Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT -TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R407C

Outdoor unit

[model names]

No.OC261

REVISED EDITION-B

PUH-P1VGAA

PUH-P1.6VGAA PU-P1.6VGAA

PUH-P1.6YGAA PU-P1.6YGAA

PUH-P2VGAA PU-P2VGAA

PUH-P2YGAA PU-P2YGAA

PUH-P2.5VGAA PU-P2.5VGAA

PUH-P2.5YGAA PU-P2.5YGAA

PUH-P3VGAA PU-P3VGAA

PUH-P3YGAA PU-P3YGAA

PUH-P4VGAA PU-P4VGAA

PUH-P4YGAA PU-P4YGAA

PUH-P5YGAA PU-P5YGAA

PUH-P6YGAA PU-P6YGAA

Service Ref. is on page 2.

Revision:

• [PUH-5, 6YGAA1.UK PU-5, 6YGAA1.UK]

TECHNICAL CHANGES, SPECIFICATIONS,

DATAand PARTS LIST have been partially

modified.

COMPRESSOR CONVERSION KIT(TFD-230)

has been added to the PARTS LIST(page 69).

• Please void OC261 REVISED EDITION-A.

CONTENTS

1. TECHNICAL CHANGES ·································3

2. SAFETY PRECAUTION··································4

3.

COMBINATION OF INDOOR AND OUTDOOR UNITS

4. PART NAMES AND FUNCTIONS··················7

5. SPECIFICATIONS···········································8

6. DATA·····························································15

7. OUTLINES AND DIMENSIONS····················18

8. WIRING DIAGRAM·······································22

9. WIRING SPECIFICATIONS··························26

10.

REFRIGERANT SYSTEM DIAGRAM

11. TROUBLESHOOTING···································31

12. DISASSEMBLY PROCEDURE ·····················36

13. PARTS LIST··················································40

14. OPTIONAL PARTS························Back Cover

··············27

···6

Model name indication

Page 2

[Service Ref.]

PUH-P1VGAA.UK

PUH-P1.6VGAA.UK PU-P1.6VGAA.UK

PUH-P1.6YGAA.UK PU-P1.6YGAA.UK

PUH-P2VGAA.UK PU-P2VGAA.UK

PUH-P2YGAA.UK PU-P2YGAA.UK

PUH-P2.5VGAA.UK PU-P2.5VGAA.UK

PUH-P2.5YGAA.UK PU-P2.5YGAA.UK

PUH-P3VGAA.UK PU-P3VGAA.UK

PUH-P3YGAA.UK PU-P3YGAA.UK

PUH-P4VGAA.UK PU-P4VGAA.UK

PUH-P4YGAA.UK PU-P4YGAA.UK

PUH-P5YGAA.UK PU-P5YGAA.UK

PUH-P6YGAA.UK PU-P6YGAA.UK

PUH-P1VGAA1.UK

PUH-P1.6VGAA1.UK PU-P1.6VGAA1.UK

PUH-P1.6YGAA1.UK PU-P1.6YGAA1.UK

PUH-P2VGAA1.UK PU-P2VGAA1.UK

PUH-P2YGAA1.UK PU-P2YGAA1.UK

PUH-P2.5VGAA1.UK PU-P2.5VGAA1.UK

PUH-P2.5YGAA1.UK PU-P2.5YGAA1.UK

PUH-P3VGAA1.UK PU-P3VGAA1.UK

PUH-P3YGAA1.UK PU-P3YGAA1.UK

PUH-P4VGAA1.UK PU-P4VGAA1.UK

PUH-P4YGAA1.UK PU-P4YGAA1.UK

PUH-P5YGAA1.UK PU-P5YGAA1.UK

PUH-P6YGAA1.UK PU-P6YGAA1.UK

2

Page 3

1 TECHNICAL CHANGES

(REVISED EDITION-A)

PUH-P1, 1.6, 2, 2.5, 3, 4VGAA.UK ➔ PUH-P1, 1.6, 2, 2.5, 3, 4VGAA1.UK

PUH-P1.6, 2, 2.5, 3, 4YGAA.UK ➔ PUH-P1.6, 2, 2.5, 3, 4YGAA

PU-P1.6, 2, 2.5, 3, 4VGAA.UK ➔ PU-P1.6, 2, 2.5, 3, 4VGAA1.UK

PU-P1.6, 2, 2.5, 3, 4YGAA.UK ➔ PU-P1.6, 2, 2.5, 3, 4YGAA

● Strainer (#50) for stop valve of liquid pipe side and Filter Drier are not used.

(REVISED EDITION-A)

PUH-P1, 1.6, 2, 2.5, 3, 4VGAA.UK ➔ PUH-P1, 1.6, 2, 2.5, 3, 4VGAA

PUH-P1.6, 2, 2.5, 3, 4, 5, 6YGAA.UK ➔ PUH-P1.6, 2, 2.5, 3, 4, 5, 6YGAA

PU-P1.6, 2, 2.5, 3, 4VGAA.UK ➔ PU-P1.6, 2, 2.5, 3, 4VGAA1.UK

PU-P1.6, 2, 2.5, 3, 4, 5, 6YGAA.UK ➔ PU-P1.6, 2, 2.5, 3, 4, 5, 6YGAA1.UK

● Microcomputer of Outdoor Controller Board has changed since Filter Drier is not used.

(The limit of discharging temperature has been added.)

(REVISED EDITION-A)

PUH-P5YGAA.UK ➔ PUH-P5YGAA

● The method of connecting the Compressor ’s terminals has changed from Faston type to

1.UK

Screw type.

1.UK

1.UK

1.UK

1.UK

(REVISED EDITION-B)

PUH-P5YGAA1.UK PUH-P6YGAA1.UK

PU-P5YGAA1.UK PU-P6YGAA1.UK

● Compressor has changed due to the change in refrigerant oil.

Refrigerant oil : 3MA-POE ➔ 3MAW-POE

Compressor model : ZR61KCE-TFD-522 ➔ ZR61KCW-TFD-522

ZR72KCE-TFD-522 ➔ ZR72KCW-TFD-522

3

Page 4

2

SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

· Do not use copper pipes which are broken, deformed or discolour .

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

-The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

-If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

· Use a vacuum pump with a reverse flow check valve.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

· Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge,

refrigerant recovery equipment)

-If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerant oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

· Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

· Be especially careful when managing the tools.

-if dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

· Do not use the drier which is sold in the field.

-The drier for R407C refrigerant is pre-attached to outdoor unit refrigerant circuit.

-Some drier in the field are not in conformity with R407C refrigerant.

4

Page 5

Gravimeter

Unit

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair

·After recovering the all refrigerant in the unit, perform repair work.

·Do not release refrigerant in the air.

·After completing the repair work, recharge the specified amount of liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

5

Page 6

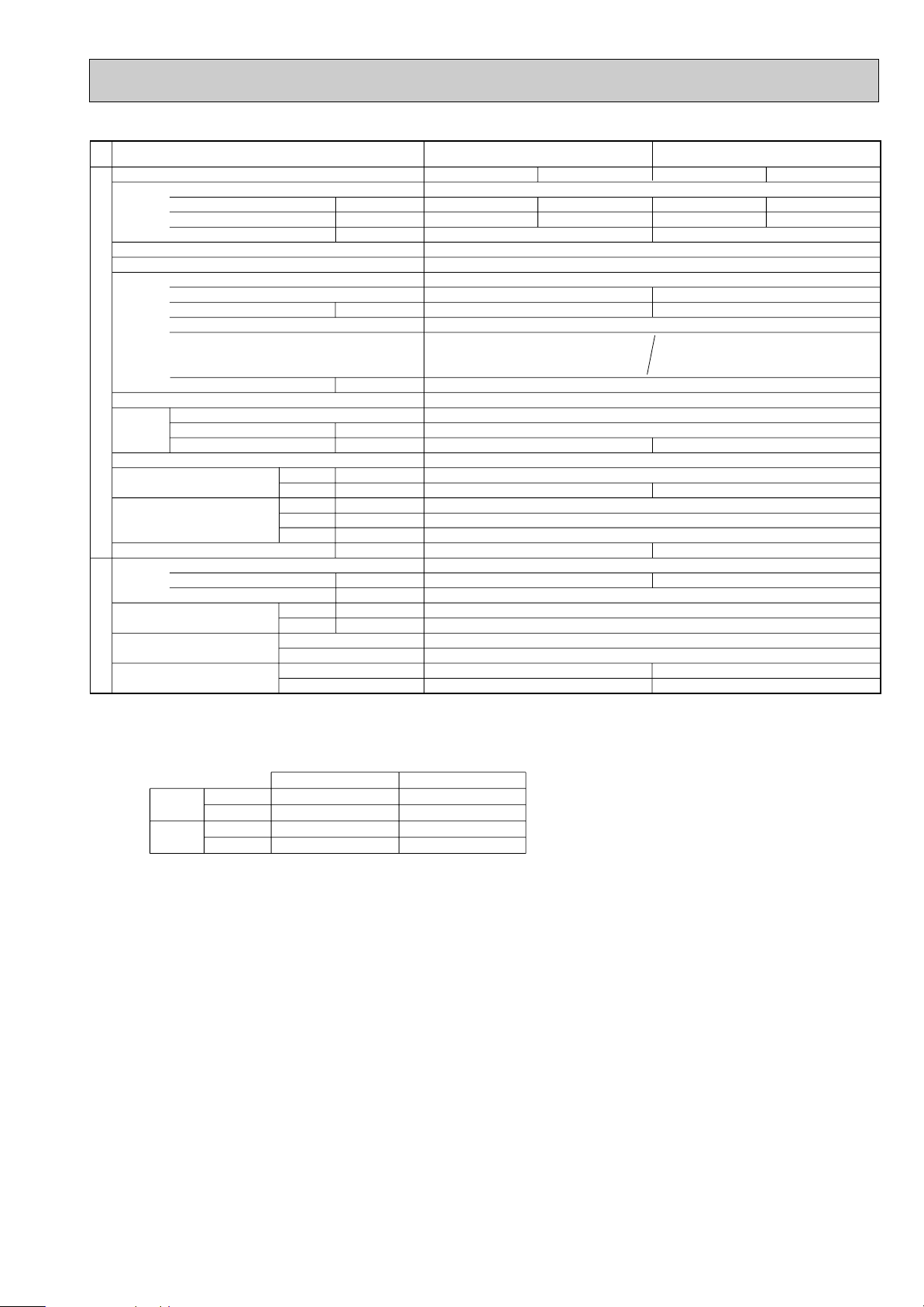

3 COMBINATION OF INDOOR AND OUTDOOR UNITS

Heat pump type

Outdoor unit

PUH-P • GAA.UK

PUH-P • GAA

1.UK

Cooling only type

PU-P • GAA.UK

PU-P • GAA1.UK

PEHD-P·

EAH

PCH-P·GAH

1

PKH-P·GALH

1

PKH-P·FALH

2

PSH-P·GAH

1

PLH-P·KAH

1

.UK

PLH-P·AAH

1

.UK

PEAD-P·

EA

PCA-P·GA

1

PKA-P·GAL

1

PKA-P·FAL

2

PSA-P·GA

1

PLA-P·KA1.UK

PLA-P·AA1.UK

PMH-P·BA

1

PMH-P·BA

2

PCA-P·HA

MEE 01K048

OC182

OC176

OC175

OC212

OC235

OC236

MEE 01K048

OC182

OC176

OC175

OC212

OC240

OC241

OC238

OC279

OC289

Y

—

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

V

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

Indoor unit

1.6Service

Manual No.

Service Ref.

2 2.5 3 4 5 6 1.6 2 2.5 3 4 5 6

Heat pump with

electric heater

Heat pump without

electric heater or

Cooling only

REVISED

EDITION-B

REVISED

EDITION-B

REVISED

EDITION-B

REVISED

EDITION-B

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-B

REVISED

EDITION-B

REVISED

EDITION-B

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

1

V

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

—

—

—

—

V

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Y

—

—

—

—

—

—

—

—

—

—

—

—

—

6

Page 7

4 PART NAMES AND FUNCTIONS

Air intake

Air outlet

(Expels warm air during cooling)

Air intake

Air outlet

Air intake

Air outlet

Air intake

Air outlet

PUH-P1VGAA.UK

PU(H)-P1.6VGAA.UK

PU(H)-P1.6YGAA.UK

PUH-P1VGAA

PU(H)-P1.6VGAA

PU(H)-P1.6YGAA

1.UK

1.UK

1.UK

PU(H)-P2VGAA.UK PU(H)-P2YGAA.UK

PU(H)-P2.5VGAA.UK PU(H)-P2.5YGAA.UK

PU(H)-P3VGAA.UK PU(H)-P3YGAA.UK

PU(H)-P2VGAA

PU(H)-P2.5VGAA

PU(H)-P3VGAA

1.UK PU(H)-P2YGAA1.UK

1.UK PU(H)-P2.5YGAA1.UK

1.UK PU(H)-P3YGAA1.UK

PU(H)-P4VGAA.UK

PU(H)-P4YGAA.UK

PU(H)-P4VGAA

PU(H)-P4YGAA

CHARGELESS SYSTEM

1.UK

1.UK

PU(H)-P5YGAA.UK

PU(H)-P6YGAA.UK

PU(H)-P5YGAA1.UK

PU(H)-P6YGAA

1.UK

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR PIPING LENGTH AT SHIPMENT.

(Max.20m(PU(H)-P1~P2.5) / 30m(PU(H)-P3~P6))

The refrigerant circuit with LEV(Linear Expansion Valve) and a large accumulator always control the optimal refrigerant

level regardless of the length (20/30m max. and 5m min.) of piping. The additional refrigerant charging work during

installation often causes problems. Heretofore it is completely eliminated. This unique system improves the quality

and reliability of the work done.It also helps to speed up the installation time.

7

Page 8

5 SPECIFICATIONS

kW

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

OUTDOOR UNIT

REFRIGERANT PIPING

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C(43˚F)

Refrigerant piping length (one way) : 5m (16ft)

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3 phase 415V 50Hz

2. Guaranteed operating range

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

Service Ref.

PUH-P1VGAA.UK

PUH-P1VGAA

1.UK

PUH-P1.6VGAA / YGAA.UK

PUH-P1.6VGAA

1 / YGAA1.UK

Cooling

1.11

4.92

Single,50Hz,220-230-240V

30

RE189VHSMT

0.9

45(1,590)

46

48

50(110)

1.7(3.8)

6.35(1/4)

12.7(1/2)

Max. 30m

Max. 30m

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

30

Plate fin coil

Propeller (direct) o 1

0.07

Reverse cycle

900(35-7/16)

330+20(13+3/4)

650(25-5/8)

R407C

0.57(Ester)MEL56

Flared

Flared

Heating

1.02

4.52

Cooling

1.59

7.36 / 2.49

Single,50Hz,220-230-240V / 3-ph,50Hz,380-400-415V

36/20

RE277VHSMT/RE277YFKM

1.3

45(1,590)

47

49

55(121)

2.5(5.5)

9.52(3/8)

15.88(5/8)

Max. 40m

Max. 40m

Heating

1.64

7.59 / 2.56

Internal thermostat

HP switch

Discharge thermo

Thermal relay

HP switch

Discharge thermo

Internal thermostat

HP switch

Discharge thermo

1. Heat pump

8

Page 9

Service Ref.

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

kW

A

A

PUH-P2VGAA / YGAA.UK

PUH-P2VGAA

Cooling

1 / YGAA1.UK

Heating

Single, 50Hz, 220-230-240V/3-ph, 50Hz, 380-400-415V(4wires)

2.29

10.26 / 3.70

2.36

10.57 / 3.82

62 / 31

External finish

Refrigerant control

Compressor

Model

Motor output

kW

NE36VMJMT / NE36YEKMT

1.6

Starter type

Protection devices

Crankcase heater

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Fan motor output

Airflow

kW

/min(CFM

K

W

)

55(1,940)

Internal thermostat

Discharge thermo

Defrost method

Noise level

Dimensions

Weight

Cooling

Heating

W

D

H

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

49

71(157)

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Liquid

Gas

Indoor side

kg(lbs)

L

mm(in.)

mm(in.)

2.6(5.7)

Outdoor side

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Height difference

Piping length

Max. 40m

Max. 40m

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C(43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3 phase 415V 50Hz

PUH-P2.5VGAA / YGAA.UK

PUH-P2.5VGAA

Cooling

2.77

11.90 / 4.48

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE41VMJMT / NE41YEKMT

Line start

Thermal relay

HP switch

HP switch

Discharge thermo

38

Plate fin coil

Propeller (direct) o 1

0.07

Reverse cycle

48

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

R407C

1.2 (Ester)MEL56

9.52(3/8)

15.88(5/8)

Flared

Flared

1 / YGAA1.UK

Heating

2.68

11.51 / 4.34

77 / 35

1.9

50(1,770)

50

82(181)

3.1(6.8)

Max. 50m

Max. 50m

9

Page 10

Service Ref.

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

kW

A

A

PUH-P3VGAA / YGAA.UK

PUH-P3VGAA1 / YGAA1.UK

Cooling

Heating

Single, 50Hz, 220-230-240V/3-ph, 50Hz, 380-400-415V(4wires)

3.27

14.81 / 5.29

3.48

15.76 / 5.63

93 / 47

External finish

Refrigerant control

Compressor

Model

Motor output

kW

NE52VNJMT / NE52YDKMT

2.5

Starter type

Protection devices

Crankcase heater

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Fan motor output

Airflow

/min(CFM

K

W

kW

Propeller (direct) o 1

)

50(1,770)

Internal thermostat

Discharge thermo

0.07

Defrost method

Noise level

Dimensions

Weight

Cooling

Heating

W

D

H

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

49

51

855(33-5/8)

82(181)

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Liquid

Gas

Indoor side

kg(lbs)

L

mm(in.)

mm(in.)

3.3(7.3)

15.88(5/8)

Outdoor side

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Height difference

Piping length

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C(43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3 phase 415V 50Hz

PUH-P4VGAA / YGAA.UK

PUH-P4VGAA

Cooling

3.43

15.71 / 5.55

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE56VNJMT / NE56YDKMT

Line start

HP switch

Thermal relay

HP switch

Discharge thermo

38

Plate fin coil

Reverse cycle

900(35-7/16)

330+20(13+3/4)

R407C

1.3 (Ester)MEL56

9.52(3/8)

Flared

Flared

Max. 50m

Max. 50m

1 / YGAA1.UK

Heating

3.62

16.58 / 5.86

99 / 49

2.7

Propeller (direct) o 2

0.07+0.07

85(3,000)

51

53

1,260(49-5/8)

96(212)

4.0(8.8)

19.05(3/4)

10

Page 11

Service Ref.

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

kW

A

A

PUH-P5YGAA.UK

PUH-P5YGAA

Cooling

4.70

7.60

1.UK

Heating

3-ph, 50Hz, 380-400-415V(4wires)

5.04

8.15

65.5

External finish

Refrigerant control

Linear Expansion Valve

Compressor

Model

ZR61KCE-TFD-230 (YGAA.UK)

ZR61KCW-TFD-522 (YGAA

Motor output

kW

3.5

Starter type

Protection devices

Crankcase heater

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Fan motor output

Airflow

K

/min(CFM

W

kW

)

Internal thermostat, thermal relay, HP switch, Discharge thermo

95(3,360)

Defrost method

Noise level

Dimensions

Weight

Cooling

Heating

W

D

H

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

55

56

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Liquid

Gas

Indoor side

kg(lbs)

L

mm(in.)

mm(in.)

4.6(10.1)

1.690 (Ester) 3MAW-POE

Outdoor side

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Height difference

Piping length

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

Cooling

Munsell 5Y 7/1

Hermetic

1.UK)

Line start

38

Plate fin coil

Propeller (direct) o 2

0.07 +0.07

Reverse cycle

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

122(269)

R407C

1.774 (Ester) 3MAW-POE

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

PUH-P6YGAA.UK

PUH-P6YGAA

5.58

9.03

74

ZR72KCW-TFD-522

4.2

100(3,530)

57

58

4.9(10.8)

1.UK

Heating

5.91

9.56

11

Page 12

2. Cooling only type

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Charge

Oil (Model)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Refrigerant piping length (one way) : 5m (16ft)

/min(CFM

K

Cooling

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

kW

A

A

kW

W

kW

dB

L

PU-P1.6VGAA / YGAA.UK

PU-P1.6VGAA1 / YGAA1.UK

Cooling

Single, 50Hz, 220-230-240V / 3-ph, 50Hz, 380-400-415V(4wires)

1.59

7.36 / 2.49

36 / 20

RE277VHSMT/RE277YFKM

Internal thermostat, HP switch, Discharge thermo / Thermal relay,Discharge thermo,HP switch

)

1.3

30

45(1,590)

47

650(25-5/8)

55(121)

2.5(5.5)

0.57 (Ester)MEL56

PU-P2VGAA / YGAA.UK

PU-P2VGAA1 / YGAA1.UK

Cooling

2.29

10.26 / 3.70

62 / 31

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE36VMJMT/NE36YEKMT

Propeller (direct) o 1

Max. 40m

Max. 40m

1.6

Line start

Plate fin coil

0.07

55(1,940)

—

900(35-7/16)

330+20(13+3/4)

71(157)

R407C

2.6(5.7)

9.52(3/8)

15.88(5/8)

Flared

Flared

PU-P2.5VGAA / YGAA.UK

PU-P2.5VGAA1 / YGAA1.UK

NE41VMJMT/NE41YEKMT

38

48

855(33-5/8)

1.2 (Ester)MEL56

Cooling

2.77

11.90 / 4.48

77 / 35

1.9

50(1,770)

82(181)

3.1(6.8)

Max. 50m

Max. 50m

2. Guaranteed operating range

Indoor

Cooling

3. Above data based on indicated voltage

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3phase 415V 50Hz

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B.

46˚C

D.B.

-5˚C

12

Page 13

Service Ref.

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

kW

A

A

PU-P3VGAA / YGAA.UK

PU-P3VGAA

1

/ YGAA1.UK

Cooling

Single, 50Hz, 220-230-240V/3-ph, 50Hz, 380-400-415V(4wires)

3.27

14.81 / 5.29

93 / 47

External finish

Refrigerant control

Compressor

Model

Motor output

kW

NE52VNJMT / NE52YDKMT

2.5

Starter type

Protection devices

Internal thermostat

OUTDOOR UNIT

Discharge thermo

Crankcase heater

W

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

kW

/min(CFM

K

)

Propeller (direct) o 1

0.07

50(1,770)

Defrost method

Noise level

Dimensions

Weight

Cooling

W

D

H

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

49

855(33-5/8)

82(181)

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Liquid

Gas

Indoor side

kg(lbs)

L

mm(in.)

mm(in.)

3.3(7.3)

15.88(5/8)

Outdoor side

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Height difference

Piping length

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Refrigerant piping length (one way) : 5m (16ft)

PU-P4VGAA / YGAA.UK

PU-P4VGAA1 / YGAA1.UK

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE56VNJMT / NE56YDKMT

Line start

Thermal relay

HP switch

HP switch

Discharge thermo

38

Plate fin coil

—

900(35-7/16)

330+20(13+3/4)

R407C

1.3 (Ester)MEL56

9.52(3/8)

Flared

Flared

Max. 50m

Max. 50m

Cooling

3.43

15.71 / 5.55

99 / 49

2.7

Propeller (direct) o 2

0.07+0.07

85(3,000)

51

1,260(49-5/8)

96(212)

4.0(8.8)

19.05(3/4)

2. Guaranteed operating range

Indoor

Cooling

Upper limit

Lower limit

D.B. 35˚C , W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz/3 phase 415V 50Hz

Outdoor

D.B. 46˚C

D.B. -5˚C

13

Page 14

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

W

D

H

Charge

Oil (Model)

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Refrigerant piping length (one way) : 5m (16ft)

kW

kW

kW

K

/min(CFM

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

ZR61KCW-TFD-522 (YGAA

W

)

L

PU-P5YGAA.UK

PU-P5YGAA

ZR61KCE-TFD-230 (YGAA.UK)

Internal thermostat, thermal relay, HP switch, Discharge thermo

95(3,360)

4.6(10.1)

1.690 3MAW-POE

1.UK

Cooling

3-ph, 50Hz, 380-400-415V(4wires)

4.70

7.60

65.5

3.5

55

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

1.UK)

Line start

38

Plate fin coil

Propeller (direct) o 2

0.07+0.07

—

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

122(269)

R407C

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

PU-P6YGAA.UK

PU-P6YGAA1.UK

Cooling

5.58

9.03

74

ZR72KCW-TFD-522

4.2

100(3,530)

57

4.9(10.8)

1.774 3MAW-POE

2. Guaranteed operating range

Indoor

Cooling

3. Above data based on indicated voltage

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

D.B. 35˚C , W.B.22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B.

46˚C

D.B.

-5˚C

14

Page 15

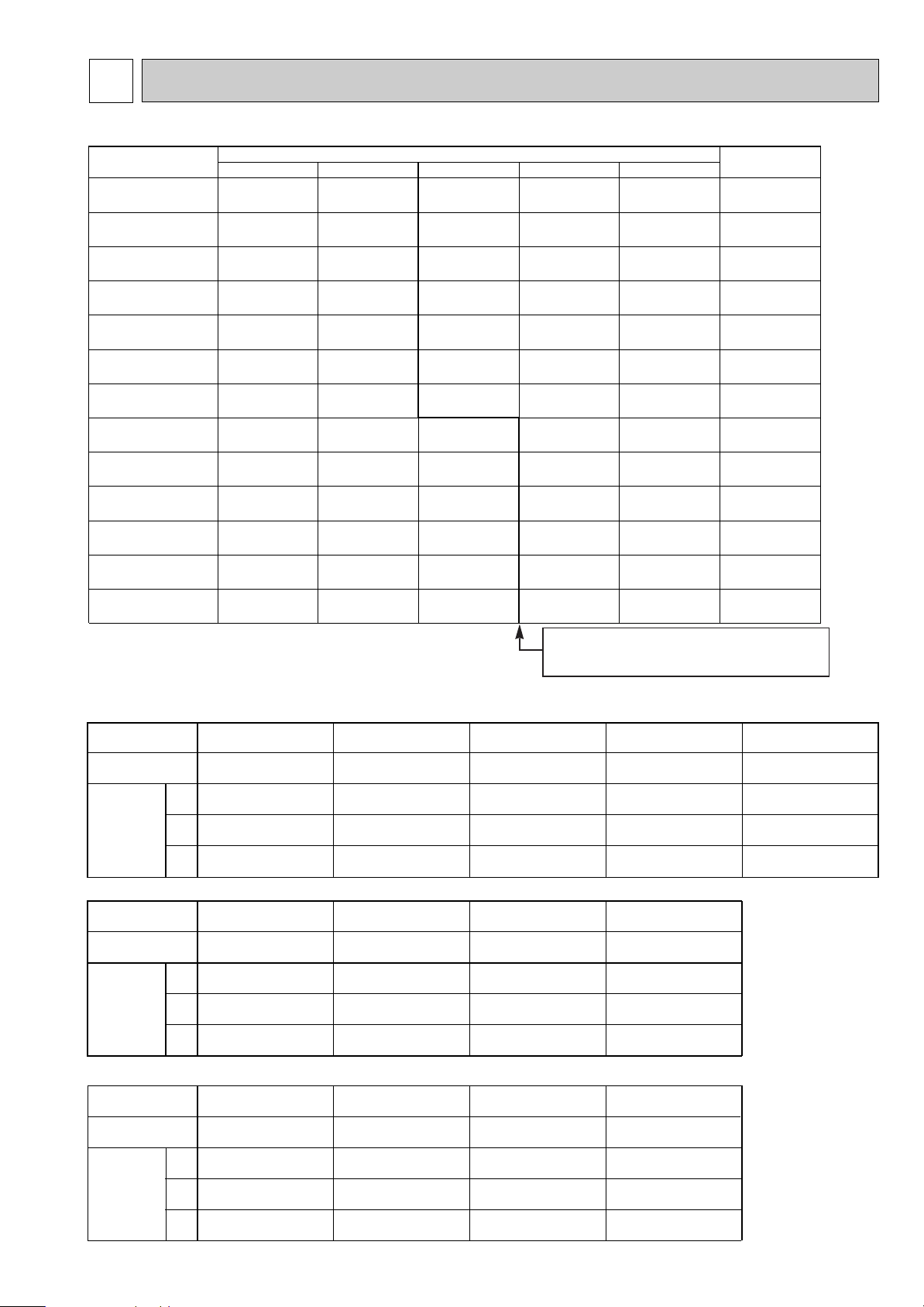

6 DATA

Piping length (one way)

10m 20m 30m

40m

50m

Factory

charged

1.6

2.4

2.4

2.5

2.5

2.9

2.9

2.9

2.9

3.4

3.4

4.0

4.3

1.7

2.5

2.5

2.6

2.6

3.1

3.1

3.1

3.1

3.7

3.7

4.3

4.6

1.8

2.6

2.6

3.1

3.1

3.3

3.3

3.3

3.3

4.0

4.0

4.6

4.9

—

3.0

3.0

3.7

3.7

3.9

3.9

3.9

3.9

4.7

4.7

5.3

5.6

—

—

—

—

—

4.5

4.5

4.5

4.5

5.4

5.4

6.0

6.3

1.7

2.5

2.5

2.6

2.6

3.1

3.1

3.3

3.3

4.0

4.0

4.6

4.9

Service Ref.

PUH-P1VGAA(1).UK

PUH-P1.6VGAA(1).UK

PU-P1.6VGAA(1).UK

PUH-P1.6YGAA(1).UK

PU-P1.6YGAA(1).UK

PUH-P2VGAA

(1).UK

PU-P2VGAA

(1).UK

PUH-P2YGAA

(1).UK

PU-P2YGAA

(1).UK

PUH-P2.5VGAA(1).UK

PU-P2.5VGAA(1).UK

PUH-P2.5YGAA(1).UK

PU-P2.5YGAA(1).UK

PUH-P3VGAA

(1).UK

PU-P3VGAA

(1).UK

PUH-P3YGAA

(1).UK

PU-P3YGAA

(1).UK

PUH-P4VGAA

(1).UK

PU-P4VGAA

(1).UK

PUH-P4YGAA

(1).UK

PU-P4YGAA

(1).UK

PUH-P5YGAA

(1).UK

PU-P5YGAA

(1).UK

PUH-P6YGAA

(1).UK

PU-P6YGAA

(1).UK

Compressor model

Winding

Resistance

( " )

U-V

(R-C)

U-W

(S-C)

W-V

U-V

(R-C)

U-W

(S-C)

W-V

RE277VHSMT RE277YFKM

Unit

PUH-P1.6VGAA(1).UK

PU-P1.6VGA(1).UK

PUH-P2VGAA

(1).UK

PU-P2VGAA

(1).UK

NE36VMJMT

1.80

3.00

—

10.8

10.8

10.8

5.01

5.01

5.01

NE36YEKMT

0.89

2.03

—

Unit

Compressor model

Winding

Resistance

( " )

PUH-P5YGAA

(1).UK

PU-P5YGAA

(1).UK

PUH-P6YGAA

(1).UK

PU-P6YGAA

(1).UK

ZR61KCE-TFD

ZR61KCW-TFD

(at 25°C) (at 25°C)

(at 20°C)

[Except P5, P6]

ZR72KCW-TFD

0.628 ~ 0.722

0.628 ~ 0.722

0.628 ~ 0.722

0.517

0.517

0.517

PUH-P4YGAA

(1).UK

PU-P4YGAA

(1).UK

NE56YDKMT

3.32

3.32

3.32

PUH-P3VGAA

(1).UK

PU-P3VGAA

(1).UK

NE52VNJMT

0.64

1.67

—

3.59

3.59

3.59

PUH-P3YGAA

(1).UK

PU-P3YGAA

(1).UK

PUH-P1VGAA

(1).UK

PUH-P1.6YGAA(1).UK

PU-P1.6YGA(1).UK

PUH-P2YGAA

(1).UK

PU-P2YGAA

(1).UK

U-V

(R-C)

U-W

(S-C)

W-V

Unit

Compressor model

Winding

Resistance

( " )

PUH-P2.5VGAA(1).UK

PU-P2.5VGAA(1).UK

NE41VMJMT

PUH-P2.5YGAA(1).UK

PU-P2.5YGAA(1).UK

NE41NEKMT

5.00

5.00

5.00

PUH-P4VGAA

(1).UK

PU-P4VGAA

(1).UK

NE56VNJMT

0.62

1.59

—

RE189VHSMT

2.79

3.36

—

0.87

2.22

—

NE52YDKMT

1. REFILLING REFRIGERANT CHARGE (R407C : kg)

2. COMPRESSOR TECHNICAL DATA

15

This is a dividing line between the ones that

need no refrigerant charge and the ones that

need additional refrigerant charge.

Page 16

3. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

MODE

HEATING

SPL(dB) LINE

PUH-P2VGAA(1).UK

PUH-P2YGAA

(1).UK

PU-P2VGAA

(1).UK

PU-P2YGAA

(1).UK

48

49

90

80

70

60

50

40

30

20

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

COOLING

MODE

HEATING

SPL(dB) LINE

PUH-P2.5VGAA(1).UK

PUH-P2.5YGAA

(1).UK

PU-P2.5VGAA

(1).UK

PU-P2.5YGAA

(1).UK

48

50

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PUH-P1VGAA(1).UK

COOLING

MODE

HEATING

46

SPL(dB)48LINE

MICROPHONE

1m

1m

UNIT

GROUND

PUH-P1.6VGAA(1).UK

PUH-P1.6YGAA

PU-P1.6VGAA

PU-P1.6YGAA

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

NOISE

10

SPL(dB)49LINE

MODE

(1).UK

(1).UK

COOLING

HEATING

47

(1).UK

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

16

Page 17

PUH-P3VGAA(1).UK

PUH-P3YGAA

PU-P3VGAA

PU-P3YGAA

90

(1).UK

(1).UK

(1).UK

MODE

COOLING

HEATING

SPL(dB) LINE

49

51

PUH-P4VGAA(1).UK

PUH-P4YGAA

PU-P4VGAA

PU-P4YGAA

90

(1).UK

(1).UK

(1).UK

MODE

COOLING

HEATING

SPL(dB)

51

53

LINE

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

PUH-P5YGAA(1).UK

PU-P5YGAA

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

SPL(dB) LINE

MODE

(1).UK

COOLING

HEATING

55

56

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

PUH-P6YGAA(1).UK

PU-P6YGAA

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

MODE

(1).UK

COOLING

HEATING

SPL(dB) LINE

57

58

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

17

Page 18

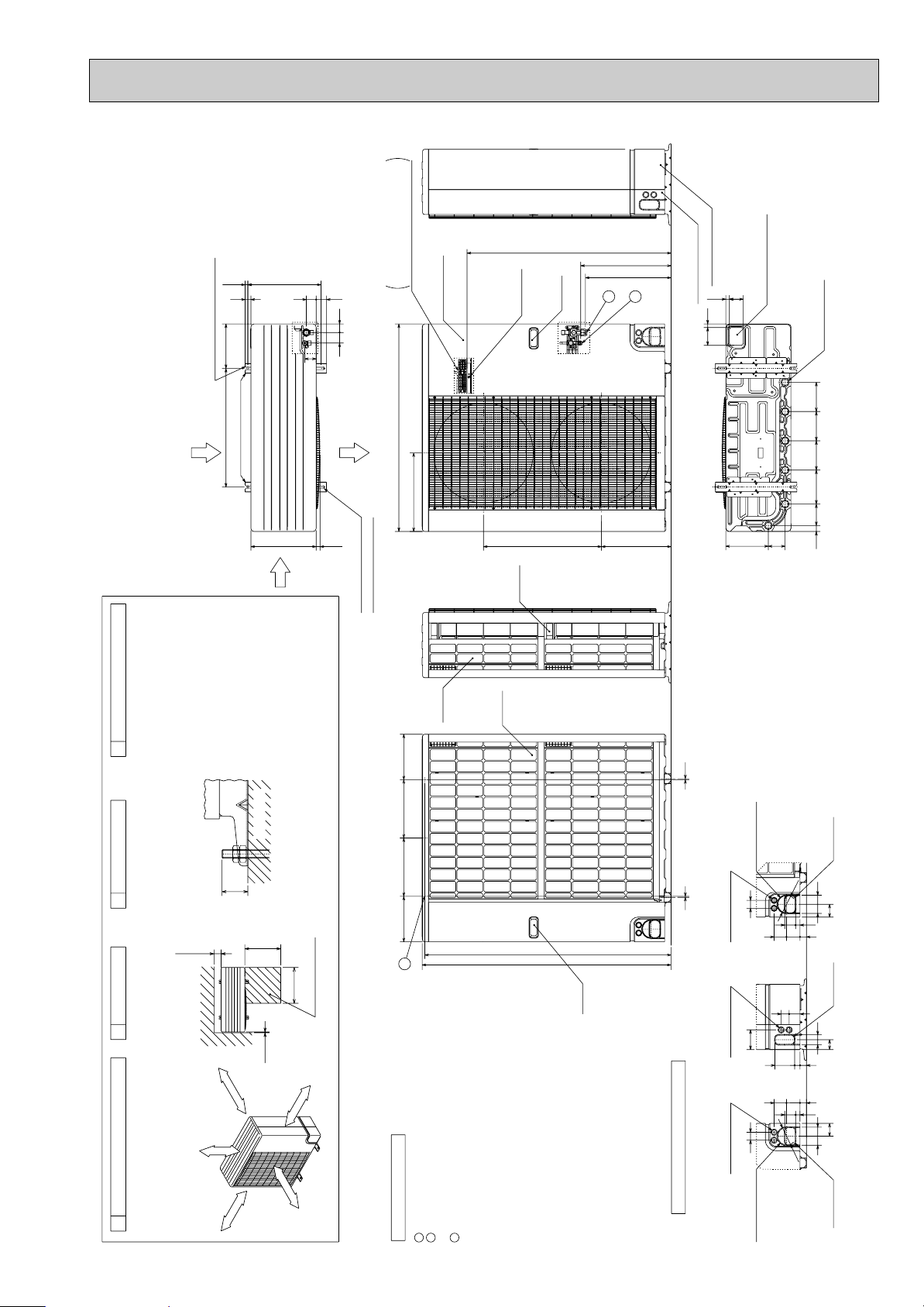

7 OUTLINES AND DIMENSIONS

321

T

SR

w1 248

w1 196

500

Power Supply Wiring Hole

(2-[27Knock-Out)

Right Piping Hole

(Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

Terminal Connections

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

70

70

15515515510930

21585

Bottom Piping Hole

(Knock-Out)

Drain Hole

(5-[33holes)

18

18

424

900

318

Handle for moving

Earth Point

Service Panel

Front Piping Cover

Rear Piping Cover

1

2

Side Air

Intake

200200

53

370

(14)

412

29

330

55

4351

Rear Air Intake

Air Discharge

2-U Shaped notched holes

(Foundation Bolt M10)

2-12x40 oval holes

(Foundation Bolt M10)

20

28

58

Installation Feet

Rear

Air

Intake

Side

Air

Intake

Handle for

moving

3

230220220230

637

650

3030

Rear Trunking Hole

(Knock-Out)

< Rear Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

40

33

22 55

68 63

65

92

Rear Piping Hole

(Knock-Out)

[92

Piping Knock-Out Hole Details

. .

Refrigerant GAS pipe connection (FLARE)P1.6V(Y)GAA: [15.88 (5/8F)

. .

Refrigerant LIQUID pipe connection (FLARE)P1.6V(Y)GAA: [9.52 (3/8F)

. .

Height of STOP VALVE connection location.

1

2

Front Trunking Hole

(Knock-Out)

< Right Side >< Front Side >

Explanation of Notes

40

68 63

22 55

65

92

33

27

100

50

50

100

33

[92

Front Piping Hole

(Knock-Out)

5540

3

. .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface.

Use Self Tapping screws 5 x L15 or less.(Obtained locally)

w1

. .

Refrigerant GAS pipe connection (FLARE)P1VGAA : [12.7 (1/2F)

. .

Refrigerant LIQUID pipe connection (FLARE)P1VGAA : [6.35 (1/4F)

1

2

Over 10mm

FRE

E

Over 500mm

Less than

30mm

FREE SPACE (Around the Unit)

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

FOUNDATION BOLTS

1

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

SERVICE SPACE

Dimensions of space needed

for service access are

shown in the below diagram.

2

Over500

Over500

PIPING-WIRING DIRECTIONS

43

FOUNDATION

<Foundation bolt height>

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

Service Space

Over 100mm

Over 10mm

Over10

Over100

PUH-P1VGAA(1).UK

PUH-P1.6VGAA(1).UK

PUH-P1.6YGAA(1).UK

PU-P1.6VGAA(1).UK

PU-P1.6YGAA(1).UK

Unit : mm

18

Page 19

PUH-P2VGAA(1).UK

321TSR

w1 376

w1 428

Handle

Rear

Air

Intake

Side

Air

Intake

Installation Feet

2-U Shaped notched holes

(Foundation Bolt M10)

Side Air

Intake

Rear Air Intake

Air Discharge

2-12x40 oval holes

(Foundation Bolt M10)

Terminal Connections

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

Earth Point

Service Panel

Rear Piping Cover

Front Piping Cover

Bottom Piping Hole

(Knock-Out)

Drain Hole

(5-[33holes)

Power Supply Wiring Hole

(2-[27Knock-Out)

Rear Piping Hole

(Knock-Out)

< Rear Side >

Rear Trunking Hole

(Knock-Out)

40

33

22 55

68 63

65

92

[92

Piping Knock-Out Hole Details

Front Piping Hole

(Knock-Out)

Front Trunking Hole

(Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

< Front Side >

Right Piping Hole

(Knock-Out)

< Right Side >

40

68 63

22 55

65

92

33

27

100

50

50

100

33

[92

5540

70

70

15515515510930

21585

18

18

627

442

900

318

Handle

1

2

200500200

53

370

(14)

412

29

330

55

43

51

20

28

58

Handle

3

230220220230

840

855

3030

. . .

Refrigerant GAS pipe connection (FLARE) [15.88 (5/8F)

. . .

Refrigerant LIQUID pipe connection (FLARE) [9.52 (3/8F)

. . .

Height of STOP VALVE connection location.

. . .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface together.

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

Explanation of Notes

1w12

3

Over10

Over100

Over500

Over500

Service Space

Less than

<Foundation bolt height>

30mm

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

SERVICE SPACE

2

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

Dimensions of space needed

for service access are

shown in the below diagram.

FOUNDATION

FOUNDATION BOLTS

3

PIPING-WIRING DIRECTIONS

4

FREE SPACE (Around the Unit)

1

FRE

E

Over 10mm

Over 500mm

Over 10mm

Over 100mm

PUH-P2YGAA(1).UK

PUH-P2.5VGAA(1).UK

PUH-P2.5YGAA(1).UK

PUH-P3VGAA(1).UK

PUH-P3YGAA

(1).UK

PU-P2VGAA(1).UK

PU-P2YGAA(1).UK

PU-P2.5VGAA(1).UK

PU-P2.5YGAA(1).UK

PU-P3VGAA(1).UK

PU-P3YGAA(1).UK

Unit : mm

19

Page 20

PUH-P4VGAA(1).UK

4

PIPING-WIRING DIRECTIONS

3

FOUNDATION BOLTS

FOUNDATION

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

SERVICE SPACE

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

30mm

<Foundation bolt height>

Less than

Over500

Over100

Service Space

Over500

1

FREE SPACE (Around the Unit)

Dimensions of space needed

for service access are

shown in the below diagram.

2

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Over10

Over 10mm

FRE

E

Over 500mm

Over 100mm

Over 10mm

Explanation of Notes

. . .

Refrigerant GAS pipe connection(FLARE) [19.05 (3/4F)

. . .

Refrigerant LIQUID pipe connection(FLARE) [9.52 (3/8F)

. . .

Height of STOP VALVE connection location.

. . .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface together.

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

3

2

w1

1

PUH-P4YGAA(1).UK

PU-P4VGAA(1).UK

PU-P4YGAA(1).UK

Unit : mm

29

200500200

2-U Shaped notched holes

(Foundation Bolt M10)

Installation Feet

Rear Air Intake

Side Air

Intake

330

598

Handle

1033

W1 428

W1 376

1

2

33

352

Rear Piping Cover

Front Piping Cover

18

70 18

Bottom Piping Hole

70

(Knock-Out)

85 215

Drain Hole

(5-[33Holes)

30 109 155 155 155

Terminal Connections

Left...Power supply Wiring

412

370 (14)

28

50

53

4351

58

Air Discharge

20

2-12x40 oval holes

Right..Indoor/Outdoor Wiring

Service Panel

900

318

(Foundation Bolt M10)

Side

Air

Intake

Rear

Air

Earth Point

Handle

Intake

230220220

230

3030

Rear Piping Hole

[92

6368

5522

(Knock-Out)

92

65

33

Rear Trunking Hole

(Knock-Out)

< Rear Side >

3

1246

1260

40

Power Supply Wiring Hole

(2-[27Knock-Out)

Handle

Right Piping Hole

(Knock-Out)

4055

1002733

6368

5522

[92

50

50

33

65

92

< Right Side >

100

Power Supply Wiring Hole

(2-[27Knock-Out)

40

< Front Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

Piping Knock-Out Hole Details

Front Piping Hole

Front Trunking Hole

(Knock-Out)

(Knock-Out)

20

Page 21

PUH-P5YGAA(1).UK

398

w1 478

w1 422

1033

Earth Point

Terminal Connections

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

Handle

Side

Air

Intake

Rear

Air

Intake

Handle

Side Air

Intake

2-12x40 oval holes

(Foundation Bolt M10)

2-U Shaped notched holes

(Foundation Bolt M10)

Rear Air Intake

Air Discharge

Handle

Service Panel

Drain Hole

(5-[33Holes)

Bottom Piping Hole

(Knock-Out)

Rear Piping Cover

Front Piping Cover

[92

92

65

6368

5522

33

40

Rear Trunking Hole

(Knock-Out)

< Rear Side >

Rear Piping Hole

(Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

4055

[92

33

100

50

50

1002733

92

65

5522

6368

40

< Right Side >

Right Piping Hole

(Knock-Out)

< Front Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

Front Trunking Hole

(Knock-Out)

Front Piping Hole

(Knock-Out)

Piping Knock-Out Hole Details

70 18

1890

14814814817230 109

21585

598

1

2

1050

352

50

225600

53

370 (14)

29

330

20

Installation Feet

4453

58

3

230295295230

55

1246

1260

FOUNDATION

30mm

<Foundation bolt height>

Less than

Over500

Over100

Service Space

Over500

Over10

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

SERVICE SPACE

1

FREE SPACE (Around the Unit)

23

FOUNDATION BOLTS

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

Dimensions of space needed

for service access are

shown in the below diagram.

4

PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

Over 10mm

FRE

E

Over 500mm

Over 100mm

Over 10mm

Explanation of Notes

. . .

Refrigerant GAS pipe connection(FLARE) [19.05 (3/4F)

. . .

Refrigerant LIQUID pipe connection(FLARE) [9.52 (3/8F)

. . .

Height of STOP VALVE connection location.

. . .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface together.

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

3

2

1

w1

PU-P5YGAA(1).UK

PUH-P6YGAA(1).UK

PU-P6YGAA(1).UK

Unit : mm

21

Page 22

8 WIRING DIAGRAM

PUH-P1, 1.6, 2, 2.5, 3, 4VGAA.UK

PUH-P1, 1.6, 2, 2.5, 3, 4VGAA1.UK

22

Page 23

PUH-P1.6, 2, 2.5, 3, 4, 5, 6YGAA.UK

PUH-P1.6, 2, 2.5, 3, 4, 5, 6YGAA1.UK

23

Page 24

PU-P1.6, 2, 2.5, 3, 4VGAA.UK

PU-P1.6, 2, 2.5, 3, 4VGAA1.UK

24

Page 25

PU-P1.6, 2, 2.5, 3, 4, 5, 6YGAA.UK

PU-P1.6, 2, 2.5, 3, 4, 5, 6YGAA1.UK

25

Page 26

9 WIRING SPECIFICATIONS

WIRING SPECIFICATIONS FOR 220~240V 50Hz

(INDOOR-OUTDOOR CONNECTING CABLE)

Cross section

of cable

Round

Flat

Flat

Round

Wire size

2

)

(mm

2.5

2.5

1.5

2.5

Number

of wires

3

3

4

4

Clockwise : S1-S2-S3

w Pay attention to stripe of yellow and green

Not applicable

(Because center wire has no cover finish)

From left to right : S1-Open-S2-S3

Clockwise : S1-S2-S3-Open

w Connect S1 and S3 to the opposite angle

PU(H)-P1VGAA

(1).UK~P6YGAA(1).UK

(Except PUH-8YE,PUH-10YE)

Polarity

applicable

L(m)

✽6

(50)

✽2

Not

✽5

(45)

✽3

60

✽4

✽1 : Power supply cords of appliances shall not be lighter than design 245 IEC or 227 IEC.

✽2 : In case that cable with stripe of yellow and green is available.

2

✽3 : In case of regular polarity connection (S1-S2-S3), wire size is 1.5mm

.

✽4 : In case of regular polarity connection (S1-S2-S3).

✽5 : In the flat cables are connected as this picture, they can be used up to 80m.

(3C Flat cable ✕ 2)

S1 S2 S3

✽6 : Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, Humidity or materials, etc.

26

Page 27

10 REFRIGERANT SYSTEM DIAGRAM

Indoor unit

Outdoor unit

Thermistor

(TH2)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Distributor

with

strainer

Flared

connection

Drier

Liner expansion valve

Bypass

valve

Thermistor

(TH5)

Thermistor

(TH1)

Muffler

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Capillary

tube w1

Refrigerant flow in cooling

Refrigerant flow in heating

w1 : O.D.4.0✕I.D.2.0-L400(PUH-P5YGAA

(1)

.UK)

O.D.4.0✕I.D.3.0-L450(PUH-P6YGAA

(1)

.UK)

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Indoor unit

Outdoor unit

Thermistor

(TH5)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L350)✕2pcs

Distributor

with

strainer

Flared

connection

Refrigerant flow in cooling

Refrigerant flow in heating

Liner expansion valve

Drier

Thermistor

(TH1)

Indoor coil

thermistor

(TH2)

Thermistor

(TH4)

Muffler

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Strainer

Indoor unit

Outdoor unit

Thermistor

(TH1)

Strainer

Flared

connection

Flexible tube

Service

port

Accumulator

Ball valve

(#50)

Strainer

Compressor

Refrigerant pipe

P1···12.7A({1/2")

P1.6~P3···15.88A({5/8")

(with heat insulator)

Refrigerant pipe

P1···6.35A({1/4")

P1.6~P3···9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

(#100)

Strainer

(#100)

Strainer

Drier

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Muffler

Thermistor(TH4)

Linear expansion valve

(#50)

Strainer

Refrigerant flow in cooling

Refrigerant flow in heating

PUH-P1, 1.6, 2, 2.5, 3VGAA.UK

PUH-P1.6, 2, 2.5, 3YGAA.UK

PUH-P4VGAA.UK

PUH-P4YGAA.UK

<4-way valve solenoid coil>

Heating : ON

Cooling : OFF

PUH-P5YGAA.UK PUH-P6YGAA.UK

PUH-P5YGAA

1.UK PUH-P6YGAA1.UK

27

Page 28

Indoor unit

Outdoor unit

Thermistor

(TH2)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Distributor

with

strainer

Flared

connection

Drier

Thermistor

(TH5)

Thermistor

(TH1)

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Refrigerant flow in cooling

Stop valve

(with service port)

Liner expansion valve

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

(#50)

Strainer

Indoor unit

Outdoor unit

Thermistor

(TH5)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L350)✕2pcs

Distributor

with

strainer

Flared

connection

Refrigerant flow in cooling

Liner expansion valve

Drier

Thermistor

(TH1)

Indoor coil

thermistor

(TH2)

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Strainer

PU-P1.6, 2, 2.5, 3VGAA.UK

Indoor unit

Outdoor unit

Thermistor

(TH1)

Strainer

Flared

connection

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

15.88A({5/8")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

Drier

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Strainer

PU-P1.6, 2, 2.5, 3YGAA.UK

PU-P4VGAA.UK

PU-P4YGAA.UK

PU-P5YGAA.UK PU-P6YGAA.UK

PU-P5YGAA

1.UK PU-P6YGAA1.UK

28

Page 29

Indoor unit

Outdoor unit

Thermistor

(TH5)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L350)✕2pcs

Distributor

with

strainer

Flared

connection

Refrigerant flow in cooling

Refrigerant flow in heating

Liner expansion valve

Thermistor

(TH1)

Indoor coil

thermistor

(TH2)

Thermistor

(TH4)

Muffler

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

PUH-P1, 1.6, 2, 2.5, 3VGAA1.UK

Indoor unit

Outdoor unit

Thermistor

(TH1)

Strainer

Flared

connection

Flexible tube

Service

port

Accumulator

Ball valve

Compressor

Refrigerant pipe

P1···12.7A({1/2")

P1.6~P3···15.88A({5/8")

(with heat insulator)

Refrigerant pipe

P1···6.35A({1/4")

P1.6~P3···9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Muffler

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Refrigerant flow in heating

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

PUH-P1.6, 2, 2.5, 3YGAA

1.UK

PUH-P4VGAA1.UK

PUH-P4YGAA1.UK

<4-way valve solenoid coil>

Heating : ON

Cooling : OFF

29

Page 30

Indoor unit

Outdoor unit

Thermistor

(TH5)

Strainer

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-R350)✕2pcs

Distributor

with

strainer

Flared

connection

Refrigerant flow in cooling

Liner expansion valve

Thermistor

(TH1)

Indoor coil

thermistor

(TH2)

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

PU-P1.6, 2, 2.5, 3VGAA1.UK

Indoor unit

Outdoor unit

Thermistor

(TH1)

Strainer

Flared

connection

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

15.88A({5/8")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

PU-P1.6, 2, 2.5, 3YGAA

1.UK

PU-P4VGAA1.UK

PU-P4YGAA1.UK

30

Page 31

11 TROUBLESHOOTING

1 blink

2 blinks

LED1

(Green)

LED2

(Red)

1 blink

2 blinks

1 blink

2 blinks

3 blinks

4 blinks

•Negative Phase detection

•The wires of power supply and connecting

wires of indoor / outdoor units are crossed

with one another.

•51CM connector open

•Start-up time is up

•Indoor / outdoor unit connector mis-wiring

•Excessive numbers of indoor units per an

outdoor unit (five or more)

•Mis-wiring of indoor / outdoor unit connection

wires (crossed wiring or disconnection)

•Indoor / outdoor unit transmission error

(Transmitting error: Outdoor controller side)

•Indoor / outdoor unit transmission error

(Signal receiving error: Indoor controller side)

•Indoor / outdoor unit transmission error

(Transmitting error: Indoor controller side)

•Indoor / outdoor unit transmission error

(Signal receiving error :Outdoor controller side)

•Remote controller transmission error

(Transmitting error: Indoor controller side)

•Undefined error code

•Remote controller transmission error

(Signal receiving error: Remote controller side)

•Remote controller transmission error

(Transmitting error: Remote controller side)

•Remote controller transmission error

(Signal receiving error: Indoor controller side)

1 Check if the wires of power supply are connected to their

corresponding terminals on TB1.

2 Check if the wirings are correct on power supply (TB1) and

outdoor power supply board (TB2).

1 Check if the wirings are correct on the connecting wires of

indoor / outdoor units.

2 Check if a single outdoor unit connects five or more indoor

units.

1 Check if the connectors of 51CM (51C) on

outdoor controller board are disconnected.

2 Check the continuity of connector 51CM (51C) by using a

tester.

1 Check if the wirings are correct on indoor units or remote

controllers.

2 Check if there is noise on the transmission lines of remote

controllers.

3 Turn the power off and let the units operate again to confirm.

1 Check if there is noise on the transmission lines of remote

controllers.

2 Check if there is noise on the connecting wires of

indoor/outdoor units.

3 Turn the power off and let the units operate again to confirm.

To be continued on the next page.

1 Check if the wirings are correct on the connecting wires of

indoor / outdoor units.

2 Check if there is noise on the wires of power supply and

connecting wires of indoor / outdoor units.

3 Check if there is noise on both indoor and outdoor

controller board.

4 Turn the power off and let the units operate again to confirm.

Indication (O.B)

Error Name Inspection method

LED1 (Green)

LED2 (Red)

1. SELF-DIAGNOSTIC FUNCTION

• The blinking patterns of two LEDs—LED1(Green) and LED2(Red)—show the diagnoses of troubles in case of malfunction.

• By 7SEG indicator board indicates the operation mode and inspection types. For the details, refer to “OCT03 REVISED

EDITION-C”.

31

Page 32

From the preceding page.

Indication (O.B)

LED1

(Green)

3 blinks

4 blinks

LED2

(Red)

1 blink

2 blinks

3 blinks

4 blinks

5 blinks

1 blinks

2 blinks

3 blinks

•Abnormal high discharge temperature(TH4)

•Abnormal high pressure (High-pressure

switch 63H has been tripped)

•Protection from overheat operation (TH3)

•Compressor's overcurrent (Overload)

•Thermal relay (51C) has been tripped

•Overcurrent has locked the operation of

compressor in start-up.

•Open / short circuit of discharge thermistor (TH4)

•Open / short circuit of liquid pipe thermistor (TH3)

•Open / short circuit of EVA / COND pipe

thermistor (TH5)

•Abnormality of room temperature thermistor

(Indoor unit side: TH1)

•Abnormality of Liquid pipe thermistor

(Indoor unit side:TH2)

•Abnormality of EVA / COND pipe thermistor

(Indoor unit side: TH5)

•Abnormality of drain sensor

(Indoor unit side : (DS))

•Malfunction of drain-up machine

•Abnormality of pipe temperature

Error Name Inspection method

1 Check if ball valves are open.

2 Check the continuity of connector (TH4) on outdoor controller

board by using a tester.

3 Check if the unit fills the refrigerant at the same amount as

specified.

1 Check if indoor / outdoor units have a short cycle on their air

ducts.

2 Check if the connector of 52C (63H) on outdoor controller

board is disconnected.

3 Check if the units get their heat exchanger and filter dirty and

clogged.

4 Measure resistance values among terminals on linear

expansion valve by using a tester.

1 Check if outdoor unit has a short cycle on its air duct.

2 Check if the connector of TH3 on outdoor controller board is

disconnected.

1 Check if ball valves are open.

2 Measure resistance values among terminals on compressor

by using a tester.

3 Check if outdoor unit has a short cycle on its air duct.

4 Check if the connector of 51CM (51C) on outdoor controller

board is disconnected.

5 Check if the units get their heat exchanger and filter dirty and

clogged.

1 Check if the connectors of TH4, TH3, and TH6 on outdoor

controller board are disconnected.

2 Measure the resistance values of each thermistor

(TH4, TH3, and TH6).

1 Check if the connectors of CN20, CN21, and CN29 on

outdoor controller board are disconnected.

2 Measure the resistance values of each thermistor

(TH1, TH2, and TH5).

1 Check if the connector of CN31 on outdoor controller board

is disconnected.

2 Measure the resistance value of drain sensor.

3 Measure resistance values among terminals on drain-up

machine by using a tester.

1 Check if the connectors of CN20, CN21, and CN29 on

outdoor controller board are disconnected.

2 Check if ball valves are open.

3 Check if the wirings are correct on the connecting wires of

indoor / outdoor units.

32

Page 33

M

4

6

2

3

5

1

Blue

Brown

Yellow

Orange

Red

White

Linear expansion valve

(LEV)

Parts name

Check points

Disconnect the connector then measure the resistance using a tester. (Surrounding temperature 10:~30:)

Disconnect the connector then measure the resistance using a tester. (Surrounding temperature 20:)

(Refer to the next pege for a detail.)

Liquid temperature

thermistor (TH3)

Discharge temperature

thermistor (TH4)

Condenser/evaporator

temperature thermistor

(TH6)

Normal

160k"~410k"

4.3k"~9.6k"

4.3k"~9.6k"

TH3

TH4

TH6

Abnormal

Open or short

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20C°)

4-WAY VALVE

SOLENOID COIL

(21S4)

Normal

1430"

Normal

(1) - (5)

White - Red

(2) - (6)

Yellow - Brown

(3) - (5)

Orange - Red

(4) - (6)

Blue - Brown

Abnormal

Abnormal

150" ±10%

Open or short

Open or short

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20°)

BYPASS VALVE

SOLENOID COIL

(21R)

PUH-P5/6YGAA.UK

only

Normal

P5, P6

1970"

P1, P1.6

1920" ±7%

P2~P6

1516" ±7%

Abnormal

Open or short

Measure the resistance between the terminals using a tester.

CRANKCASE

HEATER (HC)

Normal Abnormal

Open or short

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20C°)

FAN MOTOR(MF)

Normal

57.4" ±10%

99.7" ±10%

Motor lead wire

Abnormal

Open or short

White — Black

White — Red

Red

Black

White

Orange

Protector

OPEN :130i5:

CLOSE :88i15:

2. HOW TO CHECK THE PARTS

PUH-P1, 1.6, 2, 2.5, 3, 4VGAA

PU-P1.6, 2, 2.5, 3, 4VGAA

(1).UK PUH-P1.6, 2, 2.5, 3, 4, 5, 6YGAA(1).UK

(1).UK PU-P1.6, 2, 2.5, 3, 4, 5, 6YGAA(1).UK

33

Page 34

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

< Thermistor for lower temperature >

Temperature (:)

Resistance (K")

500

400

300

200

100

0

25

50 75 100 120

< Thermistor for higher temperature >

Temperature (:)

Resistance (K")

<Thermistor characteristic graph>

Thermistor for

lower temperature

Liquid temperature thermistor(TH3)

Condenser/evaporator temperature

thermistor(TH6)

Thermistor R0=15k' ±3%

Fixed number of B=3480k' ±2%

Rt=15exp { 3480( ) }

1

273+t

1

273

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

30: 4.3k'

40: 3.0k'

Thermistor for

Discharge temperature thermistor(TH4)

higher temperature

Thermistor R120=7.465k' ±2%

Fixed number of B=4057k' ±2%

Rt=7.465exp { 4057( ) }

1

273+t

1

393

20: 250k'

30: 160k'

40: 104k'

50: 70k'

60: 48k'

70: 34k'

80: 24k'

90: 17.5k'

100: 13.0k'

110: 9.8k'

Linear expansion valve

① Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the controller board.

• Valve position can be changed in proportion to the number of pulse signal.

<Connection between the controller board and the linear expansion valve>

Linear expansion valve

4

M

6

2

5

White

1

Red

3

Orange

Blue

Brown

Yellow

[4

[3

[2

[1

Brown

Red

Blue

Orange

Yellow

White

Connector(CNLEV)

Controller board

DC12V

6

5

4

3