Mitsubishi PLA-RP71BA2, PLA-RP50, PLA-ZRP35, PLA-ZRP50, PLA-ZRP60BA Installation Manual

...

Air-Conditioners

PLA-RP·BA Series

PLA-ZRP·BA Series

INSTALLATION MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Anwendung vor Installation der Klimaanlage die vorliegende Bedienungsanleitung und das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil extérieur pour une utilisation sûre et correct.

INSTALLATIEHANDLEIDING

Lees deze handleiding en de installatiehandleiding van het buitenapparaat zorgvuldig door voordat u met het

installeren van de airconditioner begint.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de

aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, prima di installare il condizionatore d’aria leggere attentamente il presente manuale

ed il manuale d’installazione dell’unità esterna.

εΓΧεΙΡΙΔΙΟ ΟΔΗΓΙΩΝ εΓΚΑΤΑΣΤΑΣΗΣ

Για σωστή και ασφαλή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο, καθώς και το εγχειρίδιο εγκατάστασης

της εξωτερικής μονάδας, πριν από την εγκατάσταση της μονάδας κλιματιστικού.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual e o manual de instalação da unidade exterior antes de instalar o aparelho de ar condicionado.

INSTALLATIONSMANUAL

Læs af sikkerhedshensyn denne manual samt manualen til installation af udendørsenheden grundigt, før du

installerer klimaanlægget.

INSTALLATIONSMANUAL

Läs bruksanvisningen och utomhusenhetens installationshandbok noga innan luftkonditioneringen installeras så

att den används på ett säkert och korrekt sätt.

MONTAJ ELKİTABI

Emniyetli ve doğru kullanım için, klima cihazını monte etmeden önce bu kılavuzu ve dış ünite montaj kılavuzunu

tamamıyla okuyun.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для обеспечения безопасной и надлежащей эксплуатации внимательно прочтите данное руководство и

руководство по установке наружного прибора перед установкой кондиционера.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PARA EL INSTALADOR

PER L’INSTALLATORE

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝεΙ ΤΗΝ εΓΚΑΤΑΣΤΑΣΗ

PARA O INSTALADOR

TIL INSTALLATØREN

FÖR INSTALLATÖREN

MONTÖR İÇİN

ДЛЯ УСТАНОВИТЕЛЯ

English

Deutsch

Français

Nederlands

Español

Italiano

ελληνικά

Português

Dansk

Svenska

Türkçe

Русский

Contents

1. Safety precautions .....................................................................................2

2. Installation location ....................................................................................3

3. Installing the indoor unit ............................................................................3

4. Installing the refrigerant piping ..................................................................5

5. Drainage piping work .................................................................................6

Note:

The phrase “Wired remote controller” in this installation manual refers only to the PAR-21MAA.

If you need any information for the other remote controller, please refer to either the installation manual or initial setting manual which are

included in these boxes.

6. Electrical work ...........................................................................................7

7. Test run ....................................................................................................14

8. System control ........................................................................................17

9. Installing the grille ....................................................................................17

10. Easy maintenance function .....................................................................19

1. Safety precautions

Before installing the unit, make sure you read all the “Safety precau-

►

tions”.

Please report to your supply authority or obtain their consent before

►

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

• Ask a dealer or an authorized technician to install the unit.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specically made for use with refrigerant

specied in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to mini-

mize the risk of damage from earthquakes, typhoons, or strong winds. An

incorrectly installed unit may fall down and cause damage or injuries.

The unit must be securely installed on a structure that can sustain its weight.

•

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration in the room from exceeding the

safety limit in the event of refrigerant leakage. Should the refrigerant leak

and cause the concentration limit to be exceeded, hazards due to lack of

oxygen in the room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a ame, poisonous gases will be released.

• All electric work must be performed by a qualied technician according to

local regulations and the instructions given in this manual.

• Use only specied cables for wiring. The wiring connections must be made

securely with no tension applied on the terminal connections. Also, never

splice the cables for wiring (unless otherwise indicated in this document).

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels afxed to the main unit.

Failure to observe these instructions may result in overheating or a re.

• The terminal block cover panel of the unit must be rmly attached.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them.

• The user should never attempt to repair the unit or transfer it to another

location.

• After installation has been completed, check for refrigerant leaks. If refrig-

erant leaks into the room and comes into contact with the ame of a heater

or portable cooking range, poisonous gases will be released.

• When installing or relocating, or servicing the air conditioner, use only the

specied refrigerant (R410A) to charge the refrigerant lines. Do not mix it

with any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high

pressure in the refrigerant line, and may result in an explosion and other

hazards.

The use of any refrigerant other than that specified for the system will

cause mechanical failure or system malfunction or unit breakdown. In the

worst case, this could lead to a serious impediment to securing product

safety.

1.1. Before installation (Environment)

Caution:

•

Do not use the unit in an unusual environment. If the air conditioner is in-

stalled in areas exposed to steam, volatile oil (including machine oil), or sulfuric gas, areas exposed to high salt content such as the seaside, the performance can be signicantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

ow, or accumulate. If combustible gas accumulates around the unit, re or

explosion may result.

• Do not keep food, plants, caged pets, artwork, or precision instruments in

the direct airow of the indoor unit or too close to the unit, as these items

can be damaged by temperature changes or dripping water.

1.2. Before installation or relocation

Caution:

• Be extremely careful when transporting the units. Two or more persons

are needed to handle the unit, as it weighs 20 kg or more. Do not grasp the

packaging bands. Wear protective gloves as you can injure your hands on

the ns or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufcient capacity. Otherwise,

a short circuit, overheating, or re may result.

• When installing the power lines, do not apply tension to the cables.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation. Starting operation just after turning on the power switch can severely

damage the internal parts.

• Before starting operation, check that all panels, guards and other protective parts are correctly installed. Rotating, hot, or high voltage parts can

cause injuries.

2

• When the room humidity exceeds 80% or when the drainpipe is clogged,

water may drip from the indoor unit. Do not install the indoor unit where

such dripping can cause damage.

• When installing the unit in a hospital or communications office, be prepared for noise and electronic interference. Inverters, home appliances,

high-frequency medical equipment, and radio communications equipment

can cause the air conditioner to malfunction or breakdown. The air conditioner may also affect medical equipment, disturbing medical care, and

communications equipment, harming the screen display quality.

• Thermal insulation of the refrigerant pipe is necessary to prevent condensation. If the refrigerant pipe is not properly insulated, condensation will be

formed.

• Place thermal insulation on the pipes to prevent condensation. If the drain-

pipe is installed incorrectly, water leakage and damage to the ceiling, oor,

furniture, or other possessions may result.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all are nuts to specication using a torque wrench. If tightened

too much, the are nut can break after an extended period.

• Be sure to ground the unit. If the unit is not properly grounded, electric

shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse),

and molded case circuit breaker) with the specied capacity. If the circuit

breaker capacity is larger than the specied capacity, breakdown or re

may result.

• Do not operate the air conditioner without the air lter set in place. If the air

lter is not installed, dust may accumulate and breakdown may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation.

• After stopping operation, be sure to wait at least ve minutes before turning off the main power switch. Otherwise, water leakage or breakdown may

result.

2. Installation location

Refer to the outdoor unit installation manual.

3. Installing the indoor unit

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories.

Accessory name Q'ty

Installation template 1

1

Washers (with insulation)

2

Washers (without insulation)

Pipe cover (for refrigerant piping joint)

Small diameter

3

Large diameter

Band 8

4

Screw with washer (M5 × 25) for mounting grille 4

5

Drain socket 1

6

Insulation 1

7

Flare nut 1/4F(P60) 1

8

4

4

1

1

Fig. 3-1

950

20-45 20-45

160

160

840

150

90

187.5

860-910

810

840

135

+5

0

17

Min. 2500

Fig. 3-2

60

284 377

B

A

90

170

140

*

*

24

190

*

(Z)RP71, 100, 125, 140 85 77

Fig. 3-3

20-45

(7.5)(7.5)

620

950

605

860-910

160

160

70

-

105

50

*

*

Min. 500

20-45

C

D

+5

0

35

17

Models A B

(Z)RP35, 50 80 74

(Z)RP60 87 74

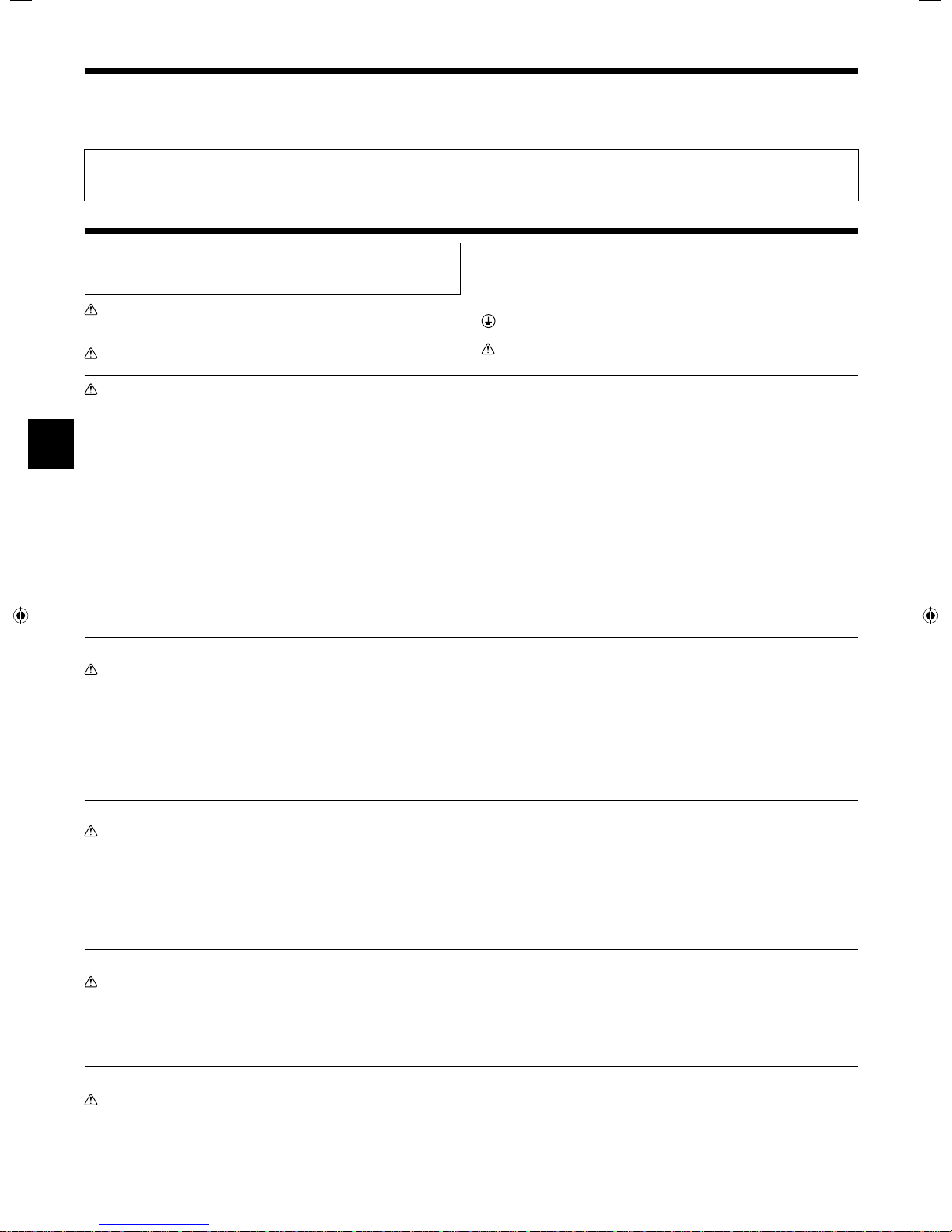

3.2. Ceiling openings and suspension bolt installation

locations (Fig. 3-2)

Caution:

Install the indoor unit at least 2.5m above oor or grade level.

For appliances not accessible to the general public.

• Using the installation template (top of the package) and the gauge (supplied as

an accessory with the grille), make an opening in the ceiling so that the main unit

can be installed as shown in the diagram. (The method for using the template

and the gauge is shown.)

* Before using, check the dimensions of template and gauge, because they

change due to uctuations of temperature and humidity.

* The dimensions of ceiling opening can be regulated within the range shown

in Fig.3-2; so center the main unit against the opening of ceiling, ensuring

that the respective opposite sides on all sides of the clearance between them

becomes identical.

• Use M10 (3/8") suspension bolts.

* Suspension bolts are to be procured at the eld.

• Install securely, ensuring that there is no clearance between the ceiling panel &

grille, and between the main unit & grille.

Outer side of main unit

A

Bolt pitch

B

Ceiling opening

C

Outer side of Grille

D

*Note that the space between ceiling panel of the unit and ceiling slab, etc. must be 10 to 15 mm.

When the optional multi-functional casement is installed, add 135 mm to the

*

dimensions marked on the gure.

Grille

E

Ceiling

F

Multi function casement (option)

G

Entire periphery

H

Models C D

PLA-RP35/50/60/71BA(2)

PLA-ZRP35/50/60BA

PLA-RP100/125/140BA(2)

PLA-RP100BA3

PLA-ZRP71/100/125/140BA

241 258

281 298

3.3. Refrigerant and drainage piping locations of

indoor unit

The gure marked with * in the drawing represent the dimensions of the main unit

excluding those of the optional multi function casement. (Fig. 3-3)

(mm)

Drain pipe

A

Ceiling

B

Grille

C

Refrigerant pipe (liquid)

D

Refrigerant pipe (gas)

E

Water supply inlet

F

Main unit

G

* When the optional multi-functional casement is installed, add 135 mm to the

dimensions marked on the gure.

(mm)

3

3. Installing the indoor unit

C

A

1

+5

B

E F

A

B

D E

D Ceiling

E Rafter

F Beam

G Roof beam

A

C

D

E

F

0

C

G

17

Fig. 3-6

B

G

F

B

A

A

D

100 100 90

90

70°

I

350

Fig. 3-4

C

2

605

810

H Use inserts rated at 100-150 kg each

(procure locally)

I Suspension bolts M10(3/8")(procure

locally)

J Steel reinforcing rod

Fig. 3-5

A Suspension bolt

A

B Ceiling

C Nut

D Washer (with insulation)

B

E Mounting plate

F Washer (without insulation)

G Check using the Installation gauge

+5

Min. 30

)

240

(

105

0

A=17

C

D

Fig. 3-8

J

K

Û

*158

100

130

*155

G

H

A Unit

B Grille

C Pillar

H

I

A

B

D

C

Main unit

A

B Ceiling

C Gauge

D Ceiling opening dimensions

Fig. 3-7

A Main unit

B Ceiling

C Installation template

(Top of the package)

D

Screw with washer(accessory)

N

*167

3.4. Branch duct hole and fresh air intake hole (Fig. 3-4)

At the time of installation, use the duct holes (cut out) located at the positions

shown in Fig3-4, as and when required.

L

• A fresh air intake hole for the optional multi function casement can also be made.

Note:

The gure marked with * in the drawing represent the dimensions of the main

Û

M

unit excluding those of the optional multi function casement.

When installing the optional multi function casement, add 135 mm to the di-

mensions marked on the gure.

When installing the branch ducts, be sure to insulate adequately. Otherwise

condensation and dripping may occur.

Branch duct hole

A

Indoor unit

B

Fresh air intake hole

C

Drain pipe

D

Refrigerant pipe

E

Branch duct hole diagramL ø125 burring hole pitch

F

(view from either side)

14-ø2.8 burring hole

G

ø150 cut out hole

H

ø175 burring hole pitch

I

Fresh air intake hole diagram

J

3-ø2.8 burring hole

K

ø100 cut out hole

M

Ceiling

N

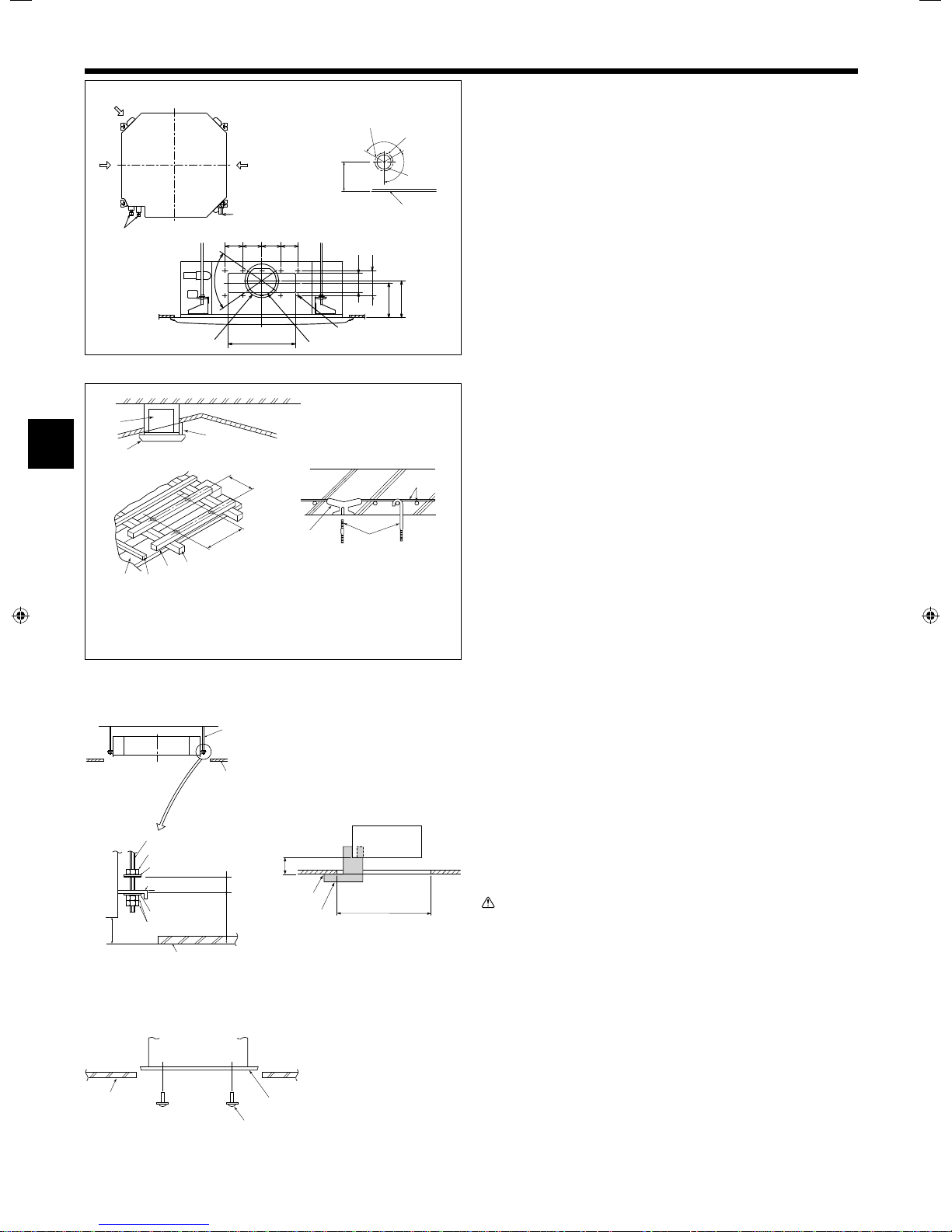

3.5. Suspension structure (Give site of suspension

strong structure) (Fig. 3-5)

• The ceiling work differs according to the construction of the building. Building

constructors and interior decorators should be consulted for details.

(1) Extent of ceiling removal: The ceiling must be kept completely horizontal and

the ceiling foundation (framework: wooden slats and slat holders) must be rein-

forced in order to protect the ceiling from vibration.

(2) Cut and remove the ceiling foundation.

(3) Reinforce the ends of the ceiling foundation where it has been cut and add ceil

J

ing foundation for securing the ends of the ceiling board.

(4) When installing the indoor unit on a slanted ceiling, attach a pillar between the

-

ceiling and the grille and set so that the unit is installed horizontally.

Wooden structures

1

• Use tie beams (single storied houses) or second oor beams (2 story houses) as

reinforcing members.

• Wooden beams for suspending air conditioners must be sturdy and their sides

must be at least 6 cm long if the beams are separated by not more than 90 cm

and their sides must be at least 9 cm long if the beams are separated by as much

as 180 cm. The size of the suspension bolts should be ø10 (3/8"). (The bolts do

not come with the unit.)

Ferro-concrete structures

2

Secure the suspension bolts using the method shown, or use steel or wooden

hangers, etc. to install the suspension bolts.

3.6. Unit suspension procedures (Fig. 3-6)

Suspend the main unit as shown in the diagram.

Figures given in parentheses represent the dimensions in case of installing optional

multi function casement.

1. In advance, set the parts onto the suspension bolts in the order of the washers

(with insulation), washers (without insulation) and nuts (double).

• Fit the washer with cushion so that the insulation faces downward.

• In case of using upper washers to suspend the main unit, the lower washers (with

insulation) and nuts (double) are to be set later.

2. Lift the unit to the proper height of the suspension bolts to insert the mounting

plate between washers and then fasten it securely.

3. When the main unit cannot be aligned against the mounting hole on the ceiling,

it is adjustable owing to a slot provided on the mounting plate.

• Make sure that A is performed within 17-22 mm. Damage could result by failing

to adhere to this range. (Fig. 3-7)

Caution:

Use the top half of the box as a protective cover to prevent dust or debris

from getting inside the unit prior to installation of the decorative cover or

when applying ceiling materials.

3.7. Conrming the position of main unit and

tightening the suspension bolts (Fig. 3-8)

• Using the gauge attached to the grille, ensure that the bottom of the main unit is

properly aligned with the opening of the ceiling. Be sure to conrm this, otherwise

condensation may form and drip due to air leakage, etc.

• Conrm that the main unit is horizontally levelled, using a level or a vinyl tube

lled with water.

• After checking the position of the main unit, tighten the nuts of the suspension

bolts securely to fasten the main unit.

• The installation template (top of the package) can be used as a protective sheet

to prevent dust from entering the main unit when the grilles are left unattached for

a while or when the ceiling materials are to be lined after installation of the unit is

nished.

* As for the details of tting, refer to the instructions given on the Installation tem-

plate.

4

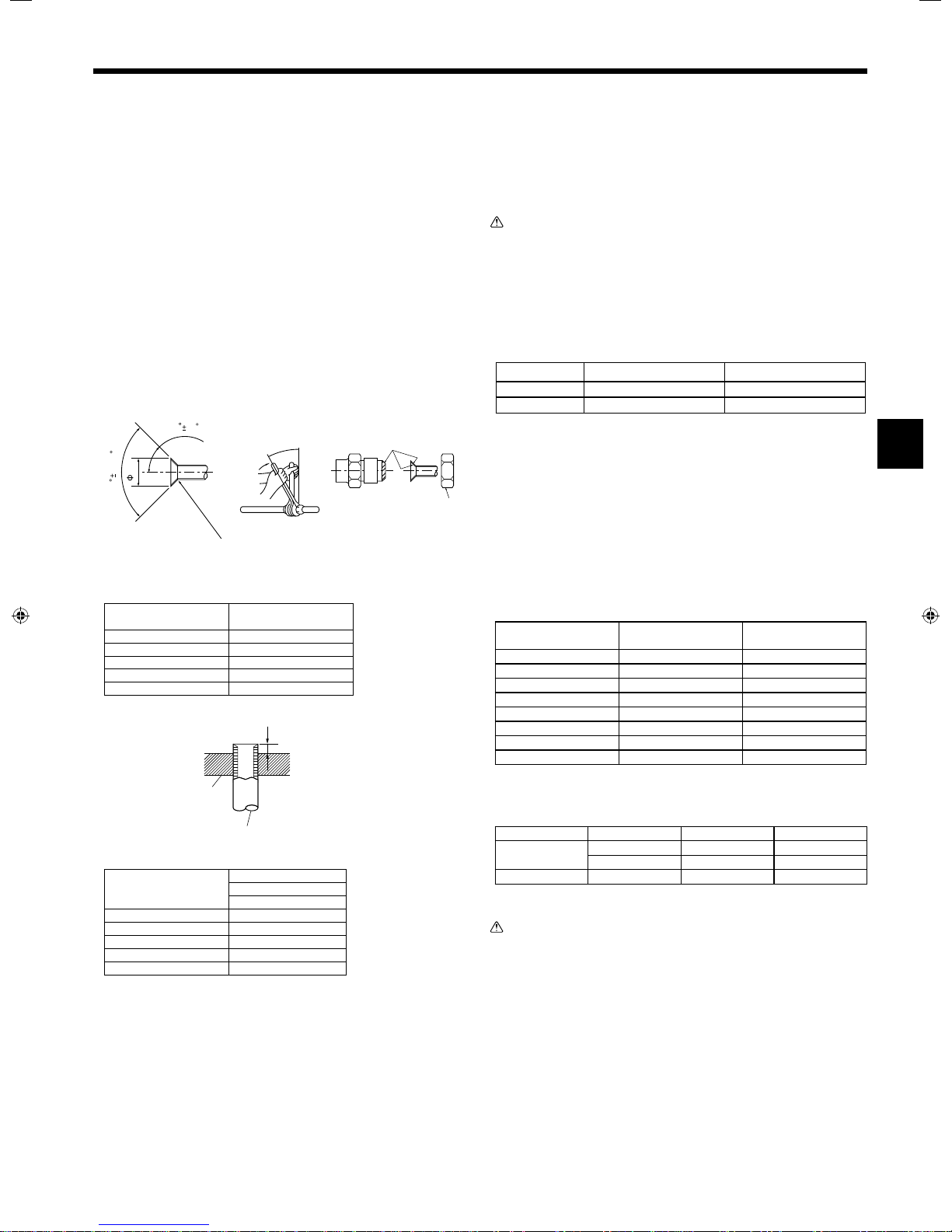

4. Installing the refrigerant piping

A

90 0.5

A Flare cutting dimensions

45 2

A

Copper pipe O.D. Flare dimensions

Copper pipe O.D.

[15.88 (5/8")

[19.05 (3/4")

R0.4 - R0.8

(mm) [A dimensions (mm)

[6.35 8.7 - 9.1

[9.52 12.8 - 13.2

[12.7 16.2 - 16.6

[15.88 19.3 - 19.7

[19.05 23.6 - 24.0

(mm)

[6.35 (1/4")

[9.52 (3/8")

[12.7 (1/2")

B

Fig. 4-1

B

EDie

FCopper pipe

E

F

Fig. 4-2

B (mm)

Flare tool for R410A

Clutch type

0 - 0.5

0 - 0.5

0 - 0.5

0 - 0.5

0 - 0.5

4.1. Precautions

For devices that use R410A refrigerant

• Use ester oil, ether oil or alkylbenzene oil (small amount) as the refrigera-

tion oil applied to the ared sections.

• Use C1220 copper phosphorus for copper and copper alloy seamless

pipes, to connect the refrigerant pipes. Use refrigerant pipes with the thick-

nesses specied in the table below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric com-

pounds, oxidants, debris, or dust.

Warning:

When installing or relocating, or servicing the air conditioner, use only the

specied refrigerant (R410A) to charge the refrigerant lines. Do not mix it

with any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high

pressure in the refrigerant line, and may result in an explosion and other haz-

ards.

The use of any refrigerant other than that specied for the system will cause

mechanical failure or system malfunction or unit breakdown. In the worst

case, this could lead to a serious impediment to securing product safety.

(Z)RP35, 50 (Z)RP60-140

Liquid pipe

Gas pipe

• Do not use pipes thinner than those specied above.

C

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C or

D

more, thickness of 12 mm or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam in-

sulation materials (specic gravity of 0.03, thickness of 9 mm or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening are nut.

• Use 2 wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. In

sulate carefully.

Flare nut tightening torque

B

Copper pipe O.D.

(mm)

[

6.35 17 14-18

[6.35 22 34-42

[9.52 22 34-42

[12.7 26 49-61

[12.7 29 68-82

[15.88 29 68-82

[15.88 36 100-120

[19.05 36 100-120

Apply refrigerating machine oil over the entire are seat surface.

C

Use correct are nuts meeting the pipe size of the outdoor unit.

D

Available pipe size

Liquid side

Gas side [12.7 Ο [15.88 Ο [15.88 Ο

Ο : Factory are nut attachment to the heat exchanger.

Warning:

When installing the unit, securely connect the refrigerant pipes before starting the compressor.

[

6.35 thickness 0.8 mm

[

12.7 thickness 0.8 mm

Flare nut O.D.

(mm)

(Z)RP35, 50 (Z)RP60 (Z)RP71-140

[6.35 Ο [6.35 —

— [9.52 Ο [9.52 Ο

[

9.52 thickness 0.8 mm

[

15.88 thickness 1.0 mm

Tightening torque

(N·m)

-

5

4. Installing the refrigerant piping

,

Fig. 4-3

5. Drainage piping work

Refrigerant pipe and

insulating material

Pipe cover (large)

Pipe cover (small)

Refrigerant pipe (gas)

Refrigerant pipe (liquid)

Band

Pipe

Insulating material

Squeeze

Cross-sectional view of connection

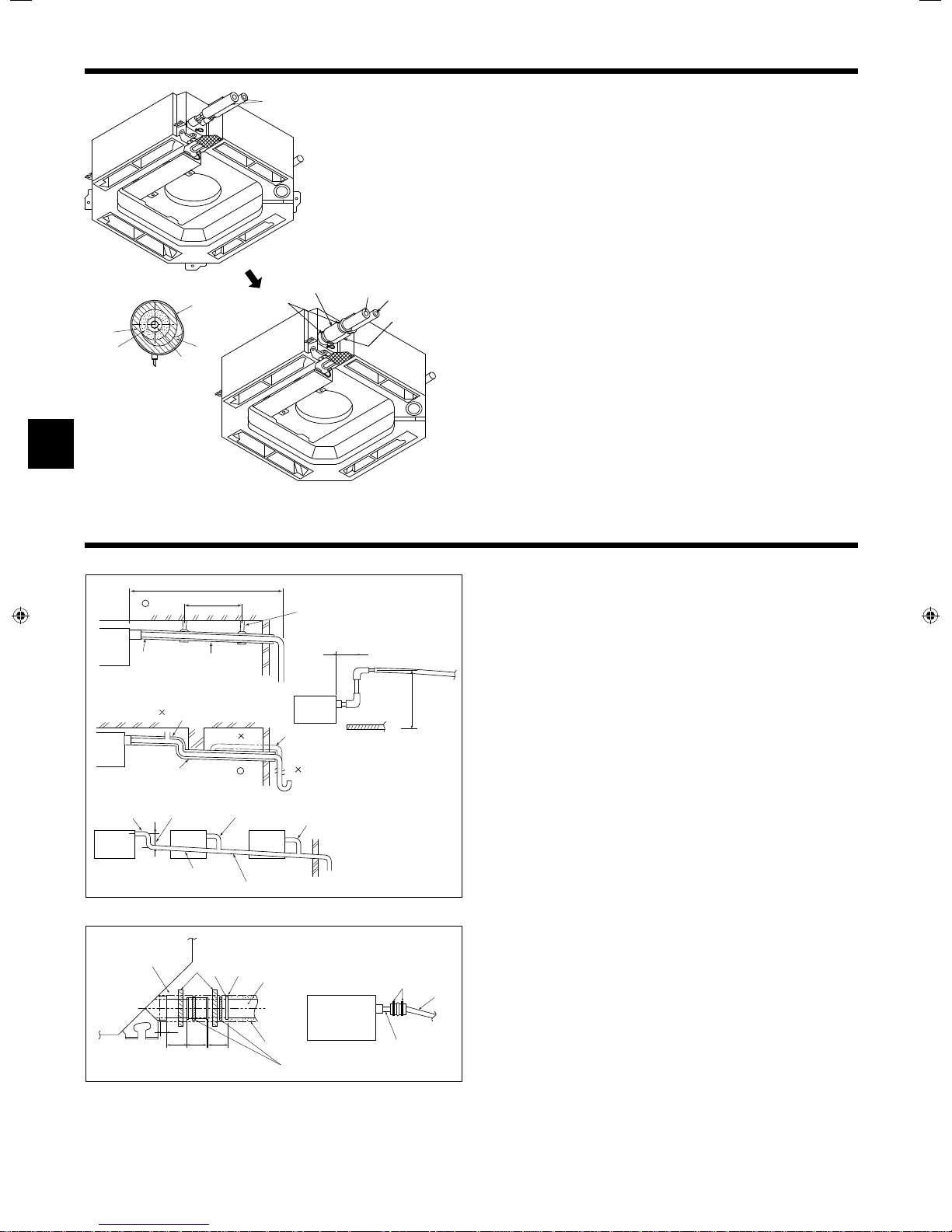

4.3. Indoor unit (Fig. 4-3)

Heat insulation for refrigerant pipes:

1 Wrap the enclosed large-sized pipe cover around the gas pipe, making sure

that the end of the pipe cover touches the side of the unit.

2 Wrap the enclosed small-sized pipe cover around the liquid pipe, making sure

that the end of the pipe cover touches the side of the unit.

3 Secure both ends of each pipe cover with the enclosed bands. (Attach the

bands 20 mm from the ends of the pipe cover.)

• After connecting the refrigerant piping to the indoor unit, be sure to test the pipe

connections for gas leakage with nitrogen gas. (Check that there is no refrigerant

leakage from the refrigerant piping to the indoor unit.)

4.4. For twin/triple combination

Refer to the outdoor unit installation manual.

5.1. Drainage piping work (Fig. 5-1)

Max. 20 m

1.5 - 2 m

Max. 15 cm

Fig. 5-1

(mm)

11

25 25 25

• Use VP25 (O.D. ø32 PVC TUBE) for drain piping and provide 1/100 or more

downward slope.

• Be sure to connect the piping joints using a polyvinyl type adhesive.

• Observe the gure for piping work.

• Use the included drain hose to change the extraction direction.

Correct piping

1

Wrong piping

2

Insulation (9 mm or more)

A

Downward slope (1/100 or more)

B

Grouped piping

O.D. ø32 PVC TUBE

D

Make it as large as possible

E

Indoor unit

F

Make the piping size large for grouped

G

piping.

1.Connect the drain socket (supplied with the unit) to the drain port. (Fig. 5-2)

(Fix the tube using PVC adhesive then secure it with a band.)

2.Install a locally purchased drain pipe (PVC pipe, O.D. ø32).

(Fix the pipe using PVC adhesive then secure it with a band.)

3.Insulate the tube and pipe. (PVC pipe, O.D. ø32 and socket)

4.Check that drain ows smoothly.

5.Insulate the drain port with insulating material, then secure the material with a

band. (Both insulating material and band are supplied with the unit.)

Unit

A

Insulating material

B

Band

C

Drain port (transparent)

D

Insertion margin

E

Matching

F

G

H

I

J

K

Support metal

C

Air bleeder

K

Raised

L

Odor trap

M

Downward slope (1/100 or more)

H

O.D. ø38 PVC TUBE for grouped piping.

I

(9 mm or more insulation)

Up to 85 cm

J

Drain pipe (O.D. ø32 PVC TUBE)

Insulating material (purchased locally)

Transparent PVC pipe

O.D. ø32 PVC TUBE(Slope 1/100 or more)

Drain socket

Fig. 5-2

6

Loading...

Loading...