Page 1

MITSUBISHI

^

Industrial

Sewing

INSTRUCTION

Single-Needle

Electronic

Model

Bar

Machine

MANUAL

PL

Lockstitch

K-0303

Tack

Machine

A

MITSUBISHI

ELECTRIC

Page 2

In

order

to operate

carefully

1.

2.

3.

and

CONSTRUCTION

SPECIFICATIONS

INSTALLATION

3.1

3.2

3.3

3.4

3.5

4.

HANDLING

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

properly

installing

Connection

Work

Lamp

Power

Cable

Changing

Installation

Threading

Threading

Removing

Adjusting

Replacing

Winding

Thread

Lubrication

the

sewing machine in

handle

and

the

Machine

of

Leads

maintain

Head

the

best condition at all times, please read this Insturction Manual

the

sewing

machine.

-

CONTENTS

-

Leads

Connector

the

Power

Phase

Sequence

THE

SEWING

of

Needle

the

Needle

the

Bobbin

the

Inner

the

Pressure 8

the

Work

the

Bobbin

Tension

MACHINE

Thread

Thread

Hook

Holder

Thread

Clamp

HEAD

Frame

1

2

3

4

5

5

5

6

6

6

6

8

9

9

10

5.

6.

CONTROL

5.1

Switch

5.2

SCALE

5.3

PATTERN

5.4

SPEED

5.5

±JOG

5.6

STOP/MOVE

5.7

RESET/HOME

5.8

PR0M1/PR0M2

5.9

Error

5.10

Work

5.11

START

OPERATION

6.1

Switch

6.2

Switch

6.3

Sewing

SWITCHES

Panel

switch

Switch

Switch

Switch

Indication

Holder

Switch

Switch

Switch

Lift

(Foot

AND

Select

Switch

SettingonSwitch

Function

Checking

Operation

THEIR

Switch

Switch)

Panel

FUNCTIONS

11

11

12

12

12

12

13

13

13

14

14

15

15

15

Page 3

7.

CAUTIONS

8.

CHECKING

8.1 Adjusting

8.2

8.3

8.4

8.5

8.6

8.7

9.

HANDLING

10.

AUXILIARY

10.1

10.1.1

10.1.2

10.1.3

10.2

ON

USE

AND

MAINTENANCE

the

Needle Bar

Adjusting

LIMI-STOPZMotor

Fuse

CleaningofFan

Adjusting

the

the

Home

Filter

V-Belt

Position

Tension

PreventionofMalfunction

OF

PROM

FUNCTIONS

SW1

Repeat

function

Home

position

return

Enlargement/reduction

SW2

Stop

(UP) Position 17

DuetoNoise,

cancellationatpower

(SCALE)

and

Grounding

cancellation

turning

on

16

18

19

19

20

20

20

21

22

23

23

23

Page 4

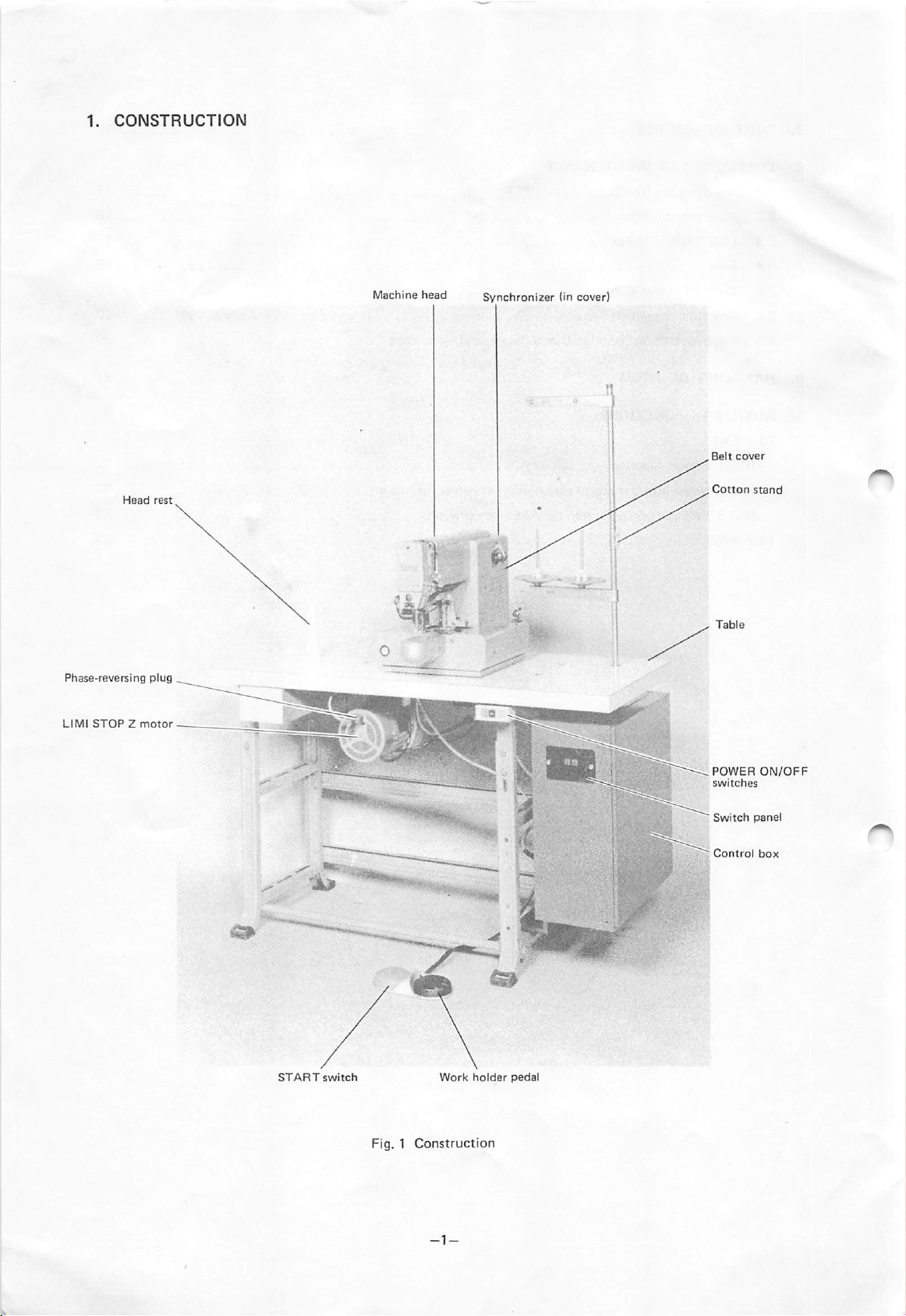

,

Belt

,

Cotton

cover

stand

POWER

switches

Switch

ON/OFF

panel

Page 5

2.

SPECIFICATIONS

Table

1

Machine

Needle

Applicable

Work

Control

Sewing

Max.

Stitch

Sewing

Sewing

Returntohome

head

bar

holder

system

area

sewing

length

pattern

operation

stroke

needle

lift

speed

position

Oscilating

bartack

41.2

DP X 5

15

Full-electronic,

mm

mm

hook,

machine

#16

cylinder head, single-needle lockstitch,

(Standard)

microcomputer

incorporated

control

30 X30mm (X-Y dual axial drive by stepping motors)

2,000 spm (intermittent feed)

0.2~6.2

mm

....

(for feed length lessthan 2 mm)

Sewing pattern is reproduced with data stored in PROM.

the

PROM is replaceable and two PROMs are incorporated in

control

box (stitching pattern data have been stored in one of PROM).

PROM

Maximum 2,000 stitches can be stored in each

(2732A).

Operation starts from home position and ends at the home position.

This

function

sewing.

After

the

the

home position in X axis and Y axis directions simultaneously.

is used

whenXand/orYpositions

needle stops at UP position,

deviate

the

work holder returns

during

to

Every after turning on the power, the work holder returns to the

home

position.

Operation

Sewing

Test

Scale

Pattern

Error

k.

09

® o

|i

Q_

v>

mensions

D

Weight

START

speed

setting

function

function

selection

indicator

Permissible

Maximum

(Enlargement/Reduction)

function

voltage

input

regulation

power

source

Stitching starts from

switch

(foot

switch)isdepressed.

the

home position when START

Sewingspeed can be set in nine steps within a rangefrom 200 spm

to

2,000

spmatabout

2000

spm

increment.

Operation check and test stitching are possible.

Pattern stored in PROM can be enlarged or reducted in X axis

direction and Y axis direction independently within a range from

0% (real scale)to199%

Any

one

of 20

patterns

(10

patterns

Troubleorfailureisalarmed.

±10%ofrated

800

VA

535

mm (width) x

have

voltage

(full scale) at 1%

can be selected.

been

stored)

1,200

mm (length) x

increment.

1,110

mm (height)

(cotton stand is not included in the height)

125 kg (Total weight includingweights of head and table)

-2-

Page 6

3.

INSTALLATION

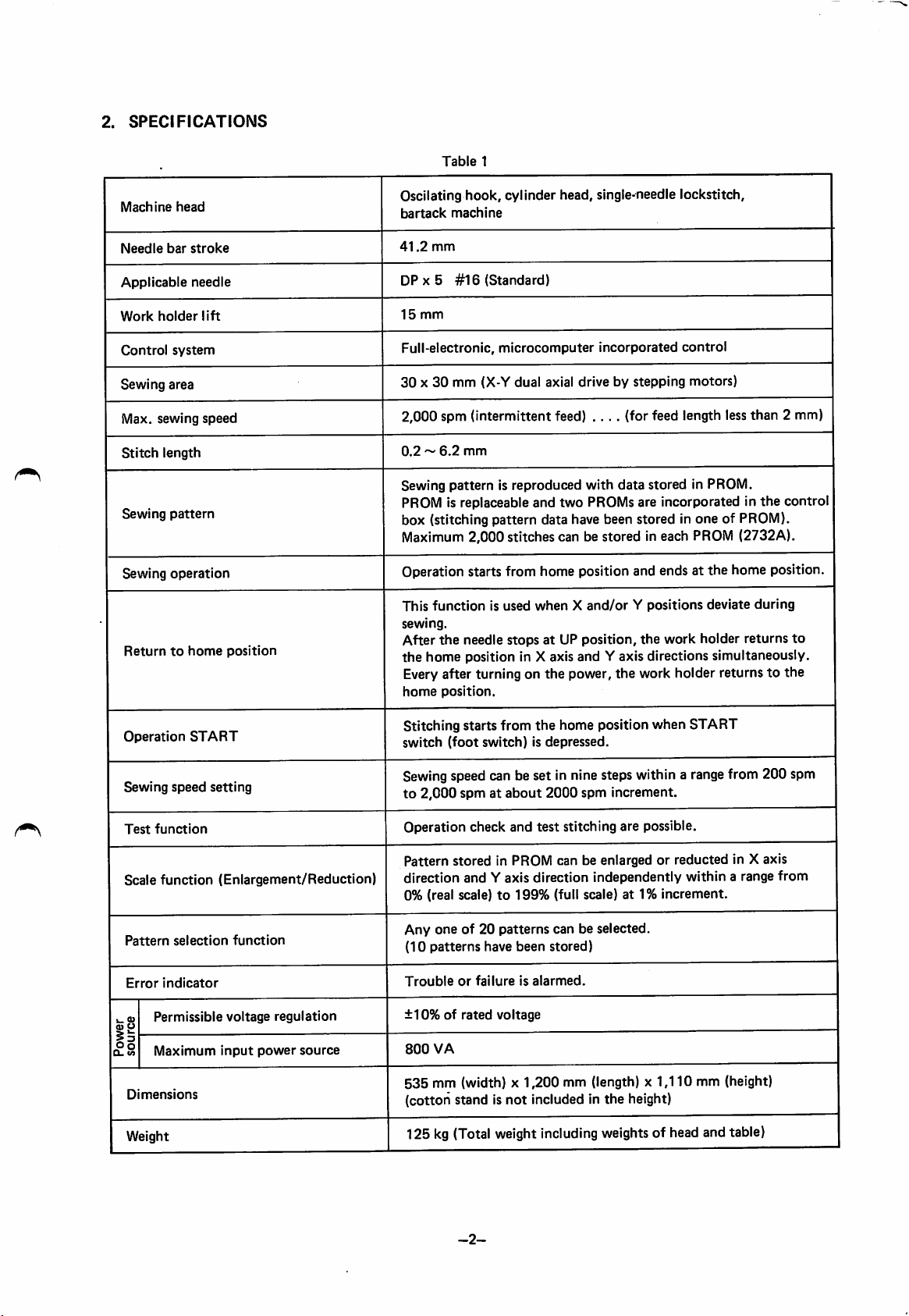

3.1 Installing

3.1.1 Install

3.1.2

3.1.3

3.1.4

Put

Take

Set

Using

the

Machine Head

the

furnished head resttothe

each one

out

each

the

one

furnished

rubber

machine head from

rubber

two

pad Into

pad

into

wood

four

recesses

the

recessatfour

screws,

secure

table.

(See Fig. 1)

foundinthe

table.

shipping case and place it on

cornersofbase

the

basetothe

bottom.

table.

the

table, as shown in Fig. 2.

Notes:

(1) If

(2)

About

5mm

Block

Hinge

Rubber

the

tableisnot

head,

when

For

preventionofspringupof

thick

below

securedtothe

the

headisleaned.

the

head,asshown

QD

a

pad

Base

in Fig. 2.

table

the

with

base,

Wood

Rubber

pad

Fig. 2

wood

screws,itmay

it is

recommendedtoinstall a

screw

Wood

spring

screw

Rubber

pad

Rubber

pad

up,

duetogravityofthe

blockofabout5mm

-3-

Page 7

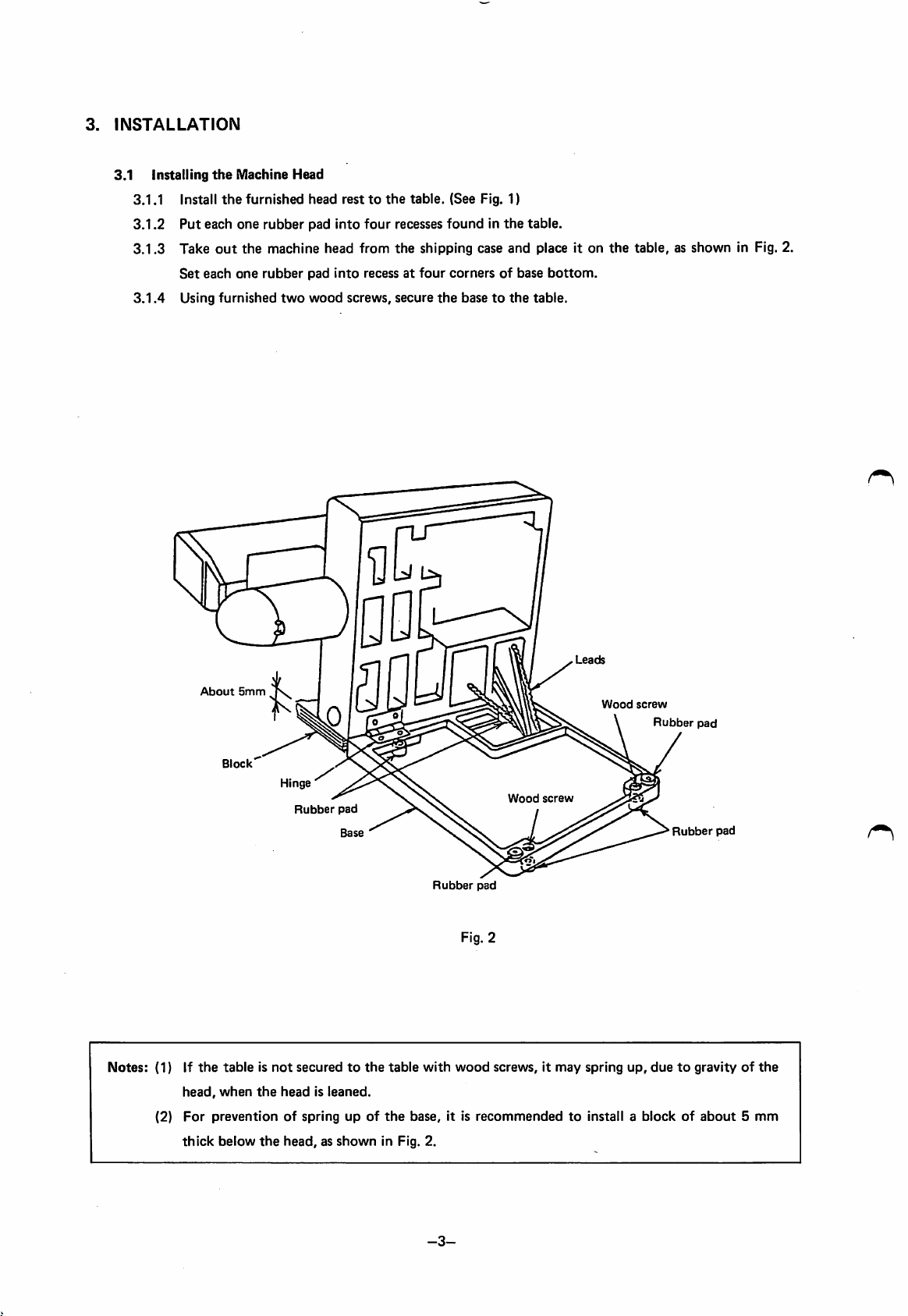

3.2

Connection

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

of

Leads

Pass

the

leads

corresponding

Bundle

the

leads

Install

the

belttothe

Raise

upright

Install

the

belt

from

the

head

through

connectorsofcontrol

with

lead

clamp.

pulleys.

the

machine

cover.

head.

the

box.

hole

providedinthe

(See Fig. 5.)

table

and

connect

themtothe

Machine head (leaned against

Leads

Lead

Control

Motor

box

clamp

position

adjusting

head

rest)

nut

Fig.3 Connectionof machinehead to control box

Head

Table

LIMlSTOPZmotor

rest

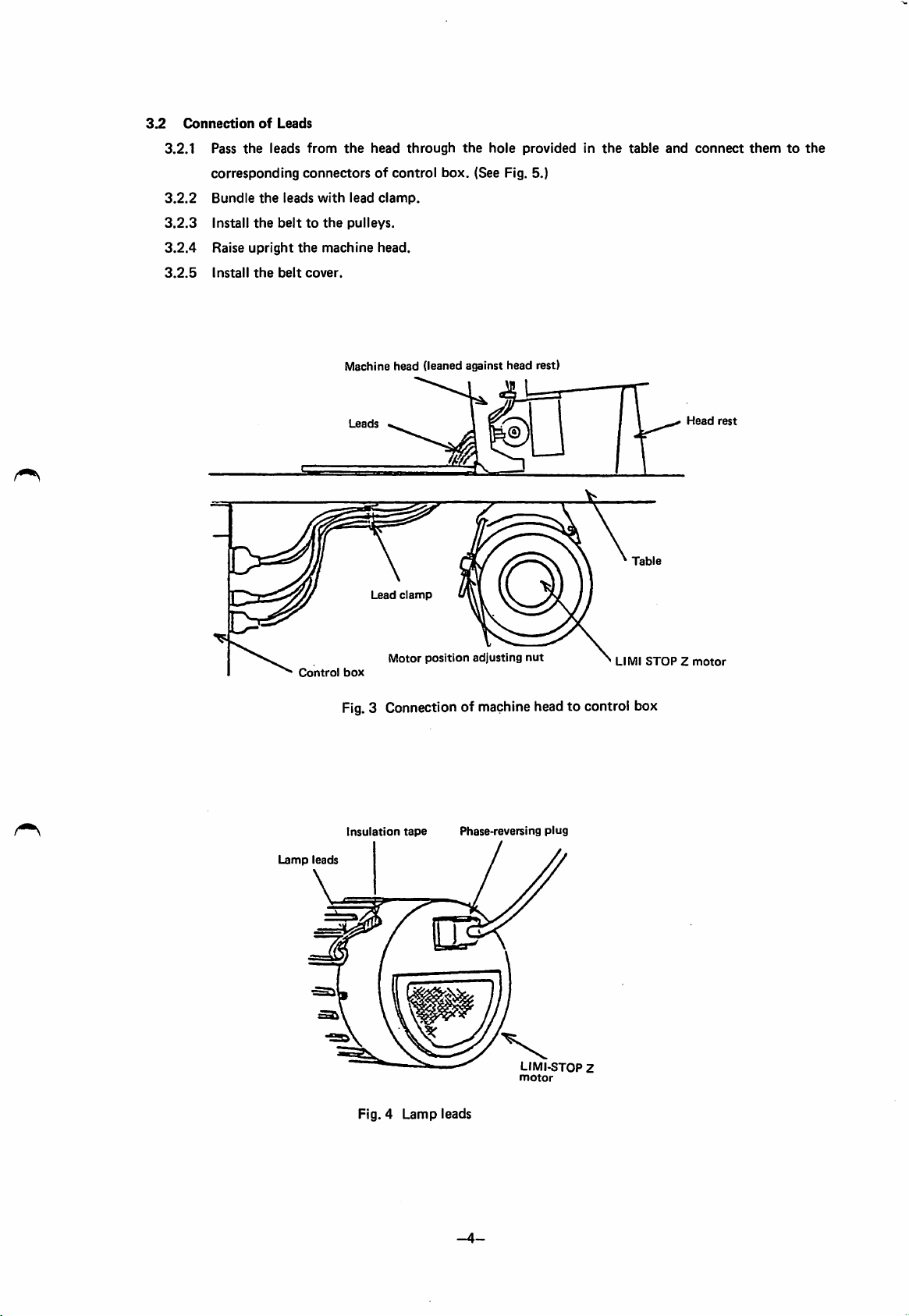

Lamp

leads

Insulation

Fig. 4

tape

Lamp

Phase-reversing

leads

-4-

plug

LIMI-STGP Z

motor

Page 8

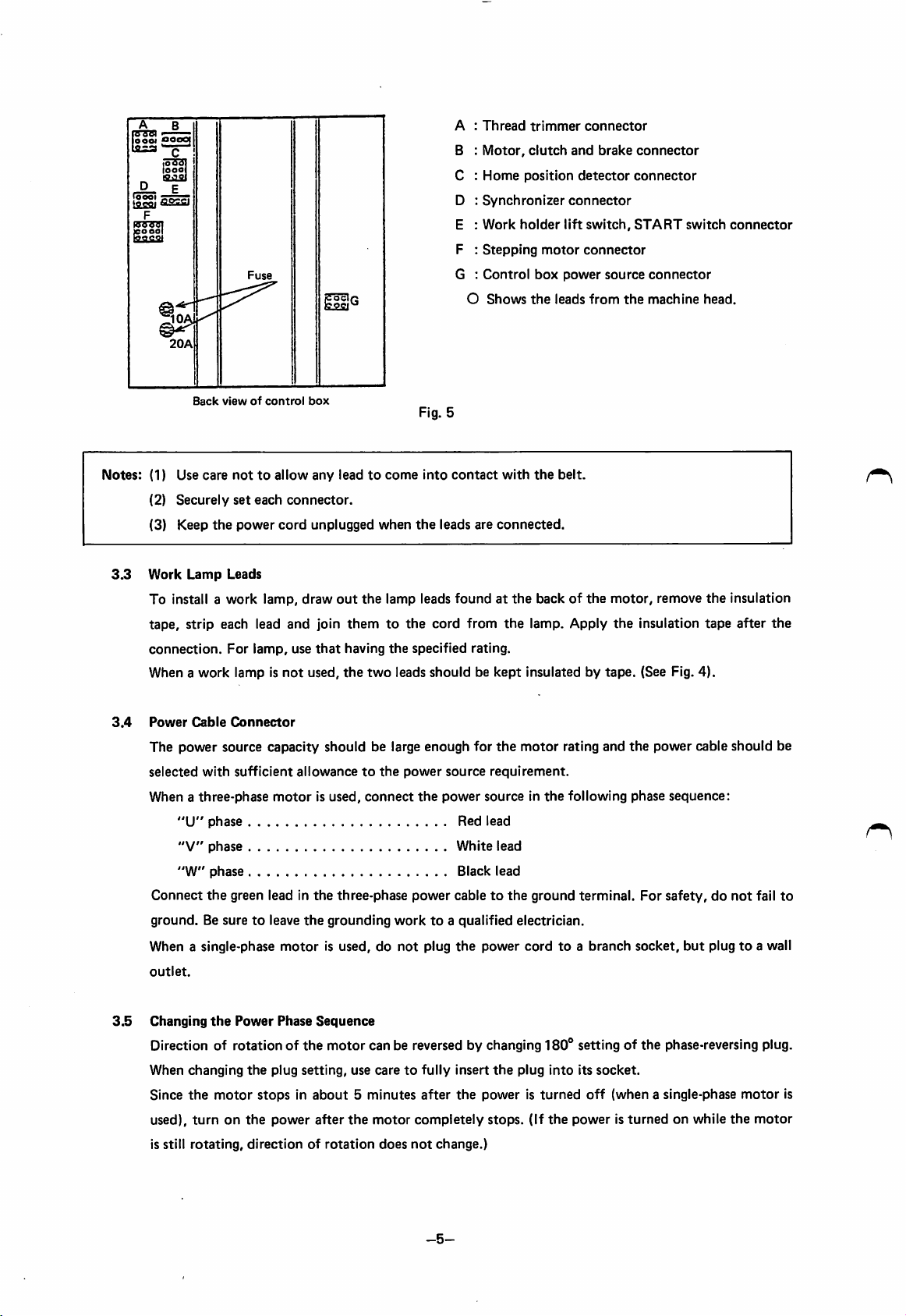

OOOl

oeooj

iggglaaza

Back

viewofcontrol

box

Fig. 5

A :

Thread

B :

Motor,

C :

Home

D :

Synchronizer

E :

Work

F ;

Stepping

G :

Control

O

Shows

trimmer

clutch

position

holder

motor

box

the

connector

and

detector

connector

lift

switch,

connector

power

leads

brake

from

source

the

connector

connector

START

connector

machine

switch

head.

connector

Notes:

(1) Use

(2)

(3) Keep

3.3

Work

To install a

tape, strip each lead

connection.

When a

3.4

Power

The

selected

When a

Connect

ground.Besuretoleave

When a single-phase

outlet.

care

Securely

the

Lamp

work

Cable

power

with

three-phase

"U"

phase

"V"

phase

"W"

phase

the

nottoallow

set

each

power

cord

Leads

work

lamp,

For

lamp,

lamp is

Connector

source

capacity

sufficient

motor

green lead in

any

leadtocome

connector.

unplugged

draw

out

and

join

themtothe

use

that

having

not

used,

the

should

allowancetothe

is used,

the

three-phase

the

grounding

motor

is used, do

when

the

lamp leads

the

two

be large

connect

into

the

leads are

cord

specified

leads

shouldbekept

enough

power

the

power

worktoa

not

plug

contact

foundatthe

from

rating.

for

source

requirement.

power

sourceinthe

Red

lead

White

Black

cabletothe

qualified

the

power

with

the

connected.

backofthe

the

lamp. Apply

insulated by

the

motor

lead

lead

ground

electrician.

cordtoa

belt.

rating

following

terminal.

branch

motor,

the

tape.

and

remove

insulation

(See Fig.

the

power

phase

For

safety,donot

socket,

the

tape

4).

cable

sequence:

but

plugtoa wall

insulation

after

the

should

be

fail

to

3.5

Changing

Direction of rotation of the motor can be reversed by changing

When

Since

used),

is still

the

Power

changing

the

motor

turnonthe

rotating,

Phase

Sequence

the

plug

setting,

use

caretofully

stopsinabout5minutes

power

after

the

motor

directionofrotation

does

insert

after

the

completely

not

change.)

-5-

180®

the

plug

into

poweristurned

stops.

(If

the

setting of the phase-reversing plug.

its

socket.

off

(when a single-phase

poweristurned

on while

motor

the

is

motor

Page 9

4.

HANDLING

4.1

THE

SEWING

Installation

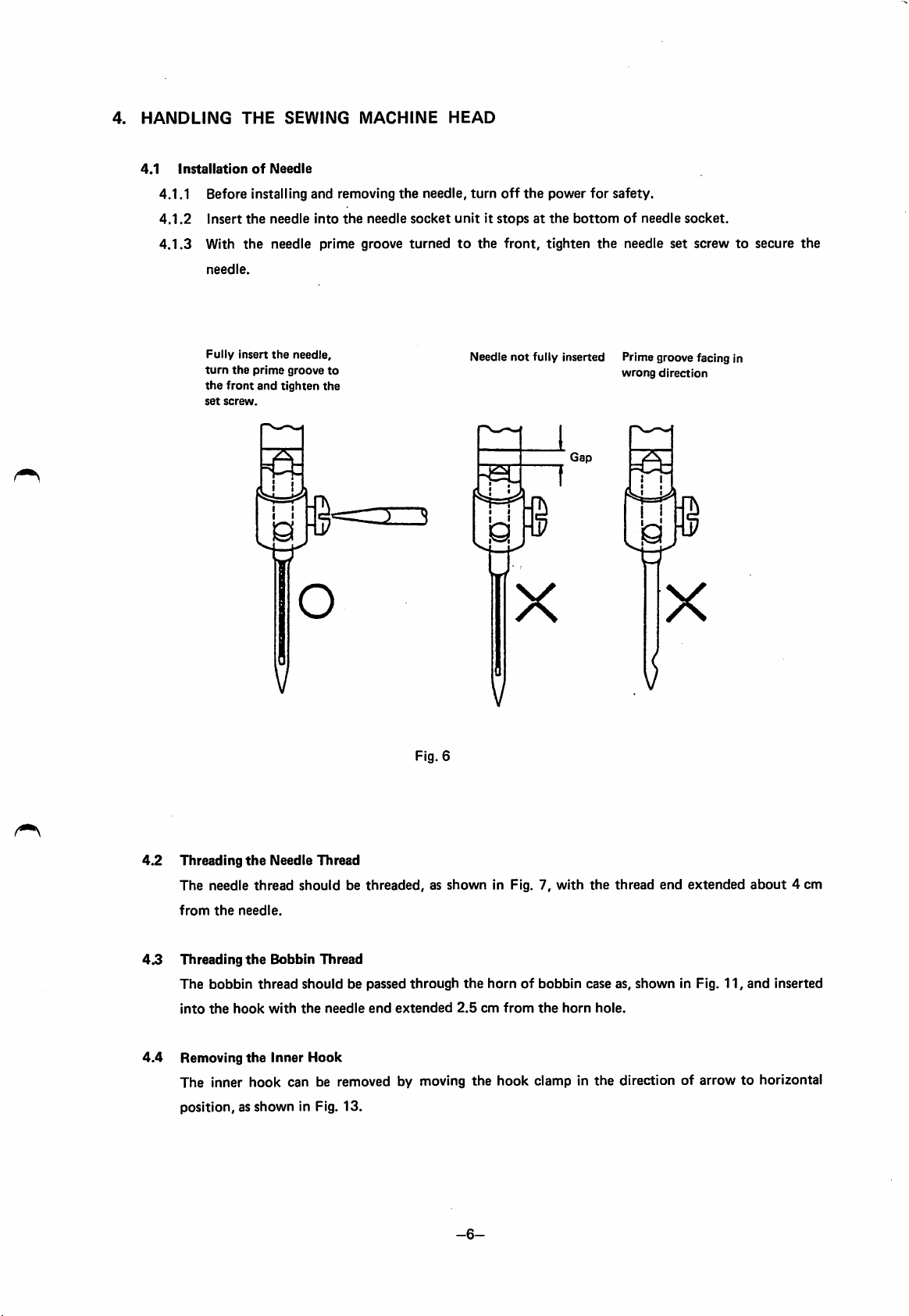

4.1.1 Before installing and removing

4.1.2

4.1.3

Insert

With

needle.

Fully

turn

the

front

set

screw.

Insert

the

of

the

the

prime

and

Needle

needle

needle

the

needle,

groove

tighten

into

prime

to

the

MACHINE

the

needle

groove

2_3

d

HEAD

the

needle,

socket

unititstopsatthe

turnedtothe

turn

off

front,

Needle

N=H

I I

the

power

for

safety.

bottomofneedle

tighten

not

fully inserted Prime groove facing in

1

Gap

the

needle

wrong

socket.

set

direction

screwtosecure

the

4.2

4.3

Threading

The

needle

from

the

Threading

The

bobbin

into

the

the

needle.

the

hook

o

V

Needle

Thread

thread

shouldbethreaded,asshown

Bobbin

thread

with

Thread

should

the

needle

be passed

end

Fig. 6

through

extended

V

X

V

in Fig. 7,

the

hornofbobbin

2.5cmfrom

the

with

horn

the

thread

case as,

hole.

end

shown

X

in Fig.

extended

11,

about

and

4 cm

inserted

4.4

Removing

The inner

the

Inner

Hook

hook

can be removed by moving

the

hook

clamp in

the

direction of arrow to horizontal

position, as shown in Fig. 13.

-6-

Page 10

I

a

Fig. 7

-7-

Page 11

Work

holder

set

Clamp

screw

frame

Pressure

Fig. 8

spring

socket

Work

holder

shaft

4.5

4.6

Adjusting

4.5.1

the

Work

Holder

To increase pressure,

Pressure

loosen

clockwise using a spanner (thereby length

4.5.2

To

4.5.3

4.5.4

Replacing

To

a

decrease

With

work

replace

desired

pressure,

the

standard

holder.Inthis

the

Work

Holder

the

clamp

clamp

frame.

turn

adjustment,

case,

Clamp

frame,

the

the

decrease

remove

nut

work

fabric(s)

the

Frame

the

shown

holder

pressure.

set

screws

in Fig. 8

"A"

becomes larger).

clockwise.

thicker

than

shown

and

turn

the

about

6 mm

may

in Fig.8,remove

work

holder

notbeheld

the

clamp

shaft

downbythe

frame

and

counter

install

-8-

Page 12

4.7

Winding

4.7.1

4.7.2

4.7.3

4.7.4

4.7.5

the

Bobbin

Pass

the

thread

stand,asshown

Set

the

STOP/MOVE

position

and

(Refertopara.

When

the

threadiswound

MOVE

switchto"MOVE"

If

the

threadiswound

the

thread

guide

wound

thread

It is

recommended

nylon

threadiswound

Thread

drawn

in Fig. 9.

depress

5.6.)

toward

layers.

that

out

switch

the

up,

position.

up

smaller

polyester

with

from

the

to

START

set

the

conically,

diameter

low

tension.

cotton

"STOP"

switch.

STOP/

move

thread

of

or

Bobbin

Thread

guide

4.8

Thread

Needle

Balanced

tension

tension

Tension (Fig.

thread

tension

o

needle

and

thread

bobbin

10)

shouldbebalanced

tread

Tight

or

tension

loose

with

needle

bobbin

Fig.

the

thread

10

bobbin

tension

thread

Tension

adjusting

threadasshown

nut

Fig. 9

below.

X

Loose

needle

tensionortight

thread

tension

n

thread

bobbin

-9-

Page 13

4.8.1

4.8.2

Bobbin

The

cotton

gradually goes down

held

released.

To

adjust

Needle

The

thread

standard

thread

by fingers

adjust

screw

thread

needle

tension

bobbin

#60isthat

tension,

shown

tension

thread

and

turn

in Fig.

tension

(Fig. 11)

thread

when

the

the

(Fig. 12)

justed in referencetobobbin

To adjust,

nut

shown

turn

in Fig.

the

tension regulator

12.

the

the

bobbin

11.

thread

tension

bobbin

thread

thread

should

for

case

end

case is

tension

be

ad

tension.

thumb

is

Tension

adjusting

Increase

Decrease

screw

Fig. 11

4.9

Lubrication

Apply several drops of lubricating oil to

Pour lubricating oil through

the

red

Note

markonthe

that

too

Oil

filler

much

hole

oil

oil

gauge.

may

the

oil filler hole in

spill

when

"A",

"B",

the

headisleaned.

Cover,

"C"

and

"D"

shown in Fig. 7 everyday.

the

bed, shown in Fig. 13, until

left

Tension

thumb

Fig.

12

the

oil level reaches

regulator

nut

Increase

Oil

gauge

Hook

clamp

Fig.

13

-10-

Page 14

5.

CONTROL

5.1

Switch

SWITCHES

Panel

Pattern

AND

enlarge/reduction

THEIR

FUNCTIONS

setting

(SCALE)

Error

lamp

indica^n

Terror)

Jog

switch

6.2

(±JOG)

Speed

Pattern

SCALE

setting

select

Switch

dial

(SPPED)

swich

X-SCALE

(PATTERN)

%

PATTERN

Fig.

14

Y-SCALE

PROM

MOVE

HOME

PROM

%

select

switch

ERROR

(PR0M1/PR0M2)

/(STOP/MOVE)

RESET

PROM

2

Reset/home

Select

switch

select

(RESET/HOME)

return

switch

(1) Let the patterns stored in PROM be 100% in size, they can be enlarged or reduced within a range

from 0% to 199% in X axis and Yaxis independently (stitch length isenlarged or reduced).

(2)

Pattern

Ex.

is enlargedorreduced in referencetothe

Switch

• •

X-SCALE

%

L

range

The

third

"00"or"1

home

position.

setting

shouldbewithin

from

"000"to"199".

digit (hundred) is

150%

(1.5

a

either

times)

Fig, 15 SCALE switch setting

-11-

Page 15

Notes: (1) When pattern is enlarged, it should be verified

that

the

enlarged pattern is within

sewing area. (Refer to para. 5.5.1.)

(2) Machine speed RPM may be decreased when enlarged pattern isstitched. (Refer to Table 2.)

5.3

PATTERN

Desired pattern can be selected by this switch (patterns are stored from

5.4

SPEED

The

courseofstitching.

5.5

±JOG

5.5.1

Switch

Switch

maximum

Switch

Test

function

After

the

(1)

Only

stitching

the

When

the

direction.

(2)

When

and

pattern,

then

When

the

position

thus

pressing

ting

speed (regular stitching speed) is

work

holder

the

work

holder

directionata fixed

JOG

switchisheldat"+"

the

switchisset

work

holder

the

switchisheldat"+"

the

work

holder

the

work

returns

the

work

permitting

to

switchisheld

holder

and

remains

startofstitching

the

START

testbyoperating

returnstothe

advances in

at

moves

reaches

holder

the

home

at"

returns

switch,orpermit

the

speed

in

the

goes

to

stopped

(+)

JOG

home

position.

position,

opposite

position

up,

position.

position,

the

the

while

end

and

home

there,

by de

switch.

set

by this switch. Speed

position

of

andislowered,

Stitching

"0"

in PROM).

cannot

I

®^ j

start

position

Fig.16Directionofinching

the

range of

be changed in mid

1

operation

5.6

STOP/MOVE

The

switch is

(1)

Bobbin

When

position,

usual

Switch

setat"STOP"

winding

the

START

the

sewing machine runs at

operation,

position

mostly

switch is depressed

the

switchissetat"MOVE"

for

after

about

-12-

bobbin

lowering

600

spm,

position.

winding.

the

work

but

the

holder

work

with

holder does

this

switch

not

setat"STOP"

moveatall. In

Page 16

5.7

RESET/HOME

(1)

(2)

5.8

PR0M1/PR0M2

Switch

"RESET"

"HOME'

(1)

(2)

(3) If

PROMs

Fig.

10

PR0M1.

the

in

(When

17.

patterns

further

PR0M2

it.

are

patterns

the

patternisstoredinthe

(4)

This

switchisusedtoselect

(5)

PR0M1

pattern

Before

"9.

and

storedinthe

PROMisloadedorunloaded,

HANDLING

Select

found

have

and

sewing

PR0M2.

Switch

at

the

places

been

stored

by us in

mustbestored,

store

the

desired

machineisshipped,

PR0M2.)

PROM

Stitchingismade

OF

selected

PROM",

PROM.

without

When

the

machine

When

tion,

and

When

holder

(When

movementisreset.

the

the

machine

all

machine

the

automatically

the

goes up and

In usual

shown

between

operation,

in

the

remove

patterns

no

with

read

fail.

switch is

switchissettothis

switchisset

needleisataposition

the

set

rightward

stops

with

the

movement

is

reset.

leftward

returnstothe

work holder returnstothe

the

switch is

PROMl

("RESET"

position

during

needle

stoppedatUP

("HOME"

home

other

position.

than

setat"HOME"

\ /

•••

T/

v

Notch

P.C

board

position),

stitching

position),

UP

the

position,

home position.)

position.

PROM

2

1 1

1 1

o

all

opera

position

work

it

O

O

o

o

o

5.9

Error

Indication

The following

(1)

ERROR

"error"

1

lamps light and operation stops when

Green No

Red

(2)

(3)

ERROR

Green

ERR0R1,

Two

and

2

red lamps

ERROR

ERROR

(ERROR

2) lights on

2

1

pattern

Pattern

6.2

mm.

The

work

->•

Scale

The

needle is

Set

"HOME"

holder

-13-

the

following troubles occur.

dataisstoredorstored

is enlarged excessively

holder

runs

over

its

down

the

pattern.

not

at UP position

the

RESET/HOME switchto"RESET"

position.

returnstothe

The

home

goesupto

data

and

movable

when

position.

UP

Fig. 17

are

improper.

stitch

range

the

power is

position,

length exceeds

turned

on.

and

then

and

the

work

Page 17

Two

5.10

Work

red lamp (ERROR 1

and

ERROR

Holder

2) flickering

Lift

Switch

The

LIMI-STOP Z

the

beltisoutofpulley

cause of

trouble

motor

and

turnonthe

or sewing machine itself is locked or

-*•

Turn

off

the

power,

power

again.

The work holder goesdown when this switch (pushbutton) isdepressed,and goesup whenit isdepressed

again. (See Fig. 1)

5.11

START

When this switch is depressed, sewing

Switch

(Foot

Switch)

starts

from

the

home

position. (See Fig. 1)

eliminate

the

-14-

Page 18

6.

OPERATION

6.1

6.2

Switch

SettingonSwitch

In

ordertocheck

Set

the

SCALE

ranging

As

at

Switch

When

each

for

the

from

the

left

Function

the

function

each

switches

"0"to"9",

RESET/HOME

position (settingatshipping).

Checking

above-instructed

as

follows:

Panel

function,

(both

and

switch,

preparatory

set

for

SPEED

the

each

switchonthe

X axis

and

switchto"4".

STOP/MOVE

operation

switch

Y axis)to"100",

switch

and

has

been

completed,

panelasfollows;

the

the

(1) Home return: Set the RESET/HOME switch to

to

make

sure

the

work

holder

to

para.

5.7.)

(2) Work holder lowering

(3) Work holder movement:

When

the

above-mentioned

occur.

By

performing

the

test,

To check stitching condition, set stitching speedto"low

para.

6.3.

motion:

check

test is

the

dimensions

The

work

holder

is

depressed

The

work

JOG

the

endofthe

to

the

when

holderistracing

made,

(it will

holder

switchissetat"+"

home

position

the

switchissetto"NEUTRAL"

only the work holder

and

should go down when

lift

when

the

should move tracing

position.

pattern,itshould

(the

work

the

pattern).

(Refertopara.

moves

locationofthe

work

switch" and proceed as instructed in

PATTERN

PR0M1/PR0M2

turnonthe

"RESET",

returnstothe

switchisdepressed

When

lifttotheUPposition,

holder

switchtoany

switch,

power

and then to "HOME"

home

position.

the

work

holder lift switch

again).

the

given

pattern

the

work

holder

stops

anditdoes

position

while

5.5)

and stitching motion does not

holder.

position

set

and

when

reaches

and

not

the

them

check

(Refer

the

return

go up

work

Note: In

6.3

order

to make yourself familiar with each switch function, it is recommendedtooperate switches

on

the

Sewing

switch panel

Operation

without

needle

thread

before starting sewing work.

(1) ReferringtoFig. 14, properly set switches on

the

switch panel,

(2) Set up a fabric and depress the work holder lift switch to let down the work holder. Then depress

the

START switch,

Once stitching starts, it continues even when

work

holderatUP position

the

sewing machine will

after

thread trimming.

-15-

start

stitching.

the

START switch is released, and stops with

the

Page 19

7.

CAUTIONS

(1)

(2) If

(3) When a

(4) Sewing

ON

USE

Before

replacementofPROMinPROM

any

alarm

(ERROR)

new

patternisstitched

relationship

The

maximum

However, it

between

maximum

speed

speed

shouldbeproperly

the

automatically

Table 2 Relationship between maximum sewing speed and stitch length

lamp

lights,

trace

for

the

work

holder

dependsonstitch

changes

set

for

CO

Stitch

CO

length

cassette,

first

movement

carefully

its

cause

referringtothe

time,orpattern

and

length.

dependingonstitch

individual fabric.

read

section8."HANDLING

descriptioninpara.

is enlarged, be suretoperform

the

pattern.

length.

(Refertopara.

Max.

speed

5.4.)

OF

5.9.

PROM".

testtocheck

5.4~6.2

CO

4.8~5.2

4.0~4.6

2.8~3.2

2.2~2.6

Less

than

(5)

Dust

enteredinthe

cover

shouldbekept

(6) When

the

power is

(7) When adjustment is made on

the

mechanisms

(8) Do

not

apply a

in

the

circuit

control

close.

turned

on,

or

control

multimetertothe

might

be damaged

unit

might

foot

the

sewing machine, be suretoturn

box

interior.

duetovoltage

(9) When single-phase motor is used, do

sec. until

the

motor

running

is stabilized

mm

2.0

cause

should

not

control

circuit

not

immediately depress

after

600

spm

850

1100

1300

1550

1800

2000

malfunctionortrouble.

be placed on

the

START

off

During

operation,

the

control

switch.

the

power before gaining access to

for checking or adjustment. Otherwise semiconductors

from

the

multimeter.

the

switching on

the

START switch,

power.

but

wait for

about

box

10

-16-

Page 20

8.

CHECKING

AND

MAINTENANCE

8.1 Adjusting the Needle Bar

(1)

Adjust

needle

on

the

arm

when

(2) If the adjustment is

barstop

the

Stop

(UP) Position (Fig. 18)

(UP)

position sothat the thread holeof takeup

sewing

machineisstopped.

out

of alignment over 1 mm, loosen the synchronizer shaft coupling set screw

and turn the coupling to adjust the needle bar stop (UP) position.

Stopping timing delays when the coupling isturned clockwise,and advances when turned counter

clockwise.

(3) If the needle bar stops too early, the needle threed may

stitching.

If

the

needle stop timing delays, the needle stops at a lower position and the wiper might be

caught by the

trimmer

cannot

needle,

enter

or the

the

cam

movable

groove.

knife

does not

move

since

leverIsaligned

leave

the needle eye at start of

the

cam

follower

roller

withthemark

of thread

Notes: Although

recommendedtomake

1.

2. There are

3.

the

needle

Draw

out

the

three

of

needle

DOWN

one

(blueisnotinuse.

Turn

the

first

rotate

the

disc).

stop

(DOWN) position is

the

following

synchronizer

position detecting discs in

position,

disc (red)toalign

cover

the

checking:

toward

second

the

not

the

the

one

(black) is

matching

requiredtobe adjusted for usual

cable

(See Fig.

synchronizer:

holes

18).

the

for

detectionofUP

(hold

the

first one (red) is for

first disc on its

position,

operation,

detection

and

the

circumference

it is

third

to

Page 21

8.2

Adjusting

(1) Install

thatitdoes

X-Y

Position

the

Home

Position

the

home position detecting disc so

not

come

detector.

detecting

into

contact

(2) The home position should be established so

that

the

disc

stepped

meets

the

portion

center

of

of

(small).

(3) The X-Y detector (large) is for detection

at

the

limits

range.

When

notch

in

the

home

ing machine stops and

lights when

shownes

position

the

notch

of

work

detecting

holder

in Fig. 22 is

"ERROR"

is sensed.

the

X-Y

disc,

discj

Fig.

with

detecting

detector

movable

provided

the

19

the

sew

lamp

Position

detecting

Detector

disc

element

Fig.

20

Stepped

detecting

Detector element

portion

disc

of

,

(smalD^B

Detector element (large)

X-Y

detector

(small)

Home

position

detercting

X-Y

disc

detector

(large)

Page 22

8.3

LIMIT-STOPZMotor

8.3.1

Filters

Periodically clean

may

8.3.2

Motor

The

If

motor

(1)

(2)

(3) Remove

(4)

(5) Remove

(6)

(7)

(8)

(9)

(10) When

the

air filters at the end cover and on pulley side. (Note

cause

overheattothe

motorisusually

stop

position becomes inaccurate,

is braked, check

Turn

off

not

the

powertostop

the

pletely).

Remove

Remove

Check

replace

Holding

The

If

screw

clutch

To

and

When

brake

Assemble

cannot

the

belt

and

the

cable plug (for brake) connectedtothe

three

bracket

the

bracket.

the

brake

lining

it.

the

clutch

shaftbyhand,

driven

member

they

cannotberemoved,

them

into

the

shaft.

replace

bearing.

the

brake

lining, remove

brake

lining is installed, align

lining. (Whenever bearing is

each

part

be

set

in place, lightly

strongly.)

the

brake

lining is replaced,

it can

To

smoothly

match

the

rotate

brake

motor).

requiredtobe

motorinthe

the

motor

pulley.

mounting

The

brake

and

brake

(cup)

and

prepare

tapp>ed

in reverse

lining,

and

holesinthe

try

operation

start

overhauled.

rotation

becomes unstable,ormetallic sound occurs when

following

motor.

screws.

assembly

brake

the

(About

will be

disc

for

carefully

lining

two

bearingonthe

the

removed,

stepstothe

tap

the

turn

the

for

the

motor

that

order:

2 min. is

removed

condition.Ifthe

pull it.

canberemoved

bolts

(M5 x

cup

and

tapped

install a

disassembling.Inassembling,ifthe

required

control box from

together

0.8

thread

boss

(madeofaluminum)toremove

pulley

side

hole

mentionedatstep

new

bearing.)

until

the

the

with

the

brake

lining is

together

and

with

lengthofmin.45mm)

install a

bracket.

(7)

clutch shaft end with mallet. (Do

clutch

shaftbyhand

after

assemblingtomake

matching.

and

depress

the

pedalatleast

100

clogged air filter

motor

stops

com

bracket.

found

worn

the

clutch

shaft.

new

brake

lining

with

holes in

clutch

shaft

not

tap

times.

the

out,

and

the

the

it

sure

Cautions:

8.4

• During disassembling

or

damage.

•

Since

bearingofspecial

Fuse

For

fuse, each

to

Fig. 5. (Sizeoffuses:

one

and

assembling,

specificationisused,

glass-tube fuseof10A

06.4x30)

carefully

rating

-19-

handle

addresstous

and

20A

rating is used.

the

brake

when

cup

it is

avoiding its

replaced.

For

deformation

locationoffuses,

refer

Page 23

8.5

CleaningofFan

The

cooling

withascrewdriver

8.6

Adjusting

If

tensionofthe

ing

machineisoperatedathigh

In

this

case,

8.7

PreventionofMalfunction

Filter

fan

filterislocatedonthe

and

the

V-Belt

LIMI-STOP Z

tighten

the

(1) Malfunction caused by noise

box,

synchronizer

150V,

electrician.)

(2) Do

prequency

not

grounding

locate

welders.

clean

the

filter

Tension

speed.

V-belt by moving

DuetoNoise,

and

sewing

is indispensable

the

sewing

bottomofcontrol

from

timetotime.

motor

V-belt is

and

the

motor

Grounding

too

position

maybeeliminatedtoa

machine

machine

for

near

head.

safety. Leave

equipment

small,

(When

box.

the

belt

adjusting

certain

the

that

generates

Remove

may

nut

the

largely

shown

filter

flatter

extentbygrounding

source

the

voltage is larger

grounding

intense

by levering it

when

in Fig. 3.

work

noise,

such

the

to

out

the

sew

control

than

AC

qualified

as high-

-20-

Page 24

9.

HANDLING

The

PROMs

They should be handled with

(1) Before loading and unloading PROM, be sure to turn off the power.

(2)

When

bend

OF

PROM

are

installedasshown

in Fig.

the

following cautions:

a screwdrive is used to remove

pinsofPROM.

17.

PROM,

take care not to

It is recommended to use an ICremover (ex.: TAKARATOOL S/S, Type P-63) for removalof

(3) Do not directlytouch the

might

occur.

(4)

Do

not

place

the

P.O.

sheetoraluminum

(5)

PROMs

is installed in wrong

should be installed in the control box,so that notch is

foil.

(6) For entering new patterns into

writer

PT-100or100A

(7) For erasure of patterns stored in

PROM

pinsand

board

and

PROM

direction,itmightbedamaged.

PROM,

can be used

when

PROM,

PROM

on statically

an optional

MB8516

PROM

eraser (incorporatedin

sockets on the

PROM

or MB8516H (Fujitsu) is used

charged

damage

cloth or

the P. C. board pattern, nor to

P.O.

board.

Otherwise

plastic,

but

place

downwardasshowninFig.

writer

(PTN-4000)

PROM

must be

for

PROM.

writer) must be used.

PROM.

contact trouble

on a

metallic

17. If

PROM

used

(PROM

(

-21-

Page 25

10.

AUXILIARY

The

(The

DIP

switches

switches

FUNCTIONS

SW1

and

are

protected

SW2 on

with

the

CPU

transparent

cardinthe

cover.

control

After

the

box

setting,

Switch

Switch

Switch

Switch

have

the

following

be suretoinstall

functions;

the

cover again.

Oj

DOWN

!SW2 H

10.1

10.1.1

SW1

Repeat

function

When

(a)

switchisat

holderstopsat the UPposition

With

(a)

switch

work holder lift switch is depressed to

However,

of stitching by depressing the START switch again.

Therefore, stitching can be

function is

the work holder

very

"OFF"

setat"ON",

helpful

when

(settingatshipping),

(even

when the STARTswitch is kept depressed.

the

work

"ON",

remains

lowered

repeated

pattern is

with the work holder

Fig. 23

holder

Transparent

only

goesupwhen

cover

DetailsofSW1

one

pattern

the

and

SW2

canbestitched

and

poweristurnedonor

or RESET/HOME switch isset to "RESET" position.

when

the stitching iscompleted, permitting resumption

sewn

repeatedly, or

maintainedatlowered

when

the embroidery

position. The

clamp

Switch

(setat"OFF")

the

work

when

the

frame

is

Page 26

10.1.2 Home position return cancellation at power turning on

With

(i)

switchofSW1

tion

when

the

POWER ON switch is depressed with

If the needle is not at UP position, however, the ERROR lamps

sewing machine does not start when the START switch is depressed.

In this case,let return the work holderby operatingthe

The ERROR lamps will go out and the work holder will return to the home position after the

needle

goes

up.

With switch set at

needle is located, when the power is turned on. The work holder does not return to the home

position

The work holder can be returnedtothe

This function is used to avoid home position return at

otherwise

10.1.3

Enlargement/reduction (SCALE) cancellation

When switch is at

5.2) and sewing area measuring each 25 mm in left and right directions, and each 15 mm in for

ward

By setting switch to

restrictionisimpossedonthe

In this case,

and

and

backward

switch

the

the

machine

work

the

pattern stored in the PROM is stitched in

is provisional,

setat"OFF",

"ON",

the ERROR lamps

does

not

start.

home position when

holder may collide with

"OFF",

directionsisavailable.

"ON",

the

enlargement/reduction of parttern is possible (refertopara.

the enlargement/reduction function can be reset, and no electrical

sewing

area.

and

has no

funciton.

the

work

other

holder

the

part

automatically

needle is at UP position.

"1"

and

RESET/HOME

"1"

and

"2"

(red) light, no matter where

the

RESET/HOMEswitch isoperated.

the

time

the

of machine).

the

real size (100%).

returnstothe

"2"

(red) light and the

switch (referto para.5.7).

power is turned on (when,

home

posi

the

10.2

SW2

These

DIP

switches

Table3shows

(a),@

fabric

rotating angle) after the synchronizer detects the needle

and

starts

When

pulses

and

therefore

angle).

are

usedtoset

timingateach

(D)switches

when

and

are

the

arm

(^switches

feeding

fabric

switch

setting.

setat"OFF"

shaft

rotatesby11

are

setto"OFF",

start

timing

Switch/Setting

(a)

"OFF"

®

"OFF"

©

"OFF"

@

"OFF"

feed

timing.

when

delays

Table

the

pulses

for

by2

3

sewing

example,

pulses

Timing

8

4

2

1

machineisshipped,

(one

pulse

correspondsto5.6"ofarm

DOWN

position.

numberofpulses

(equivalentto11.2"ofarm

pulses

pulses

pulses

pulse

thereby

becomes

shaft

feeding

of

shaft

equalto13

rotating

-23-

Page 27

Fabric

feed

timing

canbechecked

(1)

With

the

needleatUP

(2) Depress

(3)

Operate

(4) While

(5)

Without

(6) Depress

(7) By turning

(8) Sicne

referencetoheightofthe

the

work

the

JOG

the

operationissuspended,

the

V-belt,

the

START

the

balance wheel by

the

work

(9) Inseveral seconds

ing

that

the

V-belt is

position,

holder

switch

return

switchto"ON".

holder

after

as follows;

turnonthe

lift

switchtolower

and

depress

the

head.

hand,

movement

needle.

the

START

out

of position) and

power.

the

work

holder.

the

HALT

switchtosuspend

lean

the

the

machine

work

head

holder

and

remove

is driven by

corresponds to fabric feed timing, visually check

switch is

setto"ON",

the

LIMIT-STOP Z

the

ERROR

However, checking can be continued by turning the balance wheel by hand.

the

machine

the

the

V-belt.

stepping

operation.

motor.

(alarm) lamp lights (indicat

motor

clutch will be disengaged.

the

timing in

-24-

Page 28

MITSUBISHI

HEAD OFFICE MITSUBISHI DENKI SLOG MARUNOUCHI TOKVO 100 TELEX

(8502) ROD Printed in Japan

ELECTRIC

CORPORATION

J24532

CABLE MELCO TOKYO

Loading...

Loading...