Mitsubishi Electric NZ2MFB2-16A, NZ2MFB1-32T, NZ2MFB1-32TE1, NZ2MFB1-32DT, NZ2MFB1-32DTE1 User Manual

...Page 1

CC-Link IE Field Network Basic

Remote

-NZ2MFB2-16A

-NZ2MFB1-32D

-NZ2MFB2-16R

-NZ2MFB1-32T

-NZ2MFB1-32TE1

-NZ2MFB1-32DT

-NZ2MFB1-32DTE1

I/O Module User's Manual

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the programmable

controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

WARNING

● When a communication failure occurs in the network, data in the CPU module on the master station

are held. Check the data link status of each station stored in the special register (SD) and configure an

interlock circuit in the program to ensure that the entire system will operate safely.

● When the module is disconnected due to a communication failure in the network or the CPU module is

in the STOP state, all outputs are held or turned off according to the function setting switch setting.

Configure an interlock circuit in the program to ensure that the entire system will always operate

safely even in such a case. If not, an accident may occur due to an incorrect output or malfunction.

● Outputs may remain on or off due to a failure of the module. Configure an external circuit for

monitoring output signals that could cause a serious accident.

● Do not use any "use prohibited" signals as a remote I/O signal since they are used by the system. Do

not write any data to the "use prohibited" areas in the remote register. Doing so may result in an

accident due to an incorrect output or malfunction.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

1

Page 4

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing a

odule. Failure to do so may result in electric shock or cause the module to fail or malfunction.

m

[Installation Precautions]

CAUTION

● Use the module in an environment that meets the general specifications in this manual. Failure to do

o may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

s

● Do not directly touch any conductive parts and electronic components of the module. Doing so ca

c

ause malfunction or failure of the module.

● Securely connect the cable connectors. Poor contact may cause malfunction.

[Wiring Precautions]

WARNING

n

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

esult in electric shock or cause the module to fail or malfunction.

r

2

Page 5

[Wiring Precautions]

CAUTION

● Individually ground the FG terminal of the programmable controller with a ground resistance of 100

ohms or less. Failure to do so may result in electric shock or malfunction.

● Tighten any unused terminal screws within the specified torque range. Undertightening can cause a

short circuit due to contact with a solderless terminal.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when a terminal block screw comes loose,

resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause short

circuit, fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, fire, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● When an overcurrent caused by an error of an external device or a failure of the programmable

controller flows for a long time, it may cause smoke and fire. To prevent this, configure an external

safety circuit, such as a fuse.

● Mitsubishi Electric programmable controllers must be installed in control panels. Wiring and

replacement of a module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring methods, refer to "INSTALLATION AND WIRING" in this

manual.

3

Page 6

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws or connector screws. Failure to do so may cause the module to

fail or malfunction.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a fire.

● Do not drop or apply strong shock to the module. Doing so may damage the module.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● After the first use of the product, do not connect/remove the terminal block more than 50 times (IEC

61131-2 compliant). Exceeding the limit may cause malfunction.

● Before handling the module or connection cables, touch a conducting object such as a grounded

metal to discharge the static electricity from the human body. Failure to do so may cause the module

to fail or malfunction.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

5

Page 8

INTRODUCTION

Thank you for purchasing the CC-Link IE Field Network Basic remote I/O module (hereafter abbreviated as I/O module).

This manual describes the procedures, system configuration, parameter settings, functions, and troubleshooting of the

relevant products listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the I/O module to handle the product correctly.

When applying the program and circuit examples provided in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

NZ2MFB2-16A, NZ2MFB1-32D, NZ2MFB2-16R, NZ2MFB1-32T, NZ2MFB1-32TE1, NZ2MFB1-32DT, NZ2MFB1-32DTE1

6

Page 9

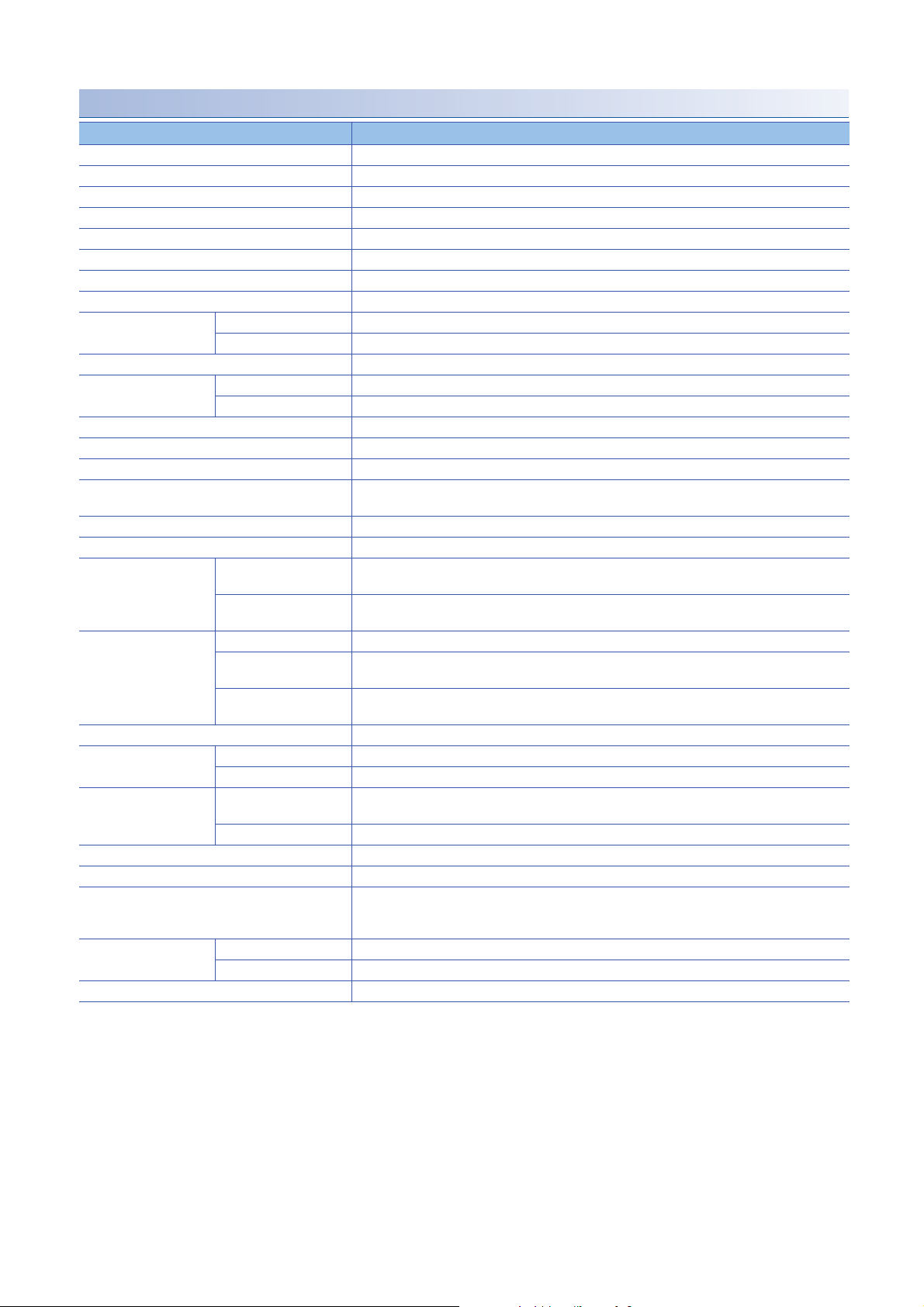

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CHAPTER 1 PRODUCT LINEUP 11

1.1 Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 I/O Combined Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 2 PART NAMES 13

CHAPTER 3 SPECIFICATIONS 15

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Output module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

I/O combined module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.4 List of Functions of Each Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

CONTENTS

CHAPTER 4 PROCEDURES BEFORE OPERATION 40

CHAPTER 5 SYSTEM CONFIGURATION 42

CHAPTER 6 INSTALLATION AND WIRING 44

6.1 Before Using the I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Input modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Output module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2 Setting Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

IP address setting switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Function setting switch setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.3 Installation Environment and Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

6.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Mounting the module on a DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

6.5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Wiring with terminal block for module power supply and FG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Wiring of Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Wiring of external device and I/O terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CHAPTER 7 PARAMETER SETTING 63

7.1 Network Configuration Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

CHAPTER 8 FUNCTIONS 65

7

Page 10

8.1 Input Response Time Setting Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2 Output HOLD/CLEAR Setting Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

8.3 Protection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.4 SLMP communication function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

CHAPTER 9 PROGRAMMING 69

9.1 Precautions for Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.2 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

CHAPTER 10 MAINTENANCE AND INSPECTION 75

CHAPTER 11 TROUBLESHOOTING 77

11.1 Checking the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

11.2 CC-Link IE Field Network Basic Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.3 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

11.4 Examples of Troubles with the I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Troubleshooting for input circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Troubleshooting for output circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

11.5 Method for Checking Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.6 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

I/O module specific error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

CC-Link IE Field Network Basic related error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

APPENDICES 94

Appendix 1 Remote I/O Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

List of remote I/O signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Details of remote input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Details of remote output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix 2 Remote Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

List of remote register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Appendix 3 Setting IP Addresses and Subnet Masks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Appendix 4 Diagnostic Information of Slave Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Diagnostic information list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Diagnostic information details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix 5 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix 6 EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Measures to comply with the EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Requirements to compliance with the Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Appendix 7 How to Check Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Appendix 8 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

INDEX 118

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

8

Page 11

RELEVANT MANUALS

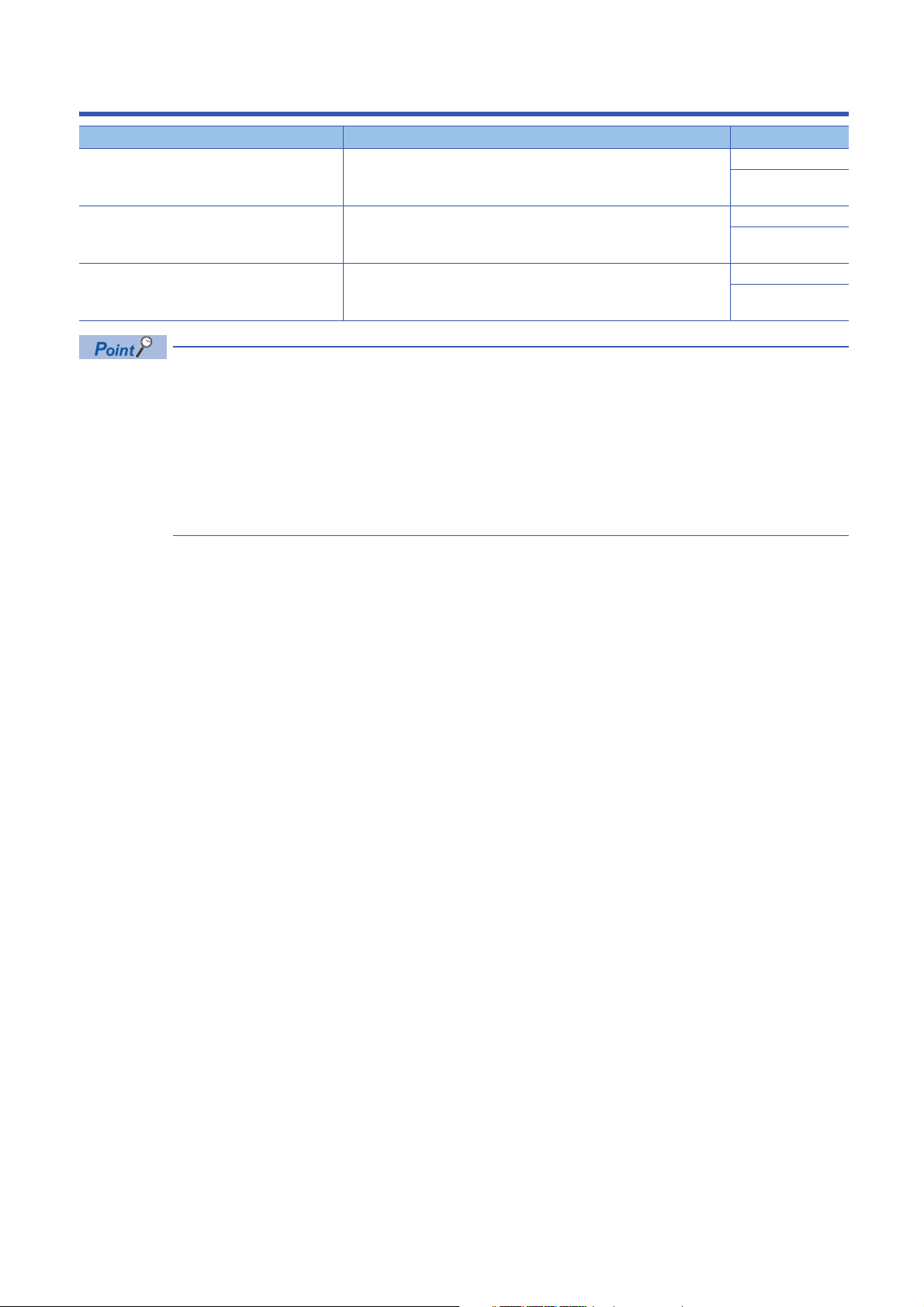

Manual name [manual number] Description Available form

CC-Link IE Field Network Basic Remote I/O Module

User's Manual

[SH-081763ENG] (this manual)

CC-Link IE Field Network Basic Reference Manual

[SH-081684ENG]

SLMP Reference Manual

[SH-080956ENG]

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

Part names, specifications, procedures before operation, system

configuration, installation, wiring, parameter settings, functions, programming,

and troubleshooting of the I/O module

Specifications, procedures before operation, system configuration,

programming, functions, parameter settings, and troubleshooting of CC-Link

IE Field Network Basic

The protocol (SLMP) used for data reading or writing from an external device

to the Ethernet-equipped module

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

9

Page 12

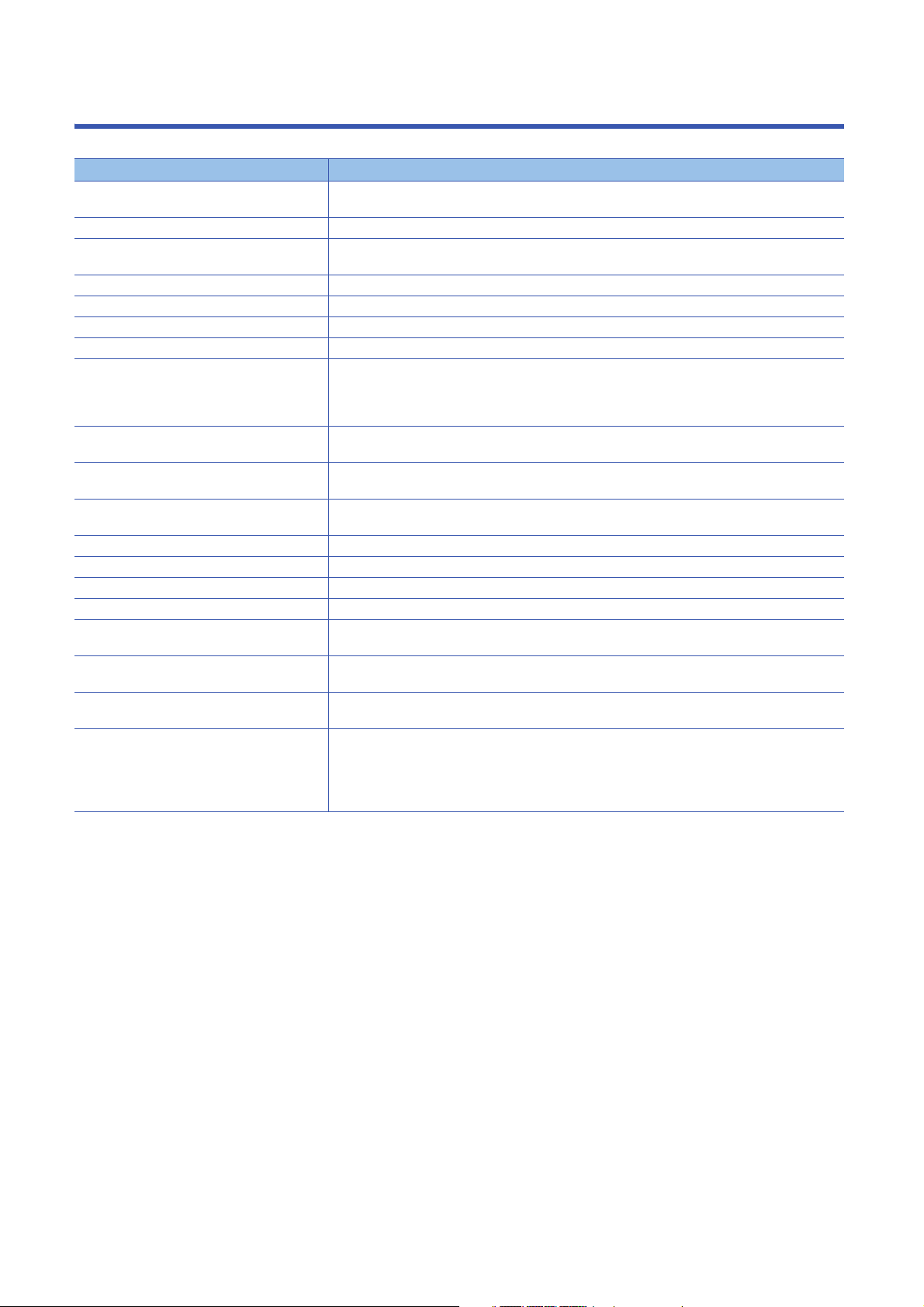

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Cyclic transmission A function by which data are periodically exchanged among stations on the same network using link

Disconnection A process of stopping data link if a data link error occurs

I/O combined module A generic term for CC-Link IE Field Network Basic remote I/O modules where a digital signal can be input

I/O module A generic term for CC-Link IE Field Network Basic remote I/O modules

Input module A generic term for CC-Link IE Field Network Basic remote I/O modules where a digital signal can be input

Label A label that represents a device in a given character string

Link device A device (RX, RY, RWr, RWw) in a CPU module that is used for communications with a slave station

Link scan (link scan time) After sending requests to all the slave stations and then receiving the responses from all the slave

Master station A station that controls the entire CC-Link IE Field Network Basic. Only one master station can be used in

Output module A generic term for CC-Link IE Field Network Basic remote I/O modules where a digital signal can be

Reference response time A time period taken from when a slave station on CC-Link IE Field Network Basic receives a request from

Remote input (RX) Bit data input from a slave station to the master station

Remote output (RY) Bit data output from the master station to a slave station

Remote register (RWr) Word data input from a slave station to the master station

Remote register (RWw) Word data output from the master station to a slave station

Reserved station A station reserved for future use. This station is not actually connected on CC-Link IE Field Network

Slave station A station that performs cyclic transmission with the master station on CC-Link IE Field Network Basic. The

SLMP The abbreviation for Seamless Message Protocol. This protocol is used to access an SLMP-compatible

Subnet mask A number used to logically divide one network into multiple subnetworks and manage them easily. The

devices on CC-Link IE Field Network Basic

and output

stations, the master station on CC-Link IE Field Network Basic starts sending another request to the slave

stations. The link scan time is a time period taken for the master station to start sending another request

after sending the previous requests.

a network.

output

the master station until it returns the response to the master station.

Basic, but counted as a connected station

station exchanges I/O signals (bit data)/I/O data (word data) with another station.

device or a programmable controller connected to an SLMP-compatible device from an external device.

following Ethernet network systems can be configured:

• A small-scale Ethernet network system in which multiple network devices are connected

• A medium- or large-scale network system in which multiple small-scale network systems are connected

via routers or other network communication devices

10

Page 13

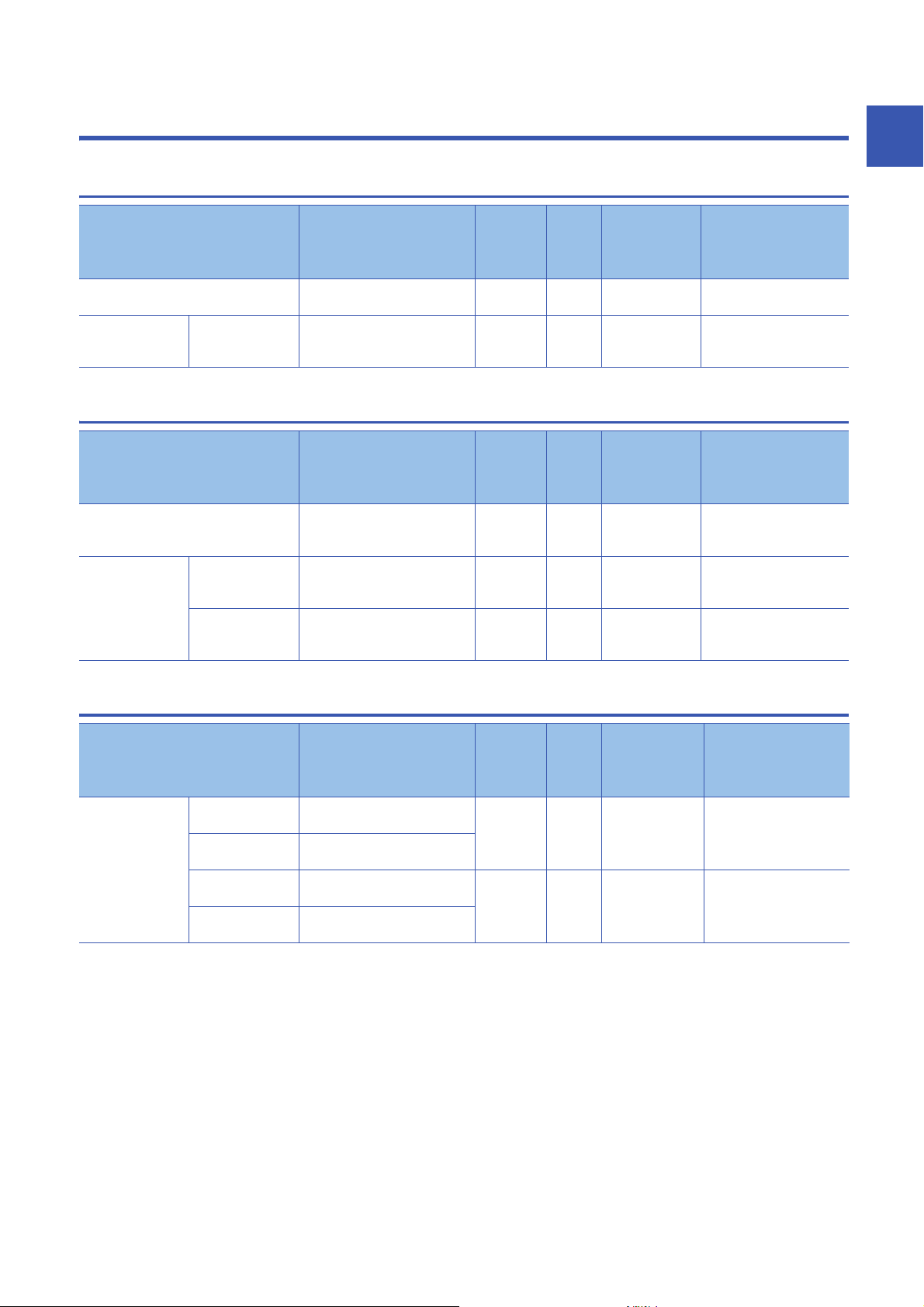

1 PRODUCT LINEUP

1.1 Input Module

1

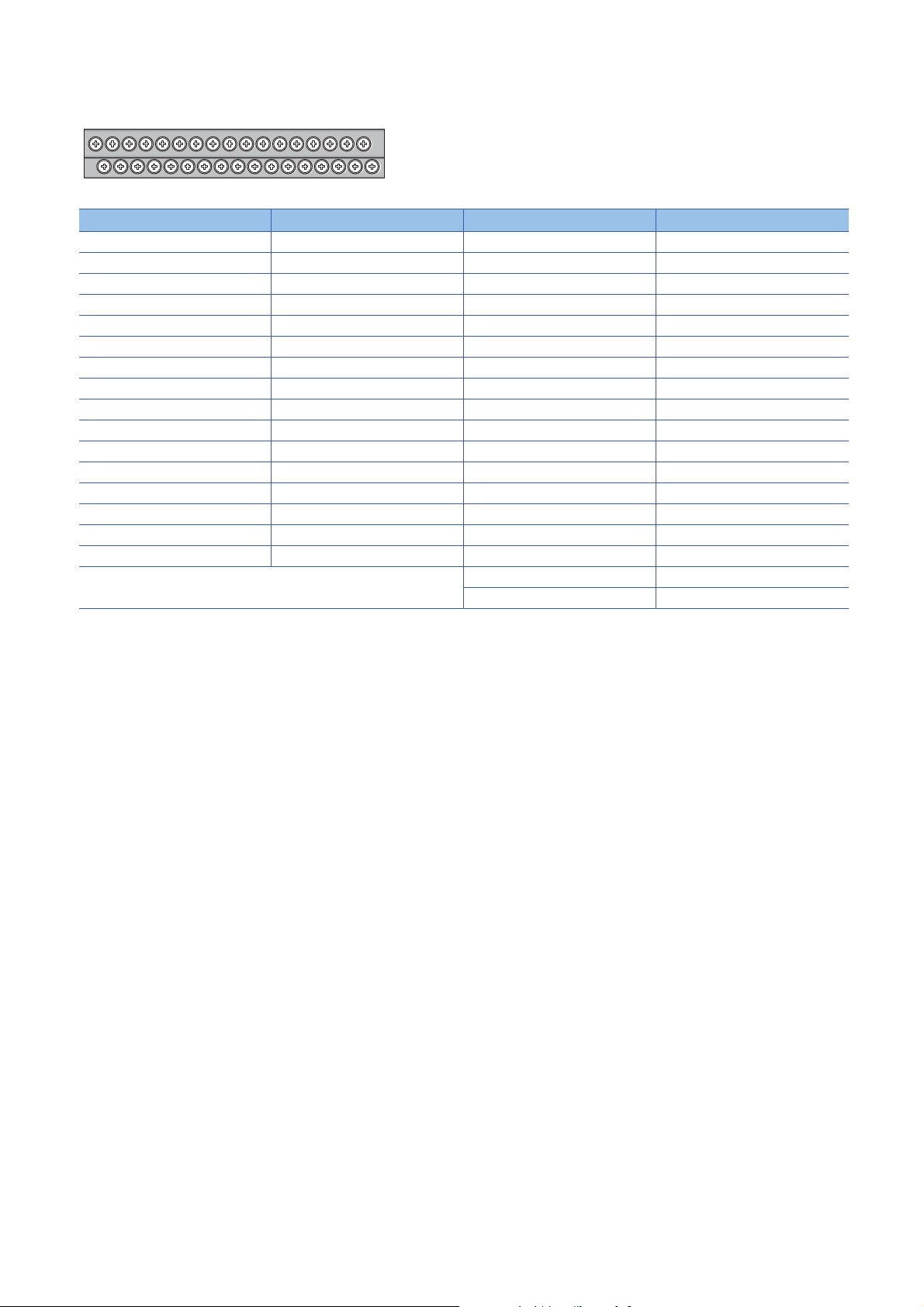

Module name Input specifications Module

power

supply

current

AC input module Screw terminal block

DC input module Positive common/

negative common

shared type

100 to 120VAC, 16 points

Screw terminal block

24VDC, 32 points

64mA 0.31kg NZ2MFB2-16A Page 16 NZ2MFB2-

71mA 0.30kg NZ2MFB1-32D Page 19 NZ2MFB1-

1.2 Output Module

Module name Output specifications Module

power

supply

current

Contact output module Screw terminal block

Transistor output

module

Sink type Screw terminal block

Source type Screw terminal block

240VAC/24VDC, 2A/point, 16

points

12 to 24VDC, 0.5A/point, 32

points

12 to 24VDC, 0.1A/point, 32

points

153mA 0.35kg NZ2MFB2-16R Page 22 NZ2MFB2-

85mA 0.30kg NZ2MFB1-32T Page 25 NZ2MFB1-

84mA 0.30kg NZ2MFB1-32TE1 Page 28 NZ2MFB1-

Weight Model Reference

16A AC input module

32D DC input module

Weight Model Reference

16R contact output module

32T transistor output

module

32TE1 transistor output

module

1.3 I/O Combined Module

Module name Input specifications, output

specifications

DC input/transistor

output module

Input part: Positive

common type

Output part: Sink

type

Input part: Negative

common type

Output part: Source

type

Screw terminal block

24VDC, 16 points

Screw terminal block

24VDC, 0.5A/point, 16 points

Screw terminal block

24VDC, 16 points

Screw terminal block

24VDC, 0.1A/point, 16 points

Module

power

supply

current

79mA 0.30kg NZ2MFB1-32DT Page 31 NZ2MFB1-

79mA 0.30kg NZ2MFB1-

Weight Model Reference

32DT DC input/transistor

output module

32DTE1

Page 35 NZ2MFB132DTE1 DC input/transistor

output module

1 PRODUCT LINEUP

1.1 Input Module

11

Page 14

MEMO

12

1 PRODUCT LINEUP

1.3 I/O Combined Module

Page 15

2 PART NAMES

(7)

(1) (2) (4)

(3) (5) (6)

(8)

(9)

This chapter describes part names of the I/O module.

No. Name Application

(1) Ethernet port Port connector for network connection. Connect an Ethernet cable.

100M LED Indicates the link status.

SD/RD LED Indicates the status of data communication.

(2) PW LED Indicates the power supply status of the I/O module.

RUN LED Indicates the operating status of the I/O module.

D LINK LED Indicates the data link status of the I/O module.

ERR. LED Indicates the error status of the I/O module.

(3) Function setting switch Used for the input response time setting function and output HOLD/CLEAR setting function.

(4) IP address setting switch Switch for setting the fourth octet of IP address

(5) X0 LED to XF LED Indicates the ON/OFF status of the inputs.

Y10 LED to Y1F LED Indicates the ON/OFF status of the outputs.

(6) I/O PW LED Indicates the status of the power supply from the external power supply.

(7) Terminal block for module

power supply and FG

(8) DIN rail hook A hook to mount an I/O module on a DIN rail

(9) I/O terminal block A terminal block for I/O power supply and I/O signals

*1 The status of actual input signals that are externally input is indicated on the LEDs regardless of the status of the remote input signal.

*2 Output commands from the I/O module are indicated on the LEDs regardless of the status of the external power supply.

2

For wiring method and precautions, refer to the following.

Page 61 Wiring of Ethernet cable

On: Linkup in progress

Off: Linkdown in progress

On: Data being sent or received

Off: Data not sent/received

On: Power supply ON

Off: Power supply OFF

On: Operating normally.

Off: A major error has occurred.

On: Data link in operation. (cyclic transmission in progress)

Flashing: Data link stop (cyclic transmission stopped)

Off: Data link not performed. (disconnected)

On: A moderate error or major error has occurred.

Flashing: A minor error has occurred.

Off: Operating normally.

For function details and setting method, refer to the following.

Page 65 Input Response Time Setting Function

Page 66 Output HOLD/CLEAR Setting Function

Page 51 IP address setting switch setting

*1

On: Input ON

Off: Input OFF

*2

On: Output ON

Off: Output OFF

On: External power supply ON

Off: External power supply OFF

A terminal block to connect the module power supply (24VDC) and FG.

2 PART NAMES

13

Page 16

MEMO

14

2 PART NAMES

Page 17

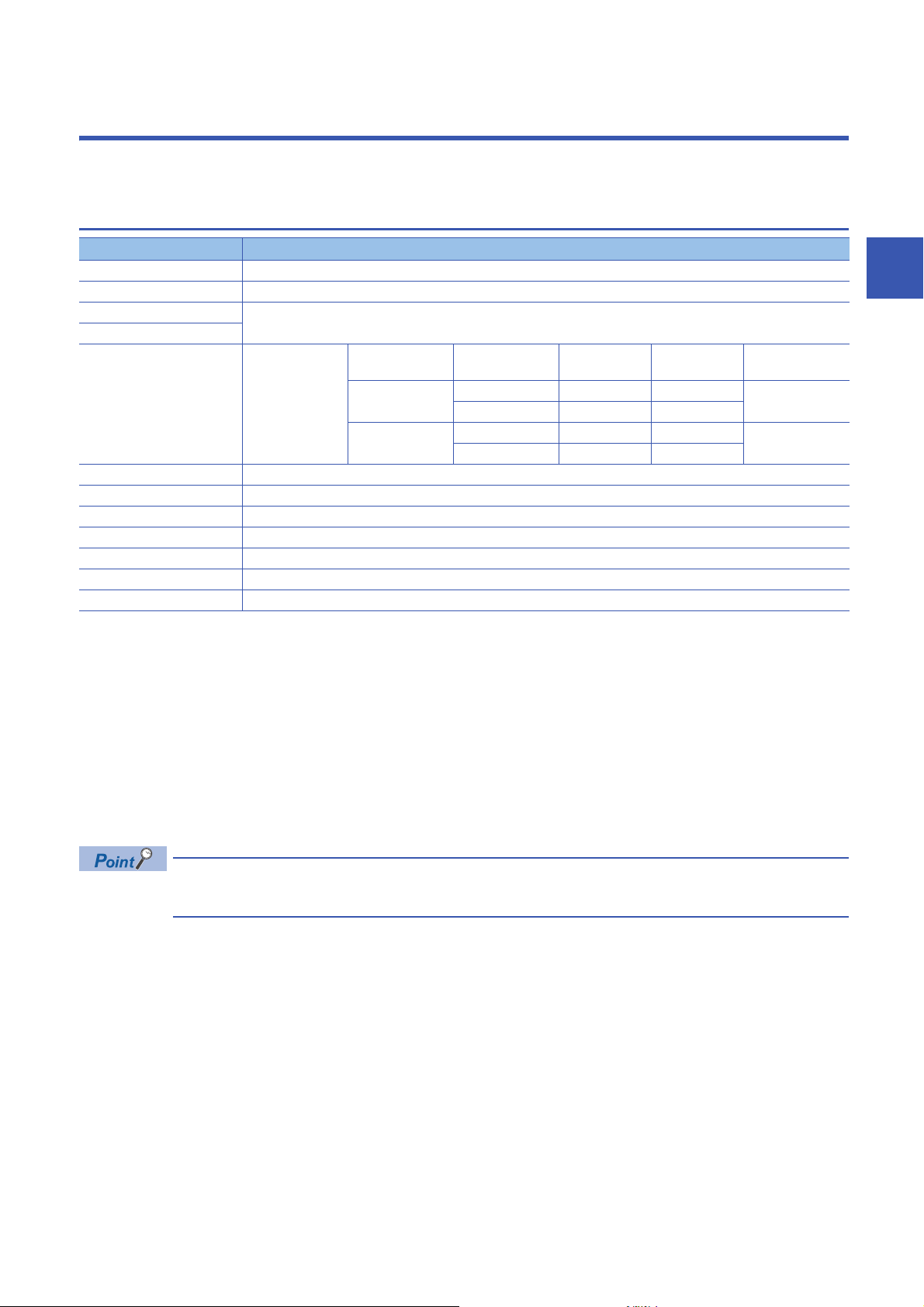

3 SPECIFICATIONS

This chapter describes the specifications of the I/O module.

3.1 General Specifications

Item Specifications

Operating ambient temperature 0 to 55

Storage ambient temperature -25 to 75

Operating ambient humidity 5 to 95%RH, non-condensing

Storage ambient humidity

Vibration resistance Compliant with JIS

Shock resistance Compliant with JIS B 3502 and IEC 61131-2 (147m/, 3 times each in X, Y, and Z directions)

Operating atmosphere No corrosive gases, flammable gases, less conductive dust

Operating altitude

Installation location Inside a control panel

Overvoltage category

Pollution degree

Equipment class Class

*1 Do not use or store the I/O module under pressure higher than the atmospheric pressure of altitude 0m. Doing so may cause

malfunction. When using the I/O module under pressure, please consult your local Mitsubishi representative.

*2 When the programmable controller is used at altitude above 2000m, the withstand voltage performance and the upper limit of the

operating ambient temperature decrease. Please consult your local Mitsubishi representative.

*3 If the environment satisfies the operating ambient temperature, operating ambient humidity and other conditions, the module can be

used even outside the control panel.

*4 This indicates the section of the power supply to which the equipment is assumed to be connected between the public electrical power

distribution network and the machinery within premises.

Category applies to equipment for which electrical power is supplied from fixed facilities. The surge voltage withstand level for up to

the rated voltage of 300V is 2500V.

*5 This index indicates the degree to which conductive material is generated in terms of the environment in which the equipment is used.

Pollution degree 2 is when only non-conductive pollution occurs. A temporary conductivity caused by condensing must be expected

occasionally.

*1

*4

*5

B 3502 and IEC

61131-2

0 to 2000m

or less

2 or less

*2

Frequency Constant

Under intermittent

vibration

Under continuous

vibration

*3

5 to 8.4Hz 3.5mm 10 times each in X,

8.4 to 150Hz 9.8m/

5 to 8.4Hz 1.75mm

8.4 to 150Hz 4.9m/

acceleration

Half amplitude Sweep count

Y, and Z directions

3

To ensure that this product complies with the EMC Directive, refer to the following.

Page 108 EMC and Low Voltage Directives

3.1 General Specifications

3 SPECIFICATIONS

15

Page 18

3.2 Performance Specifications

Input module

NZ2MFB2-16A AC input module

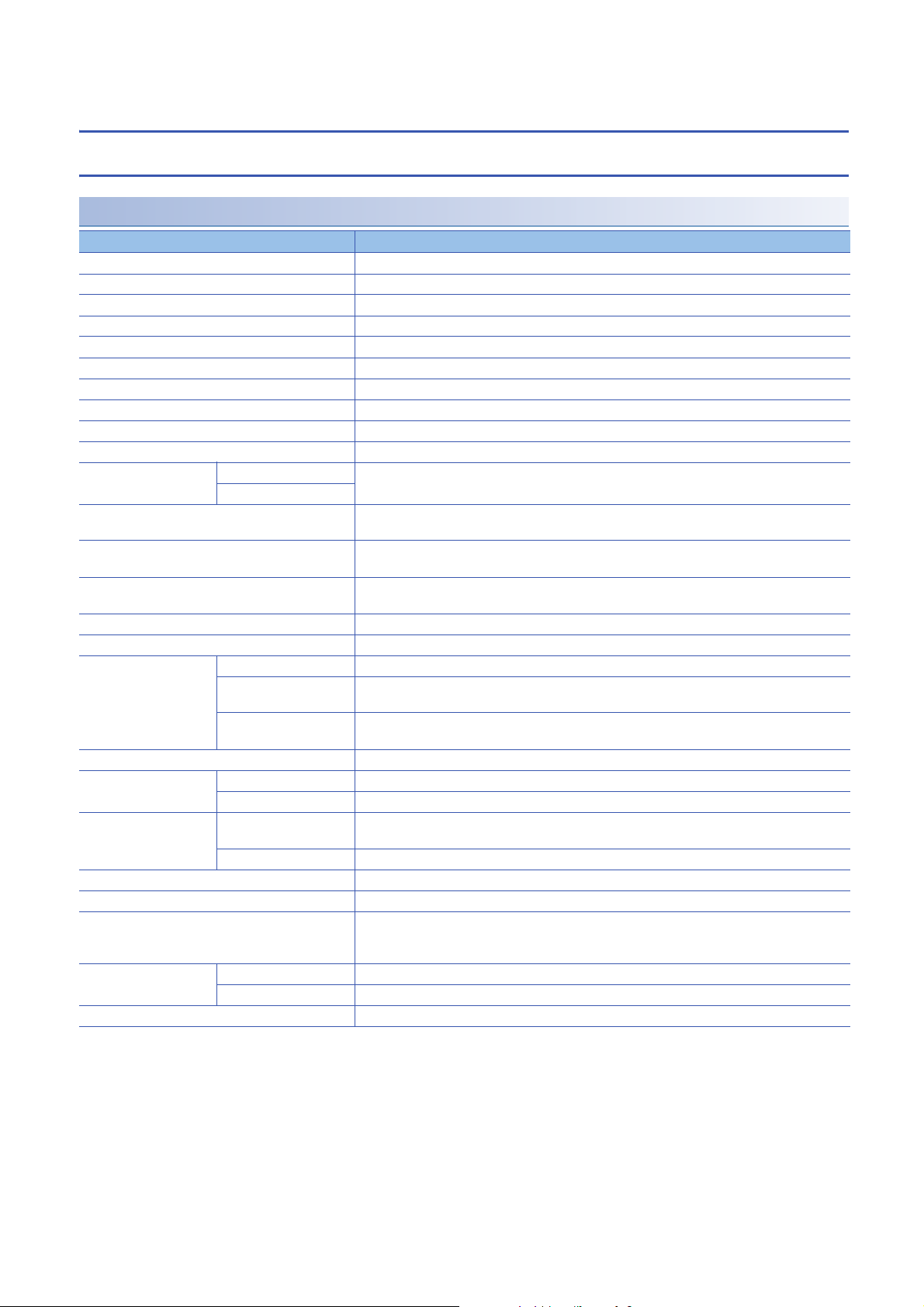

Item NZ2MFB2-16A

Station type Slave station

Number of input points 16 points

Rated input voltage/rated frequency 100 to 120VAC (+10%/-15%), 50/60Hz (3Hz)

Rated input current 8.2mA (100VAC, 60Hz), 6.8mA (100VAC, 50Hz)

Inrush current 200mA maximum within 1ms

Input voltage distortion ratio Within 5%

Max. number of simultaneous input points 100%

ON voltage/ON current 80VAC or more/5mA or more (50Hz, 60Hz)

OFF voltage/OFF current 30VAC or less/1.7mA or less (50Hz, 60Hz)

Input impedance Approx. 15k (60Hz), approx. 18k (50Hz)

Input response time OFFON 20ms or less (100VAC 60Hz)

ONOFF

Withstand voltage 1400VACrms for 1 minute between all AC external terminals and the ground

Insulation resistance 10M or higher between all AC external terminals and the ground, all DC external terminals and the

Noise immunity Noise voltage: 1500Vp-p (AC type), 500Vp-p (DC type), noise width 1s, noise frequency 25 to 60Hz

Protection degree IP1X

Wiring method for common 16 points/common (2-wire, screw terminal block type)

External interface Communication part RJ45 connector

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.31kg

Terminal block for module

power supply and FG

Terminal block for input Page 62 Applicable solderless terminal

Current 64mA or less (24VDC, all points ON)

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*2 It is recommended to use the bar solderless terminal for wiring.

510VACrms for 1 minute between all DC external terminals and the ground

ground (500VDC insulation resistance tester)

(noise simulator condition)

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

Page 59 Applicable solderless terminal

*1

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

*2

16

3 SPECIFICATIONS

3.2 Performance Specifications

Page 19

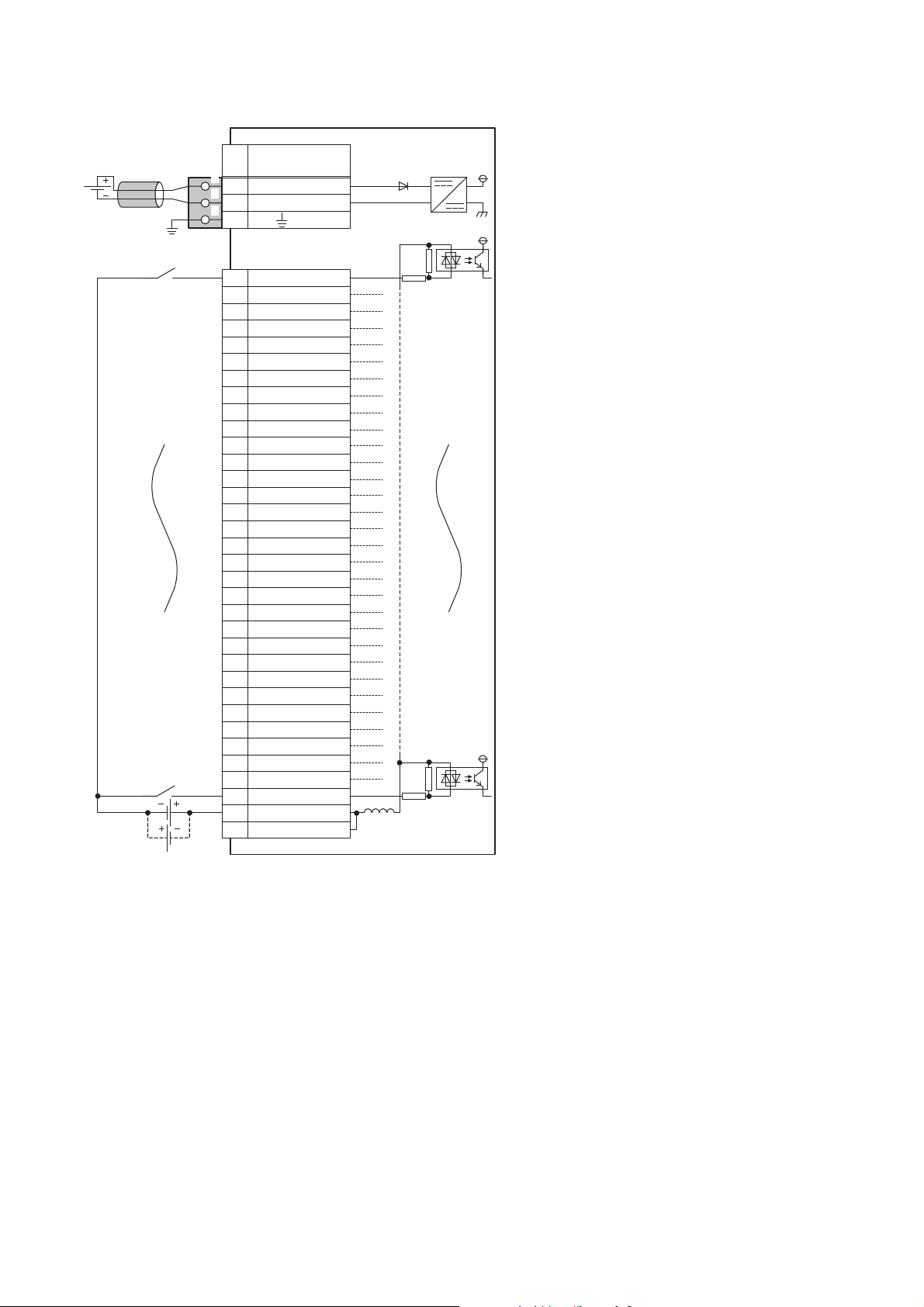

■External connection

FG

1

2

3

UNIT POWER

CABLE

1

2

3

X01

COM B2

X13

COM B4

X25

COM B6

7

COM B8

X49

COM B10

X511

COM B12

X613

COM B14

X715

COM B16

X817

COM B18

X919

COM B20

XA21

COM B22

XB23

COM B24

XC25

COM B26

XD27

COM B28

XE29

COM B30

XF31

COM B32

COM A33

COM B34

+24V

24G

X3

Signal name

Pin

No.

Non-insulated

Terminal block

for input

Terminal block for module

power supply and FG

*1

Module power

supply

AC100 to 120V

3

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

17

Page 20

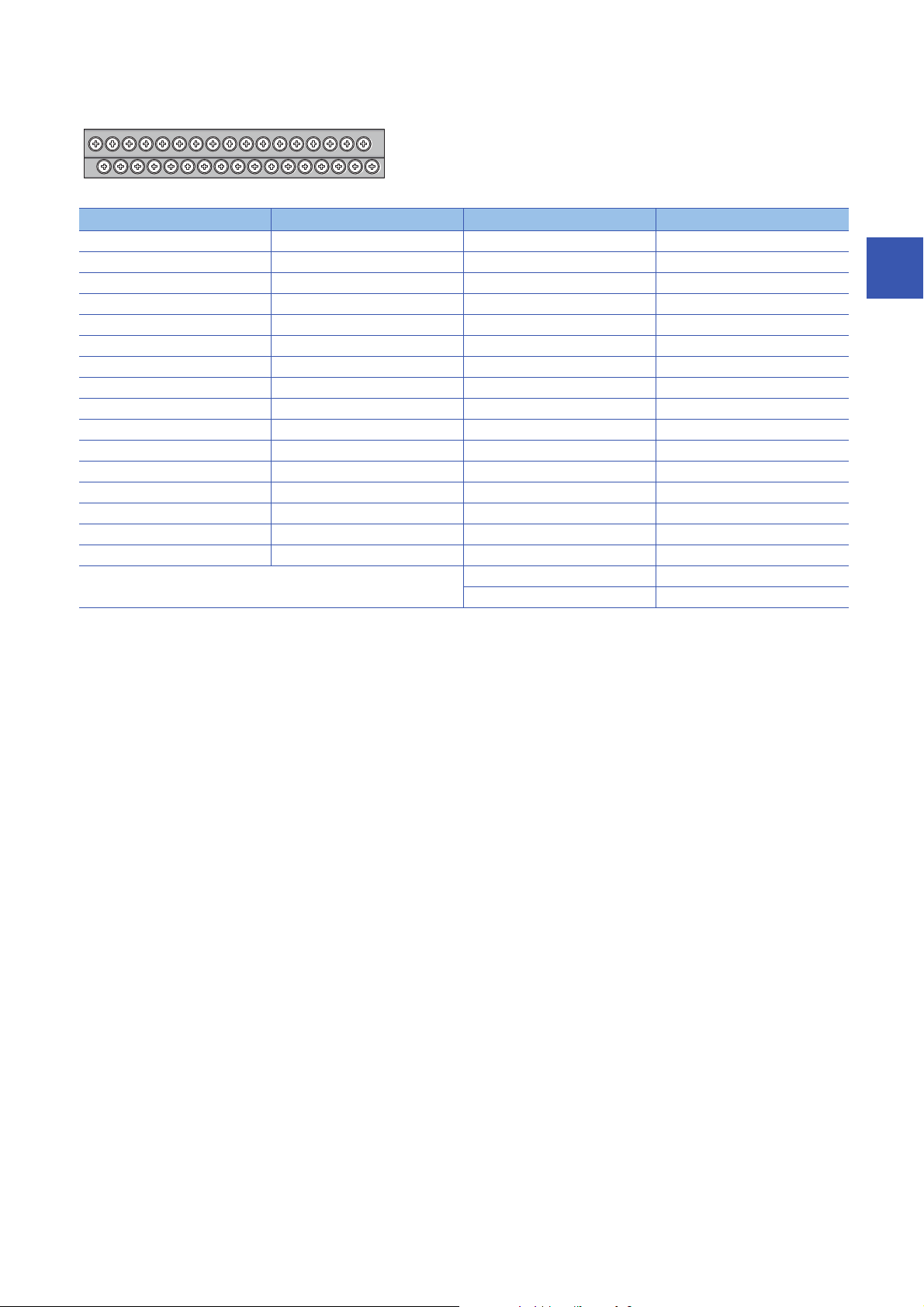

■Terminal block for input

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1X017X8

2 COM B 18 COM B

3X119X9

4 COM B 20 COM B

5X221XA

6 COM B 22 COM B

7X323XB

8 COM B 24 COM B

9X425XC

10 COM B 26 COM B

11 X5 2 7 X D

12 COM B 28 COM B

13 X6 29 XE

14 COM B 30 COM B

15 X7 31 XF

16 COM B 32 COM B

33 COM A

34 COM B

18

3 SPECIFICATIONS

3.2 Performance Specifications

Page 21

NZ2MFB1-32D DC input module

Item NZ2MFB1-32D

Station type Slave station

Number of input points 32 points

Rated input voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Rated input current 6.0mA TYP. (for 24VDC)

Isolation method Photocoupler isolation

Max. number of simultaneous input points 100%

ON voltage/ON current 15VDC or more/4mA or more

OFF voltage/OFF current 5VDC or less/1.7mA or less

Input resistance 3.8k

Input response time OFFON 0ms

ONOFF

Input type Positive common/negative common shared type

Withstand voltage 500VAC for 1 minute between all DC external terminals and the ground

Insulation resistance 10M or higher between all DC external terminals and ground (500VDC insulation resistance tester)

Noise immunity

Protection degree IP2X

Wiring method for common 32 points/common (two points) (1-wire, screw terminal block type)

External interface Communication part RJ45 connector

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.30kg

*2

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Terminal block for module

power supply and FG

Terminal block for input Page 62 Applicable solderless terminal

Current 71mA or less (24VDC, all points ON)

*3

*1 If the input response time is set to "0ms", the actual input response time is 80s at OFF ON, and 160s at ON OFF.

*2 It is the noise immunity of when the input response time setting value is other than "0ms". Note that the module is easily affected by

noise if "0ms" is set.

*3 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*4 It is recommended to use the bar solderless terminal for wiring.

*1

/0.2ms/1ms/1.5ms/5ms/10ms/20ms/70ms

(Initial setting: 10ms)

Noise voltage 500Vp-p, noise width 1s, noise frequency 25 to 60Hz (DC type noise simulator

condition)

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

*4

Page 59 Applicable solderless terminal

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

3

3 SPECIFICATIONS

3.2 Performance Specifications

19

Page 22

■External connection

FG

1

2

3

UNIT POWER

CABLE

1

2

3

X01

X12

X23

X34

X45

X56

7

X78

X89

X910

XA11

XB12

XC13

XD14

XE15

XF16

X1017

X1118

X1219

X1320

X1421

X1522

X1623

X1724

X1825

X1926

X1A27

X1B28

X1C29

X1D30

X1E31

X1F32

COM33

COM34

+24V

24G

X6

Signal name

Pin

No.

Non-insulated

Terminal block

for input

Terminal block for module

power supply and FG

*1

Module power

supply

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

20

3.2 Performance Specifications

Page 23

■Terminal block for input

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1X017X10

2X118X11

3X219X12

4X320X13

5X421X14

6X522X15

7X623X16

8X724X17

9X825X18

10 X9 26 X19

11 XA 27 X1 A

12 XB 28 X1B

13 XC 29 X1C

14 XD 30 X1D

15 XE 31 X1E

16 XF 32 X1F

33 COM

34 COM

3

3 SPECIFICATIONS

3.2 Performance Specifications

21

Page 24

Output module

NZ2MFB2-16R contact output module

Item NZ2MFB2-16R

Station type Slave station

Number of output points 16 points

Rated switching voltage/current 24VDC 2A (resistance load)/point, 8A/common

Minimum switching load 5VDC 1mA

Maximum switching load 264VAC 125VDC

Output response time OFFON 10ms or less

ONOFF 12ms or less

Life Mechanical 20 million times or more

Electrical Rated switching voltage/current load 100 thousand times or more

Maximum switching frequency 3600 times/hour

Surge suppressor None

Fuse None

Withstand voltage 2300VACrms for 1 minute between all AC external terminals and the ground

Insulation resistance 10M or higher between all AC external terminals and the ground, all DC external terminals and the

Noise immunity Noise voltage: 1500Vp-p (AC type), 500Vp-p (DC type), noise width 1s, noise frequency 25 to 60Hz

Protection degree IP1X

Wiring method for common 16 points/common (2-wire, screw terminal block type)

External interface Communication part RJ45 connector

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.35kg

Terminal block for module

power supply and FG

Terminal block for output Page 62 Applicable solderless terminal

Current 153mA or less (24VDC, all points ON)

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*2 It is recommended to use the bar solderless terminal for wiring.

240VAC 2A (COS = 1)/point, 8A/common

Page 46 Relay life (contact switching life)

510VACrms for 1 minute between all DC external terminals and the ground

ground (500VDC insulation resistance tester)

(noise simulator condition)

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

Page 59 Applicable solderless terminal

*1

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

*2

22

3 SPECIFICATIONS

3.2 Performance Specifications

Page 25

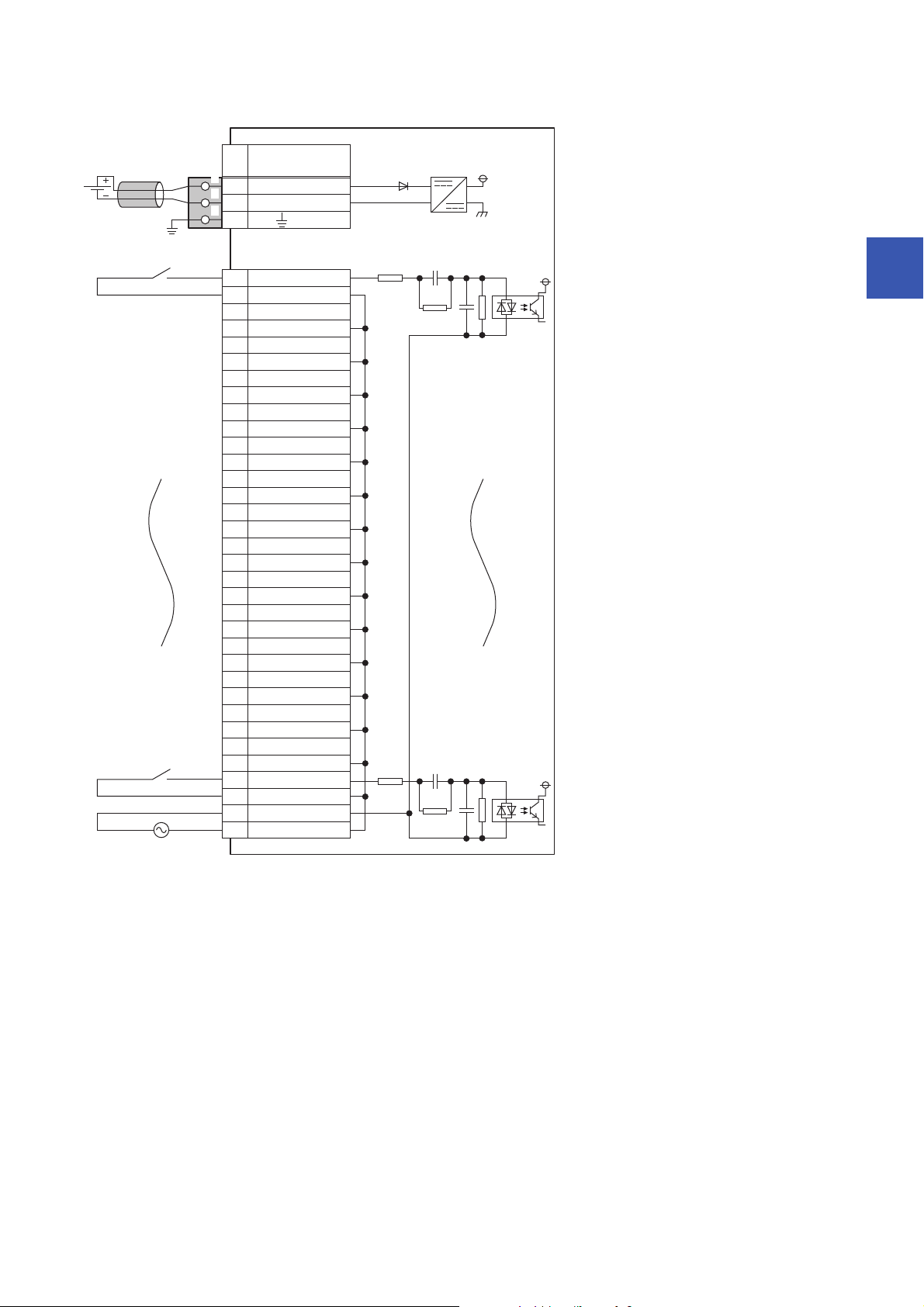

■External connection

FG

1

2

3

UNIT POWER

CABLE

1

2

3

Y01

COM B2

Y13

COM B4

Y25

COM B6

7

COM B8

Y49

COM B10

Y511

COM B12

Y613

COM B14

Y715

COM B16

Y817

COM B18

Y919

COM B20

YA21

COM B22

YB23

COM B24

YC25

COM B26

YD27

COM B28

YE29

COM B30

YF31

COM B32

COM A33

COM B34

+24V

24G

Y3

Signal name

Pin

No.

Non-insulated

Terminal block

for output

Terminal block for module

power supply and FG

*1

Module power

supply

Load

Load power

supply

Load

Internal circuit

100/200VAC

or 24VDC

3

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

23

Page 26

■Terminal block for output

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1Y017Y8

2 COM B 18 COM B

3Y119Y9

4 COM B 20 COM B

5Y221YA

6 COM B 22 COM B

7Y323YB

8 COM B 24 COM B

9Y425YC

10 COM B 26 COM B

11 Y5 2 7 Y D

12 COM B 28 COM B

13 Y6 29 YE

14 COM B 30 COM B

15 Y7 31 YF

16 COM B 32 COM B

33 COM A

34 COM B

24

3 SPECIFICATIONS

3.2 Performance Specifications

Page 27

NZ2MFB1-32T transistor output module

Item NZ2MFB1-32T

Station type Slave station

Number of output points 32 points

Rated load voltage 12/24VDC (ripple rate: 5% or less) (Allowable voltage range: 10.2 to 28.8VDC)

Max. load current 0.5A/point, 5A/common

Isolation method Photocoupler isolation

Max. inrush current Current is limited by the overload protection function.

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 0.3VDC(TYP.)0.5A, 0.6VDC(MAX.)0.5A

Output response time OFFON 0.5ms or less

ONOFF 1.5ms or less (resistance load)

Surge suppressor Zener diode

External power supply for

output part

Output type Sink type

Withstand voltage 500VAC for 1 minute between all DC external terminals and the ground

Insulation resistance 10M or higher between all DC external terminals and ground (500VDC insulation resistance tester)

Noise immunity Noise voltage 500Vp-p, noise width 1s, noise frequency 25 to 60Hz (DC type noise simulator

Protection degree IP2X

Wiring method for common 32 points/common (two points) (1-wire, screw terminal block type)

Protection function Overload protection

External interface Communication part RJ45 connector

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.30kg

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*2 It is recommended to use the bar solderless terminal for wiring.

Voltage 12/24VDC (ripple rate: 5% or less) (Allowable voltage range: 10.2 to 28.8VDC)

Current 25mA or less (TYP. 24VDC per common) External load current is not included.

condition)

function

Overheat protection

function

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Terminal block for module

power supply and FG

Terminal block for output Page 62 Applicable solderless terminal

Current 85mA or less (24VDC, all points ON)

Limited current when detecting overcurrent: 1A or more/point

Activated to each point.

Activated to each point.

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

Page 59 Applicable solderless terminal

*1

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

*2

3

3 SPECIFICATIONS

3.2 Performance Specifications

25

Page 28

■External connection

FG

1

2

3

UNIT POWER

CABLE

1

2

3

+24V

24G

YF

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YA

YB

YC

YD

YE

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

Y1F

CTL+

COM-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

33

34

CTL+

COM-

Signal name

Pin

No.

Non-insulated

Terminal block for module

power supply and FG

*1

Module power

supply

Terminal block

for output

Load

Load

Load

Load power

supply

External power supply for the output part

and load power supply (common)

External power supply

for the output part

Constant-voltage

circuit

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

26

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

Page 29

■Terminal block for output

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1Y017Y10

2Y118Y11

3Y219Y12

4Y320Y13

5Y421Y14

6Y522Y15

7Y623Y16

8Y724Y17

9Y825Y18

10 Y9 26 Y19

11 YA 27 Y1 A

12 YB 28 Y1B

13 YC 29 Y1C

14 YD 30 Y1D

15 YE 31 Y1E

16 YF 32 Y1F

33 CTL+

34 COM-

3

3 SPECIFICATIONS

3.2 Performance Specifications

27

Page 30

NZ2MFB1-32TE1 transistor output module

Item NZ2MFB1-32TE1

Station type Slave station

Number of output points 32 points

Rated load voltage 12/24VDC (ripple rate: 5% or less) (Allowable voltage range: 10.2 to 28.8VDC)

Max. load current 0.1A/point, 2A/common

Isolation method Photocoupler isolation

Max. inrush current Current is limited by the overload protection function.

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 0.1VDC(TYP.)0.1A, 0.2VDC(MAX.)0.1A

Output response time OFFON 0.5ms or less

ONOFF 1.5ms or less (resistance load)

Surge suppressor Zener diode

External power supply for

output part

Output type Source type

Withstand voltage 500VAC for 1 minute between all DC external terminals and the ground

Insulation resistance 10M or higher between all DC external terminals and ground (500VDC insulation resistance tester)

Noise immunity Noise voltage 500Vp-p, noise width 1s, noise frequency 25 to 60Hz (DC type noise simulator

Protection degree IP2X

Wiring method for common 32 points/common (two points) (1-wire, screw terminal block type)

Protection function Overload protection

External interface Communication part RJ45 connector

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.30kg

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*2 It is recommended to use the bar solderless terminal for wiring.

Voltage 12/24VDC (ripple rate: 5% or less) (Allowable voltage range: 10.2 to 28.8VDC)

Current 25mA or less (TYP. 24VDC per common) External load current is not included.

condition)

function

Overheat protection

function

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Terminal block for module

power supply and FG

Terminal block for output Page 62 Applicable solderless terminal

Current 84mA or less (24VDC, all points ON)

Limited current when detecting overcurrent: 1 to 3A/point

Activated to each point.

Activated to two points.

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

Page 59 Applicable solderless terminal

*1

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

*2

28

3 SPECIFICATIONS

3.2 Performance Specifications

Page 31

■External connection

UNIT POWER

CABLE

FG

1

2

3

1

2

3

+24V

24G

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YF

YA

YB

YC

YD

YE

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

Y1F

COM+

CTL-

Signal name

Pin

No.

Non-insulated

Terminal block for module

power supply and FG

*1

Module power

supply

Terminal block

for output

Load

Load

External power supply for

the output part and load

power supply (common)

Constant-voltage

circuit

3

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

29

Page 32

■Terminal block for output

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1Y017Y10

2Y118Y11

3Y219Y12

4Y320Y13

5Y421Y14

6Y522Y15

7Y623Y16

8Y724Y17

9Y825Y18

10 Y9 26 Y19

11 YA 27 Y1 A

12 YB 28 Y1B

13 YC 29 Y1C

14 YD 30 Y1D

15 YE 31 Y1E

16 YF 32 Y1F

33 COM+

34 CTL-

30

3 SPECIFICATIONS

3.2 Performance Specifications

Page 33

I/O combined module

NZ2MFB1-32DT DC input/transistor output module

Item NZ2MFB1-32DT

Input specifications Output specifications

Station type Slave station

Number of input points 16 points

Rated input voltage 24VDC (ripple rate: 5% or less) (Allowable voltage

Rated input current 6.0mA TYP. (for 24VDC)

Isolation method Photocoupler isolation

Max. number of simultaneous input points 100%

ON voltage/ON current 15VDC or more/4mA or more

OFF voltage/OFF current 5VDC or less/1.7mA or less

Input resistance 3.8k

Input response time OFFON 0ms

ONOFF

Input type Positive common type

Number of output points 16 points

Rated load voltage 24VDC (ripple rate: 5% or less) (Allowable

Max. load current 0.5A/point, 4A/common

Isolation method Photocoupler isolation

Max. inrush current Current is limited by the overload protection

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 0.3VDC(TYP.)0.5A, 0.6VDC(MAX.)0.5A

Output response time OFFON 0.5ms or less

ONOFF 1.5ms or less (resistance load)

Surge suppressor Zener diode

External power supply for

output part

Output type Sink type

Protection function Overload protection

Wiring method for common 16 points/common (1-wire, screw terminal block

Withstand voltage 500VAC for 1 minute between all DC external terminals and the ground

Insulation resistance 10M or higher between all DC external terminals and ground (500VDC insulation resistance tester)

Noise immunity

Protection degree IP2X

External interface Communication part RJ45 connector

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

*2

Volt ag e 24VDC (ripple rate: 5% or less) (Allowable

Current 15mA or less (TYP. 24VDC per common)

function

Overheat protection

function

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

range: 20.4 to 28.8VDC)

*1

/0.2ms/1ms/1.5ms/5ms/10ms/20ms/70ms

(Initial setting: 10ms)

voltage range: 20.4 to 28.8VDC)

function.

voltage range: 20.4 to 28.8VDC)

External load current is not included.

Limited current when detecting overcurrent: 1A

or more/point

Activated to each point.

Activated to each point.

type)

Noise voltage 500Vp-p, noise width 1s, noise frequency 25 to 60Hz (DC type noise simulator

condition)

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

16 points/common (1-wire, screw terminal

block type)

*4

3

3 SPECIFICATIONS

3.2 Performance Specifications

31

Page 34

Item NZ2MFB1-32DT

Input specifications Output specifications

Applicable solderless

terminal

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Weight 0.30kg

Terminal block for module

power supply and FG

I/O terminal block Page 62 Applicable solderless terminal

Current 79mA or less (24VDC, all points ON)

Page 59 Applicable solderless terminal

*3

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

*1 If the input response time is set to "0ms", the actual input response time is 80s at OFF ON, and 160s at ON OFF.

*2 It is the noise immunity of when the input response time setting value is other than "0ms". Note that the module is easily affected by

noise if "0ms" is set.

*3 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*4 It is recommended to use the bar solderless terminal for wiring.

32

3 SPECIFICATIONS

3.2 Performance Specifications

Page 35

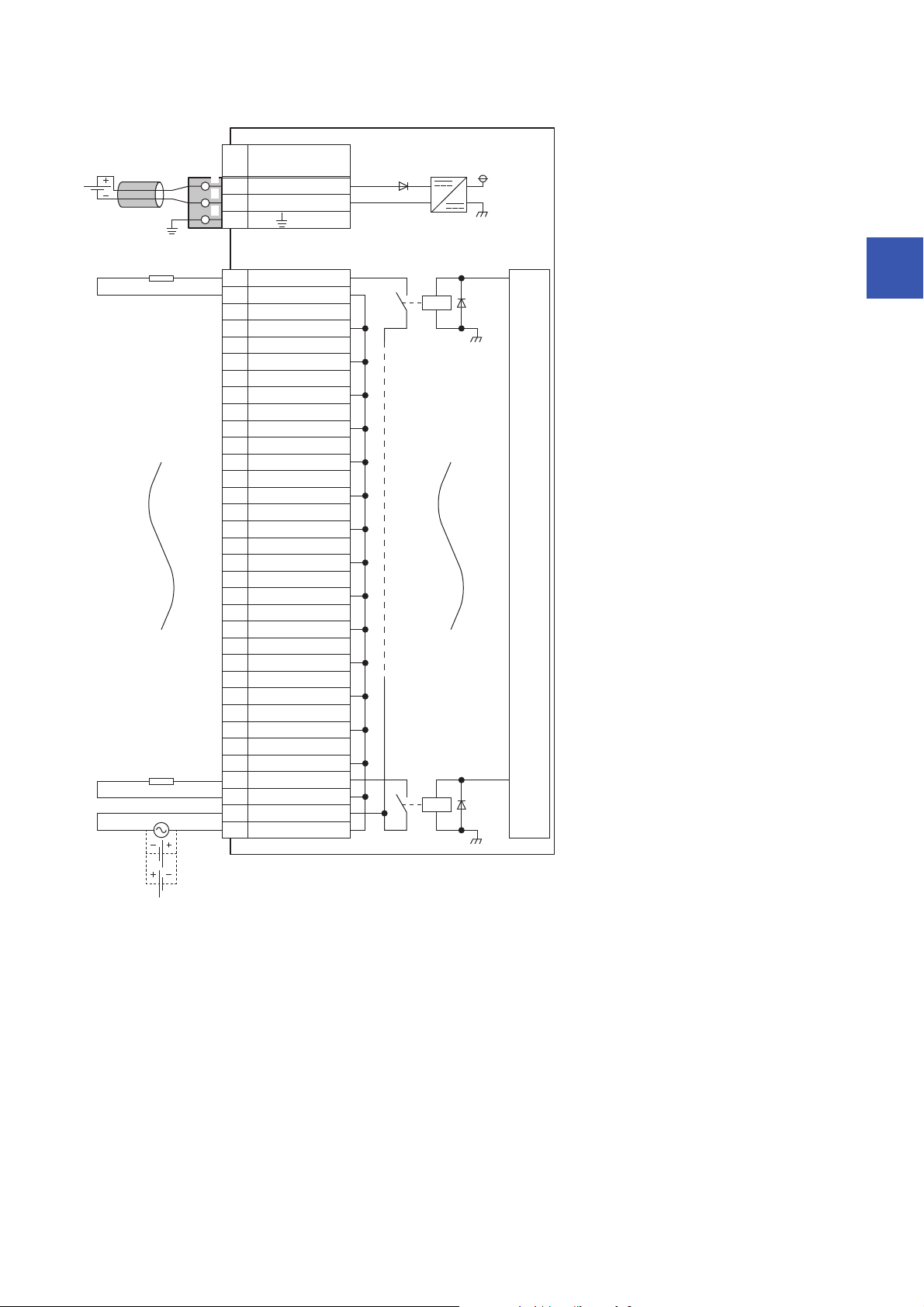

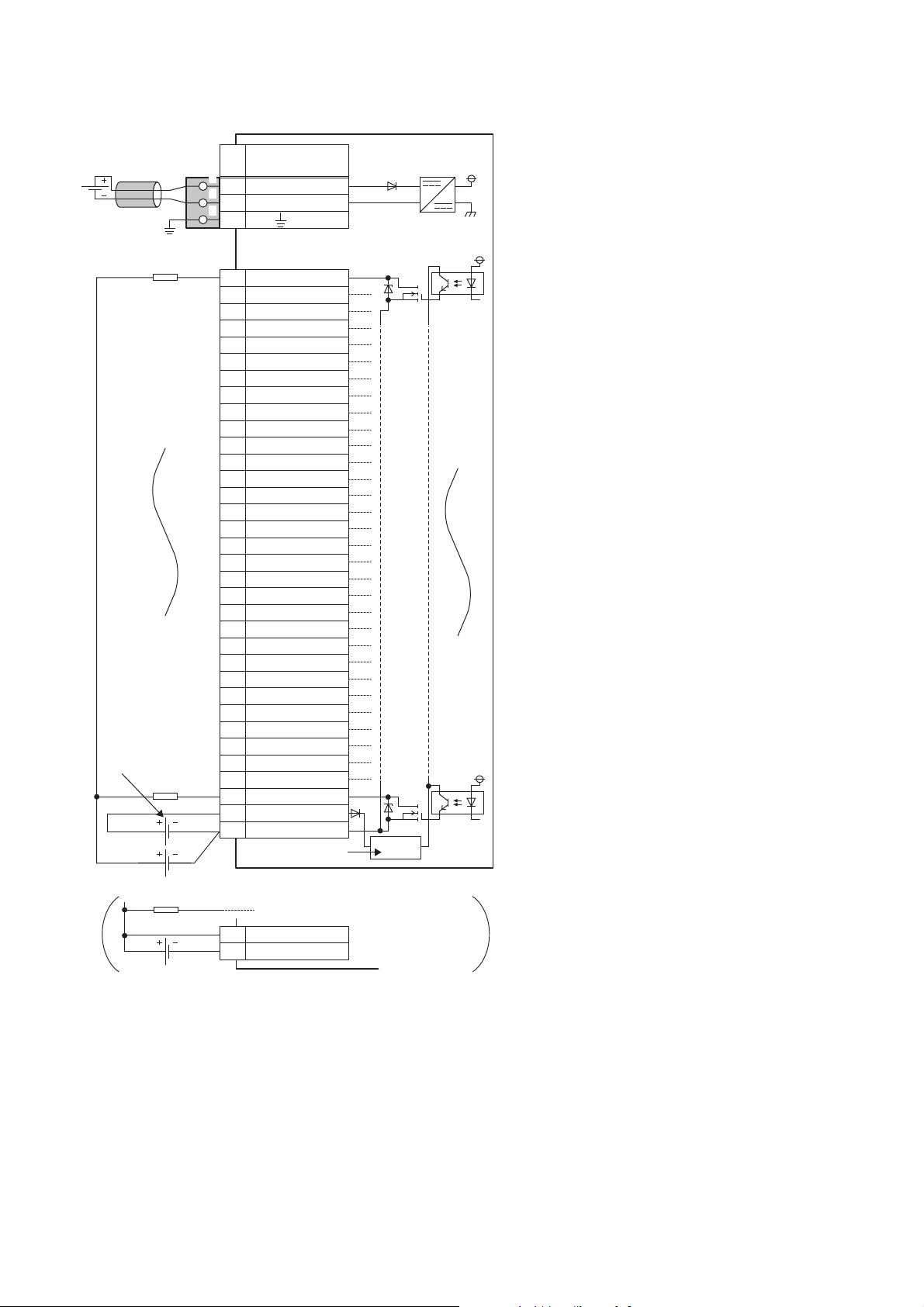

■External connection

FG

1

2

3

1

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

+24V

24G

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

33

34

COM+

COM-

X0

X1

X2

X3

X4

X5

X7

X8

X9

XA

XB

XC

XD

XE

XF

X6

Y1F

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

COM+

COM-

Signal name

Pin

No.

Non-insulated

UNIT POWER

CABLE

Terminal block

for I/O

Connector for module

power supply and FG

*1

Module power

supply

Load

Load

Load

External power supply for the output part

and load power supply (common)

External power supply

for the output part

Load power

supply

Constant-voltage

circuit

3

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

33

Page 36

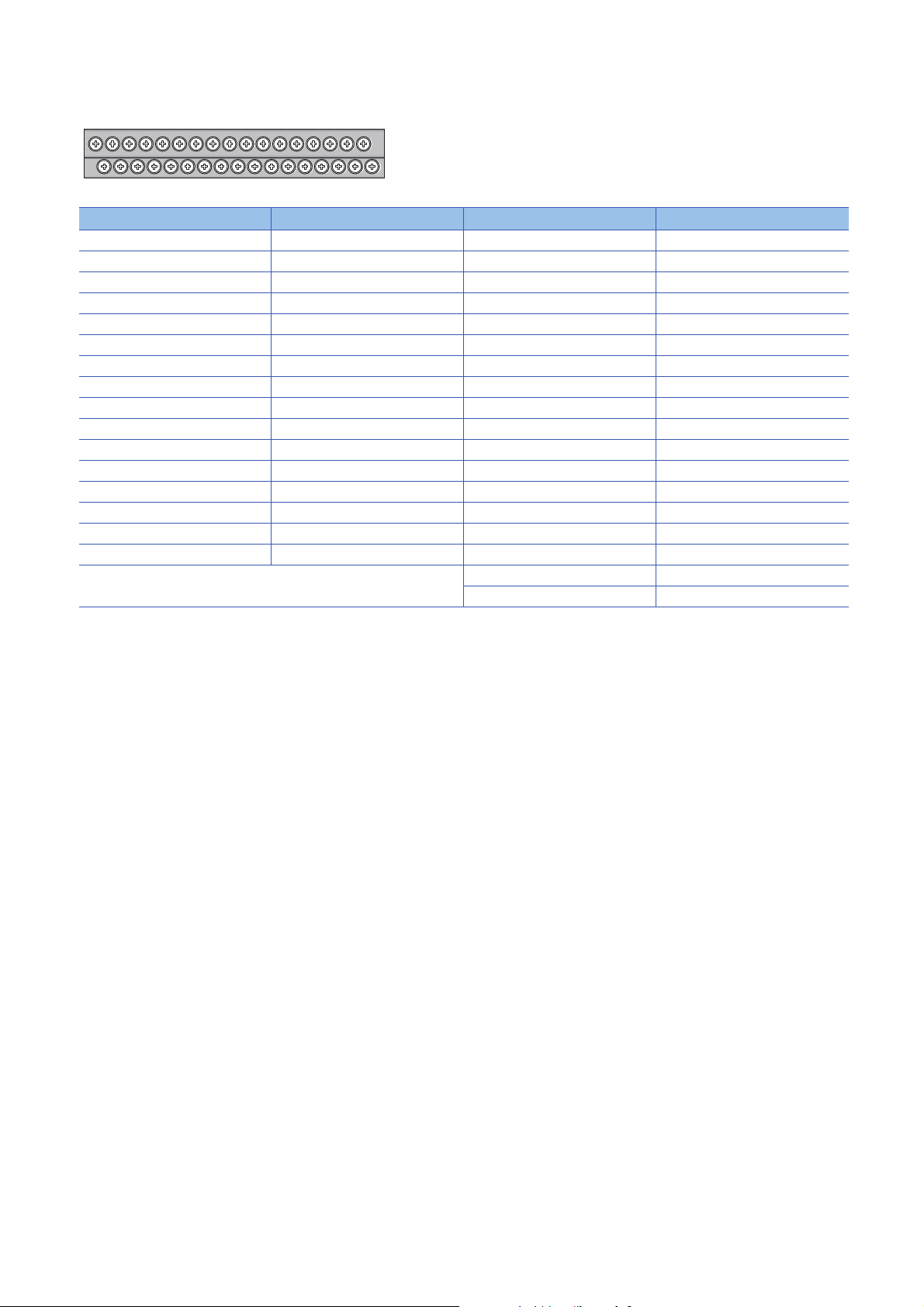

■I/O terminal block

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1X017Y10

2X118Y11

3X219Y12

4X320Y13

5X421Y14

6X522Y15

7X623Y16

8X724Y17

9X825Y18

10 X9 26 Y19

11 XA 27 Y1 A

12 XB 28 Y1B

13 XC 29 Y1C

14 XD 30 Y1D

15 XE 31 Y1E

16 XF 32 Y1F

33 COM+

34 COM-

34

3 SPECIFICATIONS

3.2 Performance Specifications

Page 37

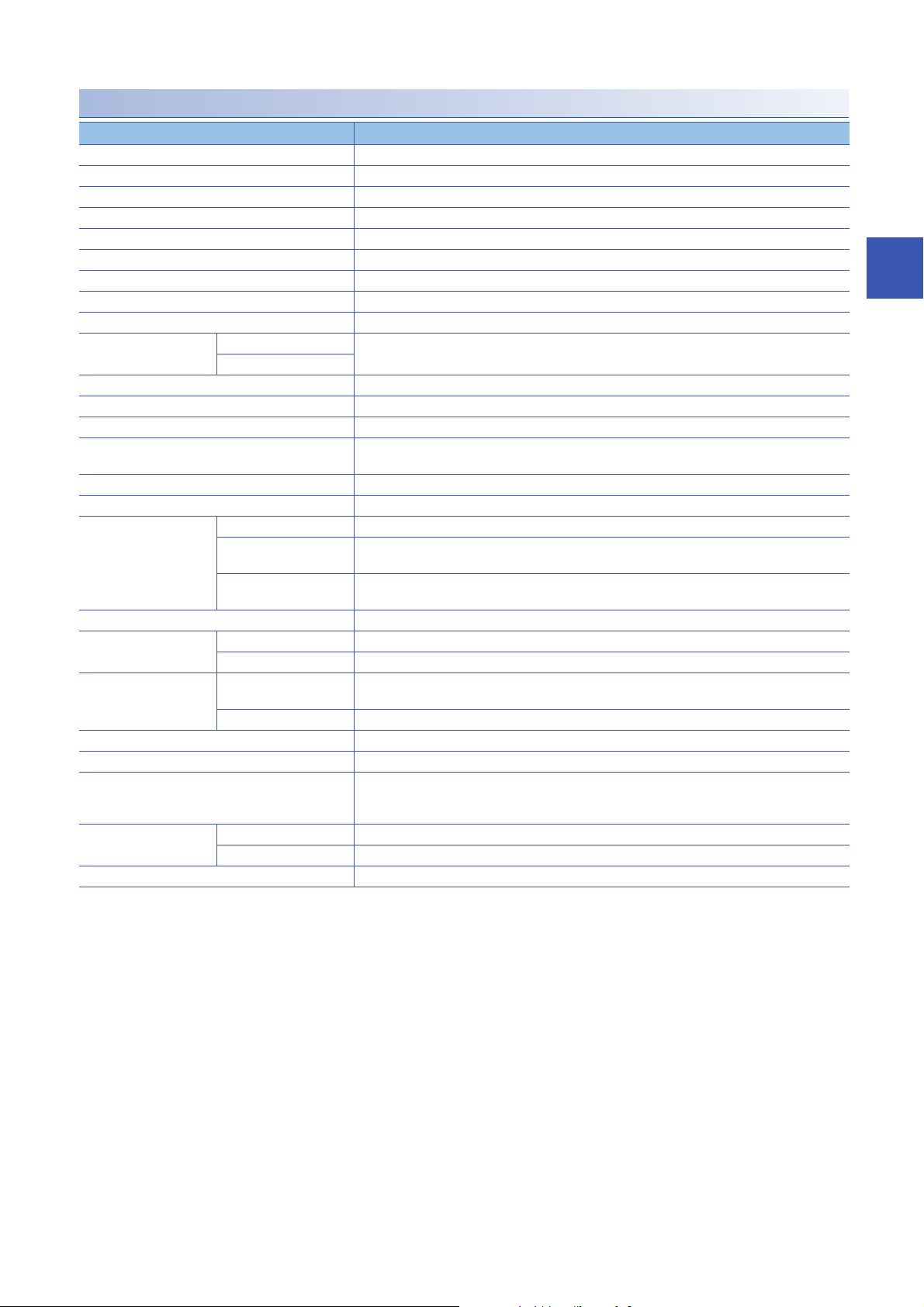

NZ2MFB1-32DTE1 DC input/transistor output module

Item NZ2MFB1-32DTE1

Input specifications Output specifications

Station type Slave station

Number of input points 16 points

Rated input voltage 24VDC (ripple rate: 5% or less) (Allowable voltage

Rated input current 6.0mA TYP. (for 24VDC)

Isolation method Photocoupler isolation

Max. number of simultaneous input points 100%

ON voltage/ON current 15VDC or more/4mA or more

OFF voltage/OFF current 5VDC or less/1.7mA or less

Input resistance 3.8k

Input response time OFFON 0ms

ONOFF

Input type Negative common type

Number of output points 16 points

Rated load voltage 24VDC (ripple rate: 5% or less) (Allowable

Max. load current 0.1A/point, 1.6A/common

Isolation method Photocoupler isolation

Max. inrush current Current is limited by the overload protection

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 0.1VDC(TYP.)0.1A, 0.2VDC(MAX.)0.1A

Output response time OFFON 0.5ms or less

ONOFF 1.5ms or less (resistance load)

Surge suppressor Zener diode

External power supply for

output part

Output type Source type

Protection function Overload protection

Wiring method for common 16 points/common (1-wire, screw terminal block

Withstand voltage 500VAC for 1 minute between all DC external terminals and the ground

Insulation resistance 10M or higher between all DC external terminals and ground (500VDC insulation resistance tester)

Noise immunity

Protection degree IP2X

External interface Communication part RJ45 connector

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al (compliant with IEC 60715)

Applicable wire size For power supply Stranded wire: 0.3 to 1.5 (22 to 16 AWG), terminal slot size: 2.8mm 2.0mm

Applicable solderless

terminal

*2

Volt ag e 24VDC (ripple rate: 5% or less) (Allowable

Current 20mA or less (TYP. 24VDC per common)

function

Overheat protection

function

Module power supply part Terminal block for module power supply and FG (Two-piece spring clamp terminal block (push-in

I/O part 34-point one-piece terminal block

For I/O Core: 0.3 to 2.0 (22 to 14 AWG)

Terminal block for module

power supply and FG

I/O terminal block Page 62 Applicable solderless terminal

range: 20.4 to 28.8VDC)

*1

/0.2ms/1ms/1.5ms/5ms/10ms/20ms/70ms

(Initial setting: 10ms)

voltage range: 20.4 to 28.8VDC)

function.

voltage range: 20.4 to 28.8VDC)

External load current is not included.

Limited current when detecting overcurrent: 1

to 3A/point

Activated to each point.

Activated to two points.

16 points/common (1-wire, screw terminal

type)

Noise voltage 500Vp-p, noise width 1s, noise frequency 25 to 60Hz (DC type noise simulator

condition)

type))

Tightening torque range for terminal screw (M3 5.2 screw): 0.59 to 0.88Nm

Page 59 Applicable solderless terminal

*3

block type)

*4

3

3 SPECIFICATIONS

3.2 Performance Specifications

35

Page 38

Item NZ2MFB1-32DTE1

Input specifications Output specifications

Number of occupied stations One station

Reference response time 1ms

Communication cable An Ethernet cable that meets the 100BASE-TX standard

Module power supply Voltage 24VDC (ripple rate: 5% or less) (Allowable voltage range: 20.4 to 28.8VDC)

Current 79mA or less (24VDC, all points ON)

Weight 0.30kg

*1 If the input response time is set to "0ms", the actual input response time is 80s at OFF ON, and 160s at ON OFF.

*2 It is the noise immunity of when the input response time setting value is other than "0ms". Note that the module is easily affected by

noise if "0ms" is set.

*3 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

*4 It is recommended to use the bar solderless terminal for wiring.

For details, refer to the following.

CC-Link IE Field Network Basic Reference Manual

36

3 SPECIFICATIONS

3.2 Performance Specifications

Page 39

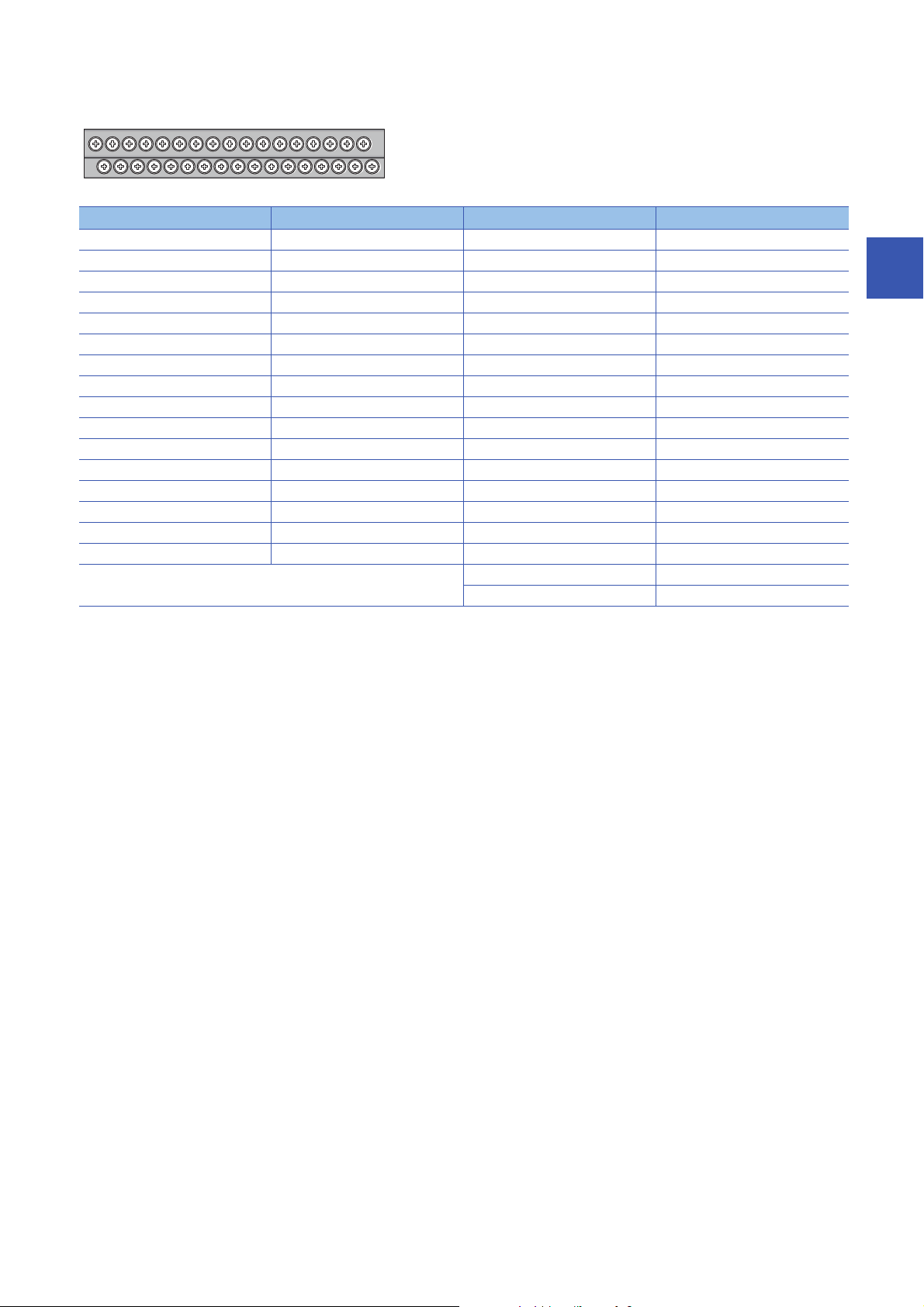

■External connection

FG

1

2

3

1

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

+24V

24G

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

X0

X1

X2

X3

X4

X5

X7

X8

X9

XA

XB

XC

XD

XE

XF

X6

Y1F

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

COM+

COM-

Signal name

Pin

No.

Non-insulated

UNIT POWER

CABLE

Terminal block

for I/O

Connector for module

power supply and FG

*1

Module power

supply

Load

Load

External power supply for

the output part and load

power supply (common)

Constant-voltage

circuit

3

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

3 SPECIFICATIONS

3.2 Performance Specifications

37

Page 40

■I/O terminal block

13579111315171921232527293133

246810121416182022242628303234

Pin number Signal name Pin number Signal name

1X017Y10

2X118Y11

3X219Y12

4X320Y13

5X421Y14

6X522Y15

7X623Y16

8X724Y17

9X825Y18

10 X9 26 Y19

11 XA 27 Y1 A

12 XB 28 Y1B

13 XC 29 Y1C

14 XD 30 Y1D

15 XE 31 Y1E

16 XF 32 Y1F

33 COM+

34 COM-

38

3 SPECIFICATIONS

3.2 Performance Specifications

Page 41

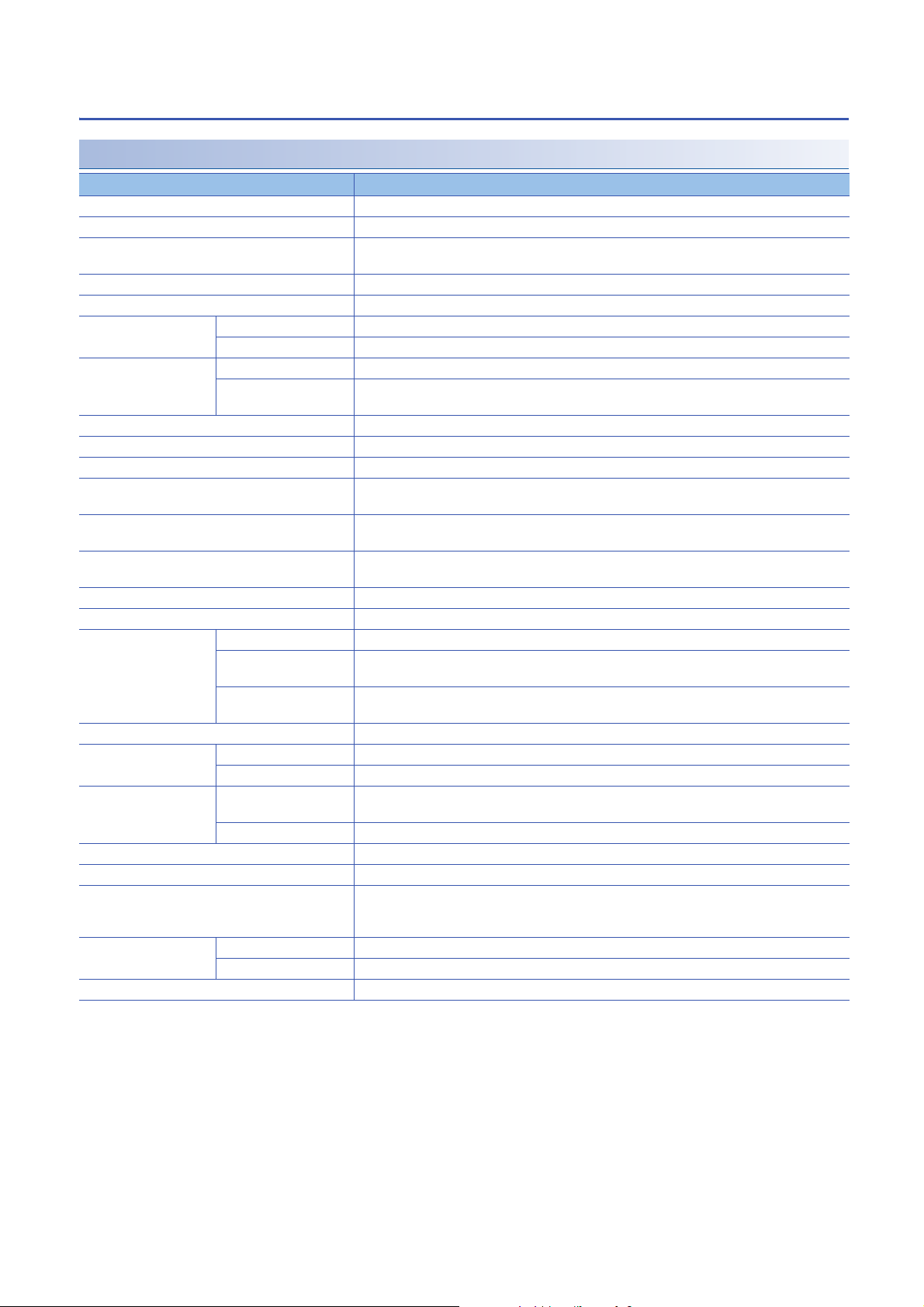

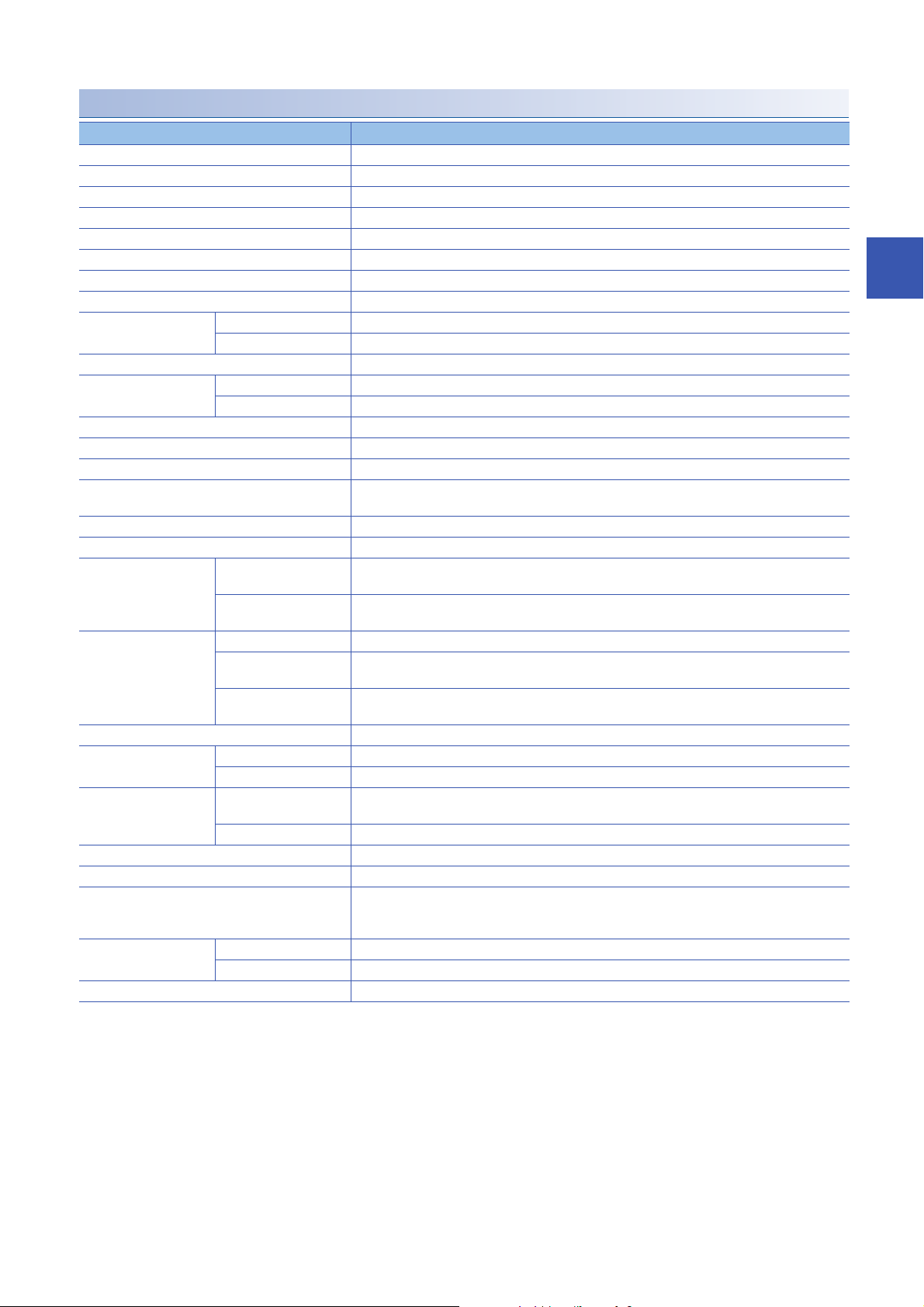

3.3 Function List

This section lists the functions of I/O modules.

Item Description Reference

Input function The ON/OFF status (X signal) of inputs is notified to Remote input (RX) of the master

station.

Output function The ON/OFF status (Y signal) of outputs is controlled with Remote output (RY) of the

master station.

Input response time setting function This function prevents an incorrect input due to noise by setting the response time

until the module recognizes an actual input as the X signal.

Output HOLD/CLEAR setting function When the I/O module is disconnected from data link, or the CPU module operating

status is STOP, whether to hold or clear the last output value can be set by this

function.

Protection function The overload protection function and overheat protection function protect the internal

circuit from overcurrent and its heat.

SLMP communication function SLMP can be used to communicate with the I/O module. Page 68 SLMP

Page 65 Input Response

Time Setting Function

Page 66 Output HOLD/

CLEAR Setting Function

Page 67 Protection

Function

communication function

3.4 List of Functions of Each Module

This section lists the functions of each module.

: Available, : Not available

Model name Input function Output function Input response

time setting

function

NZ2MFB2-16A

NZ2MFB1-32D

NZ2MFB2-16R

NZ2MFB1-32T

NZ2MFB1-32TE1

NZ2MFB1-32DT

NZ2MFB1-32DTE1

Output HOLD/

CLEAR setting

function

Protection

function

SLMP

communication

function

3

3 SPECIFICATIONS

3.3 Function List

39

Page 42

4 PROCEDURES BEFORE OPERATION

This chapter describes the procedures before operation.

1. IP address setting switch setting

Set the fourth octet of IP address of I/O module.

Page 51 IP address setting switch setting

2. Function setting switch setting

Set the input response time setting and output HOLD/CLEAR setting of the I/O module.

Page 54 Function setting switch setting

3. Connection

Mount the I/O module on the DIN rail.

Page 57 Mounting the module on a DIN rail

4. Wiring

Wire the power supply, Ethernet cables, and external devices to the I/O module.

Page 59 Wiring

5. Parameter setting and programming

Set the network parameter of the master station and create a program.

Page 63 Network Configuration Setting

Page 69 PROGRAMMING

To replace the module, follow the procedure described below:

• Turn off the module power supply and remove the I/O module.

• Prepare a new I/O module and perform the procedure before operation, from "IP address setting switch

setting" to "Parameter setting and programming". At this time, the settings of IP address setting switch and

function setting switch must be the same as the settings for I/O module before replacement.

• Check that the D LINK LED and RUN LED of I/O module are on and ERR. LED is off before restarting

control operation.

40

4 PROCEDURES BEFORE OPERATION

Page 43

MEMO

4

4 PROCEDURES BEFORE OPERATION

41

Page 44

5 SYSTEM CONFIGURATION

Applicable master station

For the CPU module that can be used as the master station of CC-Link IE Field Network Basic, refer to the following.

CC-Link IE Field Network Basic Reference Manual

Compatible software version

For the compatible software version, always keep GX Works3/GX Works2 up to date.

When the latest software version is necessary, please consult your local Mitsubishi representative.

Applicable profile

A profile is required to use the I/O module in the network configuration setting of CC-Link IE Field Network Basic.

When the latest profile of the I/O module is necessary, please consult your local Mitsubishi representative.

The profile is a setting file that stores information required for the start-up, operation, and maintenance of devices supporting

the CC-Link family.

A module is added to the "Module List" of the network configuration setting window by profile registration to GX Works3/GX

Works2.

For the profile registration, refer to the following.

Operating manual for the tool to be used

Ethernet cable

For the specifications of the Ethernet cable, refer to the following.

CC-Link IE Field Network Basic Reference Manual

Hub

For compatible hubs, refer to the following.

CC-Link IE Field Network Basic Reference Manual

42

5 SYSTEM CONFIGURATION

Page 45

MEMO

5

5 SYSTEM CONFIGURATION

43

Page 46

6 INSTALLATION AND WIRING

IN

COM

Inductive

load

IN

COM

Inductive

load

This chapter describes the installation and wiring of the I/O module.

6.1 Before Using the I/O Modules

Input modules

Precautions common to all input modules

■Number of simultaneous ON points

The number of input points that can be turned on at the same time varies depending on the input voltage and ambient

temperature. Refer to the maximum number of simultaneous input points of the specifications of each input module. (

Page 16 Performance Specifications)