Mitsubishi PFD-P250VM-E, PFD-P500VM-E, PUHY-P250YHM-A(-BS), PUHY-P500YSHM-A(-BS), PQHY-P250YHM-A DATA BOOK

Page 1

CLOSE CONTROL SYSTEM

PFD-P250VM-E

PFD-P500VM-E

PUHY-P250YHM-A(-BS)

PUHY-P500YSHM-A(-BS)

PQHY-P250YHM-A

Page 2

CLOSE CONTROL SYSTEM

Energy Saving Technology

Low Running Cost

The inverter driven compressors can maximize the energy efficiency of PFD series,

leading to reduction of power consumption.

PFD series coefficient of performance (COP) are over 3.00 in cooling mode.

[Sensible heat factor (SHF) : 0.93]

Low Power Consumption

Plus, new PFD series adopt advanced R410A refrigeration and control technology to offer

lower power consumption.

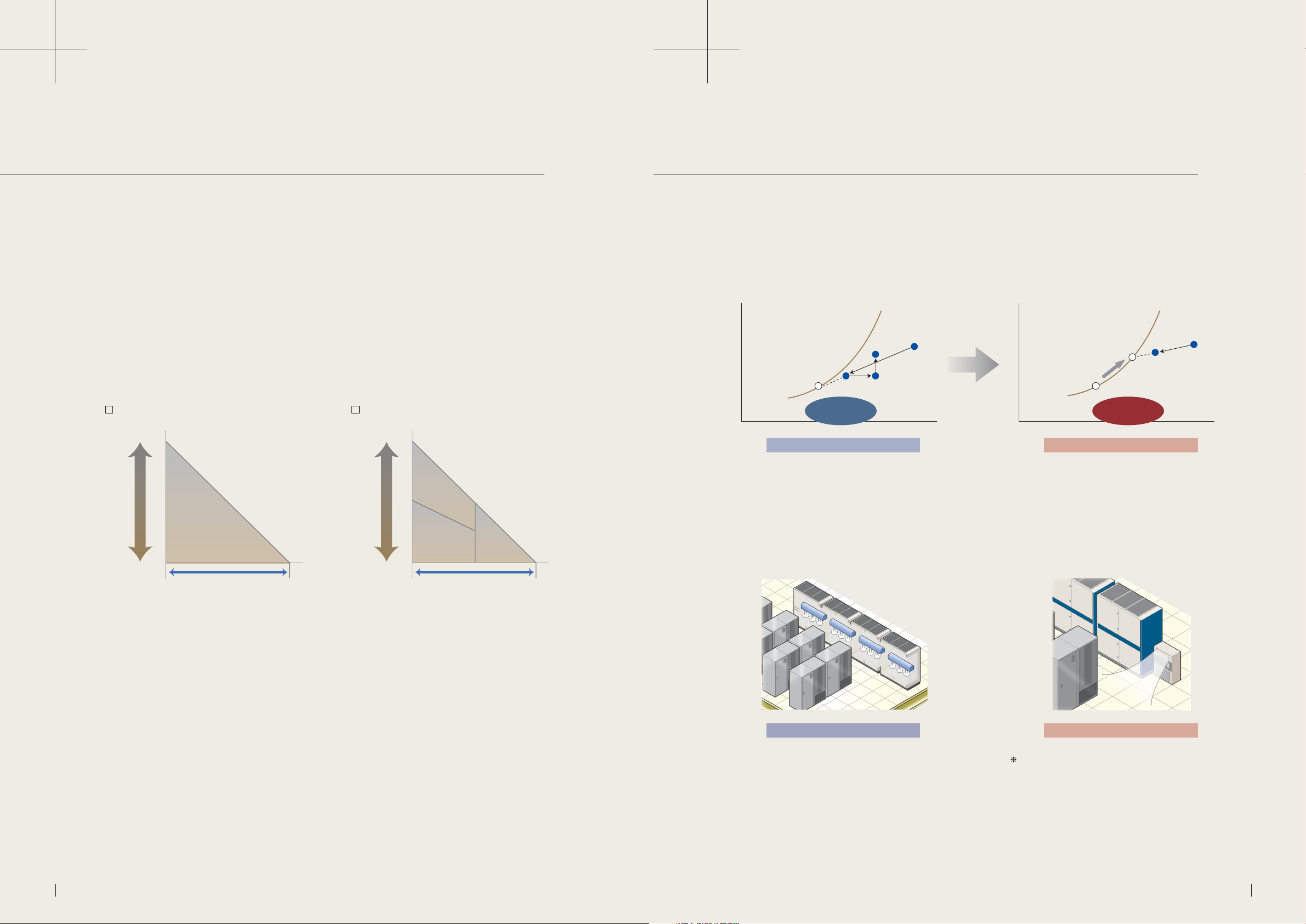

Inverter-driven capacity control

10HP Outdoor Unit

100%

20HP Outdoor Unit

100%

Energy Saving Technology

Minimum Humidifiers

PFD series work without a humidifier in most specifications. Due to the use of an optimized

inverter driven compressor, PFD series minimize the excessive dehumidification whereas other

systems need a separate humidifier for each indoor unit.

Saturation line

Cool down

Temperature (DB)

Absolute Humidity

Evaporation

Temperature

Common Close Control Air Conditioner

Reheating

Humidifier

needed!

Saturation line

Cool down

Humidification

Temperature (DB)

Increase evaporation

temperature by reducing

compressor speed.

Absolute Humidity

Evaporation

Temperature

No humidifier

needed!

PFD Series

Inverter Control

Compressor Capacity Control

34%

Large

PFD series operates highly efficiently with using

newly developed inverter compressor

Load

Small

No.2

Compressor

Inverter Control

No.1

Compressor Capacity Control

20%

Compressor

Inverter Control

Large

No.1

Compressor

Inverter Control

Load

Small

This system will also help to minimize maintenance costs by removing the need for a humidifier and

doing away with the need to install water pipes for individual units.

Common Close Control Air Conditioner

A humidifier can be incorporated inside of the units.

Consult our sales office in your area for more detailed

information.

PFD Series

PFD series will not have excessive dehumidification

3 4

Page 3

CLOSE CONTROL SYSTEM

MITSUBISHI ELECTRIC’s Close Control System (PFD series) is

specifically designed for computer rooms, laboratories etc,

where strict control of humidity and temperature is a must.

It possesses “High Reliability”, “Energy Saving Technology”, and

“Easy Installation / Maintenance”.

It can be connected to a computer network using our AG-150A

controller, in order to monitor from a distance and provide remote

email alarms.

High Reliability

Precise Room Temperature Control

(Cooling)

PFD series maintain a nearly constant

room temperature (within ±1.0

˚C) without

the typical temperature changes that

occur with conventional ON/OFF control

systems with inverter driven compressor.

Suction air temp

Time

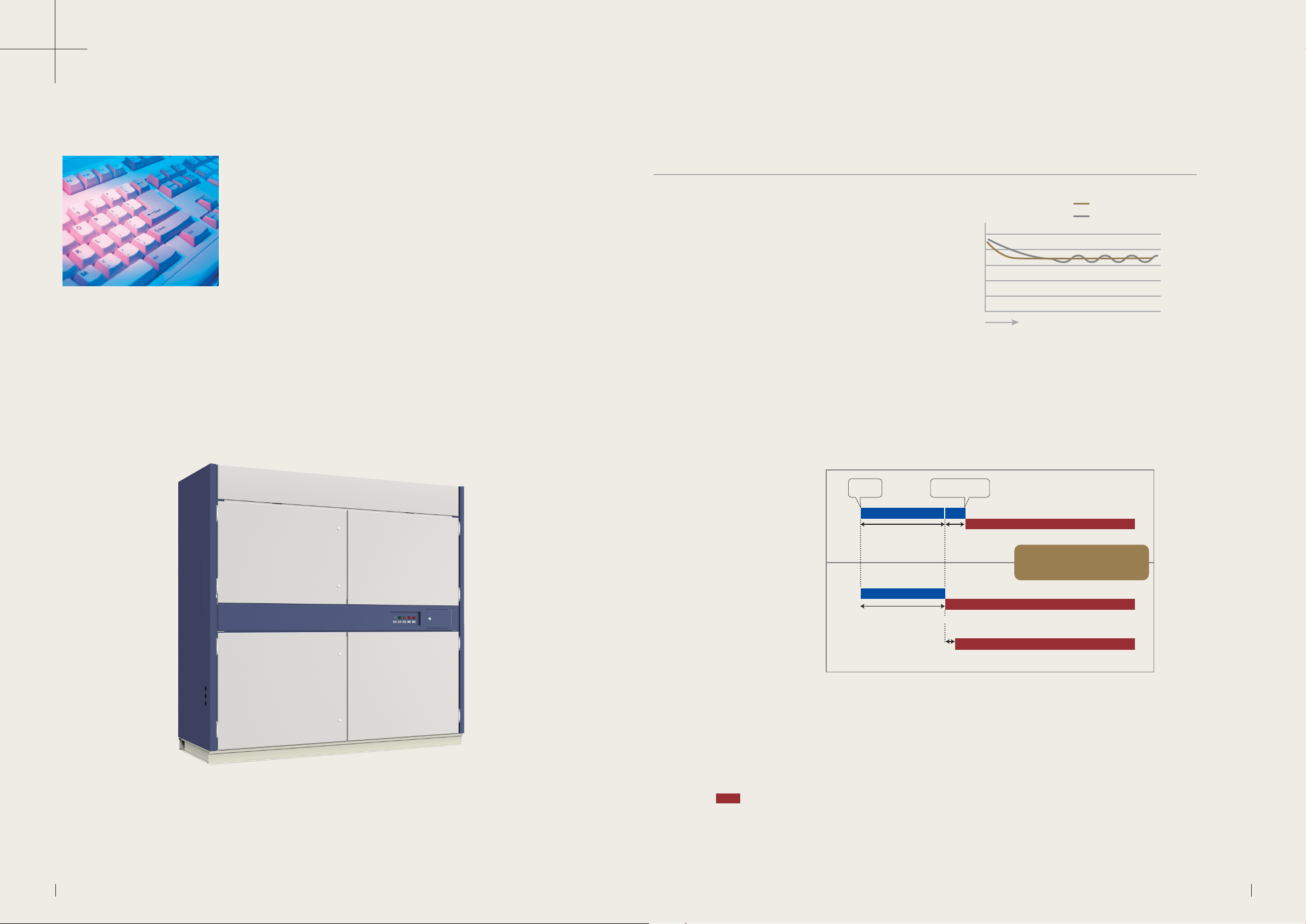

Quick Recovery from Power Failure

After an initial setting of outdoor unit is completed within 20 seconds of power recovery, thermo ON

signal will turn on and it will take 5 seconds for an outdoor unit fan and compressor operation to start.

PFD unit will restart within 20 seconds+(indoor unit address/2). To prevent the inrush current when

recovering from power failure, the indoor unit system will restart one by one.

(example)

PFD

ON / OFF controlled air condditioner

OUTDOOR

UNIT

INDOOR

UNIT

Power

recovery

Initial setting

Within 20 sec

Initial setting

Within 20 sec + (indoor unit address /2)

Thermo ON =

Compressor ON

5 sec

1 sec.

Indoor units start one by one every sec.

Compressor in operation

Ex. In case of indoor unit address 1

Oudoor unit recovery in 25 sec

Indoor unit recovery in 20.5 sec

Indoor unit in operation

Indoor unit in operation

Protection of Confidential Information

As a compressor has been incorporated into the outdoor unit, the compressor can be serviced without

entering a computer room. Our close control system can protect confidential information.

NEW

PFD System Rotation

One unit in a system will alternatively be in stand-by position as a back-up unit in case of malfunction.

PFD series provide you with highly reliable computer room cooling system

1

2

Page 4

CLOSE CONTROL SYSTEM

Energy Saving Technology

Low Running Cost

The inverter driven compressors can maximize the energy efficiency of PFD series,

leading to reduction of power consumption.

PFD series coefficient of performance (COP) are over 3.00 in cooling mode.

[Sensible heat factor (SHF) : 0.93]

Low Power Consumption

Plus, new PFD series adopt advanced R410A refrigeration and control technology to offer

lower power consumption.

Inverter-driven capacity control

10HP Outdoor Unit

100%

20HP Outdoor Unit

100%

Energy Saving Technology

Minimum Humidifiers

PFD series work without a humidifier in most specifications. Due to the use of an optimized

inverter driven compressor, PFD series minimize the excessive dehumidification whereas other

systems need a separate humidifier for each indoor unit.

Saturation line

Cool down

Temperature (DB)

Absolute Humidity

Evaporation

Temperature

Common Close Control Air Conditioner

Reheating

Humidifier

needed!

Saturation line

Cool down

Humidification

Temperature (DB)

Increase evaporation

temperature by reducing

compressor speed.

Absolute Humidity

Evaporation

Temperature

No humidifier

needed!

PFD Series

Inverter Control

Compressor Capacity Control

34%

Large

PFD series operates highly efficiently with using

newly developed inverter compressor

Load

Small

No.2

Compressor

Inverter Control

No.1

Compressor Capacity Control

20%

Compressor

Inverter Control

Large

No.1

Compressor

Inverter Control

Load

Small

This system will also help to minimize maintenance costs by removing the need for a humidifier and

doing away with the need to install water pipes for individual units.

Common Close Control Air Conditioner

A humidifier can be incorporated inside of the units.

Consult our sales office in your area for more detailed

information.

PFD Series

PFD series will not have excessive dehumidification

3 4

Page 5

Easy Installation/Maintenance Unit Combination

Small Installation Space

PFD series are specifically designed to minimize the size of the indoor units and save on

valuable computer room space.

Service Space (Indoor)

PFD-P250VM-E

200mm

Indoor unit

1. To open the gate fold maintenance pannel fully, space of 1000mm or more required.

500mm

600mm or more

PFD-P500VM-E

500mm200mm

Indoor unit

600mm or more 1

Piping length

With long pipe-runs of up to 165m, top-bottom differentials of 50m (40m if the outdoor unit is

installed below indoor unit, 15m if the outdoor temperature is under 10˚C), flexible design is

available with both air and water cooled outdoor unit.

PFD + Air cooled outdoor unit

When connecting PFD-P500VM-E and P500 outdoor unit, either 1 or 2 refrigerant circuit connection

is available depending on system size and usage. With 2 refrigerant circuit connection, one circuit can back

up the other.

If installation and large number of units are to be installed, single refrigerant circuit can be selected.

PFD-P250VM-E PUHY-P250YHM-A

PFD-P500VM-E

At factory shipment, this model of indoor unit is

designed and set to accommodate a single

refrigerant circuit.

Connection of two refrigerant circuits to the indoor

unit requires setting change and pipe work.

PUHY-P250YHM-A x 2

PFD-P500VM-E

PUHY-P500YSHM-A

PFD + Water cooled outdoor unit

When connecting PFD-P500VM-E unit and water cooled outdoor unit, only 2 refrigerant circuit connection is

available and single refrigerant connection is not available.

PQHY-P250YHM-A x 2

Top-bottom differential

50m

Outdoor unit

Furthest piping length

165m

Top-bottom differential

50m

Heat source unitHeat source unit

Furthest piping length

165m

PFD-P250VM-E PQHY-P250YHM-A

PFD-P500VM-E

Single refrigerant circuit connection is not available

with water-cooled unit.

Operation Zone

Indoor unit

Same length with two refrigerant circuit connection

Indoor unit

100

80

60

40

20

Relative humidity (%)

21.5

15 20

Indoor Temperature: ˚C (DB)

3025 35 40

Indoor Temperature:

12~24˚C (WB)

Outdoor Temperature:

-15~43˚C (DB)

PFD series will be able to satisfy various installation conditions

5 6

Page 6

OUTDOOR UNIT

AIR COOLED OUTDOOR UNIT WATER COOLED HEAT SOURCE UNIT

Outdoor Unit

High-capacity reluctance DC motor driven compressor

Motor efficiency greatly improved

+

Reduced suction refrigerant heating loss

First in Industry

Japan Machinery Federation

Executive Award-winning

Low Noise in All Directions

Daytime

Low

Low

Noise

Noise

Low

Low

Noise

Noise

57dB

Night mode can reduce sound level by sensing ambient temperature condition.

(This function is available in setting at site.)

Nighttime

44dB

(10HP)

Heat source Unit

Cold climate capability

Because the system is water

cooled, the outdoor air temperature

does not affect capacity.

Futhermore, water cooling means

no defrost operation is required,

so rapid starting assures quick and

continuous cooling in the hottest

conditions.

Heat recovery

When used in combination with the

City Multi WR2 series, Heat recovery

between Heat Source Units is possible.

Example of water cooled system diagram

Total cooling

capacity (%)

100

95

90

15 20 25 30 35

PFD

Indoor

unit

Heat source unit

exchanger

Expansion tank

Pump

Heat

Thermal

storage tank

Auxiliary heat

source

Pump

Lossnay

Cooling tower

Heating Heating Heating Cooling

Indoor

Indoor

unit

Indoor

unit

BC controller

unit

* The water circuit

is closed.

Heat recovery

Heat taken

from water

Heat recovery

Heat radiated

to water

GL

* The water circuit

is closed.

Water cooled

General air

cooled air

conditioning

system

Outdoor air

temperature

˚CDB)

(

* Example only.

PFD series are made in Japan under a stringent

quality control system of Mitsubishi Electric.

7 8

Water cooled PFD series offers reliability and

energy-saving that computer rooms require.

Page 7

Remote Controller

Embedded MA remote controller and display lamps on the PFD unit enables easy control

and operation.

A

PFD-P500VM-E

B

CDE

Operating

Power

Check

*With PFD-P250VM-E, there is

only one failure display.

Local

Normal

F

No.1

No.2

Failure

Failure

A

Power display lamp

B

Operation display lamp

C

Check display lamp

D

Normal / Local switch

E

No.1 Failure display lamp

F

TEST RUN

TEMP.

ON/OFF

FILTER

CHECKTEST

TIMER SET

PAR-20MAA

No.2 Failure display lamp

* When Local operation is available

at maintenance, please set

“Normal / Local” switch to “Local”.

Then “Check” lamp will be lit.

Centralized Controller

New Design New Functions

Backlight Color liquid crystal display

Backlight makes it easy to see and control units.

One can identify whether a unit is ON or OFF from a

distance.

Control in the night with no lights is possible.

New Functions

Controllable units/groups

Controls up to 50 units/groups (including indoor units,

LOSSNAY, DIDO/AI/PI controller)

Up to 150 units can be controlled via expansion

controller;PAC-YG50ECA (AG-150A software needs to be

upgraded)

Touch panel

9 inch wide, high-resolution

Touch panel enables operation of units by touching with

index finger.

When object unit is touched, orange box appears around

the unit icon indicating the unit selected.

USB memory compatible

All measurement/initial setting CSV data extractable with

USB memory.

Can save and overwrite setting data.

Monitoring functions

Temperature/Humidity (using AI controller with WEB

browser) *

General equipment such as lights on LCD (using DIDO

controller)

Interlock function from AI controller, DIDO controller to

indoor units and between DIDO units are available.

AG-150A interlock with DIDO controller or free contact on

an indoor unit available.

1

Energy saving functions

Seasonal scheduling and automatic switch over *

Yearly scheduling on LCD *

*1 License required.

*Ver. 2.30 or later

1

1

With a new colored touch panel, and continuation of all the conventional G-50A functions,

AG-150A visualizes its functions from basic control to advanced operations and bringing an

ultimate controller to reality.

Expansion Controller PAC-YG50ECA

Dimensions: 250(W) x 217(H) x 97.2(D) mm

: 9-7/8(W) x 8-9/16(H) x 3-7/8(D) in.

Centralized controller AG-150A

With a connection of a Expansion Controller,

maximum of 150 units/groups can be connected

to AG-150A.

Option : Black surface cover

PAC-YG71CBL

System structure

Central Control PC

(TG-2000A)

*Ver. 6.10 or later

Remote

Monitoring PC

Remote monitoring

via a Web browser

A

M-NET

PUHY-P250YHM-A

PUHY-P500YHM-A

M-NET

Internet

Switching Hub

LAN

(100BASE-TX)

AG -

15 0

Power supply unit

(PAC-SC51KUA)

Hub

Hub

AG-150A / GB-50A

VPN

Modem

Router

Note : Use a security device such as a VPN router when connecting the

AG-150A/GB-50A to the Internet to prevent unauthorized access.

M-NET

Modem

Mobile phone

of service person

PFD-P250VM-E

PFD-P500VM-E

Service company

/Sales office

VPN

Router

Remote

monitoring PC

Remote monitoring

via a Web browser

9 10

Page 8

Indoor Unit

Indoor Unit

PFD-P250VM-E (down flow

)

Specification

Model name PFD-P250VM-E

Cooling

Capacity

Sensible Heat Capacity

Power source

Power input

Current

Fan Type X Quantity

Airflow rate

Motor output

Refrigerant

External finish

External dimension

Protection device Fan

Refrigerant piping diameter Liquid / Gas

Sound pressure level

Net weight

Operating temperature range Indoor

(Outdoor)

(Water)

Note: 1. Cooling / Heating capacity indicates the maximum value at operation under the following condition.

<Cooling>

<Heating>

Pipe length : 7.5m Height difference: 0m

2. The sound pressure level is measured in an anechoic room.

3. Heating can be used only by the indoor warming-up.

4. Works not included : Installlation / foundation work, electric connection work, duct work, insulation work,

The power source switch and other items are not specified in the specifications.

5. It is necessary to change pulley and v-belt when using it by the power supply frequency 60Hz.

Indoor : 27˚C (80.6˚F) DB / 19˚C (66˚F) WB Outdoor : 35˚C (95˚F) DB (Air cooled) / Water temperature 30˚C (86˚F) (Water cooled)

Indoor : 20˚C (68˚F) DB Outdoor : 7˚C (45˚F) DB / 6˚C (43˚F) WB (Air cooled)/ Water temperature 20˚C (68˚F) (Water cooled)

kW

BTU/h

kW

BTU/h

kW

A

3

/min

m

kW

mm

dB (A)

kg

12

(-15 ~ 43˚C

(10 ~

28.0

95,500

26.0

88,700

3N~380 / 400 / 415V (50Hz) , 400 / 415V (60Hz)

5.3 / 5.0 / 4.9

Sirocco fan x 1

R410A

Galvanized steel plate (with polyester coating)

<MUNSEL 2.9GY 8.6 / 0.3 (White) or similar>

<MUNSEL 7.2PB 3.2 / 5.3 (Blue) or similar>

1950(H) x 1380(W) x 780(D)

Thermal switch

ø 9.52 Brazed / ø 22.2 Brazed

~ 24˚C (54 ~ 75˚F) W.B.

(5 ~ 109˚F) D.B.

45˚C

(50 ~ 113˚F)

)

)

Heating

31.5

107,500

2.5

160

2.2

59

380

15 ~ 28˚C (59 ~ 82˚F) D.B.

(-15 ~ 15.5˚C

(10 ~

(5 ~ 60˚F) W.B.

45˚C

(50 ~ 113˚F)

PFD-P500VM-E (down flow

)

Specification

Model name PFD-P500VM-E

(10 ~

Heating

63.0

215,000

(5 ~ 60˚F) W.B.

45˚C

(50 ~ 113˚F)

)

)

Cooling

Capacity

Sensible Heat Capacity

Power source

Power input

Current

Fan Type X Quantity

Airflow rate

Motor output

Refrigerant

External finish

External dimension

Protection device Fan

Refrigerant piping diameter Liquid / Gas

Sound pressure level

Net weight

)

)

Operating temperature range Indoor

(Outdoor)

(Water)

Note: 1. Cooling / Heating capacity indicates the maximum value at operation under the following condition.

<Cooling>

<Heating>

Pipe length : 7.5m Height difference: 0m

2. The sound pressure level is measured in an anechoic room.

3. Heating can be used only by the indoor warming-up.

4. Works not included : Installlation / foundation work, electric connection work, duct work, insulation work,

The power source switch and other items are not specified in the specifications.

5. It is necessary to change pulley and v-belt when using it by the power supply frequency 60Hz.

Indoor : 27˚C (80.6˚F) DB / 19˚C (66˚F) WB Outdoor : 35˚C (95˚F) DB (Air cooled) / Water temperature 30˚C (86˚F) (Water cooled)

Indoor : 20˚C (68˚F) DB Outdoor : 7˚C (45˚F) DB / 6˚C (43˚F) WB (Air cooled)/ Water temperature 20˚C (68˚F) (Water cooled)

kW

BTU/h

kW

BTU/h

kW

A

3

/min

m

kW

mm

dB (A)

kg

Single refrigerant circuit : ø 15.88 Brazed / ø 28.58 Brazed

Two refrigerant circuits : ø 9.52 x 2 Brazed / ø 22.2 x 2 Brazed

12

(-15 ~ 43˚C

(10 ~

56.0

191,100

52.0

177,400

3N~380 / 400 / 415V (50Hz) , 400 / 415V (60Hz)

5.0

9.5 / 9.0 / 8.7

Sirocco fan x 2

320

4.4

R410A

Galvanized steel plate (with polyester coating)

<MUNSEL 2.9GY 8.6 / 0.3 (White) or similar>

<MUNSEL 7.2PB 3.2 / 5.3 (Blue) or similar>

1950(H) x 1980(W) x 780(D)

Thermal switch

63

520

~ 24˚C (54 ~ 75˚F) W.B.

(5 ~ 109˚F) D.B.

45˚C

(50 ~ 113˚F)

15 ~ 28˚C (59 ~ 82˚F) D.B.

)

(-15 ~ 15.5˚C

)

External Dimensions

Air inlet

1950

Air outlet

1380

11 12

780

External Dimensions

Air inlet

Air outlet

1980

1950

780

Page 9

Outdoor Unit

Heat Source Unit

PUHY-P250, P500Y(S)HM-A (-BS)

(connected with PFD series.)

Specification

Model name PUHY-P250YHM-A (-BS) PUHY-P500YSHM-A (-BS)

Cooling

Capacity

kW

BTU/h

28.0

95,500

Power source

Power input

Current

Fan Type X Quantity

Airflow rate

Motor output

kW

A

m3/min

kW

6.8

11.4 / 10.9 / 10.5

Propeller fan x 1

0.46 x 1

Refrigerant

External finish

External dimension Height(H) x Width(W) x Depth(D)

Protection device

High pressure protection

mm

Inverter circuit (COMP. / FAN)

Compressor

Pre-coated galvanized steel sheets (+ powder coating for-BS type)

1710 (without legs 1650) x 920 x 760

High pres. Sensor & High pres. Switch at 4.15 MPa (601psi)

Over-heat protection, Over-current protection

Fan motor

Refrigerant piping diamete

Sound pressure level

Net weight

Operating temperature range

Liquid / Gas

Outdoor

(Indoor)

ø 9.52 Brazed (ø 12.7, total length>=90m) / ø 22.2 Brazed

dB (A)

kg

-15 ~ 43˚C (5 ~ 109˚F) D.B.

(12 ~24˚C (54 ~ 75˚F) W.B.)

Note: 1. Cooling / Heating capacity indicates the maximum value at operation under the following condition.

<Cooling> Indoor : 27

<Heating> Indoor : 20

˚C (80.6˚F) DB / 19˚C (66˚F) WB Outdoor : 35˚C (95˚F) DB

˚C (68˚F) DB Outdoor : 7˚C (45˚F) DB / 6˚C (43˚F) WB

Pipe length : 7.5m Height difference: 0m

2. The sound pressure level is measured in an anechoic room.

3. Heating can be used only by the indoor warming-up.

4. Works not included : Installlation / foundation work, electric connection work, duct work, insulation work,

The power source switch and other items are not specified in the specifications.

External Dimensions

PUHY-P250YHM-A PUHY-P500YHM-A

Heating

31.5

107,500

3N~380 / 400 / 415V (50Hz / 60Hz)

6.6

11.1 / 10.5 / 10.2

22.8 / 21.8 / 21.0

185

R410A

<MUNSEL 5Y8 / 1 or similar>

1710 (without legs 1650) x 920 x 760

Over-heat protection

Thermal switch

ø 15.88 Brazed / ø 28.58 Brazed

57

200

-15 ~15.5˚C (5 ~ 60˚F) W.B.

(15 ~ 28˚C (59 ~ 82˚F) D.B.)

-15 ~ 43˚C (5 ~ 109˚F) D.B.

(12 ~24˚C (54 ~ 75˚F) W.B.)

Cooling

56.0

191,100

13.6

22.2 / 21.0 / 20.4

Propeller fan x 2

185 x 2

0.46 x 2

60

200 x 2

-15 ~15.5˚C (5 ~ 60˚F) W.B.

(15 ~ 28˚C (59 ~ 82˚F) D.B.)

Heating

63.0

215,000

13.2

PQHY-P250YHM-A

(connected with PFD series.)

Specification

Model name PQHY-P250YHM-A

Cooling

Capacity

kW

BTU/h

Power source

Power input

Current

kW

A

Compressor Type

Motor output

kW

Heat exchanger Type

Water volume in the plate

3

Circulating water Volume

/h

m

cfm

Pressure drop

kPa

Refrigerant

External finish

External dimension

Height(H) x Width(W) x Depth(D)

Protection device High pressure protection

mm

High pressure sensor, High pressure switch 4.15 MPa (601psi)

Compressor

Inverter

Refrigerant piping diameter Liquid / Gas

Sound pressure level

Net weight

dB (A)

kg

ø 9.52 Brazed (ø 12.7, total length >=90m) / ø 22.2 Brazed

Operating temperature range Water

(Indoor)

(12 ~24˚C (54 ~ 75˚F) W.B.)

Note: 1. Cooling / Heating capacity indicates the maximum value at operation under the following condition.

<Cooling> Indoor : 27˚C (80.6˚F) DB / 19˚C (66˚F) WB Water temperature : 30˚C (86˚F)

<Heating> Indoor : 20˚C (68˚F) DB Water temperature : 20˚C (68˚F)

Pipe length : 7.5m Level difference : 0m

2.The ambient temperature of the heat source unit needs to be kept below 40˚C (104˚F) DB.

3.The ambient relative humidity of the heat source unit needs to be kept below 80%.

4.The heat source Unit should not be installed at outdoor.

5.Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

6.Be sure to provide interlocking for the unit operation and water circuit.

7. It is measured in anechoic room.

External Dimensions

28.0

95,500

3N~380 / 400 / 415V (50Hz / 60Hz)

5.45

9.2 / 8.7 / 8.4

Inverter scroll hermetic compressor

6.3

plate

5.0

5.76

3.4

17

R410A

Acrylic painted steel plate

1160 (1100 without legs) x 880 x 550

Over-heat protection

Over-heat protection, Over-current protection

49

195

10 ~ 45˚C (50 ~ 113˚F)

Heating

31.5

107,500

5.51

9.3 / 8.8 / 8.5

10 ~45˚C (50 ~ 113˚F)

(15 ~ 28˚C (59 ~ 82˚F) D.B.)

Intake

air

Discharge air

760

Left side view

920

Top view

Intake

air

Front view

80 760 80

(Mounting pitch)

Bottom view

760

Intake

air

760

724(721 727)

(Mounting pitch)

240

1410

1650

1710

Intake

air

Discharge air

Left view

1710

1650

Intake

air

920760

Outdoor unit 1

30

920

Outdoor unit 2

Intake

air

880

Front view Right side view Rear view

(880)

550

1160

550

(550)

13 14

Page 10

Loading...

Loading...