Page 1

Air-Conditioners For Building Application

INDOOR UNIT

PEFY-P-VMH-A

GB

D

F

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALA CIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

E

I

NL

P

GR

RU

TR

MONTAJ ELK‹TABI

Emniyetli ve do¤ru biçimde nas›l kullan›laca¤›n› ö¤renmek için lütfen klima cihaz›n› monte etmeden önce bu elkitab›n› dikkatle okuyunuz.

Page 2

3

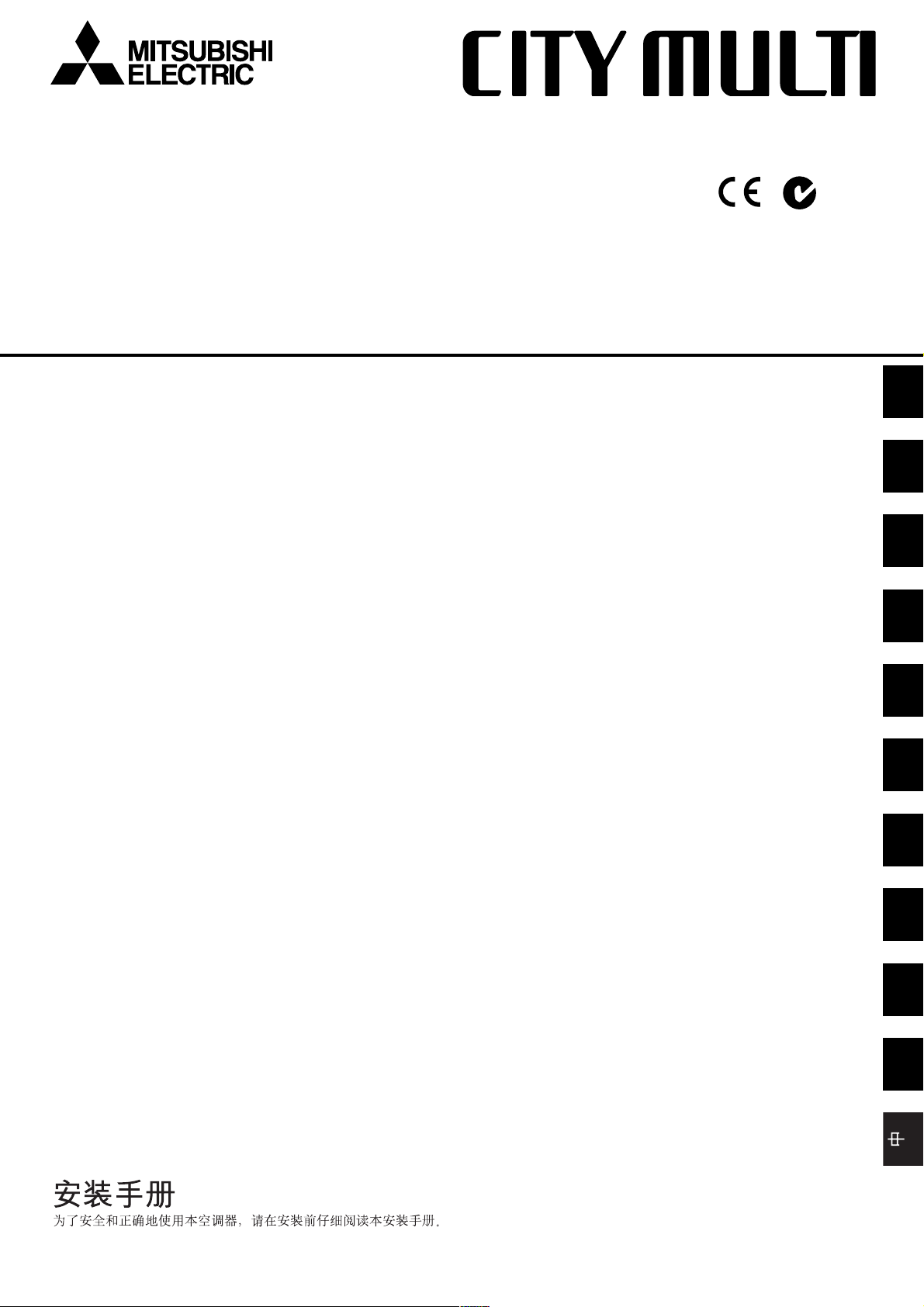

[Fig. 3.1.1]

3.1

[Fig. 3.1.2]

Type 40~140

Type 40~140

Type 200 · 250

700

70

C

100~200

450

F

G

23

380

JF

B

B

420

150~200

A

250

340

A

B

A Fan and motor removal door

B Duct dimension

Type A B C D

B

340

PEFY-P40·50·63VMH-A 680 754 550 600

PEFY-P71·80VMH-A 930 1004 800 850

PEFY-P100·125·140VMH-A 1130 1204 1000 1050

PEFY-P200·250VMH-A 1250 1326 1100 1100

B

D

D

814

E

H

B

C

A

B

I

844

38

23

K

LL

30±10

Type 200 · 250

800

200~300

450

F

G

B

70

C

D

D

B Duct dimension

C Electrical components case

D Air inlet

E Top of unit

1034

1067

60

23

470

H

B

C

A

B

I

38

23

K

30±10

F Access door

G Servicing space

H Air outlet

I Hanging bolt spacing

J Ceiling

K 100 min.

L 20 min.

LL

JF

4

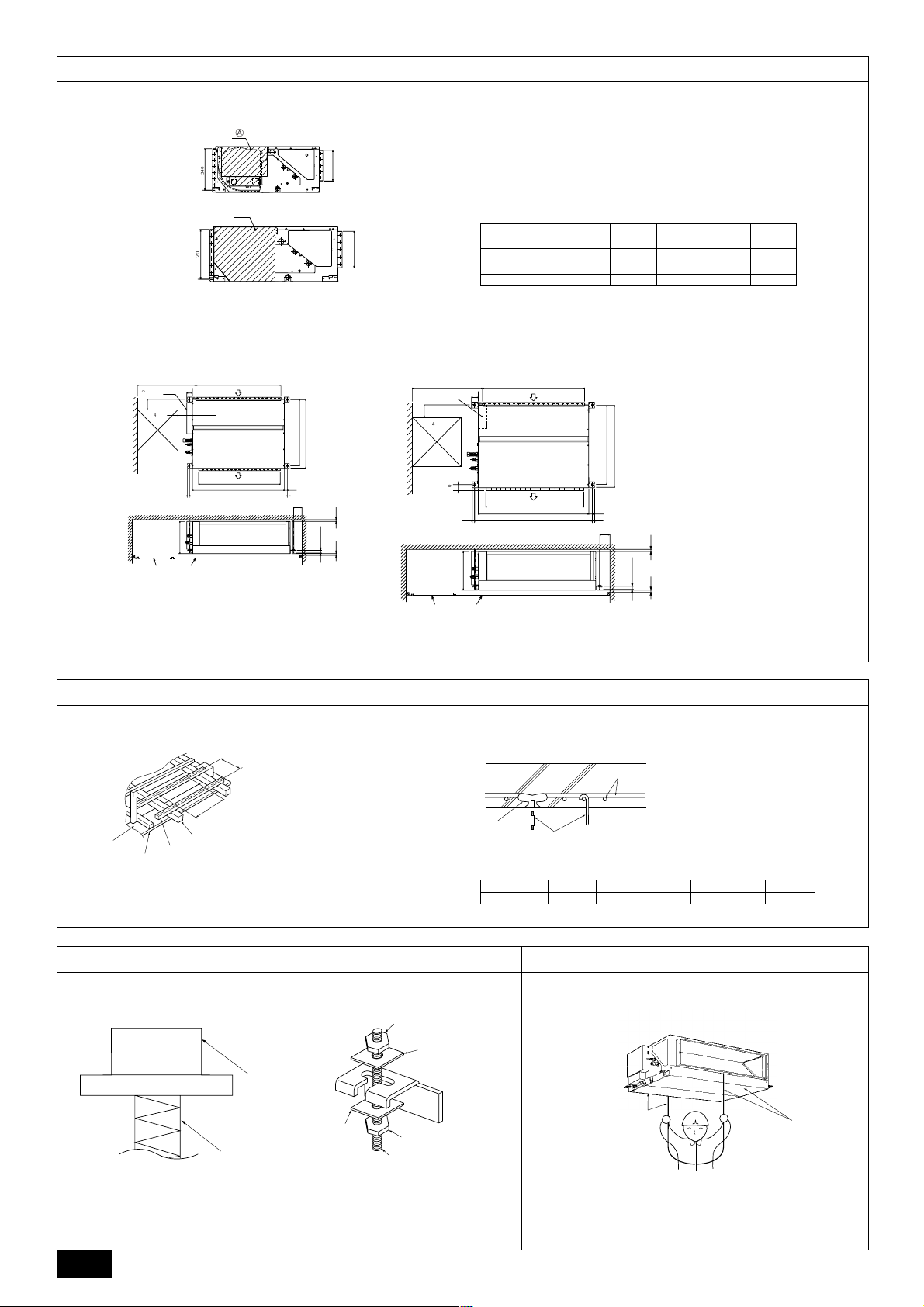

4.1

[Fig. 4.1.1] [Fig. 4.1.2]

E

A Ceiling board

B Edge beam

C Tie beam

E

A

B

C

D

D Square timber for hanging the air

conditioner

E Pitch

F

G

Product Weight (kg)

Model name 40 50 · 63 71 · 80 100 · 125 · 140 200 · 250

PEFY-P-VMH 44 45 50 70 100

5

[Fig. 5.1.1] [Fig. 5.2.1]

[Fig. 5.1.2]

C

D

H

F Insert: 100 to 150 kg (1 piece)

(field supply)

G M10 hanging bolt (field supply)

H Reinforcement

5.25.1

2

A Unit body

B Lifting machine

A

D

B

C Nuts (field supply)

D Washers

E M10 Hanging bolt (field supply)

C

E

A Bottom of indoor unit

A

A

Page 3

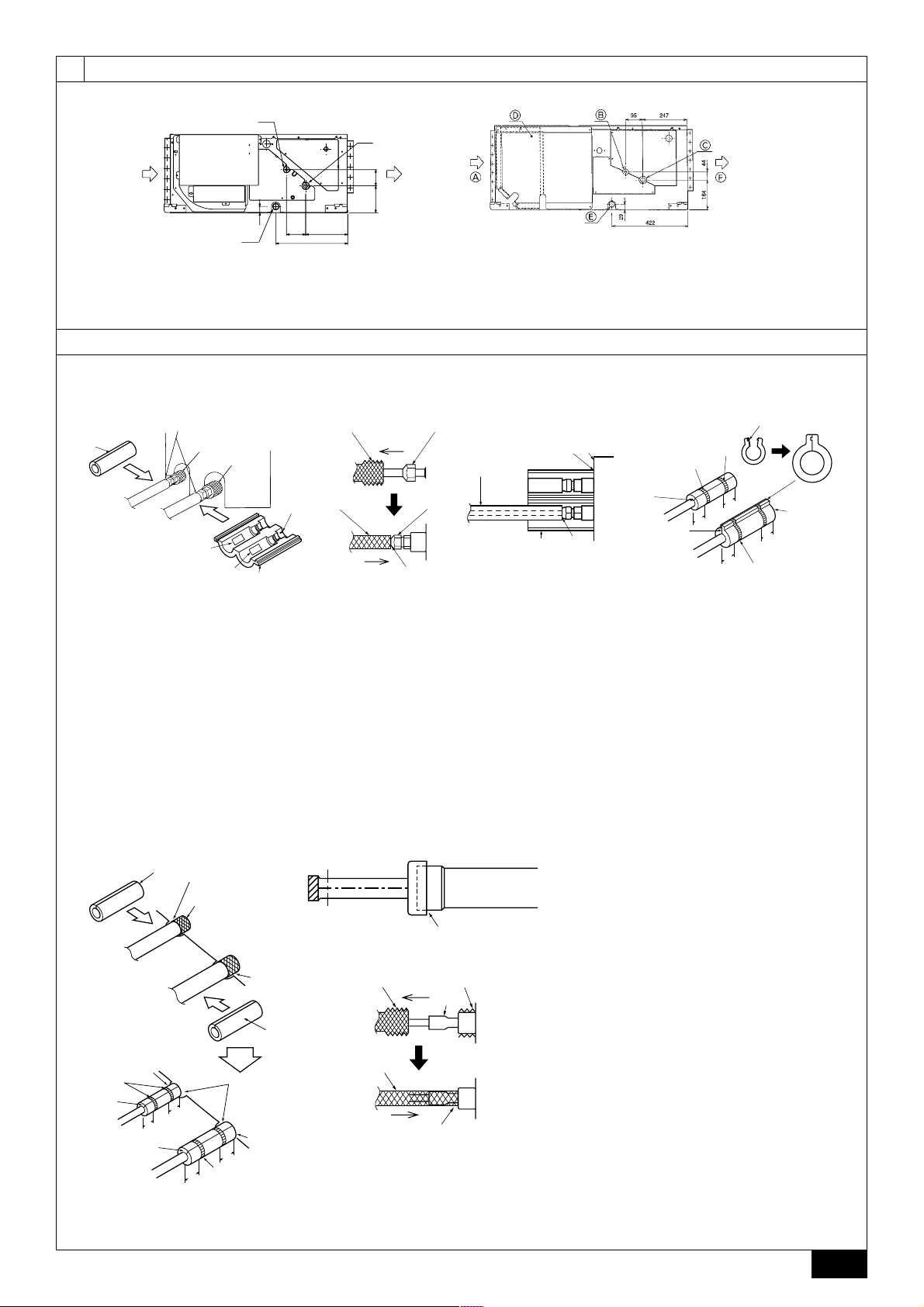

6

V

U

V

U

I

T

S

20

20

20

20

6.2

[Fig. 6.2.1]

A

[Fig. 6.3.1]

Type 40 - 140

A

E

A Thermal insulation tubing 1

B Caution:

Pull out the thermal insulation on the refrigerant piping at the site, insert the flare

nut to flare the end, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

C Liquid end of refrigerant piping

D Gas end of refrigerant piping

E Site refrigerant piping

F Main body

G Marked “GAS”

H Marked “OUTSIDE”

I Flared insulation (supplied) 2

J Marked “INSIDE”

B

C

D

77130

F

30

E

Type 40 - 140

92 200

343

Type 200 · 250

A Air inlet B Refrigerant piping (liquid)

C Refrigerant piping (gas) D Control box

E Drain outlet F Air outlet

6.3

B

K

C

D

F

K

J

G

H

I

N

M

L

P

O

E

QR

M

I

F

O

O

K Thermal insulation

L Pull

M Flare nut

N Return to original position

O Ensure that there is no gap here

P Plate on main body

Q Outside

R Inside

S Remove tape

T Thermal insulation tubing (small) (supplied) 1

U Tie (large) (supplied) 4

V Ensure that there is no gap here. Place join upwards.

[Fig. 6.3.2]

Type 200 · 250

A

B

C

E

D

G

M

N

O

R

P

Q

F

I

J

K

20

20

K

H

E

L

20

J

20

O

S

T

A Thermal insulation tubing 1

B Caution:

Pull out the thermal insulation on the refrigerant piping

at the site, braze the piping, and replace the insulation

in its original position.

Tak e care to ensure that condensation does not f orm on

exposed copper piping.

C Refrigerant piping (liquid)

D Refrigerant piping (gas)

E Main body

F Thermal insulation tubing 2

G Site refrigerant piping

H Ensure that there are no gaps between the insulation

and the main body.

I Thermal insulation tubing (small) (supplied) 1

J Ties (large) (supplied) 4

K Ensure that there is no gap here. Place join upwards.

L Thermal insulation tubing (medium) (supplied) 2

M Cut

N Release gas before removing the brazing.

O Thermal insulation

P Pull

Q Flared pipe end

R Wrap with damp cloth

S Return to original position

T Ensure that there is no gap here.

3

Page 4

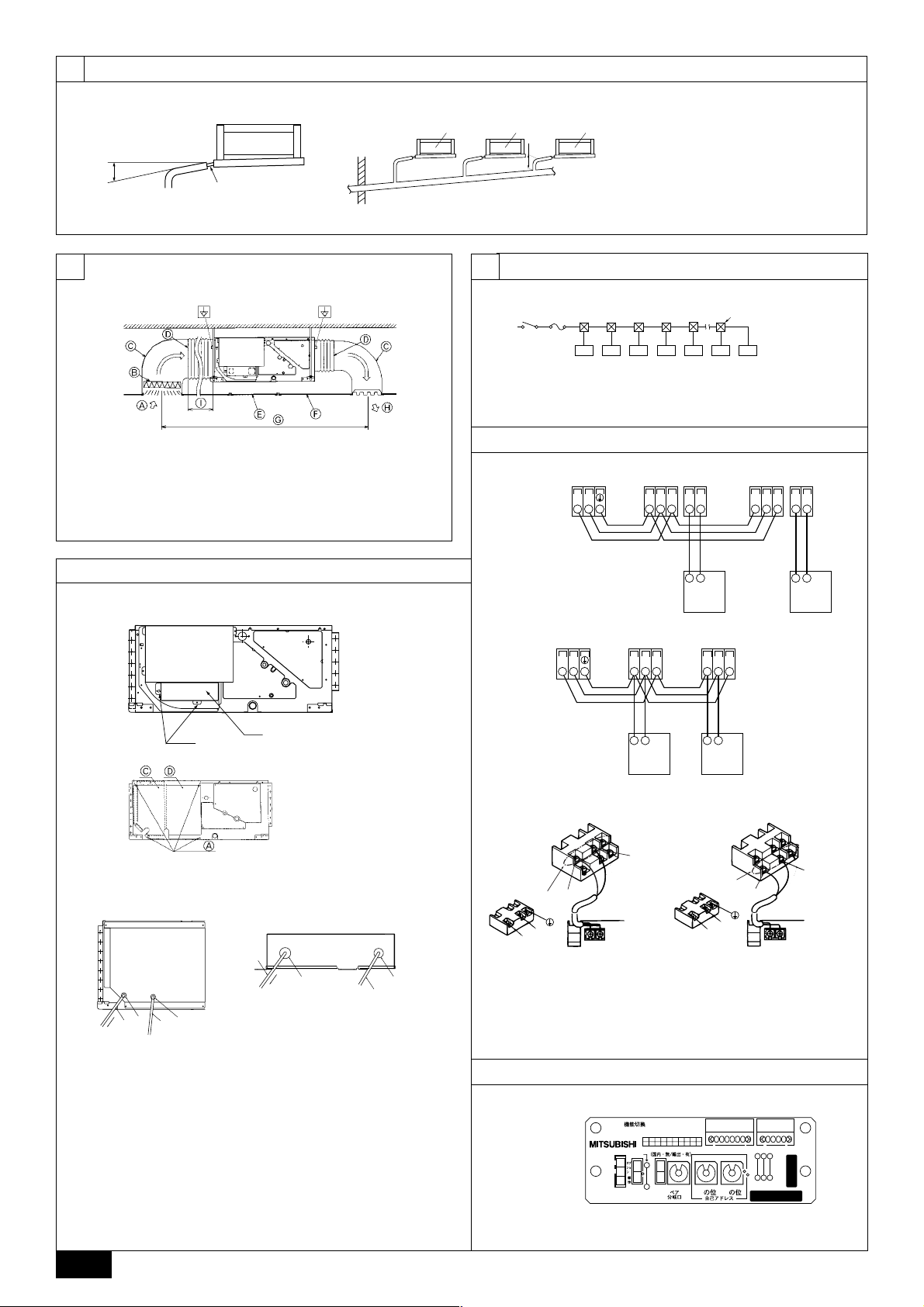

7

C C C

[Fig. 7.2.1]

A

B 1

7.2

E

D 2

A Downward slope 1/100 or more

B Drain hose (Accessory)

C Indoor unit

D Collective piping

E Maximize this length to approx. 10 cm

8

[Fig. 8.0.1]

A Air inlet B Air filter (supplied at site)

C Duct D Canvas duct

E Access door F Ceiling

G Ensure sufficient length to prevent short cycling

H Air outlet I Keep duct-work length 850 or more

9.3

[Fig. 9.3.1]

B

A Screws

B Terminal box cover

C Control box cover

D Control box

B

A D

C

[Fig. 9.3.2]

C

BAE

A

D

9

9.1

[Fig. 9.1.1]

AB

DE

CCCCCCC

A Switch 16 A B Overcurrent protection 16 A

C Indoor unit D Total operating current be less than 16 A

E Pull box

9.2

[Fig. 9.2.1]

[Fig. 9.2.2]

L

B

M1M2 21

TB3

B

M1M2

TB3

1

B

N

DC10~13V

AB

12

E

AA

SM1M2 SM1M2

TB5 TB15 TB5 TB15

C

AA

SM1M2 SM1M2

TB5 TB5

A Terminal block for

indoor transmission

cable

B Terminal block for

outdoor transmission cable

C

C

C Remote controller

[Fig. 9.2.4][Fig. 9.2.3]

2

A

C

D

M1

DC24~30V

N

L

12

(A, B)

A Non-polarized

B Upper level (TB15)

C Remote Controller

D Lower level (TB5)

21

C

M2

A

C

A To pre v ent external tensile force from applying to the wiring connection sec-

tion of power source terminal block use buffer bushing like PG connection

or the like.

B Power source wiring

C Tensile force

D Use ordinary bushing

E Transmission wiring

4

[Fig. 9.5.1]

ON

W254613G03

FP-AD-R

MADE IN JAPAN

1

JP1

3

2

1

SWCSWA

<Address board>

9.5

240V 220V

SW5

SW14

SW1

10

SW12

0

0

10

N0

N0

CN828161

SW11

1

CN62

0

JP2

JP3

JP4

Page 5

Contents

1. Safety precautions ...................................................................................... 5

1.1. Before installation and electric work.......................................... 5

1.2. Precautions for devices that use R407C refrigerant.................. 5

1.3. Before getting installed.............................................................. 6

1.4. Before getting installed (moved) - electrical work...................... 6

1.5. Before starting the test run ........................................................ 6

2. Indoor unit accessories ............................................................................... 6

3. Selecting an installation site ....................................................................... 7

3.1. Installation and servicing space ................................................ 7

3.2. Combining indoor units with outdoor units ................................ 7

4. Fixing hanging bolts .................................................................................... 7

4.1. Fixing hanging bolts .................................................................. 7

5. Installing the unit ......................................................................................... 7

5.1. Hanging the unit body ............................................................... 7

5.2. Confirming the unit’s position and fixing hanging bolts ............. 7

6. Refrigerant pipe and drain pipe specifications ............................................ 8

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This symbol is

displayed on the main unit label.) <Color: yellow>

: Beware of electric shock (This symbol is displayed on the main unit label.)

<Color: yellow>

Warning:

Carefully read the labels affixed to the main unit.

6.1. Refrigerant pipe and drain pipe specifications .......................... 8

6.2. Refrigerant pipe, drain pipe and filling port................................ 8

6.3. Request for refrigerant piping connection ................................. 8

7. Connecting refrigerant pipes and drain pipes ............................................. 8

7.1. Refrigerant piping work ............................................................. 8

7.2. Drain piping work....................................................................... 9

8. Duct work .................................................................................................... 9

9. Electrical wiring ........................................................................................... 9

9.1. Power supply wiring ................................................................ 10

9.2. Connecting remote controller, indoor and outdoor

transmission cables................................................................. 10

9.3. Connecting electrical connections........................................... 10

9.4. Selecting the static pressure ................................................... 10

9.5. Setting addresses.................................................................... 10

9.6. Sensing room temperature with the built-in sensor in

a remote controller .................................................................. 10

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly , dust or water may enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge the it with a refrigerant different from the refrigerant (R407C or

R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly , water leakage , electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

GB

D

F

E

INL

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage , electric shock,

or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for typhoons and other strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an air c leaner, humidifier , electric heater, and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

1.2. Precautions for devices that use R407C

refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large

amount of chlorine which may cause the refrigerator oil of the new unit to

deteriorate.

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper allo y seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur , o xides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator

oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of mineral

oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refriger-

ant in the cylinder will change and performance may drop.

5

PGRRUTR

Page 6

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may

cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector , reverse flow chec k valve,

refrigerant charge base, vacuum gauge, refrigerant recovery equipment.)

- If the conventional refrigerant and refrigerator oil are mixed in the R407C,

the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deterio-

rate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

GB

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

D

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

F

E

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit. P erform collective drainage w ork

together with the outdoor unit, as required.

• The indoor models should be installed the ceiling over than 2.5 m from

floor.

INL

1.4. Before getting installed (moved) - elec-

trical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use an y PP bands f or a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot

and may be cold, depending on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

PGRRUTR

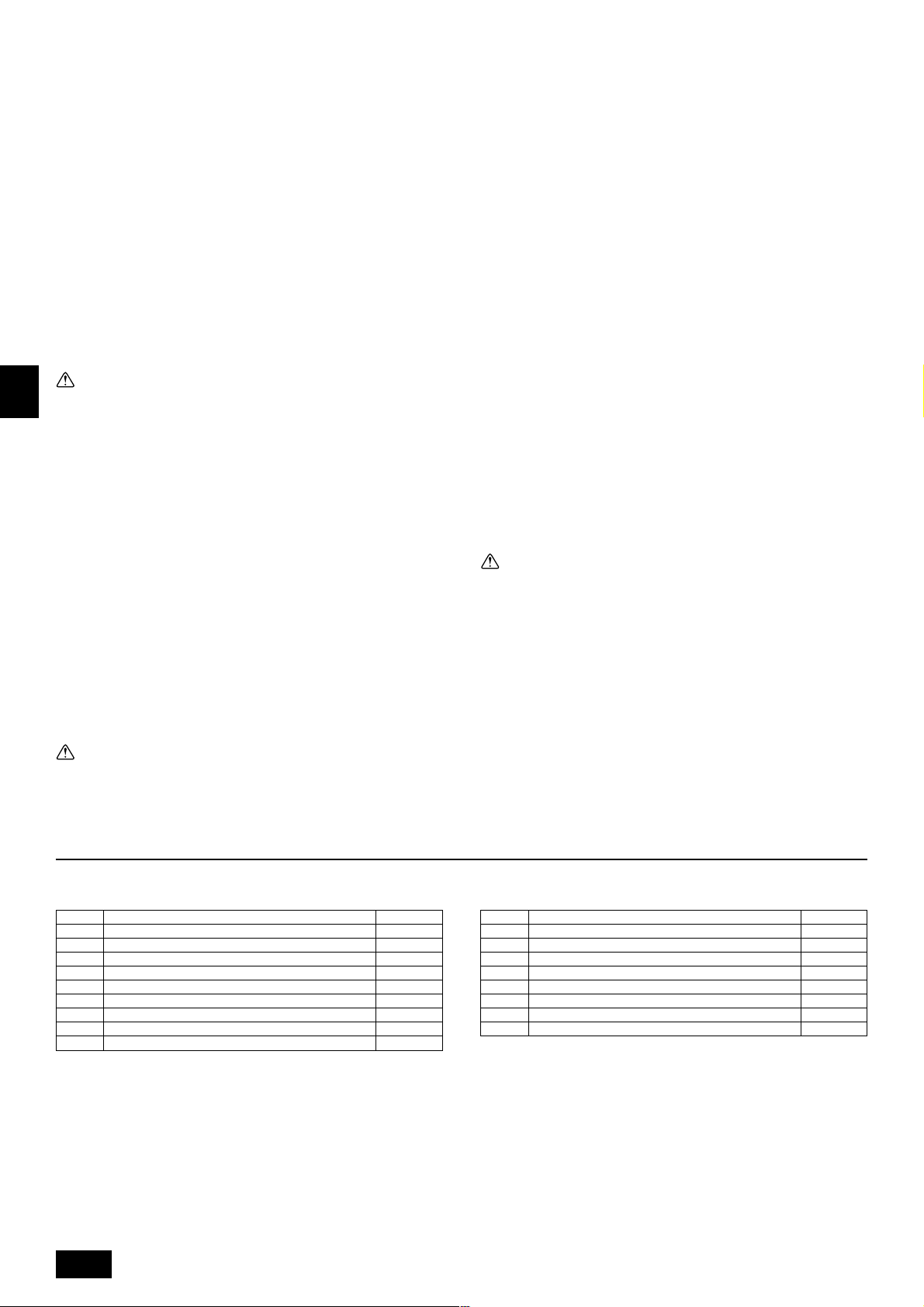

2. Indoor unit accessories

The unit is provided with the following accessories:

Type 40 - 140 Type 200 · 250

No. Accessories Quantity

1 Insulation pipe (small) 1

2 Insulation cover 1

3 Tie band (small) 1

4 Tie band (large) 6

5 Drain hose 1

6 Washer 8

7 Insulation pipe (large) 1

8 Hose band 1

9 Attachment connector 2

6

No. Accessories Quantity

1 Insulation pipe (small) 1

2 Insulation pipe (medium) 1

3 Tie band (small) 1

4 Tie band (large) 6

5 Drain hose 1

6 Washer 8

7 Insulation pipe (large) 1

8 Hose band 1

Page 7

3. Selecting an installation site

• Select a location so that air can be blown into all corners of the room.

• Avoid locations exposed to outside air.

• Select a location free of obstructions to the airflow in and out of the unit.

• Avoid locations exposed to stream or oil vapour.

• Avoid locations where combustible gas may leak, settle or be generated.

• Av oid installation near machines emitting high-frequency waves (high-frequency

welders, etc.)

• Avoid locations where the airflow is directed at a fire alarm sensor. (Hot air

could trigger the alarm during the heating operation.)

• Avoid places where acidic solutions are frequently handled.

• Avoid places where sulphur-based or other sprays are frequently used.

Warning:

Install the indoor unit on a ceiling strong enough to sustain its weight.

If the ceiling lacks strength, it may cause the unit to fall do wn, resulting in an

injury.

3.1. Installation and servicing space

Refrigerant piping, drain piping, wiring, and other components should be installed

outside the

hinder fan maintenance.

[Fig. 3.1.1] (P. 2)

areas, and free of the access doors to ensure that they do not

Type 40 - 140

Type 200 · 250

A Fan and motor removal door

B Duct dimension

4. Fixing hanging bolts

Note:

Always install access doors in the specified positions for service maintenance.

Type A B C D

PEFY-P40·50·63VMH-A 680 754 550 600

PEFY-P71·80VMH-A 930 1004 800 850

PEFY-P100·125·140VMH-A 1130 1204 1000 1050

PEFY-P200·250VMH-A 1250 1326 1100 1100

Warning:

Install the unit on a ceiling strong enough to support its weight.

• If the unit is mounted on a structure of insufficient strength it may fall

causing injury.

[Fig. 3.1.2] (P. 2)

Type 40 - 140

Type 200 · 250

B Duct dimension C Electrical components case

D Air inlet E Top of unit

F Access door G Servicing space

H Air outlet I Hanging bolt spacing

J Ceiling K 100 min.

L 20 min.

3.2. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit installation

manual.

GB

D

F

4.1. Fixing hanging bolts

(Use M10 hanging bolts. The bolts should be supplied in the field.)

(Give site of suspension strong structure.)

Hanging structure

• Ceiling: The ceiling structure varies from building to one another. For detailed

information, consult your construction company.

1 Reinforcing the ceiling with additional members (edge beam, etc.) must be

required to keep the ceiling at level and to prevent the ceiling from vibrations.

2 Cut and remove the ceiling members.

3 Reinforce the ceiling members, and add other members for fixing the ceiling

boards.

For wooden construction

• Use the tie beam (for one story building) or second-floor beam (for two story

building) as strength members.

• To hang the air-conditioner, use a hard square timber of more than 6 cm if the

distance between beams is less than 90 cm and a hard square timber of more

than 9 cm if the distance between beams is less than 180 cm.

5. Installing the unit

5.1. Hanging the unit body

ss

s Bring the indoor unit to an installation site as it is packed.

ss

ss

s To hang the indoor unit, use a lifting mac hine to lift and pass through the

ss

hanging bolts.

[Fig. 5.1.1] (P. 2)

A Unit body

B Lifting machine

[Fig. 5.1.2] (P. 2)

C Nuts (field supply)

D Washers

E M10 Hanging bolt (field supply)

[Fig. 4.1.1] (P. 2)

A Ceiling board B Edge beam

C Tie beam

D Square timber for hanging the air conditioner

E Pitch

For reinforced concrete construction

• As shown in the figure below , fix the hanging bolts , or use square timbers to fix

the hanging bolts.

[Fig. 4.1.2] (P. 2)

F Insert: 100 to 150 kg (1 piece) (field supply)

G M10 hanging bolt (field supply)

H Reinforcement

Product Weight (kg)

Model name 40 50 · 63 71 · 80 100 · 125 · 140 200 · 250

PEFY-P-VMH 44 45 50 70 100

5.2. Confirming the unit’s position and

fixing hanging bolts

ss

s Use the gage supplied with the panel to confirm that the unit body and

ss

hanging bolts are positioned in place. If they are not positioned in place,

it may result in dew drops due to wind leak. Be sure to check the positional

relationship.

ss

s Use a level to check that the surface indicated by

ss

that the hanging bolt nuts are tightened to fix the hanging bolts.

ss

s To ensure that drain is dischar ged, be sure to hang the unit at le vel using

ss

a level.

[Fig. 5.2.1] (P. 2)

A Bottom of indoor unit

Caution:

Be sure to install the unit body at level.

AA

A is at level. Ensure

AA

E

INL

PGRRUTR

7

Page 8

6. Refrigerant pipe and drain pipe specifications

To avoid dew drops, provide sufficient antisweating and insulating work to the refrigerant and drain pipes.

When using commercially available refrigerant pipes, be sure to wind commercially available insulating material (with a heat-resisting temperature of more than

100 °C and thickness given below) onto both liquid and gas pipes.

Be also sure to wind commercially available insulating material (with a form

polyethylene’s specific gravity of 0.03 and thickness given below) onto all pipes

which pass through rooms.

1 Select the thickness of insulating material by pipe size.

Pipe size Insulating material’s thickness

6.4 mm to 25.4 mm More than 10 mm

28.6 mm to 38.1 mm More than 15 mm

2 If the unit is used on the highest story of a building and under conditions of

high temperature and humidity, it is necessary to use pipe size and insulating

material’s thickness more than those given in the table above.

3 If there are customer’s specifications, simply follow them.

6.1. Refrigerant pipe and drain pipe specifications

GB

Type 40 - 140 (mm)

Item

Refrigerant piping

(flared joints)

D

Type 200 · 250 (mm)

Item

Refrigerant piping

F

(flared joints)

Drain piping 32

Drain piping 32

Model

Liquid piping ø6.35 ø9.52

Gas piping ø12.7 ø15.88 ø19.05

Model

Liquid piping ø12.7

Gas piping ø25.4 ø28.58

40 50 - 80 100 - 140

200 250

6.2. Refrigerant pipe, drain pipe and filling

E

INL

port

[Fig. 6.2.1] (P. 3)

Type 40 - 140

Type 200 · 250

A Air inlet B Refrigerant piping (liquid)

C Refrigerant piping (gas) D Control box

E Drain outlet F Air outlet

6.3. Request for refrigerant piping connection

Connecting refrigerant piping

• After connecting refrigerant piping, insulate the joints (flared joints) with ther-

PGRRUTR

mal insulation tubing as shown below.

[Fig. 6.3.1] (P. 3)

Type 40 - 140

A Thermal insulation tubing 1

B Caution:

Pull out the thermal insulation on the refrigerant piping at the site, insert the flare

nut to flare the end, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

C Liquid end of refrigerant piping D Gas end of refrigerant piping

E Site refrigerant piping F Main body

G Marked “GAS” H Marked “OUTSIDE”

I Flared insulation (supplied) 2 J Marked “INSIDE”

K Thermal insulation L Pull

M Flare nut N Return to original position

O Ensure that there is no gap here P Plate on main body

Q Outside R Inside

S Remove tape

T Thermal insulation tubing (small) (supplied) 1

U Tie (large) (supplied) 4

V Ensure that there is no gap here. Place join upwards.

[Fig. 6.3.2] (P. 3)

Type 200 · 250

A Thermal insulation tubing 1

B Caution:

Pull out the thermal insulation on the refrigerant piping at the site, braze the piping, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

C Refrigerant piping (liquid) D Refrigerant piping (gas)

E Main body F Thermal insulation tubing 2

G Site refrigerant piping

H Ensure that there are no gaps between the insulation and the main body.

I Thermal insulation tubing (small) (supplied) 1

J Ties (large) (supplied) 4

K Ensure that there is no gap here. Place join upwards.

L Thermal insulation tubing (medium) (supplied) 2

M Cut

N Release gas before removing the brazing.

O Thermal insulation P Pull

Q Flared pipe end R Wrap with damp cloth

S Return to original position T Ensure that there is no gap here.

Caution:

Before removing the brazing, cut off the end of the pipe to release an y gas. If

the gas is not released, the pipe may fly off.

1. Remove and discard the rubber bung which is inserted in the end of the unit

piping.

2. Flare the end of the site refrigerant piping.

3. Pull out the thermal insulation on the site refrigerant piping, braze the unit

piping, and replace the insulation in its original position.

* Before brazing the refrigerant piping, always wrap the piping on the main

body , and the thermal insulation piping, with damp cloths to pre vent heat

shrinkage and burning the thermal insulation tubing. Take care to ensure

that the flame does not come into contact with the main body itself.

Refrigerant amount adjustment

Refer to the installation manual for the outdoor unit for details on adjusting the

amount of refrigerant.

7. Connecting refrigerant pipes and drain pipes

7.1. Refrigerant piping work

This piping work must be done in accordance with the installation manuals for both

outdoor unit and BC controller (simultaneous cooling and heating series R2).

• Series R2 is designed to operate in a system that the refrigerant pipe from an

outdoor unit is received by BC controller and branches at the BC controller to

connect between indoor units.

• For constraints on pipe length and allowable difference of elevation, refer to

the outdoor unit manual.

• The method of pipe connection is flare connection (only 40~140).

• The method of pipe connection is brazing connection (only 200 · 250).

Cautions On Refrigerant Piping

ss

s Be sure to use non-oxidative brazing for brazing to ensure that no for-

ss

ss

s Be sure to apply refrigerating machine oil over the flare connection seat-

ss

ss

s Provide a metal brace to support the refrigerant pipe so that no load is

ss

8

eign matter or moisture enter into the pipe.

ing surface and tighten the connection using a double spanner.

imparted to the indoor unit end pipe. This metal brace should be provided 50 cm away from the indoor unit’s flare connection.

Page 9

Warning:

When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant (R407C or R22) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to mal-

function and result in severe damage.

Caution:

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur , o xides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil

in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and

the compressor may fail.

• Use Suniso 4GS or 3GS (small amount) refrigerator oil to coat the flare

and flange connection part. (For models using R22)

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator

oil to coat flares and flange connections. (For models using R407C)

- The refrigerant used in the unit is highly hygroscopic and mixes with water

and will degrade the refrigerator oil.

8. Duct work

• When connecting ducts, insert a canvas duct between the main body and the

duct.

• Use non-combustible duct components.

• Install sufficient thermal insulation to prevent condensation f orming on air inlet

and air outlet duct flanges, and air outlet ducts.

[Fig. 8.0.1] (P. 4)

A Air inlet B Air filter (supplied at site)

C Duct D Canvas duct

7.2. Drain piping work

1. Ensure that the drain piping is downward (pitch of more than 1/100) to the

outdoor (discharge) side. Do not provide any trap or irregularity on the way.

(1)

2. Ensure that any cross-wise drain piping is less than 20 m (excluding the difference of elevation). If the drain piping is long, pro vide metal braces to pre v ent it

from waving. Nev er provide an y air v ent pipe. Otherwise drain may be ejected.

3. Use a hard vinyl chloride pipe VP-25 (with an external diameter of 32 mm) for

drain piping.

4. Ensure that collected pipes are 10 cm lower than the unit body’s drain port as

shown in 2.

5. Do not provide any odor trap at the drain discharge port.

6. Put the end of the drain piping in a position where no odor is generated.

7. Do not put the end of the drain piping in any drain where ionic gases are

generated.

[Fig. 7.2.1] (P. 4)

A Downward slope 1/100 or more

B Drain hose (Accessory)

C Indoor unit

D Collective piping

E Maximize this length to approx. 10 cm

E Access door F Ceiling

G Ensure sufficient length to prevent short cycling

H Air outlet I Keep duct-work length 850 or more

Caution:

Inlet duct is 850 mm or more necessary to construct.

Always install horizontal.

GB

D

F

9. Electrical wiring

Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers in accordance with “Engineering Standards For Electrical Installation” and supplied

installation manuals. Special circuits should also be used. If the power circuit lacks capacity or has an installation failure, it may cause a risk of electric shock or fire.

1. Be sure to take power from the special branch circuit.

2. Be sure to install an earth leakage breaker to the power.

3. Install the unit to prevent that any of the control circuit cables (remote controller, transmission cables) is brought in direct contact with the power cable outside the unit.

4. Ensure that there is no slack on all wire connections.

5. Some cables (power, remote controller , transmission cab les) abov e the ceiling

may be bitten by mouses. Use as many metal pipes as possible to insert the

cables into them for protection.

<Table 1>

System configuration For a single-refrigerant system For a multi-refrigerant system

Transmission cable length Less than 120 m More than 120 m Regardless of length

Building, clinic, hospital or communications

Facility example

(for noise judgment)

Types of transmission

cables

2. Remote controller cables

Types of cables

Cable diameter

Length

Non-shielding wire for up to 10 m; the same specifications

as “1.” Wiring transmission cables for more than 10 m

More than 0.5 to 0.75 mm

Add any portion in excess of 10 m to within the longest al-

lowable transmission cable length 200 m (Shielding portion

is more than 1.25 mm

Residence or independent store

without noise

VCTF, VCTFK, CVV, CVS, VVR,

VVF , VCT or shielding wire CVVS

or CPEVS

Network remote controller

2

2

)

station without noise supposedly generated

from inverter equipment, private power generator, high-frequency medical equipment,

radio-used communications equipment and

so on

6. Never connect the power cable to leads f or the transmission cables . Otherwise

the cables would be broken.

7. Be sure to connect control cables to the indoor unit, remote controller, and the

outdoor unit.

8. Put the unit to the ground on the outdoor unit side.

9

9. Select control cables from the conditions given in page

.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do not connect the earth cable to any gas pipe, water pipe, lightening rod, or telephone

earth cable. Incomplete grounding may cause a risk of electric shock.

Types of control cables

1. Wiring transmission cables

• Types of transmission cables

Design wiring in accordance with the following table <Table 1>.

• Cable diameter

More than 1.25 mm

Shielding wire CVVS or CPEVS

2

All facilities

E

INL

PGRRUTR

9

Page 10

9.1. Power supply wiring

• Power supply cords of appliances shall not be lighter than design 245 IEC or

227 IEC.

• A switch with at least 3 mm contact separation in each pole shall be provided

by the Air conditioner installation.

Power cable size: more than 1.5 mm

[Fig. 9.1.1] (P. 4)

A Switch 16 A

B Overcurrent protection 16 A

C Indoor unit

D Total operating current be less than 16 A

E Pull box

[Selecting non-fuse breaker (NF) or earth leakage breaker (NV)]

To select NF or NV instead of a combination of Class B fuse with switch, use the

following:

• In the case of Class B fuse rated 15 A or 20 A,

NF model name (MITSUBISHI): NF30-CS (15 A) (20 A)

NV model name (MITSUBISHI): NV30-CA (15 A) (20 A)

Use an earth leakage breaker with a sensitivity of less than 30 mA 0.1 s.

Caution:

GB

Do not use anything other than the correct capacity breaker and fuse. Using

fuse, wire or copper wire with too large capacity may cause a risk of malfunction or fire.

9.2. Connecting remote controller, indoor

D

2

and outdoor transmission cables

(Remote contoroller is optionally available.)

• Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-wire)

F

The “S” on indoor unit TB5 is a shielding wire connection. For specifications

about the connecting cables, refer to the outdoor unit installation manual.

• Install a remote controller following the manual supplied with the remote controller.

• Connect the “1” and “2” on indoor unit TB15 to a MA remote controller. (Non-

E

polarized 2-wire)

• Connect the “M1” and “M2” on indoor unit TB5 to a M-NET remote controller.

(Non-polarized 2-wire)

• Connect the remote controller’s transmission cab le within 10 m using a 0.75 mm

INL

core cable. If the distance is more than 10 m, use a 1.25 mm2 junction cable.

[Fig. 9.2.1] (P.4) MA Remote controller

[Fig. 9.2.2] (P.4) M-NET Remote controller

A Terminal block for indoor transmission cable

B Terminal block for outdoor transmission cable

C Remote controller

• DC 9 to 13 V between 1 and 2 (MA remote controller)

• DC 24 to 30 V between M1 and M2 (M-NET remote controller)

[Fig. 9.2.3] (P.4) MA Remote controller

PGRRUTR

[Fig. 9.2.4] (P.4) M-NET Remote controller

A Non-polarized B Upper level (TB15)

C Remote Controller D Lower level (TB5)

• The MA remote controller and the M-NET remote controller cannot be used at

the same time or interchangeably.

Note:

Ensure that the wiring is not pinched when fitting the terminal box cover.

Pinching the wiring may cut it.

Caution:

Install wiring so that it is not tight and under tension. Wiring under tension

may break, or overheat and burn.

• Fix power source wiring to control box b y using buff er bushing f or tensile force .

(PG connection or the like.) Connect transmission wiring to transmission terminal block through the knockout hole of control box using ordinary bushing.

• After wiring is complete, make sure again that there is no slack on the connections, and attach the cover onto the control box in the reverse order removal.

Caution:

Wire the power supply so that no tension is imparted. Otherwise disconnection, heating or fire result.

9.3. Connecting electrical connections

Verify that the model name on the operating instructions on the cover of the

control box is the same as the model name on the nameplate.

Step 1

Remove the screws holding the terminal box cover in place.

• Type 40 - 140 (2 screws) Fig.1

• Type 200 · 250 (4 screws) Fig.2

[Fig. 9.3.1] (P. 4)

Fig.1

Fig.2

A Screws B Terminal box cover

C Control box cover D Control box

Note:

Ensure that the wiring is not pinched when fitting the terminal box cover.

Pinching the wiring may cut it.

Caution:

Install wiring so that it is not tight and under tension. Wiring under tension

may break, or overheat and burn.

• Fix power source wiring to control box by using buffer bushing for tensile

force. (PG connection or the like.) Connect transmission wiring to transmission terminal block through the knockout hole of control box using ordinary

bushing.

• After wiring is complete, make sure again that there is no slack on the connections, and attach the cover onto the control box in the reverse order removal.

[Fig. 9.3.2] (P. 4)

A To prevent external tensile force from applying to the wiring connection section

of power source terminal block use buffer bushing like PG connection or the

like.

B Power source wiring C Tensile force

D Use ordinary bushing E Transmission wiring

Caution:

Wire the power supply so that no tension is imparted. Otherwise disconnection, heating or fire result.

9.4. Selecting the static pressure

Type 40 - 140

2

The external static pressure can be changed over as required. For the selection

of the static pressure, insert an attachment between the connector of the motor

lead wire and the control box.

The relationship between the attachment and the external static pressure is shown

below.

Attachment (Red) ....... External static pressure 200 Pa

Attachment (Blue) ...... External static pressure 50 Pa

Type 200 · 250

The external static pressure can be changed over as required.

For the selection of static pressure, replace the connector of the motor lead wire

by the connector (blue) inside the control box for insertion.

9.5. Setting addresses

(Be sure to operate with the main power turned OFF.)

[Fig. 9.5.1] (P. 4)

<Address board>

• There are two types of rotary switch setting available: setting addresses 1 to

9 and over 10, and setting branch numbers.

1 How to set addresses

Example: If Address is “3”, remain SW12 (for 1 to 9) at “0”, and match

SW11 (for over 10) with “3”.

2 How to set branch numbers (Series R2 only)

Match the indoor unit’s refrigerant pipe with the BC controller’s end connection number. Remain other than R2 at “0”.

• The rotary switches are all set to “0” when shipped from the factory. These

switches can be used to set unit addresses and branch numbers at will.

• The determination of indoor unit addresses varies with the system at site. Set

them referring to technical data.

Notes:

Please set the switch SW5 according to the power supply voltage.

• Set SW5 to 240 V side when the power supply is 230 and 240 volts.

• When the power supply is 220 volts, set SW5 to 220 V side.

10

9.6. Sensing room temperature with the

built-in sensor in a remote controller

If you want to sense room temperature with the built-in sensor in a remote controller, set SW1-1 on the control board to “ON”.

Page 11

Содержание

1. Меры предосторожности ....................................................................... 60

1.1. Перед установкой прибора и выполнением

электроработ ......................................................................... 60

1.2. Меры предосторожности для приборов, в которых

используется хладагент R407C ........................................... 61

1.3. Перед выполнением установки ............................................ 61

1.4. Выполнение электроработ до установки

(перемещения) ....................................................................... 61

1.5. Перед началом пробной эксплуатации................................ 61

2. Материалы для прибора, устанавливаемого в помещении ................ 62

3. Выбор места для установки................................................................... 62

3.1. Установка и пространство для обслуживания прибора .... 62

3.2. Сочетание приборов, устанавливаемых внутри и

4. Закрепление навесных болтов .............................................................. 62

5. Установка прибора ................................................................................. 63

GB

1. Меры предосторожности

снаружи .................................................................................. 62

4.1. Закрепление навесных болтов ............................................ 62

5.1. Подвешивание корпуса прибора .......................................... 63

5.2. Проверка положения прибора и укрепление навесных

болтов ..................................................................................... 63

1.1. Перед установкой прибора и

D

F

E

INL

PGR

RUTR

выполнением электроработ

s До установки прибора убедитесь, что Вы прочли все

“Меры предосторожности”.

s “Меры предосторожности” содержат важные указания

по технике безопасности. Убедитесь, что Вы им следуете.

Символика, используемая в тексте

Предупреждение:

Описывает меры предосторожности, необходимые для предотвращения

получения травмы или гибели пользователя.

Осторожно:

Описывает меры предосторожности, необходимые для предотвращения

повреждения прибора.

Символика, используемая в иллюстрациях

: Указывает действие, которое следует избегать.

: Указывает на важную инструкцию.

: Указывает, что данная часть должна быть заземлена.

: Указывает на необходимость проявлять осторожность по отношению

к вращающимся частям. (Этот символ указан на этикетке основного

прибора.) <Цвет: желтый>

: Опасайтесь электрошока (Этот символ указан на этикетке основного

прибора.) <Цвет: желтый>

Предупреждение:

Внимательно прочтите текст на этикетках главного прибора.

Предупреждение:

• Обратитесь к дилеру или квалифицированному технику для

выполнения установки кондиционера воздуха.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• Установите прибор на такой конструкции, которая выдержит его вес.

- Недостаточно прочное основание может вызвать падение прибора и

привести к т равме.

• Используйте указанные кабели для электропроводки. Выполняйте

соединения с соблюдением требований безопасности, чтобы кабели

не приводили к повреждению клемм.

- Недостаточно надежные соединения могут вызвать перегрев и стать

причиной пожара.

• Подготовьтесь к возможным сильным ураганам и ветрам,

землетрясениям: установите прибор в соответствующем месте.

- Неправильная установка может вызвать падение прибора и причинить

травму.

• Всегда используйте освежители воздуха, увлажнители,

электрообогреватели и другие средства, рекомендуемые Митцубиси

Электрик.

60

6. Техничиеские условия трубы хладагента и дренажной трубы ........... 63

6.1. Техничиеские условия трубы хладагента и дренажной

трубы ...................................................................................... 63

6.2. Труба хладагента, дренажная труба и

заливочный канал ................................................................. 63

6.3. Просьба о подсоединении труб хладагента ........................ 63

7. Соединение труб хладагента и дренажных труб ................................. 64

7.1. Прокладка труб хладагента ................................................. 64

7.2. Прокладка дренажных труб ................................................. 64

8. Вентиляционный канал .......................................................................... 64

9. Электрическая проводка ....................................................................... 65

9.1. Проводка подачи электропитания ...................................... 65

9.2. Подсоединение пульта дистанционного управления,

кабелей передачи внутри и снаружи .................................. 65

9.3. Выполнение электросоединений ......................................... 66

9.4. Выбор статического давления ............................................. 66

9.5. Установка адресов ............................................................... 66

9.6. Определение температуры в помещении встроенным

датчиком пульта дистанционного управления ................... 66

- Обратитесь к услугам квалифицированногоу техника для установки

дополнительных приспоосблений. Неправильная установка,

выполненная пользователем, может вызвать утечку воды, электрошок

или пожар.

• Никогда не ремонтируйте прибор самостоятельно. Если требуется

ремонт кондиционера воздуха, обратитесь к дилеру.

- Если прибор неправильно отремонтирован, это может вызвать утечку

воды, электрошок или пожар.

• Не прикасайтесь к лопастям теплообменника.

- Неправильное обращение с прибором может привести к травме.

• При утечке газа охлаждения во время установки проветрите

помещение.

- При контакте газа охлаждения с огнем будут выделяться ядовитые

газы.

• Устанавливайте кондиционер согласно инструкциям, приведенным

в данном Руководстве по установке.

- Неправильная установка может вызвать утечку воды, электрошок или

пожар.

• Все электроработы должны выполняться квалифицированным

лицензированным электриком согласно Электротехническим

Станадартам и Нормам проведения внутренней проводки и

инструкциям, приведенным в данном руководстве; всегда

используйте отдельную схему.

- При недостаточной мощности источника питания или неправильном

выполнении электроработ может возникнуть электрошок или пожар.

• Надежно установите крышку (панель) коробки терминала выводов

наружного прибора.

- Если крышка (панель) коробки терминала выводов не установлена

надлежащим образом, то в наружный прибор может попасть пыль или

вода, что, в свою очередь, может привести к пожару или электрошоку.

• При установке и перемещении кондиционера на другой объект не

заряжайте его другим хладагентом, кроме хладагента (R407С или

R22), указанного на приборе.

- При смешении другого хладагента или воздуха с первоначальным

хладагентом может произойти сбой цикла охлаждения и прибор может

быть поврежден.

• Если кондиционер установлен в небольшом помещении, необходимо

принять меры для предотвращения концентрации хладагента свыше

безопасных пределов в случае утечки хладагента.

- Проконсультируйтесь с дилером относительно соответствующих мер

по предотвращению превышения допустимой концетрации. В случае

утечки хладагента и превышения допустимых лимитов концентрации

может возникнуть опасносная ситуация в связи с недостатком

кислорода в помещении.

• При перемещении и повторной установке кондиционера

проконсультируйтесь с дилером или квалифицированным

техником.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• По завершении установки убедитесь в отсутствии утечки газа

охлаждения.

- При утечке газа охлаждения и попадании его под воздействие

обогревателя, печи, духовки или другого источника тепла могут

образоваться ядовитые газы.

• Не переделывайте и не изменяйте предохранительных установок

на защитных устройствах.

- При коротком замыкании и насильственном включении выключателей

давления, термовыключателей или других элементов, кроме тех,

которые указаны Митцубиси Электрик, может возникнуть пожар или

взрыв.

Page 12

• Если Вы хотите избавиться от этого изделия, проконсультируйтесь

с Вашим дилером.

1.2. Меры предосторожности для

приборов, в которых используется

хладагент R407C

Осторожно:

• Не используйте имеющиеся трубы хладагента.

- Использование старых труб хладагента и старого масла охлажднения,

содержащих большие количества хлорина, может привести к порче

масла охлаждения нового прибора.

• Используйте трубы хладагента, изготовленные из раскисленной

фосфором меди типа С1220 (CU-DHP), как указано в JIS H3300

“Бесшовные трубы из меди и медных сплавов”. Кроме этого

убедитесь, что внутренняя и внешняя поверхность труб чистая, без

частиц серы, окисей, пыли/грязи, частиц стружки, масел, влаги или

других загрязнений.

- Загрязнение внутренней поверхности труб хладагента может вызвать

ухудшение остаточного масла охлаждения.

• Храните предназначенные для установки трубы в помещении,

герметически закрытыми с обоих концов до припайки. (Углы и

другие соединнеия храните в пластмассовом пакете.)

- Попадание в цикл охлаждения пыли, грязи или воды, может ухудшить

масло и вызвать проблемы с компрессором.

• Используйте в качестве масла охлаждения масло сложного или

простого эфира или алкинбензол (небольшое количество) для

покрытия раструбов и фланцевых соединений.

- Масло охлаждения испортится при смешивании с большим количеством

минерального масла.

• Используйте для заполнения системы жидкий хладагент.

- При использовании газового хладагента для герметизации системы,

состав хладагента в баллоне изменится, а рабочие показатели прибора

могут ухудшиться.

• Не используйте другие хладагенты, кроме хладагента R407С

- При использовании другого агента (например, R22), наличие в нем

хлорина может вызвать сбой цикла охлаждения и привести к ухудшению

масла охлаждения.

• Используйте вакуумный насос с контрольным клапаном обратного

хода.

- Масло вакуумного насоса может проникнуть обратно в цикл охлаждения

и привести к ухудшению масла охлаждения.

• Не используйте указанные ниже инструменты с обычным

хладагентом.

(Манифольд, зарядный шланг, детектор обнаружения утечки газа,

конт рольный клапан, основу заряда хладагентом, вакуумный

датчик, оборудование для сбора хладагента).

- Смешивание обычного хладагента и масла охлаждения с R407С может

вызвать ухудшение масла охлаждения.

- Смешивание воды с R407С может вызвать ухудшение масла

охлаждения.

- Хладагент R407С не содержит хлорина. Поэтому детекторы утечек газа,

предназначенные для обычных хладагентов, не обнаруживают его.

• Не используйте зарядный баллон.

- Использовние зарядного баллона может вызвать ухудшение хладагента.

• Обращайтесь с инструментами особенно внимательно.

- Попадание в цикл охлаждения пыли, грязи или воды может вызвать

ухудшение масла охлаждения.

1.3. Перед выполнением установки

Осторожно:

• Не устанавливайте прибор там, где возможна утечка горючего газа.

- При утечке газа и его скоплении около прибора может произойти взрыв.

• Не используйте кондиционер воздуха в местах содержания

продуктов, домашних животных, растений, точных приборов или

предметов искусства.

- Качество продуктов и т.д. может ухудшиться.

• Не используйте кондиционер воздуха в особых условиях.

- Наличие масел, пара, сульфурных испарений и т.д. может вызвать

значительное ухудшение рабочих показателей кондиционера или

повредить его элементы.

• При установке прибора в больнице, на станции связи или в

аналогичном помещении обеспечьте достаточную защиту от шума.

- Преобразовательное оборудование, частный электрогенератор,

высоковольтное медицинское оборудование или оборудование для

радиосвязи могут вызвать сбой в работе кондиционера или его

отключение. С другой стороны, кондиционер может мешать работе

такого оборудования создаваемым шумом, который нарушает ход

медицинских процедур или радиовещания.

• Не устанавливайте прибор на конструкции, которая может стать

причиной утечки.

- При влажности в помещении свыше 80 % или при засорении дренажной

трубы, с внутреннего прибора может капать конденсирующаяся влага.

Выполняйте дренаж одновременно внутреннего прибора и наружного

прибора, когда это требуется.

• Внутренние модели следует устанавливать на потолке на высоте

не менее 2,5 м.

1.4. Выполнение электроработ до

установки (перемещения)

Осторожно:

• Заземлите прибор.

- Не подсоединяйте провод заземления к газовой трубе, водяной трубе,

громоотводу или линии заземления телефонной проводки. При

неправильном заземлении может возникнуть электрошок.

• Проложите сетевой кабель так, чтобы он не был натянут.

- Натяжение может привести к разрыву кабеля и стать источником

перегрева и пожара.

• Установите прерыватель цепи, если требуется.

- Если прерываетль цепи не установлен, это может приветси к

электрошоку.

• Используйте сетевой кабель достаточной мощности напряжения.

- Кабели слишком малой мощности могут прогореть, вызвать перегрев

и пожар.

• Используйте прерыватель цепи и предохранитель указанной

мощности.

- Предохранитель или прерыватель большей мощности или стальной или

медный провод могут вызвать поломку прибора или пожар.

• Не мойте детали кондиционера.

- Мытье деталей кондиционера может вызвать электрошок.

• Проявляйте осторожность, следите, чтобы установочное основание

не было повреждено после длительного использования.

- При неустранении повреждения основания прибор может упасть и

причинить травму или повреждение имущества.

• Проложите дренажные трубы в соответствии с инструкциями в

данном Руководстве по установке для обеспечения надлежащего

дренирования. Оберните трубы термоизоляционным материалом

для предотвращения конденсации.

- Неправильная прокладка дренажных труб может вызвать утечку воды

и повредить мебель и другое имущество.

• Будьте очень внимательным при транспортировке прибора.

- Нельзя, чтобы перемещение прибора выполнял один человек, если вес

прибора превышает 20 кг.

- Для упаковки некоторых изделий используются пластиковые ленты.

Не применяйте их для транспортировки, это опасно.

- Не трогайте лопасти теплообменника голыми руками. Вы можете

порезаться.

- При перемещении наружного прибора подвешивайте его в указанных

точках основания прибора. Также поддерживайте его в четырех точках,

чтобы он не соскользнул.

• Утилизируйте упаковочные материалы с соблюдением правил

безопасности.

- Такие упаковочные материалы, как гвозди и другие металлические или

деревянные части, могут причинить порез и другую травму.

- Удалите пластиковый упаковочный пакет и устраните его так, чтобы

он был недоступен детям. Дети могут задохнуться и умереть, если будут

играть с пластиковым упаковочным пакетом.

1.5. Перед началом пробной

эксплуатации

Осторожно:

• Подключите электропитание прибора не менее чем за 12 часов до

начала работы.

- Запуск прибора сразу после подключения сетевого питания может

серьезно повредить внутренние части прибора. Сетевой выключатель

должен оставаться во включенном положении в течение всего периода

эксплуатации прибора.

• Не прикасайтесь к выключателям мокрыми руками.

- Прикосновение к выключателю мокрыми руками может вызвать

электрошок.

• Не прикасайтесь к трубам хладагента во время работы и сразу после

выключения прибора.

- В течение и сразу после эксплуатации прибора трубы хладагента могут

быть горячими или холодными, в зависимости от условий протекающего

в трубах, компрессоре и других элементах цикла охлаждения

хладагента. Вы можете обжечь или обморозить руки при прикосновении

к трубам хладагента.

• Не используйте кондиционер воздуха, если его панели и крышки

сняты.

- Вращающиеся, горячие части или части под напряжением могут

причинить травму.

• Не отключайте питание немедленно после выключения прибора.

- Всегда подождите не менее пяти минут до отключения питания. Иначе

может возникнуть утечка воды и другие проблемы.

GB

D

F

E

INL

PGR

RUTR

61

Page 13

2. Материалы для прибора, устанавливаемого в помещении

Прибор поставляется вместе со следующими материалами:

Тип 40 - 140 Тип 200 · 250

o

N

1 Изоляционная труба (малая) 1

2 Изоляционный чехол 1

3 Стяжная лента (малая) 1

4 Стяжная лента (большая) 6

5 Дренажный шланг 1

6 Шайба 8

7 Изоляционная труба (большая) 1

8 Шланговая лента 1

9 Соединитель для приставки 2

Аксессуары Количество

o

N

1 Изоляционная труба (малая) 1

2 Изоляционная труба (средние) 1

3 Стяжная лента (малая) 1

4 Стяжная лента (большая) 6

5 Дренажный шланг 1

6 Шайба 8

7 Изоляционная труба (большая) 1

8 Шланговая лента 1

Аксессуары Количество

3. Выбор места для установки

• Выберите место, где воздух будет выдуваться во все углы помещения.

• Избегайте мест, открытых для воздуха с улицы.

• Выберите место, свободное от препятствий на пути воздушного потока

на входе и на выходе из прибора.

GB

• Избегайте мест, подверженных воздействию пара или масляных

испарений.

• Избегайте мест, где возможна утечка горючих газов, их оседание или

генерирование.

D

• Избегайте установки прибора рядом с агрегатами, испускающими

высокочастотное излучение (высокочастотные сварочные установки и

т.д.)

• Избегайте мест, где поток воздуха будет направлен на датчик пожарной

сигнализации. (Горячий воздух может привести в действие сигнализацию

F

при работе в режиме обогрева.)

• Избегайте мест, где часто идет работа с кислотными растворами.

• Избегайте мест, где часто используются серные или иные распылители.

Предупреждение:

E

Устанавливайте внутренний прибор на потолок, обладающий

достаточной прочностью, чтобы выдержать его вес.

Если прочность потолка недостаточна, это может привести к падению

прибора, что, в свою очередь может привести к травме.

INL

3.1. Установка и пространство для

обслуживания прибора

Трубы хладагента, дренажные трубы, электропроводка и иные компоненты

должны устанавливаться вне зон, помеченных

смотровых дверок с тем, чтобы они не препятствовали работам по

техоблуживанию вентилятора.

[Fig. 3.1.1] (P. 2)

Тип 40 - 140

PGR

Тип 200 · 250

A Дверца для снятия вентилятора и мотора

B Размер вентиляционного канала

, а также вдали от

Примечание:

Обязательно устанавливайте смотровые дверцы в указанных позициях

для проведения работ по техобслуживанию.

Ти п A B C D

PEFY-P40·50·63VMH-A 680 754 550 600

PEFY-P71·80VMH-A 930 1004 800 850

PEFY-P100·125·140VMH-A 1130 1204 1000 1050

PEFY-P200·250VMH-A 1250 1326 1100 1100

Предупреждение:

Устанавливайте данный прибор на потолок, обладающий достаточной

прочностью, чтобы выдержать его вес.

• Если прибор установлен на сооружение недостаточной прочности,

возможно падение прибора и нанесение травмы.

[Fig. 3.1.2] (P. 2)

Тип 40 - 140

Тип 200 · 250

B Размер вентиляционного канала C Коробка с электрокомпонентами

D Воздухозаборник E Верх прибора

F Смотровая дверца G Пространство для обслуживания

H Выход воздуха I Расстояние для подвесного болта

J Потолок K минимум 100

L минимум 20

3.2. Сочетание приборов,

устанавливаемых внутри и снаружи

Сочетание приборов, устанавливаемых внутри и снаружи, описано в

руководстве по установке наружных приборов.

4. Закрепление навесных болтов

4.1. Закрепление навесных болтов

(Используйте навесные болты М10. Болты приобретаются на месте.)

(Убедитесь в конструктивной прочности места подвески.)

RUTR

Навесная конструкция

• Потолок: Потолочные перекрытия разные в разных зданиях. Для

получения детальной информации обратитесь в соответствующую

строительную фирму.

1 Потребуется укрепить потолочное перекрытие с помощью

дополнительных усиливающих элементов (рандбалки и т. д.), чтобы

потолок был ровным и не вибрировал.

2 Удалите усиливающие потолочные элементы.

3 Дополнительно усильте эти элементы и добавьте новые усиливающие

элементы для закрепления потолочного настила.

Для деревянных конструкций

• В качестве усиливающих элементов используйте анкерную балку (в

одноэтажных зданиях) или балку второго этажа (в двухэтажных зданиях).

62

• Для навешивания кондиционера используйте четырехкантный брус более

6см, если расстояние между балками менее 90 см; используйте

четырехкантный брус более 9 см, если расстояние между балками менее

180 см.

[Fig. 4.1.1] (P. 2)

A Подшивка потолка B Рандбалка

C Анкерная балка

D Четырехкантный брус для навешивания кондиционера

E Наклон

Для железобетонных конструкций

• Как показано на иллюстрации ниже, закрепите навесные болты или

используйте для закрепления навесных болтов четырехкантные брусья.

[Fig. 4.1.2] (P. 2)

F Вставка: 100 до 150 кг (1 шт.) (приобретается на месте)

G Навесной болт М10 (приобретается на месте)

H Укрепление

Масса изделия (кг)

Название модели 40 50 · 63 71 · 80 100 · 125 · 140 200 · 250

PEFY-P-VMH 44 45 50 70 100

Page 14

5. Установка прибора

5.1. Подвешивание корпуса прибора

ss

s Принесите прибор, предназначенный для установки в помещении,

ss

к месту установки в упакованном виде.

ss

s Чтобы подвесить прибор, предназначенный для установки в

ss

помещении, используйте подъемное оборудование, с помощью

которого следует поднять прибор и пропустить его через навесные

болты.

[Fig. 5.1.1] (P. 2)

A Корпус прибора

B Подъемное оборудование

[Fig. 5.1.2] (P. 2)

C Гайки (Приобретается на месте.)

D Шайбы

E Навесной болт M10 (Приобретается на месте.)

5.2. Проверка положения прибора и

укрепление навесных болтов

ss

s Чтобы убедиться в том6 что корпус прибора и навесные болты

ss

установлены в требуемое положение, используйте шаблон,

поставленный вместе с панелью.

Не забудьте проверить взаимосоответствие положений.

ss

s Используйте уровень, чтобы определить, что поверхность,

ss

обозначенная

навесных болтов были плотно завинчены при закреплении

навесных болтов.

ss

s Чтобы обеспечить дренаж, убедитесь в том, что прибор установлен

ss

ровно, используйте для этого уровень.

[Fig. 5.2.1] (P. 2)

A Низ внутреннего прибора

AA

A установлена ровно. Убедитесь, чтобы гайки

AA

Осторожно:

Обязательно убедитесь в том, что корпус прибора установлен ровно.

6. Техничиеские условия трубы хладагента и дренажной трубы

Обеспечьте достаточную защиту от конденсации и изоляцию трубы

хладагента и дренажной трубы, чтобы предотвратить образование влаги.

Если используются имеющиеся в массовой продаже трубы хладагента,

обязательно оберните изоляционный материал (имеющийся в широкой

продаже, обладающий устойчивостью к температуре свыше 100 °С и

толщиной, указанной в таблице ниже) вокруг труб с жидкостью и с газом.

Также обязательно оберните имеющимся в широкой продаже изоляционным

материалом (с удельным весом полиэтилена

0,03 и толщиной, указанной в таблице ниже) все трубы, проходящие в

помещении.

1 Толщину изоляционного материала выбирайте в соответствии с размером

труб.

Размер трубы Толщина изоляционного материала

от 6,4 мм до 25,4 мм Свыше 10 мм

от 28,6 мм до 38,1 мм Свыше 15 мм

2 Если прибор используется на самом верхнем этаже здания, в условиях

высокой температуры и влажности, необходимо использовать трубы

большего размера и изоляционный материал большей толщины по

сравнению с теми параметрами, которые указаны в таблице выше.

3 Если имеются технические условия заказчика, следуйте им.

6.1. Техничиеские условия трубы

хладагента и дренажной трубы

Тип 40 - 140 (мм)

Предмет

Трубы хладагента

(соединения развальцовкой)

Дренажная труба 32

Тип 200 · 250 (мм)

Предмет

Трубы хладагента

(соединения пайкой)

Дренажная труба 32

Модель

Труба жидкости

Труба газа ø12,7 ø15,88 ø19,05

Модель

Труба жидкости

Труба газа ø25,4 ø28,58

40 50 - 80 100 - 140

ø6,35 ø9,52

200 250

ø12,7

6.2. Труба хладагента, дренажная труба

и заливочный канал

[Fig. 6.2.1] (P. 3)

Тип 40 - 140

Тип 200 · 250

A Воздухозаборник B Трубы хладагента (жидкость)

C Трубы хладагента (газ) D Коробка управления

E Дренажный выход F Выход воздуха

6.3. Просьба о подсоединении труб

хладагента

Соединения труб хладагента

• После соединения труб хладагента, изолируйте соединения (соединения

развальцовкой) трубами термоизоляции, как показано ниже.

[Fig. 6.3.1] (P. 3)

Тип 40 - 140

A Трубы термоизоляции 1

B Осторожно:

Вытяните термоизоляцию труб хладагента на площадке, вставьте гайку с

фланцем для расширения конца раструбом и установите изоляцию в

исходное положение.

Следите за тем, чтобы на открытых медных трубах не образовалась

конденсация.

C Конец трубы жидкости хладагента

D Конец трубы газа хладагента

E Трубы хладагента, устанавливаемые на площадке

F Корпус прибора G Маркировка “GAS” (ГАЗ)

H Маркировка “OUTSIDE” (НАРУЖНАЯ СТОРОНА)

I Изоляция извальцовкой (входит в комплект) 2

J Маркировка “INSIDE” (ВНУТРЕННЯЯ СТОРОНА)

K Термоизоляция L Потянуть

M Гайка с фланцем N Установить в исходное положение

O Убедитесь в отсутствии зазора P Пластина на корпусе

Q Снаружи R Внутри

S Удалить ленту

T Трубы термоизоляции (малые) (входят в комплект) 1

U Затяжка (большая) (входит в комплект) 4

V Убедитесь в отсутствии здесь зазора. Расположите швом вверх.

[Fig. 6.3.2] (P. 3)

Тип 200 · 250

A Трубы термоизоляции 1

B Осторожно:

Вытяните термоизоляцию труб хладагента на площадке, пропаяйте трубы

и установите изоляцию в исходное положение.

Следите за тем, чтобы на открытых медных трубах не образовалась

конденсация.

C Трубы хладагента (жидкость) D Трубы хладагента (газ)

E Корпус прибора F Трубы термоизоляции 2

G Трубы хладагента, устанавливаемые на площадке