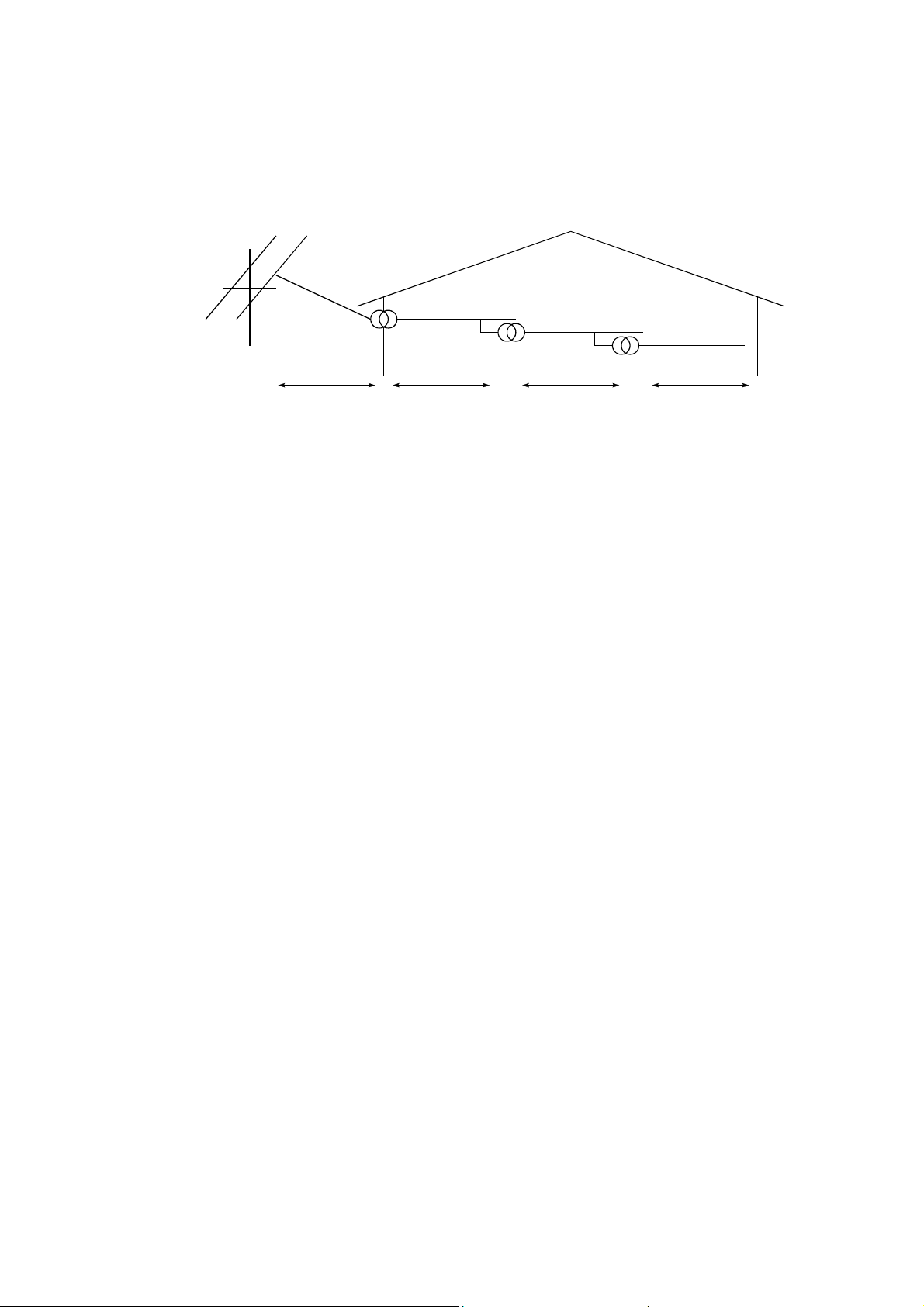

3.2.3 Power supply

The insulation specification of the power module was designed assuming

installation category II. Be sure to use the installation category II power supply to

the programmable controller.

The installation category indicates the durability level against surge voltage

generated by a thunderbolt. Category I has the lowest durability; category IV has

the highest durability.

Category III Category II Category ICategory IV

Figure 1.: Installation Category

Category II indicates a power supply whose voltage has been reduced by two or

more levels of isolating transformers from the public power distribution.

14

3.2.4 Control panel

Because the programmable controller is an open device (a device designed to be

stored within another module), be sure to use it after storing in the control panel.

(1) Electrical shock prevention

In order to prevent persons who are not familiar with the electric facility such

as the operators from electric shocks, the control panel must have the

following functions:

(a) The control panel must be equipped with a lock so that only the personnel

who has studied about the electric facility and have enough knowledge

can open it.

(b) The control panel must have a structure which automatically stops the

power supply when the box is opened.

(c) For electric shock protection, use IP20 or greater control panel.

(2) Dustproof and waterproof features

The control panel also has the dustproof and waterproof functions. Insufficient

dustproof and waterproof features lower the insulation withstand voltage,

resulting in insulation destruction. The insulation in our programmable

controller is designed to cope with the pollution level 2, so use in an

environment with pollution level 2 or below.

Pollution level 1: An environment where the air is dry and conductive dust

does not exist.

Pollution level 2: An environment where conductive dust

does not usually exist, but occasional temporary

conductivity occurs due to the accumulated dust. Generally,

this is the level for inside the control panel equivalent to

IP54 in a control room or on the floor of a typical factory.

Pollution level 3: An environment where conductive dust exits and

conductivity may be generated due to the accumulated dust.

An environment for a typical factory floor.

Pollution level 4: Continuous conductivity may occur due to rain, snow, etc.

An outdoor environment.

As shown above, the programmable controller can realize the pollution level 2

when stored in a control panel equivalent to IP54.

15

3.2.5 Module installation

(1) Installing modules contiguously

In Q2AS series programmable controllers, the left side of each I/O module is

left open. When installing an I/O module to the base, do not make any open

slots between any two modules. If there is an open slot on the left side of a

module with 100/200 VAC rating, the printed board which contains the

hazardous voltage circuit becomes bare. When it is unavoidable to make an

open slot, be sure to install the blank module (A1SG60).

3.2.6 Grounding

There are two kinds of grounding terminals as shown below. Either grounding

terminal must be used grounded.

Be sure to ground the protective grounding for the safety reasons.

Protective grounding

: Maintains the safety of the programmable

controller and improves the noise resistance.

Functional grounding

: Improves the noise resistance.

3.2.7 External wiring

(1) Module power supply and external power supply

For the remote module which requires 24VDC as module power supply, the

5/12/24/48VDC I/O module, and the intelligent function module (special

function module) which requires the external power supply, use the

5/12/24/48VDC circuit which is doubly insulated from the hazardous voltage

circuit or use the power supply whose insulation is reinforced.

(2) External devices

When a device with a hazardous voltage circuit is externally connected to the

programmable controller, use a model whose circuit section of the interface to

the programmable controller is intensively insulated from the hazardous

voltage circuit.

(3) Intensive insulation

Intensive insulation refers to the insulation with the dielectric withstand

voltage shown in Table 1.

Table 1: Intensive Insulation Withstand Voltage

(Installation Category II, source: IEC664)

Rated voltage of hazardous voltage area Surge withstand voltage (1.2/50 µs)

150 VAC or below 2500 V

300 VAC or below 4000 V

16

4. LOADING AND INSTALLATION

4.1 Installing the Module

4.1.1 Notes on handling the module

This section explains some notes on handling the CPU module, I/O module,

special function module, power supply module, and base unit.

(1) Do not drop or allow any impact to the modules case, memory card, terminal

block cover, or pin connector.

(2) Do not remove the module printed wiring board from the case. Otherwise, a

malfunction may occur.

(3) Use caution to prevent foreign matter, such as wire chips, falling into the

module during wiring. If foreign matter enters the module, remove it.

(4) Use the fallowing torque range to tighten the module fixing screws and

terminal block screws:

Screw portion Tightening torque range

Module fixing screw (M4 screw) 78 to 118 Ncm

I/O module (M3.5 screw) 59 to 88 Ncm

Power supply module terminal screws (M3.5 screw) 59 to 78 Ncm

(5) Observe the following points when you are installing the DIN rail:

(a) Applicable DIN rail type (JIS C 2812)

TH35-7.5Fe

TH35-7.5Al

TH35-15Fe

(b) DIN rail installation screw interval

When you are using the TH35-7.5Fe or TH35-7.5Al DIN rail, tighten

the DIN rail installation screw with a pitch of 200 mm (7.87 inch) or

less to maintain the strength.

DIN rail

35 mm

(1.38 inch)

DIN rail installation screw

P

P

P

P=200 mm (7.87 inch) or less

(6) When installing the base unit to DIN rail in an environment with large

vibration, use a vibration-proofing bracket (A1S-PLT-D). Mounting the

vibration-proofing bracket (A1S-PLT-D) enhances the resistance to vibration.

Depending on the environment to set up the base unit, it is also

recommended to fix the base unit to the control panel directly.

17

4.1.2 Installation environment

Avoid the following environment when you install the CPU system:

(1) A location in which the ambient temperature falls outside the range of 0 to

55 degrees Celsius.

(2) A location in which the ambient humidity falls outside the range of 10 to

90%RH.

(3) A location in which condensation may occur due to drastic changes in

temperature.

(4) A location in which corrosive gas or flammable gas exists.

(5) A location in which the system is easily exposed to conductive powder,

such as dust and iron filings, oil mist, salt, or organic solvent.

(6) A location exposed to direct sunlight.

(7) A location in which strong electrical or magnetic fields are generated.

(8) A location in which the module is exposed to direct vibration or impact.

18

4.1.3 Notes on installing the base unit

Take ease of operation, ease of maintenance, and environmental durability into

consideration when you are installing the programmable controller on the panel.

(1) Mounting dimension

Mounting dimensions of each base unit are as follows:

H

POWER

CPU 0 1 2 3 4 5 6 7

MITSUBISHI ELECTRIC CORPORATION BD626E680G52

Ws

W

MADE IN JAPAN E.S.D. A1S38B

Hs

A1S32B A1S33B A1S35B

W

Ws

220

(8.66)

200

(7.87)

255

(10.04)

235

(9.25)

325

(12.80)

305

(12.01)

A1S38B

A1S38HB

A1S38HBEU

430

(16.93)

410

(16.14)

A1S52B

(S1)

155

(6.10)

135

(5.31)

A1S55B

(S1)

260

(10.24)

240

(9.45)

A1S58B

(S1)

365

(14.37)

345

(13.58)

A1S65B

(S1)

315

(12.40)

295

(11.61)

A1S68B

(S1)

420

(16.54)

400

(15.75)

H 130 (5.12)

Hs 110 (4.33)

Dimensions: mm (inch)

19

)

(2) Module installation position

To maintain good ventilation and make it easy to replace the module, keep

the following distances between the top and bottom of the module and the

structure or other components.

A1S3B, A1S38HB, A1S38HBEU, A1S5B(S1), A1S6B(S1)

........................................................................................30 mm (1.18 inch) or over

A5B, A6B..................................................................80 mm (3.15 inch) or over

This shows the position of the panel's ceiling,

wiring duct, or components.

Duct (Height of

50mm (1.97inch)

or less)

Extension base unit

(A1S5B (S1),

A1S6B(S1))

Main base

30mm

(1.18inch)

or more

30mm (1.18inch)

or more

30mm (1.18inch)

or more

30mm (1.18inch)

or more

Duct (Height of

50mm (1.97inch)

or less)

(A5B (S1), A6B(S1))

Main base

Extension base unit

(3) Module installation direction

(a) Use the programmable controller in the following position for better

ventilation and heat dissipation:

30mm

(1.18inch

or more

30mm

(1.18inch)

or more

80mm

(3.15inch)

or more

80mm

(3.15inch)

or more

(b) Do not use the programmable controller in the following positions:

Vertical position Horizontal position

(4) Install the base unit on a level surface.

If the surface is not level, force may be applied to the printed wiring board,

causing a malfunction.

20

(5) Install the unit far from any source of vibration, such as a large magnetic

contactor and a no-fuse breaker on the same panel, or install it on a

separate panel.

(6) Keep the following distance between the programmable controller and

other devices (such as a contactor and a relay) in order to avoid the

influence of radiated noise and heat:

a device installed in front of the programmable controller

....................................................................................... 100mm (3.94 inch) or more

a device installed on the right or left of the programmable controller

....................................................................................... 50mm (1.97 inch) or more

50mm (1.97inch)

or more

50mm (1.97inch)

100mm (3.94inch)

or more

Contactor, and

relay, etc.

or more

4.2 Fail-Safe Circuit Concept

When the programmable controller is powered ON and then OFF, improper

outputs may be generated temporarily depending on the delay time and start-up

time differences between the programmable controller power supply and the

external power supply for the control target (especially, DC).

For example, if the external power supply for the control target is powered ON and

then the programmable controller is powered ON, the DC output module may

generate incorrect outputs temporarily upon the programmable controller

power-ON. Therefore, it is required to build the circuit that energizes the

programmable controller by priority.

The external power failure or programmable controller failure may lead to the

system error.

In order to eliminate the possibility of the system error and ensure fail-safe

operation, build the following circuit outside the programmable controller:

emergency circuit, protection circuit and interlock circuit, as they could cause

machine damages and accidents due to the abovementioned failures.

An example of system design, which is based on fail-safe concept, is provided on

the next page.

21

DANGER

Create a safety circuit outside the programmable controller to

ensure the whole system will operate safely even if an

external power failure or a programmable controller failure

occurs.

Install the emergency stop switch outsaid the controlpanel so

that workers can operation it easily.

Otherwise, incorrect output or malfunction may cause an

accident.

(1) For an emergency stop circuit, protection circuit and

interlock circuit that is designed for incompatible actions

such as forward/reverse rotation or for damage

prevention such as the upper/lower limit setting in

positioning, any of them must be created outside the

programmable controller.

(2) When the programmable controller detects the following

error conditions, it stops the operation and turn off all the

outputs.

The overcurrent protection device or overvoltage

protection device of the power supply module is

activated.

The programmable controller CPU detects an error

such as a watchdog timer error by the self-diagnostics

function.

In the case of an error of a part such as an I/O control

part that cannot be detected by the programmable

controller CPU, all the outputs may turn on. In order to

make all machines operate safely in such a case, set up

a fail-safe circuit or a specific mechanism outside the

programmable controller.

(3) Depending on the failure of the output module’s relay or

transistor, the output status may remain ON or OFF

incorrectly. For output signals that may lead to a serious

accident, create an external monitoring circuit.

Design a circuit so that the external power will be supplied

after power-up of the programmable controller.

Activating the external power supply prior to the

programmable controller may result in an accident due to

incorrect output or malfunction.

If load current more than the rating or overcurrent due to a

short circuit in the load has flowed in the output module for a

long time, it may cause a fire and smoke. Provide an external

safety device such as a fuse.

22

DANGER

For the operation status of each station at a communication

error in data link, refer to the respective data link manual.

The communication error may result in an accident due to

incorrect output or malfunction.

When controlling a running programmable controller (data

modification) by connecting a peripheral device to the CPU

module or a PC to a special function module, create an

interlock circuit on sequence programs so that the whole

system functions safely all the time.

Also, before performing any other controls (e.g. program

modification, operating status change (status control)), read

the manual carefully and ensure the safety.

In these controls, especially the one from an external device

to a programmable controller in a remote location, some

programmable controller side problem may not be resolved

immediately due to failure of data communications.

CAUTION

To prevent this, create an interlock circuit on sequence

programs and establish corrective procedures for

communication failure between the external device and the

programmable controller CPU.

When setting up the system, do not allow any empty slot on

the base unit.

If any slot is left empty, be sure to use a blank cover

(A1SG60) or a dummy module (A1SG62) for it.

When using the extension base unit, A1S52B(S1),

A1S55B(S1) or A1S58B(S1), attach the included dustproof

cover to the module in slot 0.

Otherwise, internal parts of the module may be flied in the

short circuit test or when an overcurrent or overvoltage is

accidentally applied to external I/O section.

Do not install the control lines or communication cables

together with the main circuit or power lines, or bring them

close to each other.

Keep a distance of 100mm (3.9inch) or more between them.

Failure to do so may cause malfunctions due to noise.

When an output module is used to control the lamp load,

heater, solenoid valve, etc., a large current (ten times larger

than the normal one) may flow at the time that the output

status changes from OFF to ON. Take some preventive

measures such as replacing the module with the one of a

suitable current rating.

23

(1) System design circuit example

AC system AC/DC system

Power supply

DC power supply

established signal

input

Start/stop circuit

Can be started

by turning ON of

RA1, which is the

programmable

controller's RUN

output.

XM

Output for warning

(lamp or buzzer)

Turned ON in RUN

status by SM403

MC

Switches the power

supply to output devices

OFF when the system

stops:

At emergency stops

At stops on reaching a

limit

Interlock circuit

Constructs external

interlock circuits for

opposing operations

such as forward and

reverse rotation, and

parts that could cause

machine damage or

accidents.

MC

Start

switch

MC

RA2

Output unit

Output unit

Transformer

Fuse

CPU module

SM52

SM403

RA1

Stop

switch

Ym

Yn

Y1

Ym

Yn

Y1

XM

SM1084

Program

MC

Input unit

RA1

MC2

MC1

MC1

MC2

RA2

L

Power supply

Start

switch

MC

Stop

switch

RA2

Output unit

Ym

Yn

Output module

Transformer

Fuse

CPU module

SM52

Ym

SM403

Yn

XM

TM

TM

MC1 N0 M10

M10N0

Program

RA1

MC

Input unit

L

RA1

MC2

MC1

MC1

MC2

XM

DC power

supply

(+)(−)

RA2

MC MC

Fuse

The setting for TM

is the time taken

to establish the

DC input signal.

Voltage relay

recommended

Output for warning

(lamp or buzzer)

Turned ON in RUN

status by SM403

Switches the power

supply to output

devices OFF when

the system stops:

At emergency stops

At stops on reaching

a limit

The procedures used to switch on the power supply are indicated below.

AC system

[1] Switch the power supply ON.

[2] Set the CPU module to RUN.

[3] Switch the start switch ON.

[4] The output devices are driven in

accordance with program when the

magnetic contactor (MC) turns ON.

[1] Switch the power supply ON.

[2] Set the CPU module to RUN.

[3] Switch RA2 ON when the DC power supply starts.

[4] Switch the timer (TM) ON when the DC power supply

reaches working voltage. (The set value for TM must

be the time it takes for 100% establishment of the DC

AC/DC system

power after RA2 is switched ON. Make this set value

0.5 seconds.)

[5] Switch the start switch ON.

[6] The output devices are driven in accordance with the

program when the magnetic contactor (MC) comes ON.

(If a voltage relay is used at RA2, no timer (TM) is

necessary in the program.)

24

(2) Fail-safe measures to cover the possibility of programmable controller

failure

Problems with a CPU module and memory can be detected by the self

diagnostics function. However, problems with I/O control area may not be

detected by the CPU module.

In such cases, all I/O points turn ON or OFF depending on the problem,

and normal operation and safety cannot be maintained.

Though Mitsubishi programmable controllers are manufactured under strict

quality control, they may fail or malfunction due to unspecified reasons. To

prevent the whole system failure, machine breakdown, and accidents, build

a fail-safe circuit outside the programmable controller.

Examples of a system and its fail-safe circuitry are described below:

<System example>

Output

16

16

points

YB0

to

YBF

Power

supply

module

CPU

module

Input

16

points

Input

16

points

Input

16

points

Input

16

points

Output

16

points

Output

16

points

Output

16

points

Output

16

points

Power

supply

module

Output

16

points

Output

16

points

Output

points

Vacant

Output module for fail-safe purpose*1

*1: The output module for fail-safe purpose should be mounted on the last

slot of the system. (YB0 to YBF in the above system.)

ON delay timer

Internal program

SM412

YB0

YB0

0.5s0.5s

CPU module Output module

YB0

YB1

to

YBF

24V

0V

*2

OFF delay timer *3

External load

L

L

T1

T2

T2T1

1s

1s

MC

+-

24VDC

MC

*2: Since YB0 turns ON and OFF alternatively at 0.5 second intervals, use a

contactless output module (a transistor is used in the above example).

*3: If an offdelay timer (especially miniature timer) is not available, construct

the failsafe circuit using an ondelay timer shown on the next page.

25

When constructing a failsafe circuit using ondelay timers only

On-delay timer

Internal program

SM412

YB0

CPU module Output module

0.5s0.5s

YB0

YB0

YB1

to

YBF

24V

0V

*1

On-delay timer

M1

M1

T2

M2

Externai load

L

to

L

M2

T1

T1

M1

T2

M2

+-

24VDC

MC

1s

1s

MC

*1: Use a solid state relay for the M1 relay.

26

4.3 Wiring

4.3.1 Power supply module specifications

(1) Table 4.1 shows the specifications of the power supply modules.

Table 4.1 Power supply module specifications

Item

Base unit position Power supply module slot

Rated input voltage

Rated input frequency 50/60 Hz ± 5 % ⎯⎯

Input voltage distortion factor Within 5 % (Refer to Section 4.4) ⎯⎯

Max. input apparent power 105 V A 41 W

Inrush current 20 A 8 ms or lower *4 81 A 1 ms or lower

5 V DC 5 A 3 A 5 A Rated output

current

protection *1

protection *2

Efficiency 65 % or higher

Allowable momentary power

failure time *3

Dielectric

withstand

voltage

Insulation resistor

Noise durability

Power indication Power LED indication (light at the time of output of 5 V DC)

Terminal screw size M3.5 × 7

Applicable wire size 0.75 to 2 mm2 (AWG 18 to 14)

Applicable solderless terminal

Applicable tightening torque 59 to 88 N⋅cm

External dimension 130 × 55 × 93.6 (5.12 × 2.17 × 3.69) mm (inch)

Weight 0.60 kg 0.50 kg

24 V DC ± 10 % ⎯⎯ 0.6 A ⎯⎯

5 V DC 5.5 A or higher 3.3 A or higher 5.5 A or higher Overcurrent

24 V DC ⎯⎯ 0.66 A or higher ⎯⎯

5 V DC 5.5 to 6.5 V Overvoltage

24 V DC ⎯⎯

Between primary

and 5 V DC

Between primary

and 24 V DC

A1S61PN A1S62PN A1S63P

100 to 240 V AC (+10 %/-15 %)

(85 to 264 V AC)

20 ms or higher 1 ms or lower

AC across input/LG and output/FG

2830 V AC rms/3 cycle

(2000 m (6562 ft.))

AC across input/LG and output/FG 10 M

measures with a 500 V DC insulation resistance tester

(1) Noise voltage 1500 Vp-p, Noise

width 1

Hz (noise simulator condition)

(2) Noise voltage IEC801-4, 2 kV

s, Noise frequency 25 to 60

Specifications

RAV 1.25 to 3.5,

RAV 2 to 3.5

24 V DC

(+30 %/-35 %)

(15.6 to 31.2 V DC)

500 V AC

⎯⎯

or higher,

Noise voltage 500 Vp-p,

Noise width 1 s, Noise

frequency 25 to 60 Hz

(noise simulator condition)

27

POINT

*1: Overcurrent protection

The overcurrent proctection device shuts off the 5VDC and/or

24VDC circuit(s) and stops the system if the current exceeding the

specified value flows in the circuit(s).

As this results in voltage drop, the power supply module LED turns

OFF or is dimly lit.

After that, eliminate the causes of overcurrent, e.g., insufficient

current capacity and short circuit, and then start the system.

When the current has reached the normal value, the initial start up

of the system will be performed.

*2: Overvoltage protection

The overvoltage protection shuts off the 5VDC circuit and stops the

system if the overvoltage of 5.5 to 6.5V is applied to the circuit.

This results in the power supply module LED turning OFF.

When restarting the system, power OFF and ON the input power

supply, and the initial start up of the system will be performed.

If the system is not booted and the LED remains off, this means

that the power supply module has to be replaced.

*3: Allowable momentary power failure period

The programmable controller CPU allowable momentary power

failure period varies with the power supply module used.

In case of the A1S63P power supply module, the allowable

momentary power failure period is defined as the time from when

the primary side of the stabilized power supply for supplying 24VDC

to the A1S63P is turned OFF until when the voltage (secondary

side) has dropped from 24VDC to the specified value (15.6VDC) or

less.

*4: Inrush current

If the power supply module is re-powered ON right after powered

OFF (within 5seconds), the inrush current exceeding the specified

value (2ms or less) may be generated. Therefore, make sure to

re-power ON the module 5seconds after power off.

When selecting a fuse or breaker for external circuit, consider the

above point as well as meltdown and detection characteristics.

28

4.3.2 Parts names

The following gives the names and description of the parts of the power supply

modules:

[9]

[3]

[4]

[6]

[7]

[9]

MELSECA1S61PN

POWER

MITSUBISHI

[1]

MELSECA1S62PN

POWER

MITSUBISHI

[8]

INPUT

100-240VAC

105VA

50 / 60Hz

OUTPUT

5VDC 5A

INPUT

100-240VAC

10 5VA

50 / 60 Hz

NC

NC

[2]

OUTPUT

5VDC 3A

24VDC 0.6A

[3]

(LG)

INPUT

100-240VAC

A1S61PN

[4]

[6]

[7]

(1) A1S61PN (2) A1S62PN

[9]

MELSECA1S63P

INPUT

DC15.6 31.2V

POWER

MITSUBISHI

OUTPUT

DC 5V 5A

[1]

[6]

+24V

24G

(FG)(FG)

(LG)

INPUT

100-240VAC

A1S62PN

[1]

[8]

NC

NC

+24V

INPUT

24G

(FG)

(LG)