Page 1

TECHNICAL & SERVICE MANUAL

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

CONTENTS

1. SPECIFICATIONS·································3

2. DATA ·····················································4

3.

REFRIGERANT SYSTEM DIAGRAM

········7

4. PARTS LIST··········································8

Indoor unit

PLH-1.6KKB

No. OC169

1998

[

Models

]

PLH-1.6KKB.UK

[

Service Ref.

]

Refer to OC150 for outdoor (PUH-

1.6VKA

3.UK) units, and OC119 for

indoor items other than this manual.

INDOOR UNIT

Ceiling Cassettes

Series PLH

FILTER

CHECK MODE

TEST RUN

CHECK

REMOTE CONTROLLER

The Slim Line.

From Mitsubishi Electric.

Page 2

Page 3

3

SPECIFICATIONS1

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Cond. drain connection O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Defrost method

Noise level

Dimensions

Weight

Refrigerating oil (Model)

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Input

Running current

Starting current

Fan(drive) o No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) o No.

Fan motor output

Airflow

Charge

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K / min (CFM)

Pa(mmAq)

kW

dB(A)

mm(in)

mm(in)

mm(in)

mm(in)

kg(lbs)

kW

A

A

kW

kW

K / min (CFM)

dB(A)

mm(in)

mm(in)

mm(in)

kg(lbs)

CC

kg(lbs)

mm(in)

mm(in)

PLH-1.6KKB.UK

Cooling

15,000

4,400

1.59

Heating

15,900

4,650

1.51

0.15

0.64

0.70

0.10

0.45

0.50

UNIT : 660(26)

UNIT : 660(26)

UNIT : 253(10)

UNIT : 19(42)

PANEL : 760(30)

PANEL : 760(30)

PANEL : 30(1-1/8)

PANEL : 3.7(8)

1.44

6.74

1.41

6.60

PLH-1.6KKB.UK

Single, 50Hz, 220-240V

33

Galvanized sheets with gray heat insulation

Plate fin coil

Turbo fan (direct) o 1

0.030

13-16(460-565)

0(direct blow)

—

Remote controller & built-in

32-37

32(1-1/4)

PUH-1.6VKA

3.UK

Single, 50Hz, 220-240V

Munsell 5Y 7/1

Capillary tube

Hermetic

RH247VFCT

1.2

Line start

Inner thermostat, High pressure switch

Plate fin coil

Propeller (direct) o1

0.065

45(1,590)

Reverse cycle

49

870(34-1/4)

295+24 (11-5/8 add 1)

650(25-5/8)

53(117)

570(MS-56)

R-22

2.2(4.8)

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 40m

Max. 40m

w1. Rating condition (Cooling)…Indoor 27°C D.B., 19.0°C W.B., Outdoor 35°C D.B.

Rating condition (Heating)…Indoor 20°C D.B., Outdoor 7°C D.B., 6°C W.B.

}

(JIS B8616)

Page 4

4

2

DATA

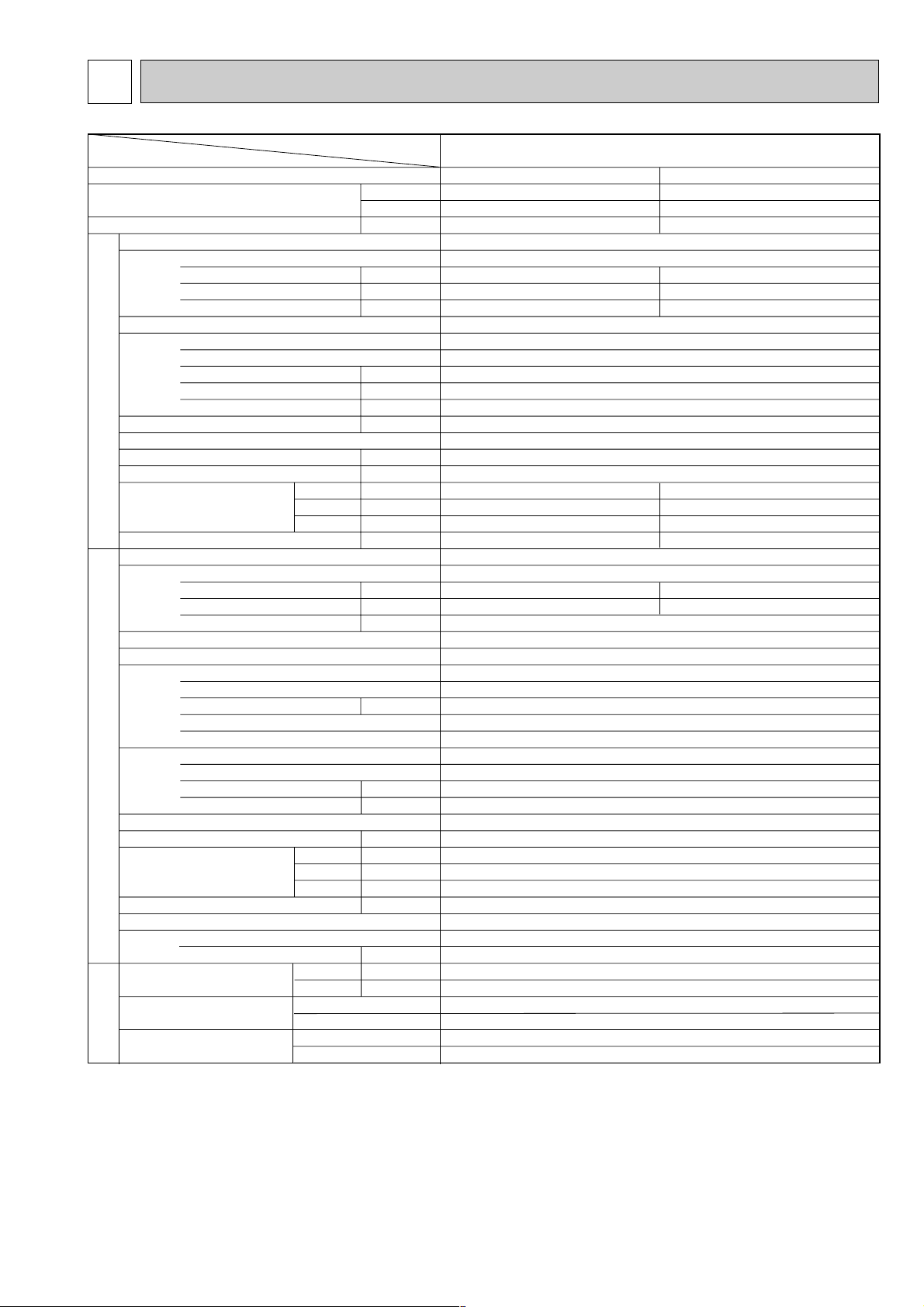

1. PERFORMANCE DATA

1) COOLING CAPACITY

Note CA :Capacity (W)

P.C. :Power consumption (kW)

Cooling capacity correction factors

P.C.

1.74

1.79

1.84

1.90

CA

3,624

3,882

4,154

4,442

P.C.

1.64

1.68

1.72

1.77

CA

3,812

4,074

4,352

4,645

P.C.

1.53

1.57

1.61

1.65

CA

3,990

4,258

4,542

4,840

P.C.

1.43

1.46

1.50

1.53

CA

4,159

4,434

4,724

5,028

P.C.

1.33

1.36

1.38

1.41

CA

4,317

4,602

4,899

5,209

P.C.

1.27

1.30

1.32

1.35

CA

4,439

4,726

5,017

5,310

20 25 30 35 40 45

Outdoor intake air D.B.$C

Indoor

intake air

W.B.$C

16

18

20

22

Service Ref.

PLH-1.6KKB.UK

Refrigerant piping length(one way)

5m

1.00

10m

0.993

15m

0.984

20m

0.978

25m

0.969

30m

0.961

35m

0.956

40m

0.948

45m

–

50m

–

Service Ref.

PLH-1.6KKB.UK

2) HEATING CAPACITY

Note CA :Capacity (W)

P.C. :Power consumption (kW)

Heating capacity correction factors

CA

3,184

3,049

2,930

P.C.

1.03

1.11

1.18

-10

CA

3,650

3,506

3,364

P.C.

1.14

1.23

1.31

-5

CA

4,160

4,003

3,844

P.C.

1.25

1.35

1.44

0

CA

4,714

4,538

4,370

P.C.

1.38

1.48

1.59

5

CA

5,312

5,112

4,942

P.C.

1.51

1.62

1.74

10

CA

5,952

5,724

5,560

P.C.

1.64

1.77

1.90

15

Outdoor intake air D.B.$C

Indoor

intake air

D.B.$C

15

20

25

Service Ref.

PLH-1.6KKB.UK

Refrigerant piping length(one way)

5m

1.00

10m

1.00

15m

1.00

20m

1.00

25m

1.00

30m

1.00

35m

0.998

40m

0.995

45m

–

50m

–

Service Ref.

PLH-1.6KKB.UK

Page 5

5

Heating

1.4

1.2

1.0

0.8

0.6

1.4

1.2

1.0

0.8

0.6

0.4

-12-10 -5 0 5 10 15

OUTDOOR W.B.($C)

INDOOR D.B. ($C)

INDOOR D.B. ($C)

15

20

25

25

20

15

TOTAL INPUT (RATIO) CAPACITY (RATIO)

Cooling

1.4

1.2

1.0

0.8

0.6

1.4

1.2

1.0

0.8

0.6

0.4

-5 5 15 25354552

OUTDOOR D.B.($C)

TOTAL INPUT (RATIO) CAPACITY (RATIO)

INDOOR W.B.($C)

INDOOR W.B.($C)

22

20

18

16

22

20

18

16

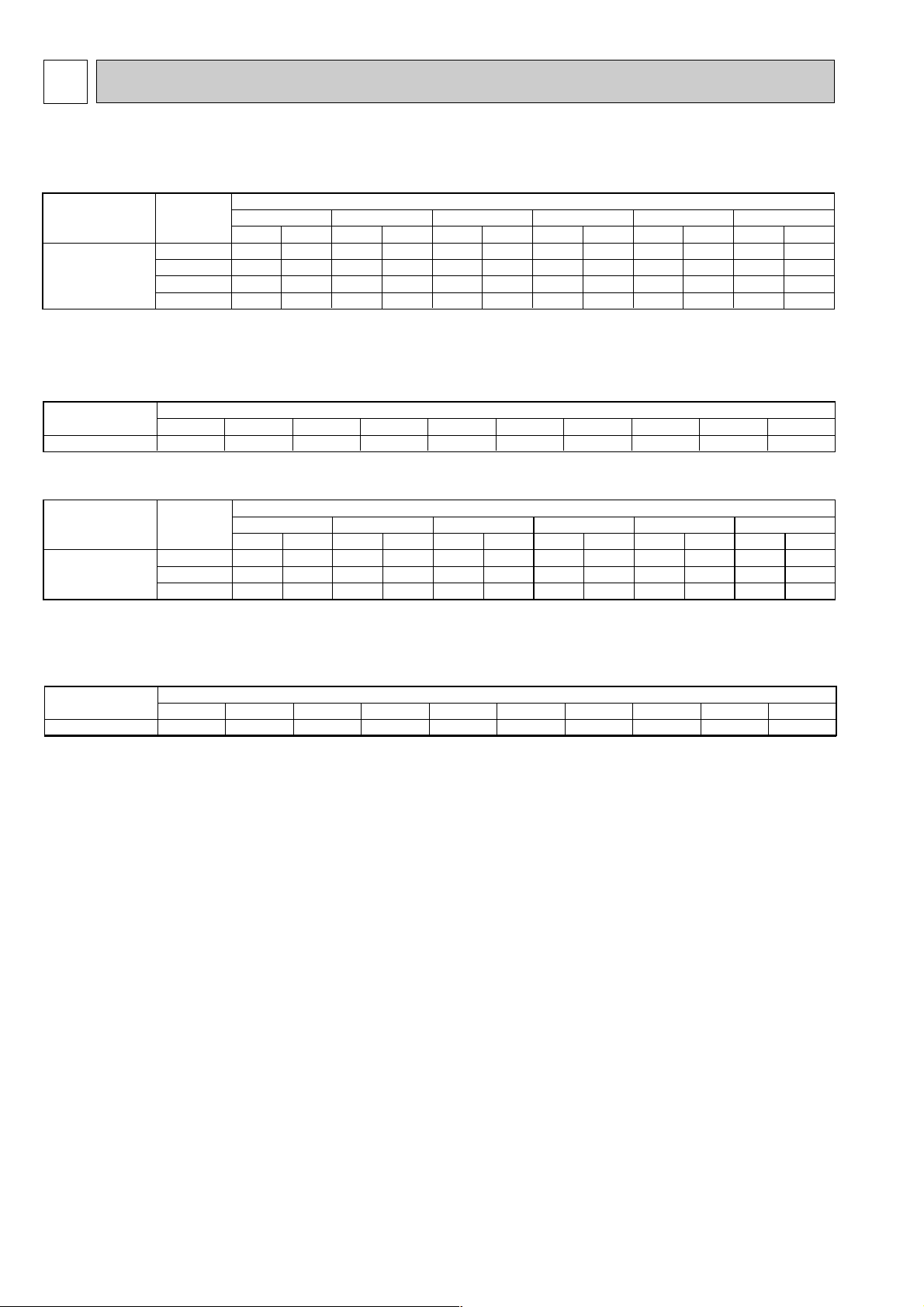

2. PERFORMANCE CURVE

PLH-1.6KKB.UK

Input (kW)

Current (A)

Starting current (A)

Input (kW)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW)

IndoorOutdoor

Cool

4,300

1.48

0.12

0.60

0.66

1.36

6.79

30

Heat

4,550

1.40

0.08

0.41

0.45

1.32

6.59

30

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Service Ref.

Power Supply

PLH-1.6KKB.UK

PUH-1.6VKA

3.UK

220V 50Hz 1phase

220V 50Hz 1phase

Cool

4,350

1.54

0.14

0.62

0.68

1.40

6.76

32

Heat

4,600

1.45

0.09

0.43

0.47

1.36

6.57

32

PLH-1.6KKB.UK

PUH-1.6VKA

3.UK

230V 50Hz 1phase

230V 50Hz 1phase

Cool

4,400

1.59

0.15

0.64

0.70

1.44

6.74

33

Heat

4,650

1.51

0.10

0.45

0.50

1.41

6.60

33

PLH-1.6KKB.UK

PUH-1.6VKA

3.UK

240V 50Hz 1phase

240V 50Hz 1phase

3. ELECTRICAL DATA

Page 6

6

Capacity

Input

Indoor unit Service Ref.

Phase,Hz

Volts

Amperes

Outdoor unit Service Ref.

Phase,Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

SHF

BF

Mode

Total

W

kW

V

A

V

A

MPa•G

(kgf/F•G)

MPa•G

(kgf/F•G)

$C

$C

$C

m

D.B.$C

W.B.$C

D.B.$C

D.B.$C

W.B.$C

PLH-1.6KKB.UKService Ref.

Cooling

4,400

1.59

Heating

4,650

1.51

6.74

1.80

(18.3)

0.54

(5.51)

78.7

48.5

8.5

5

27

19

16.1

35

24

0.83

0.21

6.60

1.70

(17.3)

0.40

(4.08)

77.2

–

0.7

5

20

15

35.2

7

6

–

–

0.64 0.45

PLH-1.6KKB.UK

1,50

240

PUH-1.6VKA

3.UK

1,50

240

Electrical circuitRefrigerant circuit

Indoor

side

Outdoor

side

Air flow

Air speed

Coverage range

K/min

m/W.

m

PLH-1.6KKB.UK

16.0

5.6

6.0

Air flow

Air speed

Coverage range

Total width of discharge outlets

K/min

m/W.

m

mm

17.0

5.9

6.4

0

Standard

High ceiling

4. STANDARD OPERATION DATA

5. OUTLET AIR SPEED AND COVERAGE RANGE

W The air coverage range is the value up to the position where the air speed is 0.25m/sec.

When air is blown out horizontally from the unit at the Hi notch position.

The coverage range should be used only as a general guideline since it varies according to the size of the room and

the furniture inside the room.

The unit of pressure has been changed to Mpa based on the international SI system.

The corversion factor is : 1 (Mpa·G) = 10.2 (kgf/cm2·G)

Page 7

7

REFRIGERANT SYSTEM DIAGRAM3

W1

O.D.{3.2oI.D.{1.6–R630

O.D.{3.2oI.D.{1.8–R600

High pressure protect switch

PLH-1.6KKB.UK / PUH-1.6VKA3.UK

Unit : mm

Page 8

8

PARTS LIST4

PANEL PARTS

PLH-1.6KKB.UK

1

2

3

4

5

6

7

T7W 560 003

R01 29H 500

R01 29H 691

R01 29H 061

T7W 14K 200

T7W 556 305

Part No. Part Name SpecificationNo.

Wining

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

AIR OUTLET GRILLE

AIR FILTER

INTAKE GRILLE

HINGE

–

GRILLE HANGER

REMOTE CONTROLLER

REMOTE CONTROLLER CABLE

12m

R.B

Remarks

(Drawing No.)

1

1

1

2

1

1

1

Q,ty/set

PLH-1.6

KKB.UK

(BG88H096H01)

7

2

3

1

4

5

6

Page 9

9

PANEL PARTS

PLH-1.6KKB.UK

1

2

3

4

5

6

7

R01 29H 002

R01 29H 085

R01 29H 223

R01 29H 063

R01 29H 056

R01 29H 047

Part No. Part Name SpecificationNo.

Wining

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

AUTO VANE

AIR GUIDE

VANE MOTOR

SPRING JOINT 1

T7W 33K 063

SPRING JOINT

PUSH BUTTON

VANE SUPPORT

8

T7W 560 258

COARD HEATER

9

R01 29H 040

GRILLE GEAR (RIGHT)

10

R01 29H 041

GRILLE GEAR (LEFT)

240V 28.2W

H

MV

Remarks

4

1

1

1

1

1

8

1

1

1

<3/SET>

Q,ty/set

PLH-1.6

KKB.UK

114

4

4

7

10

7

1

3

79

7

7

6

2

1

5

8

Page 10

10

FUNCTIONAL PARTS

PLH-1.6KKB.UK

1

3

6

7

2

5

2

13

14

24

25

26

23

16

9

20

22

18

3

4

30 2927

8

10

34

11

17

31

19

21

28

15

34

Page 11

11

Part No. Part Name SpecificationNo.

Part numbers that are circled not shown in the figure.

1

2

3

4

T7W E00 762

5

R01 29H 105

6

7

R01 41N 114

8

R01 08K 202

9

R01 29H 523

10

T7W 55K 355

11

R01 W28 266

12

R01 W28 527

T7W 580 480

13

S70 A00 529

14

15

16

17

18

19

20

T7W 521 716

21

T7W 517 716

22

T7W 515 716

23

R01 29H 255

24

25

T7W 58K 310

26

T7W 520 239

27

T7W 580 799

R01 J07 202

28

29

30

R01 08K 097

31

R01 A48 524

32

33

R01 005 533

34

S70 A00 675

Unit

Price

Amount

Q,ty/set

PLH-1.6

KKB.UK

–

–

–

–

–

–

–

–

–

–

–

–

BASE

LEG

LEG

FAN MOTOR

MOTOR MOUNT

INNER COVER

TURBO FAN

INDOOR COIL THERMISTOR

DRAIN SOCKET

DRAIN PUMP

DRAIN SENSOR

DRAIN HOSE

HEAT EXCHANGER

DRAIN PAN

CORNER SUPPORT(1)

CORNER SUPPORT(2)

CORNER SUPPORT(2)

CORNER SUPPORT(3)

LEAD WIRE COVER

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

FAN MOTOR CAPACITOR

CONTROLLER CASE

INDOOR CONTROLLER BOARD

FUSE

TRANSFORMER

ROOM TEMPERATURE THERMISTOR

BELL MOUTH

ELECTRICAL PARTS COVER

SPL WASHER

DRAIN PLUG

SENSOR HOLDER

FAN GUARD

PAI-V30F

3P(L,N,

3P(1,2,3)

2P(1,2)

2.5+F 400V

250V 6.3A

;

)

1

2

2

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

(Drawing No.)

(BG00T765G01)

(BG00K209G01)

(BG00K209G02)

(BG00T770G01 )

(BG00K210G01)

(BG00K211G01)

(BG00K212G01)

(RG00T856G01)

(BG00T861G01)

(BG25J542H04)

F1<I.B>

(BG00N936G07)

(RG00C610G01)

Wining

Diagram

Symbol

MF1

RT2

DP

DS

TB2

TB4

TB5

C1

I.B

T

RT1

Recommended

Q,ty

Page 12

HEAD OFFICE MITSUBISHI DENKI BLDG.MARUNOUCHI TOKYO100 TELEX J24532 CABLE MELCO TOKYO

CCopyright 1997 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Issued in Aug.1998. No. OC169 301

Printed in Japan.

New publication, effective Aug 1998.

Specifications subject to change without notice.

Loading...

Loading...