Page 1

AIR-COOLED SPLIT-TYPE

PACKAGED AIR CONDITIONERS

2003

TECHNICAL & SERVICE MANUAL

<Indoor unit>

Models

HEAT PUMP PEH-P8MYA, PEH-P10MYA

For use with the R407C

Page 2

Contents

Page

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT .................................... 1

[1] Storage of Piping Material .................................................................................................. 2

[2] Piping Machining ................................................................................................................ 3

[3] Necessary Apparatus and Materials and Notes on Their Handling .................................... 4

[4] Brazing ................................................................................................................................ 5

[5] Airtightness Test.................................................................................................................. 6

[6] Vacuuming .......................................................................................................................... 6

[7] Charging of Refrigerant ......................................................................................................7

2 PART NAMES AND FUNCTIONS ............................................................................................ 8

3 SPECIFICATIONS .................................................................................................................. 10

4 PART NAMES AND FUNCTIONS .......................................................................................... 12

5 ELECTRICAL WIRING DIAGRAM ......................................................................................... 15

6 TECHNICAL DATA TO MEET LVD ........................................................................................ 16

[1] Capacity/Input Ratio against Changes in Room Airflow Rate ........................................... 16

[2] Bypass Factor Curves ...................................................................................................... 17

[3] Cooling Sensible Heating Capacity Table ......................................................................... 17

[4] Airflow Characteristic Curves ............................................................................................ 18

[5] Center of Gravity (Indoor unit) .......................................................................................... 18

[6] NC Curve (Indoor unit) ...................................................................................................... 19

7 SERVICE DATA ...................................................................................................................... 20

[1] Appearance of Equipment ................................................................................................ 20

[2] Internal Construction ......................................................................................................... 20

[3] Refrigerant Circuit ............................................................................................................. 20

8 FUNCTION OF SWITCH ON INDOOR CIRCUIT BOARD ..................................................... 21

[1] DIP SW1 for model Selection (DIP SW1 has been set at factory) .................................... 21

[2] DIP SW2 for Capacity Setting (DIP SW2 has been set at factory) ................................... 21

[3] DIP SWE for Emergency Operation.................................................................................. 21

9 TEST RUN .............................................................................................................................. 22

[1] Before test run .................................................................................................................. 22

[2] Test run procedures ..........................................................................................................22

[3] Self-diagnosis ................................................................................................................... 24

[4] Remote controller diagnosis ............................................................................................. 26

Page 3

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT

Caution

Do not use the existing refrigerant piping.

• The old refrigerant and refrigerator oil in the existing

piping contains a large amount of chlorine which may

cause the refrigerator oil of the new unit to deteriorate.

Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized copper as specified in the *JIS

H3300 “Copper and copper alloy seamless pipes and

tubes”. In addition, be sure that the inner and outer

surfaces of the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

• Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

*JIS: Japanese Industrial Standard

Store the piping to be used during installation indoors

and keep both ends of the piping sealed until just

before brazing. (Store elbows and other joints in a

plastic bag.)

Use a vacuum pump with a reverse flow check valve.

• The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerator oil to deteriorate.

Do not use the following tools that have been used

with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base,

vacuum gauge, refrigerant recovery equipment)

• If the conventional refrigerant and refrigerator oil are

mixed in the R407C, the refrigerant may deteriorated.

• If water is mixed in the R407C, the refrigerator oil may

deteriorate.

• Since R407C does not contain any chlorine, gas leak

detectors for conventional refrigerants will not react to

it.

Do not use a charging cylinder.

• Using a charging cylinder may cause the refrigerant

to deteriorate.

• If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

Use ester oil, ether oil or alkylbenzene (small amount)

as the refrigerator oil to coat flares and flange connections.

• The refrigerator oil will degrade if it is mixed with a

large amount of mineral oil.

Use liquid refrigerant to seal the system.

• If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change

and performance may drop.

Do not use a refrigerant other than R407C.

• If another refrigerant (R22, etc.) is used, the chlorine

in the refrigerant may cause the refrigerator oil to deteriorate.

Be especially careful when managing the tools.

• If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

If the refrigerant leaks, recover the refrigerant in the

refrigerant cycle, then recharge the cycle with the

specified amount of the liquid refrigerant indicated

on the air conditioner.

• Since R407C is a nonazeotropic refrigerant, if additionally charged when the refrigerant leaked, the composition of the refrigerant in the refrigerant cycle will

change and result in a drop in performance or abnormal stopping.

–1–

Page 4

[1] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors. (Warehouse at site or owner’s warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

* The new refrigerator oil is 10 times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be stored

with more care than with the conventional refrigerant pipes.

–2–

Page 5

[2] Piping Machining

Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

Use only the necessary minimum quantity of oil !

Reason:

1. The refrigerator oil used for the equipment is highly hygroscopic and may introduce water inside.

Notes:

• Introducing a great quantity of mineral oil into the refrigerant circuit may also cause a compressor failure.

• Do not use oils other than ester oil, ether oil or alkylbenzene.

–3–

Page 6

[3] Necessary Apparatus and Materials and Notes on Their Handling

The following tools should be marked as dedicated tools for R407C.

<<Comparison of apparatus and materials used for R407C and for R22>>

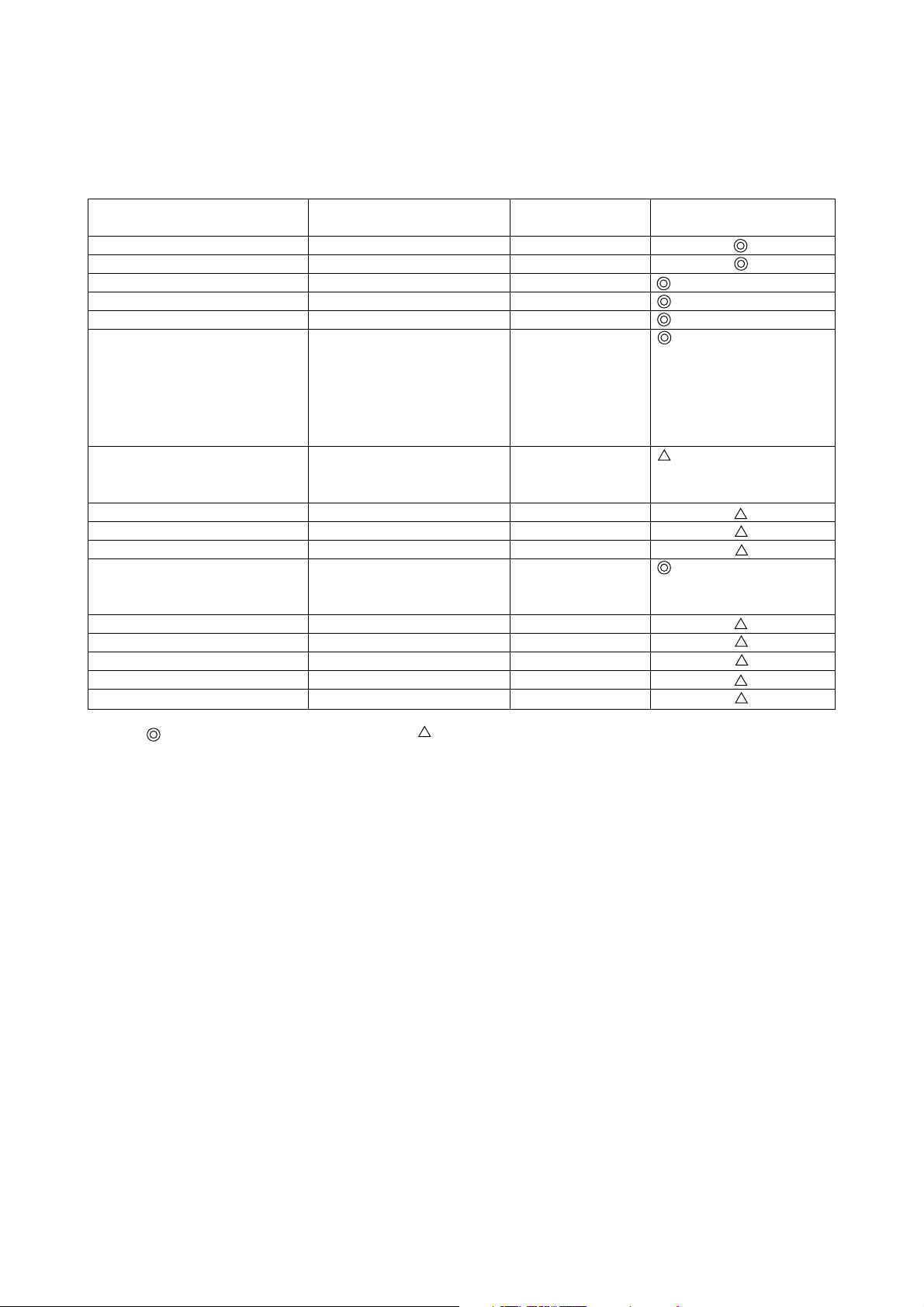

Apparatus Used Use R22 R407C

Gauge manifold Evacuating, refrigerant filling Current product

Charging hose Operation check Current product

Charging cylinder Refrigerant charging Current product Do not use

Gas leakage detector Gas leakage check Current product Shared with R134a

Refrigerant collector Refrigerant collection R22 For R407C use only

Refrigerant cylinder Refrigerant filling R22 Identification of dedi-

cated use for R407C:

Record refrigerant

name and put brown

belt on upper part of

cylinder.

Vacuum pump Vacuum drying Current product Can be used by attach-

ing an adapter with a

check valve.

Vacuum pump with a check valve Current product

Flare tool Flaring of pipes Current product

Bender Bending of pipes Current product

Application oil Applied to flared parts Current product Ester oil or Ether oil or

Alkybenzene (Small

amount)

Torque wrench Tightening of flare nuts Current product

Pipe cutter Cutting of pipes Current product

Welder and nitrogen cylinder Welding of pipes Current product

Refrigerant charging meter Refrigerant charging Current product

Vacuum gauge Checking the vacuum degree Current product

Symbols: To be used for R407C only. Can also be used for conventional refrigerants.

Tools for R407C must be handled with more care than those for conventional refrigerants. They must not come into contact

with any water or dirt.

–4–

Page 7

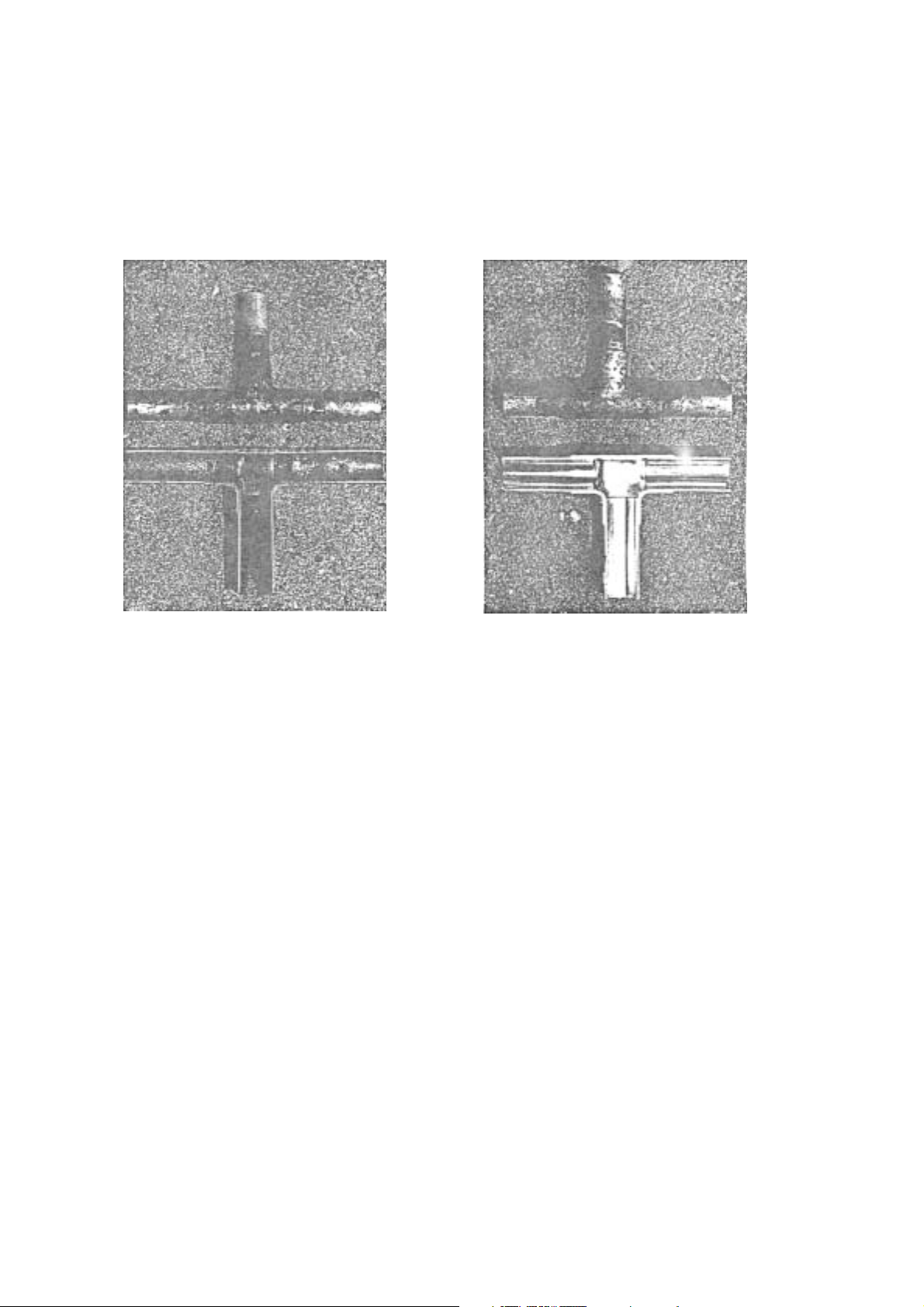

[4] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

Example: Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed:

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (Bcup-3) which requires no flux when brazing between copper pipes or between a copper

pipe and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons:

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note:

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use nitrogen.

–5–

Page 8

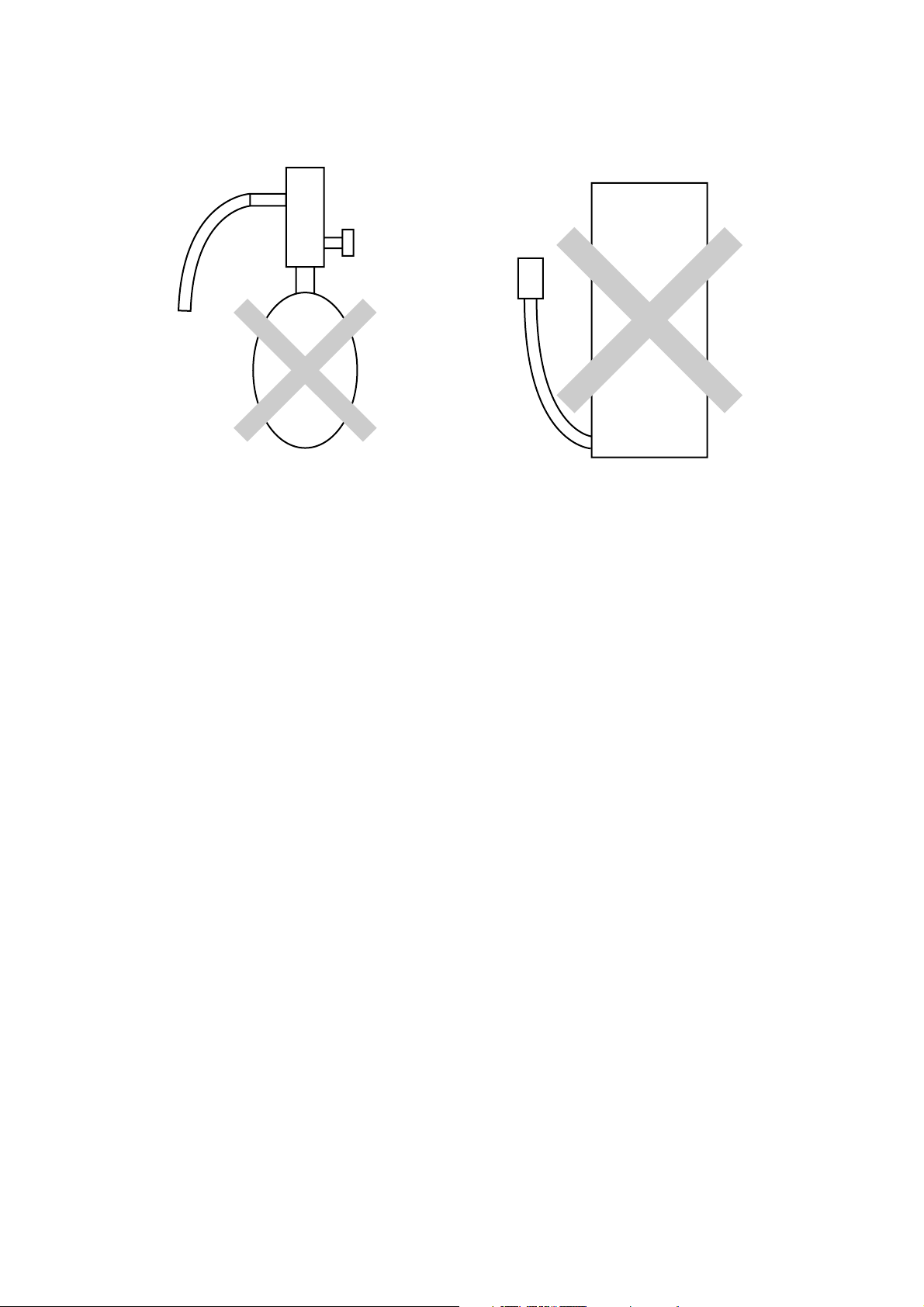

[5] Airtightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 cannot detect R407C leakage.

Halide torch R22 leakage detector

Items to be strictly observed:

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment’s airtightness, taking

temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R407C.

3. Ensure that R407C is in a liquid state when charging.

Reasons:

1. Use of oxygen as the pressurized gas may cause an explosion.

2. Charging with R407C gas will lead the composition of the remaining refrigerant in the cylinder to change and this

refrigerant can then not be used.

Note:

• A leakage detector for R407C is sold commercially and it should be purchased.

[6] Vacuuming

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure).

It is also possible to attach a check valve to the actual vacuum pump afterwards.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 0.5 Torr (500 MICRON) or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

3. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 5 Torr. Do not use a general gauge manifold since it cannot measure a

vacuum of 5 Torr.

4. Evacuating time

• Evacuate the equipment for 1 hour after –755 mmHg (5 Torr) has been reached.

• After envacuating, leave the equipment for 1 hour and make sure the that vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

–6–

Page 9

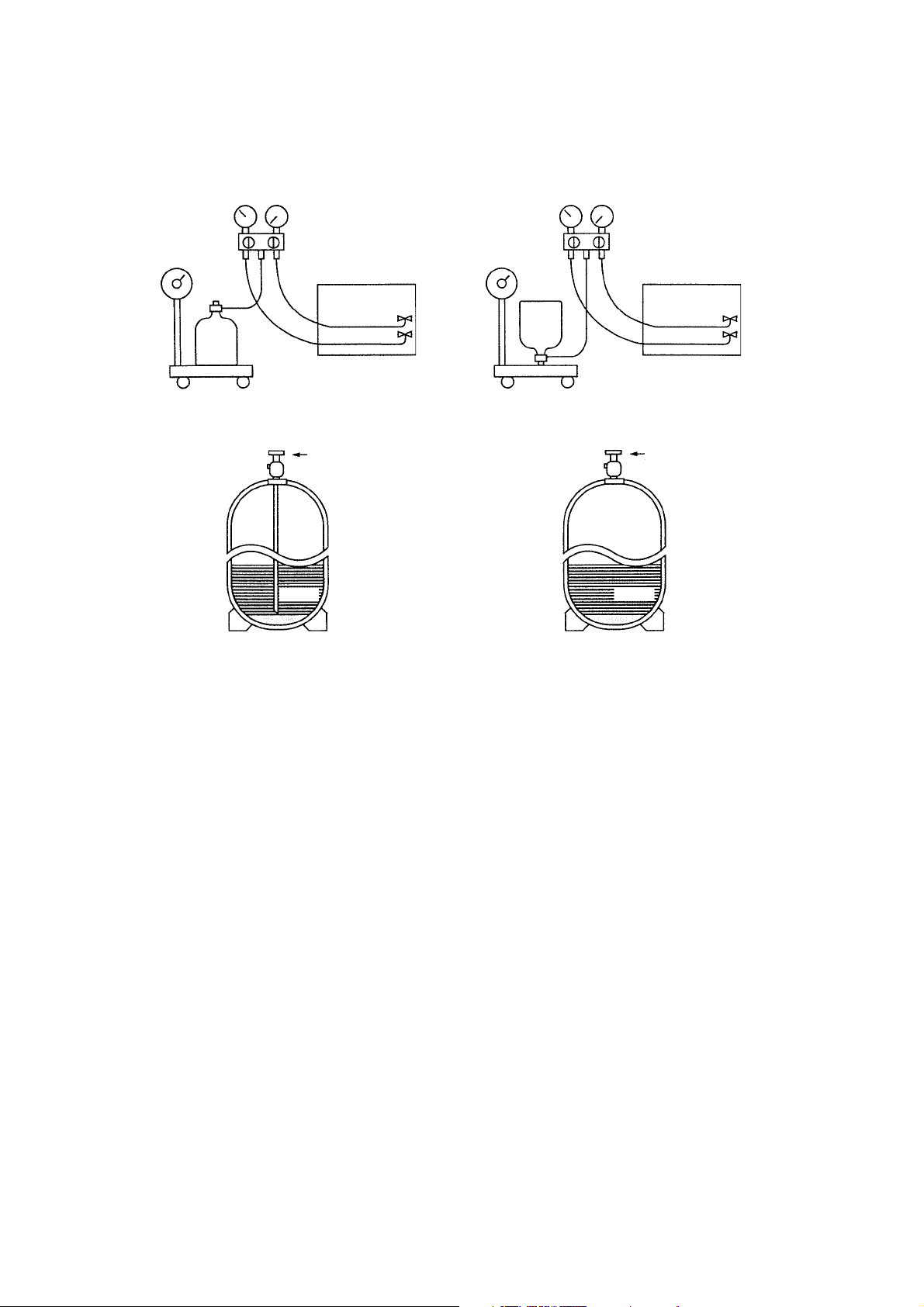

[7] Charging of Refrigerant

R407C must be in a liquid state when charging, because it is a non-azeotropic refrigerant.

For a cylinder with a syphon attached For a cylinder without a syphon attached

Cylin-

Cylin-

der

Cylinder color identification R407C-Gray Charged with liquid refrigerant

Valve

R410A-Pink

der

Valve

Liquid

Liquid

Reasons:

1. R407C is a mixture of 3 refrigerants, each with a different evaporation temperature. Therefore, if the equipment is

charged with R407C gas, then the refrigerant whose evaporation temperature is closest to the outside temperature is

charged first while the rest of refrigerants remain in the cylinder.

Note:

• In the case of a cylinder with a syphon, liquid R407C is charged without turning the cylinder up side down. Check the

type of cylinder before charging.

–7–

Page 10

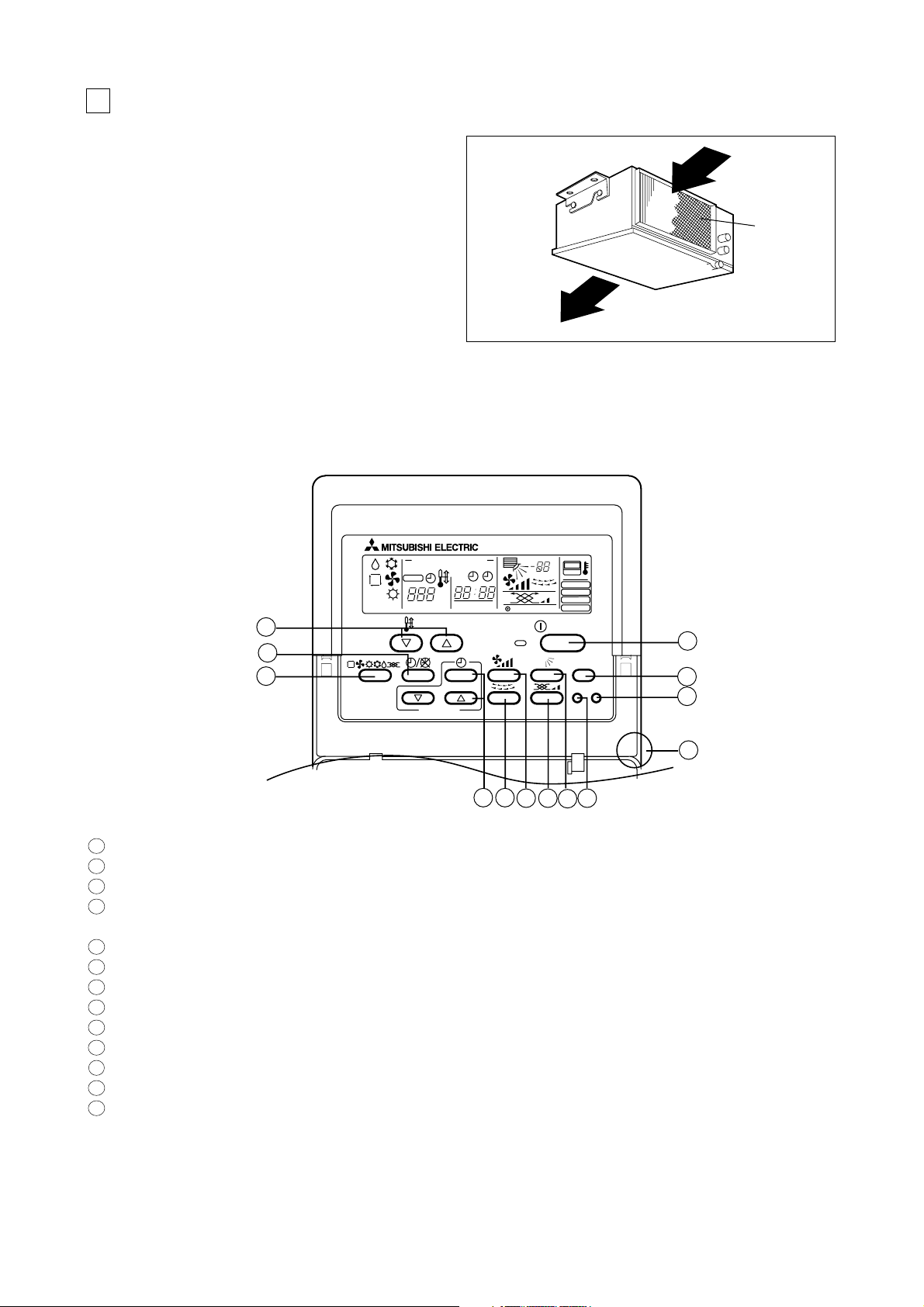

2 PART NAMES AND FUNCTIONS

Indoor unit

Air inlet

• Air inlet : Sucks the ambient air in.

• Filter : The filter bruit into the unit as standard is a

simple filter to remove visible dust and dirt. If

air pulification is one of the conditions required

for use, consult with your dealer.

• Air outlet : Blows the air back out into the room.

Air outlet

Remote controller (PAR-20MAA)

• Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

Operation buttons

CENTRALLY CONTROLLED

CHECK

STAND BY

DEFROST

1

TEMP.

ßC

ON OFF

CLOCK

ERROR CODE

2

3

PAR-20MAA

TIMER SET

1Hr.

NOT AVAILABLE

ßC

FILTER

CHECK MODE

TEST RUN

FUNCTION

ON/OFF

FILTER

CHECK TEST

12

11

10

Filter

13

4

56

1 [Room temperature adjustment] Button

2 [Timer/continuous] Button

3 [Selecting operation] Button

4 Time selection] Button

[Time-setting] Button

5 [Louver] Button (This button does not operate in this model)

6 [Fan speed adjustment] Button

7 [Up/down airflow direction] Button (This button does not operate in this model)

8 [Ventilation] Button

9 [Checking/built-in] Button

10

[Test run] Button

11

[Filter] Button (This button does not operate in this model)

12

[ON/OFF] Button

13

Position of built-in room temperature

• Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

• Never place any obstacle around the lower right-hand section of the remote controller. Doing so can result in the erroneous measurement of room temperature.

9

8

7

–8–

Page 11

Display

C

ßC

B

CLOCK

ERROR CODE

A

ON OFF

D U T S Q

CENTRALLY CONTROLLED

STAND BY

DEFROST

G

CHECK

TEMP.

H

E

F

A Current time/Timer

C Centralized control

D Abnormality control

E Operation mode: COOL, DRY, AUTO,

FAN, HEAT

F Preparing for Heating mode

G Defrost mode

H Set temperature

I Power ON

J Louver

I

1Hr.

NOT AVAILABLE

R

ßC

FILTER

CHECK MODE

TEST RUN

FUNCTION

ON/OFF

P

O

N

M

JKL

K Not available function

L Ventilation

M Function setting mode

N Test run mode

O Error check mode

P Filter sign

Q Set effective for 1 hr.

R Sensor position

S Room temperature

T Airflow

U Fan speed

Caution:

• Only the Power display lights when the unit is stopped and power supplied to the unit.

• When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not

a malfunction.

• When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch

button and

TEMP. adjustment button do not operate.

•“NOT AVAILABLE” is displayed when the Airflow direction button or Louver button are pressed. This indicates that

this room unit is not equipped with the fan direction adjustment function and the louver function.

• When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For

max. 2 minutes). Please wait until this “H0” indication disappear then start the operation.

–9–

Page 12

3 SPECIFICATIONS

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name PEH-P8MYA Quantity Symbol

Cooling Heating

Capacity kcal/h

kW

Air condition

Power source

Electrical characteristics

Remote controller temperature setting range °C

Airflow direction control

Fan

External finish

External dimension

Heat exchanger type

Air filter

Insulation material

Refrigerant piping dimension Liquid/Gas

Drain piping dimension

Noise level dB (A)

Net weight kg

External wiring

Composing parts

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power consumption kW

Operating current A

Type × Quantity

Airflow rate m3/min

External static pressure Pa

Motor output kW

Unit (H × W × D) mm

Panel (H × W × D) mm

φ

mm

φ

mm

Minimum wire thickness

Circuit breaker

Operation control device (provided)

Decoration panel (Option)

18,000 20,400

20.9 23.7

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/6 ˚C

3N~ 380/400/415V 50Hz

0.65/0.65/0.65 0.65/0.65/0.65

1.12/1.12/1.12 1.12/1.12/1.12

19 ~ 30 17 ~ 28

Sirrocco fan × 2

50/150

Galvanizing

428 × 1380 × 650

Cross fin

Polyethylene foam

12.7/25.4

25.4 (RC1)

49 (at 50 Pa)

1.6 mm

Remote controller: PAR-20MAA

–

60

0.75

–

–

70

15 A

–

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 7.5 m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

Notes:

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50 Pa setting.

–

Installation manual, Operation manual,

Remote controller

–

–10–

Page 13

Specifications of air-source heat pump type packaged air conditioner

(Ceiling concealed type indoor unit)

Model name

PEH-P10MYA

Quantity Symbol

Capacity kcal/h

kW

Air condition

Indoor side Dry bulb temperature/wet bulb temperature

Outdoor side Dry bulb temperature/wet bulb temperature

Power source

Electrical characteristics

Power consumption kW

Operating current A

Remote controller temperature setting range °C

Airflow direction control Vertical

Type × Quantity

Airflow rate m3/min

Fan

External static pressure Pa

Motor output kW

External finish

External dimension

Unit (H × W × D) mm

Panel (H × W × D) mm

Heat exchanger type

Air filter

Insulation material

Refrigerant piping size Liquid/Gas

Drain piping size

φ

φ

mm

mm

Noise level dB (A)

Net weight kg

External wiring

Minimum wire thickness

Circuit breaker

Composing parts

Operation control device (provided)

Decoration panel (Option)

Cooling Heating

22,400 26,200

26.0 30.5

27 °C/19 °C 20 °C/–

35 °C/24 °C7 °C/ 6 °C

3N~ 380/400/415V 50 Hz

0.94/0.94/0.94 0.94/0.94/0.94

1.64/1.64/1.64 1.64/1.64/1.64

19 ~ 30 17 ~ 28

–

Sirrocco fan × 2

80

50/150

1.23

Galvanizing

428 × 1,580 × 650

–

Cross fin

–

Polyethyene foam

12.7/28.58

25.4 (RC1)

53 (at 50 Pa)

80

1.6 mm

15 A

Remote controller: PAR-20MAA

–

Other mountable major options

Accessories

Special note, Non-standard specifications, etc.

1. The cooling and heating capacities are the maximum capacities that were obtained by operating in the above

air conditions and with a refrigerant pipe of about 7.5 m.

2. The actual capacity characteristics vary with the combination of indoor and outdoor units. See the technical

Notes:

informaition.

3. The operating noise is the data that was obtained by measuring it 1.5 m from the unit’s bottom in an anechoic

room. (Noise meter A-scale value)

4. The figure of Electrical characteristic, Airflow rate, Noise level, indicates, at 50 Pa setting.

–

Installation manual, Operation manual,

Remote controller

–

–11–

Page 14

4 PART NAMES AND FUNCTIONS

(1) Indoor Unit

• Models PEH-P8MYA

(B)

730

200

530

199

200

13132

(A)

400

20

(B)

1240

1280

1880

(C)

(D)

20

200

(1)

25 75

428500

928

(2)

(3)

(A)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

REFRIGERANT PIPE 25.4

(1 BRAZE)

15

20

42

156

130

344

152

AIR INLET

REFRIGERANT PIPE

(1/2 BRAZE)

130

95

42

33

12.7

AIR INLET SENSOR

650

210 116

562

DRAIN: Rc 1

104

31

40

100

1102

34

130130130130130130130130

31

24- 3.1 HOLES

AIR INLET DUCT

FLANGE

CONTROL BOX

20

4235

1280

22- 3.1 HOLES

AIR OUTLET DUCT

7053050

15

CONTROLLER

100 25

25 100

382

AIR OUTLET

WIRING HOLE 27

(AIR INLET SIDE)

CONNECT WIRE (PEH-PUH)

WIRING HOLE 27

(AIR INLET SIDE)

FLANGE

428

55 55 156

POWER SUPPLY

WIRING HOLE 27

(AIR INLET SIDE)

40

120

46

DUCT EARTH POINT

(BOTH DUCT SIDE)

1380

1320

1240

1000

1264

20

15

4513013013013013013013045

40

120

131 200 199

4- 12 HOLES

(FOR HUNGING

<FIELD SUPPLY>

BOLT M10)

98250

14

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body, and mount

an air filter onto the inlet duct side separately.

–12–

Page 15

• Models PEH-P10MYA

(B)

730

200

530

25 75

928

199

200

13132

428500

(A)

400

20

(B)

1440

1480

2080

(C)

(D)

20

200

(1)

(2)

(3)

(A)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

REFRIGERANT PIPE

28.6 (1-1/8 BRAZE)

15

20

42

156

130

344

152

AIR INLET

REFRIGERANT PIPE

(1/2 BRAZE)

130

95

42

33

12.7

AIR INLET SENSOR

650

210 116

562

DRAIN: Rc 1

104

66

40

100

1302

130130130130130130130130

34

130

66

26- 3.1 HOLES

AIR INLET DUCT

FLANGE

CONTROL BOX

20

423

FLANGE

5

45

130

40

220

46

428

55 55 156

DUCT EARTH POINT

(BOTH DUCT SIDE)

22- 3.1 HOLES

AIR OUTLET DUCT

7053050

15

CONTROLLER

100 25

25 100

382

AIR OUTLET

WIRING HOLE 27

(AIR INLET SIDE)

CONNECT WIRE

(PEH-PUH)

WIRING HOLE 27

(AIR INLET SIDE)

POWER SUPPLY

WIRING HOLE 27

(AIR INLET SIDE)

1480

130

1580

1520

1440 40

1000

1464

20

131 200 199

130

15

45130130130130

220

4- 12 HOLES

(FOR HUNGING

<FIELD SUPPLY>

BOLT M10)

98

250

14

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body, and mount

an air filter onto the inlet duct side separately.

–13–

Page 16

(2) Remote Controller

• Models PAR-20MAA

(Front view) (Side view) (Rear view)

120

130

19

83.5

46

–14–

Page 17

5 ELECTRICAL WIRING DIAGRAM

(1) Indoor Unit

• Models PEH-P8MYA/P10MYA

REMOTE CONTROLLER

REMOTE CONTROLLER

BOARD

T B 6

CN

LCD

CIRCUIT BREAKER

(FIELD SUPPLY)

PEH-P8,10MYA:15A

POWER SUPPLY

3N~PE

380/400/415V

50Hz

C0

5 2 F 5 1 F

PE

2 1

1

CN2

2

1

CN2

2

(WHITE)

(50Pa)

INDOO

CONTROLLER

1

2

CN9

3

4

5

6

7

8

9

CN2

D C 14V

T B 2

L 1

RED

L 2

WHITE

L 3

BLACK

N

PE

PE

T B 5

1

2

PE

INLET

DUCT

PE

OUTLET

DUCT

C02

PE

(RED)

(150Pa)

2

1

MF1

3

2

1

3

Note:

1. The dotted lines show field wiring.

2. Color of earth wire is yellow and green twisting.

3. Specification subject to change without notice.

4. Indoor and outdoor connecting wires are made with

polarities, make sure matching wiring and terminal.

5. Emergency operation

If a trouble occurs with either the remote controller

or the indoor microcomputer and no other trouble

exisits, emergency operation for cooling or heating

can be performed by changing the setting of switch

(SWE) on the indoor controller board.

6. SW2 is shown PEH-P10MYA setting.

In case of PEH-P8MYA setting is shown as below.

4321

ON

OFF

Caution:

SW2

1. To protect fan motor from abnormal current,over

current relays is installed.

1

2

CN3

3

L E D 1

L E D 2

L E D 3

CN03

5 3 1

1

2

CN41

3

4

1

CN29

2

1

CN21

2

1

CN20

2

T H 1

T H 2

T H 5

7 5 3 1

FAN

4

1235

SW

4321

SW

SW

X4 X5 X6

ON

OFF

ON

OFF

ON

OFF

X6X5X4

Therefore, do not change factory set value of over

INDOOR UNIT [PEH-P8, P10MYA]

F B

INDOO

POWER BOARD

CN01

1 2 3

CN2S

F1

D C 14V

1

DC

ZNR

2

14V

1

2

3

CN02

C R

4 9 F

5 1 F

1

3

52F

C12

S 1

S 2

S 3

T B 4

current relays.

TO OUTDOOR

CONNECTING

(POLER)

POWER

3N~

380/400/415V

OUTDOOR UNIT

T B 3

S1

S2

S3

T B 1

L1

L2

L3

N

PE

INDOOR UNIT

SYMBOL NAME

MF1 FAN MOTOR (INDOOR)

51F OVER CURRENT RELAY (INDOOR FAN MOTOR)

52F CONTACTOR (INDOOR FAN MOTOR)

49F INTERNAL THERMOSTAT (INDOOR FAN MOTOR)

TB2, 4, 5 TERMINAL BLOCK

TH1 ROOM TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

TH2 THERMISTOR PIPE TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

TH5 COND./EVA. TEMP. (0˚C/15kΩ, 25˚C/5.4kΩ)

F1 FUSE (4A 250VAC CLASS T)

ZNR VARISTOR

X4-6 AUXILIARY RELAY (INDOOR CONTROLLER BOARD)

SW1 SWITCH (MODEL SELECTION)

SW2 SWITCH (CAPACITY CORD)

SWE SWITCH (EMERGENCY OPERATION)

LED1 LED (POWER SUPPLY : INDOOR CONTROLLER BOARD)

LED2 LED (POWER SUPPLY : REMOTE CONTROLLER)

LED3 LED (TRANSMISSION : INDOOR-OUTDOOR)

CR SURGE KILLER

CN03, CN21, 2D

CN20-22, 29, 32

CONNECTOR (INDOOR CONTROLLER BOARD)

CN41, 90, FAN

CN01, 02, 2S CONNECTOR (INDOOR POWER BOARD)

C01, 02, 12 CONNECTOR (FAN MOTOR)

FB FERRITE CORE

OUTDOOR UNIT

SYMBOL NAME

TB3 TERMINAL BLOCK

REMOTE CONTROLLER

SYMBOL NAME

TB6 TERMINAL BLOCK

–15–

Page 18

6 TECHNICAL DATA TO MEET LVD

[1] Capacity/Input Ratio against Changes in Room Airflow Rate

• Models PEH-P8MYA

Cooling

1.05

1.0

Input

Capacity/Input ratio

Capacity

0.95

50 55 60 65

Airflow rate (m3/min)

• Models PEH-P10MYA

1.05

1.0

Capacity/Input ratio

0.95

70

50 55

Heating

Input

Capacity

60 65 70

Airflow rate (m3/min)

1.05

Cooling

1.0

Input

Capacity/Input ratio

Capacity

0.95

70 75 80 85

Airflow rate (m3/min)

1.05

1.0

Capacity/Input ratio

0.95

90

Heating

Input

Capacity

70 75 80 85

Airflow rate (m3/min)

90

–16–

Page 19

[2] Bypass Factor Curves

PEH-P8MYA

0.30

0.25

0.20

Bypass factor

0.15

0.10

50 55 60 65 70

Airflow rate (m3/min)

[3] Cooling Sensible Heating Capacity Table

(1) PEH-P8MYA (Airflow rate 60m3/min)

PEH-P10MYA

0.20

0.15

0.10

Bypass factor

0.05

0.00

70 75 80 85 90

Airflow rate (m3/min)

Outdoor

temp.

(°C)

20

25

30

35

40

43

23/16 25/18 27/19 28/20 30/22

CA

18100

17500

16900

16200

15300

14800

SHC

13700

13400

13100

12800

12500

12400

(2) PEH-P10MYA (Airflow rate 80m

Outdoor

temp.

(°C)

20

23/16 25/18 27/19 28/20 30/22

CA

22500

SHC

18100

CA

19300

18700

18100

17400

16600

16000

3

/min)

CA

24000

Indoor inlet air temperature (DB/WB°C)

SHC

13500

13300

13000

12700

12400

12300

CA

20000

19500

18900

18000

17400

16900

SHC

14400

13700

13500

13100

13000

12900

CA

20800

20300

19700

19000

18200

17700

Indoor inlet air temperature (DB/WB°C)

SHC

17900

CA

24900

SHC

18500

CA

25800

SHC

14400

14200

14000

13700

13500

13400

SHC

19200

CA

21900

21500

20900

20200

19500

19000

CA

27300

SHC

14200

13900

13700

13500

13300

13200

SHC

18800

25

30

35

40

43

21800

21000

20100

19100

18400

17800

17500

17100

16800

16600

23300

22500

21600

20600

20000

17600

17300

16800

16600

16500

24300

23500

22400

21600

21000

–17–

18300

17900

17400

17400

17300

25200

24500

23600

22700

22000

18900

18600

18300

18100

18000

26700

26000

25200

24200

23600

18600

18300

18100

17900

17800

Page 20

External static pressure (pa)

40 50 60 70 80

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

External static pressure (pa)

60 70 80 90 100

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

PEH-P8MYA

PEH-P10MYA

[4] Airflow Characteristic Curves

[5] Center of Gravity (Indoor unit)

Top of the unit

X

Item

Model name

PEH-P8MYA

X

630

unit : (mm)

Center of gravity

Y

230

Z

Y

Z

240

PEH-P10MYA

730

–18–

235

240

Page 21

[6] NC Curve (Indoor unit)

PEH-P8MYA

Measurement condition

Aux. duct

1m 2m

1.5m

Measured point

70

External static pressure: 50Pa

External static pressure: 150Pa

60

50

40

30

20

Approximate minimum

OCTAVE BAND PRESSURE LEVEL <dB> 0dB = 20µPa

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

NC60

NC50

NC40

NC30

NC20

OCTAVE BAND CENTER FREQUENCIES <Hz>

PEH-P10MYA

Measurement condition

Aux. duct

1m 2m

Measured point

1.5m

70

External static pressure: 50Pa

External static pressure: 150Pa

60

50

40

30

20

Approximate minimum

OCTAVE BAND PRESSURE LEVEL <dB> 0dB = 20µPa

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES <Hz>

NC60

NC50

NC40

NC30

NC20

–19–

Page 22

7 SERVICE DATA

[1] Appearance of Equipment

• PEH-P8MYA/P10MYA Electrical Parts Box (with cover removed)

Terminal bed

(remote controller transmission line)

Indoor power board

Terminal bed

(indoor/outdoor connecting line)

Terminal bed (power)

[2] Internal Construction

• PEH-P8MYA/P10MYA (Indoor unit)

Refrigerant piping flange connection : LP φA

Refrigerant piping flare connection : HP

Indoor circuit board

Magnetic contactor (fan motor)

Over current relay

(fan motor)

Duct flange

φ

B

Leg

(for installation)

Air filter

Heat exchanger

[3] Refrigerant Circuit

Indoor Heat exchanger

Fan motor

Sirrocco fan

Brazing connection

Cooling operation

Heating operation

Drian connection (RC1)

–20–

Electrical parts box

Model name

PEH-P8MYA

PEH-P10MYA

Drain pan

A

25.4

28.58

B

12.7

12.7

Page 23

8 FUNCTION OF SWITCH ON INDOOR CIRCUIT BOARD

[1] DIP SW1 for model Selection (DIP SW1 has been set at factory)

ON

54321

OFF

PEH-P8MYA/P10MYA : SW1-1, -4 ON, SW1-2, -3, -5 OFF

[2] DIP SW2 for Capacity Setting (DIP SW2 has been set at factory)

ON

4321

OFF

PEH-P8MYA : SW2-1, -2, -3 and, -4 OFF

ON

4321

OFF

PEH-P10MYA : SW2-1 ON, SW2-2, -3, and, -4 OFF

[3] DIP SWE for Emergency Operation

ON

OFF

When SWE is turned ON, FAN turns ON. Setting of emergency operation other than SWE is

performed at the outdoor unit. For a description of the specific emergency operation execution

method, refer to the outdoor unit (PUH-P8MYA, PUH-P10MYA) Technical & Service Manual.

–21–

Page 24

9 Test run

[1] Before test run

The test run can be carried out either from the outdoor unit or the indoor unit.

1. Check list

• After the installation, piping setup,and wiring of the indoor and outdoor units is complete, check that refrigerant is not

leaking, the power and control wires are not loose, and the poles are not reversed.

• Use a 500 V insulation resistance tester to make sure that the resistance between the power terminal and the ground

is 1.0 M or more. If it is less than 1.0 M, do not operate the unit. *Absolutely do not touch the tester to indoor/outdoor

connection terminals S, S2, and S3. An accident could occur.

• Make sure there is no malfunction in the outdoor unit.(If there is a malfunction, you can diagnose it using LED2 on the

board.)

• Check that the ball valve is fully open on both the liquid and gas ends.

• Check the electrical power phase. If the phase is reversed, the fan may rotate in the wrong direction or stop, or

unusual sounds may be produced.

• Starting at least 12 hours before the test run,send current through the crankcase heater. (If the current is running for

a shorter period of time, damage to the compressor could result.)

• For specific models requiring changing of settings for higher ceilings or selection of power supply ON/OFF capability,

make proper changes referring to the description for Selection of Functions through Remote Controller.

After the above checks are complete, carry out the test run as indicated in the following outline.

[2] Test run procedures

1. Indoor unit

STAND BY

DEFROST

CENTRALLY CONTROLLED

CLOCK

CHECK

ßC

ERROR CODE

TEMP.

ON OFF

1Hr.

NOT AVAILABLE

ßC

FILTER

CHECK MODE

TEST RUN

FUNCTION

ON/OFF

(A)

(5)

FILTER

PAR-20MAA

CHECK TEST

TIMER SET

(2)

(3)

Operating procedures

(1) Turn on the main power supply

While the room temperature display on the remote controller reads “CENTRALLY CONTROLLED”, the remote

controller is disabled.Turn off the “CENTRALLY CONTROLLED” display before using the remote controller.

(2) Press “TEST RUN” button twice

(A) The ‘TEST RUN’ indicator should light up.

(3) Press button

Cooling/drying mode : Cool air should start to blow.

Heating mode : Warm air should start to blow (after a while).

(4) Check the outdoor unit fan for correct running

The outdoor unit features automatic capacity control to provide optimum fan speeds. The fan keeps running at a low

speed to meet the current outside air condition unless it exceeds its available maximum power. Then, in actuality,

the fan may stop or run in the reverse direction depending on the outside air, which does not mean malfunction.

(5) Press the “ON/OFF” button to reset the test run in progress

• The test run will be automatically shut down after two hours in response to the AUTO STOP setting of two hours on

the timer.

• During the test run, the room temperature display shows the indoor unit tubing temperatures.

–22–

Page 25

• In the case of the test run, the OFF timer will activate, and the test run will automatically stop after two hours.

• The room temperature display section shows the control temperature for the indoor units during the test run.

• Check that all the indoor units are running properly for simultaneous twin and triple operation.

Malfunctions may not be displayed even if the wiring is incorrect.

(*1)

After turning ON the power,the system will go into startup mode,and the remote controller operation lamp (red) and

the room temperature display section’s “H0 ” will flash. Also, in the case of the indoor substrata LEDs, LED 1 and

LED 2 light up (when address is 0) or become dim (when address is not 0), and LED 3 flashes. In the case of the

outdoor substrata LED display, – and – are displayed alternatively at 1-second intervals.

• If one of the above operations does not function correctly, the following causes should be considered, and if

applicable, dealt with. (The following symptoms have been determined under test run mode. Note that “startup” in

the chart means the *1 display above.)

Remote Controller Display Outdoor Substrate LED Display

Remote controller is displaying “H0”, and operation is

not possible.

After power is turned ON,“H0 ” is displayed for 3 mins.,

then error code is displayed.

Power is turned ON,and “EE” or “EF” are displayed

after “H0” is displayed.

Display messages do not appear even when remote

controller operation switch is turned ON (operation

lamp does not light up).

Operation display appears but soon disappears even

when remote controller operations are executed.

Symptoms

After “startup” display,“00” is displayed

(correct operation).

After “startup” display,error code is

displayed.

After “startup” display, “F1” (negative

phase) is displayed.

After “startup” display, “00” or “EE” is

displayed (“EE” is displayed when a test

run is made).

After “startup” display, “EA” (error for

number of units) or “Eb” (unit number

error) is displayed.

After “startup” display, “00” is displayed

(correct operation).

After “startup” display, “00” is displayed

(correct operation).

After “startup” display, “00” is displayed

(correct operation).

• After power is turned ON, system startup lasts for about

2 mins., and “H0” is displayed (correct operation).

• Outdoor unit ’s safeguard installation connector is open.

• Negative phase and open phase of outdoor unit’s power

terminal board.

(Single phase: L, N, /triple phase: L1, L2, L3, N, )

• Incorrect connection of outdoor terminal board (Single

phase: L, N, /triple phase: L1, L2, L3, N, grounding

and S1, S2, S3)

• Outdoor unit and indoor unit construction differ.

• Wiring for the indoor and outdoor unit is not connected

correctly. (Polarity is wrong for S1, S2, S3)

• Remote controller transmission wire short.

• There is no outdoor unit for address 0 (address is

something other than 0).

• Remote controller transmission wire burnout.

• After cancellation of function selection, operation is not

possible for about 30 secs. (correct operation).

Cause

* Press the remote controller’s “CHECK” button twice consecutively to be able to run a self diagnosis. See the chart

below for content of error code displays.

LCD Nonconformity content

P1 Suction sensor error

P2 Tubing (liquid) sensor error

P4 Drain sensor error

P5 Drain overflow safeguard operation

P6 Freezing/overheating safeguard operation

LCD Nonconformity content

P8 Tube temperature error

P9 Tube (2-phase tube)sensor error

U0 ~ UP Outdoor unit nonconformity

F1 ~ FA Outdoor unit nonconformity

E0 ~ E5 Signal error between remote

controller and indoor unit

LCD Nonconformity content

E6 ~ EF Signal error between indoor and

outdoor units

---- No error history

FFFF No relevant unit

See the chart below for details of the LED displays (LED 1, 2, 3) on the indoor substrate.

LED 1 (microcomputer power supply) Displays the

LED 2 (remote controller feed) Displays the

LED 3 (indoor and outdoor signals) Displays signal between indoor and outdoor units. Check that this is flashing during normal use.

ON/OFF

of power for control.Check that this is lit during normal use.

ON/OFF

of feed to wired remote controller. Is only lit for indoor unit linked to outdoor unit with address “00”.

2. Outdoor unit

(1) Check Items

• After installation of indoor and outdoor units,and piping and electric wiring work,check that the unit is free from leaks

of refrigerant,loosened connections,and incorrect polarity.

• Check that there is no negative phase and open phase. (The F1 message for negative phase and the F2 message

for open phase will flash at LED 1 on the outdoor substrate. If this happens,rewire correctly.)

• Measure the impedance between power terminals (Single phase: L, N, /triple phase: L1, L2, L3, N, ) and the

ground with a 500 V Megger and check that it is 1.0 M or more. Do not operate the equipment if measurement is

less than 1.0 M. *Never conduct this operation on the outdoor connection wiring terminals (S1, S2, S3) as this

causes damage.

–23–

Page 26

• When there is no error at the outdoor unit. (If there is an error at the outdoor unit, it can be evaluated at LED 1 [digital

display] of the outdoor substrate.)

• The stop valves are open both the liquid and gas sides.

After checking the above, execute the test run in accordance with the following.

(2) Test run start and finish

• Operation from the indoor unit

Execute the test run using the installation manual for the indoor unit.

• Operation from the outdoor unit

Execute settings for test run start,finish and operation mode (cooling, heating) using the DIP switch SW 4 on the

outdoor substrate.

< SW4 >

OFF ON

A

1

B

2

C

D

A Stop

B Cooling

C Operation

D Heating

a) Set the operation mode (cooling, heating) using SW 4-2

b) Turn ON SW 4-1, The operation mode for SW 4-2 will be adhered to, and the test run will commence

c) Turn OFF SW 4-1 to finish the test run

• There may be a faint knocking noise emitted from the proximity of the fan during the test run. This is torque

fluctuation occurring due to control of fan revolutions. There is no problem with the product.

Note:

The SW 4-2 operation mode cannot be changed during the test run. (To change test run mode, stop the equipment

with SW 4-1, change the operation mode, then restart test run with SW 4-1.)

• If the 2-hour timer is set,the test run will stop automatically after 2 hours.

• During the test run,the room temperature display on the indoor unit will indicate the temperature of the indoor unit

piping.

[3] Self-diagnosis

Use the remote controller to look up each units error history.

1.

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

ßC

CLOCK

ON OFF

1. Change to self-diagnosis mode

Press the CHECK button twice within three seconds to show

the following

2.

3. (1)

STAND BY

DEFROST

STAND BY

DEFROST

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ßC

b)

ßC

ON OFF

CLOCK

ON OFF

CLOCK

ERROR CODE

ON OFF

CLOCK

2. Select the refrigerant address number to be self-

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

diagnosed

Press the buttons to scroll through the

refrigerant address numbers (00 to 15)and select the

refrigerant address number to be slf-diagnosed.

After three seconds from making the change,the lit refrigerant

address to be self-diagnosed will start to flash,and selfdiagnosis will commence.

3. Self-diagnosis result display

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

a)

c)

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

d)

See the above chart for details of error code contents.

(1) When there is an error history

a) Alternating display

b) Error code

c) Attribute of error search

d) Unit number

–24–

Page 27

3. (2)

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ON OFF

CLOCK

ERROR CODE

(2) When there is no error history

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

(3)

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ON OFF

CLOCK

ERROR CODE

4.

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

a)

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ßC

ON OFF

CLOCK

ERROR CODE

ON OFF

CLOCK

5.

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

ßC

CLOCK

ON OFF

(3) When the address does not exist

4. Reset error history

Display the error history at the self-diagnosis result display screen

3.

CLOCK ON OFF

The address for self-diagnosis will flash when the

button is pressed twice within three seconds.

The diagram on the left will be displayed when error history has

been reset.

Note that the error content will be redisplayed if error history

resetting is unsuccessful.

a) Alternating display

5. Canceling self-diagnosis

The following two methods can be used to cancel self-diagnosis.

Press the CHECK button twice within three seconds to cancel

self-diagnosis. The display screen will return to the status before

self-diagnosis. Press the 1 ON/OFF button to cancel selfdiagnosis. The indoor unit will stop. (This operation is ineffectual

when operation is prohibited.)

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ON OFF

CLOCK

ERROR CODE

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

–25–

Page 28

[4] Remote controller diagnosis

If operation cannot be carried out from the remote controller,use this function to

diagnose the remote controller.

1.

STAND BY

DEFROST

2.

STAND BY

DEFROST

STAND BY

DEFROST

3. (1)

STAND BY

DEFROST

CLOCK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

ßC

ßC

ßC

ßC

CLOCK

CLOCK

CLOCK

CLOCK

ON OFF

ON OFF

ON OFF

ON OFF

(1)

1Hr.

1Hr.

1Hr.

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

ßC

CHECK MODE

FUNCTION

ßC

CHECK MODE

FUNCTION

ßC

CHECK MODE

FUNCTION

FILTER

FILTER

FILTER

1. First, check the electricity current marker

If the correct voltage (DC 12 V)is not displayed on the remote

controller, the electric current marker will be lit. If the electricity

current marker is not lit, check the remote controller wiring

and the indoor unit.

(1) Electric current marker

2. Transfer to remote control mode

Hold down the CHECK button for five seconds or more to

display the diagram on the left.

Press the FILTER button to commence diagnosis of remote

controller.

3. Remote controller diagnosis results

(1) The remote control is functioning correctly.

Check other possible causes as there are no problems

with the remote controller.

(2)

STAND BY

DEFROST

(1)

STAND BY

DEFROST

(2)

STAND BY

DEFROST

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

CHECK

INDOOR UNIT

ADDRESS NO

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

1Hr.

ßC

FILTER

CHECK MODE

FUNCTION

ßC

ßC

ßC

CLOCK

CLOCK

CLOCK

ON OFF

ON OFF

ON OFF

K) When the number of data

errors generated is 02

L) Remote controller transmission data

M) Transmission data at transmission path

(2) The remote controller has a nonconformity.

The remote controller must be replaced.

Error display 1 (“NG”) flashes to show a nonconformity in

the transmitter-receiver circuit.

Potential problems other than those diagnosed for

the remote controller.

(1) Single transmission not possible if error display 2 (“E3”)

flashes.

There is “noise” on the transmission line, or damage of

other remote controllers for the indoor units can be

considered. Check the transmission path and other

controllers.

(2) Data error has occurred when error display three shows

“ERC” and number of data errors.

Number of generated data errors (maximum 66 errors).

The number of generated data errors stands for the

difference in the number of bits of transmitted data from

the remote controller and the actual number of bits that

were transmitted along the transmission path. If this error

occurs, “noise”, etc., is interfering with the transmission

data. Check the transmission path.

4. Cancel the remote controller diagnosis

Hold down the CHECK button for five seconds or more to cancel the remote controller diagnosis. The “H0” operation

lamp will flash, and the display screen will return to the status before remote controller diagnosis in approximately 30

seconds.

–26–

Page 29

— MEMO —

Page 30

— MEMO —

Page 31

— MEMO —

Page 32

Certificate Number FM33568

Certificate Number EC97J1227

Registered on March 10, 1998

HEAD OFFICE MITSUBISHI DENKI BLDG. MARUNOUCHI TOKYO 100-0005 TELEX J24532 CABLE MELCO TOKYO

The Air Conditioning & Refrigeration Systems Works acquired ISO 9001 certification under

Series 9000 of the International Standard Organization (ISO) based on a review of quality

warranties for the production of refrigeration and air conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality warranties as stipulated by the ISO. ISO 9001 certifies quality warranties based on the “design, development,

production, installation and auxiliary services” for products built at an authorized plant.

The Air Conditioning & Refrigeration Systems Works acquired environmental management

system standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO). ISO 14001 certifies the plant’s environmental

protection system and activities.

MEE03K184

Printed in Malaysia

Specifications subject to change without notice.

New publication, effective Jul. 2003.

Loading...

Loading...