Mitsubishi Electric PHV1000DXE HO, PHV1500DXE LO, PHV1500DXE HO, PHV2000DXE LO, PHV2000DXE HO Maintance Manual

9901025-2 Page 1 of 21

PHV HEAT PUMP RANGE AIR CURTAINS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

For use with Mr Slim units

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTI NG INSTALLATION

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: +44 (0) 24 7638 4646

Fax: +44 (0) 24 7638 8578

www.thermoscreens.com

English

9901025-2 Page 2 of 21

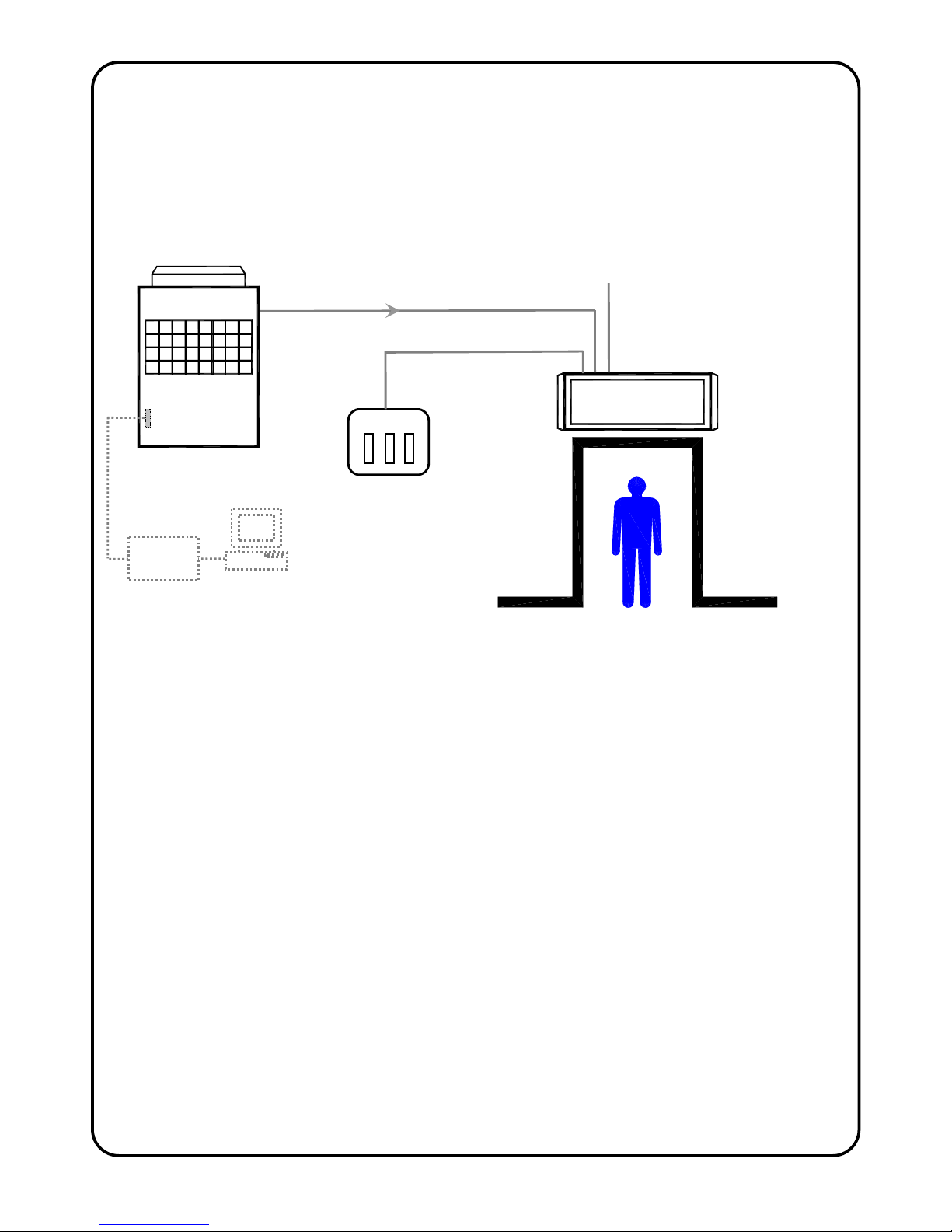

Thermoscreens / Mitsubishi Electric

Heat Pump Warm Air Curtain System

The Heat Pump Warm Air Curtain System consists of :-

• a Thermoscreens 'PHV Air Curtain' fitted with a PAC-IF010 Mitsubishi Electric Interface

PCB

• a Mitsubishi Electric 'Mr Slim Outdoor Unit'

• a Thermoscreens 'Manual Room Control' for the manual control option by the occupant

Refer to Mitsubishi Electric if the air curtain is to be controlled via a Building Management

System (BMS) or Centralised Controller. Do not install Manual Room Control and

BMS/Centralised Control components together, install either one or the other.

A communications link is supplied to the Thermoscreens Heat Pump Air Curtain from the

Mitsubishi Electric Outdoor Unit. This link provides control of the heat output of the air curtain

and tells the air curtain when the outdoor unit is in defrost mode so auxiliary electric element

heaters (if specified) can provide partial heat back-up during the few minutes of defrost.

The Air Curtain requires a permanent 3 phase electrical supply (3L+N+E) from a local

switched spur to provide power to the defrost cycle electric heating elements, the air curtain

fans and the Mitsubishi Electric Interface PCB. If the defrost cycle electric elements are not

required they can be permanently disconnected, see 'Electrical Connections', and a 1 phase

electrical supply (1L+N+E) used instead.

High and Low Output in this document refers to the heat pump heating capacity of the Air

Curtain, not to any electrical rating.

Heat Pump

Air Curtain

Mitsubishi Electric

Outdoor Unit

Communications Link

Permanent mains electrical supply

(from local switched spur) for

x Fans

x Mitsubishi Electric Interface PCB

x Defrost electric heaters (if used)

Manual Room

Control

Manual On/Off Control and

Heat Setting Control

Optional

BMS Control

Interface Board

Procon

A

32/M

9901025-2 Page 3 of 21

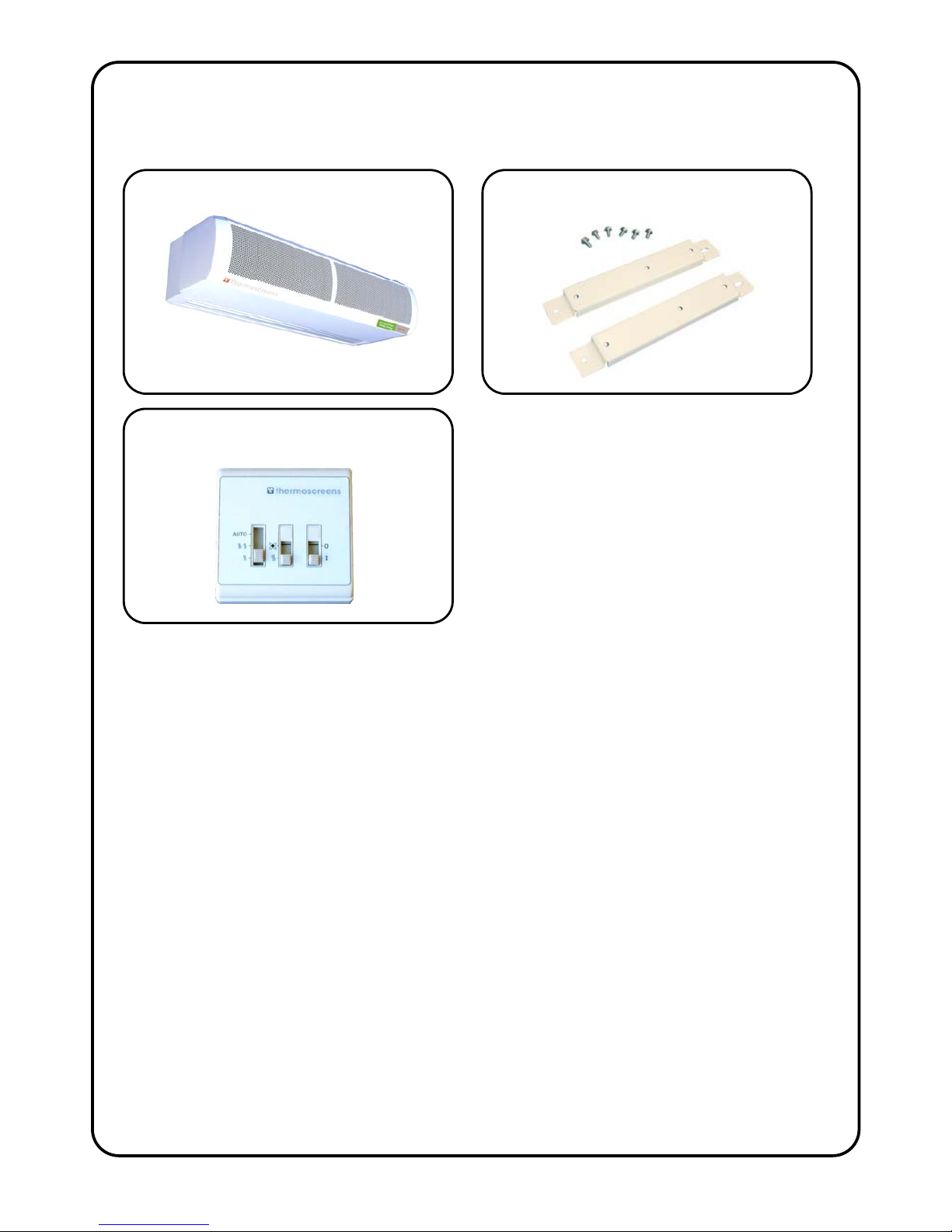

UNPACKING THE PHV HEAT PUMP AIR CURTAIN

The following items are supplied and packaged within the air curtain box.

There will also be a 'Mr Slim Outdoor Unit' supplied by Mitsubishi Electric.

The complete Thermoscreens/Mitsubishi Electric heat pump system, to provide a heat

pump warm air curtain over a doorway, including wiring, fridge pipework, etc. is to be

installed only by an approved Mitsubishi Electric refrigeration contractor.

For your records

Date of Purchase……………………………..

Place of Purchase…………………………….

Serial Number…………………………………

For warranty purposes proof of purchase is necessary so please keep a copy of your

invoice.

IMPORTANT

This Heat Pump Air Curtain in intended only for use with a Mitsubishi Electric Mr Slim

Outdoor Unit, for use on R410a with a condensing temperature of 49°C.

These instructions must be read in conjunction with the Mitsubishi Electric Mr Slim

Outdoor Unit instructions.

(All documentation supplied with each unit should be stored and kept for future reference.)

Wall Brackets and Fixing Bolts

PHV Heat Pump Air Curtain

Please note end caps are supplied loose

to be fitted during installation

Manual Room Control

If anything is missing or damaged

please contact your place of

purchase immediately.

9901025-2 Page 4 of 21

INSTALLATION OF THE HEAT PUMP AIR CURTAIN

The air curtain has been designed to be surface mounted inside of the building and

located horizontally over a doorway. It must not be installed outside of the building,

or built into a cabinet or recessed in anyway. The air curtain is intended for use as a

heating only unit.

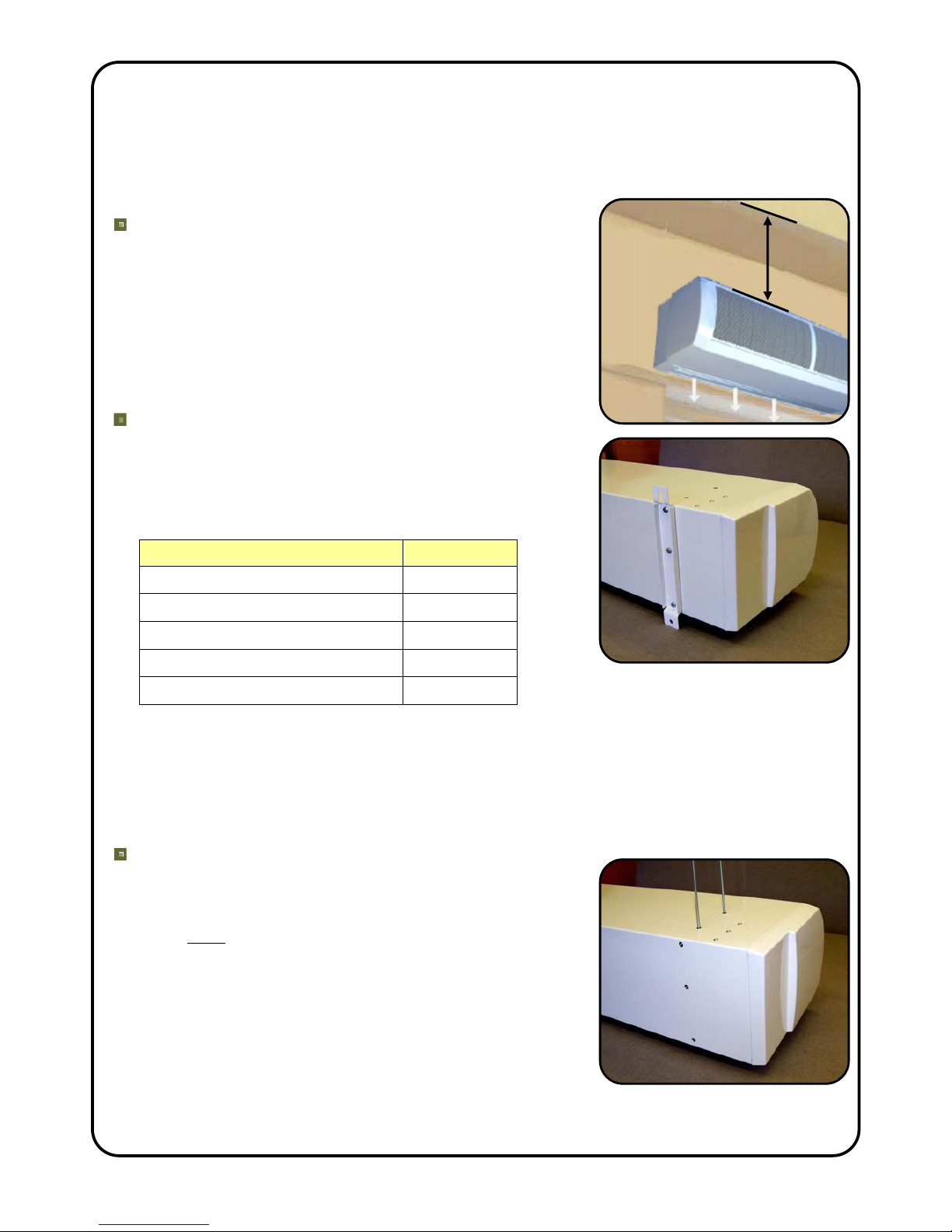

Location

The air curtain must be mounted so the discharge grille is

between 1.8m minimum and 3.75m maximum above floor

level and situated as close to the doorway as possible.

Leave a gap of 250mm minimum above the air curtain to

allow for pipework brazing operations. Beware of doorway

top edges, structural beams, door opening/closure

devices, etc. which may interfere with the air stream and

affect the location of the unit.

Wall Fixing

Bolt all of the wall brackets supplied to the rear face of the

unit as shown in the adjacent picture using the M6 bolts

supplied. Suitable wall fixing bolts (not supplied) need to

be used to fix the brackets to the wall, taking into account

the type of wall and the weight of the unit*, see table:

Air Curtain Weight (kg)

PHV1000DXE HO 39

PHV1500DXE LO 59

PHV1500DXE HO 60

PHV2000DXE LO 78

PHV2000DXE HO 80

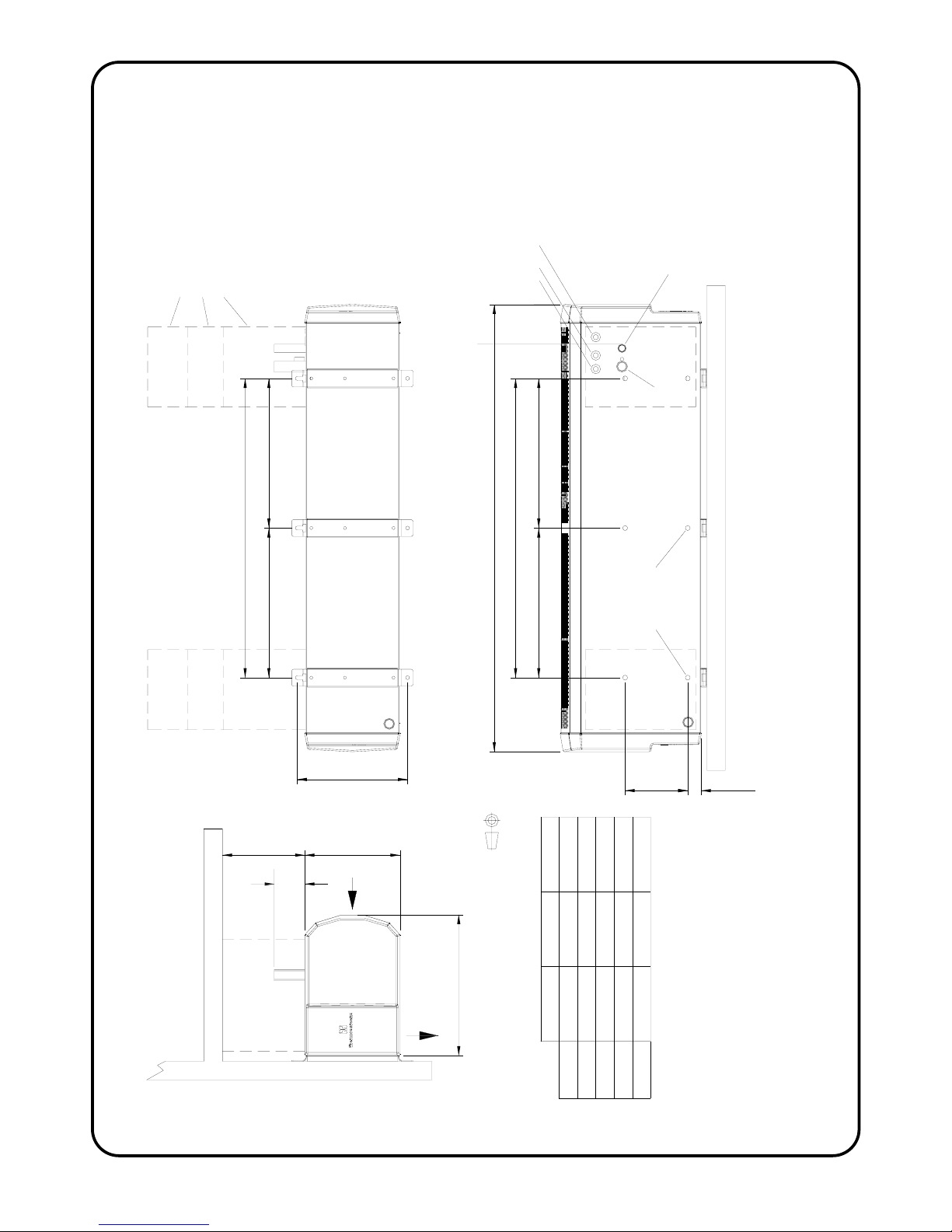

Step 1. Refer to Figure 1 for mounting details and drill the fixing points in the wall.

Step 2. Screw in the top wall bolts leaving a small gap between the head and the wall.

Lower the unit onto the bolts via the key-hole slots in the top of the wall brackets and then

screw in the bottom wall bolts.

Step 3. Ensure all fixing bolts are tightened and the air curtain is safely secured to the

wall.

Ceiling Suspension

M10 threaded inserts are provided in the top face of the

unit (see Figure 1 for positions) so it can be suspended on

M10 threaded hanging rods (not provided). All suspension

points must be used. Ensure each of the hanging rods is

secured onto a suitable structure that can support the

weight of the unit (see table above)*. Screw the hanging

rods into the inserts by a minimum or 20mm and fit

locking nuts (not supplied) to prevent the rod rotating and

coming away from the casing. Do not screw the hanging

rod too far in or it could interfere with internal components.

* It is the sole responsibility of the installer to ensure that the

building fixing locations and suspension system used are

suitable for the air curtain being installed.

250mm min

9901025-2 Page 5 of 21

295

E E

D

C C

B

A

168

36

255

377

PHV2000DXPHV1500DX

22961746

18961400

1300

700

1824

948

650 912

A (mm)

B (mm)

C (mm)

D (mm)

E (mm)

Hot Gas

Refrigerant Connection

Liquid line

Refrigerant Connection

100

Electrical Supply and

Control Wiring Inlets

for pipes

250 min.

PHV1000DX

1196

800

800

N/A

N/A

Optional sheet metal covers

to hide pipework, cables, etc.

250, 500 or 1000 high

Holes for M10 drop rods

4 for 1m unit, 6 for 1.5m/2m units

Use all drop rod holes !

FIGURE 1 – DIMENSIONS OF PHV HEAT PUMP AIR CURTAIN

9901025-2 Page 6 of 21

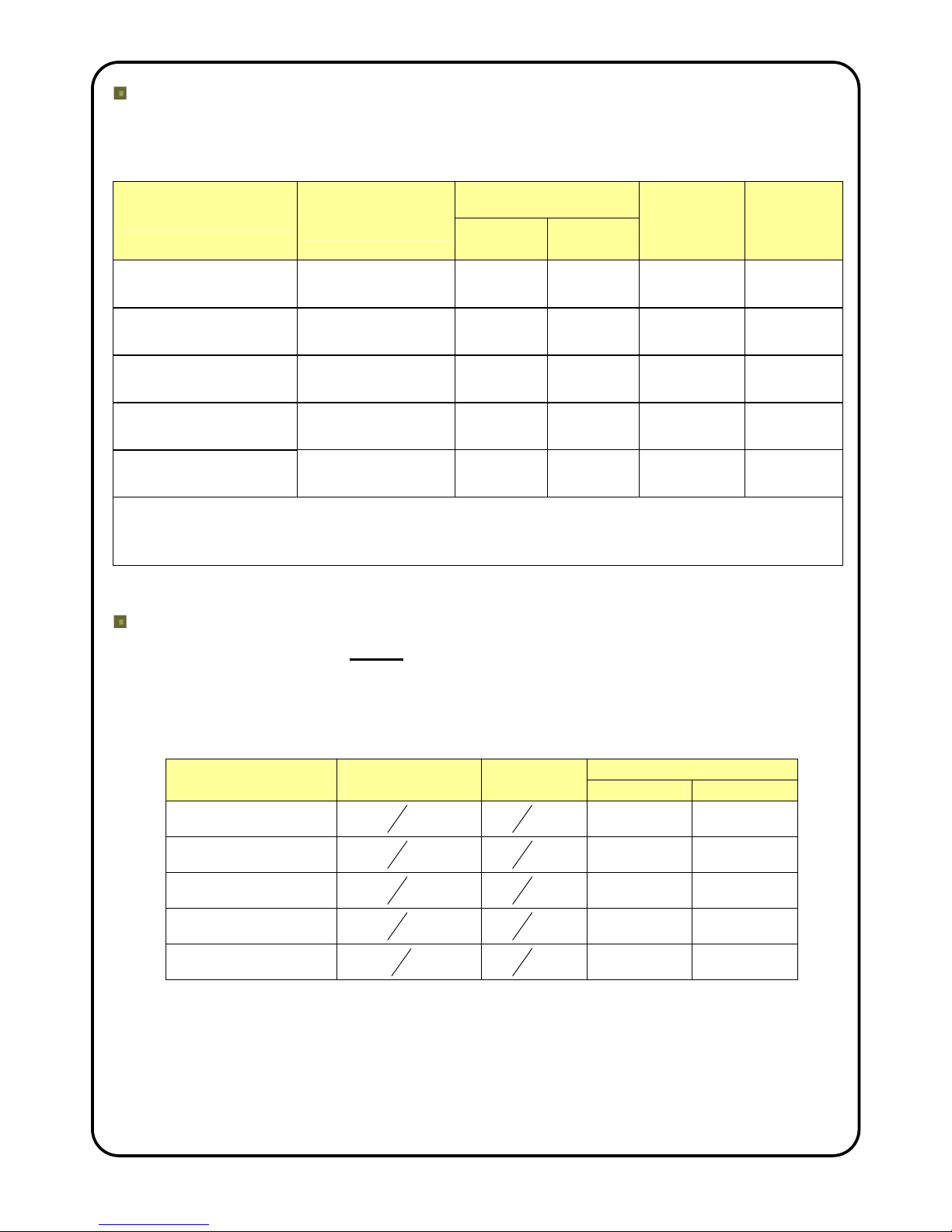

Mitsubishi Electric Outdoor Unit

The Mitsubishi Electric Outdoor Unit is selected to match its refrigerant heat output to

the size of the Air Curtain. See table below for size of outdoor unit to be used together

with performance data for the air curtain.

Heat Output (kW)

@outdoor air 7/6°C db/wb

Air Curtain

Mr Slim Outdoor

Unit

Full

Heat

Half

Heat

Max. Air

Volume

Flow Rate

(m3/h)

Max.

Noise

Level

dB(A) @3m

PHV1000 DXE HO PUHZ-RP71VHA 8.6 5.34 1400 56

PHV1500 DXE LO PUHZ-RP71VHA 10.1 5.6 2500 58

PHV1500 DXE HO

PUHZ-

RP140VKA/YKA

14.4 8.3 2600 58

PHV2000 DXE LO

PUHZ-

RP100VKA/YKA

14.1 7.9 3300 59

PHV2000 DXE HO PUHZ-RP200YKA 21.3 11.2 3130 59

Indoor Air Temperature = 20ºC

Performance figures derived from independent testing by UK test houses BRE and BSRIA in accordance with

test standard EN 14511.

The air curtain normally operates under automatic temperature control and can also run at part load.

Refrigerant Pipework

This must be carried out before connection of any electrical and controls cables

and in accordance with the Instructions that come with the Mitsubishi Electric

Outdoor Unit. This work must only be undertaken by a Mitsubishi Electric

approved Contractor.

Refrigerant installation pipework sizes are as follows :-

Maximum Pipe Run

Air Curtain

Discharge Line

(Gas)

Liquid

Line

Length Height

PHV1000 DXE HO

8

5

in.

8

3

in.

50m 30m

PHV1500 DXE LO

8

5

in.

8

3

in.

50m 30m

PHV1500 DXE HO

8

5

in.

8

3

in.

50m 30m

PHV2000 DXE LO

8

5

in.

8

3

in.

50m 30m

PHV2000 DXE HO

1

8

1

in.

8

3

in.

100m 30m

It is intended that refrigerant pipe connections to the air curtain are made using brazed

joints and these must be carried out in a professional and safe manner. If installation

pipe sizes for the discharge (gas) line and liquid line are different from the pipe

connection sizes on the air curtain, suitable pipe reducers must be used for the

connection. R410a refrigerant systems can operate at pressures up to 610 psi (c. 42

Bar). These brazed joints may well be located in a public area and a weakness leading

to an explosion could be extremely dangerous. The air curtain with its coil is

9901025-2 Page 7 of 21

manufactured in accordance with the Pressure Equipment Directive and the installation

must be carried out to a good standard of workmanship. Remove the protective plastic

film on top of the air curtain before starting work. Use a heat sink on the copper pipes

when brazing to reduce the transfer of heat to the inside of the air curtain where

sensitive components are located.

To gain access inside the Air Curtain

To gain access for connection of the electrical supply, controls

wiring and to work on the unit during commissioning, remove the

air inlet grilles and the bottom access panel.

First remove the plastic end caps if already fitted by pulling off to

the side (see picture).

Then remove each inlet grille in turn with its filter by unfastening

the M4 Pozi Head screw at the bottom corner of the grille. Use a

Pozi No.1 screwdriver to access the screw via the elongated

hole at each bottom corner of the grille (see adjacent picture).

To remove the bottom access panel unfasten the access panel

securing screws, one at each end and two in the centre

(PHV1500 and PHV2000 units) and slide the panel out forwards.

Please note: All the panels of the air curtain are covered in a

protective plastic film which should be removed.

Electrical Supply to the Air Curtain

This must be carried out AFTER the connection of the refrigerant pipework. All

electrical wiring and connections MUST be carried out by a competent qualified

electrician in accordance with the latest edition of the IEE wiring regulations

and/or local statutory regulations. (see also Wiring Diagram on Page 10)

• A local isolator having a contact separation of at least 3mm on all poles must be

fitted in the electrical supply to the air curtain and located in an accessible position

adjacent to the unit. 1 phase if defrost electric heaters are not required. 3 phase if

defrost electric heaters are required.

• The appliance must be connected using cables having an appropriate temperature

rating (heat resistant).

• Ensure that the supply cables, circuit breakers and other electrical installation

equipment are correctly sized for the air curtain being installed. See Table

overleaf.

• A 20mm size cable gland or conduit connector should be used for the Electrical

Supply into the air curtain.

• This appliance must be Earthed.

access panel

location

of screw

Loading...

Loading...