Page 1

MITSUBISHI

advanced and

ever

advancingMITSUBISHI

ELECTRIC

Industrial

Sewing

INSTRUCTION

Electronic

PLK-A

Pattern

Series

Machine

MANUAL

Sewing

Machine

<Control

Unit>

A180E207P05

Page 2

Introduction

Thank you for purchasing

read

this manual thoroughly before

(Refer to

Referto

Head>

the

separate

the

"Mitsubishi Industrial Electronic

section

for

the

the

Mitsubishi Industrial Sewing Machine

use,toensure

instruction manual for

Sewing

entire

structure

Structure

and

of

the

sewing

This

long

and

safe

PLK-A

operations.

Series. Please

PLK-A05BT.)

Machine Instruction Manual < Machine

machine

Manual

head.

This manual describesthehandling methodsofthe Mitsubishi IndustrialElectronic Sewing

Machine control unit.

1.

Specifications

Describes

2.

Precautions

feature,

for

Read this section carefully together with

3.

Operation

Describes

and

advanced

the

instructionsfor preparation beforeturning on

The

basic

Operation

operation.

following

specification

are

described:

and

so

on.

the

specifications before starting operation.

the

power, basicoperation,

4.

Teaching

Method to complete the pattern data is described

based

on concrete examples

covering from the basis operating method to complicated applied operations.

It

is also explained here the methods to correct and delete the pattern data and the

method to write the completed

5.

Message

Table

data

on the floppy disk or

P-ROM.

Errors, etc. which are raised during operation ofsewing machine, are displayed on the

operation panel.

remedies.

6.

Maintenance

Describes a simple troubleshooting

It

is also explained here methods to

sewing

7.

Control

Describes

machine.

Unit

the

No part of this manual may be copied or transcribed without a

They

are designed to indicate the cause oftrouble and method of

and

repair work.

confirm

overall electric wiring diagram

the speed ofand to adjust the electronic

and

connector connection diagram.

written

permission of Mitsubishi Electric Corporation.

The contents of this manual may

Although

this manualwas

written

be

subject to

completely and

change

without notice.

carefully,ifyou

find

an error

or have a comment

COPYRIGHT©

MITSUBISHI

ELECTRIC

1993

about

the

CORPORATION

content of

the

manual,

please

inform

usofit.

Page 3

1.

Specifications

1.1

Features

1.2

Specifications

Contents

1

1

2

Precautions

2.

for

Operation

(1) Safety 3

(2) Operation environment 3

(3) Operation 3

(4) Power voltage 3

3.

Operation

3.1

Basic

Function

(1) Sewing

of

machine

Structural

Machine

control unit 4

(2) Floppy disk unit 4

(3) Applicable floppy disk 4

(4) P-ROM

cassette

(Option) 5

(5) Functions and operating method of operation panel 5 O

(6) Teaching section operation panel 7

3.2

Basic

Operation

(1) Before starting

(2) Power ON,

Method

the

home

operation 9

position return,

and

memory

check

(3) Setting operation panel 11

(4) Operation

(5) Raising/lowering

check

presser

foot

(6) Sewing operation 12

(7) Halt 12

(8) Resewing method 13

(9)

Erroneous

3.3

Advanced

(1) Electric correction of

(2) Up counter,

motion during sewing 13

Operation 13

home

position 14

down

counter

(3) Repeat sewing 15

(4) Releasing sewing

(5) Using two

step

area

limit

work holder 15

(6) Prohibiting automatic home position return operation 15

(7) Prohibitingthread trimming in halt state (switch) 15 ^

(8) Prohibiting work holder up operation in halt

state

(Input code) 15

(9) Adjusting fabric feed timing 15

(10) Sewing machine operation using free home position 16

(11) Adjusting sewing machine

the

(12) Changing

type of floppy disks 16

speed

(13) Prohibition of thread trimming motion 17

(14) Selection of

presser

weight 17

(15) 1 pedal specifications 17

(16) Selection of

(17) Pneumatic

(18) Selection of pneumatic

(19) Label

3.4

Dip Switch

thickness

pressure2stage

holder

Function

of sewing cloth 17

work holder 18

pressure

Table

switch 18

3

4

4

9

9

12

12

14

15

16

18

18

4.

Teaching

4.1

Basic

Function

(1) Pattern input

(2) Modification

(3) Write

mode

mode

mode

-1

-

19

19

19

19

19

Page 4

(4) Delete

(5) Function

(6) Communication

4.2

Pattern

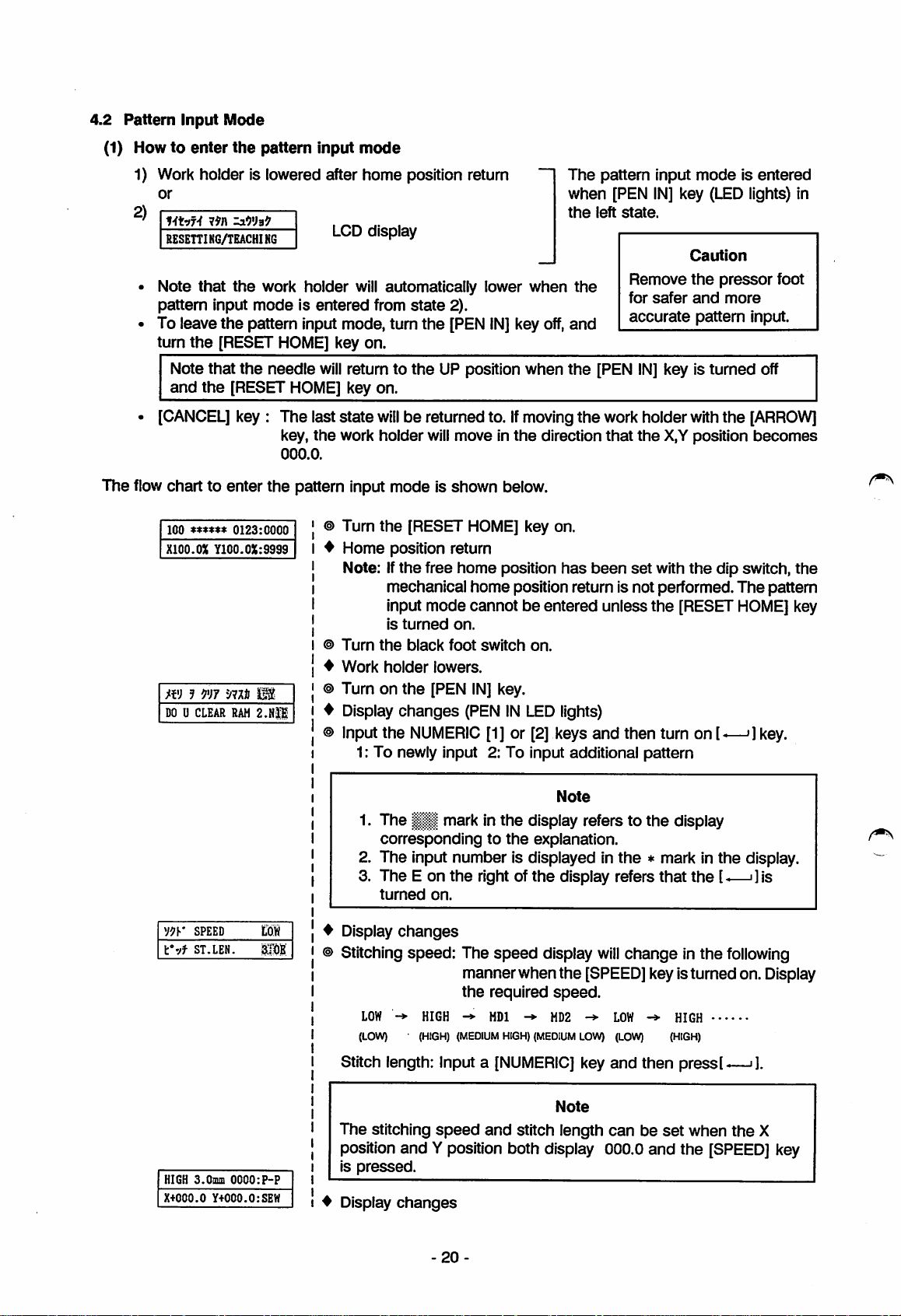

(1) How to enter

mode

mode

mode

Input Mode 20

the

pattern input mode 20

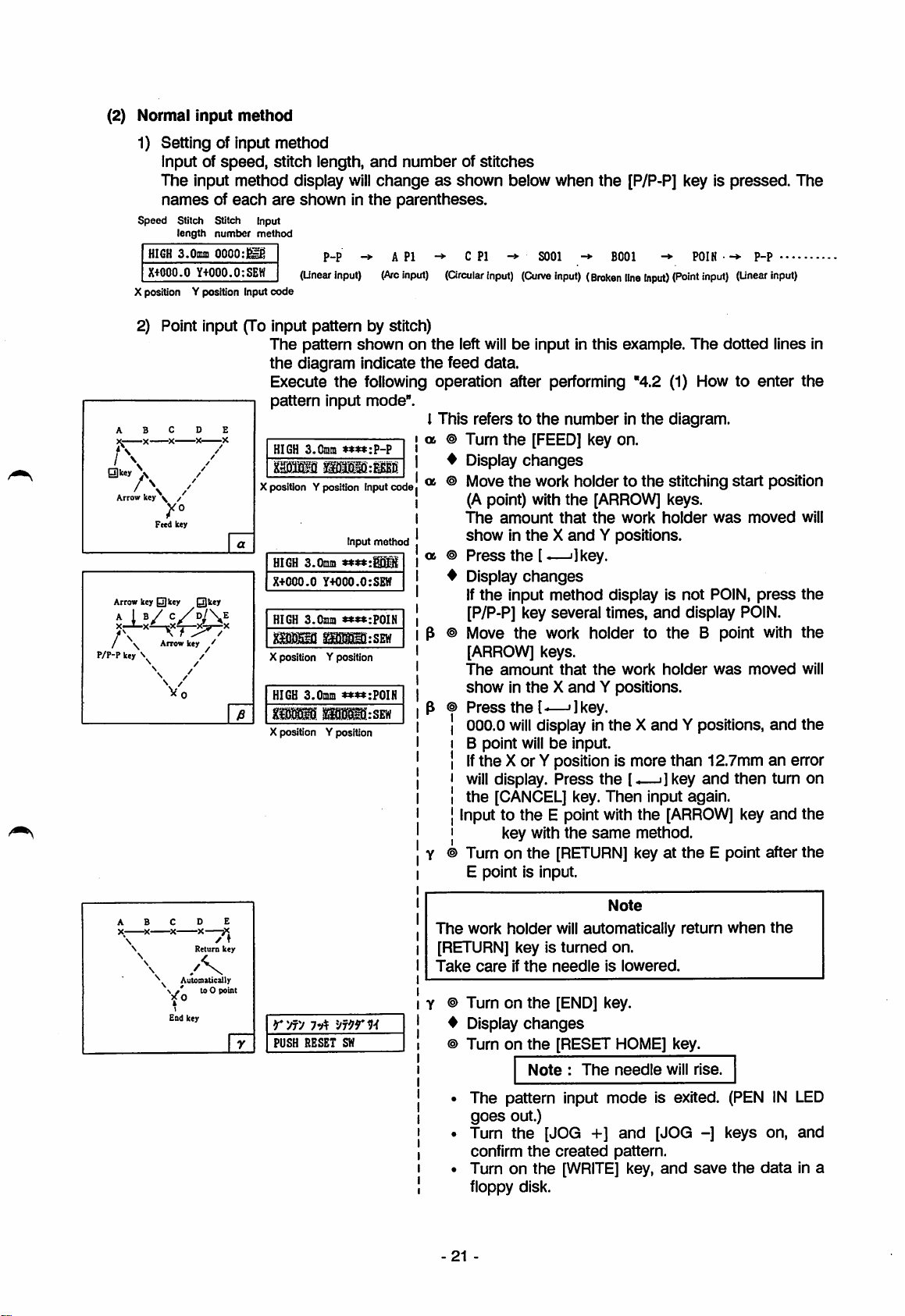

(2) Normal input method 21

1) Setting of input method 21

2) Point input (To input pattem by stitch) 21

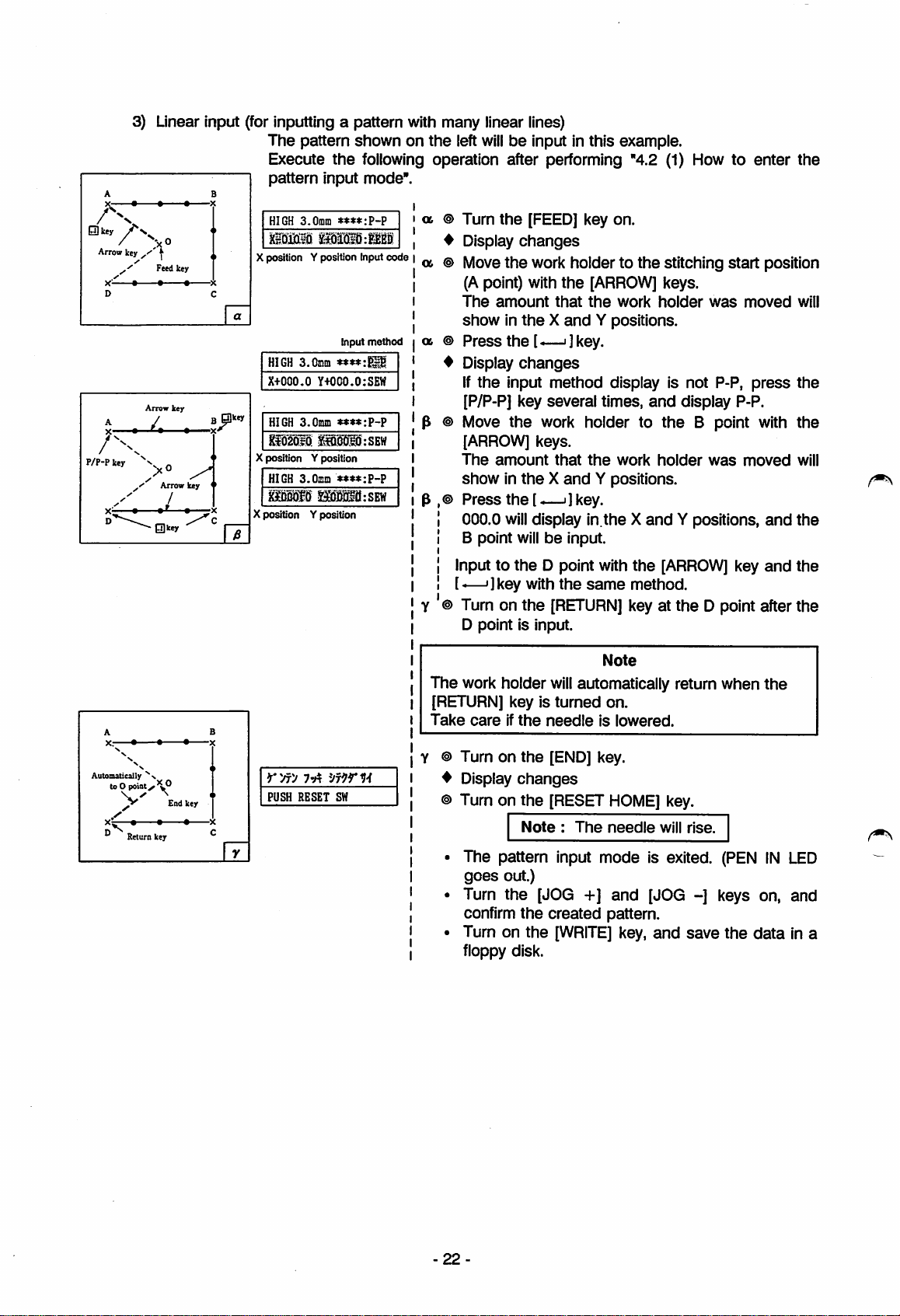

3) Linear Input (For inputting a pattern with many linear lines) 22

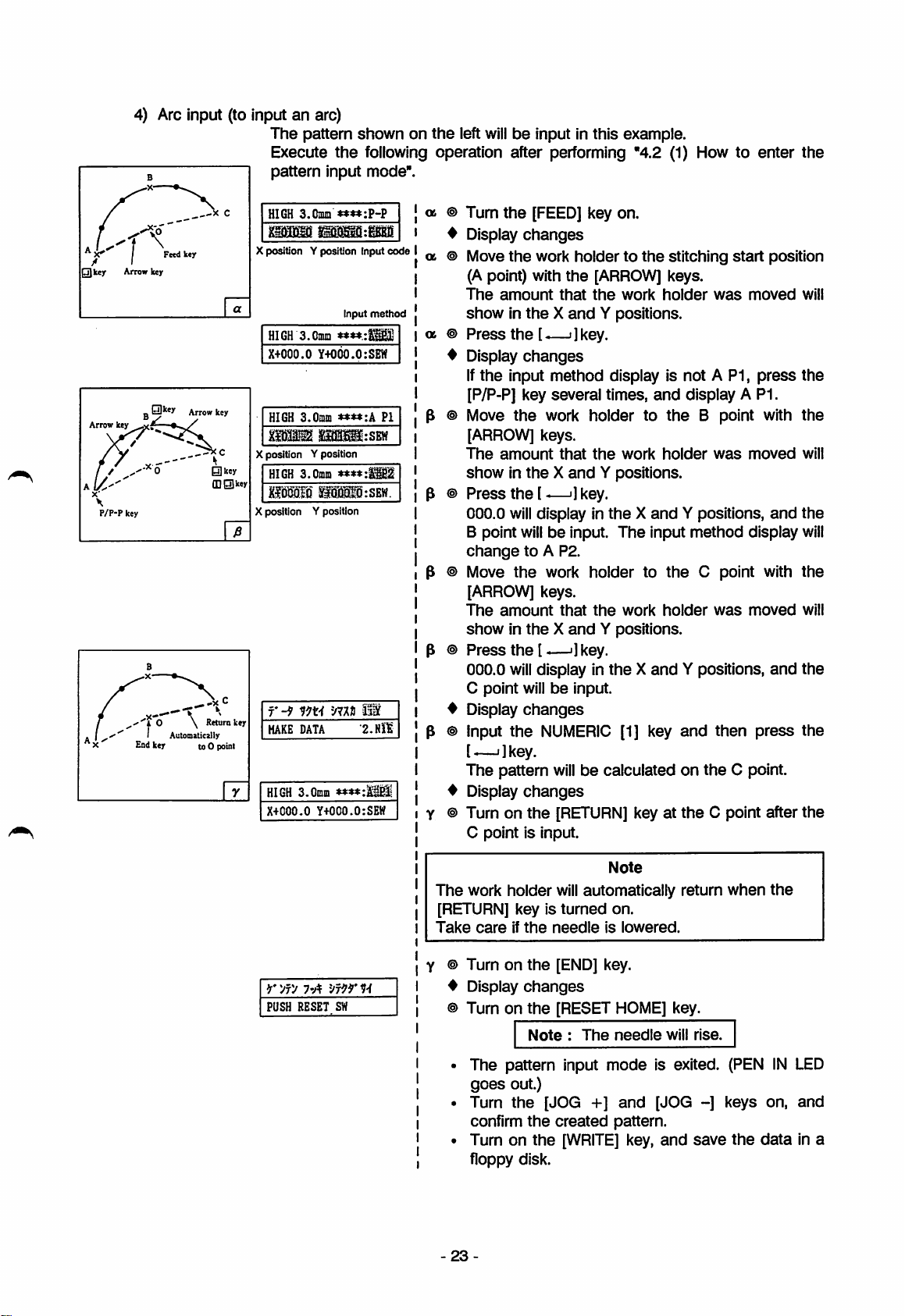

4) Arc input (To inputanarc) 23

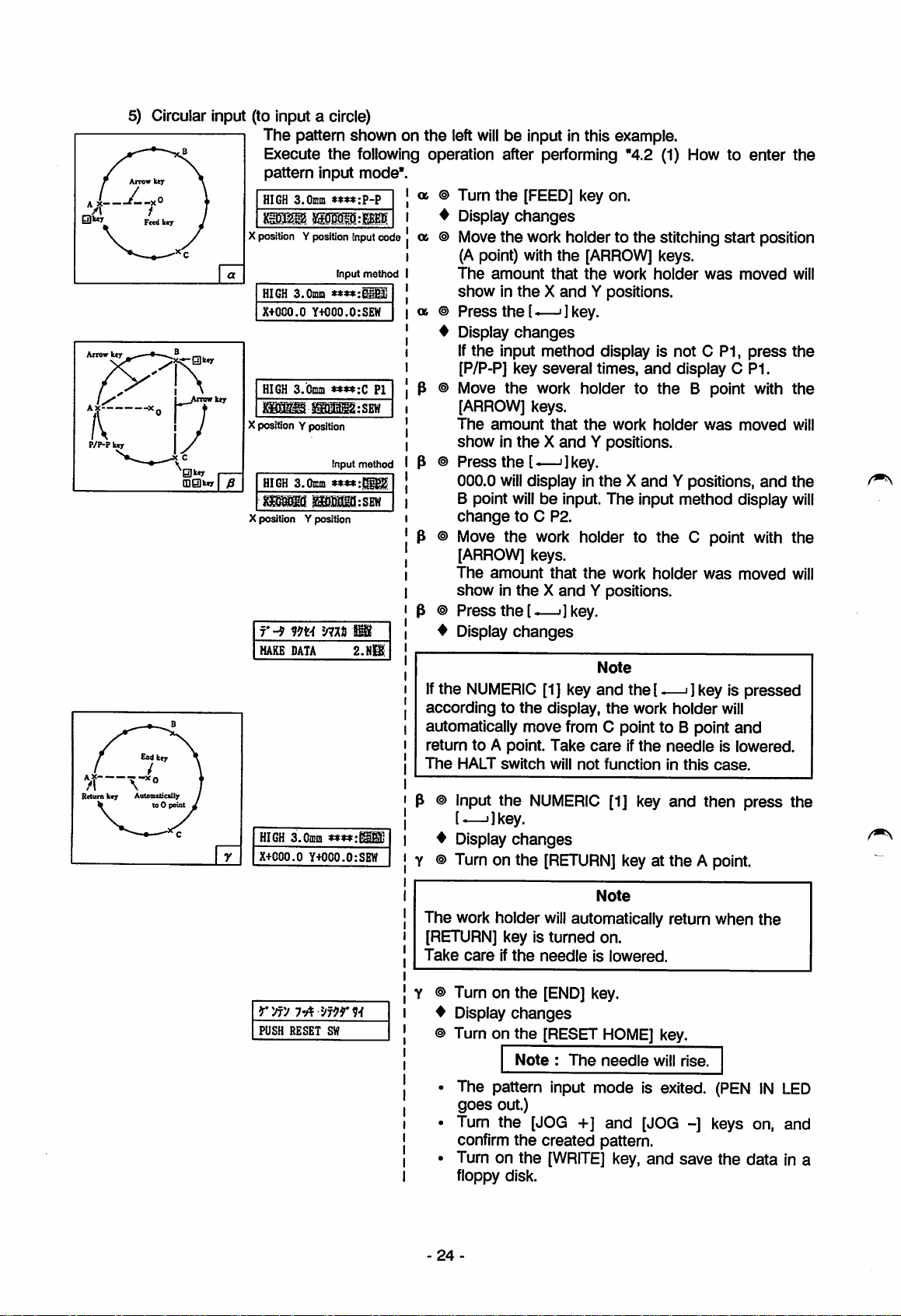

5) Circular input (To input a circle) 24

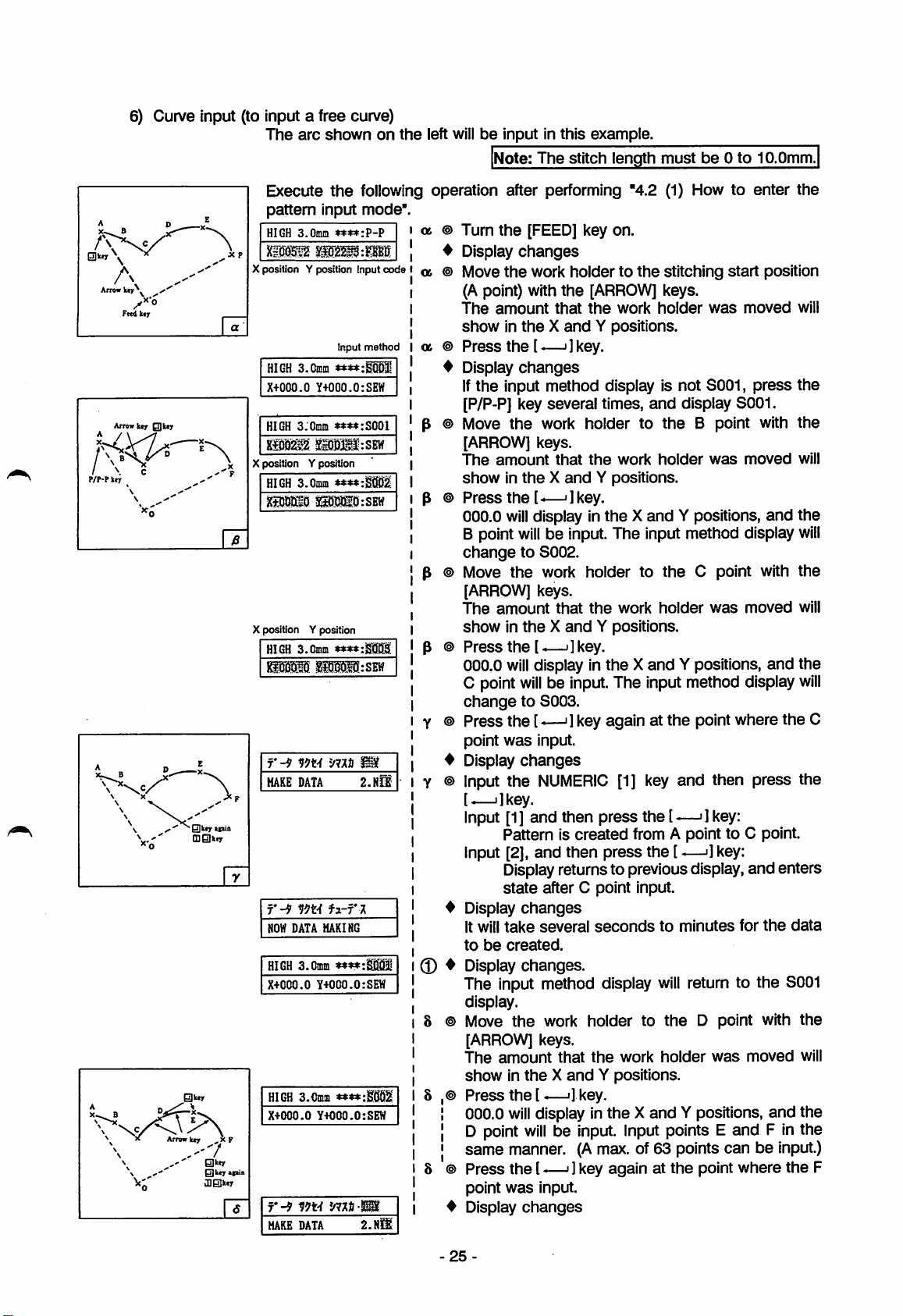

6) Curve input (To input a free curve) 25

7) Broken line input (To input a pattern with many lines) 27

Code

data

8)

(3) 1 stitch

(4)

Save

input method (To input

deletion

and

function

recall function 29

code

data) 28

(5) Special input function 29

1) Overlap stitching (The

2) Inverted overlap stitching (The

to reinforce

the

same

stitch is

same

stitch) 31

sewed

stitch is

twice to reinforce

sewed

twice from

the

stitch)

the

reverse direction

3) Parallel stitching (To stitch in parallel) 32

4) Offset stitching (To stitch inside of label, etc.)

5) Zigzag stitching (To stitch a zigzag pattern) 35

6) Back tacking 1

(To eliminate thread from coming

7) Back tacking 2 (To eliminate

end

of stitching with overlapstitching)

thread

undone

at start

from coming

and

end

of stitching)

undoneatstart

and

8) Precautions for special input function 41

(6) Conversion input function 41

1) Mirror form 41

2) Rotation (To rotate to match

4.3

Modification

(1) Main functions of modification

(2) How to

Mode

enter

modification

(3) Block modification 1 (To modify a

(4) Block modification 2 (To modify a

(5)

Feed

(6) Delete

(7) Delete all

(8)

One

(9)

Same

(10) Stitching

(To

(11) Stitching

(To

(12)

Code

(13)

Code

4.4

Write

modification (To

one

stitch (Delete

stitches

stitch addition (Add

stitch addition (Add

speed

change

the

speed

change

Mode

data

data

the

delete

addition (To

change

(Delete all

modification 1

stitching

modification 2

stitching

(To

delete

one

one

speed

speed

addtothe

the

mode

pattern to

mode

set

set

the

start point of

rangeofthe

range of

the

work holder) 42

input pattern with break line) 43

the

input pattern with curve)

the

input pattern data) 46

stitch from input pattern) 46

stitches

after specified stitch from input pattern)

stitch of desired stitch length to input pattern)

same

stitch to input pattern) 48

for all stitches after specified stitch in pattern) . 49

for Nstitches after specified stitch in pattern) 50

the

input

code

data)

input

code

data) 51

(1) Media writable 53

4.5

4.6

(2) Write

(3) Write

(4) Write

Delete

Function

method

method

method

Mode

Mode

1 (When specifying

2 (When not specifying

3 (To write in

pattern

home

position compensation) 55

number) 53

pattern

number) 54

(1) Floppy disk format 56

...

...

...

19

19

19

29

29

34

37

39

42

42

43

44

..

47

..

48

51

53

56

56

- II -

Page 5

(2)

Thread

(3) Alternate stitching 58

5.

Message

6.

Maintenance

6.1

6.2

6.3 Troubleshooting

7. Control

7.1

7.2

7.3

Table

(1)

Messages

(2)

Messages

Sewing

(1) Filter 62

(2) Sewing

(3) Replacing brake lining 62

Floppy

(1) Check of input switch signal 63

(2)

Checkofoutput

(3) Confirmation

Unit

Unit

Wiring

Connecting

Connecting

trimming prohibit 57

in sewing operation 60

in teaching operation 61

Machine Drive Motor

machine

Disk Unit

drive motor (Z motor) 62

and

Repair 62

signals 64

and

adjustment of sewing

speed

Appendix

Diagram

Diagram

Diagram

ofConnector Pins

ofEach Connector

Appendix

Appendix

Appendix

60

62

62

62

66

1—4

5-^ 8

9~25

III -

Page 6

1.

Specifications

1.1

Features

The

PLK-A

Machine which won popularity provides

(1)

Pattern

series machine which Is a

storage

media

successorofthe

much

more

features

Mitsubishi Industrial Electronic Sewing

than

that.

As pattern

P-ROM

data

(P-ROMIsan

(2)

Storage

capacity

Each floppy disk

P-ROM

The

of stitches

(3)

Stitch

The

(4)

Machine

The

machinedrive motor Iscontrolledwith

stable

(5)

Teaching

The

Input. In addition,

The

(6) Modification

The

diskorP-ROM.

per

length

stitch length

drive

rotations

machine control box provides a teaching function which allows simple

data

being

pattern

storage

media, both a floppy disk

which

was

prepared by

and

P-ROM

the

conventional model

optional specifications.)

can

store

can

store

150 patterns

16 patterns

and

and

360000 stitches of sewing

8000 stitches of sewing

pattern Is up to 8000.

and

resolution

canbeInput with a resolution from 0.1 to 12.7 mm In

motor

data

control

of

the

machine.

patterns

Input

canbemodified. After

accordingtothe

canbestoredonthe

PWM

(pulsewidth modulation) system, therebyobtaining

work holder

floppy disk or P-ROM.

the

pattern

data

Is modified. It

canbeused.

canbeused

without correction.

data

data

Intotal.

The

the

canbeeasily Input.

canbestoredonthe

Intotal.

maximum number

unit of 0.1 mm.

patternstobe

easily

floppy

(7)

Correctionofhome

By

the

home

position correcting operation on

mechanically moved In

(8) LCD (Liquid Crystal)

LCD

display Is provided on

Is

designedtoIndicate various

position

the

range from 0.1 to 12.7 mm In

display

the

operation panel for convenience of operation control.

setting

values,

the

operation panel,

operation

the

unit of 0.1 mm.

procedures,

the

error

home

position

messages,

The

etc.

can

be

display

1 -

Page 7

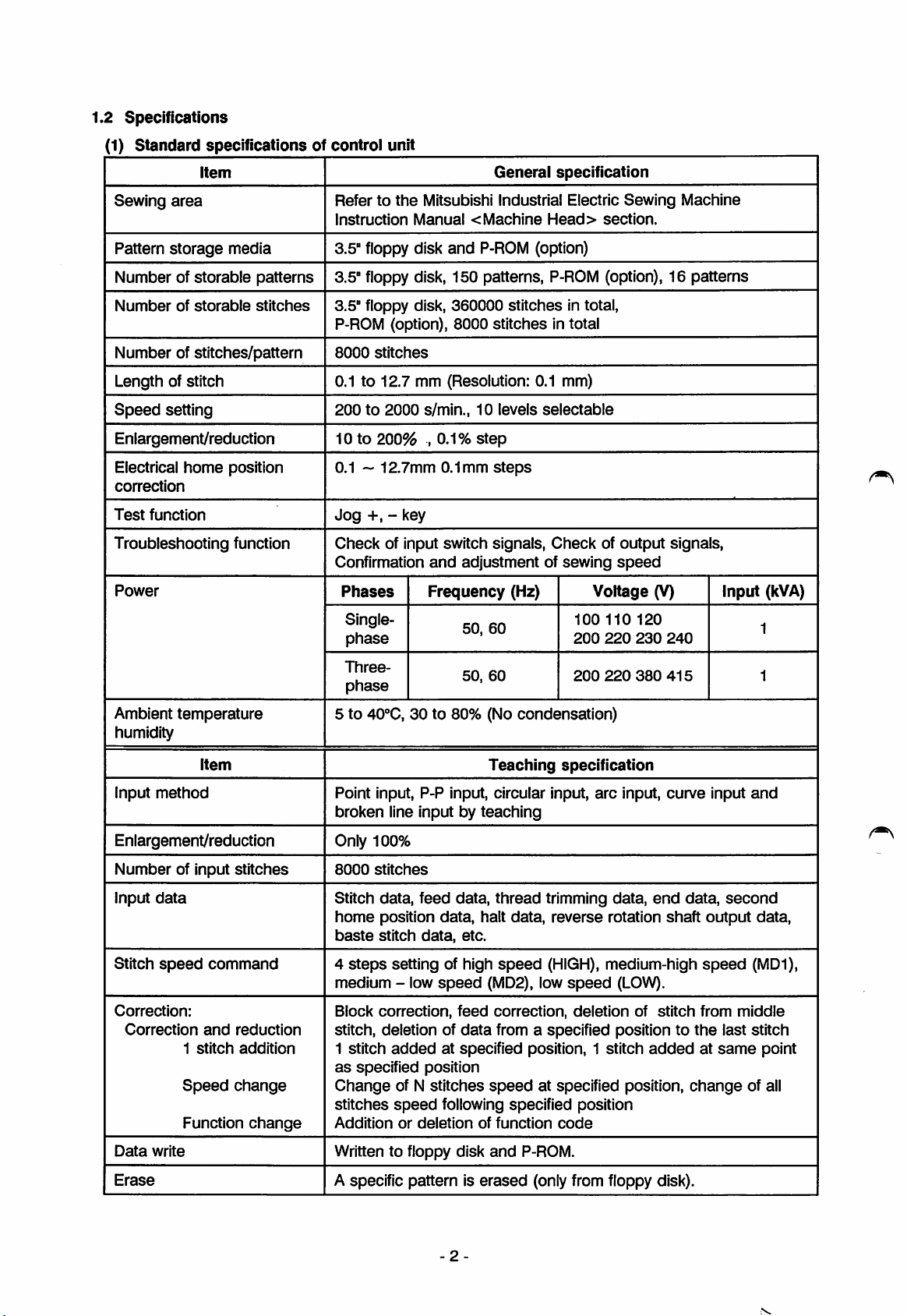

1.2

Specifications

(1)

Standard

specificationsofcontrol

unit

Item

Sewing

Pattern

Numberofstorable

Number

area

storage

of

storable

media

patterns

stitches

Number of stitches/pattern

Refertothe

Instruction

3.5" floppy disk

Mitsubishi Industrial Electric

Manual<Machine

and

3.5"floppy disk, 150 patterns,

3.5" floppy disk,

P-ROM (option), 8000

8000

stitches

P-ROM

360000

General

stitches

stitches

specification

Head>

(option)

P-ROM

in total,

in total

Length of stitch 0.1 to 12.7 mm (Resolution: 0.1 mm)

Speed

Enlargement/reduction 10 to

Electrical

correction

Test

Troubleshooting function

Power

setting

function

home

position

200to2000

200%

0.1 ~

12.7mm

Jog

-H,

- key

Check

of input switch signals.

Confirmation

Phases

Singlephase

s/min.,10levels

,0.1%

and

Frequency

step

0.1mm

steps

adjustmentofsewing

(Hz)

50,

60

selectable

Checkofoutput

100 110

200

Sewing

section.

Machine

(option), 16 patterns

signals,

speed

Voltage

220

120

230

(V)

240

Input

(kVA)

1

Three-

phase

Ambient temperature

5 to

40"'C,

humidity

Item

Input

method

Point input, P-P input, circular input,

broken

line input by

Enlargement/reduction Only 100%

Number

Input

Stitch

of input

data

speed

stitches

command

8000

stitches

Stitch data,

home

position

baste

stitch

4

steps

setting of high

medium - low

Correction:

Correction

and

1

stitch

Speed

Function

reduction

addition

change

change

Block

correction,

stitch, deletion of

1 stitch

as

Change

stitches

Addition

addedatspecified position, 1 stitch

specified

of N

speed

or

50,

60

200

30 to 80% (No condensation)

Teaching

specification

arc

teaching

feed

data,

data,

speed

data,

feed

data

thread

halt

etc.

speed

(MD2),

correction,

from a specified position to

data,

trimming

reverse

(HIGH),

low

speed

deletion

position

stitches

speed

at specified position,

following specified position

deletion

of

function

code

220

380

415

input,

curve

data,

end

rotation

shaft

medium-high

(LOW).

of

stitch

addedatsame

input

data,

output

speed

from

the

change

1

and

second

data,

(MD1),

middle

last stitch

point

of all

Data

write

Erase

Written to floppy disk

A specific pattern is

-2-

and

erased

P-ROM.

(only from floppy disk).

Page 8

2.

Precautions

(1)

Safety

for

Operation

1) Since

2) Make

(2)

Operation

1) Do not operate

2) Do not install

3) Take

4) Do not

the

sewing machine which is in operation is very dangerous, do not touch

moving portion of

the

sewing machine.

in addition, before repairing or inspecting

power.

suretoground

the

sewing machine to prevent

environment

the

sewing machine at a high temperature (higher than 40''C) or low

temperature

machine.

place

close

care

machine

vibrations.

head

use

(lower

to a

not to

the

than

5°C) place. Otherwise, malfunction or a trouble

the

sewing machine at a place where it is

heat

enter

and

source

water, liquid matter,

control

suchasa heater.

unit.

sewing machine at a place where it is

the

sewing machine,

and

electric conductor

5) The sewing machine pattern may dislocate or malfunctions may

is

appliedonthe

sewing

power

6) Ifa

radioorTV

prevent noise,

the

sewing

machine,

system.

power

keepitas

setisused

use

machine.

line.

When

far

apart

near

the

a different power

using

equipment

from

the

sewing

sewing

machine,

supplyorplace

the

make

suretoturn off

noises

and

electric

shocks.

occursinthe

exposed

to direct

such

light or at a

suchasmetal rubbish in

exposed

to excessive

occurIfa

surge

voltage (noise)

shocks

(suchashigh frequency welder)

machineaspossible

noise

may

enter

the

radio or TV

set

the

at a

and

radio

place

useaseparate

or TV

the

sewing

near

set.

away

the

and

the

To

from

(3)

Operation

1) When turning on or offthe power switch, release your foot from the start switch (footswitch).

When sewing a new pattern or enlarging/reducing a pattern, make

2)

operation

When inserting or removing

3)

When manually turning

4)

While

the

turned.

Dip switch

5)

Various functions

off

the

power for safety before changing

6)

Check

of result of

Result of teaching

mode.

(4)

Power

1)

The

voltage

power

2) Ifaninstantaneous

place.

To recover the sewing machine from

machine.

and

check

the

power is being

setting

canbeselectedbychanging

teaching

canbecheckedbythe

voltage

shouldbein

power failure occurs,

relationship

the

P-ROM

the

machine pulley,

turned

off,

the

between

cassette,

the

since

the

the

jog

range

of rating voltage

the

such

a state, turn on

the

work

holder

make

sure

to turn off

presser

presser

the

foot

shouldbein

foot is in

settingofdip

setting of dip switch.

under

the

teaching mode or under

±10%.

sewing

machineisresetoran

the

sure

to perform

and

the

pattern.

the

the

the

lower position, it

switches. Be

power switch of

power.

lower position.

sure

the

error

state

the

the

test

can

to turn

sewing

takes

sewing

be

-3

Page 9

3.

Operation

3.1

Basic

FunctionofStructural

Machine

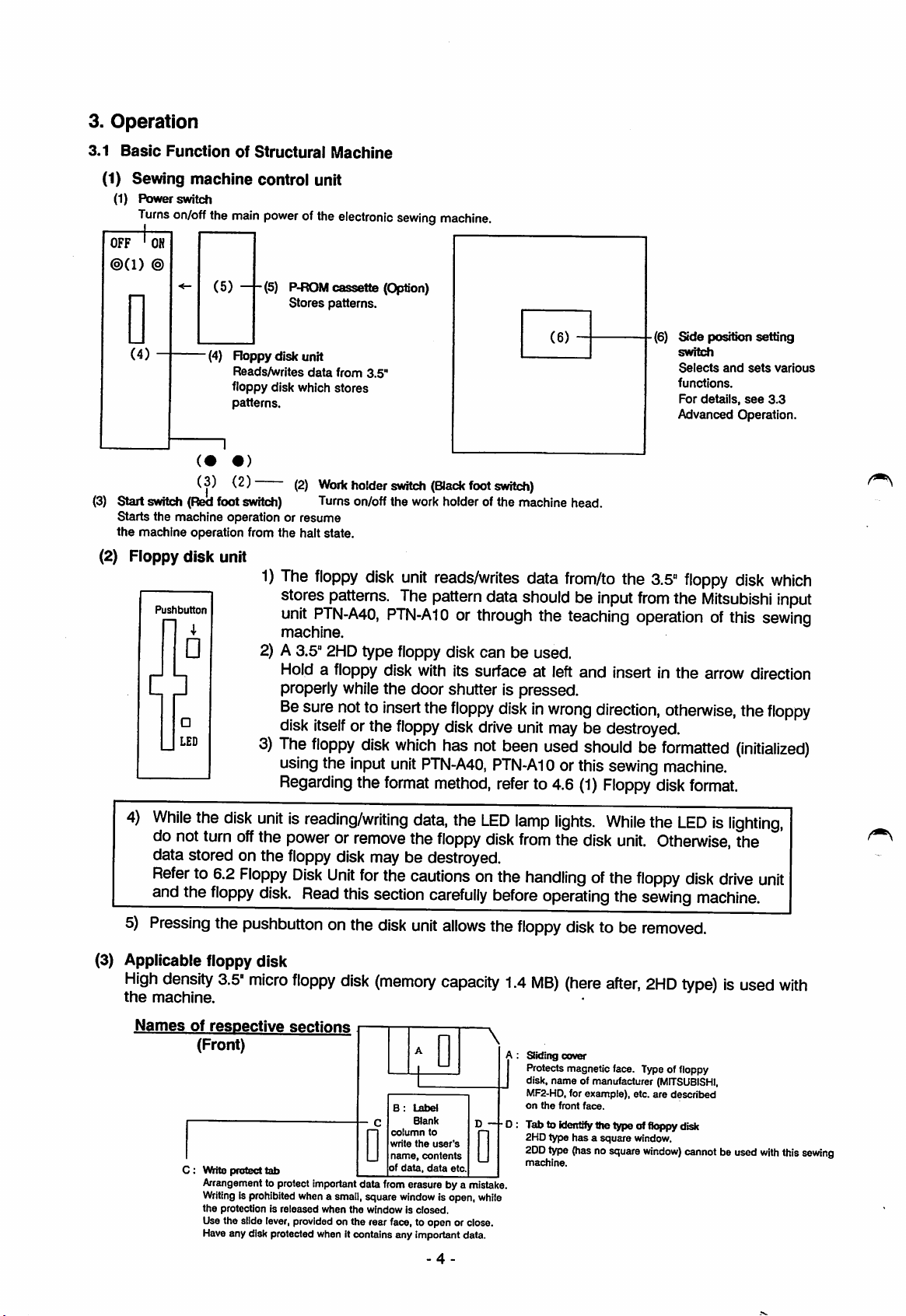

(1) Sewing

(1) Power switch

Turns

®(1)

®

machine

on/off

the

(5)

control unit

main

power

(5)

ofthe

electronic

P-ROM

cassette

Stores patterns.

sewinQ

(Option)

machine.

D

(4)

Roppy

disk unit

Reads/writes

floppy disk which

patterns.

• )

(3) (2)

(3)

Start switch(Redfoot switch) Turnson/offthe workholder of the machine head.

Starts the machine operation or

the

machine operation from

(2) Floppy

disk

unit

1)

Pushbutton

4

2) A

3)

C

•

H

•

LED

-

data

from

3.5"

stores

(2)

Work

holder

smtch

(Black

foot

switch)

resume

the

halt state.

The

floppy

stores

unit

PTN-A40,

machine.

3.5"

Hold a floppy disk with its surface at left

properly whilethe door shutter is pressed.

Be

sure

disk

itself

The

floppy

using

Regarding

disk

patterns.

2HD

type

nottoinsert

or the

disk

the

input

the

unit

reads/writes

The

pattern

data

PTN-A10orthrough

floppy

floppy

which

unit

format

disk can be used.

the

floppy

disk

has

PTN-A40,

method,

diskinwrong

drive

not

been

PTN-AI0

refer

data

shouldbeinput

the

unit

to 4.6

(6)

from/to

the

3.5"

from

teaching

and

operationofthis

insert in the arrow direction

direction,

maybe destroyed.

used

shouldbeformatted

orthis

(1)

sewing

Floppy

disk

Side

position setting

switch

Selects

and

functions.

For

details,

Advanced Operation.

floppy

the

otherwise,

sets

see

disk

Mitsubishi

the

(initialized)

machine.

format.

various

3.3

which

input

sewing

floppy

4)

While

the

disk

unitisreading/writing

do

not

turn

off

the

data stored on the

Referto6.2

and

the

5)

Pressing

(3) Applicable floppy disk

High

density

the

machine.

Names

of

C:

Floppy

floppy

respective

(Front)

Vtfirite

Arrangement

Writingisprohibited

the

Usethe slide lever,providedon the rear face, to open or close.

Haveany disk protected when it contains any important data.

disk.

the

pushbutton

3.5"

micro

protect

tab

to protect

protectionisreleased

powerorremove

floppy

sections

disk may be destroyed.

Disk

Unit

for

the

Read

this

section

onthe

floppy

important

whena small,square

when

disk

disk

(memory

B :

column

write

name,

D

of

data fromerasure bya

the

windowisclosed.

data,

the

LED

the

floppy

disk

cautionsonthe

carefully

unit

allows

capacity

Label

Blank

the

contents

data,

window

to

data

-4

user's

etc.

is open,

D - D

D

mistake.

while

lamp

from

lights.

the

disk

While

unit.

handlingofthe

before

the

\

operating

floppy

1.4

JA:Sitding

disk

MB)

(here

cover

Protects magnetic face. Typeoffloppy

disk, name of manufacturer

MF2-HD,for example), etc. are

on

the

front

Tab to identifythe type of floppy disk

2HDtype has a square window.

2DD

type

machine.

the

to be

after,

face.

(hasnosquare

the

LEDislighting,

Otherwise,

floppy

sewing

disk

machine.

removed.

2HD

type)isused

(MITSUBISHI,

described

window)

cannot

the

drive

beused

unit

with

with

this

sewing

Page 10

(4) P-ROM

Refer to

(5)

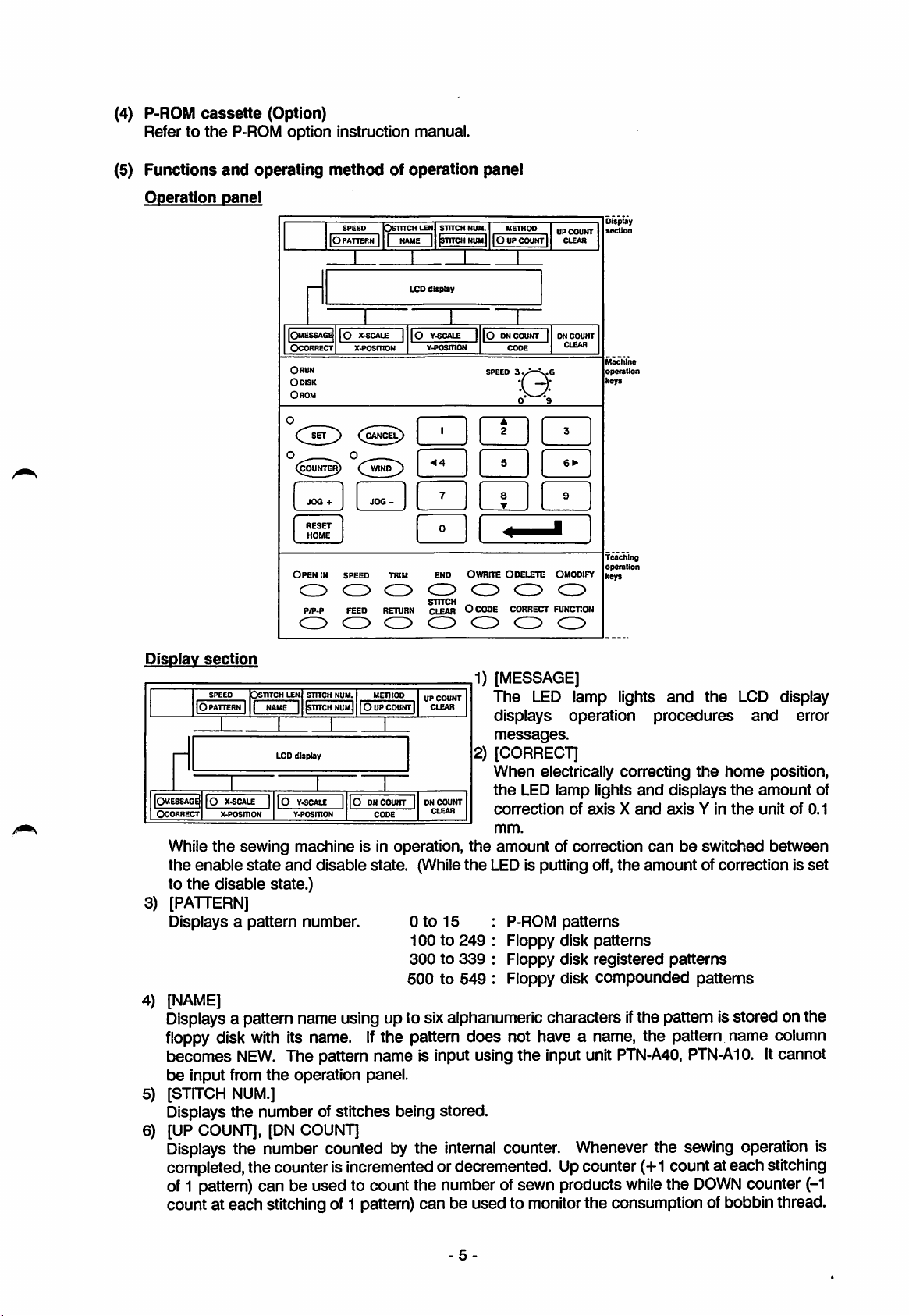

Functions

cassette

the

(Option)

P-ROM option instruction manual.

and

operating

methodofoperation

panel

Operation

oanel

SPEED

IOpattern I 1

o]

i

|Omessage|

OCORRECT

ORUN

Odisk

Orom

Open

10

(COUNTEm(WIND

RESET

HOME

in

speed

c:>

<o>

P/P-P

FEED

C3

O

Dsutchlen

X^SCALE

x.posrnoN

o

RETURN

C3

STITCH

NUM.

IstuchhumJ

NAME

1

LCD

display

1

|0

r^SCALE1|0ONCOUNT

Y-THTSniON

•<4

trim

END OWRITE ODELETE QMODIFY

srrrcH

CLEAR

SPEED

05

^

OCODE

|Oupcount|

O

METHOD

CODE

O' *9

CORRECT

CD

UP

CLEAR

ON

1

CLEAR

CO

FUNCTIO

CO

COUNT

COUNT

Display

soetion

Machine

opofalion

keys

Teaching

operation

keys

Display

section

1) [MESSAGE]

SPEED

Dstitch

LEN

STITCH

NUM.

|Omessage{

OCORRECT

While

the

to

[PATTERN]

3)

Displays a

[NAME]

4)

|0

PATTERN

1

10

X'^CALE

x-posmoN

the

sewing machine is in operation,

enable

the

disable state.)

1

NAME1jsTITCH

LCD

1

state

and

pattern

METHOD

NUmJ

10UPCOUNT

display

Y-POSmON

|0DNCOUNT

CODE

disable state. (While

number.

UP

COUNT

CLEAR

1

1 DN

COUNT

CLEAR

Oto

15

ICQto249

300to339

500

to

549

The

LED lamp lights

displays

messages.

2) [GORRECT]

When

the

correction

mm.

the

the

LEDis putting off,

electrically

LED lamp lights

amount

P-ROM

Floppy disk

Floppy

Floppy disk

operation

correcting

of

axisXand

of correction

the

patterns

patterns

disk

registered

compounded

and

the

procedures

the

home

and

displays

axisYin

canbeswitched

amount

of correction is

patterns

patterns

LCD display

and

the

amount

the

unitof0.1

Displays a pattern name using up to sixalphanumericcharactersifthe pattern isstored onthe

floppy

becomes

be

[STITCH

5)

Displays

[UP COUNT], [DN COUNT]

6)

disk

NEW.

input from

NUM.]

the

with

its name.Ifthe pattern does not have a name, the pattem name column

The pattern name is input using

the

operation panel.

numberofstitches

being

stored.

the

input unit

PTN-A40,

PTN-A10.

Displays the number counted by the internal counter. Whenever the sewing operation is

completed,the counter is incremented or decremented. Upcounter (+1 count at each stitching

of1 pattern) can be used to count the numberofsewn products

count at each stitchingof1 pattern)can be used to

monitor

while

the

DOWN

counter

the consumptionofbobbinthread.

error

position,

of

between

set

Itcannot

(-1

-5-

Page 11

7)

[X-SCALE],

Displays

of 0.1%. The enlargement/reduction can be performed independentiy on axis Xor axis

8)

[UP

COUNT

Resets the counting of the up/down counter to the

of

theupcounter

[Y-SCALE]

the

ratio of eniargement/reduction of a pattern in

CLEAR],

[DN

is "0000").

COUNT

CLEAR]

keys

the

initiai

setting vaiue (the

range

from 10 to 200% in

initiai

the

unit

Y.

setting vaiue

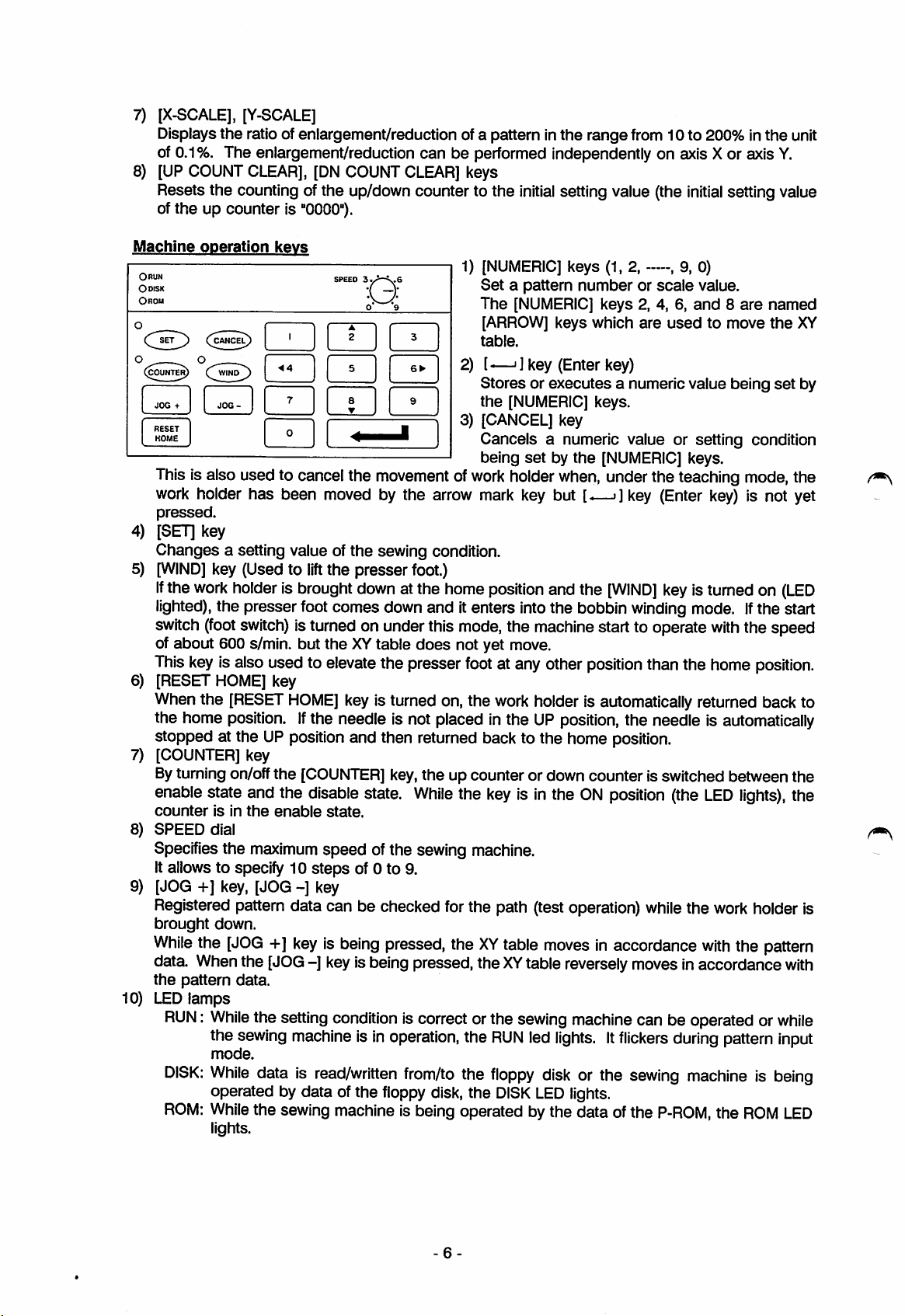

Machine

OnuN

Odisk

Orom

COUN^)

4)

5)

6)

7)

8)

9)

While

operation

- -

(^CANC^

(^WINl^

RESET

HOME

Thisis aiso used to cancel the movement of

work

hoider has been moved by the arrow mark key but

pressed.

[SET] key

Changes a setting value ofthe sewing condition.

[WiND]

if

lighted),

switch

of about 600 s/min. but

This

[RESET HOME] key

Whenthe

the home

stopped at the

[COUNTER] key

Bytuming on/offthe

enable state and the disable state.

counter

SPEED

Specifiesthe

Itallows to specify 10

[JOG +] key, [JOG

the

work

key

key (Used to

the presser foot comes downand itenters intothe bobbin

(foot

is aiso used to elevate the presser

[RESET

position.Ifthe needle is not piaced inthe

isinthe

diai

kevs

SPEED

lift

the presser foot.)

holder is brought

switch)

isturned on underthis

theXYtable

HOME]

UP

positionand then returned back to the home position.

[COUNTER]

enabie

maximum

state.

speed ofthe sewing machine.

steps

-]

key

1)

I]

3.>-k.6

u

[NUMERiC]

Setapattern

The

[NUMERIC]

[ARROW] keys which

[

table.

-j ] key (Enter key)

2)

[-

Storesorexecutes

the

[NUMERIC] keys.

3)

[CANCEL]

Cancels a numeric vaiue or setting condition

being

work

holderwhen, under the teaching mode, the

keys (1. 2,

numberorscale

key

setbythe

keys 2. 4, 6,

a numericvalue

[NUMERIC] keys.

[.—>]

down

atthe home

does

key is turned on,the

key,the up counter or down counter is switched between the

While

of 0 to 9.

position

mode,

not yet move.

foot

at anyother

work

and the

the machine start to operate

holder is automatically returned back to

UP

the key is in the

position

position,

ON

[WIND]

the needie is

position (the

Registered pattern data can be checked for the path (test operation)

brought

down.

the

[JOG+]keyisbeing

pressed,

theXYtabie

movesinaccordance

—,

9, 0)

value.

and8are

are

usedtomove

key (Enter

key

istumed on

winding

mode.Ifthe start

than the home

whiie

the

data. Whenthe [JOG-] keyisbeing pressed, theXYtable reversely moves inaccordance

the

10)

LED

RUN:

DiSK:

ROM:

pattern

lamps

data.

While

the setting

the

sewing

mode.

While

operated by data of the fioppy disk, the

While

iights.

data is

the sewing machine is being operated bythe data ofthe

condition

machineisin

read/written

iscorrectorthe

operation,

from/to

the

the

sewing

RUN

fioppy

DiSK

led

disk

LED

machinecan be operated or

lights,itfiickers

or the

lights.

sewing

during

machineisbeing

P-ROM,

being

key)

is not yet

with

the speed

position.

automatically

LED

lights),

work

hoideris

with

the

pattern

the

ROM

named

the

XY

set

by

(LED

the

pattern

with

while

input

LED

6-

Page 12

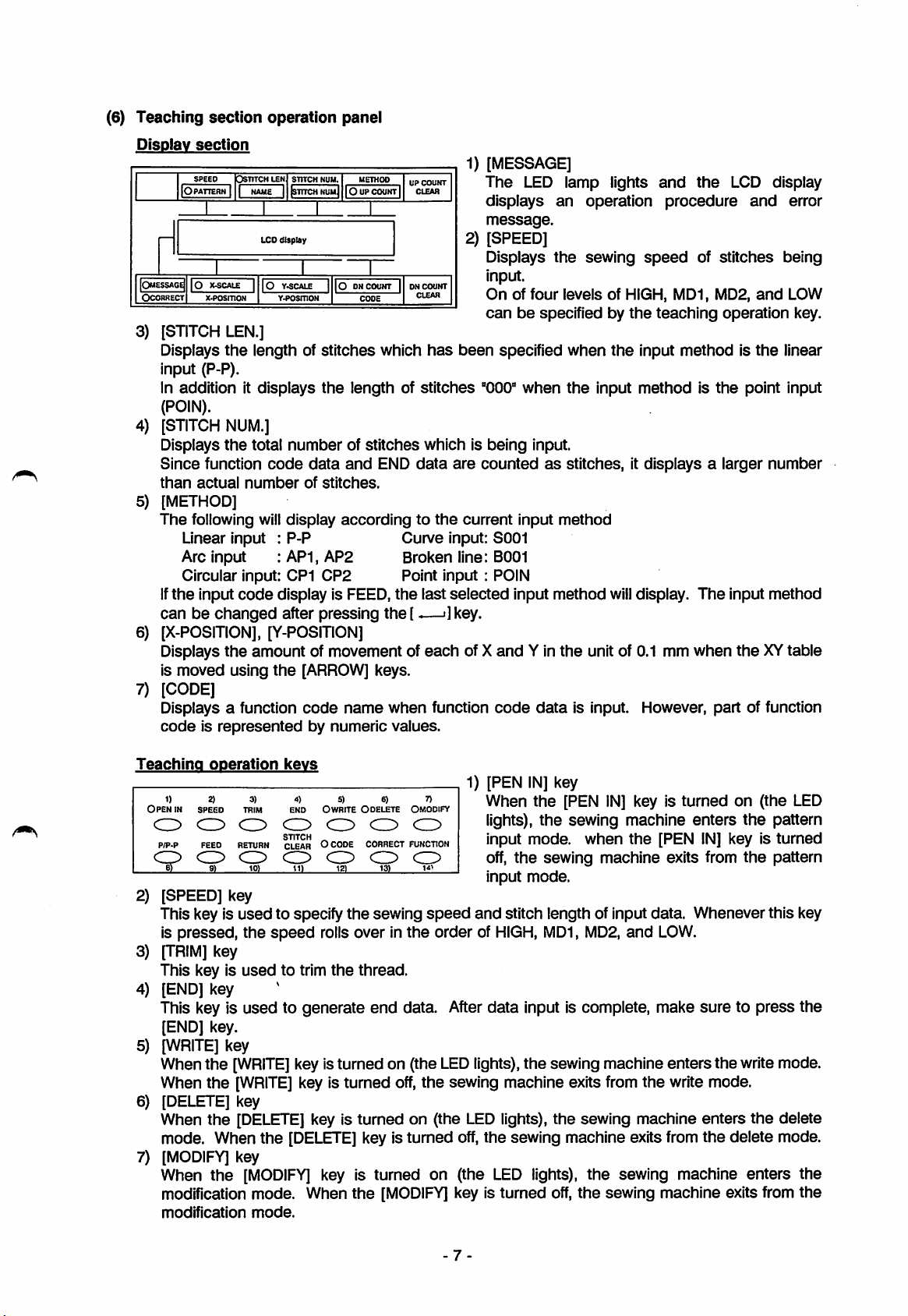

(6)

Teaching

section

operation

panel

Disoiav

IOmessag^

OCORRECT

3)

section

SPEED

|0

PATTERN

10

x.posmoN

[STITCH

Displays

DSTITCHLEN

1

1

X.SCALE

LEN.]

the

STITCH

NAME1tSTTTCH

LCD dfsptey

1

10

Y.SCALE

Y4>osrnoH

length of

NUM.

METHOD

NUmJ

10UPCOUNT

1

joONCOUNT

CODE

stitches

1

1

which

UP

DN

CLEAR

CLEAR

input (P-P).

In addition it

displays

the

length of

stitches

(POIN).

4)

[STITCH

Displays

Since

than

5)

[METHOD]

The

NUM.]

the

total

function

actual

following will

code

number

numberofstitches

data

and

END

of

stitches.

display

accordingtothe

data

Linear input : P-P Curve input: S001

Arc input : AP1, AP2 Broken line: 8001

Circular input: CP1

If

the

input

code

canbechanged

CP2

display is FEED,

after pressing

Point input : POIN

the

the[

-—i]key.

6) [X-POSITION], [Y-POSITION]

Displays

is

moved

the

amount of movement of

using

the

[ARROW]

keys.

7) [CODE]

Displays a function

codeisrepresented

code

by

name

numeric

when

values.

1) [MESSAGE]

COUNT

2) [SPEED]

COUNT

has

been

which is

are

current

last

selected

each

of X

function

The

LED lamp lights

displays

message.

Displays

an

the

operation

sewing

and

procedure

speed

the

LCD display

of

stitches

and

error

being

input.

Onoffour

canbespecifiedbythe

specified

"000"

being

when

input.

levels

of HIGH, MD1, MD2,

when

the

input

the

input

methodisthe

teaching

methodisthe

and

operation

point input

LOW

key.

linear

countedasstitches, it displays a larger number

input

method

input method

and

Y in

code

data

the

will

display.

unit of 0.1 mm when

The

input method

theXYtable

is input. However, part of function

Teaching

1)

Open

in

CO

PIP-P

CO

[SPEED] key

2)

This key is

is pressed,

[TRIM]

3)

This key is

[END] key

4)

This key is

[END] key.

[WRITE]

5)

Whenthe

When

[DELETE] key

6)

When the

mode. When

[MODIFY]

7)

When

modification

modification

operation

2)

SPEED

CO

FEED

CO

91

key

the

the

3)

TRIM

CO

RETURN

CO

10)

used

the

speed

used

used

key

[WRITE]

[WRITE]

[DELETE]

the

key

[MODIFY]

mode,

mode.

kevs

4)

0 WRITE O DELETE

CO

OCODE

CO

11)

5) 6)

CO CO

CORRECT

CO

12)

the

13)

sewing

END

CO

STITCH

CLEAR

to specify

rolls over in

to trim

to generate

the

thread.

end

key isturned on (the

key is turned

key is turned on (the

[DELETE]

key is turned

key is turned on (the

When

the

[MODIFY]

7)

Omodify

FUNCTION

CO

speed

the

order of

data. After

LED

off,

the

sewing machine exits from

key is

1) [PEN

and

IN]

key

When

lights),

input

off,

input

mode,

the

mode.

the

the

sewing

[PEN

sewing

when

IN]

key is

machine

the

machine

turned

enters

on

the

[PEN IN] key is

exits from

the

(the LED

stitch length of input data. Whenever this key

HIGH,

data

MD1,

MD2,

and

LOW.

input is complete, make

suretopress

pattern

turned

pattern

lights),the sewing machine entersthe writemode.

the

write mode.

LED

lights), the sewing machine enters

off,

the

sewing machine exits from

LED

lights), the sewing machine enters the

turned

off,

the

sewing machine exits from

the

the

delete mode.

the

delete

the

-7

Page 13

8) IP/P-P] key

The linear input (P-P), point input

(S001),

9) [FEED] key

This key is

10) [RETURN] key

When this key is

(which is

in

11)

[STITCH

This key is

mode.

12) [CODE] key

By turning on

home position data, halt data, or reverse rotation shaft data, etc.

allows

13) [CORRECT] key

When

position

and

used

the

data

being input, feed

CLEAR]

used

datatobe

the

[CORRECT] key is turned on (the

canbeset. After

break iine input (B001)

to input

pressed,

input start point) is automaticaiiy generated, if

key

to clear

the

sent/received

feed

feed

data

the

[CODE] key (the LED lights)

the

(POiN),

data.

data

until

the

number of stitches inthe pattern input mode or

to/from

correction, while

circuiar input (C P1), arc input (A P1), curve input

can

be selected with

from

the

point which is iast input to

second

the

home

input unit.

LED

the

and

lights),

[CORRECT] key is being

the

thereissecond

position is automaticaiiy

operating

the

lights),the amount of correction ofthe home position is enabled; while

being

14)

[FUNCTION]

0Ifthe

0

turned

position, various functions

During

off (the LED

key

[FUNCTION]

puts

key

isturned on

ofO,

the

amount

while

suchasthe

the

format of floppy disk, etc.

teaching, thisisusedto selectthespecial

of correction is disabled.

working

holder stays at the mechanical home

input

functionorconversion

[PEN

IN]

key.

the

home

home

position

generated.

the

modification

the

[NUMERIC]

canbeinput. This key also

amount of correction of

the

canbeoperated.

keys,

turned

on (the

[CORRECT]

input

position

data

second

the

home

LED

key is

function.

With

the keys which can be turned on or off

lighted when

the

key is

turned

on while

Note

LED

([PEN

goes

IN]

key, for example),

off if

the

key is turned off.

LED

is

8 -

Page 14

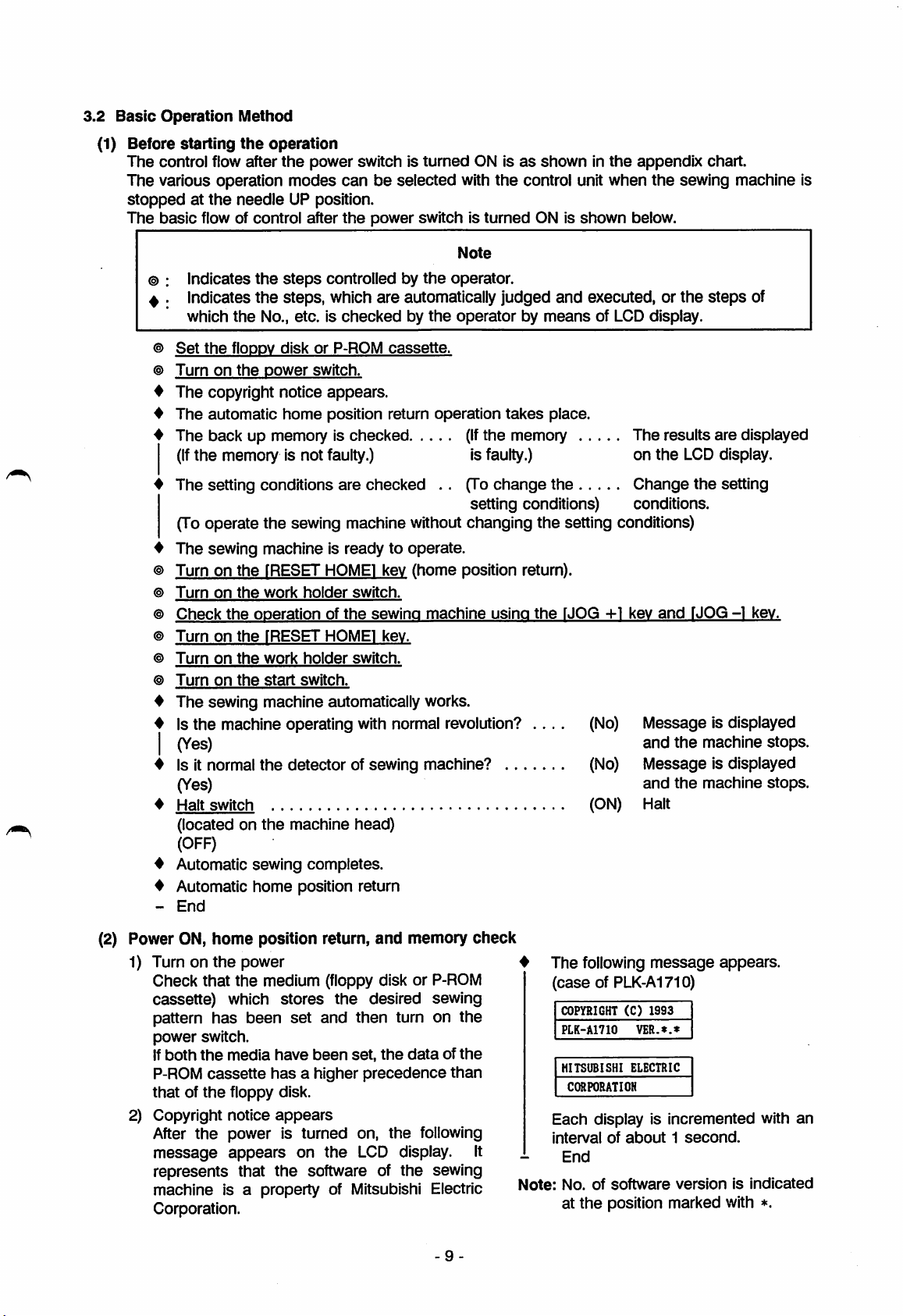

3.2

Basic

Operation

Method

Before

(1)

The

control flow after

The

various operation

stoppedatthe

The

basic

starting

Indicates

Indicates

which

Set

Turn

The

The

The back up memory is

(If

The setting conditions

the

operation

the

power switch is

modes

needle

UP position.

flow of control after

the

steps

the

steps, which

the

No., etc. is

the

floppy

on

the

power

diskorP-ROM

copyright notice

automatic

home

canbeselected

the

power

controlled by

checkedbythe

switch.

appears.

position return

checked

the

memory is not faulty.) is faulty.) on

are

checked

turned

switch is

the

are

automatically

cassette.

ON isasshowninthe

with

the

control unit

turned

Note

ON is

operator.

judged

operatorbymeans

operation

..

takes

(If

the

memory The results

(To

change

shown

and

place.

the

appendix

when

the

below.

executed, or

of LCD display.

the

Change

sewing machine is

setting conditions) conditions.

(Tooperate the sewing machine without changing the setting conditions)

The

sewing

Turn on

Turn

on

Check

Turn

on

Turn

on

Turn

on

machineisreadytooperate.

the

the

the

the

the

the

fRESET

work

operation

fRESET

work

start

HCME1

holder

of

HCME1

holder

switch.

switch.

the

switch.

sewino

key (home position return).

machine

key.

usinc

the

fJCG

+1

key

and

The sewing machine automatically works.

Is

the

machine operating with normal revolution?

(Yes)

Is it normal

the

detector

of sewing

(Yes)

Halt

switch

(located on

the

machine head)

machine?

...

(No)

(No)

(CN) Halt

Message

and

the

Message

and

the

(OFF)

Automatic

Automatic

End

sewing

home

completes.

position return

chart.

the

steps

are

displayed

LCD

display.

the

setting

fJCG-1key.

is displayed

machine

is displayed

machine

of

stops.

stops.

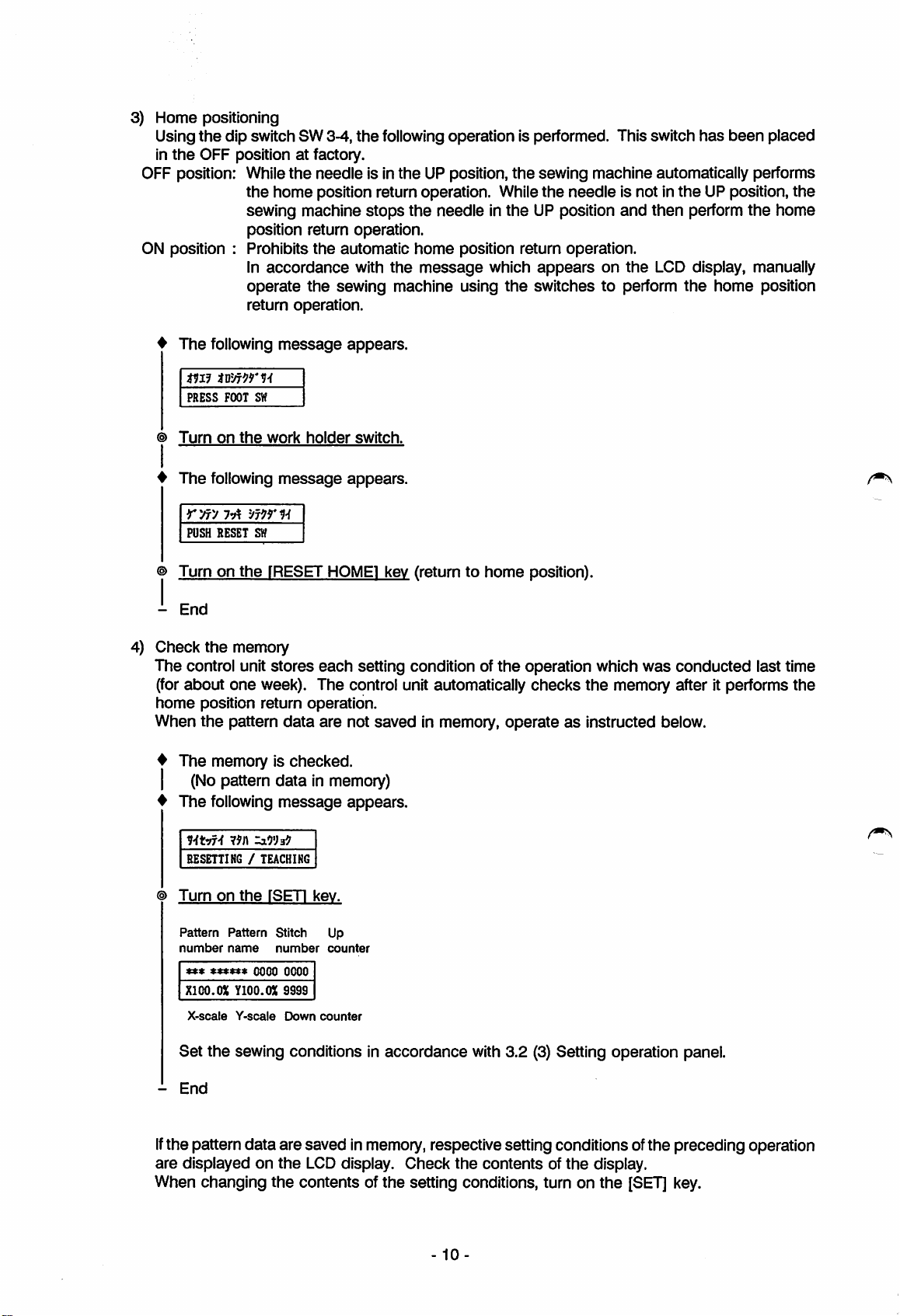

(2) Power ON,

1) Turn on

Check

cassette)

pattern

power

If

P-RCM

thatofthe

2)

Copyright

After

message

represents that

machine

Corporation.

both

home

the

that

the

which

has

switch.

the

media

cassette

position return,

power

medium (floppy disk or P-RCM

stores

been

set

and

have

been

has

a higher

the

desired

then

set,

precedence

and

turn on

the

memory

dataofthe

floppy disk.

notice

the

power is turned on,

appears

appears

on

the

software of

the

the

LCD

display. It

the

is a property of Mitsubishi Electric

sewing

the

than

following

sewing

check

The

following

(caseofPLK-A1710)

COPYRIGHT

PLK-A1710

MITSUBISHI

CORPORATION

Each

intervalofabout1second.

End

Note:

No.ofsoftware

at

(C)

1993

VER.».«

ELECTRIC

display is

the

position marked with *.

message

appears,

incremented

versionisindicated

with

an

Page 15

3) Home positioning

Using

the

dip switch SW 3-4,

in

the

OFF positionatfactory.

OFF position: While

the

sewing machine

position return operation.

ON position : Prohibits

In

accordance

operate

return

The

following

PRESS FOOT SW

®

Turn

on

the

work

♦

The

following

rvfy

PUSH RESET SW

the

following operation is performed. This switch

the

needle is in

home

position return operation. While

the

automatic

the

sewing machine using

stops

with

the

UP position,

the

home

the

message

needle in

operation.

message

message

holder

appears.

switch.

appears.

the

sewing machine automatically performs

the

the

UP position

needle

is not in

and

position return operation.

which

appears

the

switches to perform

on

has

been

the

UP position,

then

perform

the

LCD display, manually

the

home

placed

the

home

position

the

® Turnonthe

-

End

4)

Check

the

The control unit

(for

about

home

position return

When

the

The

(No

The

RESEniNG /

Turn

Pattern Pattern Stitch Up

number

t**

XI00.OX

X-scale

memory

one

week). The control unit automatically

pattern

memory is

pattern

following

TEACHING

on

the

name

******

0000

YIOO.OX

Y-scale

[RESET HOME! key (return to

stores

each

setting condition of

operation.

data

are

not

saved

in memory,

checked.

data

in memory)

message

fSETi

number

0000

9999

Down

appears.

kev.

counter

counter

home

position).

the

operation which

checks

the

was

memory after it performs

operateasinstructed below.

conducted

last time

the

Set

the

sewing conditions in

End

If

the pattern data are saved inmemory, respective setting conditions ofthe preceding operation

are

displayed on

When changing

the

LCD

the

contents of the setting conditions, turn on

display.

accordance

Check

-10-

with 3.2 (3) Setting operation panel.

the

contentsofthe

display.

the

[SET]

key.

Page 16

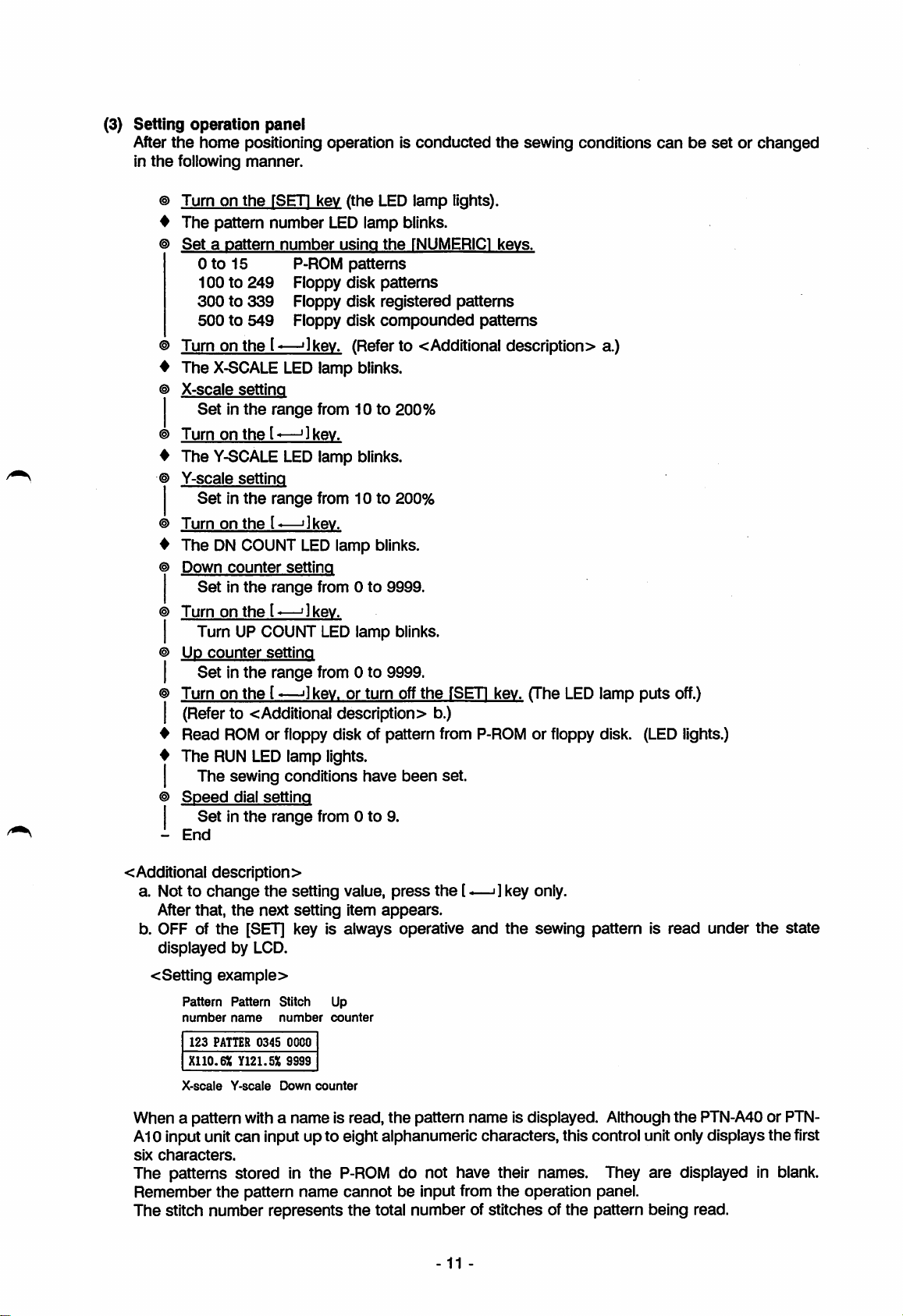

(3) Setting

After

the

in

the

operation

home

panel

positioning operation is

conducted

following manner.

the

Turn on

The

pattern

Setapattern

0to15 P-ROM

100to249

300to339

500to549

Turnon the [-—'Ikev.

The

X-SCALE LED lamp blinks.

X-scale

Setinthe

Turnonthe[-—'

The

Y-SCALE

Y-scale

Setinthe

Turnonthe

The

DN COUNT LED

Down

Setinthe

Turnonthe[^—'

Turn UP COUNT LED

Uo

counter

Setinthe

Turn on the [

fSETI kev (the LEDlamp lights).

number

number

LED lamp blinks.

usino

the

patterns

Floppy disk

patterns

Floppy disk registered patterns

Floppy disk

compounded

(Referto<Additional

settino

range

setting

counter

from 10 to

1kev.

LED lamp blinks.

range

from 10to200%

[-—'ikev.

lamp

settino

range

from 0to9999.

1kev.

settino

range

from 0 to 9999.

^—•]

kev. or turn off

blinks.

lamp

200%

blinks.

fNUMERICI

the

(Referto <Additional description> b.)

Read

ROM

or floppy disk of pattern from

The

RUN LED lamp lights.

The

Speed

Setinthe

End

sewing

dial

conditions

settino

range

have

from 0 to 9.

been

fSETl

set.

the

sewing conditions

kevs.

patterns

description> a.)

kev. (The

P-ROM

or floppy disk.

LED

canbesetorchanged

lamp puts

(LED

off.)

lights.)

<Additional description>

a. Not to

After

b. OFF of

change

that,

the

the

the

setting value,

next

setting

item

press

appears.

[SET] key is always operative

the

[-—"]key only.

and

the

sewing pattern is

displayed by LCD.

<

Setting

example

Pattern Pattern Stitch Up

number

X-scale

name

123

PATTER

X110.6X Y121.5X

Y-scale

0345

>

number

0000

9S99

Down

counter

counter

When a pattern with a nameis read, the pattern name is displayed. Although

A10 input unit

six

characters.

The patterns stored in

Remember

The stitch number represents

the

can

input up to eightalphanumeric characters,this control unit only displays

the

pattern

P-ROM

name

cannot be input from

the

do not have their names. They

the

operation panel.

total number of stitches of

11

the

are

pattern being read.

read

under

the

PTN-A40orPTN-

the

the

displayed in blank.

state

first

Page 17

(4)

Operation

After

check

1)

While

speedinaccordance

the

While

returns. When turned

check

the home position return operation isexecuted, whilethe work holder is inthe lowerposition,

the

operation using

the [JOG +] key is being turned on, the

position.

the [JOG -] key is turned

the

with

OFF,

the

[JOG +] key

and

[JOG-]key.

XY

table

(work

pattern. When the [JOG +] key is turned

ON,

the

XY

table

will

move in the direction that the pattern

theXYtable

will

stop in that position.

holder) moves at a constant

off,

the

2) WhentheXYtable comes to the end ofthe pattern by continuouslypressing the [JOG +]

the work holder rises

and

the home position return operation takes place.

When itcomes to the start of pattern after the [JOG -] key was operated repeatedly, the work

holder

in

Inthis state, by pressing the start switch,

the

3)

While

lower position; at the feed portions,

stopsatthe

the

input

pattern.

[JOG +] key,

descended

the

operation

position. Return it to home positionsofarasthere is no error

the

sewing operation

canbechecked.

can

be started or by pressing

checking the operation, at the sewing portions of the pattern, the presser foot is in the

the

presser foot is in the upper position.

table

stops

in

key,

(5) Raising/lowering

Byturning on/offthe

presser

[WIND]

foot

key (the

LED

lights/puts

ofO,

the presser foot

can

be raised/lowered.

Itis convenient to lowerthe presser foot for passing the thread. Afterthe thread is passed, turn

off

the

[WIND]

Note that ifthe start switch (red foot switch) is turned on

position,

the

key (the

sewing

LED

puts

machine

off).

rotates.

Note

while

the presser foot is inthe lower

Itis a good idea to move away the start switch to prevent the operation ofthe switch by

mistake.

(6)

Sewing

operation

Dialvalue

and

maximum sewing

1) Beforestarting the sewing operation, itis necessaryto check

the

for

speed

2) Sewing

The sewing

the

speed

the

(Do not turn

3)

Set

switch.

machine rotates

Once the sewing operation starts, evenifthe operator

releases his/her foot

machine continues the sewing operation.

machine

automatically

settings on the operation panel, particularly, for the

dial setting.

speed

speed

stitch length of

dial value determines

stitch length automatically limits

the

the

item

After

has

to

depends

speed

be

the

sewed

on the

patterntobe

speed

sewed.

the

maximum sewing

the

sewing

dial setting and

dial during operation.)

and

turn

on

the

While

speed.

work

that, byturning on the start switch,the sewing

and

starts

the

sewing operation.

from

the start switch, the sewing

After

the

sewed

rises.

the

pattern, it

stops

and

the

work holder

the

speed,

holder

sewing

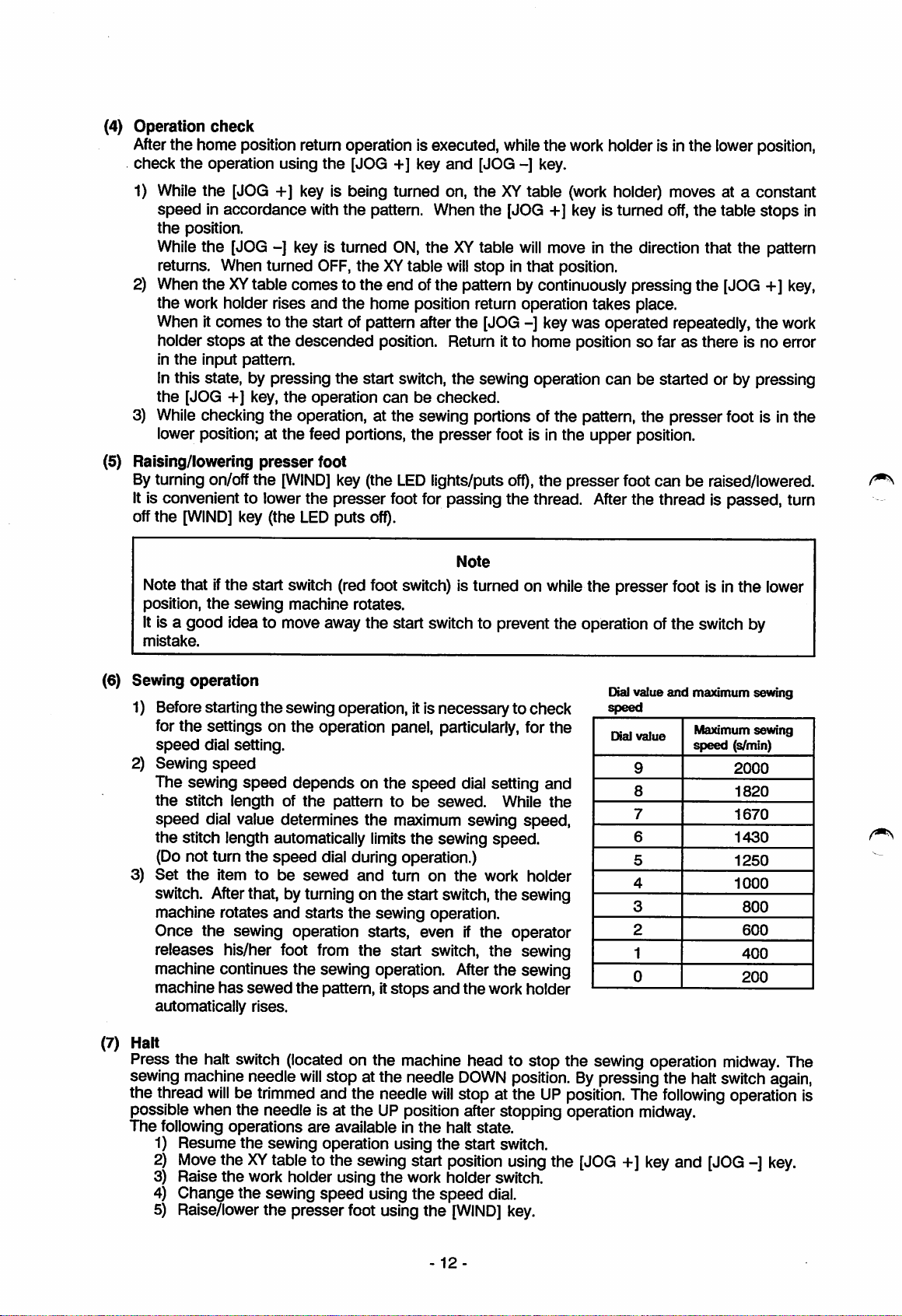

Dial

value

9

8

7

6

5

4

3

2

1

0

Maximum

speed

(s/min)

2000

1820

1670

1430

1250

1000

sewing

800

600

400

200

(7) Halt

Press the halt switch (located on the machine head to stop the sewing operation

sewingmachine needle

the thread

willbetrimmed

possible when the needle is at the UP position after stopping operation

The

following

1) Resume

2)

Move

operations

the

theXYtableto the

will

stop at the needle

and the needle

are

available in

sewing operation using

sewing

the

start

DOWN

will

stop at the

halt

the

start switch.

position

position.Bypressing the halt

UP

state.

using

position.

the

[JOG+]key

The

midway.

3) Raise the work holder using the work holder switch.

4) Change the sewing

5) Raise/lowerthe presserfoot using

speed

using the

the

-12-

speed

[WIND]

dial.

key.

following

and

[JOG-]key.

midway.

switch

again,

operationis

The

Page 18

(8)

(9)

Resewing

Using

the

If

the

sewing

XY

tabletothe

operation

Erroneous

1)

Reverse

It

judges

with following

Any

switches

vjy

REVERSE ROTATION

Turn

change

again

method

halt function,

machineisstopped

position

using

the

start

motion

turn of

during

sewino

automatically

message.

willbedisabledinsuch

the

power off

the

direction of

the

power

switch.

the

where

and,

item

switch.

sewing

machine

the

direction of

after

reversing

canberesewed.

during

the

thread

the

sewing

was

turns

occasion.

the

turns

of motor

plug, which is

operation

cut

using

when

the

machine

stopped

providedonthe

because

the

[JOG-]key

started

completely (it

the

motor

thread

and

and

takes

end

is cut,

restart

stops

about

cover,

move

the

sewing

the

operation

2 minutes),

and

back

the

on

2) Error with

When

short

Any

PG

SYNCHRONIZER DEFECT

Turn off

Above

the

thereisany

period

switches

my

the

message

detector

error on PG signal of detector,

and

the

stops

willbedisabledinsuch

power, repair

may

explained below.

3) Lock of

When

Any

vjy

MACHINE

Turn off

was

machine

the

machine

switches

imfx*}

WAS

the

caught

got

willbedisabledatsuch

LOCKED

power, remove

completely,

4) Momentarv power failure

When

the

power supply

operation

Turn to off

Vxm

POWER

stops,

the

n*7-

OFF THEN ON

then

power

any

switch

of sewino machine

showing following

occasion.

the

appear

detector

when

and

the

caughtbysome

occasion.

the

cause

of catching

the

above

was

switches

detector

interrupted for a moment, following

become

and

backonagain.

message.

backonthe

machine

reason,

error

inoperative.

the

machine

got

caught

following

and

backonthe

is raised.

power

message

operates

with high

again.

(stopsatthe

appears.

power.

message

speed

locked state)

When

the

appears

for a

as

machine

and

the

3.3

Advanced

Using

executed.

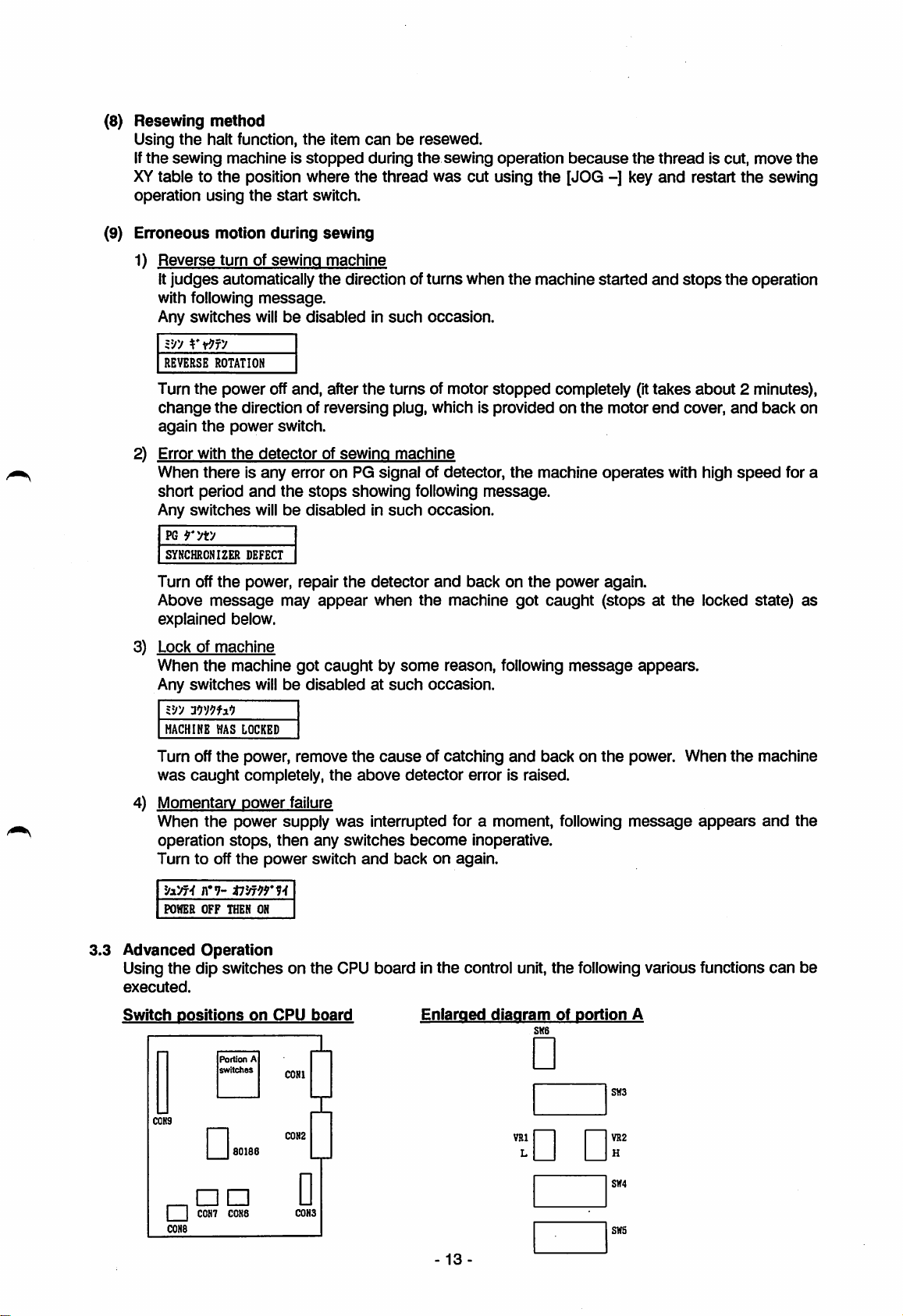

Switch

CONS

Operation

the

dip switches on

positions

Portion

switches

80186

I I

C0H7

CONS

CCN8

on

the

CPU board in

CPU

board

A

CONl

C0N2

C0N3

the

Eniaraed

-

13

control unit,

diagram

•

VRl

L

• •

the

following various functions

of

portion

SK6

A

SH3

VH2

H

SH4

SNS

can

be

Page 19

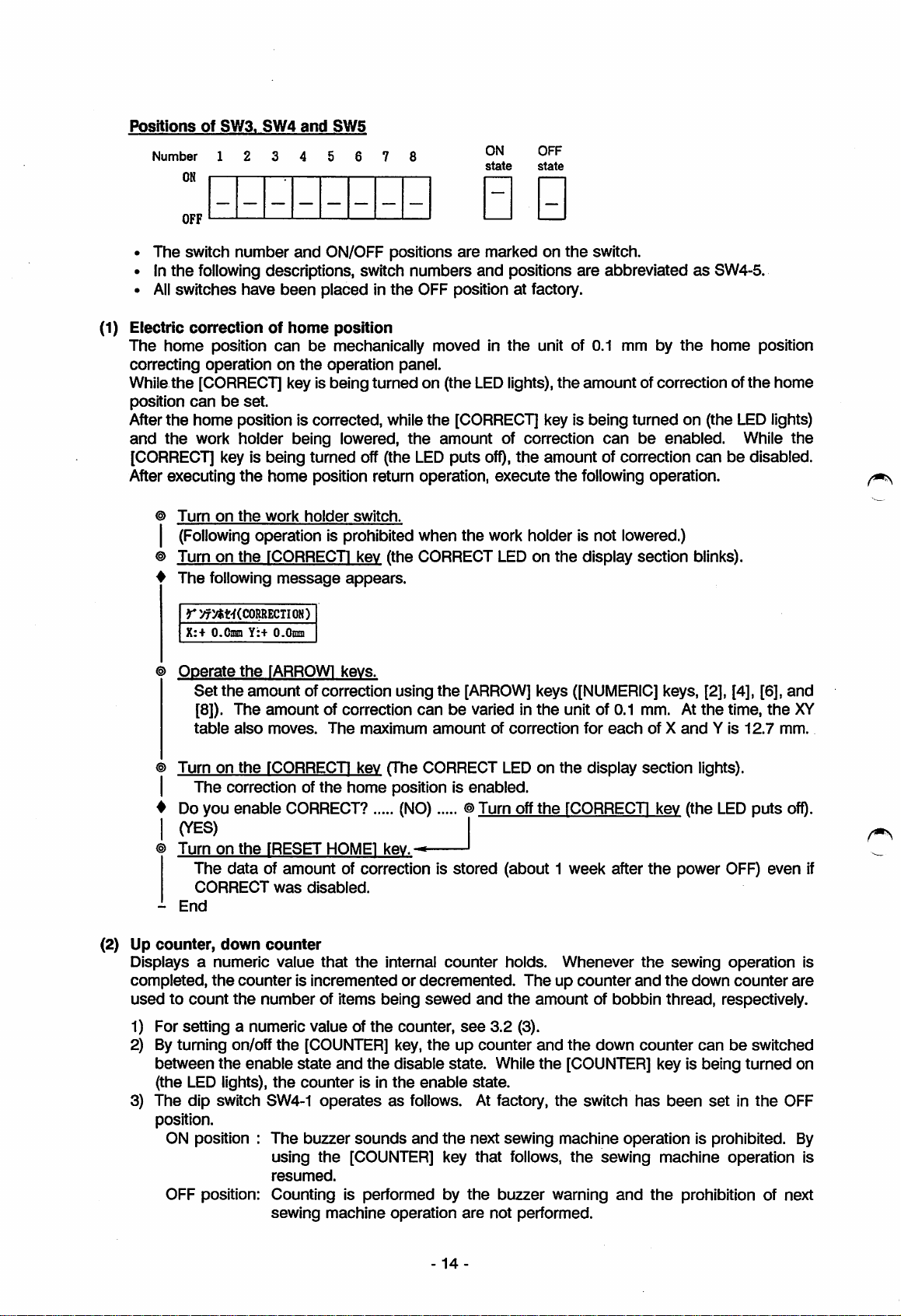

Positions

Number

of

SW3.

SW4

1 2 3 4 5 6

ON

and

SW5

ON

state

OFF

state

OFF

• The switch number

• In

the

following descriptions, switch numbers

•

All

switches

(1) Electric

The

correcting

While

position

After

and

correctionofhome

home

position

operationonthe

the

[CORRECT] key is being

canbeset.

the

home position is corrected, while

the

work

[CORRECT] key is being

After executing

Turn

on

(Following operation is prohibited

Turn on

The

following

r:^>«t'f(CORRECTIOH)

X;+

0.

and

ON/OFF positions

have

been

placedinthe

OFF position at factory.

position

can

be

mechanically moved in

holder

the

home

the

work

operation

being

lowered,

turned

position return operation,

holder

switch.

panel.

turned

on (the

the

off (the LED

when

the

rCORRECTI kev (the CORRECT

Y:+

message

O.Onm

appears.

0 0

are

marked on

and

positions

the

LED

lights),

the

[CORRECT] key is being turned on (the

amount

puts

of correction

off),

the

execute

the

work holder is not lowered.)

LEDonthe

the

switch.

are

abbreviatedasSW4-5.

unit of 0.1 mm by

the

amount

amount

the

following operation.

of correction of

can

be

of correction

display section blinks).

the

home

LED

enabled.

canbedisabled.

position

the

While

home

lights)

the

(2) Up

Displays a

completed,

usedtocount

1)

2)

The

3)

Operate

Turnonthe

Do you

Set

the

[8]).

The

table

also

The

correction of

enable

the

lARROWl

amountofcorrection

amount

moves.

kevs.

using

of correction

The

maximum

canbevaried In

fCORRECTI kev (The CORRECT LEDonthe

the

home

position is

CORRECT? (NO) ®Turn off

(YES)

Turn

on

the

[RESET

The

data

of amount of correction is stored (about 1 week after

CORRECT

End

counter,

down

numeric

the

was

counter

value

counterisincrementedordecremented.

the

number

For setting a numeric value of

Byturning on/off

between

the

(the LED lights),

dip

switch SW4-1

the

enable

the

H0ME1

disabled.

that

of items

[COUNTER]

state

and

counter

kev.^

the

internal

being

sewed

the

counter,

key,

the

disable state. While

is in

the

enable

operatesasfollows. At factory,

position.

ON position :

The

buzzer

using

resumed.

sounds

the

[COUNTER] key

and

OFF position: Counting is performed by

sewing

machine

operation

the

amount

counter

see

the

up counter

the

are

[ARROW]

of

correction

enabled.

holds.

and

the

3.2

(3).

state.

next

sewing

that

follows,

the

buzzer

not

performed.

keys

([NUMERIC] keys, [2], [4], [6],

the

unit of 0.1 mm. At

for

each

display

the

fCORRECTI kev (the

Whenever

Theupcounter

section

the

and

amountofbobbin

and

the

down

counter

the

[COUNTER] key is being

the

switch

has

ofXandYis

the

the

time,

lights).

LED

power OFF) even if

sewing

the

thread,

operation

down

respectively.

canbeswitched

been

setinthe

machine operation is prohibited. By

the

sewing

warning

and

machine

the

operation

prohibition of next

the

12.7

puts

counter

turned

and

XY

mm.

ofQ.

is

are

on

OFF

is

14-

Page 20

4)

[UP

COUNT

CLEARl

key,

[DM

COUNT

CLEAR]

key

Reset a displayvalue ofthe up counter or down counter to the

(3)

Repeat

Byturning on

placedinthe

While

still

setting value of

sewing

this switch is being turned on, when the sewing operation is completed, the

inthe lowerposition. Atthe time by turning on the start switch, the sewing operation can be

theupcounter

the

dip switch SW3-1,the repeat sewing operation is executed. This switch

OFF position at factory.

is "0000".)

immediately started. Thisfunction is very convenientto sew items

loweringthe work holder suchasan ornament sewing of parts.

initial

setting value. (The

without

frequently raisingand

work

initial

has

been

holder is

(4) Releasing sewing

By turning on

placedinthe

area

limit

the

dip

switch SW3-2,

OFF position at factory.

the

sewing

area

limit

canbereleased. This switch

Whenthe machine home position is moved, the sewing area is proportionally narrowed. To use

the

entire area, turn on this switch. This function is operative only when the power switch was

turned on. On or offoperation ofthis switch must be conducted whilethe power switch is turned

off.

(5) Using

work holder switch. After both

sewing machine

(6) Prohibiting automatic

two

step

work

holder

Byturning on

placed in

By turning on the dip switch SW3-4,

the

dip switch SW3-3,

the

OFF position at factory. When using the two

canbestarted. (Any of them

home

position return operation

the

the

work holder

two

step

canbelowered first.)

the

automatic home position return operation

work holder

step

and

the

two

canbeused.

work holder, connect the two step

step

prohibited. Thisswitch has been placed inthe OFFposition at factory.

The

work holder

While

a complicated holder

switch

are

lowered,

is being used, employing this function prevents the holder from damaging.

For the procedure,

(7) Prohibiting

thread

Byturning on the dip switch SW3-5, when

thread trimmingoperation can be prohibited. This switch has been placed in

factory.

The work holder is

see

3.2 (2).

trimming in halt

still

in the lower position.

state

(switch)

the

sewing operation is

stoppedbythe

the

halt switch, the

OFF position at

has

has

can

been

been

the

be

(8) Prohibiting work holder up operation in halt state (Input code) (Referto 4.2 (2) 8))

By turningonthe

holder up operation

In this state,

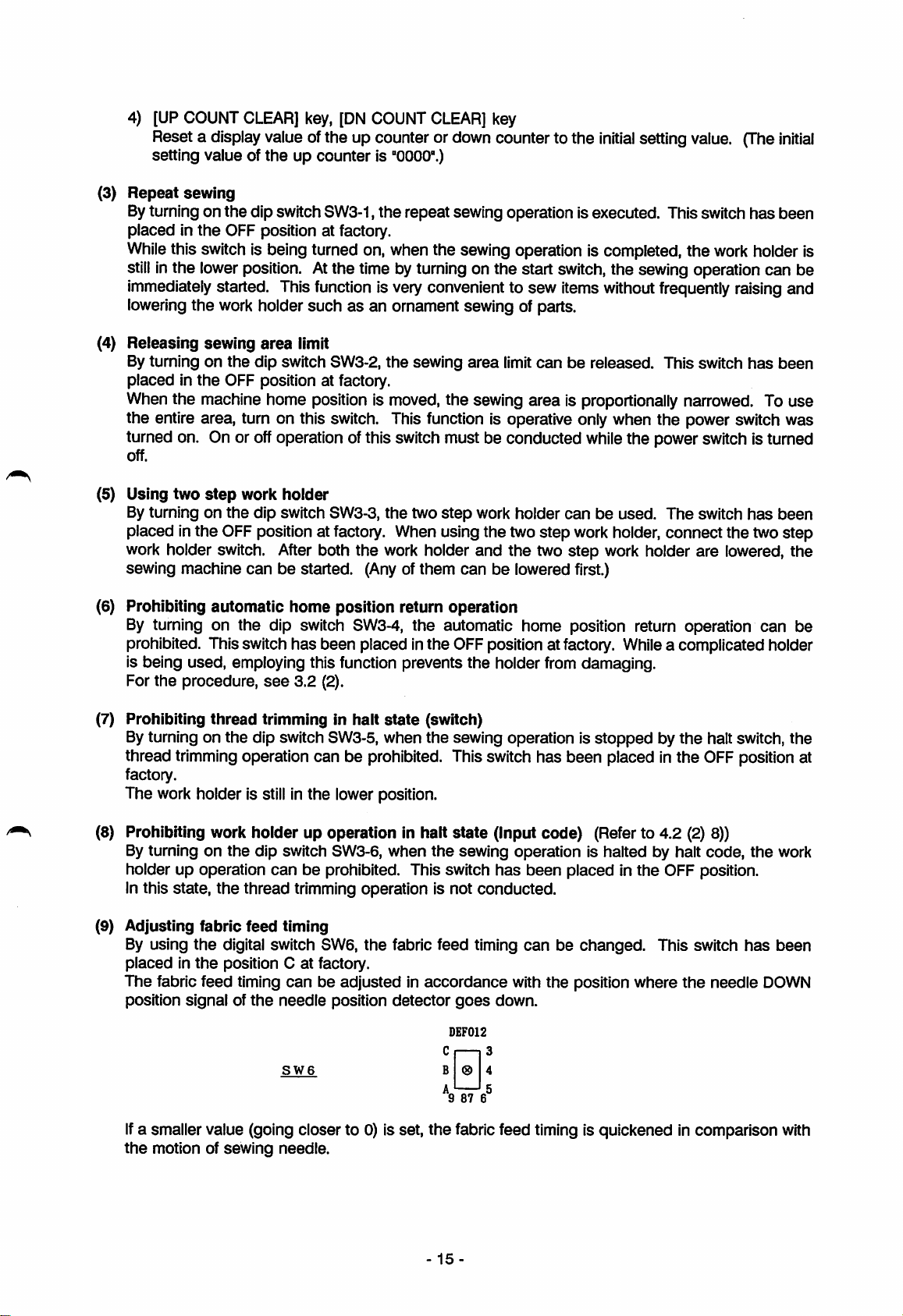

(9) Adjusting fabric

By using

placedinthe

The fabric feed timing

position

the

signalofthe

dip switch SW3-6,

canbeprohibited. This switch

the

thread trimming operation is not conducted.

feed

timing

digital switch SW6,

position Catfactory.

can

be adjusted in

needle

position

when

the

the

fabric feed timing

accordance

detector

sewing operation is halted by halt

goes

DEF012

has

can

with

down.

been

the

placed in

be

the

OFF position.

changed.

position where

This switch

the

code,

needle

cn^

SW6

If

a smaller value (going closer to 0) is set,

the

motion of

sewing

needle.

B 0 4

*9876®

the

fabric feed timing is quickened in comparison with

15-

the

has

work

been

DOWN

Page 21

(10) Sewing

position

By turning

machine

This switch

machine

canbeoperatedatany

operation using free

the

dip switch SW3-7,

has

been

placedinthe

(mechanical home position) at factory.

The

sewing operation using

position

position of

end

Contrary

return to

the

When

becomes

sewing

area

can

be

used

the

position.

to

the

pattern is

the

standard

mechanical

the

[RESET HOME] key is

the

free

home

automatically at

area

limitisreset

limit

dip

switch

SW3-2isnot

only

the

home

OFF position

the

free

when

sameasthat of

motion, it

home

position

turned

position is

the

on.

state

evenifthe

turned

home

sewing

position.

home

the

does

even

used,

where

sewing

on.

start

the

not

the

Turn

on

the

dip

Turn

on

Turn

on

Operate

Set

the

using

([NUMERIC]

the

the

the

start

switch

power

work

fARROWl

position of

the

keys [2], [4], [6],

SW3-7.

switch.

holder

switch.

kevs.

[ARROW]

the

pattern

keys

and

[8].)

(At

the

time,

the

XY

table also

moves.)

Turn

on

the

start

if

Automatic

it

End

sewing

switch.

operation

starts.

(11) Adjusting

sewing

machine

speed

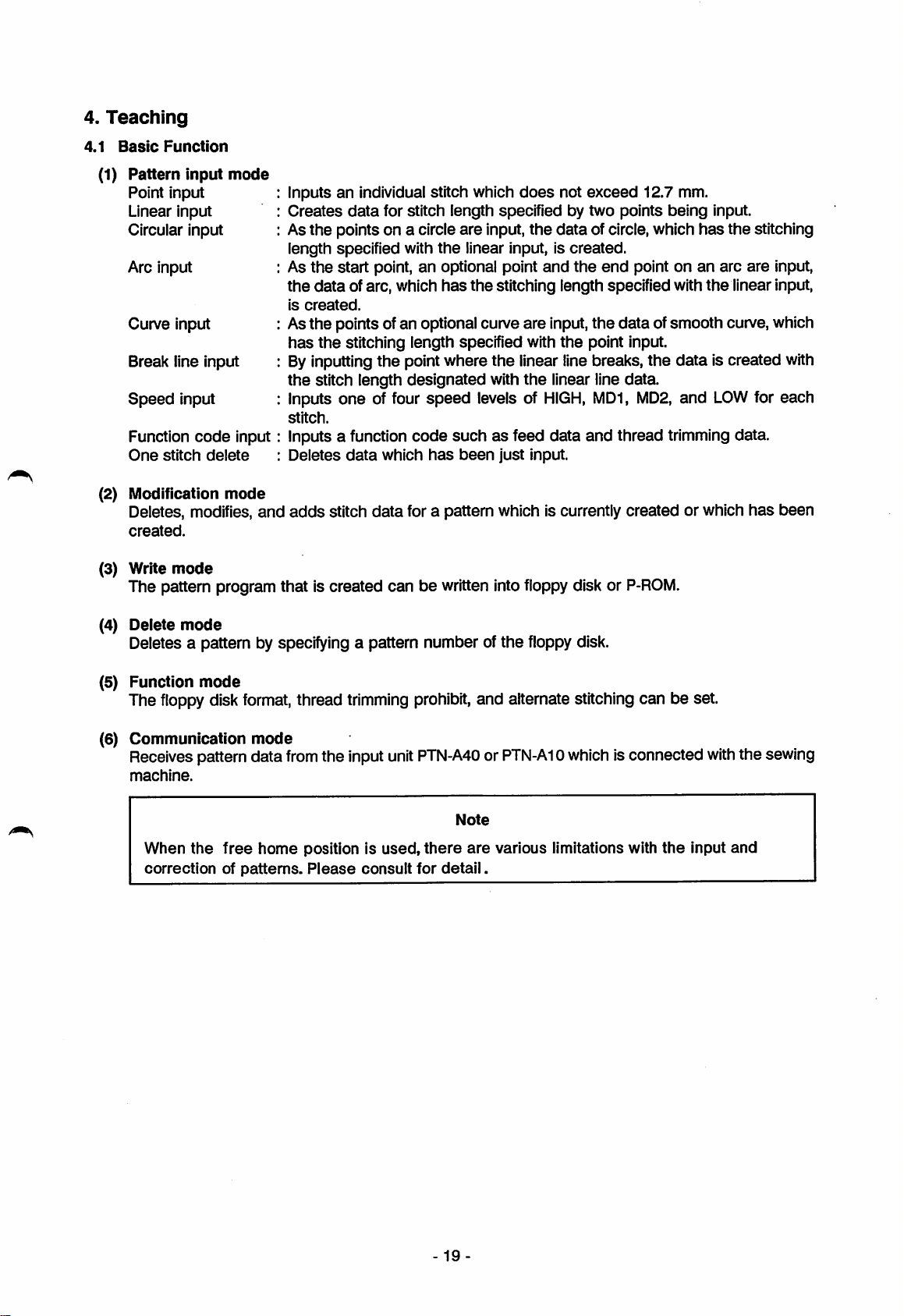

The control unit provides two independent

speed

dial is

Speed

speed.

There are other

speed.

1) Adjusting maximum

dial is

setto"9",

setto"0",

the

the

maximum

minimum

corresponding the 1 to 8 of the

By

the

way,

the

thread trimming

The max.

the

stitch length

In

the

above

speed

speed

conditions, while operating

adjust methods. Refer to 6.3.3 Confirmation and adjustment of sewing

speed

of machine is obtained by setting the

dataofless

speedisobtained.

(s/min) using VR2asshown in the following figure. To increase the

clockwise. To

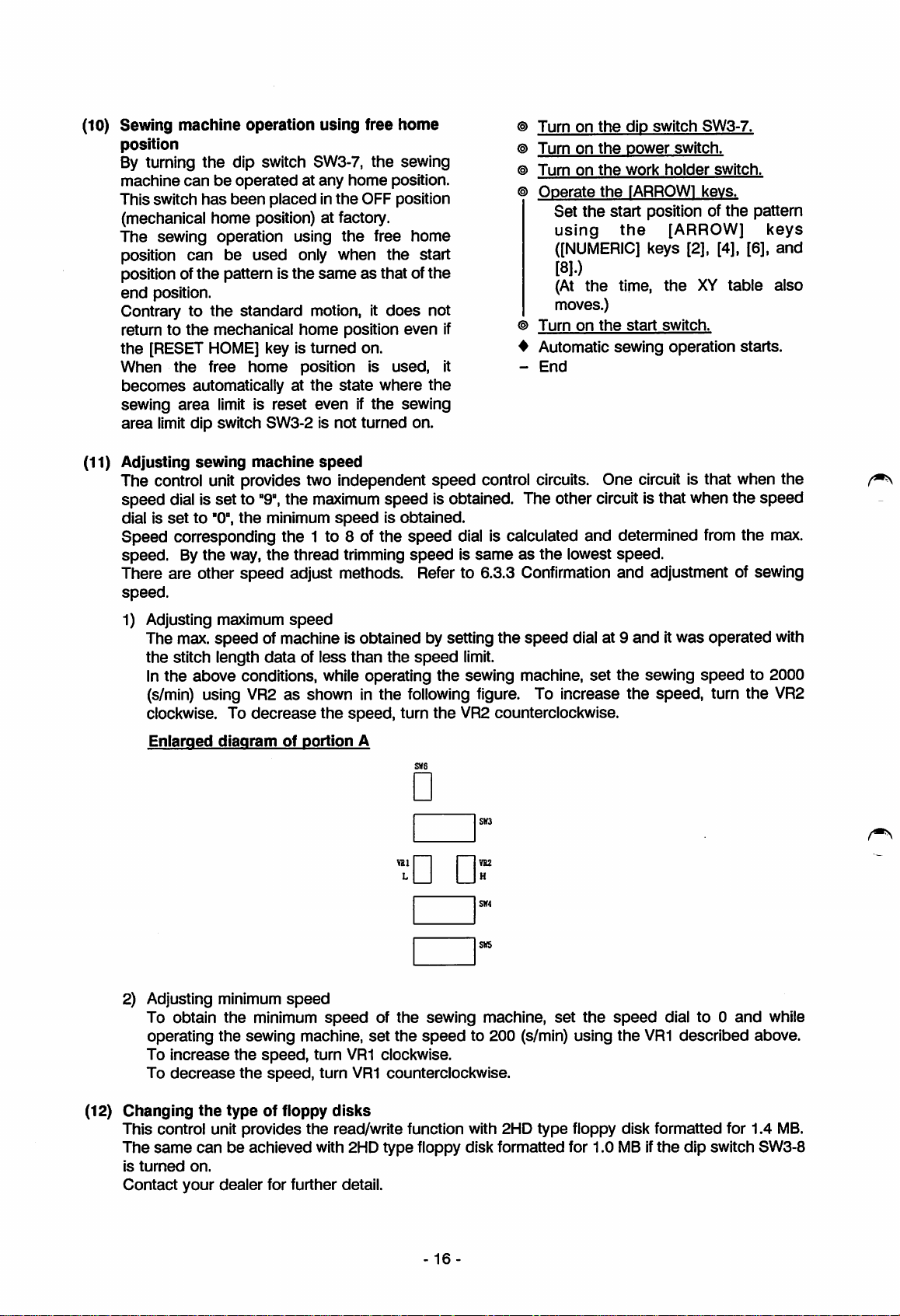

Enlarged

diagram

decrease

of

the

portion

than

speed,

A

speed

speed

speed

is obtained. The other circuitis that when the

control circuits. One circuit is that when the

dial is calculated

speedissameasthe

the

speed

turn

ong

limit.

the

sewing machine,

the

VR2 counterclockwise.

•

•

Dr

speed

and

lowest

dial at 9

set

determined from

speed.

anditwas

the

sewing

speed,

operated with

speed

turn the VR2

speed

the

max.

to 2000

s«s

2) Adjusting minimum

To obtain

operating

To

increase

decrease

To

(12)

Changing

the

This control unit provides

The

same

canbeachieved with 2HD type floppy disk formatted for 1.0MBif

is

tumed

Contact

on.

your

the

the

the

the

typeoffloppy

dealer

speed

minimum

speed

sewing machine,

speed,

speed,

for further detail.

turn

VR1 clockwise.

turn

disks

the

read/write function with 2HD type floppy disk formatted for 1.4

of

the

sewing

set

the

speed

VR1 counterclockwise.

16

machine,

to 200 (s/min) using

set

the

speed

the

VR1

dial to 0

and

described

the

dip switch SW3-8

while

above.

MB.

Page 22

(13) Prohibition of

if

the

dip

switch SW4-3 is

the

clamp

turned

also

special clamp, etc.

weight

switch is

Turn to ON

(14)

Selectionofpresser

When

in

accordance

of

thread

trimming motion

turned

on,

the

to OFF (not prohibited)atthe

SW3-5 in

order

to prohibit

weight

are

attachedtothe

with

the

weight of clamp. It is

areaslisted below.

thread

the

tread

set

trimming

shipment

trimming

standard

to OFF at

and

wiper motion

from factory.

and

wiper motion with

presser, turn on

the

shipment

are

prohibited. This

the

halt switch.

the

dip switch SW4-2

from factory. Guidelines

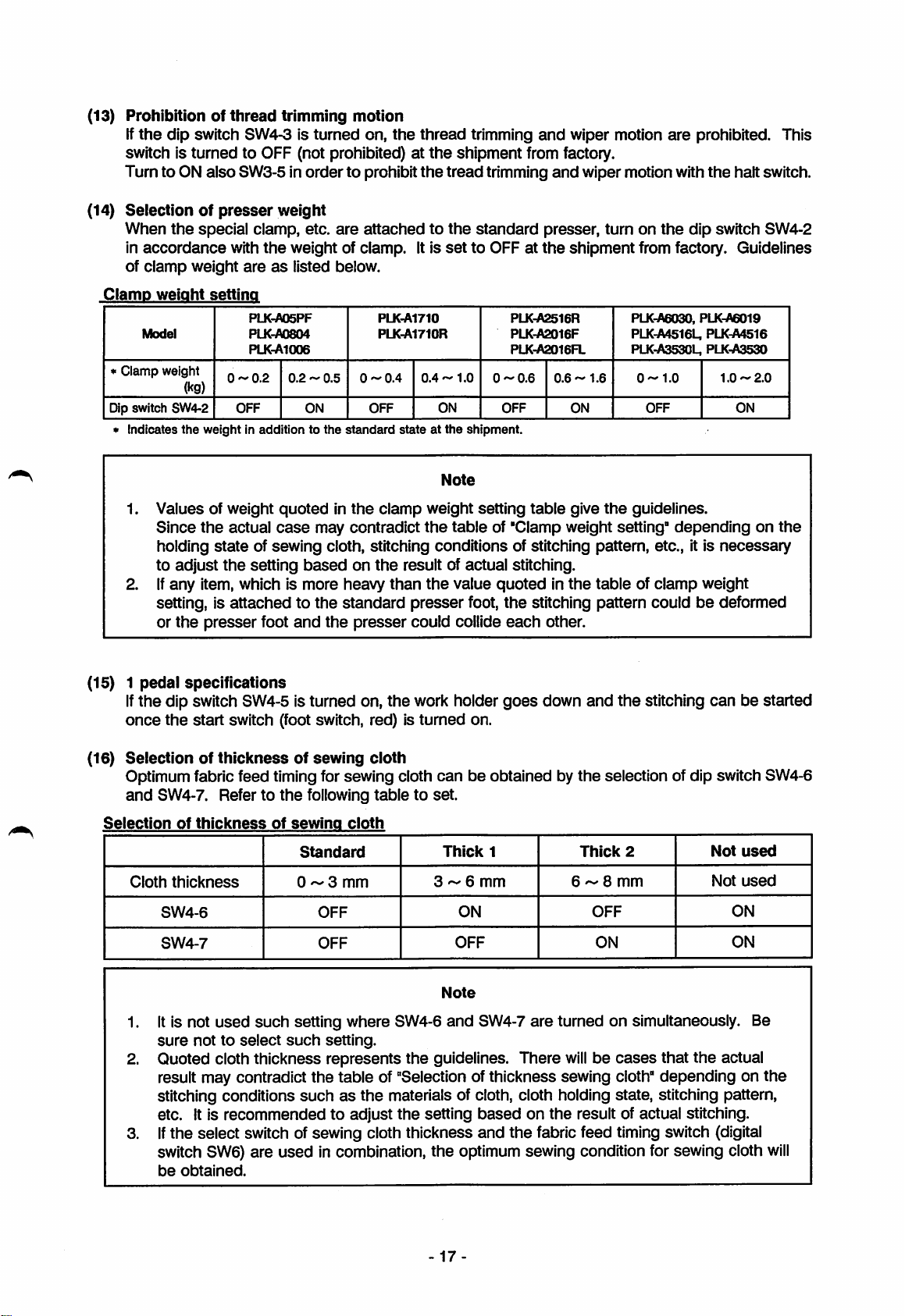

PLK-A05PF

Model

* Clamp weight

(kg)

Dip switch SW4-2

Indicates

the

1. Values of weight

Since

the

holding

to adjust

2. if

any

item, which is

setting, is

or

the

(15) 1

(16)

pedal

specifications

If

the

dip switch SW4-5 is turned on, the work holder

once

the

start

Selectionofthicknessofsewing

PLK-A0804

PLKnAlOOe

0.2-0.5

OFF

weight in addition to

ON

the

quotedinthe

actual

stateofsewing

the

case

setting

may

cloth, stitching conditions of stitching pattern, etc., it is

basedonthe

more

attachedtothe

presser

foot

CM

d

I

o

and

standard

the

switch (foot switch, red) is

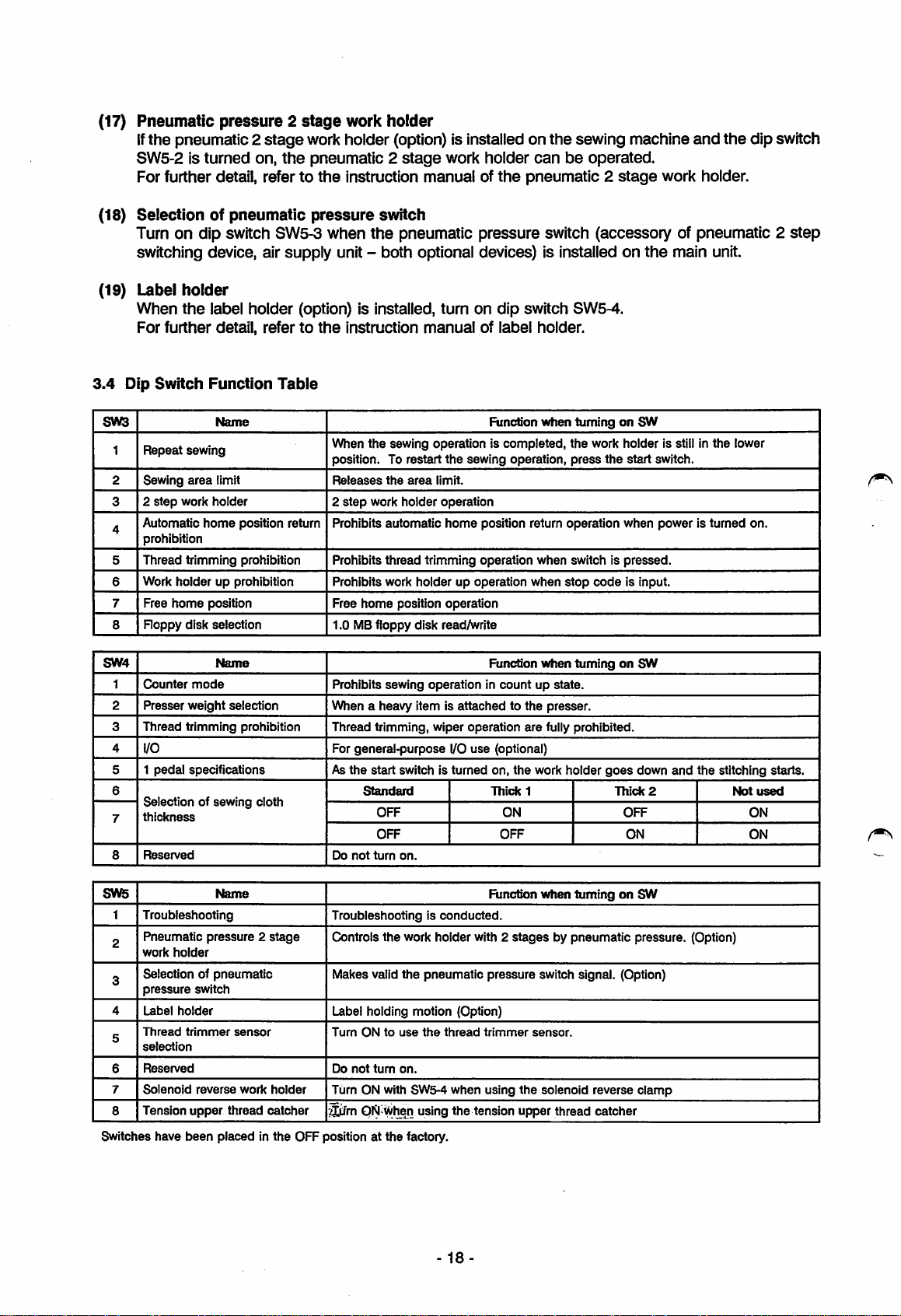

Optimum fabric feed timing for sewing cloth

and

SW4-7. Refertothe

following

PLK-A1710

PLK-A1710R

0

1

o

OFF

standard

clamp

contradict

heavy

than

presser

cloth

tabletoset.

PLKnA2516R

PLKnA2016F

PLKnA2016FL

0~0.6

ON

0

stateatthe

1

Note

weight

the

tableof'Clamp

OFF

shipment.

b

setting

table

result of actual stitching.

the

value

quotedinthe

presser

could collide

turned

foot,

on.

the

stitching pattern couldbedeformed

each

other.

goes

down

canbeobtained by

PLKnA6030. PLKnASDig

PLK-A4516U PLKnA4516

PLK-A3530L, PLK-A3530

0.6-1.6

ON

give

the

guidelines.

weight setting"

tableofclamp

and

the

the

selection of dip switch SW4-6

OFF

dependingonthe

weight

0

1

b

stitching

can

1.0-2.0

ON

necessary