Page 1

MTTSUBISHI

Industrial

INSTRUCTION

Electronic

Model

Pattern

PLK-1710

Sewing

MANUAL

Sewing

Machine

Machine

AMITSUBISHIi

A180E104P03

MITSUBIi

ELECTRIC

Page 2

In

order

condition,

and

maintain

1.

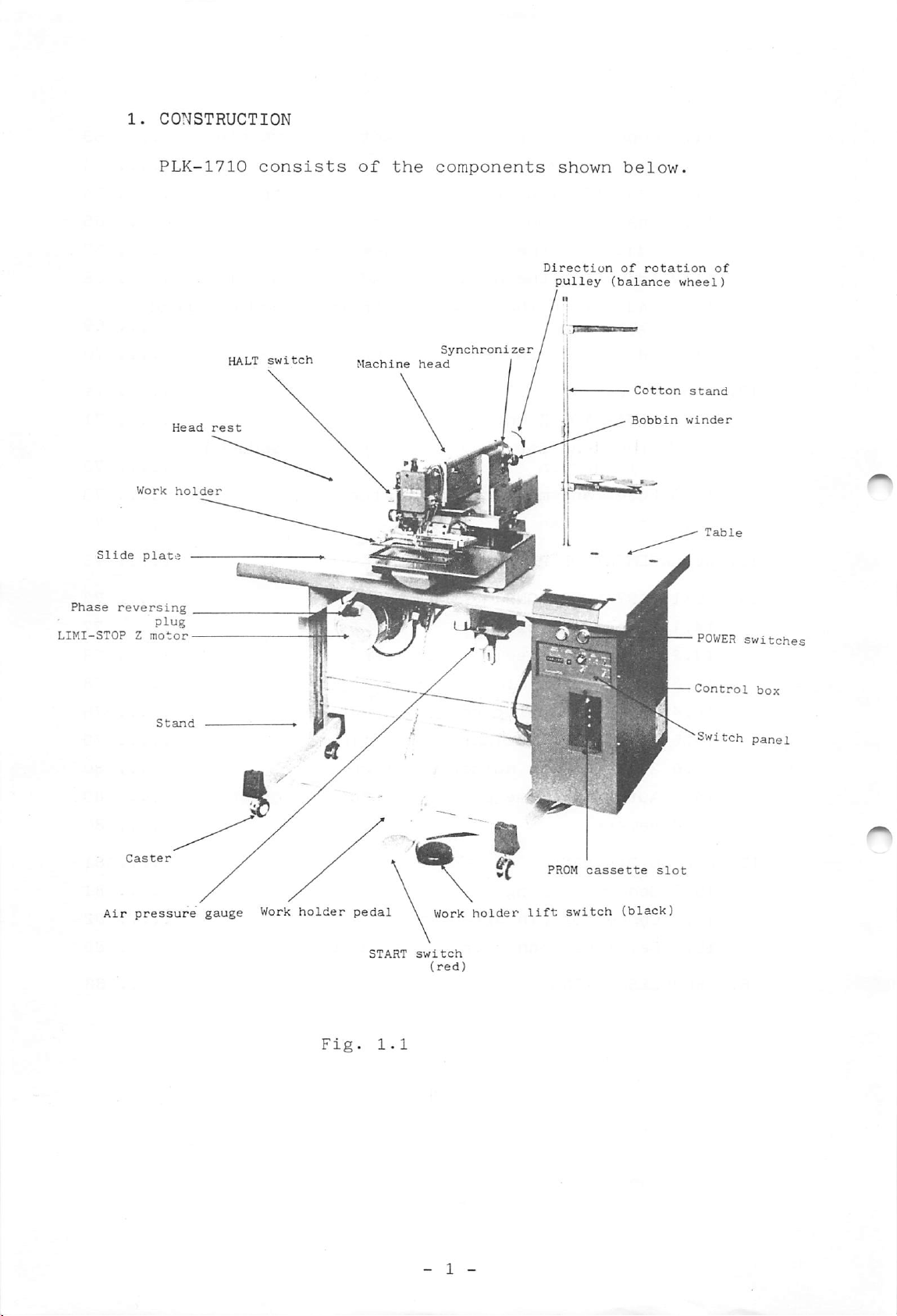

CONSTRUCTION

2.

FEATURES

3.

SPECIFICATIONS

to

operate

please

properly

your

read

Instruction

the

-CONTENTS-

sewing

machine,

machine

Manual

PLK-1710,

carefully

in

the

and

best

handle

1

2

4

3.1

3.2

4.

INSTALLATION

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

5.

PREPARATION

6.

NAME

6.1

6.2

General

Replacement

fabrics

Installing

Installing

Installing

Connecting

Work

Power

lamp

cable

Changing

Installing

AND

AND

FUNCTIONS

Switch

POWER

panel

ON

specifications

parts

the

table

the

machine

the

air

the

leads

leads

connection

direction

the

work

CAUTIONS

OF

and

OFF

for

light

tubes

of

rotation

holder

BEFORE

CONTROL

switches

head

SWITCHES

and

heavy

of

pedal

OPERATION

motor

4

6

8

8

9

.12

13

14

15

16

16

17

19

19

19

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

7.

OPRATION

7.1

SCALE

PATTERN

SPEED

±JOG

switch

select

setting

switch

RESET/HOME

STOP/MOVE

ERROR

Work

HALT

START

Work

Thread

indicators

holder

switch

switch

holder

trimmer

Inserting

switch

switch

lift

pedal

the

switch

dial

switch

switch

PROM

(option)

cassette

19

20

20

20

21

22

22

23

24

24

24

24

25

25

- A -

Page 3

7.2

Setting

the

switches

on

the

switch

panel

25

7.3

7.4

7.5

7.6

8.

GENERAL

9.

HANDLING

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

Checking

Sewing

HALT

switch

Operating

INSTRUCTIONS

THE

Lubrication

Installing

Threading

Winding

Installing

Installing

Thread

Adjusting

Adjusting

Replacing

each

operation

procedure

SEWING

the

the

the

the

the

tensions

the

the

the

function

operation

MACHINE

needle

needle

bobbin

bobbin

bobbin

work

presser

lower

and

thread

thread

holder

clamp

checking

HEAD

case

foot

frame

25

26

26

27

30

32

32

33

34

34

35

35

35

37

38

40

10.

11.

ADJUSTMENT

10.1

10.2

10.3

10.4

10.5

10.6

10.7

Adjusting

and

Thread

Adjusting

Adjusting

Adjusting

Adjusting

Air

presser

10.8

10.9

10.10

10.11

10.12

ADJUSTMENT

Adjusting

Home

Adjusting

Adjusting

Adjusting

sion

AND

hook

piping

position

OF

MAINTENANCE

the

motion

tensions

the

the

the

the

to

foot

the

the

the

the

THREAD

timing

lubrication

bobbin

needle

timing

cylinders

and

thread

wiper

adjustment

X-Y

X-Y

LIMI-STOP

TRIMMER

table

table

between

winder

stop

of

presser

for

trimmer

belt

Z

to

UP

motor

needle

hook

position

work

tension

foot

holder,

belt

motion

motion

ten

41

41

43

46

47

47

48

50

50

52

57

59

61

62

11.1

11.2

11.3

Construction

Caution

Installation

bracket

unit

of

of

thread

knife

- B -

trimmer

bracket

mechanism

and

knife

62

62

62

Page 4

11.4

Connection

of

knife

bracket

to

drive

crank

63

11.5

11.6

11.7

11.8

11.9

11.10

11.11

12.

CONTROL

12.1

12.2

12.3

12.4

13.

REPLACEMENT

14.

AUXILIARY

Knife

Installation

Installation

Adjusting

Adjusting

Adjusting

end

Hook,

SYSTEM

LIMI-STOP

Grounding

malfunction

Fuses

Cooling

FUNCTIONS

drive

bobbin

and

OF

the

the

Z

for

magnetic

fan

PROM

shaft

of

of

the

motor

trimmer

trimming

knife

needle

length

case

and

prevention

contactor

air

cam

engagement

thread

of

trimmed

bobbin

of

cylinder

tension

needle

noise-induced

release

64

64

65

67

68

thread

69

70

71

71

73

73

73

75

77

14.1

14.2

14.3

14.4

14.5

14.6

14.7

14.8

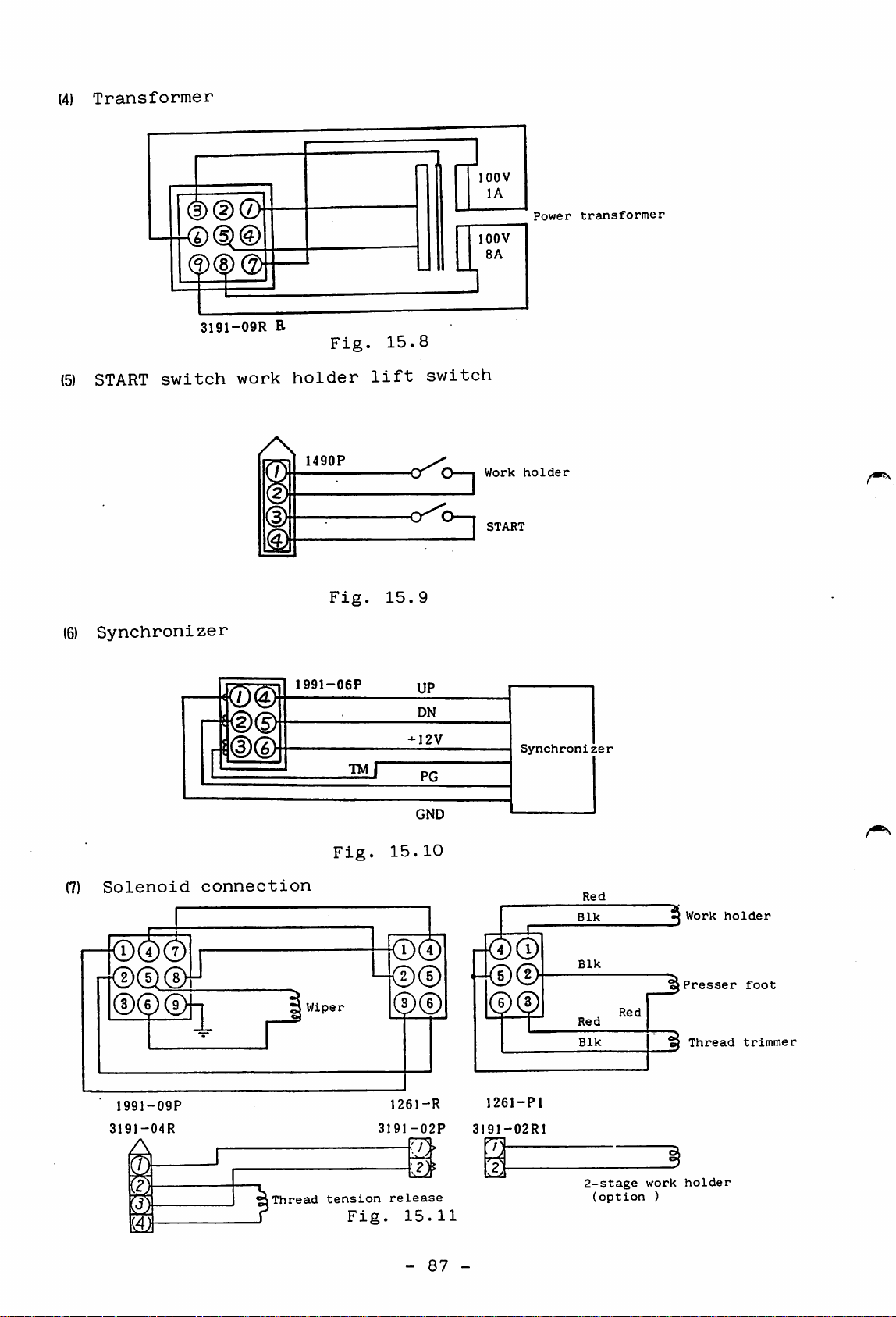

15.

WIRING

15.1

15.2

15.3

16.

TROUBLESHOOTING

Repeat

Speed

Sewing

Thread

Adjusting

2-stage

Automatic

Remarks

DIAGRAMS

General

Connector

Detailed

function

limit

area

trimming

work

wiring

connector

select

limit

the

home

pin

release

release

fabric

holder

position

arrangement

function

feed

function

wiring

function

function

timing

return

diagrams

function

77

78

78

78

79

80

80

80

81

81

82

85

88

- C -

Page 5

wn

ion

iy

below.

of

(balance

rotation

of

wheel)

I

Cotton

Bobbin

stand

winder

POWER

Control

Switch

switches

box

panel

assette

tch

(black)

slot

Page 6

2.

FEATURES

(1)

Easy

pattern

change

Stitch

stitches

By

using

written

to

4,000

is

used

(2)

High-performance

The

work

assures

(3)

Presser

Since

ed

with

It

is

small

data

(or

a

PROM

to

PROM

stitches

together

(pattern

10

holder

high-quality

foot

the

motion

presser

needle

particularly

pieces

are

patterns)

writer

easily.

when

with

fabric

driven

synchronized

foot

motion,

advantagenous

sewn

data)

(option),

optional

PROM

feed

by

stitching

moves

"floating"

up,

can

in

each

Memory

writer

mechanism

stepping

vertically,

or

when

be

stored

PROM

pattern

size

(additional)

PTN-4000A

motors

at

high

with

of

when

heavy

up

cassette.

data

can

speed.

needle

being

fabric

emblems

fabrics

to

can

be

expanded

PROM

or

through

motion

does

or

2,000

be

up

cassette

PTN-1OOO0L.

belts

synchroniz

not

occur

any

other

are

sewn.

(4)

(5)

(6)

Easy

When

replaced

Pattern

A

pattern

and

Y

199%.

"HALT"

"HALT"

and

"JOG"

are

very

By

continuously

stitched

work

stitching

holder

pattern

immediately.

replacement

enlargement/reduction

stored

direction

switch

switch

switch

helpful

pattern

in

independently

and

permitting

permitting

when

operating

and

PROM

"JOG"

resumption

is

switch

used

changed,

can

be

within

immediate

stitch-by-stitch

to

amend

the

"JOG"

the

enlarged

suspension

stitches.

switch,

of

stitching

a

work

or

range

holder

reduced

from

of

feed

checking

after

can

in

0%

to

stitching

motion

of

suspen

be

X

sion

can

be

accomplished

easily.

- 2 -

Page 7

(7)

Safety

functions

(8)

(9)

(10)

Various

by

"error

failures

Full-electronic

reliability

8-bit

Large

Double-sized

Easy

o

o

microprocessor

hook

maitenance

The

head

thread

LIMI-STOP

featuring

indication"

control

hook

can

be

trimmer

Z

motor,

maintenance-free

or

reduces

leaned

and

errors

lamps.

is

other

having

in

system

used

labor

laterally

internal

operation

in

no

use,

with

the

for

compact

control

replacement

for

mechanisms.

"frictional

is

used

are

easy

visualized

design

system.

access

clutch"

as

main

of

and

bobbin.

to

and

drive

the

(11)

motor.

Work

It

fabric

holder

permits

and

pedal

easy

parts.

and

immediate

positioning

or

alignment

of

- 3 -

Page 8

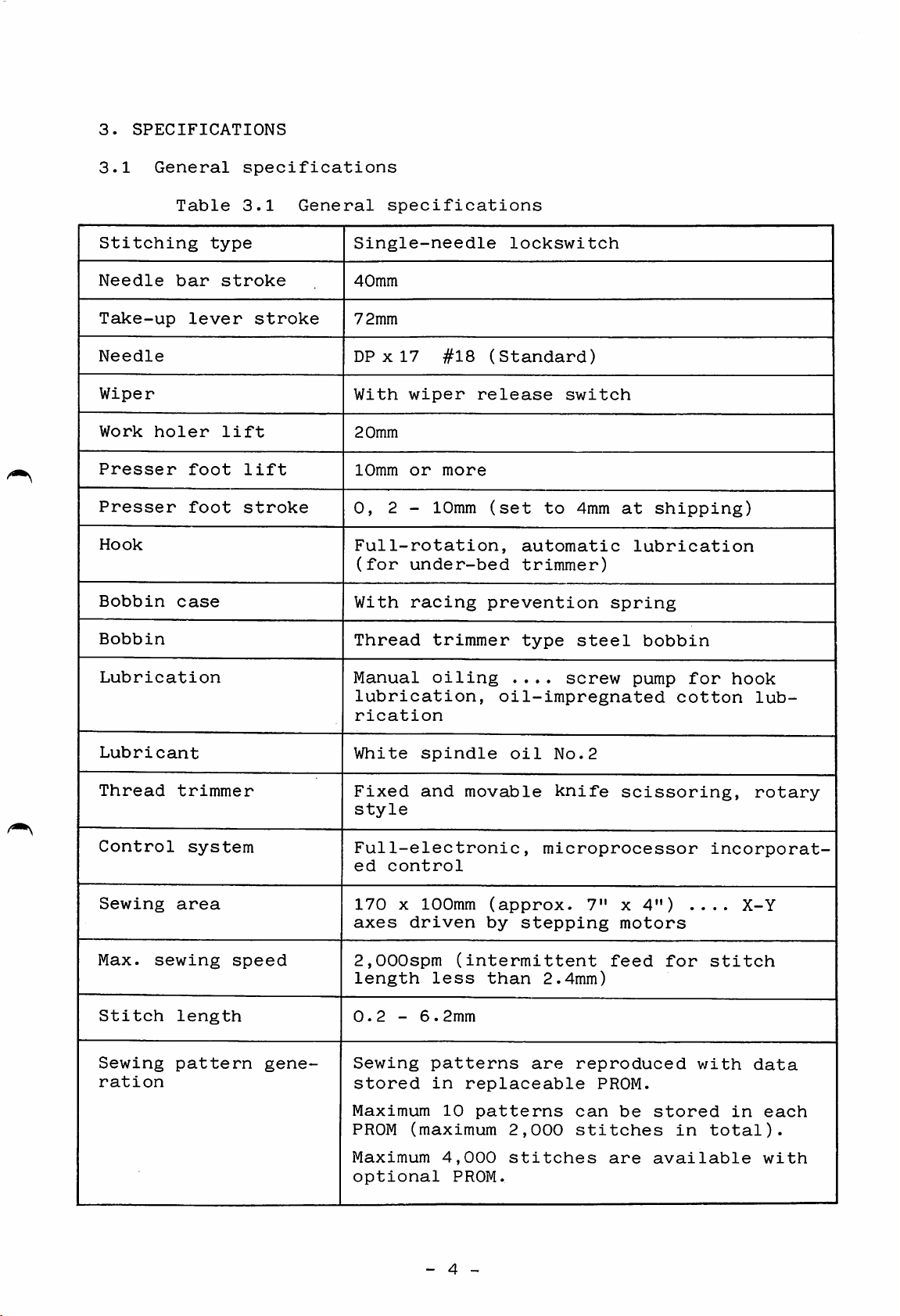

3.

SPECIFICATIONS

3.1

Stitching

Needle

Take-up

Needle

Wiper

Work

Presser

Presser

Hook

Bobbin

General

Table

bar

lever

holer

foot

foot

case

specifications

3.1

type

stroke

stroke

lift

lift

stroke

General

specifications

Single-needle

40mm

72mm

DP

X17

With

20mm

10mm

0,

Full-rotation,

(for

With

wiper

or

2 - 10mm

under-bed

racing

#18

more

lockswitch

(Standard)

release

(set

automatic

trimmer)

prevention

to

switch

4mm

at

lubrication

spring

shipping)

Bobbin

Lubrication

Lubricant

Thread

Control

Sewing

Max.

Stitch

Sewing

ration

trimmer

system

area

sewing

length

pattern

speed

gene

Thread

Manual

trimmer

oiling

lubrication,

rication

White

Fixed

spindle

and

style

Full-electronic,

ed

control

170

X 100mm

axes

driven

2,000spm

length

0.2

Sewing

stored

-

less

6.2mm

patterns

in

type

....

oil-impregnated

oil

movable

(approx.

by

stepping

(intermittent

than

are

replaceable

steel

screw

No.2

knife

pump

scissoring,

microprocessor

7"

x

motors

feed

2.4mm)

reproduced

PROM.

bobbin

cotton

4")

for

for

incorporat

....

stitch

with

hook

lub

rotary

X-Y

data

Maximum

PROM

Maximum

optional

10

patterns

(maximum

4,000

PROM.

- 4 ~

2,000

stitches

can

stitches

are

be

stored

in

available

in

total).

each

with

Page 9

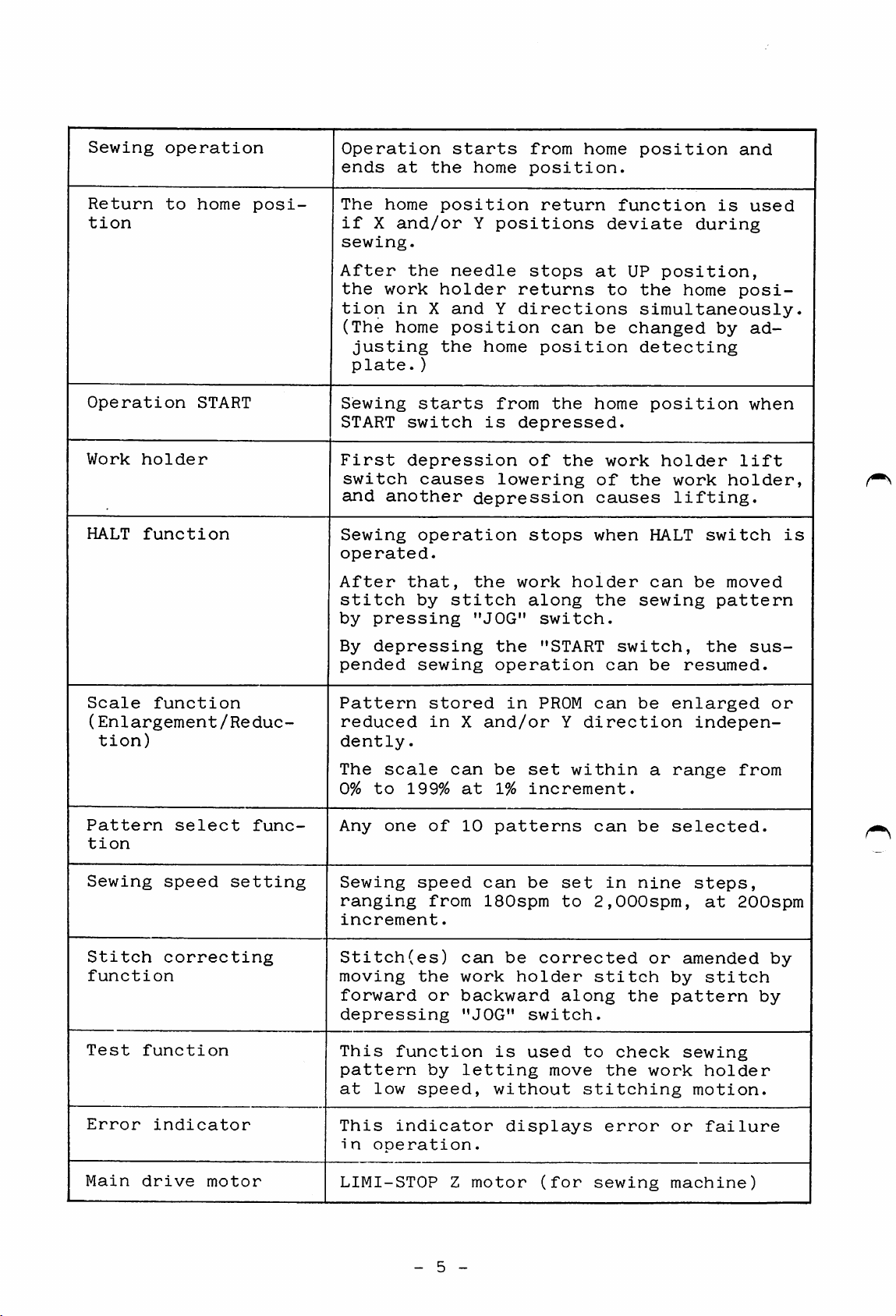

Sewing

operation

Operation

ends

starts

at

the

home

from

position.

home

position

and

Return

tion

Operation

Work

HALT

to

holder

function

home

START

posi

The

home

if

X

sewing.

After

the

work

tion

(The

justing

plate.)

Sewing

START

First

switch

and

another

Sewing

operated.

After

stitch

by

pressing

By

depressing

pended

position

and/or

the

holder

in

X

home

the

starts

switch

depression

causes

operation

that,

by

sewing

Y

positions

needle

and

Y

position

home

from

is

lowering

depression

the

stitch

"JOG"

the

operation

return

stops

returns

directions

can

position

the

depressed.

of

the

stops

work

holder

along

switch.

"START

function

deviate

at

UP

to

the

simultaneously.

be

changed

detecting

home

work

of

the

causes

when

the

sewing

switch,

can

be

position,

home

position

holder

work

lifting.

HALT

can

resumed.

is

during

by

holder,

switch

be

moved

pattern

the

used

posi

ad

when

lift

is

sus

Scale

function

(Enlargement/Reduc-

tion)

Pattern

tion

Sewing

Stitch

function

Test

Error

select

speed

correcting

function

indicator

setting

func

Pattern

reduced

dently

The

scale

0%

to

Any

one

Sewing

ranging

increment.

Stitch(es)

moving

forward

depressing

This

pattern

at

This

in

function

low

indicator

operation.

stored

in

.

199%

of

speed

from

the

or

by

speed,

X

and/or

can

be

at

1%

10

patterns

can

ISOspm

can

work

backward

"JOG"

is

letting

without

in

PROM

set

increment.

be

be

corrected

holder

switch.

used

displays

Y

within

set

to

along

move

can

be

direction

can

be

in

nine

2,000spm,

stitch

the

to

check

the

stitching

error

a

or

by

pattern

work

or

enlarged

range

selected.

indepen

from

steps,

at

200spm

amended

stitch

sewing

holder

motion.

failure

or

by

by

Main

drive

motor

LIMI-STOP

- 5 -

Z

motor

(for

sewing

machine)

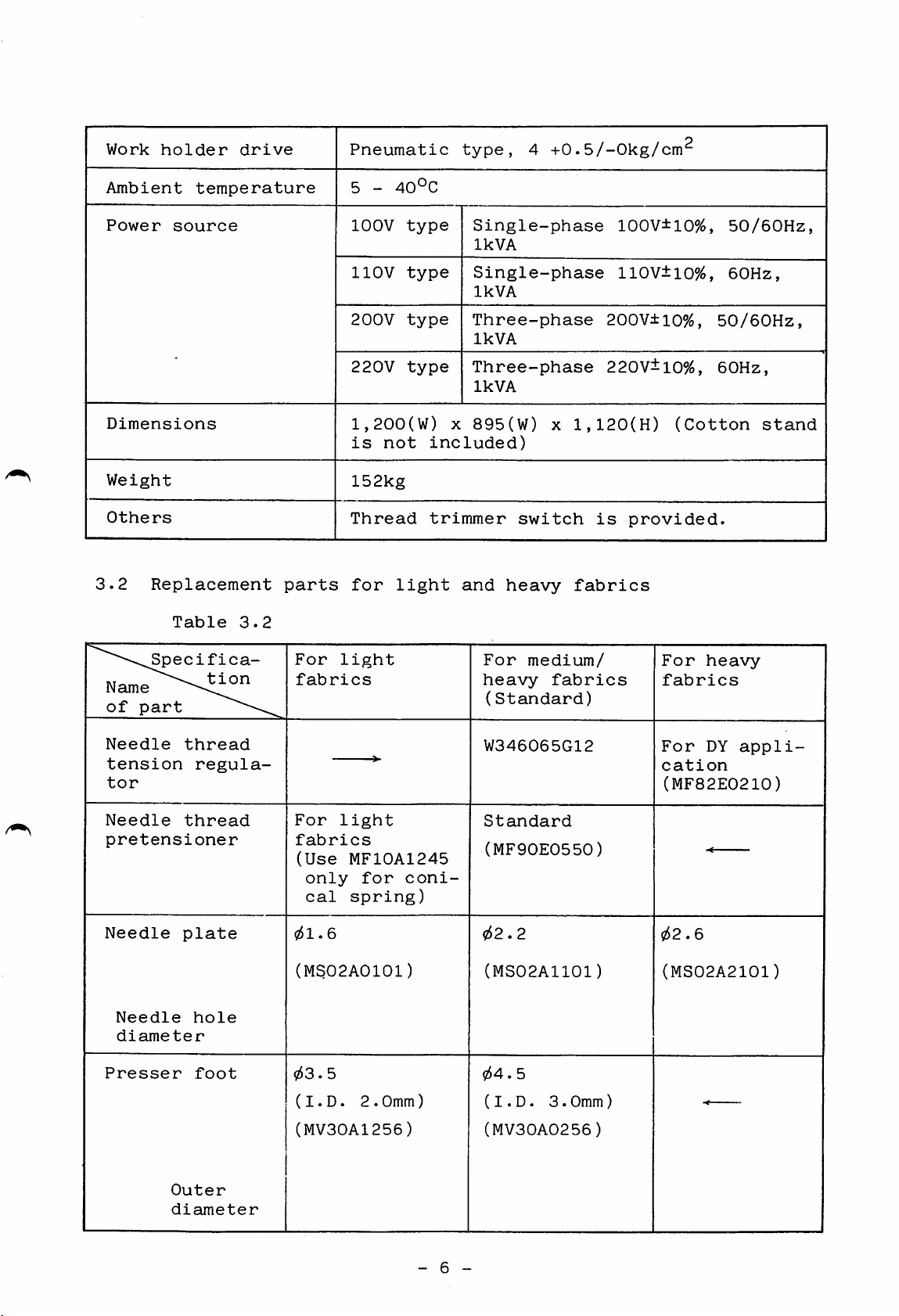

Page 10

Work

holder

drive

Pneumatic

type,

4

-hO.

5/-0kg/cm^

Ambient

Power

Dimensions

Weight

Others

3.2

temperature

source

Replacement

Table

3.2

parts

lOOV

llOV

200V

cn

220V

type

type

type

type

1

o

1,200(W)

is

not

152kg

Thread

for

light

o

X

o

included)

trimmer

Single-phase

IkVA

Single-phase

IkVA

Three-phase

IkVA

Three-phase

IkVA

895(W)

switch

and

heavy

X

1,120(H)

fabrics

100V±10%,

110V±10%,

200V±10%,

220V±10%,

is

provided.

50/60Hz,

60Hz,

(Cotton

50/60Hz,

60Hz,

stand

Specifica

Name

of

part

Needle

tension

tor

Needle

pretensioner

Needle

Needle

diameter

Presser

thread

regula

thread

plate

hole

foot

tion

For

light

fabrics

For

light

fabrics

(Use

only

cal

MF10A1245

for

spring)

?51.6

(MS02A0101)

053.5

(I.D.

2.0mm)

coni

For

medium/

heavy

fabrics

(Standard)

W346065G12

Standard

(iyiF90E0550)

?52.2

(MS02A1101)

o54.

5

(I.D.

3.0mm)

For

heavy

fabrics

For

DY

appli

cation

(MF82E0210)

052.6

(MS02A2101)

(MV30A1256)

Outer

diaimeter

- 6 -

(MV30A0256)

Page 11

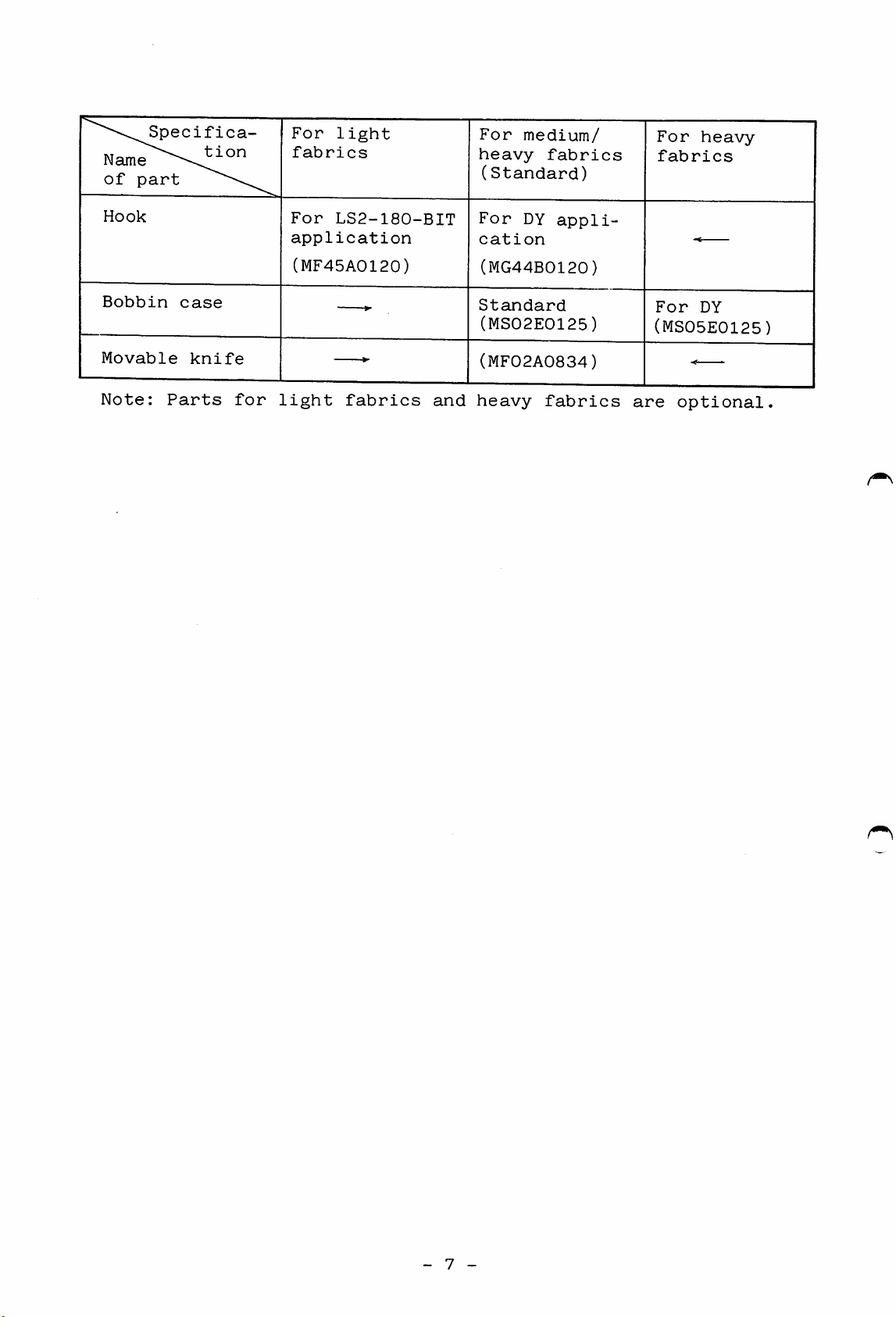

^""•"\Spe ci f i

Nain7\^°"

of

part

ca-

For

fabrics

light

For

medium/

heavy

(Standard)

fabrics

For

fabrics

heavy

Hook

Bobbin

Movable

Note:

case

knife

Parts

for

For

LS2-180-BIT

application

(MF45A0120)

light

fabrics

For

cation

Standard

(MF02A0834)

and

heavy

DY

appli

(MG44B0120)

(MS02E0125)

fabrics

For

DY

(MS05E0125)

are

optional

- 7 -

Page 12

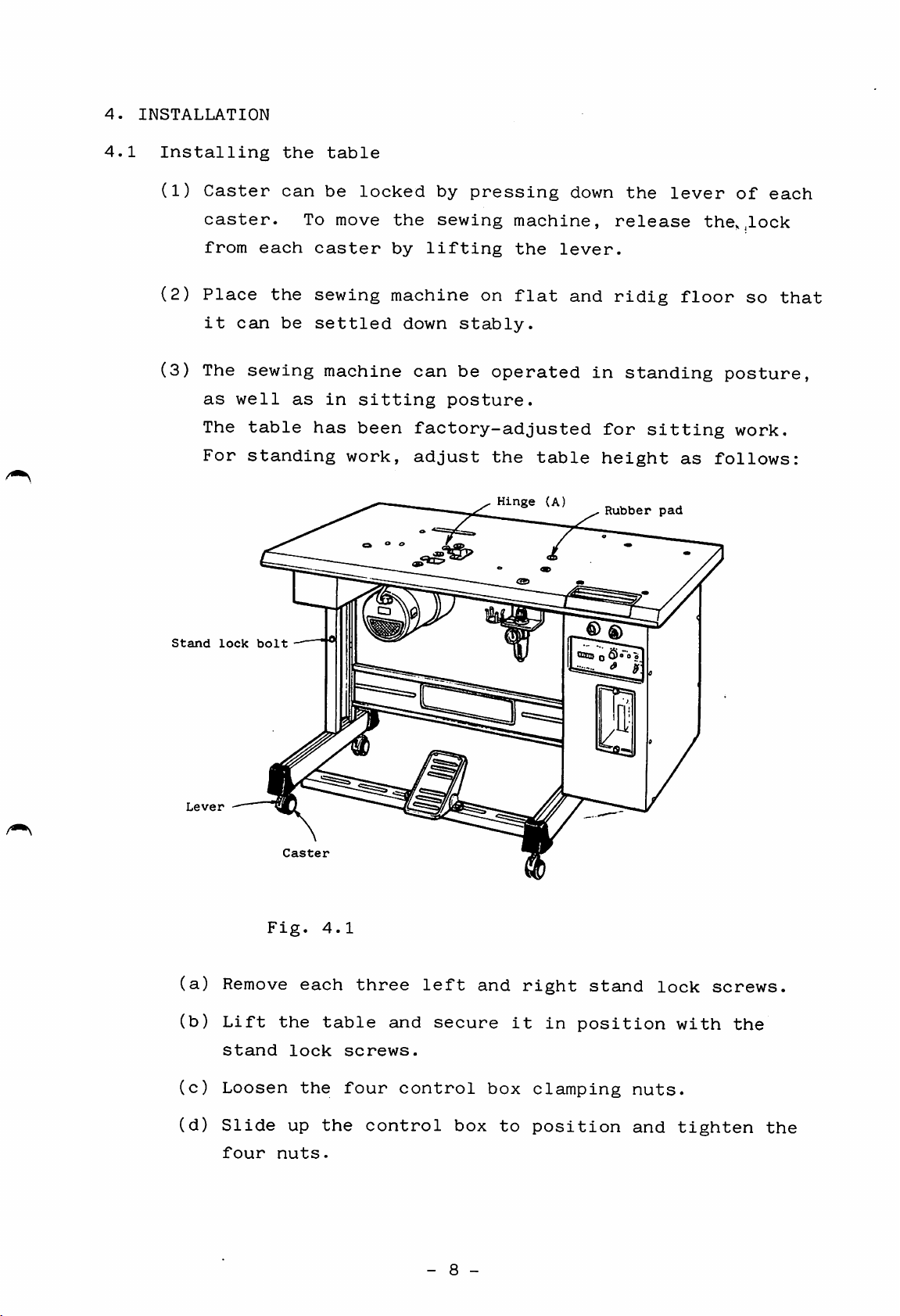

4.

INSTALLATION

4.1

Installing

(1)

Caster

caster.

from

(2)

Place

it

(3)

The

as

The

For

each

the

can

sewing

well

table

standing

the

can

be

as

table

be

To

move

caster

sewing

settled

machine

in

has

locked

sitting

been

work,

by

pressing

the

sewing

by

lifting

machine

down

can

on

stably.

be

posture.

factory-adjusted

adjust

machine,

the

flat

operated

the

table

Hinge

(A)

down

lever.

and

release

ridig

in

for

height

Rubber

the

lever

floor

standing

sitting

as

pad

of

the,,lock

so

posture,

work.

follows:

each

that

Stand

(a)

(b)

(c)

Lever

lock

bolt

Remove

Lift

stand

Loosen

Fig.

the

each

lock

the

4.1

table

screws.

four

three

left

and

control

secure

and

box

right

it

in

clamping

oao

o 0 6

» 9

stand

position

lock

nuts.

with

screws.

the

(d)

Slide

four

up

nuts.

the

control

box

- 8 -

to

position

and

tighten

the

Page 13

Notes:

1.

Table

height

should

be

changed

before

the

machine

(4)

(5)

2.

Put

Put

and

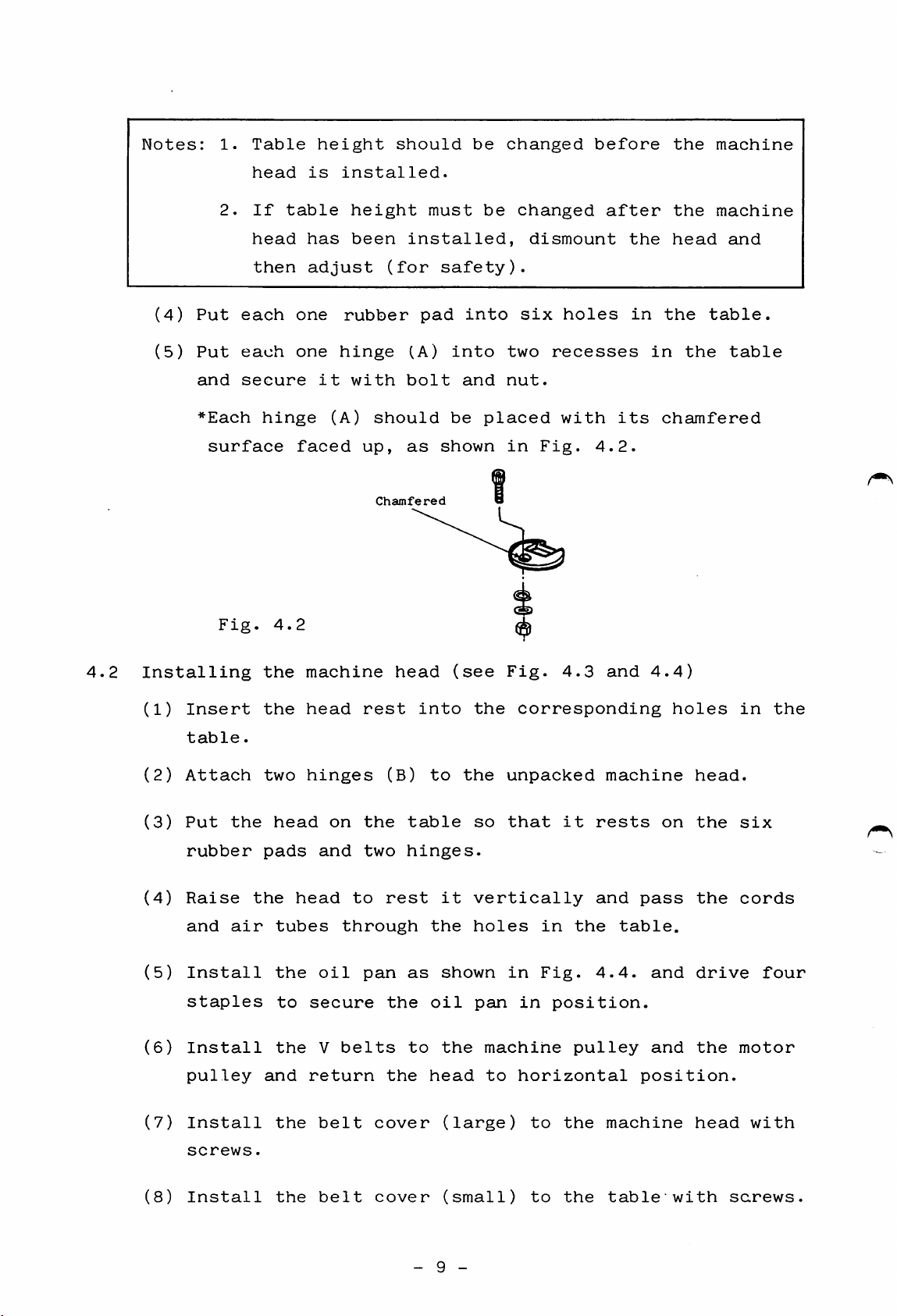

*Each

surface

Fig.

head

If

head

then

each

each

secure

hinge

4.2

table

has

adjust

one

one

faced

is

it

(A)

installed.

height

been

rubber

hinge

with

should

up,

installed,

(for

bolt

as

Chamfered

pad

(A)

must

safety).

into

be

shown

into

and

be

changed

two

nut.

placed

in

dismount

six

recesses

Fig.

holes

with

after

4.2.

the

in

its

the

head

the

in

the

chamfered

machine

and

table.

table

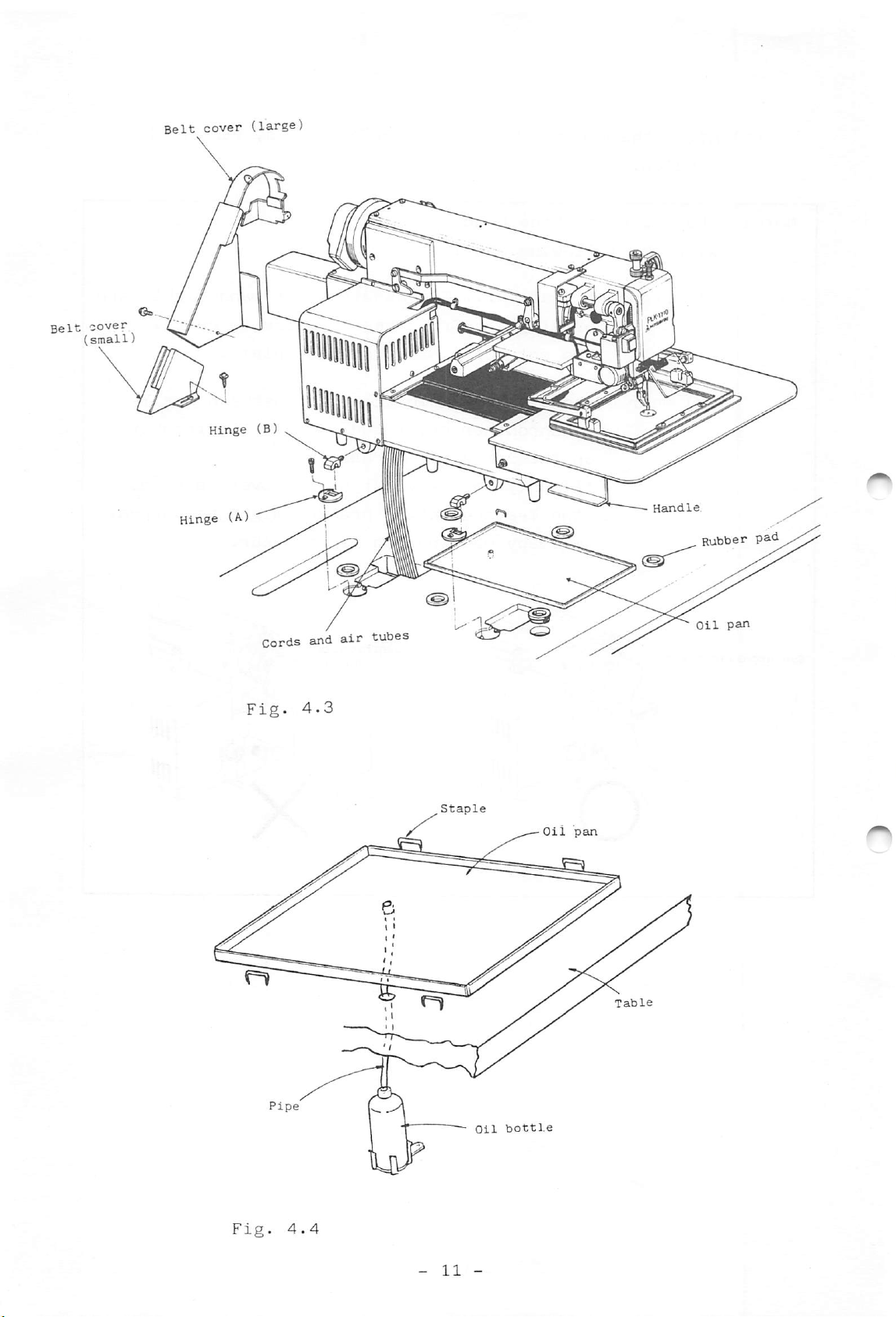

4.2

Installing

(1)

Insert

table.

(2)

Attach

(3)

Put

rubber

(4)

Raise

and

(5)

Install

staples

(6)

Install

pulley

(7)

Install

the

air

the

the

two

pads

the

head

tubes

the

the

and

the

head

to

machine

head

hinges

on

and

to

through

oil

secure

V

belts

return

belt

rest

the

two

pan

cover

head

(B)

rest

the

the

into

to

table

hinges.

it

the

as

shown

oil

to

the

head

(see

the

the

so

vertically

holes

pan

(large)

Fig.

corresponding

unpacked

that

in

in

machine

to

horizontal

to

4.3

it

in

the

Fig.

position.

pulley

the

and

machine

rests

and

table.

4.4.

machine

4.4)

holes

on

pass

and

and

position.

head.

the

the

drive

the

head

in

six

cords

four

motor

with

the

screws.

(8)

Install

the

belt

cover

(small)

- 9 -

to

the

table"

with

screws.

Page 14

(9)

After

handles.

the

machine

head

has

been

installed,

remove

the

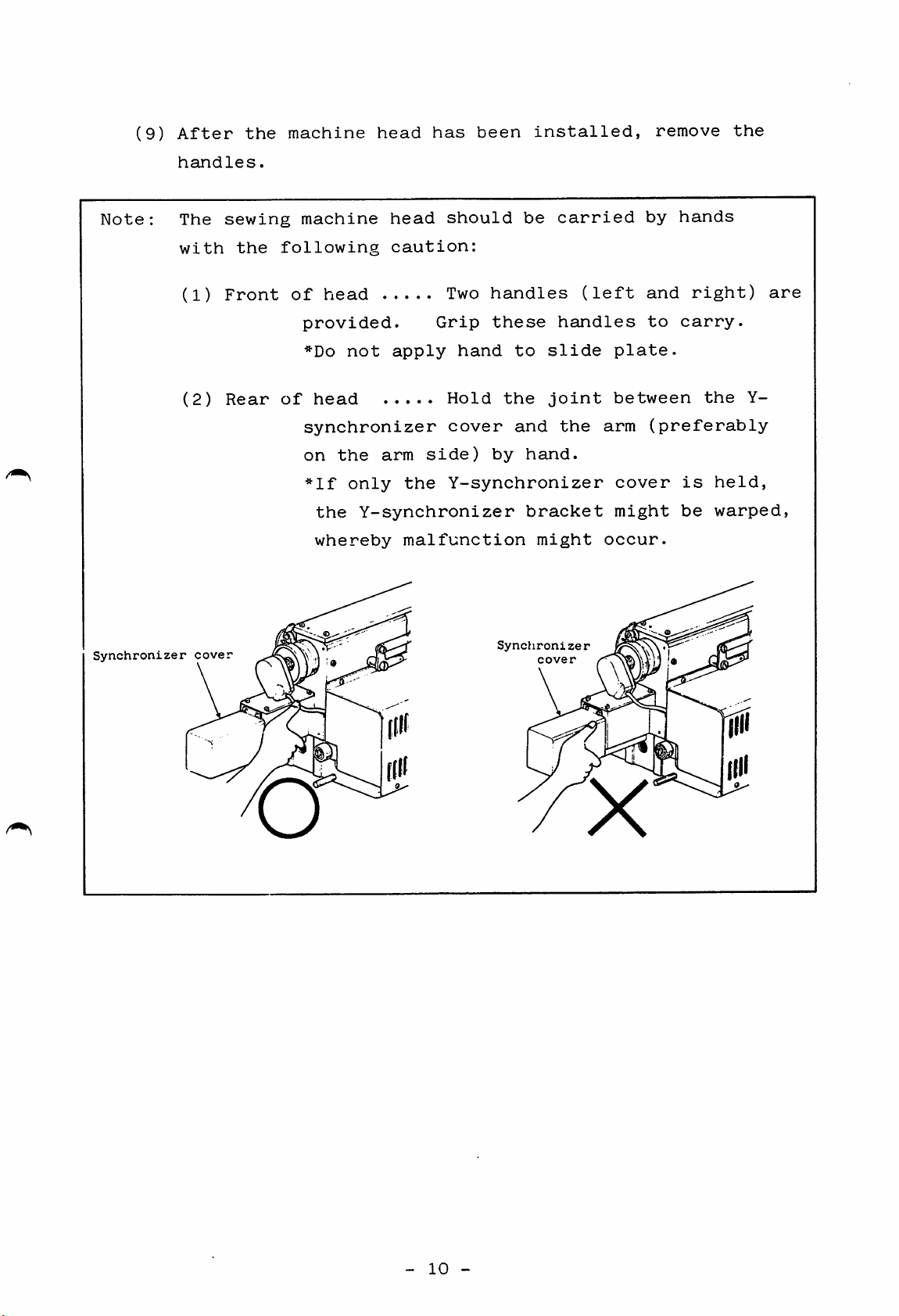

Note:

Synchronizer

The

with

(1)

(2)

cover

sewing

the

Front

Rear

machine

following

of

head

provided.

*Do

not

of

head

synchronizer

on

the

*lf

only

the

whereby

head

caution:

should

Two

Grip

apply

hand

Hold

cover

arm

side)

the

Y-synchronizer

Y-synchronizer

malfunction

be

handles

these

to

the

and

by

hand.

bracket

might

Synchronizer

cover

carried

(left

handles

slide

joint

the

plate.

between

arm

cover

might

occur.

by

hands

and

right)

to

carry.

the

(preferably

is

held,

be

warped,

are

Y-

o

X

-

10

-

Page 15

Oil

bottle

Oil

pan

Fig.

4.4

Page 16

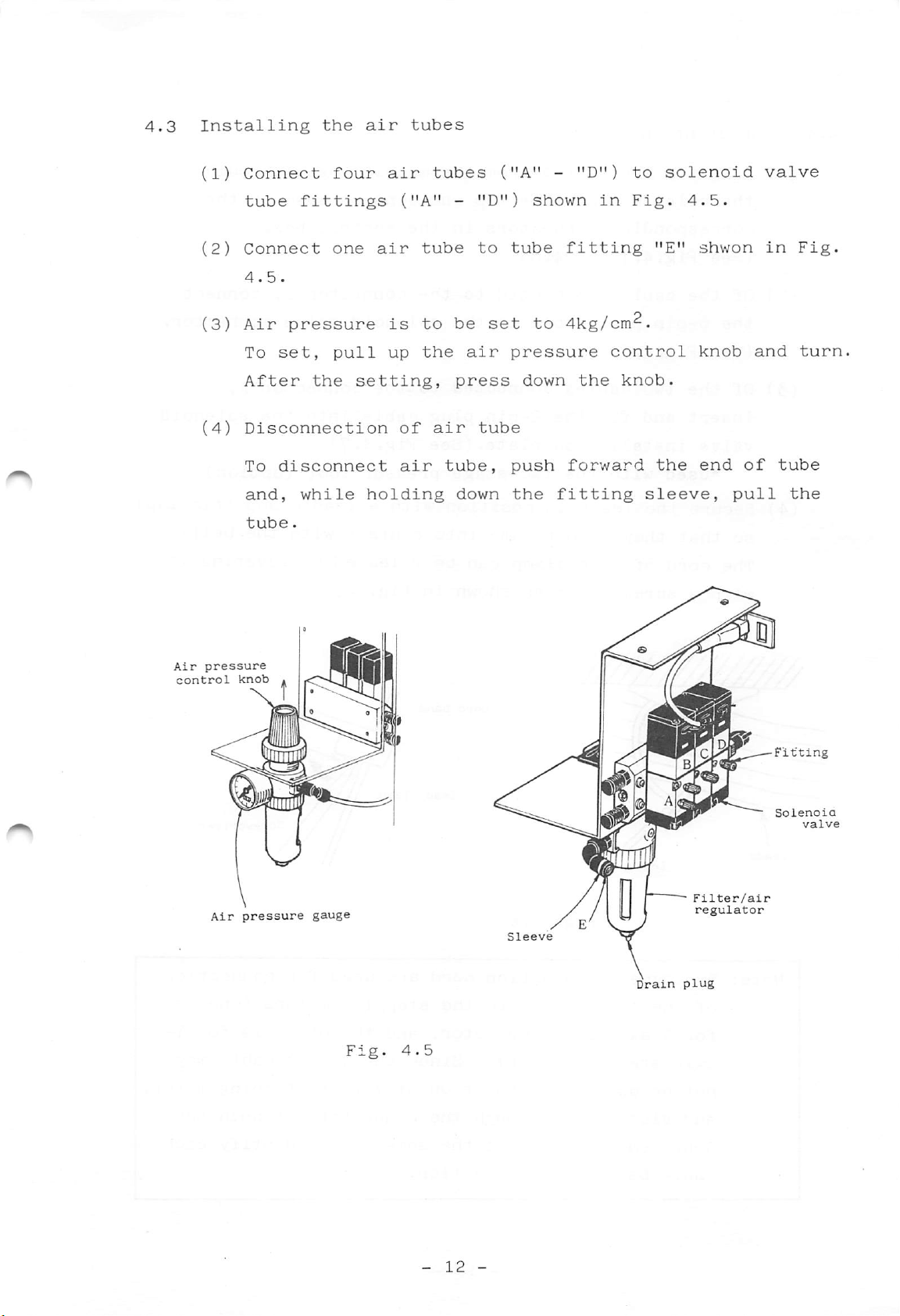

4.3

Installing

(1)

Connect

the

four

air

air

tubes

tubes

("A"

-

"D")

to

solenoid

valve

tube

(2)

Connect

4.5.

(3)

Air

To

After

(4)

Disconnection

To

and,

tube.

fittings

one

pressure

set,

disconnect

pull

the

while

air

is

up

setting,

holding

("A"

of

air

tube

to

the

air

-

be

air

press

tube,

down

"D")

to

set

tube

shown

tube

to

pressure

down

push

the

fitting

in

Fig.

fitting

4kg/cm^.

control

the

knob.

forward

"E"

the

sleeve,

4.5.

shwon

knob

end

of

pull

in

and

Fig.

turn

tube

the

Air

control

pressure

Air

knob

pressure

gauge

Fig.

4.5

Drain

C

Filter/air

regulator

plug

—Fitting

Solenoia

valve

-

12

-

Page 17

4.4

Connecting

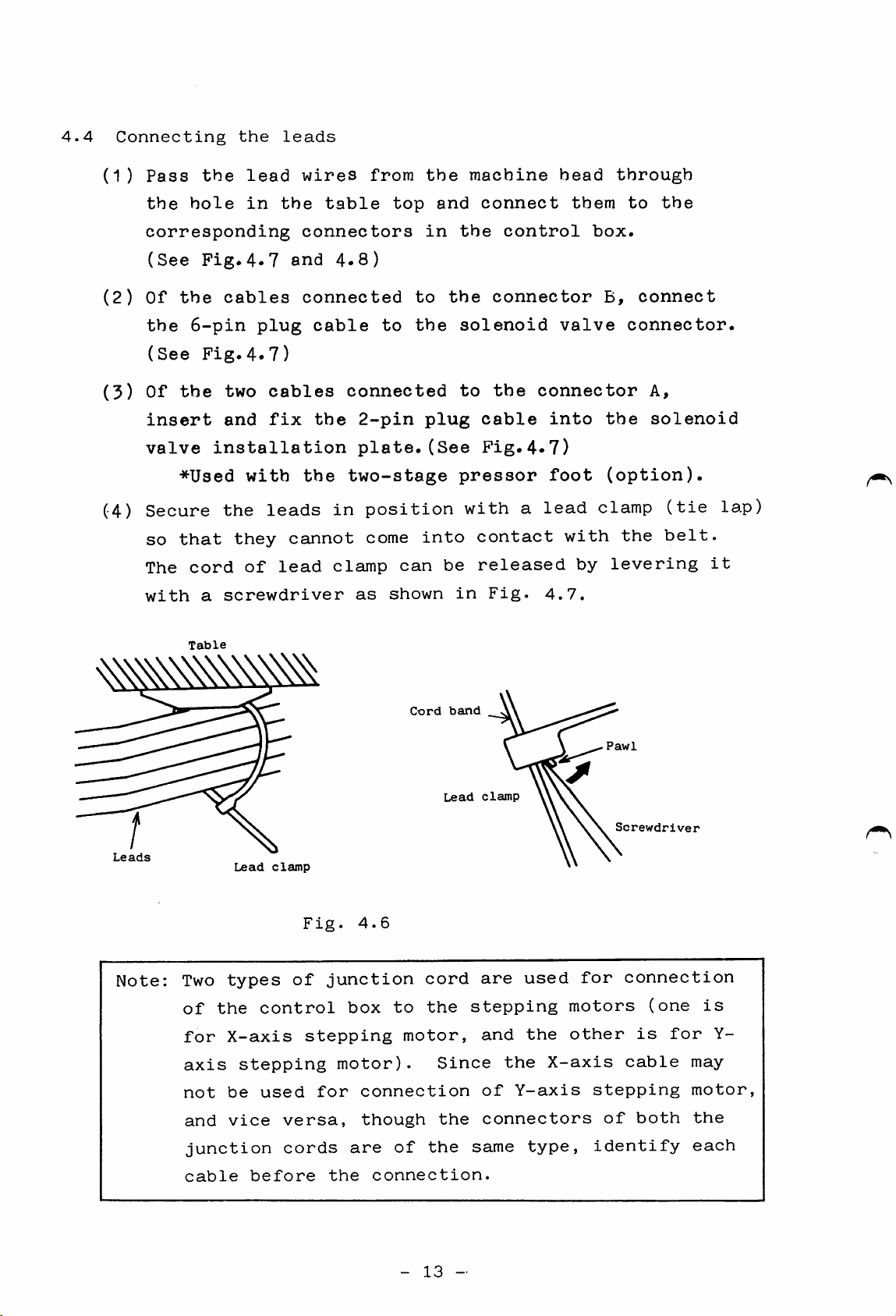

(1)

Pass

the

the

hole

the

lead

in

leads

wires

the

table

from

top

the

and

machine

connect

head

them

through

to

the

corresponding

(See

(2)

Of

the

(See

(3)

Of

insert

valve

(4)

Secure

so

The

with

Fig.4.7

the

cables

6-pin

Fig.4.7)

the

two

and

installation

*Used

the

that

cord

a

screwdriver

Table

with

they

of

plug

cables

fix

leads

lead

connectors

and

4.8)

connected

cable

the

the

in

cannot

clamp

to

to

the

connected

2-pin

plate.(See

two-stage

position

come

can

as

shown

in

plug

into

the

the

solenoid

to

cable

pressor

with

contact

be

released

in

control

connector

the

Fig.4.7)

a

Fig.

box.

valve

connector

into

foot

lead

clamp

with

by

4.7.

B,

connect

connector.

A,

the

solenoid

(option).

the

levering

(tie

belt.

lap)

it

Leads

Note:

Two

types

of

the

for

X-axis

axis

not

be

and

vice

junction

Lead

clamp

control

stepping

used

versa,

Fig.

of

stepping

cords

4.6

junction

box

motor).

for

connection

are

to

though

of

Cord

cord

the

motor,

Since

the

the

band

Lead

stepping

clamp

are

used

and

the

the

of

Y-axis

connectors

same

X-axis

type,

Pawl

for

motors

other

stepping

of

identify

Screwdriver

connection

(one

is

for

cable

both

is

Y-

may

motor,

the

each

cable

before

the

connection.

-

13

-

Page 18

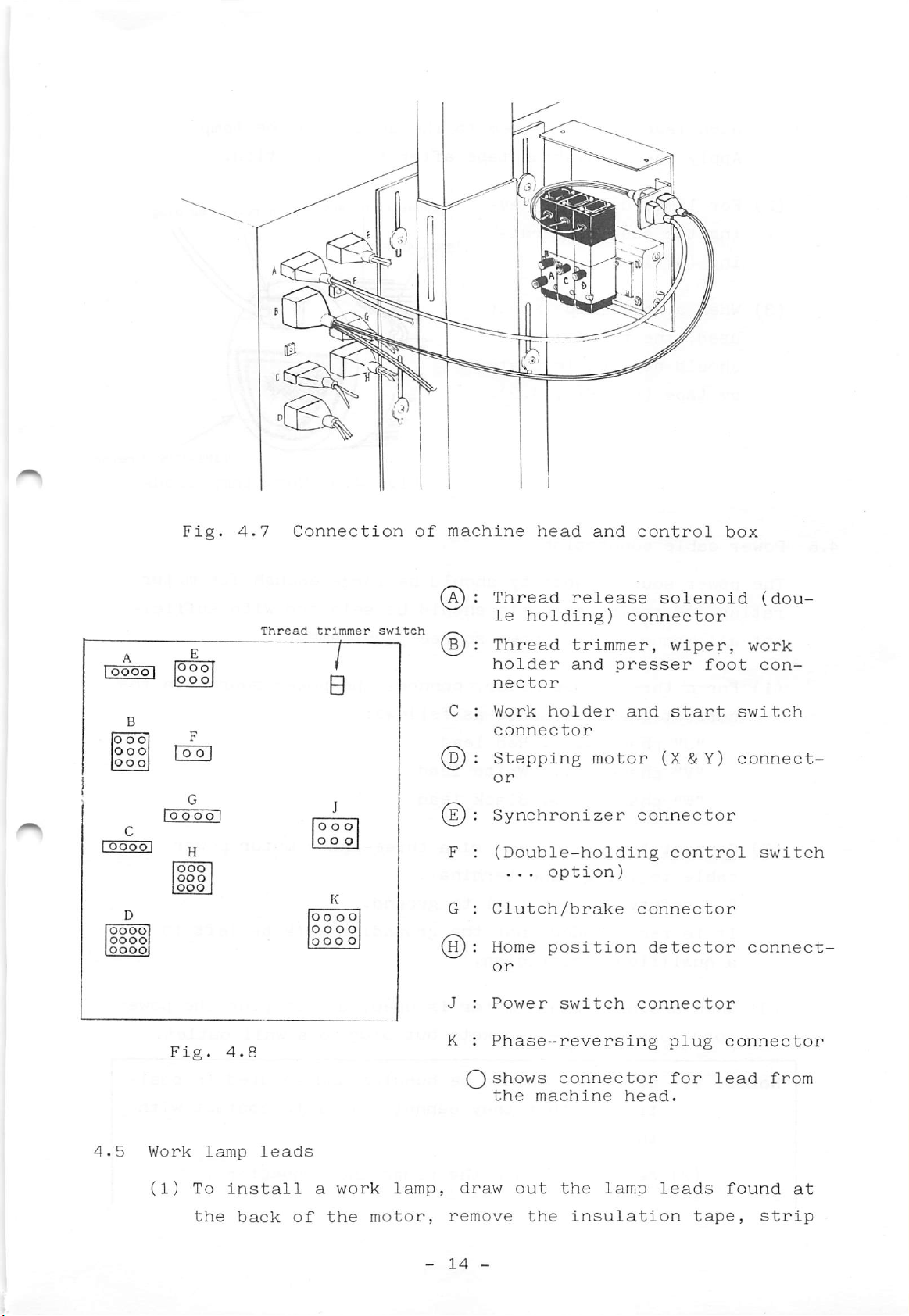

Fig.

4.7

Connection

of

machine

head

and

control

box

oooo

^ :

Thread

trimmer

switch

^ : Thread trimmer, wiper,

A

G

oooo

Fig.

oooo

oooo

oooo

4

^:

Thread

le

holder

nector

C :

Work

connector

D) :

Stepping

Synchronizer

F :

(Double-holding

G :

Clutch/brake

H):

Home

J :

Power

K :

Phase-reversing

Qshows

the

holding)

...

machine

release

and

holder

motor

option)

position

switch

connector

solenoid

connector

presser

and

(X&Y)

connector

connector

detector

connector

head.

foot

start

control

plug

for

(dou-

work

con

switch

connect-

switch

connect-

connector

lead

from

4.5

Work

(1)

To

the

lamp

leads

install

back

of

a

work

the

lamp,

motor,

-

draw

remove

14

-

out

the

the

insulation

lamp

leads

tape,

found

at

strip

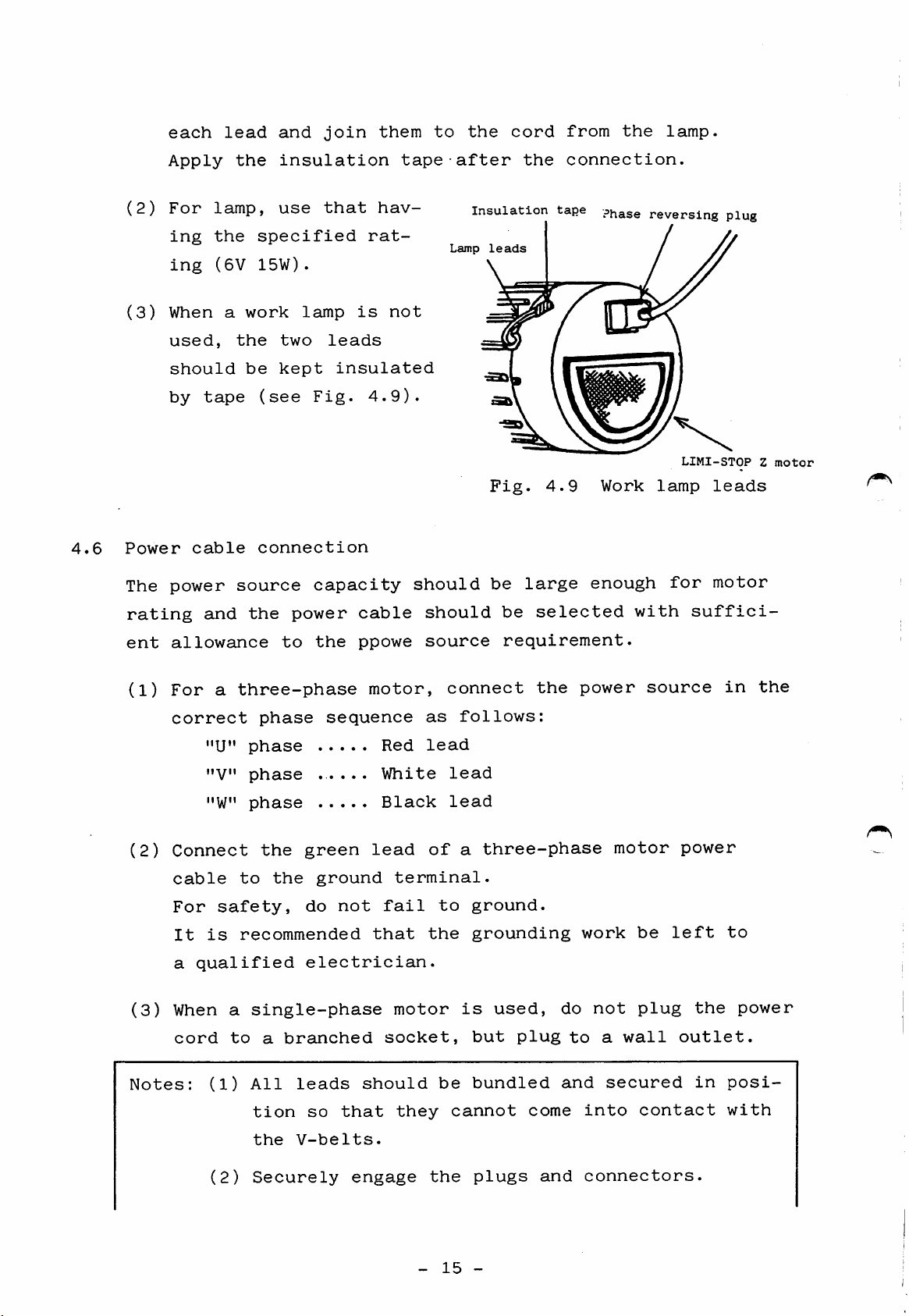

Page 19

each

lead

and

join

them

to

the

cord

from

the

lamp.

4.6

(2)

(3)

Power

The

Apply

For

ing

ing

When

used,

should

by

cable

power

lamp,

the

(6V

a

tape

the

specified

15W).

work

the

be

(see

connection

source

insulation

use

that

lamp

two

kept

leads

insulated

Fig.

capacity

rat

is

4.9).

hav

not

tape

should

after

Insulation

Lamp

leads

Fig.

be

the

tape Phase

4.9

large

connection.

Work

enough

reversing

LIMI-STOP

lamp

for

plug

leads

motor

Z

motor

rating

ent

(1)

(2)

(3)

and

allowance

For

a

correct

"U"

"V"

"W"

Connect

cable

For

safety,

It

is

a

qualified

When

cord

a

to

the

power

to

the

three-phase

phase

phase

phase

.....

phase

the

green

to

the

ground

do

recommended

electrician.

single-phase

a

branched

cable

ppowe

motor,

sequence

lead

not

that

Red

White

Black

terminal.

fail

motor

socket,

should

source

connect

as

follows:

lead

lead

lead

of

a

to

the

is

be

selected

requirement.

the

three-phase

ground.

grounding

used,

but

plug

do

to

power

motor

work

not

a

with

be

plug

wall

source

power

left

outlet.

suffici

in

to

the

the

power

Notes:

(1)

(2)

All

leads

tion

the

V-belts.

Securely

so

should

that

engage

they

-

be

the

15

bundled

cannot

plugs

-

come

and

and

secured

into

connectors.

contact

in

posi

with

Page 20

(3)

Before

starting

connection

of

leads,

unplug

the

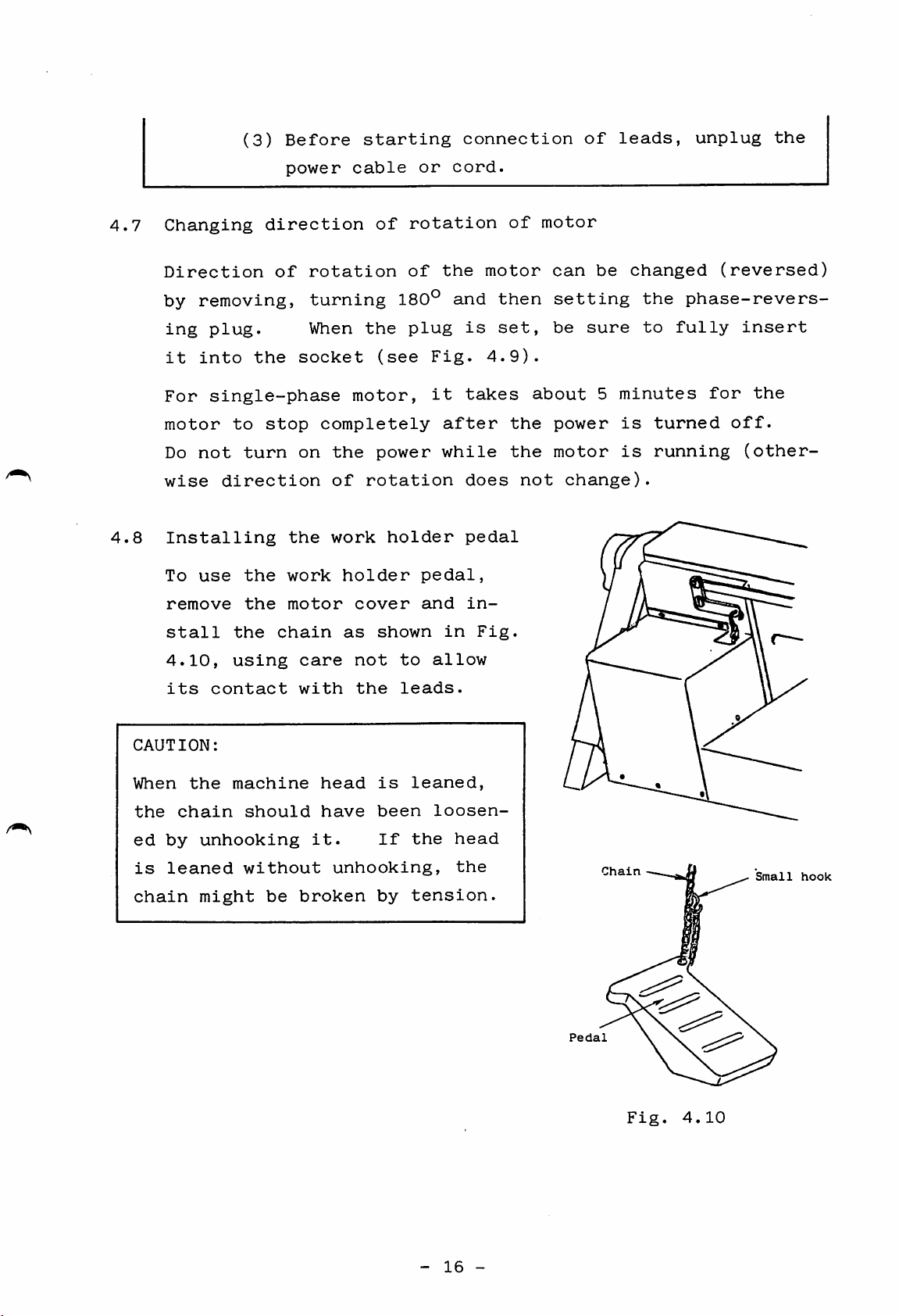

4.7

4.8

Changing

Direction

by

removing,

ing

plug.

it

into

For

single-phase

motor

Do

not

wise

Installing

To

remove

direction

use

the

to

turn

the

the

power

direction

of

rotation

turning

When

socket

stop

completely

on

the

work

motor

cable

motor,

the

of

work

holder

of

the

(see

power

rotation

holder

cover

or

rotation

of

180°

plug

Fig.

it

pedal,

and

cord.

the

and

is

takes

after

while

does

pedal

in

of

motor

then

set,

4.9).

the

the

about

not

motor

can

setting

be

power

motor

change).

be

sure

5

changed

the

to

minutes

is

turned

is

running

(reversed)

phase-revers

fully

for

insert

the

off.

(other

stall

4.10,

its

CAUTION:

When

the

chain

ed

by

is

leaned

chain

the

using

contact

the

machine

unhooking

without

might

should

be

chain

care

with

broken

as

head

have

it.

unhooking,

not

the

shown

to

leads.

is

been

If

by

in

allow

leaned,

loosen

the

head

the

tension.

Fig.

Pedal

Chain

Small

hook

Fig.

-

16

-

4.10

Page 21

5.

PREPARATION

(1)

Make

sure

AND

CAUTIONS

the

line

BEFORE

voltage

OPERATION

meets

that

specified

for

the

(2)

(3)

(4)

(5)

(6)

sewing

Make

the

(The

test

Move

is

always

Make

foot.

Make

Check

(for

To

check

machine.

sure

PROM

PROM

and

cassette

cassette

pattern

locate

the

PROM

program.)

the

located

sure the needle

sure

motor

the

the

rotational

switches,

the

direction

air

cassette

slot.

which

work

within

comes

pressure

direction

refer

of

has

is

loaded

holder

the

at

is

to

rotation,

been

by

frame

the

center

4kg/cm2.

of

the

Fig.

put

by

us

hand

of

work

LlMl-STOP

1.1

perform

properly

at

so

of

and

shipping

that

holder.

the

6.1)

the

into

has

the

needle

presser

Z

motor

following

^

(7)

steps:

1)

Press

2)

Set

the

3)

Set

(For

4)

Press

of

The

sewing

The

ed

Before

POWER

the

the

RESET/HOME

work

the

STOP/MOVE

function

the

rotation

pulley

machine

method

in

4.7.

unplugging

OFF

switch

POWER ON

holder

of

START

of

should

of

changing

and

switch

each

foot

the

front

the

switch.

switch

switch

switch

pulley

rotate

(see

power

make

to

to

let

to

switch,

(balance

clockwise

Fig.

direction

cord,

sure

RESET

down

STOP

position

the

position.

refer

momentarily

wheel).

as

1.1).

of

be

sure

the

red

work

to

Sec.

to

viewed

rotation

to

lamp

press

at

and

holder.

6.)

see

the

direction

from

is

press

^

the

describ

the

end

face

of

PROM-cassette

does

-

17

not

light.

-

Page 22

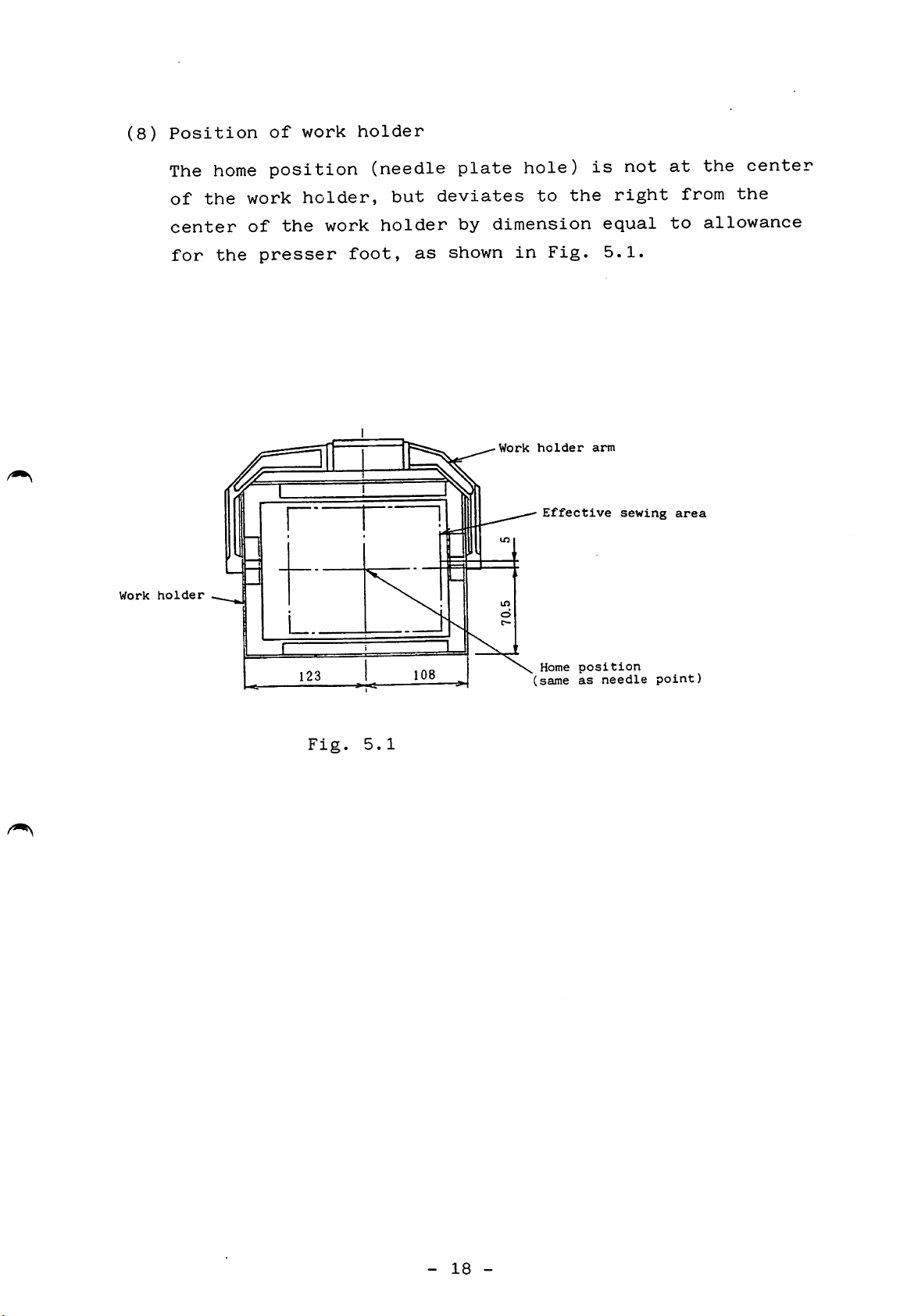

(8)

Position

of

work

holder

Work

The home

of

the

center

for

the

holder.—J

position

work

of

presser

the

1

holder,

work

(needle

foot,

but

holder

as

plate

deviates

by

shown

!

hole)

to

dimension

in

Fig.

Work

holder

Effective

the

is

equal

5.1.

arm

not

right

sewing

at

from

to

area

the

center

the

allowance

123

Fig.

5.1

108

Home

(same

position

as

needle

point)

-

18

-

Page 23

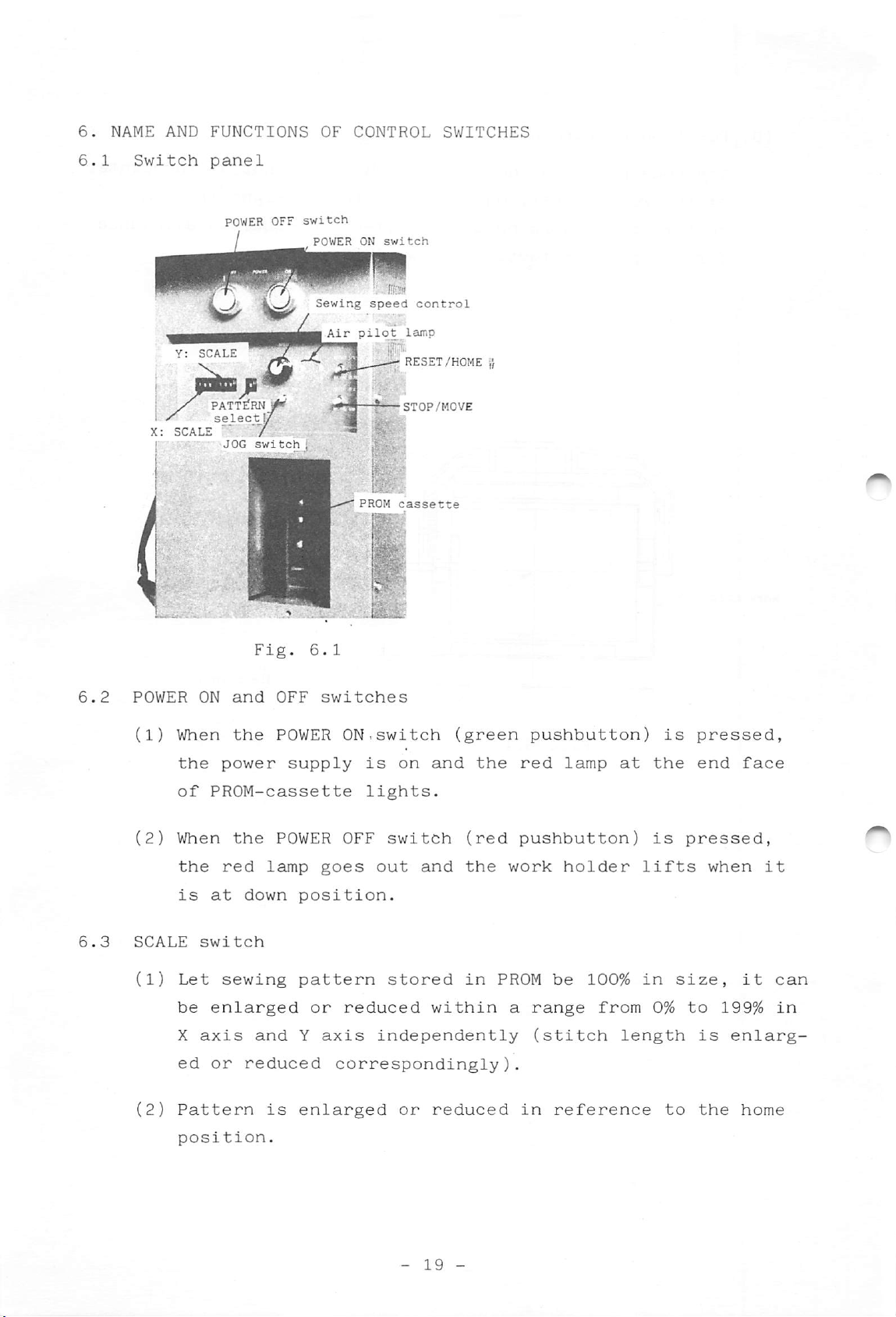

6.

NAME

AND

FUNCTIONS

OF

CONTROL

SWITCHES

6.1

Switch

/

X:

Y:

SCALE

panel

POWER OFF

SCALE

patte!rn_

select

JOG

switch

I

POWERONswitch

Sewing

Air

speed

pilot^

lamp

RESET/HOME

control

%

i

PROM

STOP/MOVE

cassette

1/

switch

6.2

6.3

POWER

(1)

(2)

SCALE

(1)

ON

and

When

the

of

When

the

is

Let

be

X

ed

the

power

PROM-cassette

the

red

at

switch

sewing

enlarged

axis

or

Fig.

OFF

POWER

supply

POWER

lamp

down

and

reduced

6.1

switches

ON.switch

is

lights.

OFF

goes

position.

out

pattern

or

reduced

Y

axis

independently

correspondingly).

on

switch

and

stored

(green

and

the

in

within

the

(red

pushbutton)

red

pushbutton)

work

PROM

a

be

range

(stitch

lamp

holder

100%

at

from

the

is

lifts

in

0%

length

is

pressed,

size,

to

pressed,

end

face

when

it

199%

is

enlarg

it

can

in

(2)

Pattern

position.

is

enlarged

or

-

reduced

19

-

in

reference

to

the

home

Page 24

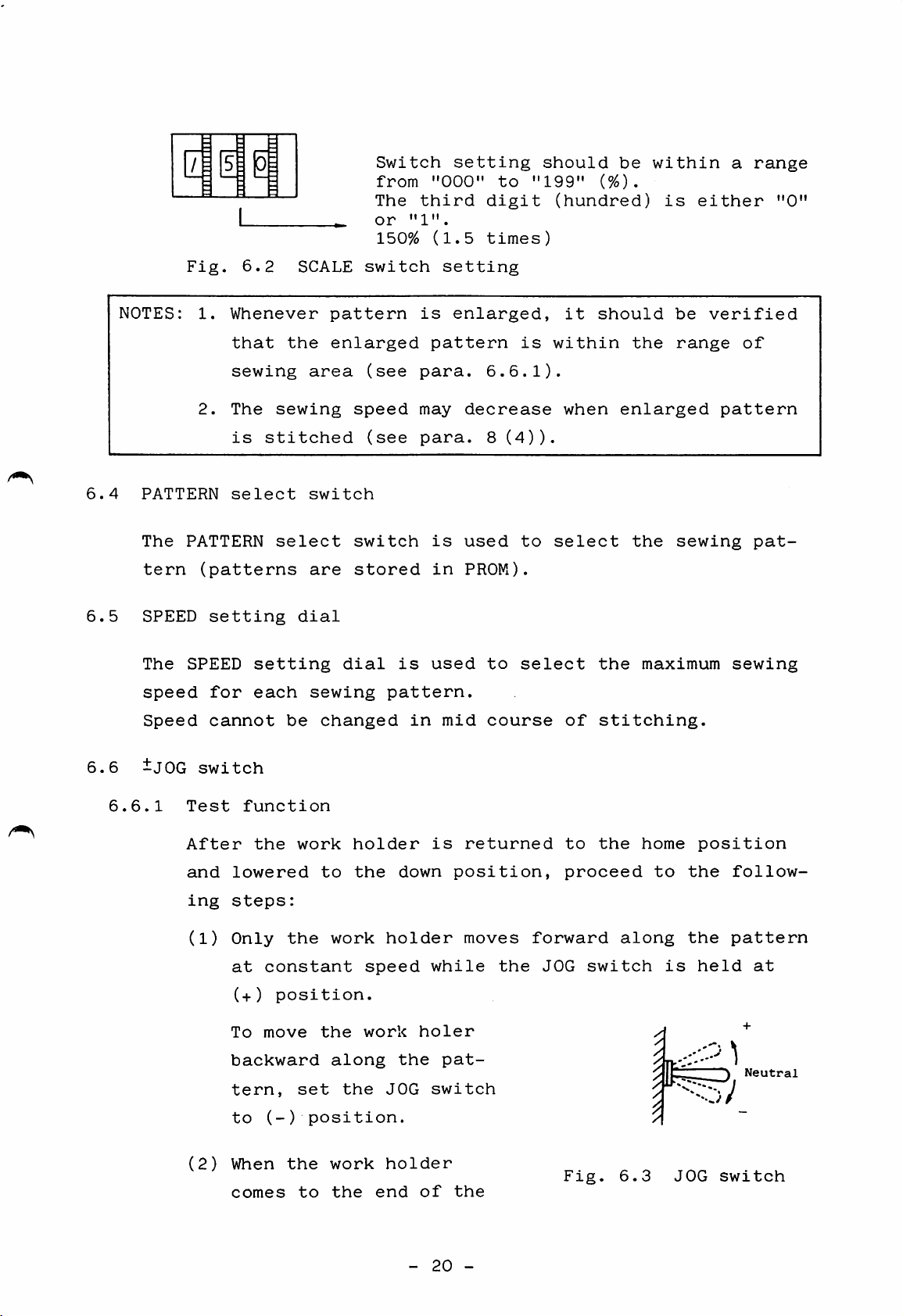

HI

Switch

from

The

or

150%

"000"

third

(1.5

setting

digit

times)

to

should

"199"

(hundred)

(%).

be

within

is

either

a

range

"0"

6.4

6.5

NOTES

PATTERN

The

tern

SPEED

The

speed

Fig.

6.2

Whenever

that

sewing

The

is

select

PATTERN

(patterns

setting

SPEED

for

the

sewing

stitched

select

setting

each

SCALE

pattern

enlarged

area

switch

are

dial

sewing

speed

switch

stored

dial

switch

(see

(see

is

pattern.

setting

is

pattern

para.

may

para.

is

in

used

enlarged,

6.6.1).

decrease

8

used

PROM).

to

is

(4)).

to

select

it

within

when

select

should

enlarged

the

be

the

range

the

sewing

maximum

verified

of

pattern

pat

sewing

6.6

6.6.1

Speed

ijOG

switch

Test

After

and

ing

(1)

(2)

cannot

lowered

steps:

Only

at

(+)

To

backward

tern,

to

When

comes

function

the

constant

move

(-)

be

changed

work

to

the

position.

the

set

position.

the

to

holder

the

work

along

the

work

the

holder

speed

work

JOG

holder

end

in

down

holer

the

of

mid

is

position,

while

pat

switch

the

course

returned

moves

the

of

to

proceed

forward

JOG

Fig.

stitching.

the

along

switch

6.3

home

to

is

the

the

JOG

position

follow

pattern

held

switch

at

Neutral

-

20

-

Page 25

pattern

the

tion.

work

with

holder

the

JOG

lifts

switch

and

set

returns

at

to

(+)

position,

the

home

posi

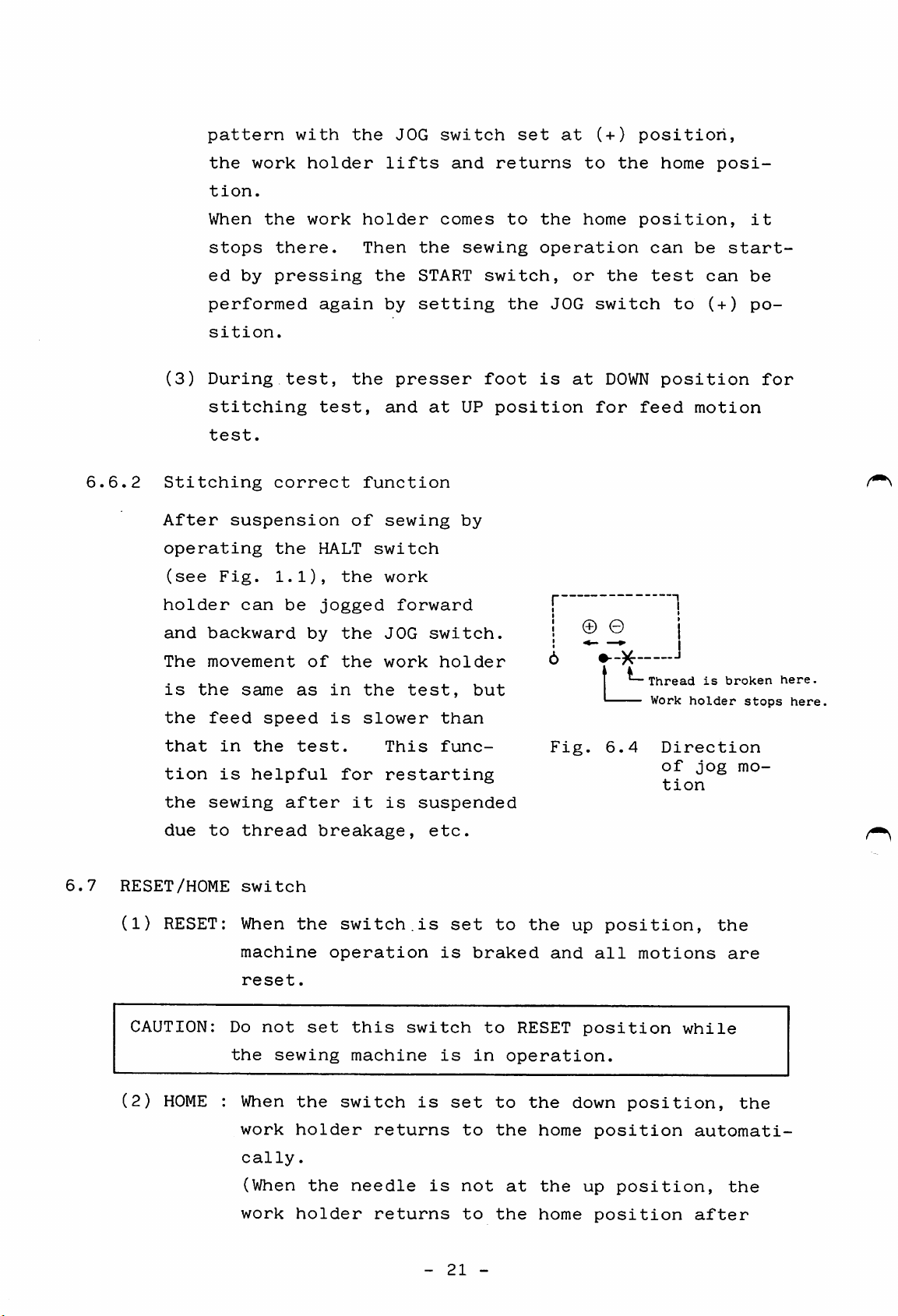

6.6.2

When

stops

ed

performed

sition.

(3)

During

stitching

test.

Stitching

After

operating

(see

holder

and

backward

The

movement

is

the

the

feed

the

by

correct

suspension

Fig.

can

same

speed

work

there.

pressing

again

test,

test,

the

HALT

1.1),

be

jogged

by

of

as

the

the

the

in

is

holder

Then

the

by

the

function

of

switch

work

JOG

work

the

slower

the

START

setting

presser

and

sewing

forward

test,

comes

sewing

at

UP

by

switch.

holder

than

switch,

foot

position

but

to

the

the

home

operation

or

JOG

is

at

© ©

the

switch

DOWN

for

-K-

L.

position,

can

test

to

position

feed

Thread

Work

be

can

(+)

motion

is

holder

start

broken

it

be

po

stops

for

here.

here,

6.7

that

tion

the

sewing

due

RESET/HOME

(1)

RESET: When

CAUTION:

(2)

HOME

in

is

to

thread

switch

machine

reset.

Do

the

: When

work

cally

(When

the

helpful

after

not

sewing

test.

breakage,

the

operation

set

the

holder

.

the

This

for

restarting

it

is

switch.is

this

machine

switch

returns

needle

func

suspended

etc.

set

is

switch

is

is

set

is

braked

in

to

not

to

to

RESET

operation.

to

the

at

the

the

home

the

Fig.

and

6.4

up

position,

all

position

down

position

up

Direction

of

tion

motions

position,

position,

jog

while

automati

mo

the

are

the

the

work

holder

returns

to

the

home

-

21

-

position

after

Page 26

the

needle

The

switch

position.

goes

is

up).

usually

to

be

set

at

the

down

(HOME)

6.8

STOP/MOVE

This

for

(1)

switch

lowering

Bobbin

When

switch

position,

motion

(2)

Lowering

When

presser

position

le

eye.

The

switch

the

the

switch

is

set

the

winding

START

set

at

the

of

the

the

STOP/MOVE

foot

when

is

at

presser

switch

STOP

main

work

presser

starts

the

usually

STOP

foot.

position,

motor

holder.

foot

switch

lowering.

thread

position

is

pressed

rotates

must

set

at

is

and

set

The

be

MOVE

for

with

the

at

to

passed

position.

bobbin

the

work

approx.

STOP

switch

winding,

STOP/MOVE

holder

600spm

position,

is

set

through

at

to

the

and

DOWN

without

the

STOP

need

6.9

ERROR

Error

needle

(1)

(2)

indicators

indicator

at

ERROR 1

Green

Red

light

ERROR 2

Red

light

the

light:

lights

UP

:

:

position

This

data

tion,

rectly

This

becomes

largement

This

is

indicator

are

indicator

indicator

not

and

the

if

not

for

the

programmed

more

of

put

into

sewing

error

present,

selected

than

the

lights

lights

sewing

lights

the

or

PROM

6.2mm

PROM

machine

failure

when

or

not

pattern.

cassette.

when

due

pattern.

when

cessette

stops

occurs.

sewing

in

stitch

to

the

pattern

good

Use

length

excessive

PROM

slot

with

condi

cor

cassette

the

en

cor

rectly.

Put

the

cassette

-

22

-

into

the

slot

Page 27

securely

in

correct

manner.

(3)

Green

ERROR

Two

Two

Two

light:

1,

red

red

green

ERROR 2

lamps

lamps

lamps

This

moves

the

light

at

is

to

er

flicker

is

Press

cause

indicator

beyond

pattern.

at

the

UP

pressed.

lift

to

the

locked

the

is

light

the

position

the

home

at

or

POWER

removed,

at

the

same

Operate

needle

the

the

the

lights

sewing

time:

when

and

position.

same

drive

OFF

press

same

when

the

time:

switch

time:

the

area.

The

the

POWER ON

RESET/HOME

return

The

belt

the

is

and,

POWER ON

Sewing

work

needle

the

main

out

after

Scale

work

pattern

holder

is

motor

of

down

not

switch

switch

hold

pulley.

the

switch.

6.10

Work

ERROR 1

time:

holder

red

lift

in

use

sition

Operate

work

holder

reset.

can

be

and

ERROR 2

(This

error

position

turning

The

RESET/HOME

work

Lower

RESET/HOME

holder

the

switch

is

is

the

used.

on

changed

used.

RESET/HOME

to

After

green

occurs

return"

the

at

work

switch.

while

the

that,

lamps

(refer

power.)

switch

the

holder

first

only

UP

the

switch

a

newly

light

when

is

position.

and

second

home

to

14.5)

operated

then

home

to

return

position

selected

as

the

"automatic

is

with

operate

pattern

same

used

po

the

to

home

for

the

the

This

er.

again.

foot

The

switch

work

(black)

holder

goes

-

is

pressed

up

23

when

-

to

the

lower

switch

the

is

work

pressed

hold

Page 28

5.11

HALT

switch

6.12

6.13

This

tion

START

Sewing

switch

(if

switch

operation

switch

Work

To

be

The

dependently.

work

When

after

start

holder

use

set

left

holders

the

this

to

suspension

if

the

(red)

"ON"

and

automatic

both

is

operated

thread

starts

is

pressed.

pedal

(option)

function,

("OFF"

right

The

are

not

of

the

work

is

SW4

when

work

START

at

home

sewing

to

suspend

broken,

from

(See

(A) on

the

holders

switch

DOWN

position

operation,

holders

for

the

home

Fig.

the

sewing

can

is

position.

return

are

the

sewing

example).

position

1.1)

CPU

circuit

machine

be

turnd

not

operative

function

the

not

at

machine

(See

is

on

function

DOWN

Fig.

when

board

shipped).

and

if

is

does

position.

opera

this

should

off

both

used

1.1)

in

the

not

6.14

Thread

When

set

at

the

thread

and

wiper

in

the

set

timing.

When

at

"OFF"

the

thread

and

wiper

work.

For

resetting

the

thread

after

operation,

trimmer

this

"ON"

previously

the

switch

position,

suspension

switch

position,

trimmer

operate

trimmer

do

not

trimmer

refer

of

switch

found

is

of

to

on

the

side

Fig.

wall

.*•

of

,_1Thread

6.5

control

trimmer

box

switch

is

v

-41!

14.4.

-

24

-

Page 29

7.

OPERATION

7.1

7.2

Inserting

Remove

PROM

orient

To

tern(s)

the

cassette

the

store

stored

PTN-IOOO-OL

For

handling

Setting

Set

follows:

SCALE

PATTERN

SPEED

the

each

switch

switch

control

the

cover

cassette

sewing

ROM

of

switches

switch

PROM

on

into

pattern(s)

in

the

writer)

the

on

dial

cassette

the

the

correctly.

PROM,

cassette,

on

the

cassette

drive

is

the

switch

100

0

to

4

slot.

to

the

an

optional

required.

refer

switch

panel

(for

9,

depending

drive

X

Before

PROM,

to

panel

to

and

slot

or

device

section

check

Y

axes)

on

and

the

erase

its

selected

insert

insertion,

sewing

(PT-4000A

13.

function

pattern

the

pat

or

as

7.3

RESET/HOME

STOP/MOVE

Checking

After

the

(1)

the

power

Home

position,

stops

(2)

Work

switch.

when

(3)

Work

and

switch

switch

each

necessary

and

position

at

holder

pressed

holder

the

function

perform

and

the

The

work

Set

Set

preparation

the

return:

then

home

down

work

to

position

motion:

holder

again).

movement:

holder

at

at

following

Set

HOME

Set

moves

DOWN

DOWN

the

position.

Press

will

the

along

position

position

has

been

check:

RESET/HOME

(see

6.7).

the

go

JOG

the

completed,

work

down

switch

sewing

switch

The

holder

(it

to

work

will

(+)

pattern.

turn

to

RESET

holder

lift

go

up

position

on

The

when

During

switch

the

work

work

the

holder

it

traces

is

returned

holder

check

lifts

the

stops

described

and

pattern

to

the

at

-

above,

25

returns

completely.

neutral

DOWN

-

to

position

position.

the

work

the

home

(If

(See

holder

position

the

during

6.6)

JOG

moves

tracing,

but

Page 30

stitching

motion

does

not

occur.

7.4

Also

For

and

Sewing

(1)

(2)

check

stitching

perform

operation

Set

each

6.

1.

Set

up

holder

Press

stitching.

goes

When

med,

sition.

on

the

the

pattern

the

switch

the

lift

the

stitching

stitching

work

test,

test

fabric

switch

START

Once

size

set

on

switch

the

holder

and

the

in

accordance

the

switch

in

the

to

lower

and

sewing

even

is

completed

when

automatically

location

sewing

work

the

the

machine

the

speed

with

panel,

holder

work

sewing

START

and

of

moves

the

to

para.

referring

and

holder.

machine

starts

switch

the

work

"low

7.4.

press

stitching,

threads

up

holder.

speed"

is

to

to

the

starts

released,

are

the

Fig.

work

UP

it

trim

po

7.5

HALT

To

After

sition

To

ing

The

stitches

The

work

NOTE:

switch

stop

thread

resume

the

sewing

work

holder

Before

form

with

the

and

restart

are

holder

test

the

operation

stitching,

trimming,

the

the

stitching,

machine

completed.

switch

starting

operation

sewing

needle

position

automatically

can

during

press

the

stops

be

moved

sewing

in

machine

the

workholder

at

press

by

operating

up

HALT.

work,

order

functions.

the

the

and

HALT

UP

START

stops

down

remove

to

make

switch

stops

position.

switch

the

JOG

when

by

the

yourself

(see

at

the

after

switch.

the

remaining

operating

needle

Fig.

DOWN

adjust

the

and

familiar

1.1).

po

per

-

26

-

Page 31

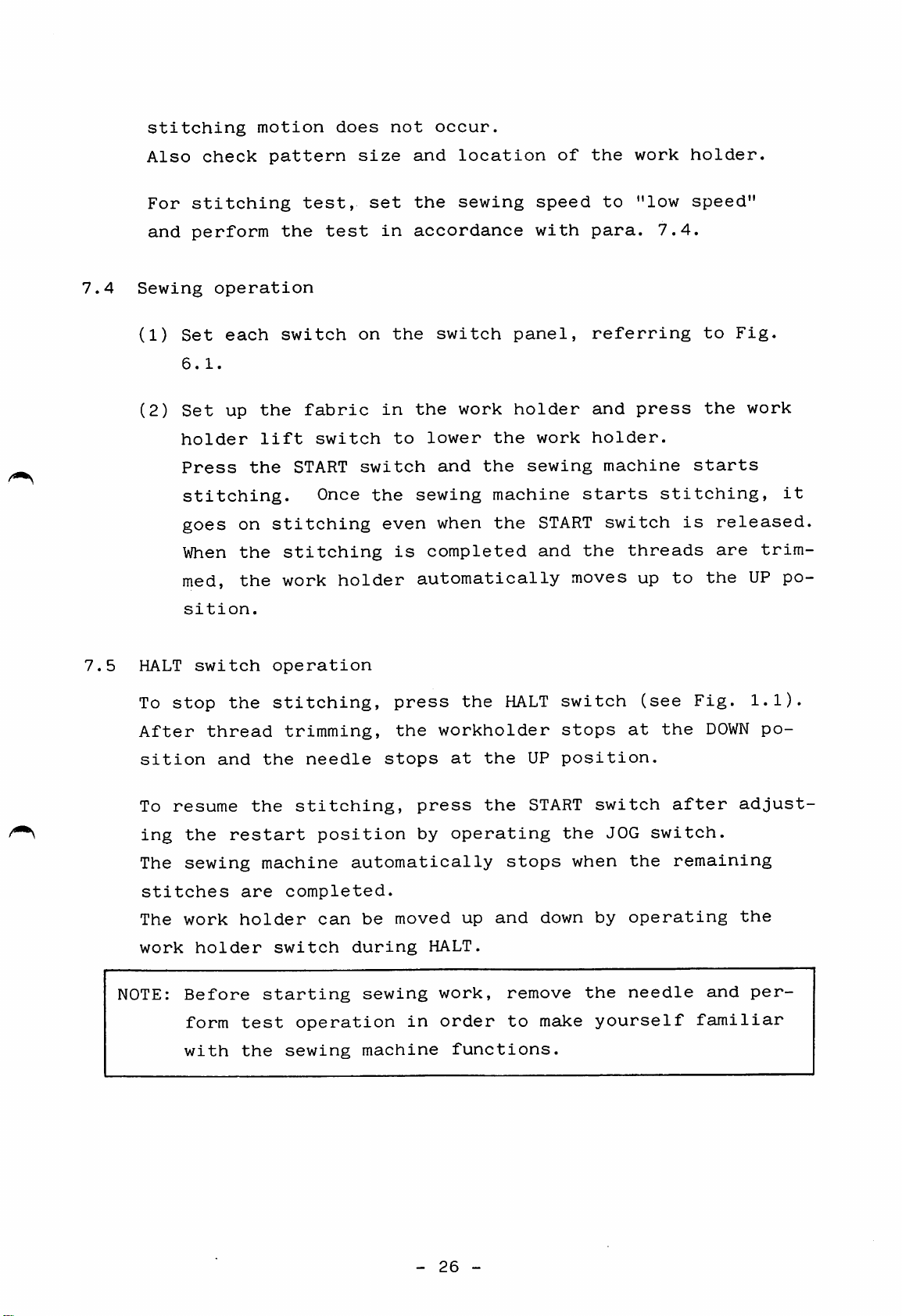

7.6

Operating

The

sewing

procedure

machine

and

should

checking

be

operated

and

checked

in

accor

dance

Checking

before

operation:

with

the

following

flow

1) Checkif the power cable is plugged into

the

power source

2) Checkifthe other

3) Check if the

installed.

outlet.

cables

PROM

cassette is correctly

correctly connected.

4) Check if the fuses are not blown.

Start

preparation

Press

the

pushbutton

Does

motor

POWER

the

rotate?

main

ON

NO

Press

OFF

chart:

Check

source

the

pushbutton

power

wiring

POWER

>

CZ)

Reference

Operation

Preparation

Judgement

item

Check

rotational

direction.

Press

pushbutton.

Change

tion

or

reversing

the

(any

inverse

power

POWER

twoofthree

settingofphase

plug.

cable

ON

connec

Set

switchtoSTOP

Press

lift

the

START

wires)

Does

the

holder

home

the

holdergodown?

Depress

work

return

position?

STOP/MOVE

the

work

switchtolet

work

holder.

Does

the

work

the

switch

oes

the

sewing

achine

start?

to

holder

down

Set

switchtoHOME

Set

switchtoRESET

NO

the

RESET/HOME

the

RESET/HOME

Press

the

the

work

POWER

switchtolift

holder.

Press

pushbutton.

the

holder

work

OFF

lift

Adjust

mechanism.

Check

of

the

connector.

the

the

main

work

connection

motor

holder

To

the

next

page

-

27

-

Page 32

Press

pushbutton.

Release

switch

Ad|ust

the

synchronizer

the

POWER

the

START

OFF

From

the

Is

too

Is

the

needle

the

previous

speed

high?

rotation

correct?

the

switch.

Does

the

stopatUP

position?

STOP/MOVE

page

direction

Release

Set

switchtoMove

START

Press

the

pushbutton.

POWER

OFF

Adjust

the

synchronizer.

Test

operation

Checkifthe

is

inserted

correctly.

Set

the

RESET/HOME

switchtoHOME.

Set

the

RESET/HOME

switchtoRESET.

Set

the

JOG

neutral

position

PROM

I

I

switch

cassette

at

/set

PATTERN

/

Set

the

\

switch.

switchto(+1

Does

the

holder

Is

the

the

sewing

ithin

the

work

Does

the

holder

No.^

SCALE

work

move?

size

of

pattern

areaofthe

holder?

work

lift?

\

/

Check

the

control

the

driving

and

circuit

work

holder

Press

the

pushbutton

POWER

OFF

mechanism

the

Adjust

mechanism.

The

preparation

completes

To

the

next

page

-

28

-

Page 33

Start

sewing

D

Set

the

stitching

speed.

(

Automatic

(Sewing)

operation

(

Setupthe

Press

the

lift

switchtoget

work

holder

Is

held

Depress

switch.

Does

machine

Is

broken

fabric.

work

down.

the

fabric

securely?

the

the

sewing

start?

the

thread

during

operation?

holder

the

YES

START

Press

the

Press

OFF

Press

work

switchtolift

holder.

holder

the

work

the

POWER

pushbutton.

the

HALT

lift

switch

PROM

Refer

para.

data

6.9

error

to

Is

trimmed

has

Does

work

Is

trimmer

satisfactory?

tension

The

operation

the

thread

when

finished?

the

properly?

the

thread

operation

Is

thread

ballanced?

stitching

sewing

wiper

well

completes

Is

the

placedinthe

position?

Depress

the

switch.

Press

the

OFF

switch.

fabric

correct

START

POWER

<Adjust

the

positionbythe

switch.

work

Adjust

machine

holder

JOG

the

sewing

-

29

-

Page 34

8.

GENERAL

(1)

Before

INSTRUCTIONS

replacement

of

PROM

in

the

PROM

cassette,

read

the

description

Insert

drive

(2)

When

6.9.

(3)

When a new

used,

area

(4)

Maximum

as

Table

SWl

(b)

(Setting

Stitch

any

confined

shown

8.1

set

length

the

slot

check

sewing

at

in

PROM

after

error

sewing

that

in

Table

Max.

at

"OFF"

shipping)

section

cassette

turning

lamp

the

by

the

speed

sewing

Max.

lights,

pattern

sewing

work

differs

8.1

speed

13.

(see

speed

into

off

is

pattern

holder

for

and

the

power.

check

used

in

depending

6.5).

each

SW1@

Stitch

remove

for

or

is

test

stitch

cause

an

within

on

from

referring

enlarged

operation.

the

length

set

at

length

the

the

stitch

"ON"

cassette

pattern

sewing

Max.

to

is

length

speed

(5)

(6)

5.4

4.8

4.0

3.2

2.6

2.4mm

(Speed

Whenever

keep

When

justment

-

-

-

-

-

6.2mm

5.2mm

4.6mm

3.8mm

3.0mm

or

limit

his

the

less

1)

the

foot

right

or

maintenance,

power

away

side

850spm

llOOspm

1300spm

1550spm

1800spm

2000spm

is

turned

from

cover

the

the

of

on

pedal

control

power

5.4

4.8

4.0

3.4

2.8

2.2

2mm

(Speed

and

switches.

-

-

-

-

-

-

or

off,

box

should

6.2mm

5.2mm

4.6mm

3.8mm

3.2mm

2.6mm

less

limit

operator

is

have

2)

opened

been

eoospm

850spm

llOOspm

1300spm

1550spm

1800spm

2000spm

should

for

off.

ad

(7)

Avoid

to

applied

check.

applying

to

a

multimeter

Otherwise,

semiconductors

-

voltage

30

to

the

internal

from

and

cause

-

the

damage

control

multimeter

to

the

circuits

may

circuits.

be

Page 35

(8)

The

not

pulley

at

the

cannot

DOWN

be

position.

turned

by

hand

if

the

presser

foot

is

(9)

While

STOP

Since

is

off,

Since

moisture

to

time

the

power

position

the

presser

the

water

involved

to

and

pulley

is

accumulated

remove

is

on,

lower

foot

can

in

air,

the

operate

the

is

be

water

presser

the

turned

in

press

(see

the

DOWN

by

the

the

Fig.

STOP/MOVE

foot

position

hand

pneumatic

drain

4.1).

(see

while

freely.

system

knob

switch

6.8).

from

the

due

to

power

to

time

-

31

-

Page 36

9.

HANDLING

THE

SEWING

MACHINE

HEAD

9.1

(1)

Lubrication

Supplying

Before

bricant

9.2.

the

starting

to

the

lubricant

daily

points

Oil

gauge''

operation,

indicated

__Filling

hole

supply

by

arrow

a

few

in

drops

Fig.

9.1

of

lu

and

(2)

Before

of

the

through

lubricant

to

add).

*For

in

the

(for

*For

ser

Filling

bed

side)

Fig.

starting

hole

lower

*1,

plate,

sewing

holes

is

E,

direction

apply

the

9.1

machine,

A,

given

turn

horizontal

lubricant

oil

the

initial

B,

0,

automatically

the

of

tank

pour

D

power

arrow.

shaft

with

operation

a

and

and

to

the

lubricant

suitable

E

(during

and

fully

The

filling

bearings).

reverse

Fig.

after

amount

regular

therefore

push

(on

the

hole

surface

arm

9.2

the

of

side

installation

lubricant

operation,

not

necessary

clamp

will

of

appear

the

and

bracket

pres-

Fill

reaches

the

the

oil

tank

center

with

mark

-

lubricant

of

32

until

oil

gauge.

-

lubricant

level

Page 37

The

oiling

rate

is

factory-adjusted.

When

readjustment

is

9.2

necessary,

NOTE:

Installing

(1)

Before

turn

(2)

Insert

For

white

#2.

off

refer

lubricant,

spindle

the

needle

attaching

the

the

needle

to

power

10.3.

use

oil

or

for

into

Slide

detaching

safety.

the

plate

needle

the

Fig.

9.3

needle,

socket

be

until

Filling

sure

it

is

hole

to

Oil

gauge

stop

Put

until

the

prime

(3)

(4)

needle

it

set

groove

ped

Secure

facing

For

the

shown

Into

stops

screw

at

the

the

front.

better

needle

in

the

and

bottom

needle

stitching,

turned

Fig.

socket

tighten

9.4.

of

screw

about

Needle

needle

it

with

is

10°

with the needle inserted

oriented

front.

N=H

socket.

the

usually

in

the

not

fully

prime

recommended

direction

Gap

Hrr

groove

Needle

of

of

oriented

improperly,

i I

i !/

needle

to

arrow

set

X

X

I)

Fig.

9.4

-

33

-

Page 38

9.3

Threading

the

needle

thread

Pass

the

Fig.

needle

9.5

thread

as

shown

in

Fig.

Arm

® C

III

thread

9.5

Fig.

guide

and

Thread

9.6

9.6

Thread

guide

Take-up

spring

9.4

Winding

(1)

Wind

thread,

cotton

tension

around

several

shown

(2)

Press

lift

the

(3)

Set

switch

panel

and

the

the

stand

the

in

the

switch

work

the

on

to

press

bobbin

end

led

thread

turns

Fig.

work

holder.

of

from

via

bobbin

to

thread

guide,

as

9.7.

holder

lower

STOP/MOVE

the

switch

STOP

the

position

START

the

the

the

(4)

switch

When

wound,

the

(see

set

thread

the

6.8).

has

STOP/MOVE

Fig.

been

switch

-

34

-

to

MOVE

9.7

position

Page 39

(5)

If

the

thread

is

wound

unevenly

(conically),

move

the

9.5

tension

evenly

(6)

When

on

NOTE:

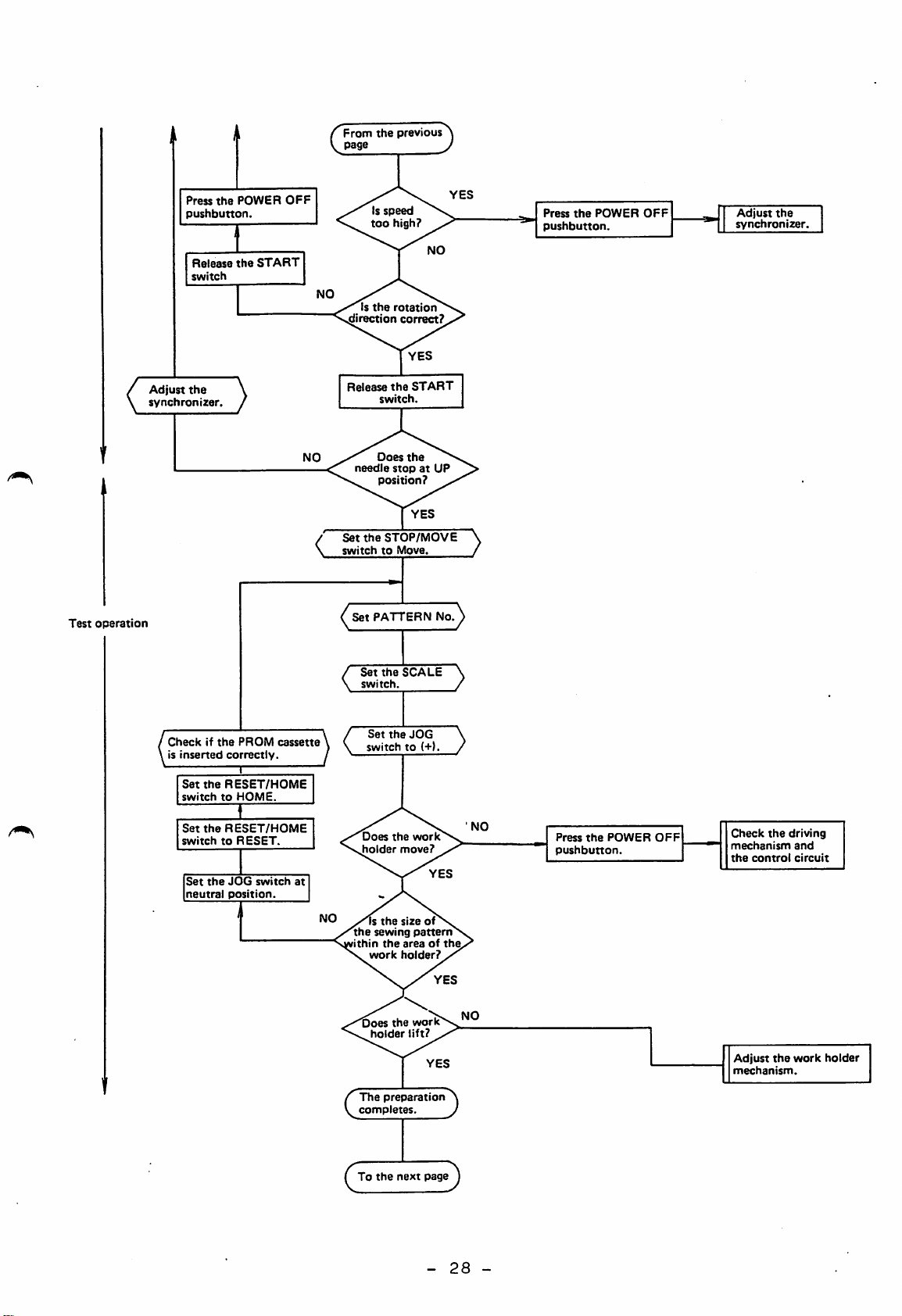

Installing

(1)

Put

the

(2)

Put

the

groove

(3)

Pull

the

When

moved

the

bobbin

the

slit

thread

on

the

polyester

bibbin

thread

from

the

bobbin

thread

(C)

(C)

the

thread

bobbin.

with

is

the

bobbin

case

and

and

guide

or

wound,

needle.

(B)

(A).

(E)

hole

(E)

nylon

a

into

into

lead

so

tension

it

(D).

to

that

thread

the

the

as

needle

is

small

thread

used,

thread

as

can

wind

possible.

should

be

the

wound

thread

be

re

9.6

make

rotates

If

counter-clockwise,

the

Installing

(1)

Locate

highest

the

S.3).

(2)

Fully

latch

NOTE:

Thread

bobbin

sure

the

bobbin

slide

clockwise.

bobbin

the

the

position

open

(A)

plate

and,

end

case.

the

(B).

bobbin

needle

the

should

bobbin

rotates

and

(see

bobbin

while

reverse

case

at

be

(B)

the

open

Fig.

case

holding

extended

the

latch,

about

Fig.

Fig.

put

100mm

9.8

9.9

it

from

into

(B).

the

9.7

Thread

When

bin

the

thread

tensions

needle

tension,

thread

the

tension

needle

-

35

is

thread

-

well

balanced