Mitsubishi PLA-RP100BA3 Service Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

SERVICE MANUAL

April 2009

No. OCH459

Indoor unit

[Model names] [Service Ref.]

PLA-RP100BA3

PLA-RP100BA3

NOTE:

• This manual describes

only service data of the

indoor units.

• RoHS compliant products have <G> mark on

the spec name plate.

CONTENTS

Model name

indication

INDOOR UNIT

ON/OFF TEMP

WIRELESS REMOTE

CONTROLLER

TEMP.

WIRED REMOTE

CONTROLLER

ON/OFF

1. REFERENCE MANUAL

2. SAFETY PRECAUTION

3. PART NAMES AND FUNCTIONS

4. SPECIFICATIONS

5. NOISE CRITERION CURVES

6. OUTLINES AND DIMENSIONS

7. WIRING DIAGRAM

8. REFRIGERANT SYSTEM DIAGRAM

9. TROUBLESHOOTING

10. SPECIAL FUNCTION

11. DISASSEMBLY PROCEDURE

...................................

...................................

...................

............................................

..........................

.......................

.........................................

....................................

.....................................

.......................

PARTS CATALOG (OCB459)

............

2

3

4

7

8

9

10

11

12

27

36

1

REFERENCE MANUAL

OUTDOOR UNIT’S SERVICE MANUAL

Service Ref. Service Manual No.

PU(H)-P100VHA#2.UK

PU(H)-P100YHA#2.UK

PUHZ-P100VHA3.UK OCH415/OCB415

PUHZ-P200YHA3 OCH424/OCB424

PUHZ-HRP100VHA2

PUHZ-HRP100YHA2

PUHZ-RP100VKA

PUHZ-RP100/200YKA

OC379

OCH425/OCB425

OCH451/OCB451

2

2

SAFETY PRECAUTION

2-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply

circuits must be disconnected.

2-2. CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilising refrigerant R410A

Use new refrigerant pipes.

In case of using the existing pipes for R22, be careful with

the followings.

· For RP100, 125 and 140, be sure to perform replace ment operation before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

Store the piping to be used indoors during

installation, and both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Tools for R410A

Gauge manifold

Charge hose

Gas leak detector

Torque wrench

Flare tool

Size adjustment gauge

Vacuum pump adaptor

Electronic refrigerant

charging scale

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Ventilate the room if refrigerant leaks during

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

3

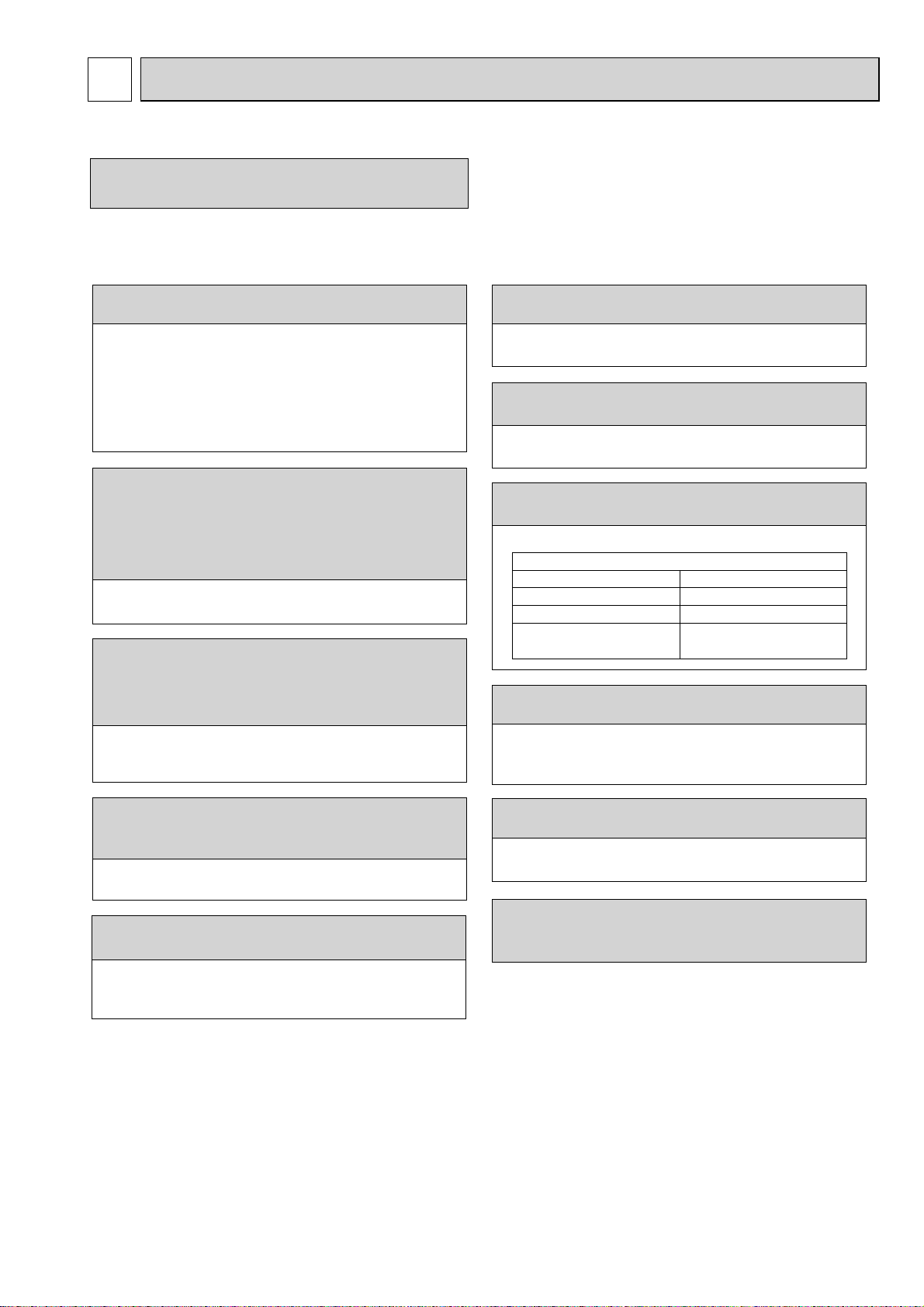

Unit

Gravimeter

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1 Gauge manifold · Only for R410A

· Use the existing fitting

· Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose · Only for R410A

· Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector · Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check · Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder · Only for R410A · Top of cylinder (Pink)

· Cylinder with syphon

8 Refrigerant recovery equipment

specifications

. (UNF1/2)

3

Liquid pipe

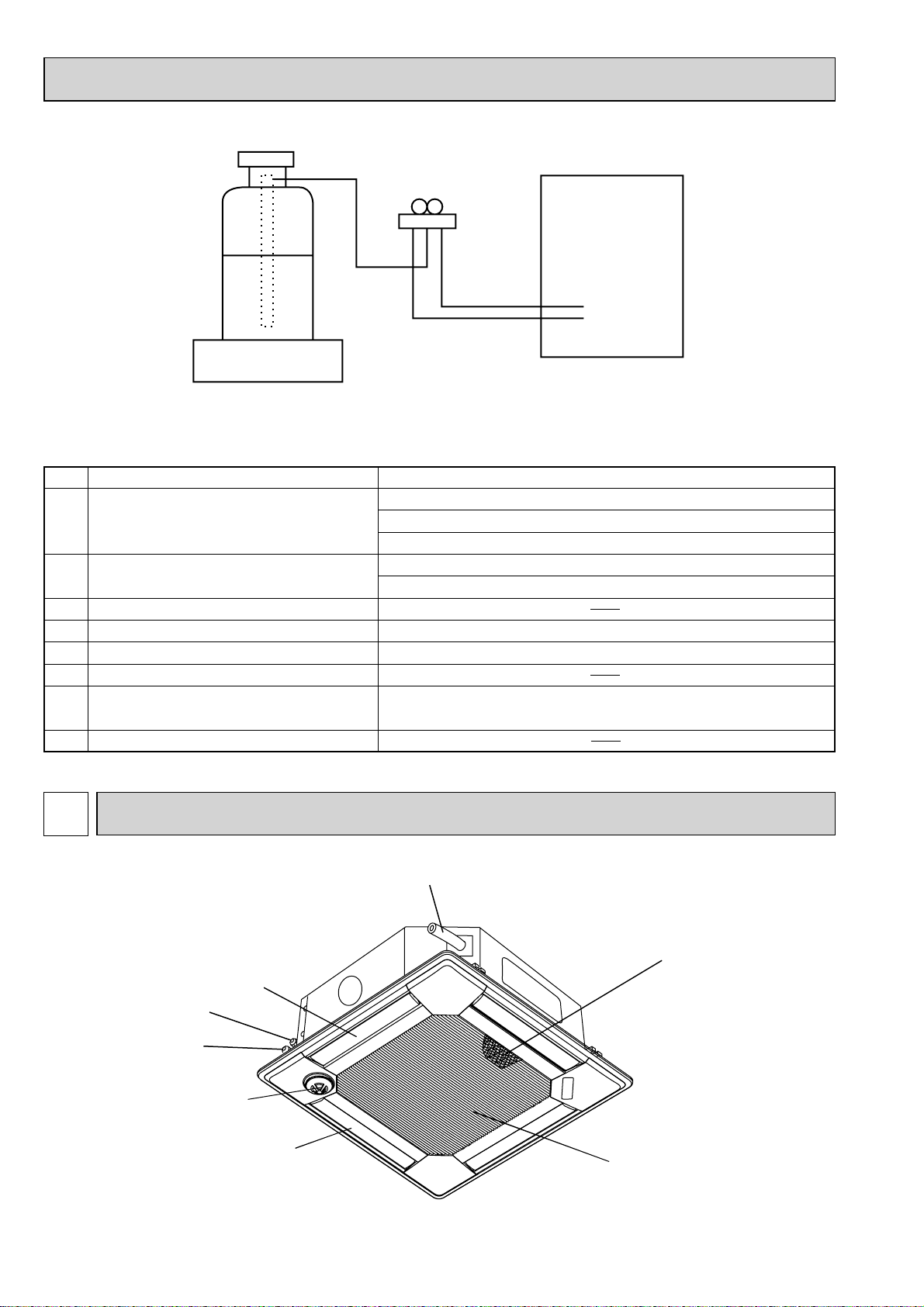

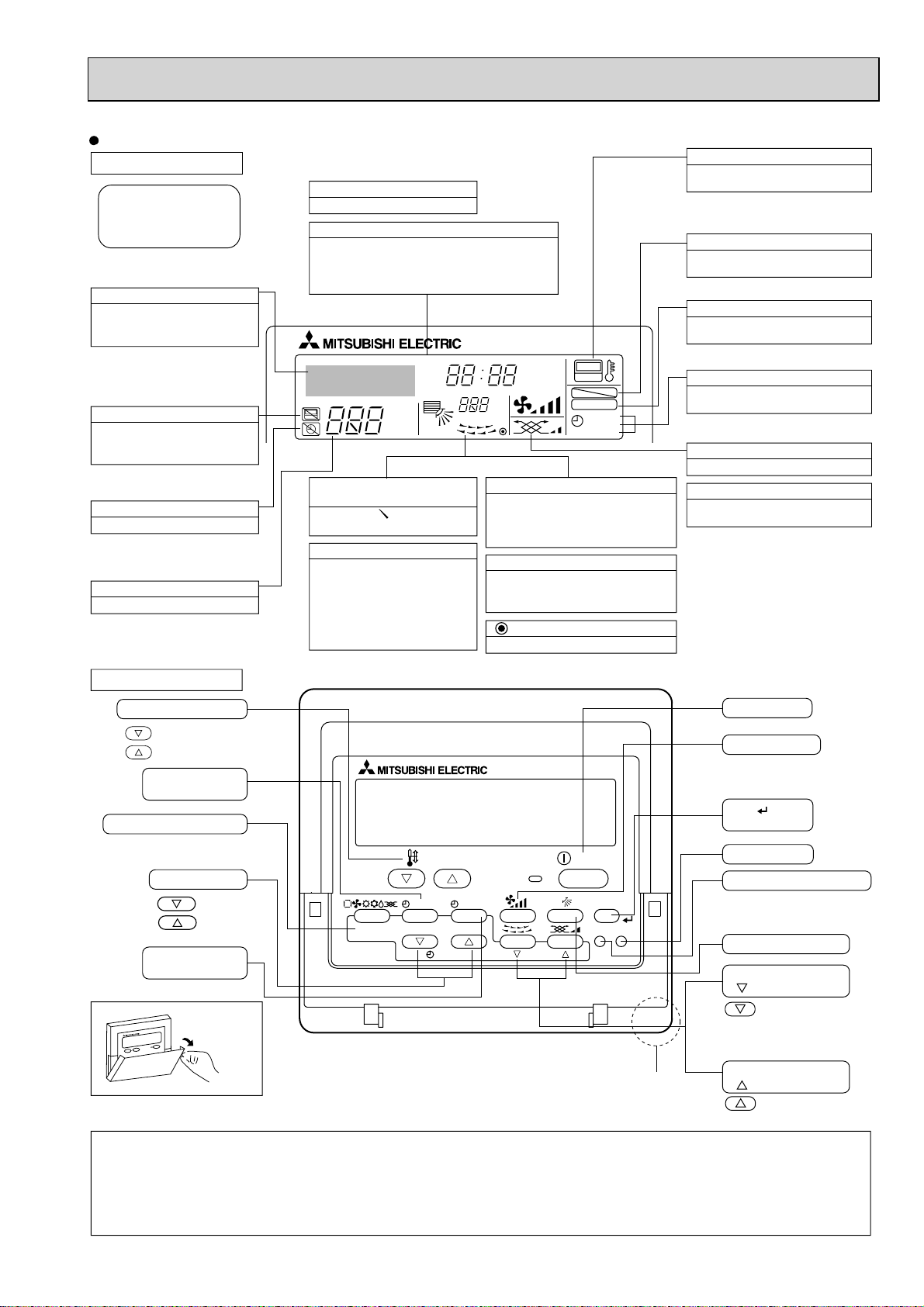

PART NAMES AND FUNCTIONS

Drain pipe

Filter

Air outlet

Gas pipe

i-see sensor

(option)

Vane

Air intake

(Intake grille)

4

Wired remote controller

Display Section

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

*Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the

remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, the time to be

switched off is shown.

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ERROR CODE

°F°C

Hr

AFTER

°F°C

ONLY1Hr.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

low or downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off in 1 hour,

when the airflow direction

also changes.

Room Temperature display

Shows the room temperature. The room

temperature display range is 8–39.

The display blinks if the temperature

is less than 8 or 39 or more.

Louver display

Indicates the action of the swing louver.

Does not appear if the louver is not

running.

(Power On indicator)

Indicates that the power is on.

ON

OFF

FUNCTION

FILTER

WEEKLY

SIMPLE

AUTO OFF

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to

clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Operation Section

Temperature setting buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

lid

Note:

L

“PLEASE WAIT” message

TEMP.

MENU

BACK DAY

MONITOR/SET

PAR-21MAA

CLOCK

ON/OFF

OPERATION

ON/OFF

FILTER

CHECK

TEST

CLEAR

Built-in temperature sensor

This message is displayed for approximately 3 minutes when power is supplied to the indoor unit or when the unit is recovering from a power failure.

L

“NOT AVAILABLE” message

This message is displayed if an invalid button is pressed (to operate a function that the indoor unit does not have).

If a single remote controller is used to operate multiple indoor units simultaneously that are different types, this message will not be displayed as

far as any of the indoor units is equipped with the function.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To return operation

number

Ventilation button

( Operation button)

To go to next operation

number

5

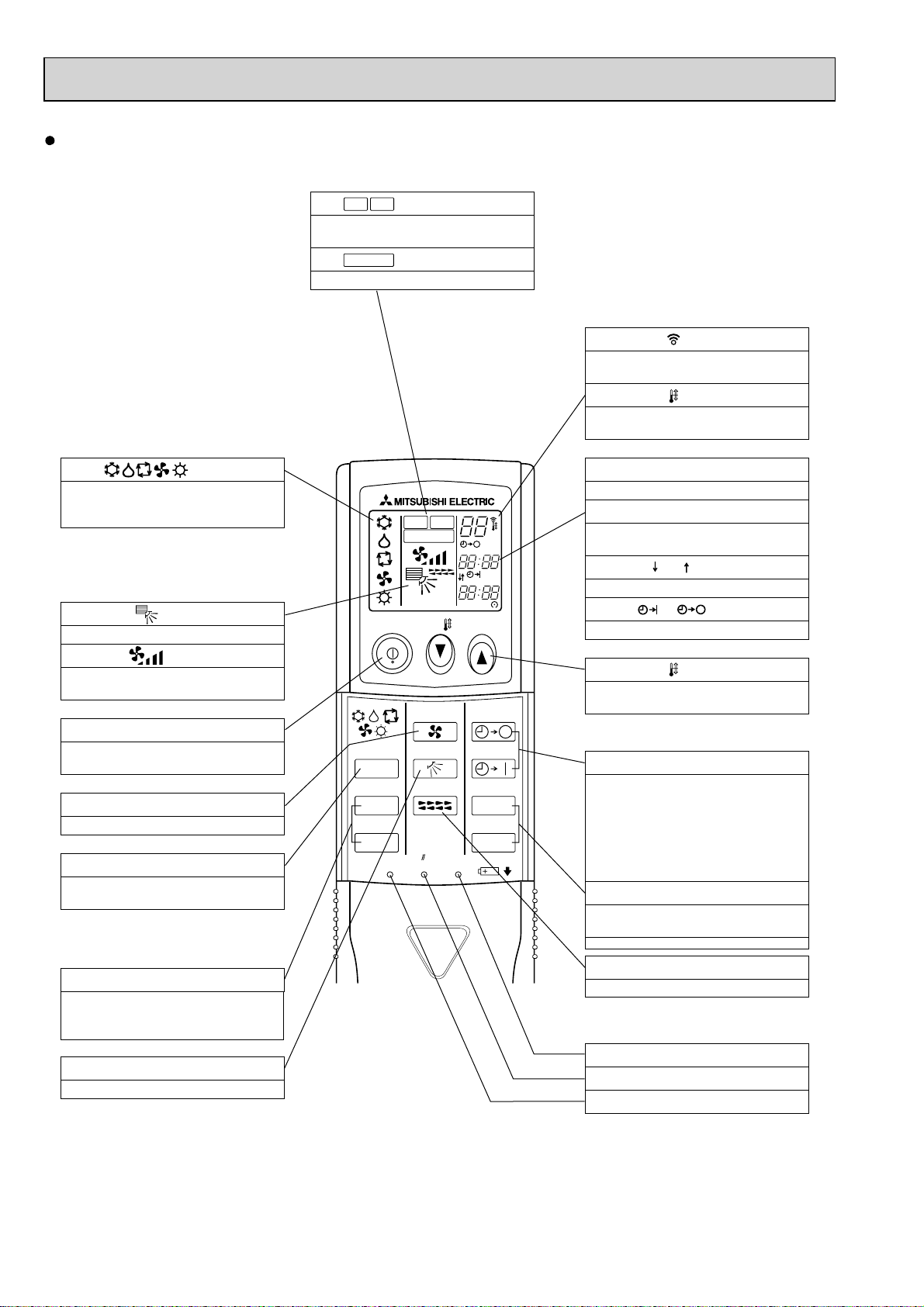

Wireless remote controller

CHECK

TEST RUN

display

CHECK and TEST RUN display indicate that

the unit is being checked or test-run.

MODEL SELECT

Blinks when model is selected.

display

display

Lights up while the signal is transmitted to

the indoor unit when the button is pressed.

display

SET TEMP. display indicates the desired

temperature which is set.

display

OPERATION MODE display

Operation mode display indicates which

operation mode is in effect.

display

The vertical direction of air flow is indicated.

display

FAN SPEED display indicates which fan

speed has been selected.

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

FAN SPEED SELECT button

Used to change the fan speed.

MODE SELECT button

Used to switch the operation mode between

cooling, drying, heating, auto and fan mode.

CHECK

TEST RUN

MODEL SELECT

NOT AVAILABLE

ON/OFF TEMP

FAN

MODE

CHECK

VAN E

LOUVER

TEST RUN

RESETSET CLOCK

°C

AMPM

AMPM

AUTO STOP

AUTO START

h

min

CLOCK display

Displays the current time.

TIMER display

Displays when in timer operation or when

setting timer.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

button

SET TEMPERATURE button sets any desired

room temperature.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be

automatically stopped at the preset time.

AUTO START (ON timer): when this switch is

set, the air conditioner will be automatically

started at the preset time.

h and min buttons

Buttons used to set the “hour and minute” of

the current time and timer settings.

CHECK-TEST RUN button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

VANE CONTROL button

Used to change the air flow direction.

LOUVER button

Changes left/right airflow direction.

(Not available for this model.)

CLOCK button

RESET button

SET button

6

4

SPECIFICATIONS

Service Ref.

Mode

Power supply (phase, cycle, voltage)

Input

Running current

External finish (Panel)

Heat exchanger

Fan Fan (drive) % No.

Fan motor output

External static pressure

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level (Low-Medium2-Medium1-High)

Field drain pipe O.D.

Dimensions

Weight

Airflow (Low-Medium2-Medium1-High)

*/min(CFM)

Pa(mmAq)

W

D

H

kW

A

kW

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Cooling

PLA-RP100BA3

Single phase, 50Hz, 230V

0.15

1.00

Munsell 6.4Y 8.9/0.4

Plate fin coil

Turbo fan (direct) % 1

0.120

20-23-26-30(710-810-920-1,060)

0(direct blow)

–

Remote controller & built-in

32-34-37-40

32(1-1/4)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 840 (33-1/16) PANEL : 950 (37-3/8)

UNIT : 298 (11-3/4) PANEL : 35 (1-3/8)

UNIT : 26 (57) PANEL : 6 (13)

Heating

0.14

0.94

7

5

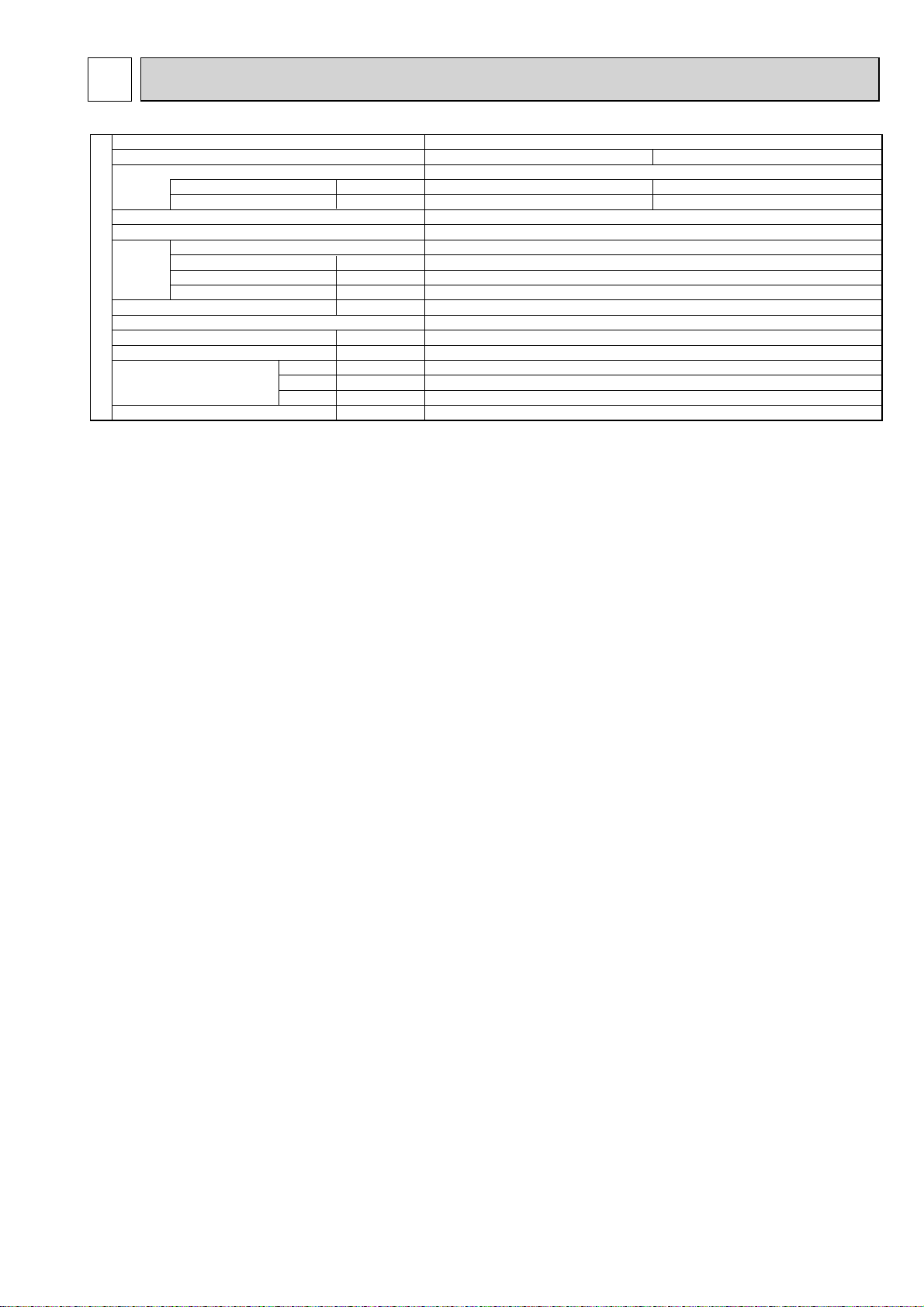

NOISE CRITERION CURVES

PLA-RP100BA3

90

80

70

60

50

40

30

APPROXIMATE

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH SPL(dB) LINE

High 40

Medium1 37

Medium2 34

Low 32

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

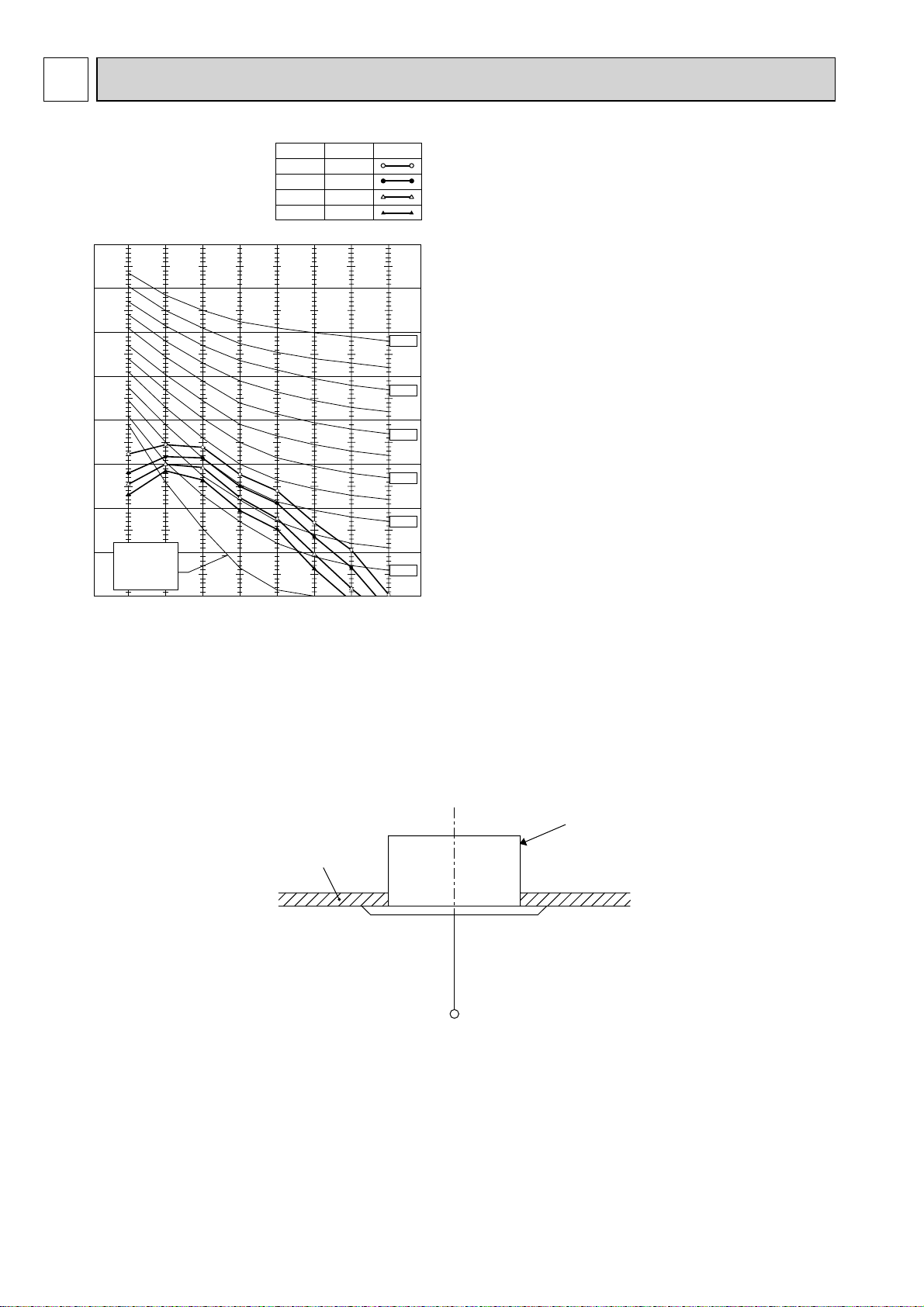

CEILING

UNIT

1.5m

MICROPHONE

8

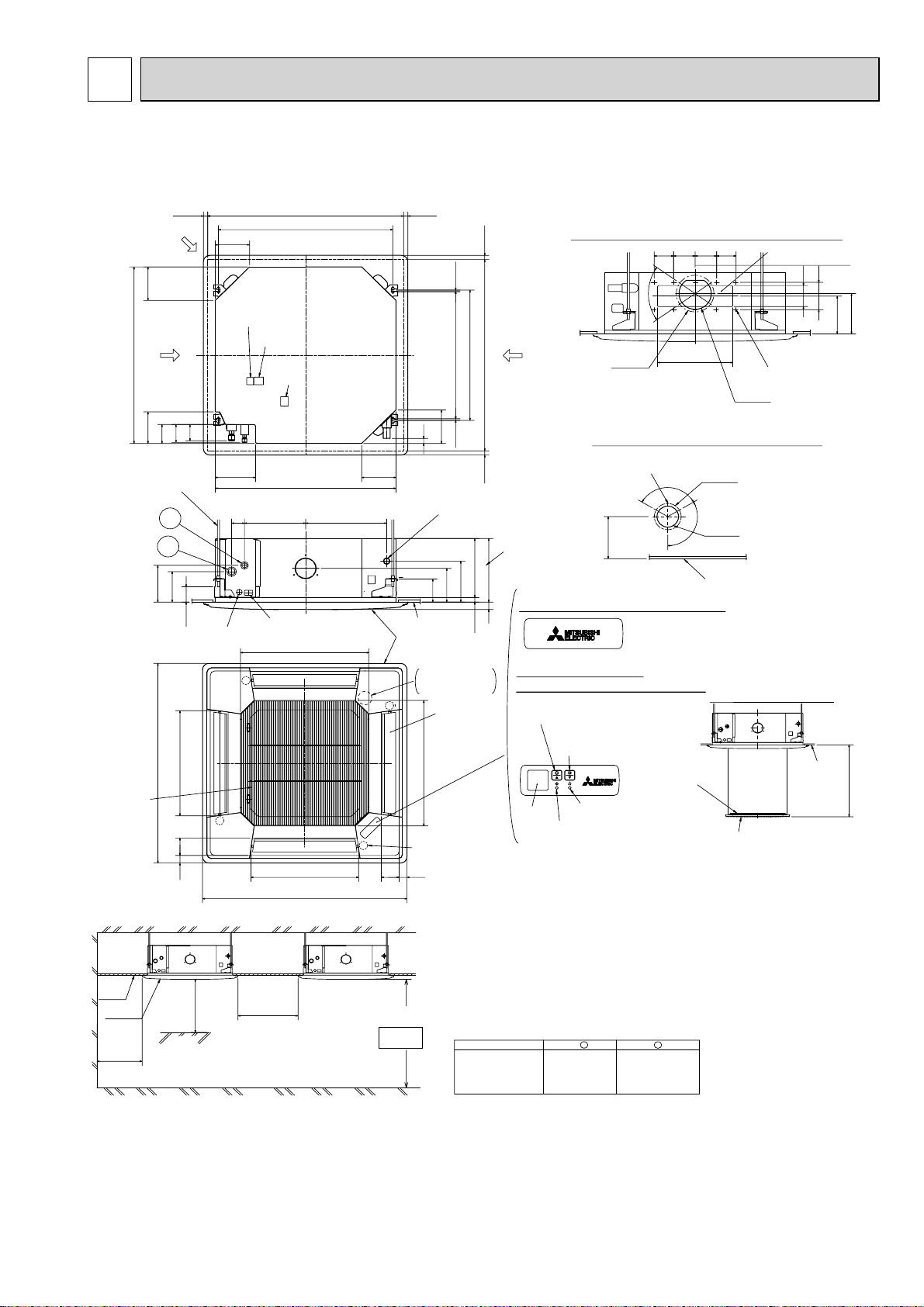

6

37728460

()

Ceiling hole

Branch duct hole

Drain pipe

connected to VP-25

Ceiling

Grille

Drain hole

Models

Auto vane

(Air outlet)

Air intake grille

Ceiling

Cut out hole

Cut out hole

Cut out hole

Burring hole pitch

Burring hole pitch

Burring hole

Burring hole

Power supply wire,

Indoor unit/Outdoor unit

connecting wire entry

Indoor unit/Outdoor unit

connecting terminal block

Indoor power supply

terminal block(Option part)

Control wire entry

Air intake hole

Air intake hole

Air outlet hole

Air outlet hole

Connected the attached

flexible pipe or socket.

Keep approximately

10 to 15mm space

between unit ceiling

and ceiling slab.

Branch duct hole

Fresh air

intake hole

Ceiling hole

Suspension bolt pitch

Suspension bolt pitch

Remote controller

terminal block

Suspension bolt

M10 or W3/8

(7.5)(7.5)

605

+35

- 5

620

DEFROST/STAND BY lamp

Receiver

Operation lamp

In case of standard grille : PLP-6BA / PLP-6BAMD

In case of wireless remote controller : PLP-6BALM Auto grille

Air intake grille up/down distance

Emergency operation

switch<Cooling>and

Emergency Up/Down switch<Up>

160

160

500

500

597

83 36

950

8336

950

597

281

17

+5

0

28835

190

156

105

140

50~70

160

840

150

90

85

77

840

187.5

20~45

860~910

20~45

810

20~45

860~910

20~45

24

160

++

+

+

+

+

+

+

+

M

M

M

M

120°

120°

:175

:125

167

158

Vane motor

2

1

Drain pump clean hole

and Drain emergency

drainage hole

130

100

70°

155

350

90 100

100 90

2

1

Refrigerant pipe

···:9.52

Flared connection

···3/8 inch

Refrigerant pipe

···:15.88

Flared connection

···5/8 inch

PLA-RP100BA3

Detail drawing of fresh air intake hole

Detail connecting of branch duct(Both aspects)

3-:2.8

14-:2.8

:150

:100

Emergency operation

switch<Heating>and

Emergency Up/Down switch<Down>

In case of auto-grille : PLP-6BAJ

Suspension bolt

lower edge

170

+

Ceiling

Air intake grille

Max. 4.0m

L.L Filter

Ceiling

Grille

Indoor unit

1500mm

or more

1000mm

or more

3000mm or more

1800mm or more

from floor

For high

attachment

Indoor unit

Obstacle

Floor

Note1. Please choose the grille from a standard grille, auto-grille.

2. As for drain pipe, please use VP-25(O.D.

:

32 PVC TUBE).

Drain pump is included.

Max. lifting height is 850mm from the ceiling.

3. As for suspension bolt, please use M10 or W3/8.

(Procured at local site)

4. Electrical box may be removed for the service purpose.

Make sure to slack the electrical wire little bit for control/power wires connection.

5. The height of the indoor unit can be adjusted with the grille attached.

6. For the installation of the optional high efficiency filter or optional multi-functional casement.

1) Requires 440 mm or more space between transom and ceiling for the installation.

2) Add 135 mm to the dimensions + marked on the figure.

3) Optional high efficiency filter must be used jointly with optional multi-functional casement .

7. When installing the branch ducts, be sure to insulate adequately.

Otherwise condensation and dripping may occur.

(It becomes the cause of dew drops/Water dew.)

8. As for necessary installation/service space, please refer to the left figure.

OUTLINES AND DIMENSIONS

PLA-RP100BA3

Unit: mm

9

7

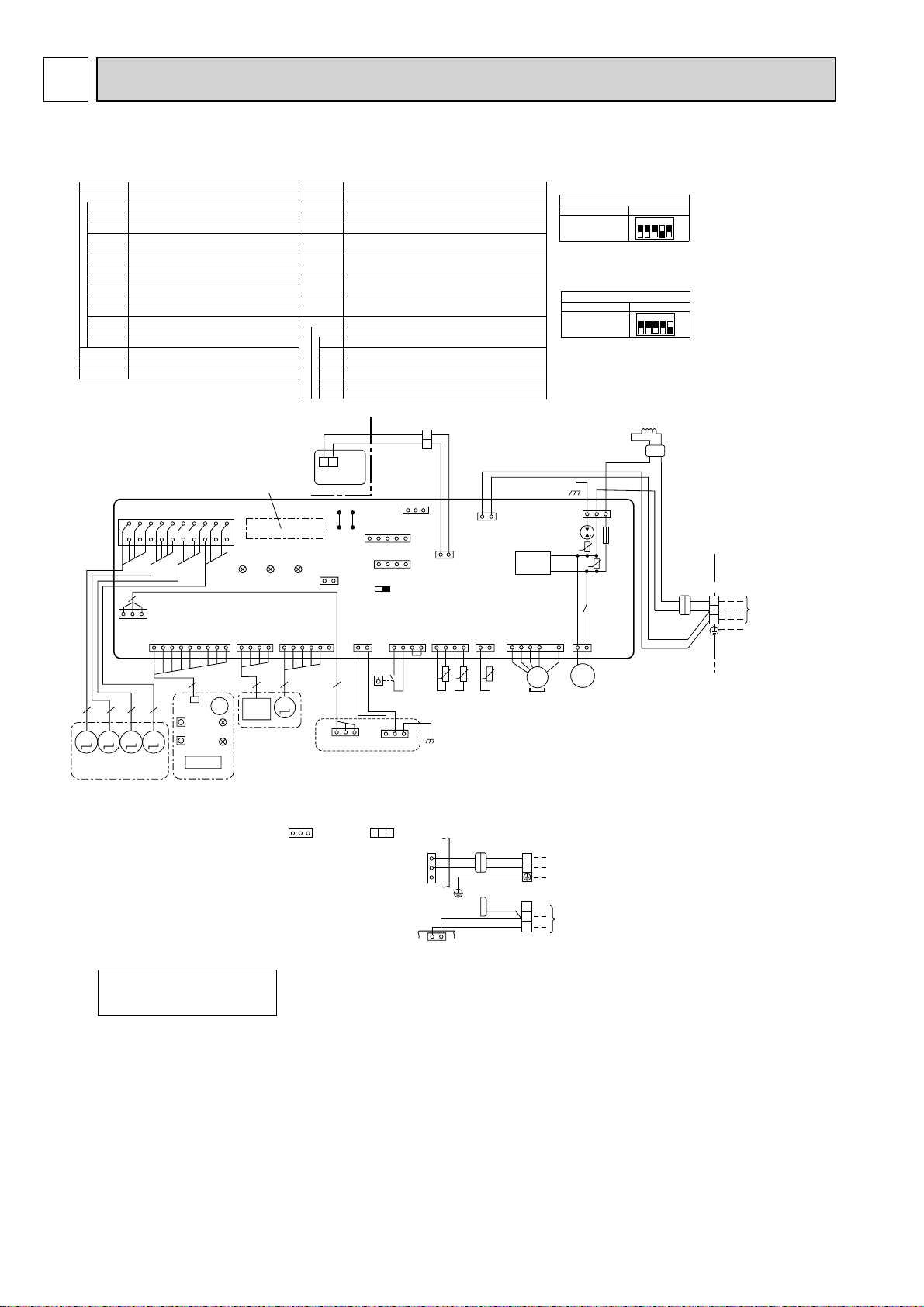

WIRING DIAGRAM

PLA-RP100BA3

[LEGEND]

SYMBOL SYMBOLNAME NAME

I.B

DCL

DP

FS

MMMM

INDOOR CONTROLLER BOARD

CN2L

CONNECTOR (LOSSNAY)

CN32

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

CN41

CN51

CONNECTOR (CENTRALLY CONTROL)

DSA

SURGE ABSORBER

FUSE

FUSE (T6.3AL250V)

LED1

POWER SUPPLY (I.B)

LED2

POWER SUPPLY (R.B)

LED3

TRANSMISSION (INDOOR-OUTDOOR)

SW1

SWITCH (MODEL SELECTION) +See table 1

SW2

SWITCH (CAPACITY CORD) +See table 2

SWE

CONNECTOR (EMERGENCY OPERATION)

X1

RELAY (DRAIN PUMP)

ZNR01,02

VAR IST OR

REACTOR

DRAIN-UP MACHINE

DRAIN FLOAT SWITCH

I.B

CNV(

WHT)

VAN E

18

20

19

3

114169

(BLK)

5555

MV

GRILLE

WIRELESS

CN90

(WHT)

9

CNB

SW1

SW2

1 3

AUTO GRILLE

CN3G

MVMVMV

Refer to tables 1 and 2

1234567891011121314151617

LED3 LED2 LED1

I-SEE SENSOR

CN4Y

(WHT)

4 5

I-SEE

BZ

SENSOR

LED2

I-SEE SENSOR

CORNER PANEL

(OPTION PART)

LED1

RU

W.B

MF

MV

TB2

TB4

TB5,TB6

TH1

TH2

TH5

OPTION PART

SW2SW1

I-SEE

SENSOR MOTOR

CN6Y

(RED)

M

MT

FAN MOTOR

VANE MOTOR

TERMINAL BLOCK (Indoor unit Power (option))

TERMINAL BLOCK (

TERMINAL BLOCK (REMOTE CONTROLLER

TRANSMISSION LINE)

ROOM TEMP. THERMISTOR

(0 / 15k, 25 / 5. 4k DETECT)

PIPE TEMP. THERMISTOR/LIQUID

(0 / 15k, 25 / 5. 4k DETECT)

COND. / EVA. TEMP. THERMISTOR

(0 / 15k, 25 / 5. 4k DETECT)

PCB FOR WIRELESS REMOTE CONTROLLER

W.B

BZ

BUZZER

LED1

LED (OPERATION INDICATION : GREEN)

LED2

LED (PREPARATION FOR HEATING : ORANGE)

RECEIVING UNIT

RU

SW1

EMERGENCY OPERATION (HEAT / DOWN)

SW2

EMERGENCY OPERATION (COOL / UP)

2

1

TB6

R.B

J42J41

Pair No.

CN2L

21

AUTO GRILLE

POWER

CNAC

(WHT)

3

U.B

CN3G

AUTOMATIC FILTER ELEVATION PANEL

(OPTION PART)

INDOOR/OUTDOOR CONNECTING LINE

TB5

TRANSMISSION

WIRES

DC12V

CN32

(WHT)

113

CN51(WHT)

51

CN41(WHT)

41

SWE

ON OFF

FLOAT SW

CN4F

(WHT)

31

4

FS

13135

CN3A

2

1

INDOOR/OUTDOOR

COMMUNICATION

21

REMOCON

CN22

(BLU)

LIQUID/PIPE

CN44

(WHT)

14

tt t

TH2 TH5 TH1

1

CN3C

(BLU)

INTAKE

CN20

(RED)

21

3

<Table 1> SW1 (MODEL SELECTION)

)

PLA-RP100BA3

<Table 2> SW2 (CAPACITY CODE)

PLA-RP100BA3

OUTDOOR

CN01

(BLK)

DSA

ZNR02

DC280V

RECTIFICATION

FAN

CNMF

(WHT)

741

MS

3~

MF

MODELS

MODELS

135

U

U

ZNR01

X1

D.U.M

31

CNP

(BLU)

M

1~

DP

SW1

SW2

FUSE

SETTING

12345

SETTING

12345

DCL

YLW

YLW

ORN

ORN

BRN

ON

OFF

ON

OFF

YLW

ORN

TB4

S1

S2

S3

+ Be sure to turn off the source power

and then disconnect fan motor connector.

(Failure to do so will cause trouble in Fan motor)

TO OUTDOOR

UNIT

Notes:

1.SymboIs used in wiring diagram above are, : Connector, :

Terminal (block).

2.Indoor and outdoor connecting wires have poIarities, make

sure to match terminal numbers (S1, S2, S3) for correct wirings.

3.Since the outdoor side electric wiring may change, be sure to check

the outdoor unit electric wiring diagram for servicing.

4.This diagram shows the wiring of indoor and outdoor connecting

wires (specification of 230V), adopting superimposed system for

power and signal.

+1:If indoor and outdoor units have separate power supplies,

refer to Fig 1.

+2:For power supply system of this unit, refer to the caution label

located near this diagram.

Please set the voltage using the

remote controller.

For the setting method, please refer to

the indoor unit Installation Manual.

+1(Fig. 1)

CN01

(BLK)

5

3

1

I.B

CN3C

(BLU)

31

I.B

YLW

ORN

INDOOR/OUTDOOR

COMMUNICATION

RED

BLU

GRN/YLW

YLW

ORN

ORN

BRN

TB2

TB4

L

N

S1

S2

S3

POWER SUPPLY

~(1PHASE)

230V 50Hz

TO OUTDOOR UNIT

10

8

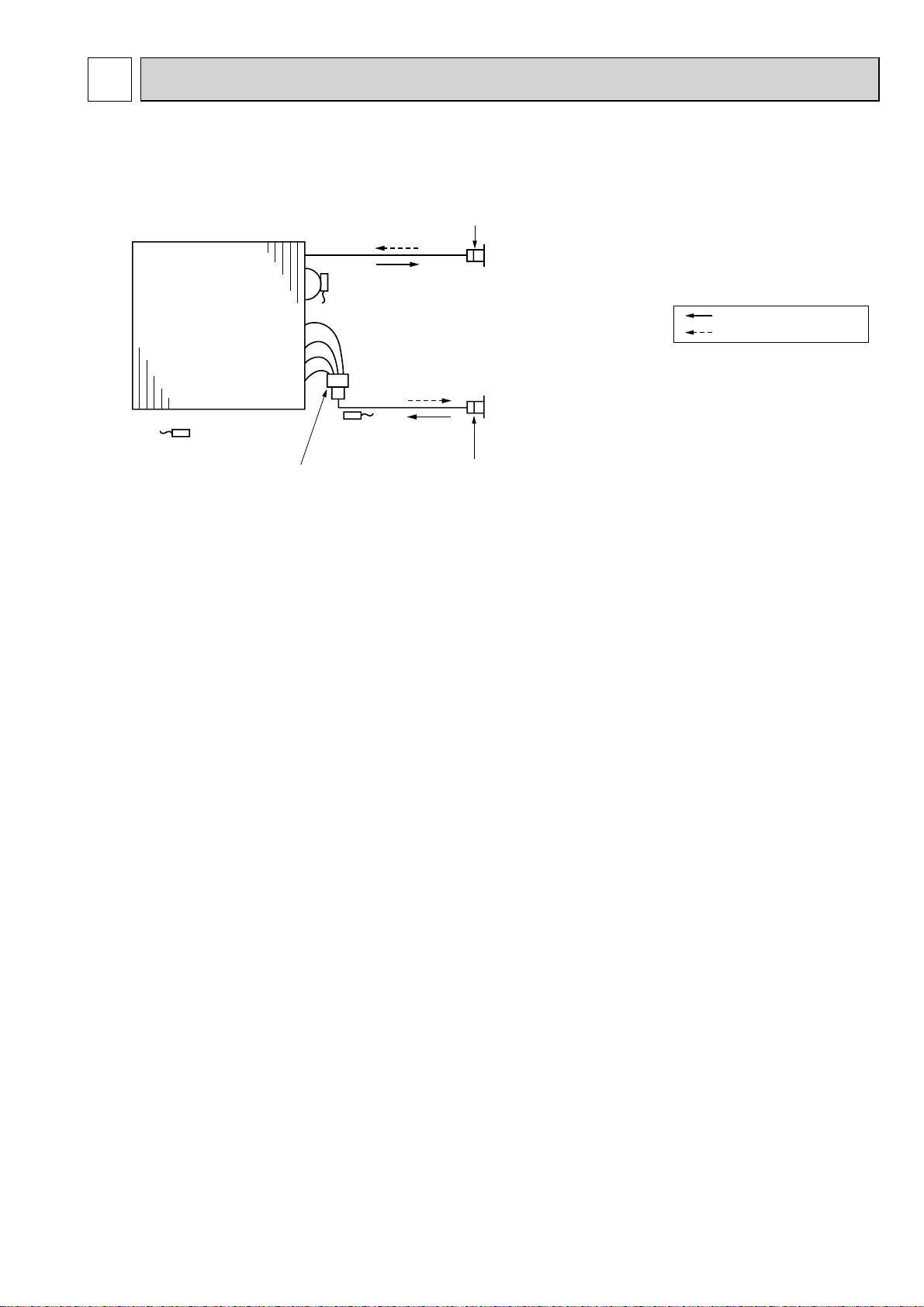

REFRIGERANT SYSTEM DIAGRAM

PLA-RP100BA3

Heat exchanger

Thermistor TH1

(Room temperature)

Thermistor TH5

(Cond./ Eva.temperature)

Thermistor TH2

Pipe temperature(Liquid)

Distributor

with strainer (#50)

Strainer (#50)

Refrigerant GAS pipe connection

(Flare)

Refrigerant flow in cooling

Refrigerant flow in heating

Refrigerant LIQUID pipe connection

(Flare)

Strainer (#50)

11

9

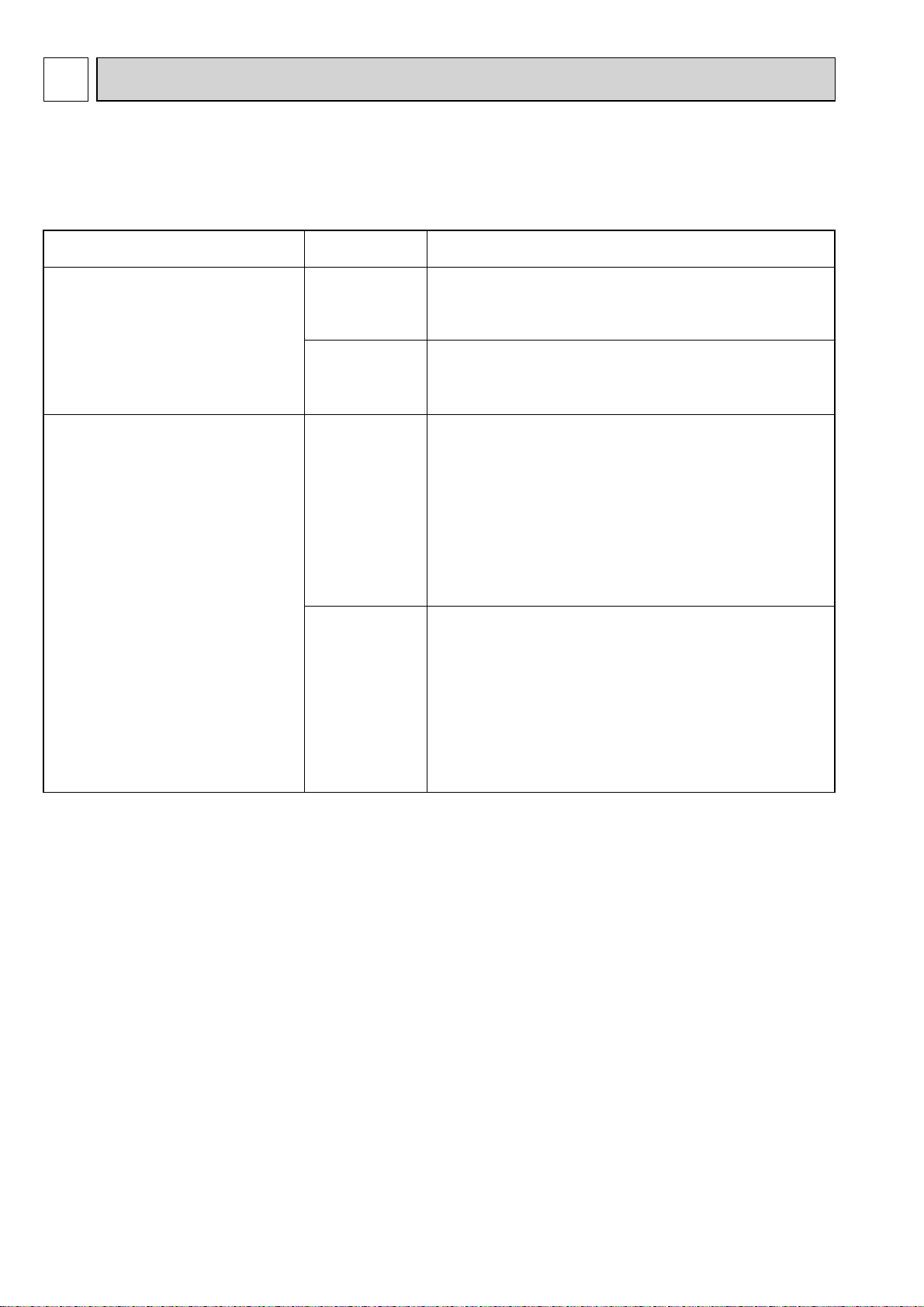

TROUBLESHOOTING

9-1. TROUBLESHOOTING

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller or controller board of outdoor unit.

Actions to be taken for service and the trouble reoccurrence at field are summarized in the table below. Check the contents

below before investigating details.

Unit conditions at service

The trouble is reoccurring.

The trouble is not reoccurring.

Error code

Displayed

Not displayed

Logged

Not logged

Actions to be taken for service (summary)

Judge what is wrong and take a corrective action according

to “9-3. Self-diagnosis action table”.

Conduct troubleshooting and ascertain the cause of the

trouble according to “9-4. Troubleshooting by inferior

phenomena”.

Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation

environment, refrigerant amount, weather when the

trouble occurred, matters related to wiring and etc.

Reset error code logs and restart the unit after finishing

service.

There is no abnormality in electrical component,

controller board, remote controller and etc.

Re-check the abnormal symptom.

Conduct trouble shooting and ascertain the cause of

the trouble

inferior phenomena”.

Continue to operate unit for the time being if the cause

is not ascertained.

There is no abnormality concerning of parts such as

electrical component, controller board, remote controller

and etc.

according to “9-4. Troubleshooting

by

12

Loading...

Loading...