Mitsubishi Electric PAC-AH125, PAC-AH140, PAC-AH250, PAC-AH500M-J, PAC-AH125M-J Installation Manual

...

GB

Air Handling Unit Controller

PAC-AH125, 140, 250, 500M-J

FOR INSTALLER

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the controller.

2

2

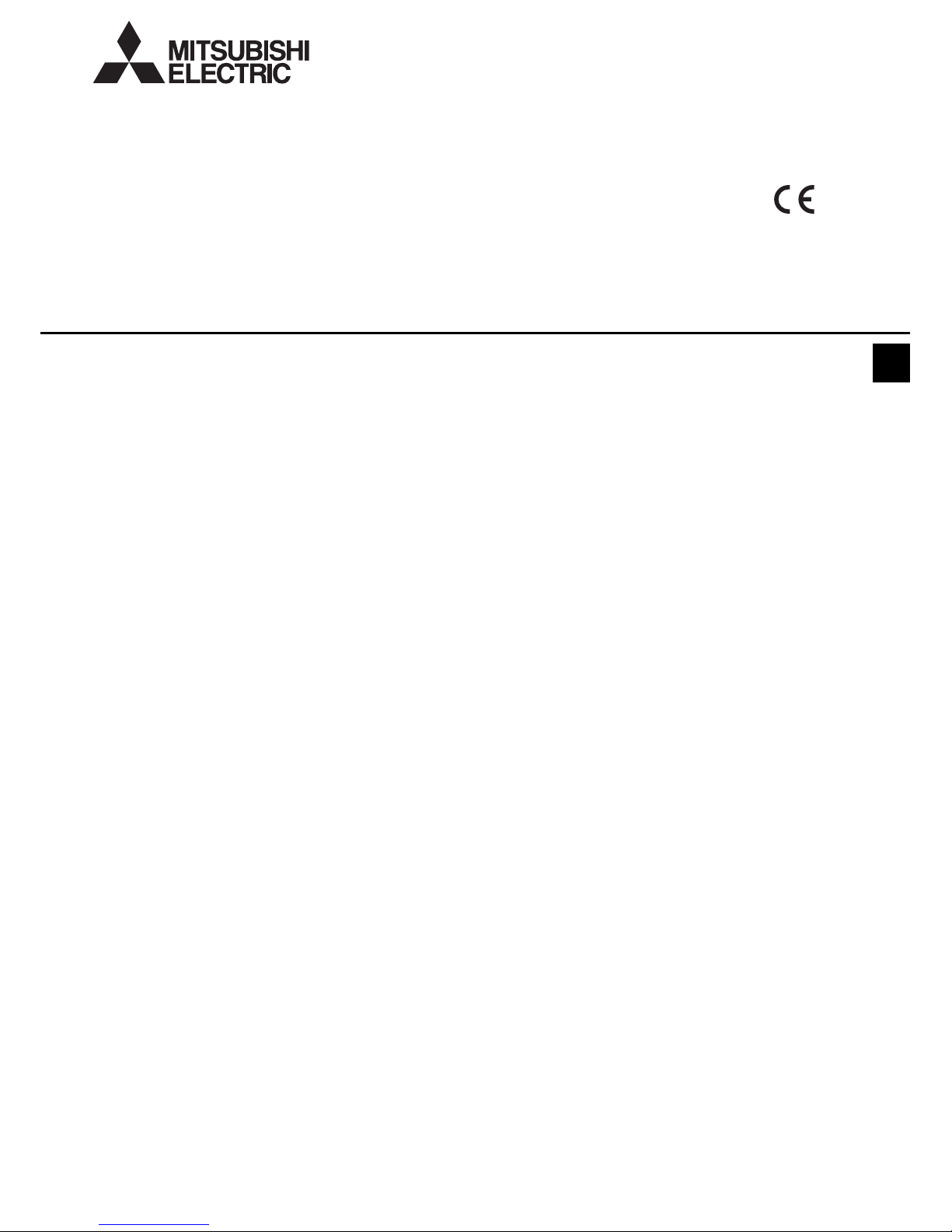

[Fig. 2.0.1]

1 Controller

2 LEV-kit

3 Thermistor

4 Clip

5 Insulation

6 Tie band

7 Installation manual

8 Tube

3

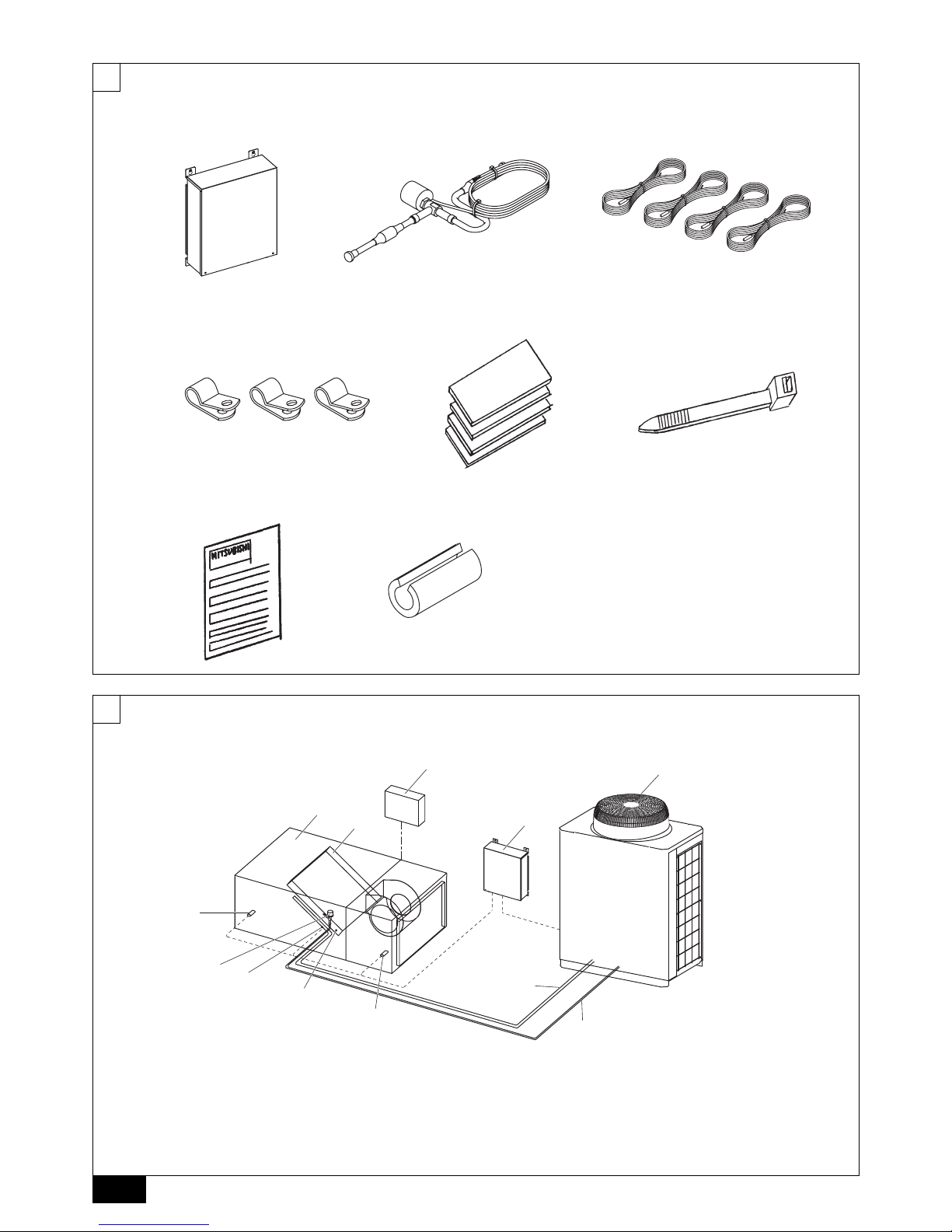

[Fig. 3.0.1]

A Air handling unit controller

(PAC-AH

·

M-J)

B Air handling unit (field supply)

C Controller (field supply)

D Outdoor unit

E Heat exchanger (field supply)

F Gas pipe

G Liquid pipe

H LEV-kit

I Thermistor (gas pipe)

J Thermistor (liquid pipe)

K Thermistor (suction air)

L Thermistor (discharge air)

12 3

4 56

78

B

L

H

I

J

K

G

F

A

C

D

E

3

4

[Fig. 4.2.1]

A Controller

B Screw (field supply)

6

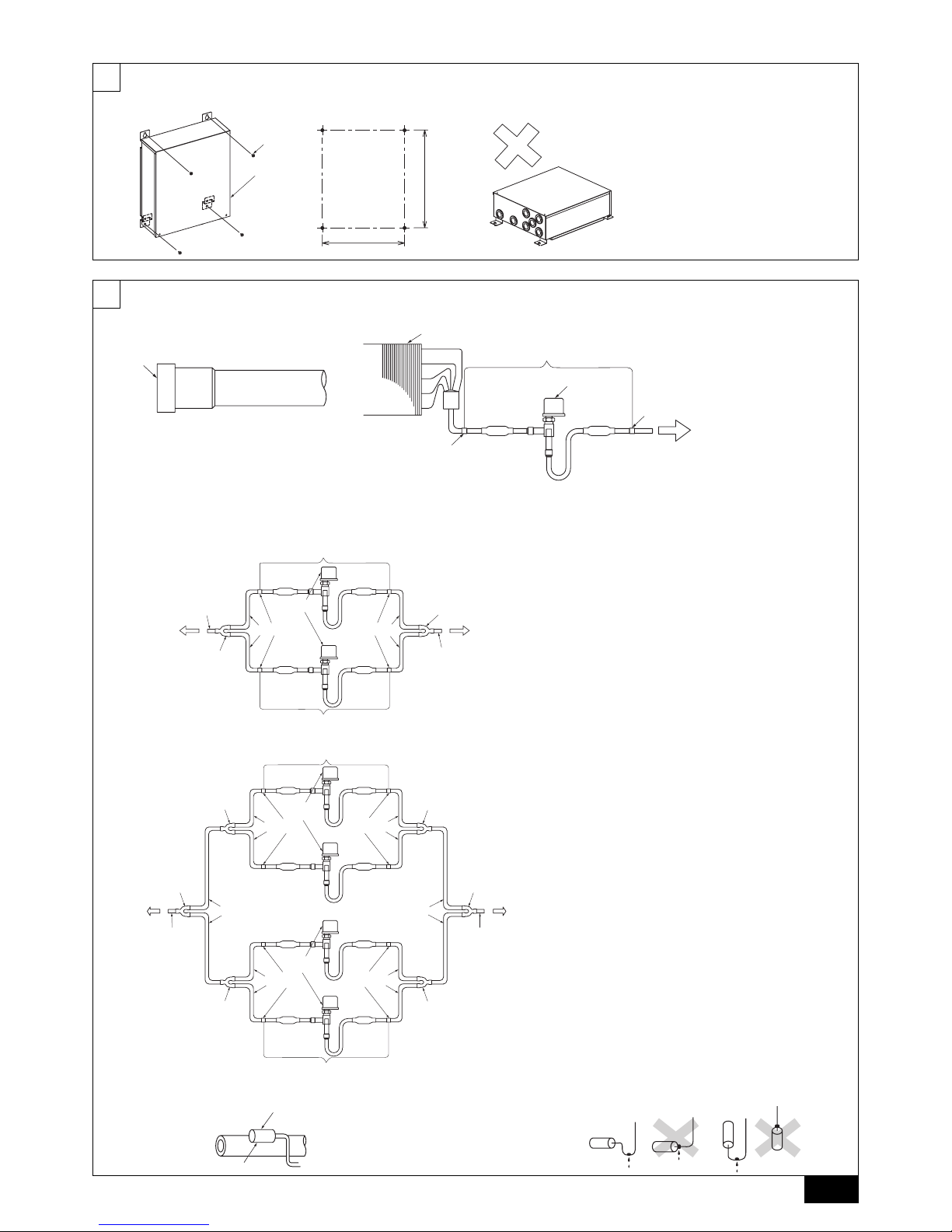

[Fig. 6.2.1]

A Remove the cap

[Fig. 6.2.2]

[Fig. 6.2.3]

A Heat exchanger (field supply)

B LEV-kit

C Brazing

D Linear expansion valve

E Outdoor unit

F Refrigerant pipe size ø9.52 (field supply)

G Distributor (field supply)

H Refrigerant pipe size ø9.52 (field supply)

[Fig. 6.2.4]

A Heat exchanger (field supply)

B LEV-kit

C Brazing

D Linear expansion valve

E Outdoor unit

F Refrigerant pipe size ø9.52 (field supply)

G Distributor (field supply)

H Refrigerant pipe size ø9.52 (field supply)

I Refrigerant pipe size

P400: ø12.7 (field supply)

P500: ø15.88 (field supply)

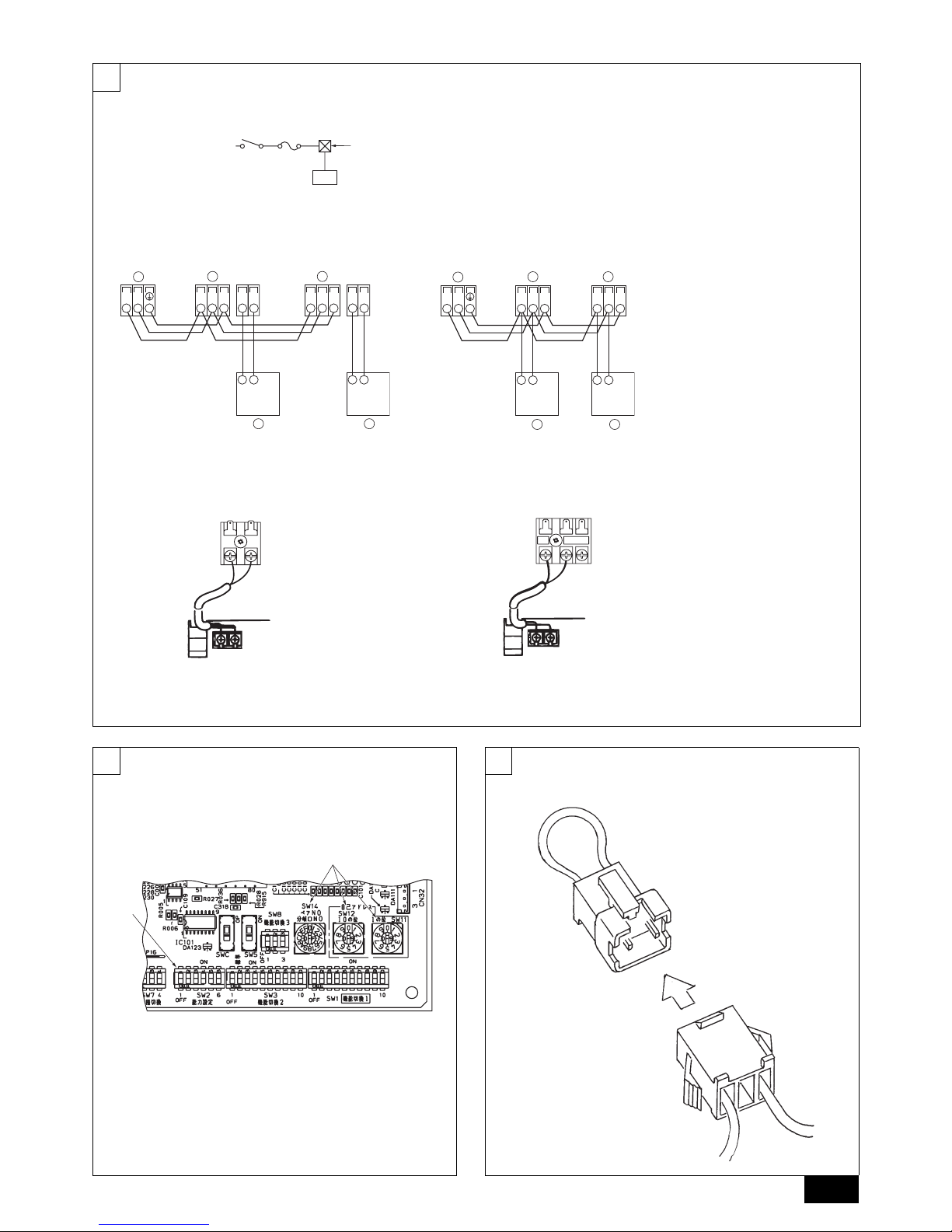

[Fig. 6.3.0.1] [Fig. 6.3.0.2]

B

A

400

274

A

B

A

D

C

C

E

A Heat exchanger (field supply)

B LEV-kit

C Brazing

D Linear expansion valve

E Outdoor unit

Type 125 - 140

G

G

H

H

C

F

C

F

D

E

A

B

B

Type 250

G

I

H

A

G

G

F

C

D

C

F

C

F

F

C

D

H

G

I

G

G

E

B

B

Type 500

A

B

A Most sensitive point of the thermistor

B Maximize the contact

4

6

[Fig. 6.3.1]

A Heat exchanger (field supply)

B Gas pipe

C Thermistor (gas pipe)

D Aluminum tape (field supply)

E Insulation

F Tie band

[Fig. 6.3.2]

A Heat exchanger (field supply)

B Gas pipe

C Thermistor (liquid pipe)

D Aluminum tape (field supply)

E Insulation

F Tie band

G Capillary tube

[Fig. 6.3.3]

A Thermistor (suction/disch arge air)

B Clip

C Screw (field supply)

D Plate (field supply)

7

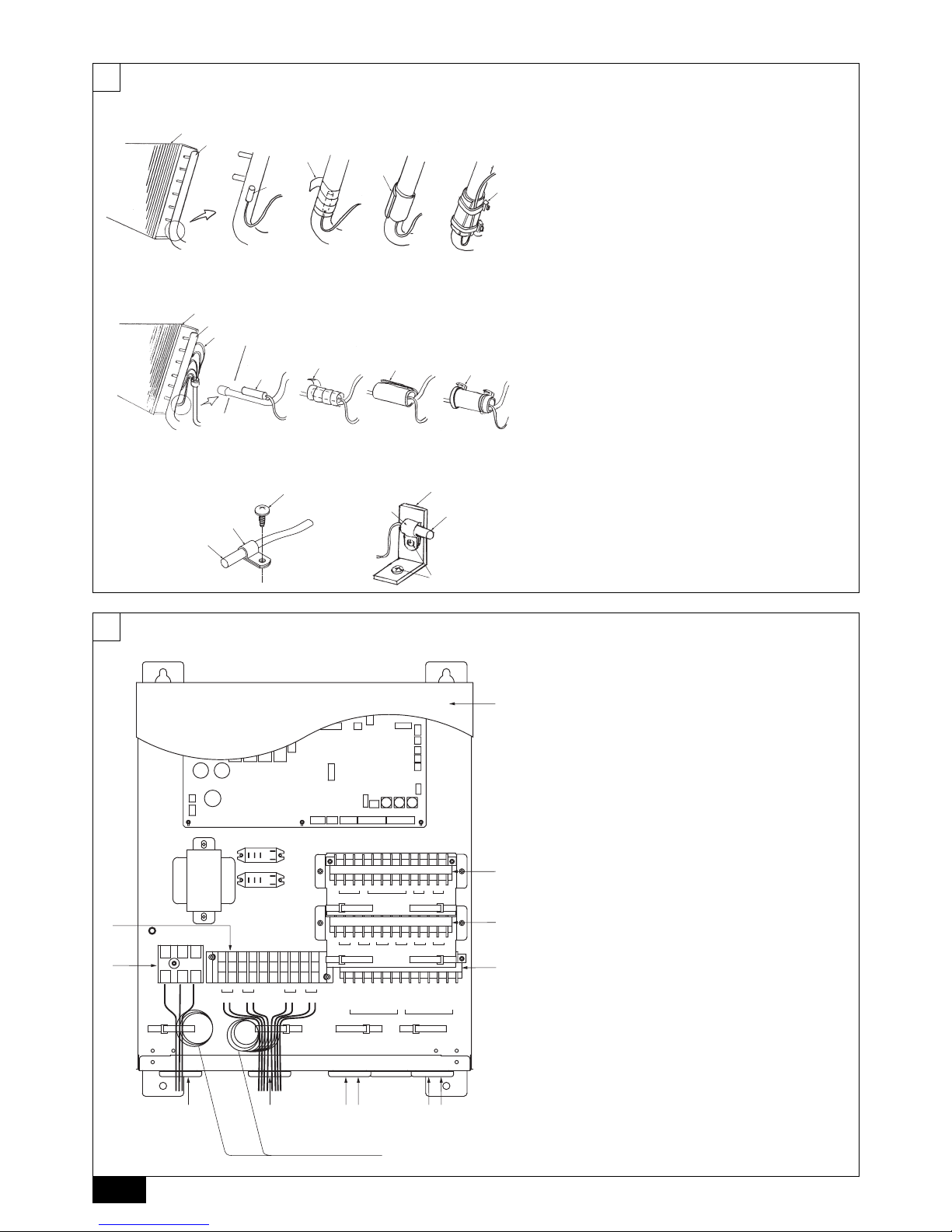

[Fig. 7.0.1]

A Cover

B Terminal block TB2

C Terminal block TB4

D Terminal block TBZ

E Terminal block TBX

F Terminal block TBY

G Power supply (220 - 240 V)/Earth

H Defrost signal

I Fan signal

J Operation signal

K Error signal (output)

L LEV-kit

M LEV-kit

N Distant signal (ON/OFF)

O Error signal (input)

P Thermistor (suction air)

Q Thermistor (gas pipe)

R Thermistor (liquid pipe)

S Thermistor (discharge air)

T To outdoor unit

U Contact signal

V To remote controller

W Analog signal

X Distant signal

Y Thermistor

Z Transmission

A

B

D

E

C

F

A

B

G

D

E

C

F

A

C

C

D

B

B

A

A

F

TUVW

NOPQR

LM

S

E

MZ

B

C

D

LYXG

G

W

H

I

T

E

G

R

E

E

N

B

L

A

C

K

R

E

D

B

R

O

W

N

Y

E

L

L

O

W

A1 A2

M1

CN2M

CN3T

M2

SW4 SW7 SW2 SW3 SW1

CN32

CN22

CN29

CN92

CN21

CN20

CN31

CN51

S

C1 C2 C4 C5 1 2 B1 B2C3

A11 A12 T31 T32 T21 T22 T11 T12 T1 T2

W

H

I

T

E

G

R

E

E

N

B

L

A

C

K

R

E

D

B

R

O

W

N

Y

E

L

L

O

W

H

D31 D32ID24 D23JD1 D2KD11 D12

Wind the wire around the

cable strap once to prevent

loose wires.

5

7

[Fig. 7.1.1]

A Switch 16 A

B Overcurrent protection 16 A

C Indoor unit

D Pull box

[Fig. 7.2.1] [Fig. 7.2.2]

A Terminal block for AHU controller/

indoor transmission cable

B Terminal block for outdoor transmis-

sion cable

C Remote controller

[Fig. 7.2.3] [Fig. 7.2.4]

A Non-polarized

B Remote Controller

89

[Fig. 8.1.1]

A Address switch

B SW2

[Fig. 9.0.1]

AB

D

C

TBY TBY TBY TBY

SM1M2 SM1M2

TB3

M1M2 21 21

AA

B

CC

TBY TBY

SM1M2 SM1M2

TB3

M1M2

AA

B

CC

DC10~13 V

AB

12

A

B

2

1

DC24~30 V

(A, B)

12

A

B

M2

M1

S

A

B

Loading...

Loading...