Mitsubishi PURY-P400, P500YEM-A Service Manual

AIR CONDITIONERS CITY MULTI

Models PURY-P400, P500YEM-A

Service Handbook

Service Handbook PURY-P400, P500YEM-A

New publication effective Mar. 2004

Specifications subject to change without notice.

Service Handbook PURY-P400, P500YEM-A

Issued in 2004 Mar. MEE03K208

Printed in Japan

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

–1–

Contents

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT..... 3

[1] Storage of Piping Material................................................................. 4

[2] Piping Machining............................................................................... 5

[3] Brazing.............................................................................................. 6

[4] Airtightness T est................................................................................ 7

[5] Vacuuming ........................................................................................ 7

[6] Charging of Refrigerant..................................................................... 8

[7] Dryer ................................................................................................. 8

2 COMPONENT OF EQUIPMENT ............................................................. 9

[1] Appearance of Components ............................................................. 9

[2] Refrigerant Circuit Diagram and Thermal Sensor........................... 17

[3] Electrical Wiring Diagram................................................................ 20

[4] Standard Operation Data ................................................................ 24

[5] Function of Dip SW and Rotary SW................................................ 26

3 TEST RUN ............................................................................................. 29

[1] Before Test Run............................................................................... 29

[2] Test Run Method ............................................................................. 33

4 GROUPING REGISTRATION OF INDOOR UNITS WITH M-NET

REMOTE CONTROLLER ...................................................................... 34

5 CONTROL ............................................................................................. 40

[1] Control of Outdoor Unit ................................................................... 40

[2] Control of BC Controller.................................................................. 49

[3] Operation Flow Chart...................................................................... 50

[4] List of Major Component Functions ................................................ 56

[5] Resistance of Temperature Sensor................................................. 59

6 REFRIGERANT AMOUNT ADJUSTMENT ........................................... 60

[1] Operating Characteristics and Refrigerant Amount ........................ 60

[2] Adjustment and Judgement of Refrigerant Amount ........................ 60

[3] Refrigerant Volume Adjustment Mode Operation............................ 62

7 TROUBLESHOO TING........................................................................... 66

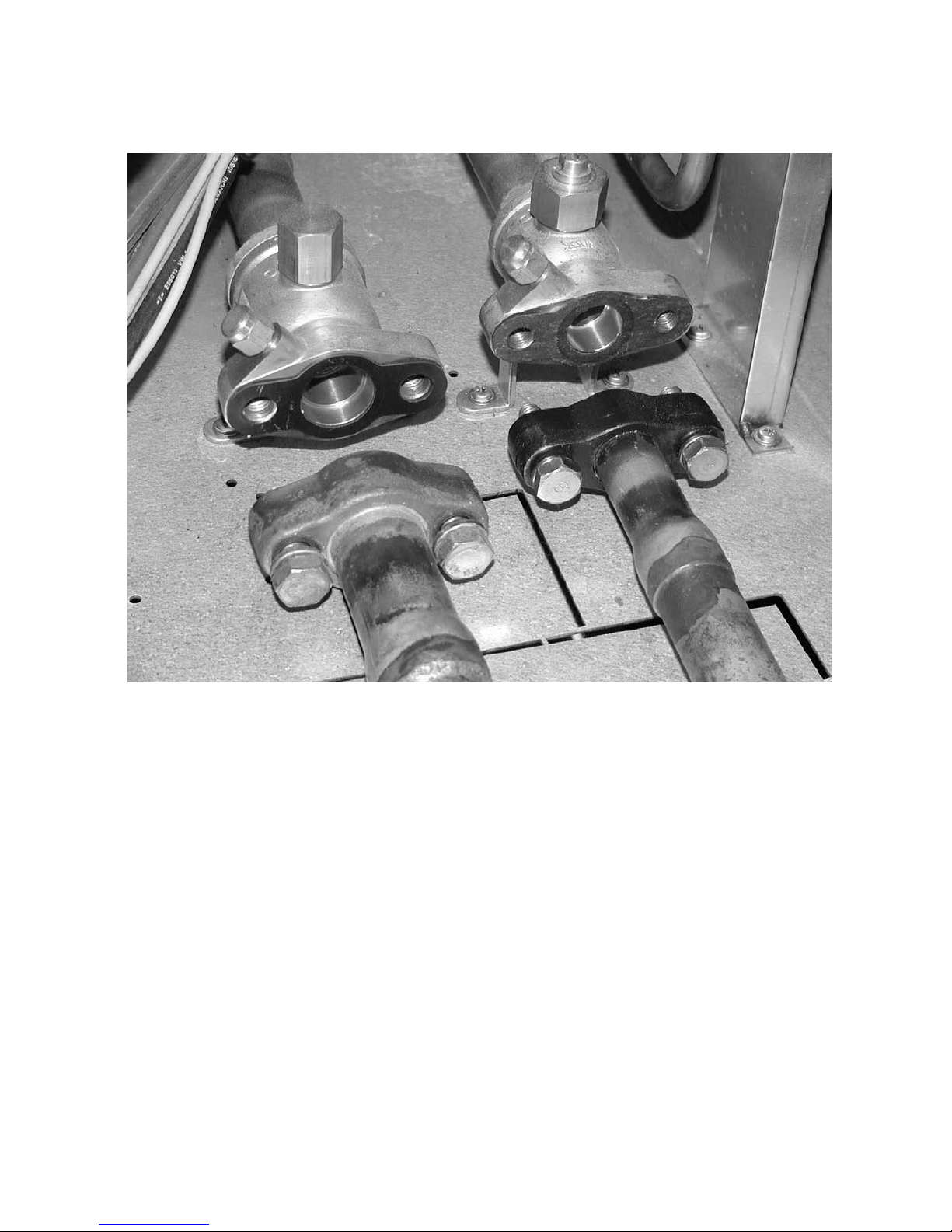

[1] Principal Parts................................................................................. 66

[2] BC Controller Disassembly Procedure.......................................... 100

[3] Self-diagnosis and Countermeasures Depending on the Check

Code Displayed............................................................................. 105

[4] LED Monitor Display ..................................................................... 127

8 PREPARATION, REPAIRS, AND REFRIGERANT REFILLING WHEN

REPAIRING LEAKS ............................................................................. 141

[1] Location of leaks: Extension piping or indoor units

(when cooling) .............................................................................. 141

[2] Location of leaks: Outdoor unit (Cooling mode)............................ 142

[3] Location of leaks: Extension piping or indoor units

(Heating mode) ............................................................................. 142

[4] Location of leaks: Outdoor unit (when heating)............................. 142

9 CHECK THE COMPOSITION OF THE REFRIGERANT ..................... 143

–2–

Safety Precautions

Before installation and electric work

Before installing the unit, be sure to read everything in the “Safety Precautions”.

The “Safety Precautions” provide critical information regarding safety. Be sure to exercise these

precautions to ensure safety.

This equipment may not be applicable to

EN61000-3-2: 1995 and EN61000-3-3: 1995.

This equipment may have an adverse effect on the

equipment on the same electrical supply system.

Please report to and seek an approval from the

local power company before connecting to the

system.

Symbols used in the text

Warning:

Describes precautions that should be observed to

prevent danger of injury to the user or death.

Caution:

Describes precautions that should be observed to

prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates important instructions that must be followed.

: Indicates a part that must be grounded.

: Risk of electric shock (This symbol is displayed on the main

unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Use the specified cables for wiring. Make the connections

securely so that the outside force of the cable is not

applied to the terminals.

- Inadequate connection and fastening may generate heat and

cause a fire.

• Have all electric work done by a licensed electrician

according to “Electric Facility Engineering Standard,”

“Interior Wire Regulations,” and the instructions given in

this manual. Always use a circuit designated solely to the

unit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed properly, dust or water

may enter the outdoor unit and fire or electric shock may

result.

• After completing service work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater,

stove, oven, or other heat source, it may generate noxious

gases.

• Do not try to defeat the safety features of devices, and do

not change the settings.

- If the pressure switch, thermal switch, or other protection

device is shorted and operated forcibly, or parts other than

those specified by Mitsubishi Electric are used, fire or

explosion may result.

▲

▲

▲

▲

▲

–3–

11

11

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT

Caution

Do not use the existing refrigerant piping.

• The old refrigerant and refrigerator oil in the existing

piping contains a large amount of chlorine which may

cause the refrigerator oil of the new unit to deteriorate.

Use pipes made of phosphorus deoxidized cover categorized under H3000 (Copper and copper alloy

seamless pipes and tubes). Be sure that the inner and

outer surfaces of the pipes are clean and free of contaminants, such as sulphur, oxides, dust/dirt, shaving particles, oils, and moisture.

• Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

Store the piping to be used during installation indoors,

and keep both ends of the piping sealed until immediately before brazing. (Store elbows and other joints

in a plastic bag.)

• If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may

result.

Use a small amount of ester oil, ether oil or

alkylbenzene as the refrigerator oil to coat flares

and flange connections.

• The refrigerator oil will degrade if it is mixed with a

large amount of mineral oil.

Use liquid refrigerant to seal the system.

• If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change

and performance may drop.

Do not use a refrigerant other than R407C.

• If another refrigerant (R22, etc.) is used, the chlorine

in the refrigerant may cause the refrigerator oil to deteriorate.

Use a vacuum pump with a reverse flow check valve.

• If other types of valves are used, the vacuum pump oil

may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

Do not use the following tools that have been used

with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base,

vacuum gauge, refrigerant recovery equipment)

• If the conventional refrigerant and refrigerator oil left

on these tools are mixed in with R407C, the refrigerant may deteriorate. If water is mixed in with R407C,

the refrigerator oil may deteriorate. Since R407C

does not contain any chlorine, gas leak detectors for

conventional refrigerants will not operate properly.

• If water is mixed in with R407C, the refrigerator oil

may deteriorate.

• Since R407C does not contain any chlorine, gas

leak detectors for conventional refrigerants will not

operate properly.

Do not use a charging cylinder.

• The use of a charging cylinder may cause the refrigerant to deteriorate.

Be especially careful when managing the tools.

• If dust, dirt, or water enters the refrigerant cycle, the

refrigerant may deteriorate.

If the refrigerant leaks, recover the refrigerant in the

refrigerant cycle; then, recharge the cycle with the

specified amount of the liquid refrigerant indicated

on the air conditioner.

• Since R407C is a non-azeotropic refrigerant, if overcharged, the composition of the refrigerant in the refrigerant cycle will change and result in a drop in performance or abnormal stopping.

–4–

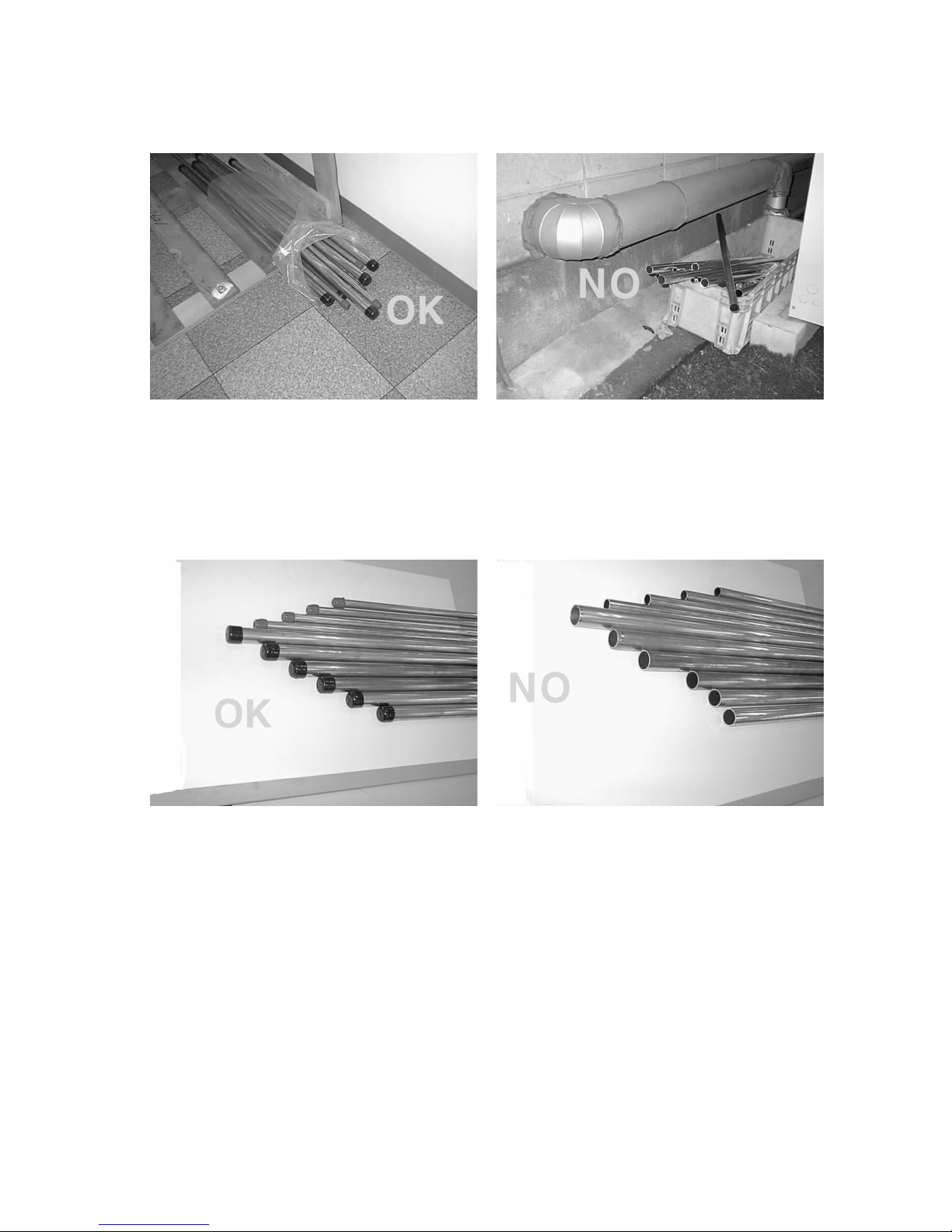

[1] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors.

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

* The new refrigerator oil is ten times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be

stored with more care than with the conventional refrigerant pipes.

–5–

Use only the necessary minimum quantity of oil.

Reason :

1. The refrigerator oil used for the equipment is highly hygroscopic and may introduce water inside.

Notes :

• Introducing a great quantity of mineral oil into the refrigerant circuit may also cause a compressor failure.

• Do not use oils other than ester oil, ether oil or alkylbenzene.

[2] Piping Machining

Use a small amount of ester oil, ether oil, or alkylbenzene to coat flange connections.

–6–

[3] Brazing

No changes have been noted from the conventional method, but special care is required to keep contaminants (i.e. oxide

scale, water, dirt) from entering the refrigerant circuit.

Example : Inside a brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed :

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (BCuP-3) which requires no flux when brazing the sections between copper pipes or between

a copper pipe and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons :

1. The new refrigerant oil is ten times more hygroscopic than the conventional oil. The probability of a machine failure

due to water infiltration is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note :

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use oxygen free nitrogen (OFN).

–7–

[4] Airtightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 cannot detect R407C

leakage.

Halide torch R22 leakage detector

Items to be strictly observed :

1. Pressurize the equipment with nitrogen up to the design pressure and then check the equipment’s airtightness,

taking temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R407C.

3. Ensure that R407C is in a liquid state when charging.

Reasons :

1. Use of oxygen as the pressurized gas may cause an explosion.

2. If gas refrigerant is used, the composition of the remaining refrigerant in the cylinder will change and this refrigerant

will become unusable.

Note :

• A leakage detector for R407C is sold commercially, and it should be purchased.

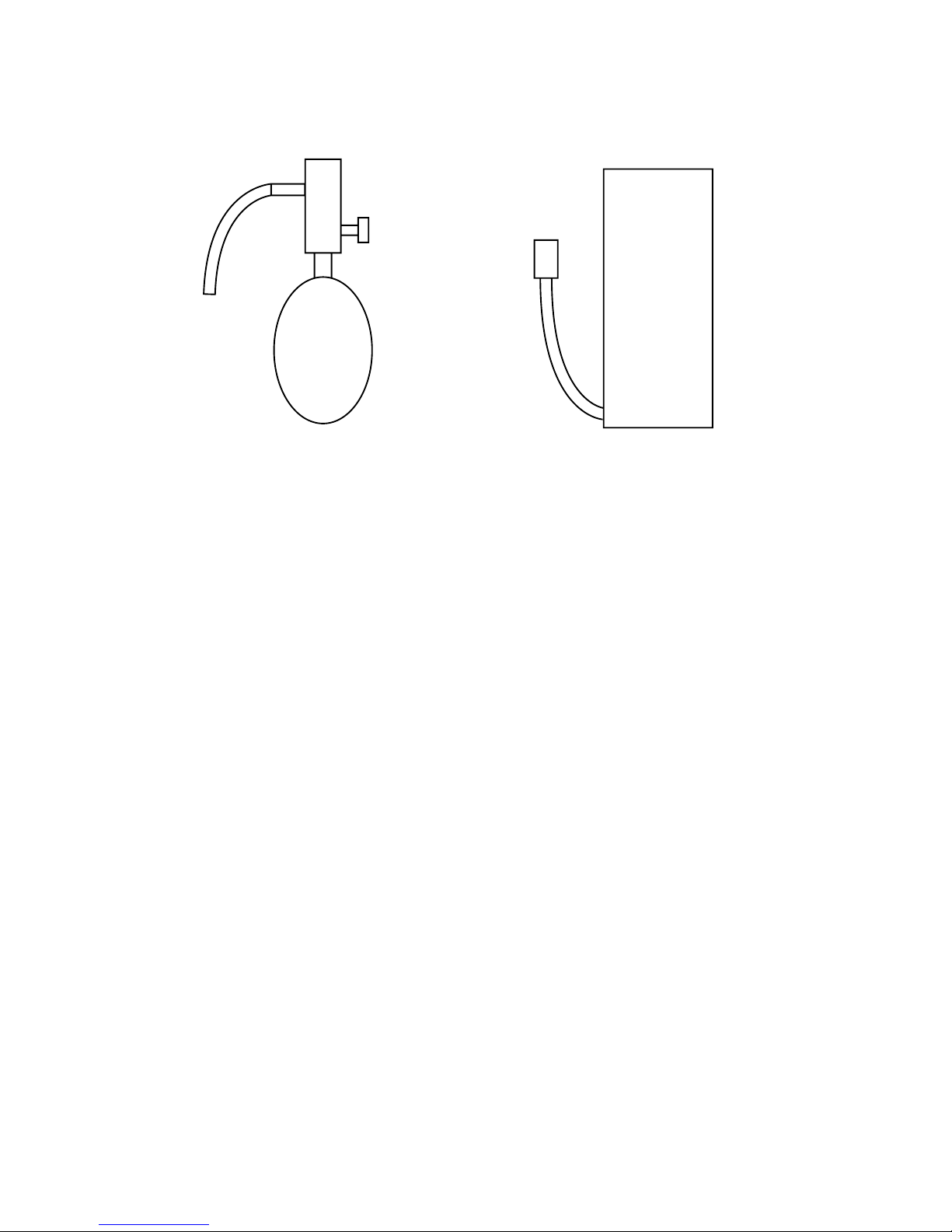

[5] Vacuuming

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the power supply is cut off due to power failure. A check valve may be added to a vacuum pump not

equipped with one.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 0.5 Torr (500 MICRON) or below after 5 minutes of operation.

Be sure to use a vacuum pump that has been properly maintained and oiled with the specified oil. If the vacuum pump

is not properly maintained, desired degree of vacuum may not be achieved.

3. Neccessary accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 5 Torr. Do not use a general gauge manifold since it cannot measure a

vacuum of 5 Torr.

4. Evacuating time

• Evacuate the equipment for 1 hour after –755 mmHg (5 Torr) has been reached.

• After envacuating, leave the equipment for 1 hour and make sure that the vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

NO

NO

–8–

Cylin-

der

Cylin-

der

Valve

Val ve

Liquid

Liquid

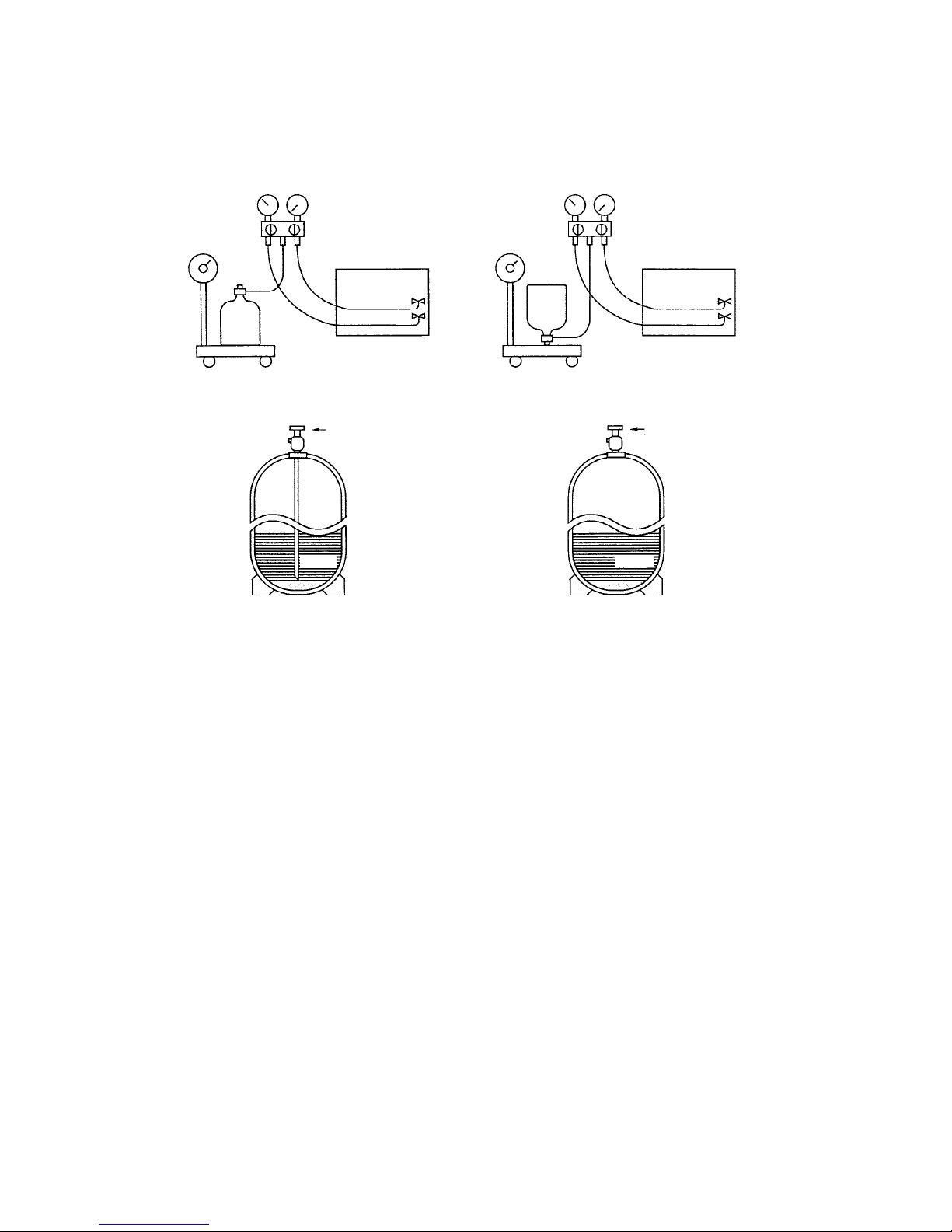

[6] Charging of Refrigerant

R407C must be in a liquid state when charging, because it is a non-azeotropic refrigerant.

For a cylinder with a syphon attached For a cylinder without a syphon attached

Cylinder color identification R407C-Gray Charged with liquid refrigerant

R410A-Pink

Reasons :

1. R407C is a mixture of three refrigerants, each with a different evaporation temperature. If the equipment is charged

with R407C gas, then the refrigerant whose evaporation temperature is closest to the outside temperature is charged

first while the rest of refrigerants remain in the cylinder.

Note :

• Do not use cylinders that are equipped with a siphon upside-down. Check the type of cylinder before charging.

[7] Dryer

1. Replace the dryer when the refrigerant circuit is opened (Ex. Change the compressor, full gas leakage). Be sure to

replace the dryer with a CITY MULTI Series Y (For use with R407C).

The use of any other product will damage the unit.

2. Do not leave the refrigerant circuit open for longer than one hour after removing the old drier.

–9–

22

22

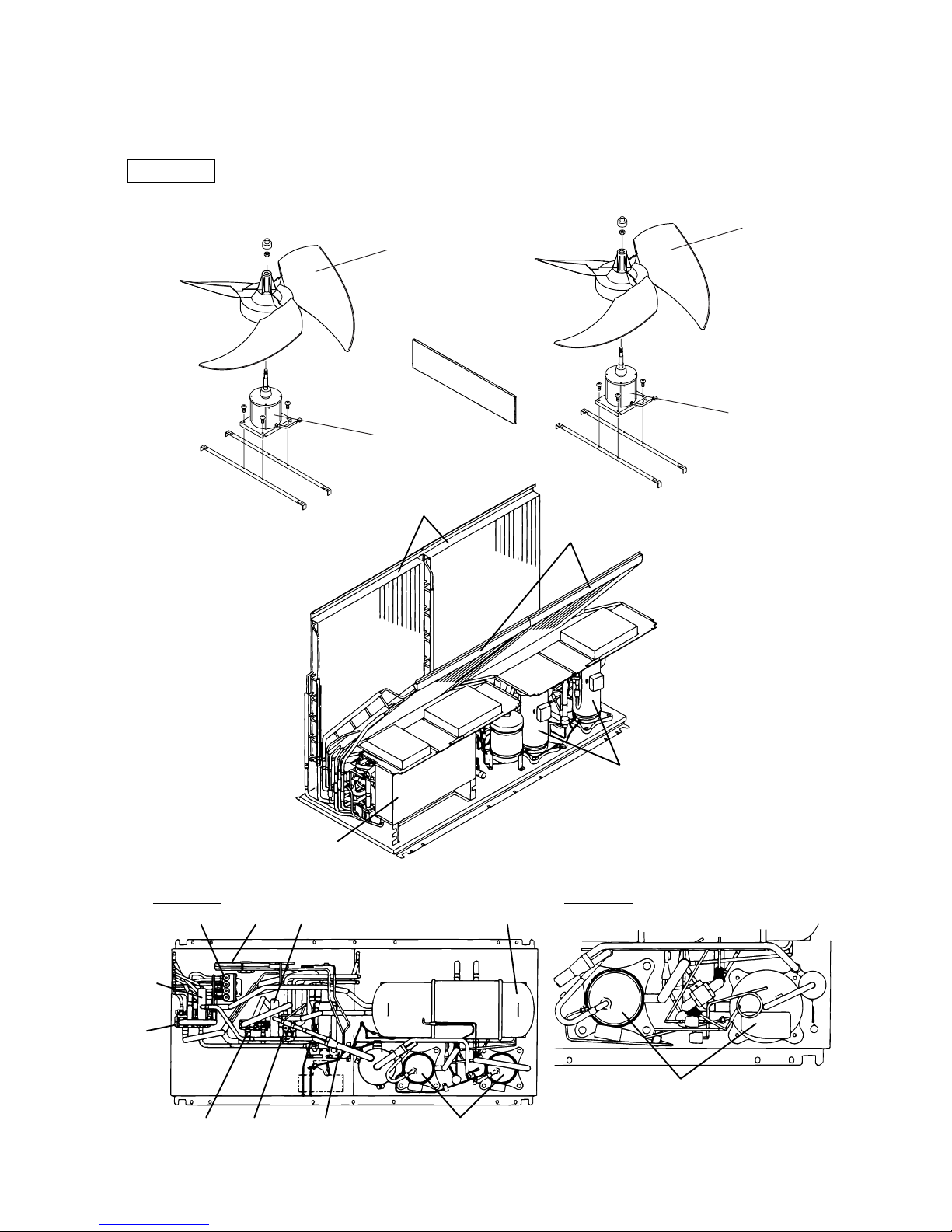

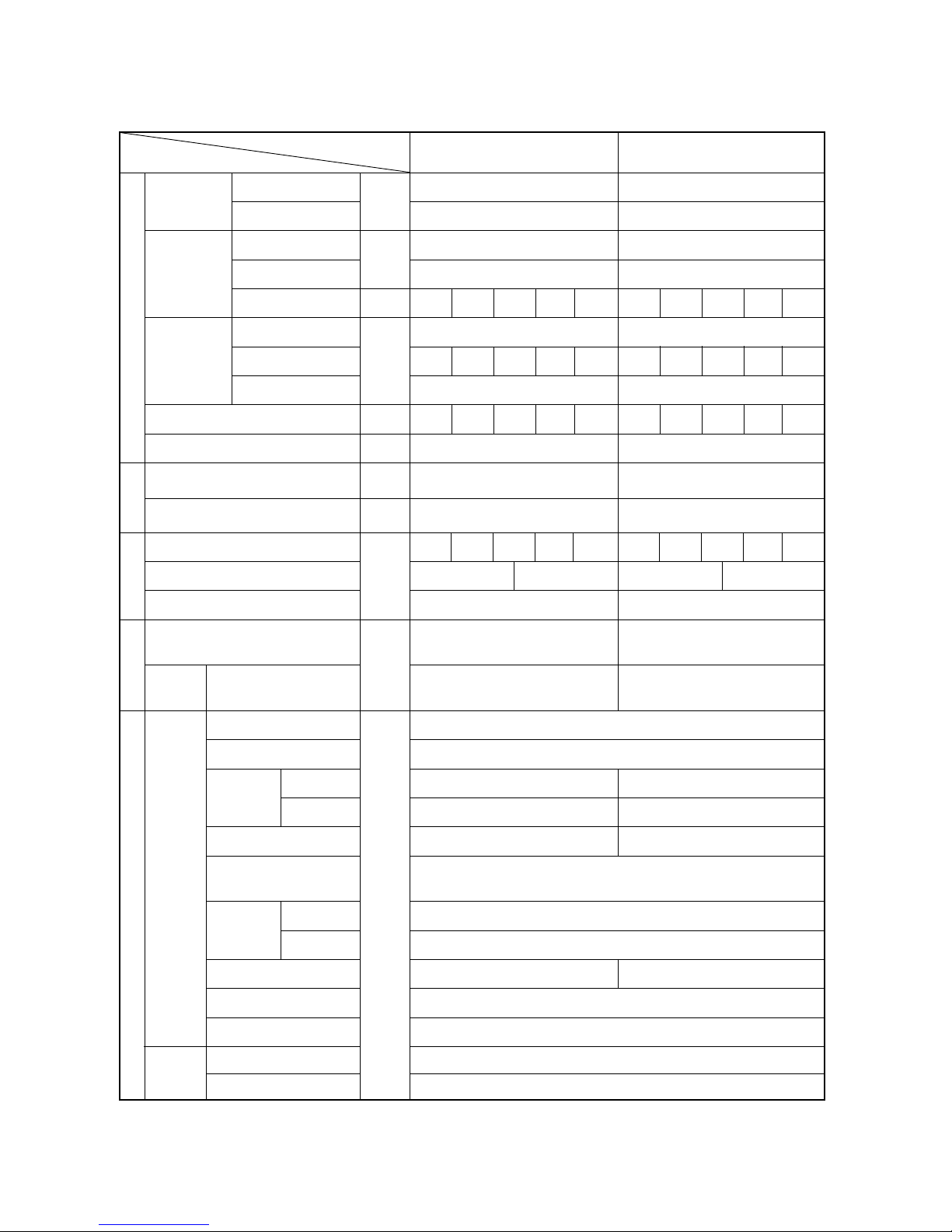

2 COMPONENT OF EQUIPMENT

[1] Appearance of Components

Outdoor unit

Heat exchanger(front)

Compressor

Heat exchanger(rear)

SV block 1

SV block 2

4–way

valve

4–way valveCS circuit

Drier

CV

block 1

CV block 2

Control box

Compressor

Compressor

P500 TYPEP400 TYPE

Accumulator

Propeller fan

Fan motor

Propeller fan

Fan motor

–10–

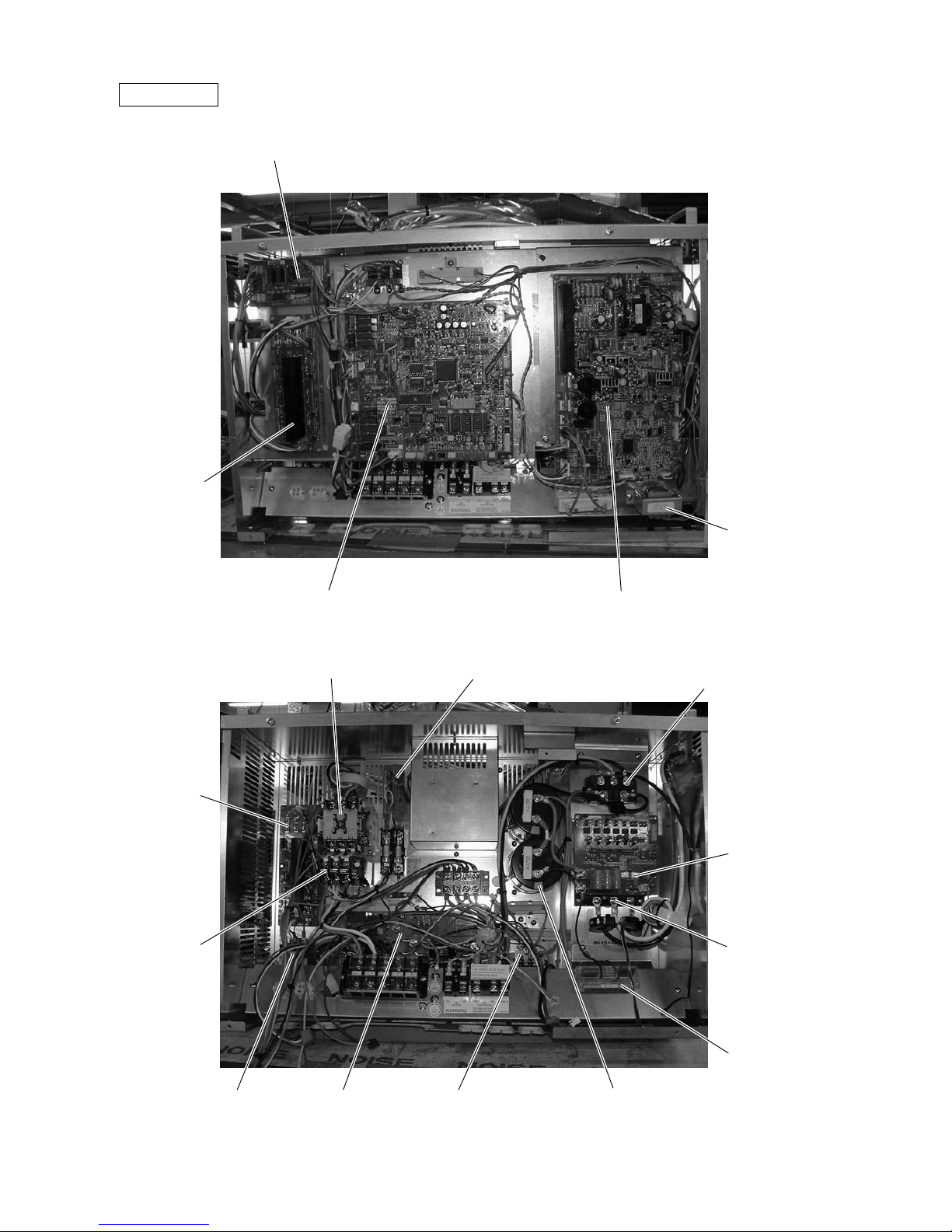

Controller Box

RELAY board

FANCON board

(for MF3)

INV boardMAIN board

Choke coil (L2)

Intelligent Power

Module (IPM)

G/A board

Y-C board

SNB board

Diode stack (DS)

Magnetic contactor (52C2)

Magnetic contactor (52C1)Magnetic contactor

(52F)

Overload relay

(51C2)

FANCON board

(for MF2)

Capacitor (C2, C3)

(Smoothing capacitor)

Noise filter

(NP)

–11–

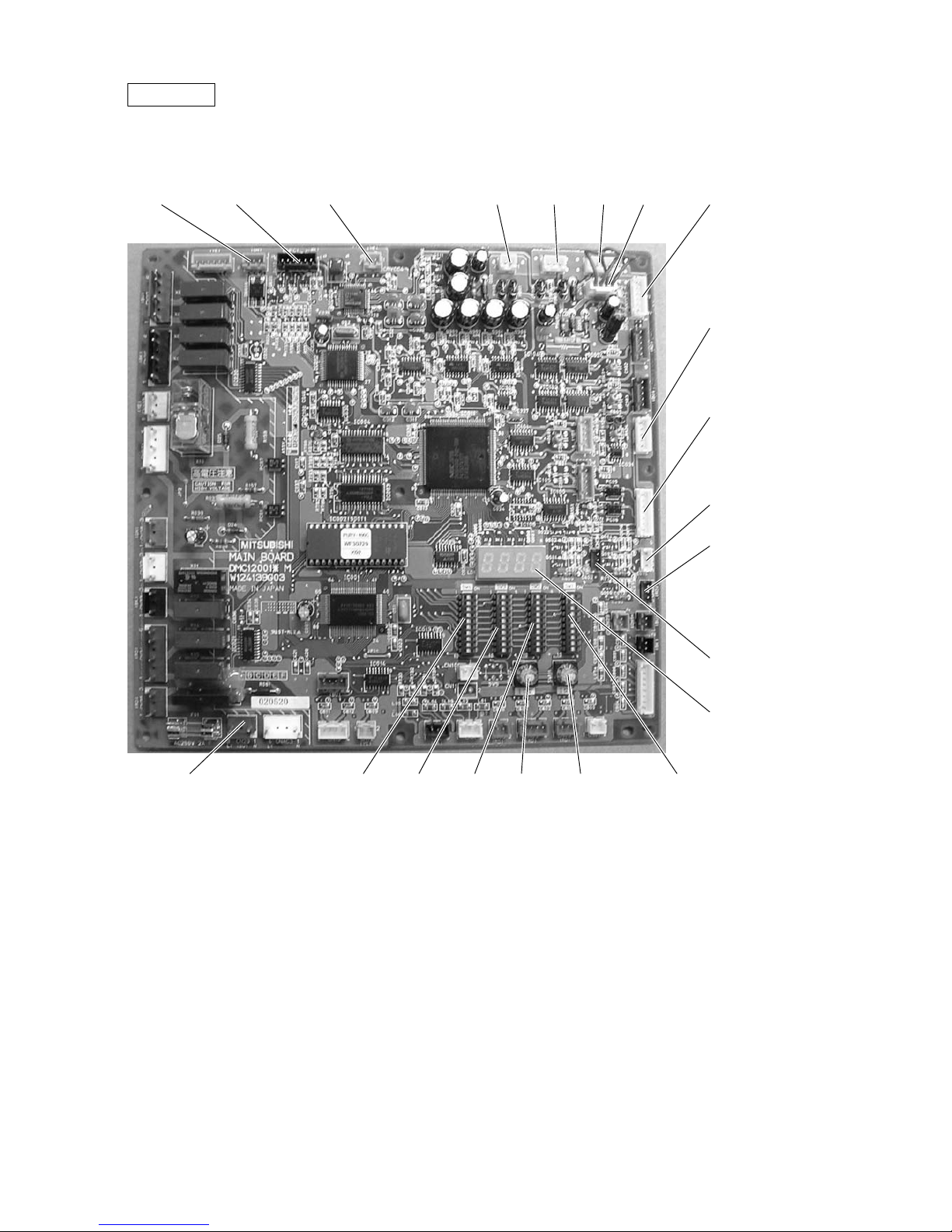

MAIN board

• PURY

CN51

Indication distance

3-4 Compressor

ON/OFF

3-5 Error Indicator

CNRS3

Serial transmission to

INV board

CN3D

SW1

CNTR CNFC1

CNVCC4

Power source

for control(5V)

CN20

Power supply

3 L1

1 N

SW3SW4 SW2 SWU2 SWU1

CNS1 CNS2

CN40

CNVCC3

Power Source

for control

1-2 30V

1-3 30V

4-6 12V

5-6 5V

CN3S

CN3N

LD1

Service LED

CN41

–12–

INV board

CNDR2

Output to

G/A board

CNTH

CN15V2

Power supply

for IPM control

CNACCT

CNAC2

Powe r

source

1 L2

3 N

5 G

CN52C

Control for

52C

CNFAN

Control

for MF1

CNR

CNRS2

Serial transmission

to MAIN board

SW1

CNVDC

1-4

DC-560V

CNVCC4

Power supply (5V)

CNL2

Choke coil

CNVCC2

Power supply

1-2 30V, 1-3 30V

4-6 12V, 5-6 5V

–13–

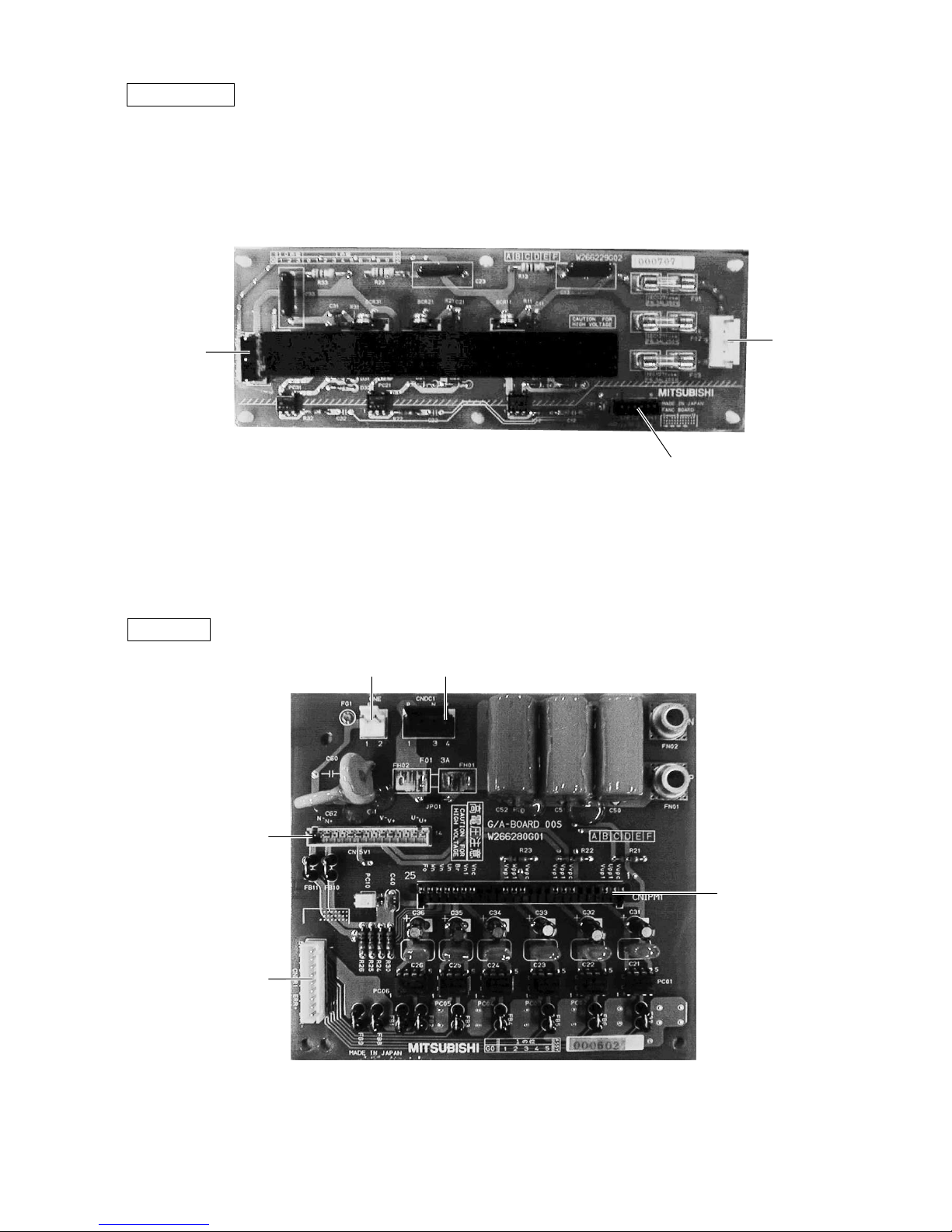

CNFAN

CNPOW

CNFC2

CN15V1

CNDR1

CNIPM1

CNE CNDC1

FANCON board

G/A board

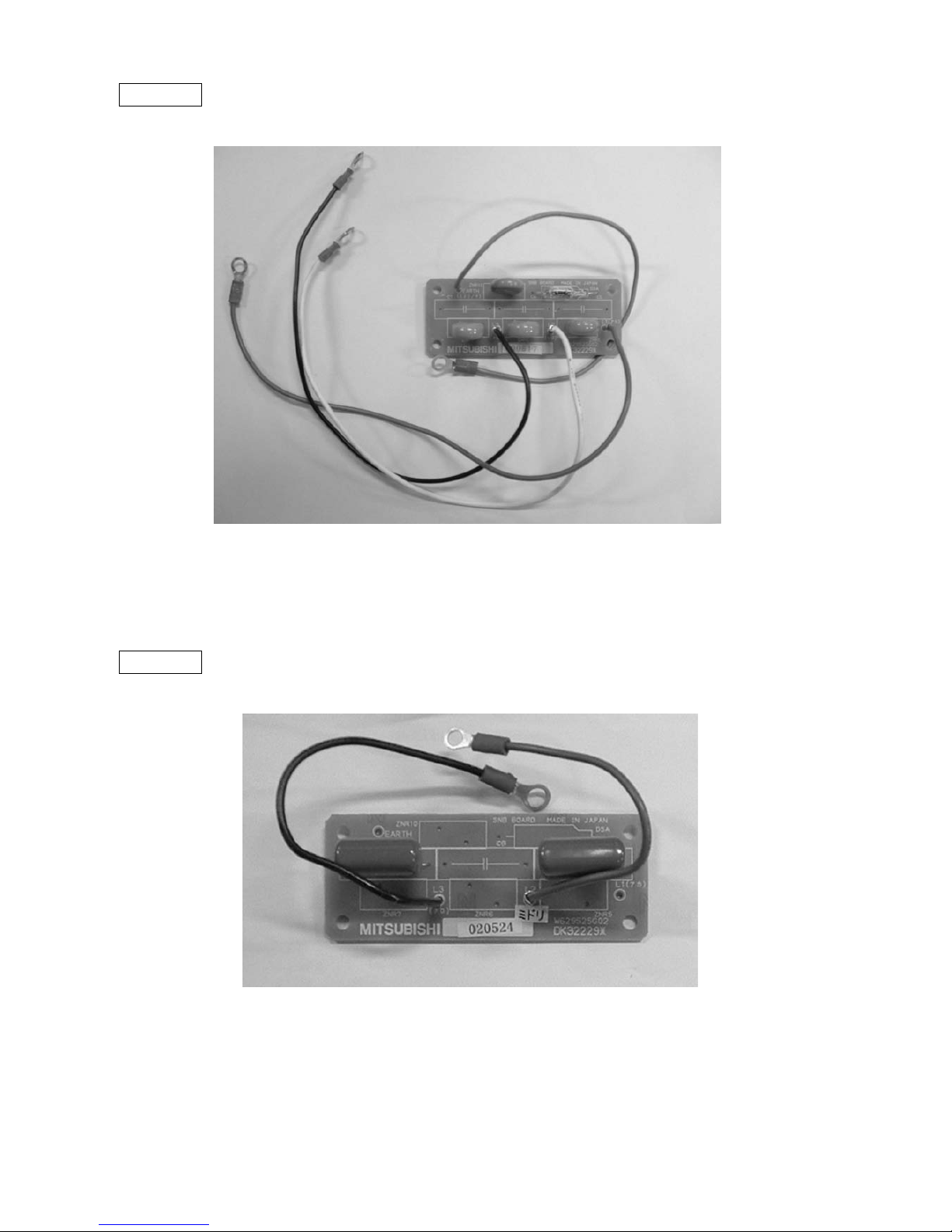

–14–

Y-C board

SNB board

–15–

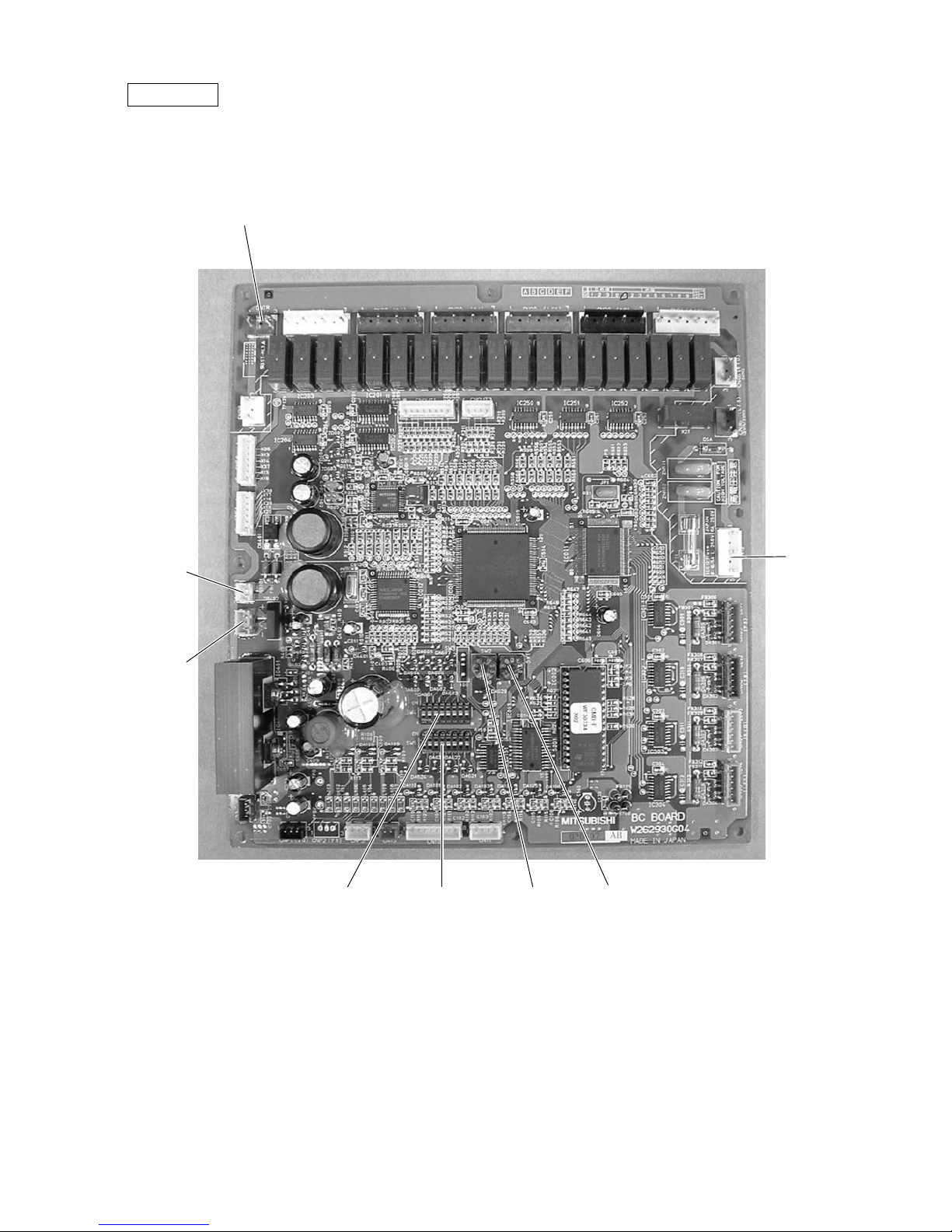

BC controller

CNTR

CN02

M-NET

transmission

CN03

CN12

Power

supply

1 EARTH

3 N

5 L

SW4 SW2 SW1SW5

–16–

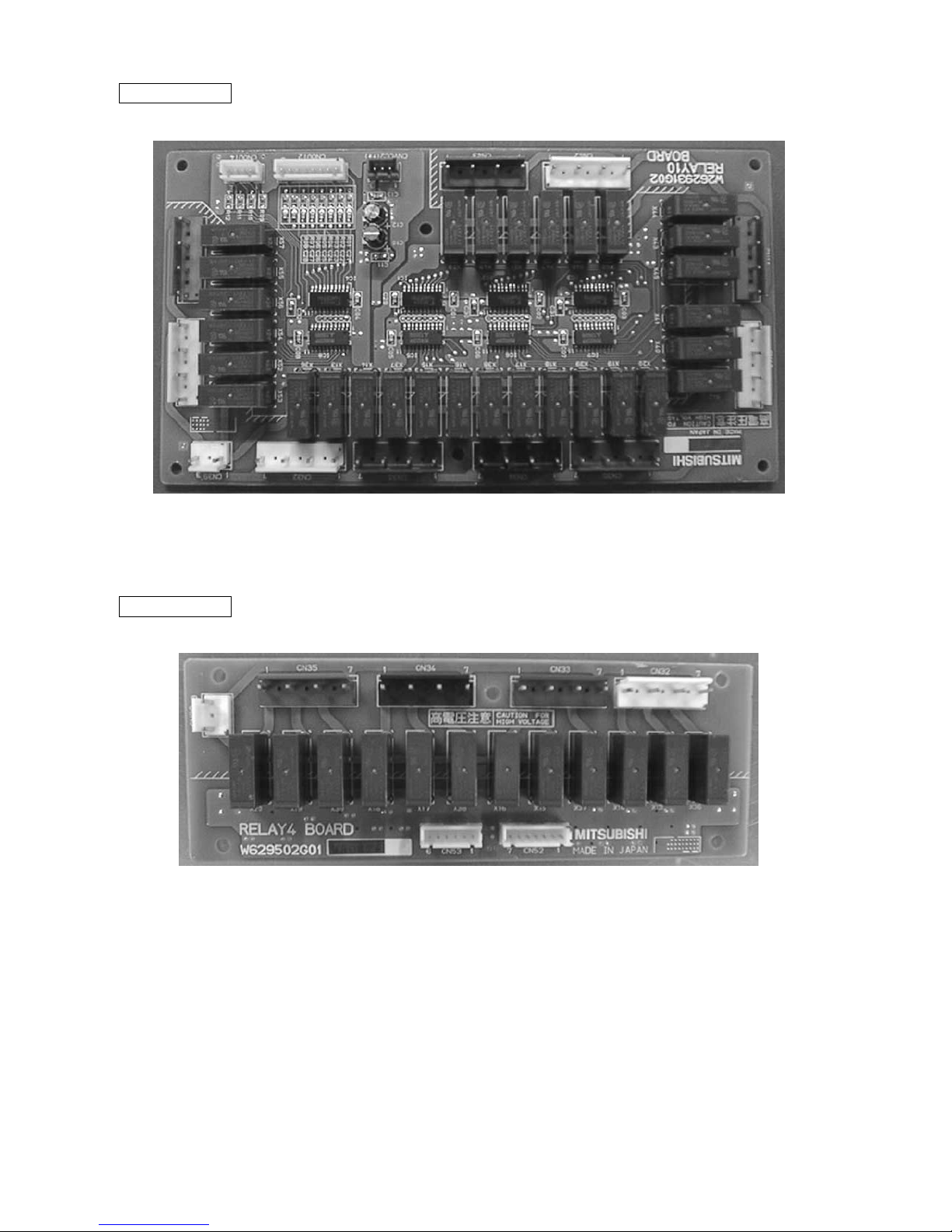

RELAY 10 board

RELAY 4 board

–17–

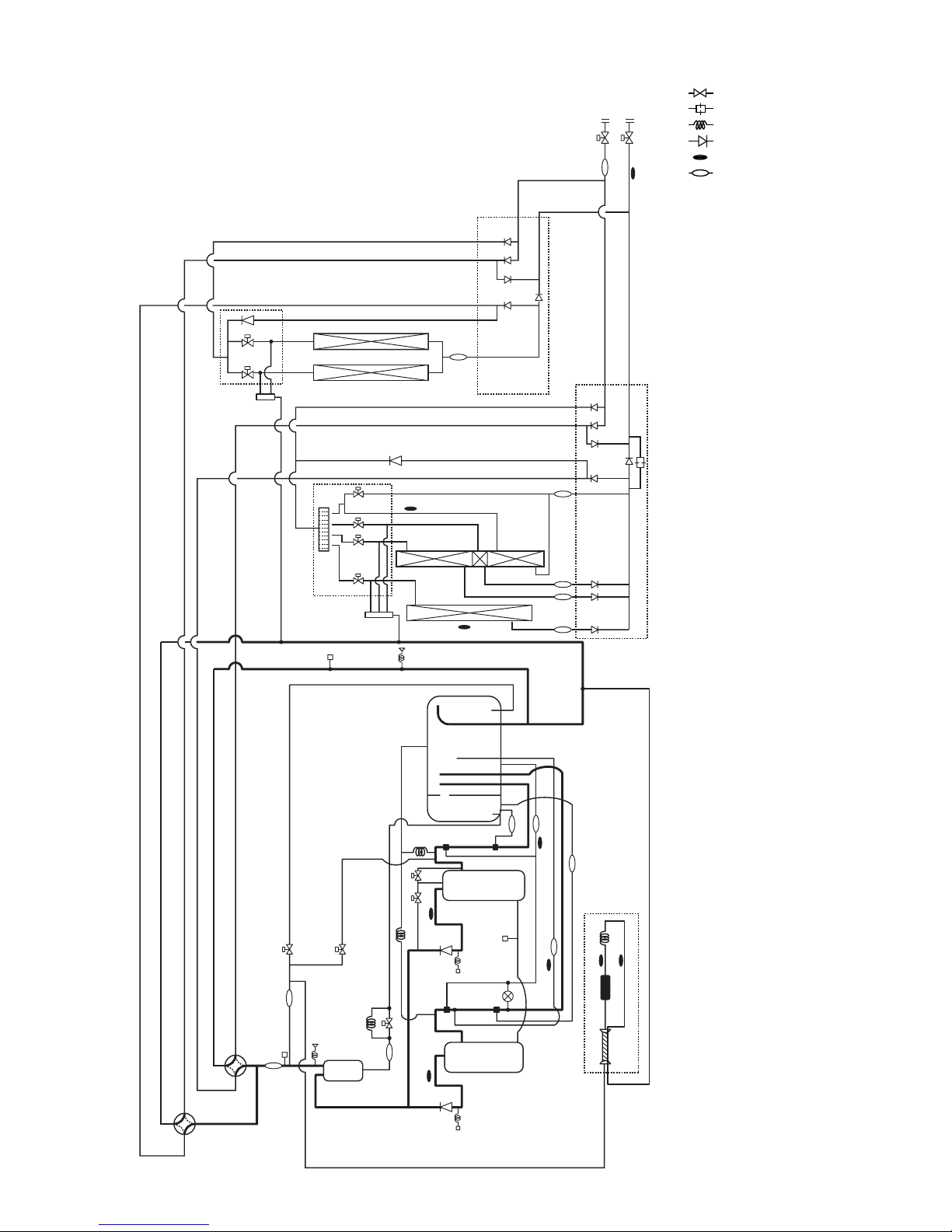

[2] Refrigerant Circuit Diagram and Thermal Sensor

PURY-P400, 500YEM-A

* SV22, SV32 For P500YEM-A only.

: Solenoid valve

: Orifice

: Capillary

: Check valve

: Thermal sensor

: Strainer

SP : Service port

ACC : Accumulator

CV3b

BV1

BV2

ST1

TH5

CV2b

ST15

TH7

TH6

CJ2

MA

SA

CJ3

CJ1

63HS

63H1

O/S

63H2

SLEV

Comp2

Comp1

CV1b

CV1a

SV32

SV22

CP3a

TH12

TH2

TH9

Drier

CP2

TH11

ST9

ST5

ST6

ST2

21S4a

21S4b

ST3

ST4

ST8

TH3

TH4

63LS

HEXf1

HEXf3

HEXb1

HEXf2

ST14

ST13

ST12

ST11

CV5b

CV7b

SV8

SV6

SV5

SV4

SV3

SV7

SV Block 2

SV Block 1

HEXf4

HEXb2

CV4b

CV4a

CV10a

Orifice

CV9a

CV8a

CV3a

CV2a

CV5a

CV6a

CV7a

CV6b

CV Block 2

CV Block 1

*

SV22, 32: P500 only

CP3b

SV4a

SV6a

SV1

CP1

CS Circuit

–18–

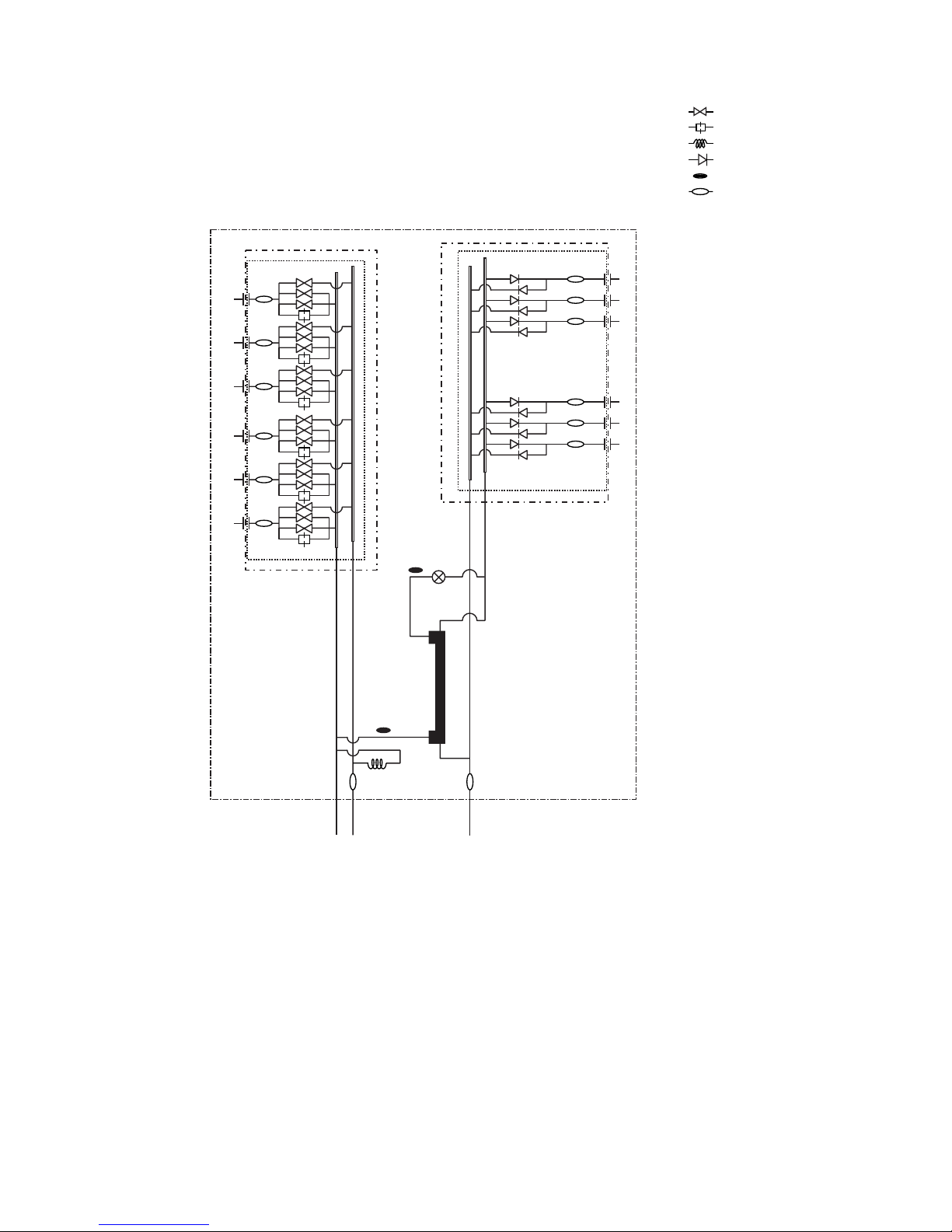

CMB-P108, 1010, 1013, 1016V-FA

SVM2

TH16

TH11

TH12

SVM1

PS3

PS1

Check

valve block

Solenoid

valve block

LEV3

LEV1

TH15

Gas/liquid

separator

: Solenoid valve

: Orifice

: Capillary

: Check valve

: Thermal sensor

: Strainer

–19–

CMB-P108V-FB

Check

valve block

LEV3a

TH25

TH22

Solenoid

valve block

CP

: Solenoid valve

: Orifice

: Capillary

: Check valve

: Thermal sensor

: Strainer

–20–

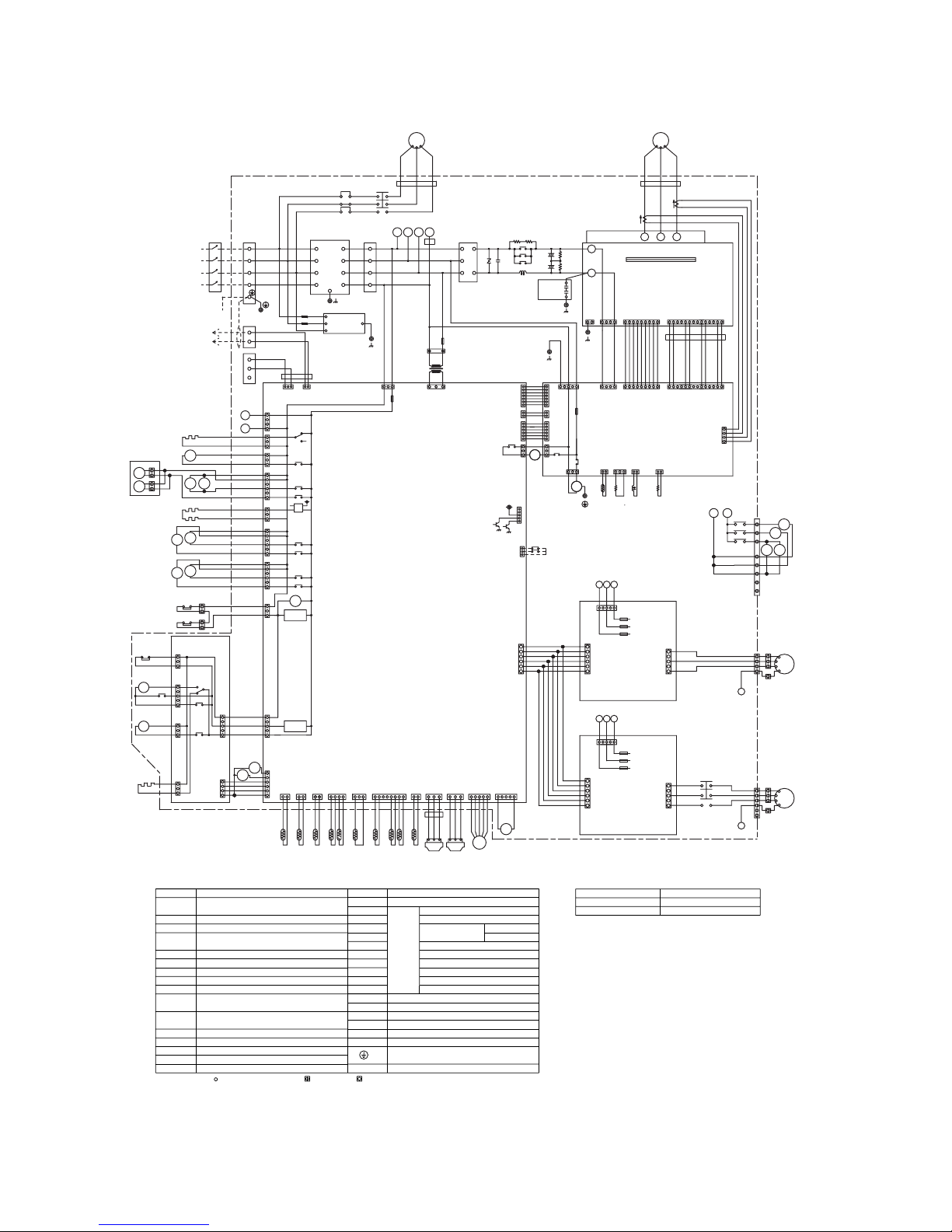

[3] Electrical Wiring Diagram

PURY-P400·500

NOTE : Mark indicates terminal bed, connector, board insertion connector

Symbol N a m e

Choke coil(Transmission)L2 TerminalT1~15

"

✻

1" are not existedPURY-P400

Appliance N a m e

<Difference of appliance>

SV1,22,32, Solenoid valve

4-way valve21S4a,4b

Electronic expansion valve(Oil return)

High pressure sensor

Low pressure sensor63LS

63HS

SLEV

(Heat exchanger capacity control)

Solenoid valve

SV3,4,5,6,

Varistor

N a m eSymbol

DCL

(Power factor improvement)

<Symbol explanation>

DC reactor

ACCT-U,W Current Sensor

ZNR4

FB1~6 Ferrite core

Fan motor (Radiator panel)

(Inverter main circuit)

52C1

MF1

Magnetic contactor

Intelligent power moduleIPM

Discharge pipe temp. detect

Radiator panel temp. detect

Compressor shell temp.

High pressure liquid temp.

OA temp. detect

Pipe temp. detect(Hex outlet)

Saturation evapo. temp. detect

Thermistor

THHS

TH10

TH9

TH6

TH5

TH2

TH11,12

Earth terminal

X1,2,4~13 Aux. relay

TH7

LD Accumulator liquid level detect

52C2

51C2

52F

4a,6a

7,8

TH3

TH4

CH11,12

SSR

CH2,3

63H1,2 High pressure switch

Crank case heater(Compressor)

Magnetic contactor(Fan motor)

PURY-P500 All exists

Magnetic contactor

Overload relay

Accumurator liquid

temp. detect

Lower

Upper

Pipe temp.(Hex inlet)

Solid state relay

Cord heater

L1

L2

L3

EARTH

SNB board

X12

X11

X10

21S4b

SV3

X13

Relay board

TH2TH7TH5TH6TH3TH4

63LS

63HS

TH11

TH9TH10 TH12

SLEV

SV1

SV4a

52C1

CH12

52F

52C2

51C2

CN51C2

(3P)

CN52C2

(5P)

CN52F

(3P)

CNCH

(3P)

CNRT2

(5P)

CNOUT2

(4P)

CNRT1

(5P)

CNOUT1

(6P)

21S4a

SV6a

SV5

MF1

6

5

F5

8A F

600VAC

F6

600VAC

8A F

FB3

1

2

3

CNX10

(3P)

Motor

(Compressor)

52F

1

2

3

4

5

6

L1 L2 L3

(6P)

CNFC1

F01 250VAC 6.3A F

F03 250VAC 6.3A F

F02 250VAC 6.3A F

N

CNPOW

(5P)

CNFC2

(6P)

1

2

3

4

5

6

1

2

3

4

5

6

V

W

N

U

MF3

1

2

3

4

5

1

2

3

4

5123 4

Fan control board

(Fancon board)

(5P)

CNFAN

CN04

F01 250VAC 6.3A F

F03 250VAC 6.3A F

F02 250VAC 6.3A F

N

CNPOW

(5P)

CNFC2

(6P)

1

2

3

4

5

6

V

W

N

U

MF2

1

2

3

4

5

1

2

3

4

5123 4

Fan control board

(Fancon board)

L1 L2 L3

(5P)

CNFAN

FB5

BlackWhite

Red

Controller Box

Inverter

controller

remote

Connect to

Indoor and

Crank case heater

(Compressor)

circuit

detection

circuit

detection

High pressure

switch

(MAIN board)

Control circuit board

Refer to the service handbook

about the switch operations.

5:Trouble

4:Compressor ON/OFF

DEMAND

NIGHT MODE

(INV board)

Power circuit board

Gate amp board

(G/A board)

BlackWhite

Red

Motor

(Compressor)

Diode

stack

Noise

Filter

Terminal

Block

Terminal

Block

BOX BODY

BOX BODY

BOX BODY

BOX BODY

BOX BODY

X10

2A F

1A F

2A F

CNAC3

(4P)

A

B

4

3

2

1

(3P)

CN20

DS

CNTR1

123

T01

F3

250VAC

CNTR

(3P)

L1 L2 L3 N

L1

TB1B

L2

L3NNL3

L2

L1

N

L3

L2

NF

L1

N

L3

L2

TB1A

L1

PE

PE

N

L3

L2

L1

Red

White

Black

12345

CNLV4

(5P)

123

(3P)

CN03

1234

CN05

(4P)

CNE

(2P)

21

(14P)

CN15V2

(7P)

CNRS3

(6P)

CNVCC2

(6P)

CNVCC3

(2P)

CNVCC4

(7P)

CNRS2

X01

3

2

1

6

5

1

2

3

4

5

6

7

1

2

1

4

3

2

9876432112

3

V

MC1

W

U

(4P)

CNVDC

(3P)

CN52C

(5P)

CNAC2

(2P)

CNVCC4

250VAC

F01

6

5

1

2

3

4

5

6

7

1

2

1

4

3

2

CNDC1

(4P)

1234

12345987612345

CNDR2

(9P)

14131110 12

121011 13 14

543216789 54321 6789

5

1

2

3

4

UVW

P

N

IPM

CNDR1

(9P)

CN15V1

(14P)

4

CNACCT

(4P)

543121678312 1 23 1 23 1234 5

2

3

4

2

5

1

3

CN33

(3P)

1

1

CN3D

(3P)

322

3

2

21131

CNS1

(2P)

CN51

(5P)

2

CNS2

(3P)

X02

X01

12V

F1

250VAC

123

Black

White

Red

123

TB3

TB7

ZNR4

C1

R5

R1

52C1

+

+

DCL

C2

C3

R2

R3

CN02

(8P)

CN01

(2P)

CNH

(3P)

CNL

(3P)

CN32

(3P)

CNLV1

(5P)

CN06CN09

12

(2P)

12

(2P)

CN37

(6P)

6

5

4

3

2

1

X09

CN36

(6P)

6

5

4

3

2

1

X06

X07

X05

(3P)

CN38

3

2

1

1

2

3

4

5

6

(6P)

CN34

(2P)

CN07

21

U

W

MC2

V

1

3

5

6

4

2

6

5

4

3

2

1

52C2

51C2

-W

ACCT

-U

ACCT

M1

M2

S

M1

M2

1

2

3

4

5

1

2

3

4

5

6

1

2

3

4

5

4

1

2

3

X02

X03

3

2

1

1

2

3

5

4

1

2

3

1

2

3

52C2

X01

9695

A2A1

1314

A1A2

(3P)

CN35

3

2

1

12

34

SSR

CH2

CH3

CH11

X04

X08

CNFAN

(3P)

321

X02

L2

R7

THHS

R6

(2P)

CN30V

(2P)

CNL2

12 1 23 12 12

(2P)

CNTH

(3P)

CNR

BOX BODY

FB2FB1

FB4

FB6

T1

T2

T3

T4

T5

T6

T9

BOX BODY

T15

T13

SV22

SV32

T12

T14

63H2

63H1

T11

T10

T8

T7

8

7

6

5

4

3

2

1

A B

SV8

X12

SV4

SV6

SV7

X13

X11

CN06

Y-C

board

CN05

Fan motor

(Heat exchanger)

Fan motor

(Heat exchanger)

Power source

380/400/415V

50/60Hz

✻

1

3N~

+

~

-~

~

–21–

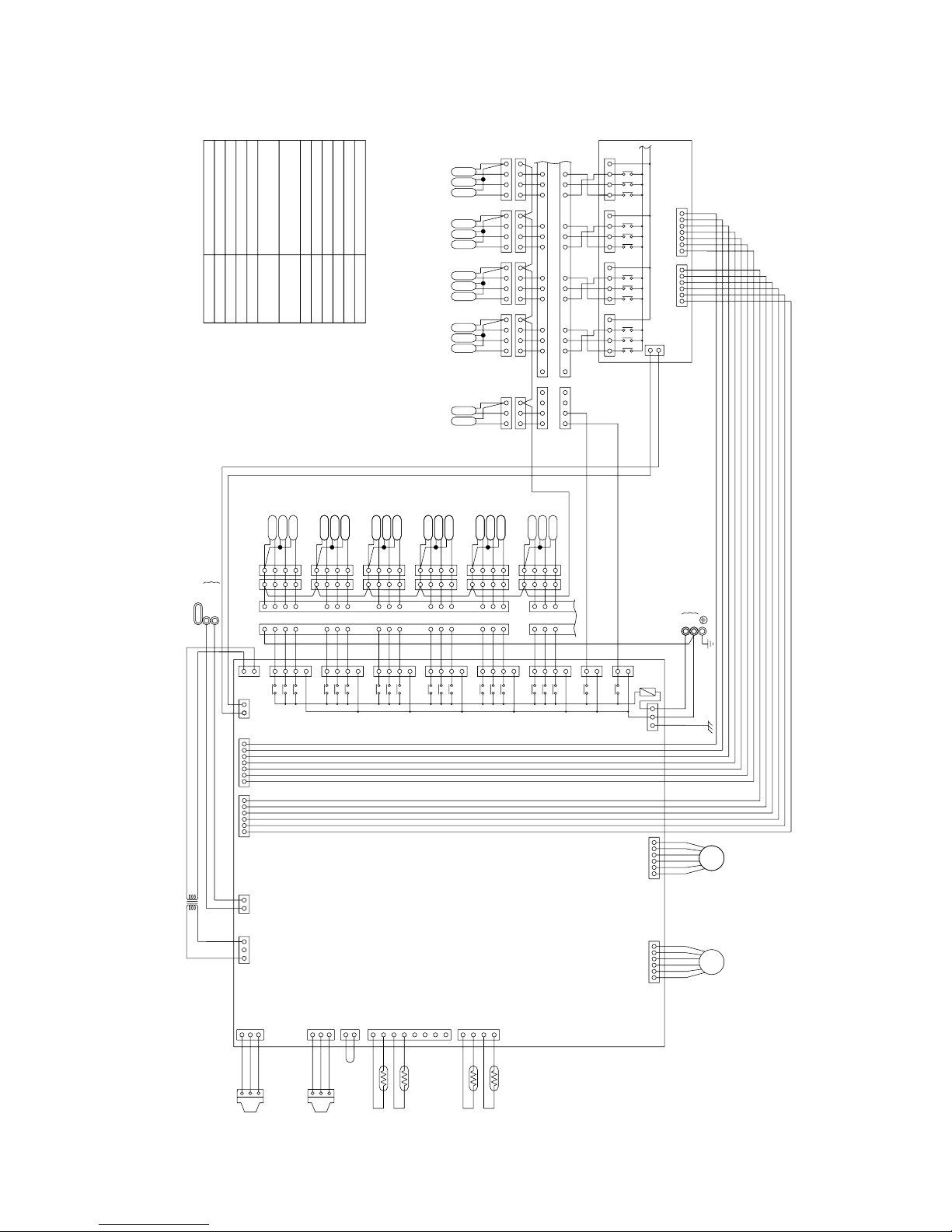

CMB-P108·1010V-FA

5

1

2

34

4

1

2

3

1

2

3

1

2

3

SVM1

SVM2

131415

9

101112

5

6

78

4

4

5

6

87

9

12 11 10

15 14 13

16

16

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

SV7B

SV8B

SV9B

SV10B

SV7A

SV8A

SV9A

SV10A

SV7C

SV8C

SV9C

SV10C

SV1B

SV1A

SV1C

1

5

6

7

8

9

10

11

12

13

14

15

16

3

2

4

8

9

10

11

12

13

3

2

4

1

5

6

7

14

15

16

4

3

2

1

SV2C

SV2A

SV2B

SV3C

SV3A

SV3B

SV4C

SV4A

SV4B

SV5B

SV5A

SV5C

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

SV6B

SV6A

SV6C

1

2

3

4

1

2

3

4

33

2

1

2

1

X60

X21

CN46

CN36

3

1

3

1

Power source

L

N

~220V~240V 50/60Hz

Transmission line

Shield wire

CONT.board

CN38

1

3

1

CNTR

CN50CN51

7654321123456

CN02

CN12

13

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

3

TR

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

DC 30V

6

54

3

2

1

6

54

3

2

1

LEV3 LEV1

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN03

CN13

CN10

CN11

CN07 CN05

TH11

TH12

TH15

TH16

PS1

PS3

22V

TB02

M2

M1

CN26

CN27

CN28

CN29

CN30

CN31

TB01

220~240V

LEV1

7654321123456

CN35

TB01

RELAY4 Board

CN32

CN33

CN34

CN39

3

1

X14

X13

X36

X37

X15

X16

X18

X17

X38

X39

X19

X20

CN52CN53

57317531753175133 3

F01

250VAC

6.3A F

T8T9

T7

T10

T1

T5

T4

T3

T2

T6

PE

3

2

1

3

2

1

EARTH

Fuse AC250V 6.3A F

F01

Terminal

T1 ~ 10

SVM1, 2

Solenoid valve

TB02

TB01

Terminal block

(for Transmission)

Solenoid valve

Solenoid valve

Solenoid valve

Terminal block

(for power source)

Pressure sensor

Expansion valve

Thermistor sensor

Transformer

NameSymbol

SV1 ~ 10A

SV1 ~ 10B

SV1 ~ 10C

TR

TH11, 12, 15, 16

LEV1, 3

PS1, 3

Note1: Never connect the power line to the

terminal block for transmission (TB02)

<

Symbol explanation

>

–22–

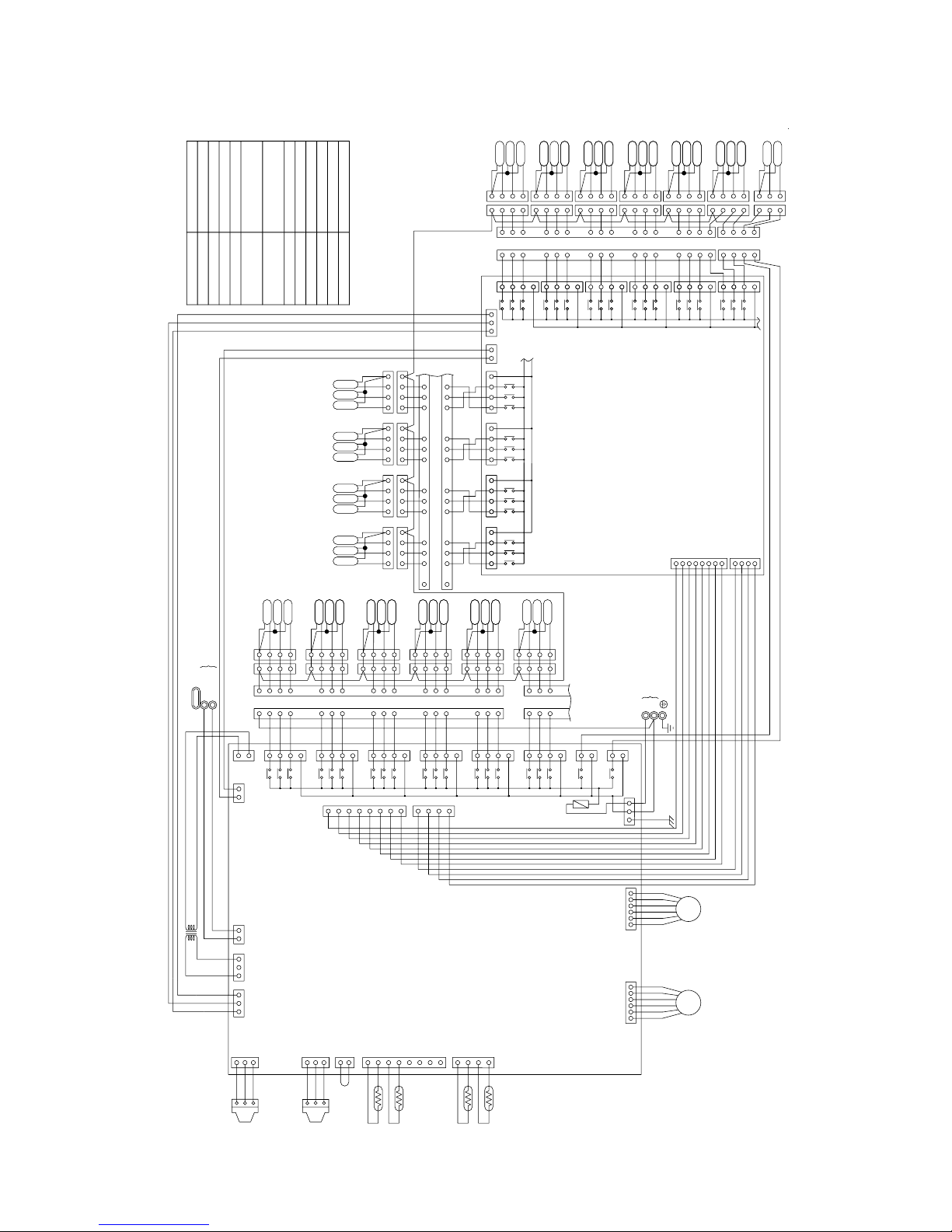

CMB-P1013·1016V-FA

3

2

1

Power source

L

TB01TB01

N

~220V~240V 50/60Hz

1

2

3

SVM2

SVM1

1

3

2

8

8

9

9

10

10

11

11

12

12

13

13

3

2

4

4

1

5

5

6

6

7

7

14

14

15

15

16

16

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

1

2

3

4

1

2

3

4

3

3

4

4

2

2

1

1

SV11B

SV11A

SV11C

SV16C

SV16A

SV16B

SV15C

SV15A

SV15B

SV14C

SV14A

SV14B

SV13C

SV13A

SV13B

SV12C

SV12A

SV12B

131415

9

101112

5

6

78

4

4

5

6

87

9

12 11 10

15 14 13

16

16

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

SV7B

SV8B

SV9B

SV10B

SV7A

SV8A

SV9A

SV10A

SV7C

SV8C

SV9C

SV10C

SV1B

SV1A

SV1C

1

5

6

7

8

9

10

11

12

13

14

15

16

3

2

4

8

9

10

11

12

13

3

2

4

1

5

6

7

14

15

16

4

3

2

1

SV2C

SV2A

SV2B

SV3C

SV3A

SV3B

SV4C

SV4A

SV4B

SV5B

SV5A

SV5C

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

SV6B

SV6A

SV6C

1

2

3

4

1

2

3

4

33

2

1

2

1

3

1

3

1

CN36

CN46

X21

X60

Transmission line

Shield wire

1

2

3

8

7

6

5

4

3

2

1

4

CNTR

1

3

220~240V

CN35

CN31

CN30

CN29

CN28

CN27

CN26

CN38

M1

M2

TB02

TR

22V

PS3

PS1

TH16

TH15

TH12

TH11

CN32

7531

CN33

CN34

33

CN05CN07

CN11

CN10

CN13

CN02

CN03

12321

1

2

3

4

8

7

6

5

4

3

2

1

1

2

CNP3

3

2

1

CNP1

3

2

1

LEV1LEV3

1

2

3

45

6

1

2

3

45

6

DC 30V

X35

X11

X12

X34

X9

X10

X33

X7

X8

X32

X5

X6

X31

X3

X4

X30

X1

X2

X14

X13

X36

X37

X15

X16

21

CNVCC1

3

X38

X39

X17

X19

X18

X20

X45

X42

X43

X40

X44

X41

CN40

CN41

CNOUT4

CNOUT2

4

1

2

3

4

5

6

7

8

3

2

1

X48

X51

X47

X46

X50

X49

CN43

CN42

CN44

CN45

X55

X56

X52

X53

X57

X54

3

CNVCC2

12

31

753175317531

1

3

5

7

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

CNOUT1

CNOUT3

CN12

53

1

31

CN39

CONT.board

RELAY10 board

F01

250VAC

6.3A F

PE

EARTH

T16

T15

T14

T13

T12

T11

T8T9

T7

T10

T1

T5

T4

T3

T2

T6

3

2

1

3

2

1

Terminal

T1

~

16

Solenoid valve

SVM1, 2

PS1, 3

SV1

~

16A

SV1

~

16B

SV1

~

16C

Fuse AC250V 6.3A FF01

Symbol

Name

Pressure sensor

Terminal block

(for power source)

Solenoid valve

Solenoid valve

Solenoid valve

Terminal block

(for Transmission)

TB01

TB02

<

Symbol explanation

>

Transformer

Thermistor sensor

Expansion valve

TR

LEV1, 3

TH11, 12, 15, 16

Note1: Never connect the power line to the terminal

block for transmission (TB02)

–23–

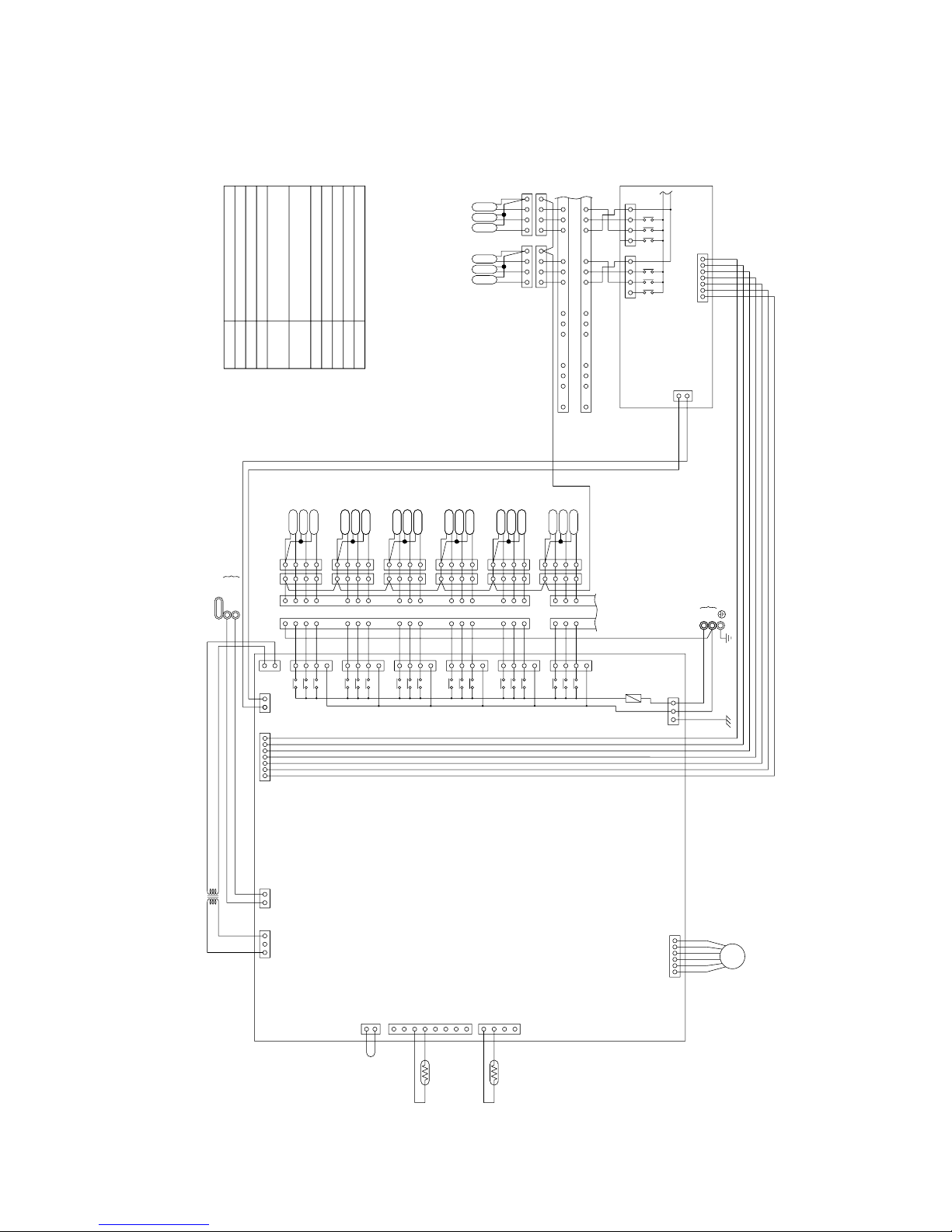

CMB-P108V-FB

131415

9

101112

5

6

78

4

4

5

6

87

9

12 11 10

15 14 13

16

16

1

2

3

4

2

3

4

1

2

3

4

1

2

3

4

SV7B

SV8B

SV7A

SV8A

SV7C

SV8C

1

SV1B

SV1A

SV1C

1

5

6

7

8

9

10

11

12

13

14

15

16

3

2

4

8

9

10

11

12

13

3

2

4

1

5

6

7

14

15

16

4

3

2

1

SV2C

SV2A

SV2B

SV3C

SV3A

SV3B

SV4C

SV4A

SV4B

SV5B

SV5A

SV5C

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

SV6B

SV6A

SV6C

1

2

3

4

1

2

3

4

33

2

1

2

1

Power source

L

N

~220V~240V 50/60Hz

Transmission line

Shield wire

CONT.board

CN38

1

3

1

CNTR

CN50

7654321

CN02

CN12

1

53

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

3

TR

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

DC 30V

6

54

3

2

1

LEV3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN03

CN13

CN10

CN11

CN07

TH12

TH15

22V

TB02

M2

M1

CN26

CN27

CN28

CN29

CN30

CN31

TB01

220~240V

7654321

TB01

RELAY4 Board

CN32

CN33

CN39

3

1

X14

X13

X36

X37

X15

X16

CN52

75317513

F01

250VAC

6.3A F

T8

T7

T1

T5

T4

T3

T2

T6

PE

EARTH

F01

Fuse AC250V 6.3A F

Terminal

T1

~

8

TB02

TB01

Terminal block

(for Transmission)

Solenoid valve

Solenoid valve

Solenoid valve

Terminal block

(for power source)

Expansion valve

Thermistor sensor

Transformer

Name

Symbol

SV1

~

8A

SV1

~

8B

SV1

~

8C

TR

TH12, 15

LEV3

Note1: Never connect the power line to the

terminal block for transmission (TB02)

<

Symbol explanation

>

–24–

[4] Standard Operation Data

1 Cooling operation

100 100 100 50 50 125 125 125 100 25

10 10 10 10 10 10 10 10 10 10

Hi Hi Hi Hi Hi Hi Hi Hi Hi Hi

360 360 360 340 340 410 410 410 360 280

Discharge (TH11/TH12)

Heat exchanger outlet (TH5)

Inlet

Accumulator

Outlet

Suction (Comp) (No.1/No.2)

Low pressure saturation

temperature (TH2)

Upper (TH4)

Liquid level

Lower (TH3)

Shell bottom (Comp No.1/No.2)

CS circuit (TH9)

Circulating refrigerant

configuration (αOC)

LEV inlet

Heat exchanger outlet

DB/WB

Set

-

m

-

kg

A

V

Pulse

Outdoor

unit

Indoor

unit

Outdoor unit

Items

Ambient temp.

Indoor unit

Piping

Condition

Indoor

Outdoor

No. of units

No. of units in operation

Model

Main pipe

Branch pipe

Total piping length

Outdoor unit

Sectional temperature

Pressure

LEV opening

Indoor unit fan notch

Refrigerant volume

Total electrical current

Voltage

Indoor unit

BC controller (1, 3)

Oil return (SLEV)

380/400/415 380/400/415

P400 P500

High pressure/Low pressure

(after O/S) (before MA)

MPa

°C

92/102 97/102

42

45

67

6/12 12/12

1

30

1

60/51 65/50

16

0.23

26

12

2.11/0.43 2.11/0.42

2.01/2.01 2.01/2.01

BC

controller

High/Intermediate

27.0/19 27.0/19

35.0/24.0 35.0/24.0

55

55

55

55 55

27.1 29.2

26.7/25.4/24.5 33.5/31.9/30.7

2000 300 2000 350

200 344

–25–

Sectional temperature

2 Heating operation

Discharge (TH11/TH12)

Heat exchanger inlet (TH5)

Inlet

Accumulator

Outlet

Suction (Comp) (No.1/No.2)

Low pressure saturation

temperature (TH2)

Upper (TH4)

Liquid level

Lower (TH3)

Shell bottom (Comp No.1/No.2)

CS circuit (TH9)

Circulating refrigerant

configuration (αOC)

LEV inlet

Heat exchanger outlet

100 100 100 50 50 125 125 125 100 25

10 10 10 10 10 10 10 10 10 10

Hi Hi Hi Hi Hi Hi Hi Hi Hi Hi

600 600 600 450 450 650 650 650 600 350

DB/WB

Set

-

m

-

kg

A

V

Pulse

Outdoor unit

Items

Ambient temp.

Indoor unit

Piping

Condition

Indoor

Outdoor

No. of units

No. of units in operation

Model

Main pipe

Branch pipe

Total piping length

Outdoor

unit

Indoor

unit

Outdoor unit

Pressure

LEV opening

Indoor unit fan notch

Refrigerant volume

Total electrical current

Voltage

Indoor unit

BC controller (1, 3)

Oil return (SLEV)

380/400/415 380/400/415

P400 P500

2.01/1.72 2.01/1.72

MPa

°C

High pressure/Low pressure

(after O/S) (before MA)

88/93 88/93

– 3 – 1

– 6 – 7

– 6 – 7

– 5/2 – 5/0

– 10

30

– 6

43/45 40/33

5

0.28

81

34

2.11/0.35 2.11/0.31

BC

controller

High/Intermediate

20.0/- 20.0/-

7.0/6.0 7.0/6.0

55

55

55

55 55

27.1 29.2

24.6/23.4/22.5 30.8/29.2/28.2

60 1400 60 1600

122

–26–

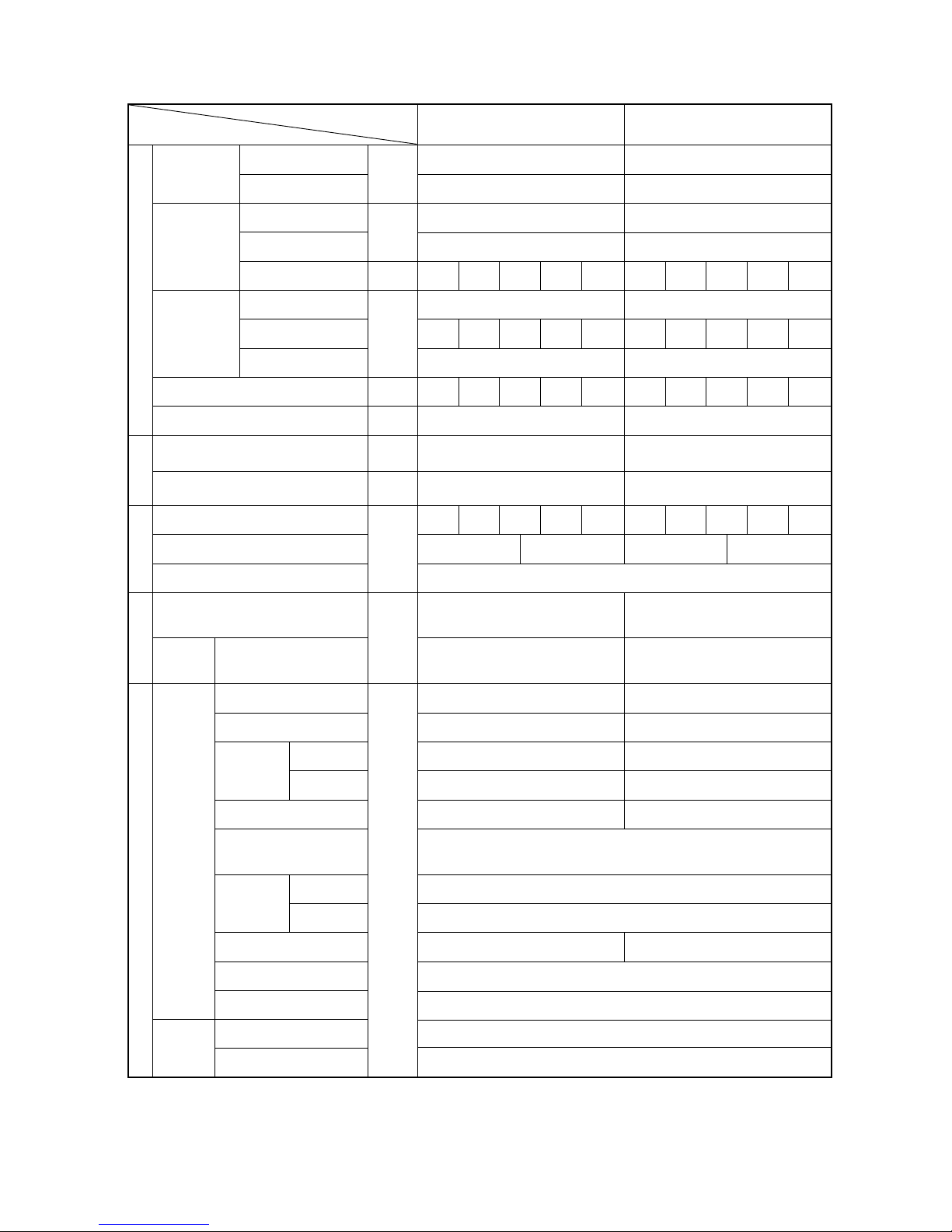

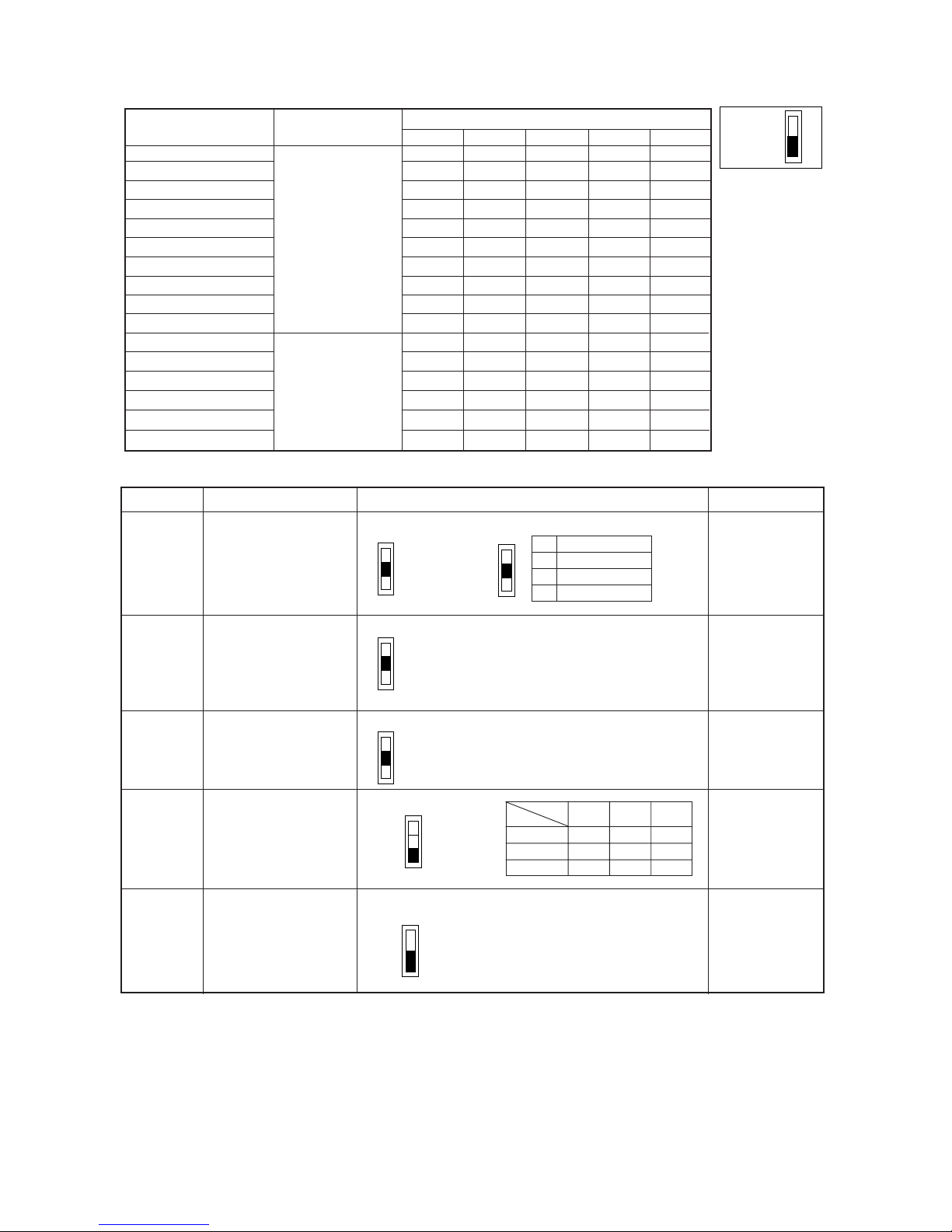

Function According to Switch Operation Switch Set Timing

When Off When On When Off When On

SWU 1 ~ 2

SW1

1 ~ 8

Refer to LED monitor display on the outdoor board.

9 ~ 10

SW2

1

2

3

4

5

6

7

8

9

10

SW3

1

2

3

4

5

6

7

8

9

10

SW4

1

2

3

4

5

6

7

8

9

10

Centralized control not

connected.

Storing of refrigeration

system connection

information.

Store IC•OC error history.

Ordinary control

-

Ordinary control

-

-

SW3-2 Function Invalid

Stop all indoor units.

– 8°C

7°C

Ordinary control

Ordinary control

Ordinary control

-

-

Model 400

SW4-2 Function invalid

-

-

-

-

-

-

-

-

[5] Function of Dip SW and Rotary SW

(1) Outdoor unit

1 Variable capacity unit

MAIN board

Centralized control

connected.

Deletion of refrigeration

system connection

information.

Erase IC·OC error history.

• Refrigerant volume

adjustment operation.

• Ignore liquid level errors

-

Start forced defrosting.

-

-

SW3-2 Function Valid

Test run all indoor units

test run ON.

– 10°C

12°C

2deg lower than normal

Pump Down Operation

High pressure / 1.5 ~ 2.5 K

higher than normal

-

-

Model 500

SW4-2 Function valid

-

-

-

-

-

-

-

-

Changes as shown below by on → off change

0 %→3 %→6 %→9 %→12 %→ – 6 %→ – 3 %→0 %

Unit Address Setting

For self-diagnosis/

operation monitoring

Centralized Control

Switch

Deletion of connection

information.

Deletion of error history.

• Adjustment of Refrigerant Volume

• Ignore liquid level errors

-

-

Forced defrosting

-

-

SW3-2 Function Valid/

Invalid

Indoor Unit Test Operation

Defrosting starting

temperature.

Defrosting ending

temperature.

Target low-pressure

change

Pump Down Function

Target high-pressure

change

-

-

Models

SW4-2 Function valid/

Invalid

Configuration compensation value

-

-

-

-

-

-

-

-

Switch Function

During normal

operation with

power on

Invalid 2 hours

after compressor

starts.

Before power is turned on.

-

Before power is turned on.

Before power is turned on.

During normal operation with

power on

-

-

-

-

During normal operation with

power on.

When SW3-1 is ON after power is

turned on.

During normal operation with

power on.

During normal operation with

power on. (Except during defrosting)

During normal operation with

power on.

While the compressor is stopped.

During normal operation with

power on.

-

When switching on the power.

When switching on the power.

When SW4-1 is ON

-

-

-

-

-

-

-

-

During normal

operation with

power on.

10 minutes or

more after

compressor

starts.

Set on 51 ~ 100 with the rotary switch.*2

Note 1: Factory setting is SWU 1 to 2 = 00, SW3 - 10 = set by model. All other switches are set to OFF.

Note 2: If the address is set from 01 to 50, it automatically becomes 100.

–27–

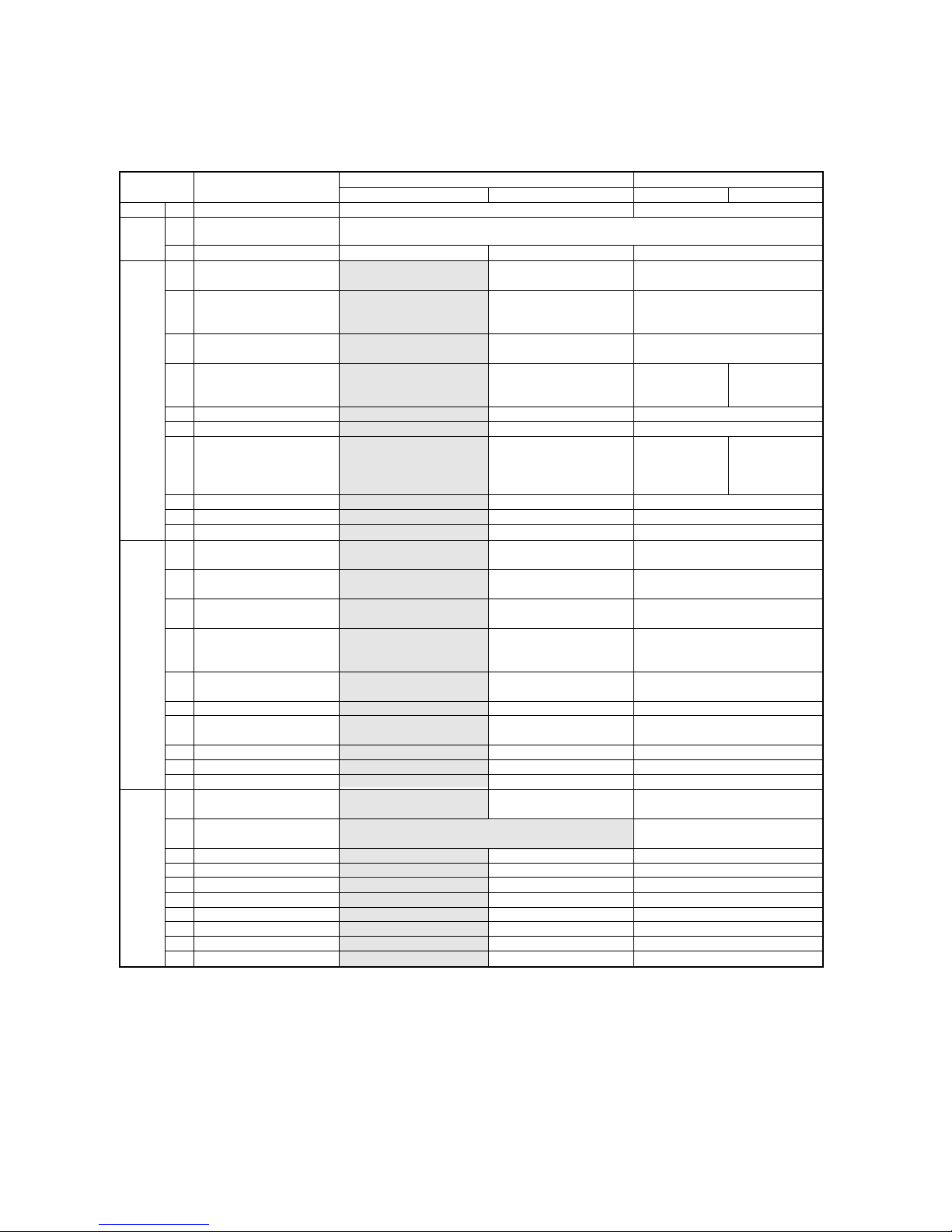

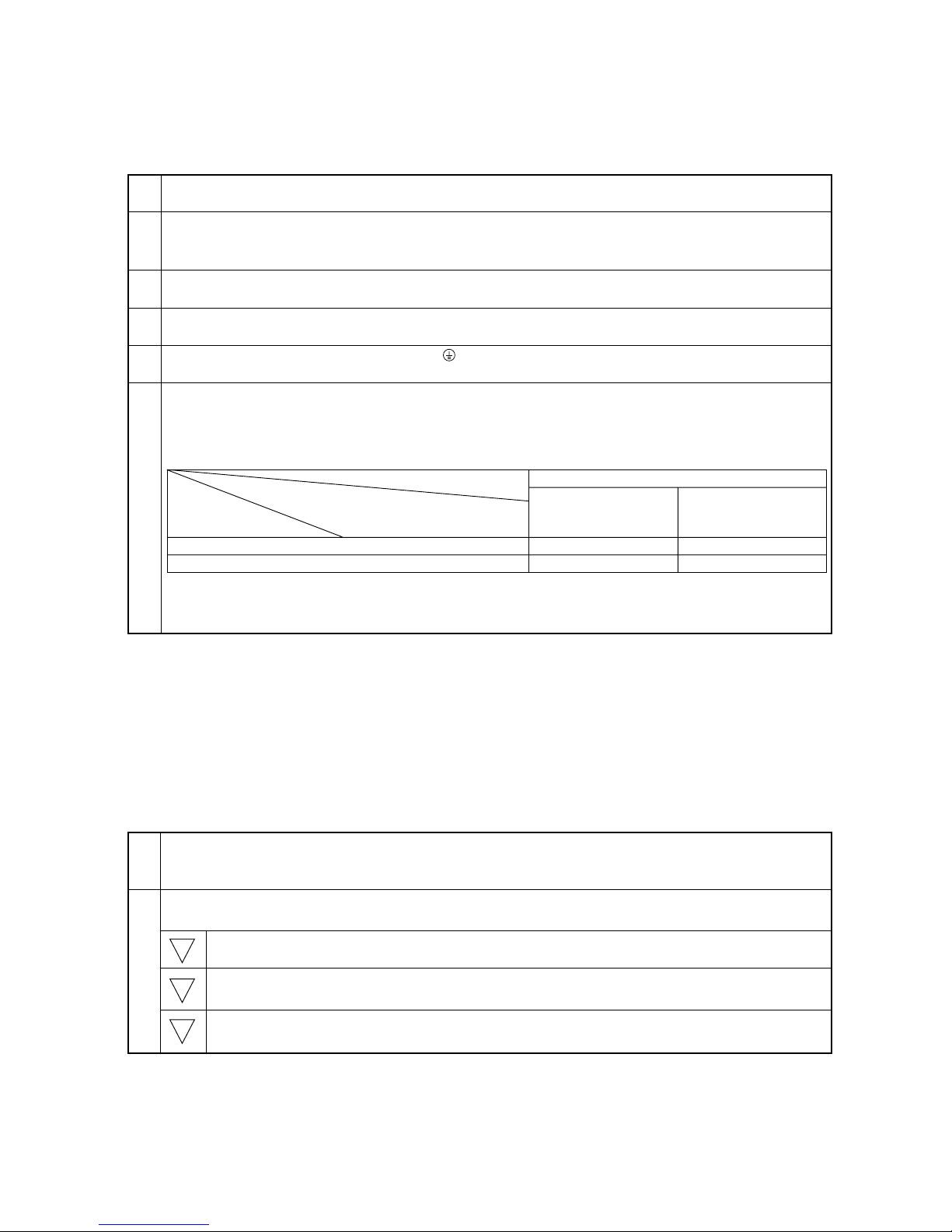

(2) Indoor unit

DIP SW1, 3

Model P71 P80 P100 P125 P140 P200 P250

Capacity (model name) code

14 16 20 25 28 40 50

SW2 setting

Model P20 P25 P32 P40 P50 P63

Capacity (model name) code

45 681013

SW2 setting

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Note 1: The shaded part indicates the setting at factory shipment. (For the SW not being shaded, refer to the

2: When both SW1-7 and SW1-8 are set to ON, the fan stops at the heating thermostat of OFF.

table belo

Note 3: Changes to SW1, 2, 3, and 4 are only registered/effective when the remote controller is off.

Resetting of the power sourse is not required.

w.)

Setting of DIP SW2

Indoor unit inlet

None

100h

Ineffective

Fan output display

At stationary heating

Very low speed

SW1-7 setting

Ineffective

Ineffective

Heat pump

None

None

None

1st setting

Down blow B, C

Effective

–

Effective

–

–

Built in remote controller

Provided

2500h

Effective

Thermo. ON signal display

Always in heating mode

Low speed

Set airflow

Effective

Effective

Cool.only

Provided

Provided

Provided

2nd setting

Horizontal

–

Ineffective

Ineffective

–

–

Room temp. sensor position

Clogged filter detect.

Filter duration

OA intake

Remote display select.

Humidifier control

Heating thermo. OFF airflow

Heating thermo. OFF airflow

Power failure automatic

return

Power source start/stop

Model selection

Louver

Vane

Vane swing function

Vane horizontal angle

V

Vane first angle

ane angle set for cooling

–

Heating 4deg up

–

–

Alw

PLFY-VLMD-B only

ays ineffective for PKFY-P.VAM

Not provided for PKFY-P.VAM

Provided for PLFY-P.VGM (ON) setting

Always down blow B,C for PKFY-P.VAM

Horizontal (ON) setting for PLFY-P. VLMD-A

Ineffective (ON) setting for floor

standing

SW1

SW3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Switch SW name

Operation by SW

Switch set timing

OFF ON OFF ON

Remarks

At unit stopping

(at remote

controller OFF)

Cooling capacity saving

for PKFY-P. VAM,

effective/ineffective

Model

Switch

SW1

SW3

3

6

7

3

4

6

8

PLFY-P

VAM-A(2)

OFF

OFF

VLMD-B

VKM-A

OFF

ON

ON

ON

OFFONON

ON

PEFY-P

VML-A VMH-A

20~80VMM-A

100~140VMM-A

OFF

OFF ON

OFF ON

ON

ON

OFF

OFF

OFF

OFF

ON OFF

ON OFF ON

ON

ON

ON

OFF

PDFY-P

PFFY-P

PCFY-P

PKFY-P

VM-A

ON

VLRM-A, VLEM-A

OFF

VGM-A

PMFY-P

VBM-A

ON

VAM-A VGM-A

OFF OFF

OFF

OFF

OFF

OFF

OFF

–28–

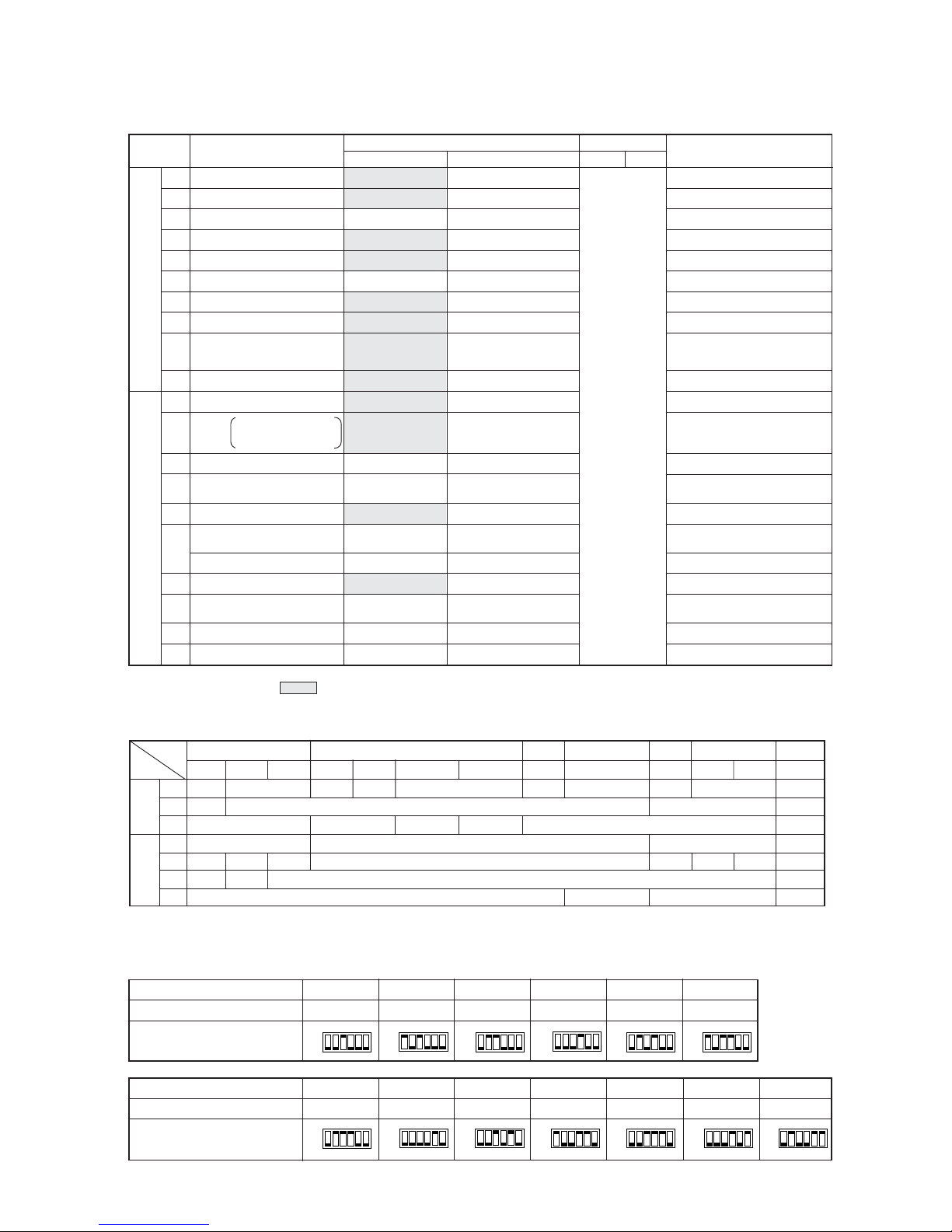

Ceiling height

3 3.5 m

2 2.8 m

1 2.3 m

Switch Function Operation by switch Switch set timing

SWA

SWA

SWA

SWB

SWC

Ceiling height setting

External static

pressure setting

For options

Setting of air outlet opening

Airflow control

(PLFY-P-VKM-A) (PCFY-P-VGM-A)

(PLFY-P125VLMD -B)

(PLFY-P-VKM-A)

(PLFY-P-VKM-A, PCFY-P-VGM-A, PKFY-P-VGM-A, PDFY-P-VM-A)

❇

The ceiling

height setting

is changed by

SWB setting.

❇

As this switch is used by interlocking with SWC,

refer to the item of SWC for detail.

SWA

SWB

123

2-way 3.5 m 3.8 m 3.8 m

3-way 3.0 m 3.3 m 3.5 m

4-way 2.7 m 3.0 m 3.5 m

❇

Set to the option to install the high-efficiency

filter

After powering

After powering

After powering

After powering

After powering

3

1

2

2-way

4-way

3-way

3

1

2

3

1

2

3

1

2

Option

Standard

(PDFY-P20 ~ 80VM-A, PEFY-P20 ~ 80VMM-A)

100Pa

50Pa

30Pa

❇

For other models, change the setting of static pressure by replacing the connector.

Setting of DIP SW4 Setting of DIP SW5

1234 5

ON OFF ON OFF

ON OFF ON OFF

OFF

OFF

OFF OFF ON

ON OFF OFF

OFF

ON

ON

OFF ON OFF ON

OFF

OFF

OFF ON ON

ON

–

–

–

–

–

–

––

–

–––

–

–

–

–

–

–

ON ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF OFF OFF

–

ON ON ON

–

OFF OFF OFF

–

ON OFF OFF

–

OFF OFF ON

–

ON ON ON OFF

PMFY-P-VBM-A

PLFY-P125VLMD-B

PDFY-P20 ~ 80VM-A

PLFY-P40 ~ 63VKM-A

PLFY-P80 ~ 125VAM-A(2)

PCFY-P-VGM-A

PKFY-P-VGM-A

PKFY-P-VAM-A

PEFY

PLFY-P20~100VLMD-B

-P20 ~ 80VMM-A

PFFY-P-VLEM-A, P-VLRM-A

PEFY-P20 ~ 32VML-A

PEFY-P40 ~ 140VMH-A

PEHY-P200·250VMH-A

PDFY-P100·125VM-A

PEFY-P100 ~ 140VMM-A

Model Circuit board used

SW4

Phase control

Relay selection

220V

240V

–29–

33

33

3 TEST RUN

[1] Before Test Run

(1) Check points before test run

1 Neither refrigerant leak nor loose power source/ transmission lines should be found.

2 Confirm that the resistance between the power source terminal block and the ground exceeds 2MΩ by measuring

it with a DC 500 V megger. Do not run if it is lower than 2MΩ.

Note: Never apply a megger to the main board as it will damage the main board.

3 Confirm that the ball valves on gas, liquid, and oil balance sides are fully open.

Note: Be sure to close the cap.

4 Be sure that the crankcase heater has been powered by turning the main power source on at least 12 hours

before starting the test run. The shorter powering time causes compressor trouble.

5 If any of the power supply wires (L1, L2, L3, N, .) are incorrectly connected, it is possible to damage the unit.

Please exercise caution.

6 A transmission booster (RP) is required when the number of connected indoor unit models in a cooling system

exceeds the number of models specified in the chart below.

Note: The maximum number of units that can be controlled is determined by the model of the indoor unit, the

type of remote controller, and their capabilities.

The number of indoor units and the total number of remote controllers is displayed in the parenthesis.

(*1) If even one unit that is higher than 200 exists in the cooling system, the maximum capacity will be “200 or

higher”.

* Please refer to the installation manual for more details.

* Before turning the power of the outdoor unit on, first turn on the transmission booster. (If the outdoor unit are mistakenly

turned on first, turn on the transmission booster, and then reset the outdoor unit power.)

(2) Caution at inverter check

Because the inverter power portion of the electrical part box in the outdoor unit have many parts with high voltage, be

sure to follow the instructions shown below to avoid the risk of electric shock.

During energizing power source, never touch inverter power portion because high voltage (approx. 580 V) is

applied to inverter power portion.

At the time of checking

Shut off the main power, and check the inverter with a tester.

Wait for 10 minutes after shutting off the main power source.

Open the main board mounting panel, and check whether the voltage at both ends of electrolytic

capacitor is 20V or less (if over wait until it is less than 20V)

200 or lower

200 or higher

Remote controller PAR-F 25MA

Prior to Ver. E After Ver. F

16 (32) 20 (40)

16 (32) 16 (32)

(*1)

Capability of the

connected indoor units

Remote controller type

Number of connected indoor units that

can be connected without a RP.

1

2

1

2

3

Loading...

Loading...