Mitsubishi PEH-RP200MYA, PEH-RP250MYA Service Manual

TECHNICAL & SERVICE MANUAL

AIR-COOLED SPLIT-TYPE

PACKAGED AIR CONDITIONERS

HEAT PUMP PEH-RP200MYA

PEH-RP250MYA

Models

<Indoor unit>

2005

For use with the R410A or R407C

Page

Contents

1 SAFETY PRECAUTION ..........................................................................................................

2PART NAMES AND FUNCTIONS ............................................................................................

3 SPECIFICATIONS ..................................................................................................................

4 OUTLINE AND DIMENSIONS................................................................................................

5 ELECTRICAL WIRING DIAGRAM .........................................................................................

6 TECHNICAL DATA ................................................................................................................

[1] Capacity/Input Ratio against Changes in Room Airflow Rate ...........................................

Capacity table

[4] Correction factors

...................................................................................................................

..............................................................................................................

[5] Airflow Characteristic Curves ............................................................................................

[7] Standard Operation Data ................................................................................................

NC Curve (Indoor unit) ......................................................................................................

7 SERVICE DATA ......................................................................................................................

[1] Appearance of Equipment ................................................................................................

[2] Internal Construction.........................................................................................................

[3] Refrigerant Circuit .............................................................................................................

8 FUNCTION OF SWITCH ON INDOOR CIRCUIT BOARD .....................................................

[1] DIP SW1 for model Selection (DIP SW1 has been set at factory) ....................................

[2] DIP SW2 for Capacity Setting (DIP SW2 has been set at factory) ...................................

[3] DIP SWE for Emergency Operation ..................................................................................

9 TEST RUN ..............................................................................................................................

[1] Before test run ..................................................................................................................

[2] Test run procedures ..........................................................................................................

[3] Self-diagnosis ...................................................................................................................

[4]

Remote controller diagnosis

.............................................................................................

[6] Center of Gravity (Indoor unit) ..........................................................................................

[8]

[2] Bypass Factor Curves ......................................................................................................

[3]

1

3

5

7

10

11

11

13

18

19

21

23

23

24

24

25

25

25

25

26

26

26

29

30

20

22

12

- 1 -

1

SAFETY PRECAUTION

Cautions for units utilizing refrigerant R410A or R407C

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Keep the inner and outer surfaces of the pipes

clean and free of such contaminants as sulfur,

oxides, dust, dirt, shaving particles, oil, and

water.

In addition, use pipes with specified thickness.

Store the pipes to be installed indoors, and keep

both ends of the pipes sealed until immediately

before brazing. (Keep elbows and other joints

wrapped in plastic.)

Use a small amount of ester oil, ether oil, or

alkylbenzene to coat flares and flanges.

In case of using the existing pipes for R22, be careful with

the followings.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge liquid refrigerant (as opposed to gaseous

refrigerant) into the system.

If gaseous refrigerant is charged into the system, the

composition of the refrigerant in the cylinder will change

and may result in performance loss.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse-flow check

valve.

Do not use refrigerant other than R410A or

R407C.

If a vacuum pump that is not equipped with a reverse-flow

check valve is used, the vacuum pump oil may flow into

the refrigerant cycle and cause the refrigerating machine

oil to deteriorate.

Prepare a set of tools for exclusive use with R407C

and another set for exclusive use with R410A.

The following tools are necessary to use R410A

or R407C

refrigerant.

Exercise special care when handling the tools for

use with R407C.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the

refrigerant will change, and the unit may experience power

loss.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A or R407C

These types of contaminants inside the refrigerant pipes

may cause the refrigerant oil to deteriorate.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate or

cause the unit to malfunction.

Infiltration of a large amount of mineral oil may cause the

refrigerating machine oil to deteriorate.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A or R407C on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

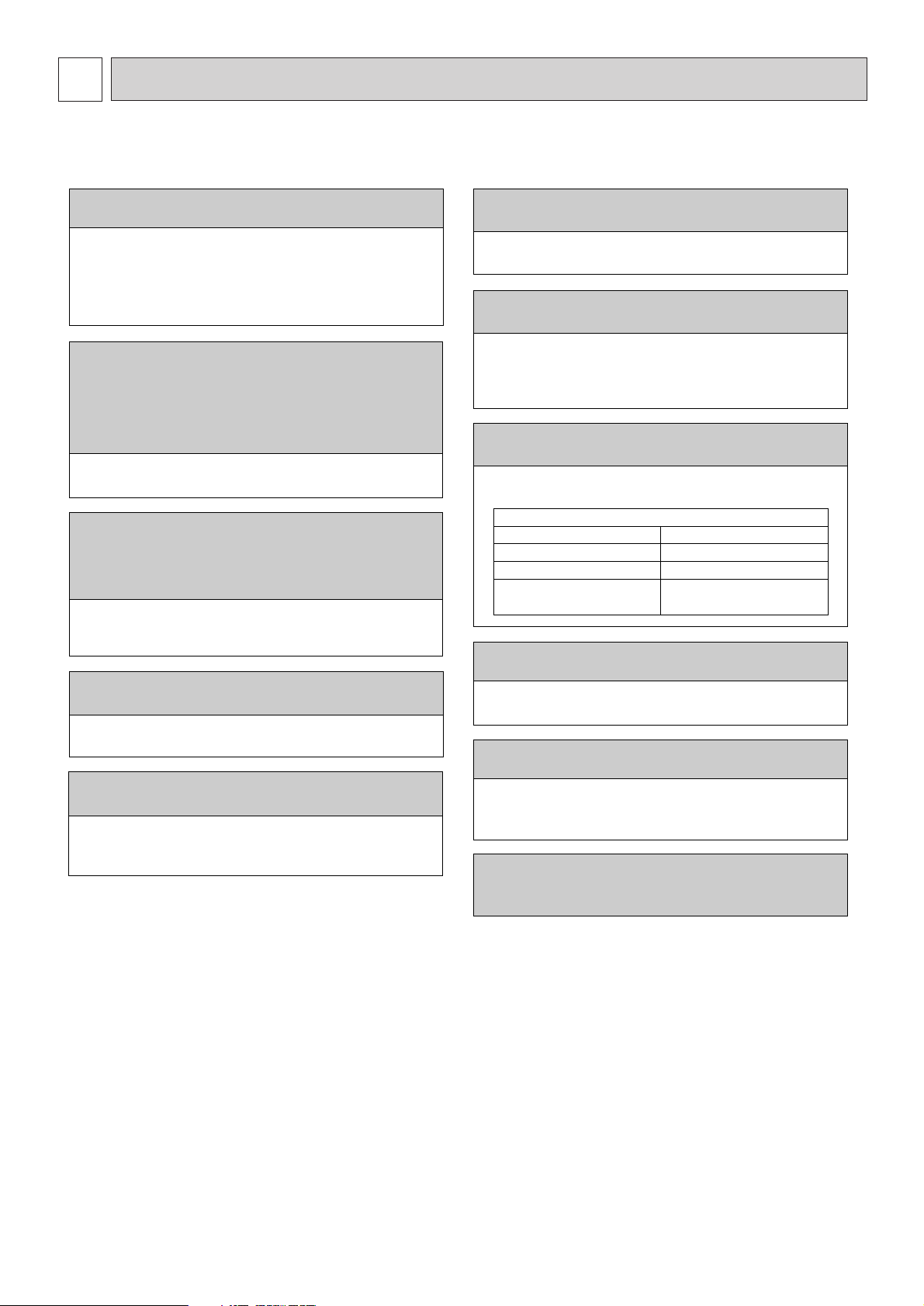

No. Specifications

1 Gauge manifold ·Only for R410A or R407C

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A or R407C

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A or R407C Top of cylinder:R410A(Pink), R407C(Gray)

Cylinder with syphon

8 Refrigerant recovery equipment

- 2 -

Unit

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

Gravimeter

- 3 -

2

PART NAMES AND FUNCTIONS

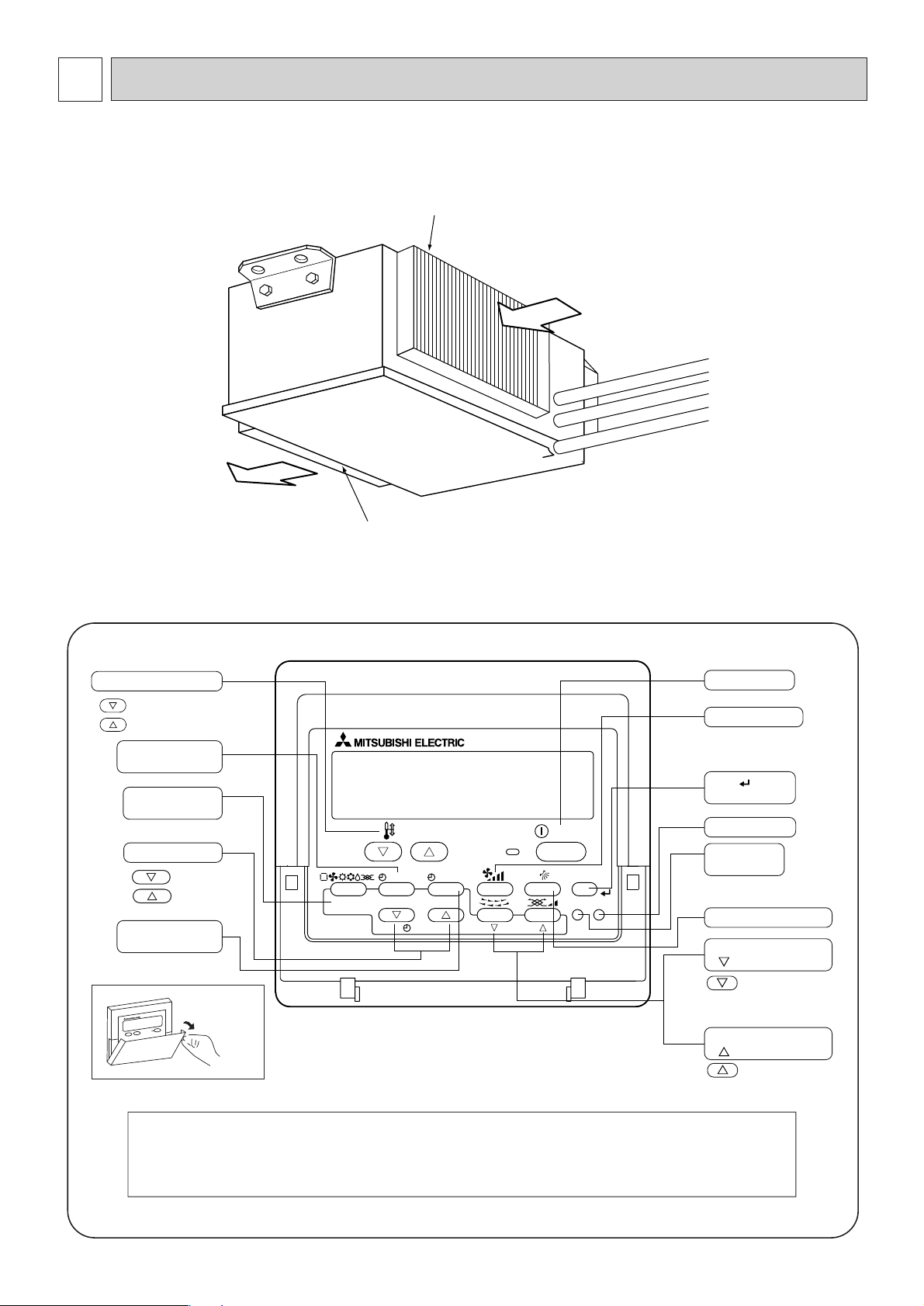

● Indoor Unit

PEH-RP200MYA

PEH-RP250MYA

Air intake duct flange

Air outlet duct flange

Air outlet

Air intake

(sucks the air inside the room into the unit)

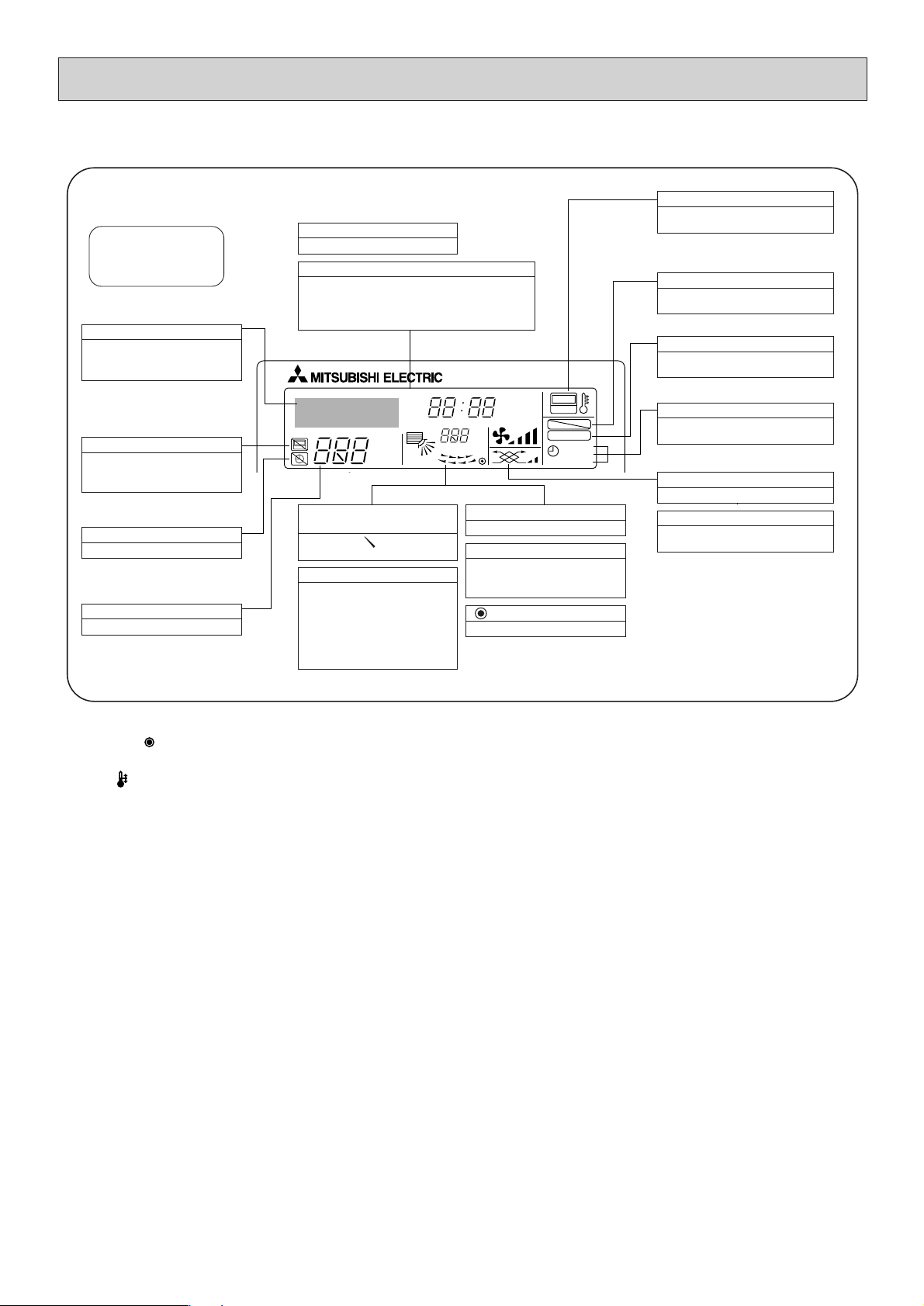

● Operation buttons

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button

(Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Airflow Up/Down button

Louver button

(

Operation button)

To preceding

operation number.

Ventilation button

(

Operation button)

To next operation

number.

Note:

If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if the feature is not present

at the parent unit.

Check button

(Clear button)

- 4 -

Caution

● Only the (Power on indicator) lights when the unit is stopped and power supplied to the unit.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the screen (For max. 3minutes).

Please wait until this “PLEASE WAIT” disappear then start the operation.

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

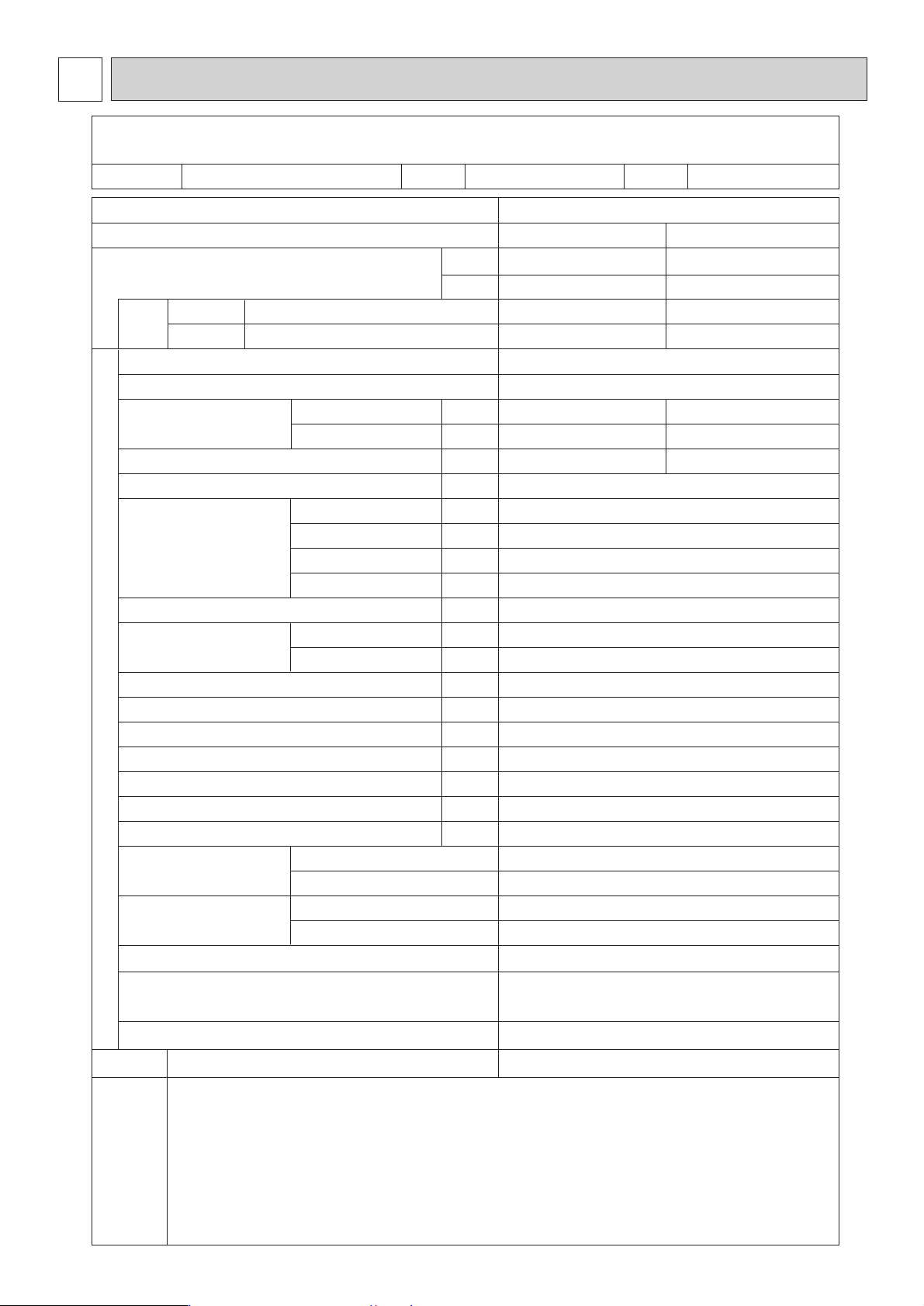

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name PEH-RP200MYA

PEH-RP200MYAService Ref.

PEH-RP200MYAService Ref.

PUHZ-RP200YHAService Ref.

Outdoor

unit

Indoor unit

Quantity Symbol

Capacity kcal/h

kW

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power source

Power consumption kW

Operating current A

Remote controller temperature setting range °C

Airflow direction control

Type × Quantity

Airflow rate m

3

/min

External static pressure

Pa

Motor output kW

External finish

Unit (H × W × D) mm

Panel (H × W × D) mm

Heat exchanger type

Air filter

Insulation material

Refrigerant piping size Liquid/Gas

φ

mm

φ

mm

Drain piping size

Noise level dB(A)

Net weight kg

Minimum wire thickness

Circuit breaker

Operation control device (provided)

Decoration panel (Option)

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 5m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The

5. Refer to the service manual of outdoor unit for the outdoor unit’s specifications.

figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50/60/70 Pa setting.

Cooling Heating

16,300 19,300

19.0 (10.0~22.4) 22.4 (10.0~25.0)

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/6 ˚C

3N~ 380/400/415V 50Hz

0.65/0.65/0.65 0.65/0.65/0.65

1.12/1.12/1.12 1.12/1.12/1.12

19 ~ 30 17 ~ 28

–

Sirrocco fan × 2

60

50/60/70 (150/155/160)

0.75

Galvanizing

428 × 1380 × 650

–

Cross fin

Saran net

Polyethylene foam

9.52/25.4

25.4 (R1)

48/49/49 (at 50/60/70 Pa)

70

1.6 mm

15 A

Remote controller: PAR-21MAA

–

–

Electrical characteristics

Fan

External dimension

External wiring

Composing parts

Notes:

Installation manual, Operation manual,

Remote controller

–

Air con-

dition

- 5 -

3

SPECIFICATIONS

PEH-RP250MYA

Cooling Heating

18,900 23,200

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/ 6 °C

3N~ 380/400/415V 50 Hz

0.94/0.94/0.94 0.94/0.94/0.94

1.64/1.64/1.64 1.64/1.64/1.64

19 ~ 30 17 ~ 28

–

Sirrocco fan × 2

80

50/60/70 (150/155/160)

1.23

Galvanizing

428 × 1,580 × 650

–

Cross fin

Saran net

Polyethyene foam

12.7/28.58

25.4 (R1)

52/53/53 (at 50/60/70 Pa)

80

1.6 mm

15 A

Remote controller: PAR-21MAA

–

–

Installation manual, Operation manual,

Remote controller

–

PUHZ-RP250YHA

PEH-RP250MYA

PEH-RP250MYA

22.0 (12.5~28.0) 27.0 (15.7~31.5)

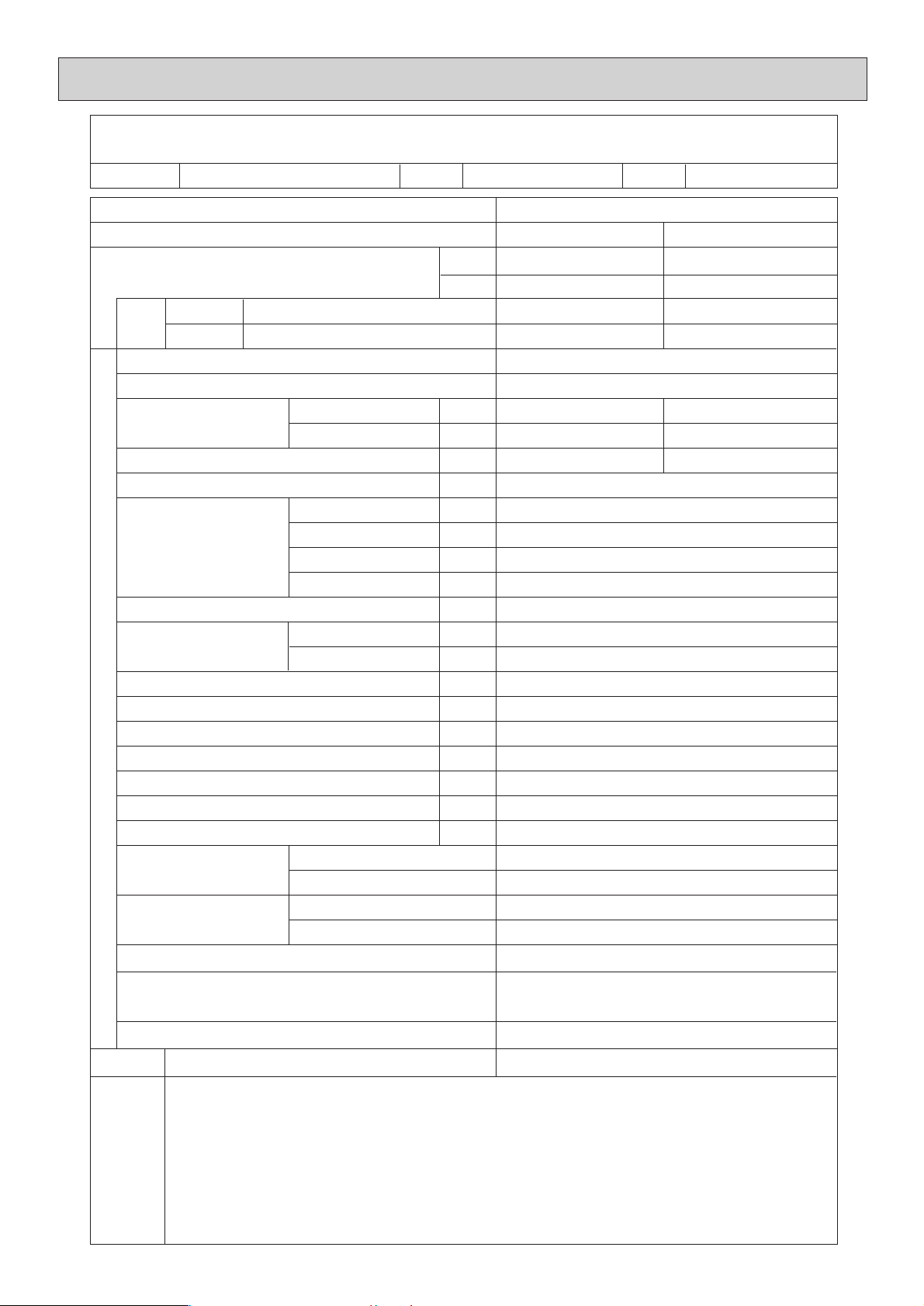

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name

Service Ref.

Service Ref.

Service Ref.

Outdoor

unit

Indoor unit

Quantity Symbol

Capacity kcal/h

kW

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power source

Power consumption kW

Operating current A

Remote controller temperature setting range °C

Airflow direction control

Type × Quantity

Airflow rate m

3

/min

External static pressure

Pa

Motor output kW

External finish

Unit (H × W × D) mm

Panel (H × W × D) mm

Heat exchanger type

Air filter

Insulation material

Refrigerant piping size Liquid/Gas

φ

mm

φ

mm

Drain piping size

Noise level dB(A)

Net weight kg

Minimum wire thickness

Circuit breaker

Operation control device (provided)

Decoration panel (Option)

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 5m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The

5. Refer to the service manual of outdoor unit for the outdoor unit’s specifications.

figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50/60/70 Pa setting.

Electrical characteristics

Fan

External dimension

External wiring

Composing parts

Notes:

Air condition

- 6 -

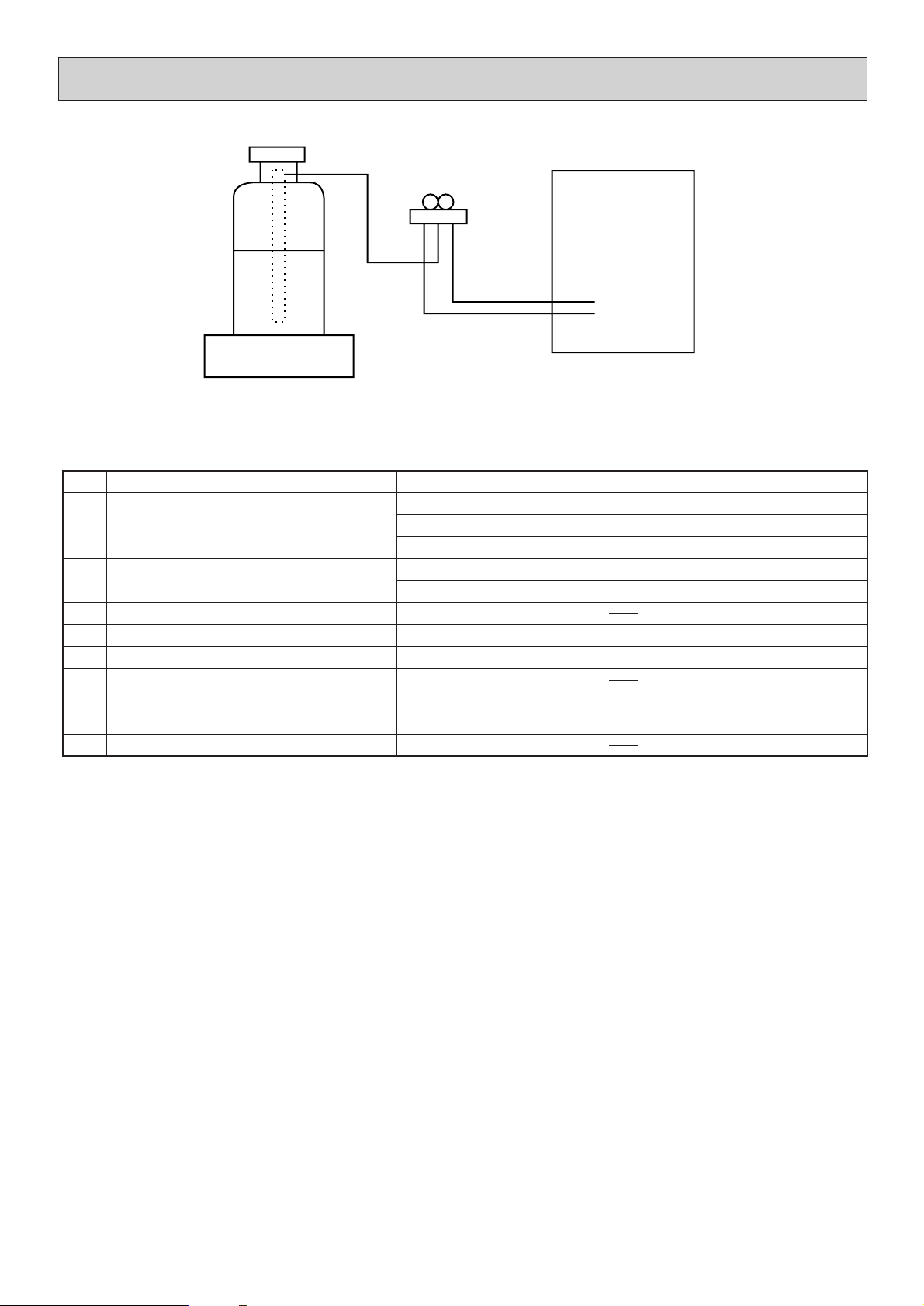

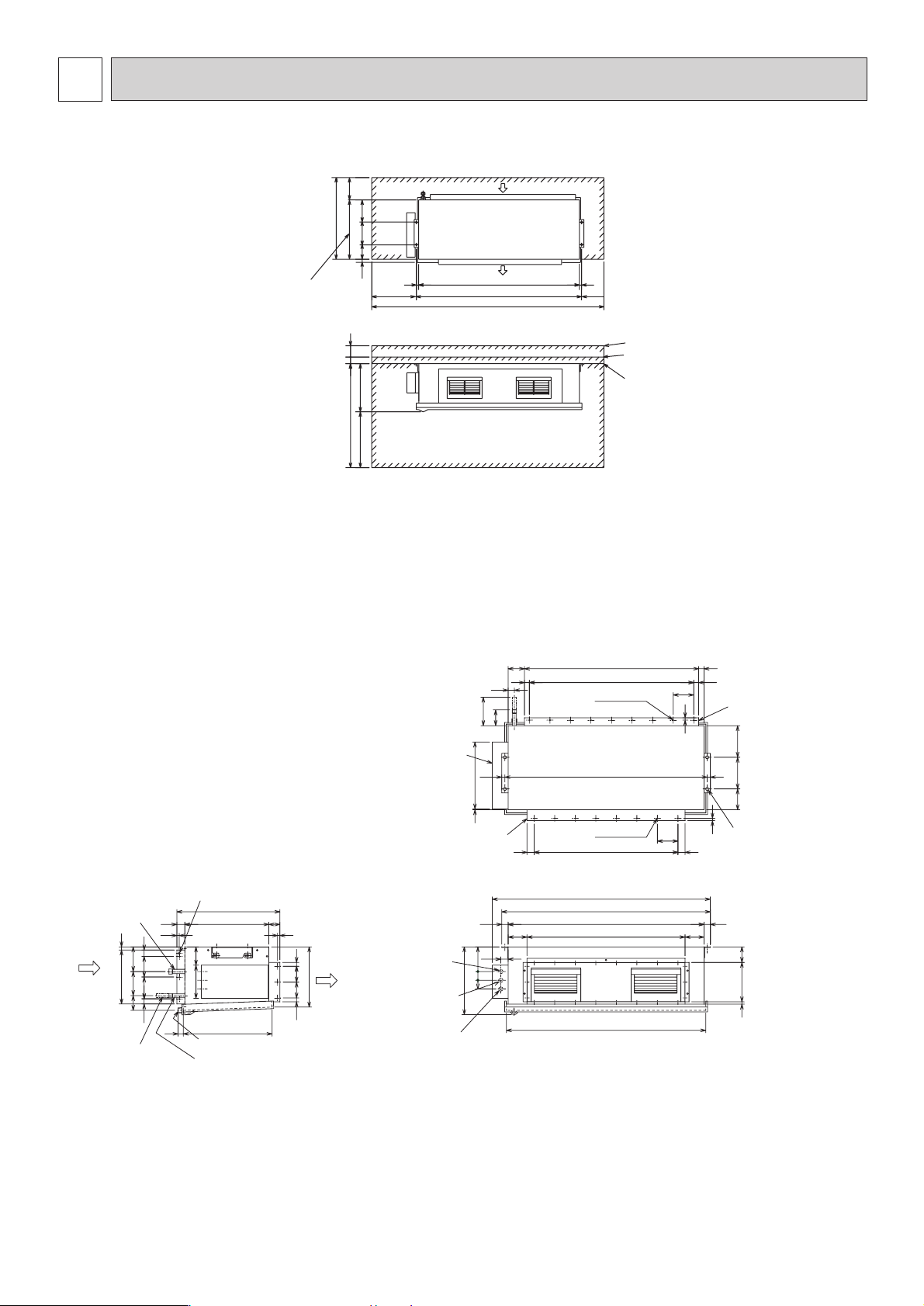

(1) Indoor Unit

• Model PEH-RP200MYA

928

1240

20

530

13132

200

199

400

730

200

1280

1880

200

20

428500

25 75

(1)

(2)

(3)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

(A)

(A)

(C)

(B)

(B)

(D)

Note: When connecting duct to the return air duct flange, remove the air filter attached to the unit body, and mount

an air filter onto the return air duct side separately.

Return air

sensor

Left side view

Top view

Front view

Rubber bush <For the

power supply wiring>

(Return air side)

Rubber bush <For the

outdoor unit connecting

wiring> (Return air side)

Rubber bush <For the

controller wiring>

(Return air side)

Accessory:

Refrigerant connecting

pipe ø12.7(1/2 braze)

[Use only for R407C]

Refrigerant pipe

ø25.4(1 braze)

Refrigerant pipe

ø9.52(3/8 braze)

Supply air

Return air

Control box

Supply air

duct flange

Return air

duct flange

24-ø3.1 Holes

4-ø12 Holes

22-ø3.1 Holes

7X130Pitch=910

8X130Pitch=1040

Drain R1

15

190

100

13042

152

14

250 98

1264

120 1000

1320

40

45

130

45

120

40

15

1280

20

20

1240

31

130

31

104 1102 34

382

562

33

95

42

20

344

130

50

10025 100

15

25

70530

156

428

650

15

<For hanging bolt M10>

[Field supply]

40

199200131

1380

1565555

46

5 423

116210

- 7 -

4

OUTLINE AND DIMENSIONS

- 8 -

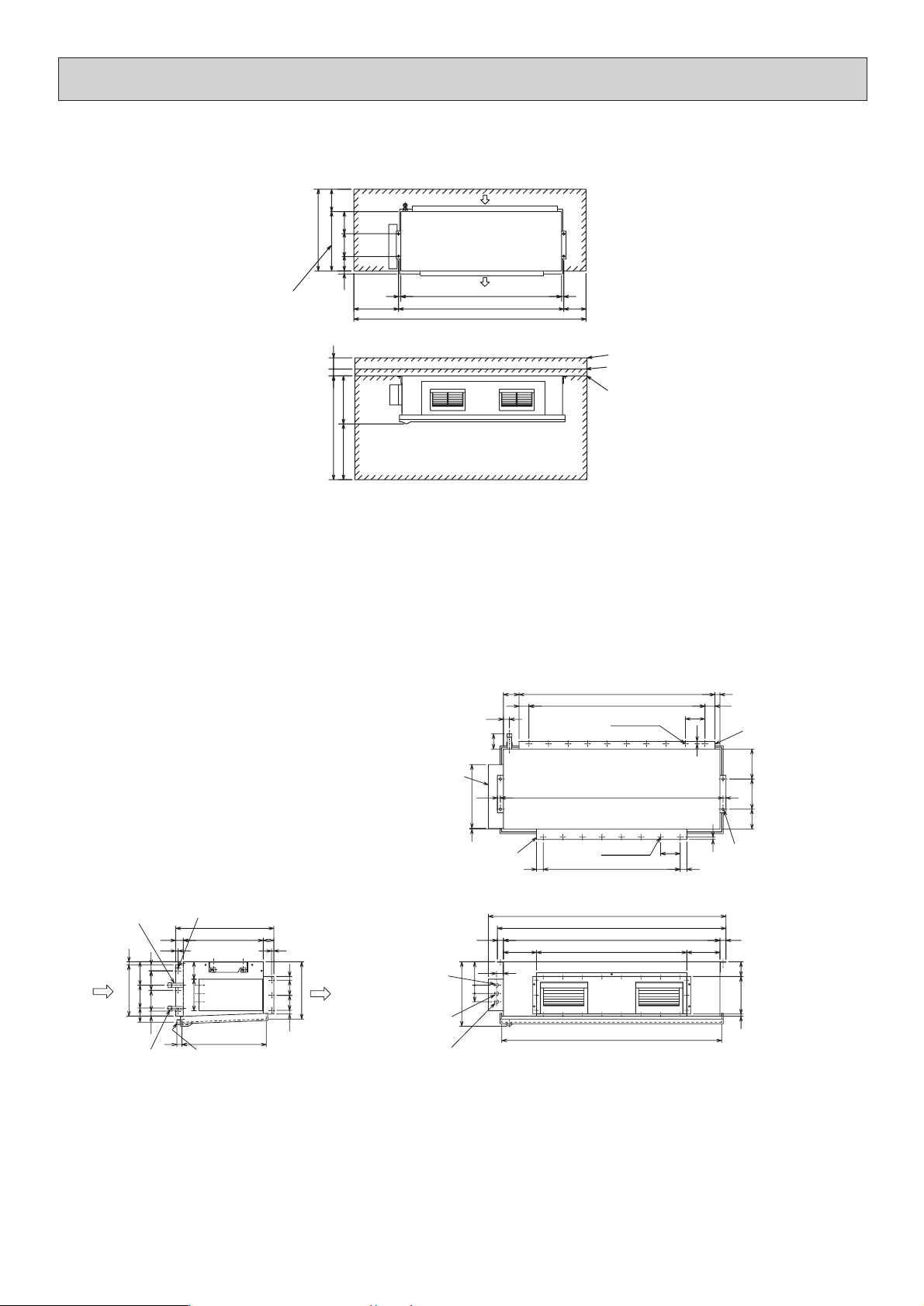

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

1440

20

530

13132

200

199

400

730

200

1480

2080

200

20

(A)

(C)

(B)

(B)

(D)

928

428500

25 75

(1)

(2)

(3)

(A)

• Model PEH-RP250MYA

Note: When connecting duct to the return air duct flange, remove the air filter attached to the unit body, and mount

an air filter onto the return air duct side separately.

Return air

sensor

Rubber bush <For the

power supply wiring>

(Return air side)

Rubber bush <For the

outdoor unit connecting

wiring> (Return air side)

Front view

Left side view

Top view

Refrigerant pipe

ø12.7(1/2 braze)

Return air

Rubber bush <For the

controller wiring>

(Return air side)

Supply air

Refrigerant pipe

ø28.58(1-1/8 braze)

Supply air

duct flange

26-ø3.1 Holes

Control box

4-ø12 Holes

Return air

duct flange

Drain R1

22-ø3.1 Holes

<For hanging bolt M10>

[Field supply]

1440

130

669X130Pitch=1170

45 7X130Pitch=910

15

199

100

40

42 130

152 156

14

250 98

1464

220 1000

1520

40

130

45

220

40

15

1480

20

20

66

104 1302 34

382

562

33

95

42

20

344

130

50

10025 100

15

25

70530

428

650

15

200131

1580

1565555

46

5 423

116210

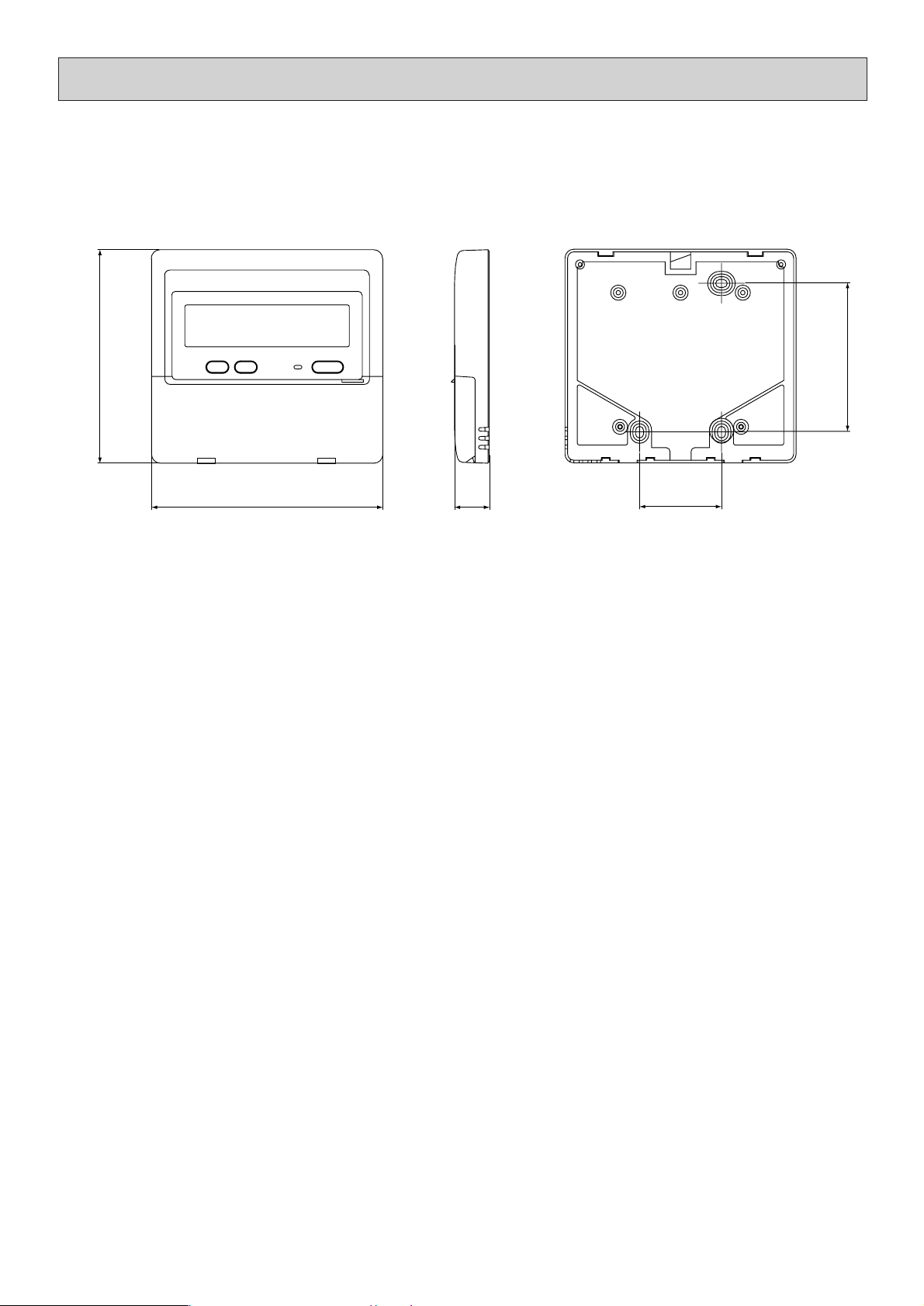

(2) Remote Controller

• Model

PAR-21MAA

- 9 -

120

(Front view) (Side view) (Rear view)

130

19

83.5

46

Loading...

Loading...