Page 1

SERVICE TECHNICAL GUIDE

SPLIT-TYPE, AIR CONDITIONERS

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

Wireless type Models

MS-A•WA · MU-A•WA

MSZ-A•NA · MUZ-A•NA

No. OBT16

· MUZ-A•NA -

MSY-A•NA · MUY-A•NA

Inverter-controlled multi system type Models

· MXZ-A•NA

CONTENTS

1. MS MICROPROCESSOR CONTROL··················3

2. MSZ,MSY MICROPROCESSOR CONTROL·······6

3. MXZ MICROPROCESSOR CONTROL··············20

U

Page 2

1. MS MICROPROCESSOR CONTROL ···························································3

Indoor unit models Outdoor unit models

MS-A09WA MU-A09WA

MS-A12WA MU-A12WA

1-1. COOL OPERATION················································································3

1-2. DRY OPERATION ··················································································3

1-3. AUTO VANE OPERATION·····································································5

2. MSZ, MSY MICROPROCESSOR CONTROL ···············································6

Indoor unit models Outdoor unit models

MSZ-A09NA MUZ-A09NA

MSZ-A12NA MUZ-A12NA

MSZ-A15NA MUZ-A15NA

MSZ-A17NA MUZ-A17NA

MSZ-A24NA MUZ-A24NA

MSY-A15NA MUY-A15NA

MSY-A17NA MUY-A17NA

MSY-A24NA MUY-A24NA

2-1. COOL OPERATION···············································································6

2-2. DRY OPERATION ·················································································7

2-3. HEAT OPERATION ···············································································7

2-4. AUTO CHANGE OVER ··· AUTO MODE OPERATION························9

2-5. OUTDOOR FAN MOTOR CONTROL·················································10

2-6. AUTO VANE OPERATION ··································································10

2-7. INVERTER SYSTEM CONTROL ························································12

2-8. OPERATIONAL FREQUENCY CONTROL OF OUTDOOR UNIT······16

2-9. EXPANSION VALVE CONTROL (LEV CONTROL) ···························17

3. MXZ MICROPROCESSOR CONTROL·······················································20

Outdoor unit models

MXZ-2A20NA

MXZ-3A30NA

3-1. INVERTER SYSTEM CONTROL·························································20

3-2. EXPANSION VALVE CONTROL (LEV CONTROL) ····························22

3-3. OPERATIONAL FREQUENCY RANGE···············································27

3-4. HEAT DEFROSTING CONTROL·········································

3-5.

DISCHARGE TEMPERATURE PROTECTION CONTROL ·····BACK PAGE

3-6. OUTDOOR FAN CONTROL················································

BACK PAGE

BACK PAGE

2

Page 3

1

95

86

77

68

59

50

ºF

50 59 68 77 86 95

Set temperature

Initial room temperature

Set temperature and

initial room temperature in dry mode

ºF

MS MICROPROCESSOR CONTROL

MS-A09WA MU-A09WA

MS-A12WA MU-A12WA

1-1. COOL ( ) OPERATION

1. Thermostat control

Thermostat is ON or OFF by difference between room temperature and set temperature

Initial temperature difference Thermostat

Difference between room

temperature and set temperature during operation.

Set temperature

Room temperature minus set temperature : -1.8 degrees or more·····································ON

Room temperature minus set temperature : less than -1.8 degrees···································OFF

2. Indoor fan speed control

Indoor fan operates continuously at the set speed by FAN SPEED CONTROLbutton

regardless of the thermostat’s OFF-ON.

In AUTO the fan speed is as follows.

Initial temperature difference

Fan speed

Difference between room

temperature and set temper-

ature during operation ( T)

-1.8deg.

Room temperature minus set temperature : 3.1 degrees or more·······························High

Room temperature minus set temperature : Between 1.8 and 3.1 degrees

···················

Room temperature minus set temperature : less than 1.8 degrees ····························Low

3. Coil frost prevention

Med.

1.8 deg.

3.1 deg.

① Temperature control

When the indoor coil thermistor RT12 reads 37 ºF or below the coil frost prevention mode starts immediately.

However, the coil frost prevention doesn’t work for 5 minutes since the compressor has started.

The indoor fan operates at the set speed and the compressor stops for 5 minutes.

After that, if RT12 still reads below 37 ºF this mode prolonged until the RT12 reads over 37 ºF.

② Time control

When the three conditions as follows have been satisfied for 1 hour and 45 minutes, compressor stops for 3 minutes.

a. Compressor has been continuously operating.

b. Indoor fan speed is Low or Med.

c. Room temperature is below 79 ºF.

When compressor stops, the accumulated time is cancelled and when compressor restarts, time counting starts from the

beginning.

Time counting also stops temporarily when the indoor fan speed becomes High or the room temperature exceeds

79 ºF. However, when two of the above conditions (b.and c.) are satisfied again. Time accumulation is resumed.

-1.3deg.

5.4 deg.

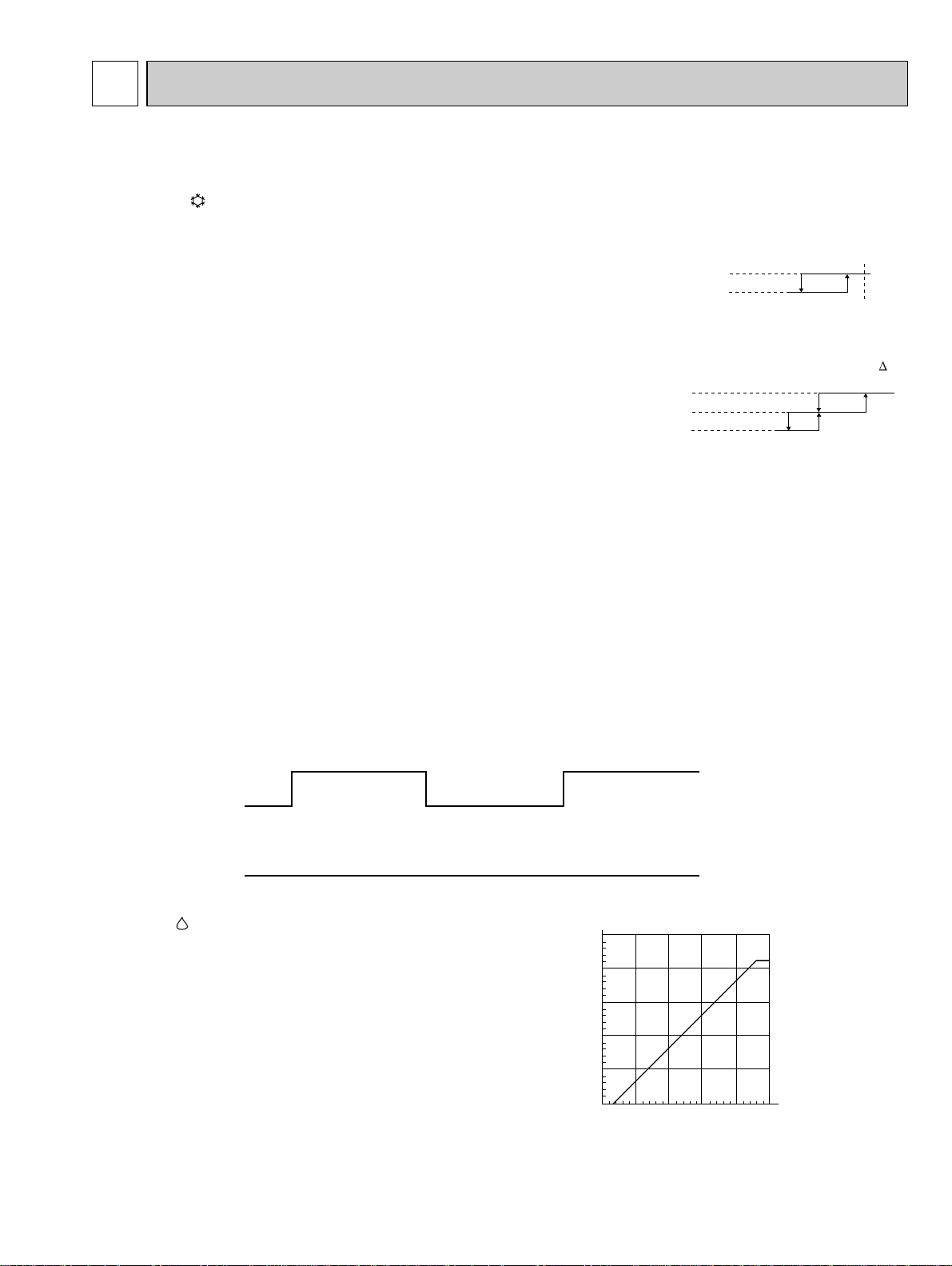

Operation chart

Example

Compressor

Outdoor fan

Indoor fan

1-2. DRY ( ) OPERATION

Set temperature is as shown on the right chart.

The system for dry operation uses the same refrigerant circuit as the

cooling circuit.

The compressor and the indoor fan are controlled by the room temperature.

By such controls, indoor flow amounts will be reduced in order to

lower humidity without much room temperature decrease.

ON

OFF

(continuously at set speed)

ON

OFF

ON

3

Page 4

1. Thermostat control

Thermostat is ON or OFF by difference between room temperature and set temperature.

Initial temperature difference Thermostat

Room temperature minus set temperature : -1.8 degrees or more·····································ON

Room temperature minus set temperature : less than -1.8 degrees···································OFF

2. Indoor fan speed control

Indoor fan operates at the set speed by FAN SPEED CONTROLbutton.

When thermostat OFF (compressor OFF) fan speed becomes Very Low.

In AUTO the fan speed is as follows.

Initial temperature difference

Fan speed

Room temperature minus set temperature : 3.1 degrees or more·······························High

Room temperature minus set temperature : Between 1.8 degrees and 3.1 degrees

···

Room temperature minus set temperature : less than 1.8 degrees·····························Low

3. The operation of the compressor and indoor/ outdoor fan

Compressor operates by room temperature control and time control.

Set temperature is controlled to fall 4°F from initial room temperature.

Indoor fan and outdoor fan operate in the same cycle as the compressor.

•When the room temperature is 73°F or over:

When the thermostat is ON, the compressor repeats 8 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

•When the room temperature is under 73°F.

When the thermostat is ON, the compressor repeats 2 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

Med.

Difference between room

temperature and set temperature during operation

Set temperature

-1.8 deg.

-1.3 deg.

Difference between room

temperature and set temper-

ature during operation ( T)

4.5 deg.

1.8 deg.

3.1 deg.

Operation time chart

Example

ON

Thermostat

Indoor fan

Outdoor fan

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

OFF

Compressor

8 minutes

3 minutes

4 minutes

1 minute

4. Coil frost prevention

Coil frost prevention is as same as COOL mode. (2-1.3.)

The indoor fan maintains the actual speed of the moment. However ,when coil frost prevention works while the compressor

is not operating it’s speed becomes the set speed.

4

Page 5

1-3. AUTO VANE OPERATION

1. Horizontal vane

ECONO COOL ( ) operation (ECONOmical operation)

When ECONO COOL button is pressed in COOL mode, set temperature is automatically set 3.6 degrees higher than

that in COOL mode.

Also the horizontal vane swings in various cycle according to the temperature of indoor heat exchanger (RT12).

SWING operation makes you feel cooler than set temperature. So, even though the set temperature is higher than that

in COOL mode, the air conditioner can keep comfort. As a result, energy can be saved.

ECONO COOL operation is cancelled when ECONO COOL button is pressed once again or VANE CONTROL

button is pressed or change to other operation mode.

<SWING operation>

In swing operation of ECONO COOL operation mode, the initial air flow direction is adjusted to “Horizontal”.

According to the temperature of indoor coil thermistor RT12 at starting of this operation, next downward blow time is

decided. Then when the downward blow has been finished, next horizontal blow time is decided.

For initial 10 minutes the swing operation is performed in table G~H for quick cooling.

Also, after 10 minutes when the difference of set temperature and room temperature is more than 3.6 degrees, the

swing operation is performed in table D~H for more cooling.

The air conditioner repeats the swing operation in various cycle as follows.

Temperature of indoor

coil thermistor RT12

A

B

C

D

E

F

G

H

59°F or less

59°F to 63°F

63°F to 64°F

64°F to 68°F

68°F to 70°F

70°F to 72°F

72°F to 75°F

more than 75°F

Downward blow time

(second)

2

5

8

11

14

17

20

23

Horizontal blow time

(second)

23

20

17

14

11

8

5

2

5

Page 6

2

MSZ,MSY MICROPROCESSOR CONTROL

MSZ-A09NA MSY-A15NA MUZ-A09NA MUY-A15NA

MSZ-A12NA MSY-A17NA MUZ-A12NA MUY-A17NA

MSZ-A15NA MSY-A24NA MUZ-A15NA MUY-A24NA

MSZ-A17NA MUZ-A17NA

MSZ-A24NA MUZ-A24NA

2-1. COOL ( ) OPERATION

1. Thermostat control

Thermostat is ON or OFF by difference between room temperature and set temperature

Room temperature minus set temperature : -1.8 degrees or more·····································ON

Room temperature minus set temperature : less than -1.8 degrees···································OFF

2. Indoor fan speed control

Indoor fan operates continuously at the set speed by FAN SPEED CONTROLbutton

regardless of the thermostat’s OFF-ON.

In AUTO the fan speed is as follows.

Room temperature minus set temperature : 3.1 degrees or more·······························High

Room temperature minus set temperature : Between 1.8 and 3.1 degrees

Room temperature minus set temperature : less than 1.8 degrees ····························Low

3. Coil frost prevention

Temperature control

When indoor coil thermistor detects following temperature for 90 seconds, operational frequency

of compressor is controlled according to the following table.

Temperature of indoor coil thermistor

50°F or more

46°F to 50°F Raise 6Hz

43°F to 46°F

37°F to 43°F

37°F or less

The indoor fan maintains the actual speed of the moment.

4. Low outside temperature operation

If the outside temperature falls to 64°F or less during operation in COOL mode, the unit enters the low outside temperature

operation mode.

<Operation>

(1) If the unit enters the low outside temperature operation mode, the outside fan rotation speed gets slow down.

(2) Even when the unit is in the "thermostat-off" status under the low outside temperature operation mode, the outside fan

rotation does not stop.

(3) In this mode to detect the exact outside temperature the compressor turns OFF with the outdoor fan ON for 3 minutes

once 1 hour; if the outside temperature rises over 64°F, the unit goes back to the normal COOL mode, and if the

outside temperature is still 64°F or less, the unit stays in the low outside temperature operation mode.

(4) Dew drop prevention

When the ambient temperature thermistor RT65 reads 10°F or less, as coil frost or dew drop from indoor unit may

occur, the compressor turns OFF with the outdoor fan ON for prevention of them.

Initial temperature difference Thermostat

Initial temperature difference

···················

Operation frequency

Compressor is turned OFF for 5 minutes when temperature of

indoor coil thermistor continues 37°F or less for 5 minutes or more.

Fan speed

Med.

Normal (variable)

Fixed

Lower 3Hz

Lower 6Hz

Difference between room

temperature and set temperature during operation.

Set temperature

-1.8deg.

Difference between room

temperature and set temper-

ature during operation ( T)

1.8deg.

-1.3deg.

5.4deg.

3.1deg.

WOther protections work as well as in the normal COOL mode.

6

Page 7

2-2. DRY ( ) OPERATION

95

86

77

68

59

50

ºF

50 59 68 77 86 95

Set temperature

Initial room temperature

Set temperature and

initial room temperature in dry mode

ºF

Set temperature is as shown on the right chart.

The system for dry operation uses the same refrigerant circuit as the

cooling circuit.

The compressor and the indoor fan are controlled by the room temperature.

By such controls, indoor flow amounts will be reduced in order to

lower humidity without much room temperature decrease.

Difference between room

1. Thermostat control

Thermostat is ON or OFF by difference between room temperature and set temperature.

Initial temperature difference Thermostat

Room temperature minus set temperature : -1.8 degrees or more·······································ON

Room temperature minus set temperature : less than -1.8 degrees······································OFF

2. Indoor fan speed control

Indoor fan operates at the set speed by FAN SPEED CONTROLbutton.

When thermostat OFF (compressor OFF) fan speed becomes Very Low.

In AUTO the fan speed is as follows.

Initial temperature difference

Fan speed

Room temperature minus set temperature : 3.1 degrees or more·······························High

Room temperature minus set temperature : Between 1.8 and 3.1 degrees

···················

Med.

Room temperature minus set temperature : less than 1.8 degrees ····························Low

3. Coil frost prevention

Coil frost prevention is as same as COOL mode. (2-1.3.)

The indoor fan maintains the actual speed of the moment. However ,when coil frost prevention works while the compressor

is not operating it’s speed becomes the set speed.

4. Low outside temperature operation

Low outside temperature operation is as same as COOL mode. (2-1.4.)

temperature and set temperature during operation

Set temperature

-1.8deg.

-1.3deg.

Difference between room

temperature and set temperature during operation ( T)

4.5deg.

1.8deg.

3.1deg.

2-3. HEAT ( ) OPERATION (MSZ)

1. Thermostat control

Thermostat is ON or OFF by difference between room temperature and set temperature.

Room temperature minus set temperature : less than 3.6 degrees····································ON

Room temperature minus set temperature : 3.6 degrees or more······································OFF

2. Indoor fan speed control

(1) Indoor fan operates at the set speed by FAN SPEED CONTROLbutton.

In Auto the fan speed is as follows.

Set temperature minus room temperature:

Set temperature minus room temperature:

Set temperature minus room temperature: less than

Difference between room

temperature and set temperature during operation

Initial temperature difference Thermostat

Set temperature

3deg.

3.6deg.

Difference between room

temperature and set temper-

Initial temperature difference

3.6 degrees

or more

······································ High

Between 0.4 and 3.6 degrees ····················

0.4 degrees····································

Fan speed

Med.

Low

ature during operation

3.6deg.

0.4deg.

3deg.

7.2deg.

7

Page 8

(2) Cold air prevention control

MSZ-A09/12/15/17

1 When the compressor is not operating,

(1) if the temperature of room temperature thermistor RT11 is less than 66°F, the fan stops.

(2) if the temperature of room temperature thermistor RT11 is 66°F or more and

1) if the temperature of RT12 is less than 32°F, the fan stops.

(

2 When the compressor is operating,

NOTE : When 3 minutes have passed since the compressor started operation, this control is released regardless of the

MSZ-A24

1 When the compressor is not operating,

2 When the compressor is operating,

NOTE : When 3 minutes have passed since the compressor started operation, this control is released regardless of the

3. Overload starting

When the room temperature thermistor RT11 reads 64°F or more, the compressor runs with its maximum frequency regulated

for 10 minutes after the start-up.

4. Defrosting

(1) Starting conditions of defrosting

When the following conditions a) ~ c) are satisfied, the defrosting starts.

a) The defrost thermistor reads 27°F or less.

b) The cumulative operation time of the compressor has reached any of the set valuesw (40, 45, 55, 65, 75, 85, 95, 105,

115, 125, 150 minutes(MUZ-A09/12/15/17))/(31,35,45,55,65,75,85,95,105,115,150minutes(MUZ-A24)).

c) More than 5 minutes have passed since the start-up of the compressor.

w Set value of compressor operation time (here in after referred to as defrost interval)

This is decided by the temperature of defrost thermistor and ambient temperature thermistor, the previous defrosting

time. For example, the first defrost interval is 40 minutes long, and the second is 45 minutes long. The third and subse-

quent intervals are set to be longer, and less frequent, depending on defrosting time.

The third and subsequent defrost intervals follow any of the three patterns …5 or 10 to 20 minutes longer, the same, or

5 or 10 to 20 minutes shorter compared with the previous defrost interval … with the longest 125 minutes and the

shortest 40 minutes.

(2) Releasing conditions of defrosting

Defrosting is released when any of the following conditions is satisfied:

a) The defrost thermistor continues to read 50°F or more (MUZ-A09/12) / 41°F or more (MUZ-A15/17) / 59°F or more

(MUZ-A24) for 30 seconds.

b) Defrosting time has exceeded 10 minutes.

c) Any other mode than HEAT mode is set during defrosting.

(2) if the temperature of RT12 is 32°F or more, the fan operates at Very Low.

(1) if the temperature of RT12 is 104°F or more, the fan operates at set speed.

(2) if the temperature of RT12 is less than 104°F and

(1) if heating operation starts after defrosting, the fan stops.

(2) if the temperature of room temperature thermistor RT11 is 66°F or less, the fan stops.

(3) if the temperature of room temperature thermistor RT11 is more than 66°F, the fan operates at Very Low.

temperature of RT11 and RT12.

(1) if the temperature of room temperature thermistor RT11 is 59°F or less, or RT12 is less than 64°F,

the fan stops.

(2) if the temperature of room temperature thermistor RT11 is more than 59°F, or RT12 is more than 64°F,

the fan operates at Very Low.

(1) if the temperature of RT12 is 64°F or more, the fan operates at set speed.

(2) if the temperature of RT12 is less than 64°F and

(1) if heating operation starts after defrosting, the fan stops.

(2) if the temperature of room temperature thermistor RT11 is 59°F or less, the fan stops.

(3) if the temperature of room temperature thermistor RT11 is more than 59°F, the fan operates at Very Low.

temperature of RT11 and RT12.

8

Page 9

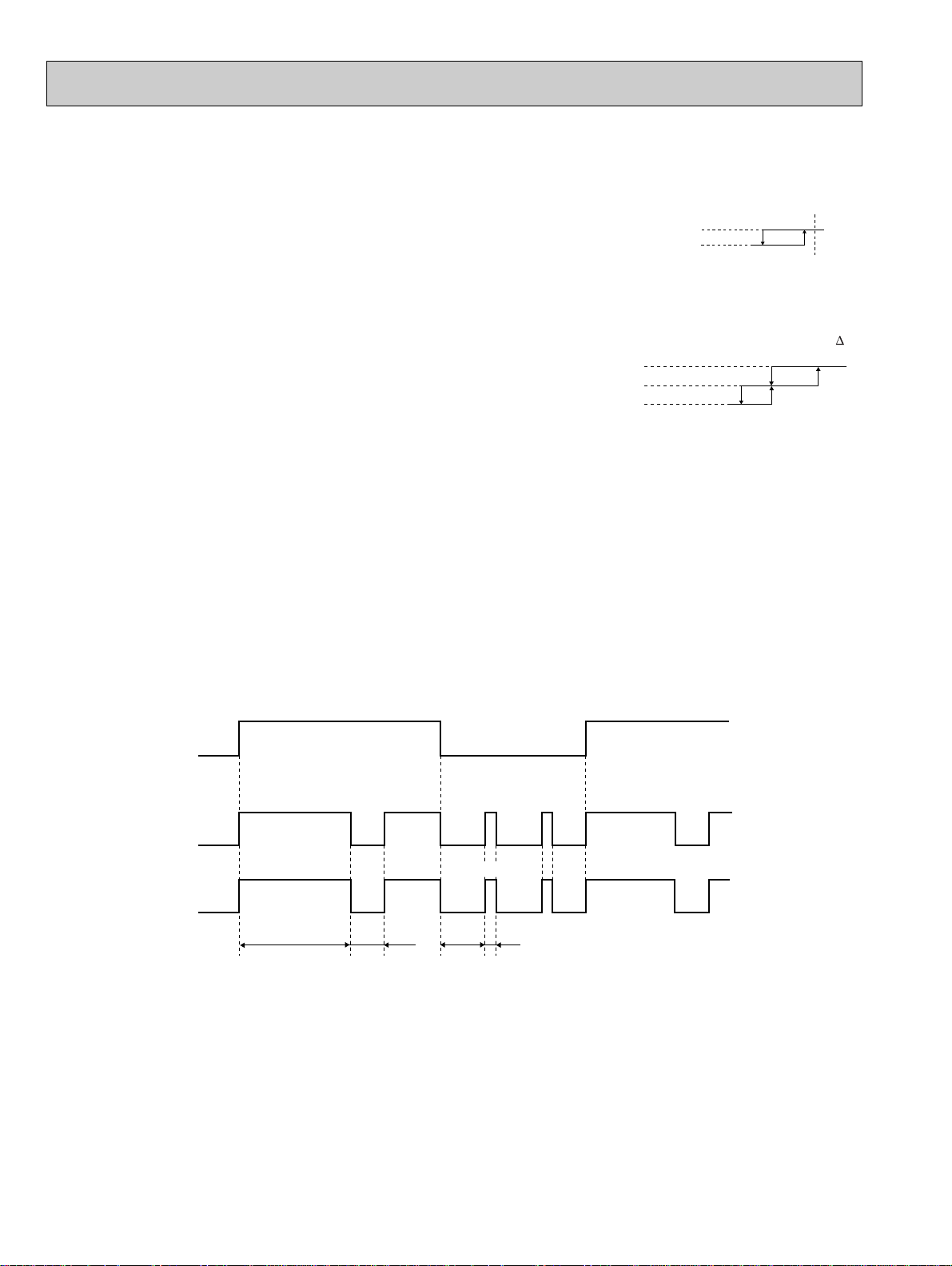

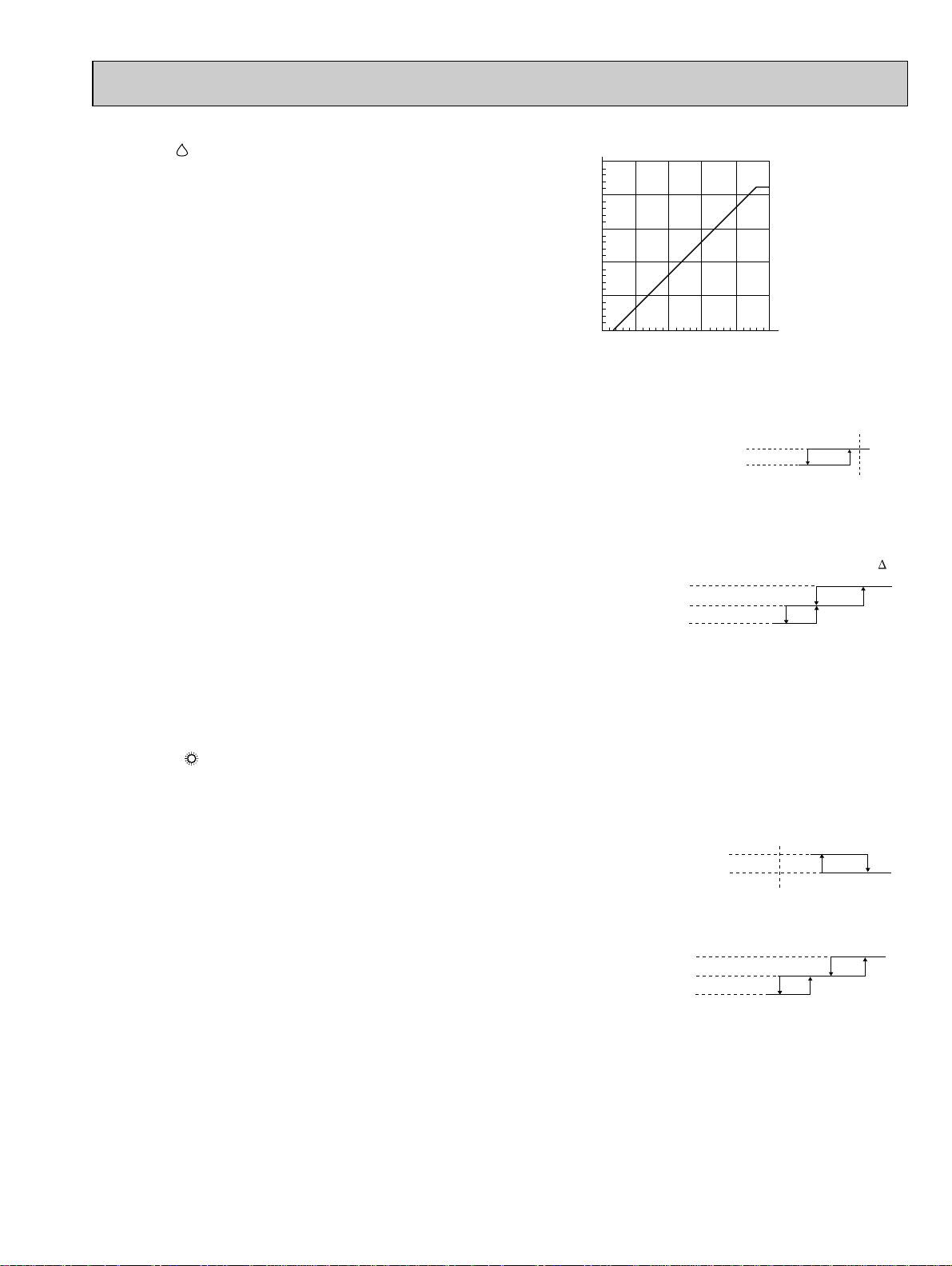

Time chart of defrosting in HEAT mode (reverse type)

set position

set speed

set position

set speed

Indoor fan

Compressor normal

Outdoor fan

R.V. coil

(21S4)

OFF (COOL)

OFF

Maximum frequency

horizontal

Horizontal vane

Very Low (temperature of indoor coil thermistor > 64°F)

30

seconds

30

seconds

30

seconds

40

seconds

5 seconds 5 seconds

40

seconds

OFF

OFF

OFF

ON (HEAT)

ON ON

ON (HEAT)

<indoor unit>

<outdoor unit>

2-4. AUTO CHANGE OVER ··· AUTO MODE OPERATION (MSZ)

1. Mode selection

Once desired temperature is set, unit operation is switched automatically between COOL and HEAT operation.

(1) Initial mode

At first indoor unit operates only indoor fan with outdoor unit OFF for 3 minutes to detect present room temperature.

Following the conditions below, operation mode is selected.

1 If the room temperature thermistor RT11 reads more than set temperature, COOL mode is selected.

2 If the room temperature thermistor RT11 reads set temperature or less, HEAT mode is selected.

(2) Mode change

In case of the following conditions the operation mode is changed.

1 COOL mode changes to HEAT mode when 15 minutes have passed with the room temperature 4 degrees below the

set temperature.

2 HEAT mode changes to COOL mode when 15 minutes have passed with the room temperature 4 degrees above the

set temperature.

In the other cases than the above conditions, the present operation mode is continued.

NOTE1: Mode selection is performed when multi standby (refer to NOTE2) is released and the unit starts operation with

ON-timer.

NOTE2: If two or more indoor units are operating in multi system, there might be a case that the indoor unit, which is

operating in AUTO ( ), cannot change over the other operating mode (COOL HEAT) and becomes a

state of standby.

9

Page 10

(3) Indoor fan control/ Vane control

COOL

Fan speed

Up

Down

Up

Down

Mode

HEAT

(MUZ)

Compressor frequency (Hz)

MUZ-A09/12/15/17/24

MUY-A15/17/24

<Relation between compressor frequency and fan speed.>

44

33

44

33

Up

Down

Fan speed

High

Low

Compressor frequencyMin. Max.

As the indoor fan speed and the horizontal vane position depend on the selected operation mode, when the operation

mode changes over, they change to the exclusive ones.

2-5. OUTDOOR FAN MOTOR CONTROL

Fan speed is switched according to the compressor frequency.

2-6. AUTO VANE OPERATION

1. Horizontal vane

(1) Cold air prevention in HEAT operation. (MUZ)

When any of the following conditions occurs in HEAT operation, the vane angle changes to Horizontal position automatically to prevent cold air blowing on users.

① Compressor is not operating.

➁ Defrosting is performed.

➂ Indoor coil thermistor RT12 temperature does not exceed 102ºF within about 3 minutes after compressor starts.

NOTE: When 2 or more indoor units are operated with multi outdoor unit, even if any indoor unit turns thermostat off,

this control doesn’t work in the indoor unit.

(2) ECONO COOL ( ) operation (ECONOmical operation)

When ECONO COOL button is pressed in COOL mode, set temperature is automatically set 3.6 degrees higher than

that in COOL mode.

Also the horizontal vane swings in various cycle according to the temperature of indoor heat exchanger (RT12).

SWING operation makes you feel cooler than set temperature. So, even though the set temperature is higher than that

in COOL mode, the air conditioner can keep comfort. As a result, energy can be saved.

ECONO COOL operation is cancelled when ECONO COOL button is pressed once again or VANE CONTROL

button is pressed or change to other operation mode.

10

Page 11

<SWING operation>

In swing operation of ECONO COOL operation mode, the initial air flow direction is adjusted to “Horizontal”.

According to the temperature of indoor coil thermistor RT12 at starting of this operation, next downward blow time is

decided. Then when the downward blow has been finished, next horizontal blow time is decided.

For initial 10 minutes the swing operation is performed in table G~H for quick cooling.

Also, after 10 minutes when the difference of set temperature and room temperature is more than 3.6 degrees, the

swing operation is performed in table D~H for more cooling.

The air conditioner repeats the swing operation in various cycle as follows.

Temperature of indoor

coil thermistor RT12

A

B

C

D

E

F

G

H

59°F or less

59°F to 63°F

63°F to 64°F

64°F to 68°F

68°F to 70°F

70°F to 72°F

72°F to 75°F

more than 75°F

Downward blow time

(second)

2

5

8

11

14

17

20

23

Horizontal blow time

(second)

23

20

17

14

11

8

5

2

11

Page 12

2-7. INVERTER SYSTEM CONTROL

POWER P.C. BOARD

Power

supply

INVERTER P.C. BOARD

R64A R64B

CT

TR821

DB65

X64

L62 L63

C63A

C63B

C63C

DB61

L61

P

W

V

U

N

CT761

CT781

IPM

U

W

MC

V

+

Booster chopper circucuit

SYMBOL

IPM

C63A/C63B/C63C

CT761/CT781

CT

DB61

R64A, R64B

X64

DB65

TR821

L61

NAME

INTELLIGENT POWER MODULE

SMOOTHING CAPACITOR

CURRENT TRANSFORMER

CURRENT TRANSFORMER

DIODE MODULE

CURRENT-LIMITING RESISTOR

RELAY

DIODE MODULE

SWITCHING POWER TRANSISTOR

REACTOR

FUNCTION

It supplies three-phase AC power to compressor.

It stabilizes the DC voltage.

It measures the current of the compressor motor.

It measures the value of current which is supplied to the main power

supply circuit.

It converts the AC voltage to DC voltage.

It absorbs the rush current not to run into the main power supply circuit

when the electricity turns ON.

It short-circuits the resistance which restricts rush current during the

normal operation after the compressor startup.

Booster

chopper

circuit

Function of main parts

It improves power factor.

It rectifies AC and controls its voltage.

2-7-1-2. Outline of main power supply circuit

1. At the start of operation

Main power supply circuit is formed when X64 (Relay) is turned ON at compressor startup.

To prevent rush current from running into the circuit when power supply is turned ON,

R64A and R64B (Current-limitting resistor) are placed in sub circuit.

2. At normal operation

1 When AC runs into POWER P.C. board, its external noise is eliminated in the noise filter circuit.

2 After noise is eliminated from AC, it is rectified to DC by DB61 (Diode module).

3 DC voltage, to which AC has been rectified by process 2, is stabilized by C63A, C63B and C63C (Smoothing capacitor)

and supplied to IPM (Intelligent power module).

4 DC voltage, which has been stabilized in process 3, is converted to three-phase AC by IPM and supplied to

compressor.

5 CT761 and CT781 (Current Transformer), which are placed in the power supply circuit to compressor, are used to

measure the value of phase current and locate the polar direction of rotor with algorithm. PWM (Pulse width modulation)

controls impressed voltage and frequency with those information.

2-7-1. MUZ-A09/12/15/17

MUY-A15/A17

2-7-1-1. Inverter main power supply circuit

12

Page 13

3. Purpose of PAM adoption

W

MC

V

U

W

V

U

IPM

CB3

CB2

+CB1

PFC

CT61

N/F

CT2

CT1

X64

R64A/R64B

L

POWER

SUPPLY

POWER BOARD

P. C. BOARD

FILTERNOISE

PAM : Pulse Amplitude Modulation

PAM has been adopted for the efficiency improvement and the adaptation to IEC harmonic current emission standard.

Outline of simple partial switching method

In conventional inverter models, diode module rectifies AC voltage to DC voltage, smoothing capacitor makes its DC waveform

smooth, and IPM converts its DC voltage to imitated AC voltage again in order to drive the compressor motor.

However, it has been difficult to meet IEC harmonic current emission standard by above circuit because harmonic gets

generated in the input current waveform and power factor gets down. The simple partial switching method with PAM, which has

been adopted this time, places and utilizes the booster chopper circuit (L61, DB65 and TR821) before rectifying AC voltage in

the general passive-method converter circuit. As harmonic gets suppressed and the peak of waveform gets lower by adding

booster chopper circuit as mentioned above and by synchronizing the timing of one-time switching with the zero-cross point of

waveform, the input current waveform can be improved and the requirement of IEC harmonic current emission standard can be

satisfied. Since the switching times is just once by synchronizing with the zero cross point, this simple partial switching method

has the feature of lower energy loss compared to active filter method. In addition, output and efficiency is enhanced by

combining with vector-controlled inverter in order to boost the voltage of power supplied to IPM.

Input current waveform without PAM Input current waveform with PAM

Due to the time of no electricity;

· Power factor gets worse.

· Harmonic gets increased.

Input voltage

Input current

Energized time is short in

case L inductance is small.

Owing to the increase of energized time;

· Power factor gets better.

· Harmonic gets suppressed.

Release of energy stored in L

Peak gets down.

Energized time is

extended by optimization

of L inductance.

No electricity runs into

diode module because the

voltage at both sides of smoothing

capacitor is higher than input voltage.

Compulsory energizing

by switching.

4. Intelligent power module

IPM consists of the following components

· IGBT (x6) : Converts DC waveform to three-phase AC waveform and outputs it.

· Drive Circuit : Drives transistors.

· Protection circuit : Protects transistors from overcurrent.

Since the above components are all integrated in IPM, IPM has a merit to make the control circuit simplify and miniaturize.

5. Smoothing capacitor

C63A, C63B and C63C stabilize the DC voltage and supply it to IPM.

6. Elimination of electrical noise

Noise filter circuit, which is formed by *CMC COILS capacitors placed on the POWER P.C. board, eliminates electrical

noise of AC power that is supplied to main power supply circuit. And this circuit prevents the electrical noise generated in

the inverter circuit from leaking out.

*CMC COILS; Common mode choke coils

2-7-2. MUZ-A24

MUY-A24

2-7-2-1. Inverter main power supply circuit

13

Page 14

SYMBOL

IPM

CB1~3

CT1~2

CT61

L

PFC

R64A, R64B

X64

NAME

INTELLIGENT POWER MODULE

SMOOTHING CAPACITOR

CURRENT TRANSFORMER

CURRENT TRANSFORMER

REACTOR

POWER FACTOR CONTROLLER

CURRENT-LIMITING RESISTOR

RELAY

FUNCTION

It supplies three-phase AC power to compressor.

It stabilizes the DC voltage.

It measures the current of the compressor motor.

It measures the current of the main power supply circuit.

It rectifies AC, controls its voltage and improves the power factor of

power supply.

It restricts rush current with the resistance.

It short-circuits the resistance which restricts rush current during the

compressor operates.

Function of main parts

2-7-2-2. Outline of main power supply circuit

1. At the start of operation

Main power supply circuit is formed when X64 (Relay) is turned ON at compressor startup.

To prevent rush current from running into the circuit when power supply is turned ON, R64A and R64B

(Current-limiting resistor) are placed in sub circuit.

2. At normal operation

1 When AC runs into noise filter P.C. board, its external noise is eliminated in the noise filter circuit.

2 After noise being eliminated from AC, it is rectified to DC by L (Reactor) and PFC (Power factor controller). If the operating

frequency becomes 25Hz or more, DC voltage rises to 370V.

3 DC voltage, to which has AC been rectified by process 2, is stabilized by CB1~3 (Smoothing capacitor) and supplied to

IPM (Intelligent power module).

4 The DC (Bus voltage), which has been stabilized in process 3, is converted to three-phase AC by IPM and supplied to

compressor.

5 CT1 and CT2 (Current Transformer), which are placed in the power supply circuit to compressor, are used to measure the

value of phase current and locate the polar direction of rotor with algorithm. PWM (Pulse width modulation) controls impre ssed voltage and frequency with those information.

3. Power factor improvement

Booster coil L (Reactor) and PFC rectify AC to DC and control its voltage.

In the motor drive system of sine wave control, power factor can be improved by reducing harmonics PFC and L (Reactor)

stabilize the voltage of DC supplied to inverter circuit and make its waveform smooth.

4. Power transistor module

IPM consists of the following components.

· Power Transistors (x6): Converts DC waveform to three-phase AC waveform and outputs it.

· Drive Circuit

: Drives transistors.

· Protection circuit

: Protects transistors from over current.

Since the above components are all integrated in IPM, IPM has a merit that can get the control circuit simplified and mini-

aturized.

5. Smoothing capacitor

CB1, CB2 and CB3 stabilize the DC voltage and supply it to IPM.

6. Elimination of electrical noise

Noise filter circuit, which is formed by *CMC COILS and capacitors placed on the noise filter P.C. board, eliminates electrical

noise of AC power that is supplied to main power supply circuit. In short, common mode noise is absorbed in this circuit.

Moreover, normal mode noise is absorbed in another noise filter circuit which is formed by *NMC COILS and capacitors.

Both noise filter circuit exists for preventing the electrical noise generated in the inverter circuit from leaking out.

*CMC COILS; Common mode choke coils

*NMC COILS; Normal mode choke coils

14

Page 15

2-7-3. Sine wave control

In these air conditioners, compressor equips brushless DC motor which doesn't have Hall element.

In short, the motor is sensorless. However, it's necessary to locate the polar direction of rotor in order to drive brushless DC

motor efficiently. The general detection method of the polar direction for such a DC motor is to locate it from the voltage induced

by unenergized stator.

Therefore, It is necessary to have a certain period of time in which the stator is being unenergized for the rotor position

detection when the voltage of supplied power is impressed.

So the motor has been driven by square wave control (the conventional motor drive system) which energizes the motor only

when the range of electrical angle is within 120_ because it is forced to be unenergized within 30_ at start & end of one heap

in one waveform cycle (180_) when the voltage is impressed.

However, torque pulsation occurs at rotation in this method when the current-carrying phases are switched over to other

phases in sequence. Therefore, sine wave control system is adopted for these air conditioners because it can make the

phase-to-phase current waveform smoother (sine wave) in order to drive the motor more efficiently and smoothly.

2-7-4. Characteristics of sine wave control in case of brushless DC motor

● Although ordinary three-phase induction motor requires energy to excite the magnetic field of rotor, brushless DC motor

doesn't need it. So, higher efficiency and torque are provided.

● This control provides the most efficient waveform corresponding to the rotation times of compressor motor.

● The rotation can be set to higher compared to the conventional motor drive system. So, the time in which air conditioner

can be operated with energy saved is longer than conventional models. This can save annual electric consumption.

● Compared to square wave control, the torque pulsation is reduced at rotation so that the motor operates more quietly.

● Since response and efficiency of motor are enhanced in sine wave control, finer adjustment can be provided.

Rotor

Rotor Position Signal

Permanent magnet is embedded.

Necessary

DC Motor

AC Motor

Excited by magnetic field of stator

Unnecessary

w In brushless DC motor, permanent magnet is embedded in the rotor. Therefore, it doesn't require energy to excite the rotor

like AC motor does. However, it's necessary to control the frequency of three-phase AC current supplied to the stator

according to the polar direction of magnet embedded in the rotor so as to drive the motor efficiently. Controlling three-phase

AC current frequency also means controlling the timing to switch the polarity of stator. Therefore, the polar direction of rotor

needs to be detected.

2-7-5. Control Method of Rotation Times

Sine wave control makes the current transformers conduct real time detection of the value of the current running into the motor,

locates the rotor position from the detected value, and decides if voltage should be impressed and if frequency should be chan ged.

Compared to the conventional control and rotor position detection method, sine wave control can provide finer adjustment of the

voltage of supplied power. The value of the current running into the motor is determined by each motor characteristic.

15

Page 16

1 hour

Time

Maximum

frequency

Upper limit

frequency

Rated frequency or less

2-8. OPERATIONAL FREQUENCY CONTROL OF OUTDOOR UNIT

1. Outline

The operational frequency is as following:

First, the target operational frequency is set based on the difference between the room temperature and the set temperature.

Second, the target operational frequency is regulated by discharge temperature protection, high pressure protection,

electric current protection and overload protection and also by the maximum/minimum frequency.

2. Maximum/minimum frequency in each operation mode.

COOL

HEAT(MUZ)

DRY

Applied

model

MUZ-A09

MUZ-A12

MUZ-A15

MUY-A15

MUZ-A17

MUY-A17

MUZ-A24

MUY-A24

Minimum

frequency

32

32

10

10

15

Maximum

frequency

Minimum

frequency

Maximum

frequency

70 32 76

73 32 71 32

82

87

110

15

15

15

93

93 10

108

Minimum

frequency

32

10

15

Maximum

frequency

57

57

68

68

102

w The operation frequency in COOL mode is restricted the upper limit frequency after 1 hour as shown below for

dew prevention.

It is rated frequency or less.

16

Page 17

2-9. EXPANSION VALVE CONTROL (LEV CONTROL)

(1) Outline of LEV control

The LEV basic control is comprised of setting LEV opening degree to the standard opening degrees set for each opera-

tional frequency of the compressor. However, when any change in indoor/outdoor temperatures or other factors cause

air conditioning load fluctuation, the LEV control also works to correct LEV opening degree based on discharge temperature (Shell temperature) of the compressor, developing the unit’s performance.

Control range

Actuating speed LEV opens 40 pulse/second and close 90 pulse/second

Opening degree adjustment LEV opening degree is always adjusted in opening direction.

standard

specification

Unit OFF LEV remains at maximum opening degree (reaches maxi-

Remote controller ON LEV is positioned. (first full-closed at zero pulse and then

COOL · DRY MODE

During 1 to 5 minutes after compressor starts

HEAT MODE (MUZ)

During 1 to 15 minutes after compressor starts

More than COOL, DRY: 5/ HEAT: 15 (MUZ) minutes

have passed since compressor start-up

general operation

from minimum 33 (MUZ-A09/12/15/17,MUY-A15/17)/ 59

(MUZ-A24/,MUY-A24) pulse to maximum 500 pulse.

(When reducing the opening degree, LEV is once overclosed, and then adjusted to the proper degree by opening.

mum opening degree approximate in 15 minutes after compressor stops)

positioned.)

LEV is fixed to standard opening degree according to operational frequency of compressor.

LEV opening degree is corrected to get target discharge

temperature of compressor.

(For discharge temperature lower than target temperature,

LEV is corrected in closing direction.)

(For discharge temperature higher than target temperature,

LEV is corrected in opening direction.)

wIt may take more than 30 minutes to reach target temperature, depending on operating conditions.

Thermostat OFF LEV is adjusted to exclusive opening degree for thermostat

OFF.

Thermostat ON LEV is controlled in the same way as that after the compres-

sor has started up.

Defrosting in HEAT mode (MUZ) LEV is adjusted to open 500 pulse.

17

Page 18

(2) Time chart

OFF Time

Time

ON

Operational frequency

of the compressor

Commanded

to open

Standard

opening

degree

Opening degree is

corrected according

to discharge

temperature.

Positioning

Air conditioner ON

Air conditioner OFF

(thermostat off)

LEV opening degree

about 5 minutes <COOL, DRY>

about 15 minutes <HEAT>

06

05

04

03

02

01

LEV opening degree

A(target discharge temperature)

B

C

D

E

F

30 50 70

Operational frequency of the compressor

90 110 130

(Hz)

(3) Control data

(a) Reference value of target discharge temperature

(COOL/HEAT (MUZ)ºF)

Applied model

MUZ-A09/12

MUZ-A15/17

MUY-A15/17

MUZ-A24

MUY-A24

MUZ-A09/12/15/17/24

MUY-A15/17/24

A

50/45B53/52C60/59

54/49

60/60

58/58 64/66

60/63 60/65

D

66/68

70/76F70/76

70/74 70/82 70/85

63/67

64/70 67/70

E

18

Page 19

In COOL operation, the two indoor coil thermistors (one main and one sub) sense temperature ununiformity (super

heat) at the heat exchanger, and when temperature difference have developed, the indoor coil thermistors adjust

LEV opening degree to get approximate 10 degrees lower temperature than the target temperature in the table

above, thus diminishing super heat.

(b) Reference value of LEV standard opening degree

(COOL/ HEAT (MUZ) pulse)

Applied model

MUZ-A09/12

MUZ-A15/17

MUY-A15/17

MUZ-A24

MUY-A24

A

130/100B190/130C240/170

290/130

150/130

300/150 350/220

166/150 186/170

D

260/210

E

260/230F260/230

350/250 370/280 370/300

206/196 230/210 260/226

19

Page 20

3

SYMBOL

IPM

CB1~3

CT1~2

CT61

L

PFC

R64A, R64B

X64

NAME

INTELLIGENT POWER MODULE

SMOOTHING CAPACITOR

CURRENT TRANSFORMER

CURRENT TRANSFORMER

REACTOR

POWER FACTOR CONTROLLER

CURRENT-LIMITING RESISTOR

RELAY

FUNCTION

It supplies three-phase AC power to compressor.

It stabilizes the DC voltage.

It measures the current of the compressor motor.

It measures the current of the main power supply circuit.

It rectifies AC, controls its voltage and improves the power factor of

power supply.

It restricts rush current with the resistance.

It short-circuits the resistance which restricts rush current during the

compressor operates.

Function of main parts

W

MC

V

U

W

V

U

IPM

CB3

CB2

+CB1

PFC

CT61

N/F

CT2

CT1

X64

R64A/R64B

L

POWER

SUPPLY

POWER BOARD

P. C. BOARD

FILTERNOISE

3-1-2. Outline of main power supply circuit

1. At the start of operation

Main power supply circuit is formed when X64 (Relay) is turned ON at compressor startup.

To prevent rush current from running into the circuit when power supply is turned ON, R64A and R64B

(Current-limiting resistor) are placed in sub circuit.

2. At normal operation

1 When AC runs into noise filter P.C. board, its external noise is eliminated in the noise filter circuit.

2 After noise being eliminated from AC, it is rectified to DC by L (Reactor) and PFC (Power factor controller). If the operating

frequency becomes 25Hz or more, DC voltage rises to 370V.

3 DC voltage, to which has AC been rectified by process 2, is stabilized by CB1~3 (Smoothing capacitor) and supplied to

IPM (Intelligent power module).

4 The DC (Bus voltage), which has been stabilized in process 3, is converted to three-phase AC by IPM and supplied to

compressor.

5 CT1 and CT2 (Current Transformer), which are placed in the power supply circuit to compressor, are used to measure the

value of phase current and locate the polar direction of rotor with algorithm. PWM (Pulse width modulation) controls impre ssed voltage and frequency with those information.

MXZ MICROPROCESSOR CONTROL

MXZ-2A20NA

MXZ-3A30NA

3-1. INVERTER SYSTEM CONTROL

3-1-1. Inverter main power supply circuit

20

Page 21

3. Power factor improvement

Booster coil L (Reactor) and PFC rectify AC to DC and control its voltage.

In the motor drive system of sine wave control, power factor can be improved by reducing harmonics PFC and L (Reactor)

stabilize the voltage of DC supplied to inverter circuit and make its waveform smooth.

4. Power transistor module

IPM consists of the following components.

· Power Transistors (x6) : Converts DC waveform to three-phase AC waveform and outputs it.

· Drive Circuit : Drives transistors.

· Protection circuit : Protects transistors from over current.

Since the above components are all integrated in IPM, IPM has a merit that can get the control circuit simplified and mini-

aturized.

5. Smoothing capacitor

CB1, CB2 and CB3 stabilize the DC voltage and supply it to IPM.

6. Elimination of electrical noise

Noise filter circuit, which is formed by *CMC COILS and capacitors placed on the noise filter P.C. board, eliminates electrical

noise of AC power that is supplied to main power supply circuit. In short, common mode noise is absorbed in this circuit.

Moreover, normal mode noise is absorbed in another noise filter circuit which is formed by *NMC COILS and capacitors.

Both noise filter circuit exists for preventing the electrical noise generated in the inverter circuit from leaking out.

*CMC COILS; Common mode choke coils

*NMC COILS; Normal mode choke coils

3-1-3. Sine wave control

In these air conditioners, compressor equips brushless DC motor which doesn't have Hall element.

In short, the motor is sensorless. However, it's necessary to locate the polar direction of rotor in order to drive brushless DC

motor efficiently. The general detection method of the polar direction for such a DC motor is to locate it from the voltage induced

by unenergized stator.

Therefore, it is necessary to have a certain period of time in which the stator is being unenergized for the rotor position

detection when the voltage of supplied power is impressed.

So the motor has been driven by square wave control (the conventional motor drive system) which energizes the motor only

when

the range of electrical angle is within 120_ because it is forced to be unenergized within 30_ at start & end of one heap

in one

waveform cycle (180_) when the voltage is impressed.

However, torque pulsation occurs at rotation in this method when the current-carrying phases are switched over to other

phases in sequence. Therefore, sine wave control system is adopted for these air conditioners because it can make the

phase-to-phase current waveform smoother (sine wave) in order to drive the motor more efficiently and smoothly.

3-1-4. Characteristics of sine wave control in case of brushless DC motor

● Although ordinary three-phase induction motor requires energy to excite the magnetic field of rotor, brushless DC motor

doesn't need it. So, higher efficiency and torque are provided.

● This control provides the most efficient waveform corresponding to the rotation times of compressor motor.

● The rotation can be set to higher compared to the conventional motor drive system. So, the time in which air conditioner

can be operated with energy saved is longer than conventional models. This can save annual electric consumption.

● Compared to square wave control, the torque pulsation is reduced at rotation so that the motor operates more quietly.

● Since response and efficiency are enhanced in sine wave control, finer adjustment can be provided.

Rotor

Rotor Position Signal

Permanent magnet is embedded.

Necessary

DC Motor

AC Motor

Excited by magnetic field of stator

Unnecessary

w In brushless DC motor, permanent magnet is embedded in the rotor. Therefore, it doesn't require energy to excite the rotor

like AC motor does. However, it's necessary to control the frequency of three-phase AC current supplied to the stator

according to the polar direction of magnet embedded in the rotor so as to drive the motor efficiently. Controlling three-phase

AC current frequency also means controlling the timing to switch the polarity of stator. Therefore, the polar direction of rotor

needs to be detected.

3-1-5. Control Method of Rotation Times

Sine wave control makes the current transformers conduct real time detection of the value of the current running into the motor,

locates the rotor position from the detected value and decides if voltage should be impressed and if frequency should be chan ged.

Compared to the conventional control and rotor position detection method, sine wave control can provide finer adjustment of the

voltage of supplied power. The value of the current running into the motor is determined by each motor characteristic.

21

Page 22

3-2. EXPANSION VALVE CONTROL (LEV CONTROL)

When outdoor unit is operating,

some indoor units stop and

some operate.

• LEV opening for each indoor unit is determined by adding adjustment in accordance

with the number of operating unit and the capacity class to standard opening, based

on the operation frequency:

Ex.) Opening 130 pulse in standard opening 1 ➝ Minimum 80 pulse, Maximum 205

pulse. (Capacity code 4 at 1 unit operation) (Capacity code 1 at 3 units operation)

• After starting operation, adjustment in accordance with intake super heat, discharge

temperature is included in standard opening. w1

Note: LEV opening in each frequency at DRY operation and COOL operation is the

same. However, velocity and compressor operation frequency controls are

different. See 2-3. OPERATIONAL FREQUENCY RANGE

(As far as the indoor unit velocity control goes, refer to DRY operation in

MICROPROCESSOR CONTROL in indoor unit.)

• LEV opening for each indoor unit is determined by adding adjustment in accordance

with the number of operating unit and the capacity class to standard opening, based

on the operation frequency:

Ex.) Opening 120 pulse in standard opening 1 ➝ Minimum 70 pulse, Maximum 165

pulse. (Capacity code 4 at 1 unit operation) (Capacity code 1 at 3 units operation)

• After starting operation, opening becomes the one that adjustment in accordance

with discharge temperature was added to basic opening. w1

Thermostat ON in HEAT mode

LEV opening

Thermostat OFF in

COOL or DRY mode

Thermostat OFF in HEAT mode

Stop of all indoor unit

Indoor unit status

COOL : 5 pulse (full closed)

HEAT :140 pulse (slightly opened)

Thermostat ON in

COOL or DRY mode

Opening before stop ➝ 500 pulse in 15 minutes

When the outdoor unit operates (When the other indoor unit operates): 5 pulse.

When outdoor unit stops. (When the other indoor unit stops or thermo off):

Maintain LEV opening before stop ➝ 500 pulse in 15 minutes

• When the outdoor unit operates. (When the other indoor unit operates): 140pulse .

• When the outdoor unit stops. (When the other indoor unit stops or thermo off):

Maintain LEV opening before stop ➝ 500 pulse in 15 minutes.

w1 LEV opening when the outdoor unit is operating: Upper limit 500 pulse, Lower limit 53pulse.

Linear expansion valve (LEV) is controlled by "Thermostat ON" commands given from each unit.

Determination of LEV standard opening in each indoor unit

• The standard opening is on the straight line, which connects an each standard point in the section where divided

into seven according to the operation frequency of compressor as shown in the figure below.

(LEV opening is controlled in proportion to the operation frequency.)

Note: Opening is adjusted at the standard opening according to the indoor unit conditions.

However, inclination of standard opening in each point of opening does not change with the original curve.

• Add opening provided in Difference in Capacity in the table below to the standard opening from 1 to 8,

when capacity of the indoor unit is excluding code 1.

• Add opening provided in Difference in Operation number in the table below to determined LEV opening for

each indoor unit, when 2 or 3 indoor units are operated at the same time.

Note: Even when the adjusted standard opening exceeds the driving range from 59 to 500 pulse, actual

driving output opening is in a range from 59 to 500 pulse.

22

Page 23

The table below shows the role of Exclusive LEV and Receiver LEV in each operation mode.

Circulation

Amount

Control

High

Pressure

Protection

wEvaporation

Temperature

Protection

Discharge

Temperature

Protection

Capacity

Distribution

COOL

Exclusive LEV

Receiver LEV

Exclusive LEV

Receiver LEV

HEAT

Indoor heat

exchanger

(MXZ-3A)

Outdoor

heat

exchanger

Exclusive

LEV

Receiver

LEV

Receiver

1

2

3

4

5

200

300

400

450

500

Standard No.

Number of

operating

indoor units

<MXZ-2A>

1 unit

150

320

360

410

500

2 units

120

140

160

220

280

1 unit

120

140

160

220

280

2 units

COOL

LEV opening (pulse)

HEAT

1

2

3

4

5

150

250

350

400

450

Standard No.

Number of

operating

indoor units

<MXZ-3A>

1 unit

250

320

360

410

460

2 units

250

320

370

420

470

3 units

250

300

450

460

470

1 unit

250

300

380

400

450

2 units

250

300

380

390

440

3 units

COOL

LEV opening (pulse)

HEAT

wIn COOL mode, the two indoor coil thermistor (one main and one sub) sense temperature ununiformity (super heat) at the

heat exchanger, and when temperature dif ference have developed, the indoor coil thermistors adjust LEV opening to diminish the super heat.This action is called Evaporation Temperature Protection.

The opening pulse of the Receiver LEV is fixed to the standard No.3 in cooling operation, and so is that of each Exclusive

LEV in heating operation.

However the opening pulse will be changed to the standard No.4 or No.5 when the discharge temperature protection or highpressure protection is working.

In addition to that, it will also be changed to standard No.2 or No.1 when the opening pulse of the each Exclusive LEV

becomes 100 pulse or less in cooling operation or so does that of Receiver LEV in heating operation.

23

Page 24

Capacity code

Indoor unit

4

0971291510171224

Standard opening (pulse)

01 02 03 04 05 06 07 08

COOL

LEV Opening(code)

HEAT

126

140

130

146

134

150

138

170

140

180

142

200

182

224

228

244

09

296

272

10

310

280

Code5,6Code3,4

Difference in capacity

Difference in operation number

COOL

HEAT

3

3

6

6

Code7,8

9

9

Code9,10

12

52

Code11,12

15

55

25

65

35

75

Code13,14

Code15or above

2

-20

0

3

-30

0

4

-40

0

8 23 54 69 84 100 115 131 14638

5 14 32 41 50 59 68 77 86

MXZ-2A

MXZ-3A23

Compressor operating frequency (Hz)

4Hz

01

02

03

04

05

06

07

08

09

10

LEV Opening (code)

Standard opening (pulse)

01 02 03 04 05 06 07 08

COOL

LEV Opening(code)

HEAT

120

100

130

110

136

120

146

130

156

146

160

160

170

170

180

180

09

190

190

10

200

200

Code5,6Code3,4

Difference in capacity

Difference in operation number

COOL

HEAT

3

3

6

6

Code7,8

9

9

Code9,10

12

52

Code11,12

15

55

25

65

35

75

Code13,14

Code15or above

2

-20

0

3

-30

0

4

-40

0

MXZ-2A

MXZ-3A

24

Page 25

1 Discharge temperature

2 Each correction

• (Each gas pipe temperature thermistor - Minimum gas pipe temperature thermistor)w 1

• (Main indoor coil thermistor - Sub indoor coil thermistor)

w 1 Perform this, when number of operation units is 2 units or more.

w 2 Correct the LEV opening by discharge temperature.

COOL DRY HEAT

• •

-

•

w 2

•

w 2

•

<Correction>

(1) LEV opening correction by discharge temperature

Operation frequency

of compressor (Hz)

Minimum ~ 23

24 ~ 38

39 ~ 54

55 ~ 69

70 ~ 85

86 ~ Maximum

1 unit

95

104

120.2

136.4

149

158

2 units

136.4

140

149

154.4

158

158

1 unit

122

132.8

140

140

140

140

2 units

122

122

132.8

140

140

140

Number of operating unit Number of operating unit

COOL

HEAT

Target discharge temperature (˚F)

Operation frequency

of compressor (Hz)

Minimum ~ 14

15 ~ 23

24 ~ 32

33 ~ 41

42 ~ 50

51 ~ 59

60 ~ 68

69 ~ 77

78 ~ 86

87 ~ Maximum

1 unit

95

104

120.2

136.4

149

154.4

158

167

167

167

2 units

131

131

136.4

140

149

154.4

158

163.4

167

176

3 units

134.6

134.6

145.4

149

158

163.4

167

176

179.6

179.6

1 unit

125.6

136.4

149

154.4

154.4

154.4

154.4

154.4

154.4

172.4

2 unit

143.6

150.8

165.2

172.4

172.4

172.4

172.4

172.4

172.4

172.4

3 units

122

131

140

152.6

161.6

168.8

168.8

168.8

168.8

168.8

Number of operating unit Number of operating unit

COOL

HEAT

Target discharge temperature (˚F)

The target discharge temperature is determined according to frequency zone and number of operation unit of the

compressor.

MXZ-2A

MXZ-3A

25

Page 26

Correct the LEV opening according to the difference between target discharge temperature and discharge temperature.

Discharge temperature (˚F)

LEV opening

correction (pulse)

More than Target discharge temperature+18

Target discharge temperature+18 to Target discharge temperature+9

Target discharge temperature+9 to Target discharge temperature+3.6

Target discharge temperature+3.6 to Target discharge temperature-3.6

Target discharge temperature-3.6 to Target discharge temperature-9

Target discharge temperature-9 to Target discharge temperature-18

Target discharge temperature-18 or less

COOL

5

4

2

0

-1

-3

-4

HEAT

8

3

1

0

-1

-2

-3

Discharge temperature (˚F)

LEV opening

correction (pulse)

More than Target discharge temperature+21.6

Target discharge temperature+21.6 to Target discharge temperature+9

Target discharge temperature+9 to Target discharge temperature+5.4

Target discharge temperature+5.4 to Target discharge temperature-5.4

Target discharge temperature-5.4 to Target discharge temperature-9

Target discharge temperature-9 to Target discharge temperature-21.6

Target discharge temperature-21.6 or less

COOL

4

2

1

0

-1

-3

-8

HEAT

6

2

1

0

-1

-2

-8

Superheat

LEV opening

correction (pulse)

more than 16.2

10.8 to 16.2

5.4 to 10.8

5.4 or less

3

2

1

0

Superheat

LEV opening

correction (pulse)

more than 16.2

10.8 to 16.2

5.4 to 10.8

5.4 or less

12

8

4

0

MXZ-2A

MXZ-3A

(2) Separate correction (COOL,DRY)

(Correction by the separate super heat)

a) Correct the LEV separately by temperature difference between each gas pipe temperature and the minimum gas pipe

temperature of all.

1 Calculate each super heat of the unit from the expression below;

(Super heat) = (Each gas pipe temperature) - (Minimum gas pipe temperature)

2 Separate correction is performed according to each super heat in the table below.

MXZ-2A

MXZ-3A

26

Page 27

Number of

operating

unit

1

2

Capacity

code

1, 2, 3, 4

5, 6

7, 8

9, 10

11, 12

13, 14

15 or above

2, 3, 4, 5, 6, 7

8, 9, 10

11, 12, 13

14, 15, 16

17, 18, 19, 20, 21

22, 23, 24 or above

Min.

20

20

20

20

20

20

30

30

30

30

30

30

COOL (Hz)

Max.

65

65

65

94

94

94

94

94

94

94

94

94

DRY

(Hz)

25

25

30

75

75

75

75

52

52

52

52

94

Min.

30

30

30

30

30

30

30

58

58

58

58

58

Max.

63

63

63

92

92

92

92

92

92

92

92

92

HEAT (Hz)

Defrost

63

63

63

92

92

92

92

92

92

92

92

92

MXZ-2A

LEV opening

correction (pulse)

10.8[ RT

7.2[ RT< 10.8

RT<7.2

2

1

0

Temperature to be

decreased (˚F)

10.8[ RT

7.2[ RT< 10.8

RT<7.2

18

9

9

RT

RT

b) Correct the LEV separately by temperature difference “ RT” between main/sub indoor coil thermistor.

Number of

operating

unit

1

2

3

Capacity

code

1, 2, 3, 4

5, 6

7, 8

9, 10

11, 12

13, 14

15 or above

2, 3, 4, 5, 6, 7

8, 9, 10

11, 12, 13

14, 15, 16

17, 18, 19, 20, 21

22, 23, 24 or above

3, 4, 5, 6, 7, 8, 9, 10

11, 12, 13, 14, 15

16, 17, 18, 19, 20

21, 22, 23, 24, 25

26, 27, 28, 29

30 or above

Min.

15

15

15

15

15

15

15

24

24

24

24

24

52

52

COOL (Hz)

Max.

58

58

58

62

62

62

65

80

80

80

80

80

90

90

DRY

(Hz)

20

20

25

44

44

44

44

31

31

31

31

59

65

65

Min.

22

22

22

22

22

22

22

35

35

35

35

35

39

39

Max.

37

37

37

90

90

90

90

58

58

90

94

94

94

94

HEAT (Hz)

Defrost

37

37

37

80

80

80

80

58

58

80

80

80

80

80

In addition, decrease the target discharge temperature corresponding RT.

3-3. OPERATIONAL FREQUENCY RANGE

MXZ-3A

27

Page 28

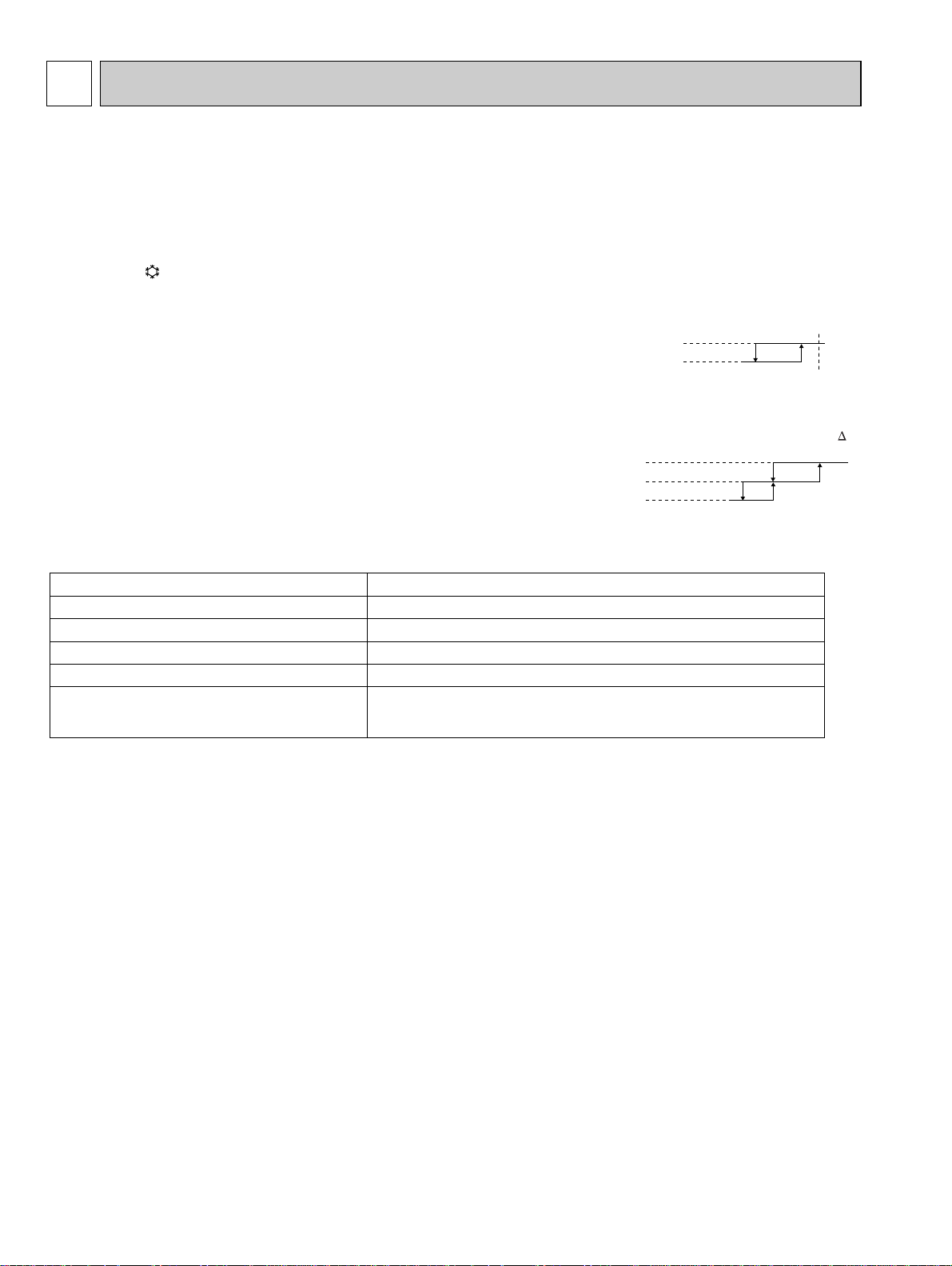

3-4. HEAT DEFROSTING CONTROL

COOL

Fan speed

Up

Down

Up

Down

Mode

HEAT

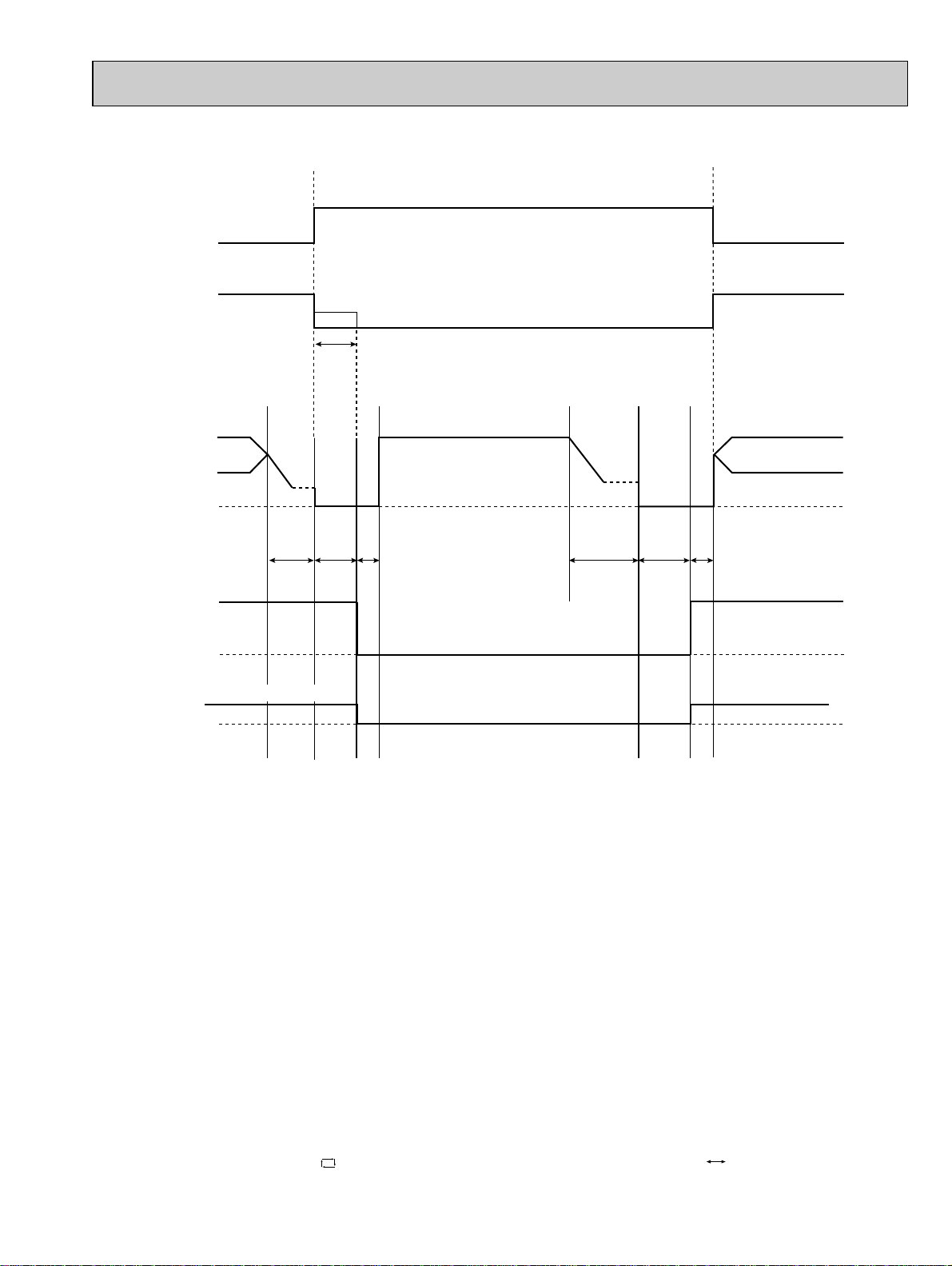

Compressor frequency

<Relation between compressor frequency and fan speed.>

40Hz

30Hz

40Hz

30Hz

Up

Down

Fan speed

High

Low

Compressor frequencyMin. Max.

(1) Conditions to enter defrosting mode

1. When temperature of defrosting thermistor is 26.6˚F or less.

2. When specified non-defrosting time, is counted in the control p.c. board is satisfied.

(Total time of compressor operating)

Going to defrosting mode at both condition of 1 and 2.

(2) Defrosting operation

1. Compressor stops for 50 seconds, Indoor fan is off, Defrosting lamp lights.

2. 4-way valve reverses flow, Compressor operates by the frequency in heat defrosting control.

3. After compressor stops for 35 seconds, 4-way valve reverses flow, then defrosting finishes.

(3) Conditions to finish defrosting mode

1. When the defrosting thermistor temperature is 55.76˚F or more.

2. When it has spent 10 minutes for defrosting.

Defrosting finishes at condition of 1 or 2.

3-5. DISCHARGE TEMPERATURE PROTECTION CONTROL

This protection controls the compressor ON/OFF and operation frequency according to temperature of the discharge

temperature thermistor.

(1) Compressor ON/OFF

When temperature of the discharge temperature thermistor exceeds 240.8˚F, the control stops the compressor.

When temperature of the discharge temperature thermistor is 176˚F or less, the controls starts the compressor.

(2) Compressor operation frequency

When temperature of the discharge temperature thermistor is expected to be higher than 240.8˚F, the control decreases 12Hz

from the current frequency.

When temperature of the discharge temperature thermistor is expected to be higher than 231.8˚F and less than 240.8˚F, the

control decreases 6Hz from the current frequency.

When temperature of the discharge temperature thermistor is expected to be higher than 219.2˚F and less than 231.8˚F, the

control is set at the current frequency.

3-6. OUTDOOR FAN CONTROL

Fan speed is switched according to the number of operating indoor unit and the compressor frequency.

Note

•When the indoor coil thermistor is 134.6˚F or more on HEAT operation, fan speed is fixed to Low speed.

Or, the indoor coil thermistor is 113˚F or less on HEAT operation, fan speed is back to normal.

CC

Copyright 2006 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD

Distributed in Apr. 2006. No. OBT16 7

Made in Japan

HEAD OFFICE: TOKYO BLDG.,2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

New publication, effective Apr. 2006

Specifications subject to change without notice.

Loading...

Loading...