Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

OUTDOOR UNIT

PUH-2.5VKA.TH PUH-2.5VKA

1.TH

PUH-3VKA.TH PUH-3VKA

1.TH

PUH-3YKA.TH PUH-3YKA

1.TH

TECHNICAL & SERVICE MANUAL

Outdoor unit

[model names] [Service Ref.]

August 2006

No.OC325

REVISED EDITION-A

PUH-1.6VKA

PUH-1.6VKA.TH

PUH-1.6VKA

PUH-2VKA

PUH-2.5VKA

PUH-2VKA.TH

PUH-2VKA

1

PUH-2.5VKA.TH

PUH-2.5VKA

PUH-3VKA

PUH-3YKA

PUH-4YKSA

PUH-5YKSA PUH-5YKSA

PUH-3VKA.TH

PUH-3VKA

1

PUH-3YKA.TH

PUH-3YKA

1

PUH-4YKSA.TH

PUH-5YKSA

PUH-6YKSA PUH-6YKSA

PUH-6YKSA

1

.TH

.TH

1

.TH

.TH

.TH

.

TH

1

.

TH

.

TH

1

.

TH

Revision:

• PUH-1.6/2/2.5/3VKA1.TH

and PUH-3YKA1.TH,

PUH-5/6YKSA1.TH are

added in REVISED

EDITION-A.

• RoHS PARTS LIST has

been added.

• Some descriptions have

been modified.

• Please void OC325.

Note:

• This manual does not cover indoor units.

• RoHS compliant products have <G> mark on the spec name

plate.

• For servicing of RoHS compliant products, refer to the RoHS

PARTS LIST.

Model name

indication

CONTENTS

1. TECHNICAL CHANGES ·································2

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

3. PART NAMES AND FUNCTIONS··················3

4. DATA ·······························································4

5. OUTLINES AND DIMENSIONS ······················5

6. WIRING DIAGRAM·········································9

7.

REFRIGERANT SYSTEM DIAGRAM

8. TROUBLE SHOOTING·································15

9. DISASSEMBLY PROCEDURE·····················24

10. PARTS LIST··················································26

11. RoHS PARTS LIST ·······································42

12. OPTIONAL PARTS ·······································54

··············14

···2

Page 2

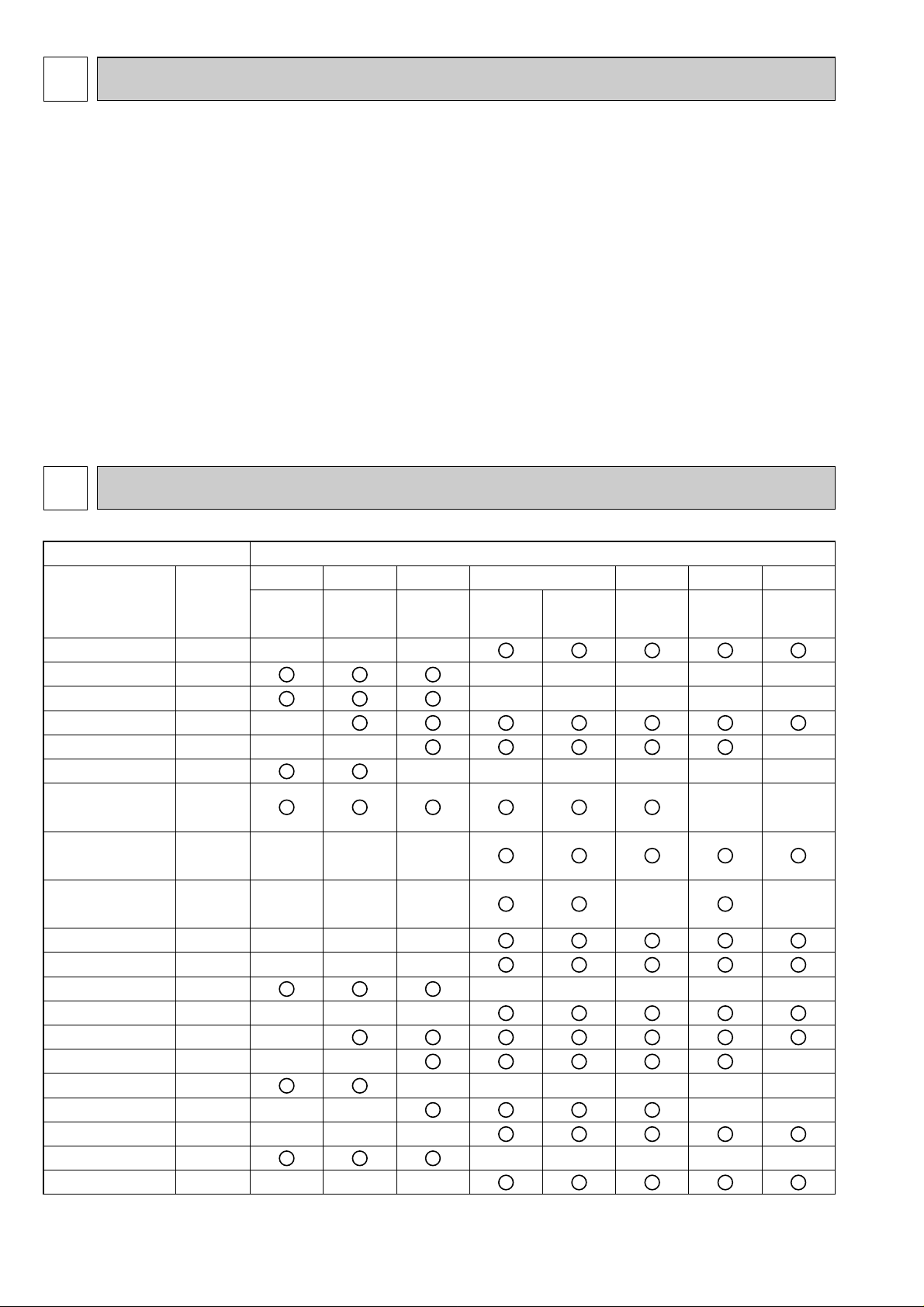

1 TECHNICAL CHANGES

Indoor unit Outdoor unit

Service

Manual No.

OC096

OC123

OC161

OC135

OC153

OC229

OC130

OC214

OC160

OC387

OC360

OC375

OC400

OC383

OC388

OC392

OC406

OC403

OC168

REVISED

EDITION-A

OC144

REVISED

EDITION-B

PUH-1.6 PUH-2 PUH-2.5 PUH-3 PUH-4 PUH-5 PUH-6

Service Ref.

PLH- • GKH(S)B

PLH- • KKHC

PLH- • KLHC

PCH- • GKH(S)A

1

PEH- • EKH(S)A2.TH

PKH- • GKL(H)

PKH- • FKHA

3

PKH- • FKH(S)A2

PSH- • GJ(H)(S)1

PSH- • GKH(S)

PLH- • AK(H)(S)

PLH- • GLH(S)B

PLH- • KAK(H)

PLH- • AAK(H)

PCH- • GAK(H)

PEH- • EAKH

PKH- • GAKL(H)

PKH- • FAK(H)

PSH- • GAK(H)

PLH- • KAK(H) .UK

PLH- • AAK(H) .UK

—

—

—

—

—

—

—

—

—

—

VKA.TH

—

—

—

—

—

—

—

—

—

—

—

—

—

VKA.TH

—

—

—

—

—

—

—

—

—

—

—

VKA.TH VKA.TH

—

—

—

—

—

—

—

—

—

—

—

—

YKA.TH

YKSA

.TH

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

YKSA

.TH

—

—

—

—

—

—

—

—

—

—

—

YKSA

.TH

VKA

1.THVKA1.TH VKA1.TH VKA1.TH YKA1.TH

YKSA

1.TH

YKSA1

.TH

PUH-1.6VKA.TH ➔ PUH-1.6VKA1.TH

PUH-2VKA.TH ➔ PUH-2VKA

1

.TH

PUH-2.5VKA.TH ➔ PUH-2.5VKA1.TH

PUH-3VKA.TH ➔ PUH-3VKA1.TH

PUH-3YKA.TH ➔ PUH-3YKA

• 4-WAY VALVE and COIL (21S4) have been changed.

1

.TH

PUH-5YKSA.TH ➔ PUH-5YKSA1.TH

PUH-6YKSA.TH ➔ PUH-6YKSA1.TH

• 4-WAY VALVE and COIL (21S4) have been changed.

• BYPASS VALVE and COIL (21R) have been changed.

2 COMBINATION OF INDOOR AND OUTDOOR UNITS

2

Page 3

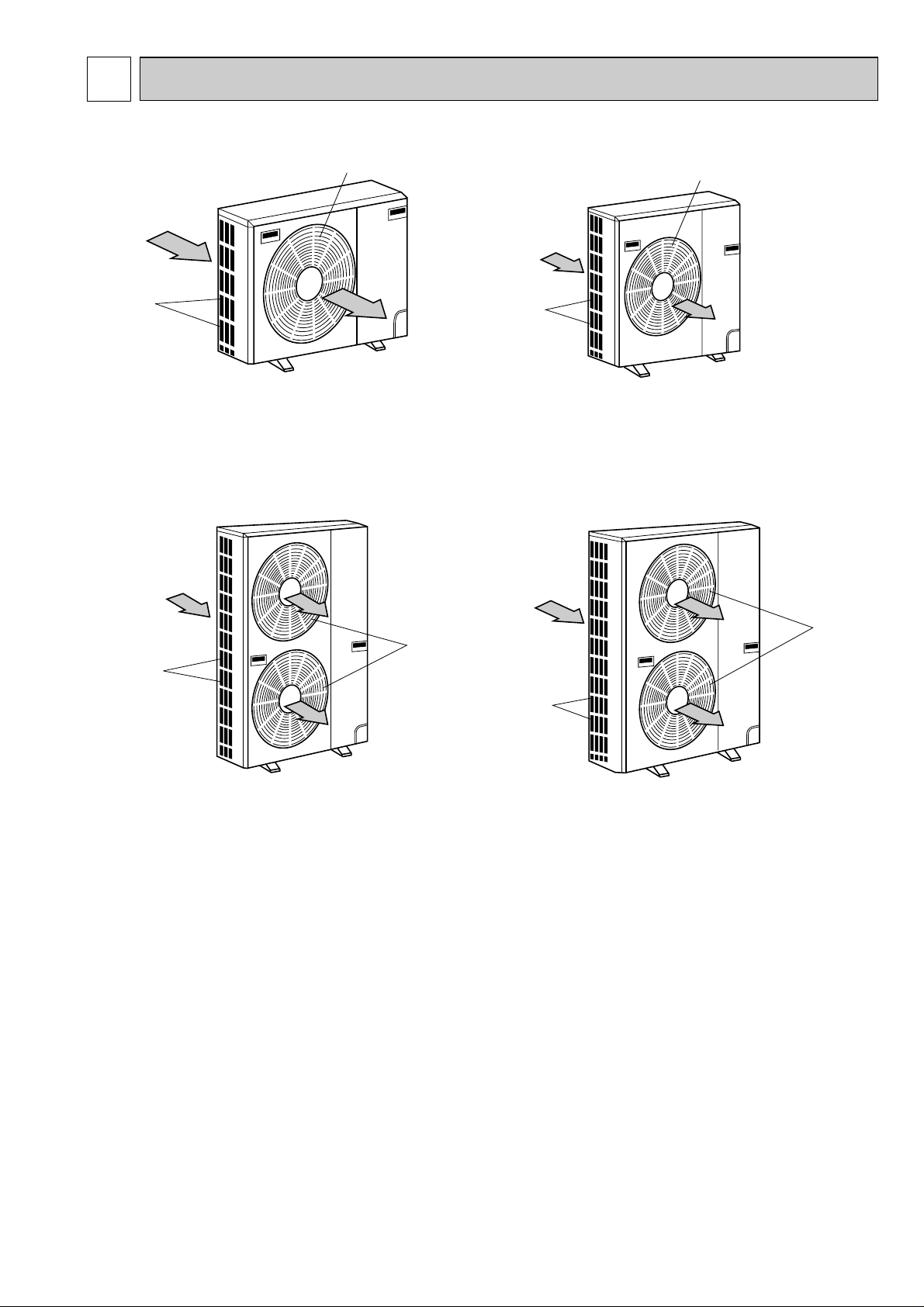

3 PART NAMES AND FUNCTIONS

PUH-1.6VKA.TH

PUH-1.6VKA

1.TH

PUH-2VKA.TH

PUH-2VKA

1.TH

Air intake

Air outlet

(Expels warm air during cooling)

PUH-4YKSA.TH

Air intake

Air outlet

PUH-5YKSA.TH

PUH-5YKSA

1.TH

PUH-6YKSA.TH

PUH-6YKSA

1.TH

Air intake

Air outlet

PUH-2.5VKA.TH

PUH-2.5VKA

1.TH

PUH-3VKA.TH

PUH-3VKA

1.TH

PUH-3YKA.TH

PUH-3YKA

1.TH

Air intake

Air outlet

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR MAXIMUM PIPING LENGTH AT SHIPMENT.

The unique refrigerant circuit and a large accumulator always control the optimal refrigerant level regardless of the length

(30m max. and 5m min.) of piping. The additional refrigerant charging work during installation often causes problems.

Heretofore it is completely eliminated. This unique system improves the quality and reliability of the work done. It also helps

to speed up the installation time.

3

Page 4

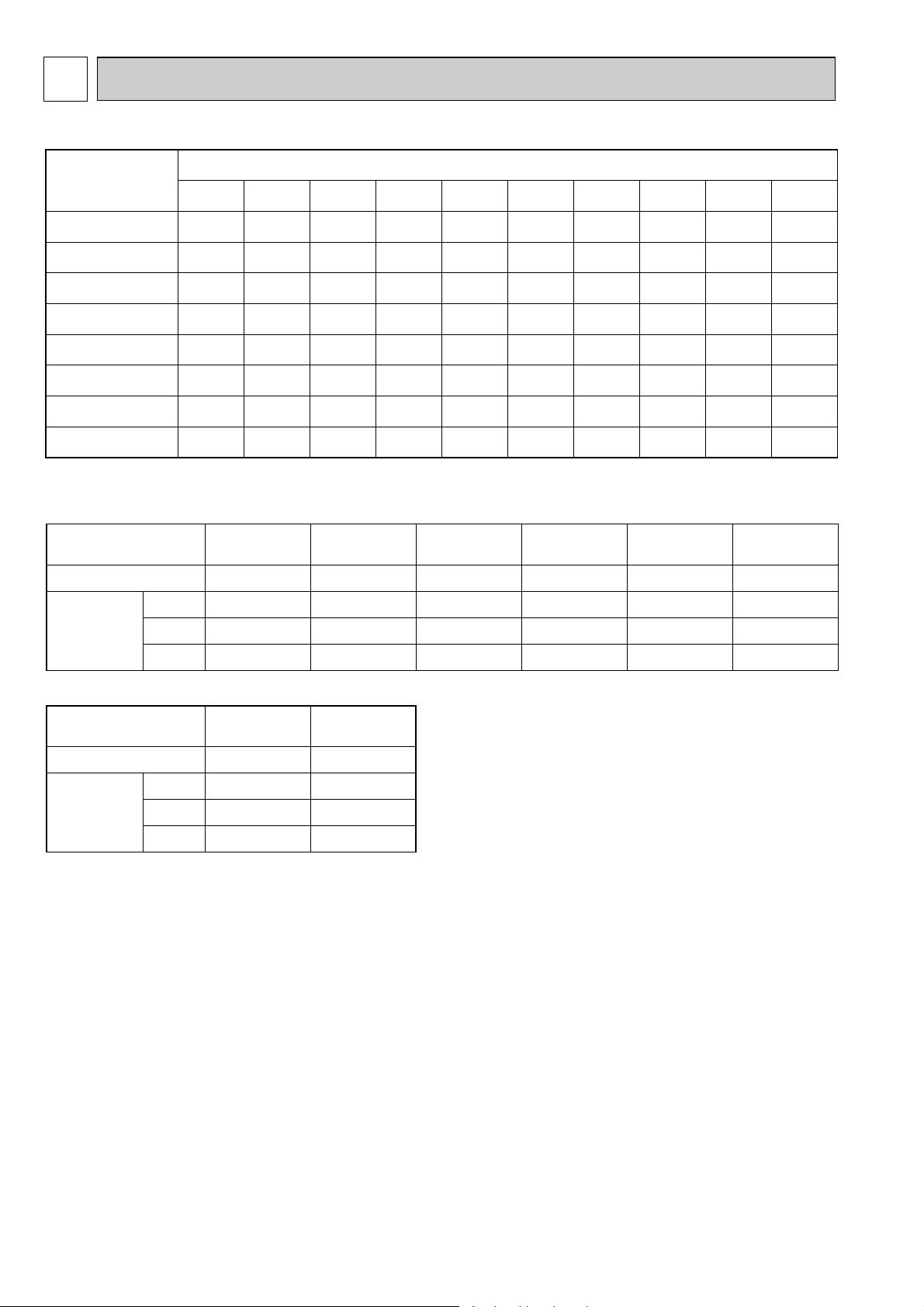

4 DATA

Service Ref.

Refrigerant piping length (one way)

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

1.5

1.5

2.1

2.5

2.5

3.5

4.7

4.3

1.7

1.7

2.3

2.7

2.7

3.6

4.8

4.4

1.8

1.8

2.4

2.8

2.8

3.8

5.0

4.6

1.9

1.9

2.5

2.9

2.9

3.9

5.1

4.7

2.1

2.1

2.7

3.1

3.1

4.1

5.3

4.9

2.2

2.2

2.8

3.1

3.2

4.2

5.4

5.0

2.3

2.3

2.9

3.1

3.3

4.4

5.6

5.2

2.4

2.4

3.0

3.1

3.4

4.5

5.7

5.3

—

—

3.1

3.1

3.6

4.6

5.9

5.5

—

—

3.3

3.1

3.7

4.8

6.0

5.6

PUH-1.6VKA.TH

PUH-2VKA.TH

PUH-2.5VKA.TH

PUH-3VKA.TH

PUH-4YKSA.TH

PUH-5YKSA.TH

PUH-3YKA.TH

PUH-6YKSA.TH

PUH-1.6VKA

1.TH

PUH-2VKA

1.TH

PUH-2.5VKA

1.TH

PUH-3VKA

1.TH

PUH-5YKSA

1.TH

PUH-3YKA

1.TH

PUH-6YKSA

1.TH

Winding

Resistance

(")

U-V

(R-C)

U-W

(S-C)

W-V

Compressor Model

Outdoor unit

PUH-1.6VKA.TH

PUH-2VKA.TH

PUH-2.5VKA.TH

PUH-3VKA.TH PUH-3YKA.TH

PUH-4YKSA.TH

PUH-1.6VKA

1.TH

PUH-2VKA

1.TH

PUH-2.5VKA1.TH

PUH-3VKA1.TH PUH-3YKA1.TH

RH247VFCT

2.00

4.55

—

NH41VMDT

1.01

2.25

—

NH38VMDT

1.30

2.70

—

NH52VNHT

0.65

1.57

—

NH52YDAT

3.70

3.70

3.70

at 20°C

Winding

Resistance

(")

Compressor Model

Outdoor unit

PUH-5YKSA.TH PUH-6YKSA.TH

PUH-5YKSA1.TH PUH-6YKSA1.TH

ZR68KC-TFD

2.31

2.31

2.31

ZR61KC-TFD

2.53-2.91

2.53-2.91

2.53-2.91

at 25°C

NH56YDAT

3.50

3.50

3.50

T1-T2

T2-T3

T3-T1

4-1. REFILLING REFRIGERANT CHARGE (R-22 : kg)

4-2. COMPRESSOR TECHNICAL DATA

4

Page 5

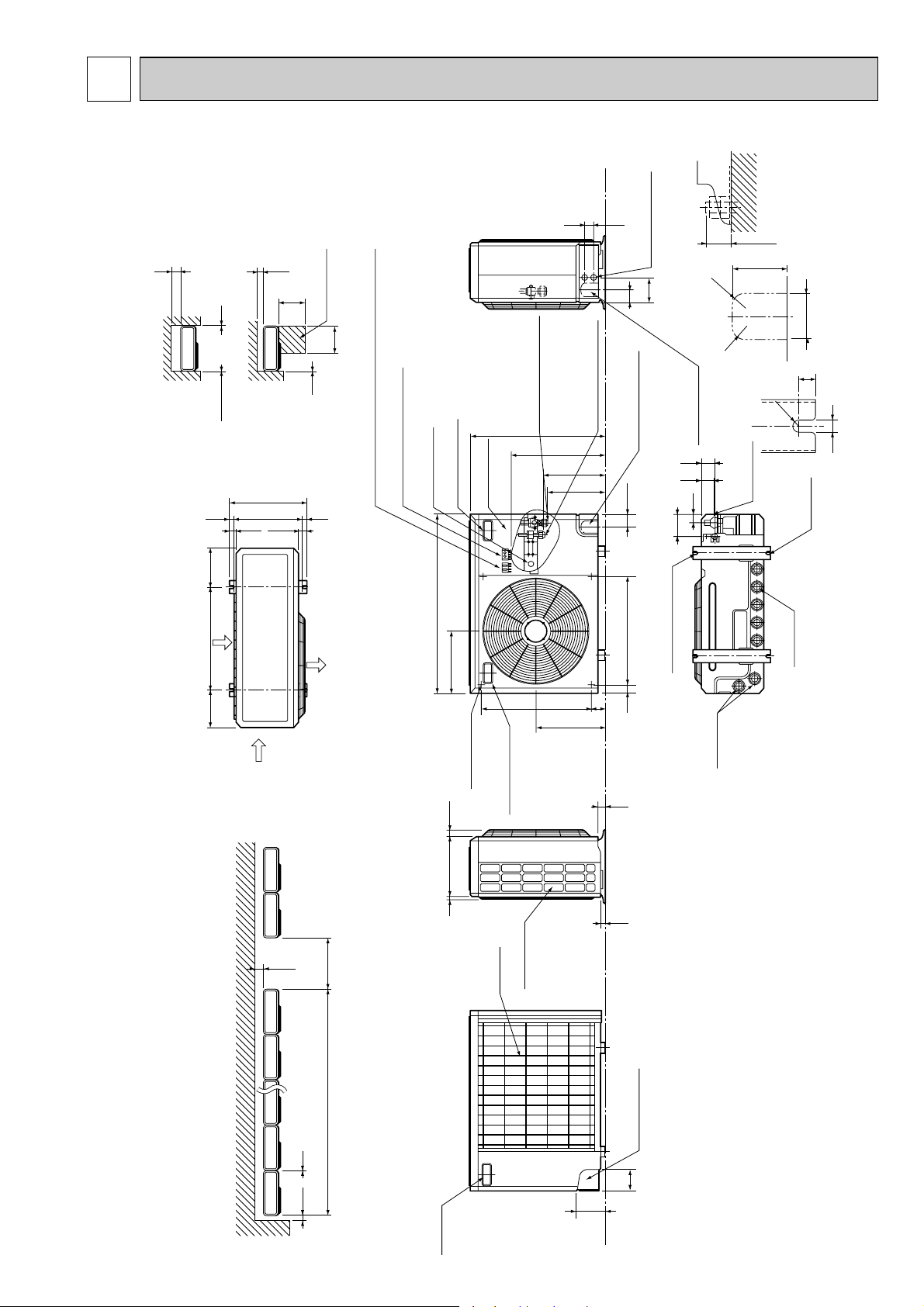

5 OUTLINES AND DIMENSIONS

100 10

1000For 10 units or less

200

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

100

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line

Handle for moving

77

524

339

282

297

444

650 (25-5/8)

40 60524

Service panel

Ground terminal

Refrigerant-pipe flared

connection

[15.88 5/8F

Refrigerant-pipe flared

connection

[9.52 3/8F

Knockout hole

for front piping

(refrigerant,drainage

and wiring)

Knockout hole

for right piping

(refrigerant,drainage

and wiring)

R20

R20

60

120

4553

25 max.

Knockout holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12✕23 Oval holes

(standard bolt M10)

Handle for moving

PUH-1.6VKA.TH PUH-1.6VKA1.TH

PUH-2VKA.TH PUH-2VKA1.TH

Unit : mm (inch)

5

Page 6

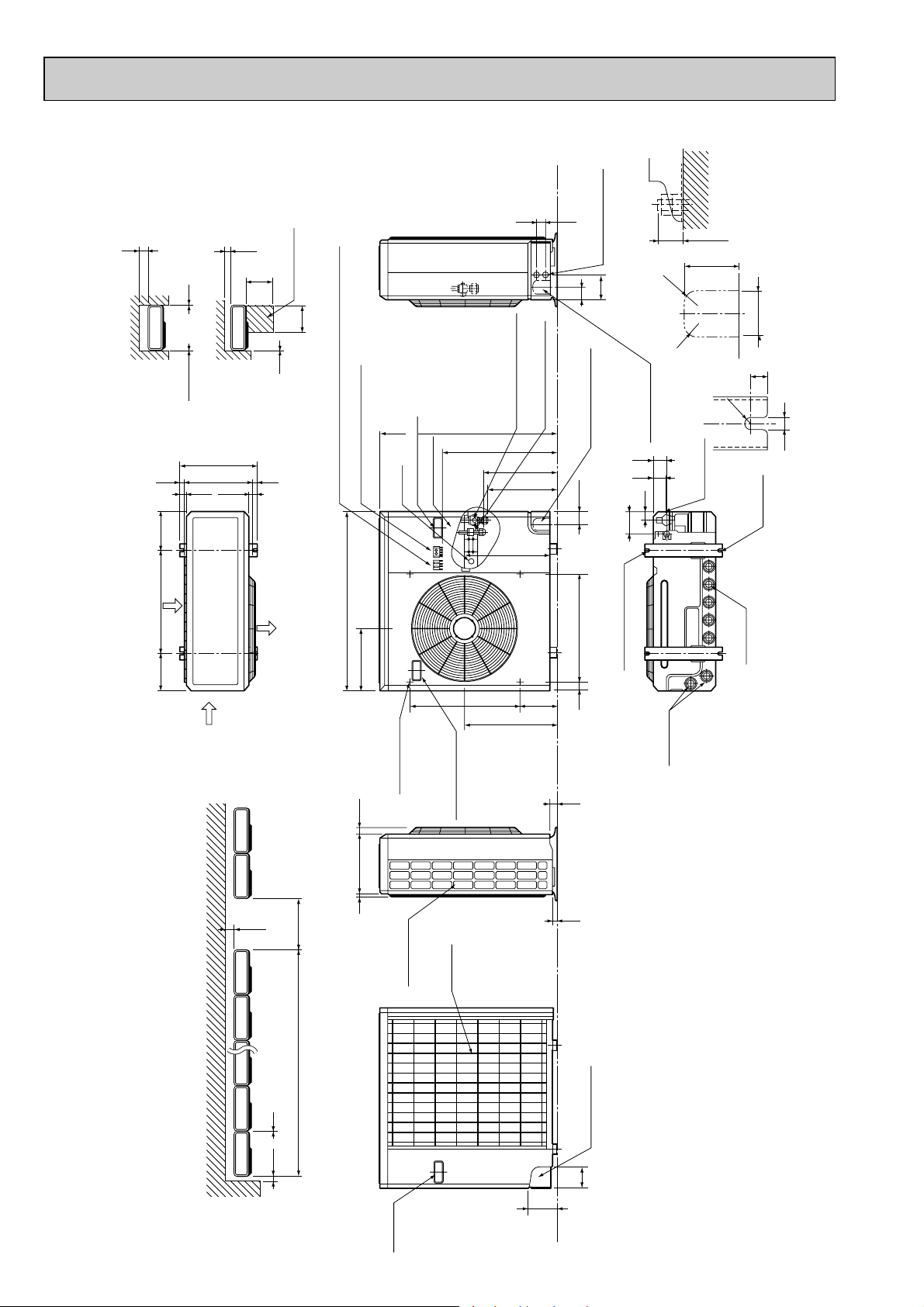

PUH-2.5VKA.TH PUH-2.5VKA1.TH

100 10

1000For 10 units or less

200

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

100

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line

Handle for moving

179 524

441

337

352

403

553

850(33-7/16)

40 60524

Service panel

Ground

terminal

Refrigerant-pipe flared

connection [15.88 5/8F

Refrigerant-pipe flared

connection [9.52 3/8F

Knockout hole

for front piping

(refrigerant,drainage

and wiring)

Knockout hole

for right piping

(refrigerant,drainage

and wiring)

R20

R20

60

120

4553

25 max.

Knockout holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12✕23 Oval holes

(standard bolt M10)

Handle for moving

PUH-3VKA.TH PUH-3VKA

PUH-3YKA.TH PUH-3YKA

1.TH

1.TH

Unit : mm (inch)

6

Page 7

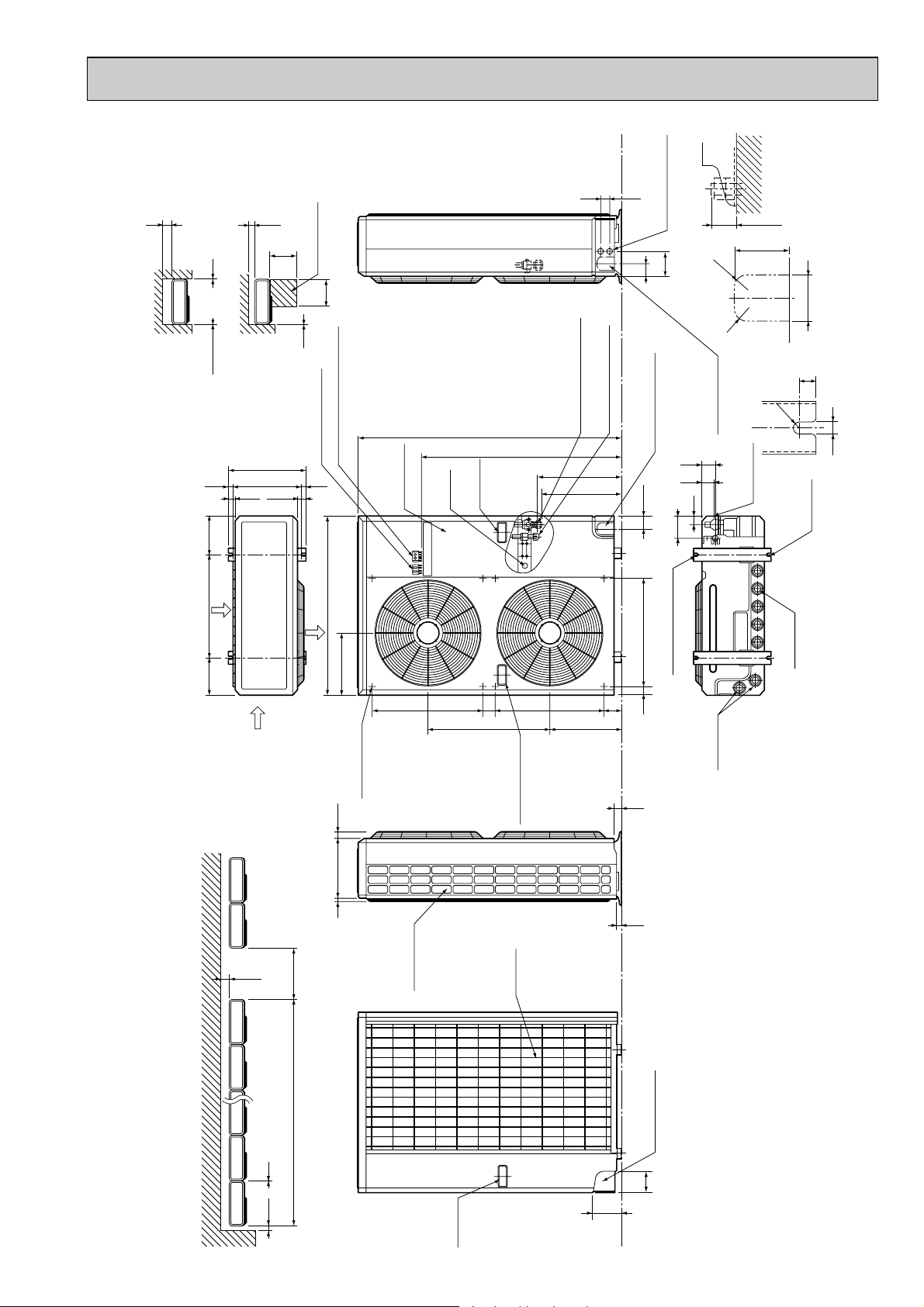

PUH-4YKSA.TH

300

Note:Allow adequate

upper clearance

10

100

500

Service space

500

4553

Unit : mm (inch)

Standard bolt length

Knockout holes for

power line 2-[27

120

60

R20

25 max.

80

65

Outdoor Unit-necessary surrounding clearance

Front opening

10

1715

185

(7-9/32)

Air intake

500(19-11/16)

185

(7-9/32)

10

Terminal block for

indoor and outdoor

unit connection

362(14-1/4)

330(13)

39.5 27.5

870(34-1/4)

Air outlet

Air intake

Terminal block for power line

302

Ground

Service panel

terminal

Handle

for moving

52461

585

Refrigerant-pipe flared

1258(49-1/2)

959

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

403

382

83 524

345

Knockout hole

for front piping

(refrigerant,drainage

104

2-12✕23 Oval holes

40 60524

R20

Knockout hole

for right piping

(refrigerant,

drainage and wiring)

and wiring)

57

52

Bottom

39

(standard bolt M10)

piping hole

Drain hole

Front right piping holes-

17

R6

2-U-shaped

notched

holes

Drain hole

detail figures

12

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

300

1000For 10 units or less

150 10

Outlet guide

installation hole

7 24(1)295(11-5/8)

Handle for moving

Side air intake

Rear fresh

air intake

33

23

Rear piping hole

95

138

Handle

for moving

7

Page 8

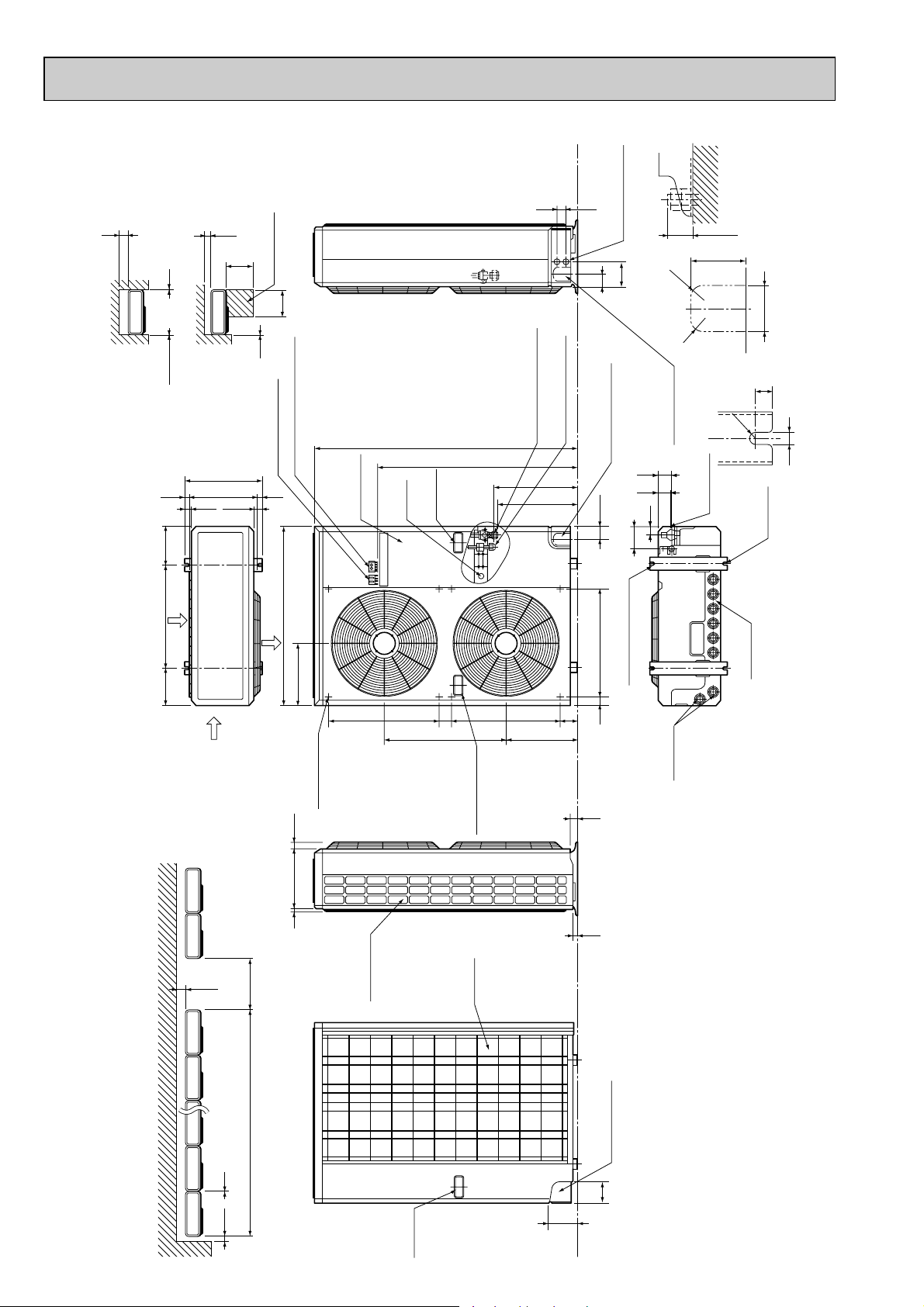

PUH-5YKSA.TH PUH-5YKSA1.TH

150 10

1000For 10 units or less

300

Outdoor Unit-necessary surrounding clearance

(Concentrated installation)

Outdoor Unit-necessary surrounding clearance

The upper side must be open.

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)345(13-9/16)

Outlet guide

installation hole

352

Air intake

Air intake

Air outlet

970(38-3/16)

185

(7-9/32)

185

(7-9/32)

600(23-5/8)

380(14-31/32)

412(16-1/4)

1715

39.5 27.5

Terminal block for

indoor and outdoor

unit connection

Terminal block for power line

300

10

10

10

Note:Allow adequate

upper clearance

100

500

500

Service space

Handle for moving

52461

585

83 524

345

382

403

959

1258(49-1/2)

90 60524

Service panel

Ground

terminal

Handle

for moving

Refrigerant-pipe flared

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knockout hole

for front piping

(refrigerant,drainage

and wiring)

Knockout hole

for right piping

(refrigerant,

drainage and wiring)

R20

R20

60

120

4553

25 max.

Knockout holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

52

57

12

R6

104

39

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12✕23 Oval holes

(standard bolt M10)

Front opening

PUH-6YKSA.TH PUH-6YKSA1.TH

Unit : mm (inch)

8

Page 9

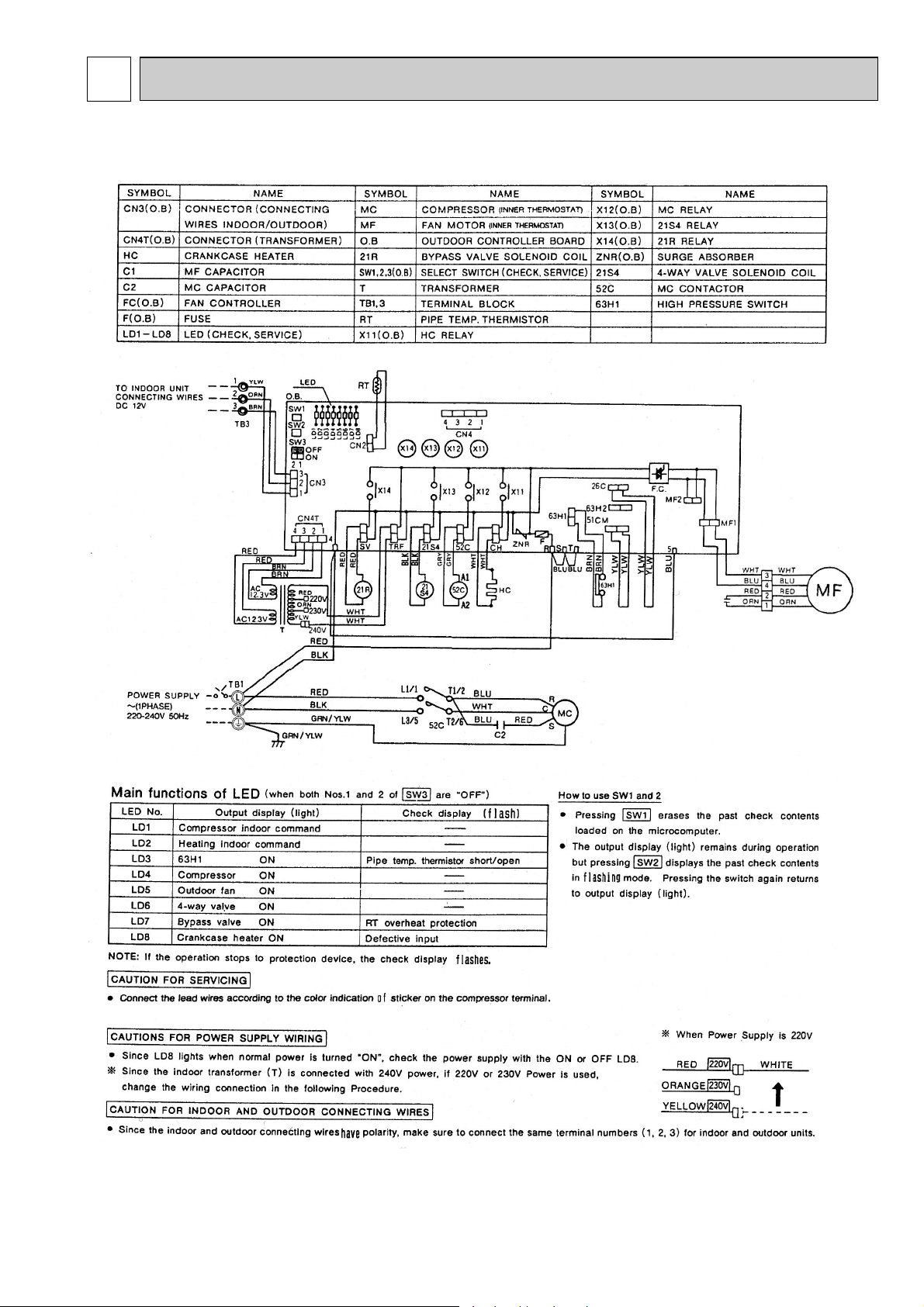

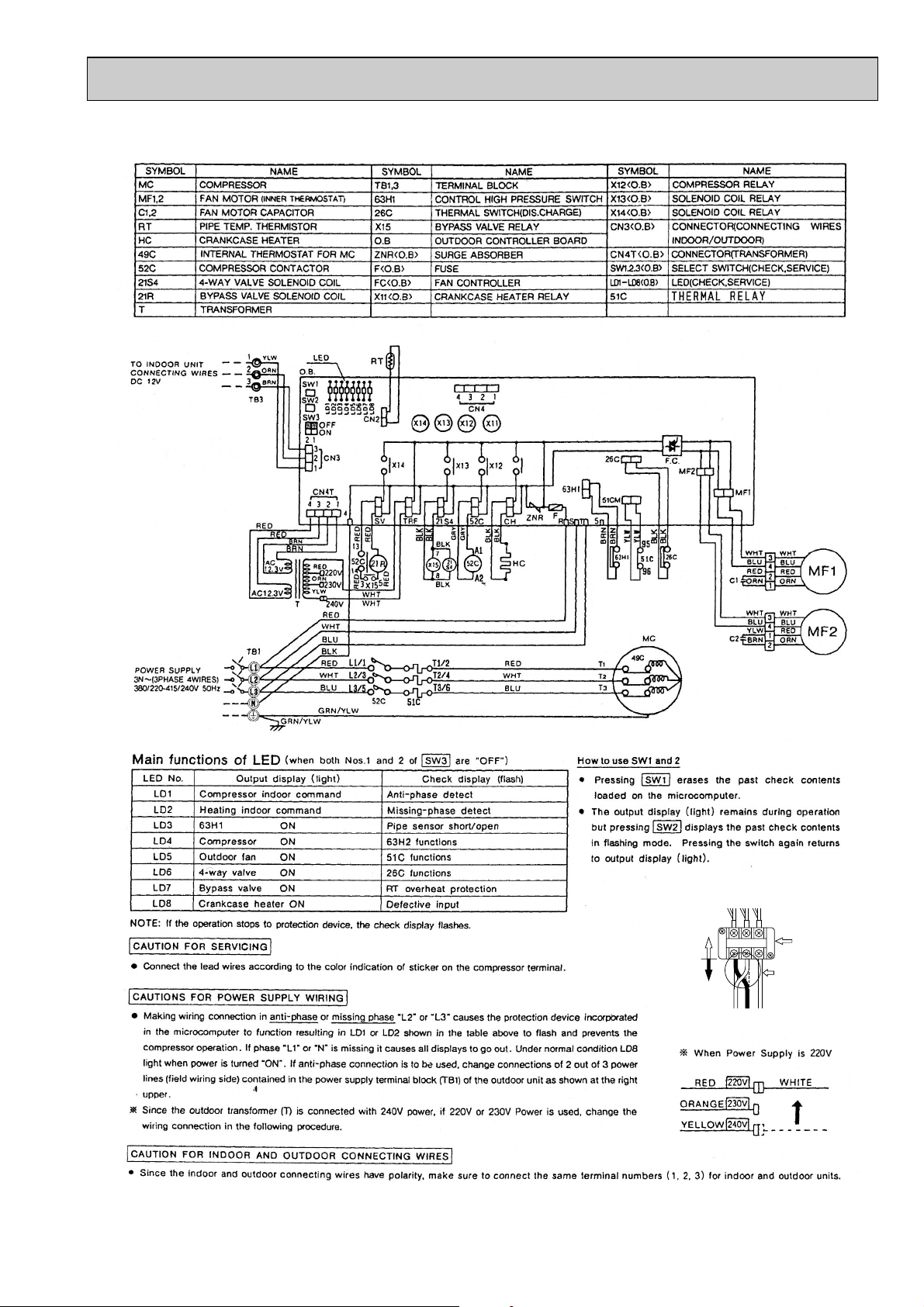

6 WIRING DIAGRAM

PUH-1.6VKA.TH PUH-2VKA.TH PUH-2.5VKA.TH PUH-3VKA.TH

PUH-1.6VKA1.TH PUH-2VKA1.TH PUH-2.5VKA1.TH PUH-3VKA1.TH

(6.3A)

CIRCUIT

BREAKER

C1

9

Page 10

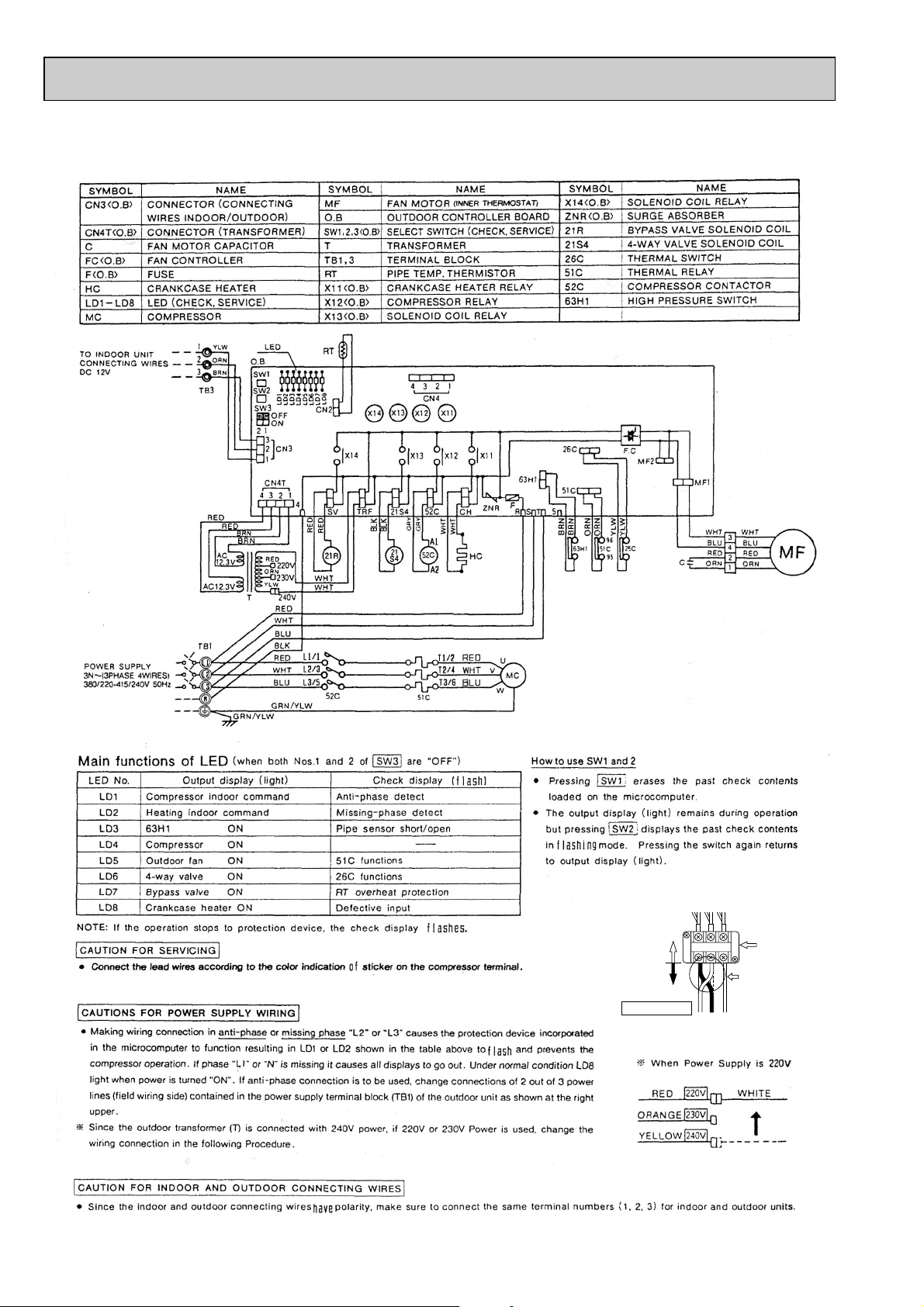

PUH-3YKA.TH PUH-3YKA1.TH

L1L2L3

Power line reconnection procedure

in case of reverse rotation

Unit side

wiring

Outdoor unit

terminal

Field wiring

Change 2 out of

1,

2 and 3.

(This example shows

reconnection of

1

and 2.)

123

Change this side

(6.3A)

CIRCUIT

BREAKER

10

Page 11

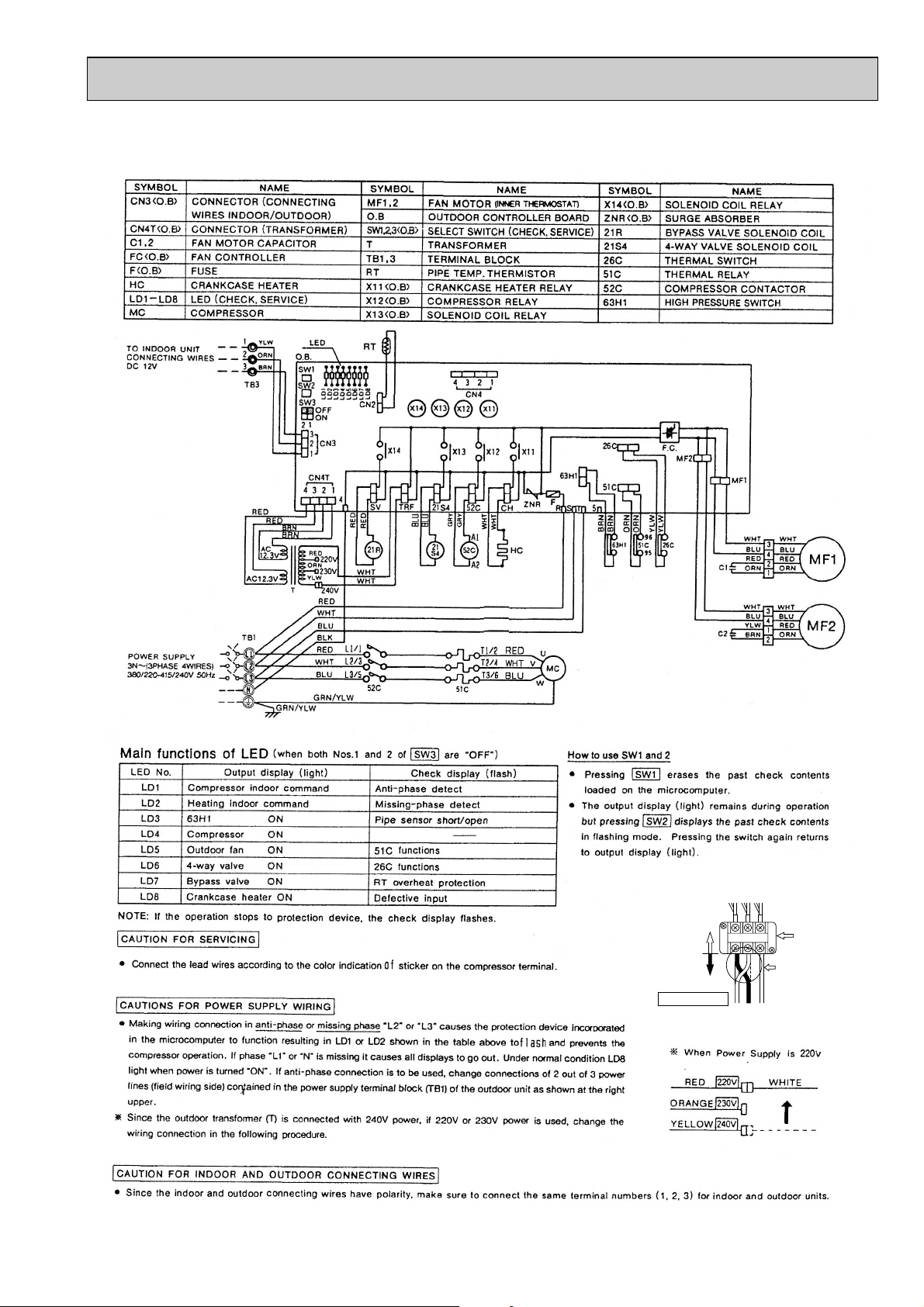

PUH-4YKSA.TH

L1L2L3

Power line reconnection procedure

in case of reverse rotation

Unit side

wiring

Outdoor unit

terminal

Field wiring

Change 2 out of

1,

2 and 3.

(This example shows

reconnection of

1

and 2.)

123

Change this side

(6.3A)

CIRCUIT

BREAKER

11

Page 12

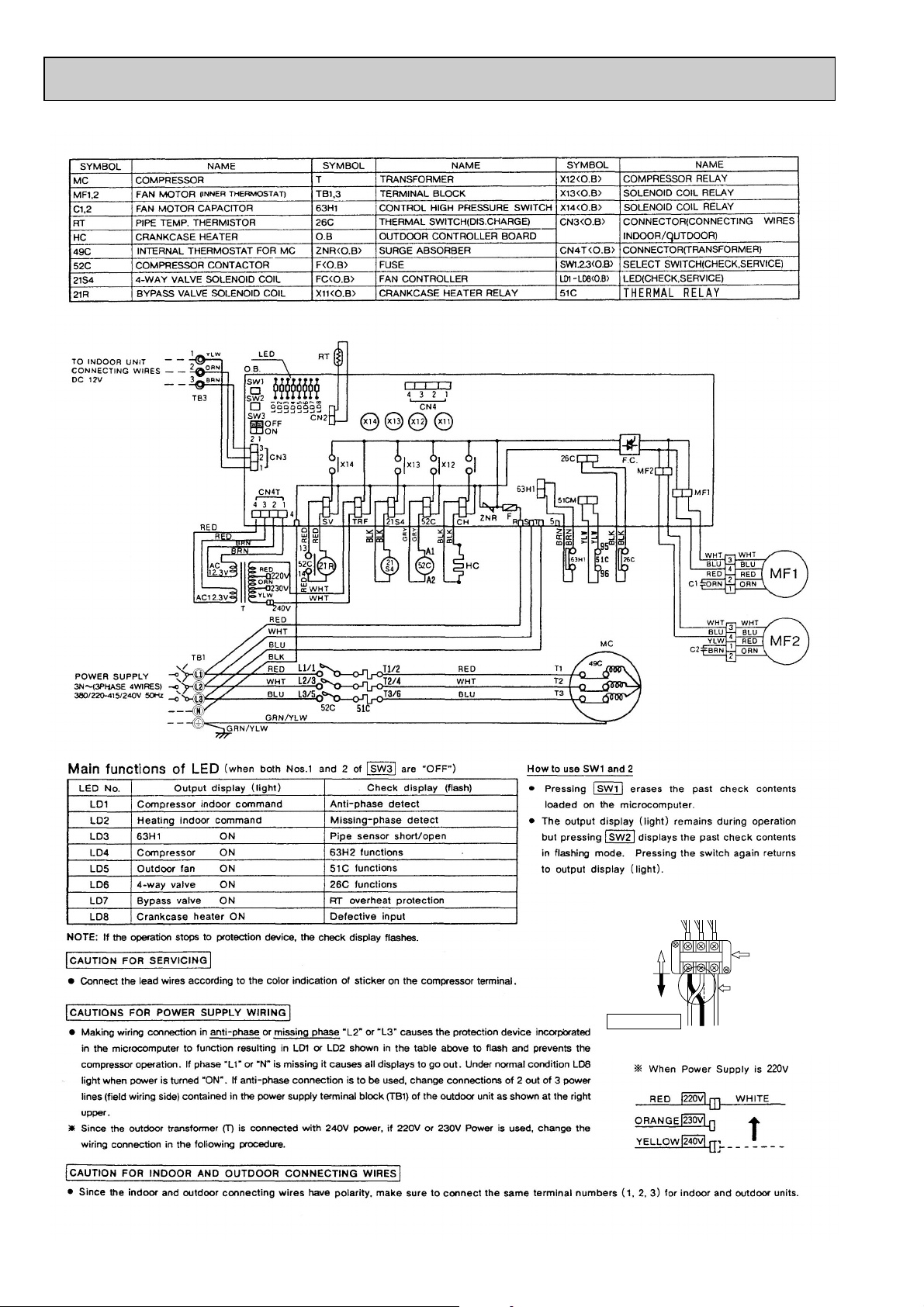

PUH-5YKSA.TH PUH-5YKSA1.TH

L1L2L3

Power line reconnection procedure

in case of reverse rotation

Unit side

wiring

Outdoor unit

terminal

Field wiring

Change 2 out of

1,

2 and 3.

(This example shows

reconnection of

1

and 2.)

123

Change this side

(6.3A)

CIRCUIT

BREAKER

12

Page 13

PUH-6YKSA.TH PUH-6YKSA1.TH

L1L2L3

Power line reconnection procedure

in case of reverse rotation

Unit side

wiring

Outdoor unit

terminal

Field wiring

Change 2 out of

1,

2 and 3.

(This example shows

reconnection of

1

and 2.)

123

(6.3A)

CIRCUIT

BREAKER

13

Page 14

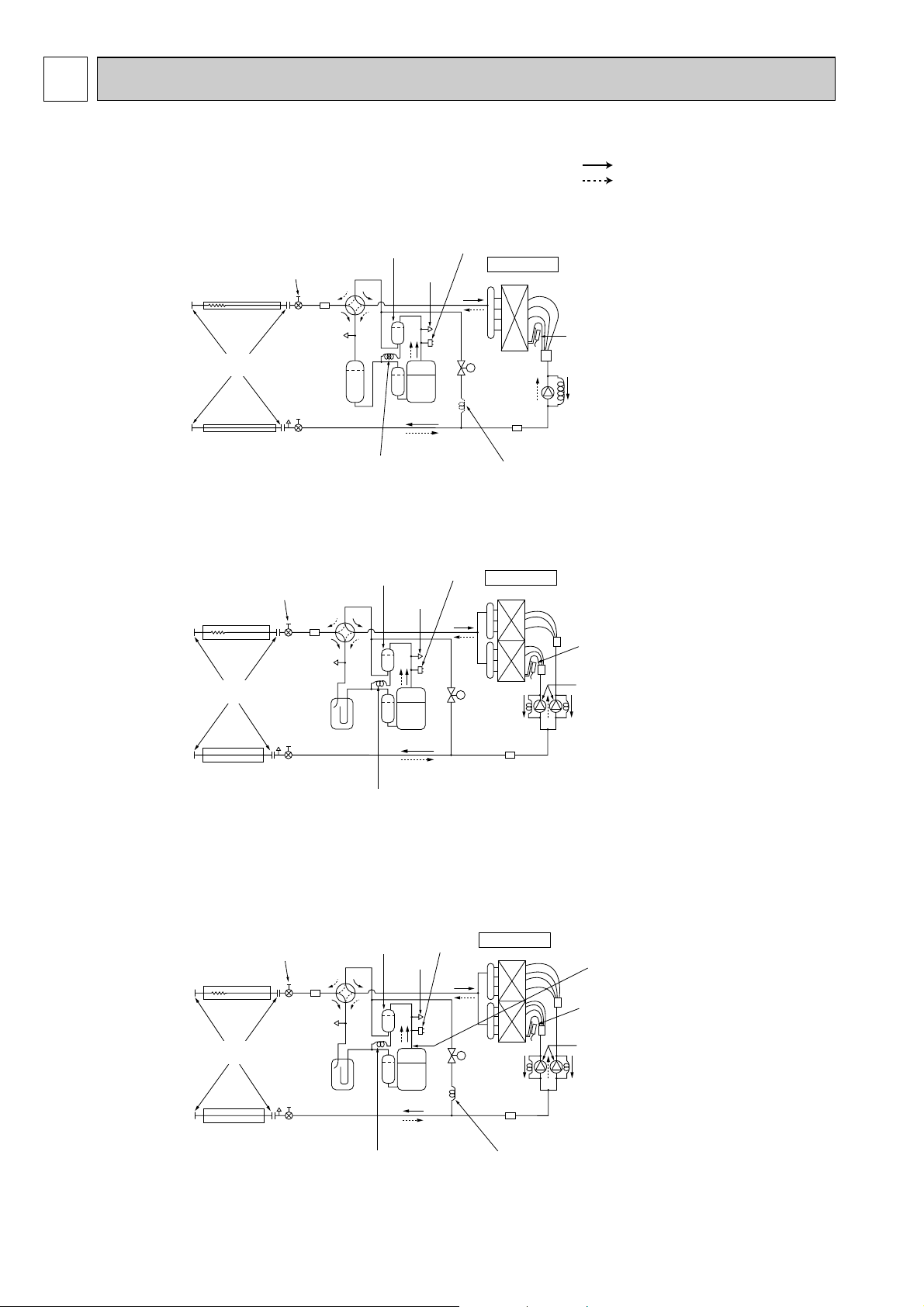

7 REFRIGERANT SYSTEM DIAGRAM

Outdoor unit

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

(option)

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

(option)

9.52A({3/8")

(with heat insulator)

Ball valve

(with service port)

Strainer

(#50)

Bypass

valve

Restrictor

valve

4-way valve

Oil

separator

Service

port

High pressure

control switch

Outdoor heat exchanger

Thermistor

(RT)

Capillary tube

PUH-5

....

(O.D.4.0✕I.D.2.4-L840)✕2

PUH-6

....

(O.D.4.0✕I.D.2.4-L1200)✕2

Flared

connection

THERMAL

SWITCH

Capillary tube

(O.D.2.5✕I.D.0.6-L1000)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)

Ball valve

(#50)

Strainer

Outdoor unit

Flexible tube

Service

port

(check)

Accumulator

Compressor

Refrigerant pipe

(option)

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

(option)

9.52A({3/8")

(with heat insulator)

Ball valve

(with service port)

Strainer

(#50)

Bypass

valve

Restrictor

valve

4-way valve

Oil separator

Service

port

High pressure

control switch

Outdoor heat exchanger

Outdoor coil

thermistor

(RT)

Capillary tube

(O.D.3.2✕I.D.2.0-L820)✕2

Flared

connection

Capillary tube

(O.D.2.5✕I.D.0.6-L1000)

Ball valve

(#50)

Strainer

Outdoor unit

Flared

connection

Flexible tube

Service

port

Accumulator

Ball valve

(#50)

Strainer

Compressor

Refrigerant pipe

(option)

15.88A({5/8")

(with heat insulator)

Refrigerant pipe

(option)

9.52A({3/8")

(with heat insulator)

Ball valve

(with service port)

Strainer

(#50)

Bypass

valve

Restrictor

valve

4-way valve

Oil separator

Service

port

High pressure

control switch

Outdoor heat exchanger

Outdoor coil

thermistor

(RT)

Capillary tube

PUH-1.6···(O.D.3.2✕I.D.1.8-L600)

PUH-2······(O.D.4.0✕I.D.2.0-L430)

PUH-2.5···(O.D.4.0✕I.D.2.4-L1550)

PUH-3······(O.D.4.0✕I.D.2.4-L1070)

Capillary tube

(O.D.2.5✕I.D.0.6-L1000)

Capillary tube

PUH-1.6 only

(O.D.3.2✕I.D.1.2-L300)

Refrigerant flow in cooling

Refrigerant flow in heating

PUH-1.6VKA.TH PUH-1.6VKA1.TH

PUH-2VKA.TH PUH-2VKA

PUH-2.5VKA.TH PUH-2.5VKA

PUH-3VKA.TH PUH-3VKA

PUH-3YKA.TH PUH-3YKA

1.TH

1.TH

1.TH

1.TH

PUH-4YKSA.TH

PUH-5YKSA.TH PUH-5YKSA1.TH

PUH-6YKSA.TH PUH-6YKSA1.TH

14

Page 15

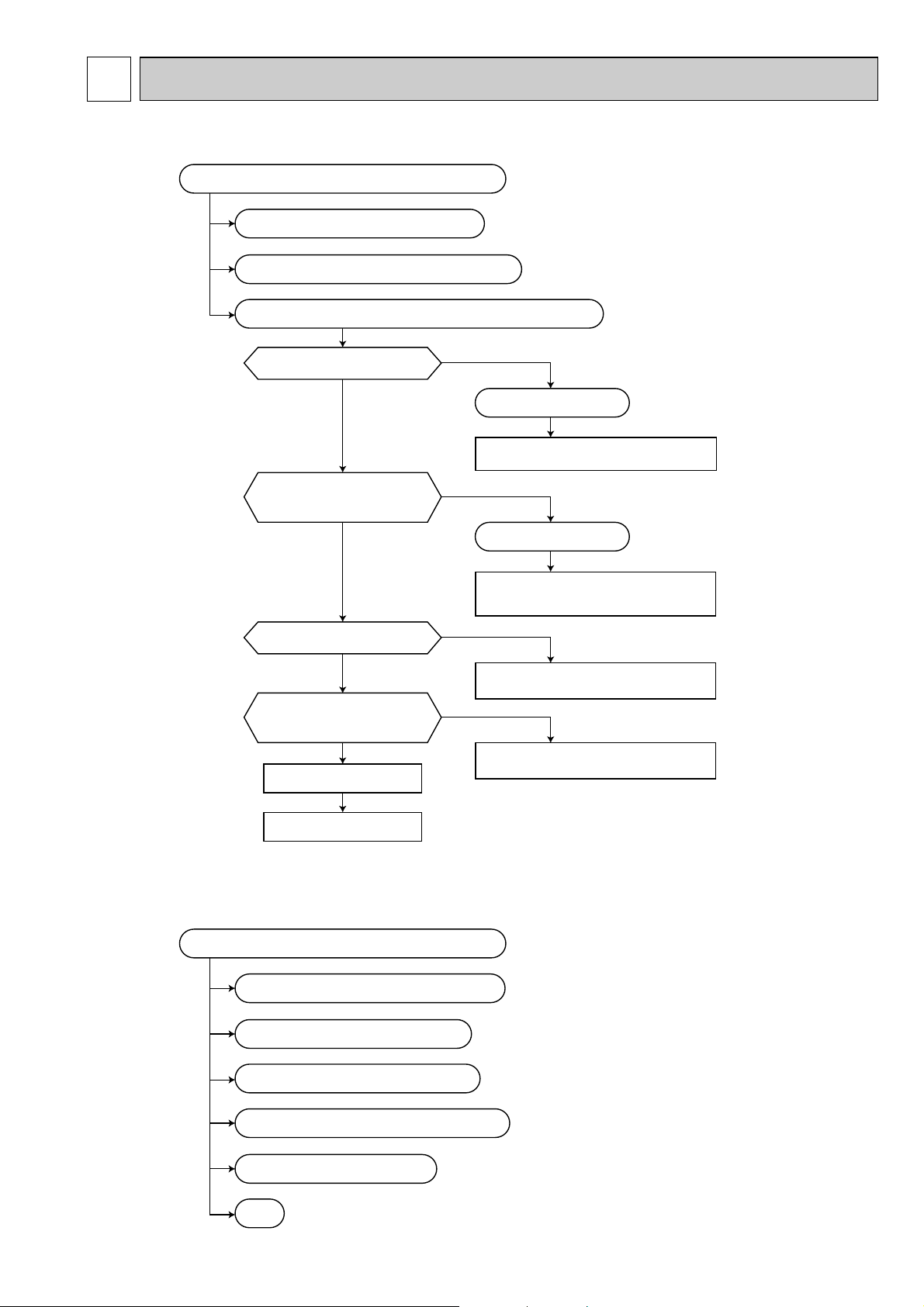

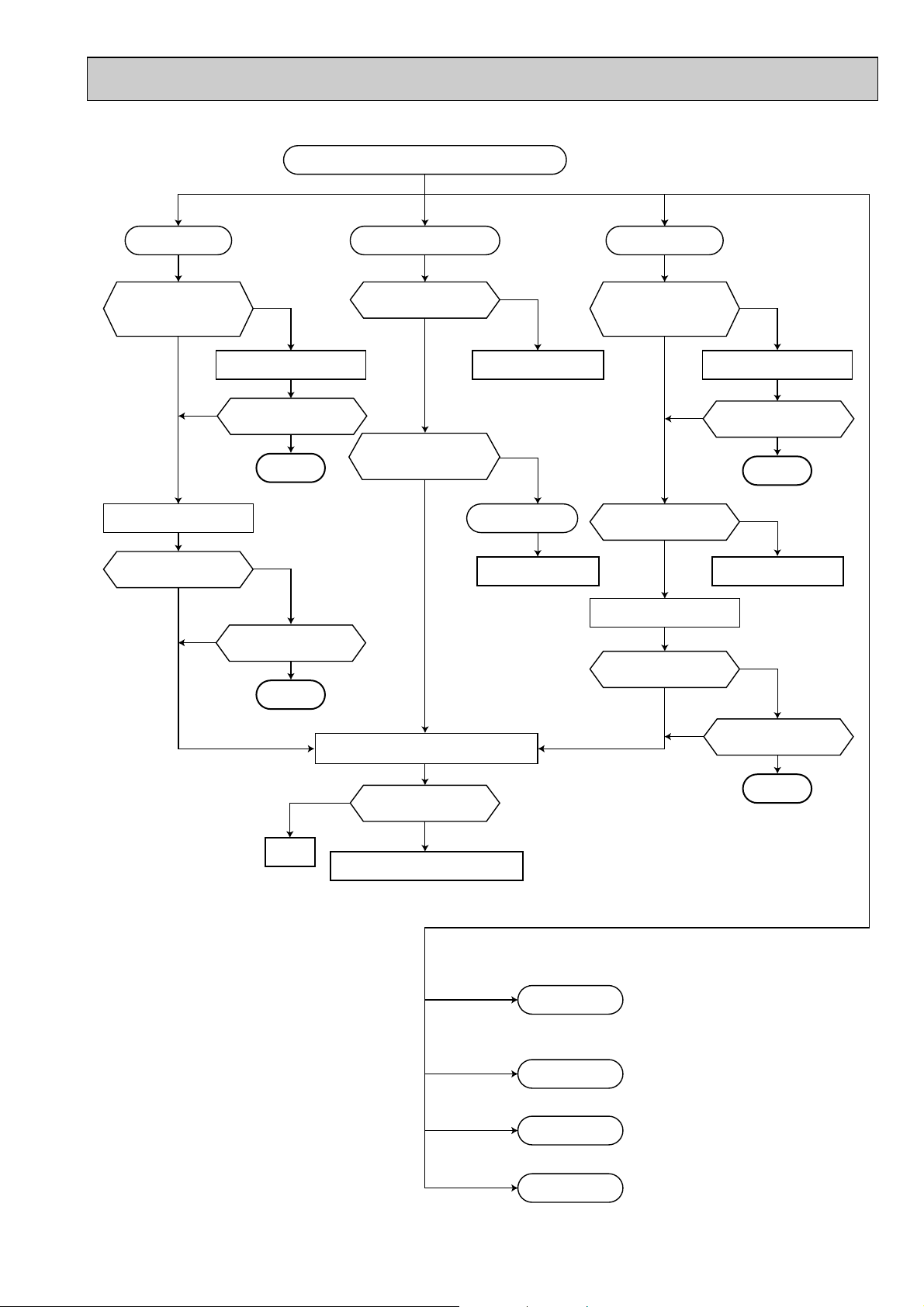

8

TROUBLESHOOTING

8-1. TROUBLESHOOTING

The unit does not operate at all or it does not keep operating.

No display appears on the remote controller.

The error code is displayed on the remote controller.

“CENTRALLY-CONTROLLED” is displayed on the remote controller.

Is the remote operation available by

the adapter for connecting the timer?

No

Does the remote controller for

central control allow the unit to be

operated or stopped with the

local remote controller?

No

Is the address setting correct?

Yes

Is the setting of multi operation

switch (SW6) correct?

Yes

Yes

No

No

······································· Refer to page 16

··························· Refer to page 17

The operation is normal.

Set the remote operation switch to the local

remote controller side.

The operation is normal.

Set the centralized remote controller to allow

the unit to be operated or stopped with the

local remote controller.

Set the address again, turn the power supply

off and turn it on again.

Yes

Replace the remote controller.

Check if the remote controller

operates normally.

The unit operates, but there are the following problems.

The room cannot be cooled or heated sufficiently. ································· Refer to page 20

The room is cooled or heated excessively.

The operating sound or the vibration is big.

The air from the unit smells strange.

Water leakage, dew dropping or splashing occurs.

The parts are removed or deformed.

Set the SW6 again, turn the power supply off

and turn it on again.

············································ Refer to page 20

········································· Refer to page 20

······························· Refer to page 21

······················································· Refer to page 21

·········································································································· Refer to page 21

Others

15

Page 16

No display appears on the remote controller.

No

Is the voltage of the indoor/outdoor

unit connecting terminal block 240V?

Power supply system

is abnormal.

No

Is the connector CN40 connected

properly?

No

Is the transmission wire of remote

controller connected properly?

Connection is defective.

Yes

The power supply wire

and the indoor/outdoor

unit connecting wire are

in reverse connection.

Replace the remote controller.

Yes or Model without CN40

Yes

Install the CN40 in only

one indoor unit.

Connection is defective.

Is the breaker for the indoor unit

turned on?

Yes

No

Is the voltage of the indoor power

supply terminal block 240V?

Yes

Yes

Is the voltage of the remote

controller terminal block DC12V?

No

Yes

Does the LED1 (DC12V) on the

indoor controller board light?

No

Does the LED2 (DC5V) on the

indoor controller board light?

Yes

When the two or

three indoor units

are connected to

an outdoor unit.

Yes

Is the connector CN40 installed in

the two or more indoor units?

No

or

Model without CN40

Yes

Is the indoor/outdoor unit connecting

wire short-circuited?

No

Yes

Is the transmission wire of remote

controller short-circuited?

No

No

Is the breaker capacity appropriate?

Yes

Turn the breaker on and

operate the unit again.

Is the breaker turned off automatically?

No

Does the unit operate normally?

No

If any error code is displayed

on the remote controller,

follow the diagnosis of the

displayed error code.

No

Is the 6.3A fuse on the indoor

controller board melted?

No

CND, CNT, CN4T

Are the wire and the connector

connected properly?

Does the LED2 (DC5V) on the

indoor controller board light?

Yes

No

Replace the breaker

Yes

Electric leakage or

overcurrent occurs.

Yes

Finished

Yes

Replace the fuse.

No

Connection is defective.

No

Normal

Turn off the power supply and turn it on again

to operate the unit in COOL or HEAT mode.

No display appears on the

remote controller.

Yes

Check the indoor controller board

16

Page 17

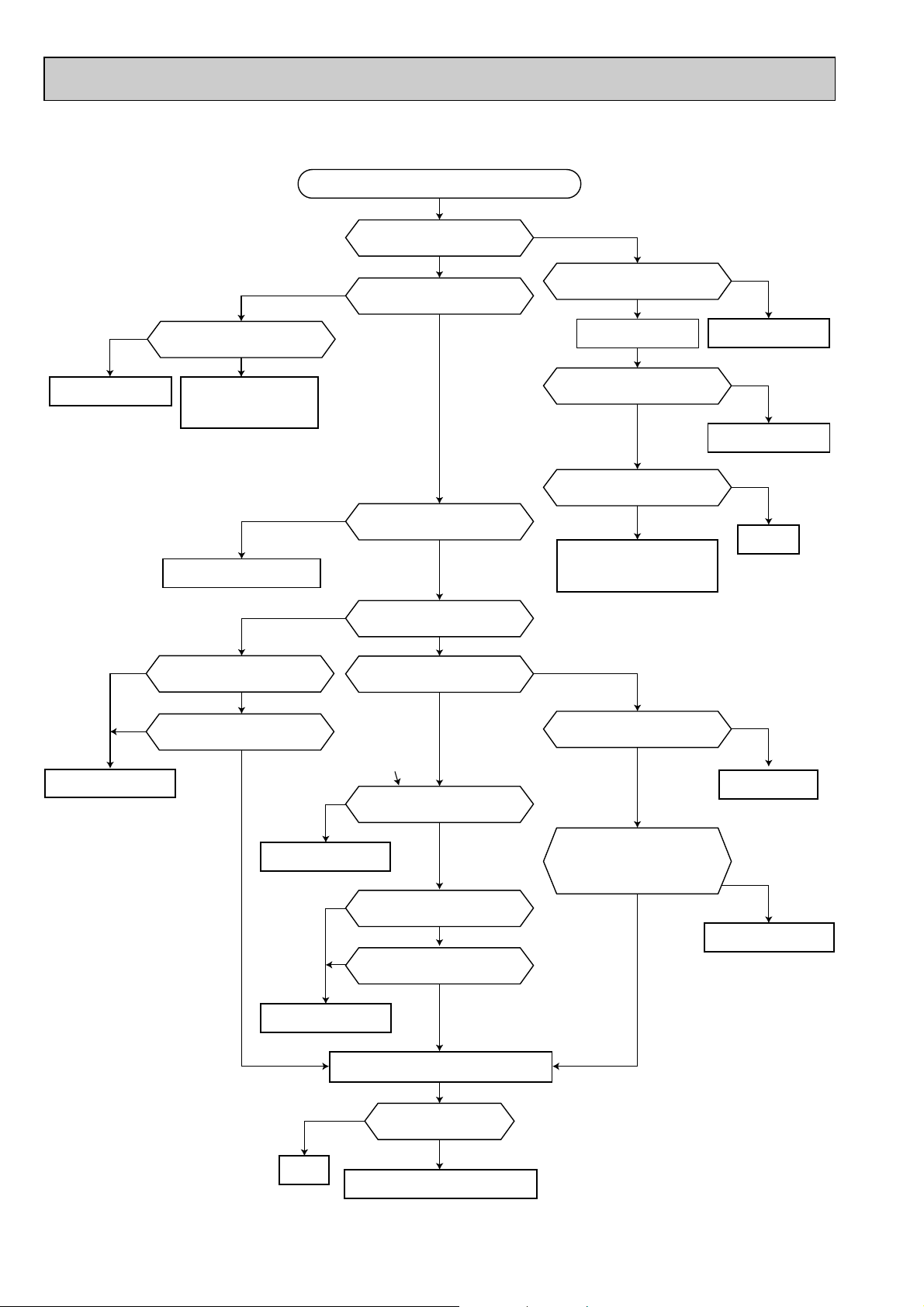

The error code is displayed on the remote controller.

Communication error Sensor is abnormal Communication error

E0 is displayed.

Turn the breaker off and

turn it on again.

Is it possible to operate

the unit?

No

Use the remote controller as it is. Use the remote controller as it is.

Yes

Is E0 displayed frequently?

Replace the remote controller.

Is E0 displayed again?

Yes

No

Yes

No

Finished

No

Does the unit operate

normally?

Yes

Finished

P1, P2 or P4 error is displayed.

Is the connector of

the abnormal sensor

connected properly?

Yes

Connection is defective.

Check the resistance of

the abnormal sensor.

Is there a short or open

circuit in the sensor?

No

Sensor is abnormal.

Replace the abnormal

sensor.

No

Yes

P3 or E4 is displayed.

Turn the breaker off and

turn it on again.

Is it possible to operate

the unit?

No

Yes

Is the transmission wire

of remote controller

connected properly?

Yes

Connection is defective.

Replace the remote controller.

Is P3 or E4

displayed again?

Yes

Yes

Is P3 or E4

displayed frequently?

No

Finished

No

No

Normal

Turn off the power supply and turn it on again

to operate the unit in COOL or HEAT mode.

No

The error code is displayed

on the remote controller.

Yes

Check the indoor controller board

Abnormality of drain pump

Freezing protection

Overheating protection

System error

P5 is displayed.

P6 is displayed.

P7 is displayed.

No

··································· Refer to page 18

··································· Refer to page 18

··································· Refer to page 18

Does the unit operate

normally?

Yes

Finished

17

P8 is displayed.

··································· Refer to page 19

Page 18

Abnormality of drain pump Freezing protection and Overheating protection

P5 is displayed.

Operate the unit again in

the COOL mode.

Does the drain pump operate?

Yes

Is the connector of the drain pump

connected properly?

Connection is defective.

Is the breaker turned off automatically?

Yes

Improve the drainage

condition.

Is the connector of the drain sensor

connected properly?

Yes

Connection is defective.

No

No

No

No

Yes

Drain sensor is defective.

P6 is displayed.

Is the filter clogged?

No

Operate the unit again.

Does the indoor unit fan rotate?

No

Are there any obstacles at the

air inlet/outlet?

No

Yes

Clean the filter.

Yes

Yes

Remove the obstacles.

Check the resistance of the drain

sensor heater.

Is there a short or open circuit in

the sensor?

Is the drain sensor connecting

properly?

No

Drain sensor is defective.

Yes

Connecting it correctly.

Yes

Replace it.

No

Turn off the power supply and turn it on again

to operate the unit in COOL or HEAT mode.

No

No display appears on the

remote controller.

Yes

Normal

Check the indoor controller board

P7 is displayed.

Is the address setting correct?

Yes

No

Set the address again, turn

the power supply off and

turn it on again.

18

Page 19

No

Is the breaker for the outdoor unit

turned on?

Turn the breaker on.

Yes

Does the LED (LD2) displayed the

different voltage light?

The power supply wire

and the indoor/outdoor

unit connecting wire are

in reverse connection.

Yes

Replace the fuse.

Yes

No

Is the 6.3A fuse on the outdoor

controller board melted?

No

P8 is displayed.

Yes

Are there the LED on the outdoor

controller board?

No

Is the breaker for the outdoor unit

turned on?

No

Is the breaker capacity appropriate?

Yes

Turn the breaker on.

Operate the unit again.

Yes

No

Replace the breaker

No

Connection is defective.

Yes

TROUBLESHOOTING

ACCORDING TO

CHECK CODE

Refer to 8-2.

Are the wire and the connector

connected properly?

Yes

Does the LED indicator blink?

No

Is the breaker turned off automatically?

No

Does the unit operate normally?

No

Is the voltage of the terminal block

for transmission wire of outdoor unit

DC12V?

No

Is the voltage of the terminal block

for transmission wire of indoor unit

DC12V?

No

Is the connector on the outdoor

controller board connected properly?

Yes

Check the resistance of the pipe

temperature thermistor.

Is there a short or open circuit in

the thermistor?

No

Turn off the power supply and turn it on again

to operate the unit in COOL or HEAT mode.

Yes

Electric leakage or

over current occurs.

Yes

Yes

Yes

No

Yes

Finished

Is the connector on the outdoor

controller board connected properly?

No

Connection is defective.

Is the indoor control wire

connected properly?

No

Connection is defective.

Connection is defective.

Replace the pipe

temperature thermistor.

Yes

Yes

Normal

No

The error code is displayed

on the remote controller.

Yes

Check the outdoor controller board.

19

Page 20

The room cannot be cooled

or heated sufficiently.

The room is cooled or

heated excessively.

The operating sound or the vibration is big.

The air from the unit smells strange.

Is the filter clogged?

No

Is the temperature

set correctly?

Yes

Is the indoor or outdoor

unit free from any objects

that block its airflow?

Yes

Is the window left open?

No

Is the selected model

appropriate to the room

size?

Yes

Yes

Clean the filter.

No

Set it correctly.

No

Short cycle occurs.

Remove the

obstacles.

Yes

Close it.

No

The appropriate

model is not

selected.

Is the temperature

set correctly?

Yes

Does the thermostat

stop working when the set

temperature has been

achieved?

Is the room temperature

thermistor installed properly?

Check the resistance of the

room temperature thermistor.

Yes

Yes

Normal

The room temperature

thermistor is defective.

No

Set it correctly.

No

No

Install it correctly.

Abnormal (open or short)

Replace it.

Check the conditions of

filter and heat exchanger.

Improve the conditions.

Normal

Turn off the power supply and turn it on again

to operate the unit in cooling or heating mode.

No

The error code is displayed

on the remote controller.

Yes

Check the indoor controller board

20

Page 21

8-2. TROUBLESHOOTING ACCORDING TO CHECK CODE

The parts are removed or deformed.

Others

Water leakage, dew dropping or splashing occurs.

Check the condition.

Replace the pipes

or insulation with

new one.

Clean the filter.

Repair the defective part.

Correct the removed

parts or replace the

deformed parts with

new one.

Is the humidity in

the room high?

Yes

No

Is the connection of drain

pipe defective?

Is the insulation of drain

pipe defective?

Is the insulation of

refrigerant pipe defective?

Yes

No

Yes

No

Yes

No

Check the condition.

Blinking

LED

LD1 Reversed phase Phases L1, L2, and L3are con-

LD2

Diagnosis of malfunction Cause Check point

Check the power supply connection.

nected improperly.

Open phase ● Phase L2is open.

● Contact of protector, such as

● Check the power supply.

● Check each protector.

thermal switch, opened when

power was turned on.

LD3 Outdoor coil thermistor is

abnormal. (Open circuit or short

circuit)

LD4 High pressure switch (63H2)

function

LD5 Thermal relay (51C) function ● 51C was connected incor-

LD6 Thermal switch (26C) function ● 26C was connected incor-

LD7 Over heat protection ● The thermistor is broken.

LD8 Input circuit of outdoor con-

troller board is abnormal.

● Outdoor coil thermistor is

broken.

● Thermistor was connected

incorrectly.

● 62H2 was badly connected.

● 63H2 was working.

● Measure the resistance of the thermistor.

● Check the thermistor. If normal, replace the

outdoor controller board.

● Check 63H2 and the outdoor fan motor.

● Check if refrigerant supply is low.

● Check if air cycle is short-cycled.

● Check 51C, the compressor, and power supply.

rectly.

● 51C was working.

● Check 26C.

rectly.

● 26C was working.

● Check if refrigerant supply is low.

● Check if the capillary tube is clogged.

● Measure the resistance of the thermistor.

● Coil temperature is over

67°C.

● Check the outdoor fan motor.

● Check if air cycle is short-cycled.

● Pulse input is abnormal. ● Replace the outdoor controller board.

21

Page 22

Parts name

Check points

Disconnect the connector then measure the resistance using a tester.

(Ambient temperature 10:~30:)

OUTDOOR COIL

THERMISTOR

(RT)

Normal

4.3k"~9.6k"

Abnormal

Open or short circuit

Measure the resistance between the terminals using a tester.CRANKCASE

HEATER (HC)

Normal Abnormal

Open or short circuit

Measure the resistance between the terminals using a tester.

(

Ambient

temperature 20C°)

FAN MOTOR

(MF, MF1, MF2)

Motor lead wire

Abnormal

Open or short

circuit

Open or

short circuit

Open or

short circuit

White — Blue

Blue — Red

Red

Blue

White

Orange

Protector

OPEN :145i8:

CLOSE :90i15:

Protector

1.6, 2, 2.5, 3 4 5 6

Normal

68.8"

88.4"

94.1"

79.4"

143.0"

195.0"

117.4"

125.3"

Normal

Terminals

PUH-1.6V PUH-2V PUH-2.5V PUH-3V PUH-3Y PUH-4Y

Abnormal

RH247VFCT NH38VMDT NH41VMDT NH52VNHT NH52YDAT NH56YDAT

U-V(R-C)

U-W(S-C)

W-V

2.00"

4.55"

—

1.30"

2.70"

—

1.01"

2.25"

—

0.65"

1.57"

—

3.70"

3.70"

3.70"

3.50"

3.50"

3.50"

Winding resistance(")

Measure the resistance between the terminals using a tester.

at 20:

Normal

Terminals

PUH-5Y PUH-6Y

Abnormal

ZR61KC-TFD ZR68KC-TFD

T1-T2

T2-T3

T3-T1

2.53-2.91"

2.53-2.91"

2.53-2.91"

2.31"

2.31"

2.31"

at 25:

1.6 2, 2.5, 3, 4, 5, 6

1920"I7% 1516"I7%

U

V

W

49C

49C

49C

T3

T2

T1

COMPRESSOR

(MC)

[PUH-1.6-4]

[PUH-5.6]

8-3. HOW TO CHECK THE PARTS

PUH-1.6VKA.TH PUH-2.5VKA.TH PUH-3YKA.TH PUH-5YKSA.TH

PUH-1.6VKA

1.TH PUH-2.5VKA1.TH PUH-3YKA1.TH PUH-5YKSA1.TH

PUH-2VKA.TH PUH-3VKA.TH PUH-4YKSA.TH PUH-6YKSA.TH

PUH-2VKA

1.TH PUH-3VKA1.TH PUH-6YKSA1.TH

22

Page 23

8-4. OUTDOOR UNIT SERVICE FUNCTIONS (OUTDOOR CONTROLLER BOARD)

(1) Compulsory defrosting

1When all of the following conditions are satisfied, pressing SW2 starts the compulsory defrosting.

● During HEAT mode

● The compressor is ON.

● The outdoor coil temperature is being displayed by LED. (Outdoor controller board dip switch SW3-1 : OFF, SW3-2 :

ON)

● The outdoor coil thermistor reads 8°C or below.

2The operation state and the termination conditions of the compulsory defrosting are the same as those of the normal

defrosting. As an exception, the defrost interval after the defrosting completion is 50 minutes.

(2) Fixed fan-output

While the compressor is operating (except during defrosting) and the fan output step is indicated by LED, pressing SW2

fixes the fan output. The fixed fan-output can be released when any of the following conditions are satisfied.

1SW2 is pressed again.

2SW3 setting is changed.

3The compressor stops.

4Defrosting operation starts.

(3) Function of switches on the outdoor controller board

SW1: Clears the check code memory (push-button switch)

SW2: Switches the output state indication and the check code display (push-button switch)

SW3-1,2: Switches the output state indication items (dip switch)

(4) 100% fan output

Fan output is fixed to 100% by shorting the connector CN22. However, the fan stops during compressor OFF or defrosting.

Open-circuit of CN22 restarts the normal fan control.

(5) Time shortening

Short circuit of the connector CN21 shortens the time as follows

1Fan control period: 30 seconds → 3 seconds

2Three-minutes time delay function : 3 minutes → 3 seconds

3Max. time of defrosting : 15 minutes → 15 seconds

4Defrost interval : 30 ~ 120 minutes → 3 ~ 12 seconds

5Compressor ON/OFF time for bypass valve ON/OFF : 30 minutes → 3 seconds

6Compressor ON time to start other functions : x minutes → x seconds

7Crankcase heater operation : 1 hour → 6 seconds

(6) Crankcase heater control

1With jumper wire J3

The crankcase heater is ON the moment the power is turned ON until the compressor starts, and then turns ON again

one hour after the compressor stops.

2Without jumper wire J3

The crankcase heater is ON the moment the power is turned ON until the compressor starts, and repeats 1-hour ON

again and 1-hour OFF, after the compressor stops.

23

Page 24

9 DISASSEMBLY PROCEDURE

Service Ref. : PUH-2.5,3VKA.TH PUH-2.5,3VKA1.TH PUH-3YKA.TH PUH-3YKA1.TH

OPERATING PROCEDURE PHOTOS

1. Removing the electrical parts

(1)

Remove the 5 screws and the top panel. (3 screws in

front and 2 screws in rear

(2)

Remove the screw of the cover panel. To remove the

cover panel, pull it toward you and unhook the catches from the side panel.

(3)

Remove the screw of the service panel. To remove the

service panel, pull it down toward you and unhook the

catches on the both sides.

)

Photo 1

Screws

Front panel

Photo 2

Outdoor controller

board

Top panel

Service panel

Panel cover

Transformer Capacitor

Contactor

2. Removing the fan motor

(1)

Remove the 3 screws of the front panel. Open the

front panel to a 45-degree angle. Then lift it and

unhook the 3 catches to remove.

(2)

Remove the propeller nut and the propeller.

(3)

Remove the 3 screws and the fan motor.

Disconnect the lead connectors.

Photo 3

Propeller

Motor support

Overcurrent

relay

Terminal blockScrews

Separator support plate

High-pressure control

switch

Lead

connectors

Valve bed

24

Propeller nut Crankcase heater

Page 25

OPERATING PROCEDURE PHOTOS

3. Removing the heat exchanger and the compressor

(1)

Remove the rear panel (2 screws in front, 1 screw on

the side, 3 screws in the rear). Remove the valve bed,

and open the rear panel to the rear to remove.

NOTE :

All panels are fixed by catches, and must be removed by

shifting up and down.

(2)

Remove the 4 screws of the right side panel and

remove the right side panel.

(3)

Remove the 3 screws of the rear guard and remove

the rear guard.

(4)

Remove the 4 screws of the separator support plate

and remove the separator support plate.

(5)

Remove the 2 screws of the motor support and

remove the motor support.

(6)

Remove the 5 screws of the valve bed.

The valve bed is fixed by the catches on the right and

left sides.

Lift it to remove.

(7)

Remove the electrical parts box.

Disconnect the connectors from the high pressure

switch, crankcase heater, shell thermo, and fan motor

lead.

(8)

Remove the 2 screws of the separator and remove the

separator.

(9)

Remove the 2 screws of the heat exchanger and

remove the heat exchanger.

Detach the welded point of pipe.

)

(

Remove the 3 nuts of the compressor and remove the

10

compressor.

Detach the welded points of the compressor suction

pipe and discharge pipe.

Photo 4

Screws

Screws

Photo 5

Heat exchanger

Accumulator

25

Photo 6

Charge plug

Ball valve

Compressor

Page 26

10 PARTS LIST (non-RoHS compliant)

E02 214 297

—

E07 001 249

E07 001 009

E07 001 232

E07 001 521

E07 001 290

E07 003 290

—

E07 001 245

E07 001 006

E07 001 522

—

E07 001 523

1

2

3

4

5

6

7

8

9

10

11

12

13

Part No. SpecificationNo.

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Part Name

Q,ty/set

PUH-1.6 PUH-2

Remarks

(Drawing No.)

TOP PANEL

SCREW

LEFT SIDE PANEL

HANDLE

FRONT PANEL

FAN GUARD

BASE

BASE

MOTOR SUPPORT

SERVICE PANEL

PANEL COVER

REAR PANEL

LABEL

REAR GUARD

(Z004M203H10)

(BG00N264G06)

(JG79C180H02)

13PCS/SET

(5✕10)

VKA.TH / VKA1.TH

1

13

1

3

1

1

1

1

1

1

1

1

1

1

13

1

3

1

1

1

1

1

1

1

1

1

STRUCTURAL PARTS

PUH-1.6VKA.TH PUH-1.6VKA1.TH

PUH-2VKA.TH PUH-2VKA1.TH

1

13

12

114

SCREW

2

3

4

5

6

78 9 10

26

Page 27

PARTS LIST (non-RoHS compliant)

E02 214 297

—

E02 214 249

E07 003 232

E07 001 009

E02 527 521

E07 003 290

—

E07 003 245

E07 001 006

E07 003 522

—

E07 003 523

1

2

3

4

5

6

7

8

9

10

11

12

13

Q,ty/set

PUH- • KA.TH/KA1.TH

2.5/3V,3Y

(5✕10)

(Z004M203H10)

(SU02Y704G04)

(JG79C180H02)

Part No. SpecificationNo.

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Part Name

Remarks

(Drawing No.)

TOP PANEL

SCREW

LEFT SIDE PANEL

FRONT PANEL

HANDLE

FAN GUARD

BASE

MOTOR SUPPORT

SERVICE PANEL

PANEL COVER

REAR PANEL

LABEL

REAR GUARD

1

13

1

1

3

1

1

1

1

1

1

1

1

13PCS/SET

STRUCTURAL PARTS

PUH-2.5VKA.TH PUH-2.5VKA

PUH-3VKA.TH PUH-3VKA

PUH-3YKA.TH PUH-3YKA

1.TH

1.TH

1.TH

SCREW

13

12

1

2

3

11

4

5

5

6

78 9

10

27

Page 28

PARTS LIST (non-RoHS compliant)

STRUCTURAL PARTS

PUH-4YKSA.TH

SCREW

13

1011 912

87

1

6

2

3

5

43

Part No.

1

E07 005 232

2

E02 527 521

3

E07 001 009

4

E07 005 290

5

E07 001 006

6

E07 005 522

7

E07 005 245

8

9

E07 005 523

10

E02 214 297

11

12

13

E07 005 249

—

—

—

Part Name

FRONT PANEL

FAN GUARD

HANDLE

BASE

PANEL COVER

REAR PANEL

SERVICE PANEL

LABEL

REAR GUARD

TOP PANEL

MOTOR SUPPORT

SCREW

LEFT SIDE PANEL

SpecificationNo.

(5✕10)

Q,ty/set

PUH-4YKSA.TH

1

2

3

1

1

1

1

1

1

1

1

13

1

28

Remarks

(Drawing No.)

(JG79C180H02)

(BG00N264G08)

13PCS/SET

(Z004M203H10)

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Unit

Price

Amount

Page 29

PARTS LIST (non-RoHS compliant)

STRUCTURAL PARTS

PUH-5YKSA.TH PUH-5YKSA1.TH

PUH-6YKSA.TH PUH-6YKSA1.TH

SCREW

13

1011 912

87

1

6

2

3

5

43

Part No.

1

E07 016 232

2

E02 527 521

3

E07 001 009

4

E07 016 290

5

E07 016 006

6

E07 016 522

7

E07 016 245

8

9

E07 016 523

10

E07 016 297

11

12

13

E07 016 249

—

—

—

Part Name

FRONT PANEL

FAN GUARD

HANDLE

BASE

PANEL COVER

REAR PANEL

SERVICE PANEL

LABEL

REAR GUARD

TOP PANEL

MOTOR SUPPORT

SCREW

LEFT SIDE PANEL

SpecificationNo.

(5✕10)

29

Q,ty/set

PUH-

5,6YKSA.TH

5,6YKSA

1.TH

1

2

3

1

1

1

1

1

1

1

1

13

1

Remarks

(Drawing No.)

(JG79C180H02)

(BG00N264G08)

13PCS/SET

(Z004M203H10)

Wiring

Diagram

Symbol

Recommended

Q,ty

Unit

Price

Amount

Page 30

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-1.6VKA.TH

PUH-1.6VKA

1

1.TH

FUSE

21

2022

THERMISTOR

192328 2427 252629

18

2

NUT

3

17

16

15

14

13

12

11

10

9

8

5

4

6

7

30

Page 31

Part No. Part Name SpecificationNo.

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

Remarks

PUH-1.6

VKA.TH VKA1.TH

E07 011 301

E07 001 501

E07 070 508

E07 011 374

E07 006 375

E07 177 240

E07 001 900

E02 010 662

E07 001 661

E07 011 932

E07 001 641

E07 177 934

E07 011 492

E07 177 937

E02 096 642

E07 177 933

E07 011 490

E07 275 490

E07 011 387

E07 275 387

E07 011 307

E07 011 388

E07 012 299

E07 011 646

E07 001 340

E07 011 339

E07 278 339

E02 063 351

E02 816 353

E07 011 451

E07 275 451

E07 006 382

E07 011 630

E07 177 936

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

PK6V85-UA

M8

3P(1,2,3)

3P(L,N,;)

240V 30W

RH247VFCT

3/8˝

5/8˝

{3.2✕{1.8✕600mm

OFF : 2.55 MPa, ON : 2.1 MPa

2.5+ 440V AC

35+ 440V AC

250V 6.3A

{3.2✕{1.2✕300mm

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

TB3

TB1

HC

MC

21S4

21S4

RT

21R

63H1

52C

T

T

C1

C2

O.B

O.B

F(O.B)

OUTDOOR FAN MOTOR

PROPELLER FAN

NUT

TERMINAL BLOCK

TERMINAL BLOCK

CRANKCASE HEATER

COMPRESSOR

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

ACCUMULA T OR

CHARGE PLUG

STRAINER

BYP ASS V AL VE

CAPILLARY TUBE

RESTRICTOR V AL VE

STRAINER

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

4-WAY VALVE

PIPE TEMPERA TURE THERMISTOR

BYPASS VALVE SOLENOID COIL

OIL SEPARATOR

HIGH PRESSURE SWITCH

COMPRESSOR CONTACTOR

TRANSFORMER

TRANSFORMER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

FUSE

HEAT EXCHANGER

CAPILLARY TUBE

Q,ty/set

PARTS LIST (non-RoHS compliant)

Part number that is circled is not shown in the figures.

31

Page 32

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-2VKA.TH

PUH-2VKA1.TH

NUT

29

FUSE

28

20

THERMISTOR

192223 212427 2526

1

18

17

16

15

2

14

13

12

3

11

456 7 8 9

10

32

Page 33

PARTS LIST (non-RoHS compliant)

Part No. Part Name SpecificationNo.

1

E07 011 301

2

E07 001 501

3

E07 070 508

4

E07 011 374

5

E07 006 375

6

E07 011 492

7

E02 007 900

8

E07 011 240

9

E02 010 662

10

E07 001 661

11

E07 001 641

12

E07 011 934

13

E07 011 932

14

E07 011 933

15

E02 096 642

16

E07 011 936

E07 011 490

17

E07 275 490

E07 011 387

18

E07 275 387

19

E07 011 307

20

E07 011 388

21

E07 011 299

22

E07 011 646

23

E07 012 340

E07 011 339

24

E07 278 339

25

E02 063 351

26

E02 946 353

E07 011 451

27

E07 275 451

28

E07 006 382

29

E07 011 630

OUTDOOR FAN MOTOR

PROPELLER FAN

NUT

TERMINAL BLOCK

TERMINAL BLOCK

BYP ASS V AL VE

COMPRESSOR

CRANKCASE HEATER

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

CHARGE PLUG

STRAINER

ACCUMULATOR

STRAINER

RESTRICTOR V AL VE

CAPILLARY TUBE

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

4-WAY VALVE

PIPE TEMPERA TURE THERMISTOR

BYPASS VALVE SOLENOID COIL

OIL SEPARATOR

HIGH PRESSURE SWITCH

COMPRESSOR CONTACTOR

TRANSFORMER

TRANSFORMER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

FUSE

HEAT EXCHANGER

PK6V85-UA

M8

3P(1,2,3)

3P(L,N,;)

NH38VMDT

240V 38W

3/8˝

5/8˝

{4.0✕{2.0✕430mm

OFF : 2.55MPa, ON : 2.1MPa

S-N18EX

2.5+ 440V AC

50+ 440V AC

250V 6.3A

Q,ty/set

PUH-2

VKA.TH

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

VKA1.TH

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

Wiring

Diagram

Symbol

MF

TB3

TB1

MC

HC

21S4

21S4

RT

21R

63H1

52C

T

T

C1

C2

O.B

O.B

F(O.B)

Recommended

Q,ty

Unit

Price

Amount

33

Page 34

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-2.5VKA.TH

PUH-2.5VKA1.TH

FUSE

30

1

2425 232629 2728

22 21

20

THERMISTOR

19

NUT

2

18

17

16

15

3

14

13

87654 9 10 11 12

34

Page 35

PARTS LIST (non-RoHS compliant)

Part No. Part Name SpecificationNo.

E07 011 301

1

E07 001 501

2

E07 070 508

3

E07 011 374

4

E07 011 646

5

E07 006 375

6

E07 001 641

7

E07 179 900

8

E07 011 240

9

E02 010 662

10

E02 010 661

11

E07 012 641

12

E07 003 932

13

E07 013 933

14

E07 011 492

15

E07 012 933

16

E07 012 936

17

E02 096 642

18

E07 011 307

19

E07 012 490

20

E07 278 490

E07 011 387

21

E07 275 387

E07 012 388

22

E07 012 299

23

E07 012 340

24

E07 012 339

25

E07 281 339

E02 138 351

26

E07 178 353

27

E07 011 451

28

E07 275 451

E07 006 382

29

E07 012 630

30

OUTDOOR FAN MOTOR

PROPELLER FAN

NUT

TERMINAL BLOCK

HIGH PRESSURE SWITCH

TERMINAL BLOCK

CHARGE PLUG

COMPRESSOR

CRANKCASE HEATER

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

CHARGE PLUG

ACCUMULATOR

STRAINER

BYP ASS V AL VE

STRAINER

CAPILLARY TUBE

RESTRICTOR V AL VE

PIPE TEMPERA TURE THERMISTOR

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

4-WAY VALVE

BYPASS VALVE SOLENOID COIL

OIL SEPARATOR

COMPRESSOR CONTACTOR

TRANSFORMER

TRANSFORMER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

FUSE

HEAT EXCHANGER

PK6V85-UA

M8

3P(1,2,3)

OFF : 2.55 MPa, ON : 2.1 MPa

3P(L,N,;)

NH41VMDT

240V 38W

3/8˝

5/8˝

{4.0✕{2.4✕1550mm

S-N18EX

3+ 440V AC

45+ 440V AC

250V 6.3A

Q,ty/set

PUH-2.5

VKA.TH

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

VKA1.TH

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

Wiring

Diagram

Symbol

MF

TB3

63H1

TB1

MC

HC

RT

21S4

21S4

21R

52C

T

T

C1

C2

O.B

O.B

F(O.B)

Recommended

Q,ty

Unit

Price

Amount

35

Page 36

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-3VKA.TH

PUH-3VKA1.TH

PUH-3YKA.TH

PUH-3YKA1.TH

28

29

30

1

2

FUSE

2325 24 222627

21 20 19

18

THERMISTOR

17

16

NUT

15

3

14

13

12

11

65478910

36

Page 37

PARTS LIST (non-RoHS compliant)

Part No. Part Name

Specification

No.

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Remarks

VKA1 YKA YKA1

.TH

VKA

PUH-3

Q,ty/set

E07 011 301

E07 001 501

E07 070 508

E07 011 646

E07 001 641

E02 890 900

E07 014 900

E07 011 240

E02 010 662

E02 010 661

E07 012 641

E07 005 308

E07 013 933

E07 003 932

E07 012 933

E07 011 492

E02 096 642

E07 011 307

E07 013 936

E07 011 387

E07 275 387

E07 012 490

E07 278 490

E07 012 388

E07 012 299

E02 010 342

E07 014 340

E02 138 351

E07 012 339

E07 281 339

E07 006 382

E07 006 375

E07 005 374

E07 011 451

E07 275 451

E07 014 451

E07 278 451

E07 011 374

E07 013 630

E02 177 353

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

PK6V85-UA

M8

NH52VNHT

NH52YDAT

240V 38W

3/8"

5/8"

[4.0O[2.4O1070mm

S-N25EX

MSO-N11KF

3+ 440V AC

250V 6.3A

3P(L,N,;)

5P(L1,L2,L3,N,;)

3P(1,2,3)

60+ 440V AC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

63H1

MC

MC

HC

26C

RT

21S4

21S4

21R

52C

51C,52C

C1

T

T

F(O.B)

TB1

TB1

O.B

O.B

O.B

O.B

TB3

C2

OUTDOOR FAN MOTOR

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

CHARGE PLUG

COMPRESSOR

COMPRESSOR

CRANKCASE HEATER

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

CHARGE PLUG

THERMAL SWITCH

STRAINER

ACCUMULATOR

STRAINER

BYP ASS V AL VE

RESTRICTOR V AL VE

PIPE TEMPERA TURE THERMISTOR

CAPILLARY TUBE

4-WAY VALVE

4-WAY VALVE

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

OIL SEPARATOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

TRANSFORMER

TRANSFORMER

FUSE

TERMINAL BLOCK

TERMINAL BLOCK

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

TERMINAL BLOCK

HEAT EXCHANGER

COMPRESSOR CAPACITOR

OFF : 2.55MPa

ON : 2.1MPa

Part number that is circled is not shown in the figures.

37

Page 38

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-4YKSA.TH

FUSE

28

1

29 26

2

3

27

25

24

23

22

NUT

NUT

THERMISTOR

4

21

7

2

20

19

18

3

17

16

15

4

14

13

12

861

7

109

115

38

Page 39

PARTS LIST (non-RoHS compliant)

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Part No. Part Name Specification

1

E07 015 301

2

E07 015 630

3

E07 001 501

4

E07 070 508

5

E07 011 646

6

E07 015 388

7

E07 001 641

8

E07 011 492

9

E07 015 900

E07 015 240

E02 010 662

E07 005 661

E07 005 308

E07 015 299

E07 015 934

E07 015 490

E07 015 387

E07 015 933

E07 181 642

E07 015 936

E07 015 307

E07 015 932

E07 015 340

E02 064 351

E07 012 339

E07 006 382

E07 014 451

E07 005 374

E07 011 374

OUTDOOR FAN MOTOR

OUTDOOR HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

BYPASS VALVE SOLENOID COIL

CHARGE PLUG

BYP ASS V AL VE

COMPRESSOR

CRANKCASE HEATER

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

THERMAL SWITCH

OIL SEPARATOR

STRAINER

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

STRAINER

RESTRICTOR V AL VE

CAPILLARY TUBE

PIPE TEMPERA TURE THERMISTOR

ACCUMULA TOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

TRANSFORMER

FUSE

OUTDOOR CONTROLLER BOARD

TERMINAL BLOCK

TERMINAL BLOCK

PK6V60-UA

M8

OFF : 2.55MPa

ON : 2.1MPa

NH56YDAT

240V 38W

3/8˝

3/4˝

{3.2✕{2.0✕820mm

MSO-N20KF 230VAC

4+ 440V AC

250V 6.3A

5P(L1,L2,L3,N,;)

3P(1,2,3)

Q,ty/set

PUH-4YKSA.TH

2

2

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

Remarks

Wiring

Diagram

Symbol

Recommended

Q,ty

MF1,2

63H1

21R

MC

HC

26C

21S4

RT

51C,52C

C1,2

T

F(O.B)

O.B

TB1

TB3

Unit

Price

Amount

39

Page 40

PARTS LIST (non-RoHS compliant)

FUNCTIONAL PARTS

PUH-5YKSA.TH

PUH-5YKSA1.TH

PUH-6YKSA.TH

PUH-6YKSA1.TH

FUSE

2

3

221 29 28 26 2527 24 23

15

THERMISTOR

21

NUT

NUT

4

20

19

2

18

17

16

3

15

14

13

4

12

11

10

1

856 7

9

40

Page 41

PARTS LIST (non-RoHS compliant)

Part numbers that are circled are not shown in the figures.

No.

E07 016 301

1

E07 017 301

E07 016 630

2

E07 017 630

3

E07 001 501

4

E07 070 508

5

E07 016 646

6

E07 016 305

E07 016 900

7

E07 017 900

8

E07 016 240

9

E02 010 662

10

E07 005 661

11

E07 016 933

12

E07 015 299

E07 017 492

13

E07 282 492

E07 016 389

E07 017 389

14

E07 281 388

E07 282 388

15

E07 001 641

E07 087 490

E07 016 490

16

E07 282 490

E07 283 490

E07 016 387

E07 017 387

17

E07 281 387

E07 282 387

18

E07 015 933

E07 016 936

19

E07 017 936

20

E07 181 642

21

E07 016 307

22

E07 016 932

23

E07 087 340

E02 138 351

24

E02 064 351

E07 012 339

25

E07 281 339

26

E07 006 382

E07 016 451

27

E07 282 451

28

E07 005 374

29

E07 011 374

30

E07 017 341

31

E07 082 936

Part No.

Part Name Specification

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

THERMAL SWITCH

COMPRESSOR

COMPRESSOR

CRANKCASE HEATER

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

STRAINER

OIL SEPARATOR

BYP ASS V AL VE

BYP ASS V AL VE

BYPASS VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

CHARGE PLUG

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

4-WAY VALVE

4-WAY VALVE

4-WAY VALVE

STRAINER

CAPILLARY TUBE

CAPILLARY TUBE

RESTRICTOR V AL VE

PIPE TEMPERA TURE THERMISTOR

ACCUMULA TOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

FAN MOTOR CAPACITOR

TRANSFORMER

TRANSFORMER

FUSE

OUTDOOR CONTROLLER BOARD

OUTDOOR CONTROLLER BOARD

TERMINAL BLOCK

TERMINAL BLOCK

RELAY

CAPILLARY TUBE

PK6V45-UA

PK6V65-UA

OFF : 2.55MPa

ON : 2.1MPa

ZR61KCTFD

ZR68KCTFD

240V 38W

3/8˝

3/4˝

{4.0✕{2.4✕840mm

{4.0✕{2.4✕1200mm

MSO-N20KF 230VAC

3+ 440V AC

4+ 440V AC

250V 6.3A

5P(L1,L2,L3,N,;)

3P(1,2,3)

LY2F 240V10A

{4.0✕{3.0✕200mm

Q,ty/set

PUH-5 PUH-6

YKSA YKSA1 YKSA YKSA1

.TH

2

2

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

Remarks

Wiring

Diagram

Symbol

MF1,2

MF1,2

63H1

26C

MC

MC

HC

21R

21R

21R

21R

21S4

21S4

21S4

21S4

RT

51C,52C

C1,C2

C1,C2

T

T

F(O.B)

O.B

O.B

TB1

TB3

X15

Recom-

mended

Q,ty

Unit

Price

Amount

41

Page 42

11 RoHS PARTS LIST (RoHS compliant)

13

1

1

3

1

1

1

1

1

1

1

1

1

13

1

1

3

1

1

1

1

1

1

1

1

1

—

E17 001 249

E12 214 249

E17 001 232

E17 003 232

E17 001 009

E17 001 521

E12 527 521

E17 001 290

E17 003 290

—

—

E17 001 245

E17 003 245

E17 001 006

E17 001 522

E17 003 522

—

E17 001 523

E17 003 523

E12 214 297

1

2

3

4

5

6

7

8

9

10

11

12

13

Part No.

No.

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

RoHS

Wiring

Diagram

Symbol

Recommended

Q,ty

Unit

Amount

Remarks

(

Drawing No.

)

Part Name

Specifications

F.ST SCREW

LEFT SIDE PANEL

LEFT SIDE PANEL

FRONT PANEL

FRONT PANEL

HANDLE

FAN GUARD

FAN GUARD

BASE

BASE

MOTOR SUPPORT

MOTOR SUPPORT

SERVICE PANEL

SERVICE PANEL

PANEL COVER

REAR PANEL

REAR PANEL

LABEL

REAR GUARD

REAR GUARD

TOP PANEL

Price

(JG79C180H02)

(SU02Y704G04)

(BG00N264G06)

(5✕10)

PUH- • KA1.TH

1.6V

13

1

1

3

1

1

1

1

1

1

1

1

1

2V

2.5/3V,3Y

13PCS/SET

(Z004M203H10)

Q,ty/set

STRUCTURAL PARTS

PUH-1.6VKA1.TH PUH-3VKA1.TH

PUH-2VKA1.TH PUH-3YKA1.TH

PUH-2.5VKA1.TH

13 121

11104

2

3

4

5

67 89

42

Page 43

RoHS PARTS LIST (RoHS compliant)

STRUCTURAL PARTS

PUH-4YKSA.TH

PUH-5YKSA1.TH

PUH-6YKSA1.TH

1011 912

87

13

1

6

2

3

5

43

Q,ty/set

Part No.

RoHS

G

1

2

3

4

5

6

7

8

9

10

11

12

13

E17 005 232

G

E17 016 232

G

E12 527 521

G

E17 001 009

G

E17 005 290

G

E17 016 290

G

E17 001 006

G

E17 016 006

G

E17 005 522

G

E17 016 522

G

E17 005 245

G

E17 016 245

G

G

E17 005 523

G

E17 016 523

G

E12 214 297

G

E17 016 297

G

G

G

E17 005 249

G

E17 016 249

—

—

—

Part Name

FRONT PANEL

FRONT PANEL

FAN GUARD

HANDLE

BASE

BASE

PANEL COVER

PANEL COVER

REAR PANEL

REAR PANEL

SERVICE PANEL

SERVICE PANEL

LABEL

REAR GUARD

REAR GUARD

TOP PANEL

TOP PANEL

MOTOR SUPPORT

F.ST SCREW

LEFT SIDE PANEL

LEFT SIDE PANEL

SpecificationNo.

(5✕10)

PUH-4

YKSA.TH

1

2

3

1

1

1

1

1

1

1

1

13

1

PUH-5,6

YKSA1.TH

1

2

3

1

1

1

1

1

1

1

1

13

1

Remarks

(Drawing No.)

(JG79C180H02)

(BG00N264G08)

13PCS/SET

(Z004M203H10)

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Unit

Price

Amount

43

Page 44

RoHS PARTS LIST (RoHS compliant)

FUNCTIONAL PARTS

PUH-1.6VKA

1

1.TH

FUSE

21

2022

THERMISTOR

192328 2427 252629

18

2

NUT

3

17

16

15

14

13

12

11

10

9

8

5

4

6

7

44

Page 45

Q,ty/set

Part No.

RoHS

Part Name SpecificationNo.

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

Remarks

PUH-

1.6VKA

1

.TH

E17 011 301

E17 001 501

E17 070 508

E17 011 374

E17 006 375

E17 177 240

E17 001 900

E12 010 662

E17 001 661

E17 011 932

E17 001 641

E17 177 934

E17 011 492

E17 177 937

E12 096 642

E17 177 933

E17 275 490

E17 275 387

E17 011 307

E17 011 388

E17 012 299

E17 011 646

E17 001 340

E17 278 339

E12 063 351

E12 816 353

E17 275 451

E17 006 382

E17 011 630

E17 177 936

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

PK6V85-UA

M8

3P(1,2,3)

3P(L,N,;)

240V 30W

RH247VFCT

3/8˝

5/8˝

{3.2✕{1.8✕600mm

OFF : 2.55 MPa, ON : 2.1 MPa

2.5+ 440V AC

35+ 440V AC

250V 6.3A

{3.2✕{1.2✕300mm

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

TB3

TB1

HC

MC

21S4

RT

21R

63H1

52C

T

C1

C2

O.B

F(O.B)

OUTDOOR FAN MOTOR

PROPELLER FAN

NUT

TERMINAL BLOCK

TERMINAL BLOCK

CRANKCASE HEATER

COMPRESSOR

BALL V AL VE (LIQ)

BALL V AL VE (GAS)

ACCUMULA T OR

CHARGE PLUG

STRAINER

BYP ASS V AL VE

CAPILLARY TUBE

RESTRICTOR V AL VE

STRAINER

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

PIPE TEMPERA TURE THERMISTOR

BYPASS VALVE SOLENOID COIL

OIL SEPARATOR

HIGH PRESSURE SWITCH

COMPRESSOR CONTACTOR

TRANSFORMER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

OUTDOOR CONTROLLER BOARD

FUSE

HEAT EXCHANGER

CAPILLARY TUBE

RoHS PARTS LIST (RoHS compliant)

Part number that is circled is not shown in the figures.

45

Page 46

RoHS PARTS LIST (RoHS compliant)

FUNCTIONAL PARTS

PUH-2VKA1.TH

NUT

29

FUSE

28

20

THERMISTOR

192223 212427 2526

1

18

17

16

15

2

14

13

12

3

11

456 7 8 9

10

46

Page 47

RoHS PARTS LIST (RoHS compliant)

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

RoHS

1