Page 1

MITSUBISHI

Industrial

INSTRUCTION

Singie-Naedie

Electronic

Sewing

MANUAL

Model

Lockstitch

Pattern

Machine

PLK-S5S0A

Sewing

Machine

'A180E102P01

A

MITSUBISHI

ELECTRIC

Page 2

In

order

to

operate

the

sewing

machine

in

the

best

condition

at

all

times,

please

the

1.

2.

3.

4.

5.

6.

read

sewing

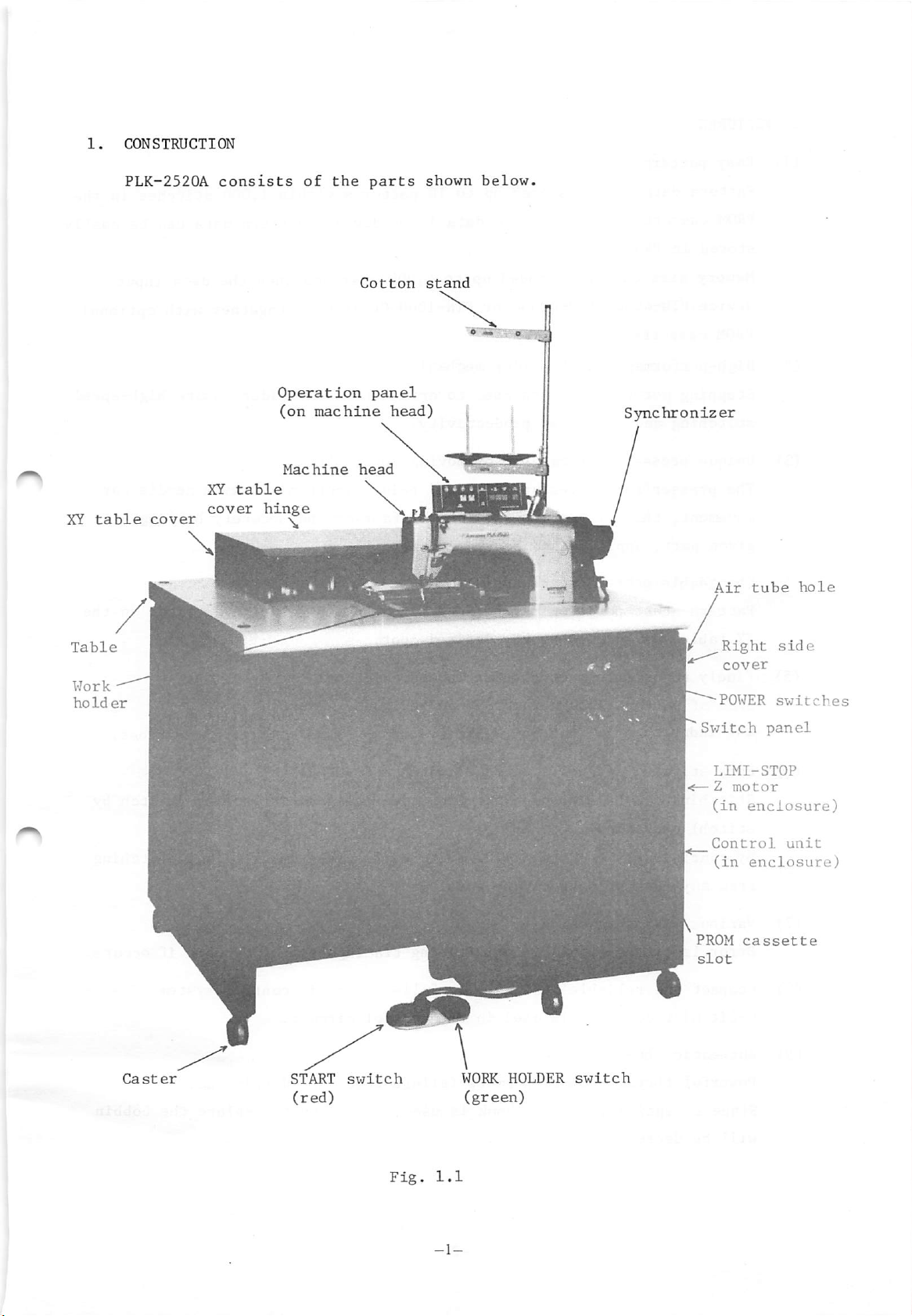

CONSTRUCTION 1

this

machine.

Instruction

Manual

-CONTENTS-

carefully

and

properly

handle

and

FEATURES

SPECIFICATIONS ^

3.1

3.2

INSTALLATION 8

PREPARATION

CONTROL

6.1

General

specifications

Replacement

BEFORE

SWITCHES

Switch

6.1.1

6.1.2

panel

Power

SCALE

parts

AND

for

medium

STATING THE OPERATION

FUNCTIONS

ON

and

OFF 13

and heavy

switches

fabrics

maintain

2

^

^

12

13

13

13

6.2

6.1.3

6.1.4

6.1.5

6.1.6

6.1.7

Foot

6.2.1

6.2.2

PATTERN

SPEED

RESET/HOME

MIRROR

ERROR

switches

WORK

START

select

setting

IMAGE

indication

HOLDER

switch

6.3 Operation panel on machine

7.

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

OPERATION

7.1

Loading

7.2

Switch

COARSE/FINE

MOVE

±JOG

UP

STOP

switch

the

setting

switches

switches

switch

FROM

on

switch

dial

select

switch

X, Y switches 1^

lamps

switch

head

select

cassette

switch

switch

panel

1^

1^

1^

1^

16

16

18

16

16

17

17

17

18

18

18

7.3

7.4

7.5

7.6

Switch

Sewing

STO ?

Operation

function

operation

switch

checking

operation

procedure

and

checking

18

19

19

20

Page 3

8.

9.

10.

CAUTIONS

HANDLING

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

9.15

9.16

9.17

9.18

9.19

9.20

9.21

ADJUSTING

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.10

10.11

ON

USE

THE

Installation

Winding

Threading

Thread

tension

Installing

Installing

Adjusting

Adjusting

Lubr

ication

Timing

adjustment

Adjusting

Thread

tension

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

THE

Thread

Installation

trimmer

Connection

Knife

driving

Installation

Installation

Adjusting

Adjusting

Adjusting

Adjusting

Hook,

bobbin

SEWING

the

the

the

the

the

the

the

the

the

the

the

the

the

the

the

the

THREAD

of

the

the

the

the

MACHINE

of

needle

bobbin

needle

bobbin

bobbin

needle

bobbin

between

hook

bobbin

needle

intensity

movable

thread

hook

presser

timing

needle

TRIMMER

mechanism

of

knife

knife

shaft

of

air

of

trimming

knife

needle

synchronizer

length

case

and

HEAD

thread

thread

case

thread

thread

needle

position

thread

thread

of

range

tension

oiling

rate

foot

of

presser

bar

stop

bracket

bracket

cylinder

cam

engagement

thread

of

needle

bobbin

tension

tension

tension

tension

thread

of

discs

(UP)

and

with

tension

discs

motion

takeup

takeup

foot

kife

driving

thread

spring

motion

position

bracket

release

end

and

spring

crank

hook

after

motion

unit

trimming

23

24

24

24

25

25

26

26

26

27

27

28

28

30

30

31

32

32

33

33

35

36

37

38

38

38

39

39

40

41

42

44

44

45

45

Page 4

11.

MAINTENANCE AND CHECKING

46

12.

13.

14.

11.1

11.2

11.3

11.4

12.1

12.2

12.3

Adjusting

Greasing

Pneumatic

Maintenance

CONTROL

LIMI-STOP

Grounding

Fuses

REPLACING

AUXILIARY

14.1

14.2

14.3

14.4

14.5

Repeat

Home

turned

Home

Thread

Adjustment

the

SYSTEM

and

THE

PROM

FU^TCTIONS

function

position

on

position

trimming

the

XY

XY

system

of

machine

Z

motor

for

prevention

magnetic

return

return

of

fabric

table

table

breakers

cancel

head

of

malfunction

cancellation

cancellation

when

HALT

feed

timing

when

switch

due

the

is

to

noise

power

is

depressed

46

47

47

47

49

49

50

50

52

53

53

53

53

54

54

15.

16.

14.6

15.1

15.2

Speed

WIRING

select

DIAGRAM

General

LIME-STOP Z

TROUBLESHOOTING

wiring

function

diagram

motor

wiring

55

56

56

57

60

Page 5

-fsmmt

•

itches

sure)

sure)

Page 6

2.

(1)

FEATURES

Easy

pattern

change

Pattern

PROM

stored

Memory

device

PROM

(2)

High-performance

Stepping

stitching

(3)

Unique

The

movement,

given

(4)

Changeable

Pattern

XY

table,

data

cassette.

in

size

PTN-4000,

cassette.

motors

presser

presser

part,

start

can be

PROM.

stored

By

using the

can be expanded up

PTN-4000AorPTN-IOOO-OL

work

holder

and

belts

and

foot

thus

applique

pattern

or

increased

foot

moves

preventing

position

located

capable

up

and

start

may

to

productivity,

any

up

data

mechanism

used

of

and

down,

floating

heavy

position

be

determined

desired

to

10

patterns

input device,

to

4,000

to

drive

moving

being

of

material.

spot,

within

stitches

1,000

pattern

when

data

the

stitches

can be

data

is used together with optional

the

work

vertically

synchronized

fabrics

by

the

and

position

holder

securely

assure

with

detector

needle

holding

in

the

easily

input

high-speed

bar

a

on

the

(5)

(6)

(7)

(8)

(9)

Finely

Size

±4%

Easy

Stitching

stitch)

By

from

Various

Error

adjustable

of

pattern

independently

stitch

operation.

continuously

any

safety

lamps

Compact and

8-bit

Automatic

Powerful

Since

microcomputer

exceptionally

aligning

can

part

are

reliable

thread

thread

pattern

stored

in

be

suspended

operating

of

pattern

functions

provided

trimmer

trimmer

in

X and Y

design

is

used

permits

large

size

PROM

(SCALE

can

directions

HALT

and

iJOG

are

facilitating

hook

switch

amended

switches,

possible.

in

the

failure-free

is

function)

be

finely

by

means

and

JOG

or

aligned

pattern

tracing

full-electronic

control

used,

circuit.

frequency

adjusted

of

switch

checking

back

control

thread

to

within

digital

in

inching

of

trouble

trimming.

replace

switches.

(stitch

and

stitching

if

system

the

by

occurs.

bobbin

will

be

decreased.

-2-

Page 7

(10)

Mirror

image

(11)

With

Eacy

simple

machine

switch

maintenance

LIMIT-STOPZmotor

is

used

The

table

XY

to

table

cover.

drive

is

easily

operation,

equipped

the

sewing

symmetrical

with

machine,

accessible

clutch

requiring

for

pattern

featuring

almost

maintenance

is

easily

almost

permanent

no

maintenance.

by removing

stitched.

the

XY

life

-3-

Page 8

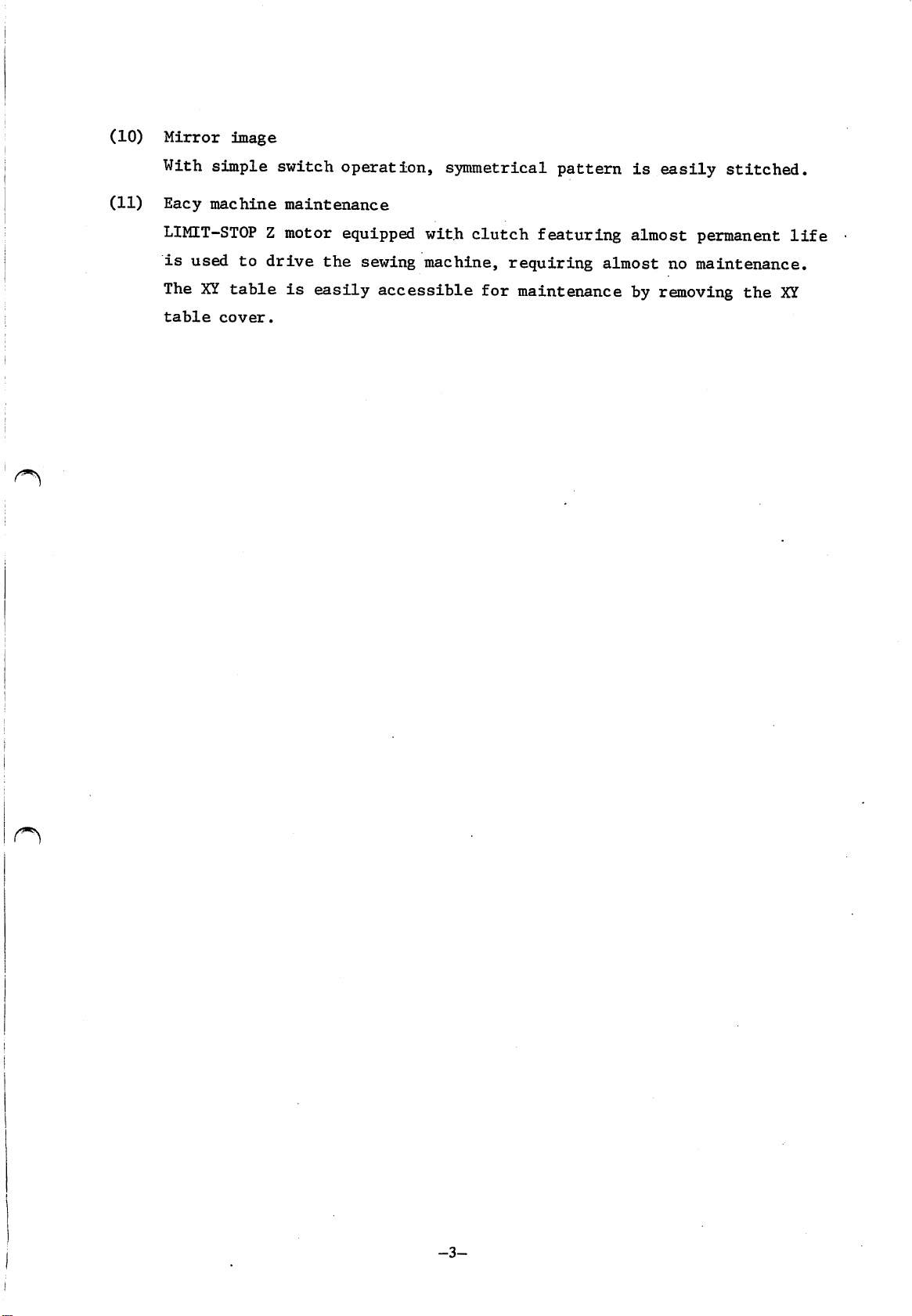

3.

SPECIFICATIONS

3.1

General

specifications

Stitching

Sewing

Needle

Take-up

Applicable

Work

Presser

Presser

Hook

Bobbin

holder

Bobbin

type

machine

bar

stroke

lever

needle

foot

foot

case

lift

lift

stroke

stroke

Single-needle

lockstitch

Model DY-359-22,

equipped

40

ram

72

mm

DP X 17

70mm

10

mm

4 -

Full-rotation,

(large

Equipped

Steel

#23

(Standard),

10

mm

type

bobbin

(set

with

(Standard)

for

racing

for

Automatic

adjustable

to4mm

automatic

thread

thread

thread

at

shipping)

lubrication

trimmer

prevention

trimmer

trimmer

use)

spring

use

Lubricat

Applicable

Thread

Control

Sewing

Max.

Stitch

Sewing

sewing

ion

trimmer

system

area

length

pattern

oil

speed

Manual

Screw

White

Rotary

and

Full

incorporated

oiling

pump

spindle

scissoring

right

electronic,

for

fied

lubrication

oil,

by

blade

microprocessor

control

240mm x 200mm (X - Y

stepping

2,000

0.2

Pattern

PROM

Maximum

motor)

spm

(intermittent

-

6.2

mm

is

reproduced

(replaceable).

10

pattern

#2

left

dual

with

(1,000

of

movable

axial

feed)

data

stitches)

hook

drive

stored

knife

by

in

can

be

stored

-4-

in

each

PROM.

Page 9

Maximum

4,000

stitches

can

be

stored

with

Sewing

Return

START

Work

operation

to

operation

holder

home

position

optional

Pattern

user's

any

desired

This

function

tions

The

work

tion

the

Stitching

in

needle

depressed

The

work

HOLDER

first

again.

PROM,

start

discretion

is

out

holder

X

axis

stops

starts

to

holder

switch

time,

position

spot.

is

of

"ON".

is

and

as

used

alignment.

returns

and

Y

at

UP

when

goes

pressed

goes

may

home

if

axis

position.

START

down

up

position

X

to

direction

when

down

when

be

set

and/or

the

switch

for

pressed

home

the

at

or

Y

posi

posi

after

is

WORK

the

down

HALT

Pattern

adjustment

operation

(SCALE

Pattern

Sewing

size

function)

•

select

speed

fine

function

setting

Sewing

depressing

After

be

moved

pattern

By

depressing

sewing

Size

of

finely

(±1%

increment)

independ

Any

one

be

selected.

Sewing

within

(about

operation

the

suspension,

stitch

in

operation

pattern

adjusted

ent

of

speed

a

range

200

the

HALT

inching

the

ly.

10

patterns

can

from

spm

can

be

switch.

by

stitch

operation.

START

can

be

stored

within

in

X

axis

be

set

180

increment)

suspended

the

switch

started

in

a

range

stored

in

spm

work

along

PROM

and

nine

to

holder

the

again,

again.

can

of

Y

axis

in

2,000

by

+4%

PROM

steps

can

sewing

the

be

can

spm,

-5-

Page 10

Stitch

correcting

function

Stitches

can

be

corrected

or

amended

by

Test

Mirror

Error

Main

Work

Power

function

image

indicator

drive

holder

source

motor

moving

forward

the

or

operating

This

holder

A

Stitches.

Trouble

LIMI-STOP

function

movement

symmetrically

or

identified.

Pneumatic

Frequency(Hz)

50

60

work

backward

±JOG

is

failure

Z

motor

Type

Voltage(V)

holder

along

switches.

used

without

turned

is

(5kg/cm2)

200,220,

380,415

stitch

the

to

check

actual

over

patter

immediately

INPUT(KVA)

by

stitch

pattern

work

sewing.

1

can

by

be

Phases

Three

Phase

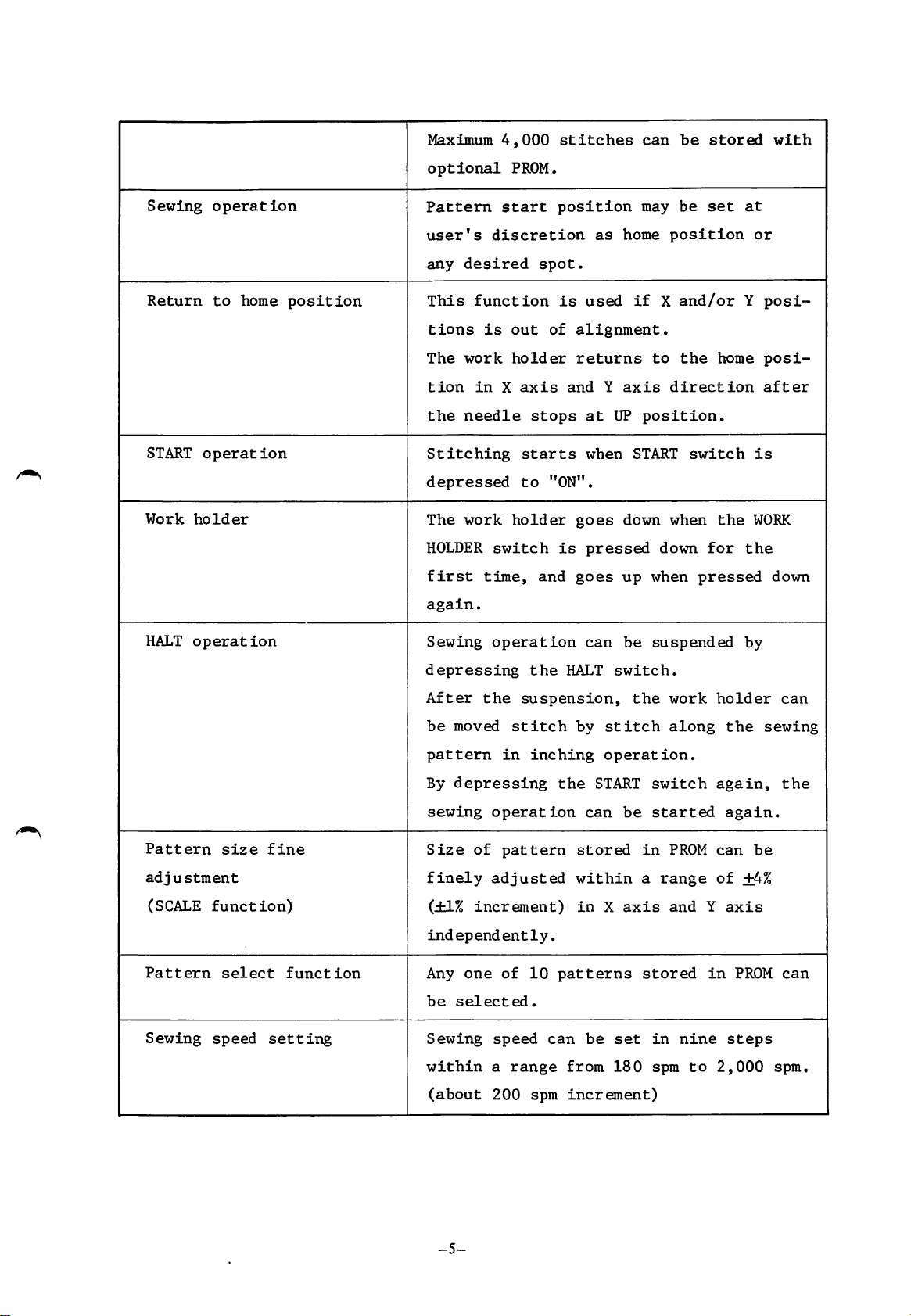

3.2

Dimensions

Weight

Replacsnent

Name

of

Thread

tension

part

parts

Specification

for

regulator

(mm)

medium

1,150

1,200

included

350

head)

Table

and

For

For

lication

mm

mm

kg

(including

3.1

heavy

medium

LS^

standard ap-

(width)

(height)

in

the

fabrics

fabric

(option)

x

1,020

(cotton

height)

weight

mm

(length)

stand

of

machine

For

heavy

(standard)

AI31C513G01

is

fabric

x

not

(W346065G02)

Pretensioner

-6-

(W487036G03)

Page 11

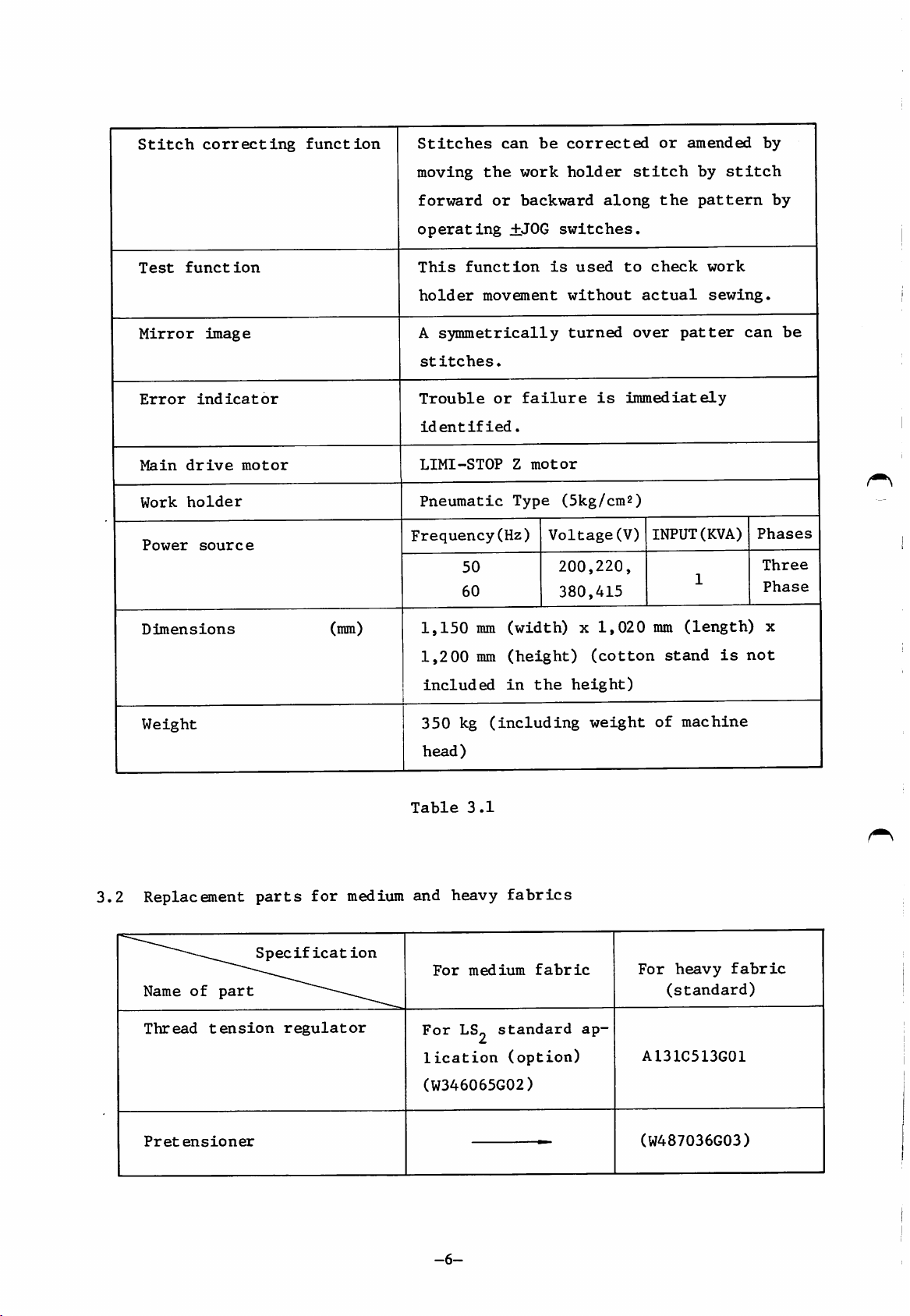

Needle

plate

(furnished)

<Z53

Presser

Hook

Bobbin

foot

case

Needle

hole

—

diameter

Outer

diameter

(W349841H02)

^3.5

(Inner

(furnished)

dia.:

(A130C201H02)

^2)

(W349841H01)

«54.5

(Inner

dia.:

(A130C201H01)

For

DY

^3)

(P975040X02)

For

DY

(A190D175P01)

Table

3.2

-7-

Page 12

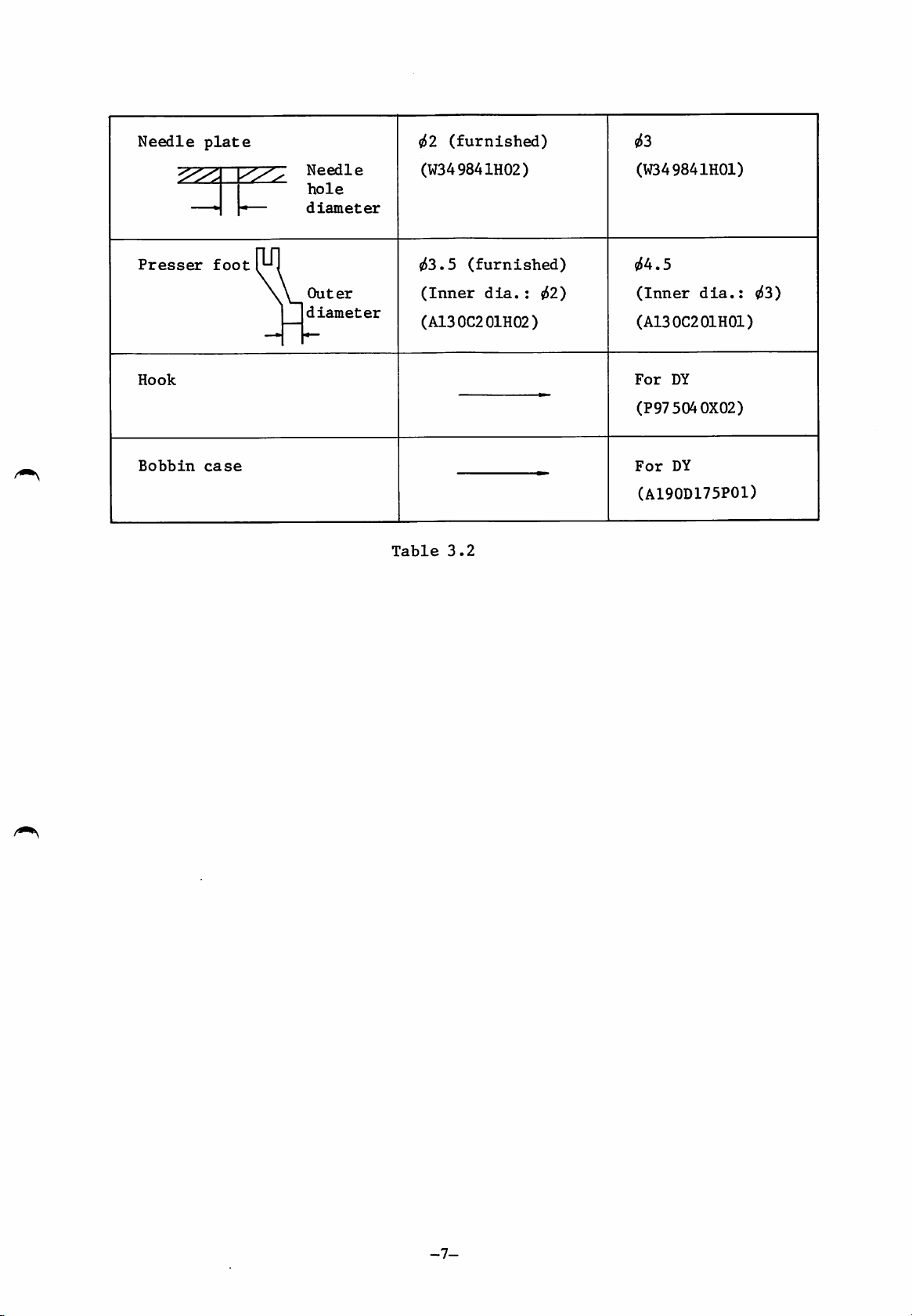

4.

INSTALLATION

4.1

4.2

4.3

4.4

Caster

For

transference

caster.

Remove

(standard

Loosen

remove

The

XY

Loosen

with

holder

is

locked

the

accessories).

wing

the

table

four

furnished

(Fig.

eye

bolts

bolts

XY

table

cover

hexagon

hexagon

4.1).

when

of

on

is

its

the

sewing

to

replace

the

cover.

provided

socket

key

Hexagon

head

lever

left

head

wrench

bolt

machine,

and

with

socket

is

pressed

them

right

bolts,

and

down.

pull

with

furnished

sides

detachable

used

turn

up

the

lever

flathead

of

the

XY

to

hinge

secure

(Fig.

the

counter-clockwise

of

table

work

each

screws

1.1),

the

cover

holder,

and

work

4,5

Work

Place

(standard

it

through

the

holder

machine

accessory)

the

cable

head

to

hole

on

the

Fig.

the

table.

operation

in

the

4.1

table.

Connect

panel

on

the

the

20-circuit

machine

flat

head,

cable

passing

Page 13

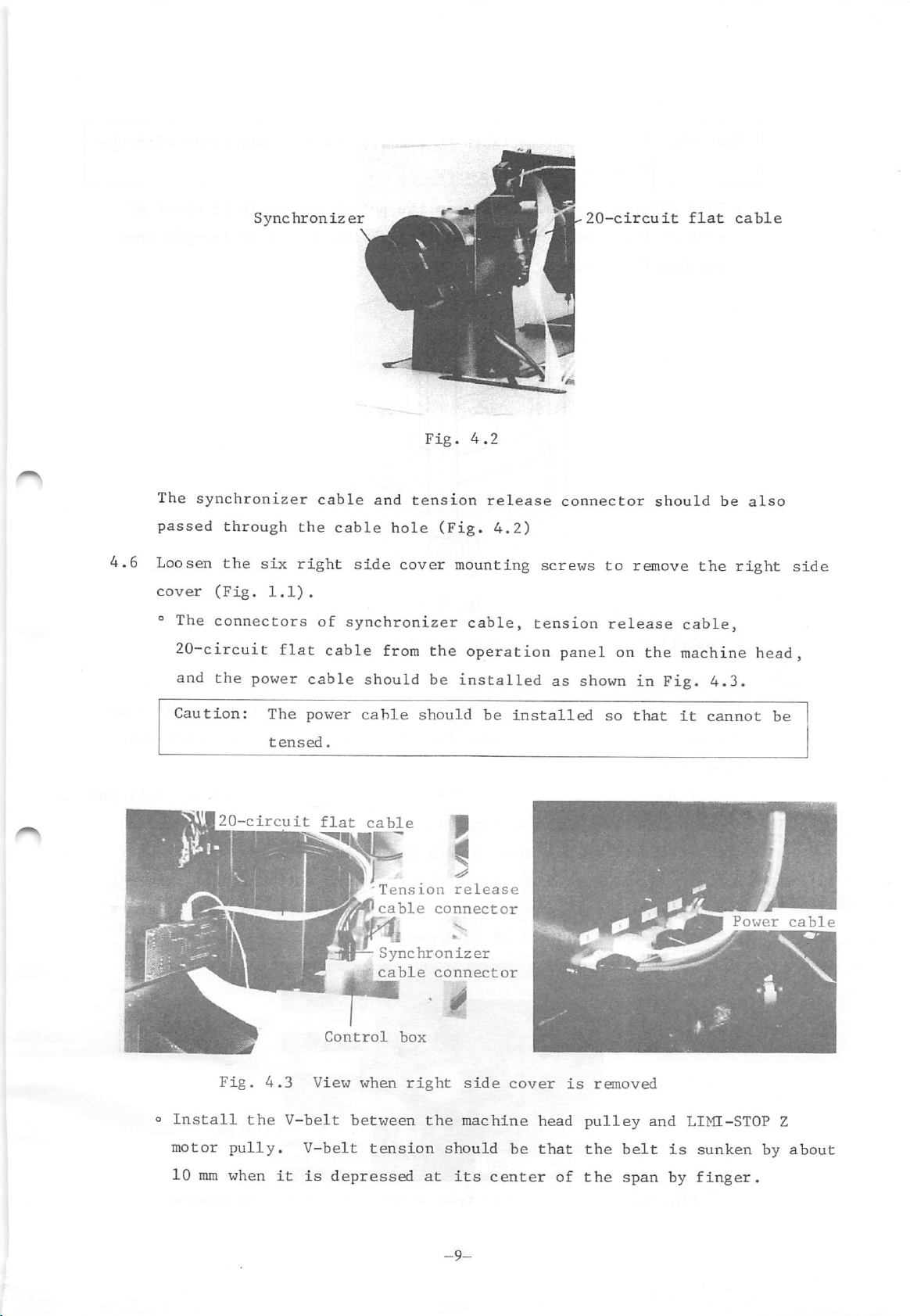

The

synchronizer

cable

and

Fig.

tension

4.2

release

20-circuit

connector

should

flat

be

cable

also

4.6

passed

Loosen

cover

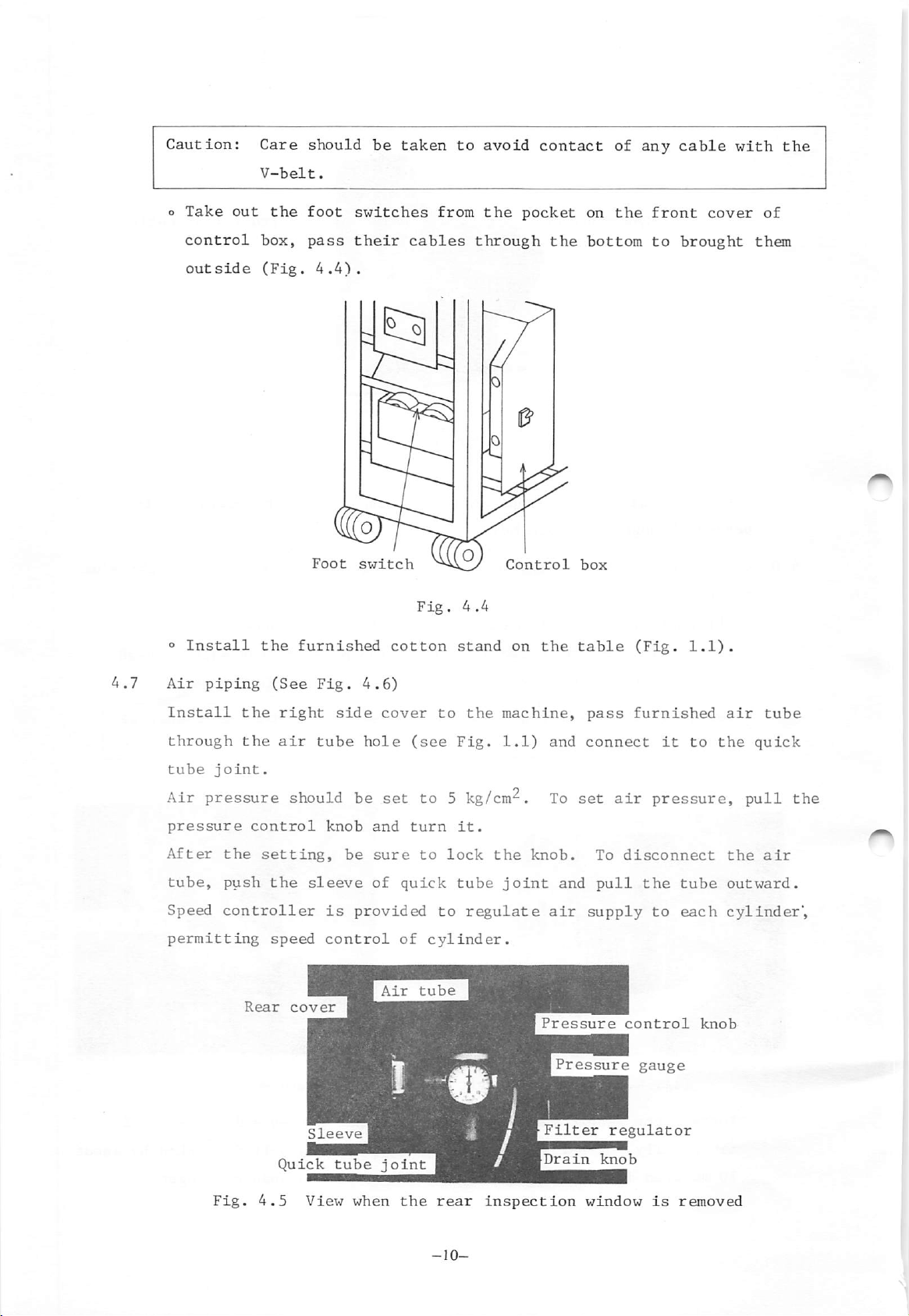

® The

20'-circuit

and

Caution:

through

the

six

(Fig.

1.1).

connectors

flat

the

power

The

tensed.

20-circuit

the

right

of

cable

cable

power

flat

cable

side

hole

cover

synchronizer

from

should

cable

cable

Tension

cable

Synchronizer

cable

(Fig.

4.2)

mounting screws

cable,

the

operation

be

installed

should

connector

connector

be

release

tension

as

installed

to

release

panel on

shown

so

remove

the

in

Fig.

that

the

cable,

machine

4.3.

it

cannot

right

head,

Power

side

be

cable

o

motor

10

Install

nun

Fig.

pully.

when

the

4.3

it

View

V-belt

V-belt

is

Control

between

depressed

when

tension

box

right

the

at

side

machine

should

its

cover

be

center

head

that

of

is

pulley

the

the

removed

and

belt

span

LIMI-STOP Z

is

sunken

by

finger.

by

about

Page 14

Caution:

0

Take

out

Care

V-belt,

the

should

foot

be

taken

switches

to

from

avoid

the

contact

pocket

on

of

the

any

front

cable

with

cover

the

of

control

outside

o

Install

Air

piping

box,

(Fig.

the

(See

pass

4.4).

Foot

furnished

Fig.

their

switch

4.6)

cables

Fig.

cotton

through

4.4

stand

Control

on

the

the

bottom

box

table

to

(Fig.

brought

1.1).

them

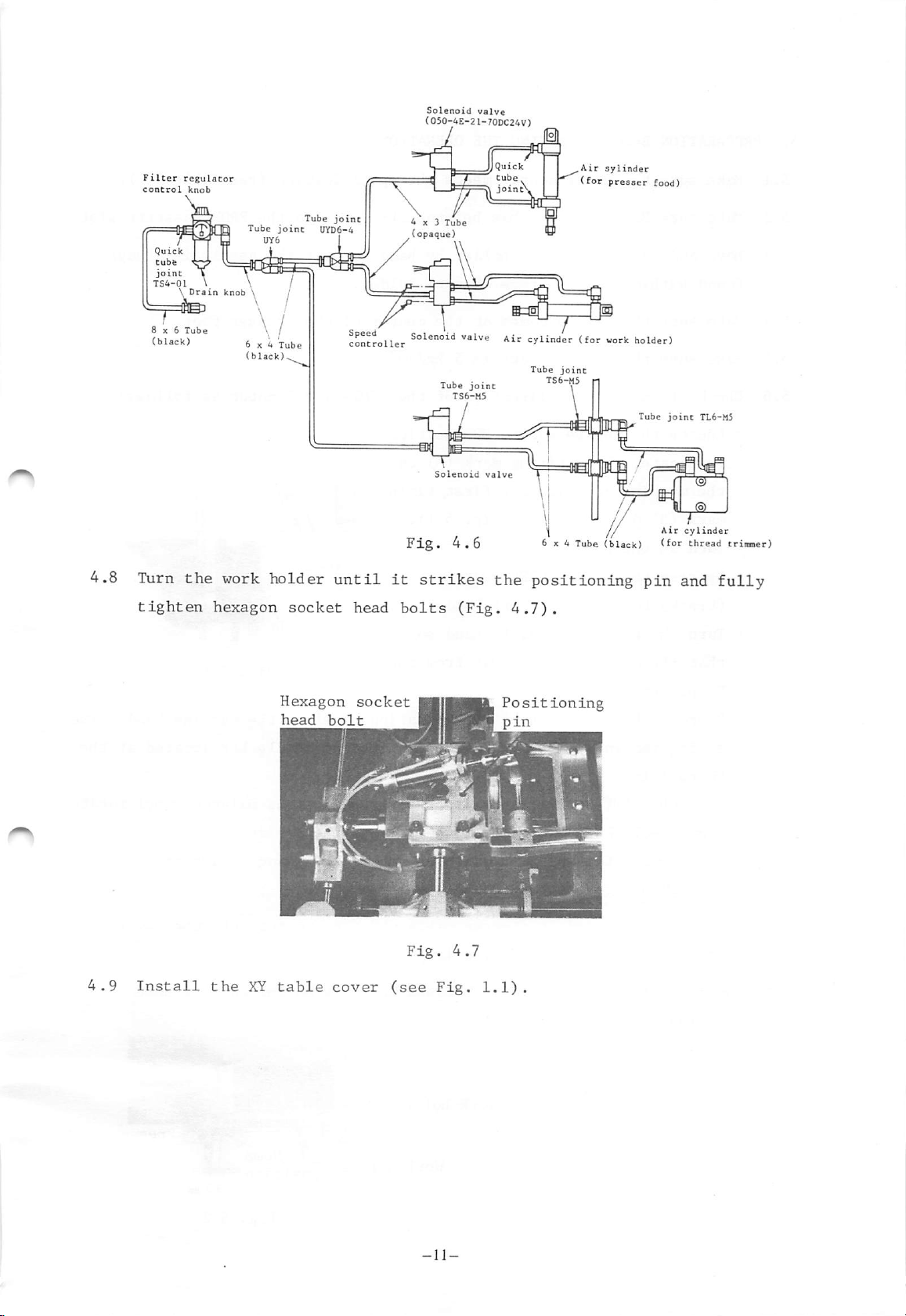

Install

through

tube

joint.

Air

pressure

pressure

After

tube,

Speed

permitting

the

right

the

air

control

the

setting,

push

the

controller

speed

Rear

Quick

side

tube

should be

knob

be

sleeve

is

provided

control

cover

Sleeve

tube

hole

and

sure

of

Air

joint

cover

to

(see

set

to 5 kg/cm^.

turn

to

quick

to

of

cylinder.

tube

the

Fig.

it.

lock

tube

regulate

machine,

1.1)

the

knob.

joint

and

To

and

air

Pressure

Pressure

Filter

pass

connect

set

To

pull

supply

regulator

furnished

it

air

pressure,

disconnect

the

to

control

gauge

to

tube

each

air

the

the

outward.

cylinder",

knob

tube

quick

pull

air

the

Fig.

4,5

View

when

the

rear

inspection

window

is

removed

Page 15

Filter

control

6x6

(black)

regulator

knob

T

CB

Tube

6x4

(black)^

joinc

Tube

Tube

UYD6-4

joint,

I

!onc2oller

Solenoid

(050-4E-2I-70DC24V)

4x3

(opaque)

Tube

Tube

TS6-H5

valve

joint

Air

cylinder

Tube

joint

TS6-M5

,Air

(for

(for

sylinder

presser

work

food)

holder)

Tube

joint

TL6-M5

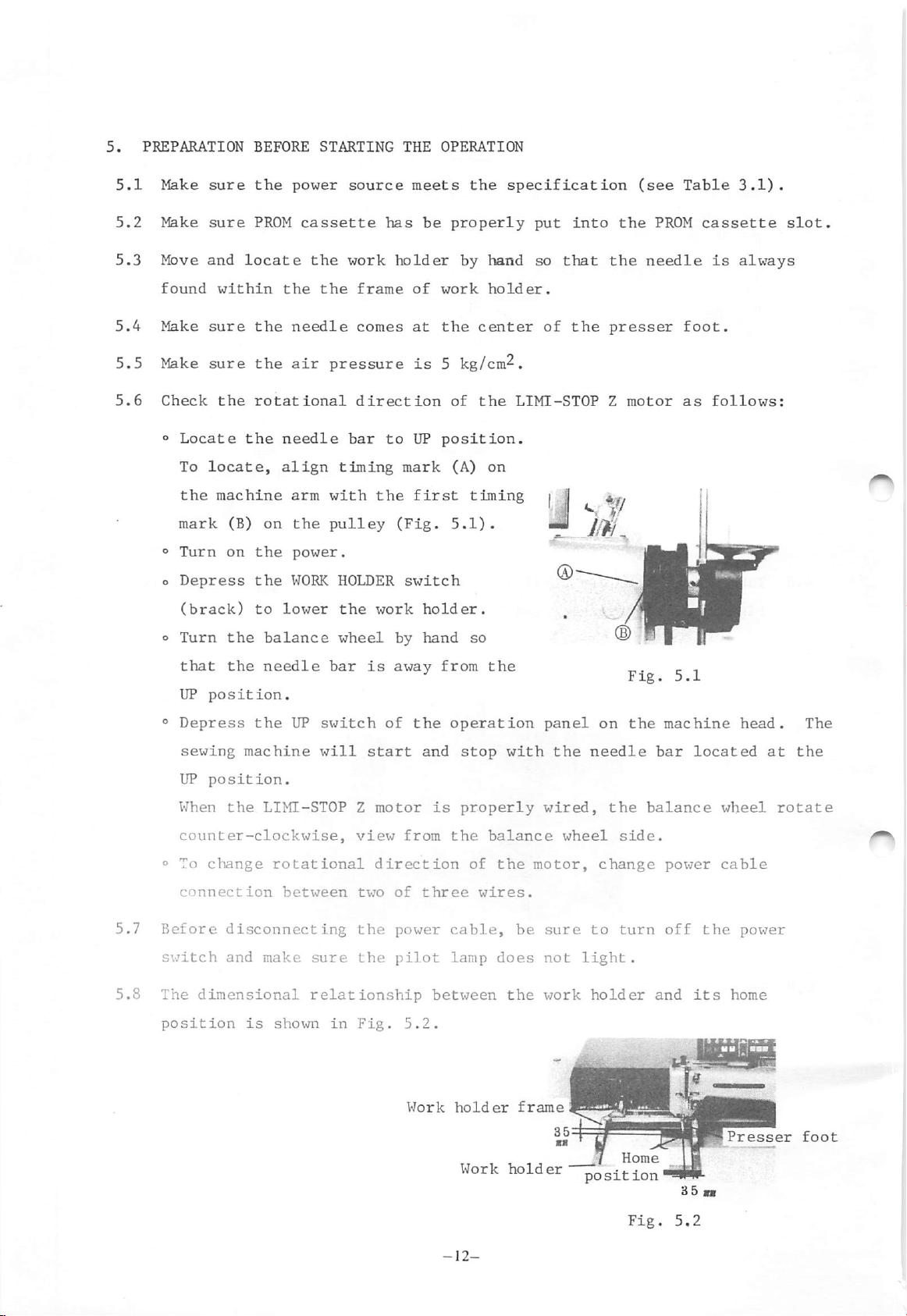

4.8

Turn

tighten

the

work

hexagon

holder

socket

Hexagon

head

until

bolt

head

socket

Fig.

it

bolts

Solenoid

4.6

strikes

(Fig.

valve

the

4.7).

Positioning

pin

•J

^

6x4

Tube

1/

jf

(black)

positioning

- '

Air cylinder

(^of

pin

and

thread

trinmer)

fully

Fig.

4.7

4,9

Install

the

XY

table

cover

(see

-11-

Fig.

1.1).

Page 16

5.

PREPARATION

5.1

5.2

5.3

Make

Make

Move

sure

sure

and

BEFORE

the

PROM

locate

STARTING

power

cassette

the

source

work

THE

has

holder

OPERATION

meets

be

the

properly

by

hand

specification

put

into

so

that

the

the

(see

PROM

needle

Table

cassette

is

3.1).

slot.

always

5.4

5.5

5.6

found

Make

Make

Check

o

Locate

To

the

mark

®

Turn

o

Depress

(brack)

o

Turn

that

UP

®

Depress

within

sure

the

sure

the

the

rotational

the

needle

locate,

align

machine

(B)

on

on

the

the

to

the balance

the

needle

position.

the

the

the

needle

air

pressure

arm

with

the

pulley

power.

WORK

lower

bar

UP

switch

frame

comes

of

at

is

direction

bar

to

UP

timing

HOLDER

the

wheel

the

work

is

mark

(Fig.

switch

by

away

of

first

the

work

the

5 kg/cm^.

of

position.

(A)

timing

5.1).

holder.

hand

^

so

from

operation

holder.

center

the

on

the

of

the

LIMI-STOP

jJ

iw

®

panel

presser

Z

motor

^

® " |

on

Fig.

the

foot.

as

-j

r.

,

5.1

machine

follows:

head.

The

5.7

5.8

sewing

UP

When

counter-clockwise,

o To

connection

Before

switch

The

position

machine

position.

the

change

disconnecting

and

dimensional

is

will

LIMI-STOPZmotor

rotational

between

make

sure

relationship

shown

in

start

view

direction

two

the

the

Fig.

of

power

pilot

and

from

three

5.2.

Work

stop

is

properly

the

of

cable,

lamp

between

holder

Work

with

balance

the

wires.

does

be

the

frame

holder

the

wired,

wheel

motor,

sure

not

work

needle

the

side,

change

to

turn

light.

holder

Home

position'

bar

balance

power

off

and

located

wheel

cable

the

its

power

home

at

rotate

the

Fig.

5.2

Page 17

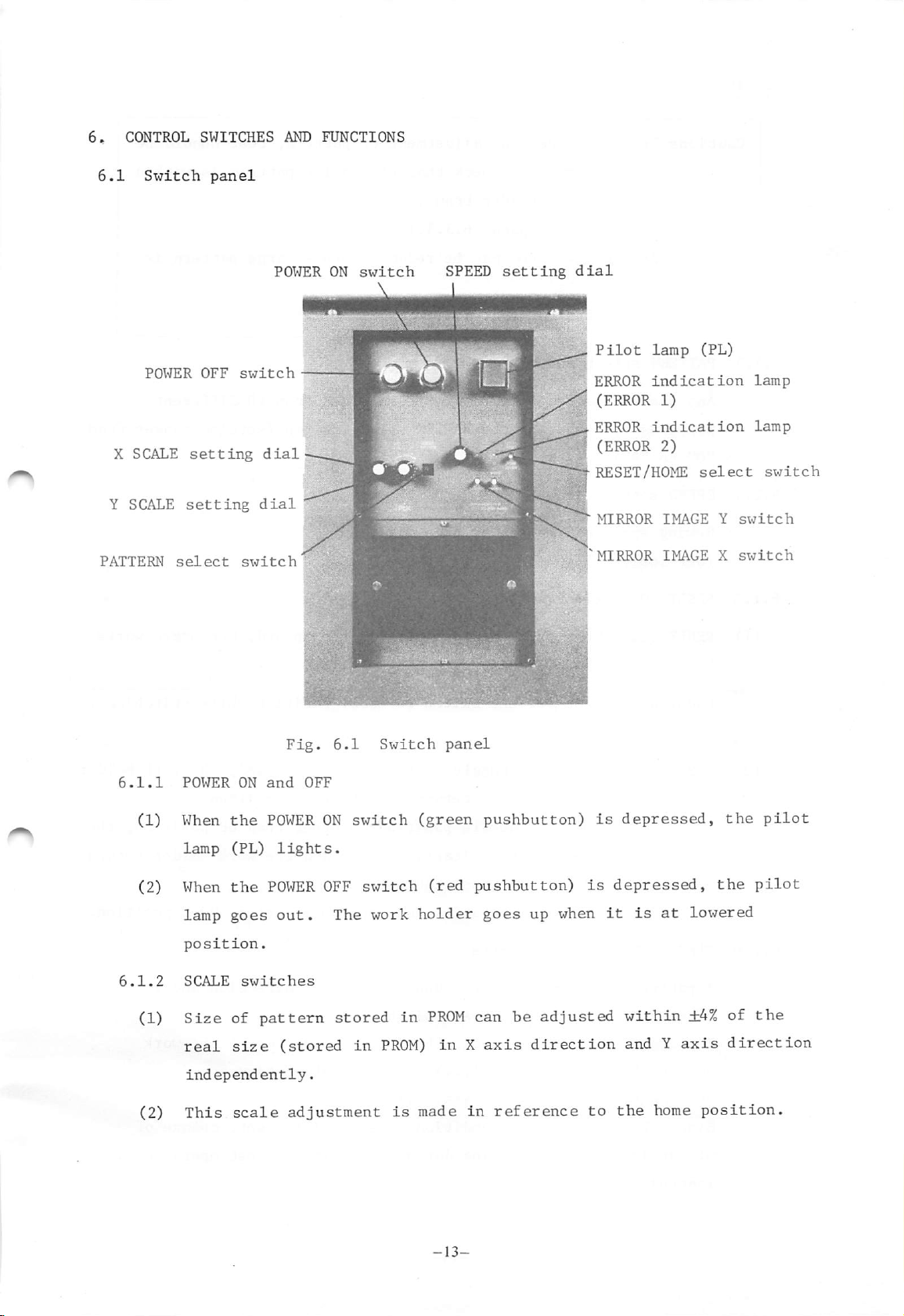

6.

CONTROL

SWITCHES

AND

FUNCTIONS

6.1

X

SCALE

Y SCALE

PATTERN

Switch

POWER

select

panel

OFF

setting

setting

switch

dial

switch

POWER

dial|

ON

switch

-

SPEED

setting

dial

Pilot

AERROR

I

(ERROR

I

ERROR

I

(ERROR

I RESET/HOME

1-

MIRROR

^MIRROR

lamp

indication

1)

indication

2)

IMAGE

IMAGE

(PL)

select

Y

X

lamp

lamp

switch

switch

switch

6.1.1

6.1.2

(1)

(2)

(1)

(2)

POWER

When

lamp

When

lamp

position,

SCALE

Size

real

independently.

This

ON

the

(PL)

the

goes

switches

of

size

scale

pattern

Fig.

and

OFF

POWER

lights.

POWER

out.

(stored

adjustment

6.1

ON

switch

OFF

switch

The work

stored

in

Switch

in

PROM)

is

panel

(green

(red

holder

PROM

inXaxis

made

pushbutton)

pushbutton)

goes

up when

can be

adjusted

direction

in

reference

is

depressed,

is

depressed,

it

within

andYaxis

to

the

is

at

home

the

the

lowered

±4%

of

direction

position.

pilot

pilot

the

Page 18

Cautions

1;

After

the

fine

adjustment

of

pattern,

test

should

be

6.1.3

6.1.4

6.1.5

2:

PATTERN

Any

one

select

of

patterns

"0"

to

"9").

SPEED

Sewing

(See

RESET/HOME

setting

speed

Table

performed

the

work

(Refer

Sewing

stitched.

(Refer

desired

by

operating

dial

can

8.1.)

select

to

speed

to

switch

be

to

holder

para.

para.

pattern

set

switch

check

may

the

frame.

6.3.3.)

8.1.)

PATTRN

by

be

can

this

that

reduced

be

dial.

the

selected

select

entire

when

switch

pattern

enlarge

from

pattern

10

different

(setting

is

within

is

ranges

from

(1)

(2)

6.1.6

RESET When

stopping

Causion;

HOME

Do

not

is

going

When

automatically

When

needle

to

In

MIRROR

A

direction

The

holder

pattern

switch

IMAGE X, Y

can

symmetrically

by

operating

setting

(MOVE

...

this

set

on.

this

the

automatically

the

home

usual

switches

does

para.

toggle

all

movements.

the

switch

toggle

returns

needle

position

operation,

these

not

6.3.2.)

switch

to

switch

position

the

turned

switches.

affect

and

to

goes

(see

is

RESET

is

the

is

up

Fig.

switch

over

axial

work

set

upward,

position

set

downward,

home

other

and

5.2).

is

in

X

movement

holder

position.

than

the

work

set

direction

traverse

the

while

UP

at

of

brake

stitching

the

position,

holder

HOME

and

the

direction

work

position.

Y

work

works

holder

the

returns

at

home

Since

mirror

ignor

ed.

return

the

image

mirror

(refer

switch

image

to

conditions

setting

para.

-14-

during

6.1.5).

are

initially

stitching

or

set,

test

change

operation

of

is

Page 19

Pattern

changes

as

shown

in

Fig.

6.2.

6.1.7

(1)

(2)

ERROR

When

at

UP

When

When

Y

(D

Fig.

6.2

indication

an

error

lamp

position

ERROR1lights

stored

n=I>

Use

data

correctly

ERROR1lights

resulting

lamps

and

are

from

lights,

proceeding

in

green

improper.

programmed

in

red

excessively

the

...

sewing

of

...

Stitch

operation

Sewing

PROM

enlarged

1

2

3

4

machine

mattern

cassette.

length

pattern.

X

Positive Positive

Negative

Negative

Positive

stops

becomes

is

with

impossible.

is

not

larger

Y

Positive

Negative

Negative

the

stored

than

needle

or

6.2

mm

(3)

(4)

(5)

(6)

When

When

When

When

ERROR2lights

sewing

XY

11.)

cij>

table

.

Move

using

area.

position

the

MOVE

ERROR2lights

i=0>

Turn

off

ERROR1and

position

1=0

Set

the

work

machine

when

holder

ERROR1and

is

blocked

in

green

The

movable

detector

work

holder

function

in

red

the

power

ERROR2light

the

power

RESET/HOME

will

return

stops

with

ERROR2flicker

or

V-belt

leaves

...

(refer

...

and

is

select

the

The

range

and

into

PROM

properly

in

turned

to

needle

in

pulley.

detector

the

to

cassette

red

switch

the

red

work

of

movable

para.

...

on.

at

holder

work

load

The

to

home

UP

...

holder

plate

range

6.3.2).

is

PROM

needle

"HOME"

position

position.

Motor

moves

not

or

beyond

is

set

(refer

of

work

loaded.

cassette.

is

not

position.

and

sewing

by

to

section

holder

at

the

machine

the

the

UP

The

sewing

1=0

(7)

When

Turn

ERROR1and

setting

c=0

Operate

off

the

ERROR2light

is

changed

the

power,

while

remedy

the

RESET/HOME

-15-

in

select

and

green

2nd

turn

.,.

home

switch.

on

PATTERN

position

the

power

select

is

used.

again.

switch

Page 20

6.2

Foot

switches

(Fig.

1.1)

6.3

6.2.1

6.2.2

WORK

The work

depressed,

START

The

depressed.

It

and

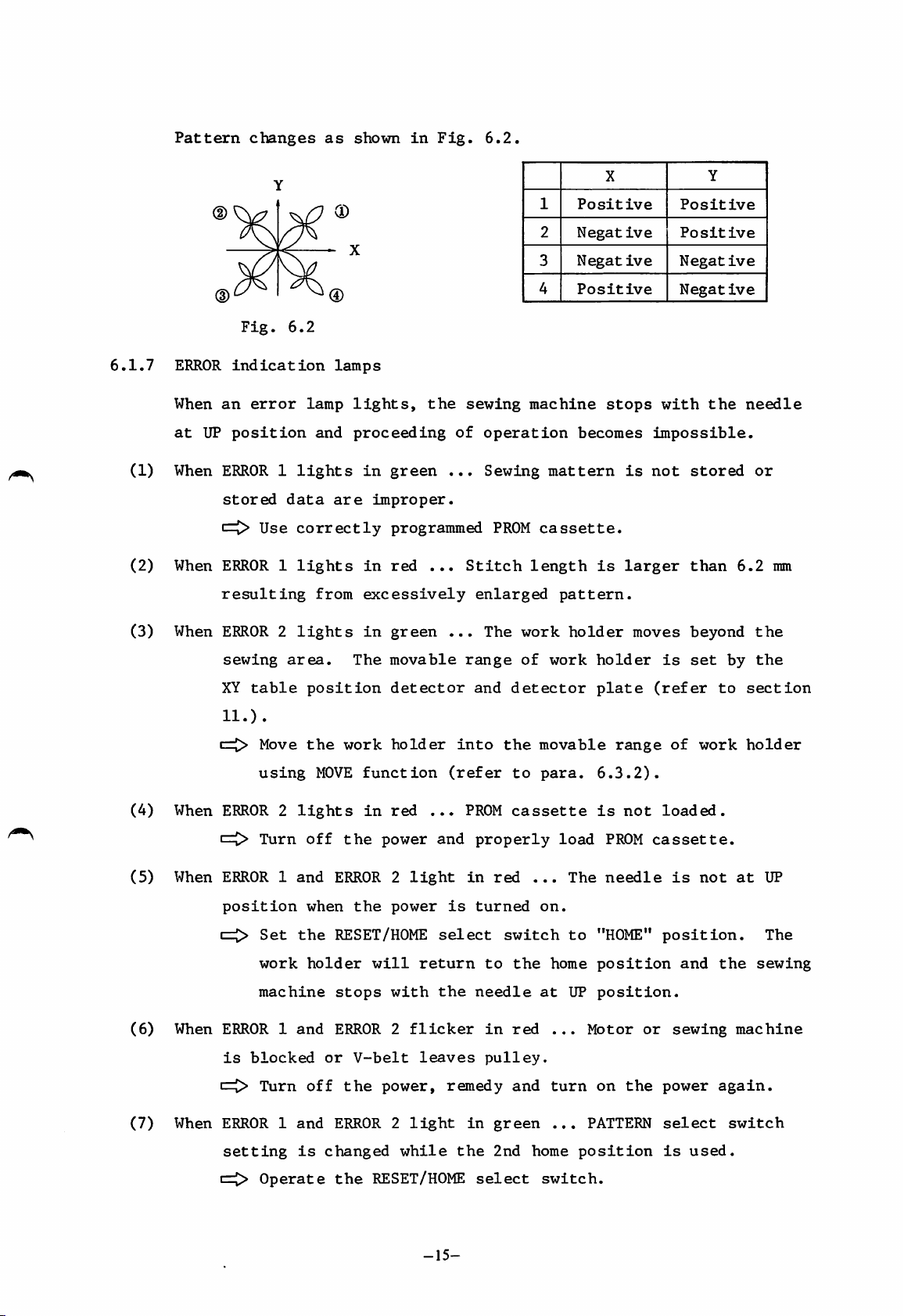

Operation

HOLDER

sewing

does

the

+X

switch

not

needle

panel

-X

switch

holder

and

machine

start,

on

MOVE

goes

goes

is

machine

+Y

down when

up

starts

however,

not

UP

-Y

COARSE

when

position.

head

FINE

the

the

stitching

if

the

+^0G

WORK

switch

work

when

HOLDER

is

depressed

the

holder

UP

switch

START

is

STOP

again.

switch

not

(brack)

(red)

at

DOWN

is

is

position

6.3.1

6.3.2

coarse/FINE

With

0.2

at

"COARSE"

MOVE

When

this

mm

switch

switch

every

stitching

MOVE

The

follows:

+X:

-X:

switches

movement

Rightward

Leftward

+Y: Upward

-Y:

Downward

select

switch

when a

position,

is

held

setting

starts,

of

movement,

movement,

movement,

movement,

switch

set

the

WORK

at

MOVE

the

down.

is

changed

presser

HOLDER

viewed

Fig.

"FINE"

switch

work

viewed

viewed

viewed

6.3

position,

is

holder

from

foot

resulting

from

from

from

from

depressed.

goes

"COARSE"

lowers.

from

the

the

the

front

the

the

on

MOVE

front

front

front

work

holder

With

moving

to

"FINE"

switch

(leftward

(rightward

(downward

(upward

this

as

long

before

operation

stitching)

stitching)

moves

switch

as

pattern

stitching)

stitching)

by

set

a

is

as

For

this

position

operation,

and

DOWN

the

position

needle

respectively.

-16-

and

the

work

holder

should

be

at

UP

Page 21

6.3.3

(1)

+JOG

TEST

switches

function

(2)

Only

the

speed

returned

When

opposite

When

end

position.

When

the

the

of

the

position,

START

During

up

for

ing

operation).

Stitch

For

correction

work

while

to

-JOG

direction.

+JOG

pattern,

-JOG

switch

the

work

correct

it

test,

holder

the

+JOG

the

home

switch

switch

the

switch

stops

is

depressed),

holder

function

or

advances

switch

position.

is

is

work

is

there

the

presser

traversing

amendment

in

is

depressed,

held

down

holder

held

down

permitting

or

foot

(the

of

the

held

the

and

goes

and

test

goes

work

stitches,

stitching

down

work

the

up

and

the

start

(the

down

after

work

work

of

+JOG

holder

the

direction

the

holder

holder

then

holder

stitching

switch

for

moves

work

work

moves

reaches

returns

reaches

is

stitching,

without

holder

at

a

fixed

holder

in

the

the

to

the

the

(xi7hen

the

operated).

and

stitch

can

be

is

home

home

goes

moved

6.3.4

6.3.5

in

forward

by

operating

depressing

This

UP

When

than

When

in

that

test

switch

to

the

This

position.

STOP

inching

the

operation.

the

the

UP

UP

function

switch

the

replenishment

or

the

the

motion

work

sewing

position,

position.

sewing

backward

+JOG

STOP

holder

machine

can

be

machine

of

bobbin

direction

or

switch

is

same

moves

this

used

-JOG

(refer

as

stops

switch

only

must

thread,

switch

that

at

with

when

be

stitch

to

of

a

speed

the

is

the

stopped

this

by

stitch

after

para.

stitching

6.3.5).

test

lower

needle

depressed

work

for

switch

function,

than

at

a

to

holder

thread

is

used.

along

is

the

position

locate

is

breakage

the

suspended

but

differs

speed

the

at

the

pattern

in

other

needle

DOWN

or

for

by

Stitching

It

is

-JOG

also

switch.

can

possible

be

resumed by

to

move

depressing

the

work

-17-

the

holder

START

by

operating

switch

(red).

the

+JOG

or

Page 22

7.

7.1

OPERATION

Loading

the

PROM

cassette

7.2

7.3

Open

necessary

care

fail

For

PROM

the

not

to

pattern

writer

install

necessary.

PROM

Switch

In

follows:

Set

one

RESET/HOME

Switch

cassette,

order

the

of

setting

SCALEXand

IG

function

switch

pattern

to

insert

writing

(PT-100,

For

to

check

positions

switch

panel

data

it

the

front

and

selection

refer

on

switch

each

to

checking

front

in

have

wrong

erasure

cover

been

cover

and

stored

direction.

again.

to

and

insert

into

from

a

the

After

PROM,

PT-IOOA, PTN-4G00, PTN-4000A,

of

to

function,

Y

switches

("0"

"HOME"

section

panel

-

"9"),

position.

PROM,

to

13.

set

the

refer

"G",

each

the

SPEED

to

Table

switch

PATTERN

setting

PROM

cassette

cassette

the

insertion,

optionally

PTN-IOGQ-OL)

7.1.

on

the

select

dial

slot,

For

switch

switch

to

"4",

in

which

using

do

available

is

handling

panel

to

and

not

of

as

any

the

When

on

(1)

(2)

(3)

the

the

power

Home

Set

sure

6.1.5)

Work

The

depressed

Work

The

switch

When

to

stops

work

above-mentioned

and

check

return

the

reset/home

the

work

.

holder

work

lowering

holder

(it

holder

work

the

the

at

holder

holder

id

depressed.

work

UP

position,

the

movement

UP

is

holder

should

goes

should

holder

position

moving

preparatory

each

function

to

"RESET"

returns

motion

go

up

when

move

reaches

and

...

down

the

return

when

refer

position

to

when

switch

tracing

the

to

the

operation

as

follows:

the

home

the

the

end

of

the

+JOG

to

para.

and

position

WORK

is

depressed

given

the

home

switch

6.3.3).

has

then

HOLDER

pattern,

position

been

to

pattern

is

released

completed,

"HOME"

(refer

switch

again).

when

it

will

(the

to

to

is

the

work

while

turn

make

para.

go

holder

+JOG

up

the

-18-

Page 23

When

does

By

performing

the

not

test

occur.

is

the

made,

test,

only

check

the

work

the

holder

dimensions

moves

and

and

location

stitching

of

the

motion

work

7.4

7.5

holder.

and

proceed

Sewing

(1)

Refering

(2)

Set

work

start

Once

released,

thread

STOP

To

Stitching

To

switch

suspend

trimming.

start

To

check

as

operation

upafabric

holder.

stitching.

stitching

trimming.

operation

stitching,

stops

stitching

stitching

instructed

to

Fig.

and

with

again,

and

Then

starts,

stops

the

in

6.1.,

depress

depress

with

depress

work

adjust

condition,

para.

properly

the

the

it

continues

the

work

the

STOP

holder

the

7.4.

set

WORK

START

at

stitching

set

switches

HOLDER

switch,

even

holder

switch

the

stitching

when

at

(see

DOWN

atart

speed

on

the

switch

the

the

the

UP

Fig.6.3).

position

position

switch

to

sewing

START

position

to

let

after

"low

panel.

down

machine

switch

after

thread

by

operating

speed"

the

will

is

the

+JOG

sewing

Note:

machine

In

is

needle

PROMXQ'ty

2716

2716

2732

2732

Note:

X 1

X 2

X 1

X 2

For

PROM

and/or

order

-JOG

starts

to

recommended

thread.

Table

use

sockets

7.1

of

make

Number

two

switches

and

yourself

to

of

1000

2000

2000

4000

(PROM

PROMs, a

should

and

sews

the

operate

stitches

combination)

P.O.

be

used.

depress

remaining

familiar

switches

board

the

with

on

Number

of

START

pattern.

each

the

switch

of

10

10

10

10

Cassette

switch

switch

patterns

panel

case

again.

function,

without

having

The

it

two

-19-

Page 24

7.6

Checking

starting

operation

Operation

procedure

and

checking

The sewing machine should be

the

following

before

(1)

(2)

(3)

(4)

flow

Is

the

plugged

and

Are

plugged?

Is

PROM

machine?

Are

chart:

power

in

connector?

all

other

cassette

fuses

power

not

operated

cable

source

cables

loaded

blown

and checked

outlet

properly

on

out?

the

in

accordance

with

Section

paragraph

refferred

Operation

Preparation

Judgement

or

to

be

to

(^Preparation

Depress

POWER

LIMI-STOP

holder

to

Depress

switch

ON

Does

Z

motor

start

Does

the

work

its

position

9

WORK

to

switch.

return

start]

?

Yes

home

HOLDER

"ON".

Check

cable

connection.

Depress

POWER

No

Set

switch

"HOME"

Set

switch

"RESET"position

power

OFF

switch.

RESET/HOME

to

position

RESET/HOME

to

Check

of

direction

rotation.

Depress

ON

switch.

/Change

reversing

plug

POWER

phase'

setting

Turn

wheel

needle

the

Depress

machine

the

holder

the

to

UP

the

Does

work

down?

balance

locate

away

position

UP

Does

sewing

7

go

the

from

switch.

No

start

Depress

HOLDER

again

Depress

OFF

WORK

switch

to

switch.

"OFF"

POWER

(i8o'»).;

{

To

the next page }

-20-

Adjust

work

mechanism.

Check

LIMI-STOP

Z

motor

connection.

the

holder

cable

Page 25

Depress

POWER

switch.

Adjust

the

synchronizer

setting.

OFF

No

(

From

previous

direction

of

rotation

correct

the

page

Is

7

need!

ion

Test

operation

Set

switch

"HOME"

Set

switch

"RESET"

set

check

PROM

RESET/HOME

RESET/HOME

JOG

to

"OFF

cassette.

to

position.

to

position.

switch

t

•

No

Set

^et

depress

+JOG

work

properly

in

the

PATTERN

SCALE

the

reference

the

holder

switch

Does

work

holder

MOVE?

Is

the

holder

positioned

patter

?

Does

work

switch./

go

No.

to

^

No

No

Depress

OFF

switch.

POWER

Check

mechanism

and

c

Adjust

work

mechanism.

drive

control

ircuit.

holder

Preparation

completed

To

the

next page )

-21-

Page 26

(

Sewing

Set

stitching

speed.

Set

a

fabric(s).

up

start

)

Automatic

sewing

operation

Depress

WORK

switch

Depress

switch

mach

HOLDER

to

running

"ON'

ion

START

to

"ON"

Depress

WORK

switch

to

Depress

OFF

depress

switch

HOLDER

"OFF".

switch.

to

again

POWER

STOP

"ON"

PROM

data

input

broken

trimmed

pf

the

trimmer

satisfactory

thread

well

Is

thread

stitching

Are

threads

at

stitching

?

Is

thread

operation

9

Is

balanced

9

Ce^

during

the

tension

end

Depress

Switch

Depress

OFF

ligned

to

switch.

START

"ON".

POWER

(Operate

JOG

switches

to

align

stitches.

Adjust

sewing

machine.

the

-22-

Page 27

8.

(1)

CAUTIONS

Before

ON

USE

replacement

of

PROMinPROM

cassette,

carefully

read

section

13

(2)

(3)

(4)

(5)

(6)

(7)

"REPLACING

The

power

If

any

ERROR

in

para.

When a

finely

ship

Maximum

(Refer

Dust

During

When

When

power

new

adjusted,

between

to

in

operation,

the

adjustment

before

THE

should

6.1.7.

pattern

sewing

item

the

power

PROM".

lamp

the

speed

12.4

control

is

gaining

be

lights,

be

work

the

is

turned

is

sure

depends

for

unit

turned

made

access

off

trace

stitched

to

holder

detail)

might

control

on,

on

before

for

perform

movement

on

cause

box

foot

the

sewing

to

the

its

cause

the

test

stitch

cover

should

mechanisms

PROM

cassette

referring

first

operation

and

the

length.

malfunction

should

not

machine,

time,

pattern.

be

be

placed

be

or

is

to

or

to

or

trouble.

kept

sure

control

loaded

the

pattern

check

close.

on

the

to

turn

box

or

unloaded.

description

size

the

relation

START

off

interior.

is

switch.

the

(8)

(9)

Do

not

ment.

voltage

Since

drain

4.5).

apply

Ohterwise

from

air

fed

knob

a

the

af

multimeter

semiconductors

multimeter.

to

the

filter

regulator

to

pneumatic

the

control

in

line

to

the

circuit

contains

eliminate

circuit

might

moisture,

accumulated

for

checking

be

damaged

depress

water

or

the

(see

adjust

due

to

Fig.

-23-

Page 28

9.

9.1

HANDLING

Installation

THE

SEWING

of

MACHINE

needle

(Fig.

HEAD

9.1)

Prime

should

to

side

Caution:

Fully

turn

the

left

set

screw.

groove

come

the

left

insert

the

Before

for

prime

side

safety.

the

groove

and

installing

needle,

to

tighten

or

removing

Needle

inserted

direction

not

the

in

needle,

fully

wrong

turn

Prime

in

off

wrong

the

groove

direction

power

facing

9.2

Winding

the

[Adjustment]

bobbin

—

Tension

for

-

Conically

smaller

-

Length

adjusting

loosen

thread

of

polyester

diameter

of

the

Fig.

(Fig.

wound

wound

would

screw

screw

and

9.1

9.2)

thread

nylon

thread

of

thread

to

increase

to

....

thread.

wound

decrease.

Small

Move

thread

Tighten

length

tension

the

layers.

of

thread

the

wound

is

thread

thread,

recommended

guide

toward

length

and

-24-

Page 29

adjusting

i

Hi

80%

capacit

be

fill

cvl

indr

of

ced

on

d

need:

and

tensio:

Tight

tensi

bobbi

on.

n

nee

dl

e

th

re

or

loo

se

th

re

ad

t

en

se

sion,

needle

or

thr

tigh

Page 30

9.5

Installing

the

bobbin

9.6

9.5.1

9.5.2

9.5.3

9.6.1

Put

bobbin

Put

and

(D).

Pull

to

rotates

If

clockwise,

(B).

Installing

Locate

uppermost

the

the

the

lead

the

make

the

lower

bobbin

case

thread

it

thread

sure

clockwise.

bobbin

the

the

position

cover.

(A).

out

the

rotates

reverse

bobbin

needle

(B)

in

from

(E)

into

the

downward

bobbin

the

case

bar

and

slit

the

counter

bobbin

to

open

the

hole

(B)

its

(C)

Fig.

9.6

(D

9.7

9.6.2

Fully

latch

latch,

Adjusting

Needle

adjusted

tension

Tension

turned

Tension

turned

open

(A)

put

the

thread

by

turning

regulating

increases

clockwise.

decreases

counter-clockwise.

the

and,

it

needle

tension

bobbin

holding

into

thread

can

the

tumb

when

when

(B).

thread

nut

case

the

tension.

be

(A).

it

it

Fig.

is

is

Fig.

9.7

9.8

-26-

Page 31

9.8

Adjusting

the

bobbin

thread

tension

9.9

9.9.1

(1)

Bobbin

adjusted

adjusting

Tension

turned

Tension

turned

Lubrication

To

1ean

Lean

the

red

thread

by

turning

screw

increases

clockwise.

decreases

counter-clockwise.

fill

ed

the

the

bac

machine

oiling

line

tension

kward

hole

(B)

(A).

oil

.

the

tank

head

(A)

can

when

when

until

be

thread

it

it

with

and

is

is

the

pour

level

machine

oil

reaches

head

through

the

9.9.2

(2)

(1)

(2)

Oiling

requiring

If

it

Oil

To

fill

leaning

Loosen

gauge

machine

When

up

to

paint,

with

sufficient

(Fig.

rate

must

used:

the

the

and

found

bed.

the

the

the

9.11).

has

readjustment

be

adjusted,

White

oil

machine

remove

on

the

oil

gauge

lower

oil

tank

Oil

gauge

been

tank

the

end

amount

factory-adjusted,

in

usual

refer

spindle

without

head

oil

top

is

oiled

of

is

,

of

white

filled

of

oil,

oil

operation.

to

para.

#2

9,25.

Fig.

9.12

Fig.

White

9.11

paint

Page 32

(3)

If

oil

is

not

sufficient,

pour

suitable

quantity

of

oil

through

the

9.10

9.10.1

9.10.2

9.10.3

•9.10.4

9.10.5

threaded

Timing

Needle

Turn

the

lowermost

Remove

face

Loosen

screw

Vertically

(C)

bar

After

hole

adjustment

bar

position

the

balance

needle

position.

the

plate

the

(B).

to

adjust

motion*.

the

adjustment,

bar

rubber

(A).

needle

move

for

between

can

wheel

(C)

the

timing

oil

to

plug

bar

gauge

needle

be

to

the

from

bracket

needle

of

tighten

(Fig.

adjusted

located

the

bar

needle

motion

as

set

the

9.12).

and

follows:

hook

motion

Fig.

(D

©

9.13

9.11

set

*

Timing

-

When

the

needle

be

of

-

With

above

(E)

with

eye.

-

There

them

needle

Adjusting

screw

of

the

lowermost

bar

in

line

the

needle

the

step,

of

hook

the

are

should

used.

the

(B).

needle

needle

position,

timing

with

bar

adjustment

the

should

center

four

be

hook

bar

bar

mark

the

bushing

inside

(D)

timing

selected

position

(C)

lower

at

be

of

motion

is

the

(B)

the

surface

aligned

needle

marks

for

at

must

edge

(A).

and

the

one

of

© d)

)

1

Fig.

For

For

DB X 1

DP X

9.14

17

9.11.1

9.11.2

Loosen

Turn

point*.

and

the

position

hook

screw

the

(A).

hook

-28-

(B)

to

adjust

timing

of

motion

of

hook

Page 33

9.11.3

Gap

the

between

hook

point

the

needle

(C)

should

(D)

be

and

©

(1)

(2)

about

*

Timing

The

follows:

When

lifted

lowermost

timing

needle

2.4

conditions

The

the

The

upper

point

0.05

of

standard

the

by

marks

bar

mm),

hook

center

gap

between

edge

(D)

mm.

hook

needle

2.4

position

at

the

should

point

(C)

(E)

should

point

timing

bar

mm

from

(refer

(A)

put

an

interval

following

be

(D)

should

of

needle.

the

and

the

be

motion

is

as

(B)

the

on

satisfied,

needle

hook

within

is

the

to

of

meet

eye

a

"^5

^^2

Fig.

♦

©

^mm

9.15

©

1.5

mm

2.4mm

9.11.4

range

Location

Position

side

surface

stopper

from

point

of

of

1.0

hook

the

mm

of

(A)

to

positioner

hook

needle

as

1.5

mm.

positioner

(B)

is

shown

to

in

the

(A)

line

should

right.

with

'A)

be

the

Fig.

adjusted

side

Fig.

9.16

surface

9.17

so

that

of

the

hook

-CB)

-29-

Page 34

9.12

Thread

tensions

9.12.1

9.12.2

9.13

9.13.1

9.13.2

Needle

tension.

Bobbin

by

thread

Needle

by

takeup

tension

(A)

(3)

Adjusting

Put

into

the

Tie

(D)

thread

thread

changing

tension

thread

changing

spring

regulator,

of

thread

pressure

the

the

the

thread

furnished

to

the

tension

intensity

(1)

bobbin

bobbin

bobbin

(C)

thread

tension

spring.

tension

(B)

takeup

of

should

intensity

of

(2)

tension

thread

with

case

through

be

can

be

of

bobbin

can

be

of

needle

movable

spring

discs

tension

polyester

(A)

and

the

hexagon key wrench

(C)

to

hang

adjusted

adjusted

case

adjusted

thread

thread

range

(B),

(C).

thread

lead

slit

the

and

out

(B).

(small)

key

in

reference

#30

Fig.

to

9.18

\

bobbin

thread

(D

-d)

-©

9.13.3

wrench,

The

standard

that

the

when

and

*The

the

down.

Standard

bobbin

adjusted

bobbin

Thread

is

turned

turned

as

shown

bobbin

thread

bobbin

bobbin

by

case

tension

clockwise,

counter-clockwise.

is

case

thread

thread

turning the

thread

increases

in

Fig.

thread

gradually

tension

tension

is

and

9.18

slowly

tension

screw

when

decreases

tension*

unwound

swung

can

be

(B)

spring

the

is

up

of ^

(A).

screw

when

Fig.

'

123

Fig.

9.19

9.20

-30-

Page 35

9.14

Adjusting

the

needle

thread

tension

9.14.1

9.14.2

(Adjusting

takeup

Loosen

turn

until

(a)

Turn

the

with

turn

round.

The

spring)

the

tension

intensity

reaches

the

takeup

the

the

needle

adjusted

Standard

-

50g

the

tension

zero.

thread

spring

spring

tension

thread

to

the

needle

intensity

stud

of

stud

stopper

standard

thread

stud

(B)

counter-clockwise

thread

(B)

(A) comes

stud

(B)

tension

tension:

of

thread

set

screw

takeup

clockwise

into

and

then

about

will

tension.

spring

contact

further

3/4

be

About

and

until

40

-M

Fig.

(D

9.21

-31-

Page 36

9.15

Adjusting

spring

the

intensity

of

thread

takeup

9.15.3

9.16

9.15.1

9.15.2

9.16.1

9.16.2

Loosen

(A).

Intensity

can

tension

Spring

tension

and

counterclockwise.

After

set

Adjusting

spring

Loosen

stud

Turn

nut

counter-clockwise

the

be

adjusted

stud

intensity

stud

decreases

the

screw

the

the

set

the

(C)

clockwise

tension

of

thread

(B).

is

when

adjustment,

(A).

movable

needle

screw

tension

by

increases

turned

it

range

thread

(B).

regulating

or

to

stud

takeup

turning

clockwise,

is

tighten

of

adjust

set

turned

takeup

tension

screw

spring

the

when

the

thumb

movable

the

Fig.

(D

9.22

©

9.16.3

range

The

thumb

decreases

counterclockwise.

*The

takeup

takeup

guide

of

takeup

movable

nut

standard

spring

spring

(D))

range

is

when

ranges

spring*.

turned

turned

movable

(gap

(A)

increases

clockwise,

range

between

and

the

from

9mm

when

of

the

thread

to

the

and

lOmm.

Fig.

9.23

-32-

Page 37

9.17

Adjusting

the

thread

tension

discs

9.17.1

9.17.2

9.17.3

9.17.4

Lift

Loosen

set

Move

(B)*in

arrow

so

that

discs

0.8mm

After

tighten

*Whenever

regulator

make

discs

0.8mm

the

screw.

the

sure

presser

the

the

in

the

(a)

to

the

the

(a)

to

Fig.

1.0mm.

thread

tension

direction

9.23,

opening

is

within

adjustment,

set

the

needle

set

screw

the

opening

is

within

1.0mm.

foot.

tension

regulator

and

of

a

screw.

is

a

regulator

indicated

position

the

range

be

sure

thread

loosened,

of

tension

range

bushing

by

tension

from

to

tension

from

liilsigl

Tl-ij;

it

0.8-1.0mm

O

Fig.

9.24

9.18

Adjusting

9.18.1

9.18.2

Tighten

by

fingers

until

Loosen

range

rate.

the

it

the

of

hook

oiling

or

stops.

adjusting

one

oiling

adjusting

small

turn

rate

screwdriver

screw

to

adjust

screw

within

oiling

(A)

a

Fig.

9.25

-33-

Page 38

9.18.3

Hook

oiling

rate

can

be

checked

by

observing

from

Caution:

Max.

(about

the

the

hook,

r\

•:\

oiling

25Chng/min)

oil

onatest

Do

not

tighten

adjusting

rate

trace,

excessively

the

oiling

screw

Standard

splashed

paper

(A).

oiling

OD

(B).

rate

Min.

oiling

©

rate

Fig.

9.25

Oil

splashed

Fig.

from

9.26

hook

(for

10

sec.)

-34-

Page 39

9.19

Adjusting

the

presser

foot

9.19.1

Adjusting

• -' P r e s s u

Height

adjusted

of

so

the

the

that

height

presser

the

of

foot

lower

presser

should

end

foot

be

^^Pressure

lr«

surface

slight

O.Smm)

turned

foot

its

To

set

shown

presser

Note

too

trouble.

when

at

stroke.

adjust,

screw

in

that

high

of

contact

by

hand

the

or

Fig.

foot.

the

or

presser

with

the

balance

to

lowermost

loosen

presser

9.27

presser

low

may

foot

fabric

locate

the

bar

and

cause

comes

(0

wheel

the

position

presser

set

move

foot

adjusted

stitching

into

is

presser

of

foot

screw

the

stroke

adjusting

Presser

. ^

bolt

foot

Fig.

adjusting

9.27

Thumb

screw

nut

18mm

9.19.2

After

needle

foot

Note:

Adjusting

Presser

within

the

passes

end

When

changes,

presser

changed.

foot

a

adjustment,

bore.

the

range

(factory-adjusted

To

Increase

arm

cover

foot

Fig.

stroke

9.27

and

to

the

thickness

height

foot

presser

stroke

from

the

stroke,

loosen

adjusting

move

center

should

can

4mm

to

the

make

of

of

fabric

of

foot

be

to

4mm).

remove

the

the

bolt

adjusting

sure

presser

the

be

stroke

adjusted

10mm

presser

shown

the

the

in

bolt

upward.

When

position,

it

is

adjusted

the

storke

to

the

uppermost

is

about

10mm.

Page 40

9.19.3

Adjusting

the

presser

foot

pressure

9.19.4

9.20

Presser

adjusted

adjusting

thumb

pressure

adjusting

and

counter-clockwise.

The

Fig.

Adjusting

motion

para.

Adjusting

foot

motion

foot

vertical

adjusted

foot

nut

decreases

standard