Mitsubishi PEHD-3EKA3.UK, PEHD-4EKSA3.UK, PEHD-5EKSA3.UK, PEHD-6EKSA.UK, PEHD-3EKHA3.UK Service Manual

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ADVANCE AND EVER ADVANCING

TECHNICAL & SERVICE MANUAL

<indoor unit> Service ref.

Models

PEHD-3EKA3.UK

PEHD-3EKHA

3.UK

PEHD-4EKSA

3.UK

PEHD-4EKHSA

3.UK

PEHD-5EKSA

3.UK

PEHD-5EKHSA

3.UK

PEHD-6EKSA.UK

PEHD-6EKHSA.UK

The Slim Line.

From Mitsubishi Electric

TM

1. FEATURES ················································ 1

2. PART NAMES AND FUNCTIONS ············· 2

3. SPECIFICATIONS······································ 5

4. DATA··························································· 9

5. REFRIGERANT SYSTEM DIAGRAM ·······14

6. OUTLINES AND DIMENSIONS ················15

7. WIRING DIAGRAM ···································16

8. DISASSEMBLY INSTRUCTIONS ············ 17

9. PARTS LIST·············································· 20

10

. OPTIONAL PARTS··································· 24

CONTENTS

INDOOR UNIT

REMOTE CONTROLLER

This manual does not cover the

following outdoor units. When

servicing them, please refer to

the service manual No.OC150A

and this manual as a set.

PUH-3YKA

2.UK

PUH-3VKA

2.UK

PUH-4YKSA

2.UK

PUH-4VKSA

2.UK

PUH-5YKSA

2.UK

PUH-6YKSA

2.UK

Page 2

1

1

FEATURES

1. NEXT GENERATION AIR-CONDITIONING VENTILATION INTERLOCKING SYSTEM "Mr.SLIM"+

"LOSSNAY"

Proper ventilation is important to improve the quality of indoor environments. It eliminates unclean air, which is not only

unpleasant, but unhealthy. This "Mr.SLIM" + "LOSSNAY" ventilation interlocking system achieves high air quality with

minimum energy consumption.

LOSSNAY's unique total heat exchanger reduces heating and cooling expenses by about 25 percent annually(in

comparison with our existing models). In addition, its mechanism of simultaneous forced air supply and exhaust enables it

to deliver high quality air.

Together, "Mr.SLIM" + "LOSSNAY" system makes next-generation air conditioning possible. This system is both people

and environment friendly.

2. TOTALLY INVISIBLE INDOOR UNIT BEHIND THE CEILING

The totally hidden indoor unit that lies above the ceiling surface enables you to utilize full floor space while allowing for

flexible interior design. This new feature is recommended for stores and offices where the user's own imagination is

allowed to be incorporated.

3. MOST SUITABLE FOR SIMULTANEOUS TWO ROOM AIR CONDITIONING

Using air ducts for cooling/heating airflow that matches the structure and purpose of the room enables you to provide two

air outlets for simultaneous cooling/heating of two rooms.

4. HIGH EXTERNAL STATIC PRESSURE(OPTION MOTOR)

The exceptional external static pressure of 130Pa allows long ducts to be used more extensively to achieve convenient

location of indoor units.(STD:70Pa)

5. DRAIN WATER LIFT-UP MECHANISM(OPTION KIT)

This allows more versatility when selecting drain piping layouts.

air outlet air outlet

Air outlet duct

Air intake duct

air intake

lndoor unit

Remote controller

Models Cooling capacity / Heating capacity

Btu/h W

PEHD-3EK(H)A3

PEHD-4EK(H)SA

3

PEHD-5EK(H)SA

3

PEHD-6EK(H)SA

26,300/30,700(37,900)

33,100/35,500(43,700)

42,300/47,400(57,700)

50,000/54,500(64,700)

7,700/9,000(11,100)

9,700/10,400(12,800)

12,400/13,900(16,900)

14,650/16,000(19,000)

Page 3

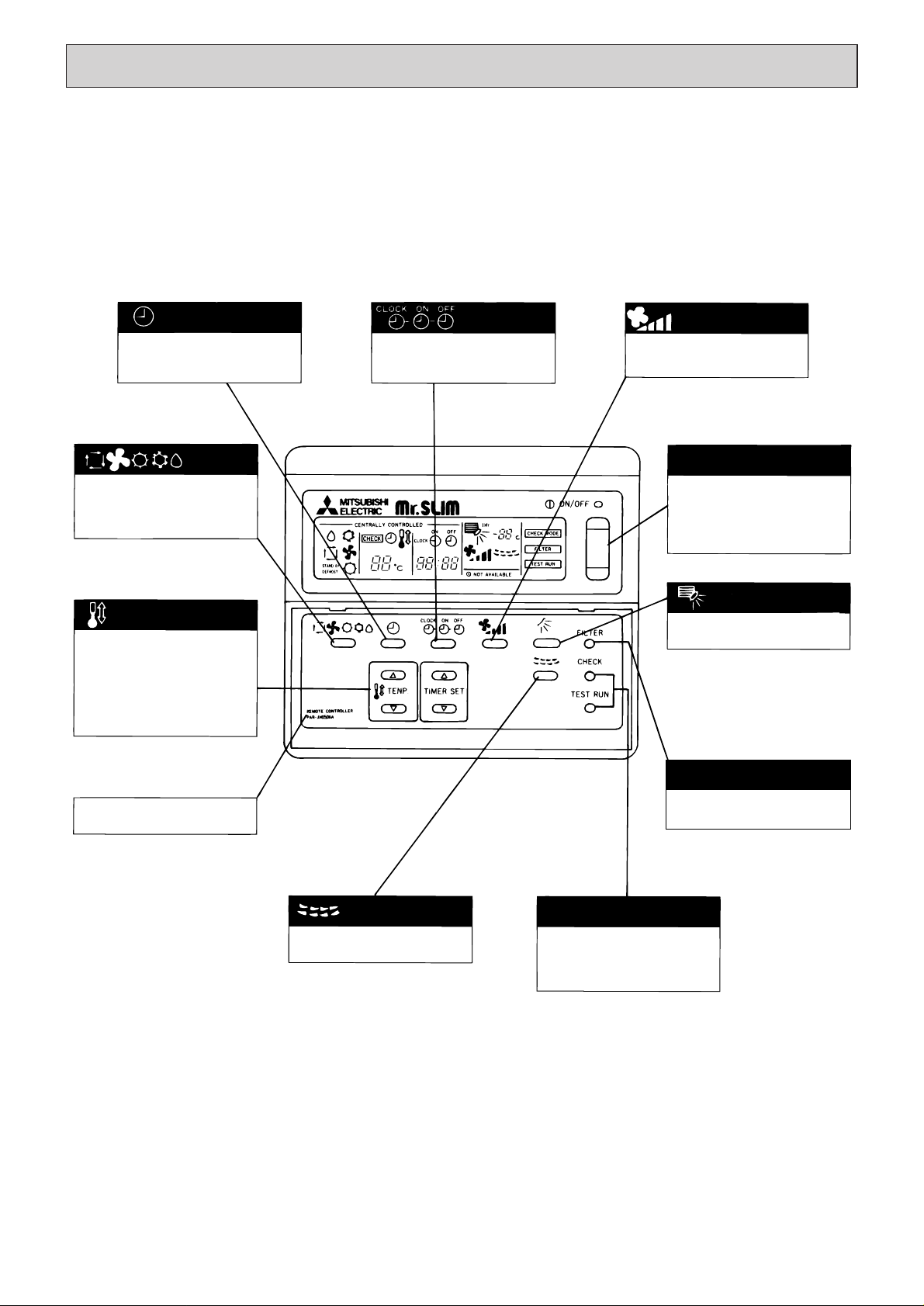

2

2

PART NAMES AND FUNCTIONS

6. ADVANCED MICROPROCESSOR

(1) Easy to use microprocessor

1) Ultra-thin remote controller

The streamlined, square controller is designed to blend well with any interior. Also, the sophisticated microprocessor allows you to easily carry out a wide range of operations.

2) Attractive liquid crystal display (LCD)

The unit's operation mode, set temperature, room temperature, timer setting, and fan speed are displayed on the

remote controller's easy-to-read Liquid Crystal Display (LCD)

3) Convenient 24-hour ON-OFF timer

The timer switches Mr.SLIM on and off automatically at the time you set. Once the timer is set, the remaining time

is shown on the LCD.

4) Self-diagnostic feature indicates faults instantly

If a problem occurs, the unit will stop operating and the set temperature indicator will change to a self-diagnostic

indicator, which shows the location of the trouble.

If the check switch is pressed twice, the unit stops operating and the check mode is initiated. The location of the

most recent problem that was stored in the memory is displayed on the LCD. This is extremely useful for

maintenance purposes.

5) Useful memory feature for storing instructions

The previous set value is memorized so that constant temperature control can be achieved. For example, if a

power failure occurs, the temperature will not have to be re adjusted afterwards.

(2) Non-polar two-wire remote controller cable

The slim, non-polar, two-wire remote controller cable makes installation simple and trouble free. Also, the remote

controller wire can be extended up to 500m.

(3) Automatic cooling/heating changeover operation

An automatic cooling and heating changeover operation system allows you to easily control comfortable year-round

air conditioning.

Once the desired temperature is set, unit operation switches automatically between cooling and heating, in

accordance with the room temperature. In addition, the use of an outdoor unit fan speed controller allows cooling even

when outdoor temperatures are as low as - 5˚C.

7. INNOVATIVE MICROPROCESSOR CONTROL SYSTEM

The most significant feature of PEHD-EK series is the advanced microprocessor control. The development of this system

is due to the recent world-wide trend in the air conditioning of larger buildings. They are moving away from centralized

duct systems to using individual split type units instead. There are a number of reasons for this change. First of all, the

duct's costly and troublesome installation is eliminated. Second, the overall air conditioning balance is excellent in split

type units. Lastly, the operation costs are low due to the flexible control of each unit. This system was developed

exclusively by Mitsubishi Electric because of high demand. The microprocessor control makes individual control, group

control, control using two remote controllers, and remote on/off and individual control possible without troublesome

equipment modifications.

● Indoor Unit

Air intake

(sucks the air inside the room into the unit)

Air outlet

Page 4

3

● Remote controller

● Once the operation of the unit is set, subsequent

operations can be performed only by pressing the

ON/OFF button repeatedly.

● Operation buttons

This switches between continuous operation and the timer

operation.

Press this button to switch the

cool, electronic dry (dehumidify)

automatic and heat modes.

This sets the room temperature. The temperature setting

can be performed in 1˚C

units.

Setting range :

Cool 19˚C to 30˚C

Heat 17˚C to 28˚C

The model name of the

remote controller is indicated.

This switches the horizontal

fan motion ON and OFF.

(This button does not operate

in this model)

Only press this button to perform an inspection check or

test operation. Do not use it

for normal operation.

This resets the filter service

indication display.

(This button dose not operate

in this model.)

This adjusts the vertical angle

of the ventilation.

(This button dose not operate

in this model)

This switches between the

operation and stop modes

each time it is pressed. The

lamp on this button lights during operation.

This sets / switches the current

time, start time and stop time.

This sets the ventilation fan

speed.

button

button

TEMP button

button

CHECK-TEST RUN

button

FILTER button

button

ON/OFF button

button

button

Page 5

4

● Display

This indicates when the unit

is controlled by optinal features such as central control

type remote controller.

The current time, start time

and stop time can be displayed in tencecond intervals

by pressing the time switch

button. The start time or stop

time is always displayed during

the timer operation.

The selected fan speed is displayed.

This indicates when the continuous operation and time

operation modes are set.

It also displays the time for

the timer operation at the

same time as when it is set.

This indicates the operation

mode.

This indicates when the stand

by mode is set from the time

the sleep operation starts

until the heating air discharges.

This indicates when the defrost operation is performed.

This indicates when a malfunction has occurred in the unit

which should be checked.

This displays the selected setting temperature.

The temperature of the suction air is displayed during

operation. The display range is

8˚C to 39˚C. The display flashes

8˚C when the actual temperature is less then 8˚C and

flashes 39˚C when the actual

temperature is greater then

39˚C.

This lamp lights during operation, goes off when the unit

stops and flashes when a malfunction occurs.

This display lights in the

check mode or when a test

operation is perfomed.

This lamp lights when electricity is supplied to the unit.

Caution

• Only the display lights whe the unit is stopped and power is supplied to the unit.

• When power is turned ON for the first time, the (CENTRAL CTRL) display appears to go off momentarily but this is not a

malfunction.

• When the central control remote control unit, which is sold separately, is used the ON - OFF button,

button and TEMP button do not operate.

• "NOT AVAILABLE" is displayed when the button and button are pressed. This indicates that this room

unit is not equipped with the fan direction adjustment function and the louver function.

CENTRALLY

CONTROLLED display

display

OPERATION MODE

display

STANDBY display

DEFROST display

CHECK display

Display

display

display

display

Operation lamp

CHECK MODE

TEST RUN

˚C

display

˚C

display

CLOCK

ON OFF

Page 6

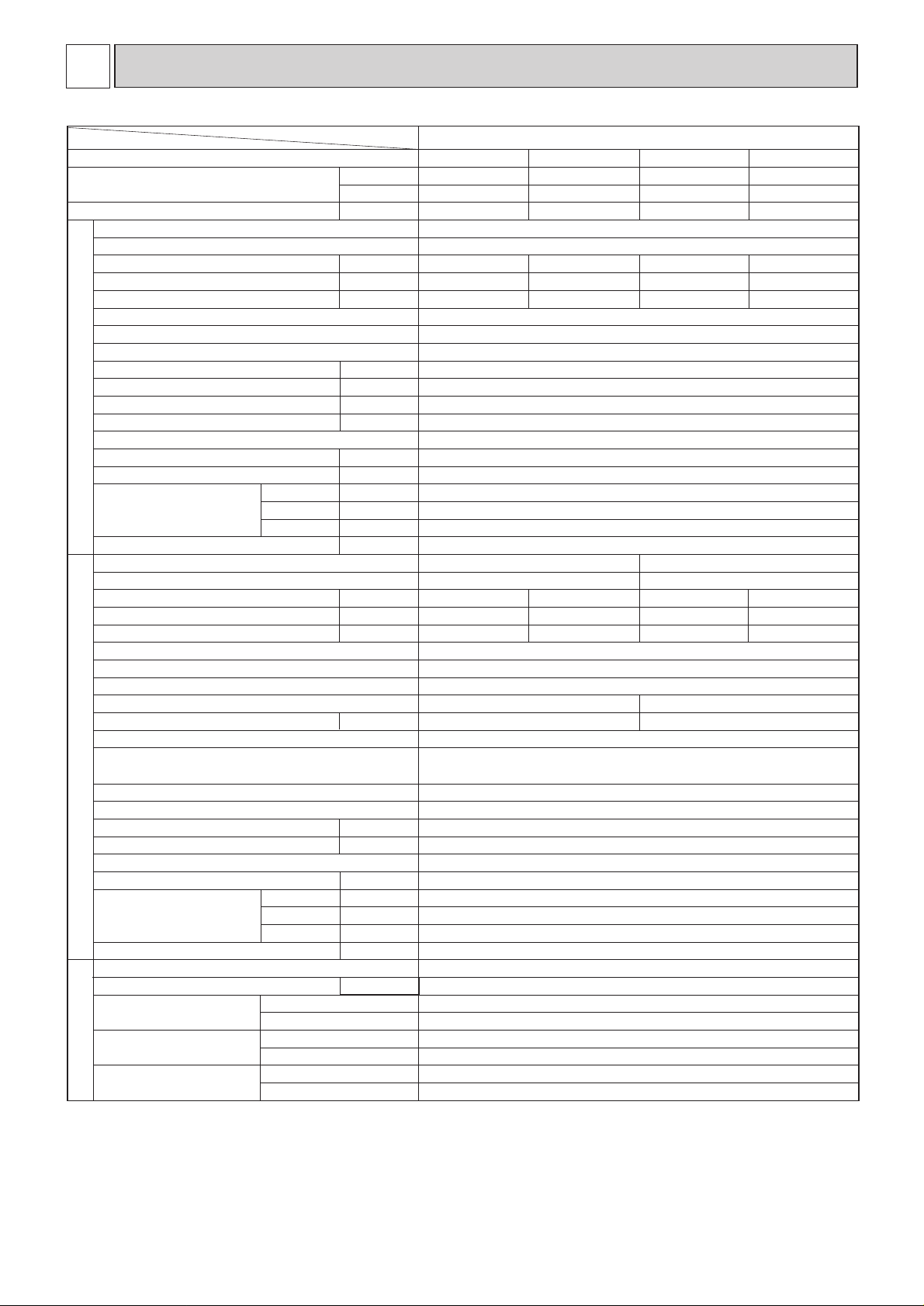

5

3

SPECIFICATION

Item

Function

Capacity

Total input

INDOOR UNIT

Model name

Power supply

Starting current

Running current

Input

External finish

Heat exchanger

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Cond.drain conn.O.D.

Dimensions

Weight

dB(A)

mm,(in)

mm,(in)

mm,(in)

mm,(in)

W

D

H

kg,(lbs)

Model name

Power supply

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

kW

Protection devices

Stater type

Heat exchanger

Fan(drive) x No.

Fan motor output

kW

Airflow

CMM,(CFM)

Defrost method

Noise level

dB(A)

Dimensions

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

Weight

Refrigerant

kg,(lbs)

Charge

Pipe size O.D.

Connection method

Between the indoor

& outdoor unit

Liquid mm,(in)

Gas mm,(in)

Indoor side

Outdoor side

Height difference

Piping length

REFRIGERANT

PIPING

OUTDOOR UNIT

kW

A

A

Btu/h

W

kW

kW

A

A

kW

kW

CMM,(CFM)

Pa(mmAq)

Model

4

4

✻✻

✻

✻

✻

✻

✻

✻

✻

✻

✻

5

1

2

3

1. External static pressure at 130Pa

2. Ex-works at 70Pa(OPTION MOTOR: 130Pa)

3. External static pressure at 70Pa

4. Rating conditions <JIS B 8615, 8616>

(INDOOR) Cooling: 27˚CDB, 19˚CWB Heating: 20˚CDB

(OUTDOOR) Cooling: 35˚CDB Heating: 7˚CDB, 6˚CWB

5. Noise level: Sound pressure level

PEHD-3EK(H)A3.UK

Cooling

26,300

7,700

3.55

Cooling

26,300

7,700

3.55

Heating

PEHD-3EK(H)A

3.UK

~/N,50Hz, 220-240V

0.40

1.70

1.90

0.40 (2.50)

1.70 (10.41)

1.90 (10.65)

0.40

1.70

1.90

0.40 (2.50)

1.70 (10.41)

1.90 (10.65)

3N~, 380/220-415/240V, 50Hz~/N, 220-240V ,50Hz

Galvanized sheets

Plate fin coil

Centrifugal (direct)x2

0.15

20-25 (700-800)

70(7)/130(13) at Hi-notch

2.1

Remote control & Built-in

37-41

32 (1-1/4)

1,175 (46-1/8)

740 (29-1/8)

325 (12-13/16)

44 (97) [46 (101)]

PUH-3YKA

2PUH-3VKA2

3.15

13.82

58

2.94

12.89

58

3.15

5.16

37

2.94

4.81

37

Munsell 5Y7/1

Capillary tube

Hermetic

NH52VND NH52YDA

2.2 2.4

Line start

Plate fin coil

Propeller (direct)x2

0.085

50 (1764)

Reverse cycle

52

870 (34-1/4)

295+24 (11-5/8 add 1)

850 (33-7/16)

75 (165)

R-22

3.2 (7.1)

9.52 (3/8)

15.88 (5/8)

Flared

Flared

Max.50m

Max.50m

Heating

30,700 (37,900)

9,000 (11,100)

3.34 (5.44)

30,700 (37,900)

9,000 (11,100)

3.34 (5.44)

V: Inner thermostat,HP switch

Y: Reversed-phase protector, Thermal relay, Thermal switch, HP switch

Page 7

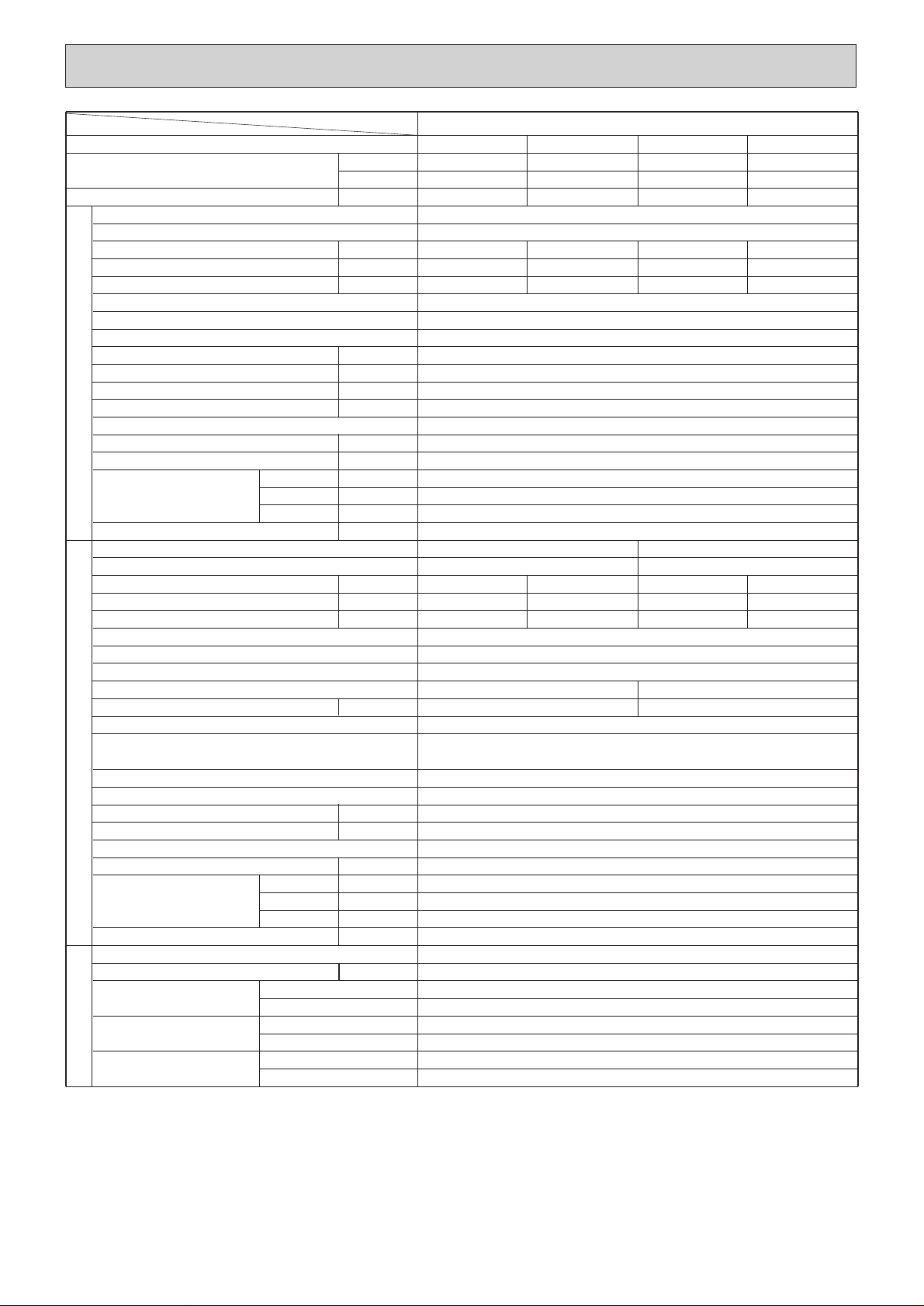

6

Item

Function

Capacity

Total input

Model name

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Cond.drain conn.O.D.

Dimensions

Weight

Model name

Power supply

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Stater type

Protection devices

Heat exchanger

Fan(drive) x No.

OUTDOOR UNIT

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Pipe size O.D.

PIPING

Connection method

REFRIGERANT

Between the indoor

& outdoor unit

Model

Cooling

✻

✻

W

kW

4

Btu/h

4

kW

A

A

kW

33,100

9,700

4.14

0.62

2.64

3.20

1

✻

CMM,(CFM)

Pa(mmAq)

2

✻

kW

✻✻

dB(A)

5

3

mm,(in)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

~/N, 220-240V, 50Hz

kW

A

A

3.52

16.30

79

kW

V: Inner thermostat, HP switch

Y: Reversed-phase protector, Thermal relay, Thermal switch, HP switch

kW

CMM,(CFM)

dB(A)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

kg,(lbs)

Liquid mm,(in)

Gas mm,(in)

Indoor side

Outdoor side

Height difference

Piping length

PEHD-4EK(H)SA3.UK

Heating

35,500 (43,700)

10,400 (12,800)

4.14 (6.54)

PEHD-4EK(H)SA

Cooling

33,100

9,700

3.82

3.UK

~/N, 50Hz, 220-240V

0.62 (3.02)

2.64 (12.58)

3.20 (13.2)

0.62

2.64

3.20

Galvanized sheets

Plate fin coil

Centrifugal (direct)x2

0.27

27-34 (950-1200)

70(7) / 130(13) at Hi-notch

2.4

Remote control & Built-in

41-46

32 (1-1/4)

1,415 (55-11/16)

740 (29-1/8)

325 (12-13/16)

62 (137) [65(143)]

PUH-4VKSA2

3N~, 380/220-415/240V, 50Hz

3.52

16.30

3.20

5.24

79

Munsell 5Y7/1

Capillary tube

Hermetic

NH56VNDT

2.7 .7

Line start

Plate fin coil

Propeller (direct) x2

0.065+0.065

95 (3350)

Reverse cycle

54

870 (34-1/4)

295+24 (11-5/8 and 1)

1258 (49-1/2)

94 (207)

R-22

4.2 (9.2)

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max.50m

Max.50m

PUH-4YKSA

40

NH56YDA

Heating

35,500 (43,700)

10,400 (12,800)

3.81 (6.21)

0.62 (3.02)

2.64 (12.58)

3.20 (13.2)

2

3.19

5.22

40

1. External static pressure at 130Pa

✻

2. Ex-works at 70Pa(OPTION MOTOR: 130Pa)

✻

✻

3. External static pressure at 70Pa

4. Rating conditions <JIS B 8615, 8616>

✻

(INDOOR) Cooling: 27˚CDB, 19˚CWB Heating: 20˚CDB

(OUTDOOR) Cooling: 35˚CDB Heating: 7˚CDB, 6˚CWB

5. Noise level: Sound pressure level

✻

Page 8

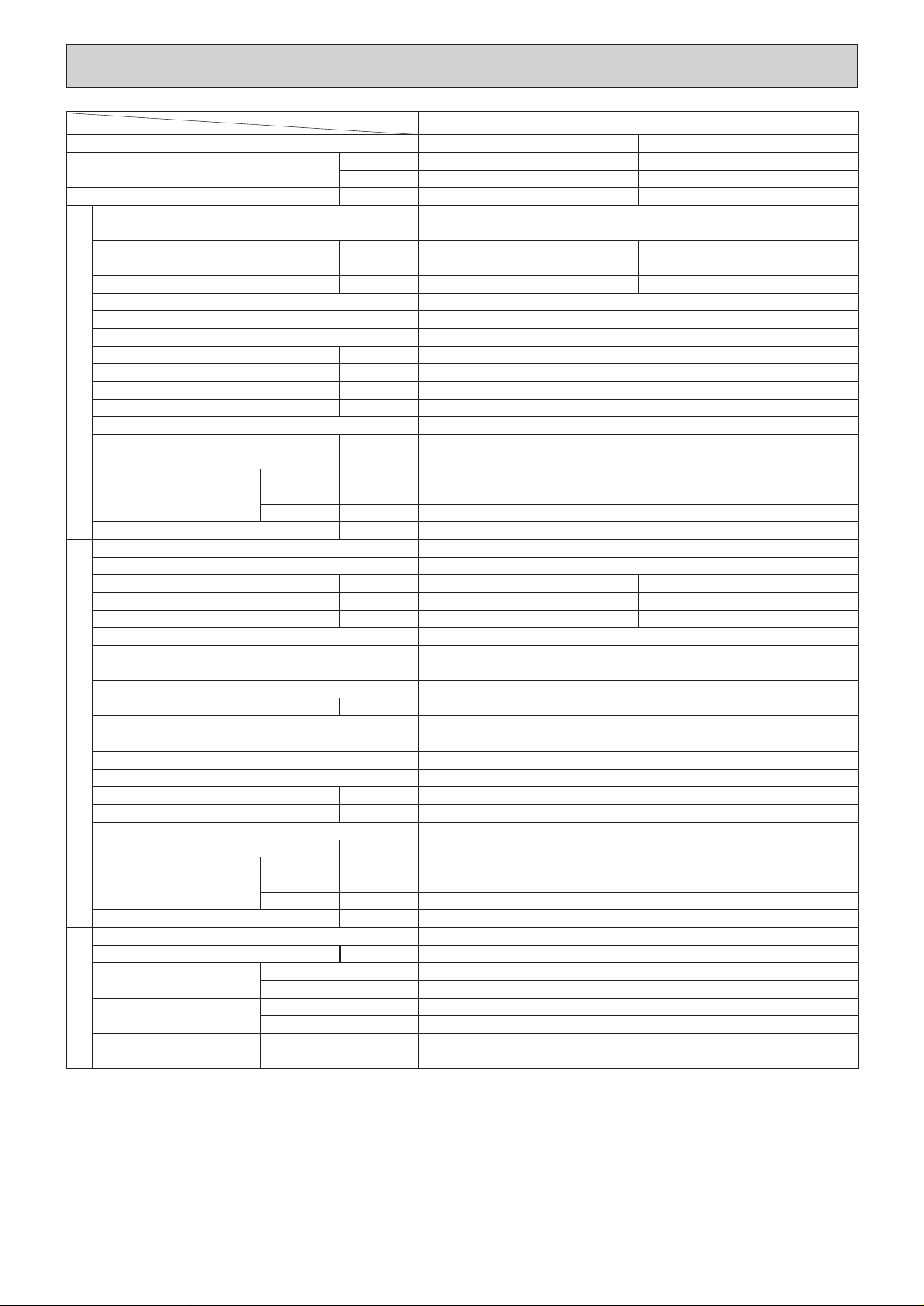

7

Item

Function

Capacity

Total input

Model name

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Cond.drain conn.O.D.

Dimensions

Weight

Model name

Power supply

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Stater type

Protection devices

Heat exchanger

Fan(drive) x No.

OUTDOOR UNIT

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Pipe size O.D.

PIPING

Connection method

REFRIGERANT

Between the indoor

& outdoor unit

Model

✽

✽

Btu/h

4

4

W

kW

kW

A

A

kW

CMM,(CFM)

Pa(mmAq)

kW

✽

dB(A)

5

mm,(in)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

kW

A

A

kW

kW

CMM,(CFM)

dB(A)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

kg,(lbs)

Liquid mm,(in)

Gas mm,(in)

Indoor side

Outdoor side

Height difference

Piping length

PEHD-5EK(H)SA3.UK

Cooling

42,300

12,400

4.85

PEHD-5EK(H)SA

3.UK

Heating

47,400 (57,700)

13,900 (16,900)

4.80 (7.80)

~/N, 50Hz, 220-240V

0.64

2.72

6.00

0.64 (3.64)

2.72 (15.17)

6.00 (18.50)

Galvanized sheets

Plate fin coil

Centrifugal (direct)x2

✽

1

0.30

33.5-42 (1180-1480)

✽

2

70(7) /130(13) at Hi-notch

3.0

Remote control & Built-in

✽

3

44-50

32 (1-1/4)

1,415 (55-11/16)

740 (29-1/8)

325 (12-13/16)

65(143) [68(150)]

PUH-5YKSA

2

3N~, 380/220-415/240V, 50Hz

4.21

6.89

53

4.16

6.81

53

Munsell 5Y7/1

Capillary tube

Hermetic

ZR-61K3-TFD

3.5

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller(direct)x2

0.085+0.085

95 (3350)

Reverse cycle

55

970 (38-3/16)

345+24 (13-9/16 add 1)

1258 (49-1/2)

114 (251)

R-22

5.4 (11.9)

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max.50m

Max.50m

✽

1. External static pressure at 130Pa

✽

2. Ex-works at 70Pa(OPTION MOTOR: 130Pa)

✽

3. External static pressure at 70Pa

✽

4. Rating conditions < JIS B 8615, 8616>

(INDOOR) Cooling: 27˚CDB, 19˚CWB Heating: 20˚CDB

(OUTDOOR) Cooling: 35˚CDB Heating: 7˚CDB, 6˚CWB

✽

5. Noise level: Sound pressure level

Page 9

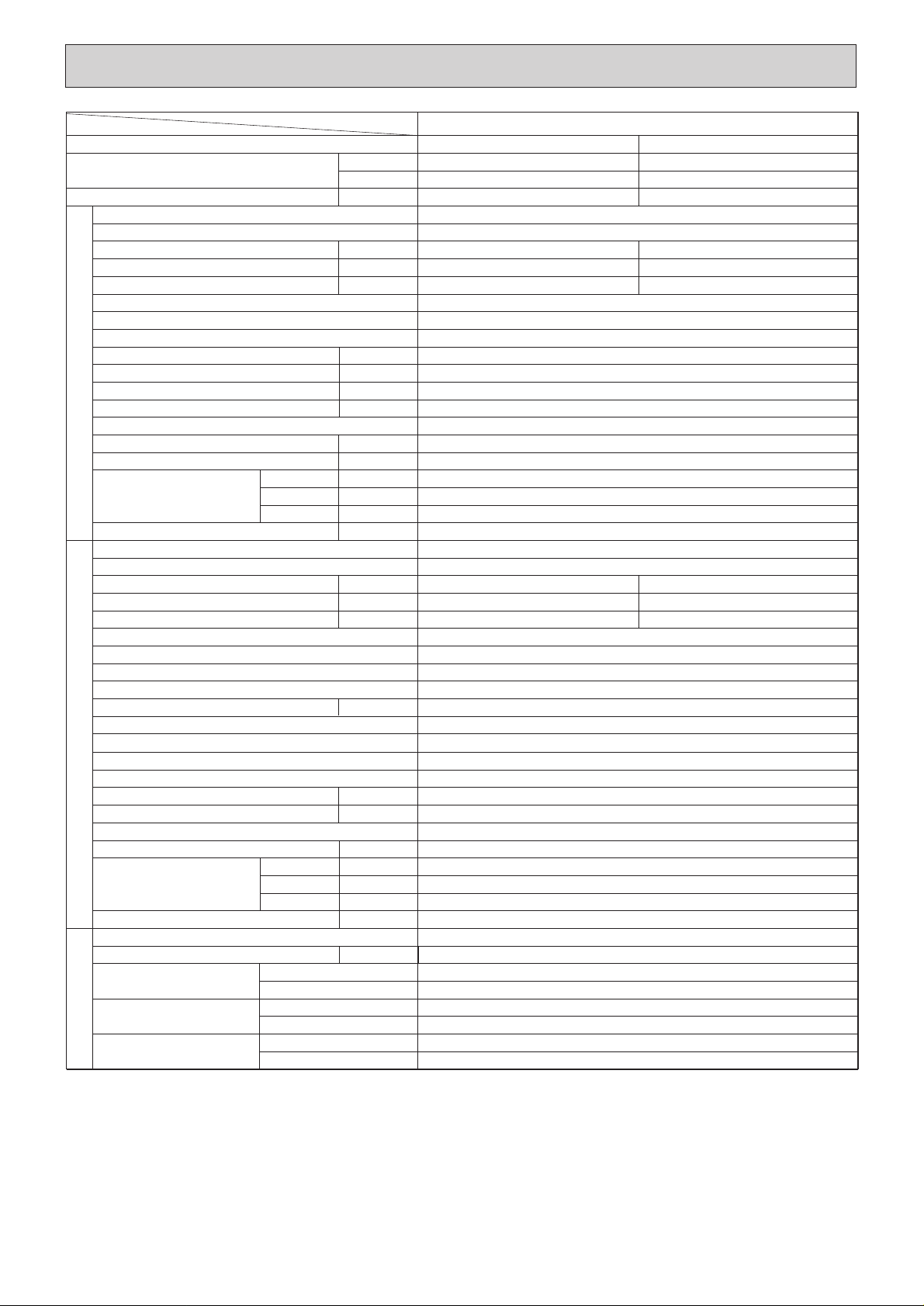

8

Item

Function

Capacity

Total input

Model name

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Cond.drain conn.O.D.

Dimensions

Weight

Model name

Power supply

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Stater type

Protection devices

Heat exchanger

Fan(drive) x No.

OUTDOOR UNIT

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Pipe size O.D.

PIPING

Connection method

REFRIGERANT

Between the indoor

& outdoor unit

Model

✽ 4

✽ 4

Btu/h

W

kW

kW

A

A

kW

CMM,(CFM)

Pa(mmAq)

kW

✽ 5

dB(A)

mm,(in)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

kW

A

A

kW

kW

CMM,(CFM)

dB(A)

W

D

H

mm,(in)

mm,(in)

mm,(in)

kg,(lbs)

kg,(lbs)

Liquid mm,(in)

Gas mm,(in)

Indoor side

Outdoor side

Height difference

Piping length

PEHD-6EK(H)SA.UK

Cooling

50,000

14,650

5.39

Heating

54,500 (64,700)

16,000 (19,000)

5.24 (8.24)

PEHD-6EK(H)SA.UK

~ /N,50Hz,220-240V

0.66

2.79

6.25

0.66 (3.66)

2.79 (15.24)

6.25 (18.75)

Galvanized sheets

Plate fin coil

Centrifugal (direct)x2

✽ 1

0.30

36.5-46 (1,280-1,620)

✽ 2

70(7) / 130(13) at Hi-notch

3.0

Remote control & Built-in

✽ 3

46-51

32 (1-1/4)

1,715 (67-1/2)

740 (29-1/8)

325 (12-13/16)

70(154) [ 73(161)]

PUH-6YKSA

2.UK

3N~ , 380/220-415/240V, 50Hz

4.73

7.74

74

4.58

7.50

74

Munsell 5Y7/1

Capillary tube

Hermetic

ZR68KC-TFD

4.0

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller(direct)x 2

0.10+ 0.10

100 (3530)

Reverse cycle

56

970 (38-3/16)

345+ 24 (13-9/16 and 1)

1,258 (49-1/2)

117 (258)

R-22

5.0 (11.0)

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max.50m

Max.50m

✽ 1. External static pressure at 130Pa

✽ 2. Ex-works at 70Pa(OPTION MOTOR: 130Pa)

✽ 3. External static pressure at 70Pa

✽ 4. Rating conditions < JIS B 8615, 8616>

(INDOOR) Cooling: 27˚CDB, 19˚CWB Heating: 20˚CDB

(OUTDOOR) Cooling: 35˚CDB Heating: 7˚CDB, 6˚CWB

✽ 5. Noise level: Sound pressure level

Page 10

9

4

DA T A

Service Ref.

Indoor

intake air

WB˚C

20 25 30 35 40 45

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

14,782 4.32 14,372 4.50 13,844 4.86 13,273 5.20 12,731 5.55 12,116 5.90

15,734 4.40 15,324 4.60 14,767 4.96 14,177 5.33 13,581 5.69 12,951 6.05

16,701 4.49 16,305 4.68 15,734 5.07 15,119 5.45 14,489 5.84 13,844 6.24

17,683 4.58 17,346 4.78 16,745 5.17 16,115 5.58 15,456 6.00 14,782 6.44

16

18

20

22

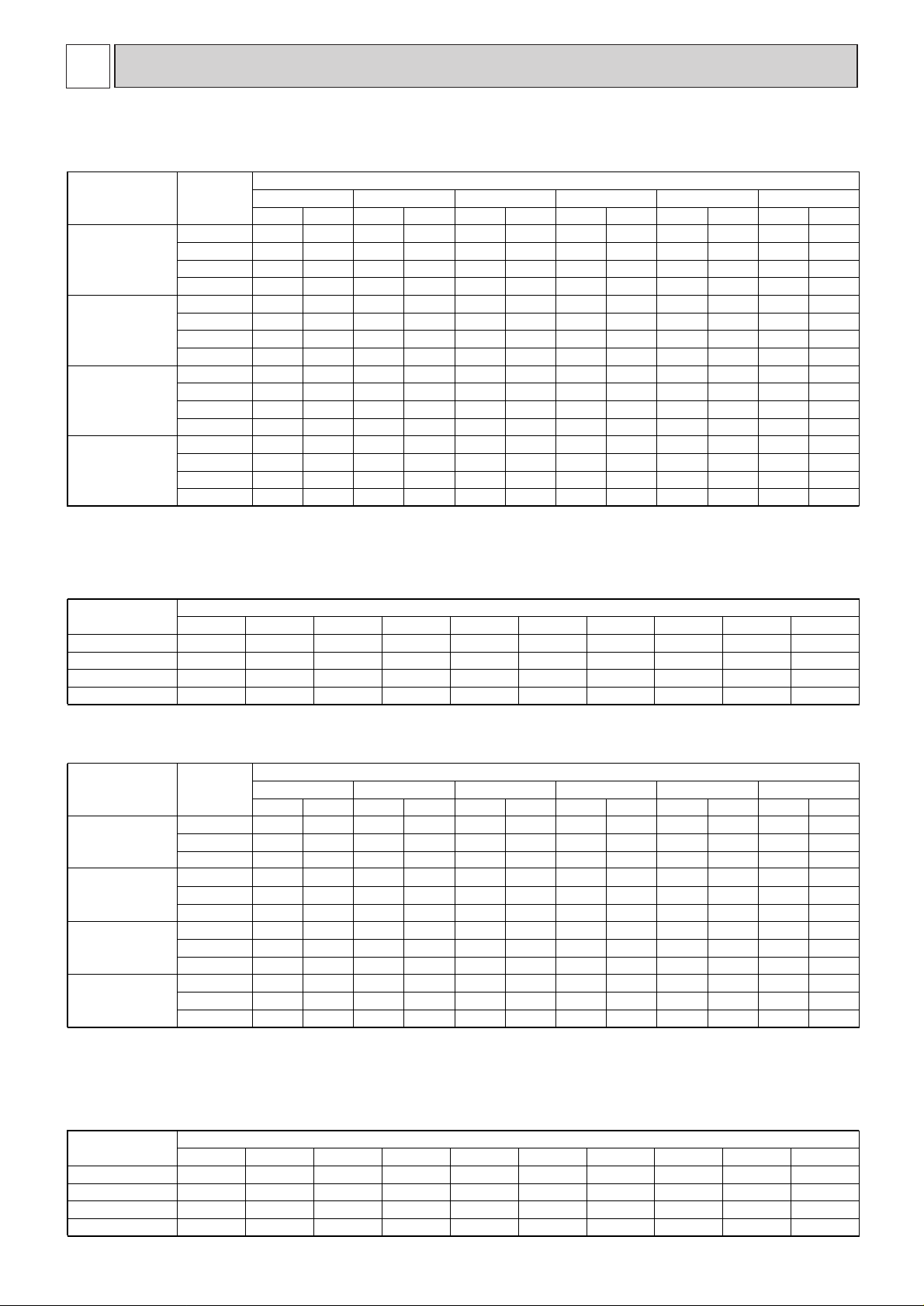

1. PERFORMANCE DATA

1) COOLING CAPACITY

Note C A: Capacity(W)

P.C.: Power consumption(kW)

PEHD-6EK(H)SA.UK

Service Ref.

PEHD-6EK(H)SA.UK

Refrigerant piping length(one way)

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

1.00 0.975 0.955 0.935 0.918 0.900 0.884 0.869 0.855 0.840

Cooling capacity correction factors

Service Ref. -10 -5 0 5 10 15

10,957 3.58 12,557 3.95 14,313 4.35 16,220 4.78 18,277 5.22 20,480 5.69

10,492 3.85 12,064 4.26 13,773 4.69 15,616 5.14 17,590 5.63 19,695 6.13

10,083 4.09 11,574 4.54 13,227 5.01 15,037 5.51 17,006 6.03 19,131 6.58

15

20

25

2) HEATING CAPACITY

Indoor

intake air

WB˚C

Outdoor intake air DB˚C

PEHD-6EK(H)SA.UK

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

Note C A : Capacity(W)

P.C.: Power consumption(kW)

Service Ref.

PEHD-6EK(H)SA.UK

Refrigerant piping length(one way)

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

1.00 1.00 1.00 1.00 1.00 1.00 0.998 0.995 0.993 0.990

Heating capacity correction factors

PEHD-3EK(H)A3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

7,839 2.87 7,623 3.00 7,315 3.21 6,984 3.43 6,637 3.64 6,283 2.9016

8,339 2.94 8,124 3.06 7,792 3.29 7,454 3.51 7,099 3.74 6,738 3.1018

8,847 2.98 8,639 3.11 8,301

8,832

9,215

3.35 7,946 3.60 7,585 3.83 7,215 3.3320

9,363 3.04 9,186 3.18 3.43 8,470 3.68 8,100 3.94 7,715 3.5622

9,875 3.09 9,603 3.23 3.46 8,798 3.69 8,361 3.92 7,915 3.1116

10,505 3.16 10,234 3.29 9,816 3.54 9,390 3.78 8,943 4.02 8,488 3.3418

11,145 3.20 10,883 3.34 10,457 3.61 10,010 3.87 9,555 4.12 9,089 3.5820

11,795 3.26 11,572 3.41 11,126 3.69 10,670 3.96 10,204 4.24 9,719 3.8322

12,623 3.92 12,276 4.10 11,780 4.39 11,247 4.68 10,689 4.98 10,118 3.9616

13,429 4.01 13,083 4.18 12,549 4.49 12,003 4.80 11,433 5.11 10,851 4.2518

14,247 4.07 13,913 4.25 13,367 4.58 12,797 4.91 12,215 5.24 11,619 4.5420

15,078 4.15 14,793 4.34 14,223 4.68 13,640 5.03 13,045 5.38 12,425 4.8622

PEHD-3EK(H)A3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

PEHD-3EK(H)A

3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

1.00 0.981 0.968 0.952 0.940 0.925 0.913 0.900 0.886 0.874

1.00 0.989 0.980 0.970 0.960 0.950 0.940 0.930 0.920 0.910

1.00 0.981 0.968 0.952 0.940 0.925 0.913 0.900 0.886 0.874

6,245 2.35 7,128 2.59 8,091 2.84 9,136 3.10 10,251 3.38 11,439 4.3715

5,975 2.53 6,849 2.78 7,786 3.05 8,793 3.34 9,865 3.64 11,007 4.2020

5,751 2.69 6,570 2.97 7,479 3.27 8,469 3.57 9,540 3.90 10,683 4.0925

7,217 2.60 8,237 2.86 9,350 3.14 10,557 3.43 11,846 3.74 13,218 4.8415

6,905 2.81 7,914 3.08 8,997 3.38 10,161 3.70 11,399 4.03 12,719 4.6620

6,646 2.98 7,592 3.29 8,642 3.62 9,786 3.96 11,024 4.32 12,345 4.5225

9,646 3.28 11,009 3.60 12,497 3.96 14,110 4.32 15,833 4.72 17,666 6.1015

9,229 3.53 10,577 3.88 12,025 4.26 13,581 4.66 15,235 5.08 16,999 5.8720

8,883 3.76 10,147 4.15 11,550 4.56 13,079 4.99 14,734 5.44 16,500 5.7025

PEHD-3EK(H)A3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

1.00 1.00 1.00 1.00 1.00 1.00 0.998 0.995 0.993 0.990

1.00 1.00 1.00 1.00 1.00 1.00 0.998 0.995 0.993 0.990

1.00 1.00 1.00 1.00 1.00 1.00 0.998 0.995 0.993 0.990

Page 11

10

2. PERFORMANCE CURVE

PEHD-3EK(H)A

3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

PEHD-6EK(H)SA.UK

Cooling

1.4

1.2

1

0.8

0.6

1.4

1.2

1

0.8

0.6

0.4

1.4

1.2

1

0.8

0.6

1.4

1.2

1

0.8

0.6

0.4

22

20

18

16

22

20

18

16

INDOOR WB

(˚C)

INDOOR WB

(˚C)

INDOOR DB

(˚C)

INDOOR DB

(˚C)

CAPACITY(RATIO)

CAPACITY(RATIO)

TOTAL INPUT(RATIO)

TOTAL INPUT(RATIO)

OUTDOOR DB

(˚C)

OUTDOOR WB

(˚C)

-12 -10 -5 0 5 10 15

-5 5 15 25 35 46

Heating

15

20

25

25

20

15

Page 12

3. FAN PERFORMANCE AND CORRECTED AIR FLOW

11

PEHD-3EK(H)A3.UK

Fan performance <130pa>

Recommended range

200

180

160

140

120

100

=

80

(1Pa 0.1mmAg)

60

Extemal static pressure (Pa)

40

20

12 16 20 24 28 32

Air flow

Corrected Air Flow

Cooling

1.1

Lo

Hi

(CMM)

Capacity

Input

1.3

1.2

Fan performance <70pa>

Recommended range

180

160

140

120

100

80

=

60

(1Pa 0.1mmAg)

40

20

Extemal static pressure (Pa)

12 16 20 24 28 32

Air flow

Heating

Lo

Hi

(CMM)

1.0

0.9

Correction factor

0.8

12 16 20 24 28 32

Air flow (CMM)

PEHD-4EK(H)SA3.UK

Fan performance <130pa>

Recommended range

200

180

160

140

120

100

=

80

(1Pa 0.1mmAg)

60

Extemal static pressure (Pa)

40

20

Corrected Air Flow

Lo

26 28 30 32 34 36 38 40

Air flow

Cooling

1.1

Hi

(CMM)

Correction factor

Capacity

Input

1.1

1.0

0.9

0.8

12 16 20 24 28 32

Air flow (CMM)

Fan performance <70pa>

Recommended range

220

200

180

160

140

120

100

=

80

(1Pa 0.1mmAg)

60

Extemal static pressure (Pa)

40

20

24 26 28 30 32 34 36 38

1.2

1.1

Lo

Air flow

Heating

Hi

(CMM)

1.0

0.9

Correction factor

0.8

24 26 28 30 32 34 36 38 40

Air flow (CMM)

1.0

0.9

Correction factor

0.8

24 26 28 30 32 34 36 38 40

Air flow (CMM)

Page 13

12

PEHD-5EK(H)A3.UK

Fan performance <130pa>

=

(1Pa 0.1mmAg)

Extemal static pressure (Pa)

Recommended range

220

200

180

160

140

120

100

80

60

40

20

Lo

Hi

Fan performance <70pa>

Recommended range

220

200

180

160

140

120

100

=

80

(1Pa 0.1mmAg)

60

Extemal static pressure (Pa)

40

20

Lo

Hi

32 34 36 38 40 42 44 46 48

Air flow

Corrected Air Flow

Cooling

1.1

1.0

0.9

Correction factor

0.8

32 34 36 38 40 42 44 46 48

PEHD-6EK(H)SA.UK

Fan performance <130pa>

=

(1Pa 0.1mmAg)

Extemal static pressure (Pa)

Recommended range

220

200

180

160

140

120

100

80

60

40

20

Lo

38 40 42 44 46 48 50

36

Air flow

(CMM)

Air flow (CMM)

(CMM)

Hi

52

Capacity

Input

32 34 36 38 40 42 44 46

Air flow

Heating

1.2

1.1

1.0

0.9

Correction factor

0.8

32 34 36 38 40 42 44 46 48

(CMM)

Fan performance <70pa>

Recommended range

200

180

160

140

120

100

=

80

(1Pa 0.1mmAg)

60

40

Extemal static pressure (Pa)

20

Lo

36

38 40 42 44 46 48

Air flow

Air flow (CMM)

Hi

50

(CMM)

Corrected Air Flow Capacity

Cooling

1.1

1.0

0.9

Correction factor

0.8

36 38 40 42 44 46

Air flow (CMM)

Input

48 50

52

Heating

1.2

1.1

1.0

0.9

Correction factor

0.8

36 38 40 42 44 46

Air flow (CMM)

48

50 52

Page 14

13

4. ELECTRICAL DATA

Models

Indoor

Outdoor

Mode

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

PUH-6YKSA

PEHD-6EK(H)SA.UK

Cool

14,300

5.20

0.56

2.59

5.75

4.64

8.10

68

Heat

15,800

(18,300)

5.12

(7.62)

0.56

(3.06)

2.59

(13.91)

5.75

(17.11)

4.56

7.96

68

Indoor ······220V 50Hz 1phase

Outdoor ···220/380V 50Hz 1/3phases

Models

Indoor

Outdoor

Mode

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

PUH-6YKSA

PEHD-6EK(H)SA.UK

Cool

14,500

5.30

0.61

2.69

6.00

4.69

7.87

71

Heat

15,900

(18,600)

5.18

(7.88)

0.61

(3.31)

2.69

(14.37)

6.00

(17.74)

4.57

7.67

71

Indoor ······230V 50Hz 1phase

Outdoor···230/400V 50Hz 1/3phases

Models

Indoor

Outdoor

Mode

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

PUH-6YKSA

PEHD-6EK(H)SA.UK

Cool

14650

5.39

0.66

2.79

6.25

4.73

7.74

74

Heat

16000

(19000)

5.24

(8.24)

0.66

(3.66)

2.79

(15.24)

6.25

(18.75)

4.58

7.50

74

Indoor·······240V 50Hz 1phase

Outdoor···240/415V 50Hz 1/3phases

PEHD-4EK(H)SA3.UKPEHD-3EK(H)A3.UK PEHD-5EK(H)SA3.UK

PUH-4YKSAPUH-4VKSAPUH-3YKA

PUH-5YKSA

PUH-3VKA

Cool

12,200

4.73

0.54

2.50

5.50

4.19

7.32

49

Heat

13,700

(16,200)

4.67

(7.17)

0.54

(3.04)

2.50

(13.82)

5.50

(16.86)

4.13

7.21

49

Cool HeatCool

9,500

3.87

0.52

2.41

2.93

3.35

16.90

79

Heat

10,200

(12,200)

3.87

(5.87)

0.52

(2.52)

2.41

(11.45)

2.93

(12.02)

3.35

16.90

79

9,500

3.69

0.52

2.41

2.93

3.17

5.29

37

10,200

(12,200)

3.68

(5.68)

0.52

(2.52)

2.41

(11.45)

2.93

(12.02)

3.16

5.28

37

Cool

7,500

3.43

0.30

1.39

1.74

3.13

14.67

54

Heat

8,900

(10,700)

3.22

(5.02)

0.30

(2.10)

1.39

(9.55)

1.74

(9.92)

2.92

13.68

54

Cool

7,500

3.43

0.30

1.39

1.74

3.13

5.23

34

Heat

8,900

(10,700)

3.22

(5.02)

0.30

(2.10)

1.39

(9.55)

1.74

(9.92)

2.92

4.88

34

PEHD-4EK(H)SA3.UKPEHD-3EK(H)A3.UK PEHD-5EK(H)SA3.UK

PUH-4YKSAPUH-4VKSAPUH-3YKA

PUH-5YKSA

PUH-3VKA

Cool

12,300

4.79

0.59

2.62

5.75

4.20

7.05

51

Heat

13,800

(16,500)

4.74

(7.44)

0.59

(3.29)

2.62

(14.30)

5.75

(17.49)

4.15

6.97

51

Cool

9,600

4.01

0.57

2.53

3.07

3.44

16.60

79

Heat

10,300

(12,500)

4.01

(6.21)

0.57

(2.77)

2.53

(12.64)

3.07

(12.64)

3.44

16.60

79

Cool

9,600

3.76

0.57

2.53

3.07

3.19

5.23

39

Heat

10,300

(12,500)

3.75

(5.95)

0.57

(2.77)

2.53

(12.64)

3.07

(12.64)

3.18

5.22

39

Cool

7,600

3.49

0.35

1.55

1.82

3.14

14.22

56

Heat

8,950

(10,850)

3.28

(5.18)

0.35

(2.25)

1.55

(9.78)

1.82

(10.08)

2.93

13.27

56

Cool

7,500

3.49

0.35

1.55

1.82

3.14

5.21

36

Heat

8,950

(10,850)

3.28

(5.18)

0.35

(2.25)

1.55

(9.78)

1.82

(10.08)

2.93

4.86

36

PEHD-4EK(H)SA3.UKPEHD-3EK(H)A3.UK PEHD-5EK(H)SA3.UK

PUH-4YKSAPUH-4VKSAPUH-3YKA

PUH-5YKSA

PUH-3VKA

Cool

12,400

4.85

0.64

2.72

6.00

4.21

6.89

53

Heat

13,900

(16,900)

4.80

(7.80)

0.64

(3.64)

2.72

(15.17)

6.00

(18.50)

4.16

6.81

53

Cool

9,700

4.14

0.62

2.64

3.20

3.52

16.30

79

Heat

10,400

(12,800)

4.14

(6.54)

0.62

(3.02)

2.64

(12.58)

3.20

(13.20)

3.52

16.30

79

Cool

9,700

3.82

0.62

2.64

3.20

3.20

5.24

40

Heat

10,400

(12,800)

3.81

(6.21)

0.62

(3.02)

2.64

(12.58)

3.20

(13.20)

3.19

5.22

40

Cool

7,700

3.55

0.40

1.70

1.90

3.15

13.82

58

Heat

9,000

(11,100)

3.34

(5.44)

0.40

(2.50)

1.70

(10.41)

1.90

(10.65)

2.94

12.89

58

Cool

7,700

3.55

0.40

1.70

1.90

3.15

5.16

37

Heat

9,000

(11,100)

3.34

(5.44)

0.40

(2.50)

1.70

(10.41)

1.90

(10.65)

2.94

4.81

37

Page 15

14

5. STANDARD OPERATION DATA

5

REFRIGERANT SYSTEM DIAGRAM

Indoor unit

Indoor

heat

exchanger

Strainer

Restrictor

valve

Thermistor

TH2

Distributor

with strainer

Capillary

tube

PEHD-3(OD4.0xID2.0xL400)

PEHD-4(OD4.0xID2.4xL550)

PEHD-5(OD4.0xID2.4xL350)

PEHD-6(OD4.0xID2.4xL300)

Refrigerant flow in cooling R.V.coil

Refrigerant flow in heating Heating : ON

Cooling : OFF

Unit : mm

PEHD-3EK(H)A3.UK

PEHD-4EK(H)SA

3.UK

PEHD-5EK(H)SA

3.UK

PEHD-6EK(H)SA.UK

Models

Mode

TotalElectrical circuitRefrigerant circuit

Indoor side

Outdoor

side

SHF

BF

Capacity

Input

Indoor unit model

Phase . Hz

Volts

Amperes

Outdoor unit-model

Phase,Hz

Volts

Amperes

W

kW

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref.Pipe length

Intake air temperature

Intake air temperature

Discharge air temperature

MPa

MPa

˚C

˚C

˚C

m

DB˚C

WB˚C

DB˚C

DB˚C

WB˚C

PEHD-6EK(H)SA.UK

Cooling Heating

14,400 16,000

5.39 5.24

PEHD-6EK(H)SA

1 . 50

240

2.79 2.79

PUH-6YKSA

3.50

415

7.74 7.50

2.00 1.74

0.47 0.36

84.5 71.6

52.7

-

5.6 -2.3

55

27 20

19 15

14.2 40.1

35 7

24 6

0.77

-

0.11

-

Cooling Heating

12,400 13,900

4.85 4.80

PEHD-5EK(H)SA

1 . 50

240

2.72 2.72

PUH-5YKSA

3.50

415

6.89 6.81

1.88 1.70

0.51 0.37

75.8 74.3

48.8

-

6.8

55

27 20

19 15

15.1 37.0

35 7

24 6

0.85

-

0.13

-

Cooling Heating

7,700 9,000

3.55 3.34

PEHD-3EK(H)A

1 . 50

240

1.70 1.70

PUH-3YKA

3.50

415

5.16 4.81

2.00 1.84

0.45 0.34

86.3 81.7

52.1

-

4.8 -2.8

55

27 20

19 15

15.2 37.8

35 7

24 6

0.78

-

0.20

-

Cooling Heating

7,700 9,000

3.55 3.34

PEHD-3EK(H)A

1 . 50

240

1.70 1.70

PUH-3VKA

1.50

240

13.82 12.89

2.04 1.86

0.47 0.34

89.6 83.9

53.1

-

4.2 -3.8

55

27 20

19 15

15.3 37.8

35 7

24 6

0.78

-

0.21

-

Cooling Heating

9,700 10,400

3.82 3.81

PEHD-4EK(H)SA

1 . 50

240

2.64 2.64

PUH-4YKSA

3.50

415

5.24 5.22

1.86 1.70

0.53 0.38

77.7 74.3

49.2

-

7.6 -1.3 -1.7

55

27 20

19 15

15.8 36.1

35 7

24 6

0.80

-

0.22

-

Cooling Heating

9,700 10,400

4.14 4.14

PEHD-4EK(H)SA

1 . 50

240

2.64 2.64

PUH-4VKSA

1.50

240

16.30 16.30

1.88 1.71

0.49 0.36

83.3 80.1

51.5

-

7.5 -1.5

55

27 20

19 15

15.8 36.3

35 7

24 6

0.80

-

0.22

-

PEHD-4EK(H)SA3.UKPEHD-3EK(H)A3.UK PEHD-5EK(H)SA3.UK

Page 16

15

6

OUTLINES & DIMENSIONS

1. INDOOR UNIT(PEHD-6)

210

12-ø3

450

450

140

282

680

3 3

30

319

261

181 40

30

A

C B 81

10

375

10

80

C B 81

A

E 13

30

D

20

35

30

1053 169

307

113

122

12-ø3

(14x22)

Lifting bolt hole

45

163

323

308

44 75

7

6

5

13

Keep duct-work length 850mm or more.

Be sure to apply the air filter (field supply) near the air inlet grille.

Service space:500 or more

81

365~465

197

81

50~150

55

Access door

Air outlet

Air inlet

3

1

2

4

Refrigerant piping flare connection (liquid ø9.52 copper tube) : HP

Refrigerant piping flare connection (gas øF copper tube) : LP

Drain 25A (male screw)

Electrical parts box

Electric Heater ··· Only PEHD-EKH(S)A Type

Drain Pump (Option)

Drain Pipe (Option) ··· Use VP25 (O.D.ø32 PVC TUBE) )

Set

1

2

3

4

5

6

7

Model

PEHD-3

PEHD-4·5

PEHD-6

A

1012

1252

1552

B

280

360

460

C

290

370

470

D

1070

1310

1610

E

1044

1284

1584

F

15.88

19.05

19.05

2. REMOTE CONTROLLER

Unit:mm (inch)

Rear side wiring arangement opening

46

83.5

130

18

120

PEHD-3EK(H)A3.UK

PEHD-4EK(H)SA3.UK

PEHD-5EK(H)SA

3.UK

PEHD-6EK(H)SA.UK

Page 17

16

7

WIRING DIAGRAM

MODELS:PEHD-3EK(H)A3, PEHD-4EK(H)SA3, PEHD-5EK(H)SA3, PEHD-6EK(H)SA WIRING DIAGRAM

SW3SW5

OFF

ON

WHT

YLW

BRN

AC10.8V

T

RED

BRN

WHT

2

1

DP

2

35

RED

ORN

MF

External static

pressure 130Pa pressure 70Pa

BRN

41

C

X3X2X1 X6X5X4

M3

BLK

GRN/YLW

2

53

6

BLK

External static

TH2

65

CN2L

LOSSNAY

CN21

PIPE

SW2

TH1

CN20

INTAKE

SW6

CN50

DRAIN

1122

2

4135

BLU

BLK

BLK

GRY

GRY

1

32

4

DS

RED

YLW

91043 1287564312431243 124321

CN4T

TRANS

RED

AC14.5V

ORN

SW1

BRN

✽

#········ Option parts

C

CN1<R.B>

CN2<R.B>

CN2L<R.B>

CN51<R.B>

F<I.B>

FS1,FS2

✽

H

✽

I.B

LCD

MF

R.B

SW1(I.B)

SW2(I.B)

SW3(I.B)

SW5(I.B)

SW6(I.B)

Capacitor (fan motor)

Connector (program timer)

Connector (remote switch)

Connector (lossnay)

Connector (centrally control)

Fuse < 6.3 A >

Thermal fuse(FS1:16A FS2:15A)

Electric heater

Indoor controller board

Liquid crystal display

Fan motor(with inner thermostat)

Remote controller board

Switch(mode selector)

Switch(address selector)

Switch(emergency operation)

Switch(model selector)

Switch(model selector)

NOTES

1.Since the indoor transfomer(T) is connected with 240V power;

if 220,230V power is used. Change the wiring connection

shown in fig: *1

When power supply is

fig: *1

230V

220V

240 YELLOW

230 ORANGE

220 RED

2. Since the outdoor side electric wiring may change be sure

to check the outdoor unit electric wiring for servicing.

3. Indoor and outdoor connecting wires are made with palarities

ensure wires match terminals.

4. Symbols used in circuit diagram above are, :Terminal block,

:connector, :PC board insertion tab.

5. Emergency operation

If trouble occurs with either the remote controller or

the indoor microcomputer and no other trouble exists,emergency operation for cooling or heating can be performed by

changing the setting of dip switch(SW3<I.B>)on the indoor

controller board (emergency dry operation is not possible).

SW1 (R.B)

SW3 (R.B)

SW4 (R.B)

SW5 (R.B)

SW6 (R.B)

SW7 (R.B)

SW8 (R.B)

SW9 (R.B)

SW10(R.B)

SW14(R.B)

SW15(R.B)

SW17(R.B)

T

TB2

I.B

CN24

HEATER

CN22

TO REMOCON

YLW

BLU

RED

8

88H1

8

88H2

3

3

88H2

88H1

7

7

5

5

PRP

PRP

BRN

ORN

YLW

RED

BLU

GRN/YLW

YLWYLW

M2

PNK

M1

M0

WHT

14

GRN/YLW

6

WHITE

ZNR

BLU

F

S

RED

CN30

OUTDOOR

R

CN51

CENTRALLY

CONTROL

CN40

REMOCON

POWER

4321321

MF

C

········ Only models PEHD-EKH(S)A

Switch (ON/OFF)

Switch(cooling/drying operation mode)

Switch(automatic operation mode)

Switch(heating operation mode)

Switch(lowers set temperature)

Switch(raises set temperature)

Switch(timer time)

Switch(timer.continuous and ON/OFF)

Switch(fan speed high/low selector)

Switch(test run)

Switch(inspection)

Switch(address selector)

Transformer

Terminal block (power)

[ Check items]

(1) Make sure that no other trouble exists with the outdoor unit.

Trouble with the outdoor unit prevents emergency operation.

(If any trouble exists with the outdoor unit,the trouble

location will be displayed on the remote controller and

the trouble position will be shown on the outdoor controller board LED.See electric circuit diagram of the outdoor

unit for details.)

(2) Make sure that there is no trouble with the indoor fan.

Emergency operation will be a continuous run with operation

by the power ON/OFF.

(ON/OFFwith the remote controller is not possible).

[Emergency operation procedure ]

(1) Set the dip switch(SW3<I.B>)on the indoor controller board

to 1 · 2 · 3 on and 4 off for cooling, and 2 · 3 · 4

on and 1 off for heeting.

(2)Turn on the outdoor unit side circuit breaker.

(3) During emergency operation indoor fan runs at High speed.

(4)Thermostat will not function.Cold air blows out for defrosting

during heating thus do not operate defrosting for a long time.

(5) Emergency cooling should be limited to 10 hours maximum

(the indoor unit heat exchanger may freeze).

TB4

TB5,TB6

TH1

TH2

X1(I.B)

X4(I.B)

X5(I.B)

X6(I.B)

ZNR

26H

✽

88H1

✽

88H1

✽

CN50

DP

#

DS

#

BLU

2

1

3

2

1

RED

TB5

TB4

TB2

L

N

4

3

2

1

TRANSMISSION WIRES

DC 12V

TO OUTDOOR UNIT

CONNECTING WIRES

DC 12V(polar)

BREAKER

POWER SUPPLY

~ (1phase)

220~ 240V 50Hz

PE

TO DUCT

CN2

213

LCD

CN1 SW17

546312

FS1

SW5

43 12567890

FS2

OFF

ON

R.B

TB6

26H

H

SW1

SW4

SW3

SW7

SW6

SW9

SW8

SW10

SW15 SW14

Terminal block (indoor/outdoor connecting line)

Terminal block (remote controller transmission line)

Thermistor (room temperature sensor 0˚C/15kΩ.25˚C/5.4kΩ )

Thermistor (pipe temperature sensor 0˚C/15kΩ.25˚C/5.4kΩ )

Auxiliary relay (drain pump)

Auxiliary relay (fan motor)

Auxiliary relay (fan motor)

Auxiliary relay (fan motor)

Varistor

Thermal switch(over heat prevention)

Contactor (electric heater)

Contactor (electric heater)

Drain sensor connector

Drain pump

Drain sensor

Page 18

17

8

DISASSEMBLY INSTRUCTIONS

Disconnect the fan motor connecter

(and the booster heater connector)

Drain pan

catches (Hidden)

Drain pan

catches (Hidden)

Filter

Bottom plate

Drain pan

Heat exchanger

Bottom plate

assembly

1

2

A

Figure1.

11

. Removing the fan motor

1. Removing the 9 screws that fix the bottom plate A, and

remove it.

2. Removing the drain pan as follows:

(1) Remove the screw that fixes the drain pan.

(2) Slide the drain pan in the direction 1, Figure1 and

unhook the drain pan catch near the drain pipe.

(3) Slide the drain pan in the direction 2, Figure1 and

unhook the 2 catches on the other side of the drain

pipe.

3. Remove the 8 screws that fix the bottom plate

assembly, and remove it.

4. Disconnect the fan motor connector from the controller

box.

(For the models with booster heater, disconnect the

booster heater connector as well.)

5. Remove the fan plate as follow:

Figure2.

(1)Remove the 4 screws1

(2)Slide down the fan plate to remove.

6. Remove the sirocco fan setting screw and the motor

fixture setting screw to remove the motor fixture.

Remove the other motor fixture as well, and then remove

the fan motor.

1

1

Fan base

Page 19

18

Figure3.

Booster heater

Fan base

Sirocco fan

Sirocco fan

Housing assembly

Housing

assembly

Piece

Piece

Leg

Bush

Bush

Motor

Motor base

(Only PEHD-3)

22

. Removing the booster heater

1. Remove the bottom plate, drain pan, and bottom plate

assembly. (Refer

1-1~3.)

2. Disconnect the booster heater connector from the controller

box.

3. Remove the 2 lower screws on the both sides of the booster

heater.

4. Loosen the 2 upper screws on the both sides of the booster

heater.

5. Removing the booster heater.

Figure4.

Booster heater

Screw holes

Page 20

19

Pump cover

33

. Removing the drain water lift-up pump

1. Remove the drain pan. (Refer 1- 2.)

2. Disconnect the drain pump connector and drain sensor

connector from the controller box.

3. Remove the two screws of the pump cover assembly.

4. Remove the drain hose from drain socket.

5. Remove the three screws of the drain pump assembly.

6. Remove the earth screw and four nuts of the drain

pump assembly.

7. Remove the drain pump from drain pump assembly.

Drain socket

assembly

Drain pump

assembly

Drain hose

Rubber plug

Drain pan cover

1

2

Drain pan

Page 21

20

9

PARTS LIST

14.15.16

1.2.3

11.12.13

4.5.6

7.8.9.10

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part No. Part Name Drawing No.

Qt'y/set

Spec.

1

1

1

1

1

1

1111

11

1

1

1

1

W631101Z04

W631188G02

W264218G02

W631186G01

W630129G01

PEHD-

PEHD-

5EKHSA3

PEHD-

5EKSA

3

PEHD-

4EKHSA3

PEHD-

4EKSA

3

PEHD-

3EKHA

3

PEHD-

3EKA

3

6EKSA

PEHD-

6EKHSA

Bottom plate 1

Bottom plate 2 ass'y

W634030G01Bottom plate 2 ass'y

W634052G01Bottom plate 2 ass'y

W634028Z01Bottom plate 1

W634050Z01Bottom plate 1

H.EX.General ass'y

W258255G10H.EX.General ass'y

W258255G09H.EX.General ass'y

W258952G08H.EX.General ass'y

Drain pan ass'y

W634034G01Drain pan ass'y

W634056G01Drain pan ass'y

Filter

W611960G04

Filter

W611960G05

Filter

1111

11

1111

11

1111

11

11

11

11

PEHD-3EKA3.UK, PEHD-3EKHA3.UK

PEHD-4EKSA

3.UK, PEHD-4EKHSA3.UK

PEHD-5EKSA

3.UK, PEHD-5EKHSA3.UK

PEHD-6EKSA.UK, PEHD-6EKHSA.UK

EXTERNAL PARTS

Page 22

21

PEHD-3EKA3.UK, PEHD-3EKHA3.UK

PEHD-4EKSA

3.UK, PEHD-4EKHSA3.UK

PEHD-5EKSA

3.UK, PEHD-5EKHSA3.UK

PEHD-6EKSA.UK, PEHD-6EKHSA.UK

BLOWER PARTS

3.4.5

8

15.16.17

18.19

9

2

10.11.12

21

13.14

6.7

6.7

1

2

8

1.20

9

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

✽

21

Part No. Part Name Drawing No.

R60 508 131

R60 508 132

R61 766 104

R61 Y01 104

R61 Y20 221

R61 Y21 221

R61 Y17 221

R61 652 130

R61 Y04 262

R61 Y05 262

R61 Y06 262

R61 652 131

Piece

Piece

Fan base ass'y

Bush

Sirocco fan

Housing ass'y

Motor

Motor support

Leg

Heater ass'y 5

Capacitor 16

Attachment

Motor base

R02K338H02 2

R02K338G82

W634058G01Fan base ass'y

W634036G01Fan base ass'y

W631187G01

W491760H02Bush

W860050H02

W631126G01

W631120G01

P714661X01Motor

P714659X01Motor

P714614X01

W241060H03

W631122Z04

W258903G07Heater ass'y 3

W258903G08Heater ass'y 4

W258903G09

P412172X01Capacitor 6

P412223X01

W353715H01

W634069Z01

PEHD-

PEHD-

3EKHA

3EKA

3

11

22

22

22

11

11

1

22

11

PEHD-

4EKSA

4EKHSA3

3

3

11

22

11

11

11

Qt'y/set

PEHD-

1

PEHD-

PEHD-

5EKSA

3

5EKHSA3

2222

11

2222

2222

22

11

11

22

1

PEHD6EKSA

2

1

2

2

2

1

1

2

PEHD-

6EKHSA

22222

with a nut

2

1

2

20-25L

2

2

<MF>150W,1Phase 220~ 240V

<MF>240W,1Phase 220~ 240V

<MF>250W,1Phase 220~ 240V

1

1

1

<C>

<C>

2

✽: Not illustrated

Page 23

22

PEHD-3EKA3.UK, PEHD-3EKHA3.UK

PEHD-4EKSA

3.UK, PEHD-4EKHSA3.UK

PEHD-5EKSA

3.UK, PEHD-5EKHSA3.UK

PEHD-6EKSA.UK, PEHD-6EKHSA.UK

CONTROL BOX PARTS

4

10

5

8

6

7

No.

Part No. Part Name Drawing No.

1

R61978247 Terminalbed

R61979247

2

R61435246

3

4

5

6

7

8

9

R61274215

10

Terminalbed

Terminalbed

Controller

Transformer work DWG.

Thermistor S

Thermistor H

Ferrite core

Ferrite core

Start relay

P436109X01

P436110X01

BA73S950H02

RG00C006G02

W855468G05

BG71V163H03

BG71V164H08

P419114X01

P419115X01

P421221X01

PEHD-

3EKA

3

PEHD-

3EKHA

PEHD-

4EKSA

3

PEHD-

4EKHSA3

3

Qt'y/set

PEHD5EKSA

111111

111111

111111

111111

111111

111111

111111

111111

PEHD-

3

5EKHSA3

222

PEHD-

6EKSA

11111111

1

1

1

1

1

1

1

1

PEHD-

6EKHSA

< TB4 >

< TB2 >

1

< TB5 >

1

< I.B >

1

<T>

1

< RT1 >

1

< RT2 >

1

1

1

LY1F< 88H1,2 >

2

2

1

9

3

Spec.

Page 24

23

PEHD-3EKA3.UK, PEHD-3EKHA3.UK

PEHD-4EKSA

3.UK, PEHD-4EKHSA3.UK

PEHD-5EKSA

3.UK, PEHD-5EKHSA3.UK

PEHD-6EKSA.UK, PEHD-6EKHSA.UK

DRAIN WATER LIFT-UP PUMP PARTS

3

4

1.2

5

No.

Part No. Part Name Drawing No.

1

2

3

4

5

R61 E96 558

Drain pump-94

Cushion

Drain socket ass'y

Drain sensor ass'y

Rubber plug

Qt'y/set

PEHD-

PEHD-

PEHD-

PEHD-

PEHD-

4EKHSA3

5EKSA

111111

444444

111111

111111

111111

3

3EKA

3

BG56J144G13 1

DB26F111H03

BB00P145G17

DE00H343G21

P312040X01

3

3

4EKSA

3EKHA

PEHD-

5EKHSA3

PEHD-

6EKSA

4

1

1

1

PEHD-

6EKHSA

1

4

1

1

1

Spec.

Page 25

24

Part No. PAC-SC51PI-E PAC-SC52PI-E PAC-SC53PI-E PAC-SC54PI-E

5m 7m 10m 15mPipe length

Pipe size OD

Connection method

Liquid:/ø9.52 Gas:/ø19.05

Indoor unit:Flared Outdoor unit:Flared

1. REFRIGERANT PIPES

For model:PEHD-4EK(H)SA3.UK, PEHD-5EK(H)SA3.UK, PEHD-6EK(H)SA.UK

Note 1.How to connect refrigerant pipes.

Factory supplied optional piping contains refrigerant at above atmospheric pressure. As long as the connection

takes no more than 5 minutes, no air will enter, and there will be no need for air purging.

Remove the blind caps and make the connections within 5 minutes. After the connections for the indoor and

outdoor units are made, open the stop valve on the outdoor unit to allow refrigerant gas to flow.

If piping length exceeds 5m, an additional charge of refrigerant is needed.

Note 2.The following main parts are contained in the optional refrigerant piping kit.

Heat insulating cover, vinyl tapes, nipples, sleeve and flange(for wall hole), connecting cables,

Part No.

Model Name

PAC-SC32PTA

Program timer

2. TIMER

Part name

Part No.

Program timer

PAC-SC32PTA

Exterior dimensions(mm)

5-4/32X4-23/32X23/32(130X120X18mm)

Installation Wall mount

Type of clock Quartz

Clock accuracy

±

50second/month at 25 ˚C

Display-Time Liquid crystal display

Liquid crystal display

Liquid crystal display

Program cycle

-Timer setting unit

-Week

24 hours

Timer setting unit 30 minutes

No. of set points 48/day

2-1 Program timer specifications

Power rating

5V DC ± 5%(Supplied by Remote Controller)

2-2 Feature of program timer

(1) Daily timer function

Daily timer can be set in 30 minute units for up to 24 hours.

Each unit can be set for unit ON, unit OFF, or setback operation.

(2) Setback operation(PAC-SK65PT)

Set back operation is useful for reducing running costs.

e.g.AT a hotel with a 24-hour system

8:00~23:00 Cooling operation with set temperature at 26 ˚C

23:00~8:00 Setback operation with 2 degrees of setback

As shown in the chart on the right, the set temperature rises 2

degrees automatically during the setback operation. When the

setback operation ends, normal operation will begin.

(3) Weekly timer function

Daily timer function can apply to each day of the week.

10

OPTIONAL PARTS

28˚C

26˚C

8:00

Normai

operation

8:00

Normai

operation

23:00

Setback

operation

Part No. PAC-05FFS-E PAC-07FFS-E PAC-10FFS-E PAC-15FFS-E

5m 7m 10m 15mPipe length

Pipe size OD

Connection method

Liquid:/ø9.52 Gas:/ø15.88

Indoor unit:Flared Outdoor unit:Flared

For model:PEHD-3EK(H)A3.UK

Page 26

25

2-3 HOW to connect program timer

(1) Install the program timer next to the remote controller the same way as the remote is controller installed.

(2) Connect the program timer and the remote controller with a 6-wire cable as shown in the figure below.

NOTE: While the program timer is connected to the remote controller, the 24

hour ON/OFF timer on the remote controller will not operate.

How to connect program timer(For PKH-2FKA

2

, 2.5/3/4FK(S)A1)

(1) Install the program timer next to the remote controller the same way as the remote controller is installed.

(2) Connect the program timer and the remote controller with a 5-wire cable as shown in the figure below.

NOTE: While the program timer is connected to the remote controller, the 24

hour ON/OFF timer on the remote controller will not operate.

2-4 Names and functions

<PAC-SC32PTA>

To Indoor unit

2.wire cable

Remote

controller

Program

timer

Connector CN 1Connector CN 1

6-wire cable

2.wire cable

Connector CN 1Connector CN 1

5-wire cable

To Indoor unit

1

2

3

ORN

BRN

RED

3. TIMER ADAPTER

This adapter is needed for system control and for operation via external contacts. Adapter connection is described on

page 25.

Part No. PAC-SA89TA-E

Used for selection of it. The day

operation pattern set by PATTERN

SETTING is to be applied in weekly

day unit setting.

When SET is displayed, clock

adjustment, change of weekly day, daily

and weekly timer setting can be

performed. When MONITOR is

displayed, all switches except

SET/MONITOR SW are invalidat-ed.

This is normal status.

Used for week day setting.

Using this switch, select "MONITOR"

or "SET" Mode.

"MONITOR" : Indicates the current

timer setting. All

switches expect MODE

SELECTOR SW are

invalidated then. This

is the normal status.

"SET" : Set to "SET" mode for clock

adjustment, charge or week

day, daily and weekly timer

setting.

During MONITOR status,

current time is displayed.

During Daily timer setting,

time desired for timer setting is displayed.

Indicates the setting

set back range.

24 hours is divided indo 48 blocks

and each block represents 30

minutes. The block display consists

of patterns.

Used for set back setting.

Set back can be done in the range

of 1, 2, 4, 6, and 8˚C.

Used to specify the setting pattern.

Used for timer in 30 minute units.

Used for setting timer in day or

week unit.

Pushing SW moves the week day

light display in order of

S➞M➞T➞W···

enabling the week day.

Used for adjustment of the current time.

Push SW to advance the time. Each time the but-

ton is pushed the time advances by 1 minute, pushing continuously advances by 1 minute at 0.5 second interval, and when the lower digit of minutes

becomes 0, indication advances in 10 minute units.

SW is used for reversing the time. Each time the

button is pushed the time reverses by 1 min-ute,

pushing continuously reverses the time by 1 minute

at 0.5 second interval, and when the lower digit

of minute becomes 0 indication reverses in 10

minute units.

WEEKLY TIMER SETTING DISPLAY CURRENT TIME DISPLAY

SET/MONITOR DISPLAY

WEEK DAY SETTING SW

MODE SELECTOR SW CLOCK ADJUSTMENT SW WEEKLY TIMER SW

DAILY TIMER SW

ON/SET BACK/ OFF SW

SET BACK SETTING SW

DAILY TIMER SETTING DISPLAY

SET BACK DISPLAY

Page 27

26

5. CENTRALIZED REMOTE CONTROLLER

Allows individual or combined control of up to 16 units.When using the PAC-805RC, the program timer adapter(PAC825AD) is also needed.

5-1 Dimensions Unit:mm

4. MULTIPLE REMOTE CONTROLLER ADAPTER

This adapter is needed for remote indication(operation/check.)

Part No. PAC-SA88HA-E

117

117

12

113

113

56.5

23.5 11

8

Part No. PAC-805RC

5-2 Functions

"ENGAGED" indicator

When this indicator is lit, transmisson is in

progress and all swiches are inoperative.

switch

This change-over switch governs the operation of the accessory remote controller.

"DUAL"

Instructions from both the accessory

remote controller and the centralized

remote controller are valid. (Priority

given to the last instruction received.)

"CENTRAL"

ON / OFF switching by the accessory

remote controller is invalidate. Operation is

controlled by the centralized remote controller only.

Inital setting is "DUAL"

LCD Matrix display

This display indicates the operational status of all connected units either by steady

lighting or by flashing.

switch

Operation ON / OFF switch.

buttons These

buttons are used to designate the

attached unit (s). (They designate the unit

to be centrally controlled.)

•When group "00" is designated ; collective ON/OFF instruction is sent to all

units.

•When group "01" - "16" is designated;

ON/OFF instruction is sent only to

the designated units.

switch

This change-over switch is for the program timer.

Use "ACTIVE" when a program timer is

connected.

Use "BYPASS" when a program timer is

not connected.

Independent "DUAL / CENTRAL" and "ACTIVE / BYPASS" setting of all the groups is prossible. When the power supply to

the centralized remote controller is cut due to power failure, all settings will return to the original "DUAL" and "BYPASS".

DUAL/CENTRAL

POWER ON/OFF

BACK AHEAD

ACTIVE/BYPASS

1

2

3

4

5

BRN

RED

ORN

YLW

GRN

non-polarity

Page 28

27

5-3 Connection method

(1) Connection in the power supply cord.

1. Connect the power supply cord to the power supply terminal-block and fix in-place with a tie-wrap. Connect a single

phase 200V AC(220, 230, 240V)to

AN

.

As Eis the GND terminal,be sure to ground the earth wire.

2. Connect the transmission line to the transmission terminal-block and fix it in-place with a tie-wrap. Use a ø1.6

(AWG14)or above two-wire cable for the transmission line.

CAUTION: Never connect the power supply cord to the transmission terminal-block.

TERMINAL-BLOCK

FOR TRANSMISSION

TERMINAL-BLOCK

OF POWER SUPPLY

Fuse(5A)

TRANSFORMER

Tie-wrap

Tie-wrap

Transmission

POWER

SUPPLY

Wiring has to be changed when

a 200,230 or 240V power is used.

(2) Connection method of centralized remote controller and power supply board.

1. Connect the centralized remote controller and power supply board with a non-polar, two-wire cable.

TO adaptor's

terminal-block

TO adaptor's

terminal-block

Non-polar

two-wire cable

Power supply board box

Centralized

remote controller

Power supply

board

Dip swirch

SW17

2. Wiring diagram

3. Be sure to set the maximum address number with the dipswitch

SW17 on the centralized remote controller.

Page 29

28

6. PROGRAM TIMER ADAPTER

This adapter is needed when a program timer(PAC-SK65PT)or a centralised remote controller(PAC-805RC)is used.

6-1 Parts included

6-2 Connection method

Connection and wiring methods differ with the type of the indoor unit used. Confirm the type before carrying out the work.

Part No. PAC-825AD

1 ADAPTER ···································x1 2 3-core cable ·································· x1 2 3-core cable ·································· x1

2 4-core cable ·································· x1 2 5-core cable ·································· x1

Length:2m(6' 7")

Length:2m(6' 7")

Length:2m(6' 7" )

Length:2m(6' 7")

Fig. 1

TERMINAL-BLOCK

FOR

TRANSMISSION

Dip switch

SW 1

Transmission cord

TRANSFORMER

Fuse(5A)

TERMINAL-BLOCK

FOR POWER

SUPPLY

POWER SUPPLY CORD

Terminal block for

transmission to

program timer or

centralized remote

controller

Wiring has to be changed when 200V power supply is used.

POWER

SUPPLY

Fig. 2

(1) Connections in the adapter box

1. Connect the power supply cord to the terminal-block and fix in-place with a tie-wrap.

Connect a single phase 200V AC(220, 230, 240V) to AN

.

As E is the GND terminal, be sure to ground the earth wire.

2. Connect the transmission line to the transmission terminal-block and fix it in-place with a tie-wrap(when a centralized

remote controller is being used).

CAUTION: Never connect the power supply cord to the transmission terminal-block.

(2) When the centralised remote controller is used, set the address number with the dipswitch SW1 of the program timer

adapter.

Page 30

29

(3)Connections from adapter 6-3 Dimensions (Unit:mm)

Fig. 3

To program timer or

centralized remote

controller

Adaptor

200-240V AC

CN30 CN50

CN51

5-core cable3-core cable

Remote controller Indoor unit

Maximum length of each cable is 10m.

Fig. 4

40

80

40 27

4 Fixing screw holes

5.5

95

200

22

22

35

86 70

230

15 15

18

15

27

35

65

3

holes

hole

7. OPTIONAL REMOTE CONTROLLER

This is for the control using two remote controllers.

Part No. PAC-JH050KA

Applied model

PEHD-3EK(H)A.UK

4/5/6 EK(H)SA

Rear side wiring arangement opening.

130

18

120

46

83.5

Page 31

30

8. OPTIONAL MOTOR

The external static pressure of 130Pa allows long ducts to be used more extensively to enable the most convenient

positioning of indoor units.

9. DRAIN WATER LIFT-UP MECHANISM

This allows more versatility when selecting drain piping layouts.

Part No. PAC-SK005MT-F

PAC-SK004MT-F

PAC-SK003MT-F

PEHD-3EK(H)A

3

.UK

PEHD-4EK(H)SA

3

.UK

PEHD-5EK(H)SA

3

.UK, PEHD-6EK(H)SA.UK

Applied model

Part No. PAC-SK002DM-F

PEHD-3EK(H)A

3

.UK, PEHD-4EK(H)SA3.UK, PEHD-5EK(H)SA3.UK, PEHD-6EK(H)SA.UK

Applied model

Page 32

HEAD OFFICE MITSUBISHI DENKI BLDG. MARUNOUCHI TOKYO100 TELEX J24532 CABLE MELCO TOKYO

MEE 99K002

Issued in June. 1999

Printed in Japan

New publication, effective June. 1999

Specifications subject to change without notice.

TM

Loading...

Loading...