Page 1

TECHNICAL & SERVICE MANUAL

AIR-COOLED SPLIT-TYPE

PACKAGED AIR CONDITIONERS

For use with the R410A

HEAT PUMP PEH-RP8MYA

PEH-RP10MYA

Models

<Indoor unit>

2004

Page 2

Page

Contents

1 SAFETY PRECAUTION ..........................................................................................................

2 PART NAMES AND FUNCTIONS............................................................................................

3 SPECIFICATIONS ..................................................................................................................

4 OUTLINE AND DIMENSIONS................................................................................................

5 ELECTRICAL WIRING DIAGRAM.........................................................................................

6 TECHNICAL DATA ................................................................................................................

[1] Capacity/Input Ratio against Changes in Room Airflow Rate...........................................

[2] Capacity table

[3] Correction factors

...................................................................................................................

..............................................................................................................

[4] Airflow Characteristic Curves............................................................................................

[6] Standard Operation Data ................................................................................................

NC Curve (Indoor unit)......................................................................................................

7 SERVICE DATA......................................................................................................................

[1] Appearance of Equipment ................................................................................................

[2] Internal Construction.........................................................................................................

[3] Refrigerant Circuit .............................................................................................................

8 FUNCTION OF SWITCH ON INDOOR CIRCUIT BOARD.....................................................

[1] DIP SW1 for model Selection (DIP SW1 has been set at factory)....................................

[2] DIP SW2 for Capacity Setting (DIP SW2 has been set at factory) ...................................

[3] DIP SWE for Emergency Operation..................................................................................

9 TEST RUN ..............................................................................................................................

[1] Before test run ..................................................................................................................

[2] Test run procedures ..........................................................................................................

[3] Self-diagnosis ...................................................................................................................

[4]

Remote controller diagnosis

.............................................................................................

[5] Center of Gravity (Indoor unit) ..........................................................................................

[7]

1

3

5

7

10

11

11

12

16

17

18

20

20

21

21

22

22

22

22

23

23

23

25

27

17

19

Page 3

- 1 -

1

SAFETY PRECAUTION

Cautions for units utilizing refrigerant R410A

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refr igerant is charged from liquid phase.)

Page 4

- 2 -

Unit

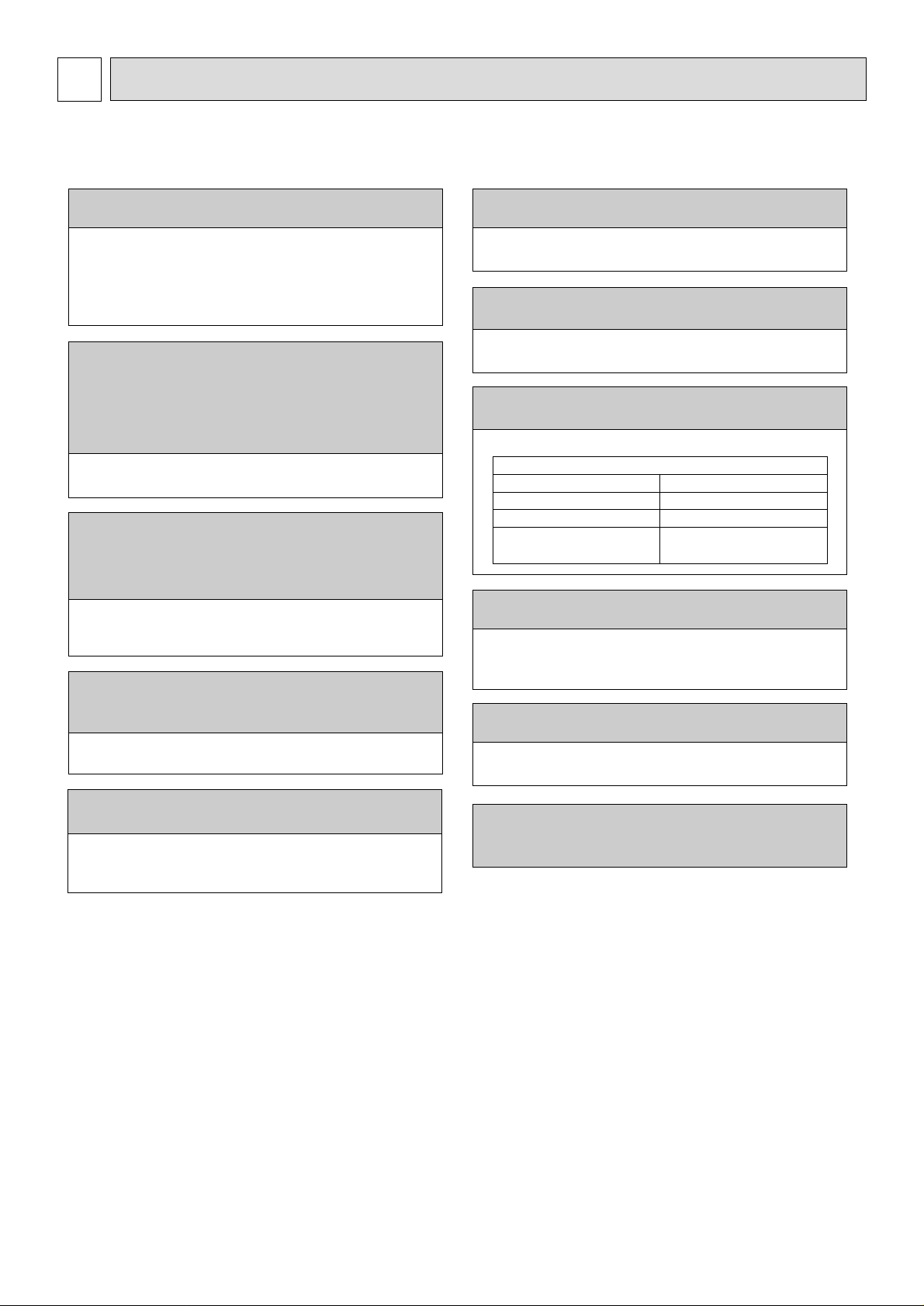

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

Cylinder with syphon

8 Refrigerant recovery equipment

Gravimeter

Page 5

- 3 -

2

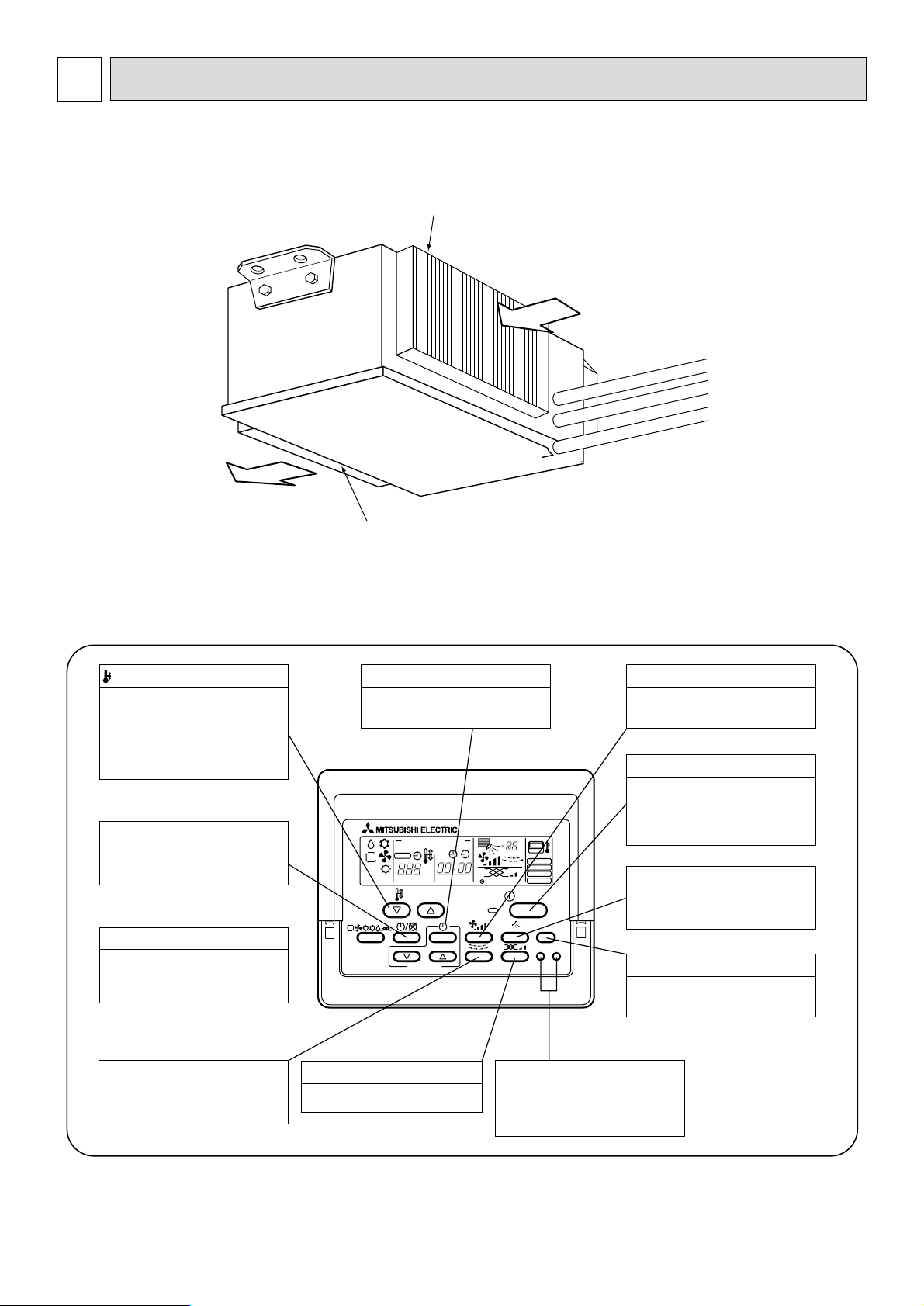

PART NAMES AND FUNCTIONS

● Indoor Unit

PEH-RP8MYA

PEH-RP10MYA

Air intake duct flange

Air outlet duct flange

Air outlet

Air intake

(sucks the air inside the room into the unit)

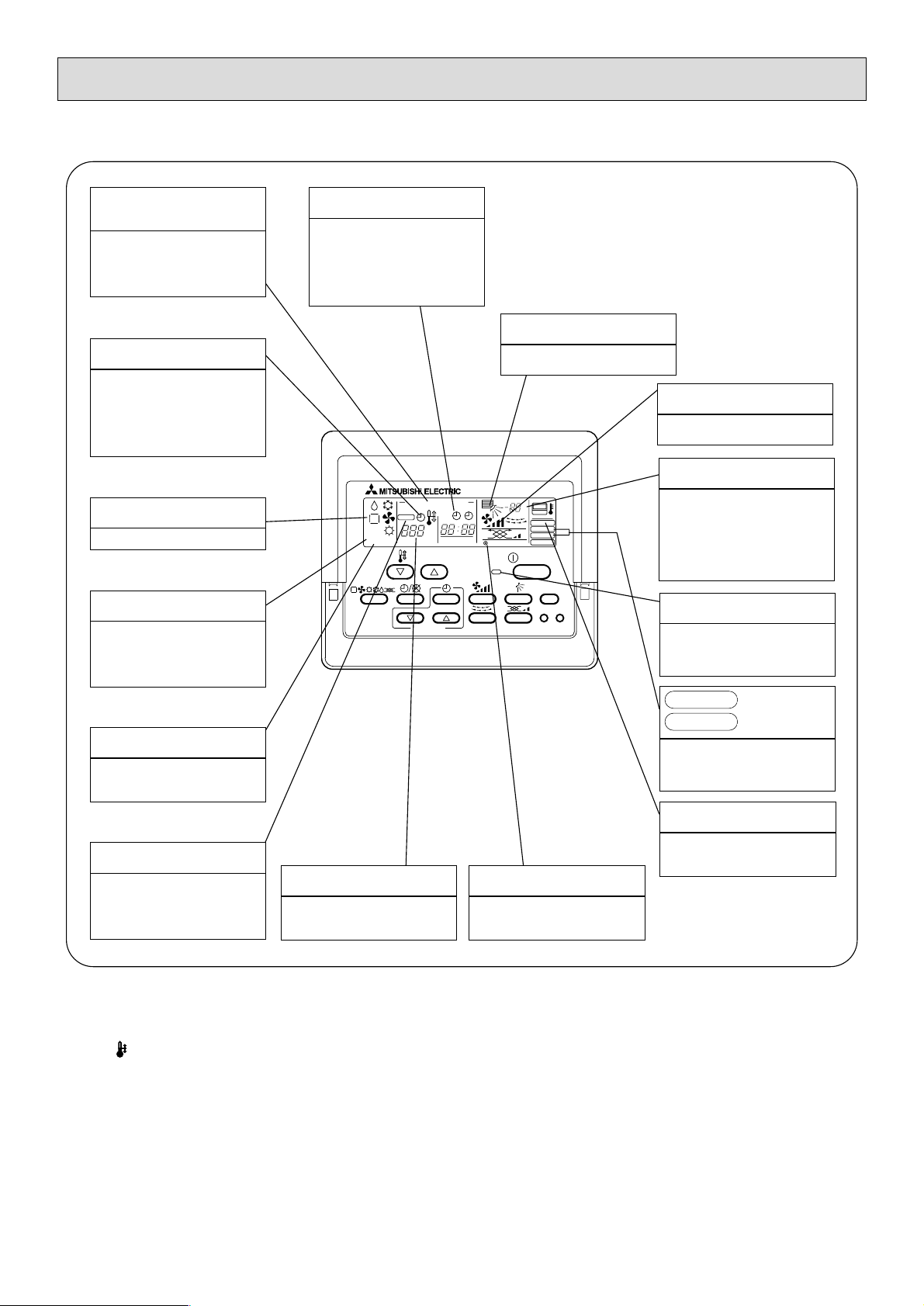

● Operation buttons

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

This sets the ventilation fan speed.

VENTILATION button

Press this button to switch the cooling,

electronic dry (dehumidify), automatic

and heating modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooling 19: to 30:

Heating 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

FAN SPEED button

(Not available for this model.)

Page 6

- 4 -

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped with

the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

CENTRALLY

CONTROLLED display

This indicates when the unit is con-

trolled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

The [STANDBY] symbol is only dis-

played from the time the heating

operation starts unit the heated air

begins to blow.

DEFROST display

This indicates when the defrost oper-

ation is performed.

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button.The start time or stop time is

always displayed during the timer

operation.

● Display

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

POWER display

This lamp lights when electricity is

supplied to the unit.

SET TEMPERATURE display

This displays the selected setting

temperature.

AIR DIRECTION display

This displays the air direction.

ROOM TEMPERATURE display

The temperature of the suction air

is displayed during operation.The

display range is 8°C to 39°C.The

display flashes 8°C when the actual

temperature is less than 8°C and

flashes 39°C when the actual temperature is greater than 39°C.

display

This display lights in the check mode

or when a test operation is performed.

CHECK MODE

TEST RUN

This lamp lights when the filter need

to be cleaned.

AIR SPEED display

The selected fan speed is displayed.

FILTER display

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

Page 7

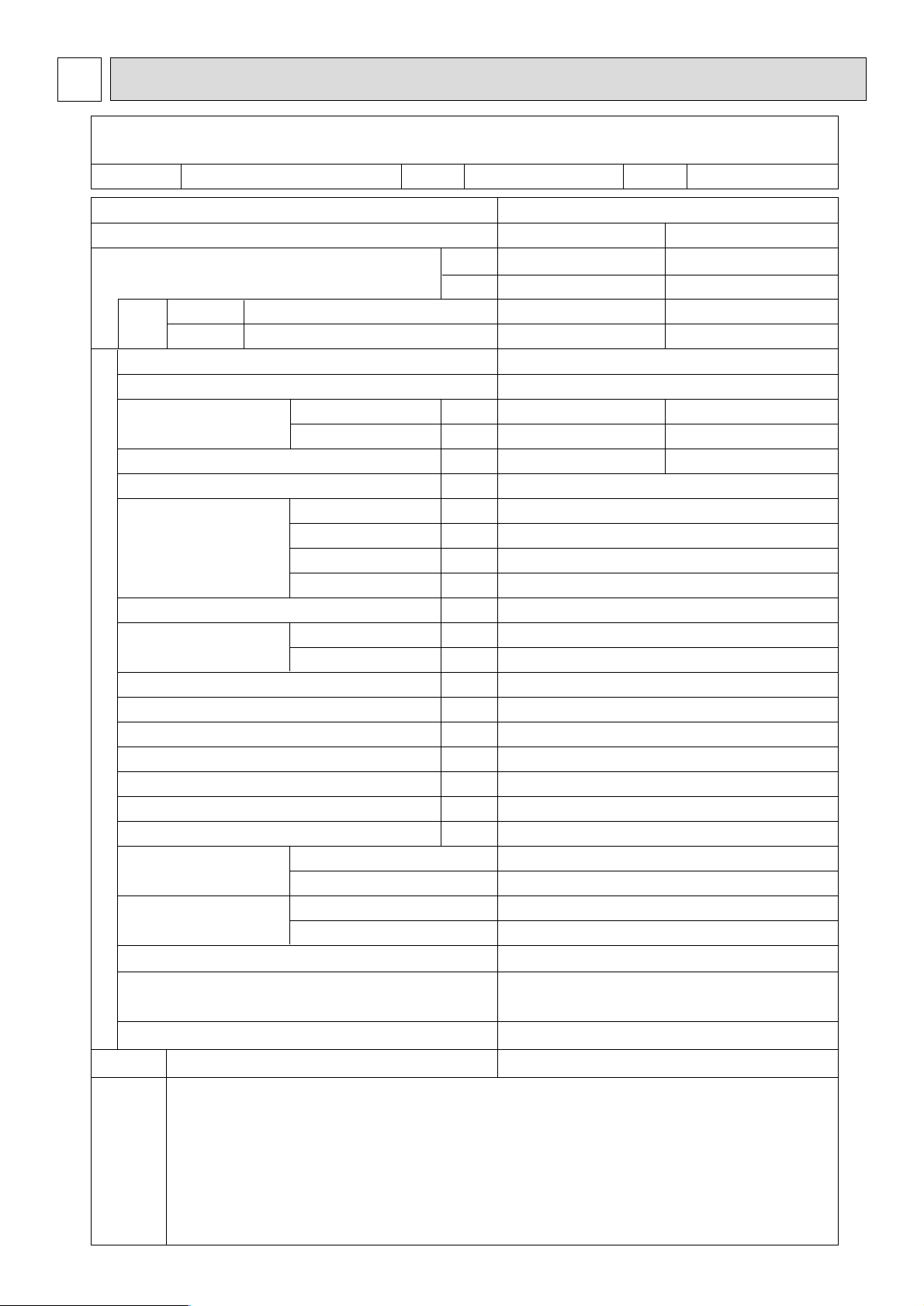

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name PEH-RP8MYA

PEH-RP8MYAService Ref.

PEH-RP8MYAService Ref.

PUHZ-RP8YHAService Ref.

Outdoor

unit

Indoor unit

Quantity Symbol

Capacity kcal/h

kW

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power source

Power consumption kW

Operating current A

Remote controller temperature setting range °C

Airflow direction control

Type × Quantity

Airflow rate m

3

/min

External static pressure

Pa

Motor output kW

External finish

Unit (H × W × D) mm

Panel (H × W × D) mm

Heat exchanger type

Air filter

Insulation material

Refrigerant piping size Liquid/Gas

φ

mm

φ

mm

Drain piping size

Noise level dB(A)

Net weight kg

Minimum wire thickness

Circuit breaker

Operation control device (provided)

Decoration panel (Option)

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 5m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The

5. Refer to the service manual of outdoor unit for the outdoor unit’s specifications.

figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50 Pa setting.

Cooling Heating

16,300 19,300

19.0 (10.0~22.4) 22.4 (10.0~25.0)

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/6 ˚C

3N~ 380/400/415V 50Hz

0.65/0.65/0.65 0.65/0.65/0.65

1.12/1.12/1.12 1.12/1.12/1.12

19 ~ 30 17 ~ 28

–

Sirrocco fan × 2

60

50/150

0.75

Galvanizing

428 × 1380 × 650

–

Cross fin

Saran net

Polyethylene foam

9.52/25.4

25.4 (RC1)

49 (at 50 Pa)

70

1.6 mm

15 A

Remote controller: PAR-20MAA

–

–

Electrical characteristics

Fan

External dimension

External wiring

Composing parts

Notes:

Installation manual, Operation manual,

Remote controller

–

Air con-

dition

- 5 -

3

SPECIFICATIONS

Page 8

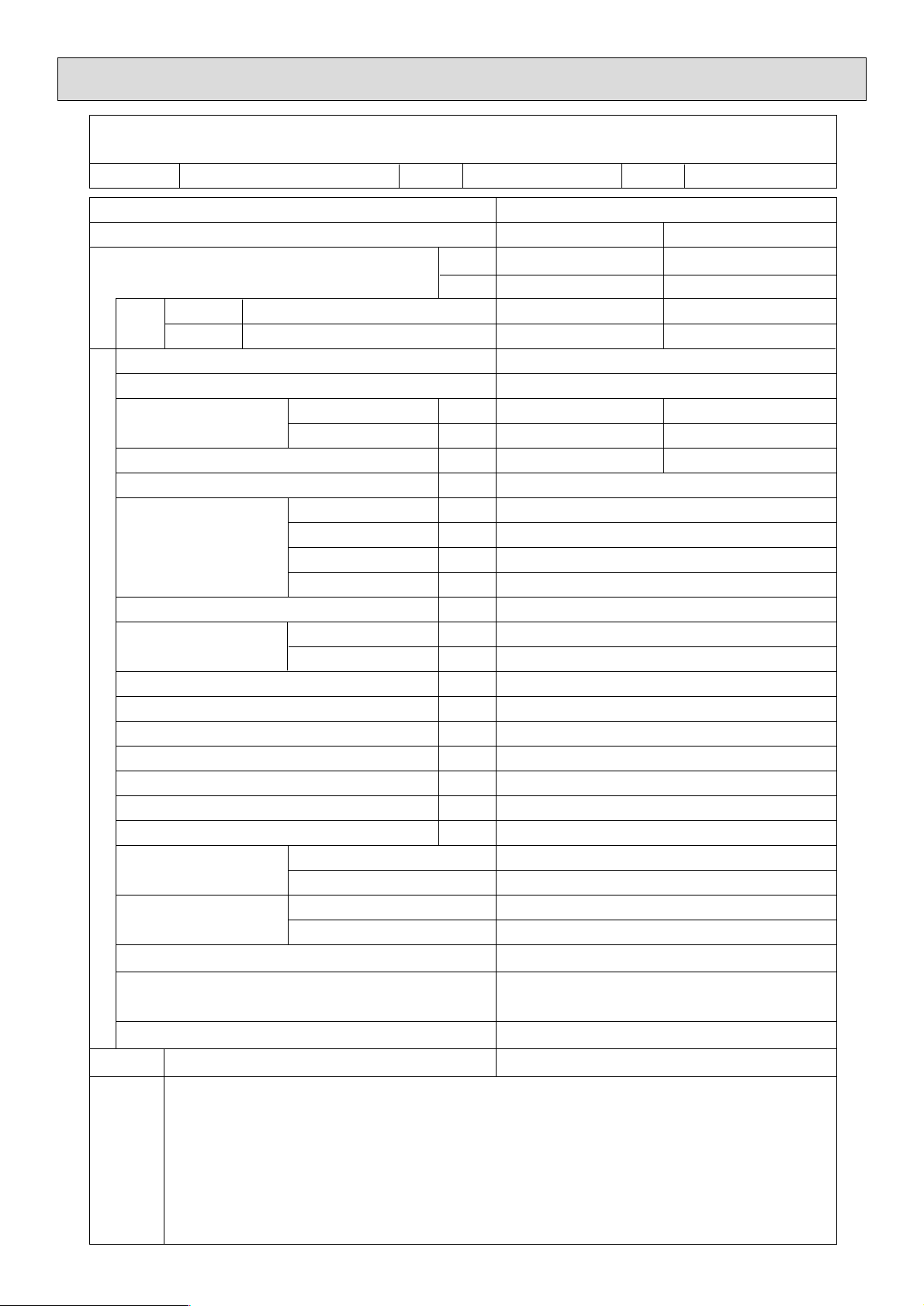

PEH-RP10MYA

Cooling Heating

18,900 23,200

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/ 6 °C

3N~ 380/400/415V 50 Hz

0.94/0.94/0.94 0.94/0.94/0.94

1.64/1.64/1.64 1.64/1.64/1.64

19 ~ 30 17 ~ 28

–

Sirrocco fan × 2

80

50/150

1.23

Galvanizing

428 × 1,580 × 650

–

Cross fin

Saran net

Polyethyene foam

12.7/28.58

25.4 (RC1)

53 (at 50 Pa)

80

1.6 mm

15 A

Remote controller: PAR-20MAA

–

–

Installation manual, Operation manual,

Remote controller

–

PUHZ-RP10YHA

PEH-RP10MYA

PEH-RP10MYA

22.0 (12.5~28.0) 27.0 (15.7~31.5)

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name

Service Ref.

Service Ref.

Service Ref.

Outdoor

unit

Indoor unit

Quantity Symbol

Capacity kcal/h

kW

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power source

Power consumption kW

Operating current A

Remote controller temperature setting range °C

Airflow direction control

Type × Quantity

Airflow rate m

3

/min

External static pressure

Pa

Motor output kW

External finish

Unit (H × W × D) mm

Panel (H × W × D) mm

Heat exchanger type

Air filter

Insulation material

Refrigerant piping size Liquid/Gas

φ

mm

φ

mm

Drain piping size

Noise level dB(A)

Net weight kg

Minimum wire thickness

Circuit breaker

Operation control device (provided)

Decoration panel (Option)

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 5m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The

5. Refer to the service manual of outdoor unit for the outdoor unit’s specifications.

figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50 Pa setting.

Electrical characteristics

Fan

External dimension

External wiring

Composing parts

Notes:

Air condition

- 6 -

Page 9

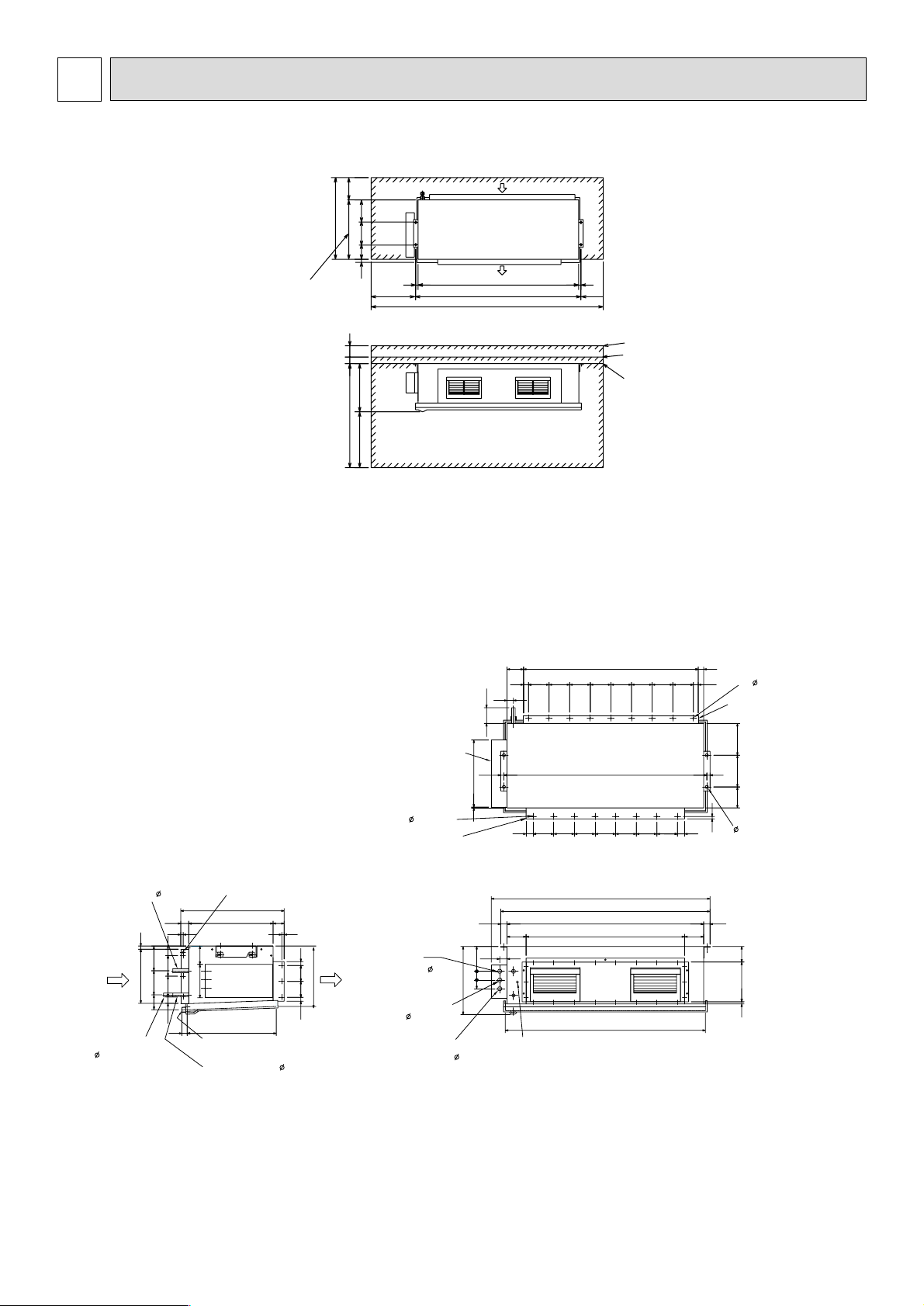

(1) Indoor Unit

• Model PEH-RP8MYA

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body , and mount

an air filter onto the inlet duct side separately.

AIR INLET SENSOR

REFRIGERANT PIPE

12.7

(1/2 BRAZE)

REFRIGERANT PIPE 25.4

(1 BRAZE)

AIR INLET

AIR OUTLET

POWER SUPPLY

WIRING HOLE 27

(AIR INLET SIDE)

CONTROLLER

WIRING HOLE 27

(AIR INLET SIDE)

CONNECT WIRE (PEH-PUH)

WIRING HOLE 27

(AIR INLET SIDE)

ACCESSORY PIPE

(USE FOR ONLY R410A)

9.52 (3/8 BRAZE)

DUCT EARTH POINT

(BOTH DUCT SIDE)

152

650

428

95

156

AIR INLET DUCT

FLANGE

24- 3.1 HOLES

34

31

1102

104

130130130130130130130130

31

344

20

15

7053050

130

130

42

42

DRAIN: Rc 1

CONTROL BOX

4- 12 HOLES

22- 3.1 HOLES

AIR OUTLET DUCT

FLANGE

33

562

382

25 100

100 25

1240

20

20

1280

15

40

120

4513013013013013013013045

40

1320

1000

120

1264

98250

14

(FOR HUNGING

BOLT M10)

<FIELD SUPPLY>

15

100

40

210 116

4235

46

55 55 156

1380

131 200 199

928

1240

20

530

13132

200

199

400

730

200

1280

1880

200

20

428500

25 75

(1)

(2)

(3)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

(A)

(A)

(C)

(B)

(B)

(D)

- 7 -

4

OUTLINE AND DIMENSIONS

Page 10

- 8 -

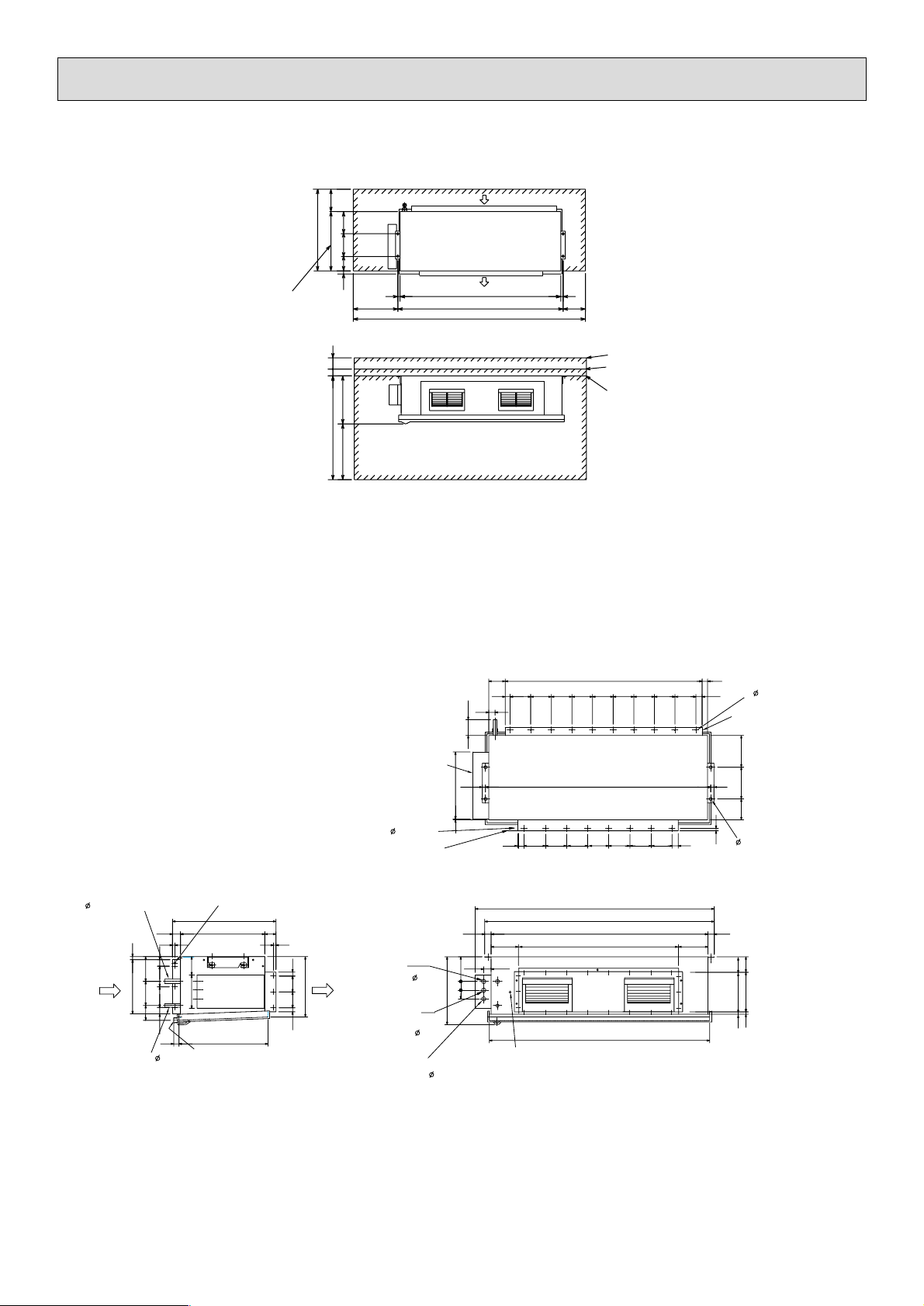

• Model PEH-RP10MYA

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body , and mount

an air filter onto the inlet duct side separately.

(B)

730

200

530

25 75

928

428500

199

200

13132

(A)

400

20

(B)

1440

1480

2080

(C)

(D)

20

200

(1)

(2)

(3)

(A)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

REFRIGERANT PIPE

28.6 (1-1/8 BRAZE)

15

20

42

156

130

344

152

AIR INLET

REFRIGERANT PIPE

(1/2 BRAZE)

130

95

42

33

12.7

AIR INLET SENSOR

650

210 116

562

DRAIN: Rc 1

104

66

40

100

1302

130130130130130130130130

34

130

66

26- 3.1 HOLES

AIR INLET DUCT

FLANGE

CONTROL BOX

20

423

FLANGE

5

45

130

40

220

46

428

55 55 156

DUCT EARTH POINT

(BOTH DUCT SIDE)

22- 3.1 HOLES

AIR OUTLET DUCT

7053050

15

CONTROLLER

100 25

25 100

382

AIR OUTLET

WIRING HOLE 27

(AIR INLET SIDE)

CONNECT WIRE

(PEH-PUH)

WIRING HOLE 27

(AIR INLET SIDE)

POWER SUPPLY

WIRING HOLE 27

(AIR INLET SIDE)

1480

130

1580

1520

1440 40

1000

1464

20

131 200 199

45130130130130

220

15

4- 12 HOLES

(FOR HUNGING

<FIELD SUPPLY>

98

250

14

BOLT M10)

130

Page 11

(2) Remote Controller

• Model

PAR-20MAA

- 9 -

120

(Front view) (Side view) (Rear view)

130

19

83.5

46

Page 12

(1) Indoor Unit

• Models PEH-RP8MYA/RP10MYA

INDOOR UNIT

SYMBOL NAME

MF1 FAN MOTOR (INDOOR)

51F OVER CURRENT RELAY (INDOOR FAN MOTOR)

52F CONTACTOR (INDOOR FAN MOTOR)

49F INTERNAL THERMOSTAT (INDOOR FAN MOTOR)

TB2, 4, 5 TERMINAL BLOCK

TH1 ROOM TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

TH2 THERMISTOR PIPE TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

TH5 COND./EVA. TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

F1 FUSE (4A 250VAC CLASS T)

ZNR VARISTOR

X4-6 AUXILIARY RELAY (INDOOR CONTROLLER BOARD)

SW1 SWITCH (MODEL SELECTION)

SW2 SWITCH (CAPACITY CORD)

SWE SWITCH (EMERGENCY OPERATION)

LED1 LED (POWER SUPPLY : INDOOR CONTROLLER BOARD)

LED2 LED (POWER SUPPLY : REMOTE CONTROLLER)

LED3 LED (TRANSMISSION : INDOOR-OUTDOOR)

CR SURGE KILLER

CN03, CN21, 2D

CN20-22, 29, 32

CONNECTOR (INDOOR CONTROLLER BOARD)

CN41, 90, FAN

CN01, 02, 2S CONNECTOR (INDOOR POWER BOARD)

C01, 02, 12 CONNECTOR (FAN MOTOR)

FB FERRITE CORE

OUTDOOR UNIT

SYMBOL NAME

TB3 TERMINAL BLOCK

REMOTE CONTROLLER

SYMBOL NAME

TB6 TERMINAL BLOCK

Note:

1. The dotted lines show field wiring.

2. Color of earth wire is yellow and green twisting.

3. Specification subject to change without notice.

4. Indoor and outdoor connecting wires are made with

polarities, make sure matching wiring and terminal.

5. Emergency operation

If a trouble occurs with either the remote controller

or the indoor microcomputer and no other trouble

exisits, emergency operation for cooling or heating

can be performed by changing the setting of switch

(SWE) on the indoor controller board.

6. SW2 is shown PEH-RP10MYA setting.

In case of PEH-RP8MYA setting is shown as below.

Caution:

1. To protect fan motor from abnor mal current,over

current relays is installed.

Therefore, do not change factory set value of over

current relays.

SW2

ON

OFF

4321

PE

- 10 -

5

ELECTRICAL WIRING DIA GRAM

REMOTE CONTROLLER

REMOTE CONTROLLER

BOARD

LCD

CN

T B 6

CIRCUIT BREAKER

(FIELD SUPPLY)

PEH-RP8,10MYA:15A

POWER SUPPLY

3N~PE

380/400/415V

50Hz

C0

5 2 F 5 1 F

1

CN2

2

1

CN2

2

2 1

(WHITE)

(50Pa)

INDOO

CONTROLLER

1

2

CN9

3

4

5

6

7

8

9

CN2

D C 14V

F B

INDOO

POWER BOARD

CN2S

D C 14V

1

2

14V

T B 2

L 1

RED

L 2

WHITE

L 3

BLACK

N

PE

T B 5

1

2

PE

INLET

DUCT

PE

OUTLET

PE

PE

DUCT

INDOOR UNIT [PEH-RP8, RP10MYA]

C02

PE

(RED)

(150Pa)

2

1

MF1

3

2

1

3

1

2

3

5 3 1

4

1

2

1

2

1

2

C R

DC

CN01

ZNR

1

2

CN3

3

L E D 1

L E D 2

L E D 3

1 2 3

F1

CN03

1

2

3

CN02

CN41

CN29

CN21

CN20

FAN

4 9 F

5 1 F

T H 1

T H 2

T H 5

4

SW

4321

SW

SW

X4 X5 X6

7 5 3 1

52F

1

C12

3

1235

ON

OFF

ON

OFF

ON

OFF

X6X5X4

T B 4

S 1

S 2

S 3

TO OUTDOOR

CONNECTING

(POLER)

POWER

3N~

380/400/415V

OUTDOOR UNIT

T B 3

S1

S2

S3

T B 1

L1

L2

L3

N

PE

Page 13

50 55 60 65

70

Capacity/Input ratio

Airflow rate (m3/min)

1.0

1.05

0.95

Cooling

Capacity/Input ratio

Heating

Airflow rate (m3/min)

50 55

60 65 70

1.0

1.05

0.95

Input

Capacity

Capacity

Input

[1] Capacity/Input Ratio against Changes in Room Airflow Rate

• Model PEH-RP8MYA

• Model

PEH-RP10MYA

- 11 -

6

TECHNICAL DATA

Cooling

1.05

1.0

Input

Capacity/Input ratio

Capacity

0.95

70 75 80 85

Airflow rate (m3/min)

1.05

Heating

Input

1.0

Capacity

Capacity/Input ratio

0.95

90

70 75 80 85

Airflow rate (m3/min)

90

Page 14

[2] Capacity table

COOLING CAPACITY (1)

PEH-RP8MYA/PUHZ-RP8YHA (Indoor unit Airflow rate 60m

3

/min)

Outdoor intake air DB˚C

2520

CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C.

18810

20140

21660

18810

20140

21660

18810

20140

21660

23085

18810

20140

21660

23085

18810

20140

21660

23085

18810

20140

21660

23085

18810

20140

21660

23085

18810

20140

21660

23085

18810

20140

21660

23085

12227

10674

8881

13731

12285

10613

15236

13897

12346

10388

16741

15508

14079

12235

17493

16313

14945

13158

18246

17119

15812

14082

18810

18730

17545

15929

18810

20140

19277

17775

18810

20140

21010

19622

20

22

24

26

27

28

30

32

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

5.82

5.93

6.12

5.82

5.93

6.12

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

5.82

5.93

6.12

6.26

18240

19570

21185

18240

19570

21185

18240

19570

21185

22610

18240

19570

21185

22610

18240

19570

21185

22610

18240

19570

21185

22610

18240

19570

21185

22610

18240

19570

21185

22610

18240

19570

21185

22610

11856

10372

8686

13315

11938

10381

14774

13503

12075

10175

16234

15069

13770

11983

16963

15852

14618

12888

17693

16635

15465

13792

18240

18200

17160

15601

18240

19570

18855

17410

18240

19570

20549

19219

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

6.15

6.26

6.41

6.15

6.26

6.41

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

6.15

6.26

6.41

6.62

17670

18905

20615

17670

18905

20615

17670

18905

20615

22040

17670

18905

20615

22040

17670

18905

20615

22040

17670

18905

20615

22040

17670

18905

20615

22040

17670

18905

20615

22040

17670

18905

20615

22040

11486

10020

8452

12899

11532

10101

14313

13044

11751

9918

15726

14557

13400

11681

16433

15313

14224

12563

17140

16069

15049

13444

17670

17582

16698

15208

17670

18905

18347

16971

17670

18905

19997

18734

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

6.52

6.70

6.84

6.52

6.70

6.84

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

6.52

6.70

6.84

7.06

Indoor

intake air

DB˚C

Indoor

intake air

WB˚C

30

NOTE: CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW)

SHF

: Sensible heat factor

- 12 -

Page 15

COOLING CAPACITY (2)

PEH-RP8MYA/PUHZ-RP8YHA (Indoor unit Airflow rate 60m

3

/min)

Outdoor intake air DB˚C

4035

CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C.

16910

18240

19760

16910

18240

19760

16910

18240

19760

21280

16910

18240

19760

21280

16910

18240

19760

21280

16910

18240

19760

21280

16910

18240

19760

21280

16910

18240

19760

21280

16910

18240

19760

21280

10992

9667

8102

12344

11126

9682

13697

12586

11263

9576

15050

14045

12844

11278

15726

14774

13634

12130

16403

15504

14425

12981

16910

16963

16006

14683

16910

18240

17586

16386

16910

18240

19167

18088

20

22

24

26

27

28

30

32

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

6.99

7.17

7.35

6.99

7.17

7.35

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

6.99

7.17

7.35

7.50

16150

17670

19000

16150

17670

19000

16150

17670

19000

20520

16150

17670

19000

20520

16150

17670

19000

20520

16150

17670

19000

20520

16150

17670

19000

20520

16150

17670

19000

20520

16150

17670

19000

20520

10498

9365

7790

11790

10779

9310

13082

12192

10830

9234

14374

13606

12350

10876

15020

14313

13110

11696

15666

15020

13870

12517

16150

16433

15390

14159

16150

17670

16910

15800

16150

17670

18430

17442

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

7.50

7.72

7.86

7.50

7.72

7.86

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

7.50

7.72

7.86

8.08

15390

16530

17860

15390

16530

17860

15390

16530

17860

19380

15390

16530

17860

19380

15390

16530

17860

19380

15390

16530

17860

19380

15390

16530

17860

19380

15390

16530

17860

19380

15390

16530

17860

19380

10004

8761

7323

11235

10083

8751

12466

11406

10180

8721

13697

12728

11609

10271

14313

13389

12323

11047

14928

14051

13038

11822

15390

15373

14467

13372

15390

16530

15895

14923

15390

16530

17324

16473

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.45

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

8.12

8.30

8.44

8.12

8.30

8.44

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

8.12

8.30

8.44

8.59

Indoor

intake air

DB˚C

Indoor

intake air

WB˚C

45

NOTE: CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW)

SHF

: Sensible heat factor

- 13 -

Page 16

COOLING CAPACITY (3)

PEH-RP10MYA/PUHZ-RP10YHA (Indoor unit Airflow rate 80m

3

/min)

NOTE: CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW)

SHF

: Sensible heat factor

Outdoor intake air DB˚C

2520

CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C.

21780

23320

25080

21780

23320

25080

21780

23320

25080

26730

21780

23320

25080

26730

21780

23320

25080

26730

21780

23320

25080

26730

21780

23320

25080

26730

21780

23320

25080

26730

21780

23320

25080

26730

15682

13992

12038

17424

15858

14045

19166

17723

16051

13900

20909

19589

18058

16038

21780

20522

19061

17107

21780

21454

20064

18176

21780

23320

22070

20315

21780

23320

24077

22453

21780

23320

25080

24592

20

22

24

26

27

28

30

32

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

6.74

6.87

7.08

6.74

6.87

7.08

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

6.74

6.87

7.08

7.25

21120

22660

24530

21120

22660

24530

21120

22660

24530

26180

21120

22660

24530

26180

21120

22660

24530

26180

21120

22660

24530

26180

21120

22660

24530

26180

21120

22660

24530

26180

21120

22660

24530

26180

15206

13596

11774

16896

15409

13737

18586

17222

15699

13614

20275

19034

17662

15708

21120

19941

18643

16755

21120

20847

19624

17802

21120

22660

21586

19897

21120

22660

23549

21991

21120

22660

24530

24086

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

7.12

7.25

7.42

7.12

7.25

7.42

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

7.12

7.25

7.42

7.67

20460

21890

23870

20460

21890

23870

20460

21890

23870

25520

20460

21890

23870

25520

20460

21890

23870

25520

20460

21890

23870

25520

20460

21890

23870

25520

20460

21890

23870

25520

20460

21890

23870

25520

14731

13134

11458

16368

14885

13367

18005

16636

15277

13270

19642

18388

17186

15312

20460

19263

18141

16333

20460

20139

19096

17354

20460

21890

21006

19395

20460

21890

22915

21437

20460

21890

23870

23478

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

7.54

7.76

7.92

7.54

7.76

7.92

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

7.54

7.76

7.92

8.18

Indoor

intake air

DB˚C

Indoor

intake air

WB˚C

30

- 14 -

Page 17

COOLING CAPACITY (4)

PEH-RP10MYA/PUHZ-RP10YHA (Indoor unit Airflow rate 80m

3

/min)

Outdoor intake air DB˚C

4035

CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C. CA

SHC(W)

SHF P.C.

19580

21120

22880

19580

21120

22880

19580

21120

22880

24640

19580

21120

22880

24640

19580

21120

22880

24640

19580

21120

22880

24640

19580

21120

22880

24640

19580

21120

22880

24640

19580

21120

22880

24640

14098

12672

10982

15664

14362

12813

17230

16051

14643

12813

18797

17741

16474

14784

19580

18586

17389

15770

19580

19430

18304

16755

19580

21120

20134

18726

19580

21120

21965

20698

19580

21120

22880

22669

20

22

24

26

27

28

30

32

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

8.09

8.30

8.51

8.09

8.30

8.51

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

8.09

8.30

8.51

8.68

18700

20460

22000

18700

20460

22000

18700

20460

22000

23760

18700

20460

22000

23760

18700

20460

22000

23760

18700

20460

22000

23760

18700

20460

22000

23760

18700

20460

22000

23760

18700

20460

22000

23760

13464

12276

10560

14960

13913

12320

16456

15550

14080

12355

17952

17186

15840

14256

18700

18005

16720

15206

18700

18823

17600

16157

18700

20460

19360

18058

18700

20460

21120

19958

18700

20460

22000

21859

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

8.68

8.94

9.10

8.68

8.94

9.10

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

8.68

8.94

9.10

9.36

17820

19140

20680

17820

19140

20680

17820

19140

20680

22440

17820

19140

20680

22440

17820

19140

20680

22440

17820

19140

20680

22440

17820

19140

20680

22440

17820

19140

20680

22440

17820

19140

20680

22440

12830

11484

9926

14256

13015

11581

15682

14546

13235

11669

17107

16078

14890

13464

17820

16843

15717

14362

17820

17609

16544

15259

17820

19140

18198

17054

17820

19140

19853

18850

17820

19140

20680

20645

0.72

0.60

0.48

0.80

0.68

0.56

0.88

0.76

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.88

0.76

0.64

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

1.00

1.00

0.96

0.84

1.00

1.00

1.00

0.92

9.40

9.61

9.78

9.40

9.61

9.78

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

9.40

9.61

9.78

9.95

Indoor

intake air

DB˚C

Indoor

intake air

WB˚C

45

NOTE: CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW)

SHF

: Sensible heat factor

- 15 -

Page 18

HEATING CAPACITY

PUHZ-RP8YHA/PUHZ-RP10YHA

Cooling capacity correction factors

Heaing capacity correction factors

[3] CORRECTION FACTORS

Outdoor intake air WB˚C

-5

CA P.C. CA P.C. CA P.C.

14224

13664

13216

17145

16470

15930

4.12

4.47

4.75

4.96

5.38

5.72

PEH-RP8MYA

(Airflow Rate

60m

3

/min)

PEH-RP10MYA

(Airflow Rate

80m

3

/min)

15

20

25

15

20

25

15456

14784

14336

18630

17820

17280

4.54

4.89

5.30

5.47

5.89

6.39

17248

16352

15680

20790

19710

18900

5.24

5.65

6.14

6.31

6.81

7.40

Service Ref.

Indoor

intake air

DB˚C

0-10

Refrigerent piping length (one way)

5m 10m 15m 20m 25m 30m 35m 40m

1.00

1.00

0.985

0.985

PEH-RP8MYA

PEH-RP10MYA

0.971

0.971

0.958

0.958

0.943

0.943

0.931

0.931

0.919

0.919

0.908

0.908

Service Ref.

Refrigerent piping length (one way)

45m 50m 55m 60m

PEH-RP8MYA

PEH-RP10MYA

0.898

0.898

0.887

0.887

0.876

0.876

0.865

0.865

Service Ref.

65m 70m

0.855

0.855

0.847

0.847

75m 80m

0.838

0.838

0.829

0.829

Refrigerent piping length (one way)

5m 10m 15m 20m 25m 30m 35m 40m

1.00

1.00

0.997

0.997

PEH-RP8MYA

PEH-RP10MYA

0.994

0.994

0.991

0.991

0.988

0.988

0.985

0.985

0.982

0.982

0.979

0.979

Service Ref.

Refrigerent piping length (one way)

45m 50m 55m 60m

PEH-RP8MYA

PEH-RP10MYA

0.976

0.976

0.973

0.973

0.970

0.970

0.967

0.967

Service Ref.

65m 70m

0.964

0.964

0.961

0.961

75m 80m

0.958

0.958

0.955

0.955

Outdoor intake air WB˚C

5

CA P.C. CA P.C. CA P.C.

PEH-RP8MYA

(Airflow Rate

60m

3

/min)

PEH-RP10MYA

(Airflow Rate

80m

3

/min)

15

20

25

15

20

25

22624

21840

20608

27270

26325

24840

6.28

6.77

7.19

7.57

8.16

8.66

25536

24640

23744

30780

29700

28620

6.98

7.54

8.06

8.41

9.08

9.71

28448

27440

26432

34290

33075

31860

7.54

8.10

8.69

9.08

9.76

10.47

Service Ref.

Indoor

intake air

DB˚C

1510

NOTE: CA : Capacity (W) P.C. : Power consumption (kW)

- 16 -

Page 19

External static pressure (Pa)

40 50 60 70 80

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

External static pressure (Pa)

60 70 80 90 100

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

PEH-RP8MYA

PEH-RP10MYA

[4] Airflow Characteristic Curves

[5] Center of Gravity (Indoor unit)

Item

Model name

PEH-RP8MYA

PEH-RP10MYA

Center of gravity

X

630

730

Y

230

235

Z

240

240

unit : (mm)

X

Y

Z

Top of the unit

• Models PEH-RP8MYA/RP10MYA

- 17 -

Page 20

[6] Standard Operation Data

The unit of pressure has been charged to MPa based on international SI system.

The converesion factor is : 1(MPa)=10.2(kgf/cm

2

)

PEH-RP10MYAPEH-RP8MYA

PEH-RP10MYAPEH-RP8MYAIndoor unit Service Ref.

3, 503, 50

400400

0.940.65

1.641.12

PUHZ-RP10YHAPUHZ-RP8YHA

3, 503, 50

400400

V

kW

A

V

HeatingCoolingHeatingCooling

Service Ref.

Mode

11.9812.0110.1510.63

67.170.271.373.0

38.747.841.447.1

3.014.64.712.2

5555

20272027

15191519

37.015.338.814.7

735735

624624

D.B.

W.B.

D.B.

D.B.

W.B.

–0.82–0.75

–0.15–0.18

SHF

BF

2.27

(23.2)

2.86

(29.2)

2.59

(26.4)

2.81

(28.7)

0.63

(6.4)

0.96

(9.8)

0.69

(7.0)

0.92

(9.4)

Phase, Hz

Volts

Input

Current

Outdoor unit Service Ref.

Phase, Hz

Volts

Current

Discharge temreature

Condensing temreature

Suction temreature

Ref. pipe length

Intake air temreature

Discharge air temreature

Intake air temreature

Discharge pressure

Suction pressure

A

˚C

˚C

˚C

m

˚C

˚C

˚C

˚C

˚C

MPa

(kgf/cm

2

)

MPa

(kgf/cm2)

Outdoor

side

Indoor

side

Refrigerant circuit Electrical circuit

- 18 -

Page 21

[7] NC Curve (Indoor unit)

PEH-RP8MYA

Measurement condition

PEH-RP10MYA

Measurement condition

OCTAVE BAND CENTER FREQUENCIES <Hz>

OCTAVE BAND PRESSURE LEVEL <dB> 0dB = 20

µPa

OCTAVE BAND CENTER FREQUENCIES <Hz>

OCTAVE BAND PRESSURE

LEVEL

<dB>

0dB = 20

µPa

- 19 -

Aux. duct

1m 2m

1.5m

Measured point

70

External static pressure: 50Pa

60

50

40

30

20

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

External static pressure: 150Pa

NC60

NC50

NC40

NC30

NC20

Aux. duct

1m 2m

Measured point

1.5m

70

External static pressure: 50Pa

60

External static pressure: 150Pa

50

40

30

20

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

NC60

NC50

NC40

NC30

NC20

Page 22

[1] Appearance of Equipment

• PEH-RP8MYA/RP10MYA Electrical Parts Box (with cover removed)

Terminal bed

(indoor/outdoor connecting line)

Terminal bed (power)

Over current relay

(fan motor)

Indoor power board

Magnetic contactor (fan motor)

Terminal bed

(remote controller transmission line)

Indoor circuit board

- 20 -

7

SERVICE DATA

Page 23

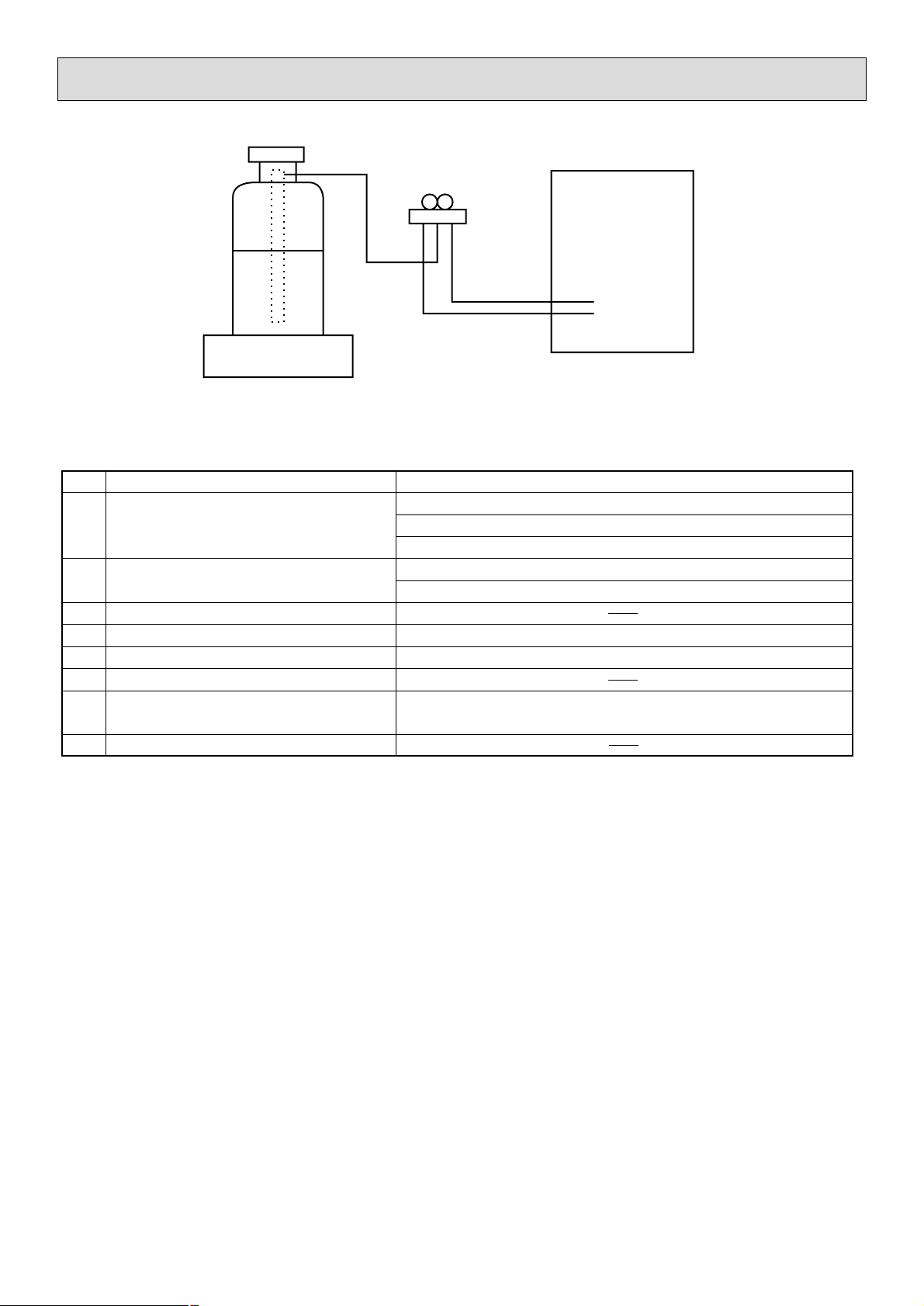

[2] Internal Construction

• PEH-RP8MYA/RP10MYA (Indoor unit)

Refrigerant piping flange connection : LP øA

Refrigerant piping flare connection : HP

ø

B

Leg

(for installation)

Duct flange

Air filter

Heat exchanger

Fan motor

Sirrocco fan

Drian connection (R1)

Electrical parts box

Drain pan

Model name

PEH-RP8MYA

PEH-RP10MYA

A

25.4

28.58

B

9.52

12.7

[3] Refrigerant Circuit

Brazing connection

Indoor Heat exchanger

Cooling operation

Heating operation

- 21 -

Page 24

[1] DIP SW1 for model Selection (DIP SW1 has been set at factory)

PEH-RP8MYA/RP10MYA : SW1-1, -4 ON, SW1-2, -3, -5 OFF

[2] DIP SW2 for Capacity Setting (DIP SW2 has been set at factory)

PEH-RP8MYA : SW2-1, -2, -3 and, -4 OFF

[3] DIP SWE for Emergency Operation

When SWE is turned ON, FAN turns ON. Setting of emergency operation other than SWE is

performed at the outdoor unit. For a description of the specific emergency operation execution

method, refer to the outdoor unit (PUHZ-RP8YHA, PUHZ-RP10YHA) Technical & Service Manual.

ON

OFF

54321

ON

OFF

4321

ON

OFF

PEH-RP10MYA : SW2-1 ON, SW2-2, -3, and, -4 OFF

ON

OFF

4321

- 22 -

8

FUNCTION OF SWITCH ON INDOOR CIRCUIT BOARD

Page 25

[1] Before test run

The test run can be carried out either from the outdoor unit or the indoor unit.

1. Check list

• After the installation, piping setup,and wiring of the indoor and outdoor units is complete, check that refrigerant is not

leaking, the power and control wires are not loose, and the poles are not reversed.

• Use a 500 V insulation resistance tester to make sure that the resistance between the power terminal and the ground

is 1.0 M or more. If it is less than 1.0 M, do not operate the unit. *Absolutely do not touch the tester to indoor/outdoor

connection terminals S1, S2, and S3. An accident could occur.

• Make sure there is no malfunction in the outdoor

unit. (If there is a malfunction, y ou can diagnose it using LED2 on the

board.)

• Check that the ball valve is fully open on both the liquid and gas ends.

• Check the electrical power phase. If the phase is reversed, the fan may rotate in the wrong direction or stop, or

unusual sounds may be produced.

• Starting at least 12 hours before the test run,send current through the crankcase heater. (If the current is running f or

a shorter period of time, damage to the compressor could result.)

• For specific models requiring changing of settings for higher ceilings or selection of power supply ON/OFF capability,

make proper changes referring to the description for Selection of Functions through Remote Controller.

After the above checks are complete, carry out the test run as indicated in the following outline.

[2] Test run procedures

1. Indoor unit

Operating procedures

(1) Turn on the main power supply

While the room temperature display on the remote controller reads “CENTRALLY CONTROLLED”, the remote

controller is disabled.Turn off the “CENTRALLY CONTROLLED” display before using the remote controller.

(2) Press “TEST RUN” button twice

(A) The ‘TEST RUN’ indicator should light up.

(3) Press button

Cooling/drying mode : Cool air should start to blow.

Heating mode : Warm air should start to blow (after a while).

(4) Check the outdoor unit fan for correct running

The outdoor unit features automatic capacity control to provide optimum fan speeds. The fan keeps running at a low

speed to meet the current outside air condition unless it exceeds its available maximum power. Then, in actuality,

the fan may stop or run in the reverse direction depending on the outside air, which does not mean malfunction.

(5) Press the “ON/OFF” button to reset the test run in progress

• The test run will be automatically shut down after two hours in response to the AUTO STOP setting of two hours on

the timer.

•

During the test run, the room temperature display shows the indoor unit tubing temperatures.

(A)

(5)

(2)

(3)

- 23 -

9

TEST RUN

STAND BY

DEFROST

PAR-20MAA

CENTRALLY CONTROLLED

CLOCK

CHECK

ßC

TEMP.

TIMER SET

ERROR CODE

ON OFF

1Hr.

NOT AVAILABLE

ßC

FILTER

CHECK MODE

TEST RUN

FUNCTION

ON/OFF

FILTER

CHECK TEST

Page 26

• In the case of the test run, the OFF timer will activate, and the test run will automatically stop after two hours.

• The room temperature display section shows the control temperature for the indoor units during the test run.

• Check that all the indoor units are running properly for simultaneous twin and triple operation.

Malfunctions may not be displayed even if the wiring is incorrect.

(*1)

After turning ON the power,the system will go into startup mode,and the remote controller operation lamp (red) and

the room temperature display section’s “H0 ” will flash. Also, in the case of the indoor substrata LEDs, LED 1 and

LED 2 light up (when address is 0) or become dim (when address is not 0), and LED 3 flashes. In the case of the

outdoor substrata LED display, – and – are displayed alternatively at 1-second intervals.

• If one of the above operations does not function correctly, the following causes should be considered, and if

applicable, dealt with. (The following symptoms have been determined under test run mode. Note that “startup” in

the chart means the *1 display above.)

Remote controller is displaying “H0”, and operation is

not possible.

After power is turned ON,“H0 ” is displayed for 3 mins.,

then error code is displayed.

Power is turned ON,and “EE” or “EF” are displayed

after “H0” is displayed.

Display messages do not appear even when remote

controller operation switch is turned ON (operation

lamp does not light up).

Operation display appears but soon disappears even

when remote controller operations are executed.

After “startup” display,“00” is displayed

(correct operation).

After “startup” display,error code is

displayed.

After “startup” display, “F1” (negative

phase) is displayed.

After “startup” display, “00” or “EE” is

displayed (“EE” is displayed when a test

run is made).

After “startup” display, “EA” (error for

number of units) or “Eb” (unit number

error) is displayed.

After “startup” display , “00” is displayed

(correct operation).

After “startup” display , “00” is displayed

(correct operation).

After “startup” display , “00” is displayed

(correct operation).

• After power is turned ON, system star tup lasts for about

2 mins., and “H0” is displayed (correct operation).

• Outdoor unit ’s safeguard installation connector is open.

• Negative phase and open phase of outdoor unit’s power

terminal board.

(Single phase: L, N, /triple phase: L1, L2, L3, N, )

• Incorrect connection of outdoor ter minal board (Single

phase: L, N, /triple phase: L1, L2, L3, N, grounding

and S1, S2, S3)

• Outdoor unit and indoor unit construction differ.

• Wiring for the indoor and outdoor unit is not connected

correctly. (Polarity is wrong for S1, S2, S3)

• Remote controller transmission wire short.

• There is no outdoor unit for address 0 (address is

something other than 0).

• Remote controller transmission wire burnout.

• After cancellation of function selection, operation is not

possible for about 30 secs. (correct operation).

Symptoms

Remote Controller Display Outdoor Substrate LED Display

Cause

* Press the remote controller’s “CHECK” button twice consecutively to be able to run a self diagnosis. See the chart

below for content of error code displays.

LCD Nonconformity content

P1 Suction sensor error

P2 Tubing (liquid) sensor error

P4 Drain sensor error

P5 Drain overflow safeguard operation

P6 Freezing/overheating safeguard operation

LCD Nonconformity content

P8 Tube temperature error

P9 Tube (2-phase tube)sensor error

U0 ~ UP Outdoor unit nonconformity

F1 ~ FA Outdoor unit nonconformity

E0 ~ E5 Signal error between remote

controller and indoor unit

LCD Nonconformity content

E6 ~ EF Signal error between indoor and

outdoor units

---- No error history

FFFF No relevant unit

See the chart below for details of the LED displays (LED 1, 2, 3) on the indoor substrate.

LED 1 (microcomputer power supply) Displays the

ON/OFF

of power for control.Check that this is lit during normal use.

LED 2 (remote controller feed) Displays the

ON/OFF

of feed to wired remote controller. Is only lit for indoor unit linked to outdoor unit with address “00”.

LED 3 (indoor and outdoor signals) Displays signal between indoor and outdoor units. Check that this is flashing during normal use.

2. Outdoor unit

(1) Check Items

• After installation of indoor and outdoor units,and piping and electric wiring work,check that the unit is free from leaks

of refrigerant,loosened connections,and incorrect polarity.

• Check that there is no negative phase and open phase. (The F1 message for negative phase and the F2 message

for open phase will flash at LED 1 on the outdoor substrate. If this happens,rewire correctly.)

• Measure the impedance between power terminals (Single phase: L, N, /triple phase: L1, L2, L3, N, ) and the

ground with a 500 V Megger and check that it is 1.0 M or more. Do not operate the equipment if measurement is

less than 1.0 M. *Never conduct this operation on the outdoor connection wiring terminals (S1, S2, S3) as this

causes damage.

- 24 -

Page 27

• When there is no error at the outdoor unit. (If there is an error at the outdoor unit, it can be evaluated at LED 1 [digital

display] of the outdoor substrate.)

• The stop valves are open both the liquid and gas sides.

After checking the above, execute the test run in accordance with the following.

(2) Test run start and finish

• Operation from the indoor unit

Execute the test run using the installation manual for the indoor unit.

• Operation from the outdoor unit

Execute settings for test run start,finish and operation mode (cooling, heating) using the DIP switch SW 4 on the

outdoor substrate.

OFF ON

1

2

A

B

C

D

< SW4 >

A Stop

B Cooling

C Operation

D Heating

a) Set the operation mode (cooling, heating) using SW 4-2

b) Turn ON SW 4-1, The operation mode for SW 4-2 will be adhered to, and the test run will commence

c) Turn OFF SW 4-1 to finish the test run

• There may be a faint knocking noise emitted from the proximity of the fan during the test run. This is torque

fluctuation occurring due to control of fan revolutions. There is no problem with the product.

Note:

The SW 4-2 operation mode cannot be changed during the test run. (To change test run mode, stop the equipment

with SW 4-1, change the operation mode, then restart test run with SW 4-1.)

• If the 2-hour timer is set,the test run will stop automatically after 2 hours.

• During the test run,the room temperature display on the indoor unit will indicate the temperature of the indoor unit

piping.

[3] Self-diagnosis

Use the remote controller to look up each units error history.

1. Change to self-diagnosis mode

Press the CHECK button twice within three seconds to show

the following

2. Select the refrigerant address number to be selfdiagnosed

Press the buttons to scroll through the

refrigerant address numbers (00 to 15)and select the

refrigerant address number to be slf-diagnosed.

After three seconds from making the change,the lit refrigerant

address to be self-diagnosed will start to flash,and selfdiagnosis will commence.

3. Self-diagnosis result display

See the above chart for details of error code contents.

(1) When there is an error history

a) Alternating display

b) Error code

c) Attribute of error search

d) Unit number

1.

2.

3. (1)

- 25 -

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

ßC

CLOCK

ON OFF

STAND BY

DEFROST

STAND BY

DEFROST

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

CHECK

INDOOR UNIT

ADDRES S NO

CHECK

INDOOR UNIT

ADDRES S NO

ßC

ßC

b)

ßC

ON OFF

CLOCK

ON OFF

CLOCK

ERROR CODE

ON OFF

CLOCK

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

a)

c)

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

d)

Page 28

4. Reset error history

Display the error history at the self-diagnosis result display screen

3.

The address for self-diagnosis will flash when the

button is pressed twice within three seconds.

The diagram on the left will be displayed when error history has

been reset.

Note that the error content will be redisplayed if error history

resetting is unsuccessful.

a) Alternating display

5. Canceling self-diagnosis

The following two methods can be used to cancel self-diagnosis.

Press the CHECK button twice within three seconds to cancel

self-diagnosis. The display screen will return to the status before

self-diagnosis. Press the 1 ON/OFF button to cancel selfdiagnosis. The indoor unit will stop. (This operation is ineffectual

when operation is prohibited.)

CLOCK ON OFF

3. (2)

(3)

4.

5.

(2) When there is no error history

(3)

When the address does not exist

- 26 -

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

ßC

ON OFF

CLOCK

ERROR CODE

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

ßC

ON OFF

CLOCK

ERROR CODE

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

a)

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

CHECK

INDOOR UNIT

ADDRES S NO

ßC

ßC

ON OFF

CLOCK

ERROR CODE

ON OFF

CLOCK

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

ßC

CLOCK

ON OFF

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRES S NO

ßC

ON OFF

CLOCK

ERROR CODE

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

Page 29

1. First, check the electricity current marker

If the correct voltage (DC 12 V)is not displayed on the remote

controller, the electric current marker will be lit. If the electricity

current marker is not lit, check the remote controller wiring

and the indoor unit.

(1) Electric current marker

2. Transfer to remote control mode

Hold down the CHECK button for five seconds or more to

display the diagram on the left.

Press the FILTER button to commence diagnosis of remote

controller.

3. Remote controller diagnosis results

(1)The remote control is functioning correctly.

Check other possible causes as there are no problems

with the remote controller.

(2) The remote controller has a nonconformity.

The remote controller must be replaced.

Error display 1 (“NG”) flashes to show a nonconformity in

the transmitter-receiver circuit.

Potential problems other than those diagnosed for

the remote controller.

(1) Single transmission not possible if error display 2 (“E3”)

flashes.

There is “noise” on the transmission line, or damage of

other remote controllers for the indoor units can be

considered. Check the transmission path and other

controllers.

(2) Data error has occurred when error display three shows

“ERC” and number of data errors.

Number of generated data errors (maximum 66 errors).

The number of generated data errors stands for the

difference in the number of bits of transmitted data from

the remote controller and the actual number of bits that

were transmitted along the transmission path. If this error

occurs, “noise”, etc., is interfering with the transmission

data. Check the transmission path.

[4] Remote controller diagnosis

If operation cannot be carried out from the remote controller,use this function to

diagnose the remote controller.

1.

2.

3. (1)

(2)

(1)

(2)

4. Cancel the remote controller diagnosis

Hold down the CHECK button for five seconds or more to cancel the remote controller diagnosis. The “H0” operation

lamp will flash, and the display screen will return to the status before remote controller diagnosis in approximately 30

seconds.

L) Remote controller transmission data

M) Transmission data at transmission path

K) When the number of data

errors generated is 02

- 27 -

STAND BY

DEFROST

STAND BY

DEFROST

STAND BY

DEFROST

STAND BY

DEFROST

CLOCK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ßC

ßC

ßC

CLOCK

CLOCK

CLOCK

CLOCK

ON OFF

ON OFF

ON OFF

ON OFF

(1)

1Hr.

1Hr.

1Hr.

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

ßC

FILTER

CHECK MODE

FUNCTION

ßC

FILTER

CHECK MODE

FUNCTION

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

STAND BY

DEFROST

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRES S NO

CHECK

INDOOR UNIT

ADDRES S NO

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

ßC

ßC

ßC

CLOCK

CLOCK

CLOCK

ON OFF

ON OFF

ON OFF

Page 30

— MEMO —

Page 31

- 29 -

Page 32

New publication, effective Nov. 2004.

Specifications subject to change without notice.