Page 1

MITSUBISHI

Industrial

Sewing

INSTRUCTION

Single-Needle

Eiectronic

MANUAL

Model

•

Lockstitch

Bar

Machine

PLK-109

Tack

Machine

n

WT90020X01

A

MITSUBISHI

ELECTRIC

Page 2

Contents

1.

Construction

2. Specifications 2

1

3. Assembling

3.1 Assembling the machine

3.2

3.3 Lamp leads 7

3.4 Electrical power connection 7

3.5 Changing

4. Handling

and

Installation 4

head

Connectionoflead

of

of

Machine Head 8

wires 5

motor

running direction 7

4.1 Installation of needle g

4.2 Threadingofneedle thread 8

4.3 Threadingof bobbin thread 9

4.4

Removal

of inner hook 9

4.5 Adjustment of work holder pressure 10

4

4.6 Replacement of work clamp 10

4.7 Installation of presser-foot ' 11

4.8 Installation of pedal-presser-foot 11

4.9 Winding up of bobbin thread 12

4.10 Thread tension 12

4.11 Lubrication 14

5. Switch Panel 15

5.1 SCALE 15

5.2 SPEED 16

5.3 PATTERN 16

5.4

JOG

5.5 RESET/HOME 17

5.6 TEST/AUTO 17

16

Page 3

5.7

5.8

WIND

ERROR

indication

18

18

6. Operation 19

6.1 Setting the PROM cassette 19

6.2 Setting the switches on switch panel 19

6.3 Checking 19

6.4

Sewing 19

6.5 Emergencystop 20

6.6 Operation procedure 21

7. Cautions on Operation 24

8. Maintenance

and

Checking 25

8.1 Ajustment of synchronizer 25

8.2 Replacementof

PROM

8.3 Cleaningoffan filter 27

26

Page 4

Page 5

2. Specifications

Head

Needle

bar

vertical

stroke

Needle applicable

Work

holder

Control system

Sewing range 50 X30mm, X-Y axes, drivenbystepping

Half-rotating hook, cylinder bed, single-needle lockstitch, electronic bartack sewing

machine

41.2

mm

DPX 17 #16 (Standard)

15

mm

Microcomputer incorporated full-electronic control

motor

Max. stitching speed 2000 spm Intermittent feed(with stitch length below1.5 mm)

Stitch length

Pattem

control

0.2~6.0

Programstored in memory (PROM)

mm

Exchangeable PROM

Memory size: Max. 10 patterns/chip, max. 1000 stitches

Sewing operation

One cycle of sewingstarts at home position, and ends at home position.ichine home

Home

Sewing

position

start

return

The function is used when the

X-Y

position deviates duringstitching. The work

holder returns to the home position after the needle stops at its UP position.

Thisfunction occurs once every time after turning on the power switch.

Sewing

starts at home positionwhen the pedal isdepressed.

(1) Pedal slightly depressed

down by toe (ON) - Workholder:

Pedal

release

(OFF) Workholder: UP

(2) Pedalfully depressed

Sewing

DOWN

starts.

After sewing,work holder automatically risesand stops.

-2-

Page 6

Emergency stop

function

'

Needlemay be stopped at UPposition in the course of

sewing.

stop, the remainingstitches can be completed in inchingmode.

After the emergency

Stitching speed

setting

Check

function

Patter enlargement/

reduction

function

(SCALE)

Patern

selection

Error

indication

The speed best suited for

given

fabrics

and

sewing

pattern can be preset within a

range from 200 spm to 2000 spm with an incrementofabout 200 spm.

Test run or test sewing is possible at a low sewingspeed permitting visualchecking.

Pattern stored in memory (PROM)can be enlargedor reduced.

Enlargementor reduction can be specifiedindependently in X and Y axes.

±

100%

with1%increment

Any oneof10 patterns is selectable.

Lamps are provided to visualize errors.

-3-

Page 7

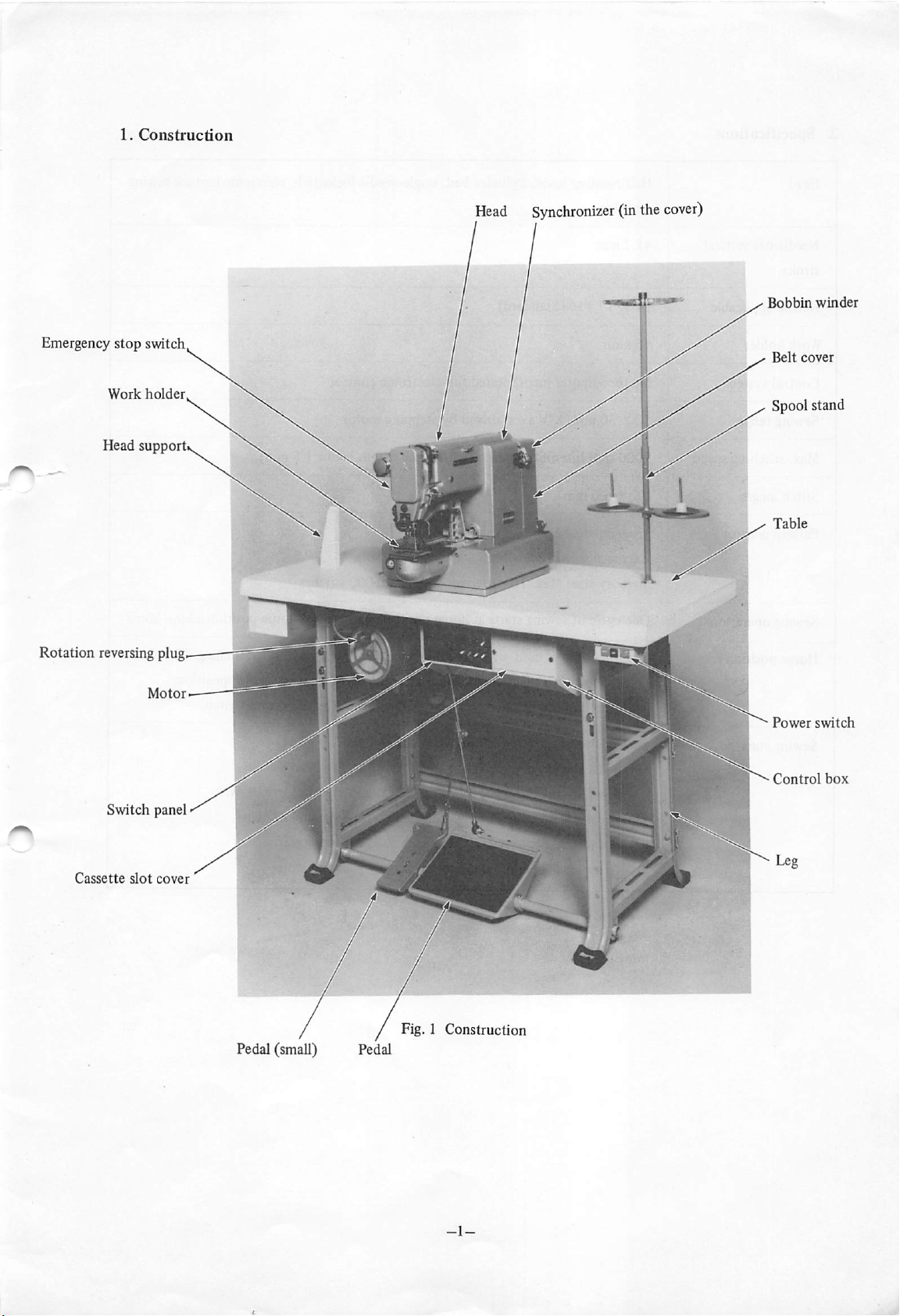

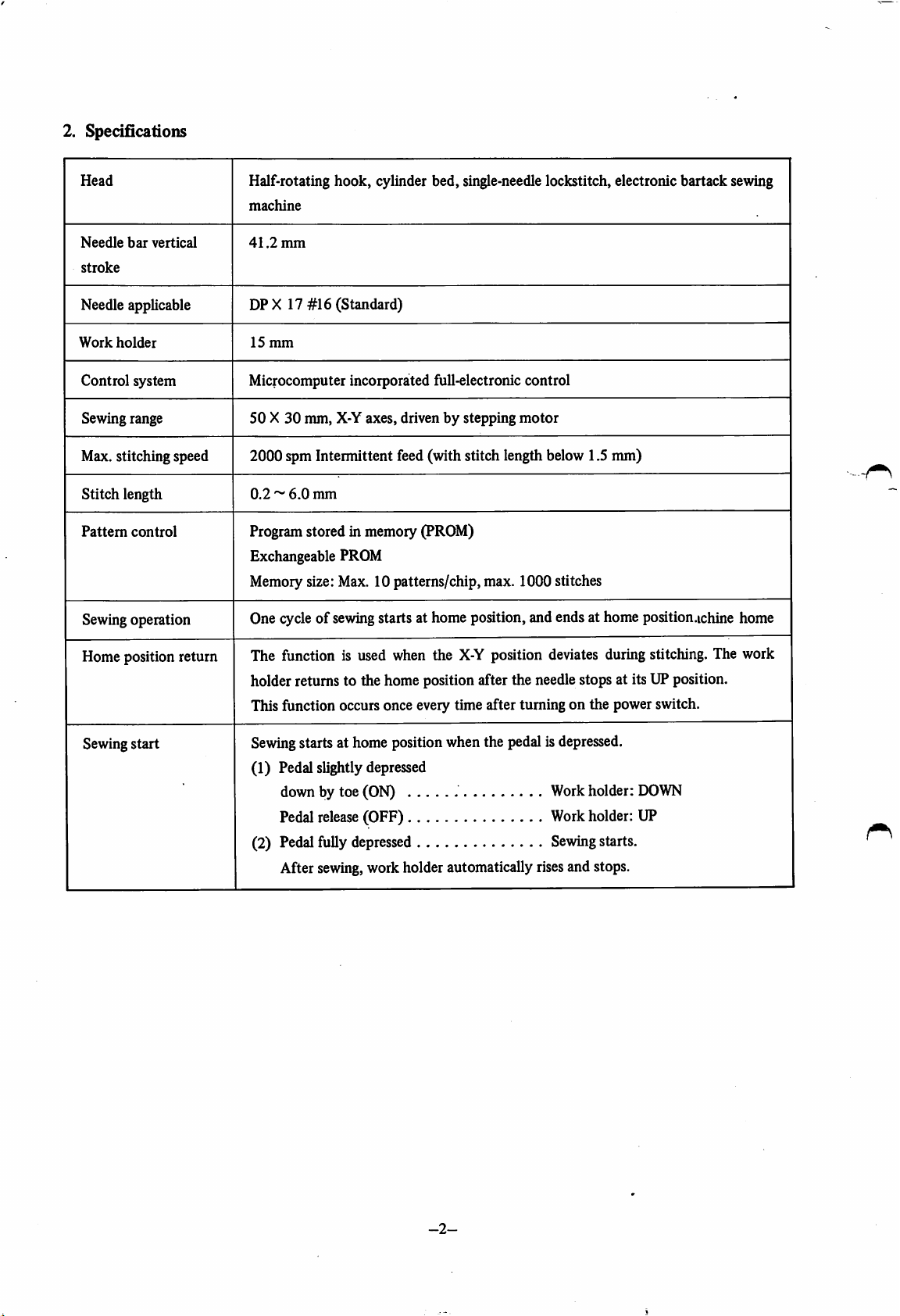

3. Assembling

and

Installation

3.1 Assembling the machine head

3.1.1. Put the furnished head support in the hole of the tableto installit upright.(Referto Fig.1Construc

tion.)

3.1.2 Install the furnished rubber pads(4 pcs.) in each recessprovidedat the table top.

3.L3 Unpack the head and

table

that

each rubber pad enters the respectiverecessesprovided in the base.

place

it on the table as shownin Fig. 2. The head should be so placedon the

3.1.4 Secure the base to the table suing the furnished two woodscrews.

3.1.5. Besure the insulation rubbers be inserted into the upper surface

of

the base at two places.

LEAD

WIRES

WOOD

SCREW

RUBBER

PAD

HINGE

RUBBER

PAD

BASE

RUBBER

PAD

WOOD

SCREW

RUBBER

PAD

Fig. 2

Caution:

In case of leaning the head downward, take care that the base may leap up with the head, if the baseis

not

secured

with

the

wood

screws.

-4-

Page 8

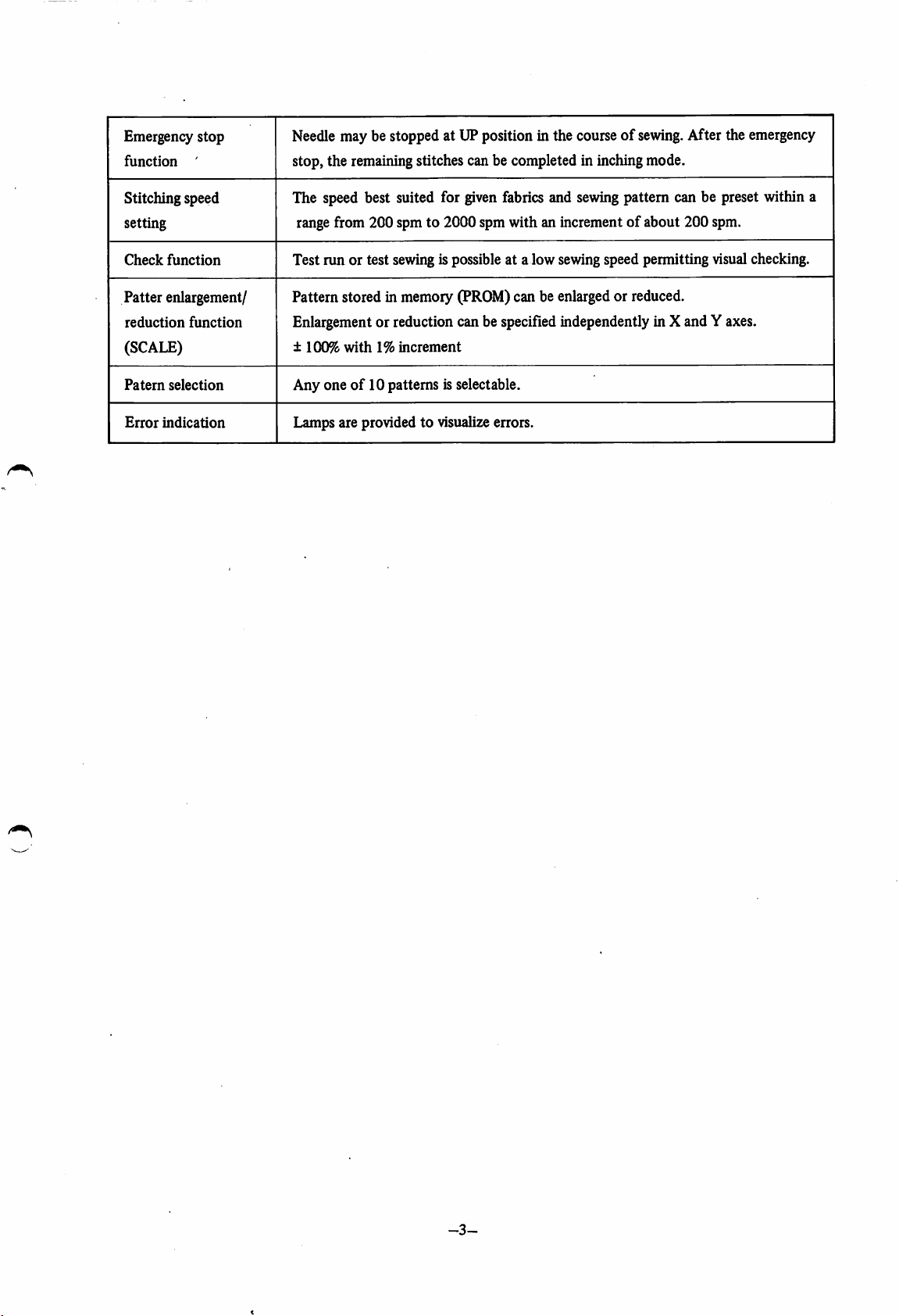

3.2

Connection

of

lead

wires

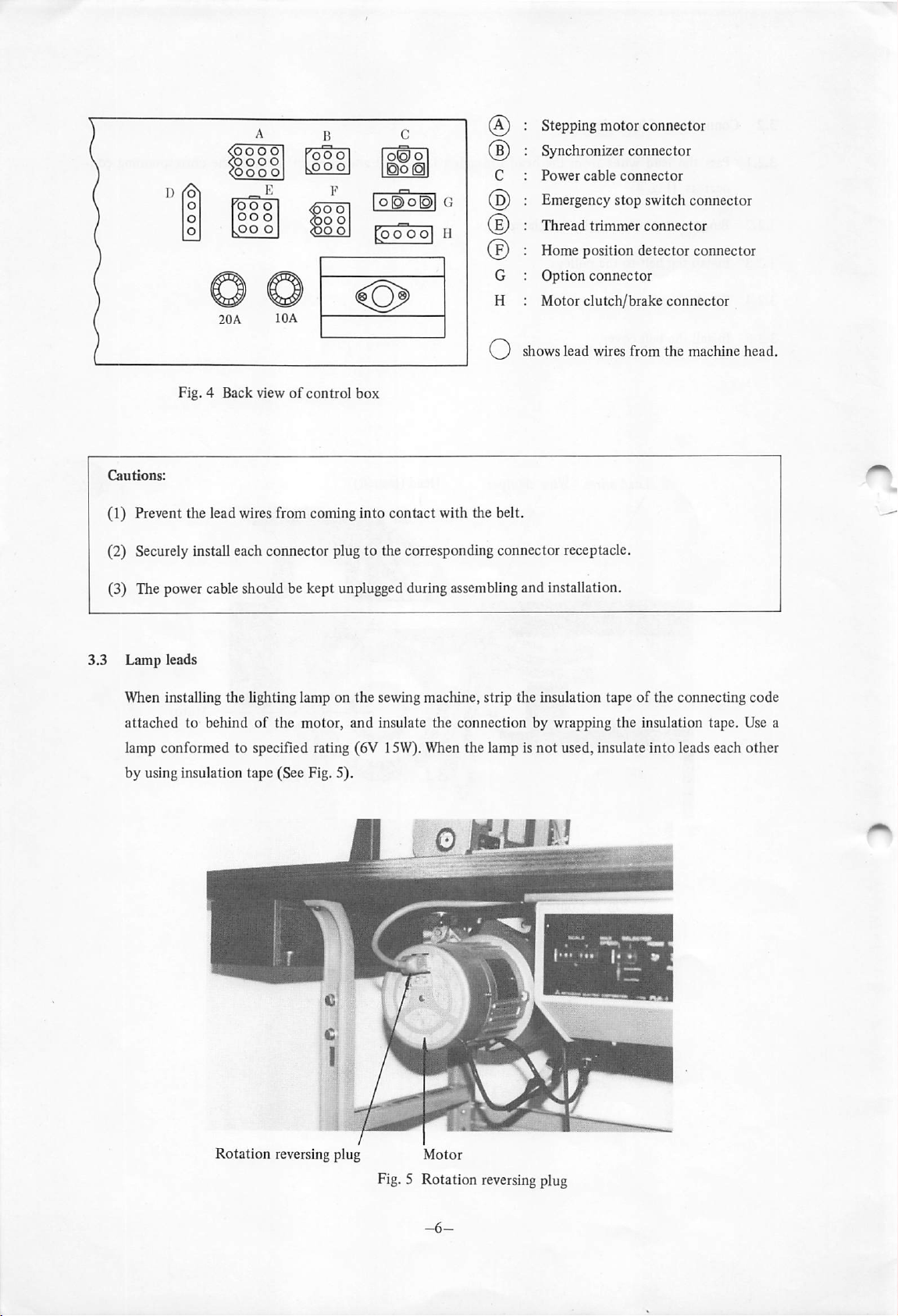

3.2.1 Pass the lead wires from the head through a table hole and connect them to the corresponding con

nectors. (Fig. 4)

3.2.2 Bind the lead wires

with

wire clamper

3.2.3 Install the belt to the pulleys.

3.2.4 Set the head upright.

3.2.5

Install

the

belt

cover.

Lead

wires

Wire

clamper. Head(leaned)

Fig. 3

Control

Connection

box

between machine

head

and

control

box

Page 9

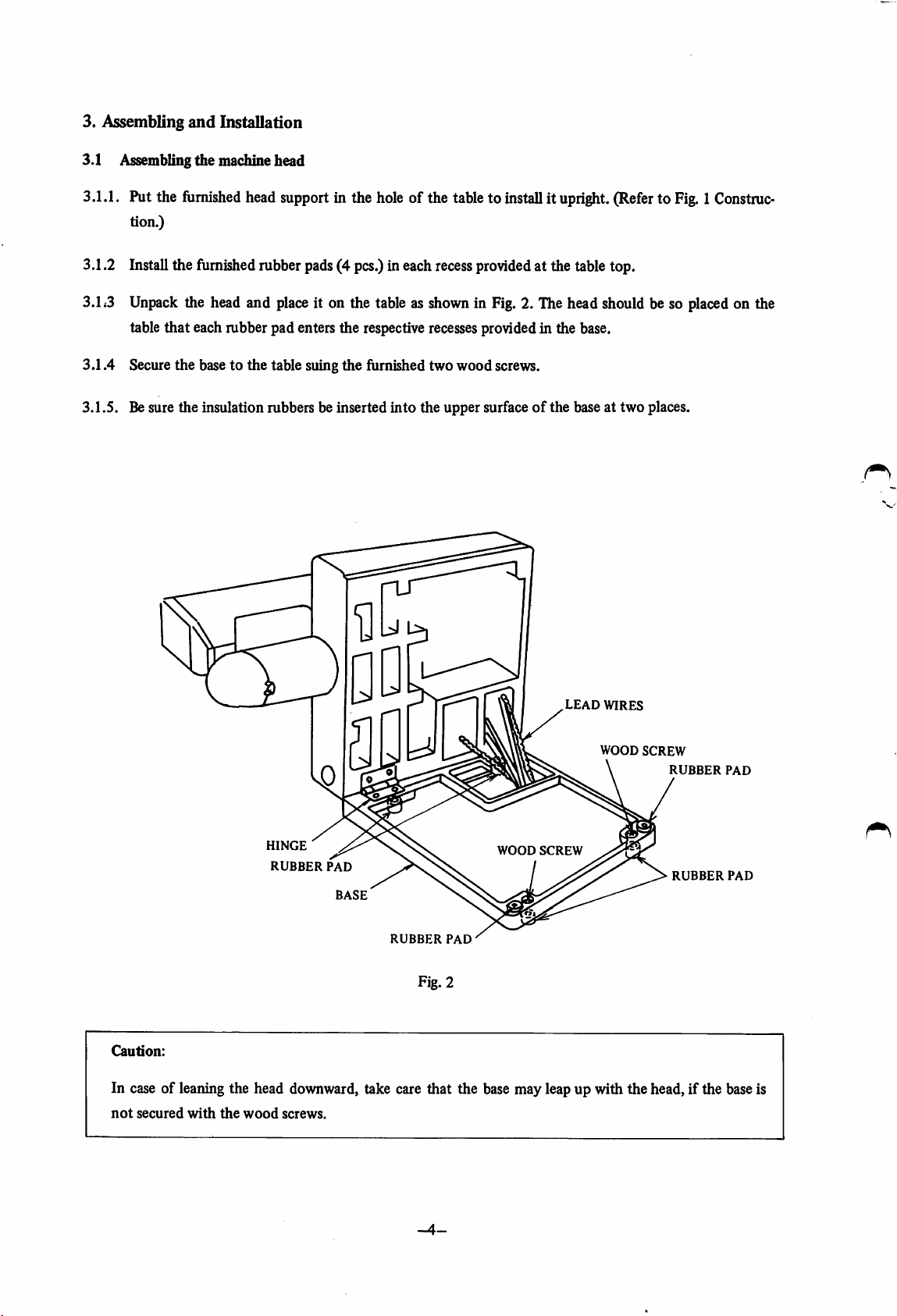

(OOOO

coooo

<poo

20A

o

IDA

O®

O

O^O^l

rocTooi

G

H

(3

Stepping

Synchronizer

Power

Emergency stop switch connector

Thread

Home

Option connector

Motor clutch/brake connector

shows

cable

position

lead

motor

trimmer

wires

connector

connector

connector

connector

detector

from

connector

the

machine

head.

Fig. 4 Back viewofcontrol

Cautions:

(1) Prevent the lead wires from coming

box

into

contact with the belt.

(2) Securelyinstall each connector plug to the correspondingconnector receptacle.

(3) The power cableshould be kept unpluggedduring assembling and installation.

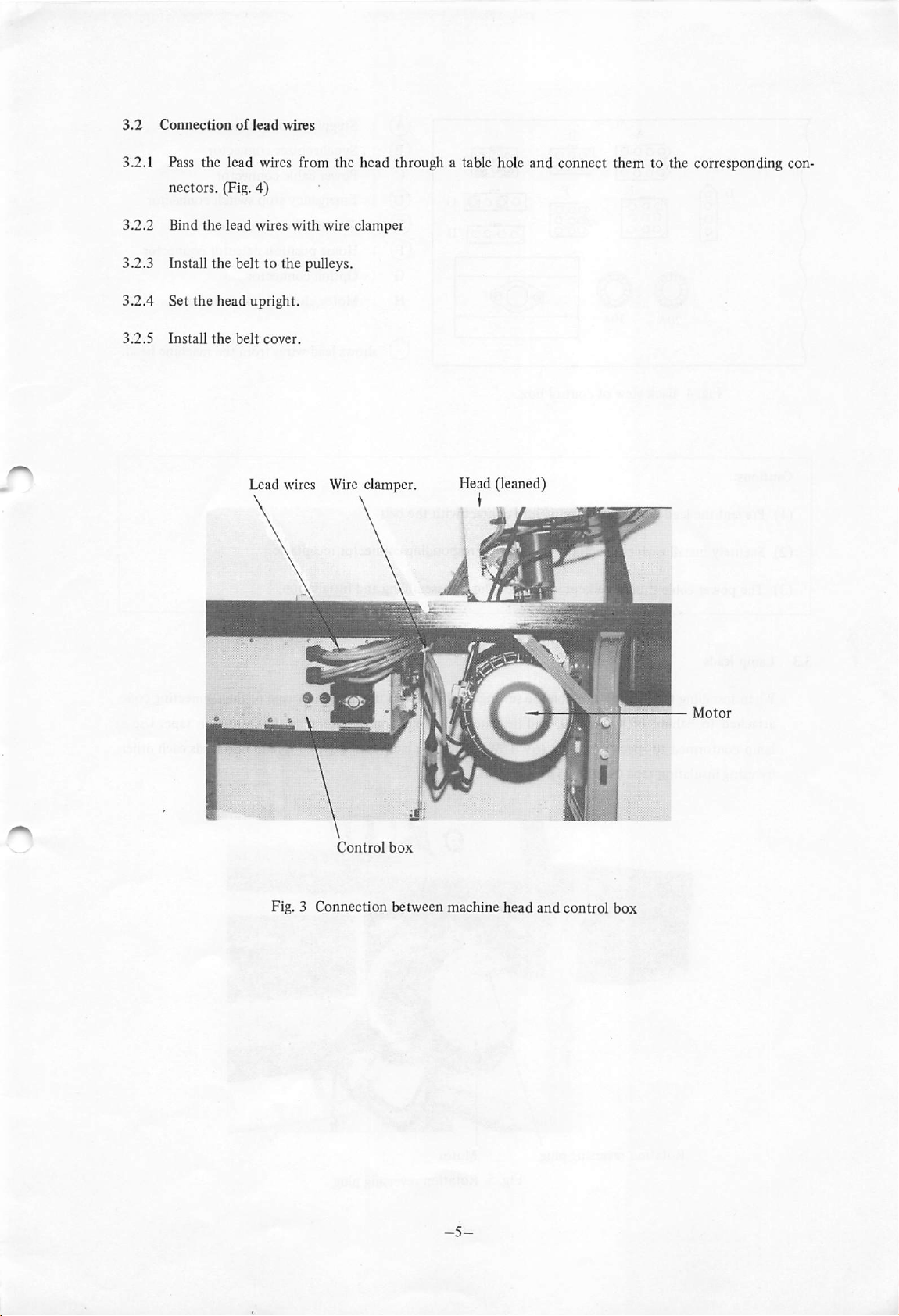

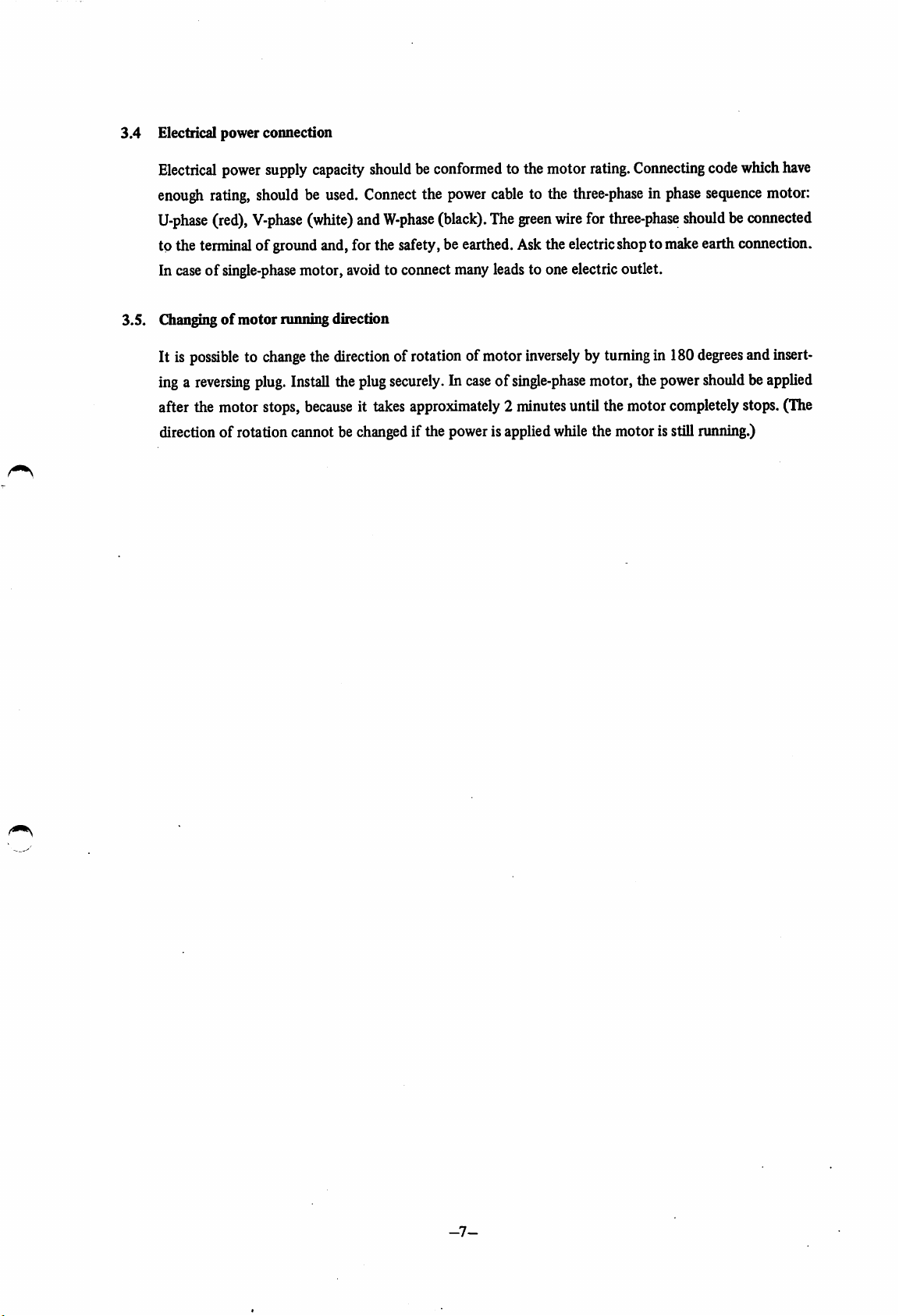

When installing the lighting lamp on the sewing machine, strip the insulation tapeofthe connecting code

attached to behind

lamp conformed to specified rating (6V 15W).When the lamp is not used, insulate into leads each other

by using insulation tape (See Fig. 5).

of

the motor, and insulate the connection by wrapping the insulation tape. Use a

Rotation reversing plug

Motor

Fig.5 Rotation

reversing

plug

Page 10

3.4

Electrical power coimection

Electrical

enough

U-phase

to the terminalof groundand,for the safety,be earthed.Askthe electricshoptomakeearth connection.

In

3.5. Changingofmotorrunning direction

It is

inga

after the motor stops,

directionof rotation cannot be

power

supply

rating,

shouldbeused.

(red),

V-phase

caseofsingle-phase

possibletochange

reversing

plug.

capacity

Connect

(white)

motor,

Install

becauseittakes

the

and

avoid

direction

theplug

changed

shouldbeconformed

the

power

W-phase

to connect manyleadsto one electricoutlet.

(black).

ofrotation ofmotor

securely.Incaseofsingle-phase

approximately2minutes

if the powerisappliedwhilethe motor is stillnmning.)

to themotor

cable

to the

The

green

wire

inverselybyturning

rating.

Connecting

three-phaseinphase

for

three-phase

in 180

motor,thepower

untilthe motor

code

sequence

shouldbeconnected

degrees

shouldbeapplied

completely

which

motor:

and

stops.

have

insert

(TTie

-7-

Page 11

4. HandlingofMachine Head

4.1

Installationofneedle

4.1.1 Beforeinstalling or removingthe needle, be sure to turn

4.1.2

Fully

bar

insert the

hole.

needle

shankinto the

needle

bar hole until it butts

off

the sewingmachine.

against

the bottom of the

4.1.3 Turn front the prime groove of the needleand secure by tighteningthe set screw.

Fully insert needle shank

needle

against bottom

hole,

and tighten set screw.

tum

I !

I I

I I

bar

hole

front

until

it

of

needle bar

prime groove

into

butts

Needle shank is

ed.

not

fully insert

Needle is installedin wrong direc

tion.

A

I I

n ! > n

N=M

d

needle

o

Fig. 6

4.2 Threadingofneedle thread

Thread the needle thread as shown in Fig. 7.

The needle thread passed through the needle eye should extend about 4 cm from the needle eye.

X

-8-

Page 12

4.3 Threading of bobbin du^ad

Pass

case

The

4.4

Removalofinner

Turn

the bobbinthread

into

the

inner

endofthe

the

bobbin

hook clamp in the direction shown by arrow in Fig. 15. Whenthe

throu^

hook.

thread

book

horizontal position, the inner

thehole of the bobbin

should

extend

hook

can be removed.

about

case

horn, asshownin

2.5cmfrom

the

holeofthe

C B

Fig.

13,and set the bobbin

bobbin

hook

case

clamp is

hom.

tumed

to the

4

Fig. 7

-9-

Page 13

4.5 Adjustment of work holder pressure

4.5.1 To increase pressure

work holder shaft by the spanner.

(Length of the work holder shaft and bracket

of

the work holder, loosen the nut shown in Fig. 8 and turn coimter-clockwisethe

"A"

becomeslargewhen the nut is turned counter-clock-

wise.)

4.5.2 By turning the

4.5.3

When

the work holder is adjusted to the standard pressure,it cannot satisfactorilyhold a fabricthicker

than 6 mm. In such a case, decrease the work holder pressure.

nut

clockwise, pressureofthe work holder can be decreased.

4.5.4 With increase of work holder pressure, thickness of fabric that can be held by the work holder de

creases.

4.6 Replacementofwork

To

replace

clamp.

the work clamp,

damp

remove

the work clampset screw

shown

in Fig.8 and

remove

the work

Work clamp set screw

Work clamp

Length

"A

Bracket

Fig. 8

Work

holder

shaft

-10-

Page 14

4.7 Installationofpiesser-foot (Fig. 9)

4.7.1 Install the presser-foot so

that

its lower

end

is in slight contact with the fabric when the fabric is

pressed down.

4.7.2 The presser-foot adjusted too high may causeskip stitch or uneven stitch.

4.7.3 The presser-foot adjusted too low may cause slippage

of

the fabric.

4.7.4 To adjust the presser-foot in height and direction, remove the rubber plug from the face plate and

loosen the presser bar

4.7.5 In

caseofchanging

set

screw shown in Fig. 9.

the thickness of the fabric, confirmthat the presser-foot doesnot touch the work

damp.

Presser

bar

set

screw

Face plate

Presser

bar

Presser-foot-

Fig. 9

4.8 Installation of pedal-presser-foot (Fig. 10)

To install the pedal-presser-foot,remove the motor cover,

and install the chain and the pedal as shown in Fig. 10.

In this

into

case,

contact

take

caretoprevent

with

the

lead

wires.

the

chain

from

Motor

cover

Chain

coming

Pedal

-11-

Fig.

10

Page 15

4.9 Windingupofbobbin thread

4.9.1 Lead the thread from the spool stand, as

shown in Fig. 11,

end

several

turns

and

twine the thread

around

the

bobbin.

4.9.2 Set upward the WIND switch on the

switch panel and then depressthe pedal.

(Refer to 5.7.)

4.9.3 After winding

switch

downward.

4.9.4.Ifthe thread is

up,

set the winding up

not

wound

cylindrically,

Bobbin

move the thread guide toward the

smaller

diameter.

Adjusting

4.9.5 Polyesterthread and nylon thread should bewound at faint tension.

4.10 Thread tension (Fig. 12)

Thread guide

nut

Fig. 11

Balance

Balanced

the

needle

tension

thread

tension

with

the

Unbalanced

Needle

or

bobbin

bobbin

thread

X

tension

thread

thread

Fig. 12

-12-

tight

tension.

loose.

X

Unbalanced

Needle

or bobbin thread tight.

tension

thread

loose

Page 16

4.10.1 Bobbin thread tension (Fig. 13)

The standard bobbin thread tension for

when thread end is held by fingers and the bobbin caseis released.

To adjust bobbin thread tension,turn the thread tensionadjusting screwshownin Fig. 13.

4.10.2 Needle thread tension (Fig. 14)

The needle thread tension should be adjusted with reference to the bobbin thread tension.

To adjust needlethread tension, turn the needlethread tensionadjustingnut shown in Fig. 14.

Bobbin

adjusting screw

flight

Loose

thread

cotton

tension

thread

#60isthat

the

bobbin case gradually goes down

Needle

adjusting

Loose

thread

Tight

tension

nut

Fig. 13

Fig. 14

-13-

Page 17

4.11

Oilgauge

Lubrication

Lubrication port

Hook clamp

OiltopositionsA,B,CandDshowninFig.7before

each oiling position.

For

oilingtotheodinletatthe

Note that too much oil might cause overflow if the head is leaned.

bed

top

(Fig.

15),

Fig. 15

fill

starting

the

oil

gaugeupto

sewing

work.

the

Use

red

marking

several

dropsofoil

with

oil.

for

rN

-14-

Page 18

5.

Switch

Panel

SCALE

SPEED1PATTERN

ERRl

O O

X Y I I

JOG

0

9

_200

RPM

0 "

2000

RPM

RESET

HOME

5.1 SCALE(Pattern Enlargemenl/Reduction)

Thepatterns

programmed

andstoredin the

of 0 to 1.99timesindependently in

ERR2

WIND

TEST

X-axis

SEW

TEST

AUTO

Fig. 16 Switch panel

memory

and

(PROM)

Y-axis

Cover

canbe

enlarged

or reducedwithina

direction. (Stitch lengthis

PROM

enlarged

cassette

range

or reduced.)

Ex.:

Hi

Use

the

switch

within010to

150%(1.5 times)

Fig. 17 Enlargement/Reduction switch

Cautions:

(1)

When

a pattern is enlarged, test should be made to make sure the

able rangerestricted by the work holder frame. (Refer 5.6.1)

(2) Whena pattern is enlarged,stitching speed may decrease. (Refer 7.4)

199%

enlarged

range.

pattern iswithin a

sew-

-15-

Page 19

5.2 SPEED(Stttchmg Speed Control)

The maximum stitching speed can be preset by this switch.

5.3 PATTERN (Pattern Selection)

The desired pattern can be selected by this switch.

5.4

JOG

The work holder can be exactly positioned by operating this switch after depressing the EMERGENCY

STOPswitch (provided on the machine head

5.4.1

When

the

JOG

switch

is set at ®

directionatan inching speed.

....

position,

Fig. 1) to stop the machine.

only

work

holder

advances

in the pattern

1

® 0 i

„

1 ^

—J

Thread

breakage

position

forwarding

5.4.2

5.4.3

When

the

tion at an

When

the

JOG

switch

indiing

JOG

speed.

switchiskept

Fig. 19 JOG switch

Stop

position

Fig. 18 Workholder movingdirection injog operation

isset at 0

©

NEUTRAL

position,

at0 or0

only

position,

work

work

holder

holder

moves

inthe

goesonforwardorbackward.

©

pattern

backwarding

direc

-16-

Page 20

5.5 RESET/HOME

5.5.1 RESET When the switch is set upward, the brake works causingimmediate

stopofthe sewing machine and the machine status is reset.

5.5.2 HOME When the switch is

home

position.

(If

the needle is not at UP position, the needle automatically goesup

set

downward,

the

work holder is

to UP position and the work holder is returned to the home posi

tion.)

In usual operation, the switch is kept downward

5.6 TEST/AUTO

Thisswitchallowsselectionbetweentest sewingand automatic sewing(regularsewing).

5.6.1

TEST

(1) Test run (Only work holder is moved The TEST/AUTO switch to be set downward.)

The work holder moves at a constant speed as far as the pedal is fully depressed by toe, and stops

when the pedal is retumed to NEUTRAL position. When the pedal is depressed by toe again, the

work holder resumes moving to complete remaining pattern motion.

The work holder does not rise when the pedal is returned to NEUTRAL position during the test

run, but rise when the pedal is retumed to NEUTRAL position after the completion of the test

run.

retumedtothe

(HOME

position)

(2) Sewing test (Work holder moves and sewing machine works The TEST/AUTO switch to be

set upward.)

The sewingmachine actually stitches the given fabric at the minimum speed as far as the pedal is

fully depressed, and stops with the needle at UP position after trimming the thread when the pedal

is returnedtoNEUTRAL position.

Whenthe pedal is fully depressedagain, the remaining pattern is sewn up.

The

work

holder

motionissameasthatintest

mn.

NEUTRAL

Slightly depressed

Fully depressed

Fig. 20 Pedal operation

-17-

Page 21

5.6.2

5.7

AUTO

(Actual

With

the

TEST/AUTO

one

cyde

(pattern)iscompleted

ing.

The

work

WIND

When

the

WIND

down

andthe

orYdirection.

When

the

pedalisreturnedtoNEUTRAL

tion.

sewing)

switchasAUTO

holder

goesupautomatically

switchis set upward and the pedal is fully

sewing

machine

starts

position,

even

when

the

afterthe

runningatmedium

position,

sewing

pedalisreturnedtoNEUTRAL

thread

the

startedbydepressing

trimming

speed,

sewing

machine

andthe

depressed

butthe

work

stops

the

pedal

continues

position

wiping

by toe, the work holder

holder

with

after

motions

does

not

the

needleatUP

the

are

move

until

start

over.

goes

inX

posi

Note:

Setting

machine

shouldbedepressed

5.8

ERROR

The

process does not advance.

5.8.1

5.8.2

indication

lamp

lightsinthe

ERR

1

"Green" The lamp

"Red" The lamp

ERR

2

"Green" The lamp

the

WIND

switchtoupward

operationatall.Tostart the

again

afterit is

following

cases

and

entered.

^ Usea conectly programmed

length becomeslarger than 6.0 mm.

50X30

position

winding

once

the

sewing

lights

lights

lights

mm.

while

motion

returnedto

machine

when

when pattern is

when

the

sewing

after

NEUTRAL

stops

with

no input data

PROM

the work

machineisrunning

sewing

operation

position.

the

needleatUP

exists

cassette.

excessively

holder

moves

or incorrect data is

enlarged

over

does

not

ends,

position,

and stitch

the

the

range

affect

pedal

thus

of

Reduce the pattern enlargement factor.

"Red" The lamp lights when temperature in the control box becomes too

high.

Consult

with

-18-

our

service

agency.

Page 22

6.

Operation

6.1 Setting the PROMcassette

Remove the coverofthe switch panel and insert the cassette into the slot.

The

cassette

After the setting, be sure to install the coveragain.

Aspecial

For handlingofthe cassette, refer to 8.2.

6.2

Setting the switches on switch panel

shouldbesetinthe

PROM

writer (PT-100,option) is necessary to eraseand rewrite programin the

correct

direction.

PROM.

In order to check the function, set the switches on the switch panel as shown in Fig. 16.(The

switch should be setto"100"

switch may be set to a suitable numeral within a range from

stored in the PROMapplied.)

6.3 Checking

When

the

above-mentioned

checkasfollows:

(1)

Home

position

(2)

Work

holder

(3)

Work

holder

the

pedalisfully

turnedto

In the

above

the

SEW

switch should be set upward.

Perform

retum:

DOWN:

motion:

depressed

NEUTRAL

checking,

TESTswitchis set

this

switching

for

both

X and Y axes, and the SPEED switch to

"0"

to '*9", depending on the program

preparatory operation has been completed, turn on the powersource and

When

the

power

switch

home

position.

When

the

pedalisslightly

down

(andgoup

The

work

holder

by toe, andstop

positon,

only

the

motion

the

work

downward

operationtocheck

isset to

when

the

should

moveinaccordance

when

stops

withthe

holder

moves

as shownin Fig. 16. To let work the

the

work

ON,

the

work

holder

depressed

by toe, the

work

pedalisreturnedtoNEUTRAL

with

the

the

patternissewn

work

andthe

holder

forits

holder

sewing

positions,

up.

lowered.)

machine

(When

remains

dimensions

"4".

The PATTERN

should

holder

position).

sewing

the

stopped

sewing

SCALE

return

should

pattern

pedal

machine,

and

location.

to the

go

when

is re

when

the

6.4

Sewing

(1) Setthe

(2) Set other

(3)

Setupa

starts

running,itwillgoon

pedalisreturnedtoNEUTRAL

TEST/AUTO

switches

fabric

and

mnning

when

switch

onthe

switch

asinstructedinsection 5.

slightly

depress

the

pedalisfully

until

the

the

sewing

position

pedal,

depressedbytoe.

cycleiscompleted

during

-19-

paneltoAUTO

the

work

the

sewing.

position.

holder

When

and

willgodown.

the

threadistrimmed

sewing

The

sewing

machine

even

machine

once

when

starts

the

Page 23

6.5 Emergency stop

The

sewing

machine

holder remains at

To start again, adjust the restarting position by the JOG switch and depress the pedal. The machine

resumesthe remaining pattem. (Refer to 5.4)

can be

DOWN

immediately

position when the sewingmaching is stopped.

stoppedbydepressing

the

emergency

stop

switch.

Thework

-20-

Page 24

6.6 Operationprocedure

Proceedinaccordance

Checking

before

starting

operation

(1) Is the power cable securely connected?

(2) Are other wiring or cables securely con

nected?

(3) Is the

(4) Are fuses (2 fuses)not blown out?

with

the

following

PROM

cassetteproperly set?

Preparation

start

Pedal

NEUTRAL

Power

switch

Does

Main

motor

run?

flowcharttooperate

ON

^

Power cable wiring

check

Power

switch

OFF

the

sewing

machine.

Section or paragraph

tobereferred

Operation

\

Preparatory

to

operation

Does No

work

holder

to home posi

tion?

WIND

switch

Slightly depress

pedal.

return

ON

HOME

switch to ON,

switchtoON-

and

Set

RESET

Adjustment of

work

holder

Does

work

holder

go

down?

Fully

depress

pedal

Power

switch

o

c

o

0

•o

u

5

Reverse

lationofrota

tion

plug.

ON

instal

reversing

sewing

Does

machine

run?

Pedal

NEUTRAL

Power

switch

OFF

mechanism

4.5

Checking

3.2,

of

3.4

1

o

X

u

-21-

Page 25

Power

Pedal

sw

NI

itch

OFF

lUTRAL

direction

rotation

rect?

Adjustment

synchronizer

Power

switch

OFF

Is

of

cor

Yes.

of

(

Testing

Adjustment

synchronizer

Check

RESET

HOME

PROM

swtich

switch

cassette

ON

ON

No.

>

Pedal

NEUTRAL

Does

needle

stop at

position?

WIND

<

^

(

(^TEST

switch

Pattern

selection

SCALE

swtich

Fully

pedal.

Does

work

move?

UP^

Yes.

OFF

^

setting

^

ON

\

depress

"

holder

>

Power

OFF

switch

Check

the

mechanism

cotnrol

box

driving

and

the

Pedal

NEUTRAL

relation^ip

between

work

Preparation

completed

Is

pattern

holder

conect?

holder

and

-22-

Adjustment

the

work

of

holder

Page 26

CJD

^

Sewing

^

Speed

AUTO

<

Fabric

up

<

start

setting

switch

ON

setting

^

^

)

Automatic

opeiation

(Actual

sewing)

Slightly depress

pedal

Is

fabric

secure

ly held?

Fully

depress

pedal

Does ^ No.

sewing machine

run

Pedal

NEUTRAL

Is Yes.

thread

broken

in

the

course

sewing?

Yes.

Pedal

NEUTRAL

PROM

data

error

Power

switch

OFF

Emergency

switch

of

fabric

properly?

ON

Is \

located

stop

No

Adjustbyop

erating

JOG

switch

thread

at

work

thread

work

the

ewing?

Does

wiper

torily?

Does

torily?^

stitching

even

Is \ No

trimmed

end

of

Ves

satisfac

Yes.

\

trimmer

satisfac

Is ^ No

No

Yes.

-23-

Fully depress

pedal

Power

switch

OFF

Adjustment

sewing

machine

of

Page 27

7.

CautionsonOperation

7.1 Before replacing

also noted that the power switch is set to OFF before insertion and removalofthe PROMcassette.

7.2

If

any ERR lamp lights, check for cause, referring to 5.8, and remedy.

PROM

in the

PROM

cassette, be sure to carefullyread 8.2 in this manual.Itshould be

7.3 When a new pattern is sewn, or pattern is enlarged, do not fail to check the relationshipbetween the

work holder and the pattern by conducting test operation.

7.4 The maximum stitching speed depends on stitch length, and is automatically restricted in connection

with stitch length as listed in Table 1.

Table

Stitch length

Below6mm

Below5mm

Below4mm

Below3mm

Below2mm

Below

1.5

mm

Max. speed

600

spm

850

spm

1100 spm

1400

spm

1600 spm

2000 spm

1

Sewing machine max. speed in con

nection with stitch length.

7.5 The

7.6 The foot

cover

of the control

malfunctionordefectofthe

device

shouldbereleased

phase

motor,

avoid

to operate the

shouldbe

machine.

from

the

pedal

closed,

pedal

before

because

during

settingthe

combination of the motor

"ON" (approx. 10 seconds).

7.7 The powershouldbe "OFF", priorto adjustmentof the

device for adjusting.

7.8

Avoid

a check of the interior control circuit

energizedby voltageof the tester and

damage

using

of these parts may be caused.

entranceof dustinto control

power

"ON" or "OFF". In

warming-up

sewing

machineoropening

a tester,

because

the parts of semiconductor are

device

caseofsingle-

afterthe

the

cover

maycause

power

of control

-24-

Page 28

8. Maintenance and Checking

8.1 Adjustment of synchronizer

Belt

cover

8.1.1

Remove

the

belt

cover.

To remove the belt cover, loosen the set screw, pull

up the belt cover and draw in the directionofanow

shown in Fig. 21.

Set

screw

Fig. 21

s

8.1.2 Adjustment

Ring

magnet

Machine

Gap

0.5-1.0

of

synchronizer gaps.

Adjust the gaps as illustrated in Fig. 22.

Directionofrotation

shaft

mm

\ /

V ' ^

. 1

\ ^

-"

Magnet

Magnet "B'

"A'

Gap

0.3—1.0

mm

8.1.3 Adjustmentofstop position

Arm

lO

\

Reference

Take-up lever

Fig. 23

Bracket

Fig.22 Synchronizer gapadjustment

Adjust the machine stop position so

lever

mark

thread

arm during

-25-

hole

the

the

DOWN

reference

;ip

meets

upward strokeofthe

that

the take-up

mark

on

take-up lever.

the

Page 29

8.2 ReplacementofPROM

Cover

PROM is installed on the

To

replace

(1)

(2) Take

(3)

(4)

PROM,

Lever

up the cassette casecover

out

the PC board from the cassette case.

Carefully

remove

Insertanew

shown in figure. PROM might be damaged,ifinstalled in wrong direction.

socketofPC

proceedasfollows

the

PROM

PROM

into the IC

from

board

in the cassette.

(see

Fig.

24 and 25):

usingascrewdriver.

theICsocket

socket

usingascrewdriver

in such way that the

PROMisinstalled

(5) Install the PC board in the cassette case and cover the cassette case.

D]

,

Printed

circuit

board

Lamp

PROM

oranyother

PROM

o

IC

socket

suitable

in the direction as

IC

pin

1

NotchofIC

means.

No.

I

Printed

board

circuit

socket

P]

Fig. 24 Cassette case

Notch

board

of

the

pin side.

IC

should

Fig. 25 PC board

come

to

the

PC

-26-

Page 30

8.3

Deaningoffan

8.3.1

Remove

the

external

filter

filter.

To remove, lever the external filter using a screwdriver.

8.3.2

8.3.3

Remove

Put

the

dust

from

extemal

the

filter

external

into

the

filter

keyway

and

to install it again.

Keyway Internal filter Extemal filter

internal

filter.

Fig. 26 Filter

Page 31

(8309)

A

ROD

MITSUBISHI

HEAD OFFtC&MITSUBtSHI DENKI BLDG.MARUNOUCKI TOKYO

ELECTRIC

CORPORATION

100

TELEX:

J24S32

CABLE MELCO TOKYO

Loading...

Loading...