Mitsubishi Electric PAC-AH63, PAC-AH140, PAC-AH250M-G Installation Manual

Air Handling Unit Controller

PAC-AH63, 125, 140, 250M-G

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the controller.

GB

FOR INSTALLER

2

A

L

B

D

E

C

F

H

J

K

I

G

2

[Fig. 2.0.1]

3

[Fig. 3.0.1]

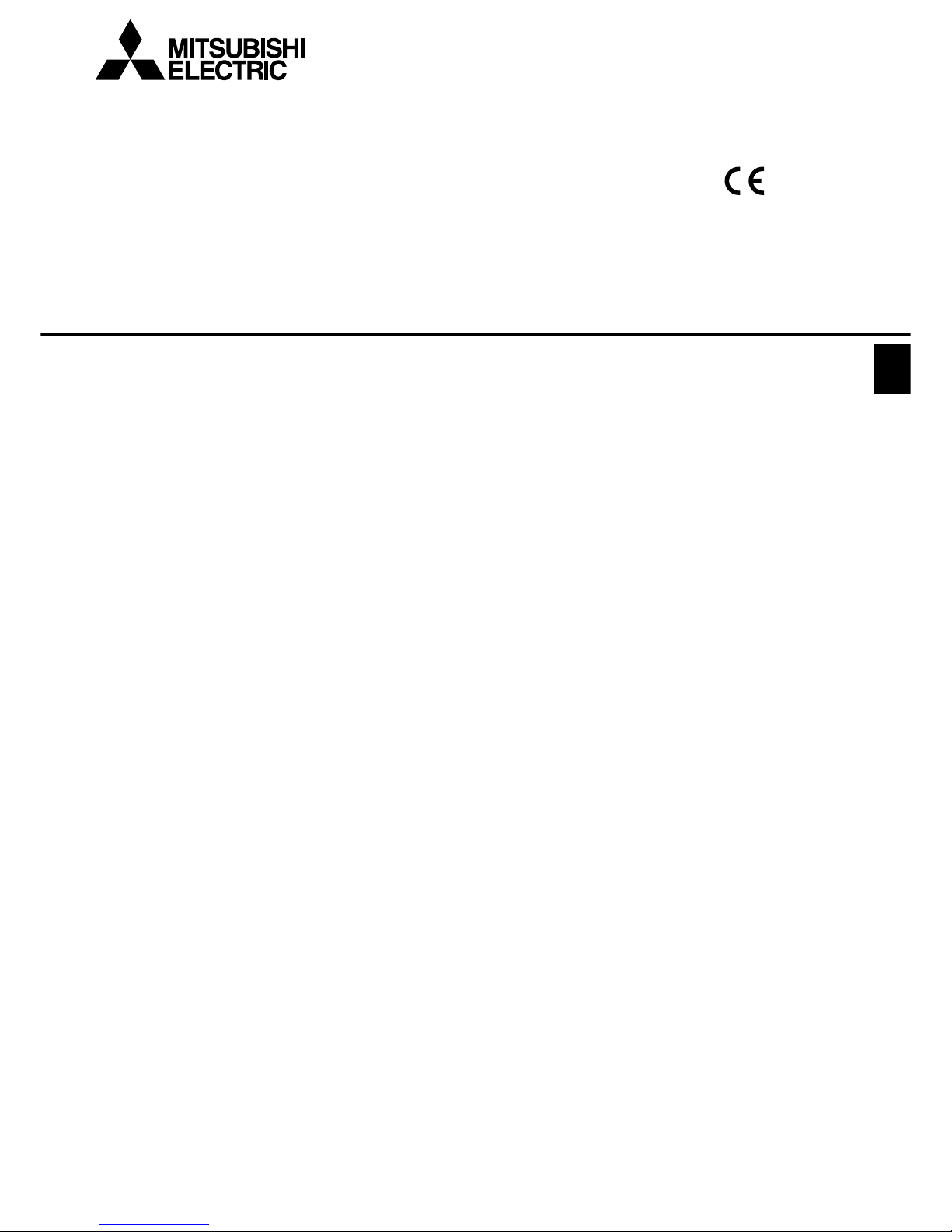

12 3

456

7

1 Controller

2 LEV-kit

3 Thermistor

4 Clip

5 Insulation

6 Tie band

7 Installation manual

8 Tube

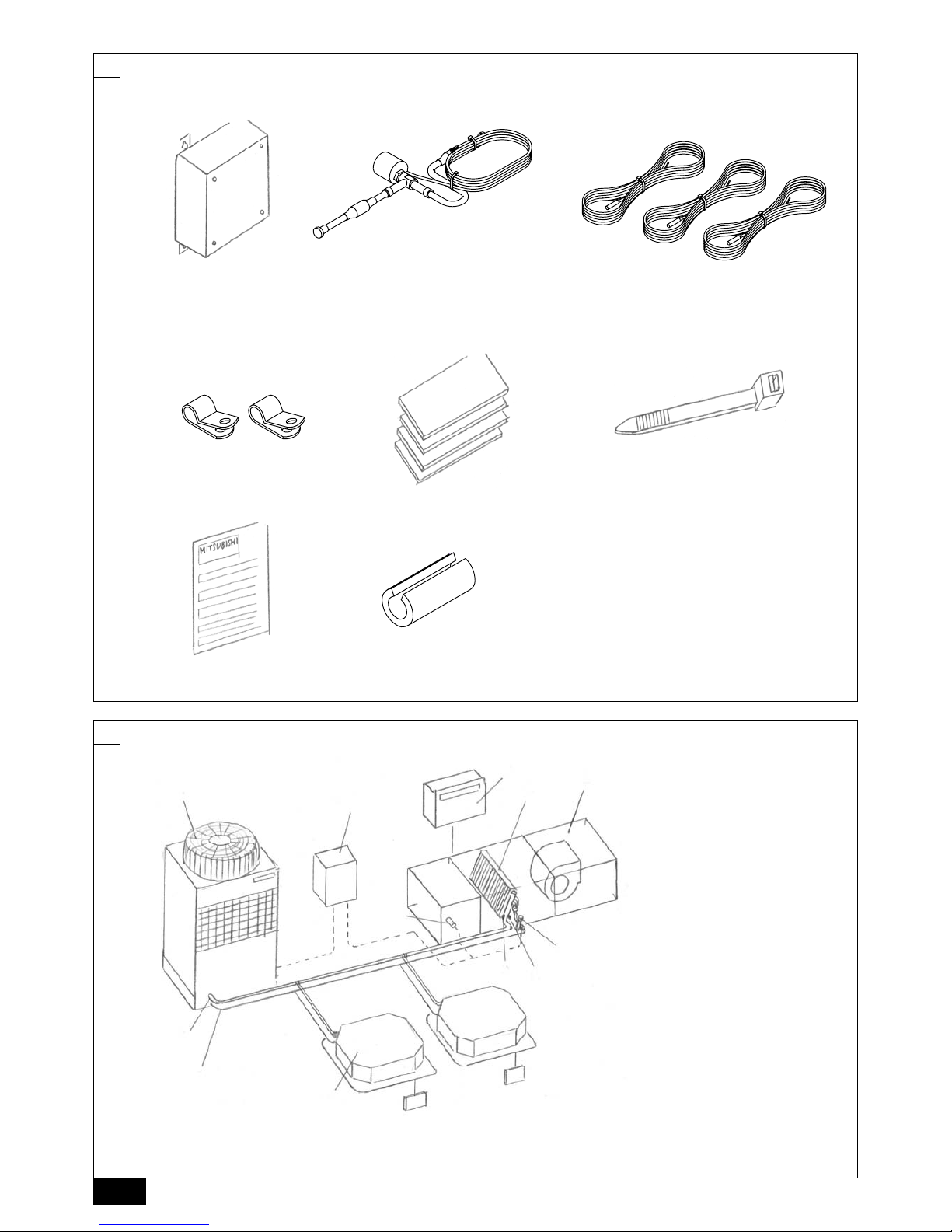

A Air handling unit controller (PAC-AH · M-G)

B Air handling unit (field supply)

C Controller (field supply)

D Outdoor unit

E Indoor unit (City Multi)

F Evaporator (field supply)

G Gas pipe

H Liquid pipe

I LEV-kit

J Thermistor (gas pipe)

K Thermistor (liquid pipe)

L Thermistor (inlet air)

8

3

A

B

D

C

C

E

G

E

B

B

G

A

C

C

H

FF

D

H

4

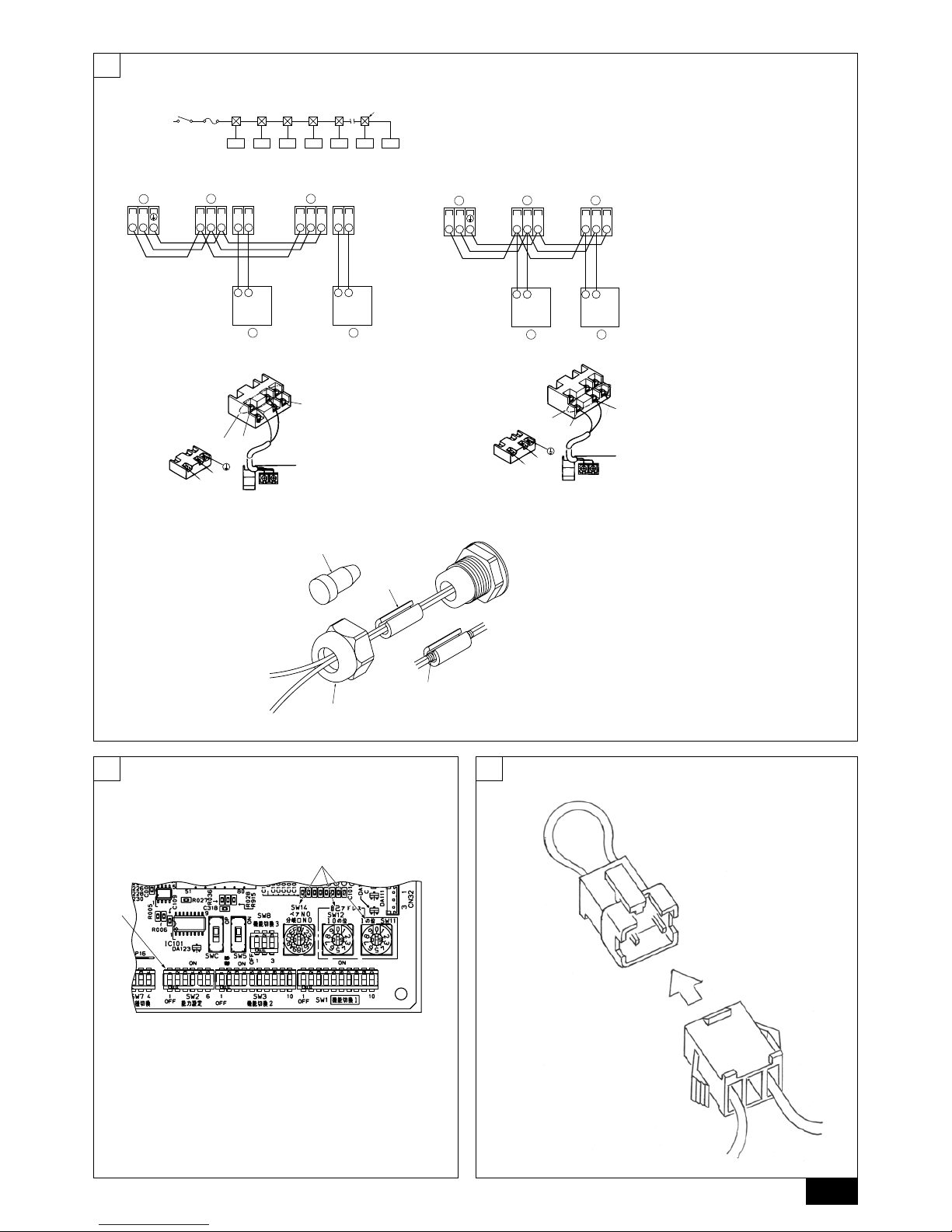

[Fig. 4.2.1]

6

[Fig. 6.2.2]

[Fig. 6.2.3]

B

A

410

260

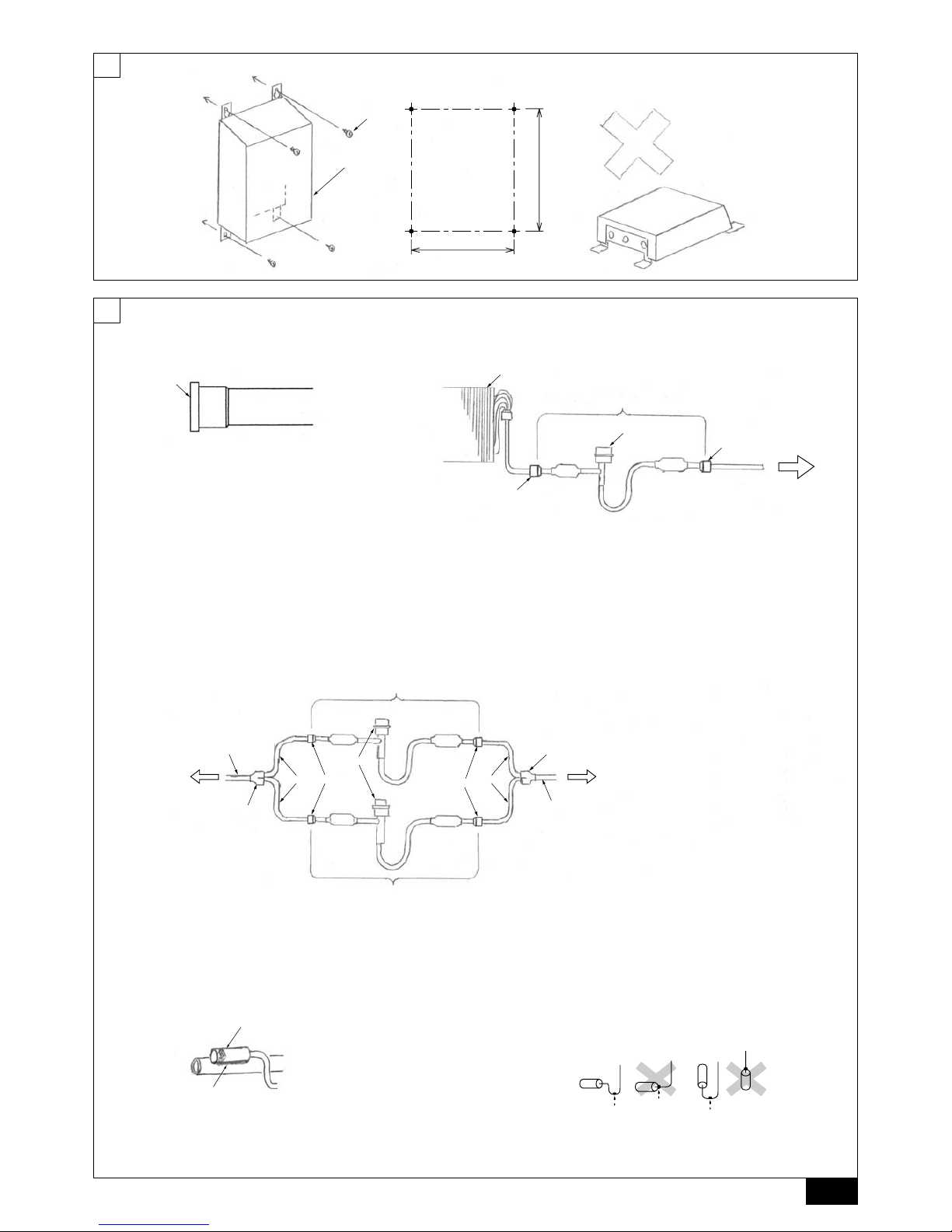

A Controller

B Screw (field supply)

A Evaporator (field supply)

B LEV-kit

C Brazing

D Linear expansion valve

E Outdoor unit

F Refrigerant pipe size ø9.52 (field supply)

G Distributor (field supply)

H Refrigerant pipe size ø9.52 (field supply)

Type 63 - 140

Type 250

A Evaporator (field supply)

B LEV-kit

C Brazing

D Linear expansion valve

E Outdoor unit

[Fig. 6.2.1]

A

A Remove the cap

[Fig. 6.3.0.1]

A

B

A Most sensitive point of the

thermistor

B Maximize the contact

[Fig. 6.3.0.2]

4

A

B

G

D

E

C

F

A

C

C

D

B

B

A

F

J

K

L

P

G

G

P

O

Q

J

R

H

I

R

D

C

O

MN

S

E

A

B

TB2

TB15

TB4

TBX

T21 T22 T11 T1 T2T12

white

yellow

green

black

red

brown

TB5

Q

7

[Fig. 7.0.1]

A Outer cover

B Inner cover

C Terminal block TB2

D Terminal block TB5 TB15

E Terminal block TBX

F Terminal block TB4

G Power supply (220 - 240 V)/Ear th

H To outdoor unit

I To remote controller

J Distant signal (ON/OFF)

K Operation signal

L Error signal

M Thermistor (gas pipe)

N Thermistor (liquid pipe)

O LEV-kit

P Distant signal

Q Thermistor

R Transmission

S Thermistor (inlet air)

A Evaporator (field supply)

B Gas pipe

C Thermistor (liquid pipe)

D Aluminum tape (field supply)

E Insulation

F Tie band

G Capillary tube

6

[Fig. 6.3.3]

A Thermistor (inlet air)

B Clip

C Screw (field supply)

D Plate (field supply)

A

B

D

E

C

F

[Fig. 6.3.1]

A Evaporator (field supply)

B Gas pipe

C Thermistor (gas pipe)

D Aluminum tape (field supply)

E Insulation

F Tie band

[Fig. 6.3.2]

5

[Fig. 7.1.1]

[Fig. 7.2.1] [Fig. 7.2.2]

[Fig. 7.2.3] [Fig. 7.2.4]

A Terminal block for AHU controller/

indoor transmission cable

B Terminal block for outdoor trans-

mission cable

C Remote controller

M2

DC24~30V

M1

(A, B)

12

D

A

C

L

N

DC10~13V

AB

12

L

N

1

2

A

C

B

A Non-polarized

B Upper level (TB15)

C Remote Controller

D Lower level (TB5)

AB

DE

CCCCCCC

A Switch 16 A B Overcurrent protection 16 A

C Indoor unit D Total operating current be less than 16 A

E Pull box

TB5 TB5

SM1M2 SM1M2

TB3

M1M2

AA

B

CC

TB5 TB15 TB5 TB15

SM1M2 SM1M2

TB3

M1M2 21 21

AA

B

CC

7

9

[Fig. 9.0.1]

8

[Fig. 8.1.1]

A Address switch

B SW2

A

B

[Fig. 7.2.5]

B

C

A

D

A Bunch of wires

B Plug

C Tube

D Insulation tape

Loading...

Loading...