Page 1

1

SPLIT-TYPE, AIR CONDITIONERS

ADVANCE AND EVER ADVANCING

TECHNICAL & SERVICE MANUAL

<indoor unit> Service ref.

Models

PED-3EJA1.UK

PED-4EJSA

1

.UK

PED-5EJSA

1

.UK

PED-6EJSA.UK

The Slim Line.

From Mitsubishi Electric

TM

1. FEATURES ················································· 1

2. PART NAMES AND FUNCTIONS ·············· 2

3. SPECIFICATIONS ······································ 4

4. DATA ··························································· 6

5. REFRIGERANT SYSTEM DIAGRAM ······· 12

6. OUTLINES AND DIMENSIONS ·················14

7. WIRING DIAGRAM ···································· 15

8. DISASSEMBLY INSTRUCTIONS ············· 16

9. PARTS LIST ·············································· 19

10

. OPERATION FLOW-CHART ·····················24

11

. MICROPROCESSOR CONTROL·············· 28

12

. TROUBLE SHOOTING ······························34

13

. OPTIONAL PARTS ····································36

CONTENTS

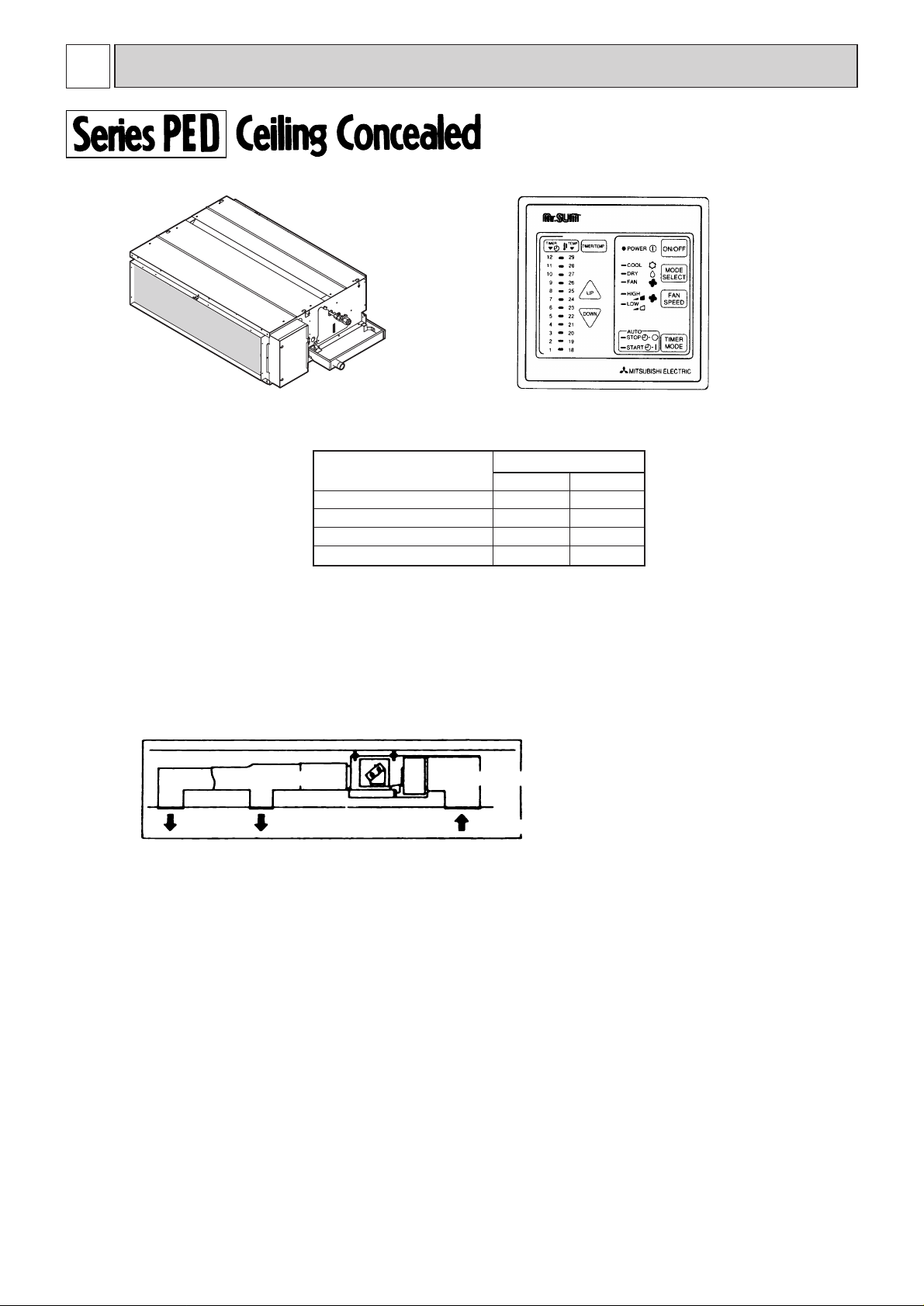

INDOOR UNIT

REMOTE CONTROLLER

This manual does not cover the

following outdoor units. When

servicing them, please refer to

the service manual No.OC149B

and this manual as a set.

PU-3VJC.UK

PU-3YJC.UK

PU-4VLJSA

2.UK

PU-4YJSA

2.UK

PU-5YJSA.UK

PU-6YJSA.UK

Page 2

1

1

FEATURES

1. TOTALLY INVISIBLE INDOOR UNIT BEHIND THE CEILING

The totally hidden indoor unit that lies above the ceiling surface enables you to utilize full floor space while allowing for

flexible interior design. This new feature is recommended for stores and offices where the user's own imagination is

allowed to be incorporated.

2. MOST SUITABLE FOR SIMULTANEOUS TWO ROOM AIR CONDITIONING

Using air ducts for cooling airflow that matches the structure and purpose of the room, enables you to provide two air

outlets for simultaneous cooling of two rooms.

3. HIGH EXTERNAL STATIC PRESSURE (OPTION MOTOR)

The exceptional external static pressure of 130Pa allows long ducts to be used more extensively to achieve convenient

location of indoor units. (STD:70Pa)

4. DRAIN WATER LIFT-UP MECHANISM (OPTION KIT)

This allows more versatility when selecting drain piping layouts.

air outlet air outlet

Air outlet duct

Air intake duct

air intake

lndoor unit

Remote controller

Models Cooling capacity

W Btu/h

PED-6EJSA.UK 14,800 50,400

PED-3EJA1.UK

PED-4EJSA

1

.UK

PED-5EJSA

1

.UK

7,600

9,700

12,400

25,900

33,100

42,300

Page 3

2

2

PART NAMES AND FUNCTIONS

5. ADVANCED MICROPROCESSOR CONTROL

(1) Ultra - thin 12mm(1/2" )remote controller.

(2) Attractive LED display .

Every operation condition is indicated on the LED display.

(3) Simultaneous display of set temperature and room temperature.

(4) Convenient 12 - hour ON-OFF timer.

This convenient timer allows the unit to be switched on and off automatically,at the time you set. Once the timer is

set,the remaining time is shown on the LED display..

(5) Self - diagnostic function indicates problems instantly on remote controller.

(6) The useful memory feature can store instructions.

The previous set value is memorized so that constant temperature control can be obtained. For example,if a power

failure occurs, this feature will conveniently memorize the previous temperature and reset accordingly.

(7) There is a polar 12 core - conductor cable between the remote controller and indoor board.The cable can be extended

up to 50m.(option)

¡¡

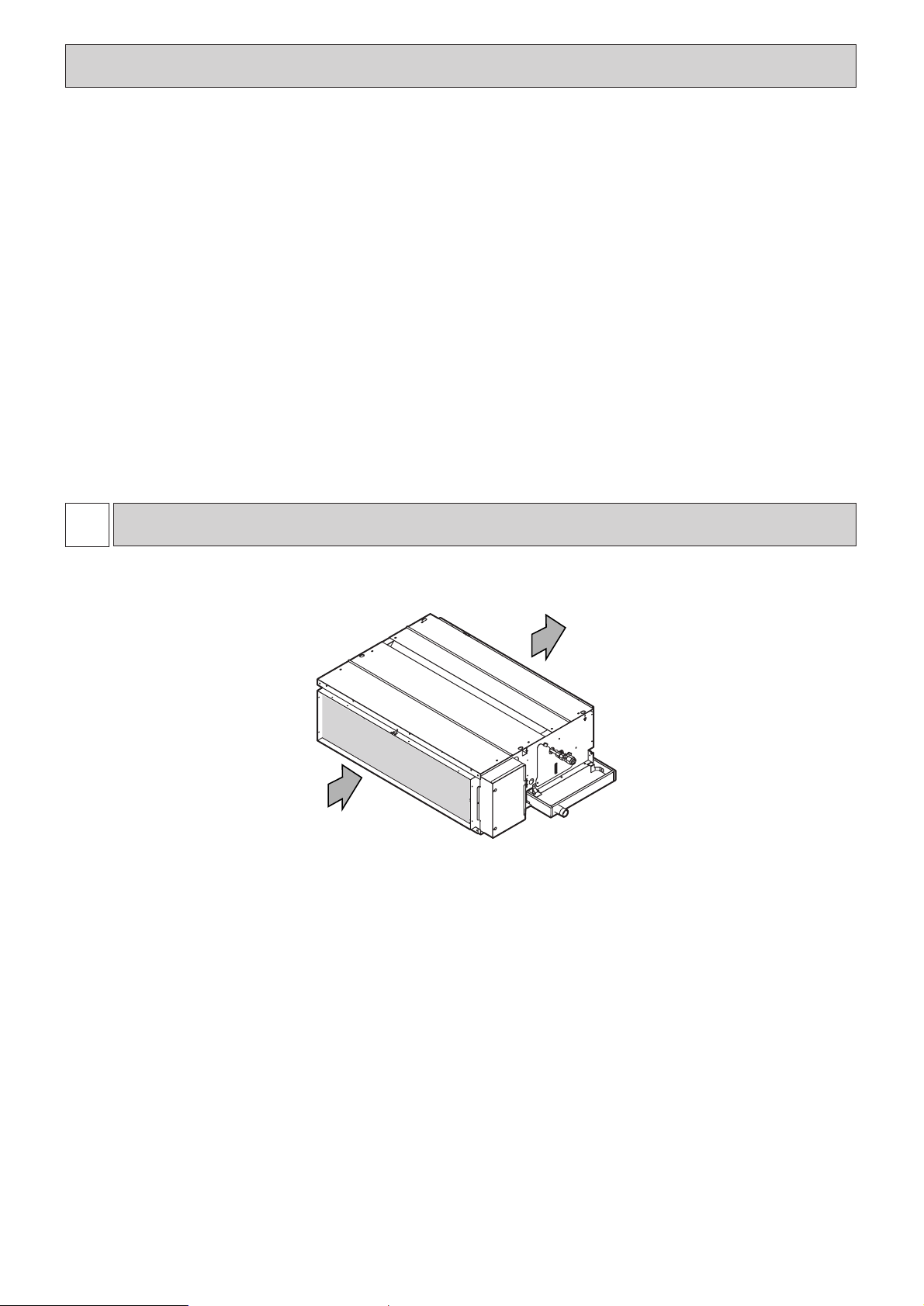

Indoor Unit

Air intake

(sucks the air inside the room into the unit)

Air outlet

Page 4

3

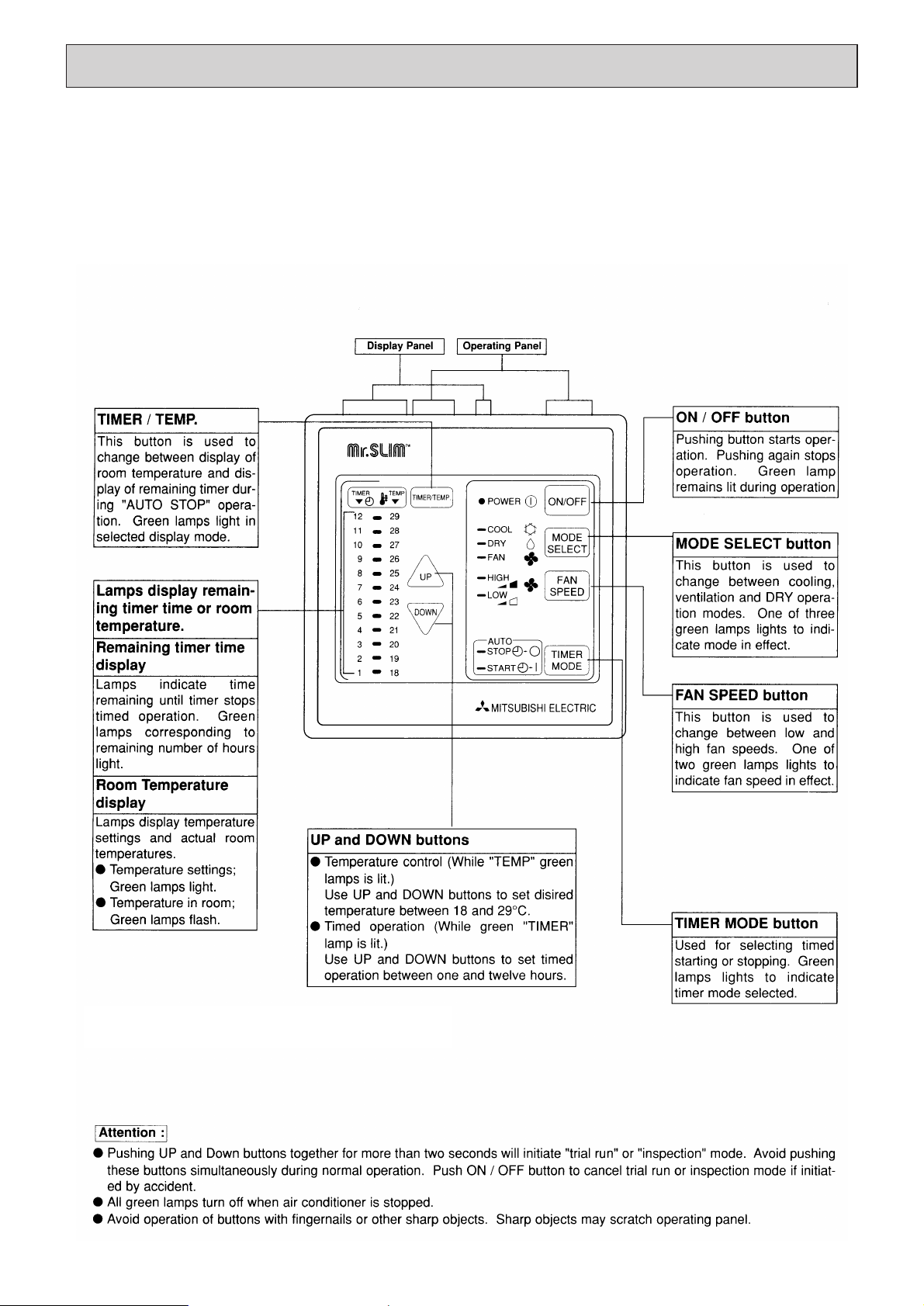

¡¡

Remote controller

¡ Settings remain in effect until changed. Air

conditioner can be operated by simply pushing

ON/OFF button once settings have been made.

¡¡

Operation buttons

(Example display readings are for explanations only

;actual display readings will differ.

Page 5

4

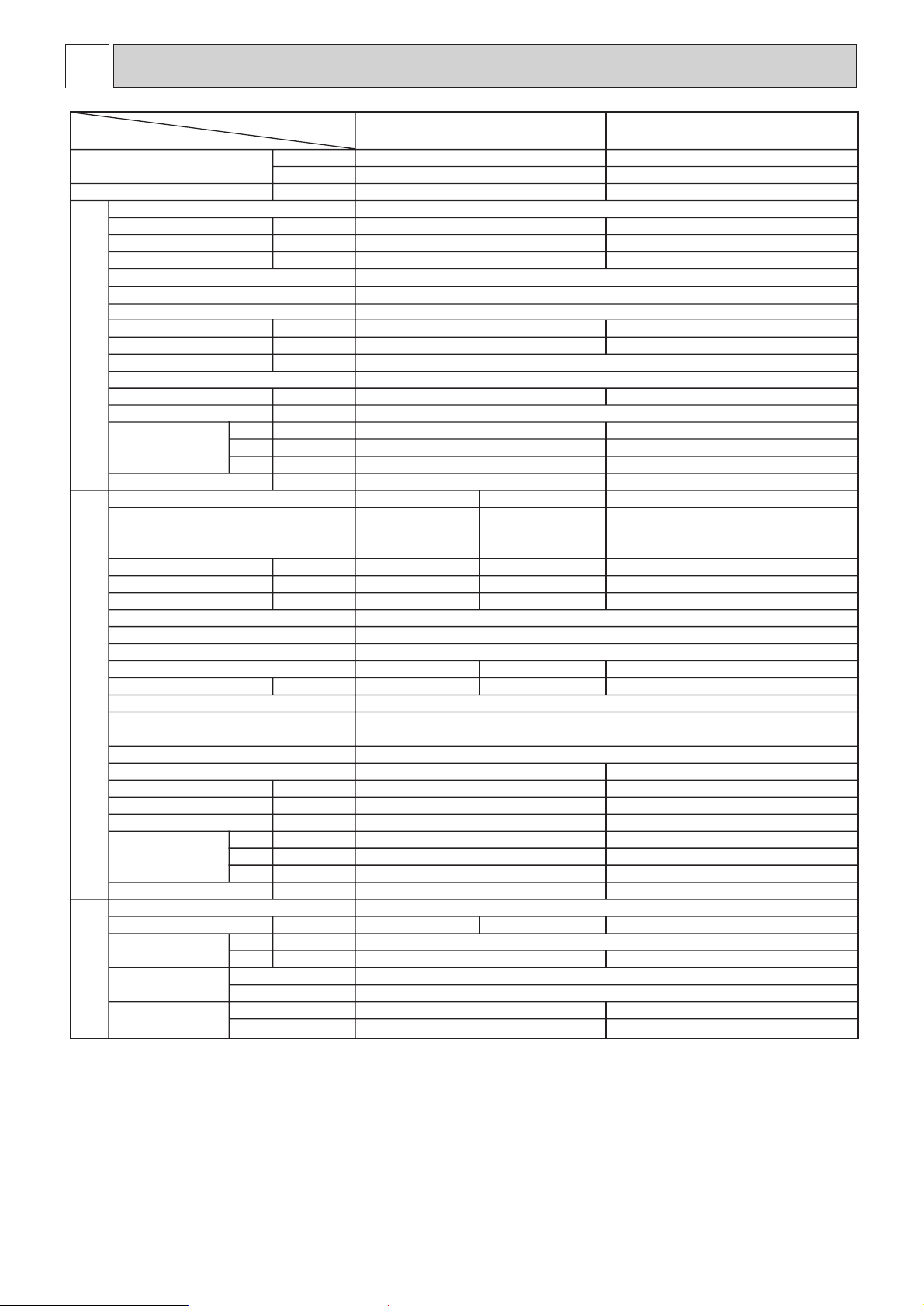

3

SPECIFICATIONS

Model

PED-4EJSA

1

.UKPED-3EJA1.UK

Item

Cooling capacity

4 Btu/h 33,100

W 9,700

Total input 4 kW 3.98

Power supply

~(1ph),50Hz,220-240V

Input kW 0.62

Running current A 2.64

Starting current A 3.2

External finish

Galvanized sheets

Heat exchanger

Plate fin coil

Plate fin coil

Fan (drive) ~No.

Centrifugal (direct)x2

Fan motor output 1 kW 0.27

Airflow (Low-High) CMM,(CFM)

27- 34(950-1200)

External static pressure 2 Pa(mmAq)

70(7)/130(13) at Hi-notch

Operation control & Thermostat

Remote control&Built-in

Noise level (Low-High)

3, 5 dB (A) 41-46

Cond. drain conn. O.D.

mm, (in)

32(1-1/4)

W mm, (in) 1415(55-11/16)

Dimensions

D mm, (in) 740(29-1/8)

H mm, (in) 325(12-13/16)

Weight

kg, (lbs) 62(137)

Model name

Power supply

Input kW 3.36

Running current A 5.5

Starting current A 38

3.52

16.3

79

External finish

Munsell 5Y 7/1

Refrigerant control

Capillary tube

Compressor

Hermetic

Model NHJ56YDAT

Motor output kW 2.7

Starter type

Line Start

Protection devices

V(L) : Inner thermostat,HP switch,LP switch

Y : Reversed-phase protector,Thermal switch,Thermal relay,HP switch,LP switch

Heat exchanger

Fan (drive) ~No.

Fan motor output kW 0.065+0.065

Airflow CMM,(CFM) 95(3352)

Noise level dB (A) 54

W mm, (in) 870(34-1/4)

Dimensions D mm, (in)

H mm, (in) 1258(49-1/2)

Weight kg, (lbs) 94(207)

Refrigerant

R-22

Charge kg, (lbs) 4.6(10.14)

NH56VNDT

2.7

3.8(8.38)

Pipe size O.D. Liquid mm, (in)

9.52(3/8)

Gas mm, (in)

(m)

(m)

19.05(3/4)

Connection method Indoor side

Flared

Outdoor side

Flared

Between the indoor Height difference 40

& outdoor unit Piping length 40

25,900

7,600

3.60

0.4

1.70

1.9

0.15

20- 25(700-800)

37-41

1175(46-1/8)

740(29-1/8)

325(12-13/16)

44(108)

PU-3YJC.UKPU-3VJC.UK PU-4YJSA.UKPU-4VLJSA.UK

3N~(3ph,4wires)

50Hz

380-415V

~(1ph)

50Hz

220-240V

3.20

5.3

36

3.20

13.9

68

3N~(3ph,4wires)

50Hz

380-415V

~(1ph)

50Hz

220-240V

NHJ52YDAT

2.2

NHJ52VNDT

2.2

Propeller(direct)X1

Propeller(direct)X2

0.085

50(1765)

52

870(34-1/4)

295+24(11-5/8 add 1) 295+24(11-5/8 add 1)

850(33-7/16)

73(161)

2.88(6.35)3.08(6.79)

15.88(5/8)

30

30

1. External static pressure at 130Pa. 4.Rating condition <JIS B 8615>

2. Ex-works at 70Pa(OPTION MOTOR :130Pa) INDOOR : 27˚CDB, 19 ˚CWB

3. External static pressure at 70Pa. OUTDOOR : 35 ˚CDB

5.Noise level : Sound pressure level

INDOOR UNIT

OUTDOOR

UNIT

REFRIGERANT

PIPING

✻

✻

✻

✻✻

✻

✻

✻

✻

✻

✻

Page 6

5

Model

PED-6EJSA.UKPED-5EJSA

1

.UK

Item

Cooling capacity

4 Btu/h 50,400

W 14,800

Total input 4 kW 5.84

Power supply

~(1ph),50Hz,220-240V

Input kW 0.66

Running current A 2.79

Starting current A 6.25

External finish

Galvanized sheets

Heat exchanger

Plate fin coil

Plate fin coil

Fan (drive) ~No.

Centrifugal (direct)x2

Fan motor output 1 kW 0.30

Airflow (Low-High) CMM,(CFM)

36.5- 46(1280-1620)

External static pressure 2 Pa(mmAq)

70(7)/130(13) at Hi-notch

Operation control & Thermostat

Remote control&Built-in

Noise level (Low-High)

3, 5 dB (A) 46-51

Cond. drain conn. O.D.

mm, (in)

32(1-1/4)

W mm, (in) 1715(67-1/2)

Dimensions

D mm, (in) 740(29-1/8)

H mm, (in) 325(12-13/16)

Weight

kg, (lbs) 70(154)

Model name

Power supply

Input kW 5.18

Running current A 8.48

Starting current A 74

External finish

Munsell 5Y 7/1

Refrigerant control

Capillary tube

Compressor

Hermetic

Model ZR72KCTFD

Motor output kW 4.2

Starter type

Line Start

Protection devices

Y : Reversed-phase protector,Thermal switch,Thermal relay,HP switch,LP switch

Heat exchanger

Fan (drive) ~No.

Fan moter output kW 0.065+0.065

Airflow CMM,(CFM) 100(3529)

Noise level dB (A) 56

W mm, (in) 970

Dimensions D mm, (in)

H mm, (in) 1258(49-1/2)

Weight kg, (lbs) 117(258)

Refrigerant

R-22

Charge kg, (lbs) 5.7(12.57)

Pipe size O.D. Liquid mm, (in)

9.52(3/8)

Gas mm, (in)

(m)

(m)

19.05(3/4)

Connection method Indoor side

Flared

Outdoor side

Flared

Between the indoor Height difference 45

& outdoor unit Piping length 45

42,300

12,400

5.3

0.64

2.72

6.0

0.40

33.5- 42(1180-1480)

44-50

1415(55-11/16)

740(29-1/8)

325(12-13/16)

65(143)

PU-5YJSA.UK PU-6YJSA.UK

3N~(3ph,4wires)

50Hz

380-415V

4.66

7.63

65.5

3N~(3ph,4wires)

50Hz

380-415V

ZR61KCTFD

3.5

Propeller(direct)X2

0.065+0.065

100(3529)

55

970

345+24(13-9/16 add 1) 345+24(13-9/16 add 1)

1258(49-1/2)

114(251)

5.1(11.24)

45

45

1. External static pressure at 130Pa. 4.Rating condition < JIS B 8615

>

2. Ex-works at 70Pa(OPTION MOTOR :130Pa) INDOOR : 27 DB, 19 WB

3. External static pressure at 70Pa. OUTDOOR : 35 DB

5.Noise level : Sound pressure level

INDOOR UNIT

OUTDOOR

UNIT

REFRIGERANT

PIPING

✻

✻

✻

✻

✻

✻

✻

✻

✻

✻

✻

Page 7

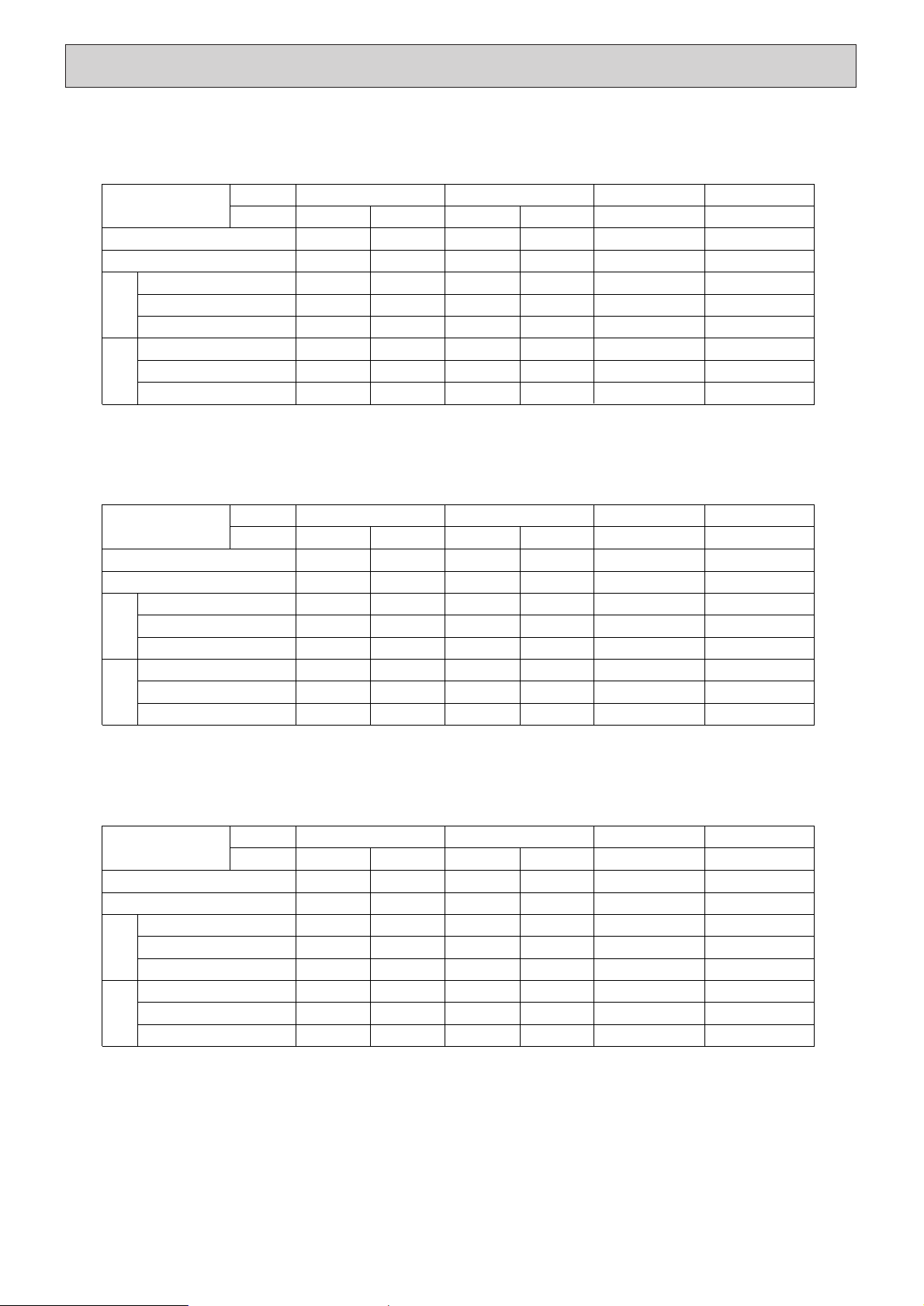

6

Service Ref.

Indoor

intake air

WB˚C

20 25 30 35 40 45

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

4.73 4.94 5.28 5.64

5.99

6.42

4.83 5.04 5.41 5.78 6.15 6.54

4.90 5.11 5.52 5.91 6.30 6.77

4.99 5.22 5.64 6.05 6.48 7.01

16

18

20

22

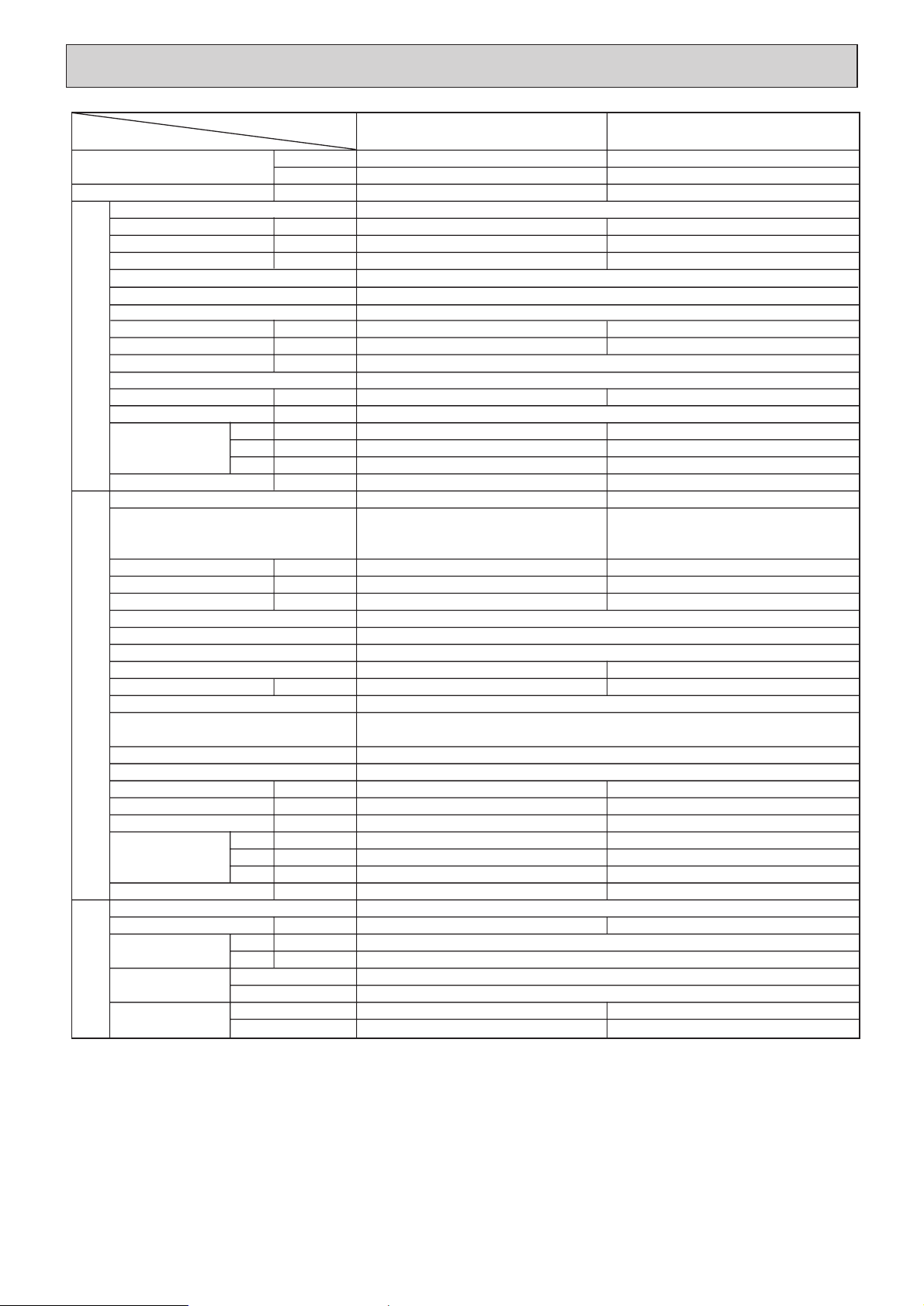

1. PERFORMANCE DATA

1) COOLING CAPACITY

Note C A: Capacity(W)

P.C.: Power consumption(kW)

PED6EJSA.UK

Service Ref.

Refrigerant piping length(one way)

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

2) COOLING CAPACITY CORRECTION FACTORS

12,623 4.29 12,276 4.48 11,780 4.79 11,247 5.12 10,689

5.44

10,118 4.33

13,429 4.38 13,083 4.57 12,549 4.91 12,003 5.25 11,433 5.58 10,851 4.64

14,247 4.45 13,913 4.64 13,367 5.01 12,797 5.36 12,215 5.72 11,619 4.97

15,078 4.53 14,793 4.74 14,223 5.12 13,640 5.49 13,045 5.88 12,425 5.31

16

18

20

22

PED5EJSA1.UK

9,875 3.22 9,603 3.36 9,215 3.60 8,798 3.84 8,361

4.08

7,915 3.24

10,505 3.29 10,234 3.43 9,816 3.69 9,390 3.93 8,943 4.19 8,488 3.48

11,145 3.34 10,883 3.48 10,457 3.76 10,010 4.04 9,555 4.29 9,089 3.73

11,795 3.40 11,572 3.56 11,126 3.84 10,670 4.13 10,204 4.42 9,719 3.99

16

18

20

22

PED4EJSA1.UK

7,737 2.91 7,524 3.04 7,220 3.26 6,893 3.48 6,551

3.69

6,201 2.94

8,231 2.98 8,018 3.10 7,691 3.34 7,357 3.56 7,007 3.79 6,650 3.15

8,732 3.02 8,527 3.16 8,193 3.40 7,843 3.65 7,486 3.88 7,121 3.37

9,241 3.08 9,067 3.22 8,717 3.48 8,360 3.73 7,995 4.00 7,615 3.61

16

18

20

22

PED3EJA1.UK

15,066 14,652 14,060 13,424 12,758 12,076

16,028 15,615 14,978 14,326 13,646 12,951

17,004 16,606 15,954 15,274 14,579 13,868

17,996 17,656 16,976 16,280 15,570 1,4830

PED- 6EJSA.UK

1.00 0.970 0.950 0.931

0.912 0.896 0.880 0.864 0.850 0.840

PED- 5EJSA1.UK

1.00 0.978 0.962 0.948

0.934 0.921

0.908 0.896

0.884 -

PED- 4EJSA1.UK

1.00 0.984 0.974 0.964

0.954 0.944

0.935 0.926

--

PED- 3EJA1.UK

1.00 0.978 0.962 0.948

0.934 0.921

--

--

4

DATA

Page 8

7

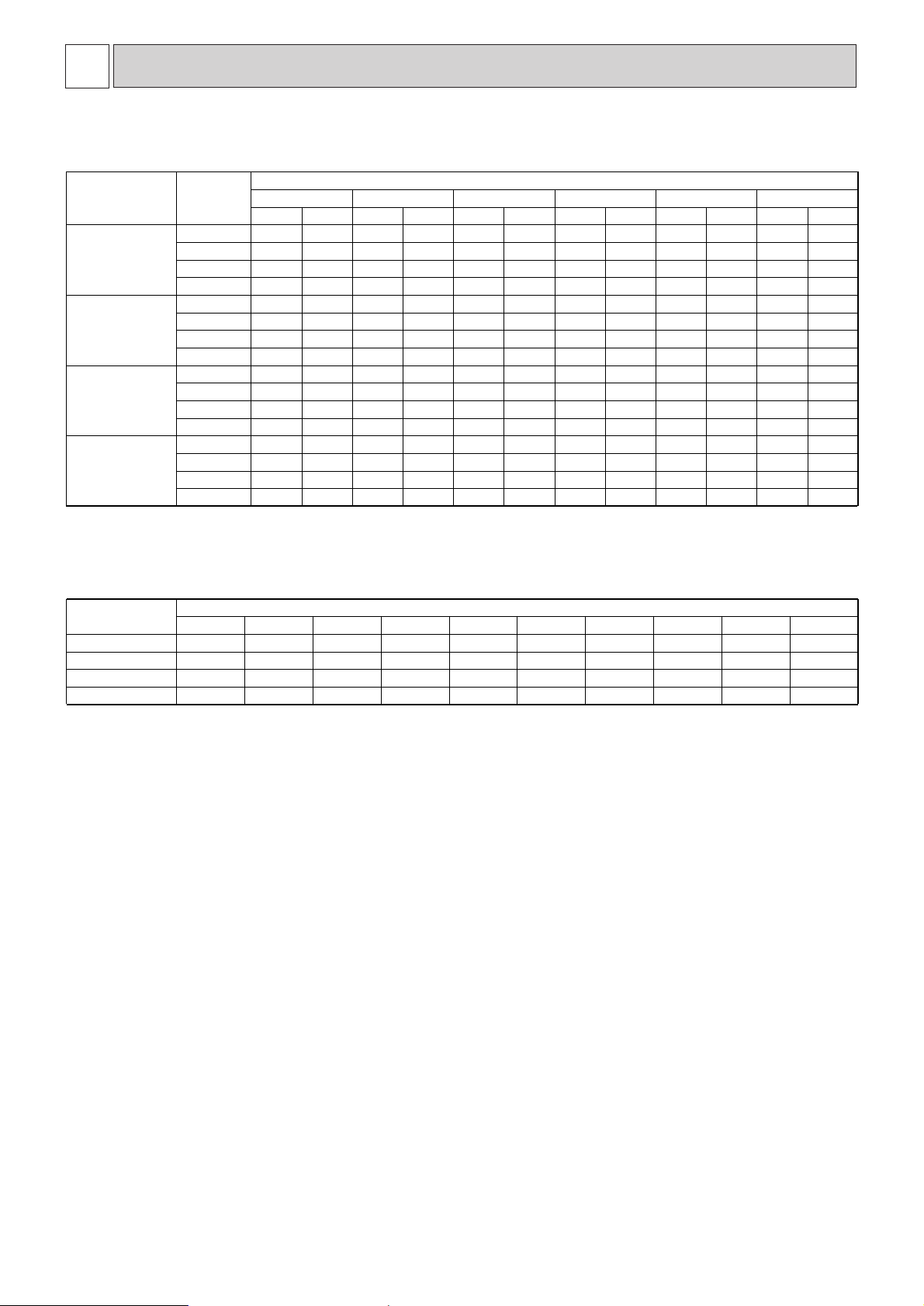

2. PERFORMANCE CURVE (CAPACITY RATIO & TOTAL INPUT RATIO)

Cooling

1.4

1.2

1

0.8

0.6

1.4

1.2

1

0.8

0.6

0.4

22

20

18

16

22

20

18

16

INDOOR WB

(˚C)

INDOOR WB

(˚C)

CAPACITY(RATIO)

TOTAL INPUT(RATIO)

OUTDOOR DB

(˚C)

-5 5 15 25 35 46

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

Page 9

8

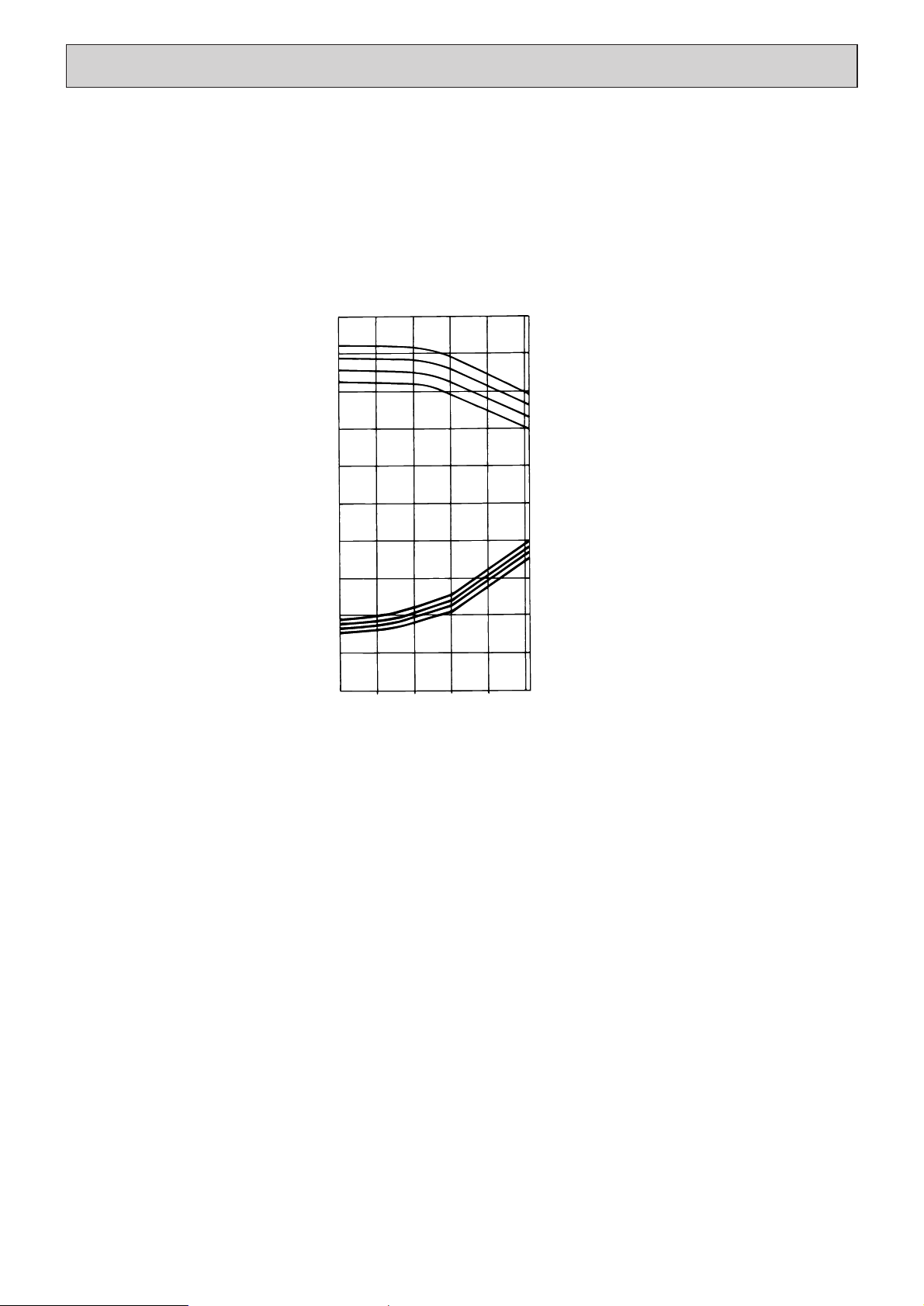

3. FAN PERFORMANCE AND CORRECTED AIR FLOW

Lo

Hi

140

120

100

200

180

160

80

60

40

20

12 16 20 24 28 32

Air flow

(CMM)

PED-3EJA1.UK

Fan performance <130pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

140

120

100

180

160

80

60

40

20

12 16 20 24 28 32

Air flow

(CMM)

Fan performance <70pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

Lo

Hi

Corrected Air Flow

Capacity

Input

1.1

1.0

0.9

0.8

12 16 20 24 28 32

Air flow (CMM)

Correction factor

Cooling

=

=

Lo

Hi

140

120

100

200

180

160

80

60

40

20

26 28 30 32 34 36 38 40

Air flow

(CMM)

PED-4EJSA1.UK

Fan performance <130pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

140

120

100

200

220

180

160

80

60

40

20

24 26 28 30 32 34 36 38

Air flow

(CMM)

Fan performance <70pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

Lo

Hi

Corrected Air Flow

Capacity

Input

1.1

1.0

0.9

0.8

24 26 28 30 32 34 36 38 40

Air flow (CMM)

Correction factor

Cooling

=

=

Page 10

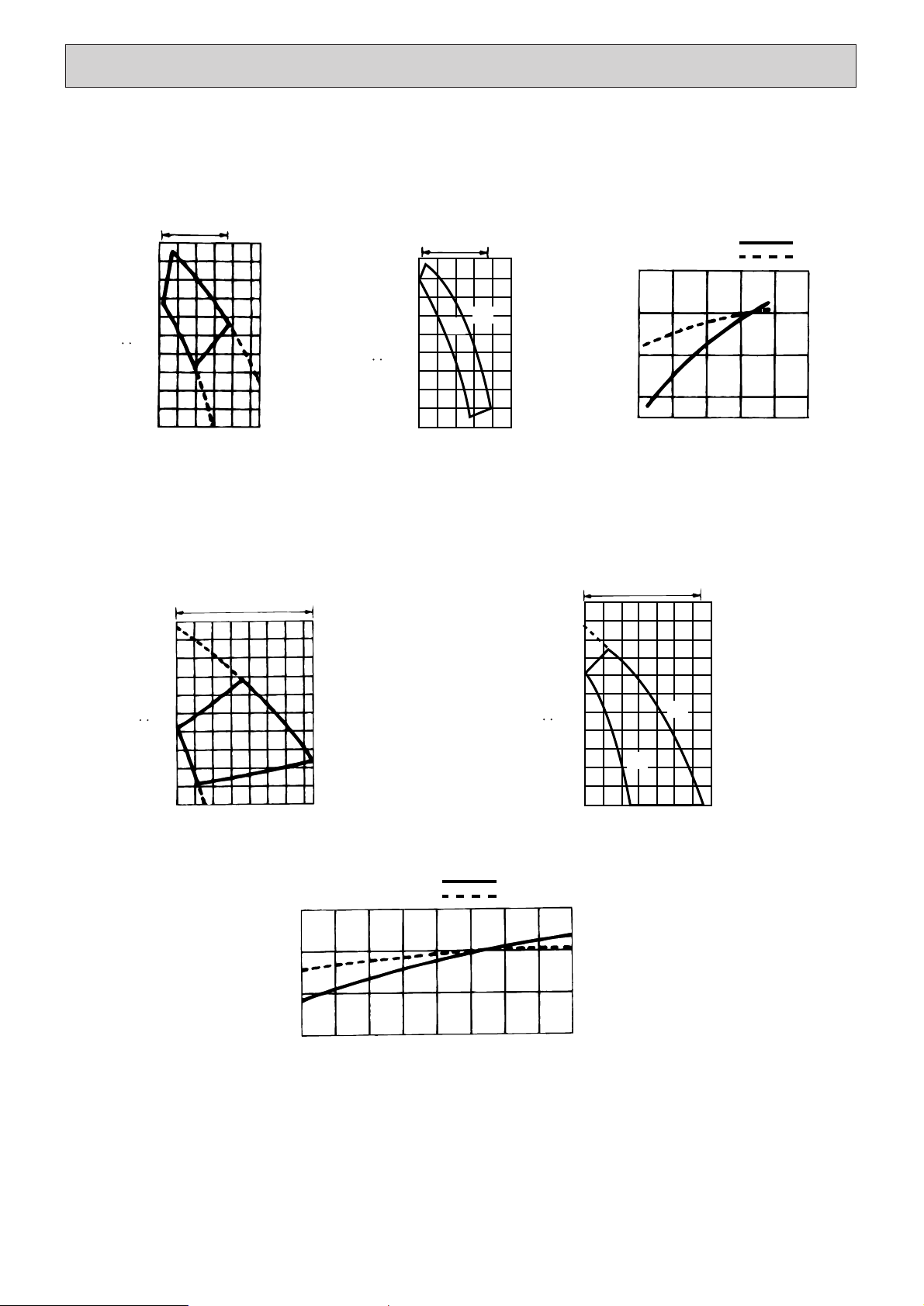

9

Lo

200

220

180

160

140

120

100

80

60

40

20

36 38 40 42 44 46 48 50

Air flow

(CMM)

PED-6EJSA.UK

Fan performance <130pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

52

=

Hi

Corrected Air Flow Capacity

Input

1.1

1.0

0.9

0.8

36 38 40 42 44 46

48 50

52

Air flow (CMM)

Correction factor

Cooling

Lo

Hi

200

180

160

140

120

100

80

60

40

20

36 38 40 42 44 46 48 50

Air flow

(CMM)

Fan performance <70pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

=

Lo

Hi

140

120

100

200

220

180

160

80

60

40

20

32 34 36 38 40 42 44 46 48

Air flow

(CMM)

PED-5EJSA1.UK

Fan performance <130pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

140

120

100

200

220

180

160

80

60

40

20

32 34 36 38 40 42 44 46

Air flow

(CMM)

Fan performance <70pa>

Recommended range

Extemal static pressure (Pa)

(1Pa 0.1mmAg)

Lo

Hi

Corrected Air Flow

Capacity

Input

1.1

1.0

0.9

0.8

32 34 36 38 40 42 44 46 48

Air flow (CMM)

Correction factor

Cooling

=

=

Page 11

10

4. ELECTRICAL DATA

Indoor ····· 220V 50Hz 1phase

Outdoor ··· 220/380V 50Hz 1/3phases

Indoor ····· 230V 50Hz 1phase

Outdoor ··230/400V 50Hz 1/3phases

Indoor ····· 240V 50Hz 1phase

Outdoor ··240/415V 50Hz 1/3phases

PU-5YJSAPU-4YJSA

PED-5EJSA

1

.UKPED-4EJSA1.UK

12,300

5.20

0.59

2.62

5.75

4.61

7.89

65.5

9,600

3.90

0.57

2.53

3.07

3.33

5.6

38

PU-4VLJSA

9,600

4.01

0.57

2.53

3.07

3.44

16.6

79

PU-3YJA

PED-3EJA1.UK

7,500

3.55

0.35

1.55

1.82

3.20

5.5

36

PU-3VJA

7,500

3.55

0.35

1.55

1.82

3.20

14.5

68

PU-6YJSA

PED-6EJSA.UK

14,700

5.76

0.61

2.69

6.00

5.15

8.56

74

PU-5YJSAPU-4YJSA

PED-5EJSA

1

.UKPED-4EJSA1.UK

12,400

5.30

0.64

2.72

6.00

4.66

7.63

65.5

9,700

3.98

0.62

2.64

3.20

3.36

5.5

38

PU-4VLJSA

9,700

4.14

0.62

2.64

3.20

3.52

16.3

79

PU-3YJA

PED-3EJA

1

.UK

7,600

3.60

0.40

1.70

1.90

3.20

5.3

36

PU-3VJA

7,600

3.60

0.40

1.70

1.90

3.20

13.9

68

PU-6YJSA

PED-6EJSA.UK

14,800

5.84

0.66

2.79

6.25

5.18

8.48

74

PU-5YJSAPU-4YJSA

PED-5EJSA

1

.UKPED-4EJSA1.UK

12,200

5.10

0.54

2.50

5.50

4.56

8.15

65.5

9,500

3.81

0.52

2.41

2.93

3.29

5.7

38

PU-4VLJSA

9,500

3.87

0.52

2.41

2.93

3.35

16.9

79

PU-3YJA

PED-3EJA

1

.UK

7,400

3.48

0.30

1.39

1.74

3.18

5.7

36

PU-3VJA

7,400

3.48

0.30

1.39

1.74

3.18

15.1

68

PU-6YJSA

PED-6EJSA.UK

14,600

5.67

0.56

2.59

5.75

5.11

8.63

74

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

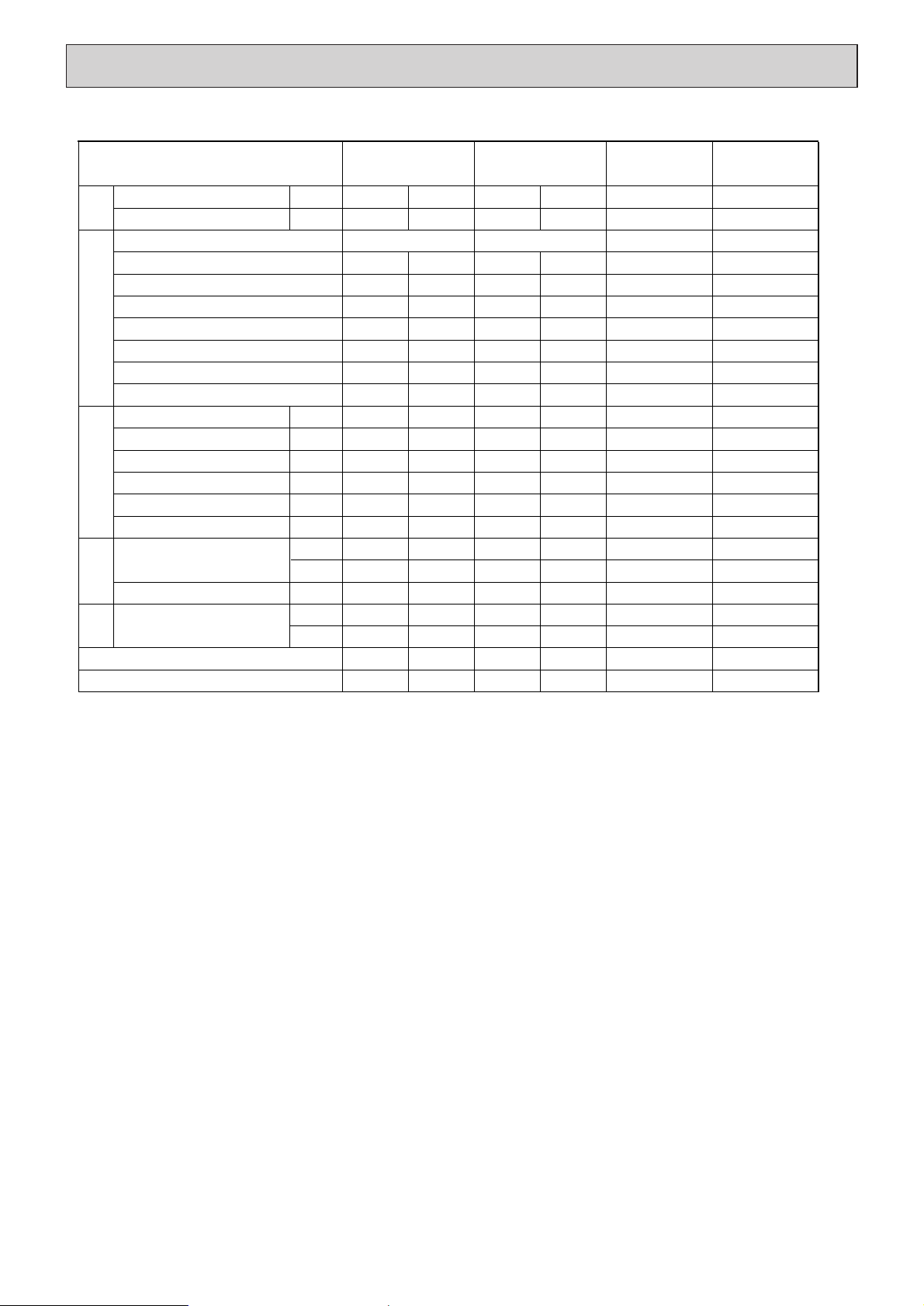

Page 12

11

Models

TotalElectrical circuitRefrigerant circuit

Indoor side

Outdoor

side

SHF

BF

Capacity

Input

Indoor unit model

Phase Hz

Volts

Amperes

Outdoor unit-model

Phase,Hz

Volts

Amperes

W

kW

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref.Pipe length

Intake air temperature

Intake air temperature

Diischarge air temperature

MPa

MPa

˚C

˚C

˚C

m

DB˚C

WB˚C

DB˚C

DB˚C

WB˚C

5. STANDARD OPERATION DATA (COOLING)

PED-5EJSA1.UK

12,400

5.30

PED-5EJSA

1

1.50

240

2.72

PU-5YJSAPU-4YJSA

3.50

415

7.63

1.84

0.40

82.9

49.3

0.3

5

27.0

19.0

15.5

35.0

24.0

0.85

0.13

9,700

4.14

1.50

240

2.64

PU-4VLJSA

1.50

240

16.3

1.80

0.52

82.1

48.5

8.1

5

27.0

19.0

15.7

35.0

24.0

0.80

0.22

9,700

3.98

1.50

240

2.64

3.50

415

5.5

1.81

0.52

74.0

48.7

8.5

5

27.0

19.0

16.0

35.0

24.0

0.80

0.22

PED-6EJSA.UKPED-4EJSA

1

.UK

14,800

5.88

PED-6EJSAPED-4EJSA

1

PU-3YJC

7,600

3.60

1.50

240

1.70

PU-3VJC

1.50

240

13.9

2.03

0.50

62.2

53.6

9.4

5

27.0

19.0

15.5

35.0

24.0

0.78

0.21

7,600

3.60

1.50

240

1.70

3.50

415

5.3

2.02

0.49

79.1

53.3

9.0

5

27.0

19.0

14.8

35.0

24.0

0.78

0.20

PED-3EJA

1

.UK

PED-3EJA

1

1.50

240

2.79

PU-6YJSA

3.50

415

8.47

2.07

0.46

78.3

53.6

4.3

5

27.0

19.0

13.6

35.0

24.0

0.74

0.14

Page 13

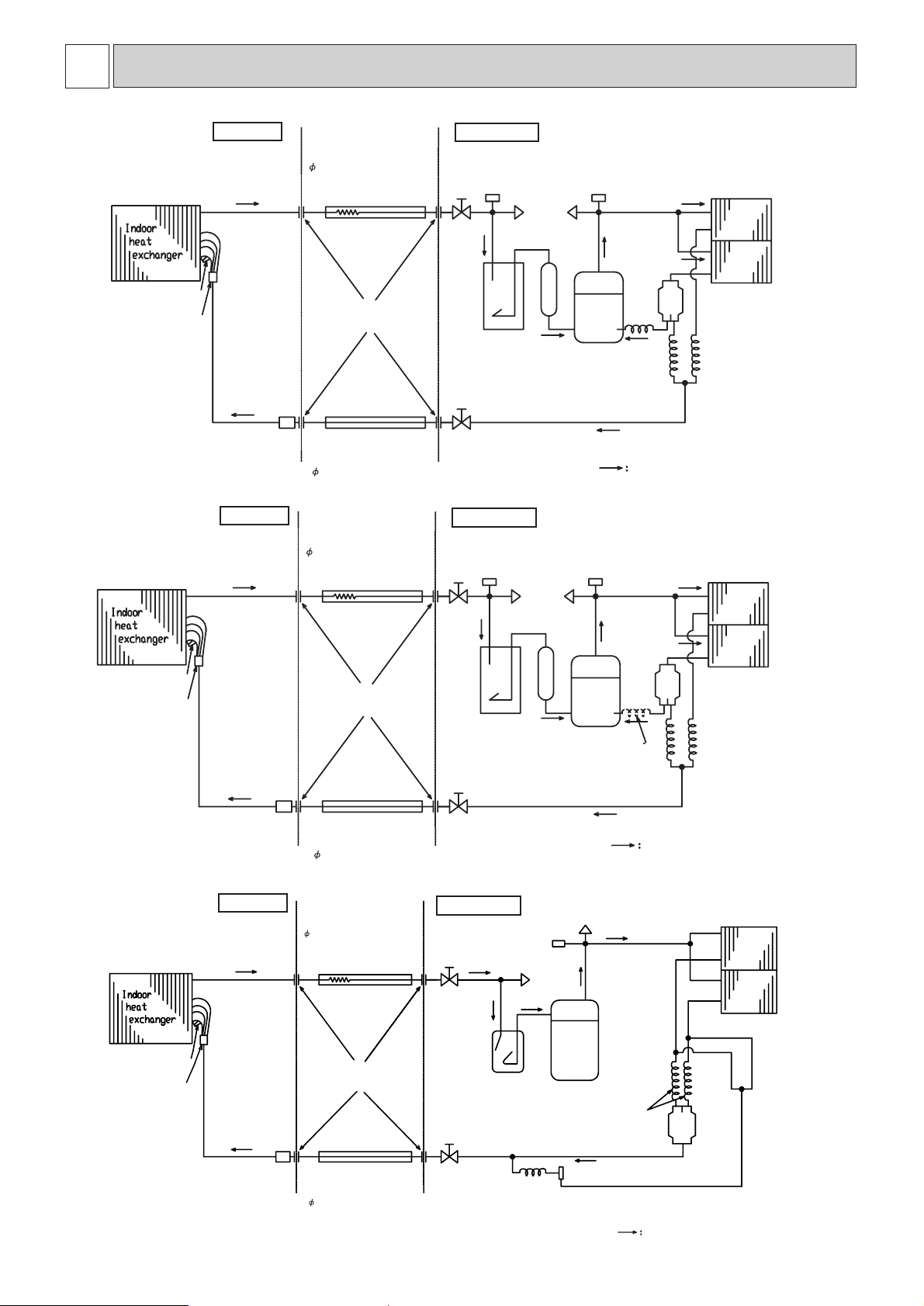

12

5

REFRIGERANT SYSTEM DIAGRAM

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

Strainer

Strainer

Strainer

Refrigerant pipe

(option)

9.52mm(3/8)

(With heat insulator)

Refrigerant pipe

(option)

9.52mm(3/8)

(With heat insulator)

Refrigerant pipe

(option)

9.52mm(3/8)

(With heat insulator)

Ball valve

(With service port)

Ball valve

(With service port)

Ball valve

(With service port)

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Capillary tube

O.D.4.0XI.D.2.4-L=400

(O.D.4.0XI.D.2.4-L=840)X2pcs

(O.D.3.2XI.D.2.0-L=840)X2pcs

(O.D.3.2XI.D.1.8-L=800)X2pcs

PU-3YJC(O.D.3.2XI.D.1.4-L=800)

PU-3VJC(O.D.3.2XI.D.2.0-L=500)

Strainer

Strainer

Strainer

Compressor

Compressor

Compressor

Outdoor heat

exchanger

Outdoor heat

exchanger

Outdoor heat

exchanger

Check

plug

Check

plug

Check

plug

High pressure

switch

High pressure

switch

High pressure

switch

Low pressure

switch

Low pressure

switch

Charge

plug

Charge

plug

Charge

plug

Accumulator

Accumulator

Ball

valve

Ball

valve

Ball

valve

Flexible tube

Flexible tube

Flexible tube

Flared

connection

Flared

connection

Flared

connection

Thermistor

RT2

Thermistor

RT2

Thermistor

RT2

Distributor

Distributor

Distributor

Refrigerant pipe

(option)

19.05mm(3/4)

(With heat insulator)

Refrigerant pipe

(option)

19.05mm(3/4)

(With heat insulator)

Refrigerant pipe

(option)

15.88mm(5/8)

(With heat insulator)

PU-5YJSA2.UK

PU-4Y(VL)JSA2.UK

PU-3V(Y)JC.UK

flow of refrigerant

flow of refrigerant

flow of refrigerant

Capillary tube for

injection

Only PU-4YJSA(O.D.3.2XI.D.1.2-L=500)

*1

*1

Indoor unit

Indoor unit

Indoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Page 14

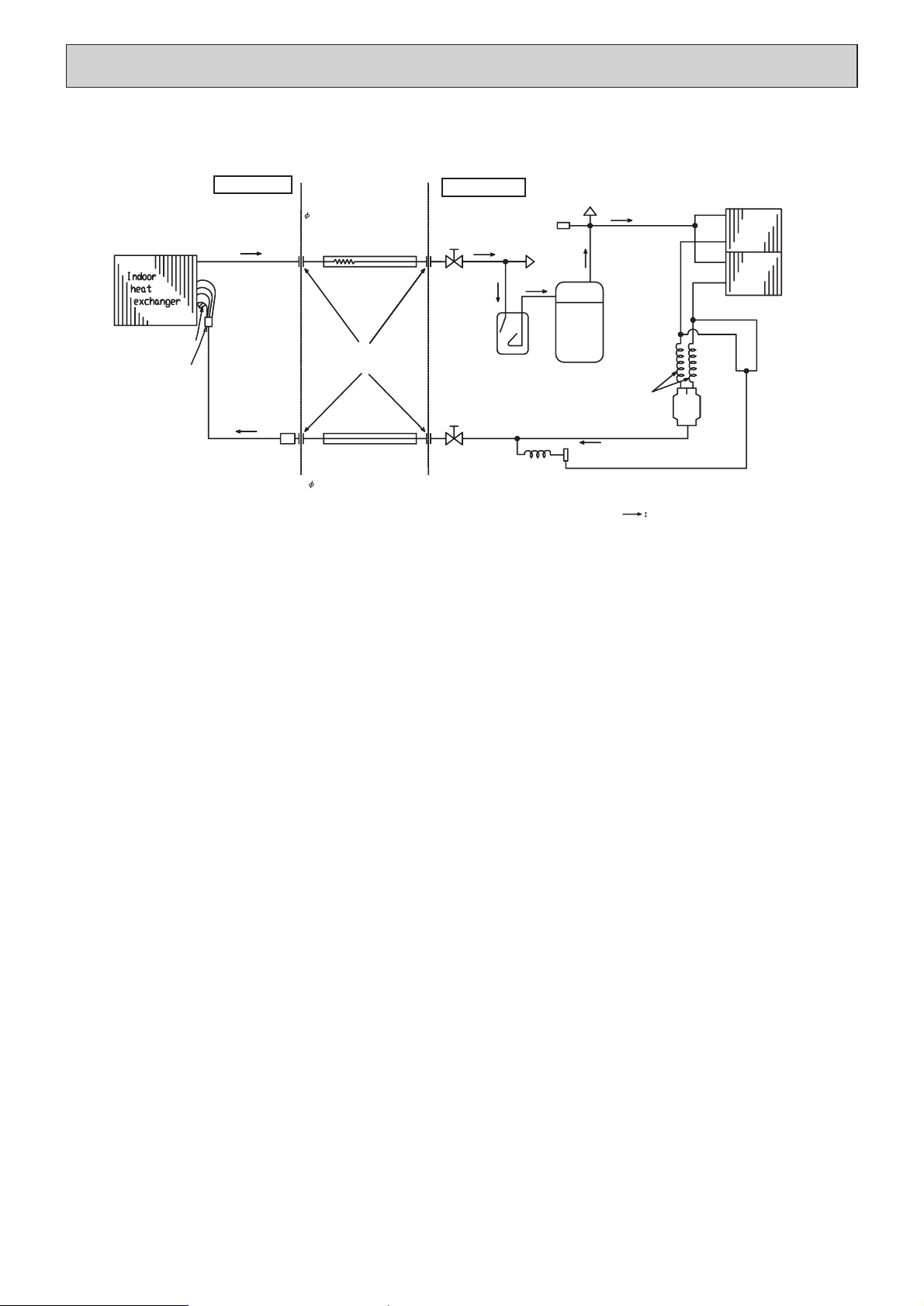

13

PED-6EJSA.UK

Strainer

Refrigerant pipe

(option)

9.52mm(3/8)

(With heat insulator)

Ball valve

(With service port)

Capillary tube

Capillary tube

O.D.4.0XI.D.2.4-L=200

(O.D.4.0XI.D.2.4-L=1200)X2pcs

Strainer

Compressor

Outdoor heat

exchanger

Check

plug

High pressure

switch

Charge

plug

Accumulator

Ball

valve

Flexible tube

Flared

connection

Thermistor

RT2

Distributor

Refrigerant pipe

(option)

19.05mm(3/4)

(With heat insulator)

PU-6YJSA.UK

flow of refrigerant

Indoor unit

Outdoor unit

Page 15

14

6

OUTLINES & DIMENSIONS

1. INDOOR UNIT

210

12-ø3

450

450

140

282

680

3 3

30

319

261

181 40

30

A

C B 81

10

375

10

80

C B 81

A

E 13

30

D

20

35

30

1053 169

307

113

122

12-ø3

(14x22)

Lifting bolt hole

45

163

323

308

44 75

6

5

13

Keep duct-work length 850mm or more.

Be sure to apply the air filter (field supply) near the air inlet grille.

Service space:500 or more

81

365~465

197

81

50~150

55

Access door

Air outlet

Air inlet

3

1

2

4

1 Refrigerant piping flare connection (liquid ø9.52 copper tube) : HP

2 Refrigerant piping flare connection (gas øF copper tube) : LP

3 Drain 25A (male screw)

4 Electrical parts box

5 Drain Pump (Option)

6 Drain Pipe (Option)···Use VP25 (O.D.ø32 PVC TUBE)

)

Set

Model

PED-3

PED-4·5

PED-6

A

1012

1252

1552

B

280

360

460

C

290

370

470

D

1070

1310

1610

E

1044

1284

1584

F

15.88

19.05

19.05

2. REMOTE CONTROLLER

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

Page 16

15

31

312

3124321

3

2

1

321

13 137

Drain sensor

Drain pump

Drain sensor connector

Drain pump connector

*

DS

*

DP

CN50

CNP

fig:*1

220V

230V

220 RED

230 ORANGE

240 YELLOW

NOTES

1.Since the indoor transfomer(T) is connected with 240V power. if 220,230V

power is used, Change the wiring connection shown in fig:

*

1

When power supply is

(indoor/outdoor connecting line)Terminal block

NAME

NAME NAME

SYMBOL EXPLANATION(

*

···· Option parts)

LD3<R.B>

F1,2<I.B>

CNR120<R.B>

CN51<I.B>

Connector (remote controller)

Capacitor (fan motor)

C

SYMBOL

LD5<R.B>

Auxiliary relay (fan motor)X5,X6(I.B)

Thermistor (pipe temperature sensor

0˚C/15kΩ.25˚C/5.4kΩ)

Terminal block (power)TB1

SYMBOL

SYMBOL

LD4<R.B>

CN120<I.B>

I.B

TB2

ZNR<I.B>

T

RT1

RT2

Indoor controller board

Fuse <6.3A>

Varistor

Transformer

X1(I.B) Auxiliary relay (drain pump)

Thermistor (room temperature sensor

0˚C/15kΩ.25˚C/5.4kΩ)

LD7<R.B>

LD8<R.B>

LD1<R.B>

Run indicator LED

Connector (centrally control)

Connector (remote controller)

Cooling indicator LED

Fan mode indicator LED

Fan high indicator LED

Indicator mode temperature LED

Indicator mode timer LED

LD12<R.B>

LD11<R.B>

LD10<R.B>

LD9<R.B>

Dry indicator LED

Fan low indicator LED

Off timer indicator LED

On timer indicator LED

LD13-24

<R.B>

Temperature/Timer remaining

time indicator LED

MF Indoor Fan motor

Function switchSW1(I.B)

SW2(I.B) Unit switch

SW3(I.B) Emergency operation switch

SW1(R.B) ON/OFF switch

SW2(R.B) Operation mode switch

SW3(R.B) Fan hige/low switch

SW5(R.B) Indicator switch

SW6(R.B) Temperature and timer setting up switch

SW7(R.B) Temperature and timer setting down switch

SW8(R.B) Timer continuous ON/OFF switch

R.B Remote controller board

GRN/YLW

BRN

BRN

BLU

BLK

BLK

GRY

GRY

YLW

GRN/YLW

BLU

RED

ORN

YLW

GRN/YLW

BLU

BLK

RED

WHT

WHT

ORN

YLW

WHT

RED

AC10.6V

AC14.5V

BRN

RED

TRANSMISSION WIRES

12VDC 12CORE CONNECTOR

TO OUTDOOR UNIT

CONNECTING WIRES

12VDC(non - polar)

CN31

HEATER

CN51

MULTIPLE

BLU

2

1

4321

DS

43 1

OFF

ON

SW5

SW8

SW3

SW2

ON

OFF

SW1

R.B

SW3

I.B

CN50

DRAIN

CN21

PIPE

CN20

INTAKE

1122

2

5

RT2

RT1

SW2

SW1

31

CND

POWER

OFF

ON

LD8 LD7

LD13

LD14

LD15

LD16

LD17

LD18

LD19

LD20

LD21

LD22

LD23

LD24

LD1

LD3

LD9

LD4

LD5

LD10

LD11

LD12

SW6

SW7

NOTES

[Check items]

(1)

(2)

[Emergency operation procedure]

MODELS: PED-3EJA1, PED-4EJSA1, PED-5EJSA1, PED-6EJSA WIRING DIAGRAM

X6X1 X5

ZNR

F2

T

CN4T

TRANS

CNT

TRANS

FAN1

F1

:OPTION PARTS

pressure 130Pa

External static

pressure 70Pa

External static

WHITE

RED

24 23

C

53 61

MF

DP

PE

BREAKER

TO DUCT

TB2

CN30

OUTDOOR

CN120

TO RC

TB1

N

L

POWER SUPPLY

~(1phase)

220 - 240VAC 50Hz

C

5461

MF

CNR120

Since the outdoor side electric wiring may change be sure

to check the outdoor unit electric wiring for servicing.

Symbols used in circuit diagram above are, :Terminal

block, :connector.

Emergency operation

If trouble occurs with either the remote controller or the

indoor microcomputer and no other trouble exists,emergency operation for cooling can be performed by changing

the setting of dip switch(SW3<I.B>)on the indoor controller

board (emergency dry operation is not possible).

Make sure that no other trouble exists with the outdoor unit.Trouble

with the outdoor unit prevents emergency operation.

(If any trouble exists with the outdoor unit, the trouble location will

be displayed on the remote controller and the trouble position will

be shown on the outdoor controller board LED.See electric circuit

diagram of the outdoor unit for details.)

Make sure that there is no trouble with the indoor fan.

Emergency operation will be a continuous run with operation by the

power ON/OFF(ON/OFFwith the remote controller is not possible).

Set the dip switch(SW3<I.B>)on the indoor controller board to 1 ·

2 on and 3 off for cooling.

Turn on the outdoor unit side circuit breaker.

During emergency operation indoor fan runs at High speed.

Thermostat will not function.Cold air blows out for defrosting during

heating thus do not operate defrosting for a long time.

Emergency cooling should be limited to 10 hours maximum(the

indoor unit heat exchanger may freeze).

(1)

(2)

(3)

(4)

(5)

1.

2.

3.

7

WIRING DIAGRAM

Page 17

16

8

DISASSEMBLY INSTRUCTIONS

Disconnect

the fan motor connecter

Drain pan

catches (Hidden)

Drain pan

catches (Hidden)

Filter

Bottom plate

Drain pan

Heat exchanger

Bottom plate

assembly

1

2

A

Figure1.

!!

. Removing the fan motor

1. Removing the 9 screws that fix the bottom plate A, and

remove it.

2. Removing the drain pan as follows:

(1) Remove the screw that fixes the drain pan.

(2) Slide the drain pan in the direction 1, Figure1 and

unhook the drain pan catch near the drain pipe.

(3) Slide the drain pan in the direction 2, Figure1 and

unhook the 2 catches on the other side of the drain

pipe.

3. Remove the 8 screws that fix the bottom plate

assembly, and remove it.

4. Disconnect the fan motor connector from the controller

box.

5. Remove the fan plate as follow:

Figure2.

(1)Remove the 4 screws 1

(2)Slide down the fan plate to remove.

6. Remove the sirocco fan setting screw and the motor

fixture setting screw to remove the motor fixture.

Remove the other motor fixture as well, and then remove

the fan motor.

1

1

Fan base

Page 18

17

Figure3.

Fan base

Sirocco fan

Sirocco fan

Housing assembly

Housing

assembly

Piece

Piece

Leg

Bush

Bush

Motor

Motor base

(Only PED-3)

Page 19

18

@@

. Removing the drain water lift-up pump

1. Remove the drain pan. (Refer 1- 2.)

2. Disconnect the drain pump connector and drain sensor

connector from the controller box.

3. Remove the two screws of the pump cover assembly.

4. Remove the drain hose from drain socket.

5. Remove the three screws of the drain pump assembly.

6. Remove the earth screw and four nuts of the drain

pump assembly.

7. Remove the drain pump from drain pump assembly.

Figure4.

Pump cover

Drain socket

assembly

Drain pump

assembly

Drain hose

Rubber plug

Drain pan cover

1

2

Drain pan

Page 20

19

9

PARTS LIST

14.15.16

1.2.3

11.12.13

4.5.6

7.8.9.10

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part No. Part Name Drawing No.

Qt'y/set

Spec.

W631101Z04

W631188G02

W264221G03

W631186G01

W630129G01

Bottom plate 1

W634050Z01Bottom plate 1

W634028Z01Bottom plate 1

Bottom plate 2 ass'y

W634030G01Bottom plate 2 ass'y

W634052G01Bottom plate 2 ass'y

H.EX.General ass'y

W262881G03H.EX.General ass'y

W262863G06H.EX.General ass'y

W262863G05H.EX.General ass'y

Drain pan ass'y

W634034G01Drain pan ass'y

W634056G01Drain pan ass'y

Filter

W611960G04

Filter

W611960G05

Filter

PED-

6EJSA

PED-

5EJSA

PED-

4EJSA

PED3EJA

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

EXTERNAL PARTS

Page 21

20

8

9

2

1

2

1.17

6.7

6.7

10.11.12

15.16

13.14

9

8

3.4.5

18

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Part No. Part Name Drawing No.

PED-

6EJSA

Qt'y/set

with a nut

20-25L

R02K338H02 222

22

22

222

2

2

2

2

22

2

1

1

1

1

11

1

1

1

1

1

1

2

2

2

1

1

2

R02K338G82

W631187G01

W860050H02

W631126G01

W631120G01

P714614X01

W631122Z04

P412223X01

<MF>250W,1Phase

<MF>240W,1Phase

220~240V

220~240V

220~240V

<C>

R60 508 131

Piece

Piece

Fan base ass'y

W634036G01Fan base ass'y

W634058G01Fan base ass'y

Bush

Sirocco fan

Housing ass'y

Motor

P714659X01Motor

P714661X01Motor

Leg

Capacitor 16

P412172X01

Capacitor 6

R60 508 132

R61 Y01 104

W491760H02BushR61 766 104

R61 Y17 221

R61 Y21 221

R61 Y20 221

W241060H03Motor supportR61 652 130

W353715H01AttachmentR61 652 131

W634069Z01Motor base

PED-

5EJSA

PED-

4EJSA

PED3EJA

: Not illustrated

<MF>150W,1Phase

✽

✽

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

BLOWER PARTS

Page 22

21

6

5

3

4

7

2

1

7

No.

1

2

3

4

5

6

7

8

9

10

Part No. Part Name Drawing No.

P436109X01

P436110X01

BG00L760G22

BG65T178H03

BG71V161H04

BG71V162H08

P419114X01

PED-

6EJSA

Qt'y/set

Spec.

<TB2>

<TB1>

<I.B.>

<T>

<RT1>

<RT2>

R61 978 247 Terminalbed

Terminalbed

Controller

Transformer

Thermistor S

Thermistor H

Ferrite core

R61 979 247

PED-

5EJSA

PED-

4EJSA

PED3EJA

1111

1111

1111

1111

1111

1111

2222

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

CONTROL BOX PARTS

Page 23

22

1

2

3

No.

1

2

3

4

5

Part No. Part Name Drawing No.

BC00C006G34

BG00K507G02

BG78R190G10

Qt'y/set

Spec.

J controller

10m

0.5m

Remote controller

Remote controller cable

Cable ( for board )

1111

1111

1111

PED-

6EJSA

PED-

5EJSA

PED-

4EJSA

PED3EJA

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

ELECTRICAL PARTS

Page 24

23

3

4

1.2

5

No.

1

2

3

4

5

Part No. Part Name Drawing No.

BG56J144G13

DB26F111H03

BB00P145G17

DE00H343G21

P312040X01

Qt'y/set

Spec.

Drain pump-94

Cushion

Drain socket ass'y

Drain sensor ass'y

Rubber plug

R61 E96 558

PED-

6EJSA

PED-

5EJSA

PED-

4EJSA

PED3EJA

1111

4444

1111

1111

1111

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

DRAIN WATER LIFT-UP PUMP PARTS

Page 25

24

10

OPERATION FLOW-CHART

PED-3EJA1.UK

PED-4EJSA

1.UK

PED-5EJSA

1.UK

PED-6EJSA.UK

Page 26

252627

Page 27

Page 28

Page 29

28

11

MICROPROCESSOR CONTROL

Page 30

29

l

Page 31

30

l

Page 32

31

l

l

after

Page 33

323334

Page 34

Page 35

12

TROUBLE SHOOTING

Page 36

35

Page 37

36

PED-4EJSA1.UK,PED-5EJSA1.UK,PED-6EJSA.UK

PED-3EJA1.UK

PAC-05FFS-E

PAC-07FFS-E

PAC-10FFS-E

PAC-15FFS-E

15.88

13

OPTIONAL PARTS

Page 38

373839

Page 39

Page 40

wrap

wrap

wrap

Page 41

40

s

Page 42

41

1

5

Power

supply

BRN

RED

ORN

YRW

GRN

BRN

RED

ORN

YRW

GRN

JST

XHP3

<Wiring>

CN51

connector(5P)

Optional multiple

display adaptor

The maximum distance between

indoor board and relay is 10m.

Wiring at the actual

place

Electrical insulation is needed.

BROWN

RED

ORANGE

YELLOW

GREEN

X1

X2

Page 43

42

8. OPTIONAL MOTOR

The external static pressure of 130Pa allows long ducts to be used more extensively to enable the most convenient

positioning of indoor units.

9. DRAIN WATER LIFT-UP MECHANISM

This allows more versatility when selecting drain piping layouts.

Part No. PAC-SK005MT-F

PAC-SK004MT-F

PAC-SK003MT-F

PED-3EJA

1

.UK

PED-4EJSA

1

.UK

PED-5EJSA

1

.UK, PED-6EJSA.UK

Applied model

Part No. PAC-SK001DM-F

PED-3EJA

1

.UK, PED-6EJSA.UK

Applied model

Page 44

HEAD OFFICE MITSUBISHI DENKI BLDG. MARUNOUCHI TOKYO100 TELEX J24532 CABLE MELCO TOKYO

MEE99K001

Issued in July. 1999

Printed in Japan

New publication, effective July. 1999

Specifications subject to change without notice.

TM

Loading...

Loading...