Page 1

Pb Solder, Pb Joints, Pb PCA

This product uses lead-free solder

on the circuit boards. For repairing

circuit boards, see "Precautions for

resoldering" in this Service Manual.

DIGITAL MONOCHROME PRINTER

MODEL

2008

P95DW

This model is RoHS-compliant.

Provide servicing referring to “NOTES

FOR SERVICING RoHS-COMPLIANT

PRODUCTS” described in the service

manual.

Before servicing this chassis, it is important that the service person reads the “SAFETY PRECAUTIONS” and “PRODUCT

SAFETY NOTICE” in this service manual.

CAUTION

Copyright © 2008 Mitsubishi Electric Corporation All Rights Reserved.

Page 2

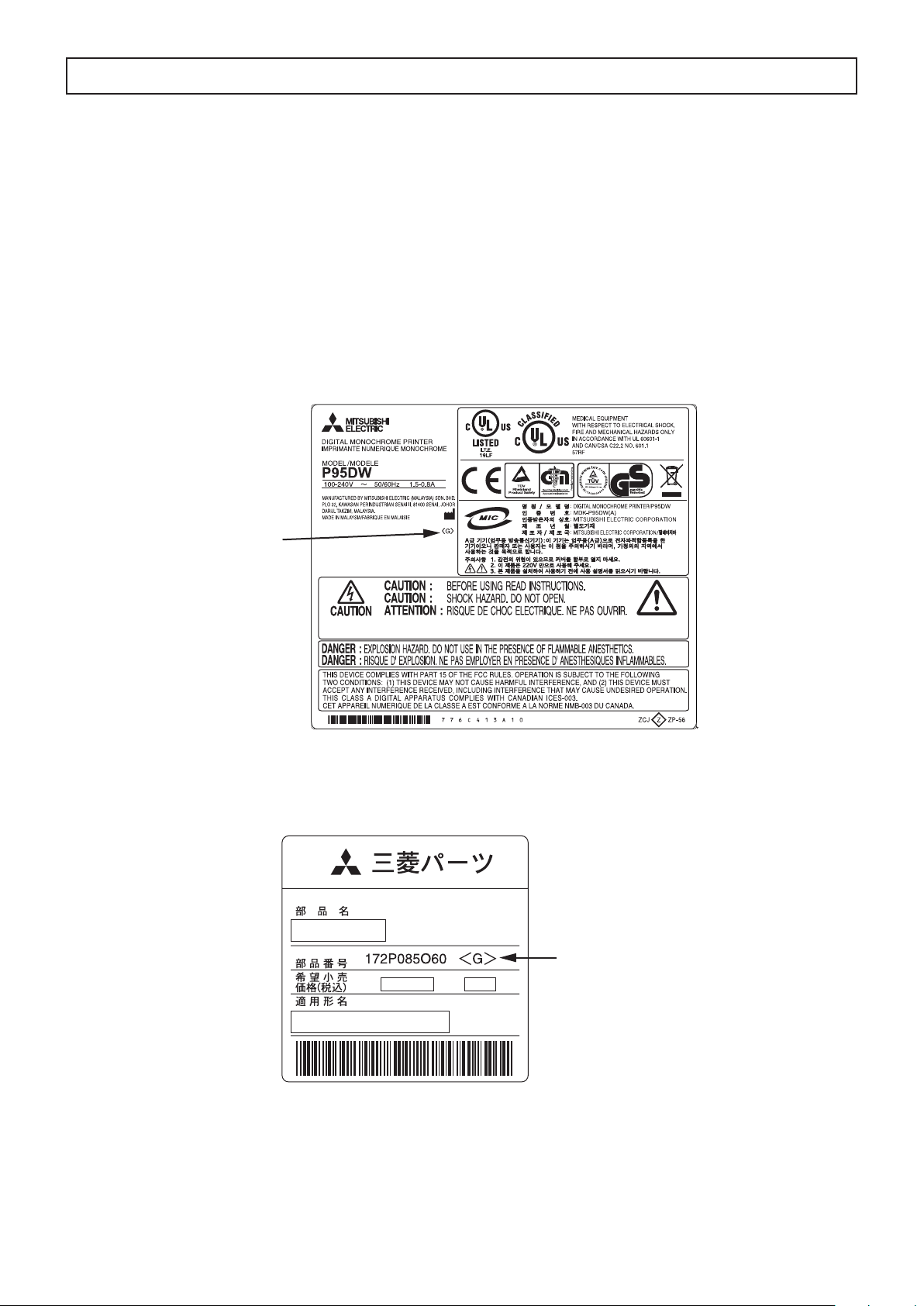

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS

Parts Name

Model Name

Parts No.

E05R

Mark position

Mark position

Follow the notes and instructions below when servicing RoHS-compliant

products.

1. For RoHS-compliant products, be sure to use RoHS-compliant service parts.

2. Check the presence of <G> marking on the rating plate to distinguish RoHScompliant product from non-RoHS-compliant product.

<G> marking

With <G> marking: RoHS-compliant product

Without <G> marking: Non-RoHS-compliant product

<Sample>

3.LabelsofRoHS-compliantservicepartsbear<G>markingforidenticationpurpose.

<Sample>

4. Don’t use non-RoHS-compliant parts with RoHS-compliant products.

5. Service parts for RoHS-compliant products are listed in the parts catalog contained

in the service manual.

- 2 -

Page 3

SPECIFICATIONS

• Power Supply

• Dot Resolution

• Printing Speed

• Gradations

• Printing Size

•

Connection Terminal

•

Cabinet Dimensions

• Weight

•

Operating conditions

: AC 100 to 240V 50/60Hz,1.5 to 0.8A

: 1280 pixels (H) x 960 pixels (V)(Standard)

(Max.1280 pixels x 5760 pixels)

: Approx.1.9sec.(Standard)

: 256gradations

: 4.0” × 3.0”(100mm × 75mm)(Standard)

(Max.4.0” × 17.7”(100mm × 450mm))

: USB interface (Series ”B” receptacle)

Hi-Speed USB (Ver. 2.0) supported

: 6.1” (W) × 3.3” (H) × 9.4” (D)

154mm (W) × 84.5mm (H) × 239mm (D)

: 2.6kg (5.8lbs)

: Temperature 41 to 104°F (5 to 40°C)

Humidity 20 - 80% RH (No dewing)

• Weight and dimensions shown are approximate.

• Designandspecicationsaresubjecttochangewithoutnotice.

- 3 -

Page 4

CONTENTS

– FILE “COVERPGE” –

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS .............................................................................. 2

SPECIFICATIONS ................................................................................................................................................. 3

CONTENTS ........................................................................................................................................................... 4

– FILE “INSTBOOK” –

FEATURES AND FUNCTIONS ............................................................................................................................. 1

INSTALLATION OF PAPER .................................................................................................................................. 2

EXAMPLE OF CONNECTION .............................................................................................................................. 3

ERROR DISPLAY ................................................................................................................................................. 3

STATUS AND MODES .......................................................................................................................................... 5

USE OF CLEANING SHEET ................................................................................................................................ 5

MAINTENANCE .................................................................................................................................................... 6

– FILE “EXPOSED” –

SAFETY PRECAUTIONS ..................................................................................................................................... 1

PRECAUTIONS FOR RESOLDERING ................................................................................................................ 2

PCB LOCATION ................................................................................................................................................... 3

DISASSEMBLY ..................................................................................................................................................... 4

1. Top ASSY ............................................................................................................................................... 4

2. Door ASSY SI ......................................................................................................................................... 4

3. Front ASSY ............................................................................................................................................ 5

4. Main PCB ASSY ..................................................................................................................................... 5

5. Power PCB ASSY .................................................................................................................................. 6

6. Front PCB ASSY / Cutter ....................................................................................................................... 7

7. Print deck ASSY ..................................................................................................................................... 8

8. Solenoide ............................................................................................................................................... 9

9. Motor unit ............................................................................................................................................... 9

10. Platen roller ASSY ................................................................................................................................ 10

11. SP sensor unit(light receiver of paper detector1 / light receiver of paper detector2) ........................... 12

12. SH sensor unit(head position sensor) .................................................................................................. 12

13. SH sensor unit(light emitter of paper detector1) .................................................................................. 13

14. SR sensor unit(Door open / close sensor) ........................................................................................... 13

15. SD sensor unit(light emitter of paper detector2) .................................................................................. 13

16. Head ASSY .......................................................................................................................................... 15

LEAD DRESS ....................................................................................................................................................... 16

– FILE “ADJ” –

SERVICE MODE AND CIRCUIT ADJUSTMENTS ............................................................................................... 1

Service 0 mode .......................................................................................................................................... 2

Service 1 mode .......................................................................................................................................... 4

Adjustmentofpaperdetectionlevel ........................................................................................................... 6

E2PROM INITIALIZATION .................................................................................................................................... 6

Factory out (Perform this process mainly after replacing the Main PCB ASSY.) ....................................... 6

Service ini (Perform this process mainly after replacing the head ASSY.) ................................................. 6

Function clear ............................................................................................................................................. 6

TEST PRINTING ................................................................................................................................................... 7

ELECTRICAL ADJUSTMENT .............................................................................................................................. 8

TEST EQUIPMENT .................................................................................................................................... 8

Power Circuit

1. Primary boost voltage .................................................................................................................... 8

2. Head voltage .................................................................................................................................. 8

– FILE “PARTSLST” –

PACKING PARTS ................................................................................................................................................. 2

LABEL ATTACHING POSITION ........................................................................................................................... 4

PARTS LIST .......................................................................................................................................................... 5

– FILE “EXPLODED” –

EXPLODED VIEW ( CHASSIS ) ................................................................................................................ 2

PARTS LIST ( CHASSIS ) .......................................................................................................................... 3

EXPLODED VIEW ( PRINT DECK ASSY ) ................................................................................................ 6

PARTS LIST ( PRINT DECK ASSY ).......................................................................................................... 7

– FILE “SCHEMATC” –

BLOCK DIAGRAMS

SCHEMATIC DIAGRAMS

- 4 -

Page 5

DIGITAL MONOCHROME PRINTER

MODEL

P95DW

P95DE

OPERATION MANUAL

THIS OPERATION MANUAL IS IMPORTANT

TO YOU.

PLEASE READ IT BEFORE USING YOUR

DIGITAL MONOCHROME PRINTER.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

DIGITAL MONOCHROME

ESPAÑOL ENGLISH

PRINTER

This digital monochrome printer complies with the requirements of the

EC Directive 93/42/EEC.

Page 6

Page 7

FOR THE MODEL P91DW(UB) ONLY

WARNING:

In the USA or Canada, use the AC power cord according to the recommendations as

below, in order to comply with UL60601-1 and CAN/CSA C22.2 No. 601.1.

Case 1. Connect to the 120V receptacle of the room or the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT,

size 16 or 18AWG, length 2.5m or shorter cord with IEC60320-1/C13 type, 125V

10A or higher rating connector and NEMA 5-15 type, 125V 10A or higher rating,

Hospital Grade plug.

Case 2. Connect to the 230V receptacle of the room or the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT,

size 16 or 18AWG, length 2.5m or shorter cord with IEC60320-1/C13 type, 250V

10A or higher rating connector and NEMA 6-15 type, 250V 10A or higher rating,

Hospital Grade plug.

CAUTION:

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own expense.

Information:

This class A digital apparatus complies with Canadian ICES-003.

"CLASSIFIED BY UNDERWRITERS LABORATORIES INC.®

WITH RESPECT TO ELECTRIC SHOCK, FIRE AND MECHANICAL HAZARDS ONLY IN

ACCORDANCE WITH UL60601-1 AND CAN/CSA C22.2 No. 601.1"

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

Page 8

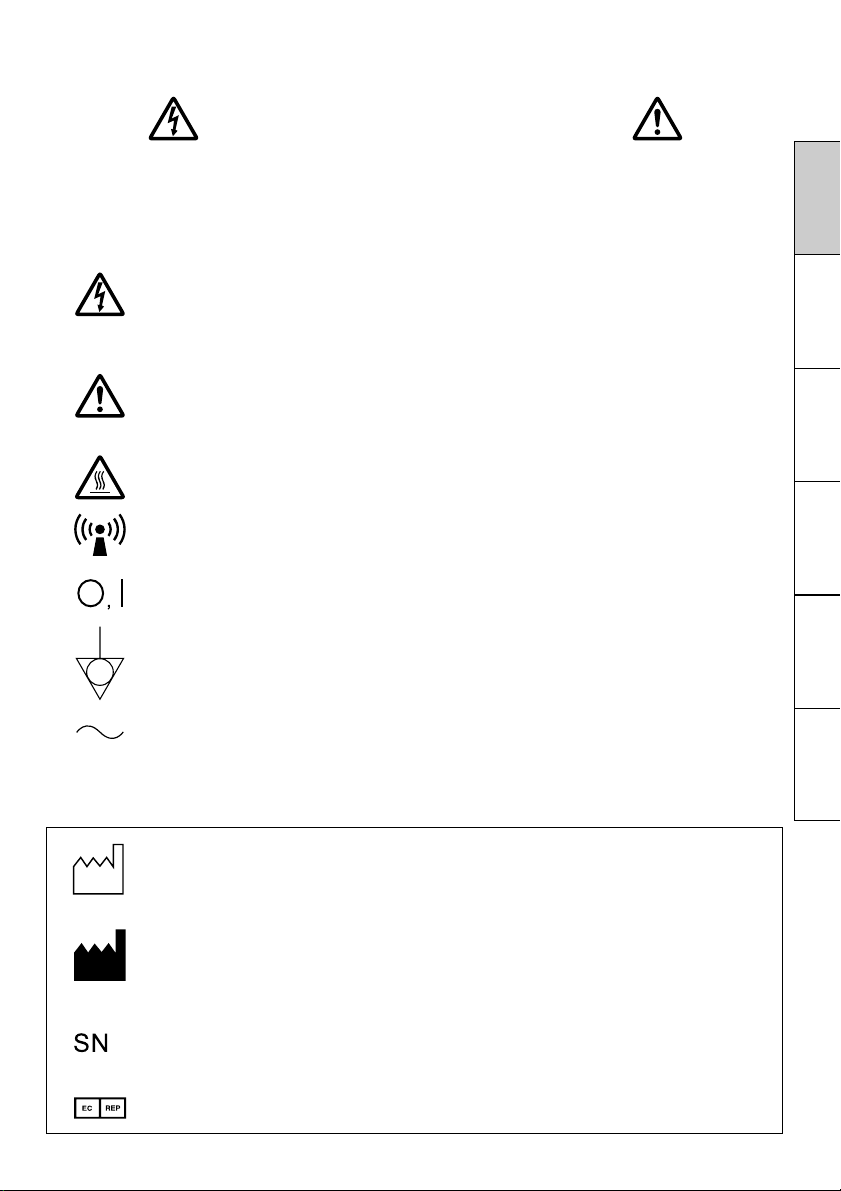

Indications according to IEC60601-1

1. Functions and intended usage of this product

This product receives signals from diagnostic imaging equipment or a personal computer,

and automatically prints and ejects the received image data on the thermal paper.

2. Classifi cation of this product

• According to the type of protection against electric shock: Equipment energized from an

external electrical power source, Class I equipment

• According to the degree of protection of the applied part against electric shock: - (No

applied part)

• According to the degree of protection against harmful ingress of water: Ordinary

equipment (Enclosed equipment without protection against ingress of water)

• According to the degree of safety of application in the presence of a fl ammable anesthetic

mixture with air or with oxygen or nitrous oxide: Equipment not suitable for use in the

presence of a fl ammable anesthetic mixture with air or with oxygen or nitrous oxide

• According to the mode of operation: Continuous operation with intermittent loading

3. Follow the applicable laws and regulations in your country or region or the hospital rules

when disposing of this product or the accessories or consumables thereof.

DANGER

:

EXPLOSION HAZARD.

DO NOT USE IN THE PRESENCE OF FLAMMABLE ANESTHETICS.

Page 9

CAUTION:

RISK OF ELECTRIC SHOCK DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR

BACK).

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

The lightning fl ash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the presence of uninsulated "dangerous voltage"

within the product's enclosure that may be of suffi cient magnitude to constitute a

risk of electric shock.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instructions

in the literature accompanying the appliance.

The “Caution, hot surface” symbol indicates that the marked item may be hot

and should not be touched.

The “Nonionizing radiation” symbol

The “OFF/ON” symbol indicates connection to or disconnection from the mains,

at least for mains switches.

The “Equipotentiality” symbol identifi es the terminals connected each other. The

potential of various parts of equipment or of a system is equalized.

The “Alternating current” symbol indicates that the equipment is suitable for

alternating current only.

When you dispose of the unit or accessories, you must obey the law in the relative area

or country and/or regulation in the relative hospital.

: Manufactured on : to be combined with date code YYYY-MM

: Manufacturers Identifi cation (name address)

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

: Serial number

: Authorised representative in the European Community

Page 10

WARNING:

Install and use this appliance in accordance with the operation manual for safety and

EMC (Electromagnetic Compatibility). If it is not installed and used in accordance with the

operation manual, it may cause interference to other equipment and/or other risk.

To prevent fi re or shock hazard, do not expose this appliance to rain or moisture.

This appliance must be earthed.

In Europe, use the AC power cord according to the recommendations as below.

Connect to the 230 V receptacle of the room or the host equipment.

The AC power cord should be VDE approved and consist of core size 0.75 mm

length 2.5 m or shorter cord with IEC60320-1/C13 type, 250 V 10 A or higher rating

connector and CEE(7)VII type, 250 V 10 A or higher rating plug.

Use the USB cable according to the recommendations as below, in order to comply with

EN60601-1-2.

The USB cable with appropriate plug should be 2 m long or shorter, comply with USB 2.0

standard High speed requirements and USB IF (USB Implementers Forum) approved.

This product is to be employed with medical equipment, just for reference purpose, not for

medical diagnostic purpose.

2

or bigger,

WARNING:

The socket outlet shall be installed near the equipment and shall be easily accessible.

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10

Information for users and Annex IV, and/or to the directive 2006/66/

EC Article 20 Information for end-users and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality

materials and components which can be recycled and/or reused.

This symbol means that electrical and electronic equipment, batteries and accumulators,

at their end-of-life, should be disposed of separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol

means that the battery or accumulator contains a heavy metal at a certain concentration.

This will be indicated as follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used electrical and electronic products, batteries and accumulators.

Please, dispose of this equipment, batteries and accumulators correctly at your local

community waste collection/recycling centre.

Please, help us to conserve the environment we live in!

Page 11

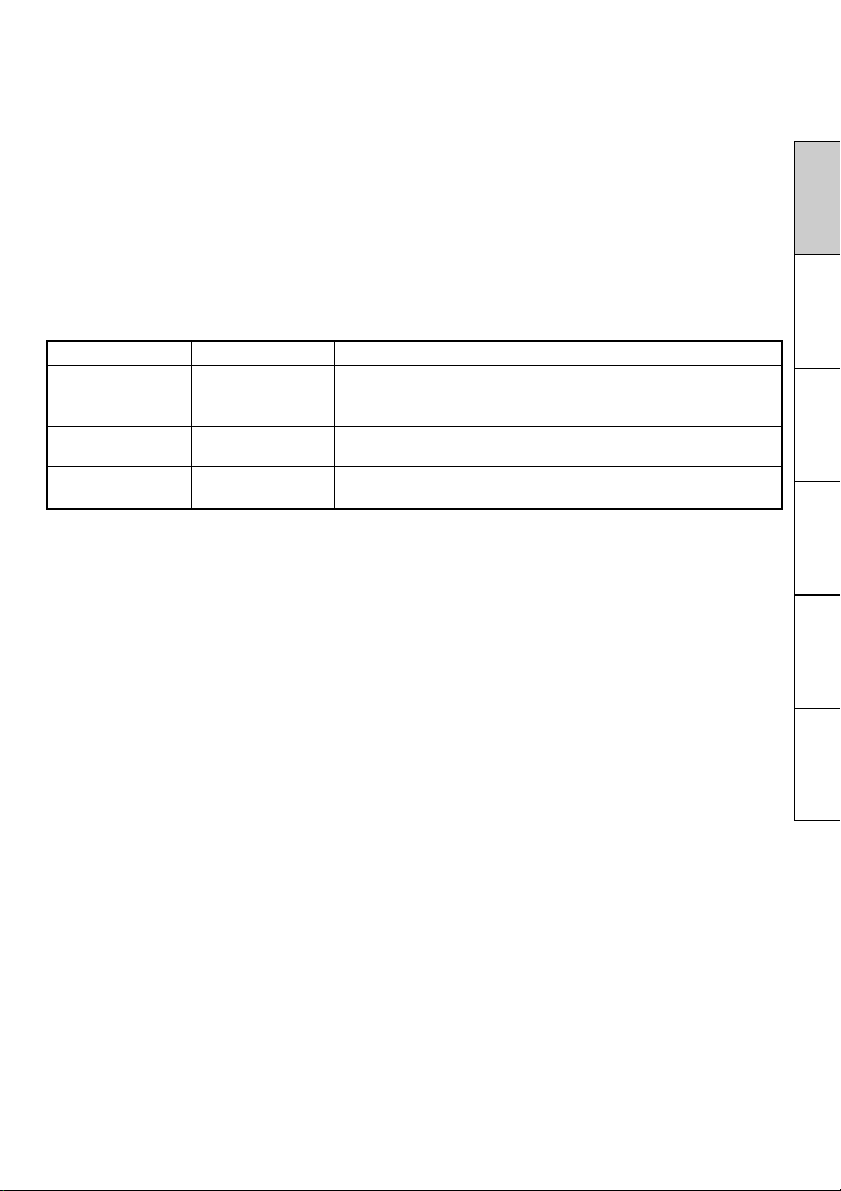

INSTRUCTIONS FOR MEDICAL USE

<according to the Medical Safety/EMC standard IEC/EN 60601-1-2>

MEDICAL ELECTRICAL EQUIPMENT needs special precautions regarding EMC and needs

to be installed and put into service according to the EMC information provided in the ACCOMPANYING DOCUMENTS.

Portable and mobile RF communications equipment can affect MEDICAL ELECTRICAL

EQUIPMENT.

Technical description

List of all cables and maximum length of the cable and other ACCECCORIES

AC power cord

USB cable

Thermal paper

Maximum length

2.5 m

2 m

Reference page in this operation manual

This page, the previous pages for safety and page 26

for accessories

This page and the previous pages for safety

Page 3 for thermal paper, page 26 for accessories

WARNING:

The use of ACCESSORIES and cables other than those specifi ed, with the exception of ca-

bles sold by the manufacturer of the Model P95DW/P95DE as replacement parts for internal

components, may result in increased EMISSIONS or decreased IMMUNITY of the Model

P95DW/P95DE.

WARNING:

The Model P95DW/P95DE should not be used adjacent to or stacked with other equipment

and that if adjacent or stacked use is necessary, the Model P95DW/P95DE should be observed to verify normal operation in the confi guration in which it will be used.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

Page 12

Guidance and manufacturer's declaration - electromagnetic emissions

The Model P95DW/P95DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P95DW/P95DE should assure that it is used in such an

environment.

Emissions test

RF emissions

CISPR 11/EN 55011

Compliance

Group 1

Electromagnetic environment - guidance

The Model P95DW/P95DE uses RF energy only for its

internal function. Therefore, its RF emissions are very

low and are not likely to cause interference in nearby

electronic equipment.

RF emissions

CISPR 11/EN 55011

Harmonic emissions

IEC/EN 61000-3-2

Voltage fluctuations/

Class B

Class A

Complies

The Model P95DW/P95DE is suitable for use in all

establishments, including domestic establishments

and those directly connected to the public low-voltage

power supply network that supplies buildings used for

domestic purposes.

flicker emissions

IEC/EN 61000-3-3

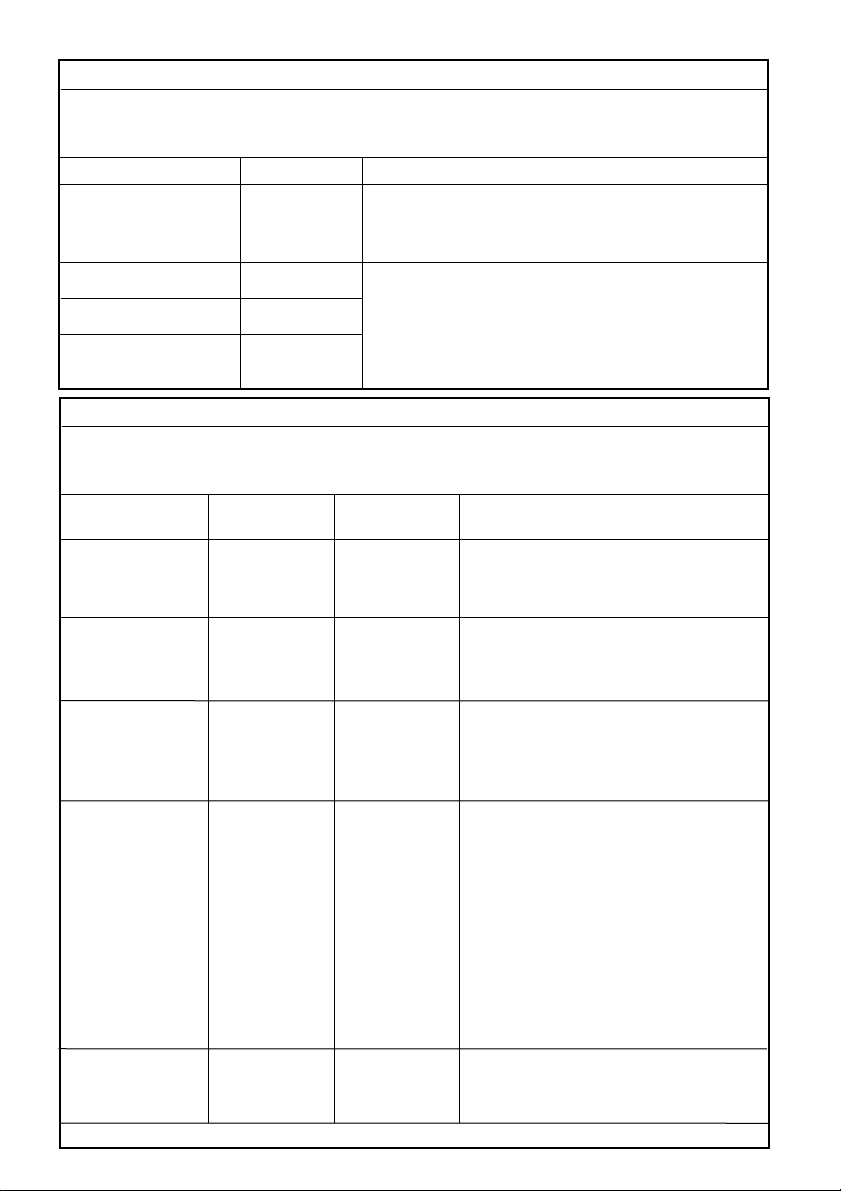

Guidance and manufacturer's declaration - electromagnetic immunity

The Model P95DW/P95DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P95DW/P95DE should assure that it is used in such an

environment.

Immunity test

Electrostatic

discharge (ESD)

IEC/EN 61000-4-2

Electrical fast

transient/burst

IEC/EN 61000-4-4

Surge

IEC/EN 61000-4-5

IEC/EN 60601

test level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input

/output lines

±1 kV line(s) to

line(s)

±2 kV line(s) to

earth

Compliance

level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input

/output lines

±1 kV line(s) to

line(s)

±2 kV line(s) to

earth

Electromagnetic environment - guidance

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Mains power quality should be that of a

typical commercial or hospital

environment.

Mains power quality should be that of a

typical commercial or hospital

environment.

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC/EN 61000-4-11

Power frequency

(50/60 Hz)

magnetic field

IEC/EN 61000-4-8

< 5% U

T

(> 95% dip in UT)

for 0.5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

< 5% U

T

(> 95% dip in UT)

for 5 sec.

3 A/m

< 5% U

T

(> 95% dip in UT)

for 0.5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

< 5% U

T

(> 95% dip in UT)

for 5 sec.

3 A/m

Mains power quality should be that of a

typical commercial or hospital

environment. If the user of the Model

P95DW/P95DE requires continued

operation during power mains

interruptions, it is recommended that the

Model P95DW/P95DE be powered from

an uninterruptible power supply or a

battery.

Power frequency magnetic fields should

be at levels characteristic of a typical

location in a typical commercial or

hospital environment.

NOTE: UT is the a.c. mains voltage prior to application of the test level.

Page 13

Guidance and manufacturer's declaration - electromagnetic immunity

The Model P95DW/P95DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P95DW/P95DE should assure that it is used in such an

environment.

Immunity test

Conducted RF

IEC/EN 61000-4-6

Radiated RF

IEC/EN 61000-4-3

IEC/EN 60601

test level

3 Vrms

150 kHz to 80

MHz

3 V/m

80 MHz to 2.5

GHz

Compliance

level

3 Vrms

3 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to

any part of the Model P95DW/P95DE,

including cables, than the recommended

separation distance calculated from the

equation applicable to the frequency of

the transmitter.

Recommended separation distance

d=1.2√P

d=1.2√P 80 MHz to 800 MHz

d=2.3√P 800 MHz to 2.5 GHz

where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey,

a

should be

less than the compliance level in each

frequency range.b

Interference may occur in the vicinity of

equipment marked with the following

symbol:

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

NOTE1. At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE2. These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV

broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which the Model P95DW/P95DE

is used exceeds the applicable RF compliance level above, the Model P95DW/P95DE

should be observed to verify normal operation. If abnormal performance is observed,

additional measures may be necessary, such as reorienting or relocating the Model

P95DW/P95DE.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

ESPAÑOL ENGLISH

Page 14

Recommended separation distances between

portable and mobile RF communications equipment and the Model P95DW/P95DE

The Model P95DW/P95DE is intended for use in an electromagnetic environment in which radiated

RF disturbances are controlled. The customer or the user of the Model P95DW/P95DE can help

prevent electromagnetic interference by maintaining a minimum distance between portable and

mobile RF communications equipment (transmitters) and the Model P95DW/P95DE as

recommended below, according to the maximum output power of the communications equipment.

Rated maximum output

power of transmitter

W

0.01

0.1

1

10

100

For transmitters rated at a maximum output power not listed above, the recommended

separation distance d in meters (m) can be estimated using the equation applicable to the

frequency of the transmitter, where P is the maximum output power rating of the transmitter in

watts (W) according to the transmitter manufacturer.

NOTE1. At 80 MHz and 800 MHz, the separation distance for higher frequency range applies.

NOTE2. These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

Separation distance according to frequency of transmitter

150 kHz to 80 MHz

d=1.2√P

0.12

0.38

1.2

3.8

12

m

80 MHz to 800 MHz

d=1.2√P

0.12

0.38

1.2

3.8

12

800 MHz to 2.5 GHz

d=2.3√P

0.23

0.73

2.3

7.3

23

Safety Notices for use in combination with other devices

1. All the equipments connected to this unit shall be certifi ed according to Standard

IEC60601-1, IEC60950-1, IEC60065 or other IEC/ISO Standards applicable to the equipments.

2. When this unit is used together with other equipment in the patient area*, the equipment shall be either powered by an isolation transformer or connected via an additional

protective earth terminal to system ground unless it is certifi ed according to Standard

IEC60601-1.

* Patient Area

R1.5m

3. The leakage current could increase when connected to other equipment.

Page 15

1

CONTENTS

CONTENTS .................................................................. 1

PRECAUTIONS ..................................................... 2 - 5

UNPACKING ................................................................ 6

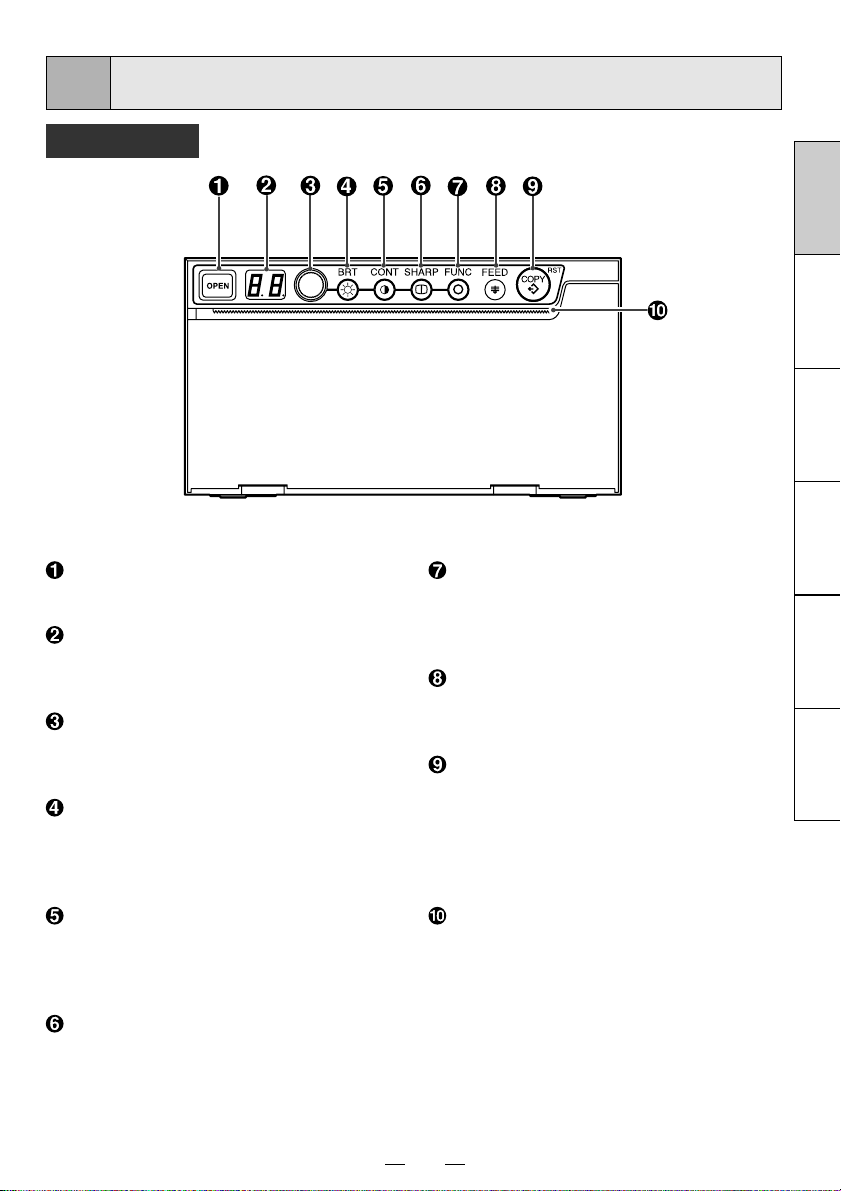

FEATURES AND FUNCTIONS ............................... 7 - 8

Front Panel ..........................................................................................7

Rear Panel ........................................................................................... 8

INSTALLATION OF PAPER .................................9 - 10

EXAMPLE OF CONNECTION ....................................11

PRINTING ...........................................................12 - 13

ADJUSTMENT OF PRINT PICTURE .................14 - 16

SETTING FUNCTION MODE ............................. 17 - 19

ERROR DISPLAY ............................................... 20 - 22

STATUS AND MODES ............................................... 23

USE OF CLEANING SHEET ..................................... 24

MAINTENANCE ......................................................... 25

SPECIFICATIONS ..................................................... 26

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

1

Page 16

2

PRECAUTIONS

In the interest of safety, please observe the following

precautions:

POWER REQUIREMENT

This digital monochrome printer is designed for operation

on 100-240V AC 50/60Hz. Never connect to any outlet

or power supply having a different voltage or frequency.

PROTECTIVE MEASURES

IF ABNORMALITIES ARISE, . . .

Use of the unit during emission of smoke or abnormal

sounds (without adopting countermeasures) is dangerous. In such a case, unplug the power cord from the

source outlet immediately, and request maintenance

services from the sales dealer.

NEVER INSERT ANY OBJECT INTO THE UNIT

Foreign objects of any kind inserted into this unit constitute a safety hazard and can cause extensive damage.

If any object should be inserted into the unit, unplug the

power cord, then contact the sales dealer.

DO NOT PLACE ANYTHING ON THE UNIT

Heavy objects placed on the unit can cause damage or

obstruct proper ventilation.

PROTECT THE POWER CORD

Damage to the power cord may cause fi re or shock haz-

ard. When unplugging, hold by the plug only and remove

carefully.

Never put heavy objects on the power cord. The cord

may be damaged causing a fi re or electric shock.

DO NOT PLACE WATER CONTAINERS ON THE UNIT

Do not place fl ower vases, and other water-holding con-

tainers on the unit. If, for some reason, water seeps to

the inside of the unit, unplug the power cord from the

source outlet, and contact the sales dealer. If used without corrective measures, the unit may be damaged.

WARNING : THIS APPARATUS MUST BE EARTHED.

AVERTISSEMENT : CET APPAREIL DOIT ETRE MIS A

LA TERRE.

This equipment is classifi ed as class , according to the

type of protection against electric shock.

DO NOT REMOVE THE CABINET

Touching internal parts is dangerous or may lead to malfunction. Contact the sales dealer to carry out internal

checks and/or adjustments. Before opening the cover to

clear a paper jam, etc., be sure to disconnect the power

cord plug.

DO NOT ATTACH A SCREW MORE THAN 6 MM

LONG ON THE BOTTOM

If a screw more than 6 mm long is attached on the bottom of the printer, it may cause internal damage.

PROTECT AGAINST DEW FORMATION

In extremely cold regions, if the unit is moved quickly

from an extremely cold place to a warmer one, dew is

likely to be formed. If dew is formed, printing is not possible.

OPERATING AMBIENT TEMPERATURE RANGE

The operating ambient temperature range is 5°C-40°C

(41°F-104°F), and humidity of 20-80%.

BE CAREFUL AROUND PRINT PAPER EXIT SLOT

Do not insert your hand or any material into the paper

exit slot during printing.

Do not touch the cutter blade inside the paper exit slot.

Otherwise, your fi nger will be injured.

DO NOT TOUCH THE THERMAL HEAD AND CUTTER

Do not touch the thermal head (located inside the unit)

and the cutter blade.

The thermal head is heated to high temperature.

This may cause injury.

INSTALLATION LOCATIONS

MAINTAIN GOOD VENTILATION

Ventilation slots and holes are provided on sides of this

unit.

Place the unit on a hard and level surface and locate at

least 4" (10 cm) from walls to ensure proper ventilation.

SUITABLE LOCATIONS

Avoid shaky places or hot-springs areas where hydrogen

sulfi de and acidic ions are likely to be generated.

AVOID PLACES WITH HIGH HUMIDITY AND DUST

Do not place the unit at locations with high humidity and/

or dust. They can cause extensive damage.

Avoid places where the unit is likely to contact oily fumes

and vapors.

AVOID PLACES LIKELY TO BE EXTREMELY HOT

Places exposed to direct sunlight, or near heating

appliances can attain extremely high temperatures,

which may deform the cabinet, or can become a prime

cause of damage.

SET THE UNIT ON A FLAT SURFACE

Do not use the unit when inclined ±10° in vertical or horizontal direction, or in an unstable place.

Uneven surfaces may disturb paper feeding or ventilation, or affect the performance of the unit.

2

Page 17

FOR LONG OPERATING LIFE

UNSUITABLE MATERIALS FOR THE UNIT

Many plastic components are used in the unit.

Coat fl aking and deformation are likely to occur if the

unit is wiped with chemical dusters, benzine, thinner or

any other solvent, if rubber or PVC items are left in contact with the unit for extended duration, or if the unit is

sprayed with insecticide.

CARE OF THE CABINET

Unplug and clean with a soft cloth slightly moistened with

a mild soap and water solution. Allow to dry completely

before operating. Never use petroleum base solutions or

abrasive cleaners.

HEAD ABRASION

The thermal head, like the video head, wears out.

When it is abraded, it becomes hard to print out fi ne

details of the picture. In such a case, it is necessary to

replace the thermal head. Consult with the sales dealer

for replacing the head.

THERMAL PAPER

Thermal papers listed in the page of SPECIFICA-

TIONS are available.

When the remaining length of the paper is about 8"

(20 cm), a color belt appears at the paper end.

Prepare for replacement of the paper. If the remaining

paper length is less than 8" (20 cm), printing becomes

uneven due to the uneven paper core surface.

When the Printed paper is touched by wet hand, the

print may be discolored.

When the paper runs out during printing, the printing

operation stops and “EP” is displayed by the indicator

on the front panel. Install new paper at this time.

Store the printed paper in a place with low humidity

free from a direct sunlight.

If the paper absorbs non-volatile organic solvents (al-

cohol, ester, katone, etc.) the print may be discolored.

Particularly, if the paper comes in contact with soft

vinyl chloride such as a transparent tape, it quickens

discoloration.

Do not use paper other than the specifi ed types.

WHEN A DEFECT IS FOUND

If you detect smoke or other smell from the unit, disconnect immediately the power cord plug from a wall socket

and ask the agent for repair. It may be dangerous to operate the unit under these conditions.

CONNECTION DEVICES

Read thoroughly Operating Precautions of the instruction booklets for the devices connected with the digital

monochrome printer.

Do not disconnect the power cord during printing.

CAUTION ON RELOCATING

When transporting this unit, make sure it is not likely to

be subjected to impacts. They can be a prime cause for

damage. Further, make sure to disconnect the power

cord from the power outlet, and the cables from the connected devices.

UNPLUG THE POWER CORD DURING A LONG

ABSENCE

Turn off the MAIN power switch and unplug the power

cord during a long absence.

Immediately after the paper is replaced, 2-3 images

may be printed with a blank part due to hand’s dust or

oil.

Avoid direct sunlight or places near heaters, etc., and

store the paper in a place with 30°C (86°F) or lower

temperature and 35-80% RH.

When the paper is rapidly transferred from a cool

place to a hot place, a vapor or a dew is generated

on the paper surface causing paper jam or degraded

printing quality.

A fi nger print or dust on the paper surface may de-

grade the printing quality.

Note:

Mitsubishi brand thermal paper is specially treated with

an anti-static coating against thermal head damage

caused by static-electricity discharge.

The use of non-treated paper may cause premature

head failure in your product.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

3

Page 18

SAFETY TECHNICAL CHECKS

Periods: According to the recommendations of the manufacturer of medical device.

Scope: a) Visual check

Housing, cables, operator controls, readout device (displays, LED etc.), labels,

accessories, instruction manual.

b) Function test

Performance check acc. instruction manual, also unity and applicability of set

and accessory test.

c) Electrical check

Safety electrical test of the confi guration in accordance with EN60601-1.

“ In the interest of safety, avoid the handling of liquids beside the set.”

RESPONSIBILITY OF THE MANUFACTURER

The manufacturer, assembler, installer or importer considers himself responsible for the effects on

safety, reliability and performance of the EQUIPMENT only if:

– assembly operations, extensions, re-adjustments, modifi cations or repairs are carried out by persons

authorized by him, and

– the electrical installation of the relevant room complies with the IEC requirements

– the EQUIPMENT is used in accordance with the instructions for use.

• Any service after expiration of the warranty period will be chargeable. Consult your dealer for advice.

TECHNICAL DESCRIPTION

The supplier will make available on request such circuit diagrams, component part lists, descrip-

tions, calibration instructions or other information which will assist the USER’s appropriately qualifi ed

technical personnel to repair those parts of the EQUIPMENT which are classifi ed by the manufac-

turer as repairable.

The use of ACCESSORY equipment not complying with the equivalent safety requirements of this

equipment may lead to a reduced level of safety of the resulting system. Consideration relating to

the choice shall include:

– use of the accessory in the PATIENT VICINITY

– evidence that the safety certifi cation of the ACCESSORY has been performed in accordance with

the appropriate EN60601-1 and/or EN60601-1-1 harmonized national standard.

The transportation and storage environmental conditions are:

Temperature : -20°C - +60°C (-4°F - +140°F)

Humidity: 90%RH or less at 40°C (104°F)

Atmospheric pressure : 50 kPa - 106 kPa

Note : The above transportation environmental conditions indicate the storage environmental con-

ditions during transport.

4

Page 19

PRODUCT OUTLINE

The digital monochrome printer P95DW/P95DE uses the thermal printing system. This printer is able

to print digital grayscale images on the thermal paper. This printer is connected to a host computer via

USB interface. Digital images such as CT, MRI, ultrasound, and CR images transmitted from the host

computer is printed via USB interface.

This printer creates prints electronically (mainly in image processing and printing processing), not optically or chemically.

INTENDED USE

The digital monochrome printer P95DW/P95DE is intended for use as a hard copy device for an image

generated by a diagnostic imaging equipment.

This product is intended to be used together with medical equipment and to be used for reference purpose, not for diagnostic purpose.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

5

Page 20

3

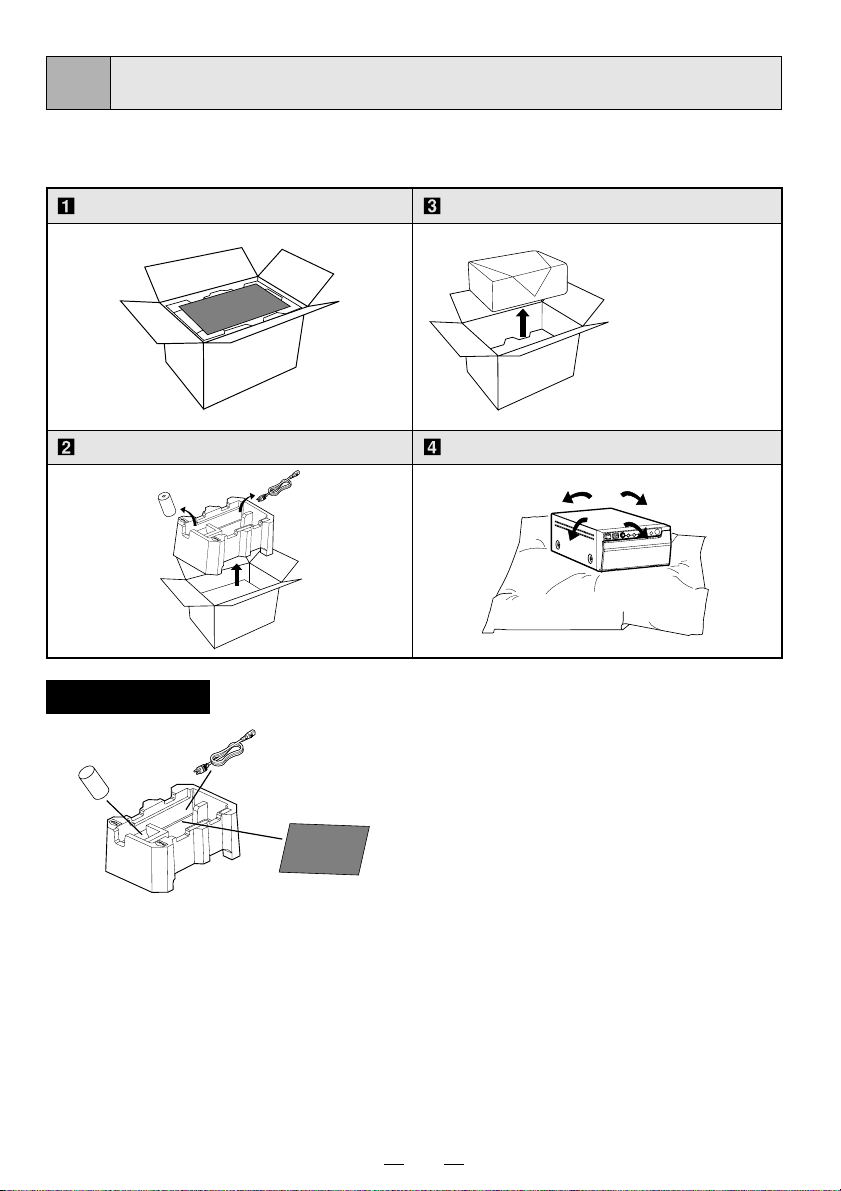

Take the unit out of the box by the following procedures. Make sure to check the

contents.

UNPACKING

Open the top of the box.

Remove

the cushion above the unit.

Accessories

Thermal paper

AC power cord

Take the unit out of the box carefully.

• Make sure to

keep the unit

horizontal.

Unwrap the unit.

Cleaning sheet

Operation manual

Printer driver (1 CD-ROM)

USB cable

6

Page 21

4

FEATURES AND FUNCTIONS

Front Panel

FRANÇAIS DEUTSCHITALIANO

OPEN button

Press to open the door.

Indicator

Displays printer status. See pages 12,

15, 16 and 18 to 23.

Adjustment dial

Changes the settings of each function.

See pages 14, 15 and 17.

BRT (brightness) button

Press this button and then turn the

adjustment dial to adjust the brightness

of the print images. See page 14.

CONT (contrast) button

Press this button and then turn the

adjustment dial to adjust the contrast of

the print images. See page 14.

SHARP (sharpness) button

Press this button and then turn the

adjustment dial to adjust the sharpness

of the print images. See pages 12 and

14.

FUNC (function) button

Press this button and then turn the

adjustment dial to select the function

mode. See pages 16 and 17.

FEED button

Button to advance the paper. See pages

12 and 13.

COPY/RST (restart) button

Button to print additional copies of

previous print-out. You can restart the

printer by pressing and holding down the

COPY/RST button for about 2 seconds.

See pages 12 and 16.

Print exit/Cutter

Printed paper will come out through this

slot. / Cut the printed paper here. See

pages 9, 12 and 24.

NEDERLANDS

ESPAÑOL ENGLISH

7

Page 22

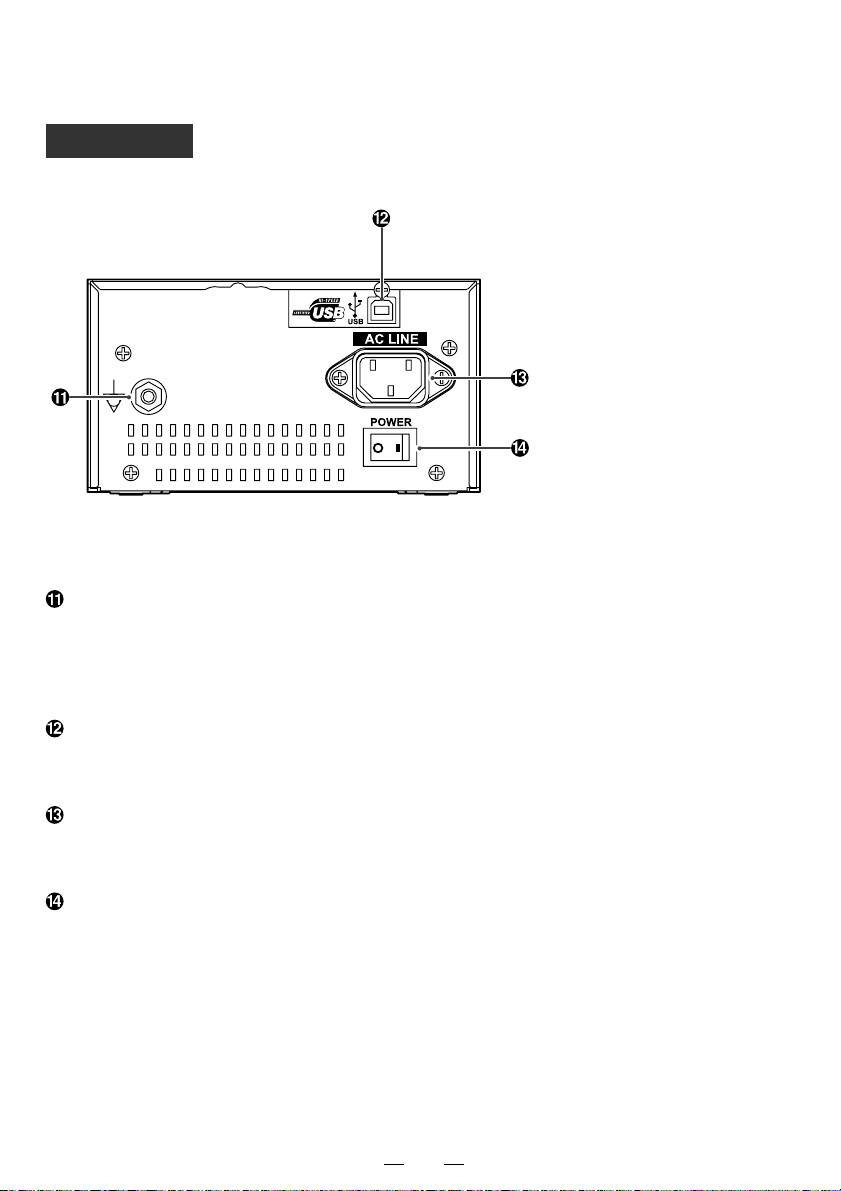

Rear Panel

Potential equalization terminal

This is used to equalize the potential of

the equipment connected to this unit.

For details refer to the installation

instruction of equipment to be connected.

USB terminal

Connects to the device equipped with a

USB interface. See page 11.

Power terminal (AC LINE)

Connect the power cord to this terminal.

See page 11.

Power switch (POWER)

Main power switch. See pages 12 and 24.

8

Page 23

5

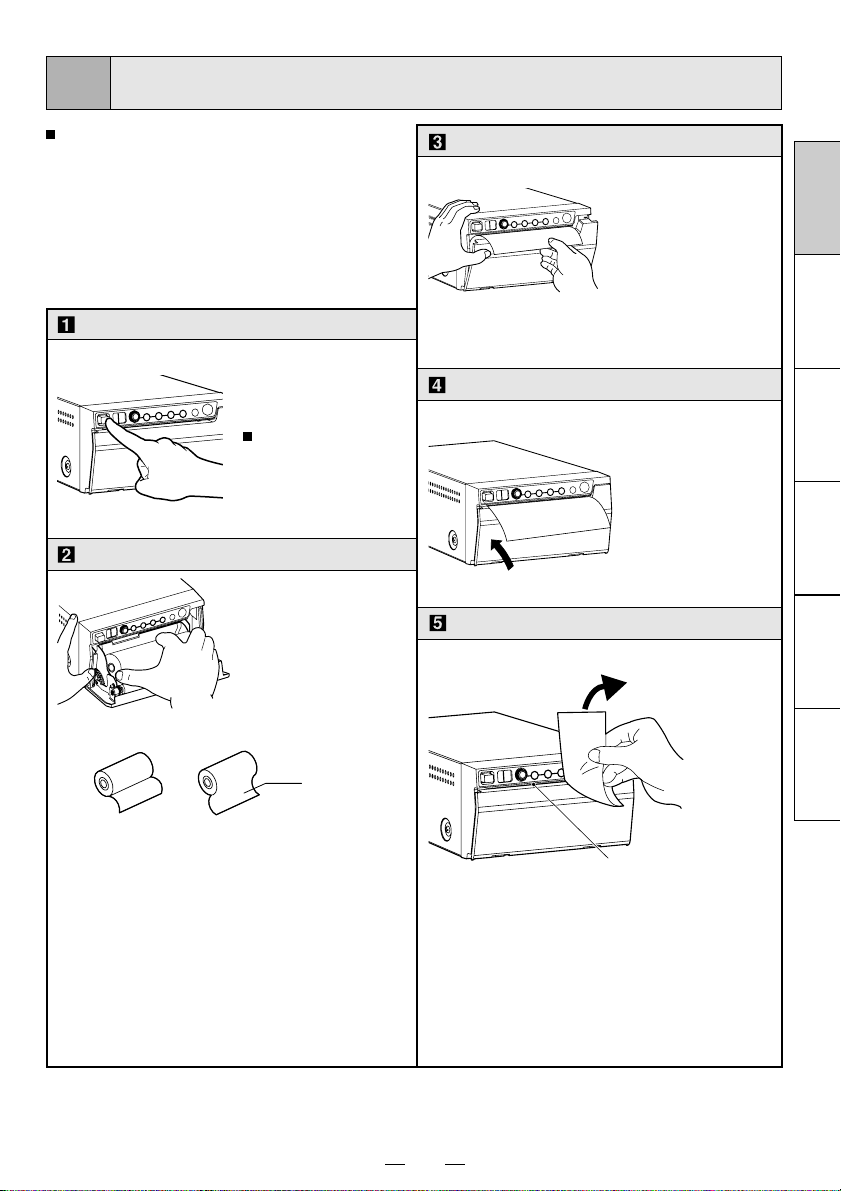

INSTALLATION OF PAPER

Moisture, fi ngerprints or dust on the

paper surface may cause a noise

at printing or deterioration in print

quality. Follow the procedure to

prevent fi ngerprint or dust on the

paper surface.

Open the door.

•

Press the OPEN

button.

The door opens.

Load the paper roll.

• Place the paper roll

in the printer.

Pull out the paper end.

• Pull out the fi rst 15-

20cm (6 in. - 9 in.)

of the paper to

remove any slack

in the roll.

Close the door.

FRANÇAIS DEUTSCHITALIANO

Cut the paper end.

NEDERLANDS

printing side

INCORRECT

Note: The printing surface is the outside.

Place the paper with the thermsensitive side (printing side) up.

When the paper roll is placed in-

versely, images can not be printed.

CORRECT

cutter

•

Cut the paper end with the cutter by

pulling the paper upwards against the

cutter blade.

9

ESPAÑOL ENGLISH

Page 24

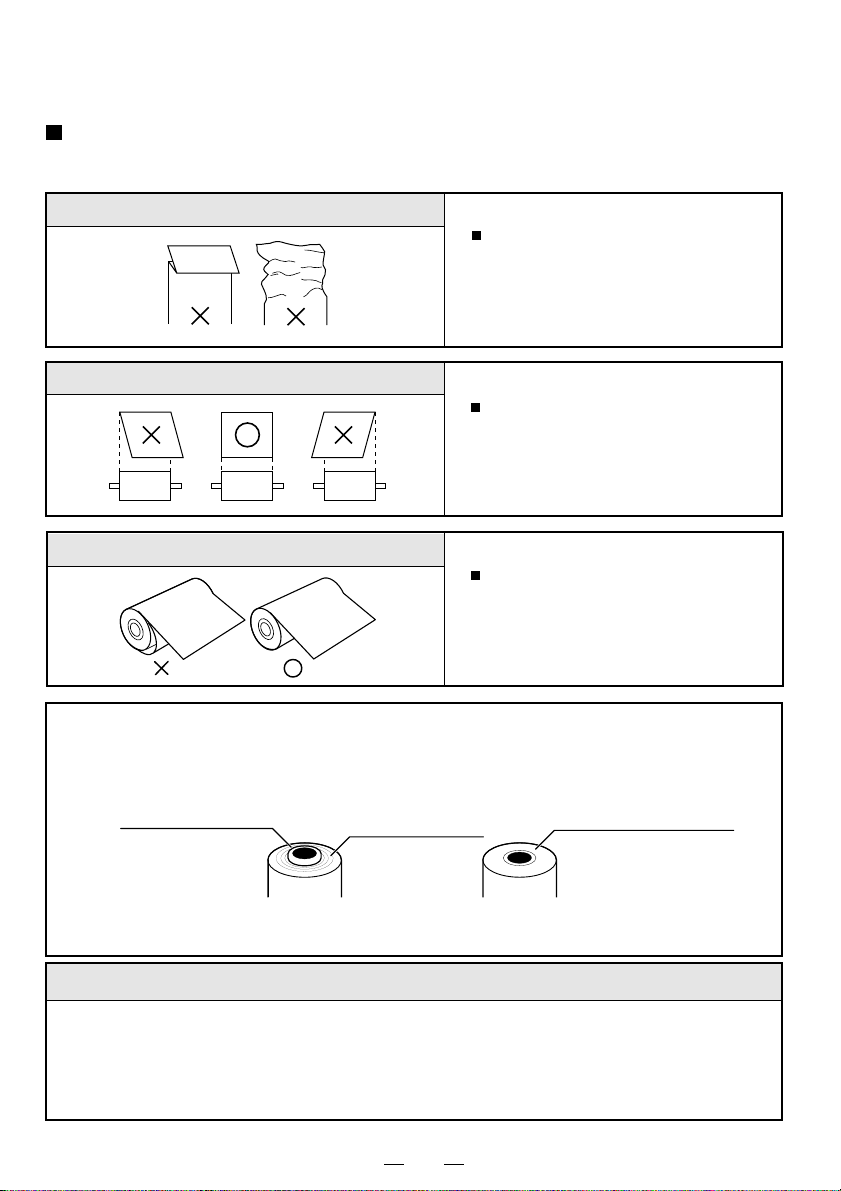

When setting the paper, observe the following precautions to prevent

paper jam.

Do not use defective paper.

Do not use bent or wrinkled paper.

Adjust the paper position correctly.

When the paper is fed out skewed

from the print exit, adjust the paper

position so that it is fed out straight.

Do not allow slack in the paper roll.

Set the paper tightly to remove any

slack.

If the side of the print paper is uneven or the core is sticking out, the amount of paper

feeding after printing may vary.

When the side of paper is uneven or the core is sticking out, install the print paper after

making the paper side even.

The core is sticking out.

INCORRECT

The paper is uneven.

CORRECT

Make the paper side even.

CAUTION

• Keep the high-density paper away from fi ngerprint, dust or moisture when storing it.

• Do not touch the rubber roller. Do not stain or damage the roller surface.

• Do not touch the thermal head (located behind the cutter). During printing, the thermal

head temperature is high.

• Do not touch the cutter blade.

10

Page 25

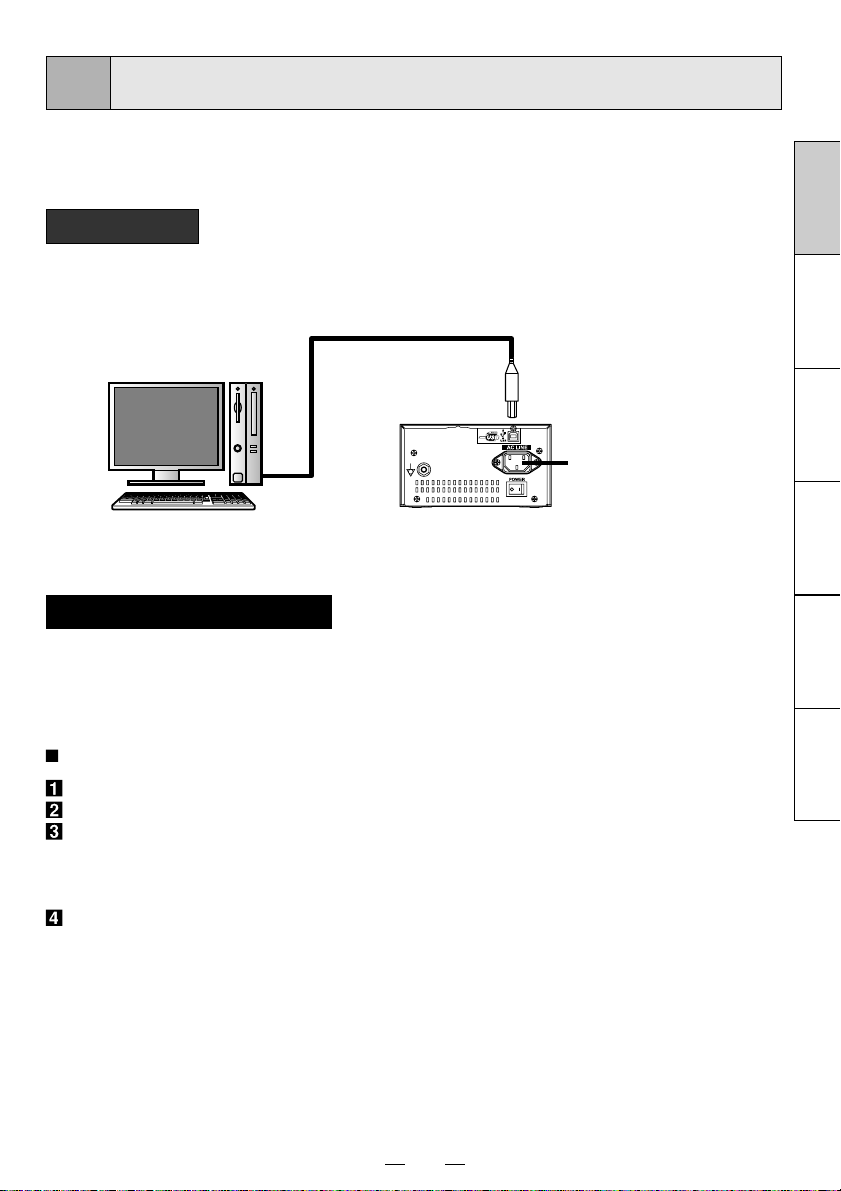

6

EXAMPLE OF CONNECTION

Connecting to various equipment with USB interface such as

medical equipment and personal computer.

Connection

Connect the digital monochrome printer with PC or medical

equipment through a USB cable.

Personal computer or

medical equipment

To USB terminal

Connect

Power cord

Rear panel

Installing printer driver

Printer driver is required to print the data from a personal computer connected with this

printer.

The printer driver for Windows® is supplied with this printer.

Refer to the “Read me” for installing the printer driver in the CD-ROM supplied with this unit.

How to open the ReadMe fi le

Install the CD-ROM in the CD-ROM drive on your PC.

Double-click on the CD-ROM icon.

Double-click on the ReadMe_E.pdf.

Adobe® Reader® or Adobe® Acrobat® Reader® is required to open ReadMe_E.pdf fi le.

You can download Adobe Reader and Acrobat Reader free from the Web site of Adobe

Systems Incorporated (http://www.adobe.com/).

Install the printer driver by following the instruction in the fi le.

Windows is the registered trademark of Microsoft Corporation in the U.S.A. and other

countries.

Adobe, Acrobat Reader and Adobe Reader are registered trademark of Adobe Systems

Incorporated.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

11

Page 26

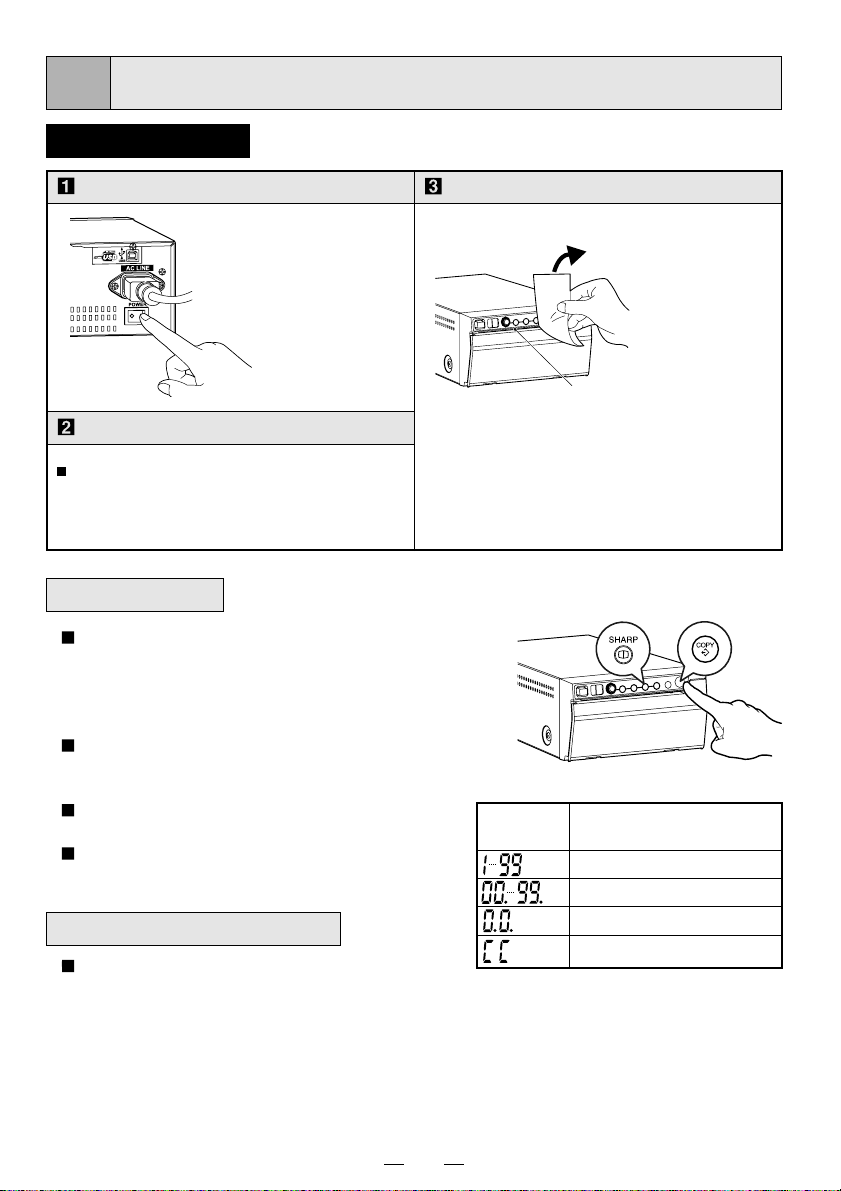

7

PRINTING

Printing method

Turn on the power.

• Press the

POWER

switch on the

rear panel to

turn on the

power.

Print a picture displayed on the screen.

Print a picture with an application

software. The image data is transferred

through USB interface.

Copy Printing

You can set the number of copies by pressing

the COPY button on the front panel. (Setting

range : 1 to 200)

You can copy the same picture as many times

as you desire until a new image data is printed.

The set number of copy printing and the number

of the remainings are displayed on the indicator

as shown right.

The number of copy print setting is not

memorized.

When pressing the SHARP button during copy

printing, continuous printing is enabled.

Cancel of Copy Printing

When pressing the FEED button during copy

printing, the copy printing is cancelled upon

completion of the current copy.

Cut the printed paper.

• Cut the printed

paper with the

cutter by

tearing off the

paper in the

upper right

direction.

cutter

• Do not pull the paper in the horizontal

direction. The paper inside the unit may

be displaced and printing performance

may not be correct.

Indicator

Number of copy printing /

remainings

1 - 99

100 - 199

Continuous printing

200

12

Page 27

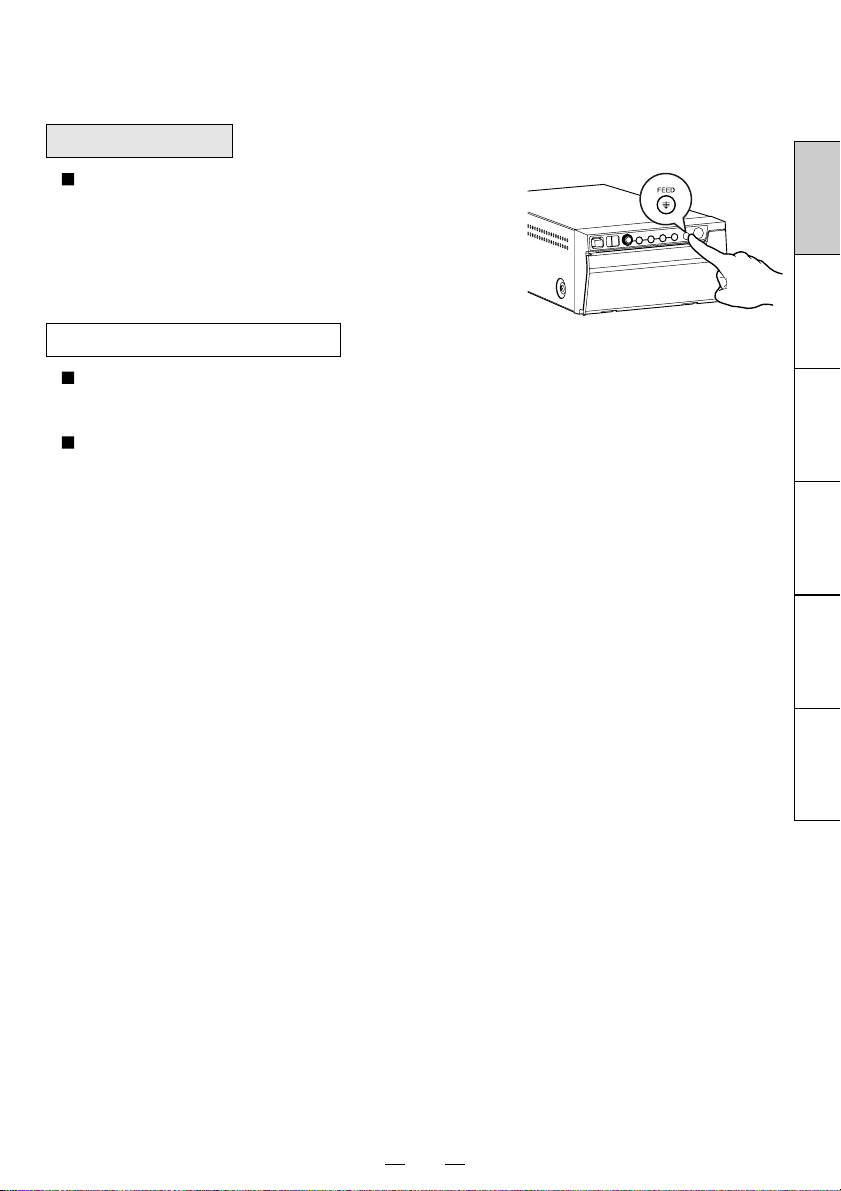

Paper Feeding

To advance the paper, press the FEED button on the

front panel.

Precautions on Printing

When dark pictures are printed repeatedly, the printer may go into overheat condition.

The printer status indicator will fl ash during overheat condition. This is normal case.

The printer will cool down before it starts printing again.

Avoid pulling out or holding the paper during printing or copying to prevent paper jam.

Do not touch the paper until printing or copying fi nishes.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

13

ESPAÑOL ENGLISH

Page 28

8

ADJUSTMENT OF PRINT PICTURE

Adjustment of Brightness, Contrast and Sharpness

You can make fi ne adjustment of brightness, contrast and

sharpness of the picture to be printed.

Control panel

• For adjustment, use the BRT “ ”, CONT “ ” or SHARP “ ” button, and the

adjustment dial “ ”.

Press the BRT, CONT or SHARP button.

Press the BRT button “ ” to adjust

the printer brightness.

• The BRT indicator lights up.

• Adjust brightness with adjustment

dial.

Press the CONT button “ ” to

adjust the contrast.

• The CONT indicator lights up.

• Adjust contrast with adjustment dial.

Press the SHARP button “ ” to

adjust the sharpness.

• The SHARP indicator lights up.

• Adjust sharpness with adjustment

dial.

14

Page 29

Change the setting.

Store the set value.

• Turn the dial clockwise

to increase the value.

• Turn the dial

counterclockwise to

decrease the value.

The setting value is displayed by the

indicator.

(example)

Setting range is -19 to +19 for brightness

and contrast and 0 to 15 for sharpness.

Press the (BRT, CONT, or SHARP)

button again to memorize the value.

The memorized value will not be lost

even when the power is turned off.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

15

ESPAÑOL ENGLISH

Page 30

Automatic restoration to the standby status from the adjustment or setting mode

Whenever the front dial and buttons are untouched for more

than 20 seconds during adjustment, the printer automatically

returns to the standby status (Indicator display : ).

In this case, the new value is not memorized and the setting

goes back to the previous value.

Resetting the values

You can reset the values of printer brightness, printer

contrast, sharpness and function mode settings.

Turn off the power.

While pressing the FUNC button, turn on the power.

The display by the indicator changes from to , and the values are reset to the

default setting.

Restarting the printer

You can restart the printer by pressing and holding down the

COPY/RST button for about 2 seconds.

When the printer restarts, the ongoing printing is cancelled,

the number of printings is reset and the printer returns to the

standby status.

The values set by the front buttons are not reset.

16

Page 31

9

SETTING FUNCTION MODE

Function mode

In this mode, the initial value setting of each function can be

changed. Each time the FUNC button is pressed, the mode is

switched as follows.

Functions

Stand-by status

Gamma curve setting

Adjustment dial lock setting

Indicator brightness setting

FRANÇAIS DEUTSCHITALIANO

Setting the function mode

By turning the adjustment dial, you can change the value

setting for each function mode. Press the FUNC button again

to memorize the new setting. The set values will not be lost

even when the power is turned off.

17

NEDERLANDS

ESPAÑOL ENGLISH

Page 32

Gamma curve setting

Indicator

• Gamma ( ) curve selection (relation between the density and

the brightness of the image) to obtain an optimum density depending on the source device. Five options are available.

Adjustment dial lock setting

Indicator

• You can select whether or not to lock the adjustment dial

functions.

: The adjustment dial is activated.

: The adjustment dial does not function. When the adjust-

ment dial is turned, an alarm sounds once. However,

when the adjustment dial lock setting is selected in the

FUNC button function, the adjustment dial function is activated.

Purpose and description

Purpose and description

18

Page 33

Indicator brightness setting

Indicator

Purpose and description

• Brightness of the indicator.

: Dim The brightness of the indicator decreases.

: Bright The brightness of the indicator increases.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

19

ESPAÑOL ENGLISH

Page 34

10

ERROR DISPLAY

In case of an error during operation, you will hear an alarm tone

or will see the LED display fl ashes.

Cause/Error display

Overheat

Cause/Error display

No paper

Symptom/Remedy

[Symptom]

• When the head gets overheated, the indicator display blinks.

When overheat occurs while more than one copy is being

processed, printing starts as soon as the error is solved.

If some images are waiting to be processed, the following buttons

function as described below.

COPY button

• Each time the COPY button is pressed, the number displayed

by the indicator increases as .

• After the error is solved, copy printing starts automatically.

FEED button

• When the number of copies has been set to more than one,

outstanding copies are cancelled.

When no image remains to be processed, the buttons are valid

during overheat status. After the error is solved, copy printing starts

automatically.

[Remedy]

Wait until the head cools down.

Symptom/Remedy

[Symptom]

• When the paper runs out or the paper is not installed, printing is not

possible and an alarm tone is heard.

In this case, all the buttons become non-functional.

• If this error occurs while more than one copy is being printed or

there are images waiting to be processed, printing is cancelled at

the time of the error.

[Remedy]

Install a new roll of paper according to “5. INSTALLATION OF

PAPER” on page 9.

When the paper is correctly installed while the printing of more

than one copy has been suspended or there are images waiting

to be processed, an alarm tone is heard. Then, printing resumes

automatically.

After the error is resolved, the unit resumes printing from the

interrupted image and fi nishes printing all the outstanding images.

20

Page 35

Cause/Error display

Symptom/Remedy

Button input

error

Cause/Error display

Door error

[Symptom]

• An alarm tone is heard once in the following cases.

• The indicator displays “ ” for one second and the button operation

becomes invalid.

• During adjusting the printer brightness or the printer contrast,

the adjustment dial exceeded the upper limit value (LED display

: ) or the lower limit value (LED display : )

• During adjusting the sharpness, the adjustment dial exceeded

the upper limit value (LED display : ) or the lower limit value (LED

display : ).

• While the adjustment dial operation is set to invalid by

the “adjustment dial lock setting” of the FUNC button, the

adjustment dial is turned (clockwise or counterclockwise).

• During setting the number of copy printing, the COPY button

exceeded the upper limit value (LED display :

).

Symptom/Remedy

[Symptom]

• When the door opens, an alarm tone is heard.

The indicator displays “ ”.

In this case, all the buttons and switches become non-functional.

• If this error occurs while more than one copy is being printed,

printing is cancelled at the occurrence of the error.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

[Remedy]

Close the door.

When the door is closed while the printing of more than one copy is

being printed, an alarm tone is heard.

After the error is resolved, the unit resumes printing from the

interrupted image and fi nishes printing all the outstanding images.

21

Page 36

Cause/Error display

Symptom/Remedy

Gear lock error

Cause/Error display

Paper pullback

error

[Symptom]

• When the thermal head does not automatically go down at the start

of printing or paper feeding, an alarm tone is heard.

• When the thermal head does not automatically go up at the end of

printing or paper feeding, an alarm tone is heard.

The indicator displays “

” and all the buttons become invalid.

• If this error occurs while more than one copy is being printed or

there are images waiting to be processed, printing is cancelled at

the occurrence of the error.

[Remedy]

Turn the power off. Then turn it on again.

Printing of the interrupted image or all the images saved in the

memory that are waiting to be processed is cancelled.

Symptom/Remedy

[Symptom]

• When the thermal paper is not correctly pulled back before starting

printing, an alarm tone is heard and printing is cancelled.

The indicator displays “

.”

• Until the paper pullback error is corrected, all the buttons and dial

do not work.

• If this error occurs while more than one copy is being printed,

printing is cancelled at the same time.

[Remedy]

Turn the power off. Then turn it on again.

Printing of the interrupted image or all the images saved in the

memory that are waiting to be processed is cancelled.

22

Page 37

11

Power off

Stand-by

Print state

STATUS AND MODES

Set state/Mode LED display Contents of LED display

Power off

During data receivingDuring data receiving

Remaining number of copies /

number of copies

1 to 99

100 to 199

200

Continuous copy printing

Printer brightness mode

Printer contrast mode

Printer sharpness mode

Function mode Gamma curve setting

Error detect state

Fine adjustment of the picture brightness

Fine adjustment of the picture contrast

Fine adjustment of the picture sharpness

Adjustment dial lock setting

Indicator brightness setting

No paper

Button input error

Door error

Gear lock error

Paper pullback error

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

23

Page 38

12

When the thermal head is dirty with dust, etc., white spots or stripes may appear on the print.

In this case, clean the thermal head by the following procedure BY USING THE SUPPLIED

CLEANING SHEET.

USE OF CLEANING SHEET

Turn on the power.

Press the POWER

switch on the rear

panel to turn on the

power.

Open the door.

Press the OPEN

button.

The door opens.

Insert the cleaning sheet.

Roll the cleaning

sheet and install

into the set.

Cleaning sheet

Close the door.

Close the door

without taking out

the cleaning sheet.

Press the FEED button.

FEED

Take out the cleaning sheet.

Print 1-2 sheets to verify the cleaning

effect.

Keep pressing the

FEED button until

you hear a beep.

Open the door.

Take out the

cleaning sheet.

Do not pull out the

cleaning sheet while

the door is closed.

CAUTION

• It is recommended that after printing 20 rolls of paper the unit be cleaned using the supplied cleaning sheet.

• If the symptom of the dirty head is not corrected even after cleaning, your set needs repairing. Contact your dealer.

• Do not pull out the sheet and the cleaning sheet while the door is closed.

This may cause extensive damage to the unit.

• Never use other cleaning sheets. It may cause damage to the thermal head.

• This cleaning sheet should be used only for cleaning the thermal head. Do not use it for other purpose.

24

Page 39

13

MAINTENANCE

Turn off the power for maintenance.

Maintenance of Main Unit

Wipe off stains of the front panel with a soft cloth.

When the panel is heavily stained, wipe with a cloth moistened

with neutral cleanser diluted by water and fi nish with a dry cloth.

Maintenance of Rubber Roller

When the rubber roller is dirty with dust, etc., a blank spot may

appear on the print.

In this case, eliminate the dust on to the rubber roller with a

blower or a brush.

The regular cleaning using a lint-free cloth, etc., which is

moistened with ethyl alcohol is recommended.

Rubber roller

Cleaning of Thermal Head

When the thermal head is dirty with dust, etc., white spots or

stripes may appear on the print.

In this case, clean the thermal head according to “12. USE OF

CLEANING SHEET”.

Note: After installation of new roll of paper, dust on the paper will

generally require 2 to 3 prints to be made before the dust

is eliminated.

FRANÇAIS DEUTSCHITALIANO

NEDERLANDS

ESPAÑOL ENGLISH

25

Page 40

14

Product name: Digital Monochrome Printer

Model: P95DW/P95DE

Power supply and

power consumption: 100-240V AC, 50/60Hz, 1.5 - 0.8A

Connection terminal: USB interface (Series "B" receptacle)

Hi-Speed USB (Ver. 2.0) supported

Resolution: 1280 x 960 pixels (Standard)

(Max. 1280 x 5760 pixels)

Gradation: 256 gradations

Printing speed: 1.9 sec (Standard)

Print size: 4" x 3" (100 mm x 75 mm) (Standard)

(Max. 4" x 17.7" (100 mm x 450 mm))

Operating conditions: Temperature 41 - 104˚F (5-40˚C)

Humidity 20 - 80% RH (No dewing)

Atmospheric pressure 70 kPa - 106 kPa

External dimensions: 6.1" x 3.3" x 9.4" (154 mm x 84.5 mm x 239 mm); W x H x D

SPECIFICATIONS

Weight: 5.8 lbs (2.6 kg)

Standard accessories: Operation manual .........................................................1 copy

AC power cord ............................................................1 piece

USB cable ...................................................................1 piece

Thermal paper ................................................................ 1 roll

Cleaning sheet ........................................................... 1 sheet

Printer driver ......................................................... 1 CD-ROM

Optional accessory: Thermal paper K95HG, KP65HM-CE, KP61S-CE,

KP61B-CE, KP91HG-CE

SERVICE INFORMATION

Before requesting service please review this operation manual to correct minor complaints.

If you are unable to correct the problem, consult your MITSUBISHI Dealer or MITSUBISHI

Service Department.

DO NOT ADJUST ANY CONTROLS NOT DESCRIBED IN THIS OPERATION MANUAL.

DO NOT REMOVE THE PROTECTIVE ENCLOSURE OF THIS UNIT.

26

Page 41

SAFETY PRECAUTIONS

S1

S2

100-240

V

AC MILLIAMMETER

INSULATING

TABLE

GROUNDING SUPPLY CONDUCTOR

PRINTER

GH

(GROUNDING)

OPEN

A

B

NOTICE : Observe all cautions and safety notes located inside the cabinet and on the chassis.

LEAKAGE CURRENT CHECK

Before returning the printer to the customer, it is recommended that leakage current be measured according to the following

methods.

1. Cold Check

With the AC plug removed from the 100-240 V AC source, place a jumper across the two AC plug prongs. Turn the printer

AC switch on. Using an ohm-meter, connect one lead to the AC plug and touch the other lead to each exposed metal part

(screwheads, metal overlays, etc.), particularly any exposed metal part having a return path to the chassis. Exposed metal

parts having a return path to the chassis should have a minimum resistance reading of 1 meg ohm. Any resistance below this

value indicates an abnormality which requires corrective action. Exposed metal parts not having a return path to the chassis will

indicate an open circuit.

2. Hot Check

Use the circuit in the Figure to perform this test.

(1) With switch S1 open, connect the printer to the measuring circuit. Immediately after connection, measure the leakage current

using both positions of switch S2, and with the switching devices in the printer in all of their operating positions.

(2) Switch S1 is then closed, energising the printer. Immediately after closing the switch, measure the leakage current using both

positions of switch S2, and with the switching devices in the printer in all of their operating positions.

Current measurements of items (1) and (2) are to be repeated after the printer has reached thermal stabilisation. The leakage

current shall not be more than 0.5 milliampere.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the printer have special safety related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessarily be obtained by using replacement

components rated for higher voltage, etc. Replacement parts which have these special safety characteristics are identied in this

service manual. Electrical components having such features are identied by shading on the schematic diagram and the parts

list of this service manual, and by the supplementary sheet for this chassis to be issued subsequently. Therefore replacements

for any safety parts should be identical in value and characteristics.

CAUTION : DOUBLE POLE/

NEUTRAL FUSING

- 1 -

Page 42

PRECAUTIONS FOR RESOLDERING

Lead-free solder is handled in a different way from eutectic solder. See below for details.

How to distinguish circuit boards using lead-free solder from those using

eutectic solder

Circuit boards using lead-free solder

A mark of Solder, Joints, PCA or LFS (for limited marking space) is printed near the board assembly number on

the component side.

Circuit boards using eutectic solder

Circuit boards using eutectic solder are divided into two groups.

- Boards having no mark of

number.

- Boards having a mark of

feltpen near the board assembly number.

* Only when there is a limited marking space on the board,

PCA as P.

* Circuit boards using lead-free solder and those using eutectic solder may be used together in the same product.

Instructions for resoldering

- For circuit boards using lead-free solder, use lead-free solder.

- For circuit boards using eutectic solder, use eutectic solder.

- Separate the soldering iron for lead-free solder from that for eutectic solder completely for use.

(It is prohibited to use a same soldering iron for lead-free solder and eutectic solder.)

- For lead-free solder, it is advisable to use a soldering iron of at least 40 W because lead-free solder has a melting point

approx. 35°C higher than that of eutectic solder as conventionally used. For wire solder, use M705ESC made by Senju

Metal Industry Co., Ltd.

- To remove solder, you can use desoldering wires for eutectic solder as conventionally used.

Solder, Joints, PCA or LFS (for limited marking space) near the board assembly

Solder, Joints, PCA or LFS (for limited marking space) that is painted out by a

Solder may be indicated as S, Joints as J, and

- 2 -

Page 43

PCB LOCATION

Main PCB ASS

Y

(936C157O01)

Power PCB ASSY

(936C154O01)

Front PCB ASSY

(936D332O01)

SR sensor unit

(door open/close sensor)

(439P013O20)

SH sensor unit

(head position sensor)

(439P013O20 )

SH sensor unit

(light emitter of paper detector1)

(264P654O20)

SP sensor unit

(light receiver of paper detector2)

(260P796O20)

SP sensor unit

(light receiver of paper detector1)

(260P796O20)

SD sensor unit

(light emitter of paper detector2)

(264P654O20)

Print deck ASSY

- 3 -

Page 44

1 4

A

2 3

B

C

b

a

a

b

2

2

2

2

Top ASSY

Door ASSY

Door ASSY SI

DISASSEMBLY

1. Top ASSY

Step No. Parts name Address

1 Top ASSY A-3 2 (4pcs.) - - - - -

2. Door ASSY SI

Step No. Parts name Address

1 Press the OPEN button to open the door ASSY.

Number of parts

Number of parts

to be removed

to be removed

Connectors or parts

to be removed

Connectors or parts

to be removed

2 Door ASSY SI C-2 a(2pcs.) - - - - -

[Note] Handle the hooks b carefully because they are easily damaged.

- 4 -

Page 45

1 4

A

2 3

B

C

a

a

a

a

1

1

3

3

5

5

4

6

4

4

4

Main PCB ASSY

Rear ASSY

Front ASSY

This side should face up.

3. Front ASSY

Step No. Parts name Address

1 Procedure of 1-1 (Top ASSY)

2 Procedure of 2-2 (Door ASSY SI)

3 Front ASSY C-2

4. Main PCB ASSY

Step No. Parts name Address

1 Procedure of 1-1 (Top ASSY)

2 Rear ASSY B-3 4 (4pcs.) / 6 (1pc.) - - - - -

3 Main PCB ASSY A-2 1 (2pcs.) All connectors

Number of parts

to be removed

3 (2pcs.) / 5 (2pcs.) / a (4pcs.)

Number of parts

to be removed

- 5 -

Connectors or parts

to be removed

ML / SW

Connectors or parts

to be removed

Page 46

1 4

A

2 3

B

C

3

7

8

8

1

1

1

1

1

3

3

Main holder

Lead barrier

AC power jack ASSY

Power unit

Power PCB ASSY

Slide and engage the power unit here.

5. Power PCB ASSY

Step No. Parts name Address

1 Procedure of 4-1 to 4-3 (Main PCB ASSY)

2 Main holder A-3 3 (2pcs.) Lead barrier

3 Power unit C-3 3 (1pc.) PH / PP

4 AC power jack ASSY B-3 8 (2pcs.) / 7(1pc.) AC

5 Power PCB ASSY A-3 1(5pcs.) - - - - -

Number of parts

to be removed

Connectors or parts

to be removed

- 6 -

Page 47

1 4

A

2 3

B

C

5

9

5

5

77

80

79

76

a

b

Front PCB ASSY

Front ASSY

CUTTER

6. Front PCB ASSY / Cutter

Step No. Parts name Address

1 Procedure of 3-1 to 3-3 (Front ASSY)

2

Front PCB ASSY (with parts 79 and 80)

3 Front PCB ASSY B-3 9 (1pc.) 79 / 80

4 Cutter B-3 5 (1pc.) - - - - -

[Note] When mounting the PCB-FRONT, put area a of the PCB- FRONT into hole b in part 79.

B-3 5 (2pcs.) FL / 76 / 77

Number of parts

to be removed

Connectors or parts

to be removed

- 7 -

Page 48

1 4

A

2 3

B

C

D

3

3

3

Print deck ASSY

7. Print deck ASSY

Step No. Parts name Address

1 Procedure of 3-1 to 3-3 (Front ASSY)

2 Print deck ASSY C-3 3 (3pcs.)

- 8 -

Number of parts

to be removed

Connectors or parts

to be removed

HA / HB / M1 / M2 /

PH / SD / SH / SR / SP

Page 49

1 4

A

2 3

B

C

12

11

11

25

Motor unit

Joint lever unit

Solenoide

8. Solenoide

Step No. Parts name Address

1 Procedure of 7-1 to 7-2 (Print deck ASSY)

2 Solenoide C-3 12 (2pcs.) Joint lever unit / 25

Number of parts

to be removed

9. Motor unit

Step No. Parts name Address

1 Procedure of 7-1 to 7-2 (Print deck ASSY)

2 Motor unit B-3 11 (2pcs.) [Note]

[Note] To mount the motor unit, tighten the screws while pushing it onto the gear.

- 9 -

Number of parts

to be removed

Connectors or parts

to be removed

Connectors or parts

to be removed

Page 50

1 4

A

2 3

B

C

32

Platen roller ASSY

Platen bush

10. Platen roller ASSY

Step No. Parts name Address

1 Procedure of 2-1 to 2-2 (Door ASSY SI)

2 Platen roller ASSY C-1 32 (1pc.) Platen bush

- 10 -

Number of parts

to be removed

Connectors or parts

to be removed

Page 51

- 11 -

Page 52

1 4

A

2 3

B

C

10

10

5

5

1

3

3

5

10

10

3

3

Rear plate

Upper plate

Sensor cover

SR sensor unit

(door open/close sensor)

SH sensor unit

(head position sensor)

SH sensor unit

(light emitter of paper detector1)

SD sensor unit

(light emitter of paper detector2)

Sensor holder

Sensor cover

Sensor holder

Sensor guide

Sensor guide

SP sensor unit

(light receiver of paper detector2)

SP sensor unit

(light receiver of paper detector1)

Paper guide

11. SP sensor unit(light receiver of paper detector1 / light receiver of paper detector2)

Step No. Parts name Address

1 Procedure of 3-1 to 3-3 (Front ASSY)

2 Procedure of 10-2 (Platen roller ASSY)

3 Paper guide C-2 5 (2pcs.) [Note]

4

[Note] Raise the paper guide in the arrow's direction for removal.

5

SP sensor unit(light receiver of paper detector1)

SP sensor unit(light receiver of paper detector2)

Number of parts

to be removed

C-1 10 (1pc.) Sensor guide

C-1 10 (1pc.) Sensor guide

Connectors or parts

to be removed

12. SH sensor unit(head position sensor)

Step No. Parts name Address

1 Procedure of 1-1 (Top ASSY)

2

SH sensor unit(head position sensor)

Number of parts

to be removed

B-3 10(1pc.) - - - - -

Connectors or parts

to be removed

- 12 -

Page 53

13. SH sensor unit(light emitter of paper detector1)

Step No. Parts name Address

1 Procedure of 3-1 to 3-3 (Front ASSY)

2 Upper plate A-2 3 (2pcs.) - - - - -

3

SH sensor unit(light emitter of paper detector1)

[Note] To mount the SH sensor unit (light emitter of paper detector1), tighten the screws while pushing the sensor cover in the

arrow's direction.

B-2 5 (1pc.)

Number of parts

to be removed

Connectors or parts

to be removed

[Note] Sensor cover / sensor holder

14. SR sensor unit(Door open / close sensor)

Step No. Parts name Address

1 Procedure of 7-1 to 7-2 (Print deck ASSY)

2 Rear plate A-3 3 (2pcs.) - - - - -

3

SR sensor unit(door open / close sensor)

B-3 10 (1pc.) - - - - -

Number of parts

to be removed

Connectors or parts

to be removed

15. SD sensor unit(light emitter of paper detector2)

Step No. Parts name Address

1 Procedure of 11-1 to 11-3 (Paper guide)

Number of parts

to be removed

Connectors or parts

to be removed

3

SD sensor unit(

[Note] To mount the SD sensor unit (light emitter of paper detector2), tighten the screws while pushing the sensor cover in the

arrow's direction.

light emitter of paper detector2)B-1 5 (1pc.)

[Note] Sensor cover / sensor holder

- 13 -

Page 54

1 4

A

2 3

B

C

Upper plate

Head ASSY

Head spring

Head spring

When attaching the upper plate,

put the arms of the head springs

in the notches of the head ASSY.

- 14 -

Page 55