Page 1

ON/OFF TEMP

MODEL SELECT

NOT AVAILABLE

CHECK

TEST RUN

˚C

AMPM

AMPM

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

No.OC297

REVISED EDITION-C

Series PLA

Ceiling Cassettes

R407C/R410A

Indoor unit

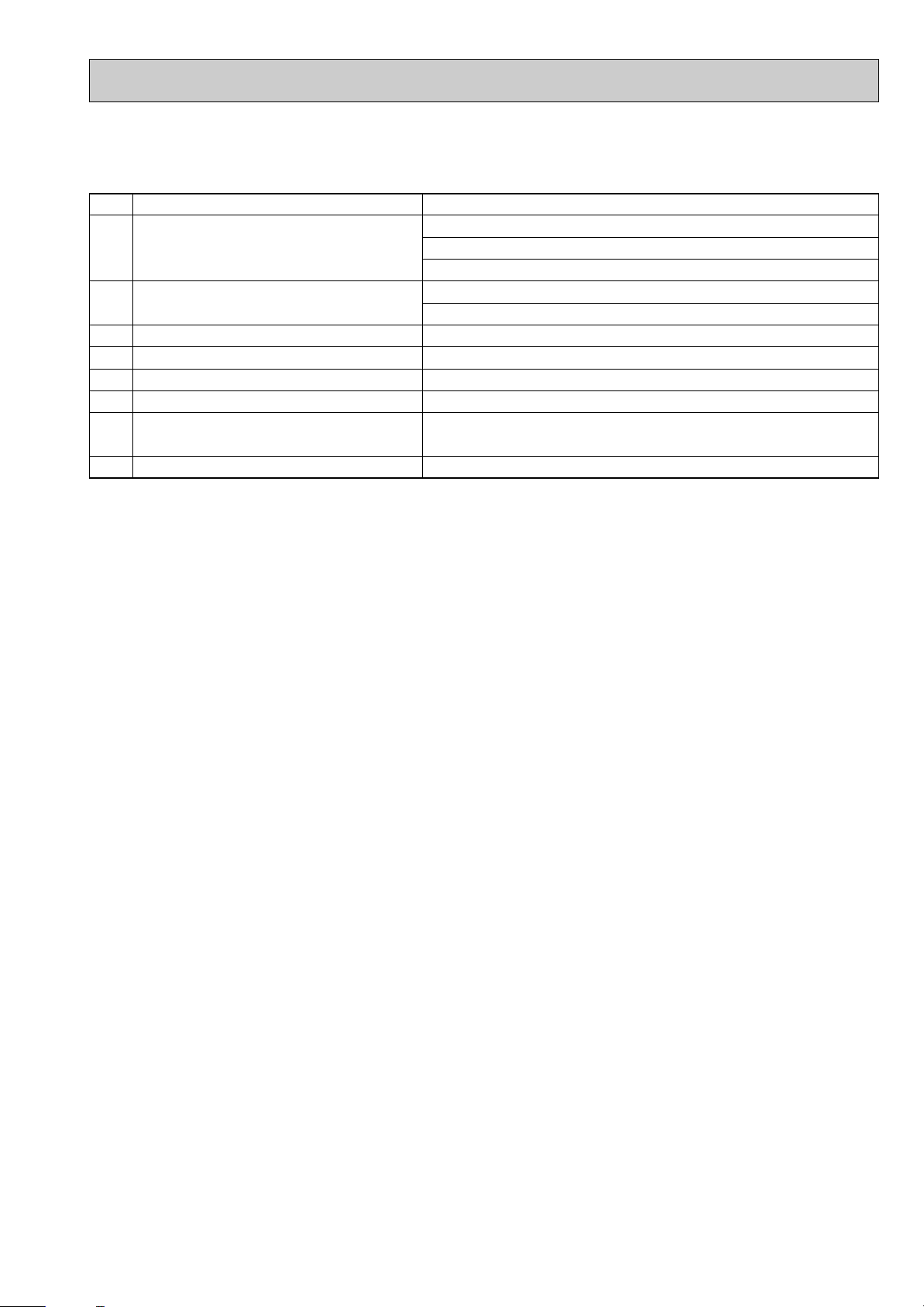

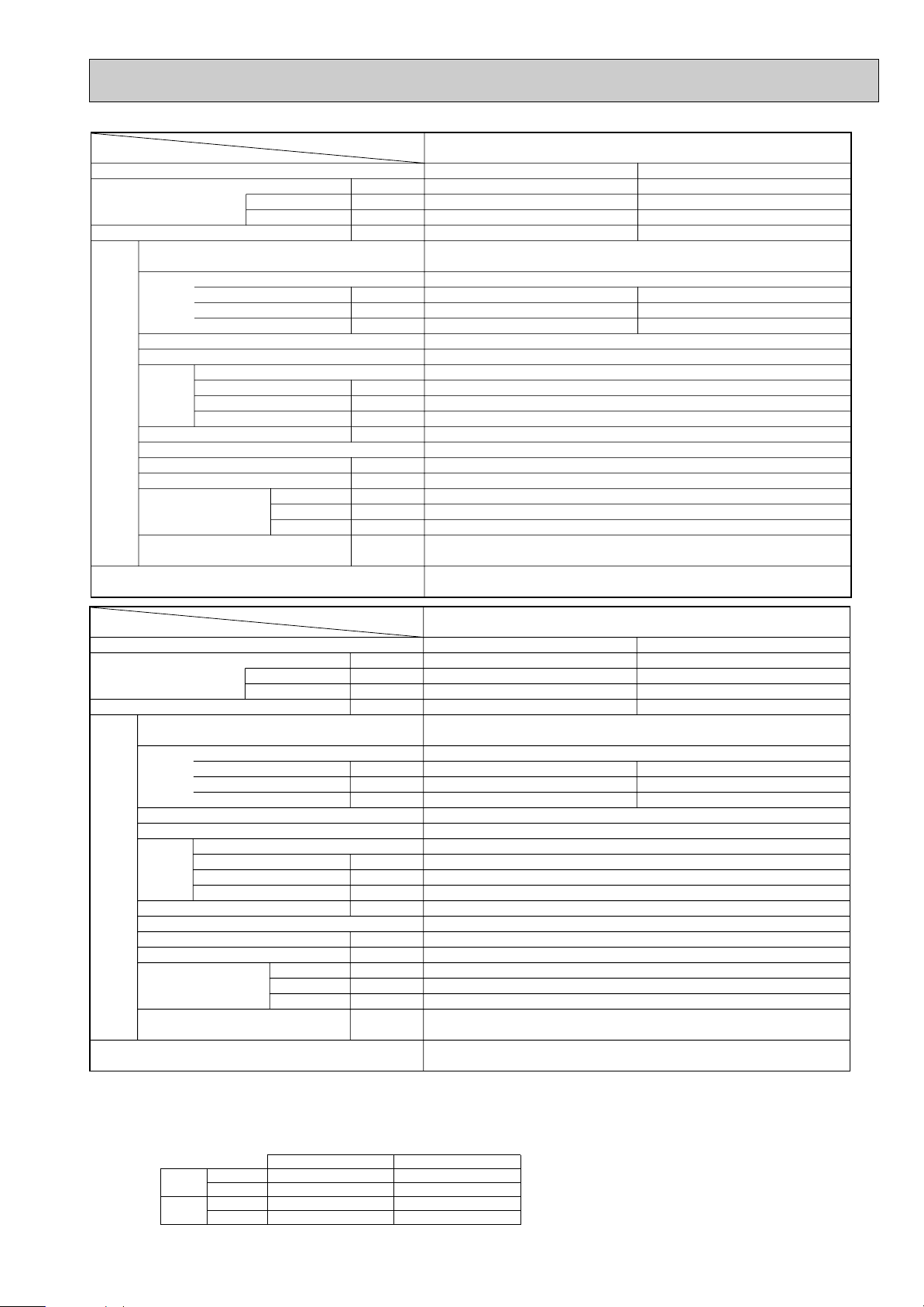

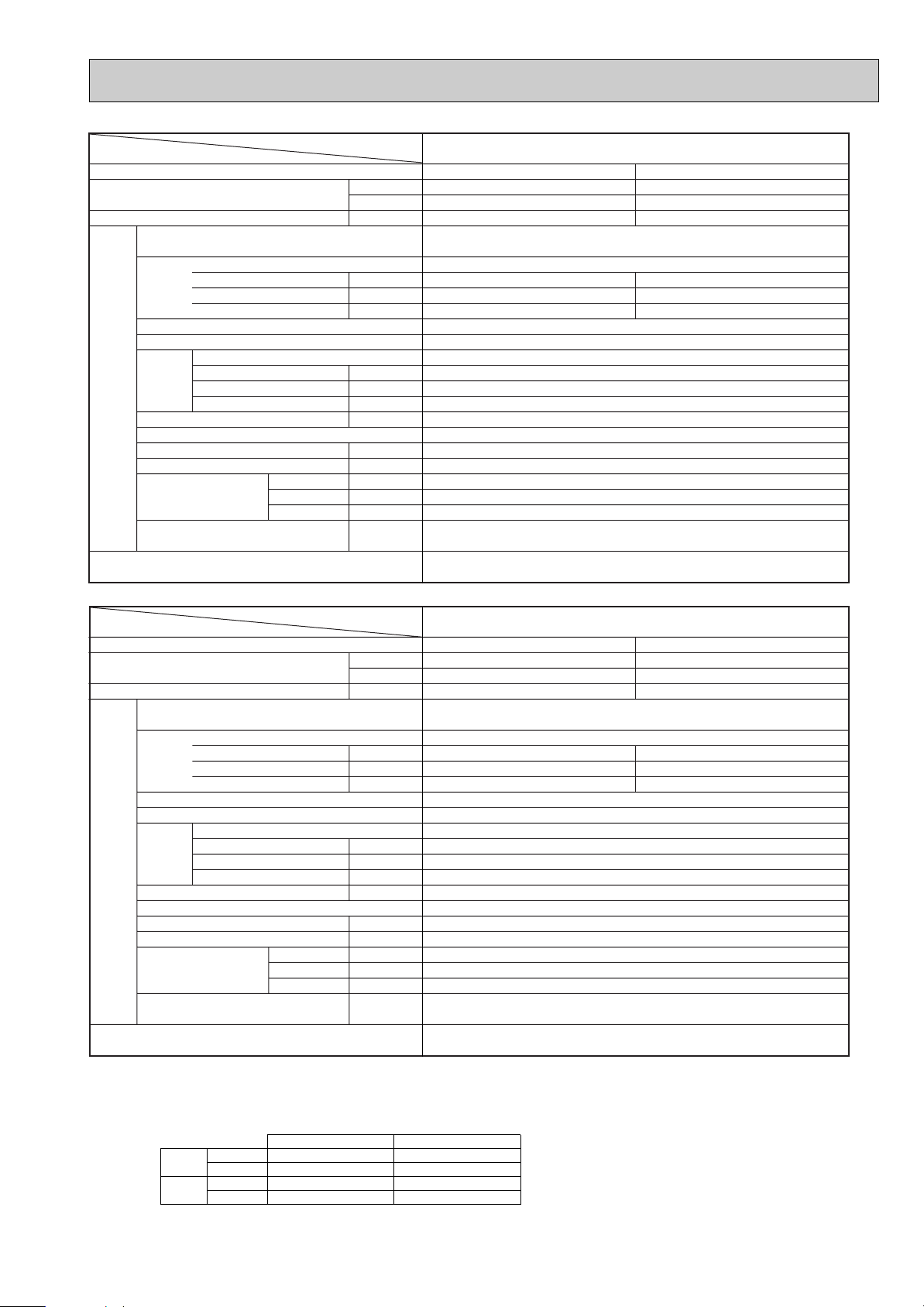

[Model names] [Service Ref.]

PLA-RP1.6AA PLA-RP1.6AA.UK

PLA-RP2AA PLA-RP2AA.UK

PLA-RP2.5AA PLA-RP2.5AA.UK

PLA-RP3AA PLA-RP3AA.UK

PLA-RP3AA1.UK

PLA-RP4AA PLA-RP4AA.UK

PLA-RP4AA1.UK

PLA-RP5AA PLA-RP5AA.UK

PLA-RP5AA1.UK

PLA-RP6AA PLA-RP6AA.UK

PLA-RP6AA1.UK

CONTENTS

Revision :

•“ 5. SPECIFICATIONS ” and

“ 12. PARTS LIST ” has been modified.

Note :

• This manual does not cover outdoor

units.

When serving them, please refer to

the service manual No.OC294

REVISED EDITION-B, OC261

REVISED EDITION-B and this

manual in a set.

•Please void OC297 REVISED

EDITION-B.

1. TECHNICAL CHANGES······························2

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

···3

3. SAFETY PRECAUTION·······························4

4. PART NAMES AND FUNCTIONS ···············8

5. SPECIFICATIONS ······································11

6. DATA ··························································21

7. OUTLINES AND DIMENSIONS·················60

8. WIRING DIAGRAM ····································61

INDOOR UNIT

9. REFRIGERANT SYSTEM DIAGRAM ········62

10. TROUBLESHOOTING ·······························63

11. DISASSEMBLY PROCEDURE ··················74

12. PARTS LIST···············································77

13. OPTIONAL PARTS ····································84

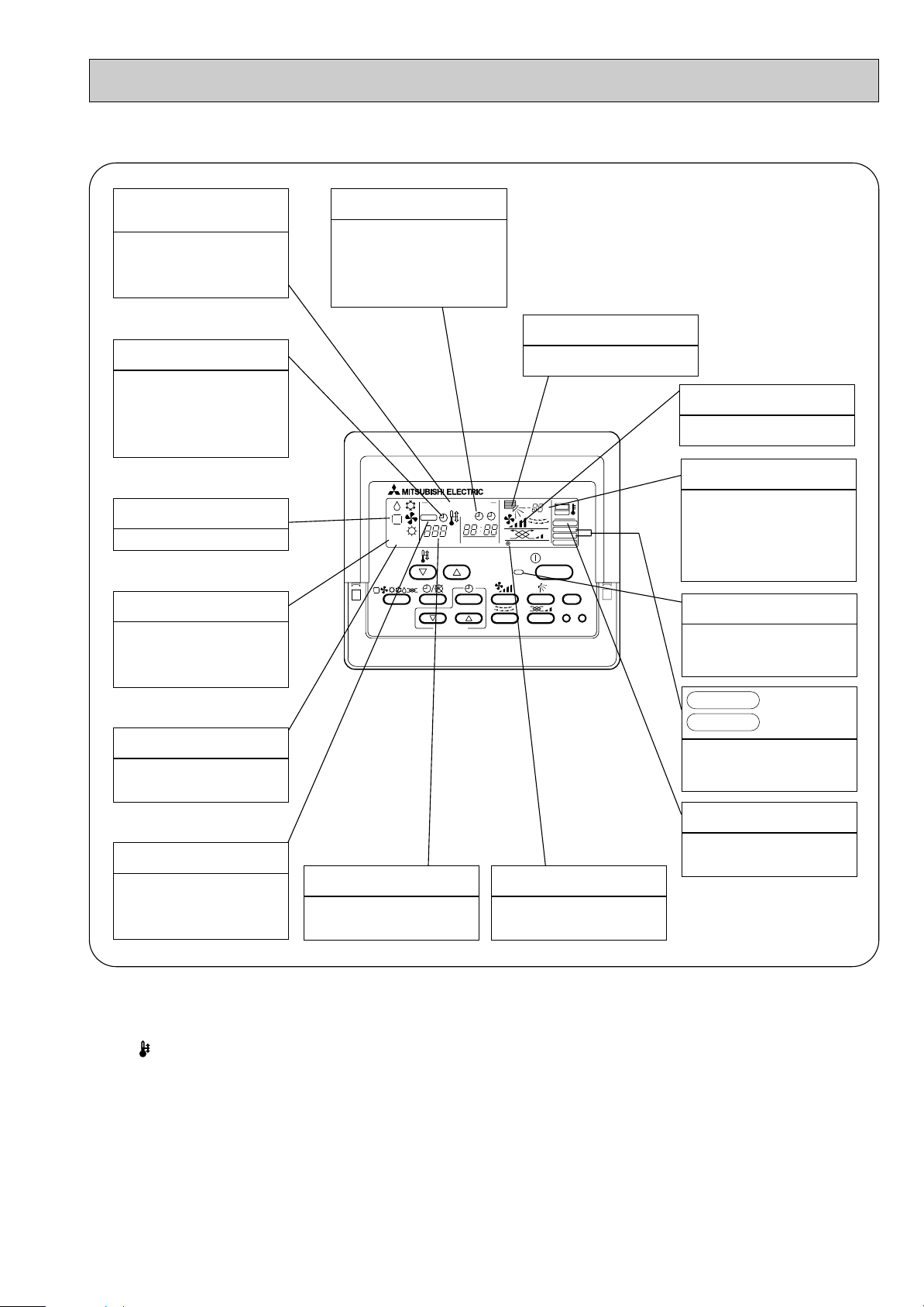

WIRELESS REMOTE

CONTROLLER

WIRED REMOTE

CONTROLLER

Page 2

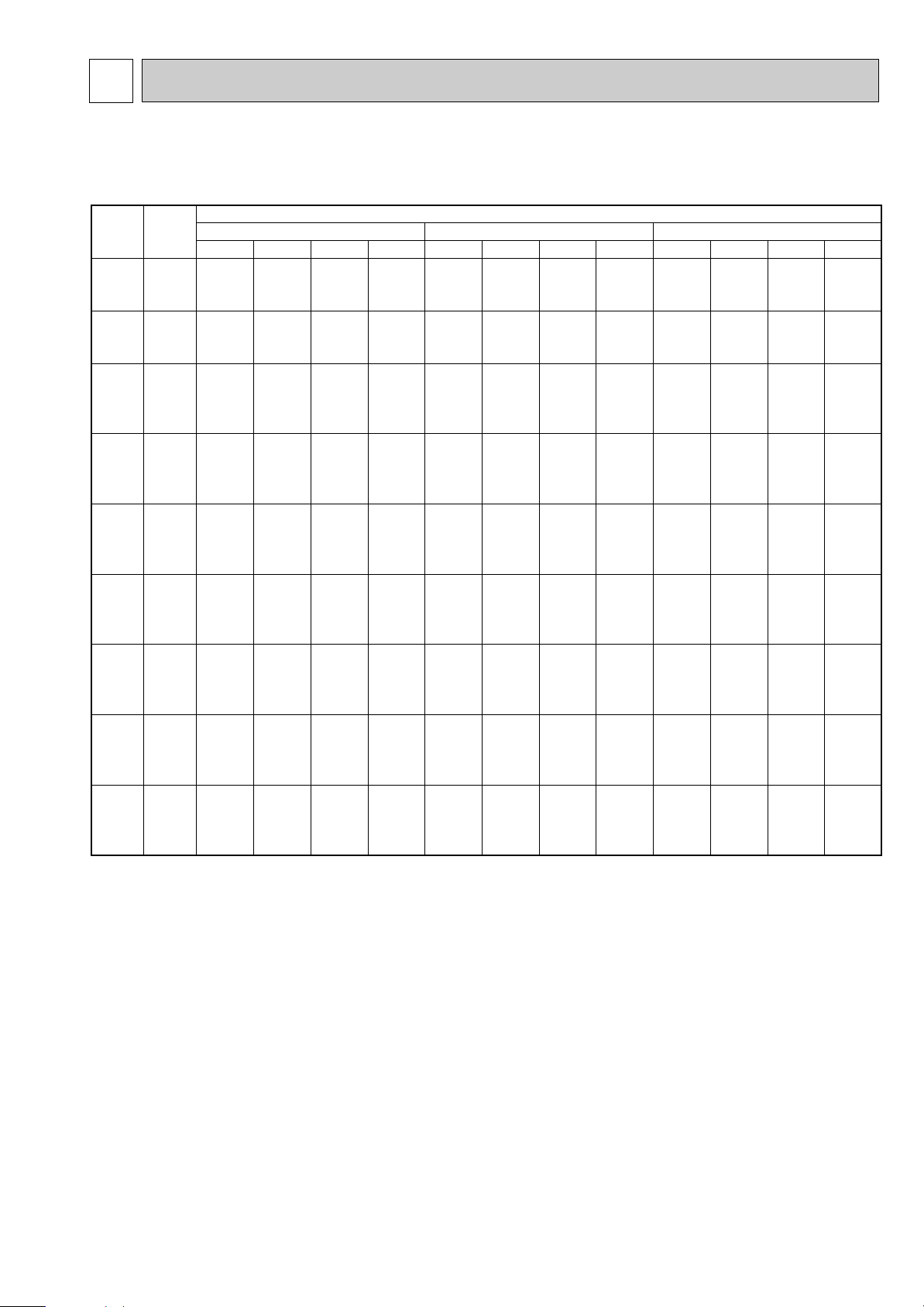

OFF

ON

4321

OFF

ON

4321

W Note: PLA-RP5AA.UK is connected to PUHZ-RP5VHA only.

PLA-RP5AA

1.UK can connect to PUHZ-RP5VHA, PUH-P5YGAA.UK, PUH-P5YGAA1.UK,

PU-P5YGAA.UK and PU-P5YGAA

1.UK.

PUHZ-RP3VHA

PUHZ-RP4VHA

PUHZ-RP5VHA

PUHZ-RP6VHA

OC294

R410A

● OC297 (PLA-RP•AA.UK)

● OC297 REVISED EDITION-A (PLA-RP•AA.UK, AA1.UK)

PUHZ-RP3VHA

PUHZ-RP4VHA

PUHZ-RP5VHA

PUHZ-RP6VHA

OC294

R410A

PUH-P3VGAA.UK

PUH-P3VGAA

1.UK

PUH-P3YGAA.UK

PUH-P3YGAA

1.UK

PUH-P4VGAA.UK

PUH-P4VGAA

1.UK

PUH-P4YGAA.UK

PUH-P4YGAA

1.UK

PUH-P5YGAA.UK W

PUH-P5YGAA

1.UK W

PUH-P6YGAA.UK

PUH-P6YGAA

1.UK

PU-P3VGAA.UK

PU-P3VGAA

1.UK

PU-P3YGAA.UK

PU-P3YGAA

1.UK

PU-P4VGAA.UK

PU-P4VGAA

1.UK

PU-P4YGAA.UK

PU-P4YGAA

1.UK

PU-P5YGAA.UK W

PU-P5YGAA

1.UK W

PU-P6YGAA.UK

PU-P6YGAA

1.UK

OC261 REVISED EDITION-A

R407C

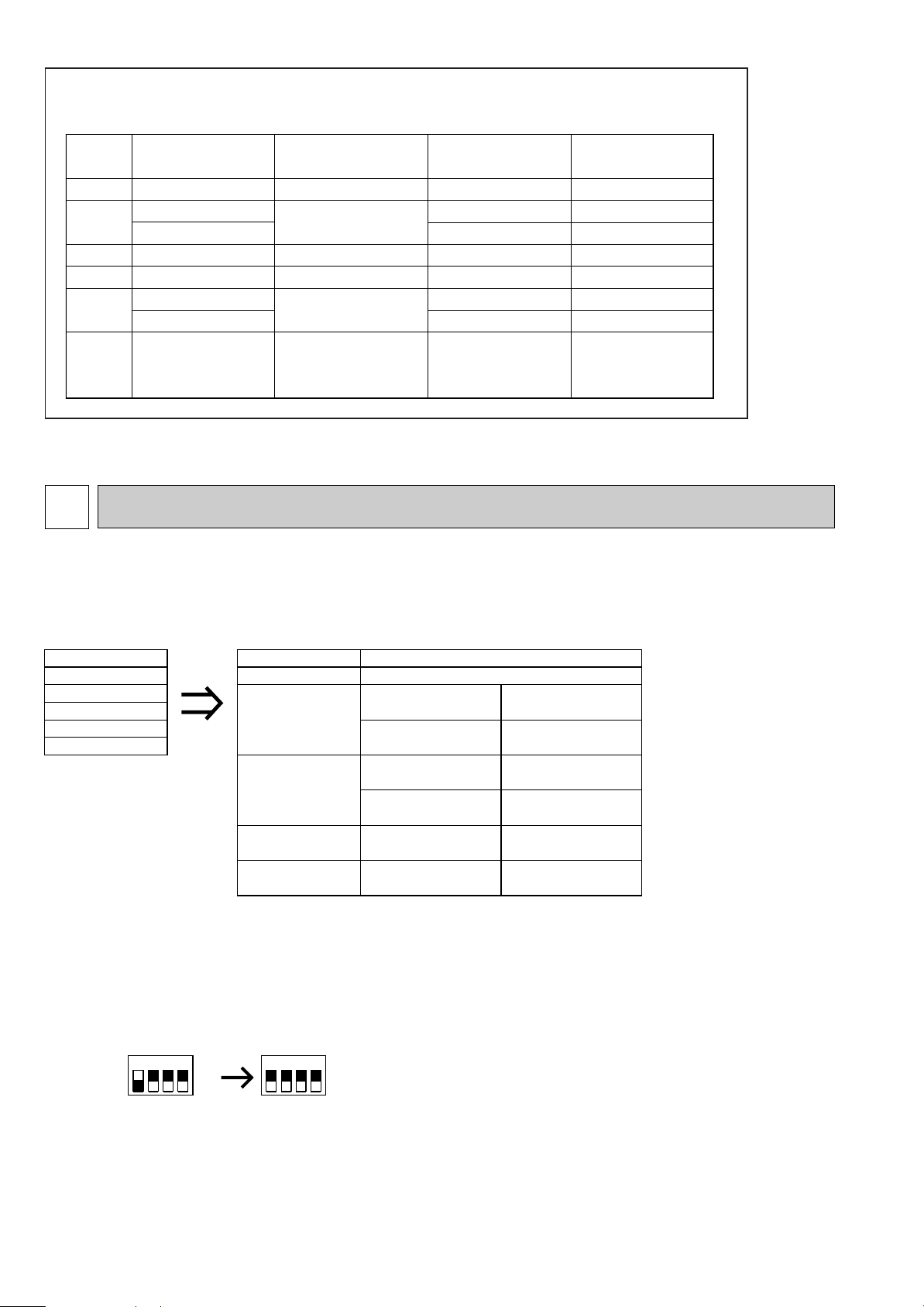

Revision:

Service Ref.

Page

11

81

12

11

13

14

IncorrectRevise point Correct

PLA-RP1.6AA.UK

PLA-RP2AA.UK

PLA-RP2.5AA.UK

PUHZ-RP4VHA

1

PUHZ-RP6VHA1

PLA-RP1.6AA.UK

PLA-RP2AA.UK

PLA-RP2.5AA.UK

Heating Total input

Cooling Total input

Heating Total input

Cooling Capacity

Heating Capacity

Cooling Total input

Cooling Capacity

FUNCTINAL PARTS

No.6 ELECTRICAL

CONTROL BOX

2.34 1.12

3.03 1.55

3.39 1.62

1.68 1.65

10,000(4,500~11,400)

14,000(6,200~15,300)

16,000(6,200~18,000)

10,000(4,900~11,400)

14,000(5,500~15,300)

16,000(5,000~18,000)

S70 E02 501 S70 E20 501

“ 5. SPECIFICATIONS ” has been modified on page 11 to 14.

“ 12. PARTS LIST ” has been modified on page 81.

1

TECHNICAL CHANGES

REVISED EDITION-A

PLA-RP3,4,5,6AA.UK PLA-RP3,4,5,6AA1.UK

1. Connectable outdoor unit has changed.

PLA-RP5AA1.UK

2. Corresponding to the addition of connectable outdoor unit, the setting of SW2 (Capacity setting) on the indoor

controller board have also changed.

PLA-RP5AA.UK

REVISED EDITION-B

• PLA-RP1.6AA.UK, PLA-RP2AA.UK and PLA-RP2.5AA.UK are added in REVISED EDITION-B.

PLA-RP5AA1.UK

2

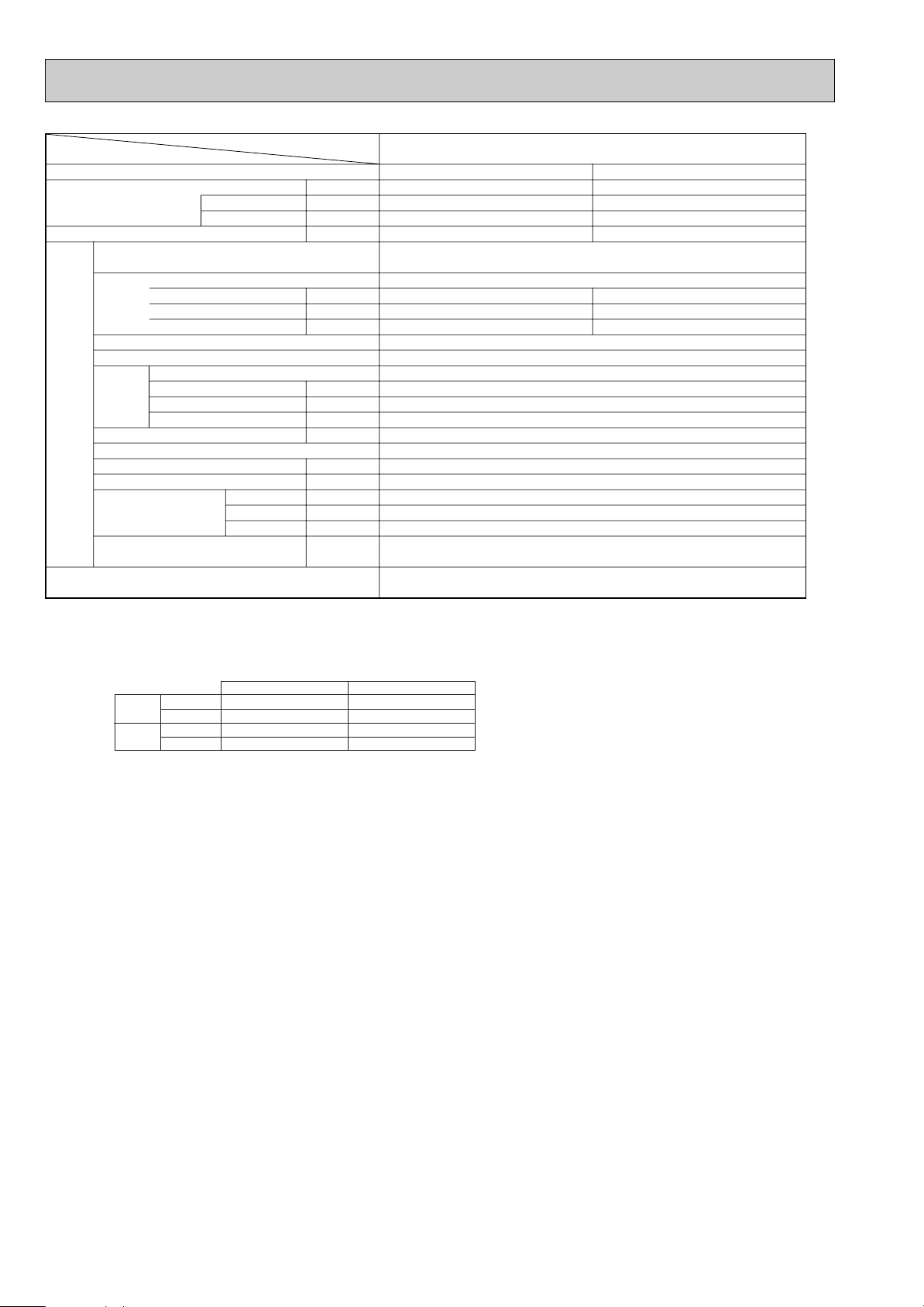

Page 3

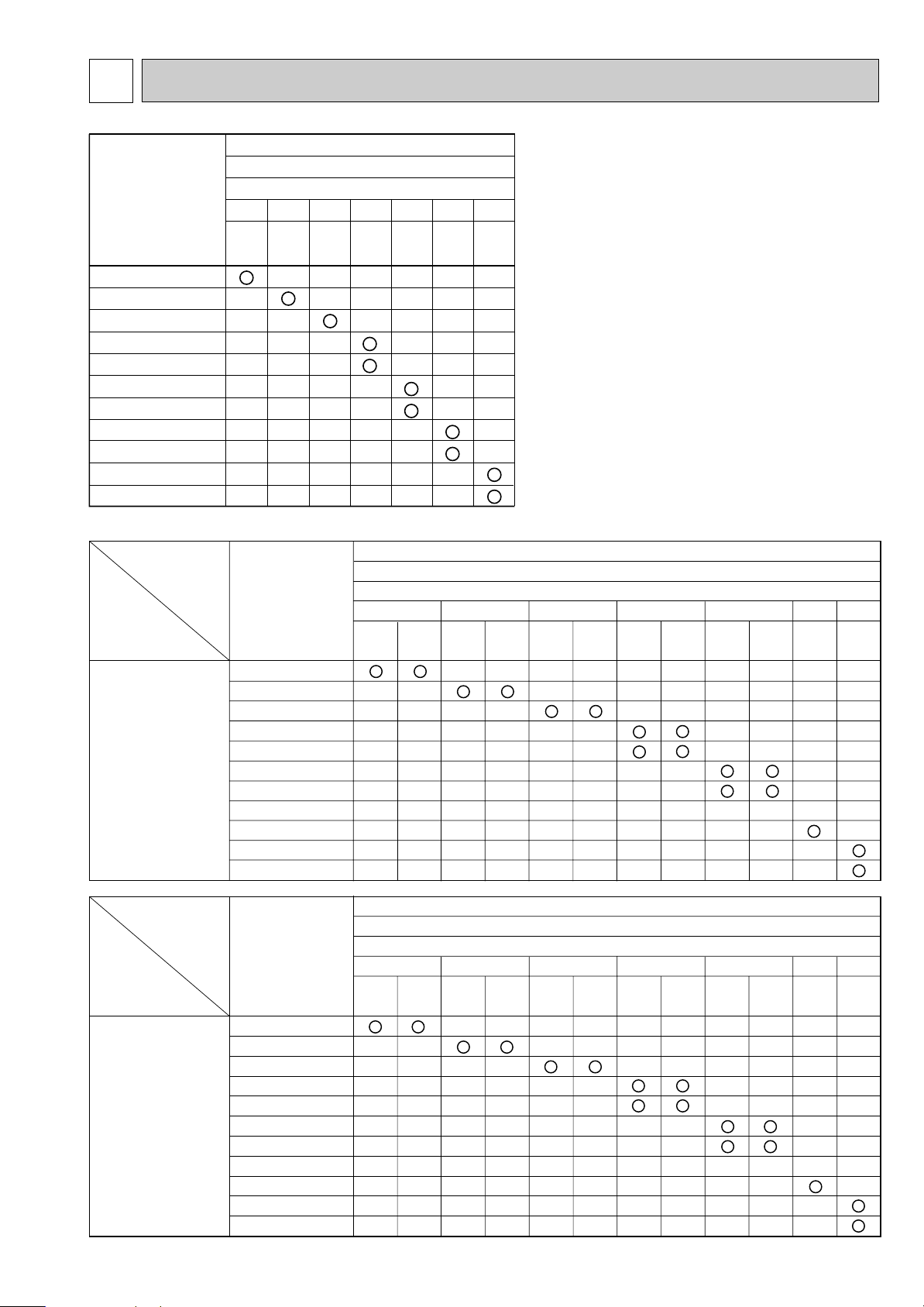

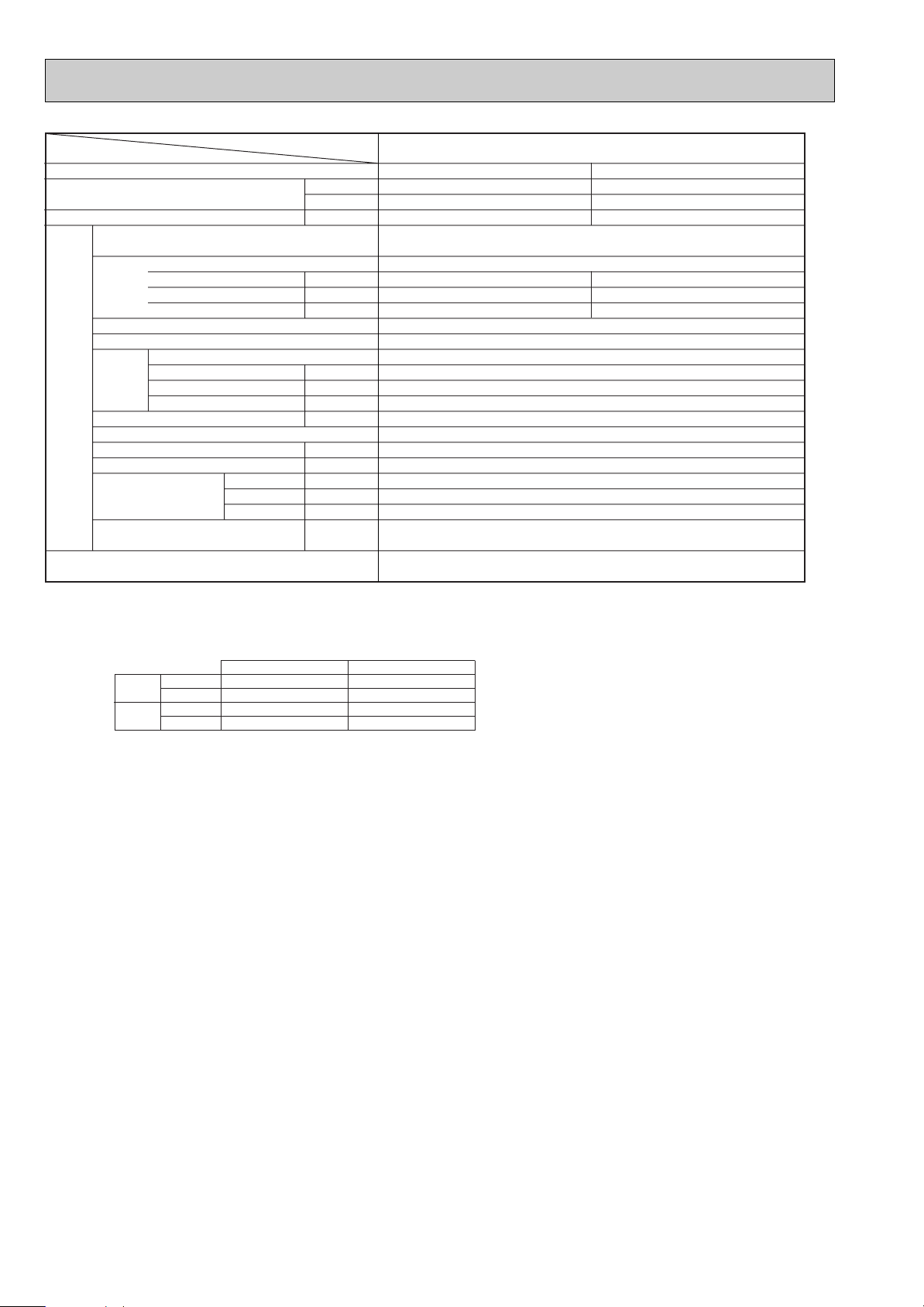

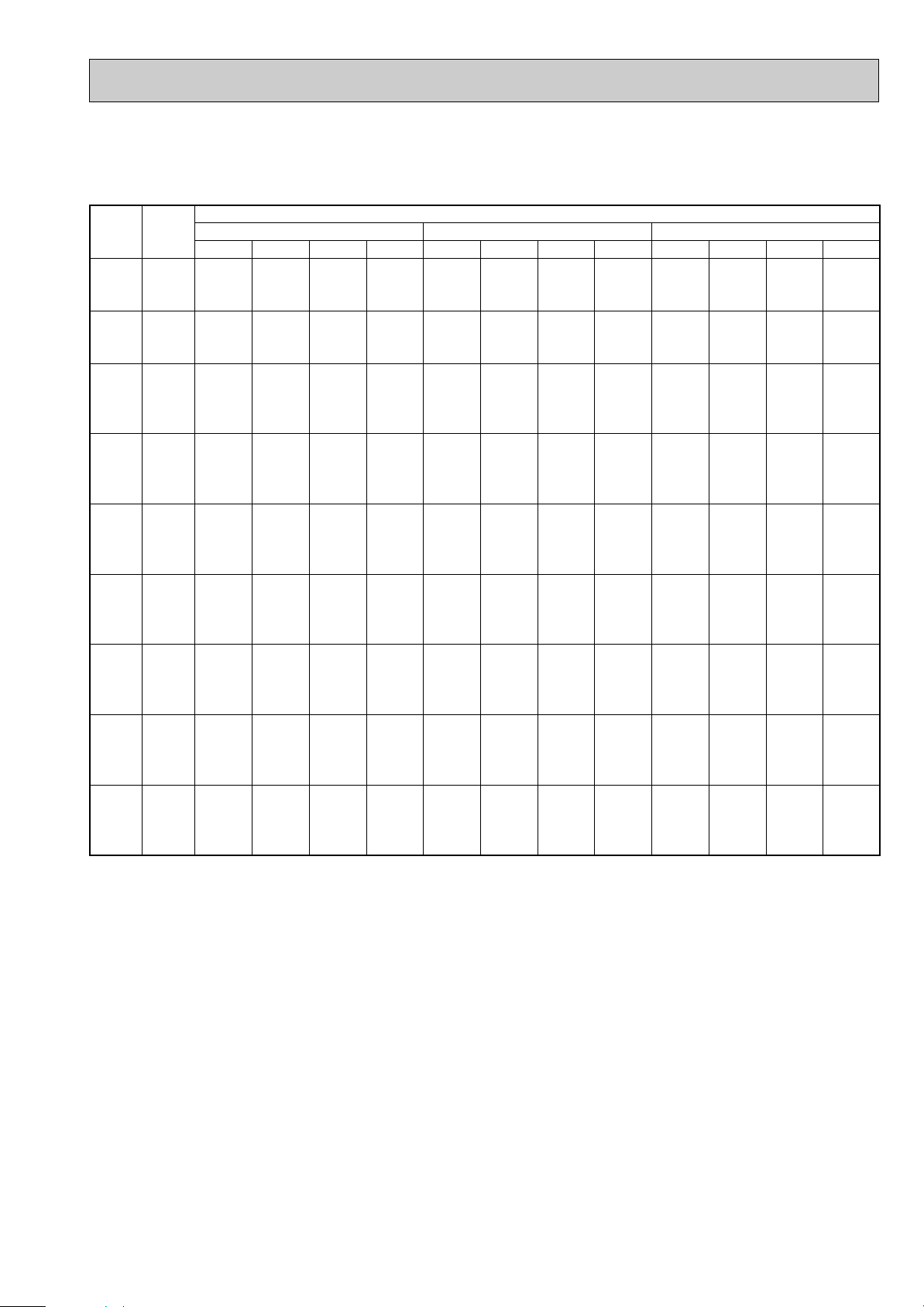

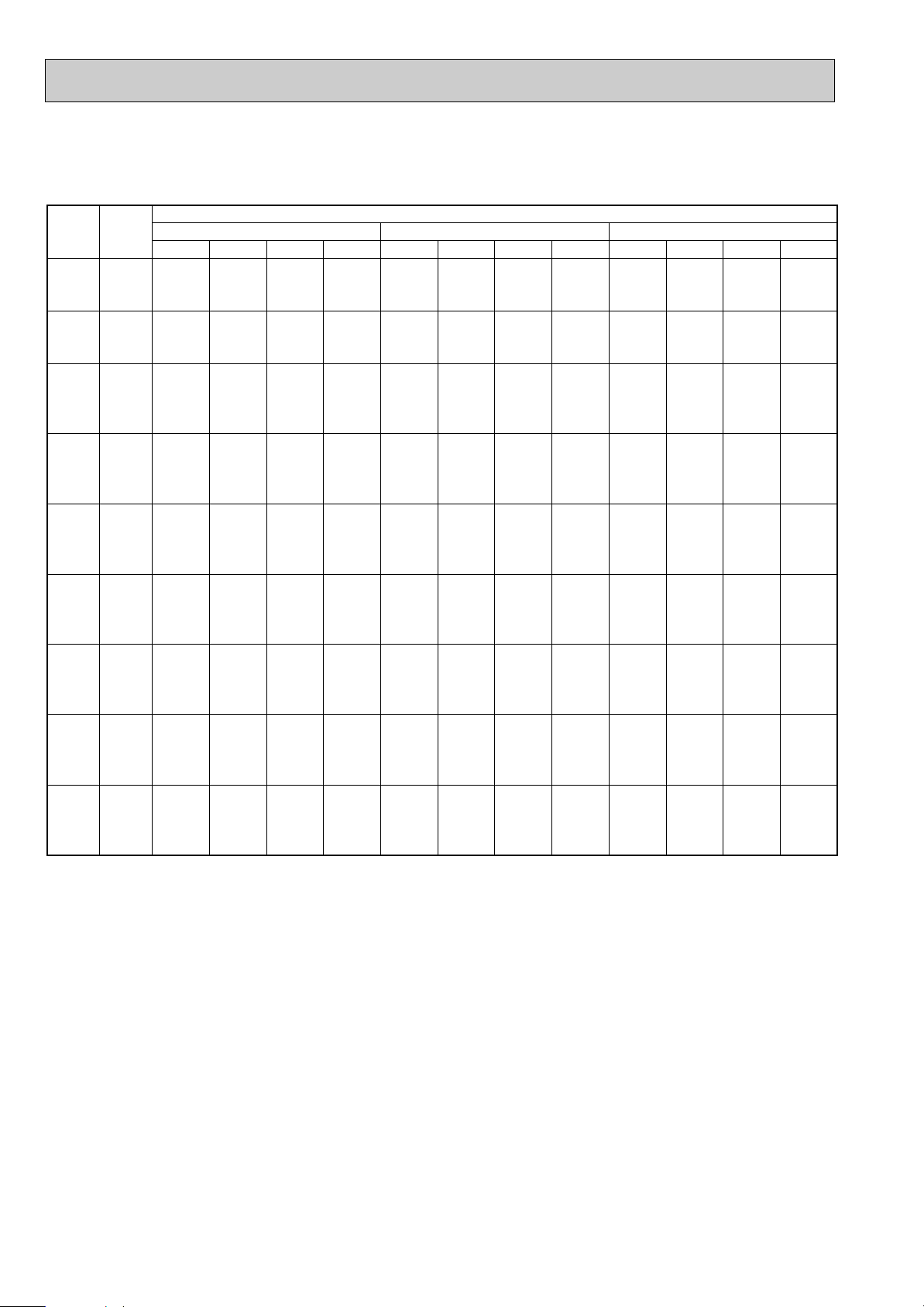

2

Heat pump type

Outdoor unit [OC261 REVISED EDITION-B

]

PUH-P

Heat pump without

electric heater

6

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

5

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

✕

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

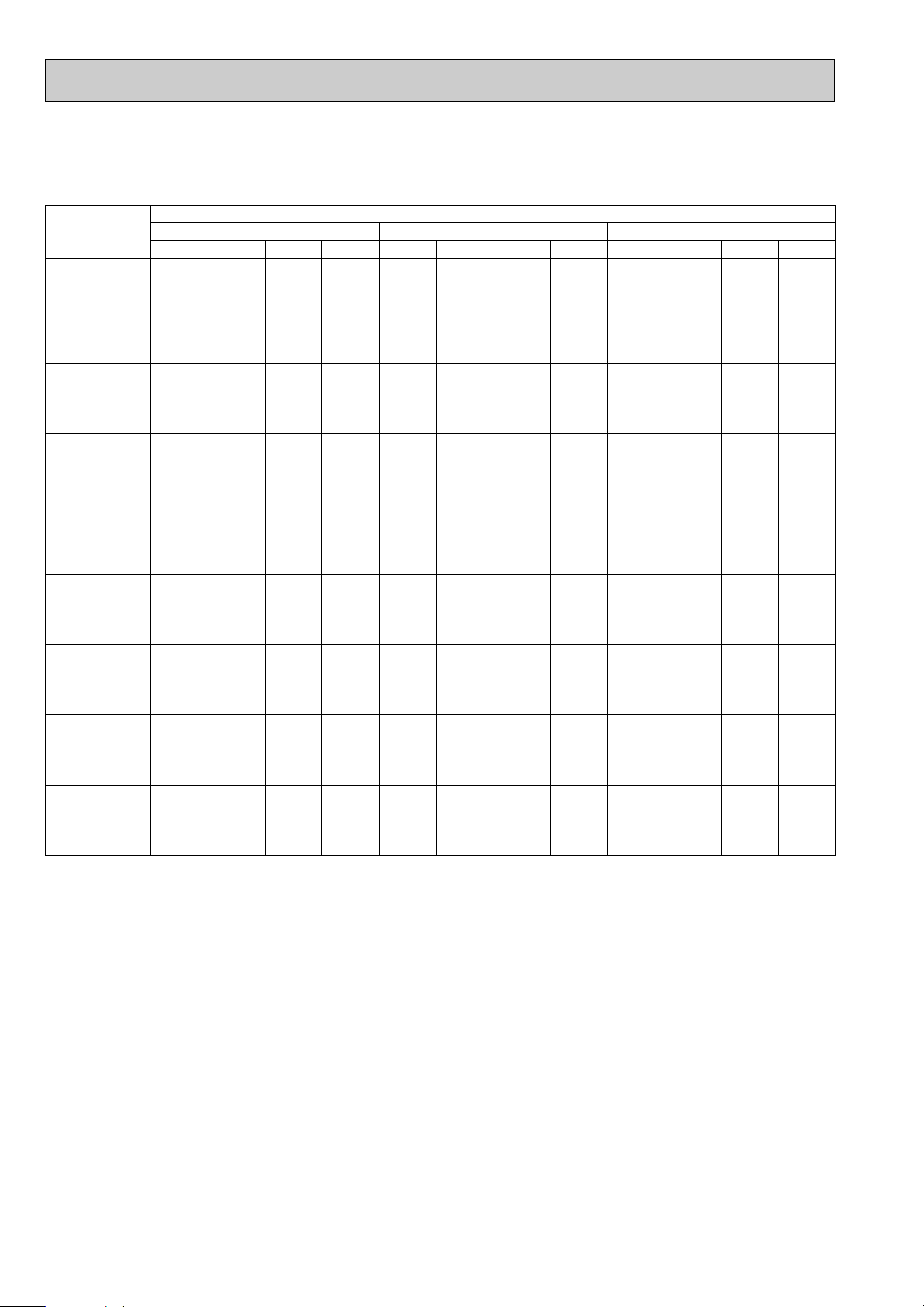

Indoor unit

Outdoor unit [OC261 REVISED EDITION-B

]

Indoor unit

PLA-RP1.6AA.UK

PLA-RP2AA.UK

PLA-RP2.5AA.UK

PLA-RP3AA.UK

PLA-RP3AA

1.UK

PLA-RP4AA.UK

PLA-RP4AA1.UK

PLA-RP5AA.UK

PLA-RP5AA1.UK

PLA-RP6AA.UK

PLA-RP6AA1.UK

PLA-RP1.6AA.UK

PLA-RP2AA.UK

PLA-RP2.5AA.UK

PLA-RP3AA.UK

PLA-RP3AA

1.UK

PLA-RP4AA.UK

PLA-RP4AA1.UK

PLA-RP5AA.UK

PLA-RP5AA1.UK

PLA-RP6AA.UK

PLA-RP6AA1.UK

31.6 2 2.5 4

Cooling only type

PU-P

6

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

5

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

✕

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

YGAA.UK

YGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

—

VGAA.UK

VGAA1.UK

—

—

—

—

—

—

—

—

—

341.6 2 2.5

Cooling only

Heat pump type

Outdoor unit [OC294 REVISED EDITION-B

]

PUHZ-RP

6

VHA

VHA

1

—

—

—

—

—

—

—

—

—

5

VHA

VHA

1

—

—

—

—

—

—

—

—

—

VHA

—

—

—

—

—

—

—

—

—

VHA

—

—

—

—

—

—

—

—

—

—

VHA

—

—

—

—

—

—

—

—

—

—

VHA

—

—

—

—

—

—

—

—

—

—

VHA

VHA

1

—

—

—

—

—

—

—

—

—

Indoor unit

PLA-RP1.6AA.UK

PLA-RP2AA.UK

PLA-RP2.5AA.UK

PLA-RP3AA.UK

PLA-RP3AA1.UK

PLA-RP4AA.UK

PLA-RP4AA1.UK

PLA-RP5AA.UK

PLA-RP5AA1.UK

PLA-RP6AA.UK

PLA-RP6AA1.UK

321.6 2.5

4

COMBINATION OF INDOOR AND OUTDOOR UNITS

(R410A Inverter)

(R407C Fixed speed)

3

Page 4

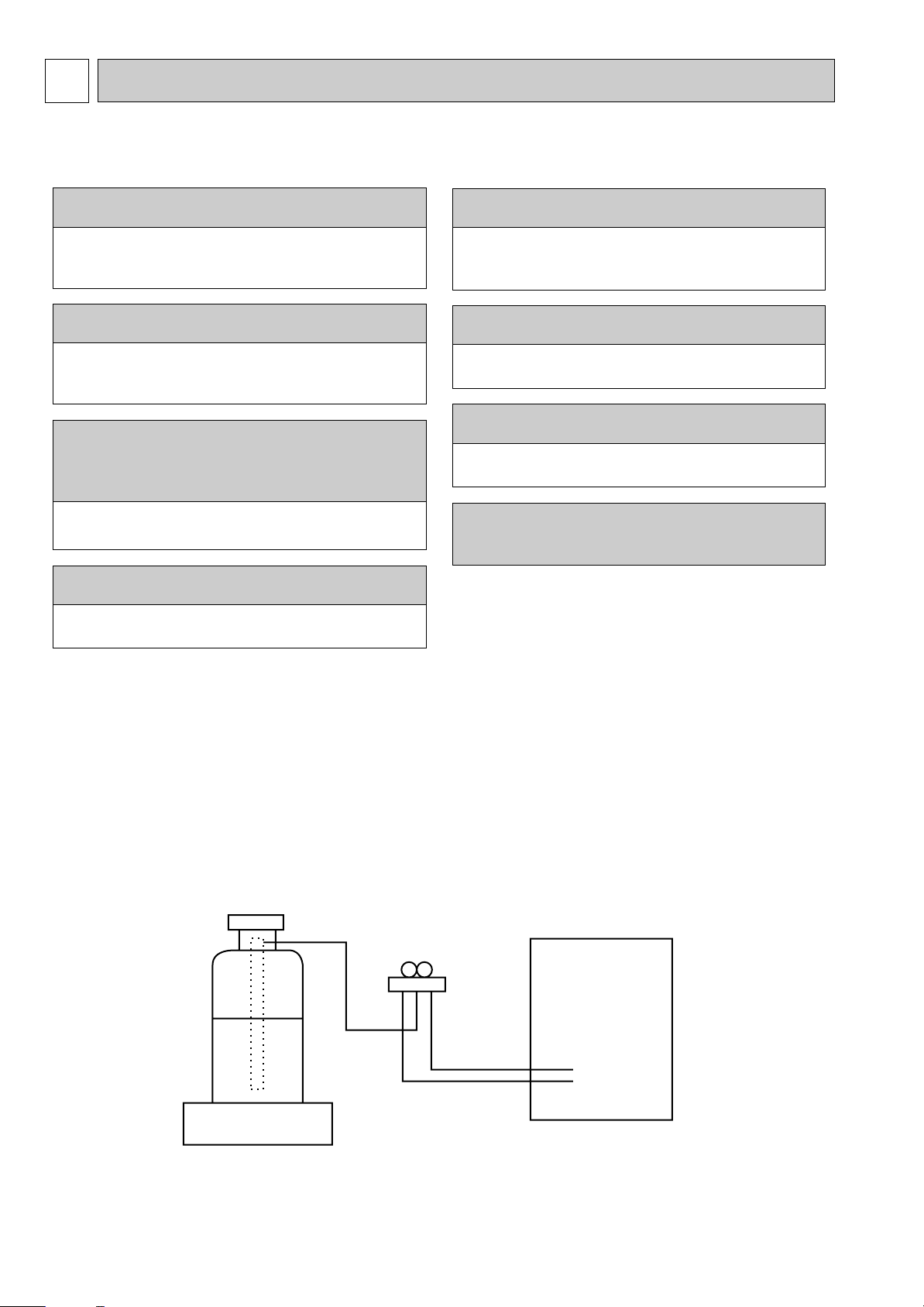

3

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Use ESTR , ETHER or HAB as the lubricant to

coat flares and flange connection parts.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil etc.

Use liquid refrigerant to charge the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

Store the piping to be used during installation

indoors with keep both ends sealed until just

before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Gravimeter

Unit

SAFETY PRECAUTION

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R407C

[1] Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

4

Page 5

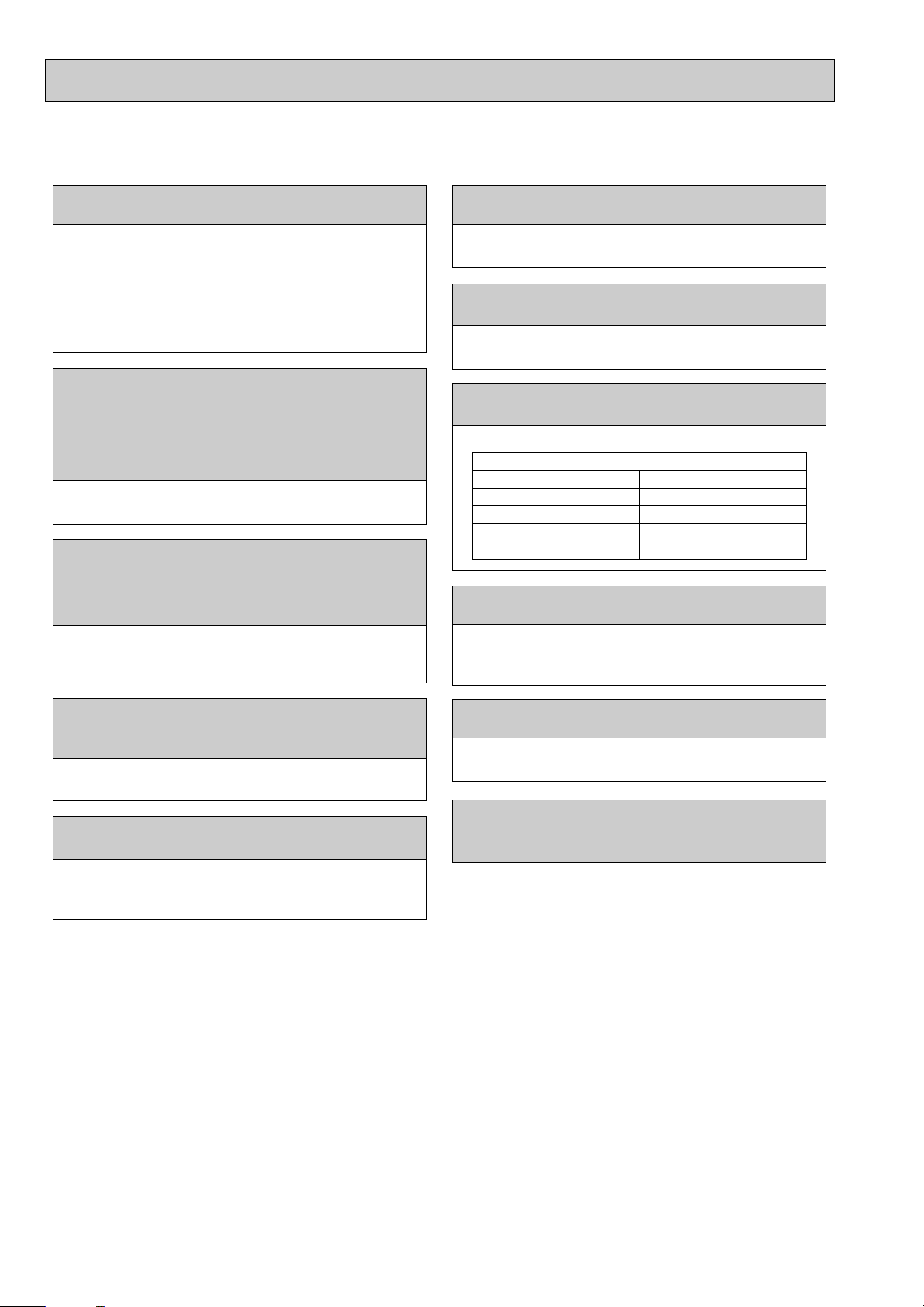

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

5

Page 6

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· For RP4, 5 and 6, be sure to perform replacement opera tion before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Cautions for units utilising refrigerant R410A

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

6

Page 7

Unit

Gravimeter

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

8 Refrigerant recovery equipment

specifications

Cylinder with syphon

. (UNF1/2)

7

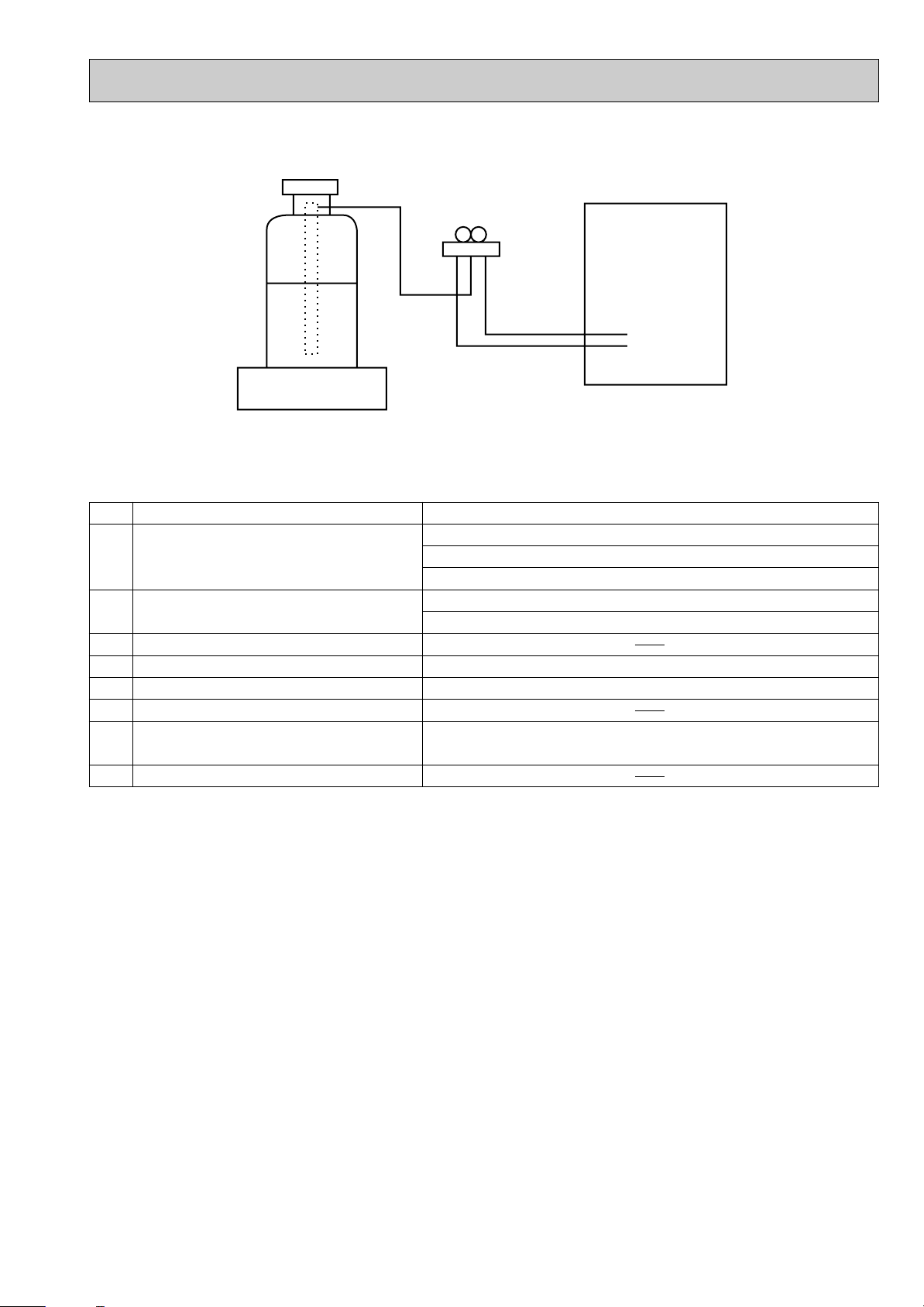

Page 8

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

This sets the ventilation fan speed.

VENTILATION button

Press this button to switch between

cool,

dry, automatic and heat modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooling 19: to 30:

Heating 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

To switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

FAN SPEED button

4

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Grille

Filter

Removes dust and pollutants

from intake air

Horizontal Air Outlet

Sets airflow of horizontal automatically

during cooling or dehumidifying.

Air Intake

Intakes air from room.

PART NAMES AND FUNCTIONS

● Indoor Unit

● Wired remote controller

On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

8

Page 9

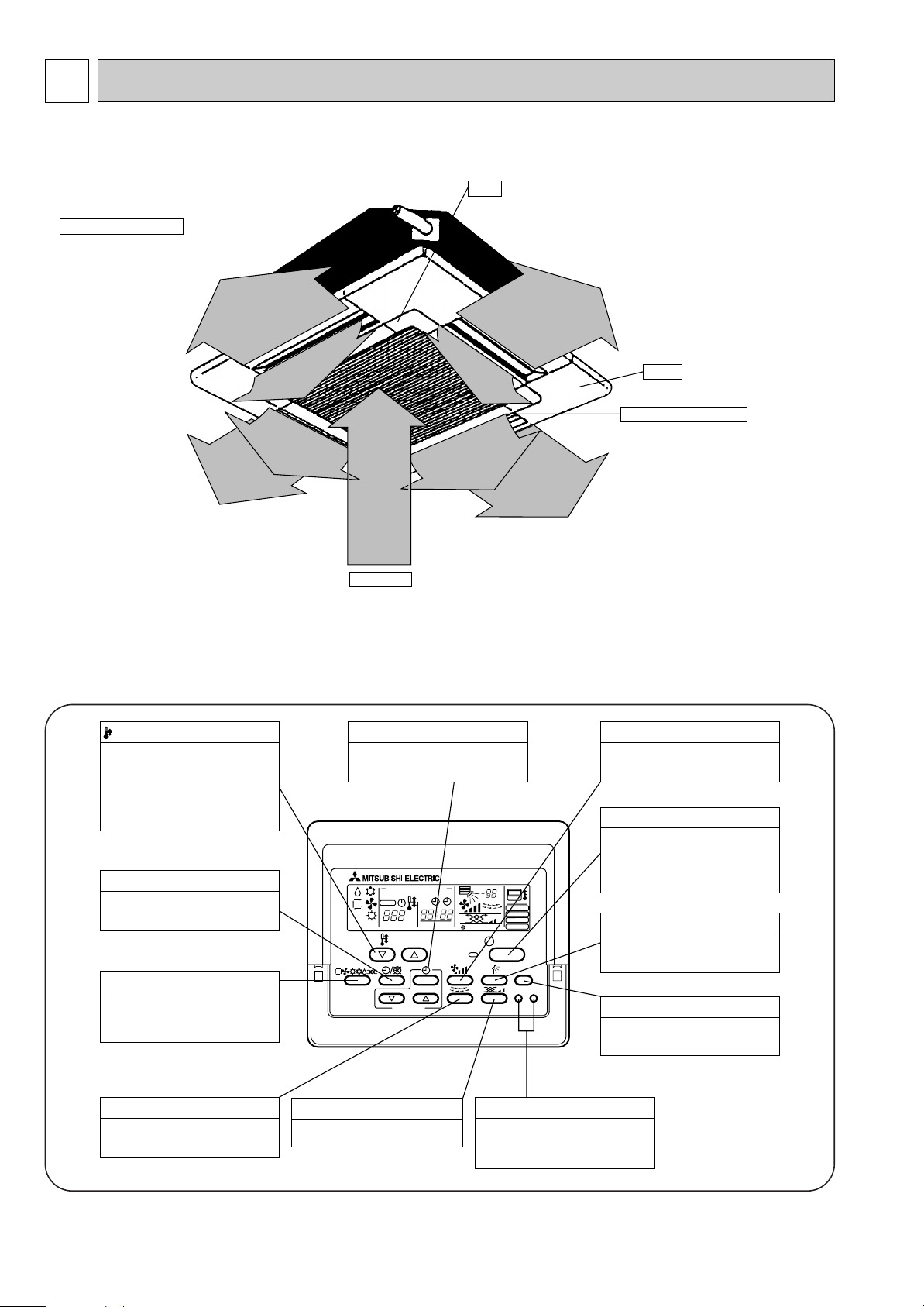

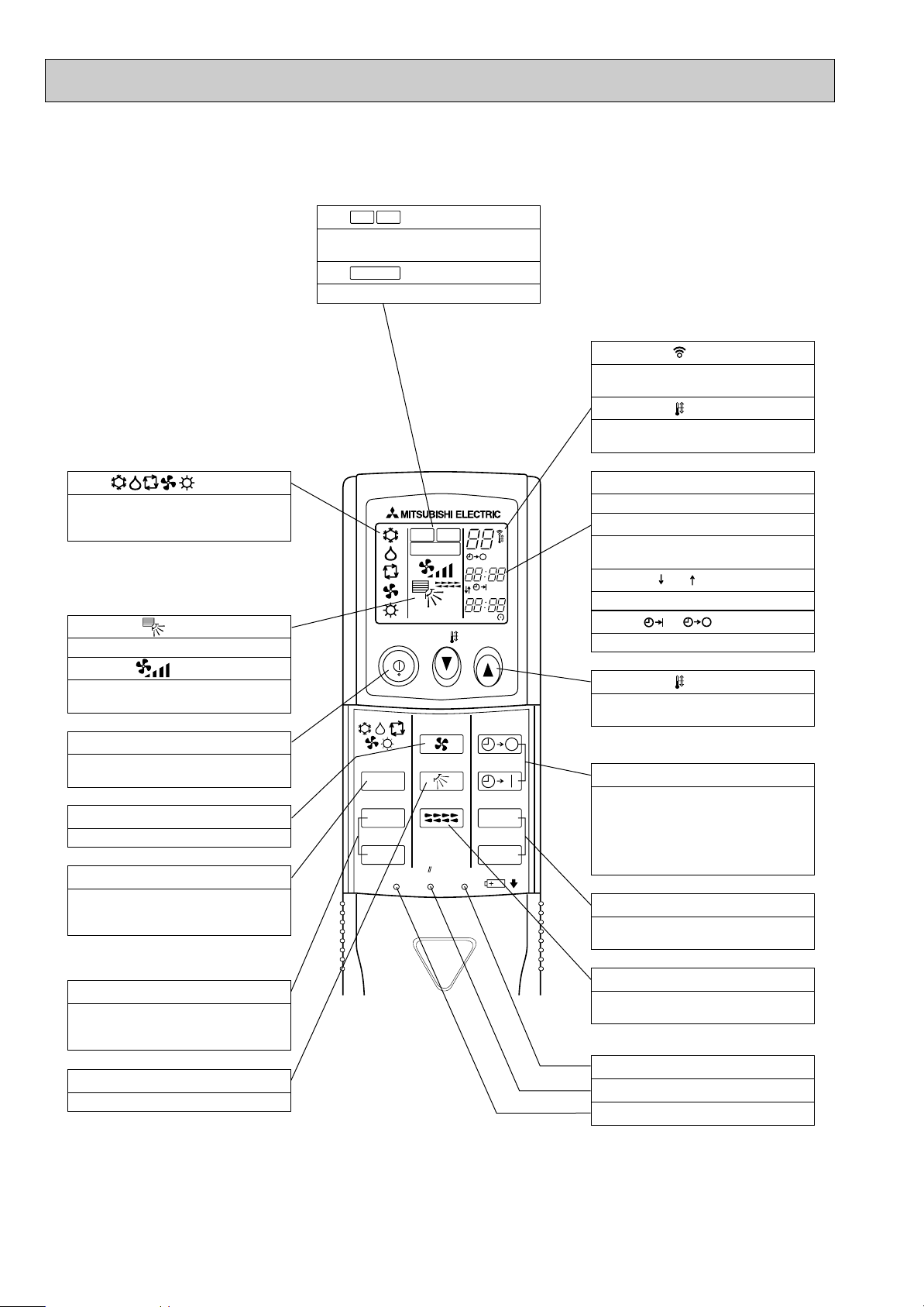

● Display

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

CENTRALLY

CONTROLLED display

This indicates when the unit is con-

trolled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

The [STANDBY] symbol is only dis-

played from the time the heating

operation starts until the heated air

begins to blow.

DEFROST display

This indicates when the defrost oper-

ation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

AIR SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air

is displayed during operation. The

display range is 8°C to 39°C. The

display flashes 8°C when the actual

temperature is less than 8°C and

flashes 39°C when the actual temperature is greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

This display lights in the check mode

or when a test operation is performed.

CHECK MODE

TEST RUN

display

FILTER display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

Caution

●Only the Power display lights when the unit is stopped and power supplied to the unit.

●When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

●“NOTAVAILABLE” is displayed when the Air speed button is pressed. This indicates that this room unit is not equipped with

the fan direction adjustment function and the louver function.

●When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

POWER display

This lamp lights when electricity is

supplied to the unit.

This lamp lights when the filter need

to be cleaned.

9

Page 10

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL SELECT

NOT AVAILABLE

CHECK

TEST RUN

˚C

AMPM

AMPM

VANE CONTROL button

Used to change the air flow direction.

CLOCK button

RESET button

SET button

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

LOUVER button

This switch the horizontal fan motion ON

and OFF.

(Not available for this model.)

MODE SELECT button

Used to switch the operation mode between

cooling, drying, blowing, heating and auto

mode.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation.

Do not use it for normal operation.

FAN SPEED SELECT button

Used to change the fan speed.

TIMER display

Displays when in timer operation or when

setting timer.

button

SET TEMPERATURE button sets any desired

room temperature.

CLOCK display

Displays the current time.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

w In case the outdoor unit is cool only type,

the heating mode is not available.

Buttons used to set the “hour and minute” of

the current time and timer settings.

h and min buttons

display

SET TEMP. display indicates desired temperature set.

display

FAN SPEED display indicates which fan

speed has been selected.

display

The vertical direction of air flow is indicated.

display

Blinks when model is selected.

display

Lights up while transmission to the indoor

unit is mode using switches.

display

CHECK&TEST RUN display indicates that

the unit is being checked or test-run.

display

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch

is set, the air conditioner will be automatically started at the preset time.

MODEL SELECT

CHECK

TEST RUN

● Wireless remote controller

10

Page 11

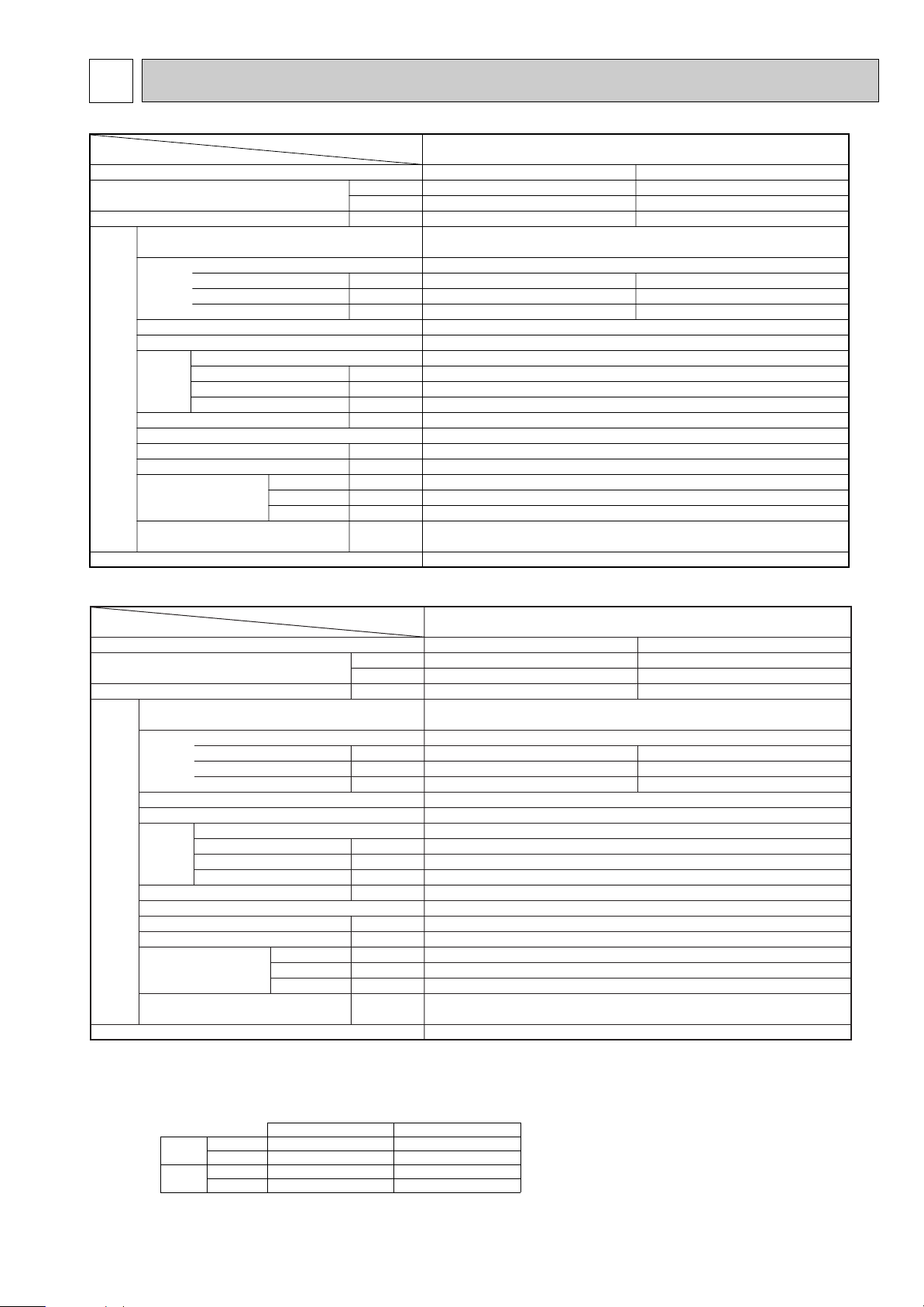

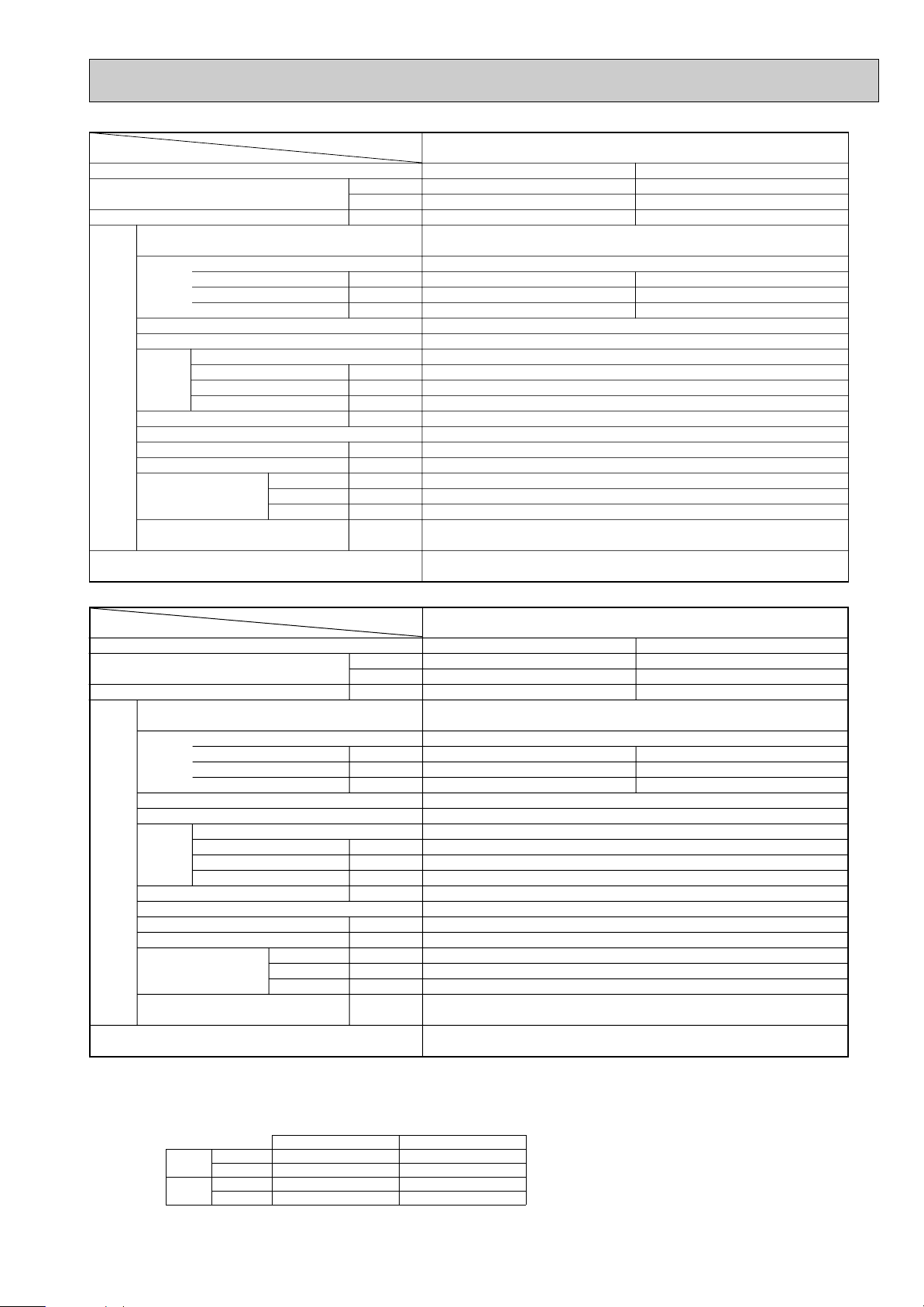

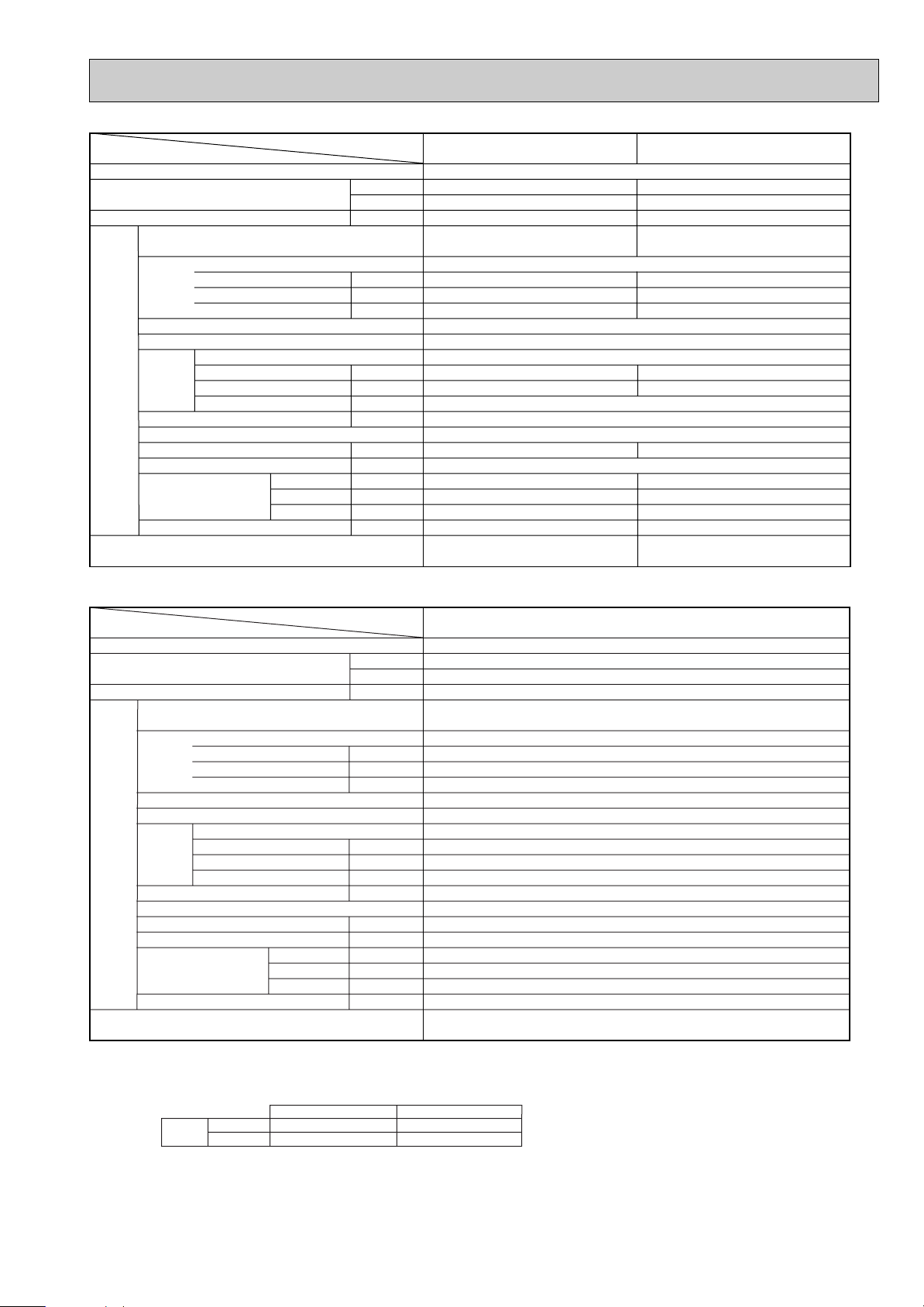

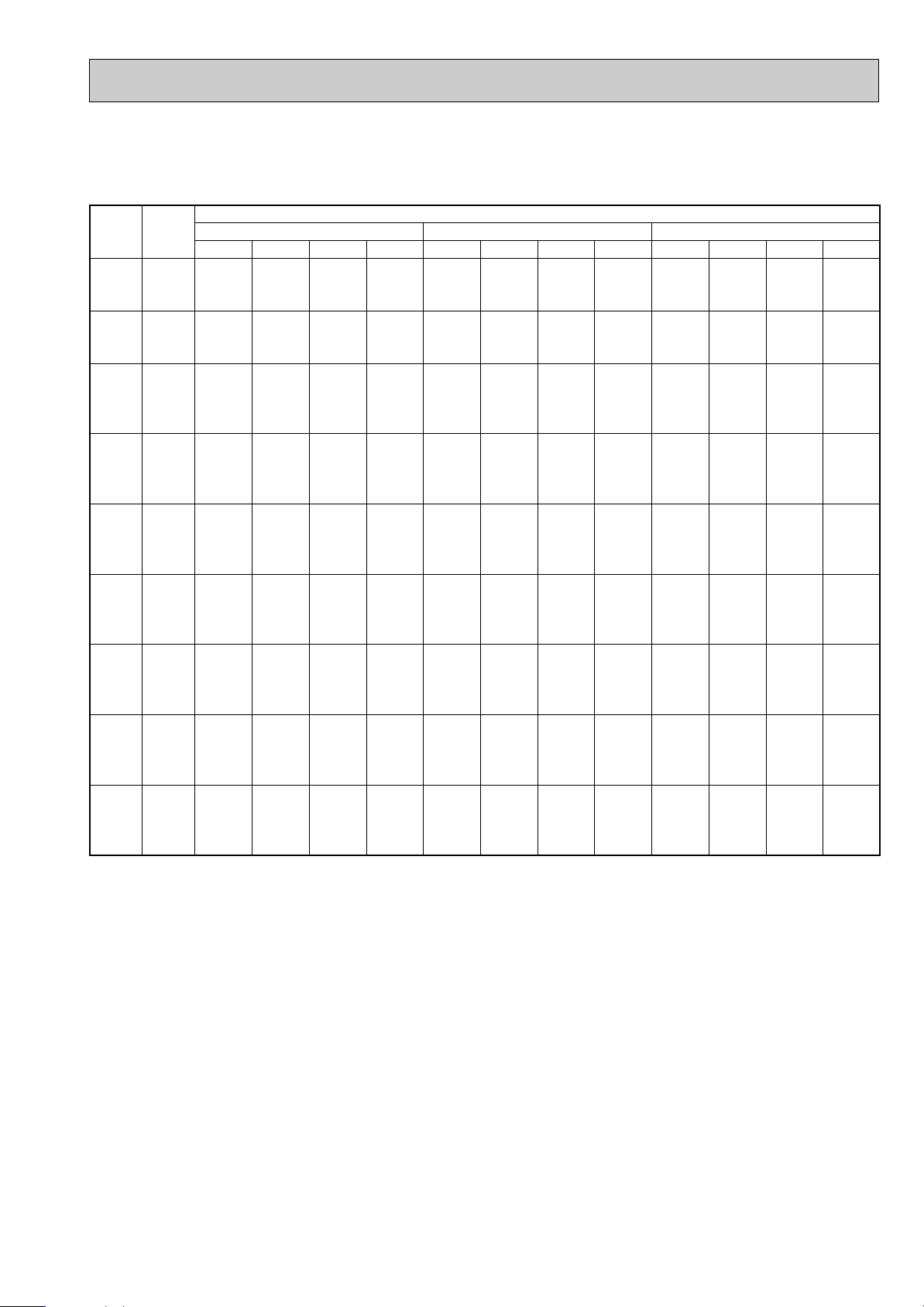

5

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle,voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP2AA.UK

Cooling Heating

17,100 20,500

5,000(2,300~5,600) 6,000(2,500~7,300)

1.55 1.62

PLA-RP2AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o1

0.070

14-15-16-18(495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

28-29-31-33

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24(53) PANEL : 5 (11)

PUHZ-RP2VHA

Outdoor unit Service Ref.

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

Outdoor unit Service Ref.

PLA-RP1.6AA.UK

Cooling Heating

12,300 14,000

3,600(1,600~4,500) 4,100(1,600~5,200)

1.07 1.12

PLA-RP1.6AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

T

urbo fan (direct) o1

0.070

11-12-13-14(390-425-460-495)

0 (direct blow)

—

Remote controller & built-in

27-28-29-31

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUHZ-RP1.6VHA

PANEL: 5 (11)

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor: D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

Heating

Upper limit

D.B. 28˚C

D.B. 21˚C, W.B. 15˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

SPECIFICATIONS

Heat pump type (1)

11

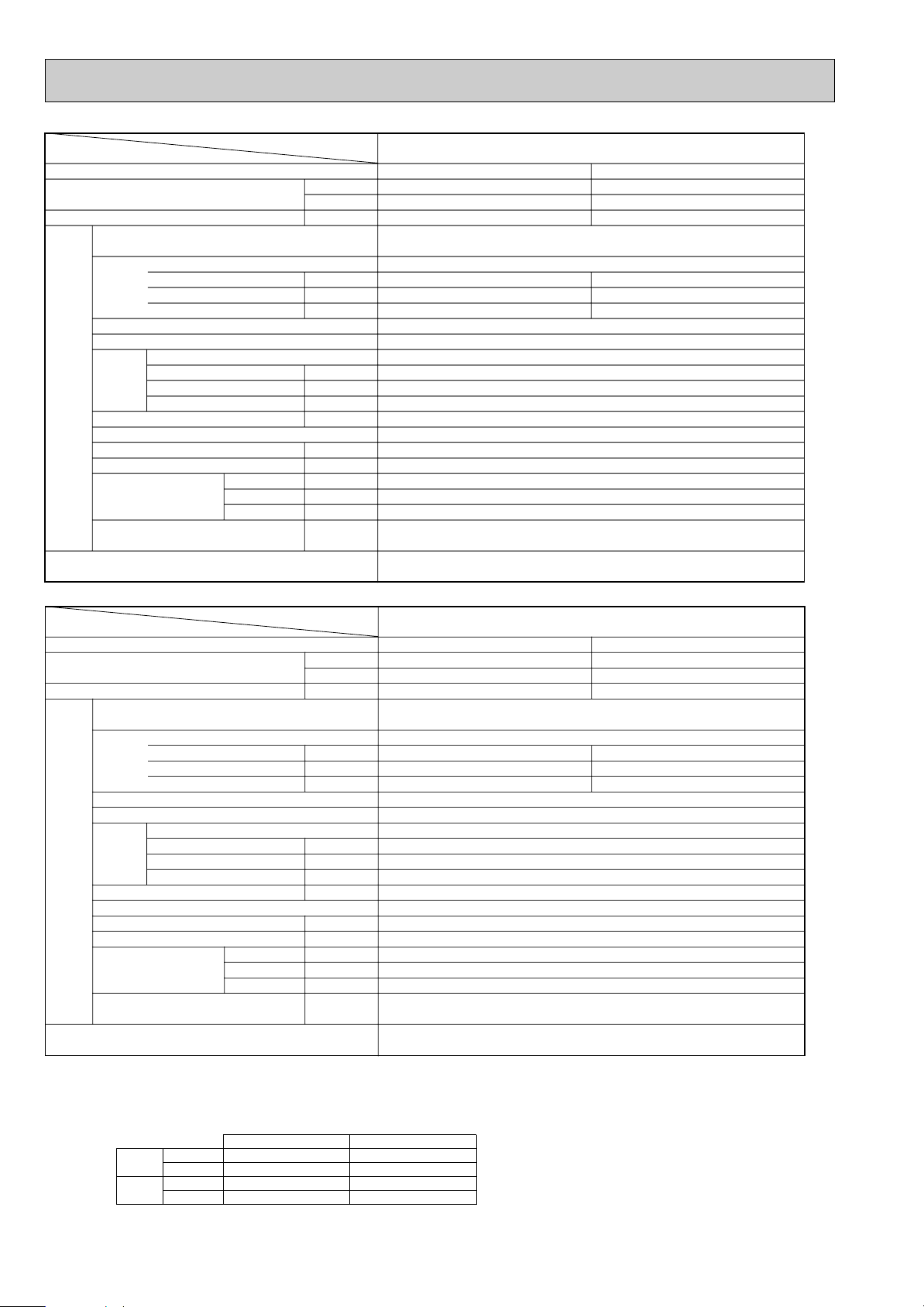

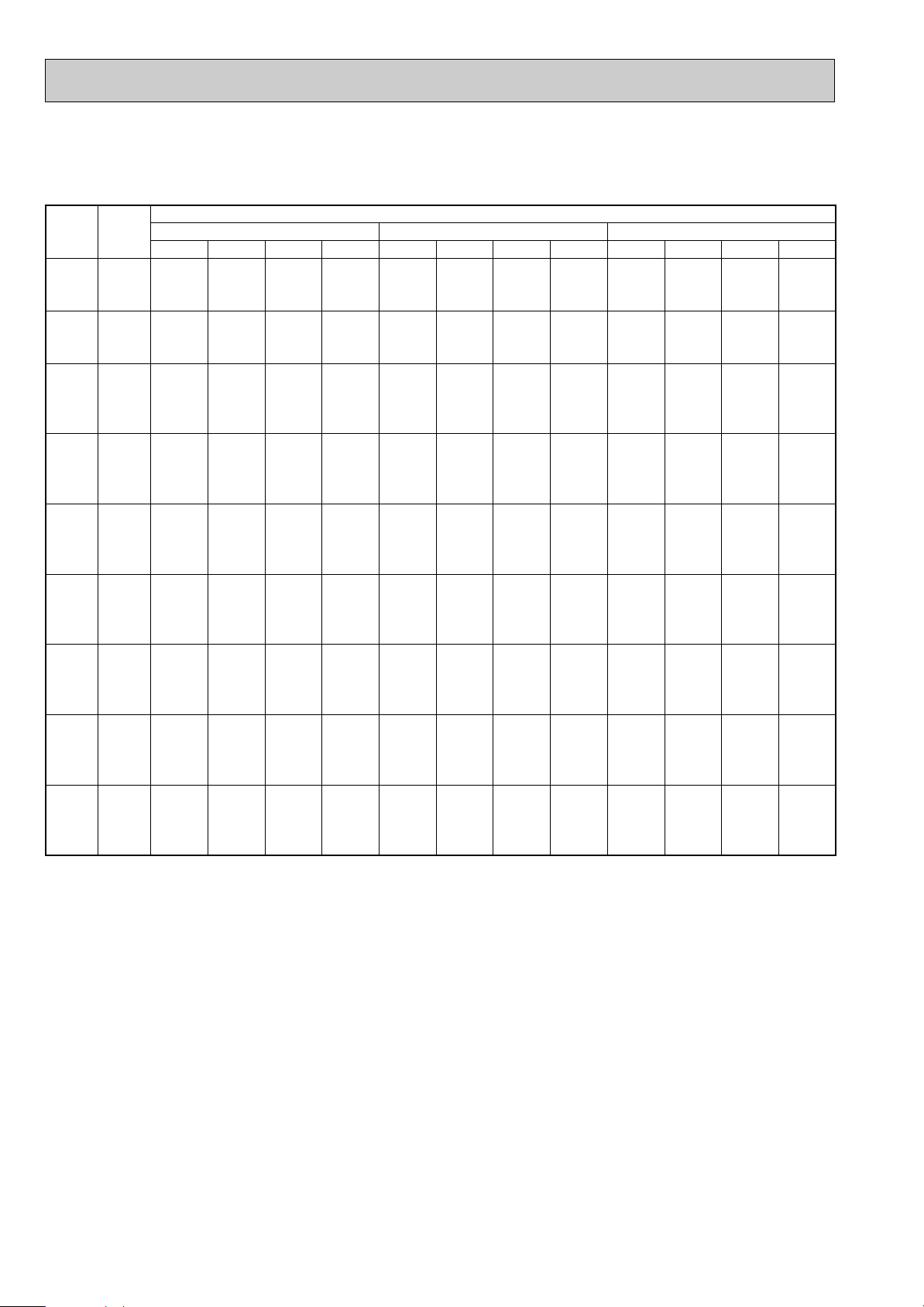

Page 12

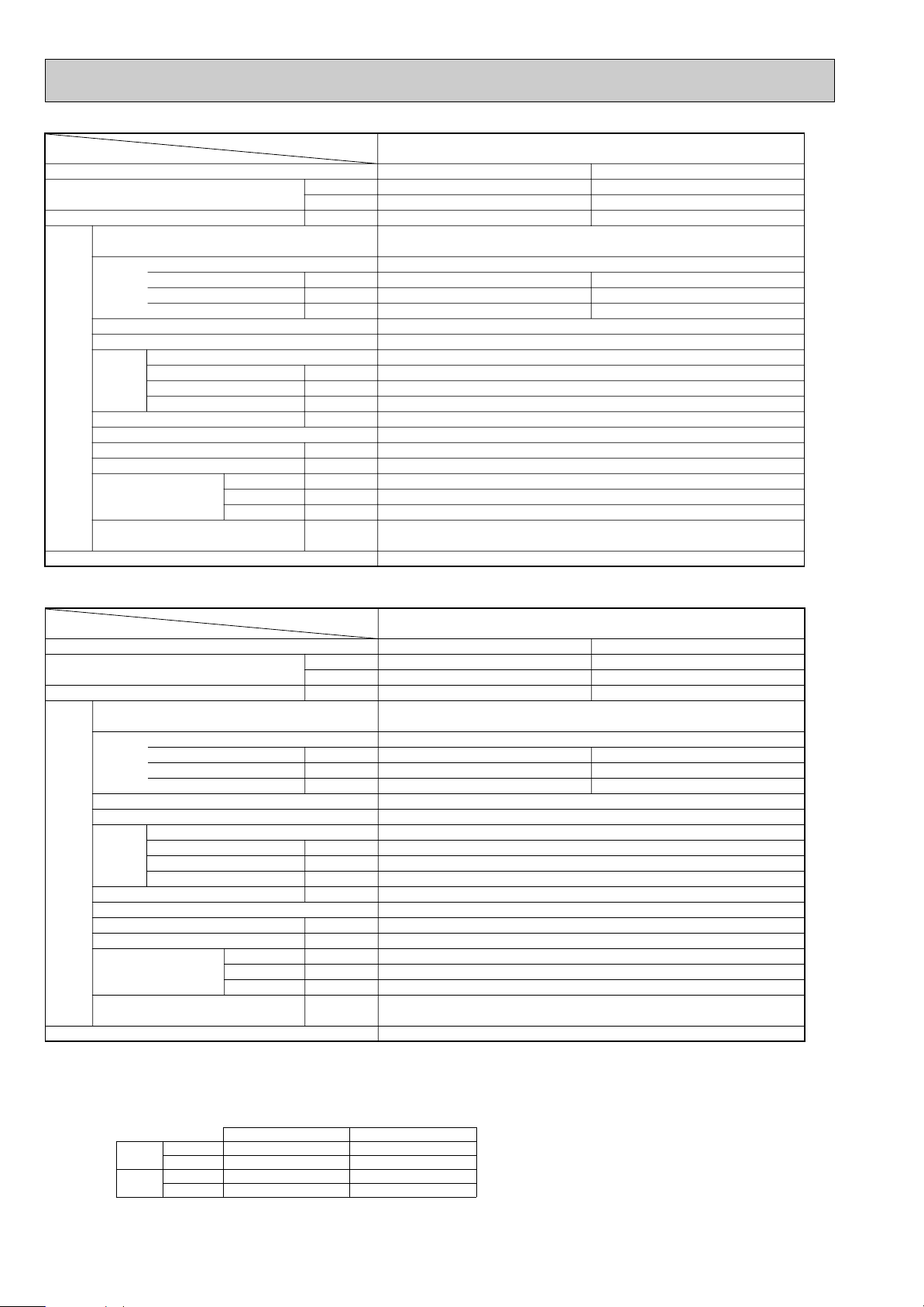

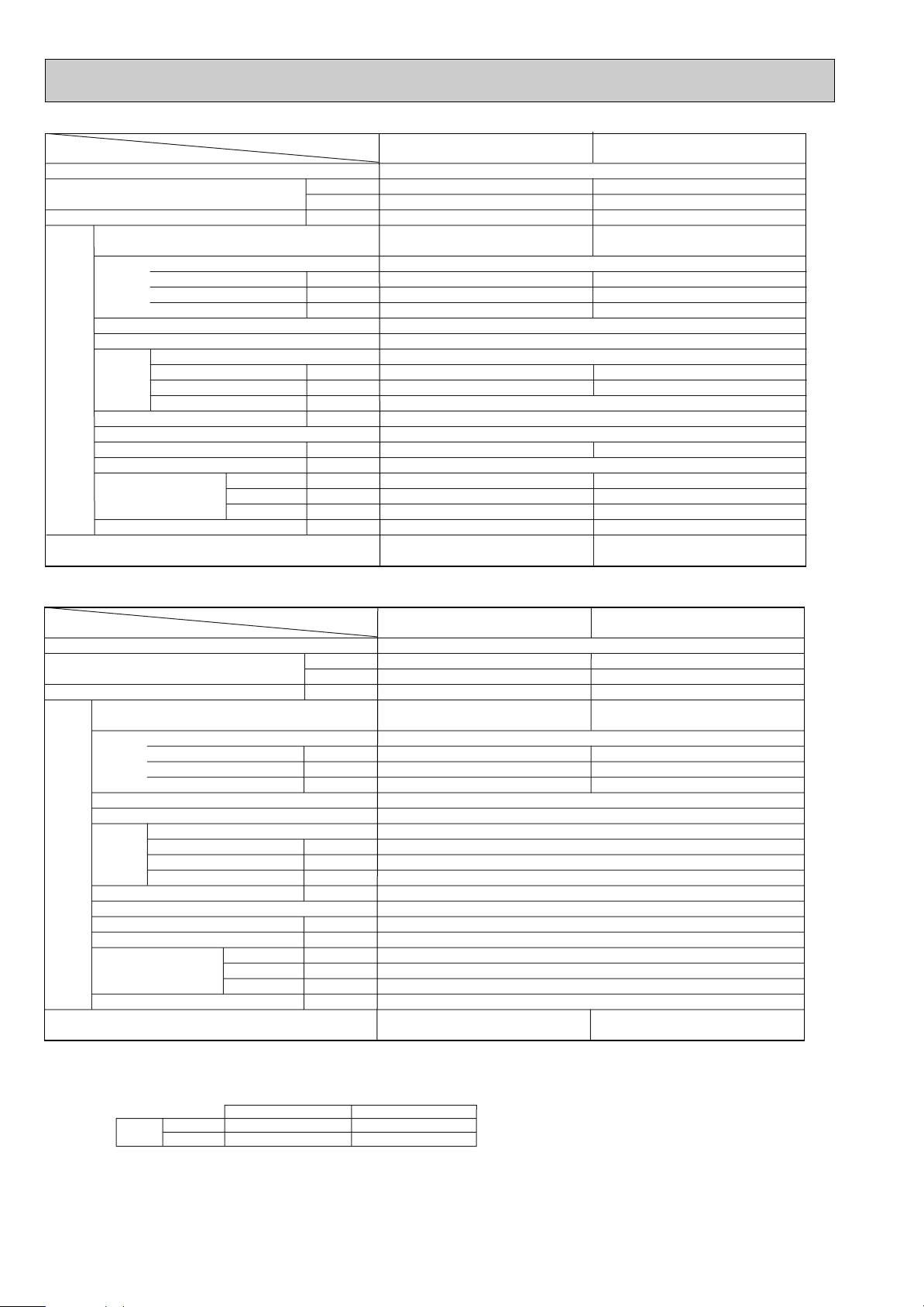

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

Outdoor unit Service Ref.

PLA-RP3AA.UK

PLA-RP3AA1.UK

Cooling Heating

24,200 27,300

7,100 (3,300~8,100) 8,000 (3,500~10,200)

1.97 2.34

PLA-RP3AA.UK

PLA-RP3AA

1.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

T

urbo fan (direct) o1

0.070

15-16-18-20 (530-565-635-705)

0 (direct blow)

—

Remote controller & built-in

28-30-32-34

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUHZ-RP3VHA

PANEL: 5 (11)

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

Heating

Upper limit

D.B. 28˚C

D.B. 21˚C, W.B. 15˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

Outdoor unit Service Ref.

PLA-RP2.5AA.UK

Cooling Heating

20,500 23,900

6,000 (2,700~6,700) 7,000 (2,800~8,200)

1.65 1.85

PLA-RP2.5AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

T

urbo fan (direct) o1

0.070

14-15-16-18(495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

28-29-31-33

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUHZ-RP2.5VHA

PANEL: 5 (11)

12

Page 13

Item

Function

Capacity

PUHZ-RP4VHA

PUHZ-RP4VHA

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan (drive) o No.

Fan

Indoor unit

Booster heater kW

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

External static pressure Pa (mmAq)

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

Unit drain pipe I.D. mm (in.)

W mm (in.)

Dimensions

D mm (in.)

H mm (in.)

Weight

Outdoor unit Service Ref.

Item

Function

Capacity

PUHZ-RP5VHA

PUHZ-RP5VHA

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan (drive) o No.

Fan

Indoor unit

Booster heater kW

Fan motor output kW

(Low-Medium2-Medium1-High)

Airflow

External static pressure Pa (mmAq)

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

Unit drain pipe I.D. mm (in.)

W mm (in.)

Dimensions

D mm (in.)

H mm (in.)

Weight

Outdoor unit Service Ref.

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

D.B. 28˚C

D.B. 17˚C

Service Ref.

Btu/h

W

W

1

kW

kW

K / min (CFM)

dB

kg (lbs.)

Service Ref.

Btu/h

W

W

1

kW

kW

K / min (CFM)

dB

kg (lbs.)

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

PLA-RP4AA.UK

PLA-RP4AA1.UK

Cooling Heating

34,100 38,200

10,000 (5,000~11,400)

10,000 (4,900~11,400)

3.03 3.39

PLA-RP4AA.UK

PLA-RP4AA

1.UK

Single phase, 50Hz, 220-230-240V

0.25 0.25

1.25 1.25

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o1

0.120

20-23-26-28 (705-810-920-990)

0 (direct blow)

—

Remote controller & built-in

33-36-39-41

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 30 (1-3/16)

UNIT : 30 (66) PANEL : 5 (11)

PUHZ-RP4VHA

PUHZ-RP4VHA

PLA-RP5AA.UK

PLA-RP5AA

1.UK

Cooling

42,700

12,500 (6,000~14,000)

12,500 (5,500~14,000)

3.89

PLA-RP5AA.UK

PLA-RP5AA

1.UK

Single phase, 50Hz, 220-230-240V

0.33 0.33

1.64

2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

urbo fan (direct) o1

T

0.120

22-25-28-30 (775-880-990-1,060)

0 (direct blow)

—

Remote controller & built-in

37-40-43-45

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

: 298 (11-3/4)

UNIT

PANEL

UNIT : 32 (71) PANEL : 5 (11)

PUHZ-RP5VHA

PUHZ-RP5VHA

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Single phase 230V 50Hz

11,200 (5,600~14,000)

11,200 (4,500~14,000)

1

Heating

47,800

14,000 (6,000~16,000)

14,000 (5,000~16,000)

4.27

1.64

2.0

: 30 (1-3/16)

1

3. Guaranteed voltage

198~264V, 50Hz

13

Page 14

Cooling

Heating

47,800 54,600

14,000 (6,200~15,300)

14,000 (5,500~15,300)

16,000 (6,200~18,000)

16,000 (5,000~18,000)

4.99 4.91

PLA-RP6AA.UK

PLA-RP6AA1.UK

Single phase, 50Hz, 220-230-240V

0.33 0.33

1.64 1.64

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

T

urbo fan (direct) o1

0.120

22-25-28-30 (775-880-990-1,060)

0 (direct blow)

Remote controller & built-in

37-40-43-45

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 30 (1-3/16)

UNIT : 32 (71) PANEL : 5 (11)

—

Service Ref.

Item

Function

Capacity

Btu/h

W

W

PUHZ-RP6VHA

PUHZ-RP6VHA

1

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP6AA.UK

PLA-RP6AA

1.UK

PUHZ-RP6VHA

PUHZ-RP6VHA1

Outdoor unit Service Ref.

NOTE: 1. Rating conditions (ISO T1)

Cooling : Indoor: D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor: D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating : Indoor: D.B. 20: (68˚F) Outdoor: D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit D.B. 35:, W.B. 22.5: D.B. 46:

Lower limit D.B. 19 :, W.B. 15: D.B. -5:

Heating

Upper limit D.B. 28

:

D.B. 21:, W.B. 15:

Lower limit D.B. 17: D.B. -11:, W.B. -12:

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit Single phase 230V 50Hz

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

14

Page 15

Heat pump type (2)

Service Ref.

Item

Function

Capacity

Btu/h

W

kW

kW

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP1.6AA.UK

Cooling Heating

15,400 16,900

4,500 4,950

1.72 1.70

PLA-RP1.6AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070

11-12-13-14(390-425-460-495)

0 (direct blow)

—

Remote controller & built-in

27-28-29-31

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUH-P1.6VGAA.UK / PUH-P1.6YGAA.UK

PUH-P1.6VGAA

1.UK / PUH-P1.6YGAA1.UK

PANEL: 5 (11)

Outdoor unit Service Ref.

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

Heating

Upper limit

D.B. 28˚C

D.B. 24˚C, W.B. 18˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz / 3 phase 400V 50HzOutdoor unit

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Service Ref.

Item

Function

Capacity

Btu/h

W

kW

kW

A

A

Total input

Service Ref.

Power supply (phase, cycle,voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP2AA.UK

Cooling Heating

19,100 21,700

5,600 6,350

2.53 2.20

PLA-RP2AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070

14-15-16-18(495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

28-29-31-33

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53) PANEL : 5 (11)

PUH-P2VGAA.UK / PUH-P2YGAA.UK

PUH-P2VGAA

1.UK / PUH-P2YGAA1.UK

Outdoor unit Service Ref.

15

Page 16

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

A

A

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP3AA.UK

PLA-RP3AA1.UK

Cooling Heating

26,300 31,400

7,700 9,200

3.42 3.48

PLA-RP3AA.UK

PLA-RP3AA

1.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 079

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070

15-16-18-20 (530-565-635-705)

0 (direct blow)

—

Remote controller & built-in

28-30-32-34

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUH-P3VGAA.UK / PUH-P3YGAA.UK

PUH-P3VGAA1.UK / PUH-P3YGAA1.UK

PANEL: 5 (11)

Outdoor unit Service Ref.

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

A

A

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP2.5AA.UK

Cooling Heating

22,900 24,900

6,700 7,300

2.57 2.40

PLA-RP2.5AA.UK

Single phase, 50Hz, 220-230-240V

0.16

0.79

1.0

0.16

0.79

1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070

14-15-16-18(495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

28-29-31-33

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16) PANEL : 30 (1-3/16)

UNIT : 24 (53)

PUH-P2.5VGAA.UK / PUH-P2.5YGAA.UK

PUH-P2.5VGAA

1.UK / PUH-P2.5YGAA1.UK

PANEL: 5 (11)

Outdoor unit Service Ref.

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

Heating

Upper limit

D.B. 28˚C

D.B. 24˚C, W.B. 18˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz / 3 phase 400V 50HzOutdoor unit

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

16

Page 17

Item

Function

Capacity

Total input

Service Ref.

Power supply (phase, cycle,voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan (drive) o No.

Fan

Indoor unit

Booster heater kW

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

External static pressure Pa (mmAq)

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

Unit drain pipe I.D. mm (in.)

Dimensions

Weight

Outdoor unit Service Ref.

Service Ref.

Btu/h

W

kW

kW

A

A

K / min (CFM)

dB

W mm (in.)

D mm (in.)

H mm (in.)

kg (lbs.)

PLA-RP4AA.UK

PLA-RP4AA1.UK

Cooling Heating

32,800 35,800

9,600 10,500

3.68 3.91

PLA-RP4AA.UK

PLA-RP4AA

1.UK

Single phase, 50Hz, 220-230-240V

0.25 0.25

1.25 1.25

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.120

20-23-26-28 (705-810-920-990)

0 (direct blow)

—

Remote controller & built-in

33-36-39-41

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 30 (1-3/16)

UNIT : 30 (66) PANEL : 5 (11)

PUH-P4VGAA.UK / PUH-P4YGAA.UK

PUH-P4VGAA

1.UK / PUH-P4YGAA1.UK

Item

Function

Capacity

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan (drive) o No.

Fan

Indoor unit

Booster heater kW

Fan motor output kW

(Low-Medium2-Medium1-High)

Airflow

External static pressure Pa (mmAq)

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

Unit drain pipe I.D. mm (in.)

W mm (in.)

Dimensions

D mm (in.)

H mm (in.)

Weight

Outdoor unit Service Ref.

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C

D.B. 28˚C

D.B. 17˚C

Service Ref.

Btu/h

W

kW

kW

A

A

K / min (CFM)

dB

kg (lbs.)

Indoor Outdoor

D.B. 46˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

PLA-RP5AA

1.UK

Cooling Heating

45,400 53,200

13,300 15,600

5.09 5.54

PLA-RP5AA1.UK

Single phase, 50Hz, 220-230-240V

0.33 0.33

1.64 1.64

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.120

22-25-28-30 (775-880-990-1,060)

0 (direct blow)

—

Remote controller & built-in

37-40-43-45

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 30 (1-3/16)

UNIT : 32 (71) PANEL : 5 (11)

PUH-P5YGAA.UK

PUH-P5YGAA

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

1.UK

Single phase 230V 50Hz / 3 phase 400V 50HzOutdoor unit

3. Guaranteed voltage

198~264V, 50Hz

17

Page 18

NOTE: 1. Rating conditions (ISO T1)

Cooling : Indoor: D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor: D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating : Indoor: D.B. 20: (68˚F) Outdoor: D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit D.B. 35:, W.B. 22.5: D.B. 46:

Lower limit D.B. 19 :, W.B. 15: D.B. -5:

Heating

Upper limit D.B. 28

:

D.B. 24 :, W.B. 18:

Lower limit D.B. 17: D.B. -11:, W.B. -12:

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit 3 phase 400V 50Hz

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input

Service Ref.

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

kW

kW

A

A

A

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Weight

kg (lbs.)

PLA-RP6AA.UK

PLA-RP6AA

1.UK

Cooling Heating

48,500 58,000

14,200 17,000

5.90 6.35

PLA-RP6AA.UK

PLA-RP6AA1.UK

Single phase, 50Hz, 220-230-240V

0.33 0.33

1.64 1.64

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.120

22-25-28-30 (775-880-990-1,060)

0 (direct blow)

Remote controller & built-in

37-40-43-45

32 (1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 30 (1-3/16)

UNIT : 32 (71) PANEL : 5 (11)

PUH-P6YGAA.UK

PUH-P6YGAA

1.UK

—

Outdoor unit Service Ref.

18

Page 19

Cooling only type (3)

NOTE: 1. Rating conditions (ISO T1)

Cooling : Indoor: D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit D.B. 35˚C, W.B. 22.5˚C D.B. 46˚C

Lower limit D.B. 19˚C, W.B. 15˚C D.B. -5˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit Single phase 230V 50Hz, 3 phase 400V 50Hz

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Weight kg (lbs.)

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input kW

Service Ref.

Power supply (phase, cycle, voltage)

Input kW

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

PLA-RP2.5AA.UK

Cooling

22,900

6,700

2.57

PLA-RP2.5AA.UK

Single phase, 50Hz, 220-230-240V

0.16

0.79

1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070

14-15-16-18 (495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

28-29-31-33

32 (1-1/4)

Outdoor unit Service Ref.

PU-P2.5VGAA.UK / PU-P2.5YGAA.UK

PU-P2.5VGAA

1.UK / PU-P2.5YGAA1.UK

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16), PANEL : 30 (1-3/16)

UNIT : 24 (53), PANEL : 5 (11)

Weight kg (lbs.)

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input kW

Service Ref.

Power supply (phase, cycle, voltage)

Input kW

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Cooling

15,400 19,100

4,500 5,600

1.72 2.53

PLA-RP1.6AA.UK PLA-RP2AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.16

0.79 0.79

1.0 1.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070 0.070

11-12-13-14 (390-425-460-495) 14-15-16-18 (495-530-565-635)

0 (direct blow)

—

Remote controller & built-in

27-28-29-31 28-29-31-33

32 (1-1/4)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16), PANEL : 30 (1-3/16)

UNIT : 24 (53), PANEL : 5 (11)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16), PANEL : 30 (1-3/16)

UNIT : 24 (53), PANEL : 5 (11)

PU-P1.6VGAA.UK / PU-P1.6YGAA.UK

PU-P1.6VGAA1.UK / PU-P1.6YGAA1.UK

PU-P2VGAA.UK / PU-P2YGAA.UK

PU-P2VGAA1.UK / PU-P2YGAA1.UK

PLA-RP1.6AA.UK PLA-RP2AA.UK

Outdoor unit Service Ref.

19

Page 20

NOTE: 1. Rating conditions (ISO T1)

Cooling : Indoor: D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit D.B. 35˚C, W.B. 22.5˚C D.B. 46˚C

Lower limit D.B. 19˚C, W.B. 15˚C D.B. -5˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit Single phase 230V 50Hz, 3 phase 400V 50Hz

3. Guaranteed voltage

198~264V, 50Hz

5. Refer to the service manual of outdoor unit for tha outdoor

unit's specifications.

Weight kg (lbs.)

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input kW

Service Ref.

Power supply (phase, cycle, voltage)

Input kW

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

PLA-RP5AA

1.UK

PLA-RP6AA.UK

PLA-RP6AA1.UK

Cooling

45,400 48,500

13,300 14,200

5.09 5.90

PLA-RP5AA

1.UK

PLA-RP6AA1.UK

PLA-RP6AA.UK

Single phase, 50Hz, 220-230-240V

0.33 0.33

1.64 1.64

2.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.120

22-25-28-30 (775-880-990-1,060)

0 (direct blow)

—

Remote controller & built-in

37-40-43-45

32 (1-1/4)

PU-P5YGAA.UK

PU-P5YGAA1.UK

PU-P6YGAA.UK

PU-P6YGAA1.UK

Outdoor unit Service Ref.

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4), PANEL : 30 (1-3/16)

UNIT : 32 (71), PANEL : 5 (11)

Weight kg (lbs.)

Service Ref.

Item

Function

Capacity

Btu/h

W

Total input kW

Service Ref.

Power supply (phase, cycle, voltage)

Input kW

Running current A

Starting current A

External finish (Panel)

Heat exchanger

Fan

Fan (drive) o No.

Fan motor output kW

Airflow

(Low-Medium2-Medium1-High)

K / min (CFM)

External static pressure Pa (mmAq)

Booster heater kW

Operation control & Thermostat

Sound level

(Low-Medium2-Medium1-High)

dB

Unit drain pipe I.D. mm (in.)

Dimensions

Indoor unit

W mm (in.)

D mm (in.)

H mm (in.)

Cooling

26,300 32,800

7,700 9,600

3.42 3.68

PLA-RP3AA1.UK PLA-RP4AA1.UK

PLA-RP3AA.UK PLA-RP4AA.UK

Single phase, 50Hz, 220-230-240V

0.16 0.25

0.79 1.25

1.0 2.0

Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) o 1

0.070 0.120

15-16-18-20 (530-565-635-705) 20-23-26-28 (705-810-920-990)

0 (direct blow)

—

Remote controller & built-in

28-30-32-34 33-36-39-41

32 (1-1/4)

PU-P3VGAA.UK / PU-P3YGAA.UK

PU-P3VGAA1.UK / PU-P3YGAA1.UK

PU-P4VGAA.UK / PU-P4YGAA.UK

PU-P4VGAA1.UK / PU-P4YGAA1.UK

PLA-RP3AA1.UK

PLA-RP3AA.UK

PLA-RP4AA1.UK

PLA-RP4AA.UK

Outdoor unit Service Ref.

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 258 (10-3/16), PANEL : 30 (1-3/16)

UNIT : 24 (53), PANEL : 5 (11)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16), PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4), PANEL : 30 (1-3/16)

UNIT : 30 (66), PANEL : 5 (11)

20

Page 21

DATA6

6-1-1. COOLING CAPACITY (1)

PLA-RP1.6AA.UK / PUHZ-RP1.6VHA

(230V)

NOTE:

CA : Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

3564

3816

4104

3564

3816

4104

3564

3816

4104

4374

3564

3816

4104

4374

3564

3816

4104

4374

3564

3816

4104

4374

3564

3816

4104

4374

3564

3816

4104

4374

3564

3816

4104

4374

2816

2557

2257

3101

2862

2586

3386

3167

2914

2581

3564

3473

3242

2931

3564

3625

3406

3106

3564

3778

3570

3281

3564

3816

3899

3630

3564

3816

4104

3980

3564

3816

4104

4330

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

0.86

0.87

0.90

0.86

0.87

0.90

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

0.86

0.87

0.90

0.92

3456

3708

4014

3456

3708

4014

3456

3708

4014

4284

3456

3708

4014

4284

3456

3708

4014

4284

3456

3708

4014

4284

3456

3708

4014

4284

3456

3708

4014

4284

3456

3708

4014

4284

2730

2484

2208

3007

2781

2529

3283

3078

2850

2528

3456

3374

3171

2870

3456

3523

3332

3042

3456

3671

3492

3213

3456

3708

3813

3556

3456

3708

4014

3898

3456

3708

4014

4241

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

0.90

0.92

0.94

0.90

0.92

0.94

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

0.90

0.92

0.94

0.97

3348

3582

3906

3348

3582

3906

3348

3582

3906

4176

3348

3582

3906

4176

3348

3582

3906

4176

3348

3582

3906

4176

3348

3582

3906

4176

3348

3582

3906

4176

3348

3582

3906

4176

2645

2400

2148

2913

2687

2461

3181

2973

2773

2464

3348

3260

3086

2798

3348

3403

3242

2965

3348

3546

3398

3132

3348

3582

3711

3466

3348

3582

3906

3800

3348

3582

3906

4134

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

0.96

0.98

1.01

0.96

0.98

1.01

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

0.96

0.98

1.01

1.04

CA

Indoor

intake air

D.B.(˚C)

Indoor

intake air

W.B.(˚C)

20 25 30

Outdoor intale air D.B.(˚C)

SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

6-1. PERFORMANCE DATA

21

Page 22

COOLING CAPACITY (2)

PLA-RP1.6AA.UK / PUHZ-RP1.6VHA

(230V)

NOTE:

CA : Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

3204

3456

3744

3204

3456

3744

3204

3456

3744

4032

3204

3456

3744

4032

3204

3456

3744

4032

3204

3456

3744

4032

3204

3456

3744

4032

3204

3456

3744

4032

3204

3456

3744

4032

2531

2316

2059

2787

2592

2359

3044

2868

2658

2379

3204

3145

2958

2701

3204

3283

3108

2863

3204

3421

3257

3024

3204

3456

3557

3347

3204

3456

3744

3669

3204

3456

3744

3992

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

1.03

1.05

1.08

1.03

1.05

1.08

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

1.03

1.05

1.08

1.10

3060

3348

3600

3060

3348

3600

3060

3348

3600

3888

3060

3348

3600

3888

3060

3348

3600

3888

3060

3348

3600

3888

3060

3348

3600

3888

3060

3348

3600

3888

3060

3348

3600

3888

2417

2243

1980

2662

2511

2268

2907

2779

2556

2294

3060

3047

2844

2605

3060

3181

2988

2760

3060

3315

3132

2916

3060

3348

3420

3227

3060

3348

3600

3538

3060

3348

3600

3849

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

1.10

1.13

1.16

1.10

1.13

1.16

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

1.10

1.13

1.16

1.19

2916

3132

3384

2916

3132

3384

2916

3132

3384

3672

2916

3132

3384

3672

2916

3132

3384

3672

2916

3132

3384

3672

2916

3132

3384

3672

2916

3132

3384

3672

2916

3132

3384

3672

2304

2098

1861

2537

2349

2132

2770

2600

2403

2166

2916

2850

2673

2460

2916

2975

2809

2607

2916

3101

2944

2754

2916

3132

3215

3048

2916

3132

3384

3342

2916

3132

3384

3635

0.79

0.67

0.55

0.87

0.75

0.63

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.95

0.83

0.71

1.00

0.99

0.87

0.75

1.00

1.00

0.95

0.83

1.00

1.00

1.00

0.91

1.00

1.00

1.00

0.99

1.19

1.22

1.24

1.19

1.22

1.24

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

1.19

1.22

1.24

1.26

CA

Indoor

intake air

D.B.(˚C)

Indoor

intake air

W.B.(˚C)

35 40 45

Outdoor intale air D.B.(˚C)

SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

22

Page 23

COOLING CAPACITY (3)

PLA-RP2AA.UK / PUHZ-RP2VHA

Indoor

intake air

D.B.(˚C)

NOTE:

Indoor

intake air

W.B.(˚C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

CA : Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

4950

5300

5700

4950

5300

5700

4950

5300

5700

6075

4950

5300

5700

6075

4950

5300

5700

6075

4950

5300

5700

6075

4950

5300

5700

6075

4950

5300

5700

6075

4950

5300

5700

6075

20 25 30

SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

3762

3392

2964

4158

3816

3420

4554

4240

3876

3402

4950

4664

4332

3888

4950

4876

4560

4131

4950

5088

4788

4374

4950

5300

5244

4860

4950

5300

5700

5346

4950

5300

5700

5832

0.76

0.64

0.52

0.84

0.72

0.60

0.92

0.80

0.68

0.56

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

0.96

0.84

0.72

1.00

1.00

0.92

0.80

1.00

1.00

1.00

0.88

1.00

1.00

1.00

0.96

1.24

1.26

1.30

1.24

1.26

1.30

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

Outdoor intale air D.B.(˚C)

4800

5150

5575

4800

5150

5575

4800

5150

5575

5950

4800

5150

5575

5950

4800

5150

5575

5950

4800

5150

5575

5950

4800

5150

5575

5950

4800

5150

5575

5950

4800

5150

5575

5950

3648

3296

2899

4032

3708

3345

4416

4120

3791

3332

4800

4532

4237

3808

4800

4738

4460

4046

4800

4944

4683

4284

4800

5150

5129

4760

4800

5150

5575

5236

4800

5150

5575

5712

0.76

0.64

0.52

0.84

0.72

0.60

0.92

0.80

0.68

0.56

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

0.96

0.84

0.72

1.00

1.00

0.92

0.80

1.00

1.00

1.00

0.88

1.00

1.00

1.00

0.96

1.31

1.33

1.36

1.31

1.33

1.36

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

4650

4975

5425

4650

4975

5425

4650

4975

5425

5800

4650

4975

5425

5800

4650

4975

5425

5800

4650

4975

5425

5800

4650

4975

5425

5800

4650

4975

5425

5800

4650

4975

5425

5800

3534

3184

2821

3906

3582

3255

4278

3980

3689

3248

4650

4378

4123

3712

4650

4577

4340

3944

4650

4776

4557

4176

4650

4975

4991

4640

4650

4975

5425

5104

4650

4975

5425

5568

0.76

0.64

0.52

0.84

0.72

0.60

0.92

0.80

0.68

0.56

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

0.96

0.84

0.72

1.00

1.00

0.92

0.80

1.00

1.00