Page 1

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

FILTER

CHECK MODE

TEST RUN

CHECK

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

SPLIT-TYPE,AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

1999

No. OC182

REVISED EDITION-B

Series PCH/PCA

Indoor unit

[Model names]

1999, 2001

PCH-P2GAH

PCH-P2.5GAH

PCH-P3GAH

PCH-P4GAH

PCH-P5GAH

PCH-P6GAH

2000, 2001

PCA-P2GA

PCA-P2.5GA

PCA-P3GA

PCA-P4GA

PCA-P5GA

PCA-P6GA

[Service Ref.]

1999

PCH-P2GAH

PCH-P2.5GAH

PCH-P3GAH

PCH-P4GAH

PCH-P5GAH

PCH-P6GAH

2000

PCA-P2GA

PCA-P2.5GA

PCA-P3GA

PCA-P4GA

PCA-P5GA

PCA-P6GA

Ceiling Suspended

2001

PCH-P2GAH

PCH-P2.5GAH

PCH-P3GAH

PCH-P4GAH

PCH-P5GAH

PCH-P6GAH

2001

PCA-P2GA

PCA-P2.5GA

PCA-P3GA

PCA-P4GA

PCA-P5GA

PCA-P6GA

CONTENTS

R407C

1

1

1

1

1

1

1

1

1

1

1

• Refer to the OCT03

REVISED EDITION-C as

regarding control

relation.PCH-P2GAH1, PCHP2.5GAH1, PCH-P3GAH1,

PCH-P4GAH1, PCHP5GAH1, PCH-P6GAH1,

PCA-P2GA1, PCA-P2.5GA1,

PCA-P3GA1, PCA-P4GA1,

1

PCA-P5GA1, and PCAP6GA1.Are added in

REVISED EDITION-B.

• Please void OC182

REVISED EDITION-A.

• This manual does not cover

outdoor units.When serving

them, please refer to the

service manual No.OC180

REVISED EDITION-A and

this manual in a set.

PCH-P2,2.5,3,4,5,6GAH

PCA-P2,2.5,3,4,5,6GA

INDOOR UNIT

PCH-P2,2.5,3,4,5,6GAH

PCA-P2,2.5,3,4,5,6GA1

REMOTE CONTROLLER

1. TECHNICAL CHANGES ··································2

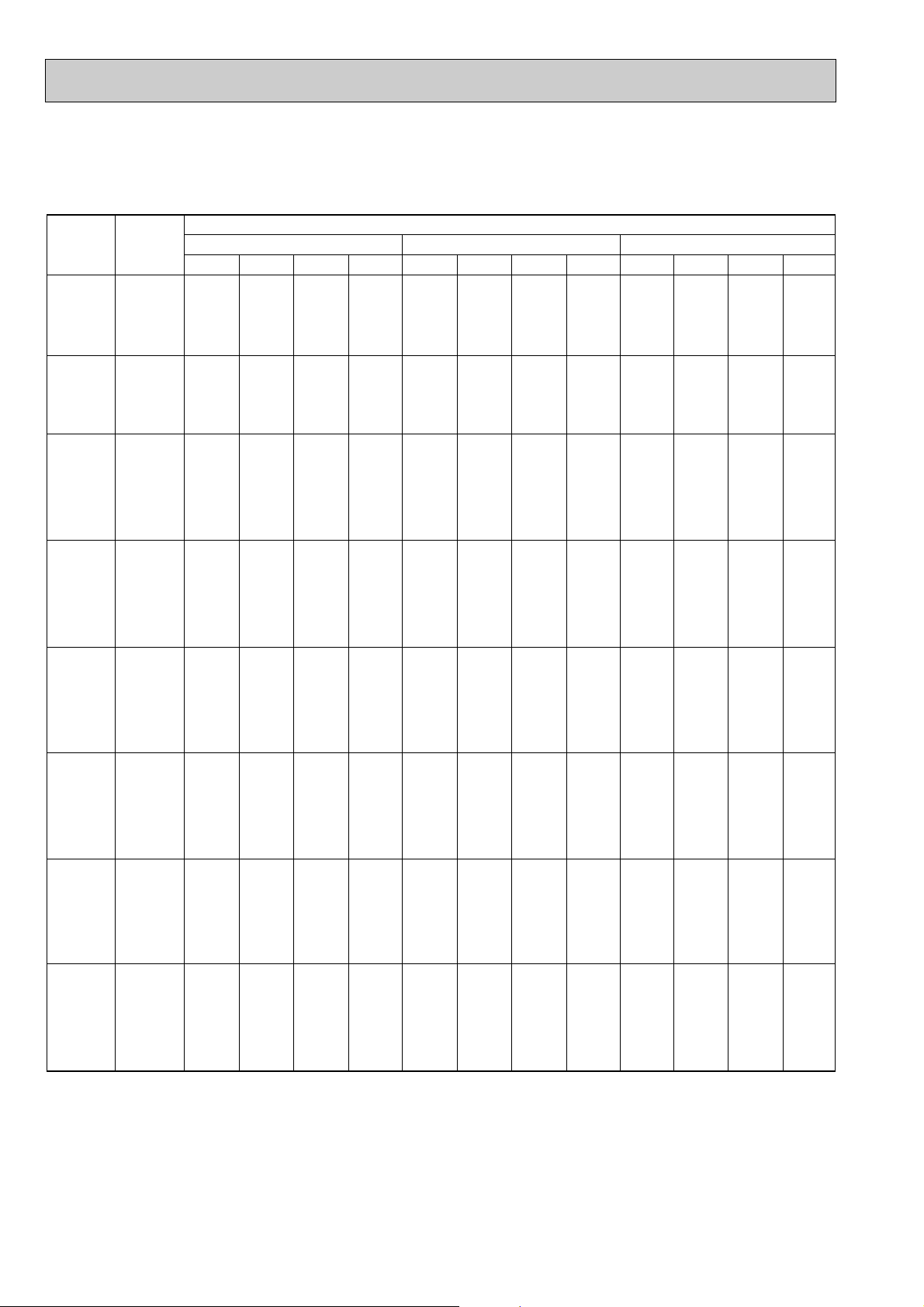

2. COMBINA TION OF INDOOR AND OUTDOOR UNITS···2

3. SAFETY PRECAUTION ···································3

4. PART NAMES AND FUNCTIONS····················5

5. SPECIFICATIONS············································9

6. DATA·······························································21

7. OUTLINES AND DIMENSIONS·····················62

8.

WIRING DIAGRAM

9.

REFRIGERANT SYSTEM DIAGRAM

············································66

··················67

10. TROUBLESHOOTING ···································69

11. DISASSEMBLY PROCEDURE·······················71

12. PARTS LIST···················································76

13. OPTIONAL PARTS ········································94

1

Page 2

1

FILTER

CHECK MODE

TEST RUN

CHECK

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

Heat pump with

electric heater

PCH-P2GAH

PCH-P2.5GAH

PCH-P3GAH

PCH-P4GAH

PCH-P5GAH

PCH-P6GAH

PCA-P2GA

PCA-P2.5GA

PCA-P3GA

PCA-P4GA

PCA-P5GA

PCA-P6GA

Heat pump without

electric heater

or

Cooling only

6YGA

—

—

—

—

—

—

—

—

—

—

—

5YGA

—

—

—

—

—

—

—

—

—

—

—

4YGA

—

—

—

—

—

—

—

—

—

—

—

3YGA

—

—

—

—

—

—

—

—

—

—

—

3VGA

—

—

—

—

—

—

—

—

—

—

—

2.5VGA

—

—

—

—

—

—

—

—

—

—

—

2VGA

—

—

—

—

—

—

—

—

—

—

—

6YGA

—

—

—

—

—

—

—

—

—

—

5YGA

—

—

—

—

—

—

—

—

—

—

4YGA

—

—

—

—

—

—

—

—

—

—

3YGA

—

—

—

—

—

—

—

—

—

—

3VGA

—

—

—

—

—

—

—

—

—

—

2.5VGA

—

—

—

—

—

—

—

—

—

—

2.5YGA

—

—

—

—

—

—

—

—

—

—

2YGA

—

—

—

—

—

—

—

—

—

—

2VGA

—

—

—

—

—

—

—

—

—

—

Indoor unit

Outdoor unit (OC180 REVISED EDITION-A)

Heat pump type

PUH-P · VGA / YGA

Cooling only type

PU-P · VGA / YGA

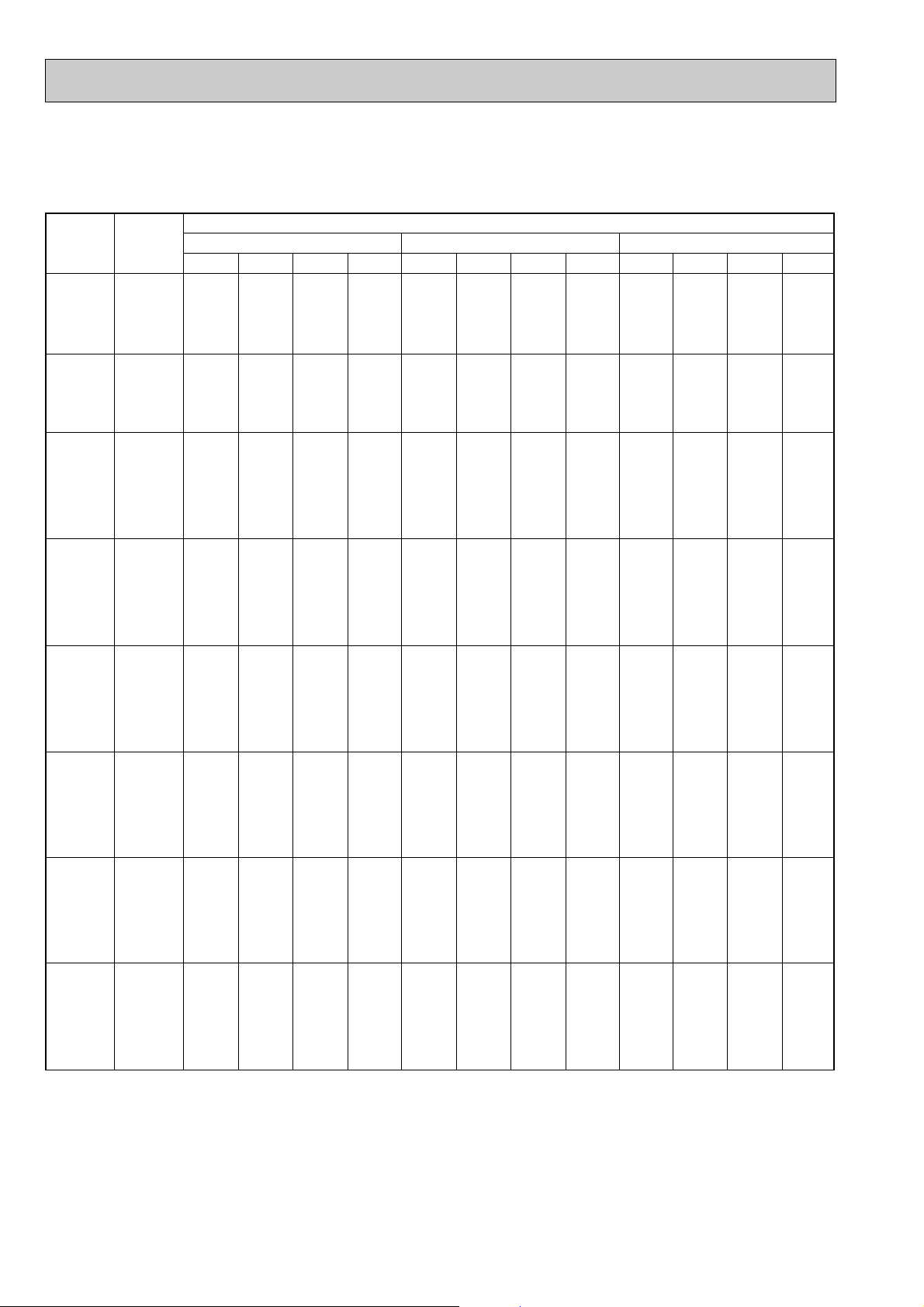

Outdoor unit (OC261)

Heat pump

with

electric heater

PCH-P2GAH1

PCH-P2.5GAH1

PCH-P3GAH1

PCH-P4GAH1

PCH-P5GAH1

PCH-P6GAH1

PCA-P2GA1

PCA-P2.5GA1

PCA-P3GA1

PCA-P4GA1

PCA-P5GA1

PCA-P6GA1

Heat pump

without

electric heater

or

Cooling only

6YGAA

. UK

—

—

—

—

—

—

—

—

—

—

5YGAA

. UK

—

—

—

—

—

—

—

—

—

—

4VGAA

. UK

—

—

—

—

—

—

—

—

—

—

3YGAA

. UK

—

—

—

—

—

—

—

—

—

—

3VGAA

. UK

—

—

—

—

—

—

—

—

—

—

2.5VGAA

. UK

—

—

—

—

—

—

—

—

—

—

2.5YGAA

. UK

—

—

—

—

—

—

—

—

—

—

2YGAA

. UK

—

—

—

—

—

—

—

—

—

—

2VGAA

. UK

—

—

—

—

—

—

—

—

—

—

4YGAA

. UK

—

—

—

—

—

—

—

—

—

—

6YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

5YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

4VGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

4YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

3YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

3VGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

2.5VGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

2.5YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

2YGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

2VGAA

. UK

—

—

—

—

—

—

—

—

—

—

—

Indoor unit

PUH-P · VGAA · UK / YGAA · UK

Heat pump type

Cooling only type

PU-P · VGAA · UK / YGAA · UK

TECHNICAL CHANGES

PCH-P2GAH ➔ PCH-P2GAH1 PCA-P2GA ➔ PCA-P2GA1

PCH-P2.5GAH ➔ PCH-P2.5GAH1 PCA-P2.5GA ➔ PCA-P2.5GA1

PCH-P3GAH ➔ PCH-P3GAH1 PCA-P3GA ➔ PCA-P3GA1

PCH-P4GAH ➔ PCH-P4GAH1 PCA-P4GA ➔ PCA-P4GA1

PCH-P5GAH ➔ PCH-P5GAH1 PCA-P5GA ➔ PCA-P5GA1

PCH-P6GAH ➔ PCH-P6GAH1 PCA-P6GA ➔ PCA-P6GA1

● Outdoor units which are connected to PCH-P·GAH, PCH-P·GAH1, PCA-P·GA and PCA-P·GA1 have been added.

● The parts No. of REMOTE CONTROLLER has changed. (The following parts numbers are interchangeable.)

➔

2

[T7W E00 713]

[T7W E06 713]

COMBINATION OF INDOOR AND OUTDOOR UNITS

2

Page 3

3

SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

· Do not use copper pipes which are broken, deformed or discolour .

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

-The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

-If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

· Use a vacuum pump with a reverse flow check valve.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

· Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge,

refrigerant recovery equipment)

-If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerant oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

· Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

· Be especially careful when managing the tools.

-if dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

· Do not use the drier which is sold in the field.

-The drier for R407C refrigerant is per-attached to outdoor unit refrigerant circuit.

-Some drier in the field are not in conformity with R407C refrigerant .

3

Page 4

Gravimeter

Unit

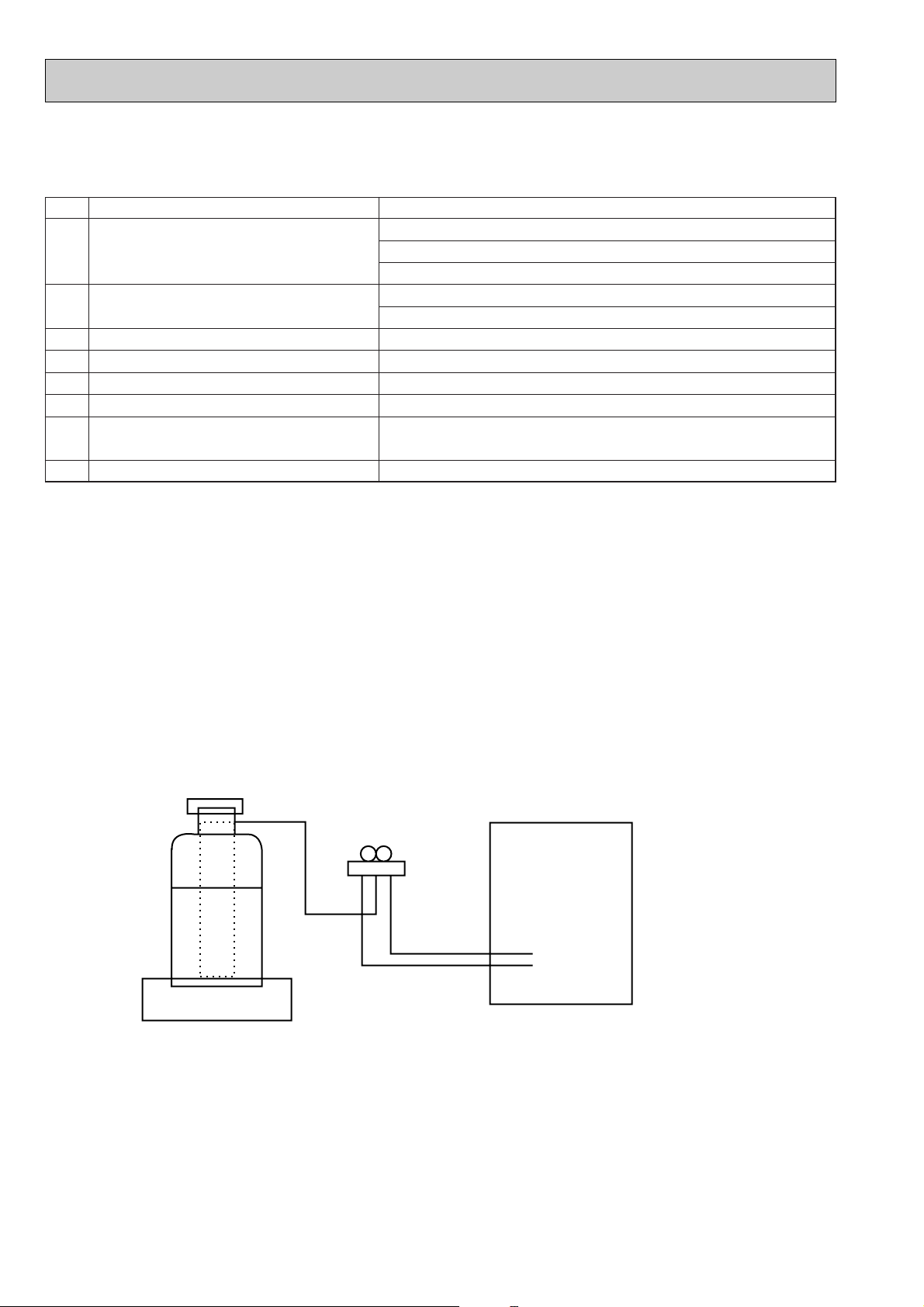

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

4

Page 5

4

Air outlet

Intake grille

Air intake

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Long-life fillter

Removes dust and foreigh matter from air coming in

through the grille (Recommended cleaning interval :

Approx, every 2,500 operating hours)

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

PCH-P2/2.5/3/4/5/6GAH

PCA-P2/2.5/3/4/5/6GA

● Operation buttons

AIR SPEED button

This sets the fan speed.

VENTILATION button

This set the ventilation fan speed.

ON/OFF button

This switches between the operation and stop modes each time it is

pressed. The lamp on this button

lights during operation.

AIR DIRECTION button

This adjusts the vertical angle of

the ventilation.

FILTER button

This resets the filter service indication display.

CHECK-TEST RUN button

Only press this button to perform

an inspection check or test operation Do not use it for normal operation.

TIMER button

This switches between continuous

operation and the timer operation.

OPERATION SWITCH button

Press this button to switch the

cooler electronic dry (dehumidify)

automatic and heater modes.

TEMP. ADJUSTMENT button

This sets the room temperature

The temperature setting can be

performed in 1°C units

Setting range

Cooler 19°C to 30°C

Heater 17°C to 28°C

TIMER ADJUSTMENT

button

This adjust the current time, start

time and stop time.

TIME SETTING button

This sets of switches the current

time. start time and stop time.

LOUVER button

This switches the horizontal fan

motion ON and OFF.

(This button does not operate in

this model)

5

Page 6

● Display

CENTRALLY

CONTROLLED display

This indicates when the unit is con-

trolled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

This indicates when the standby

mode is set from the time the sleep

operation starts until the heating air

is discharged.

DEFROST display

This indicates when the defrost oper-

ation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

FAN SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air is

displayed during operation. The display range is 8° to 39°C. The display

flashes 8°C when the actual temperature is less than 8° and flashes

39°C when the actual temperature is

greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

CHECK MODE

TEST RUN

This display lights in the check mode

or when a test operation is performed.

display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

FILTER

This lamp lights when the filter need

to be cleaned.

POWER display

This lamp lights when electricity is

supplied to the unit.

display

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a

malfunction.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

6

Page 7

● Remote controller

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

Press this button to switch the cooler,

electronic dry (dehumidify), automatic

and heater modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooler 19: to 30:

Heater 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This sets the ventilation fan speed.

VENTILATION button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

AIR SPEED button

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

PCH-P2/2.5/3/4/5/6GAH1

PCA-P2/2.5/3/4/5/6GA1

● Operation buttons

7

Page 8

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

● Display

CENTRALLY

CONTROLLED display

This indicates when the unit is controlled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

This indicates when the standby

mode is set from the time the sleep

operation starts until the heating air

is discharged.

DEFROST display

This indicates when the defrost operation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

FAN SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air is

displayed during operation. The display range is 8° to 39°C. The display

flashes 8°C when the actual temperature is less than 8° and flashes

39°C when the actual temperature is

greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

CHECK MODE

TEST RUN

This display lights in the check mode

or when a test operation is performed.

display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

FILTER

This lamp lights when the filter need

to be cleaned.

POWER display

This lamp lights when electricity is

supplied to the unit.

display

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a

malfunction.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

8

Page 9

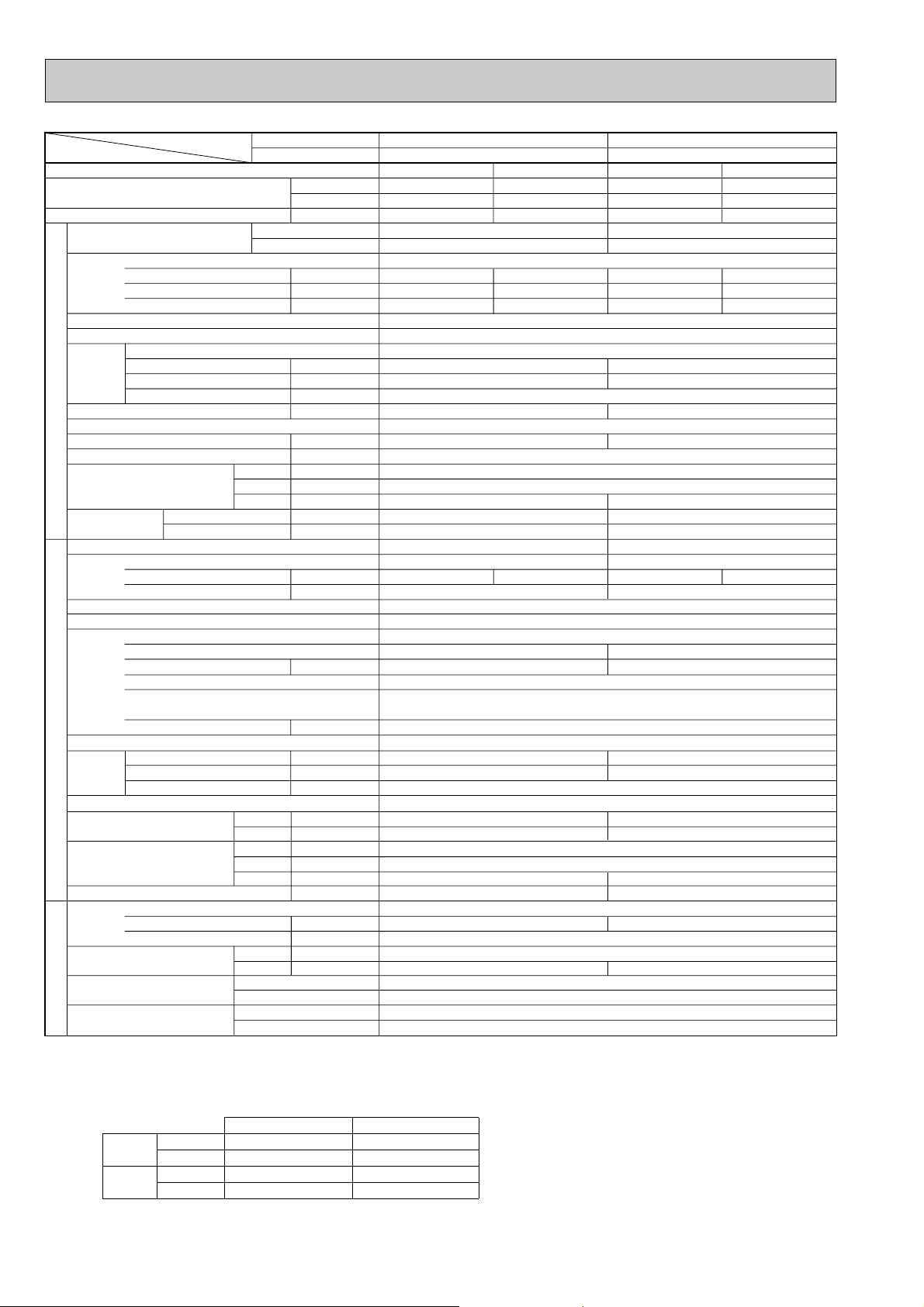

5

Service Ref.

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity w1

Total input w1

Service Ref.

Power supply

Input w2

Running current w2

Starting current w2

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

INDOOR UNITOUTDOOR UNIT

REFRIGERANT PIPING

PCH-P2GAH

PCA-P2GA

PCH-P2GAH

PCA-P2GA

PCH-P2.5GAH

PCA-P2.5GA

PCH-P2.5GAH

PCA-P2.5GA

Cooling

18,800

5,500

2.58

0.10

0.43

1.20

11.11 / 3.88

Cooling

23,900

7,000

2.76

0.13

0.55

1.27

11.78 / 4.11

Heating

22,300 (27,100)

6,550 (7,950)

2.67 (4.07)

0.10 <1.40>

0.43 <5.83>

1.20 <5.83>

11.51 / 4.02

Heating

24,900 (32,100)

7,300 (9,400)

2.71 (4.81)

0.13 <2.10>

0.55 <8.75>

1.27 <8.75>

11.55 / 4.03

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

Sirocco (direct) x 2

0.054

10-11-12-13 (353-338-424-459)

<1.4>

37-38-40-42

1,000 (39-3/8)

28.5 (63)

27 (60)

PUH-P2VGA / PUH-P2YGA

74 / 30

NE38VMJM / NE38YEJM

1.7

0.070

55(1,940)

48

49

71(157)

3.1(6.8)

Max. 40m

Max. 40m

Sirocco (direct) x 3

0.07

14-15-16-18 (494-530-565-635)

<2.1>

37-39-41-43

1,310 (51-9/16)

36 (79)

34 (75)

PUH-P2.5VGA

1 / PUH-P2.5YGA1

77 / 32

NE41VMJM / NE41YEJM

1.9

0.070

50(1,770)

48

50

82(181)

3.3(7.3)

Max. 50m

Max. 50m

Single phase, 50Hz, 220-230-240V

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

0 (direct blow)

Remote controller & built-in

26 (1)

680 (26-3/4)

210 (8-1/4)

Single phase, 50Hz, 220-230-240V / 3 phases, 50Hz, 380-400-415V (4wires)

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

Inner thermostat, HP switch, Discharge thermo. / Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

38

Plate fin coil

Propeller (direct) x 1

Reverse cycle

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

R407C

1.2 (Ester)MEL56

9.52 (3/8)

15.88 (5/8)

Flared

Flared

SPECIFICATIONS

1. Heat pump type Rating Conditions (ISO T1)

9

Page 10

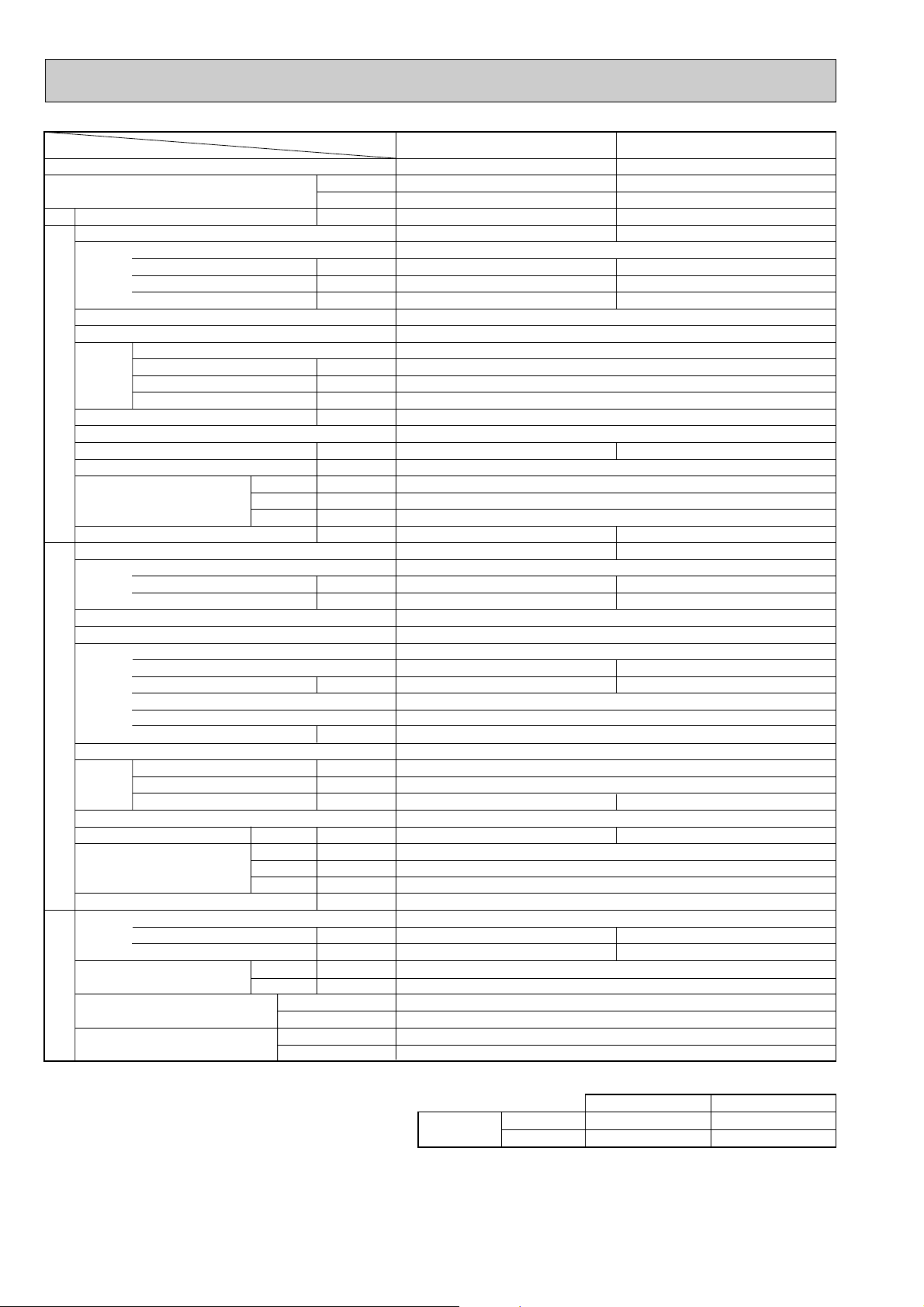

Rating Conditions (ISO T1)

Service Ref.

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity w1

Total input w1

Service Ref.

Power supply

Input w2

Running current w2

Starting current w2

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

INDOOR UNITOUTDOOR UNIT

REFRIGERANT PIPING

PCH-P3GAH

PCA-P3GA

PCH-P3GAH

PCA-P3GA

PCH-P4GAH

PCA-P4GA

PCH-P4GAH

PCA-P4GA

Cooling

25,600

7,500

3.47

0.13

0.55

1.27

14.64 / 5.46

Cooling

33,100

9,700

3.52

0.16

0.70

1.48

5.49

Heating

31,700 (38,900)

9,300 (11,400)

3.65 (5.75)

0.13 <2.10>

0.55 <8.75>

1.27 <8.75>

15.43 / 5.76

Heating

36,300 (45,600)

10,650 (13,350)

3.70 (6.40)

0.16 <2.70>

0.70 <11.25>

1.48 <11.25>

5.79

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

0.07

14-15-16-18 <494-530-565-635>

<2.1>

37-39-41-43

210 (8-1/4)

36 (79)

34 (75)

PUH-P3VGA / PUH-P3YGA

Single phase, 50Hz, 220-230-240V / 3 phase, 50Hz, 380-400-415V (4wires)

93 / 41

NE52VNJM / NE52YDJM

2.5

Propeller (direct) x 1

0.070

50 (1,770)

49

51

855 (33-5/8)

82 (181)

3.7 (8.2)

15.88 (5/8)

0.09

20-21-23-25 <706-741-812-883>

<2.7>

40-41-43-45

270 (10-5/8)

39.5 (87)

37 (82)

PUH-P4YGA

3 phase, 50Hz, 380-400-415V (4wires)

45

NE56YDJM

2.7

Propeller (direct) x 2

0.070+0.070

85 (3,000)

51

53

1,260 (49-5/8)

96 (212)

4.0 (8.8)

19.05 (3/4)

Single phase, 50Hz, 220-230-240V

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) x 3

0 (direct blow)

Remote controller & built-in

26 (1)

1,310 (51-9/16)

680 (26-3/4)

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

Reverse cycle

900 (35-7/16)

330+20 (13+3/4)

R407C

1.6 (Ester)MEL56

9.52 (3/8)

Flared

Flared

Max. 50m

Max. 50m

VGA...Inner thermostat, HP switch, Discharge thermo.

YGA...Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

10

Page 11

Rating Conditions (ISO T1)

Service Ref.

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity w1

Total input w1

Service Ref.

Power supply

Input w2

Running current w2

Starting current w2

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

INDOOR UNITOUTDOOR UNIT

REFRIGERANT PIPING

PCH-P5GAH

PCA-P5GA

PCH-P5GAH

PCA-P5GA

PCH-P6GAH

PCA-P6GA

PCH-P6GAH

PCA-P6GA

Cooling

43,700

12,800

5.49

0.24

1.06

2.20

8.39

Cooling

49,500

14,500

6.60

0.24

1.06

2.20

10.17

Heating

54,600 (64,800)

16,000 (19,000)

5.71 (8.71)

0.24 <3.00>

1.06 <12.50>

2.20 <12.50>

8.74

Heating

57,300 (67,600)

16,800 (19,800)

6.67 (9.67)

0.24 <3.00>

1.06 <12.50>

2.20 <12.50>

10.28

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

41-43-45-46

46 (101)

43 (95)

PUH-P5YGA

79

HE86YAA

4.3

95 (3,360)

53

55

42-44-46-48

48 (106)

45 (99)

PUH-P6YGA

84

HE101YAA

5.1

100 (3,530)

55

57

Single phase, 50Hz, 220-230-240V

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) x 4

0.15

27-30-32-34 <953-1,059-1,130-1,200>

0 (direct blow)

<3.0>

Remote controller & built-in

26 (1)

1,620 (63-3/4)

680 (26-3/4)

270 (10-5/8)

3 Phase, 50Hz, 380-400-415V(4wires)

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

Anti-phase protector, Internal thermostat, LP switch, HP switch,Thermal relay,Discharge thermo

38

Plate fin coil

Propeller (direct) x 2

0.075+0.075

Reverse cycle

1050 (41-5/16)

330+20 (13+3/4)

1,260 (49-5/8)

122 (269)

R407C

5.8 (12.8)

2.0 (Ester)MEL32

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

11

Page 12

2. Cooling only type Rating Conditions (ISO T1)

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

mm(in.)

mm(in.)

kg(lbs)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

kW

L

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

A

A

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

Pa(mmAq)

kW

kW

A

A

Btu/h

W

kW

Item

Service Ref.

Function

Total input

PCA-P2GA PCA-P2.5GA

Cooling

18,800

5,500

2.58

Cooling

23,900

7,000

2.76

PCA-P2GA

Single phase, 50Hz, 220-230-240V

PCA-P2.5GA

0.10

0.43

1.20

0.13

0.55

1.27

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct))2

0.054

10 -11-12-13 <353-338-424-459>

Sirocco (direct))3

0.07

14 -15-16-18 <494-530-565-635>

0 (direct blow)

——

Remote controller & built-in

37-38-40-42 37-39-41-43

26(1)

1,000(39-3/8) 1,310(51-9/16)

680(26-3/4)

210(8-1/4)

27(60)

PU-P2VGA

34(75)

PU-P2.5VGA

1

Single phase, 50Hz, 220-230-240V

11.11

74

11.78

77

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE38VMJM

1.7

NE41VMJM

1.9

Line start

Internal thermostat. High-pressure switch,Discharge thermo.

38

Plate fin coil

Propeller (direct)✕1

0.070

55 (1,940) 50 (1,770)

48

—

71 (157) 82 (181)

900 (35-7/16)

330+20 (13+3/4)

R407C

3.1 (6.8) 3.3 (7.3)

1.2 (Ester)MEL56

855 (33-5/8)

9.52 (3/8)

15.88 (5/8)

Flared

Flared

Max. 40m

Max. 40m

Max. 50m

Max. 50m

Upper limit

Lower limit

Indoor

D.B. 35:, W.B. 22.5:

D.B. 19:, W.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

INDOOR UNIT

W

Capacity

2. Guaranteed operating range

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz

o

F), W.B. 19:(66oF)

o

F), W.B. 24:(75oF)

12

Page 13

Rating Conditions (ISO T1)

Item

Function

Capacity

Total input

Service Ref.

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

OUTDOOR UNIT

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

PIPING

Connection method

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

REFRIGERANT

Between the indoor & outdoor unit

Service Ref.

K/min <CFM>

W

D

H

K/min <CFM>

Cooling

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Btu/h

W

kW

kW

A

A

kW

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

kW

W

kW

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PCA-P3GA PCA-P4GA

Cooling

25,600

7,500

3.47

PCA-P3GA

Single phase, 50Hz, 220-230-240V

0.13

0.55

1.27

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) ✕ 3

0.07

14-15-16-18 <494-530-565-635>

0 (direct blow)

Remote controller & built-in

37-39-41-43 40-41-43-45

1,310 (51-9/16)

680 (26-3/4)

210 (8-1/4) 270 (10-5/8)

34 (75)

PU-P3VGA / PU-P3YGA

Single-phase, 50Hz, 220-230-240V / 3-phase, 50Hz,380-400-415V (4wires)

14.64 / 5.46

93 / 41

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE52VNJM / NE52YDJM

2.5

VGA...Inner thermostat. High-pressure switch Discharge thermo

YGA...Anti-phase protector, Thermal relay, Discharge thermo, High-pressure switch

Propeller (direct) ✕ 1

0.070

50 (1,770)

49 51

855 (33-5/8)

82 (181)

3.7 (8.2) 4.0 (8.8)

15.88 (5/8) 19.05 (3/4)

Line start

Plate fin coil

900 (35-7/16)

330 + 20 (13+3/4)

1.6 (Ester) MEL56

9.52 (3/8)

Max. 50m

Max. 50m

20-21-23-25<706-741-812-883>

—

26 (1)

3-phase, 50Hz,380-400-415V (4wires)

38

—

R407C

Flared

Flared

Cooling

33,100

9,700

3.52

PCA-P4GA

0.16

0.70

1.48

0.09

37 (82)

PU-P4YGA

5.49

45

NE56YDJM

2.7

Propeller (direct) ✕ 2

0.070+0.070

85 (3,000)

1,260 (49-5/8)

96 (212)

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

o

F), W.B. 19:(66oF)

o

F), W.B. 24:(75oF)

2. Guaranteed operating range

Cooling

Upper limit

Lower limit

13

Indoor

D.B. 35:, D.B. 22.5:

D.B. 19:, D.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Page 14

Rating Conditions (ISO T1)

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

mm(in.)

mm(in.)

kg(lbs)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

kW

L

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

A

A

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

Pa(mmAq)

kW

kW

A

A

Btu/h

W

kW

Item

Service Ref.

Function

Total input

Upper limit

Lower limit

Indoor

D.B. 35:, W.B. 22.5:

D.B. 19:, W.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

PCA-P5GA PCA-P6GA

Cooling

43,700

12,800

5.49

0.24

1.06

2.20

0.24

1.06

2.20

Cooling

49,500

14,500

6.60

PCA-P5GA

Single phase, 50Hz, 220-230-240V

PCA-P6GA

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct)✕4

0.15

27-30-32-34 <953-1,059-1,130-1,200>

0 (direct blow)

—

Remote controller & built-in

41-43-45-46 42-44-46-48

26 (1)

1,620 (63-3/4)

680 (26-3/4)

270 (10-5/8)

43 (95)

PU-P5YGA

45 (99)

PU-P6YGA

HE86YAA

4.3

HE101YAA

5.1

95 (3,360) 100 (3,530)

122 (269)

53 55

3 phases, 50Hz, 380-400-415V (4wires)

—

R407C

5.8 (12.8)

2.0 (Ester)MEL32

1050 (41-5/16)

330+20 (13+3/4)

1,260 (49-5/8)

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

Anti-phase protector, Internal thermostat, LP switch, HP switch,Thermal relay,Discharge thermo

38

Plate fin coil

Propeller (direct)✕2

0.075+0.075

8.39

79

10.17

84

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max. 50m

Max. 50m

INDOOR UNIT

W

Capacity

2. Guaranteed operating range

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

o

F), W.B. 19:(66oF)

o

F), W.B. 24:(75oF)

14

Page 15

3. Heat pump type Rating Conditions (ISO T1)

Item

Function

Capacity w1

Total input w1

Service Ref.

Power supply

External finish

Heat exchanger

Fan Fan(drive) x No.

INDOOR UNITOUTDOOR UNIT

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan Fan(drive) x No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Input w2

Running current w2

Starting current w2

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Charge

Oil (Model)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Heating

Service Ref.

With Electric heater

Without Electric heater

Upper limit

Lower limit

Upper limit

Lower limit

With Electric heater

Without Electric heater

Btu/h

W

With Electric heater

Without Electric heater

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

/min(CFM

K

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

)

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

PCH-P2GAH1

PCA-P2GA1

Cooling

18,400

5,400

2.40

PCH-P2GAH1

PCA-P2GA1

0.10

0.43

1.20

Sirocco (direct) x 2

Sirocco (direct) x 2

0.054

10-11-12-13 (353-338-424-459)

10-11-12-13 (353-338-424-459)

PUH-P2VGAA.UK / PUH-P2YGAA.UK

PUH-P2VGAA.UK / PUH-P2YGAA.UK

Single phase, 50Hz, 220-230-240V / 3 phases, 50Hz, 380-400-415V (4wires)

10.26 / 3.70

NE36VMJMT / NE36YEKMT

NE36VMJMT / NE36YEKMT

Inner thermostat, HP switch, Discharge thermo. / Thermal relay, Discharge thermo, HP switch.

Outdoor

D.B. 46˚C

D.B. -5˚C

0.054

<1.4>

<1.4>

37-38-40-42

37-38-40-42

1,000 (39-3/8)

1,000 (39-3/8)

28.5 (63)

28.5 (63)

27 (60)

27 (60)

62 / 31

62 / 31

0.070

0.070

55 (1,940)

55 (1,940)

71 (157)

71 (157)

2.6 (5.7)

2.6 (5.7)

Max. 40m

Max. 40m

Max. 40m

Max. 40m

Heating

21,300 (26,100)

6,250 (7,650)

2.40 (3.80)

Single phase, 50Hz, 220-230-240V

0.10 <1.40>

0.43 <5.83>

1.20 <5.83>

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

14-15-16-18 (494-530-565-635)

26 (1)

PUH-P2.5VGAA.UK / PUH-P2.5YGAA.UK

11.90 / 4.48

38

Flared

Flared

1.6

1.6

48

48

49

49

0 (direct blow)

Remote controller & built-in

680 (26-3/4)

210 (8-1/4)

10.57 / 3.82

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

Plate fin coil

Propeller (direct) x 1

Reverse cycle

900 (35-7/16)

330+20 (13+3/4)

855 (33-5/8)

R407C

1.2 (Ester) MEL56

9.52 (3/8)

15.88 (5/8)

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

PCH-P2.5GAH1

PCA-P2.5GA1

Cooling

22,600

6,650

2.65

PCH-P2.5GAH1

PCA-P2.5GA1

0.13

0.55

1.27

Sirocco (direct) x 3

0.07

<2.1>

37-39-41-43

1,310 (51-9/16)

36 (79)

34 (75)

77 / 35

NE41VMJMT / NE41YEKMT

0.070

50 (1,770)

82 (181)

3.1 (6.8)

Max. 50m

Max. 50m

Heating

24,900 (32,100)

7,300 (9,400)

2.71 (4.81)

0.13 <2.10>

0.55 <8.75>

1.27 <8.75>

11.51 / 4.34

1.9

48

50

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

15

Page 16

Rating Conditions (ISO T1)

Service Ref.

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity w1

Total input w1

Service Ref.

Power supply

Input w2

Running current w2

Starting current w2

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

INDOOR UNITOUTDOOR UNIT

REFRIGERANT PIPING

PCH-P3GAH1

PCA-P3GA1

PCH-P3GAH1

PCA-P3GA1

PCH-P4GAH1

PCA-P4GA1

PCH-P4GAH1

PCA-P4GA1

Cooling

25,600

7,500

3.40

0.13

0.55

1.27

14.81 / 5.29

Cooling

33,100

9,700

3.64

0.16

0.70

1.48

15.71 / 5.55

Heating

31,300 (38,500)

9,200 (11,300)

3.50 (5.60)

0.13 <2.10>

0.55 <8.75>

1.27 <8.75>

15.76 / 5.63

Heating

36,300 (45,600)

10,650 (13,350)

3.83 (6.53)

0.16 <2.70>

0.70 <11.25>

1.48 <11.25>

16.58 / 5.86

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

0.07

14-15-16-18 <494-530-565-635>

<2.1>

37-39-41-43

210 (8-1/4)

36 (79)

34 (75)

PUH-P3VGAA.UK / PUH-P3YGAA.UK

93 / 47

NE52VNJMT / NE52YDKMT

2.5

Propeller (direct) x 1

0.070

50 (1,770)

49

51

855 (33-5/8)

82 (181)

3.3 (7.3)

15.88 (5/8)

0.09

20-21-23-25 <706-741-812-883>

<2.7>

40-41-43-45

270 (10-5/8)

39.5 (87)

37 (82)

PUH-P4VGAA.UK / PUH-P4YGAA.UK

99 / 49

NE56VNJMT / NE56YDKMT

2.7

Propeller (direct) x 2

0.070+0.070

85 (3,000)

51

53

1,260 (49-5/8)

96 (212)

4.0 (8.8)

19.05 (3/4)

Single phase, 50Hz, 220-230-240V

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) x 3

0 (direct blow)

Remote controller & built-in

26 (1)

1,310 (51-9/16)

680 (26-3/4)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

Reverse cycle

900 (35-7/16)

330+20 (13+3/4)

R407C

1.3 (Ester) MEL56

9.52 (3/8)

Flared

Flared

Max. 50m

Max. 50m

Inner thermostat, HP switch, Discharge thermo. /

Anti-phase protector. Thermal relay, Discharge thermo, HP switch.

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

Single phase, 50Hz, 220-230-240V / 3 phase, 50Hz, 380-400-415V (4wires)

16

Page 17

Rating Conditions (ISO T1)

Service Ref.

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

With Electric heater

Without Electric heater

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity w1

Total input w1

Service Ref.

Power supply

Input w2

Running current w2

Starting current w2

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Booster heater w2

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

INDOOR UNITOUTDOOR UNIT

REFRIGERANT PIPING

PCH-P5GAH1

PCA-P5GA1

PCH-P5GAH1

PCA-P5GA1

PCH-P6GAH1

PCA-P6GA1

PCH-P6GAH1

PCA-P6GA1

Cooling

42,300

12,400

4.94

0.24

1.06

2.20

7.60

Cooling

48,700

14,300

5.94

0.24

1.06

2.20

9.03

Heating

50,800 (61,000)

14,900 (17,880)

5.14 (8.14)

0.24 <3.00>

1.06 <12.50>

2.20 <12.50>

8.15

Heating

58,300 (68,500)

17,100 (20,100)

6.27 (9.27)

0.24 <3.00>

1.06 <12.50>

2.20 <12.50>

9.56

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

41-43-45-46

46 (101)

43 (95)

PUH-P5YGAA.UK

65.5

ZR61KCE-TFD

3.5

95 (3,360)

55

56

4.6 (10.1)

1.690 (Ester) MMMA-POE

42-44-46-48

48 (106)

45 (99)

PUH-P6YGAA.UK

74

ZR72KCE-TFD

4.2

100 (3,530)

57

58

4.9 (10.8)

1.774 (Ester) MMMA-POE

Single phase, 50Hz, 220-230-240V

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) x 4

0.15

27-30-32-34 <953-1,059-1,130-1,200>

0 (direct blow)

<3.0>

Remote controller & built-in

26 (1)

1,620 (63-3/4)

680 (26-3/4)

270 (10-5/8)

3 Phase, 50Hz, 380-400-415V (4wires)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

Anti-phase protector, Internal thermostat, LP switch, HP switch,Thermal relay,Discharge thermo

38

Plate fin coil

Propeller (direct) x 2

0.070+0.070

Reverse cycle

1050 (41-5/16)

330+20 (13+3/4)

1,260 (49-5/8)

122 (269)

R407C

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

w1 : ( ) Shows the total rating.

w2 : < > Shows the only booster heater rating.

17

Page 18

4. Cooling only type Rating Conditions (ISO T1)

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

mm(in.)

mm(in.)

kg(lbs)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

kW

L

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

A

A

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

Pa(mmAq)

kW

kW

A

A

Btu/h

W

kW

Item

Service Ref.

Function

Total input

PCA-P2GA1 PCA-P2.5GA1

Cooling

18,400

5,400

2.40

Cooling

22,700

6,650

2.65

PCA-P2GA

1

Single phase, 50Hz, 220-230-240V

PCA-P2.5GA

1

0.10

0.43

1.20

0.13

0.55

1.27

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct))2

0.054

10 -11-12-13 <353-338-424-459>

Sirocco (direct))3

0.07

14 -15-16-18 <494-530-565-635>

0 (direct blow)

——

Remote controller & built-in

37-38-40-42 37-39-41-43

26 (1)

1,000 (39-3/8) 1,310 (51-9/16)

680 (26-3/4)

210 (8-1/4)

27 (60)

PU-P2VGAA.UK / PU-P2YGAA.UK

34 (75)

PU-P2.5VGAA.UK / PU-P2.5YGAA.UK

Single phase, 50Hz, 220-230-240V / 3 phases, 50Hz, 380-400-415V (4wires)

10.26 / 3.70

62 / 31

11.90 / 4.48

77 / 35

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE36VMJMT / NE36YEKMT

1.6

NE41VMJMT / NE41YEKMT

1.9

Line start

Internal thermostat. High-pressure switch,Discharge thermo. / Thermal relay, HP switch, Discharge thermo.

38

Plate fin coil

Propeller (direct) ✕1

0.070

55 (1,940) 50 (1,770)

48

—

71 (157) 82 (181)

900 (35-7/16)

330+20 (13+3/4)

R407C

2.6 (5.7) 3.1 (6.8)

1.2 (Ester) MEL56

855 (33-5/8)

9.52 (3/8)

15.88 (5/8)

Flared

Flared

Max. 40m

Max. 40m

Max. 50m

Max. 50m

Upper limit

Lower limit

Indoor

D.B. 35:, W.B. 22.5:

D.B. 19:, W.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

INDOOR UNIT

W

Capacity

2. Guaranteed operating range

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95oF), W.B. 24:(75oF)

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phases 415V 50Hz

o

F), W.B. 19:(66oF)

18

Page 19

Rating Conditions (ISO T1)

Item

Function

Capacity

Total input

Service Ref.

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan

Booster heater

INDOOR UNIT

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

OUTDOOR UNIT

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

PIPING

Connection method

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

REFRIGERANT

Between the indoor & outdoor unit

Service Ref.

K/min <CFM>

Pa(mmAq)

W

D

H

K/min <CFM>

Cooling

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Btu/h

W

kW

kW

A

A

kW

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

kW

W

kW

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PCA-P3GA1 PCA-P4GA1

Cooling

25,600

7,500

3.40

PCA-P3GA

14-15-16-18 <494-530-565-635>

37-39-41-43 40-41-43-45

210 (8-1/4) 270 (10-5/8)

34 (75)

PU-P3VGAA.UK / PU-P3YGAA.UK

Single-phase, 50Hz, 220-230-240V / 3-phase, 50Hz, 380-400-415V (4wires)

14.81 / 5.29

93 / 47

NE52VNJMT / NE52YDKMT

Propeller (direct) ✕ 1

50 (1,770)

855 (33-5/8)

82 (181)

3.3 (7.3) 4.0 (8.8)

15.88 (5/8) 19.05 (3/4)

1

Single phase, 50Hz, 220-230-240V

0.13

0.55

1.27

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) ✕ 3

0.07

20-21-23-25 <706-741-812-883>

0 (direct blow)

—

Remote controller & built-in

26 (1)

1,310 ( 51-9/16 )

680 (26-3/4)

PU-P4VGAA.UK / PU-P4YGAA.UK

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE56VNJMT / NE56YDKMT

2.5

Inner thermostat. High-pressure switch Discharge thermo /

High-pressure switch Thermal relay, Discharge thermo

0.070

49 51

Line start

38

Plate fin coil

—

900 (35-7/16)

330 + 20 (13+3/4)

R407C

1.3 (Ester) MEL56

9.52 (3/8)

Flared

Flared

Max. 50m

Max. 50m

Cooling

33,100

9,700

3.64

PCA-P4GA

37 (82)

15.71 / 5.55

99 / 49

Propeller (direct) ✕ 2

0.070+0.070

85 (3,000)

1,260 (49-5/8)

96 (212)

1

0.16

0.70

1.48

0.09

2.7

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95oF), W.B. 24:(75oF)

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit Single phase 240V 50Hz / 3 phase 415V 50Hz

o

F), W.B. 19:(66oF)

2. Guaranteed operating range

Cooling

Upper limit

Lower limit

19

Indoor

D.B. 35:, D.B. 22.5:

D.B. 19:, D.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Page 20

Rating Conditions (ISO T1)

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Lo-Mi2-Mi1-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

mm(in.)

mm(in.)

kg(lbs)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

kW

L

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Mi2-Mi1-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

A

A

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

kW

K/min <CFM>

Pa(mmAq)

kW

kW

A

A

Btu/h

W

kW

Item

Service Ref.

Function

Total input

Upper limit

Lower limit

Indoor

D.B. 35:, W.B. 22.5:

D.B. 19:, W.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

PCA-P5GA1 PCA-P6GA1

Cooling

42,300

12,400

4.94

0.24

1.06

2.20

0.24

1.06

2.20

Cooling

48,700

14,300

5.94

PCA-P5GA

1

Single phase, 50Hz, 220-230-240V

PCA-P6GA

1

Munsell 0.70Y 8.59 / 0.97

Plate fin coil

Sirocco (direct) ✕4

0.15

27-30-32-34 <953-1,059-1,130-1,200>

0 (direct blow)

—

Remote controller & built-in

41-43-45-46 42-44-46-48

26 (1)

1,620 (63-3/4)

680 (26-3/4)

270 (10-5/8)

43 (95)

PU-P5YGAA.UK

45 (99)

PU-P6YGAA.UK

ZR61KCE-TFD

3.5

ZR72KCE-TFD

4.2

95 (3,360) 100 (3,530)

122 (269)

55 57

3 phases, 50Hz, 380-400-415V (4wires)

—

R407C

1050 (41-5/16)

330+20 (13+3/4)

1,260 (49-5/8)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

Internal thermostat, HP switch,Thermal relay,Discharge thermo

38

Plate fin coil

Propeller (direct) ✕2

0.070+0.070

7.60

65.5

9.03

74

9.52 (3/8)

19.05 (3/4)

Flared

Flared

Max. 50m

Max. 50m

INDOOR UNIT

W

4.6 (10.1)

1.690 (Ester) MMMA-POE

4.9 (10.8)

1.774 (Ester) MMMA-POE

Capacity

2. Guaranteed operating range

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80

Outdoor : D.B. 35:(95

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

o

F), W.B. 19:(66oF)

o

F), W.B. 24:(75oF)

20

Page 21

6

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

5,445

5,830

6,270

5,445

5,830

6,270

5,445

5,830

6,270

6,683

5,445

5,830

6,270

6,683

5,445

5,830

6,270

6,683

5,445

5,830

6,270

6,683

5,445

5,830

6,270

6,683

5,445

5,830

6,270

6,683

SHC(W)

3,376

2,915

2,383

3,812

3,381

2,884

4,247

3,848

3,386

2,807

4,683

4,314

3,887

3,341

5,118

4,781

4,389

3,876

5,445

5,247

4,891

4,410

5,445

5,713

5,392

4,945

5,445

5,830

5,894

5,480

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.42

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

P.C.

2.06

2.10

2.17

2.06

2.10

2.17

2.06

2.10

2.17

2.22

2.06

2.10

2.17

2.22

2.06

2.10

2.17

2.22

2.06

2.10

2.17

2.22

2.06

2.10

2.17

2.22

2.06

2.10

2.17

2.22

CA

5,280

5,665

6,133

5,280

5,665

6,133

5,280

5,665

6,133

6,545

5,280

5,665

6,133

6,545

5,280

5,665

6,133

6,545

5,280

5,665

6,133

6,545

5,280

5,665

6,133

6,545

5,280

5,665

6,133

6,545

SHC(W)

3,274

2,833

2,330

3,696

3,286

2,821

4,118

3,739

3,312

2,749

4,541

4,192

3,802

3,273

4,963

4,645

4,293

3,796

5,280

5,099

4,783

4,320

5,280

5,552

5,274