Page 1

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[DESIGN PRECAUTIONS]

WARNING

Create a safety circuit outside the PLC to ensure the whole system will operate safely even if an

external power failure or a PLC failure occurs. Otherwise, incorrect output or malfunction may cause

an accident.

(1) For an emergency stop circuit, protection circuit and interlock circuit that is designed for

incompatible actions such as forward/reverse rotation or for damage prevention such as the

upper/lower limit setting in positioning, any of them must be created outside the PLC.

(2) When the PLC detects the following error conditions, it stops the operation and turn off all the

outputs.

• The overcurrent protection device or overvoltage protection device of the power supply

module is activated.

• The PLC CPU detects an error such as a watchdog timer error by the self-diagnostics

function.

In the case of an error of a part such as an I/O control part that cannot be detected by the PLC

CPU, all the outputs may turn on. In order to make all machines operate safely in such a case,

set up a fail-safe circuit or a specific mechanism outside the PLC. For fail-safe circuit example,

refer to "LOADING AND INSTALLATION" of this manual.

(3) Depending on the failure of the output module's relay or transistor, the output status may remain

ON or OFF incorrectly. For output signals that may lead to a serious accident, create an external

monitoring circuit.

A - 1

Page 4

[DESIGN PRECAUTIONS]

WARNING

If load current more than the rating or overcurrent due to a short circuit in the load has flowed in the

output module for a long time, it may cause a fire and smoke. Provide an external safety device such

as a fuse.

Design a circuit so that the external power will be supplied after power-up of the PLC.

Activating the external power supply prior to the PLC may result in an accident due to incorrect

output or malfunction.

For the operation status of each station at a communication error in data link, refer to the respective

data link manual.

Otherwise, incorrect output or malfunction may cause an accident.

When controlling a running PLC (data modification) by connecting a peripheral device to the CPU

module or a PC to a special function module, create an interlock circuit on sequence programs so that

the whole system functions safely all the time.

Also, before performing any other controls (e.g. program modification, operating status change (status

control)), read the manual carefully and ensure the safety.

In these controls, especially the one from an external device to a PLC in a remote location, some PLC

side problem may not be resolved immediately due to failure of data communications.

To prevent this, create an interlock circuit on sequence programs and establish corrective procedures

for communication failure between the external device and the PLC CPU.

When setting up the system, do not allow any empty slot on the base unit.

If any slot is left empty, be sure to use a blank cover (AG60) or a dummy module (AG62) for it.

When using the extension base unit, A52B, A55B or A58B, attach the included dustproof cover to

the module in slot 0.

Otherwise, internal parts of the module may be flied in the short circuit test or when an overcurrent or

overvoltage is accidentally applied to the external I/O section.

A - 2

Page 5

[DESIGN PRECAUTIONS]

CAUTION

Do not install the control lines or communication cables together with the main circuit or power lines,

or bring them close to each other.

Keep a distance of 100mm (3.94inch) or more between them.

Failure to do so may cause malfunctions due to noise.

If having read register R outside the allowable range with the MOV instruction, the file register data

will be FFFF

file register when designing sequence programs. For instruction details, refer to the programming

manual.

When an output module is used to control the lamp load, heater, solenoid valve, etc., a large current

(ten times larger than the normal one) may flow at the time that the output status changes from OFF

to ON. Take some preventive measures such as replacing the module with the one of a suitable

current rating.

Time from when the CPU module is powered on or is reset to when it enters in RUN status depends

on the system configuration, parameter settings, and program size.

Design the program so that the entire system will always operate safely, regardless of the time.

H. Using this as it is may cause malfunctions. Pay attention not to use any out-of-range

[INSTALLATION PRECAUTIONS]

CAUTION

Use the PLC under the environment specified in the user's manual.

Otherwise, it may cause electric shocks, fires, malfunctions, product deterioration or damage.

Insert the module fixing projection into the fixing hole in the base unit to mount the module.

Incorrect mounting may cause malfunctions, a failure or a drop of the module.

In an environment of frequent vibrations, secure the module with the screw.

Tighten the screw within the specified torque range.

If the screw is too loose, it may cause a drop of the module, a short circuit or malfunctions.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

Connect the extension cable to the connector of the base unit or module.

Check for incomplete connection after installing it.

Poor electrical contact may cause incorrect inputs and/or outputs.

Insert the memory card and fully press it to the memory card connector.

Check for incomplete connection after installing it.

Poor electrical contact may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Failure to do so may damage the module.

Do not directly touch the conductive part or electronic components of the module.

Doing so may cause malfunctions or a failure of the module.

A - 3

Page 6

[WIRING PRECAUTIONS]

WARNING

Be sure to shut off all phases of the external power supply used by the system before wiring.

Failure to do so may result in an electric shock or damage of the product.

Before energizing and operating the system after wiring, be sure to attach the terminal cover

supplied with the product.

Failure to do so may cause an electric shock.

CAUTION

Ground the FG and LG terminals correctly.

Failure to do so may cause an electric shock or malfunctions.

Wire the module correctly after confirming the rated voltage and terminal layout.

Connecting a power supply of a different voltage rating or incorrect wiring may cause a fire or failure.

Do not connect multiple power supply modules to one module in parallel.

The power supply modules may be heated, resulting in a fire or failure.

Press, crimp or properly solder the connector for external connection with the specified tool.

Incomplete connection may cause a short circuit, fire or malfunctions.

Tighten terminal screws within the specified torque range.

If the screw is too loose, it may cause a short circuit, fire or malfunctions.

If too tight, it may damage the screw and/or the module, resulting in a short circuit or malfunctions.

Carefully prevent foreign matter such as dust or wire chips from entering the module.

Failure to do so may cause a fire, failure or malfunctions.

Install our PLC in a control panel for use.

Wire the main power supply to the power supply module installed in a control panel through a

distribution terminal block.

Furthermore, the wiring and replacement of a power supply module have to be performed by a

maintenance worker who acquainted with shock protection.

(For the wiring methods, refer to Section 19.7.)

A - 4

Page 7

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

Do not touch any terminal during power distribution.

Doing so may cause an electric shock.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, solder, or throw the battery into the fire.

Incorrect battery handling may cause personal injuries or a fire due to exothermic heat, burst and/or

ignition.

Be sure to shut off all phases of the external power supply used by the system before cleaning or

retightening the terminal screws or module mounting screws.

Failure to do so may result in an electric shock.

If they are too loose, it may cause a short circuit or malfunctions.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

A - 5

Page 8

[STARTUP AND MAINTENANCE PRECAUTIONS]

CAUTION

When performing online operations (especially, program modification, forced output or operating

status change) by connecting a peripheral device to the running CPU module, read the manual

carefully and ensure the safety.

Incorrect operation will cause mechanical damage or accidents.

Do not disassemble or modify each of modules.

Doing so may cause failure, malfunctions, personal injuries and/or a fire.

When using a wireless communication device such as a mobile phone, keep a distance of 25cm

(9.84inch) or more from the PLC in all directions.

Failure to do so may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Failure to do so may result in failure or malfunctions of the module.

When replacing the fuse, use a fuse specified by the manufacturer.

Using the one for the high-rated current or an electric wire may cause a fire.

Do not drop or apply any impact to the battery.

Doing so may damage the battery, resulting in electrolyte spillage inside the battery.

If any impact has been applied, discard the battery and never use it.

Before handling modules, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause failure or malfunctions of the module.

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of the product, treat it as an industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to Appendix 11.)

[TRANSPORTATION PRECAUTIONS]

CAUTION

When transporting lithium batteries, make sure to treat them based on the transportation regulations.

(Refer to Appendix 10 for details of the relevant models.)

A - 6

Page 9

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 7

Page 10

REVISIONS

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

Jul., 1996 IB (NA) 66608-A First edition

Dec., 2003 IB (NA) 66608-B

Oct., 2006 IB (NA) 66608-C

Partial correction

SAFETY PRECAUTIONS, CONTENTS, Related Manuals, Section 1.1, 1.2, 2.1,

3.1.1, 3.1.2, 3.2, 3.3.1, 3.3.2, 3.3.3, Chapter 4, Section 5.1, 5.2, 5.3, 5.4, 6.1, 6.2,

6.3, 7.1, 8.1, 8.2, 8.2.1, 8.3, 8.4.1, 8.4.3, 8.5, 8.6, 8.7, 8.7.1, 8.7.2, 8.7.3, 8.8, 8.9,

8.10, 8.10.1, 8.10.2, 9.1, 9.2, 9.3, 9.3.1, 9.3.3, 9.4, 9.5, 9.6, 9.7, 9.8, 9.9, 9.9.1,

9.9.2, 10.1, 10.2, 10.3, 10.4, 10.5, 10.6, 10.6.1, 10.6.2, 10.6.3, 10.6.4, 10.6.5,

10.6.6, 10.7, 10.7.1, 10.8, 11.1, 11.2, 11.3, 11.4, 11.5, 11.6, 11.7, 12.1, 12.1.1,

12.1.2, 12.1.3, 12.1.4, 12.1.5, 12.1.6, 12.1.7, 12.2, 12.3, 12.4, Chapter 13, 14,

Section 14.1, 14.2, 14.3, 15.1, 15.2, 15.3, 16.1.1, 16.1.2, 16.2, 16.3, Chapter 17,

Section 17.1, 17.1.1, 17.2, 17.4, 17.5, 18.1, 18.2, 18.3, 18.4, 18.6, 18.7, 19.1,

19.4.1, 19.5, 19.6, 19.7, 19.7.1, 19.7.2, 19.8, 21.1, 21.2, 21.3, 21.3.1, 21.3.2,

21.4, 21.4.1, 21.4.2, 22.2.1, 22.2.2, 22.2.3, 22.2.4, 22.2.5, 22.2.6, 22.2.7, 22.2.8,

22.2.9, 22.2.10, 22.3, 22.3.1, 22.3.2, 22.5, 22.5.1, 22.5.2, Appendix 1.1, 1.4, 1.6,

2.3, 4.4.1, 4.2, 4.3, 4.6, 4.10, 4.11, 4.12, 5.1, 5.2, 6.2

Partial addition

Section 2.2, 2.2.1, 7.2, 8.2.2, 19.8, Chapter 20, Section 20.1, 20.1.1, 20.1.2,

20.1.3, 20.1.4, 20.1.5, 20.1.6, 20.2, 20.2.1, 20.2.2, 20.2.3, 20.2.4, 20.2.5, 20.2.6,

20.2.7, 22.4, Appendix 7, 8, 9, 9.1, 9.2, WARRANTY

Partial correction

SAFETY PRECAUTIONS, Section 3.1.1, 3.1.2, 3.2, 3.3.1, 3.3.2, Chapter 4,

Section 5.3, 6.1, 7.1, 9.1, 9.3, 9.3.1, 9.9.2, 12.1.2, 12.1.5, 12.4, 14.1, 15.1, 15.2,

16.1.1, 16.1.3, 16.2, 16.3, 17.1, 17.1.1, 17.2, 17.5, 18.1, 18.2, 18.3, 19.1, 19.6,

19.7, Chapter 20, Section 20.1.3, 21.5, 21.6, 22.2.6, 22.2.7, 22.3.3, Appendix 2,

3, 5.2, 6.2, 9.2

Deletion

Section 14.2

Chapter change

Section 14.3 Section 14.2

May, 2007 IB(NA)66608-D

Dec., 2009 IB(NA)66608-E

Partial correction

Related Manuals, Section 19.7.1, 19.7.2, 20.1.3, 20.1.4, 20.2.7, 22.3,

APPENDIX 2, APPENDIX3

Partial correction

SAFETY PRECAUTIONS, Section 3.3.1, Chapter 13, Section 15.1, 16.1.2,

16.1.3, 18.3, Chapter 20, 21.3.1, 21.3.2, 22.3, 22.3.1, 22.3.3, 22.3.4, 22.3.5,

22.3.6, 22.3.7, 22.3.8, 22.3.9, APPENDIX 2, APPENDIX 3

Addition

CONDITIONS OF USE FOR THE PRODUCT, APPENDIX 2, 3, 11, 11.1, 11.2

Japanese Manual Version SH-3532-L

This manual confers no industrial property rights or any rights of any other kind, nor dose it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

1995 MITSUBISHI ELECTRIC CORPORATION

A - 8

Page 11

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

Mar., 2010 IB(NA)66608-F

Partial correction

SAFETY PRECAUTIONS, Section 3.3.1, 19.1, 19.5, 19.7.1, 21.2, 21.3.2, 22.3.7,

APPENDIX 2

A - 9

Page 12

Introduction

Thank you for purchasing the Mitsubishi programmable logic controller MELSEC-QnA series.

Before using your new PLC, please read this manual thoroughly to gain an understanding of its functions so

that you can use it properly.

Please forward a copy of this manual to the end user.

Table of Contents

1 ABOUT THIS MANUAL 1 - 1 to 1 - 2

1.1 About this Manual..........................................................................................................................1 - 1

1.2 Abbreviations and Generic Terms Used in this Manual ................................................................1 - 2

2 OVERVIEW 2 - 1 to 2 - 8

2.1 Features ........................................................................................................................................2 - 1

2.2 Additional Functions of QnACPU ..................................................................................................2 - 5

2.2.1 Overview of added functions.................................................................................................2 - 7

3 SYSTEM CONFIGURATION 3 - 1 to 3 - 25

3.1 System Configuration ....................................................................................................................3 - 1

3.1.1 Equipment configuration in a stand-alone system ................................................................3 - 1

3.1.2 Configuration of peripheral devices capable of QnACPU .....................................................3 - 2

3.2 System Configuration Overview ....................................................................................................3 - 3

3.3 System Equipment ........................................................................................................................3 - 6

3.3.1 System equipment list ...........................................................................................................3 - 6

3.3.2 Precautions when configuring the system...........................................................................3 - 21

3.3.3 QnACPU memory block diagram ........................................................................................3 - 25

4 PERFORMANCE SPECIFICATIONS 4 - 1 to 4 - 3

5 I/O NUMBER ASSIGNMENT 5 - 1 to 5 - 14

5.1 I/O Numbers ..................................................................................................................................5 - 1

5.2 I/O Number Assignment Concept..................................................................................................5 - 2

5.3 I/O Assignment with GPP Function ...............................................................................................5 - 4

5.4 Example of I/O Number Assignment .............................................................................................5 - 9

6 DATA COMMUNICATIONS WITH SPECIAL FUNCTION MODULES 6 - 1 to 6 - 5

6.1 Reading/Writing Data from/to the QnACPU Using the FROM/TO Instruction ...............................6 - 2

6.2 Reading/Writing Data from/to the QnACPU Using Special Direct Devices ...................................6 - 3

6.3 Processing for Data Communication Requests from a Special Function Module .........................6 - 5

7 AUTO REFRESH FUNCTION 7 - 1 to 7 - 14

7.1 For MELSECNET/MINI-S3............................................................................................................7 - 1

7.2 Auto Refresh Setting of CC-Link ...................................................................................................7 - 8

A - 10

Page 13

8 DEBUGGING FUNCTION 8 - 1 to 8 - 64

8.1 Function List ..................................................................................................................................8 - 1

8.2 Monitor Function............................................................................................................................8 - 2

8.2.1 Monitoring condition setting ..................................................................................................8 - 2

8.2.2 Monitor test of local device (function version B or later) .....................................................8 - 12

8.3 Write During RUN........................................................................................................................8 - 15

8.4 Execution Time Measurement.....................................................................................................8 - 19

8.4.1 Program monitor list ............................................................................................................8 - 19

8.4.2 Interrupt program monitor list ..............................................................................................8 - 22

8.4.3 Scan time measurement .....................................................................................................8 - 23

8.5 Sampling Trace Function ............................................................................................................8 - 25

8.6 Status Latch Function..................................................................................................................8 - 35

8.7 Step Operation ............................................................................................................................8 - 41

8.7.1 Step execution ....................................................................................................................8 - 42

8.7.2 Partial execution..................................................................................................................8 - 44

8.7.3 Skip function........................................................................................................................8 - 47

8.8 Program Trace Function..............................................................................................................8 - 48

8.9 Simulation Function .....................................................................................................................8 - 57

8.10 Debugging by Several People.....................................................................................................8 - 61

8.10.1 Simultaneous monitoring by several people .......................................................................8 - 62

8.10.2 Simultaneous execution of write during RUN by several people ........................................8 - 63

9 MAINTENANCE FUNCTION 9 - 1 to 9 - 21

9.1 Function List ..................................................................................................................................9 - 1

9.2 Watchdog Timer ............................................................................................................................9 - 2

9.3 Self-diagnostics Function ..............................................................................................................9 - 4

9.3.1 Interruption due to error detection.........................................................................................9 - 8

9.3.2 LED indication due to an error ..............................................................................................9 - 8

9.3.3 Resetting error ......................................................................................................................9 - 9

9.4 Error History ................................................................................................................................9 - 10

9.5 System Protect ............................................................................................................................9 - 11

9.6 Password Registration ................................................................................................................9 - 12

9.7 Online I/O Module Replacement .................................................................................................9 - 14

9.8 System Display............................................................................................................................9 - 16

9.9 LED Indications ...........................................................................................................................9 - 17

9.9.1 LED indication .....................................................................................................................9 - 17

9.9.2 Priority setting .....................................................................................................................9 - 19

10 OTHER FUNCTIONS 10 - 1 to 10 - 24

10.1 Function List ................................................................................................................................10 - 1

10.2 Constant Scan.............................................................................................................................10 - 2

10.3 Latch Function.............................................................................................................................10 - 5

10.4 Setting of the Output (Y) Status When Switching from STOP to RUN ........................................10 - 7

10.5 Clock Function.............................................................................................................................10 - 8

10.6 Remote Operation .....................................................................................................................10 - 13

10.6.1 Remote RUN/STOP ..........................................................................................................10 - 13

A - 11

Page 14

10.6.2 Remote STEP-RUN ..........................................................................................................10 - 15

10.6.3 Remote PAUSE ................................................................................................................10 - 16

10.6.4 Remote RESET.................................................................................................................10 - 18

10.6.5 Remote latch clear ............................................................................................................10 - 19

10.6.6 Relationship between remote operation and CPU module RUN/STOP key switch ..........10 - 20

10.7 Terminal Operation....................................................................................................................10 - 21

10.7.1 Operation for message display .........................................................................................10 - 21

10.7.2 Key input operation ...........................................................................................................10 - 22

10.8 Reading Module Access Time Intervals ....................................................................................10 - 23

11 COMMENTS THAT CAN BE STORED IN QnACPU 11 - 1 to 11 - 8

11.1 Function List ................................................................................................................................11 - 1

11.2 PLC name ...................................................................................................................................11 - 2

11.3 Drive Title ....................................................................................................................................11 - 3

11.4 File Title.......................................................................................................................................11 - 4

11.5 Device Comment.........................................................................................................................11 - 5

11.6 Statements/Notes........................................................................................................................11 - 7

11.7 Initial Device Value Comment .....................................................................................................11 - 8

12 OVERVIEW OF PROCESSING PERFORMED BY THE QnACPU 12 - 1 to 12 - 28

12.1 Program Execution Types ...........................................................................................................12 - 1

12.1.1 Initial execution type programs ...........................................................................................12 - 4

12.1.2 Scan execution type program .............................................................................................12 - 7

12.1.3 Low-speed execution type program ....................................................................................12 - 9

12.1.4 Standby type program.......................................................................................................12 - 16

12.1.5 Initial processing ...............................................................................................................12 - 22

12.1.6 Refresh processing of I/O module.....................................................................................12 - 22

12.1.7 END processing ................................................................................................................12 - 23

12.2 Operation Processing of RUN, STOP, PAUSE, and STEP-RUN..............................................12 - 24

12.3 Operation Processing for Instantaneous Power Failure............................................................12 - 26

12.4 Data Clear Processing ..............................................................................................................12 - 27

13 PARAMETER LIST 13 - 1 to 13 - 10

14 SELECTING MEMORY CARD MODELS 14 - 1 to 14 - 4

14.1 Applications of Memory Cards ....................................................................................................14 - 2

14.2 Selecting Memory Card Capacity................................................................................................14 - 3

15 HARDWARE SPECIFICATIONS OF CPU MODULES 15 - 1 to 15 - 7

15.1 SPECIFICATIONS ......................................................................................................................15 - 1

15.2 Part Names .................................................................................................................................15 - 2

15.3 Relationship between Switch Operations and LEDs/LED Display ..............................................15 - 5

16 POWER SUPPLY MODULE 16 - 1 to 16 - 14

16.1 Specifications ..............................................................................................................................16 - 1

A - 12

Page 15

16.1.1 Power supply module specifications ...................................................................................16 - 1

16.1.2 Power supply module selection...........................................................................................16 - 5

16.1.3 Fuse specifications..............................................................................................................16 - 7

16.2 Handling precautions...................................................................................................................16 - 8

16.3 Part Names ...............................................................................................................................16 - 10

17 BASE UNIT AND EXTENSION CABLE 17 - 1 to 17 - 11

17.1 Specifications of Base Units........................................................................................................17 - 1

17.1.1 Main base unit for high-speed access (A38HB/A38HBEU) ................................................17 - 3

17.2 Extension Cable Specifications ...................................................................................................17 - 4

17.3 Application Standards of Extension Base Units (A52B, A55B, A58B) ........................................17 - 5

17.4 Handling Precautions ..................................................................................................................17 - 7

17.5 Part Names .................................................................................................................................17 - 8

17.6 Setting of Extension Stage Numbers ........................................................................................17 - 11

18 MEMORY CARDS AND BATTERIES 18 - 1 to 18 - 9

18.1 Memory Card Specifications .......................................................................................................18 - 1

18.2 Handling Memory Cards..............................................................................................................18 - 3

18.3 Battery Specifications (CPU Module and Memory Card Batteries) .............................................18 - 4

18.4 Handling Precautions ..................................................................................................................18 - 5

18.5 Part Names of Memory Card.......................................................................................................18 - 6

18.6 Installing Batteries (CPU Module and Memory Card Batteries) ..................................................18 - 7

18.7 Installing/Removing a Memory Card ...........................................................................................18 - 8

19 LOADING AND INSTALLATION 19 - 1 to 19 - 24

19.1 Fail-Safe Circuit Concept ............................................................................................................19 - 1

19.2 Installation Environment ..............................................................................................................19 - 7

19.3 Calculation of Heat Generated by the PLC .................................................................................19 - 8

19.4 Installing the Base Units............................................................................................................19 - 10

19.4.1 Installation precautions .....................................................................................................19 - 10

19.4.2 Installation .........................................................................................................................19 - 11

19.5 Installation and Removal of Modules ........................................................................................19 - 12

19.6 Installation and Removal of the Dustproof Cover ......................................................................19 - 15

19.7 Wiring ........................................................................................................................................19 - 17

19.7.1 Wiring instructions .............................................................................................................19 - 17

19.7.2 Wiring to module terminals................................................................................................19 - 22

19.8 Precautions When Connecting Uninterruptible Power Supply Module (UPS)...........................19 - 24

20 EMC AND LOW VOLTAGE DIRECTIVES 20 - 1 to 20 - 14

20.1 Requirements for Compliance with EMC Directives....................................................................20 - 1

20.1.1 EMC standards ...................................................................................................................20 - 2

20.1.2 Installation inside the control panel .....................................................................................20 - 3

20.1.3 Cables .................................................................................................................................20 - 4

20.1.4 Power supply module..........................................................................................................20 - 9

20.1.5 Base unit .............................................................................................................................20 - 9

20.1.6 Ferrite core ........................................................................................................................20 - 10

A - 13

Page 16

20.1.7 Noise filter (power supply line filter) ..................................................................................20 - 10

20.2 Requirements for Compliance with Low Voltage Directives......................................................20 - 11

20.2.1 Standard applied for MELSEC-QnA series PLC ...............................................................20 - 11

20.2.2 Precautions when using the QnA series PLC ...................................................................20 - 11

20.2.3 Power supply.....................................................................................................................20 - 12

20.2.4 Control panel .....................................................................................................................20 - 13

20.2.5 Module installation ............................................................................................................20 - 14

20.2.6 Grounding .........................................................................................................................20 - 14

20.2.7 External wiring...................................................................................................................20 - 14

21 MAINTENANCE AND INSPECTION 21 - 1 to 21 - 15

21.1 Daily Inspection ...........................................................................................................................21 - 1

21.2 Periodic Inspection ......................................................................................................................21 - 2

21.3 Battery Replacement...................................................................................................................21 - 4

21.3.1 Battery life ...........................................................................................................................21 - 6

21.3.2 Battery replacement procedure...........................................................................................21 - 8

21.4 Fuse Replacement ....................................................................................................................21 - 12

21.4.1 Replacement of the fuse for a power supply module ........................................................21 - 12

21.4.2 Replacement of the fuse for an output module .................................................................21 - 13

21.5 When Reoperating a PLC After Storing it with a Battery Unconnected.....................................21 - 14

21.6 When a PLC is Reoperated After Stored with the Battery Over the Battery Life.......................21 - 15

22 TROUBLESHOOTING 22 - 1 to 22 - 52

22.1 Fundamentals of Troubleshooting...............................................................................................22 - 1

22.2 Troubleshooting...........................................................................................................................22 - 2

22.2.1 Troubleshooting flowchart ...................................................................................................22 - 2

22.2.2 Flow for actions when the "POWER" LED is turned OFF ...................................................22 - 3

22.2.3 Flow for actions when the "RUN" LED is turned OFF .........................................................22 - 4

22.2.4 When the "RUN" LED is flashing ........................................................................................22 - 5

22.2.5 Flow for actions when the "ERROR LED" is turned ON/flashing ........................................22 - 6

22.2.6 When the "USER" LED is turned ON ..................................................................................22 - 7

22.2.7 When the "BAT.ARM" LED is turned ON ...........................................................................22 - 7

22.2.8 Flow for actions when the output module's output load does not turn ON ..........................22 - 8

22.2.9 Flow for actions when the program cannot be written.........................................................22 - 9

22.2.10 Flow for actions when booting from a memory card is not possible..................................22 - 11

22.2.11 Flow chart used when the CPU module is not started up .................................................22 - 13

22.3 Error Code List ..........................................................................................................................22 - 15

22.3.1 Error Codes.......................................................................................................................22 - 16

22.3.2 Procedure to read an error code .......................................................................................22 - 16

22.3.3 Error code list (1000 to 1999)............................................................................................22 - 17

22.3.4 Error code list (2000 to 2999)............................................................................................22 - 22

22.3.5 Error code list (3000 to 3999)............................................................................................22 - 28

22.3.6 Error code list (4000 to 4999)............................................................................................22 - 32

22.3.7 Error code list (5000 to 5999)............................................................................................22 - 41

22.3.8 Error code list (6000 to 6999)............................................................................................22 - 42

22.3.9 Error code list (7000 to 10000)..........................................................................................22 - 44

22.3.10 Canceling of Errors ...........................................................................................................22 - 45

A - 14

Page 17

22.4 Resetting Errors ........................................................................................................................22 - 46

22.5 Fault Examples with I/O Modules..............................................................................................22 - 47

22.5.1 Faults with the input circuit and the corrective actions......................................................22 - 47

22.5.2 Faults in the output circuit .................................................................................................22 - 49

APPENDICES App - 1 to App - 163

APPENDIX 1 INSTRUCTION LIST................................................................................................. App - 1

Appendix 1.1 Sequence Instructions ......................................................................................... App - 1

Appendix 1.2 Basic Instructions................................................................................................. App - 5

Appendix 1.3 Application Instructions ...................................................................................... App - 17

Appendix 1.4 Data Link Instructions ........................................................................................ App - 38

Appendix 1.5 PID Control Instructions ..................................................................................... App - 41

Appendix 1.6 Special Function Module Instructions ................................................................ App - 42

APPENDIX 2 Special Relay List ................................................................................................... App - 48

APPENDIX 3 Special Register List ............................................................................................... App - 72

APPENDIX 4 PRECAUTIONS FOR UTILIZING THE EXISTING MELSEC-A SERIES PROGRAM FOR

QnACPU ............................................................................................................... App - 110

Appendix 4.1 Instructions....................................................................................................... App - 110

Appendix 4.2 Devices ............................................................................................................ App - 118

Appendix 4.3 Parameters ...................................................................................................... App - 120

Appendix 4.4 Timer and Interrupt Counter Operations .......................................................... App - 121

Appendix 4.5 Sequence Programs, Statements, Notes......................................................... App - 122

Appendix 4.6 Microcomputer programs ................................................................................. App - 124

Appendix 4.7 Comments........................................................................................................ App - 125

Appendix 4.8 Constant Scan Function, Error Check Function............................................... App - 126

Appendix 4.9 I/O control mode .............................................................................................. App - 127

Appendix 4.10 Data Link System............................................................................................. App - 128

Appendix 4.11 Index Register Processing ............................................................................... App - 129

Appendix 4.12 CHK Instruction, IX Instruction......................................................................... App - 130

Appendix 4.13 Accessing File Register R with Instructions ..................................................... App - 131

APPENDIX 5 ERROR CODES RETURNED TO THE REQUEST SOURCE IN GENERAL DATA

PROCESSING ...................................................................................................... App - 132

Appendix 5.1 Error Codes...................................................................................................... App - 132

Appendix 5.2 Error Contents of Error Codes Detected by the CPU Module (4000H to 4FFFH)

......................................................................................................................... App - 133

APPENDIX 6 EXTERNAL DIMENSIONS ................................................................................... App - 141

Appendix 6.1 CPU Module..................................................................................................... App - 141

Appendix 6.2 Power Supply Module ...................................................................................... App - 143

Appendix 6.3 Main Base Unit................................................................................................. App - 145

Appendix 6.4 Extension Base Unit......................................................................................... App - 147

APPENDIX 7 USE OF LOCAL DEVICE FOR SUBROUTINE/INTERRUPT PROGRAM STORAGE FILE

(FUNCTION VERSION B OR LATER) ................................................................. App - 149

APPENDIX 8 NETWORK RELAY FROM ETHERNET MODULE

(FUNCTION VERSION B OR LATER) ................................................................. App - 153

APPENDIX 9 QnACPU PROCESSING TIME............................................................................. App - 156

Appendix 9.1 Overview of QnACPU Scan Time .................................................................... App - 156

Appendix 9.2 Causes of Increasing Scan Time ..................................................................... App - 157

A - 15

Page 18

APPENDIX 10 TRANSPORTATION PRECAUTIONS.................................................................. App - 160

Appendix 10.1 Relevant Models .............................................................................................. App - 160

Appendix 10.2 Transportation Guidelines................................................................................ App - 161

APPENDIX 11 Handling of Batteries and Devices with Built-in Batteries in EU Member States

.............................................................................................................................. App - 162

Appendix 11.1 Disposal precautions........................................................................................ App - 162

Appendix 11.2 Exportation precautions ................................................................................... App - 163

INDEX Index - 1 to Index - 6

A - 16

Page 19

bout This Manual

A

Related Manuals

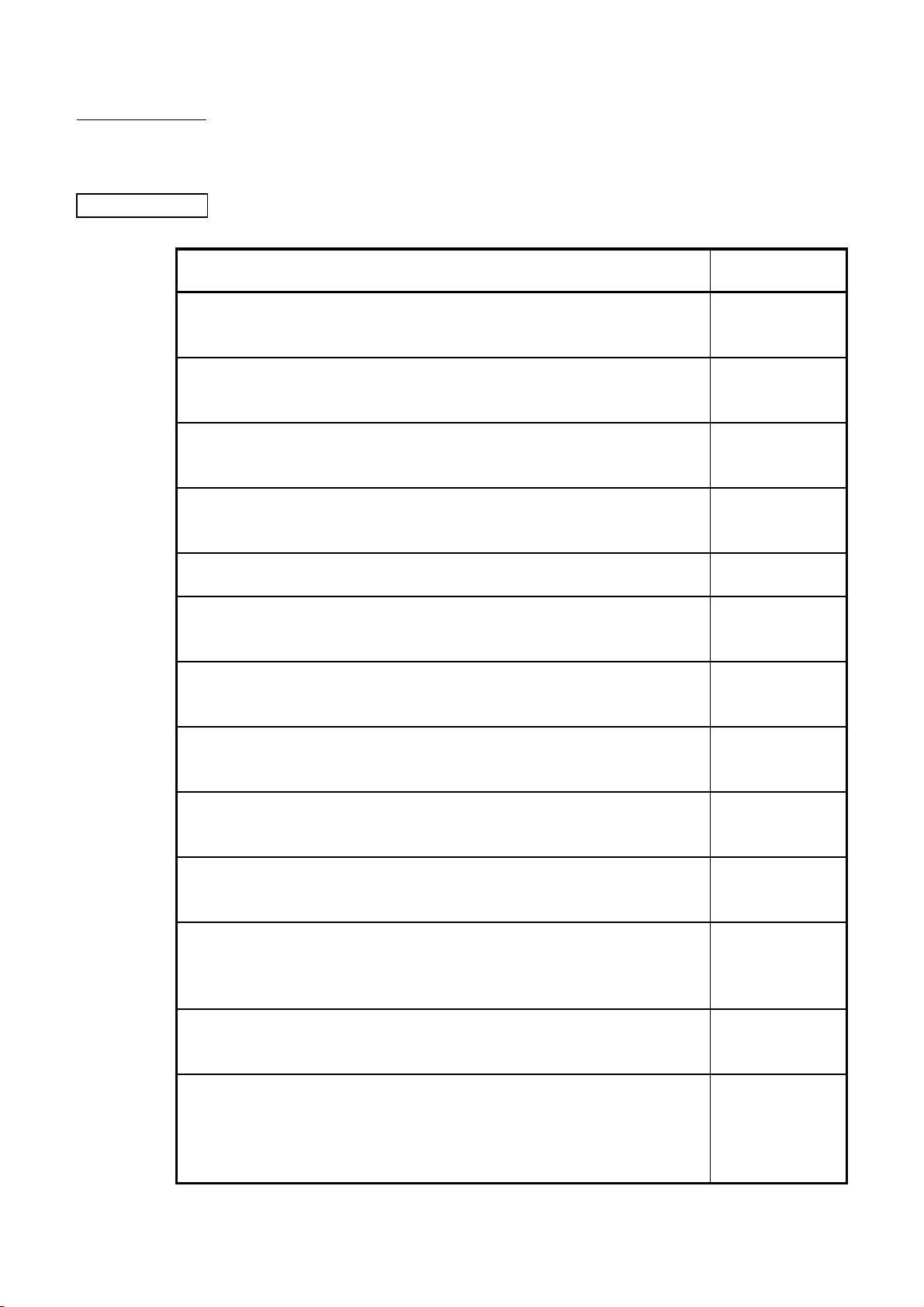

The following manuals are related to this product.

Please order those you require.

Manual Name

QnACPU Programming Manual (Fundamentals)

Explains the programming procedures, device names and program types required

for program creation. (Sold separately)

QCPU (Q mode)/QnACPU Programming Manual (Common Instructions)

Explains how to use the sequence instructions, basic instructions and application

instructions. (Sold separately)

QnACPU Programming Manual (Special Function Module)

Explains the dedicated instructions used with special function modules.

(Sold separately)

QnACPU Programming Manual (AD57 Instructions)

Explains the dedicated instructions for controlling an AD57 (S1) type CRT

controller module. (Sold separately)

QCPU (Q mode)/QnACPU Programming Manual (PID Control Instructions)

Explains the dedicated instructions to execute PID control. (Sold separately)

QCPU (Q mode)/QnACPU Programming module (SFC)

Explains MELSAP3 system configuration, performance specifications, functions,

programming, debugging and error codes. (Sold separately)

Building Block Type I/O Module User's Manual

Explains the specifications of building block type I/O modules.

(Sold separately)

MELSECNET/10 Network System (for QnA/Q4AR) Reference Manual

Describes the general concept, specifications, and part names and settings, for

MELSECNET/10. (Sold separately)

MELSECNET, MELSECNET/B Data Link System Reference Manual

Explains overviews, specifications, part names, and settings of MELSECNET (II)

and MELSECNET/B. (Sold separately)

GX Developer Version 8 Operating Manual

Explains the methods of programming, print out, monitoring, and debugging of

Developer. (Sold separately)

SW2IVD-GPPQ GPP Software package Operating Manual (Offline)

Explains offline functions such as the methods of programming, print out and file

maintenance of SW2IVD-GPPQ.

(Included with product)

SW2IVD-GPPQ GPP Software package Operating Manual (Online)

Explains online functions such as methods of monitoring and debugging of

SW2IVD-GPPQ. (Included with product)

Type SW2IVD-GPPQ GPP Software package Operating Manual (SFC)

Describes MELSAP-3 system components, performance specifications, functions,

system start-up procedure, SFC program editing method, monitoring method,

printout method and error messages.

(Included with product)

Manual No.

(Model Code)

IB-66614

(13JF46)

SH-080039

(13JF58)

SH-4013

(13JF56)

IB-66617

(13JF49)

SH-080040

(13JF59)

SH-080041

(13JF60)

IB-66140

(13J643)

IB-66690

(13JF78)

IB-66350

(13JF70)

SH-080373E

(13JU41)

IB-66774

(13J921)

IB-66775

(13J922)

IB-66776

(13J923)

A - 17

Page 20

Manual Name

Type SW2IVD-GPPQ GPP Software package Operating Manual

(Q6TEL)

Describes Q6TEL system configuration, operating methods, etc.

(Included with product)

Manual No.

(Model Code)

IB-66777

(13J924)

A - 18

Page 21

ser Precautions

U

Precautions when using QnACPU

When using a CPU module, format the memory using a peripheral device.

For details of memory format, refer to the following manuals.

• GX Developer Operating Manual

• SW IVD-GPPQ Software package Operating Manual (Online)

P

recautions for Battery

(1) The operation after removal of a battery

After removing a battery of the CPU module, format the memory using a peripheral

device to start next operation. (Refer to Section 21.5)

(2) The operation after excess of a battery life

After removing a battery of the CPU module due to its excess life, format the memory

using a peripheral device to start next operation. (Refer to Section 21.6)

A - 19

Page 22

1.

ABOUT THIS MANUAL

1 ABOUT THIS MANUAL

1.1 About this Manual

This manual serves to explain the specifications and functions of the Q2ACPU(S1),

Q3ACPU, and Q4ACPU (abbreviated as QnACPU hereafter), the specifications of other

modules, and the maintenance required for smooth system operation, to users of

MELSEC-QnA series programmable controllers.

It is divided into the following three main parts:

(1) Sections 2 and 3 These sections give the general description and system

(2) Sections 4 to 15 These sections give the specifications and functions of

configuration for the QnACPU.

Read them to learn the features of QnACPU, and the modules

that can be used and points to note when configuring a system.

QnACPU.

They describe each QnACPU function to enable you to use the

QnACPU effectively.

(3) Sections 16 to 18 These sections describe the specifications and handling of units/

modules other than the CPU module (power supply module,

base units, etc.).

Read them to learn how to handle the power supply module,

base units, memory cards, etc.

(4) Sections 19 to 20 These sections describe the loading and installation, EMC and

low voltage directives.

(5) Sections 21 to 22 These sections describe all aspects of maintenance, from

installing the QnACPU to daily inspections and troubleshooting.

Read them to learn how to install the QnACPU so as to ensure

smooth operation, and how to carry out daily inspections and

corrective action in the event of trouble.

REMARK

This manual does not cover MELSECNET(II) data link systems, MELSECNET/B data

link systems, MELSECNET/10 networks, or the SFC function.

For details on each function, refer to the following manuals.

• MELSECNET(II), MELSECNET/B Data Link

MELSECNET, MELSECNET/B Data Link System Reference Manual

• MELSECNET/10 Network

MELSECNET/10 Network System Manual for QnA/Q4AR

• SFC Function

QCPU (Q Mode)/QnACPU Programming Manual (SFC)

1 - 1

Page 23

1.

ABOUT THIS MANUAL

1.2 Abbreviations and Generic Terms Used in this Manual

The following abbreviations and generic terms are used in this manual.

(1) QnACPU................................... Abbreviation for Q2ACPU, Q2ACPU-S1,

(2) Network module......................... Abbreviation of AJ71QLP21(G), AJ71QLP21S,

(3) Ethernet module......................... Abbreviation of AJ71QE71N-B2 and

(4) Serial communication module.... Abbreviation of AJ71QC24 (N), AJ71QC24 (N)-

Q3ACPU, and Q4ACPU type CPU modules.

AJ71QLR21, AJ72QLP25 (G), AJ71QBR11,

AJ72QBR15 and AJ72QLR25 type

MELSECNET/10 network modules.

AJ71QE71N-B5T type Ethernet interface

modules.

R2 type serial communication module.

(5) CC-Link..................................... Abbreviation of Control & Communication Link

(6) GPP function.............................

(7) Personal computer..................... IBM's PC/AT or completely compatible

(8) Peripheral device capable .........

of GPP functions

(9) Q6PU......................................... Abbreviation for Q6PU programming unit.

(10) Peripheral device........................ Generic term for a device that is connected to a

(11) Built-in RAM............................... A RAM incorporated in the QnA CPU that stores

(12) Memory card..............................

(13) ACPU......................................... Generic term for a MELSEC-A series

Abbreviations for the SW IVD-GPPQ type

GPP function software package, GX Developer.

computers.

Generic term for a peripheral device capable of

running the GPP function software, for example

an IBM PC/AT.

QnACPU and can be used to operate it, for

example a IBM-PC/AT-compatible personal

computer or Q6PU.

sequence programs and other data.

Abbreviation for Q1MEM- type memory

card

programmable controller

1 - 2

Page 24

2.

OVERVIEW

2 OVERVIEW

2.1 Features

QnACPU has the following features.

(1) Large memory capacity

(a) Q4ACPU has a program capacity of 124k steps, which means that 124k steps

can be used for a single program (Q2ACPU: 28k steps, Q2ACPU-S1: 60k steps,

Q3ACPU: 92k steps).

(b) The device memory capacity is 32k words and the user can change the number

of points as required.

For example, the default number of points for internal relays (M) is 8k points, but

this can be expanded up to 32k points.

(c) Two memory cards of a maximum of 2M bytes can be installed.

Memory cards are used to store programs, comments, statements, and file

registers.

(Programs can be stored in the CPU module itself, so a memory card is not

essential to run a CPU module.)

(2) High-speed processing

(a) Higher operation processing speeds have been achieved for basic instructions

and application instructions.

A4UCPU Q4ACPU

Basic instruction

Application instruction

(b) The access time for expansion data memory (file registers: R) has been

conformed with the internal devices of the QnACPU (data registers: D, and link

registers: W).

(c) Reading/writing of the buffer memories of special function modules dedicated to

QnA (serial communication modules) have been realised processing speed-up

by six times compared to AnUCPU.

(The processing speed of the existing special function modules for ACPU use is

about the same as that when using AnUCPU.)

(d) A high-speed access base unit (A38HB/A38HBEU) is available to speed up the

processing time for accessing special function modules such as network

modules and serial communication modules that handle large quantities of data.

Simply by mounting the special function module on the high-speed access base

unit, the access processing speed is increased when the QnACPU accesses the

special function module.

0.15 s 0.075 s

0.90 s 0.225 s

2 - 1

Page 25

2. OVERVIEW

(3) Selection of program execution type that is appropriate for the control has been

realised.

There are four program execution types to be selected as follows.

(a) Initial execution type

This program type is executed once only when the QnACPU is set to RUN.

(b) Scan execution type

This program type is run continually while the QnACPU is in the RUN status.

This is equivalent to a conventional program that runs from step 0 to END

instruction. It is possible to create subroutine programs and interrupt programs

for this type of program.

(c) Low-speed execution type

This is a program type which is executed only during the surplus constant scan

time (process to preset the program execution time for constant scan time) or

during the set execution time of the low-speed execution program.

(d) Stand-by type

This type of program consists entirely of a subroutine program or interrupt

program.

(4) The SFC language MELSAP3 has been supplied.

With enhancement of step attributes and SFC control instructions, MELSAP3 makes

SFC programming even easier.

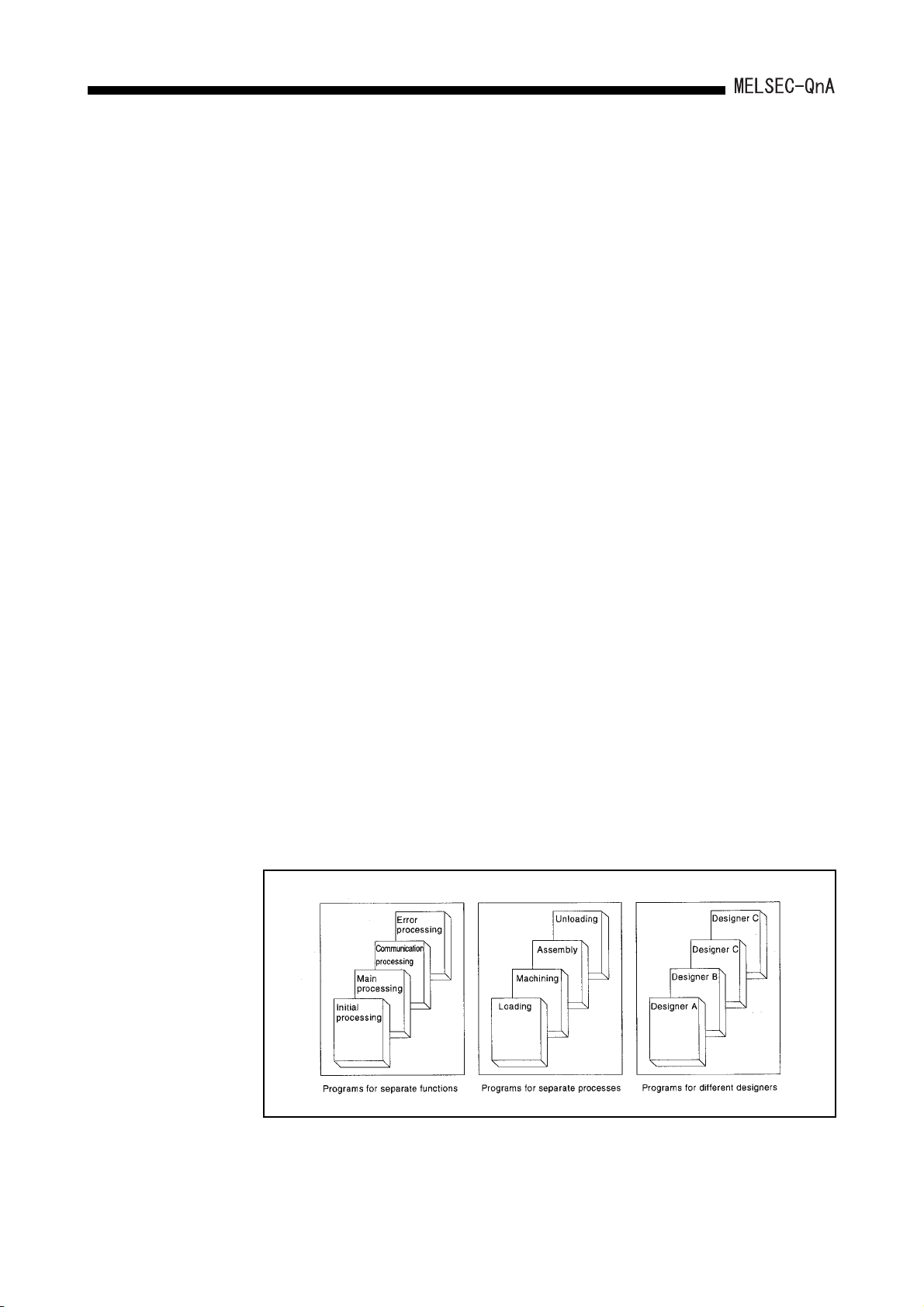

(5) A software development environment that improves program productivity has been

realized.

(a) In order to enable the design of structured programs, a file format has been

adopted for programs.

What would conventionally have been a single continuous program can now be

handled in a structured way as a number of files.

This allows for design work to be shared by several designers, and allows

management of programs in accordance with functions, processes, or

designers, etc.

2 - 2

Page 26

2. OVERVIEW

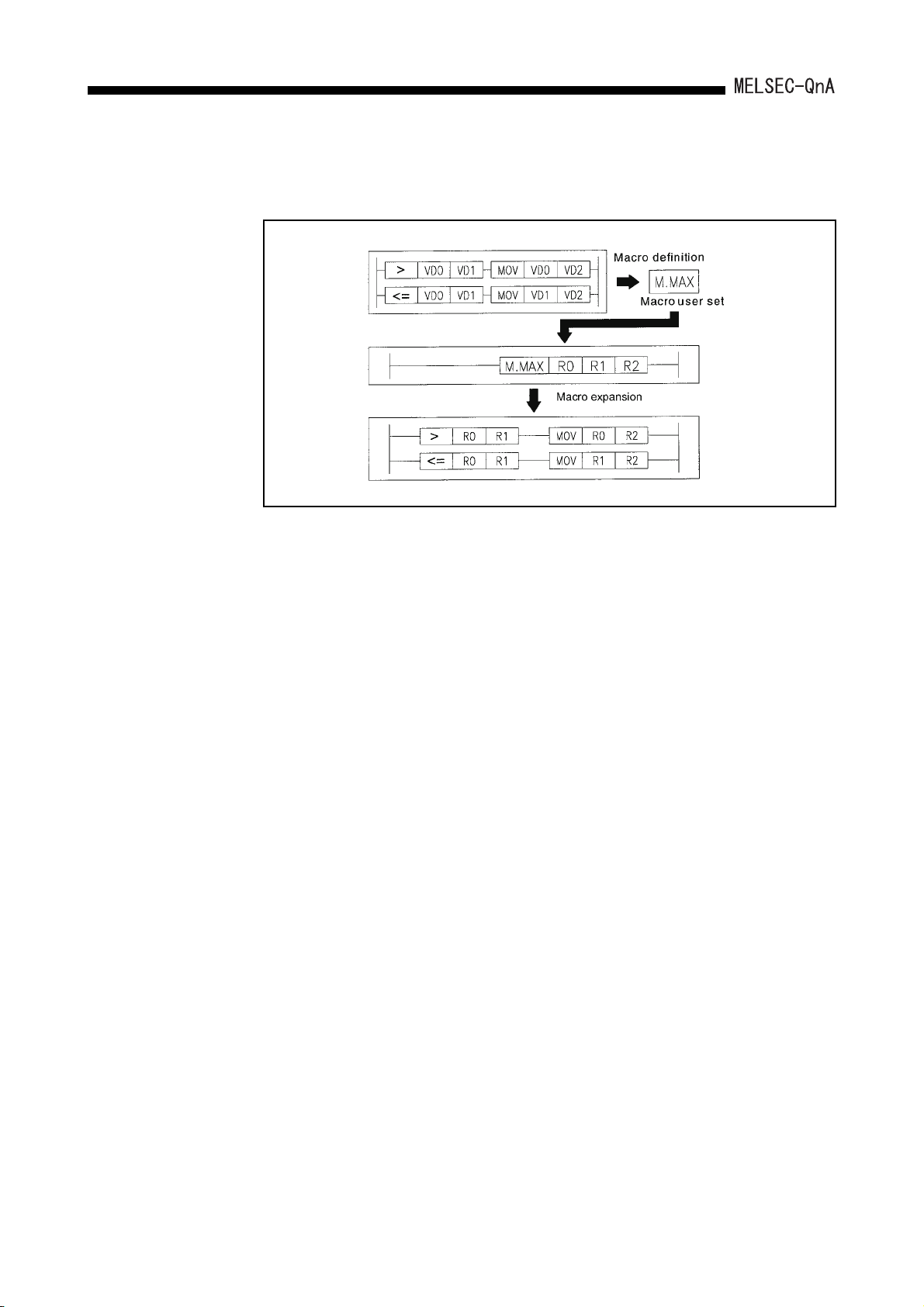

(b) The user can standardize and simplify programs by creating and using macro

instructions corresponding to functions.

(c) Devices can be used without restrictions.

1) Word device bit operations are possible.

2) Differential contacts can be used.

3) Buffer memories of special function modules can be accessed directly from a

program as devices.

4) The link data of network modules can be accessed directly from a program as

devices.

(d) Ease of operation for GPP function program editing has been improved.

1) Up to four programs, data, etc., can be edited simultaneously.

Programs and data can be cut and pasted between edited objects.

2) Ladder editing is possible while the ladder is displayed with comments.

3) Familiar operations can be performed with pull-down menus and dialog

boxes.

(e) The debugging function at start-up has been perfected.

1) Ladder modification while performing monitoring is possible.

2) Coil ON/OFF causes can be searched for.

3) The timing for monitoring can be set using a step number or device status,

allowing debugging to be conducted under the optimum conditions.

4) Devices for which index qualifications have been set can be monitored.

(f) The GPP function document creation function has been strengthened.

1) Since comments can now comprise 32 characters, they can be more detailed

than before.

2) Comments can now be set for all devices.

3) The statements and notes appended to programs can now be managed as

an integral part of the program, which makes program modifications and

utilization easier.

4) Printout data can be saved in a file.

2 - 3

Page 27

2. OVERVIEW

(g) A powerful array of support software packages is available for program creation.

1) Data conversion package

Comment data, device data, etc., which is created with spreadsheet software

and text editors available on the market, can be converted to files for GPP

function use.

Conversely, files created for GPP function use can be converted to data for

spreadsheets or text editors.

2) Macro/library package

The basic programs for accessing special function modules, and standard

programs for error detection, alarm processing, etc., have been brought

together as a package of macro and library data.

3) Ladder sequence linking package

This package is used to link multiple programs to make a single program.

This has an automatic allocation function that ensures that devices from each

program without duplicating in the created program.

4) CAD interface program

This package is used to handle sequence ladders, instruction lists, comment

data and SFC diagrams as CAD data and communicate these data to CAD

systems.

2 - 4

Page 28

2.

OVERVIEW

2.2 Additional Functions of QnACPU

New functions and instructions for special function module are added to the QnACPU.

[Additional functions]

Variety of local devices.................................................. Refer to Section 2.2.1 (1).

Monitor test of local device.................................. Refer to Section 8.2.2.

Use of local device at the subroutine/interrupt

program storage destination................................. Refer to Appendix 7.

Auto refresh setting of CC-Link...................................... Refer to Section 2.2.1 (2),

MELSECNET/10 relay communication from the

Ethernet module (Network relay).................................... Refer to Section 2.2.1 (3),

Addition of AJ71QC24N-compatible commands ............Section 2.2.1 (4)

Section 7.2.

Appendix 8.

[Added instructions for special function module]

The following instructions have been added for function version "B'' of the QnACPU:

AJ61QBT11 control instructions...................................... 13

AD75 control instructions................................................ 19

AJ71D -R4 control instructions.....................................

AJ71QE71 control instructions........................................ 10

Additional function/special function module instructions can be used for the QnACPU

described function version B in the date column of the rating plate.

Check that function version B is described on the QnACPU rating plate before using the

additional function/special function module instructions.

If your QnACPU does not have indication of function version B, skip this item and the

description of additional functions.

12

When using additional function/special function module instructions of the QnACPU, it is

necessary to match the GPP function model and the function version/version of the

applicable special function module. (Refer to Table 2.1.)

2 - 5

Page 29

2. OVERVIEW

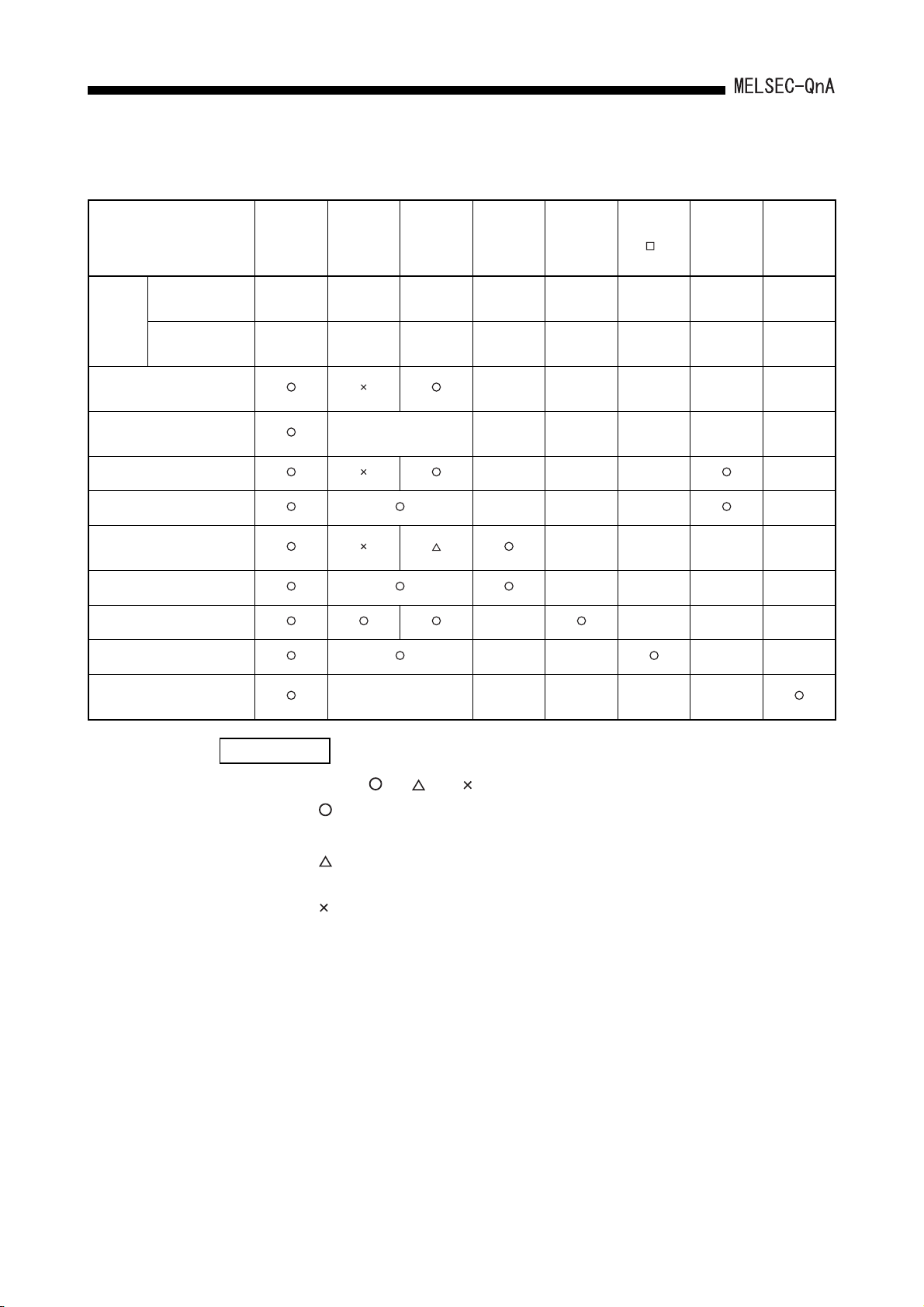

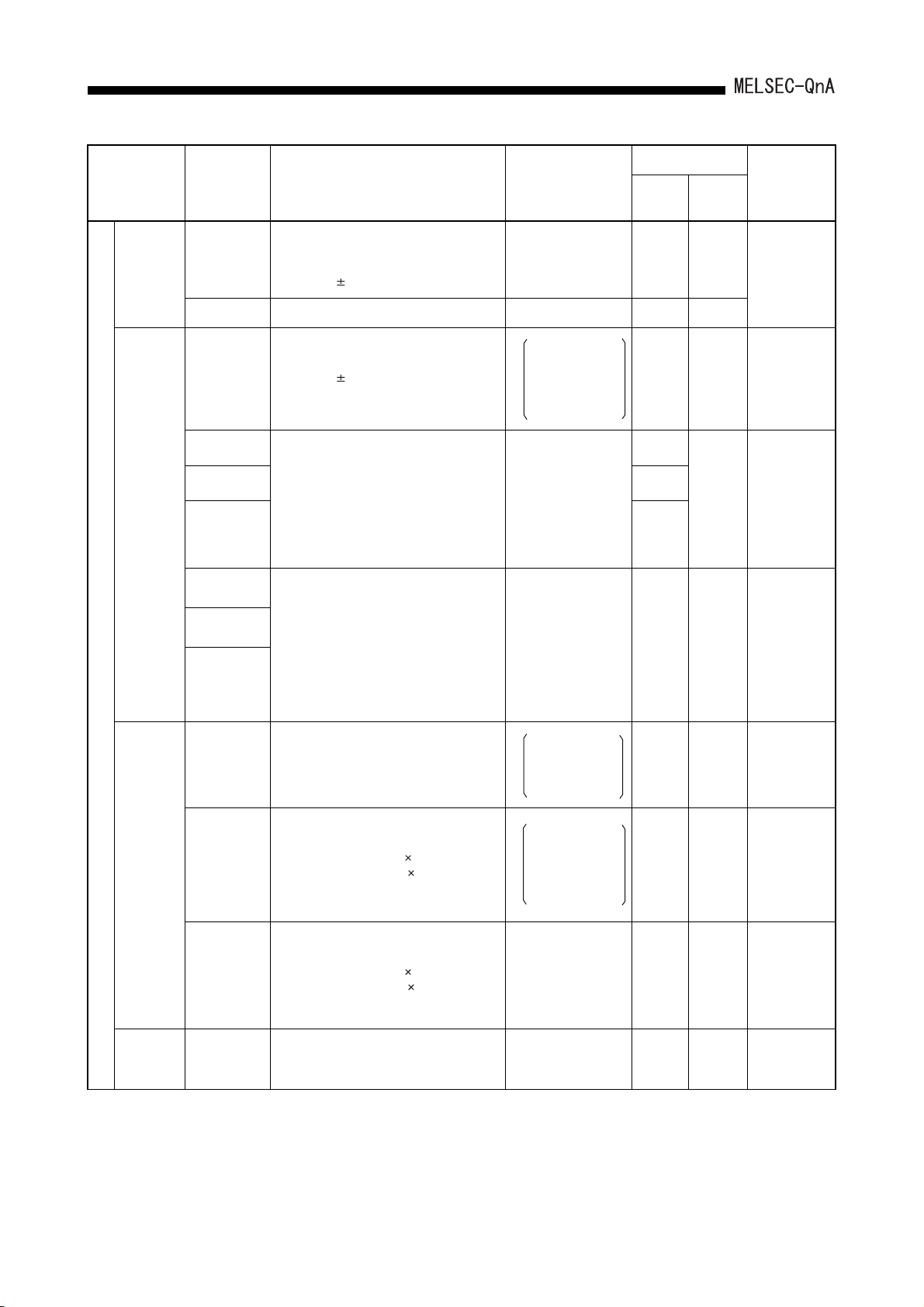

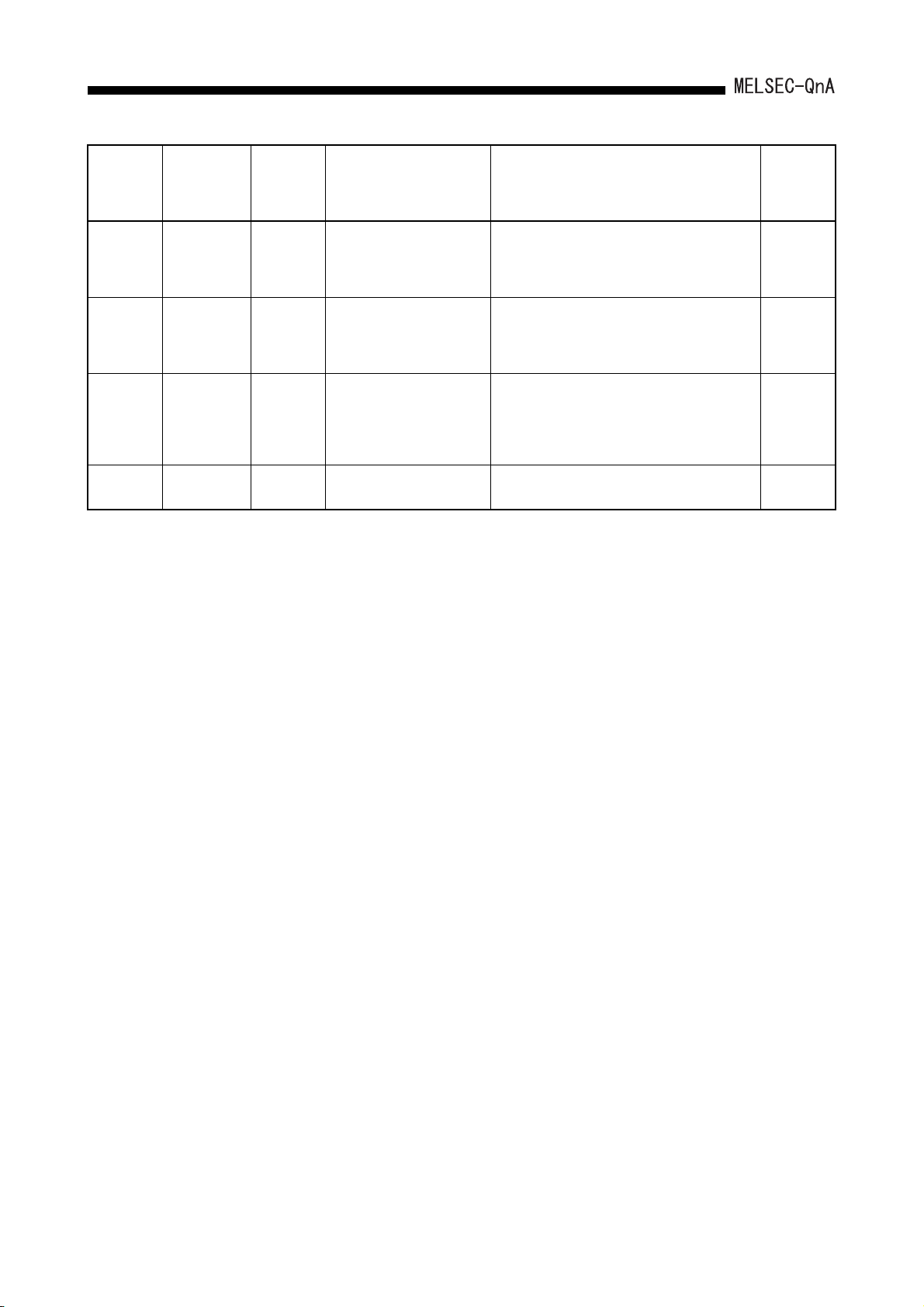

Table 2.1 List of combination between QnACPU and function version/version of special function module

SW0IVD-

Module/package Name QnACPU

Function version

Condition

Version –

Local device

monitor test

Local device switching of

subroutine/interrupt program

Auto refresh function of CC-Link – – – –

AJ61QBT11 control instructions – – – –

MELSECNET/10 relay

communication from Ethernet

AJ71QE71 control instructions – – – –

AD75 control instructions – – – –

ID interface module instructions – – – –

9707B and

later

GPPQ

SW1IVD-

GPPQ

––

No

restriction

SW2IVD-

GPPQ

No

restriction

– –––––

AJ71QE71

(B2), (B5)

9707B and

later

–

–––––

AD75P-S3

––

No

restriction

––––

AJ71

ID -R4

BC and later –

AJ61QBT11

9707B and

later

AJ71QC24

(N)(R2)

restriction

–

No

Compatibility with AJ71QC24N

commands

REMARK

–––––

1) Marks , –, and in Table 2.1 indicate as follows:

:

Essential for use of function and instruction

– :

Irrelevant to function and instruction

:

Required in the case of access to the QnACPU in other stations from

the peripheral device via Ethernet

:

Not available on peripheral devices.

2) GX Developer complies with functions of function version B.

2 - 6

Page 30

2.

OVERVIEW

2.2.1 Overview of added functions

This section shows an overview of the added functions.

(1) Variety of local device

(a) The device set as the local device at "Device" in Parameter can be monitored

and tested with a peripheral device.

This function allows checking and debug of the local device in the program

monitored with a peripheral device.

(b) The local device of the file where the subroutine program/interrupt program is

stored has made it possible to be used during execution of the subroutine

program/interrupt program.

For this function, even if an operation using the local device of the subroutine

program is carried out, the original local device cannot be overwritten. In

addition, even if an operation using the local device of the interrupt program, the

local device which is executed before starting up the interrupt program cannot be

overwritten.

(c) The following GPP function software packages are required to perform the

monitor test of the local device:

• Personal computer

GX Developer, SW2IVD-GPPQ type GPP function software package

(2) Auto refresh setting of CC-Link

(a) When setting auto refresh of the CC-Link on the peripheral function, cyclic

communication with other stations connected to the CC-Link can be

automatically performed according to the set auto refresh data.

• Remote I/O station (Communication in ON/OFF data)

• Remote device station (Communication in ON/OFF data and Word data)

• Intelligent device station (Communication in ON/OFF data and Word data)

• Local station/master station (Communication in ON/OFF data and Word data)

The auto refresh setting of the CC-Link allows communication with other stations

using the FROM/TO instruction without communicating with the master station of

the CC-Link.

(b) Auto refresh is available for up to 8 CC-Link modules for each unit of QnACPU.

Communication for 9th CC-Link module and more can be performed with the

CC-Link module using the FROM/TO instruction.

(c) The following GPP function software packages are required to perform the auto

refresh setting of the CC-Link:

• Personal computer:

GX Developer, SW2IVD-GPPQ type GPP function software package

It is necessary to upgrade the master station local station module of CC-Link to

function version B or later.

2 - 7

Page 31

2. OVERVIEW

(3) Netwotk relay from Ethernet module

(a) In the network system with mixture of Ethernet and MELSECNET/10, data can

be communicated with the QnACPU of other stations via multiple Ethernets or

MELSECNET/10 modules.

(b) For the network relay from the Ethernet module, the function version of the

Ethernet module should be upgraded to "B" or later.

(4) AJ71QC24N-compatible commands are possible.

(a) The following AJ71QC24N commands are available:

• Multiple blocks batch read: Command "0406"

• Multiple blocks batch write: Command "1406"

(b) Multiple blocks batch read/batch write is available with AJ71QC24N (-R2, R4).

Multiple blocks batch read/batch write is not available with AJ71QC24 (-R2, R4).

For commands of multiple blocks batch read/batch write, refer to the following

manual:

• Corresponding Additional Explanation for AJ71QC24N (-R2/R4)

2 - 8

Page 32

3.

SYSTEM CONFIGURATION

3 SYSTEM CONFIGURATION

This section describes the system configurations that can be used for a system centered

on a QnACPU, cautions on configuring the system, and the system equipment.

3.1 System Configuration

The following shows the configuration of equipment and peripheral device when a

QnACPU is used in a stand-alone system.

3.1.1 Equipment configuration in a stand-alone system

POINT

*1 Up to two memory cards can be installed, if required.

2

SRAM and E

CPU module.

*2 When using an A5 B extension base unit, pay particular attention to the

power supply capacity of the main base unit. In the case of I/O modules and

the special function module with a high internal current consumption,

mounting on an A6 B extension base unit is recommended.

(Refer to Section 16.1 and Section 17.3 for details.)

PROM memory cards allow file read/write when mounted on the

3 - 1

Page 33

3.

SYSTEM CONFIGURATION

3.1.2 Configuration of peripheral devices capable of QnACPU

(To RS-422 interface)

QnACPU

AC30R4-PUS cable

AC20R4-A8PU cable

RS-422 cable

Q6PU

programming unit

*2

RS-422 RS-232C

convertor

IBM-PC/AT-compatible

software package used:

RS-232C cable

*3

AJ71QC24 serial

communication module

(Mounted to the

base unit)

(To RS-422 interface/RS-232C)

(To option board slot)

Option board

*2

RS-232C cable

Dedicated cable

IBM-PC/AT-compatible

software package used:

IC memory card

reader/writer

*1

*1 For details on the IC memory card reader/writer setting, refer to Operating Manual for the

peripheral device capable of GPP functions.

*2 For connection to RS-422 interface, use the RS-422 RS-232C converter.

*3 When connecting the serial communication module and the peripheral devices capable of

GPP function, see User's Manual of the serial communication modules.

REMARK

1. For details on the system configuration for each peripheral device, refer to

the Operating Manual for each.

2. QnACPU can connect a peripheral device capable of ACPU only when

accessing an ACPU in another station via a MELSECNET/10 or

MELSECNET data link. (However, QnACPU cannot be accessed. ) In this

case, set SW2 of system setting switch 2 on the CPU module ON.

3 - 2

Page 34

3.

SYSTEM CONFIGURATION

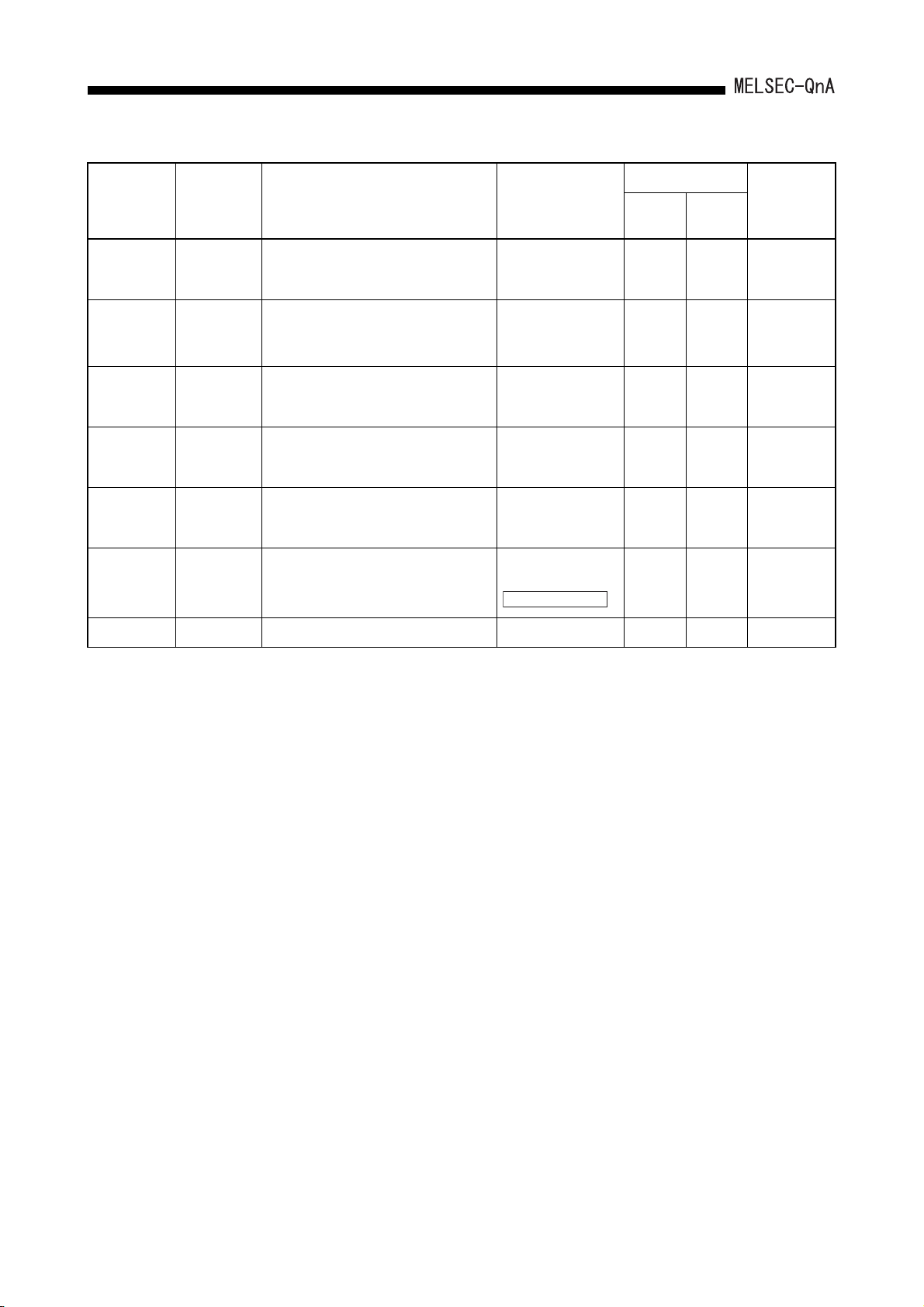

3.2 System Configuration Overview

(a) Q2ACPU system

System configuration

Maximum number of

extension stages

Maximum number of I/O

modules

Maximum number of I/O

points

Main base unit model

name

Extension base unit

model name

Extension cable model

name

Precautions

I/O number assignment

* An example when the 16-point module is installed to each slot is shown.

3rd extension stage

32 modules

512 points

A32B, A32B-S1, A35B, A38B, A38HB, A38HBEU

A62B, A65B, A68B, A52B, A55B, A58B

AC06B, AC12B, AC30B

(1) It is not possible to connect an extension base unit to an A32B main base unit. For an extension base, use A32B-S1.

(2) When using the extension base unit A52B, A55B, A58B, 5VDC is supplied from the power supply module of the main

base unit. Before use, refer to Section 17.3 and examine if it can be used.

(3) The overall distance of the extension cable must be 6.6m (21.65ft.) or shorter.

(4) When using the extension cable, do not tie it with the main circuit cables, which has high voltage, large current, or install

them close to each other.

(1) I/O numbers are allocated in accordance with the order of the numbers set for the extension base stages, regardless of

the order in which the extension cables are connected.

(2) Assign I/O numbers as if both main base unit and extension base unit have 8 slots each.

Consequently, allocations of 16 points per slot are made for the parts of the system configuration drawing indicated with

dotted lines.

(3) 16 points are assigned to an empty slot.

(4) Extension stage numbers do not need to be sequential, but any extension stage omitted from the system will occupy 8

(slots) 16 I/O points.

(5) With regard to items (2) to (4) above, the I/O allocations can be changed by setting I/O allocations in the

parameters.(Refer to Section 5.3)

3 - 3

Page 35

3. SYSTEM CONFIGURATION

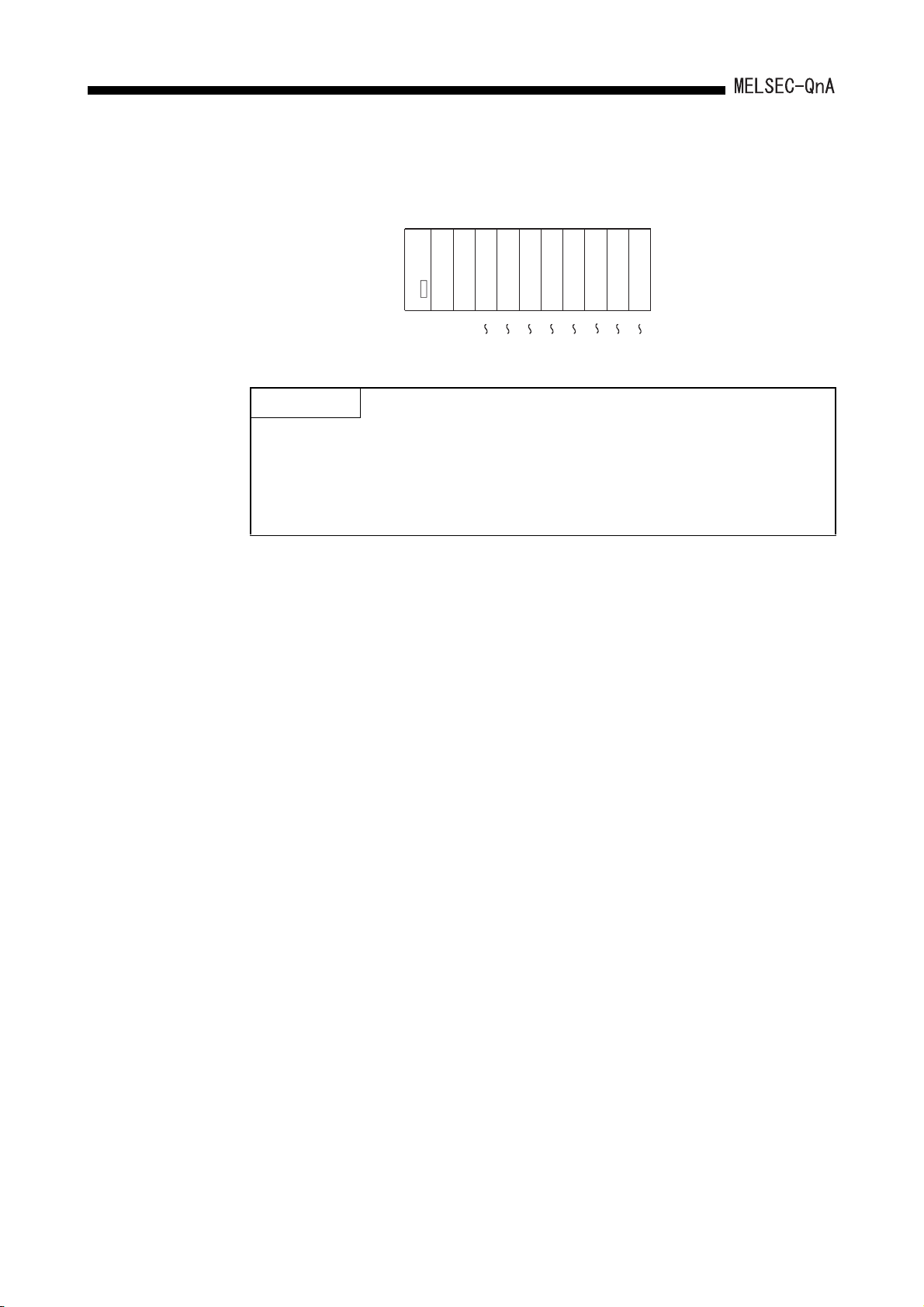

(b) Q2ACPU-S1 system

Extension

cable

1st extension

stage

2nd extension

stage

System configuration

3rd extension

stage

4th extension

stage

Main base unit (A38B)

0

23

1

CF

20

14F

1B0

1BF

230

23F

20

2F

12

C0

27

35

30

3F 4F

13

D0

DF

(21)(22)

150140

160

16F

15F

28

1C0

1D0

1DF

1CF

36

250