Mitsubishi NECS-ME 0252, NECS-ME 0152, NECS-ME Series, NECS-ME 0302, NECS-ME 0262 Technical Bulletin

...Page 1

Climaveneta Technical Bulletin

NECS_ME_0152_1604_201004_GB

NECS-ME

0152 - 1604

39,5 - 432 kW

Condenserless chiller

Refrigerant gas R410A

Can be combined with a remote condenser

Integral control and adjustment

Integrated hydronic module

(The photo of the unit is indicative and may change depending on the model)

Page 2

CERTIFICATIONS

Product certifi cations

System certifi cations

Climaveneta S.p.A.:

Quality System complying with the requirements of UNI EN ISO9001:2008 regulation

Environmental Management System complying with the requirements of UNI EN

ISO14001:2004 regulation

Page 3

SUMMARY

NECS-ME

NECS-ME

0152 - 1604

1. Product presentation

1.1 NECS-ME units

1.2 R410A refrigerant

1.3 Combination with a remote condenser

1.4 Integral control and adjustment

1.5 Hydronic unit incorporated

1.6 Silent running

1.7 Ease of installation

1.8 Versatility

1.9 Usability

2. Unit description

2.1 Standard unit composition

2.2 Certifi cation, Reference standard

2.3 Tests

2.4 Controller

2.5 Accessories

2.6 Control unit with LCD display (standard)

3. Technical data

3.1 General technical data

3.2 Cooling capacity performance

4. Operating range

5. Hydraulic data

5.1 Water fl ow and pressure dro

5.2 Hydronic groups

6. Electrical data

7. Full load sound level

8. Dimensional drawings

9. Legend of pipe connections

10. Remote condensers

11. Combinations of evaporating units and remote condensers

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° III

pg. n° 1

pg. n° 1

pg. n° 1

pg. n° 1

pg. n° 2

pg. n° 2

pg. n° 3

pg. n° 5

pg. n° 5

pg. n° 8

pg. n° 13

pg. n° 14

pg. n° 14

pg. n° 15

pg. n° 19

pg. n° 20

pg. n° A1

pg. n° A6

pg. n° B1

pg. n° B2

The units highlighted in this publication contain HFC R410A [GWP

Liability disclaimer

This bulletin is not exhaustive about: installation, use, safety

precautions, handling and transport. Refer to “General Manual

for Installation” for further informations.

This bulletin refers to standard executions, in particular for

dimension, weight, electric, hydraulic, aeraulic and refrigerant connections (whereas applicable). Contact Climaveneta

Commercial Offi ce for further drawings and schemes.

2088] fluorinated greenhouse gases.

100

Climaveneta declines any liability derived from the bulletin’s

use.

This bulletin is of exclusive property of Climaveneta, and all

forms of copy are prohibited.

The data contained herein are subject to variation without notice.

II

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 4

1. PRODUCT PRESENTATION

NECS-ME

Introduction

This section contains general information on the NECS-ME

range of products. For detailed information refer to the specifi c

sections in this bulletin.

1.1 NECS-ME units

The NECS-ME chillers are a range of remote-condensation liquid units running on R410A ecological gas.

They are indoor units with hermetic scroll compressors in a

single-circuit (2-compressor units) and twin-circuit (4-compressor unit) tandem confi guration, and braze-welded plate heat

exchangers.

1.2 R410A refrigerant

The use of R410A has improved the energy effi ciency of the

units, in full respect of the environment (O.D.P.=0)

1.3 Combination with a remote condenser

Compact units designed for residential and commercial systems.

1.4 Integral control and adjustment

The evaporating unit is supplied complete with integral microprocessor control and optional connection to a remote con-

denser.

1.5 Hydronic unit incorporated

The integrated hydronic unit comprises the main hydraulic

components; it is available in various confi gurations with single

or dual orthogonal pumps and high or low heads.

1.7 Ease of installation

All the connections of the NECS-ME units are located on the

side in order to simplify installation operations. This feature

also makes it possible to save space as the units can be positioned near the perimeter walls without compromising access

to the internal components during maintenance.

1.8 Versatility

On request, the NECS-ME units can be fi tted with an inte-

grated pump unit for circulating the liquid in the system, with

a high or low head depending on the various application requirements. As well as the primary pump, it is also possible to

add an auxiliary circulation pump which starts automatically if

the former develops a fault. This makes it possible to respect

the harshest safety aspects of the system, whilst allowing the

pumps to be rotated to balance operating hours (thus preventing risks of mechanical breakage) and to manually select one

of the two pumps.

1.9 Usability

The electronic controller of the NECS-ME features a programmable menu containing the most popular European languages

which the user can choose depending on the country in which

the unit is used (available standard in the 4-compressor unit, in

the reduced mode in the 2-compressor version).

1.6 Silent running

The NECS-ME chillers stand out for their silent running. If

specifi cally requested, the casing of the unit can incorporate

a layer of soundproofi ng made from high intermediate density

conoid sandwich material which reduces noise suffi ciently to

allow NECS-ME to be used in residential and commercial areas without having to install it in dedicated rooms (technical

rooms). The benefi t in terms of noise reduction is 4dB(A) in the

models with 2 compressors and 10dB(A) in the models with 4

compressors.

III

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 5

2. UNIT DESCRIPTION

NECS-ME

Liquid chiller with remote condensation

Water-cooled indoor unit for producing chilled water, with connection to a remote condenser fi tted with hermetic rotary scroll

compressors running on R410A, braised-welded plate exchangers and a thermostatic expansion valve. Base and panelling in

hot-galvanised and painted sheet steel.

2.1 Standard unit composition

Structure

Base and frame in hot-galvanised shaped sheet steel with a

suitable thickness.

External panelling in PET-treated colaminate sheet, suitably

thick, built to allow total access to the internal components,

ventilation of the compressor chamber (standard for NECS-ME

0152..0612, option for all the other units). Acoustic insulation

of the panel with 30 mm thick Fiberform available as an accessory. Panels fi xed with metric screws (not self-tapping).

Refrigerant circuit

Main components of the refrigerant circuit:

- single-circuit unit with two compressors in a tandem confi gu-

ration (NECS-ME 0152..0612)

- twin-circuit unit with two compressors in a tandem confi gura-

tion on both circuits (NECS-ME 0612..1604)

- R410A refrigerant

- mechanical thermostatic valves

- dryer fi lter,

- refrigerant line sight glass with humidity indicator

- high pressure safety valve

- low pressure safety valve

- high and low pressure transducers

- high and low pressure gauges on all circuits (NECS-ME

0604..1604).

Compressor

Rotary hermetic scroll compressor in a tandem layout complete

with oil sump heater, electronic overheating protection with centralised manual reset and a two-pole electric motor.

- remote ON/OFF terminals

- spring terminals

- pump enable relays (only for units without a standard hydronic

unit)

- manual and automatic pump rotation system in case pumps

stop (only for units with a two-pump hydronic unit)

- automatic pump operation rotation system for balancing operating hours (only for units with a two-pump hydronic unit)

- terminals for cumulative alarm block (BCA)

- input voltage: 400V~ ±10% - 50Hz - 3N.

2.2 Certifi cation, Reference standards

The machine complies with the following directives and their

amendments:

- 2006/42/EC Machinery Directive.

- E.C.D. 89/336/EEC + 2004/108/EC.

- 2006/95/EC Low Voltage Directive.

- 97/23/EC Pressure Equipment Directive. Module A1. TÜVItalia 0948

2.3 Tests

Tests performed throughout the production process, as indicated in ISO9001. Performance or noise tests can be performed

by highly qualifi ed staff in the presence of customers.

Performance tests include the measurement of:

- electrical specifi cations

- water fl ow rates

- operating temperatures

- power input

- power output

- pressure drops on the water side exchanger both at full load

(at selection conditions and at the most critical conditions for

the condenser) and at part load conditions.

During performance testing the main alarm states can also be

simulated.

Noise tests are performed to check noise emissions according

to ISO3744.

User side exchanger

AISI 316 steel braze-welded plate exchanger. The heat exchanger is insulated with a closed-cell condensation proof

lining in neoprene. When the unit is working, it is protected

against lack of fl ow by a differential pressure switch mounted

on the water side. The unit can work with antifreeze mixtures at

exchanger outlet temperatures as low as -8°C.

Electric power and control panel

Electric power and control panel, built to EN 60204-1/EC 204-1

standards, complete with:

- control circuit transformer,

- general door lock isolator,

- fuses and contactors for compressors (NECS-ME

0604..1604)

- circuit breakers on loads (NECS-ME 0152..0612)

- numbered electric cables (NECS-ME 0152..0612)

- auxiliary signal 4..2OmA for unit operating setpoint offset

(NECS-ME 0604..1604)

- Keyboard with multi-language interface and LCD display

(NECS-ME 0604..1604)

1

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 6

NECS-ME

2.4 Controller

The controller is available in two formats:

- W3000 Base: keyboard and LED display.

- W3000SE Compact: the keypad features functional controls

and a complete LCD display that allows assessment and intervention on the unit by means of a multi-level menu with selectable user’s language.

The diagnostics comprises a complete alarm management system, including “black box” (via PC) functions and an alarm log

(via display or also PC) for optimised analysis of unit performance.

Compatibility with the remote keyboard managing up to 10

units.

The presence of the programmable timer allows the creation

of an operating profi le containing up to 4 typical days and 10

time bands.

Common features: Heat adjustment is based on the exclusive

QuickMind algorithm, featuring a self-adaptive logic which is

useful for systems with a low water content. Alternatively, proportional or proportional-integral adjustments can be set.

For systems featuring more than one unit, the resources can

be adjusted using optional propriety devices. Consumption and

performance accounting can also be implemented. Supervision

can be easily developed via proprietary devices or the integration in third party systems by means of the most common protocols as ModBus, Bacnet, Bacnet-over-IP, Echelon LonWorks

protocols.

2.5 Accessories

- Soft start

Electronic device adopted to manage the inrush current.

Break down of the inrush current as soon as the electrical motor is switch on, lower motor’s mechanical wear, favourable

sizing for the electrical system.

- HP and LP gauges

High and low pressure gauges (only for sizes 0152..0612).

Allows immediate reading of the pressure values on both low

and high pressure circuits.

- Compressor suction valve

Shut-off solenoid valve on compressor’s suction circuit.

Simplifi es maintenance activities.

- Compr. discharge line valve

Shut-off solenoid valve on compressor discharge circuit.

Simplifi es maintenance activities.

- Extra insulation for the compressors section

Acoustic encolsure on both compressor and pump sections

(when applicable).

Noise emission reduction.

- Automatic circuit breakers

Over-current switch on the major electrical loads.

It protects compressors and/or fans from possible current

peaks.

- Input remote demand limit

Digital input (voltage free)

It permits to limit the unit’s power absorption for safety reasons or in temporary situation.

- Liquid line solenoid valve

Solenoid valve on the refrigerant circuit inlet (only for sizes

0604..1604).

It avoids liquid to migrate toward the compressors when they

are off.

- Remote phase-sequence control

Relay for controlling the phase-sequence of mains.

Protects loads against faults due to incorrect connection of

the electric line.

- Compressors’ on/off signal

Auxiliary contacts providing a voltage-free signal.

Allows remote signalling of compressor’s activation or remote

control of any auxiliary loads.

- ModBUS connectivity

Interface module for ModBUS protocols.

Allows integration with BMS operating with ModBUS protocol.

- BACnet connectivity

Interface module for BACnet protocols.

Allows integration with BMS operating with BACnet protocol.

- Echelon connectivity

Interface module for Echelon systems.

Allows integration with BMS operating with Echelon procotls.

- Auxiliary signal 4-20mA

4..20mA analogue input. Allows to change the operating setpoint according to the value of current applied to the analogue

input.

Enforce Energy Saving policies

- Multi-units control devices

(Sequencer, Manager3000, FWS3000)

Separately supplied.

2

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 7

NECS-ME

2.6 Control unit with LCD display (standard)

The new “W3000 Base” control unit is installed on all NECS-ME

0152..0612 units.

The new “W3000SE Compact” control unit is installed on all

NECS-ME 0604..1604 units.

Main functions: QuickMind, local and remote FWS supervision, dual set point management, etc, confi rm Climaveneta’s

commitment to continually developing its electronics technology.

The heat pumps, moreover, are fi tted with the original Cli-

maveneta defrosting control system called “Autotuning Defrost”

which considerably reduces defrosting times, thus improving

the energy performance of the unit. Interfaces with BMS systems: METASYS®, MODBUS®, LONWORKS®, SIEMENS®,

TREND®.

Black Box logs data relative to 200 alarm events which can be

printed with a personal computer.

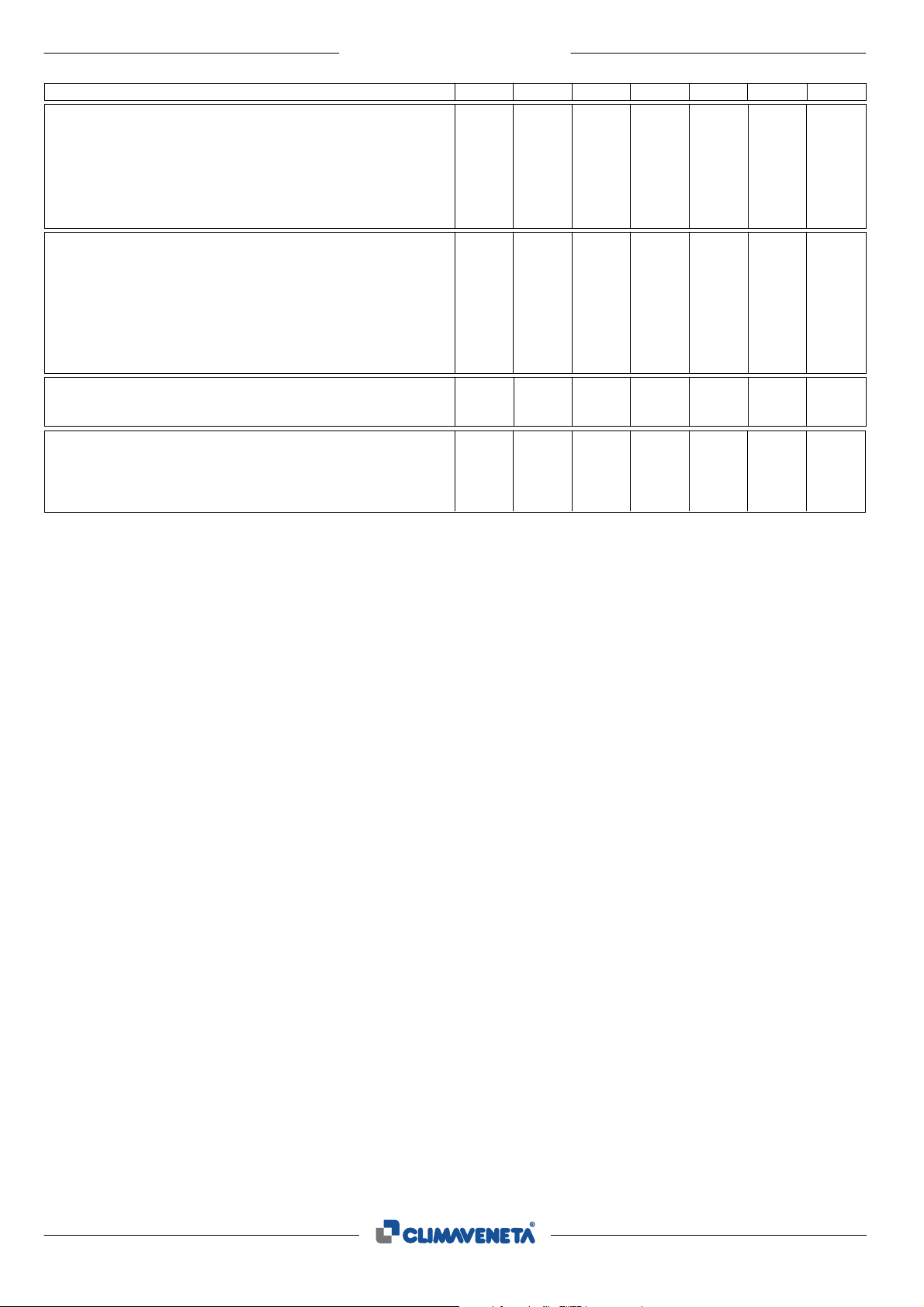

Variation output temperature

12

11

10

9

8

7

6

5

Temperatura in uscita (°C)

4

Output temperature (°C)

3

2

0.5 1.5 2.5 3.5 4.5 5.5 6.5 7.5 8.5 9.5

11.34

Step-wise regulation

Regolazione a gradini

7.54

Quickmind

5.9

4.3

Variazione temperatura in uscita

4.56

3,68

3.9

3.5

Minimum water content in the plant lt/kW

QuickMind is a special control unit which monitors the main

operating parameters, predicts system behaviour and anticipates unit settings in order to constantly optimise performance;

it allows both return and delivery water temperatures to be

chosen as adjustment parameters. It can reduce outlet temperature fl uctuations even with a small amount of water in

the system. When, for dual-compressor chillers featuring a

maximum of 12 start-ups per hour and using a traditional adjustment system, the minimum recommended water content

is 5.5 l/kW. QuickMind ensures the same chiller operates correctly even with a water content of just 2.5 l/kW and considerably reduces outlet temperature fl uctuations. The above graph

shows that outlet temperature fl uctuations with QuickMind are

limited to 4.3 °C as opposed to 7.54°C if the traditional adjustment system were used, without even ensuring an acceptable

minimum compressor start time.

Not acceptable minimum starting time compressors

Tempo minimo di accensione compressore non accettabile

3.52

3.3

3.52

3.2

3.52 3.52

3.1

3.52

3

3.52

10.5

3

11

3

3

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 8

NECS-ME

Control unit with LCD display

(optional for NECS-ME 0152..0612)

Remote keyboard

As an alternative to the standard keyboard, the NECS has

a W3000 Compact operator panel with liquid crystal display.

(LCD)

This keyboard is standard for the NECS-ME 0604..1604 units.

This keyboard features a user interface for 3 European languages that can be selected by the user. Two of these are

preset (Italian and English) and the third can be chosen from

French, German, Spanish, Swedish and Russian (to specify

when ordering). This allows the control unit interface to be chosen to suit the country of destination or, thanks to English, to be

completely independent for all geographical areas.

This same type of operator panel is also available as a remote

keyboard, to be connected to the unit by means of a serial connection up to a maximum distance of 200 metres without power

supply (in this case power is supplied by the unit), or a maximum of 500 metres with dedicated local power supply.

Note

The remote keyboard may be connected to the unit without replacing the W3000 Base operator panel originally provided on

the unit. In this case the interface fi tted locally on the unit is ex-

cluded, and access to the programming menus and the display

of the machine status is present only the additional keyboard at

remote level.

Instead, when the W3000 Base operator panel is replaced with

the W3000 Compact panel, control of the unit is possible at

both local and remote level. In this case the remote keyboard

faithfully reproduces what is shown on the control unit on board

the machine, further facilitating all the operations of confi guring

and controlling the unit.

4

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 9

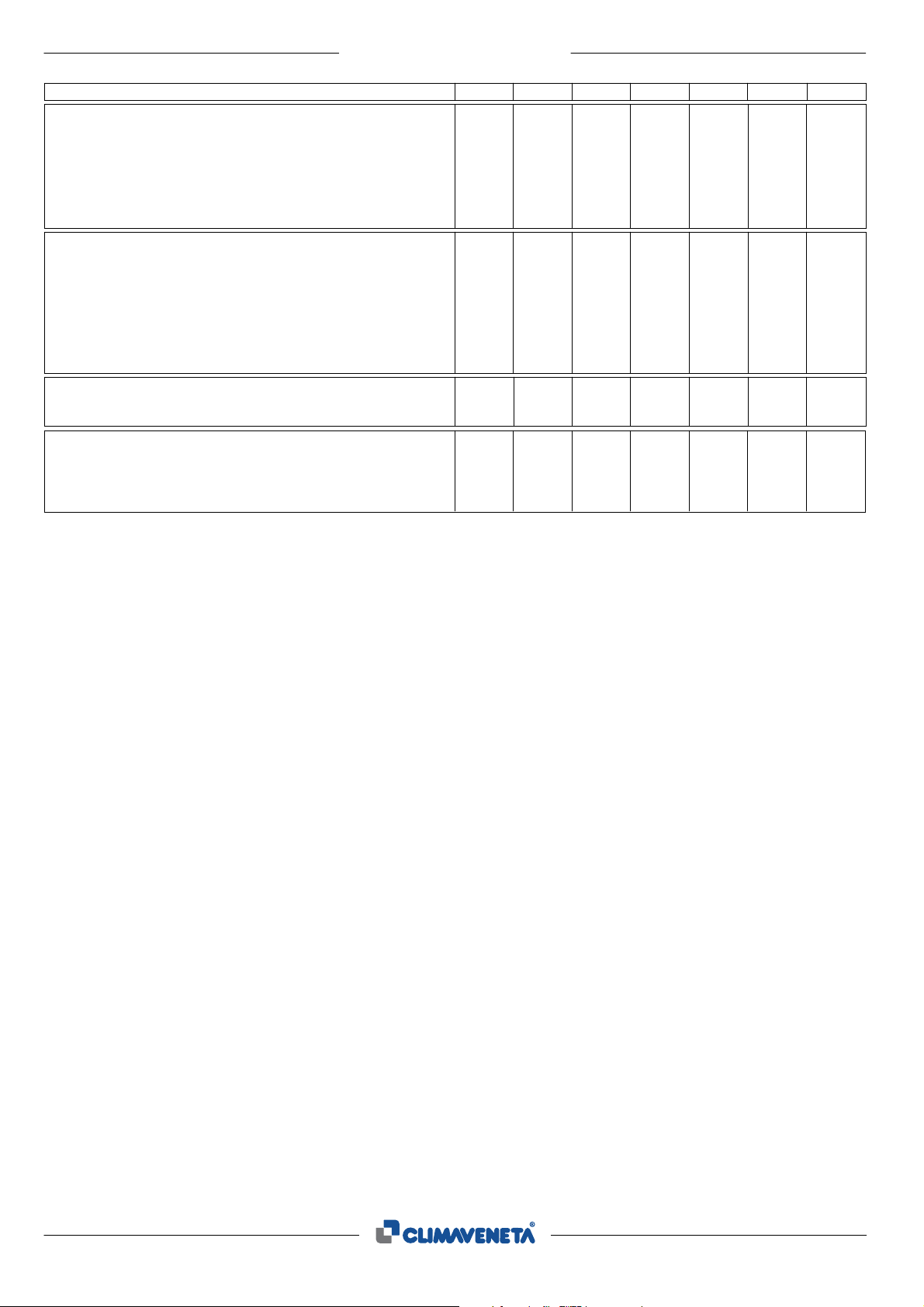

3.1 GENERAL TECHNICAL DATA

NECS-ME

B

SIZE 0152 0182 0202 0252 0262 0302 0352

NECS-ME /B

COOLING

(1)

Cooling capacity kW 39,5 45,8 53,6 60,5 67,4 80,2 92,8

Total power input (unit) kW 12,0 13,5 15,7 18,1 20,0 23,4 26,9

EER

ESEER

3,29

-

3,39

-

3,41

-

3,34 - 3,37

-

3,43

-

3,45

Heat exchanger water flow m³/h 6,80 7,89 9,23 10,4 11,6 13,8 16,0

Heat exchanger pressure drop kPa 48,0 41,3 41,0 39,1 48,4 29,4 27,6

COMPRESSORS

Number

Number of capacity

Number of circuits N°.

Type of regulation

N°. 2 2 2 2 2 2 2

N°.

2 2 2 2 2 2 2

1 1 1 1 1 1 1

STEPS STEPS STEPS STEPS STEPSSTEPSSTEPS

% 50 50 50 50 50 50 50Minimum capacity steps

R410AR410AR410A R410A R410AR410AR410AType of refrigerant

mm.

mm.

mm.

kg.

(2)

74

75

76

4443

(3)

1130

669

1255

270

1130

669

1255

280

1130

669

1255

290

1130

669

1255

295

1130

669

1255

300

1310

893

1496

410

77

4544 434342dB(A)Total sound pressure

1310

893

1496

500

NOISE LEVELS

Total sound power dB(A) 73 74 74

DIMENSIONS AND WEIGHTS

Length

Width

Height

Weight

-

--- - ---kg.Refrigerant charge

333 3 333kg.Oil charge

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Condensation temperature 47 °C

2 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

3 Standard configuration

- Not available

ELCADOC - Ver. 1.0.0.1

5

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 10

GENERAL TECHNICAL DATA

NECS-ME

B

SIZE 0412 0452 0512 0552 0612 0604 0704

NECS-ME /B

COOLING

(1)

Cooling capacity kW 105 117 131 151 170 161 186

Total power input (unit) kW 30,3 33,9 37,6 43,3 48,9 46,9 53,7

EER

ESEER

3,45

-

3,46

-

3,49

-

3,48 - 3,47

-

3,43

-

3,46

Heat exchanger water flow m³/h 18,0 20,2 22,6 25,9 29,3 27,7 31,9

Heat exchanger pressure drop kPa 35,0 33,1 32,2 28,9 36,8 32,5 31,0

COMPRESSORS

Number

Number of capacity

Number of circuits N°.

Type of regulation

N°. 2 2 2 2 2 4 4

N°.

2 2 2 2 2 4 4

1 1 1 1 1 2 2

STEPS STEPS STEPS STEPS STEPSSTEPSSTEPS

% 50 50 50 50 50 25 25Minimum capacity steps

R410AR410AR410A R410A R410AR410AR410AType of refrigerant

3,253,256 7 755kg.Oil charge

mm.

mm.

mm.

kg.

(2)

79

79

86

5447

(3)

1310

893

1496

585

1310

893

1496

615

1310

893

1496

645

1310

893

1496

680

1310

893

1496

755

2227

1020

1780

700

87

5547 464645dB(A)Total sound pressure

2227

1020

1780

950

NOISE LEVELS

Total sound power dB(A) 77 78 78

DIMENSIONS AND WEIGHTS

Length

Width

Height

Weight

-

--- - ---kg.Refrigerant charge

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Condensation temperature 47 °C

2 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

3 Standard configuration

- Not available

ELCADOC - Ver. 1.0.0.1

6

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 11

GENERAL TECHNICAL DATA

NECS-ME

B

SIZE 0804 0904 1004 1104 1204 1404 1604

NECS-ME /B

COOLING

(1)

Cooling capacity kW 207 235 263 301 339 387 432

Total power input (unit) kW 60,6 67,9 75,2 86,5 97,8 111 124

EER

ESEER

3,42

-

3,47

-

3,50

-

3,47 - 3,47

-

3,49

-

3,48

Heat exchanger water flow m³/h 35,7 40,5 45,3 51,7 58,4 66,5 74,3

Heat exchanger pressure drop kPa 38,8 38,9 39,4 36,7 46,7 49,6 54,7

COMPRESSORS

Number

Number of capacity

Number of circuits N°.

Type of regulation

N°. 4 4 4 4 4 4 4

N°.

4 4 4 4 4 4 4

2 2 2 2 2 2 2

STEPS STEPS STEPS STEPS STEPSSTEPSSTEPS

% 25 25 25 25 25 25 25Minimum capacity steps

R410AR410AR410A R410A R410AR410AR410AType of refrigerant

6,36,36,3 6,8 6,84,74,7kg.Oil charge

mm.

mm.

mm.

kg.

(2)

91

91

91

5959

(3)

2227

1020

1780

1125

2227

1020

1780

1185

2227

1020

1780

1250

2227

1020

1780

1330

2227

1020

1780

1370

2227

1020

1780

1430

91

5959 585756dB(A)Total sound pressure

2227

1020

1780

1480

NOISE LEVELS

Total sound power dB(A) 88 89 90

DIMENSIONS AND WEIGHTS

Length

Width

Height

Weight

-

--- - ---kg.Refrigerant charge

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Condensation temperature 47 °C

2 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

3 Standard configuration

- Not available

ELCADOC - Ver. 1.0.0.1

7

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 12

3.2 COOLING CAPACITY PERFORMANCE

NECS-ME

B

0152

Tc

Pf

Pat

Qev

Dpev

Pf 50,0 48,0 45,8 43,3 40,5 37,4 51,4 49,5 47,2 44,7 41,8 38,7 52,8 50,9 48,7 46,1 43,2 39,9

Pat 8,15 9,11 10,2 11,5 12,9 14,5 8,18 9,13 10,2 11,5 12,9 14,5 8,20 9,15 10,3 11,5 12,9 14,5

Qev 8,60 8,27 7,89 7,46 6,98 6,44 8,85 8,52 8,14 7,70 7,21 6,66 9,10 8,77 8,39 7,94 7,44 6,88

Dpev 76,8 71,0 64,6 57,7 50,5 43,1 81,3 75,3 68,7 61,5 53,9 46,0 85,9 79,8 73,0 65,4 57,4 49,1

45,6 43,7 41,6 39,2 36,6 33,7 47,1 45,2 43,0 40,6 37,9 34,9 48,5 46,6 44,4 41,9 39,2 36,2

8,07 9,04 10,2 11,5 12,9 14,5 8,10 9,06 10,2 11,5 12,9 14,5 8,13 9,09 10,2 11,5 12,9 14,5

7,86 7,53 7,16 6,74 6,29 5,80 8,11 7,78 7,40 6,98 6,52 6,01 8,36 8,02 7,65 7,22 6,75 6,23

64,0 58,7 53,1 47,2 41,0 34,8 68,1 62,7 56,8 50,6 44,1 37,5 72,4 66,8 60,6 54,1 47,2 40,2

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0182

Tc

Pf

Pat

Qev

Dpev

Pf 58,3 55,6 52,8 50,0 47,2 44,2 60,0 57,3 54,4 51,6 48,7 45,7 61,8 58,9 56,0 53,1 50,2 47,2

Pat 9,29 10,4 11,6 13,0 14,4 16,0 9,33 10,4 11,6 13,0 14,4 16,0 9,36 10,5 11,7 13,0 14,4 16,0

Qev 10,0 9,57 9,10 8,61 8,12 7,62 10,3 9,86 9,38 8,88 8,38 7,88 10,7 10,2 9,66 9,15 8,65 8,14

Dpev 66,8 60,8 55,0 49,3 43,8 38,6 71,0 64,6 58,4 52,4 46,7 41,2 75,4 68,5 61,9 55,6 49,7 44,0

52,9 50,5 48,0 45,4 42,7 39,8 54,7 52,2 49,6 46,9 44,1 41,3 56,5 53,9 51,2 48,5 45,7 42,8

9,18 10,3 11,5 12,9 14,3 15,9 9,22 10,3 11,6 12,9 14,4 15,9 9,26 10,4 11,6 12,9 14,4 16,0

9,11 8,70 8,27 7,81 7,34 6,85 9,42 8,99 8,54 8,08 7,60 7,11 9,73 9,28 8,82 8,35 7,86 7,36

55,1 50,2 45,4 40,5 35,8 31,2 58,9 53,6 48,4 43,3 38,4 33,5 62,8 57,2 51,6 46,3 41,0 36,0

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0202

Tc

Pf

Pat

Qev

Dpev

Pf 67,6 65,0 62,1 58,7 54,9 50,8 69,5 66,9 64,0 60,6 56,7 52,5 71,5 68,9 65,9 62,4 58,5 54,3

Pat 10,7 12,0 13,4 15,1 16,9 18,9 10,7 12,0 13,4 15,1 16,9 18,9 10,8 12,0 13,4 15,1 16,9 18,9

Qev 11,6 11,2 10,7 10,1 9,46 8,74 12,0 11,5 11,0 10,4 9,77 9,04 12,3 11,9 11,3 10,8 10,1 9,35

Dpev 65,1 60,3 55,0 49,2 43,1 36,8 69,0 64,0 58,4 52,3 45,9 39,3 72,9 67,7 61,9 55,6 49,0 42,0

61,7 59,3 56,4 53,2 49,6 45,6 63,7 61,2 58,3 55,0 51,4 47,3 65,6 63,1 60,2 56,9 53,1 49,0

10,6 11,9 13,3 15,0 16,9 18,9 10,6 11,9 13,4 15,0 16,9 18,9 10,7 11,9 13,4 15,0 16,9 18,9

10,6 10,2 9,71 9,15 8,53 7,85 11,0 10,5 10,0 9,47 8,84 8,15 11,3 10,9 10,4 9,79 9,15 8,44

54,3 50,0 45,3 40,3 35,0 29,7 57,8 53,3 48,4 43,1 37,6 31,9 61,4 56,8 51,6 46,1 40,3 34,3

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0252

Tc

Pf

Pat

Qev

Dpev

Pf

Pat 12,7 14,0 15,6 17,3 19,3 21,5 12,7 14,0 15,6 17,3 19,3 21,5 12,8 14,1 15,6 17,3 19,3 21,5

Qev

Dpev 61,9 57,5 52,4 46,9 41,1 35,0 65,6 61,0 55,8 50,0 43,8 37,3 69,4 64,7 59,3 53,2 46,6 39,7

69,5 66,7 63,6 60,0 56,1 51,7 71,7 68,9 65,7 62,1 58,0 53,6 73,9 71,1 67,9 64,2 60,0 55,4

12,5 13,9 15,5 17,3 19,3 21,5 12,6 13,9 15,5 17,3 19,3 21,5 12,6 14,0 15,5 17,3 19,3 21,5

12,0 11,5 10,9 10,3 9,65 8,91 12,3 11,9 11,3 10,7 9,99 9,22 12,7 12,3 11,7 11,1 10,3 9,54

51,5 47,5 43,1 38,4 33,5 28,6 54,9 50,7 46,1 41,1 36,0 30,6 58,4 54,0 49,2 44,0 38,5 32,8

76,2 73,4 70,1 66,3 62,0 57,2 78,4 75,6 72,3 68,4 64,0 59,1 80,6 77,8 74,5 70,5 66,0 60,9

13,1 12,6 12,1 11,4 10,7 9,86 13,5 13,0 12,4 11,8 11,0 10,2 13,9 13,4 12,8 12,2 11,4 10,5

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0262

Tc

Pf

Pat

Qev

Dpev

Pf 84,9 81,4 77,6 73,5 69,1 64,4 87,4 83,9 80,0 75,8 71,3 66,4 90,0 86,3 82,3 78,0 73,4 68,5

Pat 14,2 15,7 17,3 19,2 21,4 23,8 14,3 15,7 17,4 19,3 21,4 23,8 14,3 15,8 17,4 19,3 21,5 23,9

Qev 14,6 14,0 13,4 12,7 11,9 11,1 15,1 14,4 13,8 13,1 12,3 11,4 15,5 14,9 14,2 13,4 12,7 11,8

Dpev 76,9 70,7 64,3 57,7 51,0 44,3 81,7 75,1 68,3 61,3 54,3 47,2 86,6 79,7 72,5 65,1 57,6 50,2

77,3 74,1 70,6 66,8 62,7 58,3 79,8 76,5 72,9 69,0 64,8 60,3 82,3 78,9 75,2 71,2 66,9 62,4

14,0

13,3 12,8 12,1 11,5 10,8 10,0 13,7 13,2 12,5 11,9 11,2 10,4 14,2 13,6 13,0 12,3 11,5 10,7

63,8

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

15,5 17,1 19,1 21,2 23,6 14,1 15,5 17,2 19,1 21,3 23,7 14,2 15,6 17,3 19,2 21,4 23,8

58,5 53,1 47,5 41,9 36,3 68,0 62,5 56,7 50,8 44,8 38,8 72,4 66,5 60,4 54,2 47,8 41,5

9 10 11 Tev

Tc [°C] - Condensation temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 1.0.0.1

8

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 13

COOLING CAPACITY PERFORMANCE

NECS-ME

B

0302

Tc

Pf

Pat

Qev

Dpev

Pf 101 96,9 92,4 87,5 82,4 77,0 104 99,9 95,2 90,3 85,0 79,4 107 103 98,1 93,0 87,6 81,9

Pat 16,8 18,5 20,5 22,7 25,0 27,6 16,8 18,6 20,5 22,7 25,1 27,7 16,8 18,6 20,6 22,8 25,1 27,7

Qev 17,4 16,7 15,9 15,1 14,2 13,3 18,0 17,2 16,4 15,5 14,6 13,7 18,5 17,7 16,9 16,0 15,1 14,1

Dpev 46,8 42,9 39,0 35,0 31,0 27,1 49,7 45,6 41,5 37,2 33,0 28,8 52,8 48,4 44,0 39,5 35,1 30,6

92,0 88,1 83,9 79,5 74,7 69,7 95,0 91,0 86,7 82,1 77,3 72,1 98,1 94,0 89,5 84,8 79,8 74,5

16,6 18,3 20,3 22,4 24,8 27,4 16,6 18,4 20,3 22,5 24,9 27,5 16,7 18,5 20,4 22,6 25,0 27,5

15,8 15,2 14,4 13,7 12,9 12,0 16,4 15,7 14,9 14,1 13,3 12,4 16,9 16,2 15,4 14,6 13,7 12,8

38,6 35,4 32,1 28,8 25,5 22,2 41,2 37,8 34,3 30,8 27,3 23,7 43,9 40,3 36,6 32,9 29,1 25,4

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0352

Tc

Pf

Pat

Qev

Dpev

Pf 118 113 107 102 95,4 89,0 122 117 111 105 98,5 92,0 126 120 114 108 102 95,0

Pat 19,5 21,3 23,5 26,0 28,8 31,8 19,5 21,4 23,6 26,1 28,8 31,9 19,6 21,5 23,6 26,1 28,9 32,0

Qev 20,4 19,5 18,5 17,5 16,4 15,3 21,0 20,1 19,1 18,0 17,0 15,8 21,7 20,7 19,7 18,6 17,5 16,4

Dpev 44,8 40,9 36,9 33,0 29,2 25,4 47,7 43,5 39,3 35,2 31,1 27,1 50,7 46,2 41,8 37,4 33,1 28,9

107 102 97,3 91,9 86,2 80,2 111 106 101 95,1 89,2 83,1 115 109 104 98,3 92,3 86,0

19,2 21,1 23,2 25,7 28,5 31,5 19,3 21,2 23,3 25,8 28,6 31,6 19,4 21,3 23,4 25,9 28,7 31,7

18,5 17,6 16,8 15,8 14,8 13,8 19,1 18,2 17,3 16,4 15,4 14,3 19,7 18,8 17,9 16,9 15,9 14,8

36,8 33,6 30,3 27,0 23,8 20,6 39,4 35,9 32,4 28,9 25,5 22,1 42,0 38,4 34,6 30,9 27,3 23,7

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0412

Tc

Pf

Pat

Qev

Dpev

Pf 134 128 121 115 108 100 138 132 125 118 111 104 143 136 129 122 115 107

Pat 22,2 24,1 26,5 29,3 32,5 36,0 22,3 24,2 26,6 29,4 32,6 36,1 22,3 24,3 26,7 29,5 32,6 36,2

Qev 23,1 22,0 20,9 19,7 18,5 17,3 23,8 22,7 21,6 20,4 19,2 17,9 24,6 23,4 22,2 21,0 19,8 18,5

Dpev 57,6 52,4 47,2 42,1 37,1 32,2 61,3 55,8 50,3 44,9 39,6 34,5 65,2 59,3 53,5 47,8 42,3 36,9

122 116 110 104 96,9 90,0 126 120 114 107 100 93,4 130 124 118 111 104 96,8

21,9 23,8 26,2 29,0 32,1 35,7 22,0 23,9 26,3 29,1 32,2 35,8 22,1 24,0 26,4 29,2 32,4 35,9

20,9 19,9 18,9 17,8 16,7 15,5 21,6 20,6 19,6 18,5 17,3 16,1 22,4 21,3 20,2 19,1 17,9 16,7

47,3 43,0 38,6 34,3 30,1 25,9 50,6 46,0 41,4 36,8 32,3 27,9 54,0 49,1 44,2 39,4 34,6 30,0

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0452

Tc

Pf

Pat

Qev

Dpev

Pf

Pat 24,7 27,0 29,7 32,8 36,3 40,2 24,8 27,1 29,8 32,9 36,4 40,3 24,9 27,2 29,9 33,0 36,5 40,4

Qev

Dpev 53,5 49,0 44,3 39,6 34,9 30,3 56,9 52,1 47,2 42,2 37,3 32,4 60,4 55,3 50,1 44,9 39,7 34,5

136 130 123 116 109 101 140 134 127 120 113 105 145 138 132 124 117 109

24,4 26,7 29,3 32,4 36,0 39,9 24,5 26,8 29,5 32,6 36,1 40,0 24,6 26,9 29,6 32,7 36,2 40,1

23,3 22,3 21,2 20,0 18,8 17,4 24,1 23,1 21,9 20,7 19,4 18,0 24,9 23,8 22,7 21,4 20,1 18,7

44,1 40,3 36,4 32,5 28,5 24,6 47,1 43,1 38,9 34,7 30,5 26,4 50,2 46,0 41,6 37,1 32,7 28,3

149 143 136 128 121 112 154 147 140 133 125 116 158 152 144 137 128 120

25,7 24,6 23,4 22,1 20,8 19,3 26,5 25,4 24,1 22,8 21,4 20,0 27,3 26,1 24,9 23,5 22,1 20,6

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0512

Tc

Pf

Pat

Qev

Dpev

Pf 166 159 152 144 135 125 171 164 157 148 139 129 176 169 161 153 144 134

Pat 27,3 29,9 32,9 36,3 40,2 44,4 27,4 30,0 33,0 36,4 40,2 44,4 27,5 30,1 33,1 36,5 40,3 44,5

Qev 28,6 27,4 26,1 24,7 23,2 21,6 29,5 28,3 27,0 25,5 24,0 22,3 30,4 29,1 27,8 26,3 24,7 23,0

Dpev 51,6 47,4 43,1 38,6 34,0 29,4 54,8 50,4 45,8 41,1 36,2 31,3 58,1 53,5 48,7 43,7 38,5 33,4

151 145 138 130 122 113 156 150 142 135 126 117 161 154 147 139 131 121

26,9

26,0 24,9 23,7 22,4 21,0 19,5 26,9 25,7 24,5 23,2 21,7 20,2 27,7 26,6 25,3 24,0 22,5 20,9

42,6

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

29,5 32,5 36,0 39,8 44,1 27,1 29,6 32,7 36,1 39,9 44,2 27,2 29,8 32,8 36,2 40,1 44,3

39,1 35,4 31,6 27,8 24,0 45,5 41,8 37,9 33,9 29,8 25,7 48,5 44,5 40,4 36,2 31,8 27,5

9 10 11 Tev

Tc [°C] - Condensation temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 1.0.0.1

9

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 14

COOLING CAPACITY PERFORMANCE

NECS-ME

B

0552

Tc

Pf

Pat

Qev

Dpev

Pf 191 183 174 165 155 144 197 189 180 170 160 149 203 194 185 175 165 153

Pat 31,4 34,4 37,8 41,8 46,2 51,2 31,5 34,5 38,0 41,9 46,3 51,2 31,6 34,6 38,1 42,0 46,4 51,3

Qev 32,9 31,5 30,0 28,4 26,6 24,8 33,9 32,5 31,0 29,3 27,5 25,6 34,9 33,5 31,9 30,2 28,4 26,4

Dpev 46,5 42,7 38,7 34,6 30,5 26,4 49,4 45,4 41,2 36,9 32,5 28,2 52,4 48,2 43,8 39,2 34,6 30,0

174 166 158 149 140 130 179 172 163 154 145 135 185 177 169 160 150 139

31,0 33,9 37,4 41,4 45,8 50,8 31,1 34,1 37,6 41,5 46,0 50,9 31,3 34,2 37,7 41,7 46,1 51,0

29,9 28,6 27,2 25,7 24,1 22,4 30,9 29,6 28,1 26,6 24,9 23,2 31,9 30,5 29,1 27,5 25,8 24,0

38,4 35,1 31,8 28,4 24,9 21,5 41,0 37,5 34,0 30,4 26,7 23,1 43,7 40,1 36,3 32,5 28,6 24,7

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0612

Tc

Pf

Pat

Qev

Dpev

Pf 216 206 197 186 175 162 222 213 203 192 180 168 229 219 209 198 186 173

Pat 35,5 38,9 42,8 47,3 52,3 57,9 35,6 39,0 42,9 47,4 52,4 58,1 35,8 39,1 43,0 47,5 52,6 58,2

Qev 37,1 35,6 33,9 32,0 30,1 28,0 38,3 36,7 34,9 33,1 31,0 28,9 39,5 37,8 36,0 34,1 32,0 29,9

Dpev 59,3 54,4 49,3 44,1 38,9 33,7 63,1 57,9 52,5 47,0 41,5 35,9 67,0 61,5 55,8 50,0 44,1 38,3

196 187 178 168 158 147 202 194 184 174 163 152 209 200 190 180 169 157

35,0 38,4 42,3 46,8 51,8 57,4 35,2 38,5 42,5 47,0 52,0 57,6 35,3 38,7 42,6 47,1 52,2 57,8

33,7 32,3 30,7 29,0 27,2 25,2 34,9 33,4 31,7 30,0 28,1 26,2 36,0 34,5 32,8 31,0 29,1 27,1

48,9 44,7 40,4 36,1 31,7 27,4 52,3 47,8 43,3 38,7 34,0 29,4 55,7 51,0 46,2 41,3 36,4 31,5

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0604

Tc

Pf

Pat

Qev

Dpev

Pf 203 194 185 176 165 154 209 200 191 181 170 159 216 206 197 186 176 164

Pat 33,5 37,0 41,0 45,3 50,1 55,2 33,6 37,1 41,1 45,4 50,2 55,3 33,7 37,2 41,2 45,5 50,3 55,4

Qev 35,0 33,5 31,9 30,2 28,5 26,6 36,1 34,5 32,9 31,2 29,4 27,4 37,1 35,6 33,9 32,1 30,3 28,3

Dpev 51,8 47,5 43,2 38,7 34,3 29,9 55,1 50,5 45,9 41,2 36,5 31,9 58,5 53,7 48,7 43,8 38,8 33,9

184 177 168 159 150 140 191 183 174 165 155 145 197 188 180 170 160 149

33,2 36,6 40,5 44,9 49,6 54,8 33,3 36,8 40,7 45,0 49,8 55,0 33,4 36,9 40,8 45,2 49,9 55,1

31,7 30,4 29,0 27,4 25,8 24,0 32,8 31,4 29,9 28,4 26,7 24,9 33,9 32,4 30,9 29,3 27,6 25,7

42,7 39,2 35,6 31,9 28,2 24,5 45,6 41,9 38,0 34,1 30,2 26,3 48,7 44,6 40,5 36,4 32,2 28,1

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0704

Tc

Pf

Pat

Qev

Dpev

Pf

Pat 38,9 42,7 47,0 52,0 57,5 63,7 39,1 42,8 47,2 52,1 57,7 63,8 39,2 42,9 47,3 52,2 57,8 63,9

Qev

Dpev 50,4 46,0 41,6 37,2 32,8 28,6 53,7 49,0 44,3 39,6 35,0 30,5 57,1 52,0 47,1 42,1 37,3 32,6

215 205 195 184 172 160 222 212 201 190 178 166 229 219 208 197 185 172

38,5 42,2 46,5 51,4 56,9 63,1 38,6 42,4 46,7 51,6 57,1 63,3 38,8 42,5 46,8 51,8 57,3 63,5

36,9 35,3 33,5 31,6 29,7 27,6 38,2 36,5 34,7 32,7 30,7 28,6 39,5 37,7 35,8 33,9 31,8 29,6

41,5 37,8 34,1 30,4 26,8 23,2 44,3 40,4 36,5 32,6 28,7 24,9 47,3 43,2 39,0 34,8 30,7 26,7

237 226 215 203 191 178 244 233 222 210 197 184 251 240 228 216 203 190

40,7 38,9 37,0 35,0 32,9 30,7 42,0 40,1 38,2 36,1 33,9 31,7 43,3 41,4 39,3 37,2 35,0 32,7

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

0804

Tc

Pf

Pat

Qev

Dpev

Pf 266 253 241 227 213 199 274 261 248 235 220 206 282 269 256 242 228 213

Pat 44,3 48,2 53,0 58,5 64,9 72,1 44,5 48,4 53,2 58,7 65,1 72,3 44,6 48,6 53,3 58,9 65,3 72,4

Qev 45,7 43,6 41,4 39,1 36,7 34,3 47,2 45,0 42,8 40,4 38,0 35,5 48,6 46,4 44,1 41,7 39,2 36,7

Dpev 63,6 57,9 52,2 46,6 41,0 35,7 67,7 61,6 55,6 49,6 43,8 38,2 71,9 65,5 59,1 52,8 46,8 40,9

241 230 218 205 192 179 249 238 225 213 199 185 257 245 233 220 206 192

43,7

41,5 39,5 37,5 35,4 33,1 30,8 42,9 40,9 38,8 36,6 34,3 31,9 44,3 42,3 40,1 37,9 35,5 33,1

52,3

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

47,6 52,4 57,9 64,2 71,3 43,9 47,9 52,6 58,1 64,5 71,6 44,1 48,1 52,8 58,3 64,7 71,8

47,5 42,8 38,0 33,3 28,8 55,9 50,9 45,8 40,8 35,8 30,9 59,7 54,3 48,9 43,6 38,4 33,2

9 10 11 Tev

Tc [°C] - Condensation temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 1.0.0.1

10

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 15

COOLING CAPACITY PERFORMANCE

NECS-ME

B

0904

Tc

Pf

Pat

Qev

Dpev

Pf 300 286 273 258 242 225 309 295 281 266 250 233 318 304 290 274 258 240

Pat 49,4 54,0 59,4 65,6 72,6 80,4 49,6 54,2 59,6 65,8 72,8 80,6 49,8 54,4 59,8 66,0 72,9 80,7

Qev 51,6 49,3 46,9 44,4 41,7 38,8 53,2 50,9 48,4 45,8 43,0 40,1 54,8 52,4 49,9 47,2 44,4 41,4

Dpev 63,1 57,7 52,2 46,7 41,1 35,6 67,0 61,4 55,6 49,7 43,9 38,1 71,2 65,2 59,1 52,9 46,8 40,7

272 260 247 233 219 203 281 269 256 241 226 210 290 278 264 249 234 218

48,8 53,3 58,7 64,9 71,9 79,8 49,0 53,6 59,0 65,2 72,2 80,0 49,2 53,8 59,2 65,4 72,4 80,2

46,8 44,8 42,5 40,2 37,6 34,9 48,4 46,3 44,0 41,6 39,0 36,2 50,0 47,8 45,5 43,0 40,3 37,5

52,0 47,5 42,9 38,2 33,5 28,9 55,5 50,8 45,9 40,9 36,0 31,1 59,2 54,2 49,0 43,7 38,5 33,3

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

1004

Tc

Pf

Pat

Qev

Dpev

Pf 333 319 304 288 270 251 343 329 313 297 279 259 353 339 323 306 287 267

Pat 54,6 59,8 65,8 72,7 80,3 88,8 54,8 60,0 66,0 72,9 80,5 88,9 54,9 60,2 66,2 73,0 80,6 89,0

Qev 57,3 54,9 52,4 49,5 46,5 43,2 59,1 56,6 54,0 51,1 48,0 44,7 60,8 58,4 55,7 52,7 49,5 46,1

Dpev 63,0 58,0 52,6 47,1 41,5 35,9 67,0 61,6 56,0 50,2 44,2 38,3 71,0 65,4 59,5 53,3 47,1 40,8

303 290 276 261 244 227 313 299 285 270 253 235 323 309 295 279 261 243

53,9 59,0 65,0 71,9 79,6 88,2 54,1 59,3 65,3 72,2 79,9 88,4 54,3 59,5 65,6 72,4 80,1 88,6

52,1 49,9 47,5 44,9 42,1 39,0 53,8 51,6 49,1 46,4 43,5 40,4 55,6 53,2 50,7 48,0 45,0 41,8

52,1 47,8 43,3 38,7 34,0 29,3 55,6 51,0 46,3 41,4 36,4 31,4 59,3 54,4 49,4 44,2 38,9 33,6

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

1104

Tc

Pf

Pat

Qev

Dpev

Pf 381 365 347 329 309 287 392 376 358 339 319 297 404 387 369 350 329 306

Pat 62,7 68,7 75,7 83,6 92,5 102 63,0 69,0 75,9 83,8 92,7 102 63,2 69,2 76,1 84,0 92,9 103

Qev 65,6 62,8 59,8 56,6 53,2 49,5 67,6 64,8 61,7 58,4 54,9 51,1 69,6 66,7 63,6 60,2 56,6 52,7

Dpev 58,9 54,1 49,0 43,9 38,7 33,5 62,6 57,5 52,2 46,8 41,3 35,8 66,4 61,0 55,5 49,7 43,9 38,1

346 331 315 298 279 259 358 342 326 308 289 269 369 354 337 318 299 278

61,9 67,9 74,8 82,7 91,7 102 62,2 68,2 75,1 83,0 92,0 102 62,5 68,5 75,4 83,3 92,2 102

59,6 57,0 54,2 51,3 48,1 44,6 61,6 58,9 56,1 53,0 49,7 46,2 63,6 60,9 58,0 54,8 51,4 47,8

48,6 44,5 40,3 36,0 31,6 27,3 51,9 47,6 43,1 38,5 33,9 29,3 55,3 50,8 46,0 41,2 36,3 31,4

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

1204

Tc

Pf

Pat

Qev

Dpev

Pf

Pat 71,0 77,7 85,6 94,5 105 116 71,3 78,0 85,8 94,8 105 116 71,5 78,2 86,1 95,0 105 116

Qev

Dpev 75,3 69,0 62,6 56,0 49,4 42,8 80,0 73,4 66,6 59,6 52,6 45,6 85,0 78,0 70,8 63,4 56,0 48,7

391 374 356 336 315 293 404 387 368 348 326 303 417 399 380 359 337 314

69,9 76,7 84,6 93,6 104 115 70,3 77,1 84,9 93,9 104 115 70,6 77,4 85,3 94,2 104 116

67,3 64,4 61,2 57,8 54,2 50,4 69,6 66,6 63,3 59,9 56,2 52,2 71,9 68,8 65,4 61,9 58,1 54,0

62,1 56,8 51,4 45,8 40,3 34,8 66,3 60,7 54,9 49,1 43,2 37,4 70,7 64,8 58,7 52,5 46,2 40,0

430 412 392 371 348 324 444 425 405 383 360 335 457 438 417 395 371 346

74,1 71,0 67,6 63,9 60,0 55,9 76,4 73,2 69,7 66,0 62,0 57,7 78,7 75,4 71,9 68,1 64,0 59,6

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

1404

Tc

Pf

Pat

Qev

Dpev

Pf 489 468 446 422 397 370 504 483 460 435 409 381 519 497 474 449 422 393

Pat 83,3 89,6 97,6 107 118 131 83,6 89,9 97,8 107 119 132 83,8 90,1 98,0 108 119 132

Qev 84,2 80,7 76,8 72,7 68,3 63,6 86,8 83,1 79,2 75,0 70,5 65,7 89,3 85,6 81,6 77,3 72,7 67,8

Dpev 79,5 72,9 66,1 59,2 52,3 45,4 84,4 77,4 70,3 63,0 55,7 48,4 89,4 82,1 74,6 66,9 59,2 51,5

445 426 405 383 359 334 460 440 419 396 372 346 474 454 432 409 384 358

82,4

76,7 73,3 69,8 65,9 61,9 57,5 79,2 75,8 72,1 68,2 64,0 59,6 81,7 78,2 74,5 70,4 66,1 61,6

65,8

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

88,7 96,7 106 117 130 82,7 89,0 97,0 107 118 131 83,0 89,3 97,3 107 118 131

60,2 54,5 48,7 42,9 37,1 70,2 64,3 58,2 52,1 45,9 39,7 74,8 68,5 62,1 55,6 49,0 42,5

9 10 11 Tev

Tc [°C] - Condensation temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 1.0.0.1

11

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 16

COOLING CAPACITY PERFORMANCE

NECS-ME

B

1604

Tc

Pf

Pat

Qev

Dpev

Pf 544 522 497 471 442 413 560 537 512 485 456 426 576 553 527 499 470 439

Pat 95,6 101 110 120 132 147 95,9 102 110 120 132 147 96,1 102 110 120 133 147

Qev 93,8 89,8 85,6 81,1 76,2 71,1 96,5 92,5 88,2 83,5 78,6 73,3 99,3 95,2 90,8 86,0 81,0 75,6

Dpev 87,0 79,9 72,5 65,0 57,5 50,0 92,3 84,7 77,0 69,1 61,1 53,2 97,7 89,7 81,6 73,3 64,9 56,6

497 476 453 428 402 374 513 491 467 442 415 387 528 506 482 456 429 400

94,7 101 109 119 131 146 95,1 101 109 119 132 146 95,4 101 109 120 132 147

85,5 81,9 77,9 73,7 69,2 64,4 88,3 84,5 80,5 76,1 71,5 66,6 91,0 87,2 83,0 78,6 73,8 68,8

72,4 66,3 60,1 53,7 47,4 41,0 77,1 70,7 64,1 57,4 50,6 43,9 82,0 75,2 68,2 61,1 54,0 46,9

35 40 45 50 55 30 30 35 40 45 50 55 30 35 40 45 50 55

6 7 8 Tev

9 10 11 Tev

Tc [°C] - Condensation temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 1.0.0.1

12

NECS-ME_0152_1604_201004_*% Ref.: R410A

Page 17

4. OPERATING RANGE

60

55

50

48

45

40

Tc OUT [°C]

35

30

NECS-ME

25

-8

-5

Tev OUT [°C]

Tc OUT [°C]: Heat exchanger temperature on source side (out)

Tev OUT [°C]: Cold exchanger temperature on user side (out)

ETHYLENE GLYCOL MIXTURE

Ethylene glycol and water mixtures, used as a heat-conveying uid,

cause a variation in unit performance. For correct data, use the factors

indicated in the following table.

0 -5 -10 -15 -20 -25 -30 -35

0 12% 20% 30% 35% 40% 45% 50%

cPf 1 0,985 0,98 0,974 0,97 0,965 0,964 0,96

cQ 1 1,02 1,04 1,075 1,11 1,14 1,17 1,2

cdp 1 1,07 1,11 1,18 1,22 1,24 1,27 1,3

cPf: cooling capacity correction factor

cQ: ow correction factor

cdp: pressure drop correction factor

5

7

100-10 20

15

Limits to exchanger water temperature are valid within the minimum

- maximum water ow range indicated in the Hydraulic Data section.

Freezing point (°C)

Ethylene glycol percentage by weight

For data concerning other kind of anti-freeze solutions (e.g. propylene

glycol) please contact our Sales Department.

FOULING FACTORS

Performances are based on clean condition of tubes (fouling factor =1).

For different fouling values, performance should be adjusted using the

correction factors shown in the following table.

Encrustation factors

2

(m

°C/W) 4,4 x 10

2

(m

°C/W) 0,86 x 10

2

(m

°C/W) 1,72 x 10

-5

-4

-4

0,96 0,99 0,99 0,98 1,04 1,04 0,98 1,04 1,04

0,93 0,98 0,98 0,95 1,06 1,06 0,95 1,06 1,06

Evaporator Heat recovery Desuperheater

f1 fk1 fx1 f2 fk2 fx2 f3 fk3 fx3

1 1 1 0,99 1,03 1,03 0,99 1,03 1,03

f1 - f2 - f3: capacity correction factors

fk1 - fk2 - fk3: compressor power input correction factors

fx1 - fx2 - fx3: total power input correction factors

13

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 18

5.1 HYDRAULIC DATA

5.1 Water ow and pressure drop

Water ow in the heat exchangers is given by:

Q=Px0,86/Dt

NECS-ME

Pressure drop is given by:

Dp= K x Q2/1000

Q: water ow (m3/h)

Dt: difference between inlet and outlet water temp. (°C)

P: heat exchanger capacity (kW)

SIZE Evaporator

0152 1037 4,1 11,4 0,34

0182 664 4,8 13,2 0,39

0202 481 5,7 15,5 0,46

0252 360 6,4 17,4 0,52

0262 360 7,1 19,4 0,58

0302 154 8,5 23,1 0,69

0352 108 9,9 26,7 0,8

0412 108 11,1 30,1 0,9

0452 81 12,5 33,8 1,01

0512 63 14 37,8 1,13

0552 43 16,1 43,3 1,3

0604 42,4 18,2 48,8 1,46

0612 43 17,2 46,2 1,15

0704 30,4 19,9 53,3 1,33

0804 30,4 22,2 59,6 1,49

0904 23,7 25,2 67,6 1,69

1004 19,2 28,2 75,5 1,88

1104 13,7 32,2 86,2 2,15

1204 13,7 36,4 97,3 2,4

1404 11,2 41,4 110 2,77

1604 9,9 46,3 110 3,09

Q: water ow (m3/h)

Dp: pressure drop (kPa)

K: unit size ratio

K

Q min

3

m

/h

Q max

m3/h

C.a.

min m

3

K evap: standard mains lter included

Q min: minimum water ow admitted to the heat exchanger.

Q max: maximum water ow admitted to the heat exchang-

er.

W.c min.: minimum water content admitted in the plant, using

traditional control logic

14

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 19

5.2 HYDRONIC UNIT

NECS-ME

Available congurations

Hydronic kit with one pump

Hydronic kit with two pumps

Compact units Plug and Play.

The units in the NECS system are tted standard with a hydronic group. This houses all the main hydraulic components,

thereby optimising hydraulic and electric installation space,

time and cost.

The innovative QuickMind control tted to the units in the NECS

system, has been designed to work on systems with a low water content, offering highly professional alternatives to the installation of systems featuring storage units.

For special applications, a tank to install inside the unit is available on request.

2-pole low head pump

Horizontal one-piece centrifugal pump with one impeller, axial

suction and radial delivery, AISI 304L stainless steel pump body

impeller. The section of the shaft in contact with the liquid is

made from stainless steel. Mechanical seal made from components in ceramics/carbon/NBR/AISI304. Three phase electric

motor protected to IP55, insulation class F, suitable for continuous service.

2-pole high head pump

The hydronic group in all versions of the unit can be supplied

with a high head pump. In these cases, the pump features a

two-pole motor even in the silent-running versions.

Water-side mechanical lter (recommended)

Y-lter designed and built to capture the impurities in the hydraulic circuit. It is tted with a 0.9 mm stainless steel mesh cartridge which can be replaced without removing the valve body

from the piping.

The supply does not include the following accessories though

these are recommended to ensure correct system operation:

- MA Pressure gauges upline and downline from the unit.

- GF Flexible joints on piping.

- RI On-off valves

- T Outlet control thermometer

Second pump

A second stand-by pump for high or low pressures is available

on request. The pumps are automatically exchanged on the

basis of a rotation programme and the stand-by pump cuts in

automatically if the primary pump fails. The two-pump hydronic assembly is also tted with check valves to ensure the unit

works correctly.

Special pumps

For pumps with different congurations, please contact our

sales department.

15

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 20

NECS-ME

Conguration of hydronic unit with 1/2 pumps (0152-0612)

CIRCUITS WITH TWO OPTIONAL PUMPS

RETURN FROM HYDRAULIC SYSTEM

DISCHARGE TO HYDRAULIC SYSTEM

The hydronic group comprises:

- EV Evaporator

- Pd Differential pressure switch

- Pe Evaporator circulation pump

- SC Discharge valve

- SF Relief valve

- S1 Evaporator water inlet probe

CIRCUIT WITH TWO OPTIONAL PUMPS

- S2 Evaporator water outlet probe

- TP Drain plug

- VA Safety valve

- VR Check valve (with 2 pumps only)

CIRCUITS WITH TWO OPTIONAL PUMPS

RETURN FROM HYDRAULIC SYSTEM

DISCHARGE TO HYDRAULIC SYSTEM

The hydronic group comprises:

- EV Evaporator

- Pd Pressostato differenziale

- Pe Evaporator circulation pump

- SC Discharge valve

- SF Relief valve

- S1 Evaporator water inlet probe

- S2 Evaporator water outlet probe

- S3 Evaporator water common outlet probe (installed by

the customer)

- TP Drain plug

- VA Safety valve

- VR Check valve (with 2 pumps only)

16

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 21

2-pole low head pump

A

NECS-ME

1 pump

Dpu

[kPa]

Hu

[kPa]

Size

Pf (1)

[kW]

Q (1)

[m3/h]

Pump

ref.

F.L.I.

[kW]

F.L.A.

[A]

SA

[A]

KP1

0152 39.5 6.79 A 1.1 2.5 13.7 1037 185,3 136

0182 45.8 7.88 A 1.1 2.5 13.7 664 181,2 138

0202 53.6 9.22 A 1.1 2.5 13.7 481 175,7 132

0252 60.5 10.41 A 1.1 2.5 13.7 360 170,5 128

0262 67.4 11.59 A 1.1 2.5 13.7 360 164,9 111

0302 80.2 13.79 A 1.1 2.5 13.7 154 153,7 123

0352 95.8 15.96 B 1.5 3.2 20.6 108 176,22 145

0412 104.5 17.97 B 1.5 3.2 20.6 108 164,04 126

0452 117.4 20.19 C 2.2 4.8 37.3 81 204,85 166

0512 131.4 22.60 C 2.2 4.8 37.3 63 197,86 159

0552 150.7 25.92 C 2.2 4.8 37.3 43 187,36 149

0612 169.9 29.22

D 2.2 5.0 36.8 42,4 185,94 138

0604 160.8 27.66 D 2.2 5.0 36.8 43 192,53 154

0704 185.6 31.92 D 2.2 5.0 36.8 30,4 173,58 130

0804 207.4 35.67 E 3.0 6.0 38.3 30,4 184,56 142

0904 235.4 40.49 E 3.0 6.0 38.3 23,7 177,95 134

1004 263.0 45.24 E 3.0 6.0 38.3 19,2 170,15 122

1104 300.5 51.96 F 4.0 8.1 62.3 13,7 203,29 157

1204 339.2 58.34 F 4.0 8.1 62.3 13,7 190,25 131

1404 386.5 66.48 G 5.5 10.1 97.2 11,2 220,47 152

1604 431.6 74.24 H 7.5 13.7 133.3 9,9 234,87 176

(1) Values refer to rated operating conditions

Pf Cooling capacity of unit

Q Flow of water to evaporator

F.L.I. Power absorbed by pump

F.L.A. Current absorbed by pump

Dpu Total pressure drop of hydronic group

Hu Working head

SA Maximum starting current

350

300

250

200

Hp [Pa]

150

B

100

50

Coefcients for calculating pressure drops comprise standard

mains lter:

K P1 Unit with Hydronic group and one pump

* The presence of the dual (second) pump can noticeably reduce the useful head due to a different hydraulic circuit. Reduction approx. 5%.

H

G

C

D

F

E

I

0

0 20 40 60 80 100 120

Q [m3/h]

17

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 22

2-pole high head pump

NECS-ME

Size

0152 39.5 6.79 I 3.0 5.6 57.6 1037 252,5 203

0182 45.8 7.88 I 3.0 5.6 57.6 664 251,1 208

0202 53.6 9.22 I 3.0 5.6 57.6 481 249,3 205

0252 60.5 10.41 I 3.0 5.6 57.6 360 247,5 204

0262 67.4 11.59 I 3.0 5.6 57.6 360 245,5 191

0302 80.2 13.79 L 2.2 5.0 36.8 154 233,02 207

0352 95.8 15.96 L 2.2 5.0 36.8 108 228,87 203

0412 104.5 17.97 M 3.0 6.0 38.3 108 287,64 253

0452 117.4 20.19 M 3.0 6.0 38.3 81 281,16 246

0512 131.4 22.60 M 3.0 6.0 38.3 63 273,10 236

0552 150.7 25.92 M 3.0 6.0 38.3 43 260,20 223

0612 169.9 29.22 N 4.0 8.1 62.3 42,4 252,61 266

0604 160.8 27.66 M 3.0 6.0 38.3 43 312,97 214

0704 185.6 31.92 N 4.0 8.1 62.3 30,4 299,97 260

0804 207.4 35.67 N 4.0 8.1 62.3 30,4 279,83 228

0904 235.4 40.49 O 5.5 10.1 97.2 23,7 291,13 247

1004 263.0 45.24 O 5.5 10.1 97.2 19,2 281,73 235

1104 300.5 51.96 O 5.5 10.1 97.2 13,7 265,81 222

1204 339.2 58.34 P 7.5 13.7 133.3 13,7 327,27 272

1404 386.5 66.48 P 7.5 13.7 133.3 11,2 303,35 241

1604 431.6 74.24 Q 11.0 20.0 179.6 9,9 321,22 263

Pf (1)

[kW]

Q (1)

[m3/h]

Pump

ref.

F.L.I.

[kW]

F.L.A.

[A]

SA

[A]

KP1

1 pump

Dpu

[kPa]

Hu

[kPa]

(1) Values refer to rated operating conditions

Pf Cooling capacity of unit

Q Flow of water to evaporator

F.L.I. Power absorbed by pump

F.L.A. Current absorbed by pump

Dpu Total pressure drop of hydronic group

Hu Working head

SA Maximum starting current

450

400

350

300

250

Hp [kPa]

200

150

100

50

0 20 40 60 80 100 120

Coeffi cients for calculating pressure drops comprise standard

mains fi lter:

K P1 Unit with Hydronic group and one pump

* The presence of the dual (second) pump can noticeably reduce the useful head due to a different hydraulic circuit. Reduction approx. 5%.

Q

N

M

I

L

Q [m3/h]

P

O

18

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 23

6. ELECTRICAL DATA

Size n

0152 2 2x9 2x15.3 2x95 18 30.6 110

0182 2 2x10.1 2x16.4 2x111 20.2 32.8 127

0202 2 2x11.8 2x20.4 2x118 23.6 40.8 138

0252 2 2x13.2 2x22.6 2x118 26.4 45.2 141

0262 2 2x14.4 2x25.5 2x140 28.8 51 166

0302 2 2x17 2x30.5 2x173 34 61 204

0352 2 1x17+1x22.3 1x30.5+1x36.1 1x173+1x225 39.3 66.6 256

0412 2 2x22.3 2x36.1 2x225 44.6 72.2 261

0452 2 1x22.3+1x27.4 1x36.1+1x45.8 1x225+1x272 49.7 81.9 308

0512 2 2x27.4 2x45.8 2x272 54.8 91.6 318

0552 2 1x27.4+1x35.8 1x45.8+1x58.9 1x272+1x310 63.2 104.7 356

0604 4 4x17 4x30.5 4x173 68 122 265

0612 2 2x35.8 2x58.9 2x310 71.6 117.8 369

0704 4 2x17+2x22.3 2x30.5+2x36.1 2x173+2x225 78.6 133.2 322

0804 4 4x22.3 4x36.1 4x225 89 144.4 333

0904 4 2x22.3+2x27.4 2x36.1+2x45.8 2x225+2x272 99 163.8 390

1004 4 4x27.4 4x45.8 4x272 110 183.2 409

1104 4 2x27.4+2x35.8 2x45.8+2x58.9 2x272+2x310 126 209.4 461

1204 4 4x35.8 4x58.9 4x310 143 235.6 487

1404 4 2x35.8+2x46.5 2x58.9+2x73.6 2x310+2x394 164.6 265.0 585

1604 4 4x46.5 4x73.6 4x394 186 294.4 615

F.L.I.

[kW]

NECS-ME

Maximum values

Compressor Total unit (1) (2)

F.L.A.

[A]

L.R.A.

[A]

F.L.I.

[kW]

F.L.A.

[A]

S.A.

[A]

F.L.I. Full load power input at max admissible condition

F.L.A. Full load current at max admissible condition

L.R.A. Locked rotor amperes for single compressor

S.A. Starting current

(1) Values calculated referring to the version with the maxi-

mum number of fans working at the max absorbed current

(2) Safety values to be considered when cabling the unit for

power supply and line-protections

Power supply: 400/3/50

Voltage tolerance: 10%

Maximum voltage unbalance: 3%

19

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 24

7 FULL LOAD SOUND LEVEL

NECS-ME

B

SOUND POWER

SIZE

74 72 69 70 70 63 59 53

75 73 70 71 71 64 60 54

75 73 70 71 71 64 60 54

75 73 70 71 71 64 60 54

76 74 71 72 72 65 61 55

76 74 75 74 70 68 64 53

77 75 76 75 71 69 65 54

77 75 76 75 71 69 65 54

78 76 77 76 72 70 66 55

78 76 77 76 72 70 66 55

79 77 78 77 73 71 67 56

79 77 78 77 73 71 67 56

75 77 81 80 82 80 74 68

76 78 82 81 83 81 75 69

77 79 83 82 84 82 76 70

78 80 84 83 85 83 77 71

79 81 85 84 86 84 78 72

80 82 86 85 87 85 79 73

80 82 86 85 87 85 79 73

80 82 86 85 87 85 79 73

80 82 86 85 87 85 79 73

Working conditions

Plant (side) cooling exchanger water (in/out) 12/7 °C

Condensation temperature 47 °C

Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Such certification refers specifically to the sound Power Level in dB(A). This is therefore the only acoustic data to be considered as binding.

Octave band [Hz]

Sound power level dB(A)

2000100050025012563 80004000

Total sound

level

Standard unit

730152

740182

740202

740252

750262

760302

770352

770412

780452

780512

790552

790612

860604

870704

880804

890904

901004

911104

911204

911404

91

Total sound

level

With insulation

cover

69

70

70

70

71

72

73

73

74

74

75

75

76

77

78

79

80

81

81

81

811604

SOUND PRESSURE LEVEL

SIZE

43 41 38 39 39 32 28 22

44 42 39 40 40 33 29 23

44 42 39 40 40 33 29 23

44 42 39 40 40 33 29 23

45 43 40 41 41 34 30 24

44 42 43 42 38 36 32 21

45 43 44 43 39 37 33 22

45 43 44 43 39 37 33 22

46 44 45 44 40 38 34 23

46 44 45 44 40 38 34 23

47 45 46 45 41 39 35 24

47 45 46 45 41 39 35 24

43 45 49 48 50 48 42 36

44 46 50 49 51 49 43 37

45 47 51 50 52 50 44 38

46 48 52 51 53 51 45 39

47 49 53 52 54 52 46 40

48 50 54 53 55 53 47 41

48 50 54 53 55 53 47 41

48 50 54 53 55 53 47 41

48 50 54 53 55 53 47 41

Working conditions

Plant (side) cooling exchanger water (in/out) 12/7 °C

Condensation temperature 47 °C

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

Octave band [Hz] at 10 m

2000100050025012563 80004000

Sound pressure level dB(A)

Total sound

level

Standard unit

420152

430182

430202

430252

440262

440302

450352

450412

460452

460512

470552

470612

540604

550704

560804

570904

581004

591104

591204

591404

591604

ELCADOC - Ver. 1.0.0.1

NECS-ME_0152_1604_201004_GB Ref.: R410A

Page 25

8. DIMENSIONAL DRAWINGS

NECS-ME

0152-0612

WITHOUT PUMPS

LIQUID LINE CONNECTION

1

DELIVERY LINE CONNECTION

2

EVAPORATOR WATER INLET

3

EVAPORATOR WATER OUTLET

4

USE N°4 LIFTING ROPES WITH EQUAL LENGHT ONLY LIFTING

2

1

3

C1

4

C2

A

R1 R2

SUPPORTING BASEMENT

2

1

3

6

H

5

4

B

5

POWER INLET

MAIN ISOLATOR HANDLE

6

R3

Rif 0152 0182 0202 0252 0262 0302 0352 0412 0452 0512 0552 0612

1 Liquid line 16 18 22 22 22 22 22 28 28 28 28 35

2 Delivery line 22 22 28 28 28 28 35 35 35 35 35 42

3 - 4

Evaporator

(Victaulic connectors)

1” 1/2 1” 1/2 1” 1/2 1” 1/2 1” 1/2 2” 1/2 2” 1/2 2” 1/2 2” 1/2 2” 1/2 2” 1/2 2” 1/2

REMARKS:

For installation purposes, please refer to the documentation sent after the pur-

CLIMAVENETA may modify them at any moment.

chase-contract. This technical data should be considered as indicative.

A1

NECS_ME_0152_1604_201004_GB HFC R410A

Page 26

NECS-ME

0152-0612

WITH PUMPS

USE N°4 LIFTING ROPES WITH EQUAL LENGHT ONLY LIFTING

C1

3

4

C2

6

2

1

H

5

3

4

R1 R2

SUPPORTING BASEMENT

REMARKS:

For installation purposes, please refer to the documentation sent after the purchase-contract. This technical data should be considered as indicative.

A

B

LIQUID LINE CONNECTION

1

DELIVERY LINE CONNECTION

2

3

EVAPORATOR WATER INLET

R3

CLIMAVENETA may modify them at any moment.

EVAPORATOR WATER OUTLET

4

POWER INLET

5

6

MAIN ISOLATOR HANDLE

A2

NECS_ME_0152_1604_201004_GB HFC R410A

Page 27

NECS-ME

0604-1604

WITHOUT PUMPS

USE N°4 LIFTING ROPES WITH EQUAL LENGHT ONLY LIFTING

H

C1

C2

SUPPORTING BASEMENT

C3

C4

1

1

5

2

4

3

6

2

4

C4

C3

C2

3

C1

B

A

R4R3

EVAPORATOR WATER INLET

1

EVAPORATOR WATER OUTLET

2

LIQUID LINE CONNECTION

3

DELIVERY LINE CONNECTION

4

POWER INLET

5

MAIN ISOLATOR HANDLE

6

R1 R2

Rif 0604 0704 0804 0904 1004 1104 1204 1404 1604

1 Liquid line 22 22 28 28 28 28 35 35 35

2 Delivery line 28 35 35 35 35 35 42 42 42

3 - 4

Evaporator

(Victaulic connectors)

3” 3” 3” 3” 3” 4” 4” 4” 4”

REMARKS:

For installation purposes, please refer to the documentation sent after the pur-

CLIMAVENETA may modify them at any moment.

chase-contract. This technical data should be considered as indicative.

A3

NECS_ME_0152_1604_201004_GB HFC R410A

Page 28

USE N°4 LIFTING ROPES WITH EQUAL LENGHT ONLY LIFTING

H

C2

C1

C3

C4

NECS-ME

0604-1604

WITH PUMPS

1

5

2

4

3

6

2

C4

C3

1

4

C2

3

C1

R4 R3

SUPPORTING BASEMENT

R1 R2

REMARKS:

For installation purposes, please refer to the documentation sent after the purchase-contract. This technical data should be considered as indicative.

B

EVAPORATOR WATER INLET

1

EVAPORATOR WATER OUTLET

2

LIQUID LINE CONNECTION

3

DELIVERY LINE CONNECTION

4

A

POWER INLET

5

MAIN ISOLATOR HANDLE

6

CLIMAVENETA may modify them at any moment.

A4

NECS_ME_0152_1604_201004_GB HFC R410A

Page 29

NECS-ME

DIMENSIONS AND WEIGHTS

Size

A [mm] B [mm] H [mm] P [kg] A [mm] B [mm] H [mm] P [kg] A [mm] B [mm] H [mm] P [kg] R1 [mm] R2 [mm] R3 [mm] R4 [mm]

0152 1130 669 1255 270 1673 669 1255 385 1673 669 1255 420 600 600 800 -

0182 1130 669 1255 280 1673 669 1255 395 1673 669 1255 430 600 600 800 -

0202 1130 669 1255 290 1673 669 1255 405 1673 669 1255 440 600 600 800 -

0252 1130 669 1255 295 1673 669 1255 405 1673 669 1255 440 600 600 800 -

0262 1130 669 1255 300 1673 669 1255 415 1673 669 1255 450 600 600 800 -

0302 1310 893 1496 410 1980 893 1496 590 1980 893 1496 635 600 600 800 -

0352 1310 893 1496 500 1980 893 1496 680 1980

0412 1310 893 1496 585 1980 893 1496 770 1980 893 1496 815 600 600 800 -

0452 1310 893 1496 615 1980 893 1496 800 1980 893 1496 850 600 600 800 -

0512 1310 893 1496 645 1980 893 1496 830 1980 893 1496 880 600 600 800 -

0552 1310 893 1496 680 1980 893 1496 865 1980 893 1496 915 600 600 800 -

0604 2227 1020 1780 700 2227 1140 1780 840 2227 1140 1780 925 800 800 1000 1000

0612 1310 893 1496 755 1980 893 1496 895 1980 893 1496 945 600 600 800 -

0704 2227 1020 1780 950 2227 1140 1780 1040 2227 1140 1780 1135 800 800 1000 1000

0804 2227 1020 1780 1125 2227 1140 1780

0904 2227 1020 1780 1185 2227 1140 1780 1305 2227 1140 1780 1425 800 800 1000 1000

1004 2227 1020 1780 1250 2227 1140 1780 1370 2227 1140 1780 1490 800 800 1000 1000

1104 2227 1020 1780 1330 2227 1140 1780 1460 2227 1140 1780 1595 800 800 1000 1000

1204 2227 1020 1780 1370 2227 1140 1780 1505 2227 1140 1780 1645 800 800 1000 1000

1404 2227 1020 1780 1430 2227 1140 1780 1565 2227 1140 1780 1705 800 800 1000 1000

1604 2227 1020 1780 1480 2227 1140 1780 1645 2227 1140 1780 1820 800 800 1000 1000

NO PUMPS ONE PUMP TWO PUMPS

893 1496 725 600 600 800 -

1215 2227 1140 1780 1305 800 800 1000 1000

CLEARANCE (See fol. page)

A5

NECS_ME_0152_1604_200911_GB HFC R410A

Page 30

9. LEGEND OF PIPE CONNECTIONS

NECS-ME

UNI ISO 228/1

Pipe threads where pressure-tight joints are not made on the

threads - Designation, dimensions and tolerances

Used terminology:

G: Pipe threads where pressure-tight joints are not made on the

threads

A: Close tolerance class for external pipe threads where pres-

sure-tight joints are not made on the threads

B: Wider tolerance class for external pipe threads where pres-

sure-tight joints are not made on the threads

Internal threads: G letter followed by thread mark (only toler-

ance class)

External threads: G letter followed by thread mark and by A let-

ter for A class external threads or by B letter

for B class external threads.

Designation Description

Internal cylindrical threads where pressure-tight joints are made on the threads, dened by stand-

UNI ISO 7/1 - Rp 1 1/2

UNI ISO 7/1 - Rp 2 1/2

UNI ISO 7/1 - Rp 3

UNI ISO 7/1 - R 3

UNI ISO 228/1 - G 4 B

DN 80 PN 16

ard UNI ISO 7/1

Conventional ø 1 1/2”

Internal cylindrical threads where pressure-tight joints are made on the threads, dened by standard UNI ISO 7/1

Conventional ø 2 1/2”

Internal cylindrical threads where pressure-tight joints are made on the threads, dened by standard UNI ISO 7/1

Conventional ø 3”

External conical threads where pressure-tight joints are made on the threads, dened by standard

UNI ISO 7/1

Conventional ø 3”

Internal cylindrical threads where pressure-tight joints are not made on the threads, dened by

standard UNI ISO 228/1

Tolerance class B for external thread

Conventional ø 4”

Flange Nominal Diameter: 80 mm

Nominal Pressure: 16 bar

UNI ISO 7/1

Pipe threads where pressure-tight joints are made on the

threads - Designation, dimensions and tolerances

Used terminology:

Rp: Internal cylindrical threads where pressure-tight joints are

made on the threads

Rc: Internal conical threads where pressure-tight joints are

made on the threads

R: External conical threads where pressure-tight joints are

made on the threads

Internal cylindrical threads: R letter followed by p letter

Internal conical threads: R letter followed by c letter

External conical threads: R letter

Notes:

Conventional diameter value [in inches] identies short thread

designation, based upon the relative standard.

All relative values are dened by standards.

As example, here below some values:

UNI ISO 7/1 UNI ISO 228/1

Conventional ø 1” 1”

Pitch 2.309 mm 2.309 mm

External ø 33.249 mm 33.249 mm

Core ø 30.291 mm 30.291 mm

Thread height 1.479 mm 1.479 mm

A6

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 31

10. REMOTE CONDENSERS

NECS-ME

The new Climaveneta’s remote condensers NCE type are

available within three different acoustical versions:

standard version /B•

low-noise version /LN•

super-silenced version /SL•

All versions are available for both horizontal (H) and vertical (V)

air fl ow installation.

The NCE remote condensers are provided with a single ventilation management. The choice of the number of circuits affects

the refrigerant connections and / or the quantity of electrical

signals provided to the fans speed management, according to

the selected version.

Standard version (/B)

Unit equipped with 6 poles motor fan and D connections (Delta).

Fan speed management based on phase cutoff control is available as option. In this confi guration the units comes standard

with a built-in electrical board.

Low-noise version (/LN)

Unit equipped with 6 poles motor fan and Y connections

(Star).

Fan speed management based on phase cutoff control is available as option. In this confi guration the units comes standard

10.2 Product code

with a built-in electrical board.

Super-silenced Version SUPER-SILENZIATA (/SL)

Unit equipped with 8 poles motor fan and Y connections

(Star).

Fan speed management based on frequency control is available as option (inverter). In this confi guration the units comes

standard with a built-in the electrical board.

10.1 Electrical board

The NCE remote condensers come standard without any electrical board. The NCE are provided with a junction box which

includes the electrical connections of the fans.

The electrical board is provided as standard with all the fans

speed management options (phase cutoff signal and inverter

control), provided with all here below listed components:

main switch•

fuses on mains•

system on/off light signalling•

power contactor for fans on/off •

control circuit transformer•

protection fuses on both primary and secondary circuits •

auxiliary relay for thermal protection remote signalling.•

NCE 3 2 8 C /B - H 1C E R A

NCE

3

2

8

C

/B

H

Remote condensers type:

NCE = for NECS-ME units working with R410A refrigerant

Number of fans per row

Number of fan rows

Diameter of fans:

6 = 630 mm

8 = 800 mm

Number of coil rows:

2 rows = A

3 rows = B

4 rows = C

Noise level:

/B = standard version

/LN = quiet version

/SL = super-silenced version

Air fl ow:

H = horizontal

V = vertical

R

A

Fan speed management:

R = phase cutoff control (/B and /LN version)

Z = inverter control (/SL version only)

Anti-vibration mountings

Note:

Values indicated into outlined cells may not be included

1C

E

Number of refrigerant circuits:

1C

2C

Electrical connections:

E = junction box

Q = with built-in electrical board (standard with fan each

speed management)

B1

NECS_ME_0152_1604_201004_GB

HFC R410A

Page 32

11. COMBINATIONS OF EVAPORATING UNITS

AND REMOTE CONDENSERS

REMOTE CONDENSER BASIC VERSION

NECS-ME

Model of remote

condenser

NCE118A/B 55 11.7 21200 81 1880 1370 800 1565 28 22 145

NCE118A/B 55 13.7 21200 81 1880 1370 800 1565 28 22 145

NCE118B/B 68 15.8 19600 81 1880 1370 800 1565 35 22 157

NCE118C/B 75 18.3 18400 81 1880 1370 800 1565 35 22 168

NCE118C/B 75 20.9 18400 81 1880 1370 800 1565 35 22 168

NCE218A/B 110 23.0 42400 84 3230 1370 800 1565 42 28 279

NCE218A/B 110 27.4 42400 84 3230 1370 800 1565 42 28 279

NCE218B/B 135 30.1 39200 84 3230 1370 800 1565 42 35 302

NCE218C/B 150 33.9 36800 84 3230 1370 800 1565 42 35 324

NCE318A/B 160 38.0 63600 86 4580 1370 800 1565 42 35 413

NCE318B/B 197 42.9 58800 86 4580 1370 800 1565 54 42 447

NCE318C/B 228 48.1 55200 86 4580 1370 800 1565 54 42 481

NCE318B/B 197 47.3 58800 86 4580 1370 800 1565 54 42 447

NCE318C/B 228 54.4 58800 86 4580 1370 800 1565 54 42 481

NCE418B/B 270 60.2 78400 87 5930 1370 800 1565 64 42 592

NCE418C/B 300 67.9 73600 87 5930 1370 800 1565 64 42 637

NCE328A/B 301 77.6 123600 89 4580 2390 800 1565 2x42 2x35 680

NCE328B/B 389 87.6 114000 89 4580 2390 800 1565 2x54 2x42 742

NCE328C/B 430 97.8 106200 89 4580 2390 800 1565 2x54 2x42 804

NCE428B/B 511 109.6 152000 90 5930 2390 800 1565 2x54 2x35 982

NCE428C/B 566 122.7 141600 90 5930 2390 800 1565 2x54 2x42 1065

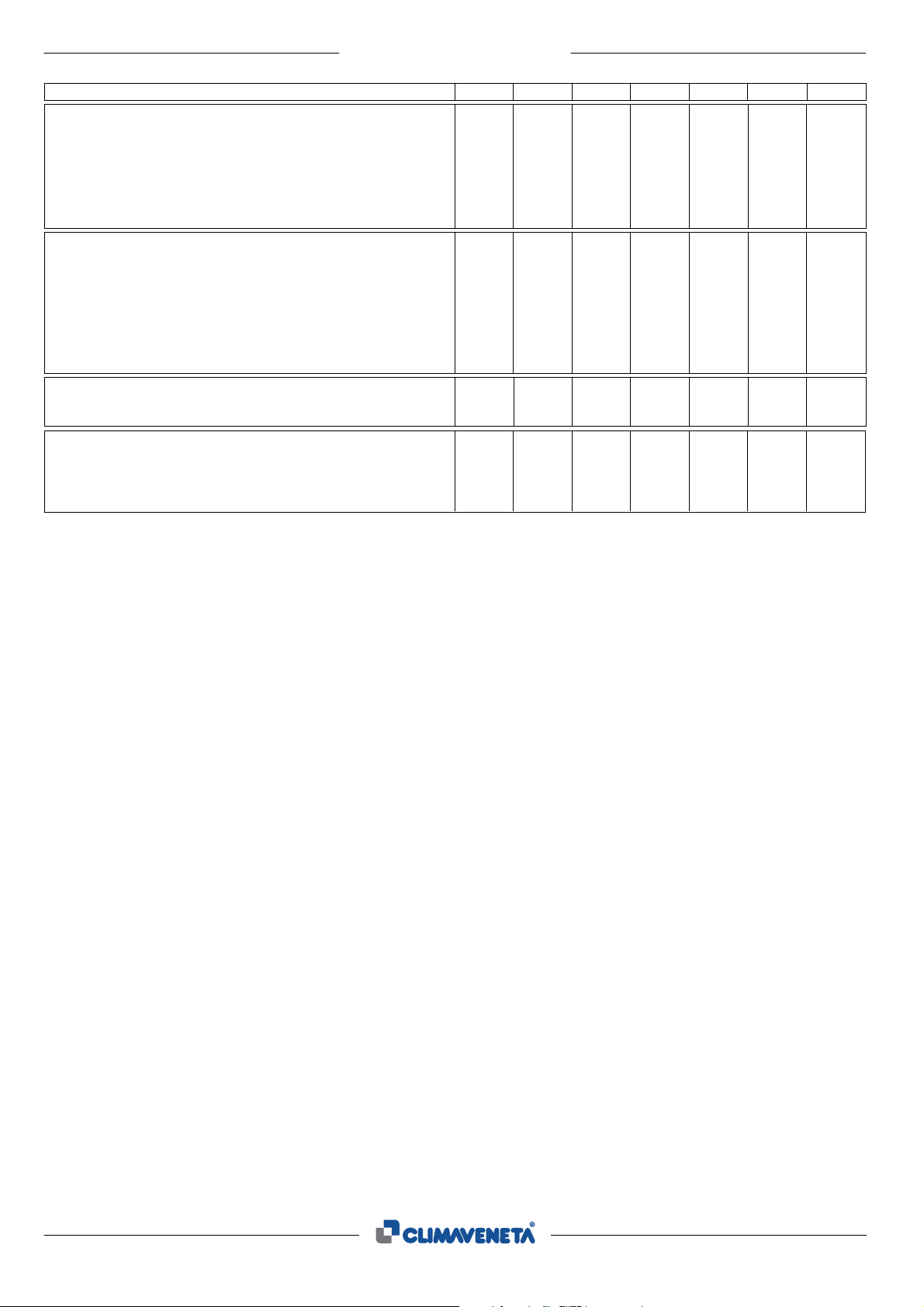

Pt (1)

[kW]

Pa

[kW]

Q

[m³/h]

Lw

[dB(A)]

L

[mm]

H

[mm]

P

[mm]

R