Page 1

Motion Controllers

MITSUBISHI ELECTRIC

MITSUBISHI ELECTRIC

Programming Manual

Common

01 01 2008

B(NA)-0300134

Version A

Q173DCPU

Q172DCPU

INDUSTRIAL AUTOMATION

Page 2

SAFETY PRECAUTIONS

(Please read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

These precautions apply only to this product. Refer to the Q173DCPU/Q172DCPU Users manual for a

description of the Motion controller safety precautions.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

Indicates that incorrect handling may cause hazardous

Depending on circumstances, procedures indicated by

results.

In any case, it is important to follow the directions for usage.

Please save this manual to make it accessible when required and always forward it to the end user.

DANGER

CAUTION

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

CAUTION may also be linked to serious

A - 1

Page 3

For Safe Operations

1. Prevention of electric shocks

DANGER

Never open the front case or terminal covers while the power is ON or the unit is running, as this

may lead to electric shocks.

Never run the unit with the front case or terminal cover removed. The high voltage terminal and

charged sections will be exposed and may lead to electric shocks.

Never open the front case or terminal cover at times other than wiring work or periodic

inspections even if the power is OFF. The insides of the Motion controller and servo amplifier are

charged and may lead to electric shocks.

Completely turn off the externally supplied power used in the system before mounting or removing the

module, performing wiring work, or inspections. Failing to do so may lead to electric shocks.

When performing wiring work or inspections, turn the power OFF, wait at least ten minutes, and

then check the voltage with a tester, etc.. Failing to do so may lead to electric shocks.

Be sure to ground the Motion controller, servo amplifier and servomotor. (Ground resistance :

or less) Do not ground commonly with other devices.

100

The wiring work and inspections must be done by a qualified technician.

Wire the units after installing the Motion controller, servo amplifier and servomotor. Failing to do

so may lead to electric shocks or damage.

Never operate the switches with wet hands, as this may lead to electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this

may lead to electric shocks.

Do not touch the Motion controller, servo amplifier or servomotor terminal blocks while the power

is ON, as this may lead to electric shocks.

Do not touch the built-in power supply, built-in grounding or signal wires of the Motion controller

and servo amplifier, as this may lead to electric shocks.

2. For fire prevention

CAUTION

Install the Motion controller, servo amplifier, servomotor and regenerative resistor on

incombustible. Installing them directly or close to combustibles will lead to fire.

If a fault occurs in the Motion controller or servo amplifier, shut the power OFF at the servo

amplifier’s power source. If a large current continues to flow, fire may occur.

When using a regenerative resistor, shut the power OFF with an error signal. The regenerative

resistor may abnormally overheat due to a fault in the regenerative transistor, etc., and may lead

to fire.

Always take heat measures such as flame proofing for the inside of the control panel where the

servo amplifier or regenerative resistor is installed and for the wires used. Failing to do so may

lead to fire.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this may

lead to fire.

A - 2

Page 4

3. For injury prevention

CAUTION

Do not apply a voltage other than that specified in the instruction manual on any terminal.

Doing so may lead to destruction or damage.

Do not mistake the terminal connections, as this may lead to destruction or damage.

Do not mistake the polarity ( + / - ), as this may lead to destruction or damage.

Do not touch the heat radiating fins of controller or servo amplifier, regenerative resistor and

servomotor, etc., while the power is ON and for a short time after the power is turned OFF. In this

timing, these parts become very hot and may lead to burns.

Always turn the power OFF before touching the servomotor shaft or coupled machines, as these

parts may lead to injuries.

Do not go near the machine during test operations or during operations such as teaching.

Doing so may lead to injuries.

4. Various precautions

Strictly observe the following precautions.

Mistaken handling of the unit may lead to faults, injuries or electric shocks.

(1) System structure

CAUTION

Always install a leakage breaker on the Motion controller and servo amplifier power source.

If installation of an electromagnetic contactor for power shut off during an error, etc., is specified in

the instruction manual for the servo amplifier, etc., always install the electromagnetic contactor.

Install the emergency stop circuit externally so that the operation can be stopped immediately and

the power shut off.

Use the Motion controller, servo amplifier, servomotor and regenerative resistor with the correct

combinations listed in the instruction manual. Other combinations may lead to fire or faults.

Use the CPU module, base unit and motion module with the correct combinations listed in the

instruction manual. Other combinations may lead to faults.

If safety standards (ex., robot safety rules, etc.,) apply to the system using the Motion controller,

servo amplifier and servomotor, make sure that the safety standards are satisfied.

Construct a safety circuit externally of the Motion controller or servo amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in the

system.

In systems where coasting of the servomotor will be a problem during the forced stop, emergency

stop, servo OFF or power supply OFF, use dynamic brakes.

Make sure that the system considers the coasting amount even when using dynamic brakes.

In systems where perpendicular shaft dropping may be a problem during the forced stop,

emergency stop, servo OFF or power supply OFF, use both dynamic brakes and electromagnetic

brakes.

A - 3

Page 5

CAUTION

The dynamic brakes must be used only on errors that cause the forced stop, emergency stop, or

servo OFF. These brakes must not be used for normal braking.

The brakes (electromagnetic brakes) assembled into the servomotor are for holding applications,

and must not be used for normal braking.

The system must have a mechanical allowance so that the machine itself can stop even if the

stroke limits switch is passed through at the max. speed.

Use wires and cables that have a wire diameter, heat resistance and bending resistance

compatible with the system.

Use wires and cables within the length of the range described in the instruction manual.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier and

servomotor.

Install a cover on the shaft so that the rotary parts of the servomotor are not touched during

operation.

There may be some cases where holding by the electromagnetic brakes is not possible due to the

life or mechanical structure (when the ball screw and servomotor are connected with a timing belt,

etc.). Install a stopping device to ensure safety on the machine side.

(2) Parameter settings and programming

CAUTION

Set the parameter values to those that are compatible with the Motion controller, servo amplifier,

servomotor and regenerative resistor model and the system application. The protective functions

may not function if the settings are incorrect.

The regenerative resistor model and capacity parameters must be set to values that conform to

the operation mode, servo amplifier and servo power supply module. The protective functions

may not function if the settings are incorrect.

Set the mechanical brake output and dynamic brake output validity parameters to values that are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Set the stroke limit input validity parameter to a value that is compatible with the system

application. The protective functions may not function if the setting is incorrect.

Set the servomotor encoder type (increment, absolute position type, etc.) parameter to a value

that is compatible with the system application. The protective functions may not function if the

setting is incorrect.

Set the servomotor capacity and type (standard, low-inertia, flat, etc.) parameter to values that

are compatible with the system application. The protective functions may not function if the

settings are incorrect.

Set the servo amplifier capacity and type parameters to values that are compatible with the

system application. The protective functions may not function if the settings are incorrect.

A - 4

Page 6

CAUTION

Use the program commands for the program with the conditions specified in the instruction

manual.

Set the sequence function program capacity setting, device capacity, latch validity range, I/O

assignment setting, and validity of continuous operation during error detection to values that are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Some devices used in the program have fixed applications, so use these with the conditions

specified in the instruction manual.

The input devices and data registers assigned to the link will hold the data previous to when

communication is terminated by an error, etc. Thus, an error correspondence interlock program

specified in the instruction manual must be used.

Use the interlock program specified in the intelligent function module's instruction manual for the

program corresponding to the intelligent function module.

(3) Transportation and installation

CAUTION

Transport the product with the correct method according to the mass.

Use the servomotor suspension bolts only for the transportation of the servomotor. Do not

transport the servomotor with machine installed on it.

Do not stack products past the limit.

When transporting the Motion controller or servo amplifier, never hold the connected wires or

cables.

When transporting the servomotor, never hold the cables, shaft or detector.

When transporting the Motion controller or servo amplifier, never hold the front case as it may fall

off.

When transporting, installing or removing the Motion controller or servo amplifier, never hold the

edges.

Install the unit according to the instruction manual in a place where the mass can be withstood.

Do not get on or place heavy objects on the product.

Always observe the installation direction.

Keep the designated clearance between the Motion controller or servo amplifier and control panel

inner surface or the Motion controller and servo amplifier, Motion controller or servo amplifier and

other devices.

Do not install or operate Motion controller, servo amplifiers or servomotors that are damaged or

that have missing parts.

Do not block the intake/outtake ports of the Motion controller, servo amplifier and servomotor with

cooling fan.

Do not allow conductive matter such as screw or cutting chips or combustible matter such as oil

enter the Motion controller, servo amplifier or servomotor.

A - 5

Page 7

CAUTION

The Motion controller, servo amplifier and servomotor are precision machines, so do not drop or

apply strong impacts on them.

Securely fix the Motion controller, servo amplifier and servomotor to the machine according to

the instruction manual. If the fixing is insufficient, these may come off during operation.

Always install the servomotor with reduction gears in the designated direction. Failing to do so

may lead to oil leaks.

Store and use the unit in the following environmental conditions.

Environment

Ambient

temperature

Ambient humidity

Storage

temperature

Atmosphere

Altitude

Vibration

Motion controller/Servo amplifier Servomotor

According to each instruction manual.

According to each instruction manual.

According to each instruction manual.

Indoors (where not subject to direct sunlight).

No corrosive gases, flammable gases, oil mist or dust must exist

1000m (3280.84ft.) or less above sea level

According to each instruction manual

Conditions

0°C to +40°C (With no freezing)

(32°F to +104°F)

80% RH or less

(With no dew condensation)

-20°C to +65°C

(-4°F to +149°F)

When coupling with the synchronous encoder or servomotor shaft end, do not apply impact such

as by hitting with a hammer. Doing so may lead to detector damage.

Do not apply a load larger than the tolerable load onto the synchronous encoder and servomotor

shaft. Doing so may lead to shaft breakage.

When not using the module for a long time, disconnect the power line from the Motion controller

or servo amplifier.

Place the Motion controller and servo amplifier in static electricity preventing vinyl bags and store.

When storing for a long time, please contact with our sales representative.

Also, execute a trial operation.

A - 6

Page 8

(4) Wiring

CAUTION

Correctly and securely wire the wires. Reconfirm the connections for mistakes and the terminal

screws for tightness after wiring. Failing to do so may lead to run away of the servomotor.

After wiring, install the protective covers such as the terminal covers to the original positions.

Do not install a phase advancing capacitor, surge absorber or radio noise filter (option FR-BIF)

on the output side of the servo amplifier.

Correctly connect the output side (terminal U, V, W). Incorrect connections will lead the

servomotor to operate abnormally.

Do not connect a commercial power supply to the servomotor, as this may lead to trouble.

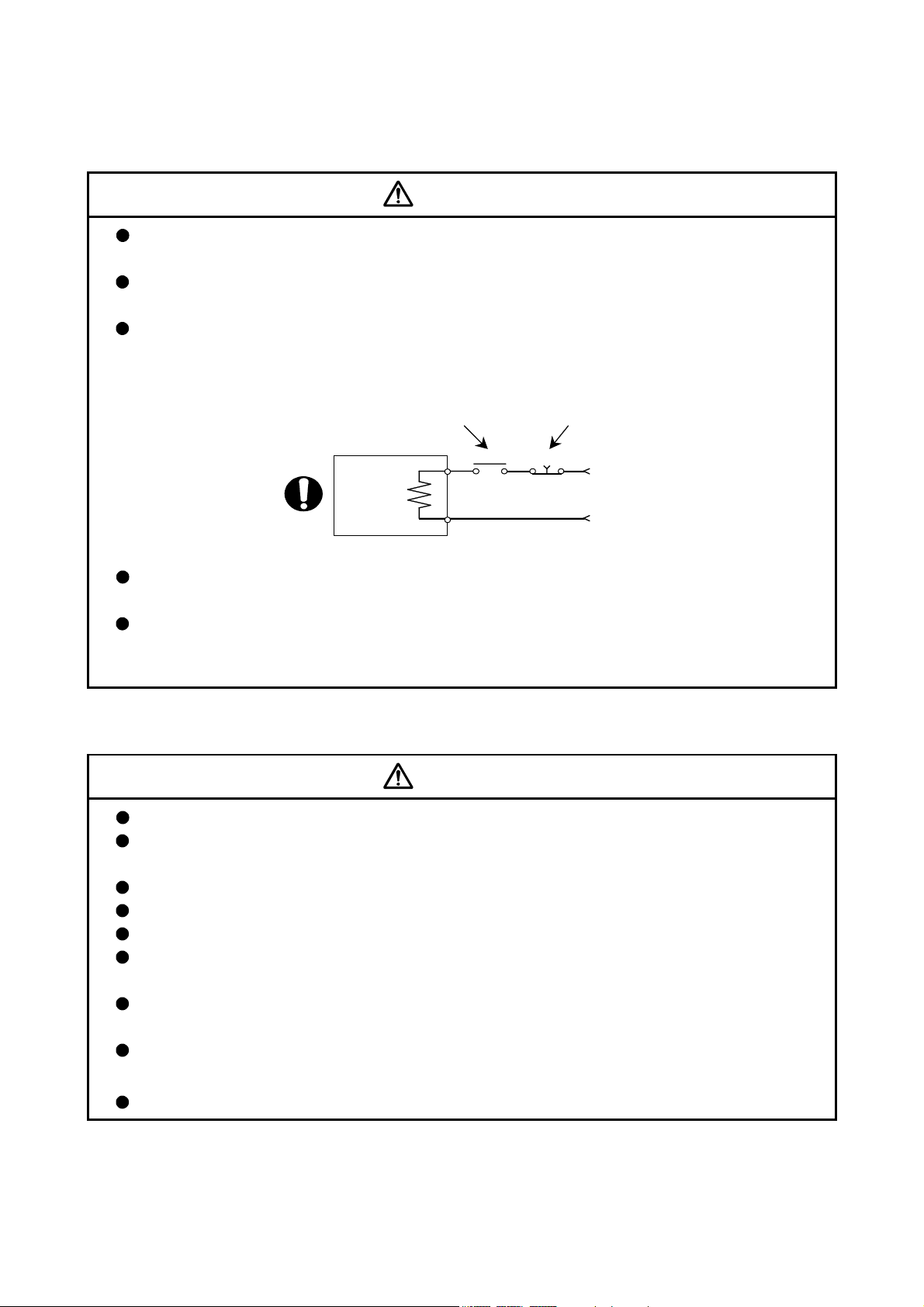

Do not mistake the direction of the surge absorbing diode

installed on the DC relay for the control signal output of brake

signals, etc. Incorrect installation may lead to signals not being

output when trouble occurs or the protective functions not

functioning.

Do not connect or disconnect the connection cables between

each unit, the encoder cable or PLC expansion cable while the

power is ON.

Securely tighten the cable connector fixing screws and fixing mechanisms. Insufficient fixing may

lead to the cables combing off during operation.

Do not bundle the power line or cables.

Servo amplifier

VIN

(24VDC)

Control output

signal

RA

(5) Trial operation and adjustment

CAUTION

Confirm and adjust the program and each parameter before operation. Unpredictable

movements may occur depending on the machine.

Extreme adjustments and changes may lead to unstable operation, so never make them.

When using the absolute position system function, on starting up, and when the Motion

controller or absolute value motor has been replaced, always perform a home position return.

A - 7

Page 9

(6) Usage methods

CAUTION

Immediately turn OFF the power if smoke, abnormal sounds or odors are emitted from the Motion

controller, servo amplifier or servomotor.

Always execute a test operation before starting actual operations after the program or

parameters have been changed or after maintenance and inspection.

Do not attempt to disassemble and repair the units excluding a qualified technician whom our

company recognized.

Do not make any modifications to the unit.

Keep the effect or electromagnetic obstacles to a minimum by installing a noise filter or by using

wire shields, etc. Electromagnetic obstacles may affect the electronic devices used near the

Motion controller or servo amplifier.

When using the CE Mark-compliant equipment, refer to the "EMC Installation Guidelines" (data

number IB(NA)-67339) for the Motion controllers and refer to the corresponding EMC guideline

information for the servo amplifiers, inverters and other equipment.

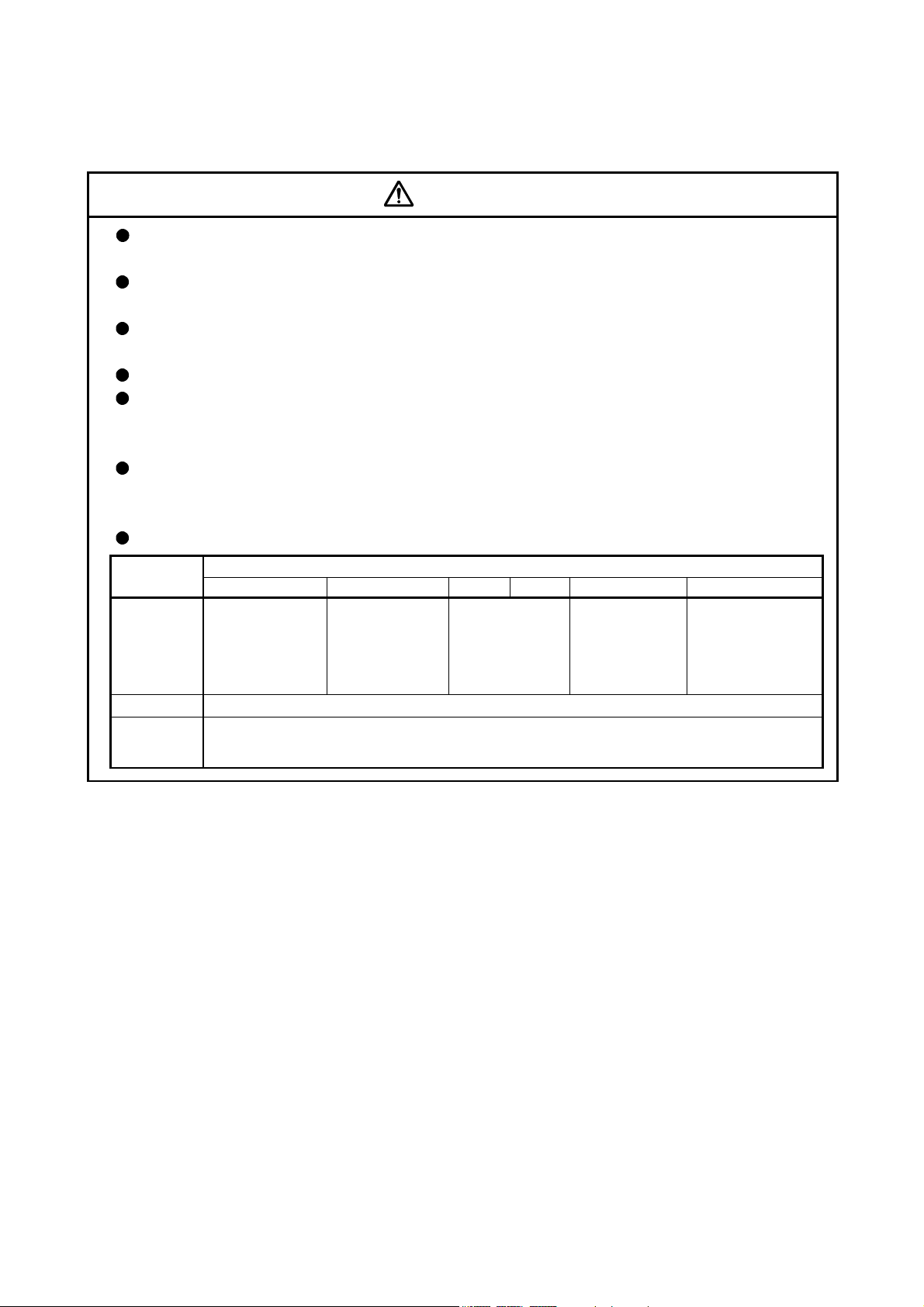

Use the units with the following conditions.

Item

Input power

Input frequency 50/60Hz ±5%

Tolerable

momentary

power failure

Q61P-A1 Q61P-A2 Q61P Q62P Q63P Q64P

100 to 120VAC

(85 to 132VAC) (170 to 264VAC) (85 to 264VAC) (15.6 to 31.2VDC)

+10% +10% +10% +30% +10%

200 to 240VAC

-15%

200 to 240VAC

-15%

Conditions

100 to 240VAC

20ms or less

-15%

24VDC

-35%

100 to 120VAC

(85 to 132VAC/

170 to 264VAC)

-15%

+10%

-15%

/

A - 8

Page 10

(7) Corrective actions for errors

CAUTION

If an error occurs in the self diagnosis of the Motion controller or servo amplifier, confirm the

check details according to the instruction manual, and restore the operation.

If a dangerous state is predicted in case of a power failure or product failure, use a servomotor

with electromagnetic brakes or install a brake mechanism externally.

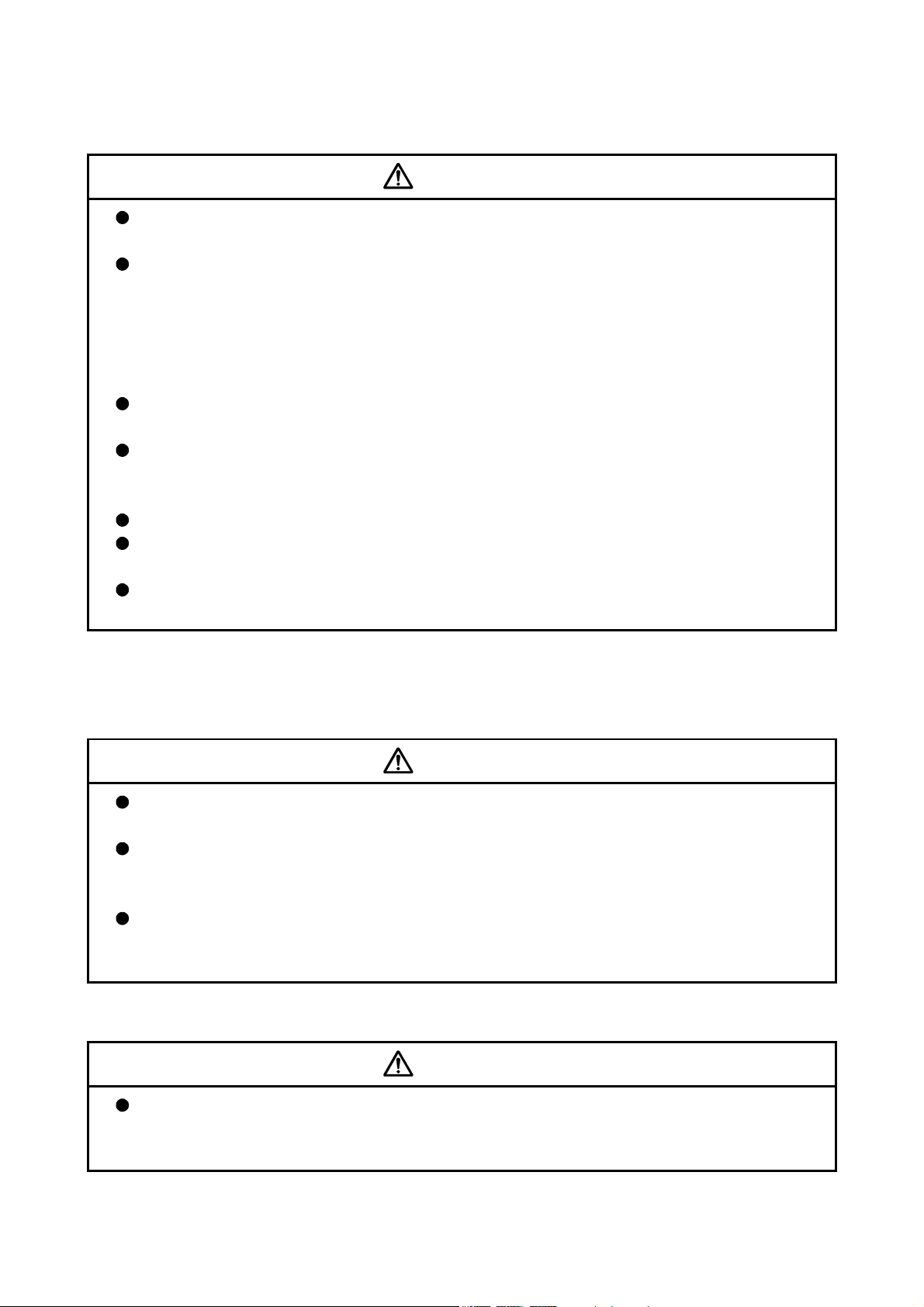

Use a double circuit construction so that the electromagnetic brake operation circuit can be

operated by emergency stop signals set externally.

Shut off with the

Shut off with servo ON signal OFF,

alarm, electromagnetic brake signal.

Servomotor

Electromagnetic

brakes

RA1

emergency stop

signal(EMG).

EMG

24VDC

If an error occurs, remove the cause, secure the safety and then resume operation after alarm

release.

The unit may suddenly resume operation after a power failure is restored, so do not go near the

machine. (Design the machine so that personal safety can be ensured even if the machine

restarts suddenly.)

(8) Maintenance, inspection and part replacement

CAUTION

Perform the daily and periodic inspections according to the instruction manual.

Perform maintenance and inspection after backing up the program and parameters for the Motion

controller and servo amplifier.

Do not place fingers or hands in the clearance when opening or closing any opening.

Periodically replace consumable parts such as batteries according to the instruction manual.

Do not touch the lead sections such as ICs or the connector contacts.

Before touching the module, always touch grounded metal, etc. to discharge static electricity from

human body. Failure to do so may cause the module to fail or malfunction.

Do not directly touch the module's conductive parts and electronic components.

Touching them could cause an operation failure or give damage to the module.

Do not place the Motion controller or servo amplifier on metal that may cause a power leakage

or wood, plastic or vinyl that may cause static electricity buildup.

Do not perform a megger test (insulation resistance measurement) during inspection.

A - 9

Page 11

CAUTION

When replacing the Motion controller or servo amplifier, always set the new module settings

correctly.

When the Motion controller or absolute value motor has been replaced, carry out a home position

return operation using one of the following methods, otherwise position displacement could occur.

1) After writing the servo data to the Motion controller using programming software, switch on the

power again, then perform a home position return operation.

2) Using the backup function of the programming software, load the data backed up before

replacement.

After maintenance and inspections are completed, confirm that the position detection of the

absolute position detector function is correct.

Do not drop or impact the battery installed to the module.

Doing so may damage the battery, causing battery liquid to leak in the battery. Do not use the

dropped or impacted battery, but dispose of it.

Do not short circuit, charge, overheat, incinerate or disassemble the batteries.

The electrolytic capacitor will generate gas during a fault, so do not place your face near the

Motion controller or servo amplifier.

The electrolytic capacitor and fan will deteriorate. Periodically replace these to prevent secondary

damage from faults. Replacements can be made by our sales representative.

(9) About processing of waste

When you discard Motion controller, servo amplifier, a battery (primary battery) and other option articles,

please follow the law of each country (area).

CAUTION

This product is not designed or manufactured to be used in equipment or systems in situations

that can affect or endanger human life.

When considering this product for operation in special applications such as machinery or systems

used in passenger transportation, medical, aerospace, atomic power, electric power, or

submarine repeating applications, please contact your nearest Mitsubishi sales representative.

Although this product was manufactured under conditions of strict quality control, you are strongly

advised to install safety devices to forestall serious accidents when it is used in facilities where a

breakdown in the product is likely to cause a serious accident.

(10) General cautions

CAUTION

All drawings provided in the instruction manual show the state with the covers and safety

partitions removed to explain detailed sections. When operating the product, always return the

covers and partitions to the designated positions, and operate according to the instruction manual.

A - 10

Page 12

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jan., 2008 IB(NA)-0300134-A First edition

Japanese Manual Number IB(NA)-0300126

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2008 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 13

INTRODUCTION

Thank you for choosing the Mitsubishi Motion controller Q173DCPU/Q172DCPU.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Motion controller you have purchased, so as to ensure correct use.

CONTENTS

Safety Precautions .................................................................................................................................. A- 1

Revisions................................................................................................................................................. A-11

Contents.................................................................................................................................................. A-12

About Manuals ........................................................................................................................................ A-14

1. OVERVIEW 1- 1 to 1-20

1.1 Overview ........................................................................................................................................... 1- 1

1.2 Features ............................................................................................................................................ 1- 3

1.2.1 Features of Motion CPU ................................................................................................................... 1- 3

1.2.2 Basic specifications of Q173DCPU/Q172DCPU ............................................................................. 1- 5

1.3 Hardware Configuration .................................................................................................................... 1- 8

1.3.1 Motion system configuration ............................................................................................................. 1- 8

1.3.2 Q173DCPU System overall configuration ........................................................................................ 1-10

1.3.3 Q172DCPU System overall configuration ........................................................................................ 1-12

1.3.4 Software packages............................................................................................................................ 1-14

1.3.5 Restrictions on motion systems ........................................................................................................ 1-17

2. MULTIPLE CPU SYSTEM 2- 1 to 2-32

2.1 Multiple CPU System ........................................................................................................................ 2- 1

2.1.1 Overview ............................................................................................................................................ 2- 1

2.1.2 Installation position of CPU module.................................................................................................. 2- 2

2.1.3 Precautions for using I/O modules and intelligent function modules............................................... 2- 3

2.1.4 Modules subject to installation restrictions ....................................................................................... 2- 4

2.1.5 How to reset the Multiple CPU system ............................................................................................. 2- 5

2.1.6 Operation for CPU module stop error............................................................................................... 2- 6

2.2 Starting Up the Multiple CPU System............................................................................................... 2- 9

2.2.1 Startup Flow of the Multiple CPU System ........................................................................................2- 9

2.3 Communication between the PLC CPU and the Motion CPU in the Multiple CPU System ............. 2-11

2.3.1 CPU shared Memory......................................................................................................................... 2-11

2.3.2 Multiple CPU high speed transmission............................................................................................. 2-14

2.3.3 Multiple CPU high speed refresh function........................................................................................ 2-25

2.3.4 Clock synchronization between Multiple CPU ................................................................................. 2-29

2.3.5 Multiple CPU synchronous startup ...................................................................................................2-30

2.3.6 Control Instruction from PLC CPU to Motion CPU .......................................................................... 2-31

3. COMMON PARAMETERS 3- 1 to 3-22

3.1 System Settings ................................................................................................................................ 3- 1

3.1.1 System data settings ......................................................................................................................... 3- 2

3.1.2 Common system parameters ........................................................................................................... 3- 4

A - 12

Page 14

3.1.3 Individual parameters ........................................................................................................................ 3-10

3.2 I/O number assignment..................................................................................................................... 3-15

3.2.1 I/O number assignment of each module .......................................................................................... 3-15

3.2.2 I/O number of each CPU modules ................................................................................................... 3-17

3.2.3 I/O number setting............................................................................................................................. 3-18

3.3 Servo Parameters ............................................................................................................................. 3-19

4. AUXILIARY AND APPLIED FUNCTIONS 4- 1 to 4-44

4.1 Limit Switch Output Function ............................................................................................................ 4- 1

4.1.1 Operations ......................................................................................................................................... 4- 1

4.1.2 Limit output setting data .................................................................................................................... 4- 4

4.2 Absolute Position System ................................................................................................................. 4- 8

4.2.1 Current value control ......................................................................................................................... 4-10

4.3 High-Speed Reading of Specified Data ............................................................................................ 4-11

4.4 ROM Operation Function .................................................................................................................. 4-12

4.4.1 Specifications of 7-segment LED/Switches...................................................................................... 4-12

4.4.2 Outline of ROM operation ................................................................................................................. 4-14

4.4.3 Operating procedure of the ROM operation function....................................................................... 4-19

4.5 Security Function .............................................................................................................................. 4-21

4.5.1 Password registration/change .......................................................................................................... 4-21

4.5.2 Password delete................................................................................................................................ 4-23

4.5.3 Password check ................................................................................................................................ 4-24

4.5.4 Password save .................................................................................................................................. 4-25

4.6 All clear function................................................................................................................................ 4-26

4.7 Communication via Network ............................................................................................................. 4-27

4.7.1 Specifications of the communications via network........................................................................... 4-27

4.7.2 Access range of the communications via network ........................................................................... 4-28

4.8 Monitor Function of the Main Cycle .................................................................................................. 4-33

4.9 Servo Parameter Reading Function.................................................................................................. 4-34

4.10 Optional Data Monitor Function ...................................................................................................... 4-35

4.11 Connect/Disconnect Function ......................................................................................................... 4-36

4.12 Remote operation ........................................................................................................................... 4-41

4.12.1 Remote RUN/STOP ........................................................................................................................ 4-41

4.12.2 Remote latch clear .......................................................................................................................... 4-43

APPENDICES APP- 1 to APP-35

APPENDIX 1 Special relays/Special registers ................................................................................... APP- 1

APPENDIX 1.1 Special relays ..............................................................................................................APP- 1

APPENDIX 1.2 Special registers .....................................................................................................APP- 5

APPENDIX 1.3 Replacement of special relays/special registers ........................................................APP-11

APPENDIX 2 System Setting Errors.................................................................................................. APP-13

APPENDIX 3 Self-diagnosis error code............................................................................................. APP-15

APPENDIX 4 Differences Between Q173DCPU/Q172DCPU and Q173HCPU/Q172HCPU ............ APP-26

APPENDIX 4.1 Differences Between Q173DCPU/Q172DCPU and Q173HCPU/Q172HCPU .........APP-26

APPENDIX 4.2 Comparison of devices................................................................................................APP-28

APPENDIX 4.3 Differences of each mode ...........................................................................................APP-35

A - 13

Page 15

About Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

(1) Motion controller

Q173DCPU/Q172DCPU Motion controller User's Manual

This manual explains specifications of the Motion CPU modules, Q172DLX Servo external signal interface

module, Q172DEX Synchronous encoder interface module, Q173DPX Manual pulse generator interface

module, Power supply modules, Servo amplifiers, SSCNET

others.

(Optional)

Q173DCPU/Q172DCPU Motion controller (SV13/SV22) Programming Manual (Motion SFC)

This manual explains the functions, programming, debugging, error lists and others for Motion SFC.

(Optional)

Manual Name

cables, Synchronous encoder cables and

Manual Number

(Model Code)

IB-0300133

(1XB927)

IB-0300135

(1XB929)

Q173DCPU/Q172DCPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)

This manual explains the servo parameters, positioning instructions, device lists, error lists and others.

(Optional)

Q173DCPU/Q172DCPU Motion controller (SV22) Programming Manual (VIRTUAL MODE)

This manual explains the dedicated instructions to use the synchronous control by virtual main shaft,

mechanical system program create mechanical module, servo parameters, positioning instructions, device

lists, error lists and others.

(Optional)

IB-0300136

(1XB930)

IB-0300137

(1XB931)

A - 14

Page 16

(2) PLC

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

This manual explains the specifications of the QCPU modules, power supply modules, base modules,

extension cables, memory card battery and others.

(Optional)

QCPU User's Manual (Function Explanation, Program Fundamentals)

This manual explains the functions, programming methods and devices and others to create programs

with the QCPU.

(Optional)

QCPU User's Manual (Multiple CPU System)

This manual explains the functions, programming methods and cautions and others to construct the

Multiple CPU system with the QCPU.

(Optional)

QCPU (Q Mode)/QnACPU Programming Manual (Common Instructions)

This manual explains how to use the sequence instructions, basic instructions, application instructions and

micro computer program.

(Optional)

QCPU (Q Mode)/QnACPU Programming Manual (PID Control Instructions)

This manual explains the dedicated instructions used to exercise PID control.

(Optional)

QCPU (Q Mode)/QnACPU Programming Manual (SFC)

This manual explains the system configuration, performance specifications, functions, programming,

debugging, error codes and others of MELSAP3.

(Optional)

I/O Module Type Building Block User's Manual

This manual explains the specifications of the I/O modules, connector, connector/terminal block

conversion modules and others.

(Optional)

Manual Name

(3) Servo amplifier

MR-J3- B Servo amplifier Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for

MR-J3-

(Optional)

Fully Closed Loop Control MR-J3- B-RJ006 Servo amplifier Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for Fully

Closed Loop Control MR-J3-

(Optional)

B Servo amplifier.

Manual Name

B-RJ006 Servo amplifier.

Manual Number

(Model Code)

SH-080483ENG

(13JR73)

SH-080484ENG

(13JR74)

SH-080485ENG

(13JR75)

SH-080039

(13JF58)

SH-080040

(13JF59)

SH-080041

(13JF60)

SH-080042

(13JL99)

Manual Number

(Model Code)

SH-030051

(1CW202)

SH-030056

(1CW304)

A - 15

Page 17

MEMO

A - 16

Page 18

1 OVERVIEW

1. OVERVIEW

1.1 Overview

This programming manual describes the common items of each operating system

software, such as the Multiple CPU system of the operating system software packages

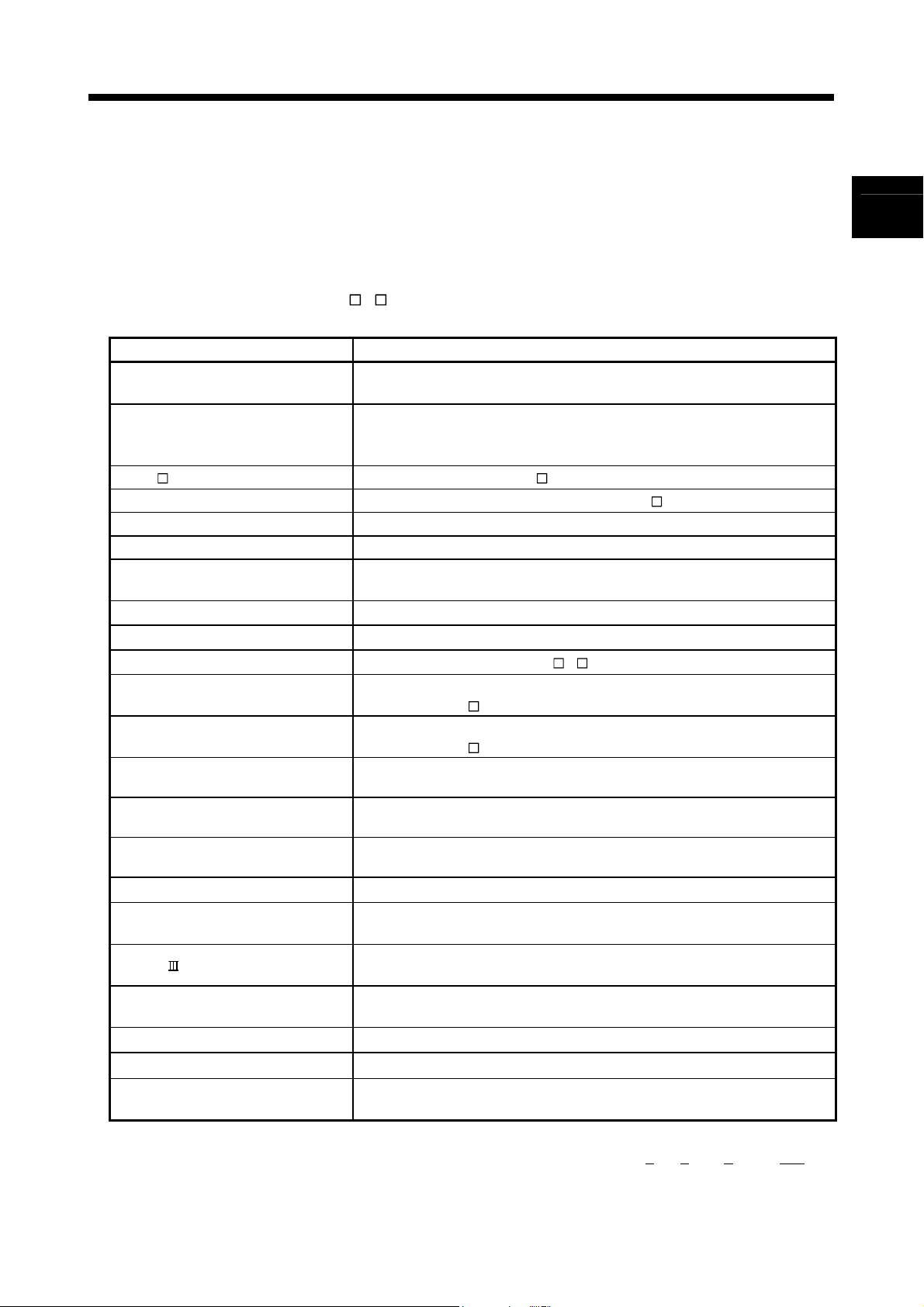

Generic term/Abbreviation Description

Q173DCPU/Q172DCPU or

Motion CPU (module)

Q172DLX/Q172DEX/Q173DPX or

Motion module

MR-J3- B Servo amplifier model MR-J3- B

AMP or Servo amplifier General name for "Servo amplifier model MR-J3- B"

QCPU, PLC CPU or PLC CPU module QnUD(H)CPU

Multiple CPU system or Motion system Abbreviation for "Multiple PLC system of the Q series"

CPUn

Self CPU Motion CPU being programmed by the currently open MT Developer project

Programming software package General name for MT Developer/GX Developer/MR Configurator

Operating system software General name for "SW8DNC-SV Q "

SV13

SV22

MT Developer

GX Developer

MR Configurator

Manual pulse generator or MR-HDP01 Abbreviation for "Manual pulse generator (MR-HDP01)"

Serial absolute synchronous encoder

or Q170ENC

SSCNET

Absolute position system

Battery holder unit Battery holder unit (Q170DBATC)

External battery General name for "Q170DBATC" and "Q6BAT"

Intelligent function module

(Note-2)

"SW8DNC-SV

In this manual, the following abbreviations are used.

Q " for Motion CPU module (Q173DCPU/Q172DCPU).

Q173DCPU/Q172DCPU Motion CPU module

Q172DLX Servo external signals interface module/

Q172DEX Serial Synchronous encoder interface module

Q173DPX Manual pulse generator interface module

Abbreviation for "CPU No.n (n= 1 to 4) of the CPU module for the Multiple CPU

system"

Operating system software for conveyor assembly use (Motion SFC) :

SW8DNC -SV13Q

Operating system software for automatic machinery use (Motion SFC) :

SW8DNC -SV22Q

Abbreviation for "Motion controller programming software

MT Developer2 (Version 1.00A or later)"

Abbreviation for "MELSEC PLC programming software package

GX Developer (Version 8.48A or later)"

Abbreviation for "Servo setup software package

MR Configurator (Version C0 or later)"

Abbreviation for "Serial absolute synchronous encoder (Q170ENC)"

High speed synchronous network between Motion controller and servo

amplifier

General name for "system using the servomotor and servo amplifier for

absolute position"

Abbreviation for "MELSECNET/H module/Ethernet module/CC-Link module/

Serial communication module"

(Note-1) : Q172DEX can be used in SV22.

(Note-2) : SSCNET: S

(Note-1)

/

ervo System Controller NETwork

1

1 - 1

Page 19

1 OVERVIEW

REMARK

For information about the each module, design method for program and parameter,

Motion CPU module/Motion unit Q173DCPU/Q172DCPU User’s Manual

PLC CPU, peripheral devices for PLC program design, I/O

modules and intelligent function module

Operation method for MT Developer Help of each software

• Design method for Motion SFC program

• Design method for Motion SFC parameter

• Motion dedicated PLC instruction

SV13/SV22

SV22

(Virtual mode)

• Design method for positioning control

• Design method for positioning control

• Design method for mechanical system

refer to the following manuals relevant to each module.

Item Reference Manual

Manual relevant to each module

Q173DCPU/Q172DCPU Motion controller (SV13/SV22)

Programming Manual (Motion SFC)

program in the real mode

parameter

program

Q173DCPU/Q172DCPU Motion controller (SV13/SV22)

Programming Manual (REAL MODE)

Q173DCPU/Q172DCPU Motion controller (SV22)

Programming Manual (VIRTUAL MODE)

1 - 2

Page 20

1 OVERVIEW

1.2 Features

The Motion CPU and Multiple CPU system have the following features.

1.2.1 Features of Motion CPU

(1) Q series PLC Multiple CPU system

(a) Load distribution of processing can be performed by controlling the

complicated servo control with Motion CPU and the machine control or

information control with PLC CPU. Therefore, the flexible system

configuration can be realized.

(b) The Motion CPU and PLC CPU are selected flexibly, and the Multiple CPU

system up to 4 CPU modules can be realized.

The Motion CPU module for the number of axis to be used can be selected.

Q173DCPU : Up to 32 axes

Q172DCPU : Up to 8 axes

The PLC CPU module for the program capacity to be used can be selected.

(One or more PLC CPU is necessary with the Multiple CPU system.)

Q03UDCPU : 30k steps

Q04UDHCPU : 40k steps

Q06UDHCPU : 60k steps

(c) The device data access of the Motion CPU and the Motion SFC program

start can be executed from PLC CPU by the Motion dedicated PLC

instruction.

(2) High speed operation processing

(a) The minimum operation cycle of the Motion CPU is made 0.44[ms], and it

correspond with high frequency operation.

(b) High speed PLC control is possible by the universal model QCPU.

(For LD instruction)

Q03UDCPU : 20[ns]

Q04UDHCPU : 9.5[ns]

Q06UDHCPU : 9.5[ns]

1 - 3

Page 21

1 OVERVIEW

(3) Connection between the Motion controller and servo amplifier with

high speed synchronous network by SSCNET

(a) High speed synchronous network by SSCNET connect between the

Motion controller and servo amplifier, and batch control the charge of servo

parameter, servo monitor and test operation, etc.

It is also realised reduce the number of wires.

(b) The maximum distance between the Motion CPU and servo amplifier, servo

amplifier and servo amplifier of the SSCNET

set to 50(164.04)[m(ft.)], and the flexibility improved at the Motion system

design.

cable on the same bus was

(4) The operating system software package for your application needs

By installing the operating system software for applications in the internal flash

memory of the Motion CPU, the Motion controller suitable for the machine can be

realized.

And, it also can correspond with the function improvement of the software

package.

(a) Conveyor assembly use (SV13)

Offer liner interpolation, circular interpolation, helical interpolation, constantspeed control, speed control, fixed-pitch feed and etc. by the dedicated

servo instruction. Ideal for use in conveyors and assembly machines.

(b) Automatic machinery use (SV22)

Provides synchronous control and offers electronic cam control by

mechanical support language. Ideal for use in automatic machinery.

1 - 4

Page 22

1 OVERVIEW

1.2.2 Basic specifications of Q173DCPU/Q172DCPU

(1) Module specifications

Item Q173DCPU Q172DCPU

Internal current consumption (5VDC) [A] 1.25 1.14

Mass [kg] 0.33 0.33

Exterior dimensions [mm(inch)] 98 (3.85)(H) 27.4 (1.08)(W) 119.3 (4.69)(D)

(2) SV13/SV22 Motion control specifications/performance

specifications

Item Q173DCPU Q172DCPU

Number of control axes Up to 32 axes Up to 8 axes

SV13

Operation cycle

(default)

SV22

Interpolation functions

Control modes

Acceleration/

deceleration control

Compensation Backlash compensation, Electronic gear, Phase compensation (SV22)

Programming language Motion SFC, Dedicated instruction, Mechanical support language (SV22)

Servo program capacity 14k steps

Number of positioning

points

Peripheral I/F Via PLC CPU (USB/RS-232)

Home position return

function

JOG operation function Provided

Manual pulse generator

operation function

Synchronous encoder

operation function

M-code function

Limit switch output

function

(a) Motion control specifications

0.44ms/ 1 to 6 axes

0.88ms/ 7 to 18 axes

1.77ms/19 to 32 axes

0.44ms/ 1 to 4 axes

0.88ms/ 5 to 12 axes

1.77ms/13 to 28 axes

3.55ms/29 to 32 axes

Linear interpolation (Up to 4 axes), Circular interpolation (2 axes),

Helical interpolation (3 axes)

PTP(Point to Point) control, Speed control, Speed-position control, Fixed-pitch feed,

Constant speed control, Position follow-up control, Speed control with fixed position stop,

Speed switching control, High-speed oscillation control, Synchronous control (SV22)

Automatic trapezoidal acceleration/deceleration,

S-curve acceleration/deceleration

3200 points

(Positioning data can be designated indirectly)

Proximity dog type (2 types), Count type (3 types), Data set type (2 types), Dog cradle type,

Stopper type (2 types), Limit switch combined type

(Home position return re-try function provided, home position shift function provided)

Possible to connect 3 modules

Possible to connect 12 modules Possible to connect 8 modules

M-code output function provided

M-code completion wait function provided

Number of output points 32 points

Watch data: Motion control data/Word device

1 - 5

0.44ms/ 1 to 6 axes

0.88ms/ 7 to 8 axes

0.44ms/ 1 to 4 axes

0.88ms/ 5 to 8 axes

Page 23

1 OVERVIEW

Item Q173DCPU Q172DCPU

Motion control specifications (continued)

Absolute position system

Number of SSCNET

systems

Motion related interface

module

(Note-1)

(Note-1) : The servo amplifiers for SSCNET cannot be used.

(Note-2) : When using the incremental synchronous encoder (SV22 use), you can use above number of modules.

When connecting the manual pulse generator, you can use only 1 module.

(Possible to select the absolute data method or incremental method for each axis)

Q172DLX : 4 modules usable Q172DLX : 1 module usable

Q172DEX : 6 modules usable Q172DEX : 4 modules usable

Q173DPX : 4 modules usable

Made compatible by setting battery to servo amplifier.

2 systems 1 system

(Note-2)

Q173DPX : 3 modules usable

(Note-2)

1 - 6

Page 24

1 OVERVIEW

Motion SFC program capacity

Motion SFC program

Operation control program

(F/FS)

/

Transition program

(G)

Execute specification

Number of devices

(Device In the Motion CPU

only)

(Included the positioning

dedicated device)

(b) Motion SFC Performance Specifications

Item Q173DCPU/Q172DCPU

Code total

(Motion SFC chart + Operation control

+ Transition)

Text total

(Operation control + Transition)

Number of Motion SFC programs 256 (No.0 to 255)

Motion SFC chart size/program Up to 64k bytes (Included Motion SFC chart comments)

Number of Motion SFC steps/program Up to 4094 steps

Number of selective branches/branch 255

Number of parallel branches/branch 255

Parallel branch nesting Up to 4 levels

Number of operation control programs

Number of transition programs 4096(G0 to G4095)

Code size/program Up to approx. 64k bytes (32766 steps)

Number of blocks(line)/program Up to 8192 blocks (in the case of 4 steps(min)/blocks)

Number of characters/block Up to 128 (comment included)

Number of operand/block Up to 64 (operand: constants, word device, bit devices)

( ) nesting/block Up to 32 levels

Descriptive

expression

Number of multi execute programs Up to 256

Number of multi active steps Up to 256 steps/all programs

Executed

task

Internal relays (M) 8192 points

Link relays (B) 8192 points

Annunciators (F) 2048 points

Special relays (SM) 2256 points

Data registers (D) 8192 points

Link registers (W) 8192 points

Special registers (SD) 2256 points

Motion registers (#) 8736 points

Coasting timers (FT)

Multiple CPU area devices (U

Operation control program Calculation expression/bit conditional expression

Transition program

Normal task Execute in main cycle of Motion CPU

Event task

(Execution

can be

masked.)

NMI task

Fixed cycle

External

interrupt

PLC interrupt Execute with interrupt instruction (D(P).GINT) from PLC CPU.

(Note): Usable number of points changes according to the system settings.

4096 with F(Once execution type) and FS(Scan execution type)

combined. (F/FS0 to F/FS4095)

Calculation expression/bit conditional expression/

comparison conditional expression

(0.88ms, 1.77ms, 3.55ms, 7.11ms, 14.2ms)

Execute when input ON is set among interrupt module QI60

Execute when input ON is set among interrupt module QI60

\G) Up to 14336 points usable

543k bytes

484k bytes

Execute in fixed cycle

(16 points).

(16 points).

1 point (888µs)

(Note)

1 - 7

Page 25

1 OVERVIEW

1.3 Hardware Configuration

This section describes the Q173DCPU/Q172DCPU system configuration, precautions

on use of system, and configured equipments.

1.3.1 Motion system configuration

This section describes the equipment configuration, configuration with peripheral

devices and system configuration in the Q173DCPU/Q172DCPU system.

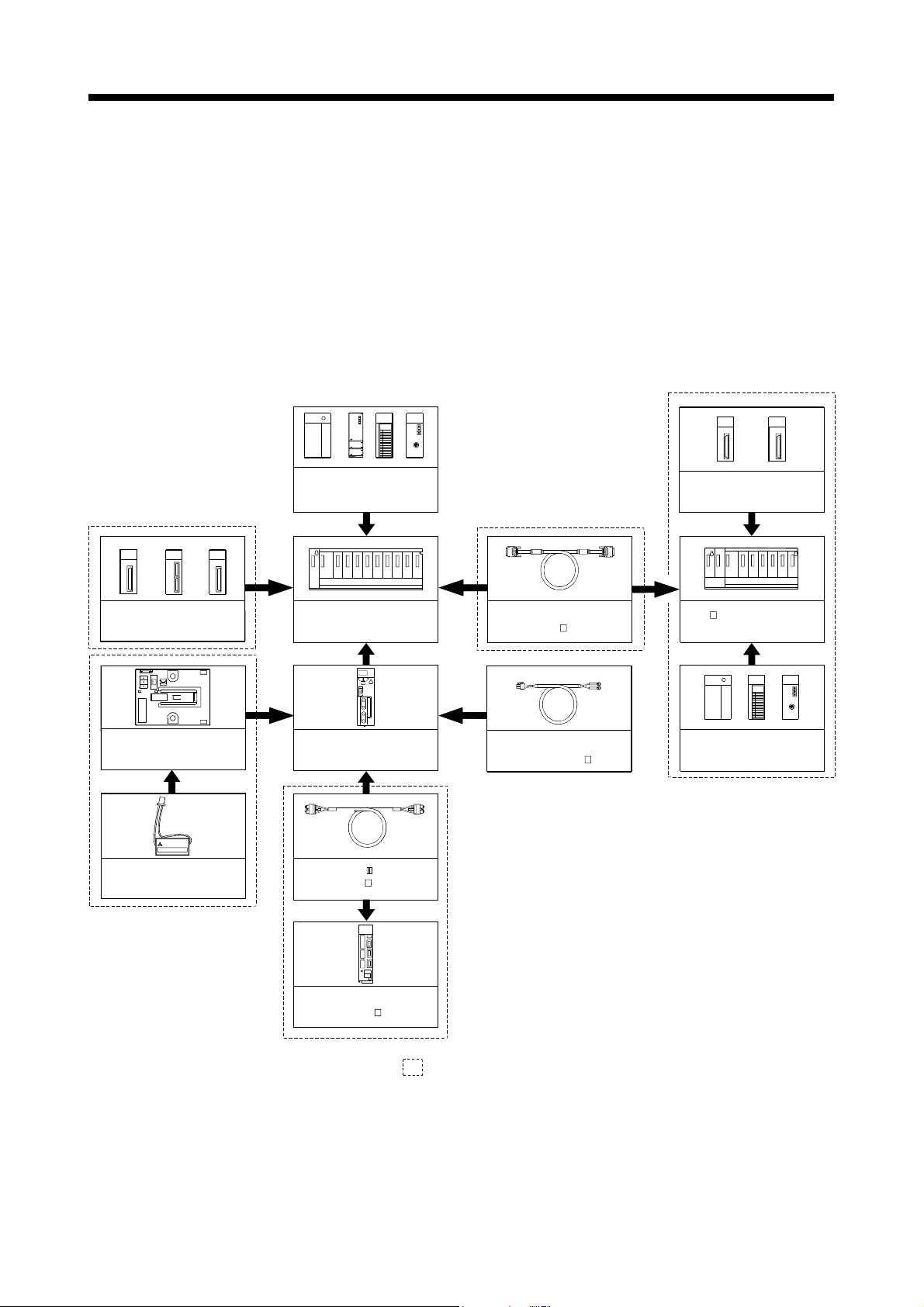

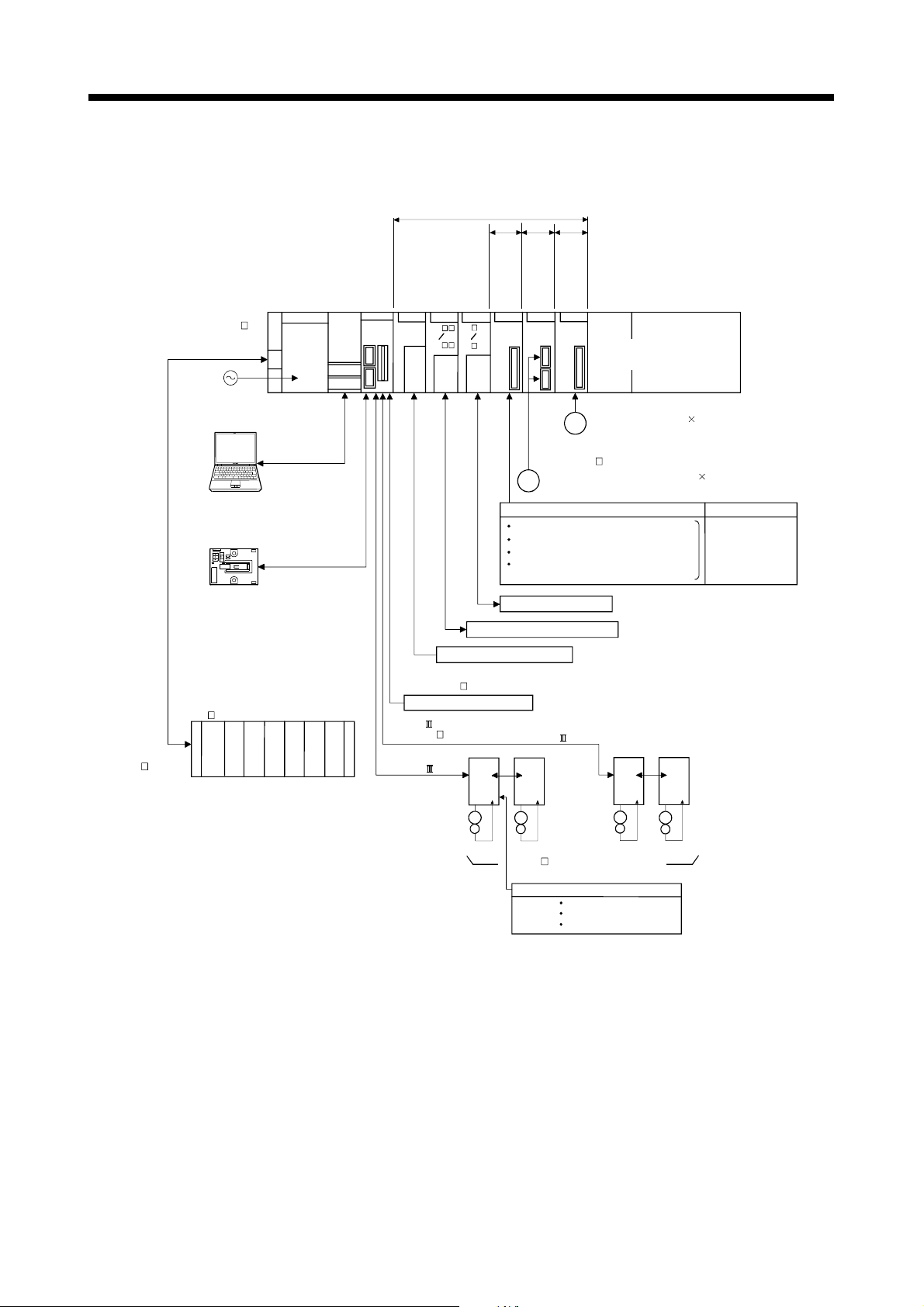

(1) Equipment configuration in Q173DCPU/Q172DCPU system

Power supply module/

QnUD(H)CPU/ I/O module/

Intelligent function module

of the Q series

Extension of the Q series module

(Note-2)

Motion module

(Q172DLX, Q173DPX)

Motion mo dule

(Q172DLX, Q172DEX, Q173DPX)

(Note-1)

Battery holder unit

(Q170DBATC)

(Note-1)

MITSUBISHI

LITHIUM BATT ERY

Battery

(Q6BAT)

Main base unit

(Q38DB, Q312DB)

Motion CPU module

(Q173DCPU/Q172DCPU)

SSCNET cable

(MR-J3BUS M(-A/-B))

Servo amplifier

(MR-J3- B)

Extension cable

(QC B)

Forced stop input cable

(Q170DEMICBL M)

Q6 B extension base unit

(Q63B, Q65B, Q68B, Q612B)

Power supply module/

I/O module/Intelligent function

module of the Q series

It is possible to select the best according to the system.

(Note-1) : Be sure to install the Battery (Q6BAT) to the Battery holder unit (Q170DBATC).

It is packed together with Q173DCPU/Q172DCPU.

(Note-2) : Q172DEX cannot be used in the extension base unit.

Mount it to the main base unit.

1 - 8

Page 26

1 OVERVIEW

(2) Peripheral device configuration for the Q173DCPU/Q172DCPU

The following (a)(b) can be used.

(a) USB configuration

(b) RS-232 configuration

PLC CPU module

(QnUD(H)CPU)

USB cable

M

S

I

T

U

B

I

S

H

I

Personal computer

PLC CPU module

(

QnUD(H)CPU)

RS-232 communication cable

(QC30R2)

M

I

T

S

U

B

I

S

H

I

Personal computer

1 - 9

Page 27

1 OVERVIEW

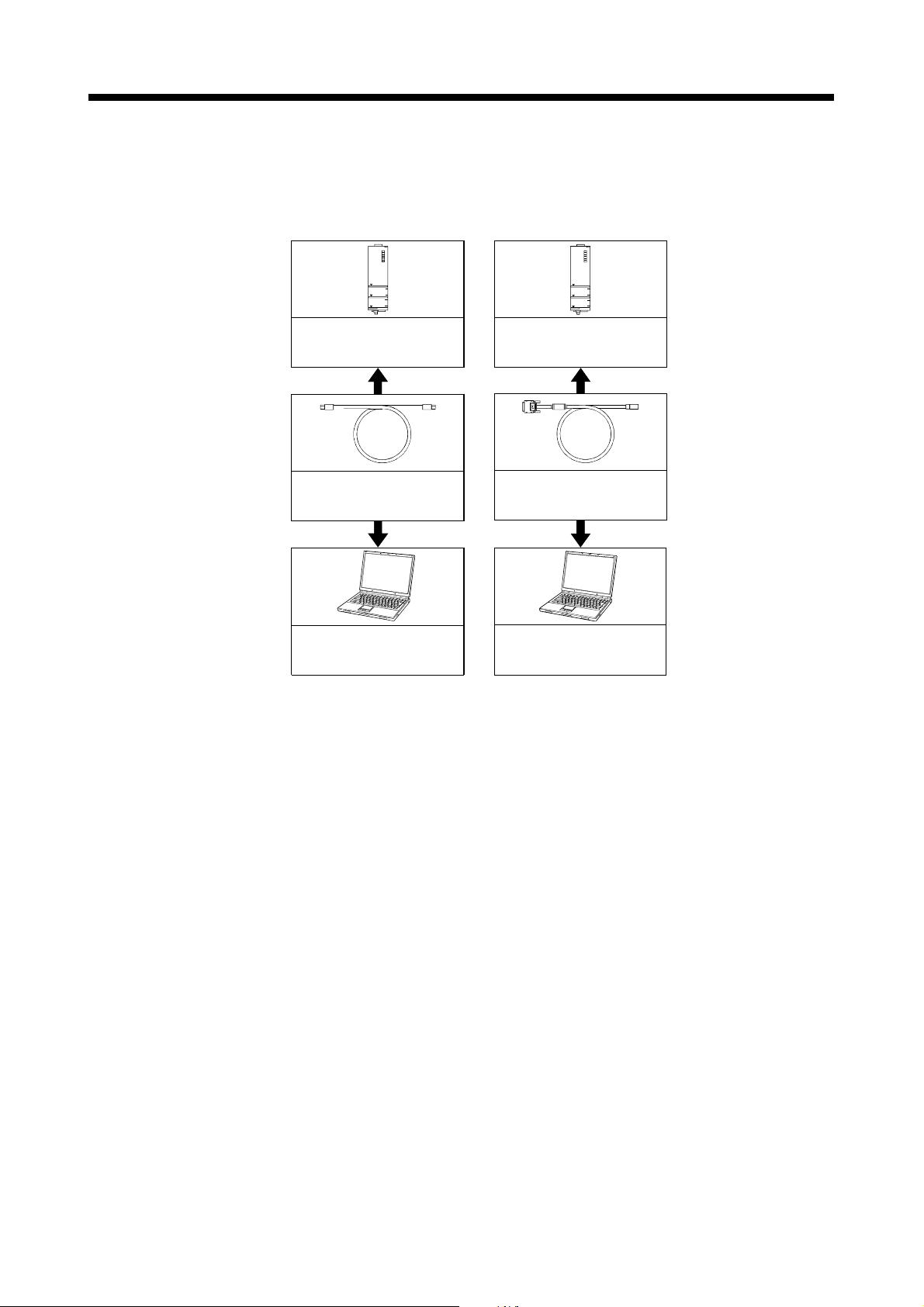

1.3.2 Q173DCPU System overall configuration

Motion CPU control module

PLC CPU/

Q61P

Motion CPU

QnUD(H)

CPU

Q173D

QI60 QX

CPU

QY

Forced stop input cab le

(Q170DEMICBL M)

EMI forced stop input (24VDC)

SSCNET cable

(MR-J3BUS M(-A/-B))

SSCNET (CN2)

Interrupt signals (16 points)

Extension cable

(QC B)

Main base un it

(Q3 DB)

100/200VAC

Personal Computer

IBM PC/AT

Battery holder unit

Q170DBATC

Extension base unit

(Q6 B)

y

l

p

p

u

s

e

r

l

e

u

d

w

o

o

P

m

UP to 7 extensions

USB/RS-232

e

e

e

l

l

l

u

a

d

s

n

o

u

r

o

e

m

t

n

x

e

o

e

r

c

s

l

h

a

o

f

a

c

r

v

n

r

n

e

t

g

y

e

i

n

S

S

s

i

Q6 AD

Q6 DA

Q172D

Q172D

EX

LX

Serial absolute synchronous encoder cable

(Q170ENCCBL M)

E

FLS

RLS

STOP

DOG/CHANGE : Proximity dog/

Speed-position switching

l

u

u

d

d

e

o

o

s

l

m

u

m

r

p

o

e

r

e

t

l

c

c

e

a

a

r

a

a

d

f

u

f

e

r

r

o

n

n

c

e

e

a

t

t

e

n

n

n

M

g

i

e

i

Q173D

PX

Manual pulse generator 3/module

P

(MR-HDP01)

Serial absolute synchronous encoder 2/module

External input s ignals

: Upper stroke limit

: Lower stroke limit

: Stop sign al

Analogue input/output

Input/output (Up to 256 points)

SSCNET (CN1)

d16

d1

I/O module/

Intelligent function module

(Up to 1 module)

(Up to 6 modules) (Q170ENC)

d1

d16

Number of Inputs

8 axes/module

(Up to 4 modules)

M

E

1 - 10

M

E

MR-J3- B model Servo amplifier,

Up to 32 axes (Up to 16 axes/system)

External input signals of servo amplifier

Proximity dog

Upper stroke limit

Lower stroke limit

M

E

M

E

Page 28

1 OVERVIEW

CAUTION

Construct a safety circuit externally of the Motion controller or servo amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in

the system.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier and

servomotor.

Set the parameter values to those that are compatible with the Motion controller, servo amplifier,

servomotor and regenerative resistor model and the system application. The protective functions

may not function if the settings are incorrect.

1 - 11

Page 29

1 OVERVIEW

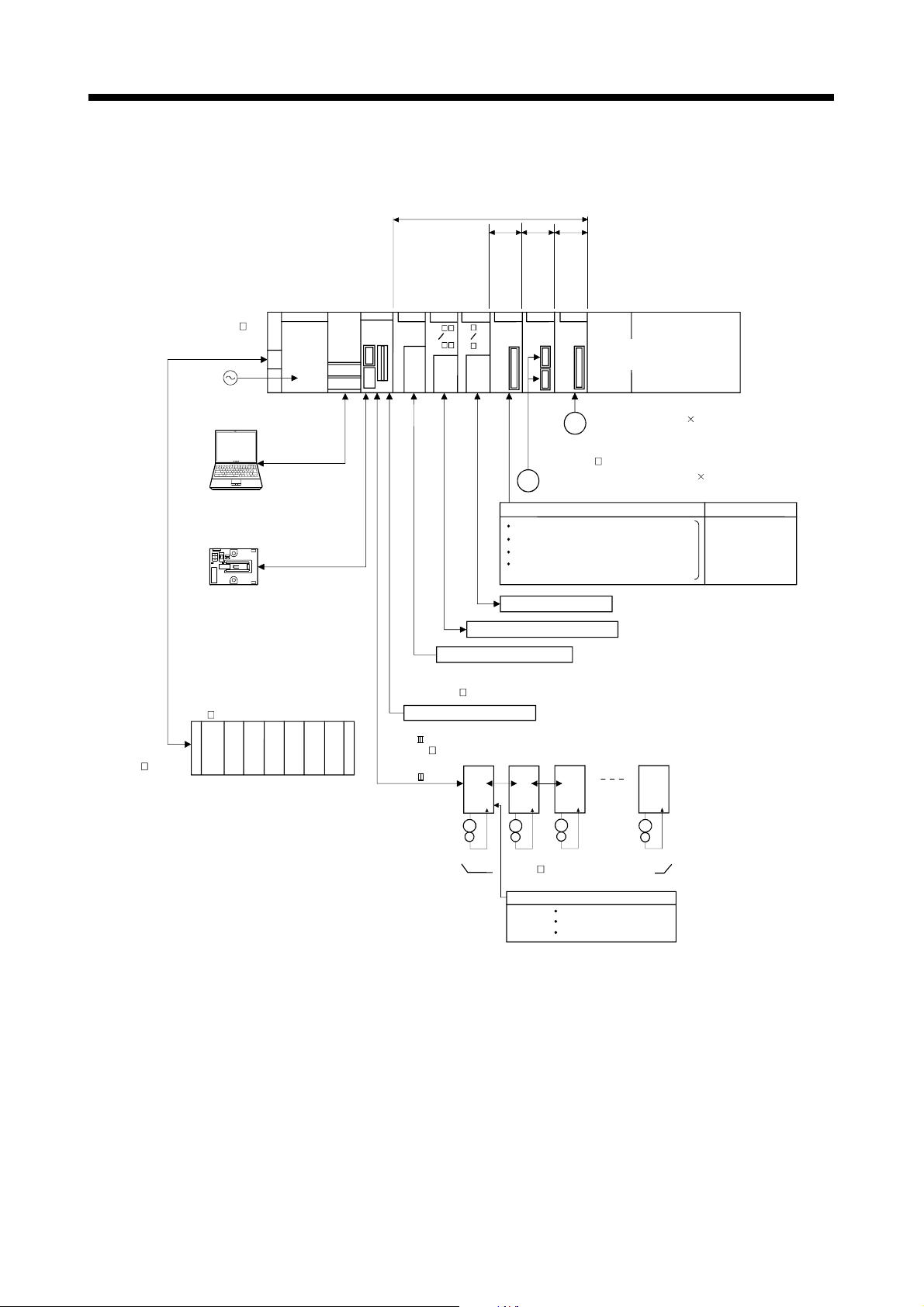

1.3.3 Q172DCPU System overall configuration

Motion CPU control module

PLC CPU/

Main base unit

(Q3 DB)

100/200VAC

Personal Computer

IBM PC/AT

Battery holder unit

Q170DBATC

USB/RS-232

Q61P

Motion CPU

QnUD(H)

CPU

Q172D

CPU

QX

QI60

QY

Interrupt signals (16 points)

e

e

l

l

Q6 AD

Q6 DA

l

a

n

r

e

t

x

e

o

v

r

e

S

Q172D

LX

u

u

d

o

m

e

c

s

l

a

f

a

r

n

e

t

g

i

n

s

i

FLS

RLS

STOP

DOG/CHANGE : Proximity dog/

Speed-position switching

d

e

s

o

s

u

l

o

m

u

r

n

p

o

r

e

t

o

l

c

r

e

a

a

r

h

a

d

f

u

c

e

o

r

n

n

n

c

e

a

t

y

n

e

n

M

g

S

e

i

Q172D

Q173D

EX

PX

P

Serial absolute synchronous encoder cable

(Q170ENCCBL M)

Serial absolute synchronous encoder 2/module

E

(Q170ENC)

External input signals

: Upper stroke limit

: Lower stroke limit

: Stop signal

Analogue input/output

Input/output (Up to 256 points)

e

l

u

d

o

m

e

c

a

f

r

e

t

n

i

I/O module /

Intelligent function module

Manual pulse generator 3/module

(MR-HDP01)

(Up to 6 modules)

(Up to 1 module)

Number of Inputs

8 axes/module

(Up to 4 mo dules)

Extension cable

(QC B)

Extension base unit

(Q6 B)

y

l

p

p

u

s

e

r

l

e

u

d

w

o

o

P

m

UP to 7 extensions

Forced stop input cable

(Q170DEMICBL M)

EMI forced stop input (24VDC)

SSCNET cable

(MR-J3BUS M(-A/-B))

SSCNET (CN1)

d2

d1

M

E

MR-J3- B model Servo amplifier,

Up to 8 axes

M

M

E

External input signals of servo amplifier

E

Proximity dog

Upper stroke limit

Lower stroke limit

d3

d8

M

E

1 - 12

Page 30

1 OVERVIEW

CAUTION

Construct a safety circuit externally of the Motion controller or servo amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in

the system.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier and

servomotor.

Set the parameter values to those that are compatible with the Motion controller, servo amplifier,

servomotor and regenerative resistor model and the system application. The protective functions

may not function if the settings are incorrect.

1 - 13

Page 31

1 OVERVIEW

1.3.4 Software packages (1) Software packages

For conveyor assembly SV13 SW8DNC-SV13QB SW8DNC-SV13QD

For automatic machinery SV22 SW8DNC-SV22QA SW8DNC-SV22QC

MT Developer2

(Note) : Operating environment to use MT Developer is WindowsR Vista/WindowsR XP/WindowsR 2000

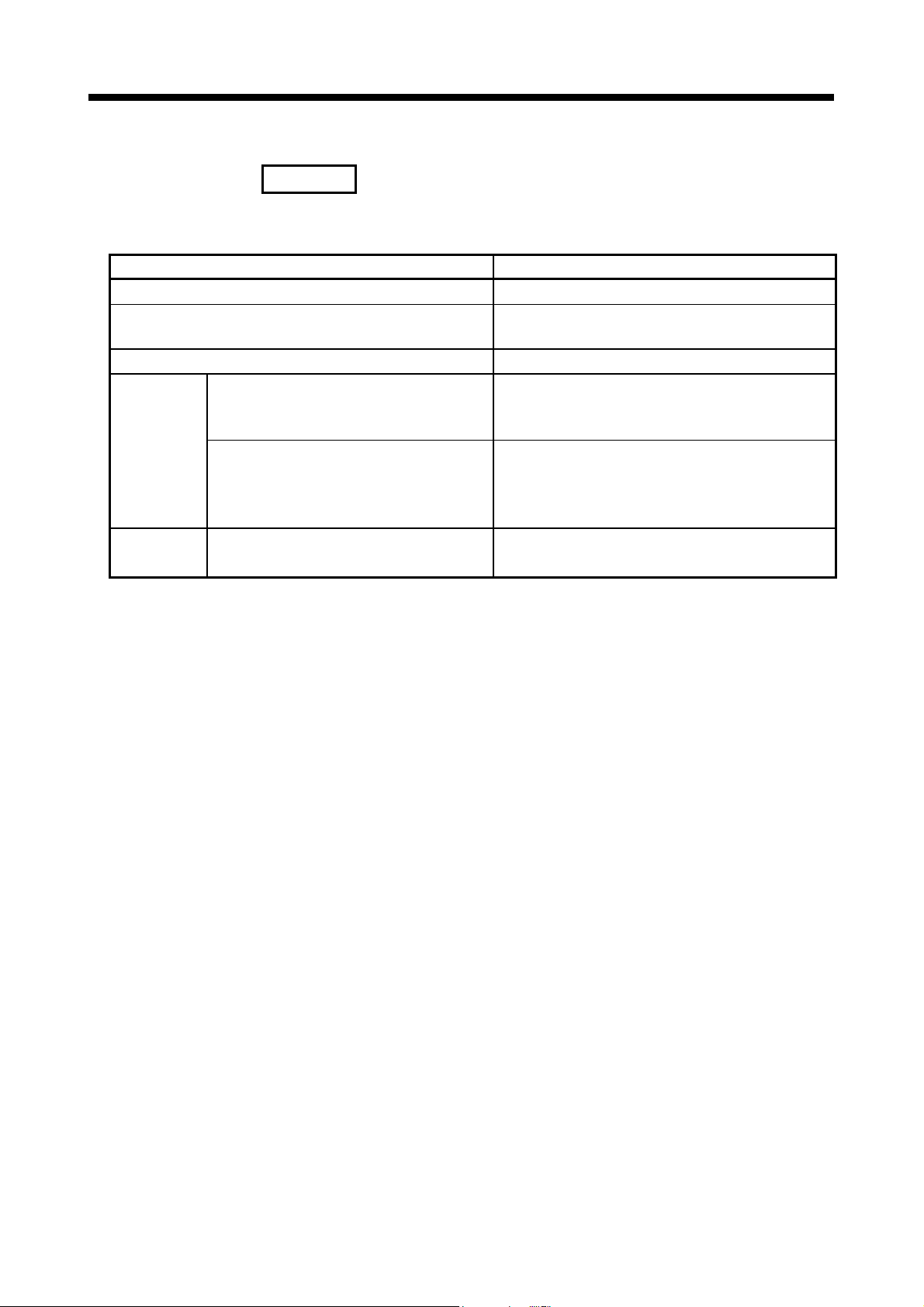

(2) Operating environment of personal computer

OS

CPU

Memory capacity Recommended 512MB or more

Video card Card compatible with MicrosoftR DirectXR 9.0c or later

Available hard disk

capacity

Disk drive CD-ROM disk drive

Display

(Note-1) : Microsoft, Windows and DirectX are either registered trademarks or trademarks of Microsoft

(Note-2) : Intel, Celeron an d Pen tium ar e tr adem arks o f In te l Corp orat ion in th e U. S. and ot he r count rie s.

(a) Operating system software

Application

Q173DCPU Q172DCPU

Software package

(b) Motion controller programming software

Part name Model name Details

Conveyor Assembly Software

Automatic Machinery So ftw a r e

Cam Data Creation Software

SW1DNC-MTW2-E

(1 CD-ROM disk)

English version only.

Operating environment is shown below.

IBM PC/AT with which Windows

version operates normally.

Item Operating environment

R

Microsoft

Microsoft

Microsoft

Microsoft

Microsoft

Microsoft

Microsoft

Microsoft

Desktop PC: Recommended Intel

Laptop PC: Recommended Intel

Installation: HD 1GB or more

Operation: Virtual memory 5 0M B or m or e

Resolution 1024×768 pixels or higher

Corporation in the United States and/or other countries.

WindowsR Vista Home Basic

R

WindowsR Vista Home Premium

R

WindowsR Vista Business

R

WindowsR Vista Ultimate

R

WindowsR Vista Enterprise

R

WindowsR XP Professional (Service Pack 2 or later)

R

WindowsR XP Home Edition (Service Pack 2 or later)

R

WindowsR 2000 Professional (Service Pack 4 or later)

Digital Oscilloscope Software

Communication System So f tw are

Document Print So ftw ar e

Operation Manual (Help)

Installation manual (PDF)

R

Vista/WindowsR XP/WindowsR2000 English

R

CeleronR Processor 2.8GHz or more

R

PentiumR Processor M 1.7GHz or more

1 - 14

Page 32

1 OVERVIEW

(3) Operating system type/version

(a) Confirmation method in the operating system (CD)

1)

1) OS software type

2) OS software version

3) Serial number

Example) When using Q173DCPU, SV22 and version 00A.

1) SW8DNC-SV22QA

2) 00A

(b) Confirmation method in MT Debeloper

The operating system(OS) type/version of connected CPU is displayed on

the installation screen of MT Developer.

(OS software)

SV 2 2 QAVER3

A or B : Q173DCPU

C or D : Q172DCPU

(4) Relevant software packages

(a) PLC software package

Model name Software package

2)

3)

00 A

OS version

3: Motion SFC compatibility

. : Motion SFC not compatibility

GX Developer SW8D5C-GPPW-E

(b) Servo set up software package

Model name Software package

MR Configurator MRZJW3-SETUP221E

1 - 15

Page 33

1 OVERVIEW

POINTS

(1) When the operation of Windows is not unclear in the operation of this software,

refer to the manual of Windows or guide-book from the other supplier.

(2) The following functions cannot be used when the computer is running under

Windows

This product may not perform properly, when these functions are used.

< Windows

• Activating the application with Windows

R

Vista, WindowsR XP or WindowsR 2000.

R

Vista/WindowsR XP>

R

compatibility mode

• Fast user switching

• Remote desktop

• Large size

R

)

• x64 Edition (64 bit Windows

< Windows

R

2000>

• Large fonts

1 - 16

Page 34

1 OVERVIEW

1.3.5 Restrictions on motion systems

(1) Combination of Multiple CPU system

(a) Motion CPU module cannot be used as standalone module.

Be sure to install the universal model PLC CPU module (Q03UDCPU/

Q04UDHCPU/Q06UDHCPU) to CPU No.1.

For Universal model PLC CPU module, "Multiple CPU high speed

taransmission function" must be set in the Multiple CPU settings.

(b) Only Multiple CPU high speed main base unit (Q38DB/Q312DB) can be

used.

(c) The combination of Q173DCPU/Q172DCPU and Q173HCPU(-T)/

Q172HCPU(-T)/Q173CPUN(-T)/Q172CPUN(-T) cannot be used.

(d) Up to four modules of PLC CPU modules (Q03UDCPU/Q04UDHCPU/

Q06UDHCPU/Motion CPU modules can be installed from the CPU slot (the

slot on the right side of power supply module) to slot 2 of the main base unit.

CPU modules called as CPU No.1 to CPU No.4 from the left sequentially.

There is no restriction on the installation order of CPU No.2 to No.4.

For CPU module except CPU No.1, an empty slot can be reserved for

addition of CPU module. An empty slot can be set between CPU modules.

However, the mounting condition when combining with the High

performance PLC CPU module/Process CPU module/PC CPU module/C

controller module is different depending on the specification of CPU

modules, refer to the Manuals of each CPU modules.

(e) It takes about 10 seconds to startup (state that can be controlled) of Motion

CPU. Make a Multiple CPU synchronous startup setting suitable for the

system.

(f) Execute the automatic refresh of the Motion CPU modules and PLC CPU

modules (Q03UDCPU/Q04UDHCPU/Q06UDHCPU) by using the automatic

refresh of Multiple CPU high speed transmission area setting.

When the High performance PLC CPU module/Process CPU module/PC

CPU module/C controller module is mounted in the combination of Multiple

CPU system, the Motion CPU module cannot be execute the automatic

refresh with these modules.

(g) Use the Motion dedicated PLC instructions that starts by "D(P).". The Motion

dedicated PLC instructions that starts by "S(P)." cannot be used. When the

High performance PLC CPU module/Process CPU module/PC CPU

module/C controller module is mounted in the combination of Multiple CPU

system, the Motion dedicated PLC instruction from these modules cannot be

executed.

1 - 17

Page 35

1 OVERVIEW

(2) Motion modules

(a) Installation position of Q172DEX

It cannot be used on the extension base unit.

(b) Q172DLX/Q173DPX can be installed on any of the main base unit/

extension base unit.

(c) Q172DLX/Q172DEX

(Note-1)

slot 0 to 2 of the main base unit. Wrong installation might damage the main

base unit.

(d) Q172EX(-S1/-S2/-S3)/Q172LX/Q173PX(-S1) for Q173HCPU(-T)/

Q172HCPU(-T)/Q173CPUN(-T)/Q172CPUN(-T)/Q173CPU/Q172CPU

cannot be used.

(e) Be sure to use the Motion CPU as the control CPU of Motion modules

(Q172DLX, Q172DEX

(Note-1)

operate correctly if PLC CPU is set and installed as the control CPU by

mistake. Motion CPU is treated as a 32-point intelligent module by PLC

CPU of other CPU.

(Note-1)

is only the main base unit.

/Q173DPX cannot be installed in CPU slot and I/O

, Q173DPX, etc.) for Motion CPU. They will not

(Note-1) : Q172DEX can be used in SV22. It cannot be used in SV13.

1 - 18

Page 36

1 OVERVIEW

(3) Other restrictions

(a) Motion CPU module cannot be set as the control CPU of intelligent function

module (except some modules) or Graphic Operation Terminal(GOT).

(b) Be sure to use the external battery.

(c) There are following methods to execute the forced stop input.

• Use a EMI terminal of Motion CPU module

• Use a device set in the forced stop input setting of system setting

(d) Forced stop input for EMI terminal of Motion CPU module cannot be

invalidated by the parameter.

When the device set in the forced stop input setting is used without use of

EMI terminal of Motion CPU module, apply 24VDC voltage on EMI terminal

and invalidate the forced stop input of EMI terminal.

(e) Be sure to use the cable for forced stop input (sold separately). The forced

stop cannot be released without using it.

(f) When the operation cycle is 0.4[ms], set the system setting as the axis select

switch of servo amplifier "0 to 7".

If the axis select switch of servo amplifier "8 to F" is set, the servo amplifiers

are not recognized.

(g) It is impossible to mount the main base unit by DIN rail when using the

Motion CPU module.

Doing so could result in vibration that may cause erroneous operation.

(h) The module name displayed by "System monitor" - "Product information list"

of GX Developer is different depending on the function version of Motion

modules (Q172DLX, Q172DEX, Q173DPX).

(Note): Even if the function version "C" is displayed, it does not correspond

to the online module change.

Module name

Function version "B" Function version "C"

Q172DLX Q172LX Q172DLX

Q172DEX MOTION-UNIT Q172DEX

Q173DPX MOTION-UNIT Q173DPX

Model display

1 - 19

Page 37

1 OVERVIEW

MEMO

1 - 20

Page 38

2 MULTIPLE CPU SYSTEM

2. MULTIPLE CPU SYSTEM

2.1 Multiple CPU System

2.1.1 Overview

(1) What is Multiple CPU system ?

A Multiple CPU system is a system in which more than one PLC CPU module

and Motion CPU module (up to 4 modules) are mounted on several main base

unit in order to control the I/O modules and intelligent function modules.

Each Motion CPU controls the servo amplifiers connected by SSCNET

(2) System configuration based on load distribution

(a) By distributing such tasks as servo control, machine control and information

(b) You can increase the number of control axes by using a multiple Motion

(c) By distributing the high-load processing performed on a single PLC CPU

(3) Communication between CPUs in the Multiple CPU system

(a) Since device data of other CPUs can be automatically read by the automatic

(b) Motion dedicated PLC instructions can be used to access device data from

2

cable.

control among multiple processors, the flexible system configuration can be

realized.

CPU modules.

It is possible to control up to 96 axes by using the three CPU modules

(Q173DCPU).

over several CPU modules, it is possible to reduce the overall system PLC

scan time.

refresh function, the self CPU can also use them as those of self CPU.

(Note): When the High performance PLC CPU module/Process CPU

module/PC CPU module/C controller module is mounted in the

combination of Multiple CPU system, the Motion dedicated PLC

instruction from these modules cannot be executed.

the PLC CPU to Motion CPU and start Motion SFC program.

2 - 1

Page 39

r

2 MULTIPLE CPU SYSTEM

2.1.2 Installation position of CPU module

Up to four PLC CPUs and Motion CPUs can be installed from the CPU slot (the right

side slot of the power supply module) to slots 2 of the main base unit.

The Motion CPU module cannot be installed in the CPU slot.

The PLC CPU module must be installed in the CPU slot (CPU No.1) in the Multiple

CPU system.

There is no restriction on the installation order for CPU modules (CPU No.2 to 4).

(Note): Refer to the manual for each CPU module when the High performance PLC

CPU module, Process CPU module, PC CPU module and C controller module

is mounted in the combination of Multiple CPU.

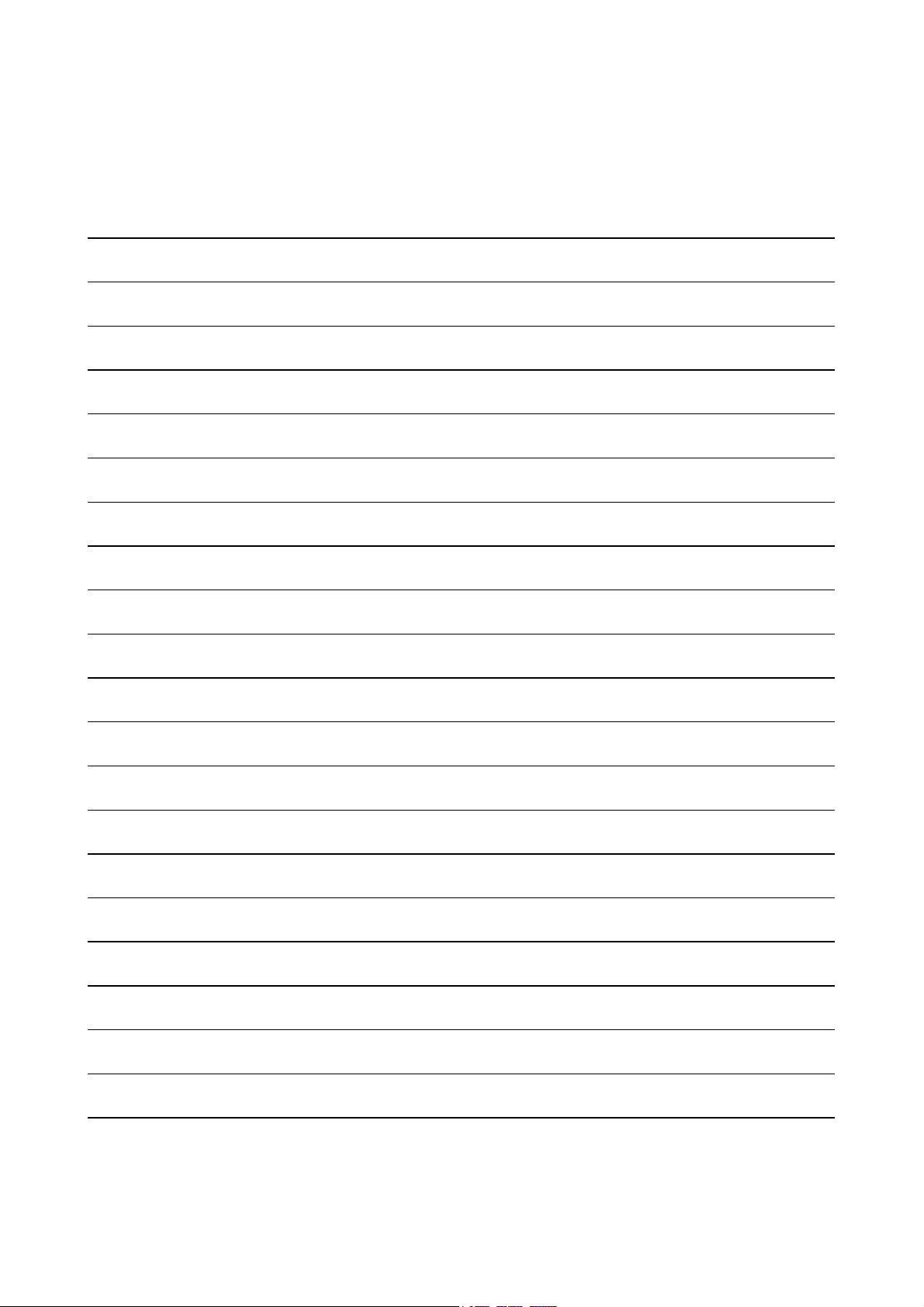

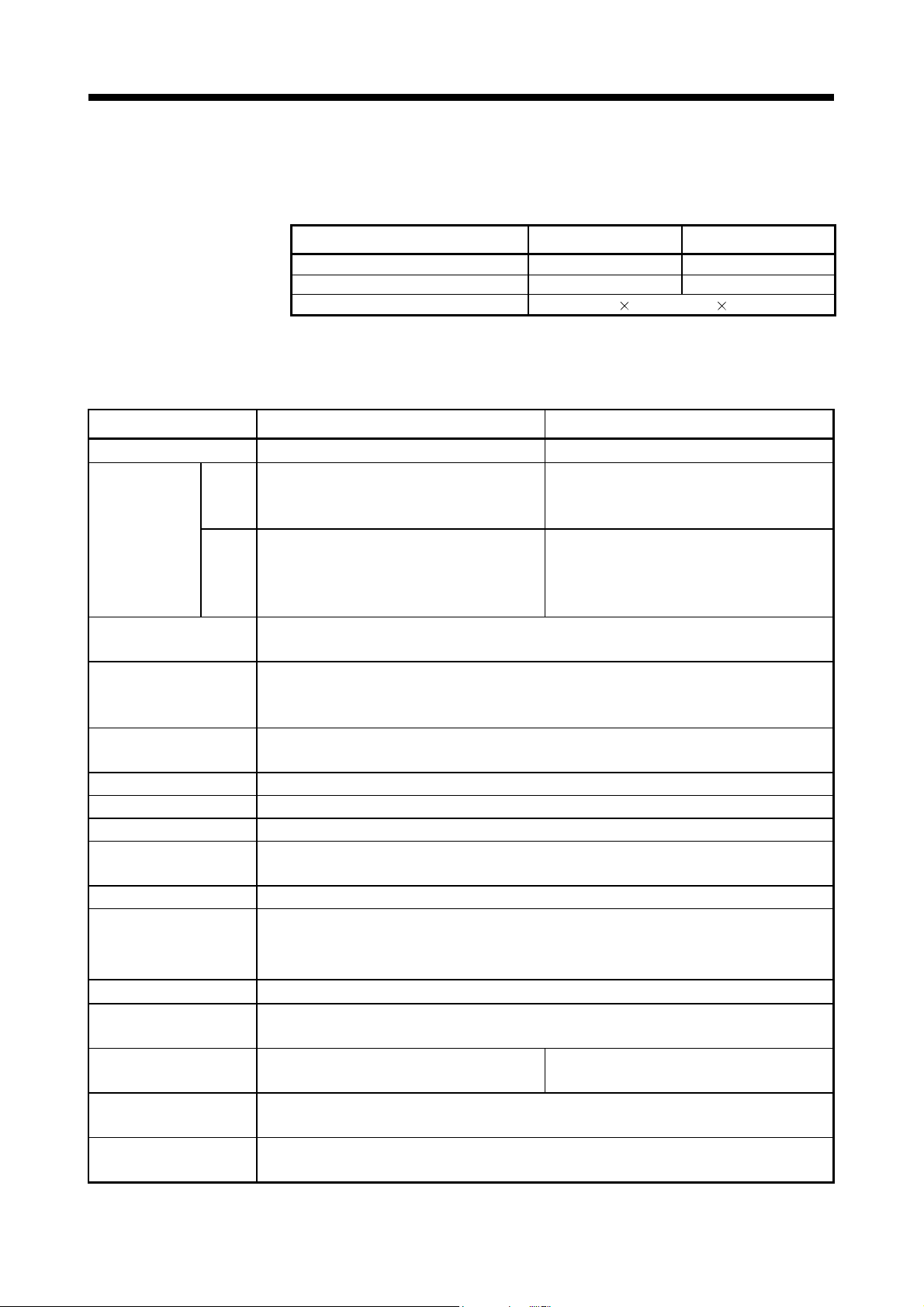

Table 2.1 Example for CPU module installation

Number of

CPUs

2

3

4

(Example 1)

Power

supply

CPU 0 1 2

QnUD(H)

Power

supply

Power

supply

Power

supply

Q17 D

CPU

CPU

CPU

CPU

No.2

No.1

CPU 0 1 2

QnUD(H)

Q17 D

CPU

CPU

CPU

CPU

No.2

No.1

CPU 0 1 2

QnUD(H)

Q17 D

CPU

CPU

CPU

CPU

No.2

No.1

An empty slot can be reserved for future addition of a CPU module.

Set the number of CPU modules including empty slots in the Multiple CPU setting, and

set the type of the slots to be emptied to "PLC (Empty)" in the CPU setting.

CPU 0 1 2

QnUD(H)

CPU

CPU

empty

Q17 D

CPU

CPU

No.3

QnUD(H)

CPU

CPU

No.3

QnUD(H)

CPU

CPU

No.3

CPU

No.4

CPU

No.4

CPU

empty

CPU

No.4

(Example 2)

Power

supply

Installation position of CPU module

—— ——

CPU 0 1 2

Q17 D

CPU

CPU

No.2

Q17 D

CPU

CPU

No.2

Q17 D

CPU

Q17 D

CPU

CPU

No.3

Q17 D

CPU

CPU

No.3

CPU

empty

QnUD(H)

QnUD(H)

Power

CPU

supply

CPU

No.1

CPU 0 1 2

QnUD(H)

Power

CPU

supply

CPU

No.1

CPU 0 1 2

QnUD(H)

CPU

CPU

empty

——

CPU

No.4

CPU 0 1 2

QnUD(H)

Power

CPU

CPU

No.4

supply

CPU012: Slot numbe

(Example 3)

CPU 0 1 2

QnUD(H)

Power

CPU

supply

CPU

CPU

No.1

CPU

empty

Q17 D

CPU

CPU

No.2

CPU

empty

Q17 D

CPU

CPU

No.3

Q17 D

CPU

Q17 D

CPU

CPU

No.4

CPU

No.1

CPU

No.2

CPU

No.3

CPU

No.4

CPU

No.1

No.2

CPU

No.3

CPU

No.4

CPU

No.1

CPU

No.2

CPU

No.3

CPU

No.4

CPU

2 - 2

Page 40

2 MULTIPLE CPU SYSTEM

2.1.3 Precautions for using I/O modules and intelligent function modules

(1) Modules controllable by the Motion CPU

Modules controllable by the Motion CPU are shown below.

• Motion modules (Q172DLX, Q172DEX, Q173DPX)

• I/O modules (QX

• Analogue modules (Q6

• Interrupt module (QI60)

, QY , QH , QX Y )

AD , Q6 AD- , Q6 DA , Q6 DA- )

(2) Compatibility with the Multiple CPU system

The intelligent function modules of function version "B" or later support the

Multiple CPU system. Be sure to use the PLC CPU as a control CPU because of

the intelligent function modules cannot be controlled by the Motion CPU.

(3) Access range from non-controlled CPU

(a) The Motion CPU can access only the modules controlled by the self CPU. It

cannot access the modules controlled by other CPUs.

(b) Access range from non-controlled PLC CPU for the modules controlled by

the Motion CPU are shown below.

Table 2.2 Access range to non-controlled module

I/O setting outside of the group

Access target

Disabled (Not checked) Enabled (Checked)

Input (X)

Output (Y)

Buffer

memory

Read

Write

(Set by PLC CPU)

: Accessible : Inaccessible

REMARK

• The function version of an intelligent function module can be checked on the rated

plate of the intelligent function module or in the GX Developer's system monitor

product information list.

• Refer to the "Q173DCPU/Q172DCPU User's Manual" for the model name which

can be controlled by the Motion CPU.

2 - 3

Page 41

2 MULTIPLE CPU SYSTEM

2.1.4 Modules subject to installation restrictions

(1) Modules subject to install restrictions for the Motion CPU are sown below. Use

Description Model name

Servo external signals

interface module

Serial absolute synchronous

interface module

Manual pulse generator

interface module

Input module QX