Mitsubishi MXZ-2D33VA-E2, MXZ-2D33VA-ET2, MXZ-2D33VA-E3, MXZ-2D33VA-ER3, MXZ-2D33VA-ET3 Service Manual

...

MXZ-2D33VA

MXZ-2D40VA

MXZ-2D42VA

MXZ-2D53VA MXZ-2D53VAH

Models

MXZ-2D33VA

-

E1, E2, E3, ER2, ER3, ET2, ET3

MXZ-2D40VA

-

E1, ER2

MXZ-2D42VA

-

E2, E3, ER3, ET2, ET3

MXZ-2D53VA

-

E1, E2, E3, ER2, ER3, ET2, ET3

MXZ-2D53VAH

-

E1, E2, E3, ER2, ER3

MXZ-3D54VA

-

E1

MXZ-3D54VA2

-

E2, E3, ER2, ER3, ET2, ET3

MXZ-3D68VA

-

E1, E2, E3, ER2, ER3, ET2, ET3

MXZ-4D72VA

-

E1, E2, E3, ER2, ER3, ET2, ET3

MXZ-4D83VA

-

E1, E2, ER1, ER2, ET2

MXZ-5D102VA

-

E1, E2, ER1, ER2, ET2

MXZ-6D122VA

-

E1, ER1, ET1

SERVICE MANUAL

OUTDOOR UNIT

CONTENTS

1. TECHNICAL CHANGES ··································· 2

2. PART NAMES AND FUNCTIONS ····················· 6

3. SPECIFICATION ················································ 7

4. NOISE CRITERIA CURVES ···························· 17

5. OUTLINES AND DIMENSIONS ······················ 20

6. WIRING DIAGRAM ·········································· 25

7. REFRIGERANT SYSTEM DIAGRAM ············· 71

8. PERFORMANCE CURVES ····························· 81

9. ACTUATOR CONTROL ··································115

10. SERVICE FUNCTIONS ···································116

11. TROUBLESHOOTING ··································· 122

12. DISASSEMBLY INSTRUCTIONS ·················· 161

INDOOR UNITS COMBINATION SHEETS

No. OBH626

REVISED EDITION-H

HFC

utilized

R410A

PARTS CATALOG (OBB626)

Please void OBH626 REVISED EDITION-G.

Revision H:

• MXZ-6D122VA- E1,

ER1, ET1

have been added.

NOTE:

RoHS compliant products have <G> mark

on the spec name plate.

Indoor unit service manual

MSZ-EF•VE Series (OBH589)

MSZ-GF•VE Series (OBH634)

MSZ-SF•VA Series (OBH555)

MSZ-SF•VE Series (OBH600)

MSZ-FH•VE Series (OBH623)

MFZ-KA•VA Series (OB409)

MFZ-KJ•VE Series (OBH666)

MLZ-KA•VA Series (OBH483)

SLZ-KA•VA Series (OC320)

SEZ-KD•VA Series (HWE07110)

PLA-RP•BA Series (OCH412)

PCA-RP•KA Series (OCH454)

PEAD-RP•JA Series (HWE08130)

2

<Preparation before the repair service>

Prepare the proper tools.

Prepare the proper protectors.

Provide adequate ventilation.

After stopping the operation of the air conditioner, turn off the power-supply breaker and remove the power plug.

Discharge the capacitor before the work involving the electric parts.

<Precautions during the repair service>

Do not perform the work involving the electric parts with wet hands.

Do not pour water into the electric parts.

Do not touch the refrigerant.

Do not touch the hot or cold areas in the refrigeration cycle.

When the repair or the inspection of the circuit needs to be done without turning off the power, exercise great caution not to

touch the live parts.

Use the specifi ed refrigerant only

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

Revision A:

• MXZ-3D54VA- E1, MXZ-3D68VA- E1, MXZ-4D72VA- E1, MXZ-4D83VA- E1 and MXZ-5D102VA- E1 have been added.

Revision B:

• INDOOR UNITS COMBINATION SHEETS for MXZ-3D54VA, MXZ-3D68VA, MXZ-4D72VA, MXZ-4D83VA and MXZ5D102VA have been added.

• 11-4. TROUBLESHOOTING CHECK TABLE (MXZ-2D) has been modified.

Revision C:

• MXZ-4D83VA-

ER1

and MXZ-5D102VA-

ER1

have been added.

Revision D:

• MXZ-2D40VA

-

ER2

,

MXZ-2D42VA

- E2, MXZ-2D53VAH

- E2,

ER2

, MXZ-3D54VA2

- E2,

ER2

and MXZ-2D33/2D53/3D68/4

D72/4D83/5D102VA

- E2,

ER2

have been added.

Revision E:

• The tables of WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT for MXZ-2D33/2D53/3D68/4D72VA- E2,

ER2

,

MXZ-2D42VA-

E2

, MXZ-2D53VAH- E2,

ER2

and MXZ-3D54VA2- E2,

ER2

have been added to 7. REFRIGERANT

SYSTEM DIAGRAM.

Revision F:

• MXZ-2D33/2D42/2D53/3D68/4D72/4D83/5D102VA

-

ET2

and MXZ-3D54VA2

-

ET2

have been added.

Revision H:

• MXZ-6D122VA- E1,

ER1, ET1

have been added.

Revision G:

• MXZ-2D33/2D42/2D53VA- E3,

ER3,ET3

, MXZ-2D53VAH- E3,

ER3

, MXZ-3D54VA2- E3,

ER3, ET3

and

MXZ-3D68/4D72VA-

E3, ER3,ET3

have been added.

MXZ-2C30VA -

E1

MXZ-2D33VA -

E1

1. Grill has been changed.

2. Ice guard has been added.

3. Electrical parts have been changed.

4. Fan motor has been changed.

5. Indoor units combinations have been added.

6. Compressor has been changed. (KNB073FGDHC

KNB073FFDHC)

TECHNICAL CHANGES

1

OBH626H

3

MXZ-2C40VA -

E1

MXZ-2D40VA -

E1

MXZ-2C52VA -

E1

MXZ-2D53VA -

E1

1. Grill has been changed.

2. Ice guard has been added.

3. Electrical parts have been changed.

4. Fan motor has been changed.

5. Indoor units combinations have been added.

MXZ-2C52VA -

E1

MXZ-2D53VAH -

E1

1. Grille has been changed.

2. Ice guard has been added.

3. Electrical parts have been changed.

4. Fan motor has been changed.

5. Indoor units combinations have been added.

6. Base heater has been added.

7. Drain socket has been removed.

MXZ-3C54VA -

E1

MXZ-3D54VA -

E1

MXZ-3C68VA -

E1

MXZ-3D68VA -

E1

MXZ-4C71VA -

E1

MXZ-4D72VA -

E1

1. Grille has been changed.

2. Ice guard has been added.

3. Power board has been changed.

4. Electrical control P.C. board has been changed.

5. Noise filter P.C. board has been changed.

6. Fan motor has been changed.

7. Indoor units combinations have been added (MSZ-FH Series).

MXZ-4C80VA2 -

E1

MXZ-4D83VA -

E1

MXZ-5C100VA2 -

E1

MXZ-5D102VA -

E1

1. Indoor units combinations have been added (MSZ-FH Series).

MXZ-4D83VA -

ER1

MXZ-5D102VA -

ER1

1. New model

MXZ-2D33VA -

E1

MXZ-2D33VA -

E2

MXZ-2D53VA -

E1

MXZ-2D42VA -

E2

MXZ-2D53VA -

E1

MXZ-2D53VA -

E2

MXZ-2D53VAH -

E1

MXZ-2D53VAH -

E2

MXZ-3D54VA -

E1

MXZ-3D54VA2 -

E2

MXZ-3D68VA -

E1

MXZ-3D68VA -

E2

MXZ-4D72VA -

E1

MXZ-4D72VA -

E2

MXZ-4D83VA -

E1

MXZ-4D83VA -

E2

MXZ-5D102VA -

E1

MXZ-5D102VA -

E2

1. Indoor units combinations have been added (MFZ-KJ Series).

MXZ-4D83VA -

ER1

MXZ-4D83VA -

ER2

MXZ-5D102VA -

ER1

MXZ-5D102VA -

ER2

1. Indoor units combinations have been added (MFZ-KJ Series).

MXZ-2D33VA -

ER2

MXZ-2D53VA -

ER2

MXZ-2D53VAH -

ER2

MXZ-3D54VA2 -

ER2

MXZ-3D68VA -

ER2

MXZ-4D72VA -

ER2

1. New model

2. Indoor units combinations have been added (MFZ-KJ Series).

OBH626H

4

MXZ-2D40VA -

ER2

1. New model

MXZ-2D33VA -

ET2

MXZ-2D42VA -

ET2

MXZ-2D53VA -

ET2

MXZ-3D54VA2 -

ET2

MXZ-3D68VA -

ET2

MXZ-4D72VA -

ET2

MXZ-4D83VA -

ET2

MXZ-5D102VA -

ET2

1. New model

MXZ-2D33VA -

E2

MXZ-2D33VA -

E3

MXZ-2D42VA -

E2

MXZ-2D42VA -

E3

MXZ-2D53VA -

E2

MXZ-2D53VA -

E3

MXZ-2D53VAH -

E2

MXZ-2D53VAH -

E3

1. Inverter P.C. board has been changed.

2. Fuse has been added.

MXZ-2D33VA -

ER2

MXZ-2D33VA -

ER3

MXZ-2D53VA -

ER2

MXZ-2D53VA -

ER3

MXZ-2D53VAH -

ER2

MXZ-2D53VAH -

ER3

1. Inverter P.C. board has been changed.

2. Fuse has been added.

MXZ-2D33VA -

ET2

MXZ-2D33VA -

ET3

MXZ-2D42VA -

ET2

MXZ-2D42VA -

ET3

MXZ-2D53VA -

ET2

MXZ-2D53VA -

ET3

1. Inverter P.C. board has been changed.

2. Fuse has been added.

MXZ-2D42VA -

ER3

1. New model

MXZ-3D54VA2 -

E2

MXZ-3D54VA2 -

E3

1. High pressure switch has been added.

2. Outdoor control P.C. board has been changed.

MXZ-3D68VA -

E2

MXZ-3D68VA -

E3

MXZ-4D72VA -

E2

MXZ-4D72VA -

E3

1. Outdoor control P.C. board has been changed.

2. High pressure switch has been changed.

MXZ-3D54VA2 -

ER2

MXZ-3D54VA2 -

ER3

1. High pressure switch has been added.

2. Outdoor control P.C. board has been changed.

MXZ-3D68VA -

ER2

MXZ-3D68VA -

ER3

MXZ-4D72VA -

ER2

MXZ-4D72VA -

ER3

1. Outdoor control P.C. board has been changed.

2. High pressure switch has been changed.

MXZ-3D54VA2 -

ET2

MXZ-3D54VA2 -

ET3

1. High pressure switch has been added.

2. Outdoor control P.C. board has been changed.

OBH626H

5

MXZ-3D68VA -

E2

MXZ-3D68VA -

E3

MXZ-4D72VA -

E2

MXZ-4D72VA -

E3

1. Outdoor control P.C. board has been changed.

2. High pressure switch has been changed.

MXZ-3D54VA2 -

ER2

MXZ-3D54VA2 -

ER3

1. High pressure switch has been added.

2. Outdoor control P.C. board has been changed.

MXZ-3D68VA -

ER2

MXZ-3D68VA -

ER3

MXZ-4D72VA -

ER2

MXZ-4D72VA -

ER3

1. Outdoor control P.C. board has been changed.

2. High pressure switch has been changed.

MXZ-3D54VA2 -

ET2

MXZ-3D54VA2 -

ET3

1. High pressure switch has been added.

2. Outdoor control P.C. board has been changed.

MXZ-3D68VA -

ET2

MXZ-3D68VA -

ET3

MXZ-4D72VA -

ET2

MXZ-4D72VA -

ET3

1. Outdoor control P.C. board has been changed.

2. High pressure switch has been changed.

MXZ-6D122VA -

E1

MXZ-6D122VA -

ER1

MXZ-6D122VA -

ET1

1. New model

OBH626H

6

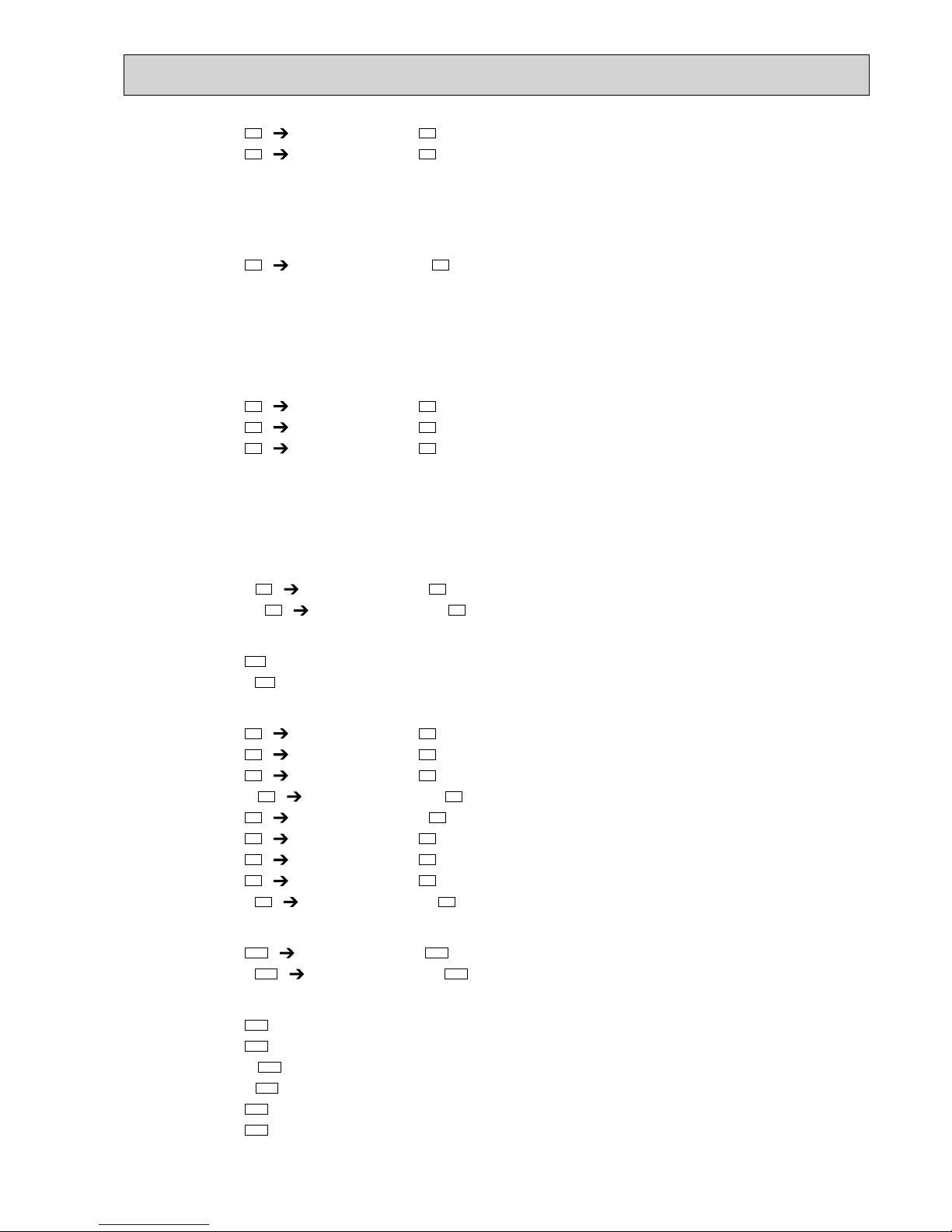

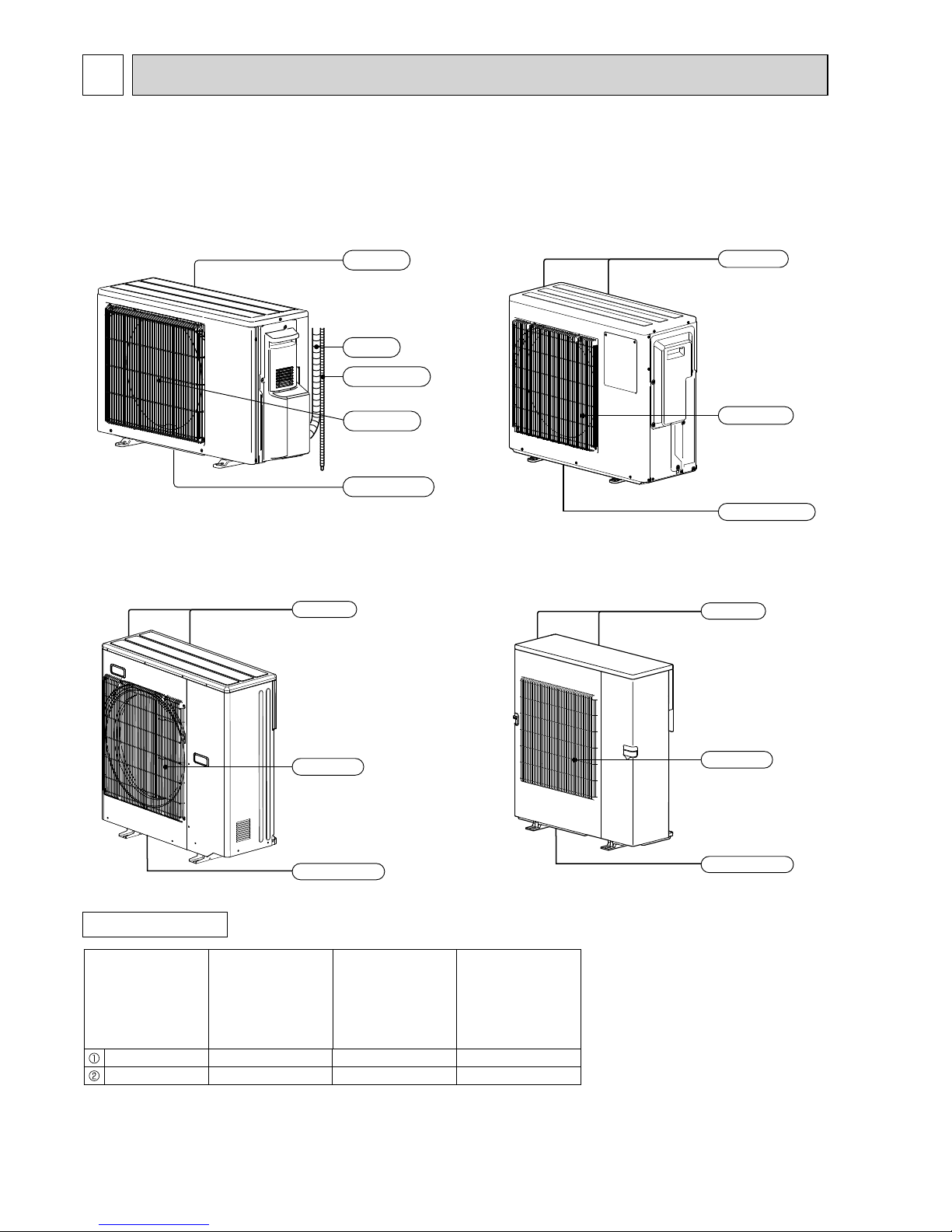

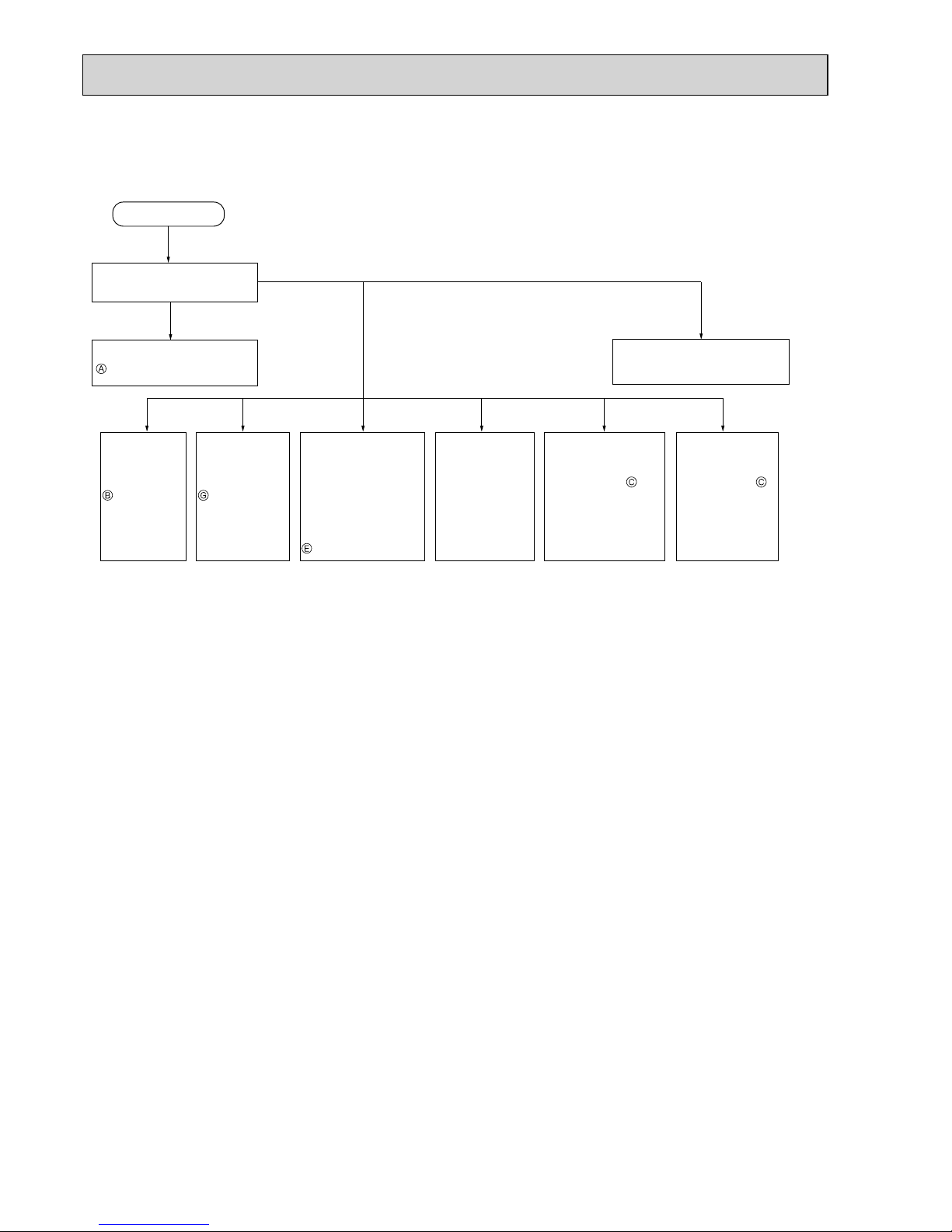

PART NAMES AND FUNCTIONS

2

ACCESSORIES

MXZ-2D33VA

MXZ-2D40VA

MXZ-2D42VA

MXZ-2D53VA

MXZ-2D53VAH

Air inlet

Air outlet

Drain outlet

Piping

Drain hose

(Back and side)

Model

MXZ-2D33VA

MXZ-2D40VA

MXZ-2D42VA

MXZ-2D53VA

MXZ-4D83VA

MXZ-5D102VA

MXZ-3D54VA

MXZ-3D54VA2

MXZ-3D68VA

MXZ-4D72VA

MXZ-6D122VA

Drain socket 1 1 1

Drain cap 2 5

Air outlet

Drain outlet

Air inlet

(Back and side)

MXZ-3D54VA

MXZ-3D54VA2

MXZ-3D68VA

MXZ-4D72VA

MXZ-4D83VA

MXZ-5D102VA

MXZ-6D122VA

Air outlet

Drain outlet

Air inlet

(Back and side)

Air outlet

Drain outlet

Air inlet

(Back and side)

OBH626H

7

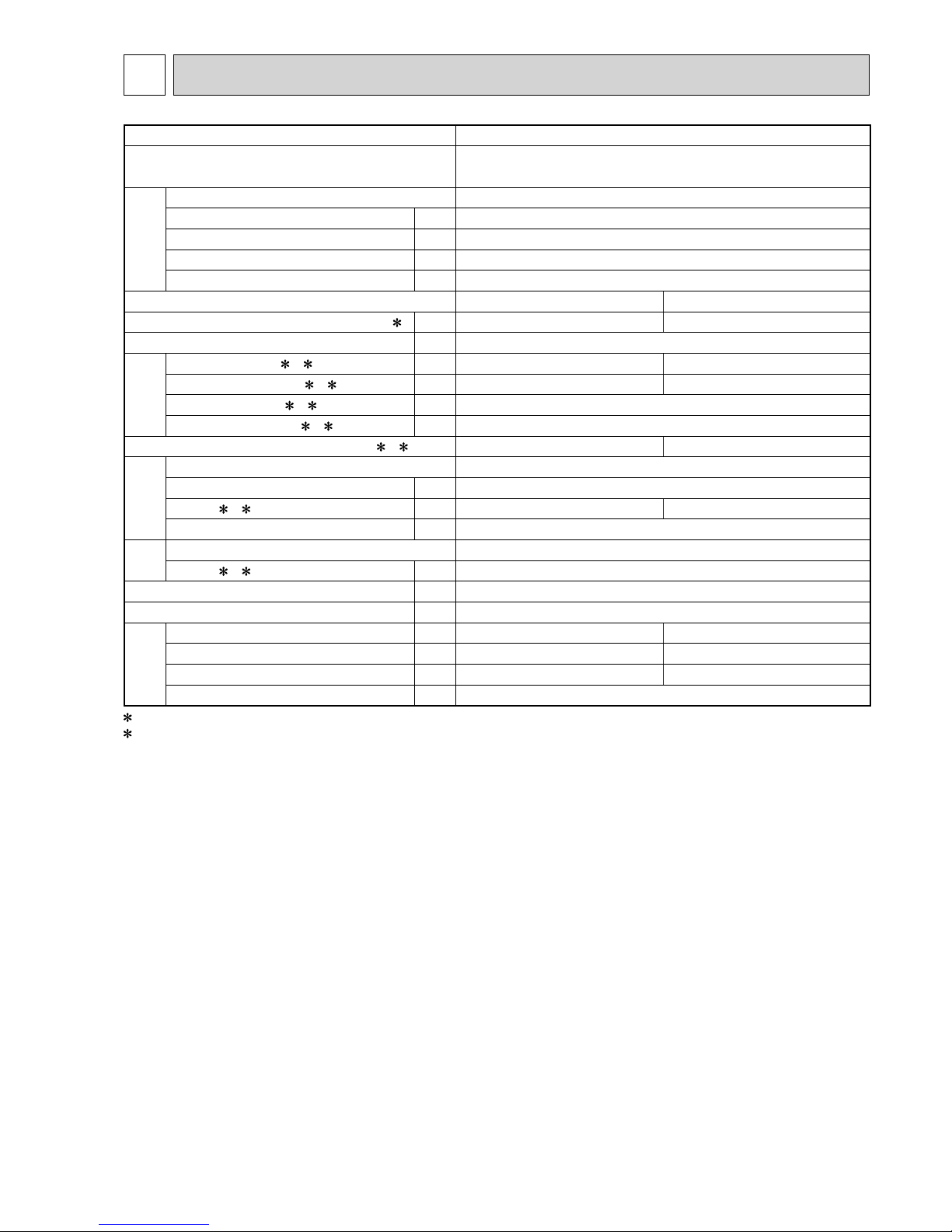

SPECIFICATION

3

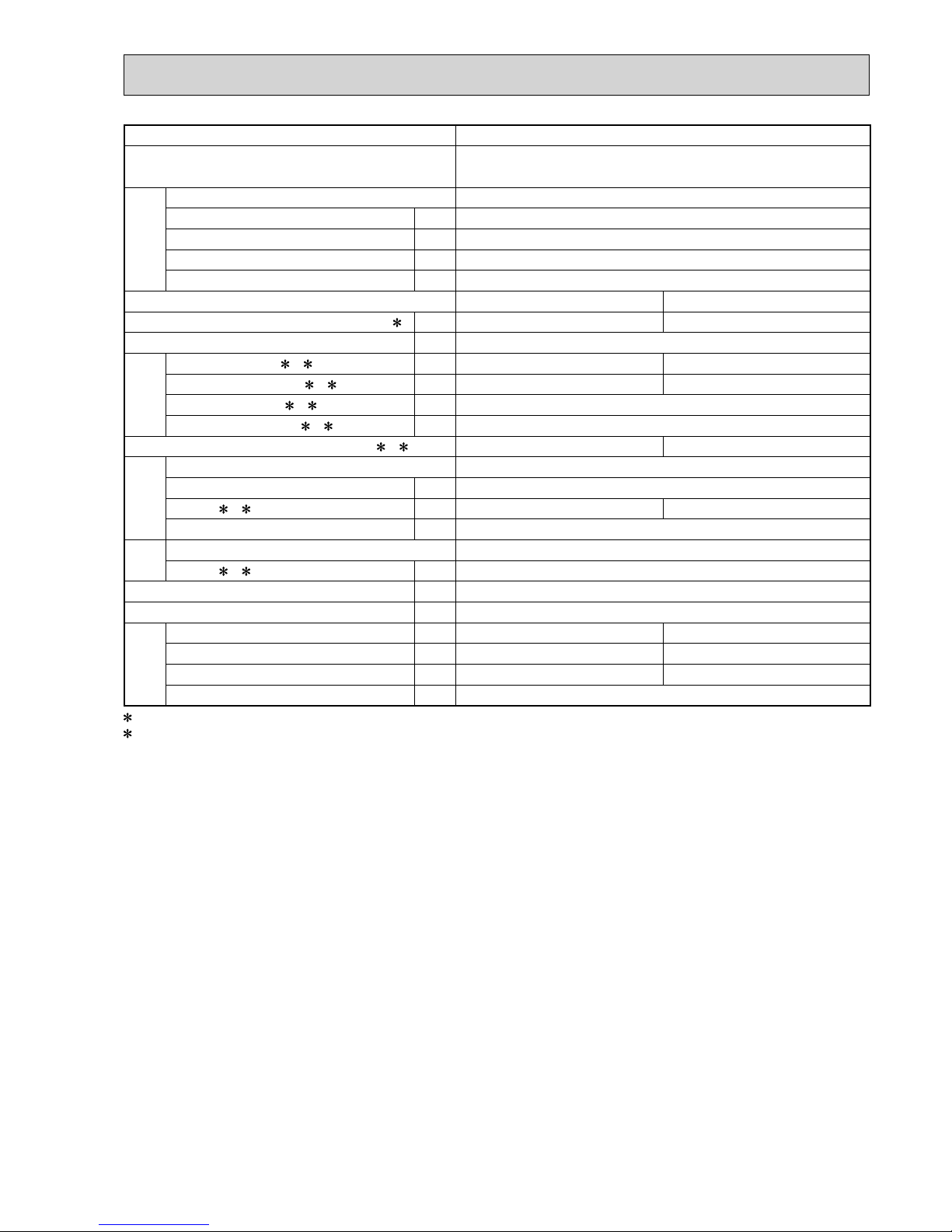

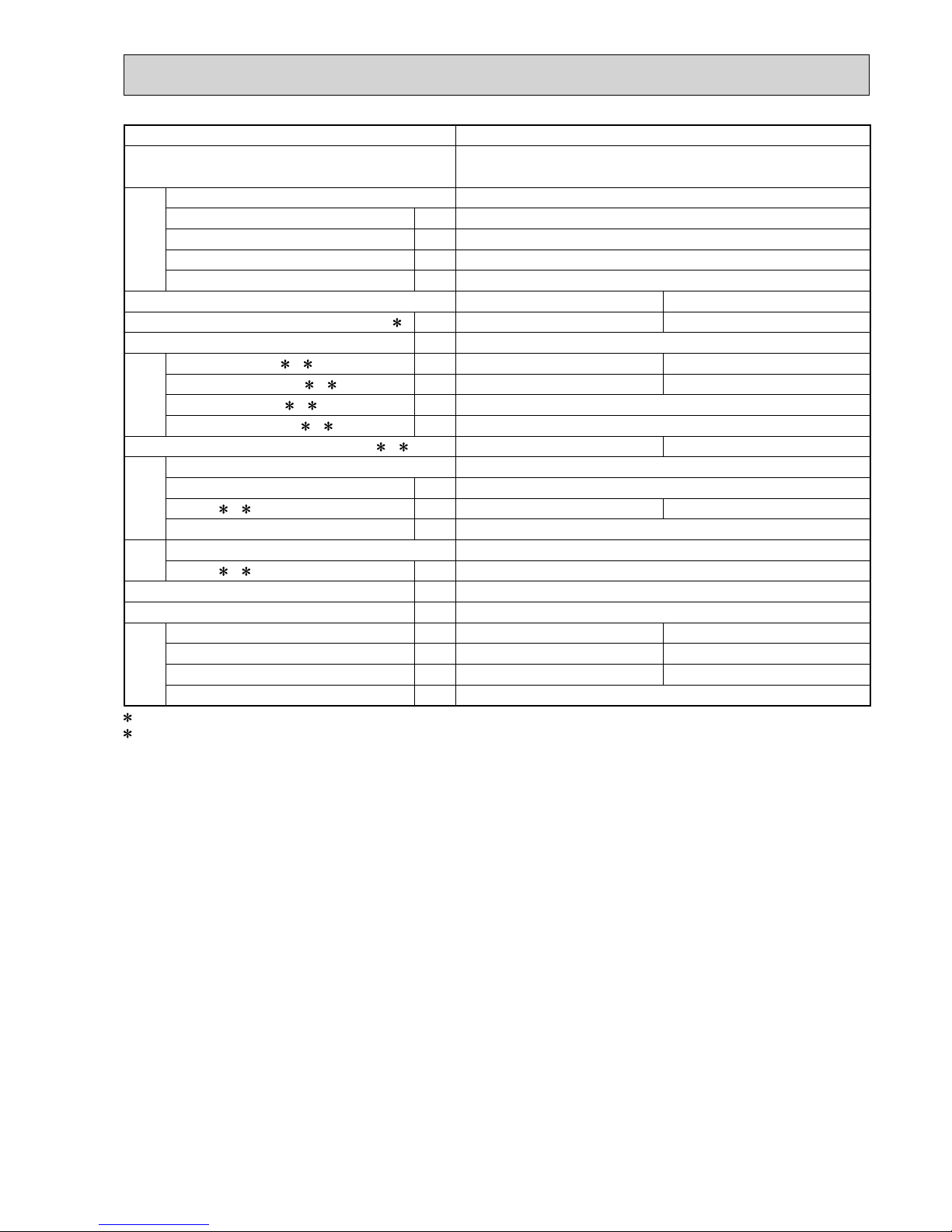

Outdoor model MXZ-2D33VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 20

Connecting pipe length m Max. 15

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 3.3 (1.1 - 3.8) 4.0 (1.0 - 4.1)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 900 960

Running current (Total)

1, 2 A 4.3 4.6

Power factor (Total)

1, 2% 90

Starting current (Total)

1, 2 A 4.6

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.67 4.17

Compressor

Model KNB073FFDHC

Output W 800

Current

1, 2 A 4.0 4.2

Refrigeration oil (Model) L 0.32 (NEO22)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg 32

Special

remarks

Air fl ow (Rated) m3 /h 1,974 2,022

Sound level (Rated) dB(A) 49 50

Fan speed (Rated) rpm 860 880

Refrigerant fi lling capacity (R410A) kg 1.15

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-SF15VA + MSZ-EF18VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

8

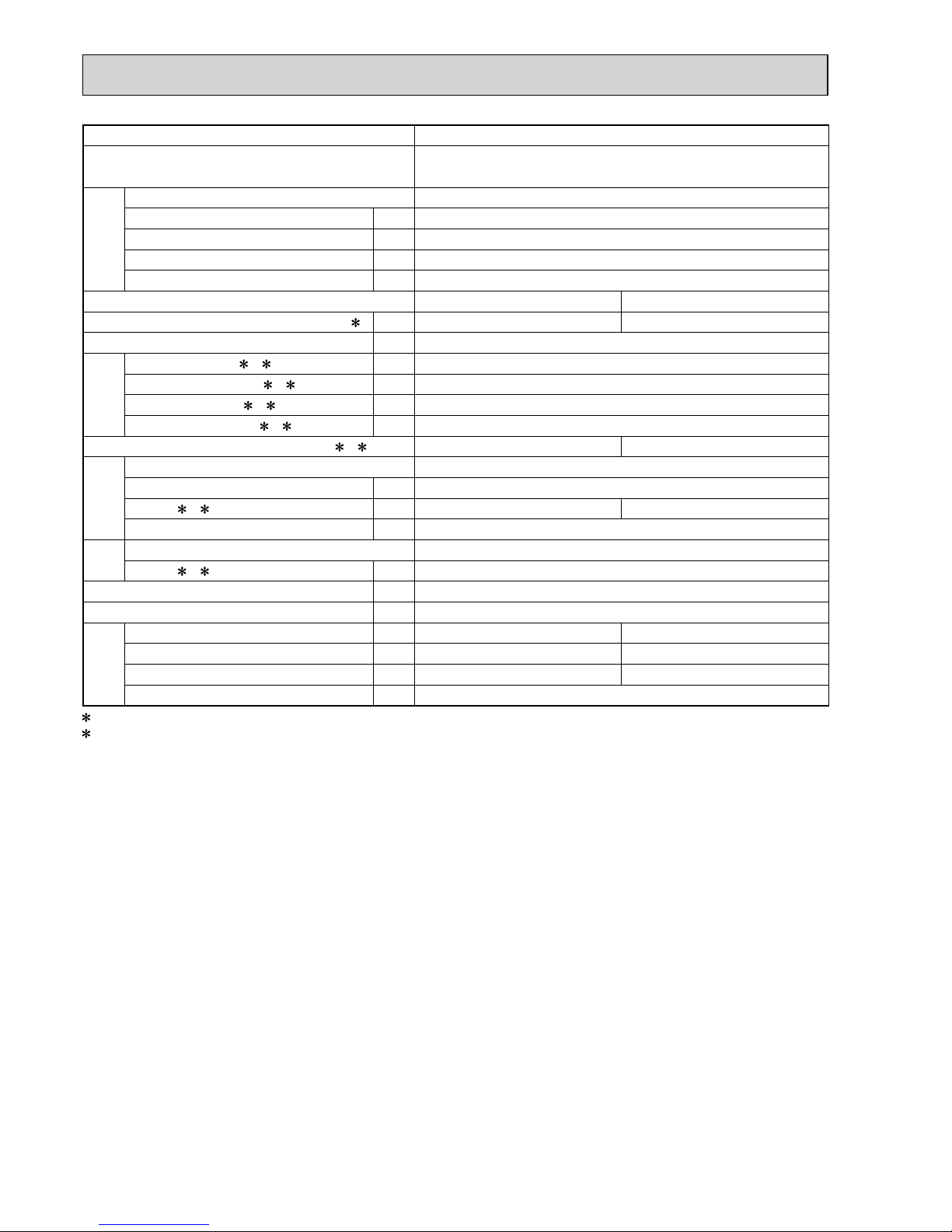

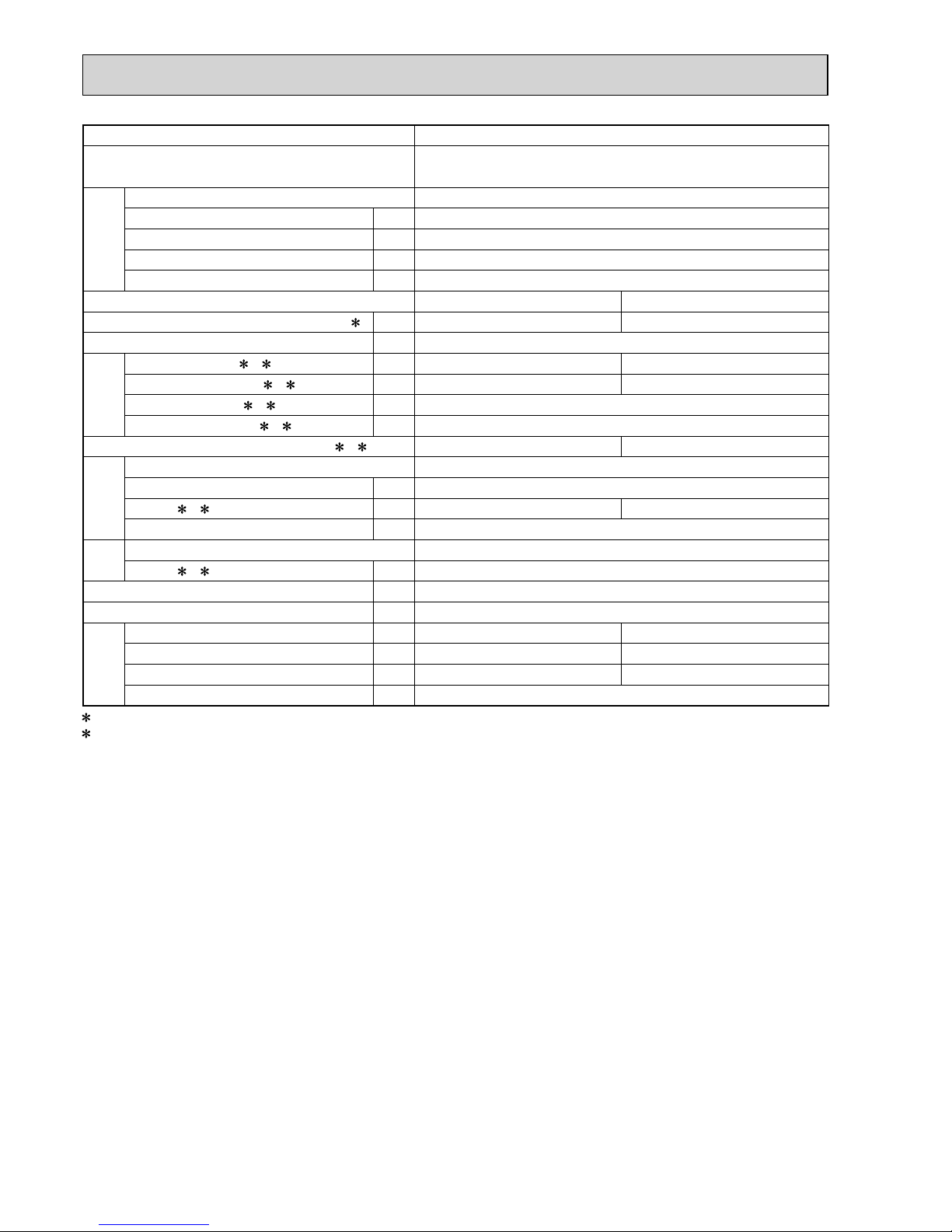

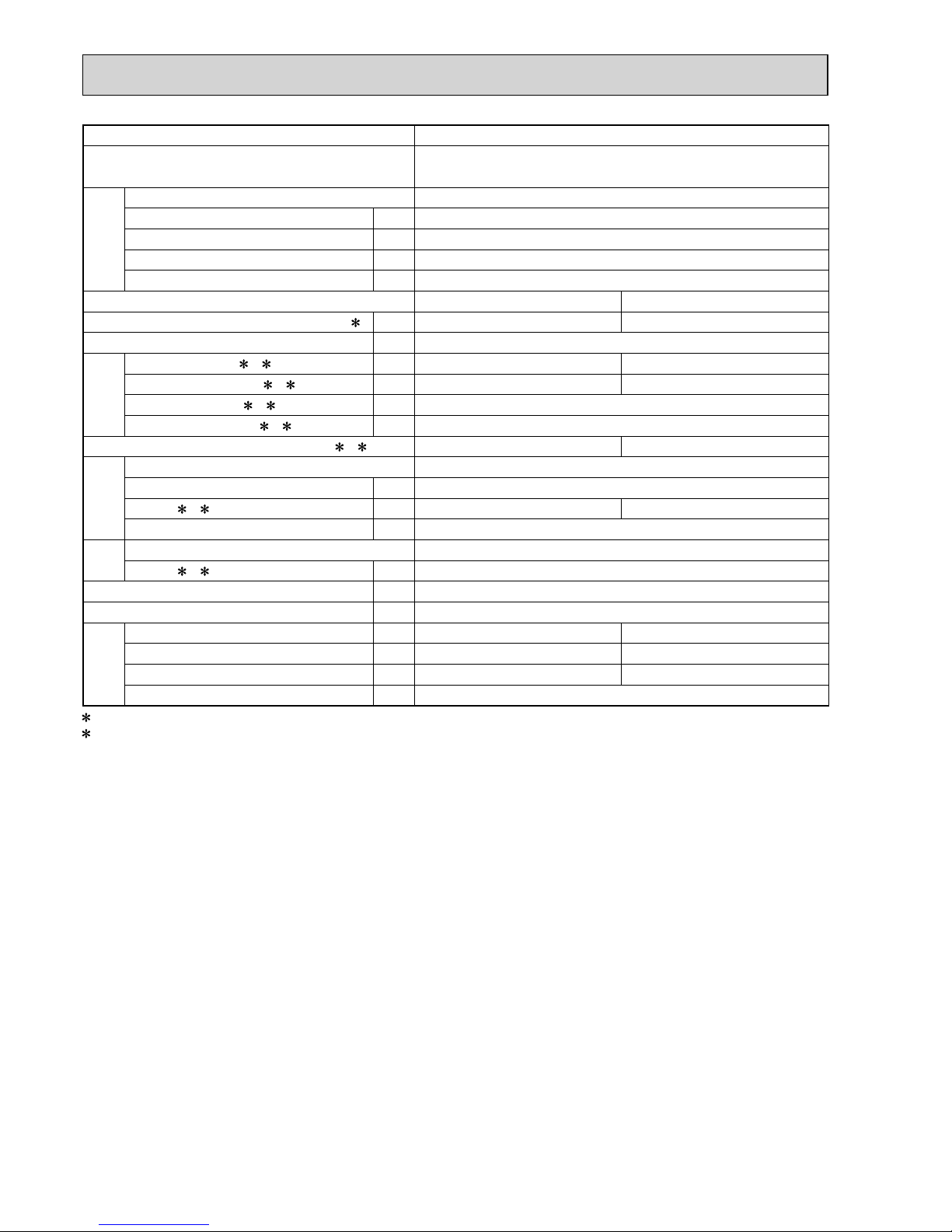

Outdoor model MXZ-2D40VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 30

Connecting pipe length m Max. 20

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 4.0 (1.1 - 4.3) 4.5 (1.0 - 4.8)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 970

Running current (Total)

1, 2 A 4.7

Power factor (Total)

1, 2% 90

Starting current (Total)

1, 2 A 4.7

Coeffi cient of performance (C.O.P) (Total)

1, 2 4.12 4.64

Compressor

Model KNB092FFDHC

Output W 1,100

Current

1, 2 A 4.4 4.2

Refrigeration oil (Model) L 0.32 (NEO22)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg 34

Special

remarks

Air fl ow (Rated) m3 /h 1,752 1,662

Sound level (Rated) dB(A) 49 50

Fan speed (Rated) rpm 840 800

Refrigerant fi lling capacity (R410A) kg 1.3

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF22VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

9

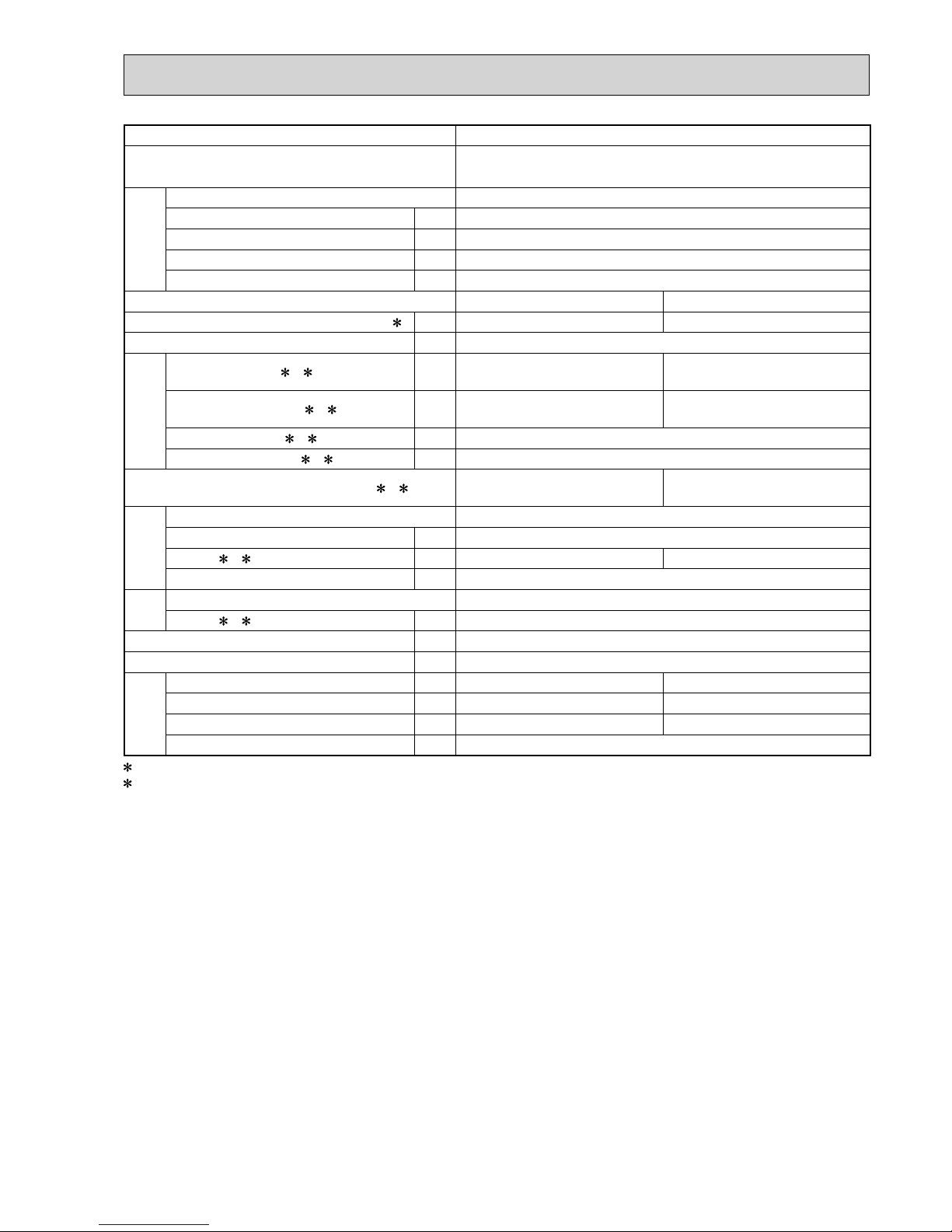

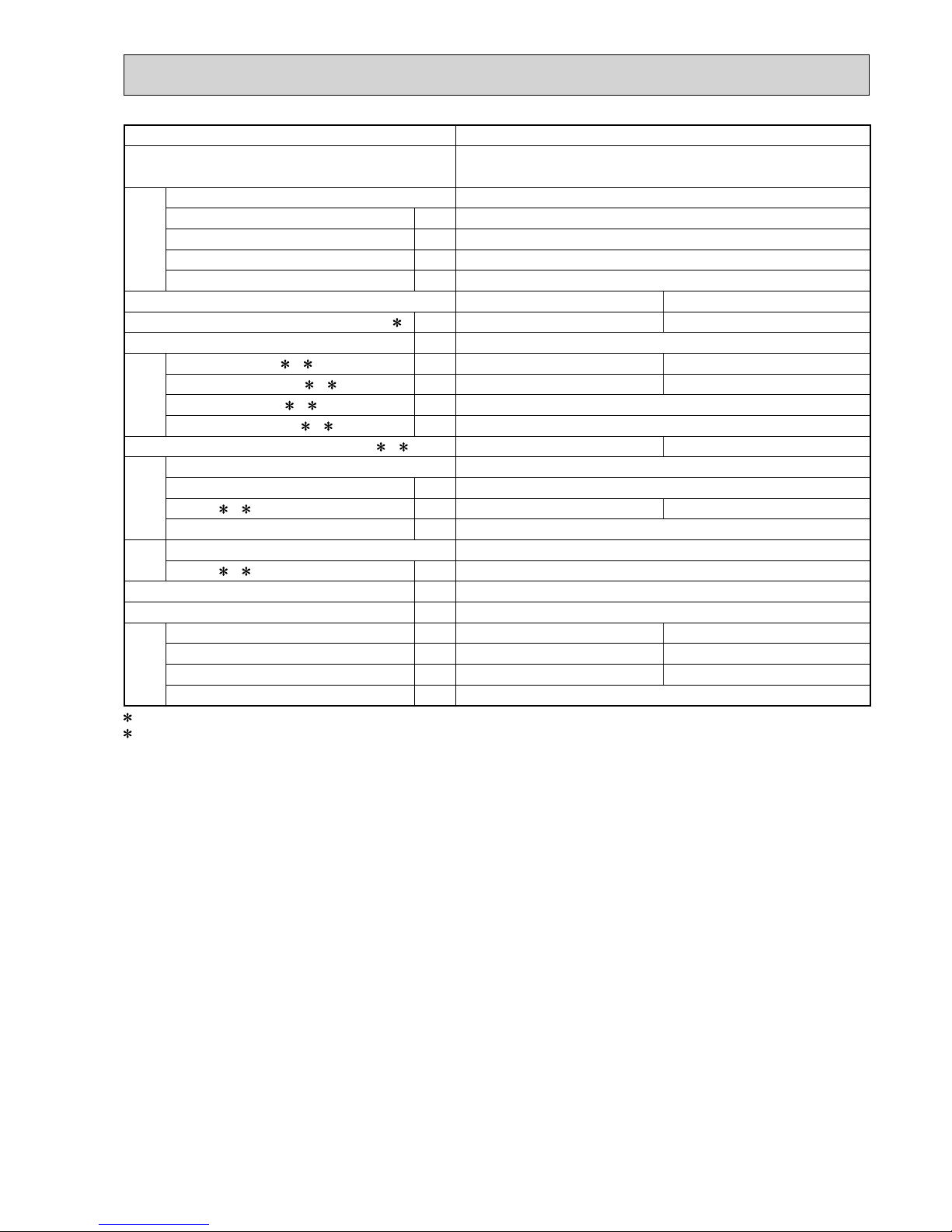

Outdoor model MXZ-2D42VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 30

Connecting pipe length m Max. 20

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 4.2 (1.1 - 4.4) 4.5 (1.0 - 4.8)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 1,000 930

Running current (Total)

1, 2 A 4.5 4.2

Power factor (Total)

1, 2% 97

Starting current (Total)

1, 2 A 4.5

Coeffi cient of performance (C.O.P) (Total)

1, 2 4.20 4.84

Compressor

Model SNB130FGBHT

Output W 1,150

Current

1, 2 A 4.0 3.6

Refrigeration oil (Model) L 0.45 (NEO22)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg 37

Special

remarks

Air fl ow (Rated) m3 /h 1,662 1,998

Sound level (Rated) dB(A) 46 51

Fan speed (Rated) rpm 800 910

Refrigerant fi lling capacity (R410A) kg 1.3

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF25VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

10

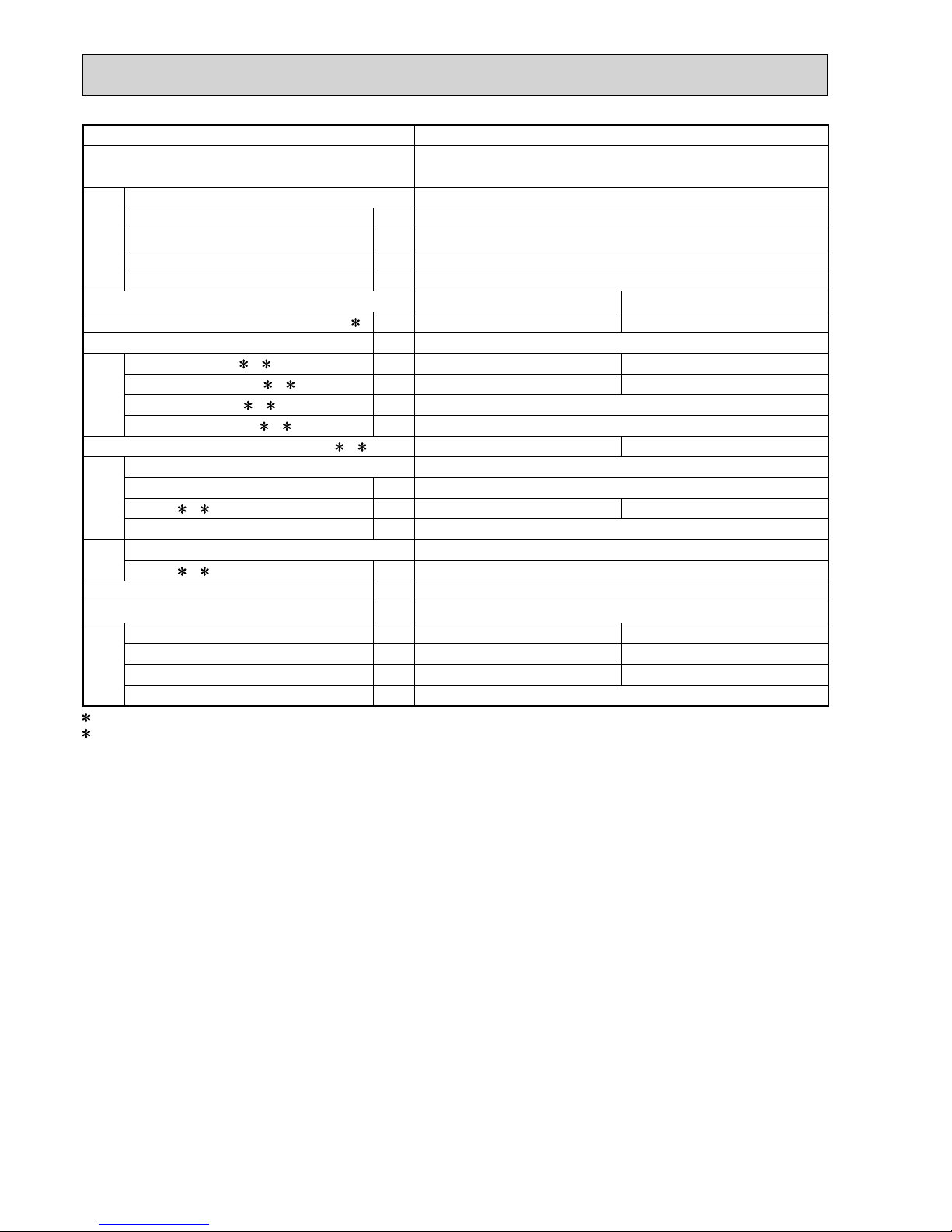

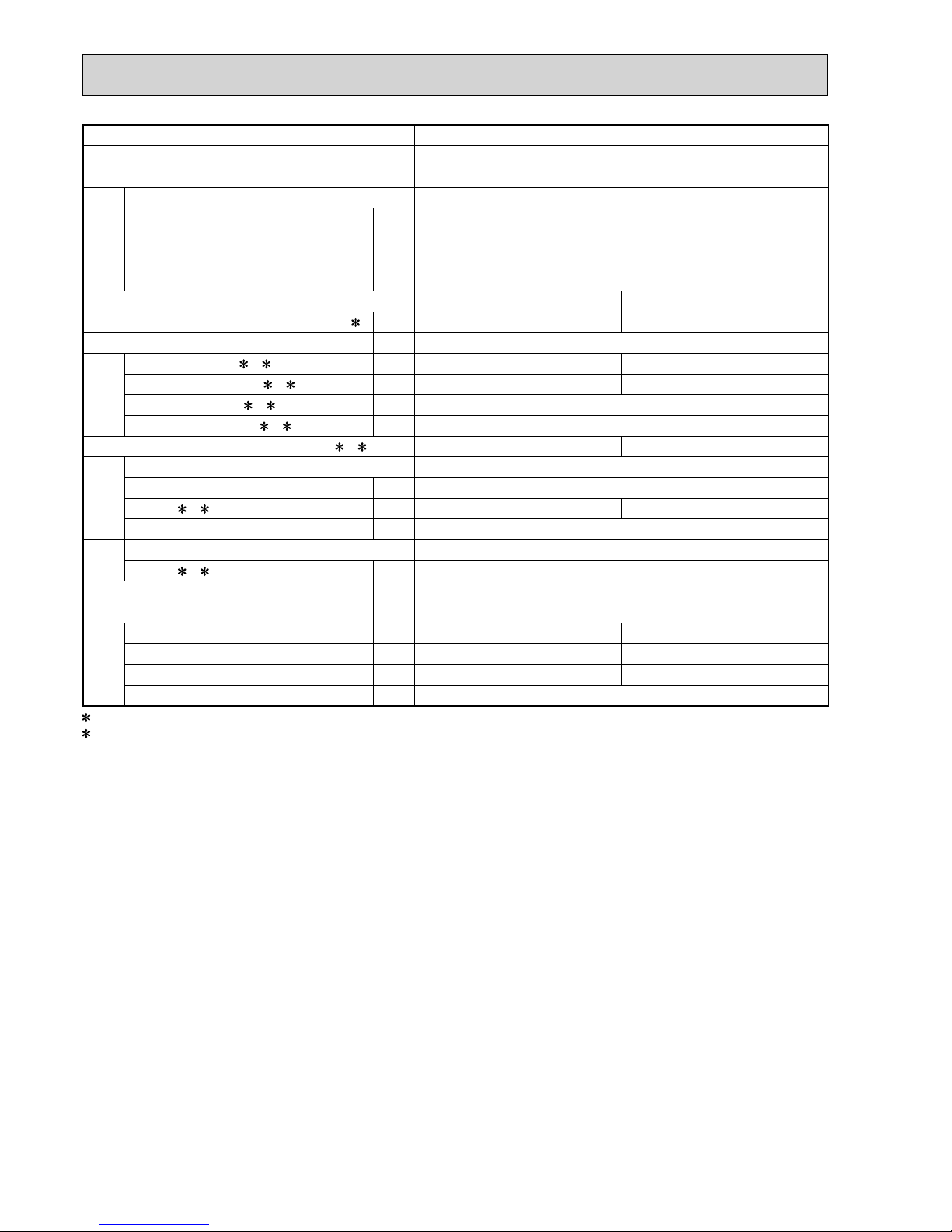

Outdoor model MXZ-2D53VA MXZ-2D53VAH

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 30

Connecting pipe length m Max. 20

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 5.3 (1.1 - 5.6) 6.4 (1.0 - 7.0)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 1,540 1,700

Running current (Total)

1, 2 A 6.9 7.6

Power factor (Total)

1, 2% 97

Starting current (Total)

1, 2 A 7.6

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.44 3.76

Compressor

Model SNB130FGBHT

Output W 1,400

Current

1, 2 A 6.6 7.2

Refrigeration oil (Model) L 0.45 (NEO22)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg MXZ-2D53VA: 37 MXZ-2D53VAH: 38

Special

remarks

Air fl ow (Rated) m3 /h 1,974 1,998

Sound level (Rated) dB(A) 50 53

Fan speed (Rated) rpm 900 910

Refrigerant fi lling capacity (R410A) kg 1.3

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF35VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

11

Outdoor model MXZ-3D54VA MXZ-3D54VA2

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 3

Piping total length m Max. 50

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 5.4 (2.9 - 6.8) 7.0 (2.6 - 9.0)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2W

MXZ-3D54VA: 1,390

MXZ-3D54VA2: 1,350

1,590

Running current (Total)

1, 2A

MXZ-3D54VA: 6.1

MXZ-3D54VA2: 5.9

7.0

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 7.0

Coeffi cient of performance (C.O.P) (Total)

1, 2

MXZ-3D54VA: 3.88

MXZ-3D54VA2: 4.00

4.40

Compressor

Model SNB130FGBH1T

Output W 1,400

Current

1, 2 A 5.72 6.62

Refrigeration oil (Model) L 0.7 (NEO22)

Fan

motor

Model SIC-71FW-F764-1

Current

1, 2 A 0.2

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 57

Special

remarks

Air fl ow (Rated) m3 /h 2,334 2,376

Sound level (Rated) dB(A) 50 53

Fan speed (Rated) rpm 650 660

Refrigerant fi lling capacity (R410A) kg 2.7

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF18VE + MSZ-EF18VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

12

Outdoor model MXZ-3D68VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 3

Piping total length m Max. 60

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 6.8 (2.9 - 8.4) 8.6 (2.6 - 10.6)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 2,190 2,380

Running current (Total)

1, 2 A 9.6 10.5

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 10.5

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.11 3.61

Compressor

Model SNB172FEGH1T

Output W 1,800

Current

1, 2 A 9.22 10.12

Refrigeration oil (Model) L 0.7 (NEO22)

Fan

motor

Model SIC-71FW-F764-1

Current

1, 2 A 0.2

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 57

Special

remarks

Air fl ow (Rated) m3 /h 2,334 2,376

Sound level (Rated) dB(A) 50 53

Fan speed (Rated) rpm 650 660

Refrigerant fi lling capacity (R410A) kg 2.7

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF25VE + MSZ-EF25VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

13

Outdoor model MXZ-4D72VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 4

Piping total length m Max. 60

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 7.2 (3.7 - 8.8) 8.6 (3.4 - 10.7)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 2,250 2,280

Running current (Total)

1, 2 A 9.9 10.0

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 10.0

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.20 3.77

Compressor

Model SNB172FEGH1T

Output W 2,000

Current

1, 2 A 9.46 9.56

Refrigeration oil (Model) L 0.7 (NEO22)

Fan

motor

Model SIC-71FW-F764-1

Current

1, 2 A 0.2

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 58

Special

remarks

Air fl ow (Rated) m3 /h 2,334 2,376

Sound level (Rated) dB(A) 50 53

Fan speed (Rated) rpm 650 660

Refrigerant fi lling capacity (R410A) kg 2.7

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF18VE + MSZ-EF18VE + MSZ-EF18VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

14

Outdoor model MXZ-4D83VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 4

Piping total length m Max. 70

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 8.3 ( 3.7 - 9.2 ) 9.0 ( 3.4 - 11.6 )

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 2,830 2,420

Running current (Total)

1, 2 A 12.4 10.6

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 12.4

Coeffi cient of performance (C.O.P) (Total)

1, 2 2.93 3.72

Compressor

Model TNB220FMCH

Output W 2,100

Current

1, 2 A 11.76 9.96

Refrigeration oil (Model) L 0.87 (NEO22)

Fan

motor

Model RC0J60-CC

Current

1, 2 A 0.4

Dimensions W x H x D mm 900 x 915 x 320

Weight kg 69

Special

remarks

Air fl ow (Rated) m3 /h 2,526 2,628

Sound level (Rated) dB(A) 49 50

Fan speed (Rated) rpm 600 620

Refrigerant fi lling capacity (R410A) kg 3.5

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF18VE + MSZ-EF22VE + MSZ-EF25VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

15

Outdoor model MXZ-5D102VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 5

Piping total length m Max. 80

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 10.2 ( 3.9 - 11.0 ) 10.5 ( 4.1 - 14.0 )

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 3,910 2,900

Running current (Total)

1, 2 A 17.2 12.7

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 17.2

Coeffi cient of performance (C.O.P) (Total)

1, 2 2.61 3.62

Compressor

Model TNB220FMCH

Output W 2,700

Current

1, 2 A 16.5 12.0

Refrigeration oil (Model) L 0.87 (NEO22)

Fan

motor

Model RC0J60-CC

Current

1, 2 A 0.4

Dimensions W x H x D mm 900 x 915 x 320

Weight kg 70

Special

remarks

Air fl ow (Rated) m3 /h 3,396 3,558

Sound level (Rated) dB(A) 53 55

Fan speed (Rated) rpm 780 810

Refrigerant fi lling capacity (R410A) kg 4.0

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF18VE + MSZ-EF18VE + MSZ-EF22VE + MSZ-EF22VE + MSZ-EF22VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

16

Outdoor model MXZ-6D122VA

Outdoor unit power supply

Single phase

230 V, 50 Hz

System

Indoor units number 2 to 6

Piping total length m Max. 80

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 7 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 12.2 ( 3.5 - 13.5 ) 14.0 ( 3.5 - 16.5 )

Breaker capacity A 32

Electrical

data

Power input (Total) 1, 2 W 3,660 3,310

Running current (Total)

1, 2 A 16.1 14.5

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 17.2

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.33 4.23

Compressor

Model MNB33FBTM-L

Output W 1,700

Current

1, 2 A 15.26 12.94

Refrigeration oil (Model) L 1.10 (FV50S)

Fan

motor

Model SIC-81FW-D888-9

Current

1, 2 A 0.3

Dimensions W x H x D mm 950 x 1,048 x 330

Weight kg 88

Special

remarks

Air fl ow (Rated) m3 /h 3,780 4,620

Sound level (Rated) dB(A) 55 57

Fan speed (Rated) rpm 650 750

Refrigerant fi lling capacity (R410A) kg 4.0

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-EF22VE +MSZ-EF22VE +MSZ-EF22VE +MSZ-EF22VE +MSZ-EF22VE +MSZ-EF22VE

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH626H

17

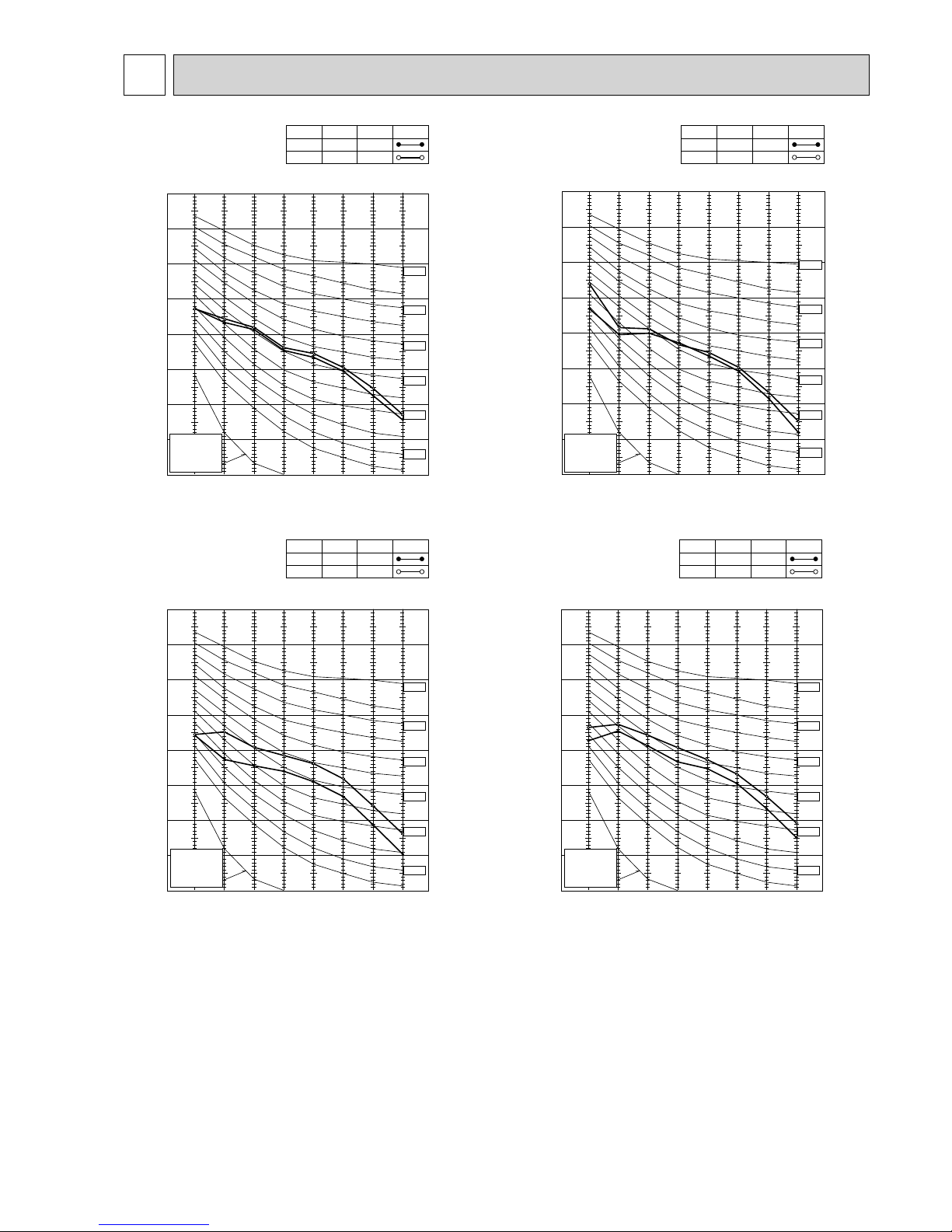

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

49

SPL(dB(A))50LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

46

SPL(dB(A))51LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

49

SPL(dB(A))50LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

50

SPL(dB(A))53LINE

NOISE CRITERIA CURVES

4

MXZ-2D53VA

MXZ-2D53VAH

MXZ-2D33VA

MXZ-2D42VA

MXZ-2D40VA

OBH626H

18

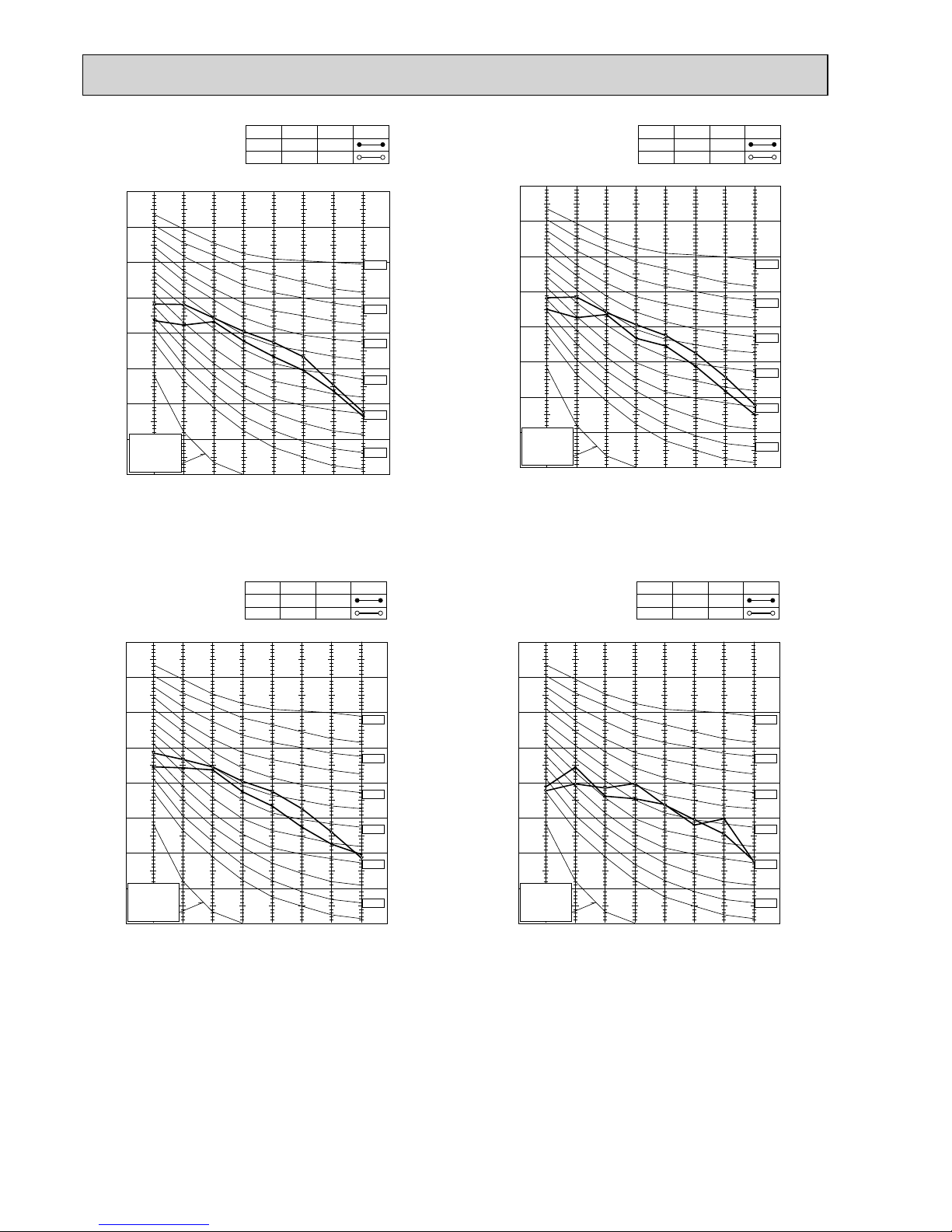

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

50

SPL(dB(A))53LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

50

SPL(dB(A))53LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

50

SPL(dB(A))53LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

48

SPL(dB(A))51LINE

MXZ-3D54VA

MXZ-3D54VA2

MXZ-3D68VA

MXZ-4D72VA MXZ-4D83VA

OBH626H

19

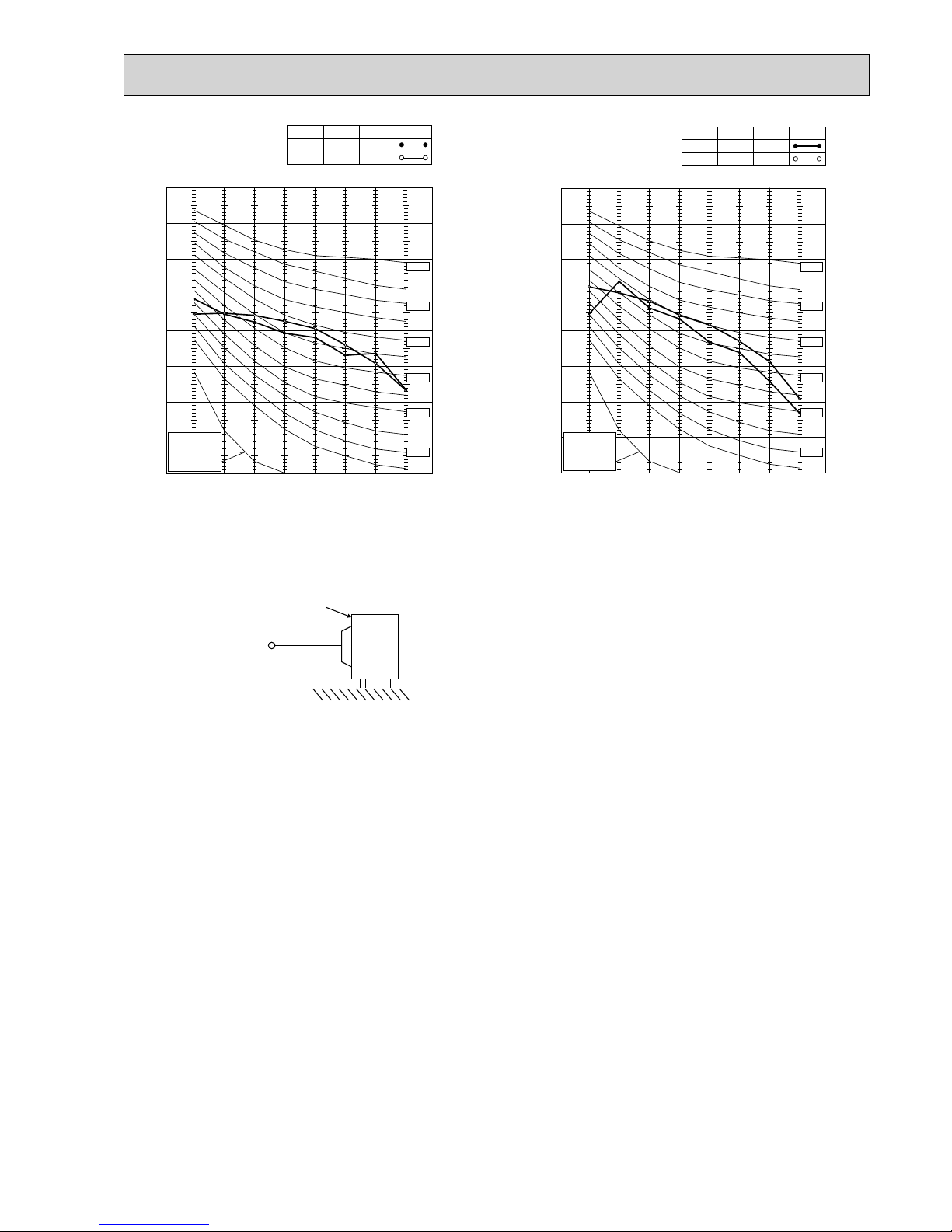

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

48

SPL(dB(A))51LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

55

SPL(dB(A))57LINE

MXZ-5D102VA MXZ-6D122VA

OUTDOOR UNIT

MICROPHONE

1m

Test conditions

Cooling :Dry-bulb temperature 35°C Wet-bulb temperature 24°C

Heating :Dry-bulb temperature 7°C Wet-bulb temperature 6°C

OBH626H

20

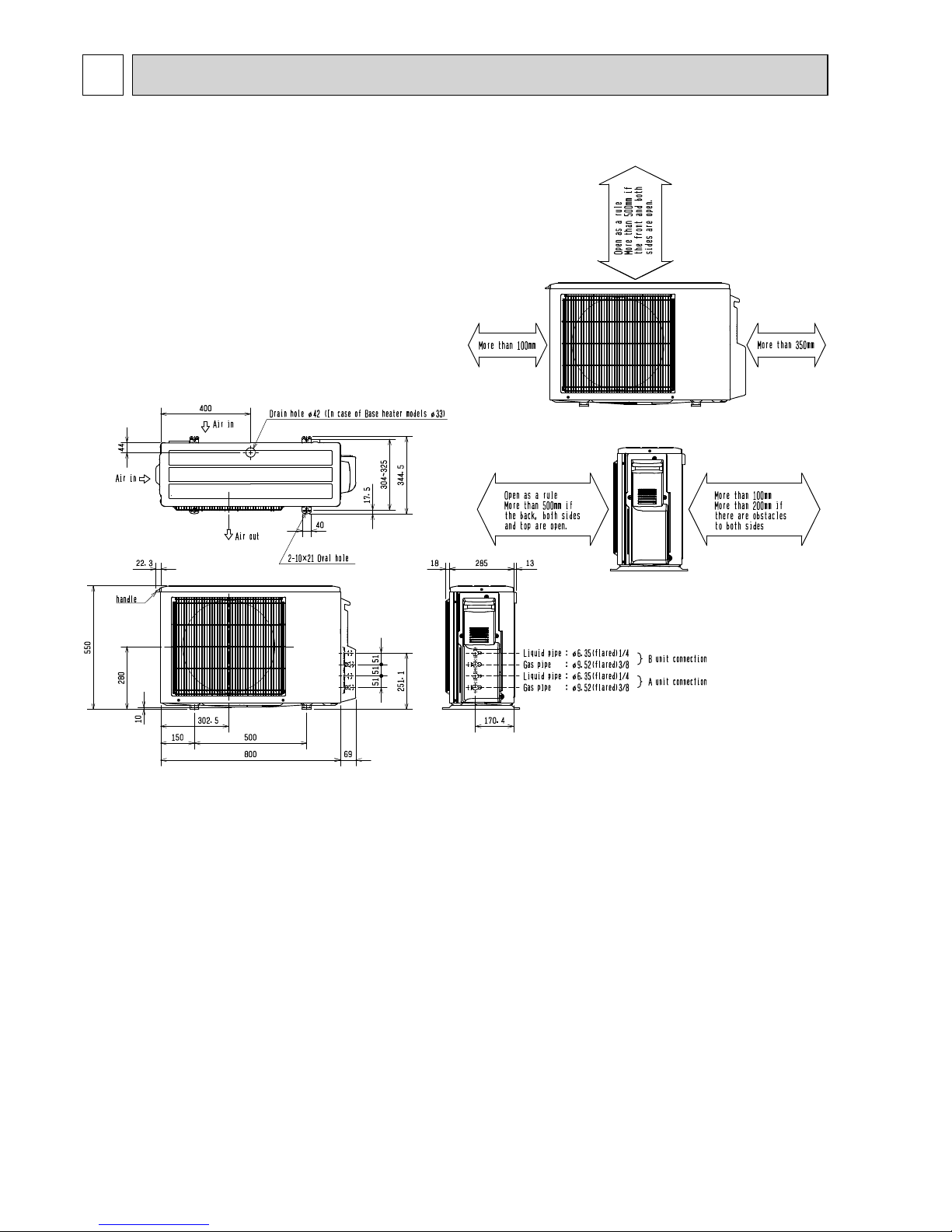

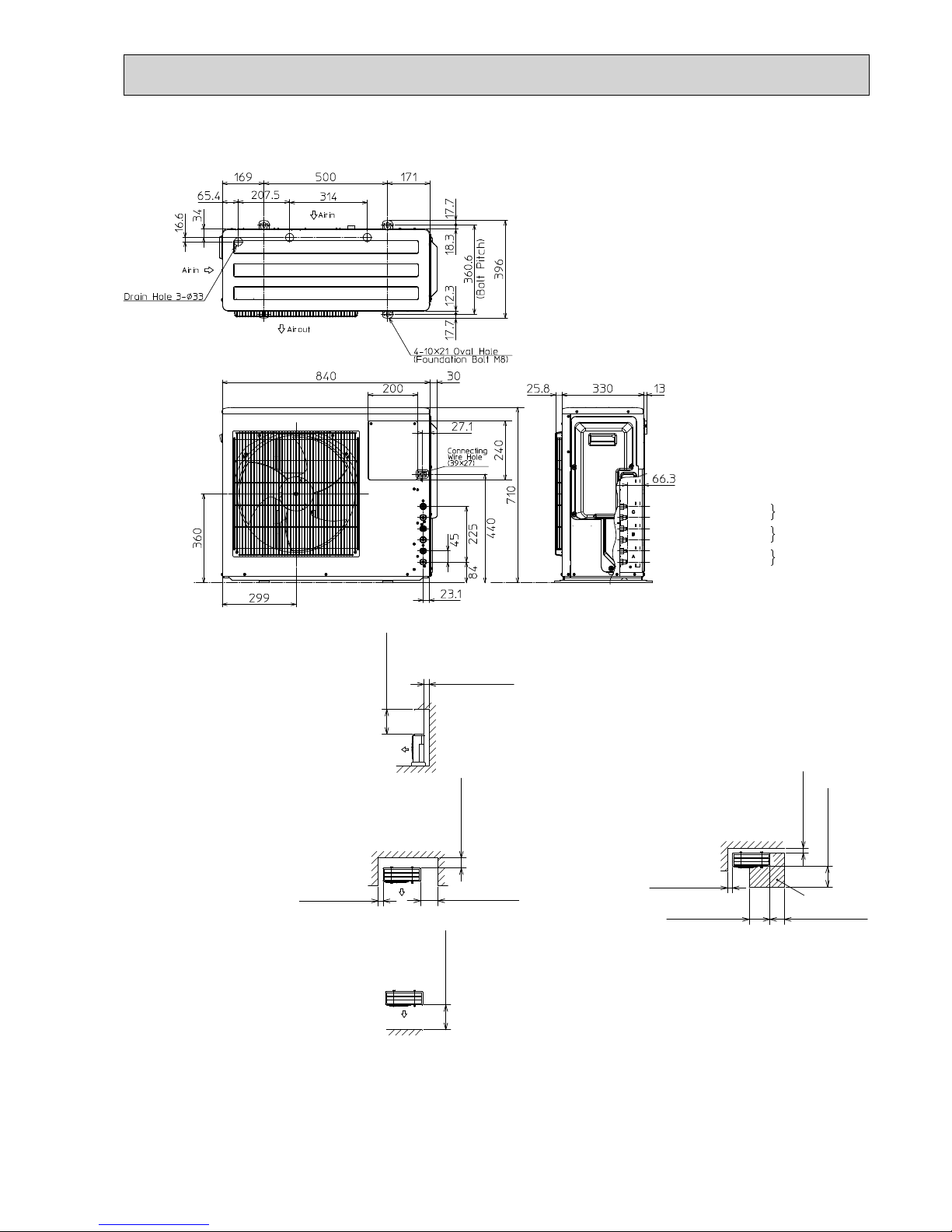

OUTLINES AND DIMENSIONS

5

MXZ-2D33VA MXZ-2D40VA MXZ-2D42VA MXZ-2D53VA MXZ-2D53VAH

Unit: mm

OBH626H

21

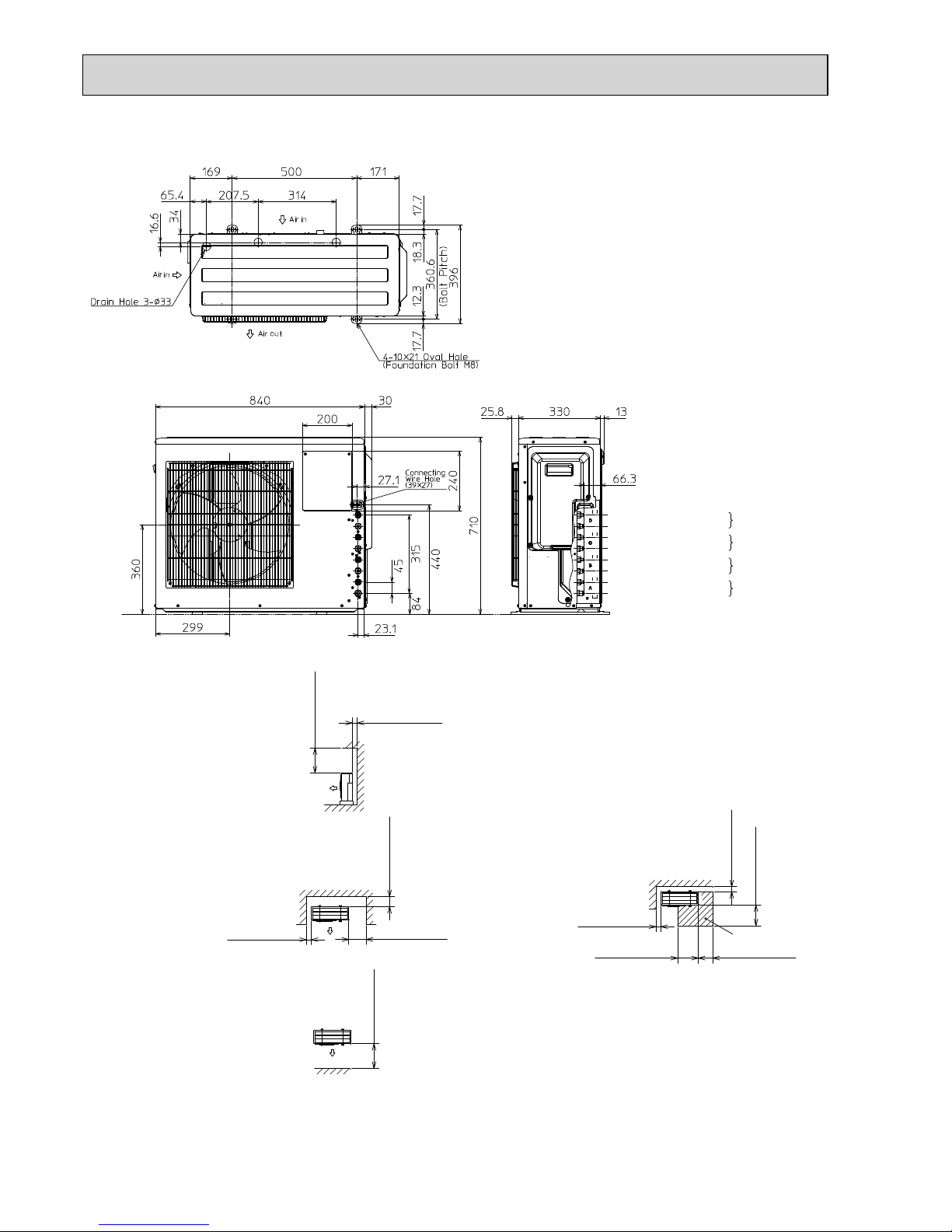

1.Installation space

Note : Leave front and both sides

free of obstruction.

Note : Leave rear, overhead and

both sides free of obstruction.

500 or more

100 or more

Note : Leave front and overhead

free of obstruction.

100 or more

350 or more

200 or more

500 or more

2.Service space

100 or more

500 or more

350 or more

350 or more

100 or more

Service space

Liquid pipe : Ø6.35(flared)1/4

C unit connection

B unit connection

A unit connection

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

MXZ-3D54VA MXZ-3D54VA2 MXZ-3D68VA

Unit: mm

OBH626H

22

MXZ-4D72VA

Unit: mm

1.Installation space

Note : Leave front and both sides

free of obstruction.

Note : Leave rear, overhead and

both sides free of obstruction.

500 or more

100 or more

Note : Leave front and overhead

free of obstruction.

100 or more

350 or more

200 or more

500 or more

2.Service space

100 or more

500 or more

350 or more

350 or more

100 or more

Service space

Liquid pipe : Ø6.35(flared)1/4

D unit connection

C unit connection

B unit connection

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

A unit connection

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø12.7(flared)1/2

OBH626H

23

MXZ-4D83VA

MXZ-5D102VA

Unit: mm

Liquid pipe : Ø6.35(flared)1/4

E unit connection

(MXZ-5D102VA)

D unit connection

C unit connection

B unit connection

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

A unit connection

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø12.7(flared)1/2

1.Installation space

Note : Leave front and both sides

free of obstruction.

Note : Leave rear, overhead and

both sides free of obstruction.

Air out

42

200 200500

315

355

(Bolt pitch)

387

40

27

16

16

11

24

Drain hole 42

(Fondation bolt M10)

(Fondation bolt M10)

2-U Shaped notched hole

2-12 x 36 Oval hole

Air in

Air in

32025 10

88

475

317

900

Handle

Handle

915

500 or more

100 or more

Note : Leave front and overhead

free of obstruction.

100 or more

350 or more

200 or more

500 or more

2.Service space

100 or more

500 or more

350 or more

350 or more

100 or more

Service space

23

612

147

405

45

Indoor and

outdoor

connect wiring

(35 x 53) hole

OBH626H

24

MXZ6D122VA

Unit: mm

34

468134

43

Handle

Air Intake

Handle

330

70

25 15

6-ø33 Drain Hole

Air in

Air out

Air in

(Foundation Bolt M10)

2-U Shaped Notched Hole

(Foundation Bolt M10)

2-12×36 Oval Hole

(Bolt pitch)

1169780250

51

71

134

40

62

10

10

10

10

175 600 175

10

10

417

31 16370

36

51

Handle

Handle

Handle

361

563

1048

950

Liquid pipe : Ø6.35(flared)1/4

E unit

connection

D unit

connection

C unit

connection

B unit

connection

A unit

connection

F unit

connection

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø9.52(flared)3/8

Liquid pipe : Ø6.35(flared)1/4

Gas pipe : Ø12.7(flared)1/2

SERVICE SPACE

1.FREE SPACE

2.SERVICE SPACE

100 or more

200 or more

350 or more

500 or more

100 or more

100 or more

350 or more 350 or more

500 or more

100 or more

500 or more

OBH626H

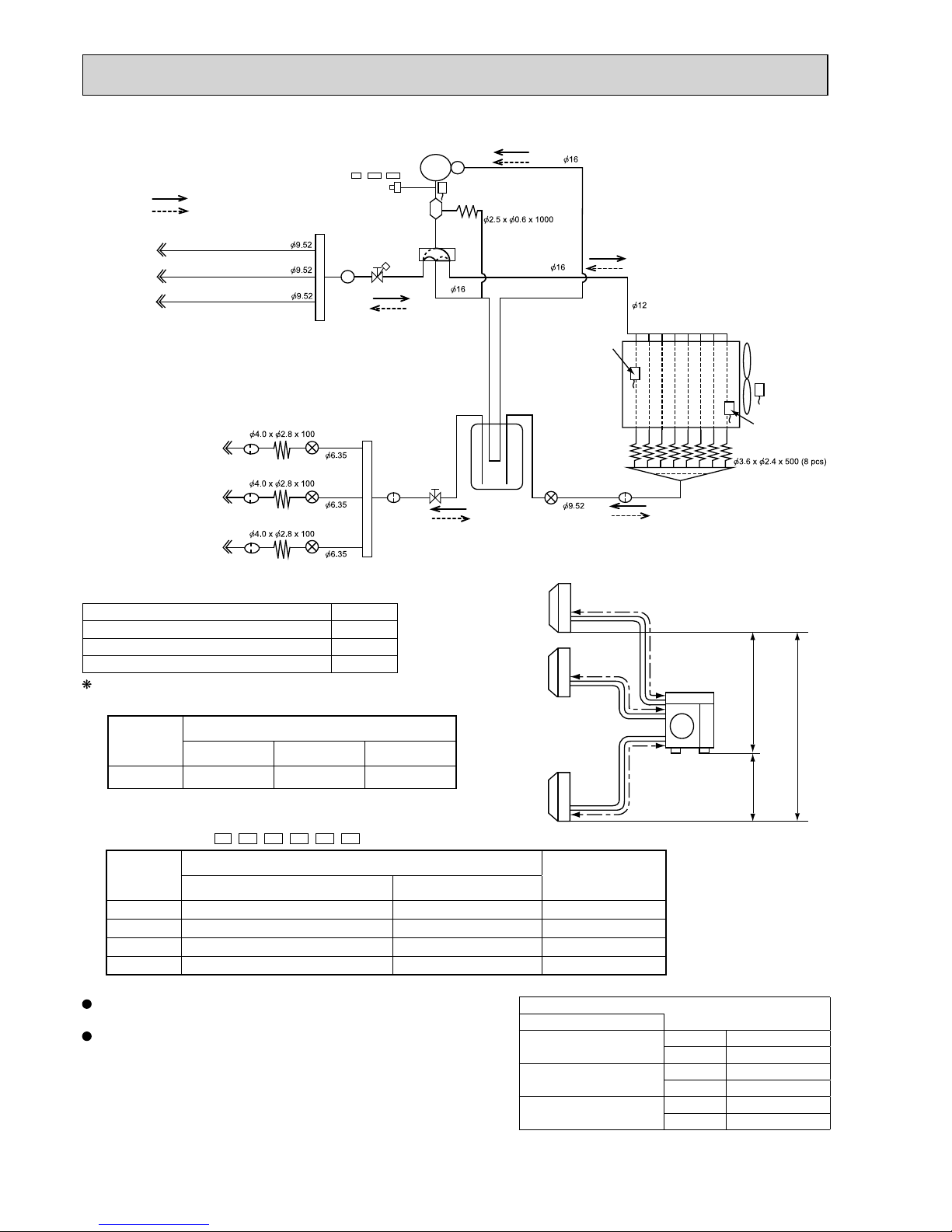

71

REFRIGERANT SYSTEM DIAGRAM

7

a

b

Outdoor

unit

Indoor

units

10 m

10 m

10 m

Max.

Height

difference

Stop valve

(with strainer #100)

LEV A

LEV B

Compressor

Defrost

thermistor

RT61

Muffler

4-way valve

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Capillary tube

Capillary tube

Strainer

#100

Stop valve

(with strainer #100)

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN- OUT

HEX-OUT

Discharge

temperature

thermistor RT62

Stop valve

(with service port)

Stop valve

(with service port)

Sub muffler

Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

table below.

UNIT: mm

MXZ-2D33VA

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b) 15 m

Total piping length (a+b) 20 m

Bending point for each unit 15

Total bending point 20

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 2 unit total)

20 m

1,150 0

WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT

MXZ-2D33VA -E2/

ER2/ET2

/E3/

ER3/ET3

No. of

MFZ-KJ

indoor units

Refrigerant piping length (L)

Maximum amount

of refrigerant

~ 20 m

None Charge-less (1,150 g) 1,150 g

1 unit 100 g additional charge (1,250 g) 1,250 g

2 units Not available -

OBH626H

72

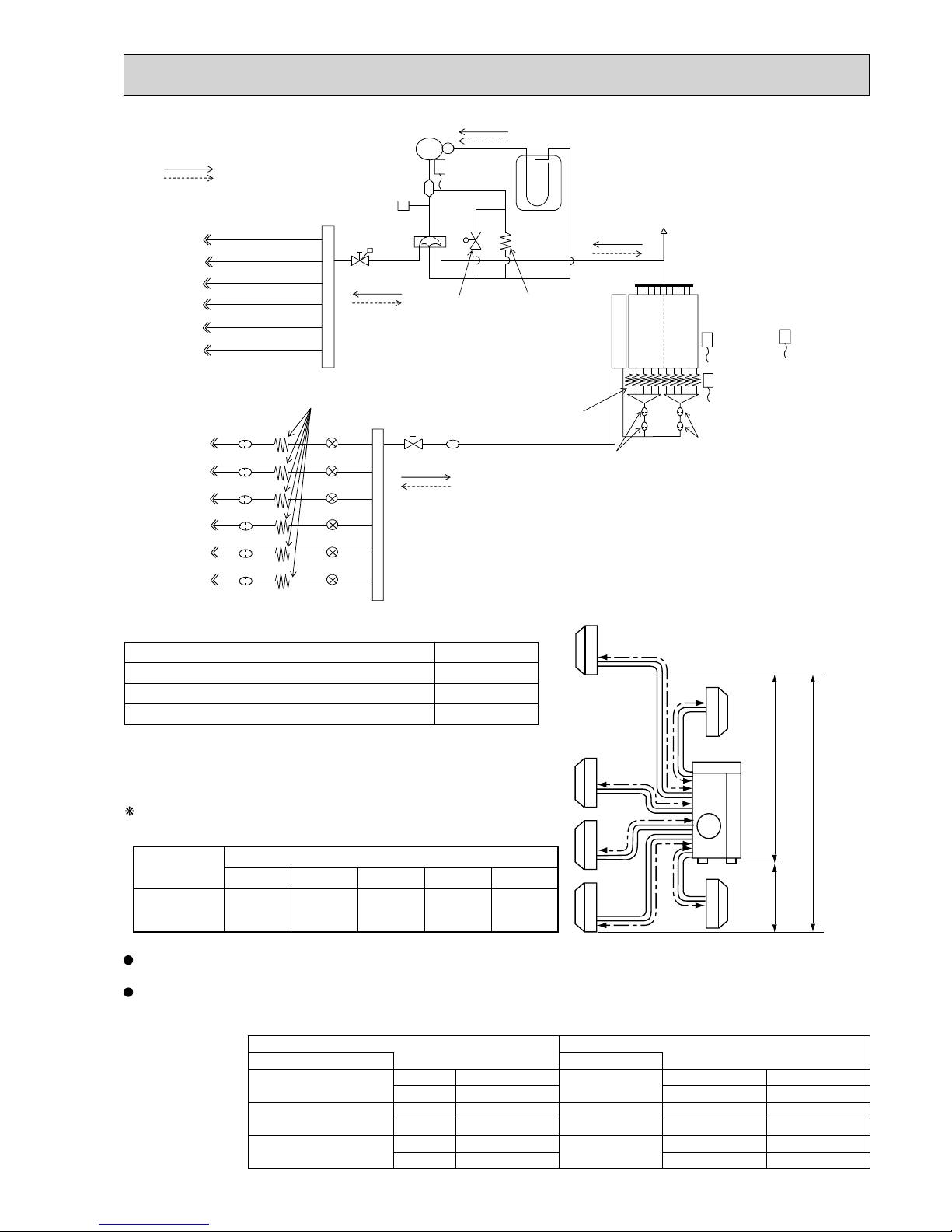

Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

table below.

UNIT: mm (inch)

Piping length each indoor unit (a, b) 20 m

Total piping length (a+b) 30 m

Bending point for each unit 20

Total bending point 30

MXZ-2D40VA

MAX REFRIGERANT PIPING LENGTH

a

b

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Refrigerant piping length (one way, 2 unit total)

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 20)

Outdoor unit

precharged

(g)

30 m

200

20 m

0

1,300

Max.

Height

difference

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Stop valve

(with strainer #100)

LEV A

LEV B

Compressor

Muffler

4-way valve

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Capillary tube

Capillary tube

Stop valve

(with strainer #100)

Refrigerant flow in cooling

Refrigerant flow in heating

Discharge

temperature

thermistor RT62

Stop valve

(with service port)

Stop valve

(with service port)

Defrost

thermistor

RT61

Distributor

Capillary tube

Strainer

#100

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN- OUT

HEX-OUT

Sub muffler

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

UNIT: mm

OBH626H

73

Stop valve

(with strainer #100)

LEV A

LEV B

Compressor

Defrost

thermistor

RT61

Distributor

Muffler

4-way valve

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Capillary tube

Capillary tube

Capillary tube

Strainer

#100

Stop valve

(with strainer #100)

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN- OUT

HEX-OUT

Discharge

temperature

thermistor RT62

Stop valve

(with service port)

Stop valve

(with service port)

Sub muffler

UNIT: mm

MXZ-2D42VA MXZ-2D53VA MXZ-2D53VAH

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b) 20 m

Total piping length (a+b) 30 m

Bending point for each unit 20

Total bending point 30

It is irrelevant which unit is higher.

a

b

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

dif

ference

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 2 unit total)

20 m 30 m

1,300 0 200

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 20)

WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT

MXZ-2D42VA -E2/E3/

ER3/ET2/ET3

MXZ-2D53VA -E2/E3/

ER2/ER3/ET2/ET3

MXZ-2D53VAH -E2/E3/

ER2/ER3

No. of

MFZ-KJ

indoor units

Refrigerant piping length (L)

Maximum amount

of refrigerant

~ 20 m ~ 30 m

None Charge-less (1,300 g) (L-20) x 20 g/m 1,500 g

1 unit 100 g additional charge (1,400 g) 100 g + (L-20) x 20 g/m 1,600 g

2 units 200 g additional charge (1,500 g) 200 g + (L-20) x 20 g/m 1,700 g

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

OBH626H

74

Strainer

#100

Power

receiver

LEV A

LEV B

LEV C

Oil separator

Compressor

Defrost

thermistor

RT61

Distributor

Muffler

4-way valve

LEV E

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Indoor unit

C

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN- OUT

HEX-OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure switch

(MXZ-3D54VA2- , , only)

E3 ET3ER3

UNIT: mm (inch)

UNIT: mm

MXZ-3D54VA MXZ-3D54VA2

MAX REFRIGERANT PIPING LENGTH

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

a

b

c

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

Piping length each indoor unit (a, b, c) 25 m

Total piping length (a+b+c) 50 m

Bending point for each unit 25

Total bending point 50

It is irrelevant which unit is higher.

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 3 unit total)

40 m 50 m 60 m

2,700 0 200 400

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 40)

WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT

MXZ-3D54VA2 -E2/E3/

ER2

/

ER3

/

ET2/ET3

No. of

MFZ-KJ

indoor units

Refrigerant piping length (L)

Maximum amount of

refrigerant

~ 40 m ~ 50 m

None Charge-less (2,700 g) (L-40) x 20 g/m 2,900 g

1 unit 100 g additional charge (2,800 g) 100 g + (L-40) x 20 g/m 3,000 g

2 units 200 g additional charge (2,900 g) 200 g + (L-40) x 20 g/m 3,100 g

3 units 300 g additional charge (3,000 g) 300 g + (L-40) x 20 g/m 3,200 g

OBH626H

75

Strainer

#100

Power

receiver

LEV A

LEV B

LEV C

Oil separator

Compressor

Defrost

thermistor

RT61

Distributor

Muffler

4-way valve

LEV E

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Indoor unit

C

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN- OUT

HEX-OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure switch

UNIT: mm

MXZ-3D68VA

MAX REFRIGERANT PIPING LENGTH

a

b

c

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

Piping length each indoor unit (a, b, c) 25 m

Total piping length (a+b+c) 60 m

Bending point for each unit 25

Total bending point 60

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 3 unit total)

40 m 50 m 60 m

2,700 0 200 400

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 40)

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT

MXZ-3D68VA -E2/E3/

ER2/ER3/ET2/ET3

No. of

MFZ-KJ

indoor units

Refrigerant piping length (L)

Maximum amount of

refrigerant

~ 40 m ~ 60 m

None Charge-less (2,700 g) (L-40) x 20 g/m 3,100 g

1 unit 100 g additional charge (2,800 g) 100 g + (L-40) x 20 g/m 3,200 g

2 units 200 g additional charge (2,900 g) 200 g + (L-40) x 20 g/m 3,300 g

3 units 300 g additional charge (3,000 g) 300 g + (L-40) x 20 g/m 3,400 g

OBH626H

76

MXZ-4D72VA

Indoor unit

D

Power

receiver

LEV A

LEV B

LEV C

LEV D

Oil separator

Compressor

Muffler

4-way valve

LEV E

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

D

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Distributor

HEX-OUT

Outdoor heat

exchanger

temperature

thermistor

RT68

Defrost

thermistor

RT61

Capillary tube

Ambient

temperature

thermistor

RT65

FAN- OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure

switch

UNIT: mm

a

b

c

d

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 12.7(1/2)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit D

Liquid 6.35(1/4)

Gas 9.52(3/8)

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b, c, d) 25 m

Total piping length (a+b+c+d)

60 m

Bending point for each unit 25

Total bending point 60

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 4 unit total)

40 m 50 m 60 m

2,700 0 200 400

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 40)

WHEN CONNECTING TO MFZ-KJ SERIES INDOOR UNIT

MXZ-4D72VA -E2/E3/

ER2/ER3/ET2/ET3

No. of

MFZ-KJ

indoor units

Refrigerant piping length (L)

Maximum amount of

refrigerant

~ 40 m ~ 60 m

None Charge-less (2,700 g) (L-40) x 20 g/m 3,100 g

1 unit 100 g additional charge (2,800 g) 100 g + (L-40) x 20 g/m 3,200 g

2 units 200 g additional charge (2,900 g) 200 g + (L-40) x 20 g/m 3,300 g

3 units 300 g additional charge (3,000 g) 300 g + (L-40) x 20 g/m 3,400 g

4 units 400 g additional charge (3,100 g) 400 g + (L-40) x 20 g/m 3,500 g

OBH626H

77

a

b

c

d

Outdoor

unit

Indoor

units

15 m

15 m

10 m

Refrigerant piping length (one way, 4 unit total)

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 40)

Max.

Height

difference

Outdoor unit

precharged

(g)

50 m

200

40 m

0

3,500

60 m

400

70 m

600

Indoor unit

D

Stop valve

(with service port)

Stop valve

Power

receiver

LEV A

LEV B

LEV C

LEV D

Oil separator

Compressor

Muffler

4-way valve

LEV F

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

D

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

High-pressure

switch

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#100

Distributor

Outdoor

heat

exchanger

Capillary tube

Defrost

thermistor

RT61

Outdoor heat

exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

HEX-OUT

FAN- OUT

MXZ-4D83VA

UNIT: mm

Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

tables below.

When diameter of refrigerant pipe is different from that of outdoor unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS CATALOG".

UNIT: mm (inch)

Piping length each indoor unit (a, b, c, d) 25 m

Total piping length (a+b+c+d) 70 m

Bending point for each unit 25

Total bending point 70

MAX REFRIGERANT PIPING LENGTH

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 12.7(1/2)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit D

Liquid 6.35(1/4)

Gas 9.52(3/8)

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

OBH626H

78

a

b

c

d

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Refrigerant piping length (one way, 5 unit total)

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 40)

e

Max.

Height

difference

Outdoor unit

precharged

(g)

50 m

200

40 m

0

4,000

60 m

400

70 m

600

80 m

800

Indoor unit

E

Stop valve

(with service port)

Stop valve

Power

receiver

LEV A

LEV B

LEV C

LEV D

Oil separator

Compressor

Muffler

4-way valve

LEV F

Indoor unit

D

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

D

Indoor unit

A

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

LEV E

Indoor unit

E

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#100

Distributor

Outdoor

heat

exchanger

Capillary tube

Defrost

thermistor

RT61

Outdoor heat

exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

High-pressure

switch

HEX-OUT

FAN- OUT

MXZ-5D102VA

UNIT: mm

Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

tables below.

When diameter of refrigerant pipe is different from that of outdoor unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS CATALOG".

UNIT: mm (inch)

Piping length each indoor unit (a, b, c, d, e) 25 m

Total piping length (a+b+c+d+e) 80 m

Bending point for each unit 25

Total bending point 80

MAX REFRIGERANT PIPING LENGTH

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 12.7(1/2)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit D

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit E

Liquid 6.35(1/4)

Gas 9.52(3/8)

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

OBH626H

79

R.V.coil

OFF Refrigerant flow in heating

ON Refrigerant flow in cooling

Compressor

Oil separator

High pressure switch

Ø6.35

Ø6.35

Ø9.52

Ø12.7

Indoor unit A

Accumulator

Ø6.35

LEV A

Ø9.52

2-way

solenoid valve

Distributor

Strainer #100

Union

Union

Header(Gas)

Stop valve

Strainer

Strainer

#50

Strainer

#50

#100

Header(Evaporator)

Charge pipe

Capillary tube

Capillary tube

Ø2.5 x Ø0.6 x 1000

Ø4.0 x Ø2.8 x 100

Ø6.35

Ø6.35

Ø9.52

Ø9.52

Compressor shell

temperature

thermistor RT62

Outdoor

heat exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

Defrost

temperature

thermistor

RT61

Capillary tube

Ø4.0 x Ø2.8 x 100

Outdoor

heat exchanger

4-way valve

Stop valve

(with service port)

Indoor unit B

Indoor unit C

Indoor unit E

Ø9.52

Indoor unit D

Indoor unit F

Indoor unit A

Indoor unit B

Indoor unit C

Indoor unit D

Indoor unit E

Strainer #100

Strainer #100

Strainer #100

Strainer #100 LEV B

LEV E

Ø6.35

Indoor unit F

Strainer #100

LEV F

LEV D

LEV C

a

b

c

d

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Refrigerant piping length (one way, 5 unit total)

Calculation : Xg = 20 g/m x (Refrigerant piping length (m) - 30)

e

f

Max.

Height

difference

Outdoor unit

precharged

(g)

50 m

400

40 m

200

4,000

60 m

600

70 m

800

80 m

1000

MXZ-6D122VA

UNIT: mm

Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

tables below.

When diameter of refrigerant pipe is different from that of outdoor unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS CATALOG".

Piping length each indoor unit (a, b, c, d, e) 25 m

Total piping length (a+b+c+d+e) 80 m

Bending point for each unit 25

Total bending point 80

MAX REFRIGERANT PIPING LENGTH

UNIT: mm (inch)

Outdoor unit union diameter Outdoor unit union diameter

For For

Indoor unit A

Liquid 6.35(1/4)

Indoor unit D

Liquid 6.35(1/4)

Gas 12.7(1/2) Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Indoor unit E

Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Indoor unit F

Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

OBH626H

80

When relocating or disposing of the air conditioner, pump down the system following the procedure below so that no refrigerant is released into the atmosphere.

1) Turn off the breaker.

2) Connect the gauge manifold valve to the service port of the stop valve on the gas pipe side of the outdoor unit.

3) Fully close the stop valve on the liquid pipe side of the outdoor unit.

4) Turn on the breaker.

5) Start the emergency COOL operation on all the indoor units.

6) When the pressure gauge shows 0.05 to 0 MPa [Gauge] (approximately 0.5 to 0 kgf/cm²), fully close the stop valve

on the gas pipe side of the outdoor unit and stop the operation. (Refer to the indoor unit installation manual about the

method for stopping the operation.)

* If too much refrigerant has been added to the air conditioner system, the pressure may not drop to

0.05 to 0 MPa [Gauge]

(approximately 0.5 to 0 kgf/cm²)

, or the protection function may operate due to the pressure increase in the high-pressure refrigerant circuit. If this occurs, use a refrigerant collecting device to collect all of the refrigerant in the system, and

then recharge the system with the correct amount of refrigerant after the indoor and outdoor units have been relocated.

7) Turn off the breaker. Remove the pressure gauge and the refrigerant piping.

When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes.

The compressor may burst and cause injury if any foreign substance, such as air, enters the pipes.

WARNING

PUMPING DOWN

OBH626H

115

ACTUATOR CONTROL

9

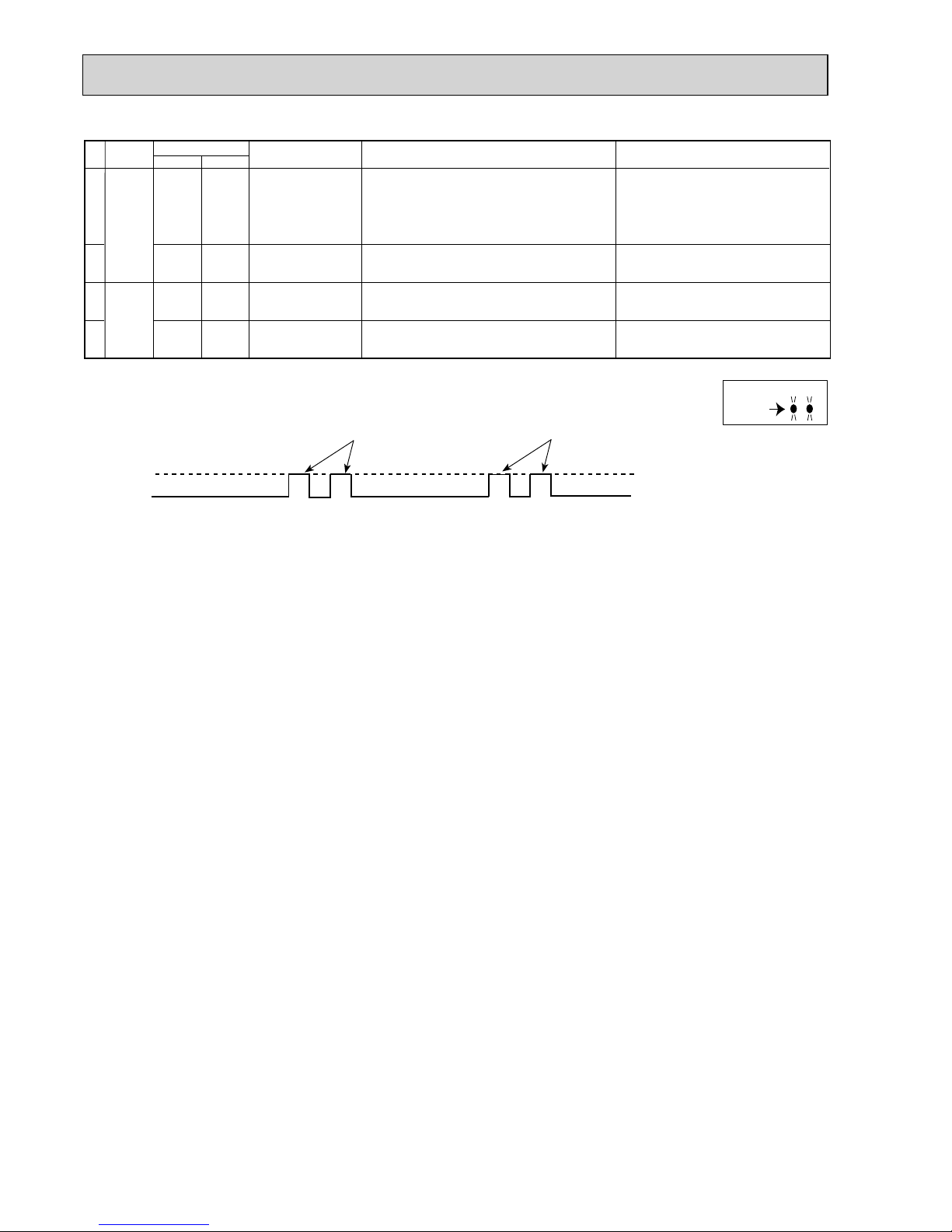

Relation between main sensor and actuator

Sensor Purpose

Actuator

Compressor LEV

Outdoor

fan motor

R.V. coil

Defrost

heater

1

Discharge temperature thermistor Protection

Indoor coil temperature thermistor

Cooling: Coil frost prevention

Heating: High pressure protection

Defrost thermistor Heating: Defrosting

Fin temperature thermistor Protection

Ambient temperature thermistor

Control/Protection

Heating: Defrosting (Heater)

Outdoor heat exchanger

temperature thermistor

Cooling: Control/Protection

Capacity code Control

1 MXZ-2D53VAH only.

MXZ-2D33VA MXZ-2D40VA MXZ-2D42VA MXZ-2D53VA MXZ-2D53VAH

MXZ-3D54VA MXZ-3D54VA2 MXZ-3D68VA MXZ-4D72VA MXZ-4D83VA MXZ-5D102VA

MXZ-6D122VA

OBH626H

116

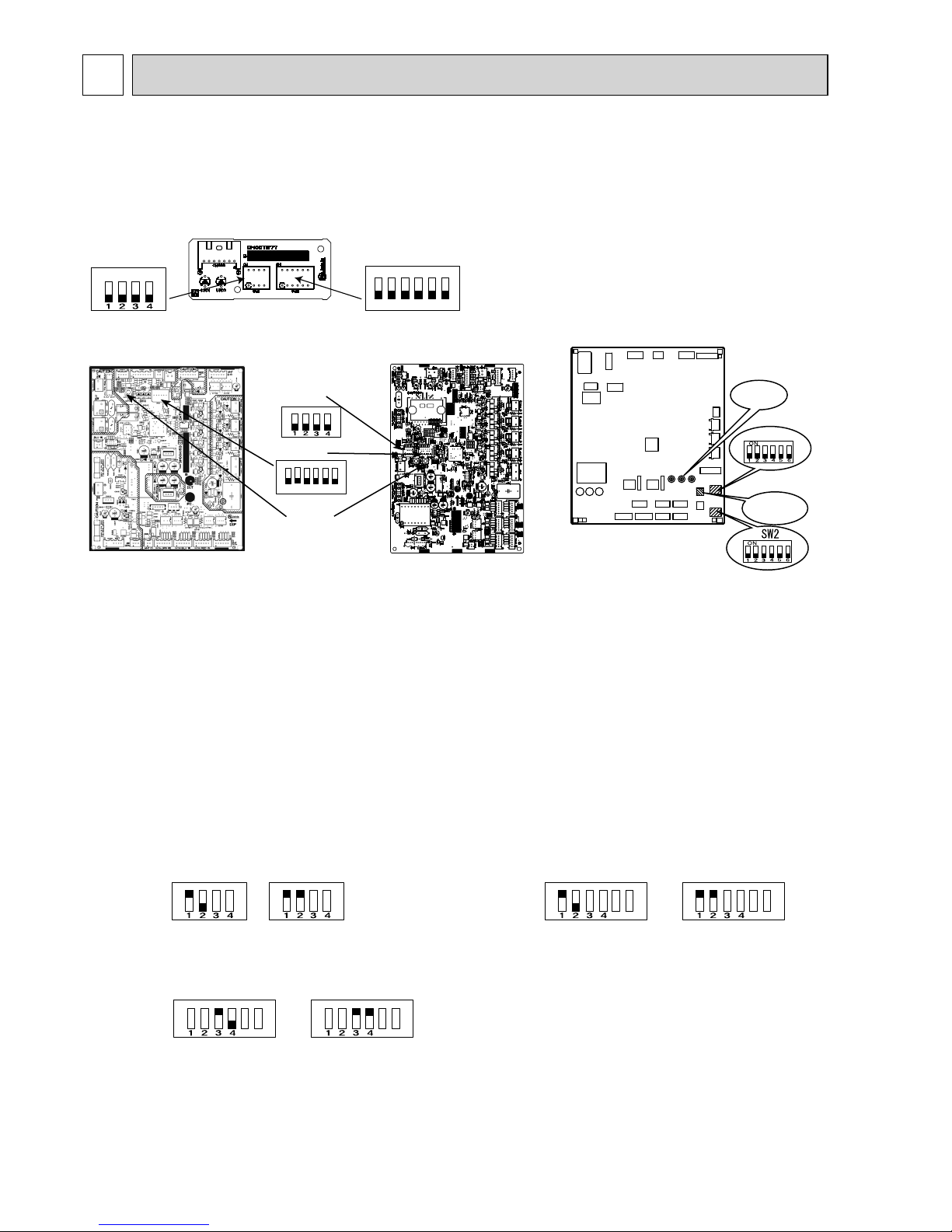

Outdoor display P.C. board

SW1 SW2

ON

123456

ON

SERVICE FUNCTIONS

10

10-1. THE POSITION OF SWITCH

MXZ-2D33VA MXZ-2D40VA MXZ-2D42VA MXZ-2D53VA MXZ-2D53VAH

MXZ-3D54VA MXZ-3D54VA2 MXZ-3D68VA MXZ-4D72VA MXZ-4D83VA MXZ-5D102VA

MXZ-6D122VA

MXZ-2D33VA MXZ-2D40VA MXZ-2D42VA MXZ-2D53VA MXZ-2D53VAH

ON

SW1

ON

SW1

Cool/Dry Heat

With this function, you can lock the operation mode of the outdoor unit.

Once the operation mode is locked to either COOL/DRY mode or HEAT mode, the air conditioner

operates in that mode only.

Default setting is required to activate this function.

Please explain this function to your customers and ask them whether they want to use it.

[How to lock the operation mode]

(1) Turn OFF the power supply and make sure that the LED goes off.

(2) Set SW1 or SW2 as shown in the figure below.

(3) Turn ON the power supply.

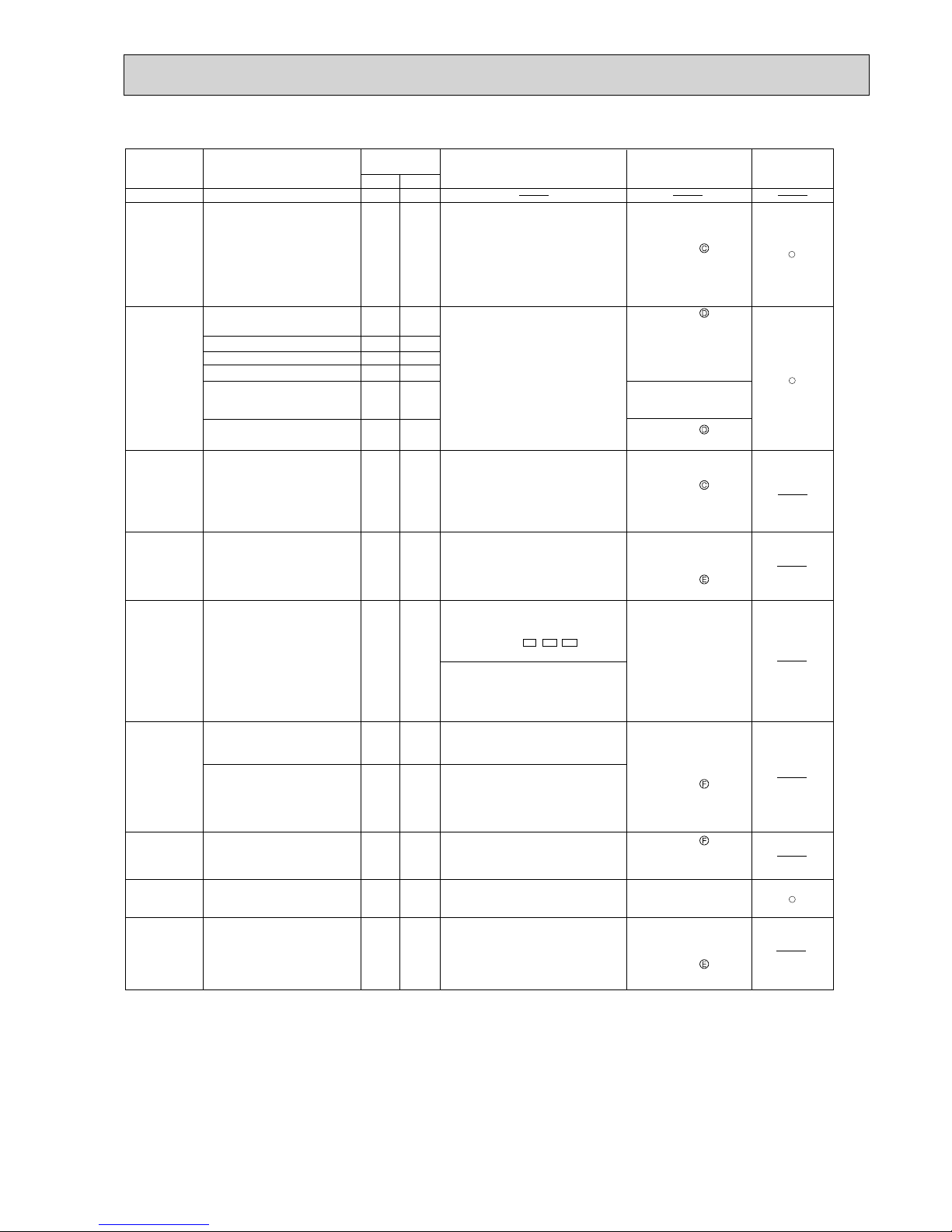

10-2. LOCKING THE OPERATION MODE OF THE AIR CONDITIONER (COOL, DRY, HEAT)

MXZ-2D33VA/2D40VA/2D42VA/2D53VA/2D53VAH

SW1 on the outdoor display P.C. board

MXZ-4D83VA/5D102VA

SW1 on the outdoor control P.C. board

MXZ-6D122VA

SW1 on the outdoor control P.C. board

ON

5

6

SW2

ON

5

6

SW2

Cool/Dry Heat

ON

5

6

SW1

ON

5

6

SW1

Cool/Dry Heat

MXZ-3D54VA/3D54VA2/3D68VA/4D72VA

SW2 on the outdoor control P.C. board

MXZ-3D54/3D68/4D72V A

MXZ-3D54V A2

Oudoor control P .C. board

ON

ON

SW2

SW871

SW1

123456

MXZ-4D83/5D102V A

Oudoor control P.C. board

Outdoor control P .C. board

SW871

SW1

LED

MXZ-6D122VA

OBH626H

117

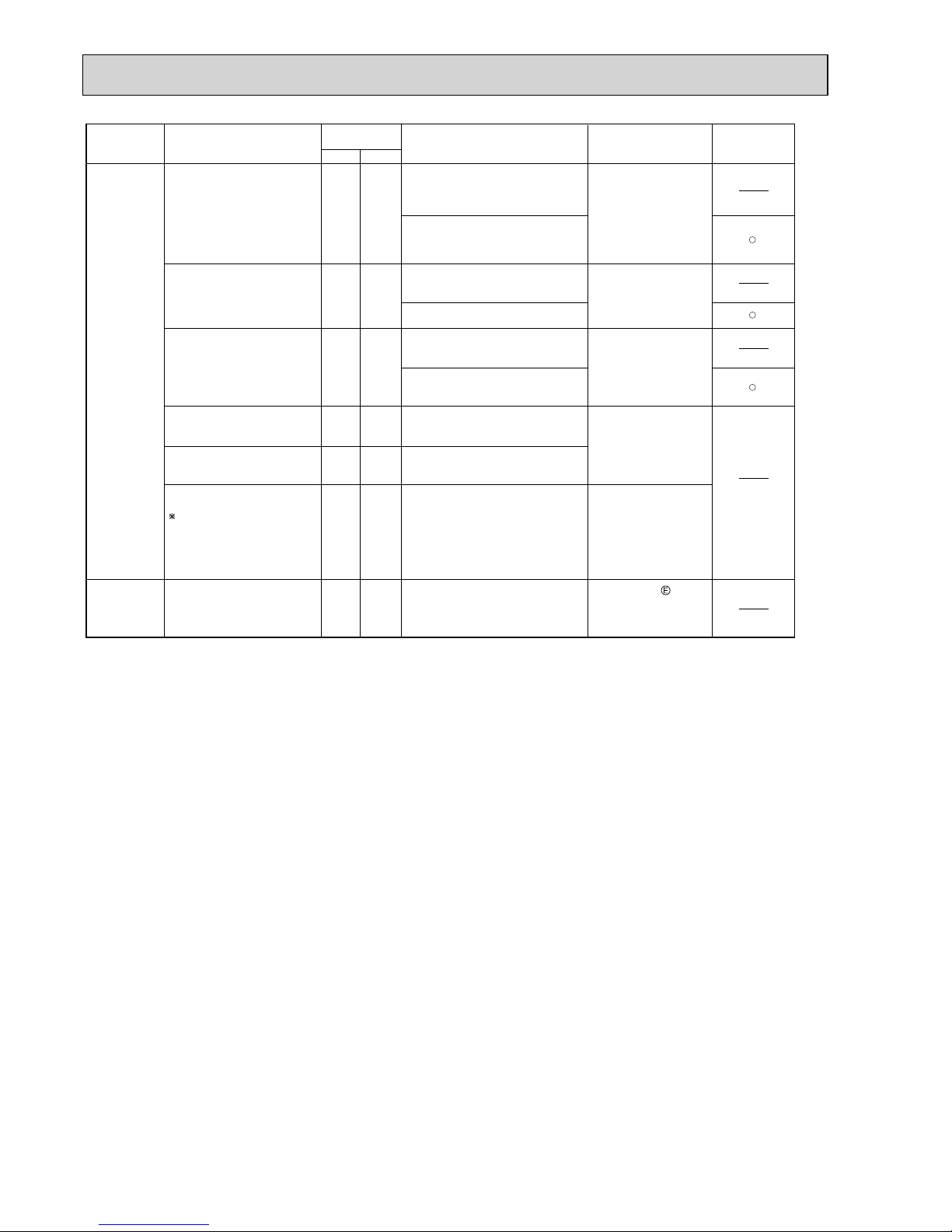

10-3. LOWERING THE OPERATING NOISE OF THE OUTDOOR UNIT

With this function, you can lower the operating noise of the outdoor unit when the operation load is small,

for example, during night time in COOL mode.

However, note that the cooling and heating capacity can also be lowered if this function is activated.

Default setting is required to activate this function.

Please explain this function to your customers and ask them whether they want to use it.

[How to lower the operating noise]

(1) Turn OFF the power supply and make sure that the LED goes off.

(2) Set the "3" Switch of SW1 to ON to enable this function. (MXZ-2D33VA/2D40VA/2D42VA/2D53VA/2D53VAH/

4D83VA/5D102VA)

Set the "3" Switch of SW2 to ON to enable this function. (MXZ-3D54VA/3D54VA2/3D68VA/4D72VA)

Set the "5" Switch of SW1 to ON to enable this function. (MXZ-6D122VA)

(3) Turn ON the power supply.

ON

SW1

MXZ-2D33VA/2D40VA/2D42VA/2D53VA/2D53VAH

SW1 on the outdoor display P.C. board

MXZ-4D83VA/5D102VA

SW1 on the outdoor control P.C. board

MXZ-6D122VA

SW1 on the outdoor control P.C. board

ON

5

6

SW2

ON

5

6

SW1

MXZ-3D54VA/3D54VA2/3D68VA/4D72VA

SW2 on the outdoor control P.C. board

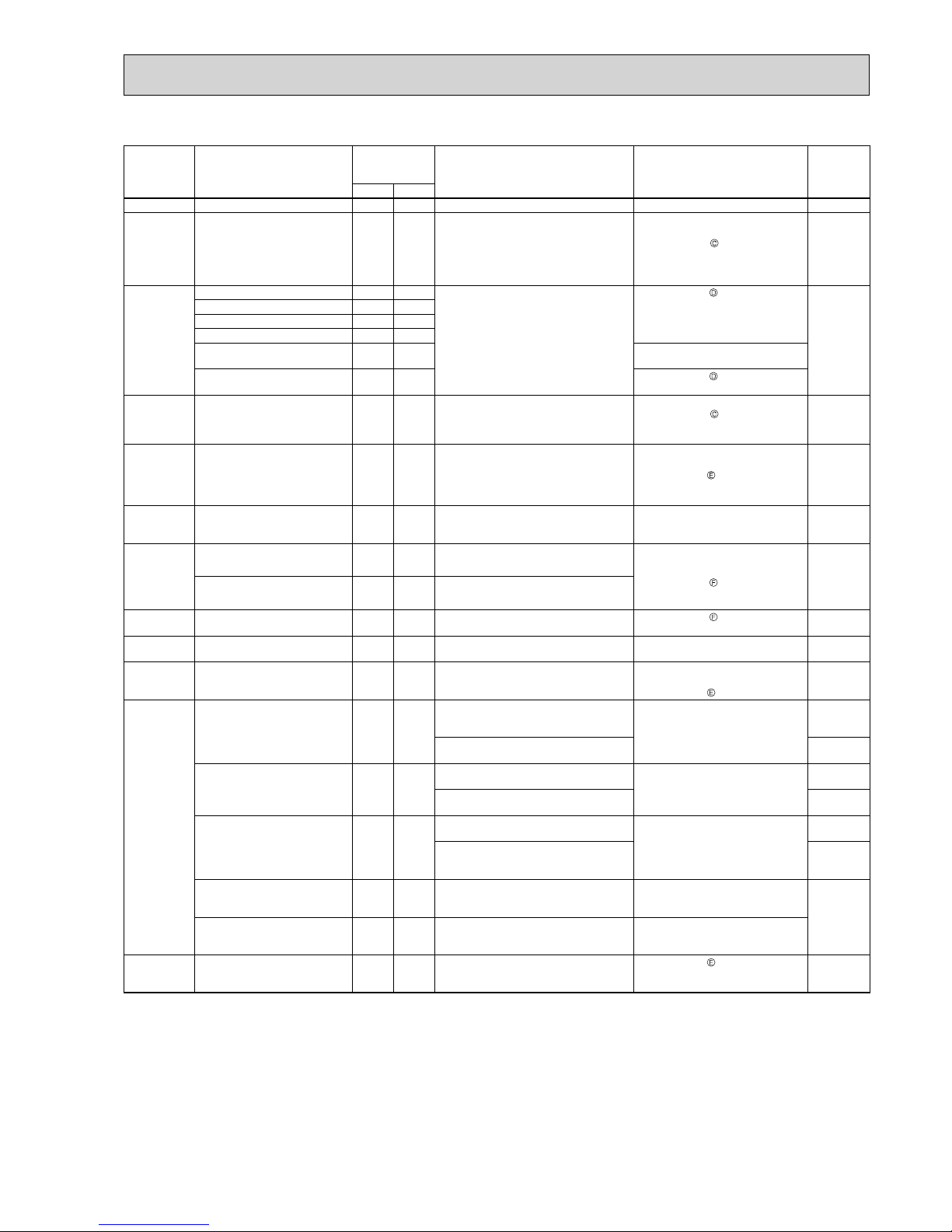

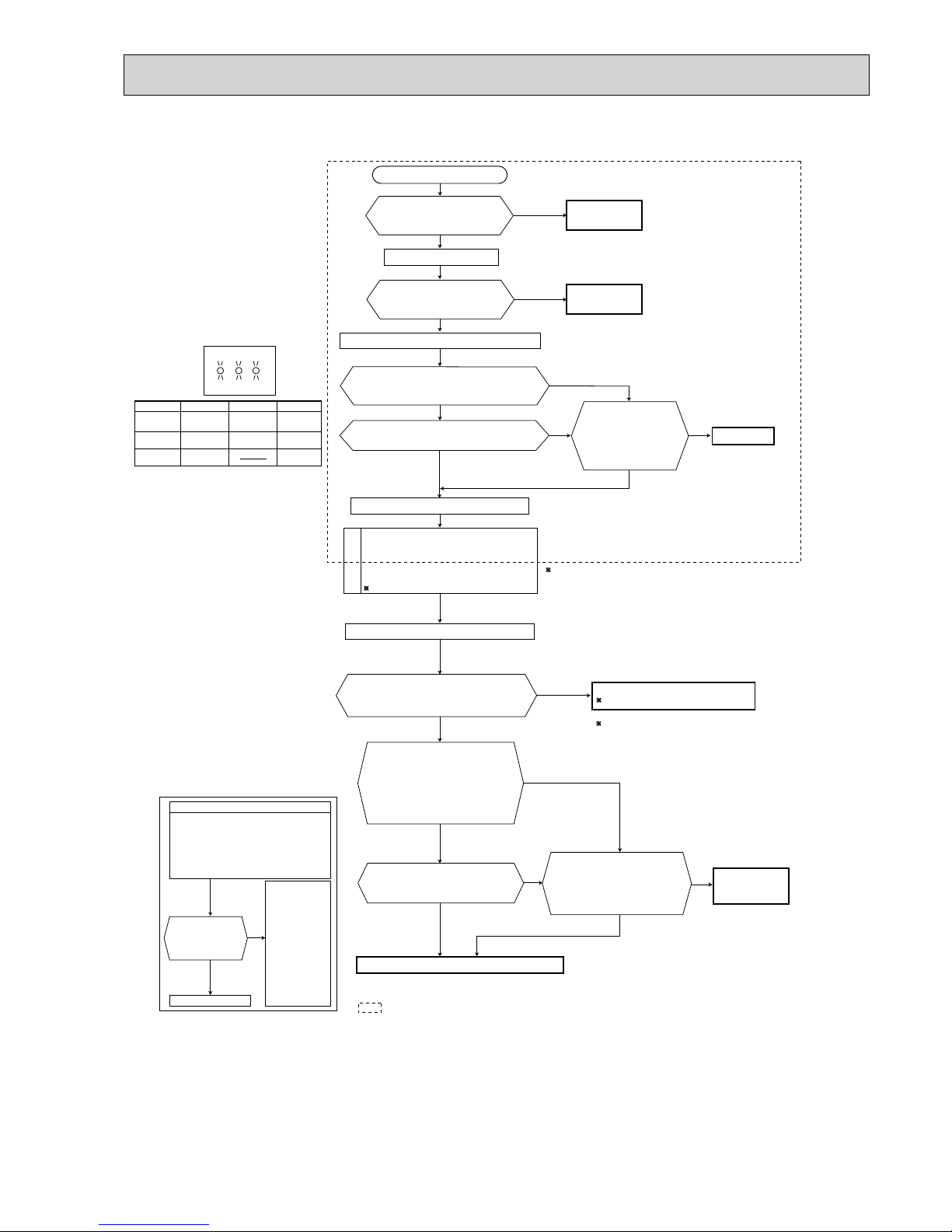

10-4. AUTOMATIC LINE CORRECTING

This outdoor unit has an automatic line correcting function which automatically detects and corrects improper wiring or piping.

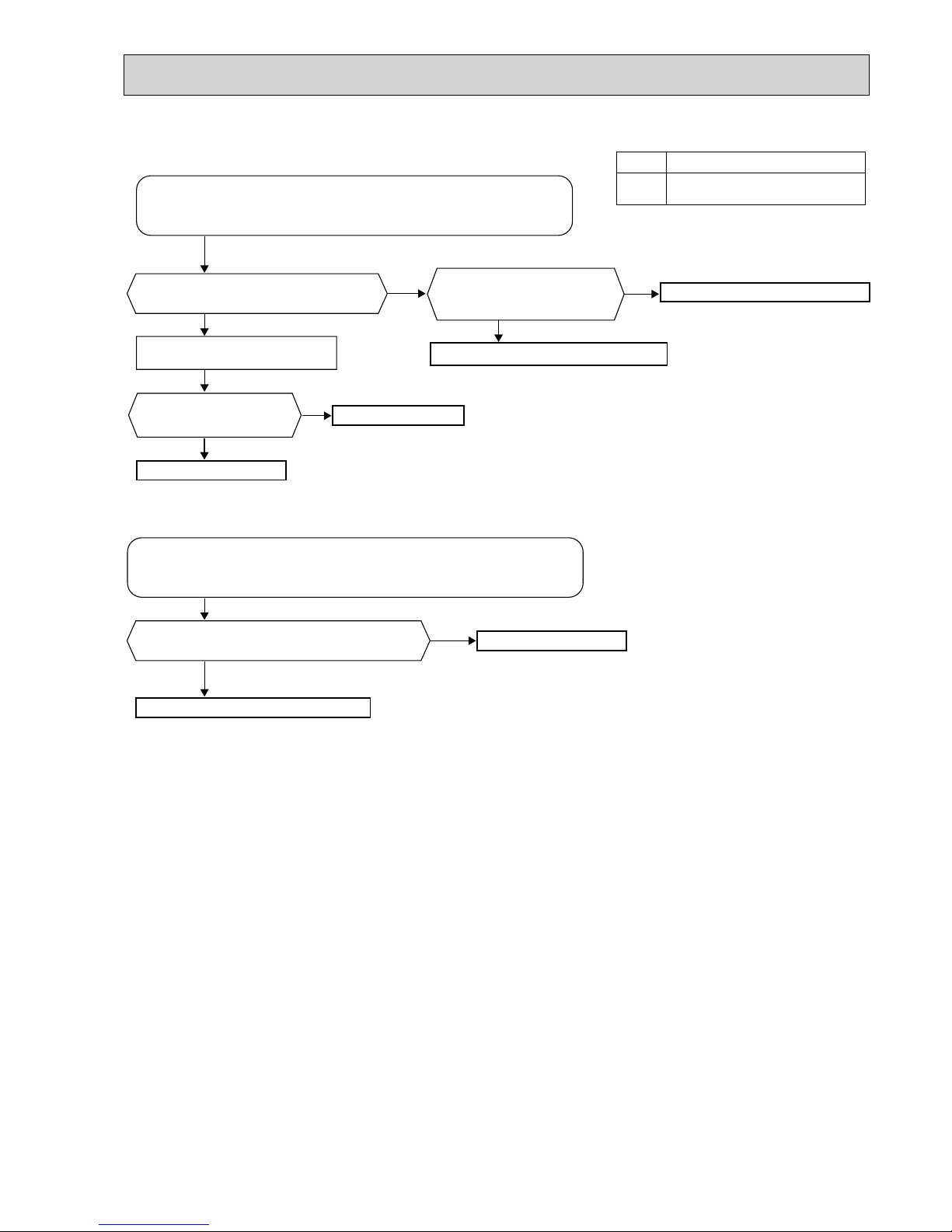

<MXZ-2D33VA/2D40VA/2D42VA/2D53VA/2D53VAH>

Improper wiring or piping can be automatically detected when one indoor unit is operated in COOL mode for 30 minutes.

When improper wiring or piping is detected, wiring lines are corrected (A to B/ B to A) with the software.

NOTE: This function may not work due to the condition or environment of the unit, such as the following:

- gas leak, closed stop valve

- unit failure such as defective LEV

- indoor/outdoor temperature

NOTE: This function does not work when the "2" of SW2 on the outdoor display P.C. board is turned OFF.

SW2

<Correct>

Indoor/outdoor

connecting wire

Terminal

block

Refrigerant pipe

Indoor unit B

Liquid/

Gas pipe

Indoor unit A

Outdoor unit

<Incorrect wiring>

Terminal

block

Indoor unit B

Liquid/

Gas pipe

Indoor unit A

Outdoor unit

<Incorrect piping>

Terminal

block

Indoor unit B

Liquid/

Gas pipe

Indoor unit A

Outdoor unit

B

A

B

A

B

A

B

A

B

A

B

A

MXZ-2D33VA/2D40VA/2D42VA/2D53VA/

MXZ-2D53VAH

SW2 on the outdoor display P.C. board

OBH626H

118

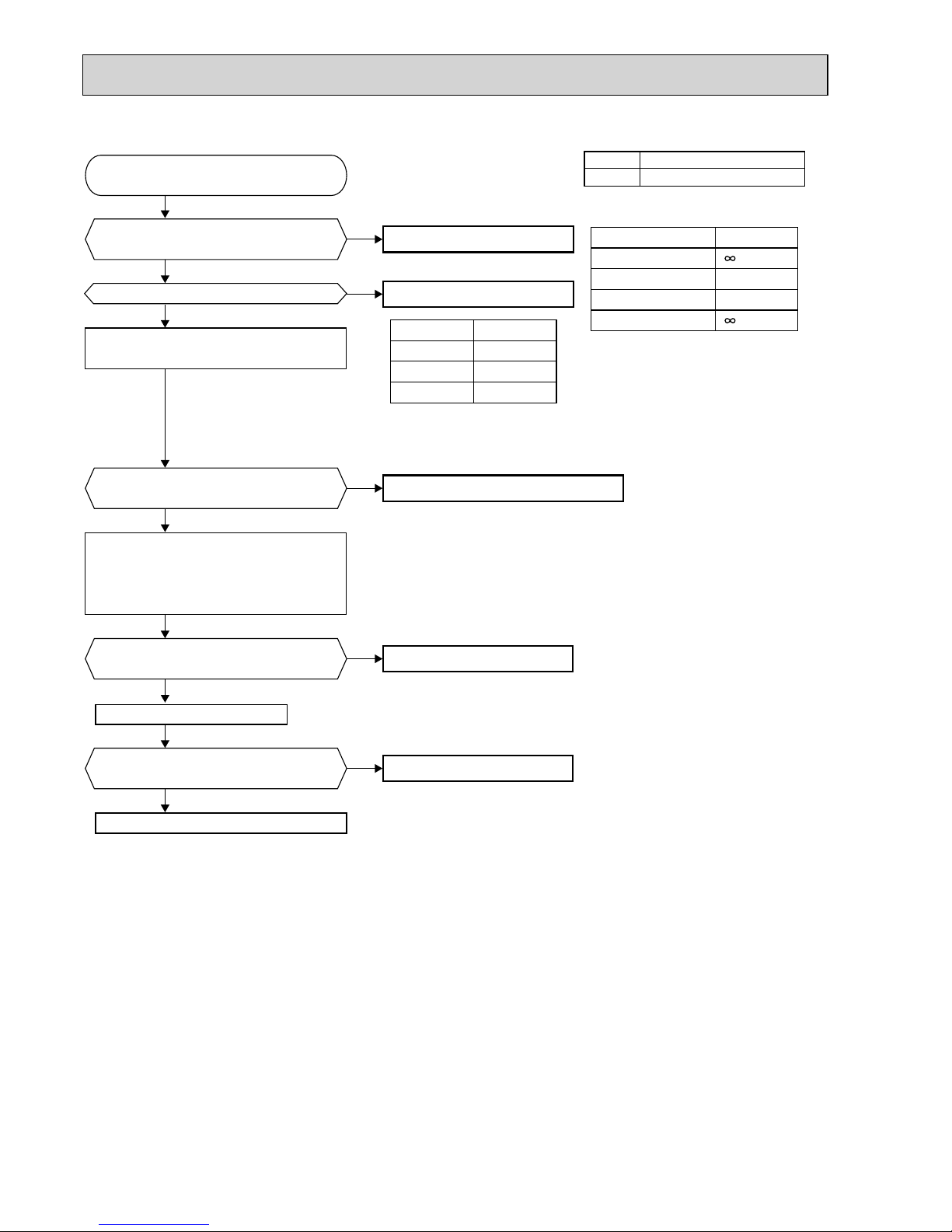

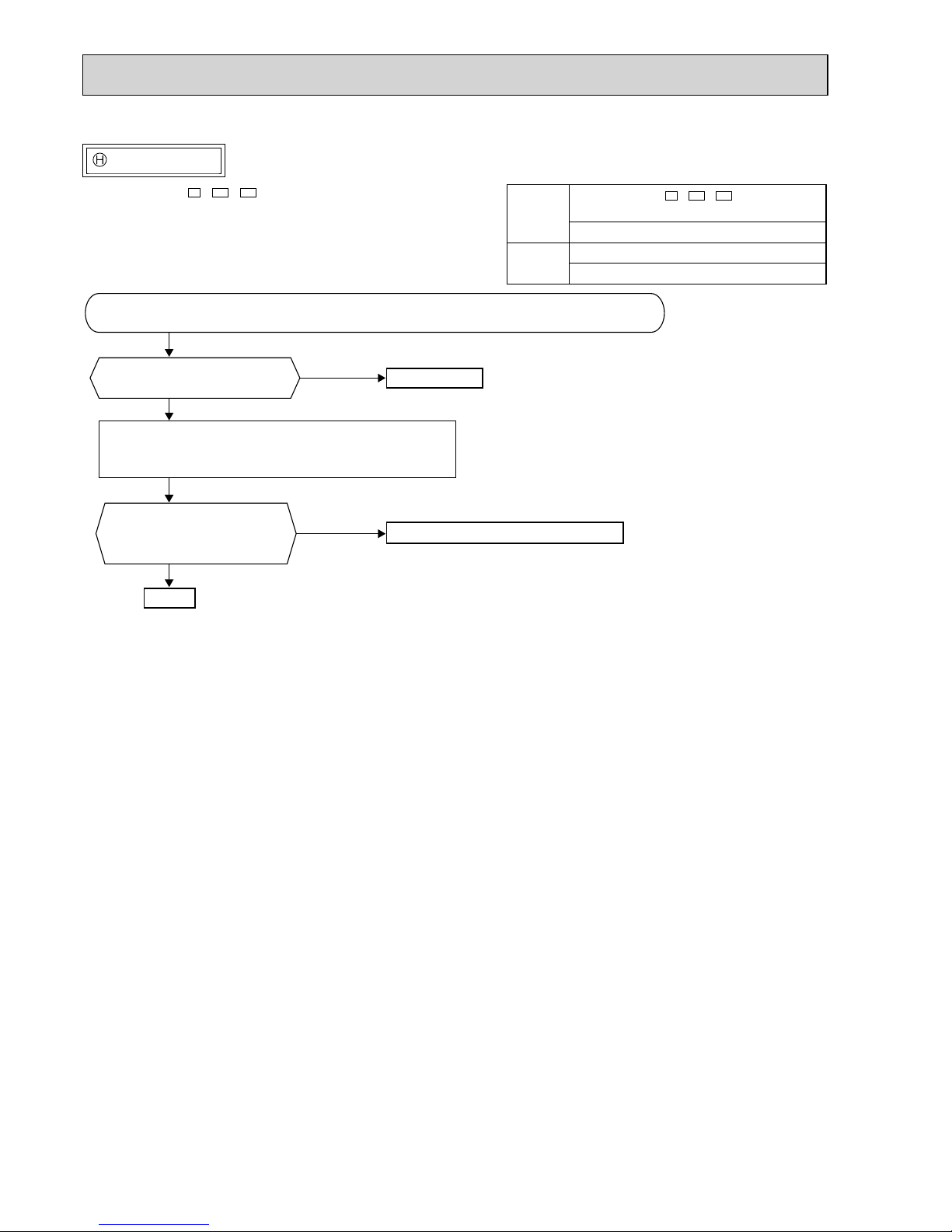

The record of automatic line correcting can be checked in the following way:

(1) Turn OFF the power supply and make sure that the LED goes off.

(2) Turn ON the "3" of SW2 on the outdoor display P.C. board.

(3) Turn ON the power supply.

(4) Check the correction state with the LED lamps on the outdoor display P.C. board.

(5) Turn OFF the power supply and make sure that the LED goes off.

(6) Turn OFF the "3" of SW2 on the outdoor display P.C. board.

(7) Turn ON the power supply.

Number of blinks

Wiring line

LED1 (Red) LED2 (Yellow)

Once Once Not corrected

3 times 3 times Corrected

SW2

<MXZ-3D54VA/3D54VA2/3D68VA/4D72VA/4D83VA/5D102VA>

Improper wiring or piping can be automatically detected by pressing the piping/wiring correction switch (SW871) on the

outdoor control P.C. board.

When improper wiring or piping is detected, wiring lines are corrected.

This will be completed in about 10 to 20 minutes.

[How to activate this function]

1. Check that outside temperature is above 0ºC.

(This function does not work when outside temperature is not above 0ºC. )

2. Check that the stop valves of the liquid pipe and gas pipe are open.

3. Check that the wiring between indoor and outdoor unit is correct.

(If the wiring is not correct, this function does not work.)

4. Turn ON the power supply and wait at least 1 minute.

5. Press the piping/wiring correction switch (SW871) on the outdoor P.C. board.

Do not touch energized parts.

LED indication during detection:

LED1 (Red) LED2 (Yellow) LED3 (Green)

Lighted Lighted Once

LED indication after detection:

LED1 (Red) LED2 (Yellow) LED3 (Green) Indication

Lighted Not lighted Lighted Completed (Problem corrected/Normal)

Once Once Once Not completed (Detection failed)

Other indications

Refer to "SAFETY PRECAUTIONS WHEN LED

FLASHES" located behind the service panel.

Make sure that the valves are open and the pipes are not collapsed or clogged.

6. Press the switch to cancel.

LED indication after cancel:

LED1 (Red) LED2 (Yellow) LED3 (Green)

Lighted Lighted Not lighted

NOTE: Indoor unit cannot be operated while this function is activated.

When this function is activated while indoor unit is operating, the operation will be stopped.

Operate indoor unit after the automatic line correcting is finished.

Pressing the switch during detection cancels this function.

The record of automatic line correcting can be checked in the following way:

Press the switch for more than 5 seconds

LED will show the record of automatic correcting for about 30 seconds as shown in the table below:

Number of blinks

Wiring line

LED1 (Red) LED2 (Yellow) LED3 (Green)

Once Once Lighted Not corrected

3 times 3 times Lighted Corrected

NOTE: Activate this function to check the correct wiring after replacing the outdoor P.C. board.

(Previous records are deleted when the outdoor control P.C. board is replaced.)

The record cannot be shown if automatic line correcting is not cancelled (Refer to "How to activate this function").

MXZ-2D33VA/2D40VA/2D42VA/2D53VA/2D53VAH

SW2 on the outdoor display P.C. board

OBH626H

119

<MXZ-6D122VA>

Improper wiring or piping can be automatically detected by pressing the piping/wiring correction switch (SW871).

When improper wiring or piping is detected, wiring lines are corrected.

This will be completed in about 10 to 20 minutes.

[How to activate this function]

1. Check that outside temperature is above 0˚C.

(This function does not work when outside temperature is not above 0˚C.)

2. Check that the stop valves of the liquid pipe and gas pipe are open.

3. Check that the wiring between indoor and outdoor unit is correct.

(If the wiring is not correct, this function does not work.)

4. Turn ON the power supply and wait at least 1 minute.

5. Press the piping/wiring correction switch (SW871) on the outdoor control P.C. board.

Do not touch energized parts.

LED indication during detection:

LED1 (Red) LED2 (Yellow) LED3 (Green)

Lighted Lighted Once

LED indication after detection:

LED1 (Red) LED2 (Yellow) LED3 (Green) Indication

Lighted Not lighted Lighted Completed (Problem corrected/ normal)

Once Once Once Not completed (Detection failed)

Other indications

Refer to "SAFETY PRECAUTIONS WHEN LED

FLASHES" located behind the service panel.

Make sure that the valves are open and the pipes are not collapsed or clogged.

6. Press the switch to cancel.

LED indication after cancel:

LED1 (Red) LED2 (Yellow) LED3 (Green)

Lighted Lighted Not lighted

NOTE: Indoor unit cannot be operated while this function is activated.

When this function is activated while indoor unit is operating, the operation will be stopped.

Operate indoor unit after the auto line correcting is finished.

Pressing the switch during detection cancels this function.

The record of auto line correcting can be confirmed in the following way:

Press the switch for more than 5 seconds.

LED will show the record of auto correcting for about 30 seconds as shown in the table below:

Number of blinks

Wiring line

LED1 (Red) LED2 (Yellow) LED3 (Green)

Once Once Lighted Not corrected

3 times 3 times Lighted Corrected

NOTE: Activate this function to check the correct wiring after replacing the outdoor P.C. board.

(Previous records are deleted when the outdoor control P.C. board is replaced.)

The record cannot be shown if automatic line correcting is not cancelled (Refer to "How to activate this function").

OBH626H

120

10-5. PRE-HEAT CONTROL