Page 1

1. Outline

This fan controller apply to following units.

These units can be operated on cooling mode at the low ambient temperature with this optional FAN CONTROLLER.

Please read carefully this manual and install following this.

Model name Q'TY

1 set 2 set

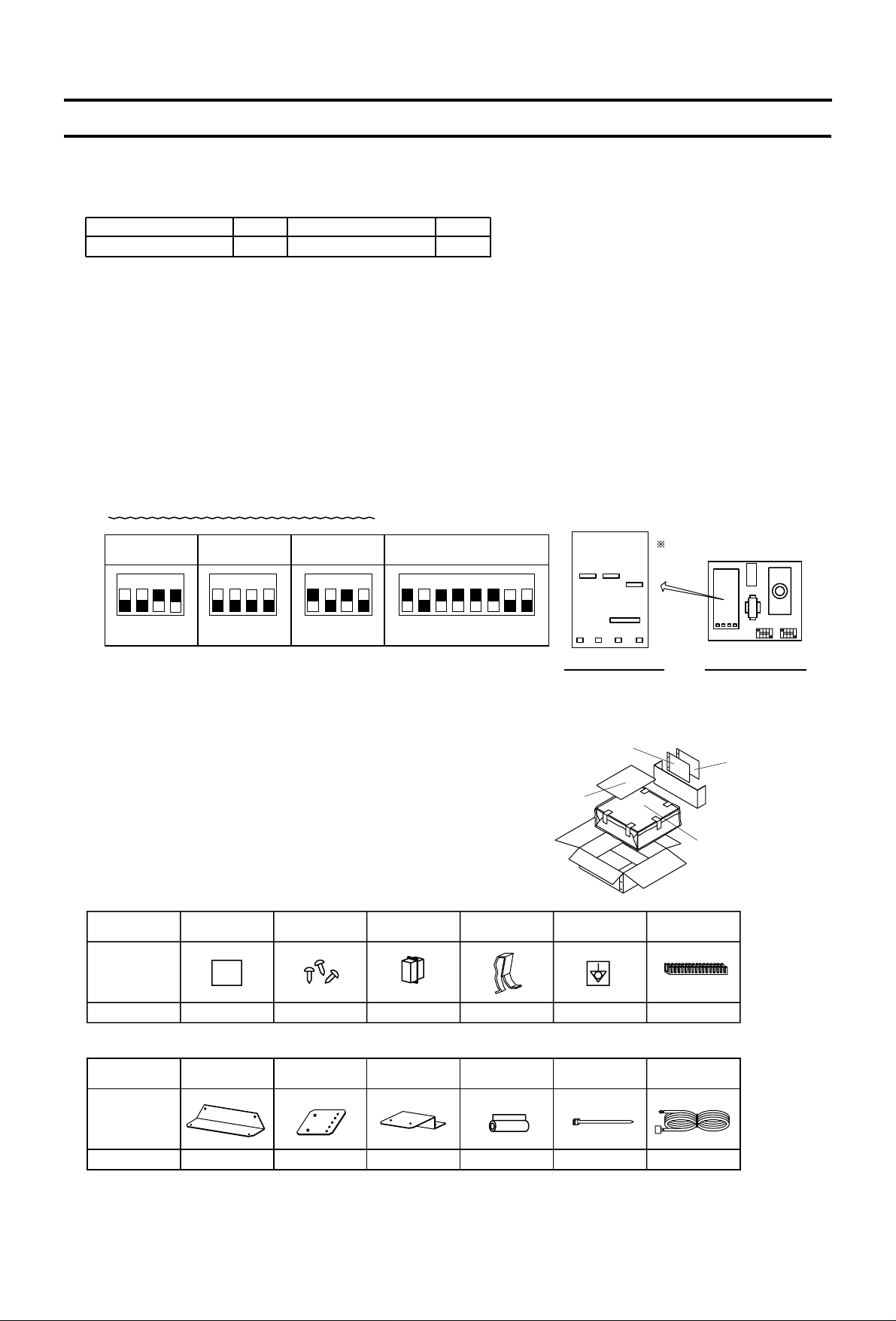

3. Parts

There are the following parts in this box, and confirm whether there are all attached.

There are two kinds of wiring sticker in this box.

Please select the pertinent one by model name.

2. Caution

Accessory assy 1

Name

Shape

Amount 2 12 1 1 1

1

2

Earth stickerWiring sticker Screw Connector cap Spring

Connector assy

Grommet

Accessory assy 2

Name

Shape

Amount 1 1 3 3 15

Attachment Attachment Attachment Pipe cover Band

(3,4 ON) (All OFF) (1,3 ON) (1,3,4,5,6 ON)

SW0 SW1 SW2 SW3

ON ON ONONON

Model name Q'TY

PRHG-15,20PRHG-8,10

34213421342134267851

Accessory assy 2

Accessory assy 1

Installation manual

(This manual)

Fan controller

SW3

SW1

SW0

SW2

Fan controller insideControl circuit board

Only SW3 direction is different.

1. Fan controller changes the outdoor fan speed.

Strong wind is injurious to fan speed controller.

Please install the windproof when unit is influenced by strong wind such as install it on the place there is no building in

surrounding or the rooftop

2. As the case may be the operation with FAN CONTROLLER generate an electromagnetic sound from fan motor.

Please consider the soundproofing wall equipment etc. when using the fan controller in the place where the noise

becomes a problem.

There is no worry which interferes to the unit though an electromagnetic sound might be generated from fan motor.

3. When shipping the fan controller, the dip switch on the control circuit board is set as follows.

Do not change factory set of all dip switches.

LOW AMBIENT COOLING PARTS; OPTION PAC-205FC (Fan controller)

-51-

Page 2

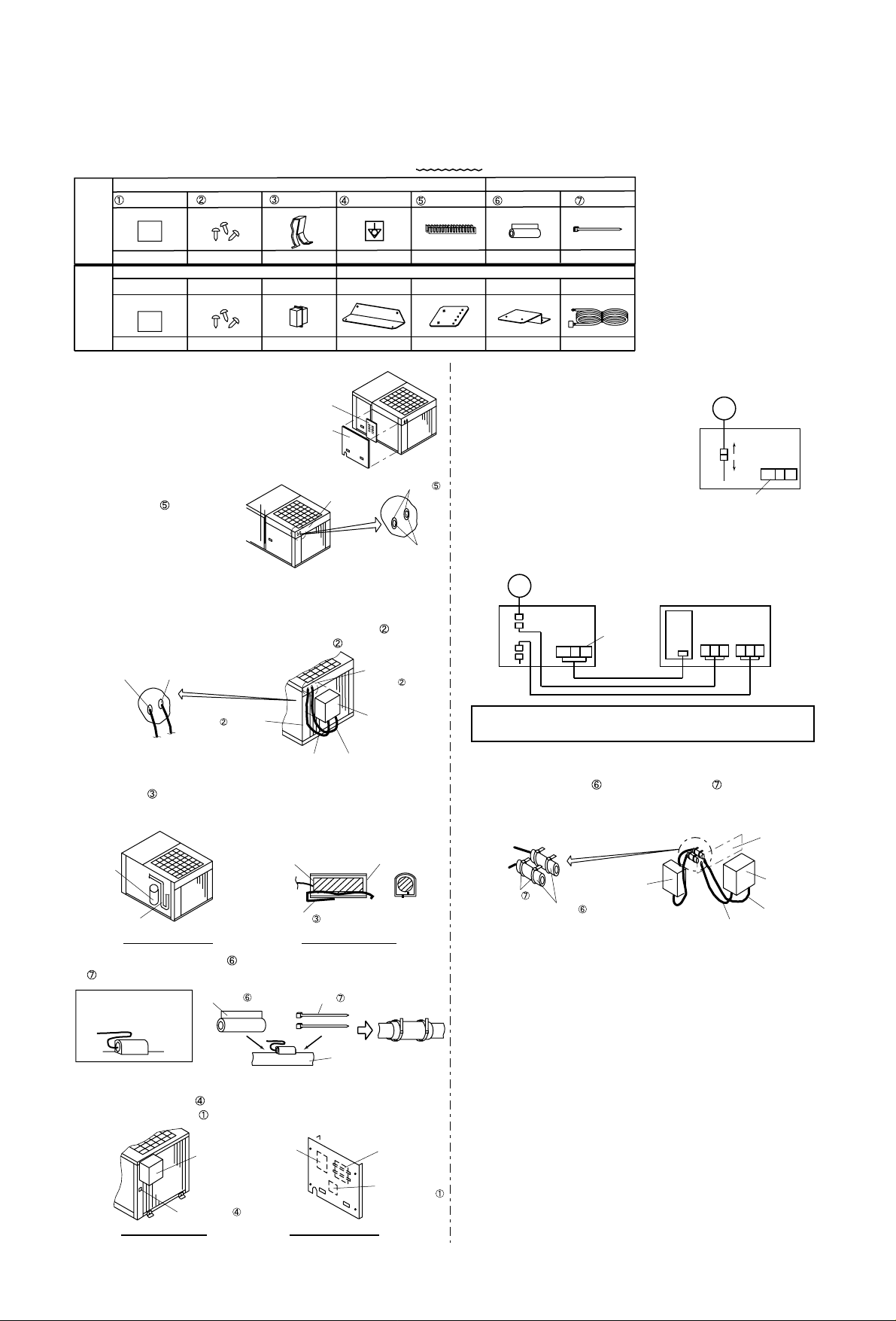

4.1. PRHG-8,10

4.1.1. Install

Insert the thermistorThermistor position

1. The service panel and control box

cover are removed.

2. Penetrate the knockout holes at

the top panel.

The grommet (2 pieces)

install to the hole for wiring

in the top panel.

4. Confirm the thermistor holder position.

The spring insert in the thermistor holder.

The thermistor (black wiring) which is connected to the fan

controller is put in the holder.

3.

6. The earth sticker and wiring sticker are put on an following place.

1. The earth sticker is put on the pillar.

2. The wiring sticker is put on the service panel cover (inside).

Put a wiring stickerPut a earth sticker

5. Please use the pipe cover (1 piece) and fix with the band

(2 pieces).

4.1.2. Wiring

3. After connect wiring, to prevent wiring being damaged with

the fin, the pipe cover (2 pieces) and band (4 pieces)

are used.

In that time, never bundle the thermistor wiring with other

wiring.

4. After wiring ends, the wiring is bundled with a remaining band.

Never bundle the thermistor and other wiring together.

5. Ensure there is not wiring mistake found, then only install the

controller box cover and service panel.

Fan

controller

Earth sticker

Unit wiring

sticker

Fan

controller

1. Disconnect connector C11 - C11.

The connector C11 removes to the motor

side and the control box side.

2. When the fan controller is installed, the connector is

connected in the control box.

The wiring from CN04 connect to the terminal block (F/C, N)

in the control box.

Please be careful, do not damage wires by the sheet metal edges

or the fin, etc.

MF2

Control box

C11

C11

Terminal block

Pipe cover Band

Pipe

Other wiringThermistor wiring

only

Compressor

Service panel

Control box

cover

Thermistor wiring

only

Other wiring

Fan controller

wiring sticker

Instruction

assy

Fan

controller

Thermistor

wiring only

Other wiring

Top panel

Control

box

Band

Pipe cover

Thermistor

wiring only

Other wiring

Install to

the top panel.

(Screw 2 pieces)

Install to the holder.

(Screw 1 piece)

Thermistor

holder position

CN04

UVW L1 L2 L3

MF2

Terminal block

Control box

Fan controller

C11

C11

Top panel

Grommet

Wiring hole

F/C N

F/C N

Thermistor Thermistor holder

Spring

The thermistor wiring is

bundled as follows before

the pipe cover is installed.

Please use the following parts during installation of fan controller.

There are two kinds of wiring sticker, please use writing as “W881927”.

Wiring from the fan controller is passed through the hole of

procedure 2.

The thermistor and other wiring should use separate wiring hole.

The fan controller install to the top panel with the screw (2

pieces) and install to the holder with the screw (1 piece).

Accessory assy 1

Wiring sticker Earth stickerScrew

Spring

Grommet

Accessory assy 2Accessory assy 1

Use

Not

use

Attachment

ONLY PU(H)-7,8,10

Accessory assy 2

Pipe cover Band

1

Attachment

1

Attachment

311

1

3

Screw Connector

9

113152

Wiring sticker

1

Connector assy

4. Instllation

-52-

Page 3

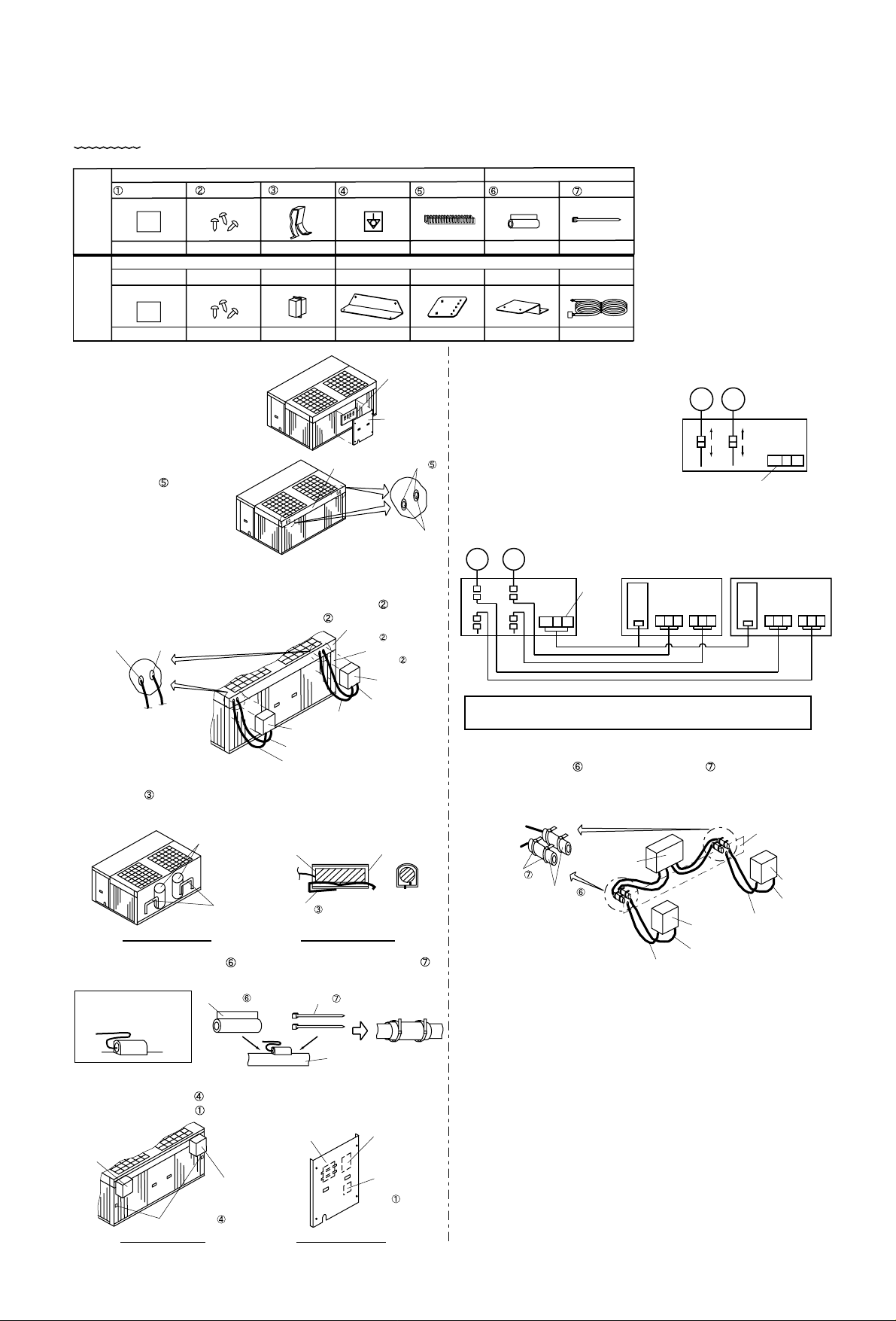

4.2. PRHG-15,20

4.2.1. Install

Insert the thermistorThermistor position

1. The service panel and control box

cover are removed.

2. Penetrate the knockout holes at

the top panel.

The grommet (2x2 pieces)

install to the hole for wiring

in the top panel.

4.

3.

6. The earth sticker and wiring sticker are put on an following place.

1. The earth sticker (2x1 pieces) is put on the pillar.

2. The wiring sticker (1 piece) is put on the service panel cover

(inside).

1.

Put a wiring stickerPut a earth sticker

4.2.2. Wiring

3.

4. After wiring ends, the wiring is bundled with a remaining band.

Never bundle the thermistor and other wiring together.

5.

2.

Earth sticker

Please be careful, do not damage wires by the sheet metal edges

or the fin, etc.

Pipe cover Band

Pipe

Thermistor holder

position

Compressor

Thermistor wiring

only

Other wiring

Band

Pipe cover

Thermistor

wiring only

Other wiring

Service panel

Control box

cover

Fan controller

wiring sticker

Instruction assy

Unit wiring sticker

Fan controller

Install to the pillar.

(Screw 1 piece)

Install to the top panel.

(Screw 2 pieces)

Other wiring

Thermistor wiring only

Other wiring

Thermistor wiring only

Fan controller

Fan controller

Control box

MF2 MF3

Terminal block

C11

C11

C21

C21

Fan

controller

Thermistor wiring only

Other wiring

Control box

Top panel

CN04

UVW L1 L2 L3

MF2 MF3

Terminal

block

CN04

UVW L1 L2 L3

Control box

Fan controller Fan controller

C11

C11

C21

C21

Fan controller

(As well as the another side.)

6. Please use the pipe cover (2x1 pieces) and fix with the band

(2x2 pieces).

Accessory assy 1

Wiring sticker Earth stickerScrew

Spring

Grommet

Accessory assy 2Accessory assy 1

Use

Not

use

Attachment

ONLY PU(H)-7,8,10

Accessory assy 2

Pipe cover Band

1

Attachment

1

Attachment

31

1

13

Screw Connector

9

1

13152

Wiring sticker

1

Connector assy

Thermistor Thermistor holder

Spring

F/C N

F/C N

Grommet

Wiring hole

The thermistor wiring is

bundled as follows before

the pipe cover is installed.

Please use the following parts during installation of fan controller. There are two kinds of wiring sticker, please use writing as

“W881927”.

The fan controller is necessary for these models by two sets. (The following accessory parts show the fan controller one set.)

Fan

controller

Thermistor wiring only

Other wiring

Top panel

Wiring from the fan controller is passed through the hole of

procedure 2.

The thermistor and other wiring should use separate wiring hole.

The fan controller install to the top panel with the screw (2x2

pieces) and install to the pillar with the screw (2x1 pieces).

Confirm the thermistor holder position. (2 places)

The spring (2x1 pieces) insert in the thermistor holder.

The thermistor (black wiring) which is connected to the fan

controller is put in the holder.

Disconnect connector C11 - C11 and

C21 - C21.

The connector C11 and C21 remove

to the motor side and the control box

side.

When the fan controller is installed, the connector is connected

in the control box.

The wiring from CN04 connect to the terminal block (F/C, N) in

the control box.

After connect wiring, to prevent wiring being damaged with the

fin, the pipe cover (2x2 pieces) and band (2x4 pieces) are

used.

In that time, never bundle the thermistor wiring with other

wiring.

Ensure there is not wiring mistake found, then only install the

controller box cover and service panel.

-53-

Page 4

5. Before starting the trial run

Please execute the following confirmations to prevent wrong connection.

If there is wrong connection, it may damage fan controller, but also damage the unit.

Confirmation

Please intercept the power supply without fail, and secure safety when you execute detaching wiring, the connector,

and the measurement machine to the following work.

Step

Step 1

Confirmation matter Check Correspondence

Connected confirmation

Step 1-1 Is fan controller's power supply input wiring position connected correctly as

shown in installed manual?

Step 1-2 Is the phase of the connection of fan controller power supply input (TB IN)

accurate?

Step 1-3 Is the phase of the connection of fan controller output (TB OUT) accurate?

Step 1-4 Is the phase of connection of fan controller output wiring to fan motor accurate?

Step 2

Drive confirmation

Step 2-1 Does the fan rotate in a correct direction, when the unit is driven ?

Step 2-2 The thermistor for the condensing temperature detection is removed to CN01.

Drive to the cooling operation.

(The unit stops abnormally when the cooling operation drive is continued for a

long time occasionally. - High pressure switch off)

Whether LED01 has blinked is confirmed.

When the unit is in operation, the fan controller output voltage measured

in TB OUT, and checked whether the output of about 200V.

There is a problem when it is an output of about 300V.

Step 2-3 The thermistor for the condensing temperature detection is surely connected

with CN01 as before.

Step 2-4

Step 1-5 Is the thermistor for the condensing temperature detection of the attachment

connected with CN01?

Step 1-6 Is the thermistor for the condensing temperature detection accurately installed

in the unit?

Step 1-7 In case of the heat pump model, the wiring for full load input is connected with

CN04?

In case of the heat pump model and the heating drive is possible, the heating

drive is executed and the voltage of CN04 is input AC198V - 264V.

In that case, the fan must be full load drive.

(The output of the power-supply voltage is confirmed in TB OUT. )

When heating cannot be driven, step 1-7, step 1-8 is executed again.

In case of the heat pump model, the wiring for full load input is connected

accurately in control box?

Step 1-8

Troubleshooting 1,2

Troubleshooting 3

Troubleshooting 4

CN04

U

TB OUT

VW L1 L2 L3

CN01

Fan controller layout

Refer to Step 1-2

Refer to Step 1-5

Step 2-2

Step 2-3

Refer to Step 1-7

Step 2-4

U : Red

V : White

W : Black

L1 : Red

L2 : White

L3 : Black

Refer to Step 1-3

TB IN

-54-

Page 5

6. Troubleshooting (PAC-205FC)

State of Machine

Cause Check point

1. The fun does not run.

Content of confirmation

3) The transformer (T01) is defective.

4) The thyristor module (SCRM) is defective.

5) The control printing wiring board is

defective.

6) The fan motor and unit side control box

are defective.

2) Connected mistake

1) The power-supply voltage is abnormal. The value of power-supply voltage is

confirmed. (TB IN)

Fan power supply wiring is connected

with fan controller power supply taking

out part, and confirm operation.

The blinking of LED01 is confirmed.

The resistance is confirmed.

(Between the lines of primary side, and

lines of secondary side.)

The content of P15 is checked. (SCRM) The content of P15 is judgment. (SCRM)

Whether the voltage is input to fan motor is

confirmed.

Whether the fan motor operation is

confirmed.

The fan controller connection is confirmed.

The unit side connection is confirmed.

Is the power-supply voltage 342-457V?

Troubleshooting

Replace the transformer in case of abnormal

resistance.

When the voltage impression and fan motor does

not work, fan motor is defective.

When the voltage is not impressed to the fan, the

unit side control box is defective.

When there is no wrong above-mentioned,

it is assumed fan controller connection state,

if abnormality relapses, the control printing board

is defective and exchange.

Replace SCRM when abnormality is found.

At the time of turning on light. (always)

The CN01 connector is removed, and measures

resistance. When the resistance is 1 kilo-ohm or

less, repair the control printing board due to the

thermistor short-circuit breakdown.

In case of thermistor is correct, the control

printing board is defective and exchange.

At the time of turning off light.

The CN01 connector is removed, and measures

resistance. When the resistance is 25 kilo-ohm or

more, repair the control printing board due to the

thermistor open breakdown.

In case of thermistor is correct, the control

printing board is defective and exchange.

The wiring mistake is corrected.

The power supply wiring is confirmed,

and corrected.

TB OUT - fan motor

Resistance between the lines of primary side

(red and white) about 310 ohm.

Resistance between the lines of secondary

side (CN02 the connector is removed from

the printing wiring board.)

Between 1-3 pin about 0.9 ohm

CN02- thermistor

NF-SCRM-TB OUT

CNU, CNV, CNW-SCRM

(The connection is noted.)

TB IN-NF wiring

TB IN-T01-CN02.

After checking item 1)-4), when the power

supply is turned on, the blinking of LED01 is

confirmed.

Please intercept the power supply without fail, and secure safety when you execute detaching wiring, the connector,

and the measurement machine to the following work.

-55-

Page 6

State of Machine

Cause Check point Content of confirmation

4) The control printing wiring board setting

is defective.

3) Connected mistake

3) Connected mistake

2) Output wiring supply reverse-phase.

1) Power supply reverse-phase.

2) Power supply reverse-phase.

Output wiring reverse-phase.

The phase of fan motor output wiring is

confirmed. (TB OUT)

The phase of fan motor output wiring is

confirmed. (TB OUT)

The phase of input voltage is confirmed.

(TB IN)

The phase of input voltage is confirmed.

(TB IN)

The set of dip switch is confirmed. (SW0-3)

(P2)

It is confirmed that the switch setting is

corresponding to the electric wiring diagram.

The control substrate is matched to setting the

electric wiring diagram.

The fan controller connection is confirmed.

The fan controller connection is confirmed.

The input voltage is confirmed. (CN04)

Is the phase of U, V, W correct?

Is the phase of L1, L2, L3 correct?

Is the phase of U, V, W correct?

Is the phase of L1, L2, L3 correct?

Troubleshooting

The phase of U, V, W is corrected.

The connected phase is confirmed.

The wiring mistake is corrected.

The phase of L1, L2,L3 is corrected.

The phase of U, V, W is corrected.

The phase of L1, L2,L3 is corrected.

NF-SCRM-TB OUT (The connection phase

is noted.)

CNU, CNV, CNW-SCRM

(The connection is noted.)

Is not AC198-264V input in CN04?

TB IN-NF wiring (The connection phase is noted.)

2. The fan rotates

oppositely.

3. The rotation speed

of fans cannot control.

Something wrong

occurs by step2-2 drive

confirmation of installed

confirmation matter.

It becomes high-

pressure abnormal

pressure.

1) During heating drive During heating drive, there is an input in CN04 and

the fan becomes full load drive. Normality

CN04- the wiring for full load input in heating

(CN04 input is AC198-264V in heating.)

There must not be connector connection in

CNX.

(CNX is compulsion full load input.

Full load when short-circuited.)

NF-SCRM-TB OUT (The connection phase is

noted.)

CNU, CNV, CNW-SCRM

(The connection is noted.)

TB IN-NF wiring (The connection phase is

noted.)

TB IN-T01-CN02 (The connection phase is

noted.)

CN02- thermistor

The connected phase is confirmed.

The wiring mistake is corrected.

In cooling, when there is an input in CN04, wiring

of CN04 is mistake connection.

The wiring is corrected.

When there is an input in CN04, the fan is full load..

When there is a connector connection in CNX,

it is removed.

The unit side connection is confirmed.

The connected phase is confirmed.

The wiring mistake is corrected.

TB OUT - fan motor

(The phase (U, V, W) is noted.)

Position of the wiring for full load input

(In heating)

Installation position of thermistor

If the position where the thermistor is installed is

wrong, the rotation speed control of the fan as

condensing temperature is impossible.

5) The thyristor module (SCRM) is defective. The content of P14 is checked. (SCRM) The content of P14 is judgment. (SCRM) SCRM exchange when abnormality is found.

-56-

Page 7

State of Machine

Cause Check point Content of confirmation

1) Connected mistake The fan controller connection is confirmed.

Troubleshooting

6) The control printing wiring board is

defective.

The blinking of LED01 is confirmed. At the time of turning on light (always)

(There is a possibility of the thermistor short-circuit.)

The CN01 connector is removed, and measures

resistance. When the resistance is 1 kilo-ohm or

less, repair the control printing board due to the

thermistor short-circuit breakdown.

In case of thermistor is correct, the control printing

board is defective and exchange.

At the time of turning off light

(There is a possibility of the thermistor open

breakdown.)

The CN01 connector is removed, and measures

resistance. When the resistance is 25 kilo-ohm or

more, repair the control printing board due to the

thermistor open breakdown.

In case of thermistor is correct, the control printing

board is defective and exchange.

After checking item 1)-5), when the power

supply is turned on, the blinking of LED01

is confirmed.

3) The control printing wiring board is

defective.

Item 1) is checked, again.After checking item 1), there is a

possibility of a defective printed circuit

board if a normal drive is not done.

After checking item 1), if there is no problem,

the control printing board is defective and exchange .

4. The f an ne v er

becomes full load

drive. (In heating)

CN04- the wiring for full load input

(CN04 input is AC198-264V in heating.)

NF-SCRM-TB OUT

CNU, CNV, CNW-SCRM

(The connection is noted.)

TB IN-NF wiring

TB IN-T01-CN02

It is confirmed that wiring is correctly connected.

The wiring mistake is corrected.

At the time of blinking

The item 2), 3) are confirmed again, and there is

no connection mistake, the control printing board

is defective and exchange.

The wiring mistake is corrected. The unit side connection is confirmed. Position of the wiring for full load input

(In heating)

2) The thyristor module (SCRM) is defective. The content of P14 is checked. (SCRM) The content of P14 is judgment. (SCRM) Replace SCRM when abnormality is found.

-57-

Page 8

Thyristor module

(SCRM)

<Judgment Method> Measure the resistance between each of the SCRM pins and judge if there is a failure or not by the resulting

values.

<Judgment Values 1> Check between G and K.

Use the smallest resistance range on the tester.

Judgment Value: 1.5 ohm 80 ohm

<Judgment Values 2>

<External View>

<Internal Circuit Diagrams>

Check between AK1 and AK2.

Use the greatest resistance range on the tester.

Judgment Value: 60 kilo-ohm ohm

K

AK1

AK1

AK1 AK1

AK2

AK2

AK2 AK2

GKGKG

GK GK GK

K

K

AK1

AK2

G

G

K

K

AK1

AK2

G

G

G

K

G

K

-58-

Loading...

Loading...