Page 1

AIR CONDITIONING SYSTEMS

Model

PFAV-P-VM-E(-F)

PUHY-P-Y(S)HM-A

DATA BOOK

Page 2

%!. System Design

1. Outdoor Installation······································59

(1) Requirement on installation site

(2) Spacing

(3) Piping direction

(4) Weather countermeasure

2. Indoor Installation·········································68

(1) Requirement on installation site

(2) Spacing

(3) Installing the Indoor Unit

(4) Separating the indoor unit to allow for easy

transportation

(5) Internal diagram

%!!. Piping design

1. R410A Piping material ··································80

2. Piping Design ················································81

%!!!. Wiring Design

1. External wiring diagram ·······························84

(1) Power supply examples

2. Electrical work···············································86

(1) Power cable specifications

3. M-NET control ···············································87

(1) Types and maximum allowable length

of cables

(2) Switch settings and address settings

4. An Example of a System to which an MA

Remote Controller is connected··················89

5. System control ··············································92

(1) System control for the indoor units

(2) System control for the outdoor units

6. Caution for refrigerant leakage····················98

!. General Cautions

1. Indoor Unit Line-up·········································1

2. Temperature range ·········································2

3. Notes on selecting equipments·····················3

(1) Notes on using the Fresh Air Intake type units

!!. Indoor Unit

1. Specifications··················································5

(1) Standard type

(2) Fresh air intake type

2. External dimensions·······································7

(1) Standard type

(2) Fresh air intake type

3. Center of gravity ···········································13

4. Electrical wiring diagram ·····························14

5. Sound Pressure Levels ································18

6. Vibration levels ·············································21

7. Fan characteristic curves·····························22

8. Optional parts················································41

!!!. Outdoor Unit

1. Specifications················································42

2. External dimensions·····································43

3. Center of gravity ···········································47

4. Electrical wiring diagram ·····························48

5. Sound Pressure Levels ································49

6. Optional parts················································51

(1) Outdoor twinning kit

!%. Capacity Tables

(1) Correction by temperature························52

(2) Correction at frosting and defrosting··········54

(3) Correction by refrigerant piping length

(cooling) (heating) ·····································54

(4) Correction by indoor unit airflow rate

(cooling) (heating) ·····································55

(5) Input correction by capacity·······················56

(6) Bypass factor·············································57

%. Controller

1. Local remote controller ································58

(1) MA Remote controller

Contents

Page 3

1

!. General Cautions

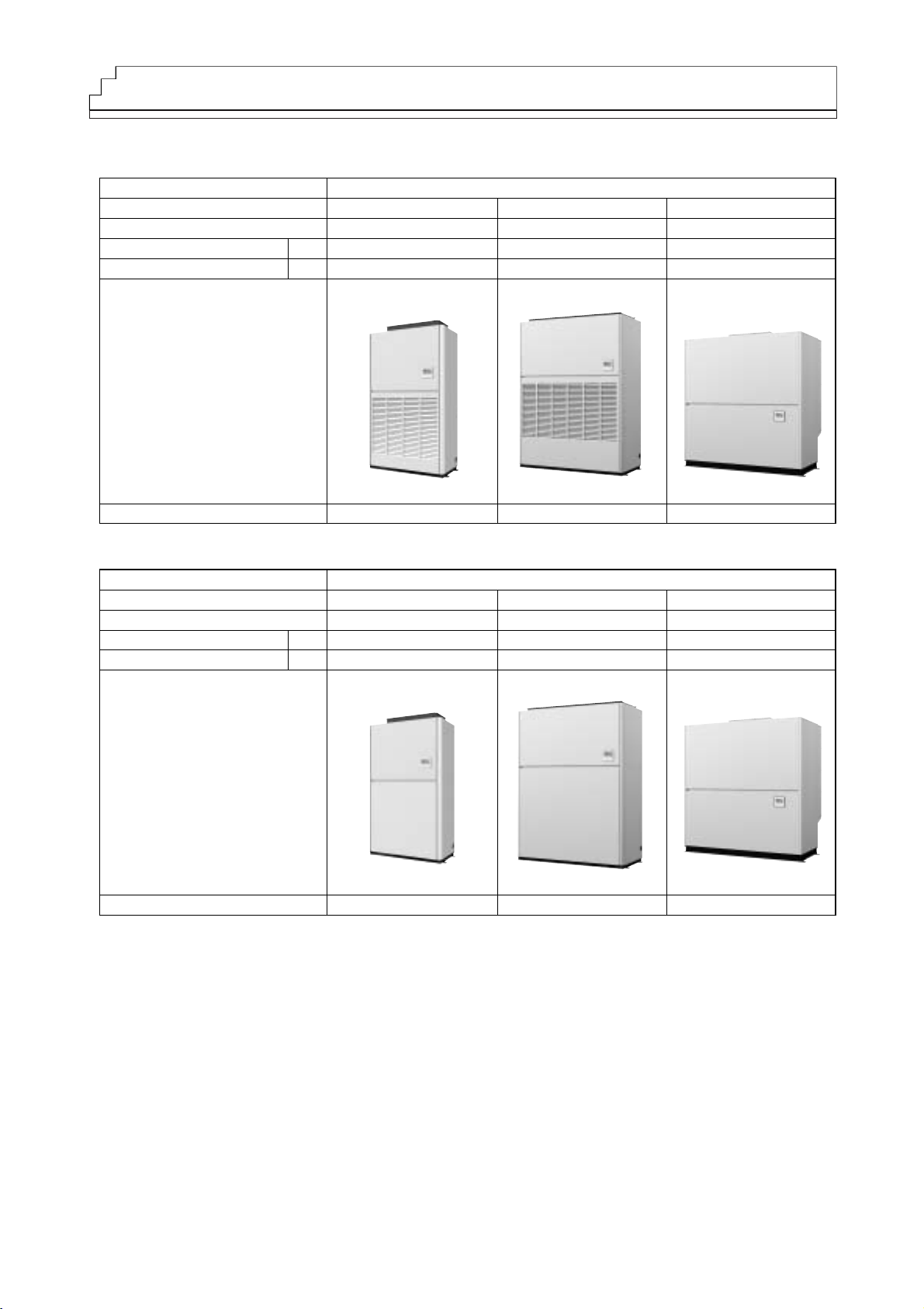

1. Indoor Unit Line-up

Model type Fresh air intake type

Model size P300 P900

Nominal HP 10HP 30HP

Nominal cooling cap. *1 kW 28.0 80.0

Nominal heating cap. *2 kW 26.5 71.0

Floor standing

PFAV-P-VM-E-F

Connectable outdoor unit type PUHY-P250YHM-A PUHY-P750YSHM-A

*Nominal conditions *1,*2 are referable at the Specification sheet.

P600

20HP

56.0

50.0

PUHY-P500YSHM-A

Model type Standard type

Model size P250 P750

Nominal HP 10HP 30HP

Nominal cooling cap. *1 kW 25.0 71.0

Nominal heating cap. *2 kW 28.0 80.0

Floor standing

PFAV-P-VM-E

Connectable outdoor unit type PUHY-P250YHM-A PUHY-P750YSHM-A

*Nominal conditions *1,*2 are referable at the Specification sheet.

P500

20HP

50.0

56.0

PUHY-P500YSHM-A

Page 4

2

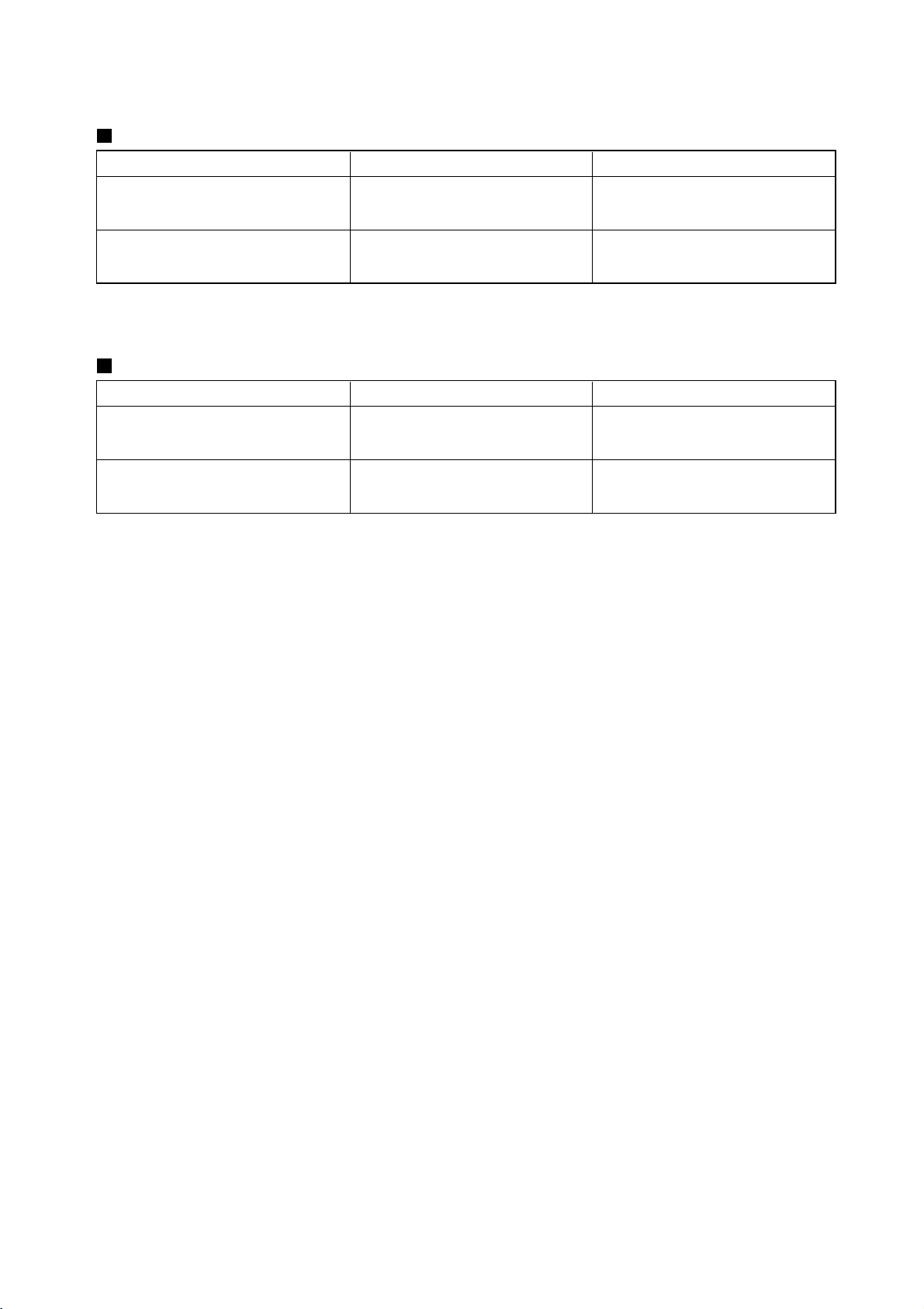

2. Temperature range

Cooling Heating

Indoor temperature

Wet-bulb temperature

10~25˚C [50~77˚F] (Note 1)

Dry-bulb temperature

15~28˚C [59~82˚F]

Outdoor temperature

Dry-bulb temperature

-5~43˚C [23~109˚F]

Wet-bulb temperature

-20~15.5˚C [-4~60˚F]

Standard type

Note 1. If units are operated for a long time at the dew point temperature of 23˚C [73˚F] or more, condensate may collect and drip from the indoor

units. If the units are operated under such conditions, cover the entire surface of all indoor units with insulating materials with a thickness of

between 0 and 20 mm [13/16 in.] to prevent condensate from collecting.

Cooling Heating (Note 2)

Indoor temperature

Wet-bulb temperature

15~35˚C [50~95˚F]

Dry-bulb temperature

0~20˚C [32~68˚F]

Outdoor temperature

Dry-bulb temperature

20~43˚C [68~109˚F]

Wet-bulb temperature

-4~15.5˚C [24~60˚F]

Fresh air intake type

Note 2. If the indoor intake air is pretreated to 0˚C in the primary treatment, the unit can be operated in the outdoor intake air temperature range of

between -20 and 15.5

˚CWB [-4 and 60˚FWB].

Page 5

3

(1) Notes on using the Fresh Air Intake type units

1Fresh air intake type indoor units supply pretreated outside air into the room. This type of units are not designed to

handle internal thermal load. Use other types of air conditioning units (e.g., CITY MULTI system) that are capable

of handling internal thermal load in combination with the Fresh Air Intake type units.

2The control mode is selectable between room temperature control and supply air temperature control. The default

mode is room temperature control. Install the supplied thermistor in a location that allows the sensor to measure

the representative room temperature.

·Fresh air intake type units are intended to be used in an environment at a temperature of 0˚CDB

[32

˚FDB] or above. If the units are operated in the fan mode at the temperature below 0˚C[32˚F],

condensation may form on the panel under certain conditions. Use caution so that the

condensation will not drip on appliances around the unit.

·The unit may be forced to operate in the heating mode to prevent cold draft when the return air

temperature (outside air temperature sensor reading) reaches 5

˚C[41˚F] or below. The fan will

stop during the defrost cycle and when there is a problem with the entire refrigerant systems.

The fan can be set to operate in the conditions above by making certain switch settings if a

sudden supply of cold air into the room during the heating season will not be a problem.

·Note that untreated outside air may be delivered directly into the room upon Thermo-OFF. Use

extra caution when the outside temperature is low. Direct exposure to outdoor air may have an

adverse effect on health or cause food spoilage.

·Fresh air intake type units are not equipped with a dehumidifying function. Take appropriate

measures to keep condensation from forming on the supply air grill and other parts that are

subject to condensation. Line the supply and return air ducts with insulation to prevent

condensation.

Common items

Room

temperature

control

(factory setting)

·Install the thermistor that is supplied with the indoor unit. Check that Switch 7-2 is set to OFF.

·Install the thermistor in a location that allows the sensor to measure the representative room

temperature.

·The unit will go into the forced Thermo-OFF mode when the return air dry bulb temperature

(outside air temperature sensor reading) is 21

˚C[70˚F] or below during cooling OR 20˚C[68˚F] or

above during heating.

·The settable temperature range on the remote controller is as follows: Cooling 19 - 30˚C[66 -

86

˚F]; Heating 17-28˚C[63 - 82˚F].

·Indoor temperature and humidity can fluctuate greatly depending on the outside air load.

Supply air

temperature

control

·Connect the connector of the supply air temperature sensor that is built in on the indoor unit to

the control board. Turn Switch 7-2 to ON.

·The unit will go into the forced Thermo-OFF mode and operate in the Fan mode when the return

air dry bulb temperature (outside air temperature sensor reading) is 14

˚C[57˚F] or below during

cooling OR 28

˚C[82˚F] or above during heating.

·Supply air temperature may fluctuate, depending on the temperature/humidity of the outside air

or on other operating conditions. Units may go in and out of the Thermo-ON/OFF mode when

the following conditions are met: The difference between the outside temperature and the preset

temperature is less than approximately 6

˚C[43˚F] due to excess capacity. They may change

depending on the air flow rate and preset temperature.

·Supply air temperature normally appears on the remote controller. When the unit operation is

not stable, this temperature may blink on the display and can be mistakenly interpreted as an

error. If this is a problem, change the setting to suppress the temperature display. Refer to the

section "How to use the remote controller" in the Instructions Manual for how to make the setting.

·The settable temperature range on the remote controller is as follows: Cooling 14 - 30˚C[57 -

86

˚F]; Heating 17-28˚C[63 - 82˚F].

·Depending on the air conditioning load, outside temperature, and due to the activation of

protection functions, the desired preset temperature may not always be achieved.

3

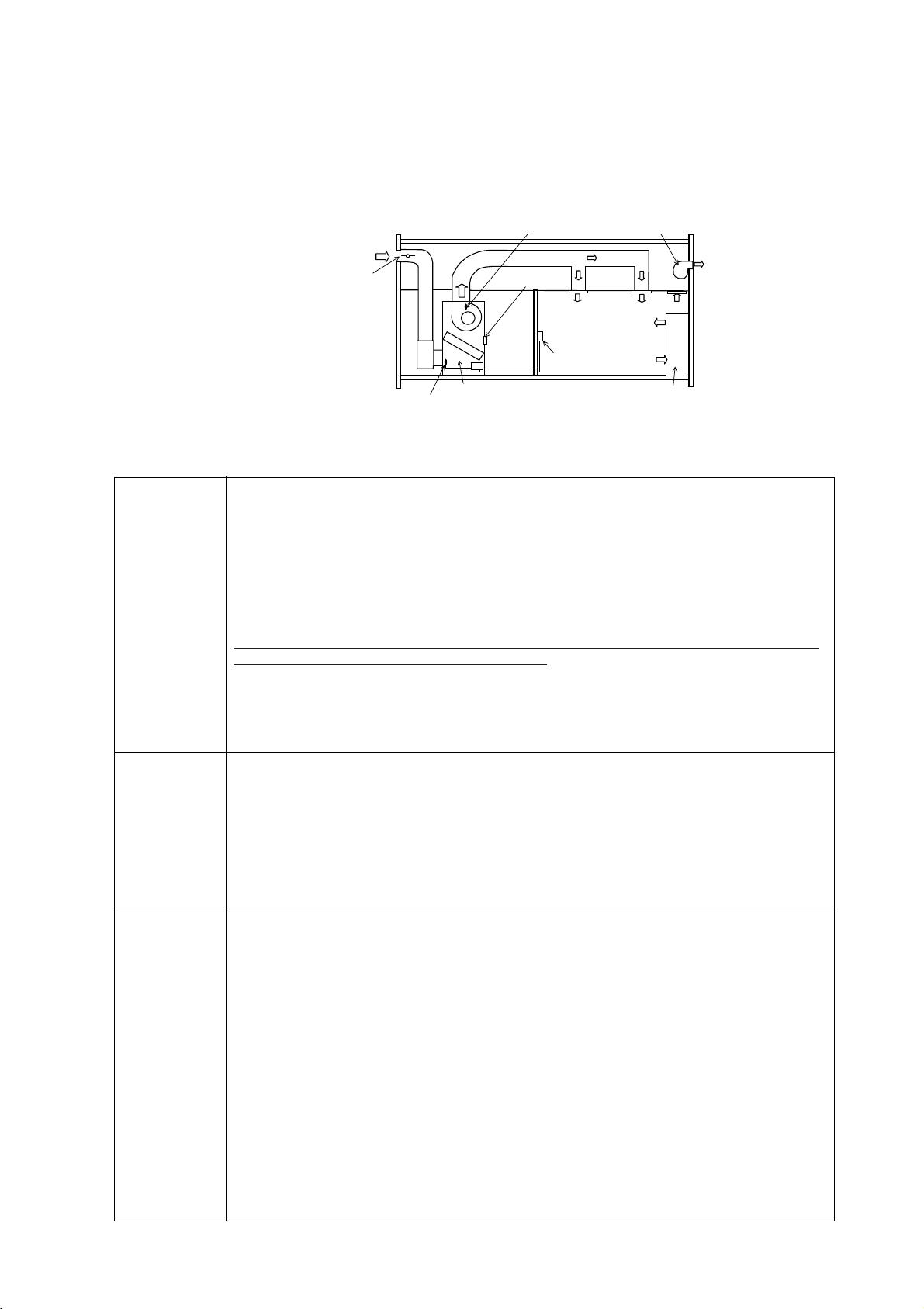

Fresh air intake type indoor unit

Indoor temperature controlling unit

Temperature sensor*2

Supply air temperature sensor*1

(Built in, not connected at the time of factory shipment)

(supplied)

Outside air damper

Outside air temperature sensor (built in)

Remote controller

(built in)

Discharge air

<Fresh Air Intake type sample installation>

*1 Enable to use the supply air

temperature control mode

*2 Enable to use the room

temperature control mode

3. Notes on selecting equipments

Page 6

4

4Fan control

The unit may be forced to operate in the heating mode to prevent cold draft when the return air temperature

(outside air temperature sensor reading) reaches 5

˚C[41˚F] or below. At the time of factory shipment, fan setting is

made so that the fan will stop during the defrost cycle and when there is a problem with the entire refrigerant

systems.

See below for switch settings and unit operation.

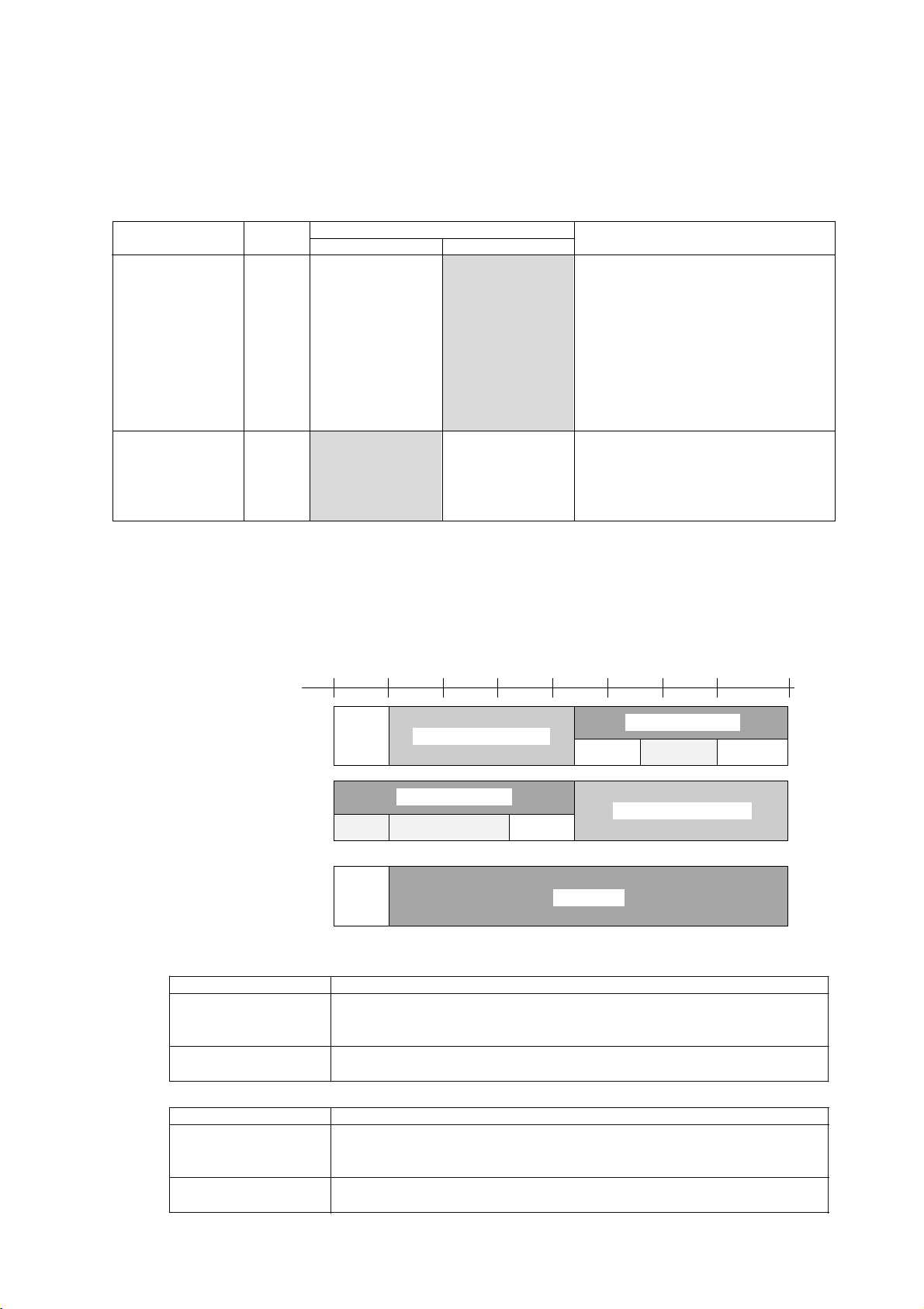

5Sample operation patterns (supply air temperature control)

The unit will follow the operation control pattern below at the nominal air flow rate and the preset temperature of

22

˚C[72˚F]. Use it only as a guide. The range changes with the air flow rate and preset temperature.

6Thermo-ON/OFF conditions (supply air temperature control)

*Settings in the shaded areas indicate factory settings.

Specifications

Forced heating

operation

Fan operation

during defrost

·Forced heating

operation disabled

·Fan stays on

when there is an

error. (The fan

stops when there

is a problem with

the fan or a

communication

error.)

·The fan turns off

when the entire

refrigerant system

is in the defrost

cycle

·Forced heating

operation enabled

·Fan turns off when

there is a problem.

·The fan turns on

during defrost

SW

SW1-7

SW3-4

Notes

When the return air temperature

reaches 5

˚C[41˚F] or below, the unit will

be forced to operate in the heating

mode to prevent cold draft regardless of

the actual operation mode setting.

If the return air temperature reaches

6

˚C[43˚F] or above, the units will

resume operation in the selected mode.

The fan will stop when there is an error,

regardless of the outside temperature.

Operation

OFF

ON

*Operating the fan during the defrost cycle can cause cold outside air to be delivered into the room, and it can also

delay normal unit operation to be resumed after the defrost cycle is completed, both of which can greatly decrease

the room temperature.

Outside temperature

[

˚F]

(

˚C)

Cooling mode

Forced

heating

operation

Cooling Thermo-OFF

Fan mode

Heating Thermo-OFF

Heating operation

Cooling operation

ControllableNote 1

Controllable

Thermo ON/OFF

Thermo ON/OFF

Supply air

temperature rises.

Forced

heating

operation

Heating mode

Fan mode

<Cooling operation>

32 41 50 59 68 77 86 95 109

051015 20 25 30 35 43

Note 1 Thermo-ON: Controllable; Thermo-OFF: Forced heating

Preset temperature

Thermo-OFF conditions

(1, 2, or 3)

Thermo-ON conditions

14

~ 30˚C [57 ~ 86˚F]

1Outside temp. < Preset temp.+0.0

2Supply air temp. < Preset temp.-2˚C lasting for consecutive 10 minutes

315 or more minutes after startup AND Supply air temp. < Preset temp.-5˚C

Supply air temp. > Preset temp +2˚C AND Return air temp. > Preset

temp.+1.5˚C, AND at least 3 minutes have passed since Thermo-OFF

<Heating operation>

Preset temperature

Thermo-OFF conditions

(1, 2, or 3)

Thermo-ON conditions

17

~ 28˚C [68 ~ 82˚F]

1Outside temp. < Preset temp.+0.0

2Supply air temp.> Preset temp.+5˚C lasting for consecutive 10 minutes

315 or more minutes after startup and Supply air temp. > Preset temp.+10˚C

Supply air temp. < Preset temp.-2˚C AND Return air temp. < Preset temp. -

1.5˚C AND at least three minutes have passed since Thermo-OFF

Page 7

1. Specifications

(1) Standard type

5

!!. Indoor Unit

Model Name

Indoor PFAV-P250VM-E

Outdoor

PUHY-P250YHM-A

Cooling

Heating

Cooling

Heating

System capacity

kW

kW

kW

kW

Cooling

Heating

25.0 (Maximum28.0)

28.0 (Maximum 31.5)

System Power input

7.46 / 7.53

8.27 / 8.34

System current

A

A

14.5-13.8-13.3 / 13.4-12.8-12.3

15.8-15.0-14.4 / 14.7-14.0-13.4

Power source 3-phase 4-wire 380-400-415V (50Hz / 60Hz)

Power input kW 0.82 / 0.89

Current A 3.4-3.2-3.1 / 2.3-2.2-2.1

Fan

Type x Quantity Sirocco fan x 2

Airflow rate

m /min

3

90

External static pressure Pa 30 / 90

Motor output kW 2.2

Refrigerant R410A

External finish

External dimension mm

1748(H) x 1200(W) x 485(D)

Protection devices Fan Over current protection

Refrigerant

piping diameter

mm

mm

Liquid pipe

9.52 Brazed (12.7 for over 90m)

Gas pipe 22.2 Brazed

Refrigerant piping allowable length

m 165

Sound pressure level dB(A) 55

Heat exchanger Cross fin (aluminum plate fin and copper tube)

Air filter Synthetic fiber unwoven cloth filter

Net weight kg 156

Operating

temperature range

Cooling

Heating

PFAV-P500VM-E

PUHY-P500YSHM-A

(PUHY-P250YHM-A x 2,

CMY-Y100VBK2)

50.0 (Maximum56.0)

56.0 (Maximum 63.0)

17.85 / 18.84

17.00 / 17.99

32.3-30.7-29.6 / 32.6-31.0-29.9

30.8-29.3-28.2 / 31.1-29.6-28.5

2.37 / 3.36

6.2-5.9-5.7 / 6.5-6.2-6.0

Sirocco fan x 1

180

30 / 130

5.5

R410A

Galvanized steel plate (with polyester coating)

MUNSELL 5Y 8 / 1 or similar

1899(H) x 1420(W) x 635(D)

Over current protection

15.88 Brazed

28.58 Brazed

165

59 / 62

265

Indoor: 10 to 25 degCWB

Indoor: 15 to 28 degCDB

(Outdoor: -5 to 43 degCDB)

(Outdoor: -20 to 15.5 degCWB)

PFAV-P750VM-E

PUHY-P750YSHM-A

(PUHY-P350YHM-A +

PUHY-P400YHM-A,

CMY-Y200VBK2)

71.0 (Maximum 80.0)

80.0 (Maximum 90.0)

26.33 / 27.40

23.93 / 25.00

48.1-45.7-44.1 / 47.5-45.1-43.5

43.4-41.2-39.8 / 42.8-40.6-39.2

4.30 / 5.37

10.9-10.4-10.0 / 10.3-9.8-9.4

Sirocco fan x 1

260

100 / 310

7.5

R410A

1860(H) x 1750(W) x 1064(D)

Over current protection

19.05 Brazed

34.93 Brazed

165

65

PP Honeycomb fabric filter

459

Note

1. Cooling / Heating capacity indicates the value at operation under the following conditions.

(Cooling) Indoor: 27degCDB / 19degCWB, Outdoor: 35degCDB

(Heating) Indoor: 20degCDB, Outdoor: 7degDB / 6degCWB

Pipe length: 7.5m, Height difference: 0m

2. The sound pressure level is measured in an anechoic room.

3. Long period operation in a high temperature and humidity atmosphere (dew point of 23

˚C or more) may cause

condensation to form in the indoor unit.

Works not included: Installation / foundation work, electric connection work, duct work, insulation work,

the power source switch and other items are not specified in the specifications.

Page 8

6

Model Name

Indoor PFAV-P300VM-E-F

Outdoor

PUHY-P250YHM-A

Cooling

Heating

Cooling

Heating

System capacity

kW

kW

kW

kW

Cooling

Heating

28.0 (Maximum 33.5)

26.5 (Maximum 28.0)

System Power input

6.73 / 6.72

7.57 / 7.56

System current

A

A

12.6-11.9-11.5 / 12.2-11.5-11.1

14.0-13.3-12.8 / 13.6-12.9-12.4

Power source 3-phase 4-wire 380-400-415V (50Hz / 60Hz)

Power input kW 0.37 / 0.36

Current A 1.9-1.8-1.7 / 1.5-1.4-1.3

Fan

Type x Quantity Sirocco fan x 2

Airflow rate

m /min

3

45

External static pressure Pa 80

Motor output kW 1.5

Refrigerant R410A

External finish

External dimension mm

1748(H) x 1200(W) x 485(D)

Protection devices Fan Over current protection

Refrigerant

piping diameter

mm

mm

Liquid pipe

9.52 Brazed (12.7 for over 90m)

Gas pipe 22.2 Brazed

Refrigerant piping allowable length

m 165

Sound pressure level dB(A) 48.5

Heat exchanger Cross fin (aluminum plate fin and copper tube)

Air filter Synthetic fiber unwoven cloth filter

Net weight kg 151

Operating

temperature range

Cooling

Heating

PFAV-P600VM-E-F

PUHY-P500YSHM-A

(PUHY-P250YHM-A x 2,

CMY-Y100VBK2)

56.0 (Maximum 67.0)

50.0 (Maximum 56.0)

14.69 / 15.05

15.43 / 15.79

26.1-24.9-24.0 / 26.2-25.0-24.0

27.4-26.1-25.1 / 27.5-26.2-25.1

0.90 / 1.26

2.9-2.8-2.8 / 3.0-2.9-2.8

Sirocco fan x 1

90

110 / 170

2.2

R410A

Galvanized steel plate (with polyester coating)

MUNSELL 5Y 8 / 1 or similar

1899(H) x 1420(W) x 635(D)

Over current protection

15.88 Brazed

28.58 Brazed

165

50 / 53

248

Indoor: 15 to 35 degCWB

Indoor: 0 to 20 degCDB

(Outdoor: 20 to 43 degCDB)

(Outdoor: -4 to 15.5 degCWB)

PFAV-P900VM-E-F

PUHY-P750YSHM-A

(PUHY-P350YHM-A +

PUHY-P400YHM-A,

CMY-Y200VBK2)

80.0 (Maximum 100.0)

71.0 (Maximum 80.0)

22.54 / 22.74

21.43 / 21.63

40.5-38.5-37.1 / 39.6-37.6-36.2

38.7-36.8-35.5 / 37.8-35.9-34.6

1.77 / 1.97

5.6-5.3-5.1 / 4.7-4.4-4.2

Sirocco fan x 1

120

210 / 330

3.7

R410A

1860(H) x 1750(W) x 1064(D)

Over current protection

19.05 Brazed

34.93 Brazed

165

57

PP Honeycomb fabric filter

437

Note

1. Cooling / Heating capacity indicates the value at operation under the following conditions.

(Cooling) Indoor,Outdoor: 33degCDB / 28degCWB

(Heating) Indoor,Outdoor: 7degDB / 3degCWB

Pipe length: 7.5m, Height difference: 0m

2. The sound pressure level is measured in an anechoic room.

3. The indoor intake air temperature should be kept more than 0 degC.

4. At factory setting, the fan temporary stops in defrosting. Change DIP SW for fan to operate in defrosting.

5. Indoor temperature and humidity cannnot be controlled with Fresh air intake type.

Works not included: Installation / foundation work, electric connection work, duct work, insulation work,

the power source switch and other items are not specified in the specifications.

(2) Fresh air intake type

Page 9

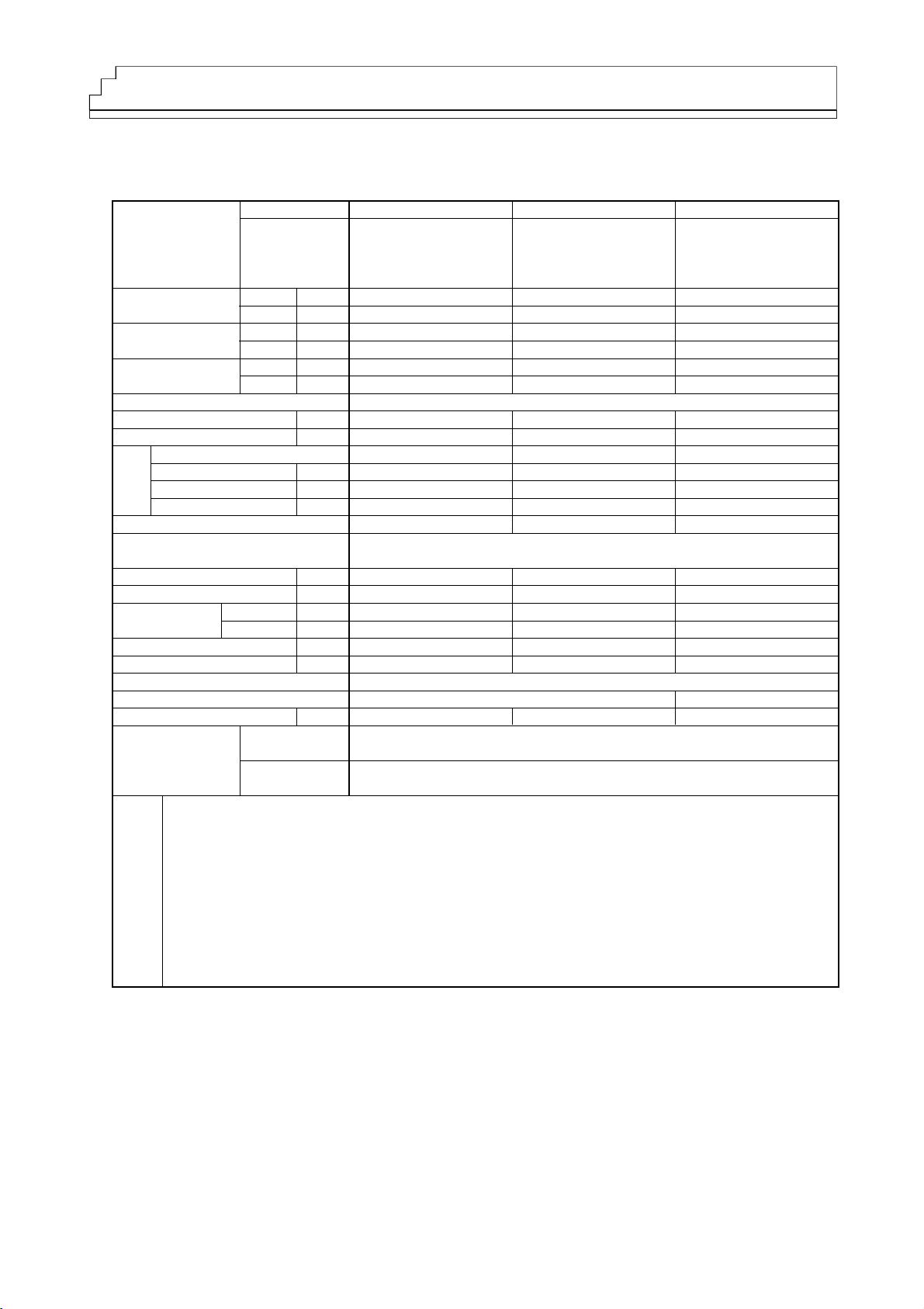

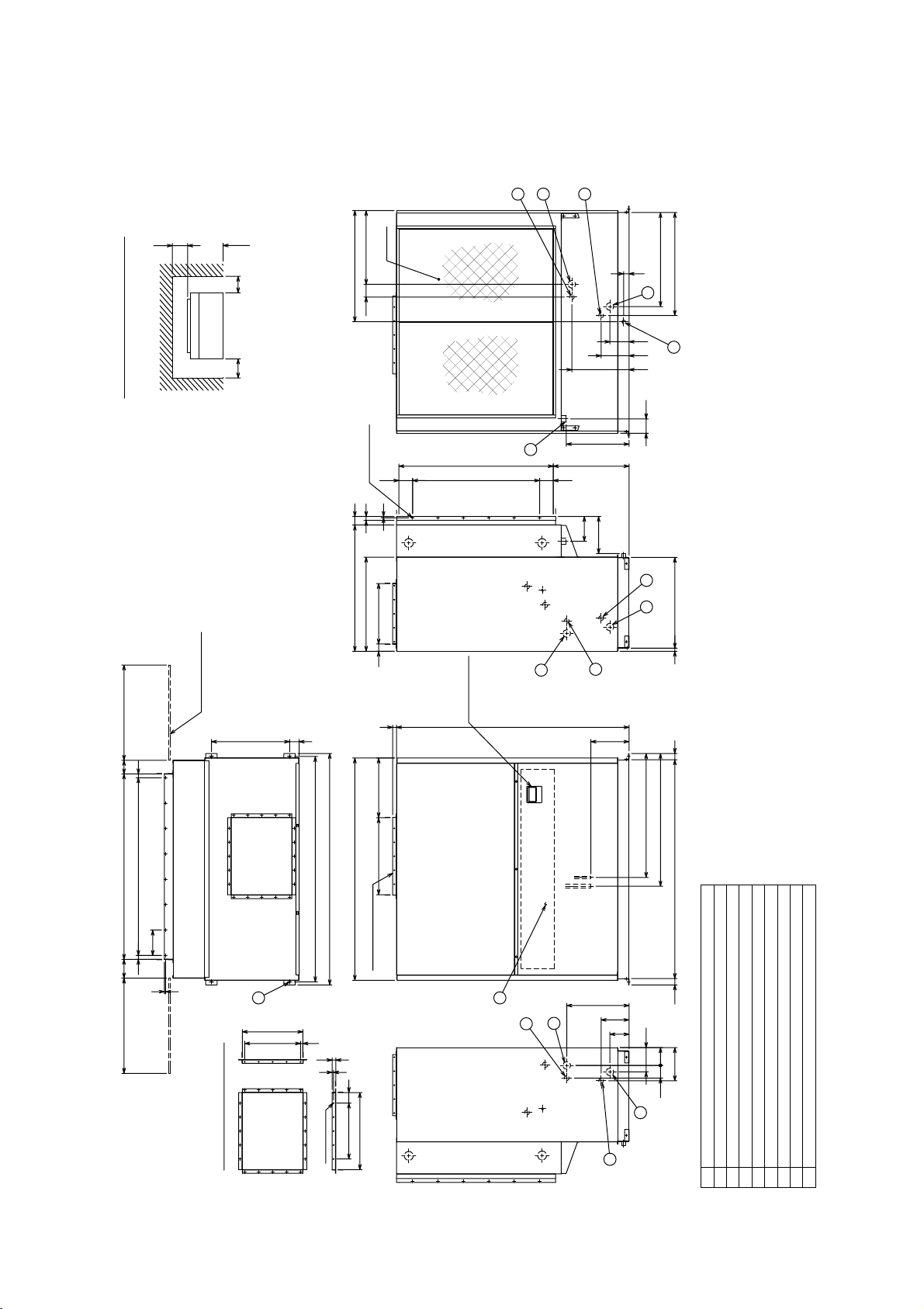

•PFAV-P250VM-E

7

2. External dimensions

(1) Standard type

30

20 19

152

300

85

8

160

Indoor unit

8

8

800

Service panel

Service panel

Service panel

(Service for fan pulley)

(Service for motor pulley)

Supply air duct flange

1650

Required space for service and air flow

50

500 100

Minimum necessary dimension.

385

105

92

7 456

215

130

40

40

39.5

39.5

2

1

3

6

5

4

60

60

90

40

485

18-ø3Holes

104

120 120

336

296

7

Rear air inlet

Supply air duct flange

Front air inlet

5

6

4

3

1

2

835

895

160X5=800

1200

1234

1262

1182

225

185

Remote controller

98

Secure the proper space for

installation work such as

piping and wiring separately.

Notes 1.Be sure to wire the transmission line and power line separately.

2.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

Earth terminal(installed in the control box)···M5

Wiring hole(The outdoor unit connection,Transmission line)······ø27

For mounting anchor bolt 4-ø12 Holes

Wiring hole······ø27

Power supply wiring hole······ø43

Drain hole······Rc 1

Refrigerant pipe<Liquid>···ø9.52 brazed

Refrigerant pipe<Gas>···ø22.2 brazed

DesignationNO.

1234567

8

Unit:mm

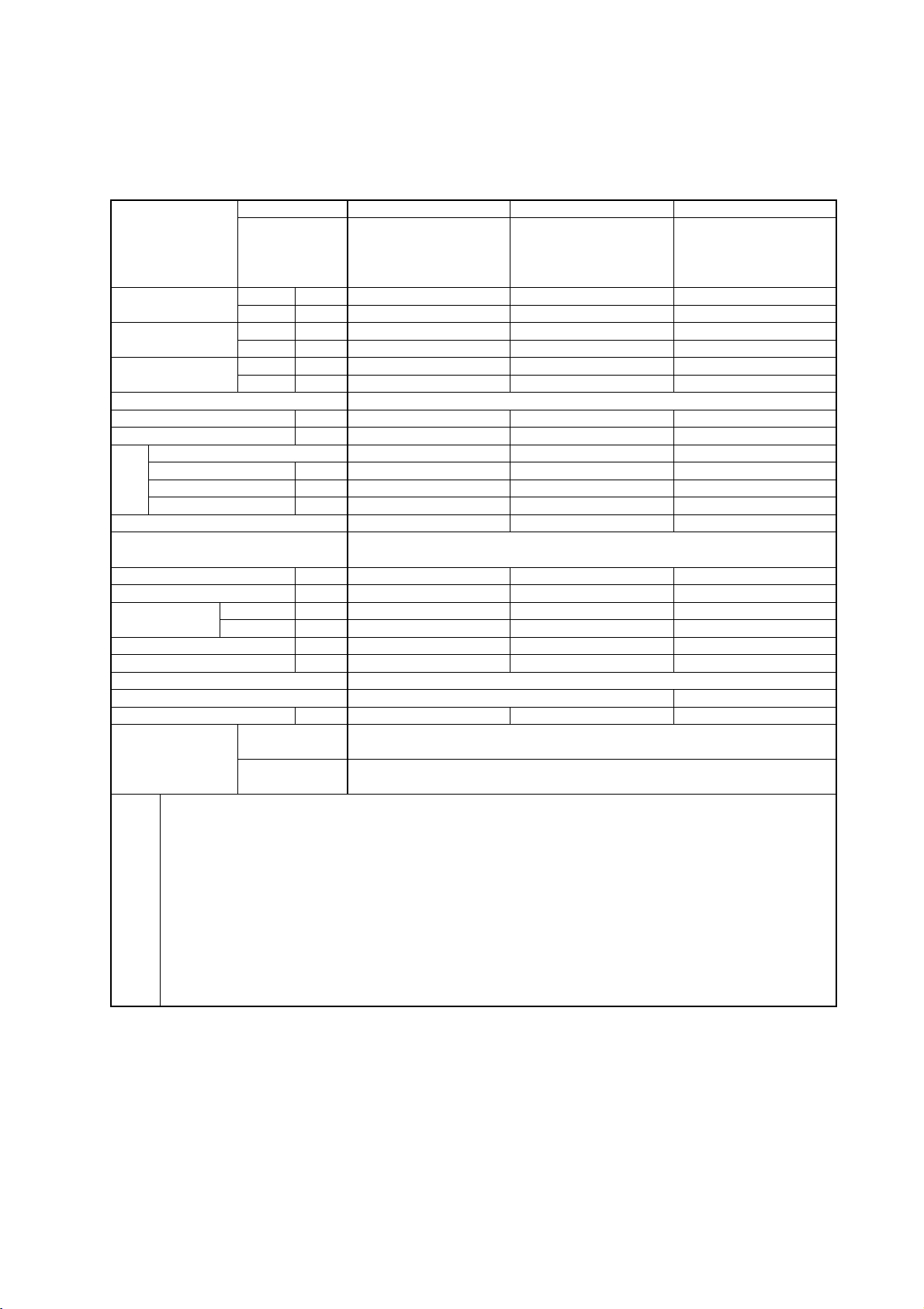

Page 10

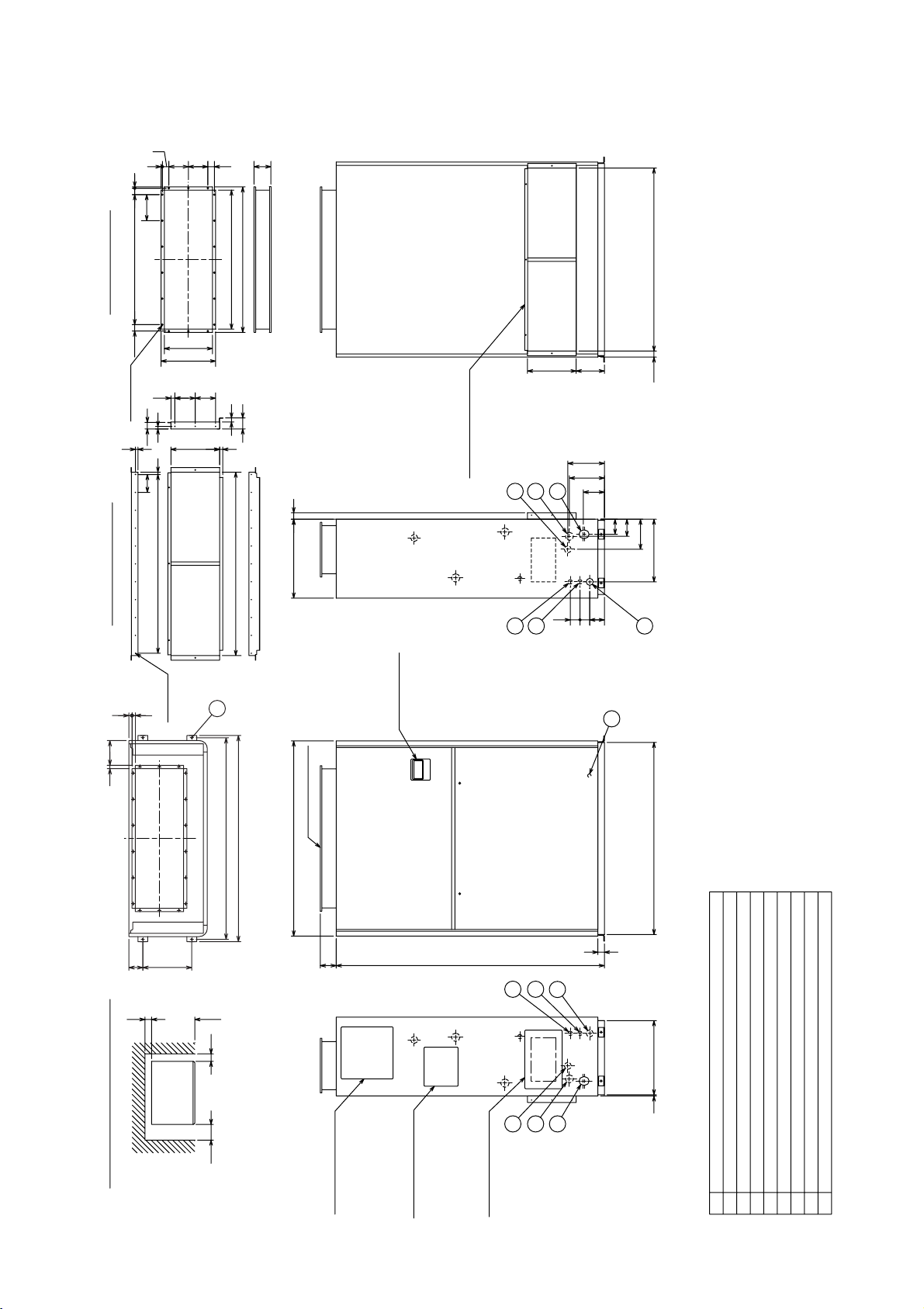

8

•PFAV-P500VM-E

8

7

6

5

4

3

2

1

NO. Designation

Refrigerant pipe<Gas>···ø28.5 brazed

Refrigerant pipe<Liquid>······ø15.88 brazed

Drain hole······Rc 1 1/4

Power supply wiring hole···ø52

Wiring hole······ø37

For mounting anchor bolt 4-ø12 Holes

Wiring hole(The outdoor unit connection,Transmission line)···ø27

Earth terminal(installed in the control box)···M5

213

Rear air inlet

Indoor unit

645

18-ø3.5Holes

Supply air duct flange

Required space for service and air flow

Secure the proper space for

installation work such as

piping and wiring separately.

Supply air duct flange

3

1

2

4

6

5

Remote controller

Front air inlet

7

Minimum necessary dimension.

247

9

484

444

9

33

20020033

118120

Notes 1.Be sure to wire the transmission line and power line separately.

2.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

169

100

92

635

49

530

6070

100

100

50

1000

1420

1478

1450

1213

1253

247X5=1235

1850

40

9602

1398

296

20

82

90

20 21

440

8

Unit:mm

Page 11

9

•PFAV-P750VM-E

Minimum necessary dimension.

Indoor unit

Required space for service and air flow

Secure the proper space for installation work

such as piping and wiring separately.

Please secure the size of *sign when you serve

the air filter from the right side of the main body.

Notes 1.Please secure the size in the service space of the air filter(*sign)

for a left side or a right side of the unit.

2.Be sure to wire the transmission line and power line separately.

3.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

4.Connect by using the connecting pipes that are supplied.

(Size on inside)

(Size on inside)

2

5

6

3

4

(Size on inside)

8

7

2

1

5

6

Air filter

12

5

6

1

(Size on inside)

47656439606

30

12

476

110X4=440

18

20-ø4.3Holes

606

110X4=440 83

42

750 500

1000

400

580100

875

810

740

450

220

150

112

493

994

741

70

35

10

1212

106

200X5=1000

(599)

106

300

195

71525

30

*750(106)

1460

200X7=1400

(146)*750

30

200

10

(50)

1722 50

1045

976

300

1830

30

61575

1822

1774

1750

140100

490

220

150

191

261

Supply air duct flange

28-ø4.3Holes

note:1

Air filter service space

Remote controller

Supply air duct flange

Drain hole<Lower side>······Rc 1

Earth terminal(installed in the control box)······M5

Wiring hole(The outdoor unit connection,Transmission line)······ø38

For mounting anchor bolt 4-ø15 Holes

Wiring hole······ø62

Drain hole<Upper part>······Rc 1 1/4

Refrigerant pipe<Liquid>···ø19.05 brazed

Refrigerant pipe<Gas>···ø34.93 brazed

DesignationNO.

1234567

8

Unit:mm

Page 12

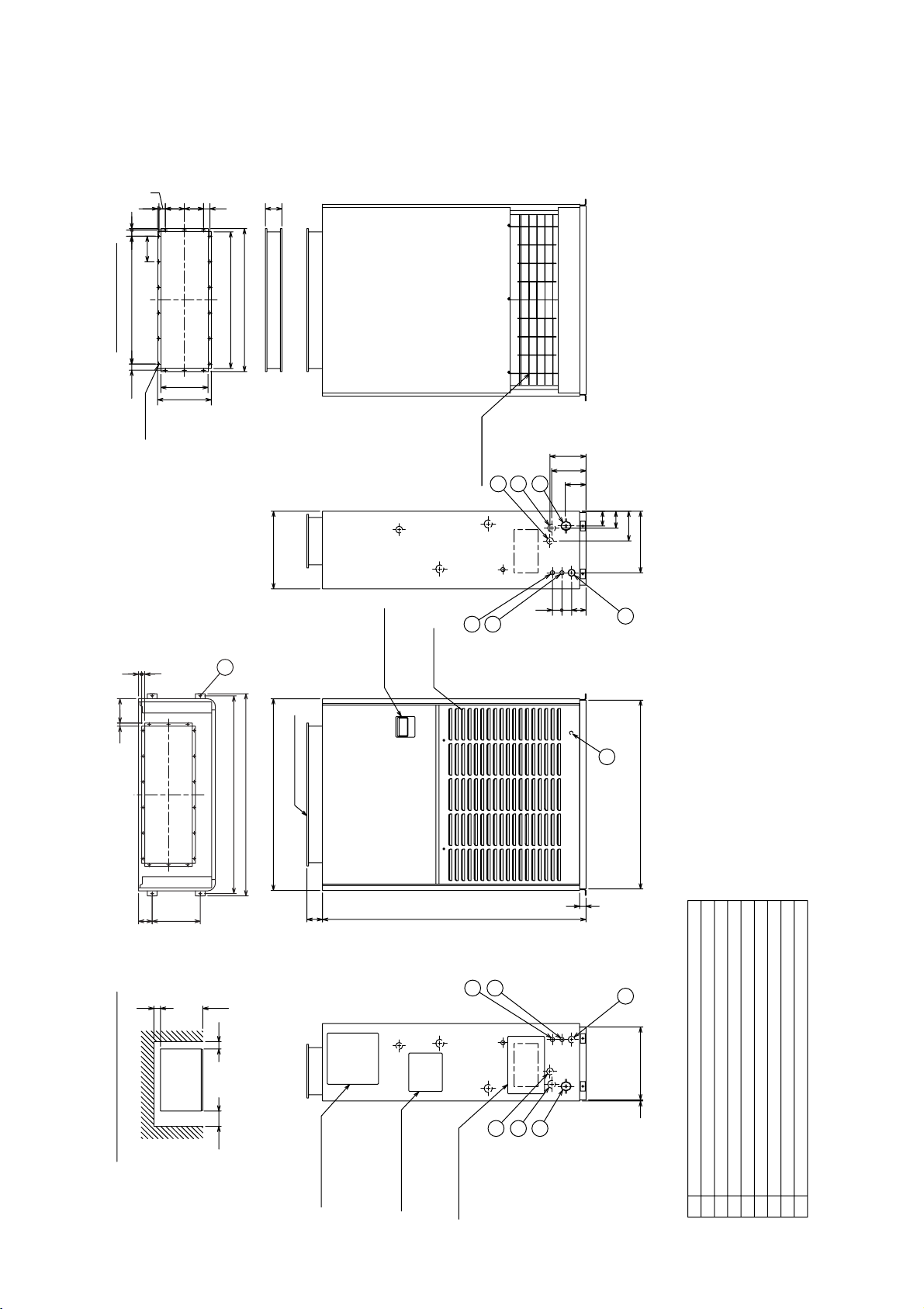

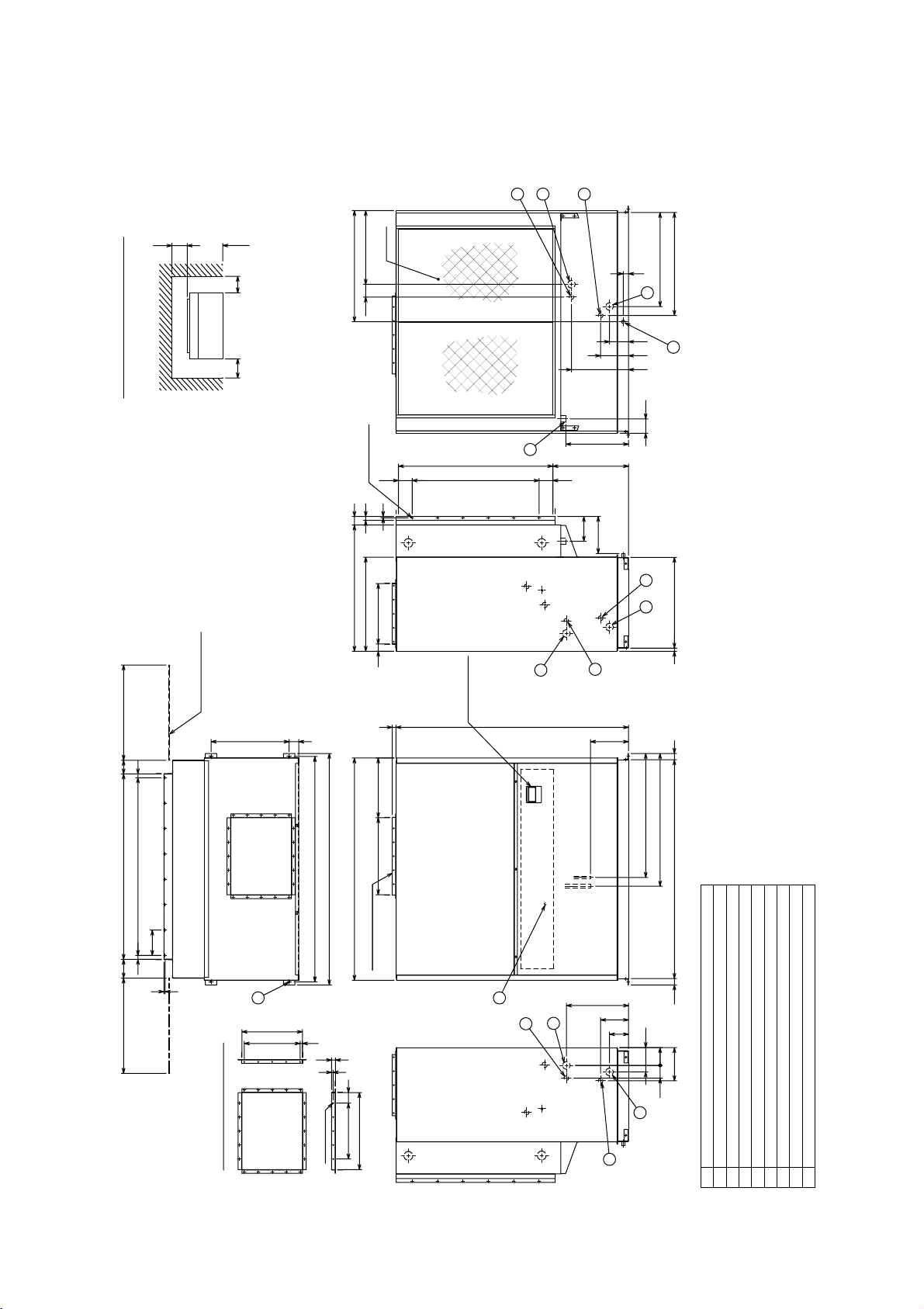

10

8

7

6

5

4

3

2

1

NO. Designation

Refrigerant pipe<Gas>

···ø

22.2 brazed

Refrigerant pipe<Liquid>

···ø

9.52 brazed

Drain hole

········

Rc 1

Power supply wiring hole

·······ø

43

Wiring hole

·····ø

27

For mounting anchor bolt 4-

ø

12 Holes

Wiring hole(The outdoor unit connection,Transmission line)

······ø

27

Earth terminal(installed in the control box)

···

M5

(1126)

37

Indoor unit

Notes 1.Be sure to wire the transmission line and power line separately.

2.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

8

8

(Service for thermistor)

(Service for motor pulley)

(Service for fan pulley)

Service panel

Secure the proper space for

installation work such as

piping and wiring separately.

300173

Rear air inlet duct flange

40

Rear air inlet duct flange

67

26

125125

15

110

30020

15

28-

ø

3 Holes

1126

Supply air duct flange

98

Remote controller

185

225

1182

1200

160X5=800

895

855

2

1

3

4

6

5

Supply air duct flange

Service panel

Service panel

7

296

336

120120104

18-

ø

3.5 Holes

485

40

90

60

60

4

5

6

3

1

2

160

39.539.5

40

40

130

215

4567

92

105

385

Minimum necessary dimension.

100500

50

Required space for service and air flow

1650

13110X10=1100

25

40

800

30

20 19

152

300

85

8

1234

1262

•PFAV-P300VM-E-F

Unit:mm

(2) Fresh air intake type

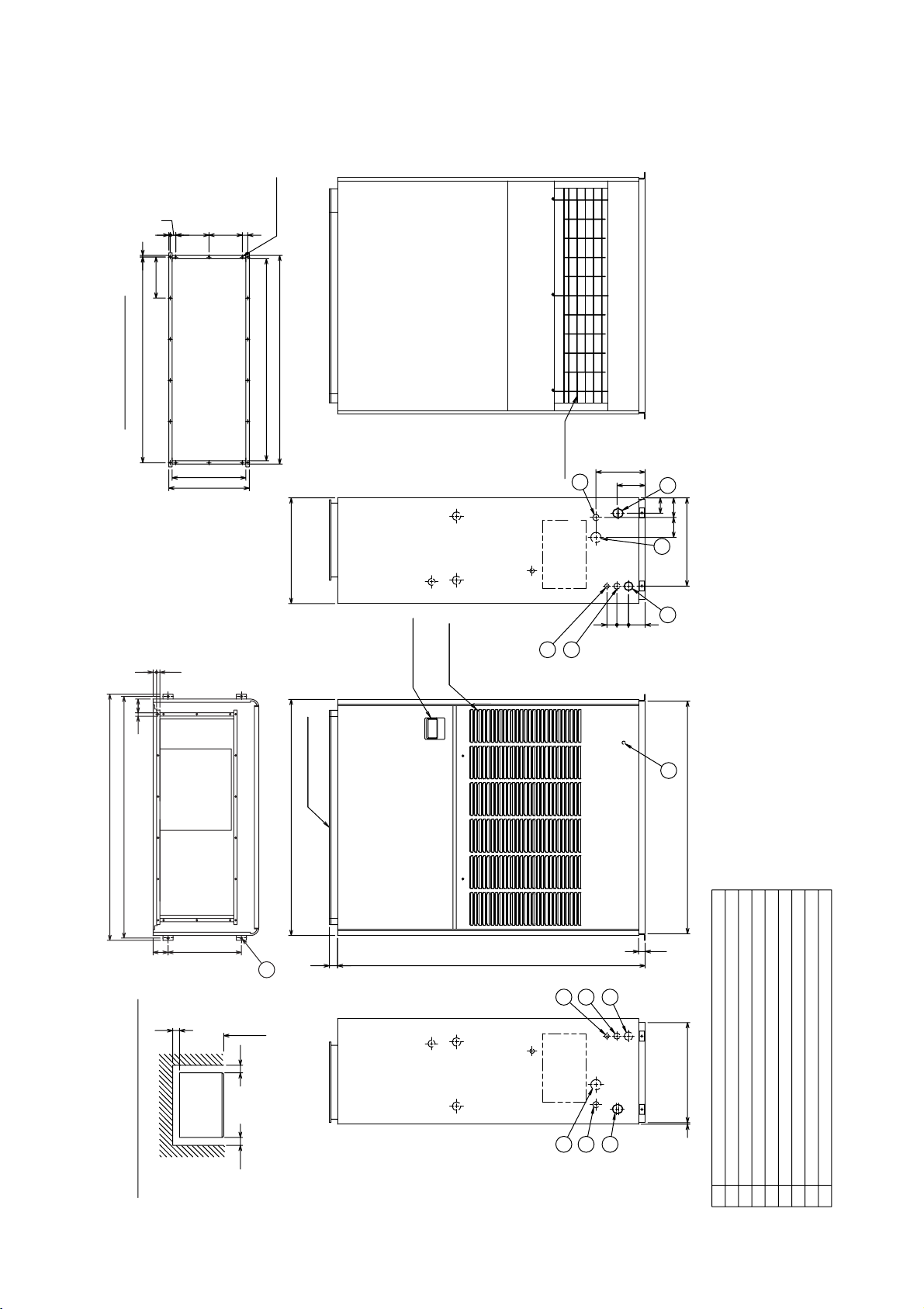

Page 13

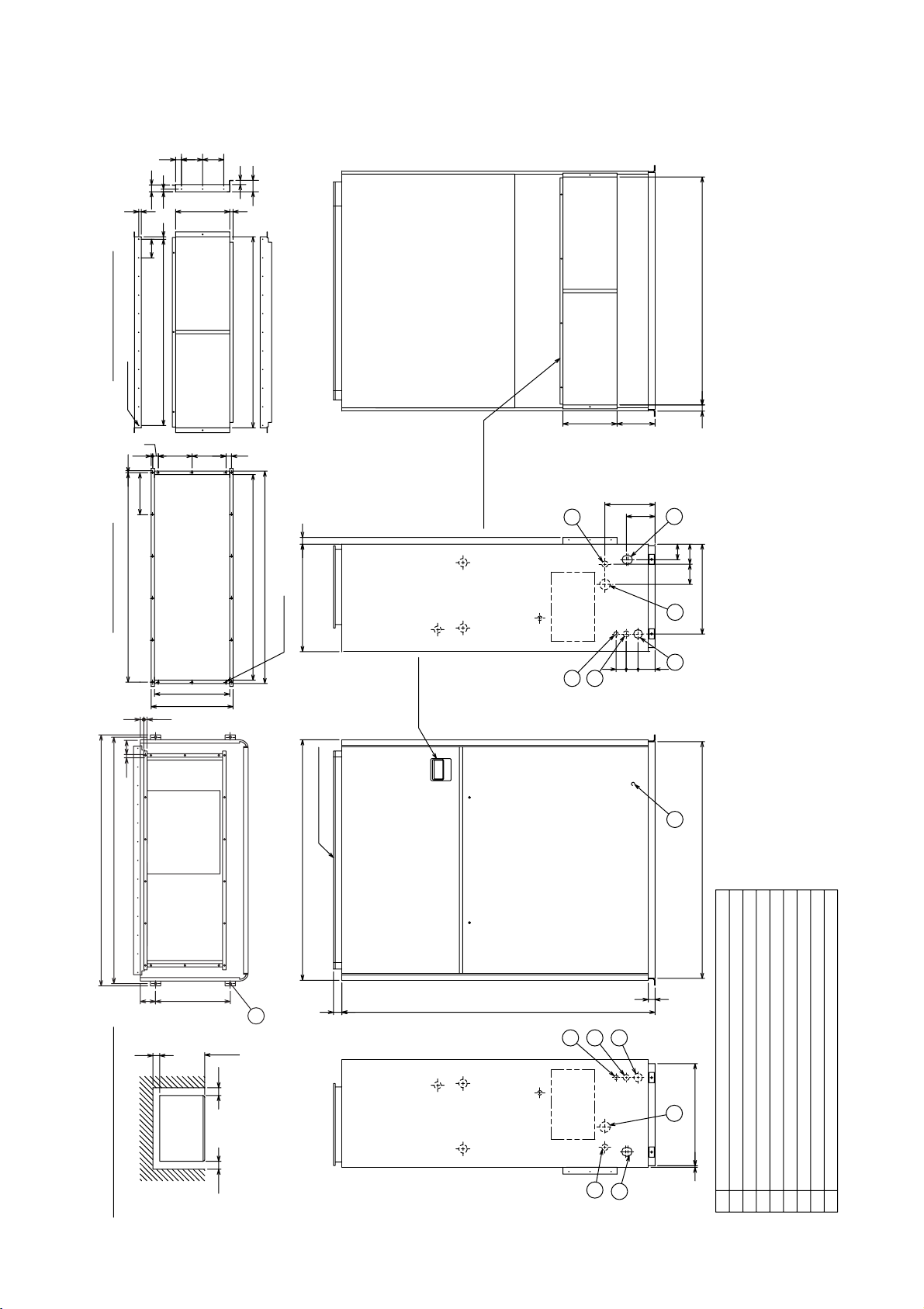

11

•PFAV-P600VM-E-F

Earth terminal(installed in the control box)

···

M5

Wiring hole(The outdoor unit connection,Transmission line)

······ø

27

For mounting anchor bolt 4-

ø

12 Holes

Wiring hole

·····ø

37

Power supply wiring hole

·······ø

52

Drain hole

········

Rc 1 1/4

Refrigerant pipe<Liquid>

···ø

15.88 brazed

Refrigerant pipe<Gas>

···ø

28.5 brazed

DesignationNO.

1 2 3 4 5 6 7

8

2

3

1

7

4

5

6

Supply air duct flange

Remote controller

Rear air inlet duct flange

2

3

14

6

5

37

(1346)

118120

Supply air duct flange

Rear air inlet duct flange

Required space for service and air flow

Minimum necessary dimension.

Secure the proper space for

Indoor unit

installation work such as

piping and wiring separately.

Notes 1.Be sure to wire the transmission line and power line separately.

2.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

18-

ø

3.5 Holes

32-

ø

3 Holes

40

1000

320224

49

67

26

125125

15

110

32020 15

1346

13

12X110=1320

35

40

9

9

169

100

92

635

530

6070100

100

50

1420

1478

1450

1213

1253

20020033

33

444

484

247

247X5=1235

1850

40

9 602

1398

296

8

20

21

8220

90

440

Unit:mm

Page 14

12

•PFAV-P900VM-E-F

Minimum necessary dimension.

Indoor unit

Required space for service and air flow

Secure the proper space for installation work

such as piping and wiring separately.

Please secure the size of *sign when you serve

the air filter from the right side of the main body.

Notes 1.Please secure the size in the service space of the air filter(*sign)

for a left side or a right side of the unit.

2.Be sure to wire the transmission line and power line separately.

3.When the room in which the unit is installed is airtight,

the pressure in the room may become negative.

This may result in problems such as the door to becoming difficult

to open etc.

To avoid these kinds of problems please ensure that a small amount of

air is able to ventilate the room via some kind of small hole or vent.

4.Connect by using the connecting pipes that are supplied.

(Size on inside)

(Size on inside)

2

5

6

3

4

(Size on inside)

8

7

2

1

5

6

Air filter

12

5

6

1

(Size on inside)

47656439606

30

12

476

110X4=440

18

20-ø4.3Holes

606

110X4=440 83

42

750 500

1000

400

580100

875

810

740

450

220

150

112

493

994

741

70

35

10

1212

106

200X5=1000

(599)

106

300

195

71525

30

*750(106)

1460

200X7=1400

(146)*750

30

200

10

(50)

1722 50

1045

976

300

1830

30

61575

1822

1774

1750

140100

490

220

150

191

261

Supply air duct flange

28-ø4.3Holes

note:1

Air filter service space

Remote controller

Supply air duct flange

Drain hole<Lower side>······Rc 1

Earth terminal(installed in the control box)······M5

Wiring hole(The outdoor unit connection,Transmission line)······ø38

For mounting anchor bolt 4-ø15 Holes

Wiring hole······ø62

Drain hole<Upper part>······Rc 1 1/4

Refrigerant pipe<Liquid>···ø19.05 brazed

Refrigerant pipe<Gas>···ø34.93 brazed

DesignationNO.

1234567

8

Unit:mm

Page 15

13

3. Center of gravity

(1) Indoor unit

•PFAV-P250,P500 (P300-F, P600-F)

•PFAV-P750 (P900-F)

W

X

Y

Z

L

445

615

835

1774

X

WModel L YXZ

PFAV-P250VM-E

PFAV-P500VM-E

PFAV-P300VM-E-F

PFAV-P600VM-E-F

1234

1450

1234

1450

300

440

300

440

573

651

573

667

156

217

161

219

835

1144

825

1113

XModel

PFAV-P750VM-E

PFAV-P900VM-E-F

1020

Page 16

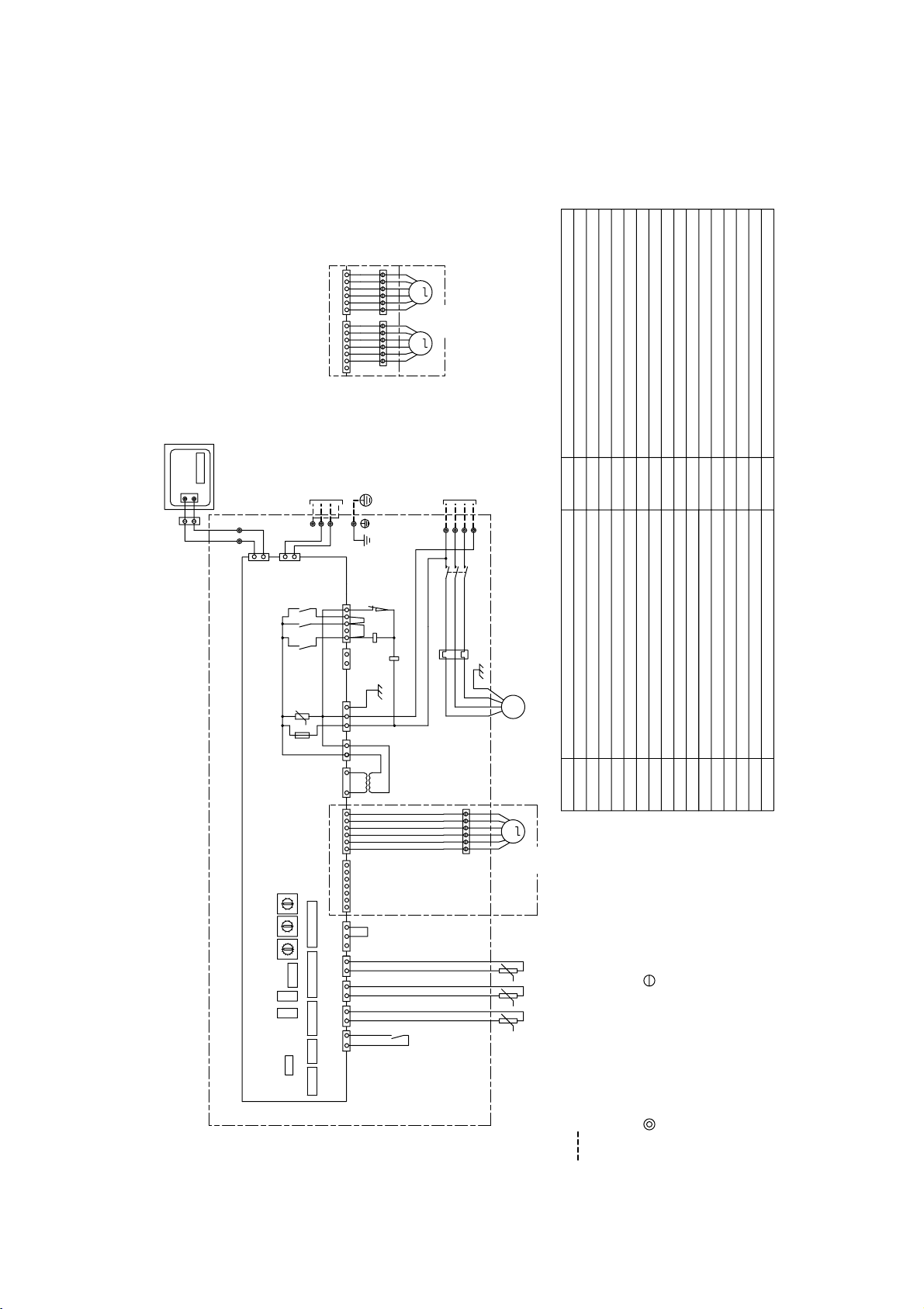

14

•PFAV-P250, 500VM-E

4. Electrical wiring diagram

(1) Standard type

Terminal bed(Indoor unit)

Liquid crystal monitor

Remote controller board

TB6

LCD

R.B.

Remote controller

Inside section of control box

Indoor/Outdoor

transmission line

Power supply

3N~

380/400/415V

50/60Hz

SWE

SWC

SW8

SW5

TH21 Thermistor(Supply air temp. detection)

Thermistor(Piping temp. detection/liquid)TH22

TH23

Auxiliary relay(Fan)X4

Switch

SW4

SW3

SW2

SW11

SW12

SW14

SW1

SW7

Thermistor(Piping temp. detection/gas)

(1st digit address set)

Switch

(Connection No. set)Switch

(For model selection)Switch

(For mode selection)Switch

(For capacity code)Switch

(For mode selection)Switch

(For model selection)Switch

(For four stages demand selection)Switch

(For trial run)Switch

(For mode selection)Switch

(For trial run of fan)Switch

CN28 Connector(Fan failure)

Over current relay(Fan motor)

Contactor (Fan motor)

Electronic linear expan. valve 1

Transformer

Varistor

Fuse<6.3A>

MA Remote controller terminal bed

Transmission terminal bed

Power source terminal bed

Fan motor

Symbol

Symbol explanation

TB15

51F

52F

LEV1

T

ZNR

F

TB5

TB2

M

Connector(Defrost output)CN33

NameSymbol

LEV2 Electronic linear expan. valve 2

(2nd digit address set)

Name

2

313 13

CN33

T

52F

ZNR

F

X06

1

1

1

CNT

CND

X4

2

1

2

11

M

CN28

3

2

1

CN20

CN21

321

X4

CN29

CN3T

CN60

CN31

R.B.

TB6

LCD

TB5

(Shield)

2

1

1

3

51F

52F

X05

X04

7

2

1

CN3A

M1

S

M2

35

CN90

CN2M

Indoor controller board

1

2

51F

CN7V

9

5

TH23TH22TH21

TB15

L2L1L3

TB2

1234567

123456

123456

LEV1

M

3

~

Fan motor

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

0

9

1

2

3

4

5

6

7

8

9

0

9

A

B

C

D

E

F

SW11

SW12

SW14 SW8 SW5 SWC

SWE

SW1 SW3 SW2 SW7 SW4

N

❈ P250

❈

P500

1234567

LEV1

654321

CN7V CN60

M

LEV2

654321 654321

M

t˚t˚t˚

Earth

U

Note: 1. (Heavy dotted line):Field wiring

2. Have all electric work done by a licensed electrician

according to the local regulations.

3. Earth leakage circuit breaker should be set up on the

wiring of the power supply.

4. Mark indicates terminal bed, connector.

5. Auto-restart function from power failure can be turned

on by setting SW1-9 dip switch to its ON position.

(Note:This function is not set to ON from the factory.)

Page 17

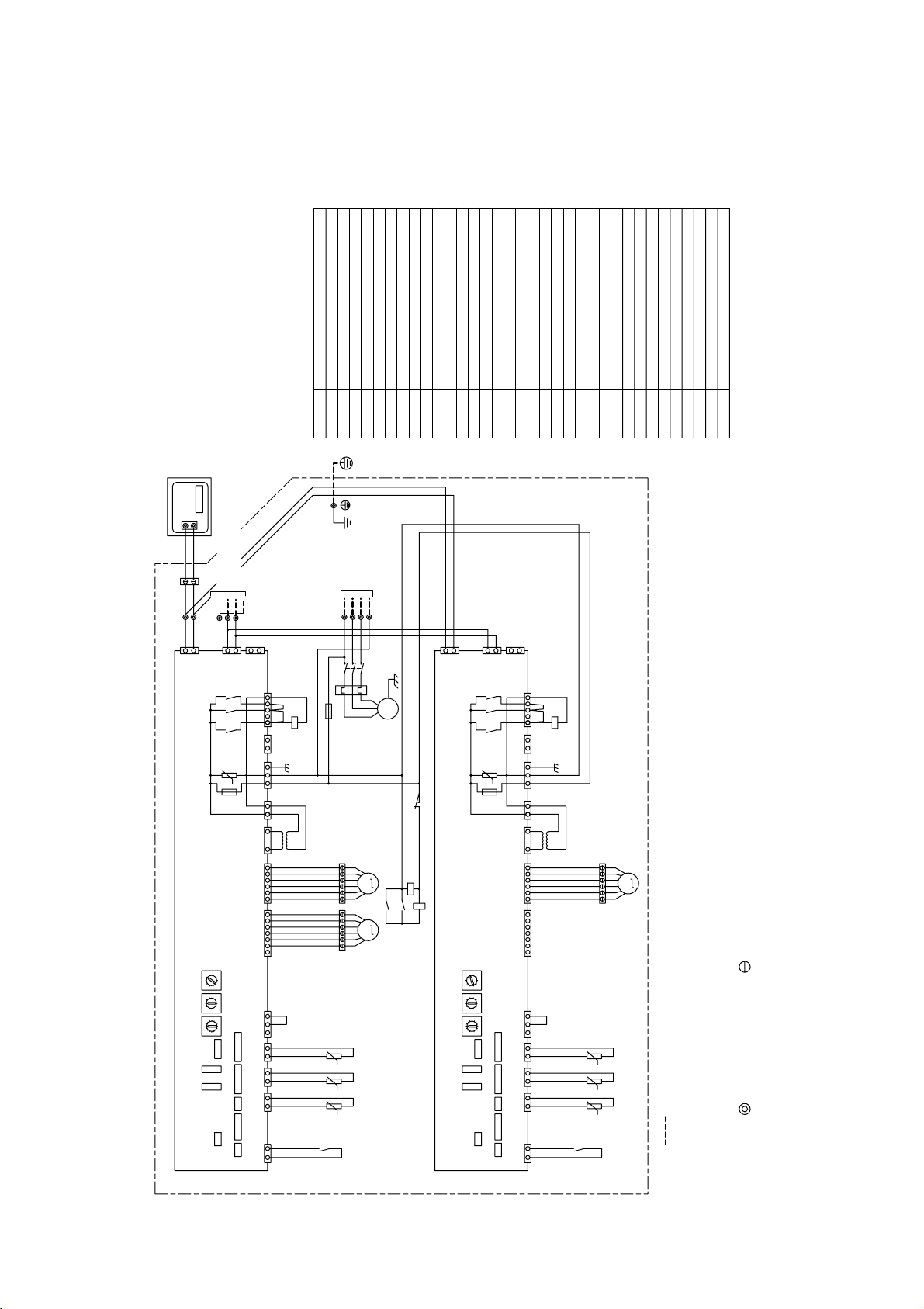

15

•PFAV-P750VM-E

X1,X2,X4

Fuse<6.3A>F1

F Fuse<6.3A>

Contactor (Fan motor)

Thermistor(Supply air temp. detection)TH21

Electronic linear expan. valve 3LEV3

Electronic linear expan. valve 2LEV2

Symbol Name

Fan motor

Electronic linear expan. valve 1

Remote controller board

Liquid crystal monitor

Power source terminal bed

Transmission terminal bed

Varistor

Transformer

Symbol explanation

MA Remote controller terminal bed

M

R.B.

LCD

TB2

TB5

TB15

ZNR

T

LEV1

Contactor (Fan motor)52F

51F Over current relay(Fan motor)

CN33 Connector(Defrost output)

Thermistor(Piping temp. detection/gas)

Thermistor(Piping temp. detection/liquid)

Switch (For model selection)SW7

SW1

SW14

SW12

SW11

SW4

SW5

SW8

Switch (For model selection)

Switch (Connection No. set)

Switch (For capacity code)

Switch (For four stages demand selection)

Switch (For mode selection)

Switch (2nd digit address set)

Switch (1st digit address set)

SW3

SW2

Switch (For mode selection)

TH22

TH23

TB6 Terminal bed(Indoor unit)

CN28 Connector(Fan failure)

SWE

SWC

Switch (For trial run)

Switch (For trial run of fan)

Switch (For mode selection)

Earth

Inside section of control box

LEV3

LEV2 LEV1

(Shield)

N

Indoor controller board No.2

31

123456

SW14

SW12

SW11

Indoor/Outdoor

transmission line

M1

S

M2

2

1

CN2M

CNP

1

3

CN28

12

X4

t˚ t˚ t˚

TH21 TH22 TH23

2121

CN21

21

CN20

CN29

CN3A

2

1

CN2M

CNP

1

3

SW8SW5

13 13

CN33

ZNR

F

X06

X05

X04

7135

CND

CN90

95

U

1

T

CN3T

31

CNT

2345

U

6

M

7

CN7V

SWE

t˚ t˚

50/60Hz

380/400/415V

9

TH23

CN29

21

t˚

M

654321

SW4

X4

X2

52F

X1

F1

SW7

SW2

654321

CN60

X2

3

1

321

CN31

SW11

SW12

SW14

CN7V

6543217

SW3 SW1

SWC

51F

CN31

123

Indoor controller board No.1

CN90

CND

CNT

CN60

CN20

SW5

1

1

5

2

2

3

1

3

4

1

56

L1

L2

TH21

SW2

SW7

1

3

CN3T

CN21

TH22

SWC

SW3

CN3A

1

2

SW4

Power supply

3N~

7

X04

X05

X06

F

ZNR

L3

52F

123456

T

CN33

31

CN28

3

1

1

2

M

M

31

3

12

12

X1

3~

X4

51F

SW1

SW8

SWE

5

TB2

1

2

3

4

5

6

7

8

0

9

A

B

C

D

E

F

8

7

6

5

4

3

2

1

0

9

1

2

3

4

5

6

7

8

9

0

TB5

0

9

8

7

6

5

4

3

2

1

9

0

1

2

3

4

5

6

7

8

F

E

D

C

B

A

9

0

8

7

6

5

4

TB15

Remote controller

LCD

TB6

R.B.

3

2

1

Note: 1. (Heavy dotted line):Field wiring

2. Have all electric work done by a licensed electrician according to

the local regulations.

3. Earth leakage circuit breaker should be set up on the wiring of the

power supply.

4. Mark indicates terminal bed, connector.

5. To enable the "auto recovery after power failure" function, set

SW1-9 of both No. 1 and No. 2 circuit boards to ON.

(Factory setting: OFF)

Page 18

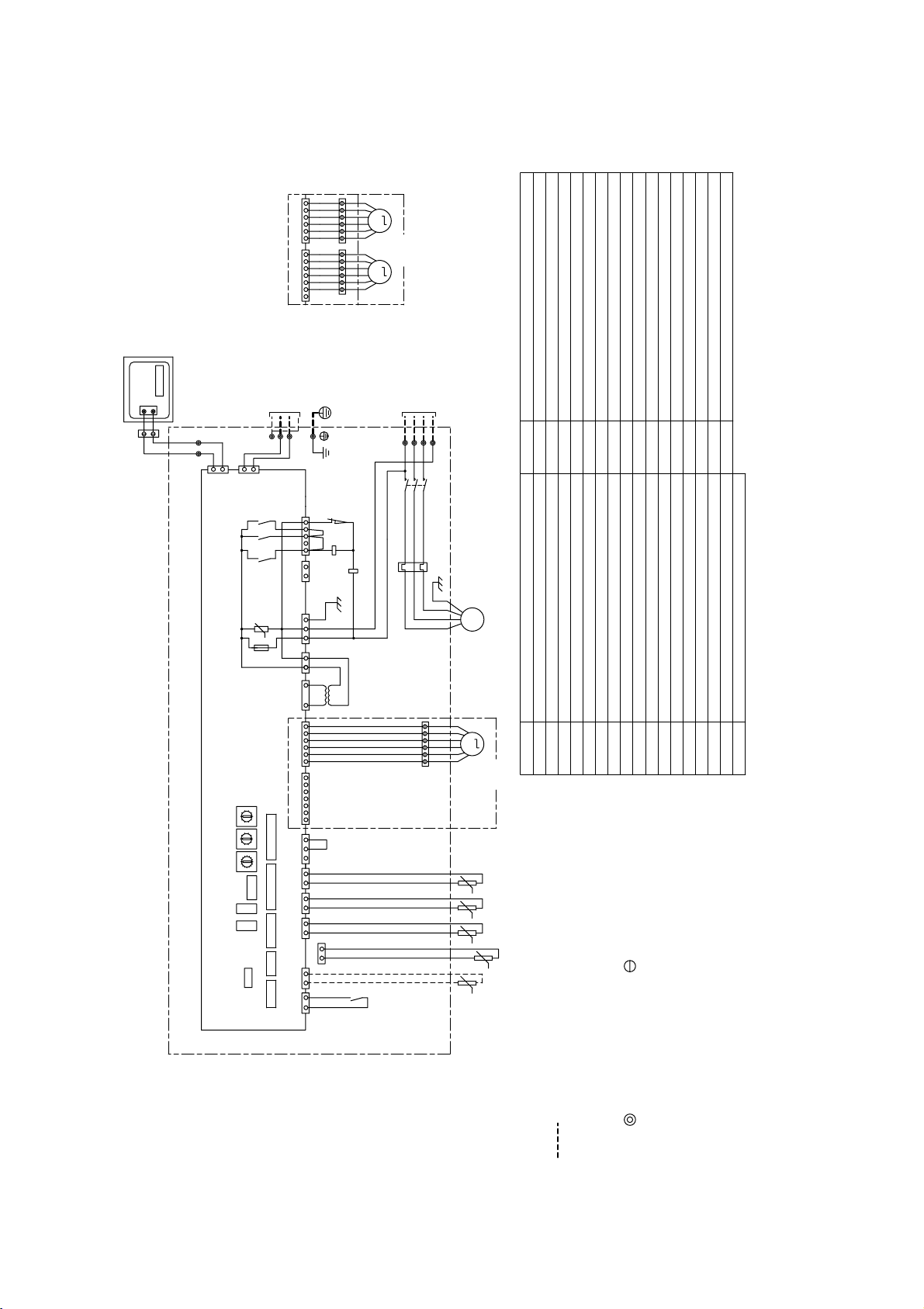

•PFAV-P300, 600VM-E-F

16

(2) Fresh air intake type

Remote controller

Inside section of control box

Indoor/Outdoor

transmission line

Power supply

3N~380/400/415V

50/60Hz

Remote controller board

Liquid crystal monitor

Terminal bed(Indoor unit)

LCD

TB6

R.B.

(accessory)

Note:7

TH24 Thermistor(Outdoor temp. detection)

2

3

1

3

1

3

CN33

T

52F

ZNR

F

XO6

1

1

1

CNT

CND

X4

2

1

2

11

M

CN28

3

2

1

CN20

CN21

3

2

1

X4

CN29

CN3T

CN60

CN31

R.B.

TB6

LCD

TB5

(Shield)

2

1

1

3

51F

52F

XO5

XO4

7

2

1

CN3A

M1

S

M2

3

5

CN90

CN2M

Indoor controller board

1

2

51F

CN7V

9

5

TH23TH22TH21

TB15

L2L1L3

TB2

1234567123456

123456

LEV1

M

3~

Fan motor

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

0

9

1

2

3

4

5

6

7

8

9

0

9

A

B

C

D

E

F

SW11

SW12

SW14 SW8 SW5 SWC

SWE

SW1 SW3 SW2 SW7 SW4

N

TH24

CN22

1

2

TH21

1

2

❈

P300

❈P

600

1234567

LEV1

654321

654321

CN7V CN60

M

LEV2

654321

M

Name

(2nd digit address set)

Electronic linear expan. valve 2LEV2

Symbol Name

Connector(Defrost output)

M

F

ZNR

T

LEV1

52F

51F

Symbol explanation

Symbol

Fan motor

Power source terminal bed

Transmission terminal bed

MA Remote controller terminal bed

Fuse<6.3A>

Varistor

Transformer

Electronic linear expan. valve 1

Contactor (Fan motor)

Over current relay(Fan motor)

Connector(Fan failure)

Switch (For trial run of fan)

Switch (For mode selection)

Switch

(For trial run)

Switch

(For four stages demand selection)

Switch

(For model selection)

Switch

(For mode selection)

Switch

(For capacity code)

Switch

(For mode selection)

Switch

(For model selection)

Switch

(Connection No. set)

Switch

(1st digit address set)

Thermistor(Piping temp. detection/gas)

SW7

SW1

SW14

SW12

SW11

SW2

SW3

SW4

Switch

X4 Auxiliary relay(Fan)

Thermistor(Piping temp. detection/liquid)

Thermistor(Supply air temp. detection)

SW5

SW8

SWC

SWE

TH23

TH22

TH21

CN33

CN28

TB15

TB5

TB2

t˚t˚t˚ t˚

t˚

Earth

U

Note: 1. (Heavy dotted line): Field wiring

2. Have all electric work done by a licensed electrician according

to the local regulations.

3. Earth leakage circuit breaker should be set up on the wiring of

the power supply.

4. Mark indicates terminal bed, connector.

5. Auto-restart function from power failure can be turned on by

setting SW1-9 dip switch to its ON position.

(Note: This function is not set to ON from the factory.)

6. Supply air thermistor is built in on the inside of the indoor unit.

A jumper is taped inside the control box without it being

connected to the connector.

Plug it into CN20 when using the supply air temperature to

control the room temperature.

Turn SW7-2 on the indoor unit to ON.

7. Indoor unit is supplied with a thermistor.

Install the sensor in the room to properly control the room

temperature.

Page 19

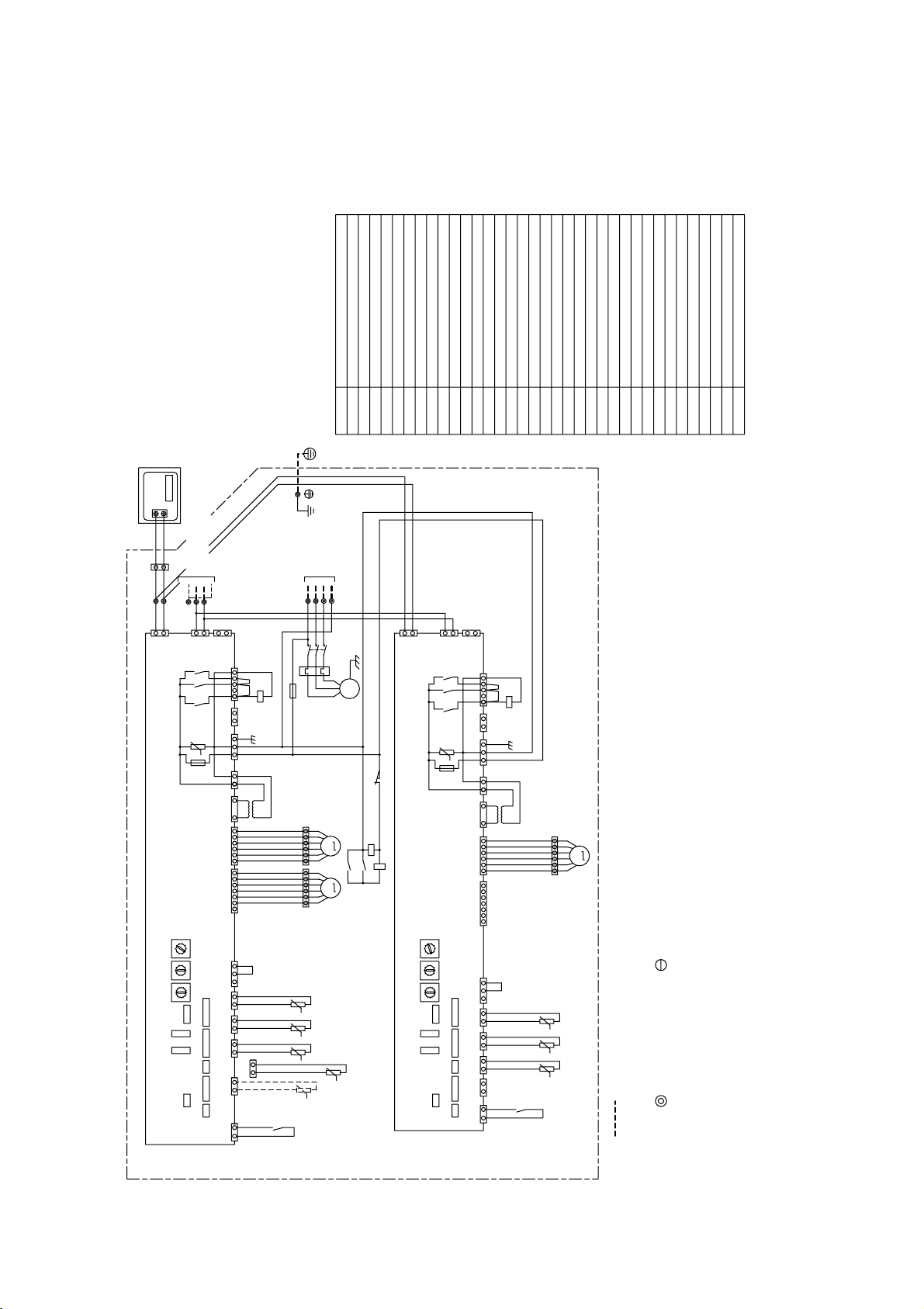

17

•PFAV-P900VM-E-F

LEV3

LEV2 LEV1

(Shield)

N

Indoor controller board No.2

TH21

TH21

31

123456

SW14

SW12

SW11

Indoor/Outdoor

transmission line

M1

S

M2

2

1

CN2M

CNP

1

3

CN20CN28

1212

X4

t˚ t˚ t˚

TH22 TH23 TH24

2121

CN29

21

CN21

CN22

CN3A

2

1

CN2M

CNP

1

3

SW8SW5

13 13

CN33

ZNR

F

X06

X05

X04

713 5

CND CN90

95

U

1

T

CN3T

31

CNT

2

t˚

345

U

6

M

7

CN7V

SWE

t˚

t˚ t˚

50/60Hz

380/400/415V

9

2

1

TH24

CN22

21

t˚

M

654321

SW4

X4

X2

52F

X1

F1

SW7 SW2

654321

CN60

X2

3

1

321

CN31

SW11

SW12

SW14

CN7V

6543217

SW3 SW1

SWC

51F

CN31

12

3

Indoor controller board No.1

CN90

CND

CNT

CN60

CN21

CN20

SW5

1

152

2

31 34156

L1

L2

TH22

SW2

SW7

13

CN3T

CN29

TH23

SWC

SW3

CN3A

1

2

SW4

Power supply

3N~

7

X04

X05

X06

F

ZNR

L3

52F

123456

T

CN33

31

CN28

3

1

1

2

M

M

313

121212

X1

3~

X4

51F

SW1

SW8

SWE

5

Remote controller

TB2

1

2

3

4

5

6

7

8

0

9

A

B

C

D

E

F

8

7

6

5

4

3

2

1

0

9

1

2

3

4

5

6

7

8

9

0

TB5

0

9

8

7

6

5

4

3

2

1

9

0

1

2

3

4

5

6

7

8

F

E

D

C

B

A

9

0

8

7

6

5

4

TB15

LCD

TB6

R.B.

3

2

1

Inside section of control box

X1,X2,X4

Fuse<6.3A>F1

F Fuse<6.3A>

Contactor (Fan motor)

Thermistor(Supply air temp. detection)TH21

Electronic linear expan. valve 3LEV3

Electronic linear expan. valve 2LEV2

Symbol Name

Fan motor

Electronic linear expan. valve 1

Remote controller board

Liquid crystal monitor

Power source terminal bed

Transmission terminal bed

Varistor

Transformer

Symbol explanation

MA Remote controller terminal bed

M

R.B.

LCD

TB2

TB5

TB15

ZNR

T

LEV1

Contactor (Fan motor)52F

51F Over current relay(Fan motor)

CN33 Connector(Defrost output)

Thermistor(Piping temp. detection/gas)

Thermistor(Piping temp. detection/liquid)

Thermistor(Outdoor temp. detection)

Switch (For model selection)SW7

SW1

SW14

SW12

SW11

SW4

SW5

SW8

Switch (For model selection)

Switch (Connection No. set)

Switch (For capacity code)

Switch (For four stages demand selection)

Switch (For mode selection)

Switch (2nd digit address set)

Switch (1st digit address set)

SW3

SW2

Switch (For mode selection)

TH22

TH24

TH23

TB6 Terminal bed(Indoor unit)

CN28 Connector(Fan failure)

SWE

SWC

Switch (For trial run)

Switch (For trial run of fan)

Switch (For mode selection)

Earth

(accessory)

Note:7

Note: 1. (Heavy dotted line): Field wiring

2. Have all electric work done by a licensed electrician according to the local regulations.

3. Earth leakage circuit breaker should be set up on the wiring of the power supply.

4. Mark indicates terminal bed, connector.

5. To enable the "auto recovery after power failure" function, set SW1-9 of both No. 1 and No. 2 circuit

boards to ON.

(Factory setting: OFF)

6. Supply air thermistor is built in on the inside of the indoor unit.

A jumper is taped inside the control box without it being connected to the connector.

Plug the jumper into CN20 on No. 1 circuit board when using the supply air temperature to control the

room temperature. Turn SW7-2 of both No. 1 and No. 2 circuit boards on the indoor unit to ON.

7. Indoor unit is supplied with a thermistor.

Install the sensor in the room to properly control the room temperature.

Page 20

18

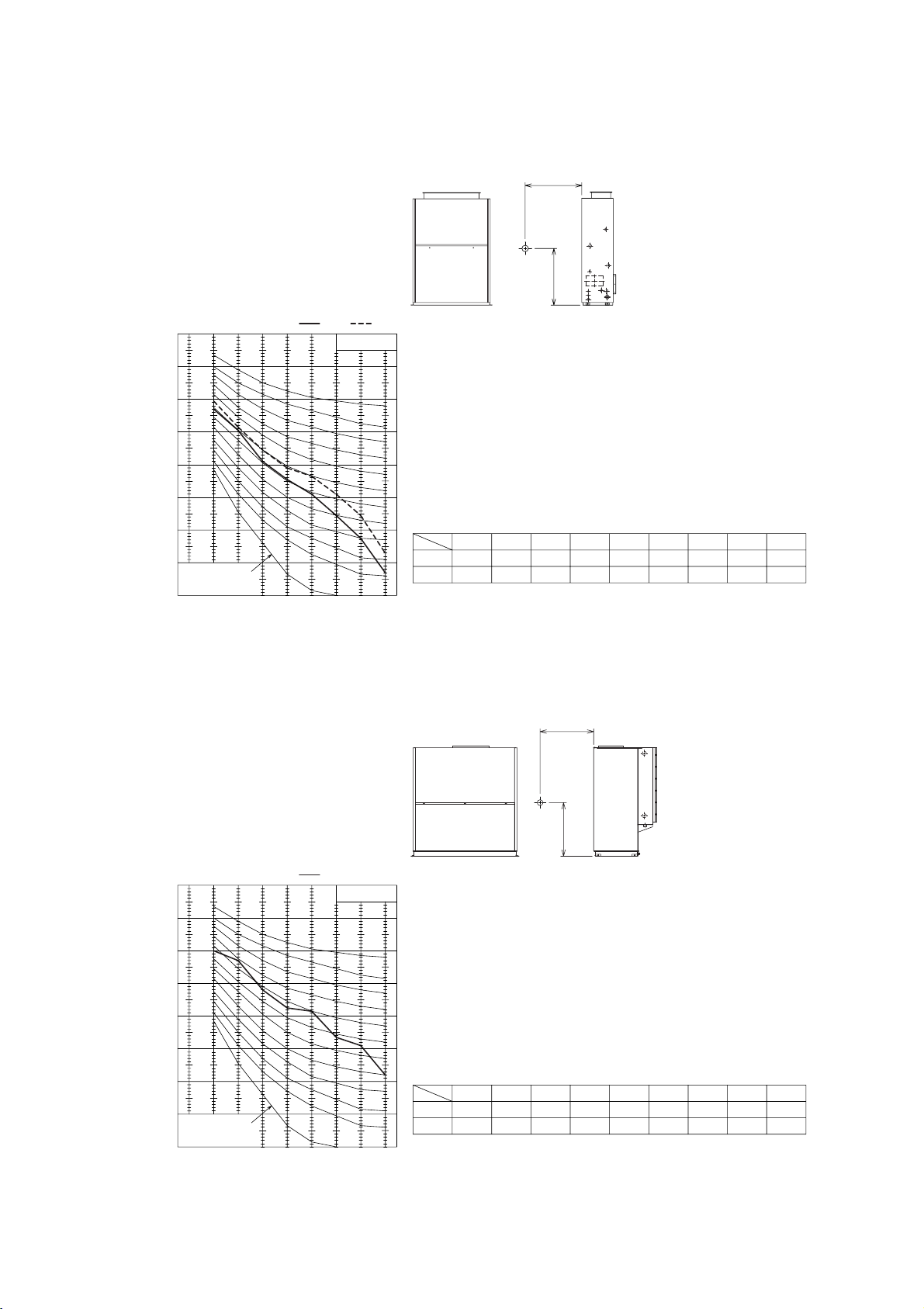

5. Sound Pressure Levels

•PFAV-P500VM-E

Power sorce : 3N 380/400/415V 50/60Hz

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

32

8000Hz55dB(A)

38.5

4000Hz

44

2000Hz

47.5

1000Hz

51

500Hz

58.5

250Hz

63

125Hz

66

32 553645.546.550596368

63Hz

50Hz

60Hz

50Hz, 60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

1m

1m

Measurement

location

Power sorce : 3N 380/400/415V 50/60Hz

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

38

8000Hz62dB(A)

46.5

4000Hz

54

2000Hz

57

1000Hz

57.5

500Hz

60

250Hz

69

125Hz

77.5

33 5941.549535656.56573.5

63Hz

50Hz

60Hz

50Hz, 60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

1m

1m

Measurement

location

•PFAV-P250VM-E

Page 21

19

•PFAV-P300VM-E-F

Power sorce : 3N 380/400/415V 50/60Hz

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

44.5

8000Hz65dB(A)

49

4000Hz

56

2000Hz

60

1000Hz

62.5

500Hz

62.5

250Hz

63.5

125Hz

72.5

44.5 6549566062.562.563.572.5

63Hz

50Hz

60Hz

50Hz/60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

1m

1m

Measurement

location

1m

1m

Power sorce : 3N 380/400/415V 50/60Hz

Measurement

location

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

25.5

8000Hz

48.5

dB(A)

32

4000Hz

37.5

2000Hz

41

1000Hz

44.5

500Hz

52

250Hz

56.5

125Hz

59.5

25.5 48.529.5394043.552.556.561.5

63Hz

50Hz

60Hz

50Hz, 60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

•PFAV-P750VM-E

Page 22

20

•PFAV-P900VM-E-F

Power sorce : 3N 380/400/415V 50/60Hz

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

23

8000Hz53dB(A)

34.5

4000Hz

41

2000Hz

46.5

1000Hz

49

500Hz

54.5

250Hz

61.5

125Hz

69.5

17 5027.534.54145.55160.567

63Hz

50Hz

60Hz

50Hz, 60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

1m

1m

Measurement

location

Power sorce : 3N 380/400/415V 50/60Hz

Note:The measuring point is the 1m from the bottom of the unit.

(1m from the front of the unit.)

32

8000Hz57dB(A)

41

4000Hz

43.5

2000Hz

51.5

1000Hz

52.5

500Hz

58

250Hz

67

125Hz

70

32 574143.551.552.5586770

63Hz

50Hz

60Hz

50Hz/60Hz

NC Curve

·OCTAVE BAND CENTER FREQUENCIES (Hz)

·Approximate minimum

audible limit on

continuous noise.

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-70

NC-60

NC-50

NC-30

NC-20

NC-40

OCTAVE BAND PRESSURE LEVEL (dB) 0 dB=20µPa

1m

1m

Measurement

location

•PFAV-P600VM-E-F

Page 23

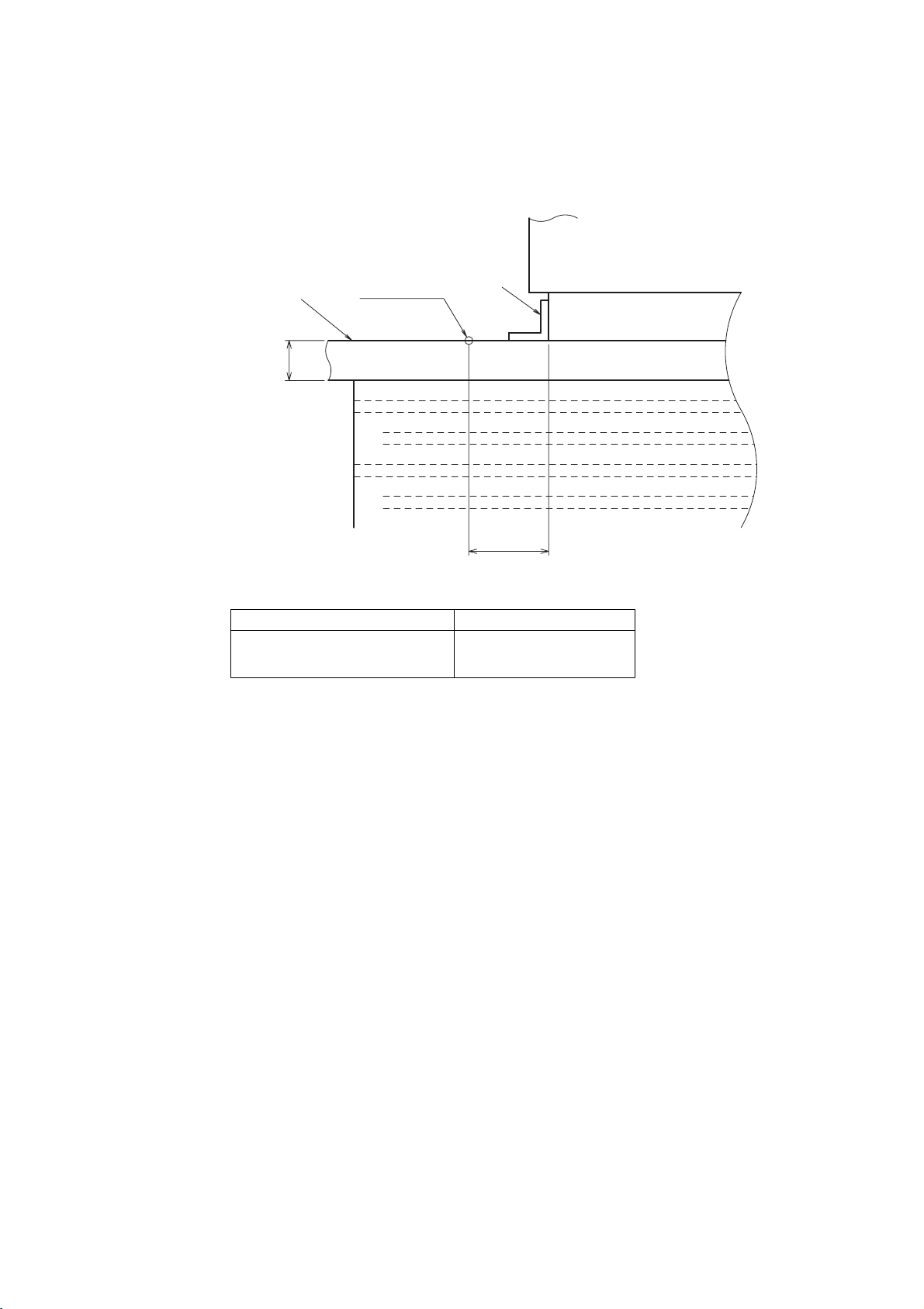

21

6. Vibration levels

•PFAV indoor unit

Concrete

Measurement

location

Leg

PFAV Unit

10cm

20cm

Vibration Levels [dBA]

40 or less

Model

PFAV-P250,500,750VM-E

PFAV-P300,600,900VM-E-F

Page 24

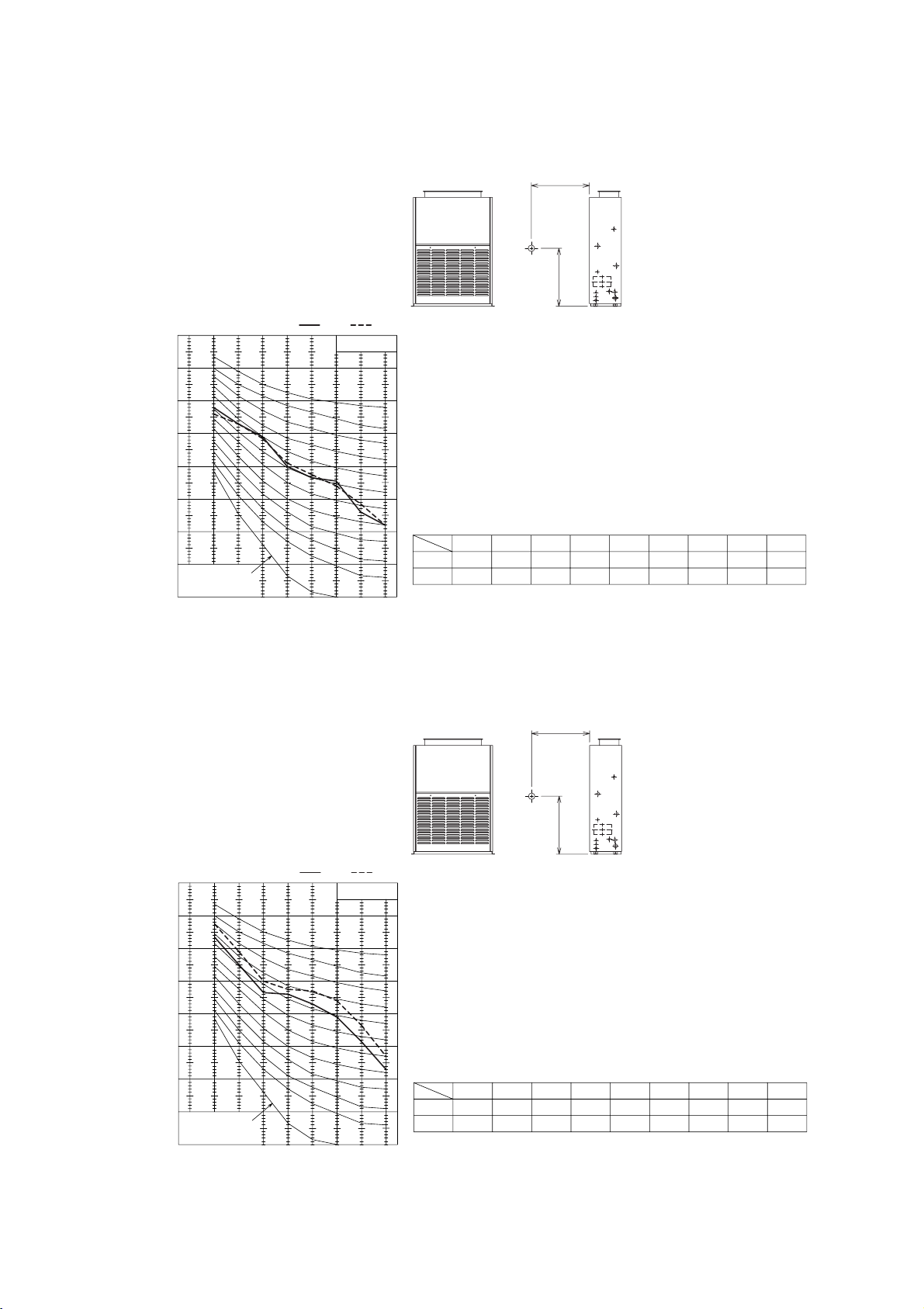

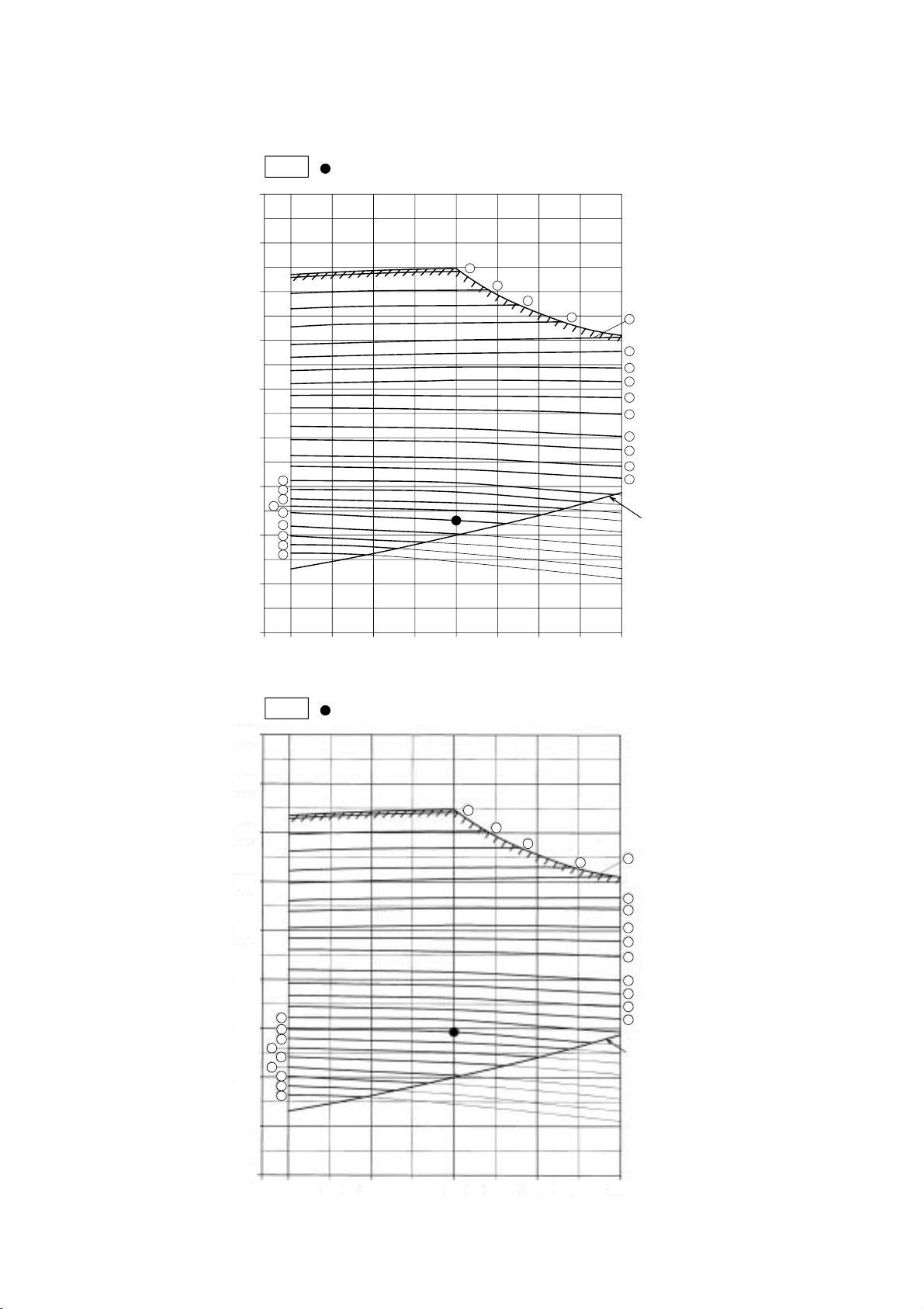

22

7. Fan characteristic curves

11070 75 80 85 90 95 100 105

100

200

300

400

500

700

900

800

600

2.2kW

0

14

13

12

11

5

6

7

8

9

10

4

1

2

3

15

20

21

22

23

16

17

18

19

······Standard

50Hz

Internal resistance

Airflow rate < m

3

/ min >

Total static pressure < Pa >

······Standard

60Hz

11070 75 80 85 90 95 100 105

100

200

300

400

500

700

900

800

600

0

23

22

21

20

19

18

17

16

2.2kW

14

13

12

11

10

9

8

7

6

5

4

3

2

1

15

Internal resistance

Total static pressure < Pa >

Airflow rate < m

3

/ min >

•PFAV-P250VM-E

Page 25

23

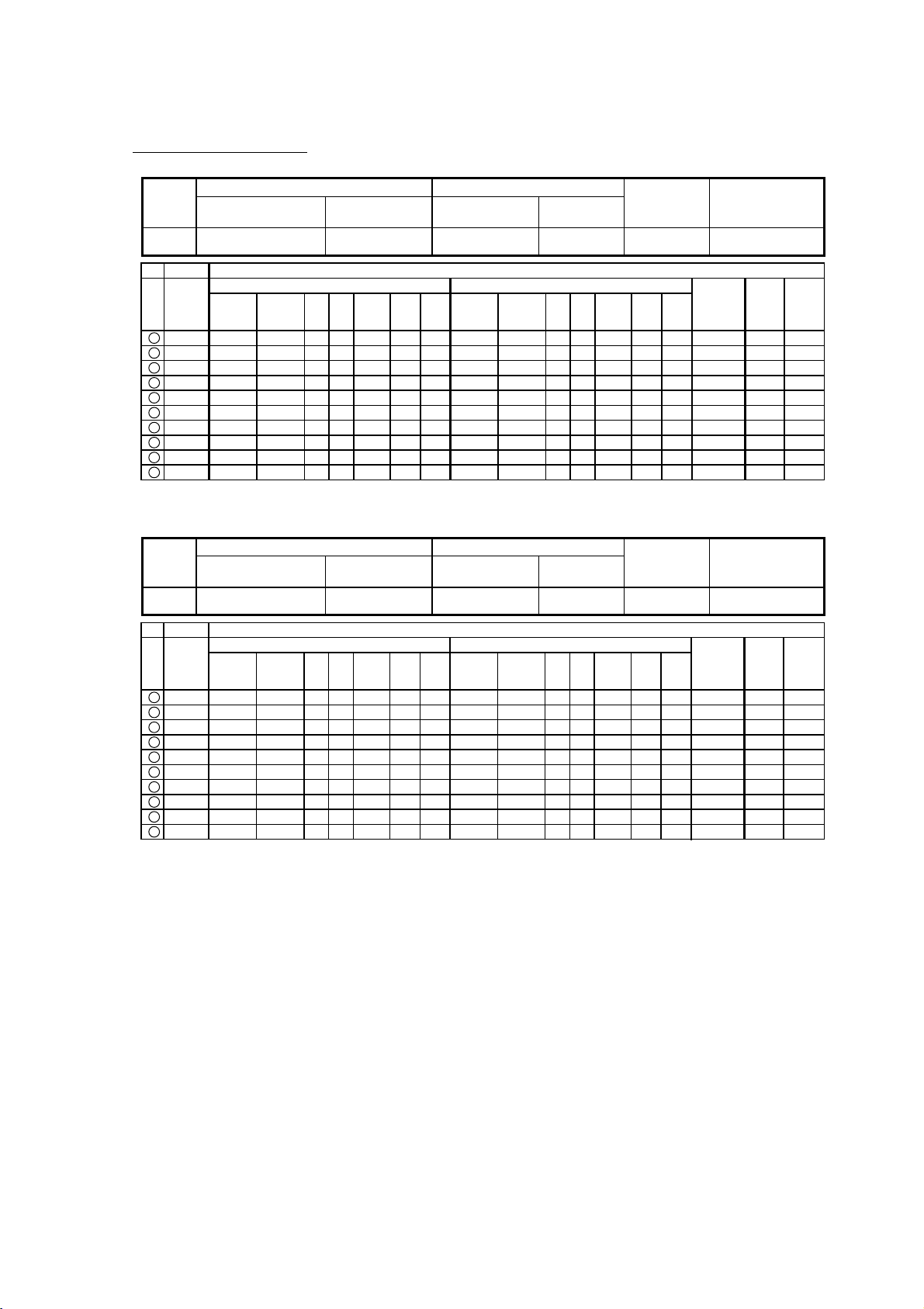

Specification(Pulley , Belt )

Standard(Factory set) <50Hz>

Motor

Motor pulley Fan pulley

V-belt (H)

<mm / in>

Over current relay

(Fan motor)

Pitch diameter

(Changeability) <PCø>

2.2kW

Bore (E) <ø>Bore (E) <ø>

Nominal

diameter (B) <ø>

140.2 28 212 20 1423 / 56 5.0A

Standard <60Hz>

Motor

Motor pulley Fan pulley

V-belt (H)

<mm / in>

Over current relay

(Fan motor)

Pitch diameter

(Changeability) <PCø>

2.2kW

Bore (E) <ø>Bore <ø>

Nominal

diameter (B) <ø>

129.1

(factory set 140.2)

28 212 20 1423 / 56 5.0A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1663

1620

1581

1540

1499

1459

1418

1378

1344

1308

1261

1225

1179

1139

1100

1060

1018

992

955

908

868

820

785

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

3

1/2

1·1/4

2

2·3/4

2·1/2

4·1/4

1·1/2

2·1/2

3

4

4·3/4

3/4

1·3/4

2·3/4

3·3/4

1/4

1

2

2

3·1/4

4·3/4

3

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

118

132

132

132

132

132

132

150

150

150

150

150

180

180

180

180

212

212

212

224

224

224

250

127

141

141

141

141

141

141

159

159

159

159

159

189

189

189

189

221

221

221

233

233

233

259

102

116

116

116

116

116

116

134

134

134

134

134

164

164

164

164

196

196

196

208

208

208

234

50

50

50

50

50

50

50

56

56

56

56

56

56

56

56

56

54

54

54

54

54

54

54

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

1270 / 50

1296 / 51

1296 / 51

1296 / 51

1296 / 51

1296 / 51

1296 / 51

1321 / 52

1321 / 52

1321 / 52

1321 / 52

1321 / 52

1372 / 54

1372 / 54

1372 / 54

1372 / 54

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1474 / 58

17.7

16.5

16.8

17.2

17.6

18.0

18.4

16.9

17.4

17.7

18.2

19.0

16.8

17.3

17.8

18.4

16.6

17.5

18.0

18.0

18.6

19.6

18.8

7.0

6.9

6.9

6.9

7.0

7.0

7.1

6.9

7.0

7.0

7.0

7.1

6.9

6.9

7.0

7.0

6.8

6.9

6.9

6.7

6.8

6.9

6.8

Rotational

speed

<rpm>

No.

Outside

diameter

<ø>

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Deflection

force

<N>

Amount

of

deflection

<mm>

14.7

15.1

15.3

15.6

15.8

14.9

14.7

15.0

15.3

15.6

16.0

14.5

15.3

15.7

16.1

16.5

16.3

16.6

15.9

16.6

15.7

16.9

17.5

6.9

7.0

7.0

7.0

7.1

6.9

6.9

6.9

7.0

7.0

7.1

6.8

6.9

6.9

7.0

7.0

6.8

6.9

6.8

6.9

6.5

6.6

6.7

Slide peace

Rotation

number

Bore (E)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

(F)

<mm>

(G)

<mm>

V-belt (H)

<mm / in>

Motor 2.2kW,1450rpm <50Hz>

Motor pulley Fan pulley

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1664

1622

1579

1535

1506

1458

1422

1375

1339

1304

1248

1221

1181

1141

1101

1060

1022

994

967

908

879

825

787

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

159

1·1/2

2·1/2

3

3·3/4

4·1/4

1·1/2

3/4

1·3/4

2·1/2

3·1/4

4·1/4

1/4

1·1/4

2·1/4

3·1/4

4·1/4

3·3/4

4·1/2

2·1/4

4

1·3/4

3·1/2

4·3/4

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

28

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

31.3

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

150

150

150

150

150

180

180

180

180

180

180

212

212

212

212

212

224

224

250

250

280

280

280

159

159

159

159

159

189

189

189

189

189

189

221

221

221

221

221

233

233

259

259

289

289

289

134

134

134

134

134

164

164

164

164

164

164

196

196

196

196

196

208

208

234

234

264

264

264

56

56

56

56

56

56

56

56

56

56

56

54

54

54

54

54

54

54

54

54

54

54

54

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

23.5

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

1321 / 52

1321 / 52

1321 / 52

1321 / 52

1321 / 52

1372 / 54

1372 / 54

1372 / 54

1372 / 54

1372 / 54

1372 / 54

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1423 / 56

1474 / 58

1474 / 58

1499 / 59

1499 / 59

1499 / 59

Rotational

speed

<rpm>

No.

Outside

diameter

<ø>

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Slide peace

Rotation

number

Bore (E)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

(F)

<mm>

(G)

<mm>

V-belt (H)

<mm / in>

Motor 2.2kW,1750rpm <60Hz>

Motor pulley Fan pulley

Deflection

force

<N>

Amount

of

deflection

<mm>

Page 26

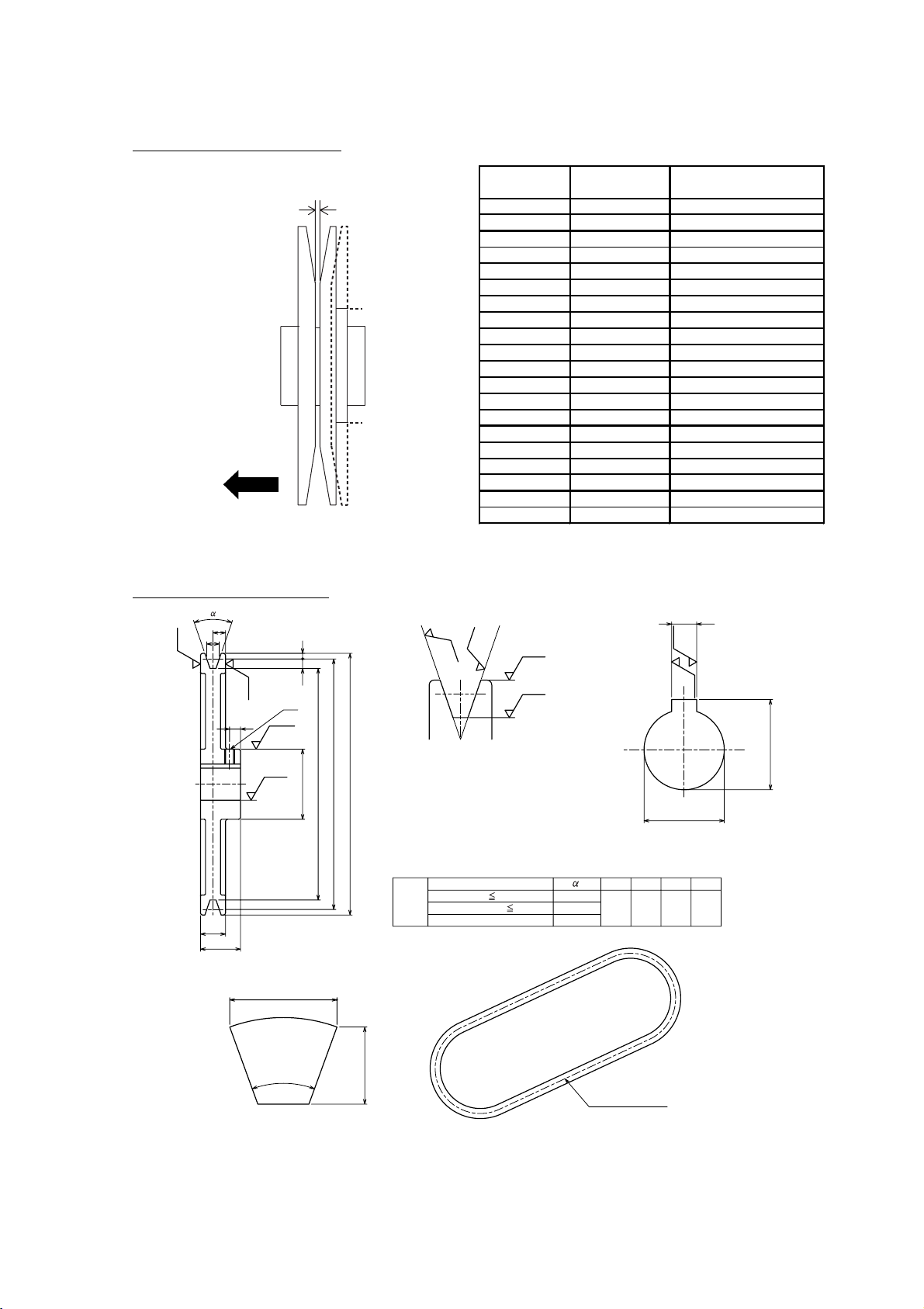

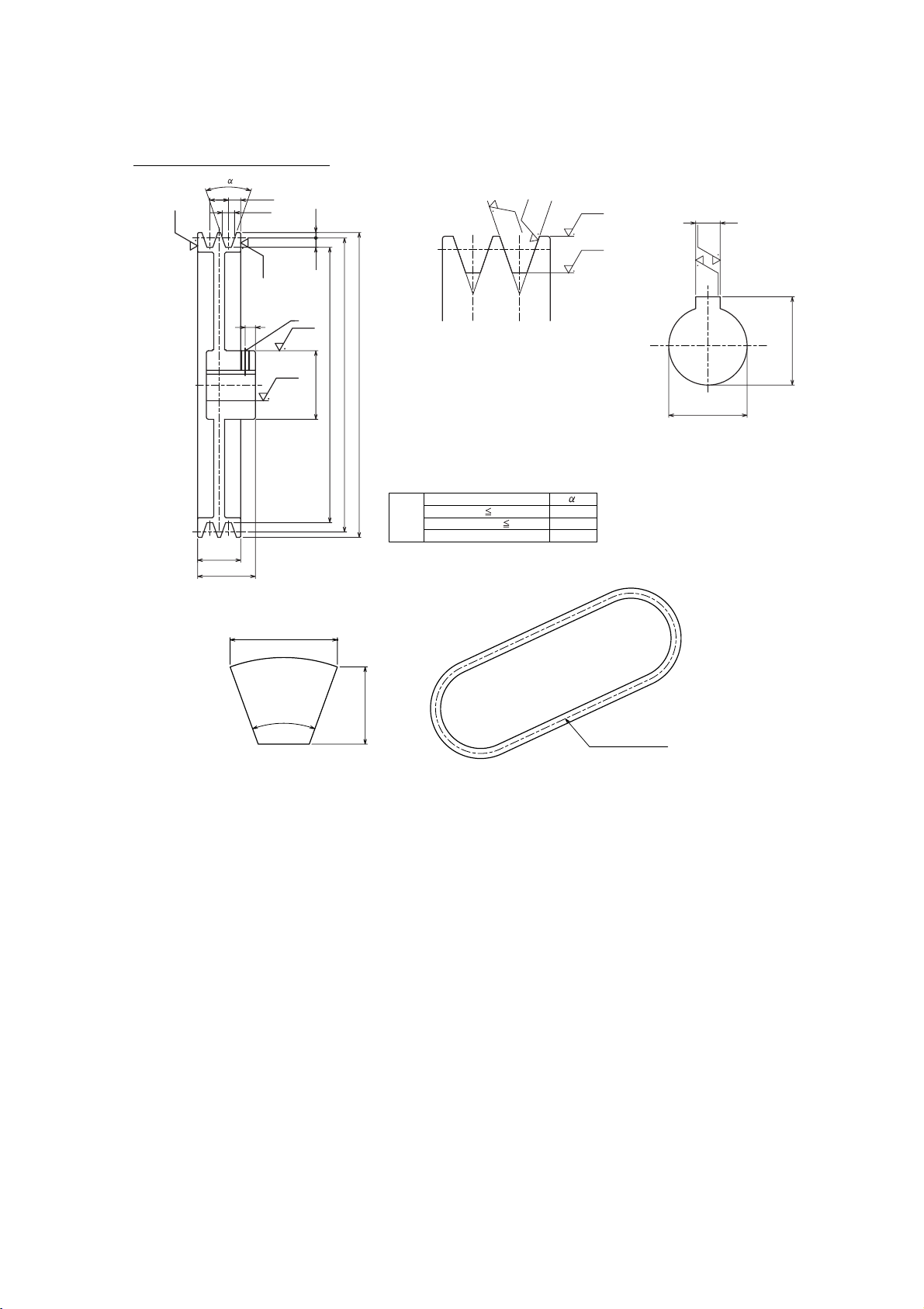

24

Variable-width pulley PC ø table

Shape of the pulley (unit:mm)

Fixed disc

must be

* See p.40 for "How to choose the pulley."

placed on

the motor

side.

Number of

turns to apply

Pulley distance

(mm)

PC ø of variable-width

pulleys for 2.2kW motor

0

1/4

1/2

3/4

1

1·1/4

1·1/2

1·3/4

2

2·1/4

2·1/2

2·3/4

3

3·1/4

3·1/2

3·3/4

4

4·1/4

4·1/2

4·3/4

(0)

(0.4)

(0.8)

(1.1)

(1.5)

(1.9)

(2.3)

(2.6)

(3.0)

(3.4)

(3.8)

(4.1)

(4.5)

(4.9)

(5.3)

(5.6)

(6.0)

(6.4)

(6.8)

(7.1)

150.0

148.8

147.5

146.3

145.1

143.9

142.6

141.4

140.2

139.0

137.7

136.5

135.3

134.1

132.8

131.6

130.4

129.1

127.9

126.7

Pulley

M8

(keyway)

e

12.5

k

5.5

o

9.5

ko

12.5

m

Rz 3.2

Rz 3.2

Rz 12.5

B (d

m

: Pulley nominal diameter)

Belt

dm:Pulley nominal diameter

201 < d

m

dm 126

34˚

36˚

38˚

Rz 6.3

Rz 6.3

Rz 3.2

Rz 3.2

C

A (d : Pulley outside diameter)

25

40

11

e

kk

m

Rz 6.3

Rz 6.3

Rz 3.2

D

E

G

F

161 < dm 200

40˚

12.5

9

H (outer center)

Page 27

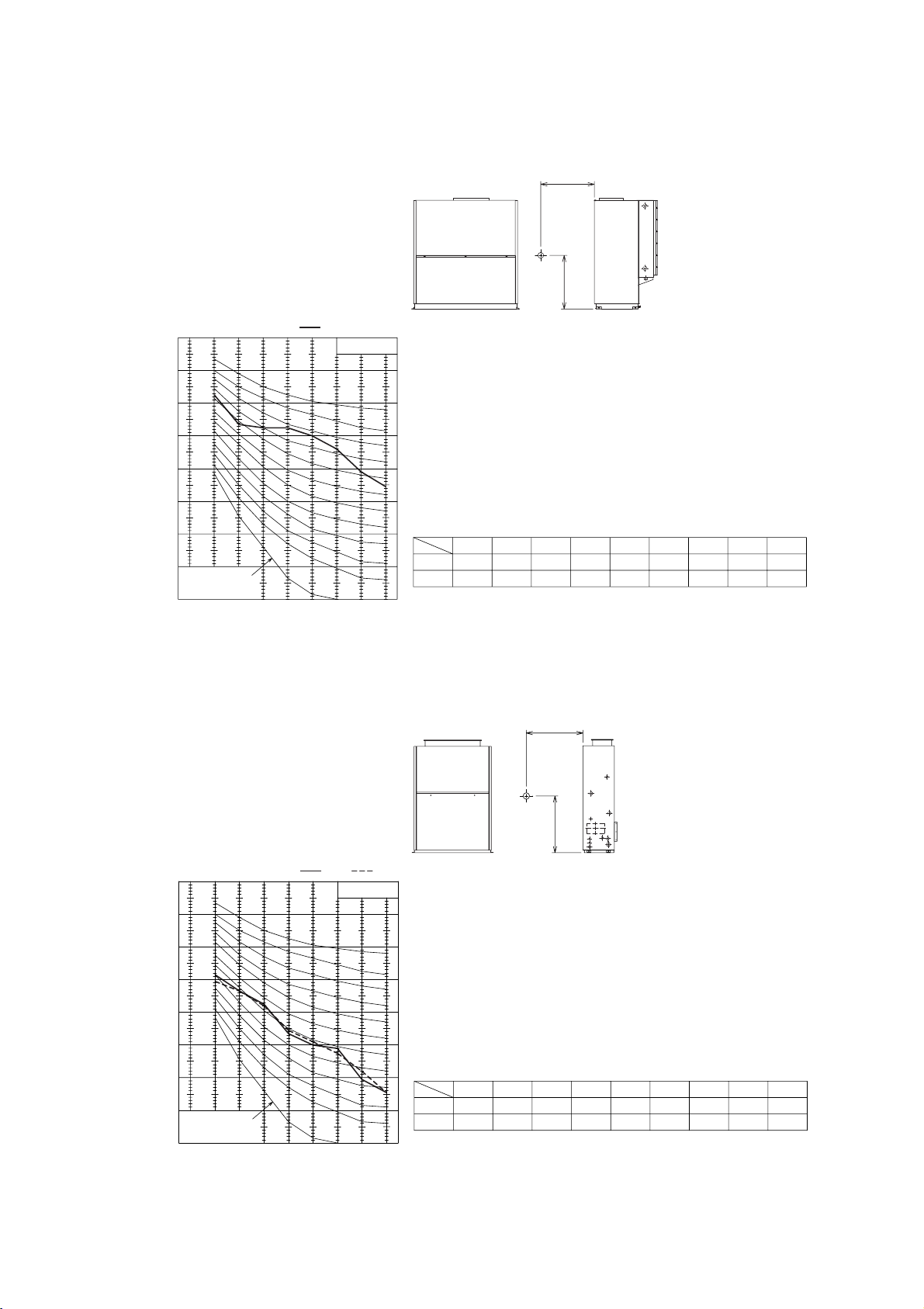

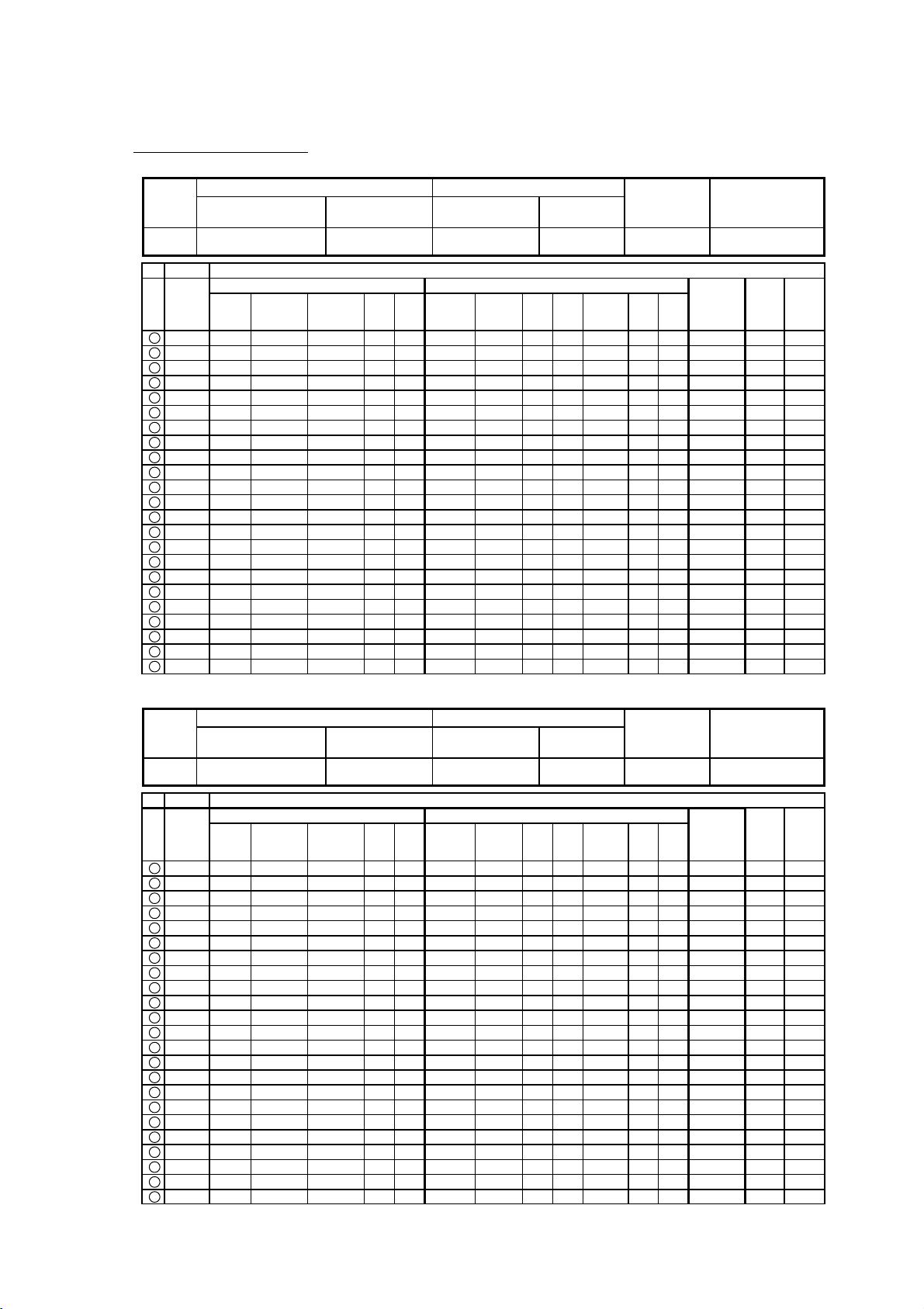

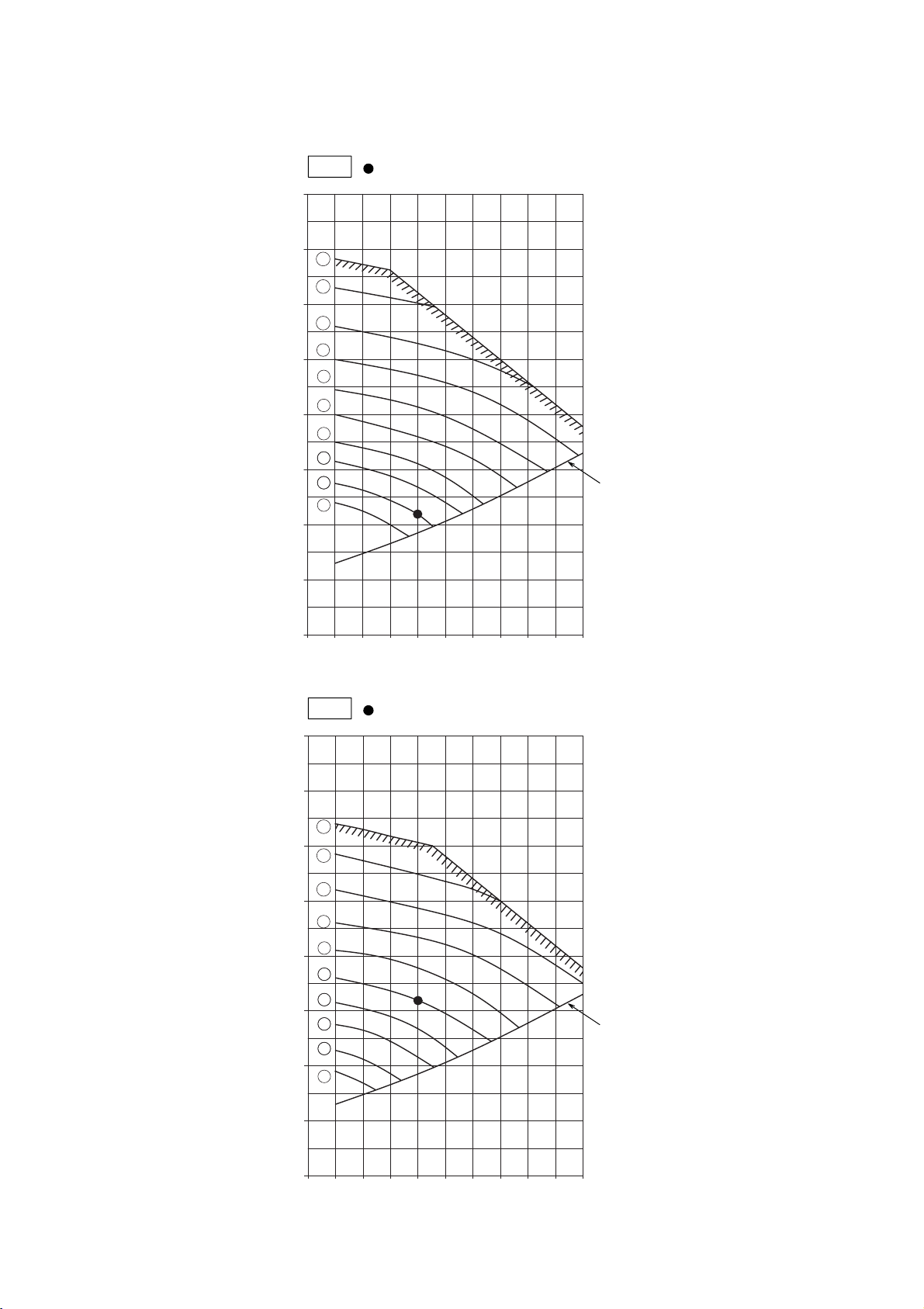

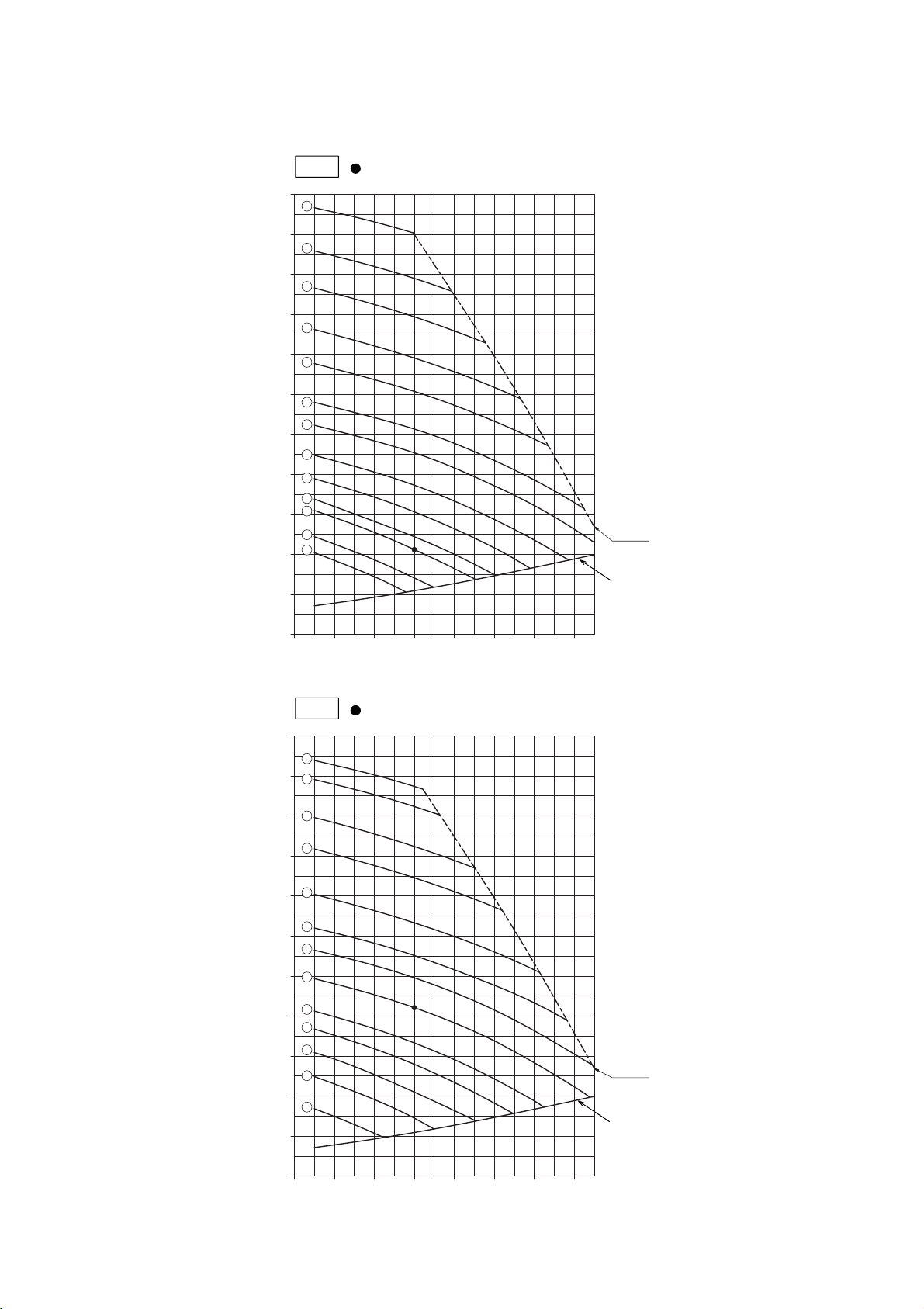

25

•PFAV-P500VM-E

180160140 220 240200

200

0

400

500

300

100

150 170 190 210 230

600

700

800

2

3

1

4

5

6

7

8

9

10

5.5KW

······Standard

50Hz

Internal resistance

Airflow rate < m

3

/ min >

Total static pressure < Pa >

······Standard

60Hz

Internal resistance

Airflow rate < m

3

/ min >

Total static pressure < Pa >

700

600

500

400

300

200

100

240230220210200190180170160150

0

140

800

3

2

1

5

6

7

8

9

10

4

5.5KW

Page 28

26

Specification(Pulley , Belt )

Standard(Factory set) <50Hz>

Motor

Motor pulley Fan pulley

V-belt (H)

<mm / in>

Over current relay

(Fan motor)

Nominal

diameter (B) <ø>

5.5kW

Bore (E) <ø>Bore (E) <ø>

Nominal

diameter (B) <ø>

118 38 236 32 1042 / 41 11A

Standard <60Hz>

Motor

Motor pulley Fan pulley

V-belt (H)

<mm / in>

Over current relay

(Fan motor)

Nominal

diameter (B) <ø>

5.5kW

Bore (E) <ø>Bore (E) <ø>

Nominal

diameter (B) <ø>

118

Note1. Use two V-belts for P500 indoor unit.

Note1. Use two V-belts for P500 indoor unit.

38 236 32 1042 / 41 11A

1

2

3

4

5

6

7

8

9

10

1135

1094

1034

979

929

884

835

796

753

712

190

170

170

180

190

200

212

236

236

250

201

181

181

191

201

211

223

247

247

261

171

151

151

161

171

181

193

217

217

231

80

71

71

71

80

80

80

80

80

80

32

32

32

32

32

32

32

32

32

32

36

36

36

36

36

36

36

36

36

36

10

10

10

10

10

10

10

10

10

10

966 / 38

889 / 35

889 / 35

915 / 36

915 / 36

940 / 37

966 / 38

1016 / 40

1042 / 41

1042 / 41

Rotational

speed

<rpm>

No.

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

145

125

118

118

118

118

118

125

118

118

156

136

129

129

129

129

129

136

129

129

126

106

99

99

99

99

99

106

99

99

71

70

70

70

70

70

70

70

70

70

38

38

38

38

38

38

38

38

38

38

41.3

42

42

42

42

42

42

42

42

42

10

10

10

10

10

10

10

10

10

10

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

V-belt (H)

<mm / in>

Motor 5.5kW,1450rpm <50Hz>

Motor pulley Fan pulley

1

2

3

4

5

6

7

8

9

10

1105

1059

1005

946

894

847

798

753

701

660

224

190

200

212

224

236

250

280

300

300

235

201

211

223

235

247

261

291

311

311

205

171

181

193

205

217

231

261

281

281

80

80

80

80

80

80

80

80

80

80

32

32

32

32

32

32

32

32

32

32

36

36

36

36

36

36

36

36

36

36

10

10

10

10

10

10

10

10

10

10

1016 / 40

915 / 36

940 / 37

966 / 38

991 / 39

1042 / 41

1042 / 41

1118 / 44

1143 / 45

1143 / 45

Rotational

speed

<rpm>

No.

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

145

118

118

118

118

118

118

125

125

118

156

129

129

129

129

129

129

136

136

129

126

99

99

99

99

99

99

106

106

99

71

70

70

70

70

70

70

70

70

70

38

38

38

38

38

38

38

38

38

38

41.3

42

42

42

42

42

42

42

42

42

10

10

10

10

10

10

10

10

10

10

Outside

diameter (A)

<ø>

Nominal

Diameter (B)

<ø>

Bore (E)

<ø>

(C)

<ø>

(D)

<ø>

(F)

<mm>

(G)

<mm>

V-belt (H)

<mm / in>

Motor 5.5kW,1750rpm <60Hz>

Motor pulley Fan pulley

23.2

25.9

27.2

27.6

27.6

28.5

28.5

27.6

28.9

29.9

3.5

3.4

3.4

3.5

3.3

3.4

3.4

3.4

3.6

3.4

21.4

23.8

24.5

24.5

24.9

24.9

25.7

25.4

26.2

27.3

3.4