Mitsubishi MSC-A09WV, MU-A09WV, MSC-A12WV, MU-A07WV, MU-A12WV Service Manual

...

HFC

utilized

R410A

SPLIT-TYPE, AIR CONDITIONERS

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

Revision:

●MXZ-A18WV - have been added.

●MSC-A07/09/12WV - Part No..have changed.

VARISTOR (NR11& NR12)

E02 336 385 ➔ E02 749 385

●Please void OB307.

E1

E1

SERVICE MANUAL

Wireless type

Models

MSC-A07WV MSC-A09WV MSC-A12WV MSC-A07WV MSC-A09WV MSC-A12WV -

Multi system type

Models

MSC-A07WV MSC-A09WV MSC-A12WV -

Inverter-controlled multi system Model

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

· MU-A07WV -

· MU-A09WV -

· MU-A12WV -

· MUH-A07WV -

· MUH-A09WV -

· MUH-A12WV -

· MUX-A10WV -

· MUX-A19WV -

· MUX-A20WV -

· MUX-A25WV -

· MUX-A26WV -

· MXZ-A18WV -

REVISED EDITION-A

No. OB307

E1E1

E1E1

E1E1

E1E1

E1E1

E1E1

E1E1

E1E1

E1E1

E1

E1

E1

MSC-A07WV MSC-A09WV MSC-A12WV -

Remote

controller

E1

E1

E1

Indication of

model name

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················6

3. INDOOR/OUTDOOR

CORRESPONDENCE TABLE ···························8

4. INDOOR UNITS COMBINATION ·······················9

5. SPECIFICATION···············································10

6. NOISE CRITERIA CURVES···························· 17

7. OUTLINES AND DIMENSIONS······················ 20

8. WIRING DIAGRAM ··········································25

9. REFRIGERANT SYSTEM DIAGRAM··············32

10. PERFORMANCE CURVES······························45

11. MICROPROCESSOR CONTROL·····················84

12. SERVICE FUNCTIONS···································102

13. TROUBLESHOOTING····································104

14. DISASSEMBLY INSTRUCTIONS···················129

15. PARTS LIST····················································144

16. OPTIONAL PARTS ·········································157

1

TECHNICAL CHANGES

MSC-07RV- ➔MSC-A07WVMSC-09RV- ➔MSC-A09WVMSC-12RV- ➔MSC-A12WV-

1. Rated voltage has changed. (220-240V➔230V)

2. Indoor model has changed.

MU-07RV- ➔MU-A07WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH130VGCT➔RN092VHSHT)

MU-09RV- ➔MU-A09WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH140VGCT➔RN099VHSHT)

MU-12RV- ➔MU-A12WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH220VHAT➔RN135VHSHT)

MUH-07RV- ➔MUH-A07WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH130VGCT➔RN092VHSHT)

MUH-09RV- ➔MUH-A09WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH165VGCT➔RN104VHSHT)

E1E4

E1E4

E1E4

E1E4

E1E4

E1E4

E1E4

E1E4

MUH-12RV- ➔MUH-A12WV-

1. Refrigerant has changed. (R22➔R410A)

2. Compressor has changed. (RH220VHAT➔RN135VHSHT)

MUX-10RV- ➔MUX-A10WV-

1. Outdoor model has changed.

2. Refrigerant has changed. (R22➔R410A)

MUX-19TV- ➔MUX-A19WVMUX-20TV- ➔MUX-A20WVMUX-25TV- ➔MUX-A25WV-

1. Refrigerant has changed. (R22➔R410A)

MUX-24RV- ➔MUX-A26WV-

1. Outdoor model has changed.

2. Refrigerant has changed. (R22➔R410A)

MXZ-18TV - ➔ MXZ-A18WV -

• Outdoor model has changed.

• Refrigerant has changed.

E1E4

E1E2

E1E1

E1E1

E1E1

E1E2

E1E2

2

Refrigerating

oil

Refrigerant

New refrigerant

R410A

HFC-32: HFC-125 (50%:50%)

Pseudo-azeotropic refrigerant

Not included

A1/A1

72.6

-51.4

1.557

64

Non combustible

0

1730

From liquid phase in cylinder

Possible

Incompatible oil

Non

Non

Previous refrigerant

R22

R22 (100%)

Single refrigerant

Included

A1

86.5

-40.8

0.94

44.4

Non combustible

0.055

1700

Gas phase

Possible

Compatible oil

Light yellow

Non

Refrigerant

Composition (Ratio)

Refrigerant handling

Chlorine

Safety group (ASHRAE)

Molecular weight

Boiling point (:)

Steam pressure [25:](Mpa)

Saturated steam density [25:](Kg/K)

Combustibility

ODP w1

GWP w2

Refrigerant charge method

Additional charge on leakage

Kind

Color

Smell

w1:Ozone Destruction Parameter : based on CFC-11

w2 :Global Warmth Parameter : based on CO

2

INFORMATION FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

New Specification Current Specification

The incompatible refrigerating oil easily separates from

refrigerant and is in the upper layer inside the suction muffler.

Raising position of the oil back hole enables to back the

refrigerating oil of the upper layer to flow back to the

compressor.

Since refrigerant and refrigerating oil are compatible each,

refrigerating oil backs to the compressor through the lower

position oil back hole.

Compressor

Suction muffler

Oil back hole

Refrigerating oil

Refrigerant

Compressor

Suction muffler

Oil back hole

Refrigerating oil /Refrigerant

Compressor

• This room air conditioner adopts an HFC refrigerant (R410A) which never destroys the ozone layer.

• Pay particular attention to the following points, though the basic installation procedure is same as that for R22 conditioners.

1 As R410A has working pressure approximate 1.6 times as high as that of R22, some special tools and piping parts/

materials are required. Refer to the table below.

2 Take sufficient care not to allow water and other contaminations to enter the R410A refrigerant during storage and

installation, since it is more susceptible to contaminations than R22.

3 For refrigerant piping, use clean, pressure-proof parts/materials specifically designed for R410A. (Refer to 2. Refrigerant

piping.)

4 Composition change may occur in R410A since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent

composition change.

NOTE : The unit of pressure has been changed to MPa on the international system of units(SI unit system).

The conversion factor is: 1(MPa [Gauge]) =10.2(kgf/ff[Gauge])

3

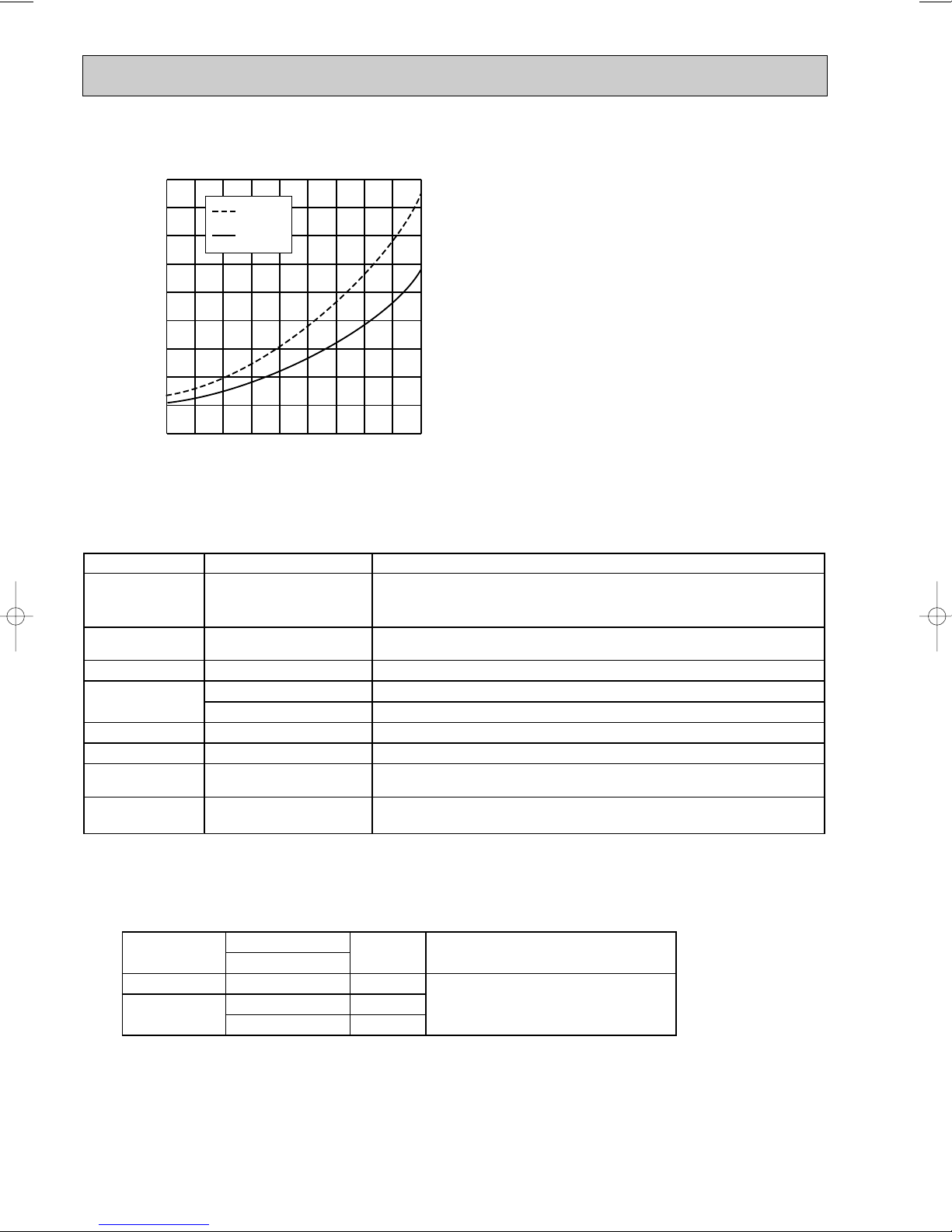

-30 -20 -10 0 10 20

30

40 50 60

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

(MPa [Gauge])

R410A

R22

Conversion chart of refrigerant temperature and pressure

Saturated liquid pressure

(:)

NOTE : The unit of pressure has been changed to MPa on the

R410A tools Can R22 tools be used?

Gas leak detector

R410A has high pressures beyond the measurement range of existing

gauges. Port diameters have been changed to prevent any other refrigerant

from being charged into the unit.

Hose material and cap size have been changed to improve the pressure

resistance.

Dedicated for HFC refrigerant.

6.35 mm and 9.52 mm

Description

Clamp bar hole has been enlarged to reinforce the spring strength in the tool.

Provided for flaring work (to be used with R22 flare tool).

Provided to prevent the back flow of oil. This adapter enables you to use

vacuum pumps.

It is difficult to measure R410A with a charging cylinder because the

refrigerant bubbles due to high pressure and high-speed vaporization

No

No

No

Yes

Yes

New

New

New

Gauge manifold

Charge hose

Torque wrench

Flare tool

Flare gauge

Vacuum pump

adapter

Electronic scale for

refrigerant charging

No : Not Substitutable for R410A Yes : Substitutable for R410A

No 12.7 mm

Wall

thickness

Outside diameter

Pipe

mm

For liquid

For gas

6.35

9.52

12.7

0.8 mm

0.8 mm

0.8 mm

Heat resisting foam plastic

Specific gravity 0.045 Thickness 8 mm

Insulation material

international system of units(SI unit system).

The conversion factor is: 1(MPa [Gauge]) =10.2(kgf/ff[Gauge])

1.Tools dedicated for the air conditioner with R410A refrigerant

The following tools are required for R410A refrigerant. Some R22 tools can be substituted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to prevent any other refrigerant being

charged into the unit. Cap size has been changed from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.

2.Refrigerant piping

1 Specifications

Use the refrigerant pipes that meet the following specifications.

• Use a copper pipe or a copper-alloy seamless pipe with a thickness of 0.8 mm. Never use any pipe with a thickness less

than 0.8mm, as the pressure resistance is insufficient.

4

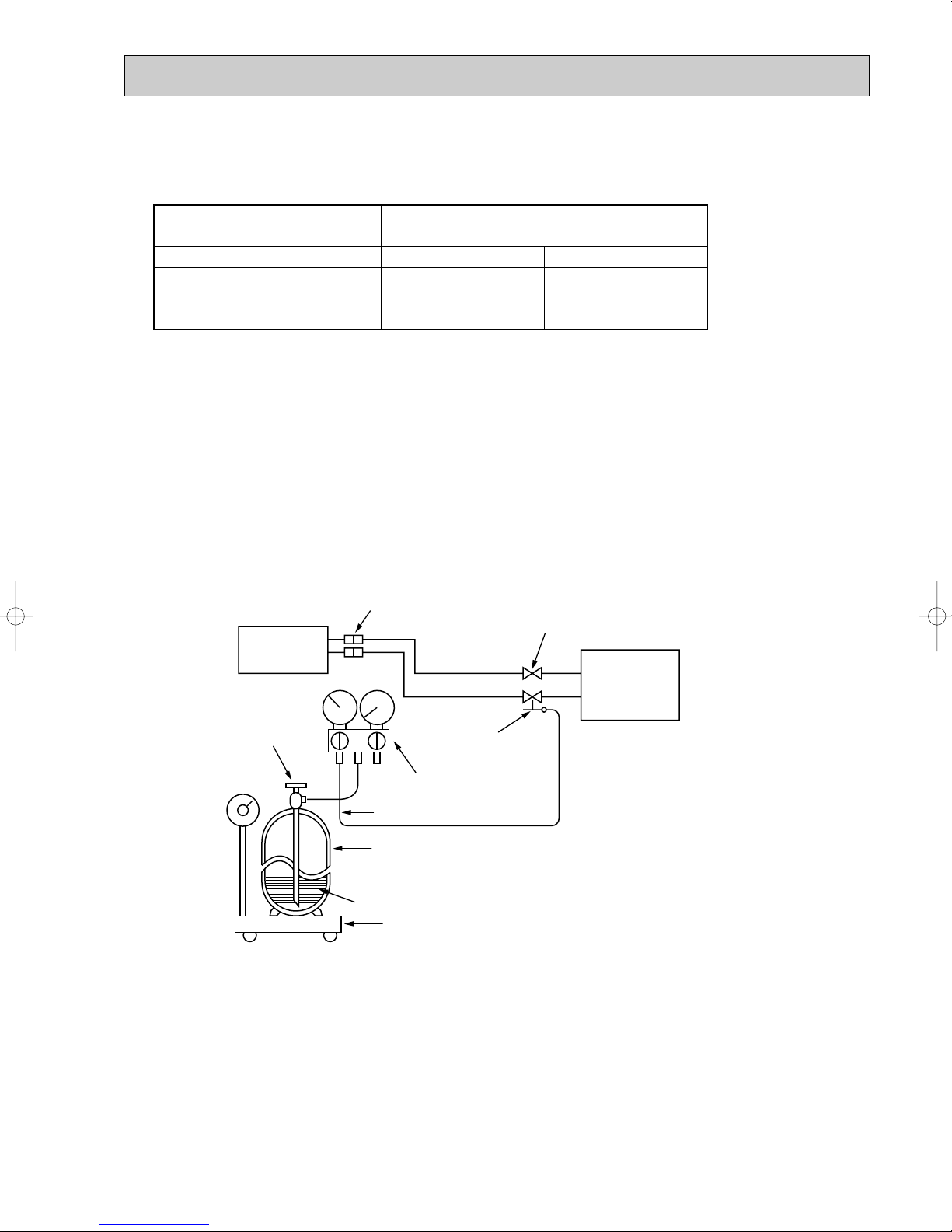

2 Flaring work and flare nut

Flaring work for R410A pipe differs from that for R22 pipe.

For details of flaring work, refer to Installation manual “FLARING WORK”.

Pipe diameter

mm

6.35

9.52

12.7

Dimension of flare nut

R410A

17

22

26

R22

17

22

24

3.Refrigerant oil

Apply the special refrigeration oil (accessories: packed with indoor unit) to the flare and the union seat surfaces.

4.Air purge

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant

circuit.

• Use the vacuum pump for air purging for the purpose of environmental protection.

5.Additional charge

For additional charging, charge the refrigerant from liquid phase of the gas cylinder.

If the refrigerant is charged from the gas phase, composition change may occur in the refrigerant inside the cylinder and the

outdoor unit. In this case, ability of the refrigerating cycle decreases or normal operation can be impossible. However,

charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

Union

Stop valve

Indoor unit

Refrigerant gas

cylinder

operating valve

Liquid pipe

Gas pipe

Service port

Outdoor unit

Gauge manifold

valve (for R410A)

Charge hose (for R410A)

Refrigerant gas cylinder

for R410A with siphon

Refrigerant (liquid)

Electronic scale for refrigerant charging

5

2

PART NAMES AND FUNCTIONS

INDOOR UNIT

MSC-A07WV MSC-A09WV MSC-A12WV -

E1

E1

E1

Air cleaning filter

(White bellows type)

Deodorizing filter

(Gray sponge type)

Panel

Air filter

Air outlet

Vertical vane

Horizontal vane

Operation section

(When the front panel is opened)

Emergency operation switch

Front panel

Air inlet

to Breaker

Power supply cord

Remote control

receiving section

Remote controller

Display section

Operation indicator lamp

Receiving section

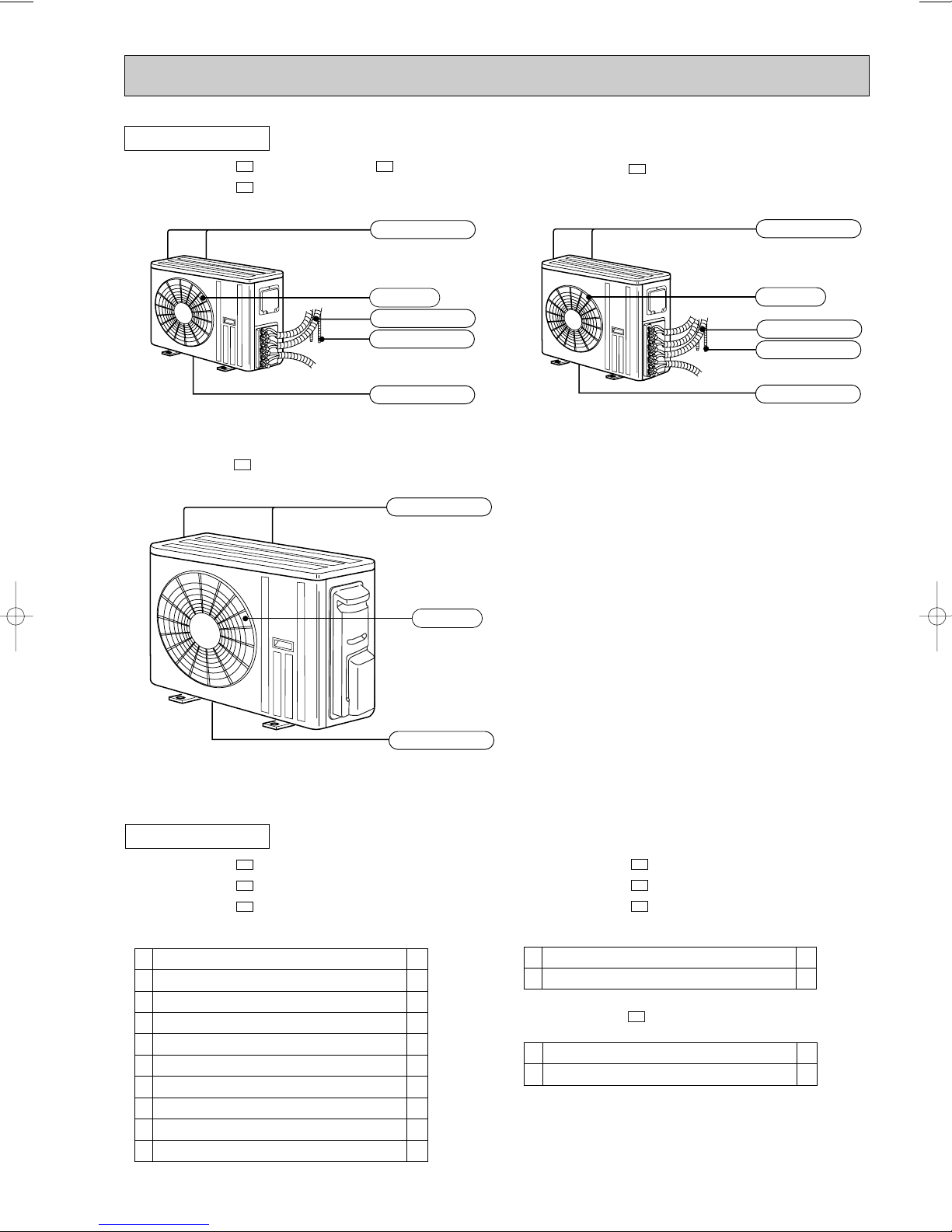

OUTDOOR UNIT

MU-A07WV - MUH-A07WV MU-A09WV - MUH-A09WV MU-A12WV - MUH-A12WV -

Air inlet

(back and side)

Piping

Air outlet

Drain outlet

E1E1

E1E1

E1E1

Drain hose

MUX-A10WV-

6

E1

Air inlet

(back and side)

Piping

Drain hose

Air outlet

Drain outlet

OUTDOOR UNIT

Installation plate

Installation plate fixing screw 4 o 25 mm

Remote controller holder

Fixing screw for 3 3.5 o 16 mm

Battery (AAA) for remote controller

Wireless remote controller

Felt tape (Used for left or left-rear piping)

Deodorizing filter

Air cleaning filter

Refrigerant oil

1

5

1

2

2

1

1

1

1

1

<Indoor unit>

1

2

3

4

5

6

7

8

9

0

Drain socket

Drain cap

1

2

<Outdoor unit: MUH type>

1

2

Air outlet

Drain outlet

Air inlet

(Back and side)

MUX-A19WV- MUX-A25WVMUX-A20WV-

E1

E1E1

MUX-A26WV-

E1

MXZ-A18WV-

Air inlet

(Back and side)

Air outlet

Piping

Drainage hose

Drain outlet

E1

Air inlet

(Back and side)

Air outlet

Piping

Drainage hose

Drain outlet

ACCESSORIES

MSC-A07WVMSC-A09WVMSC-A12WV-

E1

E1

E1

MUH-A07WVMUH-A09WVMUH-A12WV-

MXZ-A18WV-

1

Drain socket

2

Drain cap

7

E1

E1

E1

E1

1

2

MUX-A19WV-

E1

MUX-A25WV-

E1

MUX-A20WV-

E1

MUX-A10WV-

E1

MUX-A26WV-

E1

Combination of

the connectable

indoor units

OUTDOOR UNIT

A: MSC-A12WV- E1

B: MSC-A07WV-

E1

A:

B:

MSC-A09WV- E1

C:

A:

MSC-A07WV- E1

B:

A:

MSC-A12WV- E1

B:

C:

MSC-A09WV- E1

D:

A:

MSC-A12WV- E1

B:

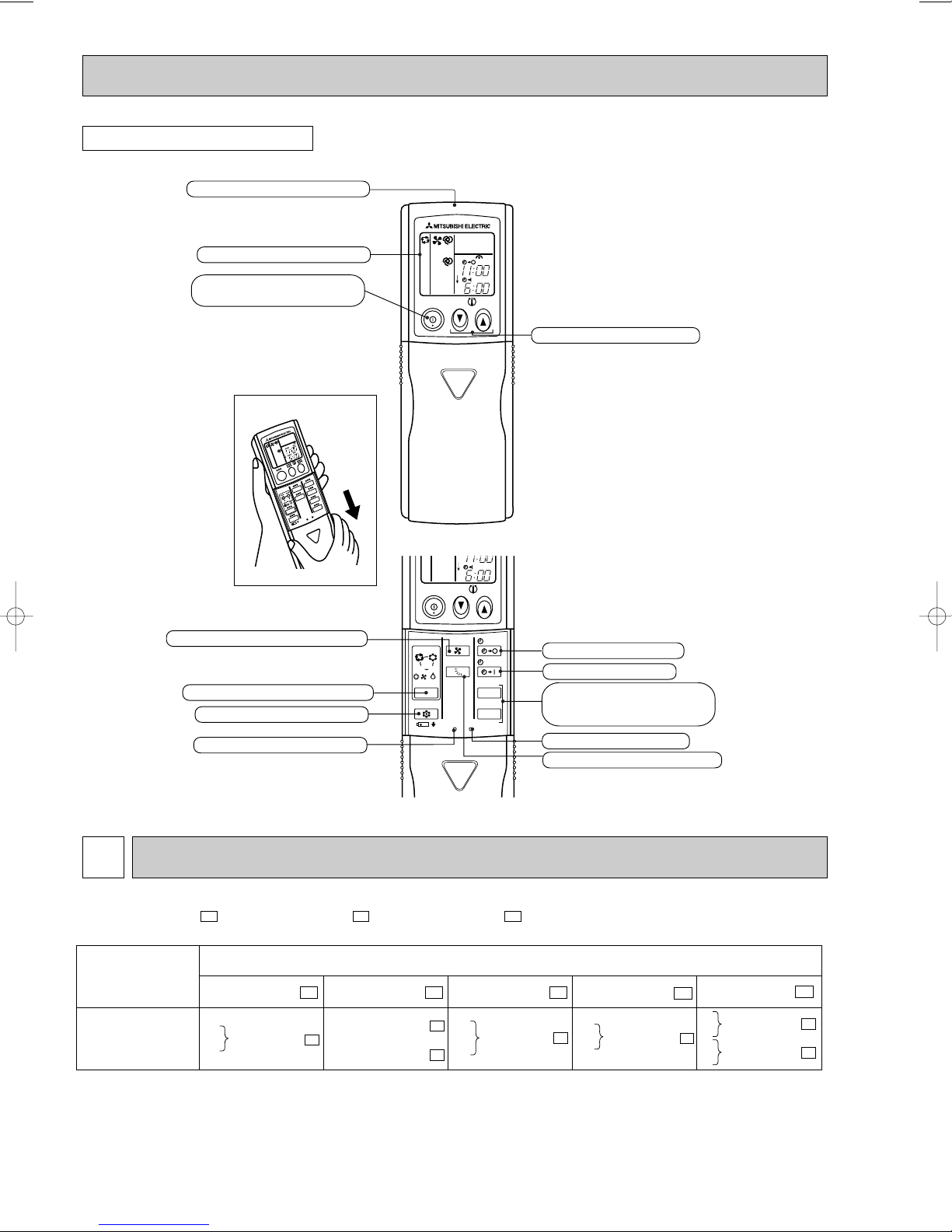

REMOTE CONTROLLER

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

Open the front lid.

FAN SPEED CONTROL button

OPERATION SELECT button

ECONO COOL button

RESET button

ON/OFF

ON/OFF

I FEEL

COOL

VANE

HEAT

DRY

/FAN

/

MODE

ECONO COOL

RESET

TOO

WARM

TOO

WARM

FAN

CLOCK

CLOCK

PM

AM

TOO

COOL

PM

AM

TOO

COOL

STOP

START

HR.

MIN.

TEMPERATURE buttons

OFF-TIMER button

ON-TIMER button

HR. button

MIN. button

(TIME SET button)

CLOCK SET button

VANE CONTROL button

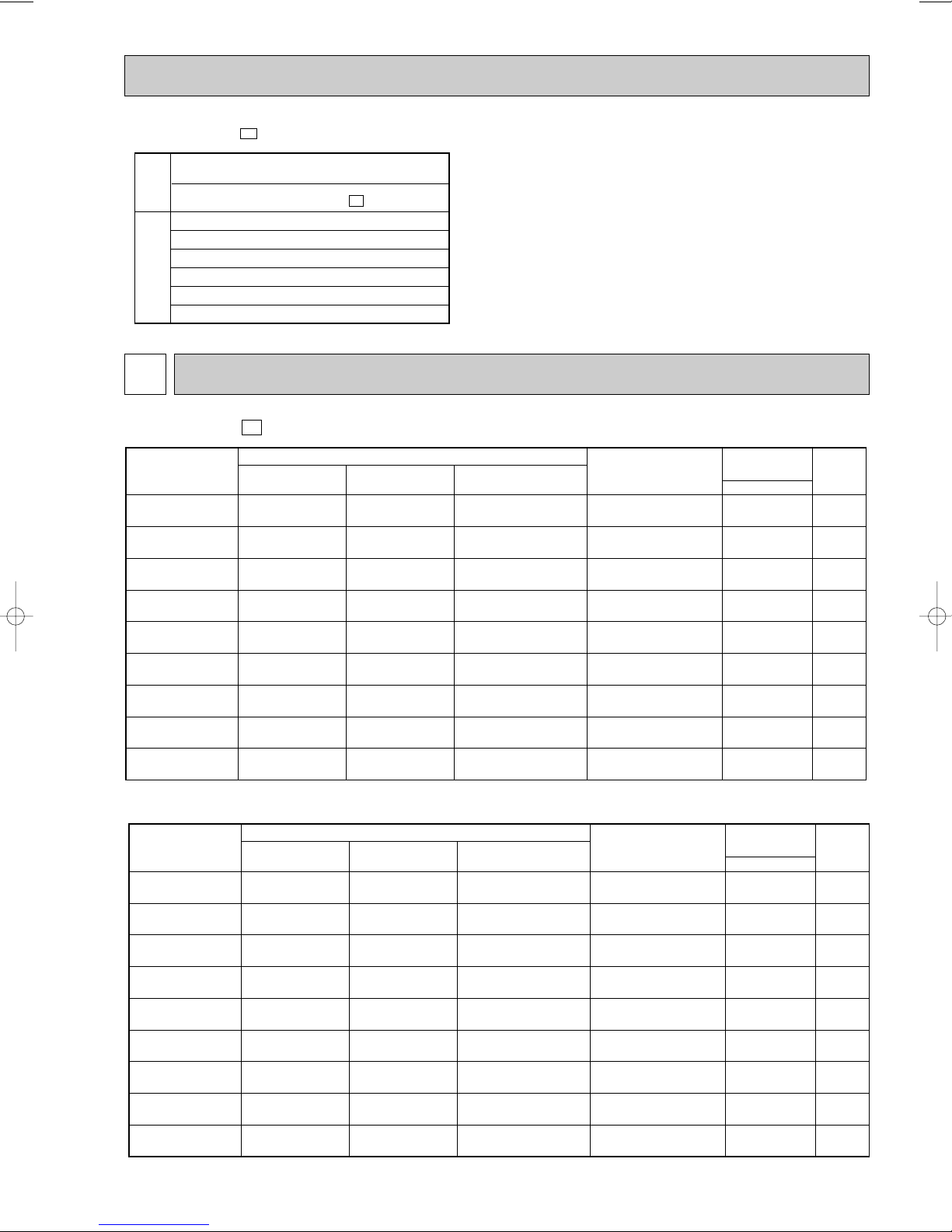

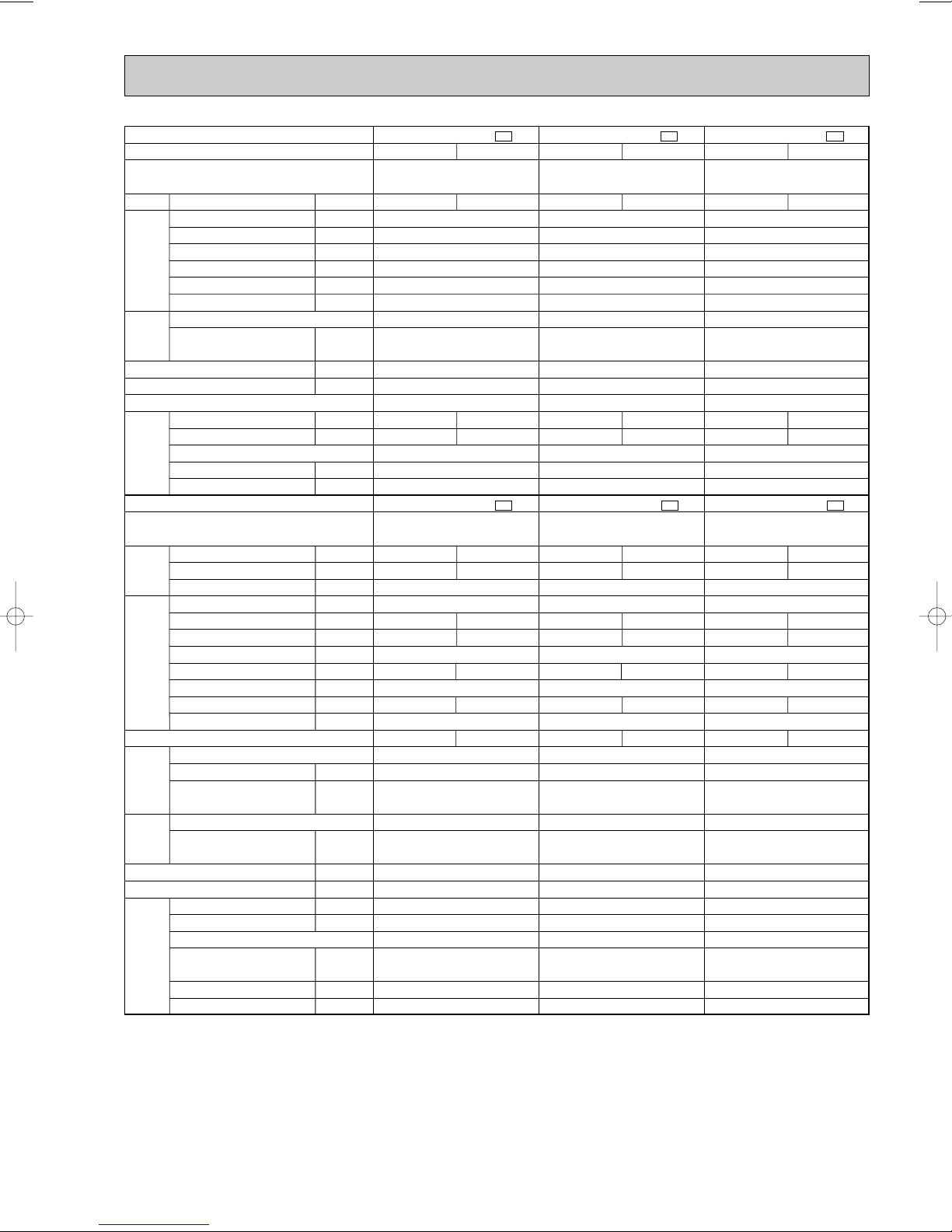

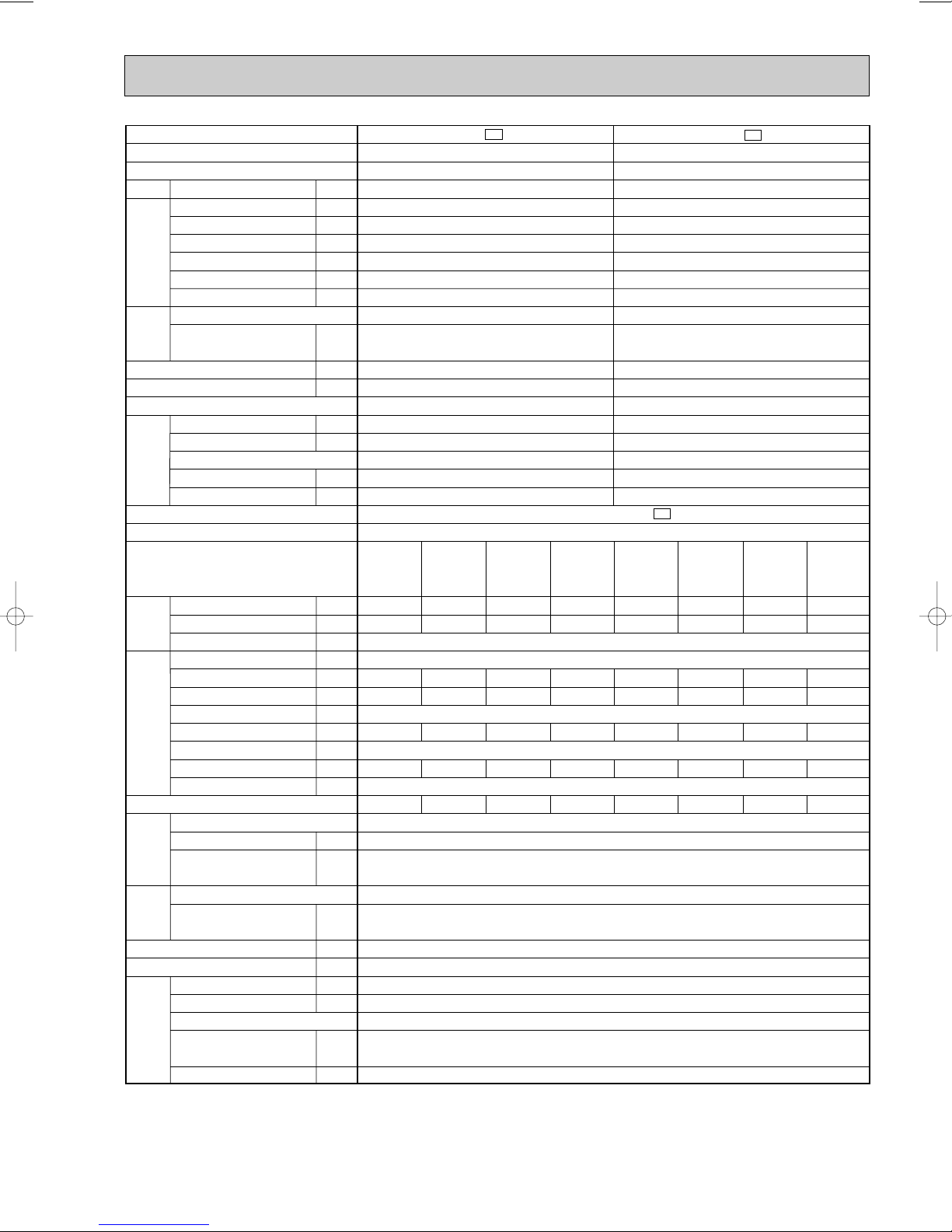

INDOOR/ OUTDOOR CORRESPONDENCE TABLE3

MSC-A07WV - MSC-A09WV - MSC-A12WV -

E1E1E1

8

07

09

12

07+07

07+09

07+12

09+09

09+12

12+12

90

90

90

90

90

90

90

90

90

3.62

3.91

5.70

7.15

7.73

7.78

8.60

8.84

8.99

2.3

(0.9-2.95)

2.5

(0.9-3.30)

3.4

(0.9-4.00)

4.6

(1.49-5.30)

4.8

(1.49-5.40)

5.0

(1.51-5.60)

5.0

(1.51-5.55)

5.3

(1.53-5.80)

5.4

(1.55-6.00)

0.750

(0.225-1.000)

0.810

(0.225-1.070)

1.180

(0.220-1.450)

1.480

(0.370-2.060)

1.600

(0.370-2.070)

1.610

(0.365-2.100)

1.780

(0.370-2.105)

1.830

(0.365-2.110)

1.860

(0.370-2.130)

–

–

–

2.3

2.5

2.98

2.5

3.1

2.65

2.3

2.5

3.4

2.3

2.3

2.02

2.5

2.2

2.65

Indoor units

combination

Unit A Unit B

Cooling capacity (kW)

Total

Outdoor unit

power consumption

(kW)

Current

(A)

Power

factor

(%)

230V

NOTE: Electrical data is for outdoor unit only.

MXZ-A18WV -

E1

NOTE: Electrical data is for outdoor unit only.

07

09

12

07+07

07+09

07+12

09+09

09+12

12+12

90

90

90

90

90

90

90

90

90

4.73

5.14

6.76

9.32

9.37

9.03

9.28

8.91

8.55

3.3

(0.9-4.0)

3.6

(0.9-4.5)

4.0

(0.9-4.8)

6.1

(1.53-6.70)

6.2

(1.53-6.80)

6.5

(1.55-7.00)

6.5

(1.55-7.0)

6.55

(1.56-7.1)

6.6

(1.58-7.2)

0.980

(0.225-1.115)

1.065

(0.225-1.195)

1.400

(0.220-1.680)

1.930

(0.300-2.070)

1.940

(0.300-2.040)

1.870

(0.295-1.980)

1.920

(0.295-2.010)

1.845

(0.295-1.950)

1.770

(0.290-1.850)

–

–

–

3.05

3.23

3.88

3.25

3.77

3.30

3.3

3.6

4.0

3.05

2.97

2.62

3.25

2.78

3.30

Indoor units

combination

Unit A Unit B

Heating capacity (kW)

Total

Outdoor unit

power consumption

(kW)

Current

(A)

Power

factor

(%)

230V

MXZ-A18WV -

E1

OUTDOOR UNIT

MXZ-A18WV-

Combination of the

connectable indoor units

07+07

07+09

07+12

09+09

09+12

12+12

E1

❈There is no combination other than this table.

4

INDOOR UNITS COMBINATION

9

5

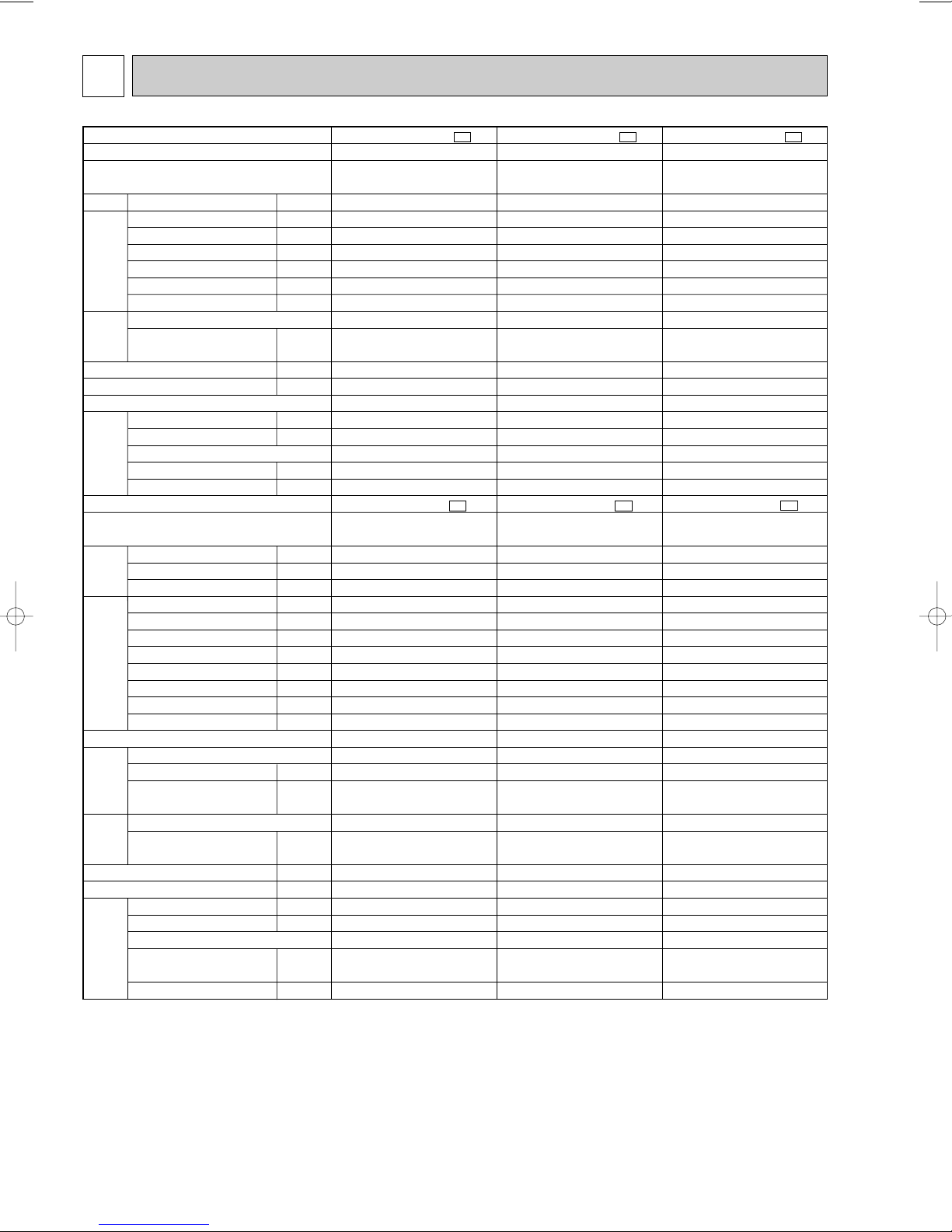

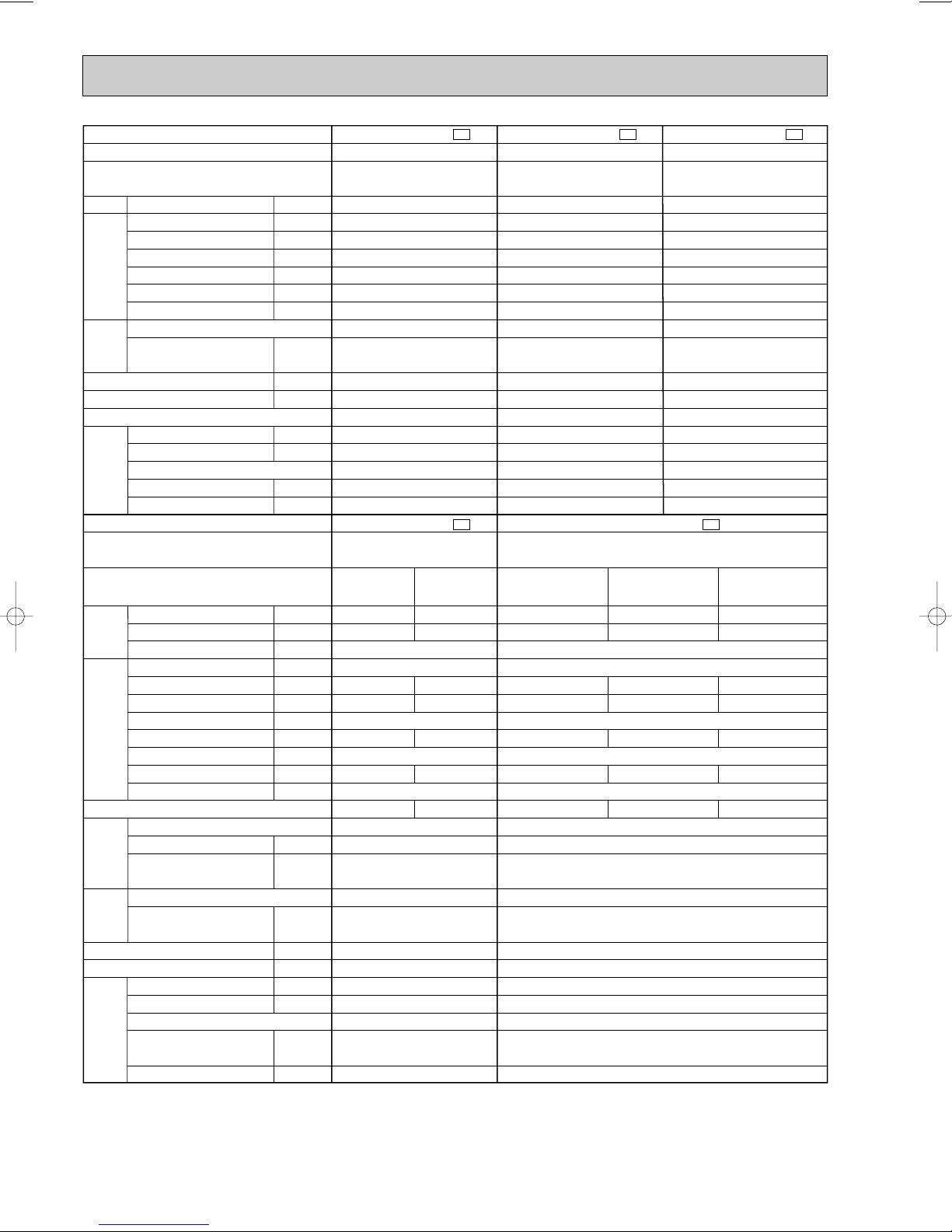

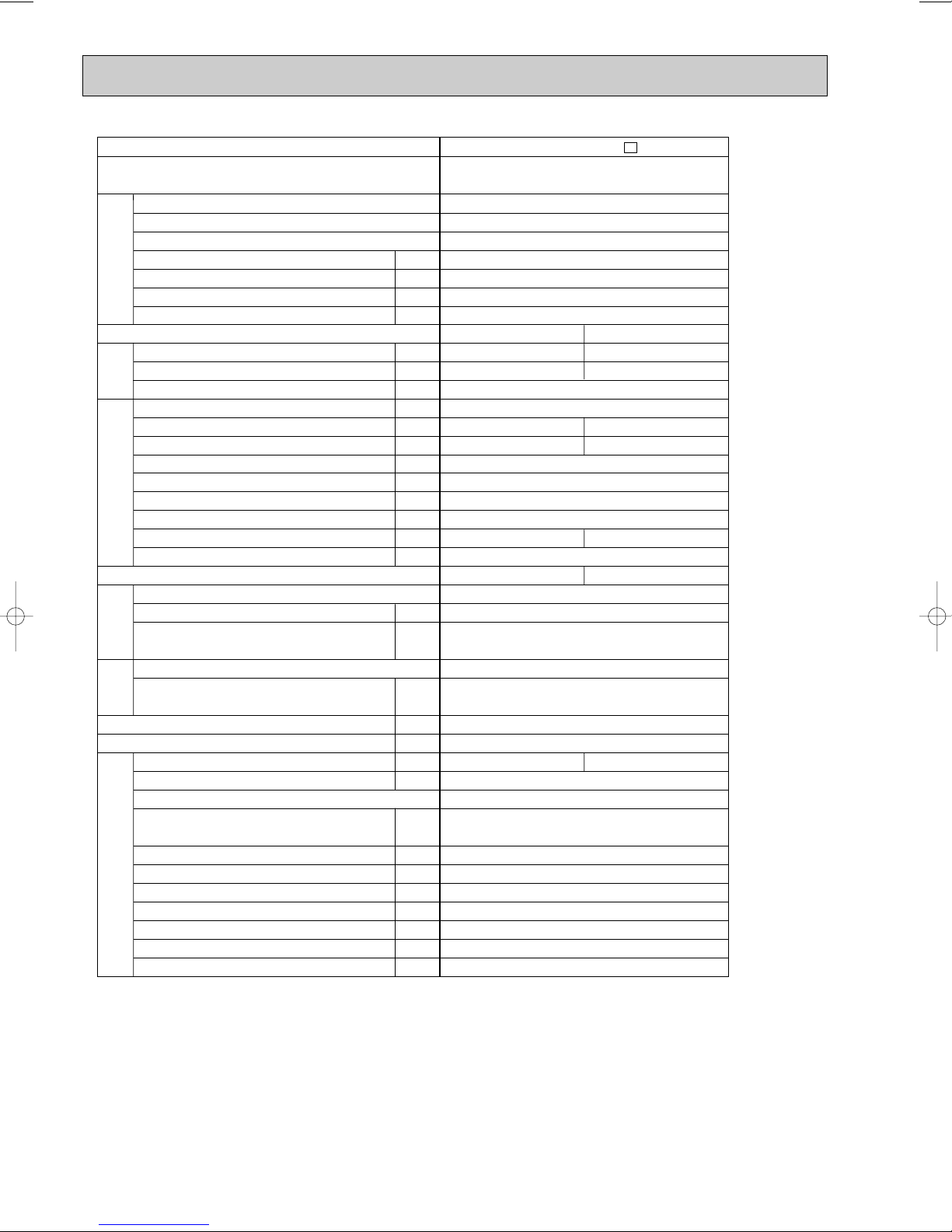

Indoor model

Function

Indoor unit power supply

Air flow(High/Med. /Low )

Power outlet

Running current

Power input

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at 20:)

Dimensions WOHOD

Weight

Air direction

Sound level(High/Med. /Low )

Fan speed (High/Med. /Low )

Fan speed regulator

Thermistor RT11(at 25:)

Thermistor RT12(at 25:)

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at 20:)

Model

Winding

resistance(at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigerating oil (Model)

K /h

A

A

W

%

A

A

"

mm

kg

dB

rpm

k"

k"

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MSC-A07WV -

E1

Single phase

230V,50Hz

10

0.17

35

90

—

0.17

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

3

10

10

MU-A07WV -

E1

Single phase

230V,50Hz

10

—

2.76

0.22

RN092VHSHT

600

C-R 3.87

C-S 6.14

RA6V23-FC

WHT-BLK 353

BLK-RED 321

780o540o255

34

45

735

1

0.75

350 (NEO22 )

Cooling

474/372 /276

RC4V19-LA

36/31 /25

900/750 /600

2.3

0.9

1,686

2.98

675

98

23

3.24

MSC-A09WV - E1

Single phase

230V,50Hz

10

0.17

35

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

3

10

10

MU-A09WV -

E1

Single phase

230V,50Hz

10

—

RN099VHSHT

700

C-R 3.40

C-S 4.56

RA6V23-FC

WHT-BLK 353

BLK-RED 321

780o540o255

34

45

735

1

0.80

350 (NEO22 )

Cooling

474/384 /306

90

—

0.17

36/31 /25

900/770 /650

2.55

1.1

1,686

3.26

745

99

24

3.04

0.22

3.27

MSC-A12WV - E1

Single phase

230V,50Hz

582/444 /324

10

0.19

40

RC4V19-KA

WHT-BLK 316

BLK-RED 299

815O278O217

10

5

3

10

10

MU-A12WV -

E1

Single phase

230V,50Hz

1.6

1,914

10

4.91

—

97

29

RN135VHSHT

900

C-R 2.79

C-S 3.36

RA6V33-DC

WHT-BLK 301

BLK-RED 332

780o540o255

36

49

825

1

0.83

620 (NEO22)

Cooling

92

—

0.19

40/33 /26

930/760 /600

3.45

1,100

4.60

0.31

3.03

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Capacity

ww

ww

w

w

w

w

w

w

w

w

w

w

ww

w

w

ww

ww

w

w

SPECIFICATION

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C

Outdoor DB35°C WB24°C

Indoor-Outdoor piping length 5m

w Reference value

10

Indoor model

Cooling

474/372 /276

Indoor unit power supply

Capacity

Air flow(High/Med. /Low )

Power outlet

Running current

Power input

Power factor

Electrical

data

Starting current

Fan motor current

Function

w

w

K /h

A

A

W

%

A

A

Model

Winding

Fan

motor

resistance(at 20:)

Dimensions WOHOD

Weight

"

mm

kg

Air direction

Sound level(High/Med. /Low )

Fan speed(High/Med. /Low )

ww

ww

dB

rpm

36/31 /25

900/750 /600

Fan speed regulator

Thermistor RT11(at 25:)

Special

remarks

Thermistor RT12(at 25:)

k"

k"

Outdoor model

Outdoor unit power supply

Capacity

Dehumidification

Outdoor air flow

Capacity

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Electrical

data

Starting current

Compressor motor current

Fan motor current

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

Coefficient of performance (C.O.P)

Model

Output

Winding

Compressor

resistance (at 20:)

Model

Winding

Fan

motor

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

W

"

"

mm

kg

dB

rpm

Fan speed regulator

Refrigerant filling

Special

remarks

capacity (R410A)

Refrigerating oil (Model)

Thermistor RT61 (at 0:)

kg

cc

k"

350 (NEO22)

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

Outdoor DB35°C WB24°C Outdoor DB 7°C/WB 6°C

Indoor-Outdoor piping length 5m

w Reference value

MSC-A07WV -

Heating

Single phase

230V,50Hz

w

w

510/420 /342

10

0.17

35

90

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

w

w

36/31 /25

w

w

950/820 /700

3

10

10

MUH-A07WV -

Single phase

230V,50Hz

2.3

2.5

0.9

1,686

10

2.98

675

2.86

655

—

98

100

23

2.76

2.64

0.22

3.24

3.62

RN092VHSHT

600

C-R 3.87

C-S 6.14

RA6V23-FB

WHT-BLK 353

BLK-RED 321

780o540o255

35

47

735

1

0.75

33.18

—

E1

w

w

w

E1

MSC-A09WV - E1

Cooling

Single phase

230V,50Hz

w

w

474/384 /306

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

w

w

w

36/31 /25

w

900/770 /650

MUH-A09WV -

Single phase

230V,50Hz

2.55

1.1

3.26

745

99

2.95

3.27

RN104VHSHT

RA6V33-DB

WHT-BLK 301

BLK-RED 332

780o540o255

350 (NEO22)

Heating

w

588/456 /342

10

0.17

35

90

—

0.17

9

5

w

39/32 /25

w

1,050/870 /700

3

10

10

1,710

10

—

24

0.31

700

C-R 3.40

C-S 4.56

38

49

825

1

1.10

33.18

3.05

—

3.52

805

99

3.21

3.69

w

w

w

E1

MSC-A12WV - E1

Cooling

Single phase

w

582/444 /324

RC4V19-KA

WHT-BLK 316

BLK-RED 299

815O278O217

w

w

w

40/33 /26

w

930/760 /600

MUH-A12WV -

Single phase

3.4

1.6

4.51

1,020

98

4.20

3.21

RN135VHSHT

RA6V33-DB

WHT-BLK 301

BLK-RED 332

780o540o255

620 (NEO22)

Heating

230V,50Hz

w

w

606/498 /396

10

0.19

40

92

—

0.19

10

5

w

39/33 /26

w

960/830 /700

3

10

10

230V,50Hz

1,710

10

—

29

0.31

900

C-R 2.79

C-S 3.36

40

49

825

1

1.15

33.18

w

w

w

E1

3.9

—

4.61

1,040

98

4.30

3.61

w

w

w

11

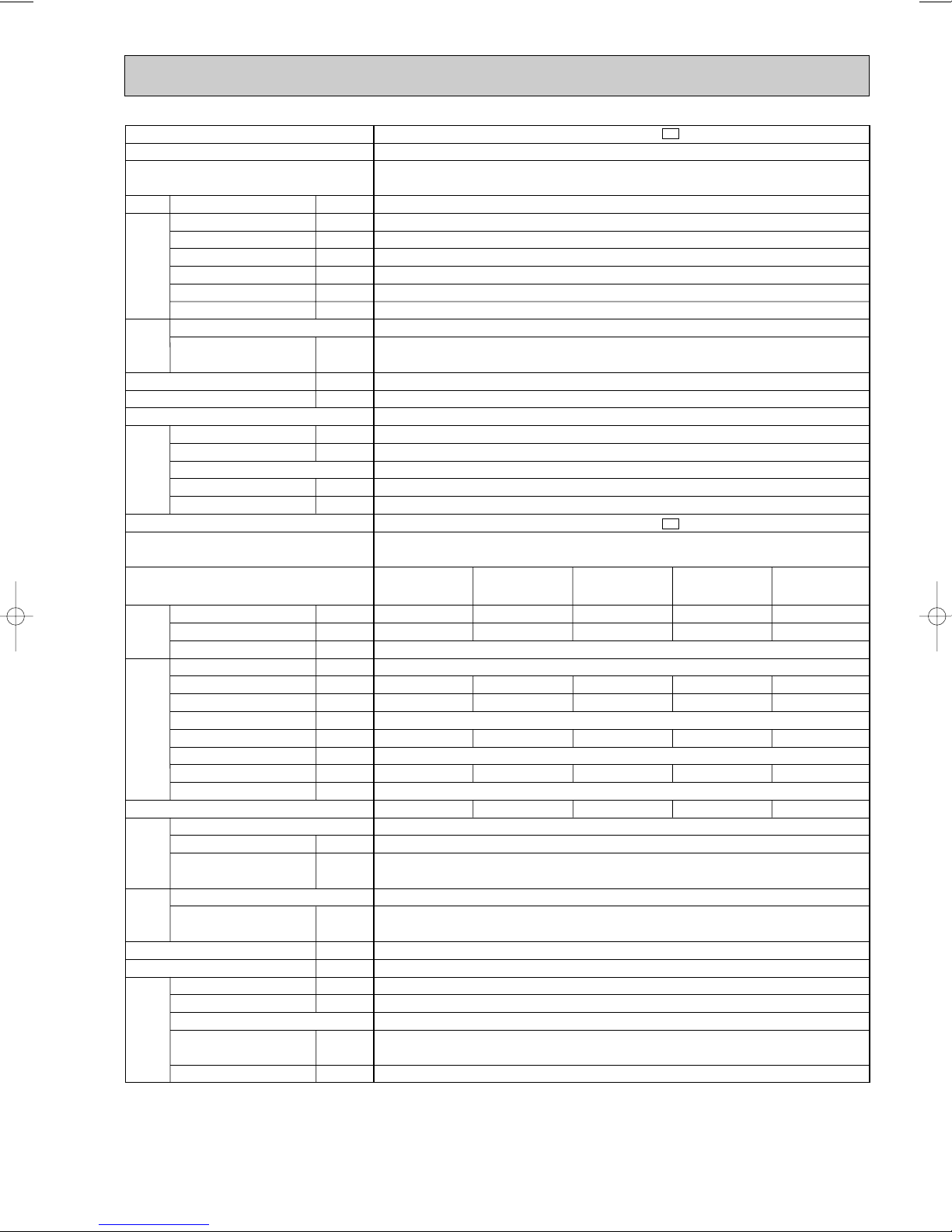

Indoor model

Function

Indoor unit power supply

Air flow (High/Med./Low)

Power outlet

Running current

Power input

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at 20:)

Dimensions WOHOD

Weight

Air direction

Sound level

(High/Med./Low)

Fan speed

(High/Med./Low)

Fan speed regulator

Thermistor RT11 (at 25:)

Thermistor RT12 (at 25:)

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance (at 20:)

Model

Winding

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigerating oil (Model)

K /h

A

A

W

%

A

A

"

mm

kg

dB

rpm

k"

k"

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MSC-A07WV -

E1

Cooling

Single phase

230V,50Hz

474/372 /276

10

0.17

35

90

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

36/31 /25

900/750 /600

3

10

10

MUX-A10WV -

E1

Single phase

230V,50Hz

1,914

10

—

21

0.29

RN092VHSHT

600

C-R 3.87

C-S 6.14

RA6V33-FC

WHT-BLK 223

BLK-RED 221

780O540O255

35

49

825

1

0.90 (Room A+B)

350 (NEO22)

Single

A or B

2.4

0.9

3.20

725

98.5

2.91

3.16

Single

A

3.5

1.4

5.73

1,280

97.1

5.16

2.65

Double

A+B

3.5+2.4

1.4+0.9

8.96

2,005

97.3

8.39

2.84

Double

A+B

1.4O2

0.2O2

3.25

730

97.7

2.96

3.50

MSC-A07WV -

E1

Cooling

Single phase

230V,50Hz

474/372 /276

10

0.17

35

90

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

36/31 /25

900/750 /600

3

10

10

MUX-A19WV -

E1

Single phase

230V,50Hz

MSC-A12WV -

E1

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance (C.O.P)

Outdoor unit power supply

Indoor unit No.

Capacity

w

w

ww

w

w

Cooling

Single phase

230V,50Hz

582/444 /324

10

0.19

40

92

—

0.19

RC4V19-KA

WHT-BLK 316

BLK-RED 299

815O278O217

10

5

40/33 /26

930/760 /600

3

10

10

Single

B

2.4

0.9

2,460

20

3.51

785

—

97.2

48

2.94

0.57

2.93

MC1 : RN145VHSHT, MC2 : RN092VHSHT

MC1 : 1,000, MC2 : 600

RA6V60-GA

WHT-BLK 90

BLK-RED 146

840O640O330

66

52

730

1

1.00 (Room A)

0.80 (Room B)

MC1 : 620 (NEO22), MC2 : 350 (NEO22)

C-R 2.43

C-S 3.80

MC1 : , MC2 :

C-R 3.87

C-S 6.14

w

ww

w

w

ww

w

w

ww

ww

ww

w

ww

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

Indoor-Outdoor piping length 5m

w Reference value

Outdoor DB35°C WB24°C Outdoor DB 7°C/WB 6°C

12

Indoor model

Function

Indoor unit power supply

w

K /h

A

A

W

%

A

A

Capacity

Air flow (High/Med./Low)

Power outlet

Running current

Power input

Power factor

Electrical

data

Starting current

Fan motor current

w

Model

Winding

Fan

motor

resistance (at 20:)

Dimensions WOHOD

Weight

Air direction

Sound level

Fan speed

Fan speed regulator

Special

remarks

Thermistor RT11 (at 25:)

(High/Med./Low)

Thermistor RT12 (at 25:)

w

(High/Med./Low)

ww

"

mm

kg

w

dB

rpm

k"

k"

Outdoor model

Outdoor unit power supply

Indoor unit No.

Capacity

Dehumidification

Outdoor air flow

Capacity

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Electrical

data

Starting current

Compressor motor current

Fan motor current

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

Coefficient of performance (C.O.P)

Model

Output

Winding

Compressor

resistance (at 20:)

Model

Winding

Fan

motor

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

W

"

"

mm

kg

dB

rpm

Fan speed regulator

Refrigerant filling

Special

remarks

capacity (R410A)

Refrigerating oil (Model)

kg

cc

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

Outdoor DB35°C WB24°C Outdoor DB 7°C/WB 6°C

Indoor-Outdoor piping length 5m

w Reference value

Single

A

2.6

0.9

3.64

815

97.3

3.07

3.06

E1

MSC-A09WV -

Cooling

Single phase

230V,50Hz

ww

474/384 /306

10

0.17

35

90

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

ww

36/31 /25

ww

900/770 /650

3

10

10

E1

MUX-A20WV -

Single phase

230V,50Hz

Single

B or C

2.9

1.2

Double

A+B or A+C

2.6+2.8

0.9+1.1

Double

B+C

1.75O2

0.3O2

2,460

20

4.86

1,075

8.18

1,850

4.86

1,090

—

96.2

98.3

97.5

47

4.29

7.61

4.29

0.57

2.61

2.81

3.02

MC1 : RN099VHSHT, MC2 : RN125VHSHT

MC1 : 650, MC2 : 800

C-R 3.40

MC1 : , MC2 :

C-S 4.56

C-R 2.86

C-S 5.72

RA6V60-GA

WHT-BLK 90

BLK-RED 146

840O640O330

65

52

730

1

0.80 (Room A)

1.00 (Room B+C)

MC1 : 350 (NEO22), MC2 : 350 (NEO22)

13

Triple

A+B+C

2.5+1.75O2

0.8+0.3O2

8.41

1,885

97.5

7.84

3.02

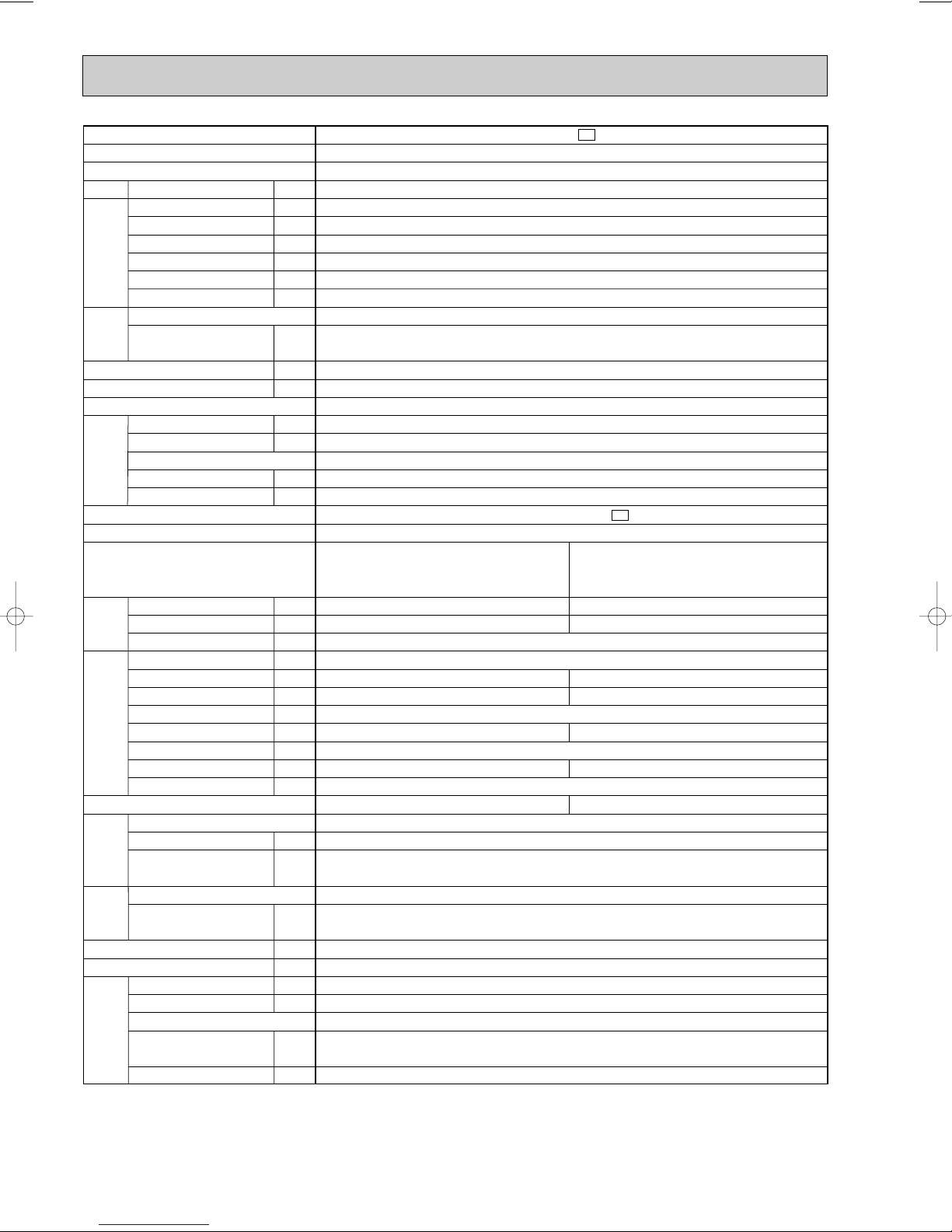

Indoor model

Function

Indoor unit power supply

Air flow (High/Med./Low)

Power outlet

Running current

Power input

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level

(High/Med./Low)

Fan speed

(High/Med./Low)

Fan speed regulator

Thermistor RT11 (at 25:)

Thermistor RT12 (at 25:)

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance (at 20:)

Model

Winding

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigerating oil (Model)

K /h

A

A

W

%

A

A

"

mm

kg

dB

rpm

k"

k"

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MSC-A12WV -

E1

(Unit A ,B)

Cooling

Single phase 230V,50Hz

582/444 /324

10

0.19

40

92

—

0.19

RC4V19-KA

WHT-BLK 316

BLK-RED 299

815O278O217

10

5

40/33 /26

930/760 /600

3

10

10

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance (C.O.P)

Outdoor unit power supply

Indoor unit No.

Capacity

MUX-A25WV -

E1

Single phase 230V,50Hz

2,460

20

—

54

0.57

MC1 : RN145VHSHT, MC2 : RN145VHSHT

MC1 : 1,000, MC2 : 1,000

RA6V60-GA

WHT-BLK 90

BLK-RED 146

840O640O330

68

52

730

1

0.95 (Room A)

0.95 (Room B)

MC1 : 620 (NEO22), MC2 : 620 (NEO22)

w

ww

w

ww

ww

Single

A or B

3.5

1.4

5.88

1,300

96.1

5.31

2.61

Double

A+B

3.5O2

1.4O2

11.49

2,540

96.1

10.92

2.67

C-R 2.43

C-S 3.80

MC1 : , MC2 :

C-R 2.43

C-S 3.80

w

ww

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

Indoor-Outdoor piping length 5m

w Reference value

Outdoor DB35°C WB24°C Outdoor DB 7°C/WB 6°C

14

Indoor model

MSC-A09WV -

Function

Indoor unit power supply

Capacity

Air flow (High/Med./Low)

Power outlet

Running current

Power input

Power factor

Electrical

data

Starting current

Fan motor current

w

K /h

A

A

W

%

A

A

Model

Winding

Fan

motor

resistance (at 20:)

Dimensions WOHOD

Weight

Air direction

Sound level

Fan speed

Fan speed regulator

Special

remarks

Thermistor RT11 (at 25:)

(High/Med./Low)

Thermistor RT12 (at 25:)

w

(High/Med./Low)

ww

"

mm

kg

w

dB

rpm

k"

k"

Outdoor model

Outdoor unit power supply

Single

Indoor unit No.

Capacity

Dehumidification

Outdoor air flow

Capacity

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Electrical

data

Starting current

Compressor motor current

Fan motor current

Coefficient of performance (C.O.P)

R/h

K /h

A(kW)

kW

A

A

W

%

A

A

A

A or B

3.4

1.2

5.28

1,180

97.2

4.75

2.79

Model

Output

Winding

Compressor

resistance (at 20:)

Model

Winding

Fan

motor

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

W

"

"

mm

kg

dB

rpm

Fan speed regulator

Refrigerant filling

Special

remarks

capacity (R410A)

Refrigerating oil (Model)

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

kg

cc

Outdoor DB35°C WB24°C Outdoor DB 7°C/WB 6°C

Indoor-Outdoor piping length 5m

w Reference value

E1

(Unit C ,D)

Cooling

Single phase 230V,50Hz

474/384 /306

ww

10

0.17

35

90

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

815O278O217

9

5

ww

36/31 /25

900/770 /650

ww

3

10

10

Single phase 230V,50Hz

Single

C or D

2.75

1.1

4.54

1,015

97.2

4.01

2.62

Double

A+B

1.95O2

0.2O2

5.46

1,210

96.4

4.93

3.02

MC1 : RN145VHSHT, MC2 : RN125VHSHT

MC1 : , MC2 :

MC1 : 620 (NEO22), MC2 : 350 (NEO22)

15

MSC-A12WV -

Single phase 230V,50Hz

MUX-A26WV -

Double

A+C or A+D

or

B+C or B+D

3.4+2.7

1.2+1.1

E1

Double

C+D

1.7O2

0.3O2

2,760

20

9.57

2,095

4.78

1,060

—

95.2

96.4

52

9.04

4.25

0.53

2.81

3.01

MC1 : 1,000, MC2 : 800

C-R 2.43

C-S 3.80

C-R 2.86

C-S 5.72

RA6V60-FA

WHT-BLK 79

BLK-RED 80

840O850O330

76

52

730

1

1.05 (Room A+B)

1.05 (Room C+D)

582/444 /324

RC4V19-KA

WHT-BLK 316

BLK-RED 299

815O278O217

930/760 /600

Triple

A+B+C

or

A+B+D

1.95O2+2.8

0.2O2+1.1

9.61

2,105

95.2

9.08

3.02

E1

Cooling

w

10

0.19

40

92

—

0.19

10

5

ww

40/33 /26

w

3

10

10

3.4+1.7O2

1.2+0.3O2

(Unit A ,B)

w

w

Triple

A+C+D

or

B+C+D

A+B+C+D

1.95O2+1.7O2

0.2O2+0.3O2

9.66

2,140

96.3

9.13

3.02

Four

9.75

2,210

98.6

9.22

3.09

Outdoor model

Indoor units number

Indoor units total capacity (Connectable)

indoor units total capacity (Simultaneous operation)

Piping total length

Connecting pipe length

Height difference (Indoor ~ Outdoor)

Height difference (Indoor ~ Indoor)

Function

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Crankcase heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance (at 20:)

Model

Winding

resistance (at 20:)

Dimensions WOHOD

Weight

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigerating oil (Model)

Thermistor RT61

Thermistor RT62

Thermistor RT63

Thermistor RT6A,6B

Thermistor RT65

Thermistor RT68

m

m

m

m

kW

R/h

K /h

A

A

W

A(kW)

W

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

k"

k"

k"

k"

k"

k"

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity System

Coefficient of performance (C.O.P)

Outdoor unit power supply

MXZ-A18WV -

E1

Single phase

230V,50Hz

2

Total model name 24

Total model name 24

Max. 30 (chargeless 20)

Max. 20

10

10

2,460

20

—

—

90.0

8.98

0.57

SNV-092FJYH (ROTARY)

1,450

U-V 2.56

V-W 2.56 W-U 2.56

RA6V49-AA

WHT-BLK 139.9 BLK-YLW 34.2

BLK-RED 205.3

840(+69)o640o330

52

725

2

1.75

450 (NE022)

13.4 (at 100:)

10.0 (at 25:)

10.0 (at 25:)

10.0 (at 25:)

17.0 (at 50:)

10.0 (at 25:)

Cooling

5.4 (1.55~6.0)

—

8.98

1,860 (370~2,130)

8.41

2.90

49

Heating

6.6 (1.58~7.2)

—

8.55

1,770 (290~1,850)

7.98

3.73

50

NOTE: Test conditions are based on ISO 5151 (Refrigerant piping length (one way) :5m

✽1 Electrical data is for only outdoor unit.

TEST CONDITIONS COOLING INDOOR DB27.0°C WB19.0°C

OUTDOOR DB35.0°C WB24.0°C

HEATING INDOOR DB20.0°C

OUTDOOR DB 7.0°C WB 6.0°C

16

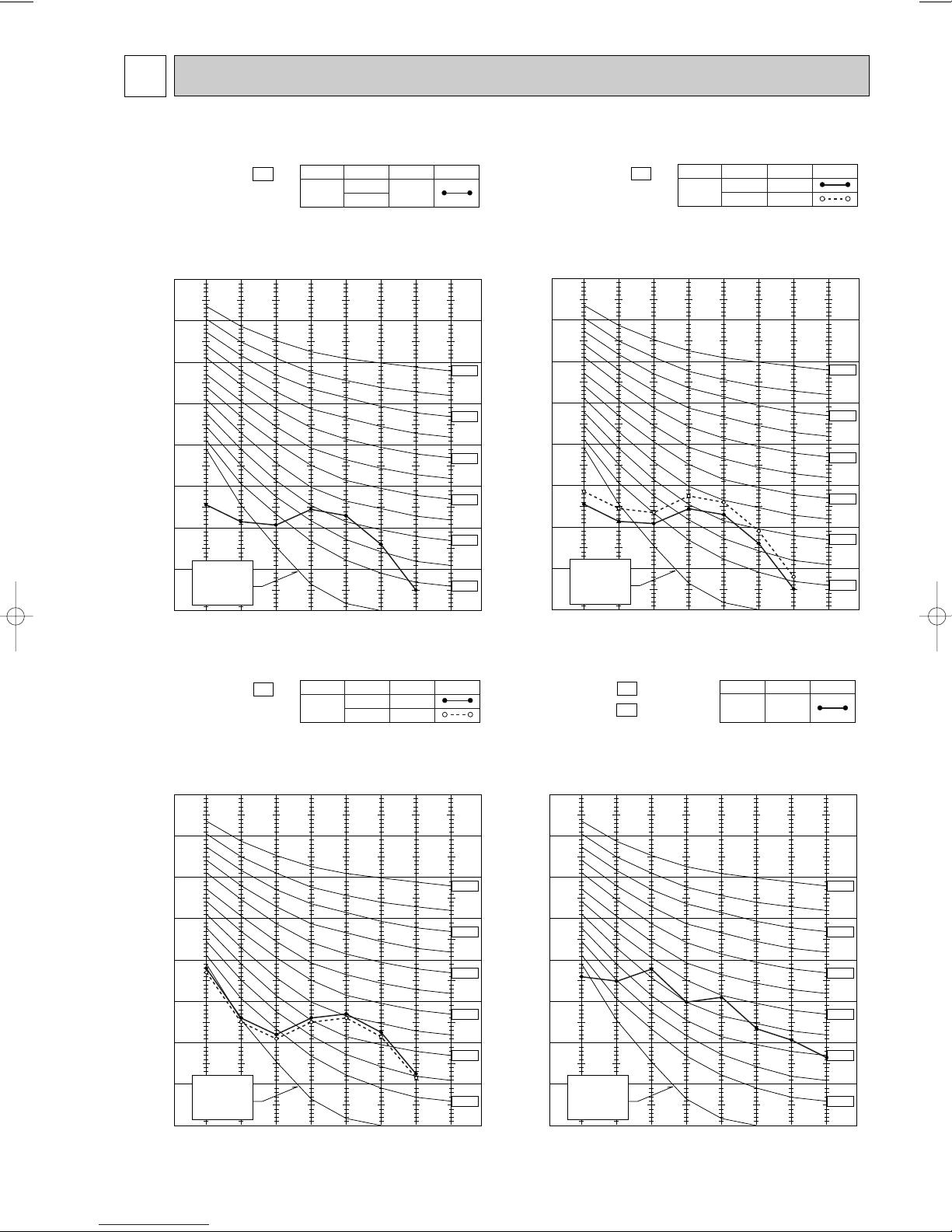

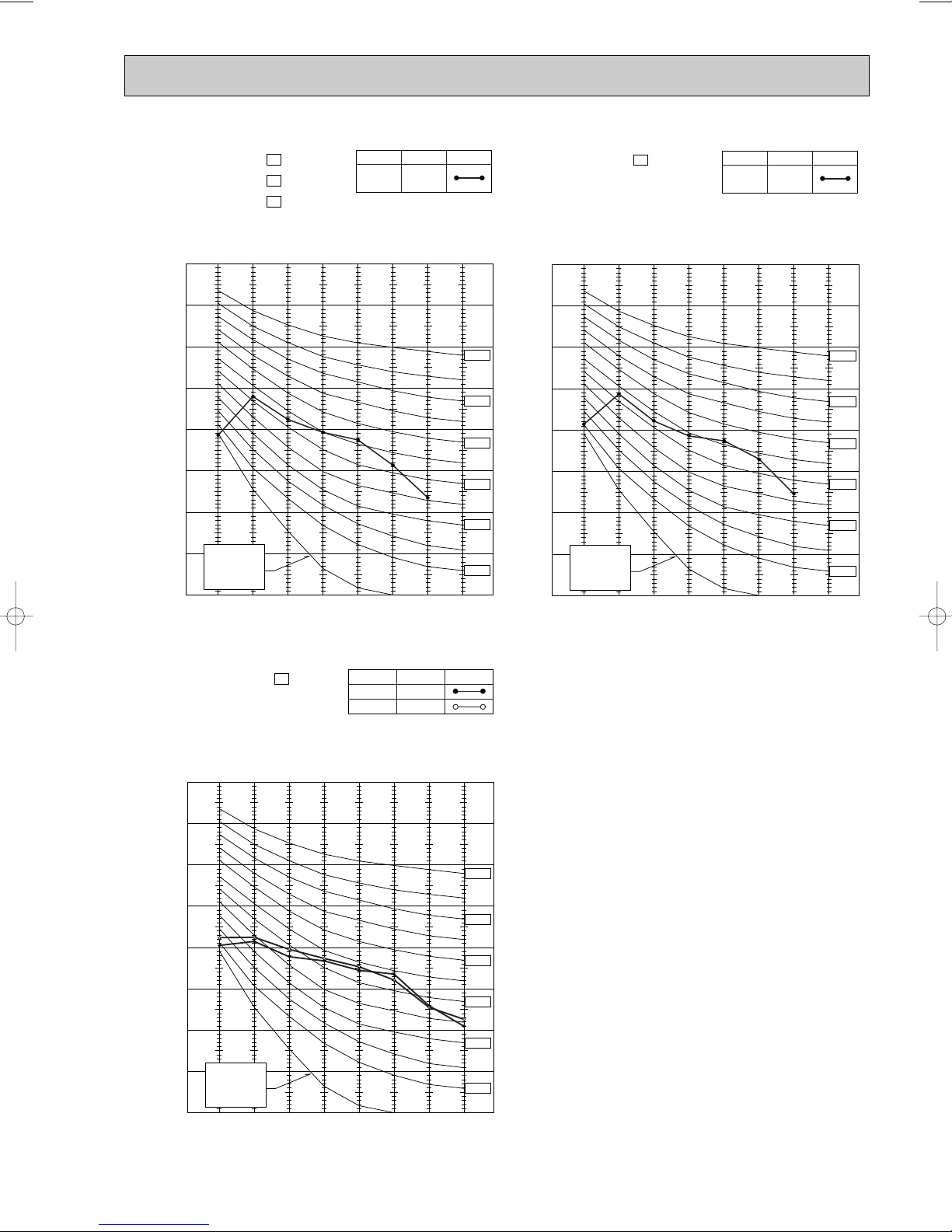

NOISE CRITERIA CURVES6

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB27: WB19:

Heating : DB20: WB -:

MSC-A07WV- E1

COOL

High

FUNCTIONFAN SPEED

36

HEAT

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions.

Cooling : DB27: WB19:

Heating : DB20: WB -:

MSC-A09WV- E1

COOL

High

FUNCTIONFAN SPEED

36

HEAT 39

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB27: WB19:

MSC-A12WV- E1

COOL

FUNCTIONFAN SPEED

40

HEAT

High

39

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

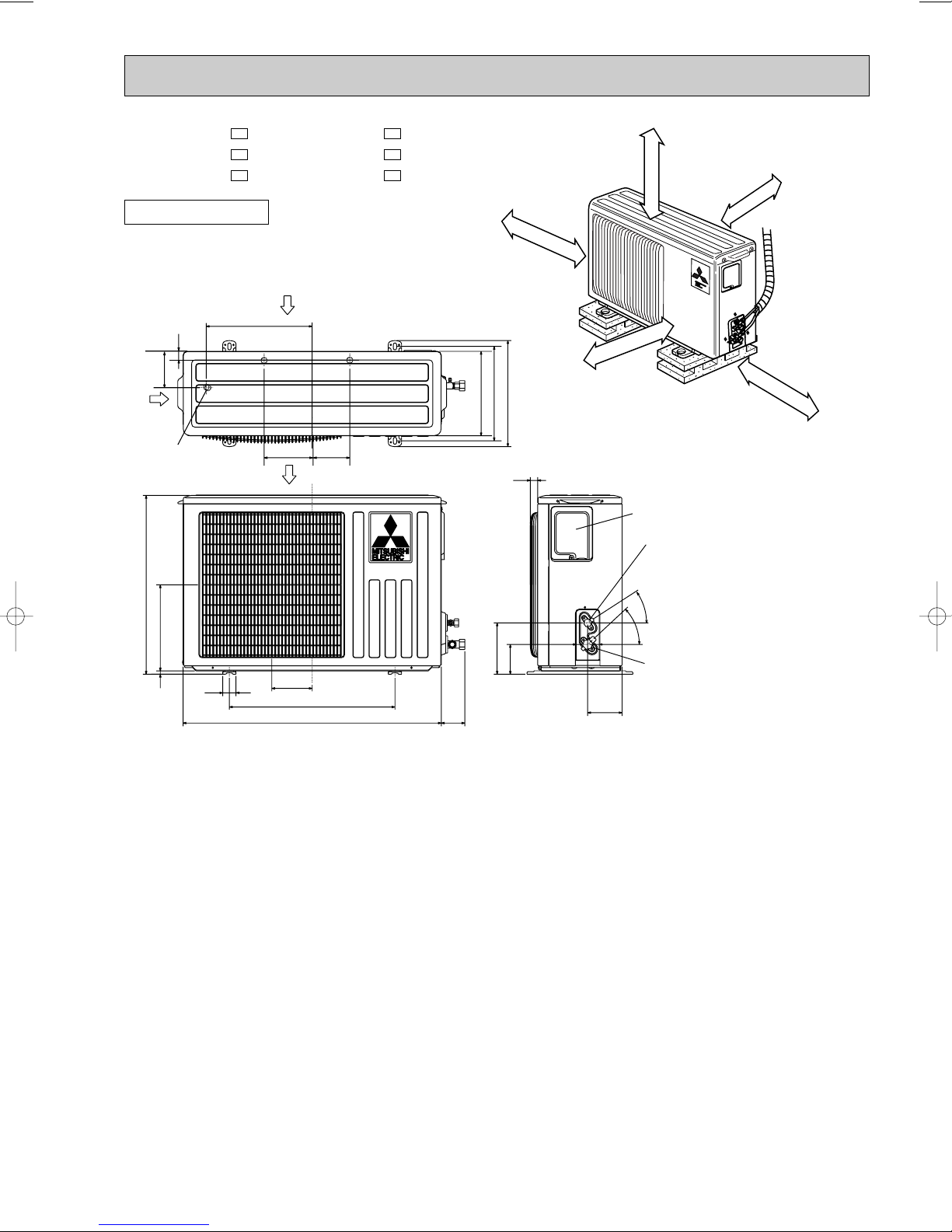

Test conditions,

Cooling : DB27: WB19:

MU-A07WV- E1

MU-A09WV- E1

COOL

FUNCTION

45

SPL(dB(A)) LINE

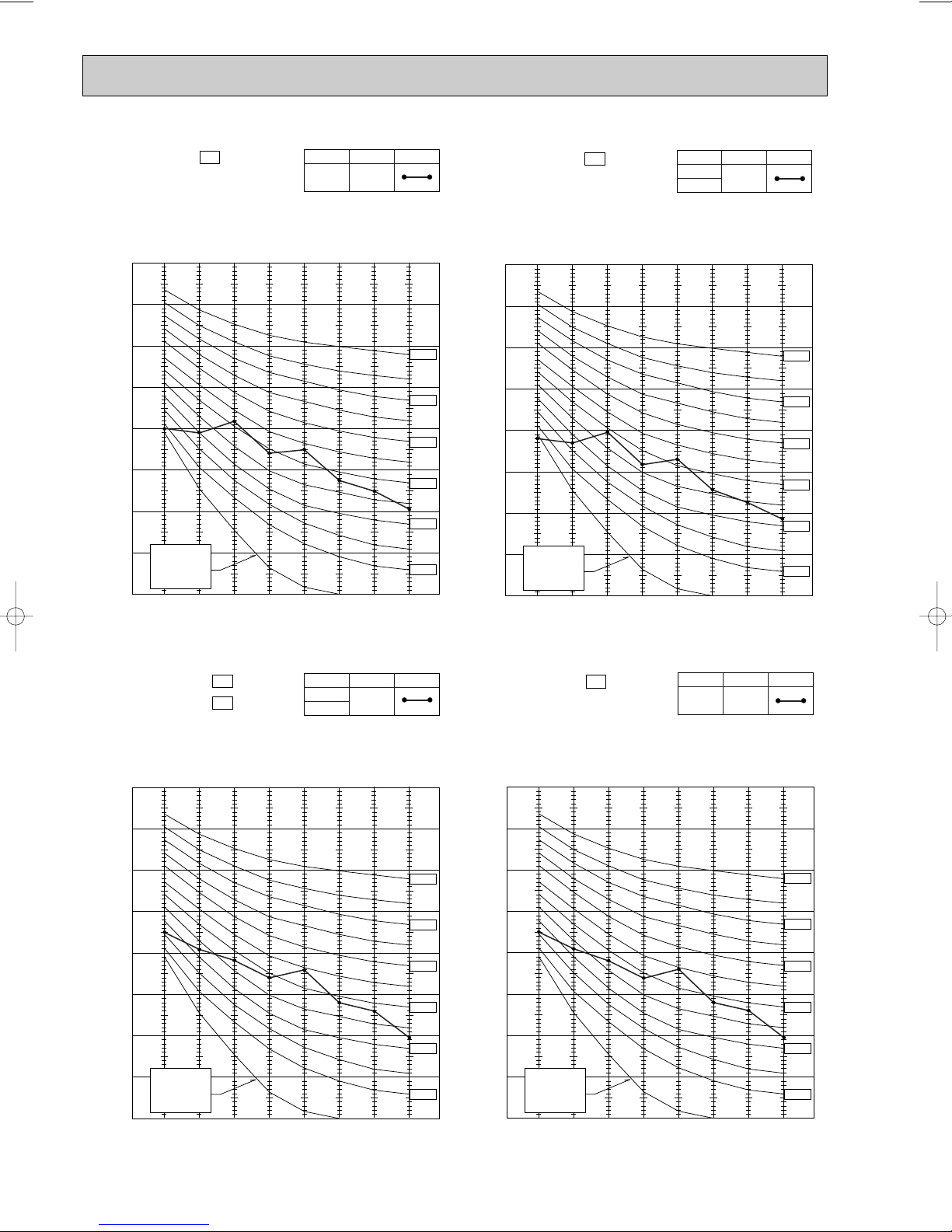

17

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling :DB35: WB24:

Heating :DB 7: WB 6:

MUH-A09WV- E1

MUH-A12WV- E1

COOL

FUNCTION

49

HEAT

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions.

Cooling : DB27: WB19:

MUX-A10WV- E1

COOL

FUNCTION

49

SPL(dB(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling :DB35: WB24:

Heating :DB 7: WB 6:

MUH-A07WV- E1

COOL

FUNCTION

47

HEAT

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling :DB35: WB24:

MU-A12WV- E1

COOL

FUNCTION

49

SPL(dB(A)) LINE

18

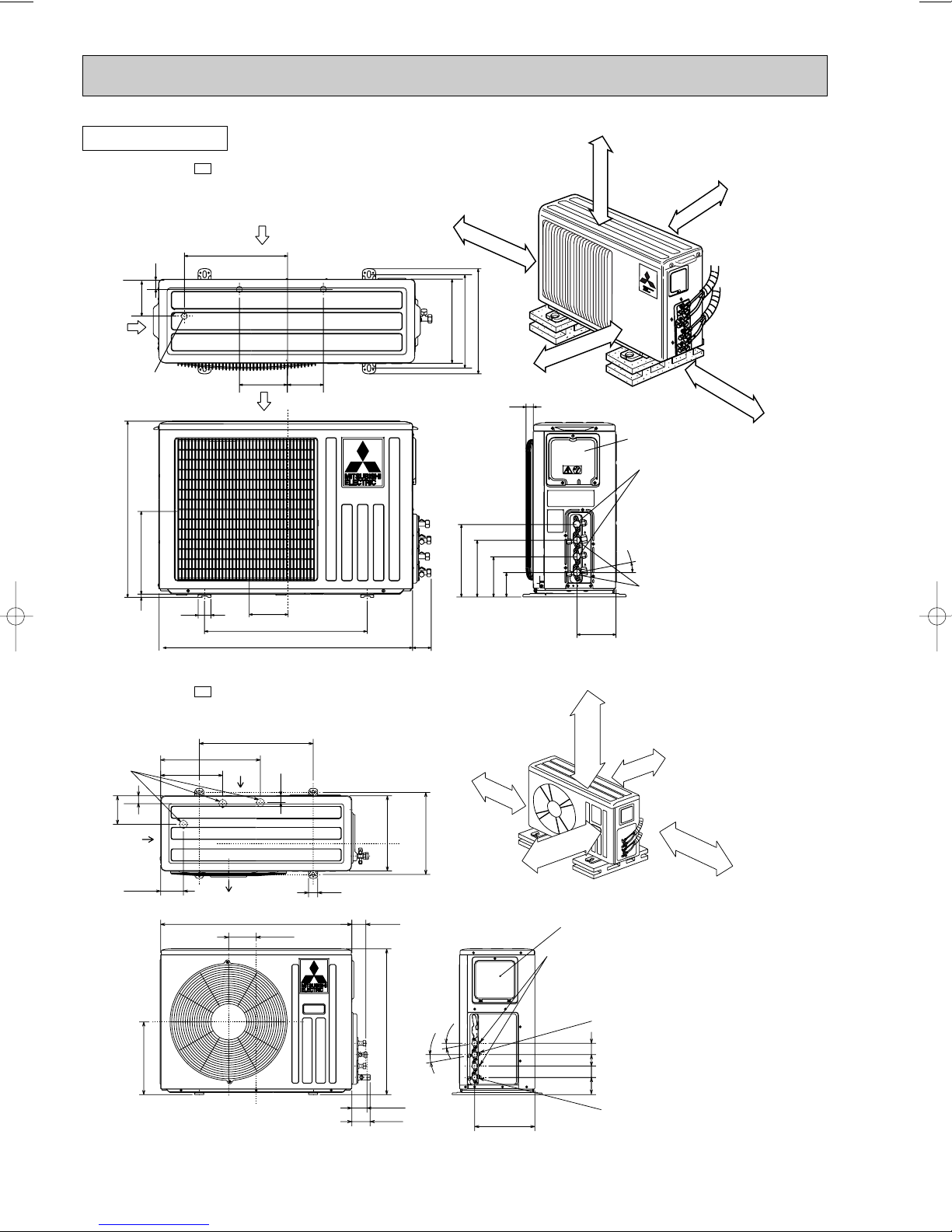

MUX-A19WV - E1

MUX-A20WV - E1

MUX-A25WV - E1

FUNCTION

COOL

SPL(dB(A)) LINE

52

MUX-A26WV - E1

FUNCTION

COOL

SPL(dB(A)) LINE

52

Test conditions.

90

Cooling :DB35: WB24:

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

MXZ-A18WV - E1

APPROXIMATE

20

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

Cooling

Heating

SPL(dB(A))50LINE

49

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

Test conditions.

90

Cooling :DB35: WB24:

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

APPROXIMATE

20

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

Test conditions.

Cooling :DB 35: WB 24:

90

Heating :DB 7: WB 6:

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB = 0.0002 MICRO BAR

APPROXIMATE

20

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

19

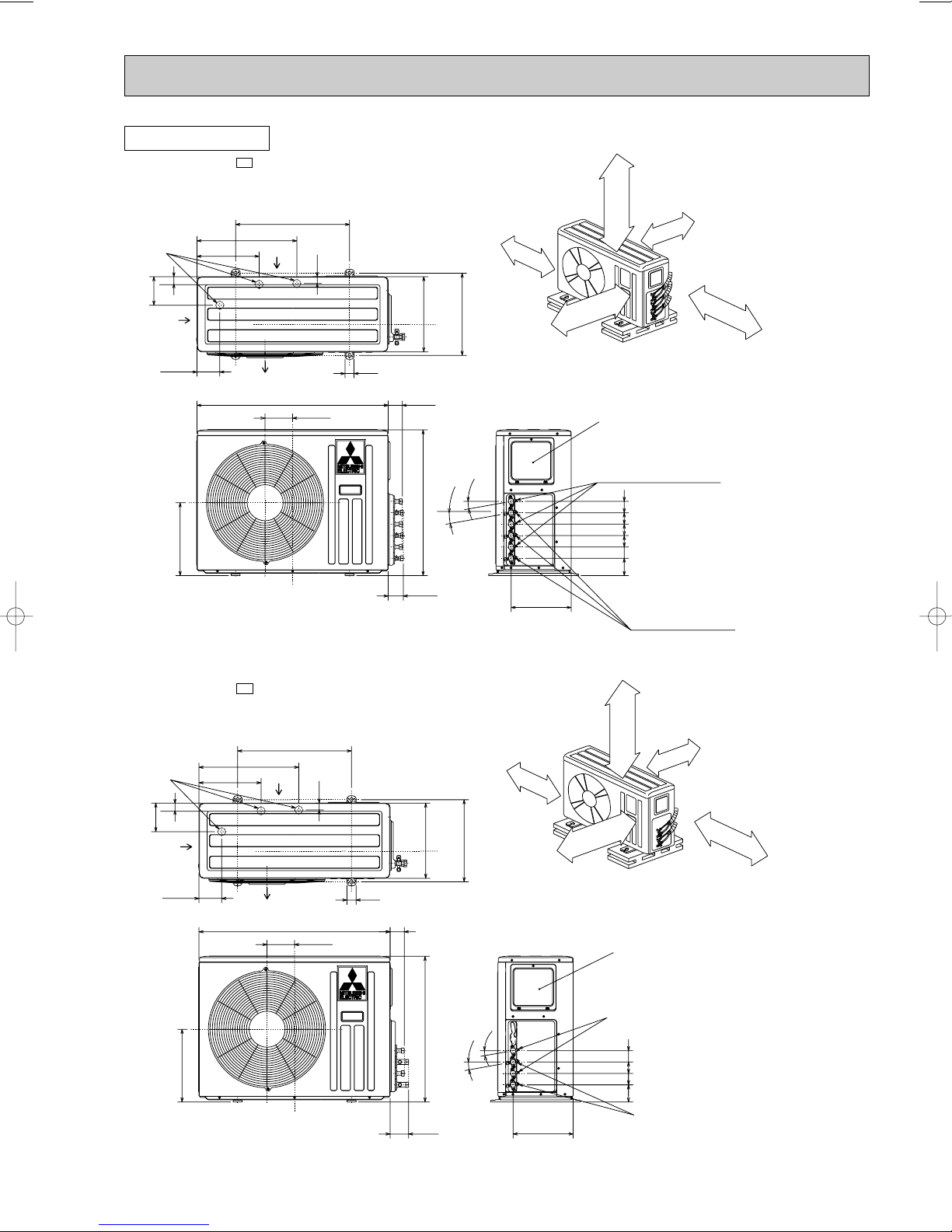

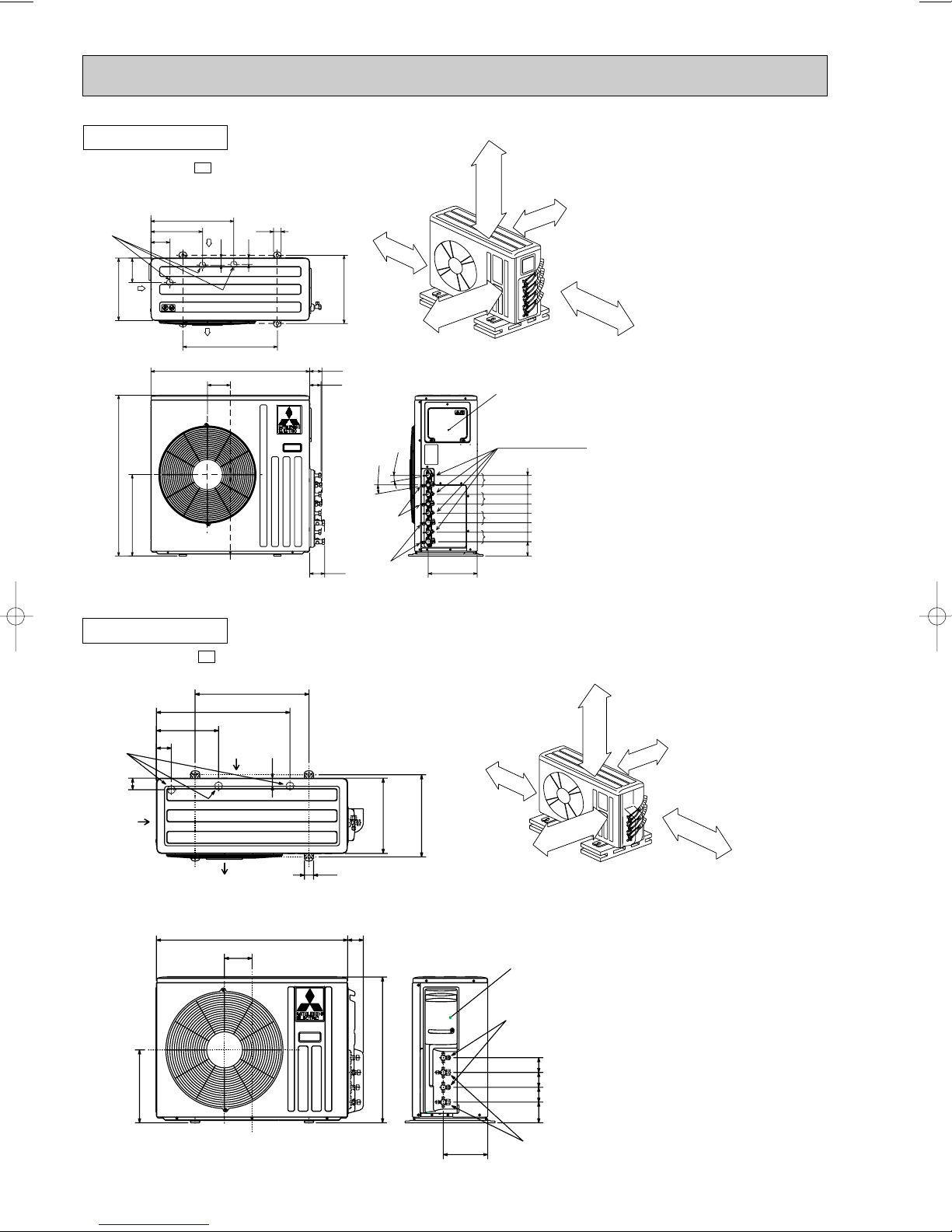

7

OUTLINES AND DIMENSIONS

MSC-A07WV MSC-A09WV -

INDOOR UNIT

Unit: mm

E1

E1

Installation plate

81.5

133.5

4.5

783

815

278

60

58

162

Wireless remote controller

606

Indoor unit

19

41

81.5

Air in

149

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

7 or more

30

Air out

215

217

326326

5

Installation plate

Liquid line

Gas line

{

Insulation

90

110

Drain hose

(Connected part O,D)

Insulation

231.5

42

2.5

81.5

Wall hole

[9.52-0.43m

[37 O.D

[16

[28

271

[65

[6.35-0.5m

[21 I.D

MSC-A12WV -

INDOOR UNIT

278

60

58

162

E1

783

815

606

161.5

Installation plate

Indoor unit

149

19

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

41

Air in

7 or more

30

Air out

215

217

326326

5

Installation plate

90

110

161.5

17.5

258

218.5

42

2.5

81.581.5

Wall hole

Liquid line

Gas line

{

Insulation

Drain hose

(Connected part O,D)

Insulation

[65

[6.35-0.5m

[9.52-0.43m

[37 O.D

[21 I.D

[16

[28

Wireless remote controller

20

MU-A07WV - MUH-A07WV MU-A09WV - MUH-A09WV MU-A12WV - MUH-A12WV -

Unit: mm

E1E1

E1E1

E1E1

REQUIRED SPACE

OUTDOOR UNIT

320

32

109

Air in

Drainage

3holes [33

540

260

10

40

Air in

147

122

110

Air out

500

780

74

100mm or more

320

285

255

25

155

90

100mm or more

400mm or more

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) [6.35

35-

43-

Gas refrigerant

pipe joint

104

Refrigerant pipe

(flared) [9.52 (MU-A07/A09WV

[12.7 (MU-A12WV

(MUH-A12WV

100mm or more

350mm or more

(MUH-A07/A09WV

)

)

)

)

21

320

25

10-

126

76

120

56

260

10

780

500

122

40

540

320

285

255

Service panel

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) [9.52

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) [6.35

Air out

Air in

Air in

176

226

109

32

110

147

Drainage

3holes [33

100mm or more

100mm or more

100mm or more

350mm or more

REQUIRED SPACE

400mm or more

OUTDOOR UNIT

500

840 61

264

10°

10°

Service panel

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

200mm or more if

there are obstacles

to both sides

Open as a rule

500mm or more if the back,

both sides and top are open

350mm or more

100mm or more

B UNIT

A UNIT

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {9.52

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {12.7

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

65

80

121

40

438

Air in

Air out

Air in

273

100

125

320

30

330

640

360

76

505050

Drainage

3holes {33

}

}

34

Unit: mm

MUX-A10WV-

E1

MUX-A19WV-

E1

22

OUTDOOR UNIT

MUX-A20WV-

Drainage

3holes {33

34

125

Air in

100

320

E1

273

500

438

Air in

30

Air out

840 61

121

Unit: mm

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

100mm or more

330

360

Open as a rule

500mm or more if the back,

40

640

65

both sides and top are open

10°

10°

264

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

C UNIT

}

B UNIT

}

A UNIT

}

5050505050

76

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {9.52

200mm or more if

there are obstacles

to both sides

350mm or more

MUX-A25WV-

Drainage

3holes {33

125

Air in

273

34

100

320

E1

500

438

Air in

30

Air out

840 61

121

330

40

640

80

100mm or more

360

Open as a rule

500mm or more if the back,

both sides and top are open

10°

10°

264

}

}

B UNIT

A UNIT

Open as a rule

500mm or more if

the front and both

sides are open

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

505050

76

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {12.7

100mm or more

200mm or more if

there are obstacles

to both sides

350mm or more

23

Service panel

D Unit

C Unit

B Unit

A Unit

{33

Drainage

3 holes

Air out

Air in

Air in

125

330

500

100

273

438

40

30

360

34

430

850

840

121

80

61

65

76

50

50

50

5050

50

50

260

10°

10°

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {9.52

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {12.7

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

200mm or more if

there are obstacles

to both sides

Open as a rule

500mm or more if the back,

both sides and top are open

350mm or more

100mm or more

OUTDOOR UNIT

Unit: mm

MUX-A26WV-

E1

OUTDOOR UNIT

MXZ-A18WV -

Drainage

3 holes

([33)

50

Air in

320

E1

500

587

273

65

Air in

Air out

840

121

34

REQUIRED SPACE

More than

330

360

40

69

640

100mm

Open as a rule

More than 200mm if the back,

both sides and top are open

Note:

*

The dimensions given along the arrrows above are required to guarantee

the air conditioner's performance. Install the unit in as wide a place as

possible for later service or repairs.

Service panel

Liquid refrigerant valve

(flared [6.35)

B UNIT

}

195

}

A UNIT

90 65 65 65

Gas refrigerant valve

(flared [9.52)

24

Open as a rule

More than100mm

if the front and both

sides are open

*

More than 100mm

200mm or more if

there are obstacles

to both sides

More than 350mm

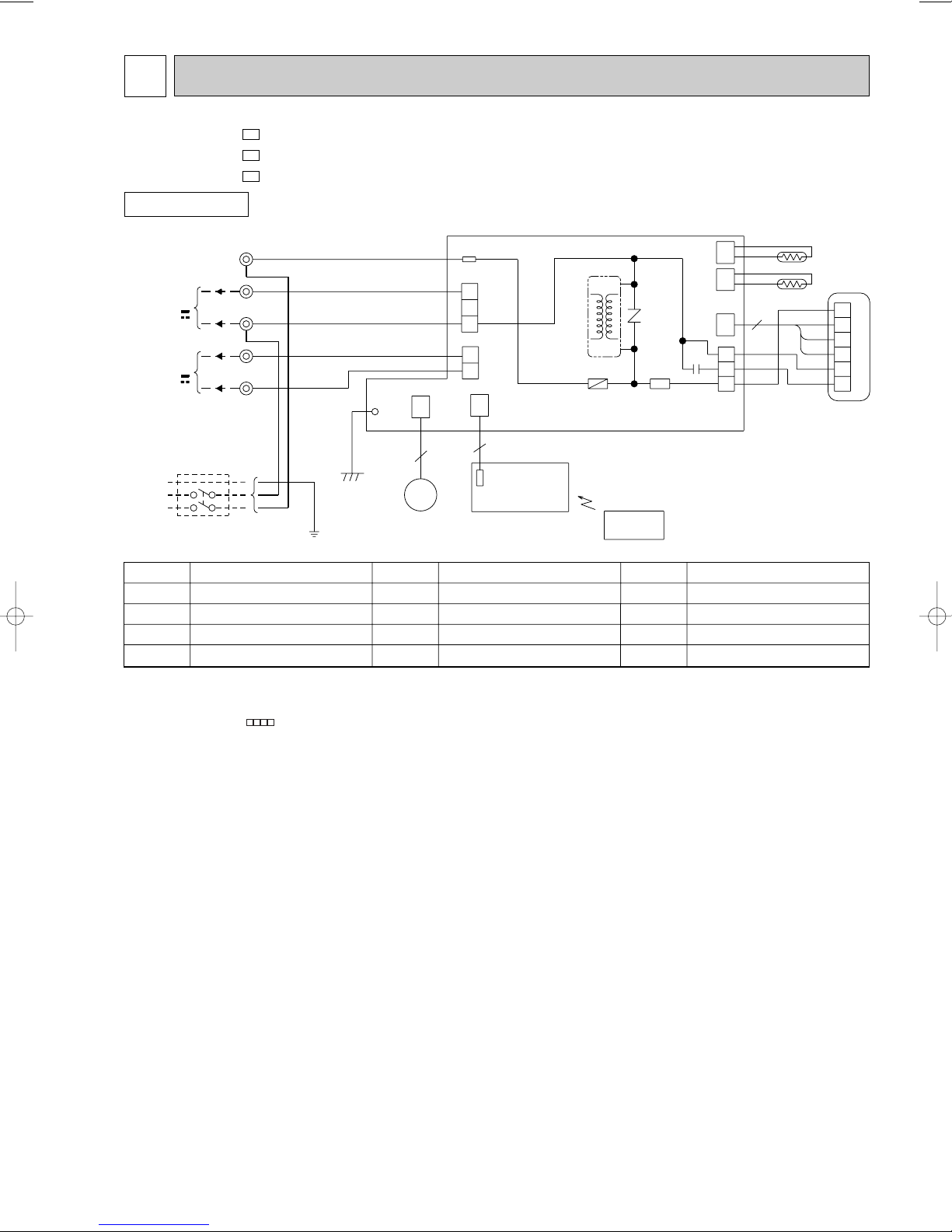

8

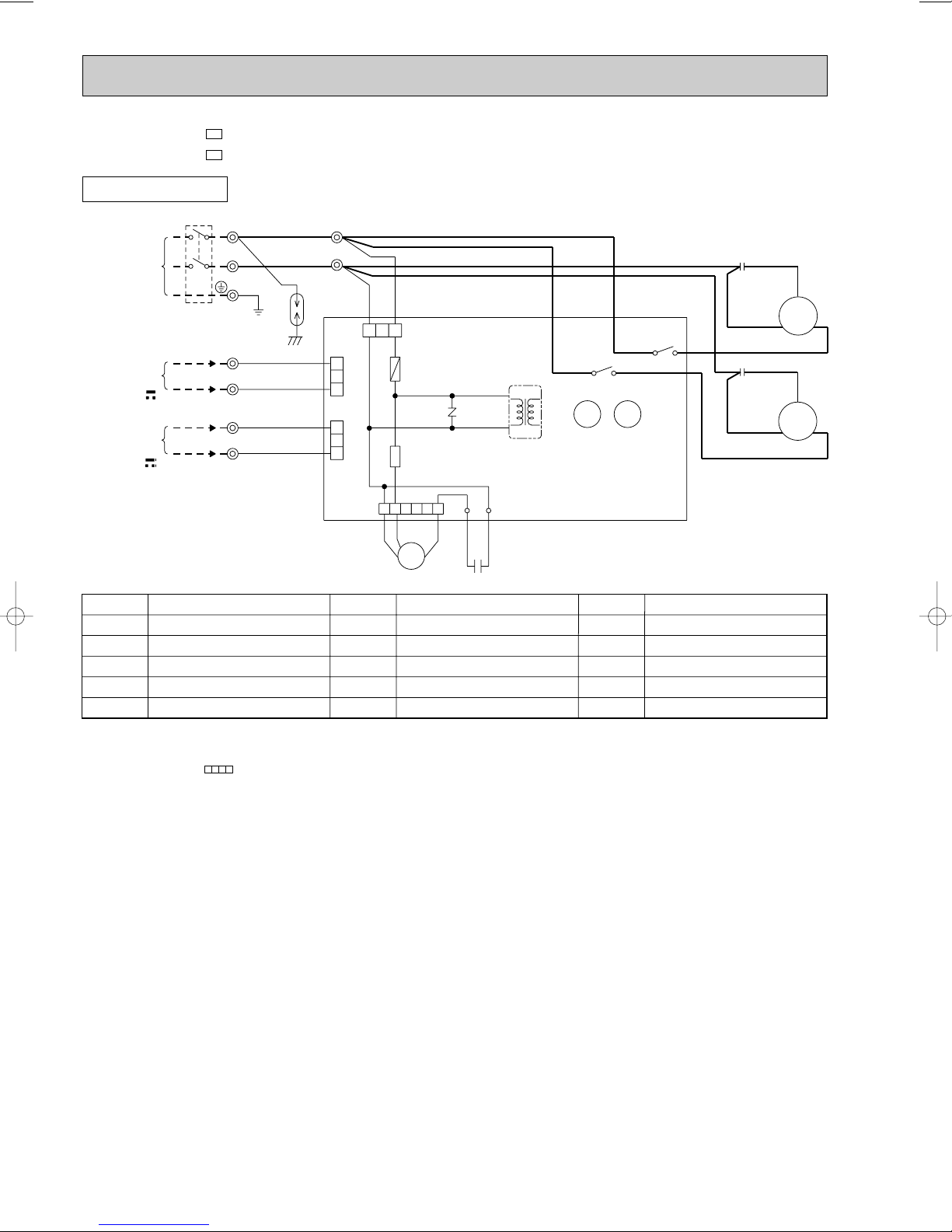

SYMBOL

NR11

RT11

RT12

SR141

NAME

NAME NAME

INDOOR FAN CAPACITOR

FUSE(3.15A)

INDOOR FAN MOTOR (INNER FUSE)

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMIST OR

INDOOR COIL THERMISTOR

SOLID STATE RELAY

TERMINAL BLOCK

SYMBOL

C11

F11

MF

MV

SYMBOL

TB

T11

TRANSFORMER

CIRCUIT BREAKER

SR141

C11

RED

WHT

3

6

5

BRN

YLW

GRY

BLK

4

3

2

1

MF

121

CN

1

3

5

111

CN

112

CN

RT12

RT11

NR11

F11

ELECTRONIC CONTROL P.C. BOARD

CN211

TAB12

CN201

3

2

1

CN202

2

1

151

CN

5

5

BRN

RED

BLU

WHT

BLK

BLU

BRN

TB

L

3

N

2

1

12V

TO OUTDOOR

UNIT

CONNECTING

POWER

SUPPLY

CORD

~/N 230V

50Hz

GRN/YLW

POWER MONITOR,

RECEIVER

P.C.BOARD

REMOTE

CONTROLLER

MV

FOR

MUH OR

MXZ TYPE

FOR

MU OR

MUX TYPE

12V

PE

101

CN

T11

GRN

LD103

WIRING DIAGRAM

MSC-A07WV MSC-A09WV MSC-A12WV -

INDOOR UNIT

E1

E1

E1

MODELS WIRING DIAGRAM

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

25

SG79J617H01

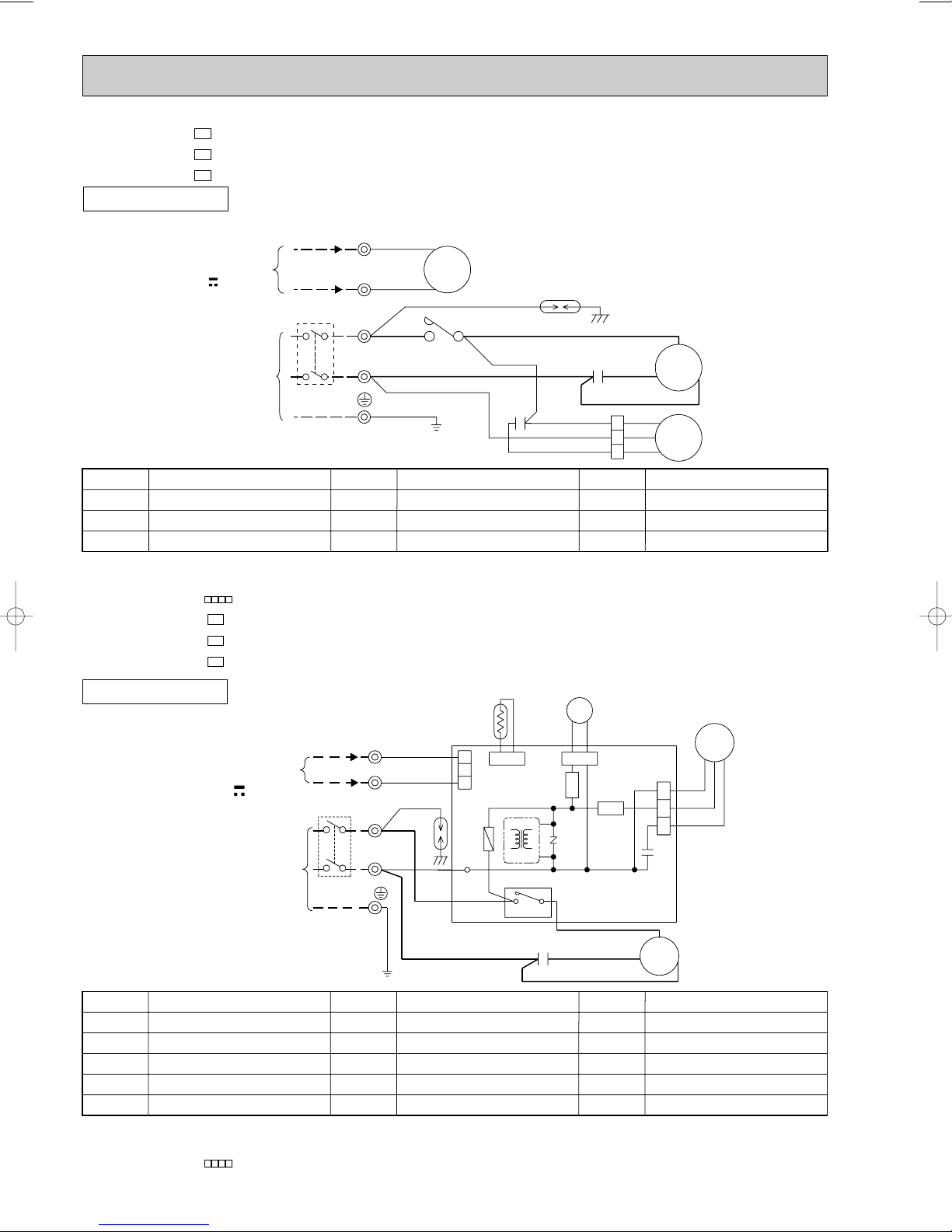

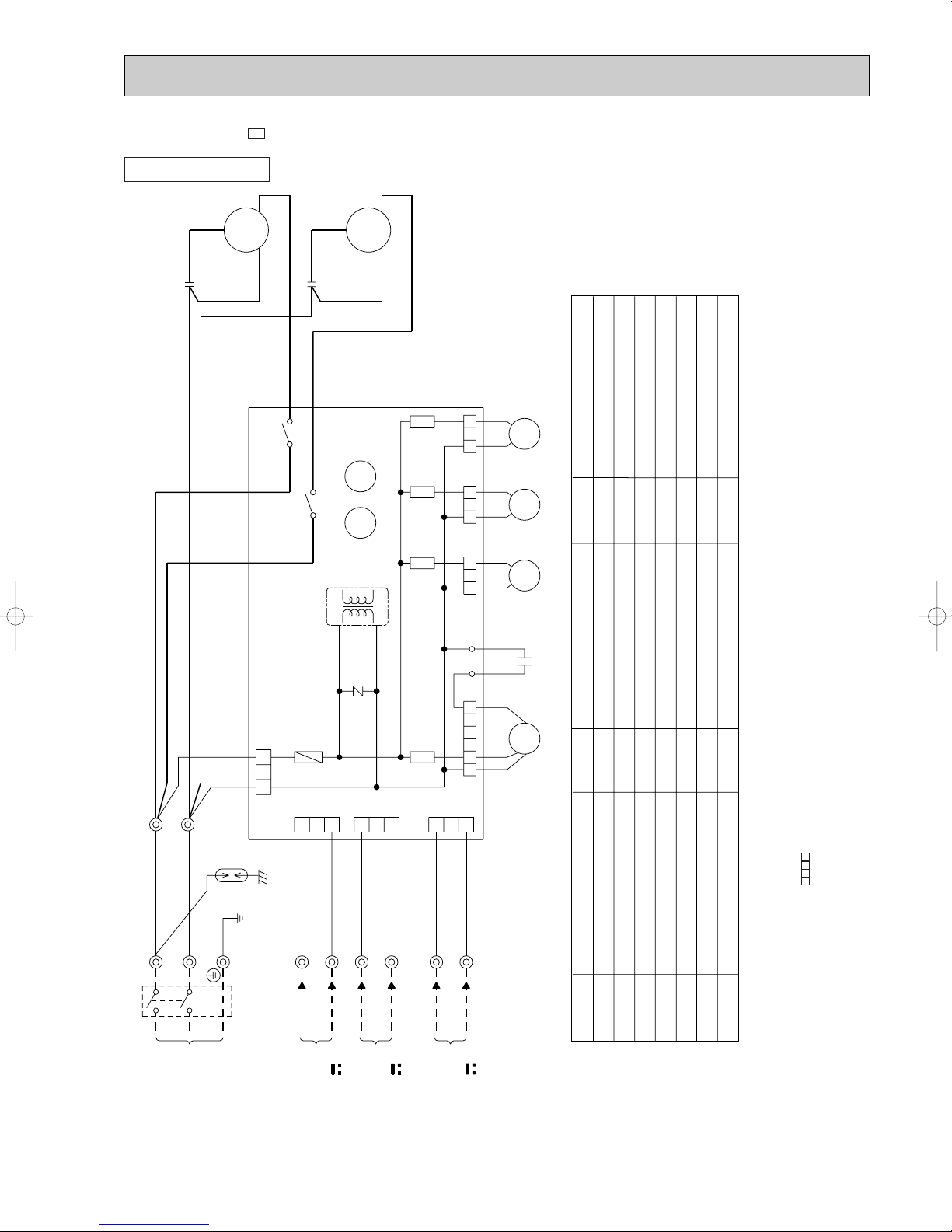

SYMBOL

TB1,TB2

21S4

52C

SYMBOL

MF

NR61

RT61

SR61,SR62

T61

SYMBOL

C1

C65

DSAR

F61

MC

NAME

NAME NAME

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE(2A)

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR(INNER FUSE)

VARISTOR

DEFROST THERMISTOR

SOLID STATE RELAY

TRANS FORMER

TERMINAL BLOCK

R.V. COIL

COMPRESSOR CONTACTOR

MU-A07WV -

MC

CN661

3

1

2

CN721

21S4

MF

SR62

SR61

TAB20

GRN/YLW

BLU

CIRCUIT BREAKER

POWER SUPPLY

BLU

BRN

DSAR

BLK

BRN

RED

DEICER P.C.BOARD

4

C1

BLK

RED

3

WHT

S

C

R

CN730

RT61

BLK

2

3

1

RED

WHT

12V

FROM

CONNECTING

INDOOR UNIT

TB2

3

N

TB1

L

N

PE

~/N

NR61

F61

T61

C65

CN711

52C

230V

50Hz

R.V.coil

heating ON

cooling OFF

MU-A09WV MU-A12WV -

E1

E1

E1

OUTDOOR UNIT

FROM

INDOOR UNIT

CONNECTING

12V

POWER SUPPLY

~/N

230V 50Hz

MODELS WIRING DIAGRAM

TB2

2

WHT

1

BLK

CIRCUIT BREAKER

TB1

PE

L

BRN

N

BLU

GRN/YLW

NO

52C

52C

COM

BRN

WHT

WHT

C2

DSAR

C1

WHT

BLU

RED

RED

BLK

1

2

3

WHT

BLK

RED

C

MC

S

R

MF

SYMBOL

C1

COMPRESSOR CAPACITOR

C2

OUTDOOR FAN CAPACITOR

DSAR

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

SURGE ABSORBER

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

MUH-A07WV MUH-A09WV MUH-A12WV -

NAME

SYMBOL

MC

MF

TB1,TB2

E1

E1

E1

MODELS WIRING DIAGRAM

NAME NAME

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR(INNER FUSE)

TERMINAL BLOCK

OUTDOOR UNIT

SYMBOL

52C

CONTACTOR

VG79B194H02

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

26

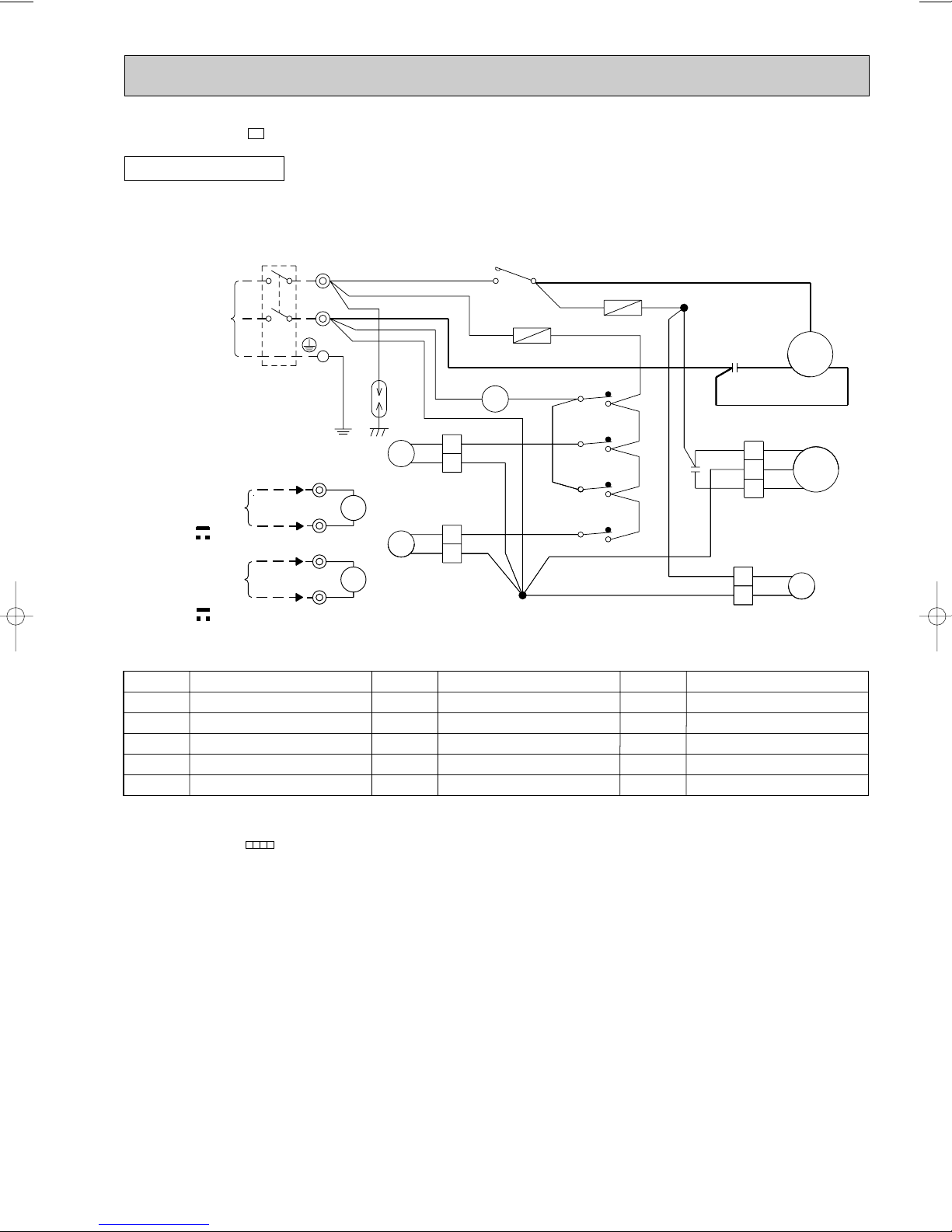

VG79B195H02

MUX-A10WV -

E1

OUTDOOR UNIT

POWER SUPPLY

~ / N

230V

50Hz

CIRCUIT BREAKER

FROM INDOOR

UNIT No.A

CONNECTING

12V

FROM INDOOR

UNIT No.B

CONNECTING

12V

MODEL WIRING DIAGRAM

TB1

2

1

2

1

L

N

PE

TB2

WHT

X1

BLK

YLW

X2

ORN

7

8

7

8

BRN

BRN

DSAR

21R1

21R2

BLU

BLU

BLU

BLU

BLU

BLU

BLU

2

1

2

1

NO

BRN

2

BLU

BLU

BLU

BLU

52C

52C

1

2

TB3

F61

BLU

COM

BRN

BLU

WHT

5

6

5

6

X1

X1

X2

X2

2

1

F62

1

3

4

3

2

4

WHT

BRN BRN BRN

WHT

1

TB3

WHT

C2

C1

WHT

BLU

RED

WHT

BLU

RED

1

2

3

2

1

WHT

BLK

RED

BLU

BLU

S

BLK

C

MC

21R

R

MF

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

DSAR

F61,F62

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

SURGE ABSORBER

FUSE(2A)

COMPRESSOR(INNER PROTECTOR)

MC

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

NAME

SYMBOL

OUTDOOR FAN MOTOR(INNER FUSE)

MF

TB1,TB2,TB3

21R

TERMINAL BLOCK

RELAY(A)

X1

RELAY(B)

X2

SOLENOID COIL

NAME NAME

SYMBOL

21R1

21R2

52C

SOLENOID COIL(A)

SOLENOID COIL(B)

COMPRESSOR CONTACTOR

VG79B203H01

27

1

2

3

123

2

1

3

RED

RED

NR61

T61

1

2

4

3

4

3

C61

LD1

WHT

WHT

OUTDOOR CONTROL

P.C. BOARD

BRN

BLU

BRN

BLU

BRN

X522

X521

BLK

SR861

LD2

RED

BLK

WHT

6

52341

BRN

BLU

BLU

TB4

CN90

TB2

X521X522

F61

CN73

CN71

FROM INDOOR

UNIT B

CONNECTING

12V

PE

CIRCUIT BREAKER

GRN/YLW

ORN

CN91

BLU

YLW

BLU

RED

RED

FROM INDOOR

UNIT A

CONNECTING

12V

1

2

C2

C1

RC

S

C

R

S

MC2

MF61

MC1

BLK

TB1

POWER SUPPLY

~/N

230V

50Hz

1

2

L

N

DSAR

BRN

MUX-A19WV MUX-A25WV -

OUTDOOR UNIT

E1

E1

MODELS WIRING DIAGRAM

SYMBOL

C1

C2

C61

DSAR

F61

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

NAME

COMPRESSOR CAPACITOR(MC1)

COMPRESSOR CAPACITOR(MC2)

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE(3.15A)

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

SYMBOL

MC1

MC2

MF61

NR61

SR861

COMPRESSOR(INNER PROTECTOR)

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR (INNER PROTECTOR)

SURGE ABSORBER

OUTDOOR FAN RELAY

NAME NAME

SYMBOL

TB1

TB2~TB4

T61

X521

X522

TERMINAL BLOCK

TERMINAL BLOCK

TRANSFORMER

COMPRESSOR CONTACTOR(MC1)

COMPRESSOR CONTACTOR(MC2)

VG79B200H02

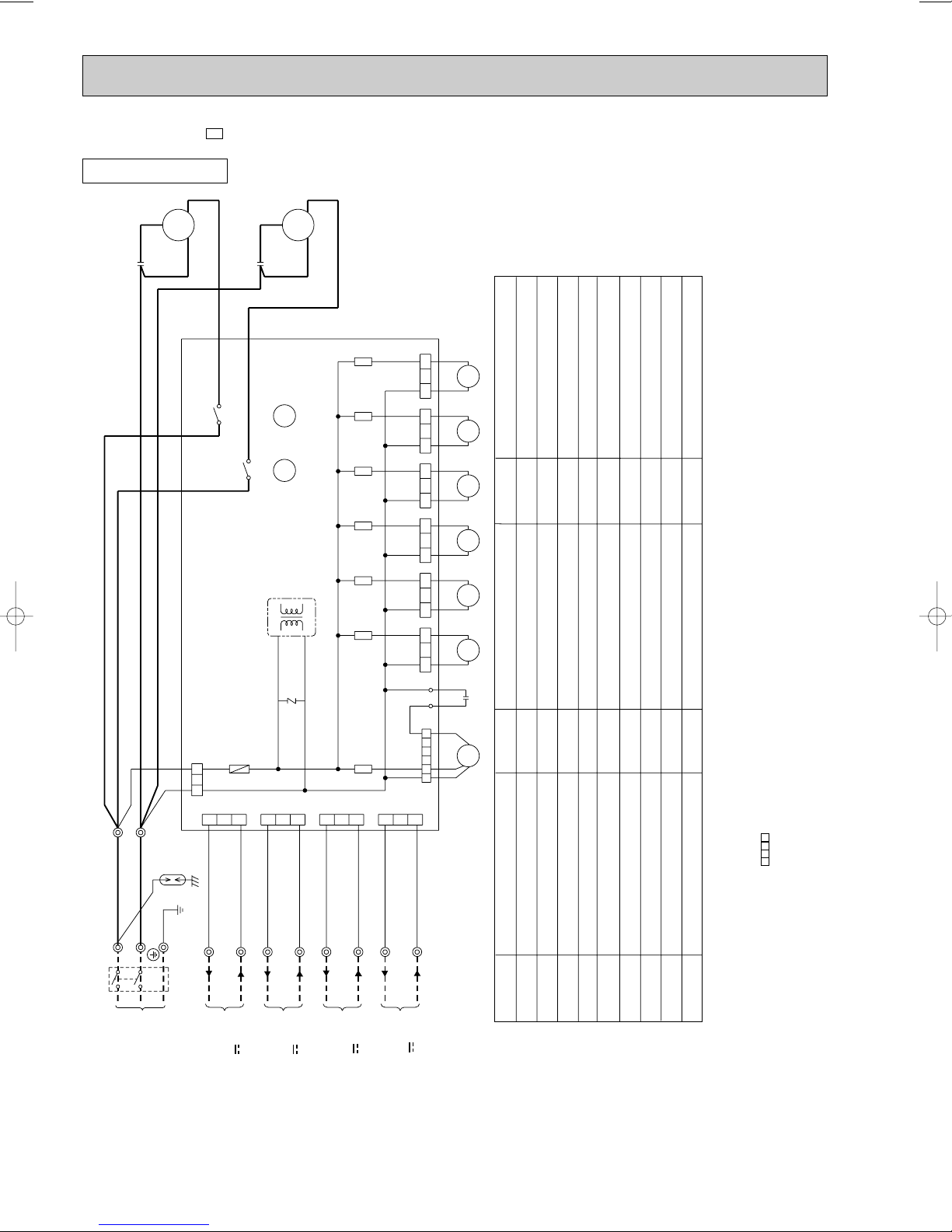

28

SYMBOL

MF61

NR61

SR861

SR863

SR865

SR866

TB1

SYMBOL

C1

C2

C61

DSAR

F61

MC1

MC2

NAME

NAME NAME

COMPRESSOR CAPACITOR(MC1)

COMPRESSOR CAPACITOR(MC2)

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE(3.15A)

COMPRESSOR(INNER PROTECTOR)

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR(INNER PROTECTOR)

SURGE ABSORBER

OUTDOOR FAN RELAY

RELAY (21RB)

RELAY (C) (21R4)

RELAY (B) (21R3)

TERMINAL BLOCK

TERMINAL BLOCK

TRANS FORMER

COMPRESSOR CONTACTOR(MC1)

COMPRESSOR CONTACTOR(MC2)

SOLENOID COIL

SOLENOID COIL (B)

SOLENOID COIL (C)

SYMBOL

TB2~TB4

T61

X521

X522

21RB

21R3

21R4

MUX-A20WV -

E1

OUTDOOR UNIT

S

MC1

RED

C1

BLU

BLU

BRN

BRN

CR

BLK

WHT

X521

MODEL WIRING DIAGRAM

S

MC2

RED

C2

43

43

X522

RC

WHT

BLK

SR865

X521

SR866

X522

SR863

T61

CN86

123123123

CN85

CN81

BLU

BLU

BLU

BLU

BLU

BLU

VG79B201H02

21R421R3

21RB

TB4

2

BRN

TB1

L

1

BLU

N

BRN

PE

OUTDOOR CONTROL P.C. BOARD

CN90

BRN

123

BLU

DSAR

GRN/YLW

CIRCUIT BREAKER

BLU

TB2

2

F61

213

YLW

1

CN71

NR61

3

BLU

2

2

ORN

1

CN73

1

SR861

3

BLU

TB3

2

2

WHT

1

LD1

LD2

652341

CN74

CN91

1

RED

RED

RED

BLK

WHT

C61

MF61

2. Use copper conductors only. (For field wiring)

/: Terminal block, : Connector

3. Symbols below indicate.

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

POWER SUPPLY

~/N

230V

50Hz

FROM INDOOR

UNIT A

FROM INDOOR

UNIT B

CONNECTING

CONNECTING

12V

12V

FROM INDOOR

UNIT C

CONNECTING

12V

29

DSAR

CIRCUIT BREAKER

L

N

2

1

2

112

1

2

BLK

RED

MF61

21R1

BLU

BLU

RED

RED

OUTDOOR CONTROL P.C. BOARD

T61

34

43

X521

X522

MC1

S

RC

MC2

S

RC

C1

C2

BLK

RED

WHT

RED

BLK

WHT

X522 X521

13

3

1

3

113

1

3

621

CONNECTING

FROM INDOOR

POWER SUPPLY

WHT

BLU

ORN

BLU

BRN

BLU

YLW

CN74CN73CN72CN71

TB1

TB3

TB2

2

2

2

2

2

BRN

BLU

TB4

2

1

BLU

F61

BRN

BLU

SR861

CN91

435

SR868

BLU

BLU

BRN

BRN

LD1

LD2

C61

NR61

CN90

WHT

123 123

21R2

BLU

BLU

SR867

21R3

BLU

BLU

SR866

123

BLU

BLU

21R4

123

SR865

BLU

BLU

21RA

123

SR864

BLU

BLU

21RB

123

SR863

CN83 CN84 CN85 CN86 CN81CN82

~/N

12V

230V

50Hz

UNIT C

FROM INDOOR

CONNECTING

12V

UNIT A

PE

GRN/YLW

FROM INDOOR

CONNECTING

UNIT D

12V

CONNECTING

FROM INDOOR

12V

UNIT B

BRN

SYMBOL

SR861

SR863

SR864

SR865

SR866

SR867

SR868

TB1~TB4

T61

SYMBOL

C1

C2

C61

DSAR

F61

MC1

MC2

MF61

NR61

NAME

NAME NAME

COMPRESSOR CAPACITOR(MC1)

COMPRESSOR CAPACITOR(MC2)

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE(3.15A)

COMPRESSOR(INNER PROTECTOR)

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR(INNER PROTECTOR)

SURGE ABSORBER

OUTDOOR FAN RELAY

RELAY (21RB)

RELAY (21RA)

RELAY (D) (21R4)

RELAY (C) (21R3)

RELAY (B) (21R2)

RELAY (A) (21R1)

TERMINAL BLOCK

TRANS FORMER

COMPRESSOR CONTACTOR(MC1)

COMPRESSOR CONTACTOR(MC2)

SOLENOID COIL (BALANCE)

SOLENOID COIL (BALANCE)

SOLENOID COIL (A)

SOLENOID COIL (B)

SOLENOID COIL (C)

SOLENOID COIL (D)

SYMBOL

X521

X522

21RA

21RB

21R1

21R2

21R3

21R4

MUX-A26WV -

E1

OUTDOOR UNIT

MODEL WIRING DIAGRAM

VG79B198H03

2. Use copper conductors only. (For field wiring)

/: Terminal block, : Connector

3. Symbols below indicate.

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

30

Loading...

Loading...