Mitsubishi Electric PLA-SM100EA, SUZ-SA71VA3, SUZ-SA100VA2, PEAD-SM71JA(L), PLA-SM71EA Service Manual

...

TECHNICAL & SERVICE MANUAL

No.TCH030

R410A

Outdoor unit

[Model Name]

[Service Ref.]

SUZ-SA71VA3 SUZ-SA71VA3.TH

SUZ-SA100VA2 SUZ-SA100VA2.TH

CONTENTS

1.

COMBINATION OF INDOOR AND OUTDOOR UNITS

.....

2

2. TECHNICAL CHANGES

...................................

3

3. PARTS NAMES AND FUNCTIONS

..................

6

4. SPECIFICATION

................................................

7

5. NOISE CRITERIA CURVES

..............................

9

6. OUTLINES AND DIMENSIONS

......................

10

7. WIRING DIAGRAM

...........................................

11

8. REFRIGERANT SYSTEM DIAGRAM

.............

13

9. ACTUATOR CONTROL

...................................

14

10. SERVICE FUNCTIONS

....................................

15

11. TROUBLESHOOTING

.....................................

15

12. DISASSEMBLY INSTRUCTIONS

....................

31

Indication of

model name

Note:

•

This service manual describes

technical data of the outdoor

units only.

HFC

utilized

R410A

January 2018

PARTS CATALOG (TCB030)

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

2

TCH030 TCH030

1

COMBINATION OF INDOOR AND OUTDOOR UNITS

Note: Please refer to the service manual of indoor unit or the technical data book for the combination data.

INDOOR UNIT SERVICE MANUAL

Model Name Service Ref. Service Manual No.

PLA-SM71/100EA PLA-SM71/100EA.UK

OCH683

OCB683

PEAD-SM71/100JA(L) PEAD-SM71/100JA(L) .UK

HWE17010

BWE017160

3

2

TECHNICAL CHANGES

Refrigerant

oil

Refrigerant

New refrigerant

R410A

HFC-32: HFC-125 (50%:50%)

Pseudo-azeotropic refrigerant

Not included

A1/A1

72.6

−51.4

1.557

64

Non combustible

0

1730

From liquid phase in cylinder

Possible

Incompatible oil

None

None

Previous refrigerant

R22

R22 (100%)

Single refrigerant

Included

A1

86.5

−40.8

0.94

44.4

Non combustible

0.055

1700

Gas phase

Possible

Compatible oil

Light yellow

None

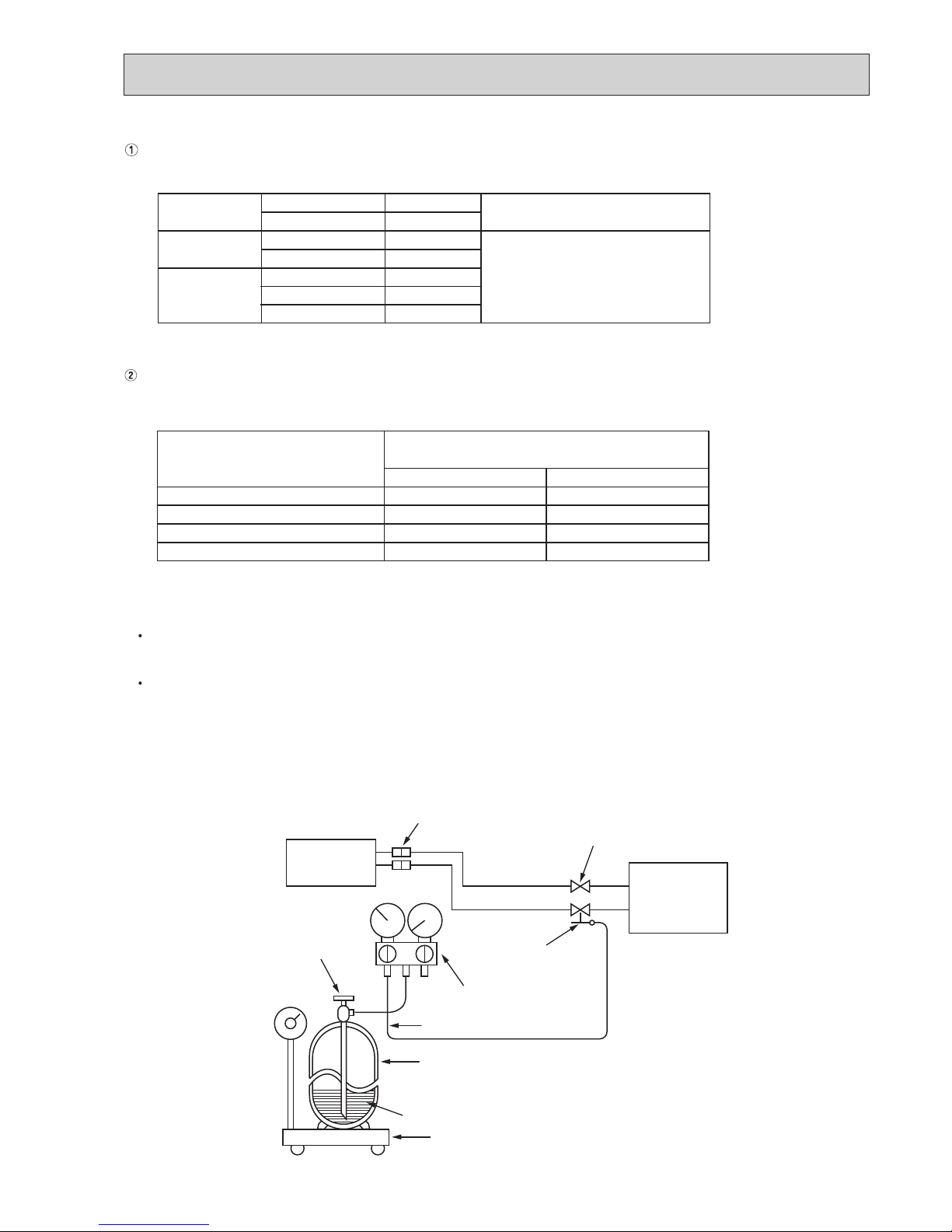

Refrigerant

Composition (Ratio)

Refrigerant handling

Chlorine

Safety group (ASHRAE)

Molecular weight

Boiling point (°C)

Steam pressure [25°C](Mpa)

Saturated steam density [25°C](Kg/K)

Combustibility

ODP *1

GWP *2

Refrigerant charge method

Additional charge on leakage

Kind

Color

Smell

*1: Ozone Depletion Potential : based on CFC-11

*2: Global Warming Potential : based on CO

2

INFORMATION FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

• This room air conditioner adopts an HFC refrigerant (R410A) which never destroys the ozone layer.

• Pay particular attention to the following points, though the basic installation procedure is same as that for R22 conditioners.

As R410A has working pressure approximate 1.6 times as high as that of R22, some special tools and piping parts/materi-

als are required. Refer to the table below.

Take sufficient care not to allow water and other contaminations to enter the R410A refrigerant during storage and installa-

tion, since it is more susceptible to contaminations than R22.

For refrigerant piping, use clean, pressure-proof parts/materials specifically designed for R410A. (Refer to 2. Refrigerant

piping.)

Composition change may occur in R410A since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent

composition change.

NOTE : The unit of pressure has been changed to MPa on the international system of units (SI unit system).

The conversion factor is: 1 (MPa [Gauge]) =10.2 (kgf/cm

2

[Gauge])

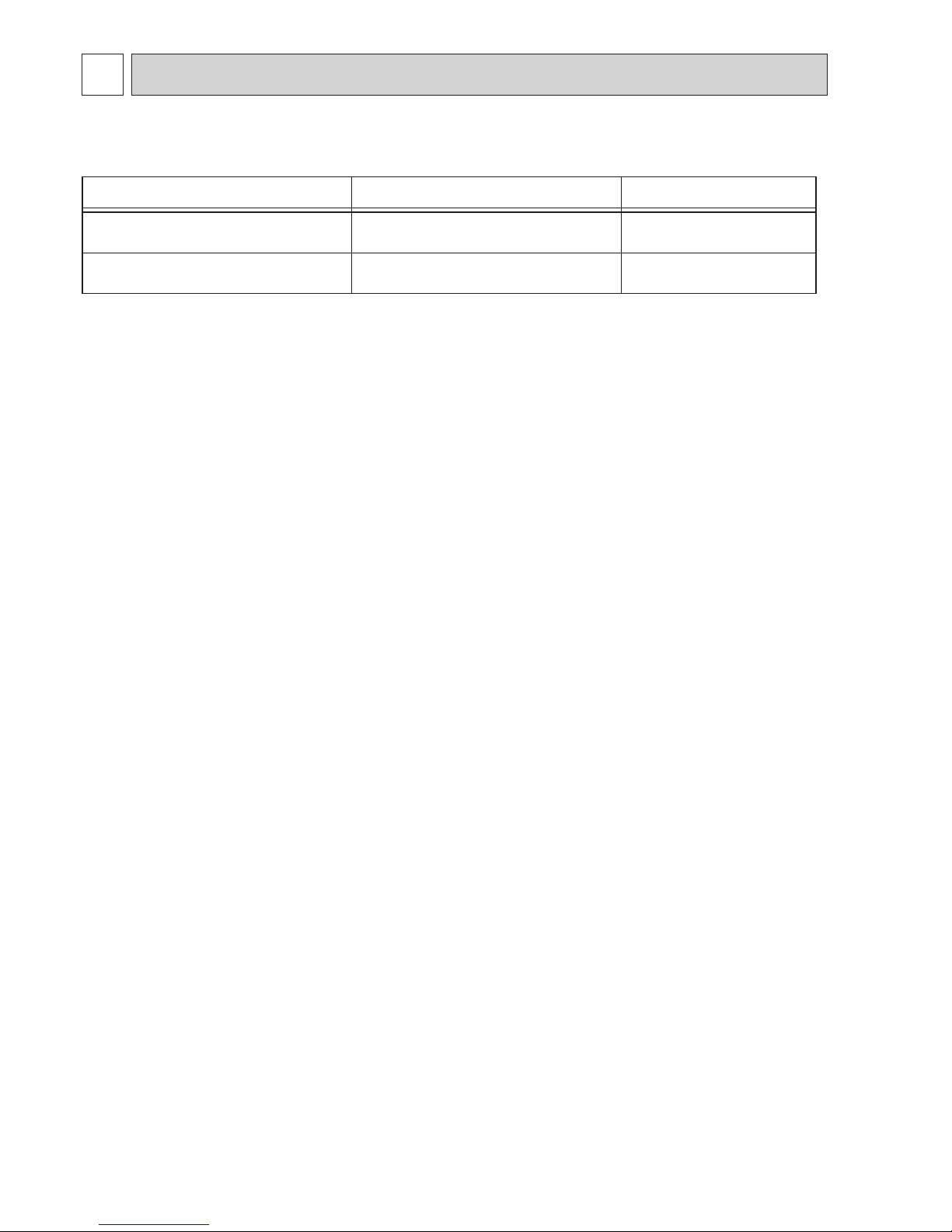

New Specification Current Specification

The incompatible refrigerant oil easily separates from

refrigerant and is in the upper layer inside the suction muffler.

Raising position of the oil back hole enables to back the

refrigerant oil of the upper layer to flow back to the

compressor.

Since refrigerant and refrigerant oil are compatible with

each other, refrigerant oil backs to the compressor through

the lower position oil back hole.

Compressor

Suction muffler

Oil back hole

Refrigerant oil

Refrigerant

Compressor

Suction muffler

Oil back hole

Refrigerant oil /Refrigerant

Compressor

4

TCH030 TCH030

R410A tools Can R22 tools be used?

Gas leak detector

R410A has high pressures beyond the measurement range of existing

gauges. Port diameters have been changed to prevent any other refrigerant

from being charged into the unit.

Hose material and cap size have been changed to improve the pressure

resistance.

Dedicated for HFC refrigerant.

6.35 mm and 9.52 mm

Description

Clamp bar hole has been enlarged to reinforce the spring strength in the tool.

Provided for flaring work (to be used with R22 flare tool).

Provided to prevent the back flow of oil. This adapter enables you to use

vacuum pumps.

It is difficult to measure R410A with a charging cylinder because the

refrigerant bubbles due to high pressure and high-speed vaporization

No

No

No

Yes

Yes

New

New

New

Gauge manifold

Charge hose

Torque wrench

Flare tool

Flare gauge

Vacuum pump

adapter

Electronic scale for

refrigerant charging

No: Not substitutable for R410A Yes: Substitutable for R410A

No 12.7 mm and 15.88 mm

1. Tools dedicated for the air conditioner with R410A refrigerant

The following tools are required for R410A refrigerant. Some R22 tools can be substituted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to prevent any other refrigerant being

charged into the unit. Cap size has been changed from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.

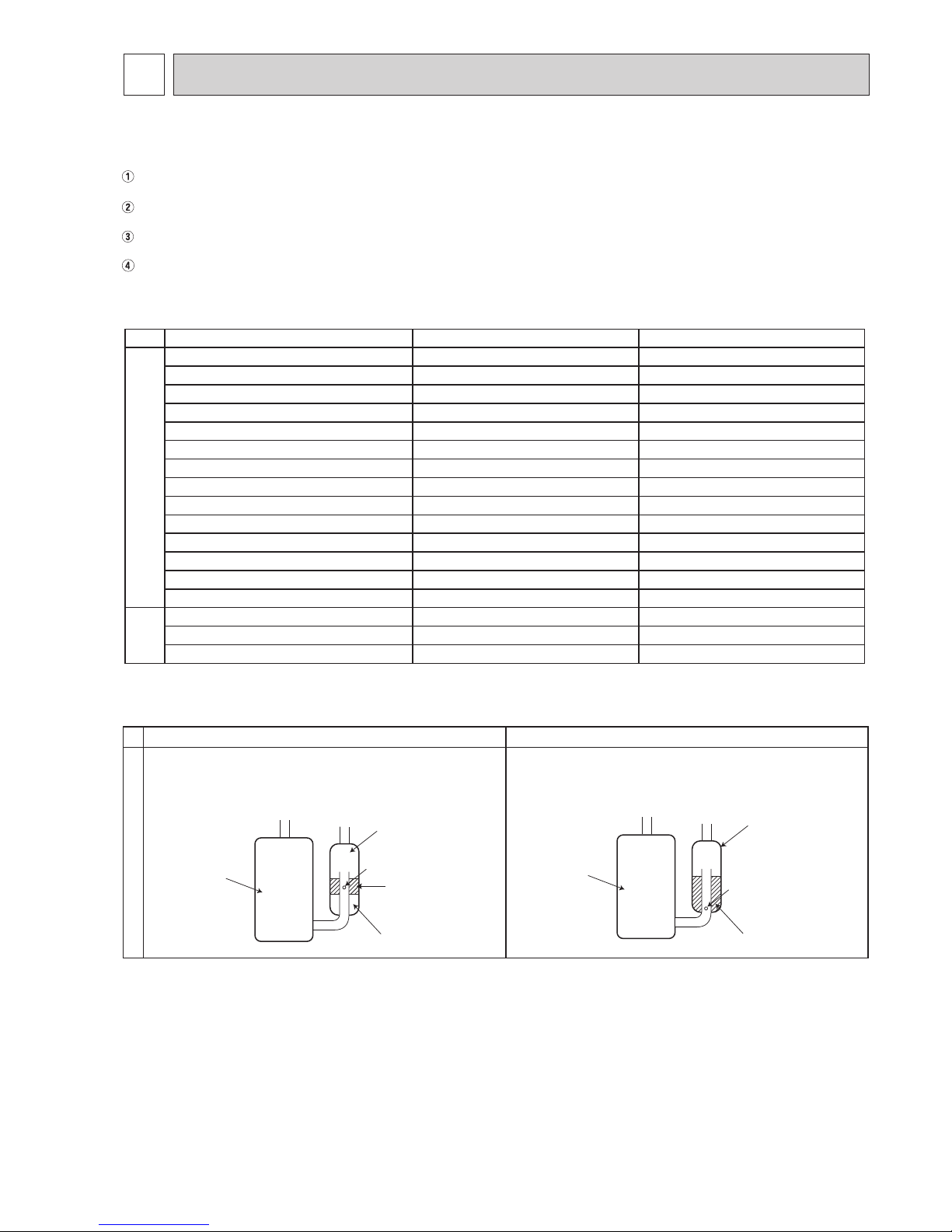

−30 −20 −10 0 10 20

30

40 50 60

−0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

(MPa [Gauge])

R410A

R22

Conversion chart of refrigerant temperature and pressure

Saturated liquid pressure

(:)

NOTE: The unit of pressure has been changed to MPa on the

international system of units (SI unit system).

The conversion factor is: 1 (MPa [Gauge]) =10.2 (kgf/cm

2

[Gauge])

5

Electronic scale for refrigerant charging

Outdoor unit

Refrigerant gas

cylinder

operating valve

Refrigerant gas cylinder

for R410A with siphon

Refrigerant (liquid)

Service port

Gauge manifold

valve (for R410A)

Union

Liquid pipe

Gas pipe

Stop valve

Indoor unit

Charge hose (for R410A)

R410A

Pipe diameter (mm)

6.35

9.52

12.7

15.88

17

22

26

29

Dimension of flare nut (mm)

R22

17

22

24

27

• Use a copper pipe or a copper-alloy seamless pipe with a thickness of 0.8 mm. Never use any pipe with a thickness less

than 0.8 mm, as the pressure resistance is insufficient.

Flaring work and flare nut

Flaring work for R410A pipe differs from that for R22 pipe.

For details of flaring work, refer to Installation manual “FLARING WORK”.

3. Refrigerant oil

Apply the special refrigerant oil (accessories: packed with indoor unit) to the flare and the union seat surfaces.

4. Air purge

Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant

circuit.

Use the vacuum pump for air purging for the purpose of environmental protection.

5. Additional charge

For additional charging, charge the refrigerant from liquid phase of the gas cylinder.

If the refrigerant is charged from the gas phase, composition change may occur in the refrigerant inside the cylinder and

the outdoor unit. In this case, ability of the refrigerating cycle decreases or normal operation can be impossible. However,

charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

2. Refrigerant piping

Specifications

Use the refrigerant pipes that meet the following specifications.

Wall thicknessOutside diameter

Pipe

mm mm

For liquid

For gas

6.35

9.52

9.52

12.7

15.88

0.8

0.8

0.8

0.8

1.0

Heat resisting foam plastic

Specific gravity 0.045

Thickness 8 mm

Insulation material

TCH030 TCH030

6

TCH030 TCH030

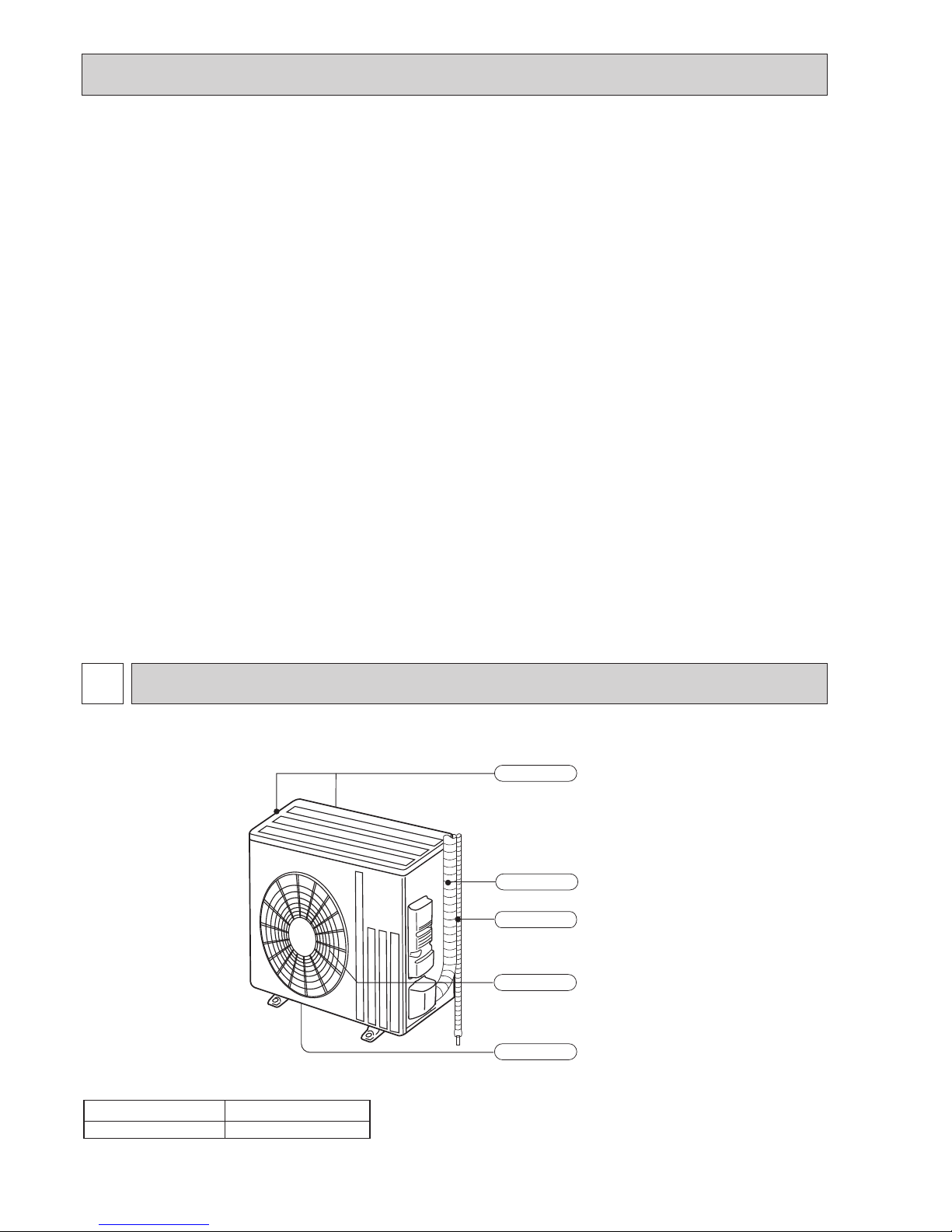

3

PARTS NAMES AND FUNCTIONS

SUZ-SA71VA3.TH

SUZ-SA100VA2.TH

Model SUZ-SA·VA2(3)

Drain socket 1

Piping

Air outlet

Drain outlet

Air inlet

(back and side)

Drain hose

Piping

Air outlet

Drain outlet

Air inlet

(back and side)

Drain hose

6. Pumping Down

When relocating or disposing of the air conditioner, pump down the system by following the procedure below so that no

refrigerant is released into the atmosphere.

1 Turn off the power supply (circuit breaker).

2 Connect the gauge manifold valve to the service port of the stop valve on the gas pipe side of the outdoor unit.

3 Fully close the stop valve on the liquid pipe side of the outdoor unit.

4 Supply power (circuit breaker).

5 Perform the refrigerant collecting operation (cooling test run).

•ForthePAR-31MAA,select“Service”→“Testrun”fromthemainmenutostartthetestrun,andthenselectthecooling

mode.

• For details or for other information about starting the test run when using remote controllers, refer to the installation manual

for the indoor unit or the remote controller.

6 Fully close the stop valve on the gas pipe side of the outdoor unit when the pressure gauge shows 0.05 to 0 MPa [Gauge]

(approx. 0.5 to 0 kgf/cm²) and quickly stop the air conditioner.

• Push the “ON/OFF” button on the remote controller to stop the air conditioner.

Notes:

1. When the extension piping is very long with a large refrigerant amount, it may not be possible to perform a pump down

operation. In this case, use refrigerant recovery equipment to collect all of the refrigerant in the system.

2. If the extension piping length for the SUZ-SA100VA is 20 m or longer, it will not be possible to perform a pump-down

operation because there is a large amount of refrigerant. In this case, collect the refrigerant in the system.

7 Turn off the power supply (circuit breaker), remove the gauge manifold valve, and then disconnect the refrigerant pipes.

.Warning: When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes.

• If the refrigerant pipes are disconnected while the compressor is operating and the stop valve (ball valve) is open,

the pressure in the refrigeration cycle could become extremely high if air is drawn in, causing the pipes to burst,

personal injury, etc.

7

7

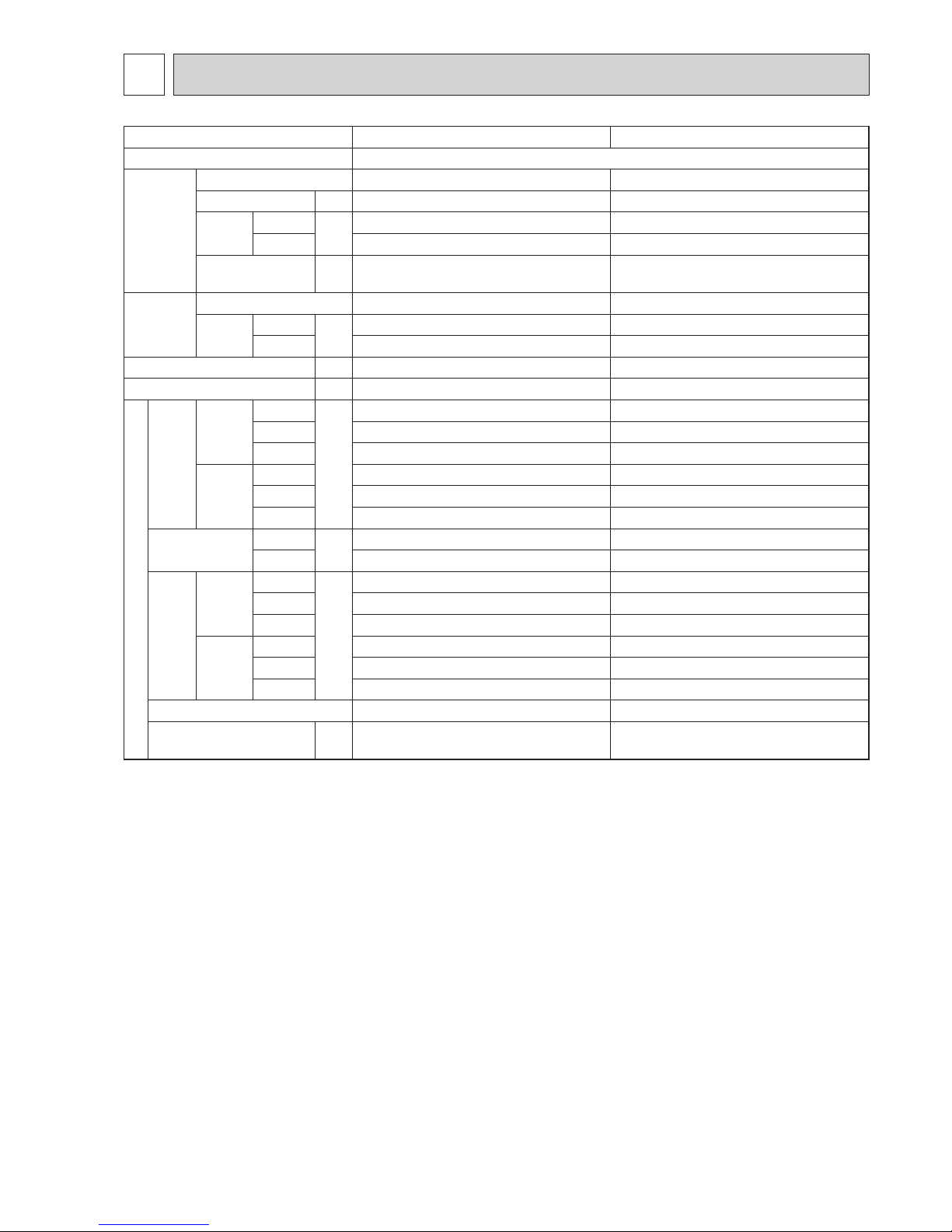

SPECIFICATION

4

NOTE: Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27°C W.B. 19°C

Outdoor D.B. 35°C

Heating : Indoor D.B. 20°C

Outdoor D.B. 7°C W.B. 6°C

Refrigerant piping length (one way): 5 m

*Measured under rated operating frequency.

Outdoor model

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Power supply Single phase 230V, 50Hz

Compressor

Model SNB140FRKMT SNB220FBGM1T

Output W 1,200 1,500

Current*

Cooling

A

8.30 11. 11

Heating 9.59 12.84

Refrigeration oil

(Model)

L 0.4 (FV50S) 0.46 (FV50S)

Fan motor

Model RC0J60-BC RC0J60-BC

Current*

Cooling

A

0.83 0.85

Heating 0.82 0.86

Dimensions W × H × D mm 840 × 880 × 330 840 × 880 × 330

Weight kg 52 56

Special remarks

Air

ow*

Cooling

High

m³/h

3,492 3,426

Med. 3,006 3,234

Low 2,226 2,394

Heating

High 2,952 3,276

Med. 2,952 3,276

Low 2,268 2,472

Sound level*

Cooling

dB(A)

55 55

Heating

55 55

Fan

speed

Cooling

High

rpm

950 950

Med. 840 900

Low 620 680

Heating

High 810 910

Med. 810 910

Low 630 700

Fan speed regulator

3 3

Refrigerantllingcapacity

(R410A)

kg 1.80 2.20

TCH030 TCH030

8

TCH030 TCH030

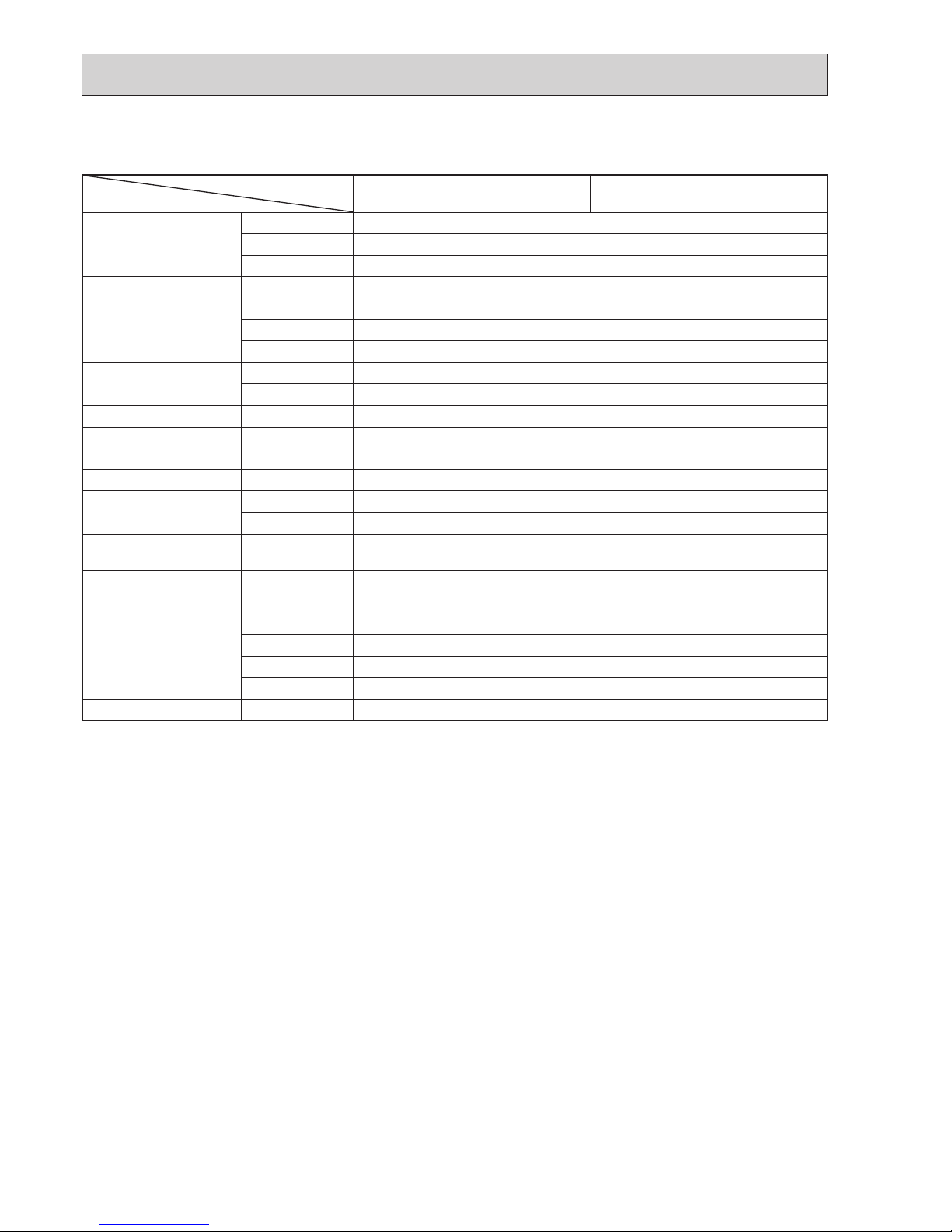

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Specifications and rating conditions of main electric parts

Model

Item

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

Smoothing

capacitor

(C61) —

(C62, C63) —

(CB1, 2, 3) 560μF450V

Diode module (DB61) —

Fuse

(F61) —

(F62) T20AL 250 V

(F701, F801, F901)

—

Intelligent power module

(IPM) —

(IC932) 5 A 600 V

IGBT module (IC700) 20 A 600V

Power factor

controller

(PFC) 20 A 600 V

(IC820) 20 A 600 V

Expansion valve coil (LEV) 12 V DC

Reactor

(L61) —

(L) 340μH20A

Current-Limiting

PTC thermistor

(PTC64, PTC65) 33Ω

Terminal block

(TB1, TB2) 3P

(TB) —

Relay

(X63) —

(X64) 20 A 250 V

(X601) 3 A 250 V

(X602) 3 A 250 V

R.V. coil (21S4) 220–240 V AC

9

9

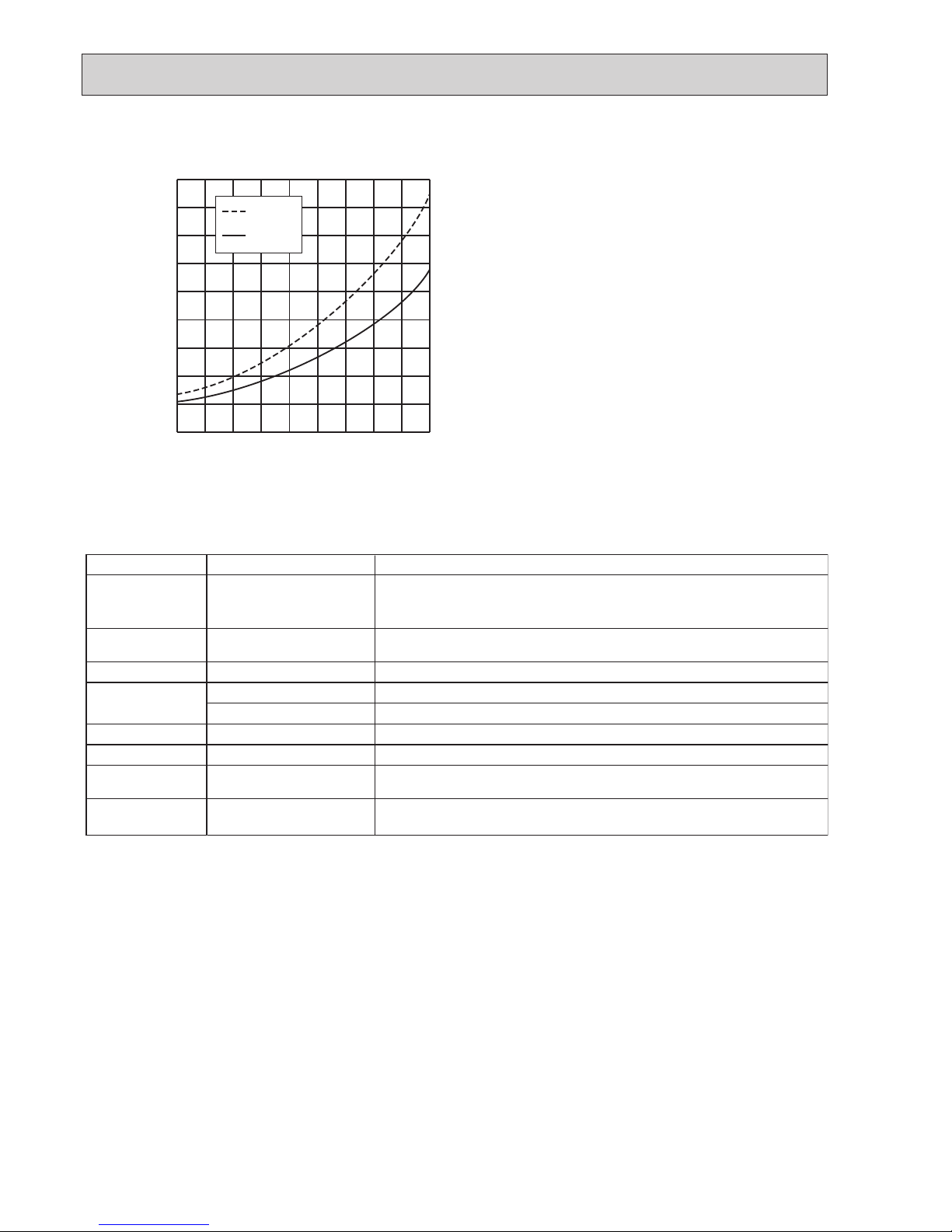

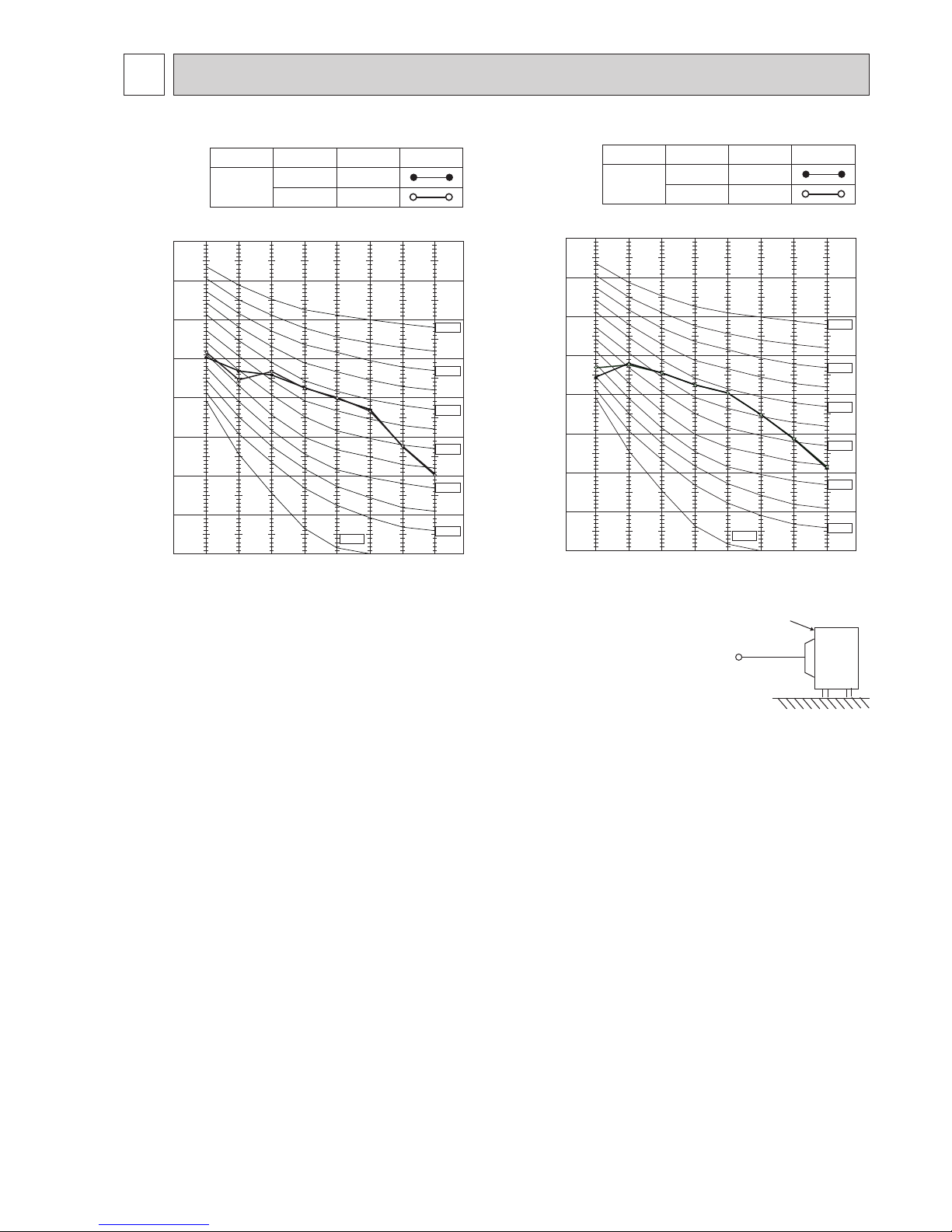

NOISE CRITERIA CURVES

5

Test conditions

Cooling: Dry-bulb temperature 35°C

Heating: Dry-bulb temperature 7°C

Wet-bulb temperature 6°C

OUTDOOR UNIT

MICROPHONE

1 m

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

COOLING

FUNCTION

SPL(dB(A)) LINE

High

FAN SPEED

HEATING

55

55

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

NC-10

SUZ-SA71VA3.TH

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

COOLING

FUNCTION

SPL(dB(A)) LINE

High

FAN SPEED

HEATING

55

55

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

NC-10

SUZ-SA100VA2.TH

10

TCH030 TCH030

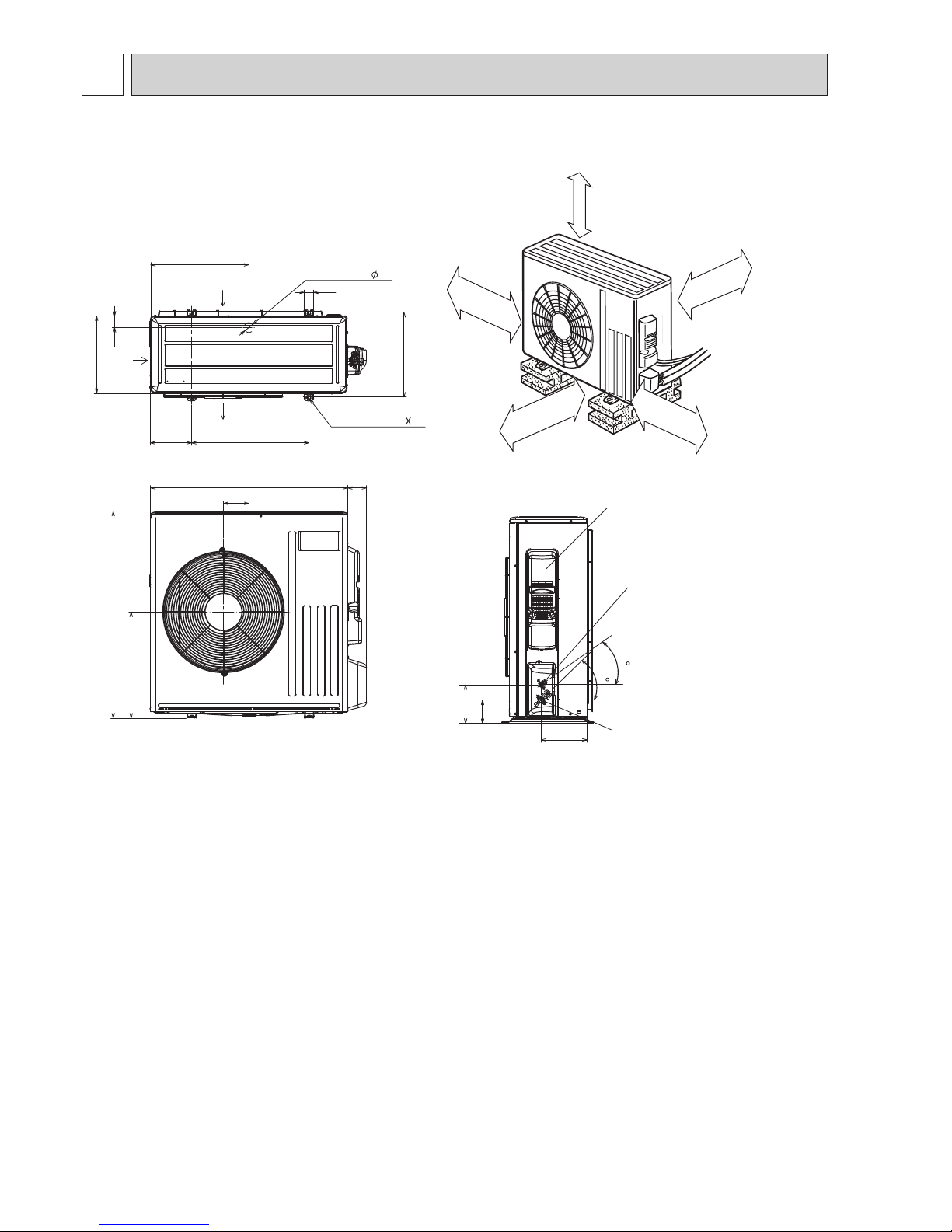

6

OUTLINES AND DIMENSIONS

Unit: mm

417.5

40

42

Drain hole

175

500

330

50

Air in

Air out

2-Oval holes 10 21

840

109

81

880

452

Service panel

99.5

164.5

195

35

44

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared)

Ø 9.52

Gas refrigerant

pipe joint

Refrigerant pipe

(flared)

Ø 15.88

350 mm or more

100 mm or more

REQUIRED SPACE

Basically, leave this space open.

Only if front and both sides are open,

leave 500 mm at minimum.

100 mm or more

500 mm or more.

Leave any two sides

among right, left or rear open.

Air in

Bolt pitch for

installation

360

SUZ-SA71VA3.TH SUZ-SA100VA2.TH

11

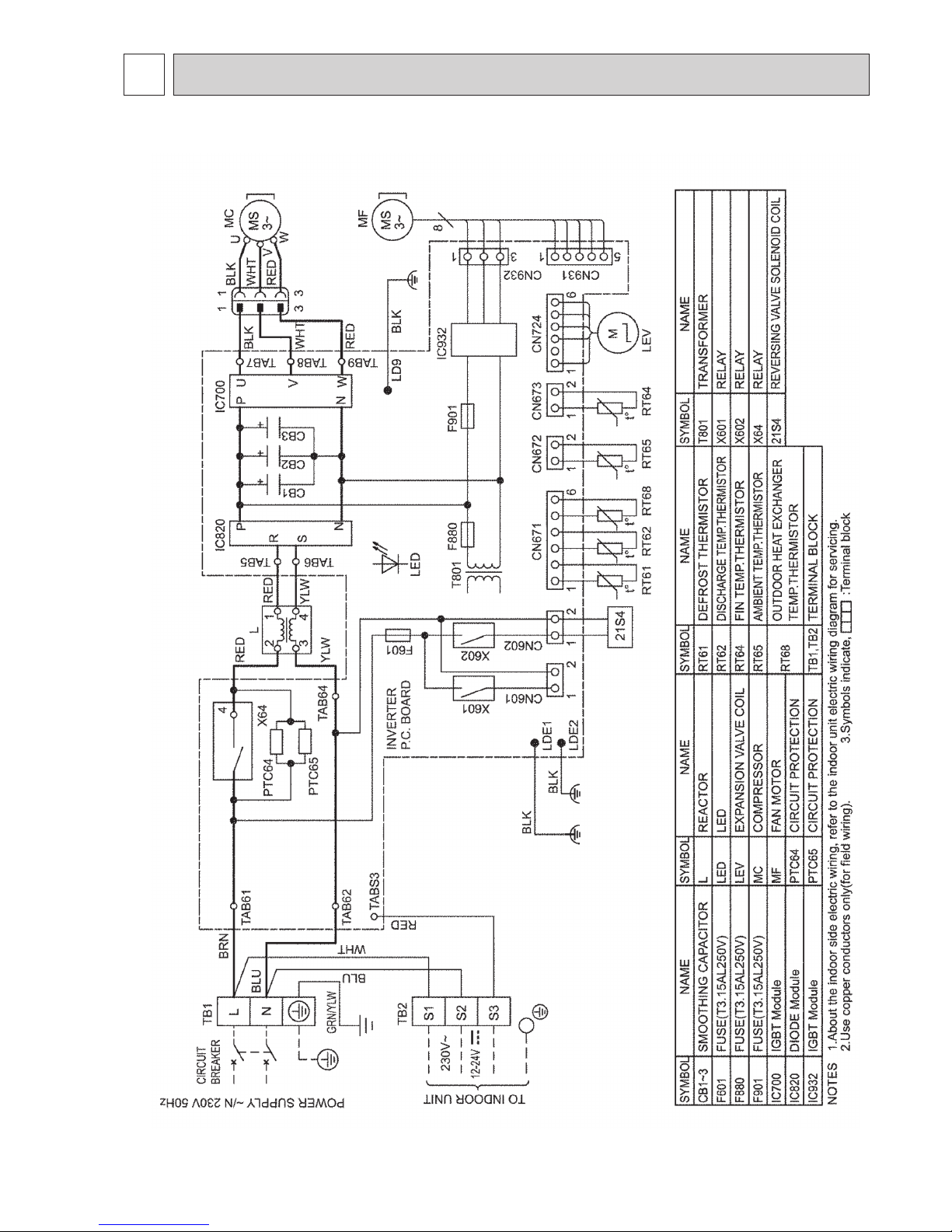

7

WIRING DIAGRAM

SUZ-SA71VA3.TH

Loading...

Loading...