Page 1

Air-Conditioners

INDOOR UNIT

PEFY-P15,P20,P25,P32,P40,P50,P63 VMS1-E

PEFY-P15,P20,P25,P32,P40,P50,P63 VMS1L-E

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

GB

D

F

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELK‹TABI

Emniyetli ve do¤ru biçimde nas›l kullan›laca¤›n› ö¤renmek için lütfen klima cihaz›n› monte etmeden önce bu elkitab›n› dikkatle okuyunuz.

E

I

NL

P

GR

RU

TR

CZ

SV

HG

PO

SL

Page 2

3

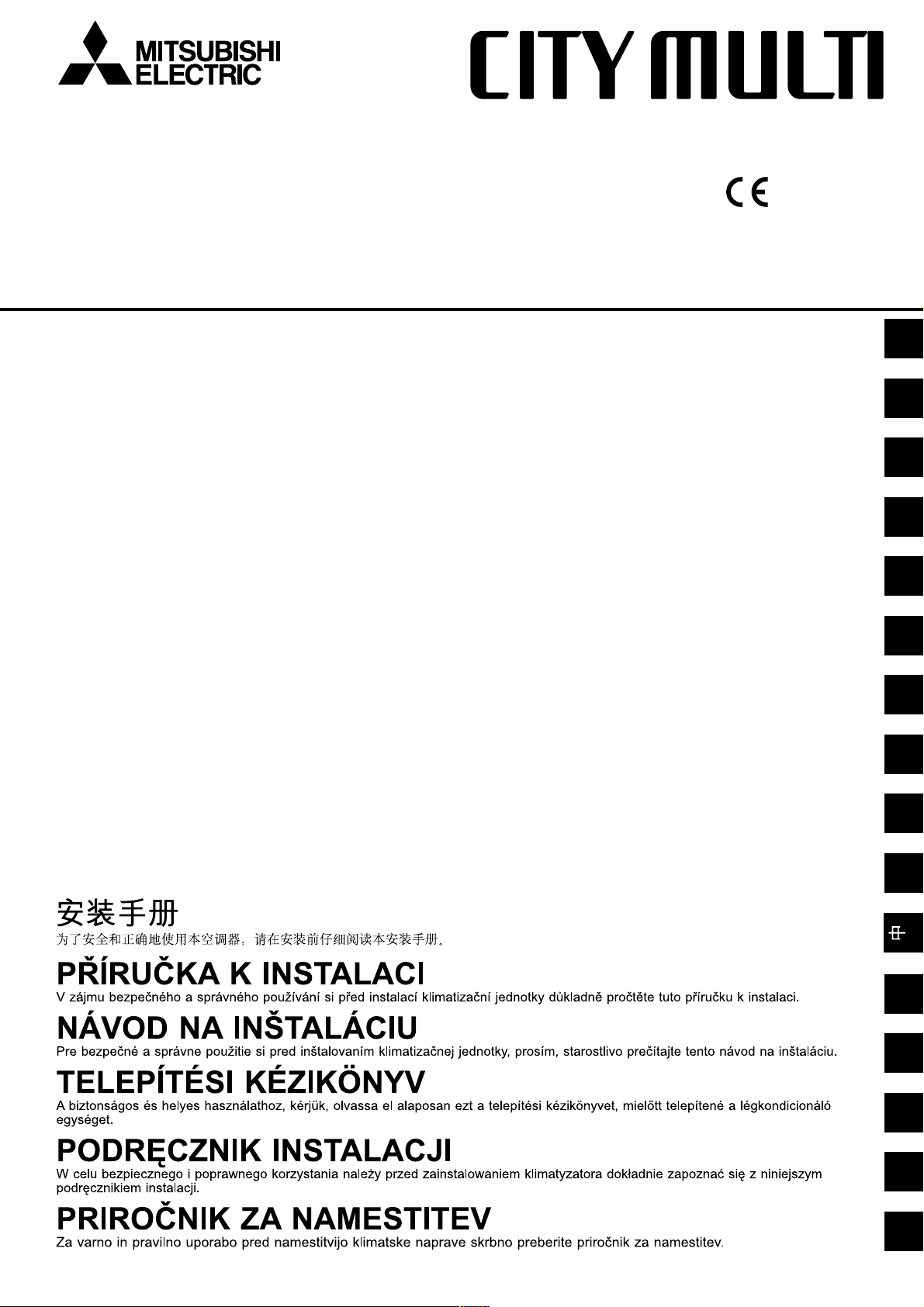

3.2

[Fig. 3.2.1]

D

C

50~150 450

23

90

B

100

20

A

450

1

C

4

625

49

2

B

A

D

B

3

200

F

E

A

E

A Access door

B Electrical parts box

C Air inlet

D Air outlet

E Ceiling surface

F Service space (viewed from the side)

G Service space (viewed from the direction of arrow)

1 600 mm or more

2 100 mm or more

3 10 mm or more

4 300 mm or more

(mm)

G

777

PEFY-P15,20,25,32VMS1(L)-E

Model

PEFY-P40,50VMS1(L)-E

PEFY-P63VMS1(L)-E

A

700

900

1100

B

752

952

1152

C

798

998

1198

D

660

860

1060

E

800

1000

1200

4

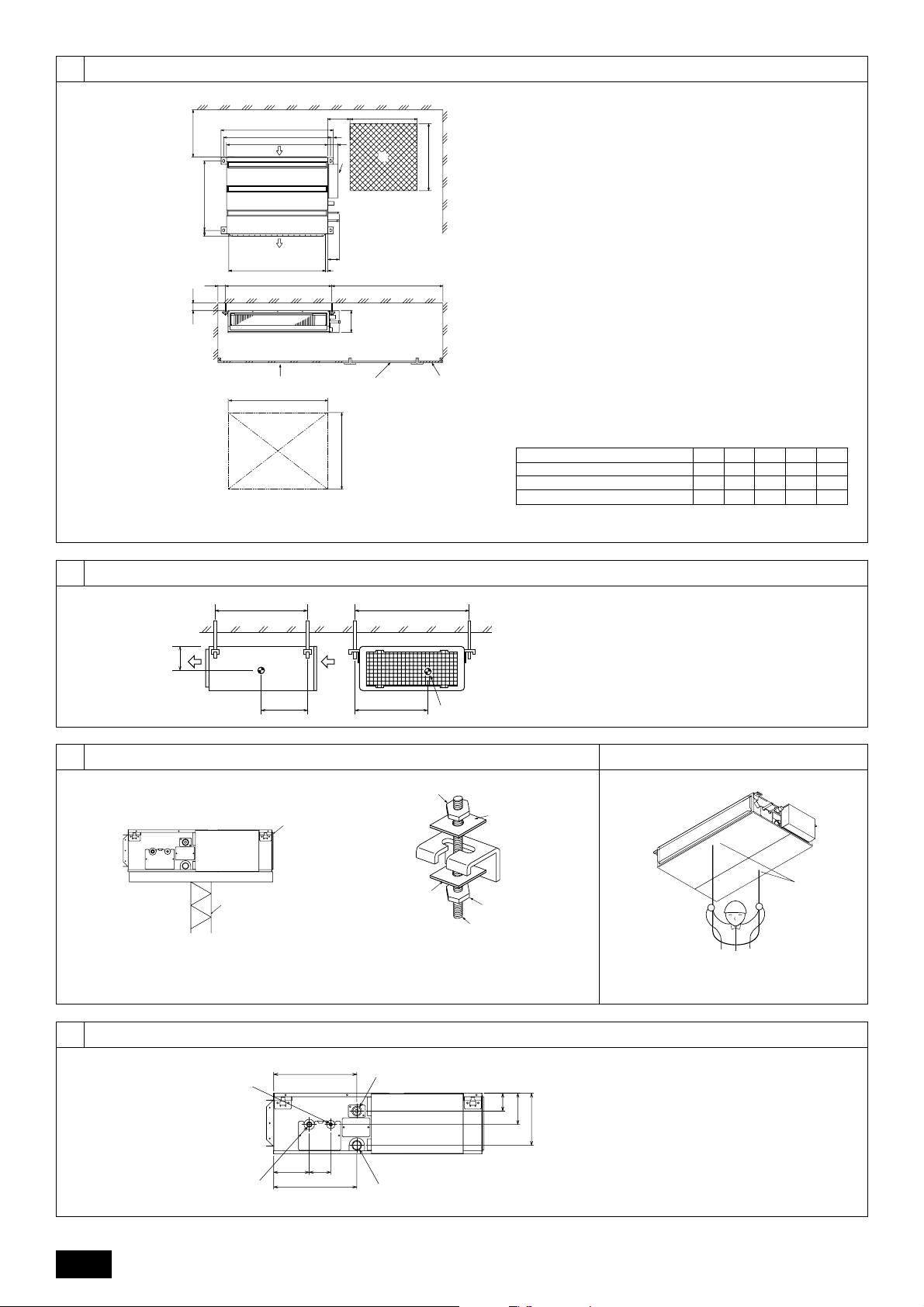

[Fig. 4.1.1]

Z

YX

5

[Fig. 5.1.1] [Fig. 5.1.2] [Fig. 5.2.1]

B

5.1

A

4.1

LW

A

C

D

D

C

A Center of gravity

E

C Nuts (field supply)

A Unit body

B Lifting machine

D Washers (accessory)

E M10 hanging bolt (field supply)

5.2

A

A Indoor unit’s bottom surface

6

[Fig. 6.2.1]

2

6.2

270

A

116 70

B

270

C

48

102

170

A Refrigerant pipe (liquid pipe): HP

D

B Refrigerant pipe (gas pipe): LP

C Drain pipe (O.D. ø32) * only on the PEFY-P·VMS1-E model

D Drain pipe (O.D. ø32, spontaneous draining)

Page 3

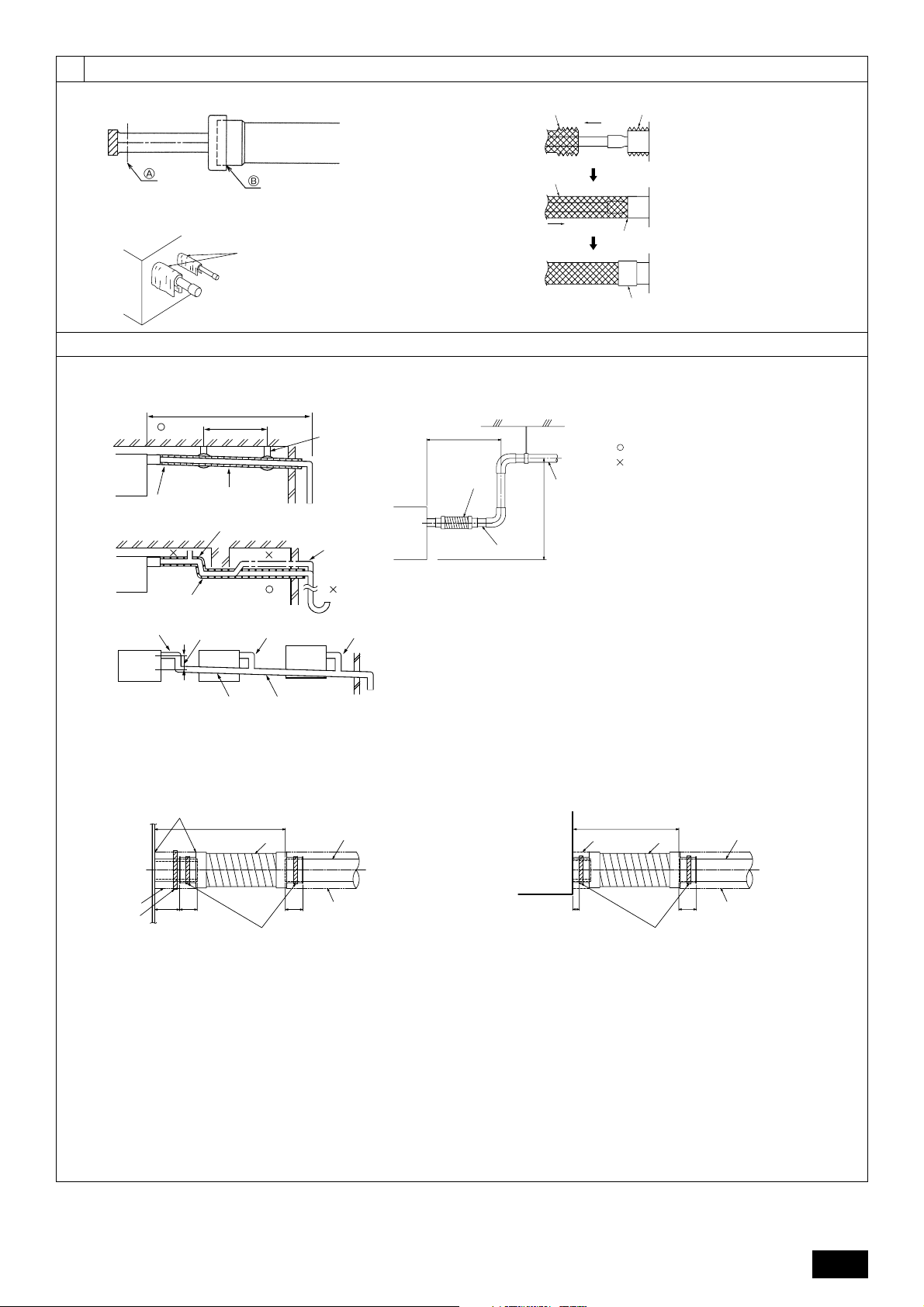

7

A

7.1

[Fig. 7.1.1]

[Fig. 7.1.2]

[Fig. 7.2.1]

[Fig. 7.1.3]

A

B

C

A

A Cut here

B Remove brazed cap

A Cool by a wet cloth

D

E

F

A Thermal insulation

B Pull out insulation

C Wrap with damp cloth

D Return to original position

E Ensure that there is no gap here

F Wrap with insulating tape

7.2

Max. 20m

1.5-2m

C

A

B

K

L

B

D

E

F

FF

D

H

I

M

D

G

Max. 300mm

N

B

J

F

O

Correct piping

Wrong piping

A Insulation (9 mm or more)

B Downward slope (1/100 or more)

C Support metal

K Air bleeder

L Raised

M Odor trap

Grouped piping

D O. D. ø32 PVC TUBE

E Make it as large as possible. About 10 cm.

F Indoor unit

G Make the piping size large for grouped piping.

H Downward slope (1/100 or more)

I O. D. ø38 PVC TUBE for grouped piping.

(9 mm or more insulation)

PEFY-P·VMS1-E model

J Up to 550 mm

N Drain hose (accessory)

O Horizontal or slightly upgradient

[Fig. 7.2.2]

K

J

F

G

A

B

C

2535 25

DE E

H

I

A Indoor unit

B Insulation pipe (long) (accessory)

C Tie band (accessory)

D Visible part

E Insertion margin

F Drain hose (accessory)

G Drain pipe (O.D. ø32 PVC TUBE, field supply)

H Insulating material (field supply)

I Tie band (accessory)

J Max.180 ± 5 mm

K To be gap free. The joint section of the insulation material meet must be

at the top.

[Fig. 7.2.3]

I

A

B

525

D

A Indoor unit

B Insulation pipe (short) (accessory)

C Tie band (accessory)

D Band fixing part

E Insertion margin

F Drain hose (accessory)

G Drain pipe (O.D. ø32 PVC TUBE, field supply)

H Insulating material (field supply)

I Max.145 ± 5 mm

F

E

G

H

C

3

Page 4

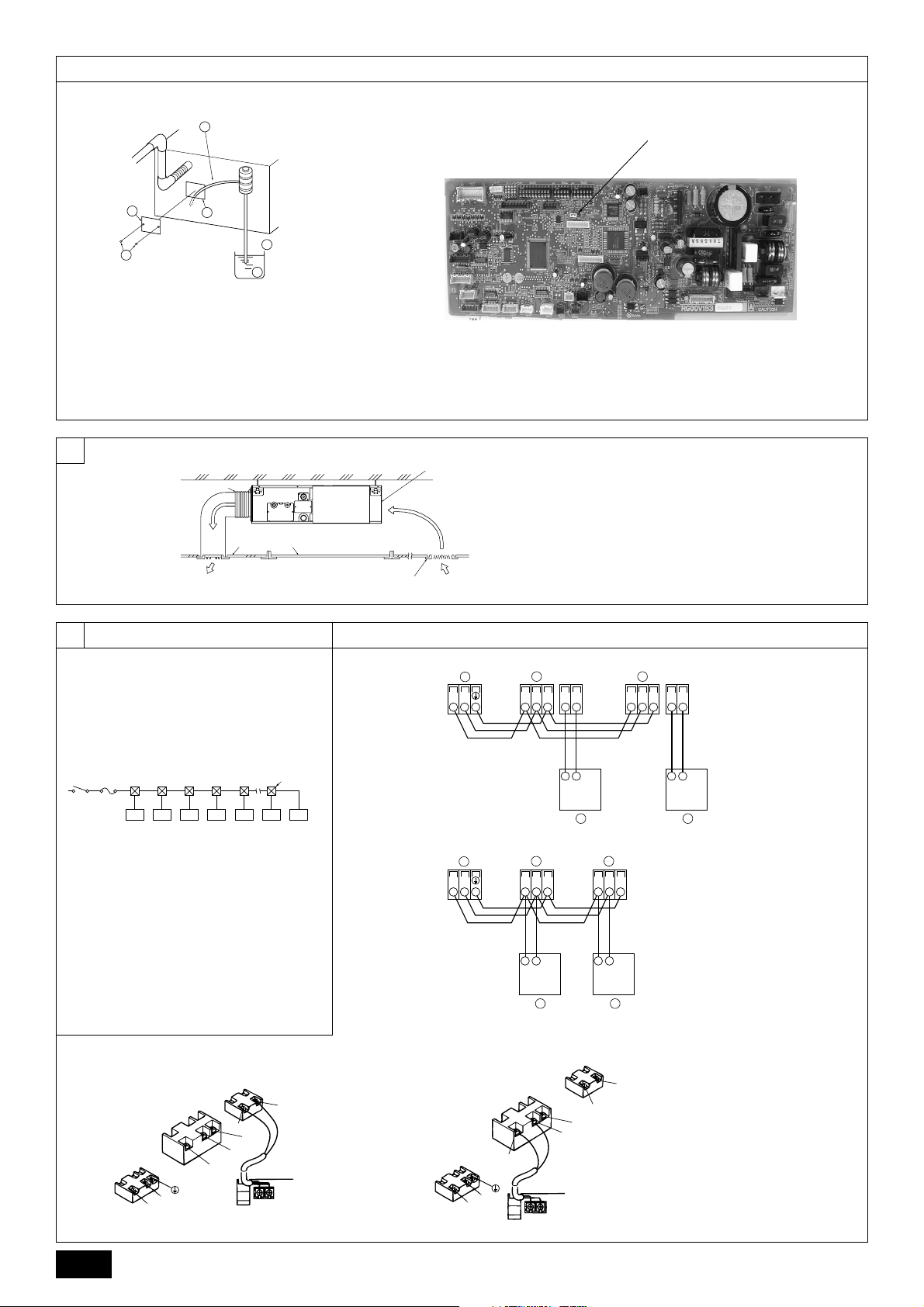

[Fig. 7.3.1]

7.3

[Fig. 7.3.2]

8

[Fig. 8.0.1]

A

B

F

A Insert pump's end 2 to 4 cm.

B Remove the water supply port.

C About 2000 cc

D Wate r

E Filling port

F Screw

E

E

DC

BA

SWE

C

D

<Indoor board>

F

A Air inlet

B Air outlet

C Access door

D Ceiling surface

E Canvas duct

F Air filter

G Inlet grille

G

9

9.1

[Fig. 9.1.1] [Fig. 9.2.1]

AB

DE

CCCCCCC

[Fig. 9.2.2]

A Switch 16 A

B Overcurrent protection 16 A

C Indoor unit

D Total operating current be less than 16 A

E Pull box

[Fig. 9.2.3] [Fig. 9.2.4]

B

D

M2

M1

N

L

1

S

2

A

DC10~13V

C

AB

12

9.2

B

M1M2 21 21

TB3

B

M1M2

TB3

N

L

SM1M2 SM1M2

TB5 TB15 TB5 TB15

AA

SM1M2 SM1M2

TB5 TB5

CC

B

D

M2

M1

DC24~30V

12

(A, B)

A

C

2

1

S

AA

CC

A Terminal block for indoor

transmission cable

B Terminal block for outdoor

transmission cable

C Remote controller

A Non-polarized

B TB15

C Remote Controller

D TB5

4

Page 5

9.3

A

B

C

[Fig. 9.3.1] [Fig. 9.3.2]

A

B

B Cover

[Fig. 9.3.3] [Fig. 9.3.4]

E

H

F

G

I

E Use PG bushing to keep the weight of the cable and external force from being

applied to the power supply terminal connector. Use a cable tie to secure the

cable.

F Power source wiring

G Tensile force

H Use ordinary bushing

I Transmission wiring

[Fig. 9.3.5]

M2 SM1

A

A Terminal bed box

B Knockout hole

C RemoveA Screw holding cover (2pcs)

J

N

L

P

M1

M2

N

N

M

L

M1 M2 S

K

L

12

O

J Power source terminal bed

K Terminal bed for indoor transmission

L Terminal bed for remote controller

M To 1-phase power source

N Transmission line DC 30 V

O Terminal bed for outdoor transmission line (TB3)

P Transmission line to the remote controller, terminal bed for indoor unit and

BC controller

[Fig. 9.5.1]

B

D

E

C

A Terminal bed

B Round terminal

C Shield wire

D The earth wire from two cables are connected together to the S terminal. (Dead-end connection)

E Insulation tape (To keep the earth wire of the shielded cable from coming in contact with the transmis-

sion terminal)

9.5

A

C

A SWA

B SWC

2

1

FD BE

<Address board>

C SW1

D SW11

E SW12

F SW14

5

Page 6

Contents

1. Safety precautions ...................................................................................... 6

1.1. Before installation and electric work .......................................... 6

1.2. Precautions for devices that use R410A

or R407C refrigerant .................................................................. 6

1.3. Before getting installed .............................................................. 7

1.4. Before getting installed (moved) - electrical work ...................... 7

1.5. Before starting the test run ........................................................ 7

2. Indoor unit accessories ............................................................................... 7

3. Selecting an installation site ....................................................................... 7

3.1. Install the indoor unit on a ceiling strong enough to sustain

its weight ................................................................................... 8

3.2. Securing installation and service space .................................... 8

3.3. Combining indoor units with outdoor units ................................ 8

4. Fixing hanging bolts .................................................................................... 8

5. Installing the unit ......................................................................................... 8

GBDFEINLPGRRUTR

4.1 Fixing hanging bolts .................................................................. 8

5.1. Hanging the unit body ............................................................... 8

5.2. Confirming the unit’s position and fixing hanging bolts ............. 8

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This symbol is

displayed on the main unit label.) <Color: Yellow>

: Beware of electric shock (This symbol is displayed on the main unit label.)

<Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for typhoons and other strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an air cleaner, humidifier, electric heater, and other accessories specified by Mitsubishi Electric.

CZSVHGPO

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• When handling this product, always wear protective equipment.

EG: Gloves, full arm protection namely boiler suit, and safety glasses.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

6

6. Refrigerant pipe and drain pipe specifications ............................................ 8

6.1. Refrigerant pipe and drain pipe specifications .......................... 9

6.2. Refrigerant pipe, drain pipe ....................................................... 9

7. Connecting refrigerant pipes and drain pipes ............................................. 9

7.1. Refrigerant piping work ............................................................. 9

7.2. Drain piping work ....................................................................... 9

7.3. Confirming drain discharge ..................................................... 10

8. Duct work .................................................................................................. 10

9. Electrical wiring ......................................................................................... 10

9.1. Power supply wiring................................................................. 11

9.2. Connecting remote controller, indoor and outdoor

transmission cables ................................................................. 11

9.3. Connecting electrical connections ........................................... 11

9.4. External I/O specifications ....................................................... 12

9.5. Selecting the external static pressure ..................................... 12

9.6. Setting addresses .................................................................... 12

9.7. Sensing room temperature with the built-in sensor in

a remote controller .................................................................. 12

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Keep the electric parts away from water (washing water etc.).

- It might result in electric shock, catching fire or smoke.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge the it with a refrigerant different from the refrigerant specified on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or par ts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• Do not use a leak detection additive.

1.2. Precautions for devices that use R410A

or R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large

amount of chlorine which may cause the refrigerator oil of the new unit to

deteriorate.

• Use refrigerant piping made of C1220 (Cu-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor trouble may result.

Page 7

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator

oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refriger-

ant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A or R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may

cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve,

refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R410A or

R407C, the refrigerant may deteriorated.

- If water is mixed in the R410A or R407C, the refrigerator oil may deteriorate.

- Since R410A or R407C does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deterio-

rate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage work

together with the outdoor unit, as required.

• The indoor models should be installed the ceiling over than 2.5 m from

floor.

1.4. Before getting installed (moved) - elec-

trical work

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carr y the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Star ting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot

and may be cold, depending on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

GBDFEINLPGRRUTRCZSVHGPO

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

2. Indoor unit accessories

The unit is provided with the following accessories:

Part No. Accessories Qty

1 Insulation pipe (long) 1

2 Insulation pipe (short) 1

3 Tie band 3

4 Drain hose 1

5 Washer 8

3. Selecting an installation site

• Select a site with sturdy fixed surface sufficiently durable against the weight of

unit.

• Before installing unit, the routing to carry in unit to the installation site should

be determined.

• Select a site where the unit is not affected by entering air.

• Select a site where the flow of supply and return air is not blocked.

Part No. Accessories Qty

6 Short pipe (ø12.7-ø15.88) : Model P50 only. 1

7 Short pipe (ø6.35-ø9.52) : Model P50 only. 1

8 Installation manual 1

9 Operation manual 1

• Select a site where refrigerant piping can easily be led to the outside.

• Select a site which allows the supply air to be distributed fully in room.

• Do not install unit at a site with oil splashing or steam in much quantity.

• Do not install unit at a site where combustible gas may generate, flow in, stagnate or leak.

• Do not install unit at a site where equipment generating high frequency waves

(a high frequency wave welder for example) is provided.

7

Page 8

• Do not install unit at a site where fire detector is located at the supply air side.

(Fire detector may operate erroneously due to the heated air supplied during

heating operation.)

• When special chemical product may scatter around such as site chemical plants

and hospitals, full investigation is required before installing unit. (The plastic

components may be damaged depending on the chemical product applied.)

• If the unit is run for long hours when the air above the ceiling is at high temperature/high humidity (due point above 26 °C), due condensation may be

produced in the indoor unit. When operating the units in this condition, add

insulation material (10-20 mm) to the entire surface of the indoor unit to avoid

due condensation.

3.1. Install the indoor unit on a ceiling strong

enough to sustain its weight

Warning:

The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down causing

injuries.

GBDFEINLPGRRUTR

4. Fixing hanging bolts

3.2. Securing installation and service space

• Select the optimum direction of supply airflow according to the configuration of

the room and the installation position.

• As the piping and wiring are connected at the bottom and side surfaces, and

the maintenance is made at the same surfaces, allow a proper space properly.

For the efficient suspension work and safety, provide a space as much as

possible.

[Fig. 3.2.1] (P.2)

A Access door B Electrical parts box

C Air inlet D Air outlet

E Ceiling surface F Service space (viewed from the side)

G Service space (viewed from the direction of arrow)

1 600 mm or more 2 100 mm or more

3 10 mm or more 4 300 mm or more

3.3. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit installation

manual.

4.1 Fixing hanging bolts

[Fig. 4.1.1] (P.2)

A Center of gravity

(Give site of suspension strong structure.)

Hanging structure

• Ceiling: The ceiling structure varies from building to one another. For detailed

information, consult your construction company.

Center of gravity and Product Weight

Model name

PEFY-P15VMS1(L)-E

PEFY-P20VMS1(L)-E

PEFY-P25VMS1(L)-E

PEFY-P32VMS1(L)-E

PEFY-P40VMS1(L)-E

PEFY-P50VMS1(L)-E

PEFY-P63VMS1(L)-E

W

625

625

625

625

625

625

625

L

752

752

752

752

952

952

1152

5. Installing the unit

5.1. Hanging the unit body

ss

s Bring the indoor unit to an installation site as it is packed.

ss

ss

s To hang the indoor unit, use a lifting machine to lift and pass through the

ss

hanging bolts.

[Fig. 5.1.1] (P.2)

A Unit body

B Lifting machine

[Fig. 5.1.2] (P.2)

C Nuts (field supply)

D Washers (accessory)

E M10 hanging bolt (field supply)

• If necessary, reinforce the hanging bolts with anti-quake supporting members

as countermeasures against earthquakes.

* Use M10 for hanging bolts and anti-quake supporting members (field supply).

X

263

263

263

275

280

280

285

Y

338

338

338

340

422

422

511

Z

105

105

105

104

104

104

104

Product Weight (kg)

19

19

19

20

24

24

28

5.2. Confirming the unit’s position and fixing hanging bolts

ss

s Use the gage supplied with the panel to confirm that the unit body and

ss

hanging bolts are positioned in place. If they are not positioned in place,

it may result in dew drops due to wind leak. Be sure to check the positional

relationship.

ss

s Use a level to check that the surface indicated by

ss

that the hanging bolt nuts are tightened to fix the hanging bolts.

ss

s To ensure that drain is discharged, be sure to hang the unit at level using

ss

a level.

[Fig. 5.2.1] (P.2)

A Indoor unit’s bottom surface

Caution:

Install the unit in horizontal position. If the side with drain port is installed

higher, water leakage may be caused.

AA

A is at level. Ensure

AA

6. Refrigerant pipe and drain pipe specifications

CZSVHGPO

To avoid dew drops, provide sufficient antisweating and insulating work to the refrigerant and drain pipes.

When using commercially available refrigerant pipes, be sure to wind commercially available insulating material (with a heat-resisting temperature of more than

100 °C and thickness given below) onto both liquid and gas pipes.

Insulate all indoor pipes with form polyethylene insulation with a minimum density

of 0.03 and a thickness as specified in the table below.

8

1 Select the thickness of insulating material by pipe size.

Pipe size Insulating material’s thickness

6.4 mm to 25.4 mm More than 10 mm

28.6 mm to 38.1 mm More than 15 mm

2 If the unit is used on the highest story of a building and under conditions of

high temperature and humidity, it is necessary to use pipe size and insulating

material’s thickness more than those given in the table above.

3 If there are customer’s specifications, simply follow them.

Page 9

6.1. Refrigerant pipe and drain pipe specifications

Model R410A R407C or R22

Item 15·20·25·32·40·50 63 15·20·25·32·40 50·63*

Refrigerant pipe

(Brazing connection)

Drain pipe O.D. ø 32 O.D. ø 32

* When the Models P50 are used with R22 or R407C, use the supplied short pipes.

Liquid pipe ø 6.35 ø 9.52 ø 6.35 ø 9.52

Gas pipe ø 12.7 ø 15.88 ø 12.7 ø 15.88

6.2. Refrigerant pipe, drain pipe

[Fig. 6.2.1] (P.2)

A Refrigerant pipe (liquid pipe): HP

B Refrigerant pipe (gas pipe): LP

C Drain pipe (O.D. ø32) * only on the PEFY-P·VMS1-E model

D Drain pipe (O.D. ø32, spontaneous draining)

7. Connecting refrigerant pipes and drain pipes

7.1. Refrigerant piping work

This piping work must be done in accordance with the installation manuals for both

outdoor unit and BC controller (simultaneous cooling and heating series R2).

• Series R2 is designed to operate in a system that the refrigerant pipe from an

outdoor unit is received by BC controller and branches at the BC controller to

connect between indoor units.

• For constraints on pipe length and allowable difference of elevation, refer to

the outdoor unit manual.

• The method of pipe connection is brazing connection.

Caution:

• Install the refrigerant piping for the indoor unit in accordance with the

following.

1. Cut the tip of the indoor unit piping, remove the gas, and then remove the

brazed cap.

[Fig. 7.1.1] (P.3)

A Cut here

B Remove brazed cap

2. Pull out the thermal insulation on the site refrigerant piping, braze the unit

piping, and replace the insulation in its original position.

Wrap the piping with insulating tape.

Note:

• When blazing the refrigerant pipes, be sure to blaze, after covering a wet

cloth to the pipes of the units in order to prevent it from burning and

shrinking by heat.

[Fig. 7.1.2] (P.3)

A Cool by a wet cloth

• Pay strict attention when wrapping the copper piping since wrapping the

piping may cause condensation instead of preventing it.

[Fig. 7.1.3] (P.3)

A Thermal insulation B Pull out insulation

C Wrap with damp cloth D Return to original position

E Ensure that there is no gap here F Wrap with insulating tape

Cautions On Refrigerant Piping

ss

s Be sure to use non-oxidative brazing for brazing to ensure that no for-

ss

eign matter or moisture enter into the pipe.

ss

s Be sure to apply refrigerating machine oil over the flare connection seat-

ss

ing surface and tighten the connection using a double spanner.

ss

s Provide a metal brace to support the refrigerant pipe so that no load is

ss

imparted to the indoor unit end pipe. This metal brace should be provided 50 cm away from the indoor unit’s flare connection.

Warning:

When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to mal-

function and result in severe damage.

Caution:

• Use refrigerant piping made of C1220 (Cu-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil

in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing.

- If dust, dir t, or water gets into the refrigerant cycle, the oil will deteriorate and

the compressor may fail.

• Use Suniso 4GS or 3GS (small amount) refrigerator oil to coat the flare

and flange connection part. (For models using R22)

•

Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil

to coat flares and flange connections. (For models using R410A or R407C)

- The refrigerant used in the unit is highly hygroscopic and mixes with water

and will degrade the refrigerator oil.

7.2. Drain piping work

• Ensure that the drain piping is downward (pitch of more than 1/100) to the

outdoor (discharge) side. Do not provide any trap or irregularity on the way.

• Ensure that any cross-wise drain piping is less than 20 m (excluding the difference of elevation). If the drain piping is long, provide metal braces to prevent it

from waving. Never provide any air vent pipe. Otherwise drain may be ejected.

• Use a hard vinyl chloride pipe O.D. ø32 for drain piping.

• Ensure that collected pipes are 10 cm lower than the unit body’s drain port.

• Do not provide any odor trap at the drain discharge port.

• Put the end of the drain piping in a position where no odor is generated.

Do not put the end of the drain piping in any drain where ionic gases are generated.

•

[Fig. 7.2.1] (P.3)

Correct piping

Wrong piping

A Insulation (9 mm or more)

B Downward slope (1/100 or more)

C Support metal

K Air bleeder

L Raised

M Odor trap

Grouped piping

D O. D. ø32 PVC TUBE

E Make it as large as possible. About 10 cm.

F Indoor unit

G Make the piping size large for grouped piping.

H Downward slope (1/100 or more)

I O. D. ø38 PVC TUBE for grouped piping. (9 mm or more insulation)

PEFY-P·VMS1-E model

J Up to 550 mm

N Drain hose (accessory)

O Horizontal or slightly upgradient

[PEFY-P·VMS1-E model]

1. Insert the drain hose (accessory) into the drain port (insertion margin: 25mm).

(The drain hose must not be bent more than 45° to prevent the hose from

breaking or clogging.)

(Attach the hose with glue for the hard vinyl chloride pipe, and fix it with the

band (small, accessory).)

2. Attach the drain pipe (O.D. ø32 PVC TUBE, field supply).

(Attach the pipe with glue for the hard vinyl chloride pipe, and fix it with the

band (small, accessory).)

3. Perform insulation work on the drain pipe (O.D. ø32 PVC TUBE) and on the

socket (including elbow).

4. Check the drainage. (Refer to [Fig. 7.3.1])

5. Attach the insulating material (accessory), and fix it with the band (large, accessory) to insulate the drain port.

GBDFEINLPGRRUTRCZSVHGPO

9

Page 10

[Fig. 7.2.2] (P.3) * only on the PEFY-P·VMS1-E model

A Indoor unit

B Insulation pipe (long) (accessory)

C Tie band (accessory)

D Visible part

E Insertion margin

F Drain hose (accessory)

G Drain pipe (O.D. ø32 PVC TUBE, field supply)

H Insulating material (field supply)

I Tie band (accessory)

J Max.180 ± 5 mm

To be gap free. The joint section of the insulation material meet must be at the top.

K

[PEFY-P·VMS1L-E model]

1. Insert the drain hose (accessory) into the drain port.

(The drain hose must not be bent more than 45° to prevent the hose from

breaking or clogging.)

The connecting part between the indoor unit and the drain hose may be disconnected at the maintenance. Fix the part with the accessory band, not be

adhered.

GBDFEINLPGRRUTR

2. Attach the drain pipe (O.D. ø32 PVC TUBE, field supply).

(Attach the pipe with glue for the hard vinyl chloride pipe, and fix it with the

band (small, accessory).)

3. Perform insulation work on the drain pipe (O.D. ø32 PVC TUBE) and on the

socket (including elbow).

[Fig. 7.2.3] (P.3) * only on the PEFY-P·VMS1L-E model

A Indoor unit

B Insulation pipe (short) (accessory)

C Tie band (accessory)

D Band fixing part

E Insertion margin

F Drain hose (accessory)

G Drain pipe (O.D. ø32 PVC TUBE, field supply)

H Insulating material (field supply)

I Max.145 ± 5 mm

7.3. Confirming drain discharge

ss

s Make sure that the drain-up mechanism operates normally for discharge

ss

and that there is no water leakage from the connections.

• Be sure to confirm the above in a period of heating operation.

• Be sure to confirm the above before ceiling work is done in the case of a new

construction.

1. Remove the water supply port cover on the same side as the indoor unit piping.

2. Fill water into the feed water pump using a feed water tank. In filling, be sure to

put the end of the pump or tank in a drain pan. (If the insertion is incomplete,

water may flow over the machine.)

3. Perform the test run in cooling mode, or turn on the switch SWE on the controller circuit board. (The drain pump and the fan are forced to operate without any

remote controller operation.) Make sure using a transparent hose that drain is

discharged.

4. After confirmation, cancel the test run mode, and turn off the main power.

the switch SWE has been turned on, turn it off, and attach the water supply

port cover into its original position.

[Fig. 7.3.1] (P.4)

[Fig. 7.3.2] (P.4)

SWE SWE

OFF ON OFF ON

When

SWE SWE

OFF ON OFF ON

A Insert pump's end 2 to 4 cm.

B Remove the water supply port.

C About 2000 cc

D Wate r

E Filling port

F Screw

<Indoor board>

8. Duct work

• When connecting ducts, insert a canvas duct between the main body and the

duct.

• Use non-combustible duct components.

• Install sufficient thermal insulation to prevent condensation forming on outlet

duct flanges and outlet ducts.

Caution:

• Keep the distance between the inlet grille and the fan over 850 mm.

If it is less than 850 mm, install a safety guard not to touch the fan.

9. Electrical wiring

Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers in accordance with “Engineering Standards For Electrical Installation” and supplied

installation manuals. Special circuits should also be used. If the power circuit lacks capacity or has an installation failure, it may cause a risk of electric shock or fire.

1. Be sure to install an earth leakage breaker to the power.

2. Install the unit to prevent that any of the control circuit cables (remote controller, transmission cables) is brought in direct contact with the power cable outside the unit.

3. Ensure that there is no slack on all wire connections.

4. Some cables (power, remote controller, transmission cables) above the ceiling

CZSVHGPO

may be bitten by mouses. Use as many metal pipes as possible to insert the

cables into them for protection.

5. Never connect the power cable to leads for the transmission cables. Otherwise

the cables would be broken.

[Fig. 8.0.1] (P.4)

A Air inlet B Air outlet

C Access door D Ceiling surface

E Canvas duct F Air filter

G Inlet grille

6. Be sure to connect control cables to the indoor unit, remote controller, and the

outdoor unit.

7. Put the unit to the ground on the outdoor unit side.

8. Select control cables from the conditions given in page

11

.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do not connect the earth cable to any gas pipe, water pipe, lightening rod, or telephone

earth cable. Incomplete grounding may cause a risk of electric shock.

Types of control cables

1. Wiring transmission cables

• Types of transmission cables

Design wiring in accordance with the following table <Table 1>.

• Cable diameter

More than 1.25 mm

2

10

Page 11

<Table 1>

System configuration For a single-refrigerant system For a multi-refrigerant system

Transmission cable length Less than 120 m More than 120 m Regardless of length

Building, clinic, hospital or communications

station without noise supposedly generated

Facility example

(for noise judgment)

Residence or independent store

without noise

from inverter equipment, private power generator, high-frequency medical equipment,

All facilities

radio-used communications equipment and

so on

Types of transmission

cables

VCTF, VCTFK, CVV, CVS, VVR,

VVF, VCT or shielding wire

CVVS or CPEVS

Shielding wire CVVS or CPEVS

Length Less than 120 m Less than 200 m

2. Remote controller cables

Types of cables

Cable diameter

Length

MA remote controller

Sheathed 2-core cable (unshielded) CVV

0.3 to 1.25 mm

2

Less than 200 m

Sheathed 2-core cable (unshielded) CVV

0.3 to 1.25 mm

Add any portion in excess of 10 m to within the longest allowable transmission cable length 200 m (Shielding portion is more than 1.25 mm

M-NET remote controller

2

2

)

GBDFEINLPGRRUTRCZSVHGPO

9.1. Power supply wiring

• Power supply cords of appliances shall not be lighter than design 245 IEC 57

or 227 IEC 57.

• A switch with at least 3 mm contact separation in each pole shall be provided

by the Air conditioner installation.

Power cable size: more than 1.5 mm

2

[Fig. 9.1.1] (P.4)

A Switch 16 A B Overcurrent protection 16 A

C Indoor unit

D Total operating current be less than 16 A

E Pull box

[Selecting non-fuse breaker (NF) or earth leakage breaker (NV)]

To select NF or NV instead of a combination of Class B fuse with switch, use the

following:

• In the case of Class B fuse rated 15 A or 20 A,

NF model name (MITSUBISHI): NF30-CS (15 A) (20 A)

NV model name (MITSUBISHI): NV30-CA (15 A) (20 A)

Use an earth leakage breaker with a sensitivity of less than 30 mA 0.1 s.

Caution:

Do not use anything other than the correct capacity breaker and fuse. Using

fuse, wire or copper wire with too large capacity may cause a risk of malfunction or fire.

9.2. Connecting remote controller, indoor

and outdoor transmission cables

• Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-wire)

The “S” on indoor unit TB5 is a shielding wire connection. For specifications

about the connecting cables, refer to the outdoor unit installation manual.

• Install a remote controller following the manual supplied with the remote controller.

• Connect the “1” and “2” on indoor unit TB15 to a MA remote controller. (Nonpolarized 2-wire)

• Connect the “M1” and “M2” on indoor unit TB5 to a M-NET remote controller.

(Non-polarized 2-wire)

• Connect the remote controller’s transmission cable within 10 m using a 0.75 mm

core cable. If the distance is more than 10 m, use a 1.25 mm2 junction cable.

[Fig. 9.2.1] (P.4) MA Remote controller

[Fig. 9.2.2] (P.4) M-NET Remote controller

A Terminal block for indoor transmission cable

B Terminal block for outdoor transmission cable

C Remote controller

• DC 9 to 13 V between 1 and 2 (MA remote controller)

• DC 24 to 30 V between M1 and M2 (M-NET remote controller)

[Fig. 9.2.3] (P.4) MA Remote controller

[Fig. 9.2.4] (P.4) M-NET Remote controller

A Non-polarized B TB15

C Remote Controller D TB5

• The MA remote controller and the M-NET remote controller cannot be used at

the same time or interchangeably.

Caution:

Install wiring so that it is not tight and under tension. Wiring under tension

may break, or overheat and burn.

9.3. Connecting electrical connections

Please identify the model name of the operation manual attached on the terminal

bed box cover with that shown on the rating name plate.

1. Remove the screw (2pcs) holding the cover to dismount the cover.

[Fig. 9.3.1] (P.5)

A Screw holding cover (2pcs) B Cover

2. Open knockout holes

(Recommend to use a screwdriver or the like for this work.)

[Fig. 9.3.2] (P.5)

A Terminal bed box B Knockout hole

C Remove

3. Fix power source wiring to terminal bed box by using buffer bushing for tensile

force. (PG connection or the like.) Connect transmission wiring to transmission

terminal bed through the knockout hole of terminal bed box using ordinary

bushing.

[Fig. 9.3.3] (P.5)

E Use PG bushing to keep the weight of the cable and external force from being

applied to the power supply terminal connector. Use a cable tie to secure the

cable.

F Power source wiring G Tensile force

H Use ordinary bushing I Transmission wiring

4. Connect the power source, Earth, transmission and remote controller wiring.

The dismounting of the terminal bed box is not needed.

[Fig. 9.3.4] (P.5)

J Power source terminal bed K Terminal bed for indoor transmission

L Terminal bed for remote controller M To 1-phase power source

N Transmission line DC 30 V

O Terminal bed for outdoor transmission line (TB3)

P Transmission line to the remote controller, terminal bed for indoor unit and BC

controller

[Shield wire connection]

[Fig. 9.3.5] (P.5)

2

A Terminal bed B Round terminal

C Shield wire

D The earth wire from two cables are connected together to the S terminal. (Dead-

end connection)

E Insulation tape (To keep the earth wire of the shielded cable from coming in con-

tact with the transmission terminal)

5. After wiring is complete, make sure again that there is no slack on the connections, and attach the cover onto the terminal bed box in the reverse order of

removal.

Notes:

• Do not pinch the cables or wires when attaching the terminal bed box

cover. Doing so may cause a risk of disconnection.

• When accommodating the terminal bed box, make sure that the connectors on the box side are not removed. If removed, it cannot operate normally.

11

Page 12

9.4. External I/O specifications

Caution:

1. Wiring should be covered by insulation tube with supplementary insulation.

2. Use relays or switches with IEC or equivalent standard.

3. The electric strength between accessible parts and control circuit should

have 2750 V or more.

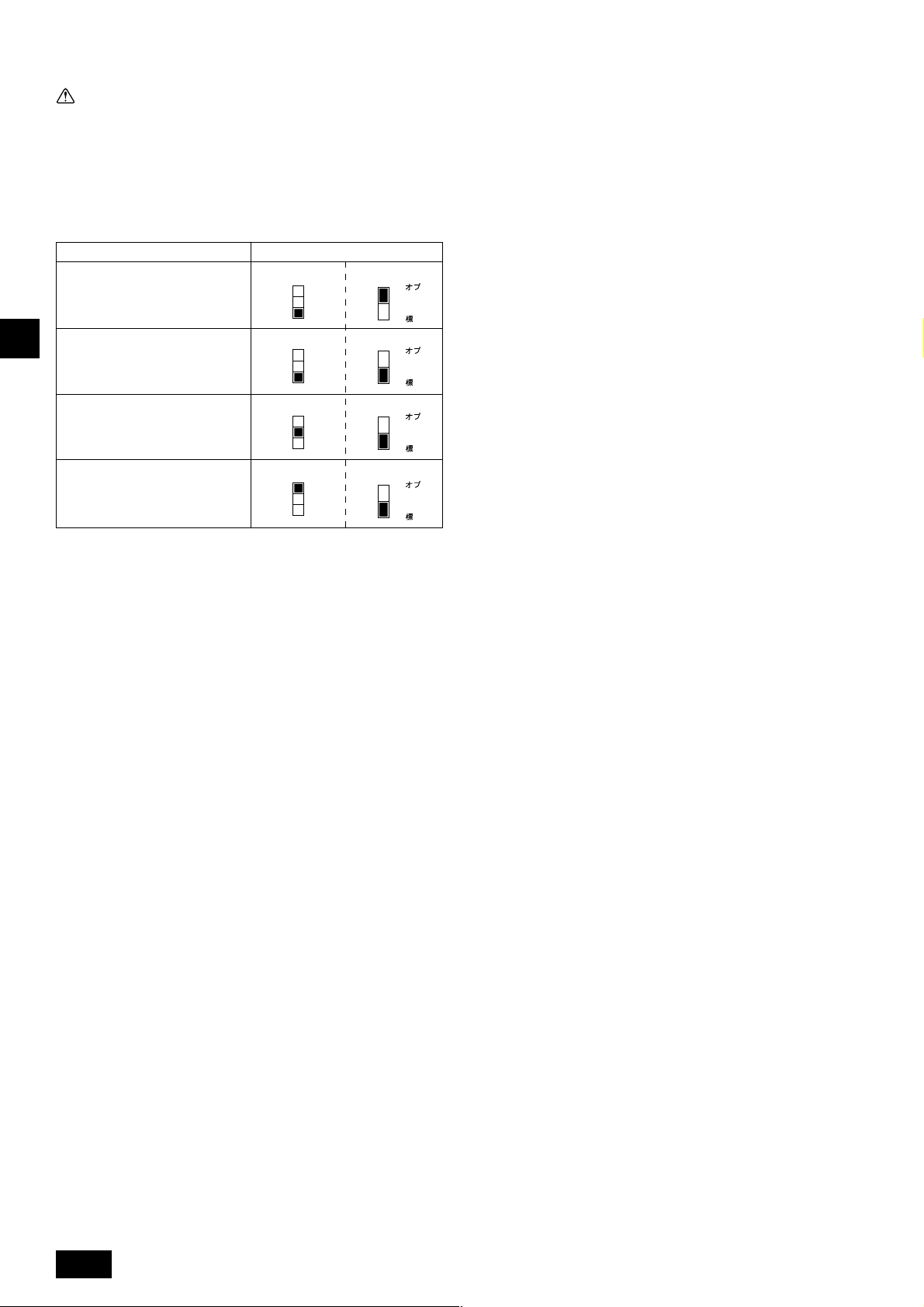

9.5. Selecting the external static pressure

As the factory setting is for use under an external static pressure of 15 Pa, no

switch operation is needed when using under the standard condition.

External static pressure Switch operation

SWC

SWC

SWC

SWC

GBDFEINLPGRRUTR

5 Pa

15 Pa

35 Pa

50 Pa

[Fig. 9.5.1] (P.5)

<Address board>

A SWA B SWC

C SW1 D SW11

E SW12 F SW14

SWA

3

2

1

SWA

3

2

1

SWA

3

2

1

SWA

3

2

1

2

1

2

1

2

1

2

1

9.6. Setting addresses

(Be sure to operate with the main power turned OFF.)

[Fig. 9.5.1] (P.5)

<Address board>

A SWA B SWC

C SW1 D SW11

E SW12 F SW14

• There are two types of rotary switch setting available: setting addresses 1 to 9

and over 10, and setting branch numbers.

1 How to set addresses

Example: If Address is “3”, remain SW12 (for over 10) at “0”, and match

SW11(for 1 to 9) with “3”.

2 How to set branch numbers SW14 (Series R2 only)

The branch number assigned to each indoor unit is the port number of the

BC controller to which the indoor unit is connected.

Leave it to “0” on the non-R2 series of units.

• The rotary switches are all set to “0” when shipped from the factory. These

switches can be used to set unit addresses and branch numbers at will.

• The determination of indoor unit addresses varies with the system at site. Set

them referring to the Data Book.

9.7. Sensing room temperature with the

built-in sensor in a remote controller

If you want to sense room temperature with the built-in sensor in a remote controller, set SW1-1 on the control board to “ON”. The setting of SW1-7 and SW1-8 as

necessary also makes it possible to adjust the air flow at a time when the heating

thermometer is OFF.

CZSVHGPO

Note:

• To perform the auto cooling/heating operation, use the built-in sensor in

a remote controller or the optional remote sensor.

12

Page 13

This product is designed and intended for use in the residential, commer-

cial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive 89/

336/EEC, 2004/108/EC

KB79H130H01

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Loading...

Loading...