Page 1

SPLIT-TYPE AIR CONDITIONERS

OUTDOOR UNIT

SERVICE MANUAL

Models

No. OBH537

MU-C08VC MU-C10VC MU-C13VC -

F1

F1

F1

Indoor unit service manual

MS-C

CONTENTS

1. TECHNICAL CHANGES ··································· 2

2. PART NAMES AND FUNCTIONS ····················· 3

3. SPECIFICATION ················································ 4

4. OUTLINES AND DIMENSIONS ························ 5

5. WIRING DIAGRAM ············································ 6

6. REFRIGERANT SYSTEM DIAGRAM ··············· 7

7. PERFORMANCE CURVES ······························· 8

8. TROUBLESHOOTING ······································11

9. DISASSEMBLY INSTRUCTIONS ···················· 12

• VC Series (OBH536)

PARTS CATALOG (OBB537)

NOTE:

• RoHS compliant products have <G> mark on the spec name plate.

TM

Page 2

TECHNICAL CHANGES1

MU-C08VC MU-C10VC MU-C13VC -

1. New model

F1

F1

F1

2

Page 3

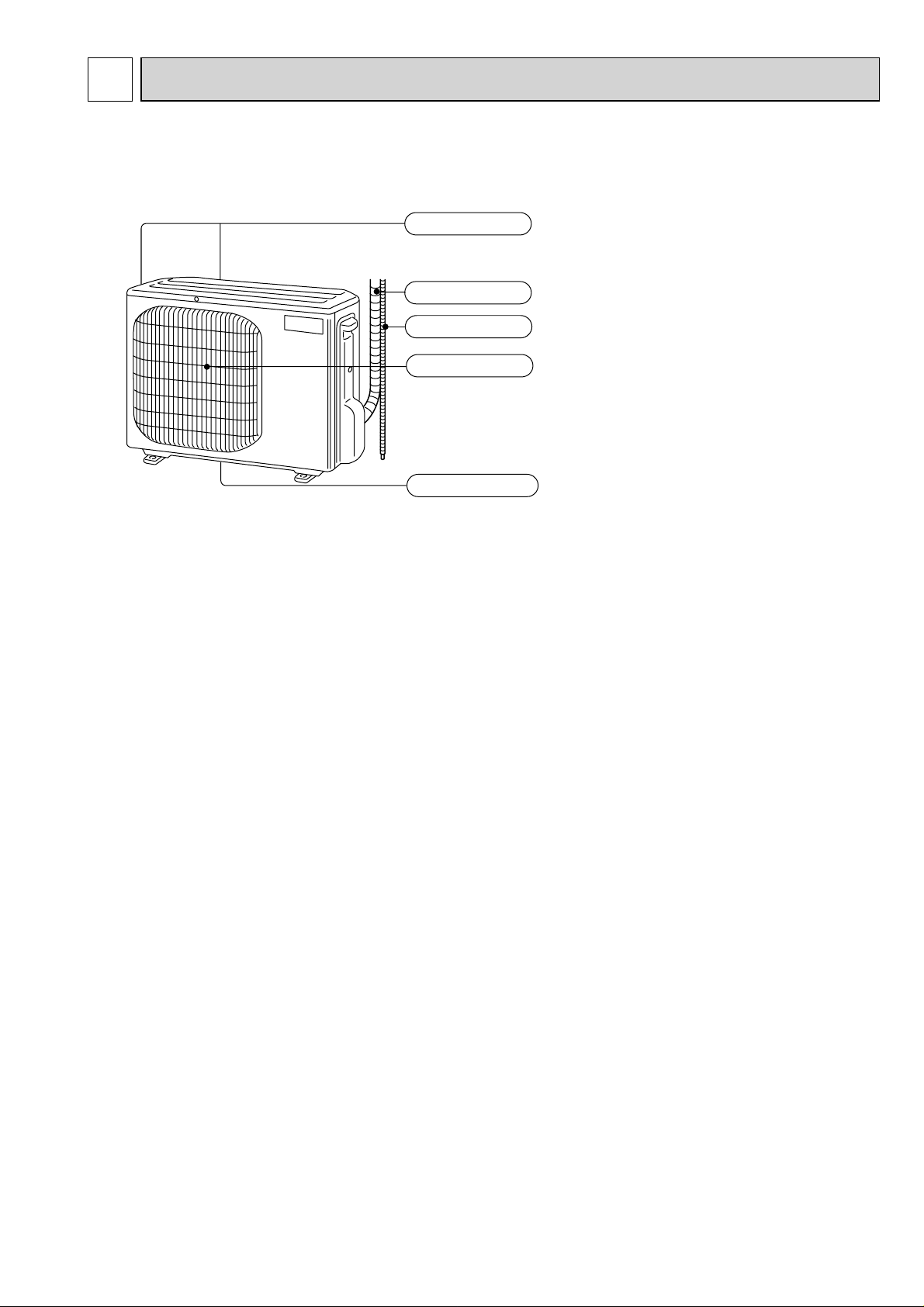

2

PART NAMES AND FUNCTIONS

MU-C08VC

MU-C10VC

MU-C13VC

Air inlet

(Back and side)

Piping

Drain hose

Air outlet

Drain outlet

3

Page 4

3

Outdoor model MU-C08VC MU-C10VC MU-C13VC

Function Cooling

Power supply

Capacity kW 2.3-2.3-2.3 2.75-2.75-2.75 3.5-3.5-3.5

Electrical

data

Coeffi cient of performance (C.O.P) (Total)

Fan

Dimensions W

Weight kg 22 25

Special

NOTE: Test conditions are based on ISO 5151.

Cooling: Indoor Dry-bulb temperature 27°C Wet-bulb temperature 19°C

Outdoor Dry-bulb temperature 35°C Wet-bulb temperature 24°C

Indoor-Outdoor piping length: 5 m

SPECIFICATION

Single phase

220-230-240 V, 50 Hz

Starting current (Total)

Model KS122VLRC KS145VLRC 2PS206D5AA02

Output W 600 700 950

Compressor

Compressor motor current

Model RA6V21-BC RA6V33-LB

Fan motor current A 0.240-0.245-0.250 0.300-0.310-0.320

motor

H D mm 684 540 255

Dehumidifi cation /h 1.0 1.2 1.6

Air fl ow /h 1,818-1,842-1,866 2,034-2,052-2,076

Sound level dB 47 49

Fan speed rpm 790-800-810 880-890-900

Fan speed regulator 1

remarks

Refrigerant fi lling

capacity (R22)

Refrigeration oil (Model)

A 15.5-16.0-16.5 19.0-20.0-21.0 22.0-23.5-25.0

3.29-3.19-3.11 3.27-3.16-3.06 3.04-2.94-2.87

A 2.89-2.89-2.88 3.44-3.44-3.43 4.93-4.96-4.99

kg 0.55

cc 300 (NM 56) 350 (NM 56)

4

Page 5

4

OUTLINES AND DIMENSIONS

MU-C08VC

MU-C10VC

MU-C13VC

Air in

17.5

Handle

540

270

10

105

381.5

Air in

Air out

243

Bolt pitch for installation

Drain hole Φ33

2 holes 10x16

500

684

Unit: mm

REQUIRED SPACE

100mm

or

more

47.5

300

264~280

installation

Bolt pitch for

40

22.5

20.8

144.6

61

Service port

255

89.6

145.5

100mm or more

Open two sides of left,

right, or rear side.

Service panel

Liquid refrigerant pipe joint

Refrigerant pipe (flared)

40°

43°

Basically open 100mm or more

without any obstruction in front

and on both sides of the unit.

100mm or more

Φ

6.35

Gas refrigerant pipe joint

Refrigerant pipe (flared)

Refrigerant pipe (flared)

350mm or more

Φ

9.52 (MU-C08/C10VC)

Φ

12.7 (MU-C13VC)

5

Page 6

5

MU-C08VC

MU-C10VC

WIRING DIAGRAM

MU-C13VC

6

Page 7

6

REFRIGERANT SYSTEM DIAGRAM

MU-C08VC MU-C10VC MU-C13VC

Refrigerant pipe

(Option)Φ9.52 (MU-C08/C10VC)

Φ12.7 (MU-C13VC)

(with heat insulator)

Flared

connection

Flared

connection

Stop valve

Refrigerant pipe

(Option)Φ6.35

(with heat insulator)

MAX. REFRIGERANT PIPING LENGTH

Stop valve

(with service port)

Compressor

Strainer

#100

Capillary tube

Φ3.0 x Φ 1.4 x 900 (MU-C08VC)

Φ3.0 x Φ 1.4 x 950 (MU-C10VC)

Φ3.0 x Φ 1.6 x 600 (MU-C13VC)

Refrigerant flow in cooling

Unit : mm

Outdoor

heat

exchanger

Model

MU-C08VC

MU-C10VC

MU-C13VC

Refrigerant piping : m

Max. lengthAMax. height

B

20 10

Piping size O.D : mm

Gas

Φ9.52

Φ12.7

MAX. HEIGHT DIFFERENCE

Indoor

unit

Max. Height

B

Refrigerant Piping

Max. Length

A

ADDITIONAL REFRIGERANT CHARGE (R22 : g)

Model

MU-C08VC

MU-C10VC

MU-C13VC

Outdoor unit precharged

550

550

550

NOTE : Calculation : Xg=15 g/m x (Refrigerant piping length (m)-7)

Refrigerant piping length (one way)

7m

0

10m

45

Liquid

Φ6.35

15m

120

Outdoor unit

20m

195

7

Page 8

PERFORMANCE CURVES7

MU-C08VC MU-C10VC MU-C13VC

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions.

Since operating conditions vary according to the areas where these units are installed. The following information has been

provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198 ~ 264 V, 50 Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : °CWB

(2) Indoor outlet air wet-bulb temperature : °CWB

(3) Outdoor intake air dry-bulb temperature : °CDB

(4) Total input: W

Indoor air wet/dry-bulb temperature difference on the left side of the chart on next page shows the difference between the

indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

How to measure the indoor air wet/dry-bulb temperature difference

1. Attach at least 2 sets of wet and-dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of the room.

5. Press the EMERGENCY OPERATION switch once to start the EMERGENCY COOL MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT OUTDOOR UNIT

Wet and dry-bulb

thermometers

7.6

7.0

6.4

5.8

5.3

4.8

4.3

7.0

6.4

5.8

5.2

4.6

10.0

9.2

8.4

7.5

6.8

6.0

Indoor intake air WB temperature (°C)

Indoor intake air WB temperature (°C)

Wet and dry-bulb

thermometers

MS-C10VC

MS-C08VC

MU-C10VC

MU-C08VC

MS-C13VC

MU-C13VC

Outdoor intake air DB temperature (°C)

8

Outdoor intake air DB temperature (°C)

Page 9

OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

Both indoor and outdoor units are under the same temperature/humidity condition.

Dry-bulb temperature (°C)

20

25

Relative humidity (%)

50

60

30 70

Air flow should be set at MAX.

The unit of pressure has been changed to MPa on the international system of units (SI unit system).

The conversion factor is : 1(MPa [Gauge]) =10.2(kgf/cm² [Gauge])

(kgf/cm² [Gauge])(MPa [Gauge])

0.9

9.0

0.8

8.0

0.7

7.0

0.6

6.0

Outdoor low pressure

5.0

0.5

MU-C08VC MU-C08VC

4.0

3.5

3.0

Outdoor unit current (A)

2.5

0.4

4.0

15 20

50

25

60

Ambient temperature (˚C)/Ambient humidity (%)

(kgf/cm² [Gauge])(MPa [Gauge])

0.8

8.0

0.7

7.0

0.6

6.0

0.5

5.0

Outdoor low pressure

4.0

3.0

0.4

0.3

15 20

MU-C10VC

50

25

60

3070 35(°C)

(%)

3070 35(°C)

(%)

2.0

15 20

50

25

60

30

70

Ambient temperature (˚C)/Ambient humidity (%)

MU-C10VC

5.0

4.5

4.0

Outdoor unit current (A)

3.5

3.0

15 20

50

25

60

30

70

°C

35(

(%)

35(

(%)

)

°C

)

Ambient temperature (˚C)/Ambient humidity (%)

Ambient temperature (˚C)/Ambient humidity (%)

9

Page 10

(kgf/cm² [Gauge])(MPa [Gauge])

0.8

8.0

0.7

7.0

0.6

6.0

0.5

5.0

Outdoor low pressure

0.4

4.0

MU-C13VC

6.0

5.5

5.0

Outdoor unit current (A)

4.5

MU-C13VC

0.3

3.0

15 20

50

25

60

3070 35(°C)

(%)

Ambient temperature (˚C)/Ambient humidity (%)

4.0

15 20

50

25

60

30

70

Ambient temperature (˚C)/Ambient humidity (%)

°C

35(

(%)

)

10

Page 11

TROUBLESHOOTING8

MU-C08VC MU-C10VC MU-C13VC

8-1. CAUTIONS ON TROUBLESHOOTING

1. Before troubleshooting, check the following:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for mis-wiring.

2. Take care of the following during servicing

1) Before servicing the air conditioner, be sure to turn OFF the main unit first with the remote controller, and then after

confirming the horizontal vane is closed, turn OFF the breaker and/or disconnect the power plug.

2) Be sure to turn OFF the power supply before removing the front panel, the

cabinet, the top panel and the electronic control P.C. board.

3) When removing the electronic control P.C. board, hold the edge of the

board with care NOT to apply stress on the components.

4) When connecting or disconnecting the connectors, hold the housing of the

connector. DO NOT pull the lead wires.

Lead wiring

8-2. TROUBLE CRITERION OF MAIN PARTS

MU-C08VC

MU-C10VC

MU-C13VC

Housing point

Part name

Compressor (MC)

INNER

PROTECTOR

MU-C08VC

155 ± 5°C OPEN

90 ± 10°C CLOSE

MU-C10VC

160 ± 5°C OPEN

90 ± 10°C CLOSE

COMPRESSOR

THERMAL

PROTECTOR

MU-C13VC

160 ± 7°C OPEN

69 ± 10°C CLOSE

Outdoor fan

motor (MF)

INNER FUSE

126 ± 2°C OPEN

Check method and criterion

Measure the resistance between the terminals with a tester.

(Coil wiring temperature -10°C ~ 40°C)

Color of

lead wire

C-R

C-S

MU-C08VC

4.24 ~ 5.19 Ω

6.76 ~ 8.28 Ω

Normal

MU-C10VC

3.19 ~ 3.91 Ω

4.76 ~ 5.83 Ω

MU-C13VC

2.55 ~ 3.13 Ω

4.23 ~ 5.18 Ω

Measure the resistance between the terminals with a tester.

(Coil wiring temperature -10°C ~ 40°C)

Color of

lead wire

WHT-BLK

BLK-RED

MU-C08VC

222 ~ 272 Ω

245 ~ 300 Ω

Normal

MU-C10VC

222 ~ 272 Ω

245 ~ 300 Ω

MU-C13VC

150 ~ 185 Ω

199 ~ 244 Ω

Figure

MU-C08/C10VC

WHT

C

P

SR

RED

MU-C13VC

SR

RED

BLK

C

FUSE

WHT

MAIN

AUX.

BLK

P

BLK

RED

WHT

11

P

: PROTECTOR

Page 12

9

DISASSEMBLY INSTRUCTIONS

<"Terminal with locking mechanism" Detaching points>

The terminal which has the locking mechanism can be detached as shown below.

There are two types ( Refer to (1) and (2)) of the terminal with locking mechanism.

The terminal without locking mechanism can be detached by pulling it out.

Check the shape of the terminal before detaching.

(1) Slide the sleeve and check if there is a locking lever or not.

Sleeve

Slide the sleeve.

Pull the terminal while

Locking lever

pushing the locking

lever.

MU-C08VC MU-C10VC MU-C13VC

OPERATING PROCEDURE

1. Removing the cabinet

(1) Remove the screws fixing the top panel. (See Photo 1.)

(2) Remove the top panel. (See Photo 1.)

(3) Remove the screw fixing the service panel. (See Photo 2.)

(4) Pull down the service panel and remove it. (See Photo 2.)

(5) Remove the screws fixing the cabinet.

(6) Remove the cabinet.

(7)

Disconnect the power supply and indoor/outdoor connecting wire.

(8) Remove the screws fixing the back panel.

(9) Remove the back panel.

(2) The terminal with this connector has the

locking mechanism.

Hold the sleeve, and

pull out the terminal

slowly.

Connector

PHOTOS

Photo 1

Screws

of the

top panel

Screws of

the top panel

Photo 2

Screw of the

service panel

Direction to

remove

Hooks

12

Screws of

the cabinet

Service

panel

Page 13

OPERATING PROCEDURE PHOTOS

2. Removing the electrical parts

(1) Remove the service panel and the cabinet.(Refer to 1.)

(2) Remove the following parts.

•Compressor capacitor (C1)

•Outdoor fan capacitor (C2)

•Terminal block (TB)

•Compressor contactor (52C)

NOTE : When attaching compressor contactor (52C)

to relay panel, make sure that the side with

printed letters is facing upward.

Model and type name

OMRON

G7L-1A-TUB-07

xxxxxxxxxxxxx

xxxxxxxxxxxx

xxxxxxxxxxxxx

xxxxxxxxxxxxx

xxxxxxxxxxxxx

xxxxxxxxxxxxx

0

2

0

1

8

6

1

4

Photo 3

Compressor

capacitor

(C1)

Terminal

block (TB2)

Earth screw of

indoor/ outdoor

connecting wire

Outdoor fan

capacitor

(C2)

Terminal

block(TB1)

Lead clamp

Connector

Compressor

contactor

(52C)

Earth screw of

power supply

3. Removing the propeller and the outdoor fan motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller nut and the propeller.

NOTE : Loosen the propeller in the rotating direction for

removal.

When attaching the propeller, align the mark on the

propeller and the motor shaft cut section.

Set the propeller in position by using the cut on the

shaft and the mark on the propeller.

(3) Remove the lead clamps and outdoor fan motor lead wires.

(4) Remove the screws fixing the outdoor fan motor.

(5) Remove the outdoor fan motor.

Photo 4

Set screws of the

outdoor fan motor

Propeller

Propeller

nut

Set screws of the

outdoor fan motor

Outdoor fan motor lead wires

Hook

Relay panel

Outdoor

fan motor

13

Page 14

OPERATING PROCEDURE PHOTOS

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the soundproof felt.

(3) Remove the screws fixing the relay panel.

(4) Remove the terminal cover.

(5) Pull out the lead wires from the glass terminal of the com-

pressor.

(6) Recover gas from the refrigerant circuit.

NOTE : Recover gas from the pipes until the pressure gauge

shows 0 kg/cm² (0MPa).

(7) Disconnect the welded part of the suction pipe and

discharge pipe.

(8) Remove the nuts fixing the compressor.

(9) Remove the compressor.

Photo 5

MU-C08/10VC

Discharge

pipe

Terminal

cover

Suction

pipe

Compressor

Compressor set nuts

(3 places)

Photo 6

MU-C13VC

Discharge

pipe

Terminal

cover

Suction

pipe

Compressor

14

Compressor set nuts

(3 places)

Page 15

15

Page 16

TM

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Copyright 2008 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD.

Distributed in Dec. 2008. No.OBH537 5

Made in Japan

New publication, effective Dec. 2008

Specifications subject to change without notice.

Loading...

Loading...