Page 1

MITSUBISHI

Industrial

Sewing

INSTRUCTION

Single-Needle

Electronic

Model

Bar

Machine

MANUAL

PLK-0604

Lockstitch

Tack

Machine

A

MITSUBISHI

ELECTRIC

Page 2

In

ordertooperate

carefully

and

properly

the

sewing machine in

handle

and

maintain

the

the

sewing

best

condition

machine.

at all times, please read this Instruction Manual

Sections 1 9 describe

technical

1.

CONSTRUCTION

2.

SPECIFICATIONS

2.1

2.2

3.

INSTALLATION

information.

Specification

Replacement

3.1 Installing

3.2

Installing

3.3

Connection

3.4

Work

Lamp

3.5

Power

Cable

3.6

Installing

Parts

the

Table

the

Machine

of

Leads

Connection

the

Work

Leads

the

handlingofthe

for

Light

and

sewing

-

CONTENTS

machine

-

and

Sections

10

14 describe

the

detailed

Heavy Fabrics 5

Head 8

Holder

Pedal 11

1

2

7

9

10

10

4.

PREPARATION

5.

CONTROL

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

6.

OPERATION

6.1 Inserting

6.2

6.3

Switch

POWER

SCALE

PATTERN

SPEED

±JOG

RESET/HOME

STOP/MOVE

Error

Work

Work

HALT

START

Switch

Switch

AND

CAUTIONS

SWITCHES

Panel

ON

Switch

Switch

Switch

Switch

Indication

Holder

Holder

Switch

Switch

the

Setting

Function

AND

and

POWER

Switch

Switch

Pedal

Lift

Switch

(Foot

Switch)

PROM Cassette 17

on Switch Panel 17

Checking 17

THEIR

OFF

BEFORE

FUNCTIONS

Switches

THE

USE

6.4 Sewing Operation 18

6.5

HALT Switch Operation 18

6.6 Operation Procedure and Checking 19

12

13

13

13

14

14

14

15

15

15

15

15

16

16

Page 3

7. CAUTIONS ON USE 22

8. NAME

9.

HANDLING

9.1

9.2

9.3

9.4

9.5

OF

MAJOR

THE

InstallationofNeedle

Threading

Threading

Removing

Lubrication

the

the

the

with

PARTS

SEWING

Needle

Bobbin

Inner

Silicone

OF MACHINE HEAD 23

MACHINE

HEAD

Thread

Thread

Hook

Oil

9.6 Adjustment of Pressure 26

9.7 Replacingthe Work Holder Clamp Frame 26

9.8 Replacing the Feed Plate 26

9.9 Adjusting the Presser Foot 27

9.10 Adjusting the Wiper 27

9.11

WindingofBobbin

Thread 28

9.12 Thread Tension 28

9.13 Lubrication 29

10.

ADJUSTMENT

10.1

Machine

AND

Head

MAINTENANCE

10.1.1 Adjusting the thread winder 30

10.1.2 Adjusting the height of

needle

bar 30

10.1.3 Adjusting the driver 30

10.1.4 Adjustingthe hook 31

10.1.5 Adjusting the thread guide (above hook) 32

10.1.6 Adjusting the work holder pressure 32

10.1.7 Replacing

10.1.8 Adjusting

10.1.9

10.1.10

Adjusting

Adjusting

the

work holder clamp frame 32

the

position of work holder solenoid 33

the

presser

foot

the

thread

trimmer

10.1.11 Adjusting the trimmed thread tail length 36

10.1.12 Adjusting the thread release (tension disc pressure) 37

10.1.13 Adjusting

10.1.14 Adjusting

10.1.15

10.1.16

Adjusting

Adjusting

10.1.17 Adjusting

10.2

Control

Box

the

wiper 37

the

needle bar

the

home

the

X-Y

the

belt tensions (X-Y table) 41

position

table

stop

(UP) position

10.2.1 Cooling fan 42

10.2.2

Fuse

10.2.3 Magneticbreaker 42

10.3

LIMI-STOPZ

10.3.1

10.3.2

10.4

Filters

Motor

PreventionofMalfunction

Motor

DuetoNoise,

and

Grounding

24

24

24

24

25

33

35

38

39

40

42

43

43

44

Page 4

11.

12.

REPLACING

AUXILIARY

THE

PROM

FUNCTIONS

12.1 SWi

12.1.1 Repeat

function

12.1.2 Home position return cancellation at power turning on

12.1.3 Enlargement/reduction (SCALE) cancellation 47

12.2 SW2 47

13.

WIRING

DIAGRAMS

13.1 General Wiring Diagram

13.2

Motor

13.3

Stepping

13.4

Synchronizer

13.5

Start

13.6

SolenoidsinMachine

13.7

HALT

13.8

Stepping

13.9

Flat

Motor

switch,

Switch

cable

outer

Motor

connection

presser switch 51

Head

Position

Detector

table

45

46

46

49

50

51

51

52

52

52

52

14.

TROUBLESHOOTING

54

Page 5

Page 6

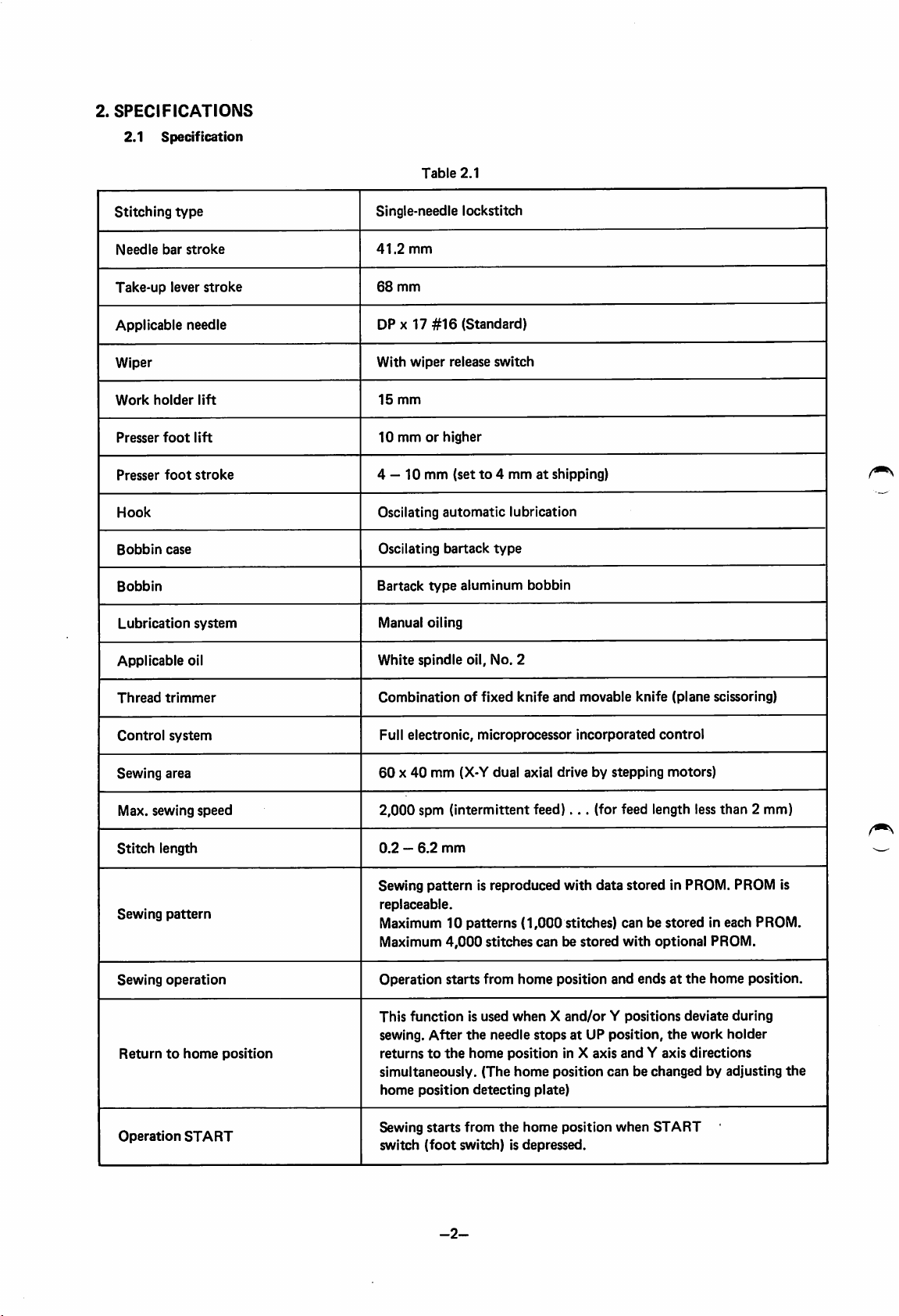

2.

SPECIFICATIONS

2.1

Specification

Table

2.1

Stitching

Needle

bar

Take-up

Applicable

Wiper

Work

holder

Presser

foot

Presser

foot

Hook

Bobbin

Bobbin

Applicable

case

Lubrication

type

stroke

lever

needle

oil

stroke

lift

lift

stroke

system

Single-needle lockstitch

41.2

mm

68

mm

DP X 17

With

15

10

4 —10mm

Oscilating

Oscilating

Bartack

Manual

White

#16

(Standard)

wiper

release

mm

mmorhigher

(setto4

automatic

bartack

type

aluminum

oiling

spindle

oil.

switch

mmatshipping)

lubrication

type

No.

bobbin

2

Thread

Control

Sewing

Stitch

Sewing

Sewing

trimmer

system

area

Max. sewing

Returntohome

Operation

speed

length

pattern

operation

START

position

Combinationoffixed

Full

electronic,

60X40

2,000

spm (intermittent

0.2—6.2

Sewing

replaceable.

pattern

mm

(X-Y

mm

microprocessor

dual

is reproduced

Maximum10patterns

Maximum

Operation

This

sewing.

returnstothe

simultaneously.

home

Sewing

switch

4,000

starts

function

After

position

starts

(foot

stitches

from

is used

the

needle

home

(The

detecting

from

the

switch)isdepressed.

knife

and

movable

incorporated

axial drive by

feed)...

with

(1,000

stitches)

canbestored

home

position

knife

control

stepping

(for feed length less

data

stored

canbestored

with

optional PROM.

and

endsatthe

whenXand/orYpositions

stopsatUP position,

position

home

plate)

home

in X axis

position

position

and

Y axis

canbechanged

when

START

(plane

scissoring)

motors)

than

2 mm)

in PROM. PROM is

in each PROM.

home

position.

deviate

the

work

during

holder

directions

by adjusting

the

-2-

Page 7

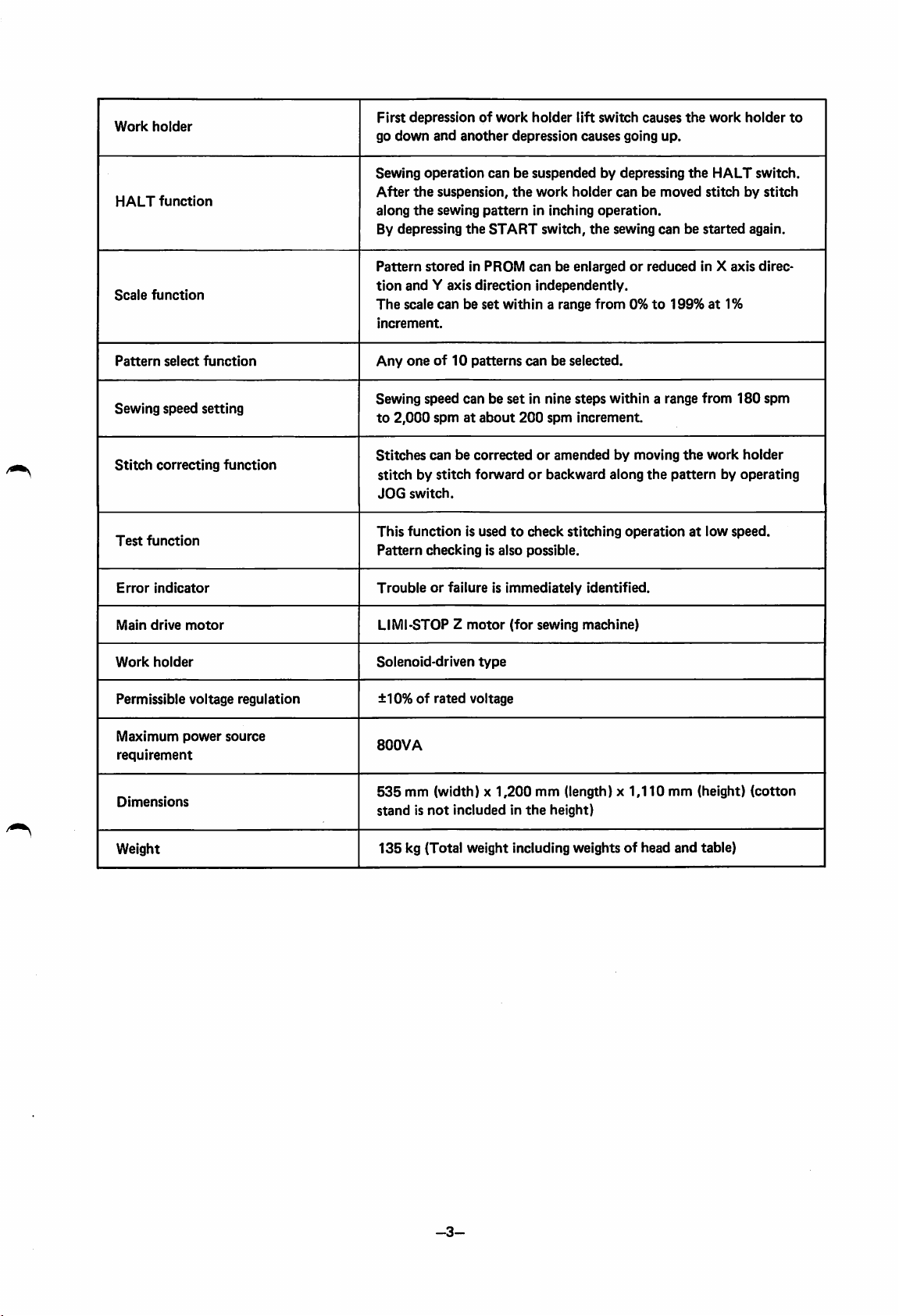

Work

holder

First

depressionofwork

go

down

and

another

holder

lift

switch

causes

depression causes going up.

the

work

holder

to

HALT

Scale

Pattern

Sewing

Stitch

Test

Error

Main

function

function

select

speed

correcting

function

indicator

drive

setting

motor

function

function

Sewing

After

along

By depressing

Pattern

tion

The

increment.

Any

Sewing

to

Stitches

stitchbystitch

JOG

This

Pattern

operation

the

suspension,

the

sewing

storedinPROM

and

Y axis

scale

canbeset

oneof10

speed

2,000

spmatabout

canbesuspendedbydepressing

pattern

the

START

direction

patterns

canbeset

canbecorrectedoramendedbymoving

forwardorbackward

switch.

function

is usedtocheck

checking

is also possible.

Troubleorfailure is

LIMl-STOP Z

motor

the

work

holder

canbemoved

in inching

switch,

canbeenlargedorreduced

operation.

the

sewing

independently.

within

a range

from0%to

canbeselected.

in nine

200

immediately

(for

steps

within

spm

increment.

along

stitching

operationatlow

identified.

sewing machine)

the

HALT

stitchbystitch

canbestarted

in X

axis

199%at1%

a range

the

from

the

work

patternbyoperating

speed.

switch.

again.

180

holder

direc

spm

Work

holder

Permissible

Maximum

requirement

Dimensions

Weight

voltage

power

regulation

source

Solenoid-driven

±10%ofrated

800VA

535

mm (width) x

standisnot

135

kg (Total weight including weights of head

type

voltage

1,200

includedinthe

mm (length) x

height)

1,110

mm (height)

and

table)

(cotton

-3-

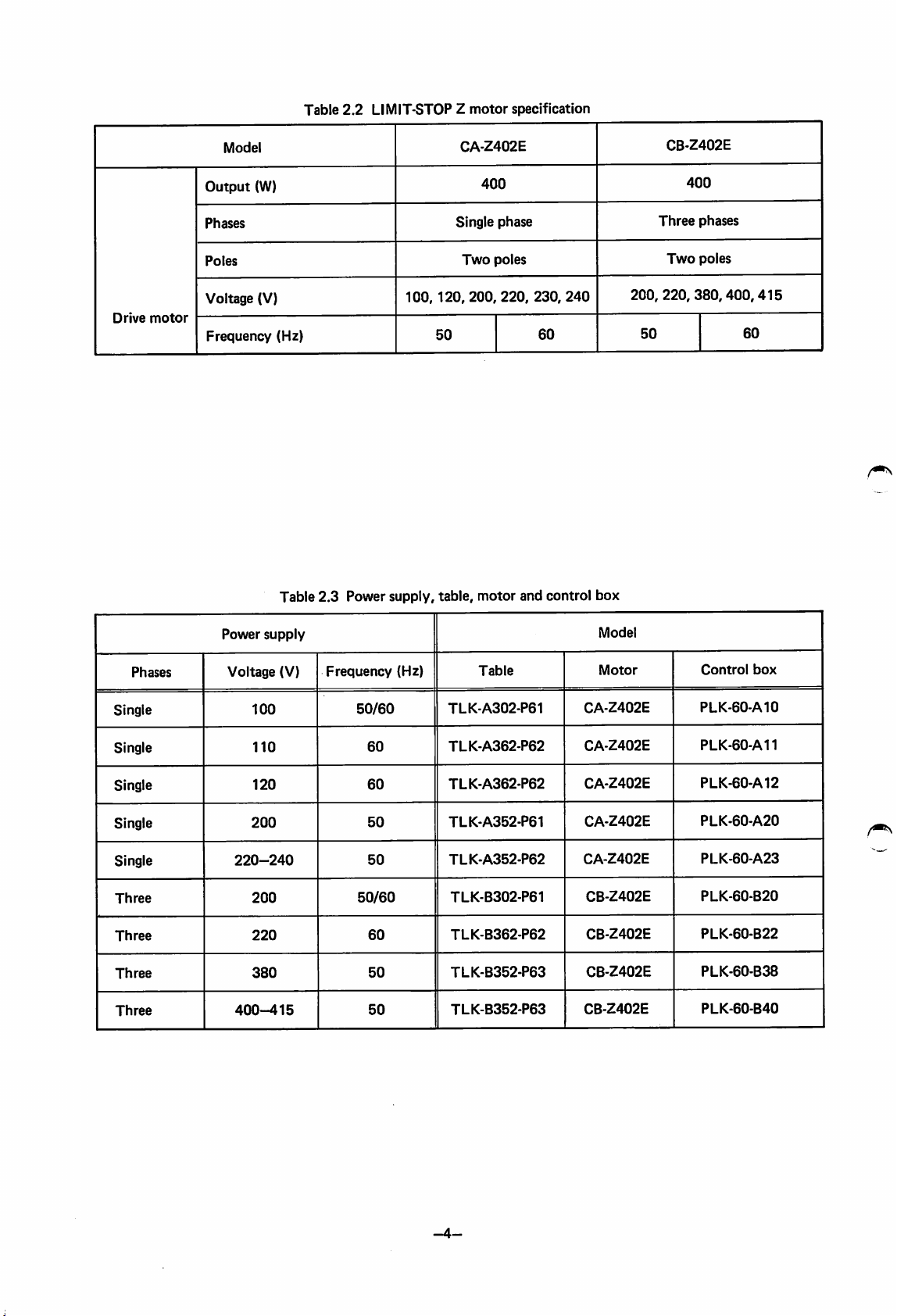

Page 8

Table

2.2

LIMIT-STOP Z

motor

specification

Drive

motor

Model

Output

Phases

Poles

Voltage

Frequency

(W)

(V)

(Hz)

Table

2.3

Power

100,

supply,

Single

120,

50

table,

CA-Z402E

400

phase

Two

poles

200,

220,

motor

and

230,

60

control

240

box

CB-Z402E

Three

Two

200, 220,

50

400

phases

poles

380,400,415

60

Phases

Single

Single

Single

Single

Single

Three

Three

Three

Three

Power

Voltage

220-240

400-415

supply

100

110

120

200

200

220

380

(V)

Frequency

50/60

60

60

50

50

50/60

60

50

50

(Hz)

Table

TLK-A302-P61

TLK-A362-P62

TLK-A362-P62

TLK-A352-P61

TLK-A352-P62

TLK-B302-P61

TLK-B362-P62

TLK-B352-P63

TLK-B352-P63

Model

Motor

CA-Z402E

CA-Z402E

CA-Z402E

CA-Z402E

CA-Z402E

CB-Z402E

CB-Z402E

CB-Z402E

CB-Z402E

Control

PLK-60-A10

PLK-60-A11

PLK-60-A12

PLK-60-A20

PLK.60-A23

PLK-60-B20

PLK-60-B22

PLK-60-B38

PLK-60-B40

box

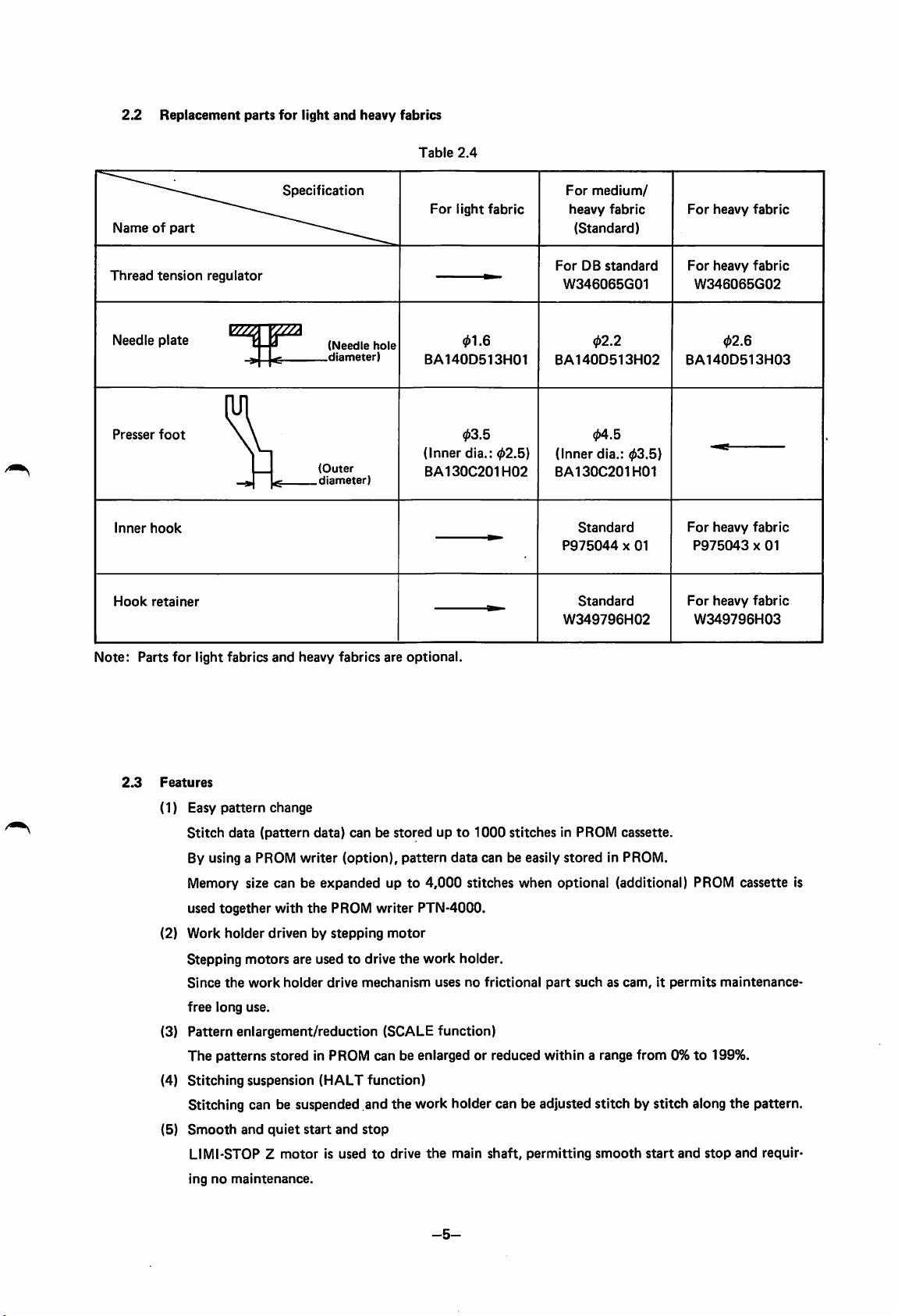

Page 9

2.2

Replacement

parts

for

light

and

heavy

fabrics

Table

2.4

Nameofpart

Thread

Needle

Presser

Inner

Hook

tension

plate

foot

hook

retainer

regulator

E^-pza

Specification

(Needle

.diameter)

(Outer

^

diameter)

hole

For

light

fabric

01.6

BA140D513H01

03.5

(Inner

dia.;

BA130C201H02

02.5)

For

medium/

heavy

fabric

(Standard)

For

DB

standard

W346065G01

02.2

BA140D513H02

04.5

(Inner dia.:

BA130C201H01

Standard

P975044X01

Standard

W349796H02

03.5)

For

heavy

fabric

For

heavy

fabric

W346065G02

02.6

BA140D513H03

For

heavy

fabric

P975043X01

For

heavy

fabric

W349796H03

Note:

2.3

Parts

for

light

fabrics

and

heavy

fabrics

are

optional.

Features

(1) Easy

(2)

(3)

(4)

pattern

Stitch

By using a PROM

Memory size

together

used

Work

change

data

(pattern

canbeexpandedupto

with

holder

drivenbystepping

data)

writer

the

canbestoredupto

(option),

PROM

writer

Stepping motors are used to drive

Since

the

work

holder

drive

mechanism

free

long

use.

Pattern

The

Stitching

enlargement/reduction

patterns

stored

suspension

in PROM can be enlarged or reduced

(HALT

function)

pattern

PTN-4000.

motor

the

(SCALE

1000

data

can be easily

4,000

stitches

work

holder.

usesnofrictional

function)

stitches

when

in PROM

stored

optional

part

within

cassette.

in PROM.

(additional) PROM

suchascam,itpermits

a range from 0%to199%.

maintenance-

Stitching can be suspended and the work holder can be adjusted stitch by stitch along the pattern.

(5)

Smooth

LIMI-STOP Z

ingnomaintenance.

and

quiet

motor

start

and

stop

is usedtodrive

the

main

shaft,

permitting

smooth

start

and

stop

cassette

and

requir

is

-5-

Page 10

(6) Test function for checking

the

pattern

The work holder movement and stitching motion can be tested at low speed.This function is very

helpful

(7) Various

oPROM

whenanew

safety

functions

cassette

oData

input

o Excessive

oWork

oMotorormachine

oV-belt

trouble.

Error

holder

outofpulleyorbreakage

indication

loading

error

enlargement

overrun

pattern

detection

alarm

standstill

lamps

is stored.

confirmation

alarm

alarm

are

usedtogive

(duetooverload)

alarm

alarms,

permitting

immediate

identification of

(8) Microprocessor incorporated full-electronic control system

8-bit

(9)

microprocessor is used in

Automatic

home

position

return

the

control

function

system.

Since the work holder automatically returnsto the home positionwhen one pattern iscompleted,

error

dose

not

accumulate.

cause

of

-6-

Page 11

3.

INSTALLATION

3.1

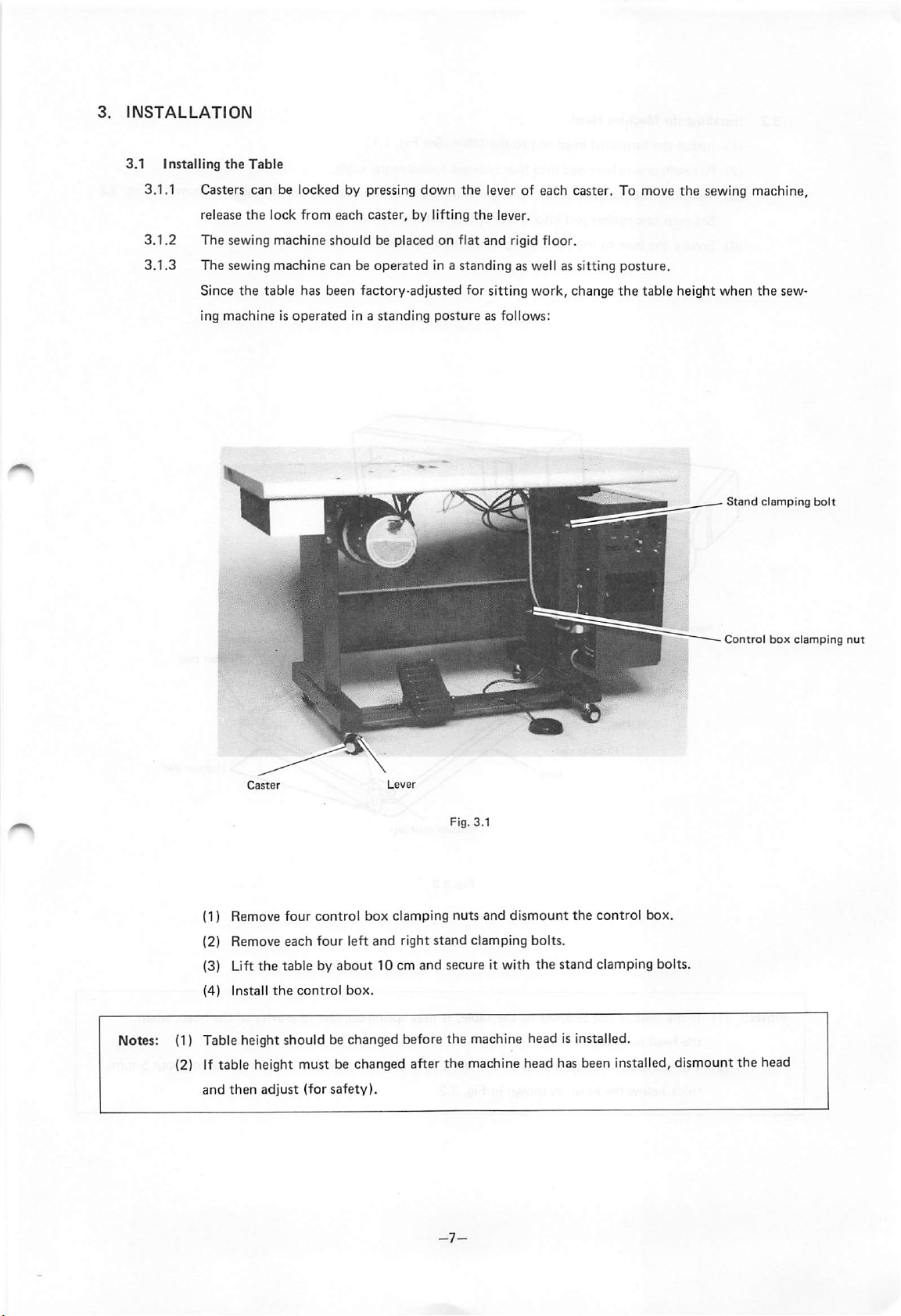

3.1.1 Casters can be locked by pressing down the lever of each caster. To move

3.1.2

3.1.3

Installing

the

release

Table

the

lock

from

each

caster, by lifting

the

The sewing machine should be placed on flat and rigid floor.

The

sewing

machine

Since

the

table has been factory-adjusted for sitting

ing

machineisoperated

canbeoperated

in a

standing

in a

standing

postureasfollows:

lever.

as well as

work,

sitting

change

the

posture.

the

table height when

sewing machine,

the

sew

Stand

clamping

bolt

Fig. 3.1

(1) Remove

(2) Remove each

(3) Lift the table by

(4)

Install

the

four

control

control

four

about

box.

box clamping nuts and

left

and

right

stand

dismount

clamping

bolts.

the

control

10 cm and secure it with the stand clamping bolts.

Notes: (1) Table height should be changed before the machine head is installed.

(2) If table height must be changed after the machine head has been installed, dismount the head

and

then

adjust

(for

safety).

box.

Control

box

clamping

nut

Page 12

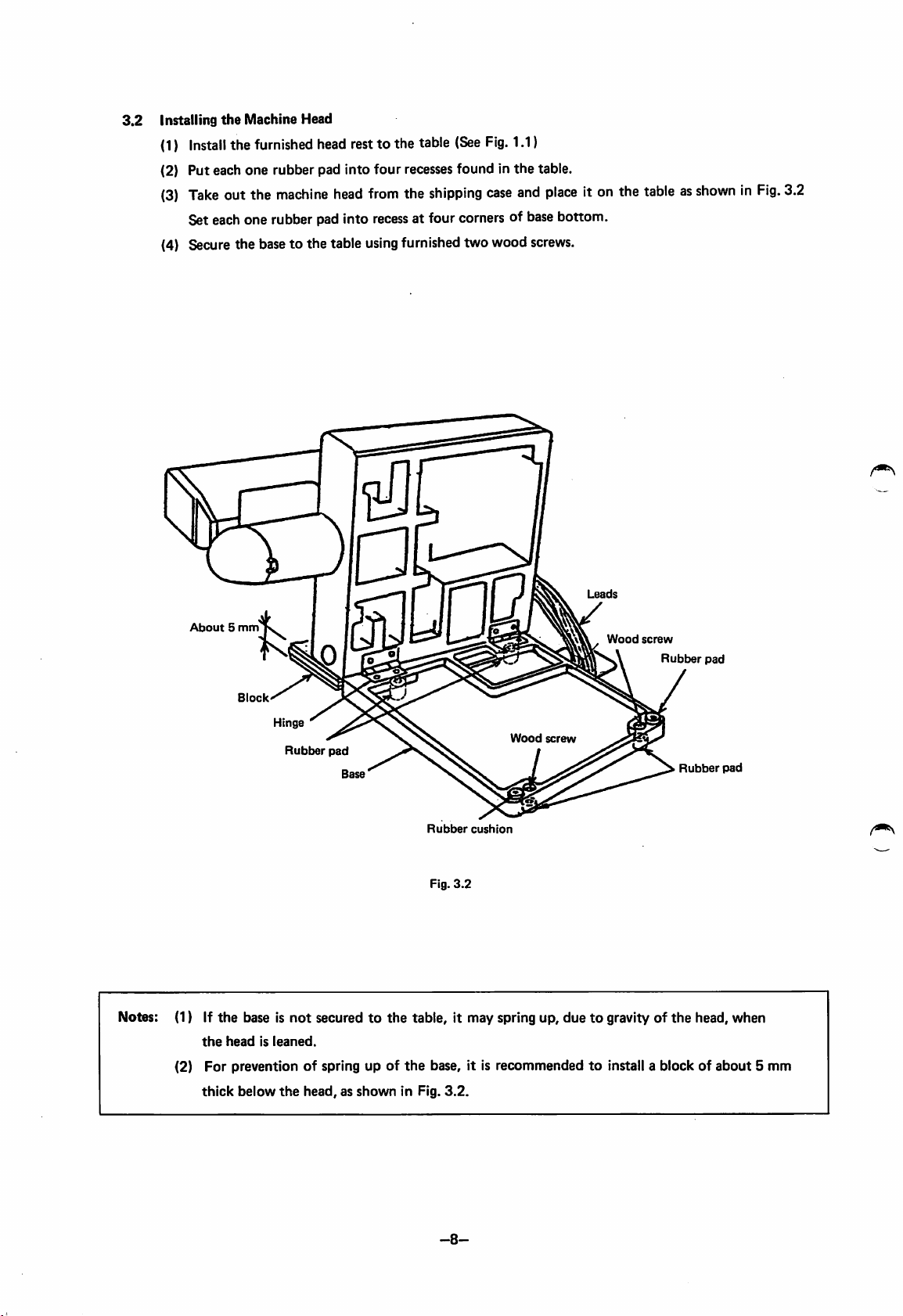

3.2

Installing

(1)

(2) Put each one rubber pad into four recesses found in

(3)

the

Machine Head

Install

the

Take

furnished

outthe

headrestto the table

machine

head

Set each one rubber pad into

from

the

shipping

recess

at four corners of base bottom.

(4) Secure the baseto the table usingfurnished two wood

El

(See

Fig.

case

1.1)

the

and

table.

place

screws.

it on the

tableasshowninFig.

3.2

About5mm

Notes: (1) If

(2)

Block

Hinge

Rubber

the

base is

not

securedtothe

the

headisleaned.

For

prevention of spring up of

thick

below

the

head,asshown

pad

P

Leads

.

Wood

M

wood

screw

Rubber

cushion

Fig.

3.2

table, it may spring up, duetogravity of

the

base, it is recommendedtoinstall a block of

in Fig.

3.2.

screw

Rubber

Rubber

the

pad

pad

head, when

about

5 mm

-8-

Page 13

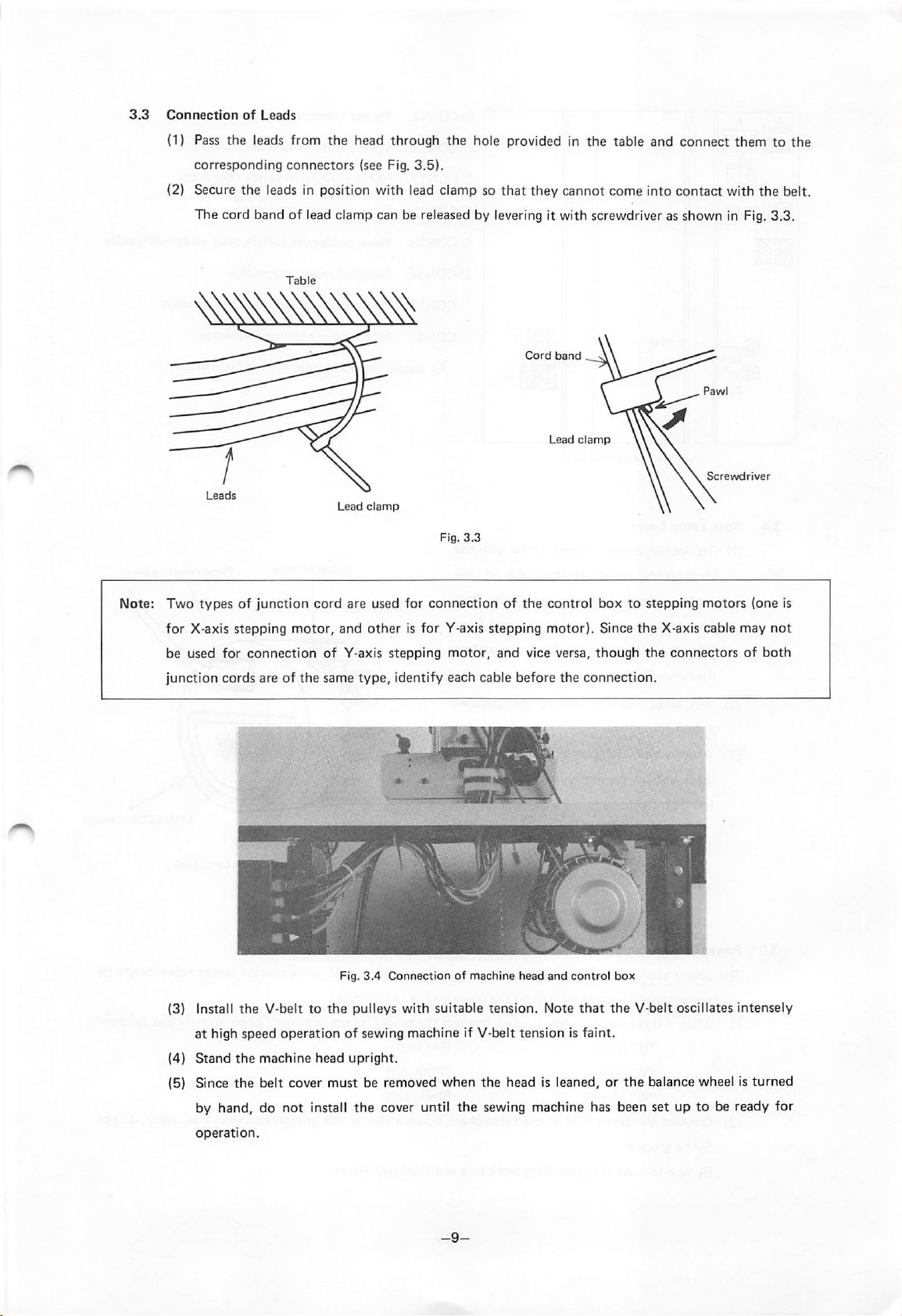

3.3

Connection

of

Leads

(1} Pass the leads from the head through the hole provided in the table and connect them to the

corresponding

(2) Secure the leads in position with lead clamp so

connectors

(see Fig.

3.5).

that

they

cannot come into contact with

The cord band of lead clamp can be released by levering it with screwdriver as shown in Fig.

Cord

band

Lead

clamp

Screwdriver

Lead

clamp

Fig.

3.3

the

belt.

3.3,

Note: Two

for

be

junction

(3) Install

(4)

(5) Since

typesofjunction

X-axis

stepping

used

for

connection

cords are of

the

V-belttothe

at

high

speed

Stand

the

machine

the

belt cover must be removed

cord

are used for

motor,

the

and

of

same

Fig.

otherisfor

Y-axis

stepping

type,

3.4

Connectionofmachine

pulleys

operationofsewing

head

upright.

connectionofthe

Y-axis

stepping

motor,

and

control

motor).

vice versa,

identify each cable before the

head

and

with

suitable

machine

when

tension.

if V-belt

tensionisfaint.

the

head is leaned, or

Note

box to stepping

Since

though

connection.

control

box

that

the

the

motors

the

X-axis

cable

the

connectorsofboth

V-belt oscillates

balance wheel is

(one is

may

intensely

turned

by hand, do not install the cover until the sewing machine has been set up to be ready for

operation.

not

Page 14

ooo

ooo

ooo

ooo

OOP

Iddbdl

00

oooo

O

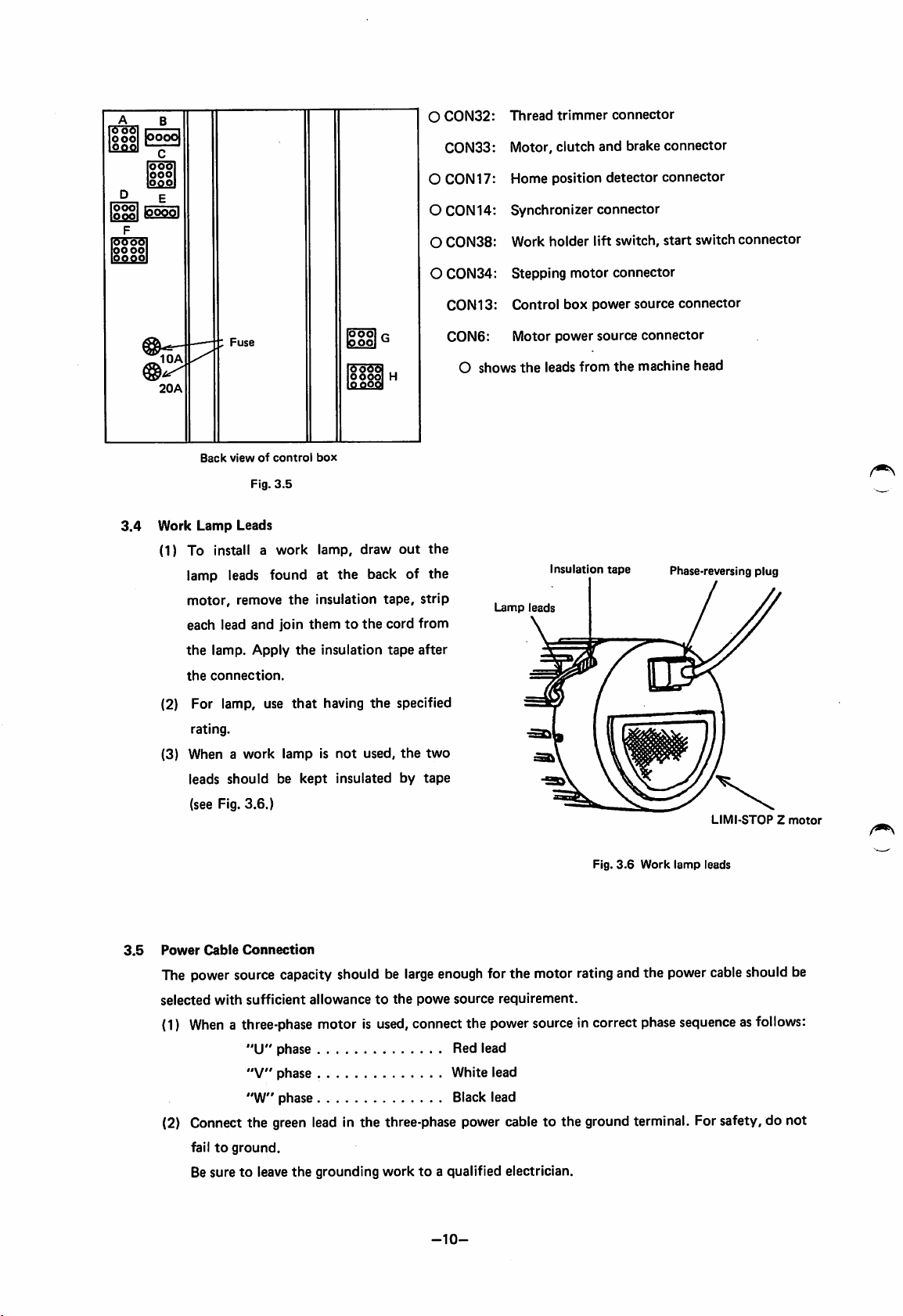

CON32:

CON33;

lOOOl

ooo

ooo

O CON 17:

OCON14:

oo

O CON38: Work holder lift switch, start switch connector

O

CON34:

CON

Thread

Motor,

Home

Synchronizer

Stepping

13:

Control

trimmer

clutch

position

motor

box

connector

and

brake

detector

connector

connector

power

source

connector

connector

connector

3.4

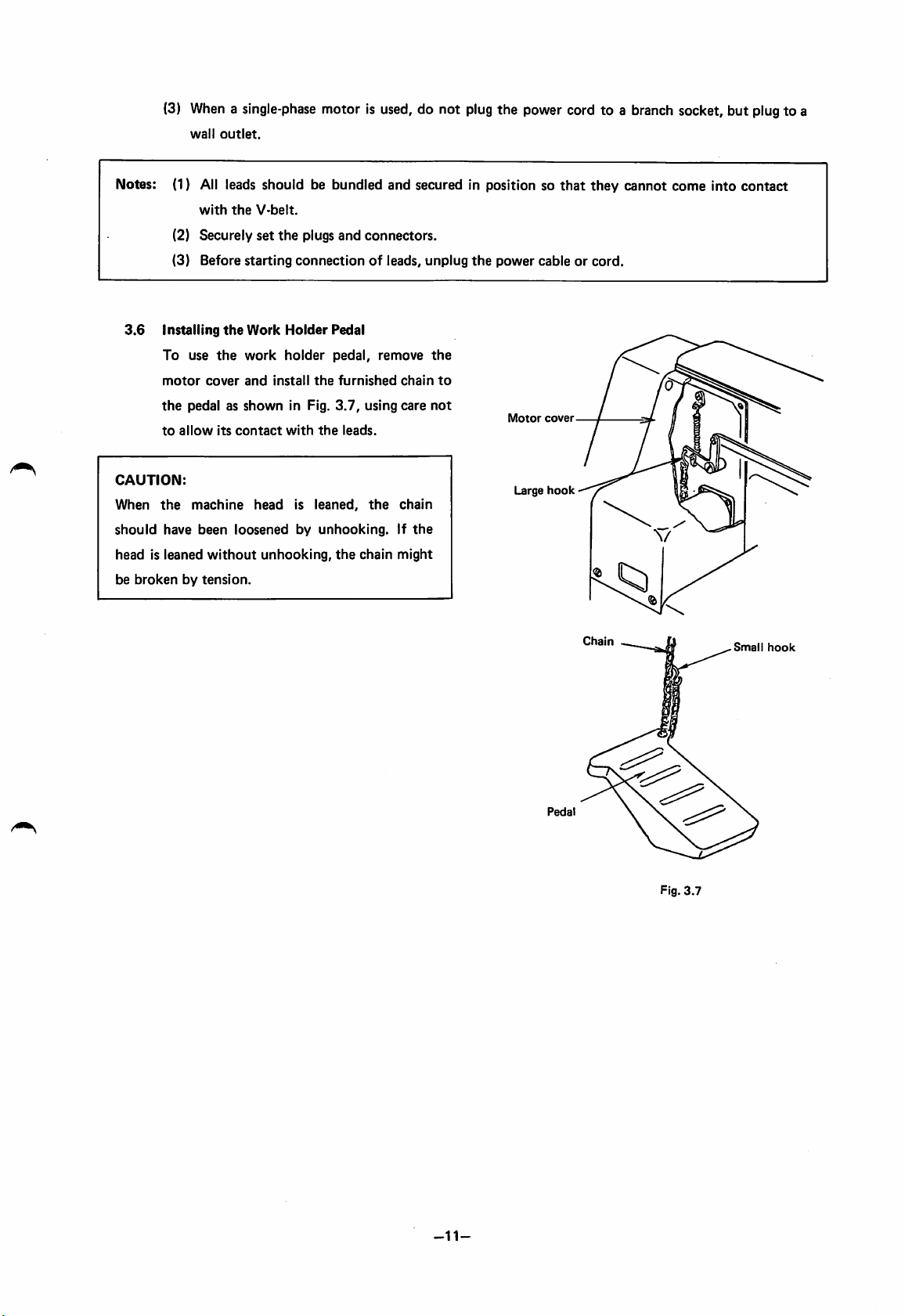

Work

(1) To install a

lamp leads found at

motor,

each

the

the

(2) For lamp, use

(3) When a

Fuse

Back

viewofcontrol

Lamp

lead

lamp. Apply

connection.

rating.

leads

should

(see Fig.

Fig.

Leads

remove

and

work

3.6.)

po^

I

odoo

oooo

box

3.5

work

lamp,

the

the

insulation tape, strip

join

themtothe

the

insulation

that

having

lampisnot

be

kept

insulated

oo

draw

back of

cord

the

used,

out

from

tape

after

specified

the

by

the

the

two

tape

C0N6:

O shows

Lamp

Motor

power

source

connector

the

leads

from

the

machine

Insulation tape Phase-reversing plug

leads

head

LIMI-STOPZmotor

Fig.

3.6

Work

3.5

Power

Cable

Connection

The power source capacity should be

selected

(1)

with

sufficient

When

a three-phase motor is used,connect the powersource in correct phasesequence asfollows:

"U"

"V"

"W"

allowancetothe

phase Red lead

phase

phase Black lead

large

enoughfor the motor ratingand the powercableshould be

powe

source

requirement.

White lead

(2) Connect the green lead in the three-phase power cable to the ground terminal. For safety, do not

failtoground.

Be

suretoleave

the

grounding

worktoa qualified electrician.

-10-

lamp

leads

Page 15

(3)

Whenasingle-phase

wall

outlet.

motor is

used,

do not

plug

the

power

cord to a

branch

socket,but

plug

to a

Notes: (1) All leads should be bundled and secured in position so

with

the

V-belt.

(2) Securely

(3) Before

3.6

installing

To

use

motor

the

pedalasshown

to

allow

CAUTION:

When

the

machine

should

have

headisleaned

be

brokenbytension.

cover

been

without

set

the

the

its

the

contact

starting

Work

work

and

install

head

plugs and

connectionofleads,

Holder

holder

the

in Fig.

with

the

is

leaned,

Pedal

pedal,

furnished

3.7,

leads.

connectors.

remove

using

the

loosenedbyunhooking.Ifthe

unhooking,

the

chain

chain

care

chain

might

unplug

the

to

not

the

power

Motor

Large

cable or

that

they cannot come into contact

cord.

cover

hook

Pedal

Chain

Fig.

3.7

Small

hook

-11-

Page 16

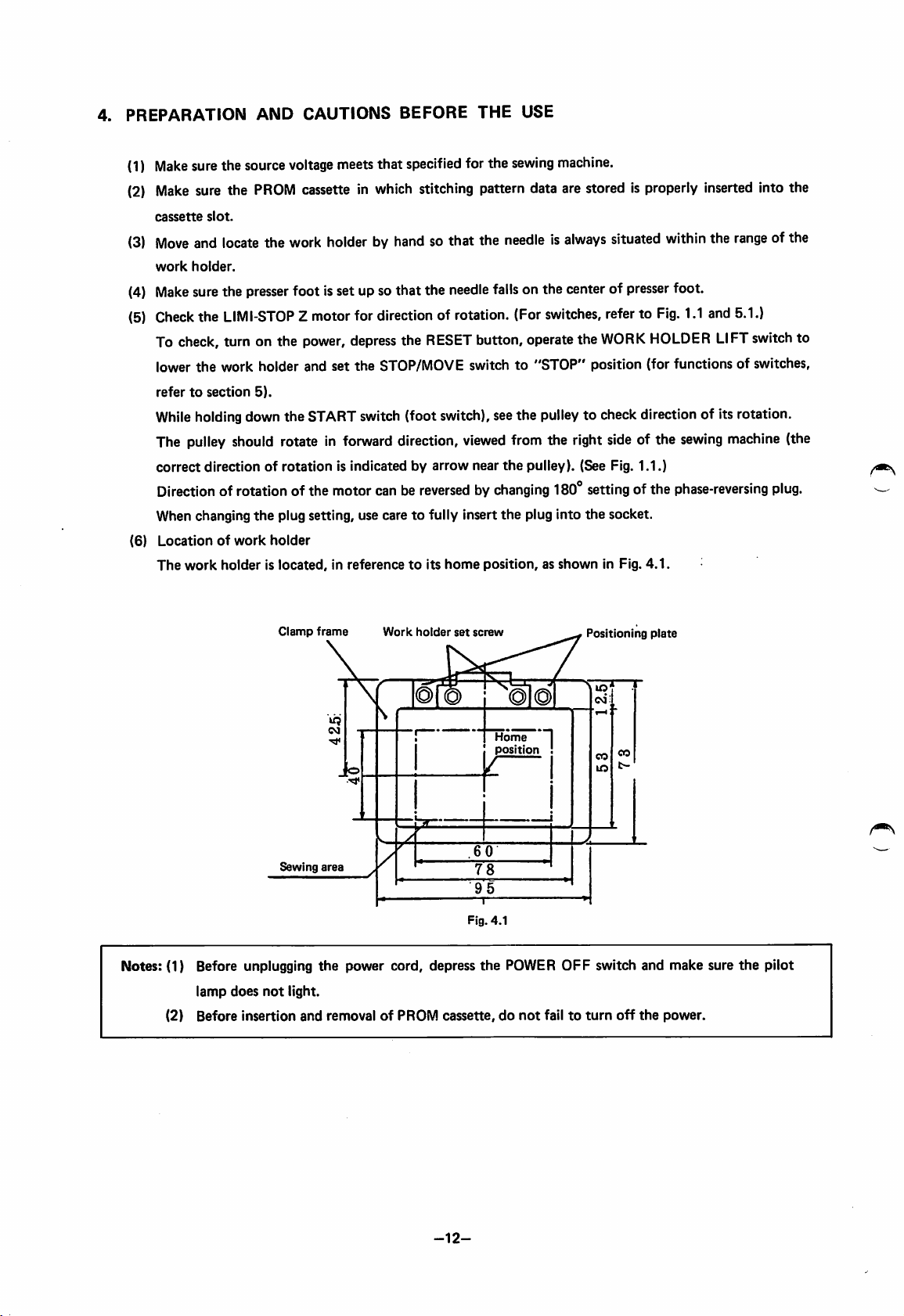

4. PREPARATION AND CAUTIONS

(1)

Make

(2)

(3)

(4)

(5)

surethe source

Make

sure the

cassette

Move

and

work

holder.

Make

surethe

Check

the

To

check,

slot.

locate

LIMI-STOPZmotor

turn on the

PROM

the

presser

voltage

work

meetsthat specified for the

cassette in

holderbyhand

foot isset up so that the

power,

which

for

directionofrotation.

depress

lower the work holder and set the

refertosection

While

holding

The

pulley

correct

Direction

When changing

(6)

Locationofwork

The

work

directionofrotationisindicatedbyarrow

5).

down the STARTswitch(foot switch),seethe pulleyto check directionof its rotation.

should

rotate in

forward

of rotationof the motor canbe

the

plug setting, use care to fully insert the plug into the socket.

holder

holderislocated,inreferencetoits

BEFORE

THE

USE

sewing

machine.

stitching pattern data are stored is properly inserted into the

sothat the

needle

the

RESET

STOP/MOVE

direction,

reversedbychanging

home

needleisalways

fallson the center of

(For

switches,

button,operate the

situated

presser

refertoFig.

WORK

HOLDER

within

foot.

1.1

the

and

LIFT

switch to "STOP" position (for functions of switches,

viewed

from the right sideof the

near

the

pulley). (See Fig.

180®

position,asshown

settingofthe

in Fig.

sewing

1.1.)

phase-reversing

4.1.

range

5.1.)

switch

machine

ofthe

to

(the

plug.

Clamp

Sewing

Notes: (1) Before unplugging

lamp

does

not

light.

(2)

Before

Insertion

frame

area

the

power cord, depress

and

removalofPROM

Work

holder

set

Fig.4.1

cassette,donot

screw

Home

position !

the

POWER

failtoturn

Positioning

I

OFF

switch and make sure

off

the

plate

power.

the

pilot

-12-

Page 17

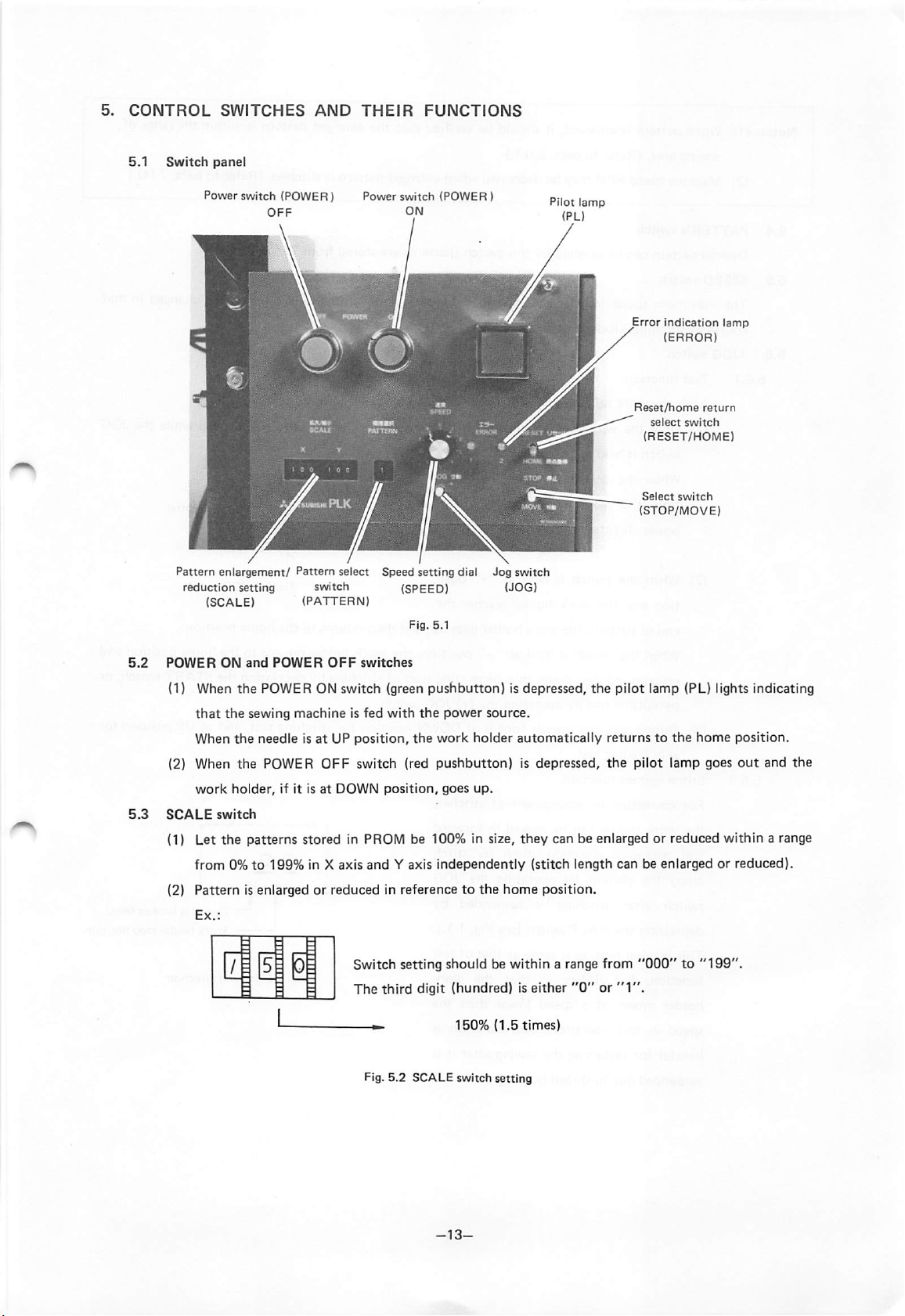

5.

CONTROL

5.1

Switch

SWITCHES

panel

AND

THEIR

FUNCTIONS

Power switch (POWER]

OFF

Pattern

enlargement/

reduction setting switch (SPEED) (JOG)

(SCALE)

Pattern

(PATTERN)

select

Power

switch

Speed

ON

setting

Fig. 5.1

(POWER)

dial

Jog

switch

Pilot

(PL)

lamp

Error

Indication

(ERROR)

Reset/home

select

switch

(RESET/HOME)

Select

switch

(STOP/MOVE)

lamp

return

5.2

5.3

POWER

(1) When

(2) When

SCALE

that

When

work

switch

ON

and

POWER

the

POWER ON switch (green

the

sewing

the

needleisatUPposition,

the

POWER

holder,

if it isatDOWN

OFF

machineisfed

OFF

switches

with

the

switch (red

position,

pushbutton)

the

power

work

holder

pushbutton)

goes

up.

is depressed,

source.

automatically

is depressed,

the

pilot lamp (PL) lights indicating

returnstothe

the

pilot lamp goes

home

(1) Let the patterns stored in PROM be 100% in size, they can be enlarged or reduced within a range

from

0%to

199%

in X axis

(2)

Patternisenlargedorreducedinreferencetothe

/i^

and

Y axis

independently

Switch setting should be

The

third

digit (hundred) is

—

Fig.

5.2

150%

SCALE switch setting

home

(1.5

(stitch

within

either

times)

length

position.

a range

"0"or"1".

canbeenlargedorreduced).

from

"000"to"199".

position.

out

and

the

-13-

Page 18

Notes:

5.4

5.5

5.6.

5.6.1

(1)

When

patternisenlarged,itshouldbeverified

sewingarea. (Refer to para. 5.6.1.)

(2)

Machine

PATTERN

Desired

SPEED

The

maximum

course of stitching. (Refertopara. 7 (4).)

±JOG

speed

switch

pattern

switch

canbeselectedbythis

speed

switch

Test

function

After

the

work

(1)

Only

the work holder

switchisheldat*'+"

When

the

tion,

the

posite

direction.

RPM

maybedecreased

(regular

holder

returnstothe

switchisset

work

holder

stitching

advances

position.

at

moves in

that

the

enlarged

when

switch

speed)

home

enlarged

(patterns

isset by

position

patternisstitched.

are

stored

this

switch.

andislowered,

in the stitching direction at a

posi

op

patterniswithin

from

"0"inPROM).

Speed

cannotbechangedinmid

fixed

the

range

(Refertopara.7(4).)

speed

while

the JOG

Neutral

of

5.6.2

(2) When

tion

the

switch is held at

and

the

work

holder

"+"

reaches

posi

the

Fig.

5.3

JOG

switch

end of pattern, the work holder goes up, and then returnstothe home position.

to

When the switch is held at " position, the work holder returns

the home position and

remains stopped there, thus permitting start of stitching by depressingthe START switch, or

permitting

(3)

During

skip

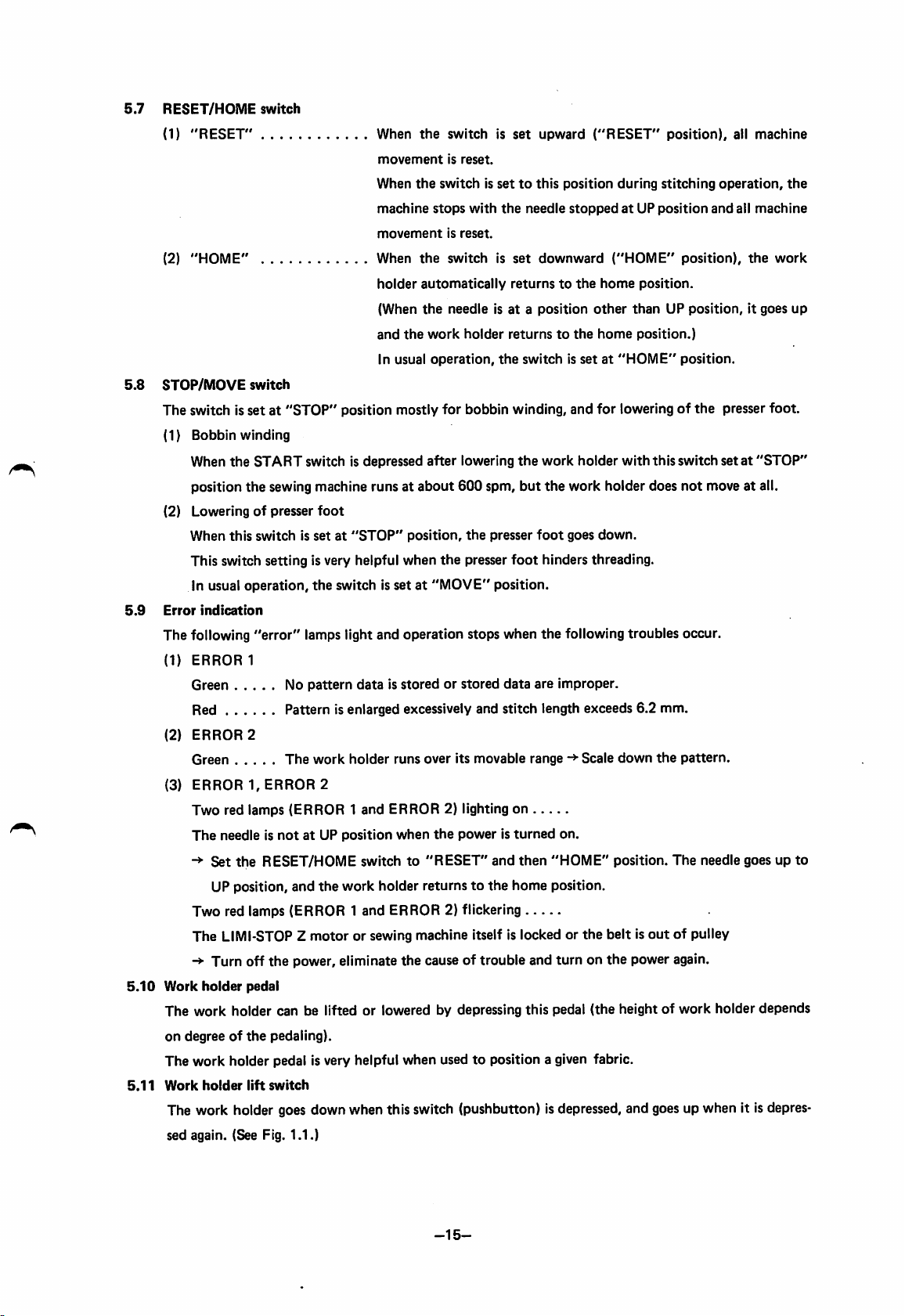

Stitch

correct

For

correction

the

work

and

backward

along the pattern by operating the JOG

switch after stitching is suspended by

depressing

This inching motion is same as

function,

holder

speed in

helpful

suspended

testbyoperating

test, the

feeding

holder

the

but

movesata

test

for

restarting

duetothread

presser

test.

function

or

amendment

can be moved in

direction

HALT switch (see Fig. 1.1.).

differs in

speed

operation.

This

the

sewing after it is

breakage.

foot is at

of

stitch

thatoftest

that

lower

function

the

stitches,

forward

by

the

than

(+)

JOG

DOWN

stitch

work

the

switch.

position for stitching test, and atUPpositionfor

| |

© ©

-K-

Threadisbroken

Work

holder

Fig.

5.4

Inching

direction

is

stop

here.

position.

-14-

Page 19

5.7

RESET/HOME

(1)

"RESET"

(2)

"HOME"

5.8

STOP/MOVE

The switch is

(1)

Bobbin

When

position

(2) Loweringofpresser

When

This switch setting is very helpful when

In usual operation,

5.9

Error

indication

The following

(1)

ERROR

Green

switch

switch

setat"STOP"

winding

the

START

the

sewing machine runsatabout

this

switchissetat"STOP"

"error"

1

No

position mostly for bobbin winding, and for lowering of

switch is depressed

foot

the

switch is setat"MOVE"

lamps light and operation stops when the following troubles occur.

pattern

dataisstoredorstored

When

the

switchisset

movementisreset.

When

the

switchissettothis

machine

movement

When

holder

(When

and

In usual

stops

with

is

reset.

the

switchisset

automatically

the

needleisataposition

the

work

holder

operation,

after

lowering

600

position,

the

the

presser

upward

position

the

needle

stoppedatUP

downward

returnstothe

returnstothe

the

switchissetat"HOME"

the

work

holder

spm,

but

the

work holder does

presser

foot

goes

foot

hinders threading.

position.

data

are

improper.

("RESET"

during

("HOME"

home

other

home

position),

stitching

position

position),

position.

thanUPposition,itgoes

position.)

position.

the

with

this

switch set at

not

down.

and

move at all.

Red Pattern is enlarged excessively and stitch length exceeds 6.2 mm.

(2)

ERROR

Green

(3)

ERROR1,ERROR

2

The

work

holder

runs

over

its movable range

2

-*•

Scale

down

the

pattern.

Two red lamps (ERROR 1 and ERROR 2) lighting on

The

needle is

Set

UP position, and

notatUP

the

RESET/HOME

position

switchto"RESET"

the

work holder

when

the

retumstothe

poweristurned

and

then

home

on.

"HOME"

position.

position.

The

needle goesupto

Two red lamps (ERROR 1 and ERROR 2) flickering

out

of pulley

5.10

The LIMI-STOP Z motor or sewing machine itself is locked or the belt is

-»•

Turn off the power, eliminate the cause of trouble and turn on the power again.

Work

holder

pedal

The work holder can be lifted or lowered by depressing this pedal (the height of work holder depends

on degreeofthe

The

5.11

Work

work

holder

pedaling).

holder pedal is very helpful when usedtoposition a given fabric.

lift

switch

The work holder goes down when this switch (pushbutton) isdepressed, and goes up when it isdepres

sed again. (See Fig.

1.1.)

all

machine

operation,

all

machine

the

work

presser foot.

"STOP"

the

up

-15-

Page 20

5.12

HALT

switch

Thisswitch isusedto suspendstitchingoperation

5.13

START

When

switch

(Foot

switch)

this switchis depressed,

sewing

(when

thread isbroken, for example),

starts from the home position.

(See

Fig.

1.1.)

(See

Fig.

1.1.)

-16-

Page 21

6.

OPERATION

6.1

6.2

6.3

inserting

Open

the

PROM

Cassette

the

switch panel front cover and Insert a PROM cassette In which necessary pattern data have

been stored Into the cassette slot, using care not to Insert It In wrong direction. After the Insertion,

Install

the

front

cover

again.

For

pattern

PTN-4000) Is necessary.

Switch

In

ordertocheck

To

check,

position

As

for

Switch

When

each

function

(1)

Home

Set

returnstothe

(2)

Work

The

the

(3)

Work

The

tion.

returntothe

to

When

occur.

By

performing

To

check

6.4.

writing

SettingonSwitch

each

set

the

SCALE switches (for X axis

ranging

the

Function

the

the

from

RESET/HOME

Checking

above-Instructed

as

follows:

return:

RESET/HOME

home

holder

lowering

work

holder

switchIsdepressed

holder

movement:

work

holder

When

the

work

home

"NEUTRAL"

the

above-mentioned

the

test,

stitching

condition,

and

erasuretoand from PROM, optional PROM writer (PT-100, PT-100A or

For

handlingofPROM cassettes, refertosection

Panel

function,

"0"to"9",

position

set

each

switchonthe

and

the

switch

and

the

STOP/MOVE

preparatory

switchto"RESET",

operation

(Refertopara.

SPEED

switch

and

Y axis)to"100",

switchto"4".

switch,

has

been

and

thento"HOME"tomake

5.7.)

panelasfollows:

set

completed,

them

11.

the

PATTERN

downward.

turnonthe

sure

power

the

switchtoany

work

motion:

shouldgodown

when

the

work

holder

lift

switch

Is depressed (It will lift

again.)

should

move

holder

position

reaches

(the

position while

testIsmade,

check

the

dimensions

set

stitching

tracting

work

the

the

given

the

endofthe

holder

work

holder Is tracing

only

the

and

locationofthe

speedto"low

pattern

pattern.Itshould

stops

andItdoes

work

holder

switch"

when

moves

work

the

JOG

switchIssetat"+"

lifttotheUPposition,

no go up

the

holder.

and

pattern).

and

when

the

(Refertopara. 5.6.)

stitching

proceedasInstructedInpara.

motion

switch Is

and

holder

does

check

when

posi

and

set

not

Note: In

on

order

to make yourself familiar with each switch function, It Is recommendedtooperate

the

switch

panel

without

needle

thread.

-17-

switches

Page 22

6.4

Sewing

Operation

{1) Referring to Fig. 5.1, properly set switches on the switch panel.

(2) Set up a

fabric

and

depress

the workholder lift

switch

to let downthe workholder.

the START switch, the sewing machine will start stitching. Once stitching starts, it continues even

when the START switch is released, and stops with the work holder at UP position after thread

trimming.

6.5

HALT

To

suspend

DOWN

Switch

stitching,

position

Operation

after

thread

depress

the

HALT

trimming.

switch

(Fig.

1.1). Stitching stops with the work holder at

To start stitching again, adjust the stitching start position by operating the JOG switch and depress the

START switch again. The sewing machine starts again and sews

the

remaining pattern.

Then

depress

-18-

Page 23

6.6

Operation

The

Checking

starting

sewing

before

operation

Procedure

machine

(1) Is

(2) Are all

(3) Is

(4)

and

Checking

shouldbeoperated

the

power

cable

source

outlet

and

other

cables properly plugged?

PROM

cassette

Are

fuses

not

blown

and

checkedinaccordance

properly

connector?

loadedonthe

plugged in

machine?

out?

power

with

the

CD

o

following

flow

chart:

Sectionorpara

graphtobe

to

Operation

Preparation

Judgement

referred

c

Set

neutral

Depress

switch.

work

Set

STOP/MOVE

"STOP"

Depress

lift

Preparation

the

pedal

position.

POWER

Does

LIMI-STOP

motor

Does

holder

its

home

position.

work

switch

start

to

ON

Z

start?

the

return

position?

switch

holder

><

No

No

to

to

Check

connection

Depress

switch

Set

"HOME"

Set

"RESET"

power

cable

POWER

RESET/HOME

position.

RESET/HOME

position.

I

OFF

>

switch

switch

to

to

Does

Check

of

direction

rotation.

Depress

switch.

Change

POWER

phase

ON

reversing

holder

down?

Does

start?

the

START

machine

work

Depress

switchto"ON

sewing

go

the

Depress

lift

switch

Depress

switch.

work

again.

POWER

holder

OFF

plug setting (180").

To

the

next

page

-19-

Adjust

holder

Check

motor

the

work

mechanism.

LIMI-STOP

cable

connection.

Z

Page 24

Adjust

setting

Depress

OFFsv*

Depress

switch

t

synchronizer

POWER

/itch

START

o

"OFF".

From

previous

speed

is

of

Depress

switchto"ON

the

atUPposition?

Set

STOP/MOVE

to

"MOVE"

the

Is

the

proper?

direction

rotation

correct?

START

Does

needle

page

stop

switch

position.

Depress

switch.

POWER

OFF

Adjust

the

synchronizer setting.

Test

operation

Depress

ON

switch

/

Check

\

cassette.

Depress

OFF

Set

RESET/HOME

to

"HOME"

Set

RESET/HOME

to

"RESET"

Set

JOG

"NEUTRAL"

POWER

PROM

POWER

switch

position.

switch

position.

to

position.

\

)

switch

switch

Set

PATTERN

(

Set

SCALE

(

No

switch

/ Set JOG switch to \

\ "+"

position.

Does

the

work

holder

move?

Ves

Is

work

properly

referencetothe

positioned

pattern?

Does

work

holder

go

up?

Preparation

completed

holder

)

>

/

Check

drive

Depress

POWER

switch

in

OFF

and

Adjust

mechanism.

control

mechanism

circuit.

work

holder

To

the

next

page

-20-

Page 25

Automatic

sewing

operation

Sewing

c

Set

stitching

<

^

Setupa

Depress

lift

switch.

start

fabric

work

)

speed^

(s)^

holder

Depress

lift

switch.

work

holder

^^-^abric

in p

Depress

Does

sewing

start

Depress

switchtoOFF.

Is

broken

stitching?

Are

trimmedatthe

of

he^v.

s<

scurely\.,_^

osition?x^

START

the

machine

running?

START

thread

during

threads

stitching?

Yes

end

No

PROM

data

input

error

Depress

POWER

OFF

switch.

Depress

HALT

Is

the

fabric properly

positioned?

Depress

START

switchto"ON".

switch

Adjust

by

operating

work

5.9

holder

JOG

position

switch

Does

wiper

work

properly?

Is

the

thread

trimmer

operation

satisfactorily?

Is

thread

tension

well

balanced?

-21-

Set

switch.

POWER

OFF

Adjust

machine.

the

sewing

Page 26

7.

CAUTIONS

(1)

Before

(2) If

any

ON

USE

replacementofPROMinPROM

alarm

(ERROR)

lamp lights,

cassette,

trace

its cause referringtothe

carefully

read

section

description

11.

in para.

5.9.

(3) When a new pattern is stitched for the first time, or pattern is enlarged, be sure to perform test to

check

(4) Sewing

The

maximum

However, it

relationship

maximum

between

speed

speed

the

dependsonstitch

automatically

shouldbeproperly

Table

7.1

work

holder

changes

set

for

individual fabric.

Relationship

and

stitch

movement

and

length.

dependingonstitch

between

length

sewing

the

pattern.

length,asshowninTable

(Refertopara.

maximum

7.1.

5.5.)

speed

Stitch

(5) Dust

(6) When

enteredinthe

cover

shouldbekept

the

control

close.

poweristurned

on,

(7) When adjustment is made on

to

the

mechanisms

(8) Do

not

apply a multimetertothe

in

the

circuit

(9) When single-phase

10 sec. until

or

control

mightbedamaged

motor

is used, do

the

motor

running is stabilized,

00

length

CO

I

5.4~6.2

CO

4.8-5.2

4.0~4.6

2.8-3.2

2.2~2.6

Less

unit

foot

the

box

mm

than

2.0

might cause malfunctionortrouble.

should

not

be placed on

sewing machine, be suretoturn

interior.

control circuit for checking or adjustment. Otherwise semiconductors

duetovoltage

not

from

the

immediately depress

after

switching on

Max.

speed

600

spm

850

1100

1300

1550

1800

2000

the

START

multimeter.

the

the

During

operation,

switch.

off

the

power before gaining access

START switch,

power.

but

the

control

wait for

box

about

-22-

Page 27

8.

NAME

OF

MAJOR

PARTS

OF

MACHINE

HEAD

Switch

Work

Cylinder

Face

HALT

holder

Eye

Presser

Presses

plate

cover

switch

guard

Wiper

foot

cover

lift

foot

switch

adjusting

Slide

r

plate

screw

Clamp

frame

Clamp

foot

Pretensioner

Work

spring

Thread

holder

tension

Qm

Slide

Top

plate

cover

Feed

plate

set

screw(4screws)

X

cover,

right

set

screw(2screws)

X-Y

cover,

Bobbin

Belt

right

winder

cover

Base

' Work

set

screw(2screws)

holder

Work

Positioning

(2

holder

plates)

plate

Fig.

8.1

-23-

Page 28

9.

HANDLING

9.1

THE

SEWING

Installation

of

Needle

(1) Before installing and removing

(2) Insert

(3) With

needle.

the

needle

the

needle prime groove

into

MACHINE

the

needle

HEAD

the

needle,

socket

unititstopsatthe

turnedtothe

turn

off

front,

the

power for safety.

bottomofneedle

tighten

socket.

the

needle set screw to secure

the

(4) For better stitching, though it depends on pattern, it is recommended to set the needle turned

about

10°inthe

Fully

turn

the

the

front

the

set

insert

prime

and

screw.

the

tighten

arrow

needle,

groove

direction.

to

Needle

inserted.

not

fully

Prime

direction

groove

facinginwrong

X

Fig.

9.1

9.2

Threading

The

from

9.3

Threading

The bobbin thread should be passed through the horn of bobbin case, as shown in Fig. 9.11, and

inserted

9.4

Removing

The

position,asshown

needle

the

into

inner

the

thread

needle.

the

the

hook

Needle

Thread

shouldbethreaded,asshown

Bobbin

the

Inner

Thread

hook

with

the

thread

Hook*

can

be removed by moving

in Fig.

9.13.

end

extended

the

in Fig.

2.5cmfrom

hook

clampinthe

9.2,

with

the

thread

end

extended

the

horn

hole.

directionofarrowtohorizontal

about

4 cm

-24-

Page 29

D6Dt

C B A

9.5

Lubrication

To

apply

felt

with

with

Silicone

silicone oiltothe

silicone

oil.

Face

Oil

plate

needle

thread,

Fig.

install

9.2

the

Thread

furnished

Needle

guide

thread

thread

with

guide having

felt

felt

and

dampen

the

Fig.

9.3

-25-

Page 30

Work

holder

Clamp

set

screw

frame

ly-|'

Length

|

A

Spring

Fig.9.4

bracket

Work

holder

shaft

Nut

9.6

AdjustmentofPressure

(1) To increase pressure, loosen

the

nut

(Fig. 9.4) and

turn

the

work holder shaft counter-clockwise

using a spanner (thereby length A becomes larger).

(2) To decrease pressure,

9.7

(3) With

Replacing

case,

the

decrease

the

(1) To replace

other

clamp

standard

Work

the

frame.

adjustment,

the

pressure.

Holder

clamp

turn

the

work holder shaft clockwise.

fabric(s)

Clamp

Frame

frame, remove

the

thicker

set

screws (Fig.

than

about

6 mm

8.1),

may

remove

the

not

be held

clamp

frame

(2) When replacing the clamp frame, do not loosen the positioning plate. Clamp frame can be ac

9.8

curately

Replacing

(1)

To

desired

(2)

The

installedbyreferringtothe

the

Feed

Plate

replace

feed

the

feed

plate,

feed

plate.

plate

shouldbeinstalledinreferencetothe

loosen

positioning

the

feed

plate

plate.

set

screws,

work

remove

holder.

the

feed

plate

down.Inthis

and

install

and

install

the

-26-

Page 31

9.9

Adjusting

{1)

{2)

the

Presser

Foot

Make sure the needle comes at the center of

the

presser

foot

hole.

Loosen the presser bar set screw (Fig. 10.10)

and adjust height of the presser foot so that

the

lower

mm

at

the

above

lowest

endofthe

the

position.

fabric

presser

when

the

(3) The vertical stroke of presser foot is factory-

adjusted to 4 mm. To increase the stroke,

remove

shown in Fig. 9.6

The

10

(4) To adjust pressure of

the

the

increases

wise,

clockwise. Fig.

adjustment. In usual operation, readjustment

of the auxiary adjusting screw Is

vertical

mm.

thumb

presser

and

the

switch cover, loosen

and

stroke

canbeincreased

the

nut

shown

foot

adjusting screw. The pressure

when

the

screwisturned

decreases

when

9.6

move it upward.

presser foot, loosen

in Fig.

turned

shows

foot

the

not

is 0 ~

presser

9.6

and

required.

0.5

bar

the

bolt

up

to

turn

clock

counter

standard

Presser

foot

set

screw

Presser

foot

is

0-0.5

mm

Fig.

9.5

Presser

foot

About

25

adjusting

mm

(Tumb

nut®

Thumb

screw

About

20

mm

Note:

Heightofthe

presser

depending on thickness of fabric.

9.10

Adjusting

(1)

(2)

the

Wiper

When

the wiper is not used, the wiper

position.

Height

of the

about 1.0 mm above the presser foot when the

at its highest position) by turning off the power.

Fig.

foot

shouldbechanged

wiper

shouldbeadjustedafter

9.7

Wiper

release

switch

release

switch

loosening

sewing

Fig.9.6

showninFig.

the

wiper

9.7 should be set at

set

screw

sothat the wiper

machineisstopped (with the take-up

Fig.

9.8

Wiper

set

screw

About1mm

T~a

forward

moves

lever

Note: When height or vertical stroke of presser foot is changed, height of wiper should be adjusted.

Page 32

9.11

WindingofBobbin

(1)

Pass

stand

thread

(2)

Set

position

(Refertopara.

(3)

When

MOVE

(4) If

the

wound

(5) It is

nylon

the

thread

as

shown

end

several

the

STOP/MOVE

and

the

threadiswound

switchto"MOVE"

the

threadiswound

thread

guide

thread

layers.

recommended

threadiswound

Thread

drawn

in Fig.

turnsonthe

depress

5.8.)

toward

that

out

from

the

9.9

and

wind

bobbin.

switch

the

START

up,

set

to

"STOP"

the

switch.

STOP/

position.

up conically, move

smaller

polyester

with

low

diameter

thread

tension.

cotton

the

of

or

/

Bobbin

Note:

9.12

When

should

Thread

Needle

the

threadiswound,

be

removed

Tension

thread

tension

the

from

the

needle.

shouldbebalanced

needle

thread

with

the

X

bobbin

Tension

adjusting

threadasshown

nut

below.

Fig.9.9

X

Thread

guide

Balanced

thread

and

thread

tension

bobbin

tension

needle

Fig.

-28-

Tight

thread

or

loose

thread

9.10

needle

tension,

bobbin

tension

Loose

needle

thread tension,

or

tight

bobbin

thread

tension

Page 33

(1)

Bobbin

The

cotton

thread

standard

thread

tension

bobbin

#60isthat

thread

the

tension

bobbin

gradually goes down when the thread end is

held by fingers and the bobbin case is

released.

To adjust tension, turn

adjust

screw

shown

(2)

Needle

thread

The

needle

thread

tension

in Fig.

tension

the

thread tension

9.11.

should

justed in referencetobobbin thread tension.

To adjust,

nut

shown

turn

in Fig.

the

tension regulator

9.12.

for

case

be

ad

thumb

Tension

Decrease

Fig.

adjusting

9.11

Tension

regulator

Decrease

Increase

thumb

screw

nut

Increase

9.13

Lubrication

(1)

Apply

(2) Pour lubricating oil

reaches

Oil filler hole ^ . Cover, left

Oil

gauge

several

dropsoflubricating oilto"A",

through

the

red

markonthe

the

oil filler hole in

oil gauge.

Hook

Note

clamp

that

Fig.

"B",

9.13

too

"C"

the

and

bed,

much

"D"

shown

oil

may

shown

in Fig.

spill

in Fig.

when

9.13,

the

9.2

until

Fig.

9.12

everyday.

the

oil level

headisleaned.

(3) Ifoil in the hook is excessive,remove the left cover, and one of two oil braid from the oil reservoir.

(4) Remove

oiltothe

the

X covers (left

retainer

shown

and

in Fig.

right)

and

feed plate, shown in Fig. 8.1,

10.27atleast

-29-

and

monthly.

apply several

drops

of

Page 34

10.

ADJUSTMENT

10.1

10.1.1

10.1.2

Machine

AND

head

Adjusting

Contact

can be

adjusted

loosening

Adjusting

(1)

Remove

shown

set

(2)

The

needle

upper

with

shown

MAINTENANCE

the

bobbin

pressure of

by removing

the

bobbin

the

heightofneedle

the

rubber

in Fig.

10.2,

screwtoadjust

standard

needle

barisat

timing

markonthe

the

lower

in Fig.

10.3.

winder

the

rubber

roller to

the

winder

set

screw.

bar

plug

from

and

loosen

heightofneedle

bar

heightisthat

the

lowest

needle

endofneedle

belt

cover,

the

face

the

position

bar is aligned

bar

the

plate,

needle

bar.

when

bushing,

pulley

and by

bar

the

the

Rubber

roller

as

as

Belt

cover.

Fig.

10.1

10.1.3

Needebar

set

Adjusting

screw

the

(1) After setting

inner

and

adjust

(2) To adjust, move

between

leftward

that

the

the

needle

Fig.

hook

hook

10.2

driver

and

the

the

and

bar

the

hook

the

driver.

the

driver

rightward

point

{Fig.

Fig.

10.3

clamptohorizontal position, as shown in Fig. 10.4, to remove

hook

retainer,

loosen

the

driver

set

screw

using a

hexagon

driver in forward or backward direction and position it so

and

needle

should

10.3)

becomes

direction.

cometothe

meets

the

zero.Atthe

The

standard

centerofthe

lower

positioninleftward/rightward

endofthe

same

time,itshouldbealso

needle

needle

when

bar

the

bushing.

lower

key

timing

Needle

bushing

wrench

that

adjusted

direction

mark

bar

the

gap

in

is

on

Page 35

(3)

The

same result can be

from

the

left

as

shown

in Fig.

side

surfaceofneedle

10.5.

A

obtained

when

when

the

hook

the

point

is positioned

hook

pointislocatedatthe

About

3.2

mm

about

3.2 mm

left

extremity,

apart

Page 36

10.1.5

Adjusting

the

thread

guide

(above

hook)

(Fig.

(1) Adjust the thread guide above the hook so

the

needle

side

surface.

If

this

(2)

Adjust

smoothly

Note

unbalanced

the

(3)

Since

largely

surface

adjustmentisimproper,

the

thread

guide so

pass

throughismade.

that

too

large gap may cause

thread

tension,

hook.

the

conditionofthe

affects

the

stitch

conditionissmooth

Thread

guide

set

thread

trimming

that

a gap

(standard

thread

uneven lengthoftrimmed

thread

quality

enough.

screw

and

guide

thread

10.7)

that

its left and right shoulders are aligned with

may

notbedone

gap:

0.8

trimming failure and

needle

surfaces

Shoulder

trimmer

with

performance,

mm)

which

Thread

properly.

that

thread

thread

guide

permits

too

carefully

needle

small gap may cause

and

jammingofthread

comes

into

check

set

screw

thread

contact

that

to

in

the

10.1.6

10.1.7

^.^nn

Adjusting

(1)

(2) Note

(3) Large

Replacing

(1)

the

work

holder

For

adjustment

that

faint

may

make

heavy

work

holder

the

work

For

replacementofclamp

procedure,

holder

(2) It is recommended

frame.

However,

when

the

the

positioning plate

work

holder

d

X

Thread

guide

pressure

refertopara.

work

holder pressure may cause slippageoffabric,

work

holder

movement,

pressure

that

may

require

clamp

frame

frame,

refertopara.

the

positioning plate is

must

bracket

position

Needle

Fig.

10.7

9.6.

causing

lower

misalignmentofpattern.

speed

than

9.7.

kept

tightened for easy replacement of clamp

be readjusted when

is changed.

Hook

retainer

specified in

the

home

but

too

large pressure

Table

7.1.

position is changed, or

-32-

Page 37

10.1.8

Adjusting

the

position of

work

holder solenoid

(1) Loosen the solenoid set screw shown in Fig. 10.8 and adjust solenoid position so

upper link is in contact with the stopeer when the solenoid is pulled (the plunger is in con

tact

with

the

solenoid

(2) Note that work holder pressure becomes extremely

the

linkislocated

Work

solenoid

bore

leftward.

holder

set

screw

bottom).

(See

Fig.

(See Fig.

10.9.)

Upper

10.9.)

link

small

and the work holder may go up if

Work

Stopper

solenoid

hoider

set

Plunger

screw

that

Work

solenoid

the

hoider

10.1.9

10.1.9.1

10.1.9.2

10.1.9.3

Fig.

10.8

Adjusting

Adjusting

(1) Timing of

shown

the

presser

the

in Fig.

foot

presser

presser

10.9.

Eccentric

foot

timing

foot vertical movement is

ring

governed

Eccentric

ring

set

screw

Fig.

10.9

by position of the eccentric ring

To adjust the timing, loosen the eccentric ring set screwand set the eccentric ring so that

the presser foot assumes the lowest position when the needle bar is at its lowest position.

(2) When the presser foot is at the lowest position the direction of the eccentric ring should

be perpendiculartothe

Adjusting

the

presser

illustrationofFig. 10.9, and face backward.

foot

vertical

stroke

(1) For adjustment procedure, refer to para. 9.9.

(2) Since the larger the vertical stroke, the larger is the noise and vibration, it is recom

mended to adjust

Adjusting

(1) Presser

the

a.

Turn

takeup lever at

crank

10.10) is parallel with the presser bar and then fix. (For this adjustment,

ring should have been properly adjusted.)

b.

Place

to the lowest position. Under this condition, adjust

foot

presser

foot

the

(right)

a fabric in position and turn the balancewheel by hand to locate the

(lower surface) is 0 —

the

stroke

as small as possible.

foot

height

height

during

stitching

balance wheel by hand with

the

highest position. Under this condition, adjust the upper feed lifting

the

sewing machine

shown in Fig. 10.8 so that the lengthwise center of

the

0.5

mm above the fabric and then tighten the presser bar

turned

bell

presser bar so

off

crank

that

to locate

the

eccentric

presser

the

(see

presser

the

Fig.

foot

Page 38

set

screw

(standard

To

prevent

be

made

smaller.

somewhat

becomes

downbythe

Since

affects

tightness

the

presser

is

recommendedtolower

smallaspossible.

When

presser

barathigher

the

presser

longer

prolonged

needle

and

the

fabricisnot

foot

presser

foottothe

larger

foot

adjustment).

stitch

skipping,

However,

and

when

presser

foot.

fabric

thread

the

fabric

causing

during

stitching,

position

footatthe

presser

fabric

the

holding

pattern

pressed

and

(2) Adjusting the lift of presser

this

gap

noise

becomes

holding

fabricispressed

time

adversely

tension

maybecaught

the

connecting

deviation,

presser

downbythe

set

adjust

bar.

foot

and

the

height

part

at stitching

should

time

seam

by

foot

presser

as

of

of

Bell

crank

pi

fl

it

Fig.

10.10

a.

Make

sure

the

adjustmentsoftiming,

Stroke and

stitching

b.

Lean

screw

With

set

the

the

shaft,asshown

rotary solenoid

While pulling

rotary

the

rod

4 — 7 mm below

height

are

standard.

the

machine

of presser

the

lifting

drive

of presser

head

foot

crank

cranksothat

in Fig.

(large)

the

drive

solenoidtomake

end

(right)

the

and

lifting

crank

(1)

setinthe

it is

10.11,

is not energized. B

crank,

sure

stopatthe

crossing line of

rotary solenoid axis center and the center of

the

rod

end

(left).

foot

loosen

fully

the

vertical

during

the

(2).

parallel

when

turn

center

position

set

shaft,

the

the

the

Presser

Presser

lifting

liftingcrank (1)

to

of

Rotary

^

foot

crank

(1)

solenoid

^

^ o ^ \

Set screw Presser foot ,

Set

screw

Presser

'lifting

Hlftlng

foot

crank

crank (2)

Fig.

10.11

Fig.

10.11

(large)

^

(2)

Stepped

c. With the presser foot at its lowest position lightly press down the lifting crank (2)

(pull

forwardinthe

Locate the lifting crank (2) so

the

stop

position

The lift of presser

clearance(2mm),

The

lift of presser

when

the

rotary

case

shown

and

secure

the

foot

at stitching

and

decreasedbymaking

foot

at stitching

solenoid is fully

in Fig.

10.11)byhand

that

the stepped bolt is positioned

lifting

crank

(2).

stop

can be increased by making smaller

it larger.

stopisthe

turned

with

the

untilitstops.

vertical stroke of

drive

crank

about

2 mm above

the

presser

fully pulled by hand.

this

foot

mpm

bolt

Page 39

10.1.10

Adjusting

the

thread

trimmer

(1) Adjust the cam follower so that the roller is found on the cam shoulder about 1 mm distant

from

the

thread

trimmer

<2)

Depress the cam follower crank in the direction of arrow shown in Fig. 10.12 by hand to

make

sure

the

roller can be engaged

(3) The roller engaging and disengaging area should be within

is

concentric

If

the

roller

with

cannot

shoulder, loosen the

(4)

contact

and

To

stop

plate

with

the

then

tighten

remove

the

the

knife

ring (circlip) shown in Fig.

shown

in Fig. 8.1 and

cam,asshown

the

arm

shaft.

be engaged and disengaged

nut

shown in Fig. 10.12, tighten the stopper screw until it comes into

cam follower crank

nut.

assembly,

four

and

loosen

10.13,

slide

in Fig.

disengaged

stopper,

E-type

feed

palte

set

10.12.

with

smoothly,

loosen

the

the

Stopper

cam

the

check

stopper

s(

groove

smoothly.

range where

that

the

screw by

I I —

the

cam groove

roller is on

about

1/3

Cam

the

turn

follower

Nu

crank

Cam

Cam

trimmer

Stop

groove

Abou'

groove

hole,

cam

thread

The

movable

canberemovedatthe

(5) To adjust

and

fixed

same

the

movable knife, loosen

knives

time.

knife position adjusting screw on

bed and adjust the knife drive crank so

movable knife

the

hook

retainer

point

when

stops

0.5

the

stitchingisstopped,

as shown in Fig. 10.13. (See Fig. 10.14.)

If

the

movable

knife is

located

and

mm

too

slide

the

the

apart

far

plate

movable

back

of

that

the

from

from

the

needle

satisfactorily,or the E-typestop ring strikes the thread guideset screwshown in

However,

tail might be

the

E-type

movable

caught

stop

knife located too

between

ring

the

Hook

fixed knife

retainer

close

and

to the

needle

the

movable knife.

hole, trimmed

Fig.

10.12

may

notbetrimmed

needle

Fig.

Shoulder

10.7.

thread

Arm

shaft

Movable

knife

Fig.

10.13

•Needle

Fixed

knife

hole

Fig.

10.14

Movable

adjusting

knife

screw

position

Page 40

10.1.11 Adjusting

(1)

Length

does not extend longer than about 22 mm from the bobbin case horn

may skip. In this case, the following checking and adjustment should be performed.

(2) Since trimmed thread contracts when bobbin thread tension is

thread is used, decrease bobbin thread tension and needle thread tension as well. For the

same reason, it is recommended to wind thread with smaller tension.

{3) When the clearance of Fig. 10.15 is more than 0.2 mm, thin thread may be cut before the

movable

To

distant

the

clearance

fixed

Fig.

Care

installed again

direction.

The

(4) Trimmed needle

shown

Thread tail length becomes

(5) For details, refertopara.

thread

stop

the

trimmed

thread

tail

length