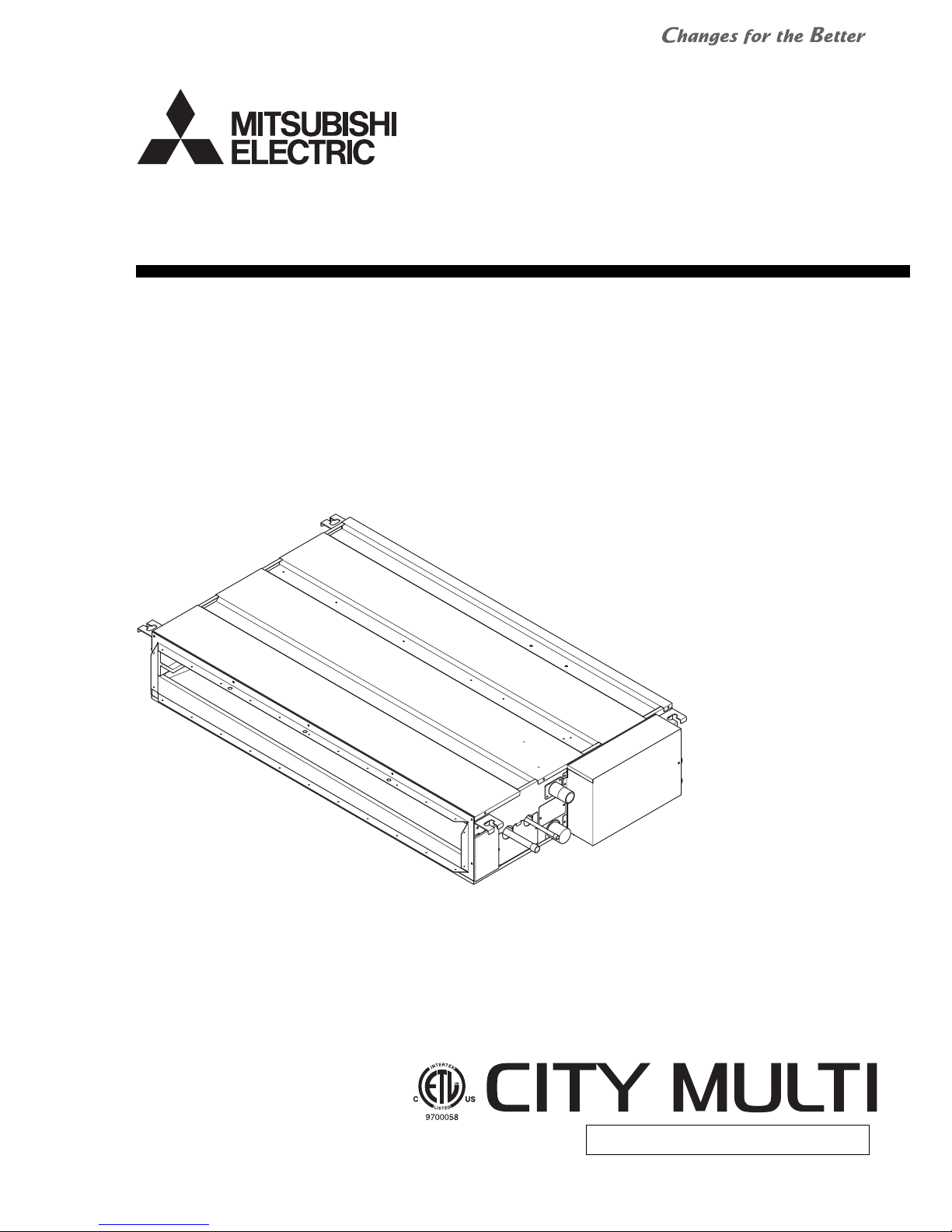

Mitsubishi PEFY-P08NMSU-E, PEFY-P18NMSU-E, PEFY-P06NMSU-E, PEFY-P12NMSU-E, PEFY-P15NMSU-E Technical & Service Manual

...Page 1

Air-Conditioners

TECHNICAL & SERVICE MANUAL

Models

PEFY-P06NMSU-E, PEFY-P08NMSU-E

PEFY-P12NMSU-E, PEFY-P15NMSU-E

PEFY-P18NMSU-E, PEFY-P24NMSU-E

For use with R410A & R22

2008

Page 2

ii

HWE08010 GB

Safety Precautions

Read before installation and performing electrical work

Symbol explanations

Thoroughly read the following safety precautions prior to installation.

Observe these safety precautions for your safety.

This equipment may have adverse effects on the equipment on the same power supply system.

Contact the local power authority before connecting to the system.

WARNING

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or death.

CAUTION

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or dam-

age to the unit.

Indicates an action that must be avoided.

Indicates important instructions.

Indicates a parts that requires grounding.

Indicates that caution must be taken with rotating parts. (This symbol is on the main unit label.) <Color: Yellow>

Indicates that the parts that are marked with this symbol pose a risk of electric shock. (This symbol is on the main

unit label.) <Color: Yellow>

WARNING

Carefully read the labels affixed to the main unit.

WARNING

Ask your dealer or a qualified technician to install the unit.

Improper installation by the user may result in water leakage, electric shock, or fire.

Properly install the unit on a surface that can withstand its

weight.

Unit installed on an unstable surface may fall and cause injury.

Only use specified cables. Securely connect each cable so

that the terminals do not carry the weight of the cable.

Improperly connected cables may produce heat and start a

fire.

Take appropriate safety measures against wind gusts and

earthquakes to prevent the unit from toppling over.

Improper installation may cause the unit to topple over and

cause injury or damage to the unit.

Only use accessories (i.e., air cleaners, humidifiers, electric

heaters) recommended by Mitsubishi Electric.

Do not make any modifications or alterations to the unit.

Consult your dealer for repair.

Improper repair may result in water leakage, electric shock,

or fire.

Do not touch the heat exchanger fins with bare hands.

The fins are sharp and pose a risk of cuts.

In the event of a refrigerant leak, thoroughly ventilate the

room.

If gaseous refrigerant leaks out and comes in contact with

an open flame, toxic gases will be generated.

Properly install the unit according to the instructions in the

Installation Manual.

Improper installation may result in water leakage, electric

shock, or fire.

Have all electrical work performed by an authorized electrician according to the local regulations and the instructions

in this manual. Use a dedicated circuit.

Insufficient power supply capacity or improper installation

of the unit may result in malfunctions of the unit, electric

shock, or fire.

Page 3

ii

HWE08010 GB

Precautions for handling units for use with R410A

WARNING

Keep electrical parts away from water.

Wet electrical parts pose a risk of electric shock, smoke, or

fire.

Securely attach the control box cover.

If the cover is not installed properly, dust or water may infiltrate and pose a risk of electric shock, smoke, or fire.

Only use the type of refrigerant that is indicated on the unit

when installing or relocating the unit.

Infiltration of any other types of refrigerant or air into the unit

may adversely affect the refrigerant cycle and may cause

the pipes to burst or explode.

When installing the unit in a small space, take appropriate

precautions to prevent leaked refrigerant from reaching the

limiting concentration.

Leaked refrigerant gas will displace oxygen and may cause

oxygen starvation. Consult your dealer before installing the

unit.

Consult your dealer or a qualified technician when moving

or reinstalling the unit.

Improper installation may result in water leakage, electric

shock, or fire.

After completing the service work, check for a refrigerant

leak.

If leaked refrigerant is exposed to a heat source, such as a

fan heater, stove, or electric grill, toxic gases will be generated.

Do not try to defeat the safety features of the unit.

Forced operation of the pressure switch or the temperature

switch by defeating the safety features for these devices, or

the use of accessories other than the ones that are recommended by Mitsubishi Electric may result in smoke, fire, or

explosion.

Consult your dealer for proper disposal method.

Do not use a leak detection additive.

CAUTION

Do not use the existing refrigerant piping.

A large amount of chlorine that may be contained in the residual refrigerant and refrigerator oil in the existing piping

may cause the refrigerator oil in the new unit to deteriorate.

Use refrigerant piping materials made of phosphorus deoxidized copper. Keep the inner and outer surfaces of the

pipes clean and free of such contaminants as sulfur, oxides,

dust, dirt, shaving particles, oil, and moisture.

Contaminants in the refrigerant piping may cause the refrigerator oil to deteriorate.

Store the piping materials indoors, and keep both ends of

the pipes sealed until immediately before brazing. (Keep elbows and other joints wrapped in plastic.)

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate or cause the

compressor to malfunction.

Use a small amount of ester oil, ether oil, or alkyl benzene

to coat flares and flanges.

Infiltration of a large amount of mineral oil may cause the refrigerator oil to deteriorate.

Charge the system with refrigerant in the liquid phase.

If gaseous refrigerant is drawn out of the cylinder first, the

composition of the remaining refrigerant in the cylinder will

change and become unsuitable for use.

Only use R410A.

The use of other types of refrigerant that contain chloride

may cause the refrigerator oil to deteriorate.

Use a vacuum pump with a check valve.

If a vacuum pump that is not equipped with a check valve is

used, the vacuum pump oil may flow into the refrigerant cycle and cause the refrigerator oil to deteriorate.

Prepare tools for exclusive use with R 410A. Do not use the

following tools if they have been used with the conventional

refrigerant: gauge manifold, charging hose, gas leak detector, check valve, refrigerant charge base, vacuum gauge,

and refrigerant recovery equipment.

If the refrigerant or the refrigerator oil that may be left on these

tools are mixed in with R410A, it may cause the refrigerator oil

in the new system to deteriorate.

Infiltration of water may cause the refrigerator oil to deteriorate.

Leak detectors for conventional refrigerants will not detect an

R410A leak because R410A is free of chlorine.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the refrigerant

in the cylinder will change and become unsuitable for use.

Exercise special care when handling tools for use with R410A.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate.

Page 4

iiiiii

HWE08010 GB

Precautions for PAC-YU25HT (Optional parts)

WARNING

Stop the operation if any malfunction occurs.

If malfunction occurs (burning smell, etc.) stop the operation and turn off the power supply. Contact your dealer or

technical representative. If the controller continues to operate after a malfunction occurs, this may cause damage,

electric shock or fire.

Do not turn on the main power until installation has been

completed.

Doing so may result in electric shock or fire.

Leave sufficient space between heater and indoor unit to allow for air movement to prevent the indoor unit from overheating.

If they are installed too closely and the indoor unit temperature exceeds 40°C, malfunctions or fire may result.

Keep the heater clean to keep the indoor unit from sucking

in accumulated dust on the heater.

Dust particles that enter the indoor unit may cause fire.

When air conditioner and heater are configured to perform

an interlocked operation, do not use any other type of cables except this external heater adapter (PAC-YU25HT).

The use of any other type of cables may result in malfunctions or fire.

Do not build a heater into the indoor unit.

Doing so may result in fire.

CAUTION

Do not install in any place exposed to flammable gas leakage.

Flammable gases accumulated around the body of PACYU25HT may cause an explosion.

Do not use in any special environment.

Using in any place exposed to oil (including machine oil),

steam and sulfuric gas may deteriorate the performance

significantly or give damage to the component parts.

Do not install in any place where acidic or alkaline solution

or special spray are often used.

Doing so may cause an electric shock or malfunction.

Do not install in any steamy place such a bathroom or kitchen.

Avoid any place where moisture is condensed into dew.Doing so may cause an electric shock or malfunction.

Do not wash with water.

Doing so may cause an electric shock or malfunction.

Do not install in any place at a temperature of more than

40°C (104°F) or less than 0°C (32°F) or exposed to direct

sunlight.

Page 5

iv

HWE08010 GB

Page 6

CONTENTS

HWE08010 GB

I

Features

[1] Features.................................................................................................................................... 1

II

Components and Functions

[1] Components and Functions...................................................................................................... 2

III

Specfications

[1] Specifications............................................................................................................................ 4

1.Specfications .......................................................................................................................... 4

2.Electrical component specifications........................................................................................ 6

IV

Outlines and Dimensions

[1] Outlines and Dimensions.......................................................................................................... 7

V

Wiring Diagram

[1] Wiring Diagram......................................................................................................................... 8

VI

Refrigerant System Diagram

[1] Refrigerant system diagram...................................................................................................... 9

VII

Microprocessor Control

[1] Microprocessor Control........................................................................................................... 10

1.Cool operation ...................................................................................................................... 10

2.Dry operation ........................................................................................................................ 11

3.Fan operation........................................................................................................................ 12

4.Heat operation ...................................................................................................................... 13

5.Auto operation [Automatic cool / heat change over operation] ............................................. 14

6.When unit is stopped control mode ...................................................................................... 15

7.Heater control ....................................................................................................................... 15

VIII

Troubleshooting

[1] Troubleshooting ...................................................................................................................... 19

1.Check methods..................................................................................................................... 19

2.DC fan motor (fan motor/indoor control board)..................................................................... 23

3.Address switch setting .......................................................................................................... 24

4.Voltage test points on the control board ............................................................................... 25

5.Dipswitch setting (Factory setting)........................................................................................ 26

IX

Disassembly Procedure

[1] Disassembly Procedure.......................................................................................................... 29

1.Control box ........................................................................................................................... 29

2.Thermistor (Intake air) .......................................................................................................... 30

3.Drainpan ............................................................................................................................... 31

4.Thermistor (Gas pipe) (Liquid pipe) ...................................................................................... 32

5.Fan and fan motor ................................................................................................................ 33

6.Bearing ................................................................................................................................. 34

7.Heat exchanger .................................................................................................................... 35

Page 7

HWE08010 GB

Page 8

[ I Features ]

- 1 -

HWE08010 GB

IFeat ures

[1] Features

Model Cooling capacity/Heating capacity

BTU/h kW

PEFY-P06NMSU-E 6000/6700 1.8/2.0

PEFY-P08NMSU-E 8000/9000 2.3/2.6

PEFY-P12NMSU-E 12000/13500 3.5/4.0

PEFY-P15NMSU-E 15000/17000 4.4/5.0

PEFY-P18NMSU-E 18000/20000 5.3/5.9

PEFY-P24NMSU-E 24000/27000 7.0/7.9

Page 9

[ II Components and Functions ]

- 2 -

HWE08010 GB

IIComponen ts and Functions

[1] Components and Functions

1. Indoor (Main) Unit

2. Remote Controller

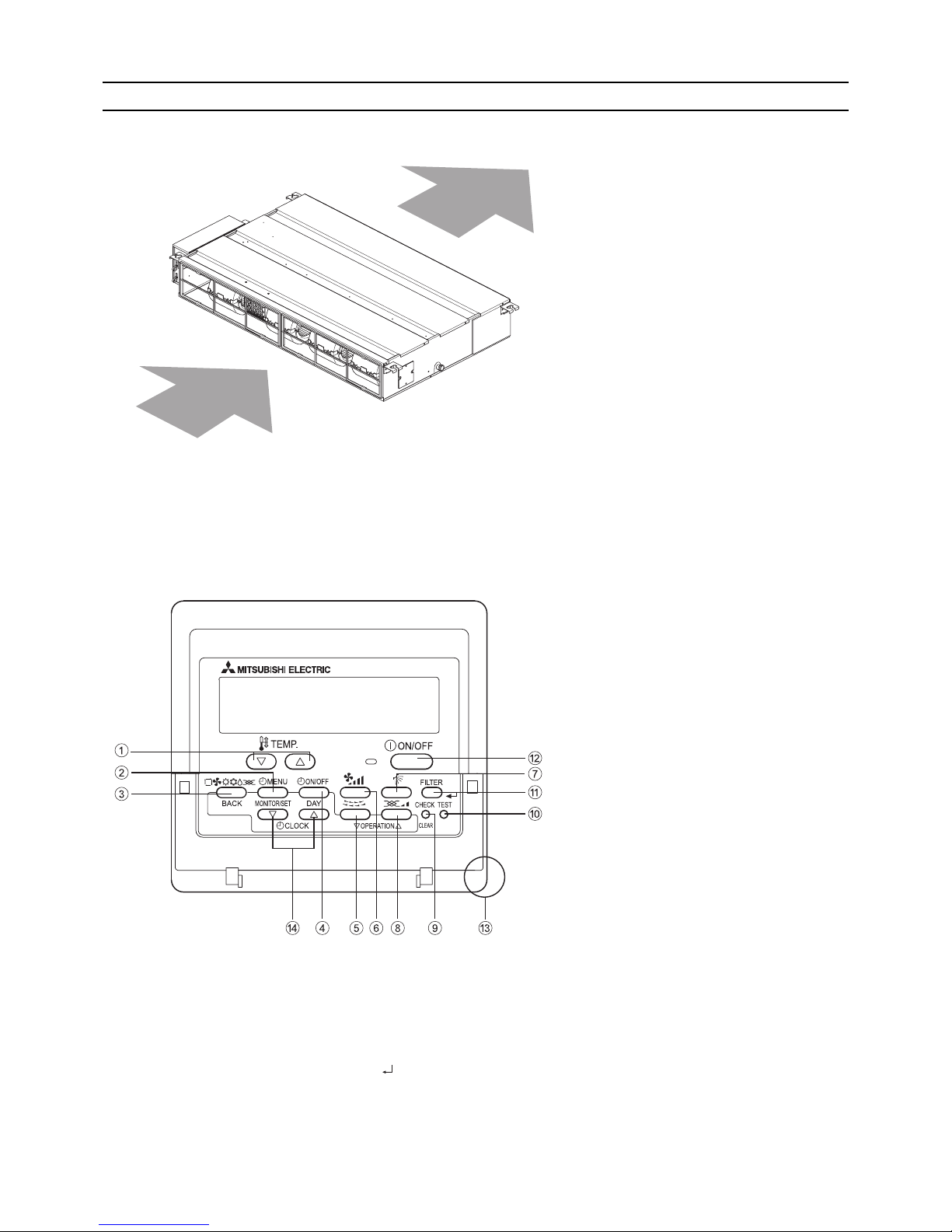

[PAR-21MAA]

Once the operation mode is selected, the unit will remain in the selected mode until changed.

(1) Remote Controller Buttons

Keep the remote controller out of direct sunlight to ensure accurate measurement of room temperature.

The thermistor at the lower right-hand section of the remote controller must be free from obstructions to ensure accurate mea-

surement of room temperature.

(A) Air

1 [Set Temperature] Button 7 [Vane Control] Button

2 [Timer Menu] Button 8 [Ventilation] Button

[Monitor/Set] Button [Operation] Button

3 [Mode] Button 9 [Check/Clear] Button

[Back] Button 10 [Test Run] Button

4 [Timer On/Off] Button 11 [Filter] Button

[Set Day] Button [ ] Button

5 [Louver] Button 12 [ON/OFF] Button

[Operation] Button 13 Position of built-in room thermistor

6 [Fan Speed] Button 14 [Set Time] Button

(A)

(A)

Page 10

[ II Components and Functions ]

- 3 -

HWE08010 GB

(2) Remote Controller Display

A Current time/Timer time I Louver swing

B Centralized control indicator J Ventilation

C Timer OFF indicator K Filter sign

D Timer mode L Sensor position

E Operation mode display: COOL, DRY, AUTO,

FAN, HEAT

M Room temperature

F Function Lock indicator N Vane setting

G Preset temperature O Fan speed

H Power indicator

Page 11

[ III Specfications ]

- 4 -

HWE08010 GB

III Specfications

[1] Specifications

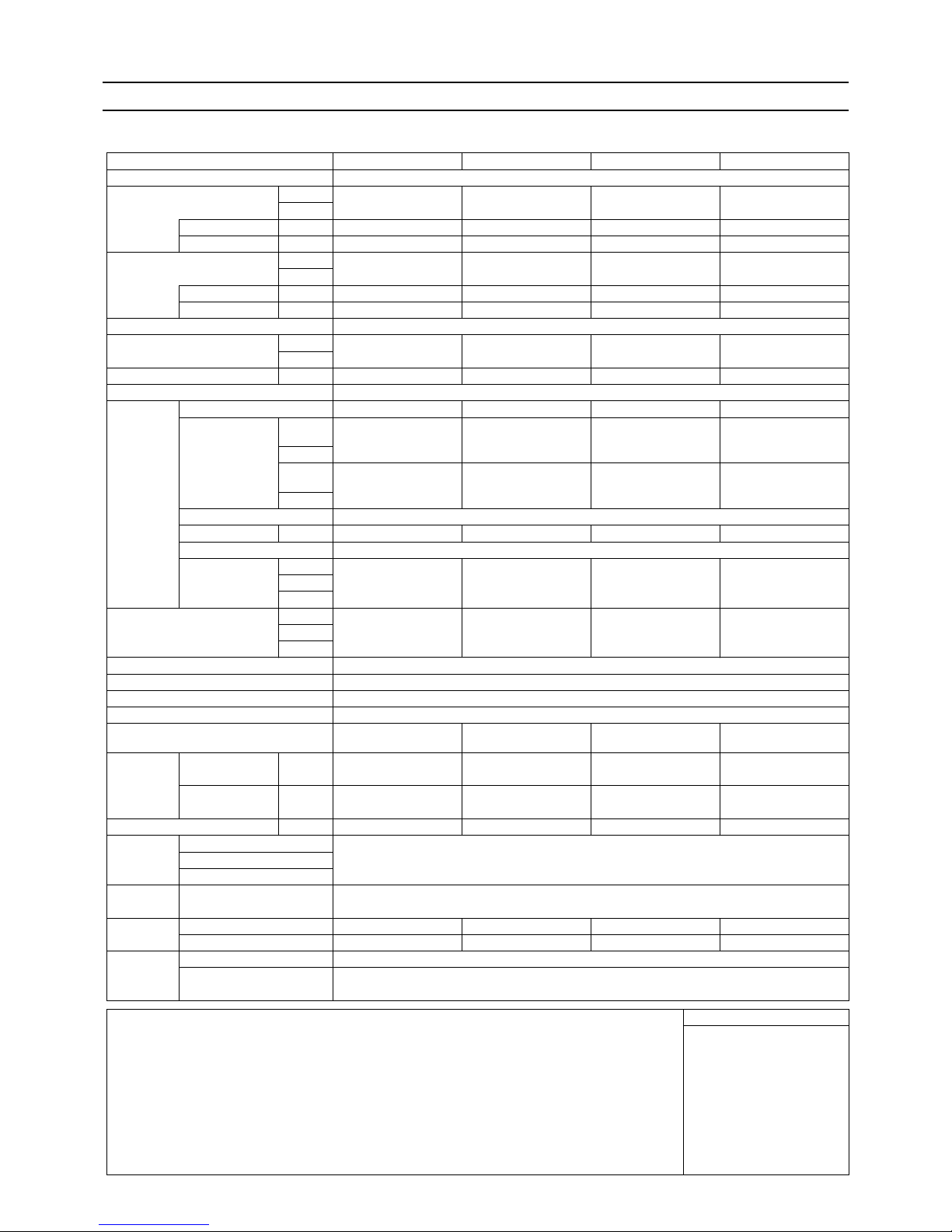

1. Specfications

Model PEFY-P06NMSU-E PEFY-P08NMSU-E PEFY-P12NMSU-E PEFY-P15NMSU-E

Power source 1-phase 208/230V 60Hz

Cooling capacity *1 BTU / h 6,000 8,000 12,000 15,000

(Nominal) *1 kW 1.8 2.3 3.5 4.4

Power input kW 0.05/0.05 0.06/0.06 0.07/0.07 0.07/0.07

Current input A 0.42/0.41 0.51/0.49 0.56/0.53 0.57/0.55

Heating capacity *2 BTU / h 6,700 9,000 13,500 17,000

(Nominal) *2 kW 2.0 2.6 4.0 5.0

Power input kW 0.03/0.03 0.04/0.04 0.05/0.05 0.05/0.05

Current input A 0.32/0.31 0.41/0.39 0.46/0.43 0.47/0.45

External finish Galvanized

External dimension H x W x D in. 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 39 x 27-9/16

mm 200 x 790 x 700 200 x 790 x 700 200 x 790 x 700 200 x 990 x 700

Net weight lbs (kg) 42(19) 42(19) 46(20) 54(24)

Heat exchanger Cross fin(Aluminium fin and copper tube)

FAN Type x Quantity Sirocco fan x 2 Sirocco fan x 2 Sirocco fan x 2 Sirocco fan x 3

External in.WG

0.02-0.06-0.14-0.20

(208V)

0.02-0.06-0.14-0.20

(208V)

0.02-0.06-0.14-0.20

(208V)

0.02-0.06-0.14-0.20

(208V)

static press Pa 5-15-35-50 5-15-35-50 5-15-35-50 5-15-35-50

in.WG

0.02-0.06-0.14-0.20

(230V)

0.02-0.06-0.14-

0.20(230V)

0.02-0.06-0.14-

0.20(230V)

0.02-0.06-0.14-

0.20(230V)

Pa 5-15-35-50 5-15-35-50 5-15-35-50 5-15-35-50

Motor type DC brushless motor

Motor output kW 0.096 0.096 0.096 0.096

Driving mechanism Direct-driven

Airflow rate cfm 176-212-247 194-247-317 211-282-370 282-335-388

(Low-Mid-High) m3 / min 5-6-7 5.5-7-9 6-8-10.5 8-9.5-11

L / s 83-100-117 91-116-150 100-133-175 133-158-183

Sound pressure level dB <A> 22-24-28 (208V) 23-26-30 (208V) 23-28-35 (208V) 28-30-33 (208V)

(Low-Mid-High) dB <A> 22-24-28 (230V) 23-26-30 (230V) 23-28-35 (230V) 28-30-33 (230V)

(measured in anechoic room) dB <A> - - - Insulation material Polystyrene foam,Polyethylene foam,Urethane foam

Air filter PP Honeycomb fabric (washable)

Protection device Fuse

Refrigerant control device LEV

Connectable outdoor unit *3

R410A,R22 CITY

MULTI

R410A,R22 CITY

MULTI

R410A,R22 CITY

MULTI

Diameter of Liquid (R410A)

in. (mm)

1/4 (6.35) Brazed 1/4 (6.35) Brazed 1/4 (6.35) Brazed 1/4 (6.35) Brazed

refrigerant (R22 ) 1/4 (6.35) Brazed 1/4 (6.35) Brazed 1/4 (6.35) Brazed 1/4 (6.35) Brazed

pipe Gas (R410A)

in. (mm)

1/2 (12.7) Brazed 1/2 (12.7) Brazed 1/2 (12.7) Brazed 1/2 (12.7) Brazed

(O.D.) (R22 ) 1/2 (12.7) Brazed 1/2 (12.7) Brazed 1/2 (12.7) Brazed 1/2 (12.7) Brazed

Diameter of drain pipe in. (mm) O.D. 1-1/4(32) O.D. 1-1/4(32) O.D. 1-1/4(32) O.D. 1-1/4(32)

Drawing External WKB94L522

Wiring WKB94L523

Refrigerant cycle Standard Document Installation Manual, Instruction Book

attachment Accessory Drain hose (flexible joint)

Optional External heater adaptor PAC-YU25HT PAC-YU25HT PAC-YU25HT PAC-YU25HT

parts

Remark

Installation Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other

items shall be referred to the Installation Manual.

Note : *1 Nominal cooling conditions *2 Nominal heating conditions Unit convertor

Indoor : 80degF D.B. / 67degF W.B. 70degF D.B. kcal/h = kW x 860

(26.7degC D.B. / 19.4degC W.B.) (21.1degC D.B.) BTU/h = kW x 3,412

Outdoor : 95degF D.B. 47degF D.B. / 43degF W.B. cfm = m3/min x 35.31

(35degC D.B.) (8.3degC D.B. / 6.1degC W.B.) lbs = kg / 0.4536

Pipe length : 25 ft. (7.6 m) 25 ft. (7.6 m)

Level difference : 0 ft. (0 m) 0 ft. (0 m) *Above specification data is

*3 PUHY-THMU,PURY-THMU,PUHY-YHMU,PURY-YHMU,PUMY-NHMU subject to rounding variation.

*The external static pressure is set to 15 Pa at factory shipment.

*Due to continuing improvement, above specification may be subject to change without notice.

Page 12

[ III Specfications ]

- 5 -

HWE08010 GB

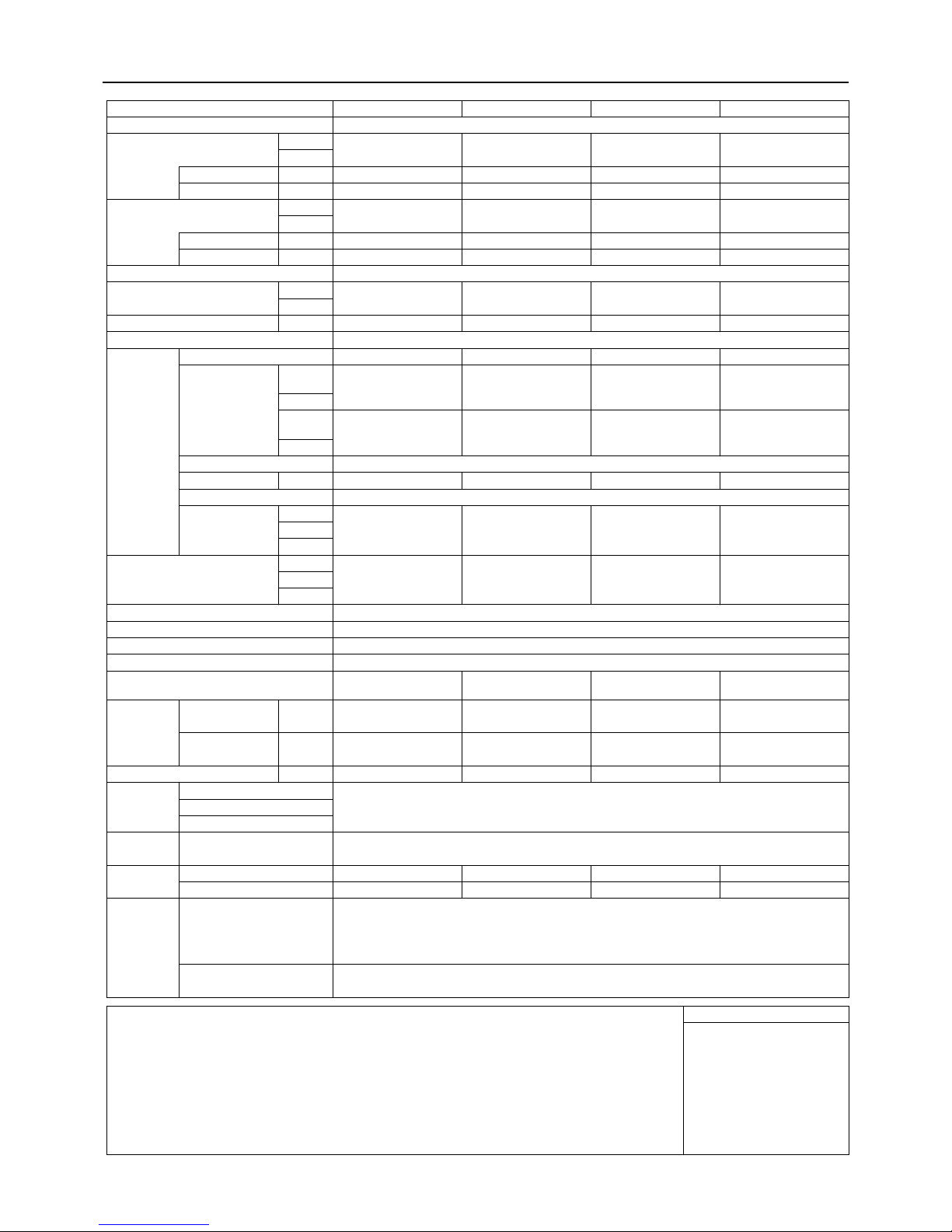

Model PEFY-P18NMSU-E PEFY-P24NMSU-E

Power source 1-phase 208/230V 60Hz

Cooling capacity *1 BTU / h 18,000 24,000

(Nominal) *1 kW 5.3 7.0

Power input kW 0.09/0.09 0.12/0.12

Current input A 0.74/0.70 0.98/0.93

Heating capacity *2 BTU / h 20,000 27,000

(Nominal) *2 kW 5.9 7.9

Power input kW 0.07/0.07 0.10/0.10

Current input A 0.64/0.60 0.88/0.83

External finish Galvanized

External dimension H x W x D in. 7-7/8 x 39 x 27-9/16 7-7/8 x 46-7/8 x 27-9/16

mm 200 x 990 x 700 200 x 1190 x 700

Net weight lbs (kg) 54(24) 62(28)

Heat exchanger Cross fin(Aluminium fin and copper tube)

FAN Type x Quantity Sirocco fan x 3 Sirocco fan x 4

External in.WG

0.02-0.06-0.14-0.20

(208V)

0.02-0.06-0.14-0.20

(208V)

static press Pa 5-15-35-50 5-15-35-50

in.WG

0.02-0.06-0.14-0.20

(230V)

0.02-0.06-0.14-

0.20(230V)

Pa 5-15-35-50 5-15-35-50

Motor type DC brushless motor

Motor output kW 0.096 0.096

Driving mechanism Direct-driven

Airflow rate cfm 353-441-529 423-565-706

(Low-Mid-High) m3 / min 10-12.5-15 12-16-20

L / s 167-208-250 200-267-333

Sound pressure level dB <A> 30-34-37 (208V) 30-35-40 (208V)

(Low-Mid-High) dB <A> 30-34-37 (230V) 30-35-40 (230V)

(measured in anechoic room) dB <A> - Insulation material Polystyrene foam,Polyethylene foam,Urethane foam

Air filter PP Honeycomb fabric (washable)

Protection device Fuse

Refrigerant control device LEV

Connectable outdoor unit

R410A,R22 CITY

MULTI

R410A,R22 CITY

MULTI

Diameter of Liquid (R410A)

in. (mm)

1/4 (6.35) Brazed 3/8 (9.52) Brazed

refrigerant (R22 ) 3/8 (9.52) Brazed 3/8 (9.52) Brazed

pipe Gas (R410A)

in. (mm)

1/2 (12.7) Brazed 5/8 (15.88) Brazed

(O.D.) (R22 ) 5/8 (15.88) Brazed 5/8 (15.88) Brazed

Diameter of drain pipe in. (mm) O.D. 1-1/4(32) O.D. 1-1/4(32)

Drawing External WKB94L522

Wiring WKB94L523

Refrigerant cycle Standard Document Installation Manual, Instruction Book

attachment Accessory Drain hose (flexible joint)

Optional External heater adaptor PAC-YU25HT PAC-YU25HT

parts

Remark

Installation Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other

items shall be referred to the Installation Manual.

Note : *1 Nominal cooling conditions *2 Nominal heating conditions Unit convertor

Indoor : 80degF D.B. / 67degF W.B. 70degF D.B. kcal/h = kW x 860

(26.7degC D.B. / 19.4degC W.B.) (21.1degC D.B.) BTU/h = kW x 3,412

Outdoor : 95degF D.B. 47degF D.B. / 43degF W.B. cfm = m3/min x 35.31

(35degC D.B.) (8.3degC D.B. / 6.1degC W.B.) lbs = kg / 0.4536

Pipe length : 25 ft. (7.6 m) 25 ft. (7.6 m)

Level difference : 0 ft. (0 m) 0 ft. (0 m) *Above specification data is

*The external static pressure is set to 15 Pa at factory shipment. subject to rounding variation.

*Due to continuing improvement, above specification may be subject to change without notice.

Page 13

[ III Specfications ]

- 6 -

HWE08010 GB

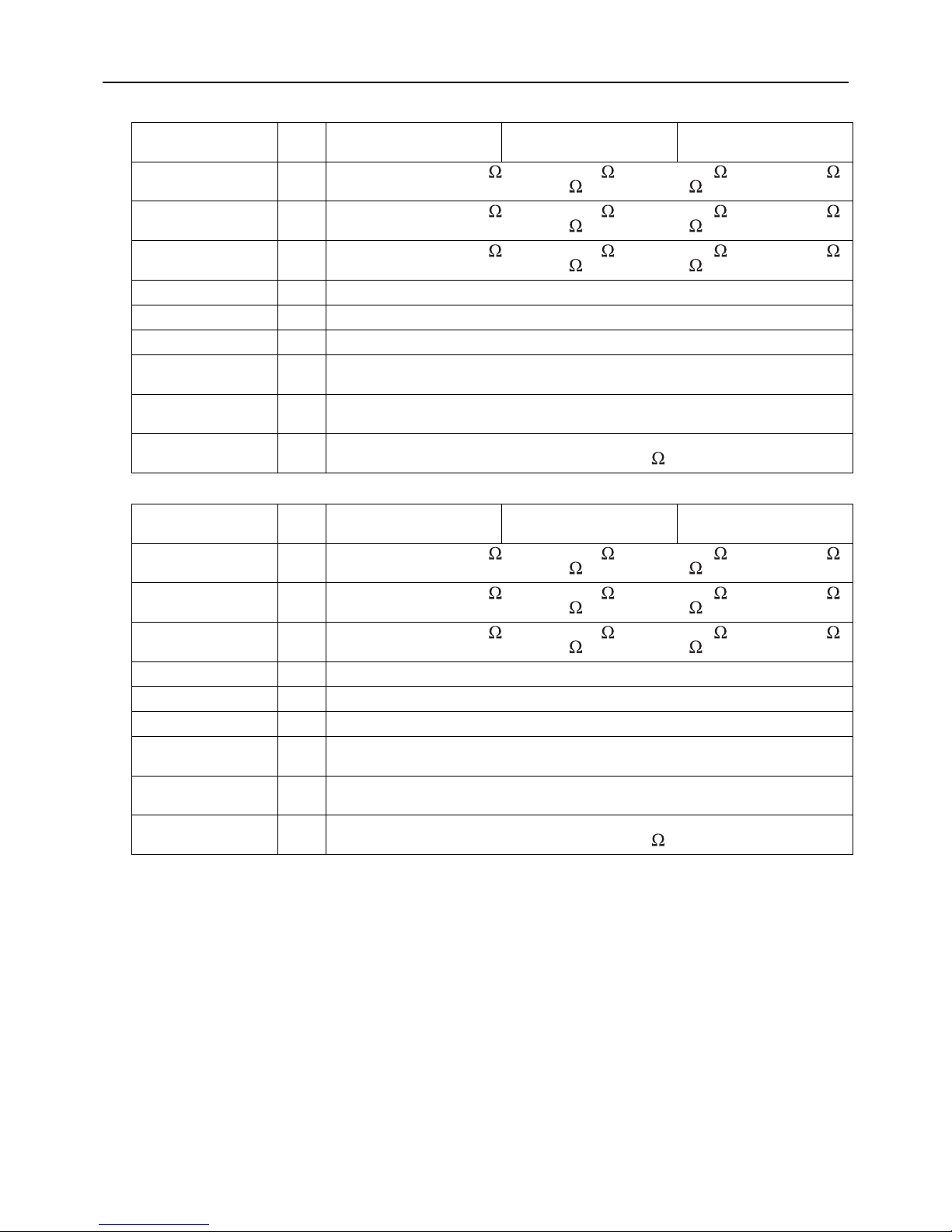

2. Electrical component specifications

Component Sym-

bol

PEFY-P06NMSU-E PEFY-P08NMSU-E PEFY-P12NMSU-E

Room temperature

thermistor

TH21 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Liquid pipe thermistor TH22 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Gas pipe thermistor TH23 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Fuse FUSE 250V 6.3A

Fan motor 8-pole, Output 96W SIC-70CW-D8114-1

Linear expansion valve LEV 12VDC Stepping motor drive port diameter ø3.2 (0~2000 pulse)

Power supply terminal

block

TB2

(L1, L2, G) 330V 30A

Transmission terminal

block

TB5

TB15

(1, 2), (M1, M2, S) 250V 20A

Drain float switch DS Open/short detection

Initial contact resistance 500 m or less

Component Sym-

bol

PEFY-P15NMSU-E PEFY-P18NMSU-E PEFY-P24NMSU-E

Room temperature

thermistor

TH21 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Liquid pipe thermistor TH22 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Gas pipe thermistor TH23 Resistance 0°C[32°F]/15k , 10°C[50°F]/9.6k , 20°C[68°F]/6.3k , 25°C[77°F]/5.4k ,

30°C[86°F]/4.3k , 40°C[104°F]/3.0k

Fuse FUSE 250V 6.3A

Fan motor 8-pole, Output 96W SIC-70CW-D896-2

Linear expansion valve LEV 12VDC Stepping motor drive port diameter ø3.2 (0~2000 pulse)

Power supply terminal

block

TB2

(L1, L2, G) 330V 30A

Transmission terminal

block

TB5

TB15

(1, 2), (M1, M2, S) 250V 20A

Drain float switch DS Open/short detection

Initial contact resistance 500 m or less

Page 14

[ IV Outlines and Dimensions ]

- 7 -

HWE08010 GB

IV Outlines and Dimensions

[1] Outlines and Dimensions

1. PEFY-P06,08,12,15,18,24NMSU-E

mm(in.)

(35-7/16)

(27-9/16)

(19-11/16)

(41-3/4)

(33-7/8)

(26)

(47-1/4)

(39-3/8)

(31-1/2)

(39-3/8)

(31-1/2)

(23-5/8)

(41-3/4)

(33-7/8)

(26)

(47-3/16)

(39-5/16)

(31-7/16)

(45-3/8)

(37-1/2)

(29-5/8)

(43-5/16)

(35-7/16)

(27-9/16)

700

Drain pipe(O.D.ø32(1-1/4))

(Emergency draining)

*2

*1

ø6.35(1/4)ø12.7(1/2)

PEFY-P18NMSU-E

900 952 998

860

9

800 1000 860

7

700

20

24

16

L

900

500

(48-25/32)

(40-29/32)

(33-1/16)

1039

1239

839

(46-7/8)

(39)

(31-1/8)

990

1190

790

KMN

9

5

J

1060

660

H

800600

7

660798752

Knockout hole ø27(1-3/32)

(Transmission wiring)

Knockout hole ø27(1-3/32)

(Power source wiring)

G

1200

F

1000

E

11

D

1060

C

1100

B

1152

PEFY-P06,08,12NMSU-E

PEFY-P15NMSU-E

PEFY-P24NMSU-E

Model A

1198

Gas pipe Liquid pipe

*1

*2

ø12.7(1/2)

ø15.88(5/8)

ø6.35(1/4)

ø9.52(3/8)

ø9.52(3/8)

ø15.88(5/8)

L-ø2.9(1/8)

2x2-ø2.9(1/8)

2xE-ø2.9(1/8)

Control box

Air filter

Suspension bolt hole

4-14x30(9/16x1-3/16) Slot

Terminal bed(Power source)

Refrigerant piping

brazing connection (liquid)

2

Refrigerant piping

brazing connection (gas)

1

Drain pipe(O.D.ø32(1-1/4))

(Spontaneous draining)

Terminal bed(Transmission)

Drain pump

Drain pipe(O.D.ø32(1-1/4))

Air

inlet

Air

outlet

(1-31/32~5-29/32)

159(6-9/32)

345 (13-19/32)

(21-21/32)

(11-13/16)

(30-19/32)

(17-23/32)

(11-13/16)

(17-23/32)

More than 300

(13/16)

(13/32)

(3-9/16)

(5-29/32)

(2-25/32)(4-19/32)

70

10(13/32)

(3-15/16)

(1-15/16) (24-5/8)

450

37(1-15/32)

200(7-7/8)

H20 (13/16)

157.5 (6-7/32)20 (13/16)

100(3-15/16)

37(1-15/32)

12 (1/2)

12 (1/2)

88(3-15/32)

100(3-15/16)xJ=K

100(3-15/16)

88 (3-15/32)

777

50(1-31/32)

50~150

50(1-31/32)

G

450

Less than 550

Less than 300

175

±5(6-29/32±7/32)

10 (13/32)

49

25(1)

More than 20

More than 10

170 (6-23/32)

102 (4-1/32)

48(1-29/32)

270 (10-21/32)

116

150(Duct)

23 (29/32)

100 25 (1)

700 (27-9/16)

677 (26-21/32)23(29/32)

C

M

B (Suspension bolt pitch)23 (29/32)

A

N

90

625 (Suspension bolt pitch)

100(3-15/16)

57(2-1/4)

D (Duct)

30 (1-3/16) 100(3-15/16)x(E-1)=F

100(3-15/16)

20 (13/16)

15 (19/32)

<accessory>

Drain hose (I.D.ø32(1-1/4))

(Actual length)

Note2

Access door

Required space for service and maintenance

Access door

Ceiling surface

Make the access door at the appointed

position properly for service maintenance.

Note 1. Use M10 screw for the Suspension bolt (field supply).

2. Keep the service space for the maintenance at the bottom.

3. This chart indicates for PEFY-P15·18NMSU-E models,which

has 3 fans.

PEFY-P06~12NMSU-E models have 2 fans.

PEFY-P24NMSU-E model have 4 fans.

4. In case of the inlet duct is used,remove the air filter(supply with

the unit), then install the filter(field supply) at suction side.

*1:R410A outdoor unit

*2:R22 outdoor unit

12

Unit : mm(in)

Page 15

[ V Wiring Diagram ]

- 8 -

HWE08010 GB

VWiring Diagram

[1] Wiring Diagram

1. PEFY-P06,08,12,15,18,24NMSU-E

8765432

1

432

1

1~

M

M

4231

M

1324 12 14567

6

5

3

1

432

1

1351213248132 4567

13

PARTS LOCATION

CONTROL BOX

I.B.

TB2TB15TB5A.B.

INSIDE SECTION OF CONTROL BOX

SW5

SW14

(Connection No.)

SWBSWA

SWC

SW12

(2nd digit)

SW11

(1st digit)

SW1

A.B.

I.B.

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

Switch (for mode selection)

ConnectorCN4Y

Switch (for model selection)

Connector (emergency operation)

Switch (for mode selection)

Switch (2nd digit address set)

Switch (connection No.set)

Switch (for static pressure selection)

Switch (for model selection)

Switch (for static pressure selection)

Switch (for mode selection)

Switch (for capacity code)

Thermistor (piping temp.detection/gas)

Thermistor (piping temp.detection/liquid)

Connector (Heater)CN24

Drainpump

Connector (Wireless)

X1 Aux. relay

ArresterDSA

VaristorZNR01,02

Fuse AC250V 6.3AFUSE

LEV

Fan motor

Float switchFS

Connector (Remote indication)

Connector (Centrally control)

CN90

Connector (Remote switch)

Connector (Damper)

CN32

CN52

CN51

CN41

Transmission terminal bedTB15

TH21 Thermistor (inlet air temp.detection)

TH23

TH22

NAMESYMBOLSYMBOL

I.B.

A.B.

Indoor controller board

Address board

Switch (1st digit address set)

SW2(I.B.)

SW5(A.B.)

SWB(A.B.)

SWA(A.B.)

SWC(A.B.)

SWE(I.B.)

SW3(I.B.)

SW11(A.B.)

SW12(A.B.)

SW14(A.B.)

SW1(A.B.)

SW4(I.B.)

TB2

TB5 Transmission terminal bed

Power source terminal bed

SYMBOL EXPLANATION

NAME

CN27

Connector (HA terminal-A)

SYMBOL NAME

NOTE: 1.The wirings to TB2,TB5,TB15 shown in dotted line are field work.

2.Mark indicates terminal bed, connector.

3.Use copper supply wire.

CN4Y CN24

(Yellow)

G

CN82

CN43

t° t°

U

LED1

LED2

DC310~340V

Rectify circuit

ZNR01

POWER SUPPLY

~ 208V/230V 60Hz

TO NEXT INDOOR UNIT

FUSE (16A)

PULL BOX

BREAKER (16A)

FUSE

X1

ZNR02

DSA

U

t°

(Green)

(Blue)

(Red)

(Red)

(Red)

(Red)

(Blue)

(Blue)

(Black)

TB5

L2

L1

TB15

12

S(SHIELD)

M2

TB2

M1

FSTH22 TH23 TH21

CN60

CN3A

CNMF

CNP

CND

CN2M

SW2SW4SW3

CN90

CN42CN81CN32

CN27

CN20CN4FCN44CN41CN52 CN51

SWE

ON

OFF

TO MA REMOTE

CONTROLLER

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

Page 16

[ VI Refrigerant System Diagram ]

- 9 -

HWE08010 GB

VI Refrigerant System Diagram

[1] Refrigerant system diagram

(A) Gas pipe thermistor TH23

(B) Gas pipe

(C) Liquid pipe

(D) Brazed connections

(E) Strainer (#100 mesh)

(F) Linear expansion valve

(G) Liquid pipe thermistor TH22

(H) Heat exchanger

(I) Room temperature thermistor TH21

(H)

(I)

(F)

(E)(E)

(C)

(G)

(A)

(D)

(B)

mm[in.]

Capacity PEFY-P06,08,12,15NMSU-E PEFY-P18NMSU-E PEFY-P24NMSU-E

Gas pipe ø12.7 [1/2] R410A: ø12.7 [1/2]

R22: ø15.88 [5/8]

ø15.88 [5/8]

Liquid pipe ø6.35 [1/4] R410A: ø6.35 [1/4]

R22: ø9.52 [3/8]

ø9.52 [3/8]

Page 17

[ VII Microprocessor Control ]

- 10 -

HWE08010 GB

VII Microprocessor Control

[1] Microprocessor Control

1. Cool operation

1. Termoregulating function

(1) Thermoregulating function (Function to prevent restarting for 3 minutes)

Room temperature desired temperature + 2°F ···Thermo ON

Room temperature desired temperature ···Thermo OFF

(2) Anti-freezing control

Detected condition :

When the liquid pipe temp. (TH22) is 32°F or less in 16 minutes from compressors start up, anti-freezing control starts and

the thermo OFF.

Released condition :

The timer which prevents reactivating is set for 3 minutes, and anti-freezing control is cancelled when any one of the following

conditions is satisfied.

1) Liquid pipe temp. (TH22) turns 50°F or above.

2) The condition of the thermo OFF has become complete by thermoregulating, etc.

3) The operation modes became mode other than COOL.

4) The operation stopped.

2. Fan

(1) By the remote controller setting (switch of 3 speeds+Auto)

When [Auto] is set, fan speed is changed depending on the value of: Room temperature - Desired temperature

3. Drain pump

(1) Drain pump control

Always drain pump ON during the COOL and DRY mode operation. (Regardless of the thermo ON/ OFF)

When the operation mode has changed from the COOL or DRY to the others (including Stop), OFF the control after the drain

pump ON for 3 minutes.

(2) Float switch control

Float switch control judges whether the sensor is in the air or in the water by turning the float switch ON/OFF.

In the water : Detected that the float switch is ON for 15 seconds.

<How to operate>

1. Press POWER [ON/OFF] button.

2. Press the operation [Mode] button to display COOL.

3. Press the [Set Temperature] button to set the desired temperature.

The set temperature changes 2°F when the [Set Temperature]

button is pressed one time. Cooling 67 to 87°F

Type Fan speed notch

3 speeds + Auto type [Low], [Med], [High], [Auto]

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Page 18

[ VII Microprocessor Control ]

- 11 -

HWE08010 GB

In the air : Detected that the float switch is OFF for 15 seconds.

2. Dry operation

1. Termoregulating function

(1) Thermo regulating function (Function to prevent restarting for 3 minutes)

Setting the Dry thermo by the thermo regulating signal and the room temperature (TH21).

Dry thermo ON Room temperature desired temperature + 2°F

Dry thermo OFF Room temperature desired temperature

(2) Frozen prevention control

No control function

2. Fan

(1) Indoor fan operation controlled depends on the compressor conditions.

<How to operate>

1. Press POWER [ON/OFF] button.

2. Press the operation [Mode] button to display DRY.

3. Press the [Set Temperature] button to set the desired temperature.

The set temperature changes 2°F when the [Set Temperature]

button is pressed one time. Dry 67 to 87°F

Room temperature

3 min. passed since starting operation

Dry thermo

ON time (min)

Dry thermo

OFF time (min)

Thermo regulating signal Room temperature (T1)

Over 64°F

ON

T1 83°F 9 3

83°F > T1 79°F 7 3

79°F > T1 75°F 5 3

75°F > T1 3 3

OFF Unconditional 3 10

Less than 64°F Dry thermo OFF

Dry thermo Fan speed notch

ON [Low]

OFF

Excluding the following Stop

Room temp. < 64°F [Low]

ON

OFF

15sec. 15sec. 15sec. 1min.30sec. 1min.30sec.

Float SW

In the water In the air In the water Error

postponement

Drain pump

abnormal

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Page 19

[ VII Microprocessor Control ]

- 12 -

HWE08010 GB

Remote controller setting is not acceptable.

3. Drain pump

(1) Same control as COOL operation

3. Fan operation

1. Fan

(1) Set by remote controller.

When [Auto] is set, fan speed becomes [Low].

2. Drain pump

(1) Drain pump control

The drain pump turns ON for the specified amount of time when any of the following conditions is met:

1) ON for 3 minutes after the operation mode is switched from COOL or DRY to another operation mode (FAN).

2) ON for 6 minutes after the float switch is submerged in the water when the float switch control judges the sensor is in the water.

(2) Float switch control

Float switch control judges whether the sensor is in the air or in the water by turning the float switch ON/OFF.

In the water : Detected that the float switch is ON for 15 seconds.

In the air : Detected that the float switch is OFF for 15 seconds.

<How to operate>

1. Press POWER [ON/OFF] button.

2. Press the operation [Mode] button to display FAN.

Type Fan speed notch

3 speeds + Auto type [Low], [Med], [High], [Auto]

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

ON

OFF

15sec. 15sec. 15sec. 1min.30sec. 1min.30sec.

Float SW

In the water In the air In the water Error

postponement

Drain pump

abnormal

Page 20

[ VII Microprocessor Control ]

- 13 -

HWE08010 GB

4. Heat operation

1. Termoregulating function

(1) Thermoregulating function (Function to prevent restarting for 3 minutes)

Room temperature desired temperature -2°F ···Thermo ON

Room temperature desired temperature ···Thermo OFF

2. Fan

(1) By the remote controller setting (switch of 3 speeds+Auto)

When [Auto] is set, fan speed is changed depending on the value of:

Desired temperature - Room temperature

Give priority to under-mentioned controlled mode

1) Hot adjust mode

2) Preheating exclusion mode

3) Thermo OFF mode (When the compressor off by the thermoregulating)

4) Cool air prevention mode (Defrosting mode)

5) Capacity increasing mode

(2) Hot adjust mode

The fan controller becomes the hot adjuster mode for the following conditions.

1) When starting the HEAT operation

2) When the thermoregulating function changes from OFF to ON.

3) When release the HEAT defrosting operation

A: Hot adjust mode starts.

B: 5 minutes have passed since the condition A or the indoor liquid pipe temperature turned 95°F or more.

C: 2 minutes have passed since the condition A. (Terminating the hot adjust mode)

*1 "STAND BY" will be displayed during the hot adjust mode.

(3) Preheating exclusion mode

When the condition changes the auxiliary heater ON to OFF (thermoregulating or operation stop, etc.), the indoor fan operates

in [Low] mode for 1 minute.

<How to operate>

1. Press POWER [ON/OFF] button.

2. Press the operation [Mode] button to display HEAT.

3. Press the [Set Temperature] button to set the desired temperature.

The set temperature changes 2°F when the [Set Temperature]

button is pressed one time. Heating 63 to 83°F.

<Display in HEAT operation>

[DEFROST]

The [DEFROST] symbol is only displayed during the defrost operation.

[STANDBY]

The [STANDBY] symbol is only displayed during the hot adjust

mode.

Type Fan speed notch

3 speeds + Auto type [Low], [Med], [High], [Auto]

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

CAB

[Extra Low]

[Low]

Set fan speed by the remote controller

Hot adjust mode *1

Page 21

[ VII Microprocessor Control ]

- 14 -

HWE08010 GB

This control is same for the model without auxiliary heater.

(4) Thermo OFF mode

When the thermoregulating function changes to OFF, the indoor fan operates in [Extra low].

(5) Heat defrosting mode

The indoor fan stops.

3. Drain pump

(1) Drain pump control

The drain pump turns ON for the specified amount of time when any of the following conditions is met:

1) ON for 3 minutes after the operation mode is switched from COOL or DRY to another operation mode (FAN).

2) ON for 6 minutes after the float switch is submerged in the water when the float swich control judges the sensor is in the water.

(2) Float switch control

Float switch control judges whether the sensor is in the air or in the water by turning the float switch ON/OFF.

In the water : Detected that the float switch is ON for 15 seconds.

In the air : Detected that the float switch is OFF for 15 seconds.

5. Auto operation [Automatic cool / heat change over operation]

1. Initial value of operation mode

(1) HEAT mode for room temperature < Desired temperature

(2) COOL mode for room temperature Desired temperature

2. Mode change

(1) HEAT mode -> COOL mode

Room temperature Desired temperature + 3°F. or 3 min. has passed

(2) COOL mode -> HEAT mode

Room temperature Desired temperature - 3°F. or 3 min. has passed

3. COOL mode

(1) Same control as cool operation

<How to operate>

1. Press POWER [ON/OFF] button.

2. Press the operation [Mode] button to display AUTO.

3. Press the [Set Temperature] button to set the desired temperature.

The set temperature changes 2°F when the [Set Temperature]

button is pressed one time. Automatic 67 to 83°F

ON

OFF

15sec. 15sec. 15sec. 1min.30sec. 1min.30sec.

Float SW

In the water In the air In the water Error

postponement

Drain pump

abnormal

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Page 22

[ VII Microprocessor Control ]

- 15 -

HWE08010 GB

4. HEAT mode

(1) Same control as heat operation

The value "3°F" is modifiable from 1.8°F to 9°F by maintenance tool.

6. When unit is stopped control mode

1. Drain pump

(1) Drain pump control

The drain pump turns ON for the specified amount of time when any of the following conditions is met:

1) ON for 3 minutes after the operation mode is switched from COOL or DRY to another operation mode (FAN).

2) ON for 6 minutes after the float switch is submerged in the water when the float switch control judges the sensor is in the water.

(2) Float switch control

Float switch control judges whether the sensor is in the air or in the water by turning the float switch ON/OFF.

In the water : Detected that the float switch is ON for 15 seconds.

In the air : Detected that the float switch is OFF for 15 seconds.

7. Heater control

1. Control specifications and DIP S/W setting

Table 1 shows how the field-installed heater is controlled. Select the desired pattern in the table below, and set the DIP S/W

on the outdoor and indoor units as shown in Table 1. See section 3 "Installation" for details. The table below shows Heater

Control patterns #A and B.

ON

OFF

15sec. 15sec. 15sec. 1min.30sec. 1min.30sec.

Float SW

In the water In the air In the water Error

postponement

Drain pump

abnormal

Table.1

Outdoor unit

setting

Condition of outdoor unit

Duct unit PE/PD/PF-NR(NL)

Î

(PEFY-P06,08,12,15,18,24

NMSU-E)

NON duct unit

(PL/PK/PC)

DIP S/W OFF

In the case of:

<TGMU>

S/W5-2 OFF

<THMU>

S/W5-10 OFF

<PUMY>

S/W4-4 OFF

N / A

DIP S/W3-4

OFF

(Indoor unit)

Heater control #A

(defrost/error:

Heater OFF)

Heater control #A

(defrost/error:

Heater ON)

DIP S/W3-4

ON

(Indoor unit)

Heater control #A

(defrost/error:

Heater ON)

DIP S/W ON

In the case of:

<TGMU>

S/W5-2 ON

<THMU>

S/W5-10 ON

<PUMY>

S/W4-4 ON

Normal drive Heater OFF Heater OFF

Defrost drive

H/P drive

H/P stop

DIP S/W3-4

OFF

(Indoor unit)

Heater control #A

(defrost/error:

Heater OFF)

Heater control #B

(defrost/error:

Heater ON)

DIP S/W3-4

ON

(Indoor unit)

Heater control #B

(defrost/error:

Heater ON)

Norm al drive

Defrost drive

H/P drive

H/P stop

Condition of O/U

㪧㪸㫉㪸㫄 㪼㫋㪼㫉㫊㩷a/b/c/d are set by㩷

maintenance tool.

a b cd

Outdoor temp.

Page 23

[ VII Microprocessor Control ]

- 16 -

HWE08010 GB

(1) On the ducted model units (except the Fresh air intake type), turning on the heater with the fan setting set to OFF requires that

the DIP S/W and connectors on the indoor units*1 are set on site. (in case of PEFY-P06,08,12,15,18,24NMSU-E)

*1: DIP SW 3-4, CN24, and CN4Y

(2) On the Fresh air intake type units, the heater cannot be turned on with the fan setting set to OFF.

(3) Non-ducted models do not require the settings described in Section (1) above.

(4) Back-up heating will not be performed when the heater turns on while demand control is performed (not a request item).

(5) This is applicable only to the R410 series. Make the settings for the following dip switches on the outdoor unit control board

before switching on the power.

2. Fan control

By using the optional parts PAC-YU25HT, fan speed can be controlled.

*depend on SW1-7/1-8

Table.2

Heater control #A

Heater OFF

Inlet air temp. set temp.

Heater ON

Inlet air temp. < set temp.-4°F

Heater control #B Heater OFF

Inlet air temp. set temp.

Heater ON

Inlet air temp. < set temp.-1.8°F

<For heater>

The value "4°F" is modifiable from 1.8°F to 9°F by maintenance tool.

Pattern Duct unit PE/PD/PF-NR(NL)

Î

(PEFY-P06,08,12,15,18,24NMSU-E)

CN4Y for FAN control (YU25) DIP S/W3-4 (Indoor unit) Fan in defrost

1

Disabled

OFF Stop (Heater OFF)

2 ON L / LL / Set * (Heater ON)

3

Enabled

OFF Stop (Heater OFF)

4 ON Stop (Heater ON)

SW3-1 SW1-7 SW1-8 Fan speed *1

OFF OFF OFF Very low

OFF ON OFF Low

OFF OFF ON Remote controller setting

OFF ON ON

Stop

(Remote controller setting *2)

ON ON ON

Stop

(Remote controller setting *2)

*1 The fan operates at the same speed settings as shown in this table

during the Heating Thermo-OFF mode.

*2 If Pattern 2 in the table above is selected for the fan control pattern,

the fan will follow the setting of the remote controller.

Set temp.

Set temp.-1.8°F

Set tem p.-4°F

Inlet air tem p .

Heater ou tput

OFF

ON

Set temp.

Set temp.-1.8°F

Inlet air temp.

Heater output

OFF

ON

Page 24

[ VII Microprocessor Control ]

- 17 -

HWE08010 GB

Reference (not applicable to the ducted models)

This is applicable only to the R410A series. Make the settings for the following dip switches on the indoor unit control board

before switching on the power.

3. PAC-YU25HT (Optional Parts) installation

The following section describes installation of the External Heater Adapter that connects to CITY MULTI air conditioner R410A

series indoor unit. This products is the special wiring parts to drive an electric heater with the air conditioner.

(1) Parts list

Check that the following parts are included in the package.

1) External output cable (with a yellow connector).............................2 in total

Two types of cables with different connectors are included.

2) Panel heater connector.................................................................. 3 in total

White: 1

Green: 2 (2 types)

(2) Connection to the indoor unit

Use the cables that fit the connectors on the indoor unit control board. The items listed in this parts list cannot be used with

the following models.

PMFY-BM

PMFY-AM

1) External output cable (with a yellow connector)

This cable is used to connect a relay circuit for an interlocked operation with either an electric or a panel heater. Connect the

cable to CN24 on the indoor unit control board.

2) Panel heater connector (with a green connector)

This connector is used to perform an interlocked operation with a panel heater. Depending on the indoor unit control board

specification, connect the cable either to CN4Y or CN22 as appropriate.

(3) Locally procured wiring

A basic connection method is shown below.

1) PEFY-P-NMSU-E and other models

Pattern NON duct unit (PL/PK/PC)

CN4Y for FAN control (YU25) *3 DIP S/W (Indoor unit) Fan in defrost

1 N/A N/A Stop (Heater ON)

*3 Refer to Section 5 "Dipswitch Setting" for further information about each switch.

CN4Y for FAN control

(PAC-YU25HT)

<Image>

CN24

CN22

X

X

Remote control board Relay circuit

Adapter

Indoor unit

control board

Outdoor unit

control board

retaeHcirtcelE

ecruosrewop

Electric Heater

or panel

heater

Red 1

White 2

• PUHY, PURY-PTGMU type Dip

switch SW5-2

“ON”

• PUHY, PURY-PYHMU type Dip

switch SW5-10

“ON”

• PUMY series Dip

switch SW4-4

“ON”

Preparations in the field

Maximum cable length

is 10 m (32ft)

wo

lleYetihW

White 1

Dip switch SW3-2 “ON”

(applicable only when a panel

heater is connected)

3

CN4Y

Page 25

[ VII Microprocessor Control ]

- 18 -

HWE08010 GB

2) PEFY-P-NMHU-E, PDFY-P-NMU-E and other models

For relay X use the specifications given below Operation coil

Rated voltage: 12VDC

Power consumption: 0.9W or less

* Use the diode that is recommended by the relay manufacturer at both ends of the relay coil.

The length of the electrical wiring for the PAC-YU25HT is 2 meters (6-1/2 ft.)

To extend this length, use sheathed 2-core cable.

Control cable type: CVV, CVS, CPEV or equivalent.

Cable size: 0.5 mm

2

~ 1.25 mm2 (16 to 22 AWG)

Don't extend the cable more than 10 meters (32ft)

(4) Wiring restrictions

Keep the length of the cable connecting to the circuit board of the indoor unit shorter than 10 meters (32ft).

Longer than 10 meters (32ft) could cause improper operation.

Use a transit relay when extending wiring such as remote wiring.

CN24

CN22

X

X

Remote control board Relay circuit

Adapter

Indoor unit

control board

Outdoor unit

control board

retaeHcirtcelE

ecruosrewop

Red 1

White 2

• PUHY, PURY-PTGMU type Dip

switch SW5-2

“ON”

• PUHY, PURY-PYHMU type Dip

switch SW5-10

“ON”

• PUMY series Dip

switch SW4-4

“ON”

Preparations in the field

Maximum cable length

is 10 m (32ft)

wo

lleYneerG

White 1

Dip switch SW3-2 “ON”

(applicable only when a panel

heater is connected)

2

Electric Heater

or panel

heater

Recommended circuit

Wiring diagram

1-phase power

supply

208V, 230V/60Hz

Control board

FS1, 2 ----- Thermal fuse

H1, H2 ----- Heater

26H --------- Overheat protection

thermostat

88H --------- Electromagnetic contactor

FS1

FS2

FS1

FS2

R

S

R

S

CN24

H2

88H

H1

88H

26H

88H

Page 26

[ VIII Troubleshooting ]

- 19 -

HWE08010 GB

VIII Troubleshooting

[1] Troubleshooting

1. Check methods

1. Component and check points

(1) Thermistor

Room temperature thermistor (TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Disconnect the connector and measure the resistance between terminals with a tester.

(Ambient temperature 10°C - 30°C[50°F-86°F])

1) Thermistor characteristic graph

(2) Fan motor (CNMF)

Refer to the page on "DC fan motor (fan motor/indoor control board)."

(3) Linear expansion valve

Disconnect the connector, and measure the resistance between terminals with a tester.

Refer to the next page for details.

Normal Abnormal

4.3k - 9.6k Open or short

(Refer to the thermistor characteristic graph below.)

Low-temperature thermistor

Room temperature thermistor (TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Drain sensor (DS)

Thermistor R

0

= 15 k 3%

Multiplier of B = 3480 k 2%

0°C 32°F 15k

10°C 50°F 9.6k

20°C 68°F 6.3k

25°C 77°F 5.2k

30°C 86°F 4.3k

40°C 104°F 3.0k

(A) Temperature (°C)[°F]

(B) Resistance (k )

Normal Abnormal

1-5 2-6 3-5 4-6 Open or short

White-Red Yellow-Brown Orange-Red Blue-Brown

200 k 10%

(A) Brown (D) Orange

(B) Red (E) Yellow

(C) Blue (F) White

Rt = 15 exp { 3480( ) }

1

273+t

1

273

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

-4 14 32 50 68 86 104 122

(A)

(B)

1

2

3

4

5

6

LEV

M

(A)

(B)

(C)

(D)

(E)

(F)

CN60

Page 27

[ VIII Troubleshooting ]

- 20 -

HWE08010 GB

1) Summary of linear expansion valve (LEV) operation

The LEV is operated by a stepping motor, which operates by receiving a pulse signal from the indoor control board.

The LEV position changes in response to the pulse signal.

Indoor control board and LEV connection

Pulse signal output and valve operation

The output pulse changes in the following order:

When the valve closes 1 -> 2 -> 3 -> 4 -> 1

When the valve opens 4 -> 3 -> 2 -> 1 -> 4

When the valve position remains the same, all output signals will be OFF.

If any output signal is missing or if the signal remains ON, the motor vibrates and makes clicking noise.

(A) Brown (F) White

(B) Red (G) Control board

(C) Blue (H) Connection (CN60)

(D) Orange (I) Drive circuit

(E) Yellow (J) Linear expansion valve

Phase

number

Output pulse

1234

ø1 ON OFF OFF ON

ø2 ON ON OFF OFF

ø3 OFF ON ON OFF

ø4 OFF OFF ON ON

4

3

6

5

2

1

(G)

(H)

(I)

(J)

(A)

(A)

(B)

(B)

(C)

(C)

(D)

(D)

(E)

(E)

(F)

(F)

12VDC

M

4

6

2

3

5

1

Page 28

[ VIII Troubleshooting ]

- 21 -

HWE08010 GB

2) LEV operation

When the power is turned on, a pulse signal of 2200 pulses is output (valve closure signal), to bring the valve to position A.

When the valve is operating normally, it is free of vibration noise. If the valve locks or when it goes from point E to A in the

figure, it makes louder noise than would be heard when there is an open phase.

Check for abnormal sound/vibration by placing the metal tip of a screwdriver against the valve and the handle side against

your ear.

3) Troubleshooting

(a) Close

(b) Open

(c) Fully open valve (2000 pulses)

(d) No. of pulses

(e) Extra tightning (80 - 100 pulse)

(f) Valve opening degree

(f)

(a)

(b)

(e)

(d)

(c)

Symptom Checking Criteria Remedy

Circuit failure on

the microcomputer

Disconnect the connectors on the control board, and connect LEDs to test the circuit as shown below.

Pulse signals are output for 10 seconds when the main power is turned on. If there

are LEDs that do not light up at all or remain lit after the pulses are turned off, there

is a problem with the driving circuit.

Replace the indoor control

board if driving

circuit failure is

detected.

Locked LEV The motor will idle and make small clicking noise if it is run while the LEV is locked.

If this clicking noise is heard both when the valve is fully closed and while it is being

opened, it indicates a problem.

Replace the LEV.

Disconnected or

shorted LEV motor

coils

easure the resistance between the coils with a tester (red-white, red-orange,

brown-yellow, brown-blue). The normal range of resistance is 150 10%

Replace the LEV.

6

5

4

3

2

1

1 k

LED

Page 29

[ VIII Troubleshooting ]

- 22 -

HWE08010 GB

(4) Drain-up mechanism

Measure the resistance between the terminals with a tester.

(coil temperature 20°C[68°F])

(5) Drain float switch (CN4F)

Disconnect the connector, and measure the resistance between terminals with a tester.

Valve closure failure (leaky valve)

To check the LEV on the indoor unit, check the indoor unit liquid pipe temperature

that appears on the operation monitor on the outdoor unit's multi control board while

operating the indoor unit in question in the FAN mode and the other indoor units in

the cooling mode.

Replace the LEV

if the amount of

leakage is great.

(A) Termistor (TH22)

Normally, the LEV is fully closed while the unit is in the FAN mode. If the valve is

leaky, liquid pipe thermistor reading will be lower than normal. If it is significantly

lower than the inlet temperature on the remote controller, valve closure failure is

suspected. If the amount of leakage is insignificant, replacement of LEV is unnecessary unless it is causing a problem.

Misconnections of

connectors or contact failure

Perform a visual check for disconnected connectors.

Perform a visual check of lead wire color.

Disconnect the

connectors on

the control board

and perform a

continuity test.

Symptom Checking Criteria Remedy

(A)

LEV

Normal Abnormal

340 Open or short

(A) Moving part

(B) Switch

(C) Magnet

Position of the moving part Normal Abnormal

Up Short (any position but short)

Down Open (any position but open)

1

3

1

2

3

4

(A)

(A)

(B)

(C)

Page 30

[ VIII Troubleshooting ]

- 23 -

HWE08010 GB

2. DC fan motor (fan motor/indoor control board)

1. CAUTION

A high voltage is applied to the connector for connection to the fan motor (CNMF).

Do not unplug the connector CNMF with the unit energized to avoid damage to the indoor control board and fan motor.

2. Troubleshooting

Symptom: Indoor unit fan does not run.

Check fan motor connector contact

(CNMF).

Replace the indoor control board.

Replace the indoor control board.

Fix the connection.

Yes

No

Yes

No

Yes

No

Check the fan motor position thermistor signal.

Get the motor to make a full rotation or more, and measure the voltage at the test point

V

FG.

(same with the voltage between fan connector 7 (+) and 4(-))

Is the fan motor connector

(CNMF) fully inserted?

Is the voltage within the

normal range?

Replace the motor.

Are 0VDC and 15VDC

displayed alternately?

Check the power supply.

Measure the voltage at the indoor control board.

294 - 340VDC (same with the voltage between fan connector 1 (+) and 4(-))

15VDC (same with the voltage between fan connector 5 (+) and 4(-))

1 - 6.5VDC (same with the voltage between fan connector 6 (+) and 4(-))

[Values for Vsp are the values that are measured with the fan motor in operation.

Vsp is 0V when the fan motor is stopped.]

V

DC

Power supply voltage

Power supply voltage V

DC

208VAC

294VDC

220VAC

311VDC

230VAC

325VDC

240VAC

340VDC

Page 31

[ VIII Troubleshooting ]

- 24 -

HWE08010 GB

3. Address switch setting

Make sure that power to the unit is turned off.

1. When using an ME remote controller, set the address with the rotary switches (SW11, SW12).

Address setting is not required when the unit remote controller is used.

On-site address setting is required for the indoor units to run.

2. Address settings vary in different systems.

Refer to the section on address setting in the outdoor unit installation manual.

3. Address is set with a combination of SW12 (10's digit) and SW11 (1's digit).

To set the address to "3," set SW12 to "0" and SW11 to "3."

To set the address to "25," set SW 12 to "2" and SW 11 to "5."

(A) Indoor unit control board

(B) Factory setting (all models)

ON

OFF

ON

OFF

(A)

(B)

1

2

Page 32

[ VIII Troubleshooting ]

- 25 -

HWE08010 GB

4. Voltage test points on the control board

1. PEFY-P06,08,12,15,18,24NMSU-E

Fuse Fuse(AC 250V 6.3A)

CND Power supply voltage (208 -

230VAC)

CN2M For M-NET transmission cable

connection (24 - 30VDC)

SWE Emergency operation

SW2 Capacity setting

SW4 Function setting

CN42 For address board connection

SW3 Function setting

CN81 For address board connection

CN32 Remote start/stop adapter

CN3A For MA remote controller cable

connection

(10 - 13 VDC (Between 1 and 3.))

CN4Y For fan control

CN52 Remote display

CN51 Centralized control

CN41 JAMA standard HA terminal A

CN44 Thermistor (liquid/gas tempera-

ture)

CN4F Float thermistor

CN24 For heater control

CN20 Thermistor (Inlet temperature)

CN3C Indoor-outdoor transmission

(0 - 24VDC)

CNMF Fan motor output

1 - 4: 310 - 340 VDC

5 - 4: 15 VDC

6 - 4: 0 - 6.5 VDC

7 - 4: Stop 0 or 15 VDC

Run 7.5 VDC

(0 - 15 pulse)

CNP Drain-up mechanism output

(200VAC)

(*1)

V

FG

Voltage on the (-) side of PC941

and C25

(Same with the voltage between 7

(+) and 4 (-) of CNMF)

V

CC

Voltage between the C25 pins

15 VDC

(Same with the voltage between 5

(+) and 4 (-) of CNMF)

Vsp Voltage between the C951 pins

0VDC (with the fan stopped)

1 - 6.5VDC (with the fan in operation)

(Same with the voltage between 6

(+) and 4 (-) of CNMF)

Fuse

CND

С25(*1)

CN2M

SWE

SW2

SW4

CN42

SW3

CN81

CN32

LED2 CN3A CN60 CN4Y

CN52

CN51

CN41

CN44

CN4F

CN20

CN24

CN3C

LED1

PC941(*1)

C951(*1)

CNMF

CNP

Page 33

[ VIII Troubleshooting ]

- 26 -

HWE08010 GB

5. Dipswitch setting (Factory setting)

1. Function setting

(1) SW1

1) Adress board

(2) SW3

*1 Please don't use SW3-9,10 as trouble might be caused by the usage condition.

1) Indoor control board

Dipswitch settings must be made while the unit is stopped.

Switch position Function Switch setting

ON OFF

1 Active Thermistor (Intake air ther-

mistor)

Built-in thermistor on the remote

controller

Indoor unit

2 Filter clogging detection Available Unavailable

3 Filter life 2500 hr 100 hr

4 Outdoor air intake Enabled Disabled

5 Remote display Thermo-ON signal Fan output

6 Humidifier operation During heating mode During heating operation

7 Fan speed Low Very low

8 Fan speed at heating Thermo-OFF Preset fan speed Follows the setting of SW1-7

9 Auto restart after power failure Enabled Disabled

10 Power start/stop Enabled Disabled

Factory setting

Switch position Function Switch setting

ON OFF

1 Unit type Cooling only Heat pump

2- - 3- - 4 Heater backup Enabled Disabled

5- - 6- - 7- - 8 Sensible temprature correction Disabled Enabled

9 Superheat setting tempurature*1 - -

10 Sub cool setting tempurature*1 - -

Factory setting

PEFY-P06NMSU-E

PEFY-P15NMSU-E

PEFY-P08NMSU-E

PEFY-P18NMSU-E

PEFY-P12NMSU-E

PEFY-P24NMSU-E

Page 34

[ VIII Troubleshooting ]

- 27 -

HWE08010 GB

2. Capacity code setting

(1) SW2

1) Indoor control board

Dipswitch settings must be made while the unit is stopped.

Factory setting

The switches are set to correspond to the unit capacity.

3. Model setting

(1) SW4

1) Indoor control board

Dipswitch settings must be made while the unit is stopped.

Note:

Changes made to the dipswitches SW1, SW2, and SW3 will become effective when the unit comes to a stop (remote controller

off). There is no need to power cycle the unit.

4. External static pressure

(1) SWA, SWC

1) Address board

Note:

Changes that are made to the dipswitches SWA and SWC immediately become effective regardless of the unit's operation

status (RUN/STOP) or the remote controller status (ON/OFF).

5. 1's and 10's digits

(1) SW11, SW12 (Rotary switch)

The use of a network remote controller (PAR-F27MEA) requires address setting.

1) Address board

Address settings must be made while the unit is stopped.

Factory setting

All models Factory

setting

(A) Option

(B) Standard

Factory setting

PEFY-P08NMSU-EPEFY-P06NMSU-E PEFY-P12NMSU-E

PEFY-P15NMSU-E PEFY-P18NMSU-E PEFY-P24NMSU-E

1

2

3

SWA SWC

1

2

3

SWA SWC

1

2

3

SWA SWC

1

2

3

SWA SWC

1

2

1

2

1

2

1

2

5[0.02] 15[0.06] 35[0.14] 50[0.20]

Pa[in.WG]

1

2

3

(B)

(A)

SWA SWC

1

2

Page 35

[ VIII Troubleshooting ]

- 28 -

HWE08010 GB

6. Connection No. setting

(1) SW14 (Rotary switch)

This switch is used when the unit connected to an R2 series of outdoor unit.

1) Address board

Note:

Changes to the dipswitches SW11, SW12, SW14, and SW15 must be made while the unit is stopped and the remote controller

is OFF.

Factory setting

Page 36

[ IX Disassembly Procedure ]

- 29 -

HWE08010 GB

IX Disassembly Procedure

[1] Disassembly Procedure

1. Control box

Exercise caution when removing heavy parts.

1. Removing the control box cover

(1) Remove the two fixing screws on the cover (A) to remove

it.

Fig.1

Fig.2

(A)

Page 37

[ IX Disassembly Procedure ]

- 30 -

HWE08010 GB

2. Thermistor (Intake air)

Exercise caution when removing heavy parts.

1. Remove the control box cover according to the procedure

in section [1].

2. Remove the thermistor.

(1) Remove the two fixing screws on the metal base (B) to re-

move it.

Fig.3

(2) Pull out the thermistor holder (C) and thermistor (D) on

the control box.

Fig.4

(B)

(C), (D)

Page 38

[ IX Disassembly Procedure ]

- 31 -

HWE08010 GB

3. Drainpan

Exercise caution when removing heavy parts.

1. Removing the filter and the bottom plate

(1) Push down the tab on the filter, and pull out the filter in

the direction of the arrow 1.

(2) Remove the fixing screws on the bottom plate (D), (E) to

remove it.

Fig.5

2. Removing the drainpan

(1) Pull out the drain pan in the direction of the arrow 1.

Fig.6

Note

Drain the water out of the drain pan before removing

it.

To avoid dew condensation, use insulated screws in

the places marked with circles in Figure 7.

Fig.7

(a) Insulation material

(D)

(a)

(a)

(a)

(a)

(E)

(a)

(E)

Page 39

[ IX Disassembly Procedure ]

- 32 -

HWE08010 GB

4. Thermistor (Gas pipe) (Liquid pipe)

Exercise caution when removing heavy parts.

1. Remove the drain pan according to the procedure in section [1].

2. Removing the Heat exchanger cover

(1) Remove the four fixing screws on the heat exchanger cov-

er (F) to remove it.

Fig.8

3. Removing the thermistor

(1) Remove the thermistor (G) from the thermistor holder (H)

on the copper tube.

Thermistor size

Liquid pipe: ø8mm

Gas pipe: ø6mm

Fig.9

HEX

(F)

(G), (H)

Page 40

[ IX Disassembly Procedure ]

- 33 -

HWE08010 GB

5. Fan and fan motor

Exercise caution when removing heavy parts.

1. Removing the filter and the bottom plate

(1) Push down the tab on the filter, and pull out the filter in the

direction of the arrow 1.

(2) Remove the fixing screws on the bottom plate (J) to re-

move it.

Fig.10

(a) Tab

2. Removing the punching metal

(1) Remove the two fixing screws on the punching metal (K)

to remove it.

Fig.11

3. Removing the fan casing (bottom half)

(1) Squeeze the tabs on the fan casing to remove it in the di-

rection of arrow 2.

4. Removing the motor cable

(1) Remove the motor cable threw the rubber bush.

5. Removing the fan motor and the Sirocco fan

(1) Remove the two motor fixing screws to remove the motor

and the Sirocco fan in the direction of arrow 3.

Fig.12

(2) Remove the four fan case fixing screws to take the top

half of the fan casing off.

Fig.13

(J)

(a)

(a)

(a)

(a)

(K)

(a)

Page 41

[ IX Disassembly Procedure ]

- 34 -

HWE08010 GB

6. Bearing

P15, P18, P24 models only.

Exercise caution when removing heavy parts.

1. Removeing the bearing

(1) Remove the two fixing screws on the bearing cover (M)

to remove it.

Fig.14

(2) Remove the two bearing retainer screws to remove the

bearing.

Fig.15

(M)

Page 42

[ IX Disassembly Procedure ]

- 35 -

HWE08010 GB

7. Heat exchanger

Exercise caution when removing heavy parts.

1. Remove the drain pan according to the procedure in section

[1].

2. Remove the heat exchanger cover according to the procedure in section [4] 2.

3. Removing the cover

(1) Remove the two fixing screws on the cover (T) to remove it.

Fig.16

(T) Pipe support plate

4. Removing the Heat exchanger

(1) Remove the fixing screws on the heat exchanger (S) to re-

move it.

Fig.17

(T)

(S)

Page 43

Jul. 2008 HWE08010

Printed in Japan

New publication, effective Jul. 2008

Specifications subject to change without notice

Loading...

Loading...